Patents

Literature

36results about How to "Solve construction technical problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

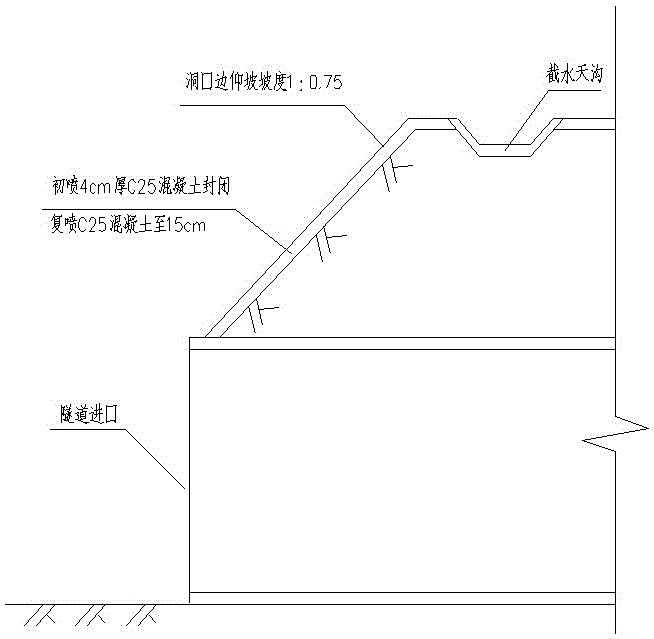

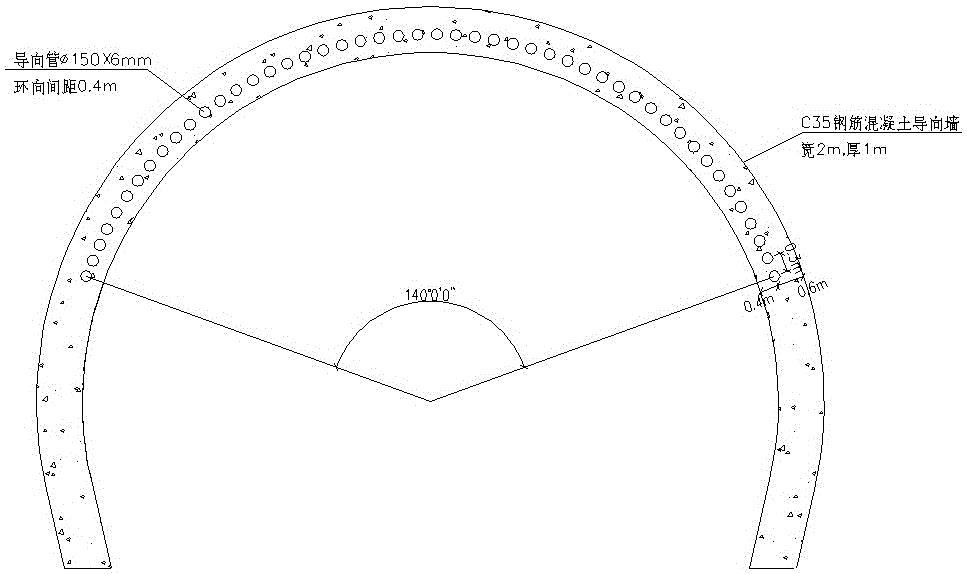

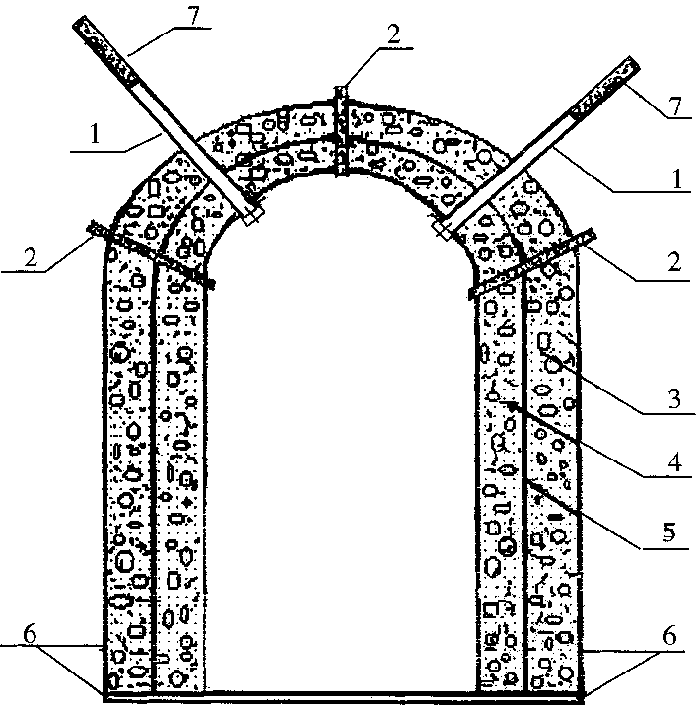

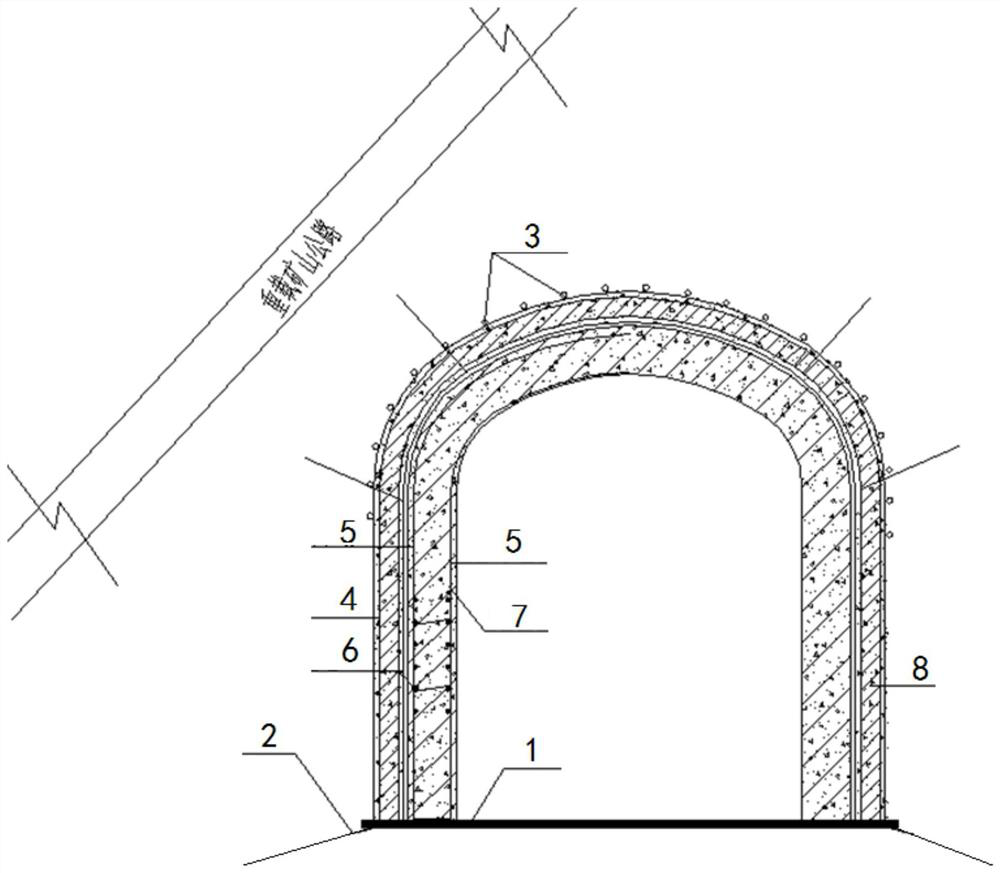

Construction method of large-cross section loess tunnel cave entering shallow buried section

InactiveCN105156121AEnsure excavation stabilityEnsure construction safetyUnderground chambersTunnel liningReinforced concreteEconomic benefits

The invention relates to a construction method of a large-cross section loess tunnel cave entering shallow buried section. The construction method comprises the following steps of: (1) firstly performing excavation protection on a face-upward slope before the cave entering construction; (2) after the face-upward slope construction in the cave entering position is completed, building a reinforced concrete guide wall; (3) after the construction of the guide wall is completed, beating a long pipe roof for forepoling; (4) constructing a leading conduit for supporting on the basis of the big pipe roof forepoling by matching a sectional-steel steel frame; and (5) using a few-part and ultra-short-step excavation construction method for constructing a tunnel, reinforcing monitoring and measurement during the construction and timely constructing primary supporting and secondary lining. The method has the advantages that the influence of tunnel excavation deformation on the ground surface can be effectively reduced; the tunnel excavation stability of the cave entering shallow buried section is ensured; the construction progress is accelerated; the technical problem of construction of the large-cross section loess tunnel cave entering shallow buried section is solved; the tunnel construction safety is ensured; meanwhile, the investment is reduced; and the economic benefits are improved.

Owner:THE 5TH ENG CO LTD OF CHINA RAILWAY 25TH BUREAU GRP +1

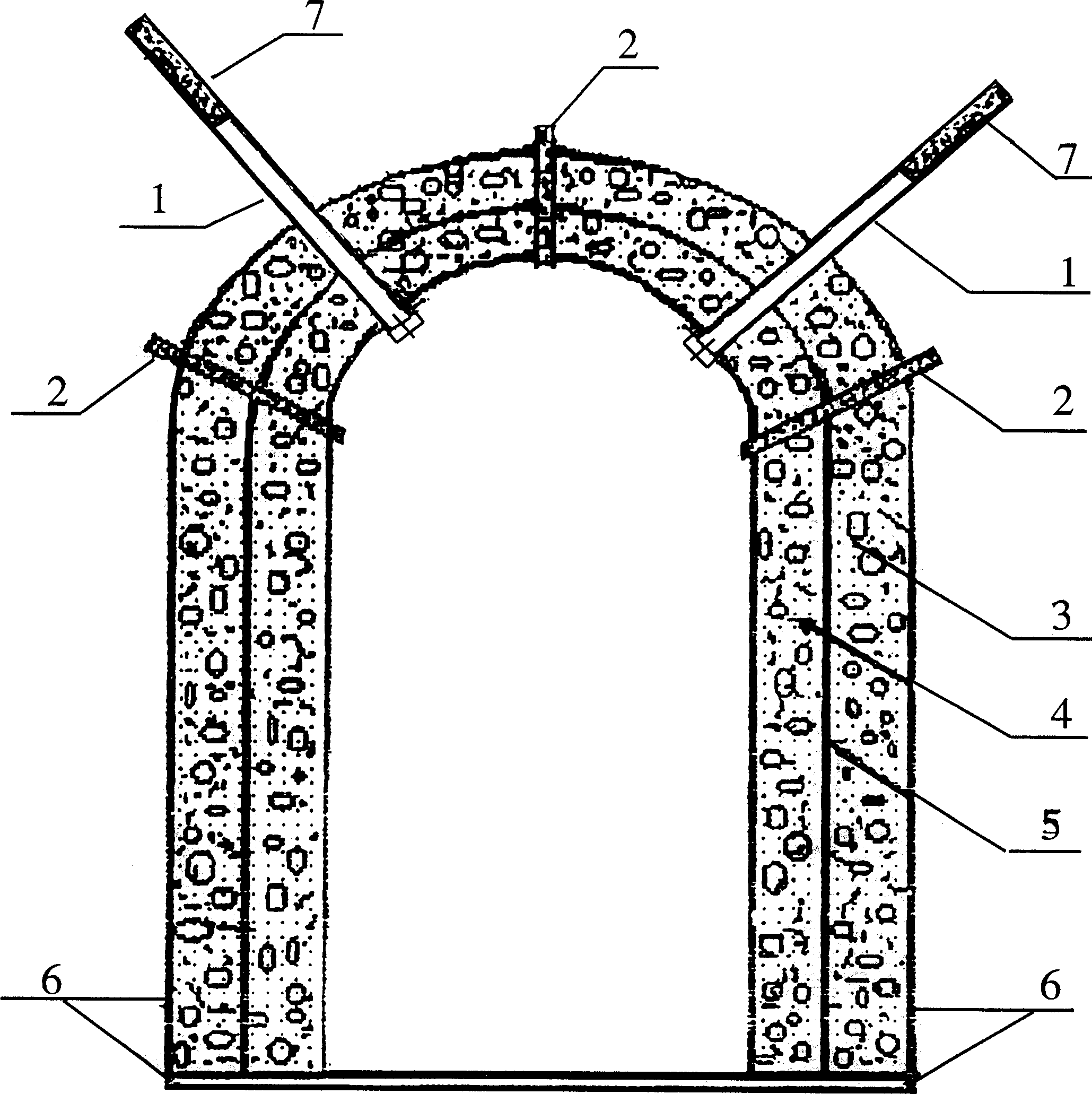

Anchor-spraying concrete for treating water and support

InactiveCN1381651ASolve construction technical problemsAchieve governanceArtificial islandsUnderground chambersShotcreteUltimate tensile strength

An anchoring-sprayed prop for controlling water in constructing underground engineering features direct use of anchorage and spraying concrete. Its construction technology includes such steps as drilling weep holes, setting up weep pipes, primary spraying, drilling anchor holes, installing anchor rods, hanging net, spraying again, blocking drainage pipes, and curing. If the bed rock encounters fault, it is necessary to spray concrete for the third time.

Owner:王衡

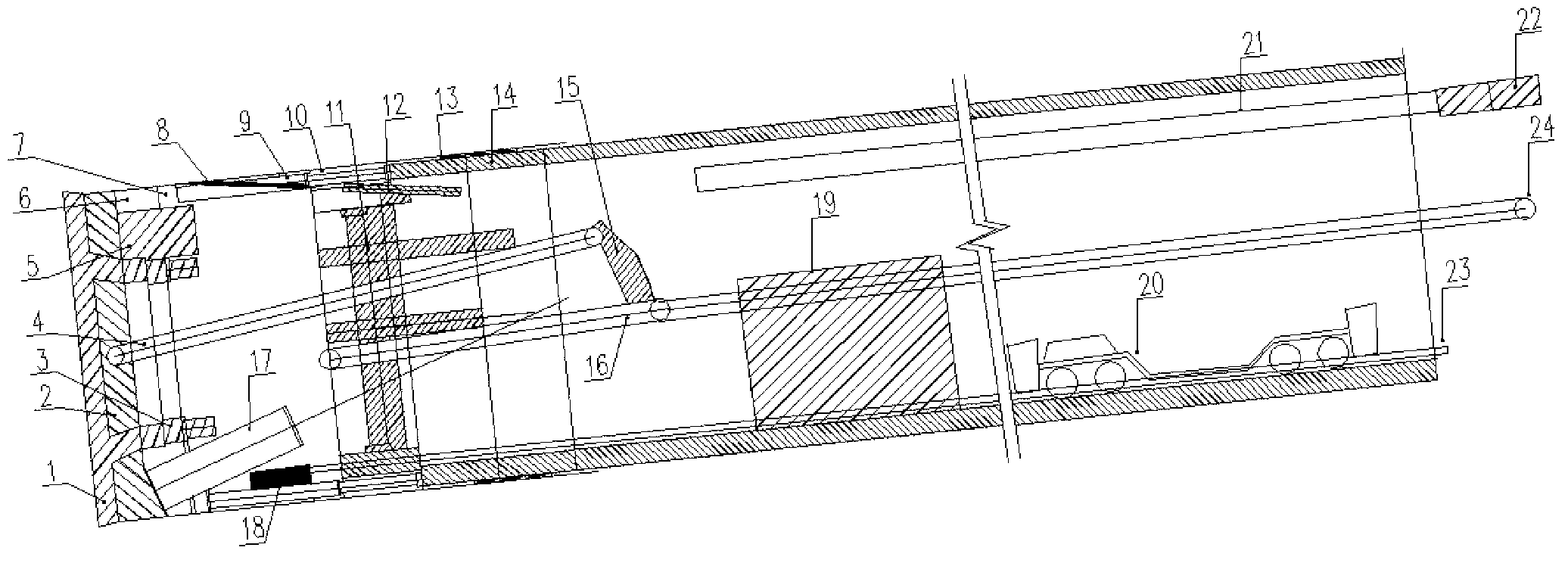

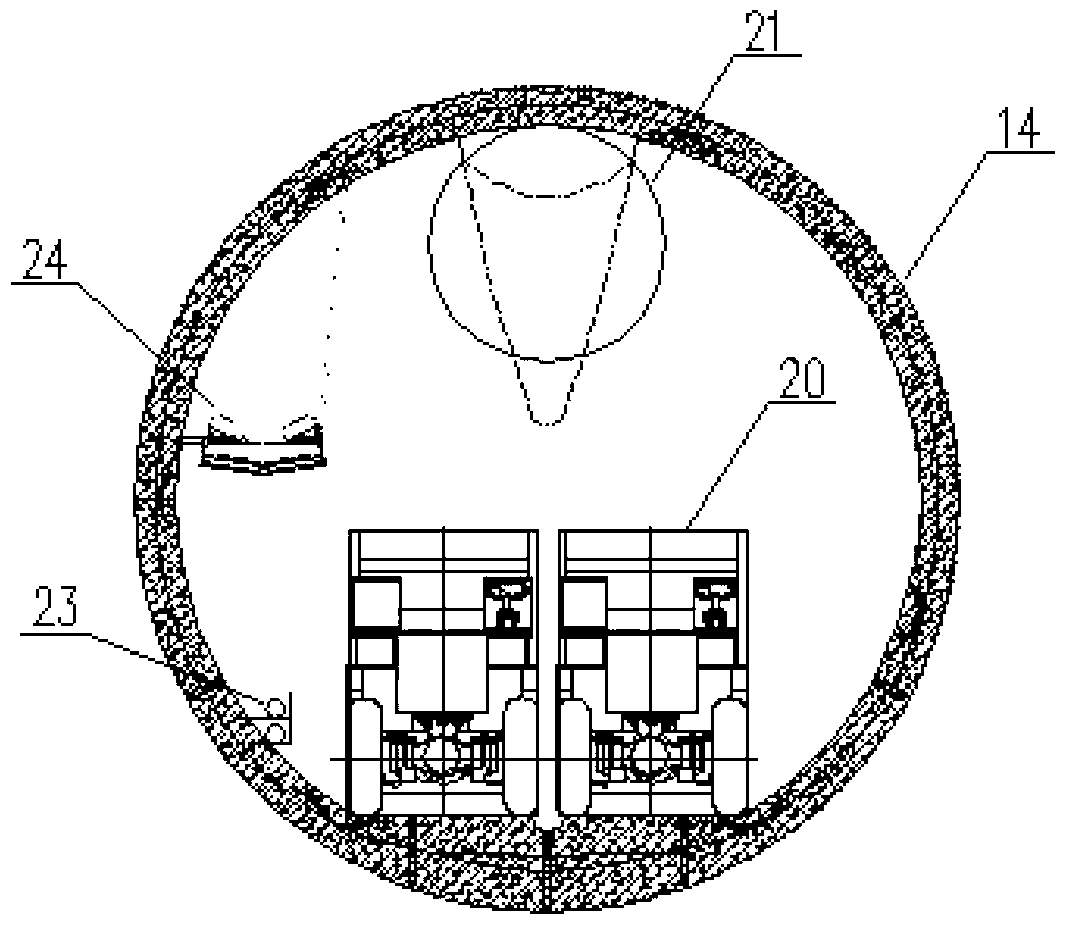

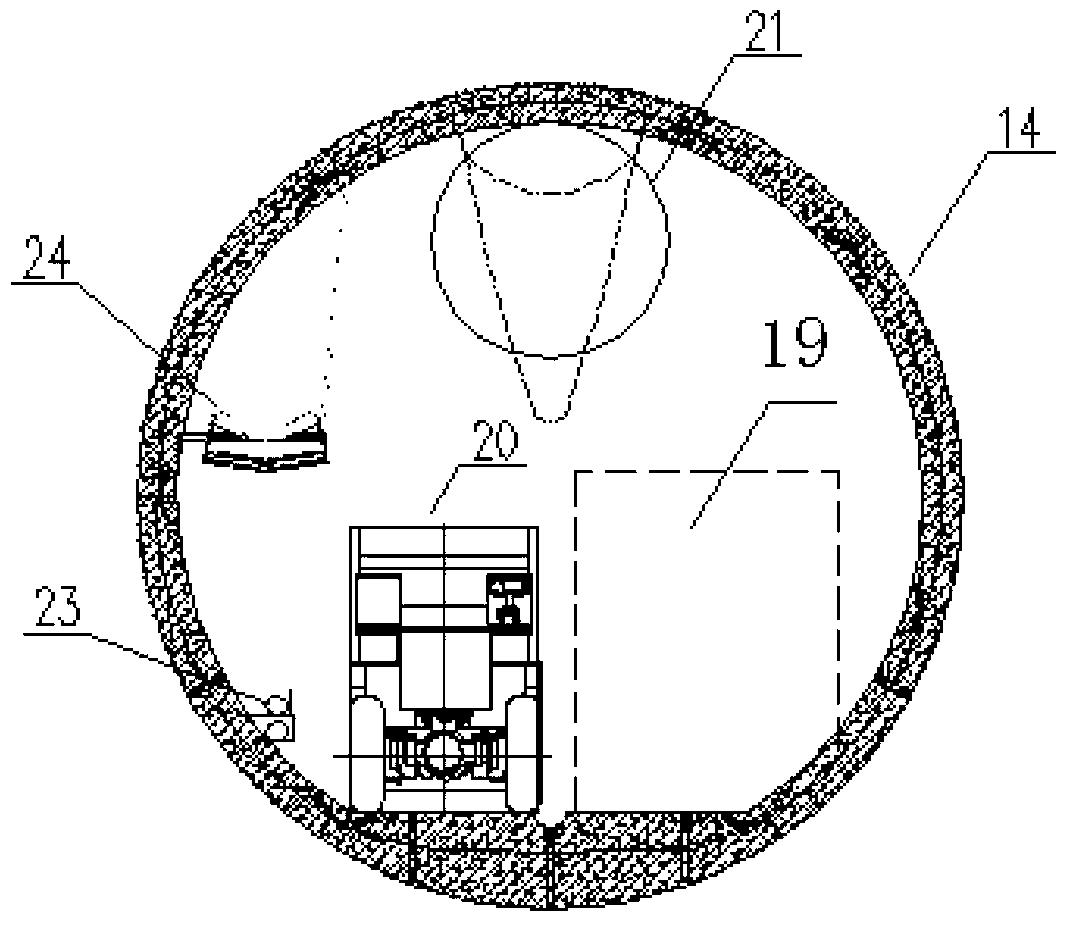

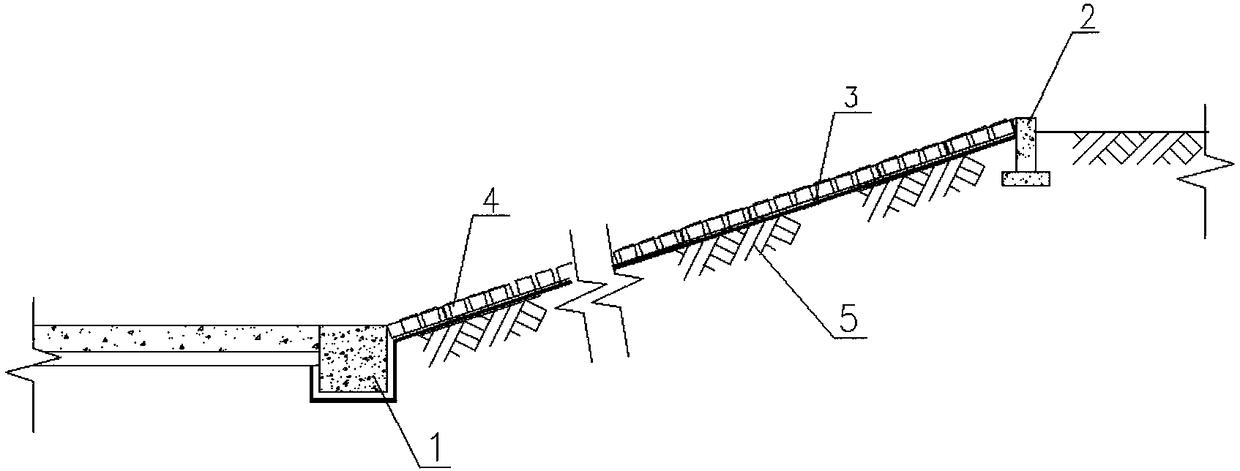

Method for constructing inclined shaft by applying TBM (Tunnel Boring Machine) with earth pressure balancing function

InactiveCN102797469ASolve construction technical problemsShort construction periodUnderground chambersTunnel/mines ventillationLine segmentAir volume

The invention relates to a method for constructing an inclined shaft by applying a TBM (Tunnel Boring Machine) with an earth pressure balancing function, wherein the method comprises the following steps: (1) judging the position of a waterproof layer in the front of TBM construction before carrying out TBM tunnelling construction; (2) drilling by utilizing an advanced detecting / grouting drilling machine to carry out underground water pre-discharging construction; (3) carrying out continuous downhill tunnelling construction by utilizing an inclined shaft TBM method; (4) conveying the air volume required for TBM construction to the last ring of lining segment of TBM construction equipment; (5) carrying out inclined shaft counter-slope underground water pump drainage; (6) carrying out long-distance large-gradient material transportation and deslagging; and (7) carrying out conversion construction in two tunnelling modes including a single shield TBM opening manner and an earth pressure balanced shielding manner. The method disclosed by the invention has the advantages of being short in construction period, rapid in speed, simple in operation and low in cost; simultaneously, the adaptability to stratum characteristics contains hard rocks and soft rocks; the geological application range of equipment is expanded; and the construction risks can be effectively lowered.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

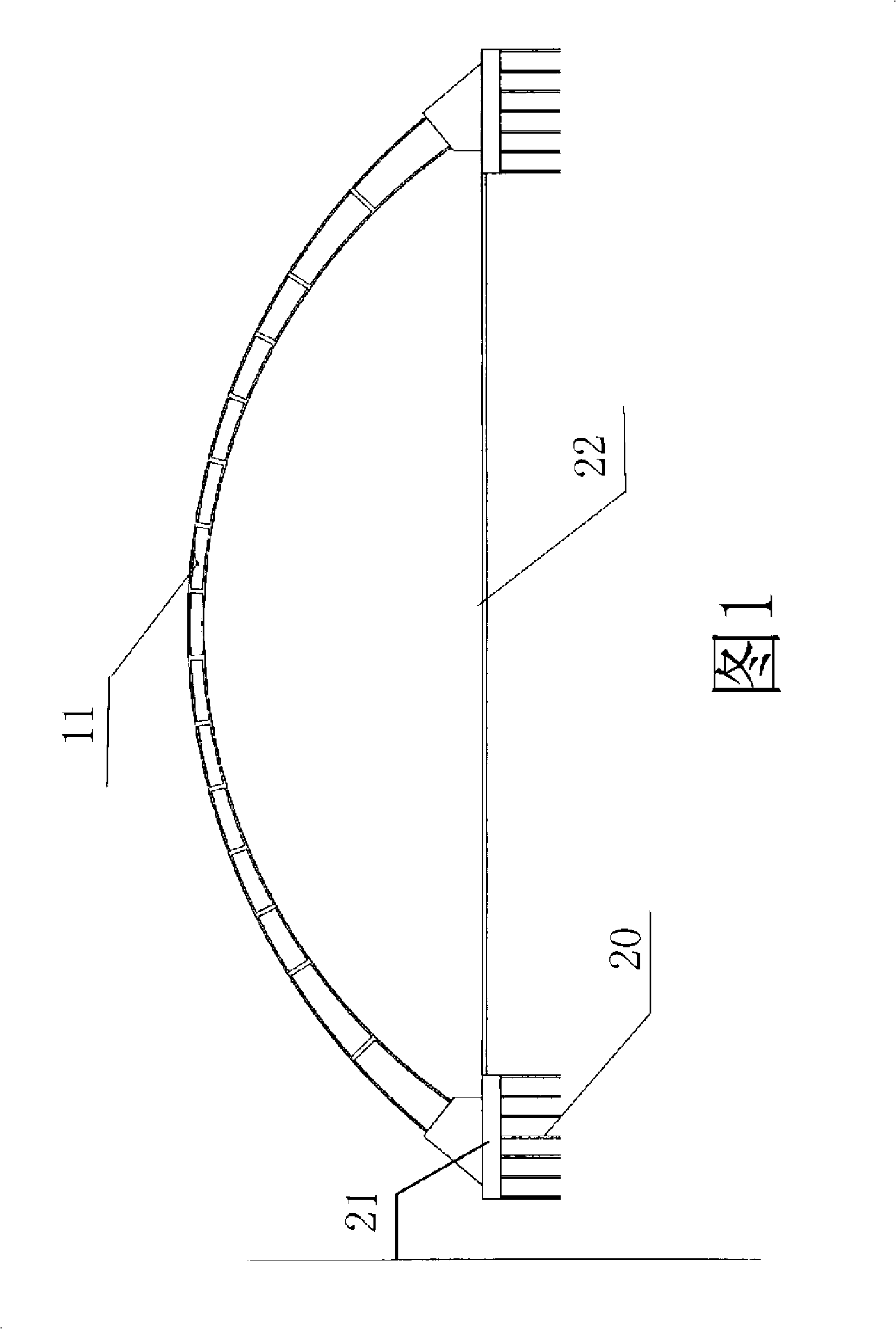

Method for building prestressed concrete through bowstring arch bridge

InactiveCN102425119ASolve the construction technical problem of constructing the arch ring after passing through the holeSolve construction technical problemsBridge erection/assemblyArch-type bridgeButtressPre stress

The invention provides a method for building a prestressed concrete through bowstring arch bridge, which solves the problem that convertible construction needs to be performed according to a beam in advance of arched roof tunneling system because of the traffic limitation of equipment, and comprises the following steps: building a stable midspan temporary buttress, and casting the box girder of the main girder of the arch bridge and a concrete arch springing which is 0.4 meter high by using a conventional method; after the concrete strength and the elastic modulus of the box girder of the main girder of the arch bridge reach above 90 percent of design values and are not less than 10 days, tensioning a longitudinal prestressed steel bundle and a horizontal prestressed steel bundle according to the design demand; when a bridge girder erection machine passes the main girder of the arch bridge, ensuring the crack-resistant safety factors of the top plate and the bottom plate of the main girder of the arch bridge to be greater than 1.1, and the safety factor of the section strength at the position of the maximum bending moment of the main girder of the arch bridge to be greater than 2.2; and from the second suspenders at both ends to the midspan direction, tensioning the suspenders in sequence, finally, tensioning the first suspenders at both ends, then, removing the midspan temporary buttress, and performing bridge deck construction. According to the method for building the prestressed concrete through bowstring arch bridge, the conversion which is simple and easy to implement between the temporary buttress and the stress structure system of an arch ring is realized.

Owner:CHINA RAILWAY 19 BUREAU GRP CO LTD

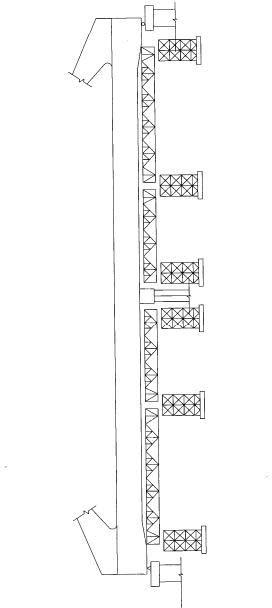

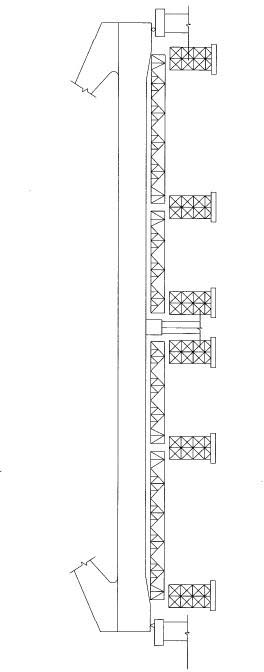

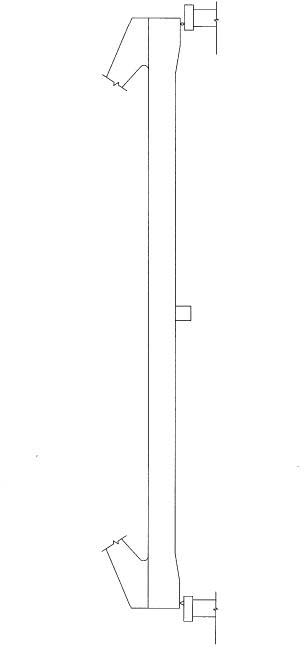

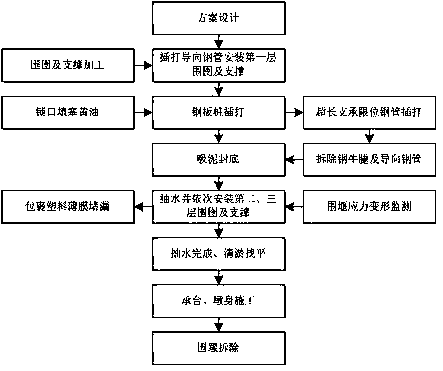

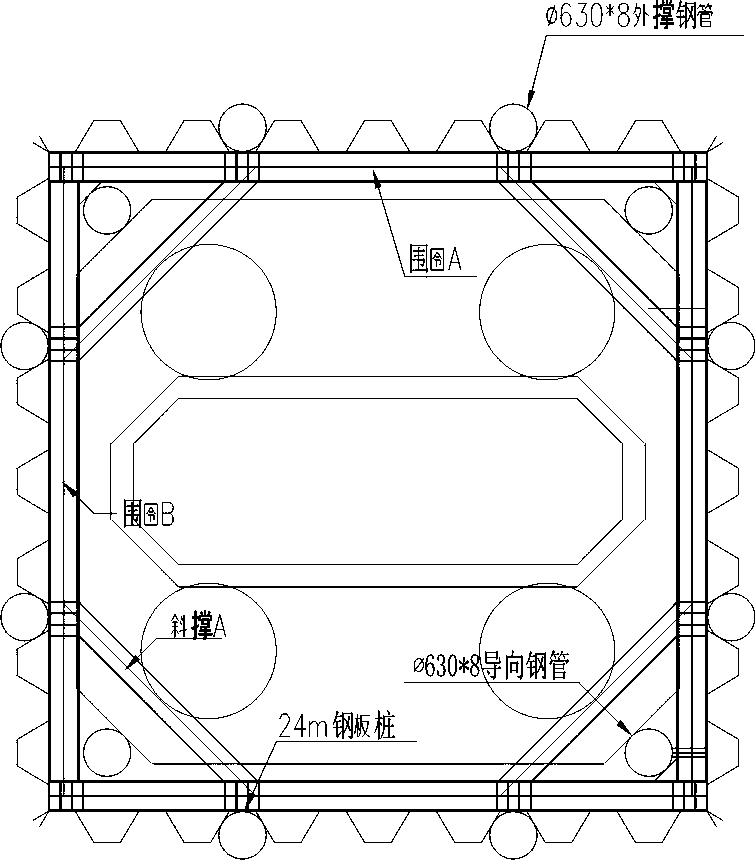

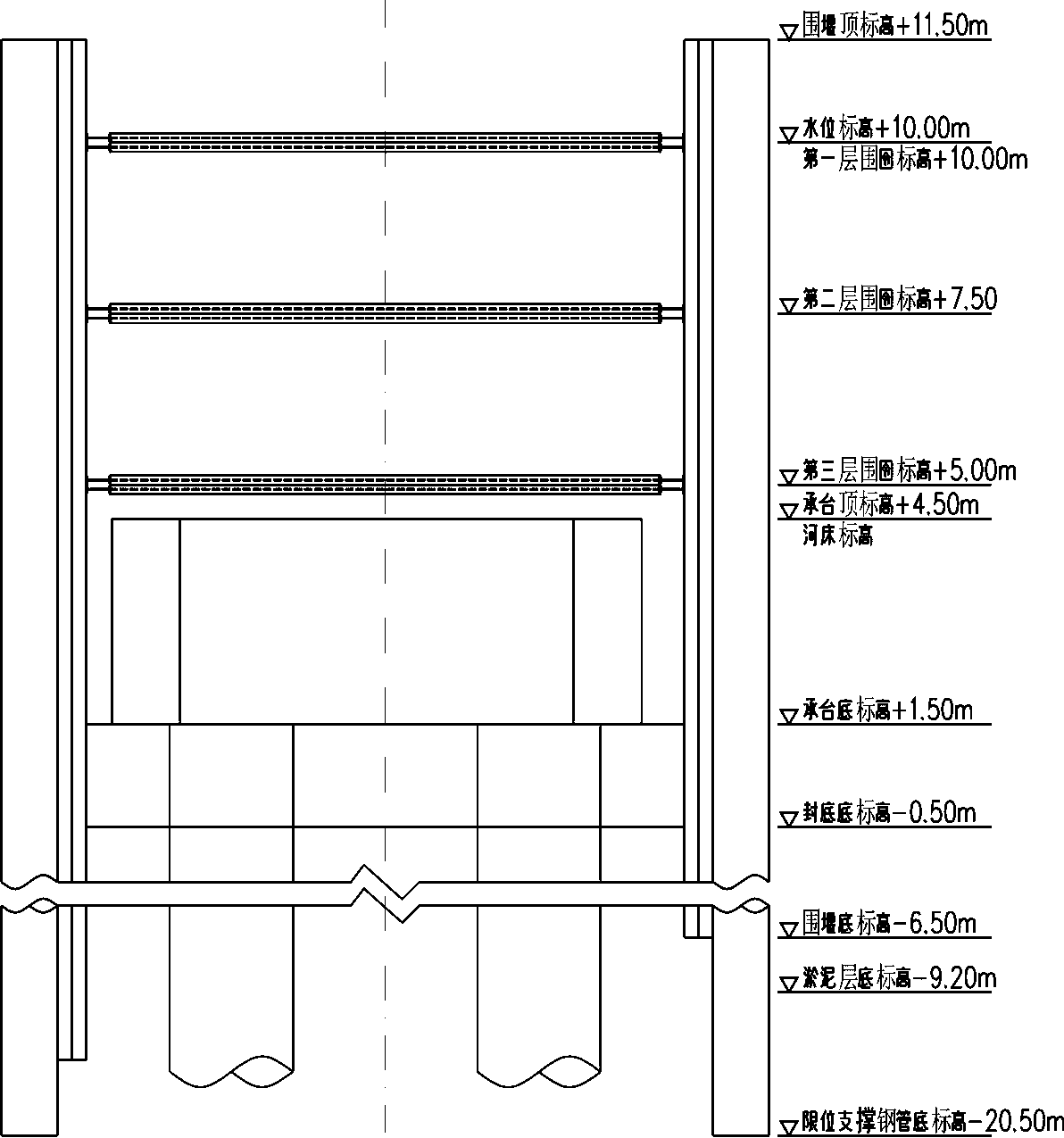

Method for steel sheet pile cofferdam construction in deepwater thick-sludge-layer environment

Owner:SICHUAN ROAD & BRIDGE GRP

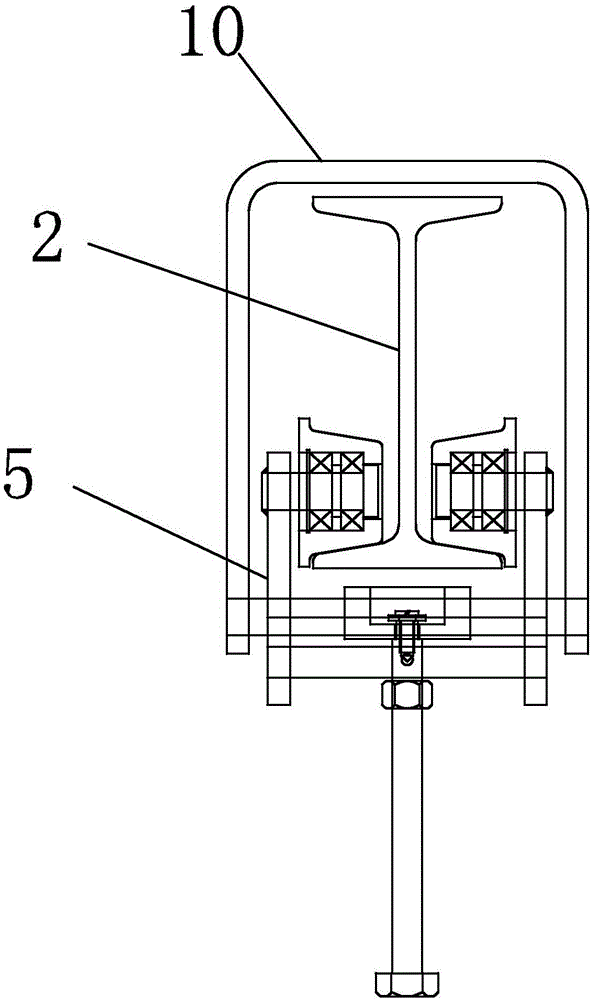

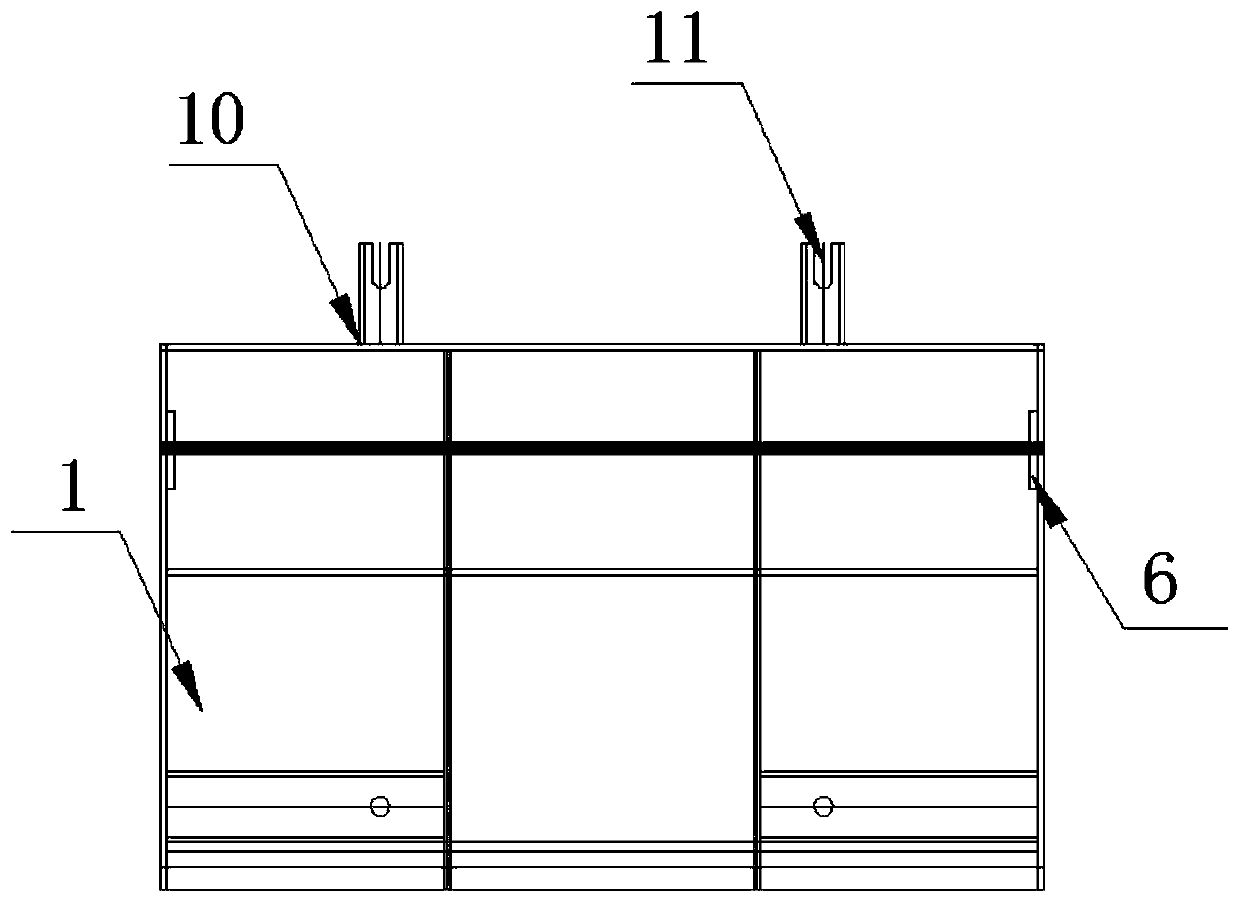

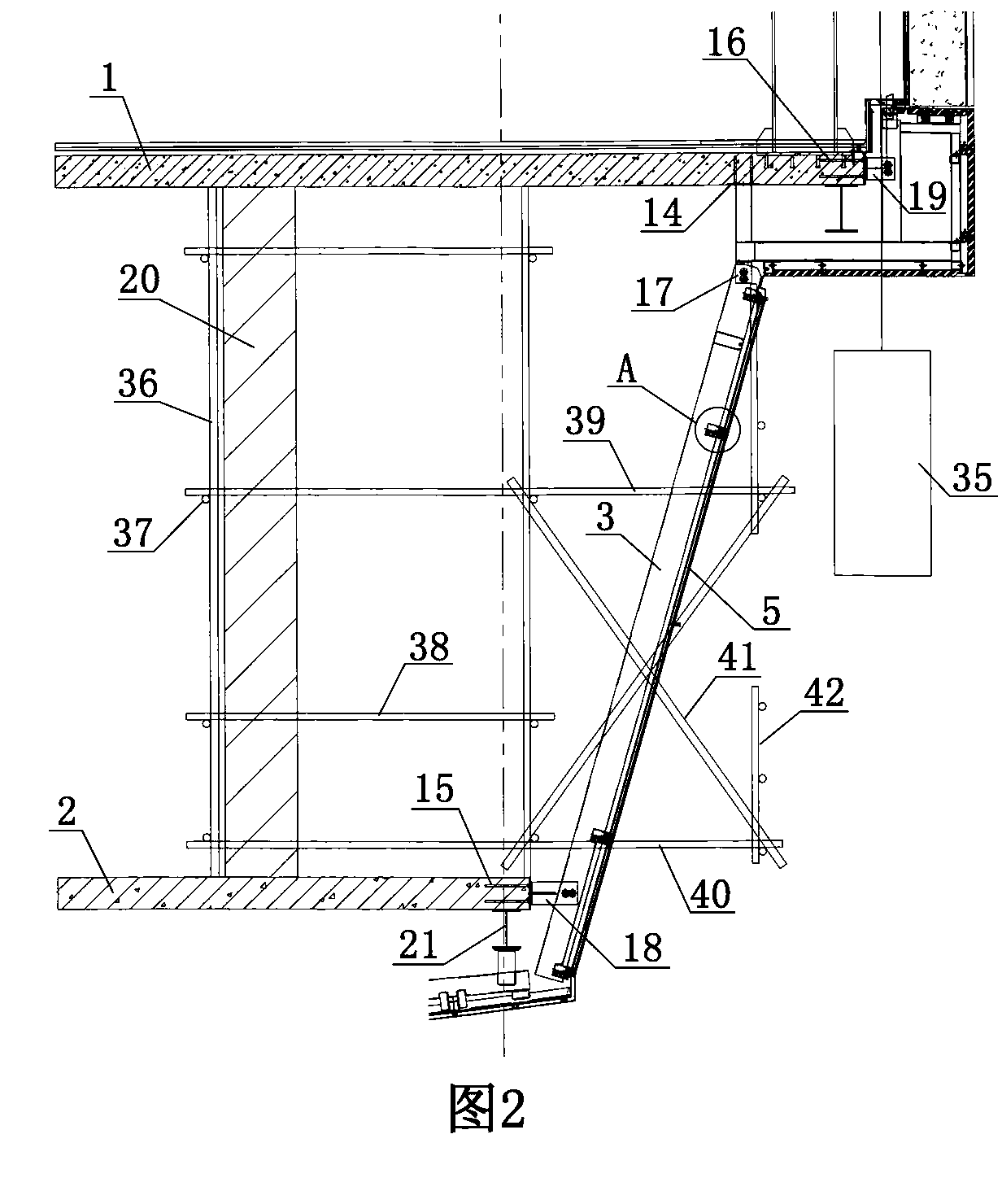

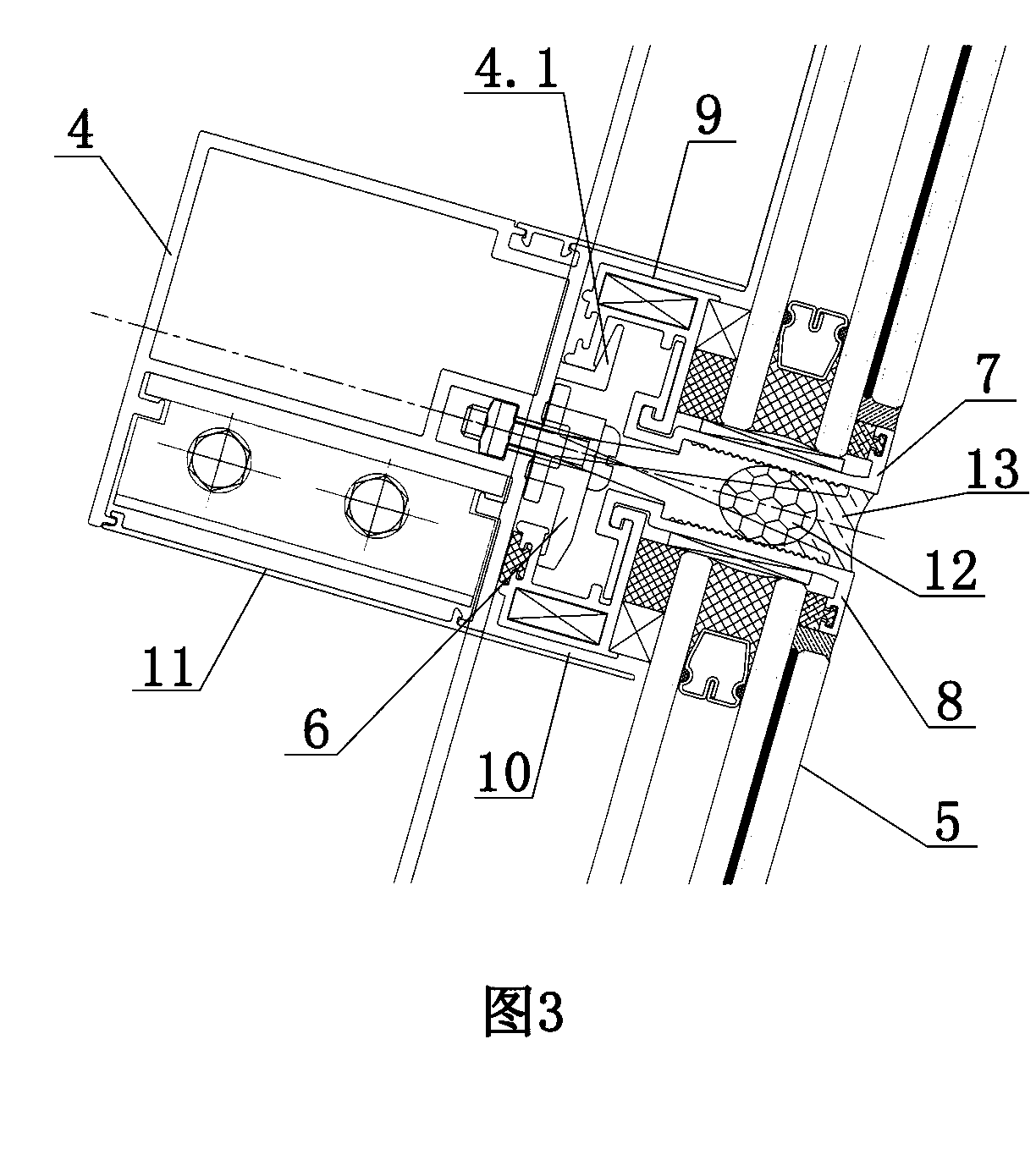

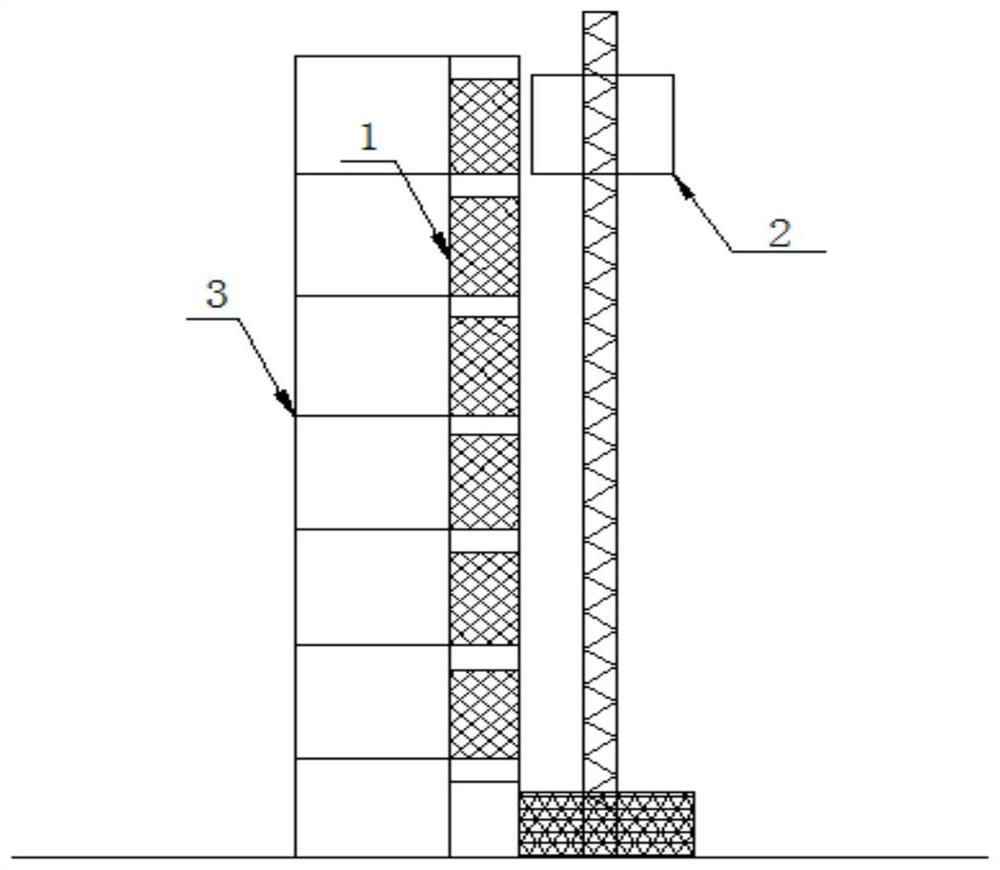

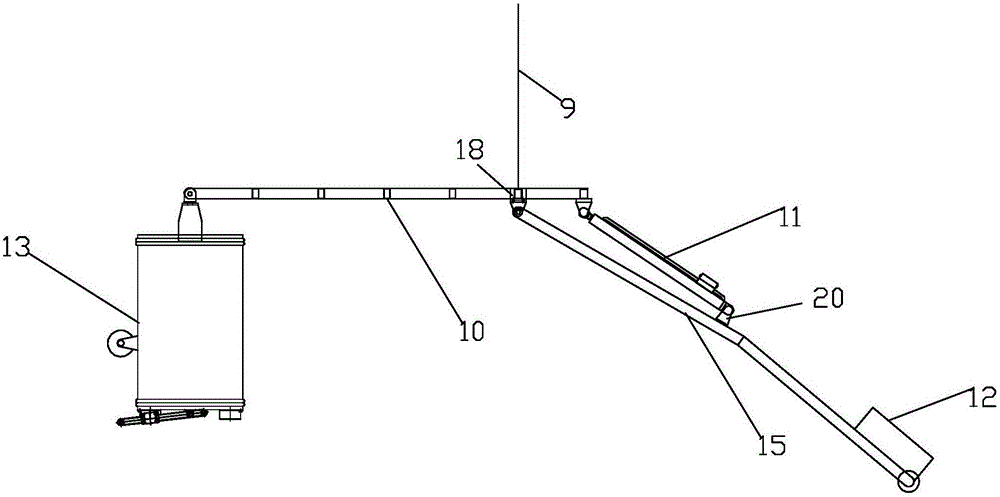

Lifting device for building curtain wall construction and construction method thereof

ActiveCN105888230AHigh reuse rateSolve construction technical problemsWallsBuilding material handlingFalseworkArchitectural engineering

The invention discloses a lifting device for building curtain wall construction with the advantages of simple structure, capacity of moving back and forth and high safety and a construction method thereof. The lifting device comprises a vertical support which is vertically mounted on a building main body, wherein a horizontal overhang main beam is mounted at the upper end of the vertical support along the horizontal direction; a traveling device is movably mounted at one end, which is far away from the vertical support, of the horizontal overhang main beam; traveling wheels are arranged on the traveling device; and the traveling device moves on the horizontal overhang main beam along the horizontal direction by virtue of the traveling wheel. According to the invention, the limitations that construction of a scaffold is unreasonable in economy and the construction is difficultly performed by using a common basket are overcome. Meanwhile, the lifting device disclosed by the invention is high in repeated utilization rate, the cost is saved, the mechanical property is good, the construction efficiency of a special curtain wall is greatly improved, and the high-altitude construction safety is guaranteed.

Owner:JANGHO GRP +1

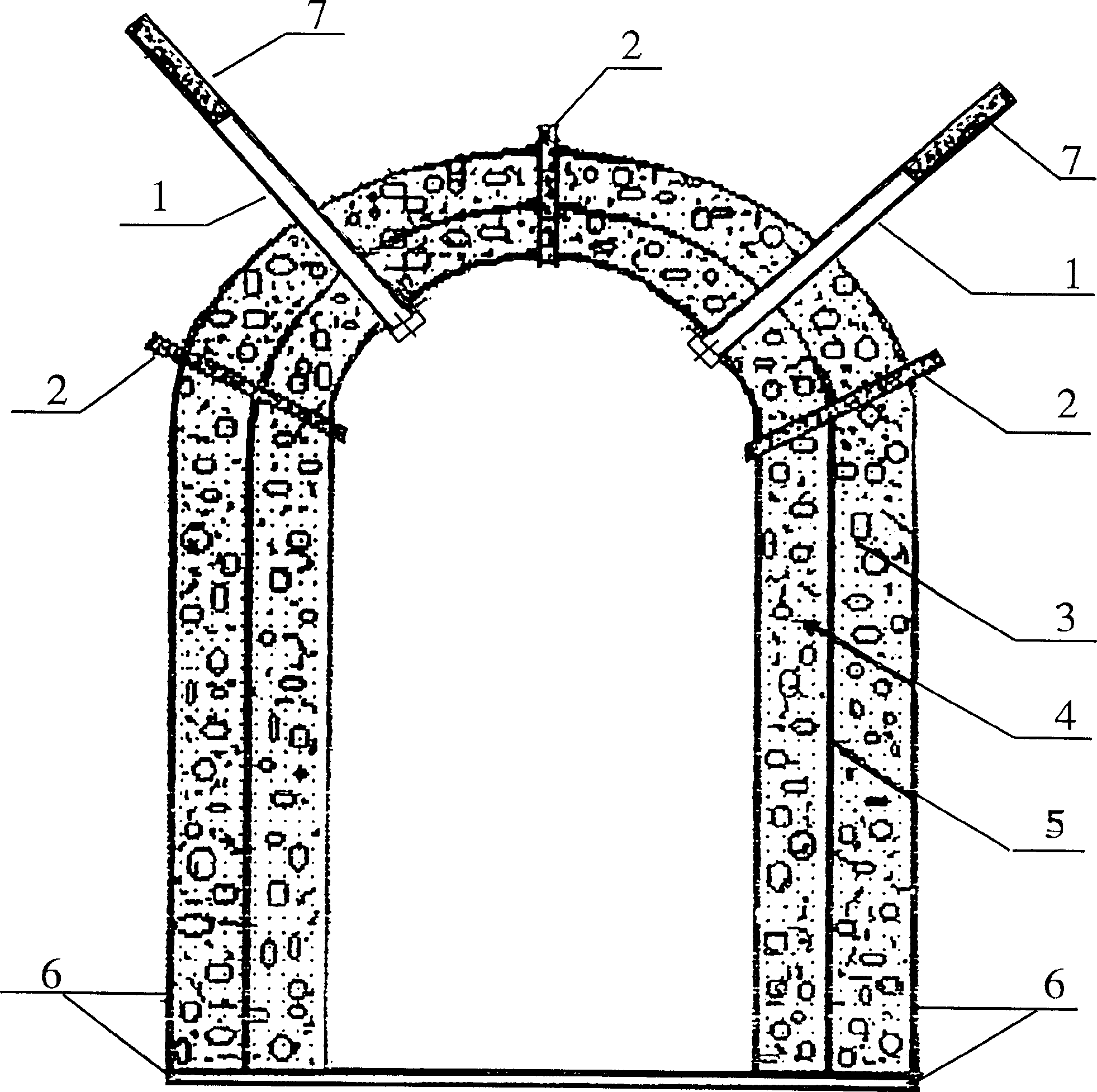

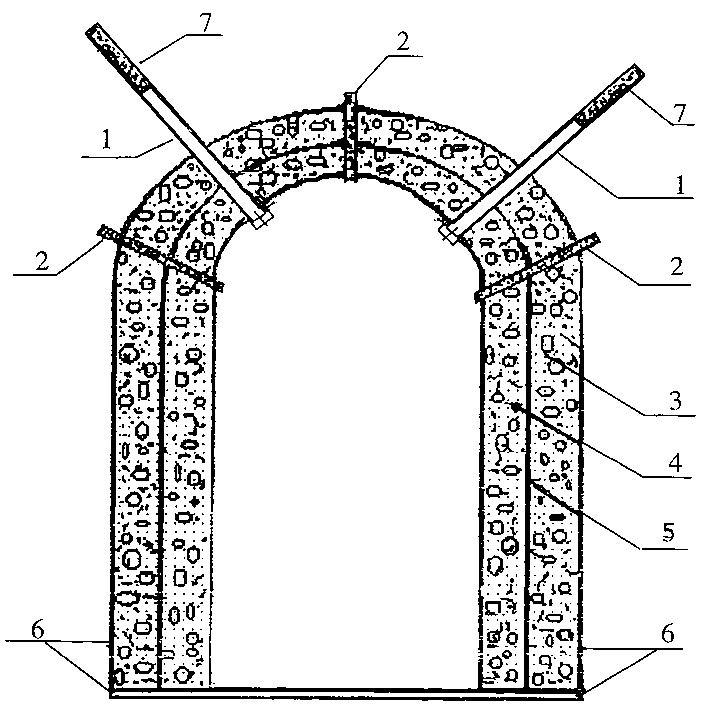

Treatment method for annularly continuous bead-like karst caves of tunnel

ActiveCN106351202ASolve construction technical problemsEasy constructionUnderground chambersTunnel liningEmergency treatmentKarst

The invention provides a treatment method for annularly continuous bead-like karst caves of a tunnel. The method comprises steps of execution of emergency treatment measures, primary support treatment of vault caves, primary support treatment of left-skewback caves and primary support treatment of right-hance caves. The treatment method for the annularly continuous bead-like caves of the tunnel is safe, reliable, scientific, feasible, convenient to construct, economical and reasonable, solves the technical problems in construction of the bead-like caves while the construction duration is short, provides reference for follow-up similar cave treatment especially treatment of the vault caves, and realizes the effects of saving time and labor and facilitating construction.

Owner:NO 4 ENG COMPANY LTD OF CCCC FIRST HARBOR ENG COMPANY

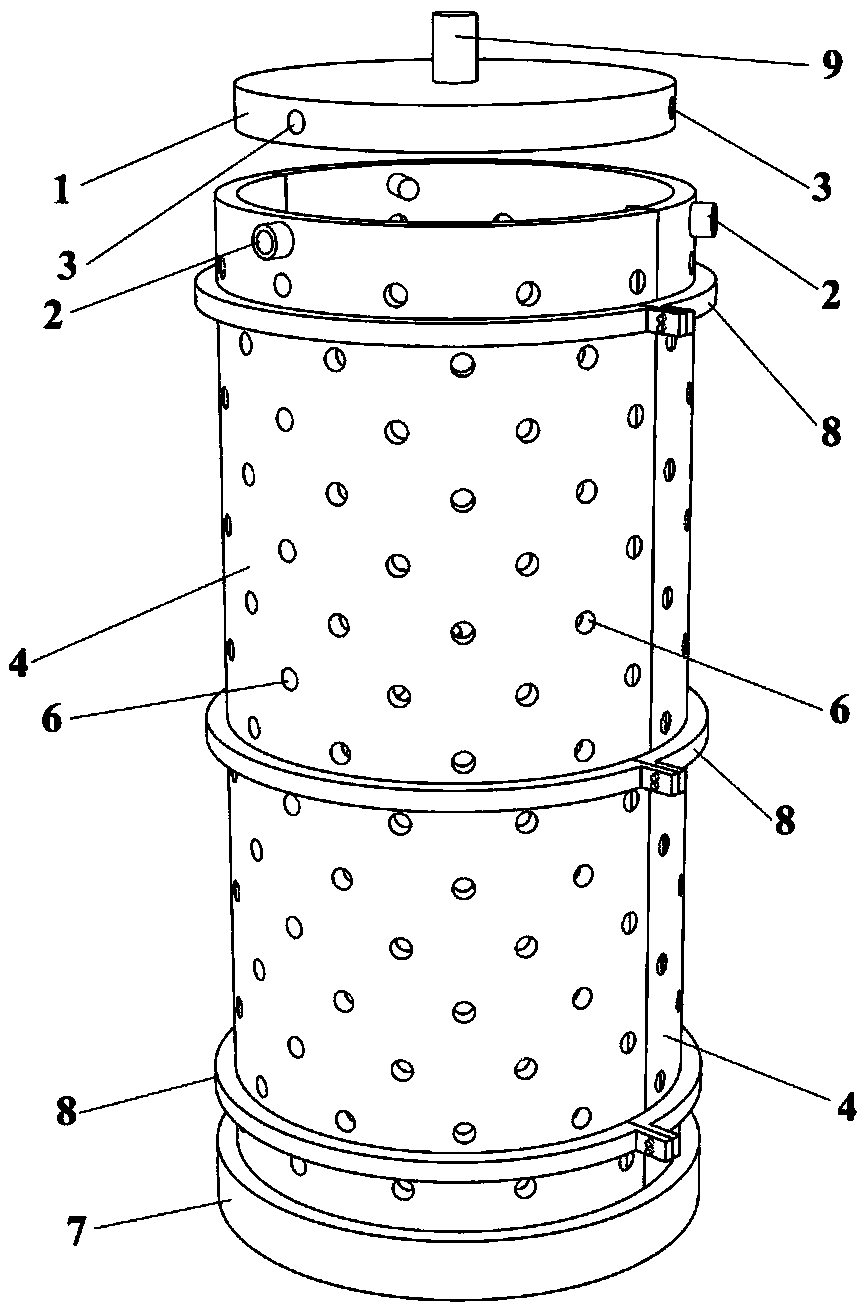

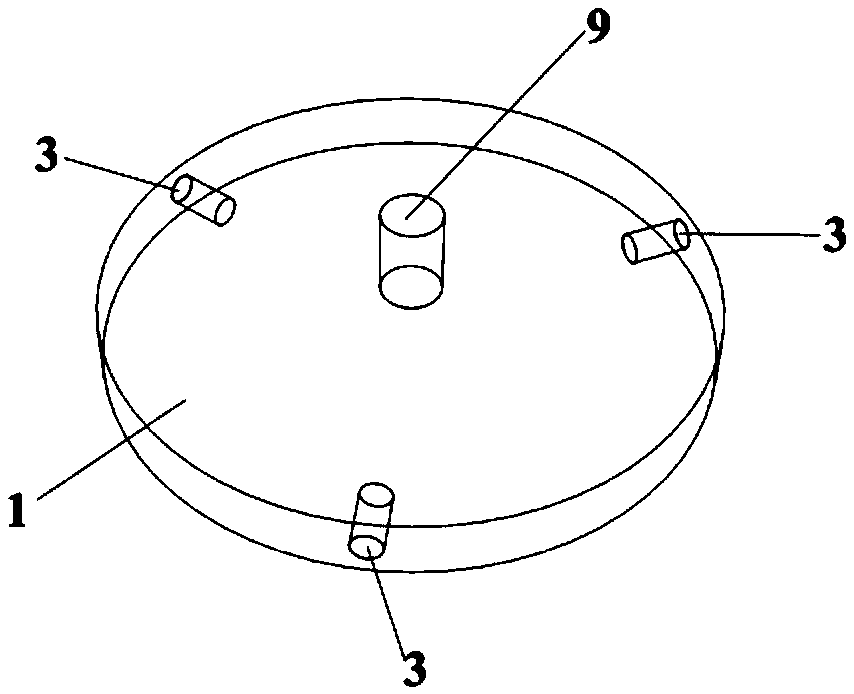

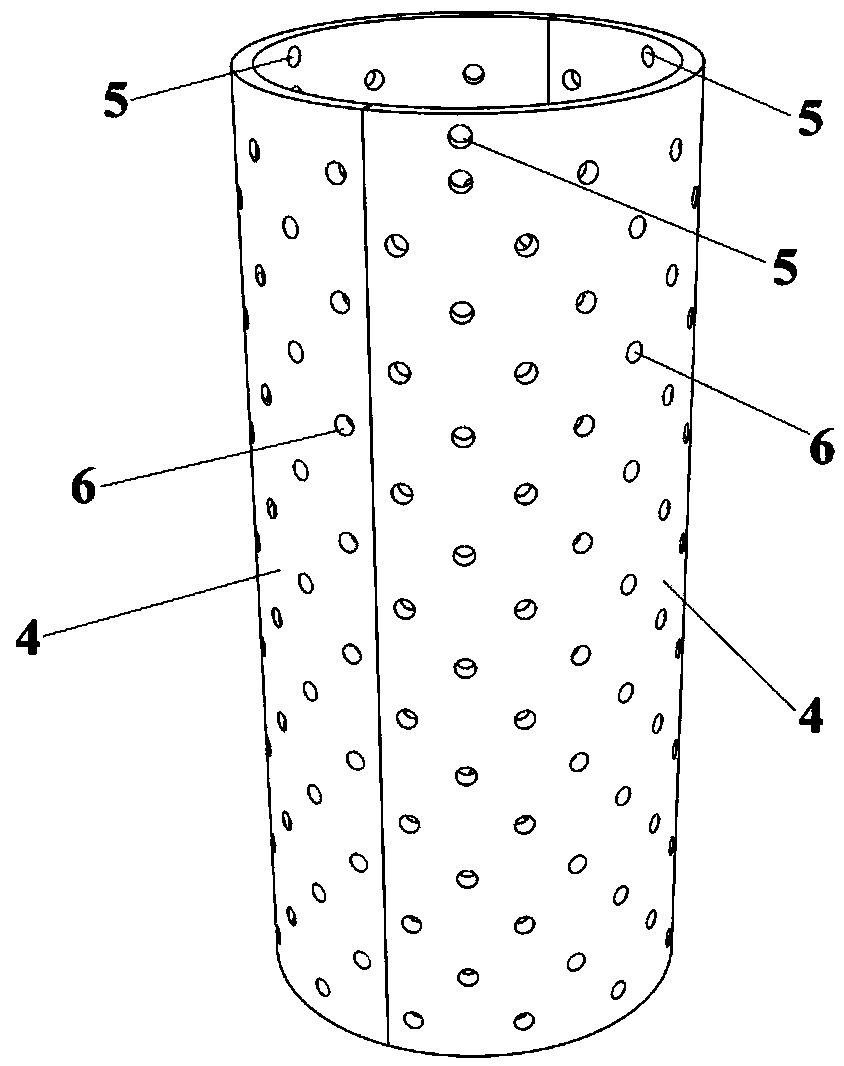

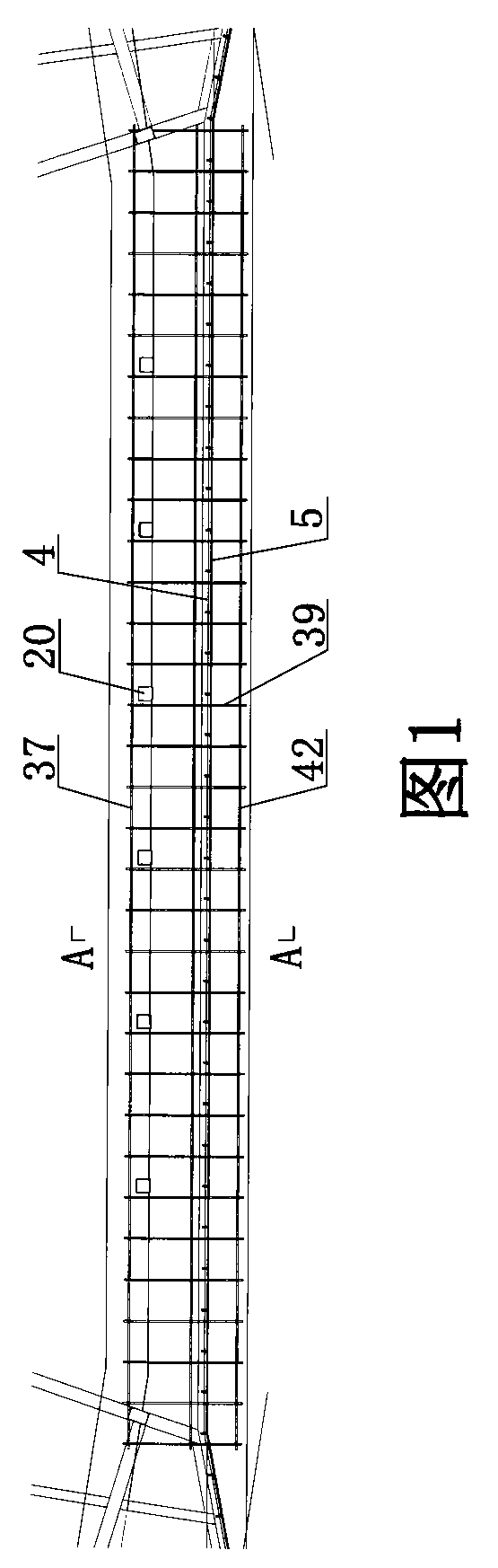

Anchor rod embedding device for true three-dimensional geomechanics model test, and operation method

ActiveCN109061108ASolve construction technical problemsSimple structurePreparing sample for investigationEarth material testingEngineeringModel test

The invention discloses an anchor rod embedding device for a true three-dimensional geomechanics model test, and an operation method. The anchor rod embedding device comprises a base, a top cover, a connecting element, a protection cylinder and hoop rings, wherein the protection cylinder consists of two semicircular cylinders and is provided with anchor rod positioning holes. When the device is used, the protection cylinder is inserted into the trough of the base and is fixed with the base into a whole through the hoop rings. By use of the device, the technical problems in the true three-dimensional geomechanics model test that the system anchor rod is difficult in embedding, the position and the direction of the anchor rod is difficult in fixing and an embedding range is limited can be solved, and meanwhile, the device has the advantages of being simple in construction, convenient in disassembling, reliable and practical, and the operation method can be easily mastered and has a wideapplication prospect.

Owner:SHANDONG UNIV

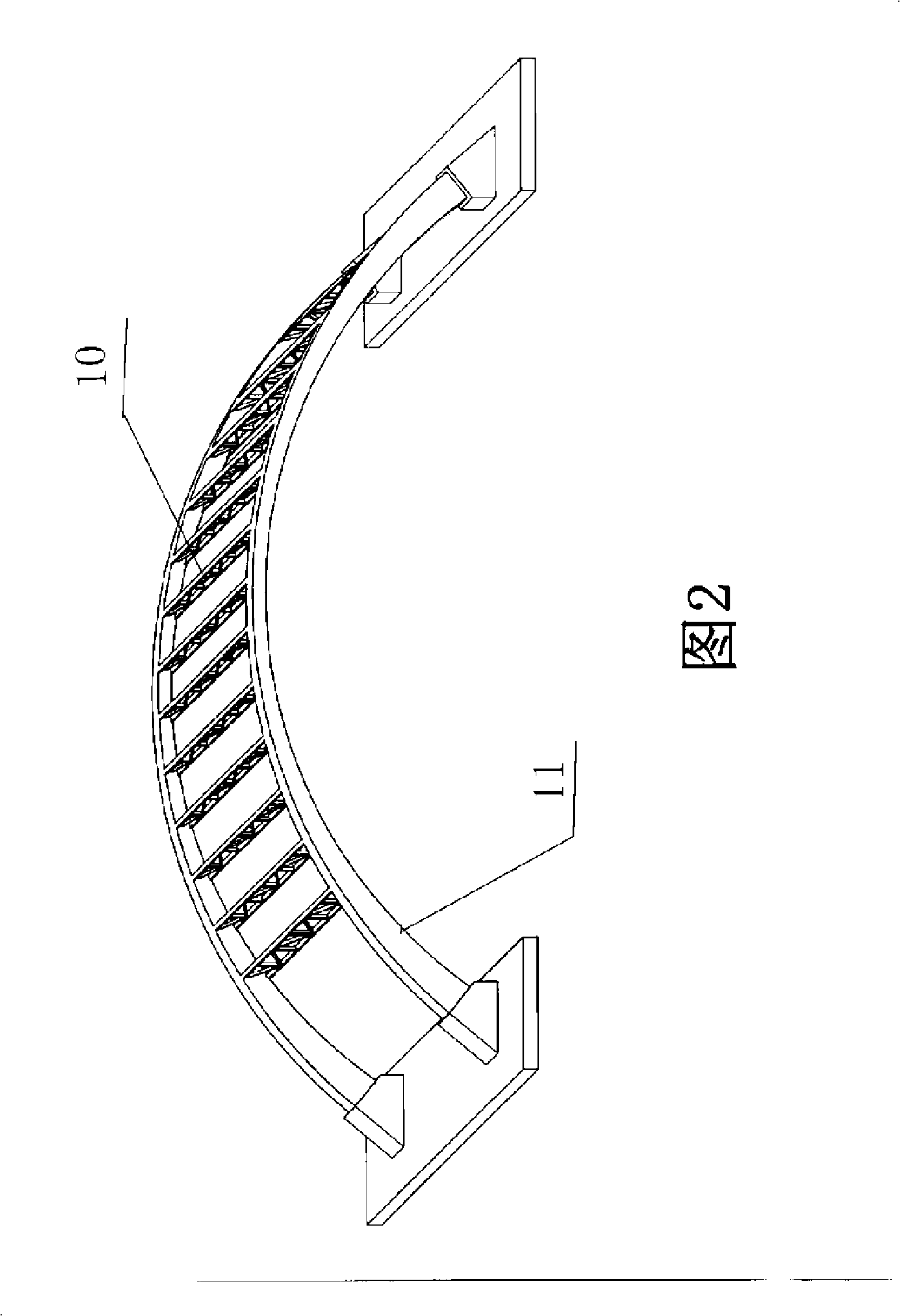

Construction method of large-span box variable cross-section reinforcement concrete arch

InactiveCN101324086AReasonable structureLight weightArched structuresVaulted structuresReinforced concreteSteel bar

The invention relates to a large-span box-shaped variable-section reinforced concrete arch construction method, comprising the steps as follows: after the foundation construction is completed, an arch springing bearing platform is formed by concrete pouring on the foundation; subsequently, an arch body supporting frame foundation construction is carried out; on the foundation of the arch body supporting frame, the arch body supporting frames are symmetrically arranged between two arch springings; on the arch body supporting frame, arch body external formwork bottom plates are symmetrically arranged from two ends of the arch springings to the center of the arch body at the same time; the bottom reinforcement of the arch body is binded on the upper surface of the external formwork bottom plate; subsequently, the arch body formworks are installed; the concrete is poured by sections from the two ends to the middle of the arch simultaneously; finally, the concrete used for sealing the arch is poured; when the formworks are removed, the formworks are removed symmetrically from the center to the two ends of the arch springing simultaneously; finally, the concrete curing of the arch body is carried out. The construction method of the invention solves the construction technical problem of large-span reinforced concrete hollow variable-section arch.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU +1

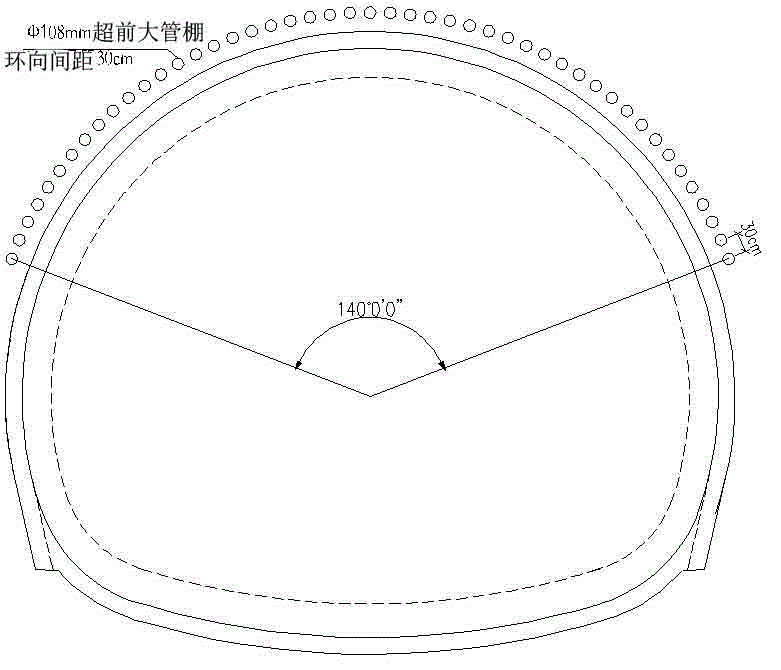

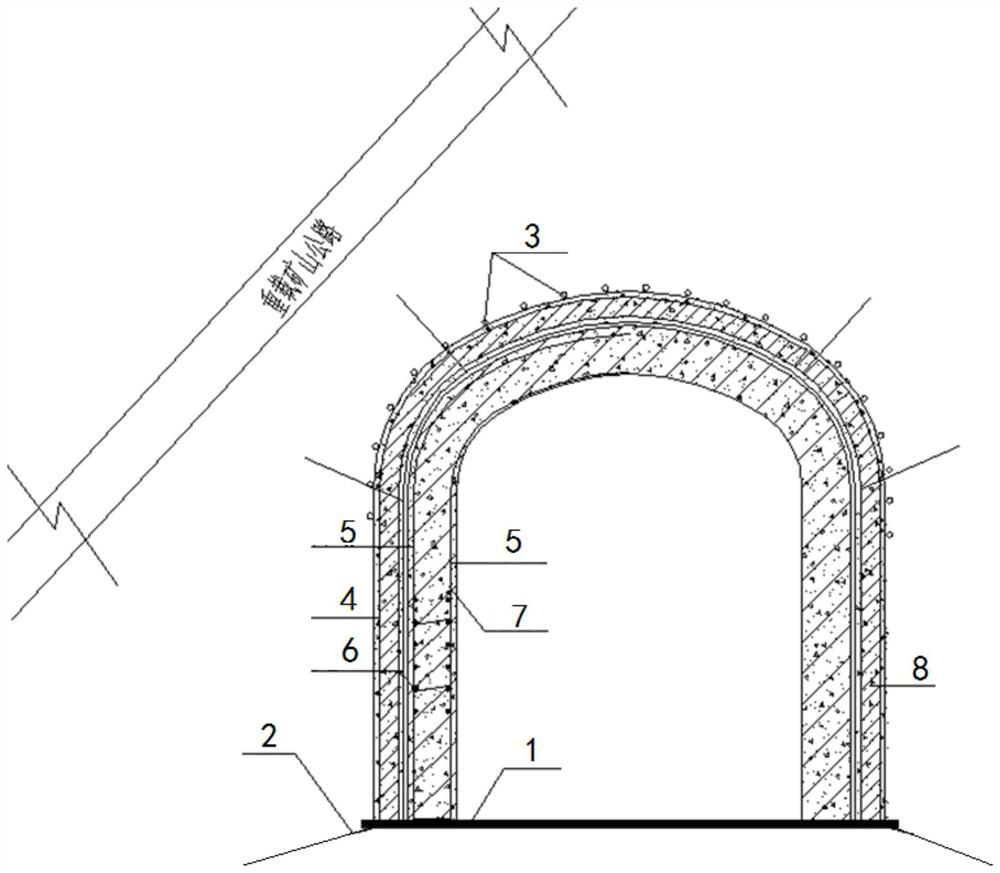

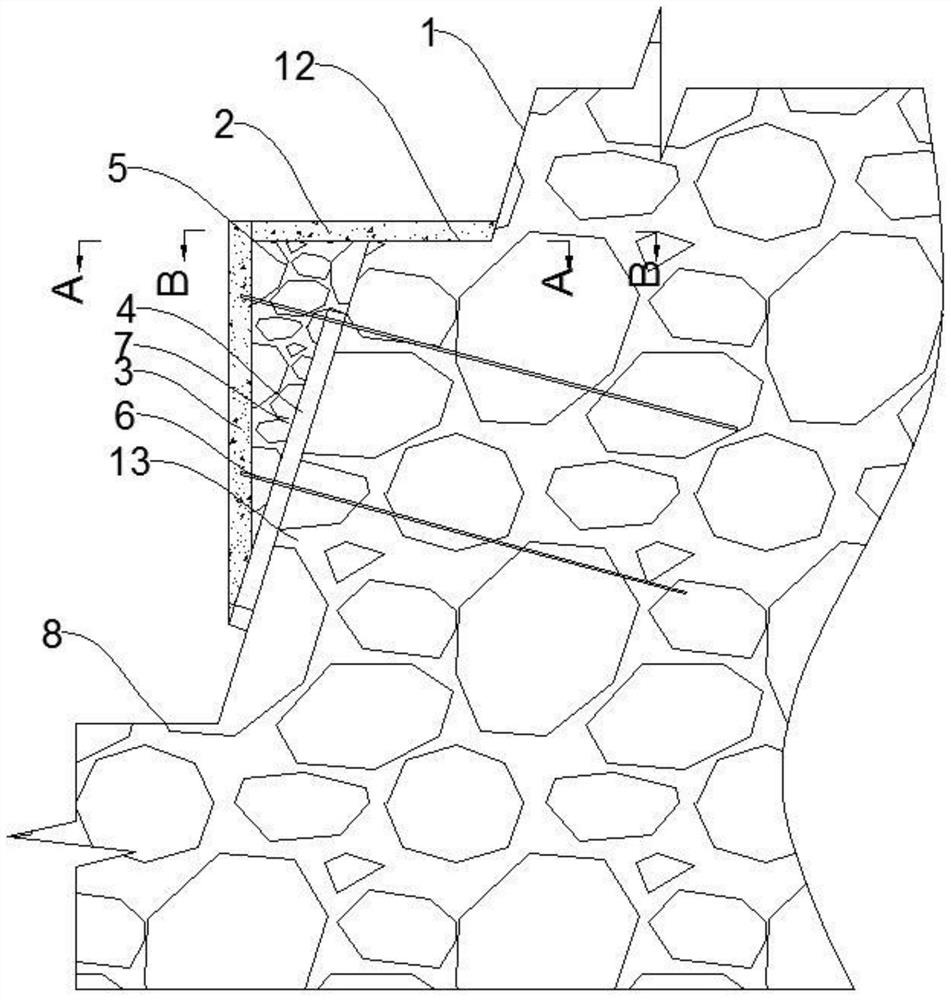

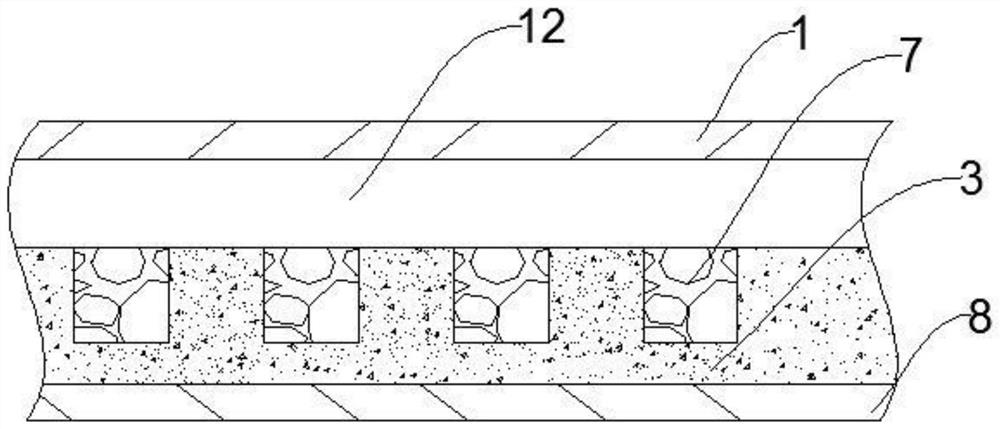

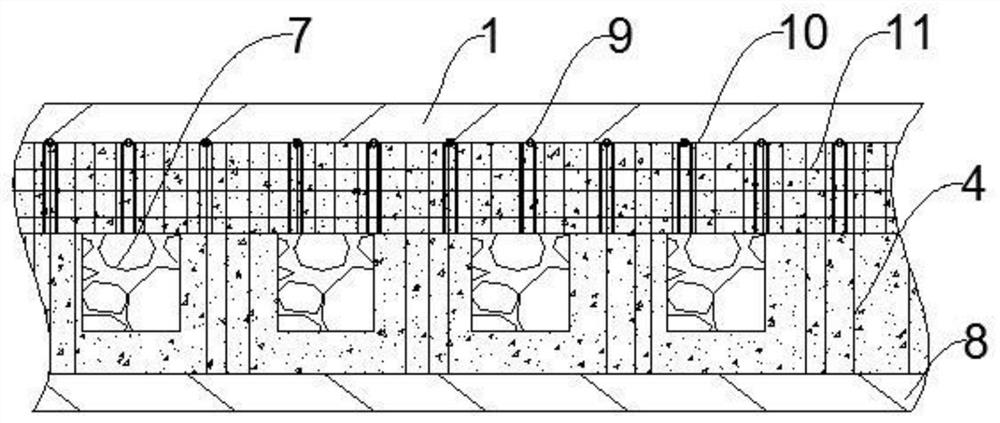

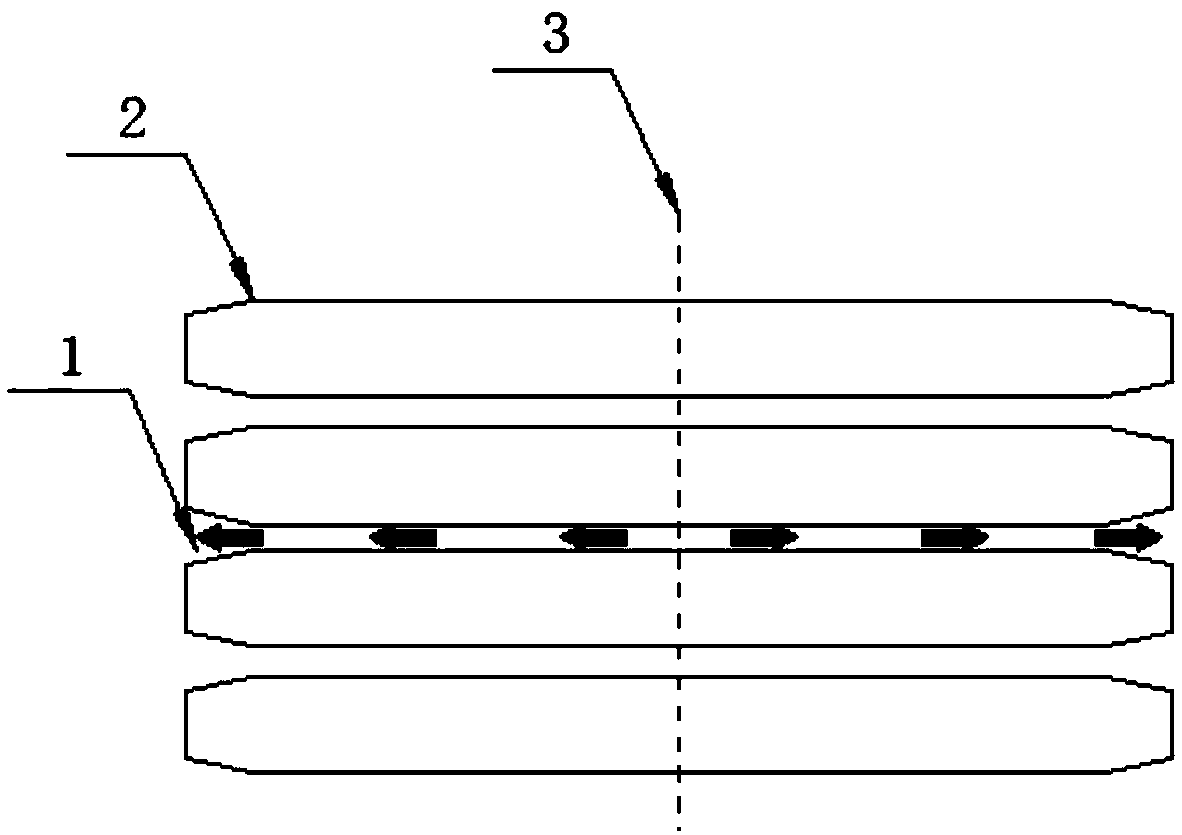

Tunnel-entering construction method for crossing shallow-layer large-load road

ActiveCN112031814AReduce deformation effectsGuaranteed stabilityMining devicesUnderground chambersSlagArchitectural engineering

The invention discloses a tunnel-entering construction method for crossing a shallow-layer large-load road, and relates to the technical field of tunnel construction. The tunnel-entering constructionmethod for crossing the shallow-layer large-load road comprises the following steps: a concrete wall is poured on the outer side of a tunnel for preliminary maintenance of the tunnel; holes are drilled in the arch crown of the tunnel and the preset position, away from an arching line, of the straight wall section of the tunnel, and mounting holes are obtained; at least two pipe sheds are pressed into any mounting hole in sequence, and every two adjacent pipe sheds are welded; grouting guide pipes are installed in the pipe sheds, and consolidation grouting is conducted in the grouting guide pipes; tunnel entering is conducted to crush surrounding rock, and primary support is conducted after slag is discharged out of the tunnel; and a lining formwork is installed in the tunnel and reinforcedconcrete lining is conducted, and the step of entering the tunnel to crush the surrounding rock is repeatedly executed. According to the tunnel-entering construction method, the technical problem that the tunnel passes through a shallow large-load mine road is solved, the tunnel construction safety is ensured, meanwhile, the investment is saved, and the economic benefit is improved.

Owner:PANGANG GRP ENG TECH

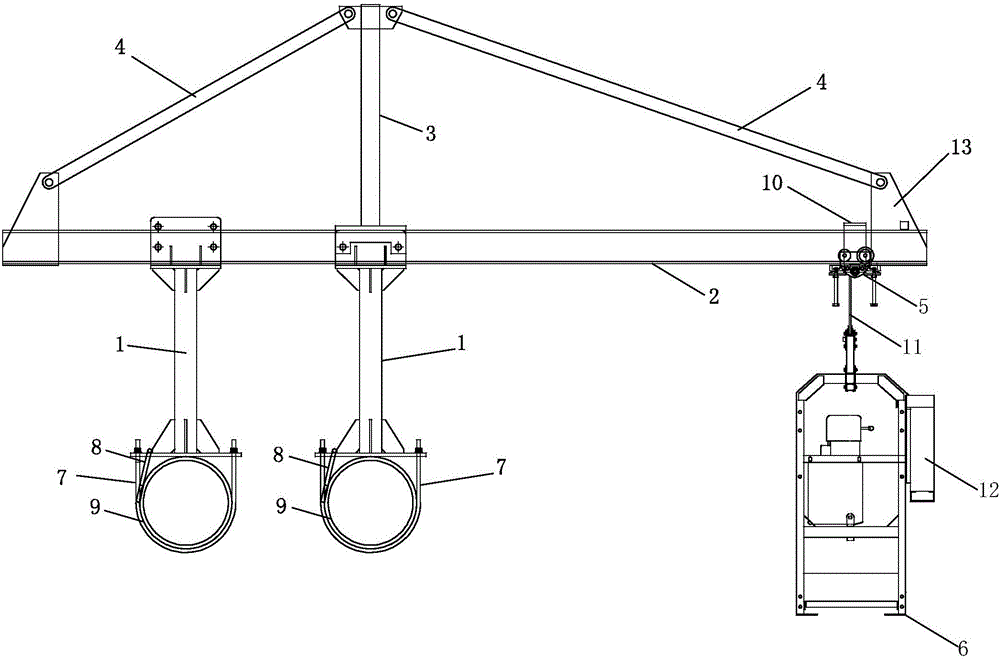

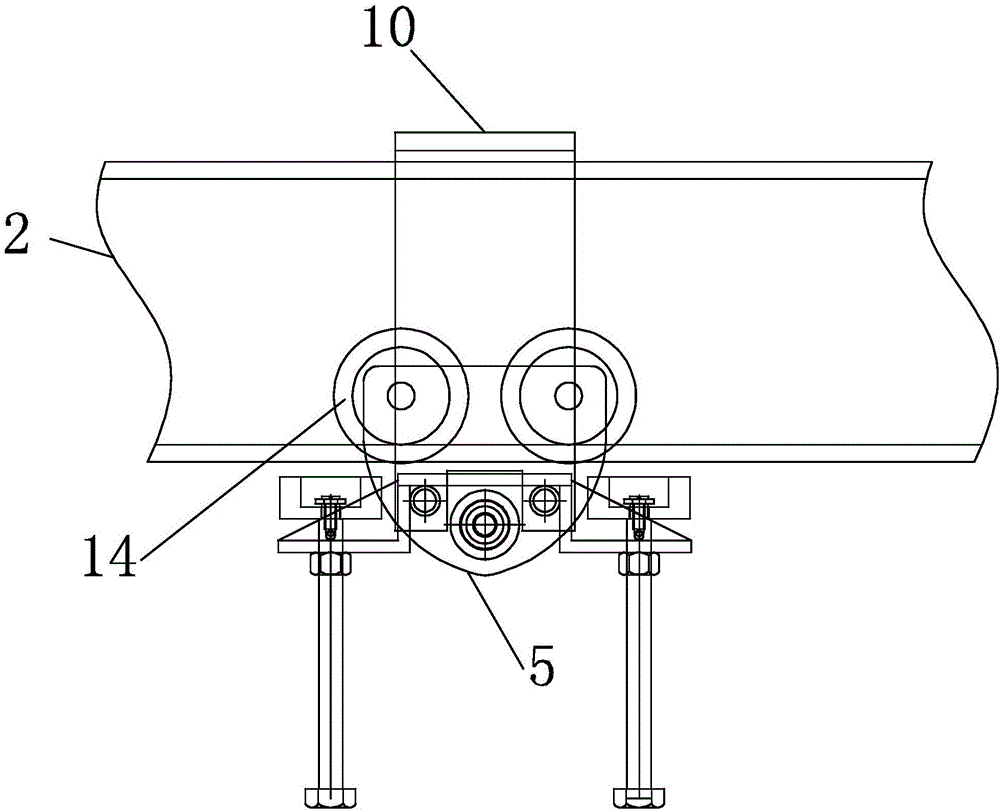

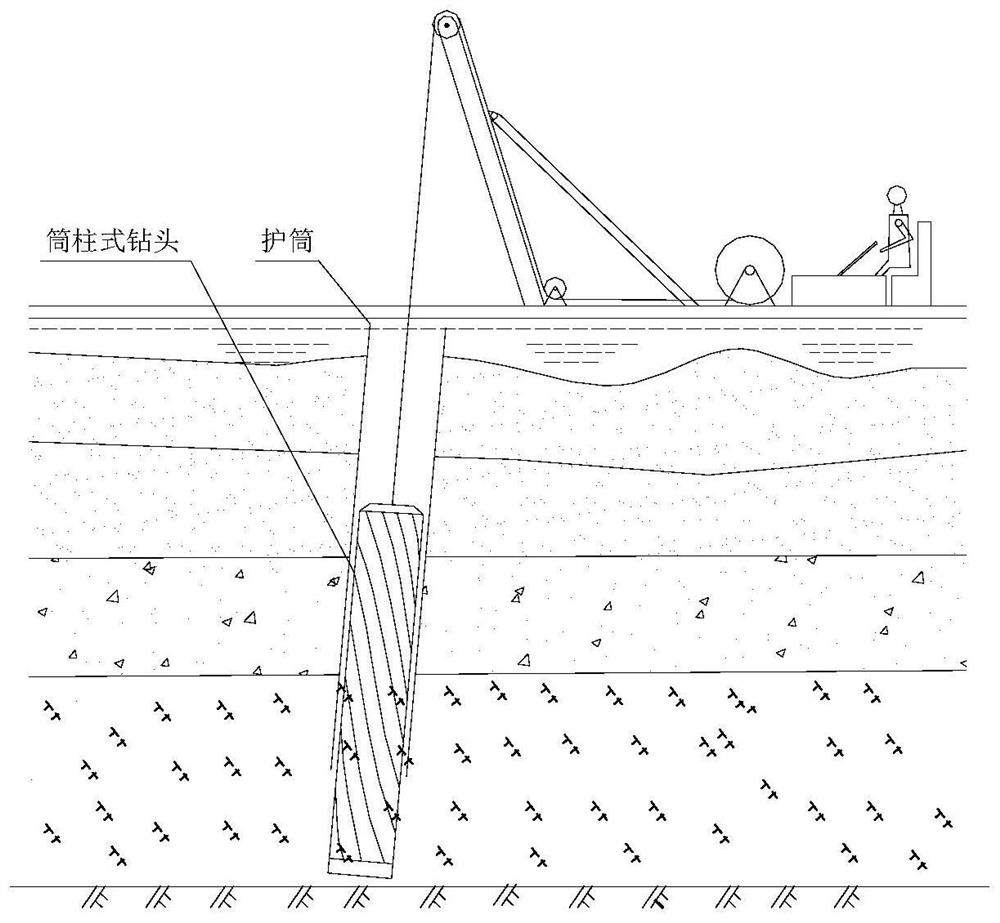

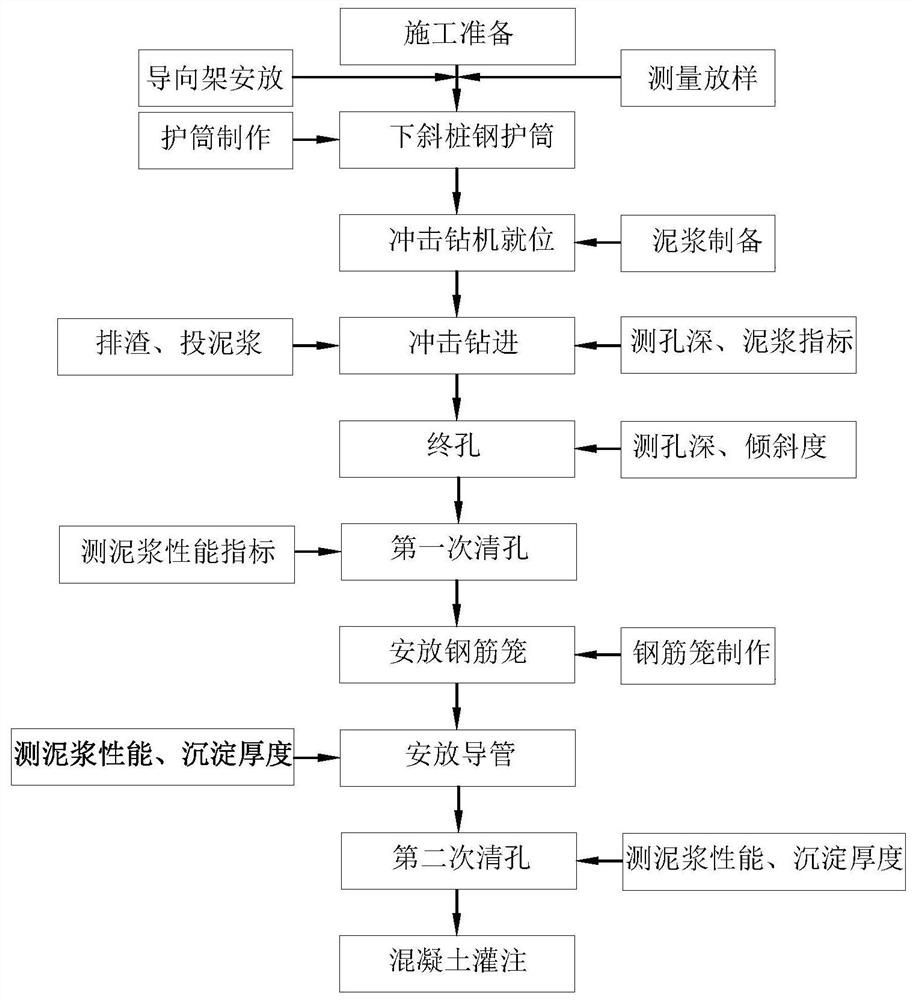

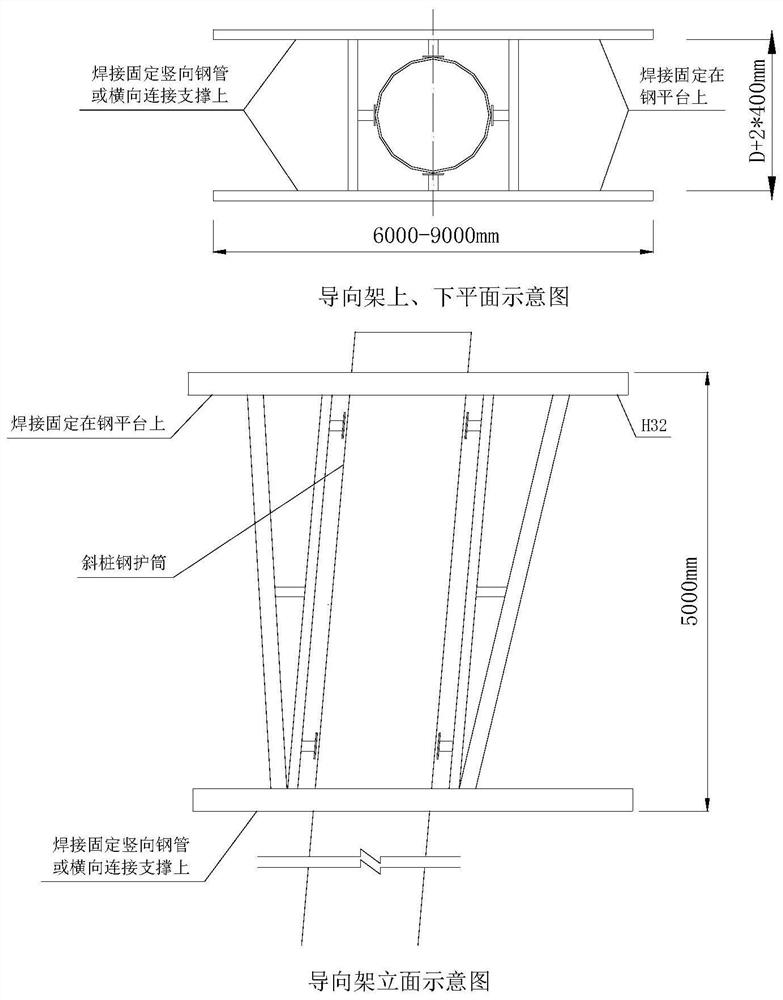

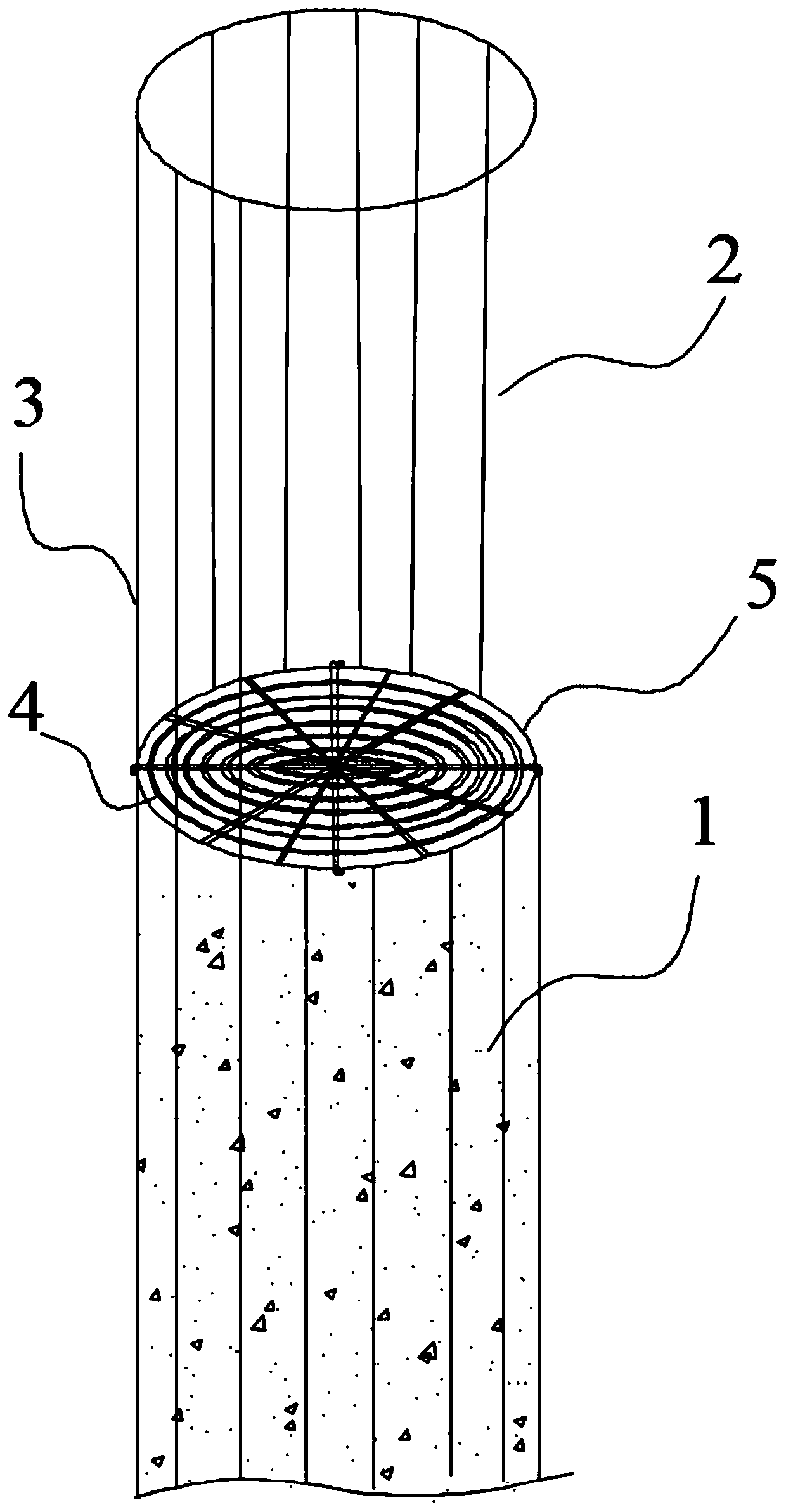

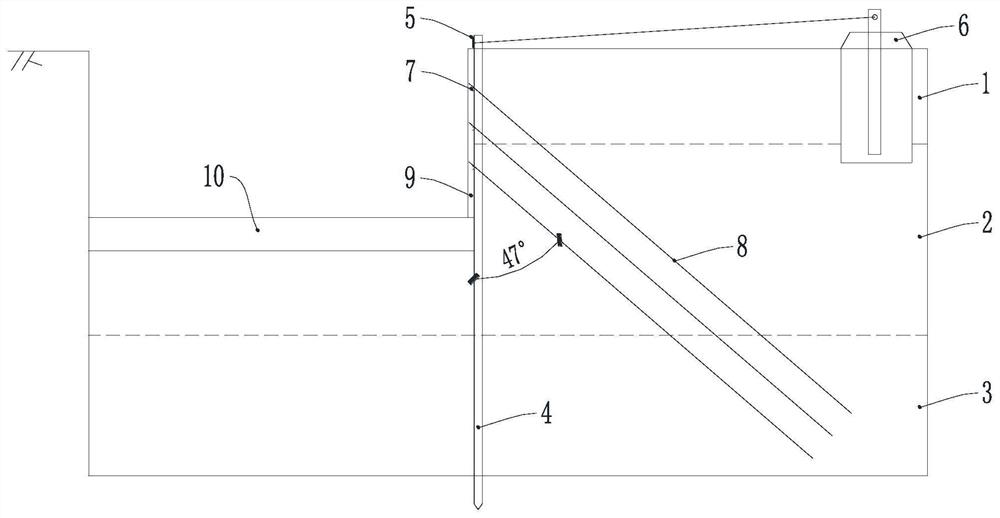

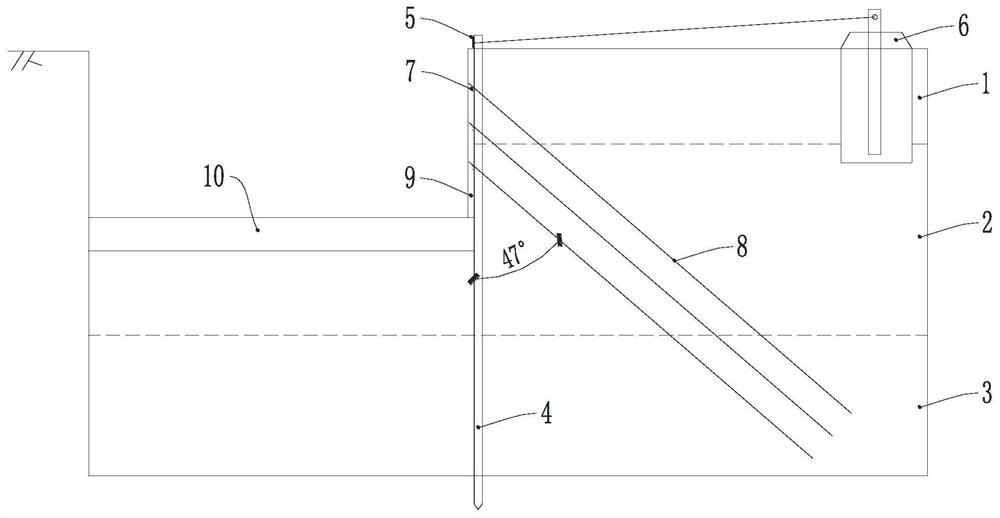

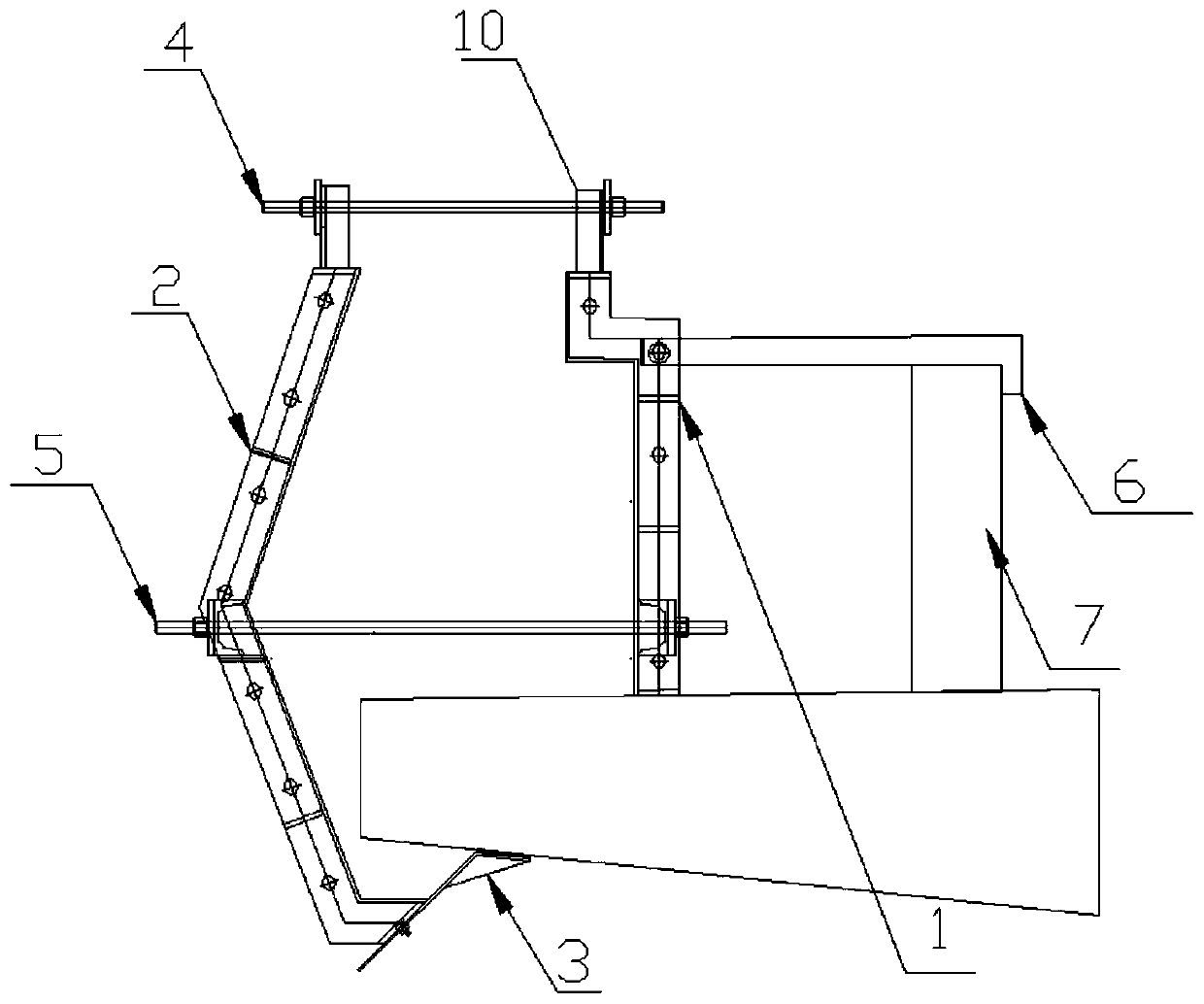

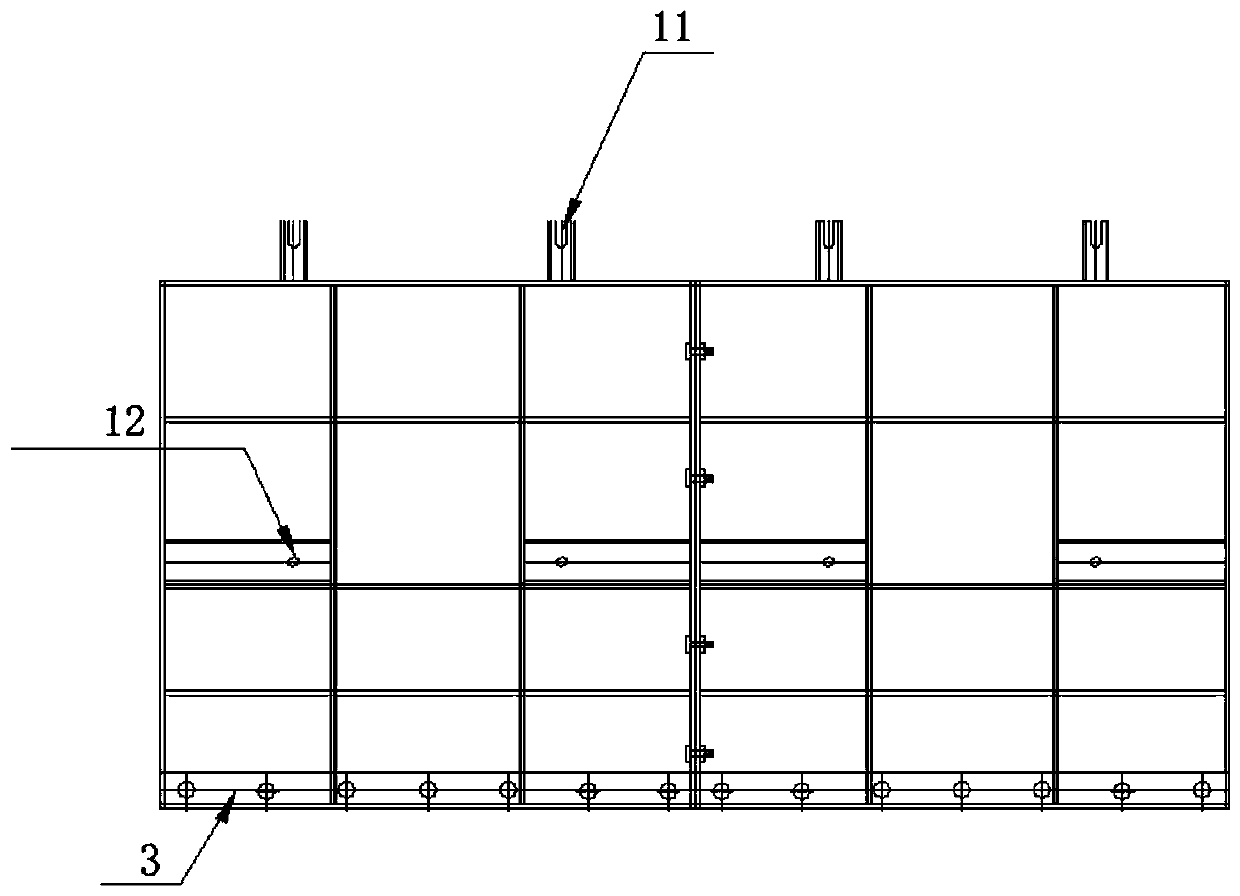

Rock-socketed oblique pile impact-drilling and pile-forming construction process

InactiveCN111663892ASolve construction technical problemsGuarantee the pile qualityEarth drilling toolsReciprocating drilling machinesRebarGuide tube

The invention discloses a rock-socketed oblique pile impact-drilling and pile-forming construction process which belongs to the technical field of port wharf tubular pile construction. The rock-socketed oblique pile impact-drilling and pile-forming construction process comprises the following steps: S1, performing a construction preparation stage; S2, mounting a steel casing guide frame; S3, performing impact holing; S4, clearing holes for the first time; S5, mounting a reinforcement cage; S6, mounting guide tubes; S7, clearing the holes for the second time; and S8, pouring concrete. Accordingto the rock-socketed oblique pile impact-drilling and pile-forming construction process disclosed by the invention, self-innovation equipment and a process are combined to solve oblique pile construction technical problems, so that oblique pile inclination and the pile-forming quality are guaranteed, and oblique pile design requirements are met.

Owner:江西省地质工程集团有限公司

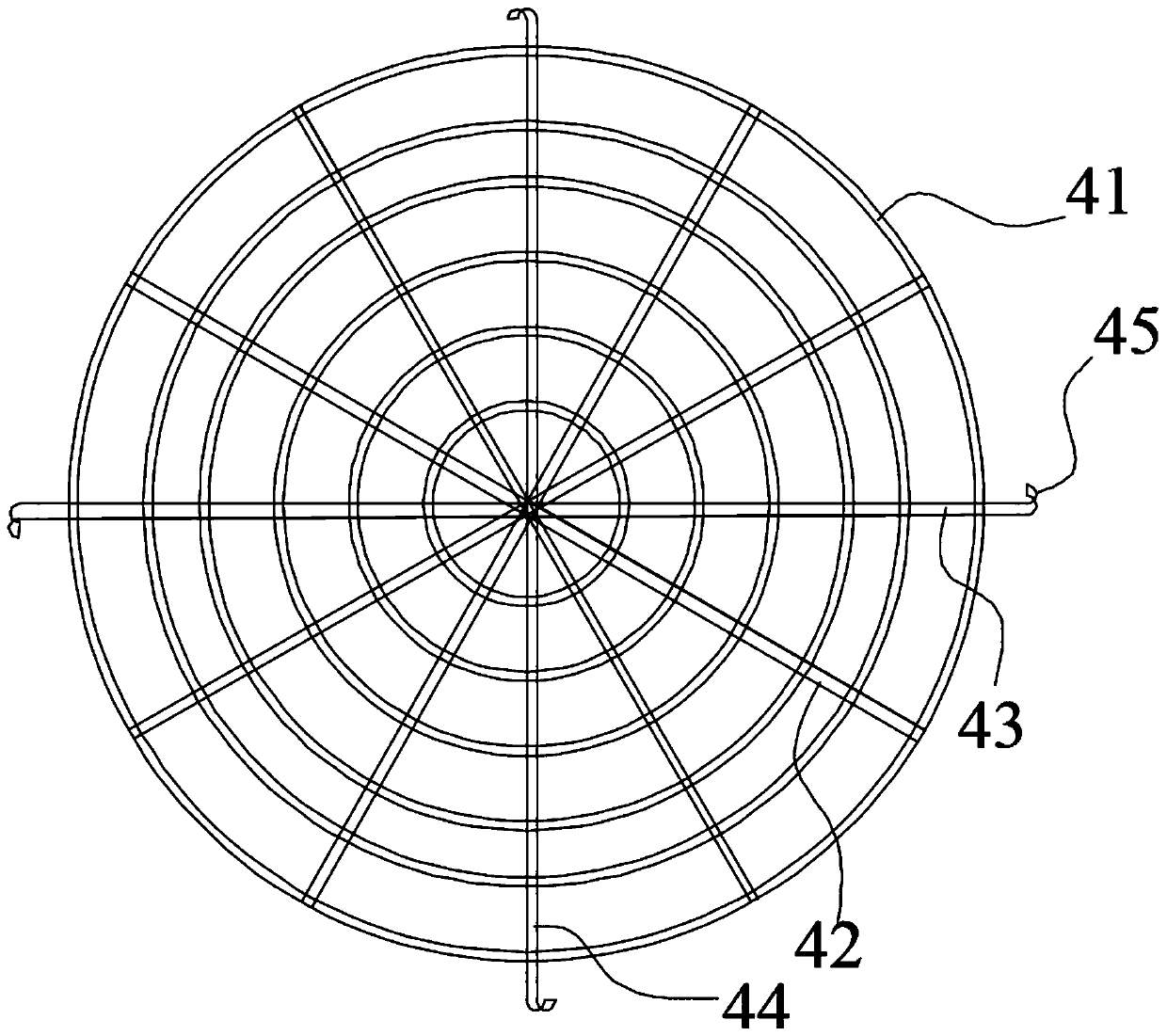

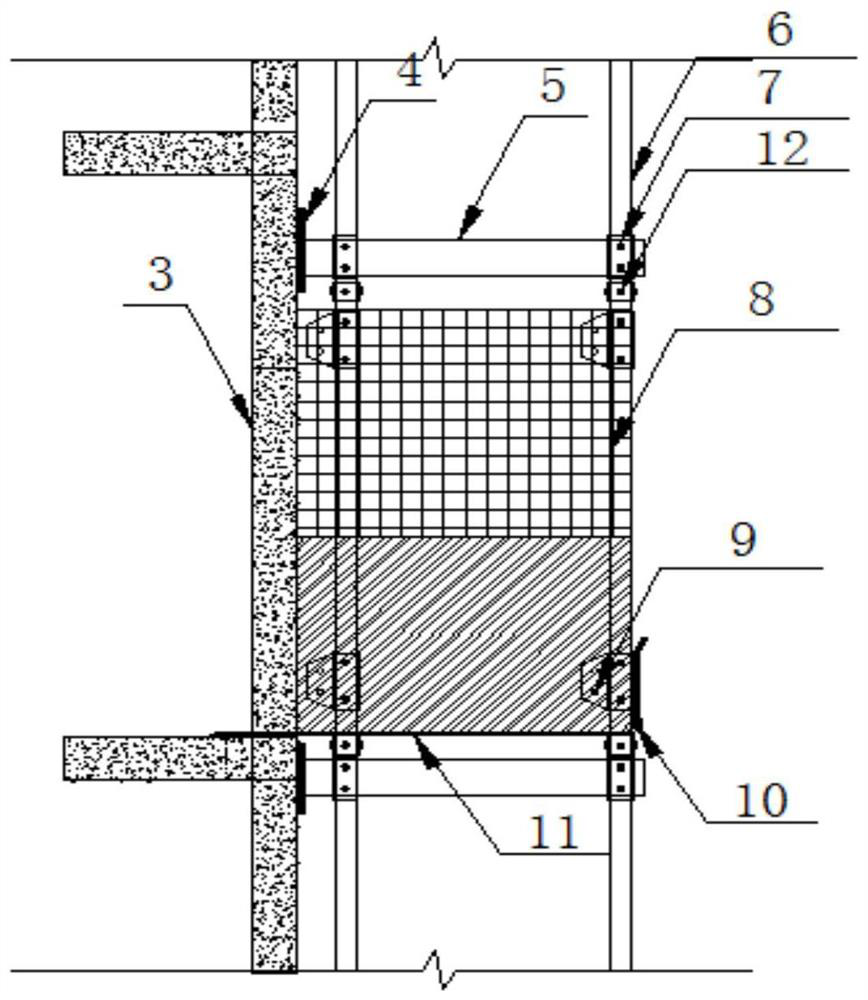

Construction method of pile breaking head of cast-in-place pile, auxiliary isolation net and preparation method of auxiliary isolation net

InactiveCN111395342AEasily brokenQuick and easy to breakDomestic netsBulkheads/pilesArchitectural engineeringRebar

The invention discloses a construction method of a pile breaking head of a cast-in-place pile, an auxiliary isolation net and a preparation method of the auxiliary isolation net. According to the method, a plurality of plastic pipes with different diameters are nested, and then the plastic pipes are fixed through radial reinforcing bars to form the auxiliary isolation net; in the concrete pouringprocess of the cast-in-place pile construction, when concrete is poured to the position of the design elevation, the auxiliary isolation net is fixed on a reinforcing cage at the position of the design elevation; concrete is continued to be poured until the pile breaking head is poured; and after the concrete of the cast-in-place pile is solidified and reaches a pile breaking state, the concrete above the auxiliary isolation net is struck by using a pile breaking machine, the pile head above the design elevation is broken down, and the construction of the pile breaking head of the cast-in-place pile is completed. The auxiliary isolation net has the advantages of simple structure, high practicability, low cost and good use effect; and therefore, the construction efficiency can be obviouslyimproved in the process of the pile breaking head of the cast-in-place pile, the damage to a main pile body in the process of breaking the pile can be greatly reduced, and the related construction technical problems in the process of the pile breaking head can be solved.

Owner:CHINA FIRST METALLURGICAL GROUP

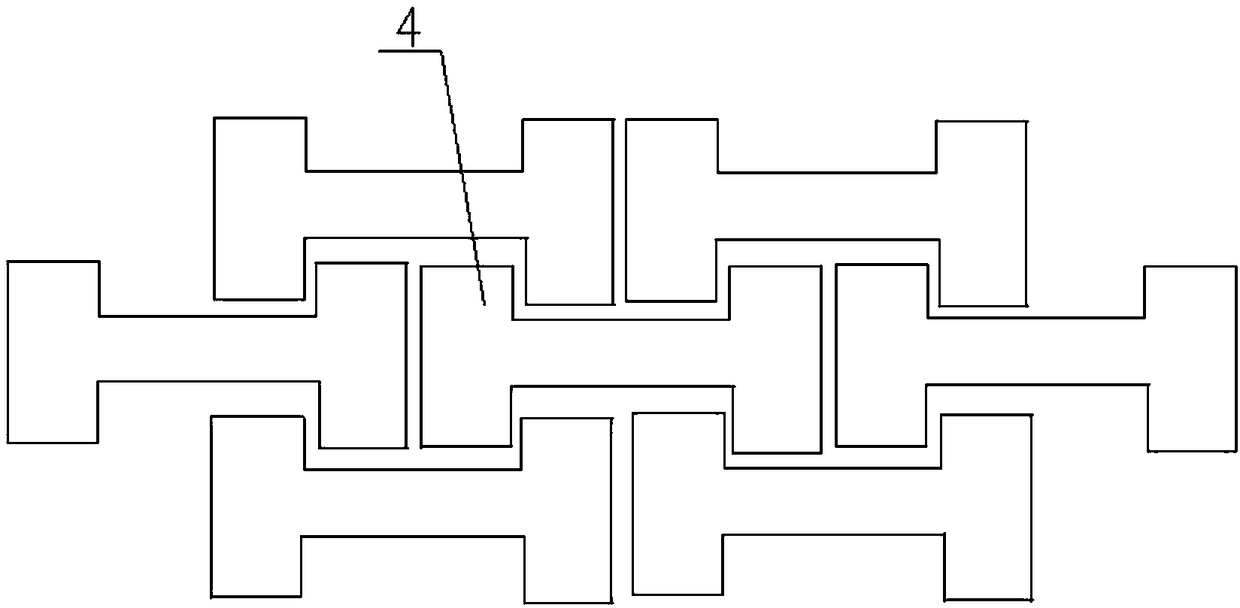

Combined protective slope and construction method thereof

InactiveCN108457247ALow costLight weightCoastlines protectionCultivating equipmentsFiltrationEngineering

The invention discloses a combined protective slope. The combined protective slope mainly comprises a lower blanket zone positioned at a river embankment blanket and an upper blanket zone positioned on a river embankment slope top as well as a protective slope main body which spreads along the river embankment slope surface and is used for connecting the upper blanket zone to the lower blanket zone, wherein reverse-filtration non-woven geotechnical cloth spreads between the protective slope main body and the river embankment slope surface. The invention further discloses a construction methodof the combined protective slope, and the construction method comprises the following steps of: pouring the lower blanket zone on the site on the bottom of the river embankment slope surface, and pouring the upper blanket zone on the site on the top of the river embankment slope surface; spreading the reverse-filtration non-woven geotechnical cloth from the river embankment blanket to the river embanked slope top on the river embankment slope surface; spreading the protective slope main body; and planting green plants. The combined protective slope adopts an interlocking block as the protective slope main body, plants green plants to assist slope protection, is environmentally friendly, is low in cost, and is relatively simple in daily maintenance and management.

Owner:WUHAN YIYE CONSTR ENG

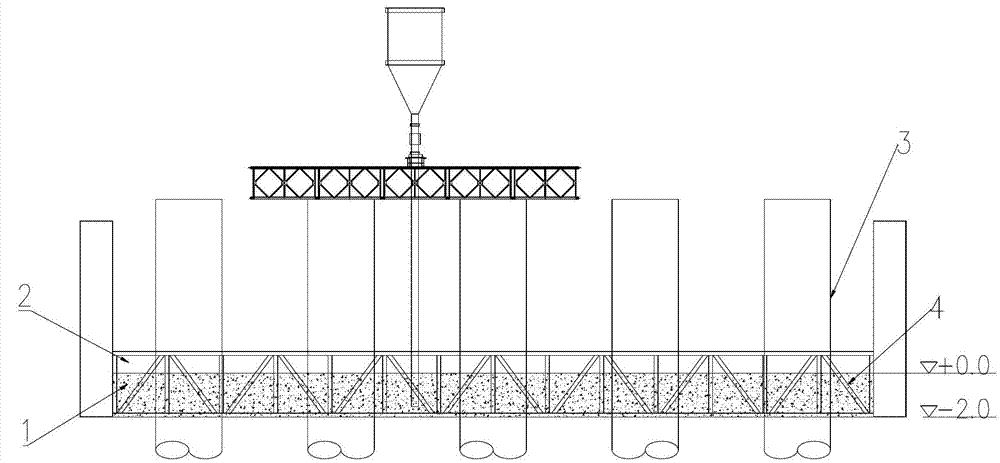

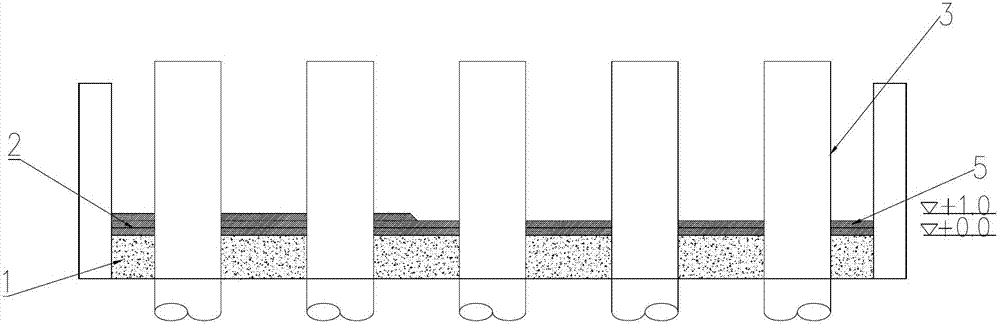

Construction method of offshore tide storage bottom sealing concrete

ActiveCN102747732BGuarantee the construction qualitySolve construction technical problemsFoundation engineeringUltimate tensile strengthConductor pipe

The invention discloses a construction method of offshore tide storage bottom sealing concrete. The construction method specifically comprises the following steps of: pouring bearing platform bottom sealing concrete in two layers during rising tide, namely when the elevation of bearing platform bottom sealing concrete is higher than water surface; using a duct pouring underwater concrete construction process for the concrete layer of which the elevation of the bearing platform bottom sealing concrete is lower than the water surface; and after the strength of the concrete of the pouring layer of which the elevation is higher than the water surface reaches demands and ebb tide, using a dry pouring construction process for the concrete layer of which the elevation of the bearing platform bottom sealing concrete is higher than the water surface. According to the actual conditions of tide, the technical problem of influence of tide on offshore bottom sealing concrete construction is effectively solved by the construction process that the underwater tide storage and dry construction are combined with bottom sealing concrete layered pouring; the construction is easy, convenient and safe, the construction period is good and the effect is good; the construction quality of the bottom sealing concrete is effectively guaranteed; favorable conditions are created for bearing platform dry construction; and the construction method has wide application prospect and excellent reference value for similar projects.

Owner:CCCC SHEC FIRST HIGHWAY ENG +2

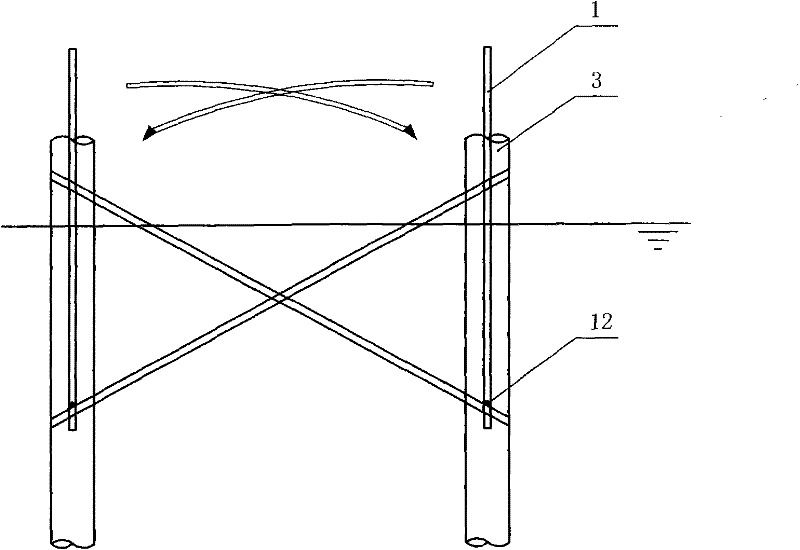

Deep foundation pit construction method under complex geological conditions

The invention discloses a deep foundation pit construction method under complex geological conditions, relates to the technical field of building construction, and solves the problem that an existing foundation pit supporting method is not safe when being used for construction under the complex geological conditions. According to the technical scheme, the method is used for vertical excavation construction of a deep foundation pit under the geological conditions that the surface layer is backfill, the middle layer is silty clay, the lower layer is medium weathered rock and the water level is high. The method comprises the steps that firstly, drainage ditches are excavated around a deep foundation pit excavation area to drain surface water; secondly, a single row of steel pipe piles are constructed along the excavation boundary of the deep foundation pit, and the portions, exposed out of the ground, of the steel pipe piles are connected through cross rods; thirdly, anchors are constructed outside the excavation range of the deep foundation pit or other fixtures are selected as anchoring points, and the cross rods and the anchoring points are tensioned; and fourthly, precipitation is conducted on the excavation area of the deep foundation pit, the deep foundation pit is excavated in a layered mode, waist beams are installed, anchor pipes are constructed, and concrete retaining walls are constructed; finally, layered excavation and supporting are repeated till the maximum design excavation depth is reached.

Owner:PANGANG GRP ENG TECH

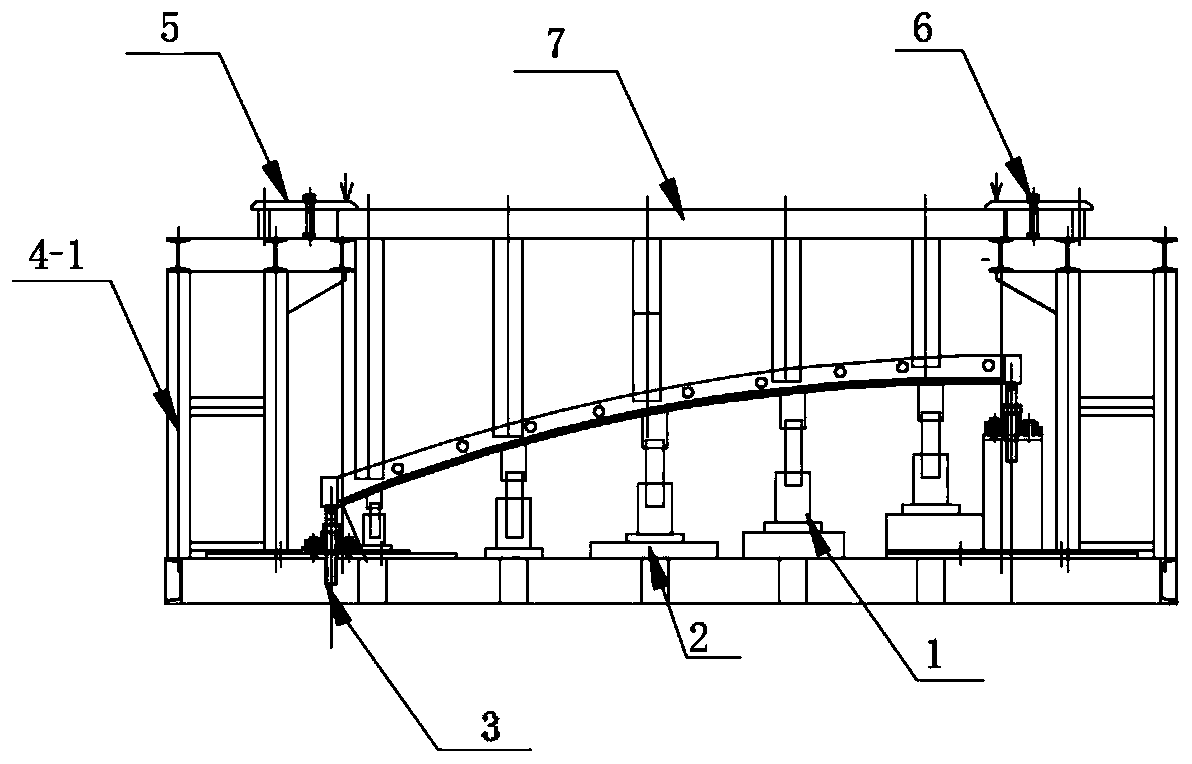

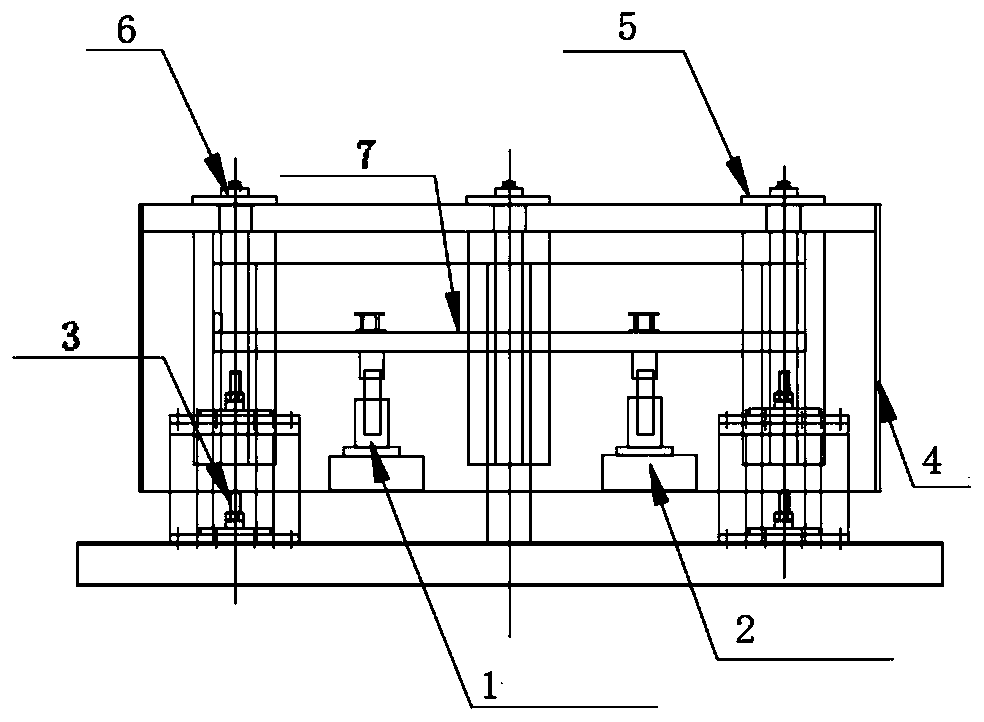

A manufacturing method of a double-curved fish-belly continuous box girder variable-section steel formwork

ActiveCN109352285BSolve the technical problem of high splicing pointsReduce gapWelding/cutting auxillary devicesAuxillary welding devicesHyperboloidMechanical engineering

The invention discloses a manufacturing method of a double-curved-surface fish-bellied continuous box beam variable-cross-section steel moulding plate. Steel moulding plate longitudinal ribs, cross ribs, steel plates, support short pillars and cross beams are processed and manufactured to form the double-curved-surface fish-bellied continuous box beam variable-cross-section steel moulding plate byutilizing a self-made steel moulding plate manufacturing device. During the manufacturing process, a BIM technology is utilized for modeling and dividing plates, assembling is carried out on the steel moulding plate manufacturing device, the whole manufacturing process is accomplished by welding, adjacent moulding plates are assembled by utilizing a flanging bolt, and the formed moulding plate issmooth in surface so as to achieve the forming quality, so that the difficulty in manufacturing and constructing technology of the double-curved-surface fish-bellied continuous box beam variable-cross-section steel moulding plate is solved.

Owner:CHINA FIRST METALLURGICAL GROUP

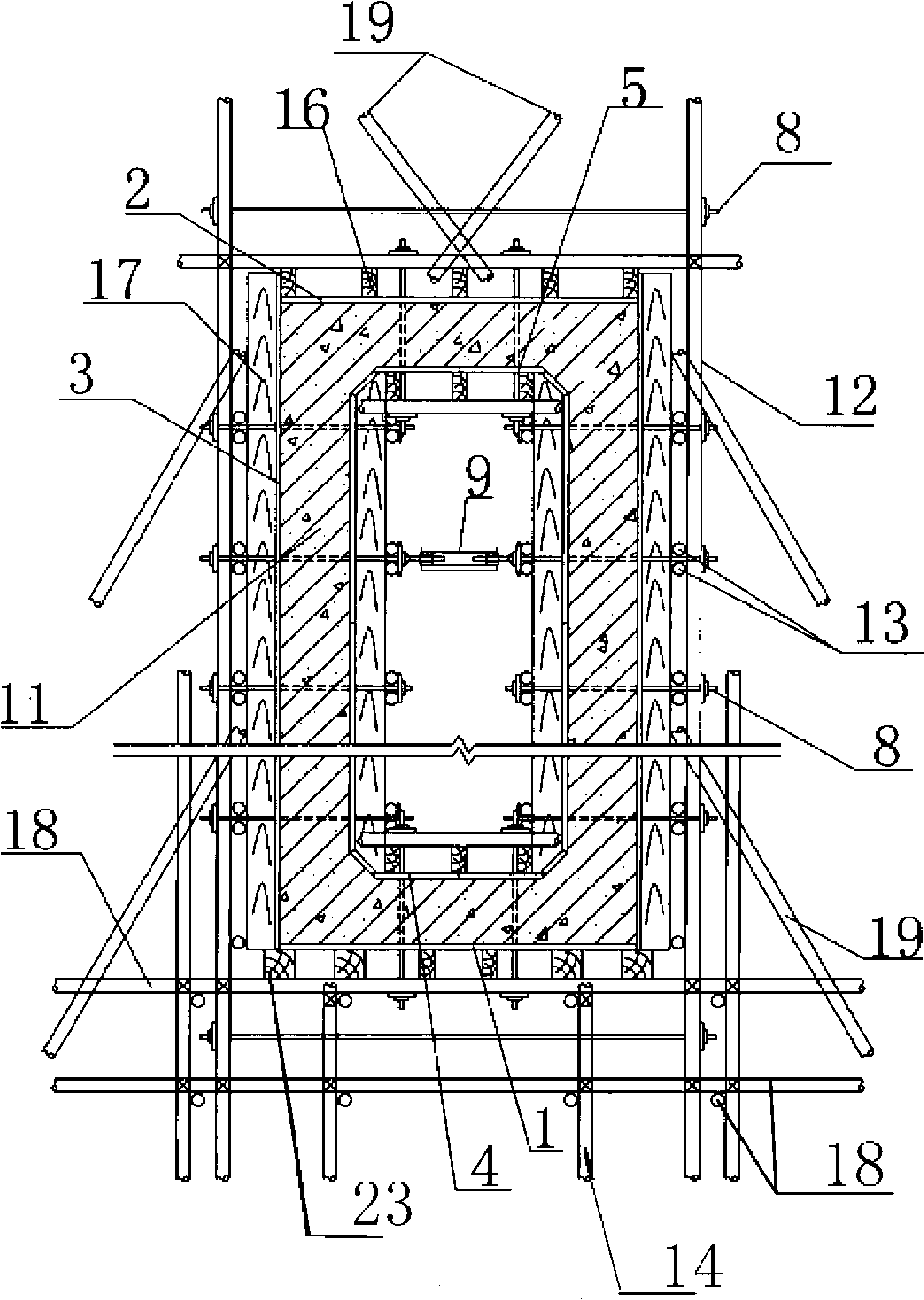

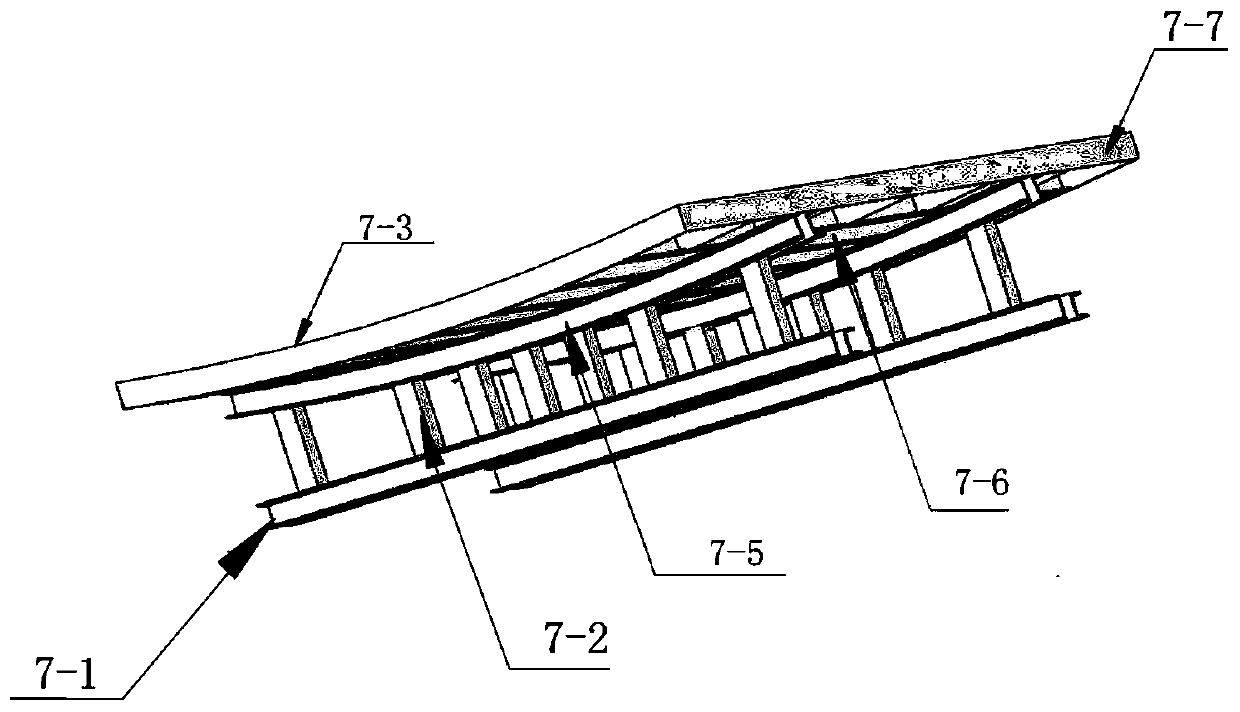

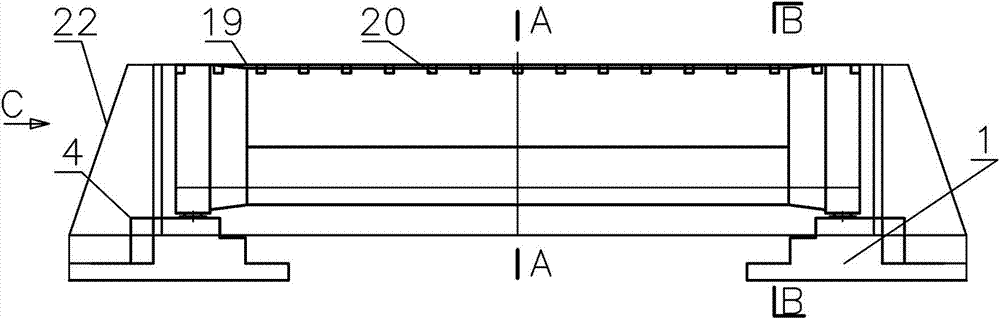

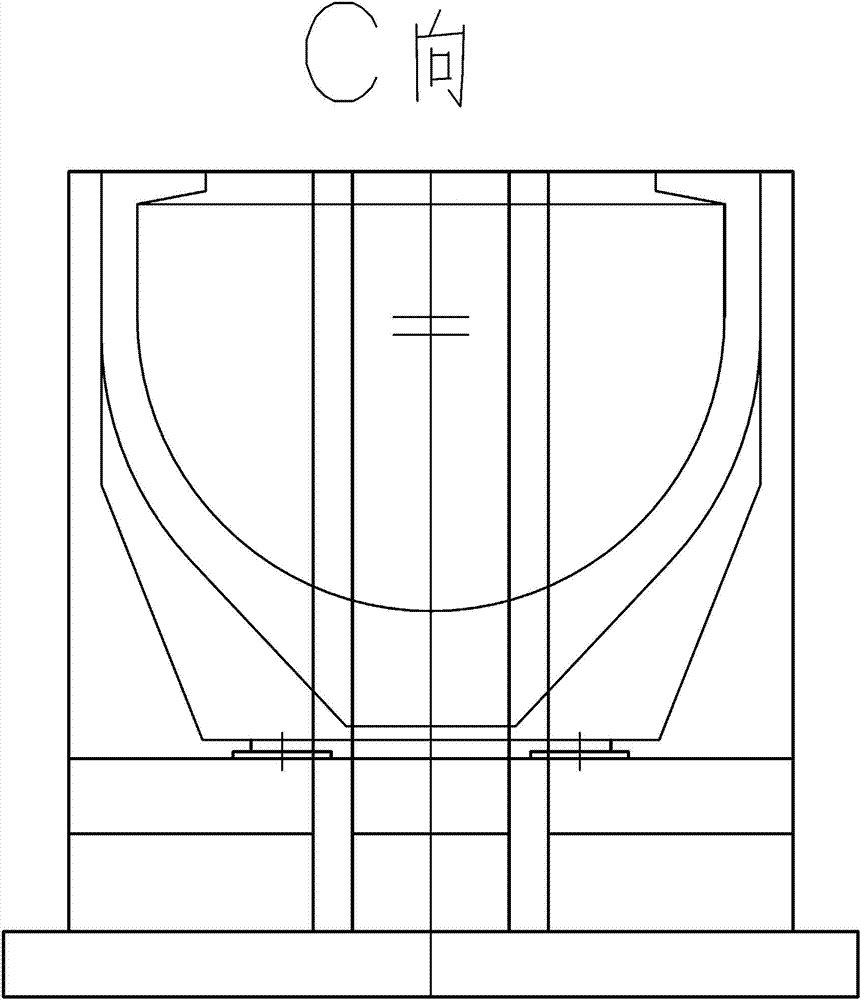

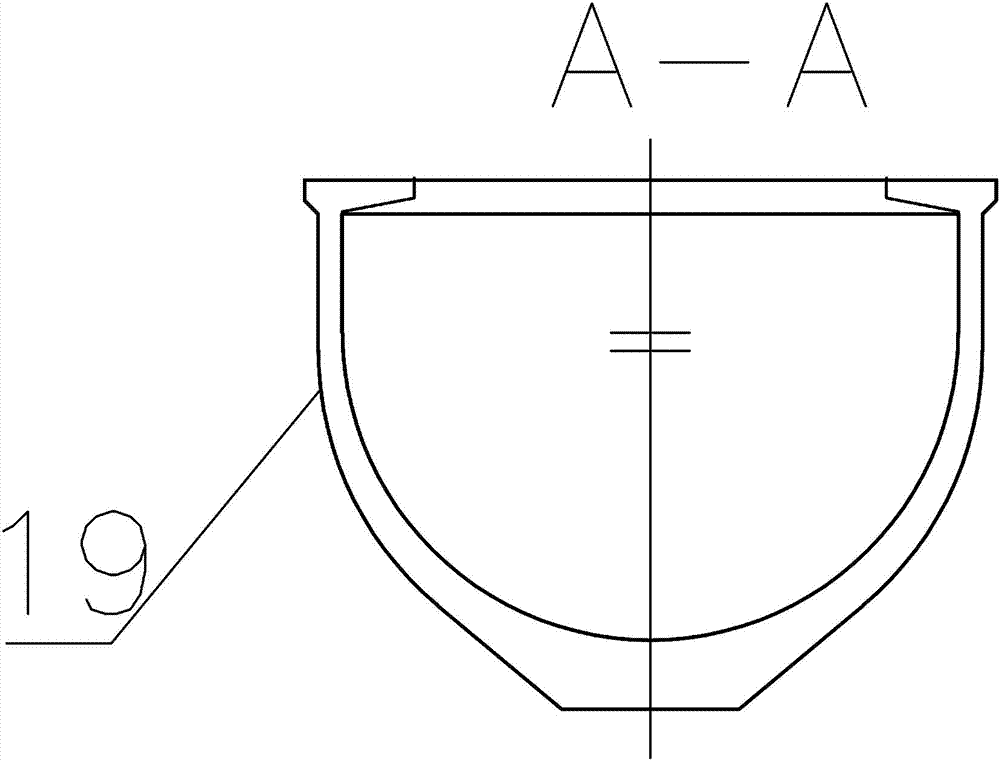

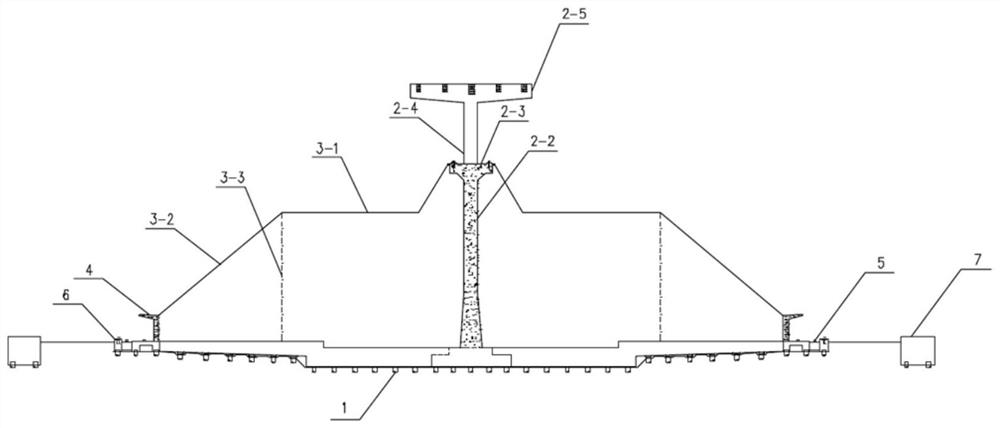

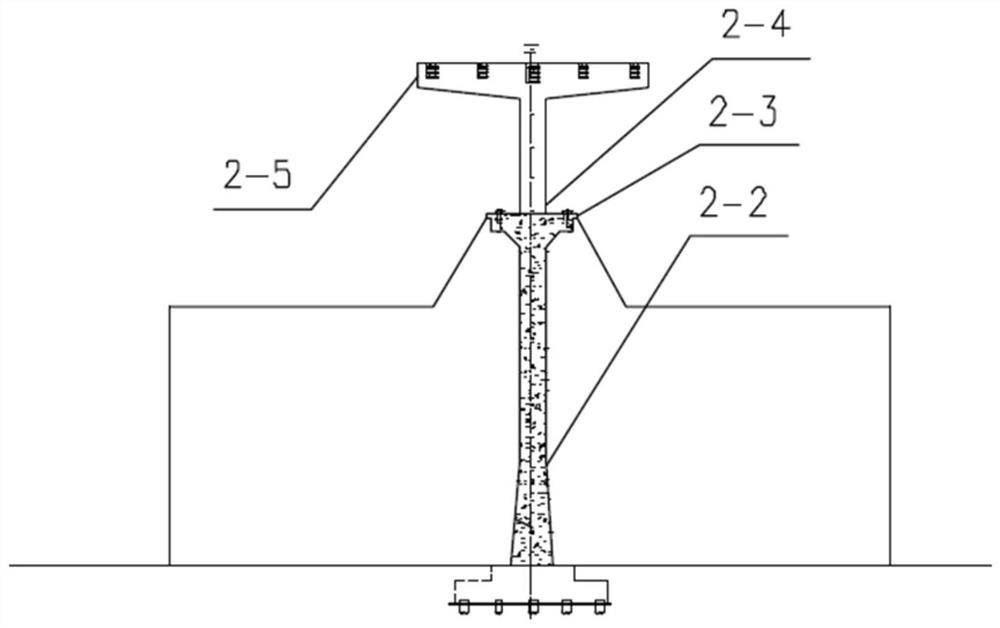

U-shaped aqueduct simulation testing device and method

ActiveCN102677624BEasy to install and removeClear weight transfer pointsHydraulic modelsButtressSimulation testing

A U-shaped aqueduct simulation testing device comprises an outer mould system and an inner mould system. In the inner mould system, an inner mould is movably hung on inner beams, one part of the inner beams are arranged in outer moulds, a plurality of track buttresses are arranged on the outer sides of one ends of the outer moulds, and track combination steel beams are arranged on the track buttresses and provided with inner mould installation tracks; the inner beams are supported by a first support leg, a second support leg, a third support leg and a fourth support leg; portal beams are connected with the upper ends of outer ribs through vertical adjusting draw bars, a transverse draw rod is respectively arranged between each two openings of the outer rib, and a square wood support body and a support unloading device are arranged between a flat section bottom and a base buttress below the outer ribs; and the outer moulds are installed in U-shaped space of a plurality of the outer ribs. According to the U-shaped aqueduct simulation testing device, large-scale aqueduct simulation testing pouring can be achieved, the technical problem of the combined steel mould construction of aqueduct simulation tests is solved, by means of the outer mould system and the inner mould system of an aqueduct producing machine, large-scale aqueduct simulation tests are achieved by using low costs.

Owner:CHINA GEZHOUBA GROUP CO LTD +1

Construction method of deep foundation pit under complex geological conditions

ActiveCN112813984BSimple stepsGuaranteed stabilityExcavationsBulkheads/pilesSurface layerSurface water

The invention discloses a deep foundation pit construction method under complex geological conditions, relates to the technical field of building construction, and solves the problem that the existing foundation pit support method is unsafe for construction in complex geological conditions. The technical scheme adopted in the present invention is as follows: when the surface layer is backfill soil, the middle layer is silty clay, the lower layer is medium weathered rock, and the vertical excavation construction of the deep foundation pit under the geological conditions of high water level, the deep foundation pit is excavated first. Drainage ditches shall be excavated around the area to discharge surface water; then a single row of steel pipe piles shall be constructed along the excavation boundary of the deep foundation pit, and the parts of the steel pipe piles exposed to the ground shall be connected by cross bars; In addition, construct the anchorage or select other fixed objects as the anchoring point, and tighten the crossbar and the anchoring point; then dewater the deep foundation pit excavation area, and excavate the deep foundation pit in layers, install waist beams, Construction of anchor pipes and construction of concrete retaining walls; finally, repeated layered excavation and support until the maximum design excavation depth is reached.

Owner:PANGANG GRP ENG TECH

Special-shaped cast-in-place bridge hanging plate construction structure and construction method thereof

InactiveCN111236074ASolve the problem of slurry leakageAvoid structural stabilityBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses a special-shaped cast-in-place bridge hanging plate construction structure and a construction method thereof. The construction structure comprises a plurality of sections of inner side steel molds, a plurality of sections of outer side steel molds and a segmented sliding template at the bottom, the tops and the middles of the inner side steel die and the outer side steel mold are connected through a first fixing screw and a second fixing screw respectively, a fixing rod is hinged to the middle of the inner side steel mold and fixed to an existing structural road beam, the segmented sliding formwork is connected to the bottom of the outer side steel die in a sliding mode, and the gap between the segmented sliding formwork and the beam bottom can be adjusted. The problem of slurry leakage at the beam bottom contact part is solved, and the structural stability of the steel film and the curve adjustability of the curve mounting adjacent part are realized.

Owner:CHINA FIRST METALLURGICAL GROUP

Construction method for crossing for complex formation of shield under ultra-deep earth

ActiveCN102996135BSolve construction technical problemsSolve the real problemTunnelsEngineeringShield tunnelling

The invention relates to a construction method for the crossing for a complex formation of a shield under ultra-deep earth, comprising the following specific steps of: 1, setting the front earth pressure of the shield; 2, improving the front earth body of the shield; 3, controlling the attitude of the shield; and 4, controlling synchronous grouting for the tail of the shield. Via the construction method disclosed by the invention, many difficulties and problems in shield construction in many complex formations can be solved, and mature ultra-deep shield tunnelling construction processes and construction technologies in sandy soil confined aquifers are formed to lay the foundation for the development of underground space exploitation to the deep in future, thus overcoming the limitation of shield projects in areas with many underground installations, and guaranteeing the sustainable development of underground shield tunnel project development and the universality of application.

Owner:SHANGHAI FOUND ENG GRP

Treatment method of beaded circular continuous karst caves in karst landform tunnels

ActiveCN106351202BSolve construction technical problemsEasy constructionUnderground chambersTunnel liningEmergency treatmentKarst

Owner:NO 4 ENG COMPANY LTD OF CCCC FIRST HARBOR ENG COMPANY

Anchor-spraying concrete for treating water and support

InactiveCN1115447CSolve construction technical problemsWater damage realizedArtificial islandsUnderground chambersSoil horizonWeep

An anchoring-sprayed prop for controlling water in constructing underground engineering features direct use of anchorage and spraying concrete. Its construction technology includes such steps as drilling weep holes, setting up weep pipes, primary spraying, drilling anchor holes, installing anchor rods, hanging net, spraying again, blocking drainage pipes, and curing. If the bed rock encounters fault, it is necessary to spray concrete for the third time.

Owner:王衡

Oblique curtain wall system and installation method thereof

InactiveCN102359208BNovel styling effectUnique shape effectWallsBuilding material handlingArchitectural engineeringHigh rise

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU

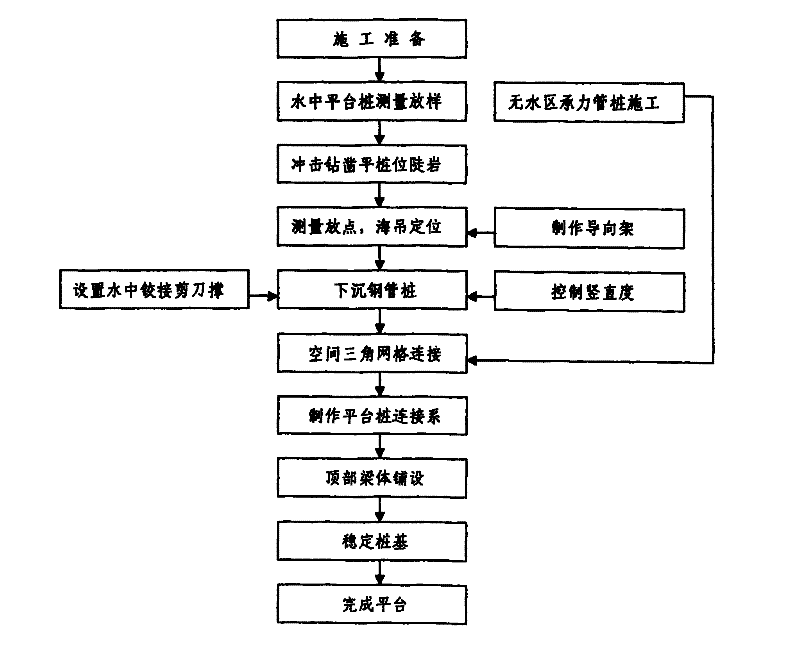

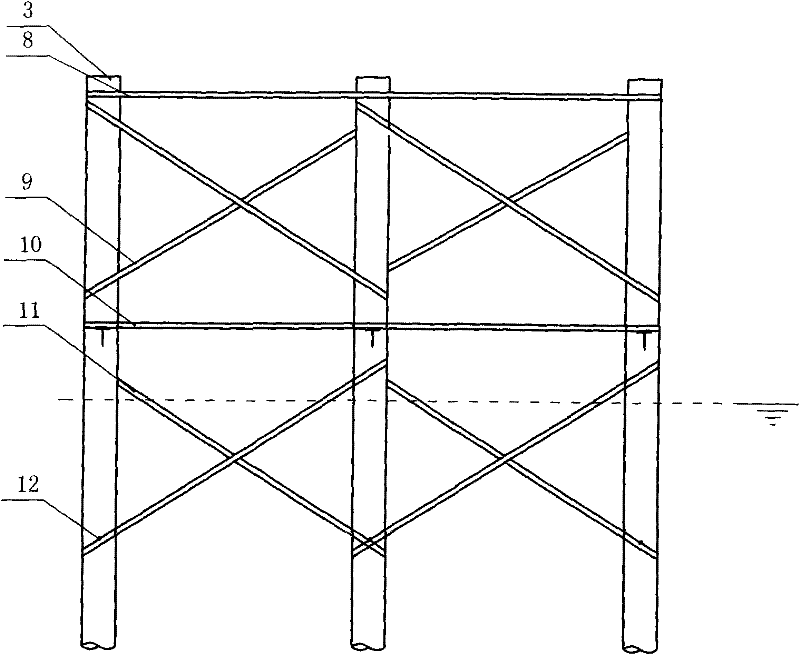

Method for putting up steel pipe pile platform of abrupt slope bare rock

ActiveCN102021901BSimple structureClear forceArtificial islandsBridge erection/assemblyBridge engineeringEconomic benefits

The invention relates to a method for putting up a steel pipe pile platform of an abrupt slope bare rock, and belongs to the technical field of bridge engineering construction. The method comprises the following steps of: planishing an abrupt slope at platform piles by using a churn drilling, so that the platform steel pipe piles are arranged; pre-embedding three positioning piles along the shoreside; connecting each of three platform steel pipe piles by using structural steel to form space triangular grids; connecting the platform steel pipe piles and the positioning piles by using the structural steel serving as a force transferring bar piece to form space triangular grids; arranging an underwater hinge joint diagonal bracing to enhance the rigidity and stability of the underwater platform steel pipe piles; and finally putting up the integral platform. The method has the advantages that compared with other conventional construction modes of caisson cofferdam or island cofferdam, themethod is convenient and quick, the constructional platform has a simple structure and is explicit in load bearing, all the steel pipe piles are turnover materials disassembled from other platforms without additional investments and can be recovered completely to realize the 'zero construction cost' of the platform, and the economic benefit is obvious; the scheme of putting up the platform is novel and simple, the construction period is short, and a process is easy to grasp; and the method is environmentally-friendly and pollution-free and has no backfills to an ocean.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

A construction method for a highly variable loading and unloading platform

ActiveCN106760566BImprove stabilitySolve construction technical problemsBuilding material handlingEngineeringElectric control

The invention mainly aims at the technical field of the construction of the loading and unloading platform. A construction method for a height-variable in-feed and out-feed platform, which is characterized by comprising the following steps: 1) measuring and laying out lines; 2) installation of the in-feed and out-feed platform frame: outside each floor corresponding to the building frame, the inner longitudinal column row, the outer The upper and lower height-adjustable crossbars are installed between the adjacent longitudinal columns in the longitudinal column row, and the height-adjustable crossbars located at the bottom together form the lower height-adjustable crossbar layer; the height-adjustable crossbars are installed The method is: cover the longitudinal column with a casing, weld a height-adjustable crossbar between adjacent casings, open holes on the outside of the casing and fasten the longitudinal column with bolts; The platform bottom plate is placed on the height-adjustable crossbar layer outside the first floor; 5) The installation of the electric control safety walkway plate; 6) The installation of the protective grille plate and the safety door. The method is simple to operate, fast to erect, and the height of the platform bottom plate is variable.

Owner:CHINA FIRST METALLURGICAL GROUP

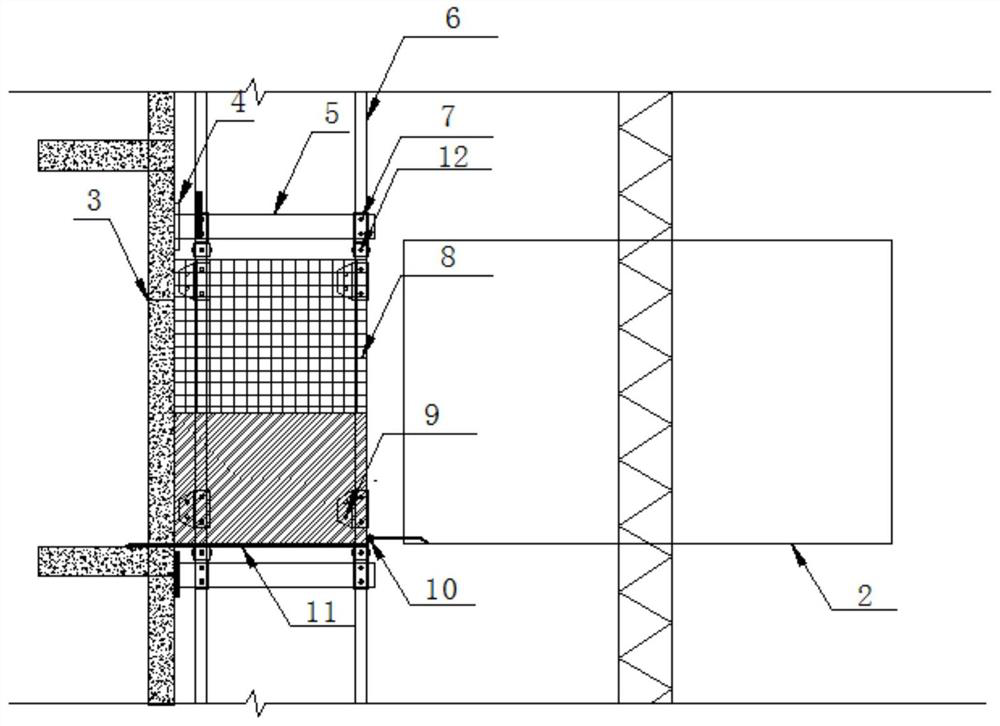

Road widening construction method for high and steep slopes

ActiveCN112921727BImprove operationRestore widthPaving reinforcementsIn situ pavingsReinforced concreteMesh reinforcement

The invention relates to a construction method for road widening on high and steep slopes, comprising the steps of: a. cleaning pumice; b. drilling bolt holes; c. grouting and anchoring the bolt holes; d. setting anchor bolt clusters (9) e. Lay steel mesh (11) on the residual road (12), and lay steel bars vertically on the collapsed slope (13) and outside the collapsed slope (13); f. The lattice beam (4) and the pile wall (3) Reinforced concrete construction; g. Pile-board wall (3) Slag backfill in the segmented area (7) Backfilling; h. Remaining road (12) Pavement reinforced concrete pouring construction. The lattice beam (4) and the pile wall (3) are fixed on the side wall and the outer side of the collapsed slope (13) by means of anchor rods or anchor cables (6), and the restoration of the residual road (12) is realized by pouring reinforced concrete , speeding up the construction progress, overcoming the problem of insufficient road (foundation) width caused by complex geological conditions due to landslides, and the problem of high cost of new roads or reconstruction roads.

Owner:PANGANG GRP ENG TECH

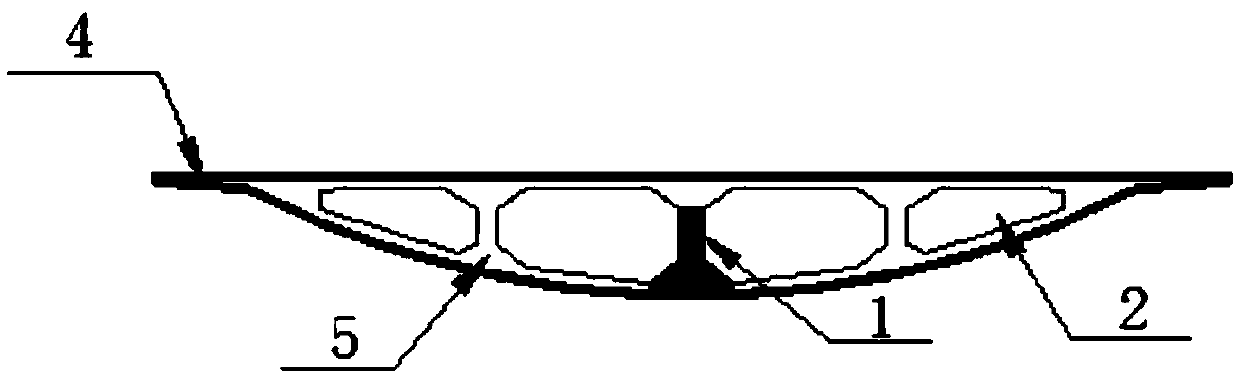

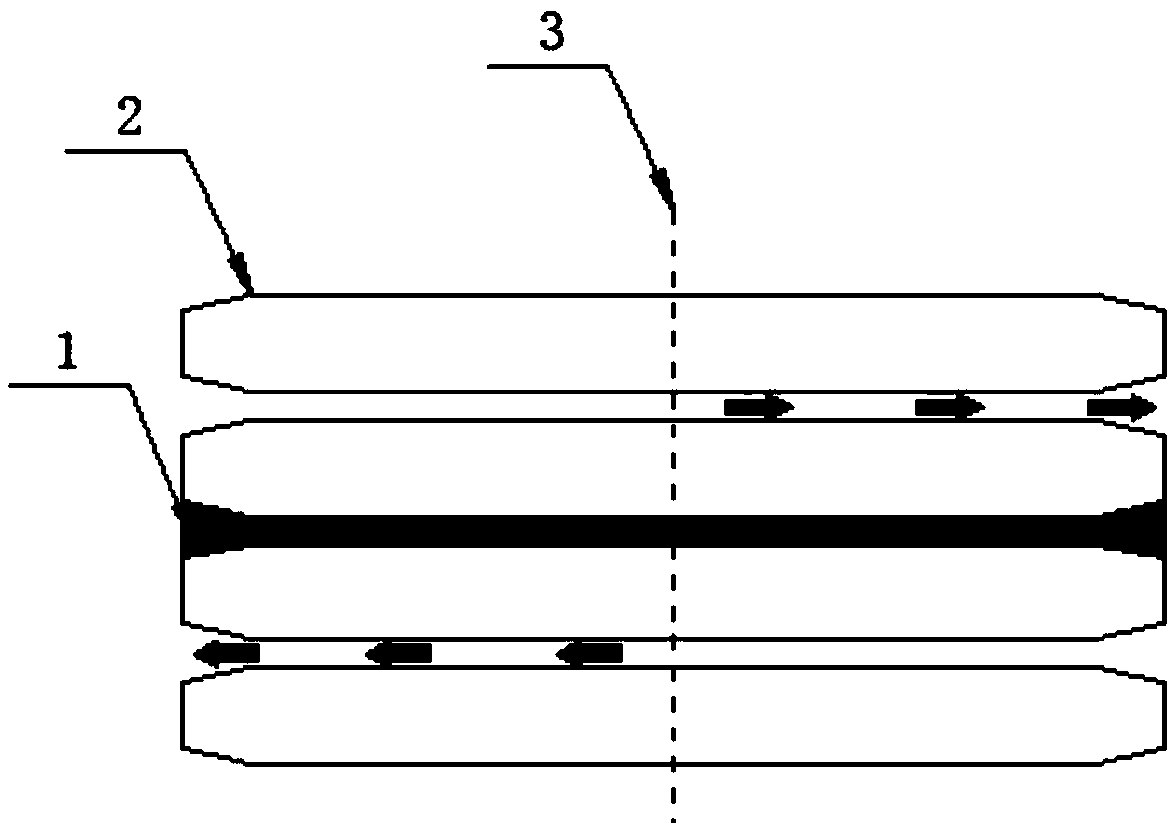

Concrete symmetrical superimposed pouring structure and construction method of fish-belly box girder with variable cross-section

ActiveCN106638262BSolve construction technical problemsImprove structural strengthBridge erection/assemblyBridge materialsBox girderBuilding construction

The invention discloses a cross-section variable fish-bellied type box girder concrete symmetric overlapping pouring structure and a construction method thereof. The structure comprises a box girder web, a box chamber, a box girder top plate and a box girder bottom plate. The method comprises the following steps that S1, a straight line perpendicular to the long side of the box chamber and passing through the theoretical load center of the box girder structure serves as a center line; S2, the box girder web is subjected to concrete pouring construction, and symmetric overlapping pouring is conducted; S3, the box girder bottom plate is subjected to concrete pouring construction, and diagonal pouring is conducted; S4, the box girder top plate is subjected to concrete pouring construction, the surface of the poured concrete is treated, and diagonal pouring is conducted; and S5, flattening treatment is conducted on the surface of the box girder top plate through a roller device, and watering maintenance is conducted on the surface of the box girder top plate. According to the cross-section variable fish-bellied type box girder concrete symmetric overlapping pouring structure and the construction method thereof, the construction quality is ensured, the appearance quality after moulds are dismounted is good, the construction schedule is greatly fastened, and the construction technique difficulty of the cross-section variable fish-bellied type box girder concrete is well solved.

Owner:CHINA FIRST METALLURGICAL GROUP

A kind of construction method for entering a hole through a shallow heavy-load highway

ActiveCN112031814BReduce deformation effectsGuaranteed stabilityMining devicesUnderground chambersReinforced concreteSlag

The invention discloses a tunnel entry construction method for crossing a shallow high-load highway, and relates to the technical field of tunnel construction. The tunnel entry construction method for crossing a shallow high-load highway includes: pouring a concrete wall on the outer side of the tunnel, so as to carry out the tunnel construction. Preliminary maintenance; drill holes at preset positions below the arching line of the tunnel vault and the straight wall section of the tunnel to obtain installation holes; press at least two pipe sheds in sequence into any installation hole, and place adjacent ones. The two pipe sheds are welded; the grouting conduit is installed in the pipe shed, and the consolidation grouting is carried out in the grouting conduit; the surrounding rock is broken into the tunnel, and the initial support is carried out after the slag is discharged outside the tunnel; Lining the formwork and lining the reinforced concrete, and repeating the steps of entering the tunnel for crushing the surrounding rock. The above-mentioned tunnel-entry construction method solves the technical problem of tunnel crossing a shallow high-load mine highway construction, ensures the safety of tunnel construction, saves investment and improves economic benefits.

Owner:PANGANG GRP ENG TECH

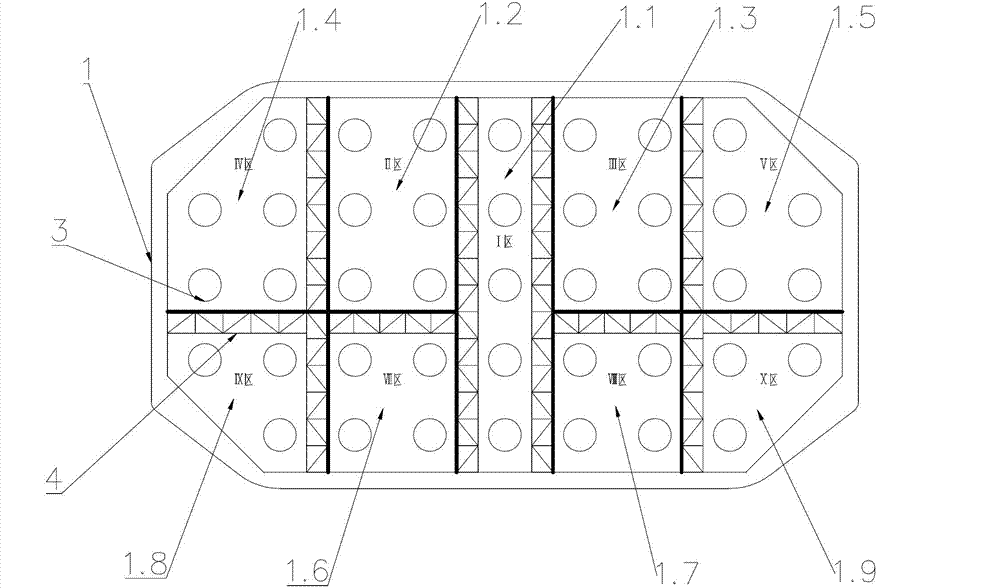

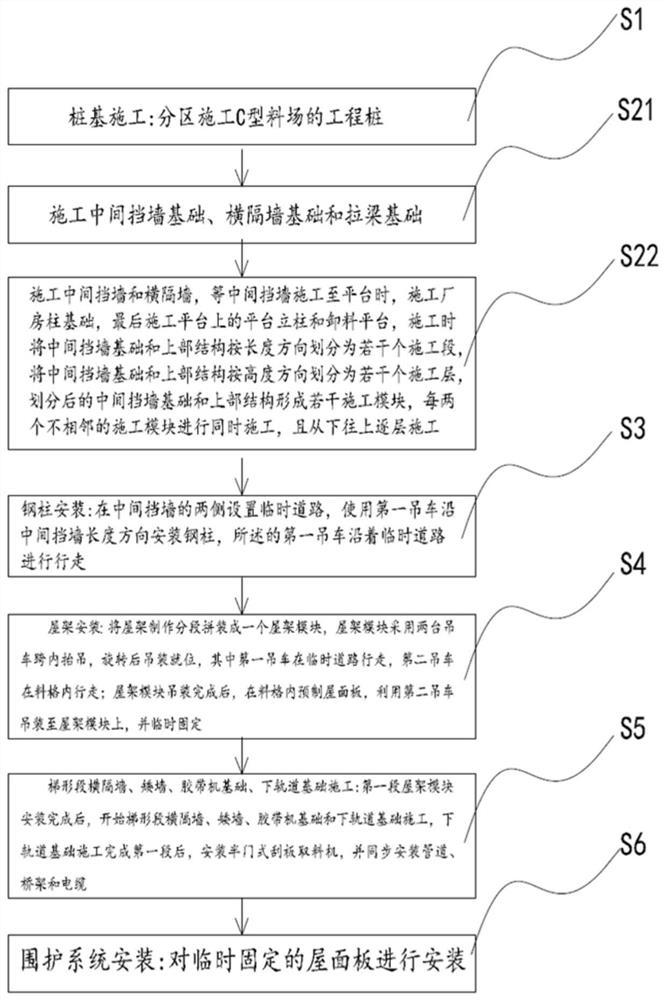

Construction technology of continuous-span common-column C-shaped stock yard

ActiveCN113863736ASolve construction technical problemsImprove construction efficiencyStrutsWallsArchitectural engineeringEngineering

The invention discloses a construction technology of a continuous-span common-column C-shaped stock yard. The construction technology comprises the working procedures of pile foundation construction, foundation and retaining wall upper structure construction, steel column installation, roof truss installation, construction of trapezoidal section transverse partition walls, low walls, a sealing-tape machine foundation and a lower rail foundation and enclosure system installation. Compared with a traditional stock yard construction technology, the construction technology has the advantages that pile foundations, civil engineering, steel structures and mechanical and electrical installation are reasonably deployed and interspersed, the construction technical problem of the C-shaped stock yard under the condition that the construction space is seriously limited is solved, the construction technology is safe and reliable, the construction efficiency is improved, and the construction quality is guaranteed.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

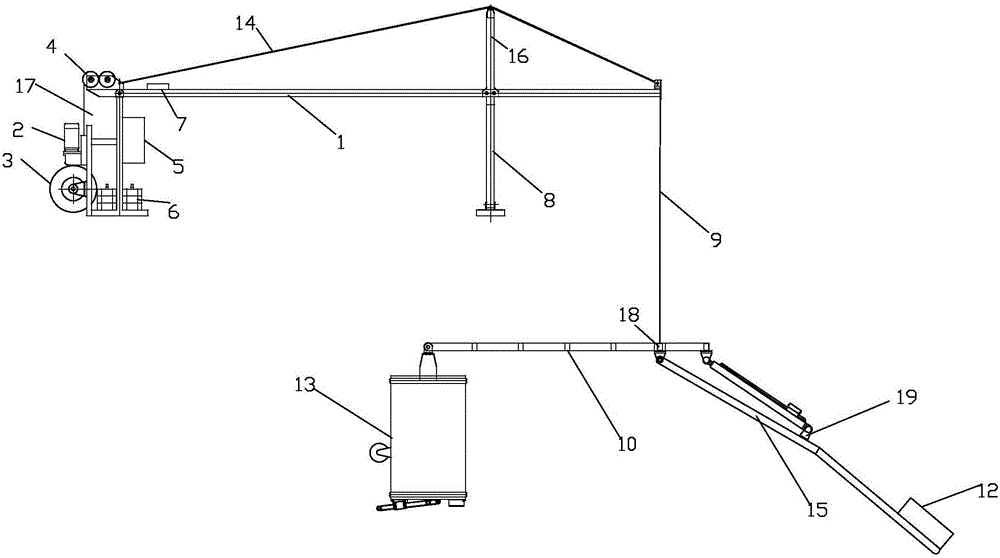

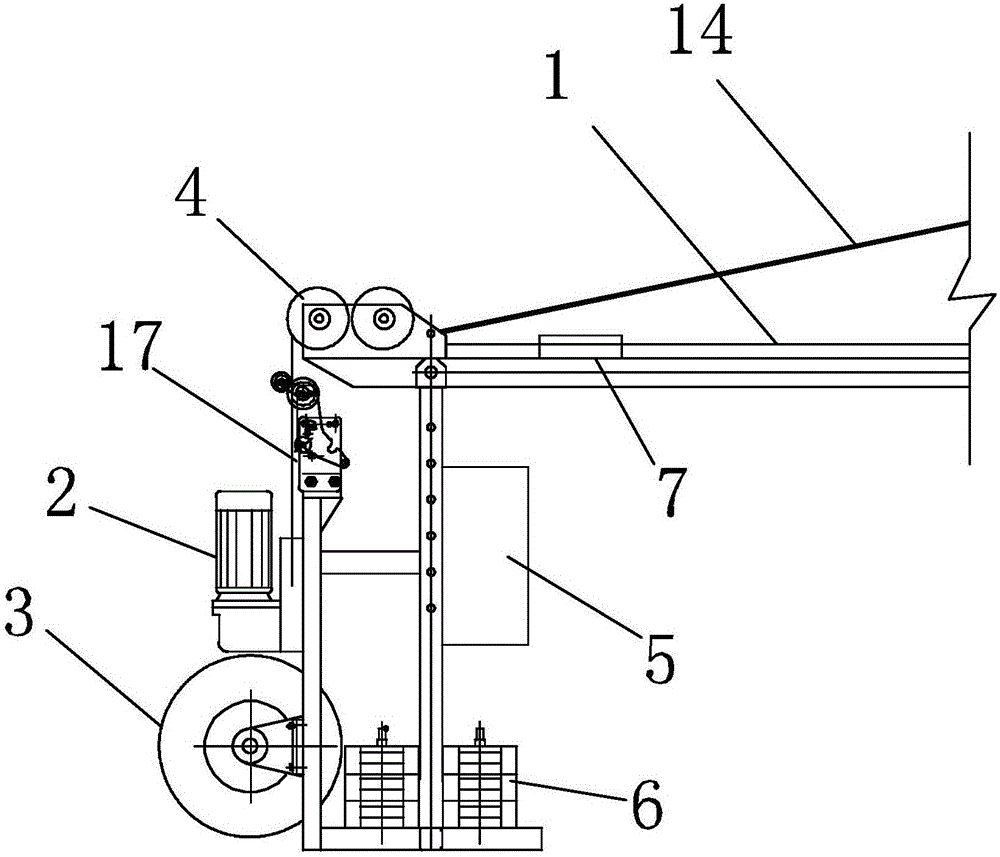

An extendable hanging basket device

The invention discloses a stretching type basket device and a construction method thereof, and the stretching type basket device is simple in structure and good in safety. The stretching type basket device comprises a hanging frame transversely erected on a floor. A lower support is arranged below the hanging frame. The hanging frame is fixed to the floor through the lower support. An adjusting support is arranged at the end, close to the interior of the floor, of the hanging frame and provided with a lifting mechanism, a rope winding mechanism, a rope guiding mechanism and a power master control box. The stretching type basket device integrates a construction operation basket, a hydraulic device and a matched safety protection system and can be used for construction of high-rise building elevation curtain walls, especially overhung overhang eave bottom ceiling curtain walls, wherein the peripheries of roofs of the high-rise building elevation curtain walls are provided with large overhung overhang eaves, joint corridors and joint bridges, the high-rise building elevation curtain walls are unique in overall elevation model, rough and uneven in inlet and outlet and overall in a linear or arc or right-V or right-W shape or other shapes and incline towards the exterior of buildings.

Owner:JANGHO GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com