Fireproof vacuum insulation panel for building external thermal insulation system and preparation method thereof

A technology for vacuum insulation panels and building exterior walls, which is used in thermal insulation, fire protection, building components, etc., can solve the problems of poor high temperature resistance and fire resistance, long production cycle, complex process, etc., and achieve excellent high temperature resistance and fire resistance. The effect of small investment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

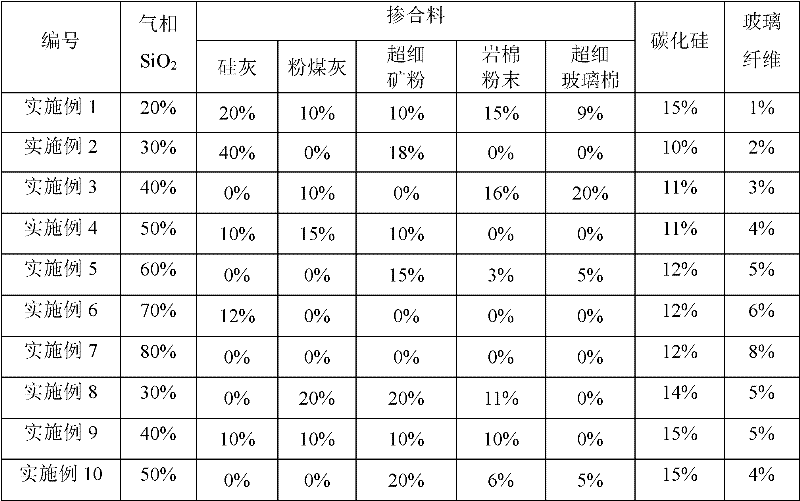

Embodiment 1

[0032] First put fumed silica, silica fume, fly ash, ultrafine mineral powder, rock wool powder, ultrafine glass wool, silicon carbide and glass fiber into the crushing mixer according to the mass percentages in Example 1 of Table 1 , crushed and mixed evenly; then pour the mixed material into a square hard mold, put it into a press, pressurize and shape it with a loading pressure of 2MPa, and obtain a composite core material; take out the formed composite core material and put it into a glass fiber aluminum-plastic composite package In the bag, vacuumize until the vacuum degree is less than 1Pa, and package to obtain the fireproof vacuum insulation panel VIP1.

Embodiment 2

[0034]First put fumed silica, silica fume, ultrafine mineral powder, silicon carbide and glass fiber into the crushing mixer according to the mass percentage in Example 2 of Table 1, crush and mix evenly; then pour the mixed material into a square hard Put it into the mold, put it into a press, pressurize and shape it with a loading pressure of 3MPa, and obtain a composite core material; take out the formed composite core material and put it in a glass fiber aluminum-plastic composite packaging bag, vacuumize until the vacuum degree is less than 1Pa, and package it. Fireproof vacuum insulation panels VIP2.

Embodiment 3

[0036] First put fumed silica, fly ash, rock wool powder, ultrafine glass wool, silicon carbide and glass fiber into the crushing mixer according to the mass percentages in Example 3 of Table 1, and crush and mix evenly; then the mixture The material is poured into a square hard mold, put into a press, and the loading pressure is 2.5MPa for press molding to obtain a composite core material; take out the formed composite core material and put it in a glass fiber aluminum-plastic composite packaging bag, and then evacuate to a vacuum The temperature is less than 1Pa, and the fireproof vacuum insulation panel VIP3 is obtained by encapsulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com