Device and Method for Preparing Filament Yarn of Composite Nanofibers

a technology of composite nanofibers and filament yarns, applied in the direction of filament/thread forming, electric heating, electric/magnetic/electromagnetic heating, etc., can solve the problems of fiber loss and unstable dispersion, difficult to manufacture continuous nanofiber yarns or filaments, and great challenges for the fiber industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

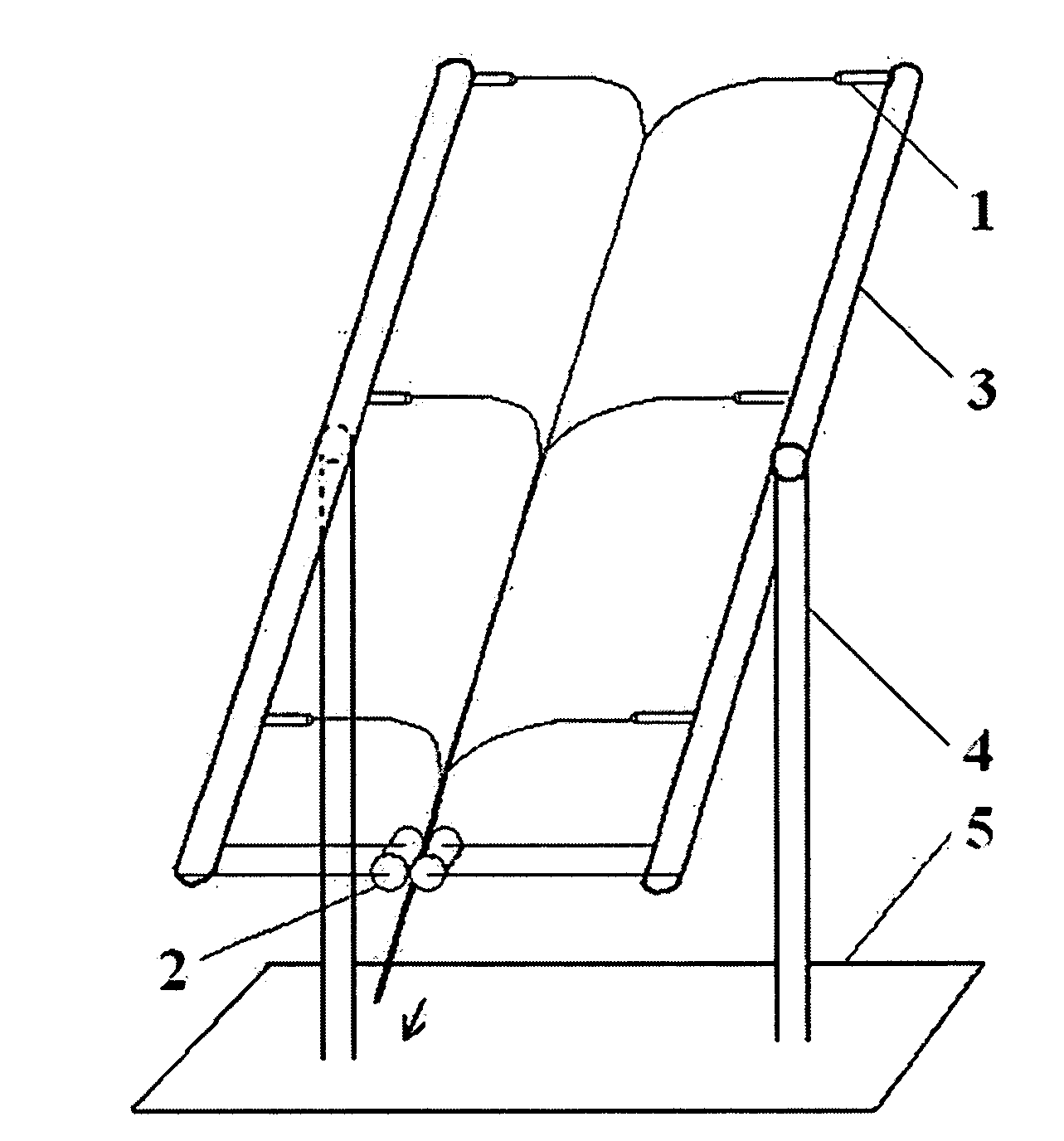

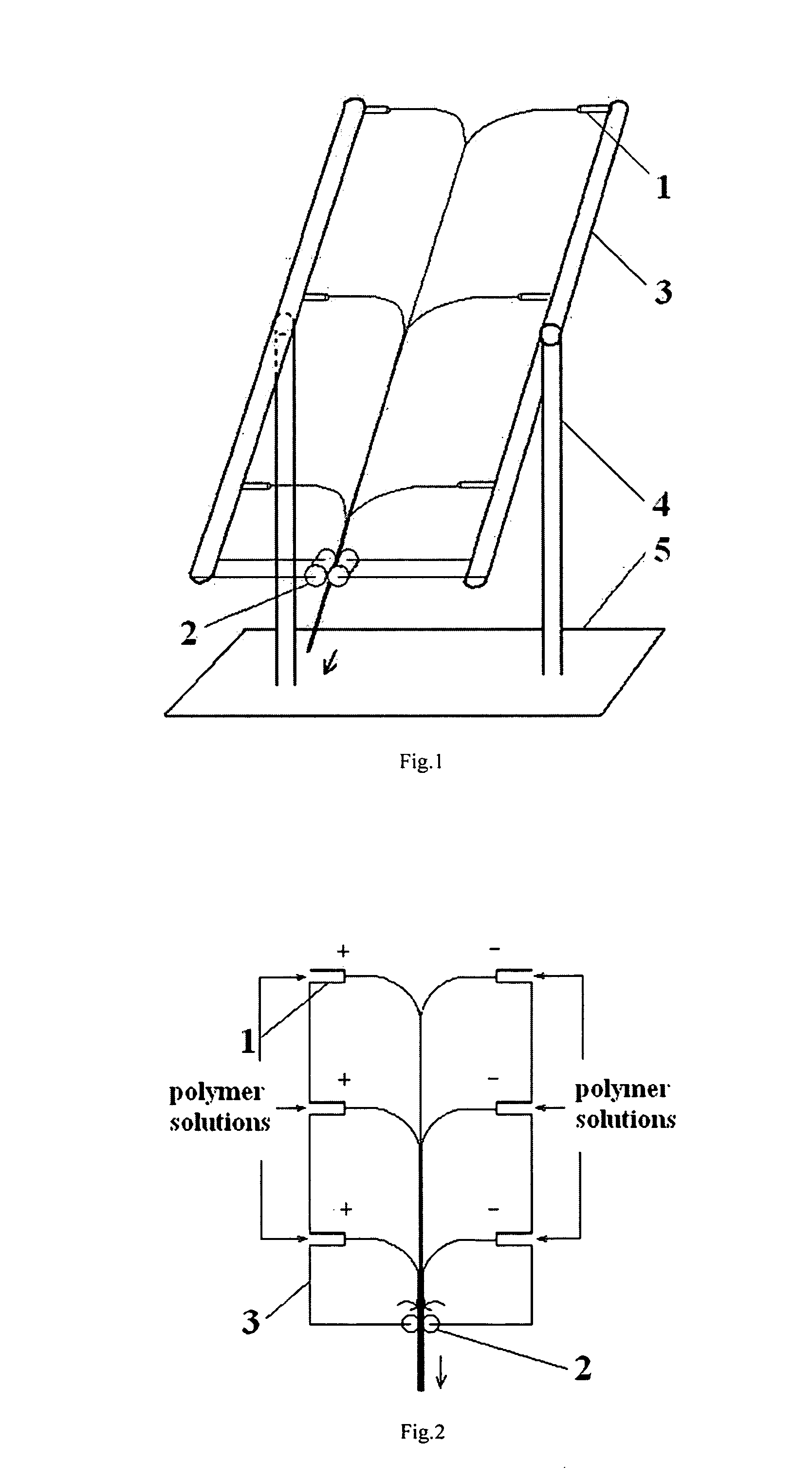

[0028]A device for electrospinning is used comprising frame 3 having three pairs of electrospinning nozzles 1 in two columns, filament guiding roller pair 2 set at the end of pairs of electrospinning nozzles. The frame 3 was set at angle of 90° to fixed sticks 4.

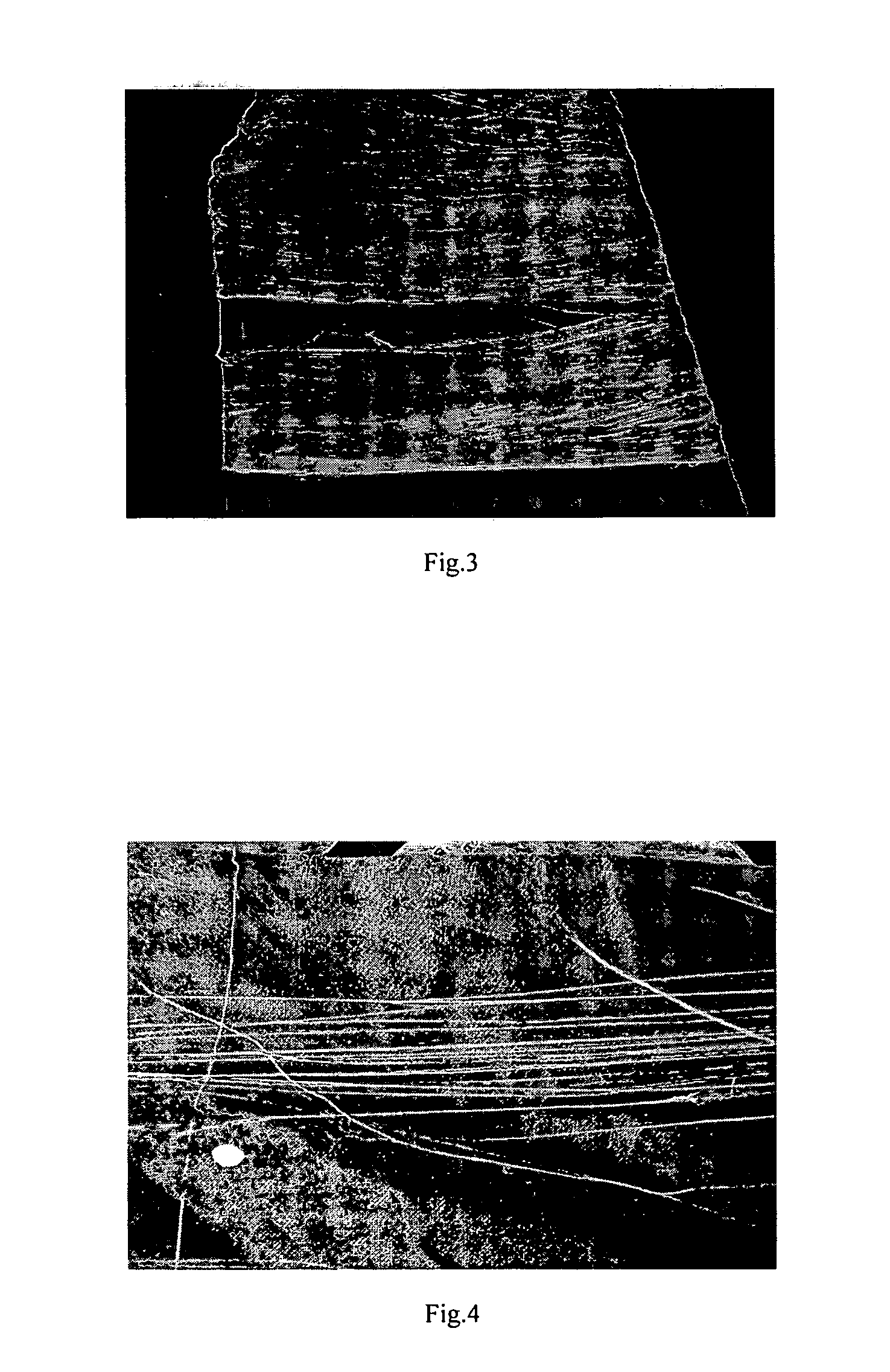

[0029]10 g poly-L-lactic acid (PLLA, Mη=100,000 g / mol) was dissolved in a mixed solvent of 50 ml acetone and 50 ml N,N-dimethyl formamide, and the prepared solution was fed to one column of electrospinning nozzles containing 3 spinnerets. 15 g poly-lactide-co-glycolide (Poly-LA-co-GA, PLGA, weight ratio of LA:GA=50:50, Mη=100,000 g / mol) was dissolved in a mixed solvent of 50 ml acetone and 50 ml N,N-dimethyl formamide, and the prepared solution was fed to the other column of electrospinning nozzles containing 3 spinnerets. Distance between two neighbouring electrospinning nozzles on the same column of frame 3 is 15 cm, and distance between two tips of oppositely disposed pair of electrospinning nozzles is 40 cm. Plane of fra...

example 2

[0030]A device for electrospinning is used comprising frame 3 having four pairs of electrospinning nozzles 1 in two columns, filament guiding roller pair 2 set at the end of pairs of electrospinning nozzles. The frame 3 was set at angle of 90° to fixed sticks 4.

[0031]10 g poly-L-lactic acid (PLLA, Mq=100,000 g / mol) was dissolved in a mixed solvent of 50 ml acetone and 50 ml N,N-dimethyl formamide, and the prepared solution was fed to one column of electrospinning nozzles containing 4 spinnerets. 10 g polycaprolactone (PCL, Mw=90,000 g / mol) was dissolved in 100 ml N, N-dimethyl formamide, and the prepared solution was fed to the other column of electrospinning nozzles containing 4 spinnerets. Distance between two neighbouring electrospinning nozzles on the same column of frame 3 is 15 cm, and distance between two tips of oppositely disposed pair of electrospinning nozzles is 40 cm. Plane of frame 3 is set at angle of 90° to fixed sticks 4. High DC voltages of ±20 kV were applied to t...

example 3

[0032]A device for electrospinning is used comprising frame 3 having three pairs of electrospinning nozzles 1 in two columns, filament guiding roller pair 2 set at the end of pairs of electrospinning nozzles. The frame 3 was set at angle of 90° to fixed sticks 4.

[0033]10 g poly-L-lactic acid (PLLA, Mη=100,000 g / mol) was dissolved in a mixed solvent of 50 ml acetone and 50 ml N,N-dimethyl formamide, and the prepared solution was fed to one column of electrospinning nozzles containing 3 spinnerets of which inner diameter is 0.8 mm. 35 g zein (Mw=35,000 g / mol) was dissolved in 100 ml aqueous ethanol solution with ethanol / water volume ratio of 80 / 20, and the prepared solution was fed to the other column of electrospinning nozzles containing 3 spinnerets of which inner diameter is 1.2 mm. Distance between two neighbouring electrospinning nozzles on the same column of frame is 15 cm, and distance between two tips of oppositely disposed pair of electrospinning nozzles is 40 cm. Plane of fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric potential / voltage | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com