Patents

Literature

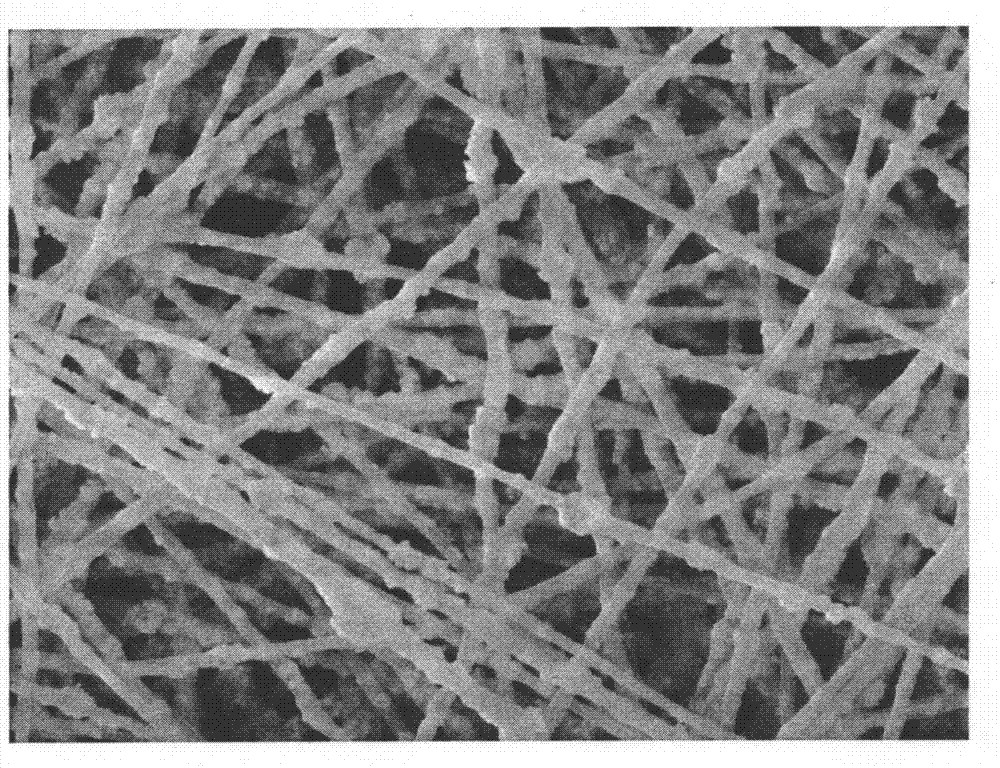

1183 results about "Composite nanofibers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene composite nanofiber and preparation method thereof

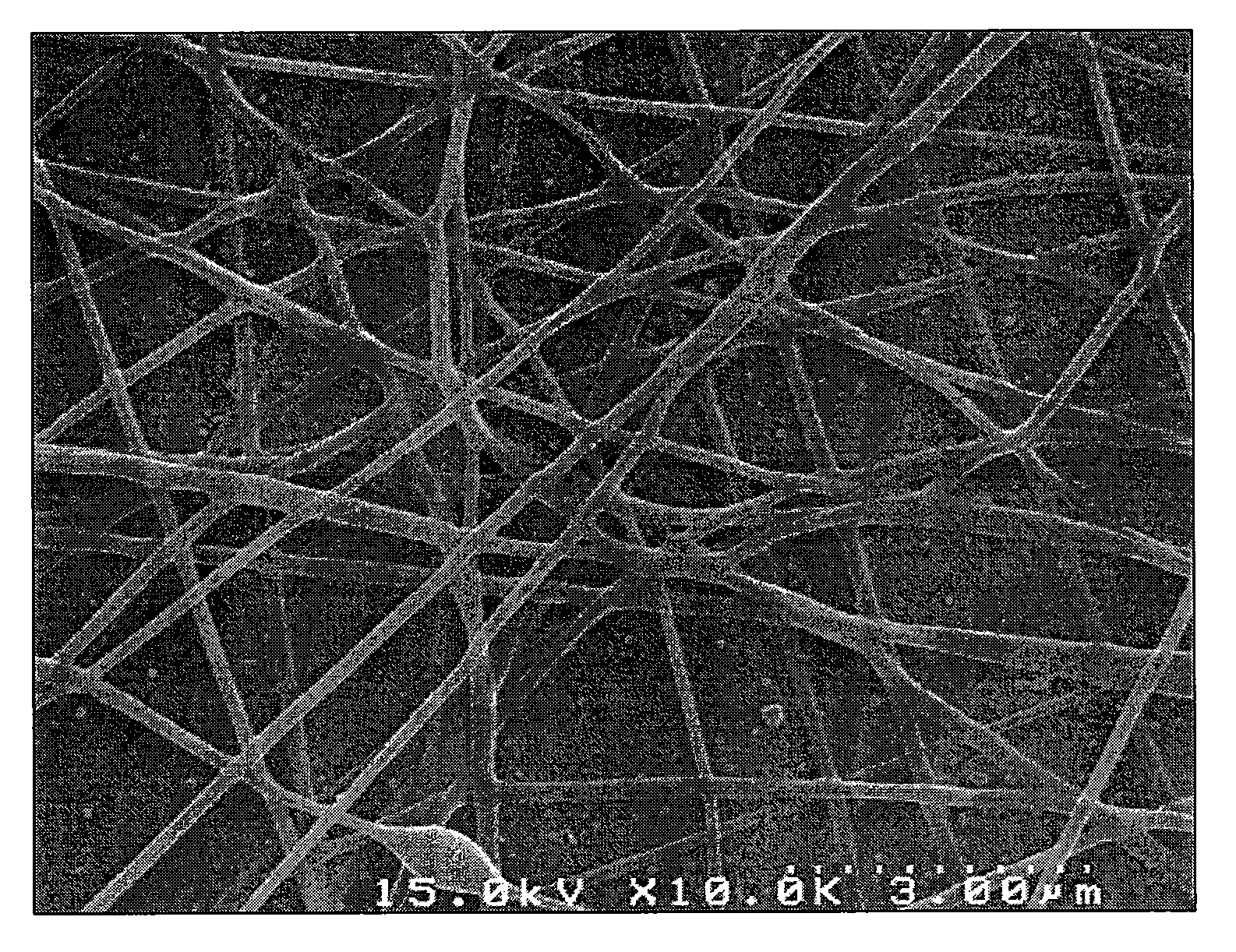

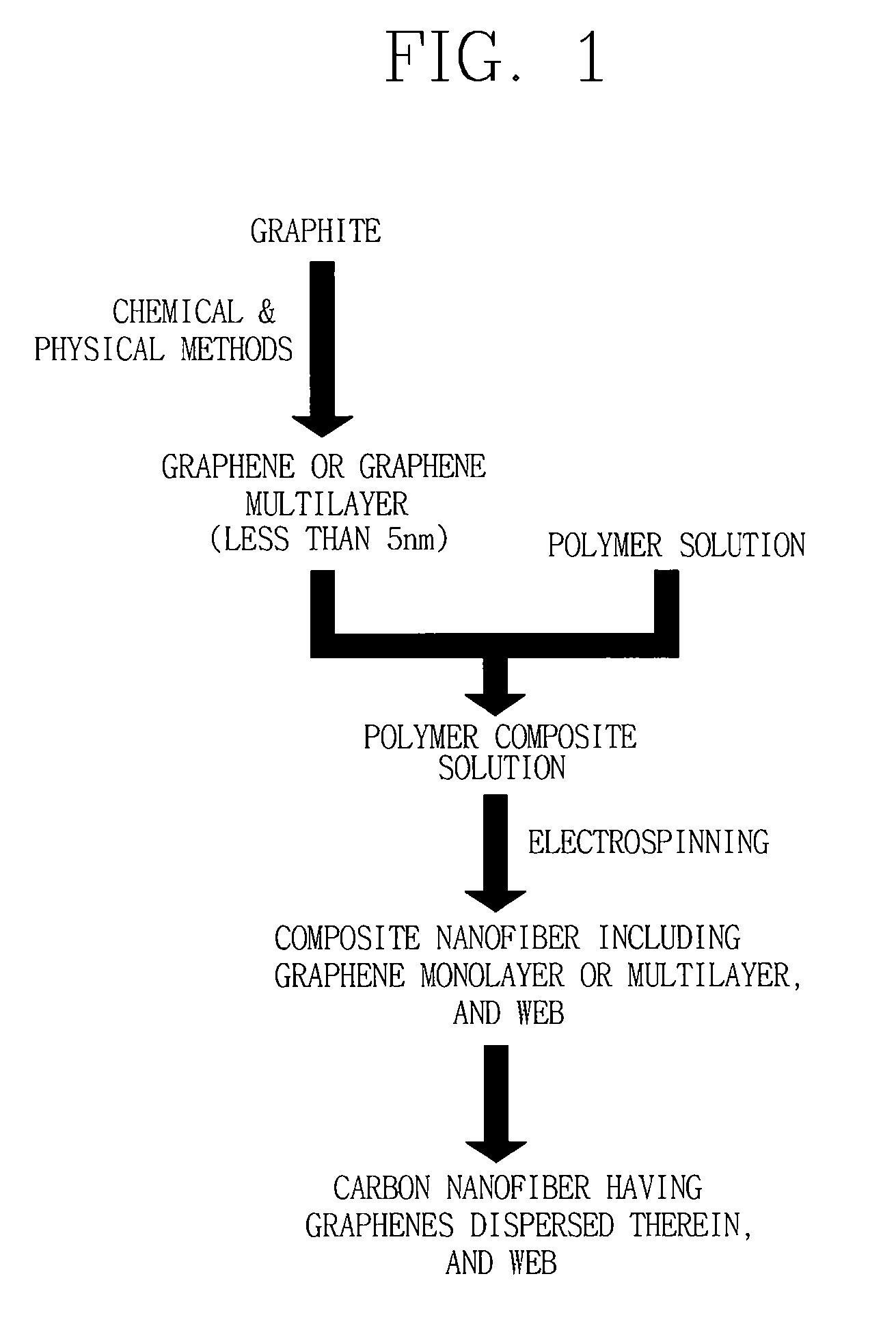

Disclosed are a graphene composite nanofiber and a preparation method thereof. The graphene composite nanofiber is produced by dispersing graphenes to at least one of a surface and inside of a polymer nanofiber or a carbon nanofiber having a diameter of 1˜1000 nm, and the graphenes include at least one type of monolayer graphenes, and multilayer graphenes having a thickness of 10 nm or less. The graphene composite nanofiber can be applied to various industrial fields, e.g., a light emitting display, a micro resonator, a transistor, a sensor, a transparent electrode, a fuel cell, a solar cell, a secondary cell, and a composite material, owing to a unique structure and property of graphene.

Owner:KOREA INST OF SCI & TECH

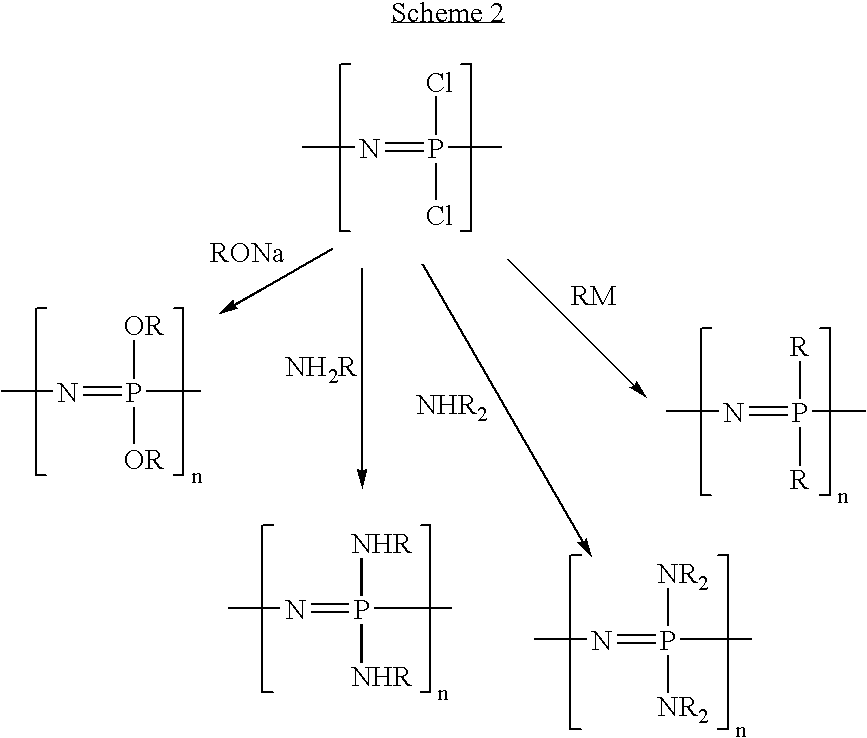

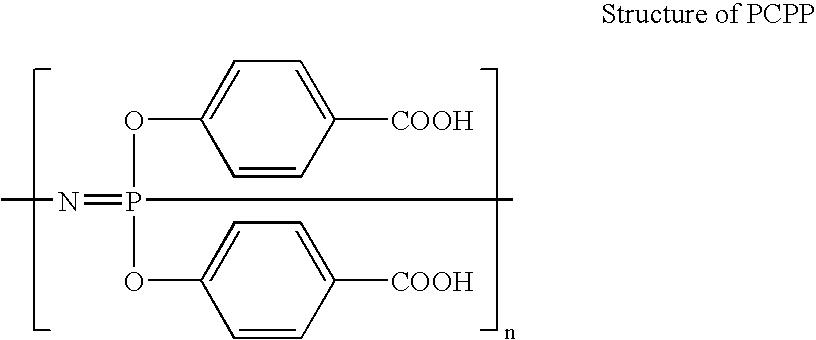

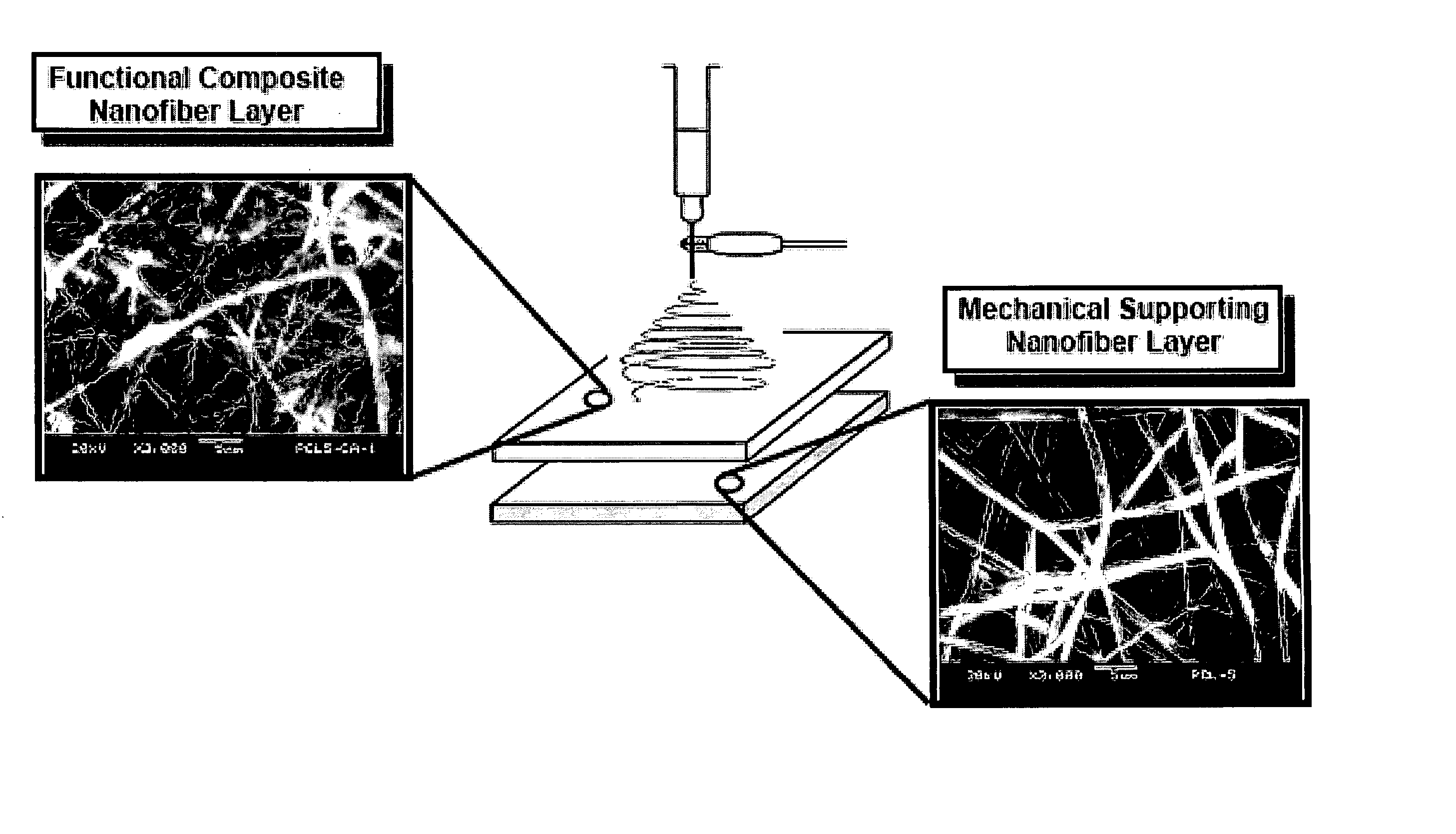

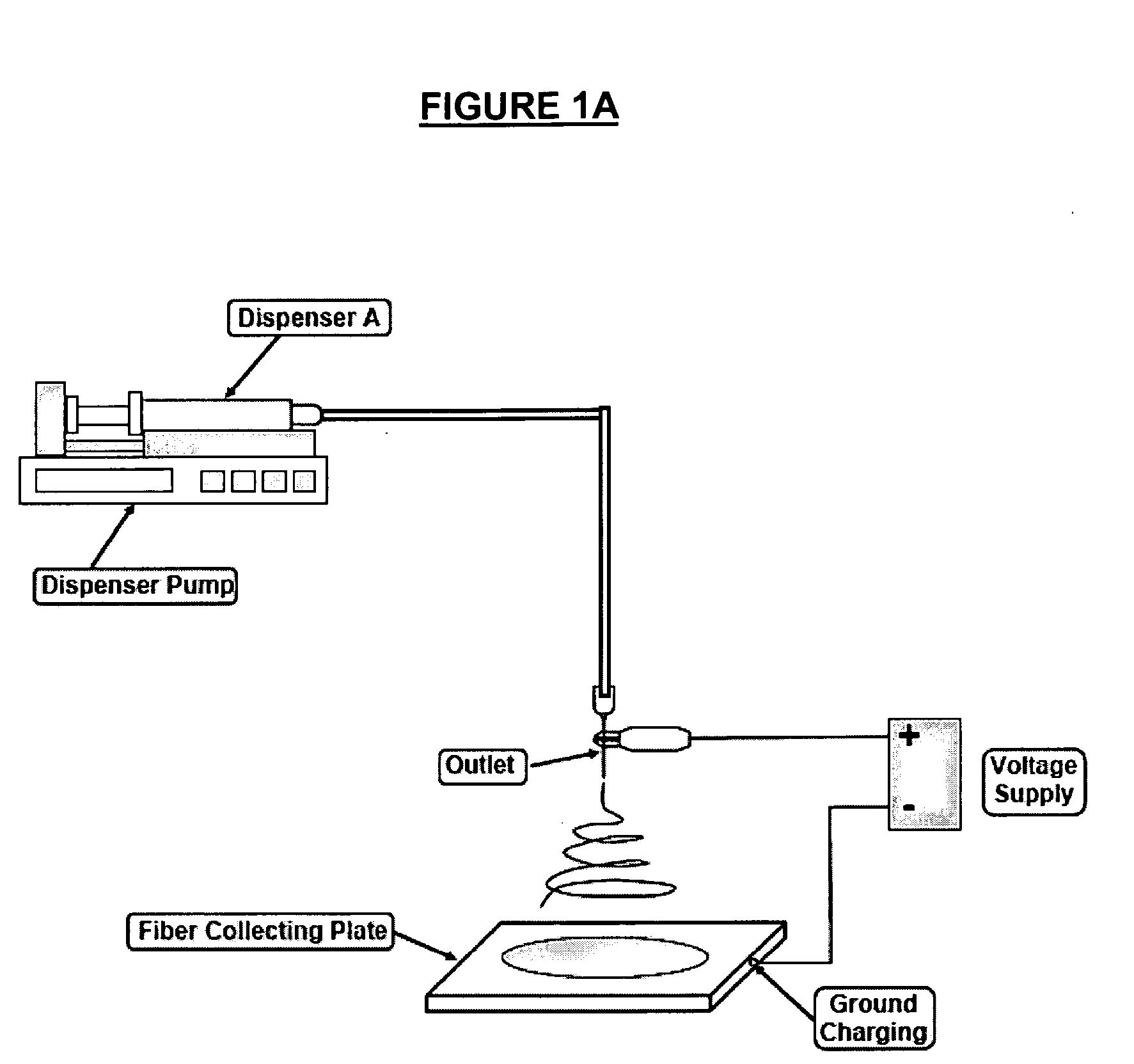

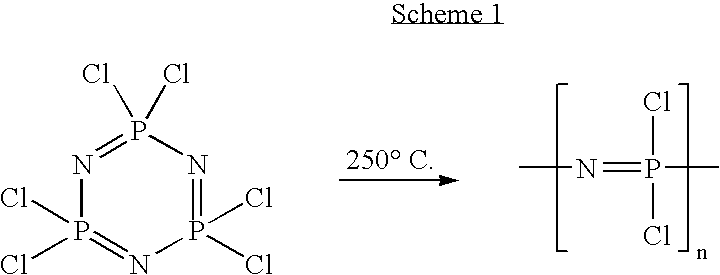

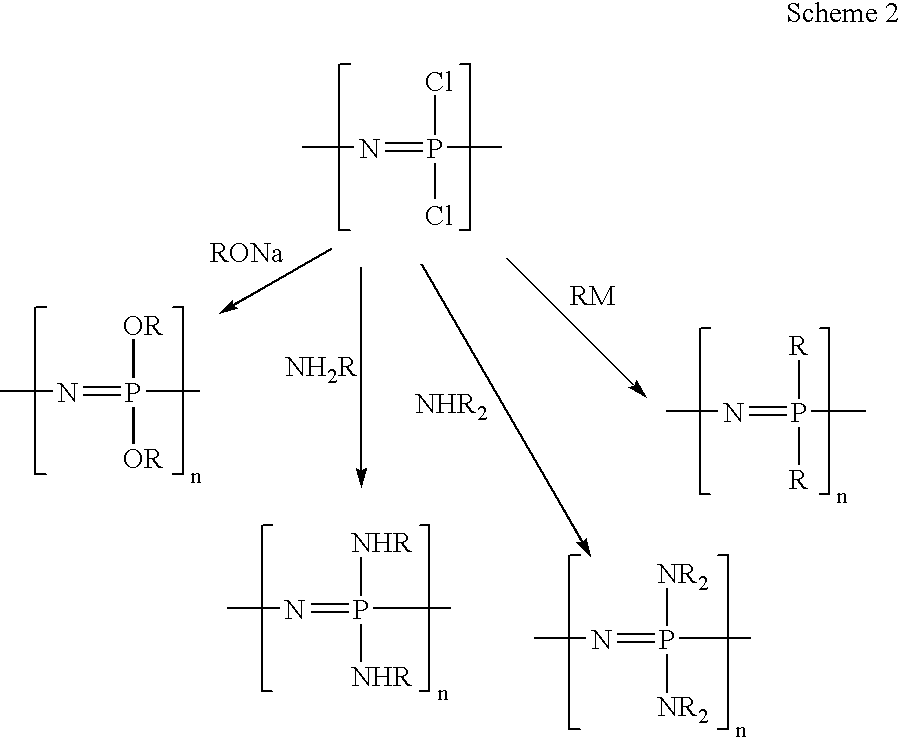

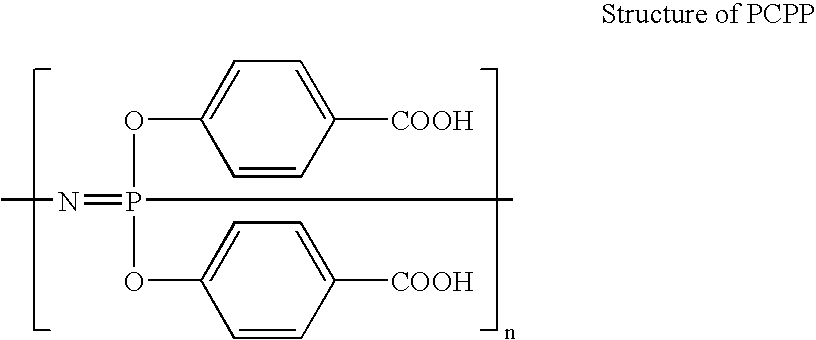

Polymeric nanofibers for tissue engineering and drug delivery

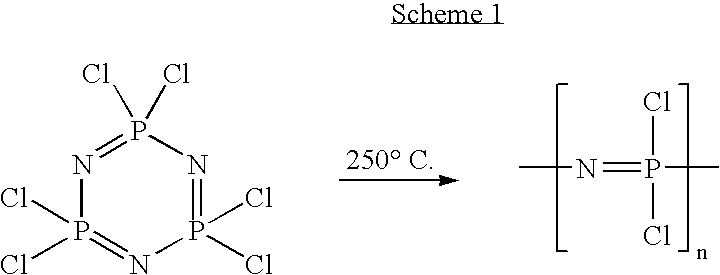

Polymeric nanofibers have been developed which are useful in a variety of medical and other applications, such as filtration devices, medical prosthesis, scaffolds for tissue engineering, wound dressings, controlled drug delivery systems, cosmetic skin masks, and protective clothing. These can be formed of any of a variety of different polymers, either non-degradable or degradable. In a preferred embodiment demonstrated in the following examples, nanofibers are formed of biodegradable and non biodegradable polyphosphazenes, their blends with other polyphosphazenes or with organic, inorganic / organometallic polymers as well as composite nanofibers of polyphosphazenes with nanosized particles such as hydroxyapatites.

Owner:PENN STATE RES FOUND

Nanofiber construct and method of preparing thereof

InactiveUS20060154063A1Improve hydrophilicityGood bone conductionPharmaceutical delivery mechanismElectro-spinningFiberComposite nanofibers

The present invention provides a composite nanofiber construct comprising: at least a first nanofiber comprising at least a polymer and at least a calcium salt nanoparticle, wherein the ratio of polymer to calcium salt nanoparticle is between the range of 99:1 and 10:90 weight percent; and at least a second nanofiber comprising at least a polymer and at least a calcium salt nanoparticle, wherein the ratio of polymer to calcium salt nanoparticle is between the range of 100:0 and 70:30 weight percent. The present invention also provides a method of preparing the composite nanofiber construct.

Owner:NAT UNIV OF SINGAPORE

Antibacterial composite nanometer fiber high-efficiency air filtering material and preparation method thereof

ActiveCN103520999AGood air filtration efficiencyImprove adhesionSynthetic resin layered productsFiltration separationFiberComposite nanofibers

The invention relates to an antibacterial composite nanometer fiber high-efficiency air filtering material and a preparation method thereof, and belongs to the field of preparation of air filtering materials. The antibacterial composite nanometer fiber high-efficiency air filtering material sequentially comprises a non-woven fabric support layer, a filter layer and a nanometer fiber filter layer, wherein the filter layer is obtained by blending antibacterial fibers and micrometer fibers. When harmful air which contains bacteria and viruses passes through the antibacterial composite nanometer fiber high-efficiency air filtering material, the antibacterial composite nanometer fiber high-efficiency air filtering material disclosed by the invention can achieve antiviral and antibacterial effects and has high filter efficiency effect on tiny particles contained in air; the antibacterial composite nanometer fiber high-efficiency air filtering material disclosed by the invention has the advantages of antibacterial effect, and high filter efficiency and relatively lower resistance on the tiny particles contained in air, can achieve the filter efficiency on oily DOP (Dioctyl-Phthalate) particles with the grain diameters of 0.3 micrometers at 99.99% and achieve the filter efficiency on sodium chloride particles of 0.07-0.2 micrometers more than 99.99%, has the advantages of light weight, softness, and the like in practical application and can be used for preparing antibacterial protective articles, such as a mask, a protective mask and application protective clothes.

Owner:BEIJING INST OF CLOTHING TECH

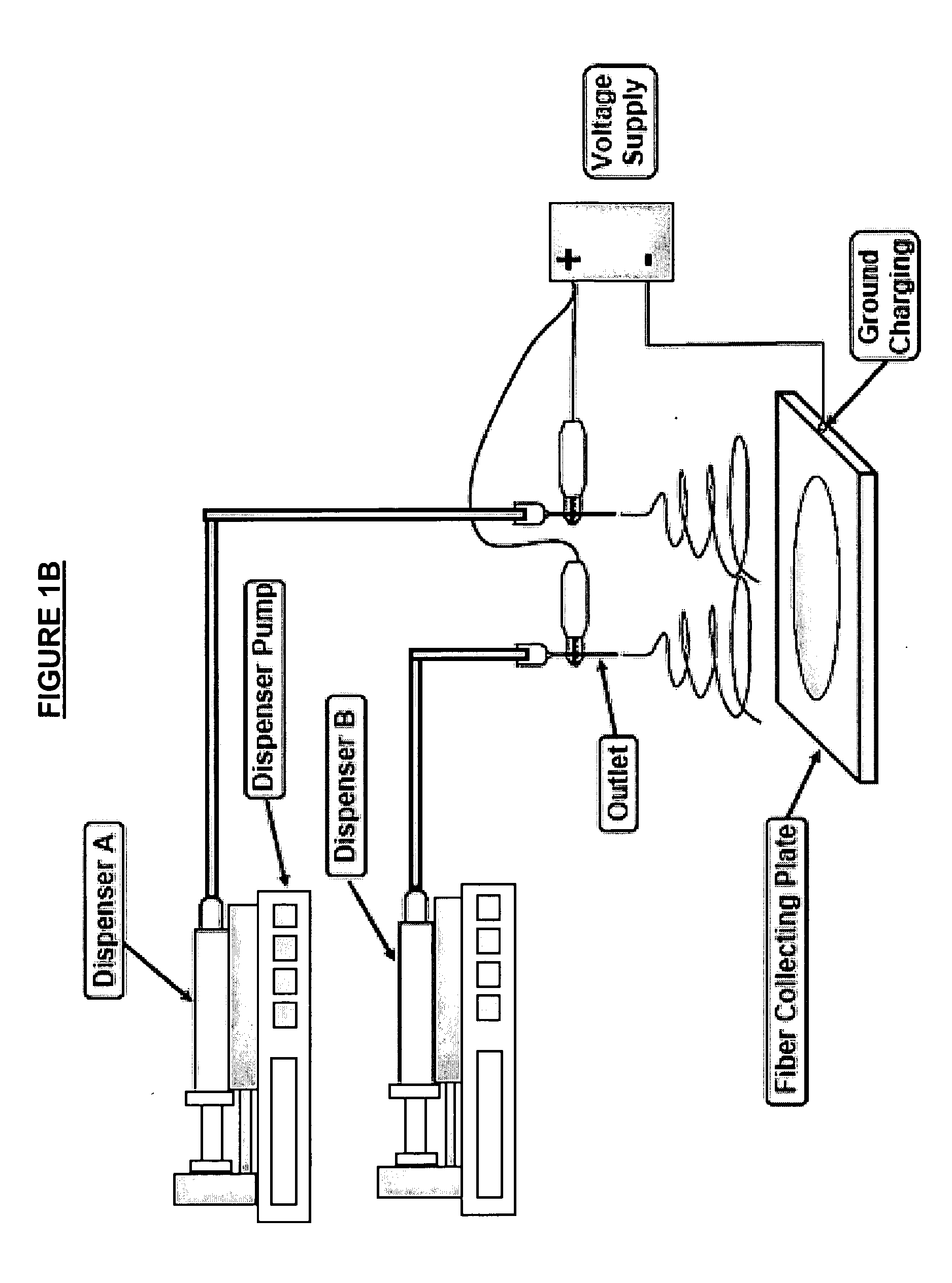

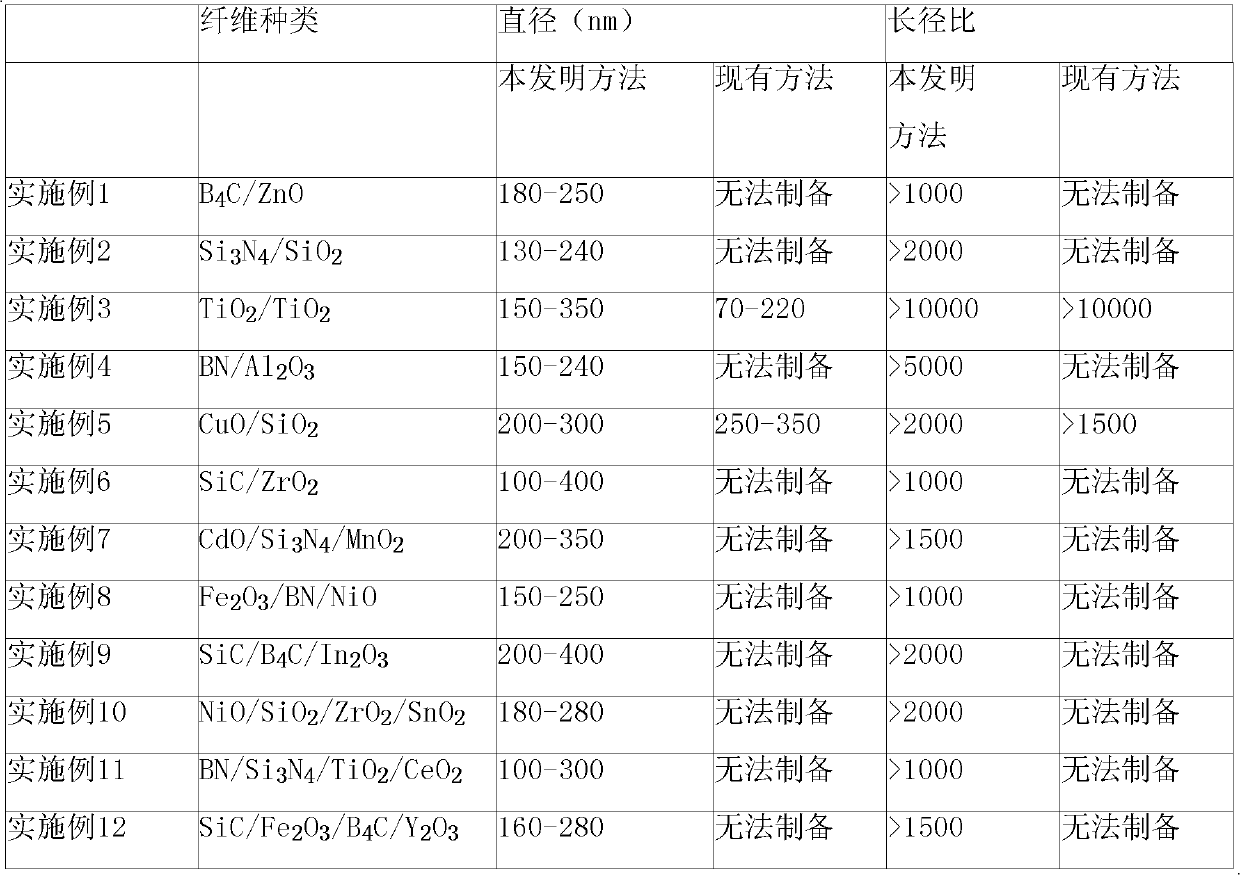

Electrostatic spinning preparation method of ceramic nanometer composite fibers

The invention discloses an electrostatic spinning preparation method of ceramic nanometer composite fibers, comprising the following concrete steps of: firstly, according to volume percentage, weighing 3-10 percent of ceramic nanometer particles with the partilce size of 10-300 nm, 3-20 percent of ceramic precursor, 5-30 percent of spinnable polymer and 40-89 percent of solvent with the total volume of 100 percent; secondly, adding the spinnable polymer into the solvent, heating in water bath and magnetically stirring; thirdly, adding the ceramic precursor into the spinnable polymer solution obtained in the second step, heating in water bath, magnetically stirring and ageing; fourthly, adding the ceramic nanometer particles into the ceramic precursor spinnable solution obtained in the third step, heating at constant temperature in the water bath and forming a spinning solution by carrying out ultrasonic dispersion and constant temperature swelling; fifthly, preparing composite nanometer fibers by the spinning solution according to an electrostatic spinning technology; and sixthly, obtaining the ceramic nanometer composite fibers by sintering the composite nanometer fibers. In the method, raw materials have wide selection conditions and wide optional range.

Owner:XIAN UNIV OF TECH

Polymeric nanofibers for tissue engineering and drug delivery

Polymeric nanofibers have been developed which are useful in a variety of medical and other applications, such as filtration devices, medical prosthesis, scaffolds for tissue engineering, wound dressings, controlled drug delivery systems, cosmetic skin masks, and protective clothing. These can be formed of any of a variety of different polymers, either non-degradable or degradable. In a preferred embodiment demonstrated in the following examples, nanofibers are formed of biodegradable and non biodegradable polyphosphazenes, their blends with other polyphosphazenes or with organic, inorganic / organometallic polymers as well as composite nanofibers of polyphosphazenes with nanosized particles such as hydroxyapatites.

Owner:PENN STATE RES FOUND

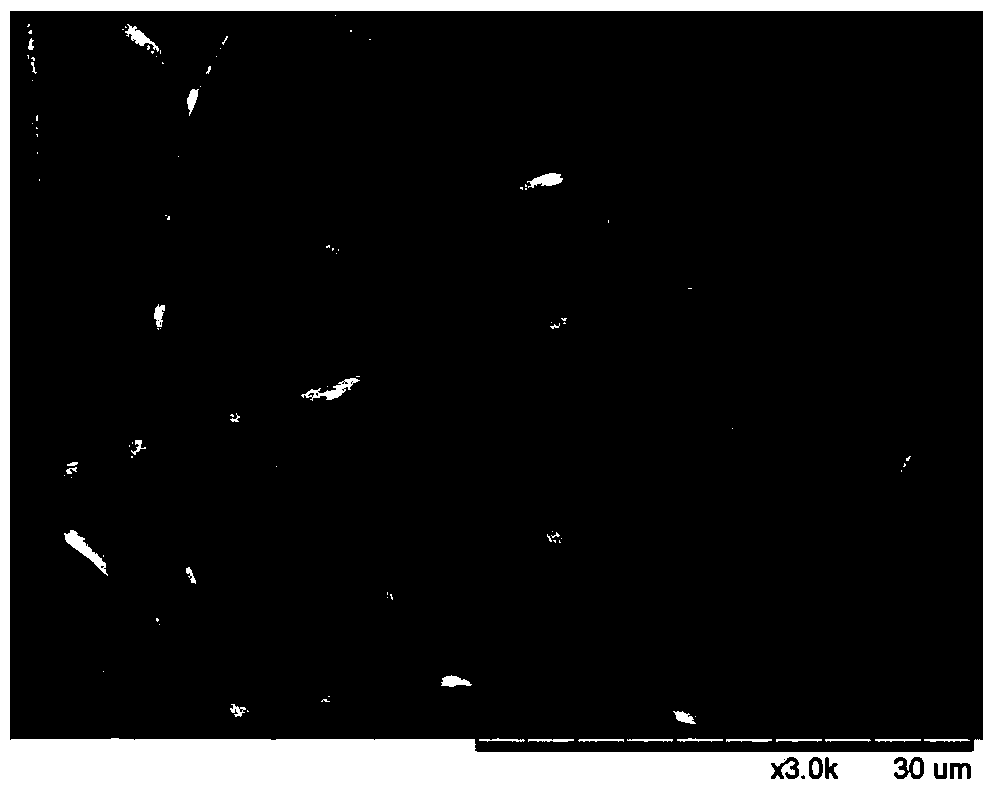

Silicon-carbon composite material with nano micropores and preparation method as well as application thereof

ActiveCN103305965AImprove lithium storage performanceImprove electrochemical performanceCell electrodesFilament/thread formingCarbon compositesCarbon fibers

The invention discloses a silicon-carbon composite material with nano micropores and a preparation method as well as application thereof. The material comprises nano-silicon (Si) particles and a carbon nanofiber matrix, wherein the nano-silicon particles are dispersed in the carbon nanofiber matrix; and nano pores and micropores communicated with the nano pores are distributed in the carbon nanofiber matrix. The method comprises the steps of dissolving the nano-Si particles and polyacrylonitrile (PAN) in a solvent to prepare a mixed spinning solution, then carrying out electrostatic spinning on the mixed spinning solution, and curing spinning trickles in a coagulating bath to obtain a porous PAN-Si composite nanofiber; and then carrying out oxidation and carbonization treatment in sequence to obtain the silicon-carbon composite material with a nano micropore structure. The silicon-carbon composite material is applied to preparation of lithium ion battery cathode materials. Compared with the prior art, the silicon-carbon composite material ensures the overall electron transport capacity of the material while reserving buffer space for expansion of the nano-Si particles.

Owner:深圳石墨烯创新中心有限公司

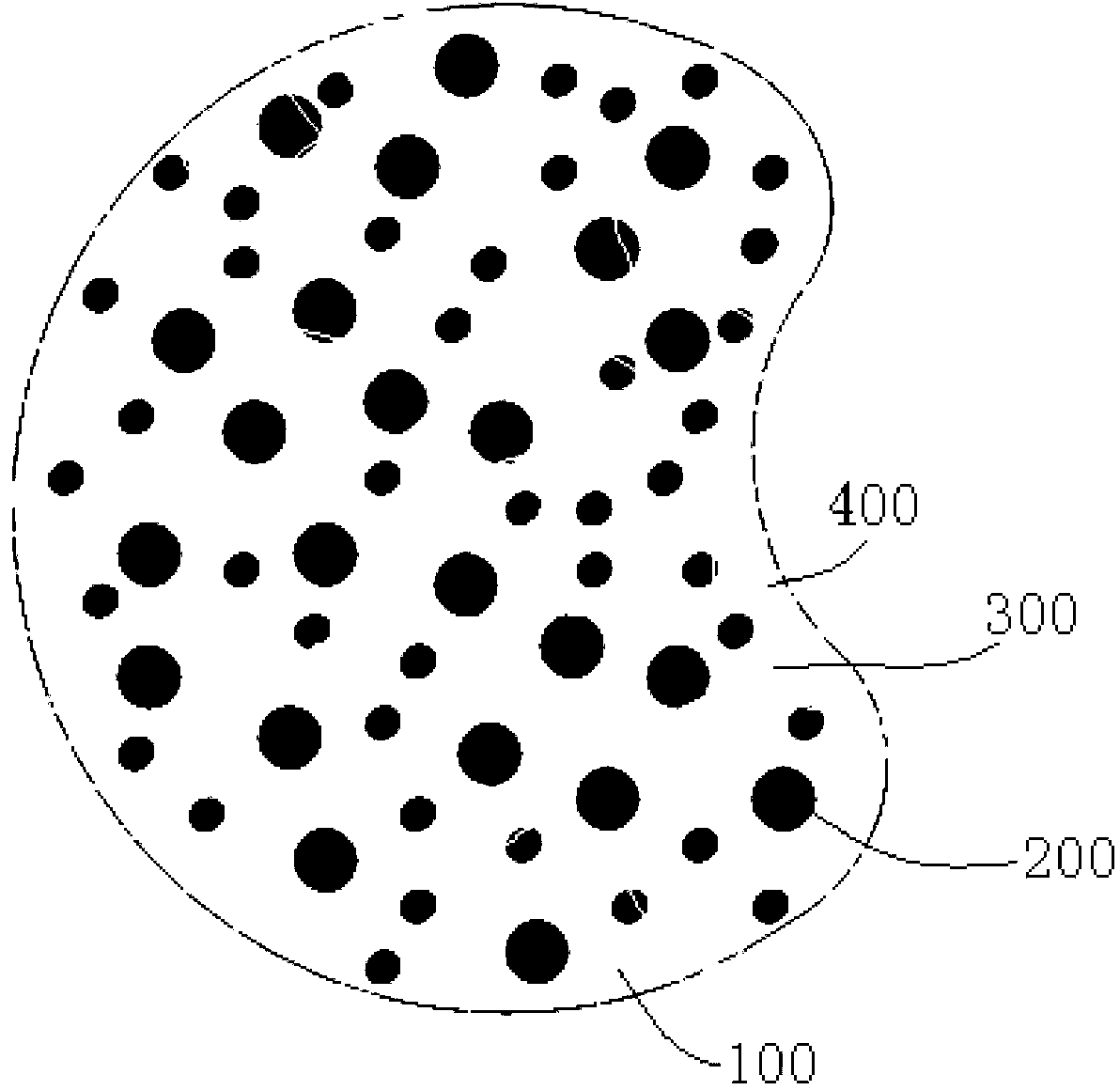

High-strength composite nano fiber long yarn and manufacturing method thereof

InactiveCN101033563ALarge specific surface areaHigh strengthFilament/thread formingWoven fabricsFiberYarn

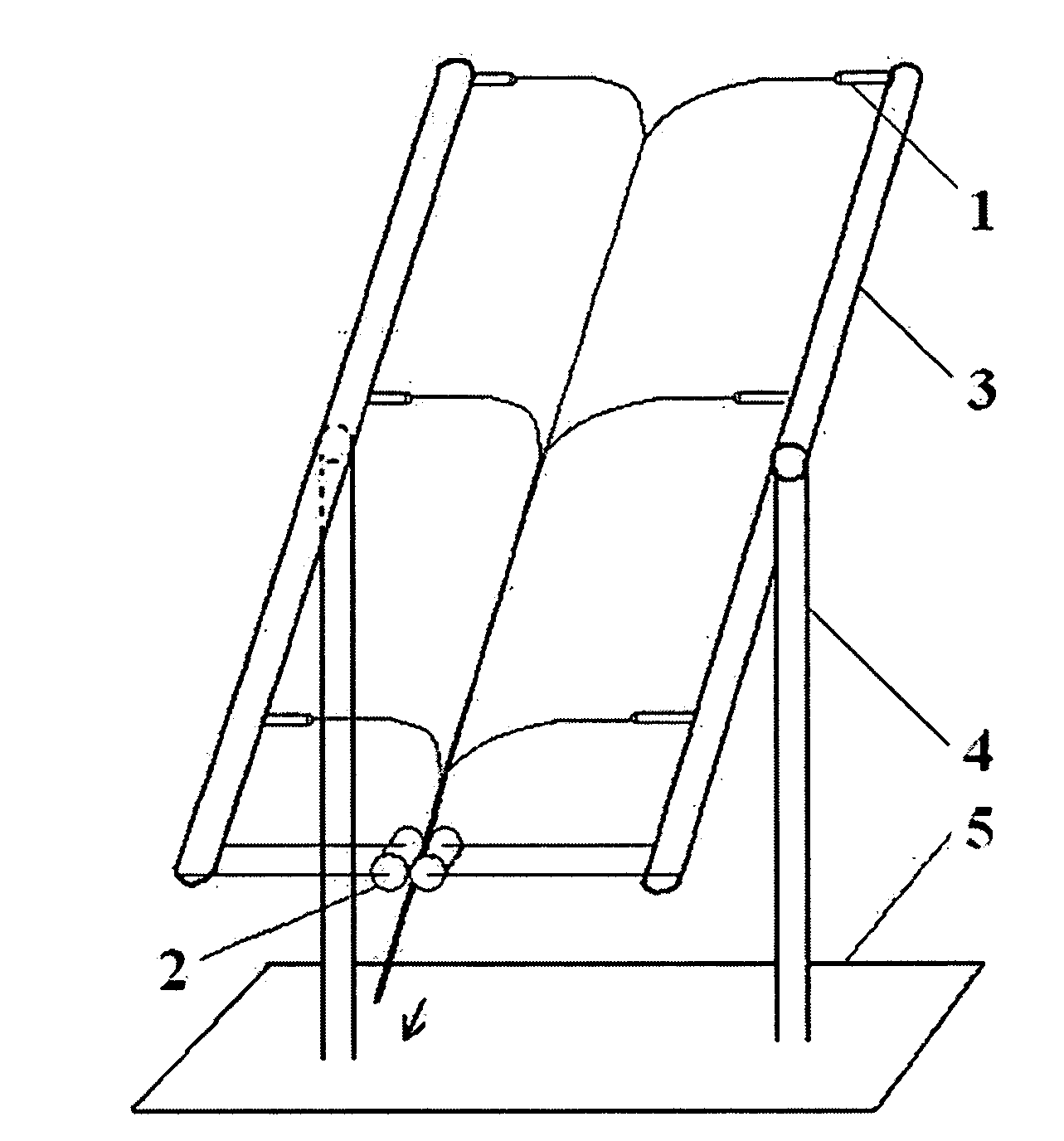

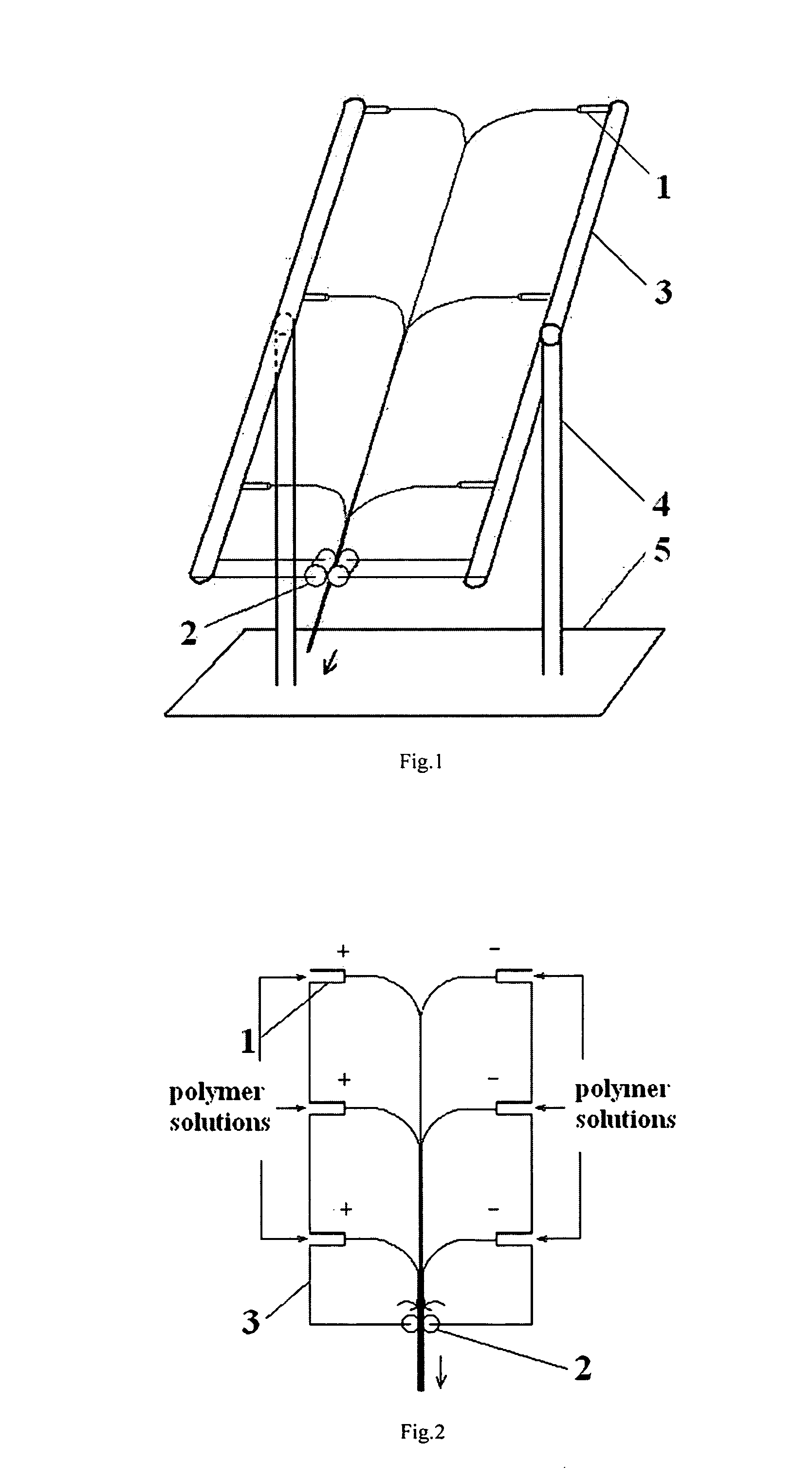

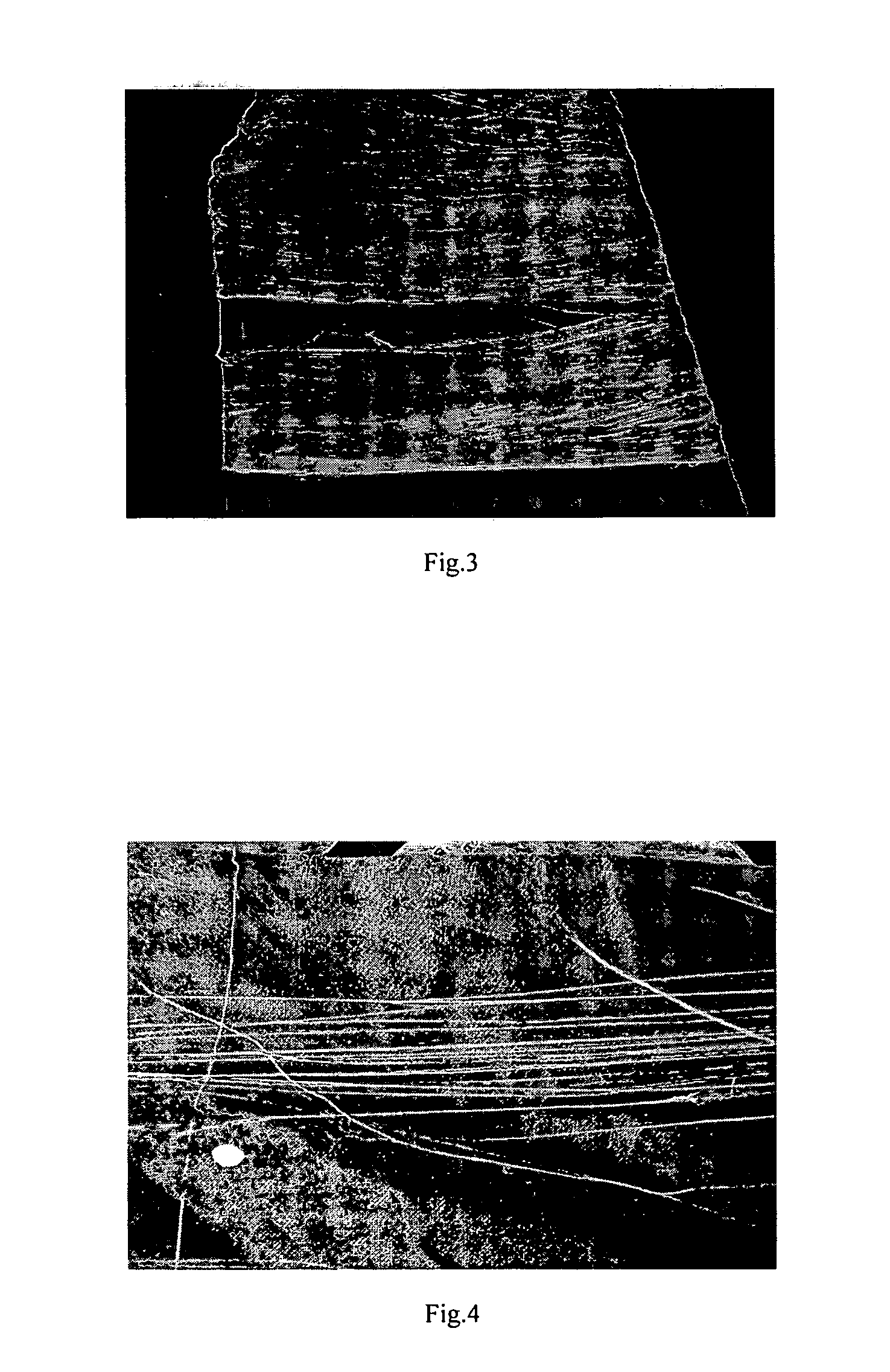

This invention relates to a high mightness compound nm fiber long yarn composed of a core and a cortex, in which, the core is macromolecular filament or long yarn and the cortex is bio-macromolecular nm fiber. The preparation method includes: taking macromolecular filament or long yarn as the leading silk of the core, putting a pair or multi-pair of spinnerets and enforcing DC high voltage with opposite polarities to the spinnerets with the spouts opposite, and the macromolecular solution at the top of the spinnerets is extended and whipped acted by the electric field force to form nm fiber with charges and the nm fibers ejected from the spinnerets carry opposite charges, so that they attract each other in the air to deposit on the core leading silk, and the core tracts forward to get high mightness macromolecular long yarn wrapped with nm fibers on the surface.

Owner:SOUTHEAST UNIV

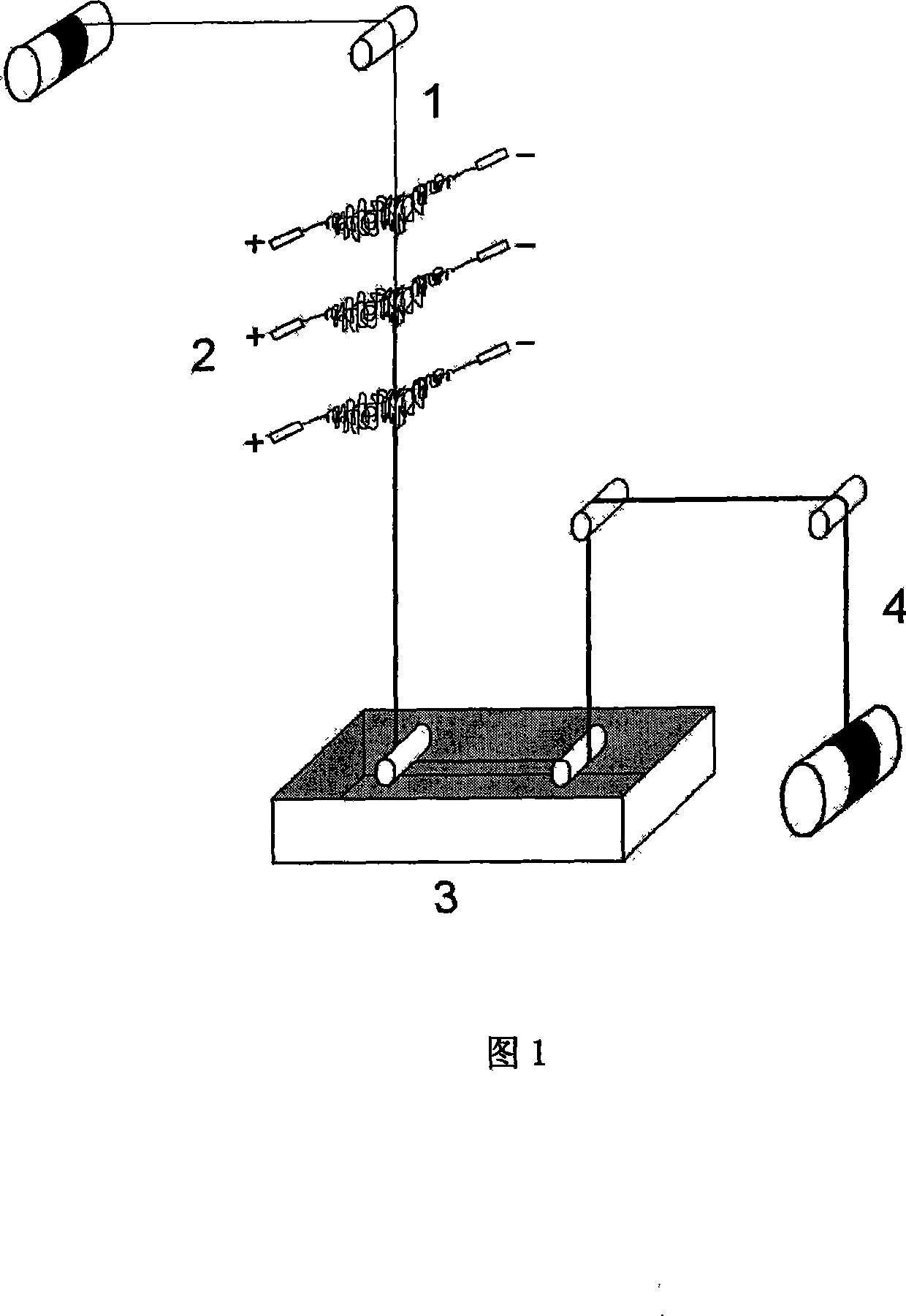

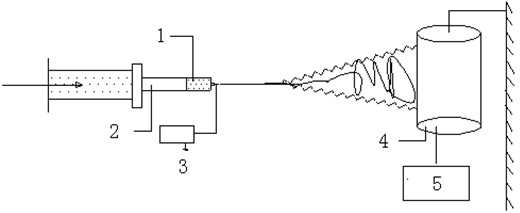

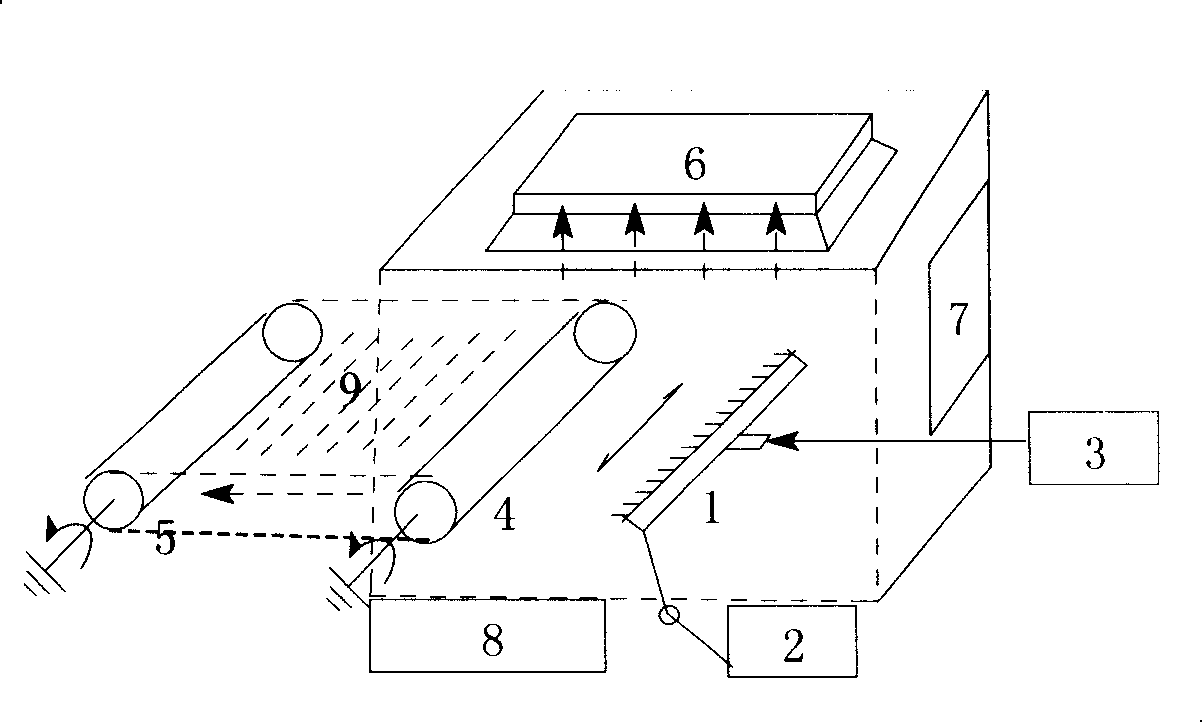

Method for preparing nano fiber endless tow

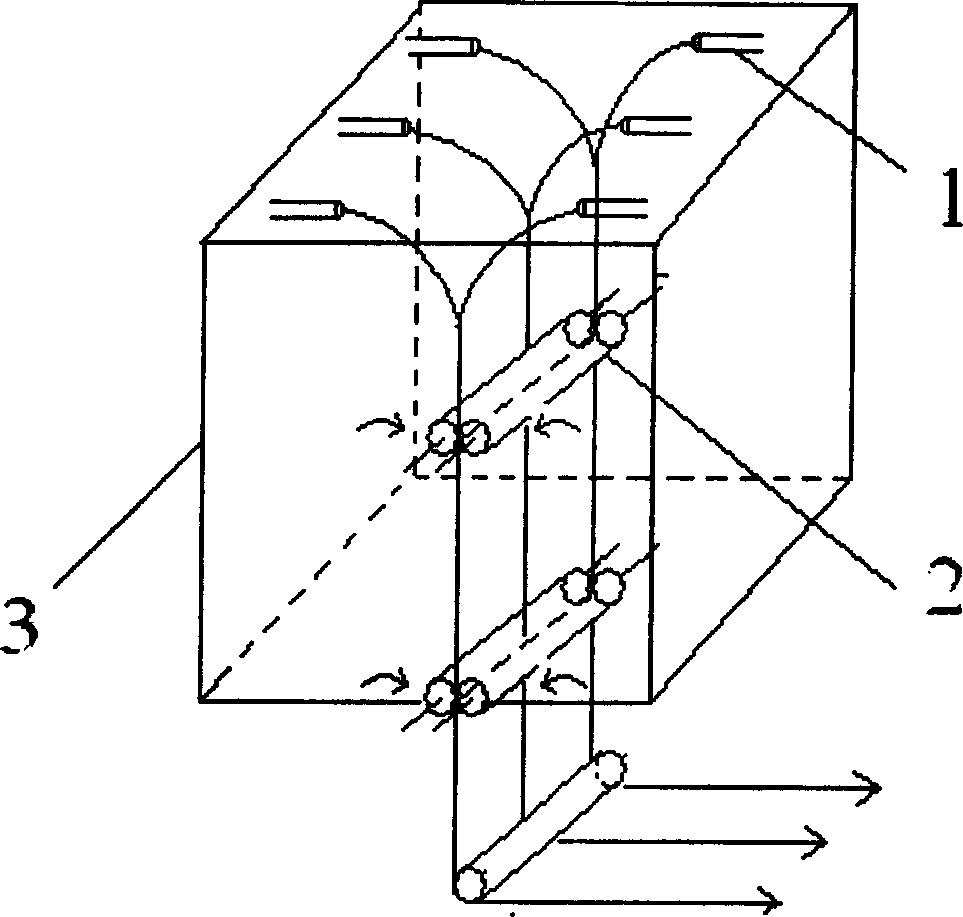

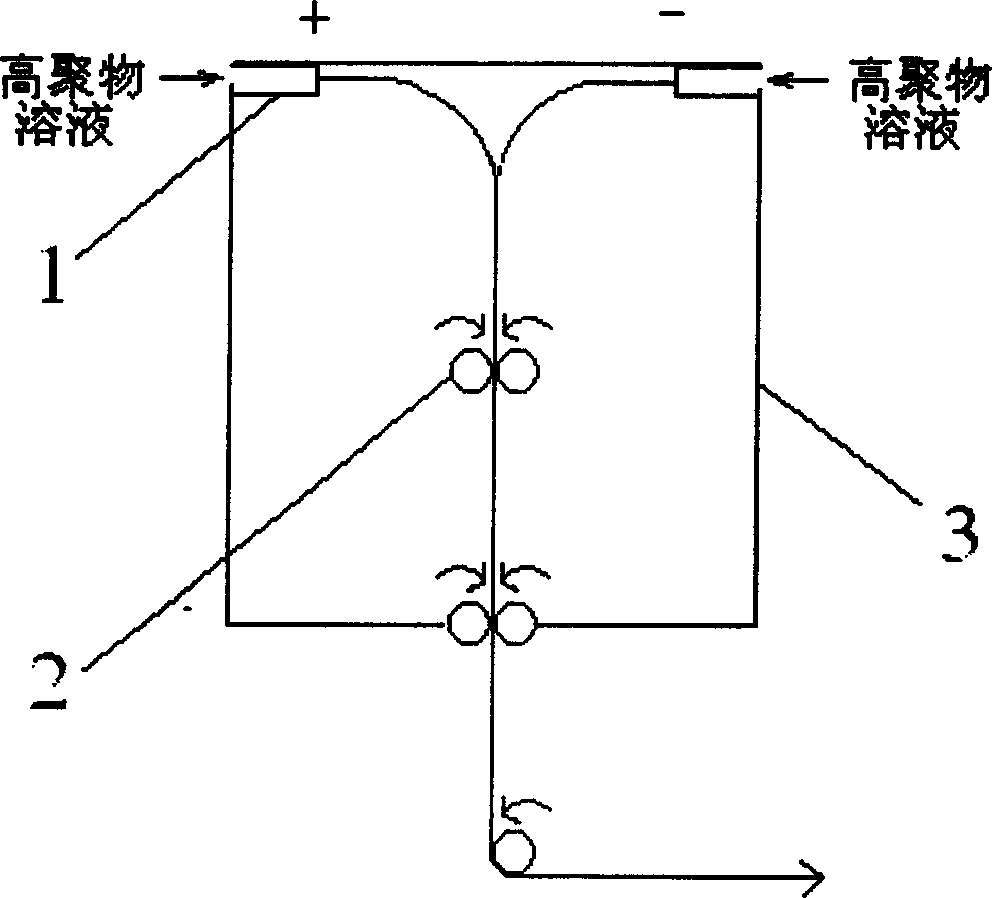

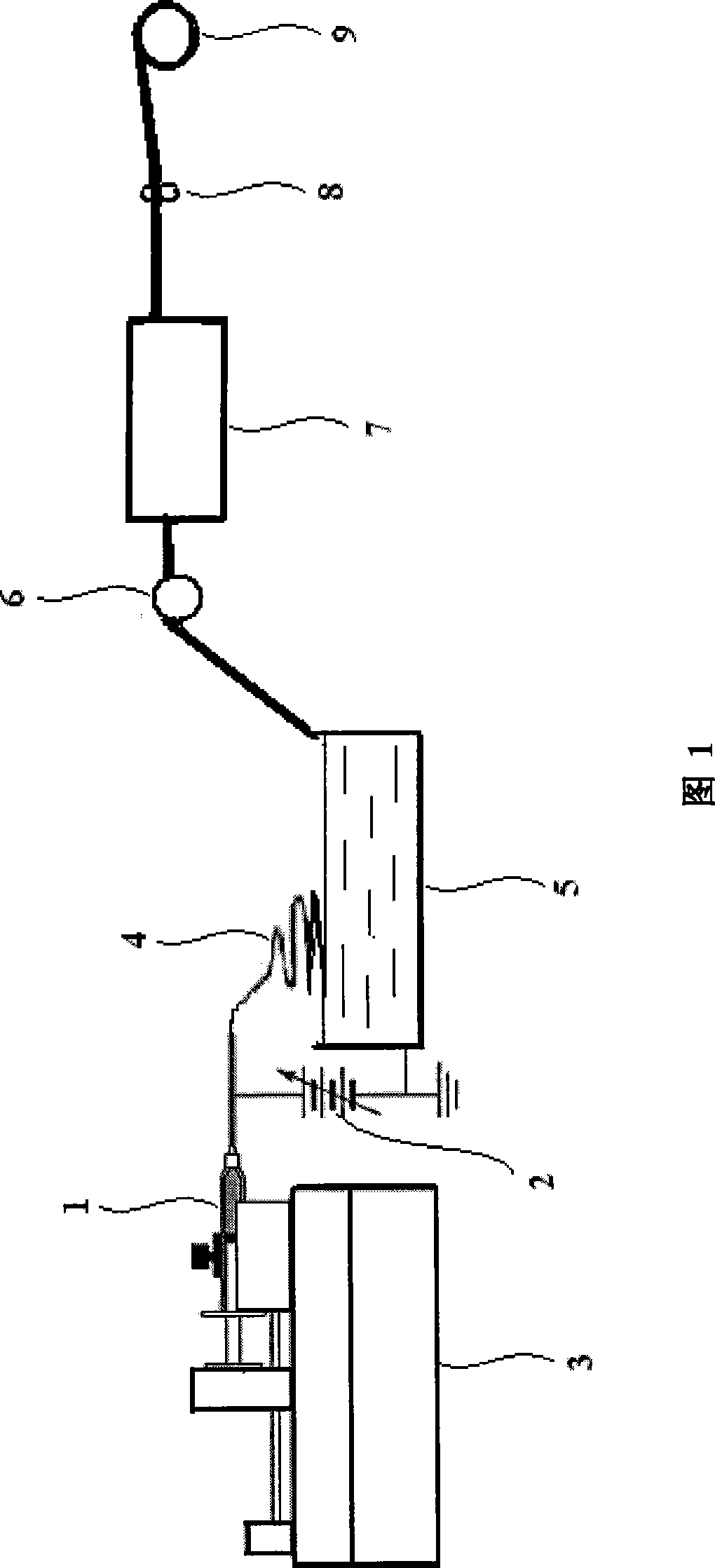

The production method of filament of nanofibers is a simply and high efficiency way. It adopts spinning trunk (3). There are two lines of nozzles (1) whose spout are opposite at the height of the top of the trunk. There are several group of pare of thread guide roller (2) in the trunk.. The distance between thread guide roller and nozzles are equal. The material process is: 1) Transport high polymer solution to nozzles in the trunk of filament of nanofibers; 2) Bring high-voltage DC of opposite polarity to bear to the nozzles. 3) High polymer solution at the top of the nozzles is stretched and whipping responded to form nanofibers which contain electric charge. The opposite nozzle spray nanofibers contains contrary electric charge. They are allure and collide in the air and form nanofibers. The nanofibers are stretched and towed by nozzle and filament of nanofibers comes into being. The operation is simple, highly effective and has no losing of nanofibers.

Owner:SOUTHEAST UNIV

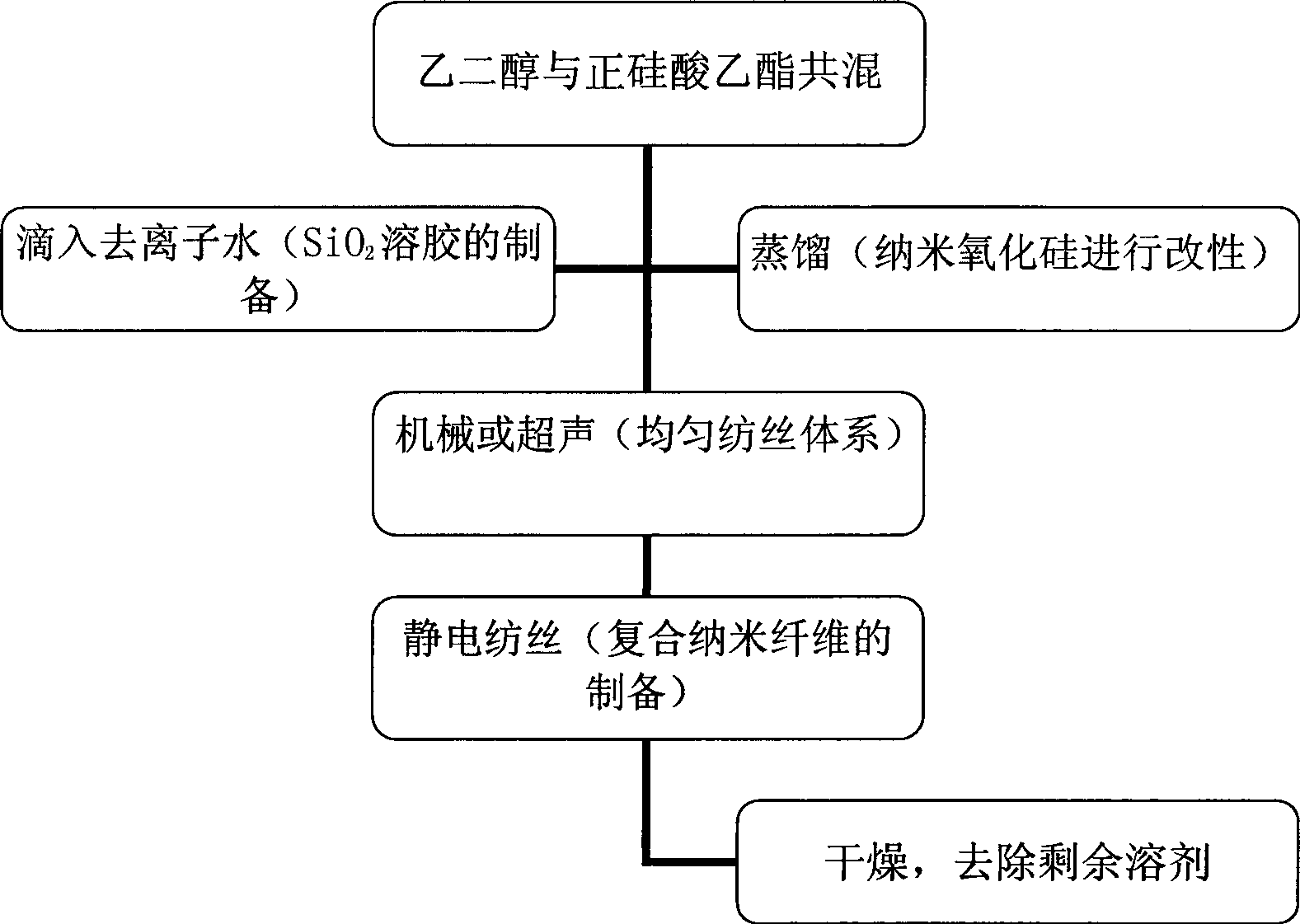

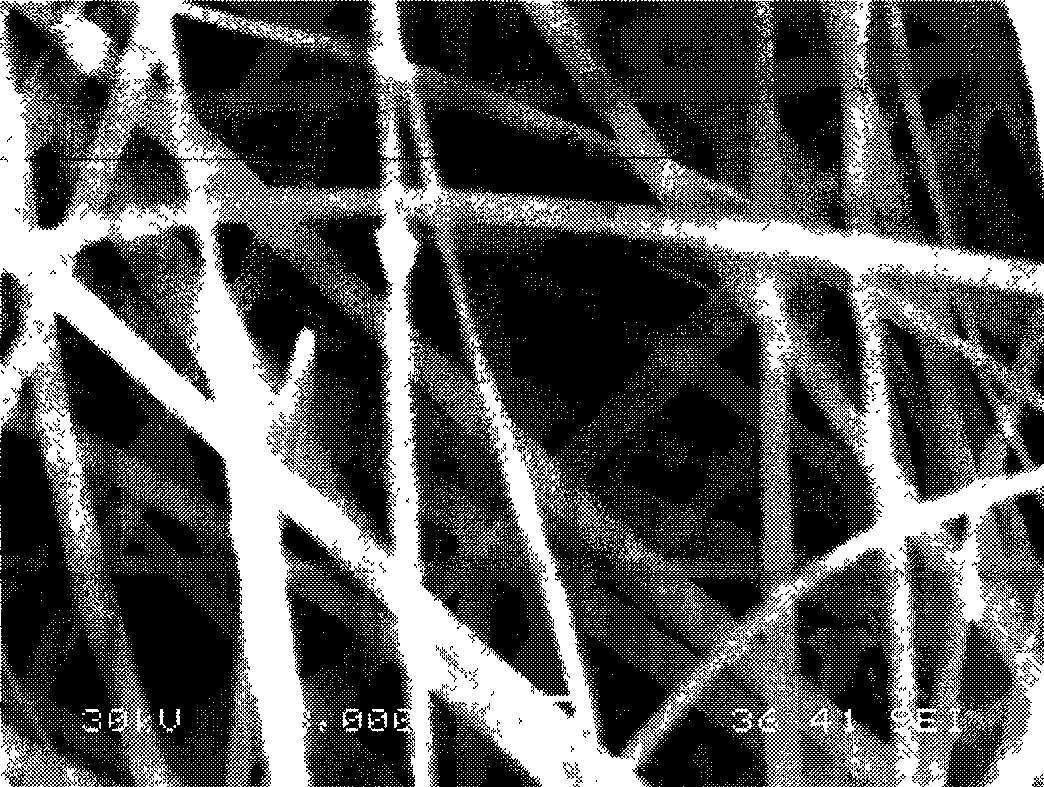

Preparation of silicon dioxide / polyvinylidene fluoride composite nano fiber film

InactiveCN101481855AHigh strengthImprove photoelectric performanceFilament/thread formingNon-woven fabricsLithium-ion batterySilicon dioxide

A preparation method of a silicon dioxide / polyvinylidene fluoride composite nano-fiber membrane relates to the technical fields of preparing modified nano-silicon dioxide by a sol-gel method, preparing a silicon dioxide / polyvinylidene fluoride nano-fiber membrane by an electrostatic spinning device and the like. The preparation method comprises the following steps: preparing the modified nano-silicon dioxide in virtue of a sol-gel principle by a one-step method; mixing the modified nano-silicon dioxide with the polyvinylidene fluoride; and preparing the composite nano-fiber by an electrostatic spinning technology. The preparation method helps relieve the disadvantages of low strength of the nano-fiber, long preparation flow of the modified nano-silicon dioxide, complex process and the like in the electrostatic spinning technology. The nano-fiber prepared by the method has the advantages of high strength, high machinability, short fiber diameter and uniform distribution and can be widely applied to a plurality of fields such as lithium ion battery diaphragm, filtering, biomedical material and the like.

Owner:JIANGNAN UNIV

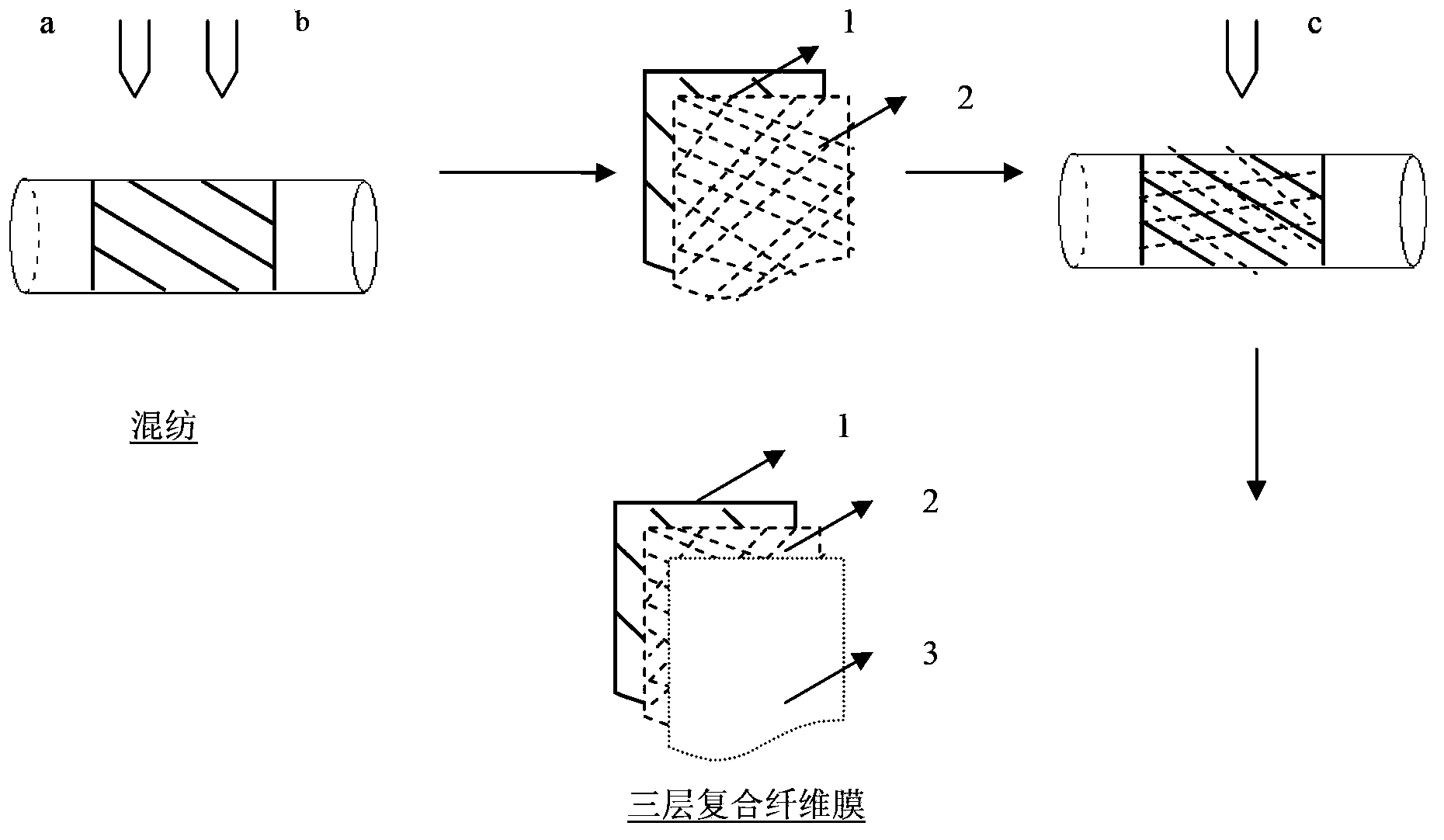

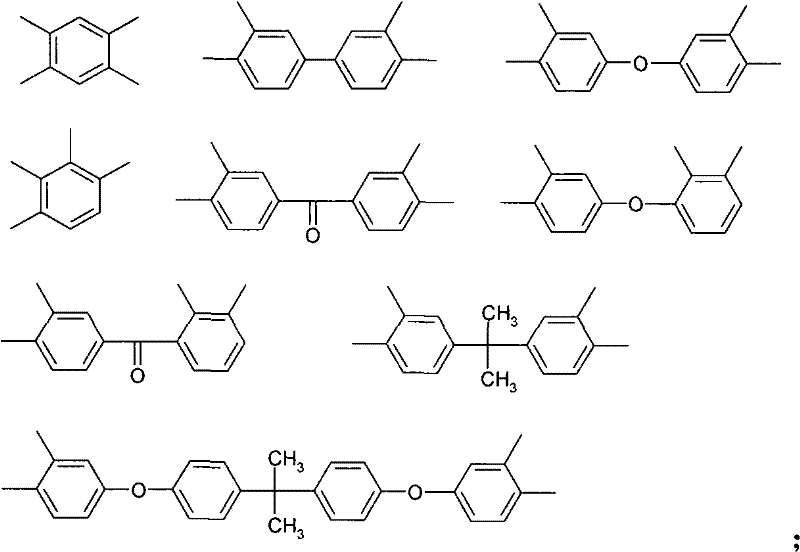

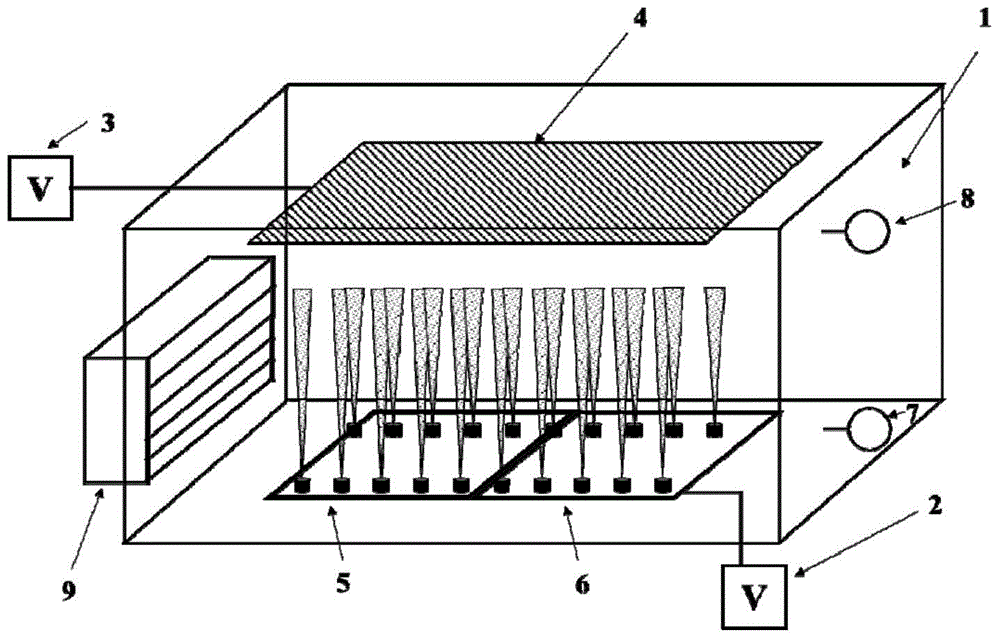

Device and Method for Preparing Filament Yarn of Composite Nanofibers

InactiveUS20080265469A1Less dispersionImprove mechanical propertiesFilament/thread formingConjugated artificial filamentsComposite nanofibersNanofiber

Device and method for preparing filament yarn of composite nanofibers. The device includes pairs of electrospinning nozzles on a frame and filament guiding roller pair under the frame. The spouts of each pair of nozzles are oppositely facing. The method includes feeding polymer solutions to the pairs of nozzles, applying high DC voltage with opposite polarity respectively to each one of the pairs of nozzles, forming composite nanofibers by attracting nanofibers with opposite charge from each nozzle and striking together of the charged nanofibers, pulling / stretching the composite nanofibers to form filament yarn of composite nanofibers, drawing down the filament yarn of composite nanofibers from the first pair of nozzles and using it as a carrier to receive the nanofibers with opposite charge electrospun from the second pair of nozzles and coated by the same so as to form multi-layer (e.g., two- or more-layer) filament yarn of composite nanofibers.

Owner:SOUTHEAST UNIV

Anti bacteria natural silk composite nano-fiber material and its preparation method

InactiveCN1904159AGood tissue compatibilityNon-toxicConjugated cellulose/protein artificial filamentsWet spinning methodsTextile fiberResist

This invention discloses a compound antibacterial silk nanometer fibrous material, accounting for weight its component proportion are: Sericin protein 58-90%; chitosan or chitin 0-40%, antibacterial agent 0-5%, electric conduction 1-4%,crossing linking 1-4%. Its process is: dissolve the pure sericin protein, antibiotics separately in polar solvent, join electric conduction medicinal preparation and crosslinking agent, using the static electricity spinning technique, making the average aperture for 0.5-5.0 micron, factor of porosity 60-90%, the mean diameter is 40-100nm and the material is nanometer textile fiber adhesive-bonded membrane. This invention has good organization compatibility with human body, Antibiotics and sericin insoluble is in homogeneous solvent, massive holes among the nanometer textile fiber adhesive-bonded membrane, which has outstanding aqueous percolation permeability, antibacterial agent distributes evenly in the nanometer textile fiber, and the medicine release effect is perfect, so it can be a kind of ideal resist bacteria injured medical material.

Owner:SUZHOU UNIV

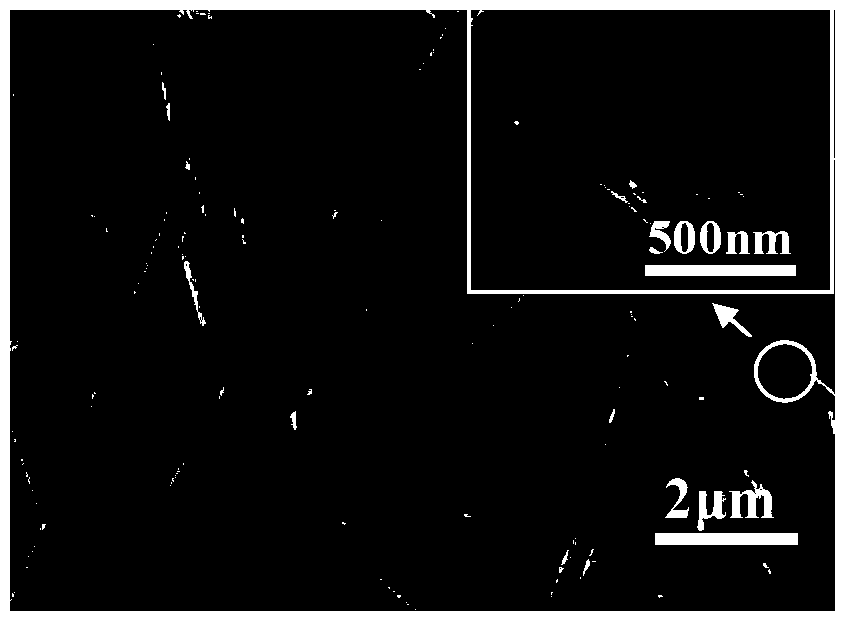

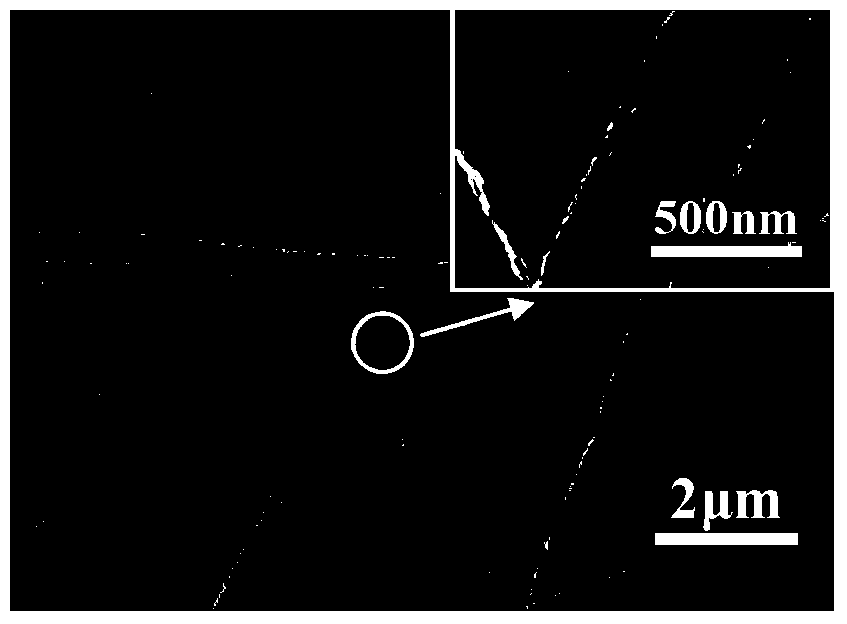

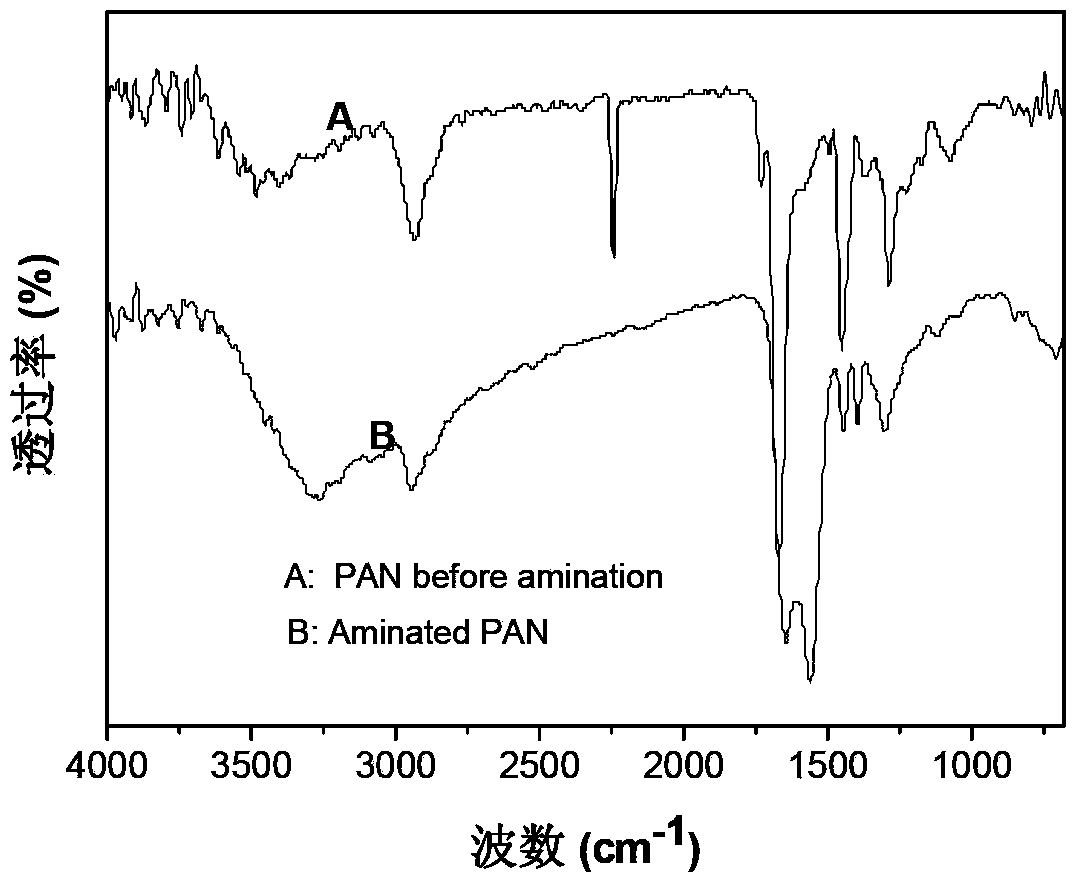

Preparation method of aminated nanofiber membrane with high specific surface area

InactiveCN103394334ALarge specific surface areaIncreased amine contentOther chemical processesFibre treatmentFiberNano structuring

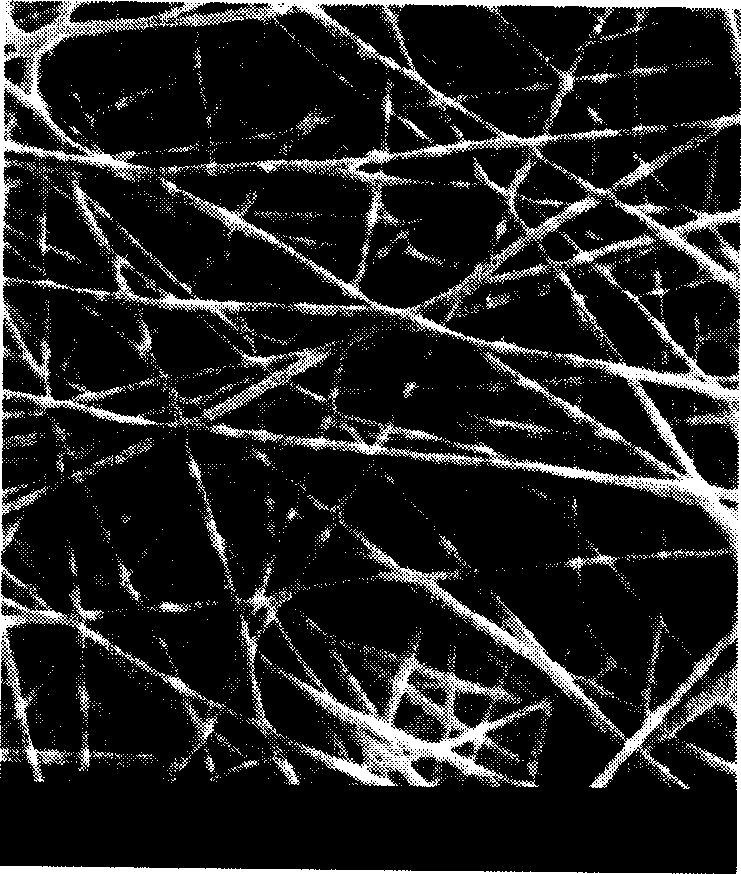

The invention relates to a preparation method of an aminated nanofiber membrane with a high specific surface area. The preparation method comprises the following steps of: dissolving two polymer materials with the weight ratio of 1: (0.1-10) or dissolving a polymer material and an inorganic salt into a solvent, dissolving while stirring at the temperature of 20-80 DEG C for 4-96h, and carrying out electrostatic spinning to obtain a composite nanofiber membrane; soaking the composite nanofiber membrane into water, regulating the pH value, soaking at the temperature of 20-95 DEG C for 2-48h, washing and drying to obtain a nanofiber membrane with a porous micro / nano structure and a high specific surface area; and immersing the nanofiber membrane with a porous micro / nano structure and a high specific surface area into water, adding an amination reaction reagent to carry out amination reaction at the temperature of 50-200 DEG C, then, taking out the fiber membrane, washing the fiber membrane to be neutral, and drying the fiber membrane to obtain the aminated nanofiber membrane with a high specific surface area. The product provided by the invention is applied to fields such as adsorption and separation of precious metal ions, heavy metal ions and transition metal ions, chemical probes, sensors, environment monitoring, catalysts, biological medicines and the like.

Owner:DONGHUA UNIV

Preparation method of inorganic/organic multi-drug controlled release composite nano fiber scaffold

InactiveCN103751851ASimple and fast operationEase of mass productionOrganic active ingredientsPharmaceutical non-active ingredientsFiberBiocompatibility Testing

The invention relates to a preparation method of inorganic / organic multi-drug controlled release composite nano fiber scaffold, which includes the steps of preparing drug loading nanoparticle with particle size of 5-500 nm, preparing mixed solution of high molecular polymer and drug, adding multiple drug loading nanoparticles into the polymer solution, ultrasonically stirring, and carrying out electrostatic spinning to obtain inorganic / organic multi-drug controlled release composite nano fiber scaffold with diameter of 50-800 nm. The preparation method provided by the invention has the advantages of mild reaction conditions, simple operation, and easy experimental apparatus, and is in favor or large-scale production; the obtained multi-drug controlled release composite nano fiber scaffold has good stability and good biocompatibility and biodegradability, and can be stored for a long period of time, and the degradation product is non-toxic. The inorganic / organic multi-drug controlled release composite nano fiber scaffold can be widely applied in the fields of tissue engineering, biomedical engineering, drug therapy and the like.

Owner:DONGHUA UNIV

Preparation method of titanium dioxide/active carbon composite nanofibrous membrane

InactiveCN102021676AAchieve mass productionImprove bindingWater/sewage treatment by irradiationOther chemical processesSpinningPhosphoric acid

The invention provides a preparation method of a titanium dioxide / active carbon composite nanofibrous membrane, characterized by comprising the following specific steps: dissolving polyacrylonitrile powder in N, N-dimethyl formamide; mixing titanium hydroxide gel with the polyacrylonitrile solution to obtain electrostatic spinning stock solution, and performing electrostatic spinning to get the composite nanofibrous membrane; placing the composite nanofibrous membrane in an electrically heated drying cabinet for being pre-oxidized; soaking the composite nanofibrous membrane in phosphoric acid or potassium hydroxide solution, washing the solution to be neutral by distilled water, and drying the composite nanofibrous membrane in the drying cabinet; and then, under nitrogen protection, heating up to 450-550 DEG C, and cooling to room temperature to get the titanium dioxide / active carbon composite nanofibrous membrane. The preparation method improves combination firmness between fibers and active ingredients of a photocatalyst, and also improves charge capacity of the fibers; the titanium dioxide / active carbon composite nanofibrous membrane is high in photo catalytic activity, good in absorption effect, reproducible and simple in a reproduction method, and can use sunlight, so that operations are easy and operation cost is low.

Owner:DONGHUA UNIV

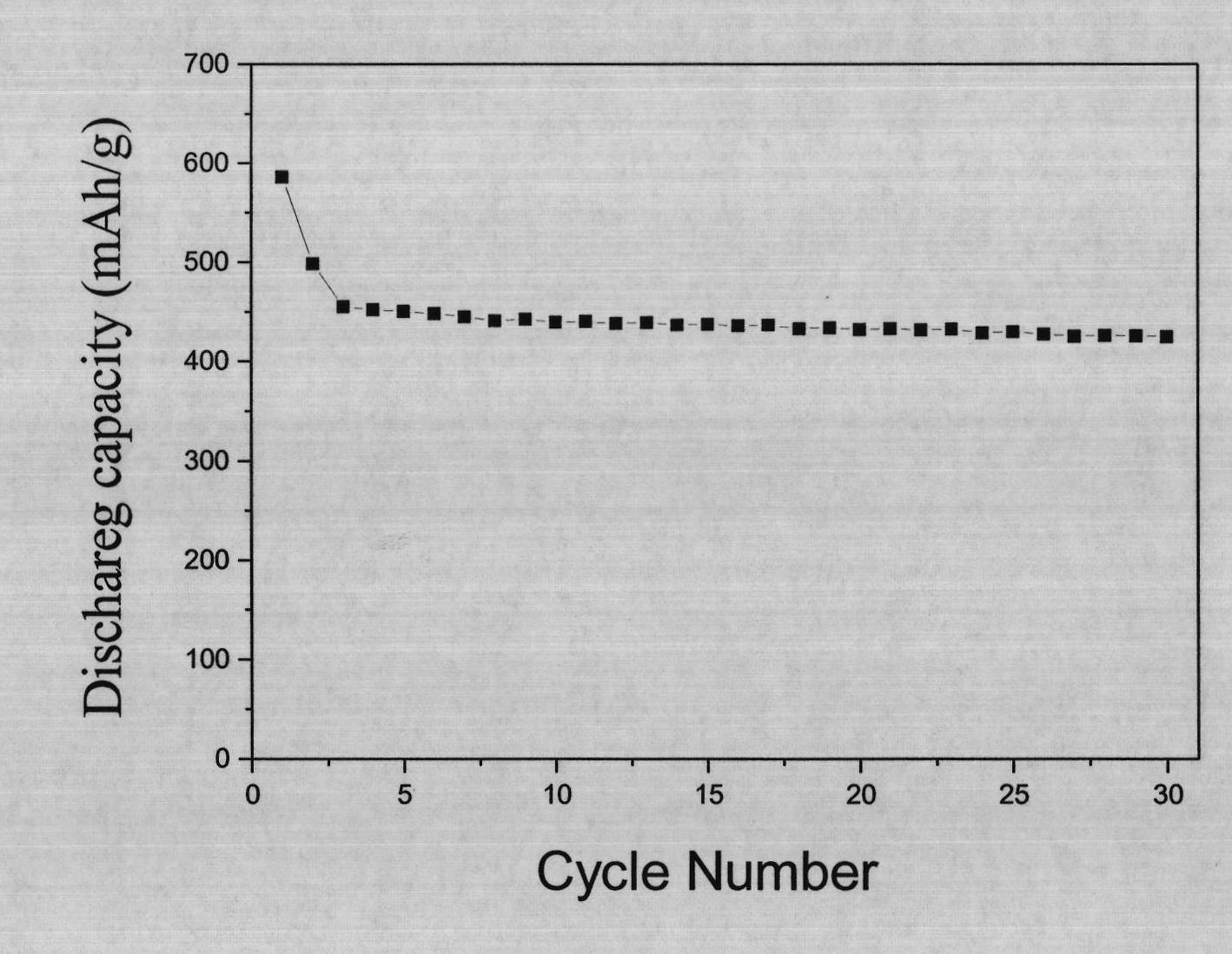

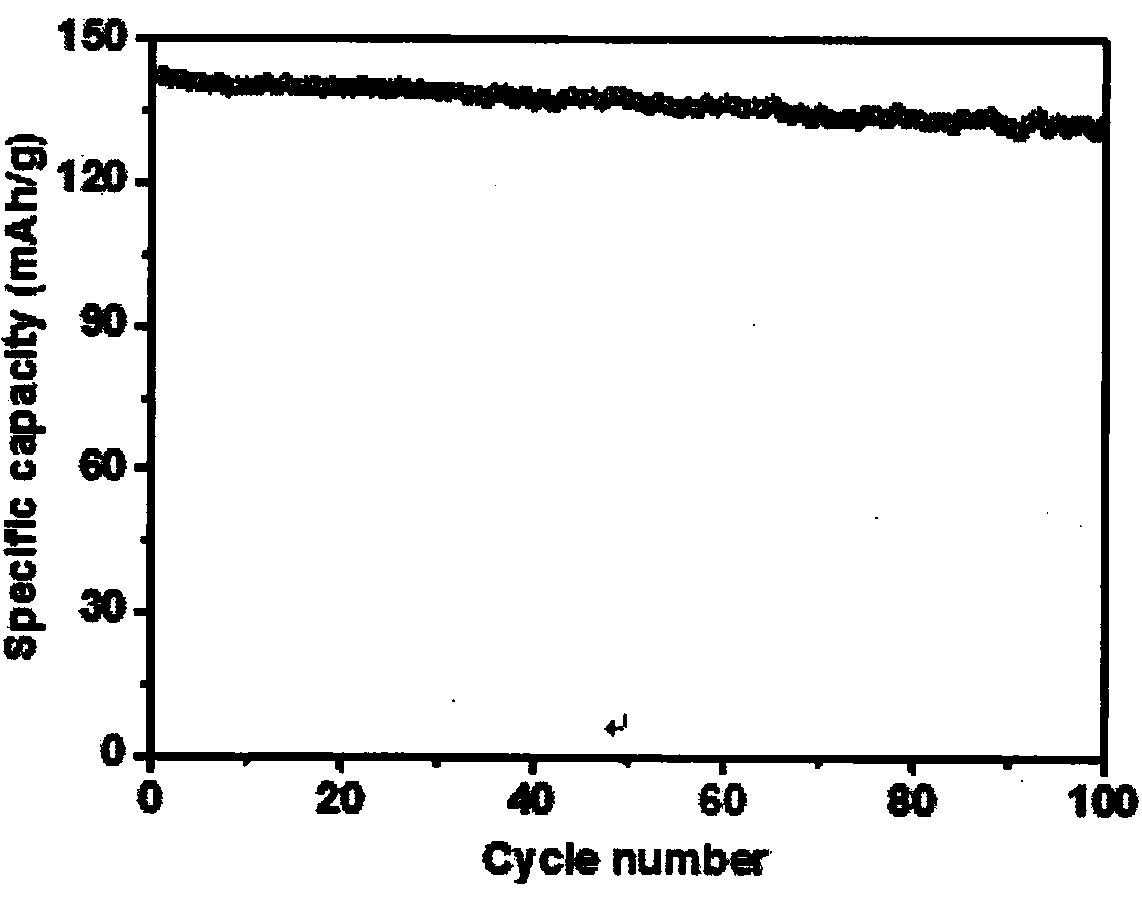

Porous carbon nanofiber anode material for lithium ion battery and preparation method thereof

InactiveCN102074683AImprove power characteristicsImprove efficiencyCell electrodesNanotechnologyFiberPorous carbon

The invention provides a porous carbon nanofiber anode material for a lithium ion battery and a preparation method thereof, belonging to the technical field of nanometer materials and chemical power sources. The material is a carbon nanofiber material with a porous structure, which is provided with larger specific surface. The preparation method comprises the following steps: firstly using an electrostatic spinning technology to prepare composite nanofiber; and then carrying out pre-oxidation and carbonization to obtain the porous carbon nanofiber. The preparation method is simple, is easy to control, and has the advantage of low production cost. The material taken as an electrode material for a lithium ion battery anode provided by the invention has higher initial discharge capacity and cyclical stability, thus improving the high power characteristics and the fast charge-discharge capacity of the anode material, and meeting development requirements on a lithium ion power battery for an electric vehicle.

Owner:JIANGNAN UNIV

Europium-doped Y7O6F9 nano fiber and preparation method thereof

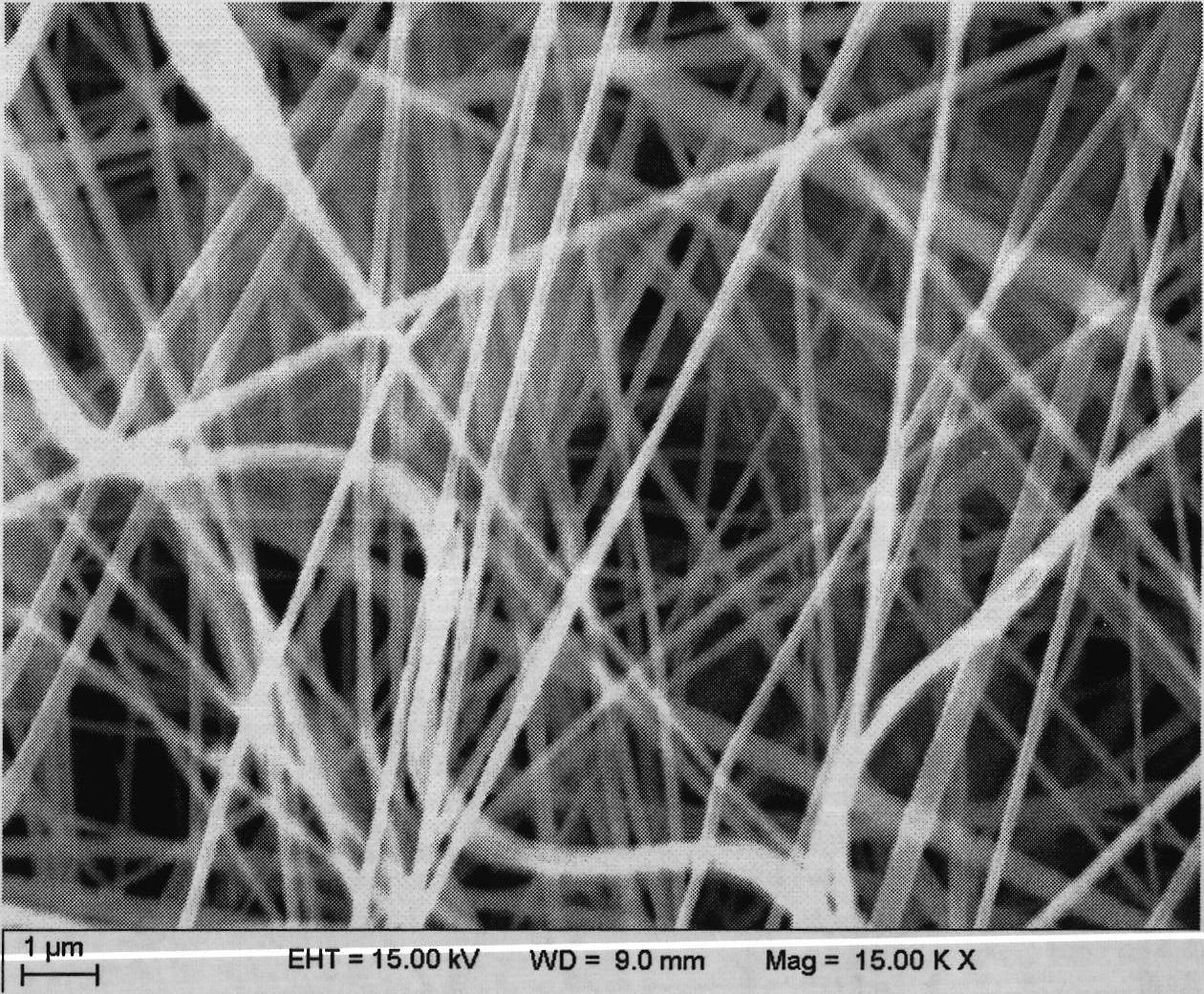

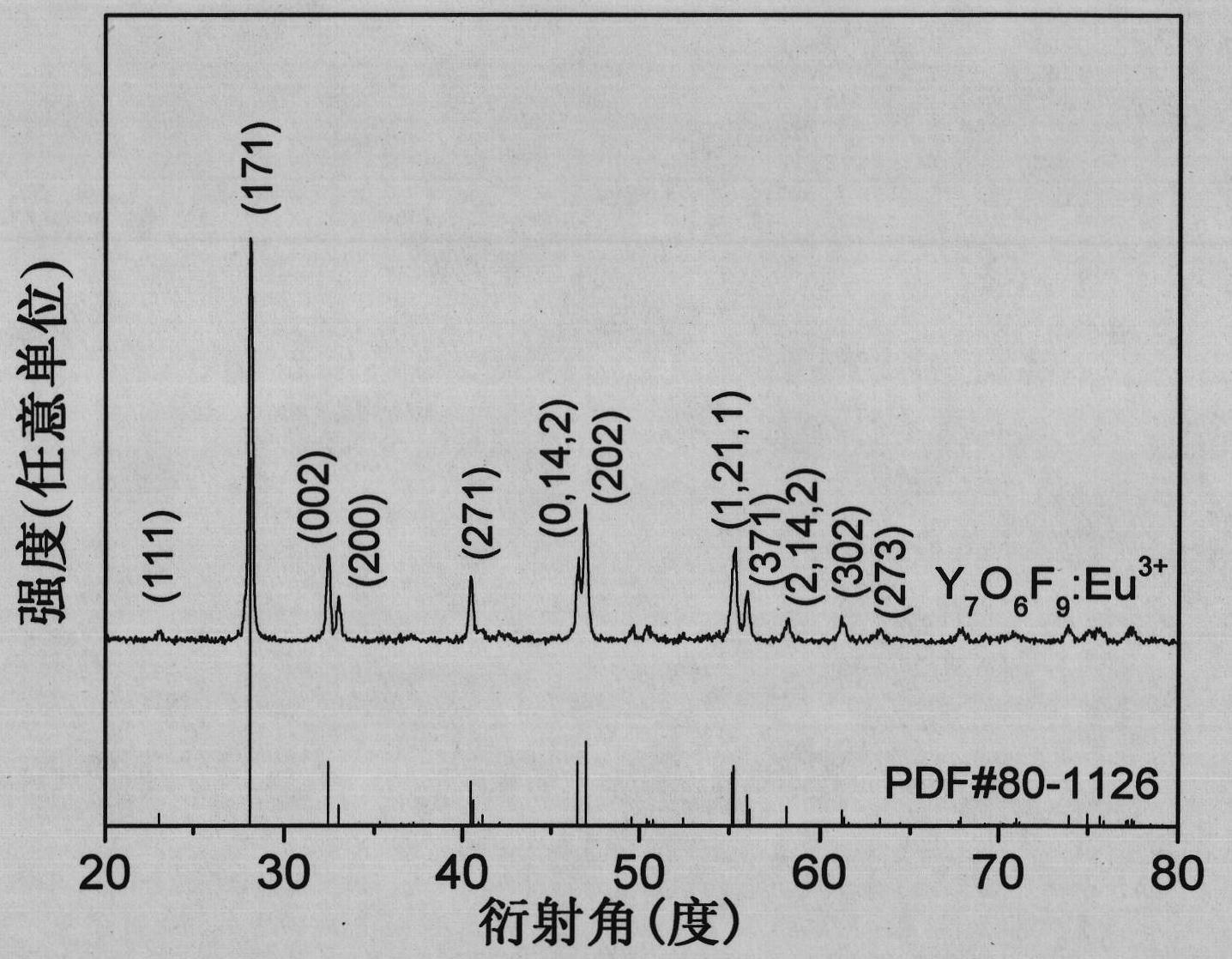

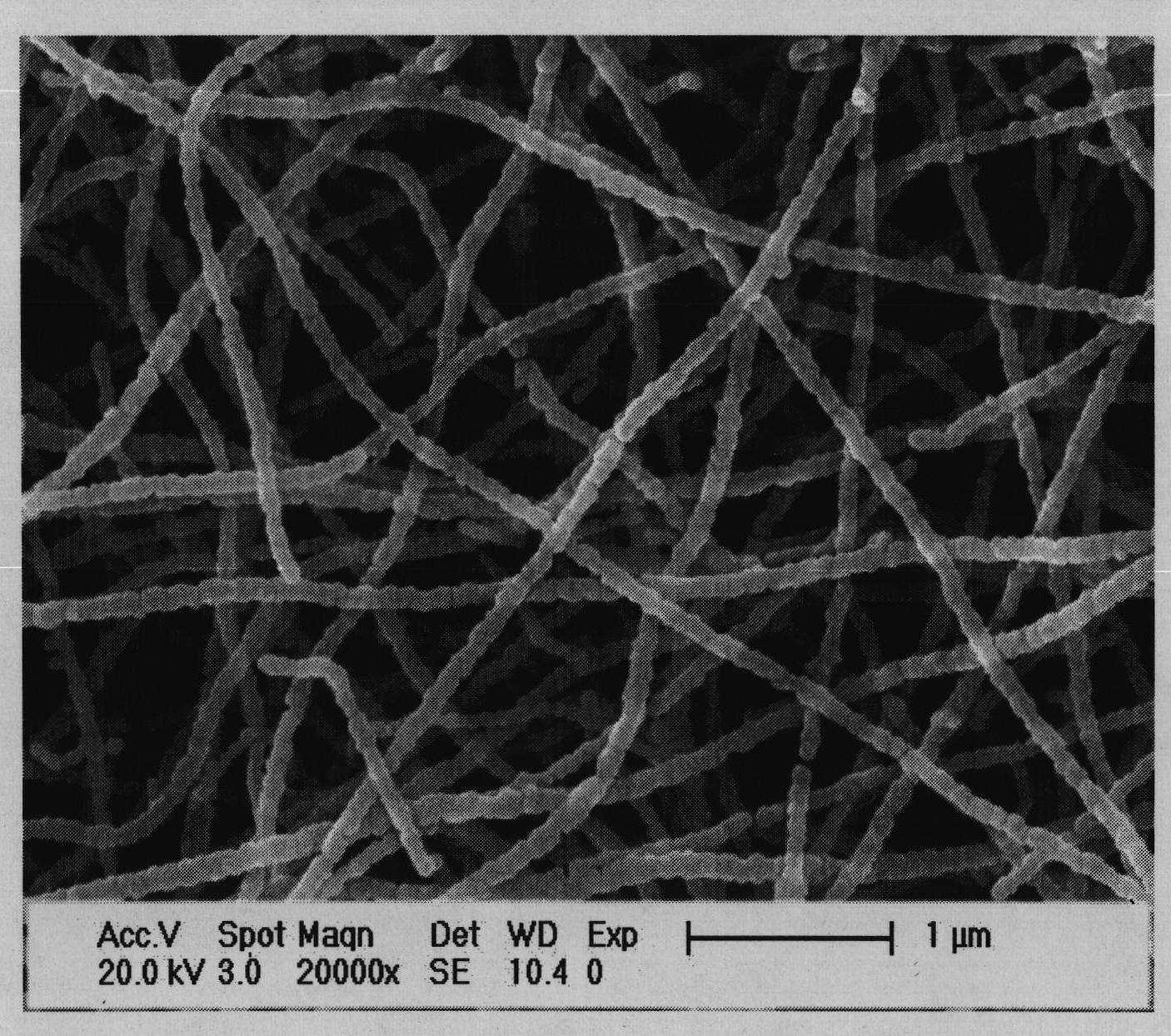

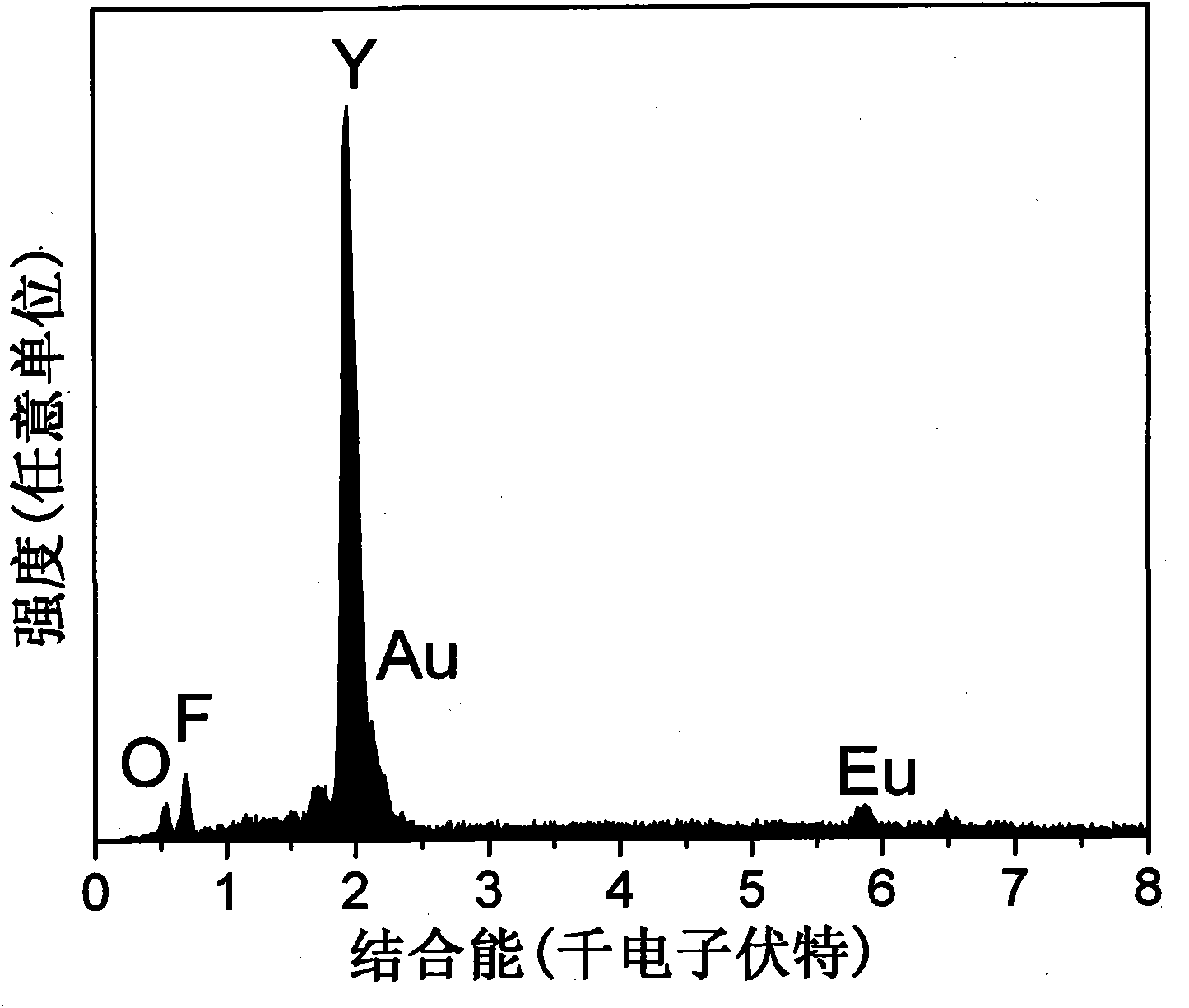

The invention relates to a europium-doped Y7O6F9 nano fiber and a preparation method thereof, belonging to the technical field of the preparation of nano materials. A rare earth fluoride / rare earth oxyfluoride composite nano fiber is prepared by the traditional electrostatic spinning technology. The preparation method provided by the invention comprises the following three steps: (1) preparation of a Y2O3:5%Eu<3+> nano fiber: preparing a PVP / [Y(NO3)3+Eu(NO3)3] composite nano fiber by adopting the electrostatic spinning technology, and then, carrying out heat treatment to obtain the Y2O3:5%Eu<3+> nano fiber; (2) preparation of a YF3:5%Eu<3+> nano fiber: fluorinating the Y2O3:5%Eu<3+> nano fiber by a double-crucible method to obtain the YF3:5%Eu<3+> nano fiber, wherein the fluorinating reagent is ammonium bifluoride; and (3) preparation of a Y7O6F9:5%Eu<3+> nano fiber: placing the YF3:5%Eu<3+> nano fiber in a muffle furnace, heating at 580 DEG C under the air atmosphere for 9 hours to obtain the Y7O6F9:5%Eu<3+> nano fiber, wherein the diameter is 181-241 nm, and the length is greater than 300 mu m. The europium-doped Y7O6F9 nano fiber is a novel important red nano fluorescent material having wide application prospects.

Owner:CHANGCHUN UNIV OF SCI & TECH

Composite nanofiber lithium battery diaphragm and making method thereof

ActiveCN103824988AHigh strengthImproved thermal dimensional stabilityCell seperators/membranes/diaphragms/spacersSecondary cellsSodium-ion batteryAramid

The invention relates to a composite nanofiber lithium battery diaphragm and a making method thereof. The composite nanofiber lithium battery diaphragm is obtained by compounding at least one layer of an aramid 1313 nanofiber film containing nanoparticles with at least one layer of a low-melting-point polymer nanofiber film containing nanoparticles, and nanofibers in the fiber films containing nanoparticles are mutually interlaced and are bonded and connected with each other at interlaced points. The aperture range and the pore closing temperature of the surface layer of the fibers in the composite nanofiber lithium battery diaphragm are 100-400nm and 130-170DEG C respectively, the fiber film does not shrink after the pore closure, the heat shrinkage is less than 2% after the fiber film is heated at 250DEG C for 1h, and the tensile strength is 100-1000MPa, so the composite nanofiber lithium battery diaphragm has the characteristics of heat closing effect, good heat dimension stability and high strength. The making method has the advantages of simple process and low cost, and the obtained composite nanofiber lithium battery diaphragm has a wide application prospect in energy storage fields of supercapacitors, sodium ion batteries and the like.

Owner:DONGHUA UNIV

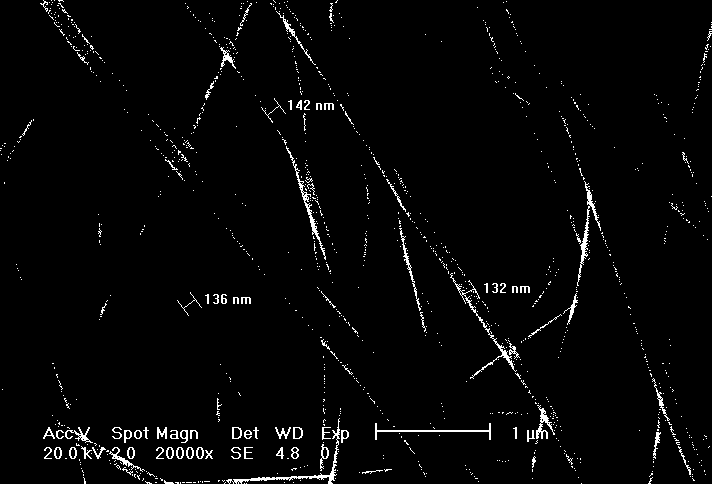

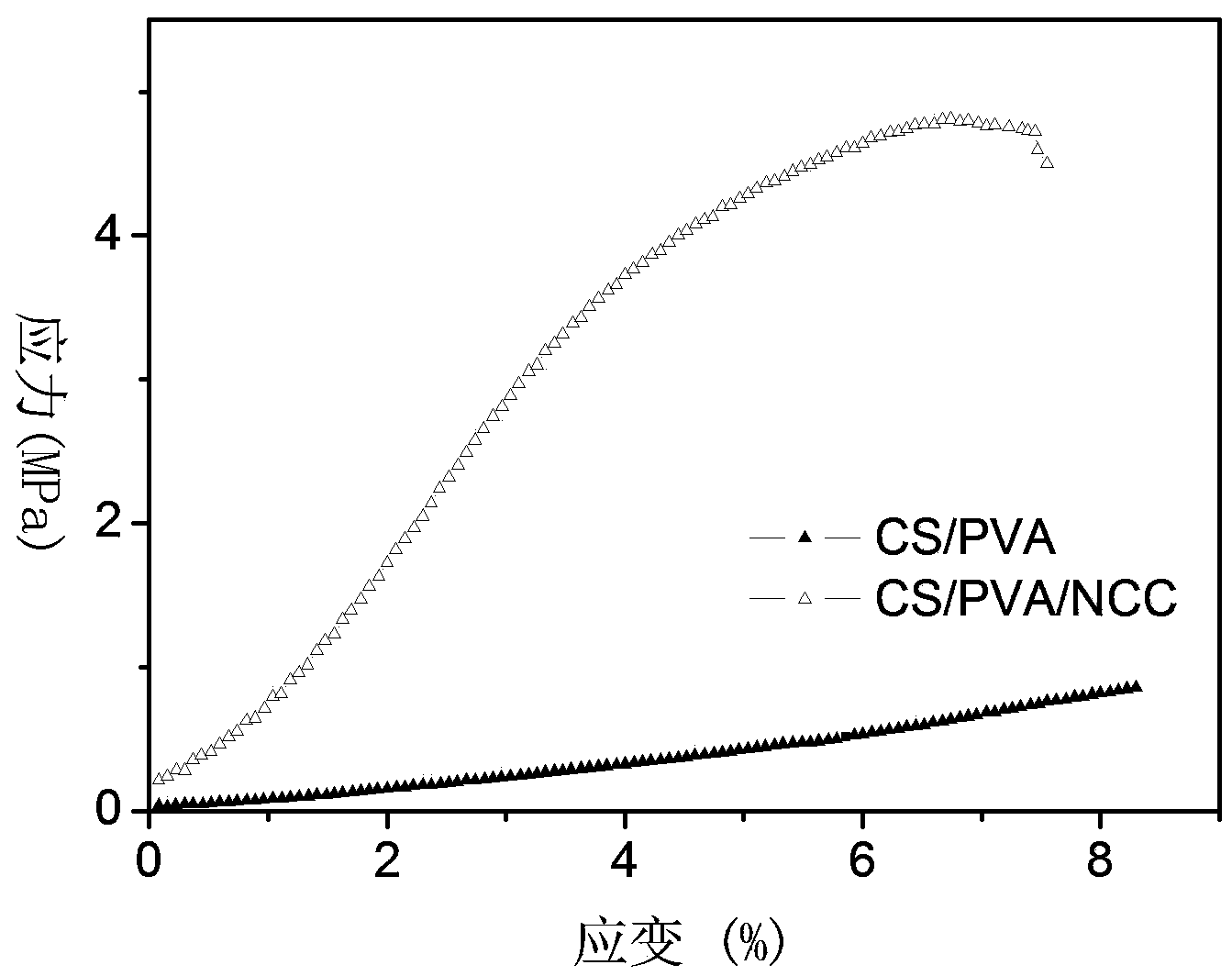

Method for preparing NCC/CS/PVA composite nano-membrane

ActiveCN103866487AAdjustable diameterLarger than surfaceNon-woven fabricsSpinning solutions preparationSpinningSilicic acid

The invention relates to a method for preparing an NCC / CS / PVA composite nanofiber membrane. NCC is rod-shaped particles, wherein the diameter of each particle ranges from 20 nm to 60 nm, and the particles are highly crystallized. The method comprises the steps that (1) an NCC / CS solution is prepared, wherein the concentration of the NCC, by weight, ranges from 0.09% to 0.21%; (2) an NCC / PVA solution is prepared, wherein the concentration of the NCC, by weight, ranges from 0.4% to 0.8%; (3) an acetic acid solution, tetraethyl orthosilicate, the NCC / CS solution obtained in the step (1) and processed through ultrasound, and the NCC / PVA solution obtained in the step (2) and processed through ultrasound are mixed to obtain a spinning solution, and the nanofiber membrane is obtained through the electrospinning technology, wherein the mass ratio of the acetic acid solution to the tetraethyl orthosilicate to the NCC / CS solution to the NCC / PVA solution is (2.5-3.5):(1.5-2.5):5:5; (4) the obtained nanofiber membrane is immersed in an alkaline solution for 2-6 hours at the normal temperature, and the membrane structure can be stable. The method for preparing the NCC / CS / PVA composite nanofiber membrane has the advantages that the nanofiber material preparation process is simple, the preparation process is environmentally friendly and free of pollution, nanofibers are excellent in mechanical performance, the surface of the nanofiber membrane is rich in modifiable functional groups, and the nanofiber membrane has a remarkable affinity effect on biomacromolecule.

Owner:TONGJI UNIV

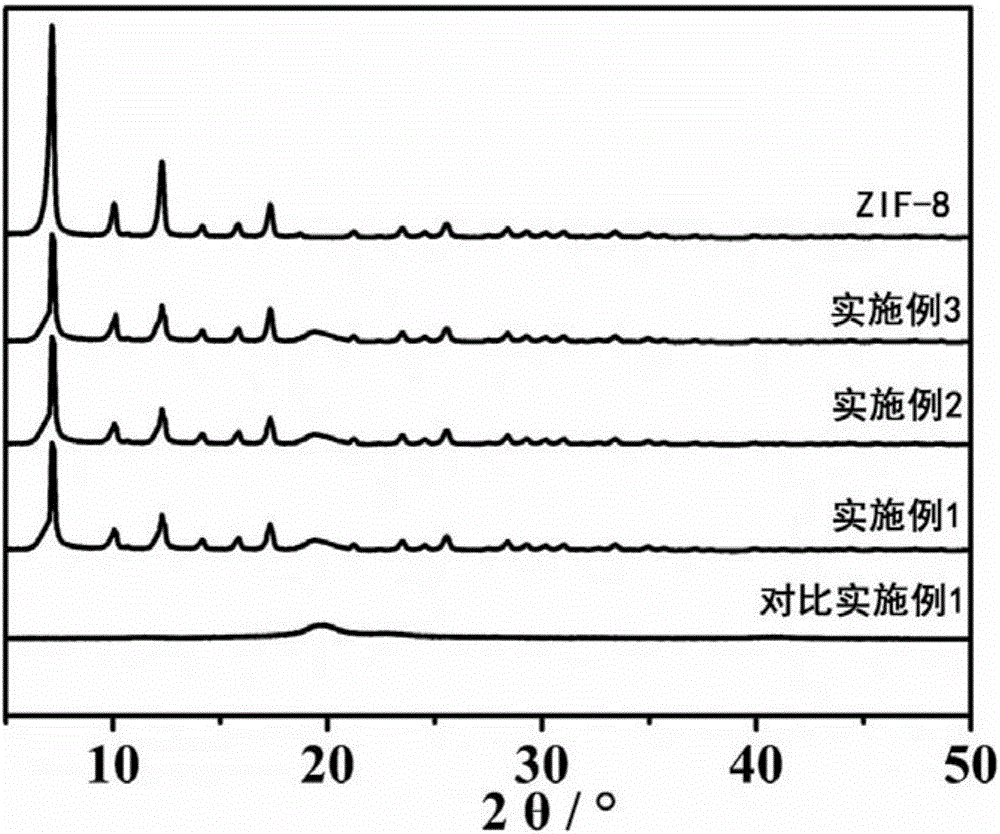

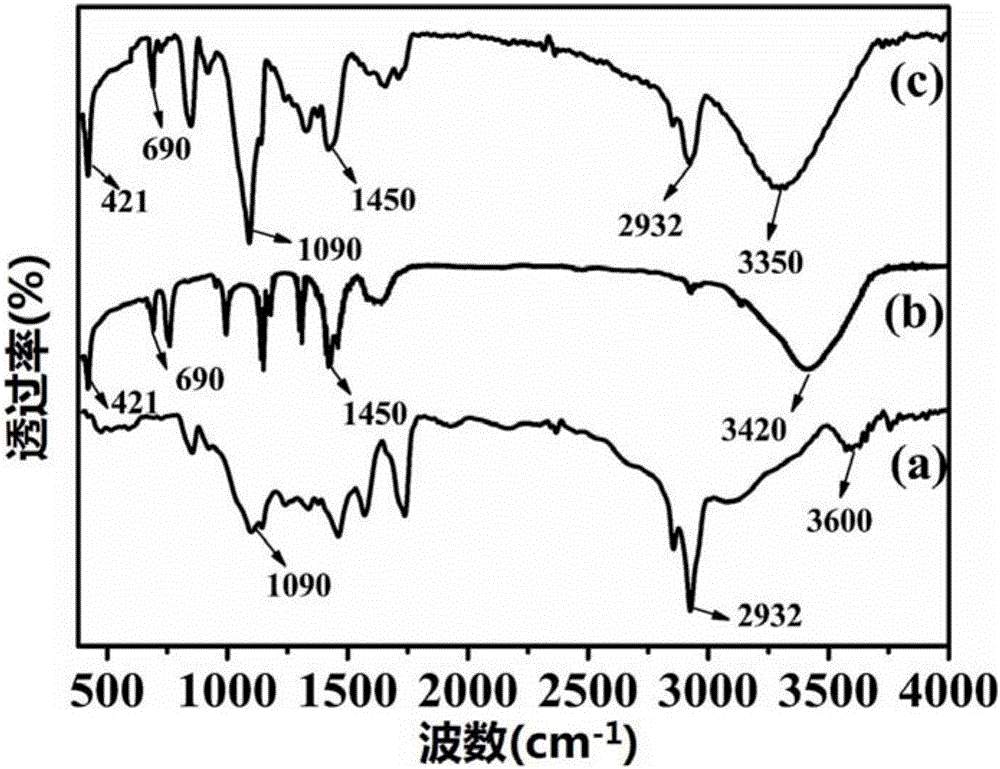

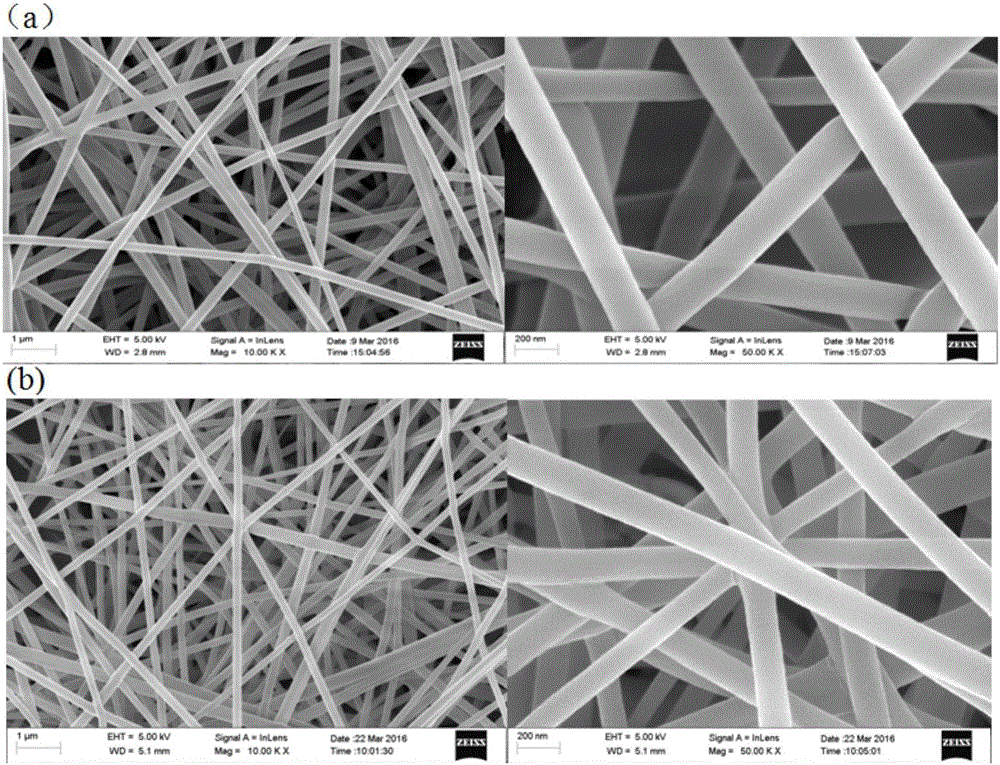

ZIF-8/poly(vinyl alcohol) (PVA) composite nanofiber membrane as well as preparation method and application thereof

InactiveCN105951304AEasy to prepareLow costMonocomponent synthetic polymer artificial filamentNon-woven fabricsMethanolChemistry

The invention discloses a ZIF-8 / poly(vinyl alcohol) (PVA) composite nanofiber membrane as well as a preparation method and application thereof, belonging to the technical field of preparation of functional nanofiber membranes. The method comprises the following steps of: (1) carrying out hybrid reaction on a methanol solution of soluble zinc salt and a methanol solution of 2-methylimidazole under room temperature and purifying an obtained reaction liquid after reaction ends, thus obtaining nano ZIF-8; (2) mixing obtained nano ZIF-8 with PVA, dissolving the mixture in deionized water, stirring the mixture to swell, then carrying out stirring heating reaction and cooling the reactant to the room temperature after reaction ends, thus obtaining an electrostatic spinning solution; and (3) putting the obtained electrostatic spinning solution in an injector to carry out electrostatic spinning, thus obtaining the ZIF-8 / PVA composite nanofiber membrane. The method not only has the effect of overcoming the defect that the ZIF-8 material is difficult to recover and industrially apply in a water phase but also has better selective adsorption property and can be applied to sewage treatment.

Owner:SOUTH CHINA UNIV OF TECH +1

Spider silk protein/polylactic acid composite nano fibre yarn and preparation method thereof

InactiveCN101418472AAvoid difficultiesHigh breaking strengthConjugated cellulose/protein artificial filamentsFilament/thread formingYarnFiber

The invention discloses a method for preparing spider silk protein / polylactic acid composite nano-fiber yarn. The method comprises the following steps of preparing a spinning solution, preparing a bath solution and then adopting an improved electrostatic spinning method to guide, heat, wind and shape bunched fibers, so as to obtain the spider silk protein / polylactic acid composite nano-fiber yarn. The composite nano-fiber yarn of the invention can be continuously spun for more than 10 hours and have no broken ends, and a certain amount of spider silk protein effectively reduces the diameter of the fibers and improves the strength of the yarn. In addition, the fracture strength and flexibility of the composite nano-fiber yarn can be further improved through secondary stretching and combined twisting, so that the composite nano-fiber yarn can be applied in biomedical materials and other fields better.

Owner:SUZHOU UNIV

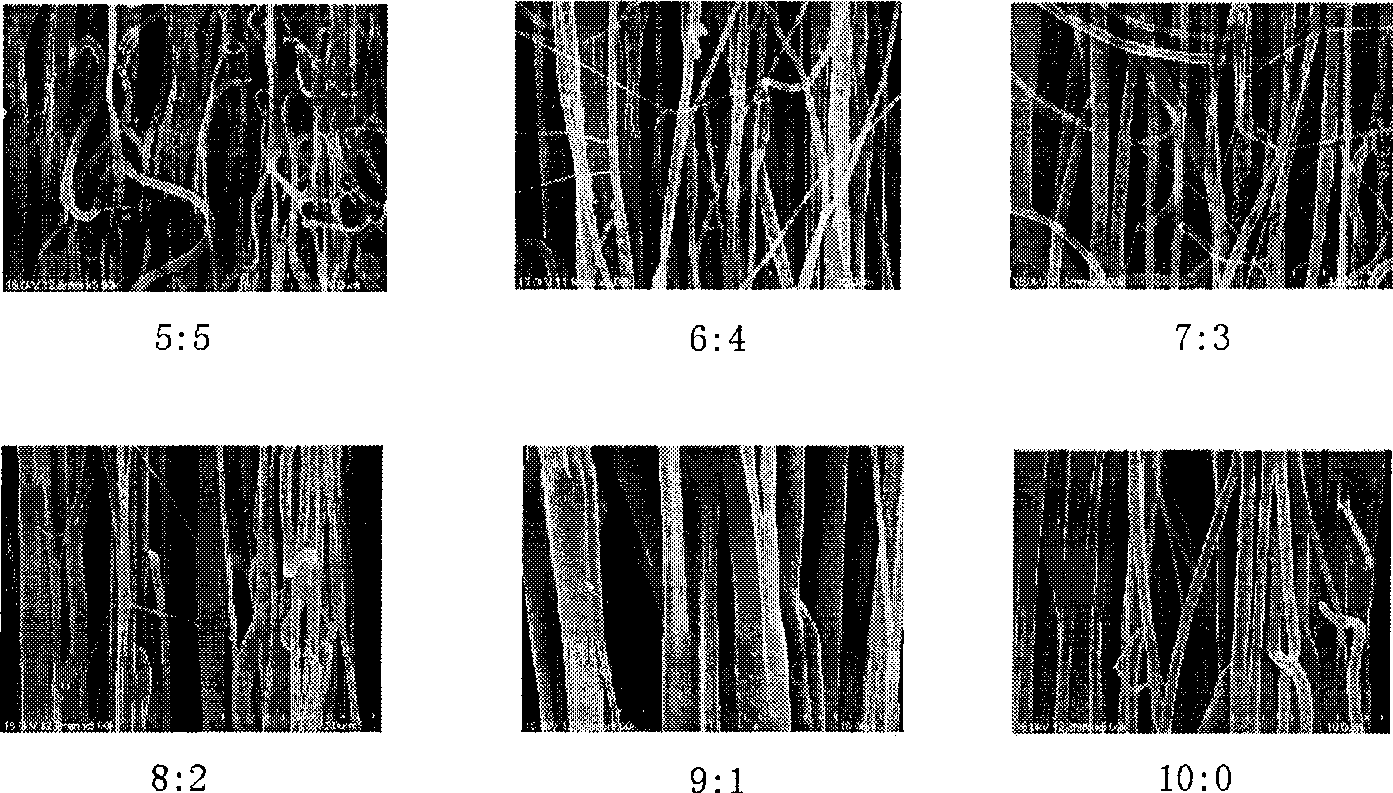

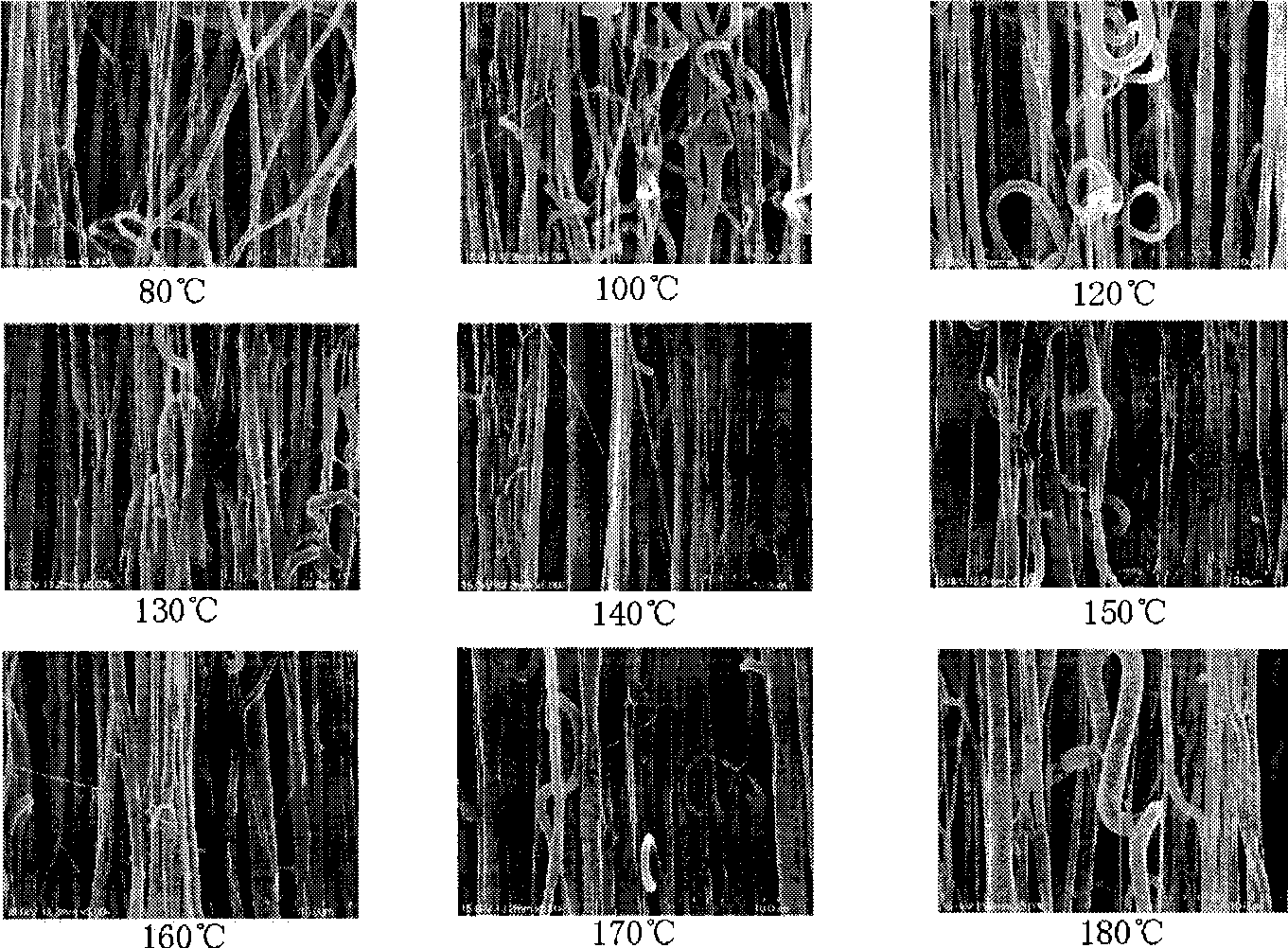

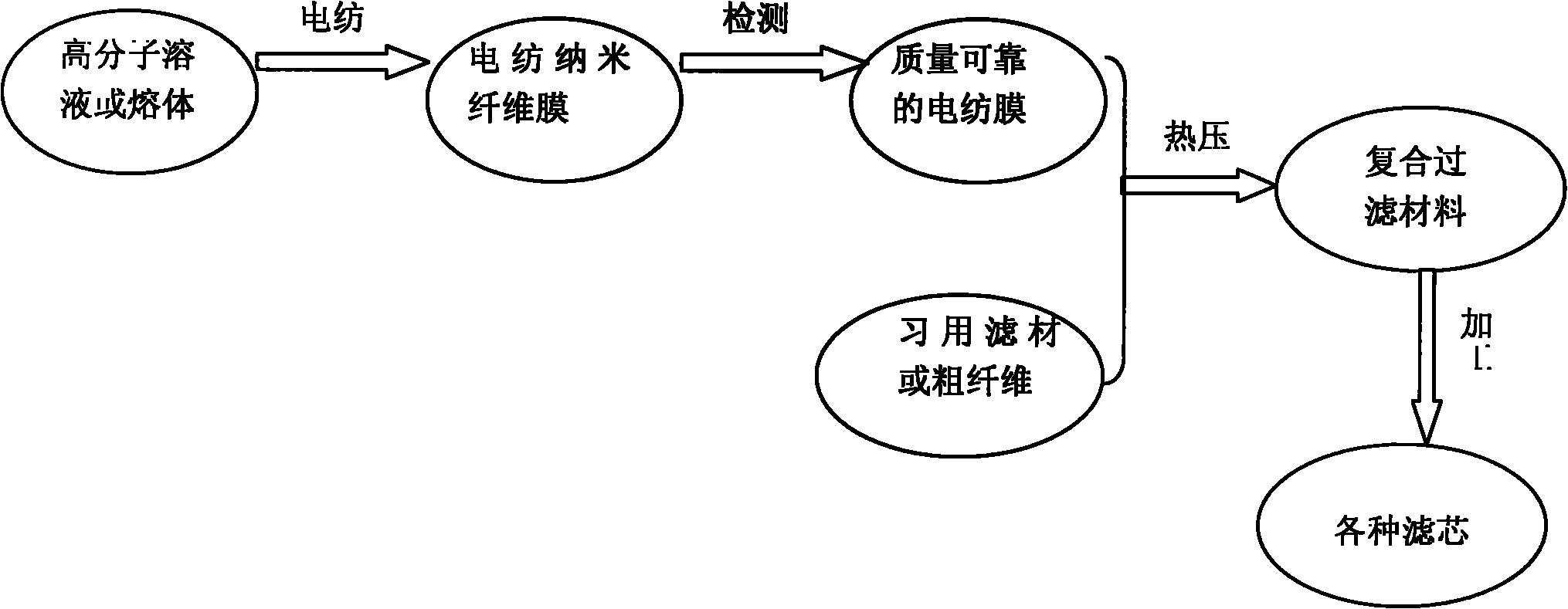

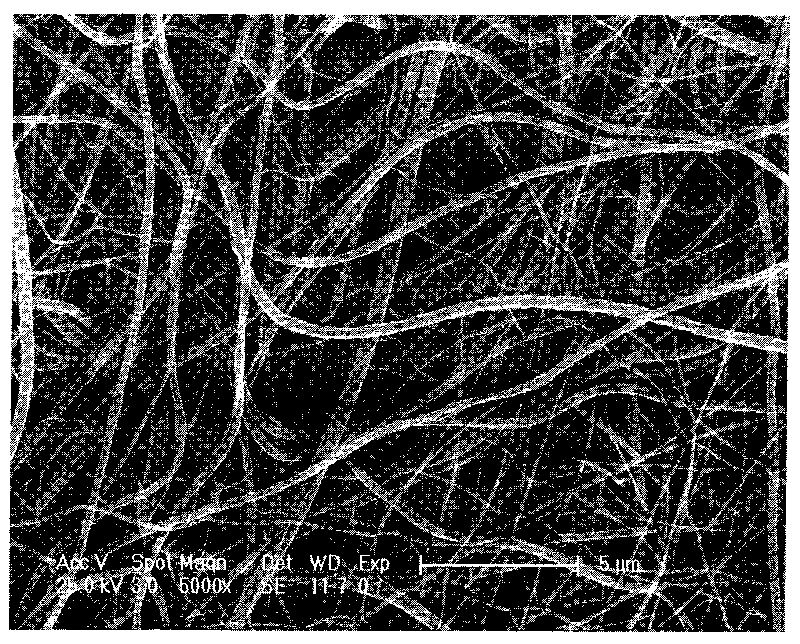

Preparation method of electric spinning-based composite nano fiber material for filters

InactiveCN101829454AExtended service lifeReduce wearLayered productsFiltration separationFiberComposite nanofibers

The invention relates to a preparation method of an electric spinning-based composite nano fiber material for filters, comprising the following steps of: preparing an electric spinning nano fiber film with reliable quality by adopting a polymer solution or a fusant through an electrostatic spinning device, and combining the electric spinning nano fiber film with a conventional filtering material to form a sandwich composite nano filtering material. Compared with the prior art, the nano fiber film with reliable quality in the invention can filter particles of 1 micrometer, and the filtering efficiency is 100%; the conventional filtering material and coarse fibers not only are used as supporting materials, but also can filter larger particles in advance, and the preparation method reduces the abrasion of the nano fiber film, prolongs the service life of the composite nano filtering material, reduces the updating time of the composite nano filtering material, and lowers filtering expenses.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Novel composite nanofiber membrane as well as preparation method and application thereof

The invention relates to a nanofiber membrane and particularly relates to a novel composite nanofiber membrane as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) dissolving any one of polyvinyl alcohol, polylactic acid and regenerated silk fibroin in an organic solvent to prepare a spinning solution with the mass fraction of 5-20 percent; (2) adding polyphenol substances to the spinning solution, and uniformly stirring to obtain a mixed spinning solution which accounts for 1-7 percent of the total mass of the polyphenol substances and the organic solvent, wherein the polyphenol substances are one or more of vegetable tannin, apple polyphenol and grape polyphenol; (3) carrying out ultrasonic treatment on the mixed spinning solution for 1-600 minutes; and (4) carrying out electrostatic spinning on the mixed spinning solution and collecting to obtain the required composite nanofiber membrane. After subjected to electrostatic spinning, the composite nanofiber membrane is smooth in surface, continuous and uniform, has the diameter of between 100nm and 800nm and can be applied to the fields of medical dressing, makeup facial masks, tea bags, controlled release of targeted drugs, food preservation and sewage purification.

Owner:HEYE HEALTH TECH CO LTD

Coaxial compound nanometre fibre film as well as preparation method and application thereof

ActiveCN102230257AImprove permeabilityHigh tensile strengthFilament/thread formingCell component detailsFiberPolymer science

The invention discloses a coaxial compound nanometre fibre film composed of compound nanometre fibres of a fluorine-containing polymer skin layer and a polyimide core layer, wherein the upper and the lower surfaces and inner holes of the film are distributed symmetrically. The coaxial compound nanometre fibre film is prepared from a fluorine-containing polymer solution and a polyamic acid solution through coaxial static spinning compounding, mechanical roller pressing and thermal imidization; the nanometre fibre film provided by the invention integrates the advantages of fluorine-containing polymer and polyimide; the fluorine-containing polymer has excellent electrolyte wetting property, liquid maintaining property and ion conductivity; and the polyimide has high mechanical strength and high heat resistance. The compound nanometre film provided by the invention is fit for high-energy lithium ion energy storage batteries and high-power electrokinetic cells.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

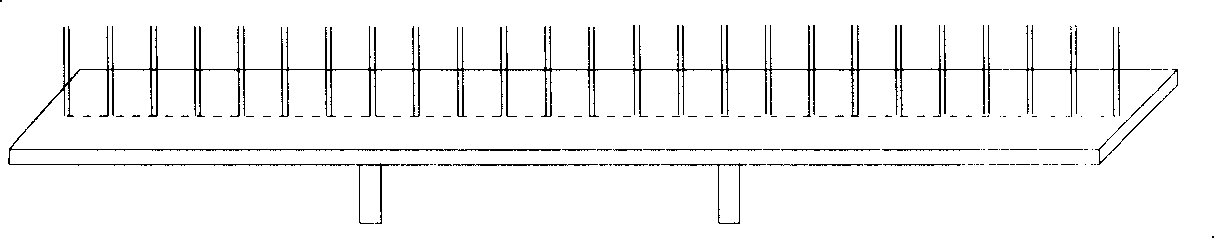

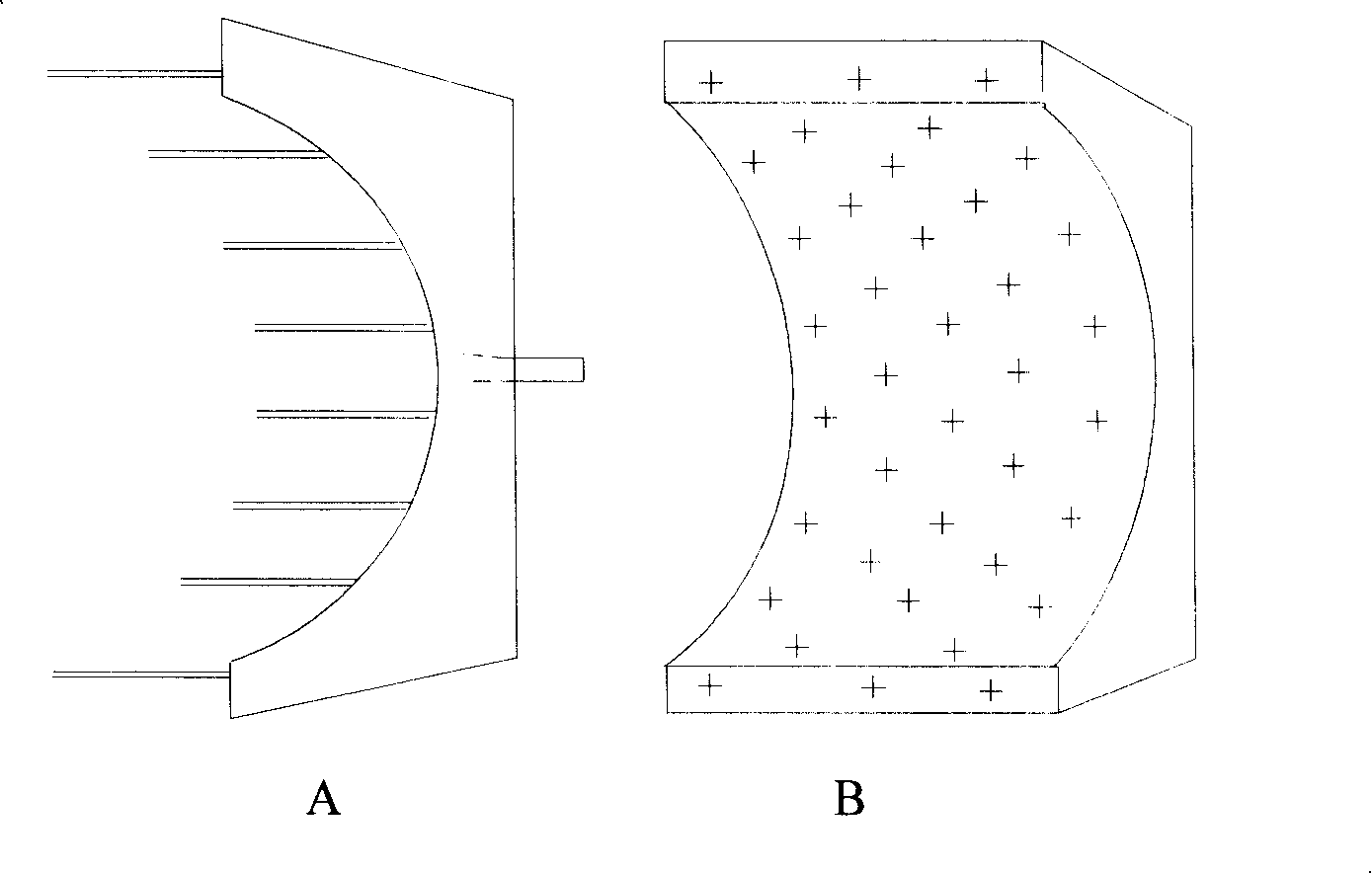

Device for directly combining nano fiber diaphragm on lithium ionic cell electrode surface and the method

InactiveCN101192681AInnovation of traditional assembly processMeet technical requirementsActive material electrodesSecondary cellsFiberCompound a

The invention relates to a device for directly preparing and compounding a nano fiber diaphragm on the surface of an electrode slice in a lithium ion battery and a method based on the device. The invention enables two processes of preparation of the diaphragm on the lithium ion battery and the assembly of the diaphragm and the electrode slice to be completed in one time. The invention is realized by an electrostatic spinning machine for the diaphragm on the lithium ion battery which can be produced continuously, and the key component is a spinneret of high-efficiency electrostatic spinning. By applying an electrostatic spinning method to directly spray a polymer nano fiber diaphragm on the surface of the electrode slice in the lithium ion battery (which takes platinum analogs as a substrate) under a specific technological condition, the two technological processes of preparation of the diaphragm on the lithium ion battery and the assembly of the diaphragm / electrode slice are completed in one time. The invention can not only produce the diaphragm on the lithium ion battery with high performance, but also renovate the traditional assembly technique of the lithium ion battery. The produced composite material of the diaphragm / electrode slice meets the technical requirements of a common lithium ion battery and a power lithium iron battery.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

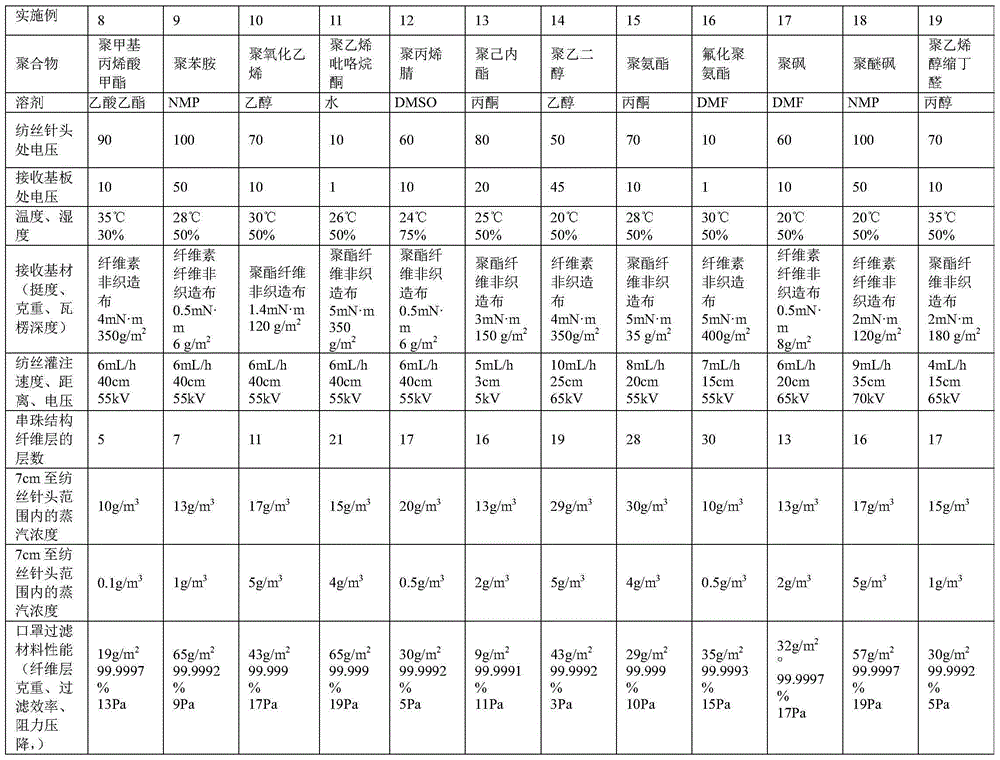

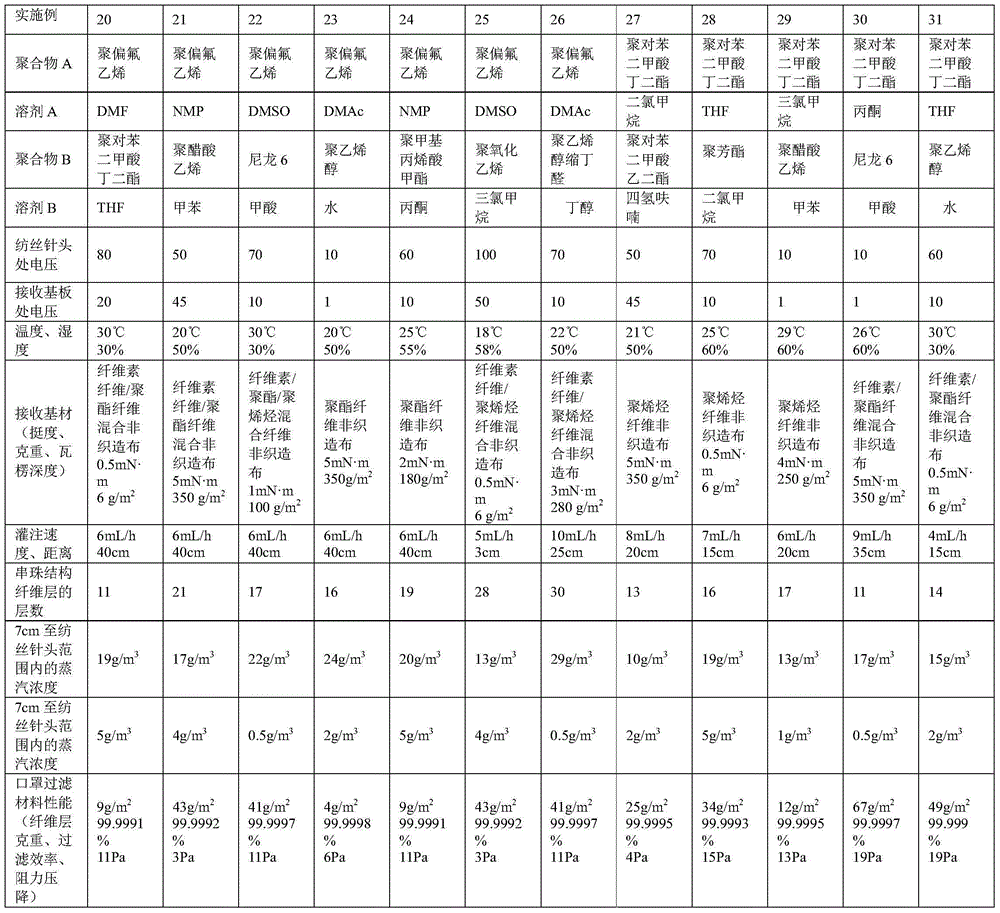

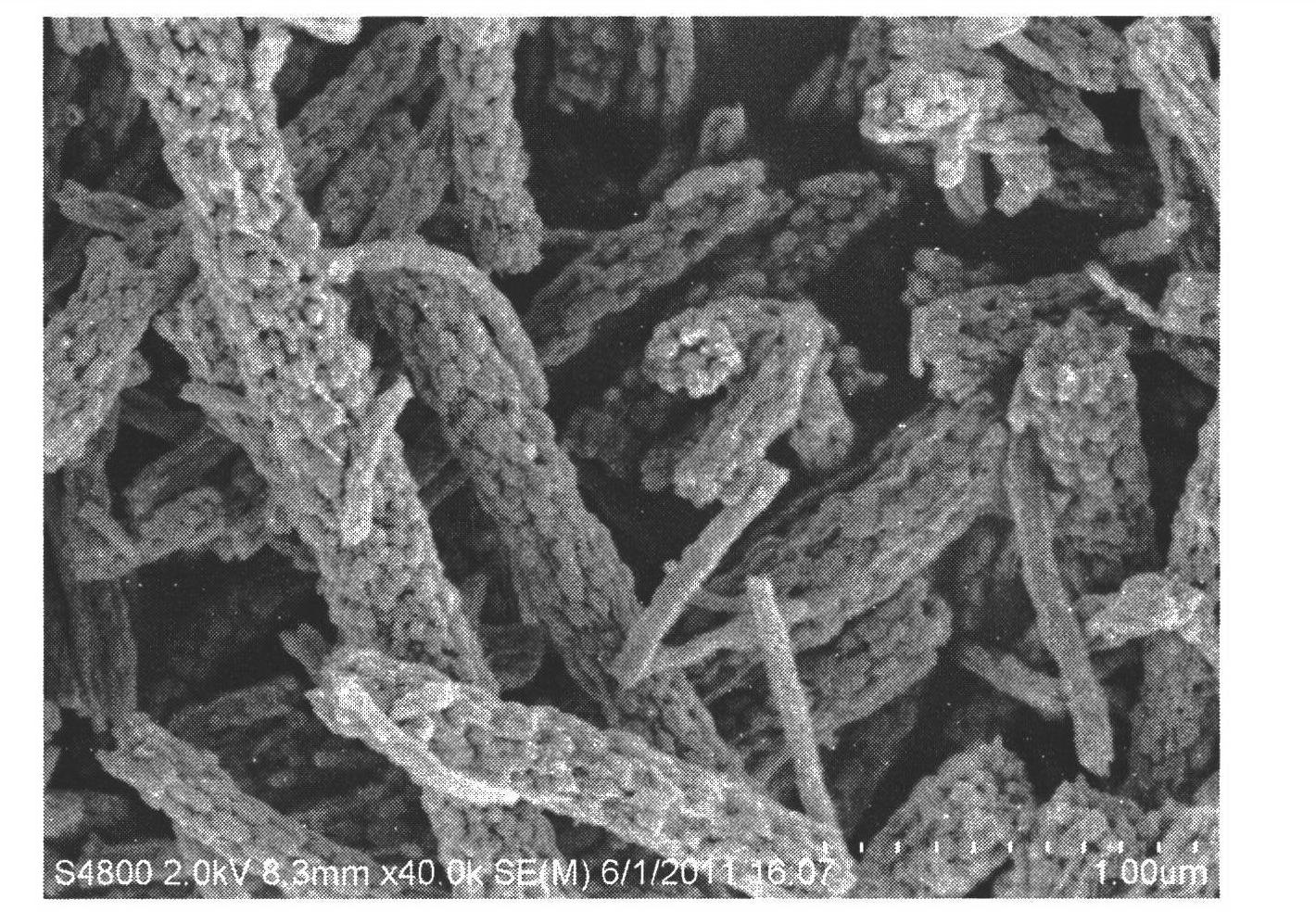

High-efficiency and low-resistance nanofiber air filtering material for gauze mask and preparation method of filtering material

ActiveCN104645715ANo adhesionFluffy structureFiltration separationProtective garmentComposite nanofibersAir filter

The invention relates to a high-efficiency and low-resistance nanofiber air filtering material for a gauze mask and a preparation method of the filtering material. According to the preparation method, by virtue of a steam field compensation and control technology, an equal-electric voltage spinning technology and a nanofiber structure with a bead structure and innovatively introducing single fibers in an electrostatic spinning process, the high-efficiency and low-resistance nanofiber air filtering material which is free of adhesion between fibers and fluffy in structure, has a three-dimensional cavity and is in a net communication structure is obtained in a one-step molding manner. According to the high-efficiency and low-resistance nanofiber air filtering material for the gauze mask, the filtering efficiency on granules which are 0.006-2.5 microns can reach over 99.999%; and the piezoresistance is less than 30Pa. The high-efficiency and low-resistance nanofiber air filtering material is simple in preparation technology, low in cost, high in filtering efficiency and small in resistance pressure drop, and has a wide application prospect in the field of individual protective masks.

Owner:DONGHUA UNIV

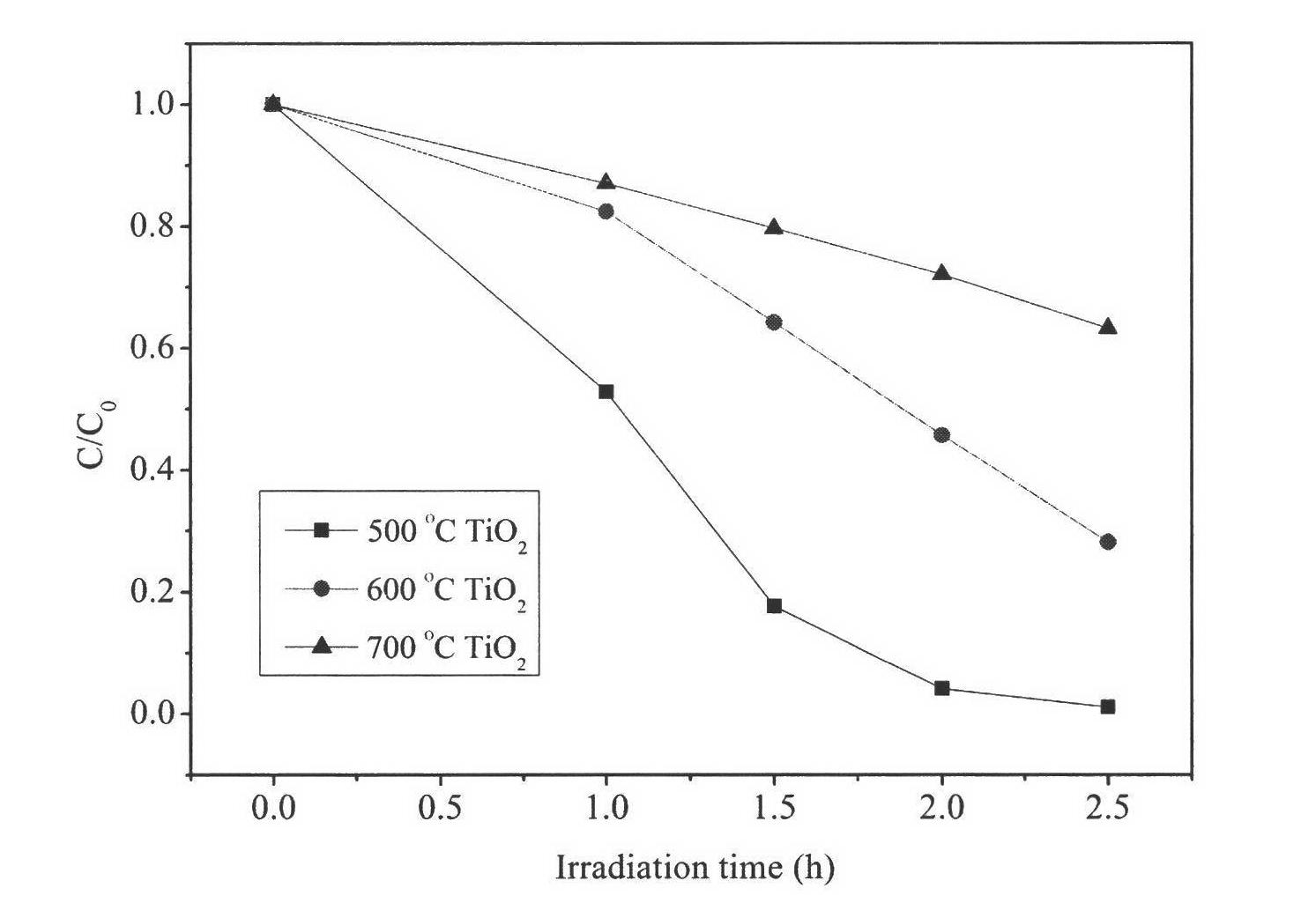

Anatase type titanium dioxide nano-fiber photocatalyst and preparation method thereof

InactiveCN102586948ASimple preparation processEasy to controlPhysical/chemical process catalystsFilament/thread formingFiberMaterials science

The invention discloses an anatase type titanium dioxide nano-fiber photocatalyst and a preparation method thereof, and belongs to the technical field of nano materials and photocatalysts. By the method, a composite nano-fiber is prepared by an electrostatic spinning technology, and then is calcinated in the air to obtain the titanium dioxide nano-fiber photocatalyst, but a sol-gel technology is not used in the process, so that process parameters are easy to adjust and control, multiple factors which influence the final crystallization degree, crystal form, granular distribution and size of a titanium dioxide nano-fiber are eliminated, and a catalytic efficient photocatalysis material can be easily obtained. The titanium dioxide nano-fiber prepared by the method has a large specific surface area, so that visible light is high in catalytic efficiency. The preparation method has a simple process and is easy to adjust and control, and the production cost is reduced. The photocatalyst can be used as a novel photocatalysis material, is high in photocatalysis efficiency under the action of the visible light and meets the requirement and the development direction of a new generation of photocatalysis materials.

Owner:JIANGNAN UNIV

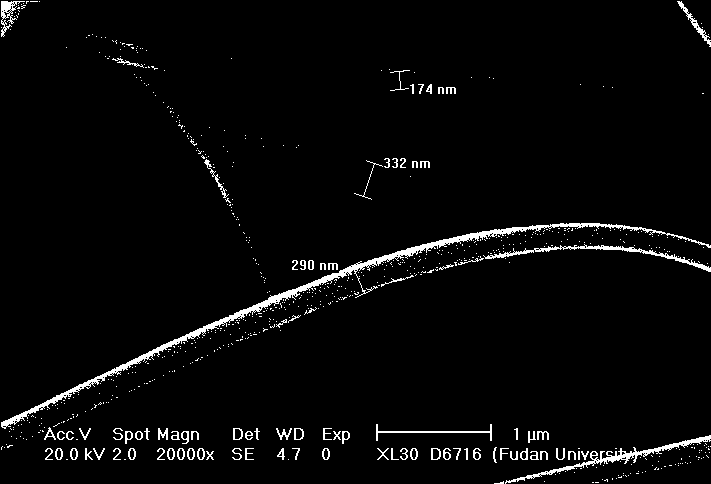

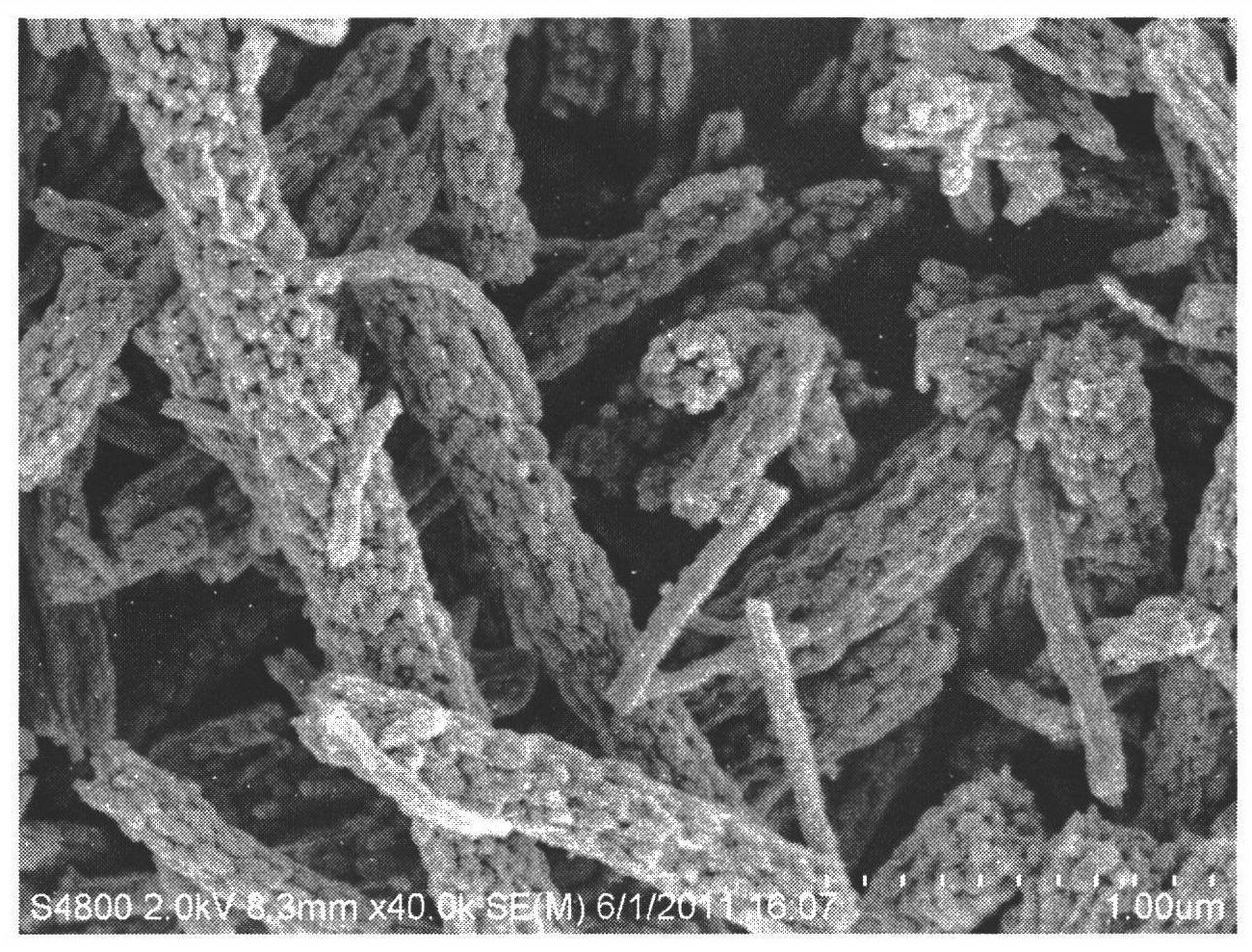

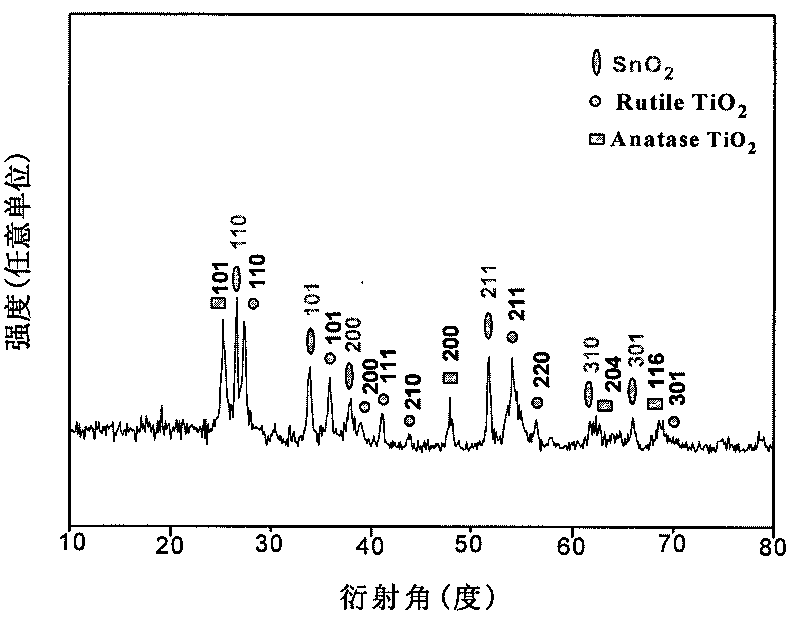

Method for preparing tin dioxide and titanium dioxide nano cable

The invention relates to a method for preparing a tin dioxide and titanium dioxide nano cable, which belongs to the technical field of nano material preparation. The method comprises the following three steps of: (1) preparation of spinning solution, adding stannic chloride and polyvinylpyrrolidone (PVP) into a mixed solvent of N, N-dimethylformamide and glycerin so as to prepare a core layer of the spinning solution, and adding PVP into a mixed liquid of butyl titanate and absolute ethyl alcohol so as to prepare a shell layer of the spinning solution; (2) preparation of (PVP+SnC14) and [PVP+Ti(OC4H9)] composite nano fiber by a coaxial electrostatic spinning technology under the condition that the voltage is 11.5-15 kV, the curing distance is 10-15 cm, the room temperature is 20-25 DEG C and the relative humidity is 45-50 percent; (3) preparation of SnO2 an TiO2 nano cable: carrying out heat treatment on the composite nano fiber to obtain the cable with cable diameter of 300-340 nm, core layer diameter of 200-220 nm, the shell layer thickness of 50-60 nm and length of more than 300 mu m.

Owner:CHANGCHUN UNIV OF SCI & TECH

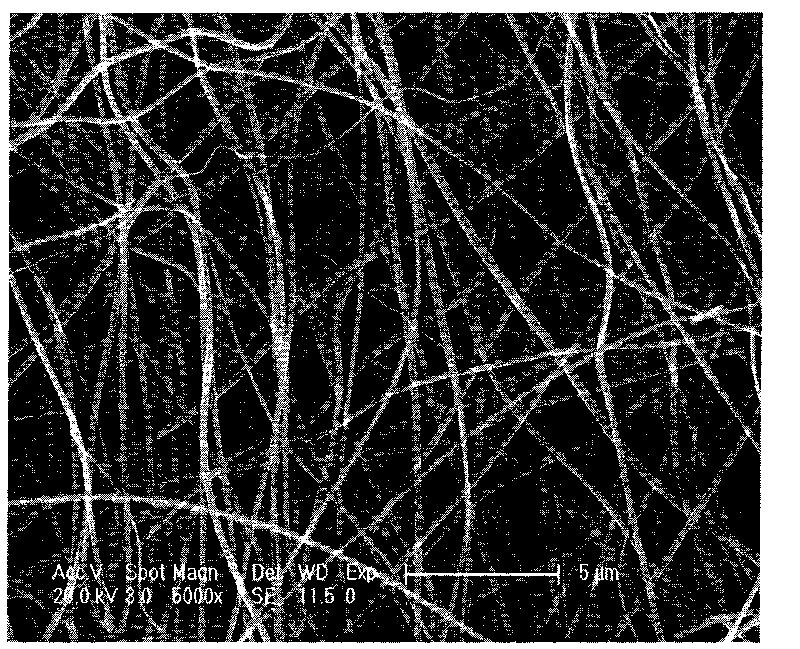

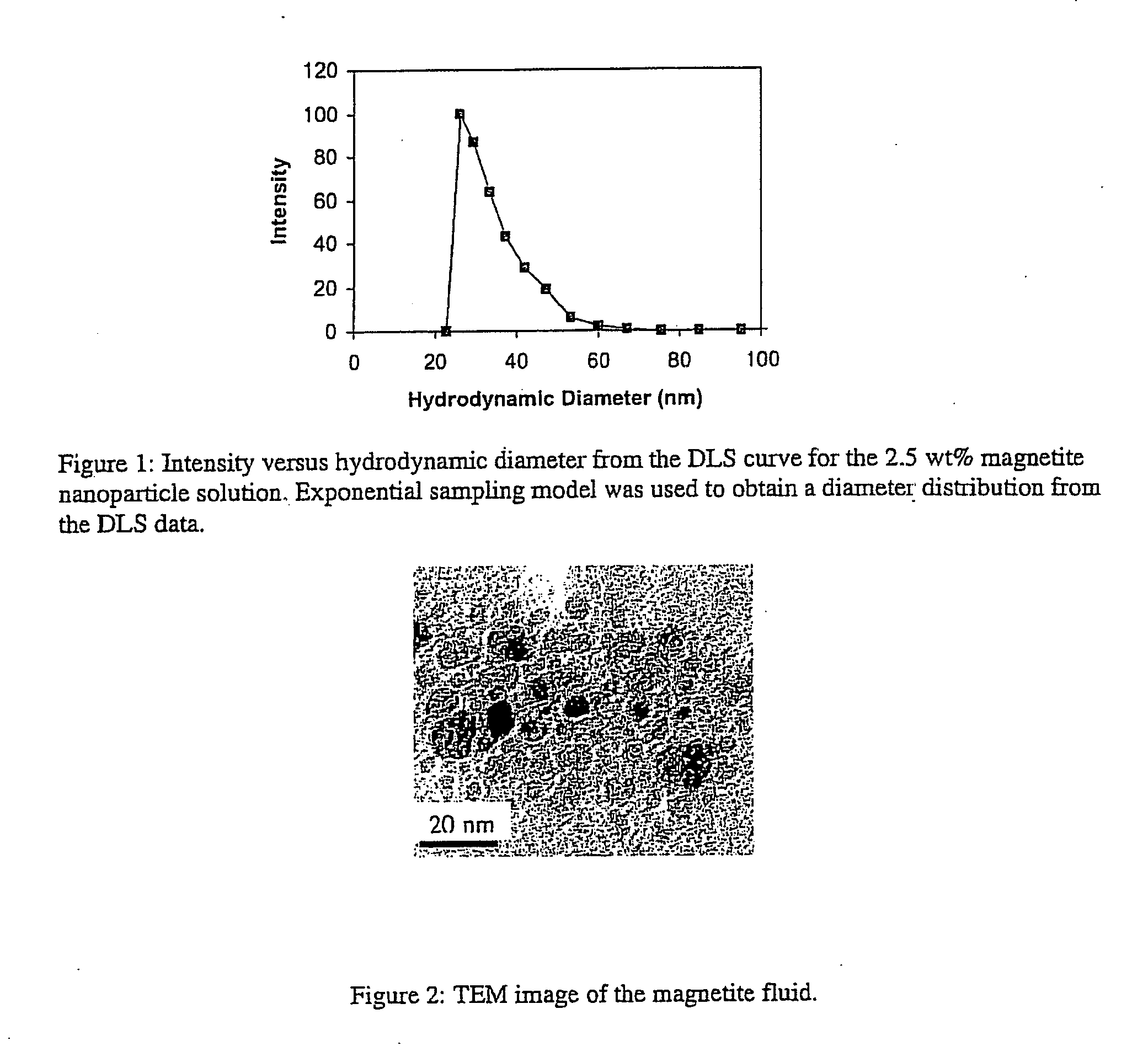

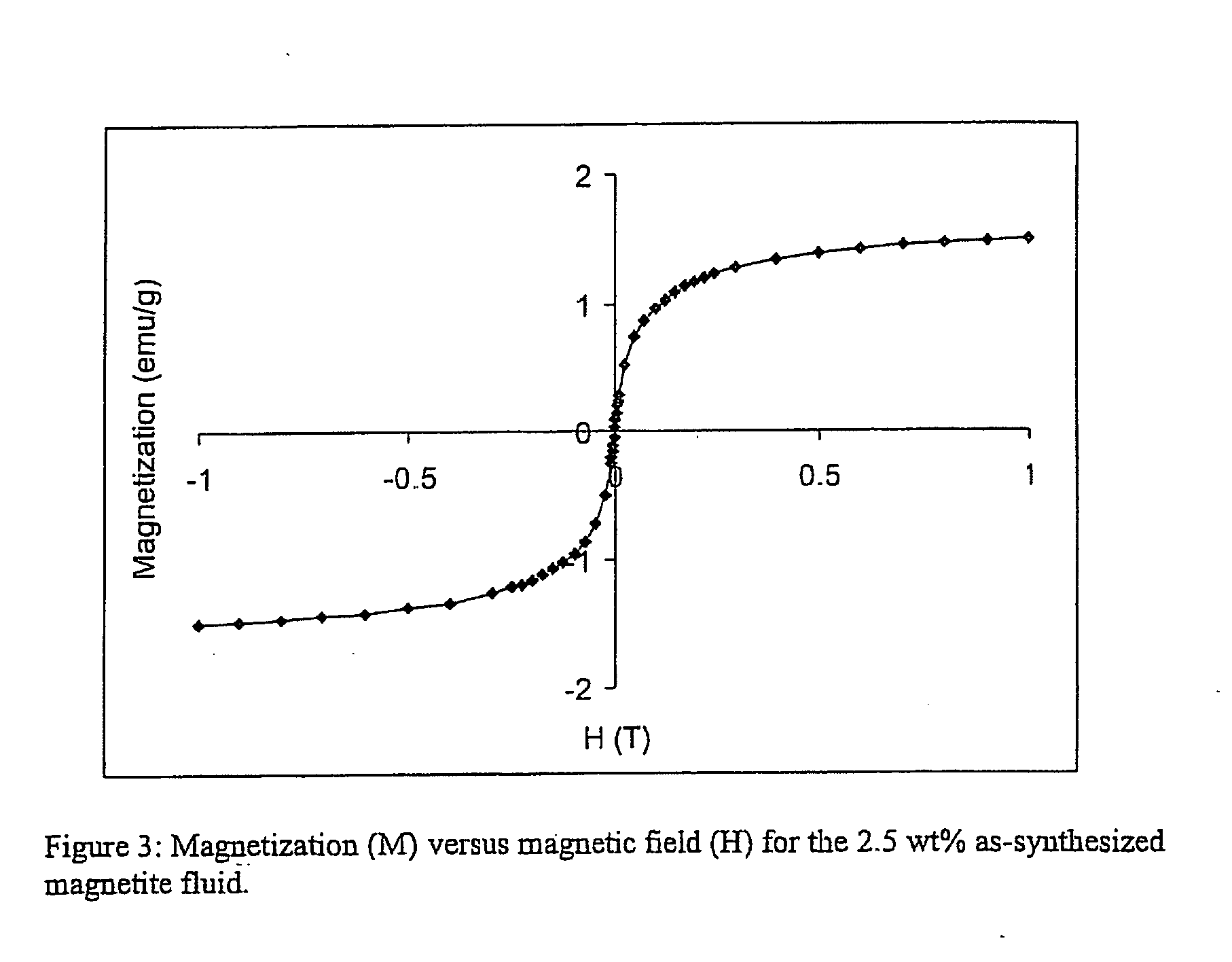

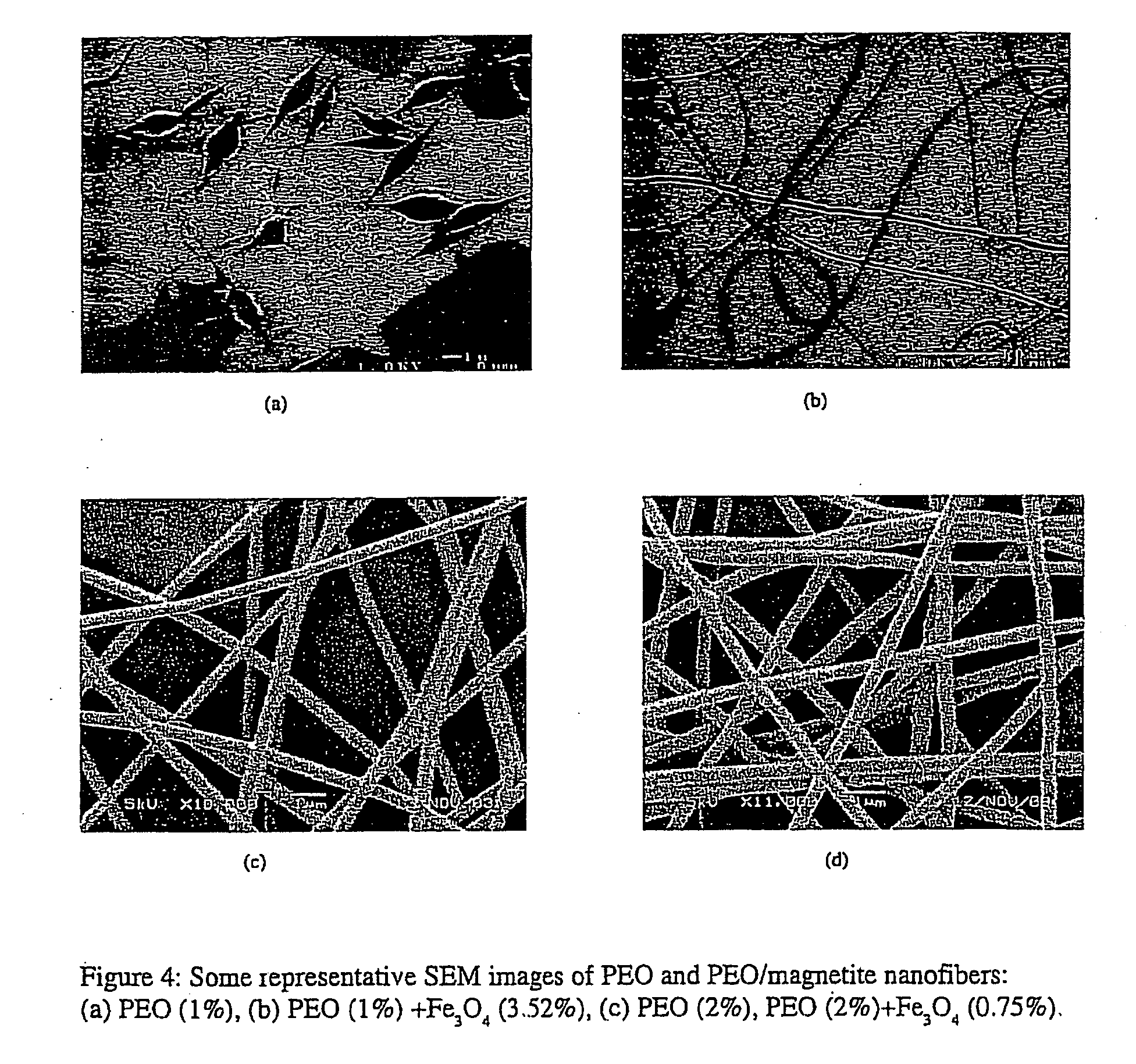

Field-responsive superparamagnetic composite nanofibers and methods of use thereof

InactiveUS20060019096A1Electro-spinningMonocomponent synthetic polymer artificial filamentFiberComposite nanofibers

The present invention relates to magnetic field-responsive fibers, which comprise magnetite particles and a polymeric matrix. The invention also provides methods of producing the same, in particular via electrospinning of a stably dispersed or monodispersed polymer solution, either aqueous or organic, comprising the magnetite particles, and applications thereof.

Owner:HATTON T ALAN +3

Composite nano fiber filtration material with photocatalysis/anti-bacterial functions and preparation method of filtration material

ActiveCN107497182AIncrease spinning speedSolve problems such as easy blockageDispersed particle separationElectro-spinningFiberSpinning

The invention relates to a composite nano fiber filtration material with photocatalysis / anti-bacterial functions and a preparation method of the filtration material. The filtration material comprises a supporting layer and a nano fiber filtration layer which adheres to the surface of the supporting layer, the nano fiber layer is uniformly filled with an photocatalyst and an antibacterial agent, and the preparation method comprises the following steps: 1, preparing a spinning liquid: dispersing a certain amount of the photocatalyst and the antibacterial agent into a solution uniformly to form a dispersion liquid, performing ultrasonic treatment, and adding a high polymer to form a stable and uniform electrostatic spinning solution; 2, performing electrostatic spinning: setting up electrostatic spinning parameters, and performing stretching on the spinning polymer solution at solid metal wire tips for wire production by utilizing an assembled needle head; and 3, performing slight dissolving treatment on the surface of the composite nano fiber filtration material by adopting solvent vapour recovery at a certain releasing speed to obtain the final composite nano fiber filtration material with the photocatalysis / the anti-bacterial functions. The composite nano fiber filtration material effectively solves a problem that the liquid outlet end of a current needle head / spray nozzle used for the electrostatic spinning is easy to block, can be directly used for decomposition of organic pollutants, inactivation of microorganism pathogenes and the like under visible light, and has excellent filtration performance at the same time.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com