Patents

Literature

675results about "Conjugated artificial filaments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

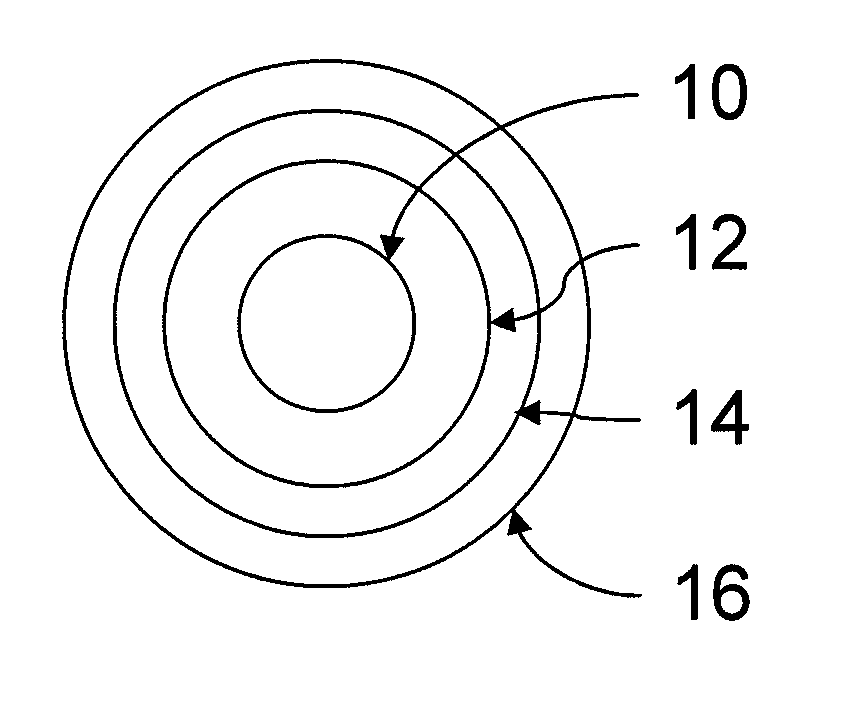

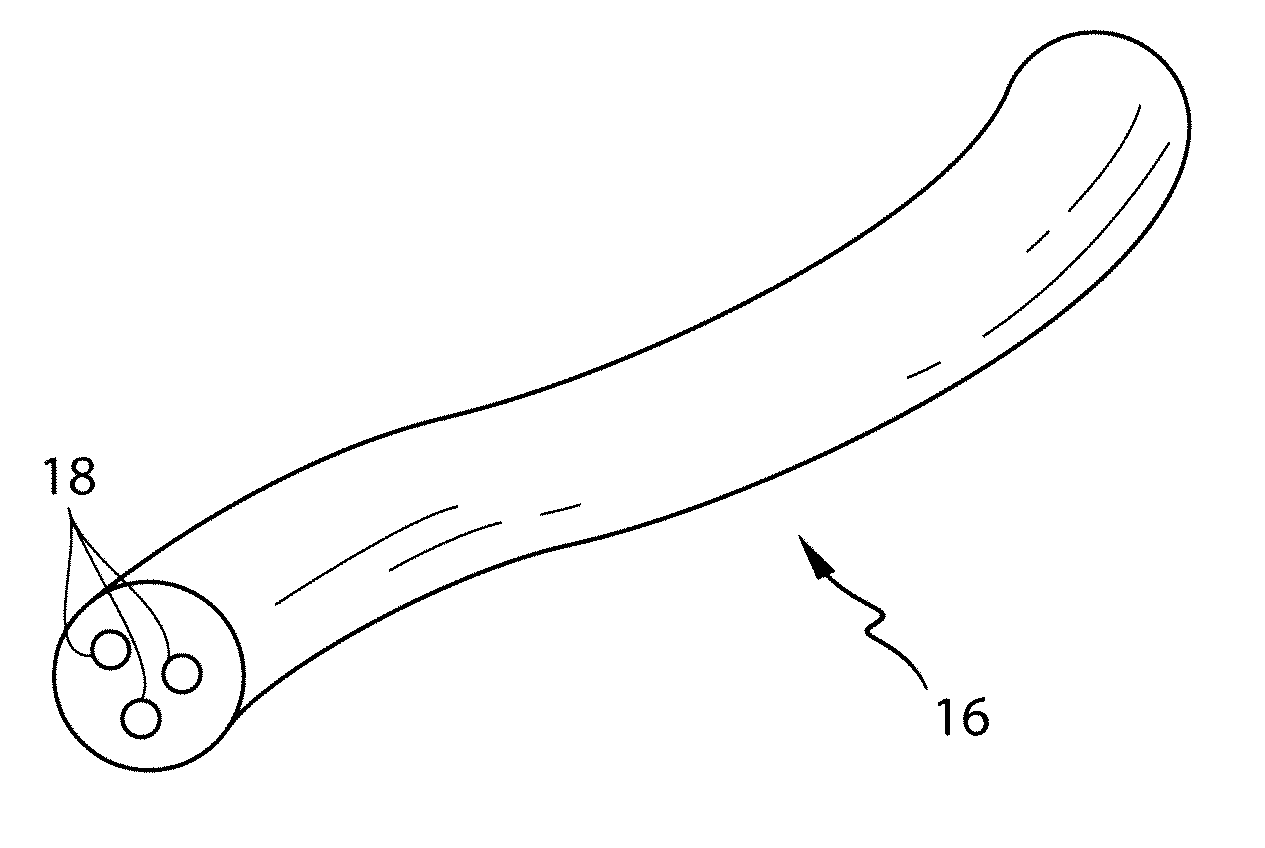

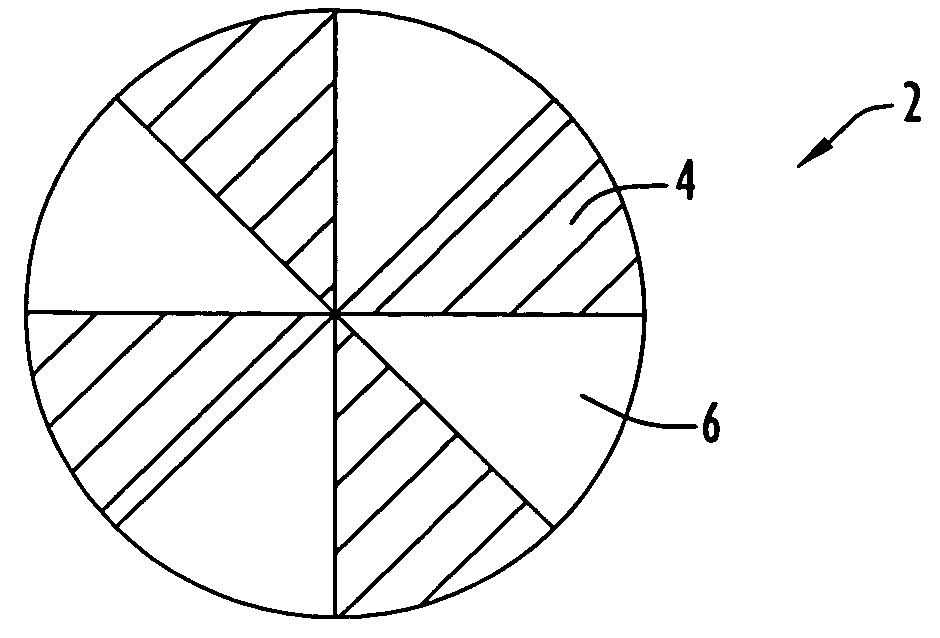

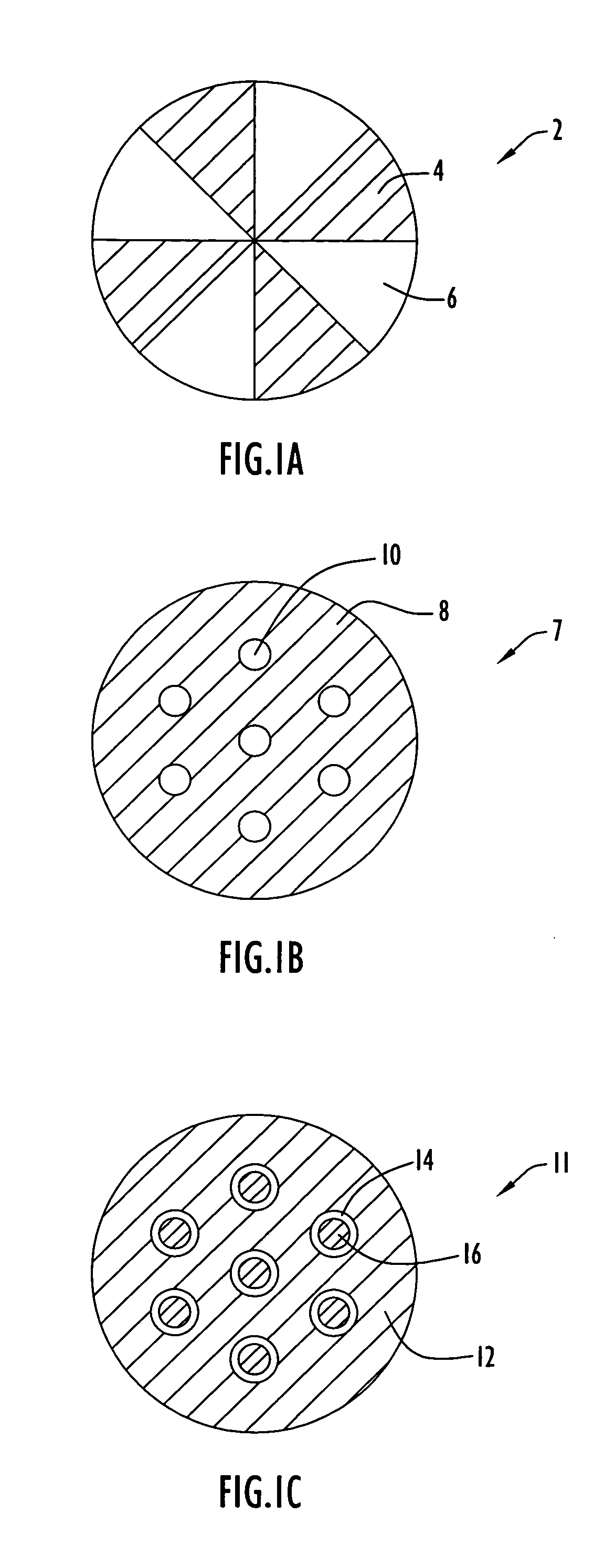

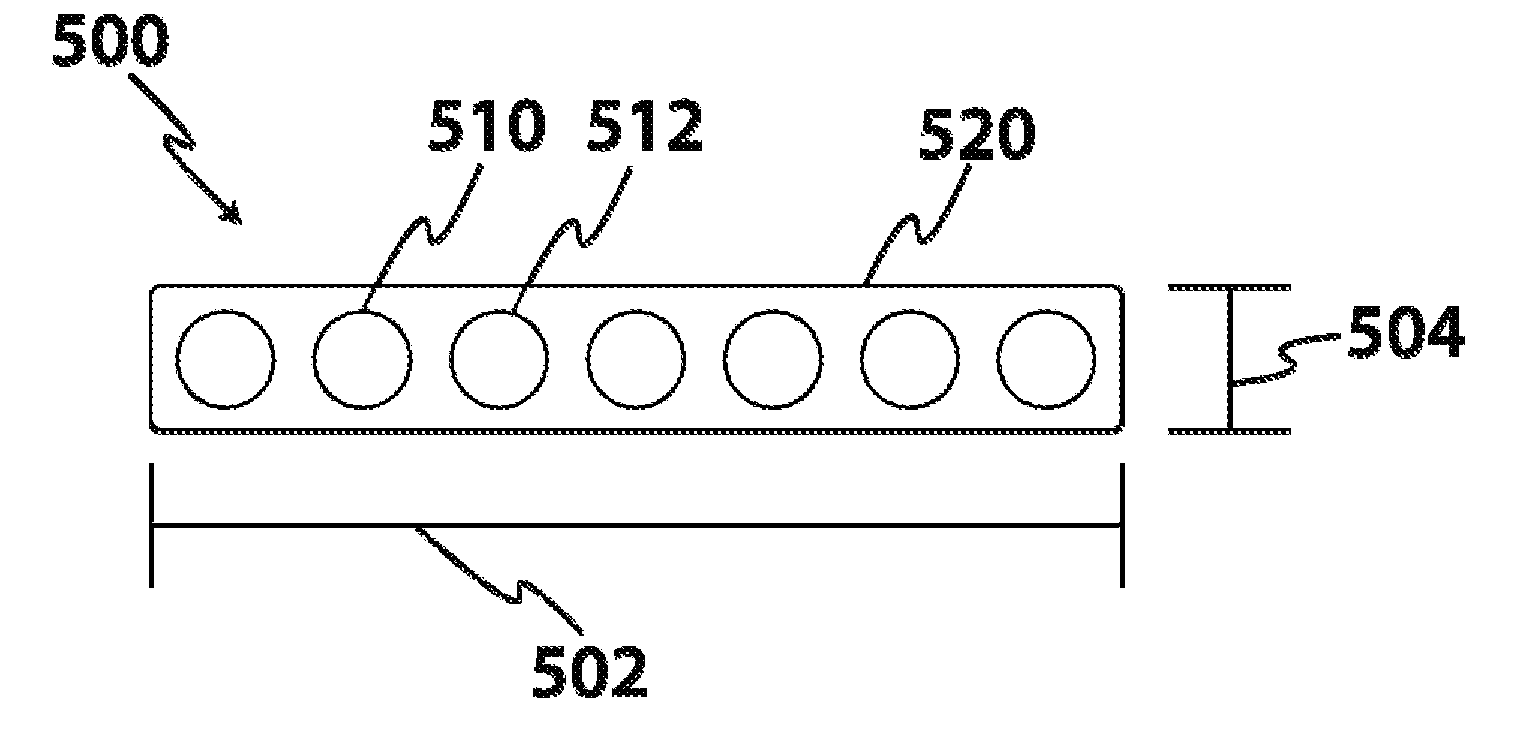

Controlling the dissolution of dissolvable polymer components in plural component fibers

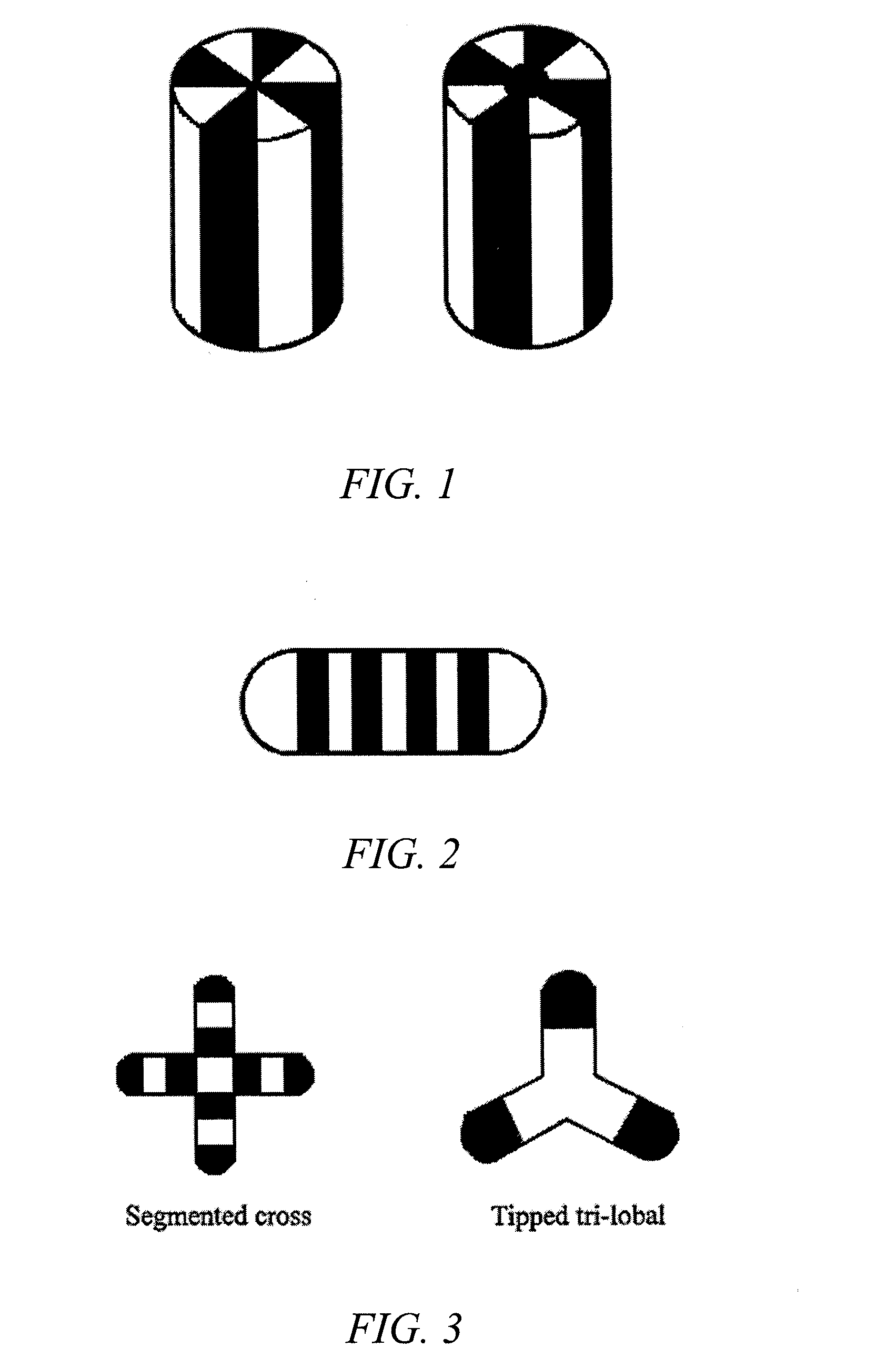

The dissolution of dissolvable components in plural component polymer fibers is achieved by providing a polymer fiber including at least two sections, where at least one fiber section includes a dissolvable component. The rate at which at least part of the fiber dissolves is controlled by at least one of a fiber section having a non-round cross-sectional geometry, and at least two fiber sections including two different dissolvable components. In an exemplary embodiment, island-in-the-sea fibers are formed with non-round and elongated cross-sectional geometries. In another embodiment, sheath-core fibers are formed in which the sheath and core include different dissolvable components.

Owner:HILLS CO

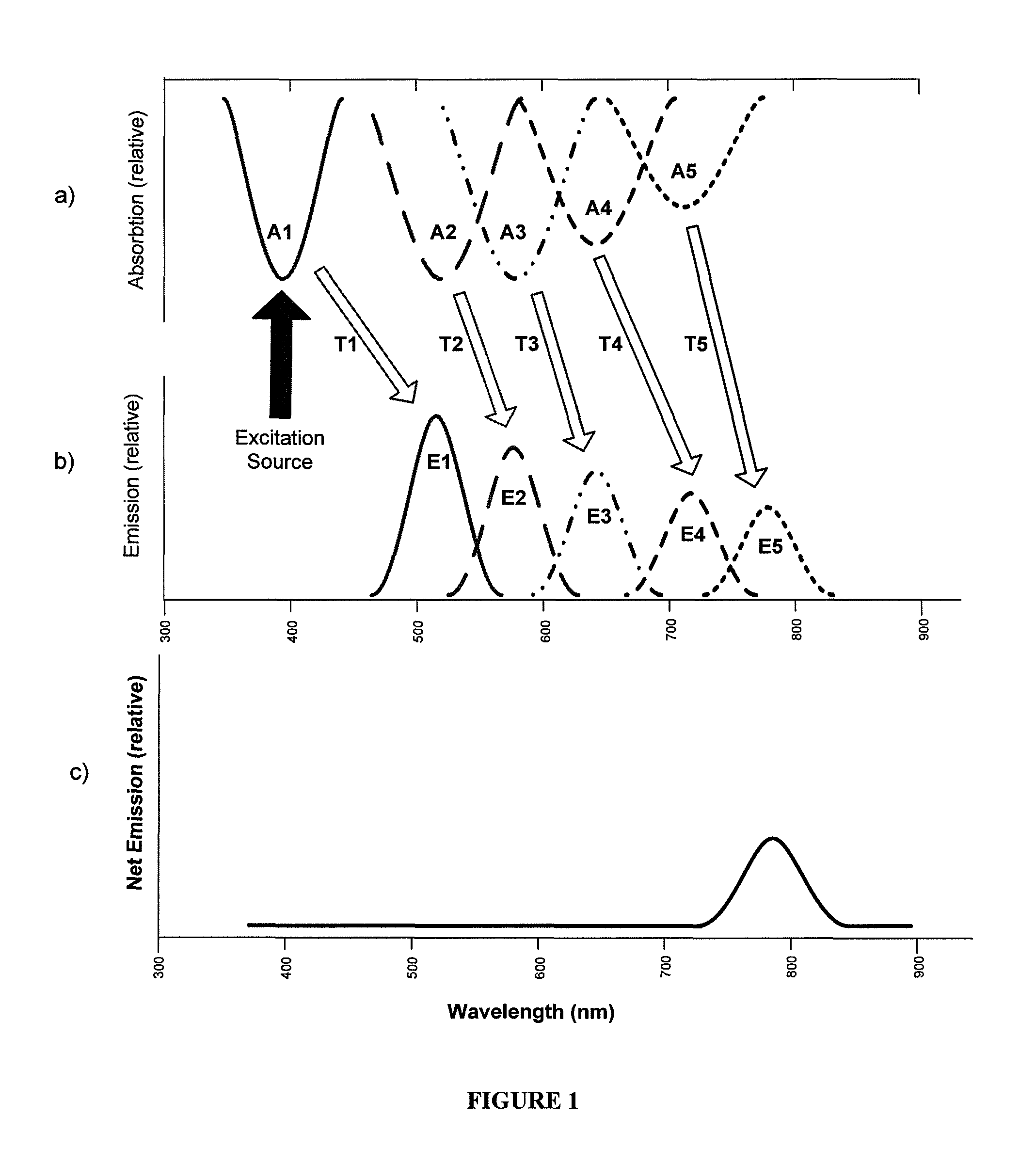

Photoluminescent fibers, compositions and fabrics made therefrom

Disclosed are photoluminescent fibers containing photoluminescent phosphorescent materials and photoluminescent fluorescent materials whose emission signature lies partly or fully in the infrared region of the electromagnetic spectrum. Also disclosed are the use of the inventive fibers, fabrics made therefrom, and objects containing the fiber.

Owner:PERFORMANCE INDICATOR LLC

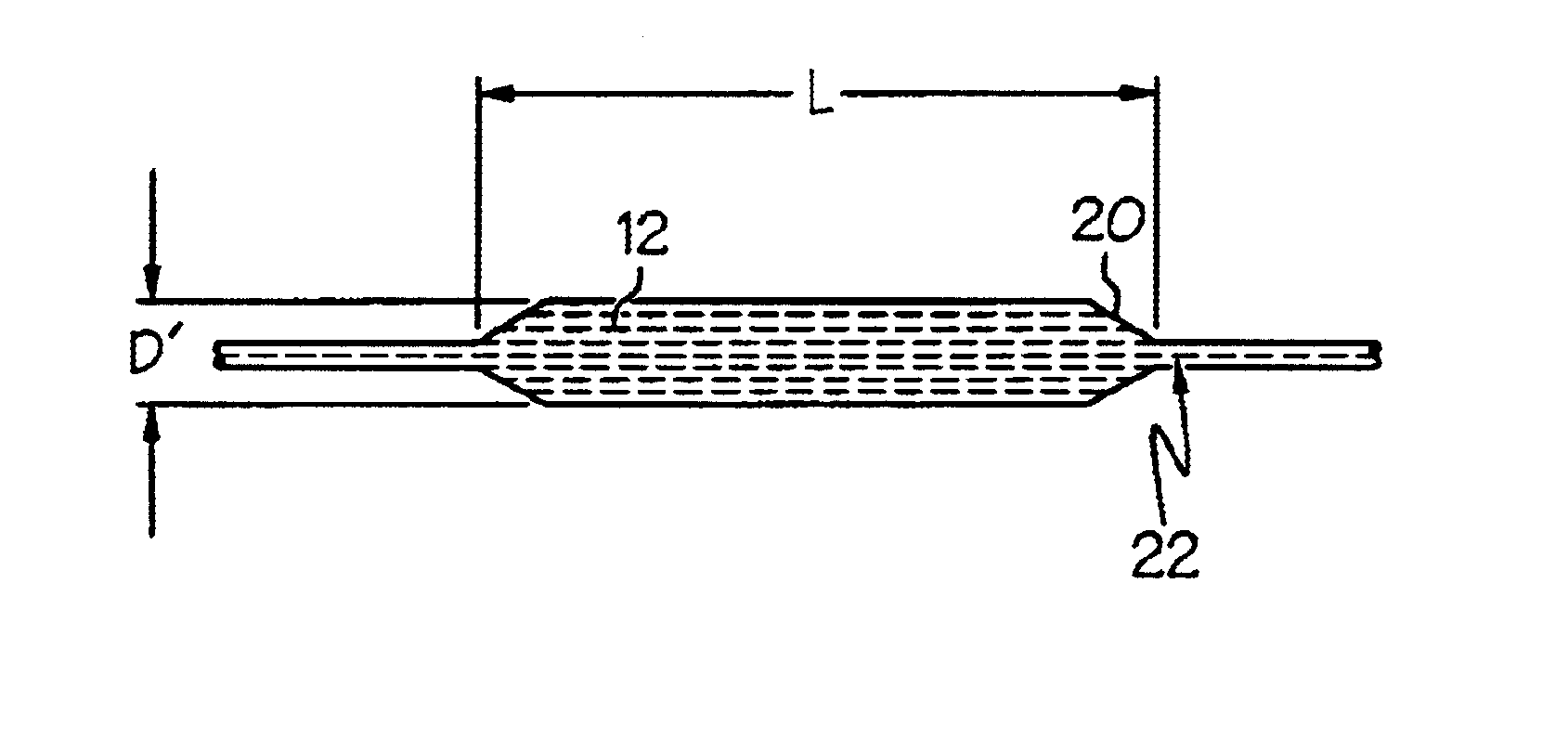

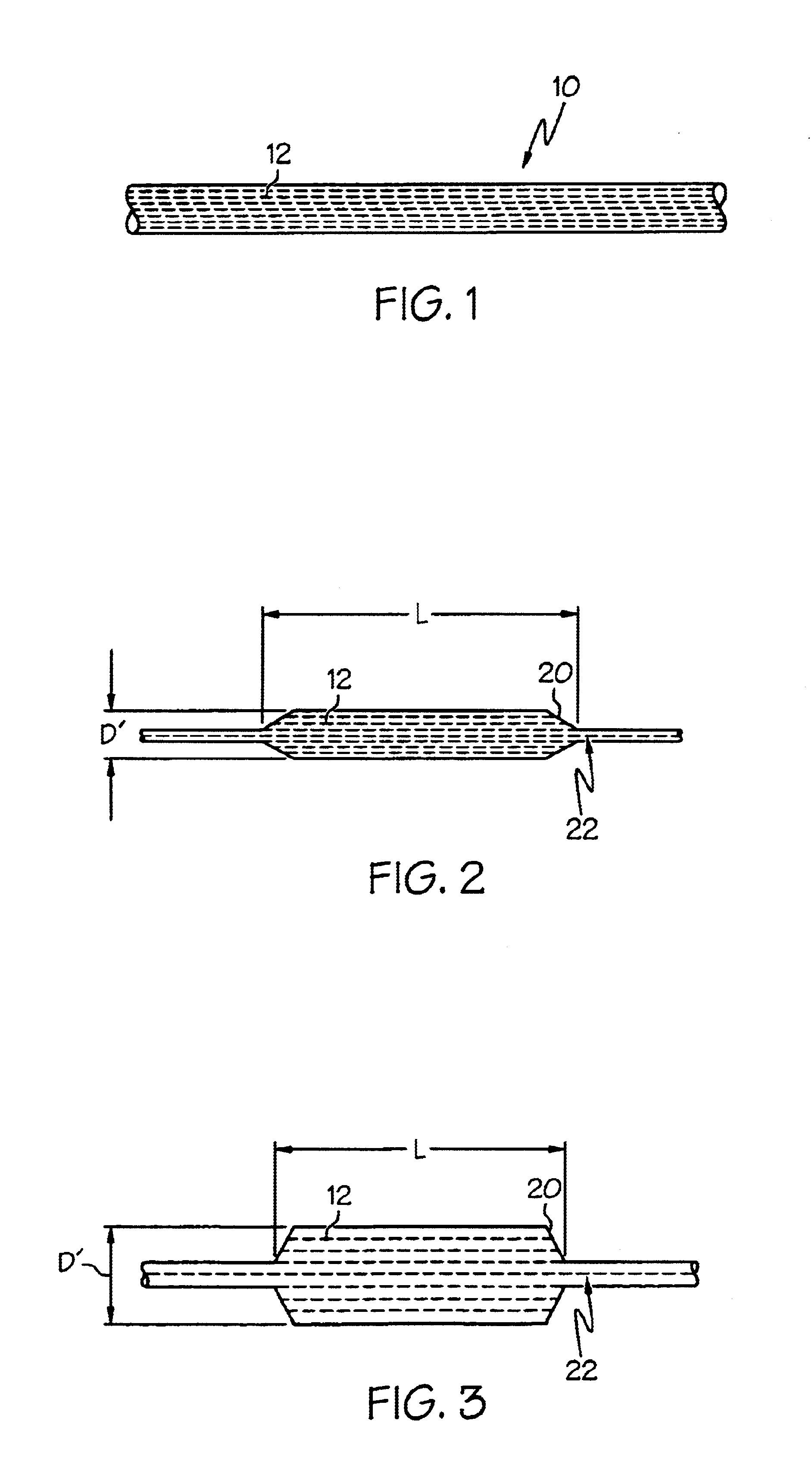

Dimensionally stable balloons

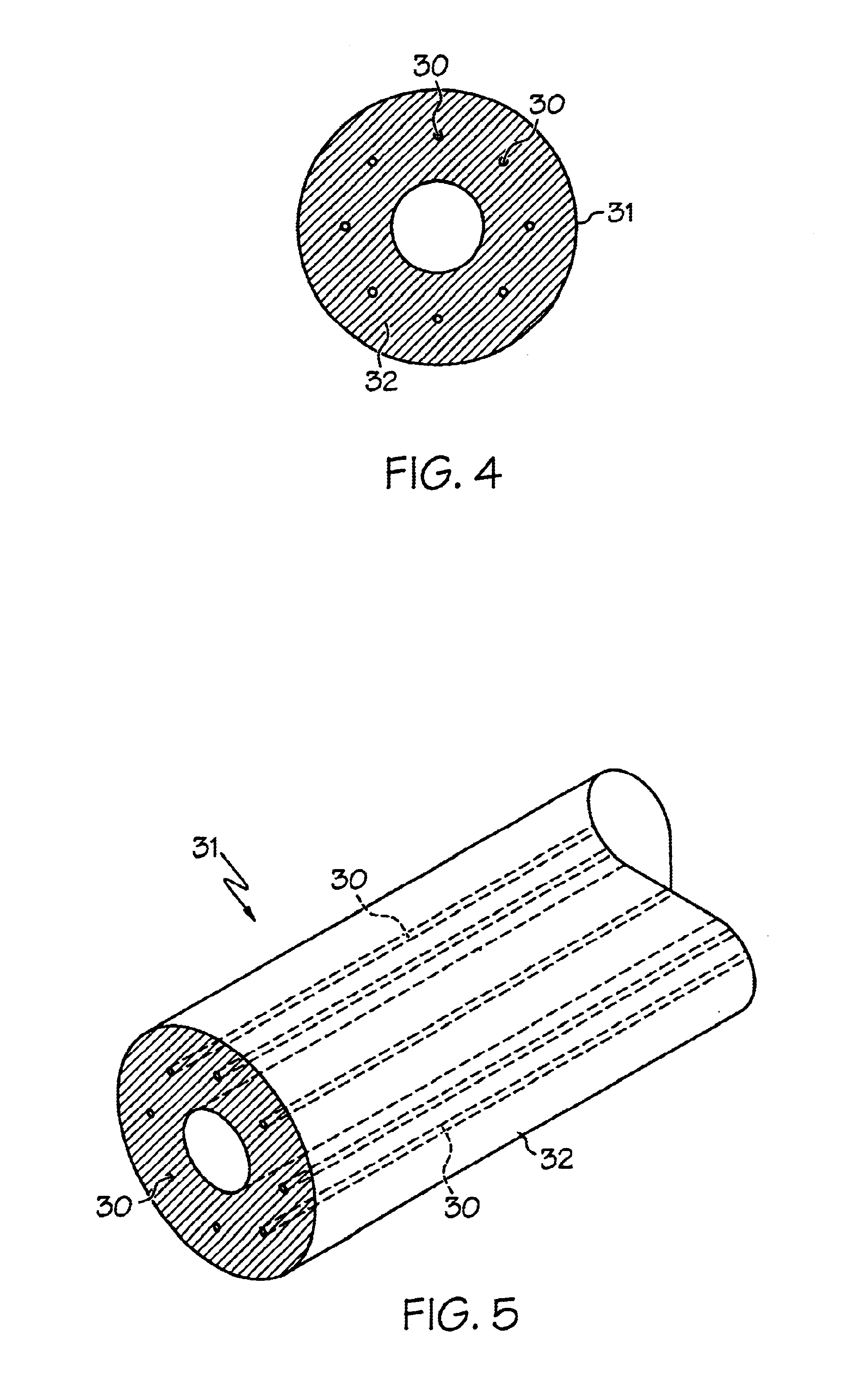

A medical balloon composed of a micro-composite material which provides for radial expansion of a balloon to a predetermined extent, but which has minimal longitudinal growing during balloon inflation. The micro-composite material includes a fibril component, a matrix component, and optionally, a compatibilizer. The fibril component may preferably be liquid crystal polymer fibers randomly scattered through out the balloon material. The liquid crystal polymers are created by extrusion at high speed. An alternative fibril component may be a PET fibers which are uniformly spaced about the balloon material and extend through out the length of the balloon material tube.

Owner:BOSTON SCI SCIMED INC

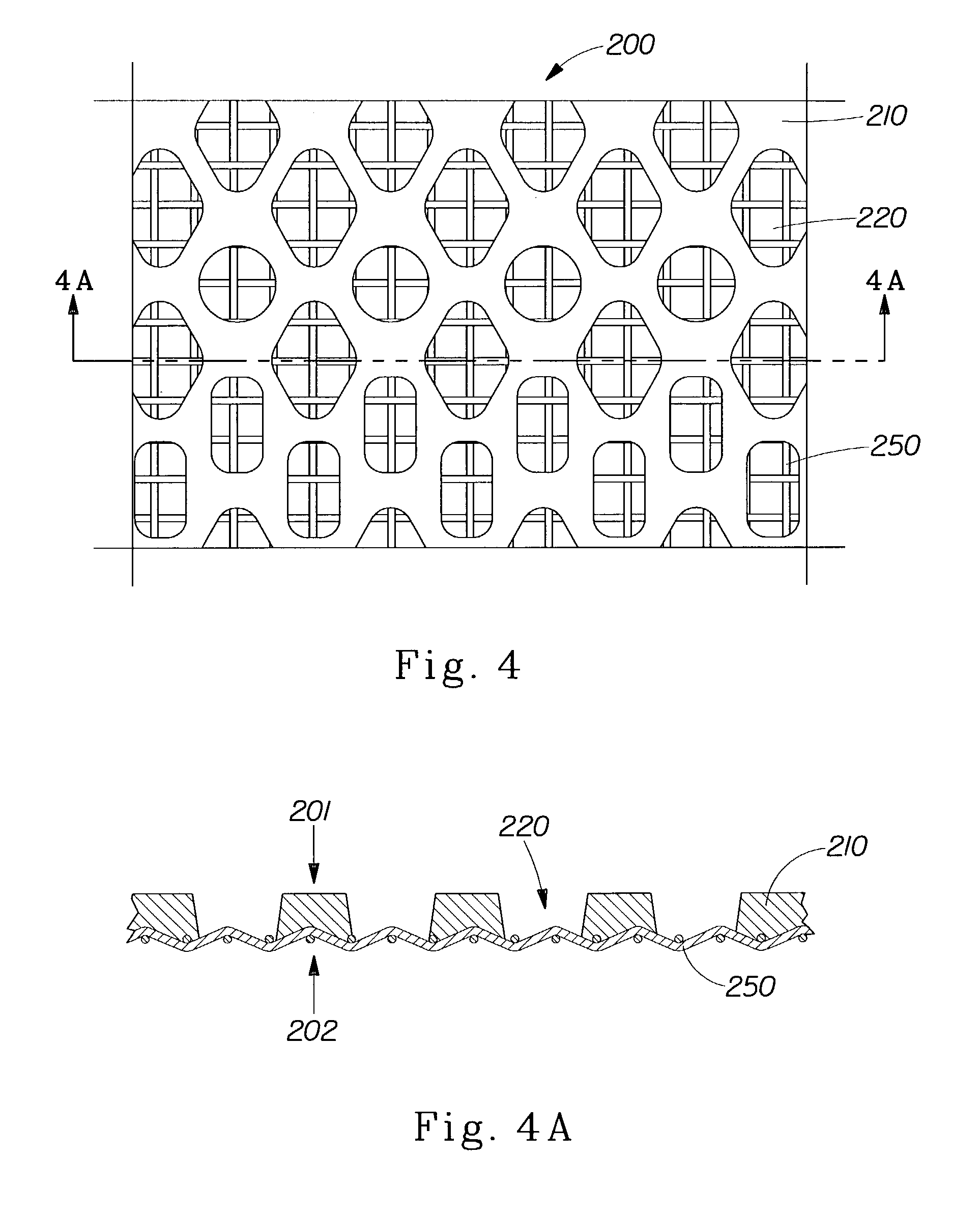

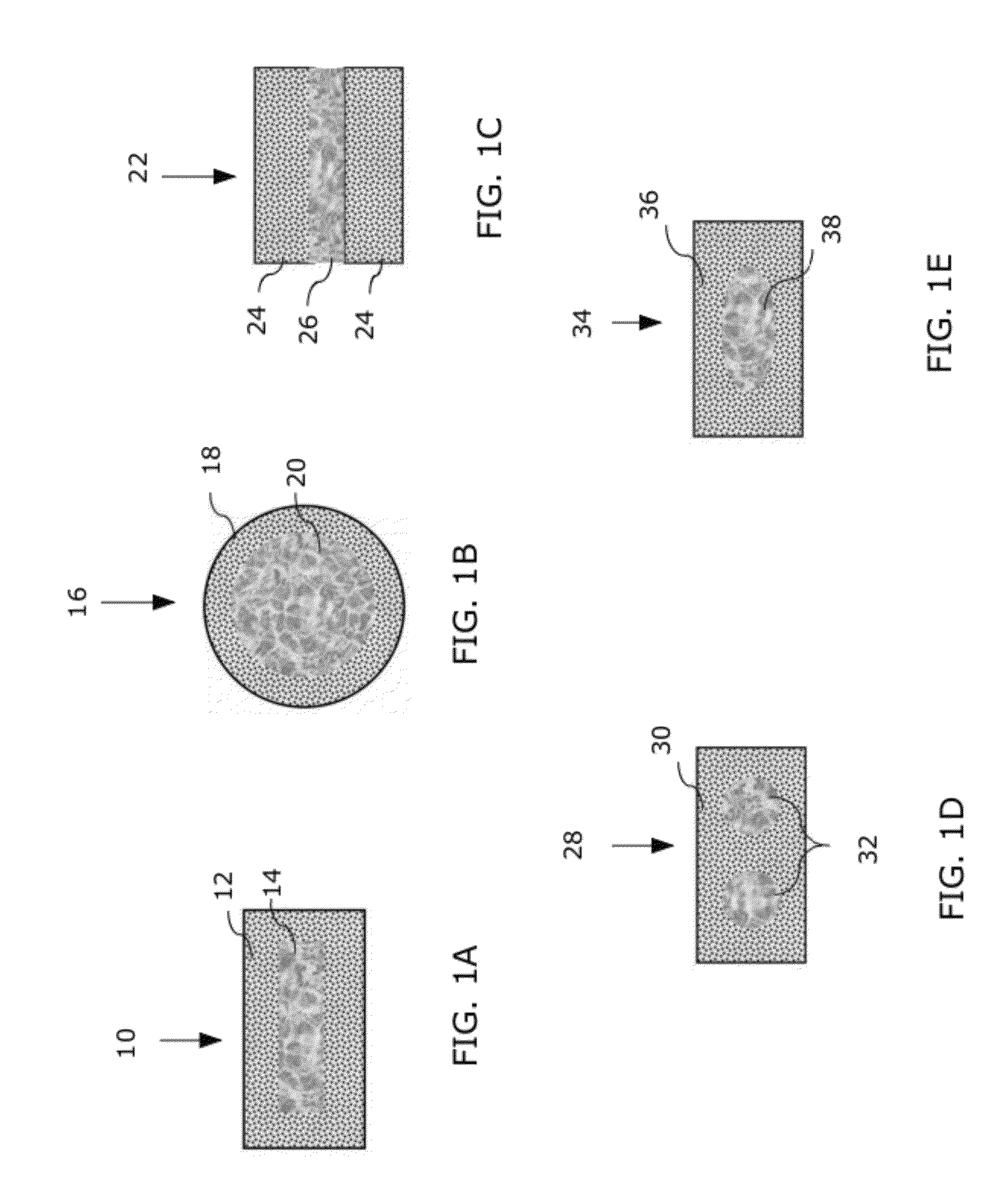

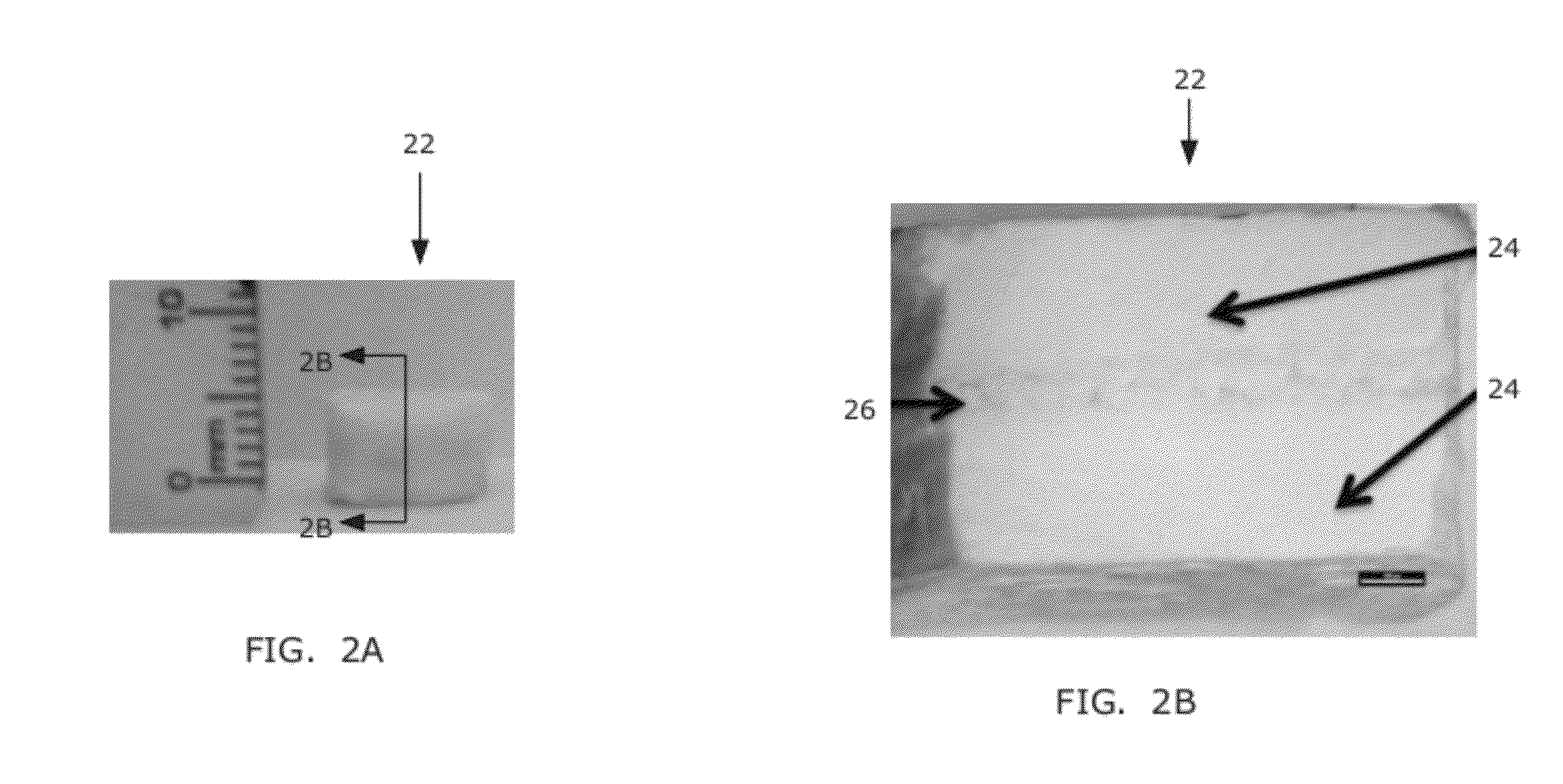

Methods and systems for forming a dual layer housing

ActiveUS20090017242A1Envelopes/bags making machinerySynthetic resin layered productsShell moldingMaterials science

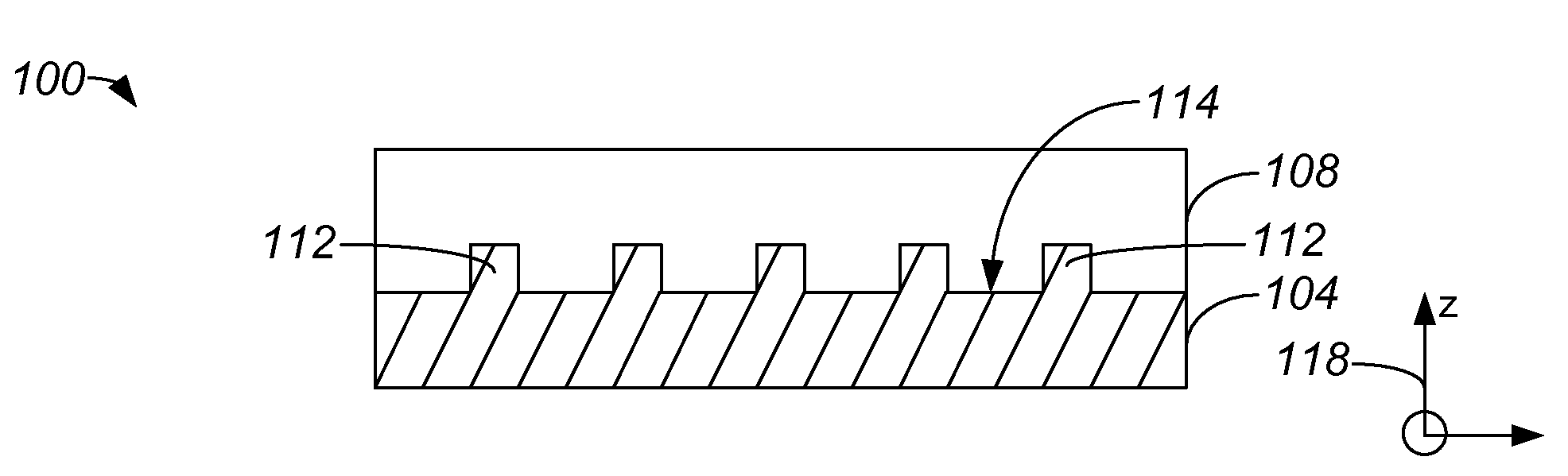

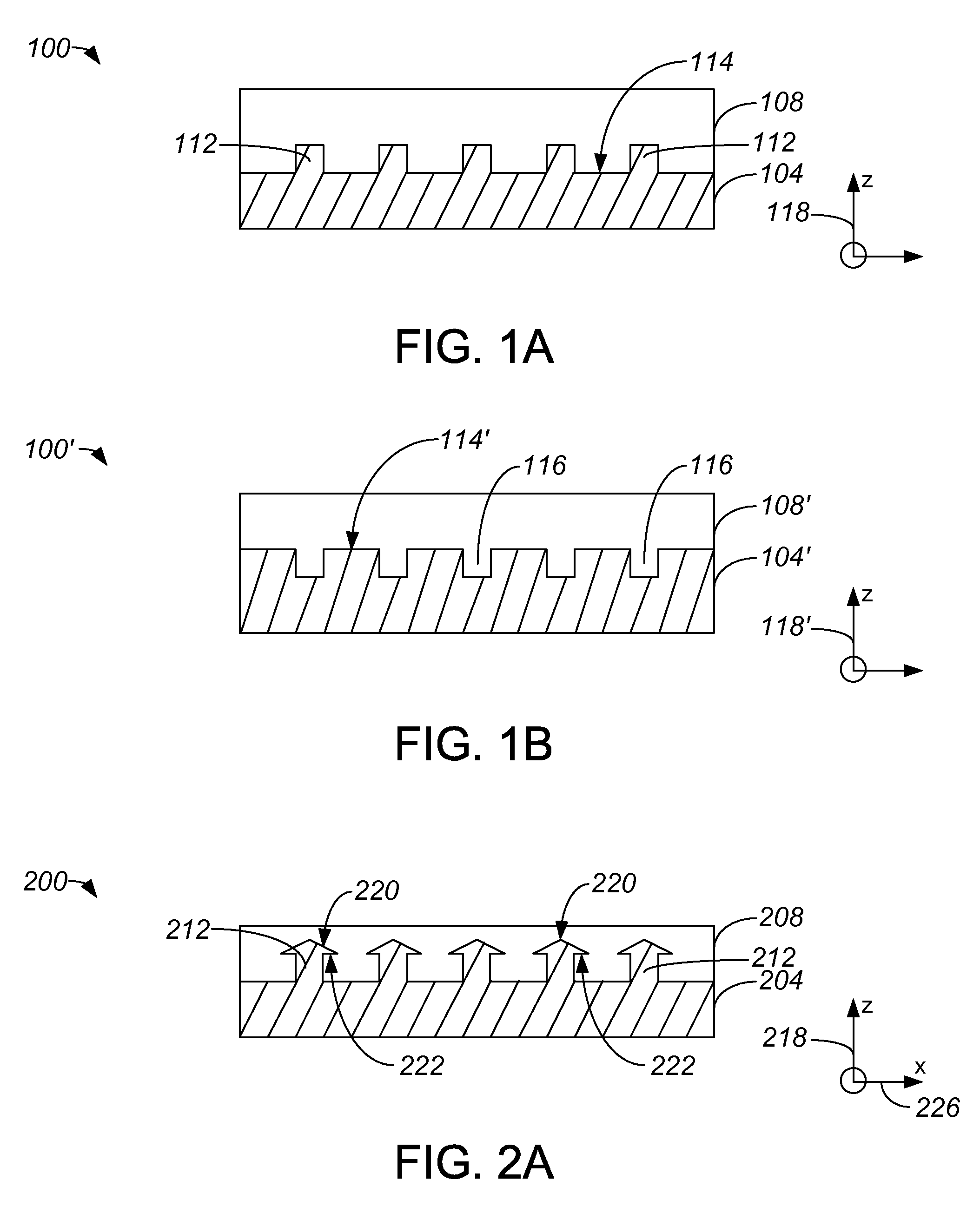

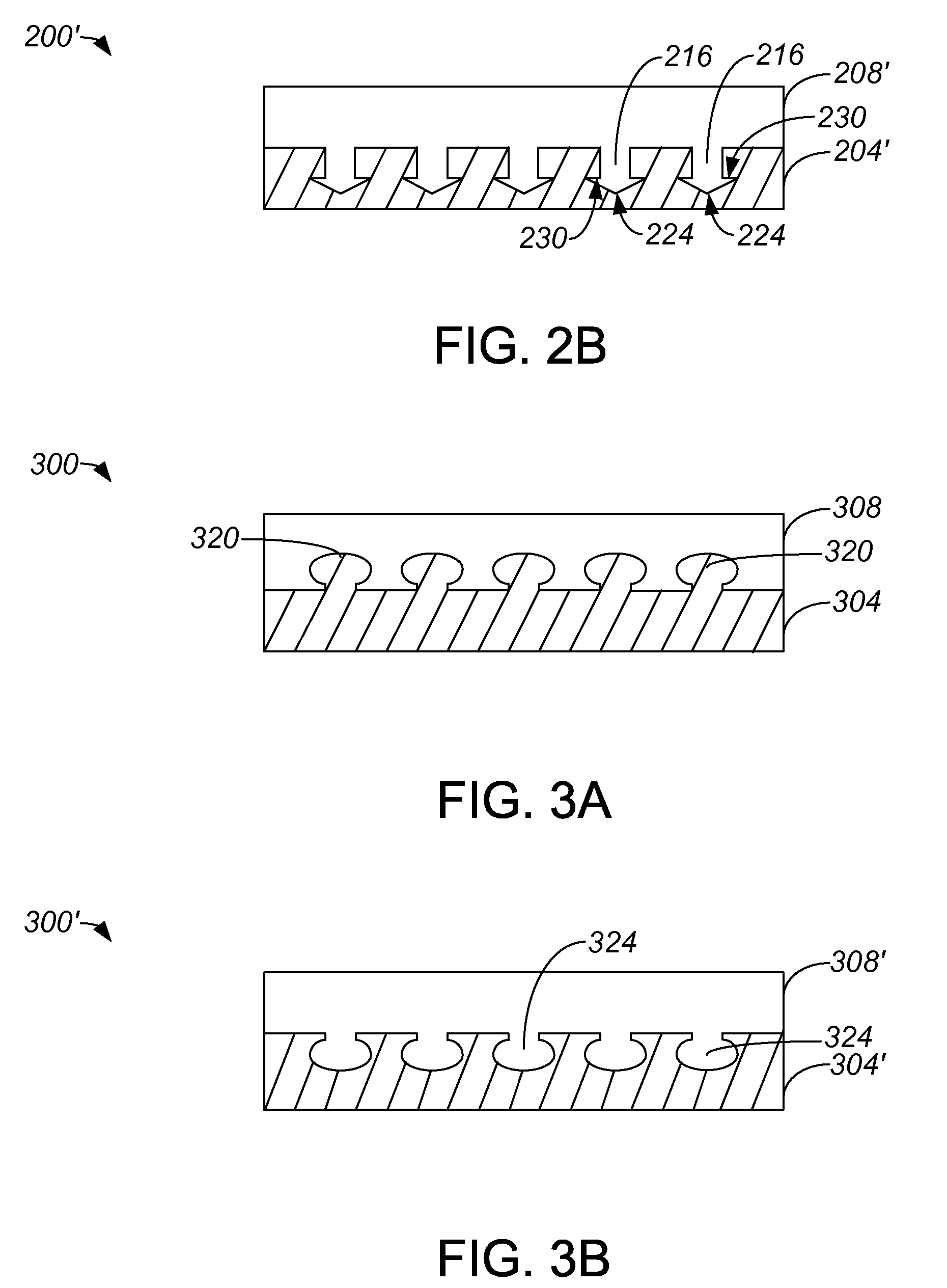

Methods and apparatus for applying internal features or complex mechanical structures to a surface of a metal part are disclosed. According to one aspect of the present invention, a method for creating an assembly that includes a substrate and a molded piece involves obtaining the substrate, and forming at least one binding feature on a surface of the substrate. The method also includes molding on a surface of the binding feature and the surface of the substrate. Molding on the surface of the binding feature and the surface of the substrate mechanically binds the molded piece to the substrate.

Owner:APPLE INC

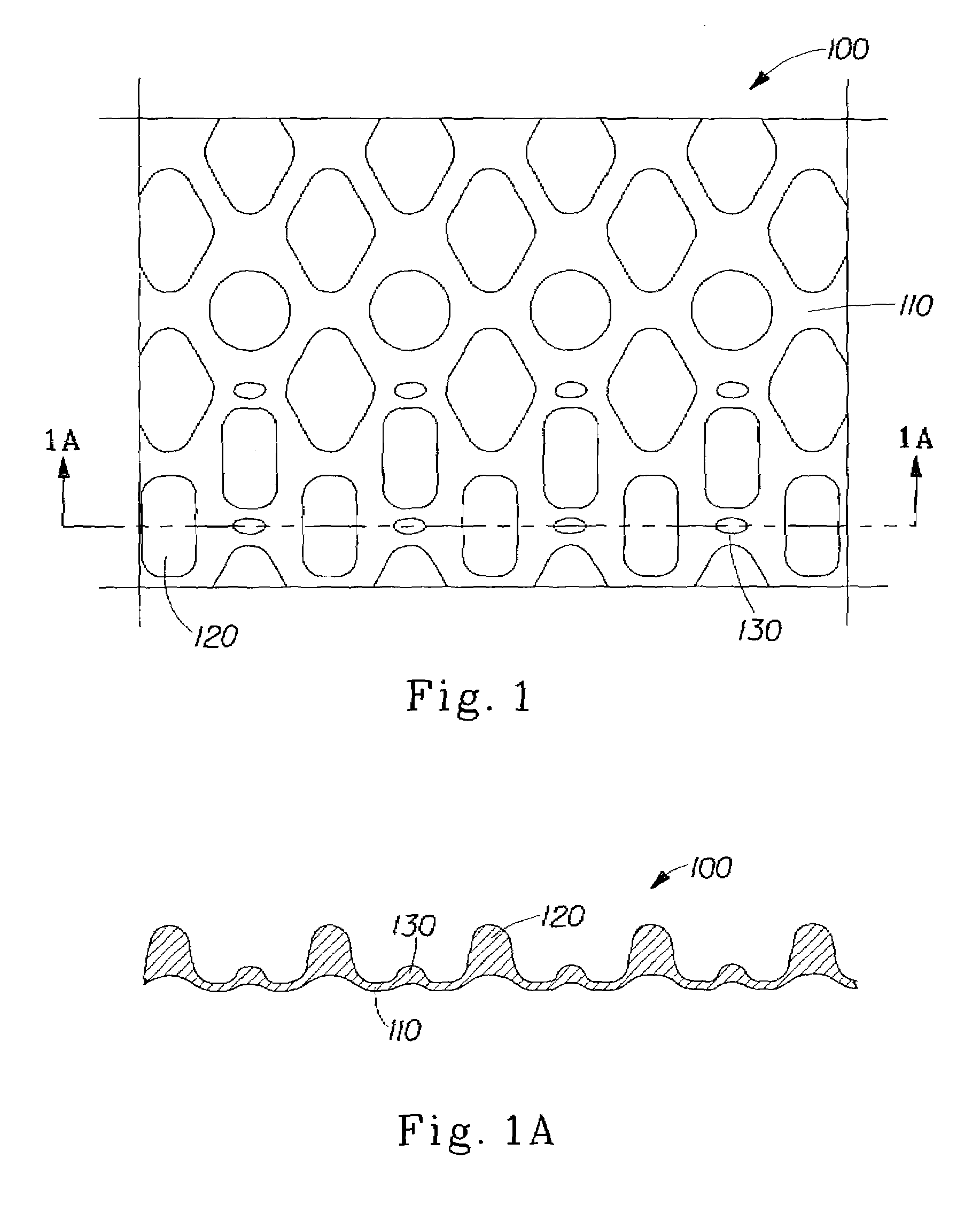

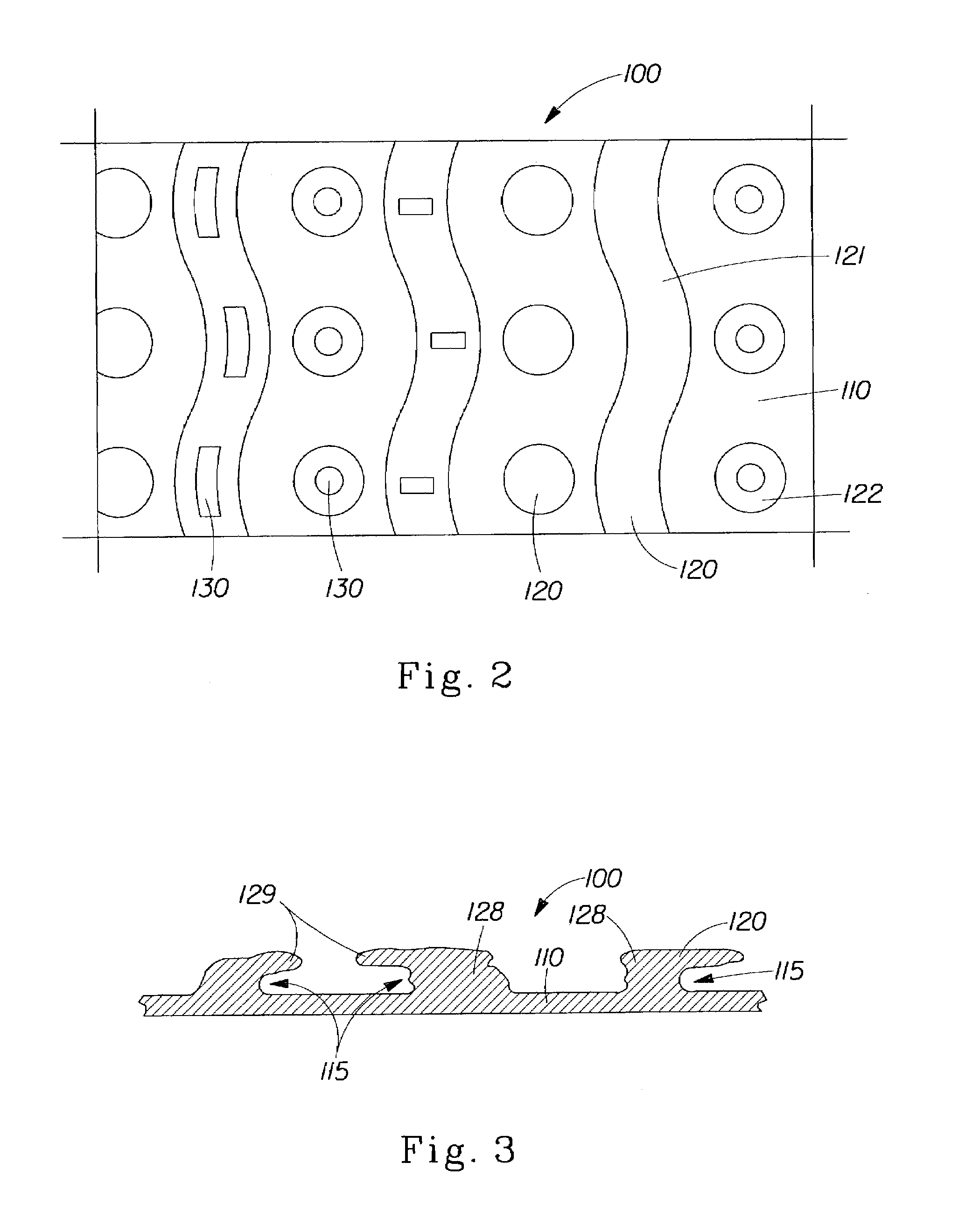

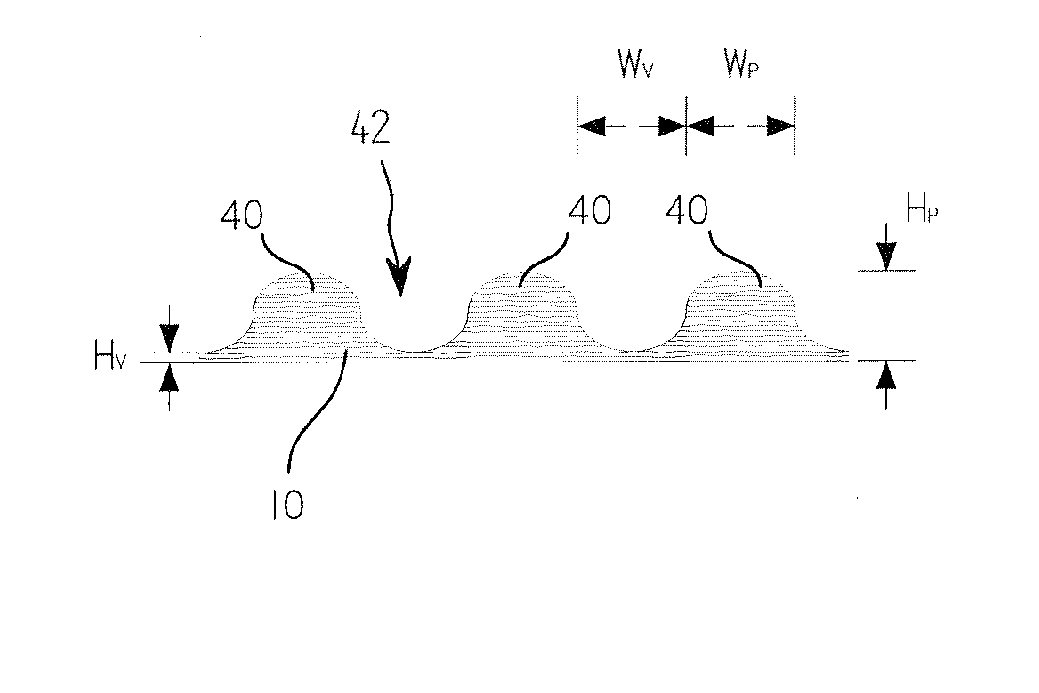

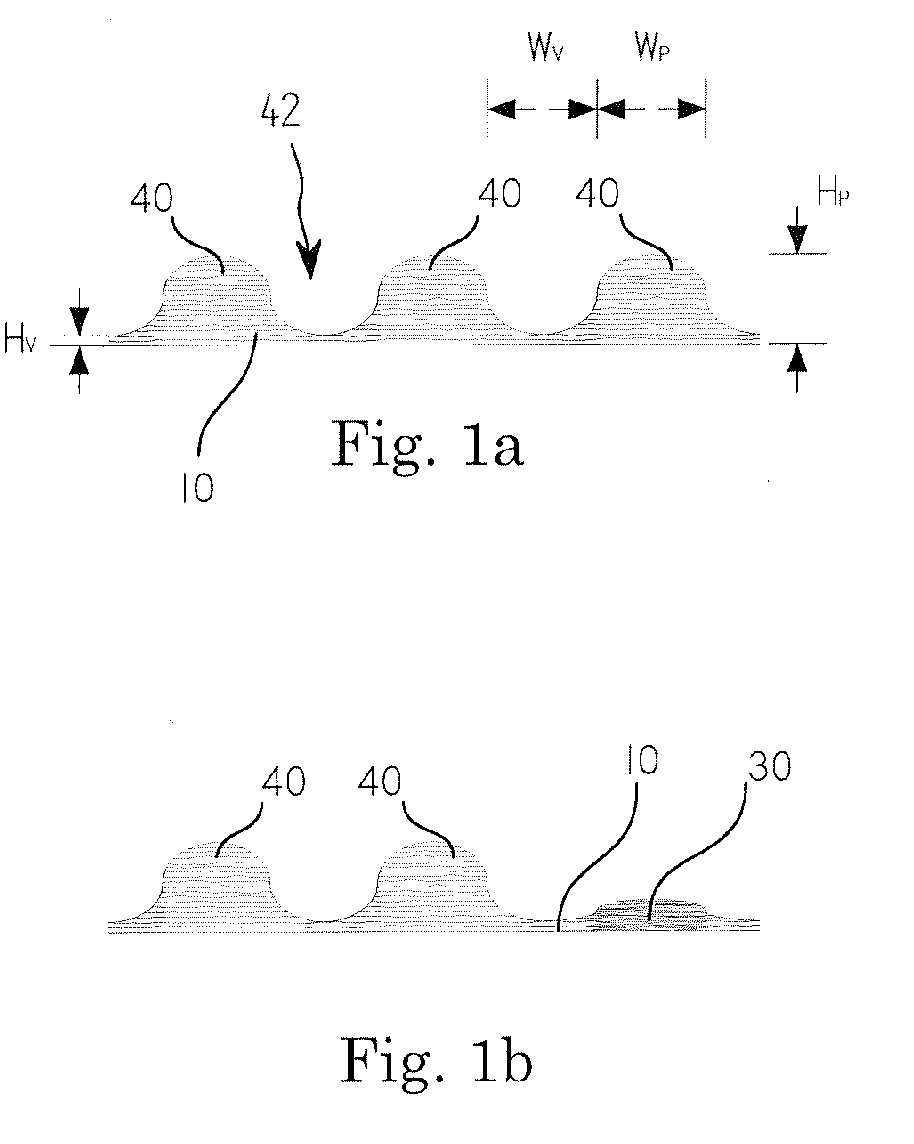

Method to arrange features on a substrate to replicate features having minimal dimensional variability

ActiveUS8349241B2Minimizing dimensional variabilityMinimizing thickness variationDecorative surface effectsNanoinformaticsFill factorVolumetric Mass Density

The present invention is directed to a method of and a mold for arranging features on a substrate to replicate the features with minimal dimensional variability. The method includes arranging features on a layer to minimize thickness variations in the layer that are attributable to density variations of the plurality of features on the layer. The features are transferred into an underlying substrate. It is believed that by forming the features so as to define a uniform fill factor in the layer, the thickness variations may be reduced, if not abrogated. To that end, one method in accordance with the present invention includes forming a flowable material on the substrate. Thereafter, a plurality of features is formed in a region of the flowable material. The plurality of features are arranged to provide a substantially uniform fill factor in the region.

Owner:MOLECULAR IMPRINTS

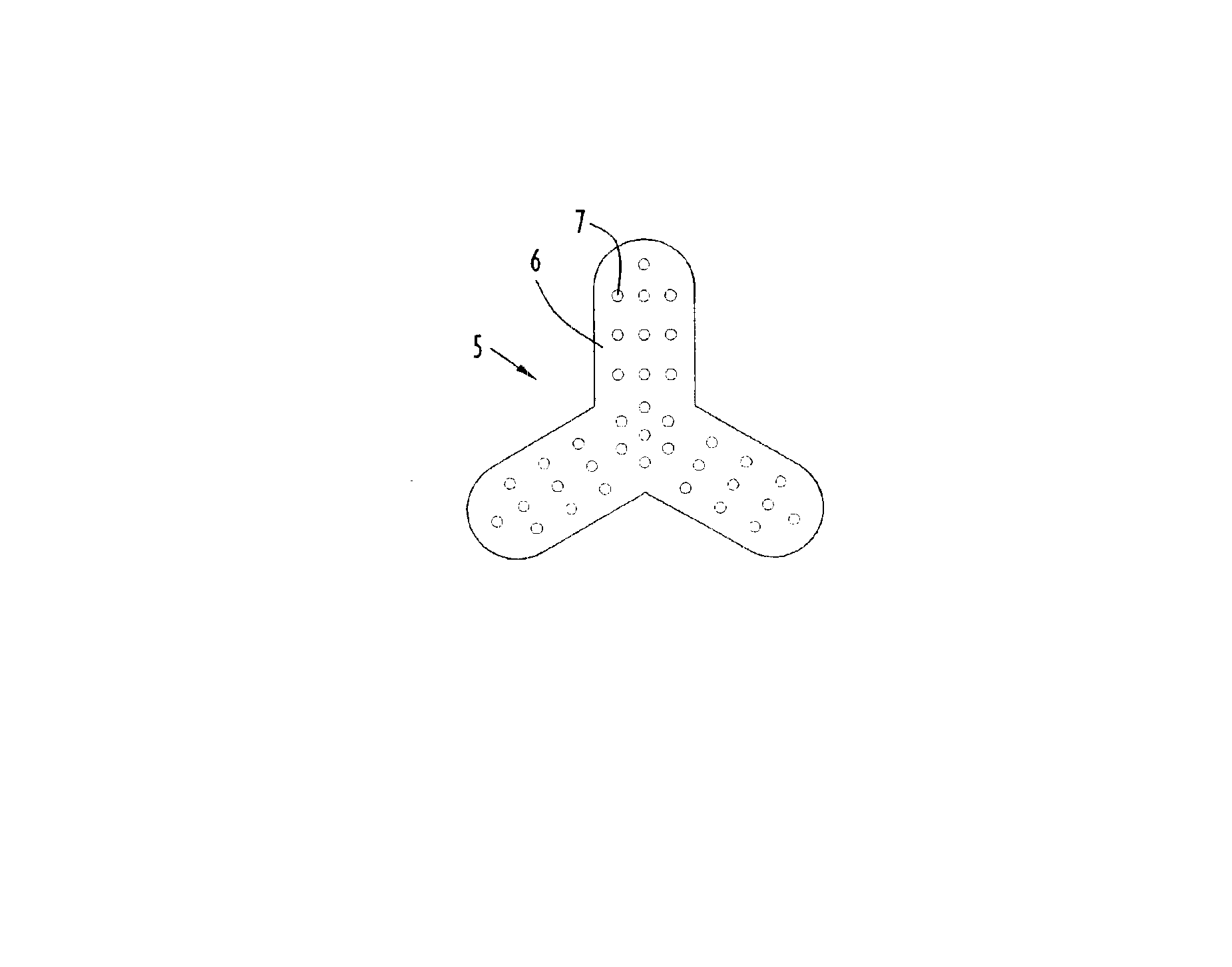

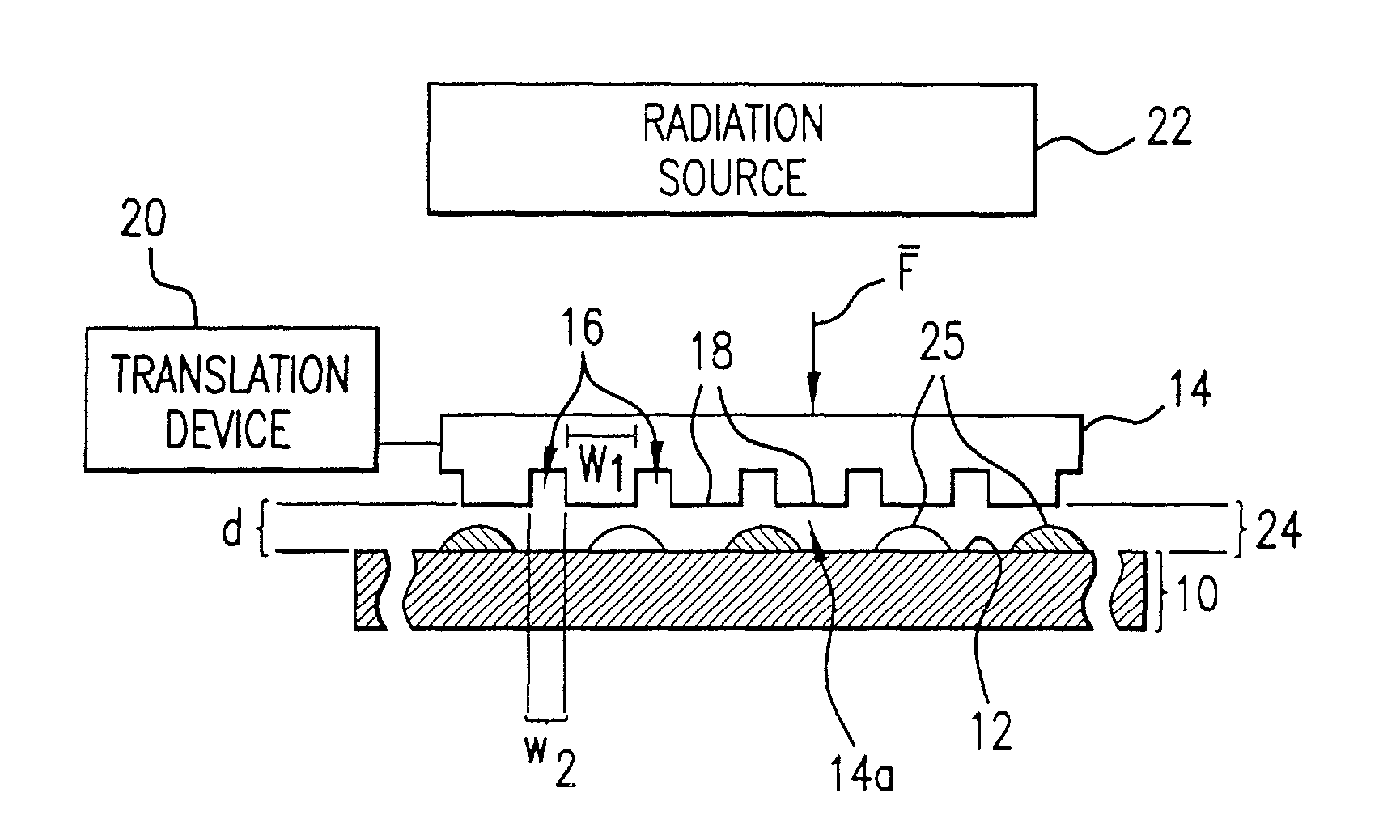

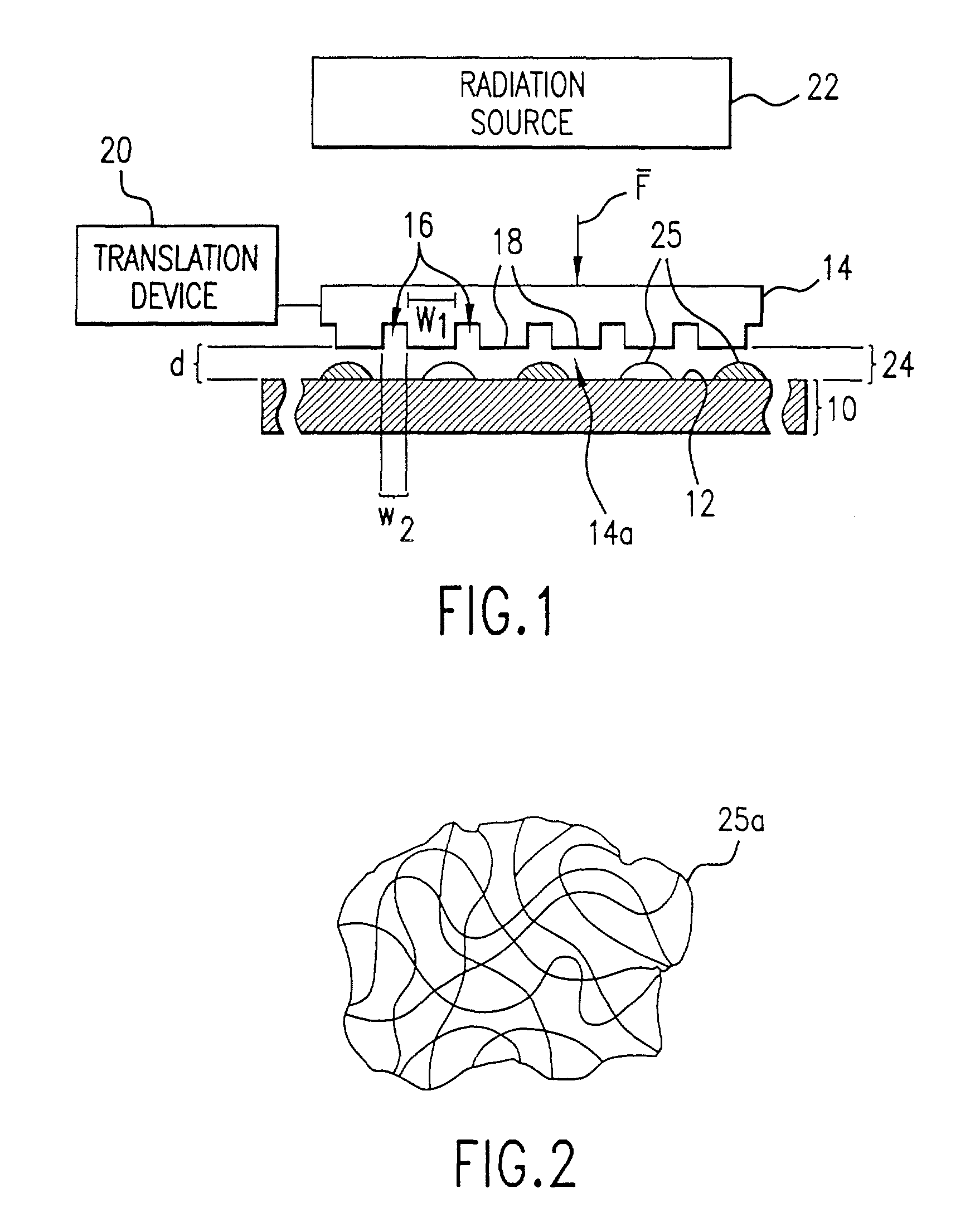

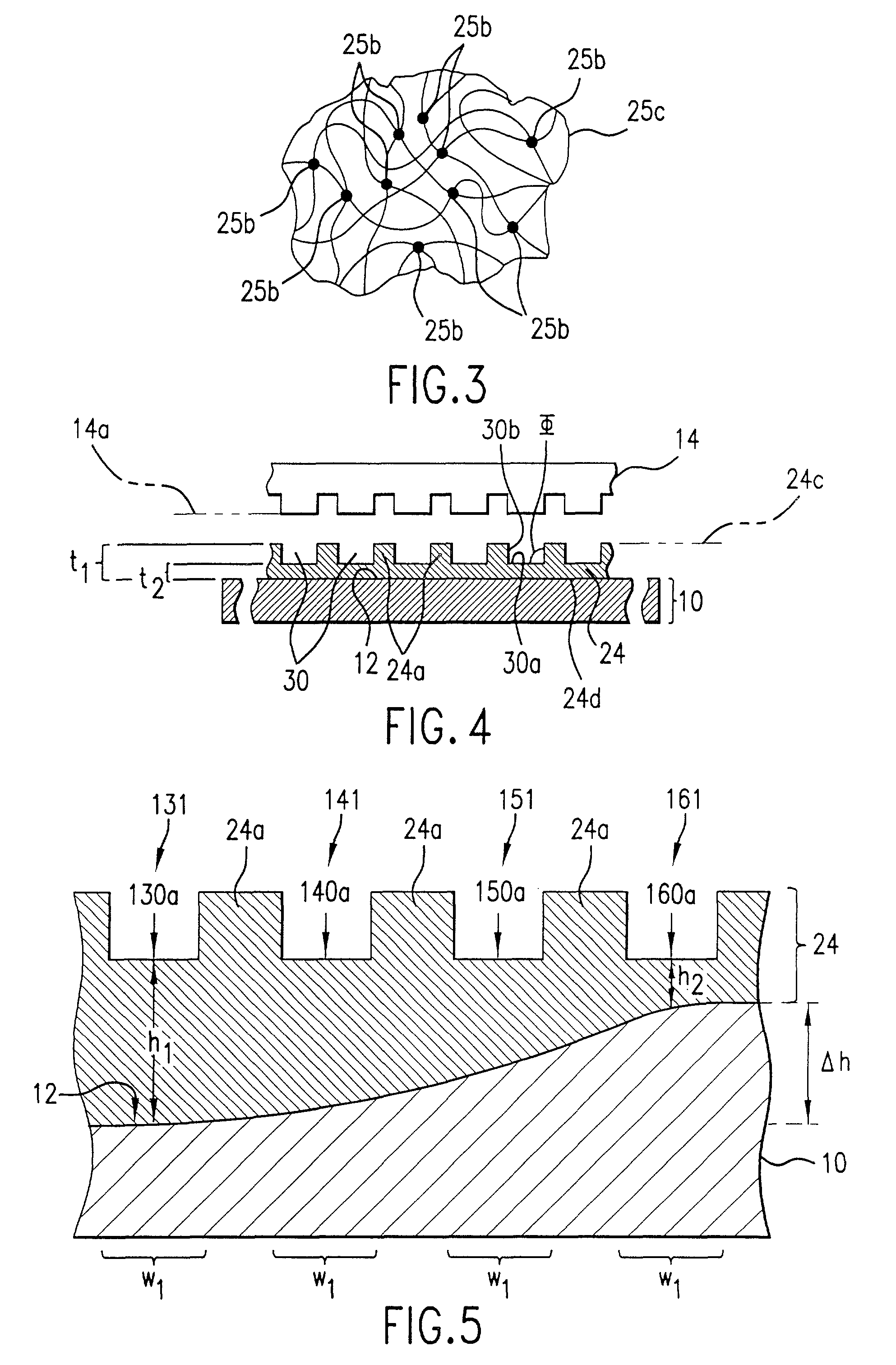

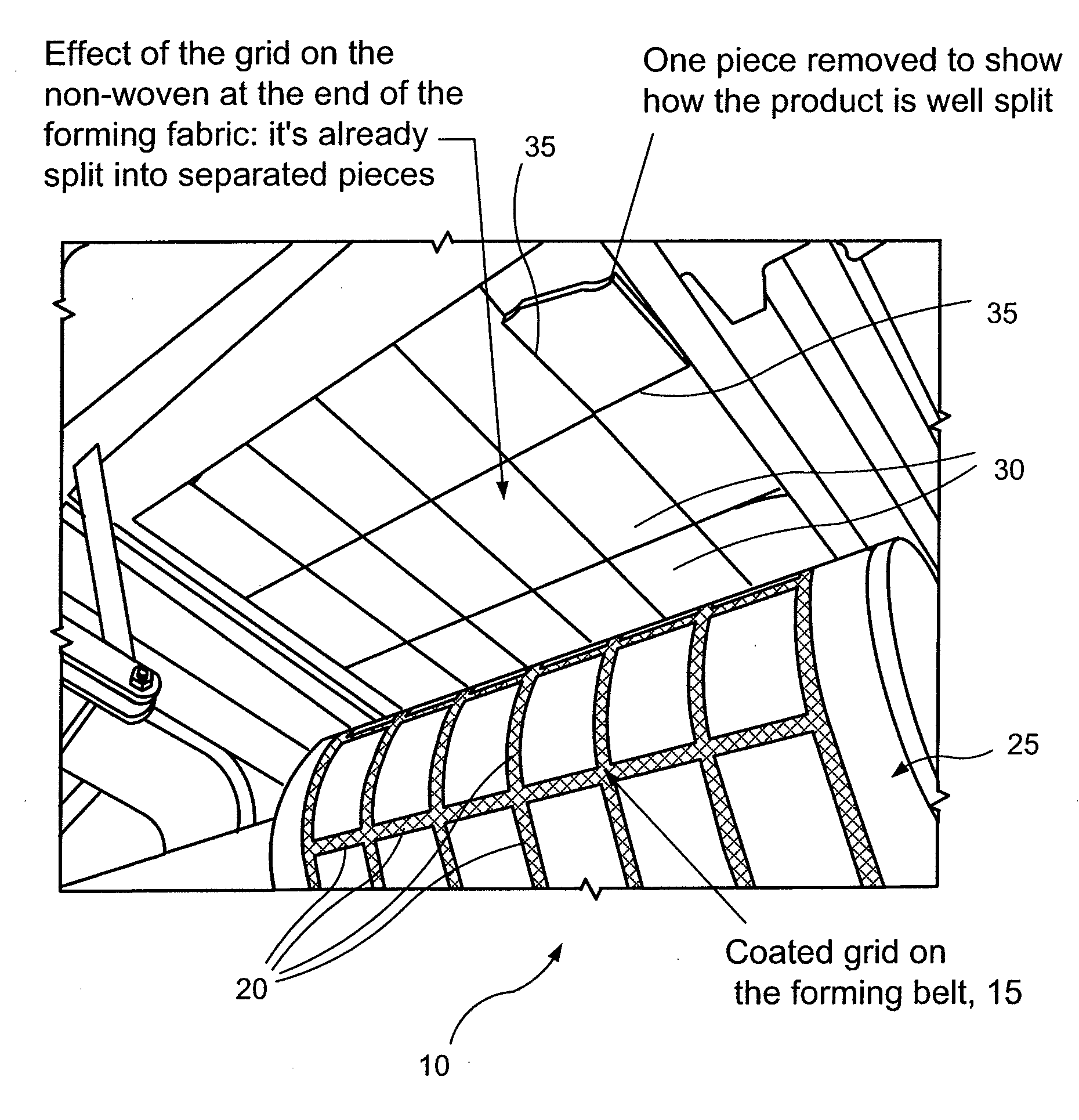

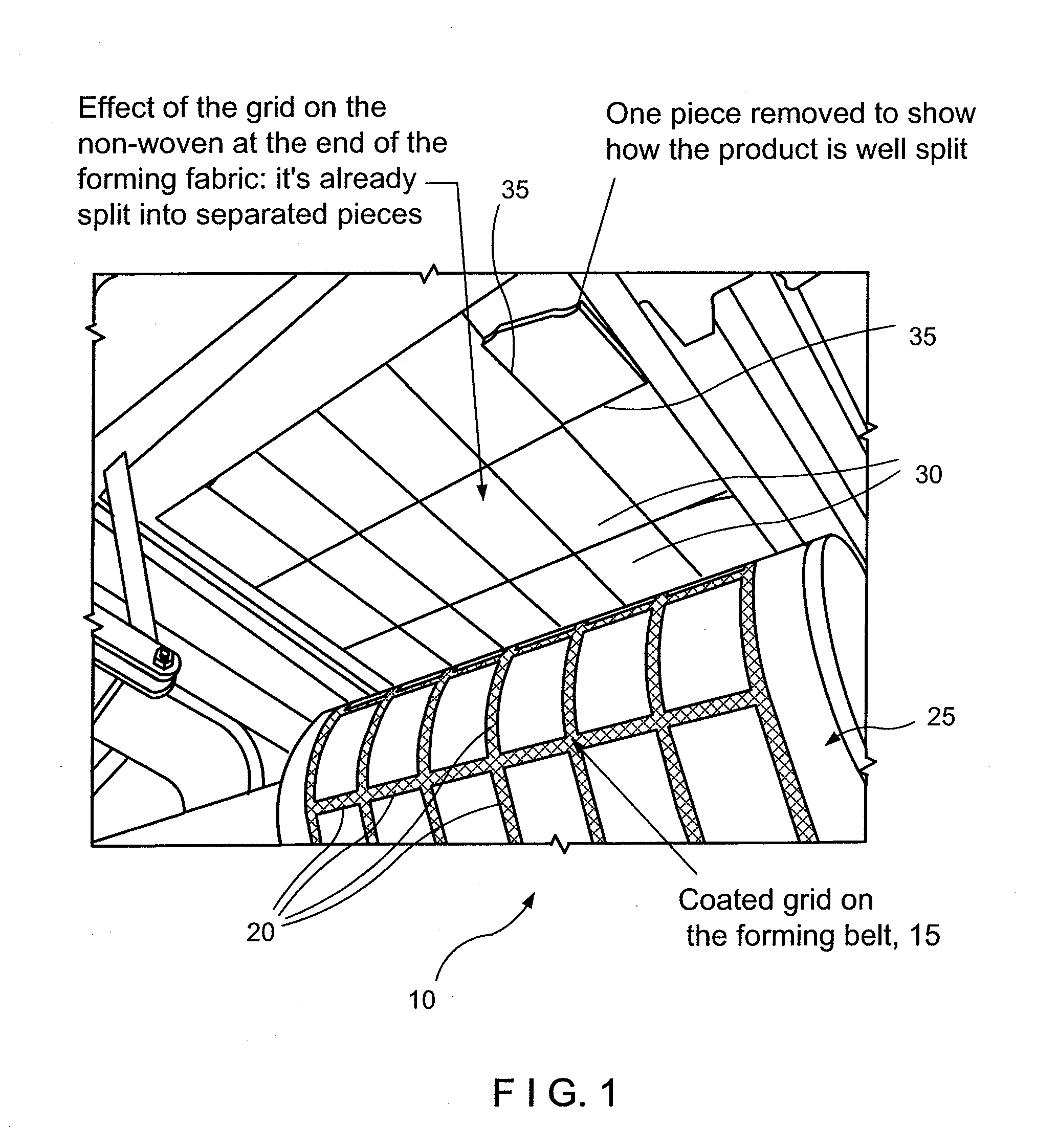

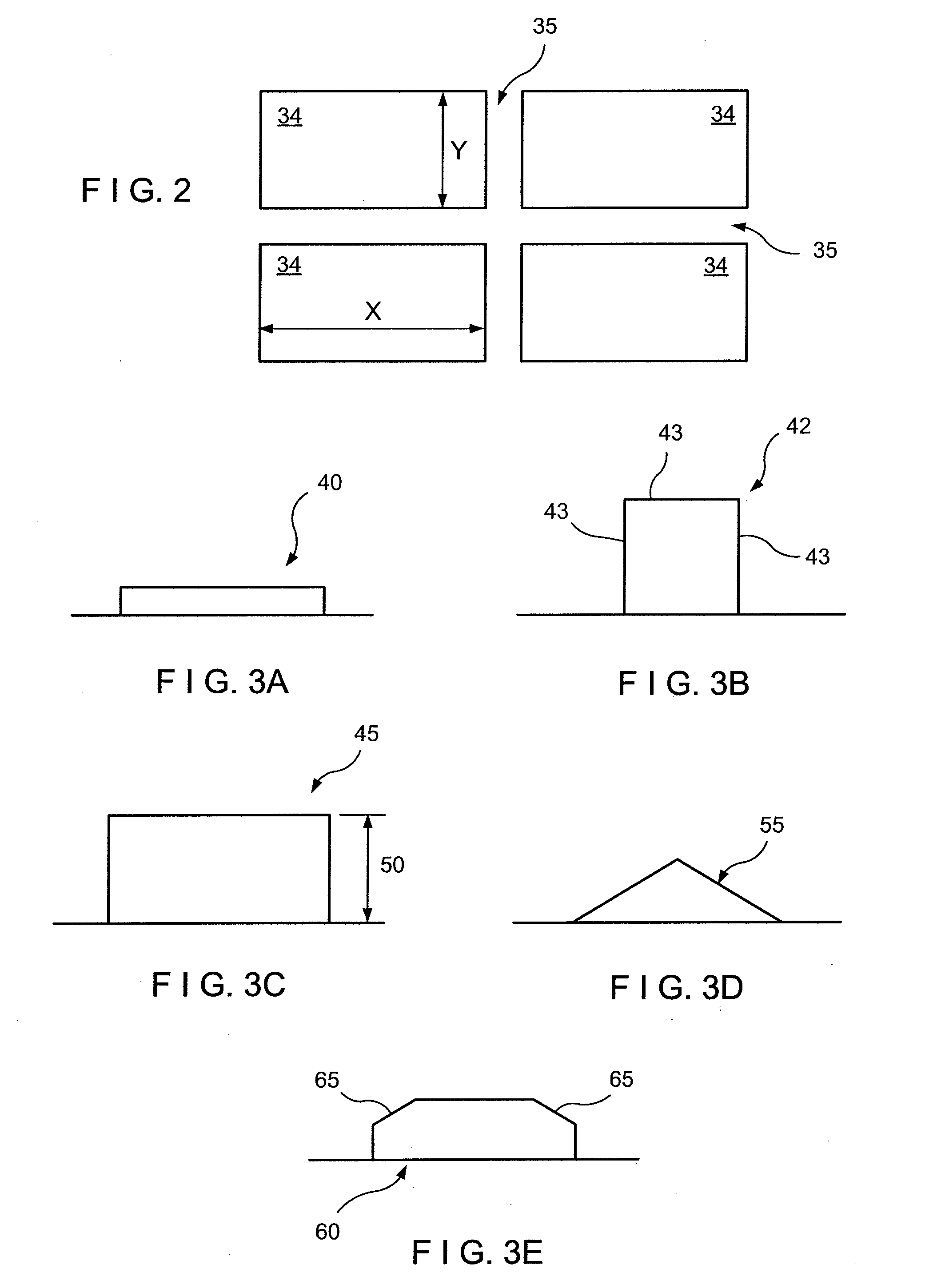

Sheet Slitting Forming Belt for Nonwoven Products

Owner:MONNERIE JEAN LOUIS +1

Filaments comprising an active agent nonwoven webs and methods for making same

Owner:THE PROCTER & GAMBLE COMPANY

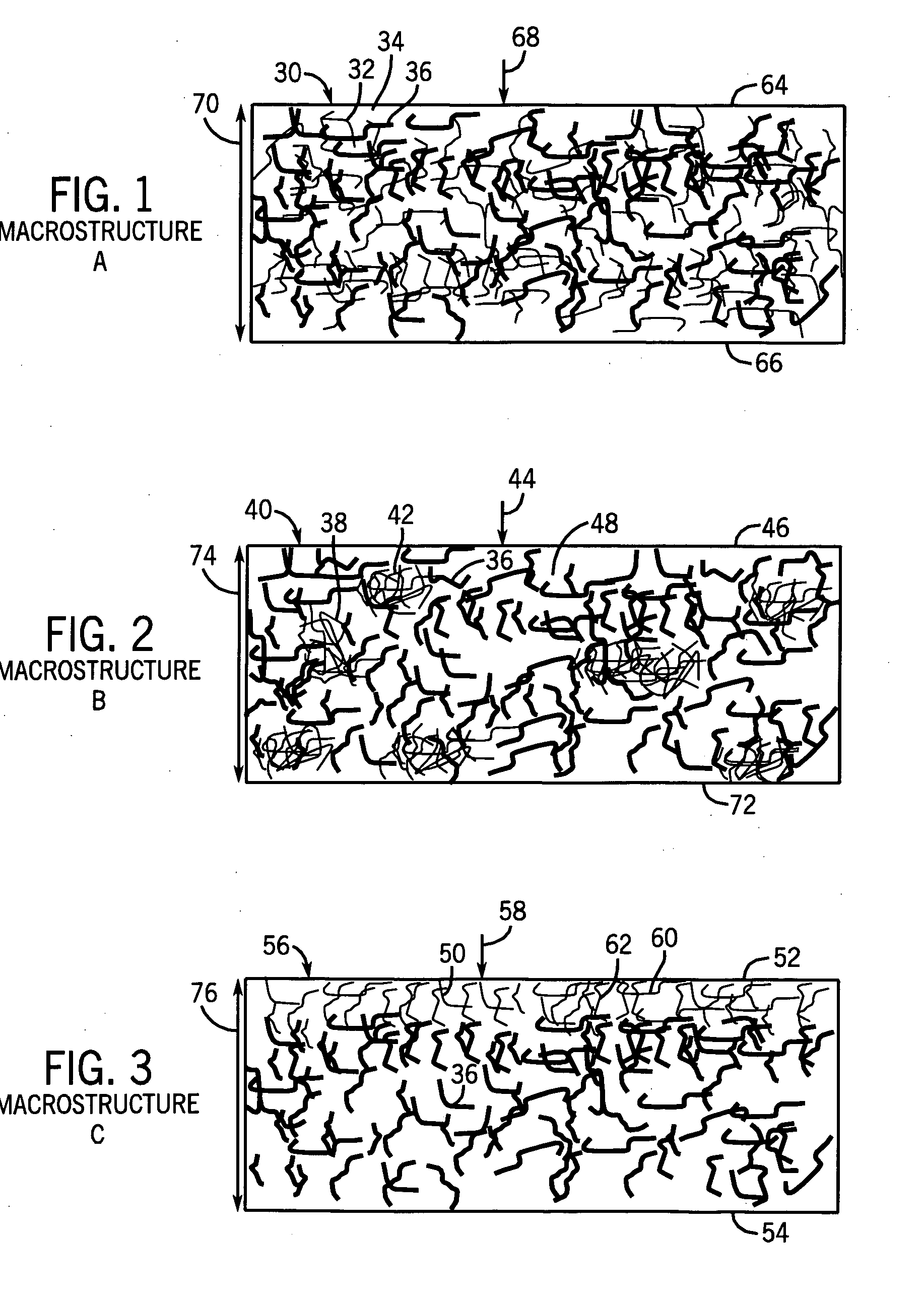

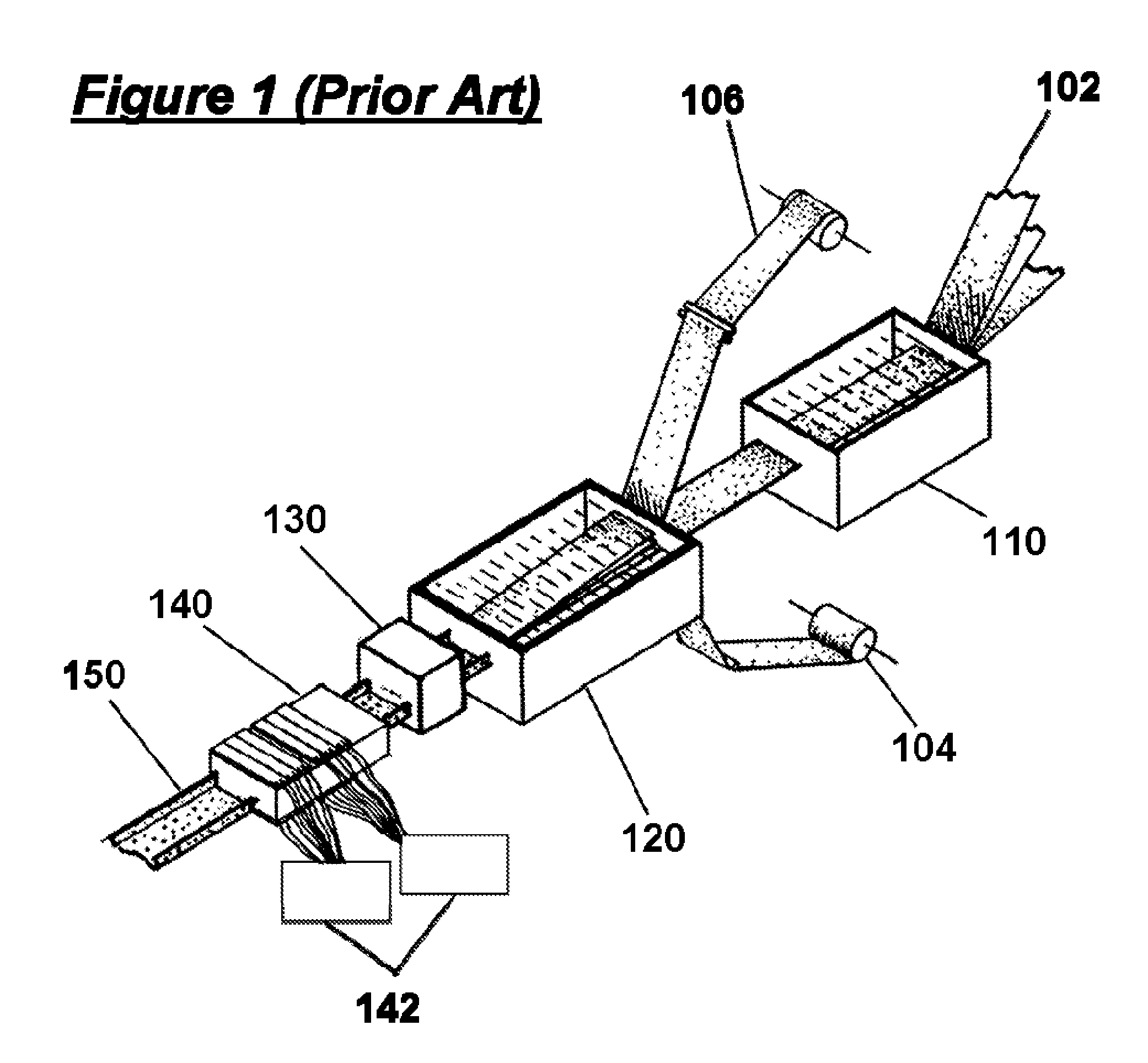

Mixed fibers and nonwoven fabrics made from the same

ActiveUS20090042475A1Improve breathabilityIncrease flexibilityLaminationLamination apparatusFiltrationSubject matter

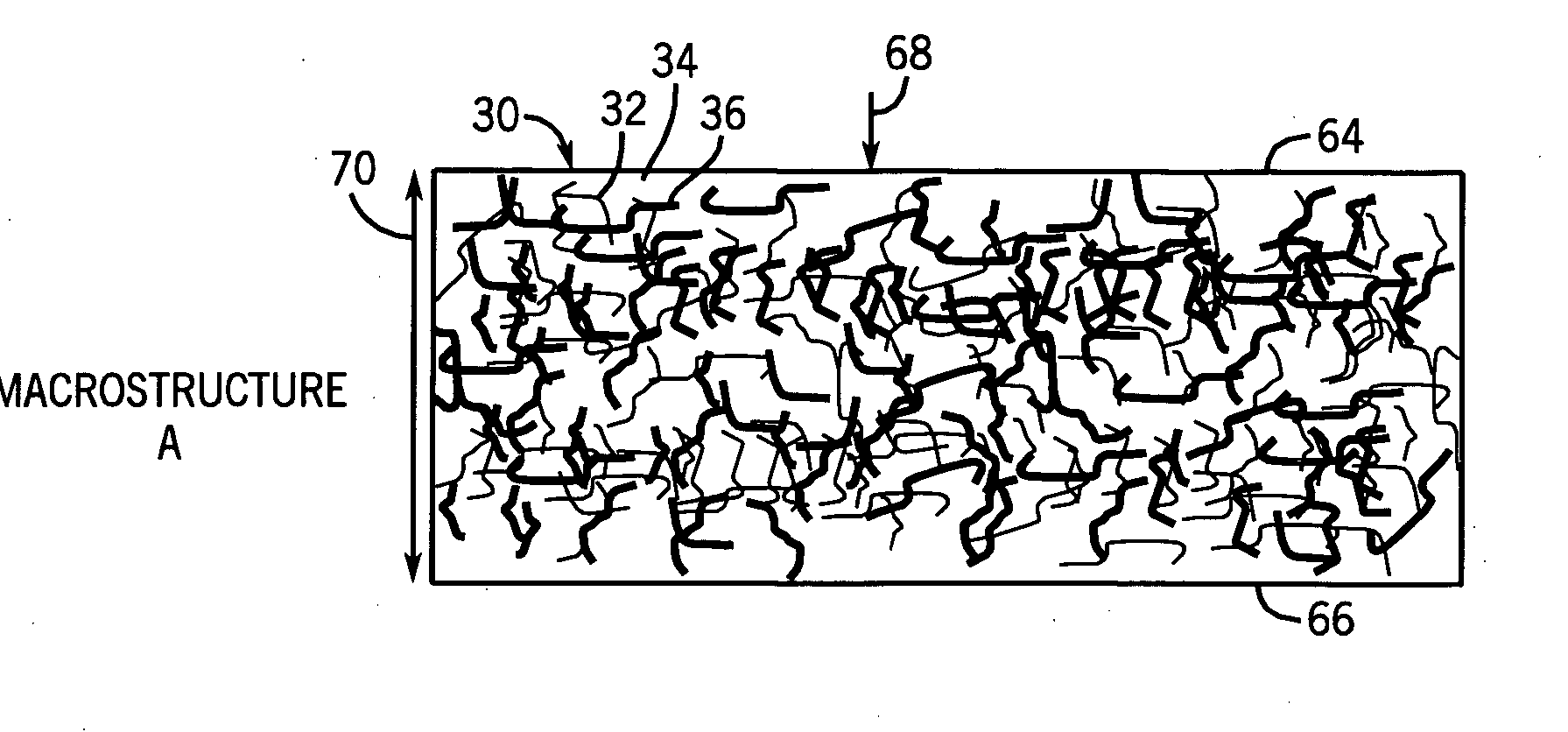

The subject matter disclosed herein relates generally to the production of a predetermined ratio of multicomponent fibers in combination with monocomponent fibers or other multicomponent fibers, preferably through a spunbonding process. After extrusion, these fibers can produce a fiber network that is subsequently bonded to produce a nonwoven fabric comprising multiple types of fibers. The multicomponent fibers within the network may be processed to remove one component by dissolution or to split the individual components into separate fibers. As a result, the fabric will be comprised of fibers with a range of diameters (micro- or nano-denier fibers as well as higher denier fibers) such that the fibers will not pack as tightly as in a homogeneous nonwoven fabric produced from one type of monocomponent or multicomponent fiber. The present invention additionally relates to methods for producing nonwoven fabrics with increased loft, breathability, strength, compressive properties, and filtration efficiency.

Owner:NORTH CAROLINA STATE UNIV

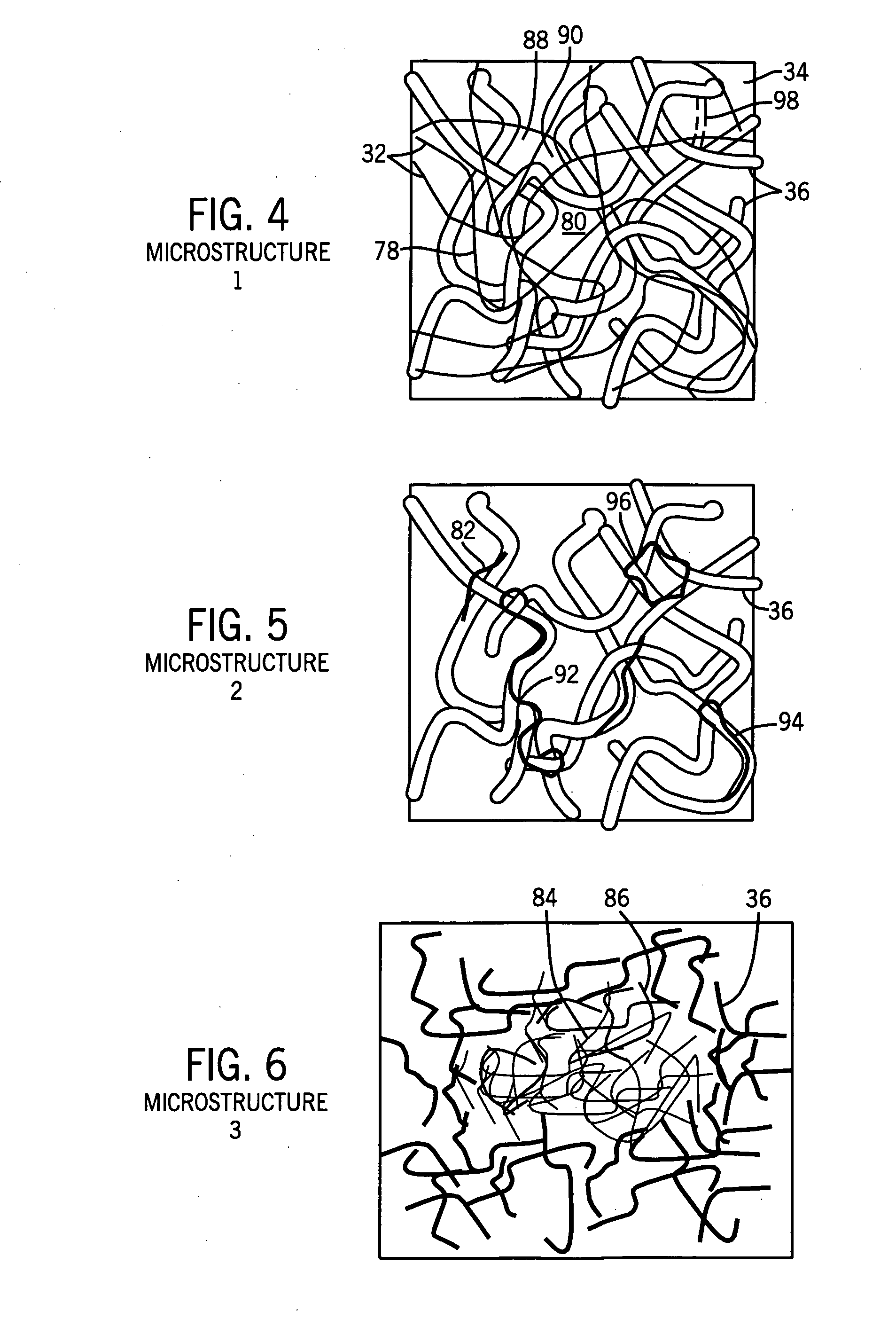

High performance filter media with internal nanofiber structure and manufacturing methodology

ActiveUS20070021021A1Improve performanceImprove efficiencyOther chemical processesIndividual molecule manipulationFiberFilter media

High performance filter media and manufacturing methodology provides nanofibers of diameter less than 1 μm incorporated and processed into internal structure of a filter medium dominantly composed of coarse fibers of diameter greater than 1 μm, to change the internal media structure.

Owner:FLEETGUARD INC

Electro-spinning process for making starch filaments for flexible structure

A flexible structure includes a plurality of starch filaments. The structure includes at least a first region and a second region, each of the first and second regions having at least one common intensive property selected from the group consisting of density, basis weight, elevation, opacity, crepe frequency, and any combination thereof. The common intensive property of the first region differs in value from the common intensive property of the second region.

Owner:THE PROCTER & GAMBLE COMPANY

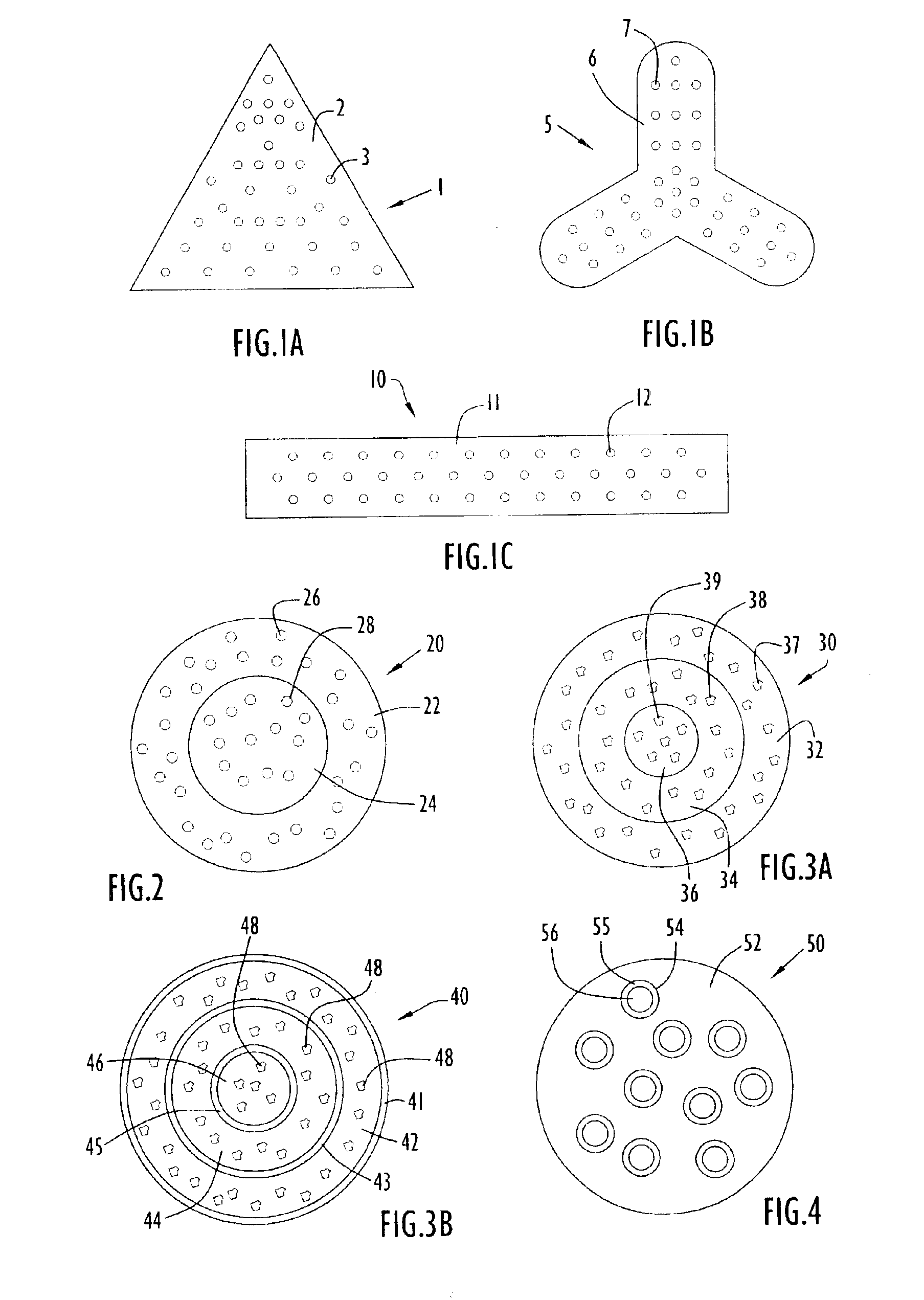

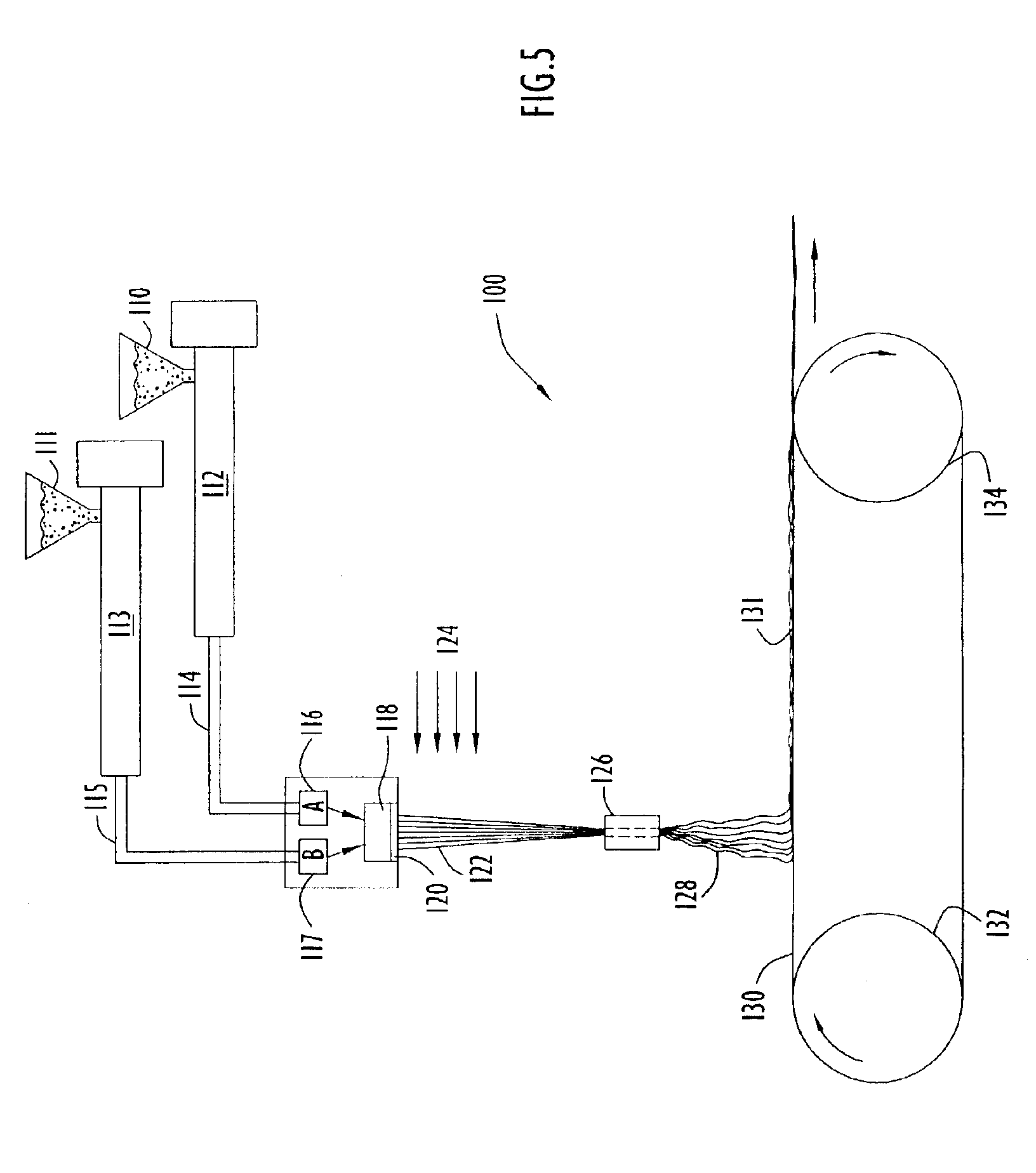

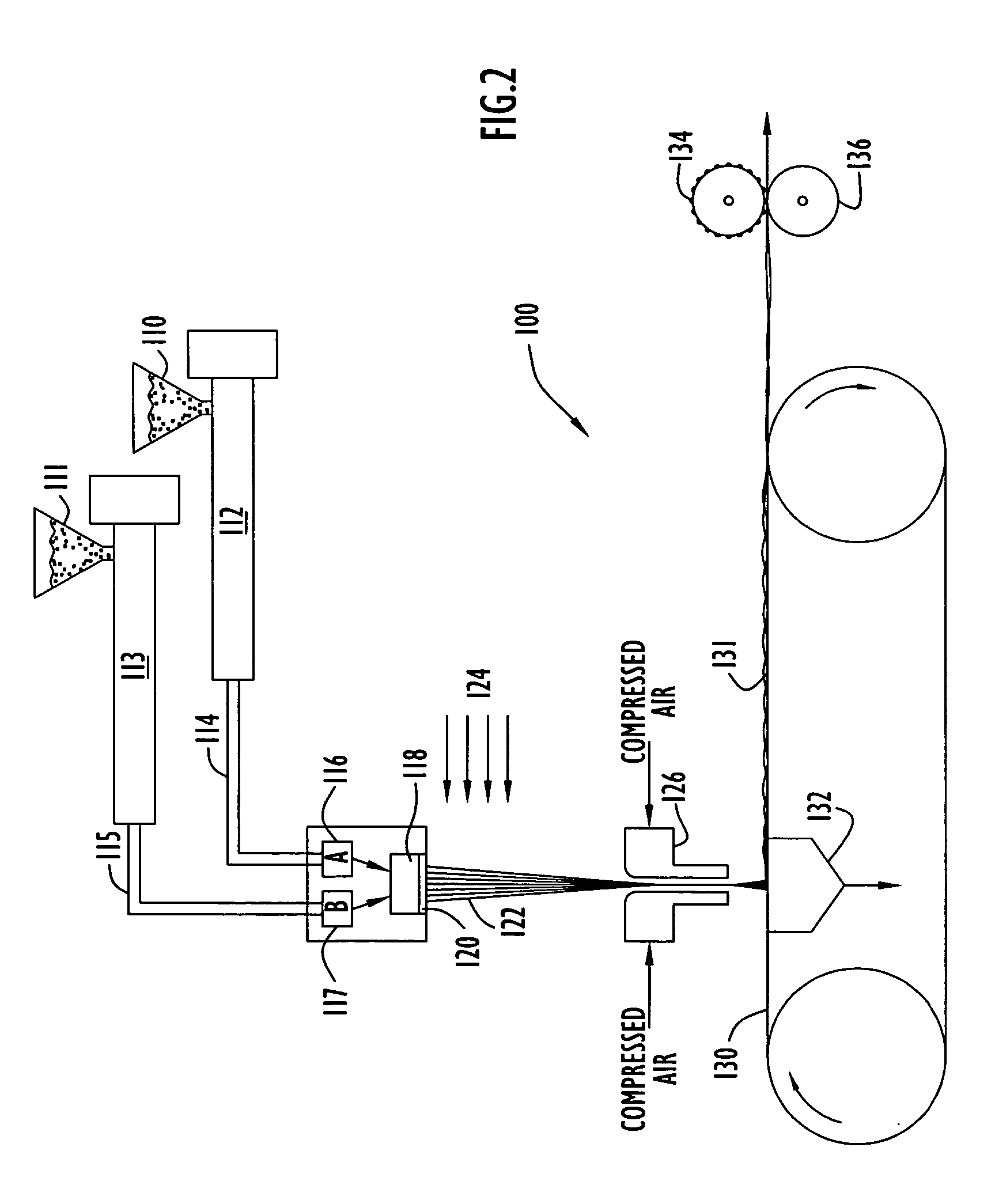

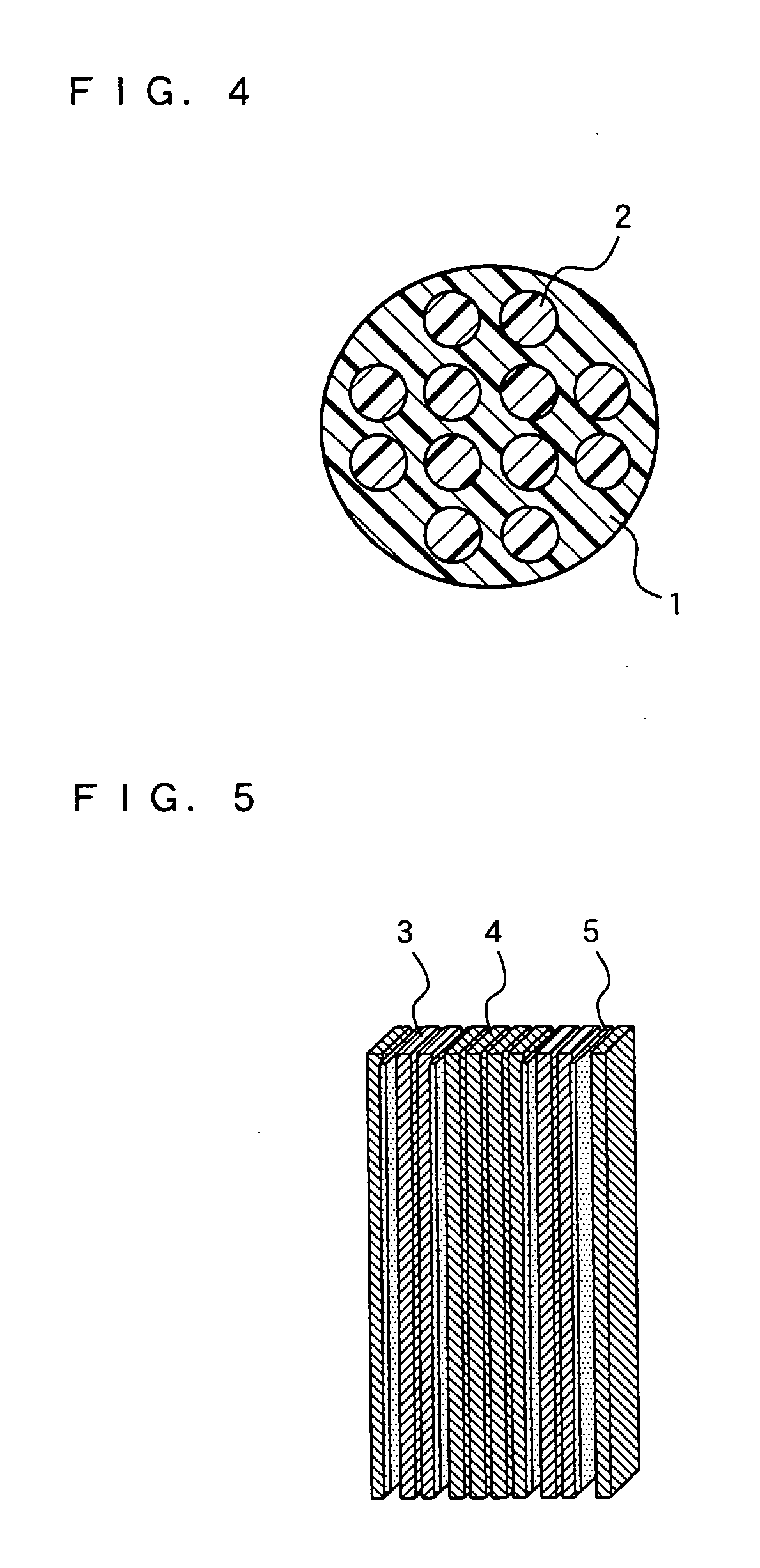

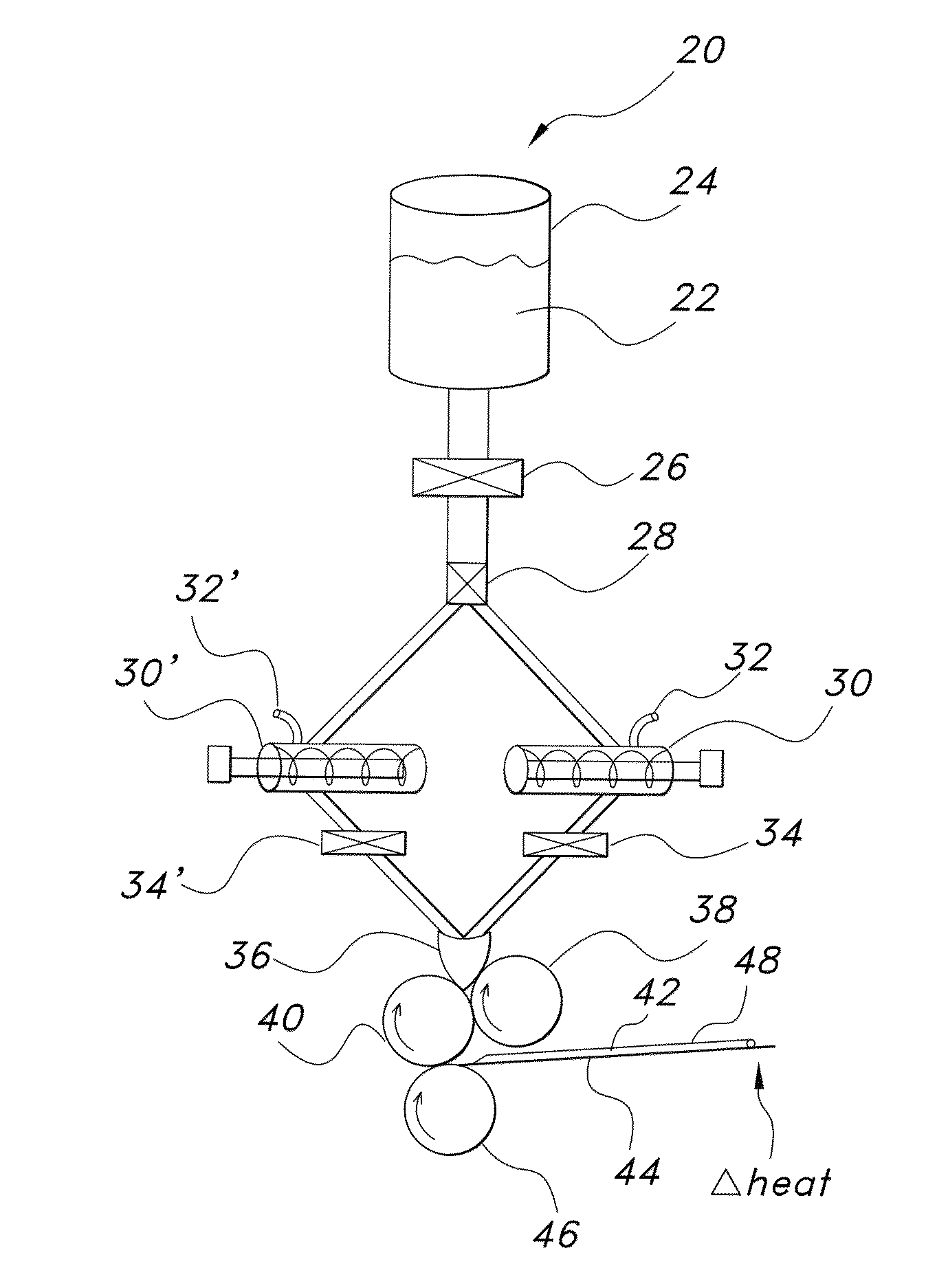

Methods and apparatus for forming ultra-fine fibers and non-woven webs of ultra-fine spunbond fibers

ActiveUS20050032450A1Filament/thread formingPaper/cardboard layered productsMolten statePolymer science

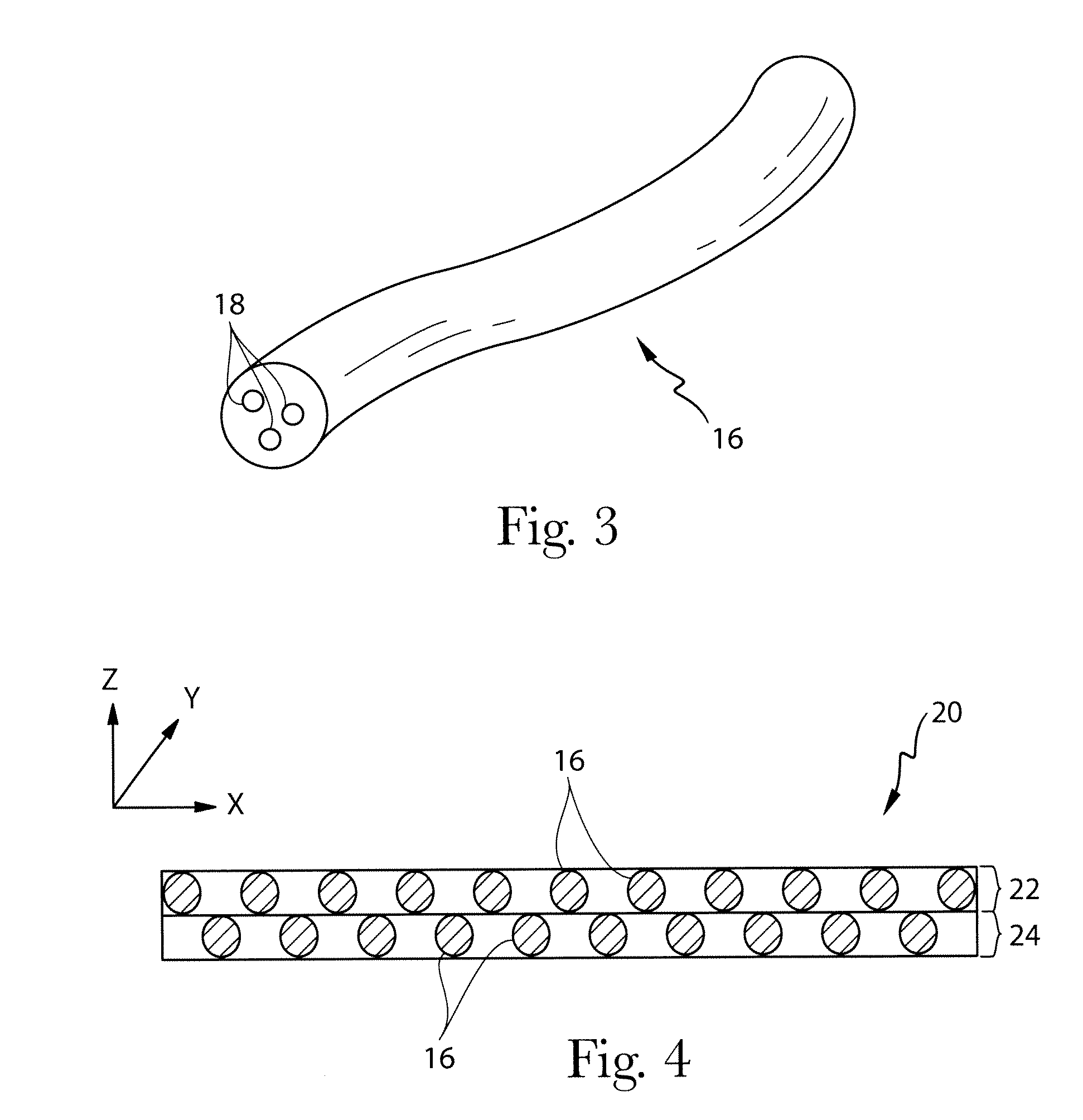

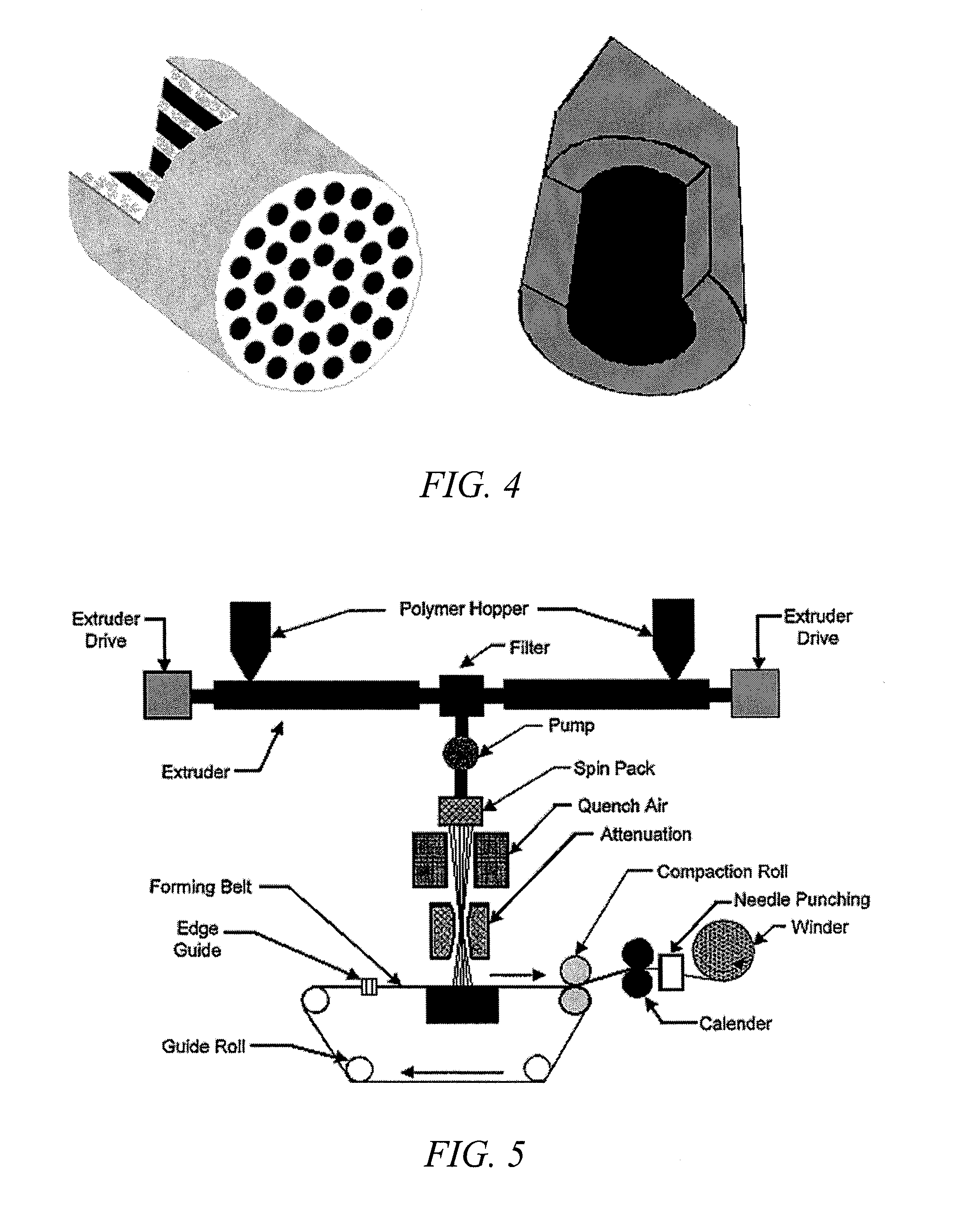

A nonwoven web product including ultra-fine fibers is formed utilizing a spunbond apparatus that forms multicomponent fibers by delivering first and second polymer components in a molten state from a spin pack to a spinneret, extruding multicomponent fibers including the first and second polymer components from the spinneret, attenuating the multicomponent fibers in an aspirator, laying down the multicomponent fibers on an elongated forming surface disposed downstream from the aspirator to form a nonwoven web, and bonding portions of at least some of the fibers in the nonwoven web together to form a bonded, nonwoven web product. The multicomponent fibers can include separable segments such as islands-in-the-sea fibers, where certain separated segments become the ultra-fine fibers in the web product. In addition, carbon tubular fibers can be formed by extruding islands-in-the-sea fibers including polyacrylonitrile or pitch sheath segments in the fibers, separating the segments of the fiber, and converting the polyacrylonitrile or pitch to carbon by a carbonization process.

Owner:HILLS CO

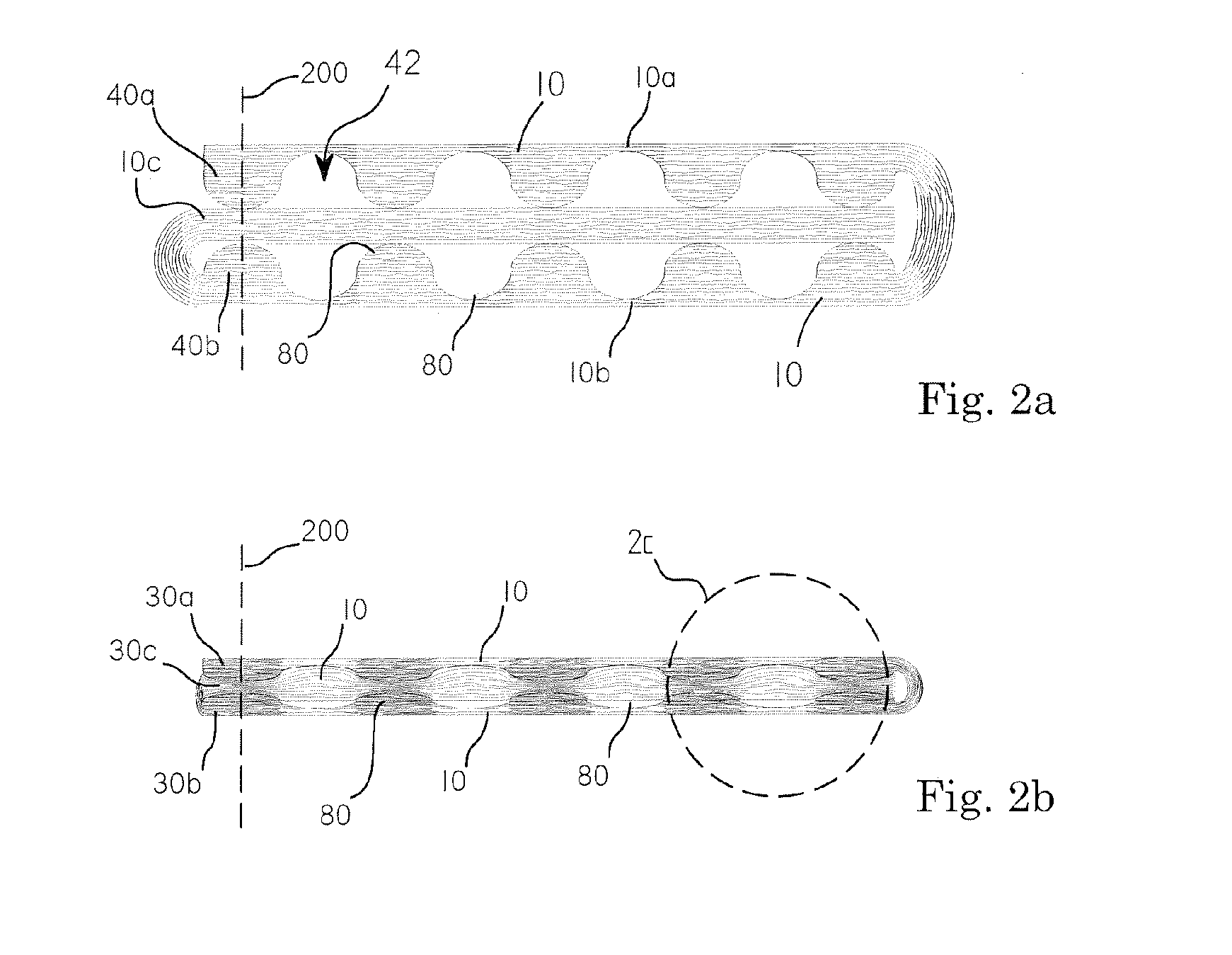

Method of making absorbent core structures with undulations

Owner:NORDSON CORP

Nonwoven fabric composed of ultra-fine continuous fibers, and production process and application thereof

InactiveUS20050079781A1Increase flexibilityIncrease softnessSynthetic resin layered productsFilament/thread formingPolymer sciencePolyvinyl alcohol

A nonwoven fabric composed of ultra-fine continuous fibers having a mean fineness of not more than 0.5 dtex is prepared. The nonwoven fabric comprises a water-soluble thermoplastic resin in a proportion of not more than 5% by weight relative to the nonwoven fabric, has an absorbing height of not less than 30 mm as determined at 20° C. after 10 minutes based on Byreck method when the nonwoven fabric immersion-treated for 60 minutes in a water of 80° C. is used, and satisfies the following formula: (B) / (A)≧0.25, wherein the symbol (B) represents a tensile strength [N / 5 cm] in the longitudinal direction and the lateral direction of the nonwoven fabric and the symbol (A) represents a fabric weight [g / m] of the nonwoven fabric. In the nonwoven fabric, not less than 30% of the surface may be coated with the water-soluble thermoplastic resin. The water-soluble thermoplastic resin may be a water-soluble thermoplastic polyvinyl alcohol, e.g., a modified polyvinyl alcohol containing an ethylene unit in a proportion of 3 to 20 mol %. The present invention provides a nonwoven fabric composed of ultra-fine continuous fibers, having a high flexibility or softness, and having a high mechanical strength even when the fiber diameter is small, and having an excellent water absorbency, as well as a production process and an application thereof.

Owner:KURARAY CO LTD

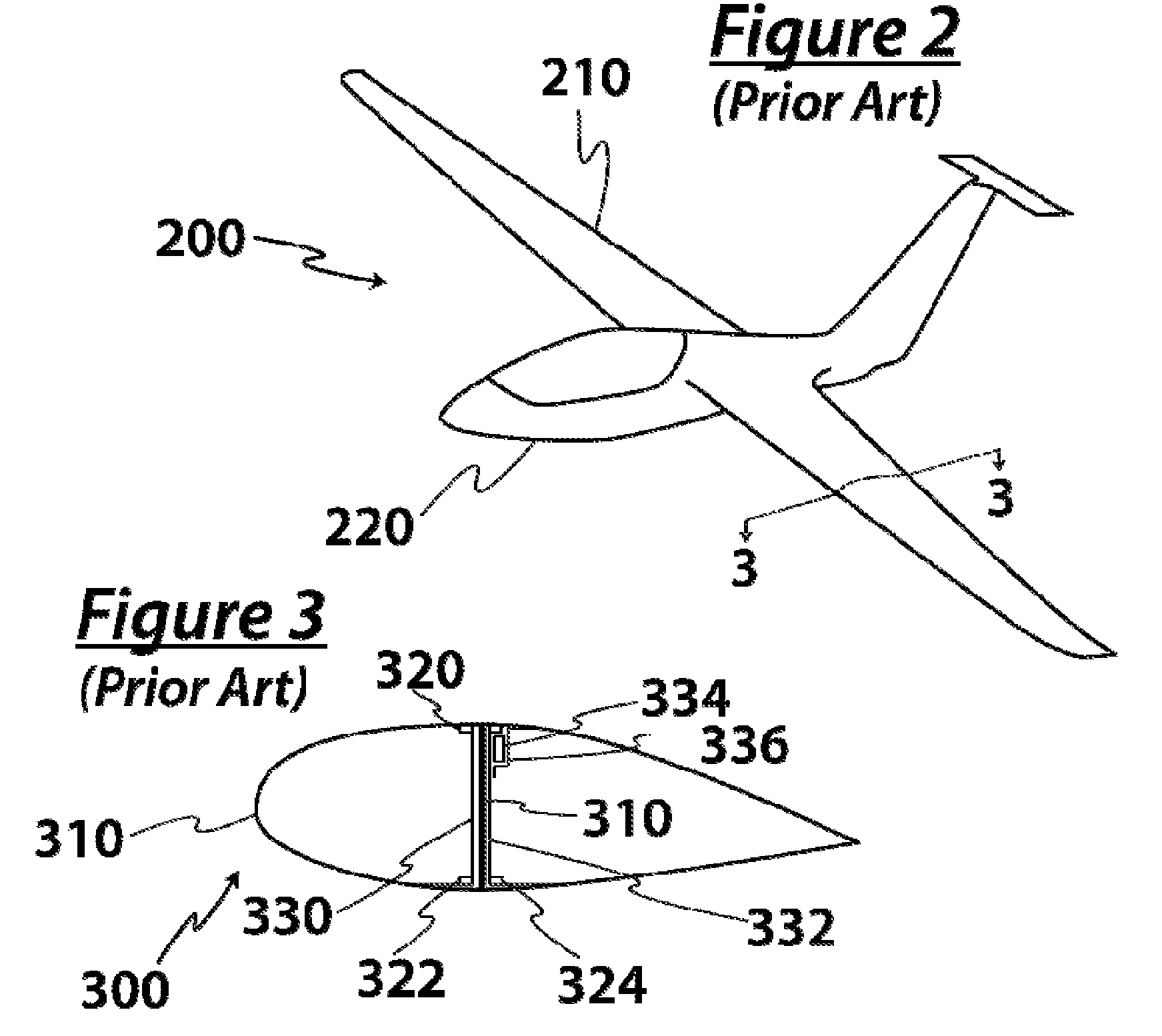

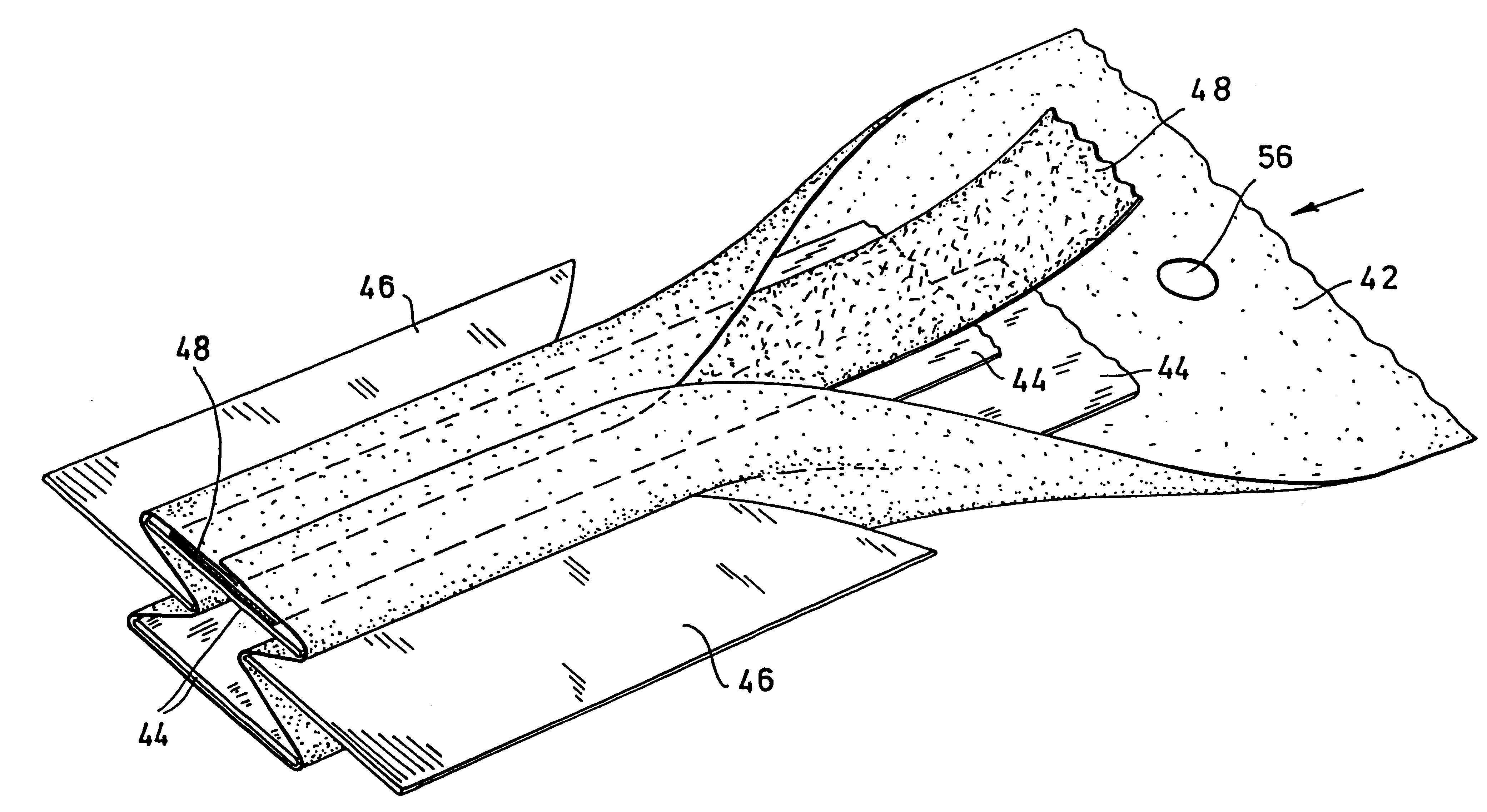

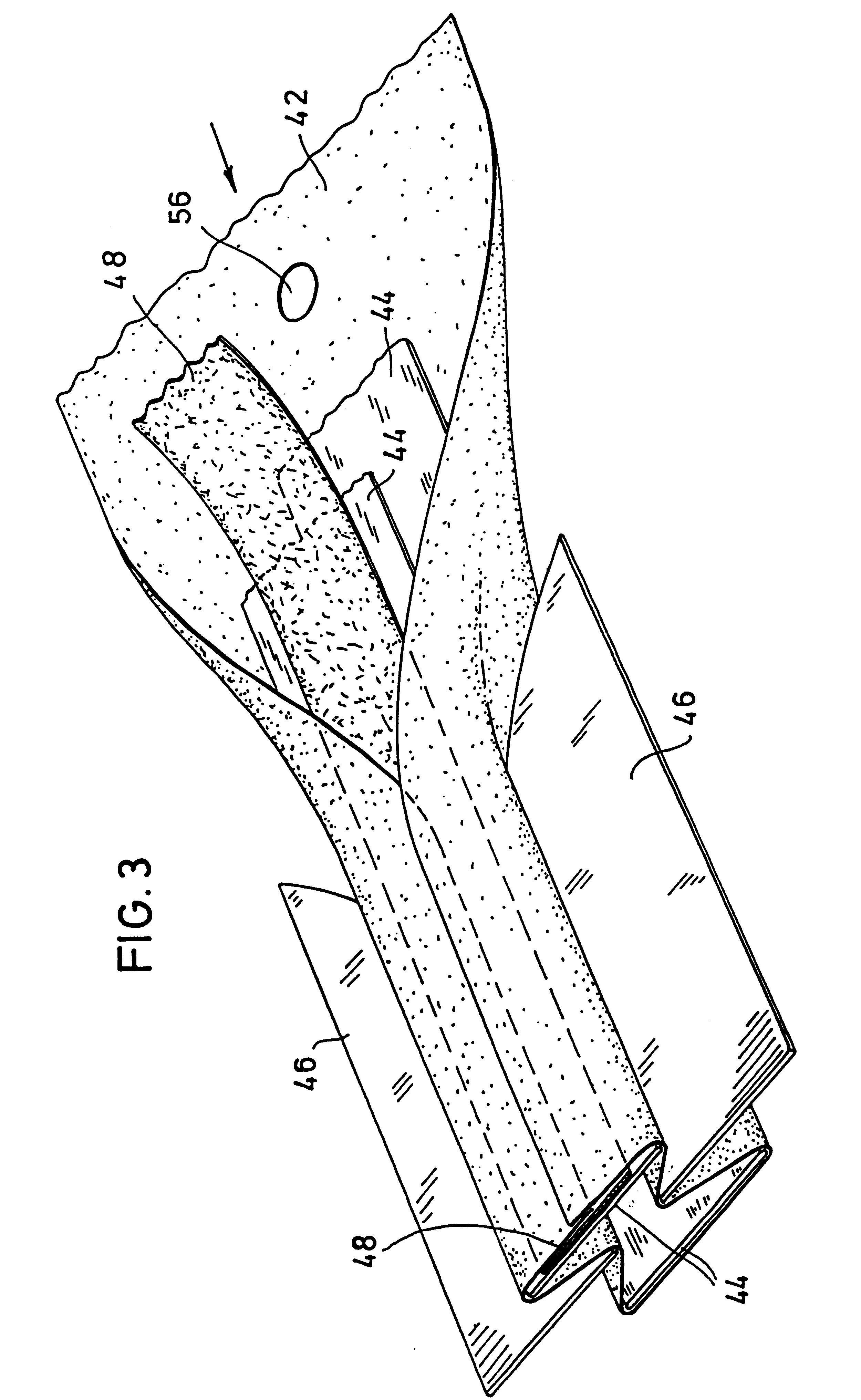

Wing and blade structure using pultruded composites

ActiveUS20090220747A1High compressive strengthIncrease pressureWingsVehicle componentsPropellerCompressive strength

Tapered layers of pre-cured composite material are integrated into a tapered, highly stressed laminate structure in order to provide improved compressive strength. The pre-cured composite material can advantageously be cured under tension as pultruded material, to further augment compressive strength. The thickness of composite layers can be tapered on their termination edges by mechanically abrading, chemical abrading, or other methods. Especially preferred embodiments include aircraft structural components such as wings, wing spars, wing skins, fuselage skins, rotor blades, propellers, and propeller blades. Preferred laminates can be constructed to have at least 6, 10, 30, 50, or 100 layers of material, and can have a maximum thickness of at least 0.15, 0.25, 0.5, 1.0, or 5.0 inches.

Owner:KAREM ABE

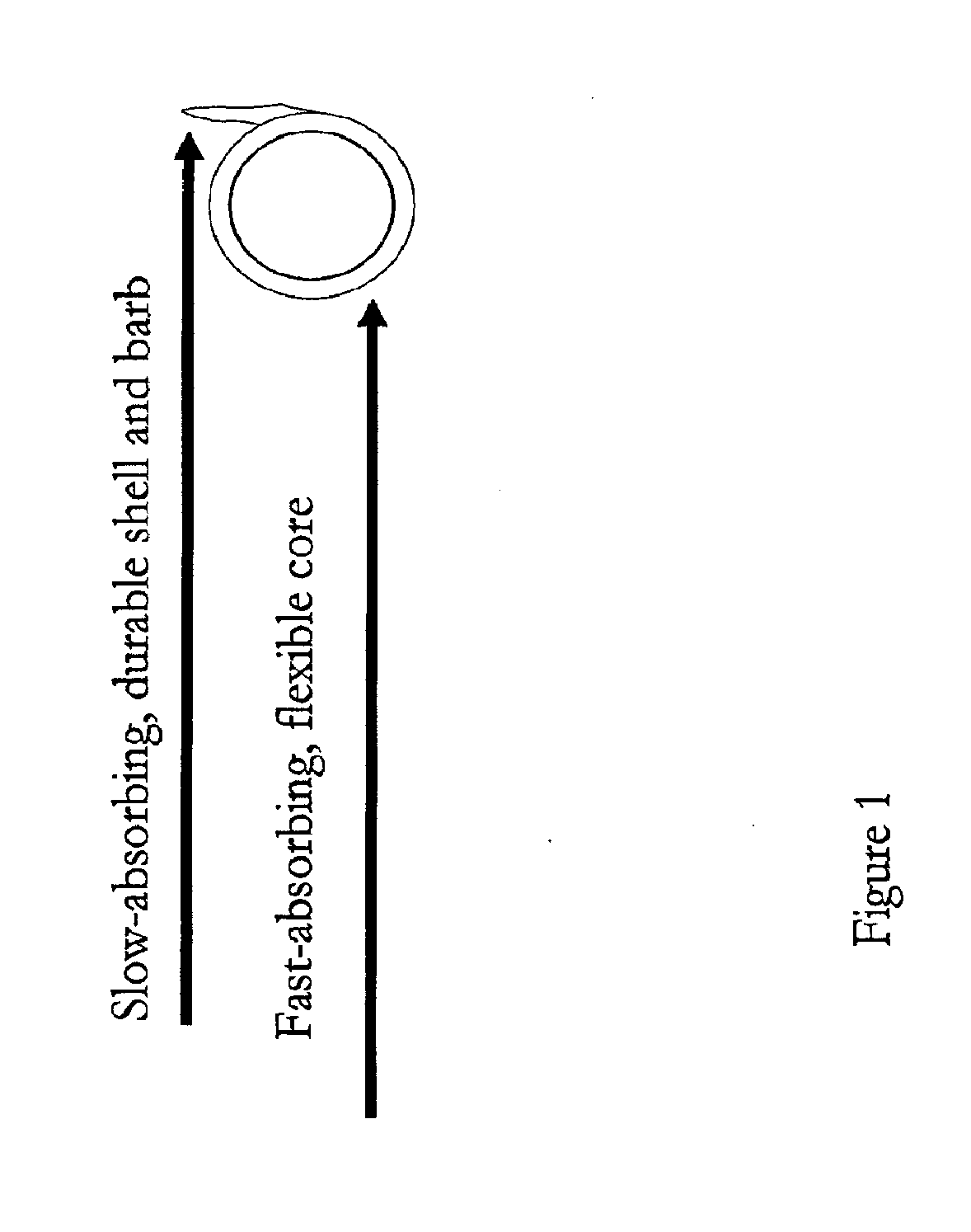

Integrated multi-zonal cage/core implants as bone graft substitutes and apparatus and method for their fabrication

A surgical implant including a cage having a first porosity and a first modulus; and a core bounded by said cage, said core having a second porosity that is higher than said first porosity of said cage, and said core having a second modulus that is lower than said first modulus of said cage. The implant may be functionally graded in a transverse direction, a longitudinal direction, or a radial direction thereof. The implant is made by preparing a first formulation for the cage within a first extruder and a second formulation for the core within a second extruder, extruding the first formulation through a co-extrusion die while simultaneously extruding said second formulation through the co-extrusion die so as to form an extrudate that includes said cage component and said core component bounded by said cage component.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

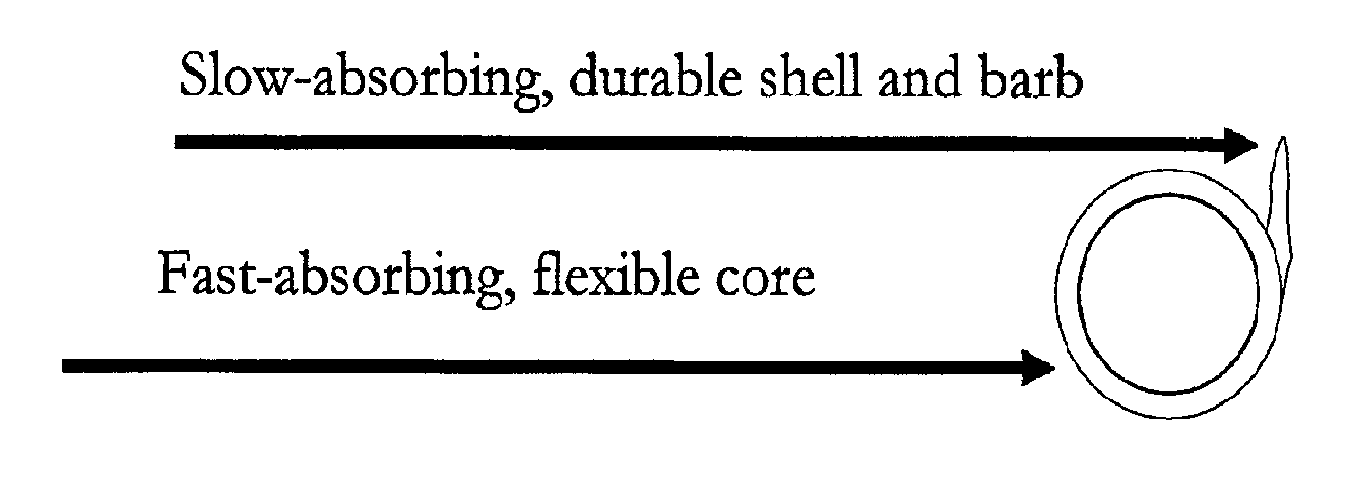

Surgical Sutures Having Increased Strength

InactiveUS20100030261A1Improve crystallizationSuture equipmentsPharmaceutical containersUltimate tensile strengthGeneral surgery

The invention relates to increasing the strength of bio-absorbable surgical sutures. The invention allows for delayed bioabsorption of suture materials to allow maintenance of mechanical strength of the suture for example in ‘barbed’ form.

Owner:MICELL TECH INC

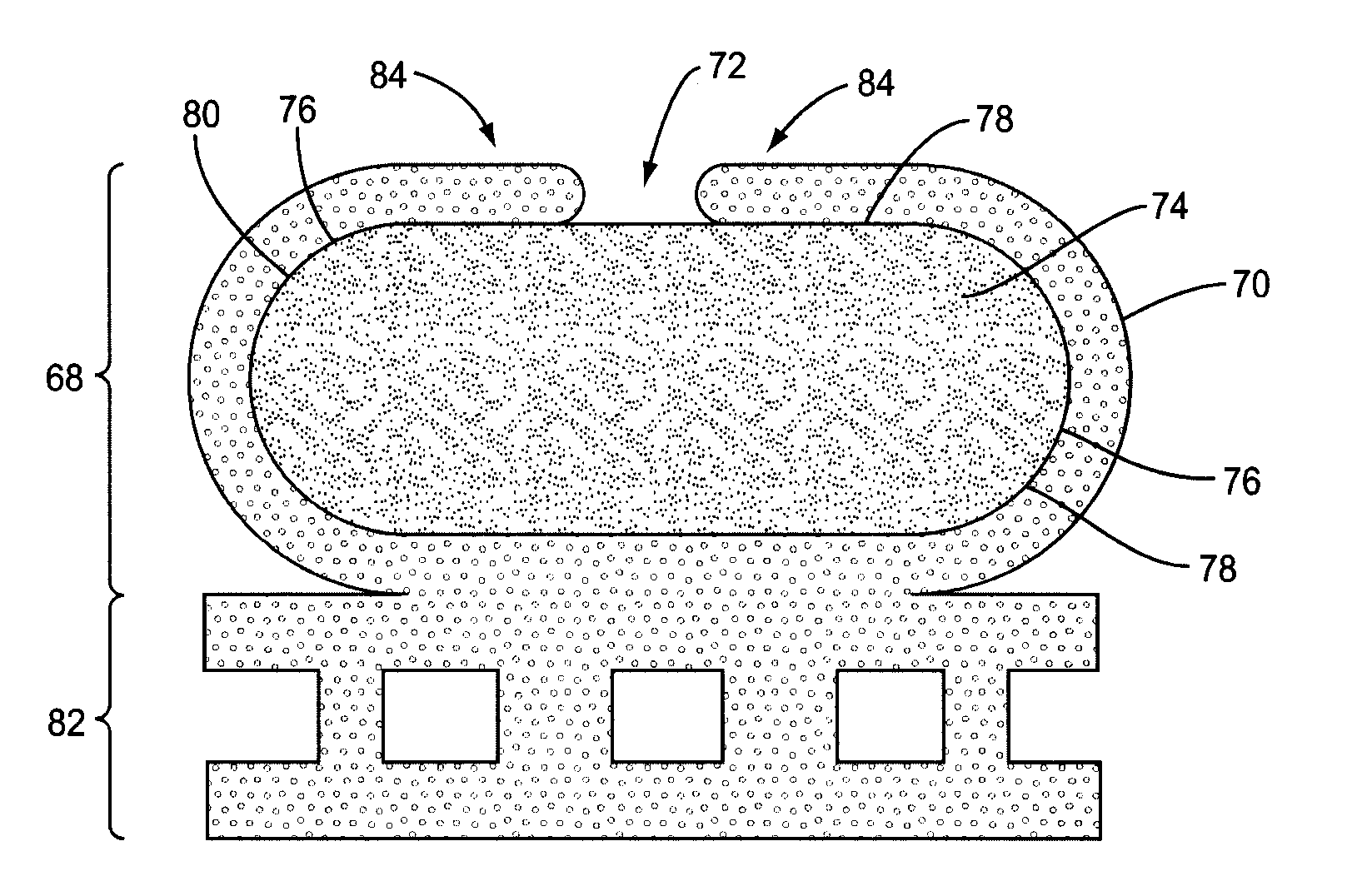

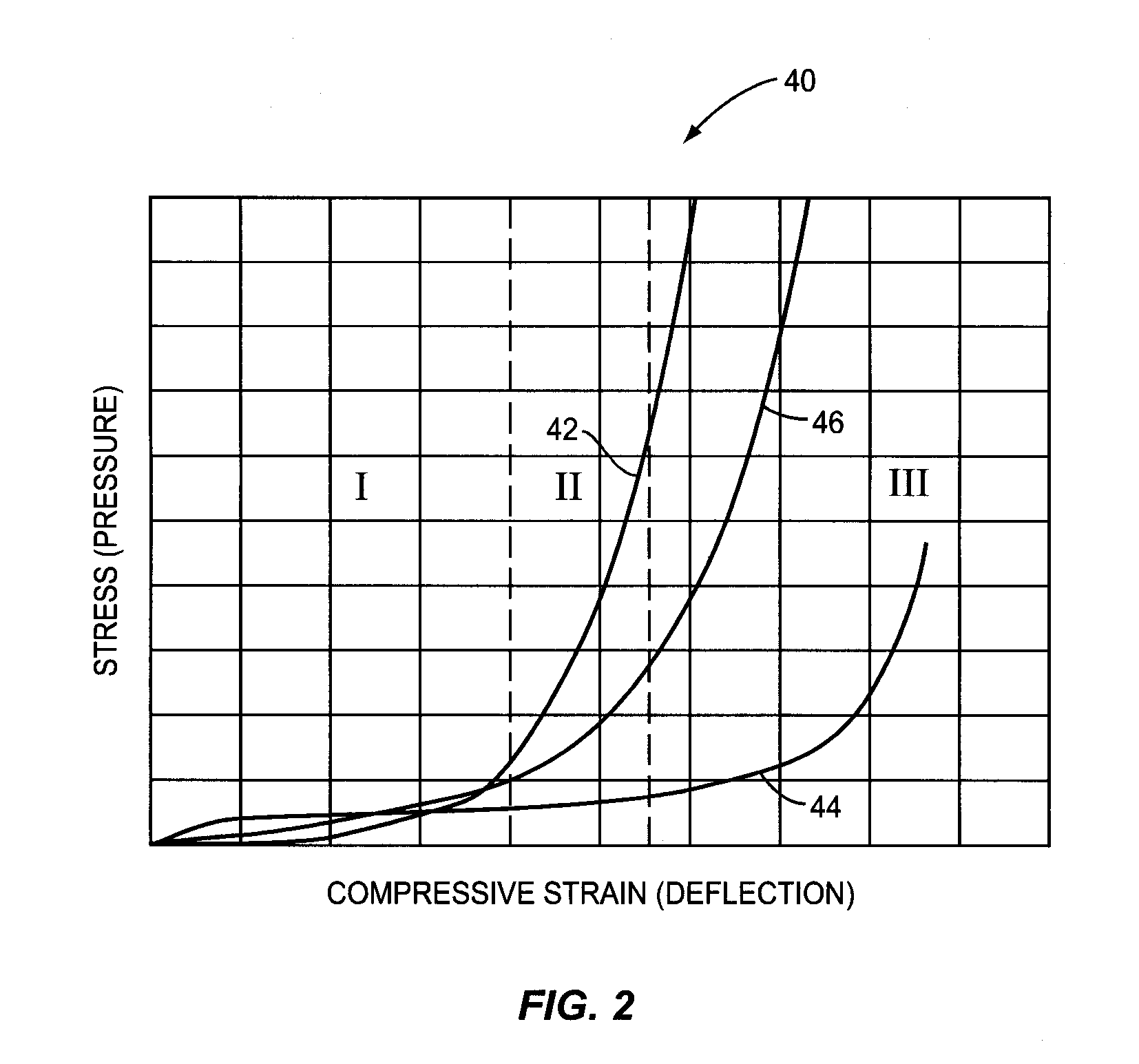

Unitary composite/hybrid cushioning structure(s) and profile(s) comprised of a thermoplastic foam(s) and a thermoset material(s)

InactiveUS20100223732A1Improved compression setLow costStuffed mattressesSpring mattressesCushioningThermoplastic

Embodiments disclosed in the detailed description include a unitary or monolithic composite or hybrid cushioning structure(s) and profile(s) comprised of a cellular thermoplastic foam and a thermoset material. The thermoset material may also be provided as cellular foam as well. In one embodiment disclosed herein, the unitary composite cushioning structure is formed from a cellular thermoplastic foam and a thermoset material. The cellular thermoplastic foam provides support characteristics to the unitary composite cushioning structure. The thermoset material provides a resilient structure with cushioning characteristics to the cushioning structure. A stratum is disposed between at least a portion of the cellular thermoplastic foam and at least a portion of the thermoset material to secure the at least a portion of the thermoset material to the at least a portion of the cellular thermoplastic foam to provide a unitary composite cushioning structure.

Owner:NOMACO

Emulsion particles as reinforcing fillers

InactiveUS6780937B2Great tractionIncrease in the tangent deltaLaminationLamination apparatusPolymer scienceEmulsion

Owner:THE GOODYEAR TIRE & RUBBER CO

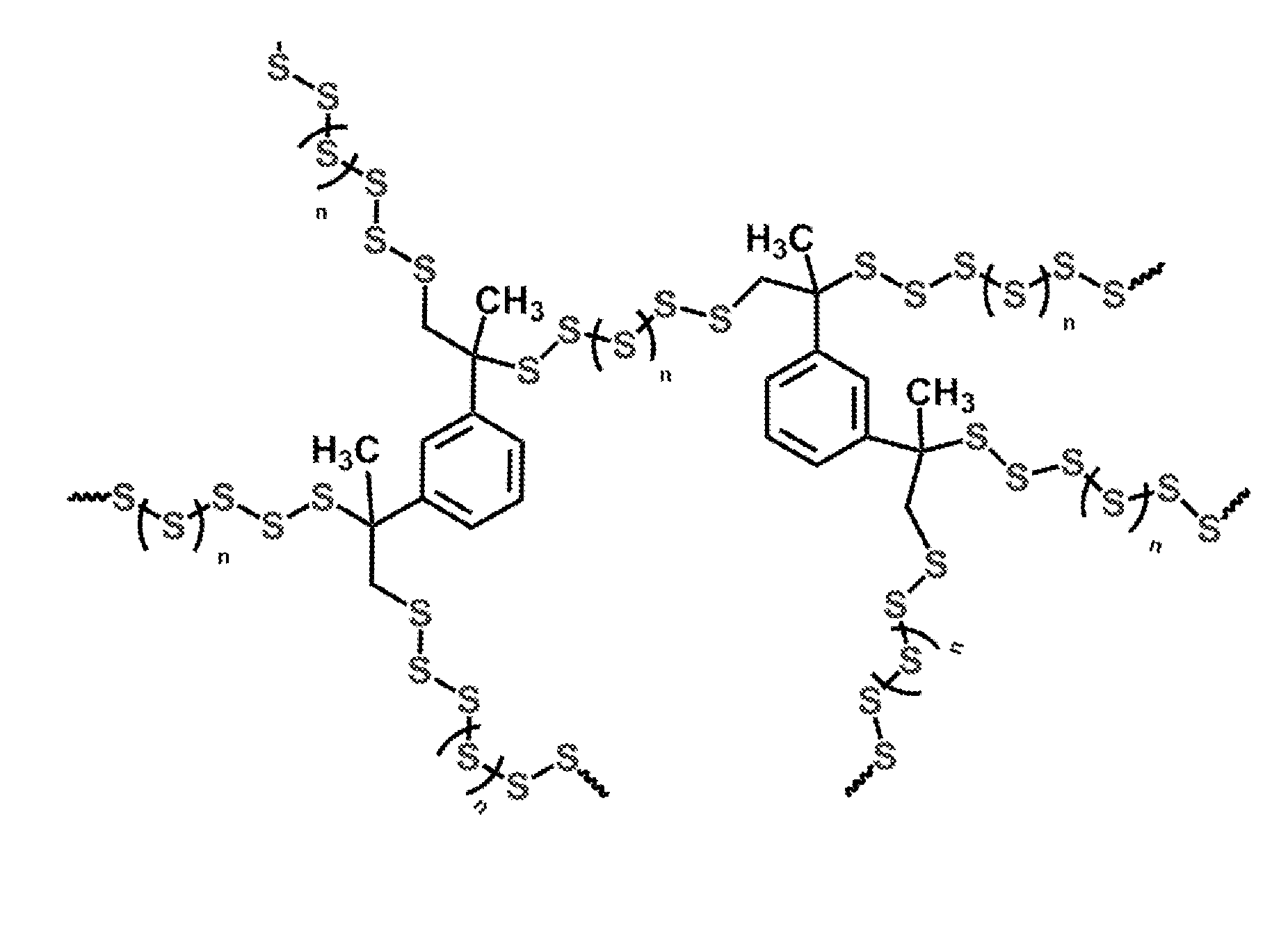

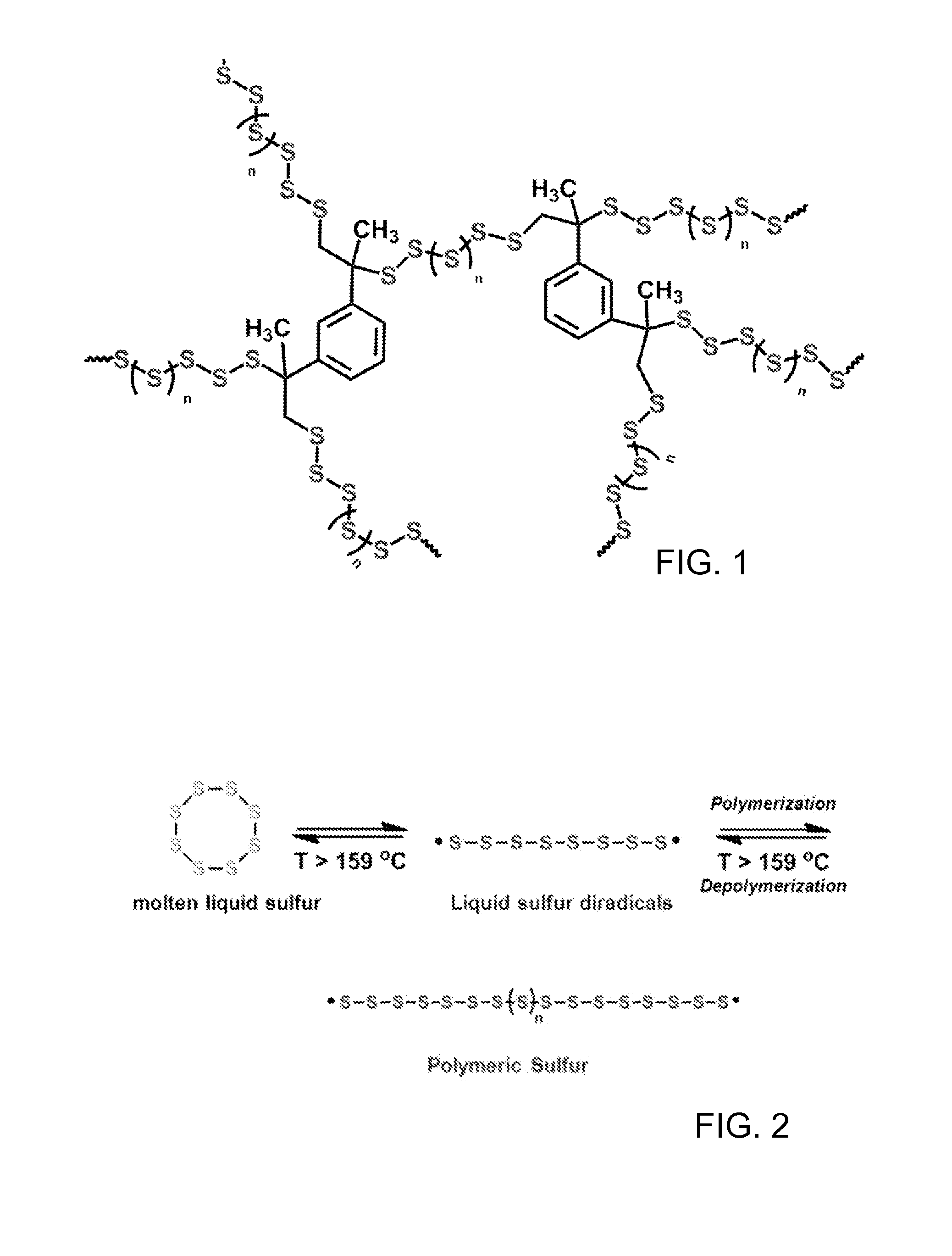

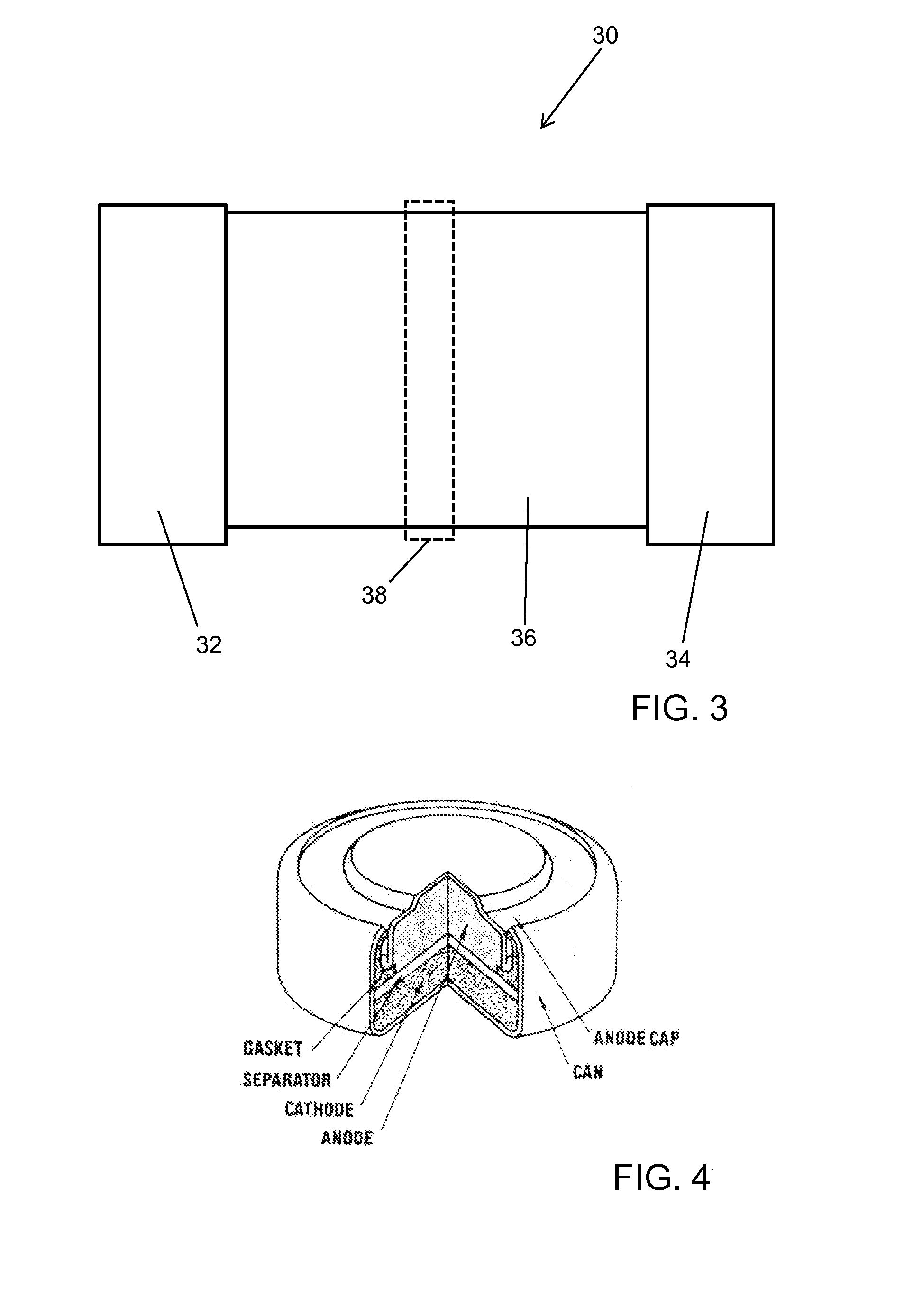

High sulfur content copolymers and composite materials and electrochemical cells and optical elements using them

ActiveUS20140199592A1Improve charging capacityImprove cycle stabilityNon-metal conductorsConductive materialElectrochemical cellThiirane

The present invention relates generally to high sulfur content polymeric materials and composites, methods for making them, and devices using them such as electrochemical cells and optical elements. In one aspect, a polymeric composition comprising a copolymer of sulfur, at a level in the range of at least about 50 wt % of the copolymer, and one or more monomers each selected from the group consisting of ethylenically unsaturated monomers, epoxide monomers, and thiirane monomers, at a level in the range of about 0.1 wt % to about 50 wt % of the copolymer.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

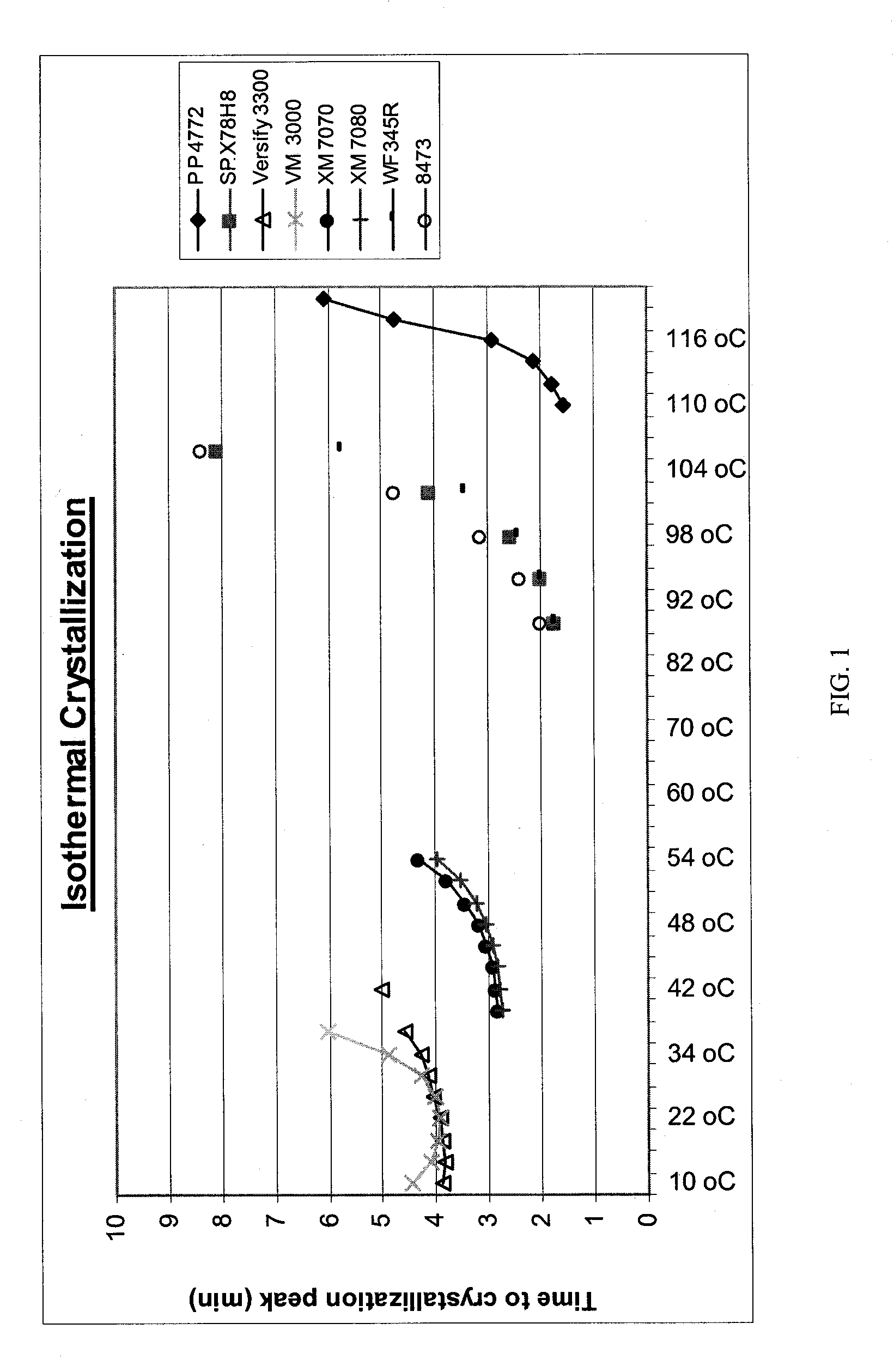

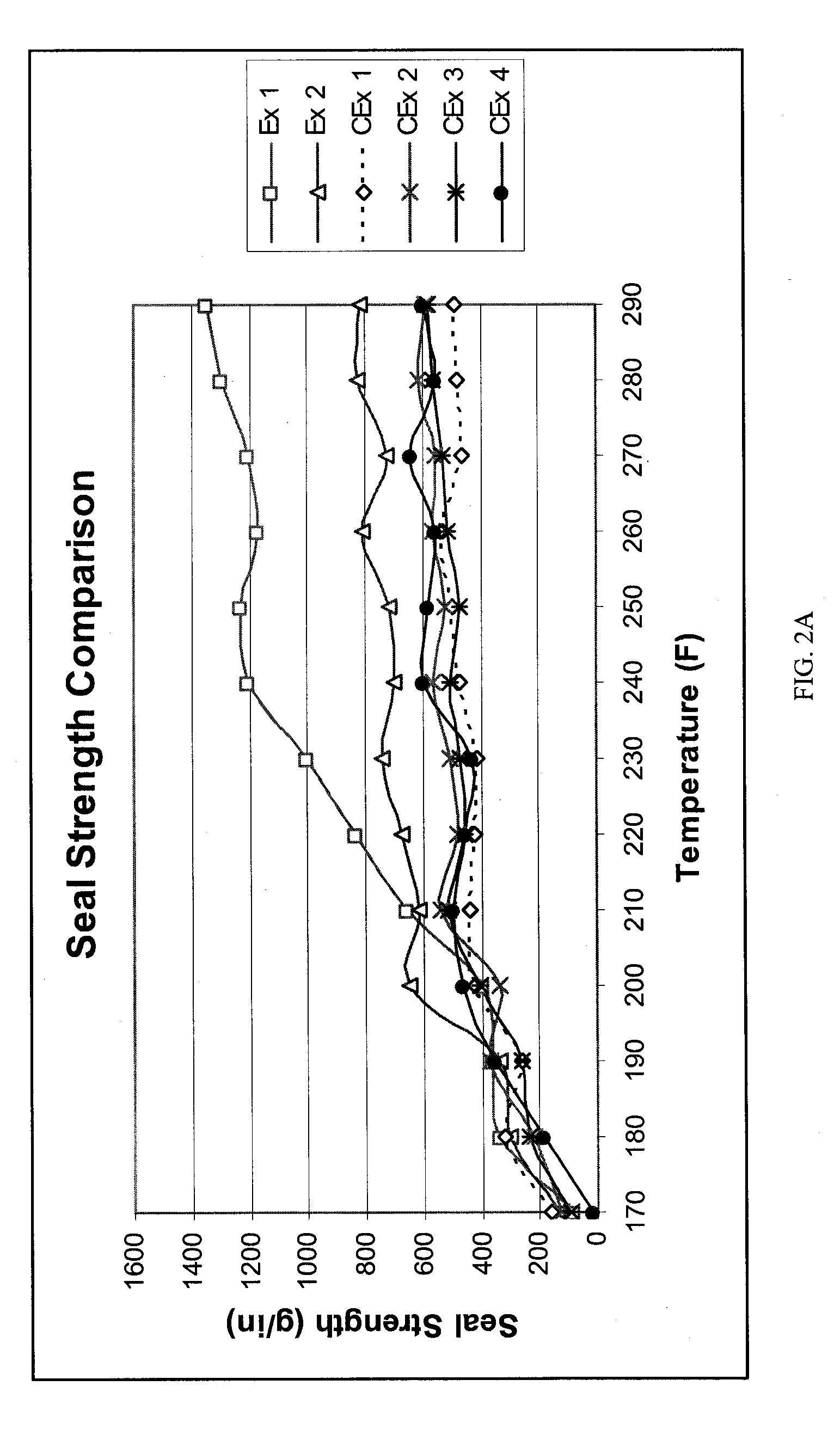

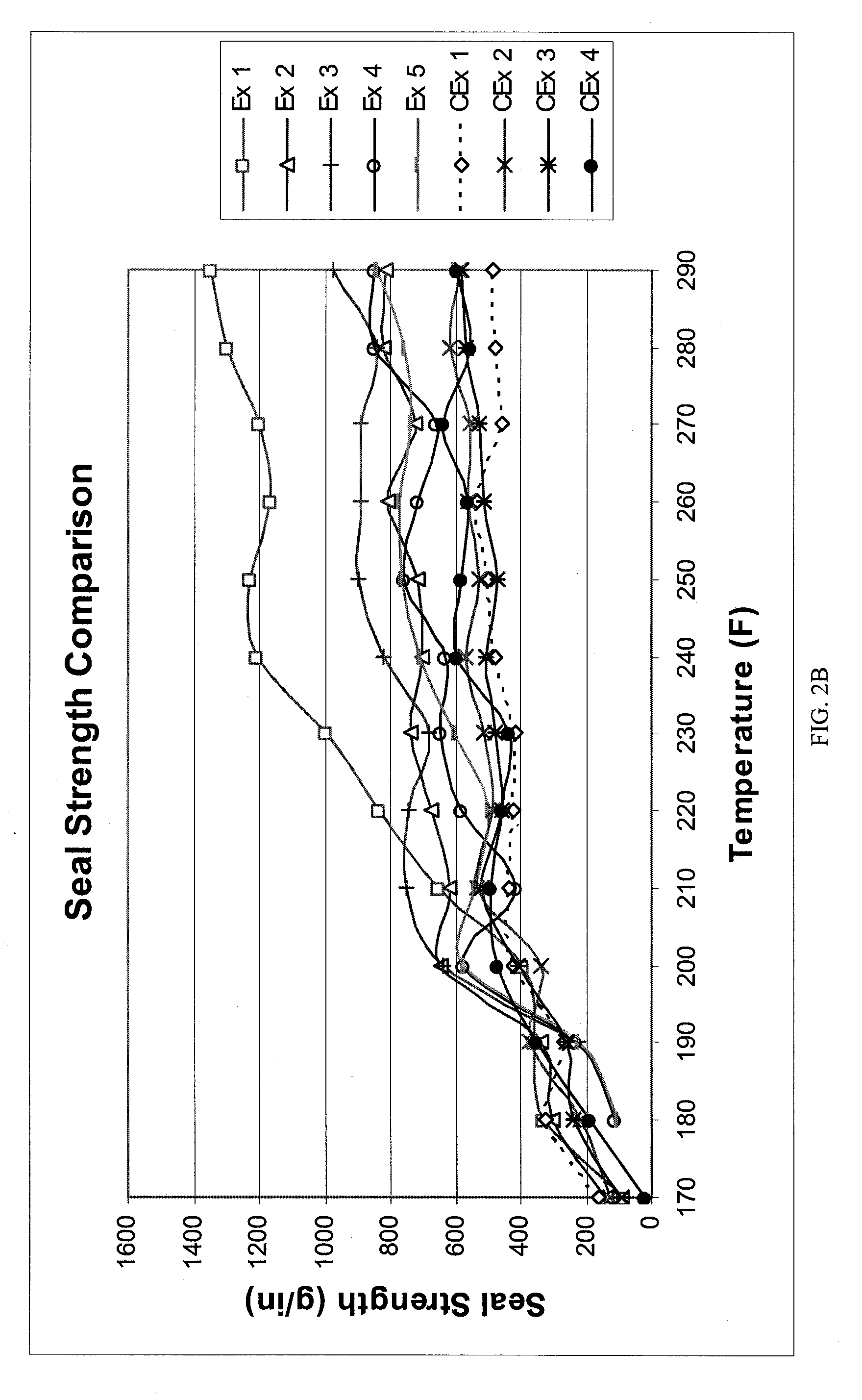

Biaxially oriented polypropylene film with high heat seal strength

ActiveUS20090087648A1Easy to processImprove seal strengthLamination ancillary operationsLayered product treatmentPolyolefinThermoplastic elastomer

A laminate film including a first polyolefin heat sealable resin layer and a second core layer including of a blend of 5-15 wt % of a metallocene-catalyzed butene-propylene or ethylene-propylene thermoplastic elastomer or ethylene-propylene plastomer or blends thereof which exhibit an isothermal crystallization temperature of 60° C. or less and 95-85 wt % of a crystalline propylene homopolymer is disclosed. The laminate film may include additional layers such as a third polyolefin resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

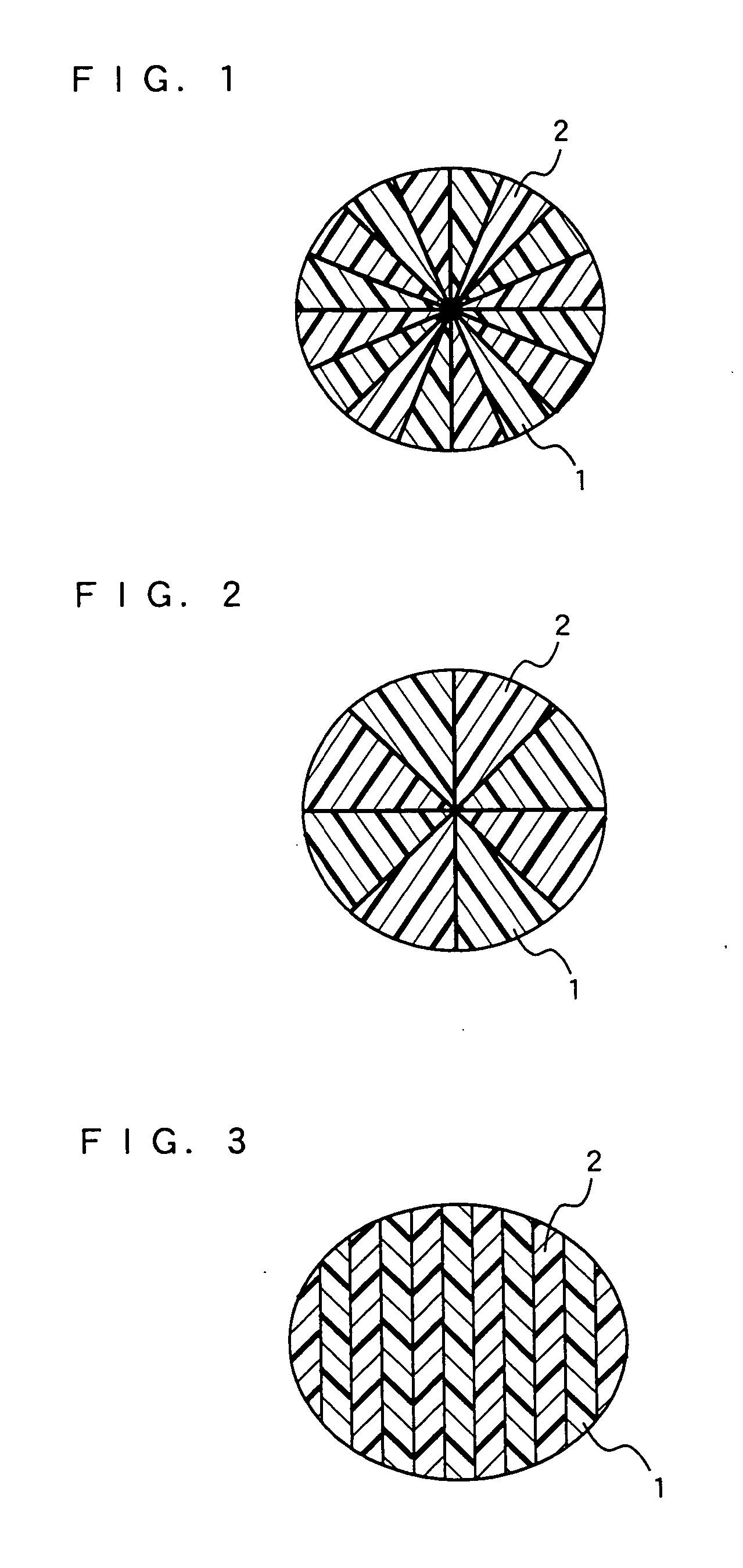

Base for synthetic leather and synthetic leathers made by using the same

ActiveUS7932192B2Good lookingMaintain good propertiesFibre treatmentSynthetic resin layered productsFiber bundleVolumetric Mass Density

A substrate for artificial leathers, comprising a nonwoven fabric body made of microfine fiber bundles and an elastic polymer impregnated therein. The substrate for artificial leathers simultaneously satisfies the following requirements 1 to 4: (1) each of the microfine fiber bundles contains 6 to 150 bundled microfine long fibers in average; (2) a cross-sectional area of the microfine long fibers constituting the microfine fiber bundles is 27 μm2 or less, and 80% or more of the microfine long fibers has a cross-sectional area of from 0.9 to 25 μm2; (3) an average cross-sectional area of the microfine fiber bundles is from 15 to 150 μm2; and (4) on a cross section parallel to a thickness direction of the nonwoven fabric body, cross sections of the microfine fiber bundles exist in a density of from 1000 to 3000 / mm2 in average. The raised artificial leathers and grain-finished artificial leathers made from the substrate for artificial leathers are excellent in the properties which are hitherto difficult to be combined.

Owner:KURARAY CO LTD

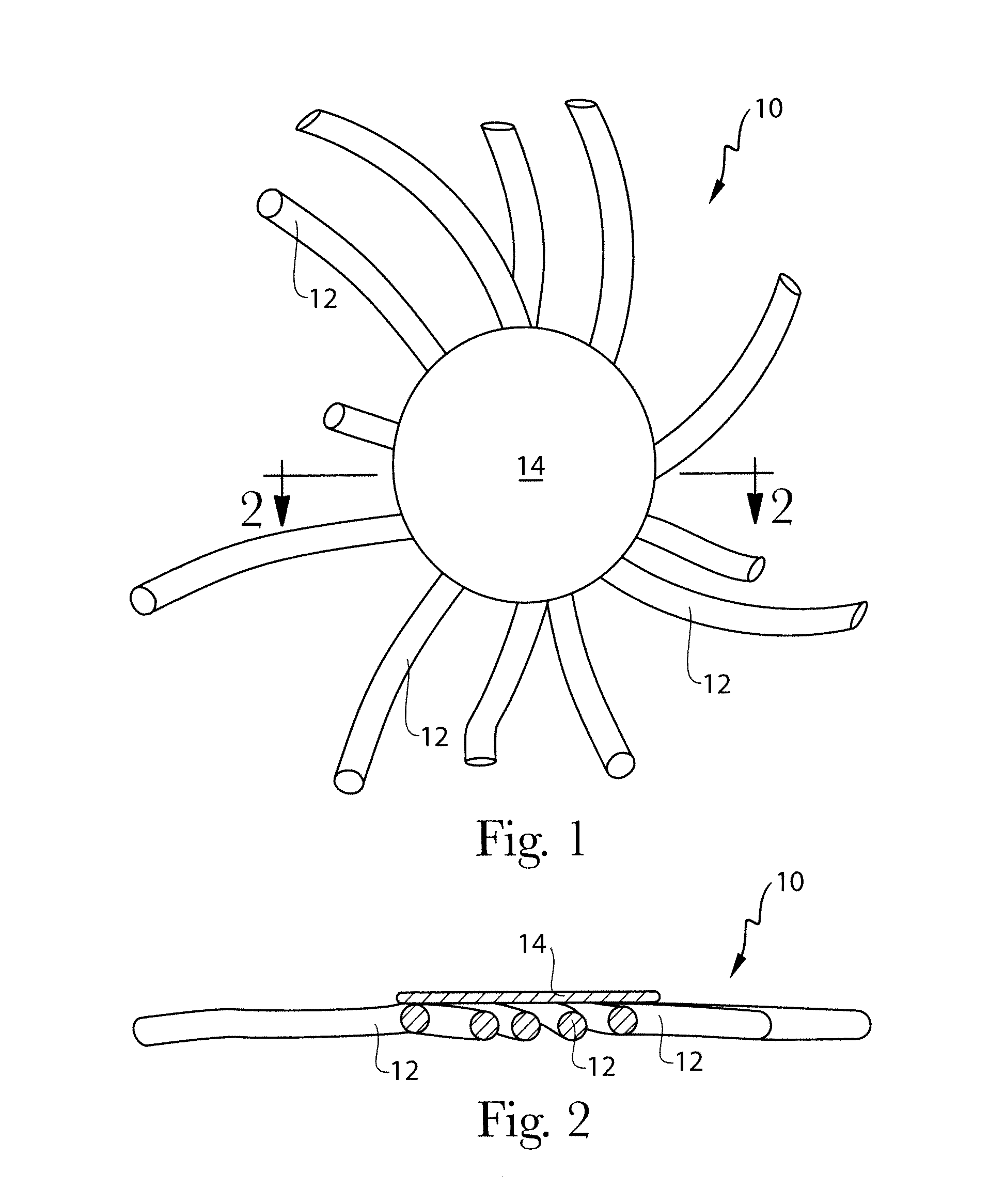

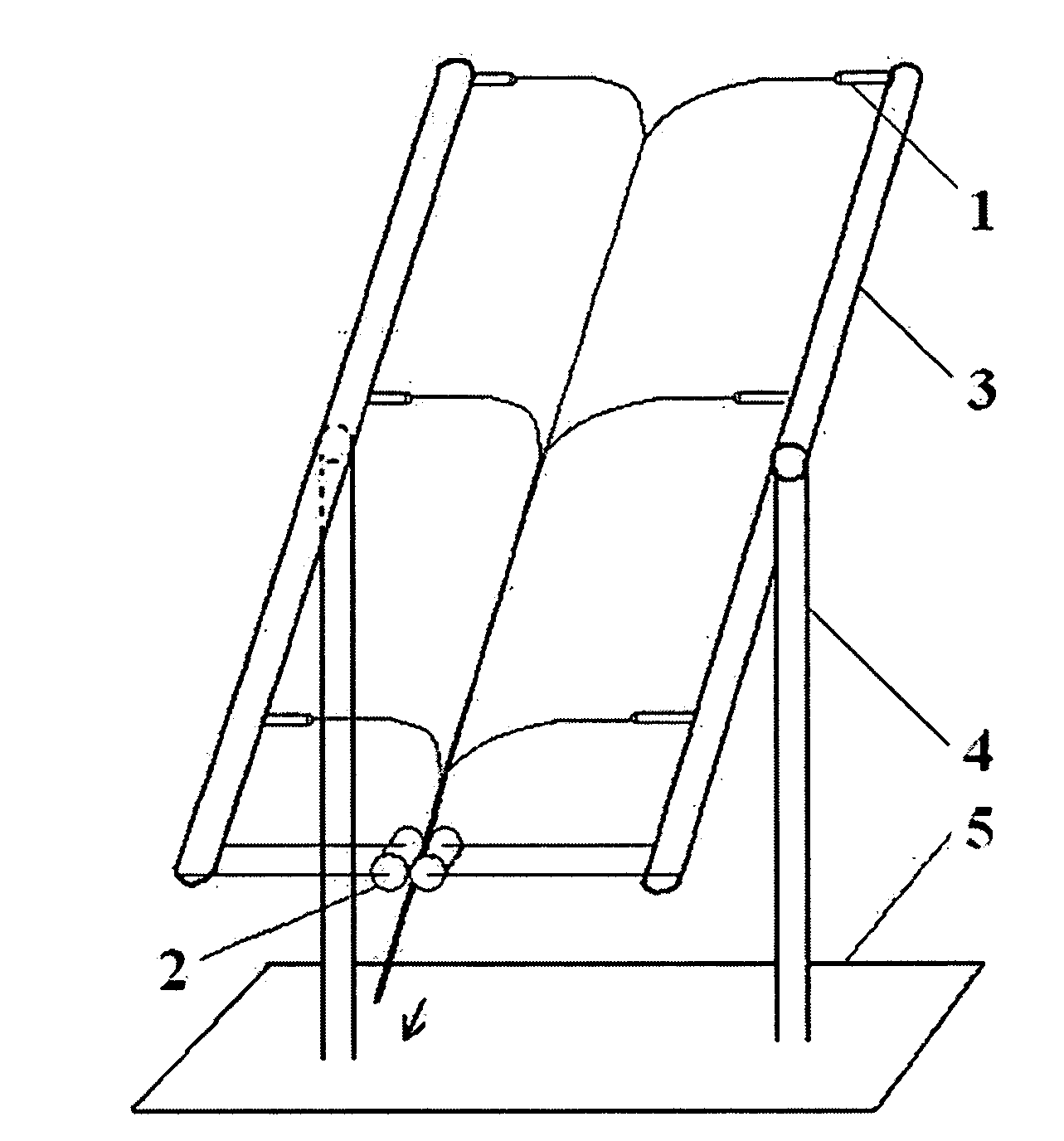

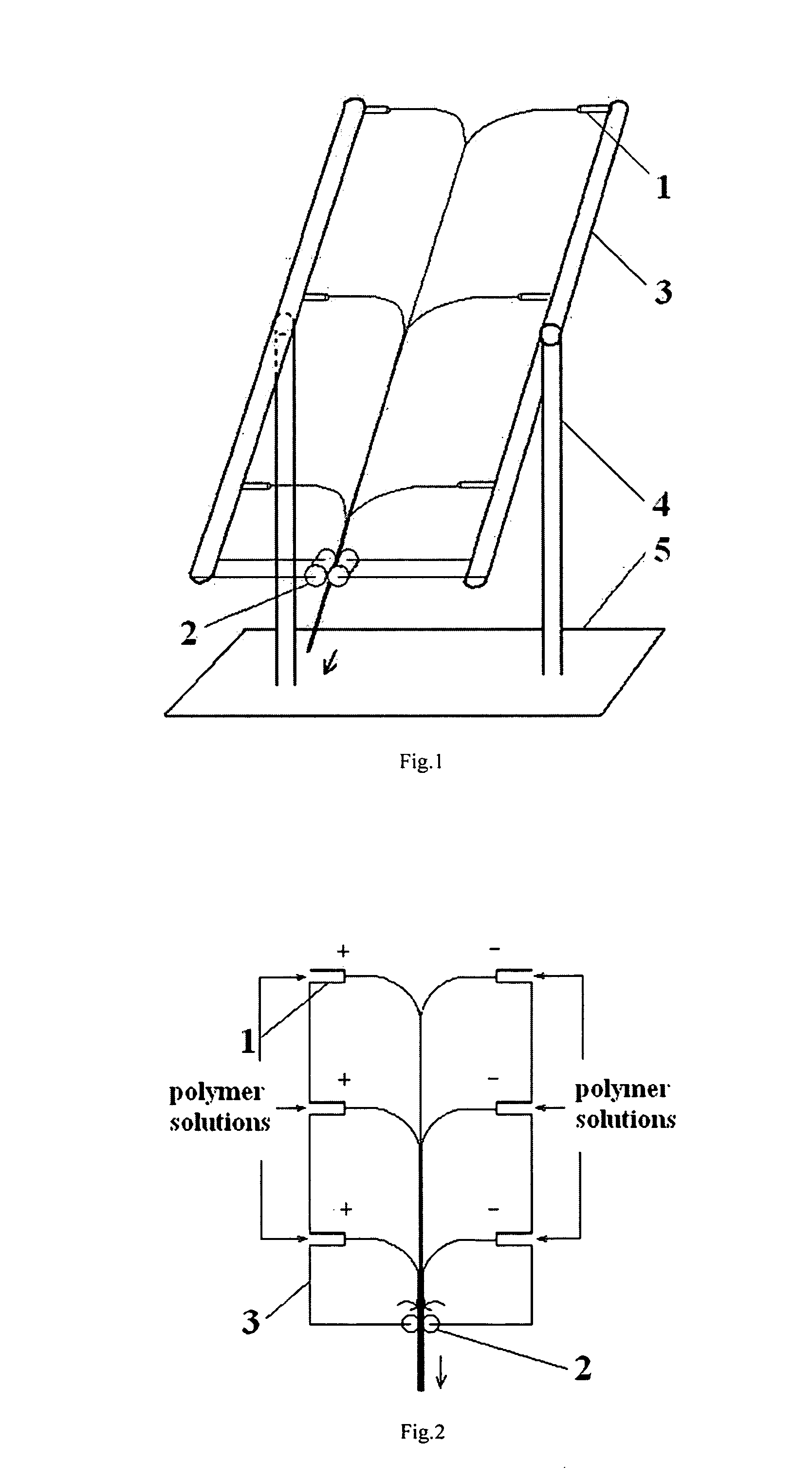

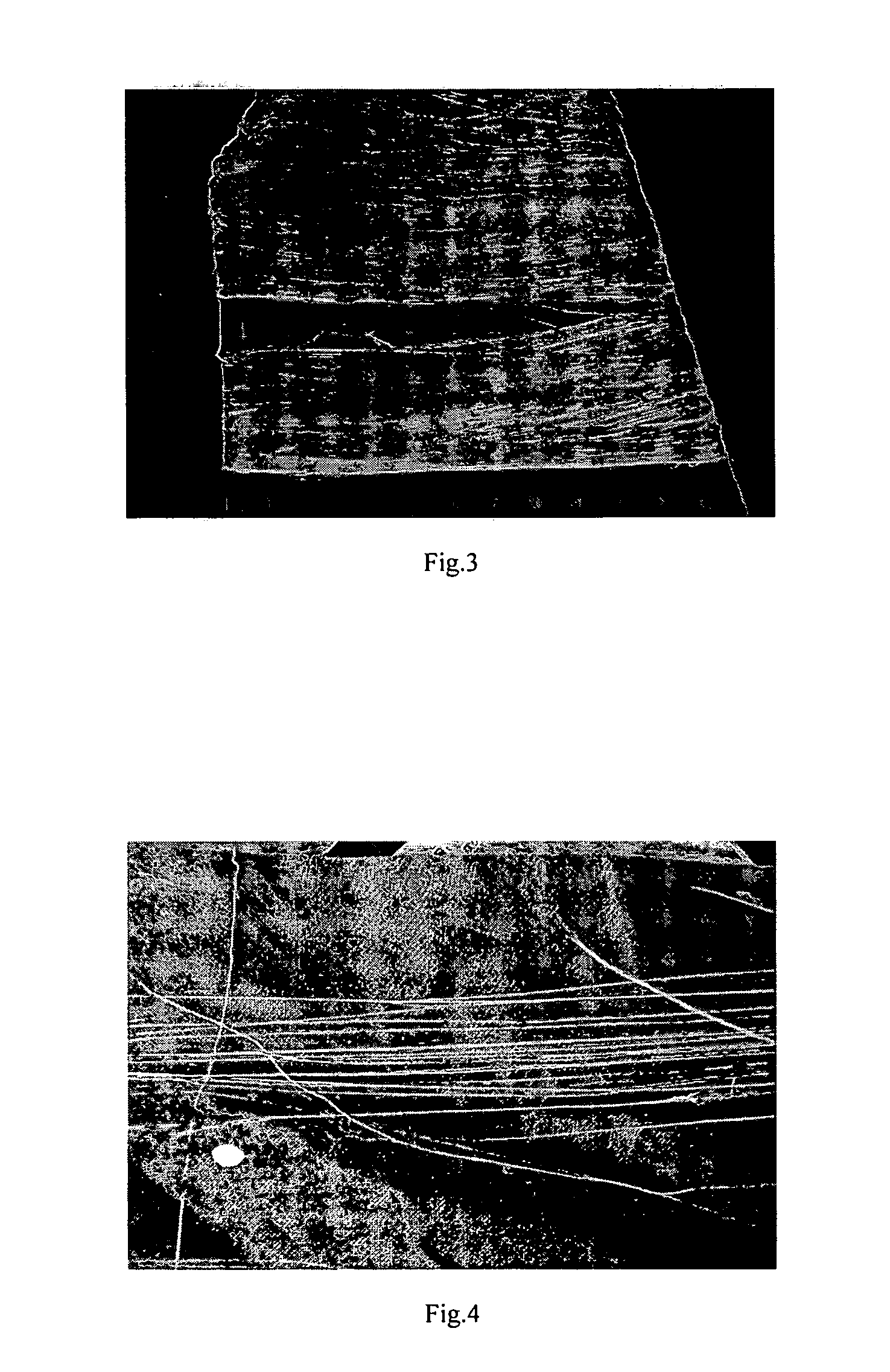

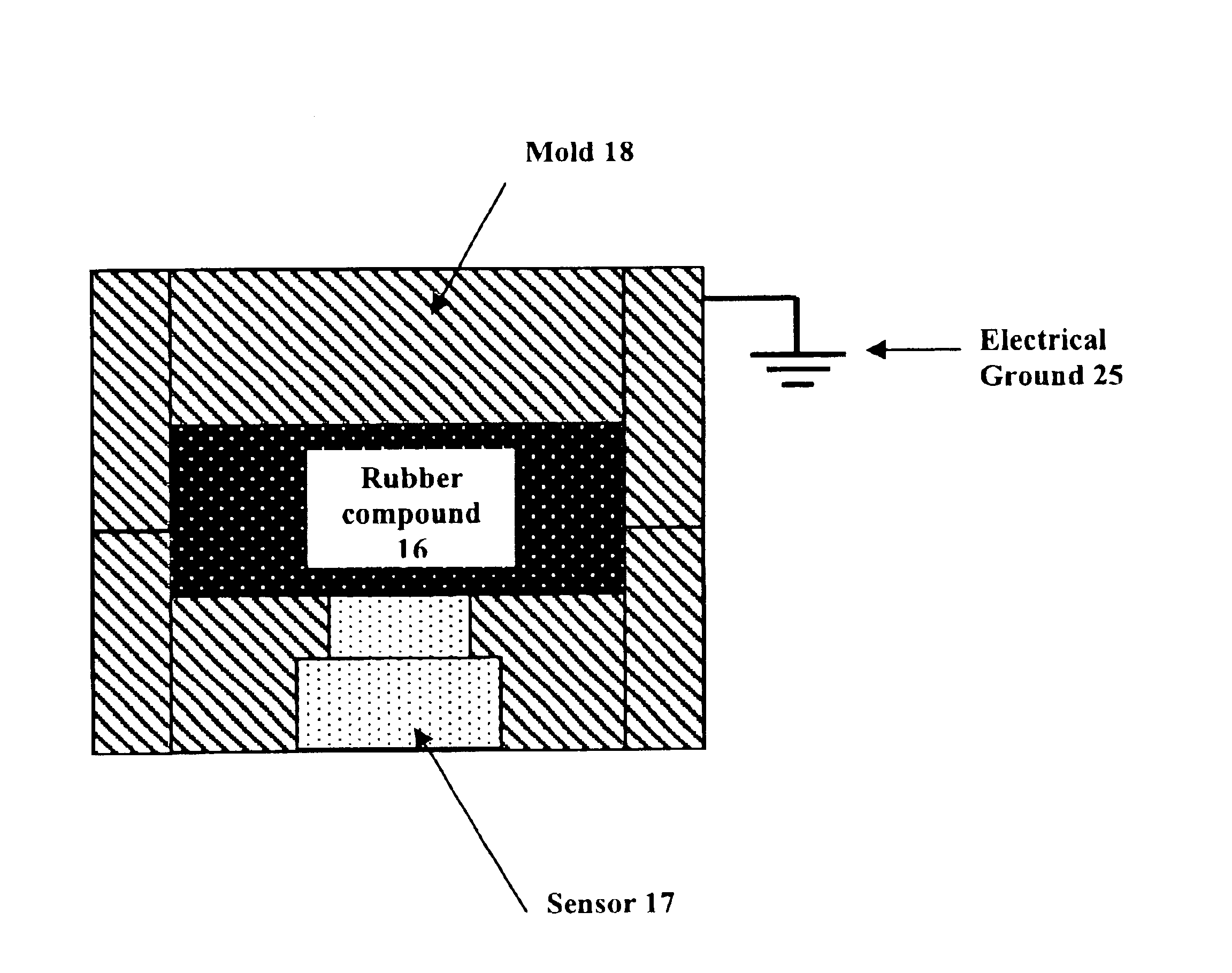

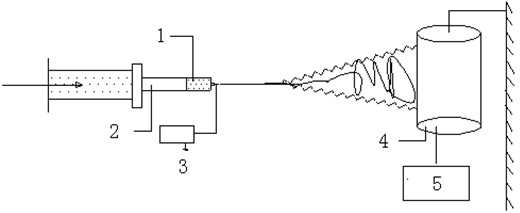

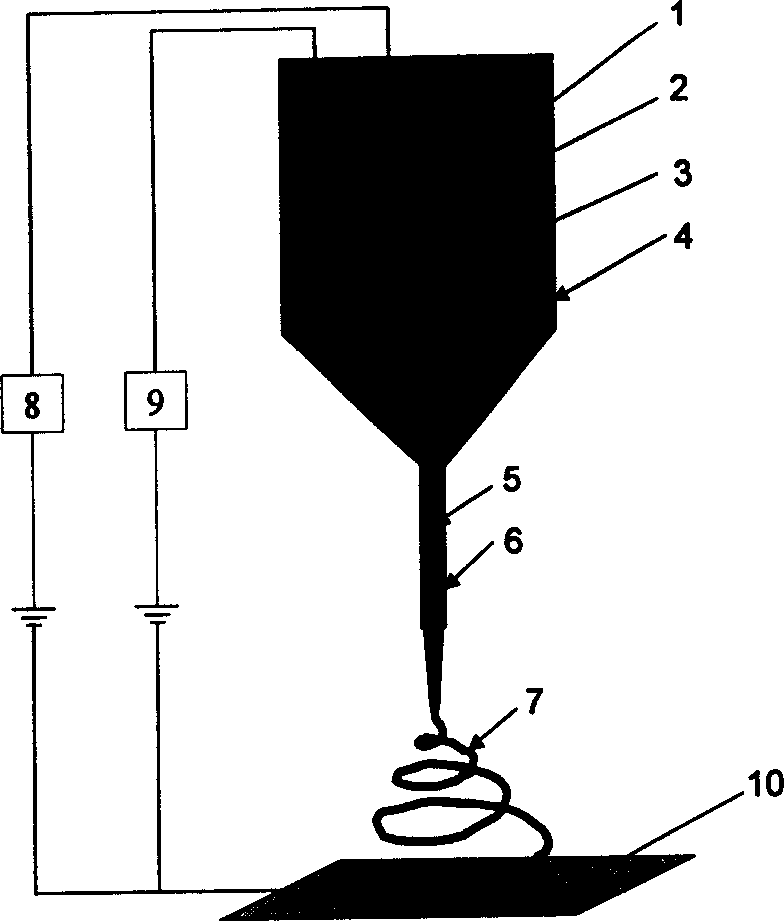

Device and Method for Preparing Filament Yarn of Composite Nanofibers

InactiveUS20080265469A1Less dispersionImprove mechanical propertiesFilament/thread formingConjugated artificial filamentsComposite nanofibersNanofiber

Device and method for preparing filament yarn of composite nanofibers. The device includes pairs of electrospinning nozzles on a frame and filament guiding roller pair under the frame. The spouts of each pair of nozzles are oppositely facing. The method includes feeding polymer solutions to the pairs of nozzles, applying high DC voltage with opposite polarity respectively to each one of the pairs of nozzles, forming composite nanofibers by attracting nanofibers with opposite charge from each nozzle and striking together of the charged nanofibers, pulling / stretching the composite nanofibers to form filament yarn of composite nanofibers, drawing down the filament yarn of composite nanofibers from the first pair of nozzles and using it as a carrier to receive the nanofibers with opposite charge electrospun from the second pair of nozzles and coated by the same so as to form multi-layer (e.g., two- or more-layer) filament yarn of composite nanofibers.

Owner:SOUTHEAST UNIV

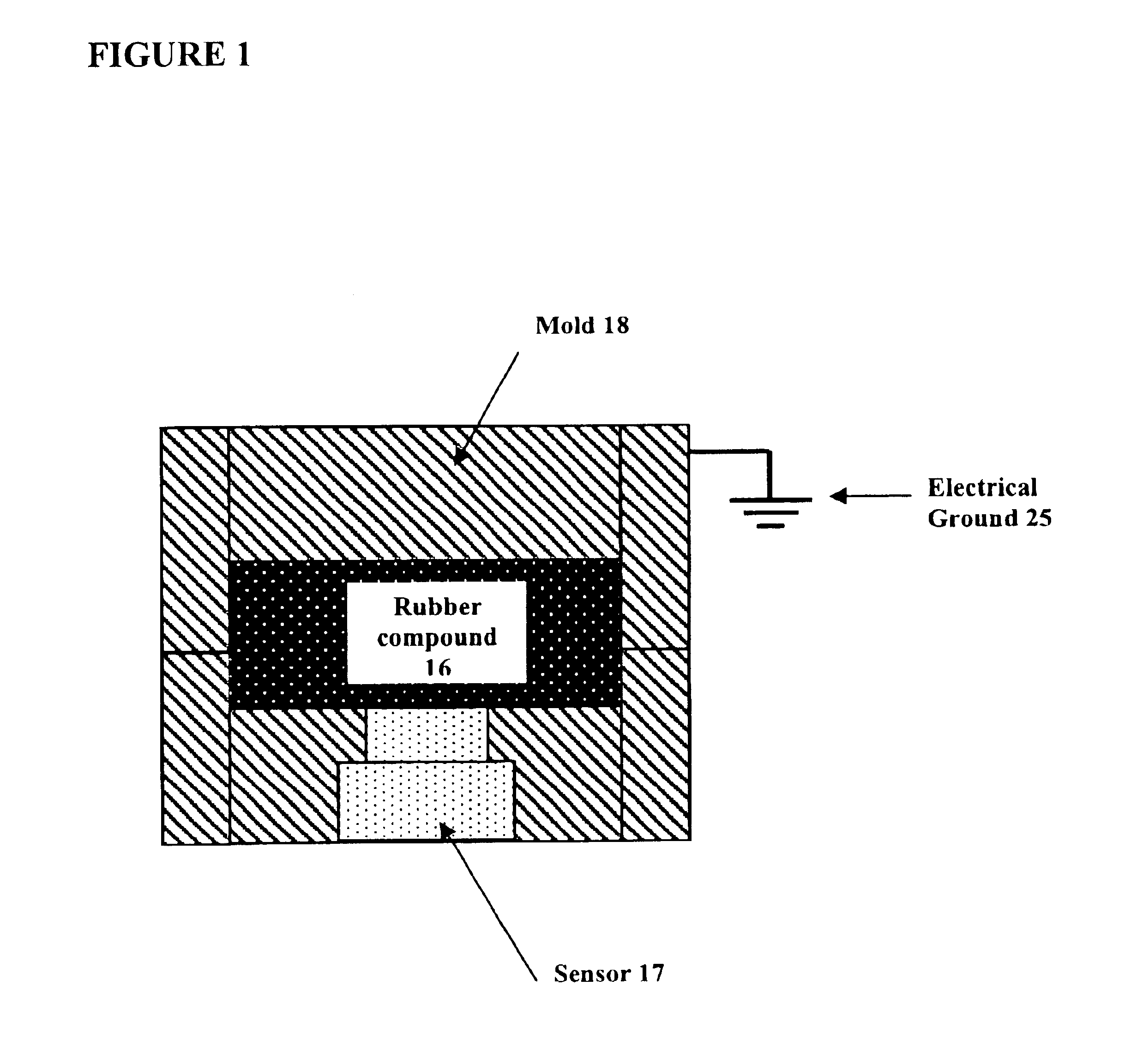

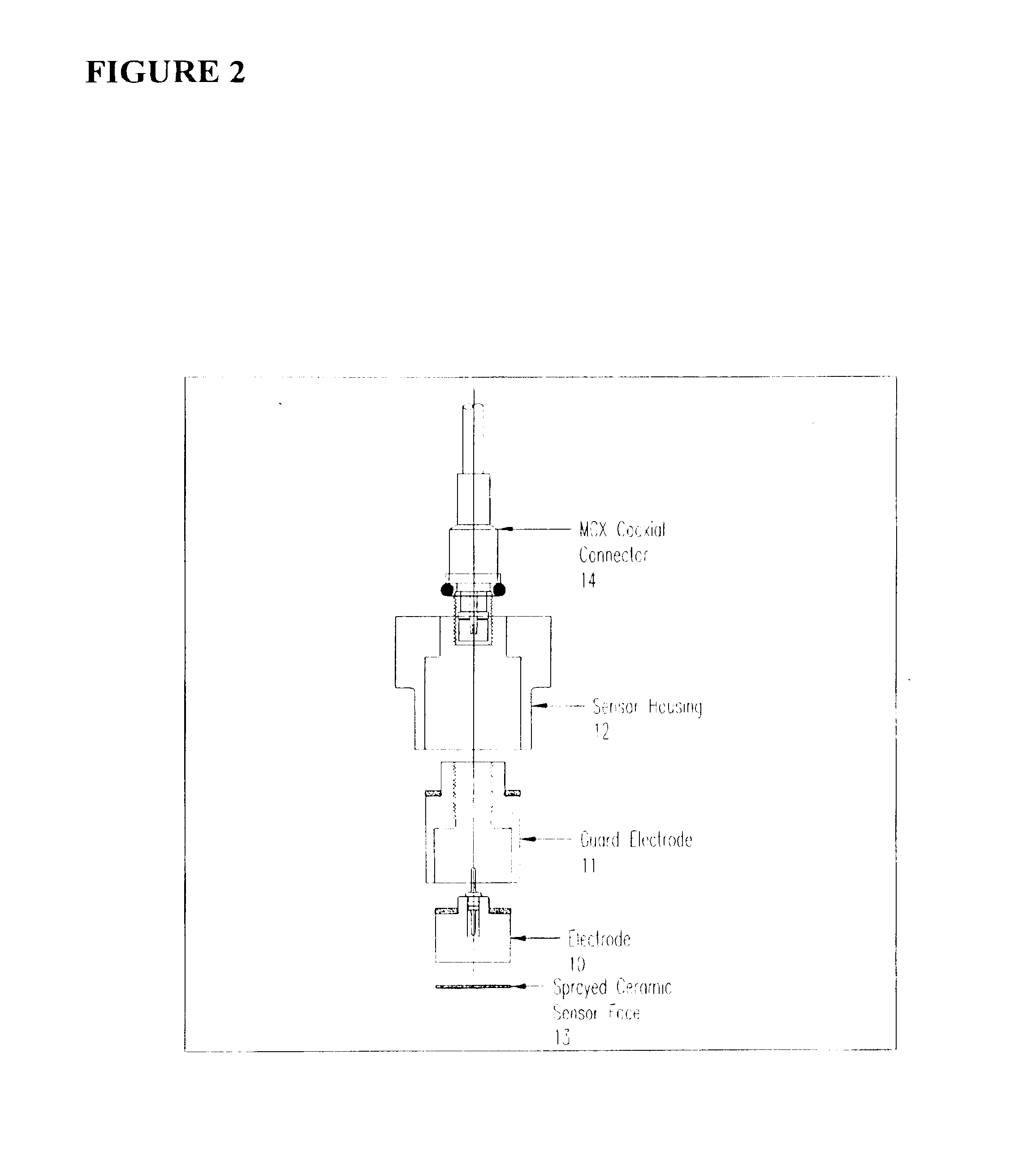

Process and apparatus for improving and controlling the vulcanization of natural and synthetic rubber compounds

InactiveUS6855791B2Unique shapeQuality improvementFlow propertiesThermometer testing/calibrationCompound aElectricity

A process for curing a natural or synthetic rubber includes the measuring of curing conditions by dielectric or impedance means to produce a process curve (impedance property data versus time) followed by analyzing the process curve with a software algorithm which defines and statistically quantifies the correlation between the process curve and the desired part properties. The correlation relationship is applied in real time to end the curing process at the optimum time and to produce rubber parts of uniform quality and with reduced process cycle time.

Owner:SIGNATURE CONTROL SYST

Process for in-line forming of pultruded composites

InactiveUS6872343B2Increase the number ofSimple formatLaminationLamination apparatusPolymer sciencePolymer chemistry

Pultruded composites of longitudinally oriented reinforcing fibers in a matrix of a thermoplastic resin are shaped in-line during the pultrusion process to provide a variety of non-linear or variable cross-section articles.

Owner:FULCRUM COMPOSITES

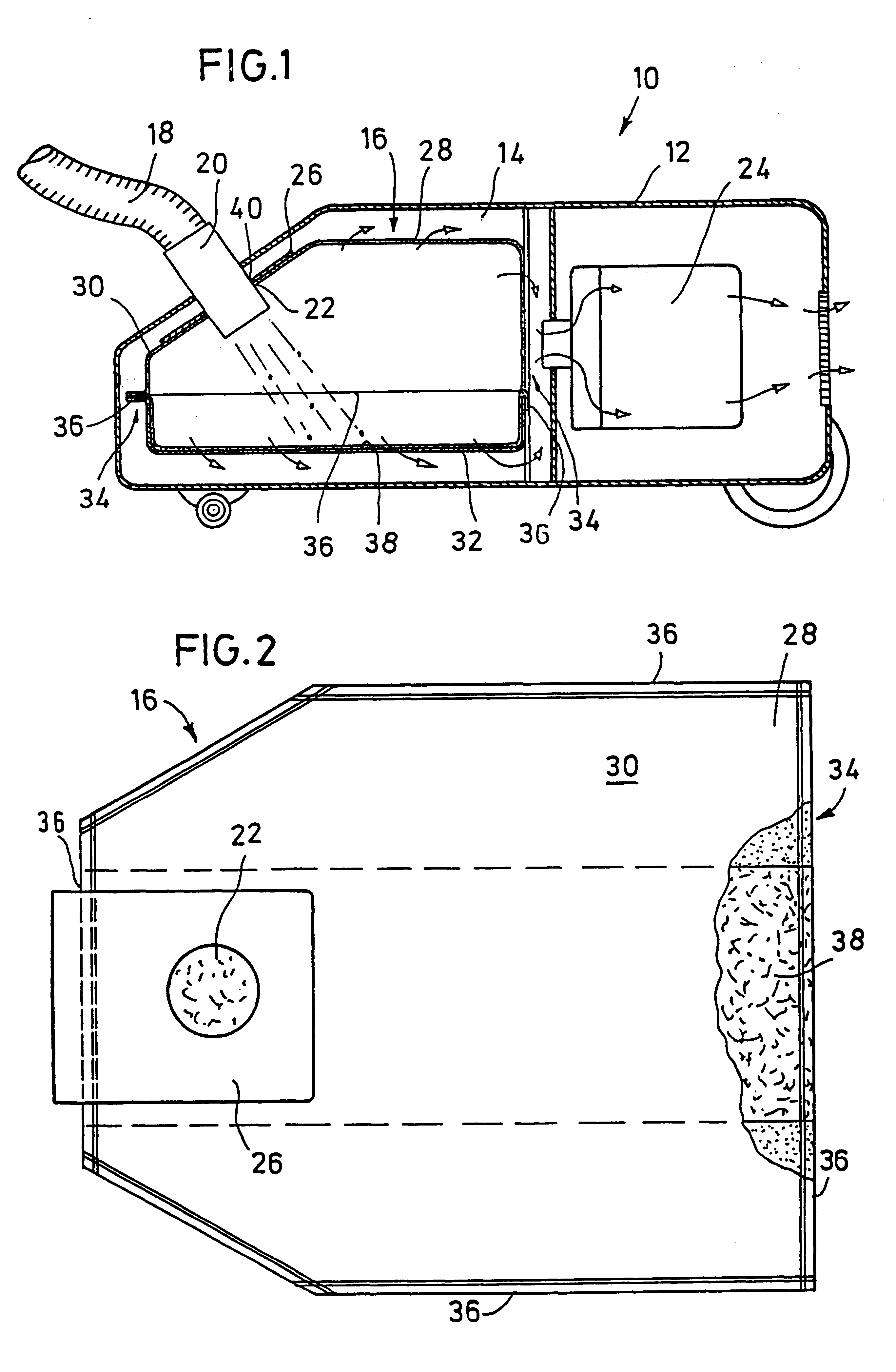

Dust bag and method of production

InactiveUS6251154B1Envelopes/bags making machineryMechanical working/deformationEngineeringFilter material

A dust bag comprises a filter bag consisting of a filter material. In a first wall portion of the filter bag, an inlet opening is provided through which the air flow to be cleaned gets into the filter bag. On the inner surface of the wall portion opposite the inlet opening, there lies a protective layer of a resistant material of great tensile strength. This protective layer extends as a strip through the filter bag and prevents damage to the inner surface of the filter bag caused by particles striking the same.

Owner:3M INNOVATIVE PROPERTIES CO

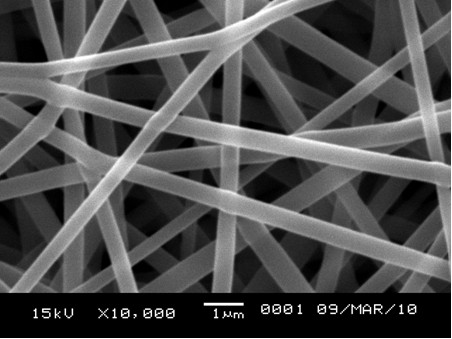

Preparation method of titanium dioxide/active carbon composite nanofibrous membrane

InactiveCN102021676AAchieve mass productionImprove bindingWater/sewage treatment by irradiationOther chemical processesSpinningPhosphoric acid

The invention provides a preparation method of a titanium dioxide / active carbon composite nanofibrous membrane, characterized by comprising the following specific steps: dissolving polyacrylonitrile powder in N, N-dimethyl formamide; mixing titanium hydroxide gel with the polyacrylonitrile solution to obtain electrostatic spinning stock solution, and performing electrostatic spinning to get the composite nanofibrous membrane; placing the composite nanofibrous membrane in an electrically heated drying cabinet for being pre-oxidized; soaking the composite nanofibrous membrane in phosphoric acid or potassium hydroxide solution, washing the solution to be neutral by distilled water, and drying the composite nanofibrous membrane in the drying cabinet; and then, under nitrogen protection, heating up to 450-550 DEG C, and cooling to room temperature to get the titanium dioxide / active carbon composite nanofibrous membrane. The preparation method improves combination firmness between fibers and active ingredients of a photocatalyst, and also improves charge capacity of the fibers; the titanium dioxide / active carbon composite nanofibrous membrane is high in photo catalytic activity, good in absorption effect, reproducible and simple in a reproduction method, and can use sunlight, so that operations are easy and operation cost is low.

Owner:DONGHUA UNIV

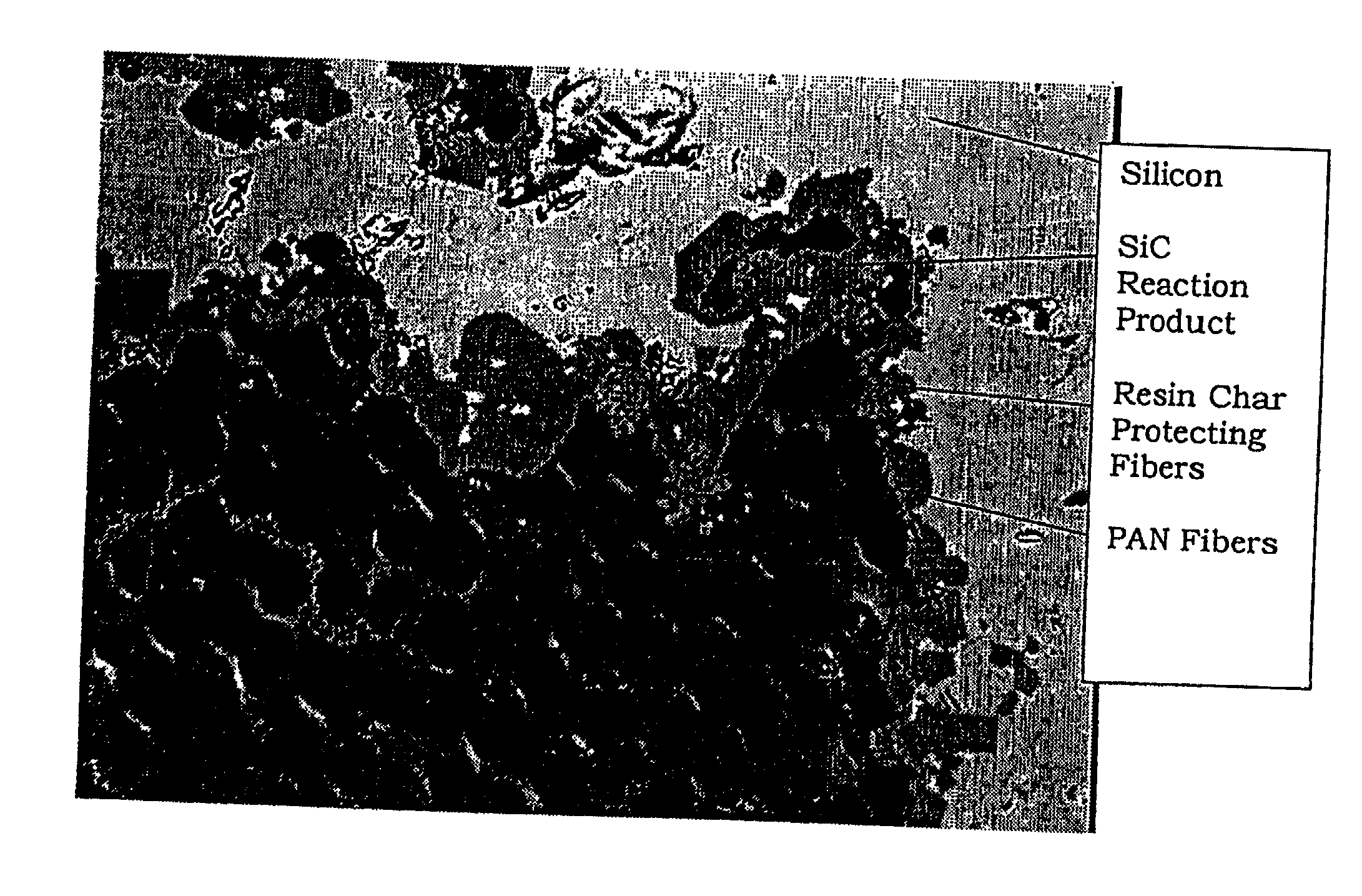

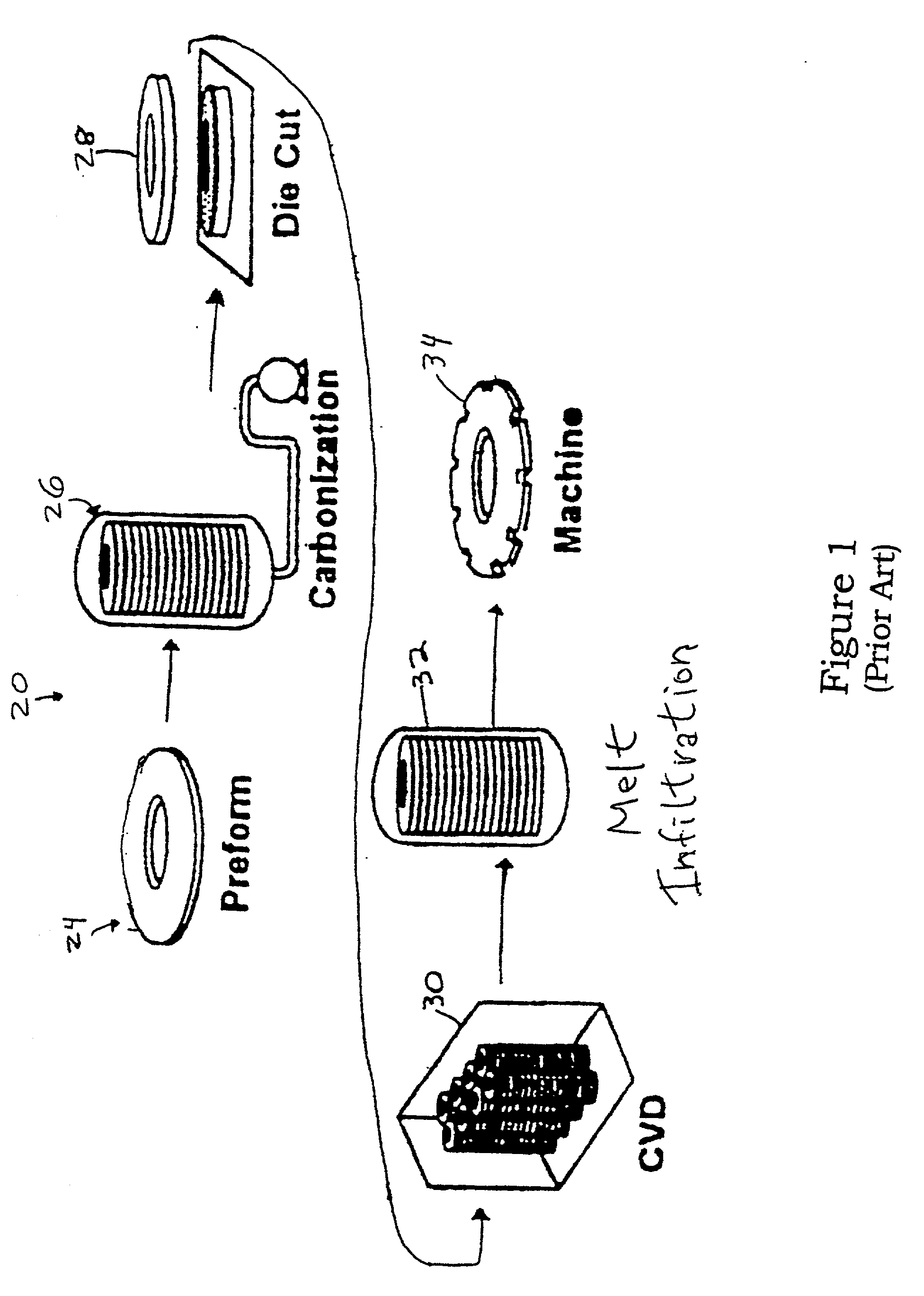

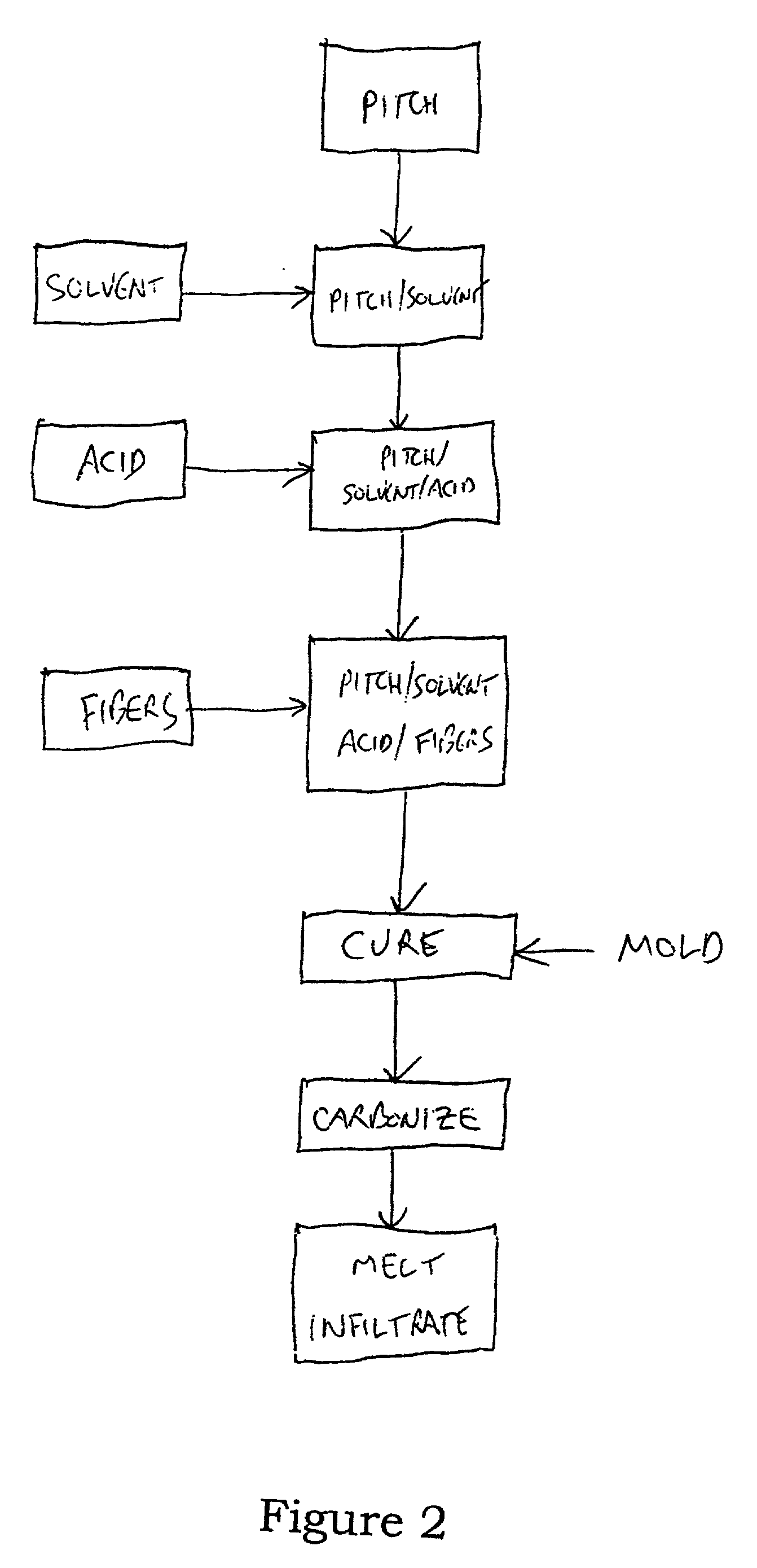

Melt-infiltrated pitch-pan preforms

InactiveUS20030180538A1Omission of costly CVD stepGood adhesionBraking discsCeramic layered productsPorosityCarbon fibers

Carbon-silicon carbide brake preforms are manufactured by carbonizing a blend of carbon (e.g., polyacrylonitrile) fibers and thermosetting pitch resin, optionally along with a lubricant such as graphite, to provide an intermediate product having open porosity and subsequently filling the pores of the intermediate product with silicon by a melt infiltration process. Molded articles that consist principally of carbon, that have relatively high strength and resistance to decomposition by frictional heat, and that are suitable for melt infiltration with silicon, are produced by, e.g.: coating randomly oriented polyacrylonitrile-derived carbon fibers, optionally mixed with finely divided carbon powder, with a thermosetting blend of (a) pitch and (b) an organic medium, at an elevated temperature to form a viscous molding compound; molding the compound at a low pressure and elevated temperature so that a solid compact is obtained; stripping a molded article made of said compound from the mold; optionally heating the molded article at gradually increasing temperatures to insure complete condensation within the article; and carbonizing the condensed molded article in an inert atmosphere at gradually increasing temperatures to produce a molded C / C intermediate article suitable for melt-infiltration with silicon. The preforms may be configured in the form of a disc brake rotor or a disc brake pad.

Owner:HONEYWELL INT INC

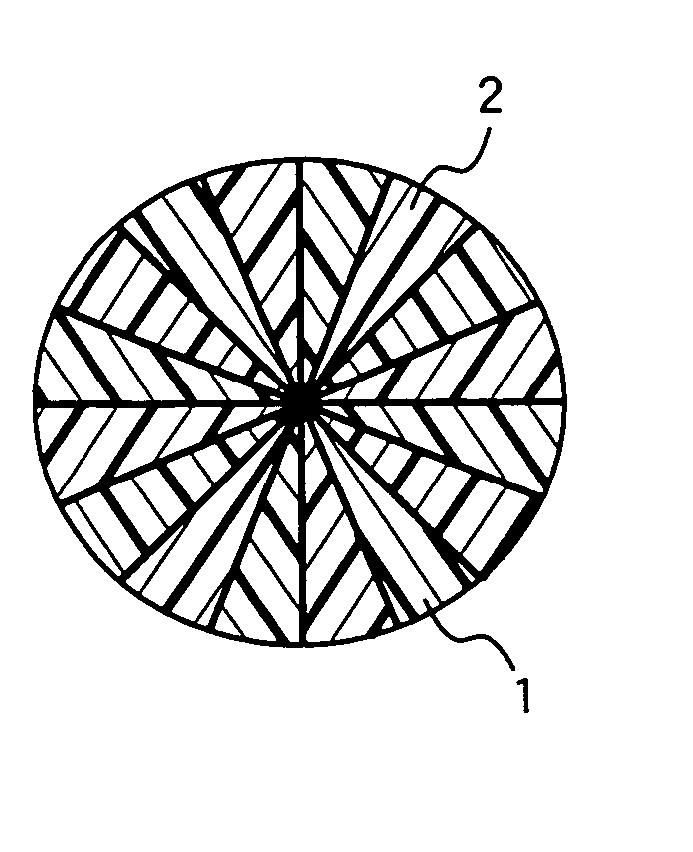

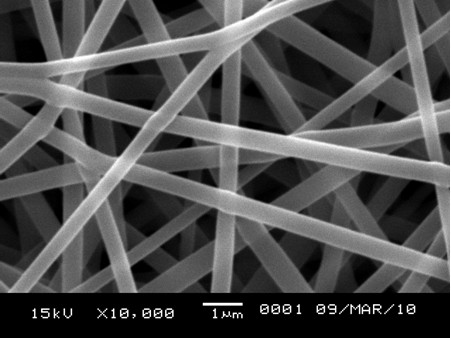

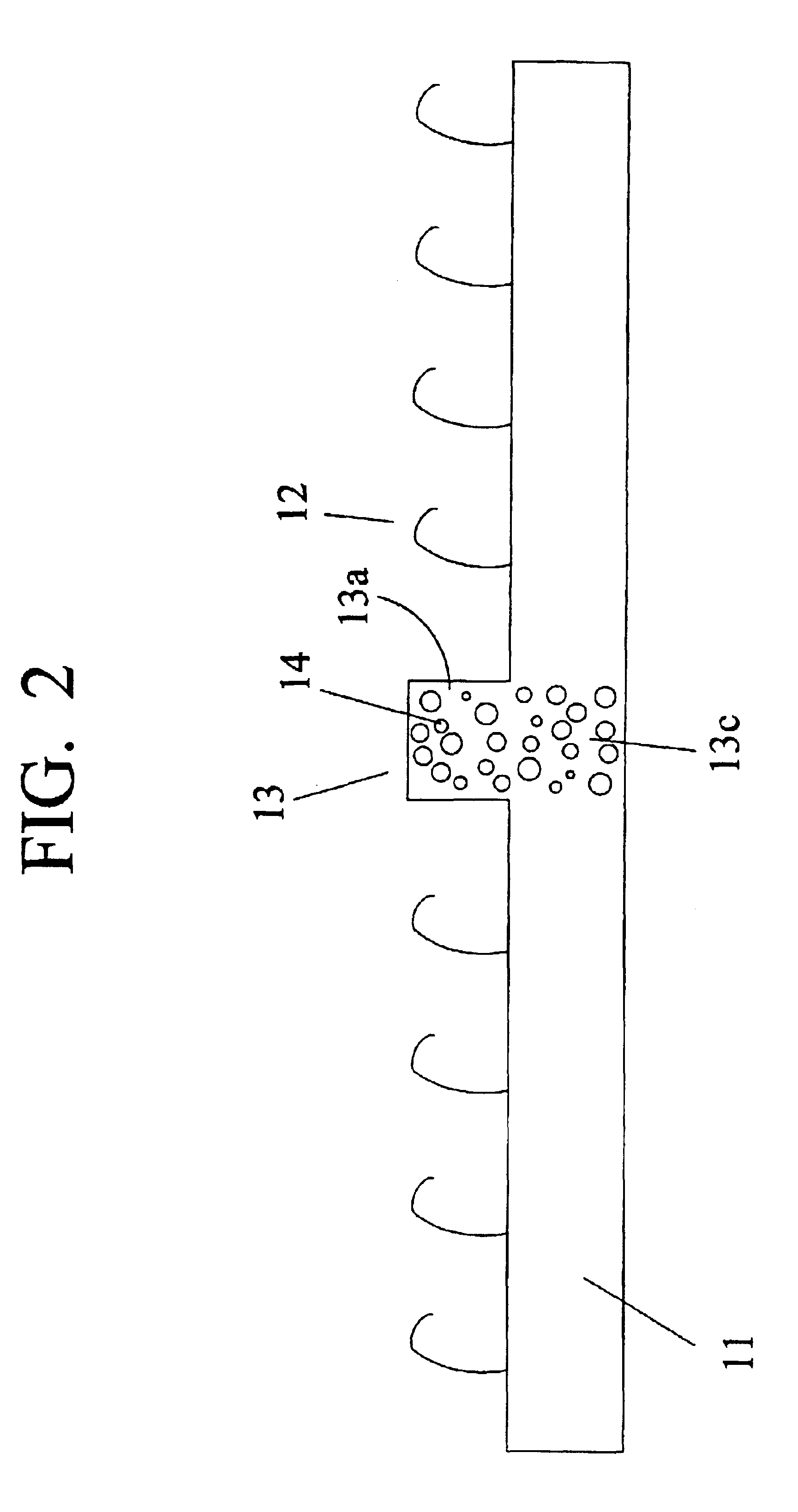

Coaxial composite continuous nano/micron fiber and its preparation method

InactiveCN1537981ASmall diameterLarge specific surface areaFilament/thread formingConjugated artificial filamentsFiberSurface layer

A coaxially composite continuous nano / micron fibre material is composed of core and surface layer, which are coaxial. Its preparing process includes such steps as respectively dissolving core material and surface layer material, loading them respectively in coaxial two containers with fine spray tube at lower end, respectively applying high-voltage DC electric field to them for driving them to be sprayed out via respective spray tubes to become coaxial composite fibre, and collected by a grounded collector.

Owner:黄争鸣 +1

Process for manufacturing a resulting multi-layer pharmaceutical film

The invention relates to the film products and methods of their preparation that demonstrate a non-self-aggregating uniform heterogeneity. Desirably, the films disintegrate in water and may be formed by a controlled drying process, or other process that maintains the required uniformity of the film. The films contain a polymer component, which includes polyethylene oxide optionally blended with hydrophilic cellulosic polymers. Desirably, the films also contain a pharmaceutical and / or cosmetic active agent with no more than a 10% variance of the active agent pharmaceutical and / or cosmetic active agent per unit area of the film.

Owner:AQUESTIVE THERAPEUTICS INC

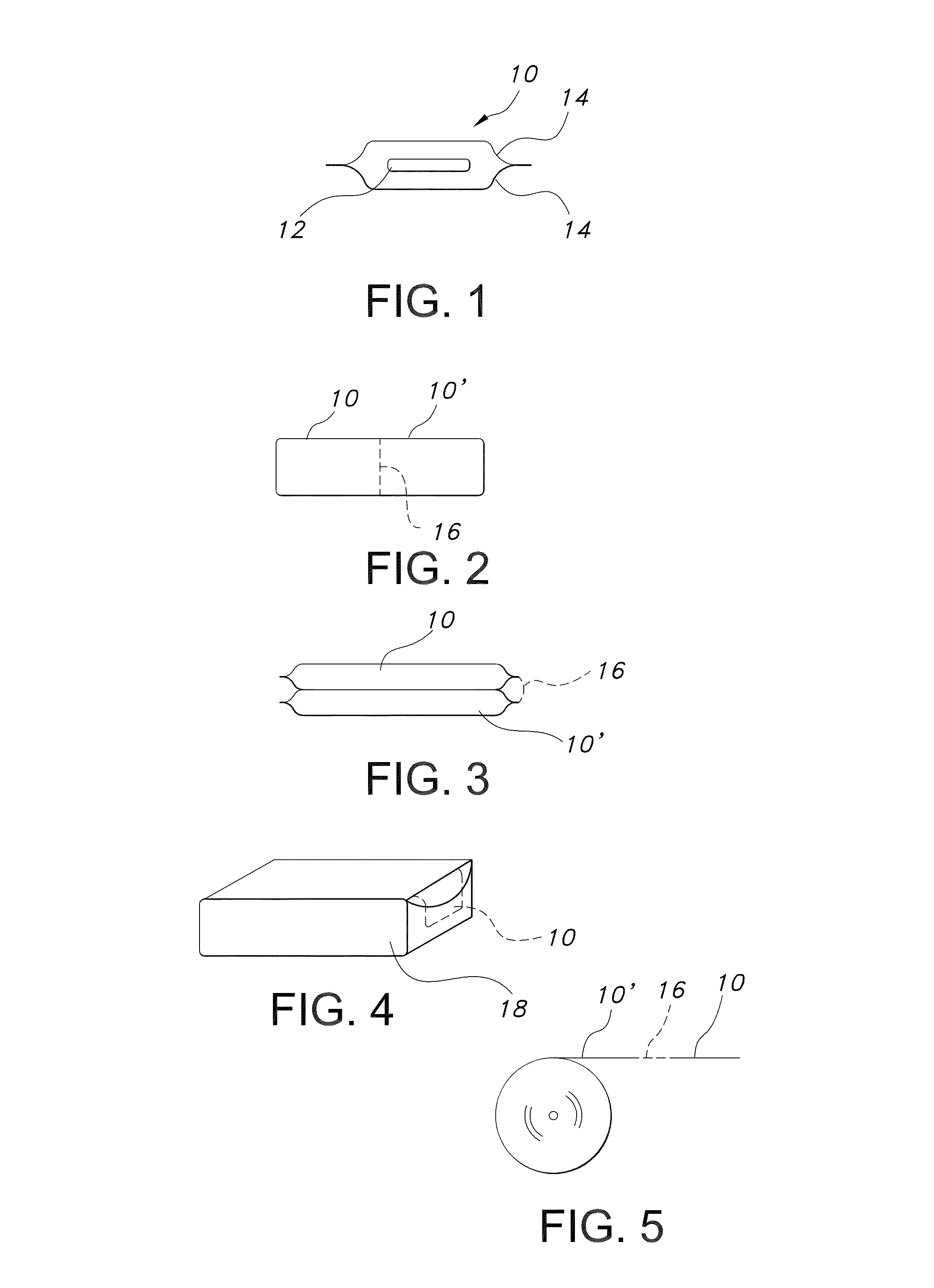

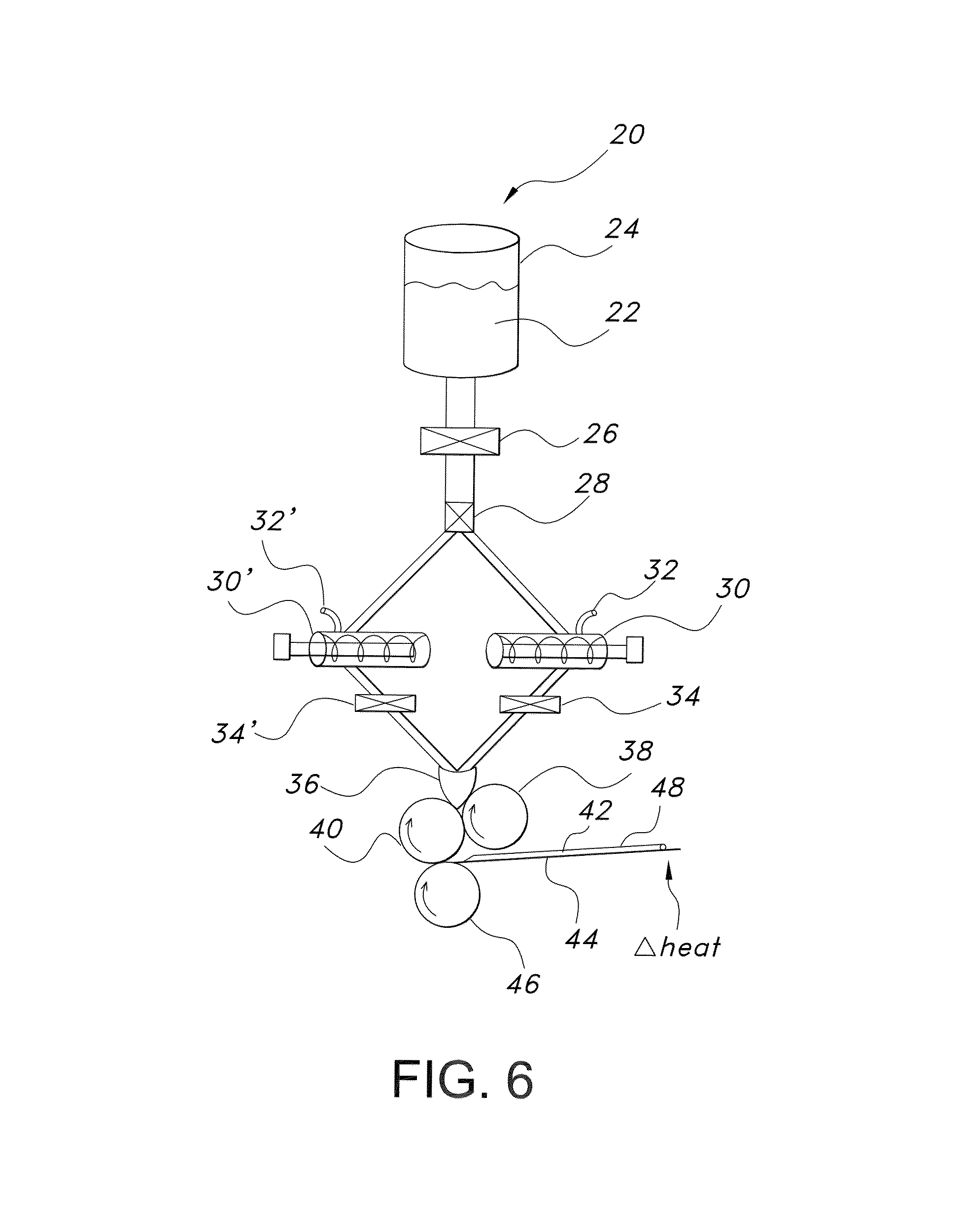

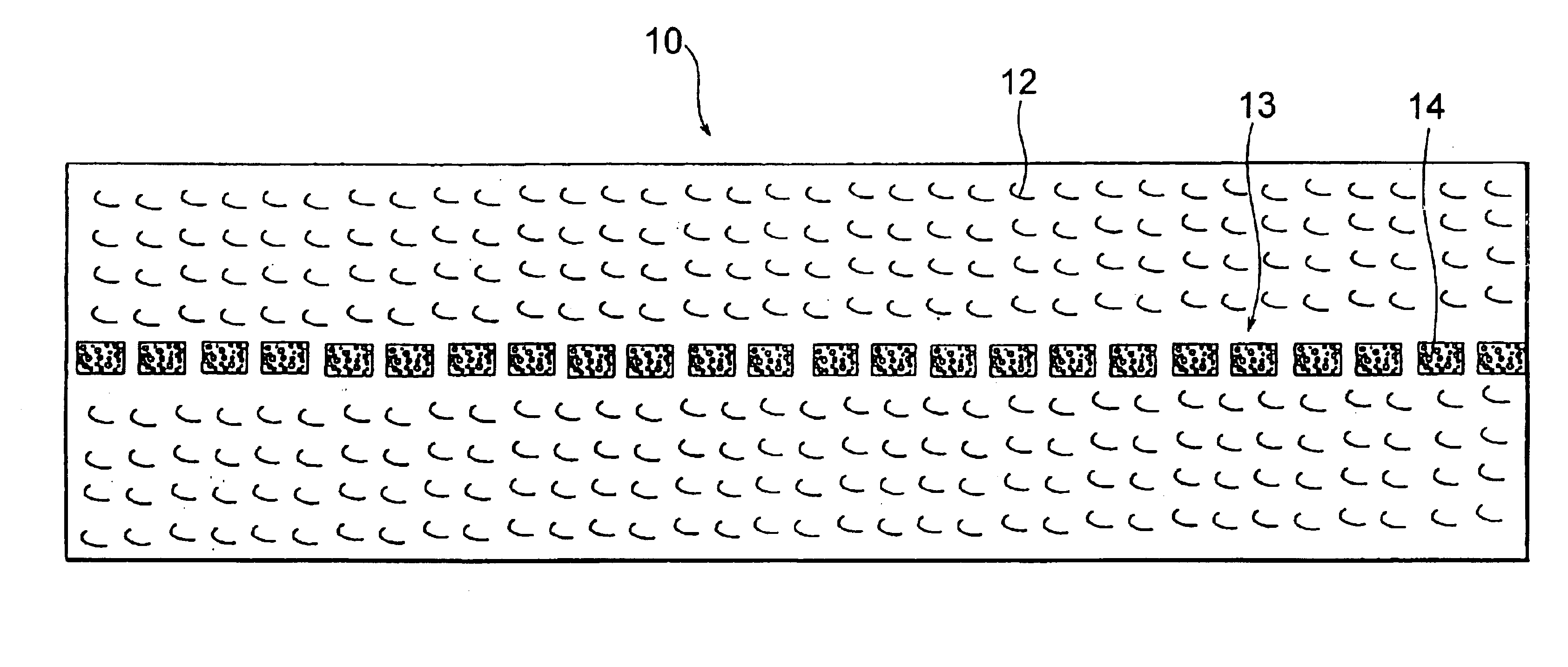

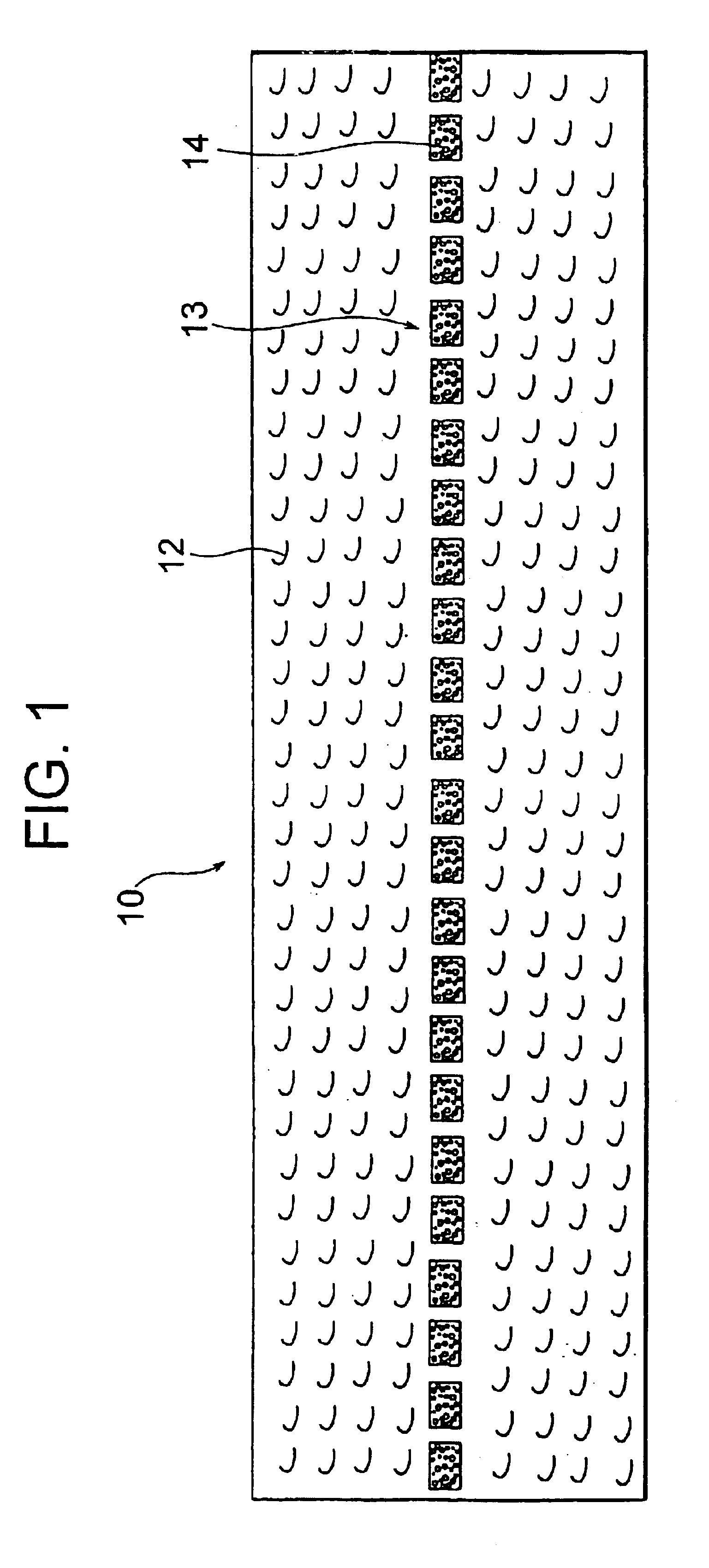

Fastener strip with discrete magnetically attractable area, and method and apparatus of making same

InactiveUS6896759B2Continuous preparationEasy to useVehicle arrangementsLaminationEngineeringFastener

The present invention provides a fastener strip having magnetically attractable particles which are not located across the entire volume of the strip, but rather are incorporated in a discrete, distinct area of the strip. The fastener strip has a base and many hook pieces which rise from a fastening surface of the base. One embodiment has a magnetically attractable body in a row which rises from the surface of the base and is located along a substantially center line of the fastener strip. The magnetically attractable particles are incorporated in the magnetically attractable body and a part of the base located below the magnetically attractable body, and the magnetically attractable particles are not dispersed across the whole area of the base. A method of manufacturing such a strip is also described here.

Owner:YKK CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com