Patents

Literature

140results about How to "No rupture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

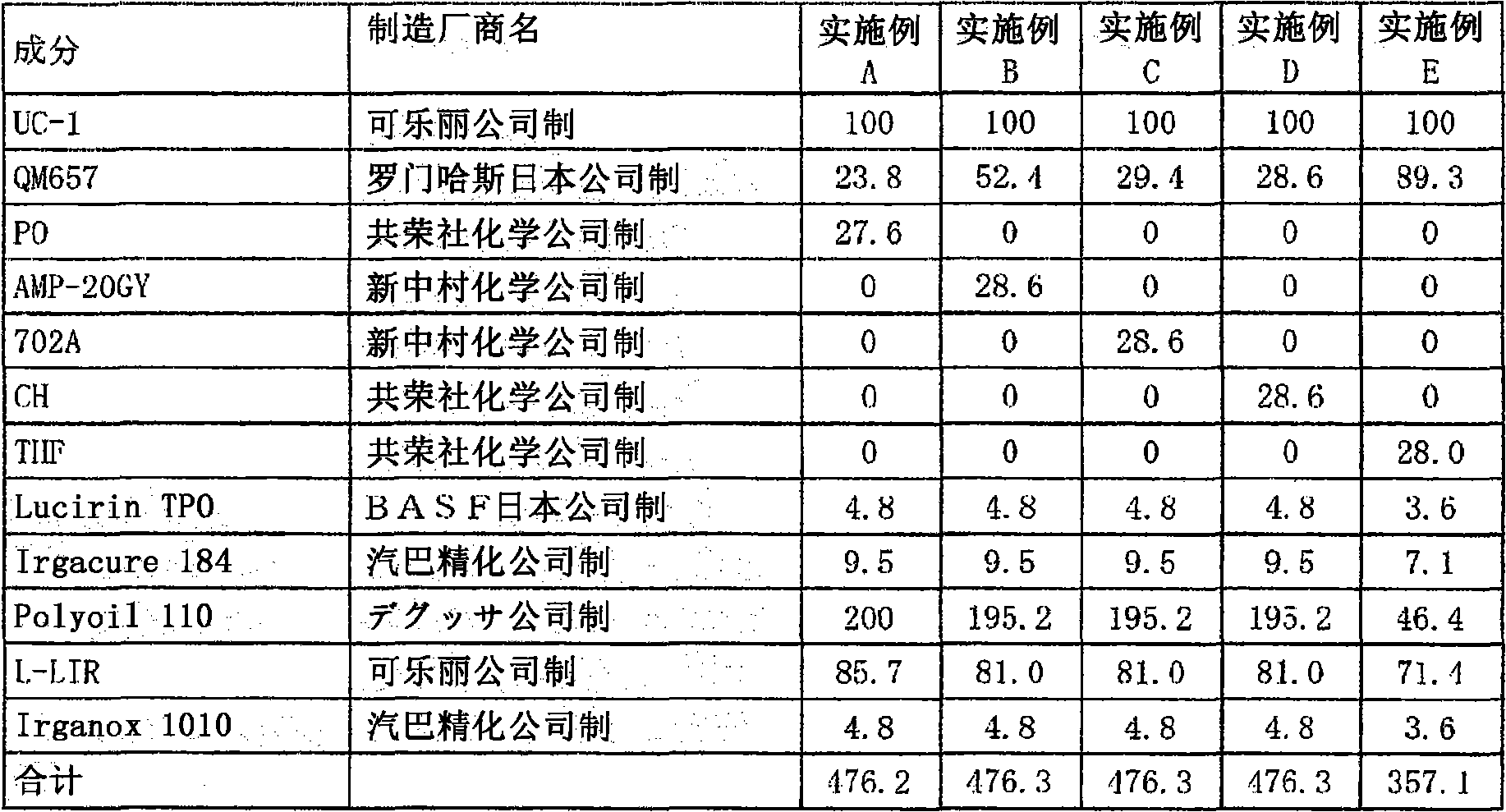

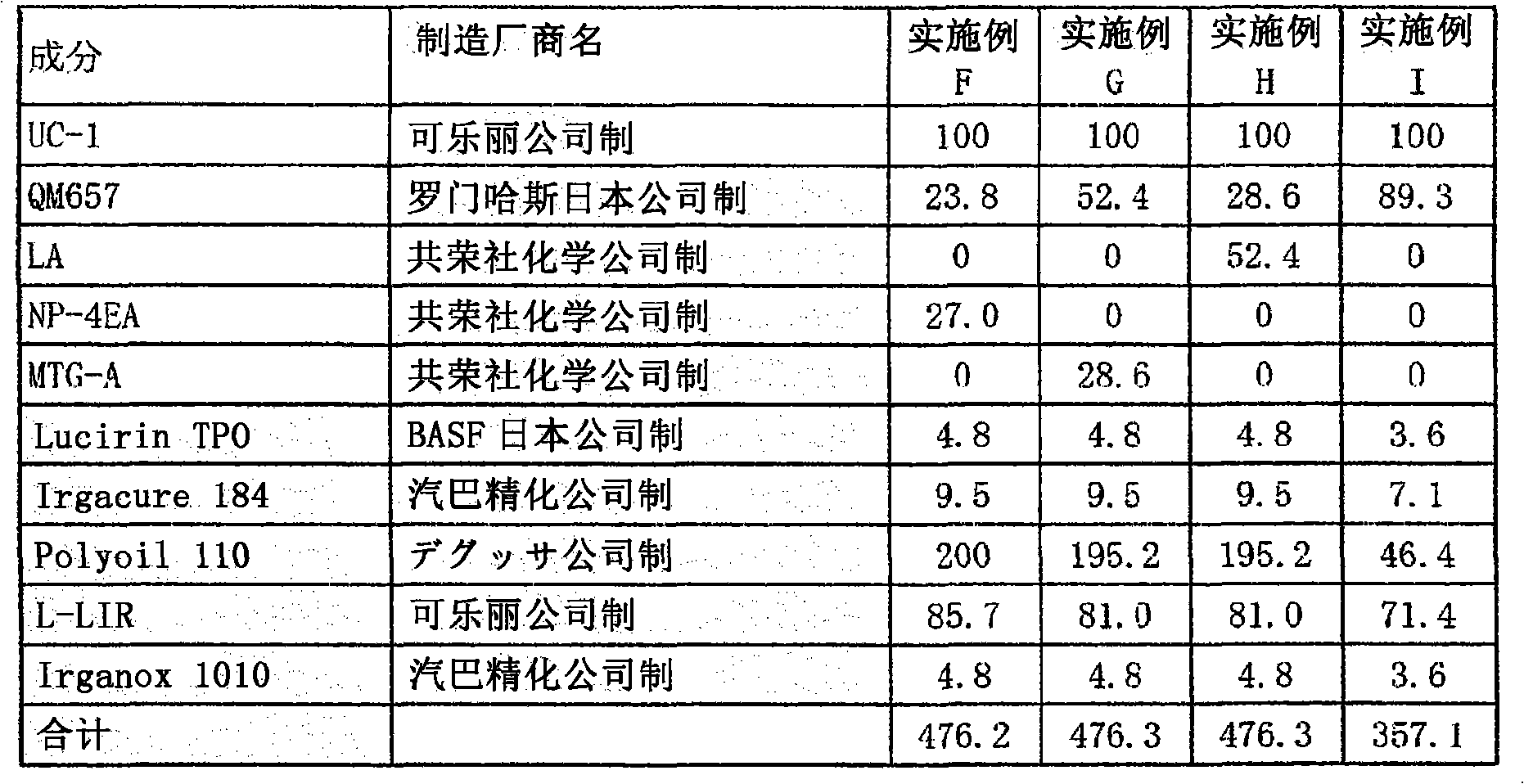

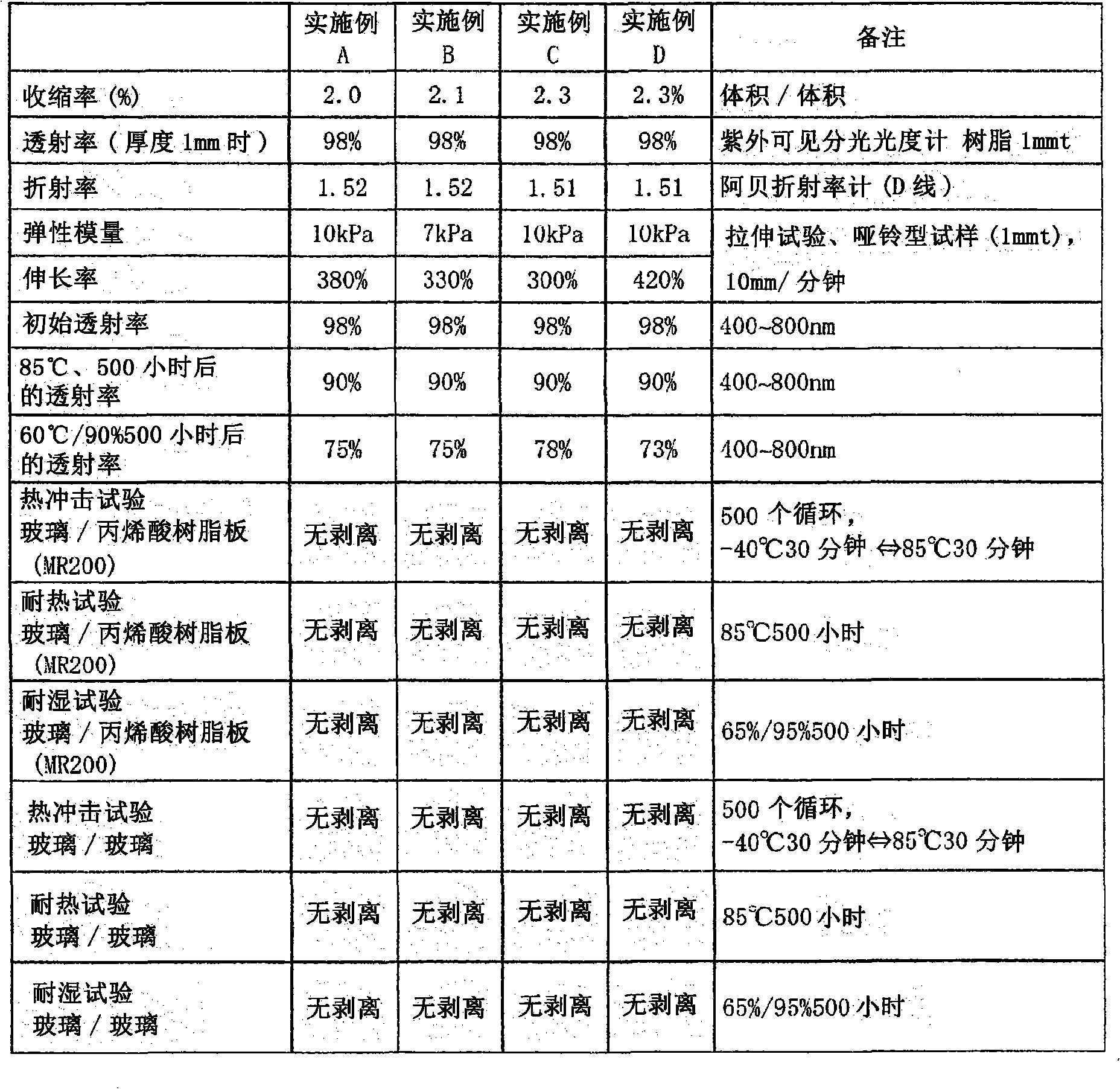

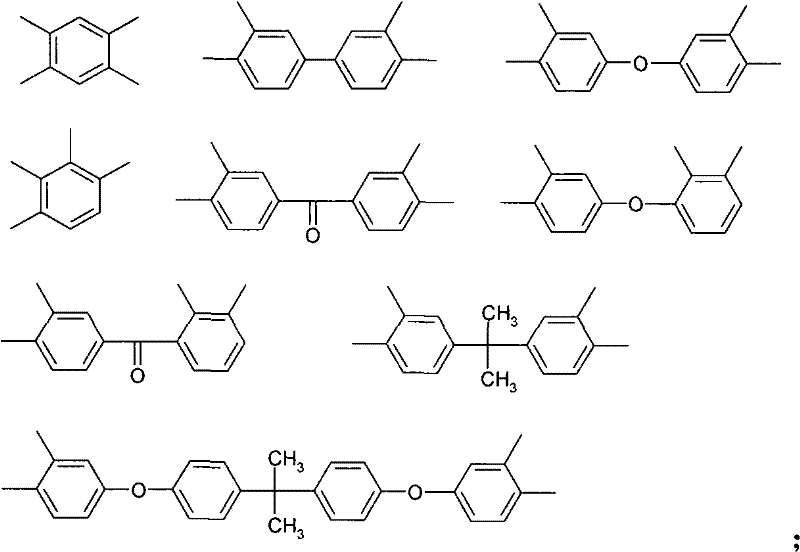

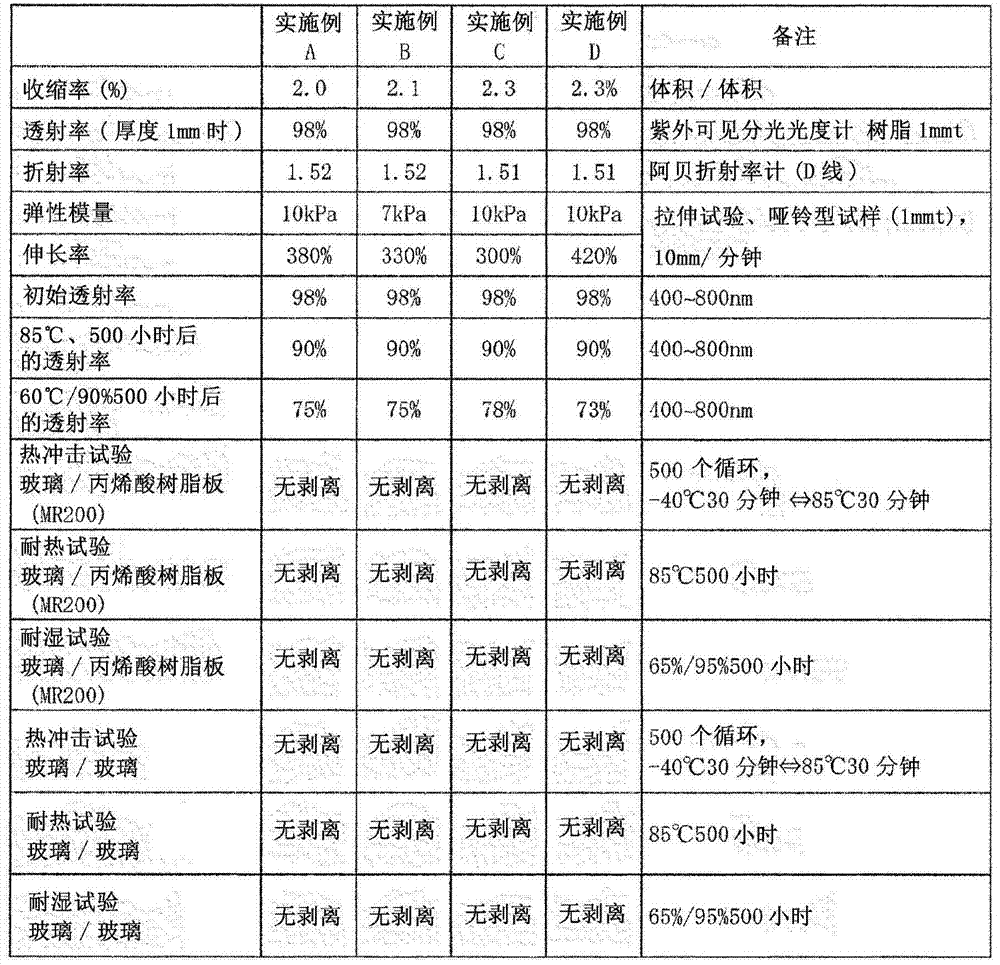

Photocurable resin composition for laminating optically functional material

ActiveCN102144009AAdhesive forceNo peelingNon-macromolecular adhesive additivesMacromolecular adhesive additivesTouch panelChemistry

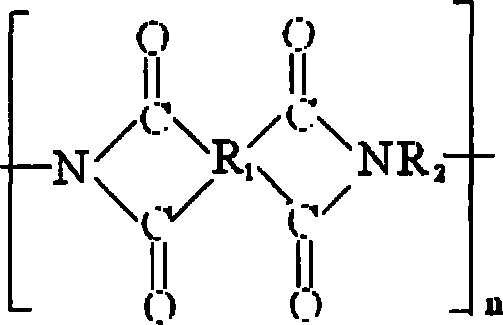

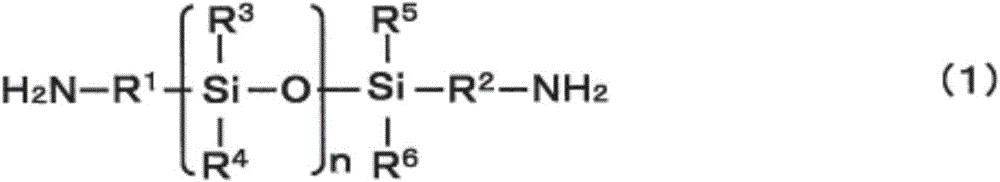

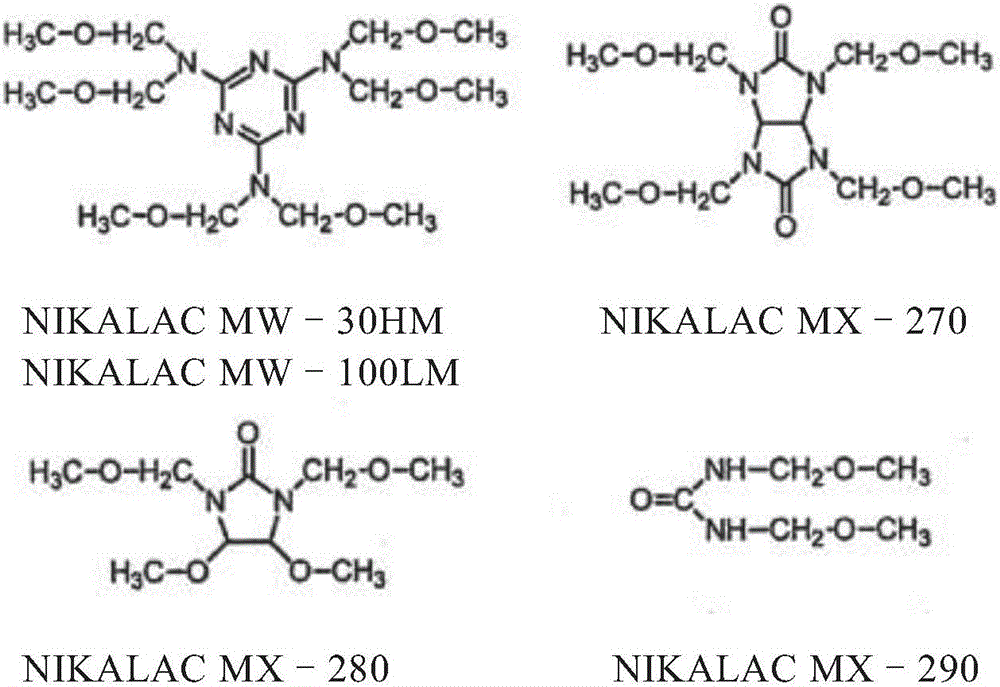

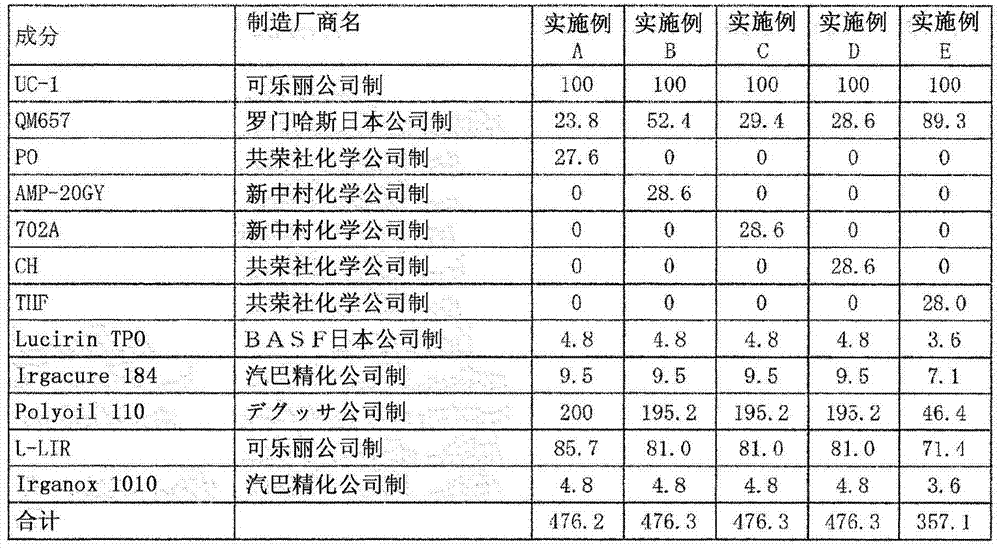

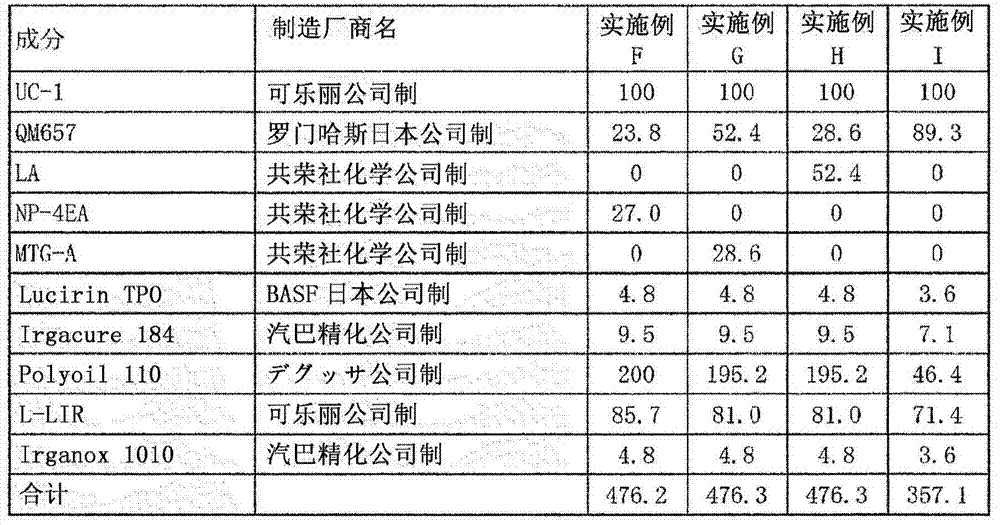

Disclosed is a photocurable adhesive composition which, in the lamination of a decorated plate or an icon sheet on a touch panel or in the lamination of a transparent substrate with a transparent electrode formed thereon on a transparent plate in an electrostatic capacitive touch panel, can impart satisfactory adhesive properties and can realize the lamination without incorporating air bubbles. Also disclosed is a photocurable resin composition for use in the lamination of a display and an optically functional material on each other, which, when a display is laminated on an optically functional material, does not cause the delamination of a bonded surface or the breaking of a glass in the display. The photocurable adhesive composition comprises (A) a (meth)acrylate oligomer having a polyisoprene, polybutadiene, or polyurethane skeleton, (B) a softening component, and optionally (C) (C1) a (meth)acrylate monomer selected from phenoxyethyl(meth)acrylate, phenoxy polyethylene glycol(meth)acrylate, 2-hydroxy-3-phenoxypropyl(meth)acrylate, and cyclohexyl(meth)acrylate, (C2) or a thiol compound. The photocurable resin composition can provide a cured product having a modulus of elasticity and an elongation at break both of which fall within given ranges.

Owner:KYORITSU KAGAKU SANGYO KK

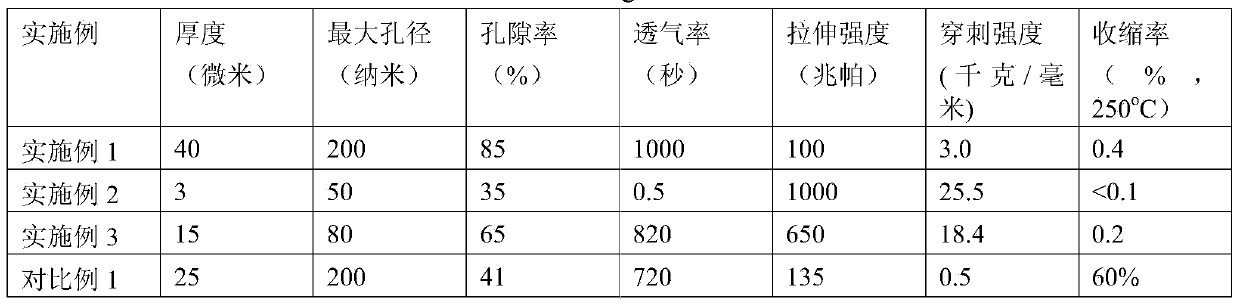

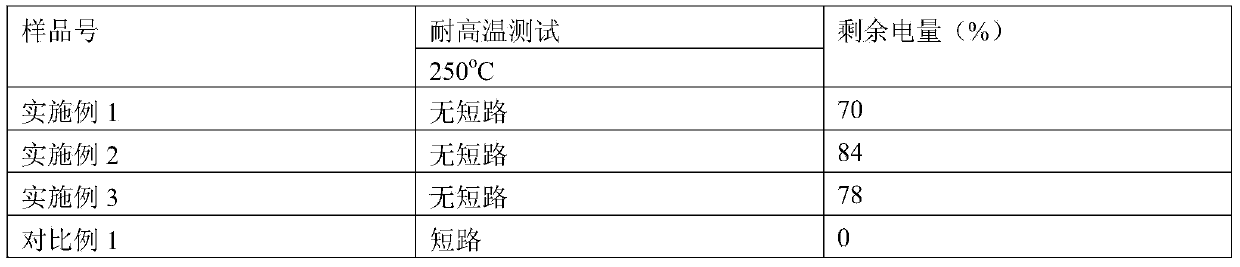

Battery diaphragm and its preparation method and lithium ion secondary battery containing the diaphragm

InactiveCN101000951AGood chemical stabilityNo ruptureSecondary cellsCell component detailsLithiumPower battery

A battery separator includes the substrate and holes distributed on it, in which, the substrate contains polyimide. The battery separator of this invention uses polyimide which is a new material bearing high temperature as substrate, so that it has excellent chemical stability, high temperature, good permeability and high mechanical strength. The lithium-ion rechargeable batteries using this invention don't appear short circuit even in 150 deg. C, thus this battery separator can be used for high-capacity and power batteries.

Owner:BYD CO LTD

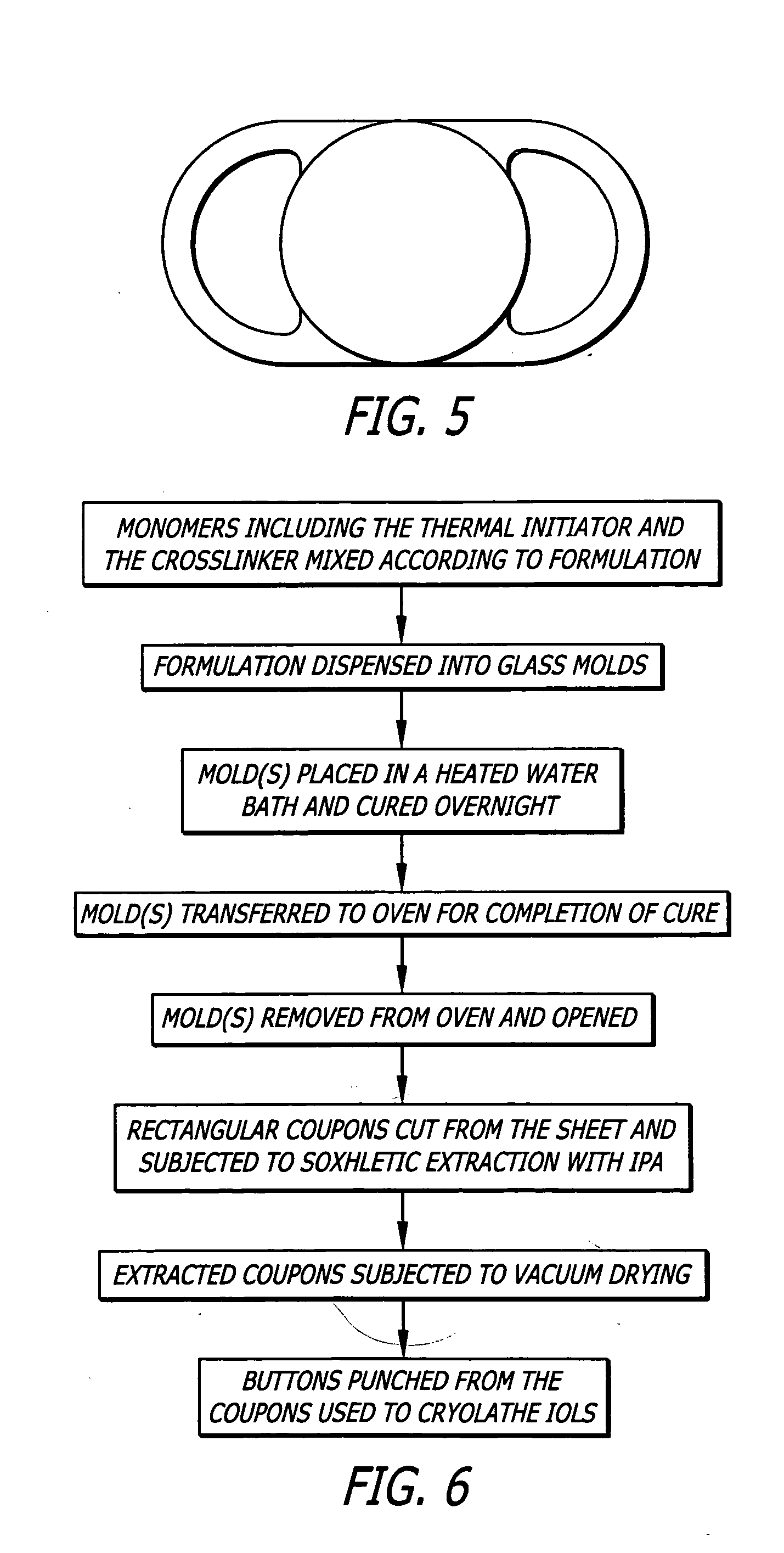

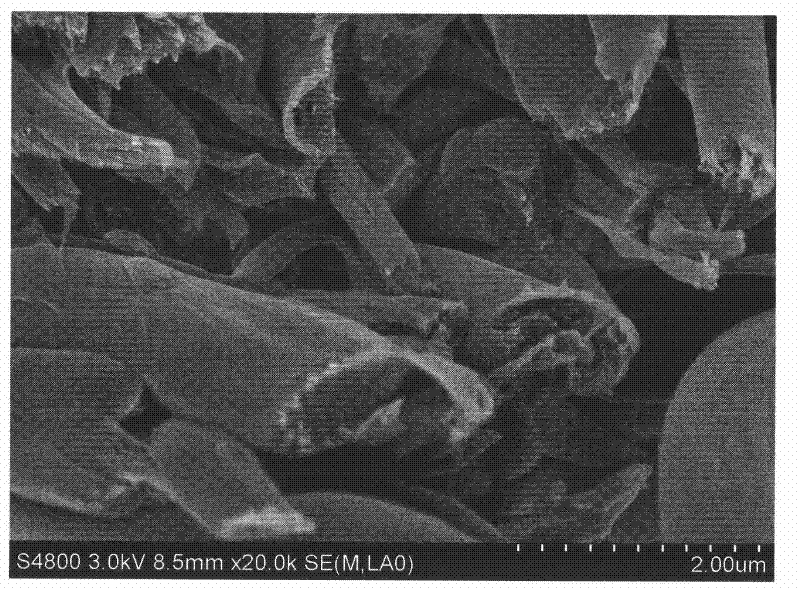

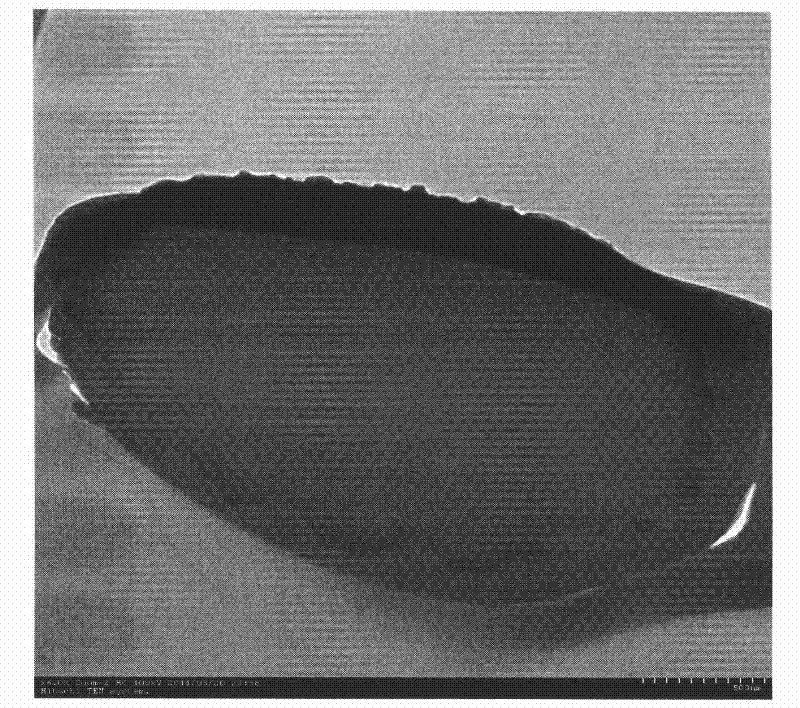

Intraocular lens materials suitable for insertion through a small bore cartridge

InactiveUS20050143751A1Low tensile strengthMinimal cartridge crazingEye treatmentIntraocular lensIntraocular lensMedicine

A polymer material useful for manufacturing an intraocular lens (IOL) suitable for insertion through an IOL inserter barrel having an inner diameter of less than 3 mm is provided. Specifically, acrylic-silicone hybrids having a tensile strength of approximately 100 psi to 400 psi and a percent elongation at break of between 50% and 400% are disclosed.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

Coaxial compound nanometre fibre film as well as preparation method and application thereof

ActiveCN102230257AImprove permeabilityHigh tensile strengthFilament/thread formingCell component detailsFiberPolymer science

The invention discloses a coaxial compound nanometre fibre film composed of compound nanometre fibres of a fluorine-containing polymer skin layer and a polyimide core layer, wherein the upper and the lower surfaces and inner holes of the film are distributed symmetrically. The coaxial compound nanometre fibre film is prepared from a fluorine-containing polymer solution and a polyamic acid solution through coaxial static spinning compounding, mechanical roller pressing and thermal imidization; the nanometre fibre film provided by the invention integrates the advantages of fluorine-containing polymer and polyimide; the fluorine-containing polymer has excellent electrolyte wetting property, liquid maintaining property and ion conductivity; and the polyimide has high mechanical strength and high heat resistance. The compound nanometre film provided by the invention is fit for high-energy lithium ion energy storage batteries and high-power electrokinetic cells.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

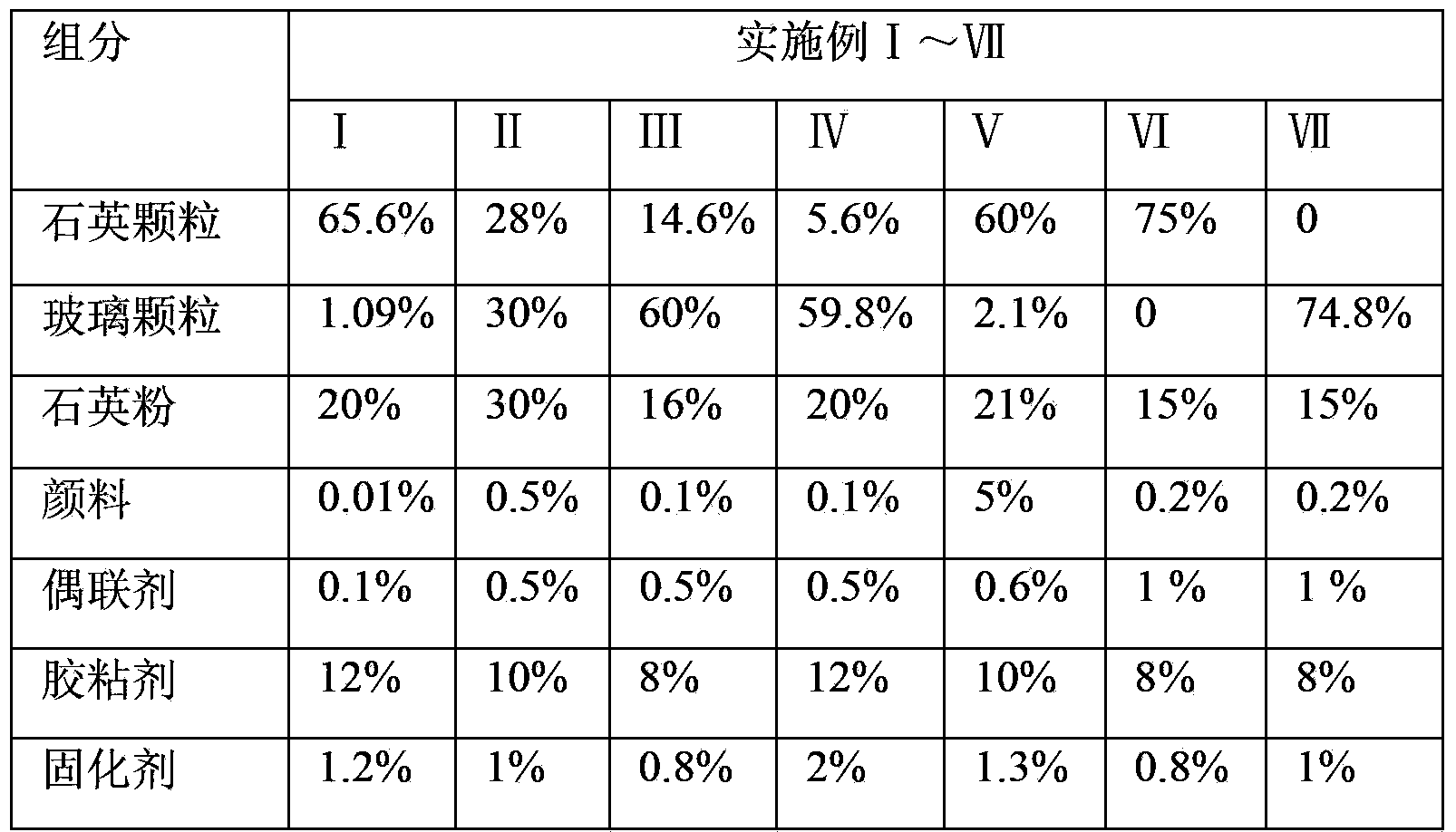

High-impact toughness man-made quartzite slab and preparation method thereof

The invention provides a high-impact toughness man-made quartzite slab and a preparation method thereof. The man-made quartzite slab comprises the following components in percentage by weight: 58-75 percent of particle raw materials, 15-33 percent of quartz powder, 0.01-10 percent of paint, 0.1-1 percent of coupling agent, 8-12 percent of adhesive and 0.8-2 percent of curing agent, wherein the particle raw materials are quartz particles, glass particles, or a mixture of the two. The man-made quartzite slab provided by the invention has the characteristics of low probability of cracking and deformation, and the like.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

Battery isolating film and method for producing the same

The invention provides a battery diaphragm. The diaphragm comprises a substrate; the substrate is provided with a via, wherein, the substrate has polyimide; the channel of the via has polyolefin. The battery diaphragm obtained from the embodiment of the invention has an excellent high temperature resistance and burst can not be happened by heating to 400 DEG C; all the heat shrinkage are not more than 1.3 percent at 400 DEG C, which is far less than the heat shrinkage of 5 percent in prior art; the average diameter of pores and porosity all meet the demand of conductivity; a suitable and fine air permeability is provided; the heat shrinkage is also far less than the battery diaphragm in prior art. The battery made by the battery diaphragm provided by the invention has excellent high temperature resistance that unsafe phenomena of explosion, smoking, firing and liquid leaking can not happen even under a high temperature of 150 DEG C.

Owner:BYD CO LTD

High-stability microcapsule used for asphalt self-repair

InactiveCN103965644AExtended service lifeWith regenerative functionBuilding insulationsEpoxyPolymethyl methacrylate

The invention provides a high-stability microcapsule used for asphalt self-repair. The microcapsule is characterized in that the microcapsule adopts polymers as wall materials and commercially available asphalt regenerant liquid as a core material; the mass ratio of the wall materials to the core material is (3:1)-(1:3); the polymers used as wall materials are melamine resin, methyl modified melamine resin, phenolic resin, epoxy resin, unsaturated polyester resin and polymethyl methacrylate resin; the core material is an asphalt regenerant, is oily liquid capable of dissolving aged asphalt and has the function of regenerating aged asphalt; after the microcapsule is mixed with molten asphalt at 200 DEG C for one hour, 95% of microcapsule is in a complete state and does not crack; the microcapsule is mixed with asphalt to generate microcracks in the asphalt aging process to crack the microcapsule and the asphalt regenerant is released to self-repair aged asphalt, thus greatly prolonging the service life of asphalt.

Owner:苏峻峰

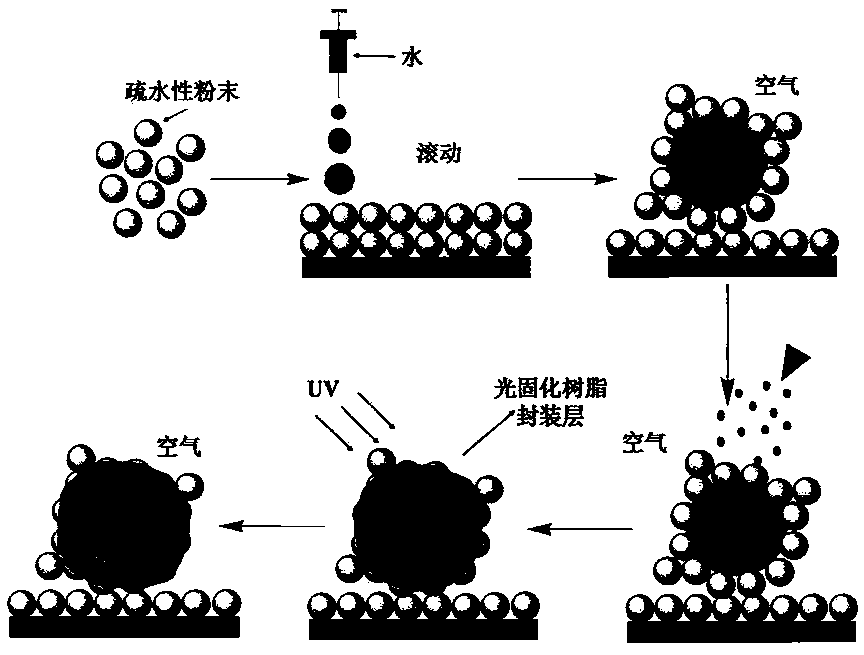

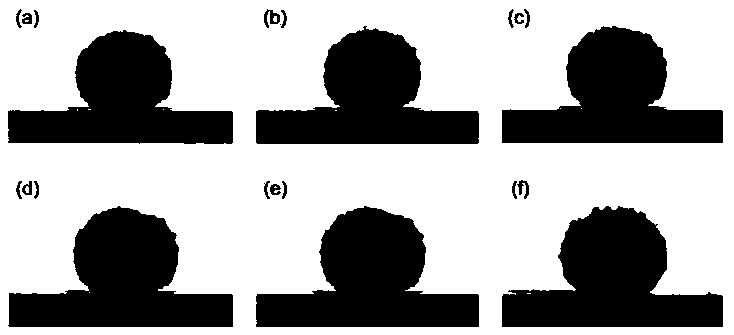

Multifunctional cigarette cracking capsule based on liquid marble and preparation method of multifunctional cigarette cracking capsule

InactiveCN105361242AFast preparation methodThe preparation method is simple and gentleTobacco smoke filtersMicro nanoAdditive ingredient

The invention provides a multifunctional cigarette cracking capsule based on a liquid marble and a preparation method of the multifunctional cigarette cracking capsule, and belongs to the fields of colloid and interface science and micro-nano encapsulating. The multifunctional cigarette cracking capsule has a structure as shown below. The preparation method of the multifunctional cigarette cracking capsule comprises the following steps: I. dropwise adding liquid drops above a stabilizing agent which is hydrophobic powder, and preparing the liquid marble by virtue of a rolling dropping method; and II. immersing the liquid marble in a photo-curable coating which contains an initiating agent or spraying the photo-curable coating containing the initiating agent outside the liquid marble, and curing through ultraviolet radiation, so that a microcapsule is obtained. The multifunctional cigarette cracking capsule based on the liquid marble disclosed by the invention is simple and mild in preparation process, and is excellent in stability, water retention and moisture preserving properties, and disinfecting property; harmful ingredients in inhaled gas of a cigarette can be removed and cigarette taste can be enhanced; therefore, the multifunctional cigarette cracking capsule has broad application prospect.

Owner:JIANGNAN UNIV

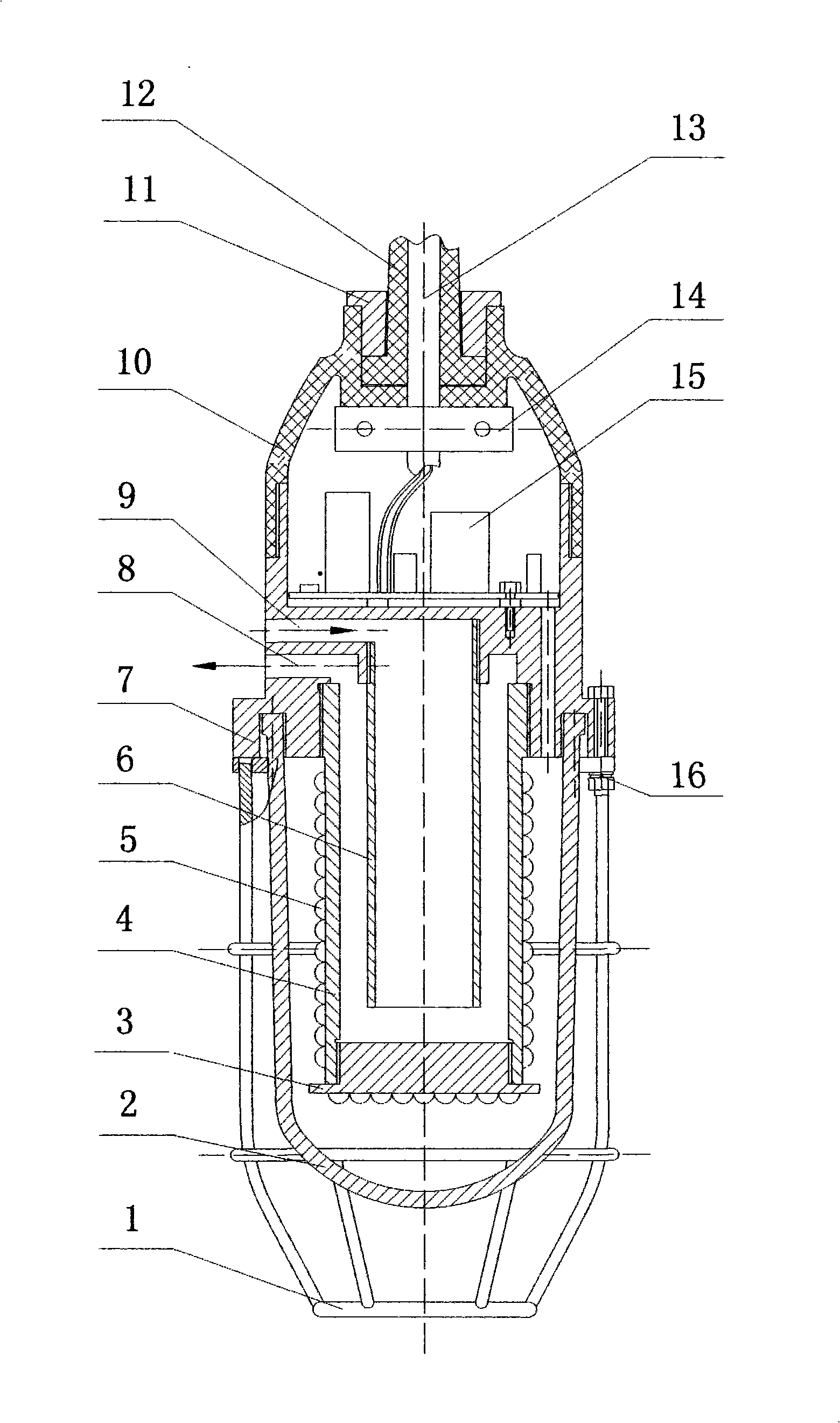

Underwater fishing lamp for high-power blue green light LED ship

ActiveCN101329040ALower working temperatureImprove securityWaterborne vesselsPoint-like light sourceGlass coverFiltration

The invention relates to a submersed marine fishing lamp with a high-power blue-green LED as a luminous source. The existing auxiliary equipment used in the luring and fishing of fishes mainly adopts a metal halide lamp which has wide light source wavelength range, after filtration in the sea, the remaining blue-ray component is little and the other colors are all absorbed by the seawater, thus causing great waste of energy resource. The purpose of the invention is to provide the submersed high-power blue-green LED marine fishing lamp. The structure of the invention consists of a high-power blue-green LED arranged on a lamp body; in the lamp body, an upper shell is fixed on the upper end of a main shell which is sequentially fixed with a circulating water insulated tube, a lower shell, a glass cover and a protecting cage from inside to outside; both the external surfaces of the lower shell and a lower baffle are fixed with a high-power blue light LED, the cable plywood used in the upper shell is fixed and connected with a power board. The application of the lamp is that the fishes in the sea are gathered by the blue-green light with the wavelength from 465nm to 490nm given out by a light source module, thus achieving the purposes of saving energy and improving the efficiency of fishing.

Owner:XIAN LIMING ELECTRONICS TECH

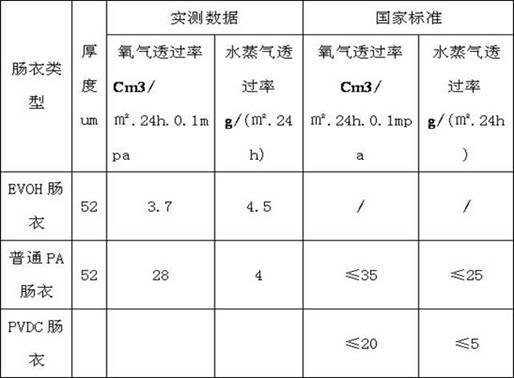

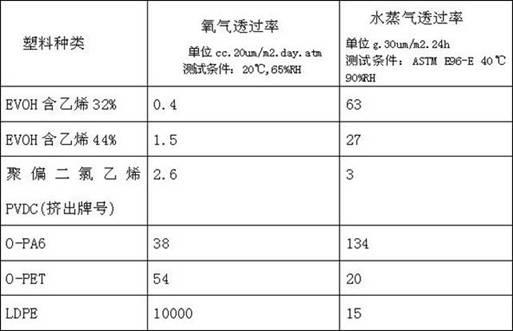

Preparation method for multi-layer co-extrusion two-way stretched high-barrier plastic casing

The invention discloses a preparation method for a multi-layer co-extrusion two-way stretched high-barrier plastic casing. The preparation method comprises the following steps of: respectively adding raw materials of each layer into an extruder for each layer for melting and plasticizing, wherein the multi-layer co-extrusion two-way stretched high-barrier plastic casing is formed by co-extruding five layers of raw materials; extruding the raw materials by a multi-layer stacked type round mold to form a multi-layer mold blank; slightly blowing and stretching the mold blank, and then immediately and rapidly cooling and molding the mold blank by using cooling water of 5-15 DEG C into a first pipe film; heating the first pipe film in a hot water tank or an infrared heating system to a proper temperature; aerating compressed air to ensure that the mold blank is transversely stretched for a multiplying power of 3 to 5 times and longitudinally stretched for a multiplying power of 2.5 to 3 times to form a second pipe film; putting the second pipe film in an infrared heating barrel for sizing; and rolling a finished product after cooling the second pipe film to a required fold diameter and shrinkage rate by using a vane. Plastic casings prepared by the preparation method have the characteristics of high barrier, high water retention and environmental protection.

Owner:南通环球塑料工程有限公司

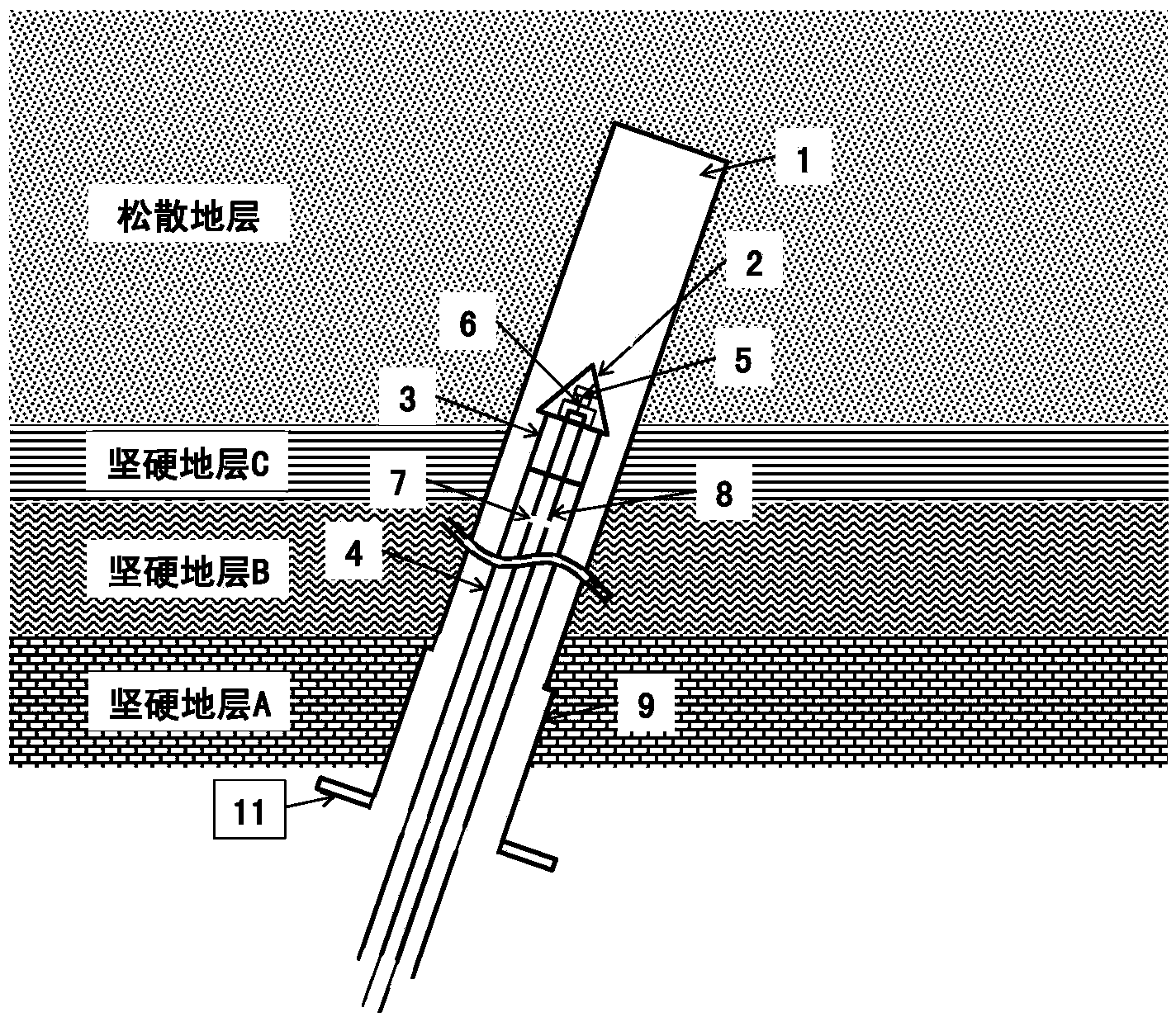

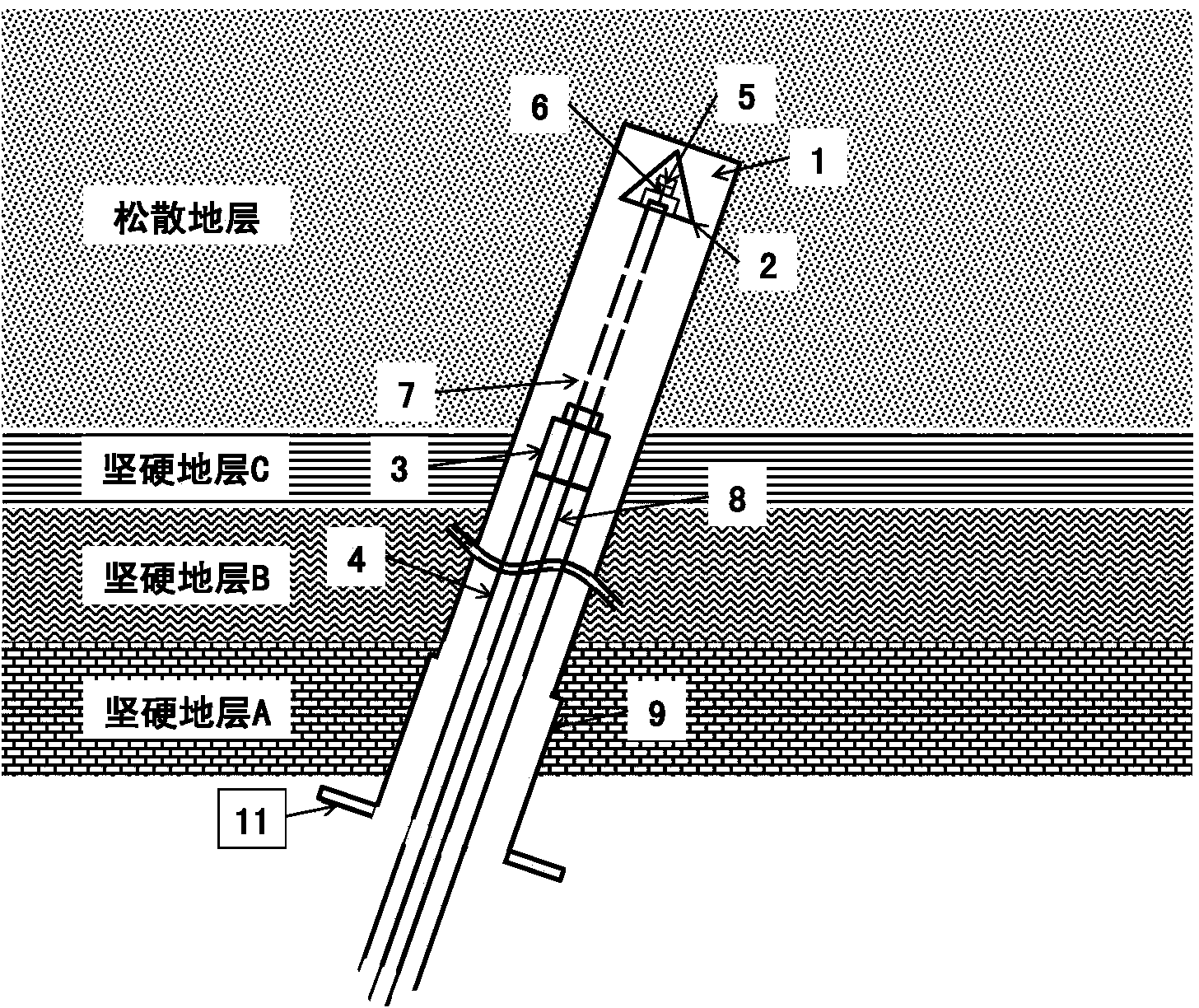

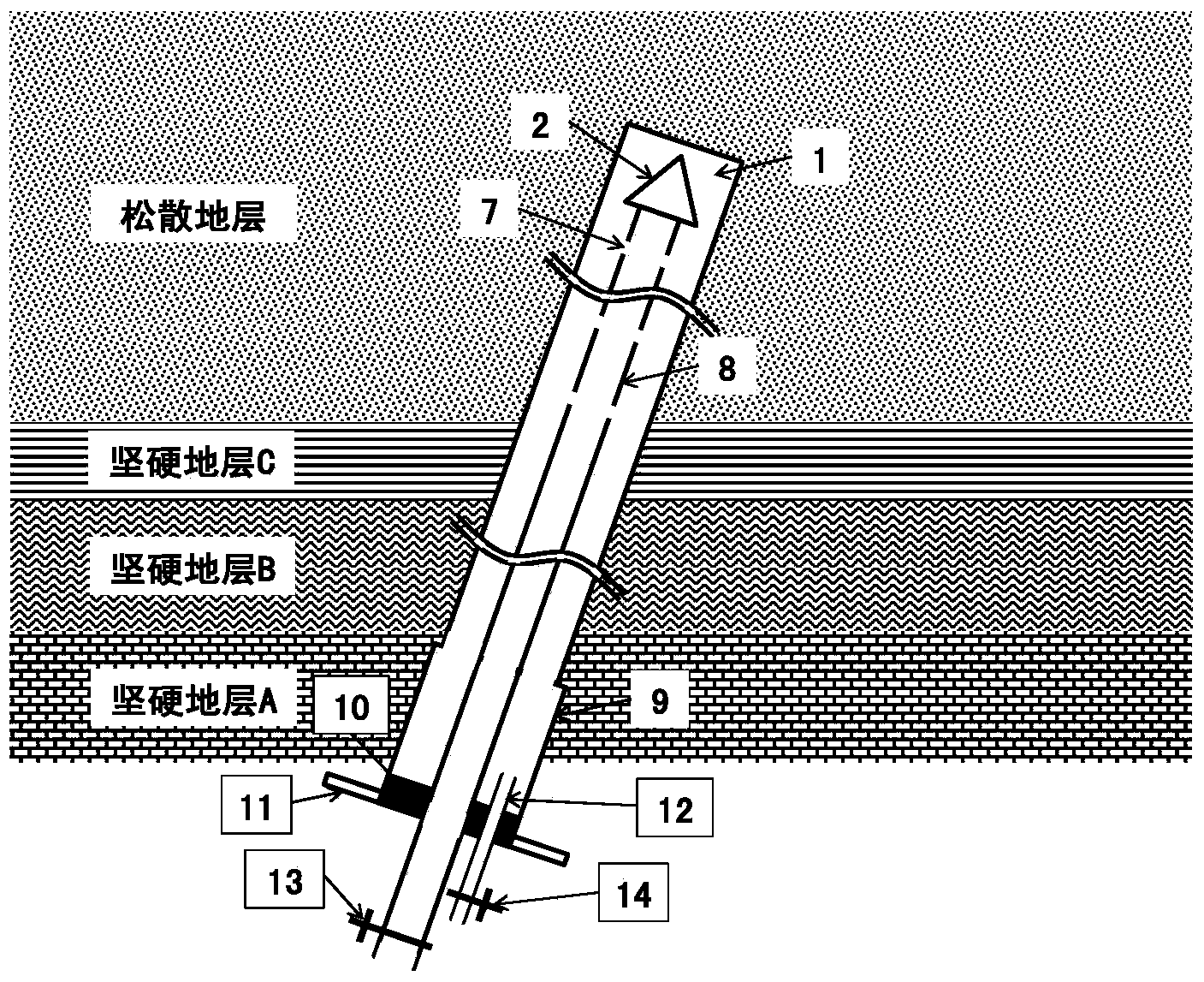

Method for controlling water inrush and sand inrush under coal mine

The invention discloses a method for controlling water inrush and sand inrush under a coal mine. The method comprises the steps that an injection pipe is arranged below by utilizing a disposable drilling bit device; a disposable drilling bit cap is separated and exited from a drilling body; the injection pipe is fixedly connected; and a special stratum is injected. The method for controlling the water inrush and the sand inrush is high in injection success rate, good in fixed injection pipe connection quality, great in injection pressure, high in drilling and injection combined efficiency and low in injection cost, and safe, quick, cheap and high-quality reconstruction can be achieved for the special stratum. The method achieves that the injection pipe is arranged below a drilling bit, high-pressure injection is performed on the special stratum by utilizing the fixedly connected injection pipe.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

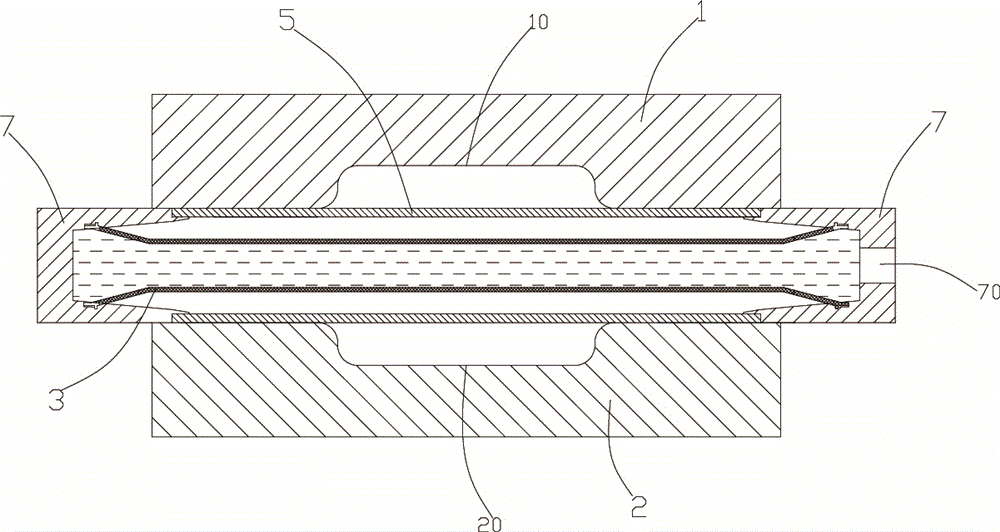

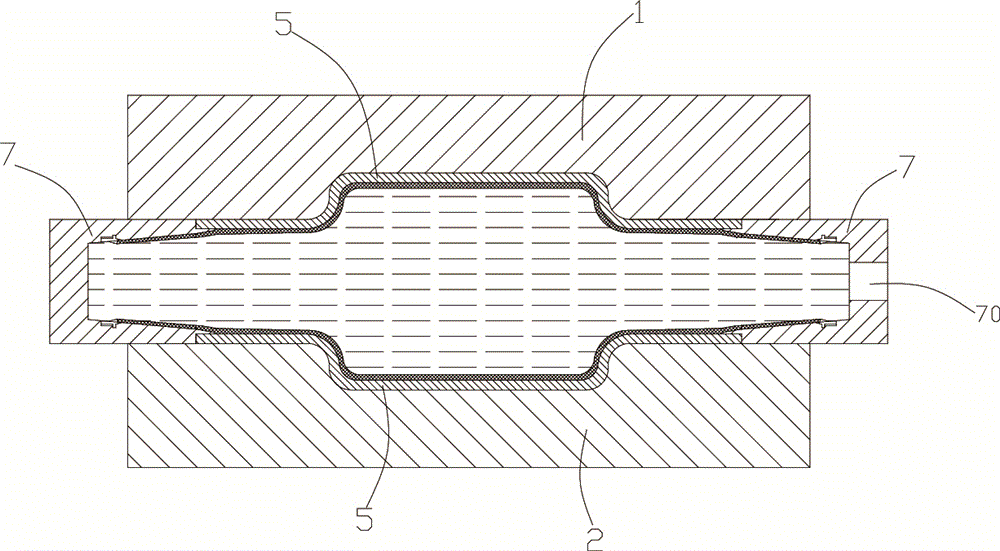

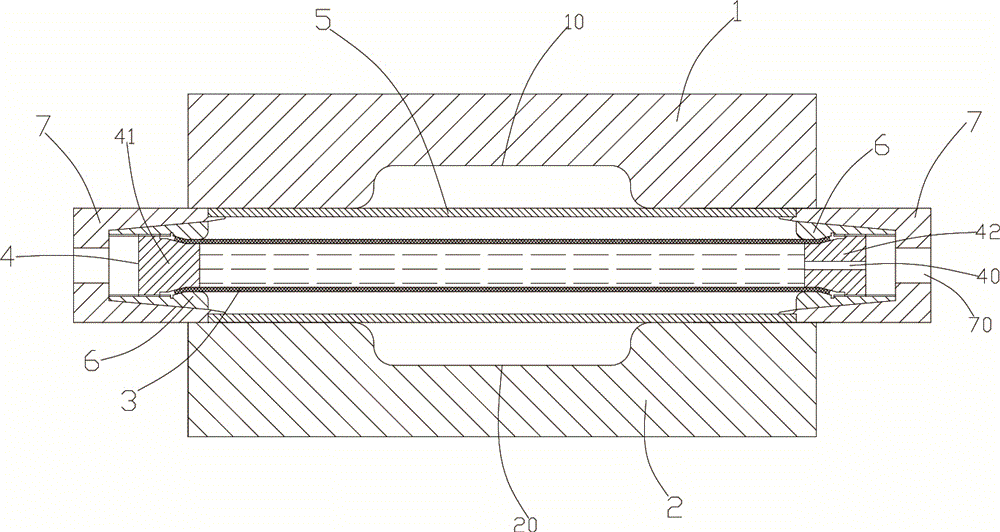

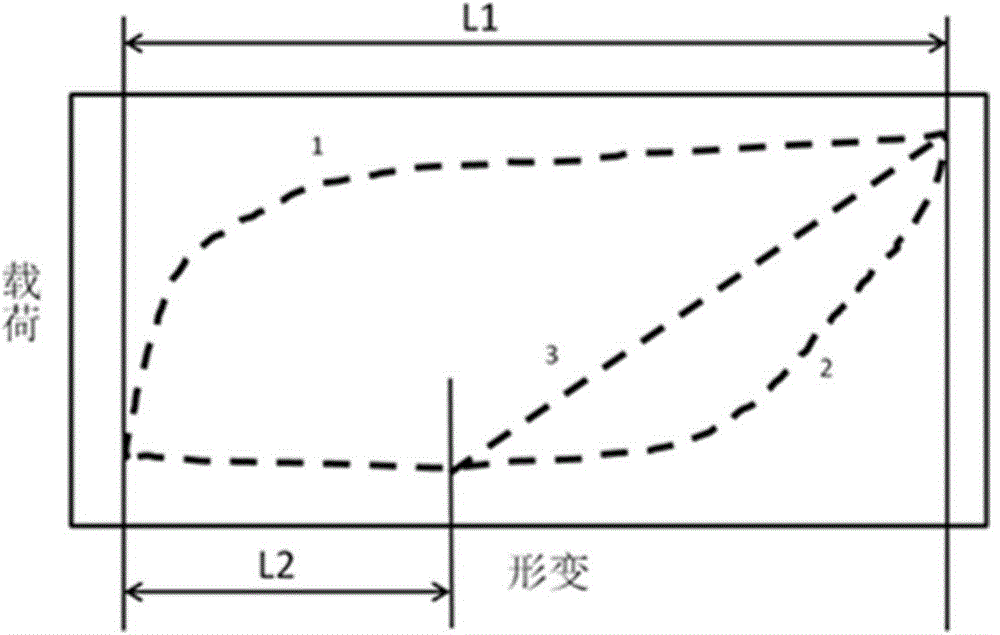

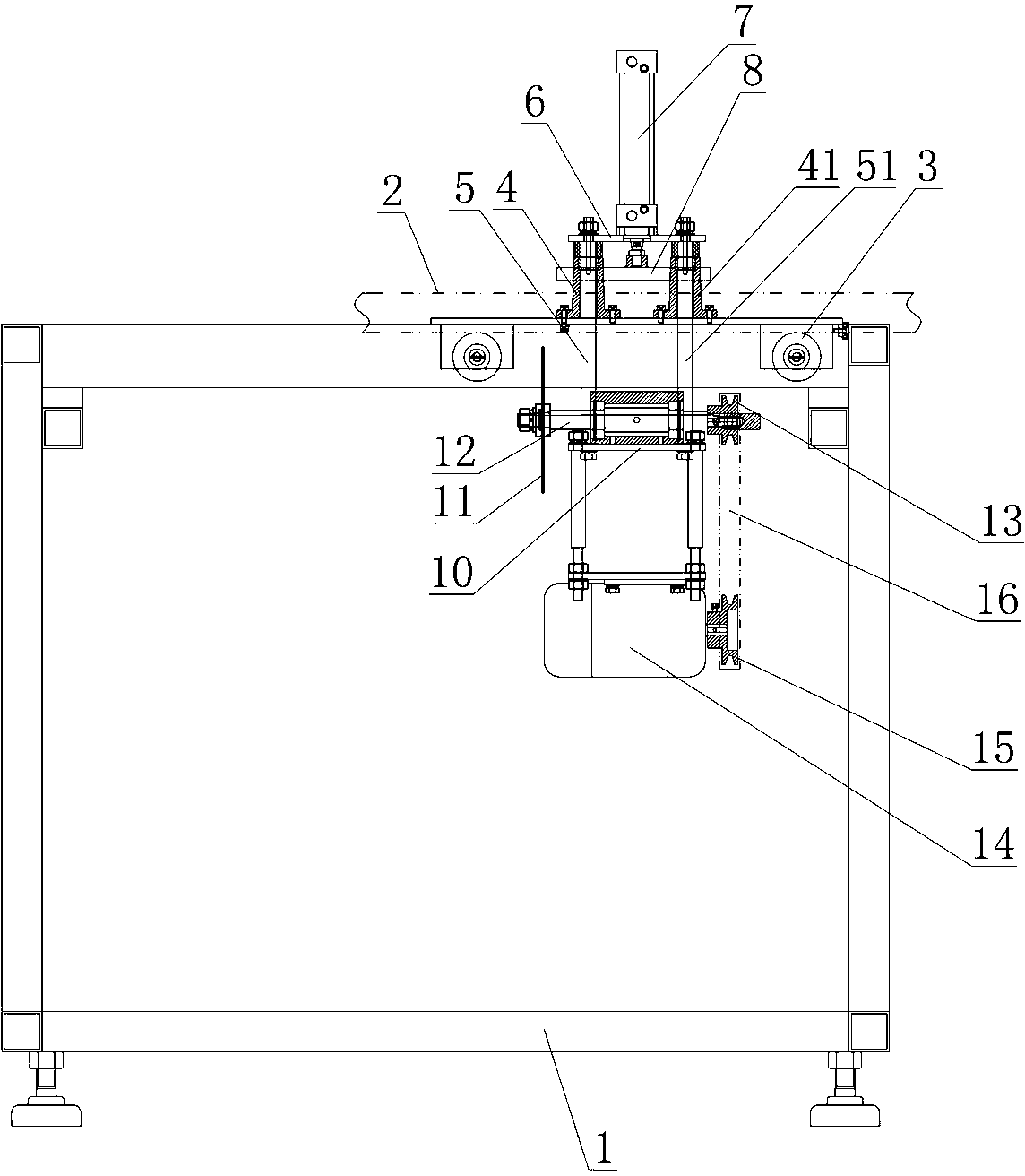

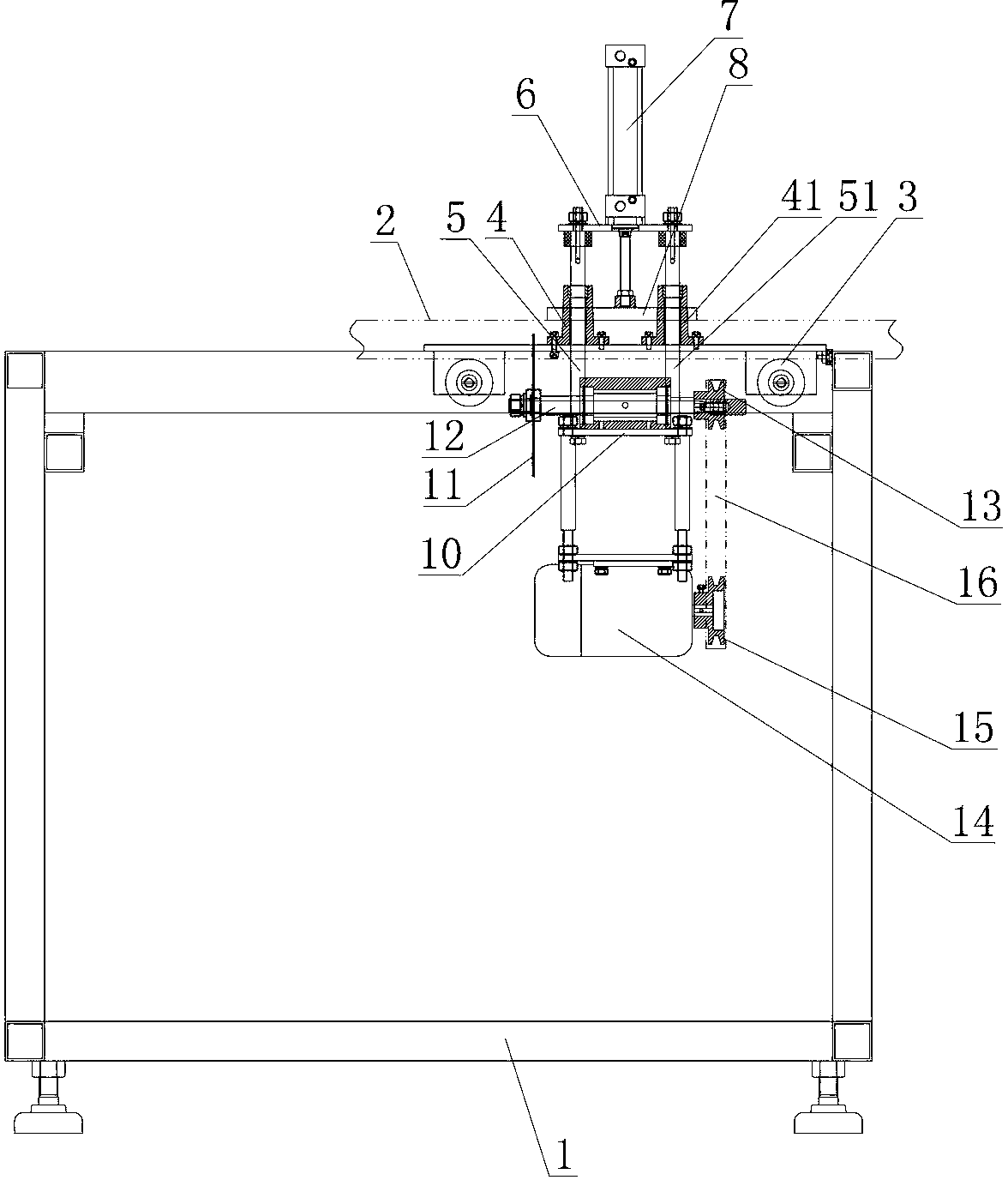

In-pipe Rubber bladder hydraulic forming device

InactiveCN105234242ASolve pollutionNo subsequent cleaning steps are requiredLiquid mediumHigh pressure

The invention discloses an in-pipe rubber bladder hydraulic forming device. The in-pipe rubber bladder hydraulic forming device comprises an upper mould and a lower mould; an upper mould cavity is arranged in the upper mould; a lower mould cavity is arranged in the lower mould; and a complete forming mould cavity is spliced after the upper mould cavity and the lower mould cavity are closed; the shape of the mould cavity is determined by shapes of different machined pipes; push rods are symmetrically arranged between the upper mould and the lower mould; a structure used for injecting a medium is arranged on one push rod, and the structure is an injection hole used for injecting the medium; a pipe is arranged between the push rods; and a rubber bladder is arranged in the pipe in a sleeving manner, and the rubber bladder penetrates through two ends in the pipe. Compared with the prior art, the in-pipe rubber bladder hydraulic forming device is advantaged in that the high-pressure medium is injected into the rubber bladder; the rubber bladder expands to deform and cling to the inner wall of the pipe, and transfers pressure to the pipe, so that the pipe deforms and clings to the inner wall of the mould cavity to be finally formed into a part; the time for injecting or discharging the liquid medium during hydraulic forming of the pipe is effectively shortened; a subsequent cleaning process is omitted; and the advantages of low equipment requirement, high production efficiency, low production cost and the like are realized.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

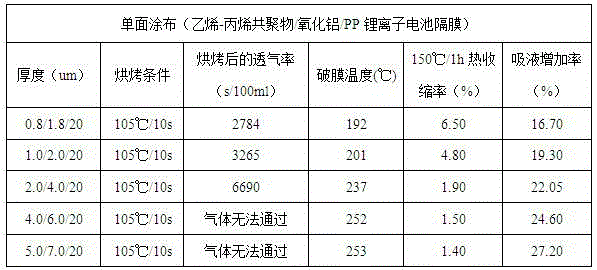

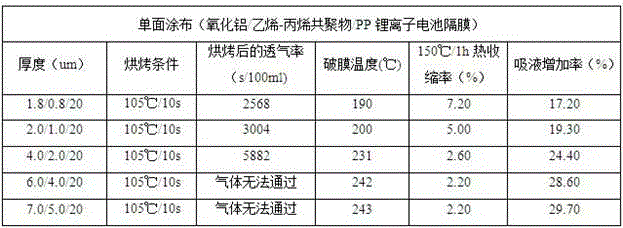

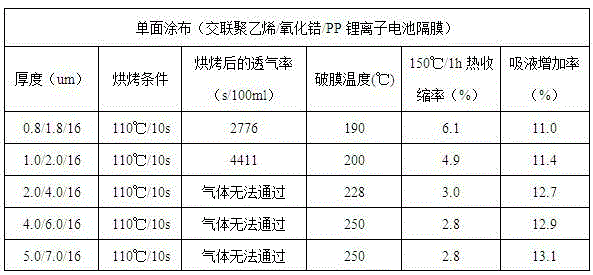

Lithium ion battery diaphragm and preparation method

ActiveCN104022250ALow closed cell temperatureAvoid thermal runawayCell component detailsPolyolefinPhysical chemistry

The invention discloses a lithium ion battery diaphragm and a preparation method thereof. The ion battery diaphragm comprises a diaphragm base material, wherein the surface of the diaphragm base material is coated with a polyolefin coating, and the coating thickness of the polyolefin coating is 1 to 4 micrometers. The diaphragm base material is coated with the polyolefin coating, and an effect for reducing the obturator temperature can be realized, so that the worsening of a thermal runaway can be prevented, when the temperature in a lithium ion battery reaches the obturator temperature, current can be disconnected at the first time, an effect for protecting the lithium ion battery can be realized, the thermal shrinkage rate of the lithium ion battery diaphragm after being roasted for 1h under the temperature of 150DEG C is less than 5 percent; compared with a non-coated lithium ion battery diaphragm, for the lithium ion battery diaphragm disclosed by the invention, the liquid absorption addition rate is 10 to 28 percent, and the charging-discharging cycling efficiency of the lithium ion battery can be further improved.

Owner:FOSHAN YINGBOLAI TECH

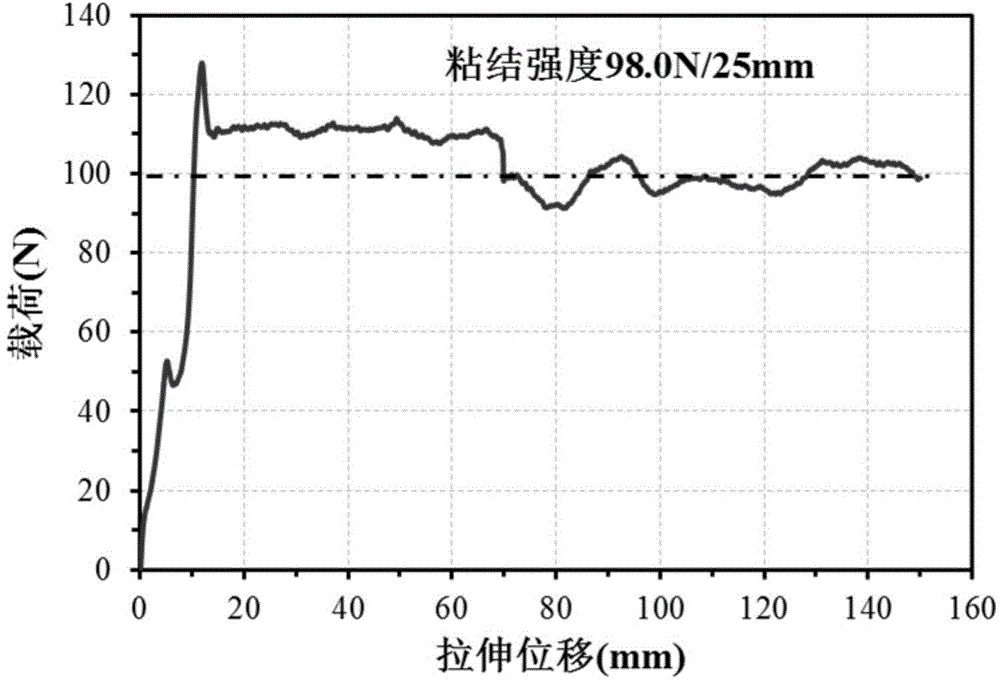

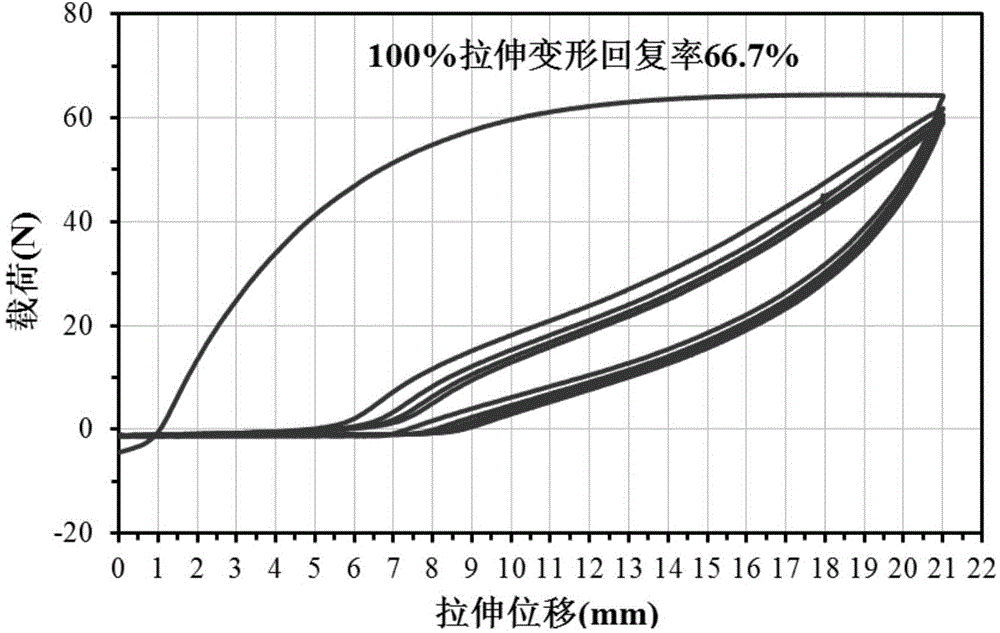

Propenyl hot-melt adhesive composition and preparation method thereof

InactiveCN105713541AImprove adhesionHigh deformation recovery rateGraft polymer adhesivesElastomerPolyolefin

The invention provides a propenyl hot-melt adhesive composition, which is characterized by comprising the following components: (A) polypropylene; (B) polyolefin elastomer; (C) polar monomer; and (D) grafting initiator; and optionally comprises (E) other auxiliary agents. The invention also provides a preparation method of the propenyl hot-melt adhesive composition.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

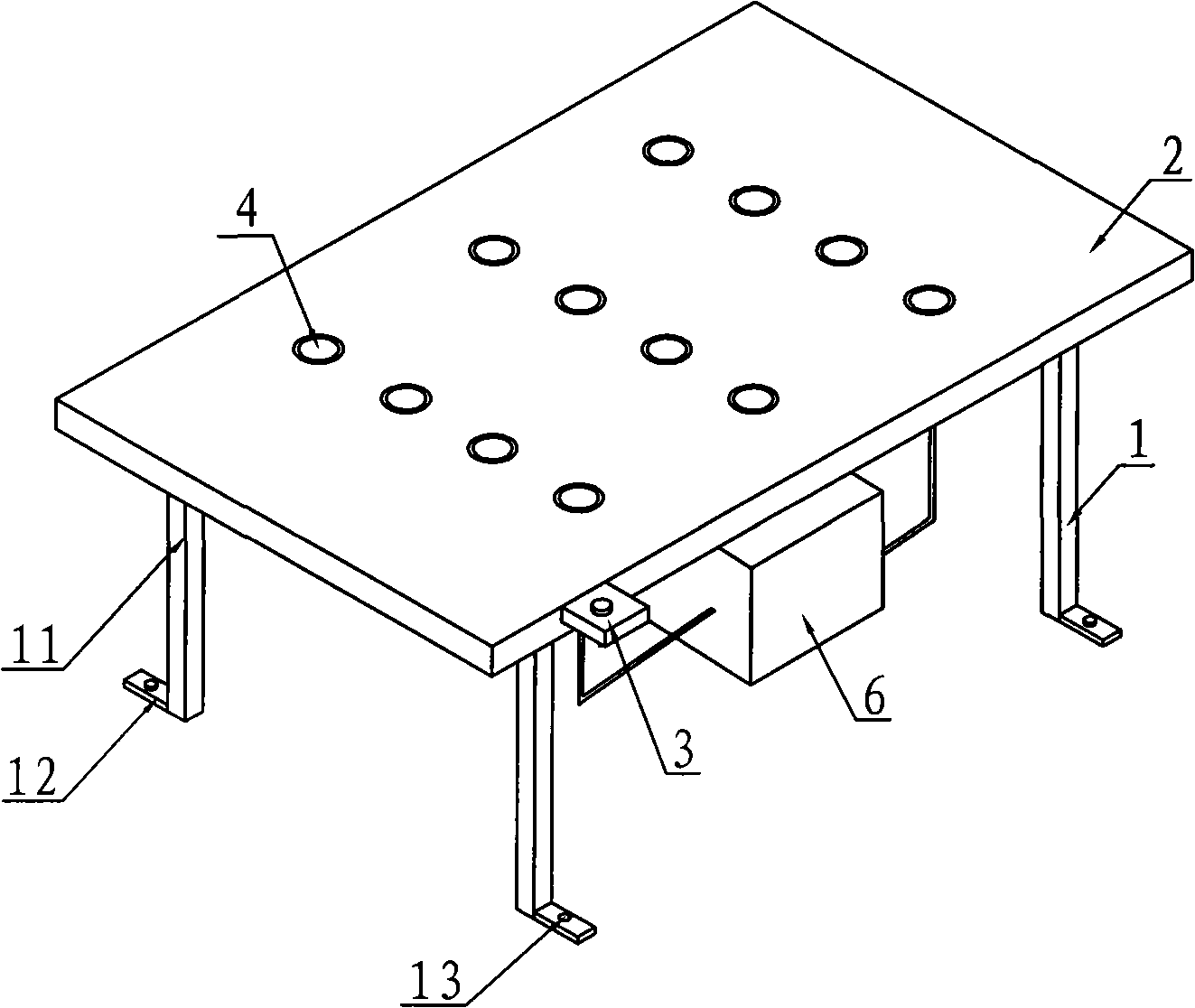

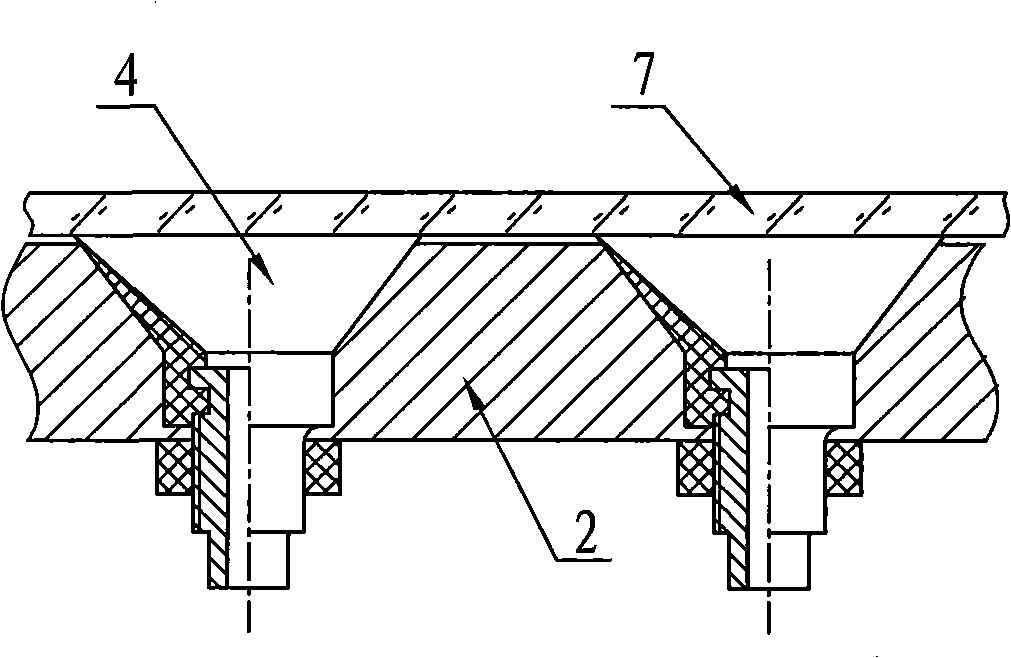

Air-breathing worktable for repairing solar cell laminates

InactiveCN102097532AEasy to tearNo ruptureLayered productsFinal product manufactureElectricitySolar cell

The invention provides an air-breathing worktable for repairing solar cell laminates. The worktable comprises a table frame, a table top board, an electric controller, suckers, a vacuum generator and a vacuum adsorption loop, wherein the suckers are uniformly distributed on the table top board; the top surfaces of all the suckers are arranged in the same plane and are 0.1-0.5mm higher than the upper end face of the table top board; and the suckers are connected with the vacuum generator via the electric controller and the vacuum adsorption loop. When the solar cell laminates are repaired, the electric controller electrifies an electromagnet at the A end of a three-position three-way reversing valve, the vacuum generator and the suckers are connected, the suckers suck the workpiece, and then the electromagnet at the A end of the three-position three-way reversing valve is diselectrified and maintains the vacuum adsorption state, so the operator can tear off the back film, and then an electromagnet at the B end of the three-position three-way reversing valve is electrified, the suckers are separated form the workpiece, and at the moment, the operator can move away the treated solar cell laminates. The worktable has the following beneficial effects: the back film can be conveniently torn off and the laminates can not bend and cause breaking of the cell plates.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

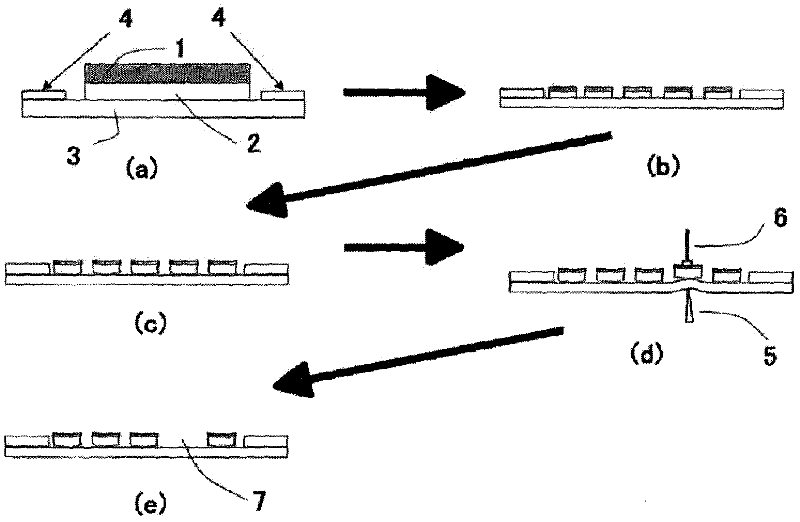

Method for processing wafer

InactiveCN102208366AGood adhesionReduce the bonding areaSemiconductor/solid-state device detailsSolid-state devicesWaferingDicing tape

A method for processing wafer includes sticking a surface protection sheet for dicing onto a surface of a wafer and cutting the sheet together with the wafer to protect the surface of the wafer from being contaminated by deposition of a dust such as swarf and the like, and picking up a chip without causing cracking or chipping in the chip after a dicing step, in the steps of dicing the wafer and then picking up the chip. The method includes: sticking the surface protection sheet for dicing onto the surface of the wafer; cutting the sheet together with the wafer; subsequently giving a stimulus to the surface protection sheet for dicing to peel the end of the chip from the dicing tape; and then picking up the chip.

Owner:NITTO DENKO CORP

Production process for casting spherical end cover

ActiveCN101890478AQuality improvementIncrease success rateFoundry mouldsFoundry coresMass ratioCasting mold

The invention relates to a production process for casting a spherical end cover, which sequentially comprises the following steps of: mold manufacturing, namely manufacturing an upper formwork, a lower formwork and a mold sleeve according to the shape of the spherical end cover; core manufacturing; core setting; pouring, namely preheating a casting mold formed by the core setting, spraying a heat-resisting material on the internal surface of the preheated casting mold, preserving the heat of the sprayed casting mold, pouring casting liquid at the tapping temperature of between 1,500 and 1,550 DEG C into a cavity for 5 to 15 seconds at the pouring temperature of between 1,380 and 1,440 DEG C, and preserving the heat of a casting for 60 to 100 minutes, wherein the process yield is 45 to 60 percent, and the heat-resisting material is quartz powder and diatomite in a mass ratio of 6:1-9:1; and mold opening. The process has the advantages of simpleness, capability of improving the quality of the casting, and high processing efficiency.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

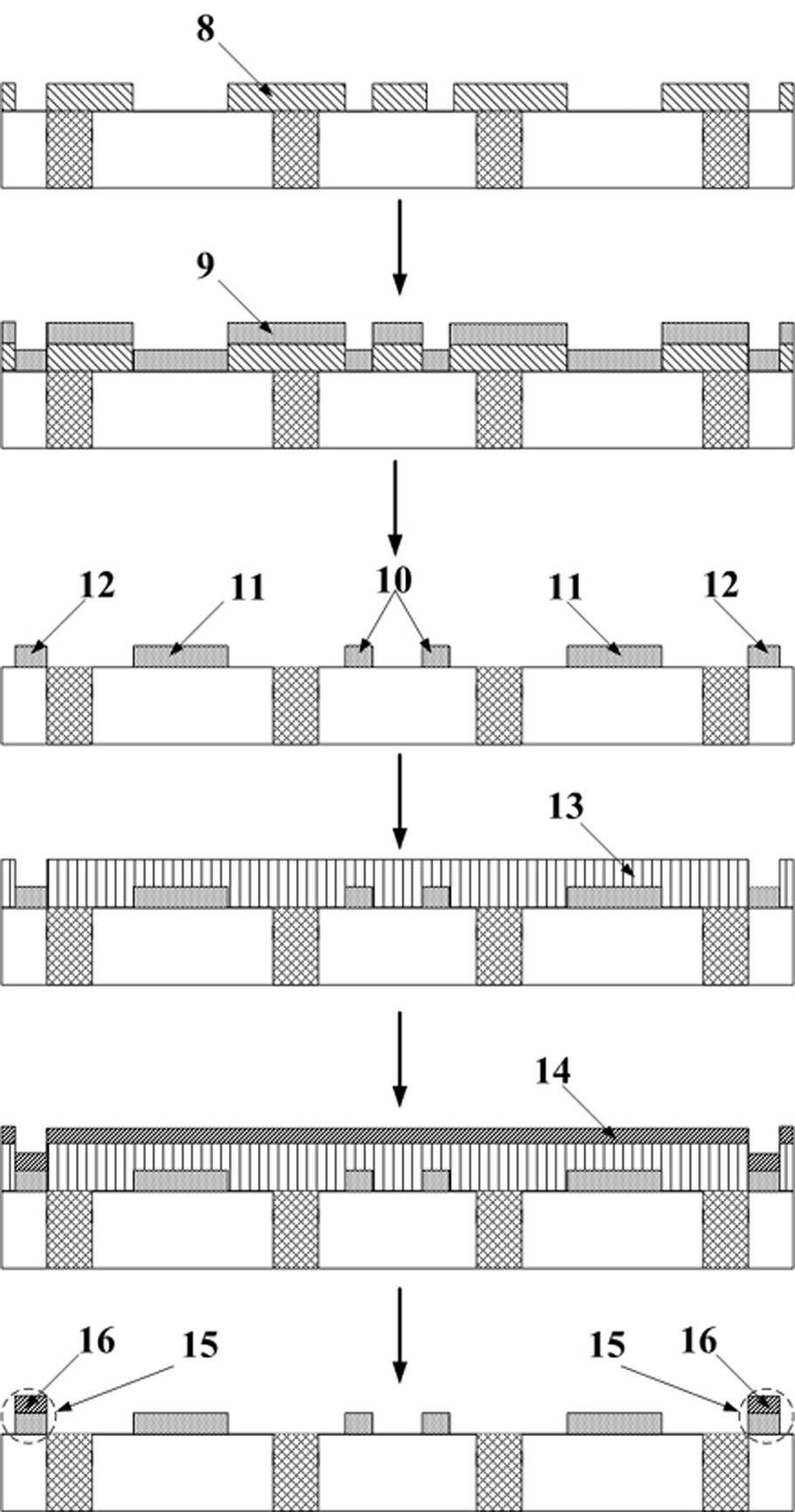

Thermal type wind sensor based on anisotropic heat-conducting substrate and preparation method therefor

InactiveCN102147421ABlock lateral heat conduction effectNo ruptureIndication/recording movementFluid speed measurement using thermal variablesHeat conductingEngineering

The invention discloses a thermal type wind sensor based on an anisotropic heat-conducting substrate; a chip of the sensor comprises the anisotropic heat-conducting substrate; four heating elements are symmetrically distributed at the center of the upper surface of the anisotropic heat-conducting substrate; four thermal sensing temperature-measuring elements are symmetrically distributed at the periphery of the four heating elements; the back surface of the anisotropic heat-conducting substrate is contacted with external environment so as to detect wind speed and wind direction; a glass heat-insulation inner ring is inlaid among the heating elements in the anisotropic heat-conducting substrate and silicon substrates under the thermal sensing temperature-measuring elements; a glass heat-insulation outer ring is inlaid among the silicon substrates under the thermal sensing temperature-measuring elements and silicon substrates at the edge of the chip; the two glass heat-insulation rings can ensure that the thickness of the anisotropic heat-conducting substrate is thinned to be about 100 microns by a thinning technology on one hand, the total power consumption of the sensor can be reduced on the other hand so that the sensor keeps higher signal sensitivity and shorter thermal response time under the lower power consumption.

Owner:SOUTHEAST UNIV

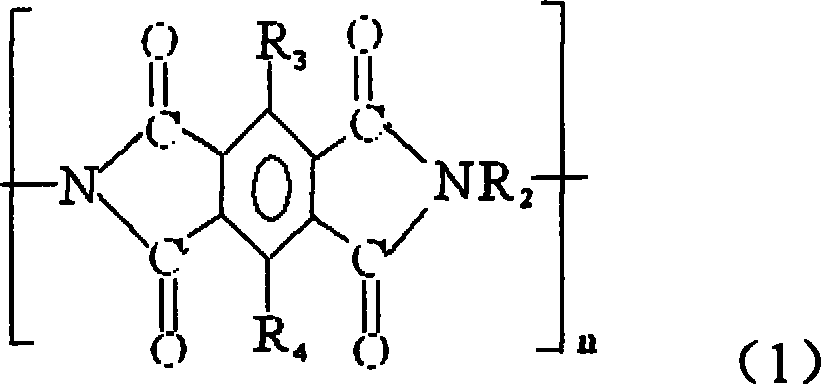

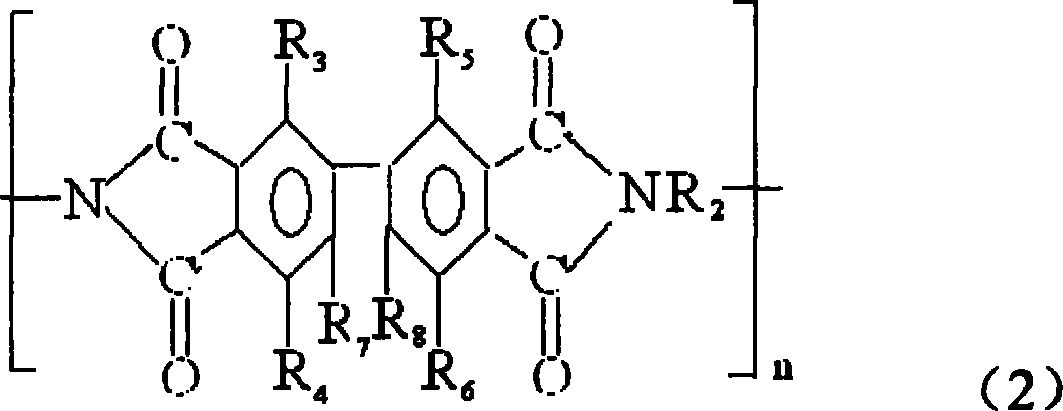

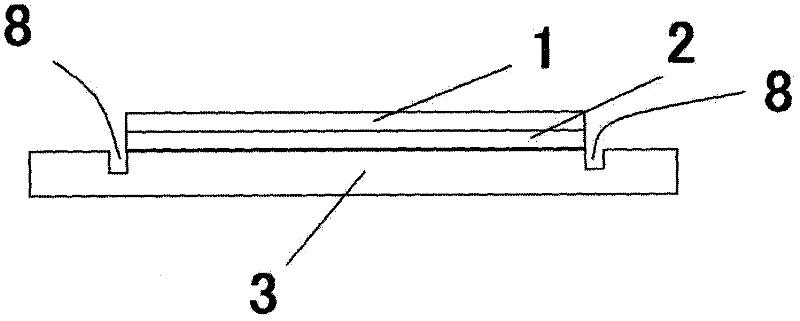

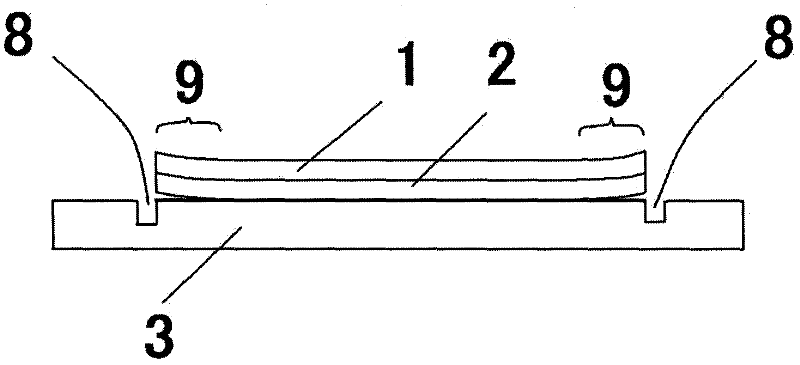

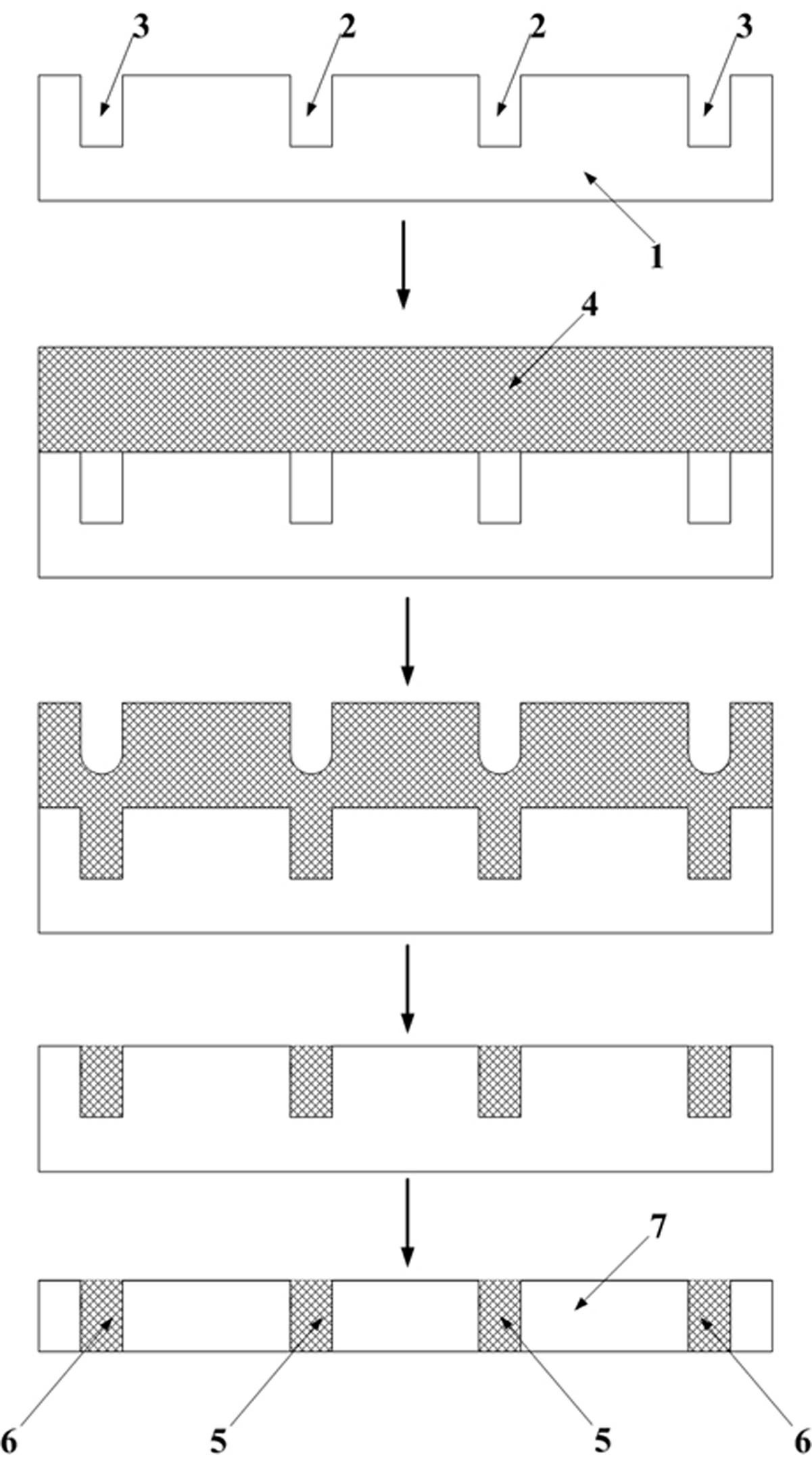

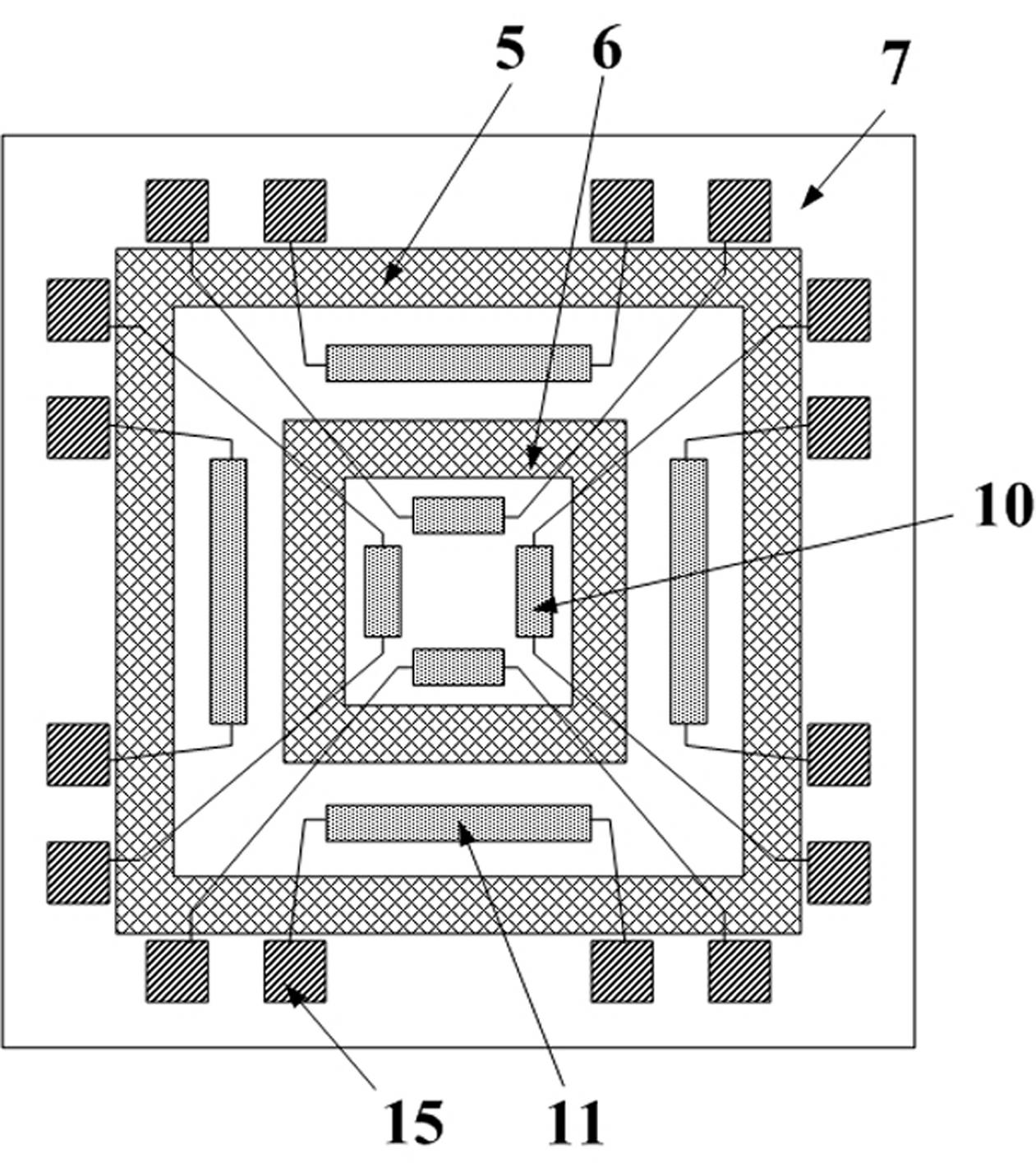

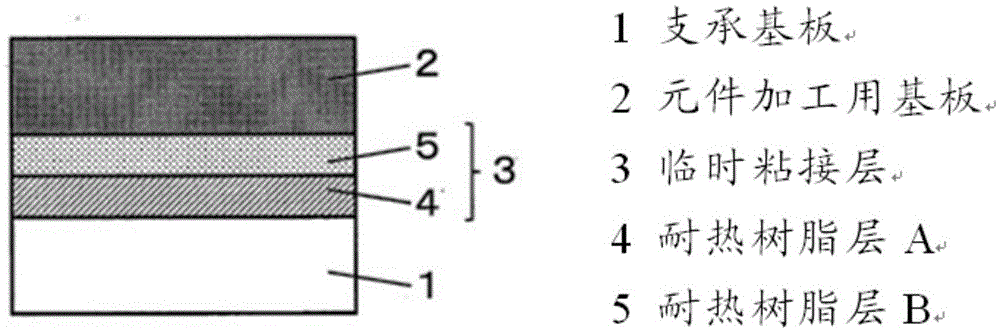

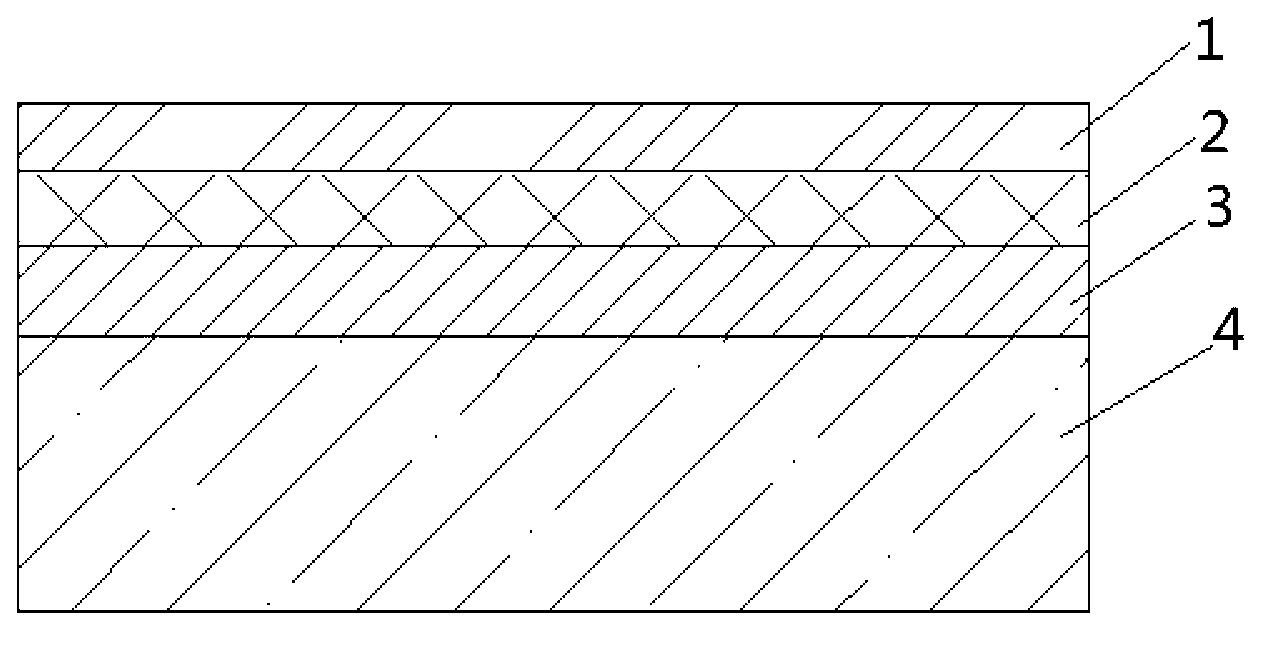

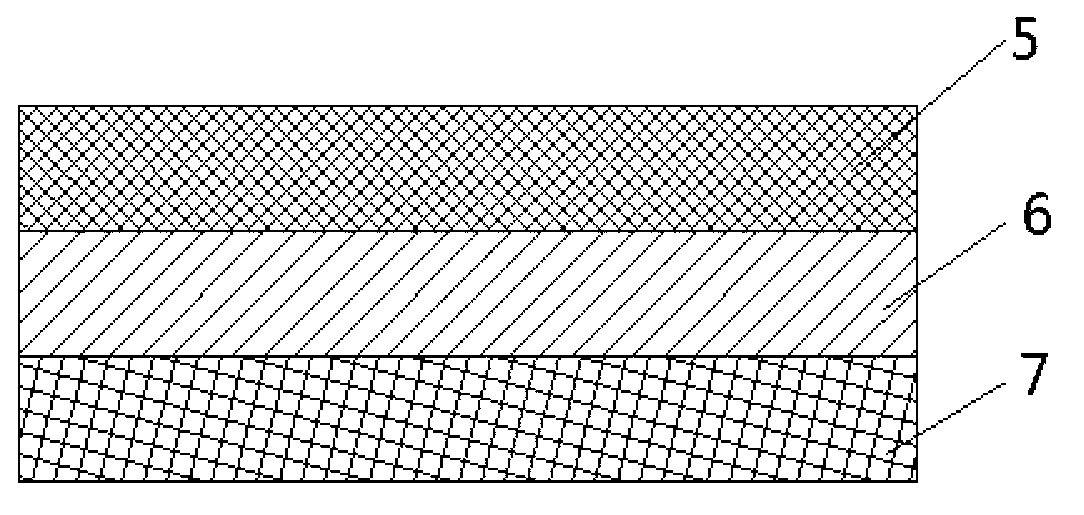

Element-processing layered structure, method for manufacturing element-processing layered structure, and method for manufacturing thin element using same

InactiveCN105612600AImprove productivityFull heat resistanceSynthetic resin layered productsSolid-state devicesLayered structureEngineering

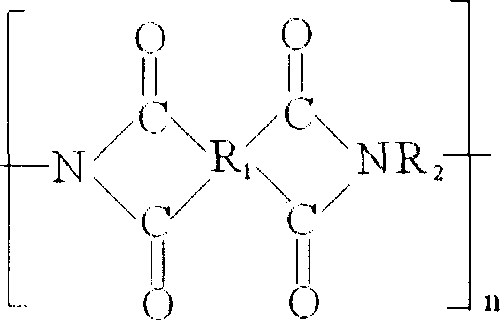

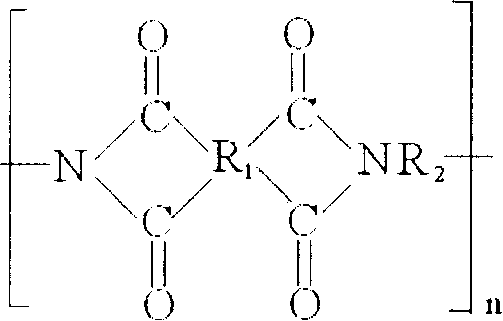

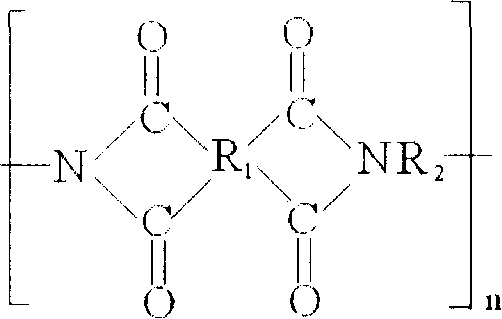

To provide an element-processing layered structure in which there is no generation of volatile compounds or occurrence of cracking in a substrate due to separation or the like during the steps for polishing the back surface and forming the back-surface circuits of a semiconductor circuit formation substrate, separation being possible in mild conditions at room temperature, and essentially no temporary adhesive remaining on the semiconductor circuit formation substrate side after separation. An element-processing layered structure in which an element-processing substrate is layered on a support substrate with temporary adhesive layers interposed therebetween, wherein the element-processing layered structure is characterized in that: the temporary adhesive layers are layered in the order of heat-resistant resin layer (A), heat-resistant resin layer (B), from the support substrate side; and the adhesive force between the heat-resistant resin layer (B) and the element-processing substrate is lower than the adhesive force between the heat-resistant resin layer (A) and the support substrate, and the adhesive force between the heat-resistant resin layer (B) and the heat-resistant resin layer (A).

Owner:TORAY IND INC

Photocurable resin composition for laminating optically functional material

InactiveCN103589347AAdhesive forceNo peelingOrganic non-macromolecular adhesiveGraft polymer adhesivesMeth-Polyethylene glycol

Disclosed is a photocurable adhesive composition which, in the lamination of a decorated plate or an icon sheet on a touch panel or in the lamination of a transparent substrate with a transparent electrode formed thereon on a transparent plate in an electrostatic capacitive touch panel, can impart satisfactory adhesive properties and can realize the lamination without incorporating air bubbles. Also disclosed is a photocurable resin composition for use in the lamination of a display and an optically functional material on each other, which, when a display is laminated on an optically functional material, does not cause the delamination of a bonded surface or the breaking of a glass in the display. The photocurable adhesive composition comprises (A) a (meth)acrylate oligomer having a polyisoprene, polybutadiene, or polyurethane skeleton, (B) a softening component, and optionally (C) (C1) a (meth)acrylate monomer selected from phenoxyethyl(meth)acrylate, phenoxy polyethylene glycol(meth)acrylate, 2-hydroxy-3-phenoxypropyl(meth)acrylate, and cyclohexyl(meth)acrylate, (C2) or a thiol compound. The photocurable resin composition can provide a cured product having a modulus of elasticity and an elongation at break both of which fall within given ranges.

Owner:KYORITSU KAGAKU SANGYO KK

Poly(p-phenylenebenzobisoxazole) porous membrane, preparation method and application thereof

InactiveCN103746086AUniform structure distributionAperture adjustableCell seperators/membranes/diaphragms/spacersElectrolyte accumulators manufactureFiberLithium

The invention relates to a poly(p-phenylenebenzobisoxazole) porous membrane, a preparation method and an application thereof, and belongs to the technical field of lithium ion secondary batteries, wherein the membrane is composed of poly(phenylenebenzobisoxazole) (POB) fiber, the thickness of the membrane is 3-40 microns; pores on the surface and inside the membrane are distributed uniformly, the pore diameter is adjustable, the membrane has good air permeability, excellent resistance to high temperature and high tensile strength. The preparation method of the membrane is that a POB solution is subjected to vacuum defoamation treatment, solvent exchange after curtain coating and film forming, and freeze drying to obtain the membrane. The POB membrane provided by the invention can be used as the barrier film of a lithium ion secondary battery and has good performance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Pipe pressing cutting device for cutting PVC pipe

The invention discloses a pipe pressing cutting device for cutting a PVC pipe. The pipe pressing cutting device comprises a machine frame, wherein a plurality of supporting rollers are arranged inside the machine frame at intervals in a supported mode, all the supporting rollers form a pipe placing plane together, at least two guide sleeves are arranged on a position, between any two adjacent supporting rollers, of the top of the machine frame, a guide column is movably arranged inside each guide sleeve, the upper ends of all the guide columns are fixed with an upper support which is vertically provided with a telescopic air cylinder, and a clamping block is fixed on a piston rod of the telescopic air cylinder. The lower ends of all the guide columns are all fixed with a lower support, a cutting piece is movably arranged inside the lower support in a supported mode, and the cutting piece is driven by a driving mechanism to rotate. When the piston rod of the telescopic air cylinder stretches out, and after the clamping block downward presses the pipe, the surplus route length of the piston rod inside the telescopic air cylinder guarantees that along with continuous stretching-out of the piston rod, the upper support is pushed to move upward, and the cutting piece of the lower support is driven to cut the pipe from bottom to top. The pipe pressing cutting device has the advantages of being capable of improving cutting quality of the pipe.

Owner:张家港市金远东机械有限公司

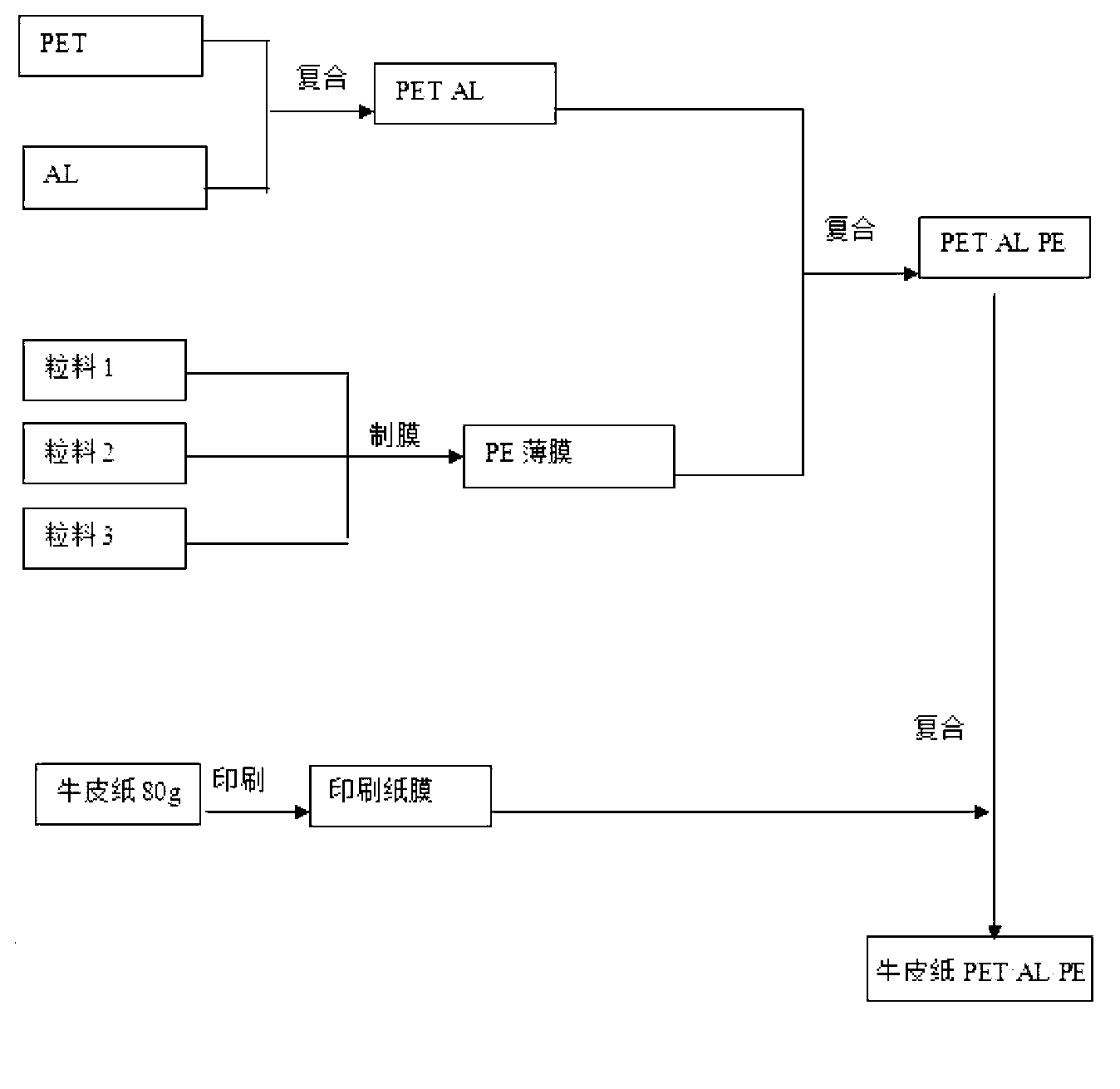

Composite heavy packaging film

Owner:HUANGSHAN NOVEL

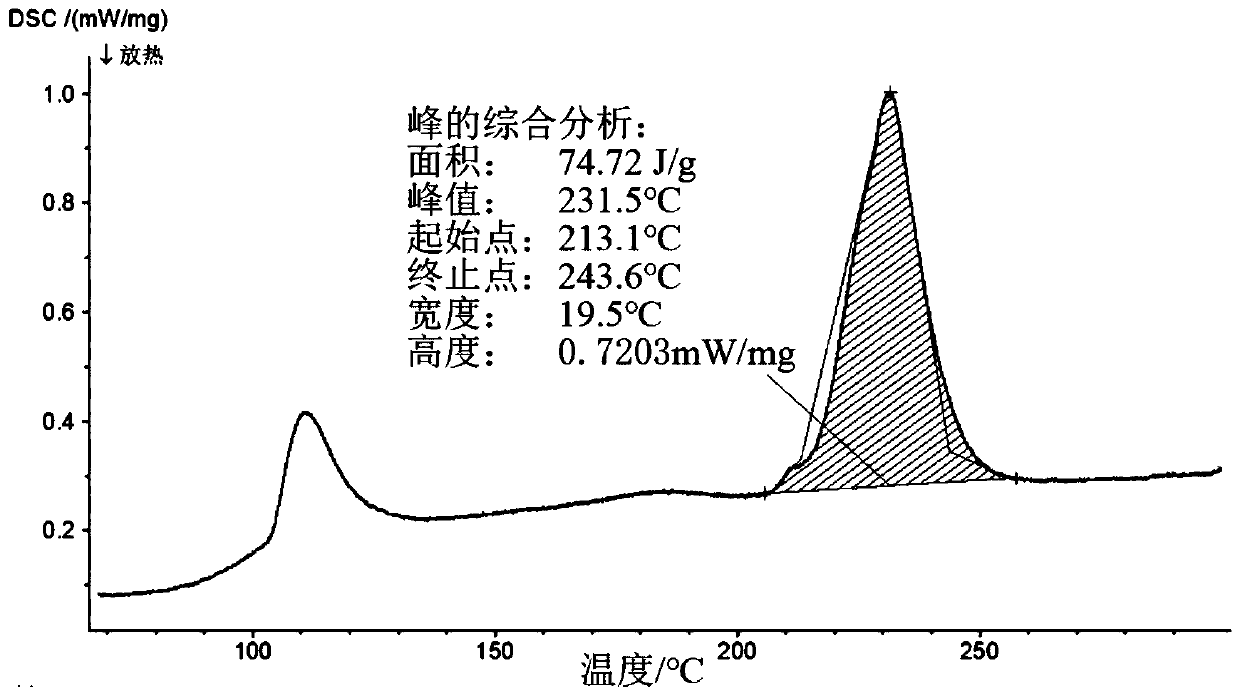

Two-stage micro-packaging composite heat storage material and preparation method and use thereof

ActiveCN109777369AHigh heat storage densityReduce leakageHeat-exchange elementsPotassium nitratePhase change enthalpy

The invention belongs to the field of heat storage materials, and relates to a two-stage micro-packaging composite heat storage material and a preparation method and use thereof. The preparation method comprises the following steps that (1) a shaped packaging material and a phase change material are pre-sintered after being mixed; (2) a premix obtained after pre-sintering treatment is subjected topress forming and sintered to obtain the micro-packaging composite phase change heat storage material. According to the method, by setting the pre-sintering step, the bonding effect of the phase change material and the shaped packaging material is improved; by sequentially carrying out the process steps of pre-sintering, press forming and re-sintering, the phase change material is uniformly adsorbed into pores of the shaped packaging material, so that the prepared micro-packaging composite phase change heat storage material is high in heat storage density and good in forming degree and has nocracking phenomenon; by adjusting the mass ratio of sodium nitrate to potassium nitrate, the phase change enthalpy of the two-stage micro-packaging composite heat storage material can vary within 74.5-93.67 J / g.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

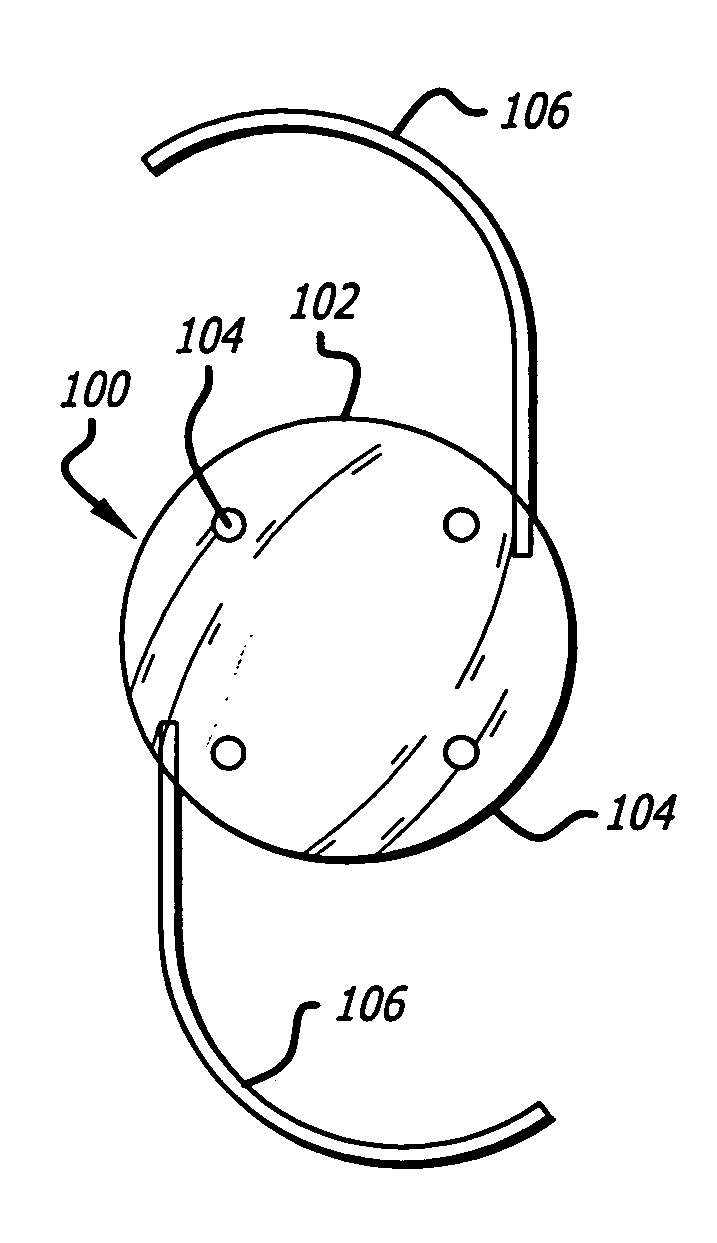

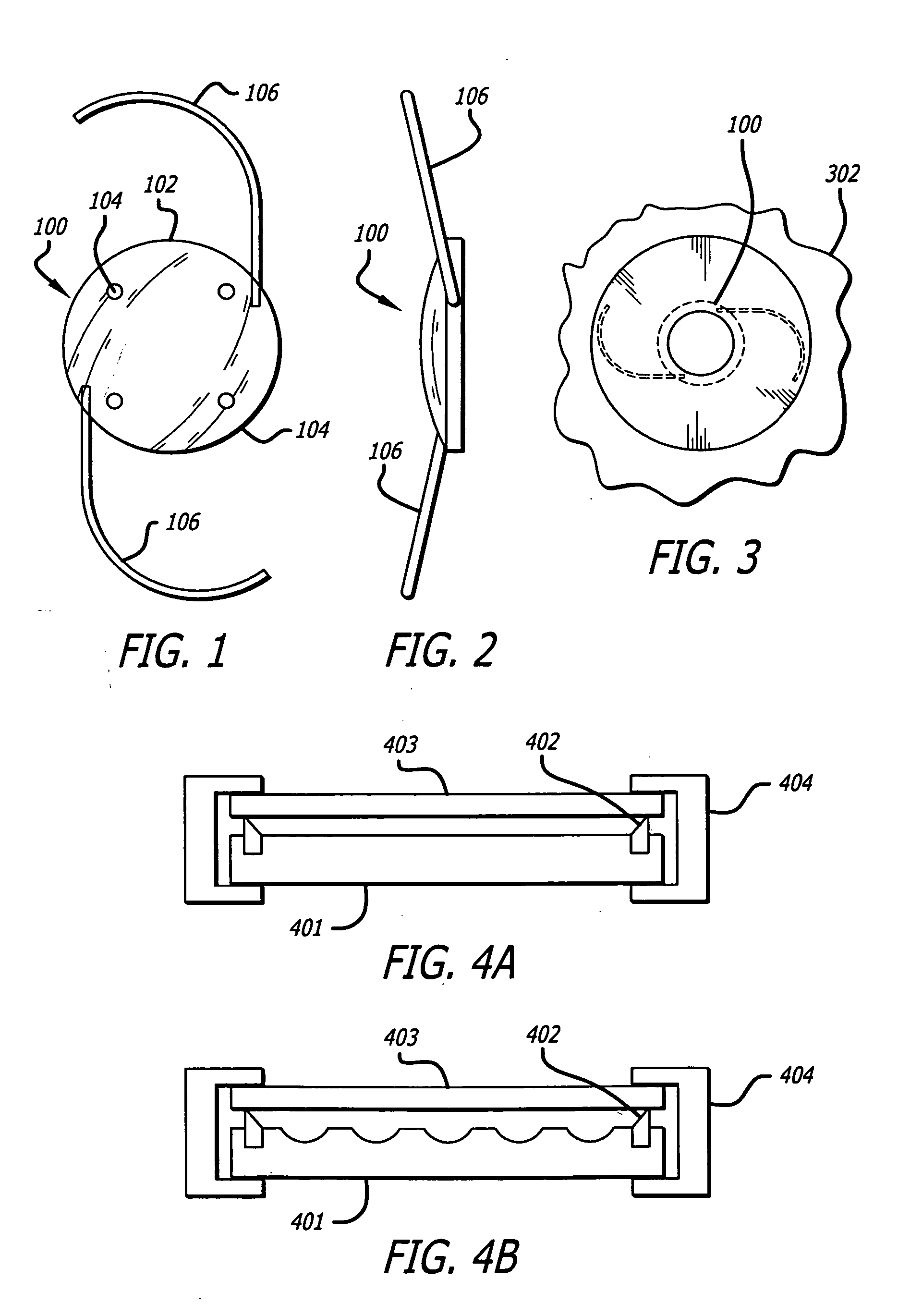

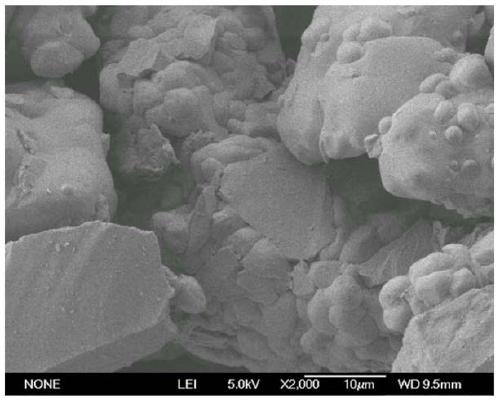

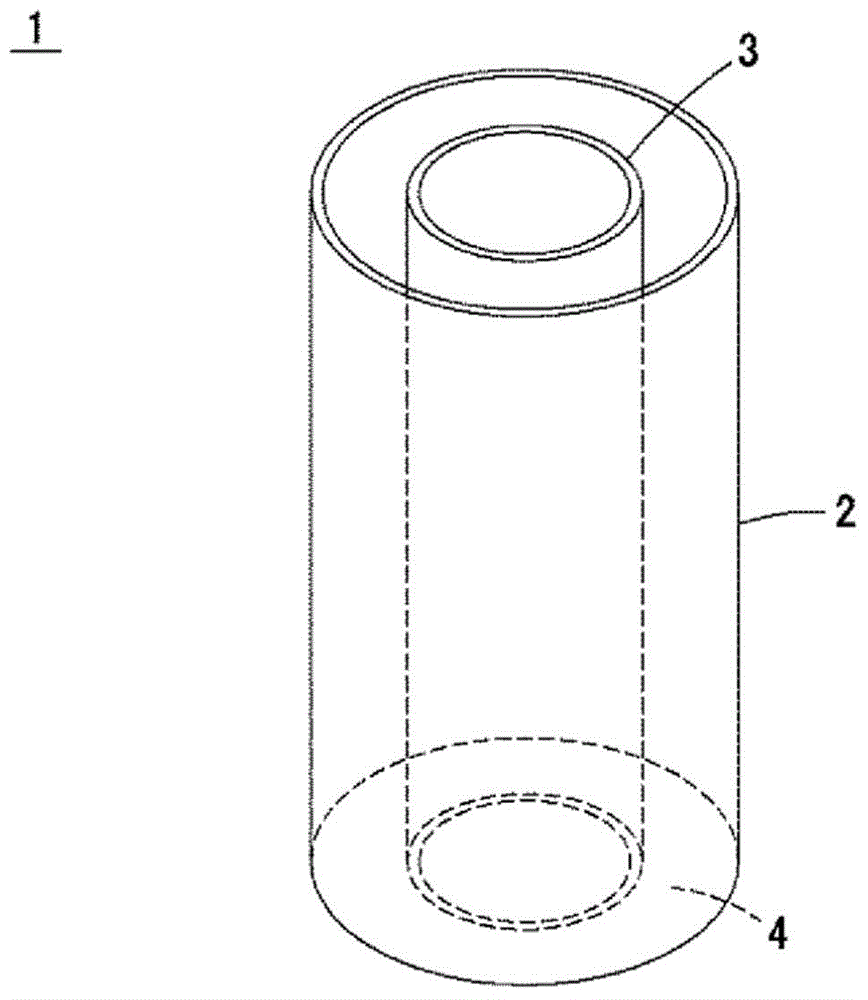

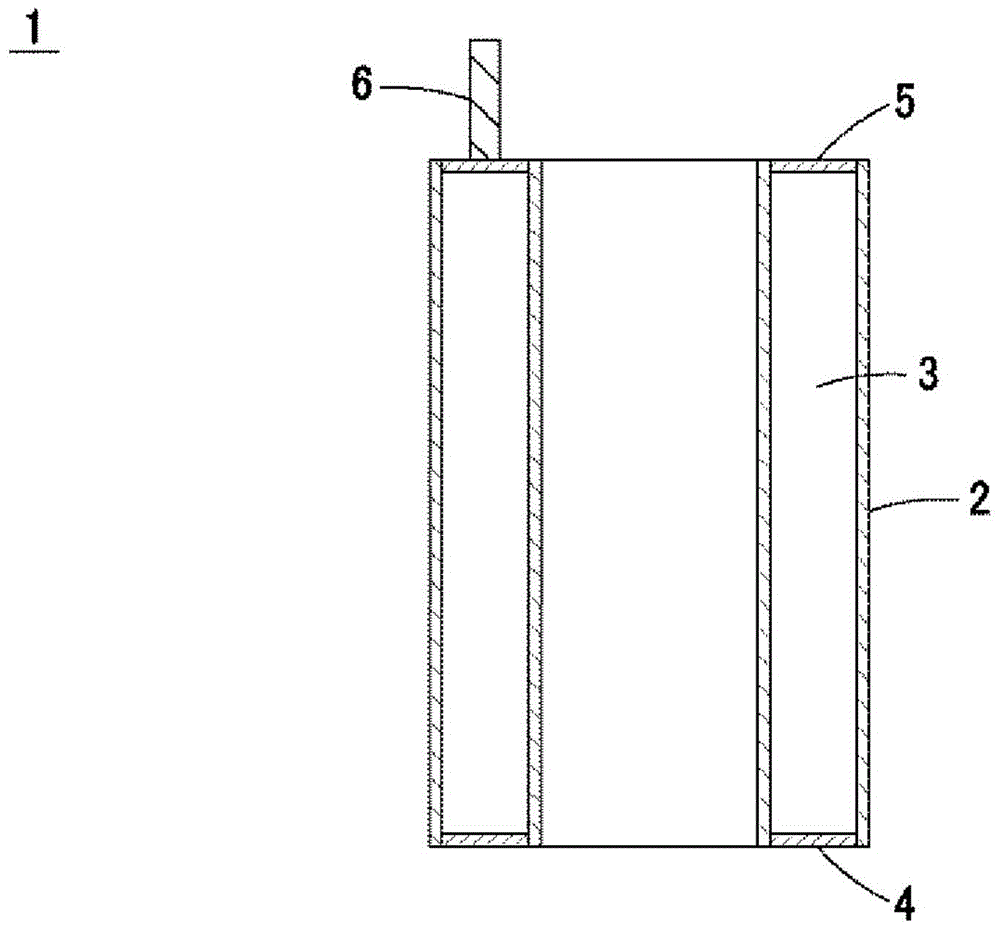

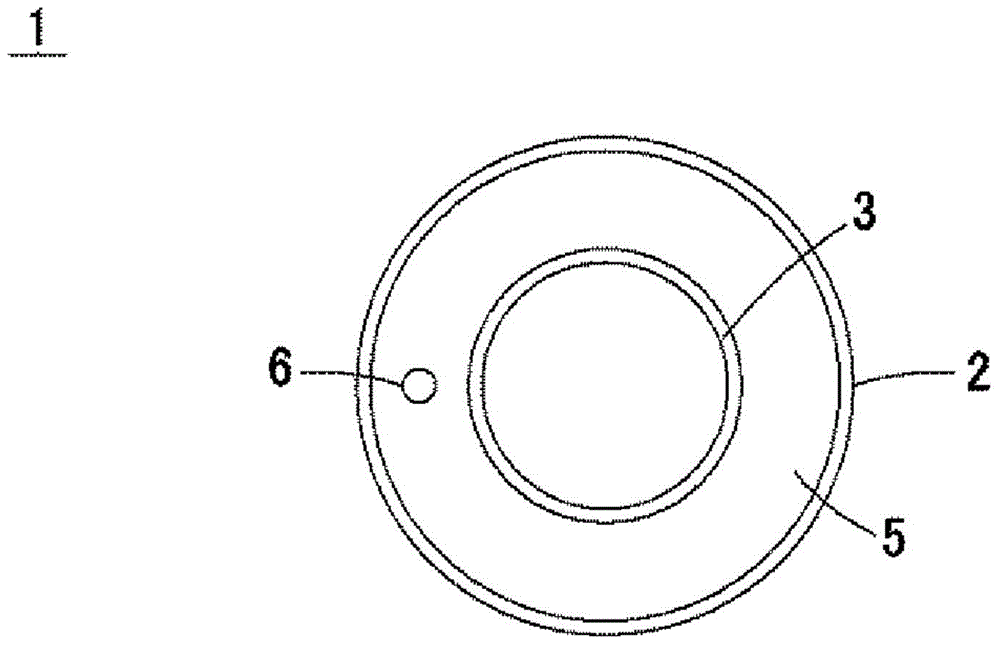

CYLINDRICAL Cu-Ga ALLOY SPUTTERING TARGET AND PRODUCTION METHOD THEREFOR

ActiveCN105008578ASmall Ga concentration fluctuationsHigh densityVacuum evaporation coatingSputtering coatingMaterials scienceHot isostatic pressing

A cylindrical Cu-Ga alloy sputtering target having no cracks or breaks, and having no variation in relative density or Ga concentration. Hot isostatic pressing is used; a Cu-Ga alloy powder or a Cu-Ga alloy molded body is filled in to a cylindrical capsule (1) such that the filling density is at least 60%, the capsule (1) having a thickness of at least 1.0 mm and less than 3.5 mm; the capsule (1) is hot isostatically pressed; and a Cu-Ga alloy sintered body is obtained.

Owner:MITSUI MINING & SMELTING CO LTD

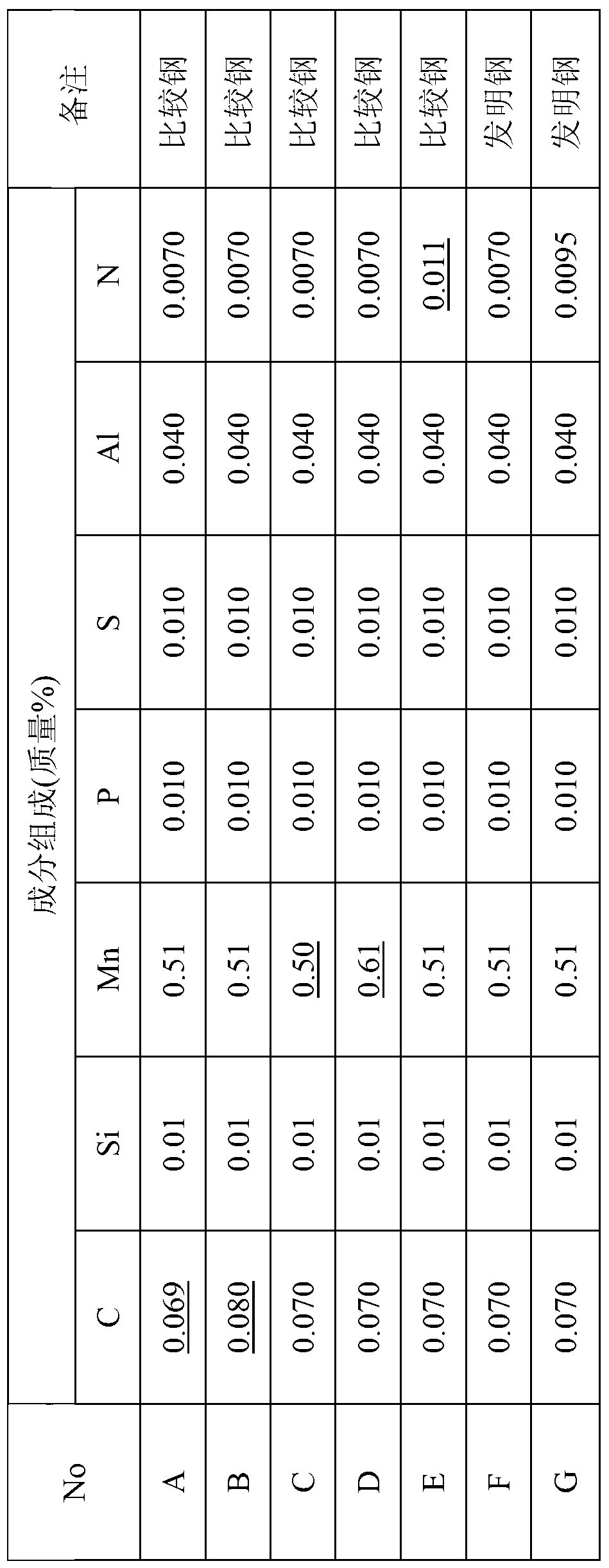

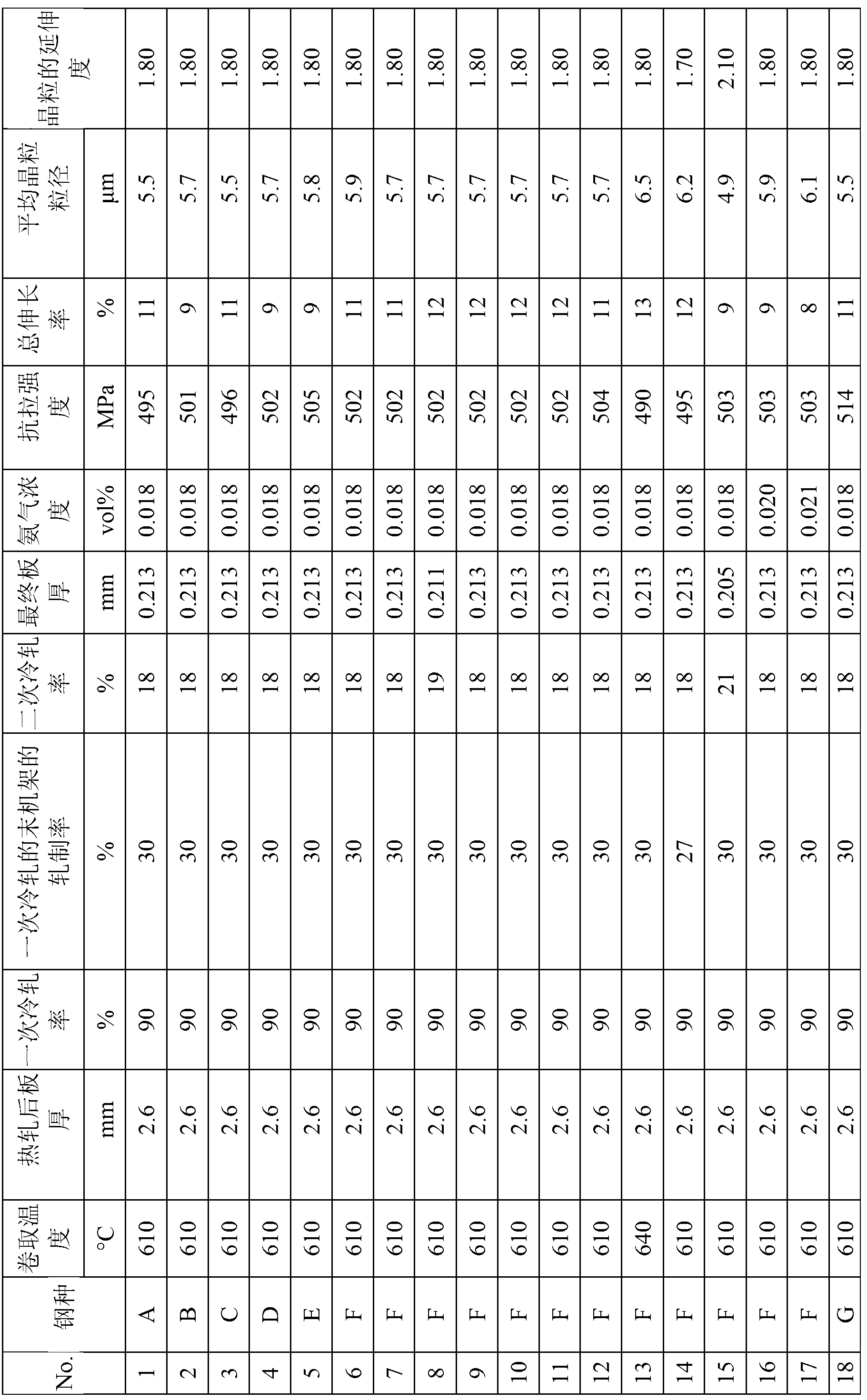

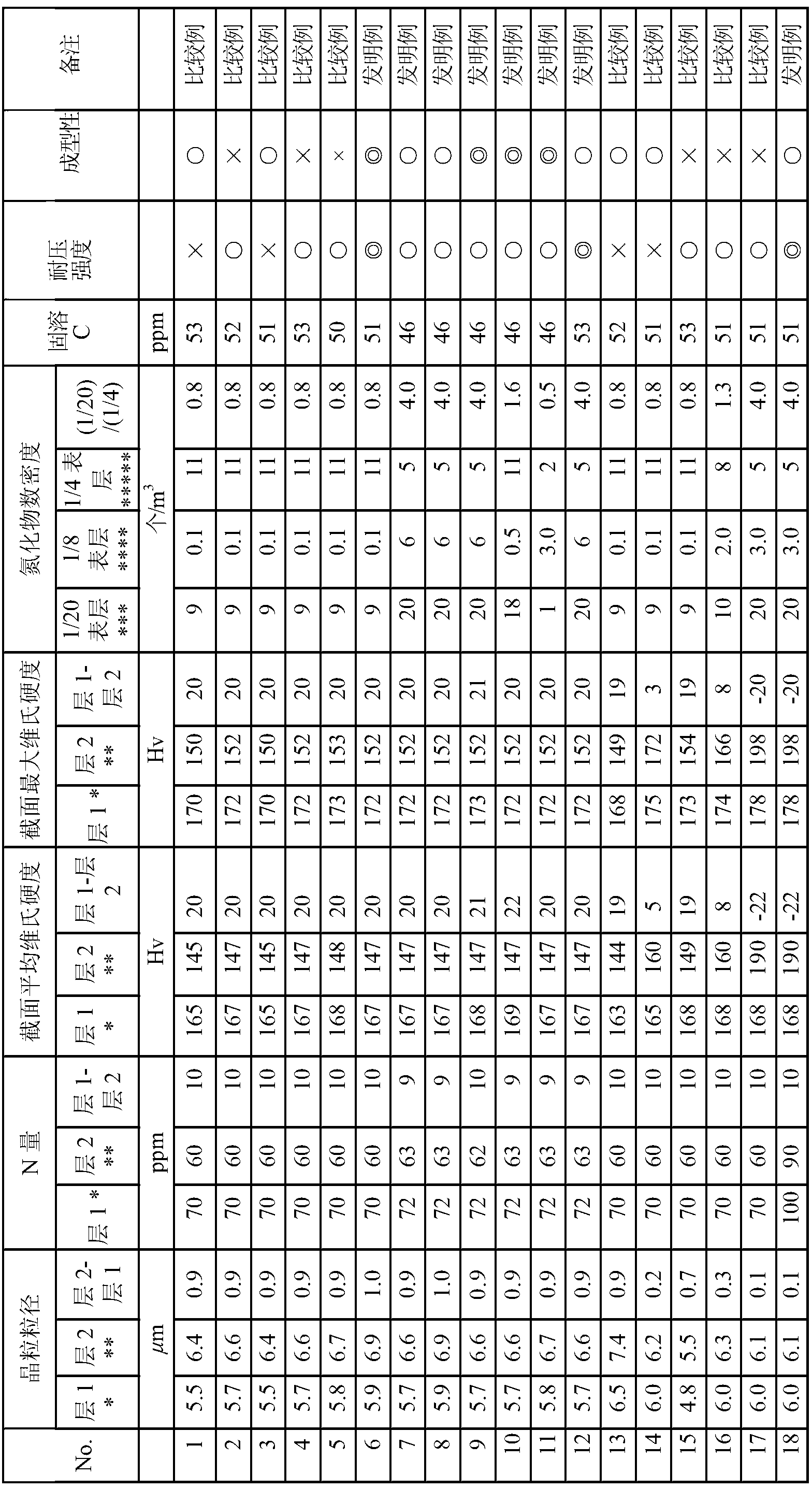

Steel sheet for can, and process for producing same

InactiveCN103270183AHigh strengthEasy to processFurnace typesHeat treatment furnacesThick plateMaterials science

The present invention provides a steel sheet for cans which has high strength and high processability, characterized by containing, in terms of mass%, 0.070-0.080%, excluding 0.080%, C, 0.003-0.10% Si, 0.51-0.60% Mn, etc. and by having, in a rolling-direction cross-section thereof, an average crystal-grain diameter of 5 [mu]m or more and a crystal-grain elongation rate of 2.0 or less. The steel sheet is further characterized in that the hardness difference obtained by subtracting the average Vickers hardness of a cross-section ranging from the surface to a depth of 1 / 8 the sheet thickness from the average Vickers hardness of a cross-section ranging from a depth of 3 / 8 the sheet thickness to a depth of 4 / 8 the sheet thickness is 10 points or more and / or the hardness difference obtained by subtracting the maximum Vickers hardness of the cross-section ranging from the surface to a depth of 1 / 8 the sheet thickness from the maximum Vickers hardness of the cross-section ranging from a depth of 3 / 8 the sheet thickness to a depth of 4 / 8 the sheet thickness is 20 points or more. The steel sheet is furthermore characterized by having a tensile strength of 500 MPa or higher and an elongation at fracture of 10% or higher. Also provided is a process for producing the steel sheet. This steel sheet for cans, which has high strength and high processability, is suitable for use as a material for easy-to-open cans.

Owner:JFE STEEL CORP

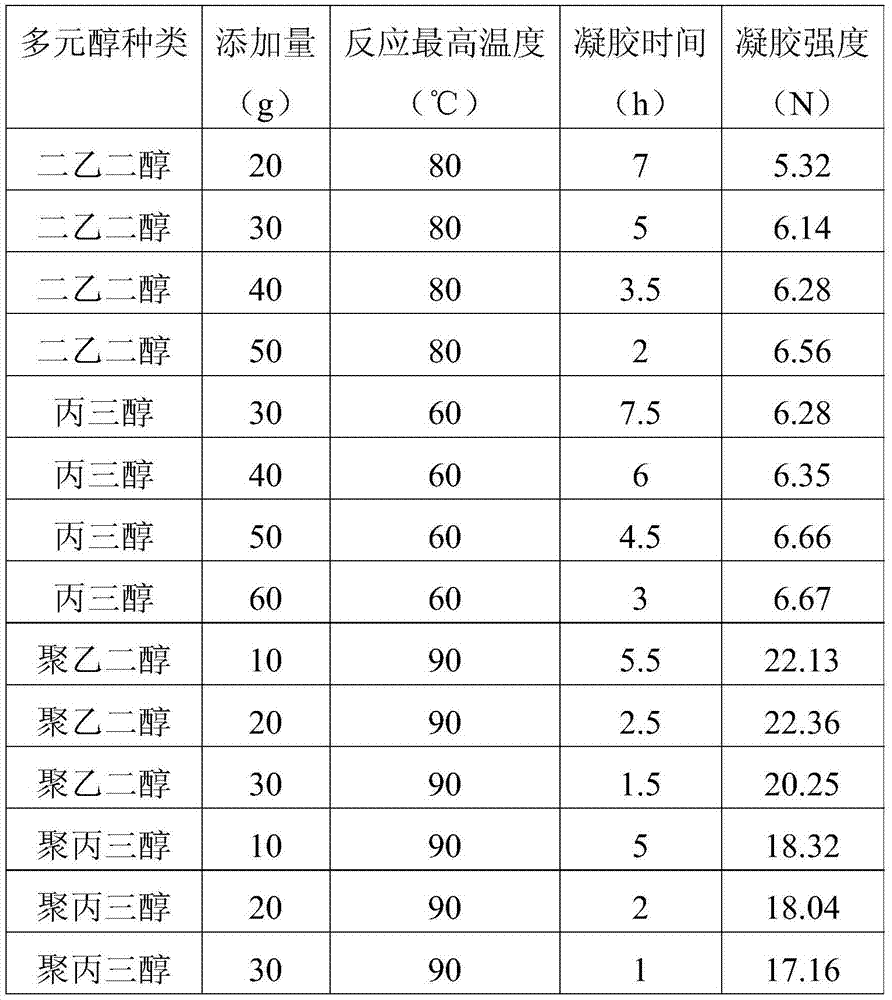

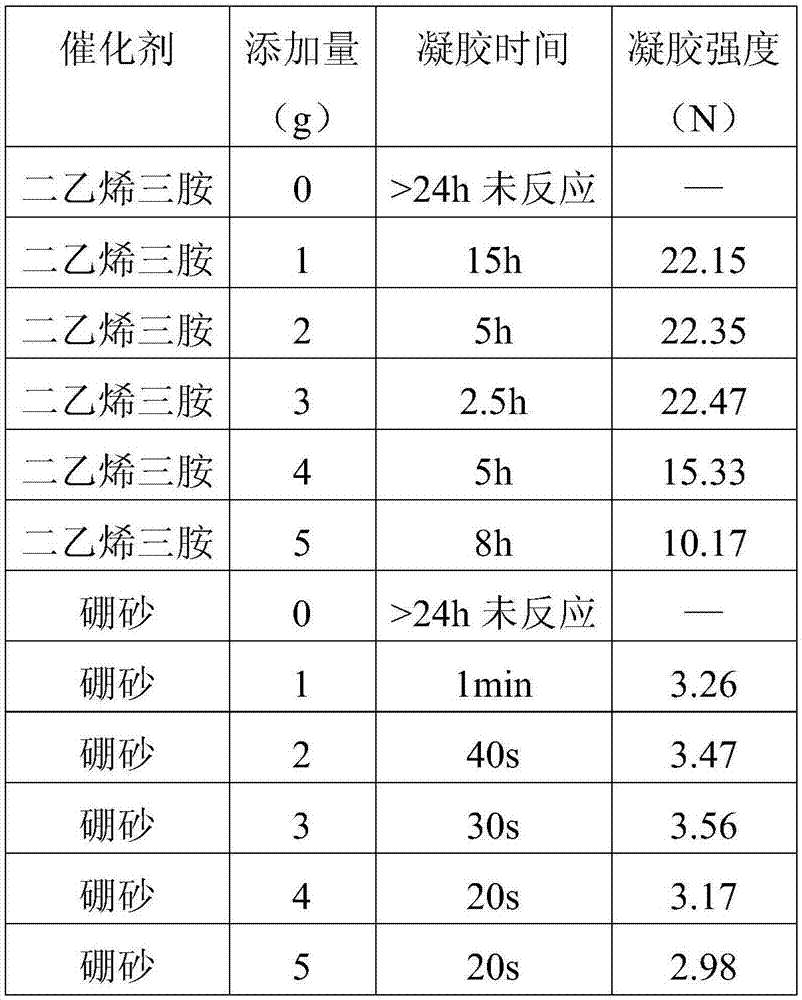

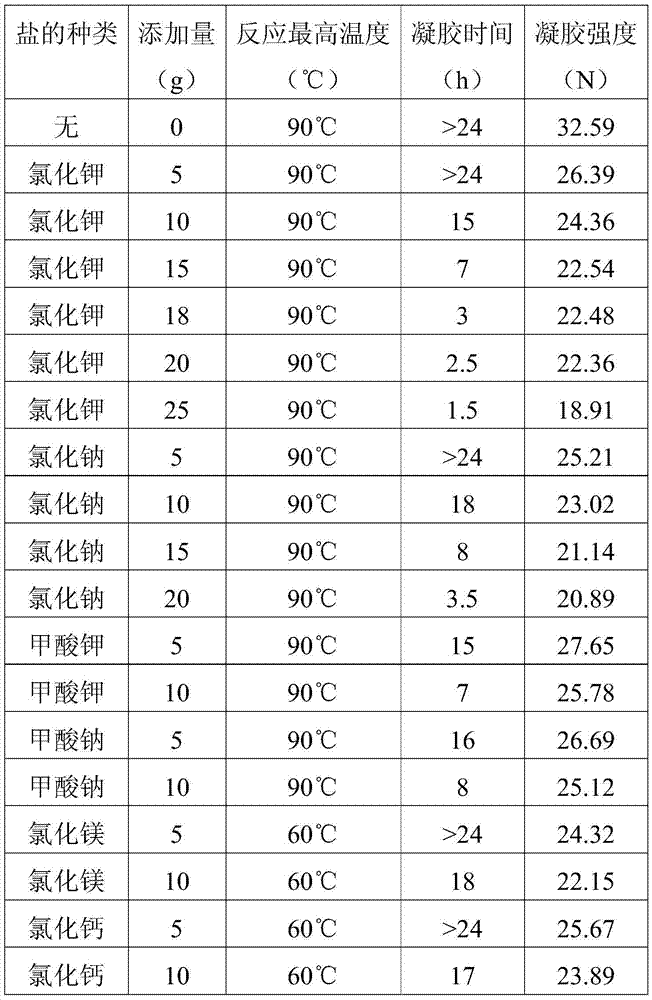

Hydrogen-bonding hydrogel suitable for plugging cracks and caves

ActiveCN105441046AGel forming time is controllableMeet construction requirementsDrilling compositionPolyolHydrogen

The invention discloses hydrogen-bonding hydrogel suitable for plugging cracks and caves. The hydrogen-bonding hydrogel comprises raw materials in parts by weight as follows: 5-10 parts of polyvinyl alcohol, 10-30 parts of polyols, 1-5 parts of a catalyst, 15-25 parts of salt, 0-100 parts of a weighting agent and 100 parts of water. The gelling time of the hydrogel is controllable, the initial setting time of the hydrogel is 120-240 min according to requirements of different layers, the time interval can basically meet most construction requirements, and the hydrogel can be formed from the room temperature to 90 DEG C; the hydrogel has sufficient strength, has certain cementing power with a formation, and cannot be crushed or remain in the cracks when bearing the pressure difference between a fluid in a well and the formation.

Owner:YANGTZE UNIVERSITY +1

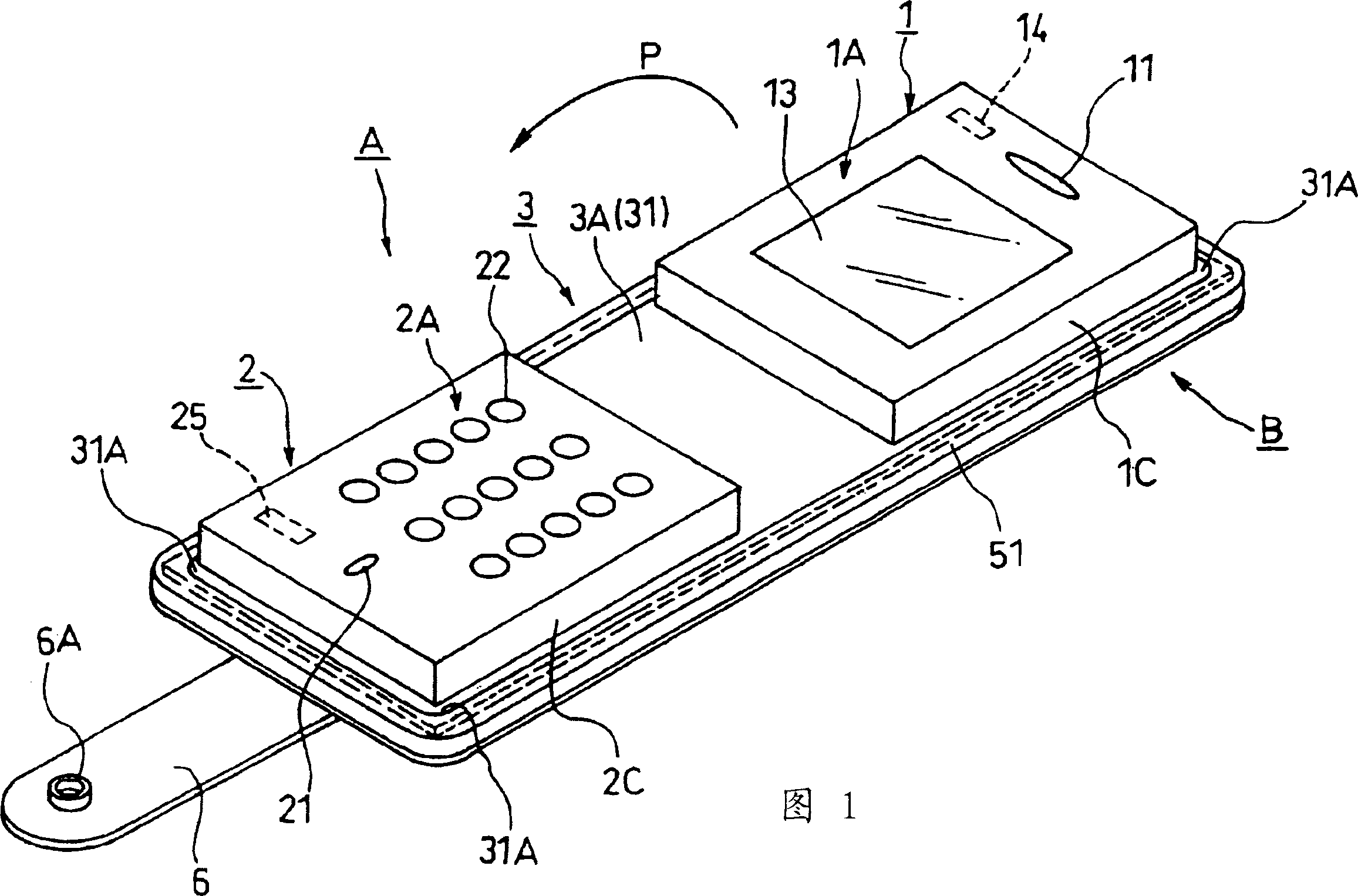

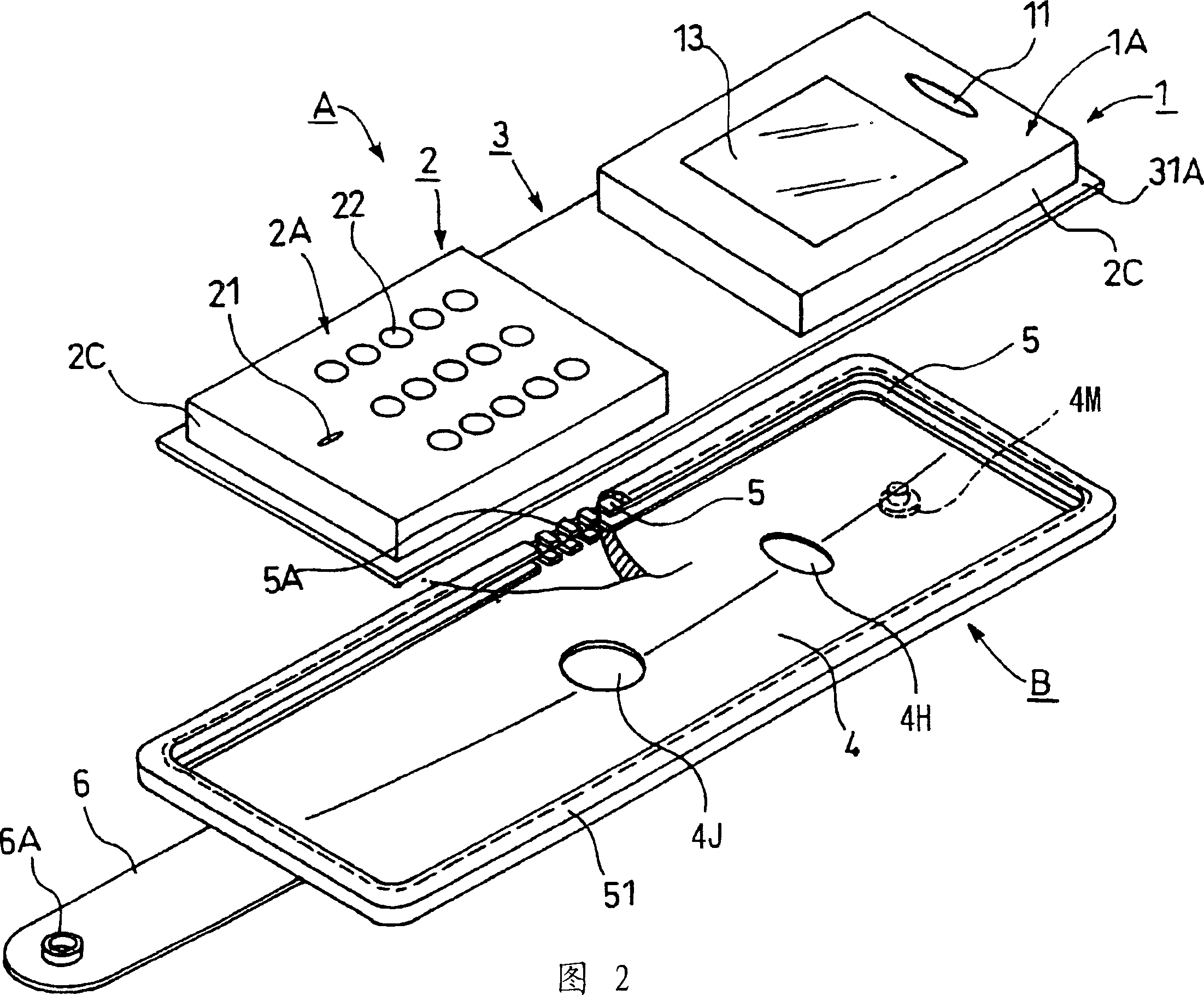

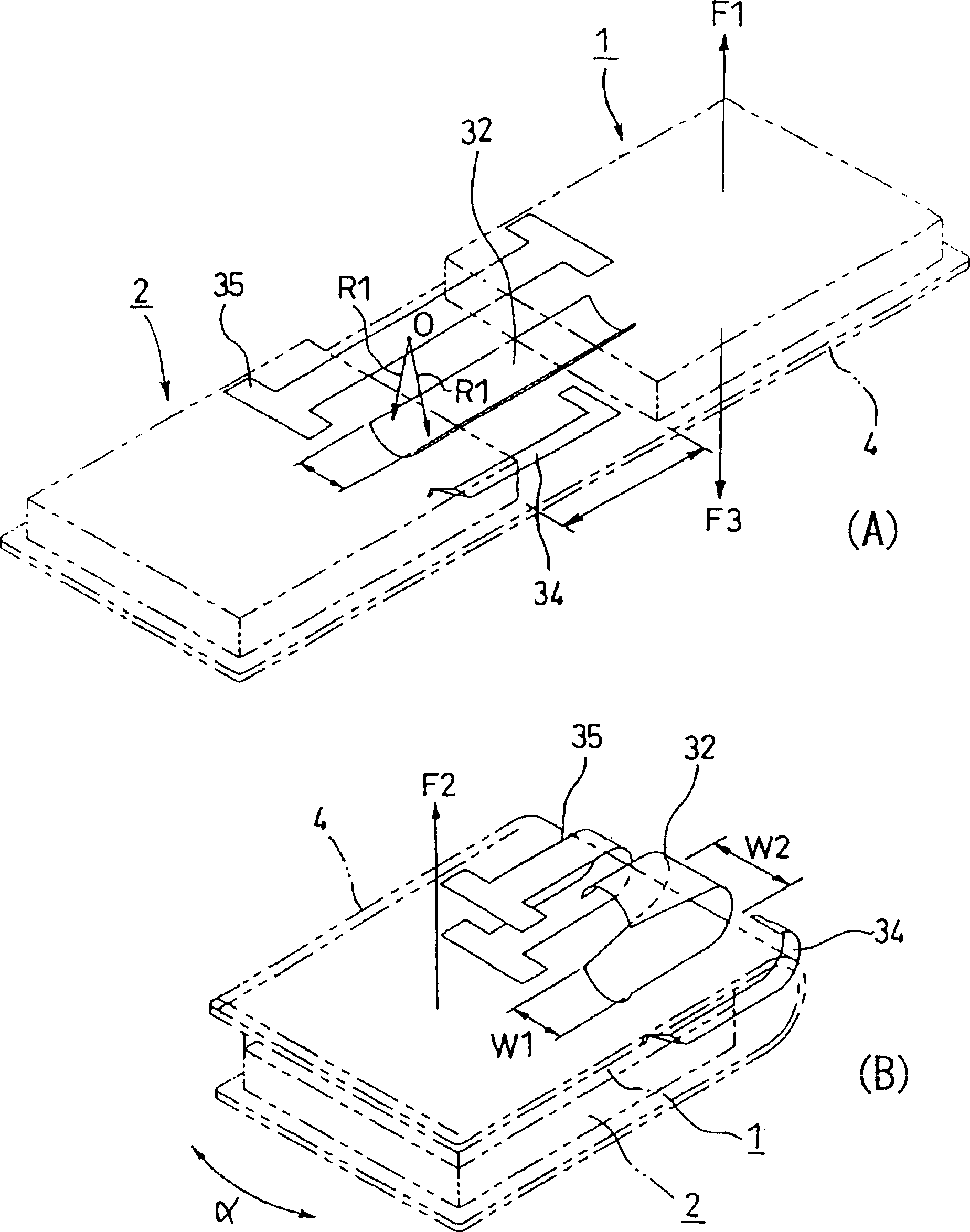

Connection device, small-sized electronic apparatus with the same, and folding portable terminal device

InactiveCN1898938AEasy to readEliminates the inconvenience of inputting to the operating unitTelephone set constructionsTerminal equipmentStructural engineering

The invention provides a connection device which is capable of pivotally connecting two housings without a connecting section projecting from the housings, and capable of stably holding the housings when the housings are in an open state. A connection device has a first and a third connection member (31, 33) that have flexibility and foldably fix an upper housing (1) and a lower housing (2) with a connection section in between. The connection device further has a second connection member (32) that has a restoring force and rigidity returning from a folded state to an open state and has a cross-section with a circular-arc shape curved and recessed toward the folding direction of the upper and lower housings.

Owner:PANASONIC CORP

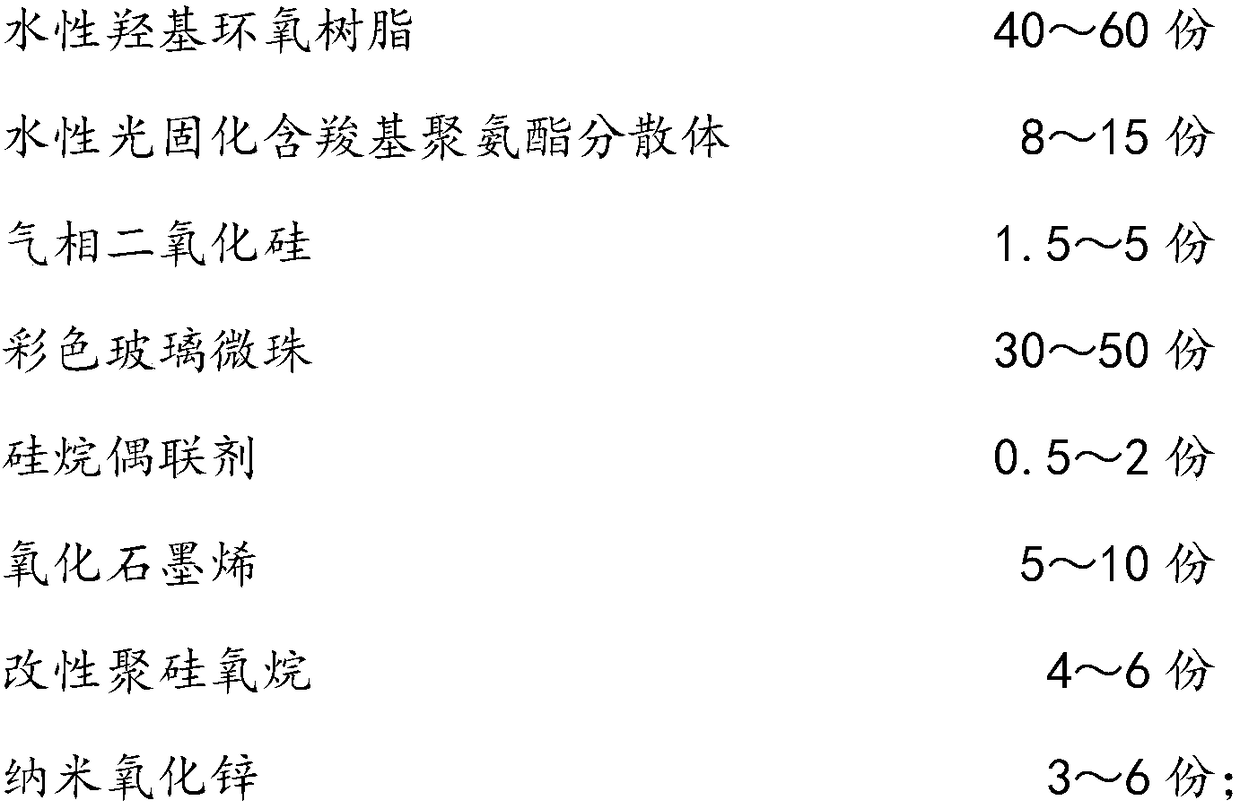

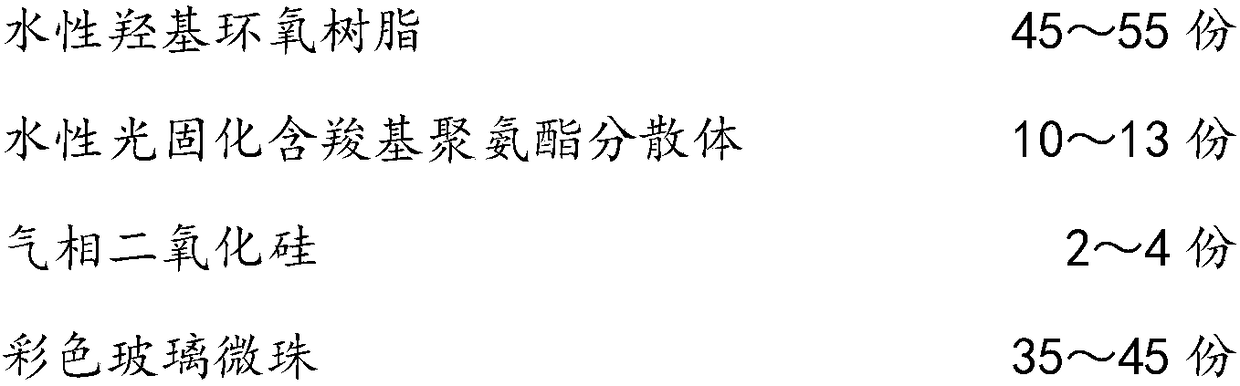

Epoxy color sand sealant and preparation method thereof

The invention provides an epoxy color sand sealant and a preparation method thereof. The epoxy color sand sealant is prepared from a component A and a component B, wherein the component A is preparedfrom the following components in parts by weight: 40 to 60 parts of water-based hydroxyl epoxy resin, 8 to 15 parts of a water-based photocuring carboxylated polyurethane dispersoid, 1.5 to 5 parts offumed silica, 30 to 50 parts of color glass micro beads, 0.5 to 2 parts of a silane coupling agent, 5 to 10 parts of graphene oxide, 4 to 6 parts of modified polysiloxane and 3 to 6 parts of nano zinc oxide; the component B is prepared from the following components in parts by weight: 20 to 40 parts of a water-based epoxy curing agent, 2 to 3 parts of fumed silica, 20 to 30 parts of color glass micro beads, 20 to 25 parts of glitter powder and 0.5 to 1.5 parts of a rheological agent; a mass ratio of the component A to the component B is 1: (1 to 1.5). According to the epoxy color sand sealantand the preparation method thereof which are provided by the invention, the surface of a cured adhesive film is excellent in mechanical intensity and hardness, and the scratching resistance and the wear resistance are enhanced.

Owner:厦门百安兴新材料有限公司

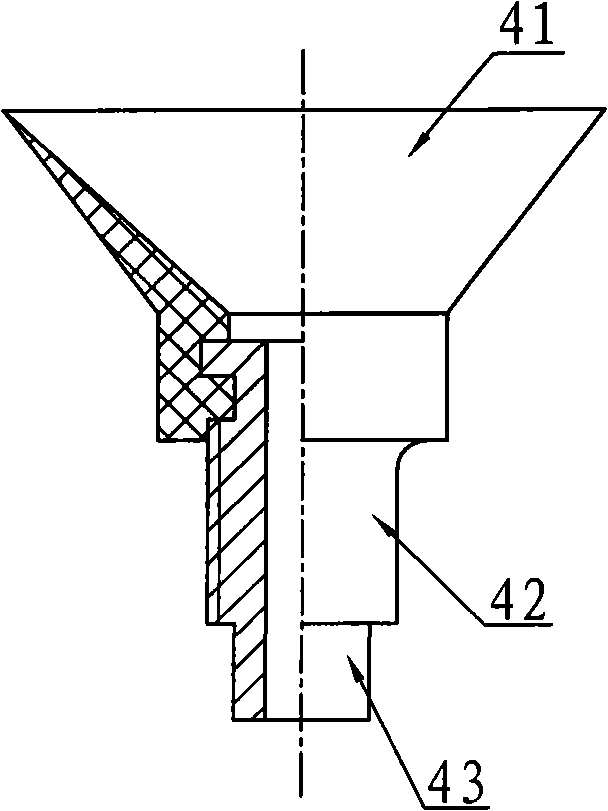

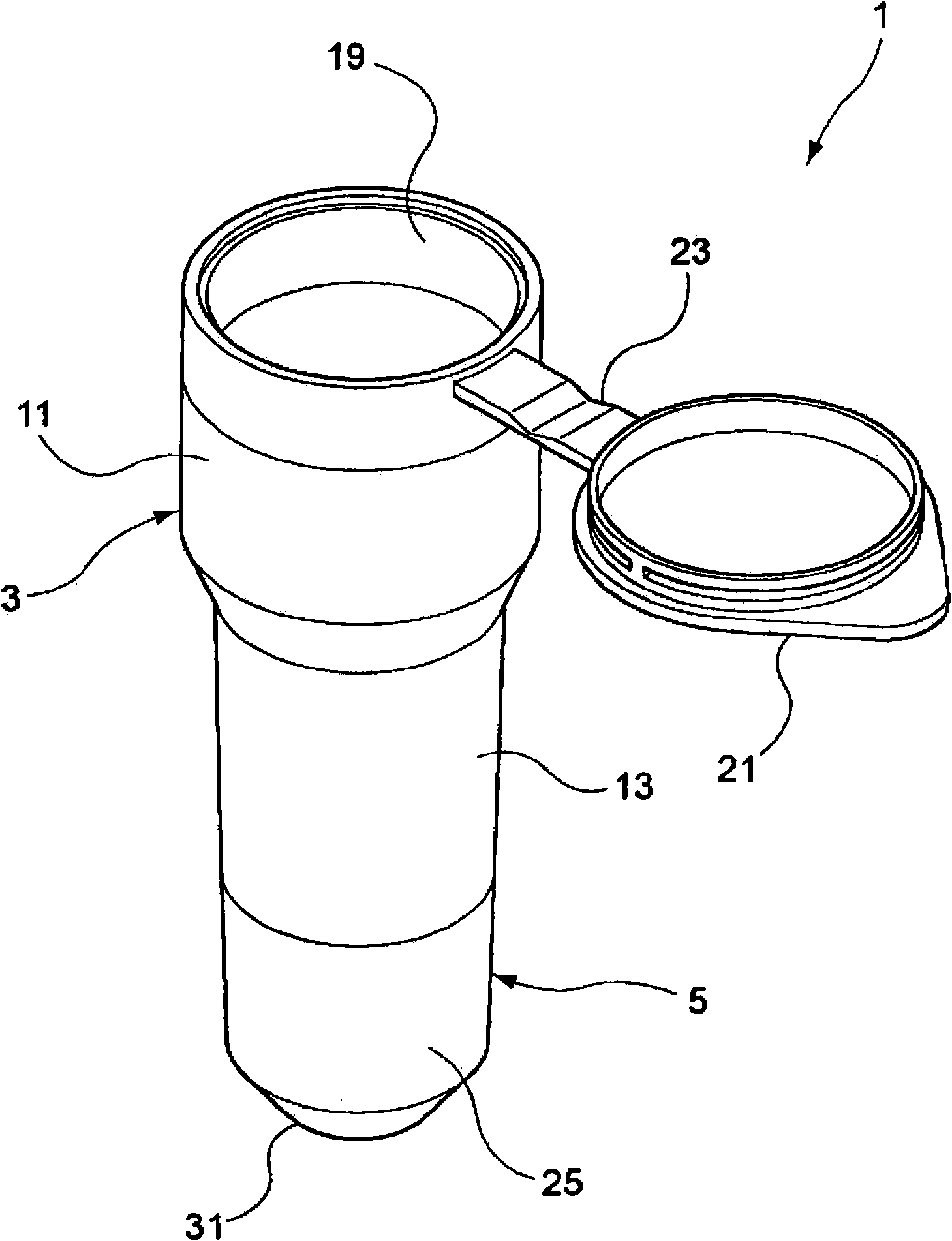

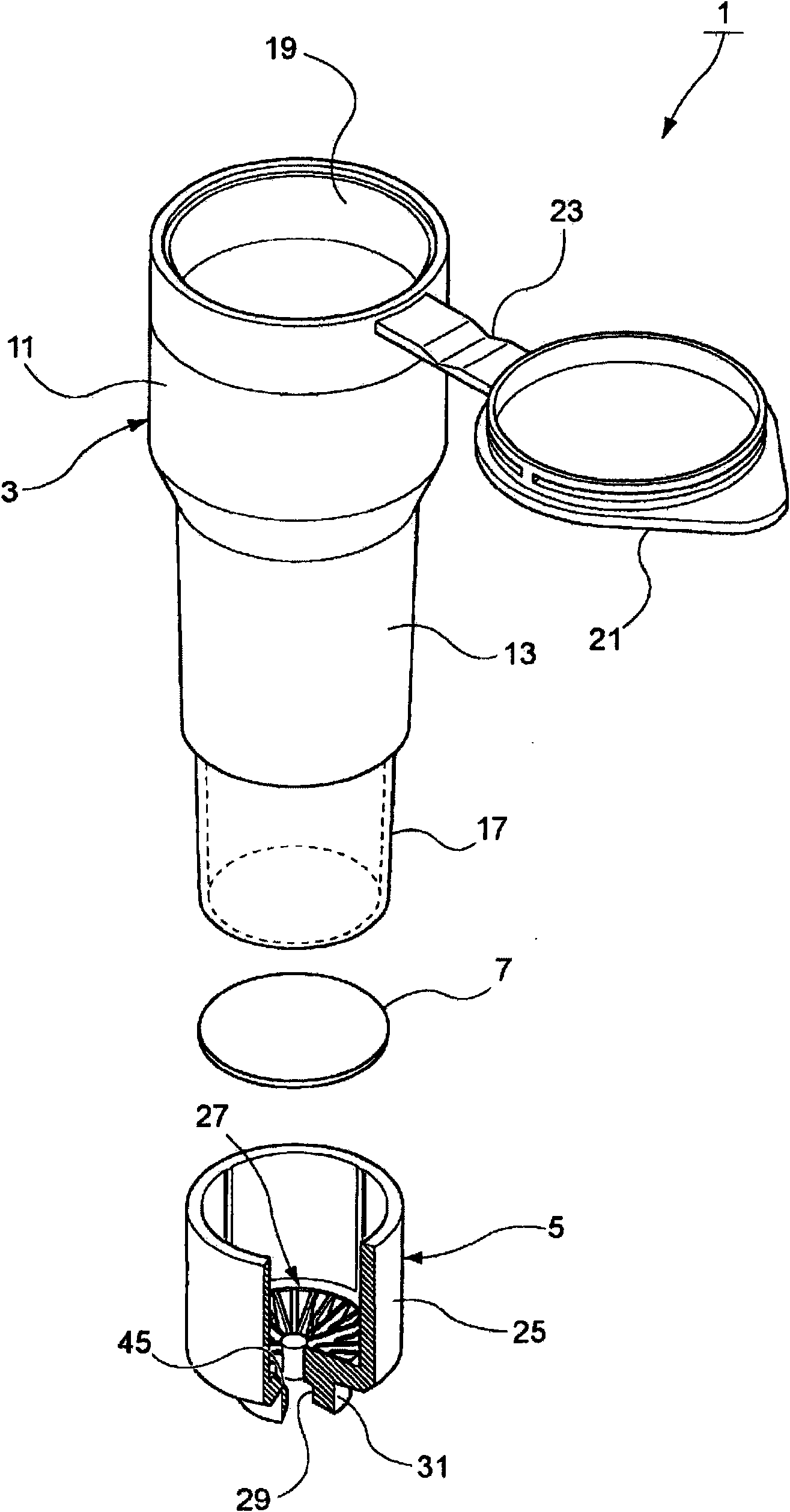

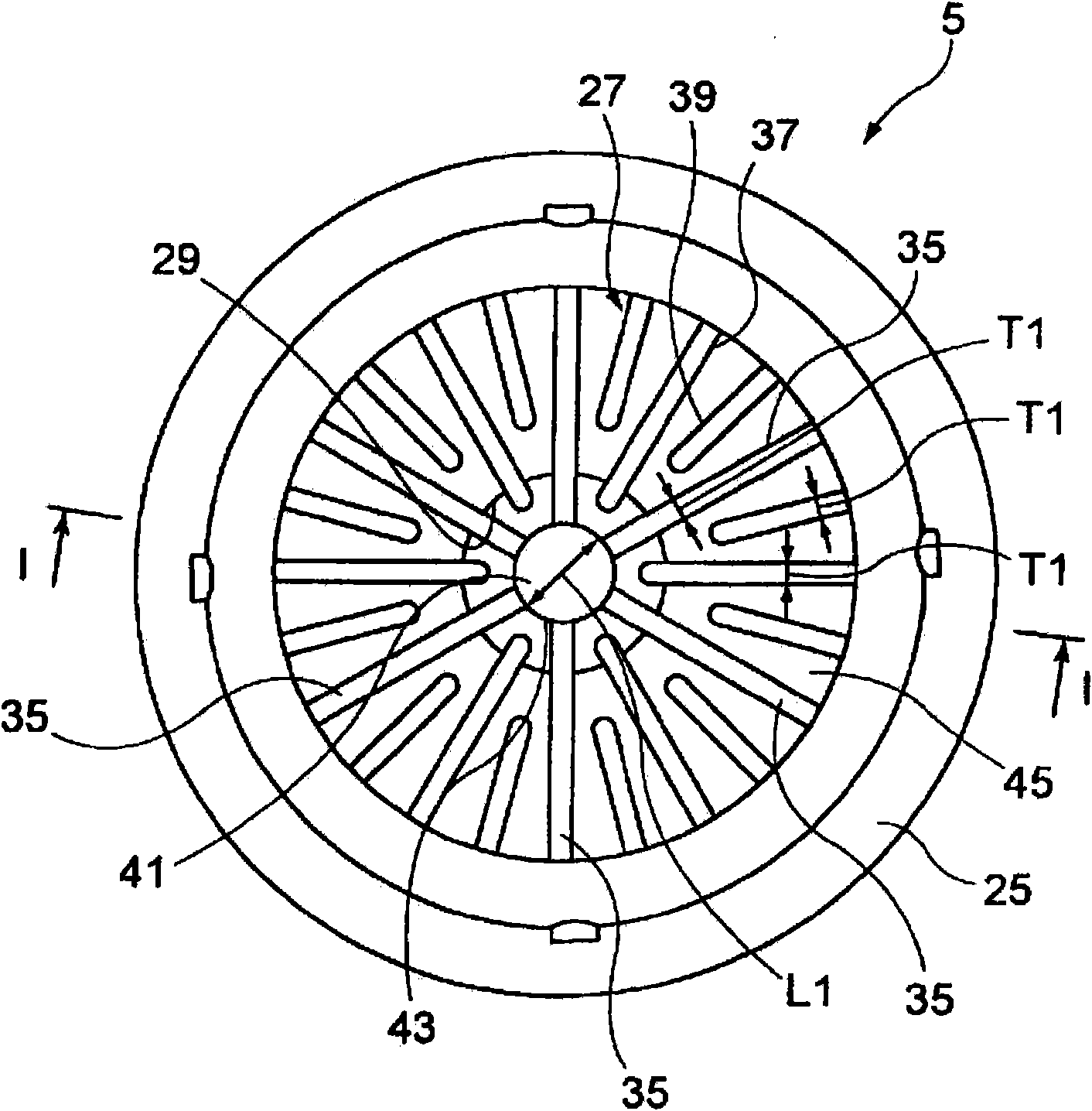

Porous filter cartridge

InactiveCN101925396AImprove filtering effectEfficient extractionWithdrawing sample devicesUltrafiltrationFiltrationWaste management

This aims to provide a porous filter cartridge which is hardly contaminated, which is advantageous in the cost aspect, and which can perform efficient filtration and extraction without any breakage. The porous filter cartridge includes a porous filter retained in the bottom and inside of a bottomed cylindrical cap 5 having a discharge opening 29 formed in the center of the bottom. A plurality of ribs 35, 37 and 39 for supporting the porous filter are erected radially around the discharge opening 29 in the bottom of the cap 5. At least any of those ribs is connected across the discharge opening 29 at the central portion of the discharge opening 29, and a protruding face 41 protruding toward the porous filter is formed on the crest face of a connected rib portion 43.

Owner:KURASHIKI BOSEKI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com