Patents

Literature

180results about How to "Improve crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

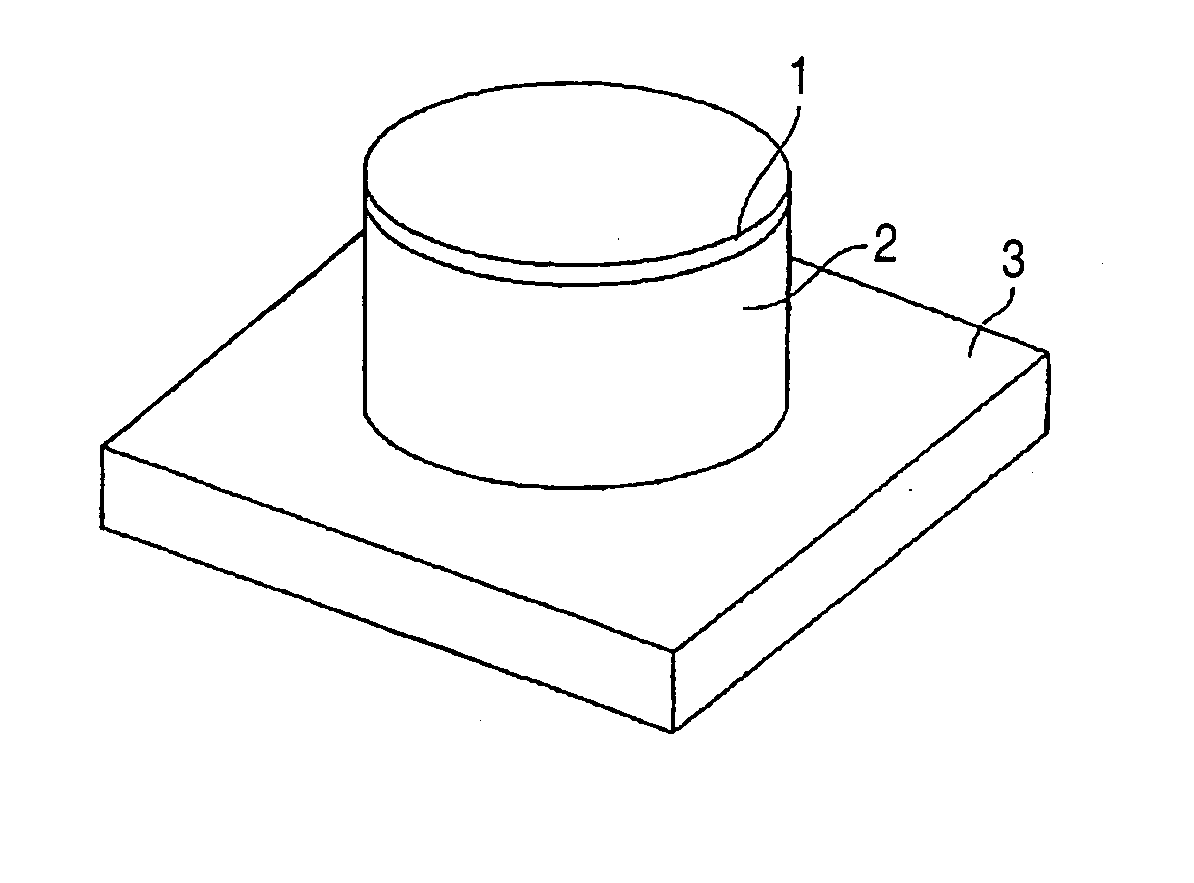

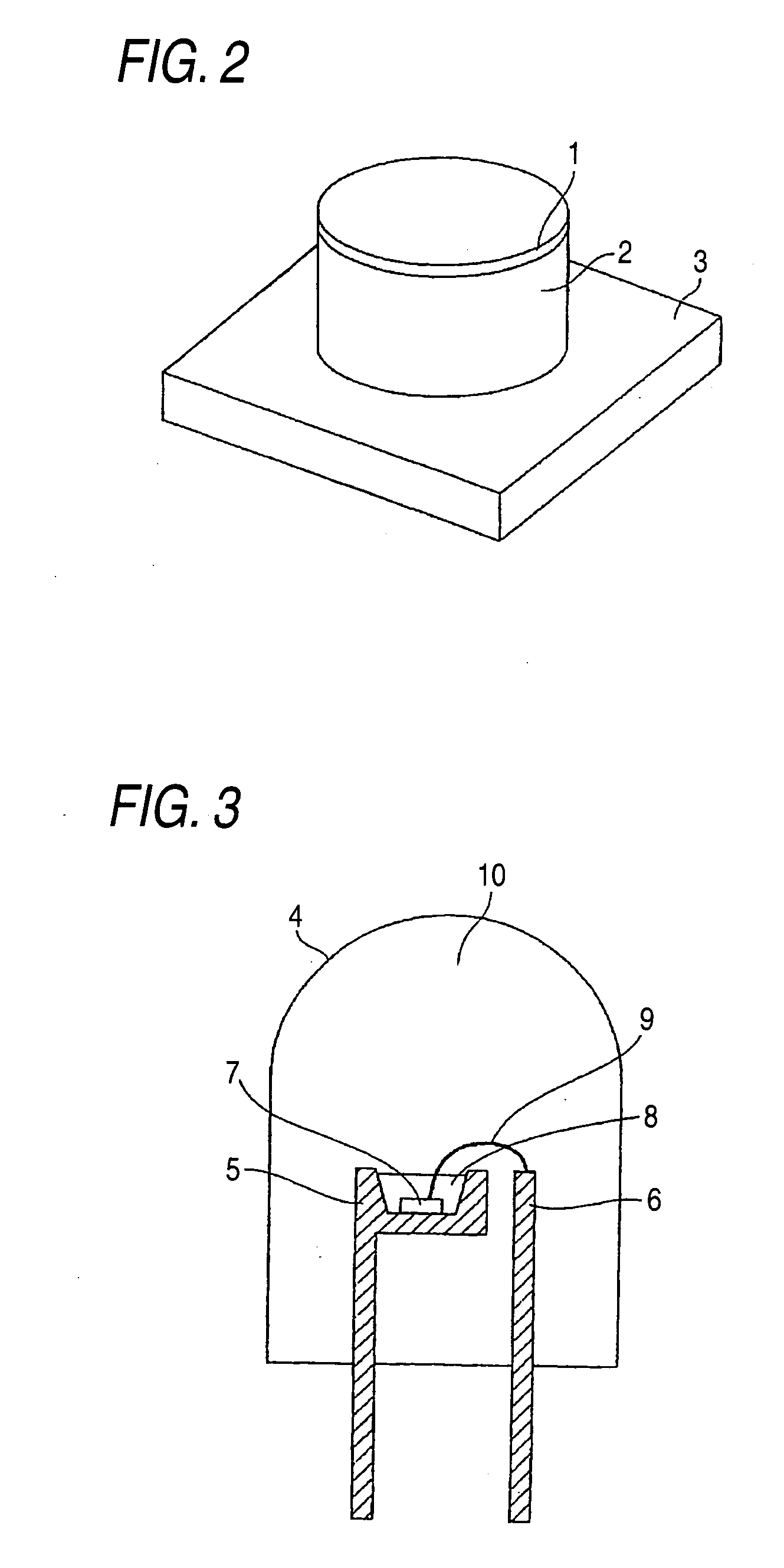

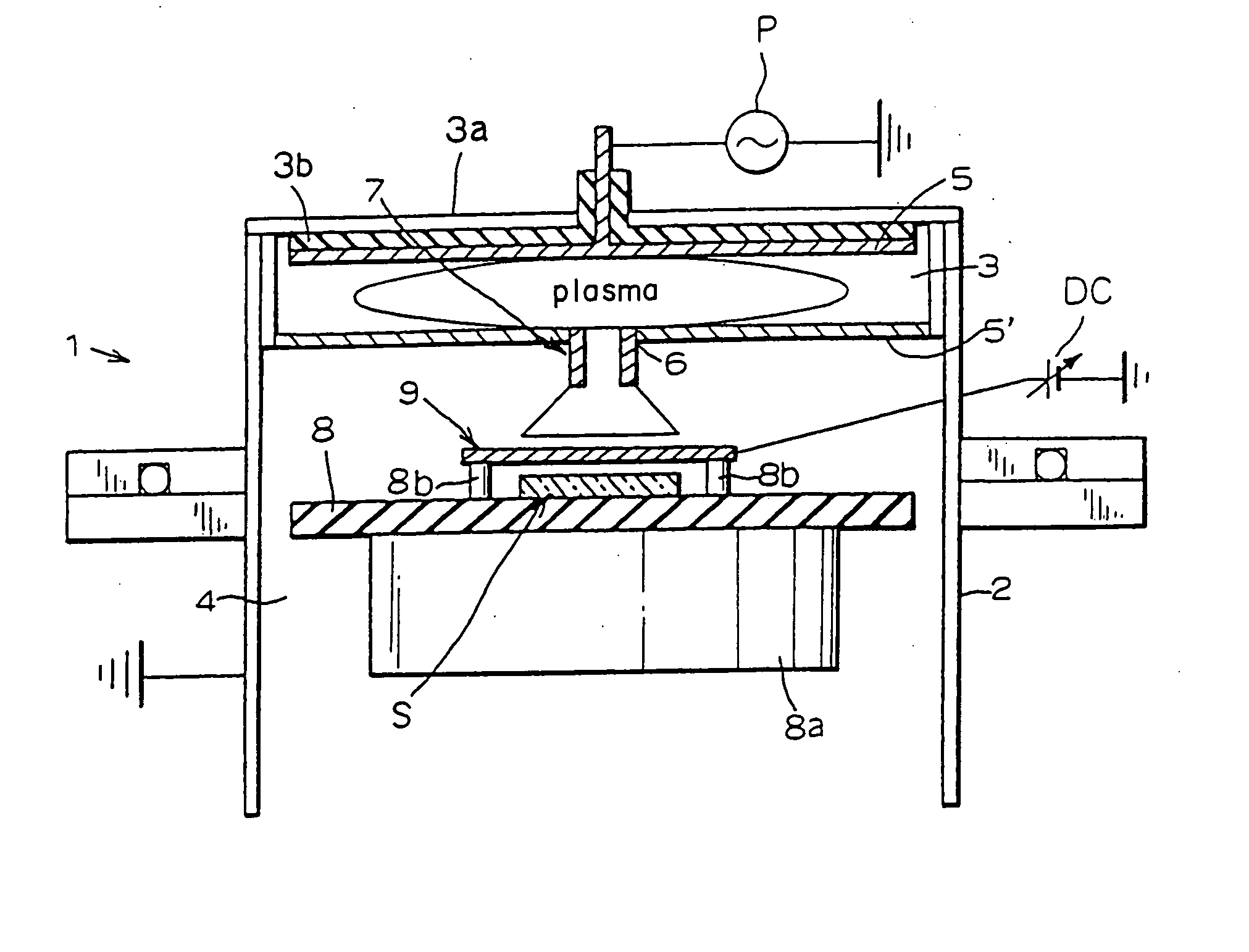

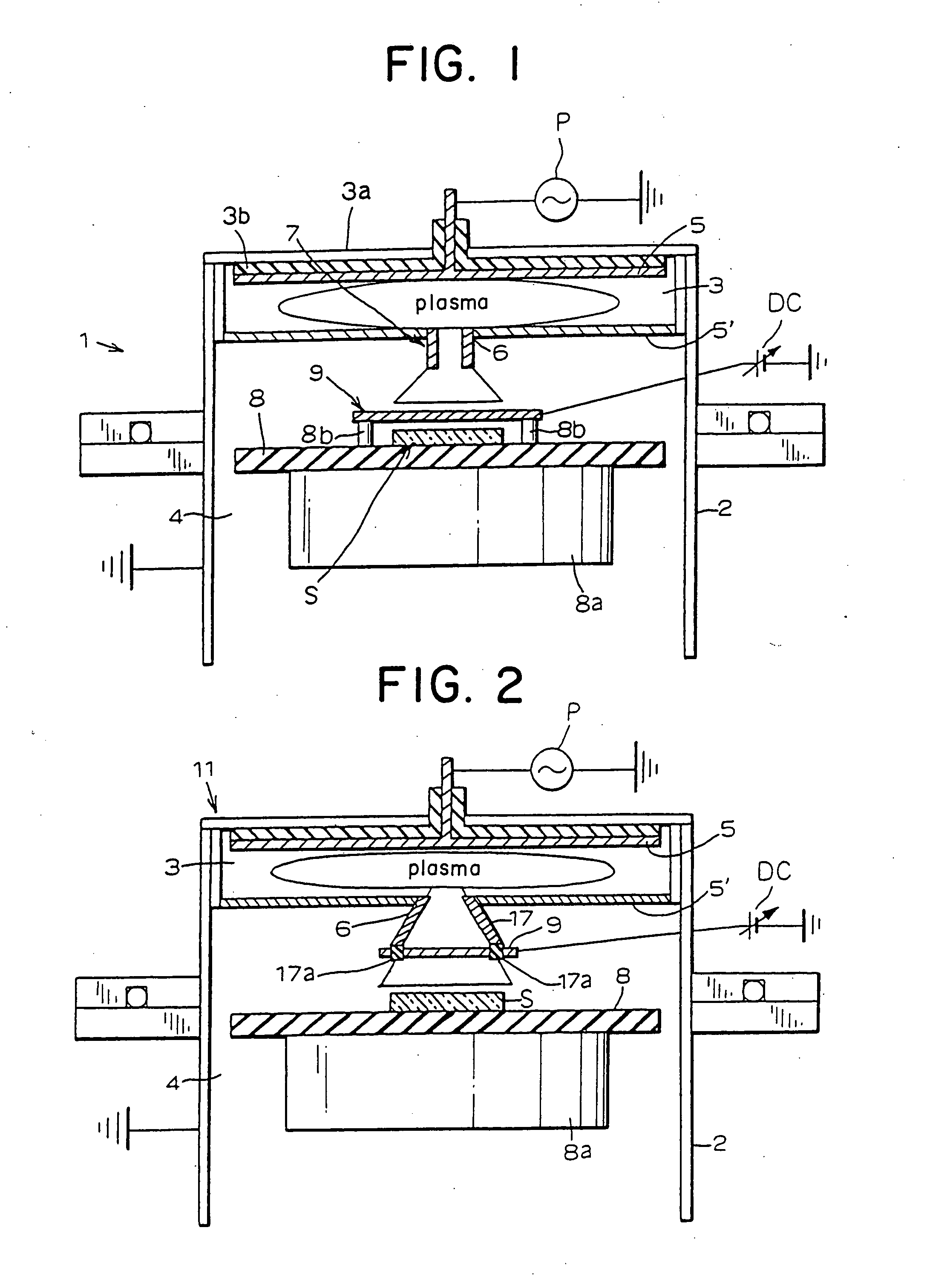

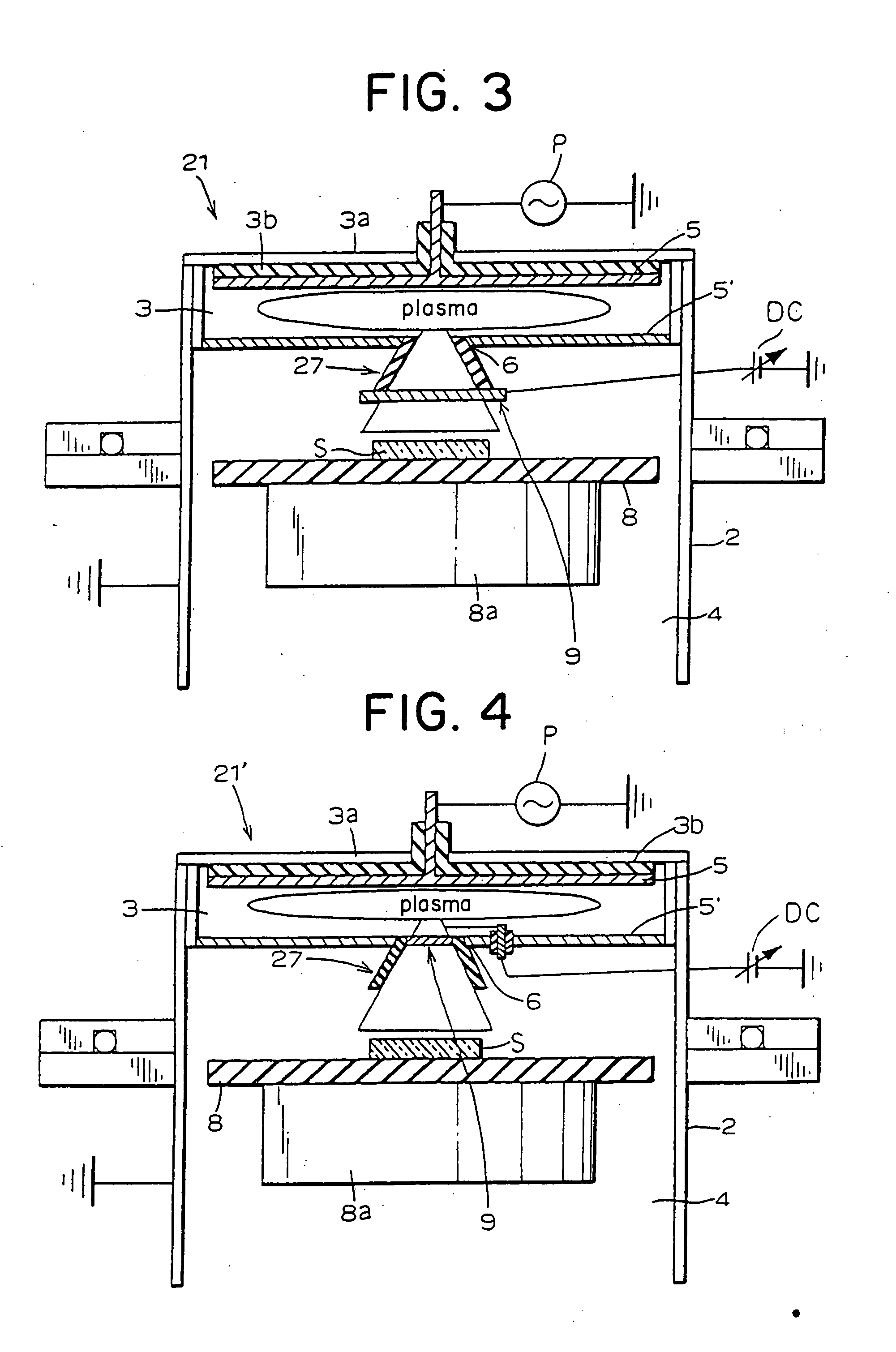

Surface treatment apparatus

InactiveUS20060191479A1Reduce harmFilm formationElectric discharge tubesSemiconductor/solid-state device manufacturingMolecular physicsCharged particle

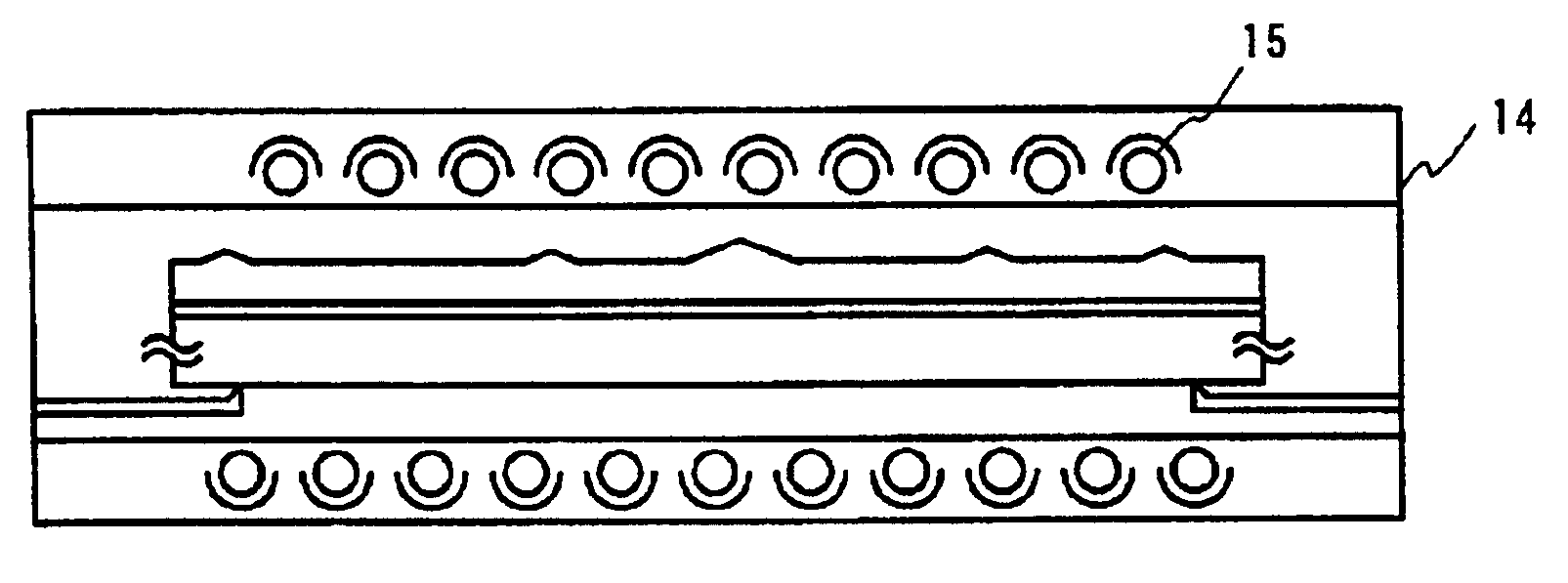

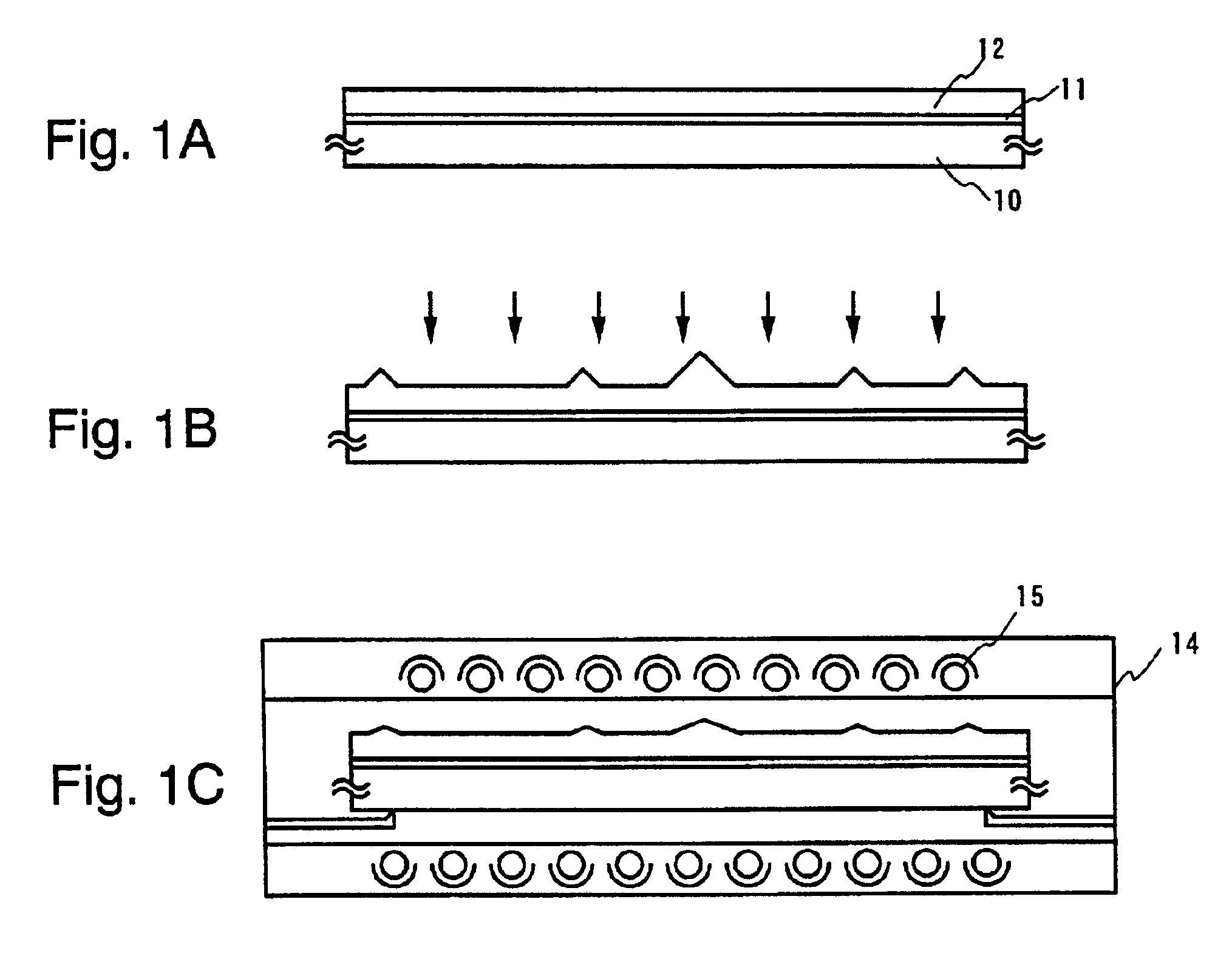

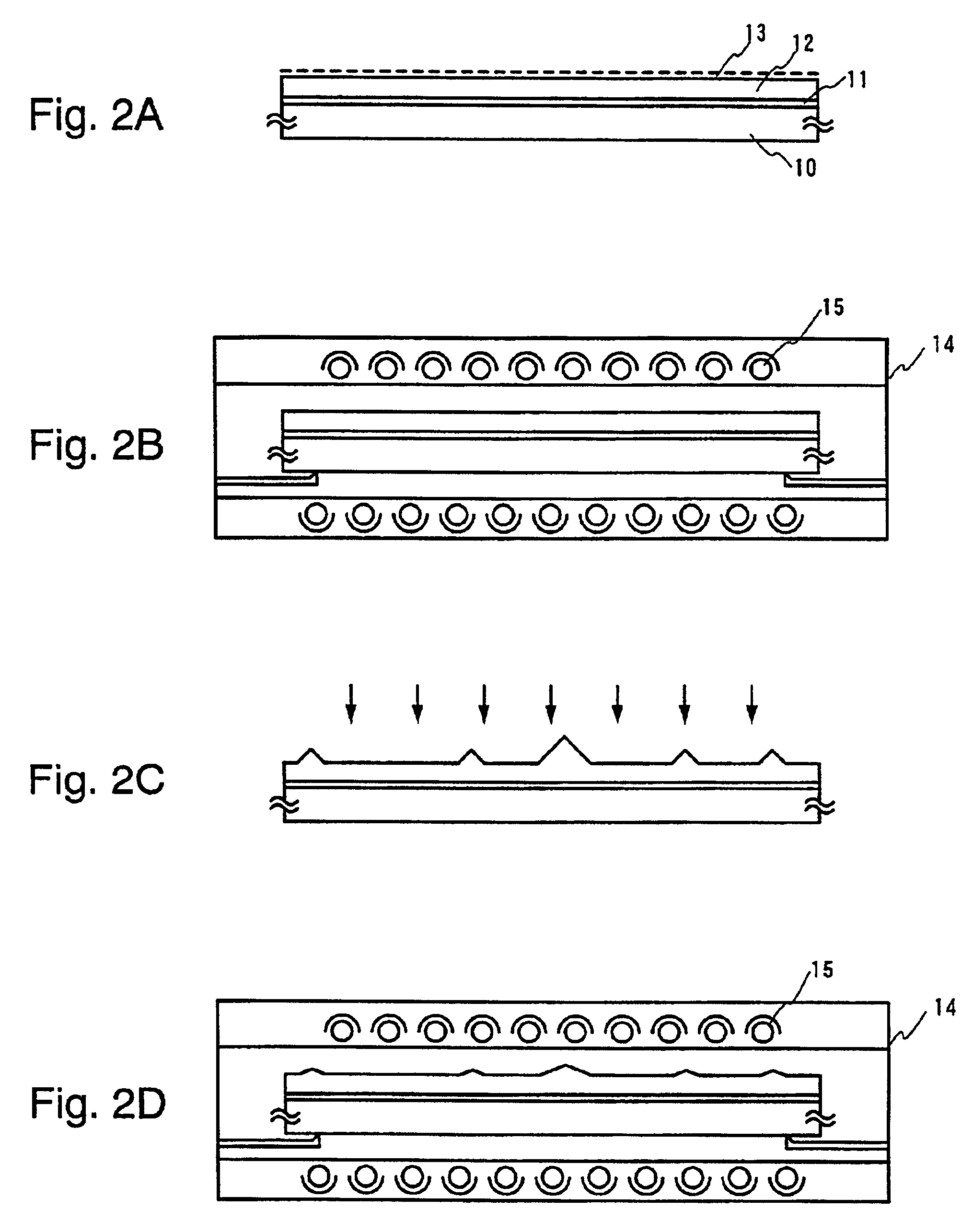

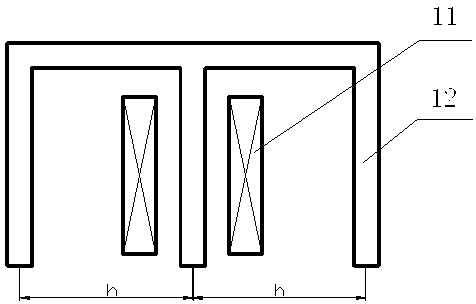

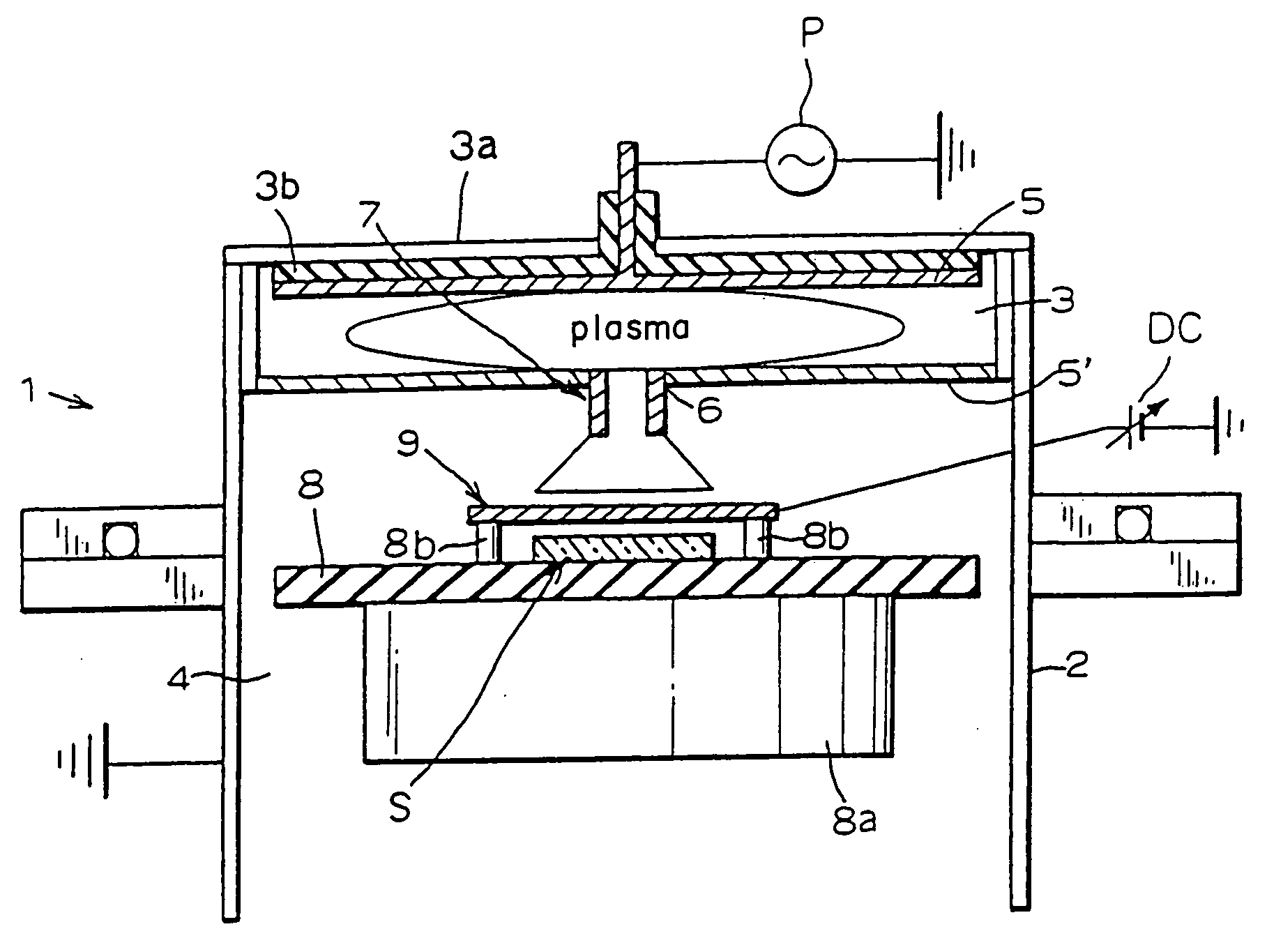

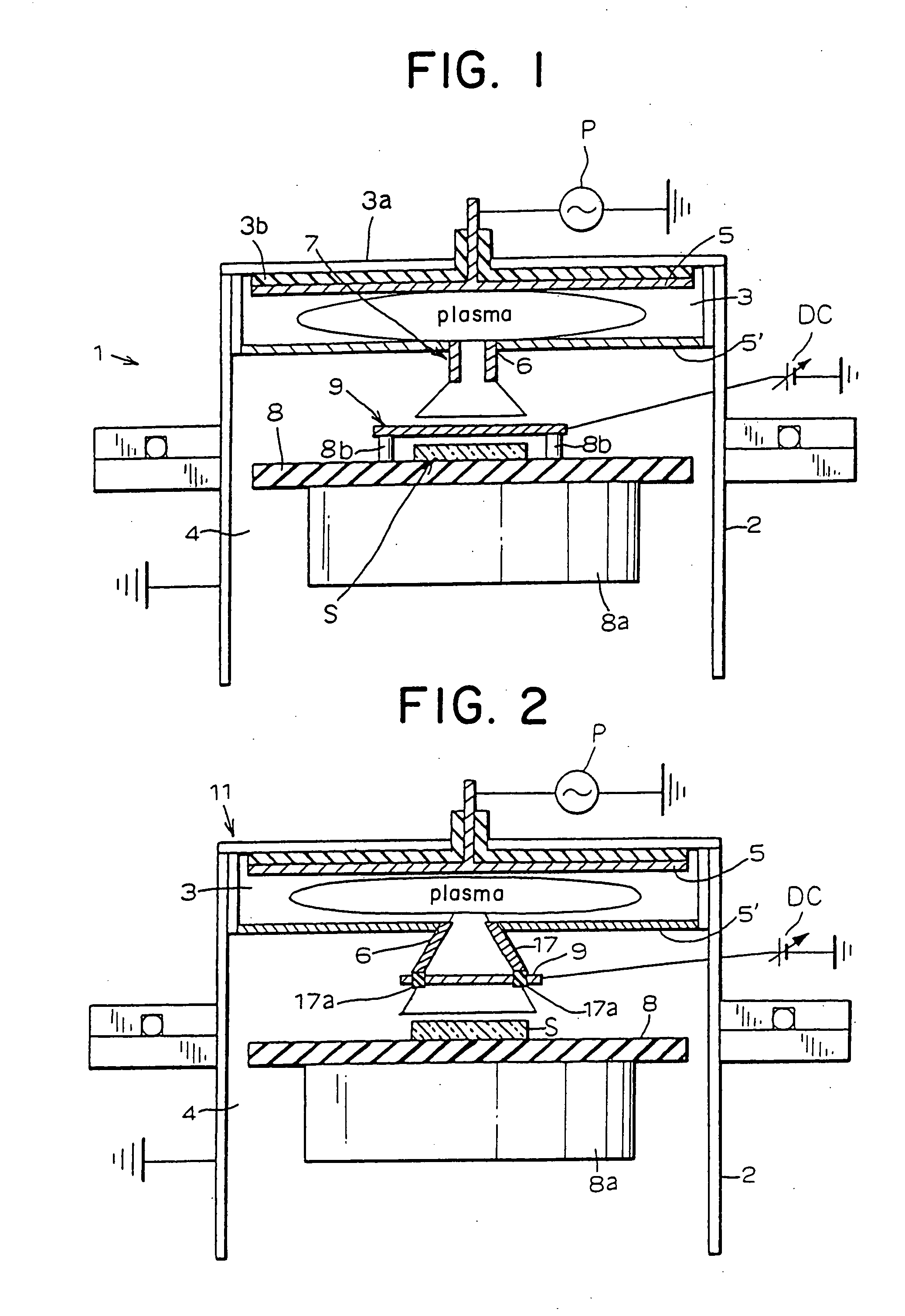

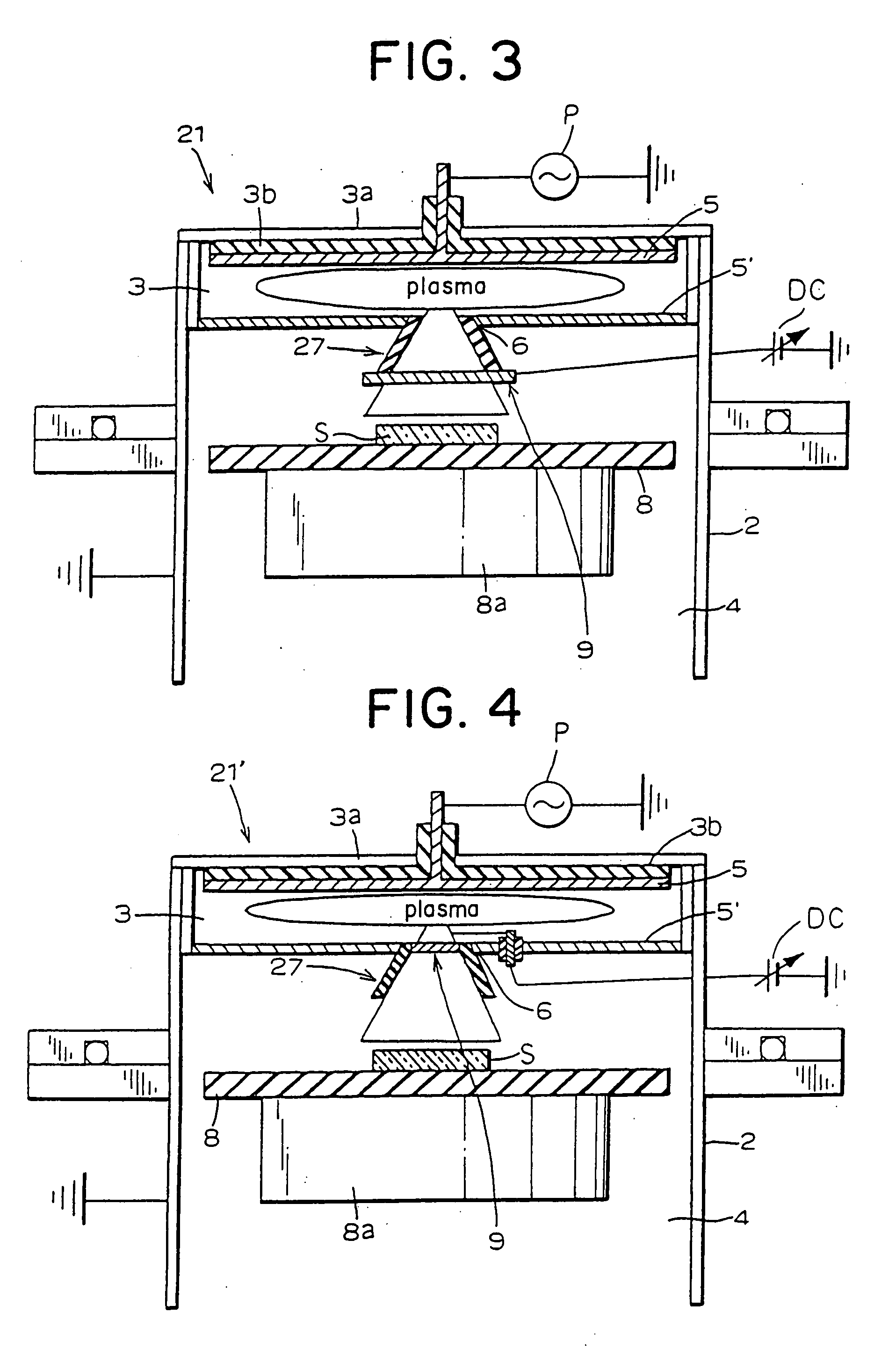

The present invention has an object to provide a surface treatment apparatus, which can form a high-quality film at a high speed while preventing deterioration of the film due to collisions of charged particles. The surface treatment apparatus (1) of the present invention comprises a casing (2) partitioned to two chambers, that is, a plasma generating chamber (3) provided with plasma generating electrodes (5, 5′) and a substrate processing chamber (4) provided with a substrate supporting table (8). A plasma vent (6) is formed in the electrode (5′) that composes the partition between the chambers (3, 4). A conductive mesh-shaped sheet (9) is disposed in a direction across the plasma between the plasma vent (6) and a substrate (S) on the substrate supporting table (8). The sheet (9), to which a variable bias is applied, captures charged particles in the plasma so that the charged particles can be excluded from the plasma.

Owner:MIZUKAMI HIROYUKI +3

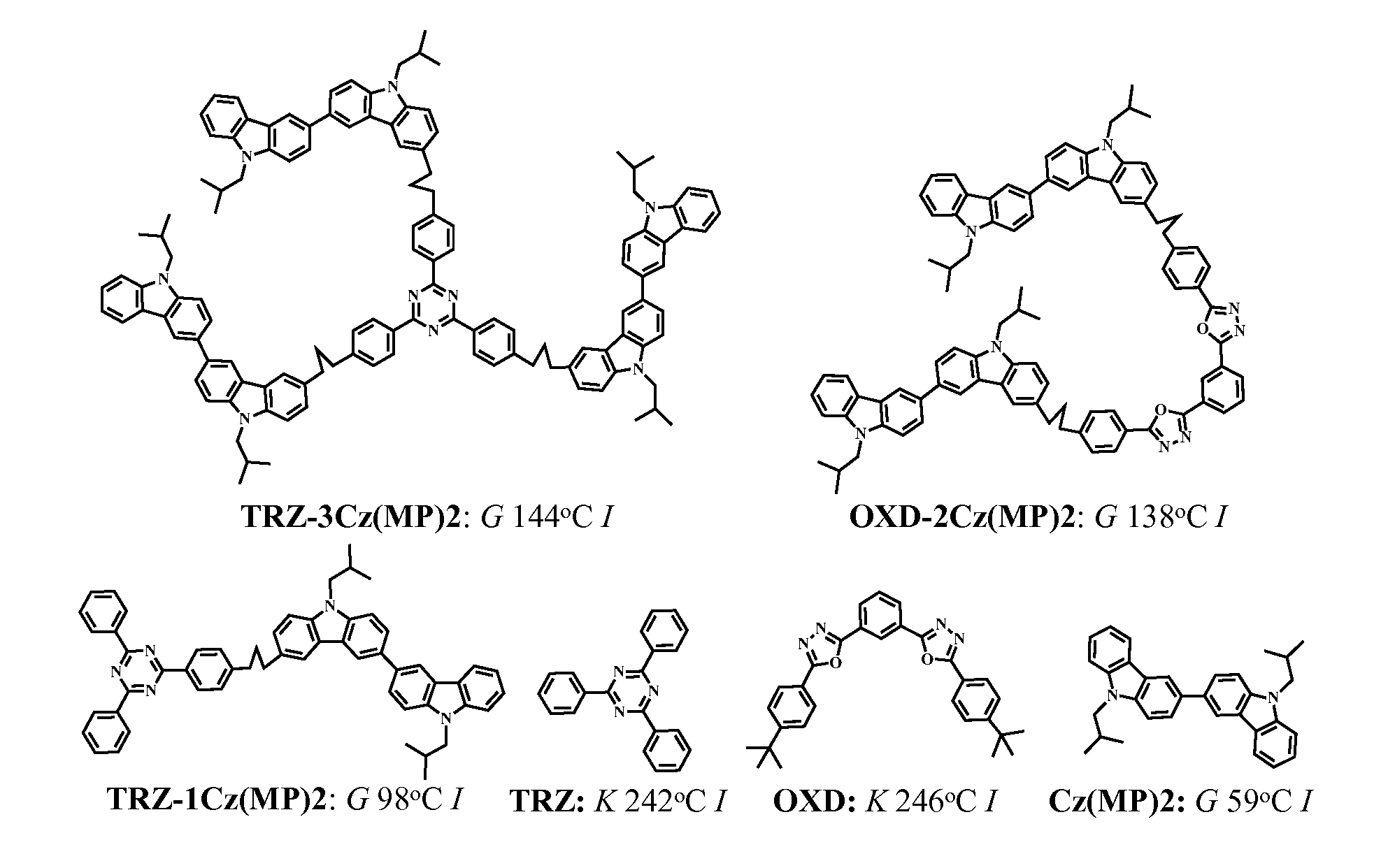

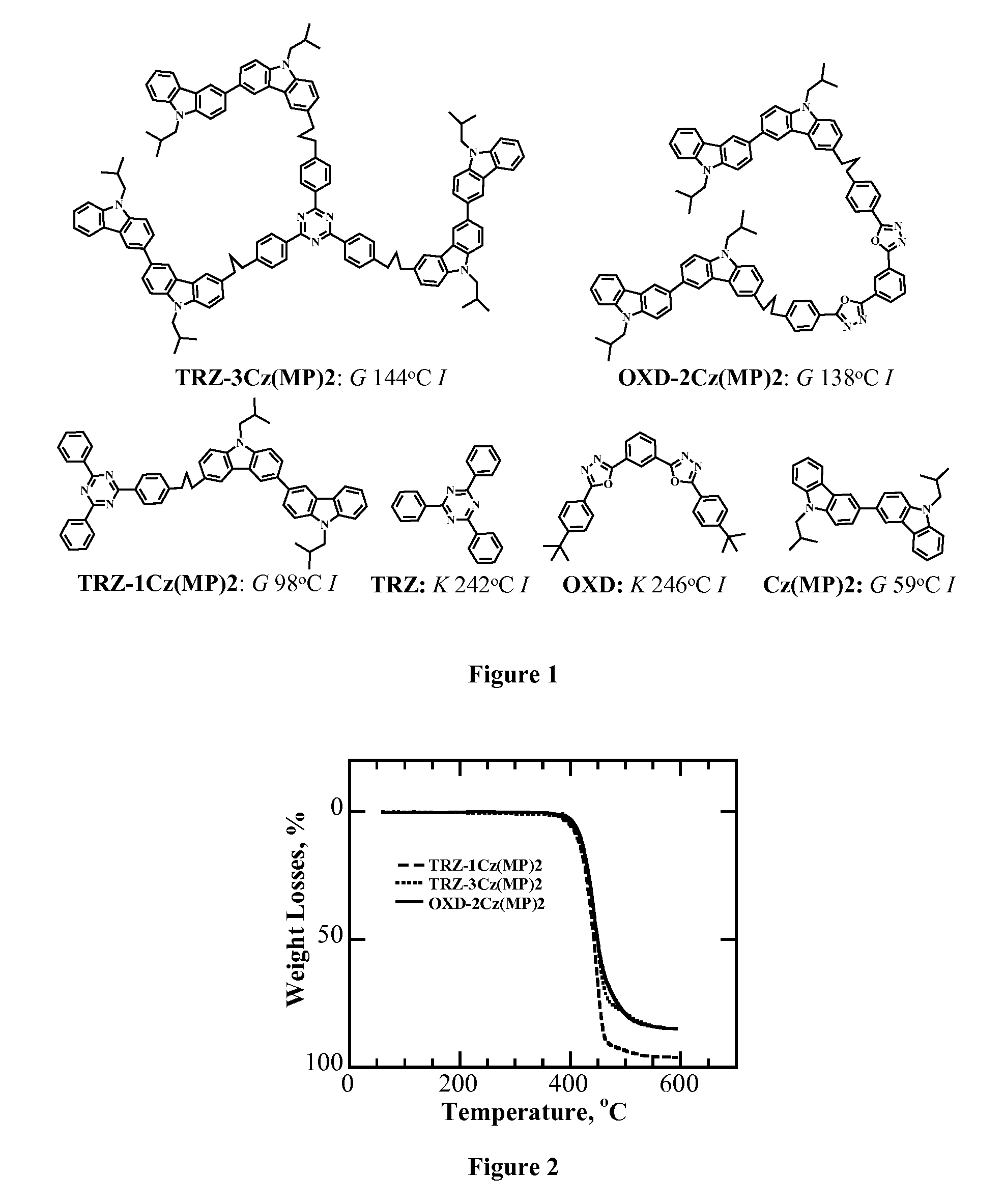

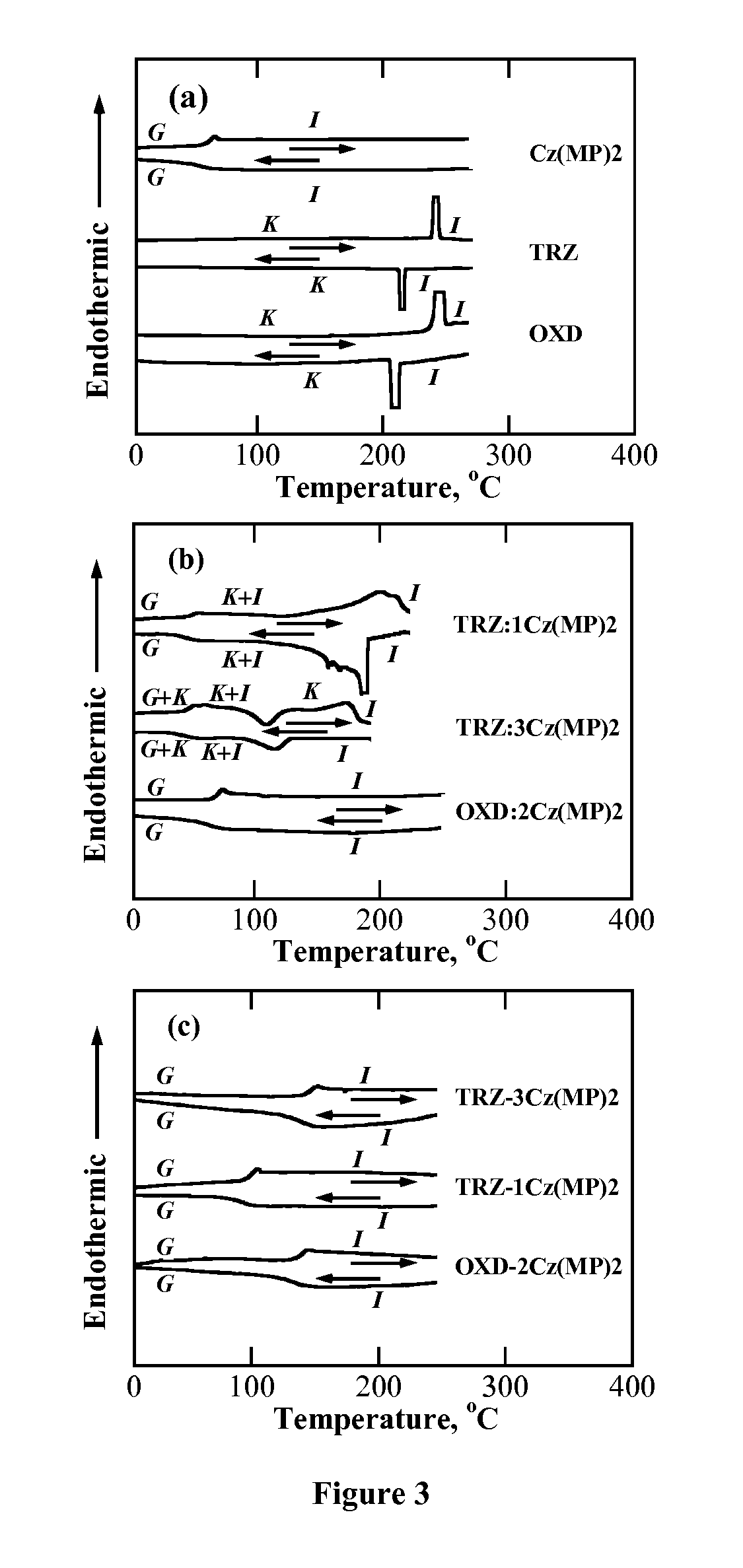

Hybrid Host Materials For Electrophosphorescent Devices

ActiveUS20100184942A1Improve solubilityIncrease entropyGroup 4/14 element organic compoundsGroup 5/15 element organic compoundsHost materialGlass transition

Compounds (including polymers) for use in hybrid host materials which can be used in electroluminescent devices. The compounds comprise at least one electron-transporting moiety and at least one hole-transporting moiety which are joined by a flexible linker. Hybrid host materials comprising the compounds exhibit stability against phase separation, elevated glass transition temperature, morphological stability against crystallization, and isolation of the electron transporting moiety and hole transporting moiety π-systems.

Owner:UNIVERSITY OF ROCHESTER

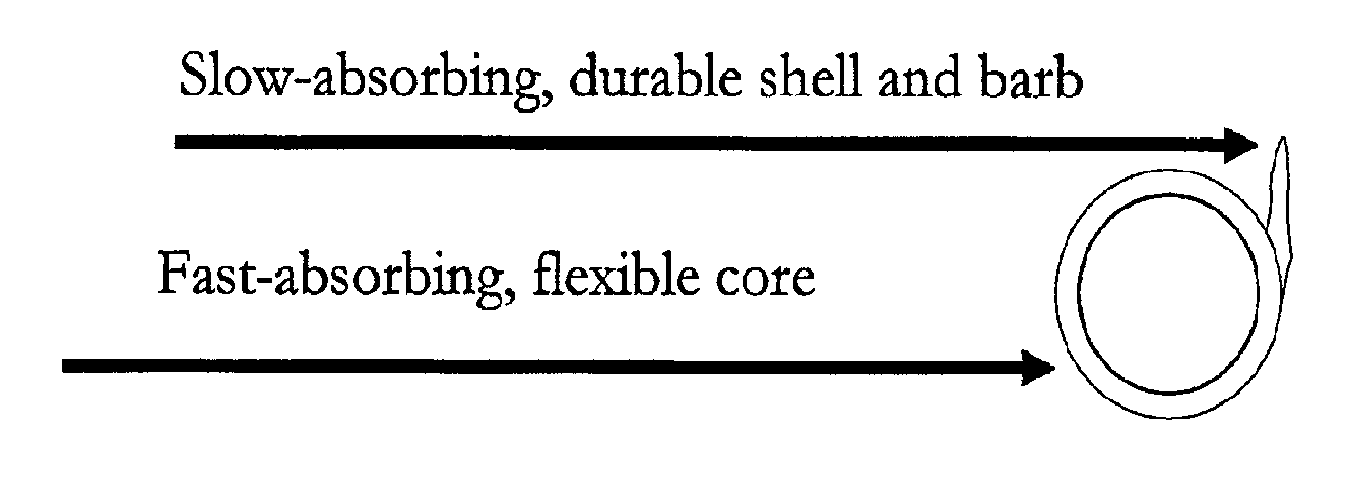

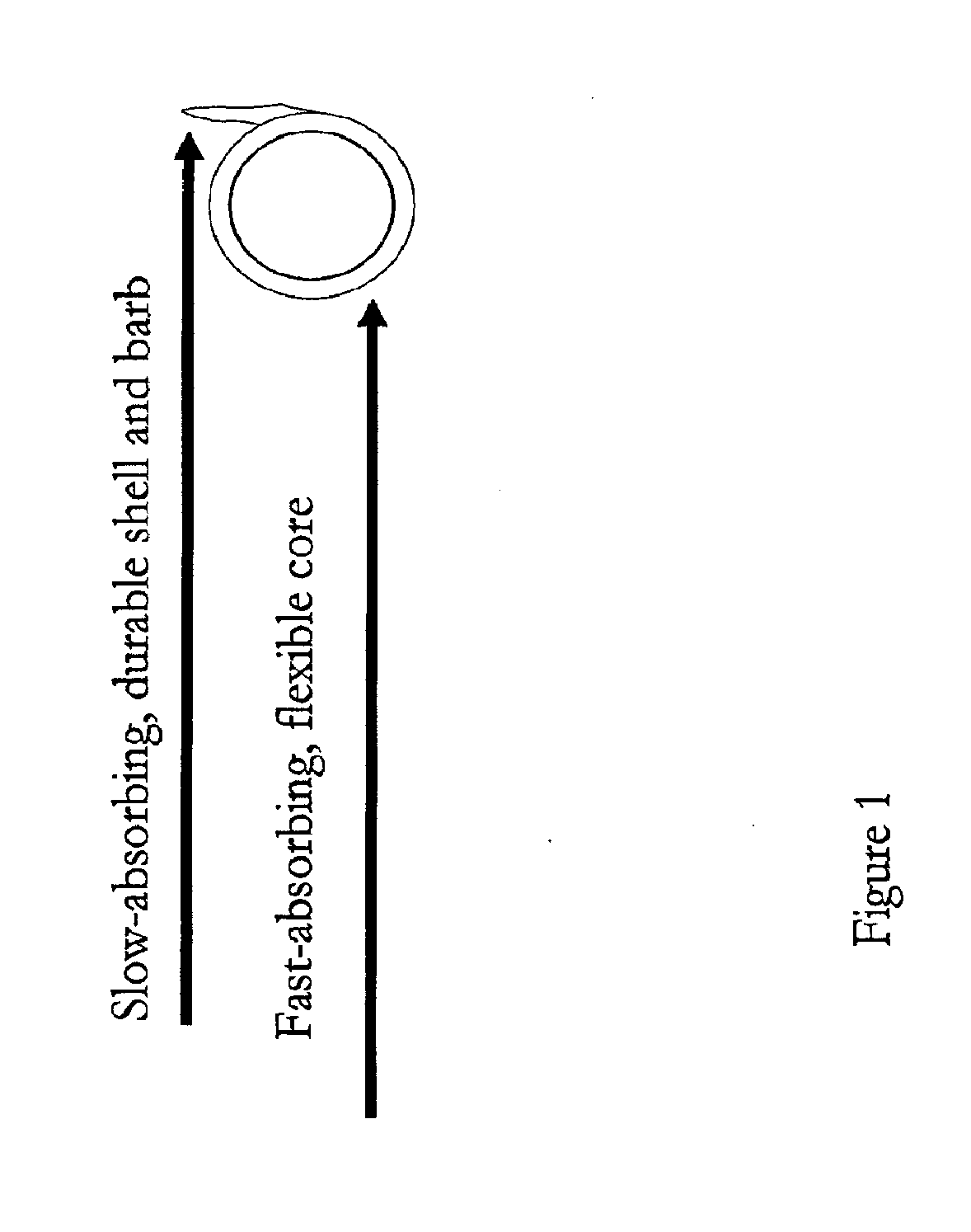

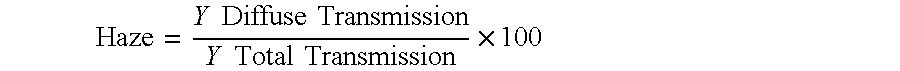

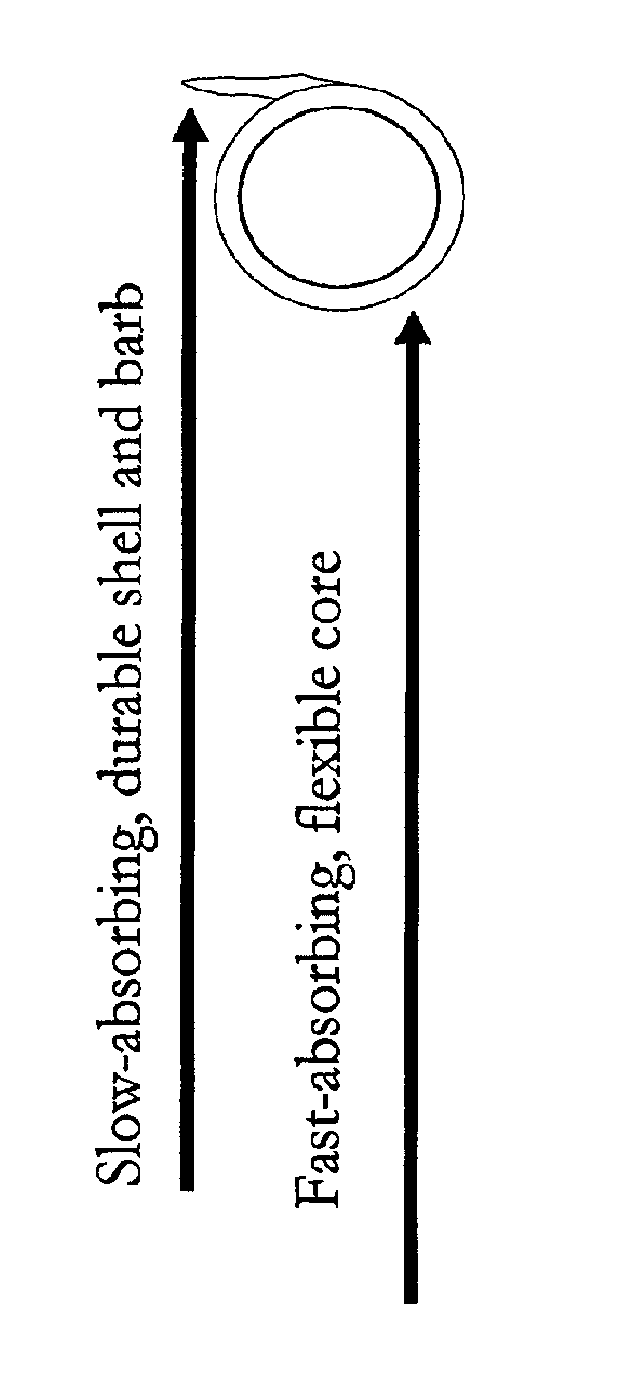

Surgical Sutures Having Increased Strength

InactiveUS20100030261A1Improve crystallizationSuture equipmentsPharmaceutical containersUltimate tensile strengthGeneral surgery

The invention relates to increasing the strength of bio-absorbable surgical sutures. The invention allows for delayed bioabsorption of suture materials to allow maintenance of mechanical strength of the suture for example in ‘barbed’ form.

Owner:MICELL TECH INC

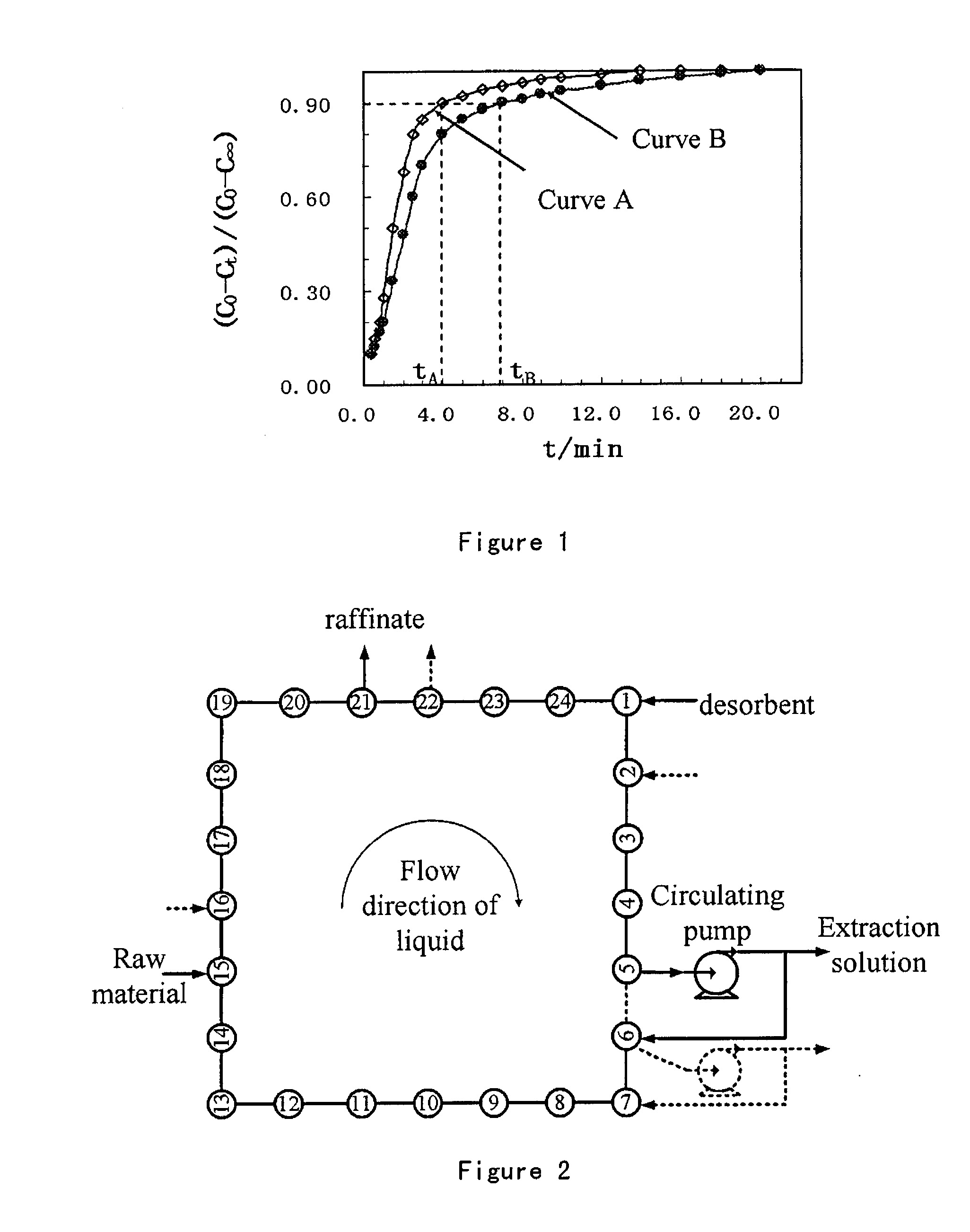

Agglomerated zeolite adsorbents and process for producing the same

ActiveUS20110105301A1Large hole volumeImprove mass transfer effectMolecular sieve catalystsOther chemical processesSorbentIon exchange

An agglomerated zeolite adsorbent which comprises 95-99.5 mass % of X zeolite and 0.5-5.0 mass % of binder, wherein the exchangeable cationic sites of said X zeolite are occupied by Group IIA metal and / or K, the total pore volume of said adsorbent is no less than 0.26 mL / g as measured by mercury porosimetry, the volume of pores with pore diameters from 100 to 500 nm is at least 60% based on the total pore volume. During shaping, a pore-forming agent is added to this adsorbent, and then the adsorbent is alkali treated for in-situ crystallization, followed by ion exchange. Said adsorbent has high adsorption capacity, fast mass transfer rate and good mechanical strength. Said adsorbent is suitable for liquid phase adsorptive separation of para-xylene from C8 aromatic hydrocarbons and is also suitable for adsorptive separation of other alkyl aromatic hydrocarbons isomers.

Owner:CHINA PETROCHEMICAL CORP +1

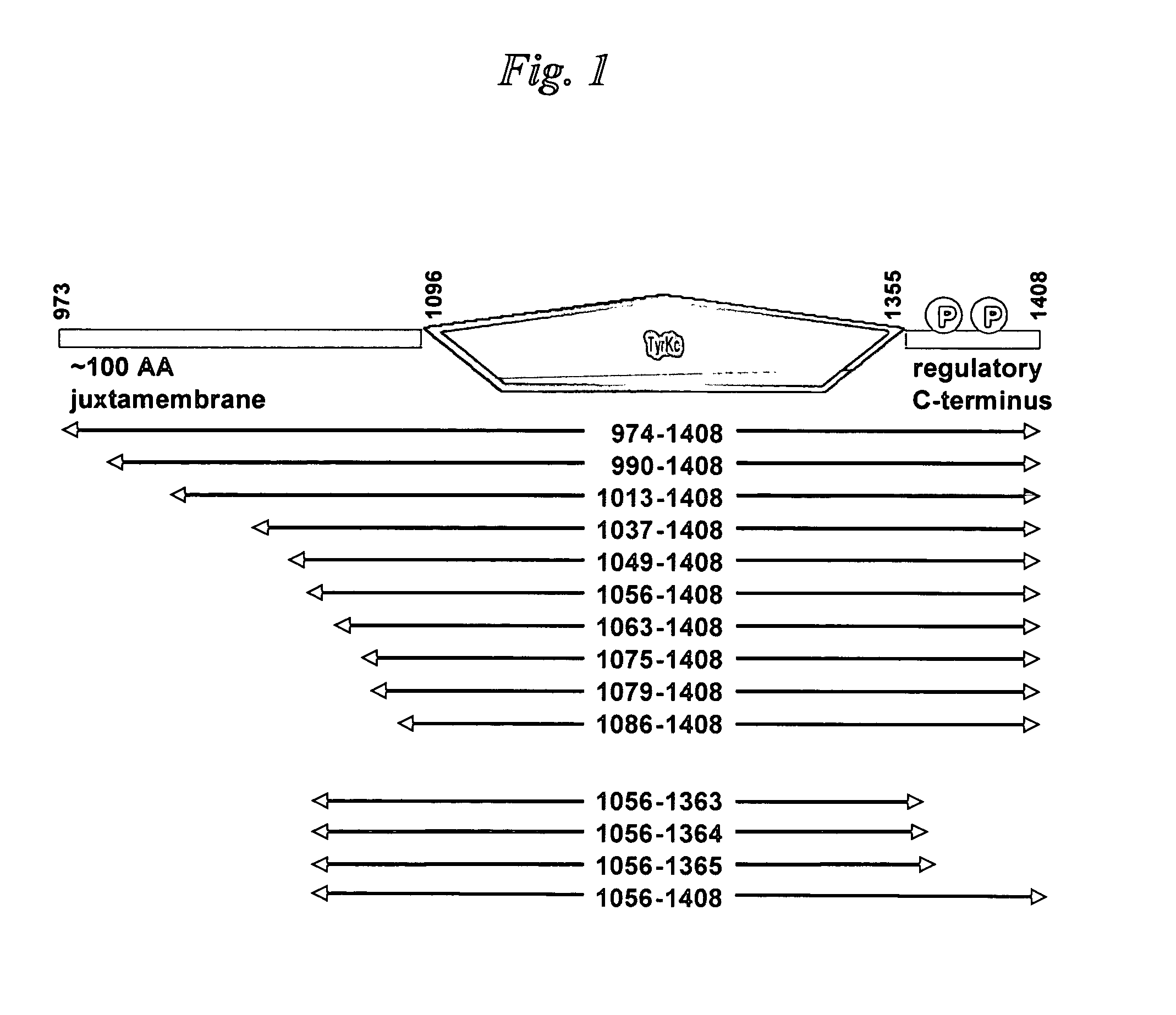

Nucleic acids encoding kinase and phosphatase enzymes, expression vectors and cells containing same

InactiveUS7517970B2Good quality crystalImprove crystallizationSugar derivativesHydrolasesActive enzymeSystematic variation

Methods for expressing active enzymes are described that involve co-expressing a first enzyme with a second enzyme that has an enzymatic activity that reverses a modification on the first enzyme and / or for identification of soluble and / or active catalytic domains by systematic variation of fragment lengths around catalytic domain boundaries.

Owner:PLEXXIKON INC

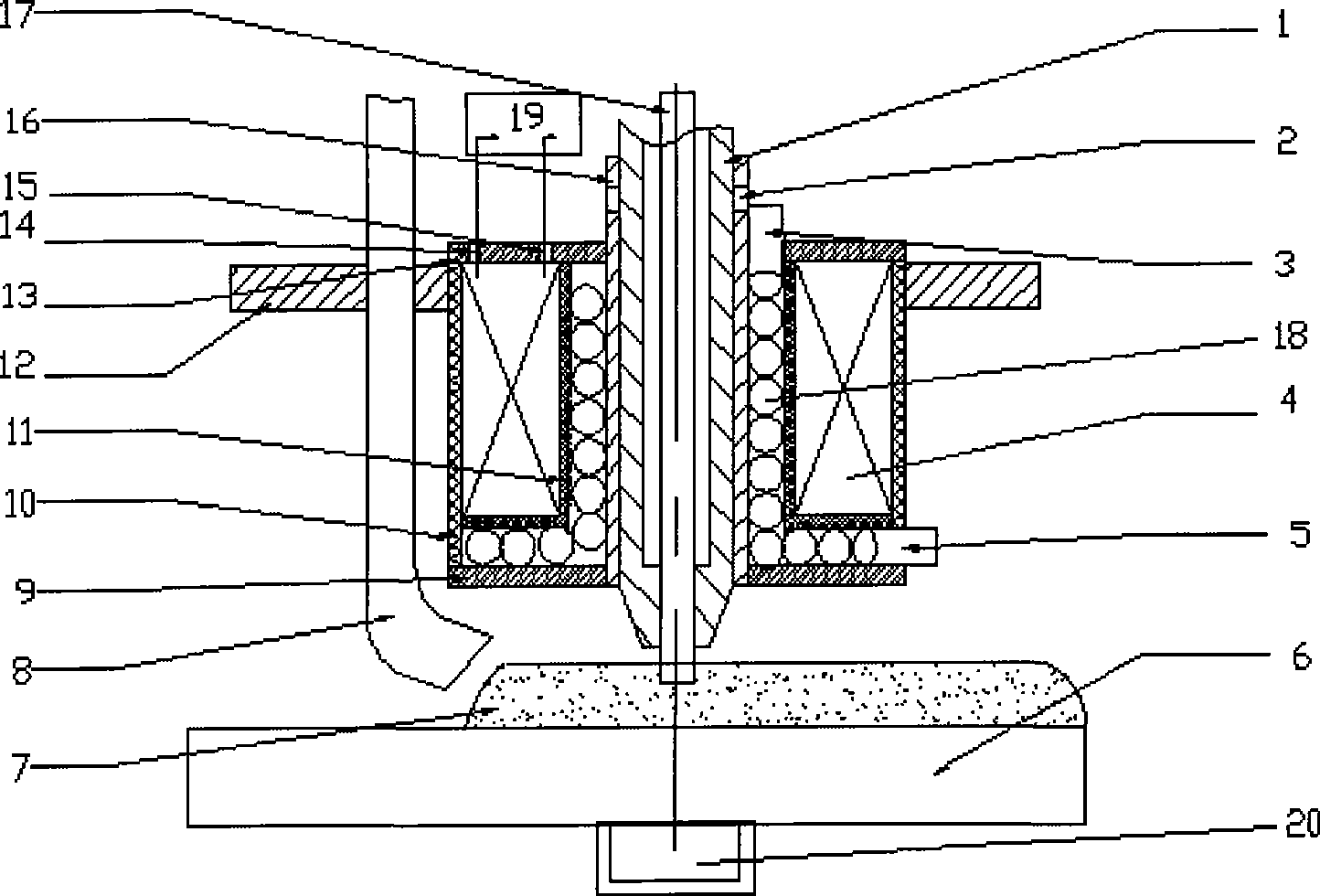

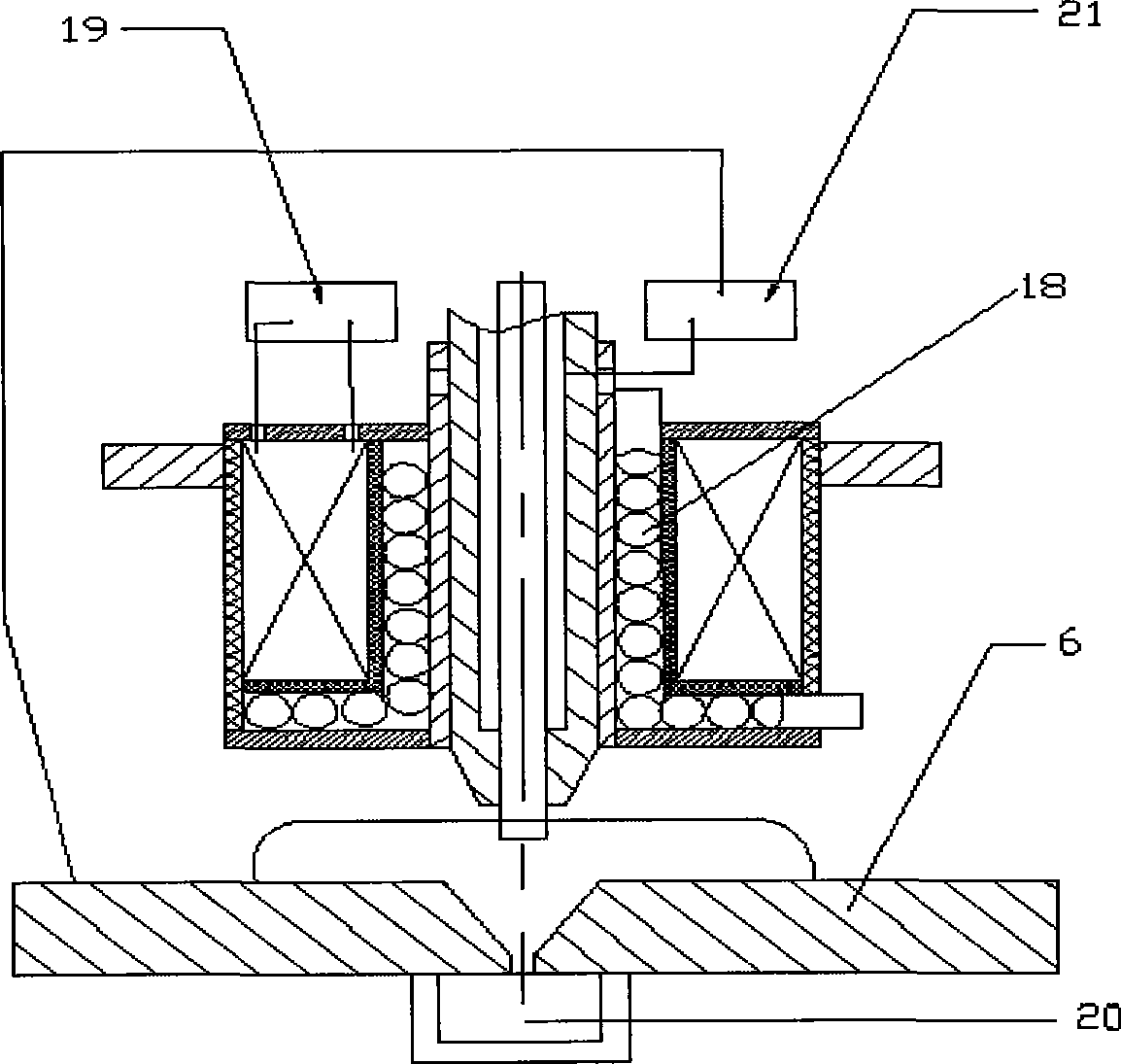

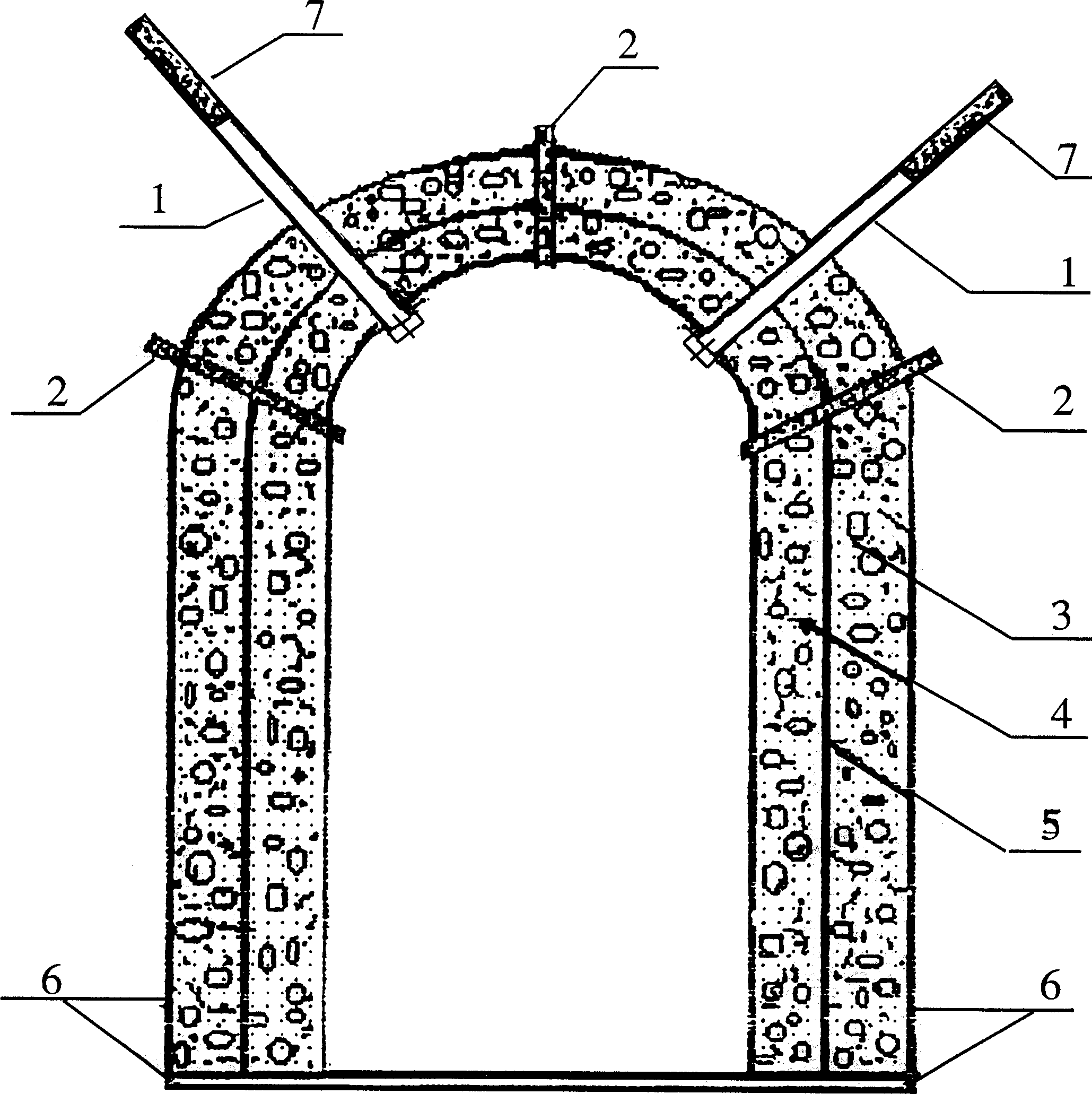

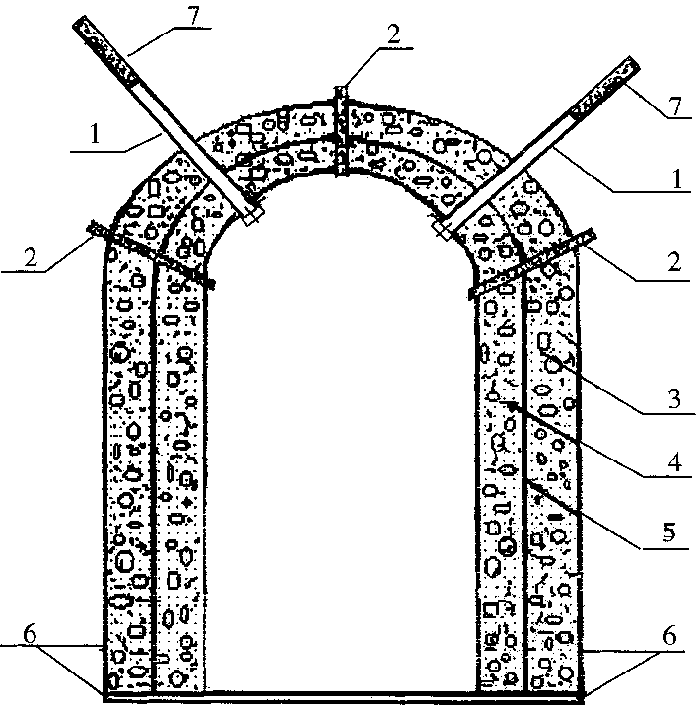

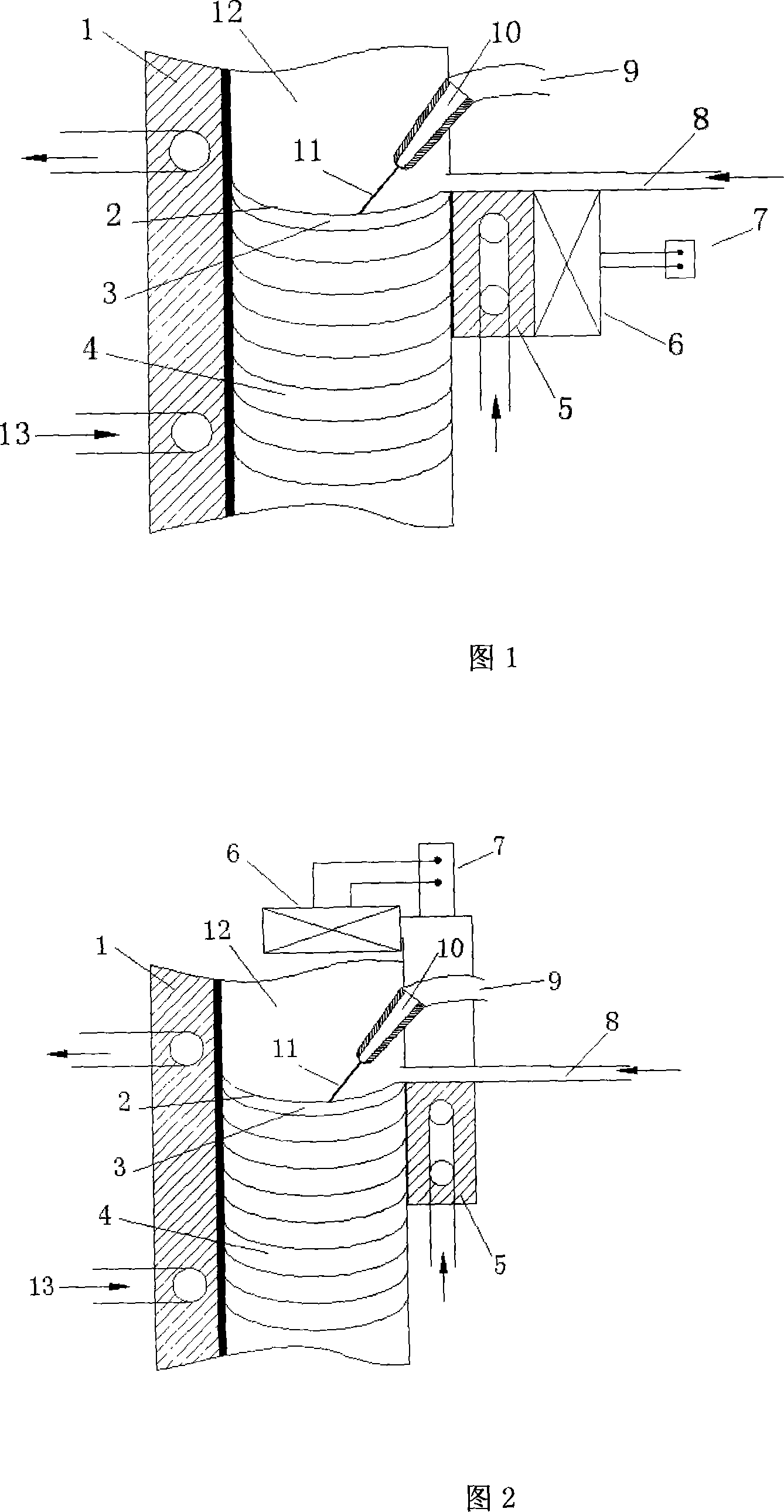

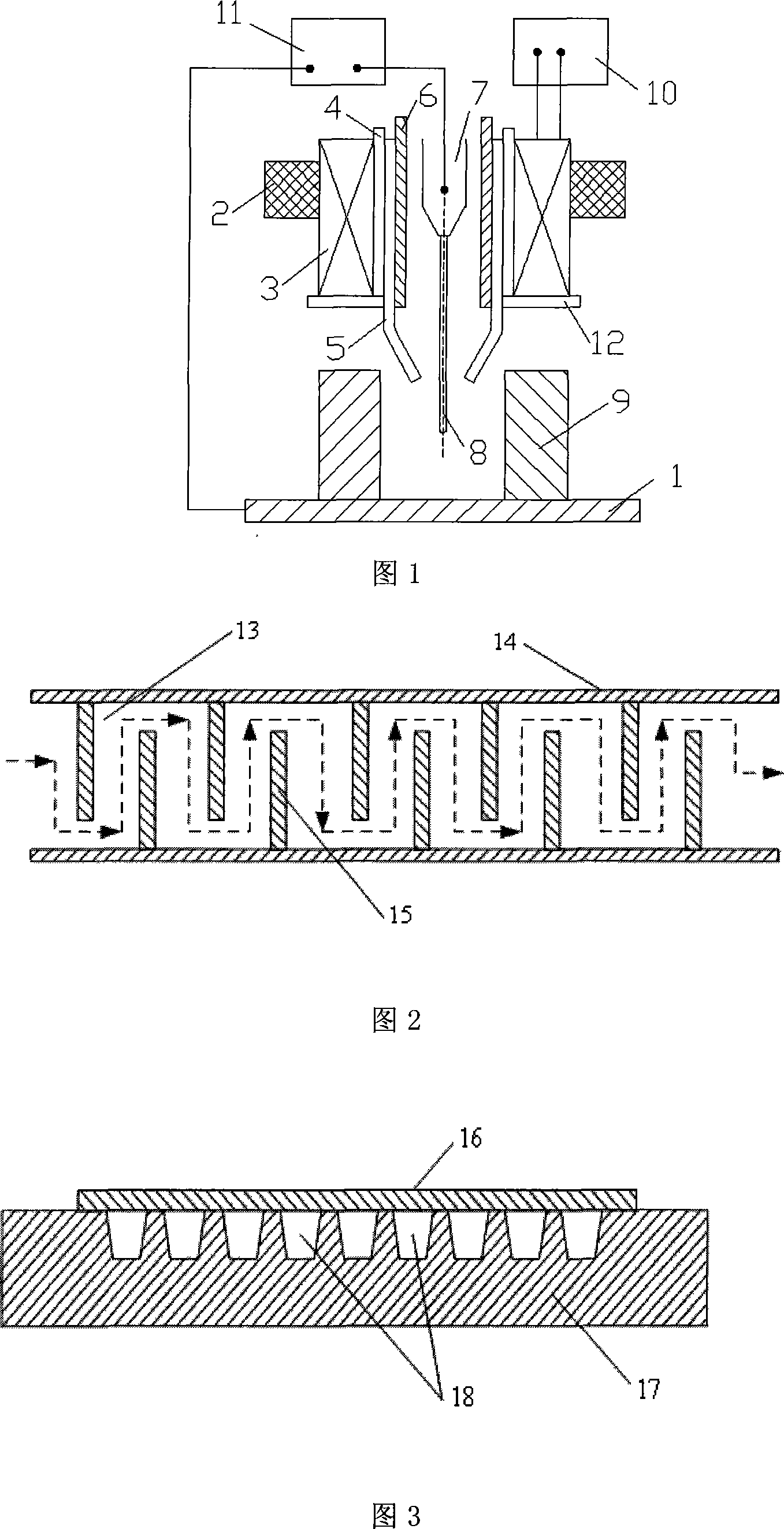

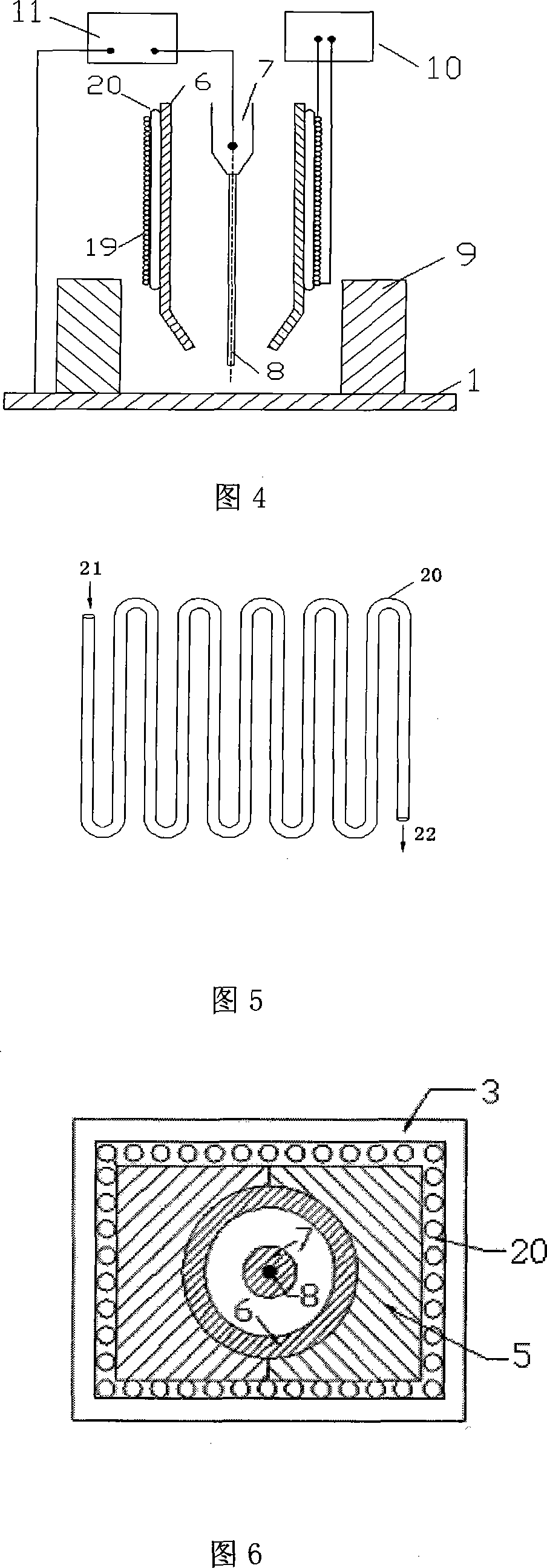

Moderate and high strength large-thickness component electromagnetic controlling narrow gap or ultra-narrow gap pulse efflux molten electrode gas-shield welding method and equipment

InactiveCN101143401AOvercoming arcingImprove crystallizationTransformers/inductances coolingWelding/cutting media/materialsElectric arcEngineering

The invention relates to a gas shielded welding method and device of a narrow gap or a super-narrow gap impulse jet current consumable electrode controlled by electromagnetic of the heavy section part with middle and high strength. The invention uses a magnetic coil (3) to provide excitation current processed by an excitation source, which can generate an extra magnetic field. Under the conditions of narrow gap or super-narrow gap, high feed rate, fused drop spray transfer and impulse welding current, the process of the gas shielded welding of the rotating jet current consumable electrode with high-melting frequency pulse that is controlled by the electromagnetic for the heavy section part with middle and high strength can be realized. The device of the invention comprises the excitation source, excitation equipment, auxiliary equipment and a water cooling system. The excitation equipment is the magnetic coil (3) with or without a conducting core (5). The excitation equipment is fixed on a welding burner (6), which is positioned above a work piece (9). The excitation current provided by the excitation source (10) produces stationary or time-varying electromagnetic mixing magnetic field that has the combination control over the processes of arc welding, wire burn-off, drop transfer, melting bath flow and welding line coagulation, which finally forms the welding line of good quality.

Owner:CHONGQING UNIV

Oxygen scavenging monolayer bottles

InactiveUS20020183448A1Lower cost of capitalReduce manufacturing costLiquid degasificationBottlesPolyesterOxygen

Monolayer packages comprised of an oxygen scavenging composition suitable for direct contact with package contents and recycle with other polyester bottles are disclosed. The oxygen scavenging composition is comprised of a modified copolymer which is comprised of predominantly polyester segments and an oxygen scavenging amount of oxygen scavenging segments. The polyester segments comprise segments derived from typical bottling and packaging polyesters such as PET and PEN. Use of these oxygen scavenging copolymers in bottles provides a clear and rigid monolayer bottle similar in appearance to unmodified polyester bottles. In a series of preferred embodiments, bottles fabricated with the oxygen scavenging copolymers of this invention are over 99 wt % PET and contain less than 50 ppb of extractable components.

Owner:COLORMATRIX HLDG

Surgical sutures having increased strength

InactiveUS8636767B2Improve crystallizationSuture equipmentsPharmaceutical containersUltimate tensile strengthGeneral surgery

The invention relates to increasing the strength of bio-absorbable surgical sutures. The invention allows for delayed bioabsorption of suture materials to allow maintenance of mechanical strength of the suture for example in ‘barbed’ form.

Owner:MICELL TECH INC

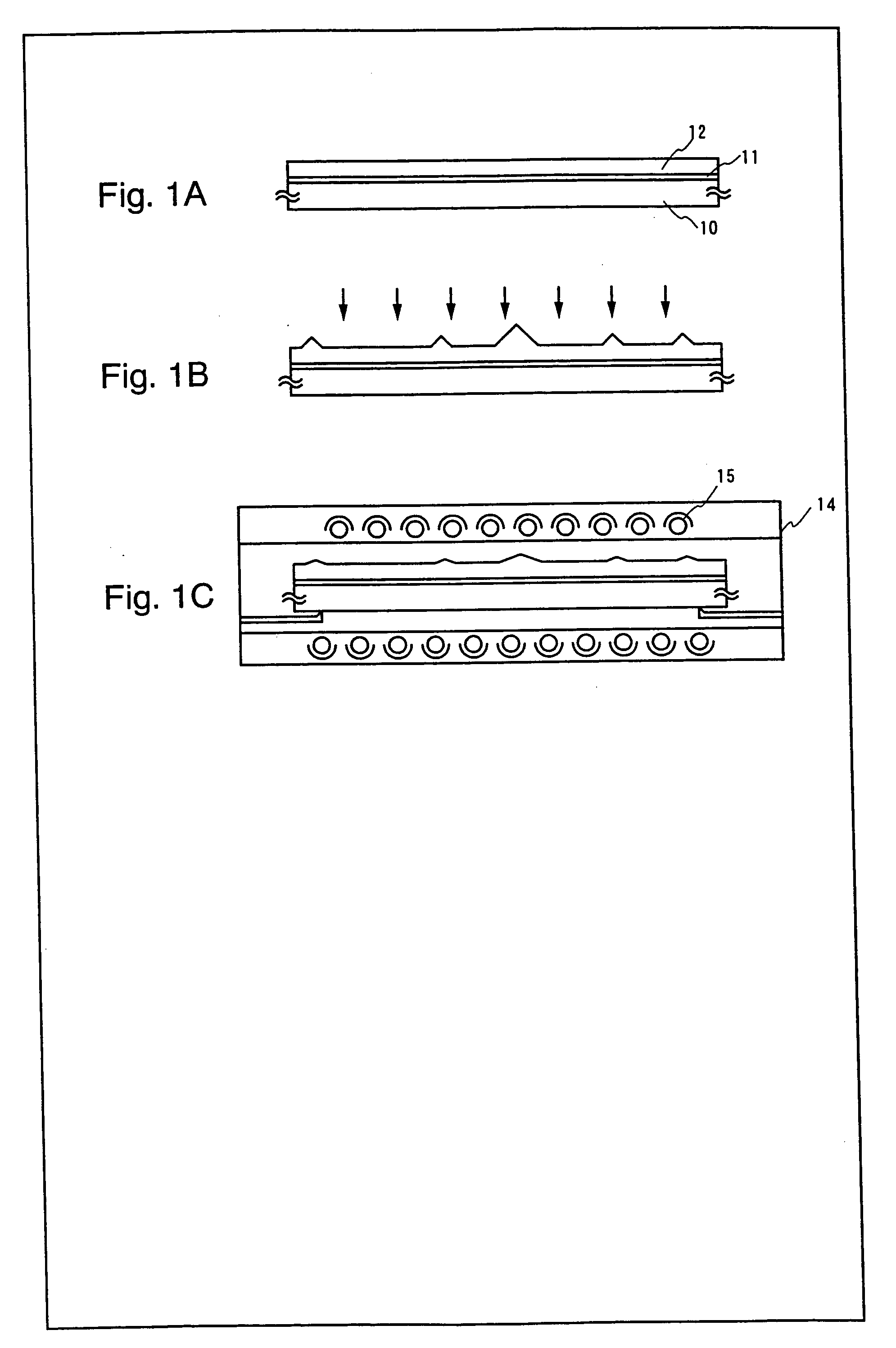

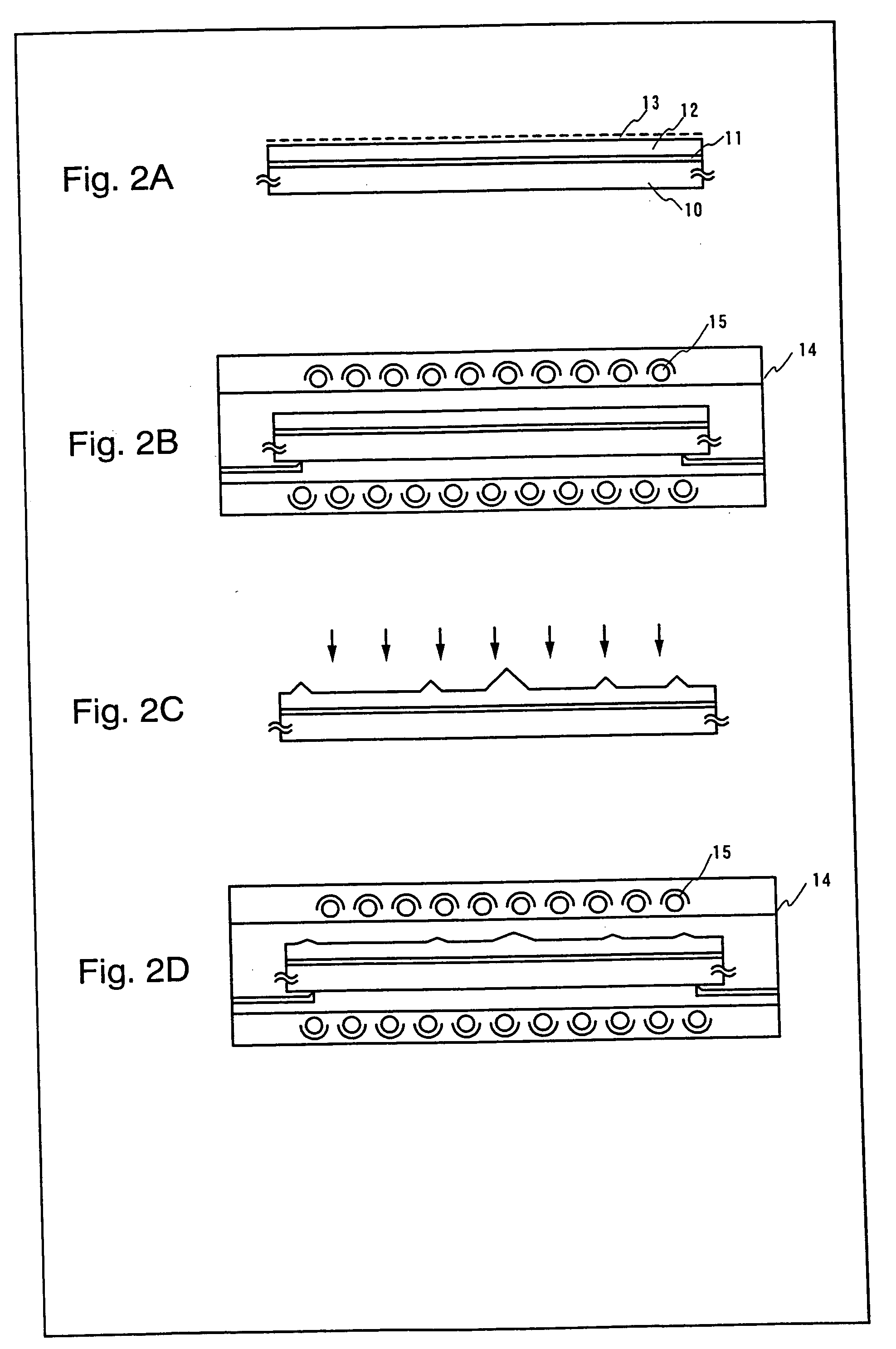

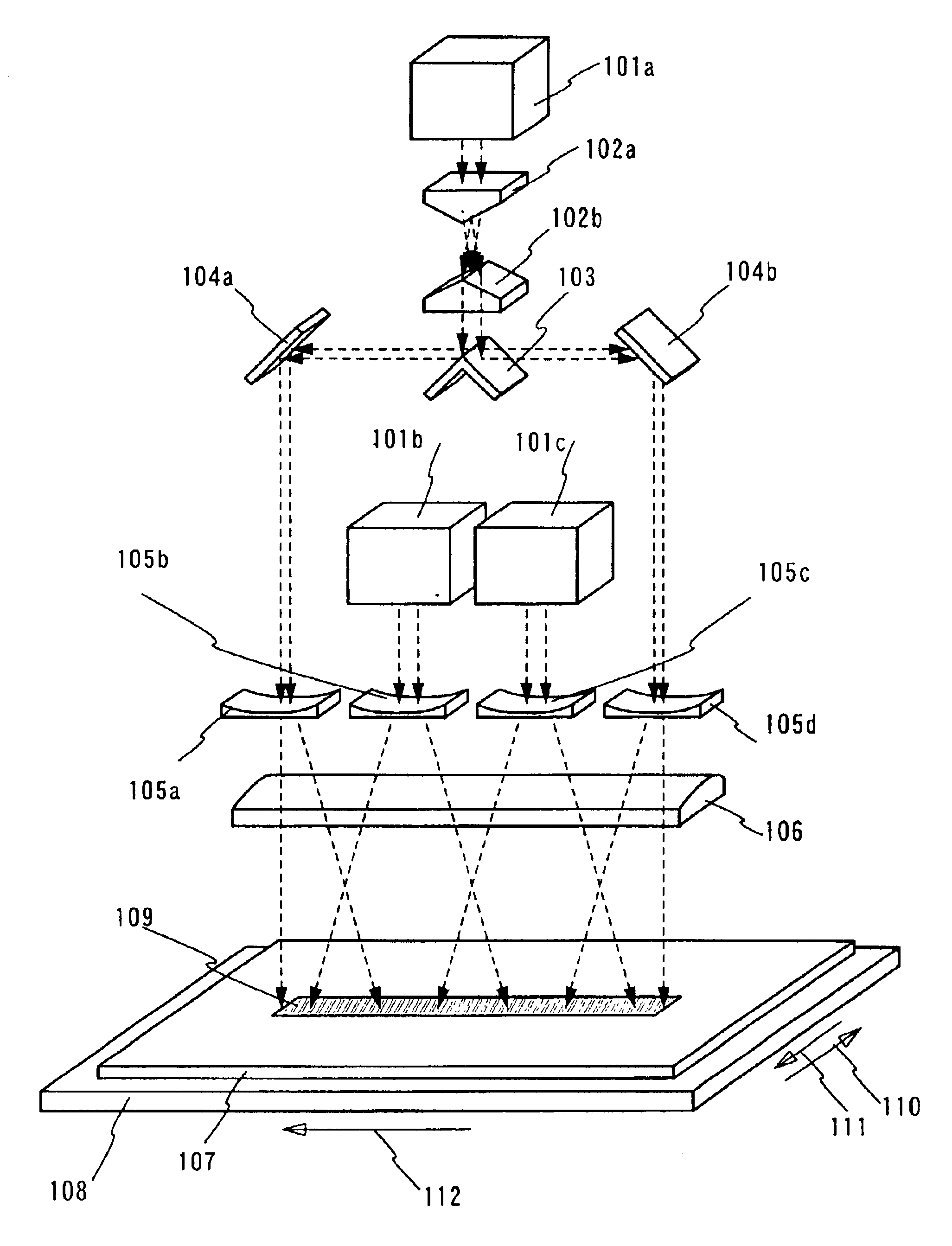

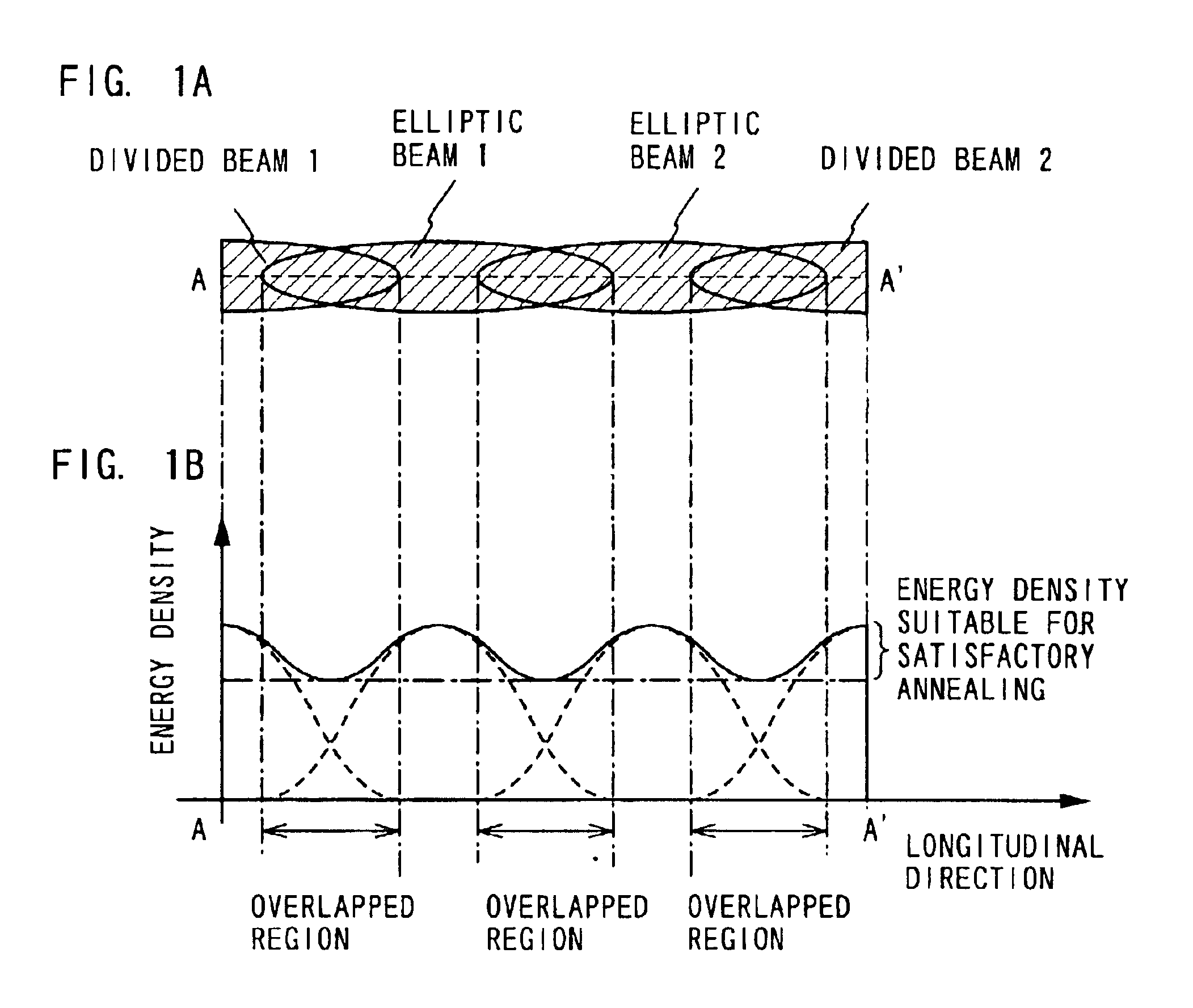

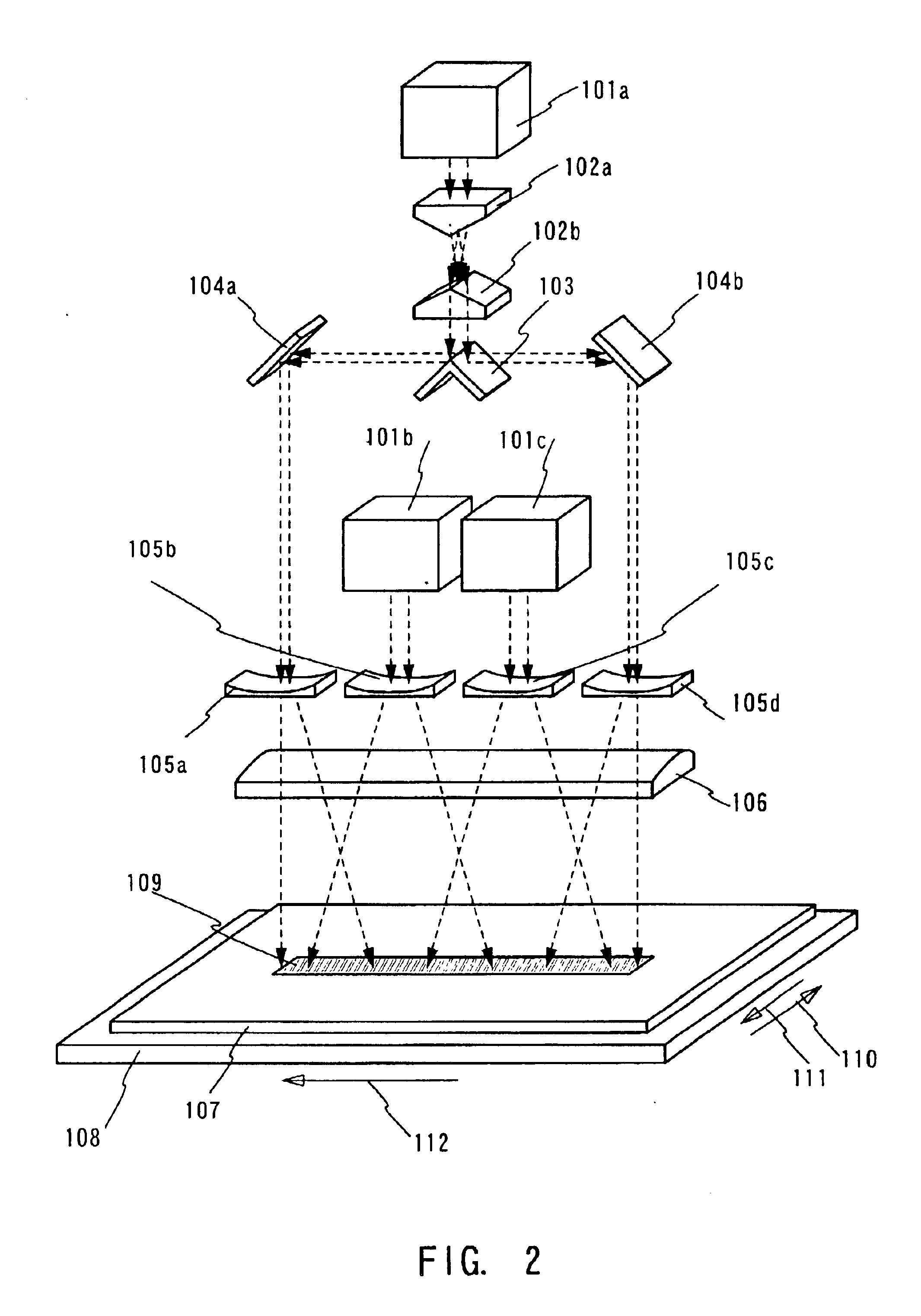

Laser irradiation apparatus, laser irradiation method, and method of manufacturing a semiconductor device

InactiveUS6852947B2Reduce weightIncreased durabilityTransistorLaser detailsUltrasound attenuationLaser light

At edges of laser light on an irradiation surface or in the vicinity thereof, the energy density is attenuated gradually due to aberration of a lens or the like. Since such regions (attenuation regions) do not have enough energy density for annealing of an irradiation object, uniform annealing of the irradiation object is not possible.In the present invention, one of the plural laser beams is divided into two laser beams so that each section of the two laser beams serves as an edge of the resultant laser light. Each attenuation region of the two laser beams is synthesized with an attenuation region of another laser beam. In this way, laser light every part of which has an energy density suitable for satisfactory annealing of an irradiation object can be obtained from plural laser beams having attenuation regions.

Owner:SEMICON ENERGY LAB CO LTD

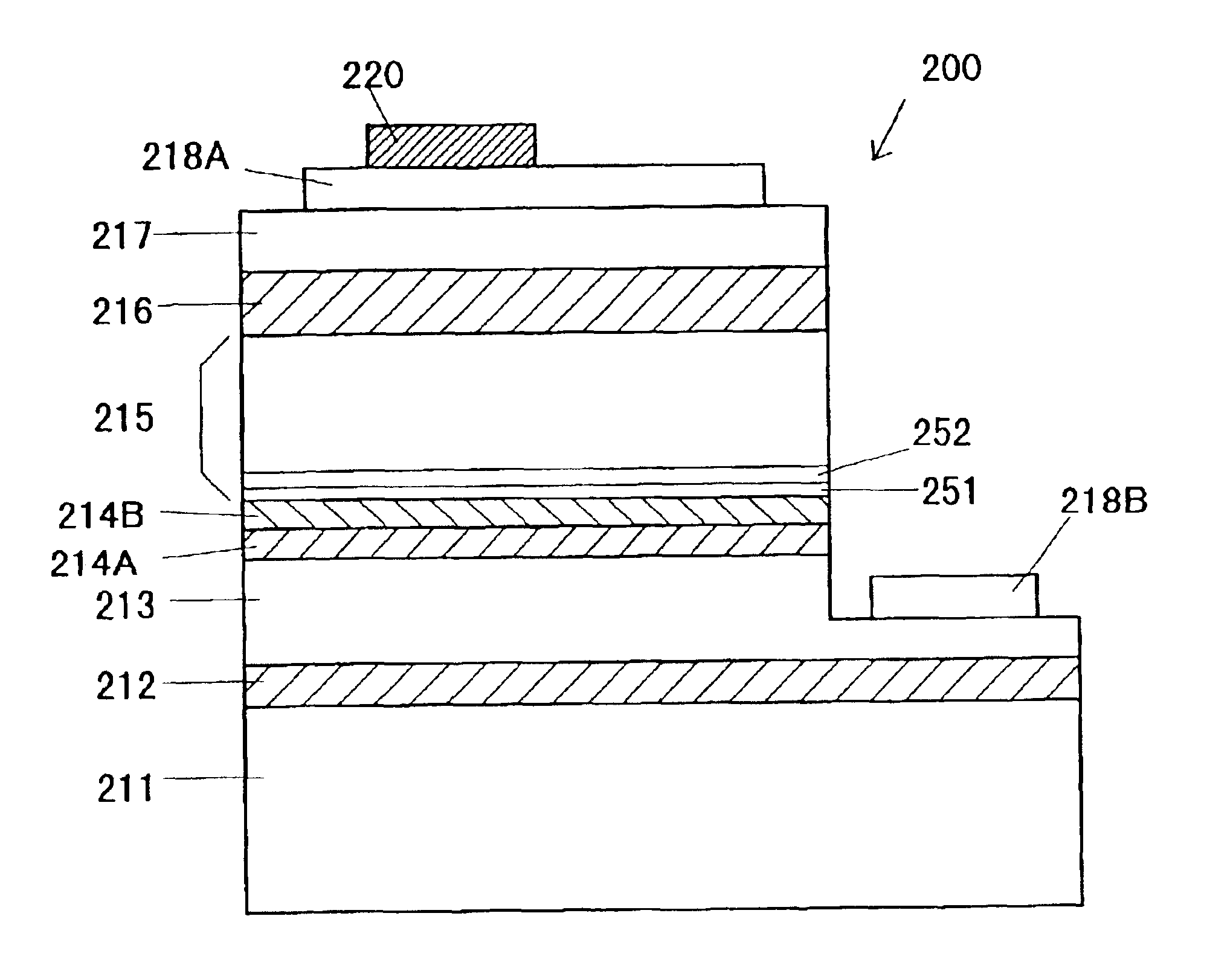

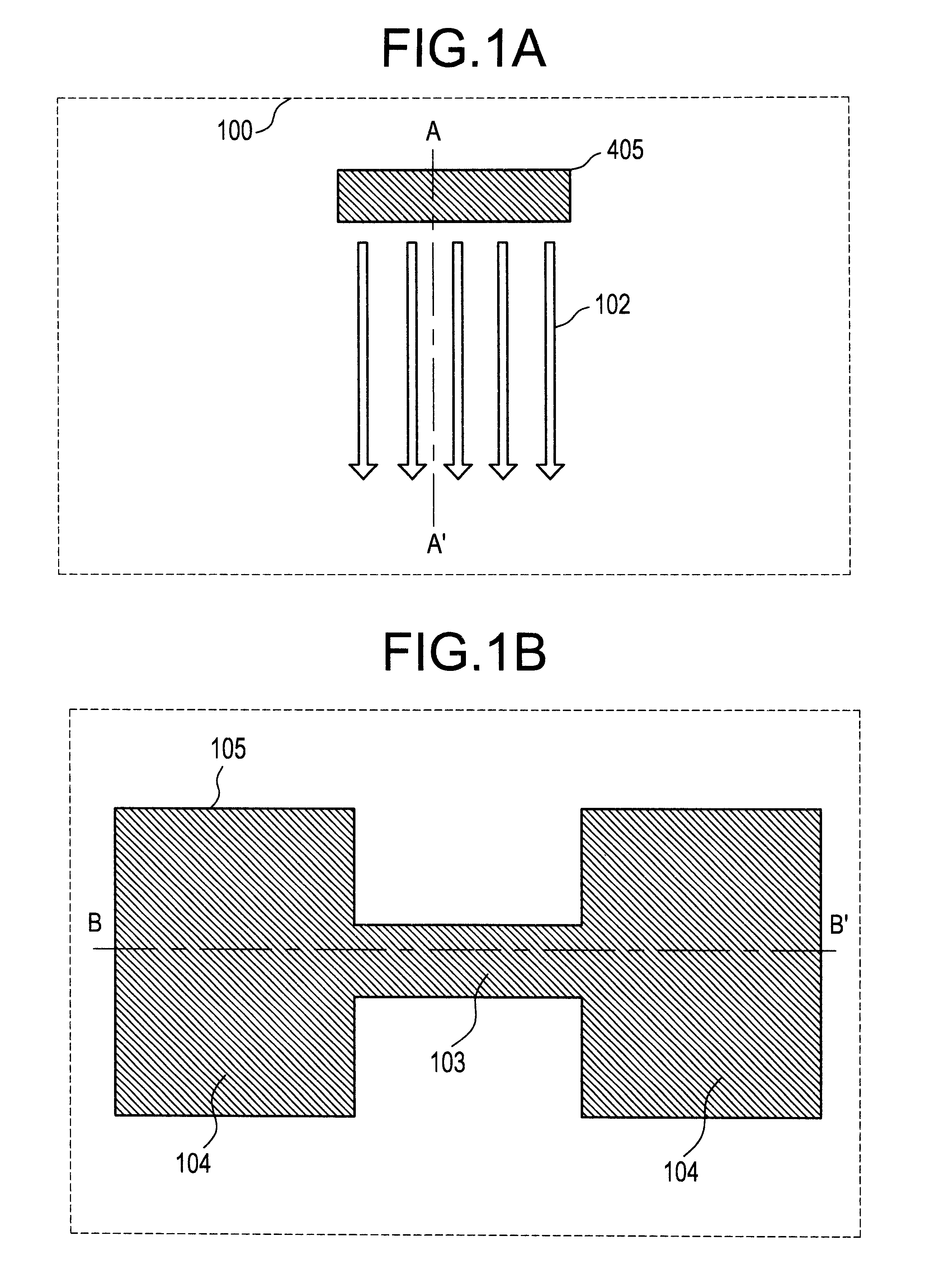

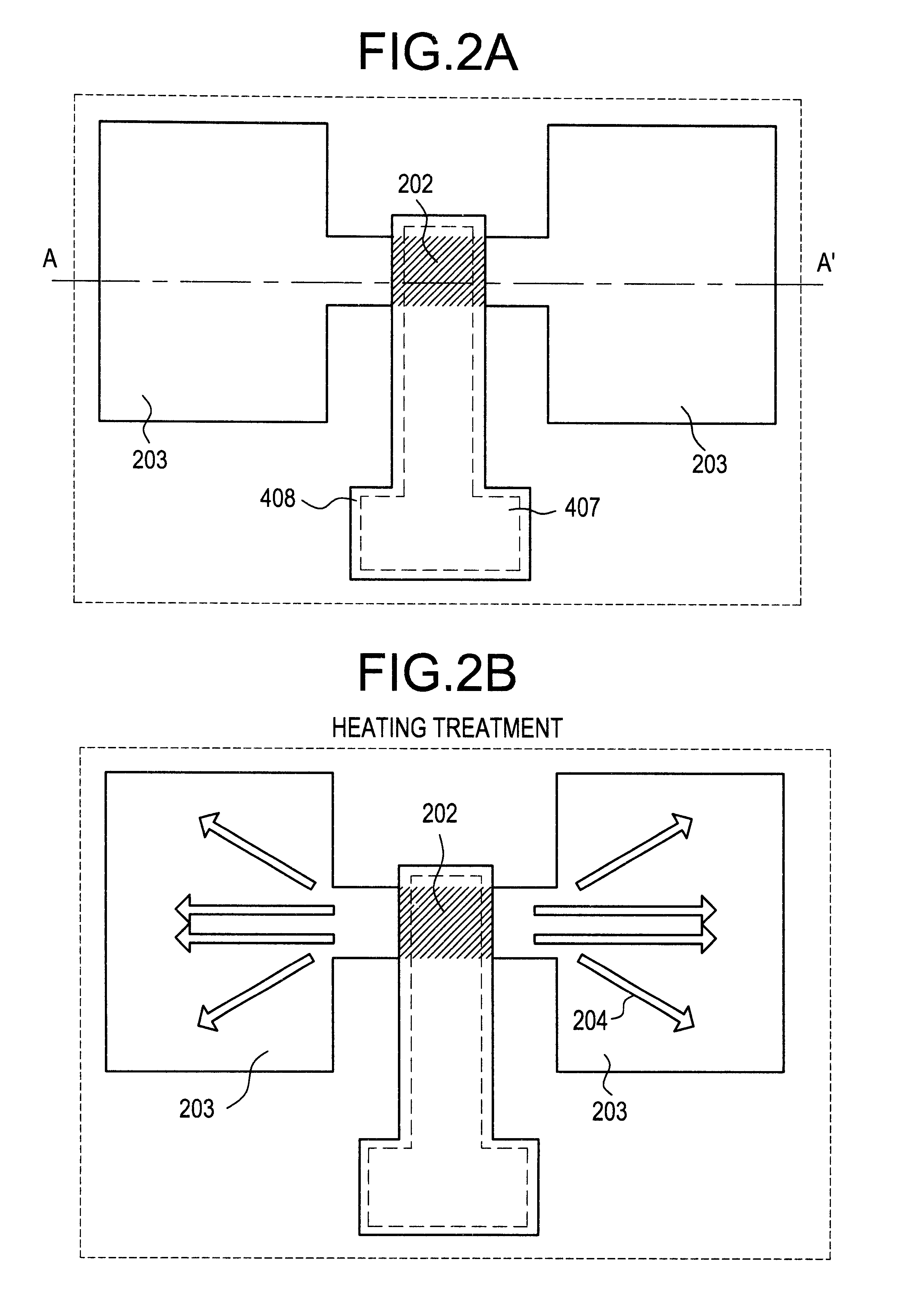

Semiconductor device and method for producing the same

InactiveUS6316789B1Improve crystallizationPromote crystallizationTransistorSolid-state devicesAmorphous siliconNickel acetate

The solution (for example, a nickel acetate solution) containing a metal element such as nickel which accelerates the crystallization of silicon is applied to an amorphous silicon film by spin coating using a mask, to retain nickel in contact with the surface of the amorphous silicon film. Then, heating treatment is performed to crystallize selectively the amorphous silicon film, so that an amorphous region and a crystalline region are formed in the silicon film. In this state, the silicon film is heated to diffuse the metal element from the crystalline region to the amorphous region, thereby decreasing a concentration of the metal element in the crystalline region.

Owner:SEMICON ENERGY LAB CO LTD

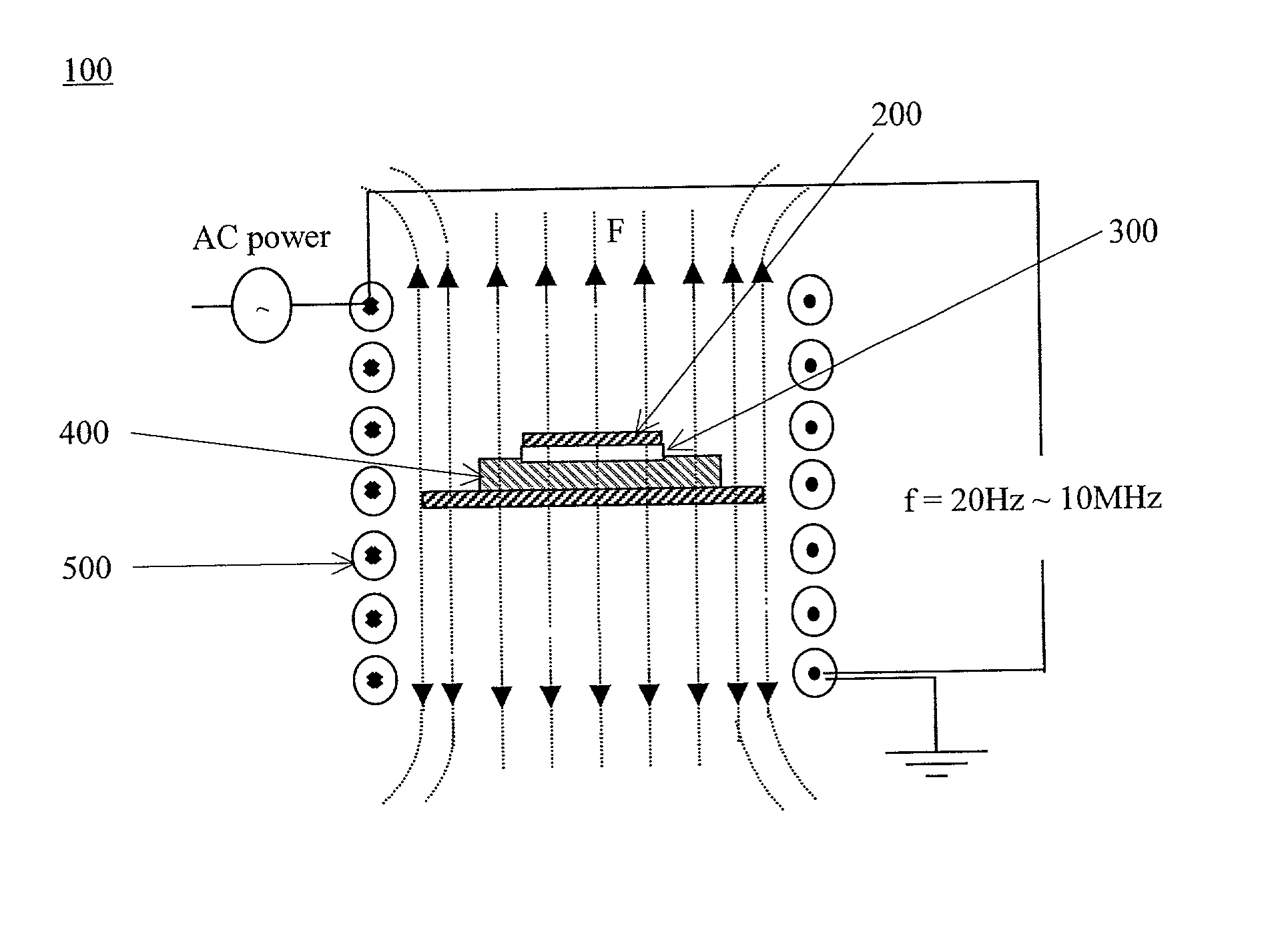

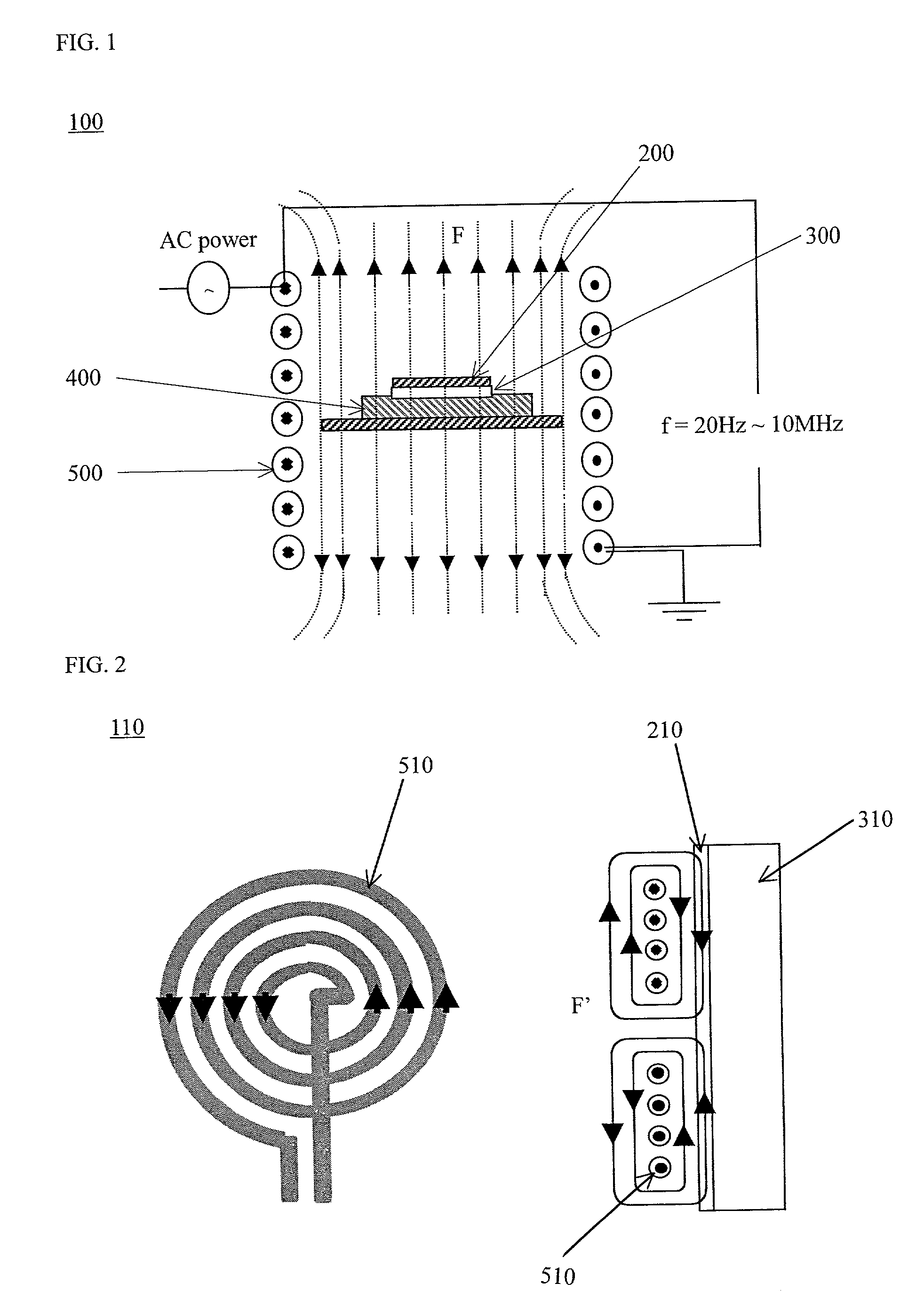

Methods and apparatuses for heat treatment of semiconductor films upon thermally susceptible non-conducting substrates

InactiveUS20030010775A1Improve uniformityMaximize goalFurnaces without endless coreTransistorEngineeringSolar cell

The present invention relates to methods and apparatuses for heat treatment of semiconductor films upon thermally susceptible non-conducting substrates at a minimum thermal budget are required, and more particularly, to a polycrystalline silicon thin-film transistors (poly-Si TFTs) and PN diodes on glass substrates for various applications of liquid crystal displays (LCDs), organic light emitting diodes (OLEDs), and solar cells. According to the methods and apparatus of the present invention, the semiconductor films can be heat-treated without damaging the thermally susceptible substrates; e.g., crystallization of amorphous silicon films at the minimum thermal budget acceptable for the use of glass, enhancing kinetics of dopant activation at the minimum thermal budget acceptable for the use of glass.

Owner:KIM HYOUNG JUNE

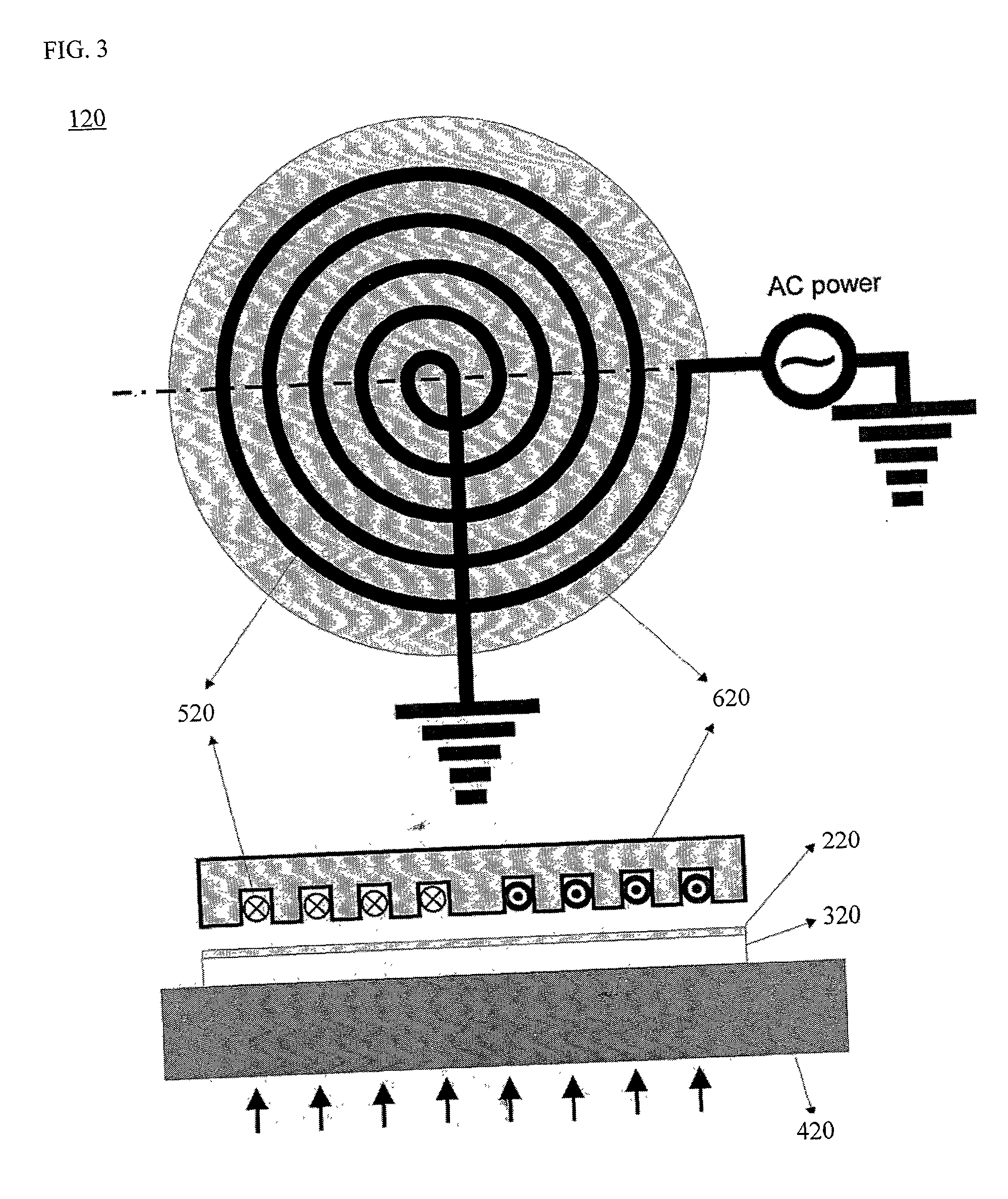

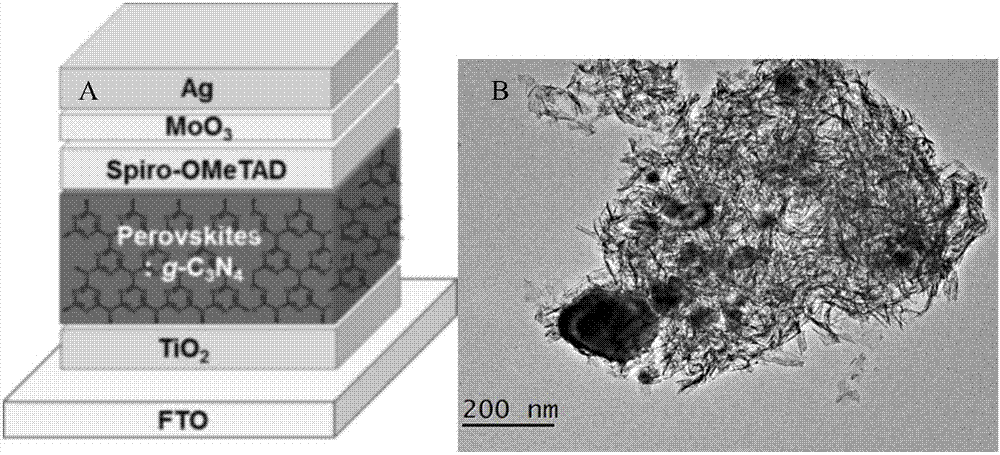

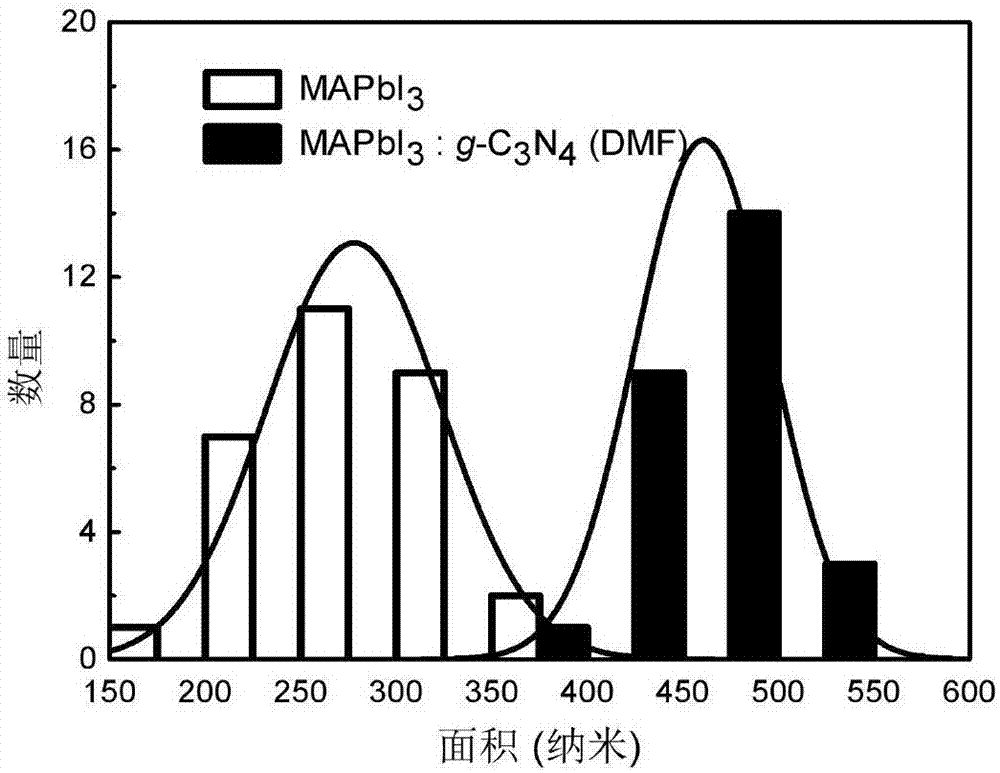

Method for preparing perovskite solar cell on basis of two-dimensional material graphene-phase carbon nitride

ActiveCN107887511AImprove crystallizationStable manufacturingSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsSolvent

The invention provides a method for preparing a perovskite solar cell on the basis of a two-dimensional material graphene-phase carbon nitride. The graphene-phase carbon nitride is doped into a perovskite precursor solution to prepare the perovskite solar cell. The method has the following advantages that (1) the raw material required for synthesis of the material is low in cost, and the product is small in toxicity; (2) solvent volatilization during the annealing process is effectively slowed down, so that a perovskite thin film crystal is more uniform and compact; (3) the grain crystal sizeof a perovskite layer is increased, a crystal boundary easy to combine with charge is effectively reduced, and the filling factor of a device is improved; (4) a surface of the perovskite thin film ispassivated, and the hysteresis phenomenon of the device is effectively improved; and (5) the conductivity of the surface of the perovskite thin film is improved, the contact resistance of the interface is reduced, and the short-circuit current of the device is increased. The preparation process is simple and convenient and is low in preparation difficulty; by doping of the graphene-phase carbon nitride, the smoothness and the uniformity of the perovskite thin film can be effectively improved; and by a series of gradient doping, the device performance is remarkably changed.

Owner:SUZHOU UNIV

One-Pot Process for the Preparation of Antiemetic Agent, 1,2,3,9-Tetrahydro-9-Methyl-3[(2-Methyl)-1H-Imidazole-1-Yl)Methyl]-4H-Carbazol-4-O

InactiveUS20080009635A1Improve reaction speedReduce yieldOrganic chemistryHydrocarbon solventsAcetic acid

A one-pot industrial process for preparing 1,2,3,9-tetrahydro-9-methyl-3-[(2-methyl-1H-imidazole-1-yl)methyl]-4H-carbazol-4-one of Formula-(I) from 1,2,3,9-tetrahydro-9-methyl-4H-carbazol-4-one of Formula-(IV) involves reaction of Formula (IV) with HNR1R2 salt and paraformaldehyde, where R1,R2 are independently alkyl groups or together forms a cyclic alkyl group, in a solvent system of acetic acid and hydrocarbon solvent to form a crude mixture of intermediate compounds of Formula (III) and (VIII), which is converted to ondansetron (Formula (I)) without isolation by reaction with 2methyimidazole in a suitable solvent system in the same pot.

Owner:IPCA LAB LTD

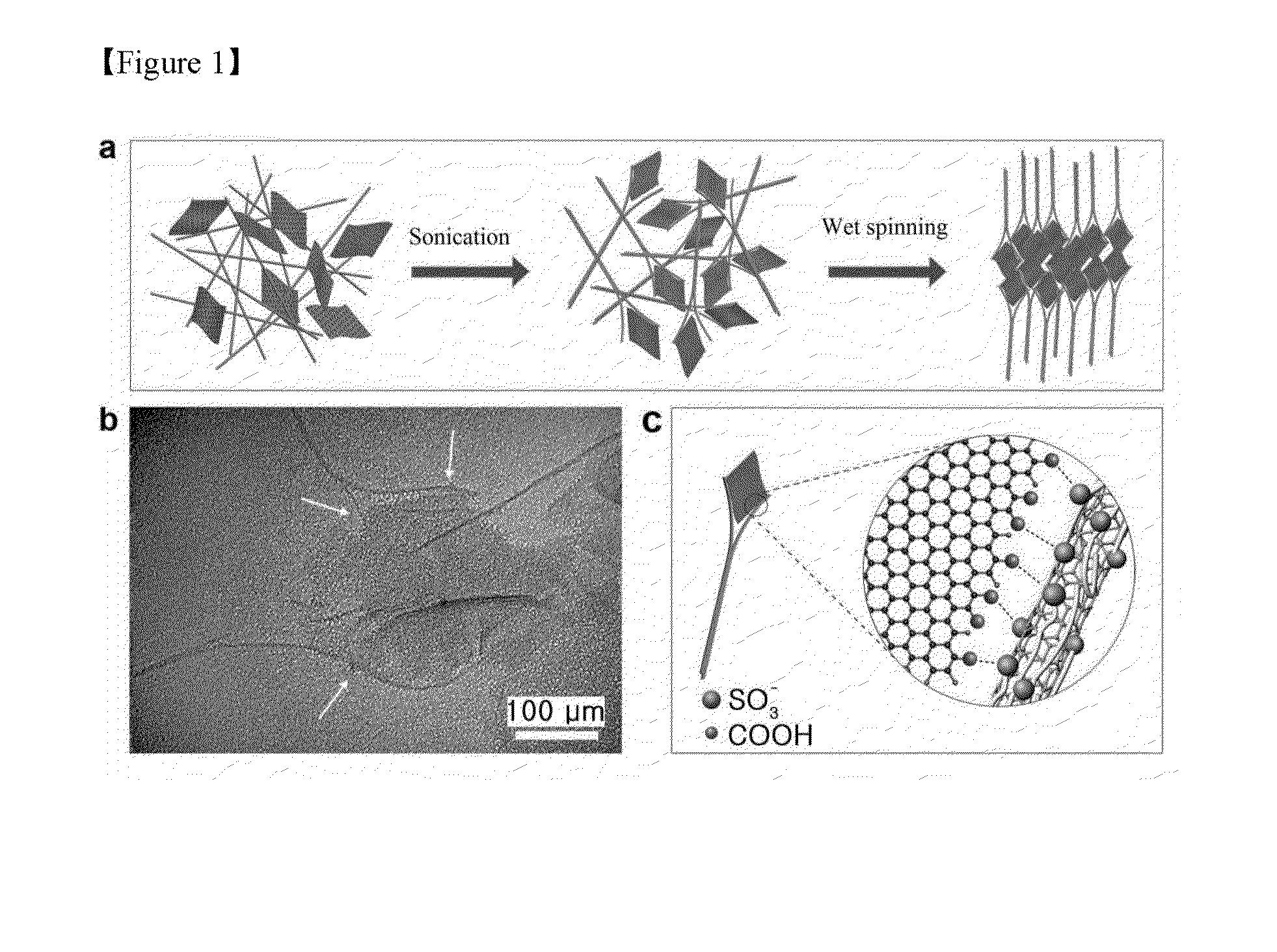

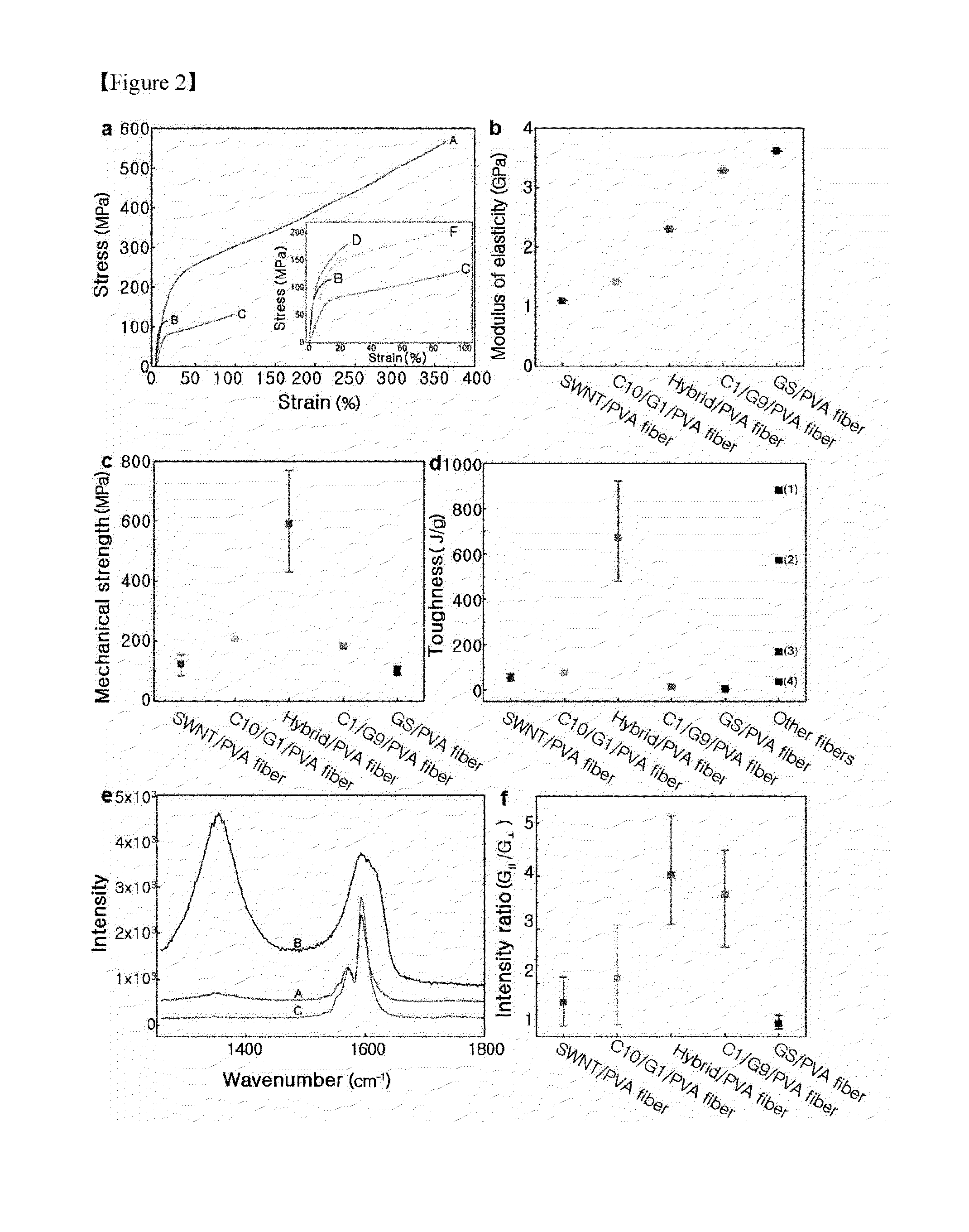

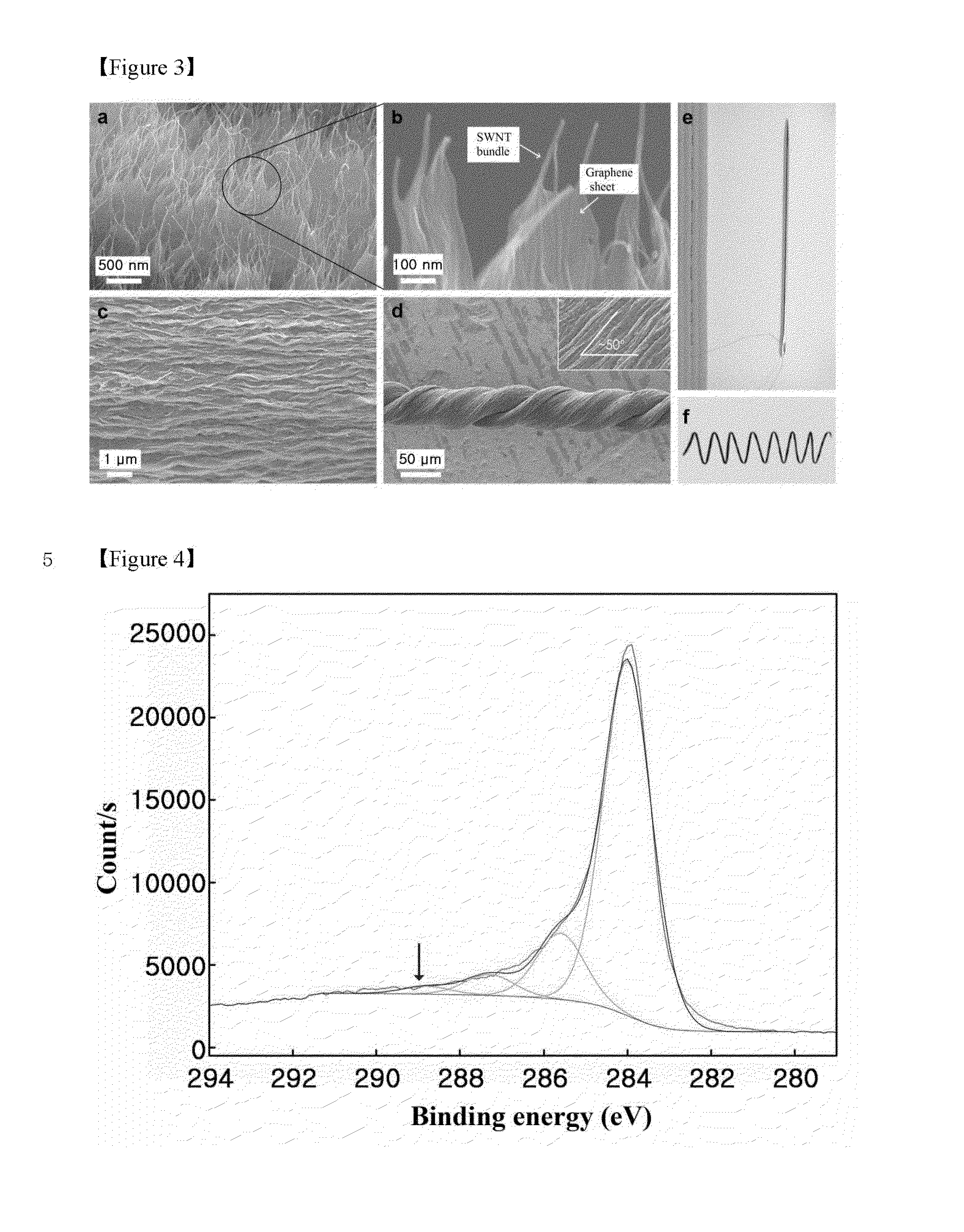

Hybrid polymer composite fiber including graphene and carbon nanotube, and method for manufacturing same

ActiveUS20140001417A1Improve toughnessEliminate needNon-metal conductorsMaterial nanotechnologyFiberHydrogen

The present invention relates to a graphene-based hybrid polymer composite fiber and a method for manufacturing same, and more particularly, to a hybrid composite fiber including the graphene, a carbon nanotube, and a polymer, wherein the graphene and the carbon nanotube are combined by means of self-organization through hydrogen bonding, so as to be very tough and flexible, without involving stretching, and to a method for manufacturing the hybrid composite fiber.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

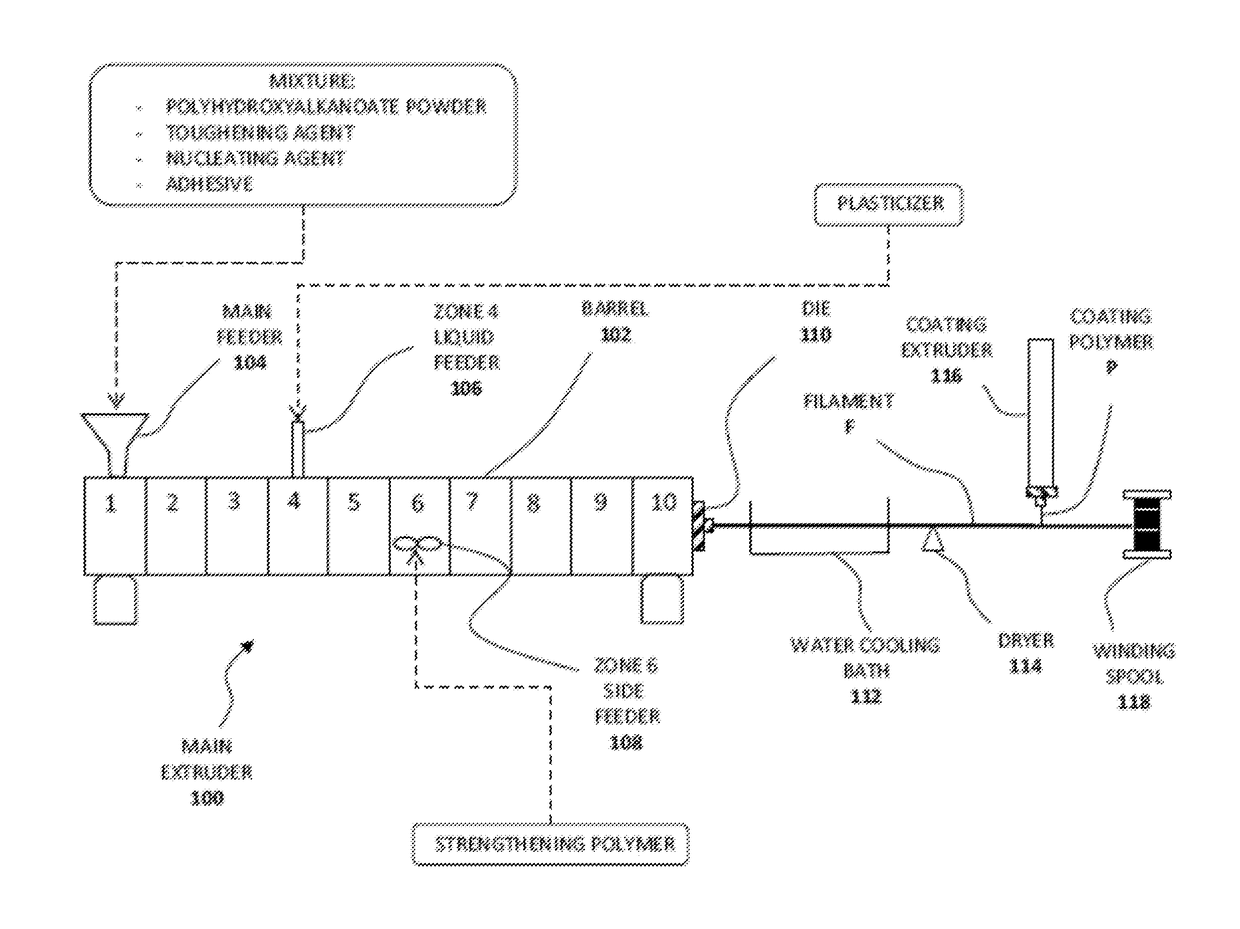

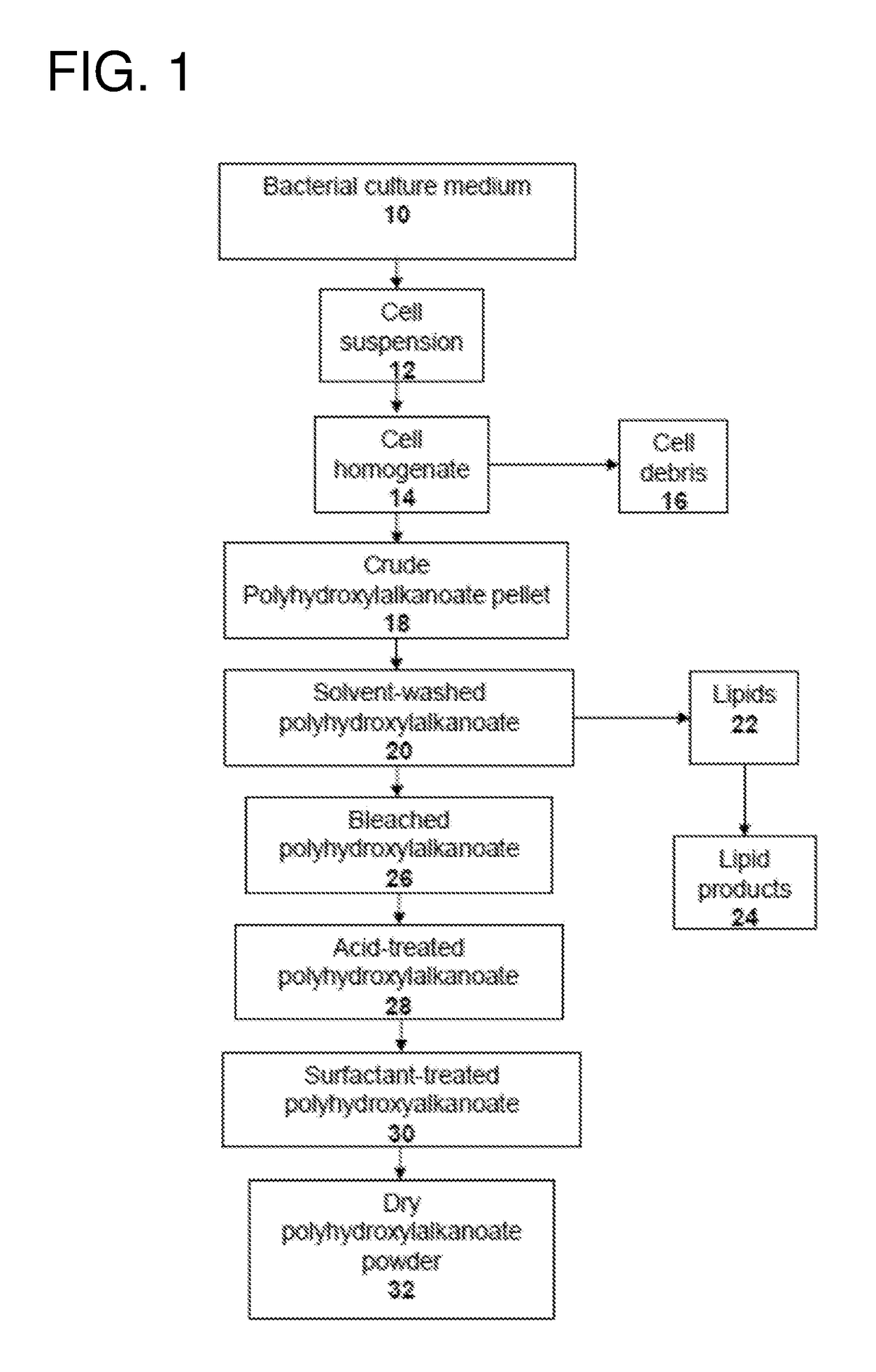

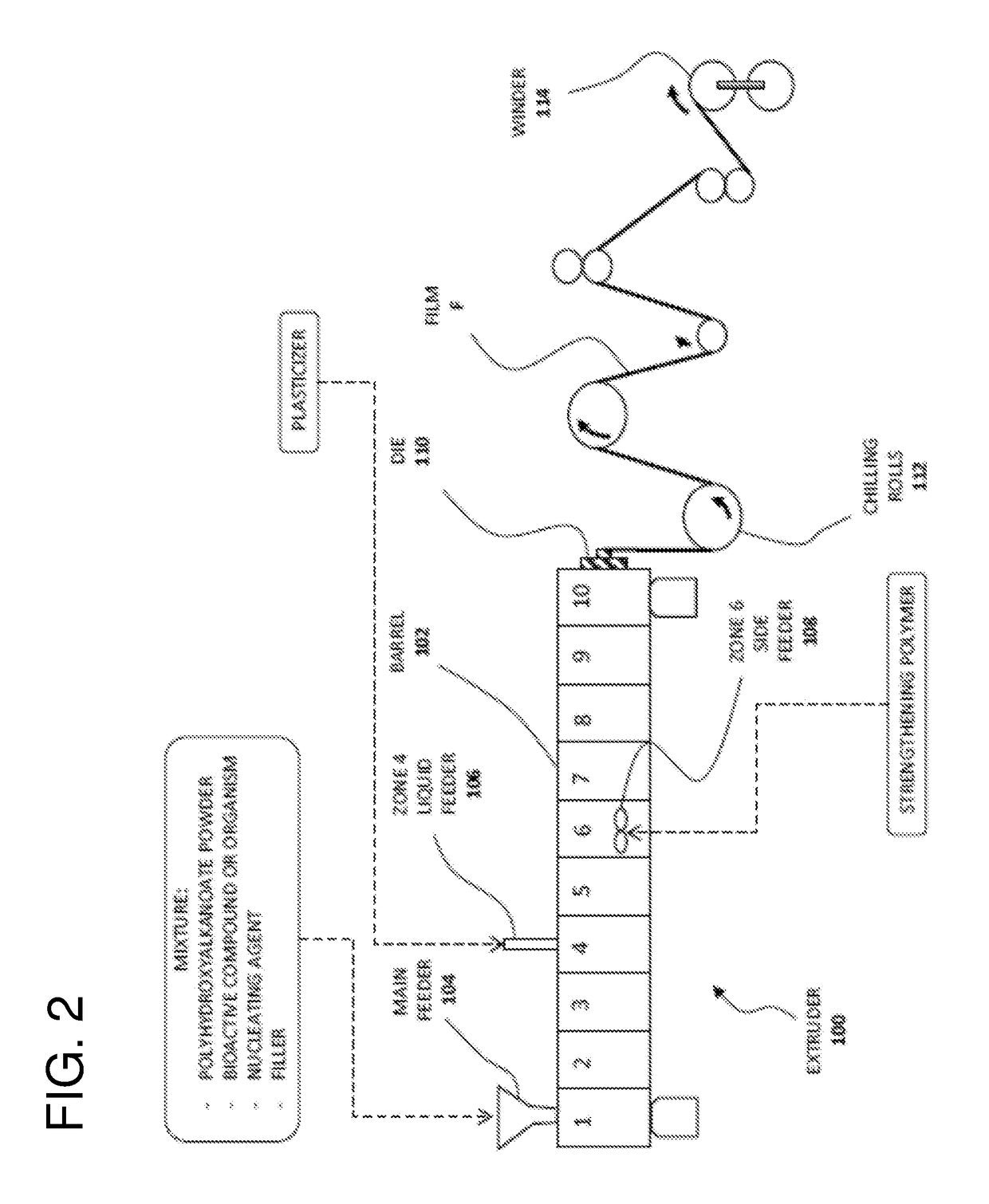

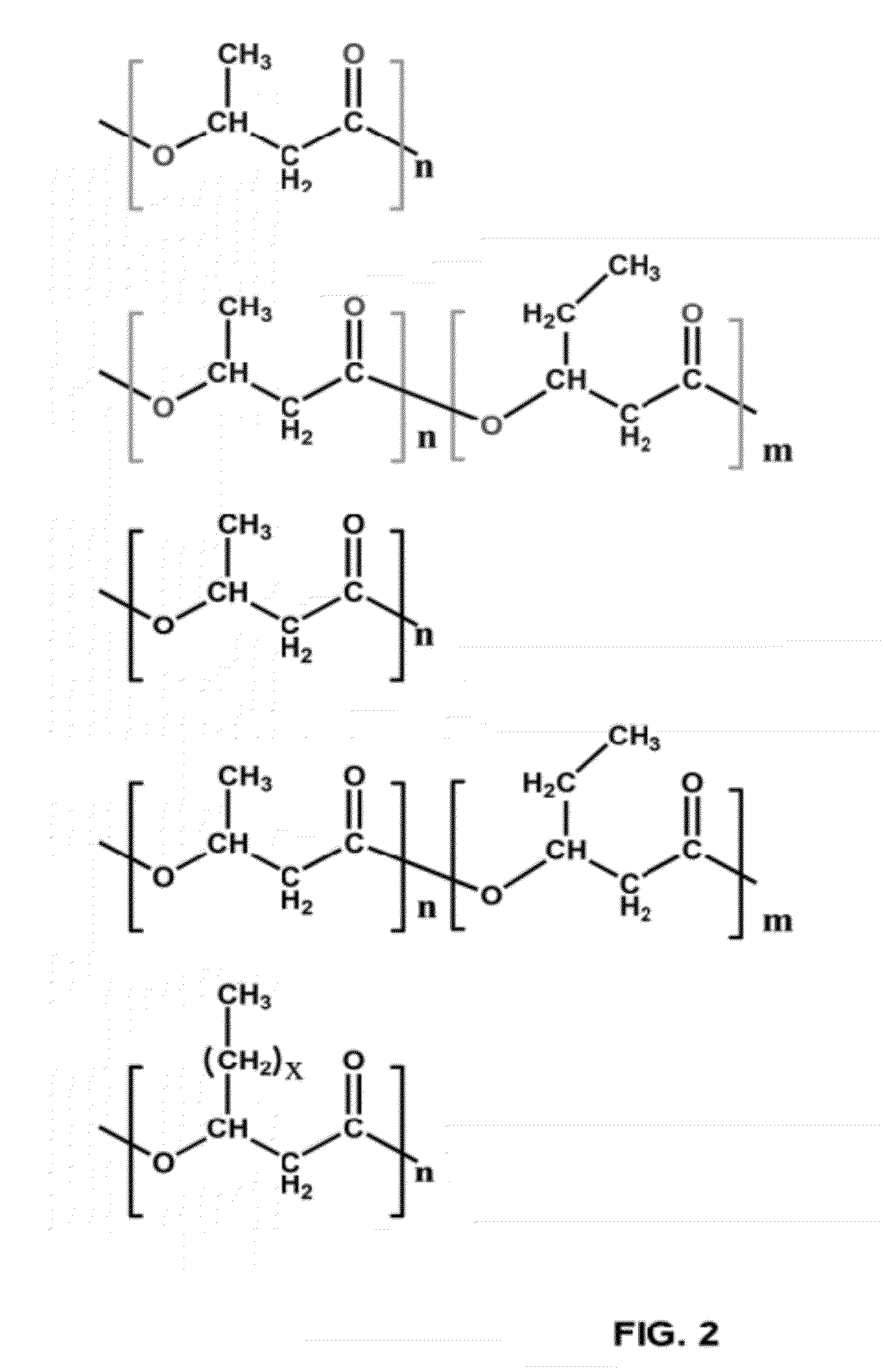

Bioactive biopolymer films and coatings

ActiveUS20170245494A1Improve crystallization kineticsImprove crystallizationBiocideClimate change adaptationFertilizerPesticide

A multi-layer bioactive and biodegradable film. The multi-layer film includes one or more bioactive compounds or microorganisms for promoting growth and health of a plant, the bioactive compounds or microorganisms contained between layers of the film, wherein each one of the layers comprises about 60% to about 75% (m / m) polyhydroxyalkanoate. The bioactive compounds or microorganisms may include any one of or a combination of: a metabolite, an anti-microbial compound, an enzyme, a live microorganism, a fertilizer, a plant growth hormone, a preservative, a pesticide or an herbicide. Release of one or more bioactive compounds may be achieved in a timed and controlled manner.

Owner:TERRAVERDAE BIOWORKS

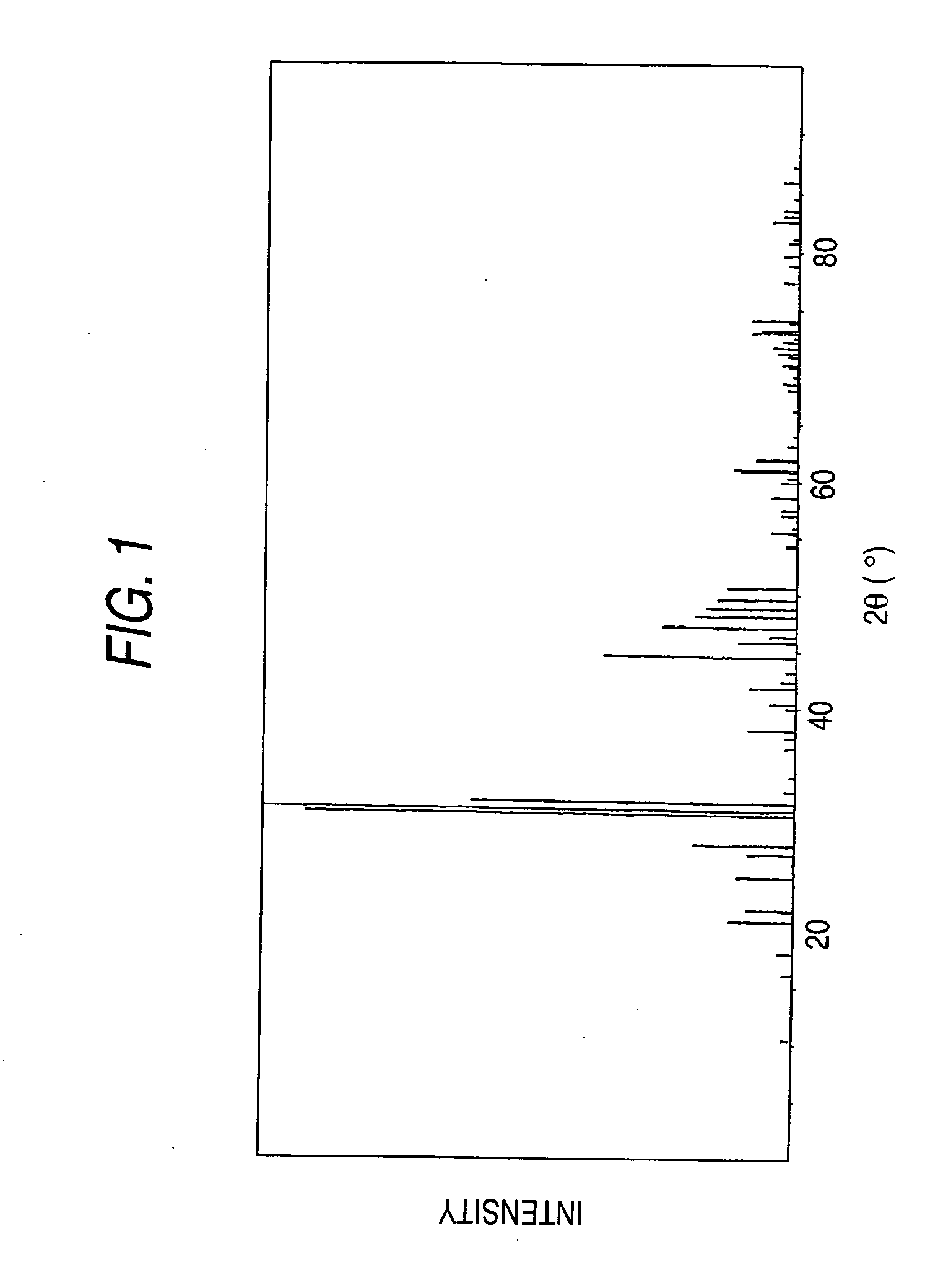

Light emitting device and illuminator using the same

InactiveUS20050145854A1Improve crystallizationCompensation effectDischarge tube luminescnet screensElectroluminescent light sourcesQuantum efficiencyLuminous intensity

An object of the present invention is to provide a light emitting device having a high emission intensity, and a light emitting device having a high emission intensity and a good color rendering property. The present invention provides a light emitting device which comprises: a first light emitter emitting light of from 350 to 415 nm and a second light emitter emitting visible light by exposure to the light from the first light emitter, wherein said second light emitter comprises a phosphor capable of satisfying any one of the following conditions (i) to (iv): (i) the phosphor comprises: (a) a crystal phase whose Eu concentration providing the maximum emission intensity at any one of excitation wavelengths of from 350 to 415 nm is higher than that providing the maximum emission intensity at an excitation wavelength of 254 nm; and (b) a crystal phase which is activated by Eu having at least 1.1 times the concentration providing the maximum emission intensity at an excitation wavelength of 254 nm and 0.5 to 9 times the concentration providing the maximum emission intensity at an excitation frequency of 400 nm: (ii) the phosphor comprises a crystal phase having an Eu—Eu mean distance, as calculated from the Eu concentration in a crystal matrix, of 4 Å or greater but not greater than 11 Å: [0001](iii) the phosphor has a quantum absorption efficiency αq of 0.8 or greater: [0002](iv) the phosphor has a product αq·ηi of a quantum absorption efficiency αq and an internal quantum efficiency ηi of 0.55 or greater.

Owner:MITSUBISHI CHEM CORP

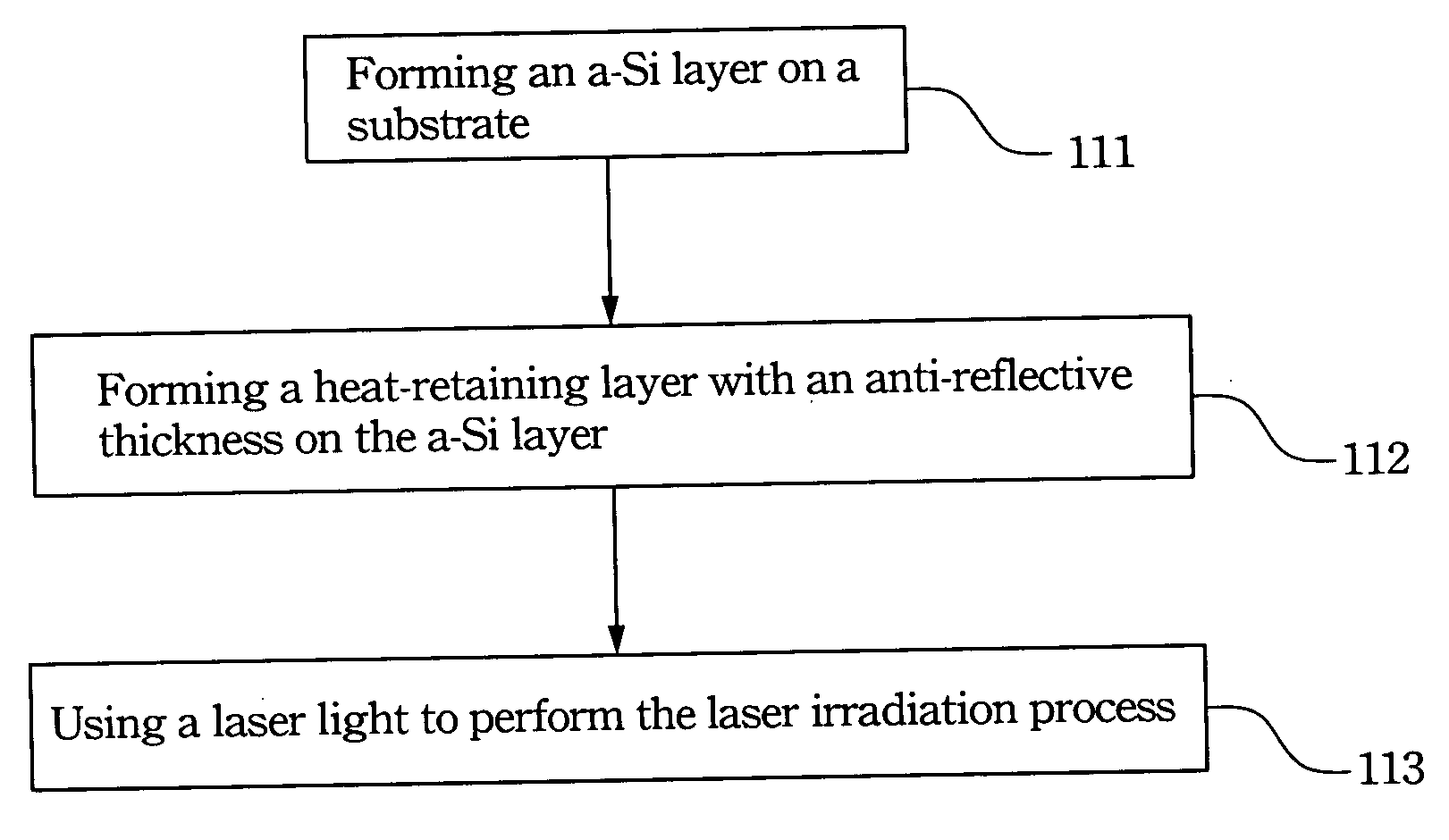

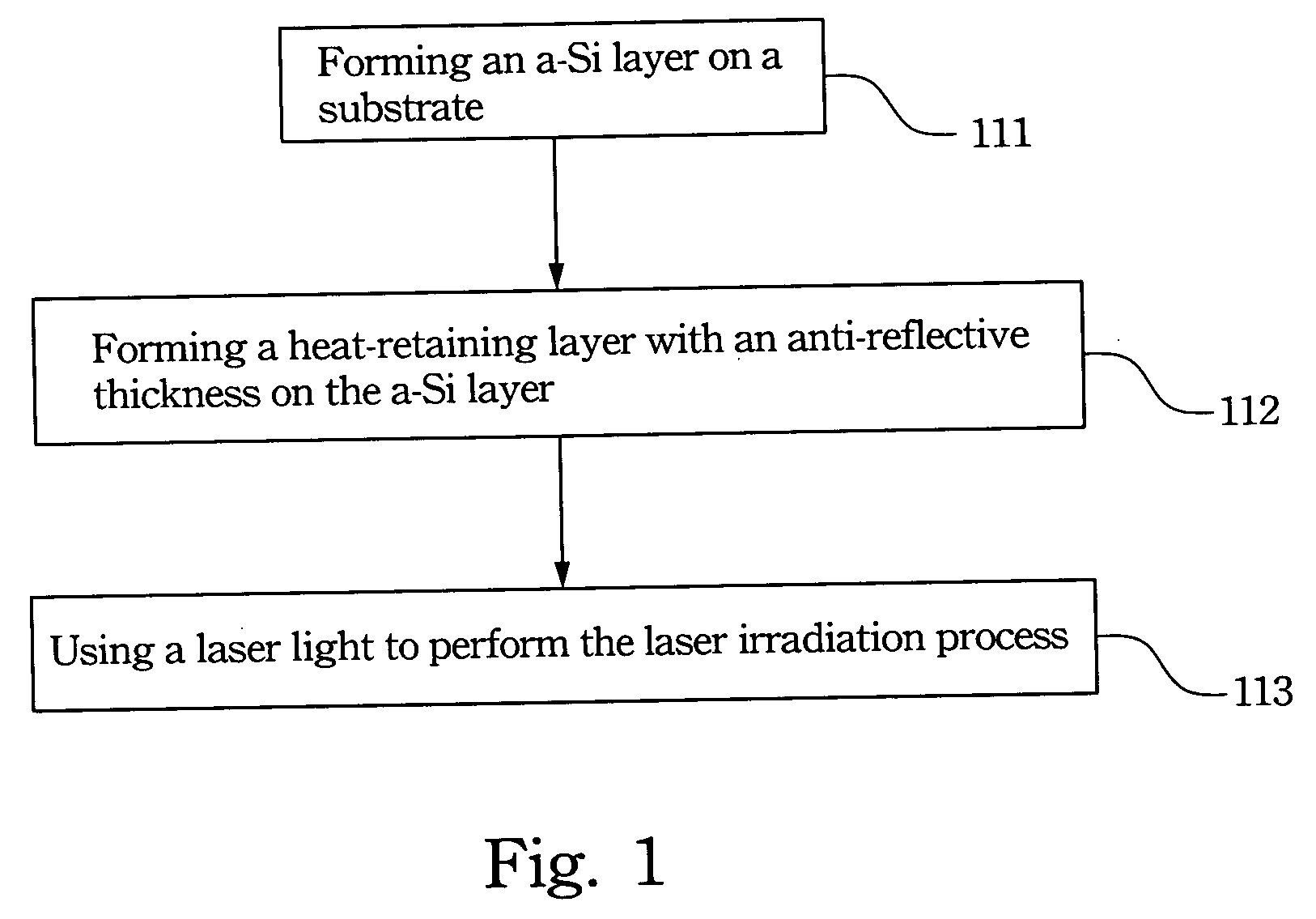

Method of enhancing laser crystallization for polycrystalline silicon fabrication

InactiveUS20060088986A1High crystallinityFine grainSolid-state devicesSemiconductor/solid-state device manufacturingLaser crystallizationOptoelectronics

An amorphous silicon layer and at least a heat-retaining layer are formed on a substrate in turn. Wherein, the heat-retaining layer is controlled to have an anti-reflective thickness for reducing the threshold laser energy to effect the melting of the amorphous silicon layer. Then, a laser irradiation process is performed to transform the amorphous silicon layer into a polycrystalline silicon layer. During the laser irratiation process, a portion of the laser energy transmits the heat-retaining layer to effect the melting of the amorphous silicon layer, and another portion of the laser energy is absorbed by the heat-retaining layer.

Owner:IND TECH RES INST

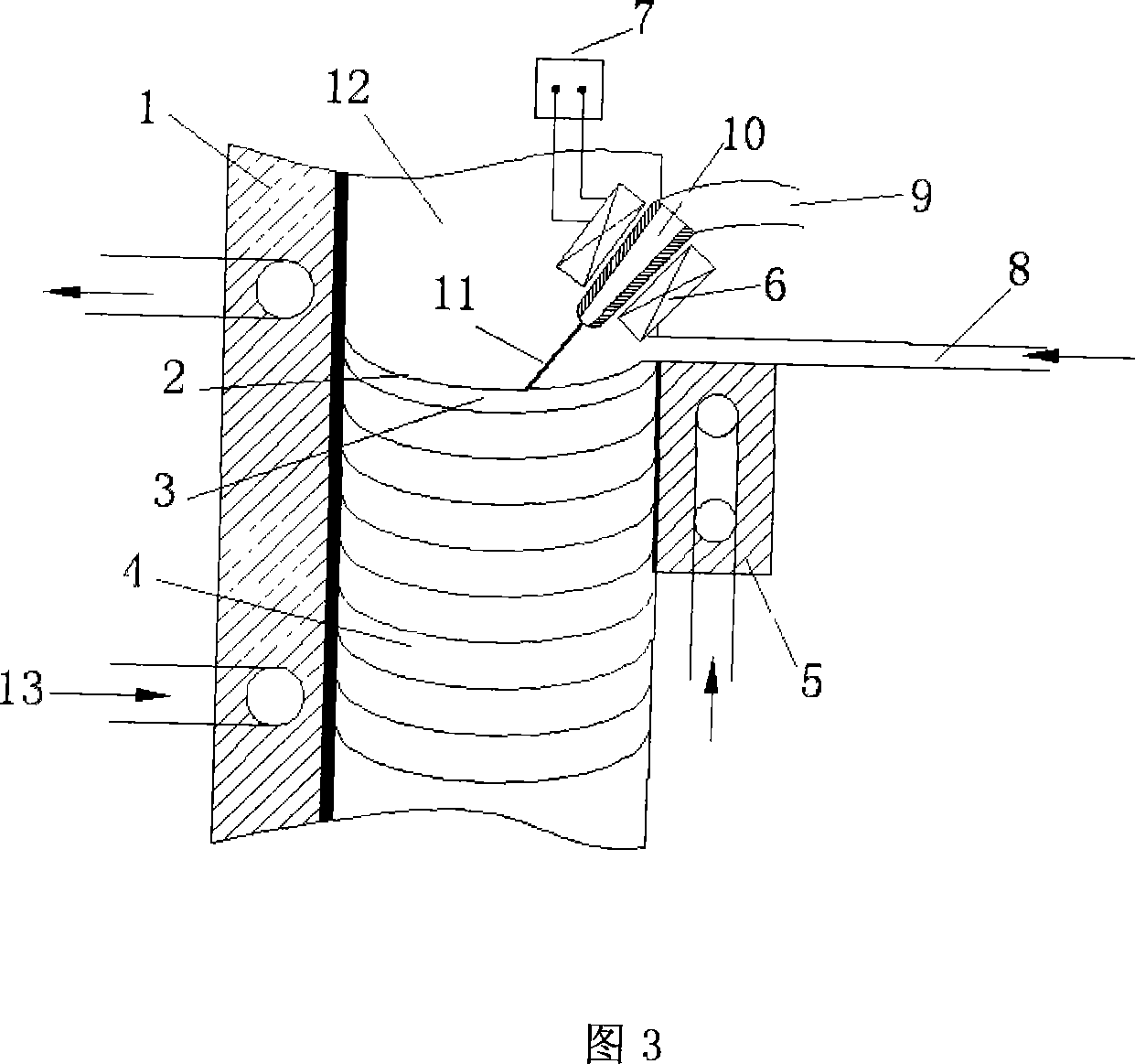

Method and equipment for electromagnetic composite double-face submerged arc welding of diphase stainless steel thick plate

InactiveCN101462196AImprove crystallizationReduce sensitivityArc welding apparatusChemical industryWelding power supply

The invention discloses a method for welding a dual-phase stainless steel and a device thereof. The method comprises: dual-side surfacing of heavy current submerged arc is controlled by an electromagnetic-composite field of the dual phase stainless steel of heavy plates without a grooveb; excitation current is provided by an excitation power supply to generate an additional longitudinal electromagnetic field; and a submerged arc welding process of the dual-phase stainless steel of the heavy plates without the groove is comprehensively controlled and realized by the electromagnetic field. The welding device is provided with the excitation power supply, a welding power supply, an excitation welding device, a device of an auxiliary electric field and a water cooling system. The excitation device consists of excitation coils, is fixed on a welding torch, and generates the additional longitudinal electromagnetic field which is coaxial with the welding torch, and the water cooling system is arranged in a bracket of the excitation coils. The device can realize the submerged arc welding of the dual-phase stainless steel of the heavy plates without the groove, with high efficiency, high quality and low cost through the electromagnetic-complex submerged arc welding; meanwhile, the device can be used for welding the dual-phase stainless steel of the heavy plates in industries, such as shipbuilding, chemical industry and so on.

Owner:CHONGQING UNIV

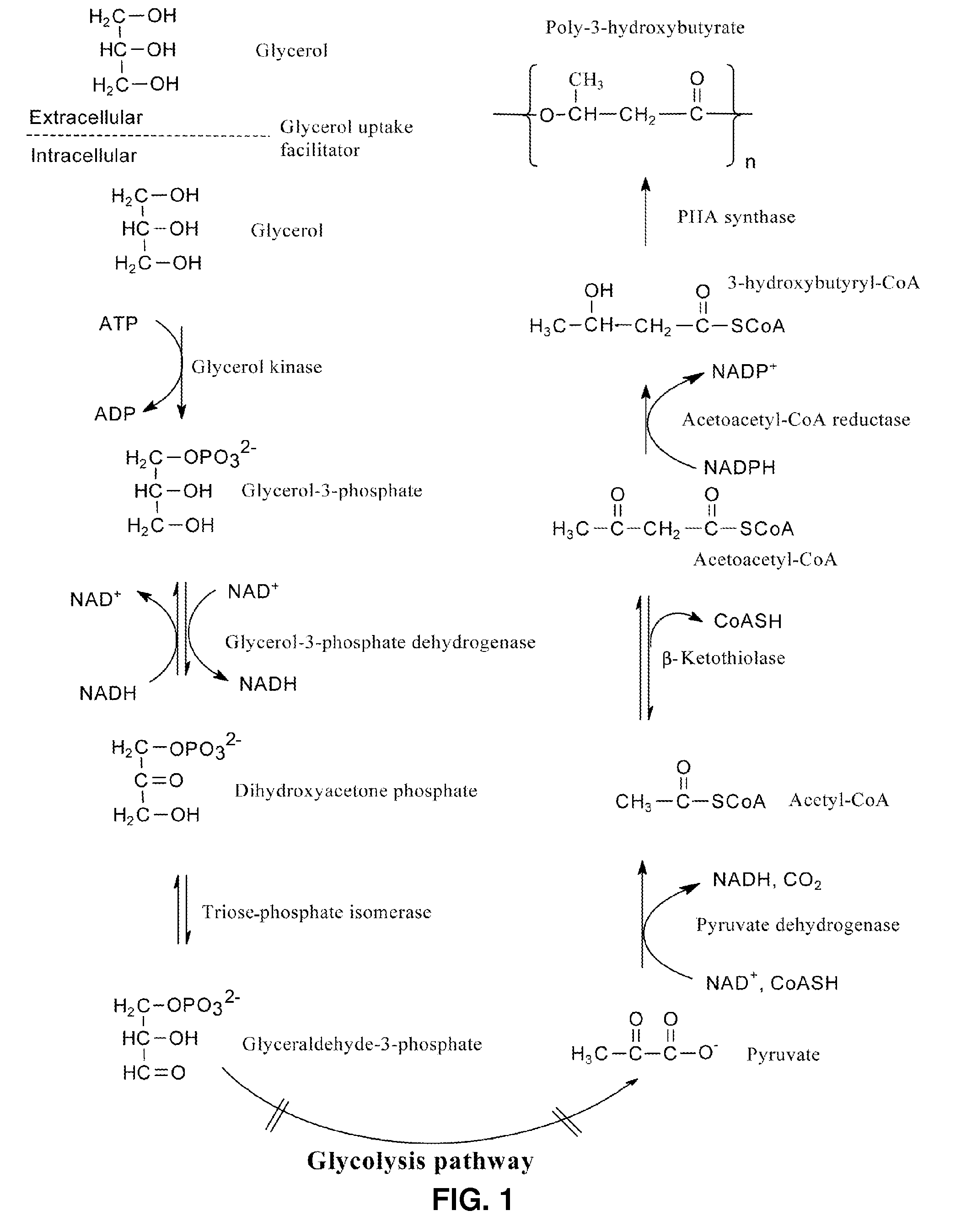

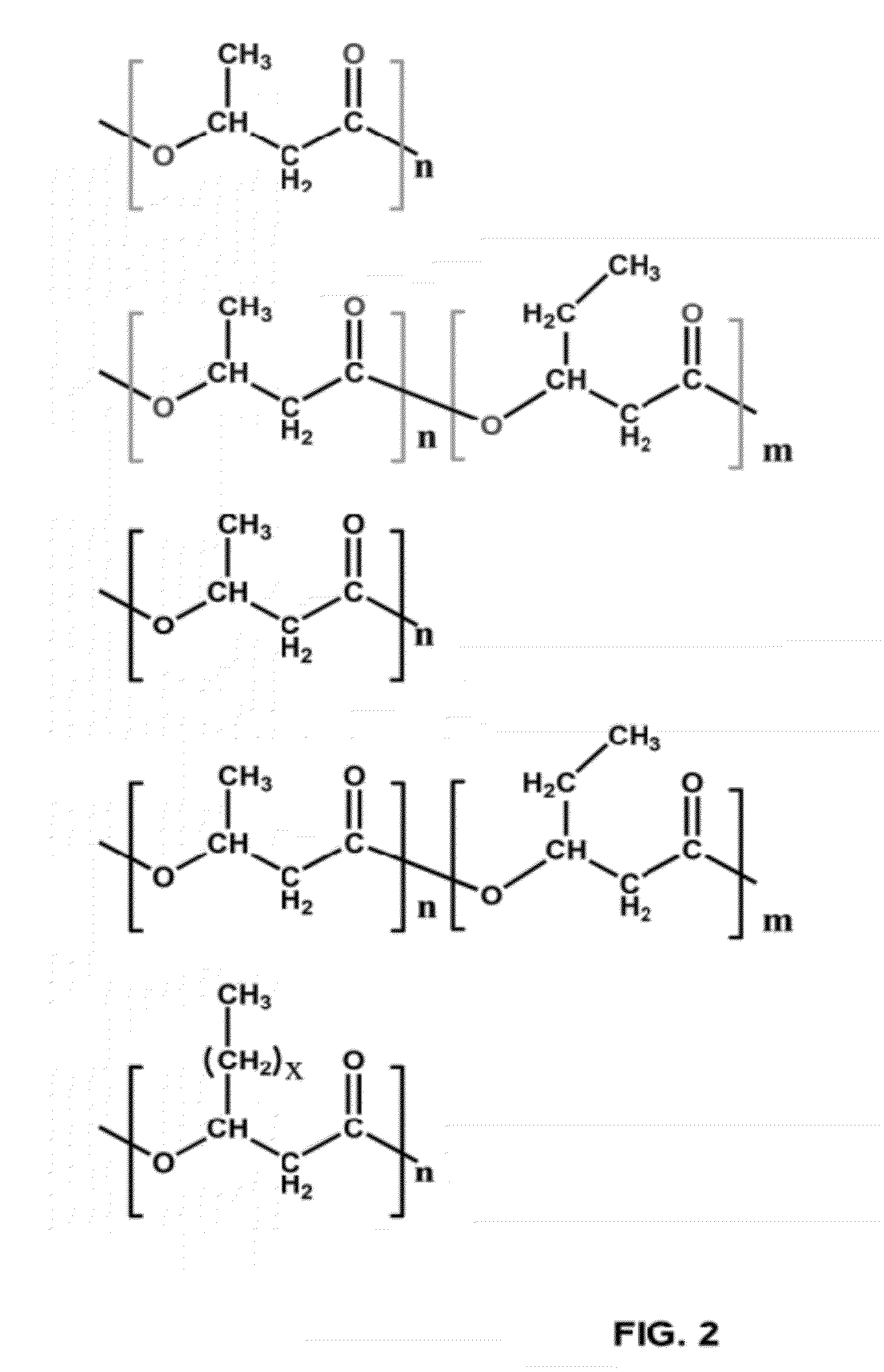

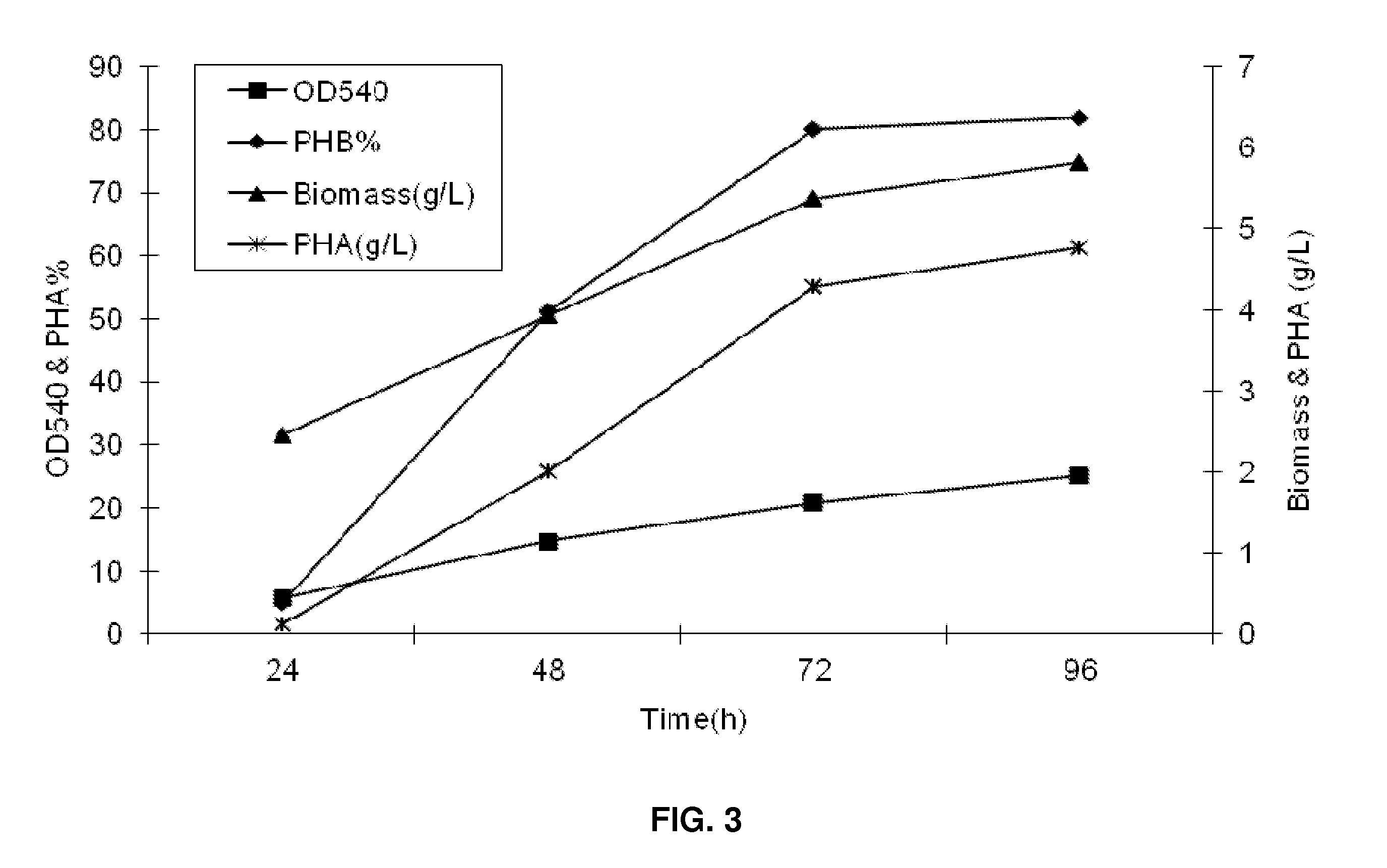

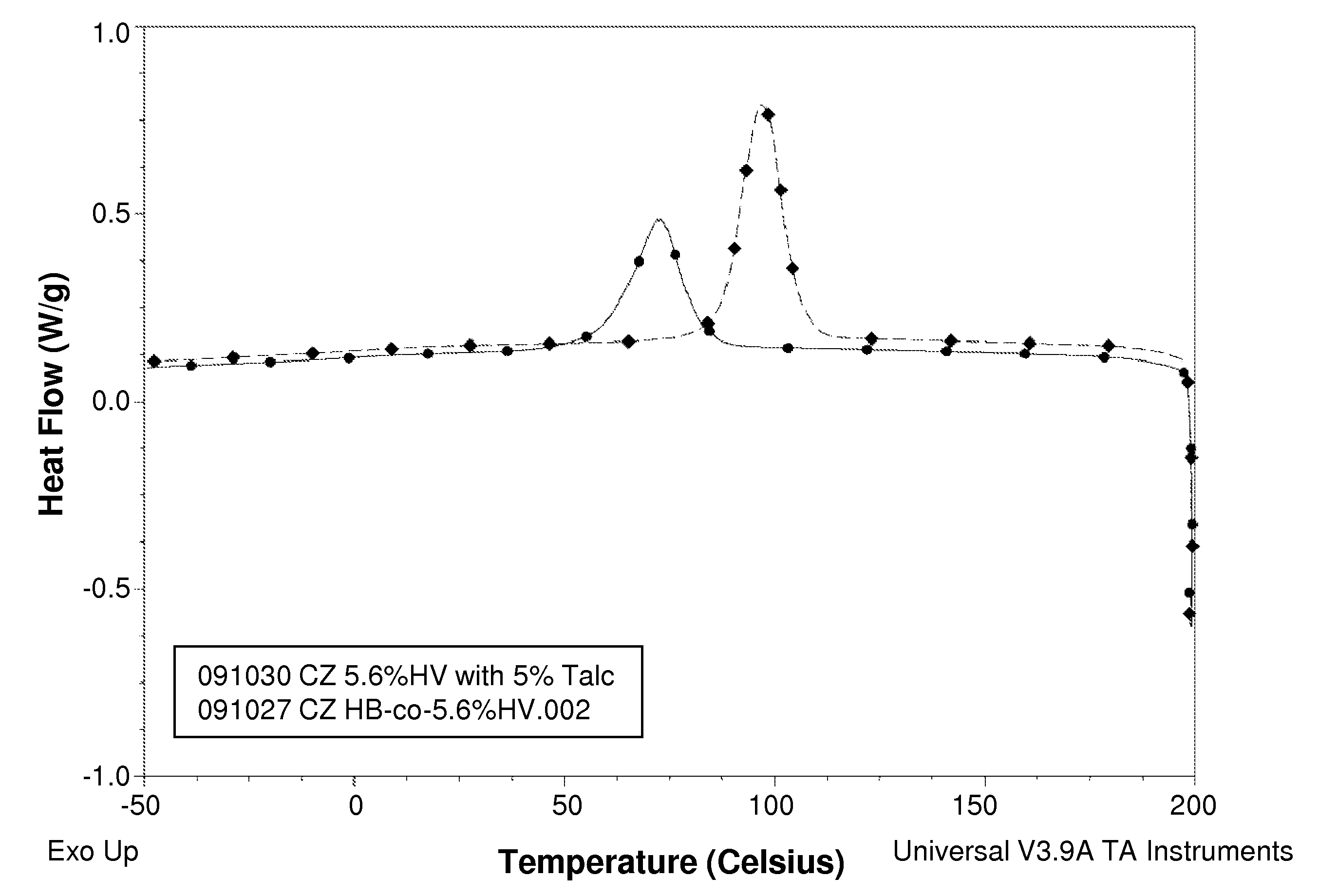

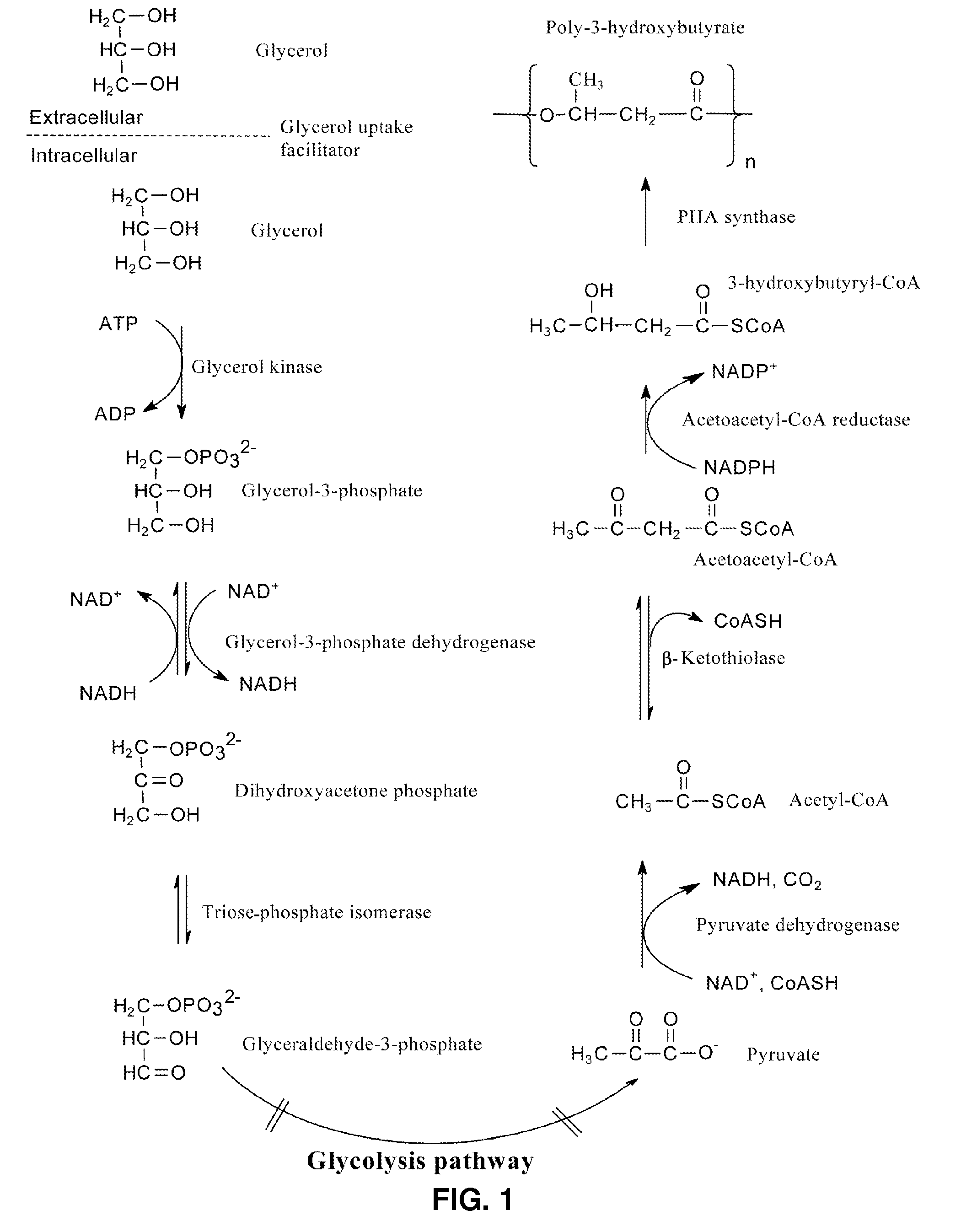

Methods for producing polyhydroxyalkanoates from biodiesel-glycerol

Methods are provided for producing biodegradable polyhydroxyalkanoates (PHAs) with desired geometry, molecular mass, mechanical and / or physical-chemical properties from glycerol, an inexpensive carbon source and byproduct of the biodiesel industry. Microorganisms capable of converting carbon to PHA can be used to convert biodiesel-glycerol to poly-3-hydroxybutyrate (PHB) or other monomer or copolymer PHAs via fermentation. The microorganisms are cultured in a medium comprising glycerol as a primary carbon source and one or more low molecular mass organic acids as a secondary carbon source. Biomass can be harvested from the culture medium and crude PHA extracted and purified, thereby recovering purified PHA with the desired property. After PHA isolation, a nucleating agent can be added to improve certain physical-chemical properties of the PHA, e.g., crystallization temperature, to enhance performance of the PHA during injection molding.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Method for manufacturing a semiconductor device

The crystallization method by laser light irradiation forms a multiplicity of convexes (ridges) in the surface of an obtained crystalline semiconductor film, deteriorating film quality. Therefore, it is a problem to provide a method for forming a ridge-reduced semiconductor film and a semiconductor device using such a semiconductor film. The present invention is characterized by heating a semiconductor film due to a heat processing method (RTA method: Rapid Thermal Anneal method) to irradiate light emitted from a lamp light source after crystallizing the semiconductor film by laser light, thereby reducing the ridge.

Owner:SEMICON ENERGY LAB CO LTD

Methods for producing polyhydroxyalkanoates from biodiesel-glycerol

ActiveUS20120135480A1Increased elongation-to-breakIncreased resistance to breakingBiofuelsFermentationBiodieselGlycerol

Methods are provided for producing biodegradable polyhydroxyalkanoates (PHAs) with desired geometry, molecular mass, mechanical and / or physical-chemical properties from glycerol, an inexpensive carbon source and byproduct of the biodiesel industry. Microorganisms capable of converting carbon to PHA can be used to convert biodiesel-glycerol to poly-3-hydroxybutyrate (PHB) or other monomer or copolymer PHAs via fermentation. The microorganisms are cultured in a medium comprising glycerol as a primary carbon source and one or more low molecular mass organic acids as a secondary carbon source. Biomass can be harvested from the culture medium and crude PHA extracted and purified, thereby recovering purified PHA with the desired property. After PHA isolation, a nucleating agent can be added to improve certain physical-chemical properties of the PHA; e.g., crystallization temperature, to enhance performance of the PHA during injection molding.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Surface treatment apparatus

InactiveUS20100170440A9Reduce harmFilm formationElectric discharge tubesSemiconductor/solid-state device manufacturingMolecular physicsCharged particle

The present invention has an object to provide a surface treatment apparatus, which can form a high-quality film at a high speed while preventing deterioration of the film due to collisions of charged particles. The surface treatment apparatus (1) of the present invention comprises a casing (2) partitioned to two chambers, that is, a plasma generating chamber (3) provided with plasma generating electrodes (5, 5′) and a substrate processing chamber (4) provided with a substrate supporting table (8). A plasma vent (6) is formed in the electrode (5′) that composes the partition between the chambers (3, 4). A conductive mesh-shaped sheet (9) is disposed in a direction across the plasma between the plasma vent (6) and a substrate (S) on the substrate supporting table (8). The sheet (9), to which a variable bias is applied, captures charged particles in the plasma so that the charged particles can be excluded from the plasma.

Owner:MIZUKAMI HIROYUKI +3

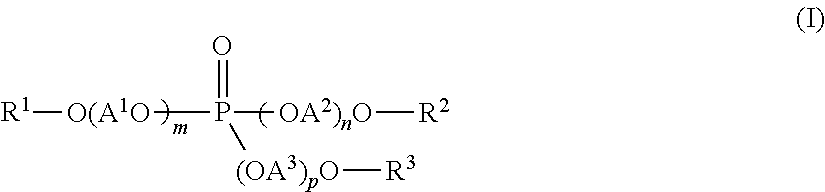

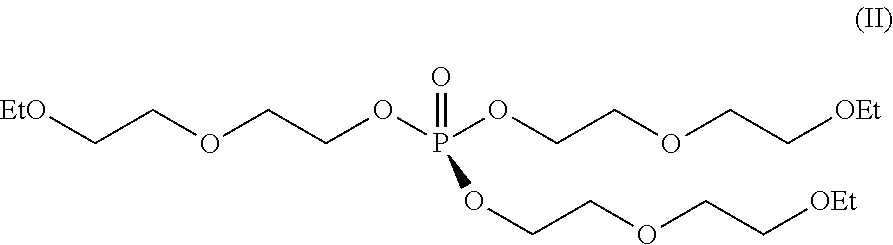

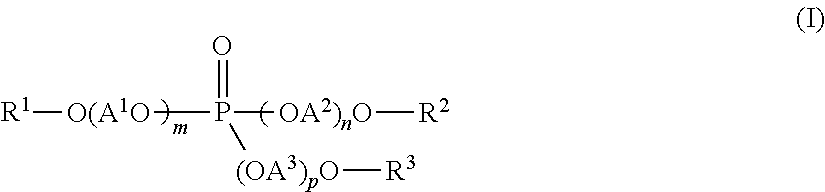

Process for production of polylactic acid resin composition

ActiveUS20120296017A1Improve crystallization speedImprove compatibilityGroup 5/15 element organic compoundsPhosphoric Acid EstersViscosity

A method for producing a polylactic acid resin composition, including the following steps (1) and (2): step (1): subjecting an organic crystal nucleating agent to a wet pulverization in the presence of a carboxylic acid ester having a weight-average molecular weight of from 150 to 600 and a viscosity at 23° C. of from 1 to 500 mP·s and / or a phosphoric ester having a weight-average molecular weight of from 150 to 600 and a viscosity at 23° C. of from 1 to 500 mPa·s to give a finely pulverized organic crystal nucleating agent composition; and step (2): melt-kneading a raw material for a polylactic acid resin composition comprising the finely pulverized organic crystal nucleating agent composition obtained in the step (1) and a polylactic acid resin. The polylactic acid resin composition obtainable by the method of the present invention can be suitably used in various industrial applications, such as daily sundries, household electric appliance parts, packaging materials for household electric appliance parts, and automobile parts.

Owner:KAO CORP

Anchor-spraying concrete for treating water and support

InactiveCN1381651ASolve construction technical problemsAchieve governanceArtificial islandsUnderground chambersShotcreteUltimate tensile strength

An anchoring-sprayed prop for controlling water in constructing underground engineering features direct use of anchorage and spraying concrete. Its construction technology includes such steps as drilling weep holes, setting up weep pipes, primary spraying, drilling anchor holes, installing anchor rods, hanging net, spraying again, blocking drainage pipes, and curing. If the bed rock encounters fault, it is necessary to spray concrete for the third time.

Owner:王衡

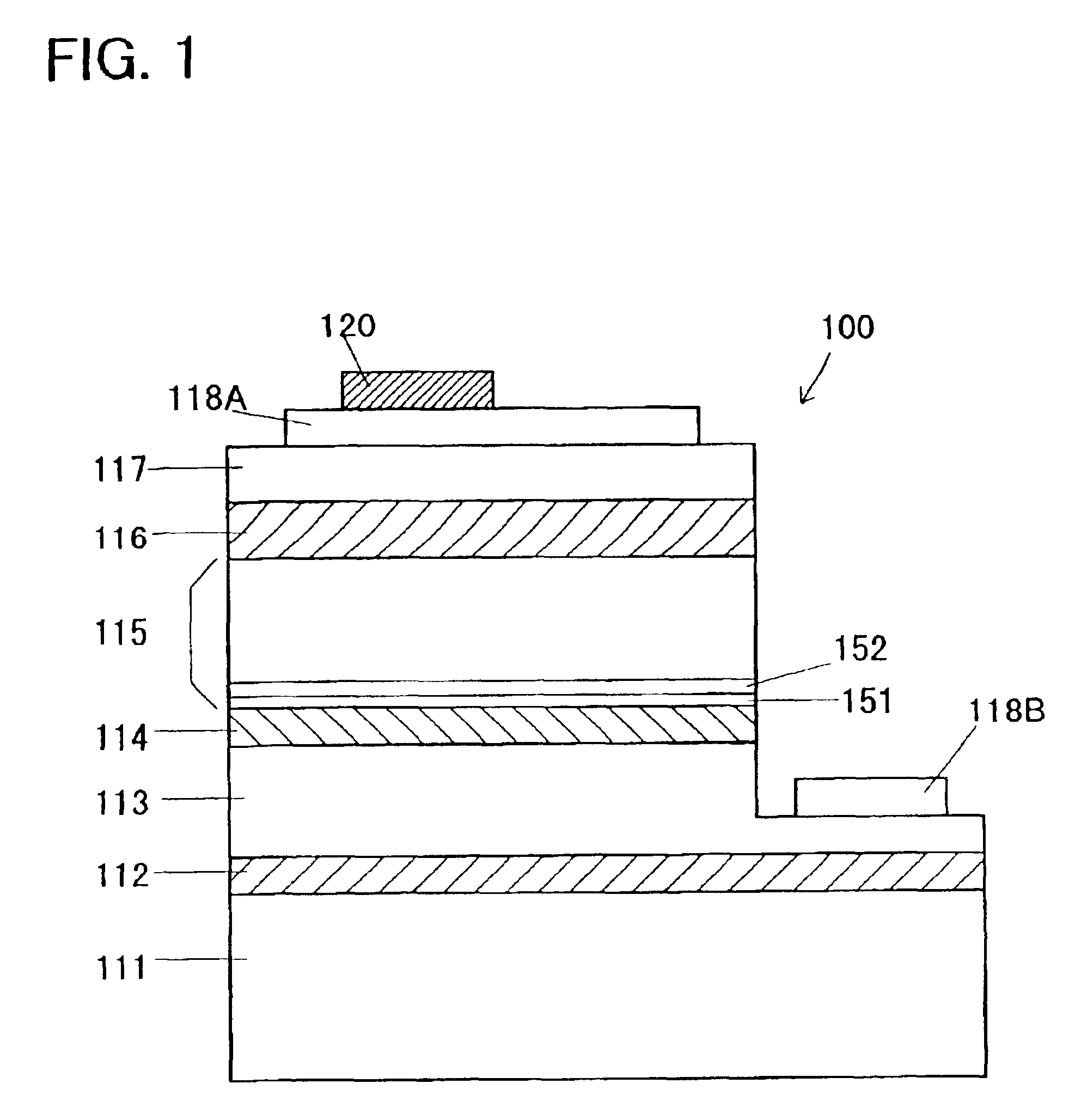

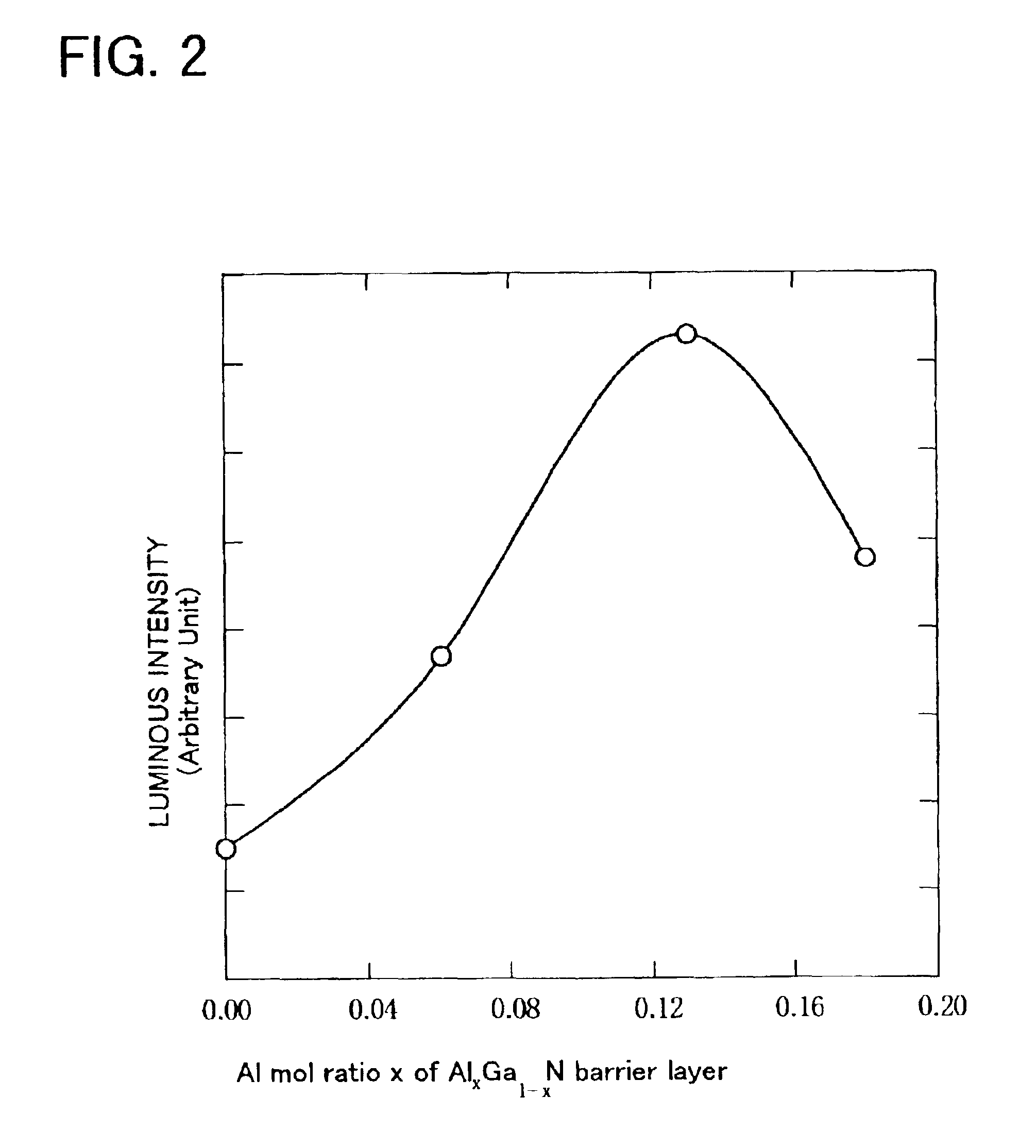

Light-emitting semiconductor device using gallium nitride compound semiconductor

InactiveUS6853009B2Improve luminous efficiencyLarge band gap energySolid-state devicesNanoopticsLuminous intensityQuantum well

A barrier layer made of AlxGa1-xN (0<x≦0.18) is formed in a light-emitting semiconductor device using gallium nitride compound having a multi quantum-well (MQW) structure. By controlling a composition ratio x of aluminum (Al) or thickness of the barrier layer, luminous intensity of the device is improved.An n-cladding layer made of AlxGa1-xN (0<x≦0.06) is formed in a light-emitting semiconductor device using gallium nitride compound. By controlling a composition ratio x of aluminum or thickness of the n-cladding layer, luminous intensity of the device is improved.A p-type layer and an n-type layer are formed in a light-emitting semiconductor device using gallium nitride compound having a double-hetero junction structure. By controlling a ratio of a hole concentration of the p-type layer and an electron concentration of the n-type layer approximates to 1, luminous intensity of the device is improved.

Owner:TOYODA GOSEI CO LTD

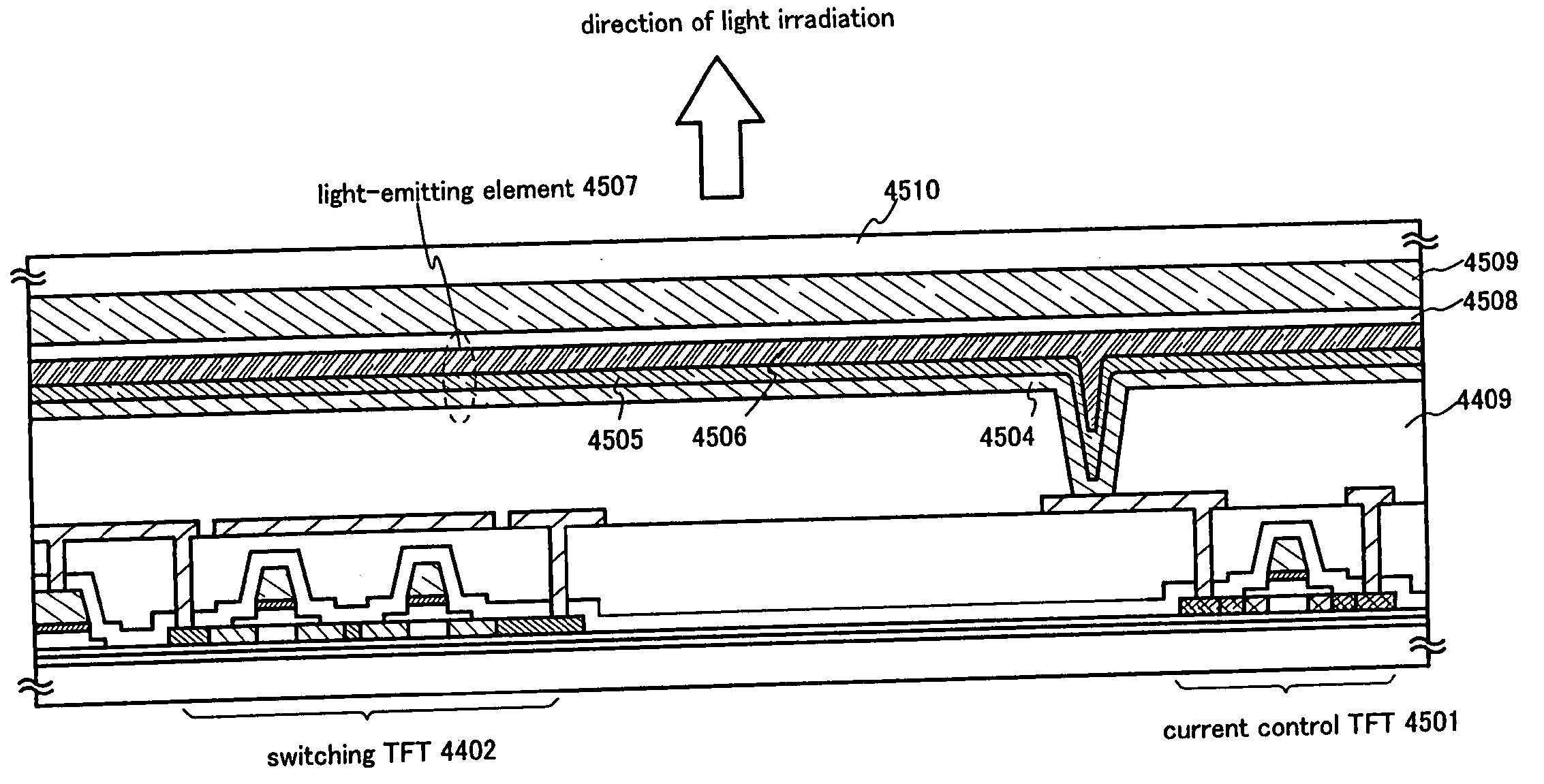

Method for manufacturing a semiconductor device

InactiveUS20040259389A1Reducing ridgeReduce weightTransistorSolid-state devicesLaser lightIrradiation

The crystallization method by laser light irradiation forms a multiplicity of convexes (ridges) in the surface of an obtained crystalline semiconductor film, deteriorating film quality. Therefore, it is a problem to provide a method for forming a ridge-reduced semiconductor film and a semiconductor device using such a semiconductor film. The present invention is characterized by heating a semiconductor film due to a heat processing method (RTA method: Rapid Thermal Anneal method) to irradiate light emitted from a lamp light source after crystallizing the semiconductor film by laser light, thereby reducing the ridge.

Owner:SEMICON ENERGY LAB CO LTD

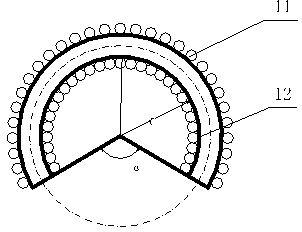

Electromagnetic control electro-gas welding method and equipment thereof

InactiveCN101172312AStir wellImprove crystallizationArc welding apparatusEngineeringElectromagnetic shielding

The invention relates to an electromagnetically controlled gas-electric vertical welding (EMS-EGW) method, which is to set an external magnetic field above or / and near the side of the gas-electric vertical welding (EGW) molten pool (3), such as an excitation coil that provides an excitation current by an excitation power supply , produce time-varying or constant electromagnetic stirring and external magnetic field to produce electromagnetic stirring effect; the electromagnetic field promotes the forced movement of the metal fluid in the gas-electric vertical welding pool, and comprehensively controls the solidification process of the weld metal. With the cooperation of gas protection, the method of electromagnetically controlled gas-electric vertical welding (EMS-EGW) is realized on the workpiece. The electromagnetic control gas-electric vertical welding (EMS-EGW) device of the present invention adds excitation equipment on the existing basis, and the excitation equipment is composed of an excitation coil and an excitation power supply that provides excitation current for the excitation coil. The invention breaks through the traditional gas-electric vertical welding method, and provides a new idea for improving gas-electric vertical welding; reduces welding defects, reduces welding costs, improves welding quality and production efficiency, and ensures product reliability; The appearance is well formed; the equipment is simple and easy to popularize and apply.

Owner:CHONGQING UNIV

Method and device for refining weld joint structures by using pulsed magnet fields in welding process

ActiveCN102848058AStir wellImprove crystallizationWelding accessoriesWelding defectMaterials science

The invention relates to a processing technology for refining weld joint structures in a welding process, in particular to a method and a device for refining weld joint structures by using pulsed magnet fields in the welding process, and belongs to the technical field of welding. The method for refining weld joint structures by using pulsed magnet fields in the welding process includes that welding is performed by using an ordinary gas metal arc welding method, an applied magnetic field is added above a gas metal arc welding pool, mechanical movement and welding gun movement of the magnet fields are synchronous, electric arc and melt drip transition action is controlled by the magnet fields in a welding process, metal melt in the gas metal arc welding pool is forced to move, an electromagnetic stirring effect is produced, and weld joint structures are finally refined in the welding process. According to the method and the device, in the welding process, the weld joint structures are refined, welding defects are reduced, and further the cost is reduced, and the welding quality and the production efficiency are improved.

Owner:BAOSHAN IRON & STEEL CO LTD

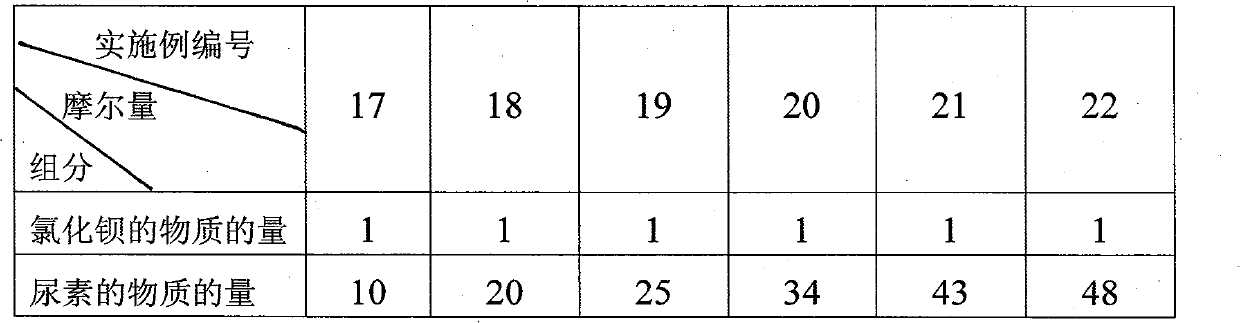

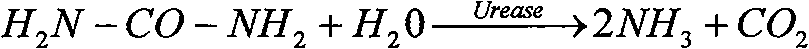

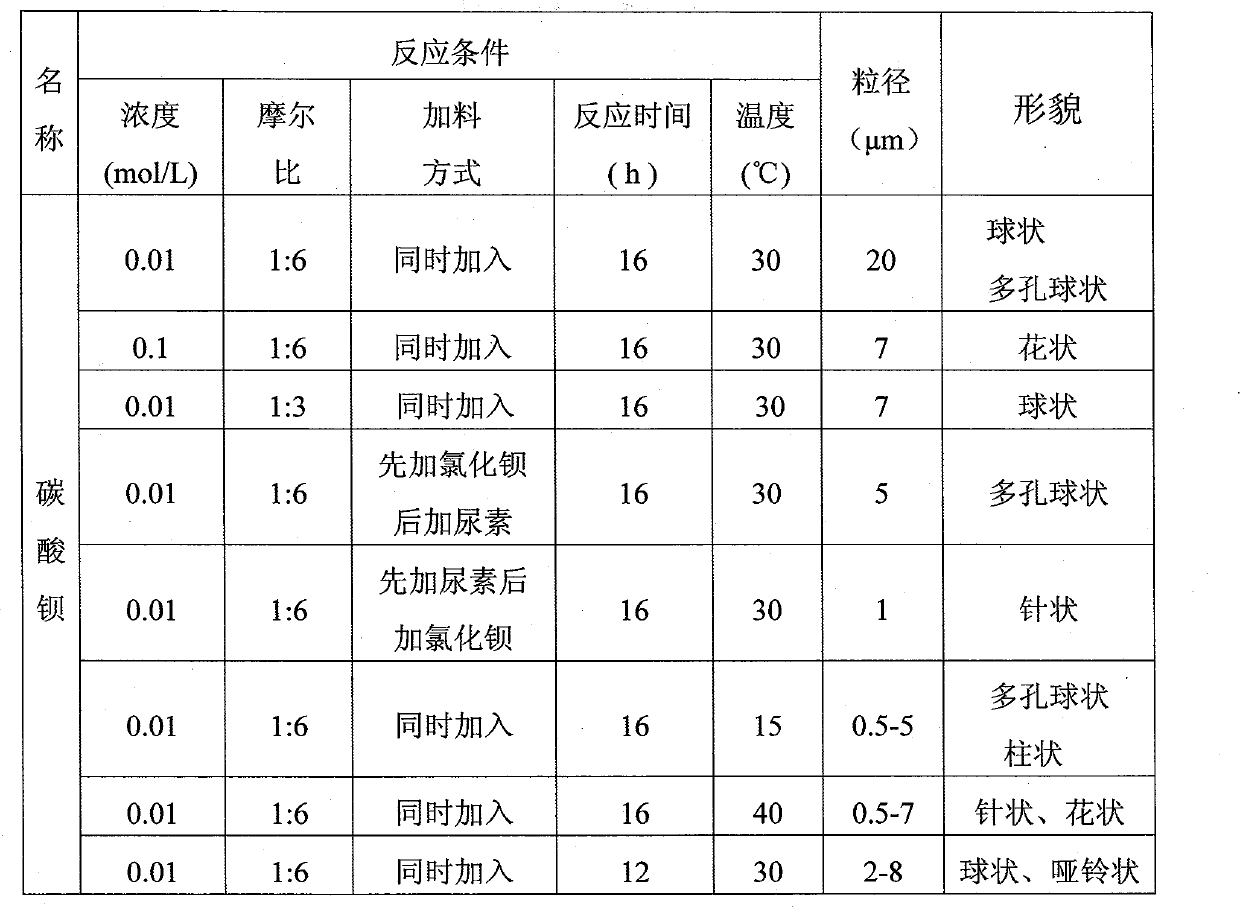

Method for preparing barium carbonate and strontium carbonate through microorganism mineralization

InactiveCN101906440AEasy to trainSustainable useMicroorganism based processesFermentationStrontium carbonateMicroorganism

The invention discloses a method for preparing barium carbonate and strontium carbonate through microorganism mineralization. The method is characterized by comprising the following steps of: taking a culture medium inoculated with bacillus pasteurii and used for culturing the bacillus pasteurii, taking barium chloride according to a principle that 0.001 to 2mol of barium chloride is added into 1L of culture medium, and taking carbamide according to the mass ratio of barium chloride to carbamide of 1:1-1:48; adding the barium chloride and the carbamide into the culture medium inoculated with bacillus pasteurii and used for cultivating the bacillus pasteurii, and reacting the mixture with stirring for 12 to 54 hours at the temperature of 10 to 100 DEG C to obtain a reactant with barium carbonate; and after standing to age the reactant for 1 to 24 hours, filtering the reactant, washing the solid with water, and drying the solid to obtain white powder of barium carbonate. The method is also suitable for preparing strontium carbonate. The method can be used for preparing barium carbonate and strontium carbonate products of different shapes, sizes and function characteristics and is practical.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Thermoplastic Resin Composition

A purpose of the invention is to provide a thermoplastic resin composition which enhances crystallization during molding, has high thermal deformation temperature, has high rigidity, induces less pealing on the molding surface, and gives excellent appearance, thus being preferably used as the facility parts of automobiles, and those of electric and electronics products. The (A) 100 parts by weight of a polyamide resin structured by the following monomers (1) and (2) is blended with (B) 5 to 100 parts by weight of a liquid crystalline polyester amide resin:(1) a diamine component containing an aliphatic diamine component unit having 4 to 12 carbon atoms arranged in straight chain and / or an aliphatic diamine component unit having 4 to 12 carbon atoms having side chain, and a derivative thereof; and(2) a dicarboxylic acid component containing 40 to 100% by mole of terephthalic acid component unit and 0 to 60% by mole of isophthalic acid component unit, and a derivative thereof.

Owner:POLYPLASTICS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![One-Pot Process for the Preparation of Antiemetic Agent, 1,2,3,9-Tetrahydro-9-Methyl-3[(2-Methyl)-1H-Imidazole-1-Yl)Methyl]-4H-Carbazol-4-O One-Pot Process for the Preparation of Antiemetic Agent, 1,2,3,9-Tetrahydro-9-Methyl-3[(2-Methyl)-1H-Imidazole-1-Yl)Methyl]-4H-Carbazol-4-O](https://images-eureka.patsnap.com/patent_img/8248cb64-9651-4786-8c08-49e307ca69de/US20080009635A1-20080110-C00001.png)

![One-Pot Process for the Preparation of Antiemetic Agent, 1,2,3,9-Tetrahydro-9-Methyl-3[(2-Methyl)-1H-Imidazole-1-Yl)Methyl]-4H-Carbazol-4-O One-Pot Process for the Preparation of Antiemetic Agent, 1,2,3,9-Tetrahydro-9-Methyl-3[(2-Methyl)-1H-Imidazole-1-Yl)Methyl]-4H-Carbazol-4-O](https://images-eureka.patsnap.com/patent_img/8248cb64-9651-4786-8c08-49e307ca69de/US20080009635A1-20080110-C00002.png)

![One-Pot Process for the Preparation of Antiemetic Agent, 1,2,3,9-Tetrahydro-9-Methyl-3[(2-Methyl)-1H-Imidazole-1-Yl)Methyl]-4H-Carbazol-4-O One-Pot Process for the Preparation of Antiemetic Agent, 1,2,3,9-Tetrahydro-9-Methyl-3[(2-Methyl)-1H-Imidazole-1-Yl)Methyl]-4H-Carbazol-4-O](https://images-eureka.patsnap.com/patent_img/8248cb64-9651-4786-8c08-49e307ca69de/US20080009635A1-20080110-C00003.png)