Coaxial compound nanometre fibre film as well as preparation method and application thereof

A technology of composite nanofibers and nanofibers, which can be used in fiber processing, conjugated synthetic polymer rayon, textiles and papermaking, etc., can solve problems such as unfavorable batch preparation, cumbersome steps, etc., and achieve excellent chemical stability and uniform distribution. , the effect of excellent air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

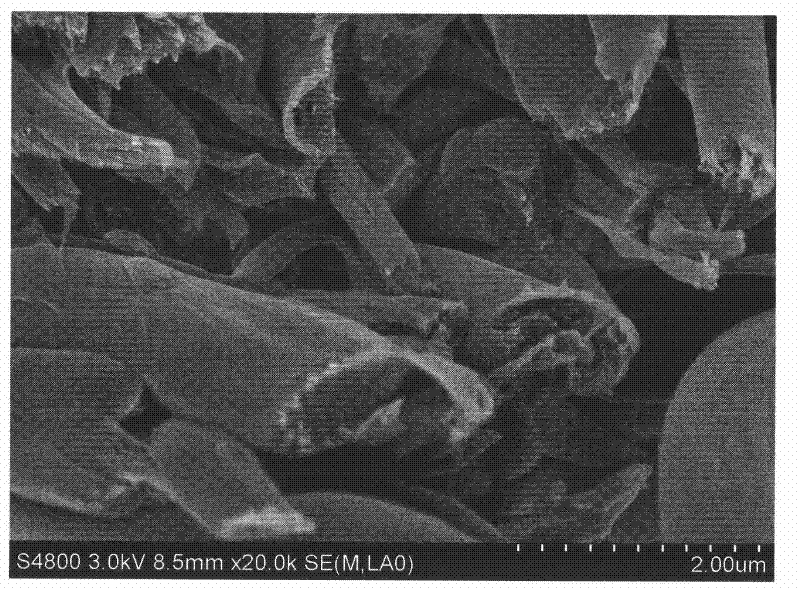

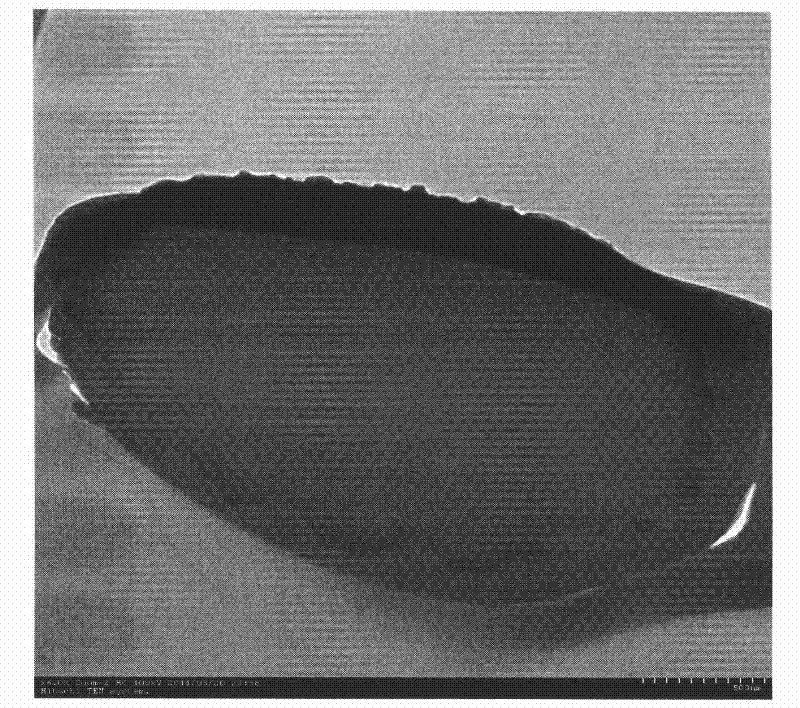

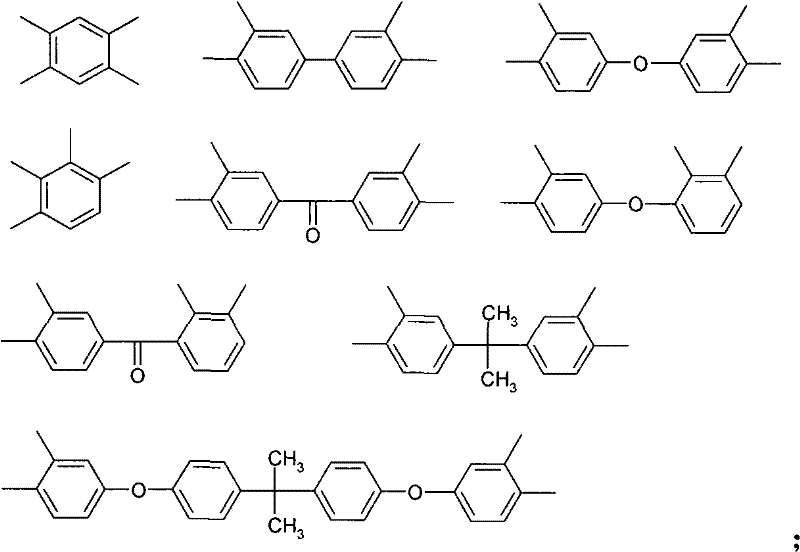

[0049] Add 4.36 grams of pyromellitic dianhydride, 4.00 grams of diaminodiphenyl ether, and 45.5 milliliters of N,N-dimethylacetamide into a 150 milliliter four-neck flask, and then stir the reaction in an ice bath at 0-5°C , the reaction time was 24 hours to obtain a uniform polyamic acid solution (15% by mass fraction). After the reaction, the polyamic acid solution was stored in a refrigerator at 4°C. Take out 1.66g of polyamic acid solution in a 50ml volumetric flask, add N,N-dimethylacetamide to make the volume to 50ml, prepare a solution of 0.0050g / ml, and use an Ubbelohde viscometer in a water bath at 30°C Its intrinsic viscosity was determined to be 2.11dL / g. Take out 1.0 milliliter polyamic acid solution as inner fluid, 1.0 milliliter vinylidene fluoride-hexafluoropropylene copolymer solution (mass fraction is 15%, solvent is N, N-dimethylformamide) as outer fluid, carries out coaxial electrostatic For spinning, the inner diameter of the needle is 1.0 mm, the thickn...

Embodiment 2

[0051] Add 5.88 grams of biphenyltetracarboxylic dianhydride, 4.97 grams of diphenylsulfone diamine, and 60.3 milliliters of N,N-dimethylacetamide into a 150 milliliter four-neck flask, and then stir the reaction in an ice bath at 0-5°C , the reaction time was 24 hours to obtain a uniform polyamic acid solution (15% by mass fraction). After the reaction, the polyamic acid solution was stored in a refrigerator at 4°C. Take out 1.6667 g of polyamic acid solution in a 50 ml volumetric flask, add N,N-dimethylacetamide to make it volume to 50 ml, prepare a solution of 0.0050 g / ml, and use an Ubbelohde viscometer in a water bath at 30°C Its intrinsic viscosity was determined to be 1.89dL / g. Take out 1.0 milliliter polyamic acid solution as the inner fluid, 1.0 milliliter polyvinylidene fluoride solution (mass fraction is 15%, solvent is N, N-dimethylformamide) as the outer fluid, carry out coaxial electrospinning, needle The diameter of the lumen is 1.0 mm, the thickness of the ou...

Embodiment 3

[0053] Add 5.88 grams of biphenyltetracarboxylic dianhydride, 2.16 grams of p-phenylenediamine, and 43.4 milliliters of N,N-dimethylacetamide into a 150 milliliter four-neck flask, and then stir the reaction in an ice bath at 0-5°C. The reaction time was 24 hours, and a uniform polyamic acid solution (15% by mass fraction) was obtained. After the reaction, the polyamic acid solution was stored in a refrigerator at 4°C. Take out 1.6667 g of polyamic acid solution in a 50 ml volumetric flask, add N,N-dimethylacetamide to make it volume to 50 ml, prepare a solution of 0.0050 g / ml, and use an Ubbelohde viscometer in a water bath at 30°C Its intrinsic viscosity was determined to be 1.49dL / g. Take out 1.0 ml of polyamic acid solution as the inner fluid, and 1.0 ml of vinylidene fluoride-chlorotrifluoroethylene copolymer solution (the mass fraction is 15%, the solvent is N, N-dimethylacetamide) as the outer fluid, and carry out coaxial Electrospinning, the diameter of the inner cav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com