Patents

Literature

98results about How to "Solve the problem of slurry leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lining construction method for suspension rail type trolley

ActiveCN103939114AFast constructionReduced demoulding timeUnderground chambersTunnel liningRebarBuilding construction

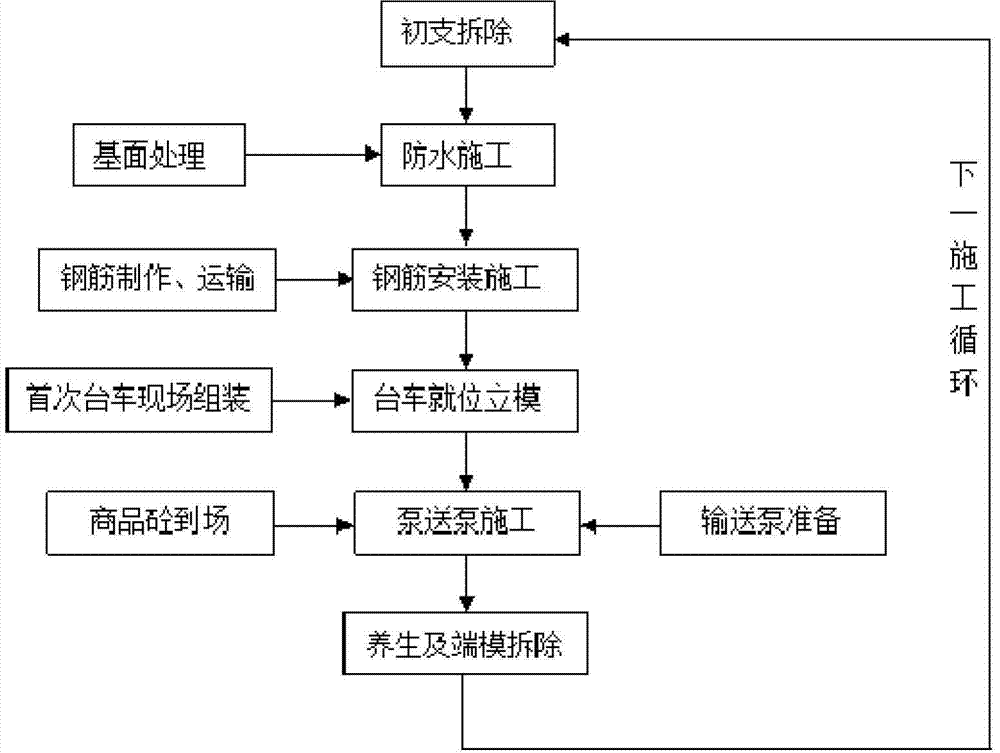

The invention discloses a lining construction method for a suspension rail type trolley. The method comprises the following steps that (1) a primary support is dismounted, 1 / 3 to 1 / 2 of the primary support of a pilot tunnel is dismounted to adapt to the height of the trolley, then the surface of the dismounted portion is leveled, and the dismounted portion of the primary support of the pilot tunnel is a side wall of the primary support of the pilot tunnel; (2) water preventing construction is carried out, and waterproof plates are arranged on the contact faces of a top longitudinal beam, a buckle arch primary support and a designed two-lining buckle arch; (3) steel bars are machined and mounted, and the pre-machined and formed steel bars are transported to an operating face, and are mounted according to design requirements; (4) the trolley is mounted in place, the trolley is lifted, a formwork is lifted to a design position, and concrete pouring is carried out. According to the lining construction method for the suspension rail type trolley, the two-lining buckle arch concrete construction formwork dismounting and shutting time is greatly shortened, the construction period is shortened, and the continuous construction performance is good. Labor cost for splicing and dismounting the formwork and a scaffold is greatly saved. Pouring precision and quality are improved.

Owner:CHINA RAILWAY ERJU 1ST ENG +1

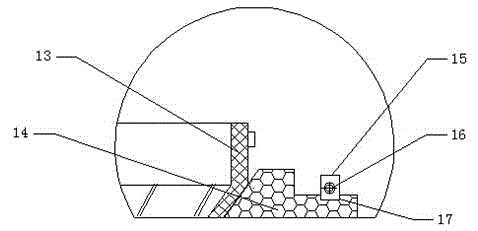

Anti-scouring concrete repairing device

ActiveCN109016145ARealize quantitative stirring and mixingReduce generationDischarging apparatusBuilding repairsEngineeringSlurry

The invention discloses an anti-scouring concrete repairing device. The anti-scouring concrete repairing device comprises a mixing and stirring device and a slurry supplement pipe. The mixing and stirring device is used for stirring concrete slurry, and the concrete slurry is injected into concrete cracks through the slurry supplement pipe. The anti-scouring concrete repairing device is characterized in that the mixing and stirring device can cyclically work to prepare materials first and then to discharge the materials, and a plurality of pipelines arranged between the mixing and stirring device and the slurry supplement pipe. The anti-scouring concrete repairing device has the advantages that the cracks are fully filled, the probability of slurry leakage is lowered, the surface flatnessis high after reinforcement, and a grouting pipe can slide in the cracks to achieve slurry supplement; the mounting stability of a support is high, and a wall is not likely to be damaged, or the adhesion strength of a plate body is high; intermittent material supplement and quantitative stirring are conducted, so that raw material waste is reduced, the cracks are fully filled, the probability of slurry leakage is lowered, the surface flatness is high after reinforcement, the grouting pipe can slide in the cracks to achieve slurry supplementation; and the mounting stability of the support is high, and the wall is not likely to be damaged, or the adhesion strength of the plate body is high.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

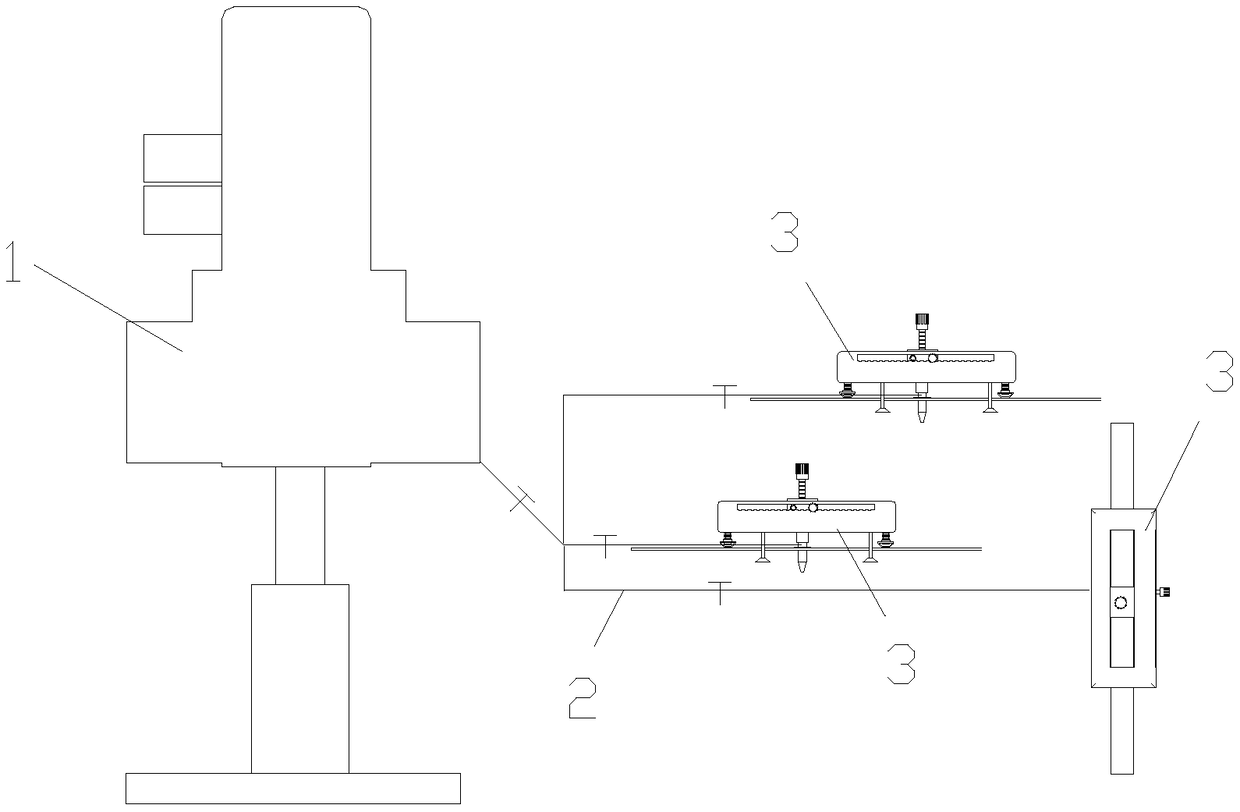

Hydraulic device for moulding board of precast beam

ActiveCN102152392AAvoid interferenceAvoid collisionAuxillary shaping apparatusHydraulic cylinderConcrete beams

The invention discloses a hydraulic device for a moulding board of a precast beam. The hydraulic device is connected between the moulding board of a precast T-shaped concrete beam and a ground surface and consists of foundation embedded parts, a hydraulic system, a slideway system and a location system. The foundation embedded parts are pre-embedded on the ground surfaces on the left side and right side of the moulding board of the precast T-shaped concrete beam and comprises a hydraulic cylinder base embedded part, a cushion rail foundation embedded part and a vertical tie bar foundation embedded part. The hydraulic system comprises a hydraulic pumping station, a hydraulic control valve block, a hydraulic cylinder and a high-pressure oil pipe. The slideway system comprises a slide rail, a slide block and a cushion rail. The location system comprises a lower tie bar, a vertical tie bar and an aslant tie bar. The device replaces a gantry crane, so the interference of the gantry crane on the concrete casting construction is avoided, the efficiency for disassembling and assembling a lateral moulding board and the utilization ratios of the moudling board and a concrete pedestal are enhanced, and in the demoulding process, the collision between the moulding board of the precast T-shaped concrete beam and the beam is avoided, so the phenomena of collision damage, knocked-off corner and concrete slurry leakage of the beam are reduced.

Owner:中铁十四局集团房桥有限公司

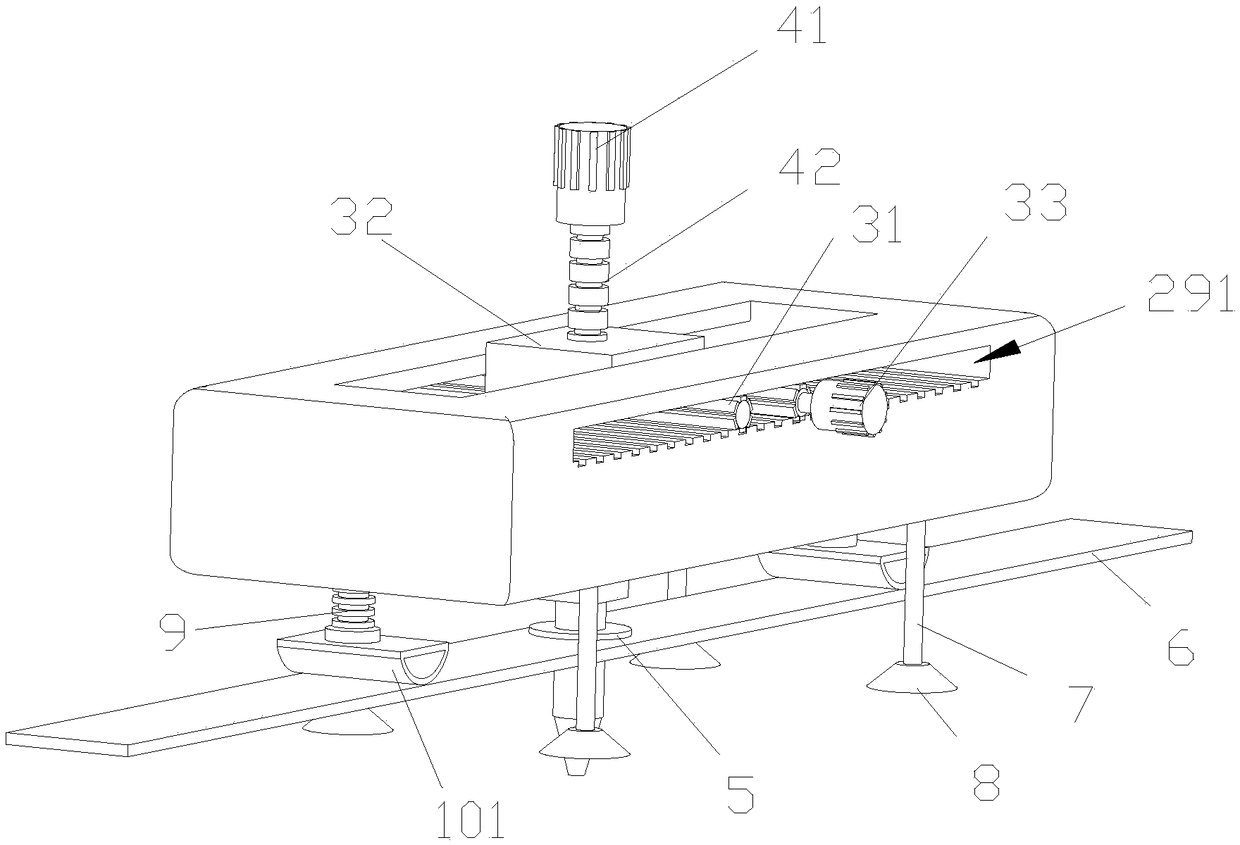

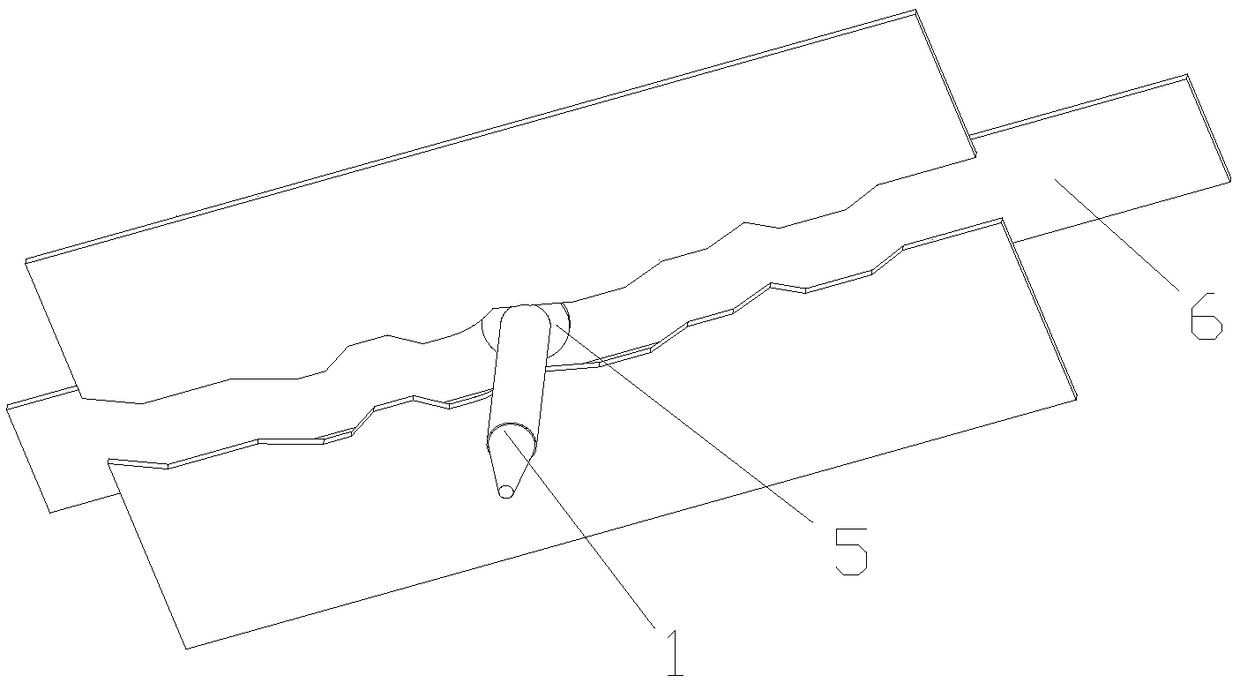

Automatic slurry filling device for concrete crack defect with high adhesion strength

The invention discloses an automatic slurry filling device for a concrete crack defect with high adhesion strength, which comprises a slurry filling pipe, wherein the concrete slurry is injected intothe concrete crack through the slurry filling pipe; and also comprises a machine frame, an electric sliding element, an electric lifting element, a rubber sleeve, a trowel, a first supporting rod, a first sucking disc, a second supporting rod and a abutted element; the electric sliding element is in sliding fit with the machine frame, the electric lifting element is arranged on the electric sliding element, the lifting end of the electric lifting element is connected with the slurry filling pipe, and the trowel is sleeved at the periphery of the slurry filling pipe through the rubber sleeve. The first sucking disc is arranged on the end part of the first supporting rod; the connecting end of the abutted element is slidably mounted on the end part of the second supporting rod, and the abutted end of the abutted element can be contacted with the trowel. The device has the advantages that the crack can be fully filled, the slurry leakage condition is reduced, the flatness of the surface after filling the slurry is high, the slurry filling pipe can achieve sliding and grouting in the crack, and the installation stability of a bracket is high, no damage is caused on a wall body or the adhesion strength of a plate body is high.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

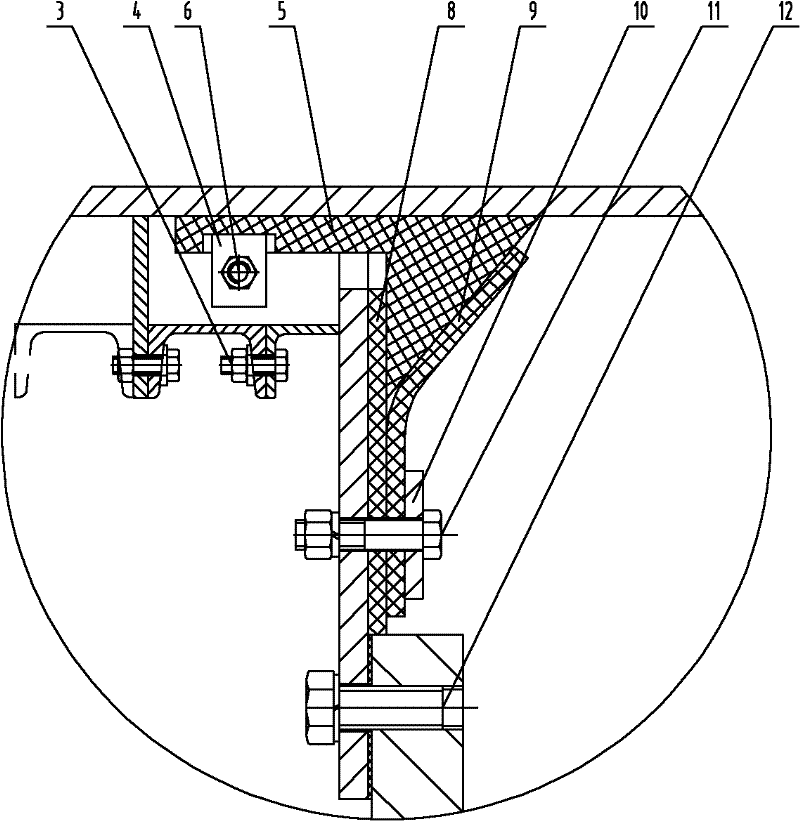

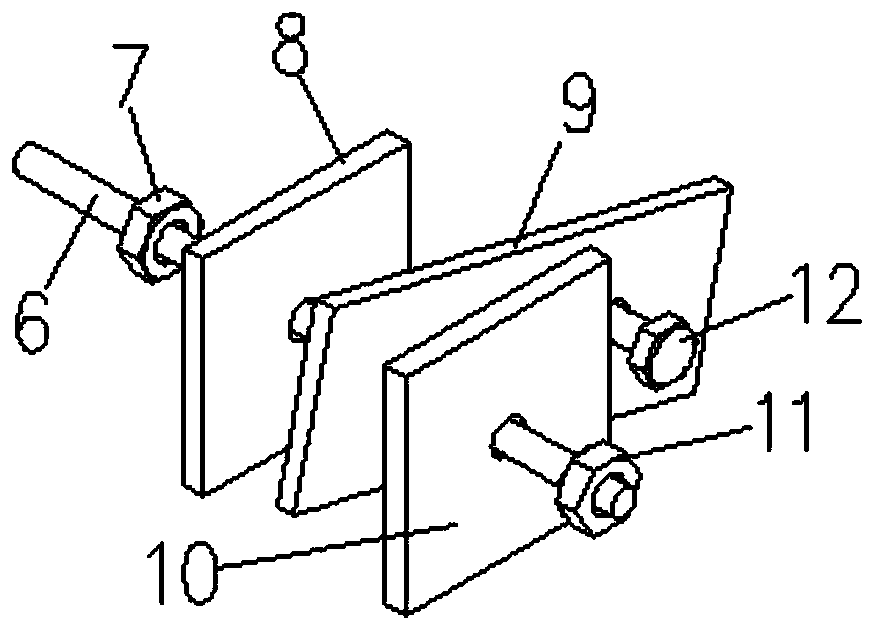

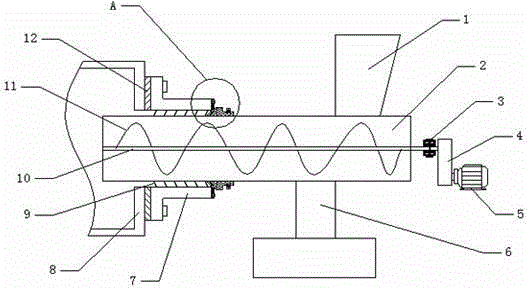

Dual sealing device for feeding of ball mill

InactiveCN102357382AImprove working environmentSolve the problem of slurry leakageEngine sealsGrain treatmentsWear resistantBall mill

The invention provides a dual sealing device for feeding of a ball mill, which is applied in the technical field of large-scale ball mills. The sealing device comprises an inlet pipe, an auxiliary mounting beam, connecting bolts, a compressing snap ring, compressing angle sealing rubber, an adjusting bolt, a mounting flange, an inner wear resistant rubber slab, an outer wear resistant rubber slab, a compressing plate, a compressing plate bolt, a mounting flange bolt and a feeding bushing. The invention is characterized in that: the dual sealing device for feeding of a ball mill is formed by assembling the auxiliary mounting beam, the mounting flange, the inner wear resistant rubber slab, the compressing plate, the outer wear resistant rubber slab and the compressing angle sealing rubber; during installation, the mounting flange is fixed on the inlet pipe through the auxiliary mounting beam, the compressing angle sealing rubber is fixed on a feeding pipe through the compressing snap ring, one side of the compressing angle sealing rubber parallelly contacts with the inner wear resistant rubber slab, and the other side of the compressing angle sealing rubber contacts with a slope of the outer wear resistant rubber slab. According to the invention, the movable compressing angle sealing rubber, the twofold contacted inner and outer wear resistant rubber slabs and the detachable auxiliary mounting beam are utilized in the dual sealing device; therefore, the advantages of convenient installation, simple adjusting and improvement of work environment for sealing members are obtained.

Owner:NORTHERN HEAVY IND GRP CO LTD

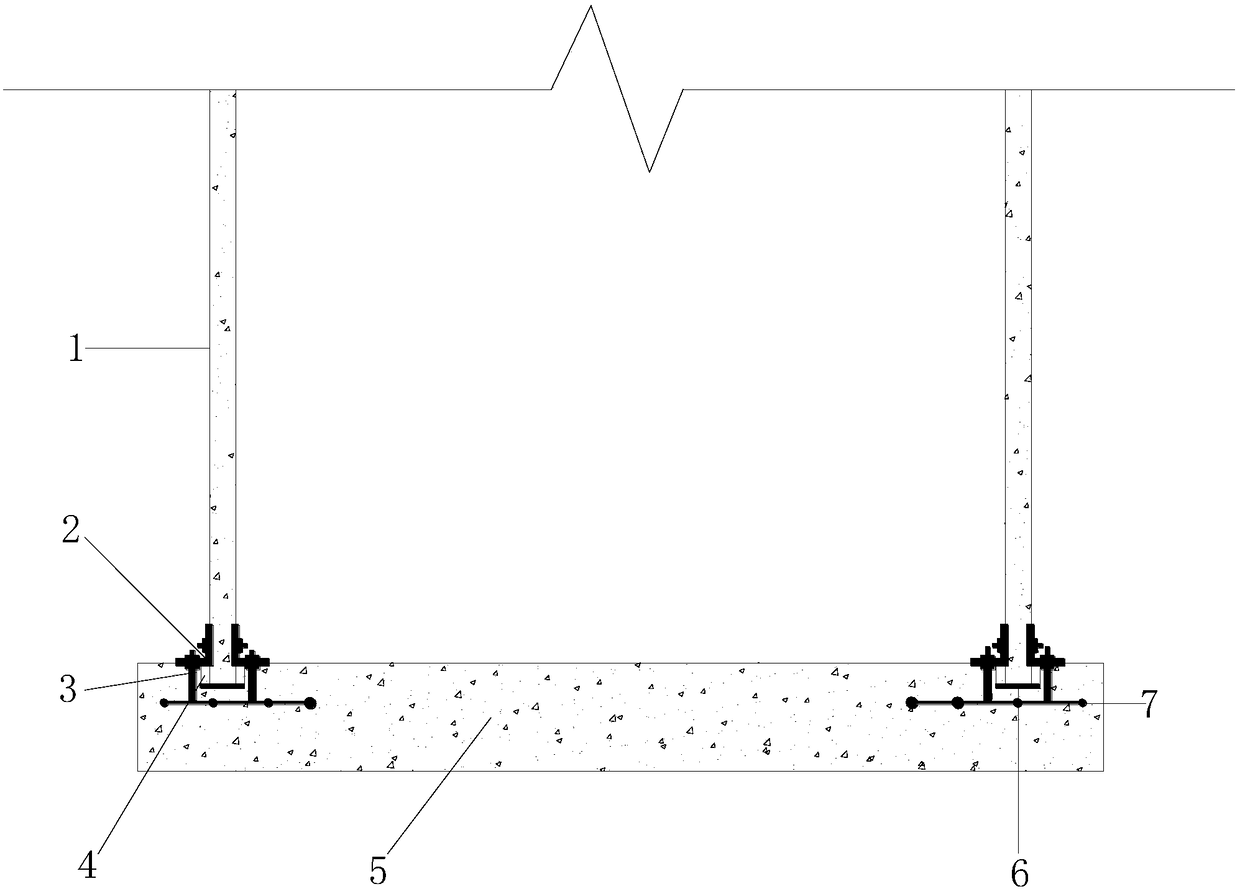

Prefabricated thin concrete slab formwork structure and construction method

InactiveCN108265738ABottom firmly fixedPrecise Positioning and PerpendicularityFoundation engineeringThin slabGrout

The invention relates to a prefabricated thin concrete slab formwork structure. The prefabricated thin concrete slab formwork structure comprises prefabricated thin concrete slabs, a cushion layer, grooves, integrally-embedded connecting screws, angle iron, leveling base grout layers and cast-in-situ bored piles. The prefabricated thin concrete slabs adopt rabbets for connection, are provided withscrew holes and connected through the evenly-distributed angle iron. The connecting angle iron on the inner side is of an embedded type. The angle iron is provided with lead screw through holes connected with the integrally-embedded connecting screws. Grid cloth anti-crack tapes are arranged in seams between the prefabricated thin concrete slabs. Connecting studs are evenly welded to the angle iron on the inner sides of the prefabricated thin concrete slabs. Lugs are evenly arranged at the tops of the prefabricated thin concrete slabs. The prefabricated thin concrete slab formwork structure has the beneficial effects that an inner formwork of a sliding formwork system is evenly divided into cavities at equal intervals, adjustable sand partition plates are arranged in the cavities to forma limiting balance weight frame, and bags between the partition plates are filled with sand to achieve regional ballasting; and a plate vibrator and a vibrating leveling beam are arranged on a lower panel of a sliding formwork, so that the slope concrete pouring quality is further improved.

Owner:HANGZHOU JIANGRUN TECH LIMITED

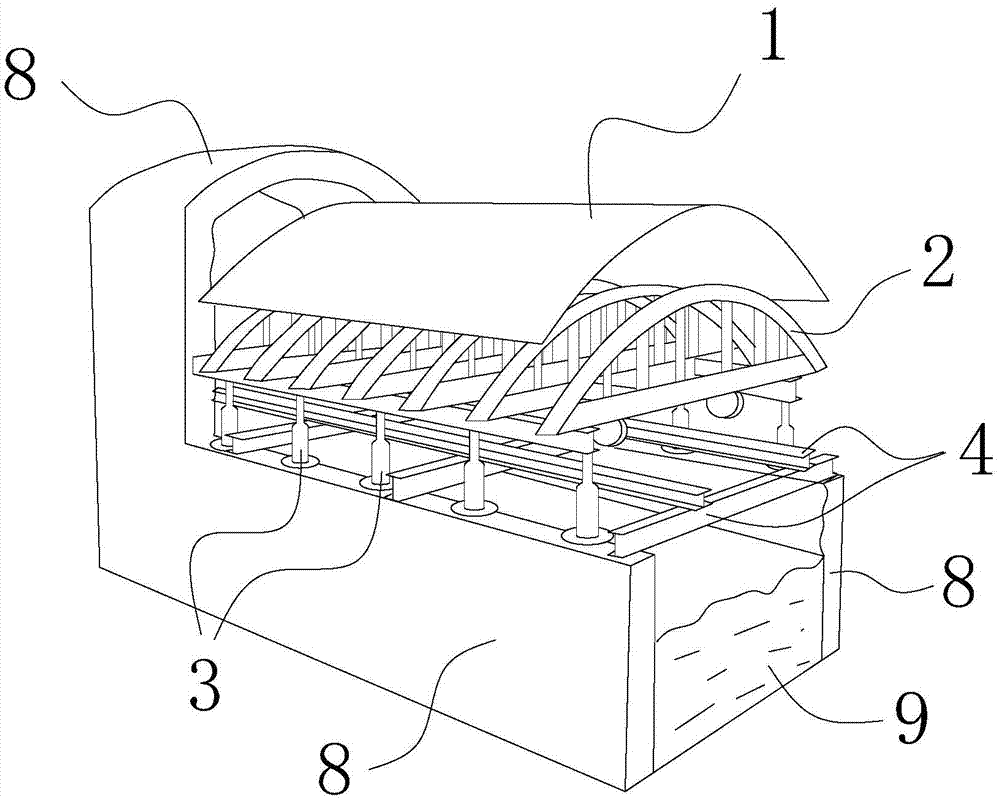

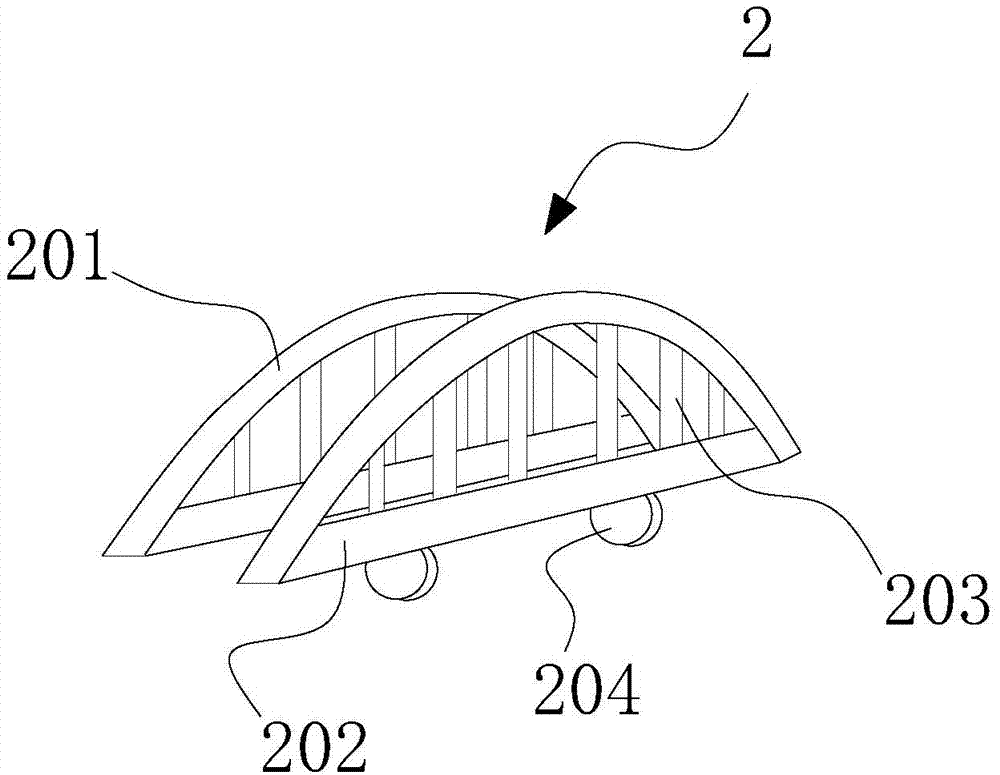

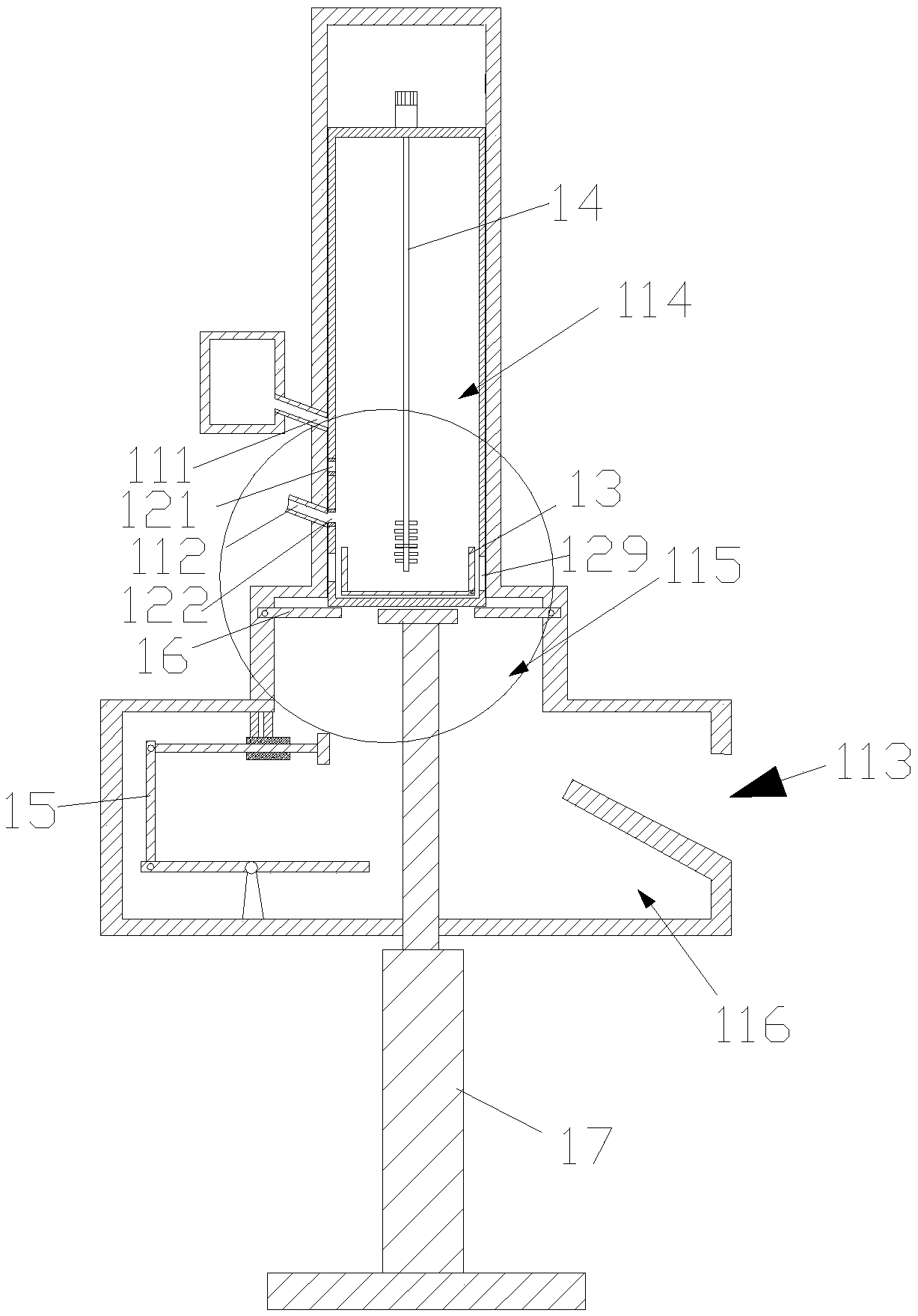

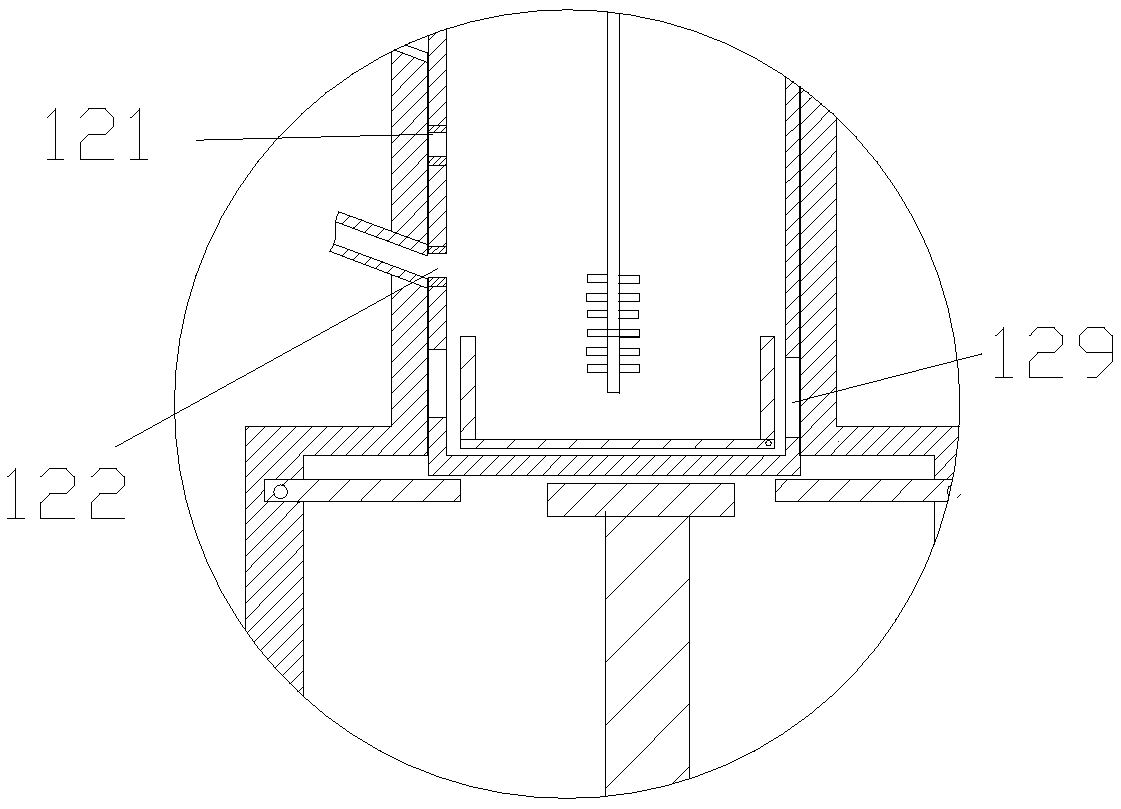

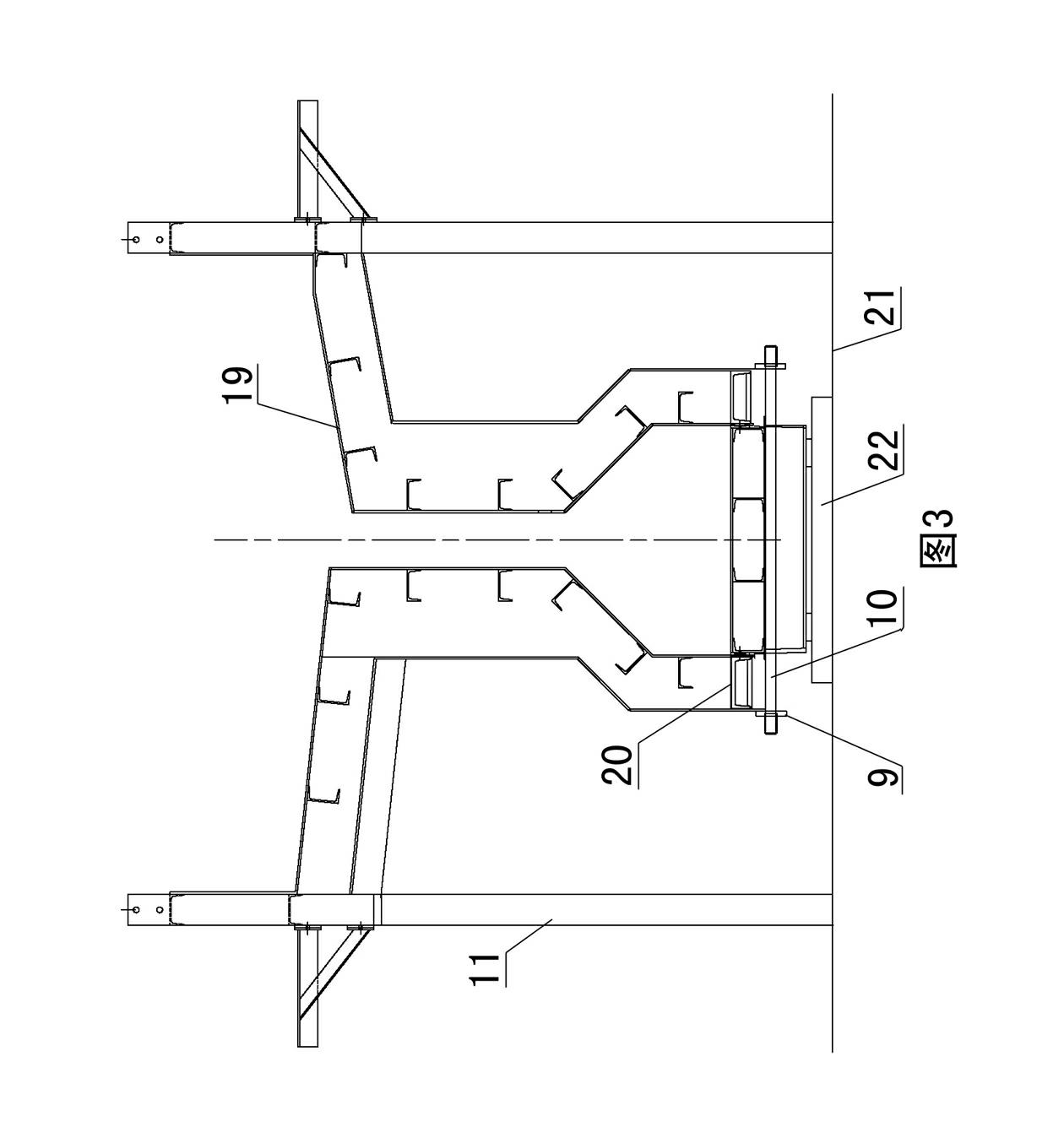

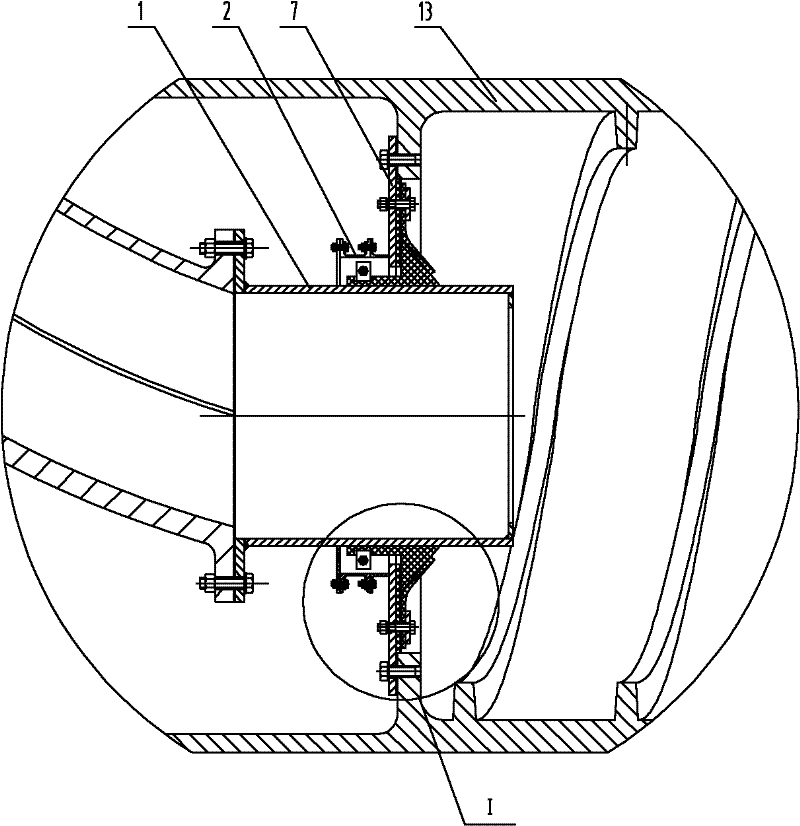

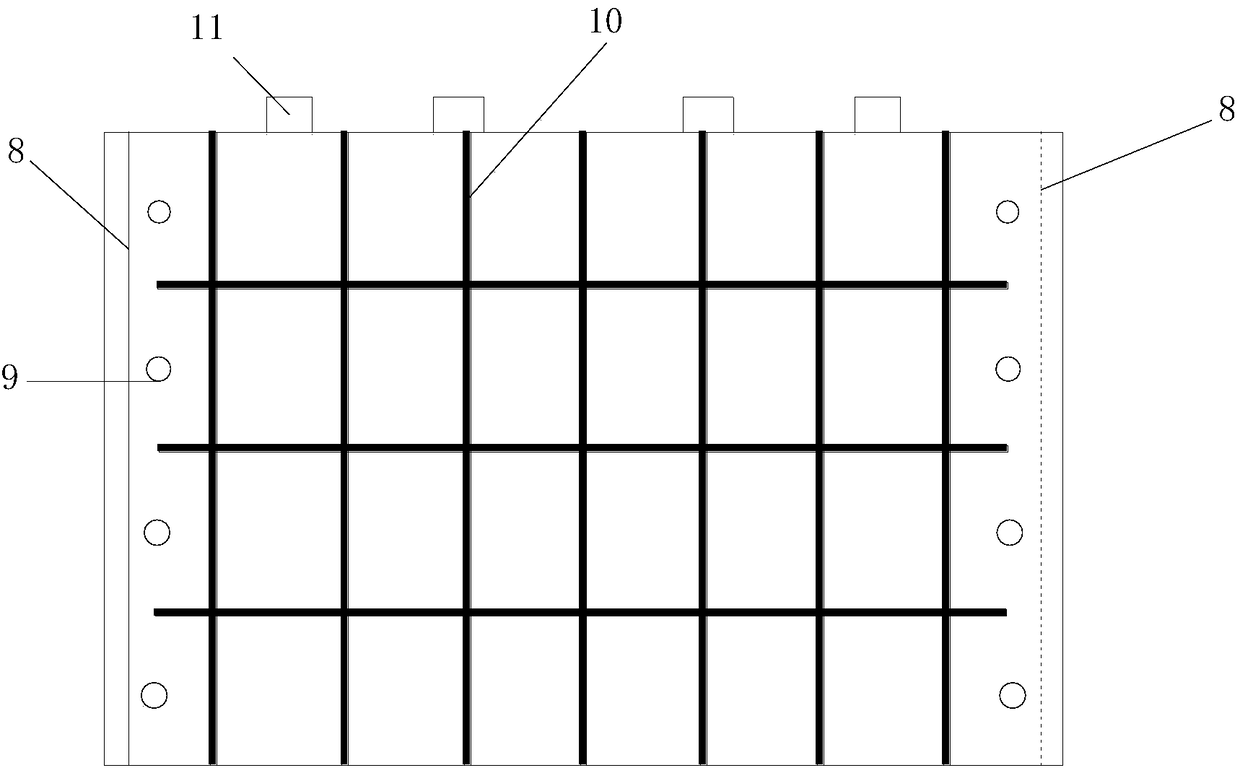

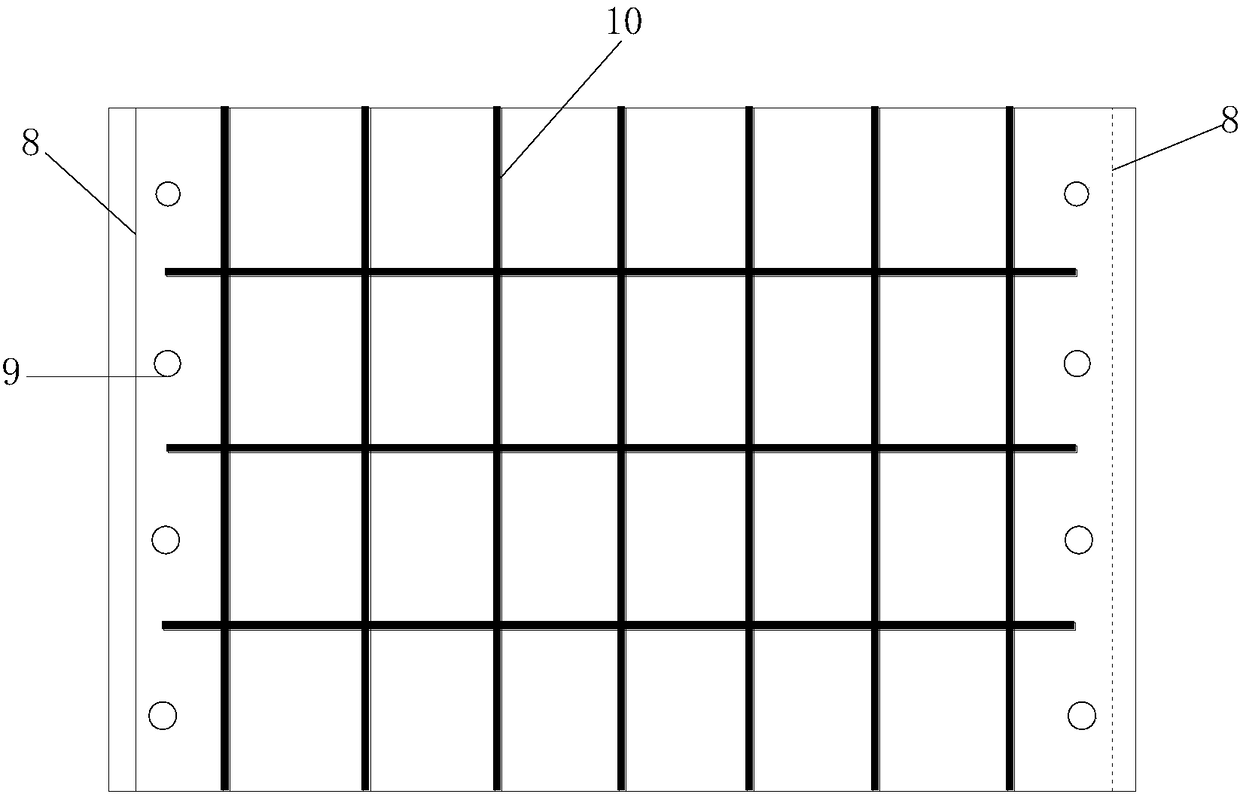

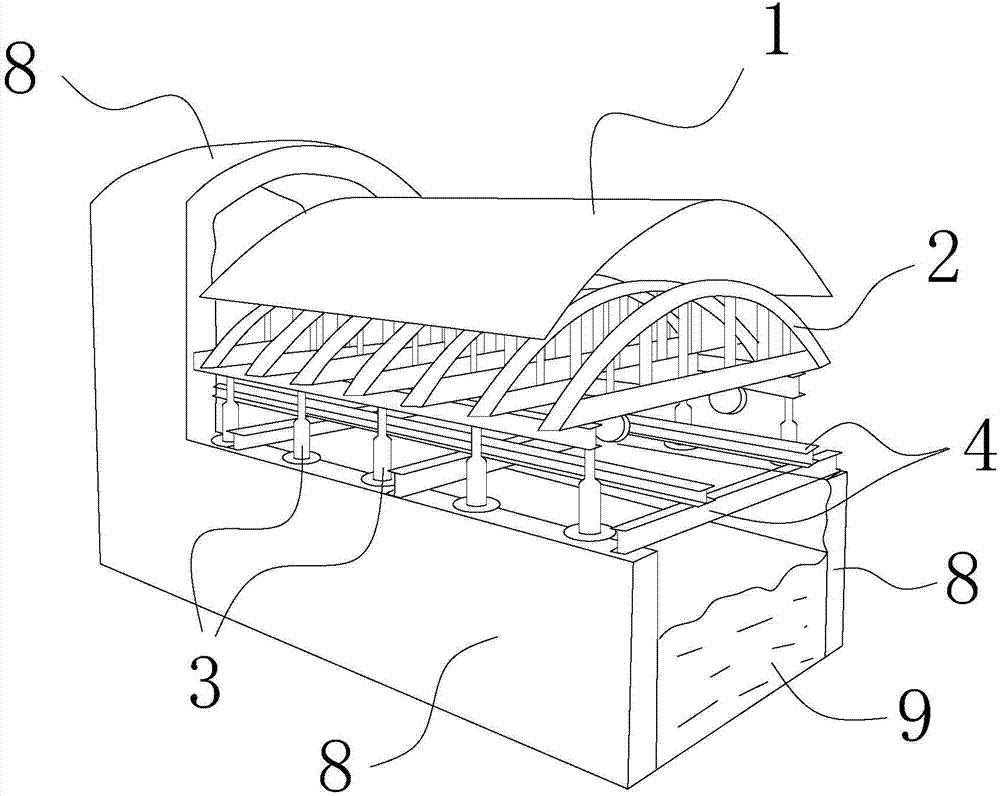

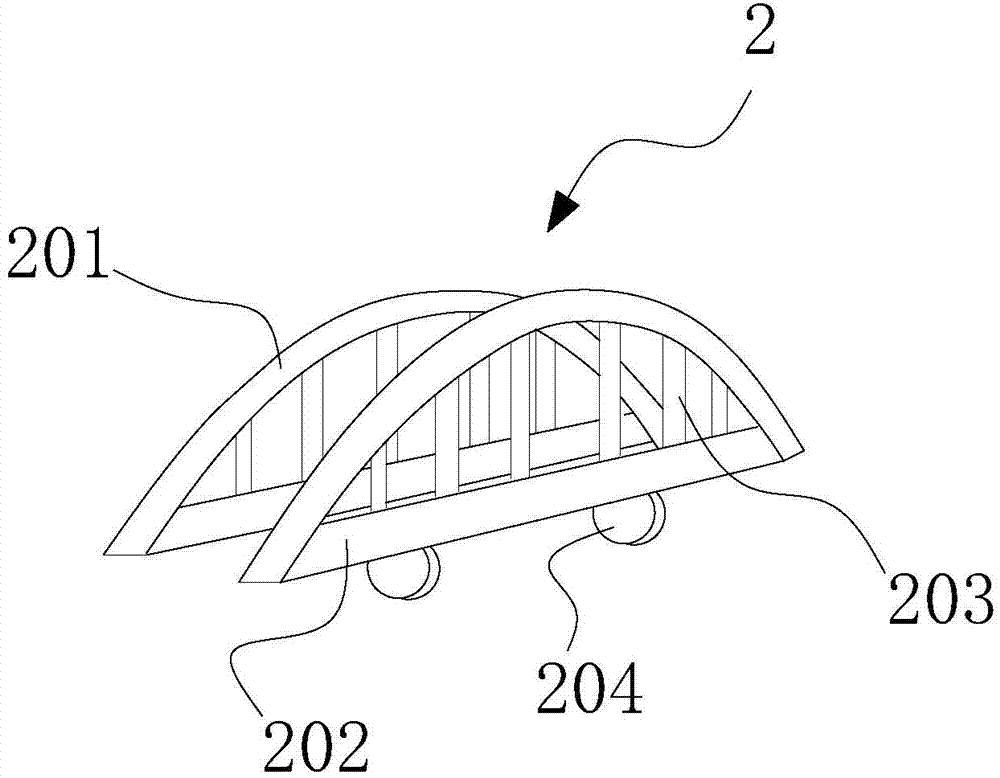

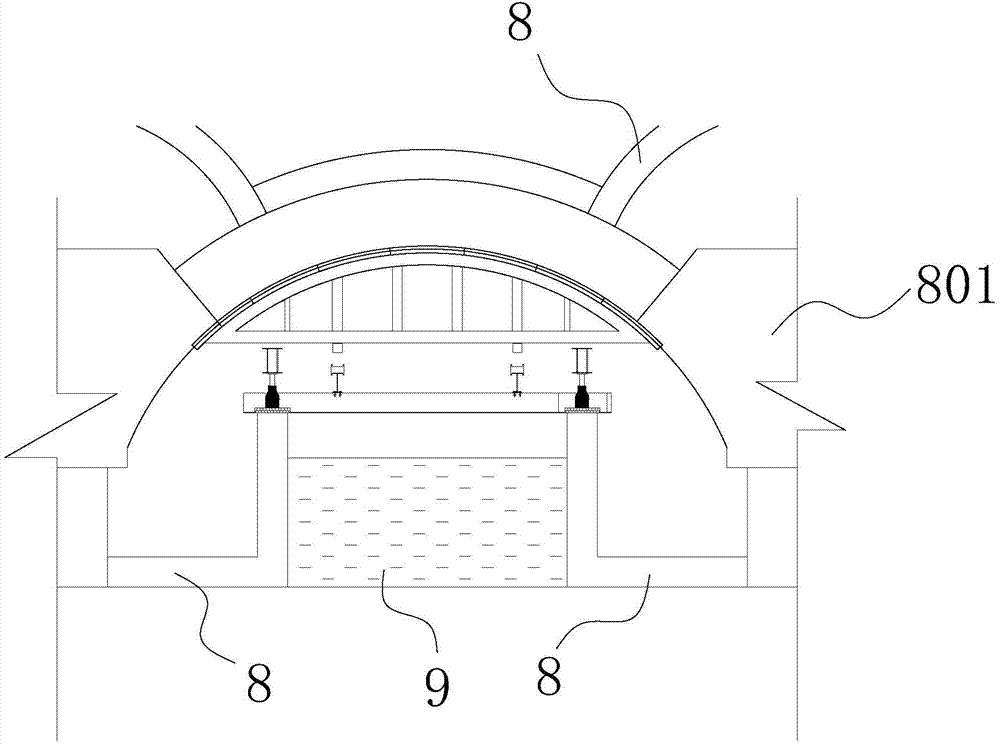

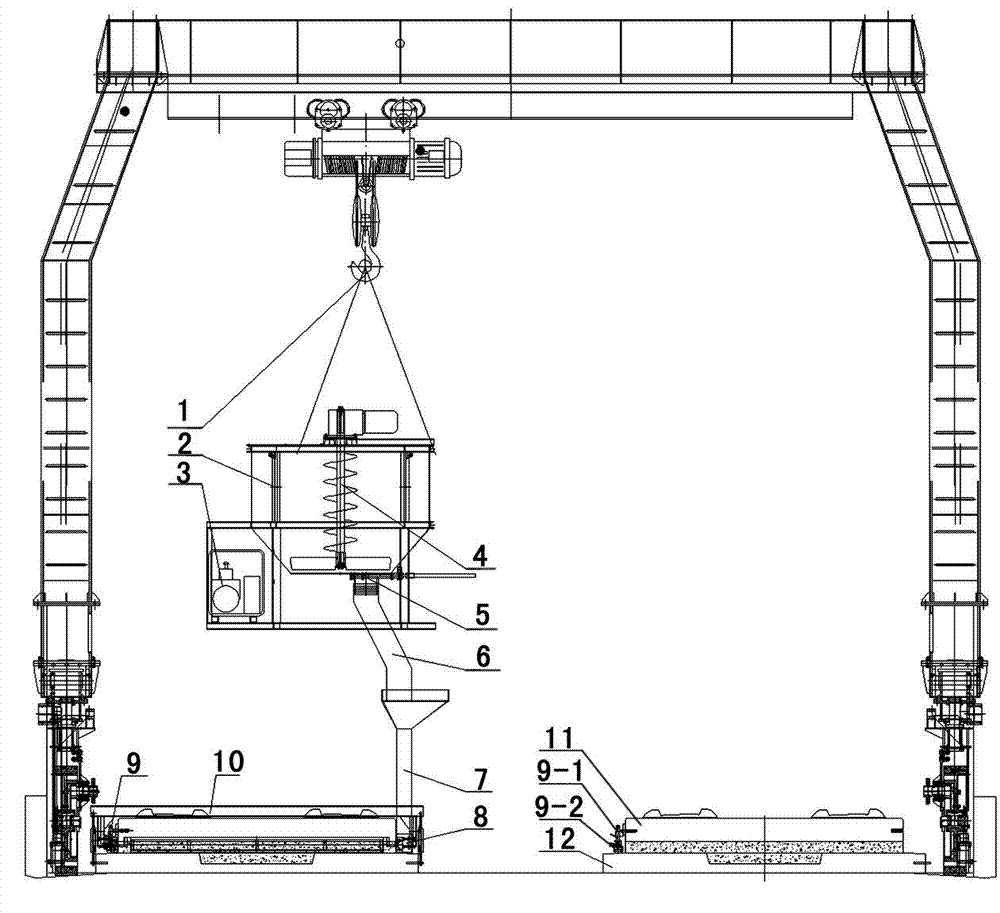

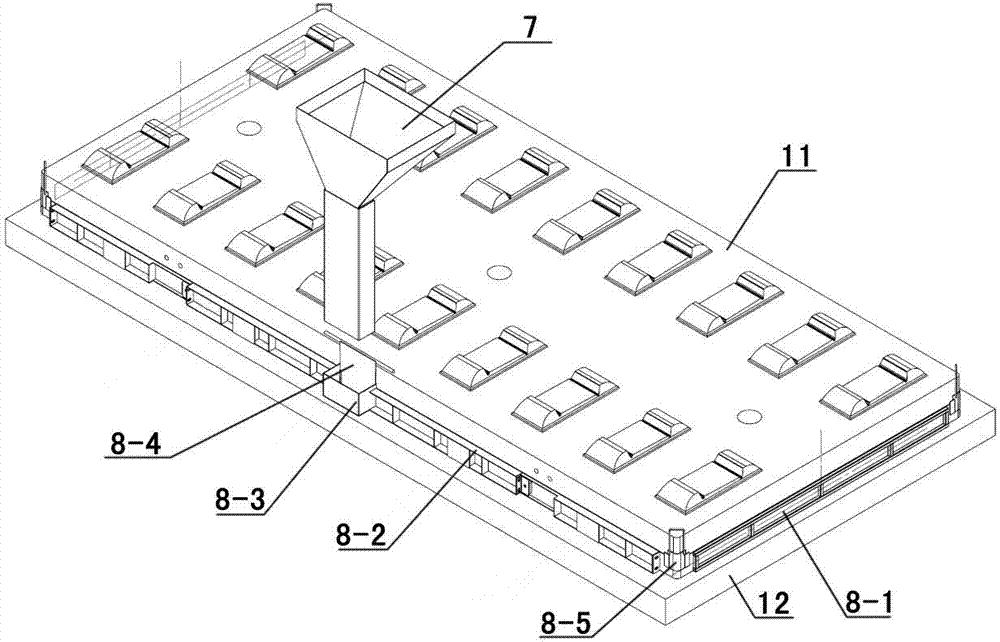

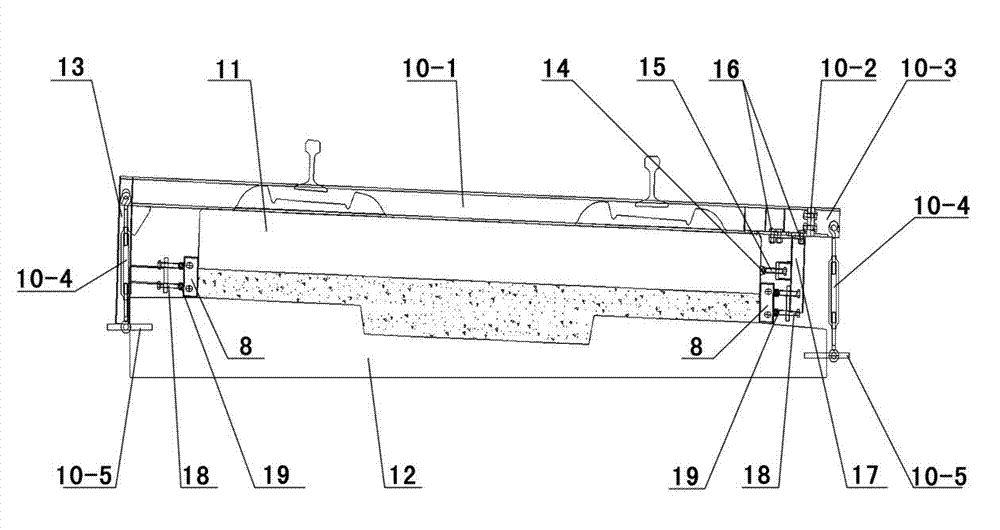

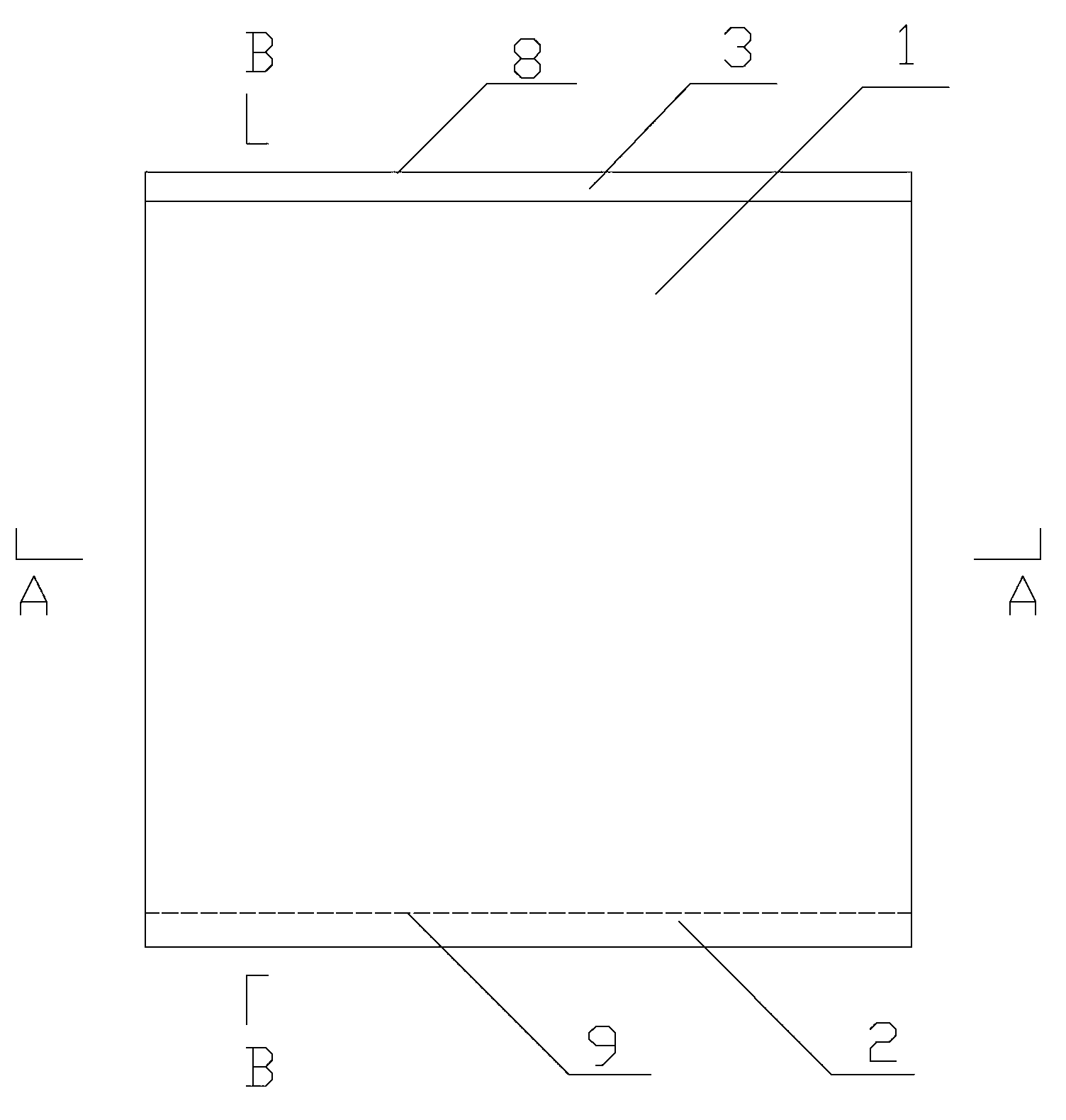

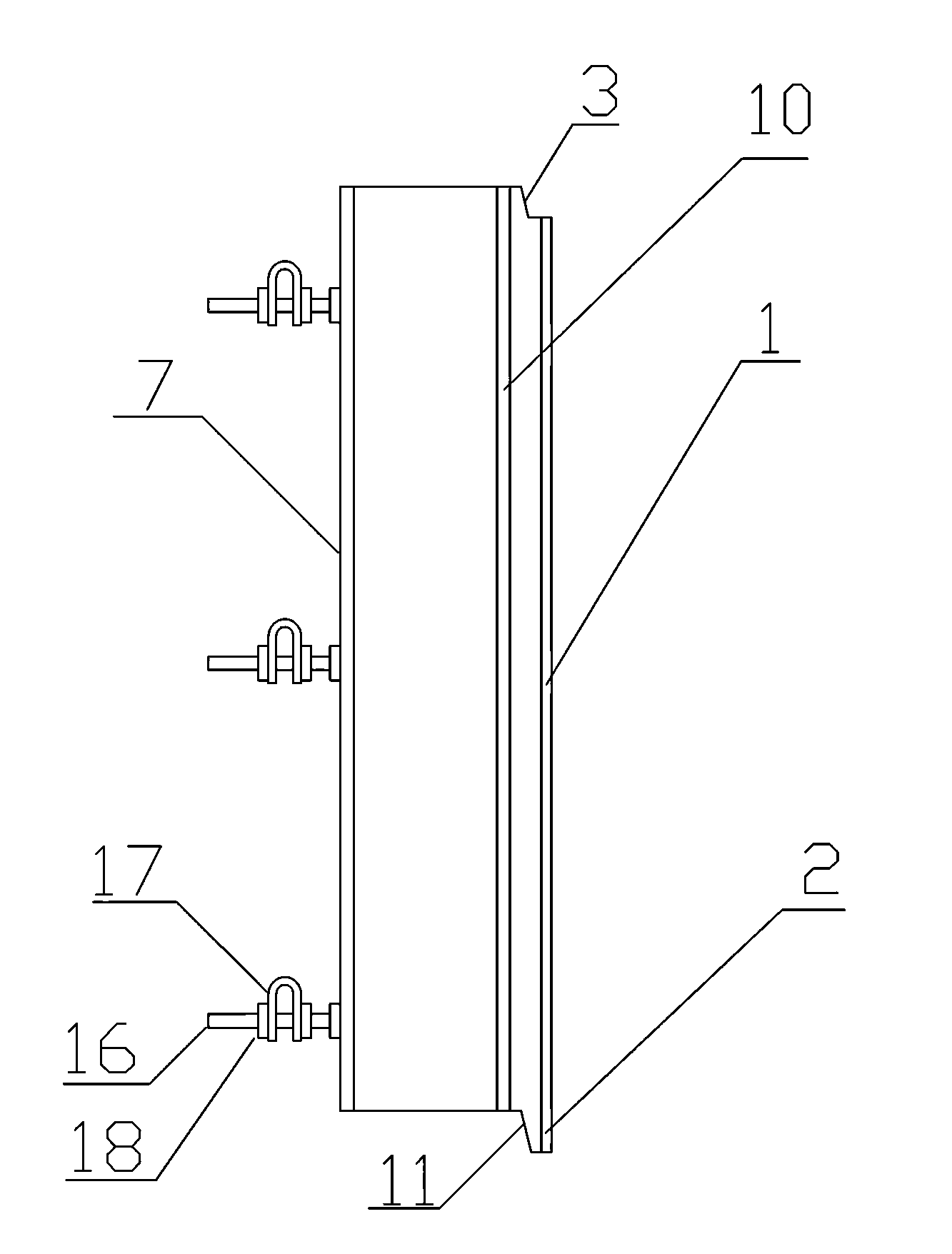

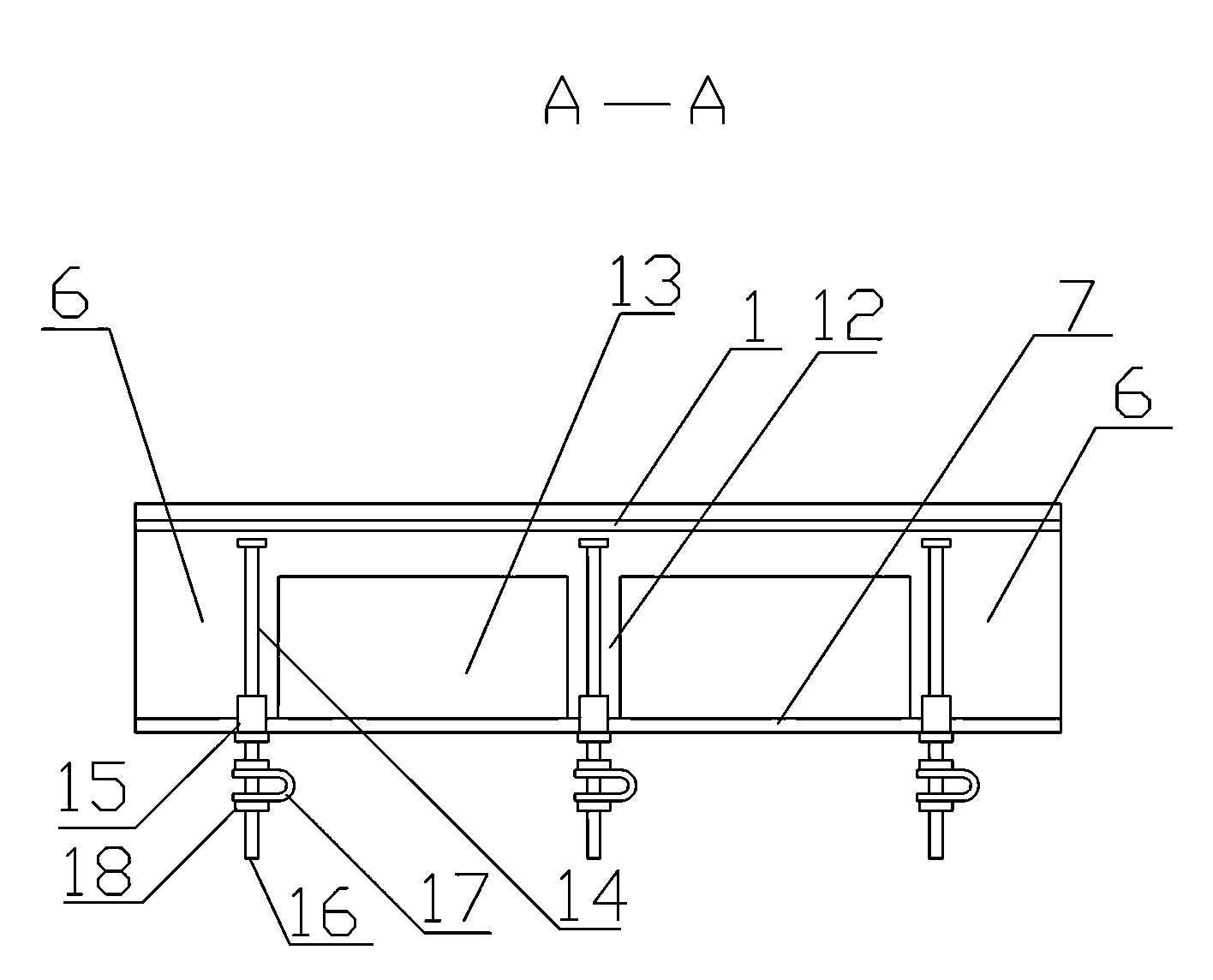

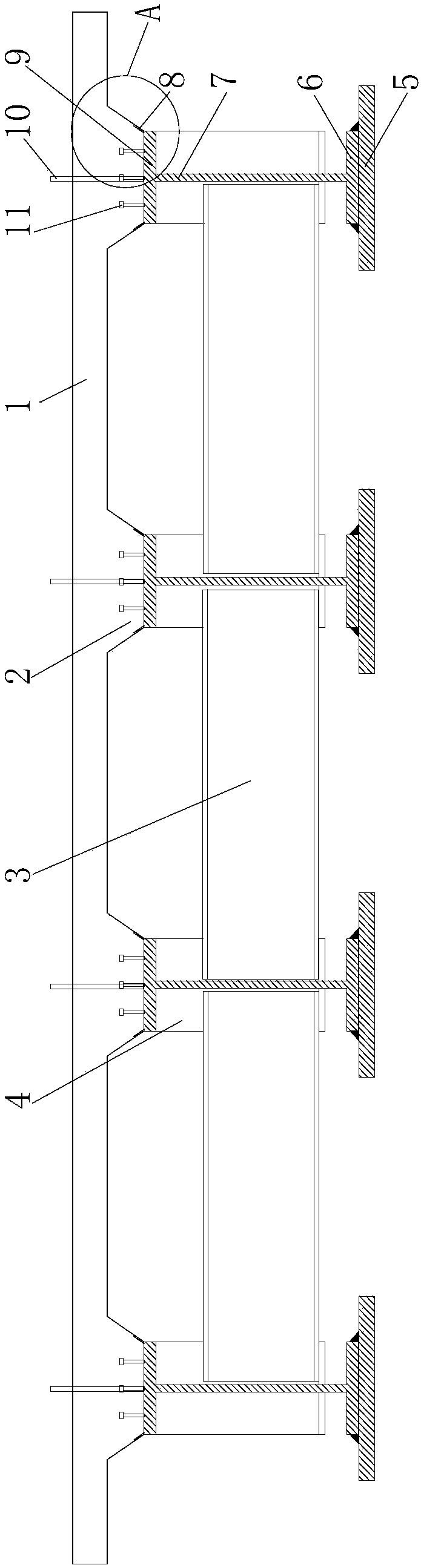

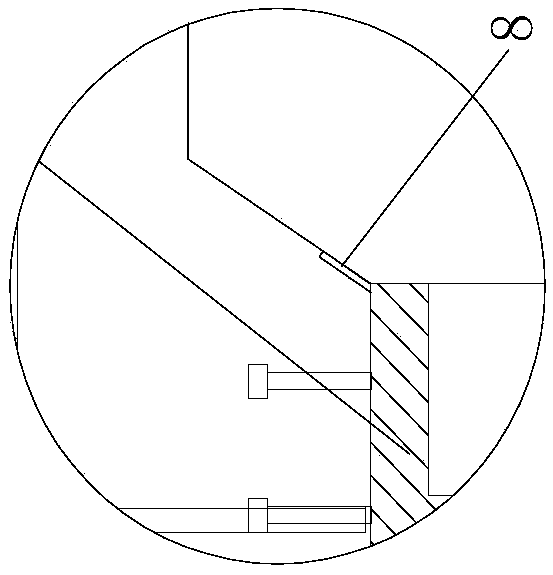

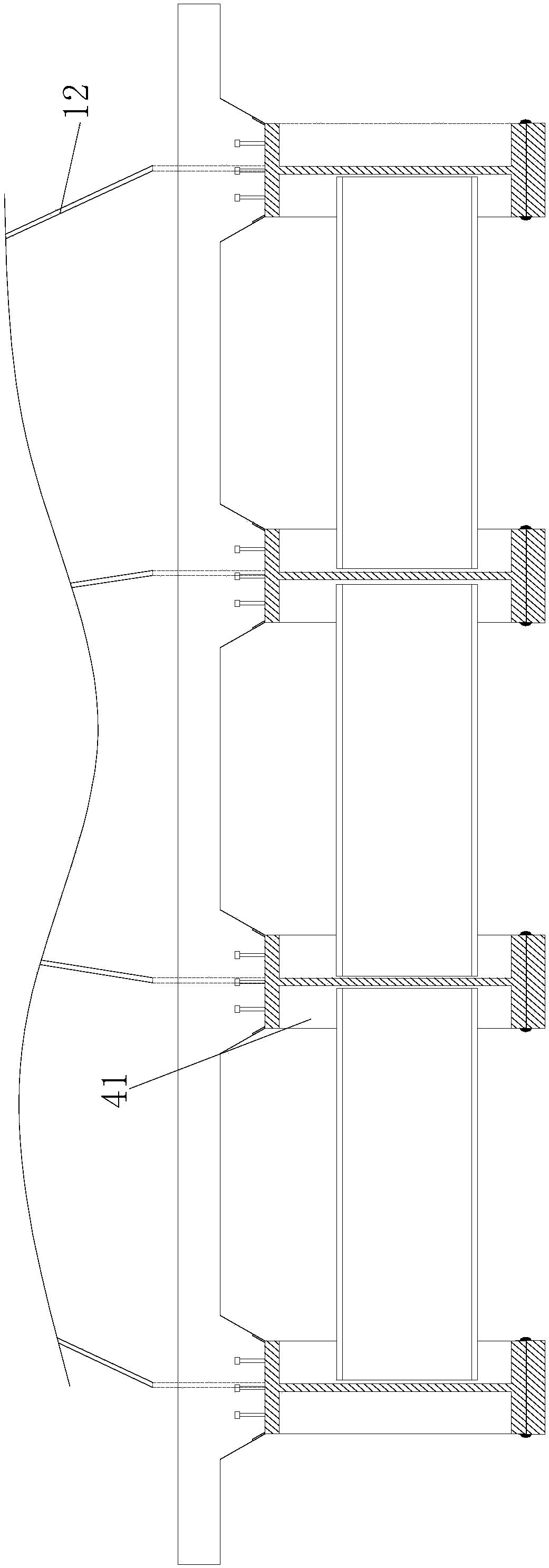

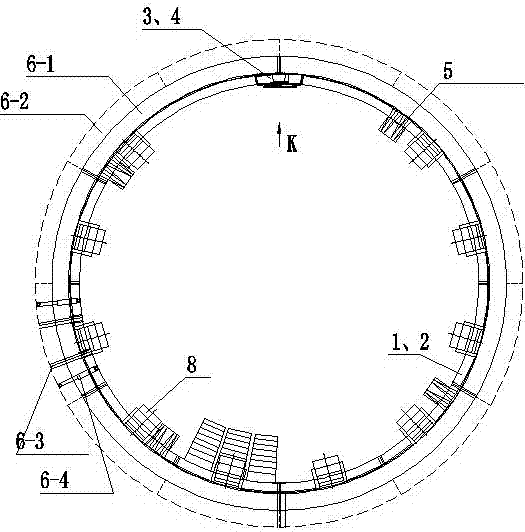

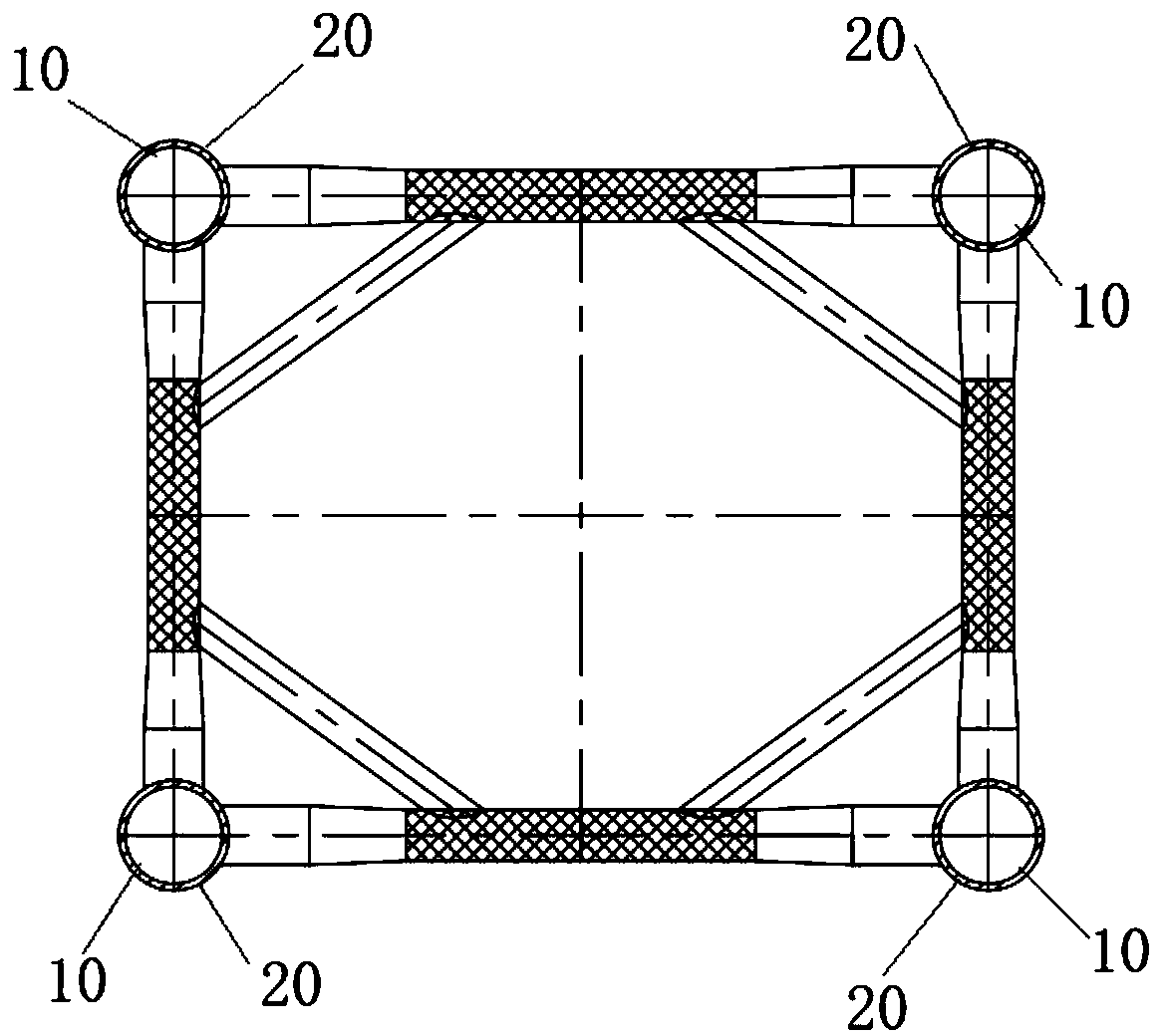

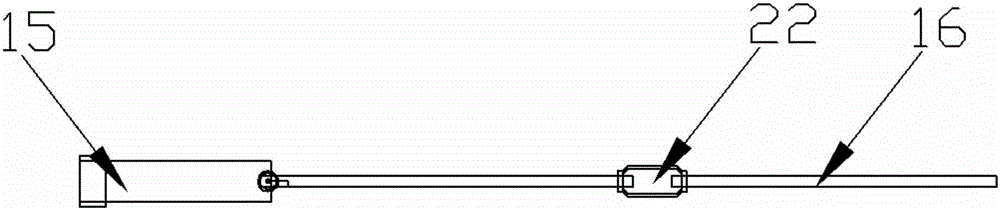

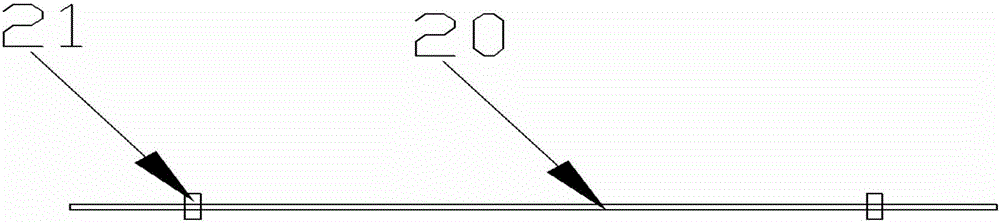

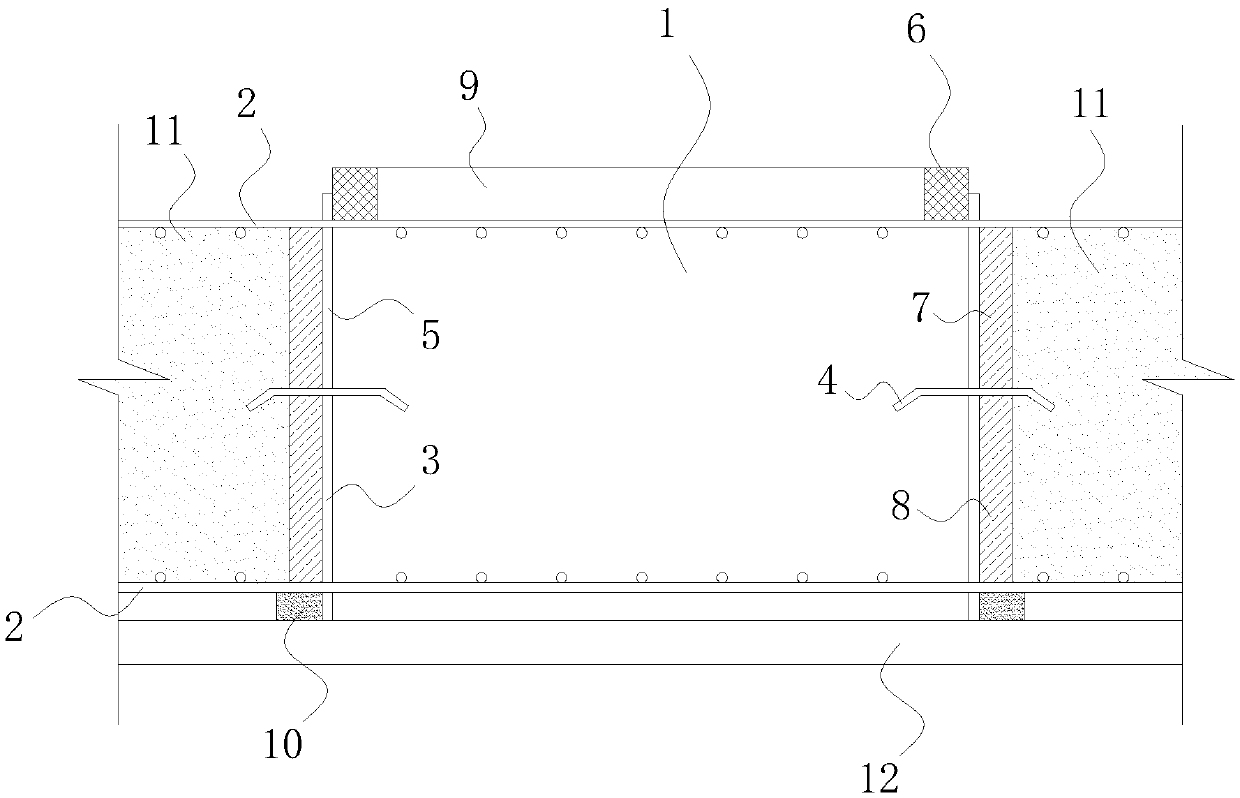

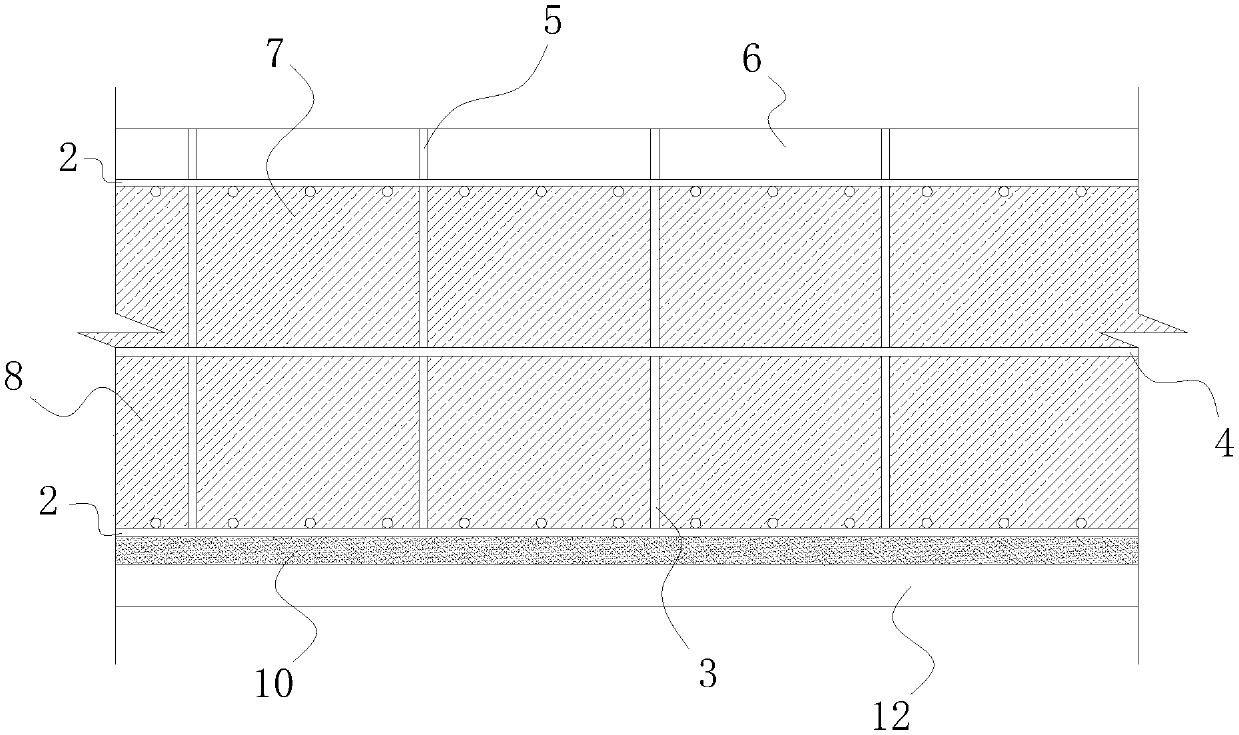

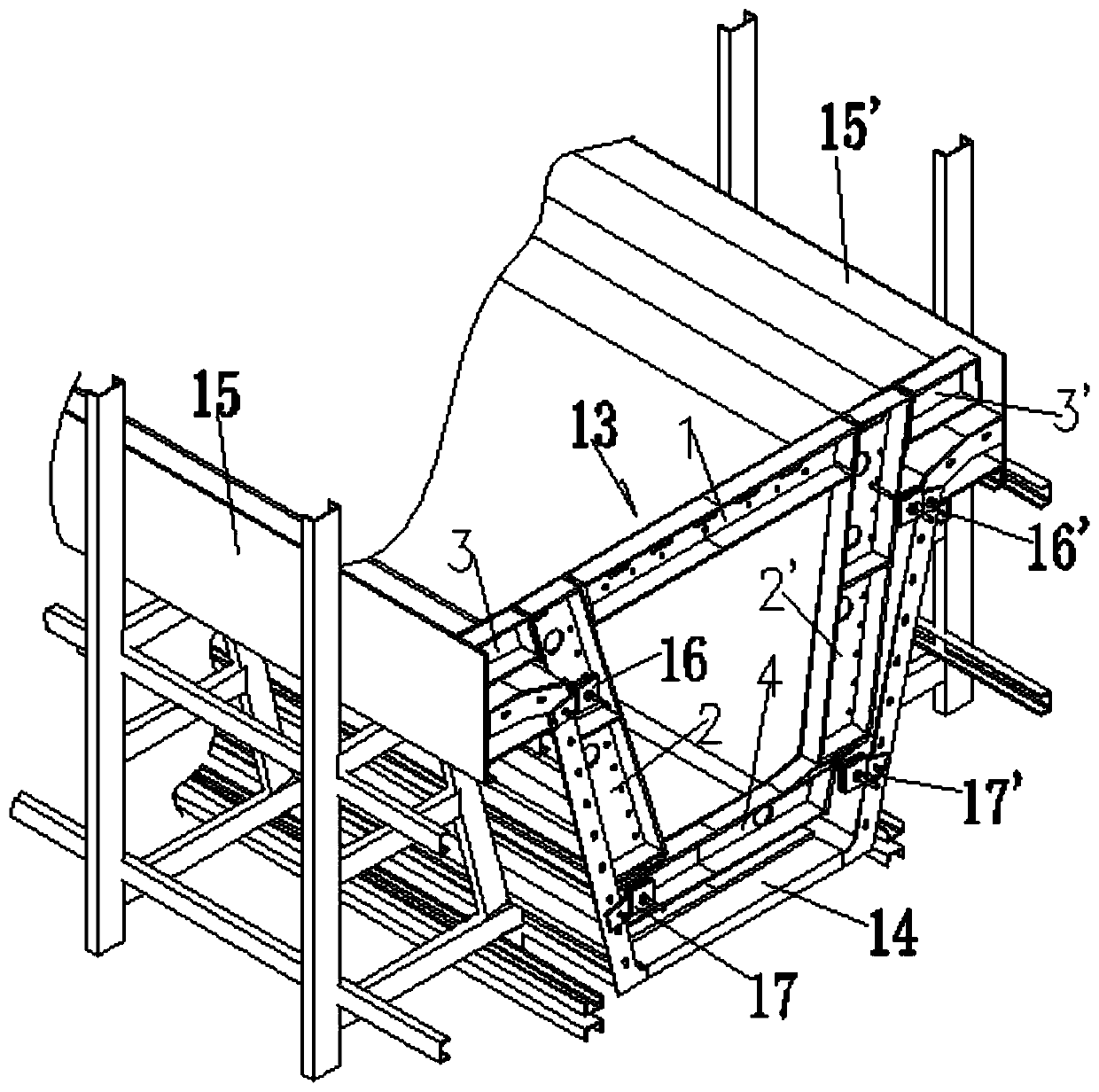

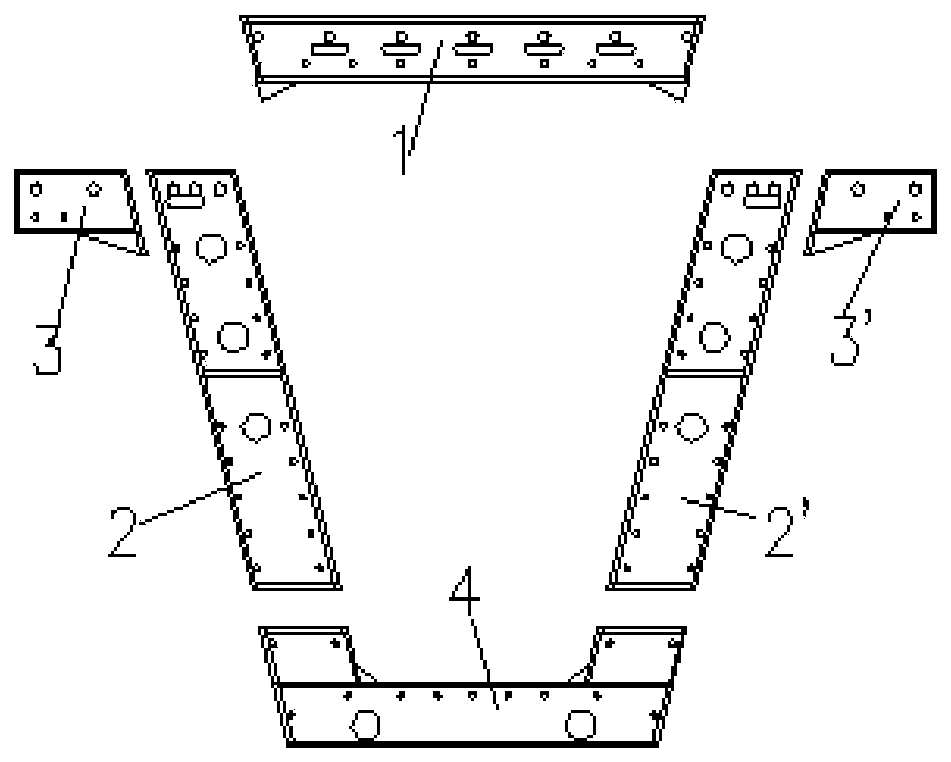

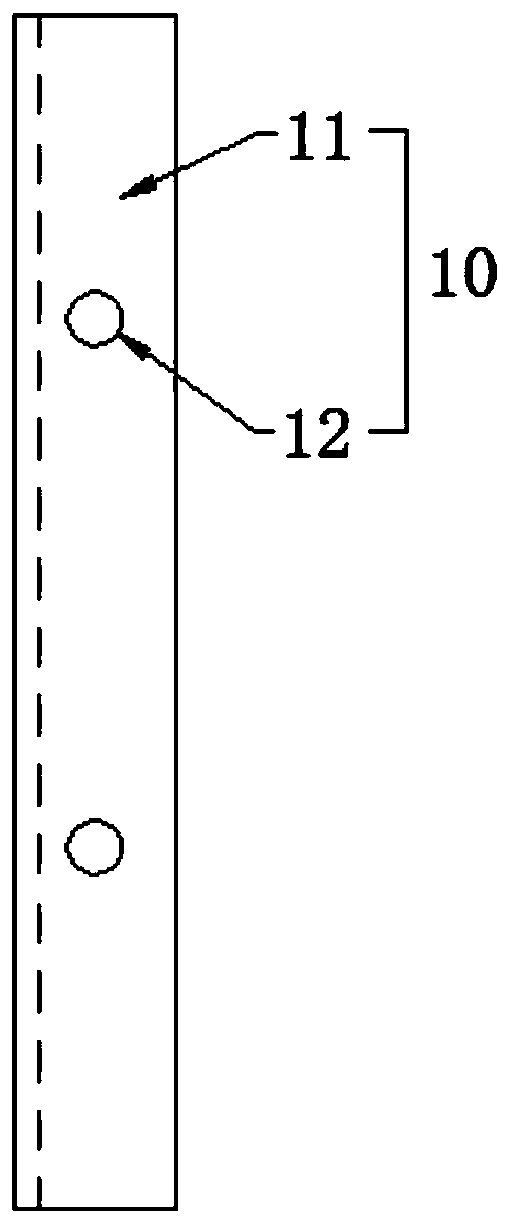

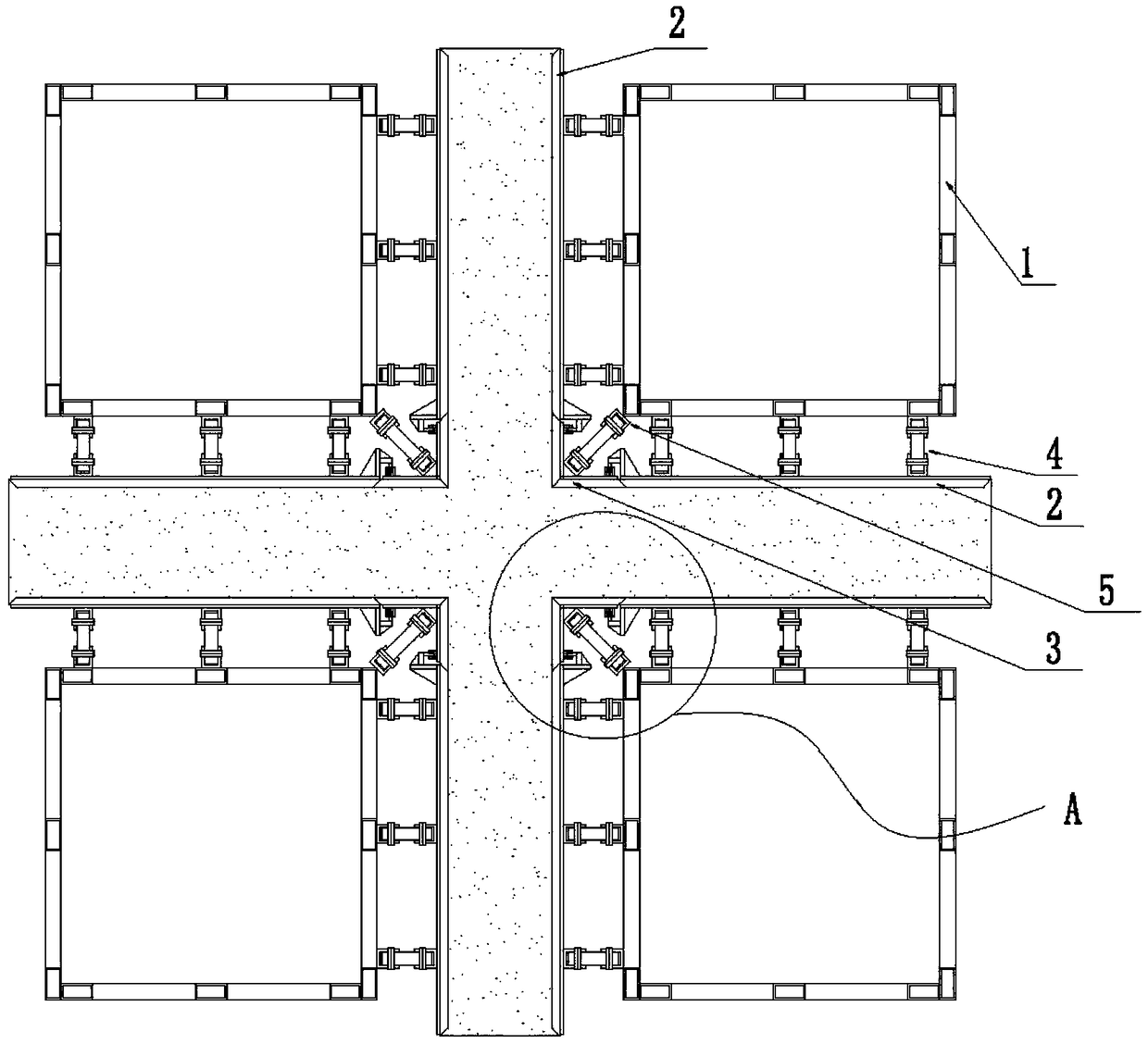

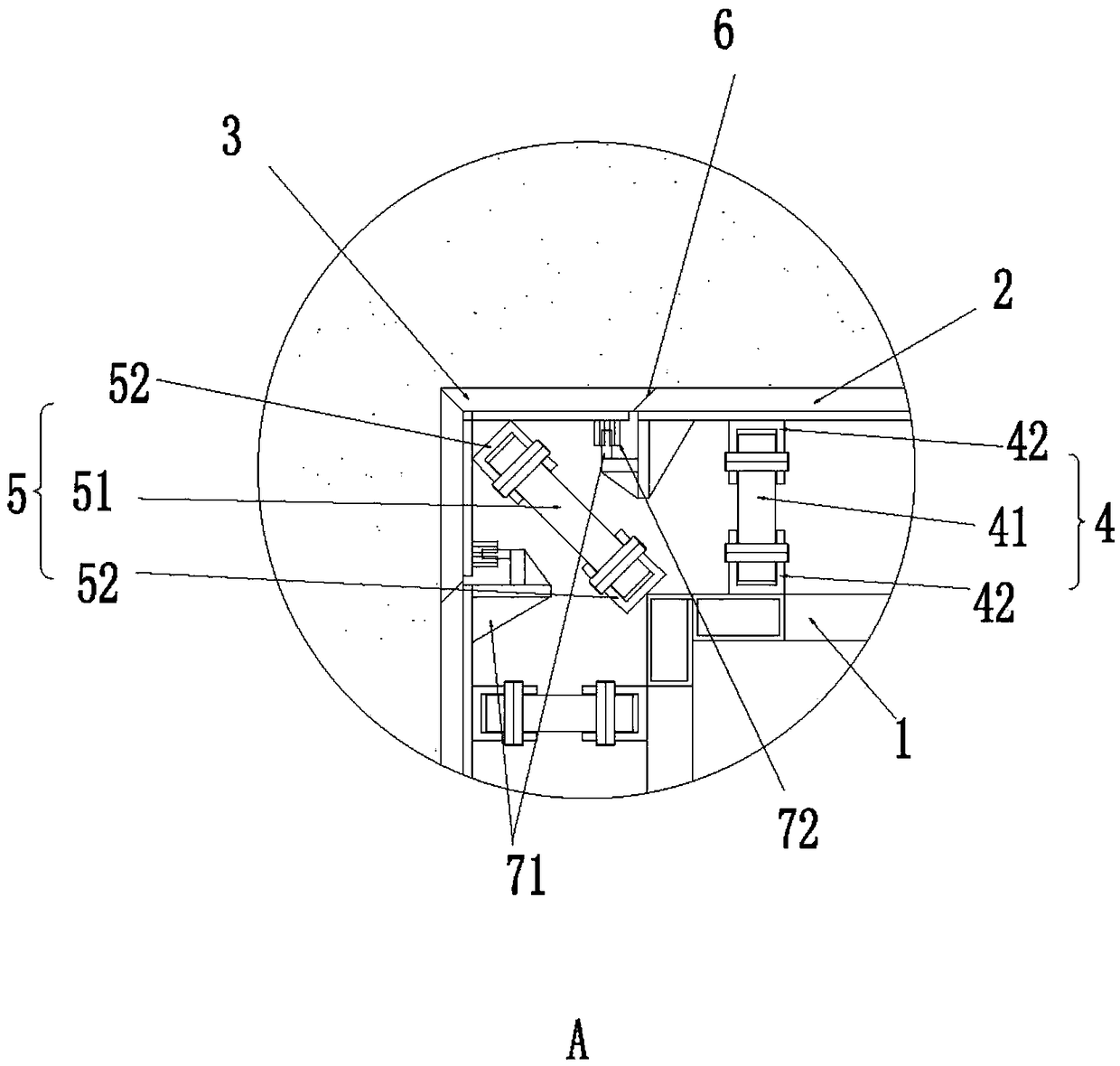

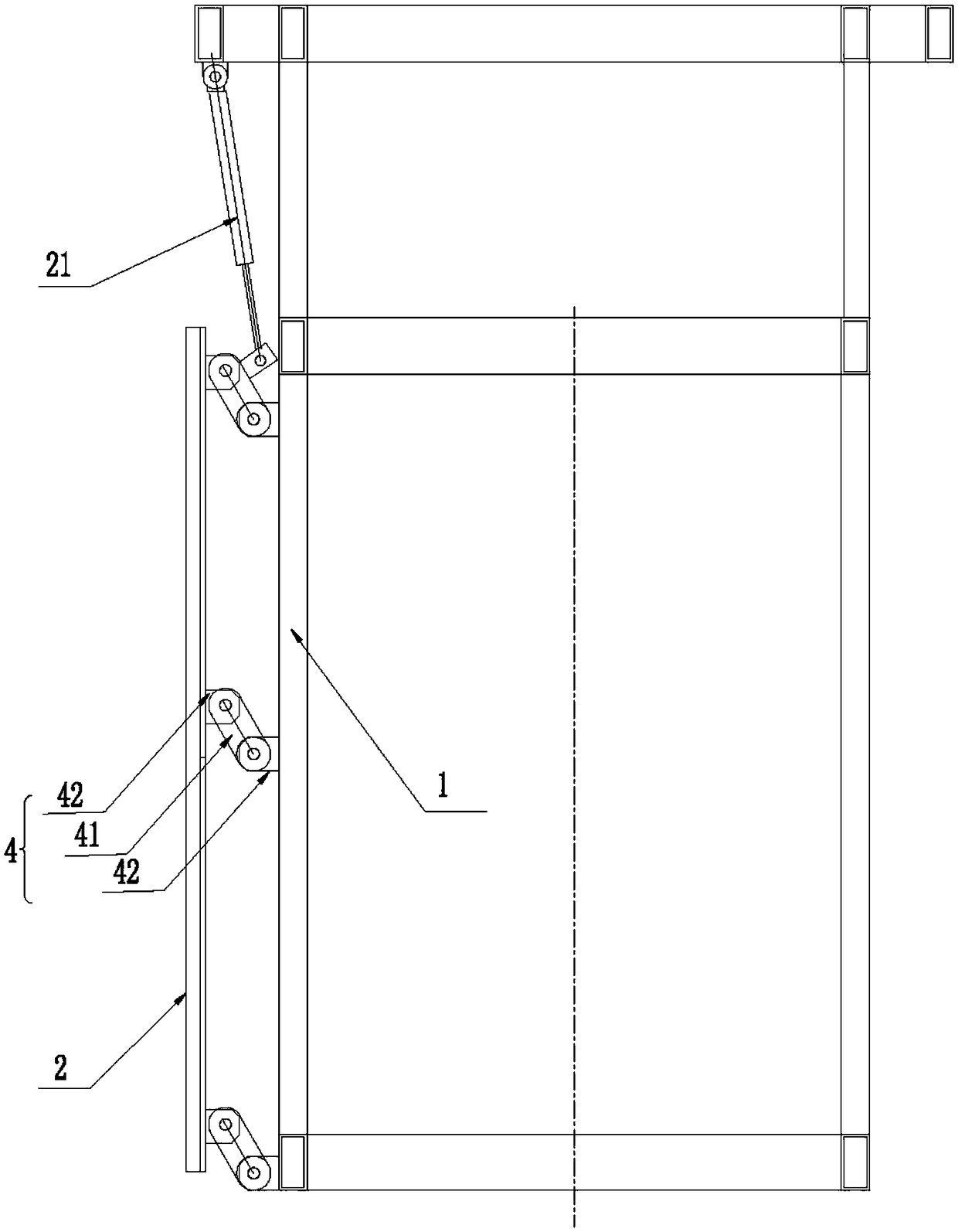

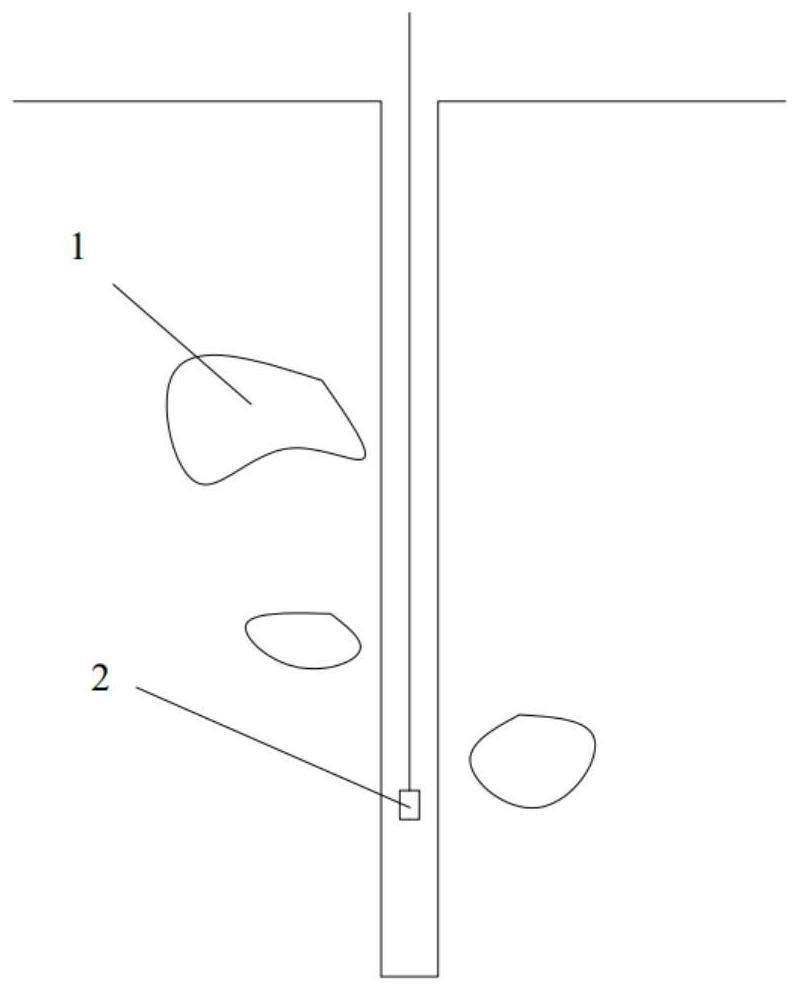

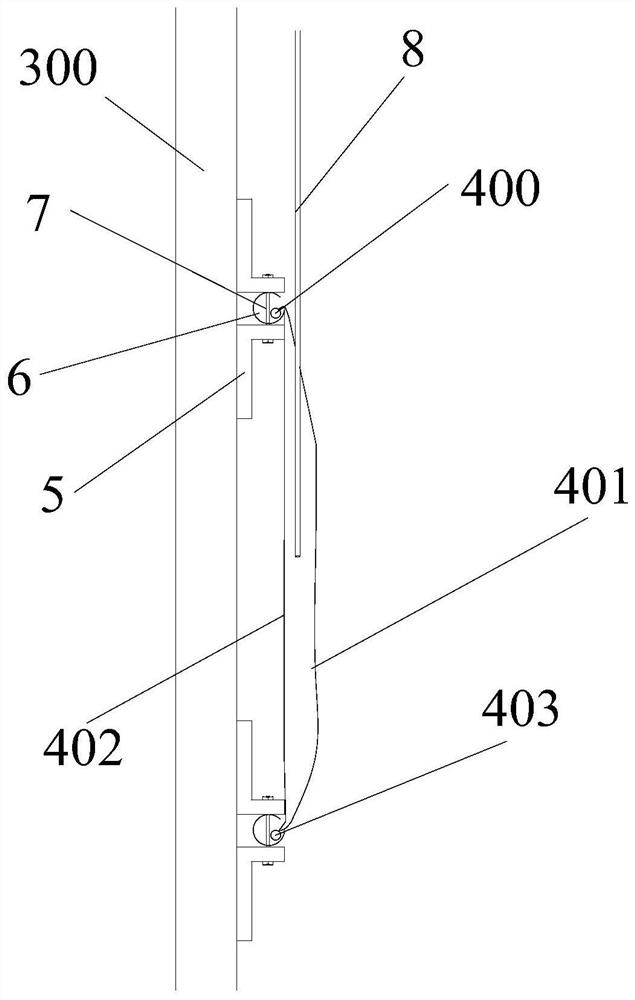

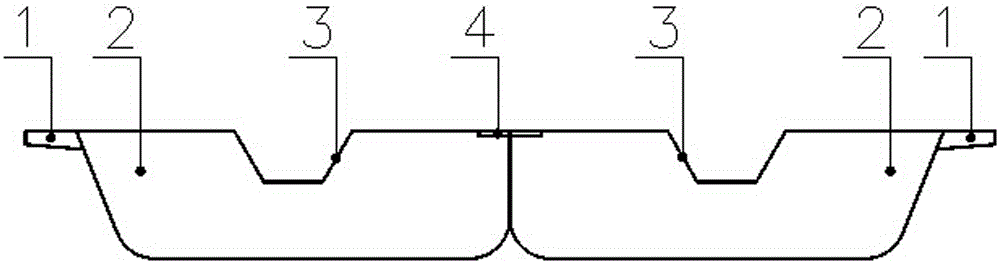

Suspension rail type construction trolley

ActiveCN103939113AShorten the timeFast constructionUnderground chambersTunnel liningCircular segmentTunnel construction

The invention discloses a tunnel construction trolley, and relates to a suspension rail type construction trolley which comprises a formwork, mould bases and jacking mechanisms. The mould bases comprise upper arches, middle web members, lower chord pull rods and walking mechanisms. The formwork is fixedly connected with the upper arches. The upper arches are of an arc structure, and the lower chord pull rods are straight rods. Two ends of the upper arches are fixedly connected with two ends of the lower chord pull rods, and the arch structure is formed by the upper arches and the lower chord pull rods. The middle web members are arranged in the middle of the arch structure, and are connected with the upper arches and the lower chord pull rods. The walking mechanisms are arranged at the bottoms of the lower chord pull rods. The jacking mechanisms are arranged at the bottoms of the lower chord pull rods, and are detachably connected with the lower chord pull rods. According to the construction trolley, construction speed can be improved, the construction period is shortened, and continuous construction is facilitated. Labor cost for splicing and dismounting the mould bases can be lowered, rail foundation laying cost can be lowered, and cost can be saved; the problem that pouring precision between adjacent linings cannot be improved and the problem of slab staggering and pulp leakage are solved, and the pouring quality of concrete is guaranteed.

Owner:CHINA RAILWAY ERJU 1ST ENG +1

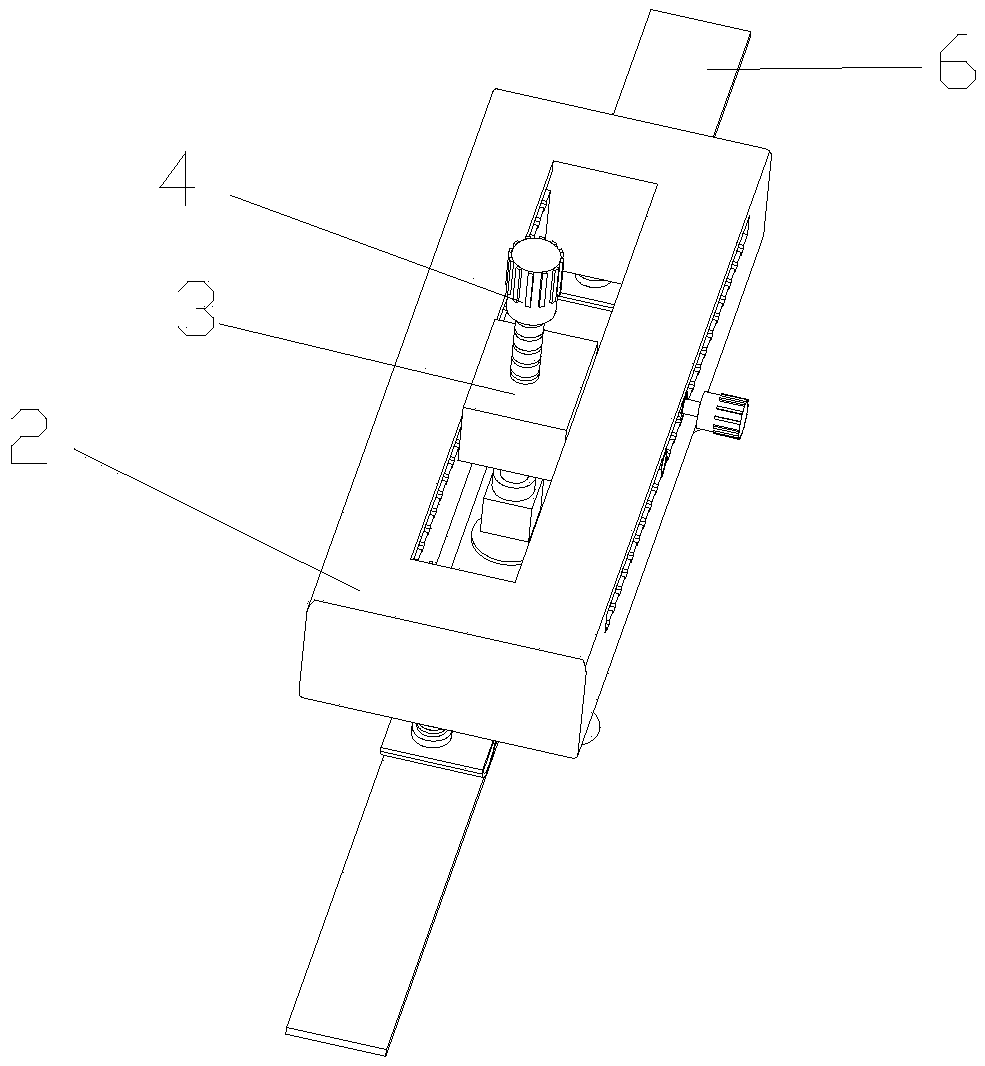

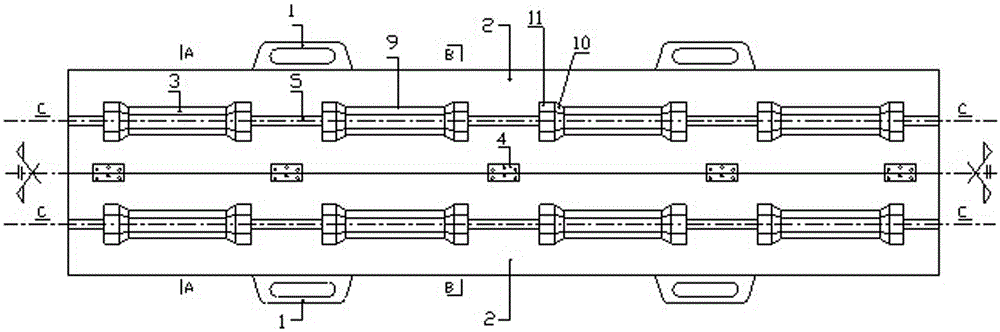

CRTS III type slab ballastless track self-compacting concrete casting tooling and method

The invention provides a CRTS III type slab ballastless track self-compacting concrete casting tooling and method. The casting tooling comprises a base slab, a track slab, a transferring hopper, a casting funnel, a slurry blocking template, a three-dimensional fine regulator, a track slab pressing device, a track slab lateral sliding preventing device and a slurry blocking template pressing device. The middle casting mode is changed into the lateral surface casting, and the problems of casting efficiency and air exhaust in the CRTS III type slab ballastless track construction are solved. The track slab lateral sliding preventing device, the track slab pressing device and the slurry blocking template pressing device effectively solve the problems of upward floating, lateral sliding and slurry leakage of the track slab in the casting process, so the fine regulation and the casting construction of the CRTS III type slab ballastless track are more convenient and fast, and the casting quality is better. The construction process has the advantages that in the use process, the weight is light, the rigidity is high, the efficiency is high, the operation is simple and convenient, the work intensity is low, and the construction process can adapt to the construction of road segments such as bridges, tunnels and roadbeds.

Owner:LANGFANG HELI TIANYI MACHINERY & EQUIP

Dry-hang external wall insulation board and novel application thereof as dismounting-free building template

InactiveCN103306389ANo displacementSolve the problem of slurry leakageWallsHeat proofingArchitectural engineeringBulk water

The invention discloses a dry-hang external wall insulation board and a novel application thereof as a dismounting-free building template. The dry-hang external wall insulation board comprises a panel, upper and lower wall boards, two side wall boards, a bottom plate and an insulation core material, wherein the panel is arranged at the top ends of the wall boards; the outer side surface of the upper wall board extends out of the upper side surface of the panel; a bulk water slope is arranged between the top edge of the outer side surface of the upper wall board and the bottom edge of the upper side surface of the panel; the lower side surface of the panel extends out of the outer side surface of the lower wall board; the part of the panel, extending out of the lower wall board forms a pressure plate mounted by being matched with the bulk water slope; a pressure plate slope is arranged between the bottom edge of the lower side surface of the panel and the top edge of the outer side surface of the lower wall board; a pouring connection piece is embedded between the panel and the bottom plate; the pouring connection piece comprises a fixing rod, a nut at the outer end of the fixing rod and a screw rod matched with the nut; the nut is arranged at the end of the bottom plate; the screw rod extends out of the bottom plate; a U-shaped opening positioning sleeve is arranged on the screw rod; fastening nuts are arranged at the two ends of the U-shaped opening positioning sleeve. The dry-hang external wall insulation board is suitable for dismounting-free self-insulation self-decoration templates of cast-in-situ shear walls and beam columns.

Owner:许浒

Whole-span prefabricated H-steel-concrete composite beam bridge and construction method

InactiveCN108342973AImprove integritySolve fatigueBridge structural detailsBridge erection/assemblyWelding residual stressBridge deck

The invention discloses a whole-span prefabricated H-steel-concrete composite beam bridge and a construction method. The whole-span prefabricated H-steel-concrete composite beam bridge comprises an H-steel combination and a concrete bridge plate which is poured on the H-steel combination; the H-steel combination comprises H-steels placed in parallel in the bridge width direction; and the whole-span length is the length direction of the H-steels. The whole-span prefabricated H-steel-concrete composite beam bridge has the advantages that the construction of a bridge deck slab is simple and the hoisting weight of the bridge deck slab is light; during making, factory machining and manufacturing procedure does not exist and the later mounting and erecting difficulty is reduced; and meanwhile, as the H-steels can avoid adverse effects such as welding residual stress, more stable mechanical property, better bearing capacity and better durability are obtained; and the making cost can be greatly reduced. Compared with the steel plate girder in the prior art, the whole-span prefabricated H-steel-concrete composite beam bridge has the advantages that the welding or bolting process can be eliminated; construction processes uneasy to control, such as prestressed structure steel strand tensioning and grouting, hollow slab girder hinge joint connection and so on do not exist; the quality of aprofiled-steel composite beam can be effectively guaranteed; and requirements on equipment and technical skills of workers can be reduced.

Owner:CHONGQING JIAOTONG UNIVERSITY

High-pressure circulation grouting minitype steel pipe pile and construction method thereof

The invention discloses a high-pressure circulation grouting minitype steel pipe pile and a construction method thereof. The minitype steel pipe pile comprises a minitype steel pipe, a cement static slurry filling body, a cement static slurry protective layer and leakproof lag piles. The construction method comprises the following steps: (1) carrying out geological survey; (2) designing the minitype steel pipe pile; (3) formulating a scheme; (4) carrying out rotary jet grouting treatment on a slurry leaking layer; (5) carrying out pipe-following drilling; and (6) pouring the cement static slurry filling body and the cement static slurry protective layer, wherein the leakproof lag piles are applied to engineering of an underground soil body with the slurry leaking layer. According to the invention, advantages of the minitype steel pipe and cement static slurry are combined, and the high-pressure circulation grouting technology is adopted to form the cement static slurry filling body andthe cement static slurry protective layer on the internal and external parts of the minitype steel pipe, so that problems about pipe-holding and jamming of a drilling tool caused during the forming process of the minitype steel pipe pile are solved, and corrosion resistance of the minitype steel pipe pile and frictional resistance between the soil bodies are improved; and in addition, the leakproof lag pile technology better solves the problems about slurry leakage during pipe-following drilling and the pile forming and grouting processes.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

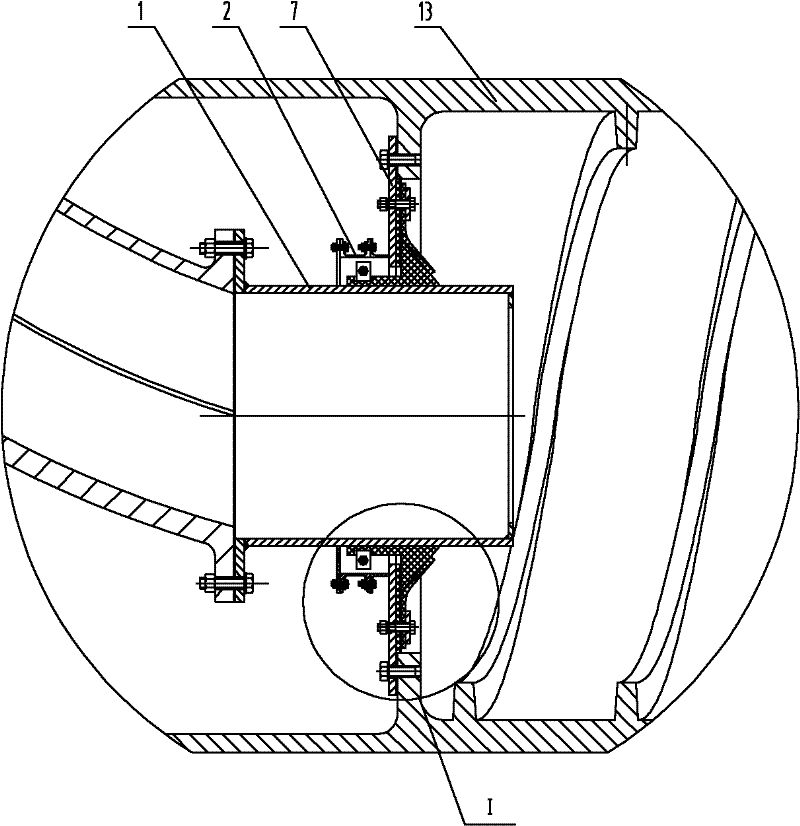

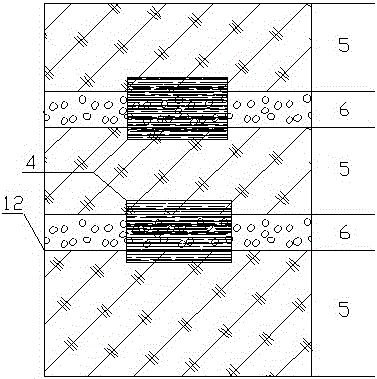

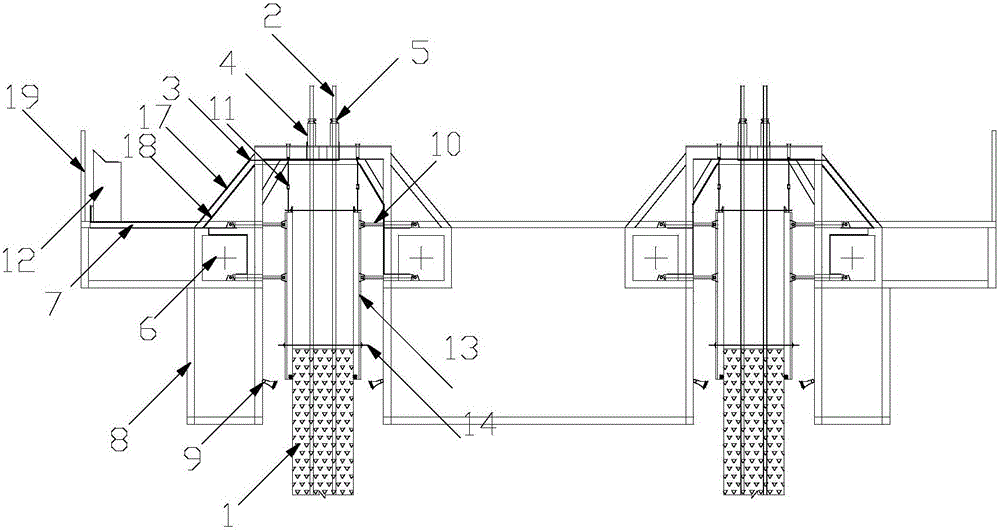

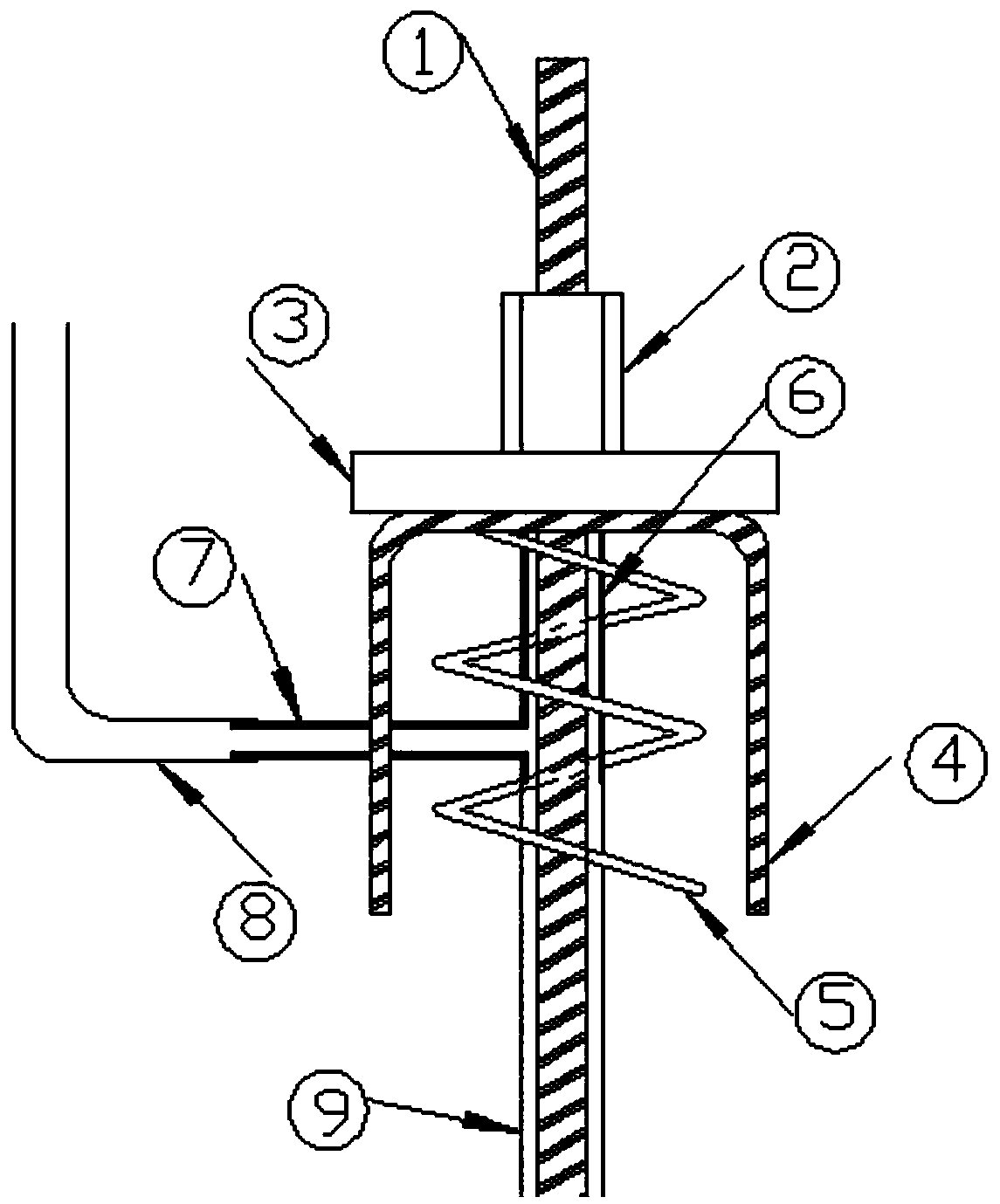

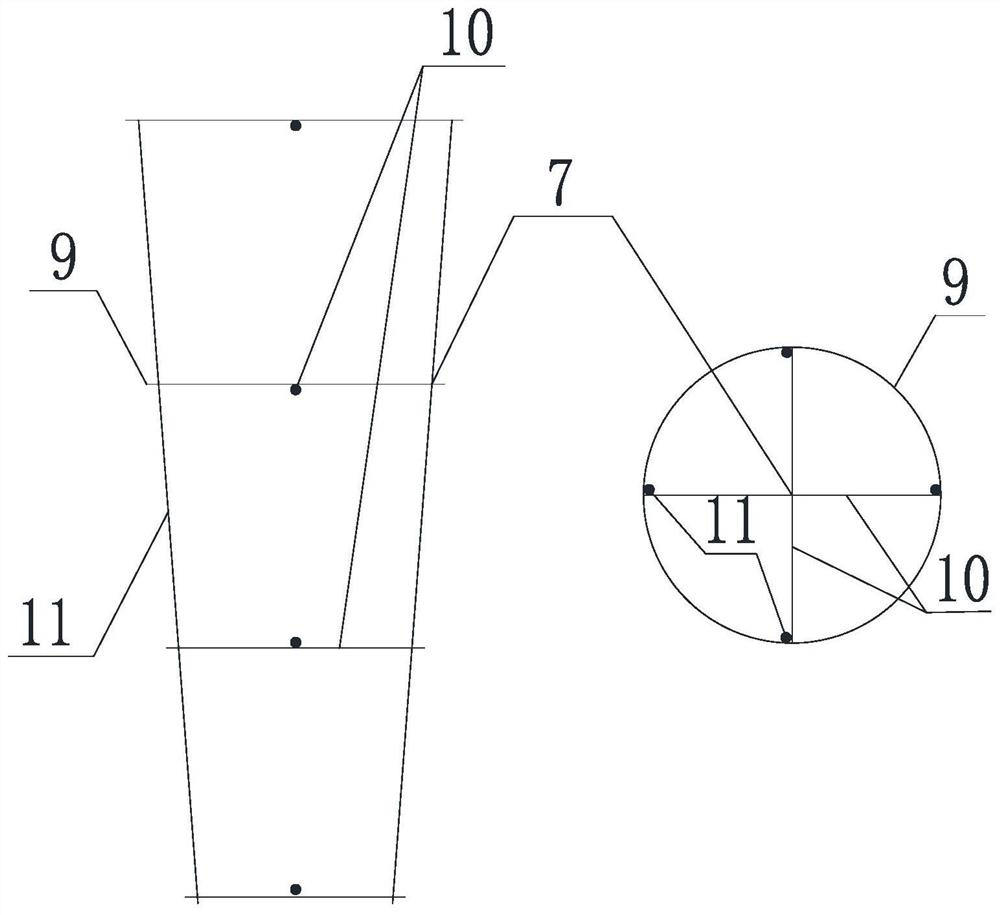

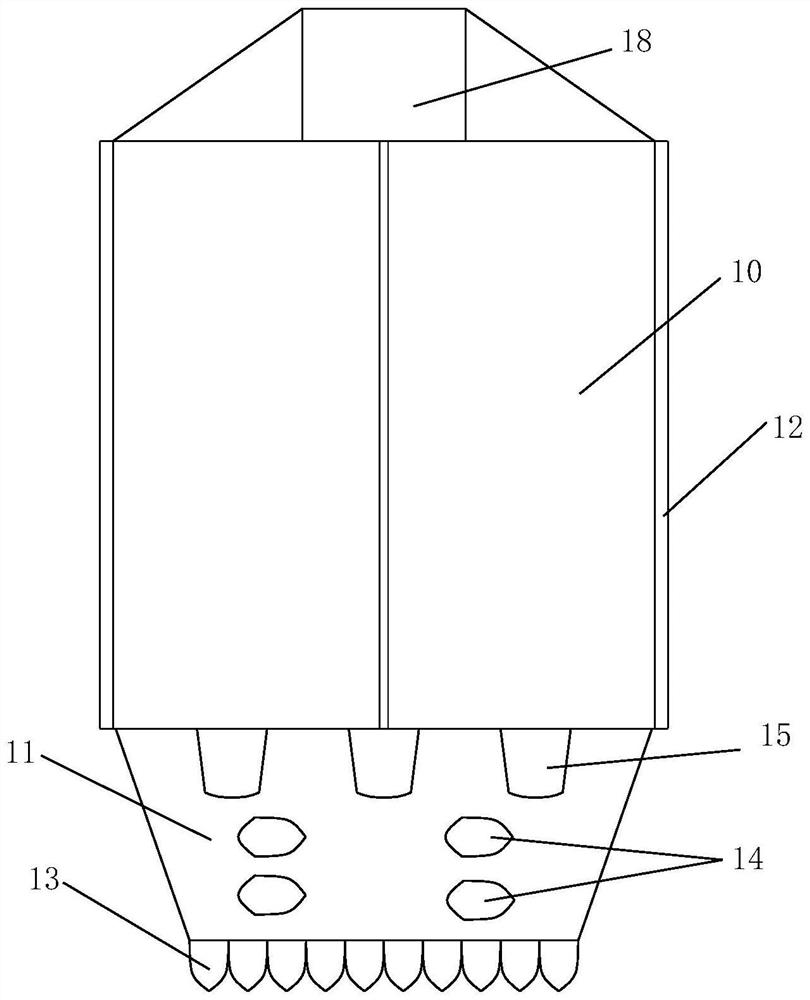

Vertical shaft non-suspension segmented stepping descending type integral metal formwork

ActiveCN107083976ASolve the problem of uneven pouringSolve the problem of slurry leakageUnderground chambersHydro energy generationSlurrySilica gel

The invention discloses a vertical shaft non-suspension segmented stepping descending type integral metal formwork with a convergent opening being in a door bolt type and belongs to the technical field of vertical shaft engineering construction. An opening of an upper C-type formwork is connected with an upper convergent opening sealing module. An opening of a lower C-type formwork is connected with a lower convergent opening sealing module. The upper convergent opening sealing module and the lower convergent opening sealing module are each provided with a demoulding oil cylinder. The inner walls of the upper C-type formwork and the lower C-type formwork are connected with a plurality of evenly distributed longitudinal supporting guide devices used for driving the upper C-type formwork and the lower C-type formwork to move vertically and oppositely. A circular-ring-shaped supporting shoe, a silica gel plate and a silica gel air bag are fixed to the lower end of the lower C-type formwork. By means of the vertical shaft non-suspension segmented stepping descending type integral metal formwork, the problems of unevenness of a convergent opening of an integral movable metal formwork with a T-plate, slurry leakage and poor operability and usability in the prior art are solved, and the problem that when a formwork is suspended with a wire rope, the formwork needs to be erected on floating rock at the shaft bottom, and the requirement for safe explosion distance cannot be met is solved.

Owner:CHINA COAL NO 5 CONSTR

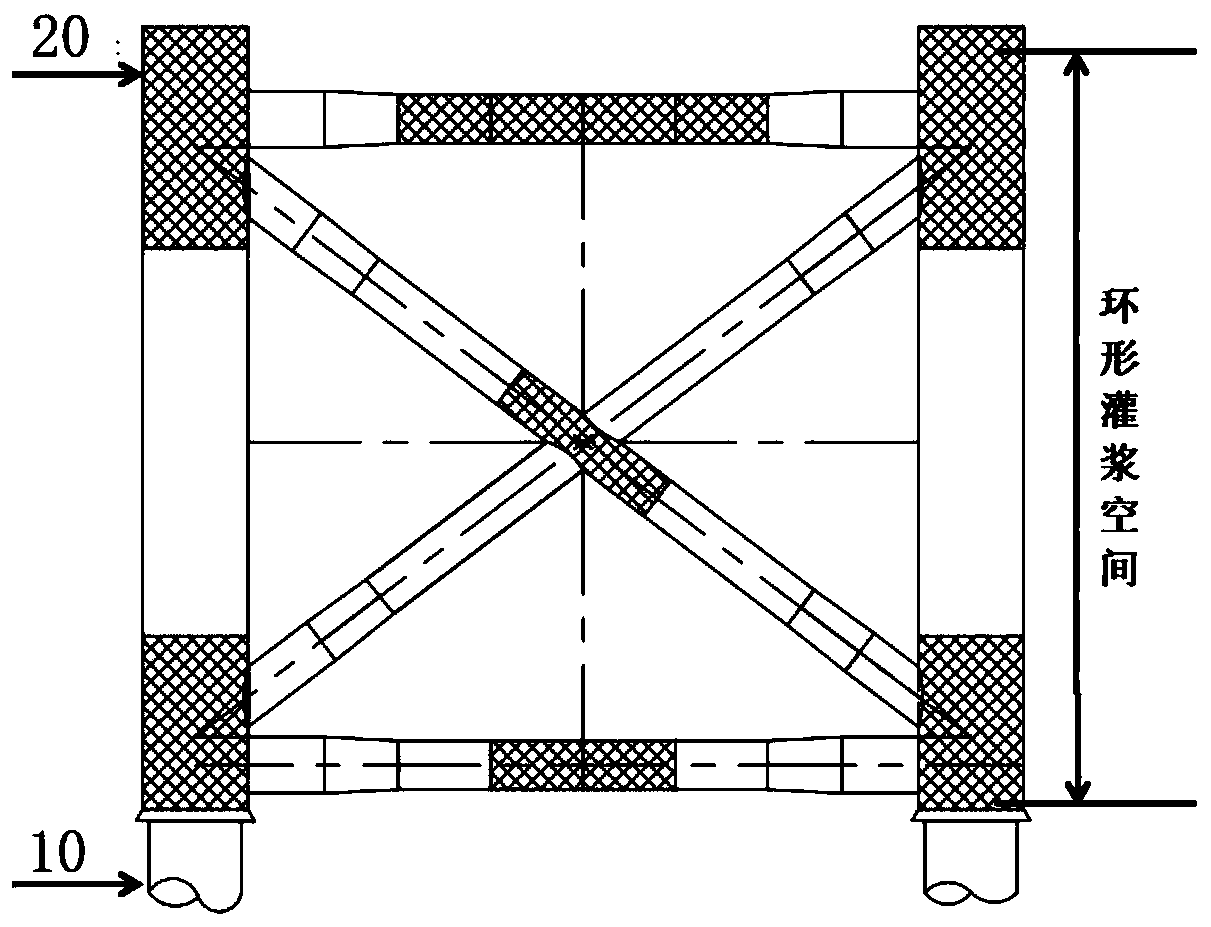

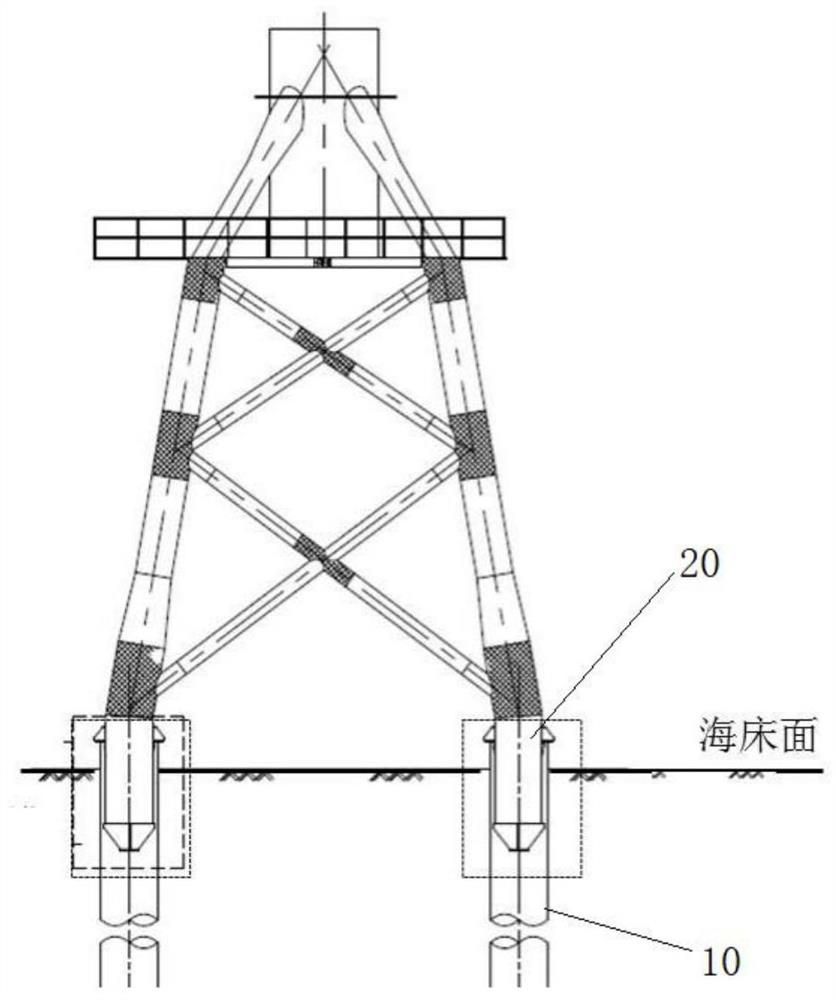

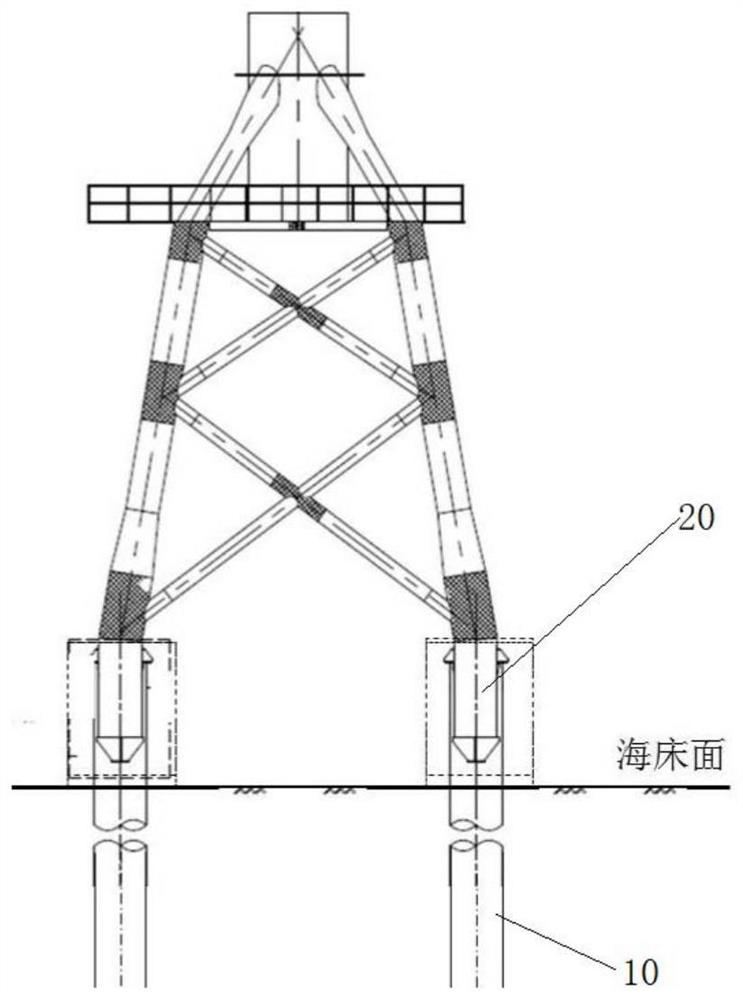

Underwater grouting construction system and method of straight pile outer-sleeve type jacket with first pile method

PendingCN110241826AEasy constructionReduce construction costsFoundation engineeringMetres above sea levelBuilding construction

The invention discloses an underground grouting construction system and method of a straight pile outer-sleeve type jacket with a first pile method. The construction system comprises a steel pipe pile and a jacket sleeving the outer side of the steel pipe pile, and a annular grouting space is formed between the steel pipe pile and the jacket; a main grouting pipe, a spare grouting pipe and a bottom sealing pipe are arranged on the jacket, the main grouting pipe, the spare grouting pipe and the bottom sealing pipe correspondingly penetrate through the jacket and communicate with the annular grouting space. The construction method comprises the steps that the steel pipe pile is piled, and the jacket sleeves the outer side of the steel pipe pile; a rubber bag in a packer is filled and bulged by pumping grouting materials through the bottom sealing grouting pipe, and the situation that grouting materials are hardened is waited; the annular grouting space is grouted through the grouting pipe; when water in the annular grouting space completely flows out from the outlet above sea level, the valve on the outlet is closed, and grouting is conducted continuously until the end of grouting. According to the underground grouting construction system and method of the straight pile outer-sleeve type jacket with the first pile method, the construction technology is simple, the grouting efficiency and quality are improved, and the success rate and the quality of underwater grouting of the jacket are guaranteed.

Owner:中交港湾(上海)科技有限公司 +3

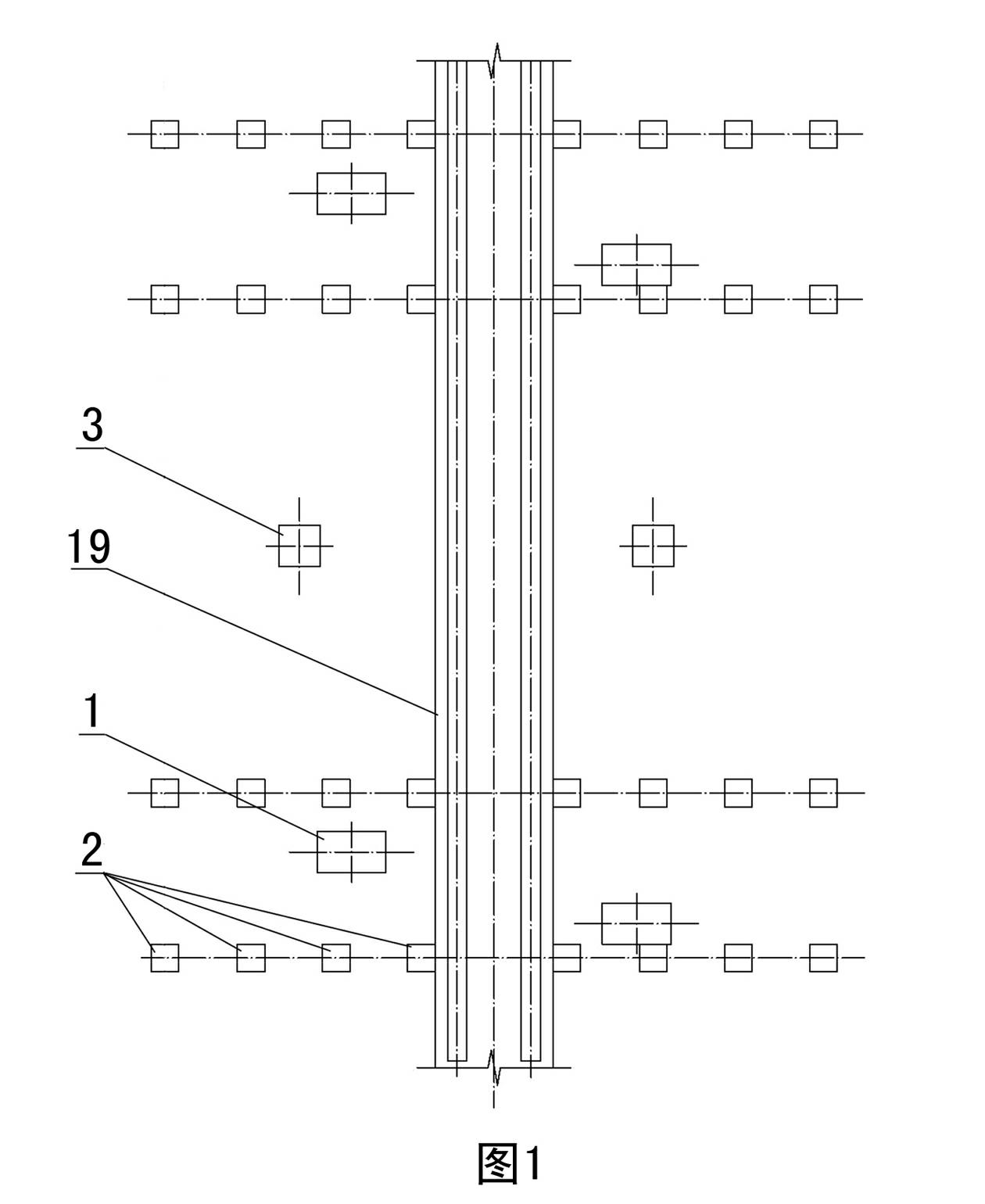

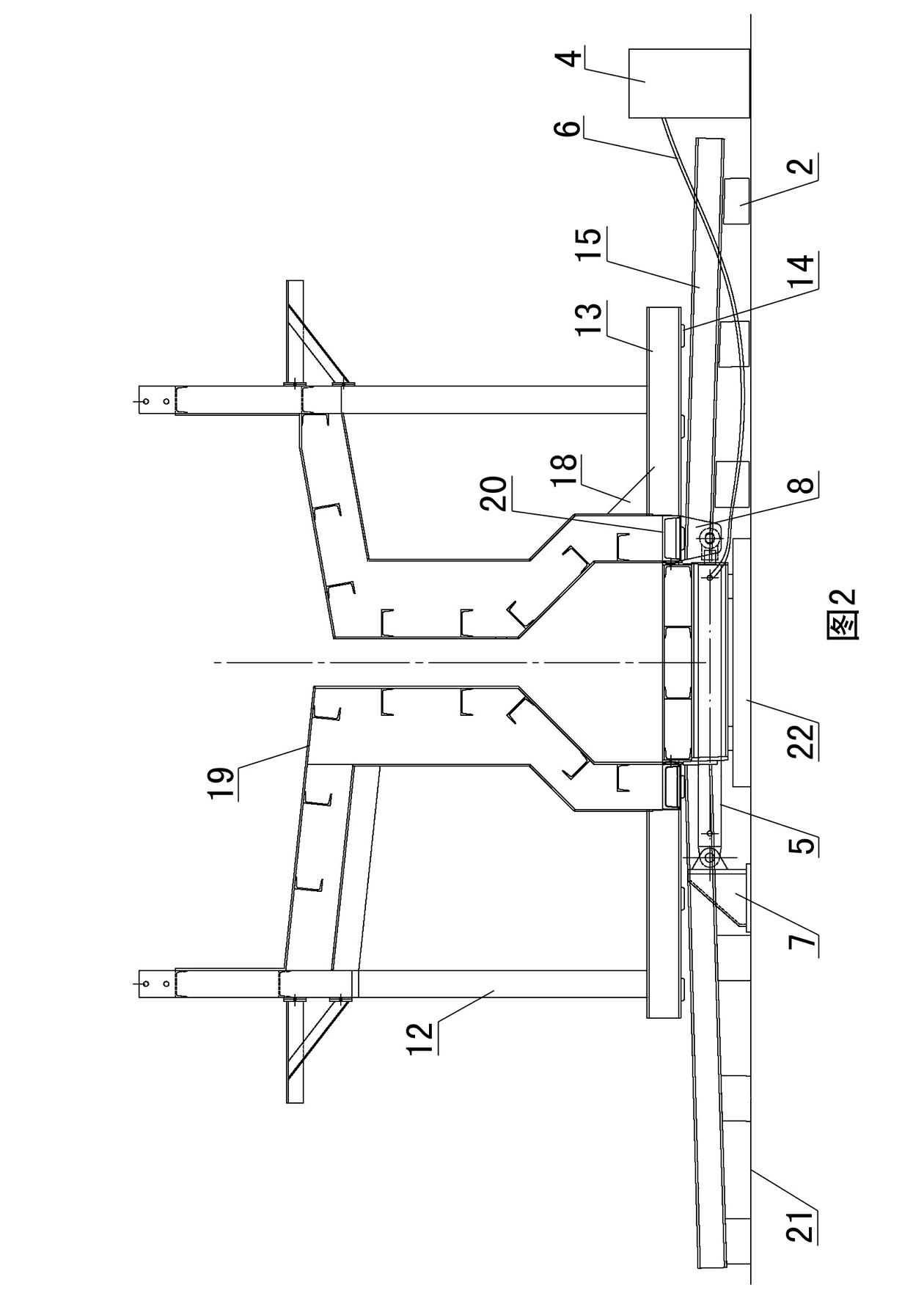

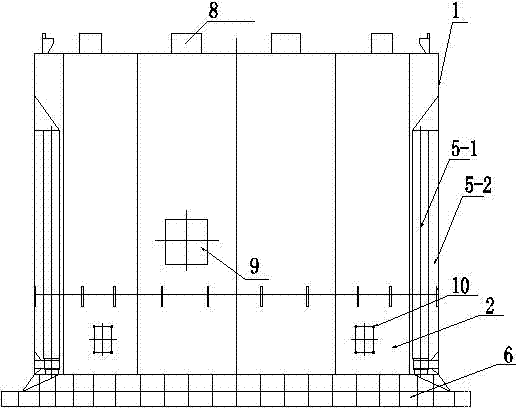

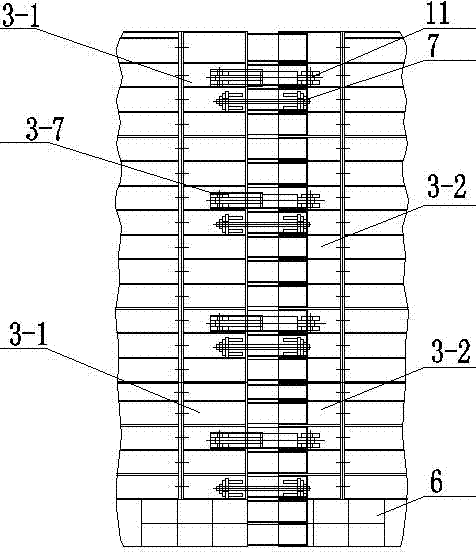

High pier sliding and turning integrated construction formwork system

ActiveCN105780661ASolve health problemsEliminate frictionBridge erection/assemblyBuilding construction

A high pier sliding and turning integrated construction formwork system comprises steel pipe upright pipes (2) embedded in concrete (1). The steel pipe upright pipes (2) penetrate cross beams of carrying frames (3) and penetrate hydraulic jacks (4) installed on the cross beams of the carrying frames. A surrounding ring (6) is fixed to the side surface of each carrying frame, a work platform (7) is laid above each surrounding ring, and a decorative lifting basket (8) provided with an automatic sprinkling maintenance device (9) is installed below each surrounding ring. Each formwork (13) is located on the inner side of the corresponding carrying frame and adjusted through connection of hydraulic levers (10) capable of transversely adjusting the position of the formwork and the corresponding surrounding ring. The top end of each formwork is lifted to the cross beam of the corresponding carrying frame through lifting rods (11) capable of transversely sliding along the part of the cross beam of the corresponding carrying frame. Steel channels for filling of rubber rods are arranged below the formworks. After the formworks are installed, the rubber rods are compressed to be tightly attached to the concrete poured last time. The formwork system is high in safety, good in construction appearance quality, good in maintenance effect and capable of greatly improving the construction efficiency and effectively preventing paste leakage in the concrete pouring process.

Owner:NO 6 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

Basement post-cast strip structure and construction method thereof

InactiveCN109577377ASolve the phenomenon of slurryImpairment of construction qualityArtificial islandsProtective foundationBasementSlurry

The invention relates to a building construction structure, in particular to a basement post-cast strip structure and a construction method thereof. The basement post-cast strip structure comprises upper and lower steel bar binding layers, a lower support column, a water-stop steel plate, an upper support column, an upper fast-ribbed formwork and a lower fast-ribbed formwork, two parallel concretebarrier strips are laid on a concrete cushion on the lower portion of a post-cast strip, a cavity between the two concrete barrier strips vertically corresponds to the post-cast strip, the concrete barrier strips extend along the length direction of the post-cast strip, and the upper ends of the concrete barrier strips are abutted to the lower steel bar binding layer to support the lower steel bar binding layer. The concrete barrier strips can serve as a supporting structure for lower steel bars, lower flowing slurry is stopped when concrete on two sides of the post-cast strip are poured, construction quality is ensured, the concrete barrier strips can subsequently serve as part of a surface protection layer of a water-resistant plate and can be permanently closed in the structure, and subsequent detachment is omitted.

Owner:成都建工第二建筑工程有限公司

Prefabricated box girder end die capable of being rapidly positioned and dismounted

PendingCN111360978AQuick dismantlingDemolition preciseMouldsMould panelsStructural engineeringBox girder

The invention provides a prefabricated box girder end die capable of being rapidly positioned and dismounted. The prefabricated box girder end die is characterized in that two end heads of a top plateare welded to inner sides of upper ends of a left web and a right web respectively; a left flange plate and a right flange plate are welded to outer sides of upper ends of the left web and the rightweb respectively and are flush with the upper top plate respectively; a bottom plate is welded at lower end heads of the left web and the right web, and a whole end die is formed accordingly; a comb plate is welded to the upper end of a bottom die; after a left side lateral die, a right side lateral die and the bottom die are mounted on a prefabricated beam pedestal respectively, girder steel barsare bound and prestressed pipes are mounted; front end heads of drawing screws of a first positioning device, a second positioning device, a third positioning device and a fourth positioning device with the same structure are welded to upper parts of the left web and the right web of the end die and left and right sides of the bottom plate respectively; and the whole end die is placed between theleft side lateral die and the right side lateral die, the bottom is aligned to the comb plate on the bottom die, the end die is controlled to move forwards by tightly screwing positioning screw caps,and accurate positioning and fixation of the end die are realized.

Owner:NO 1 ENG CO LTD OF CR11BG +2

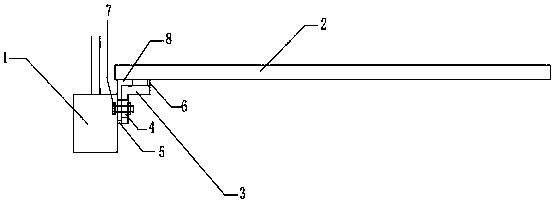

Post-tensioning method prestressed grouting stock outlet structure

PendingCN108756253ASolve poor exhaustSolve the problem of slurry leakageBuilding material handlingPre stressArchitectural engineering

The invention discloses a post-tensioning method prestressed grouting stock outlet structure. The post-tensioning method prestressed grouting stock outlet structure comprises a prestressed tendon, ananchor ring, an anchor bearing plate and a corrugated pipe, the anchor ring is installed on the outer portion of the prestressed tendon in a sleeving mode, the corrugated pipe is connected with a vertical steel pipe, and the corrugated pipe and the vertical steel pipe are connected in a sealing mode. The corrugated pipe and the vertical steel pipe are installed on the outer portion of the prestressed tendon in a sleeving mode, the anchor bearing plate is installed on the outer portion of the vertical steel pipe in a sleeving mode, and the vertical steel pipe is further connected with a horizontal steel pipe. A plastic hose is connected to the other end of the horizontal steel pipe, and the interiors of the corrugated pipe, the vertical steel pipe, the horizontal steel pipe and the plastichose mutually communicate. According to the post-tensioning method prestressed grouting stock outlet structure, the problem of poor exhaust and leakage during hole grouting is solved through the mutual communication of the vertical steel pipe, the horizontal steel pipe and the corrugated pipe, meanwhile, the vertical steel pipe is connected with the anchor bearing plate, and the stiffness of components is improved.

Owner:HUADONG BUILDING CO LTD OF CHINA CONSTR FIFTH ENG BUREAU +1

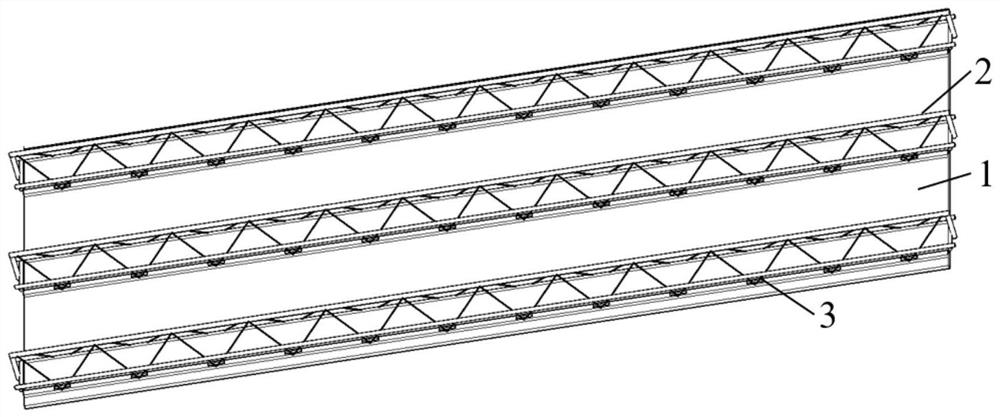

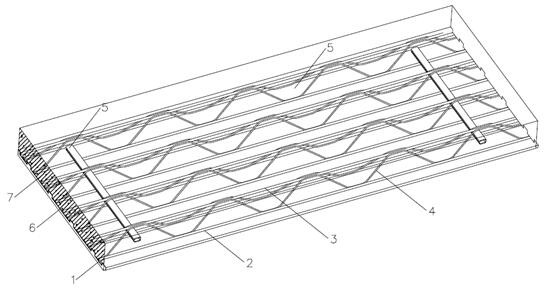

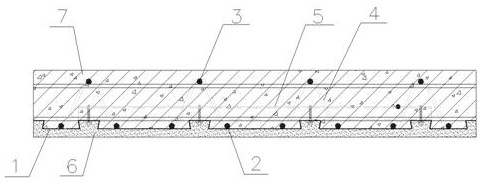

Assembled form-removal-free steel bar truss floor support plate

PendingCN112982782AImprove mechanical propertiesReduce thicknessFloorsBuilding reinforcementsFloor slabArchitectural engineering

The invention discloses an assembled form-removal-free steel bar truss floor support plate. Each floor unit comprises a concrete bottom plate, a steel bar truss and a connecting piece, wherein the steel bar truss is connected with one surface of the concrete bottom plate through the connecting piece, a decorative layer is arranged on the other surface of the concrete bottom plate, and the end parts of the decorative layers of the adjacent floor units are staggered with the end parts of the concrete bottom plates. The concrete bottom plates are adopted as formworks for pouring concrete during construction, and do not need to be removed after construction is completed, so that the construction period is shortened, and the construction cost is reduced; and meanwhile, the mechanical property of the concrete bottom plates is good, the concrete bottom plates can be used as a part of a floor structure, and are stressed cooperatively with concrete of an upper cast-in-place structure layer, so that the thickness of a floor plate can be reduced, the use amount of upper cast-in-place concrete and truss steel bars is reduced, and the floor clearance is increased. The end parts of the decorative layers of the adjacent floor units are staggered with the end parts of the concrete bottom plates, so that the decorative layers of the adjacent plate ends can be overlapped and meshed with the concrete bottom plates when the floor support plates are laid in the construction stage, and slurry leakage is effectively avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

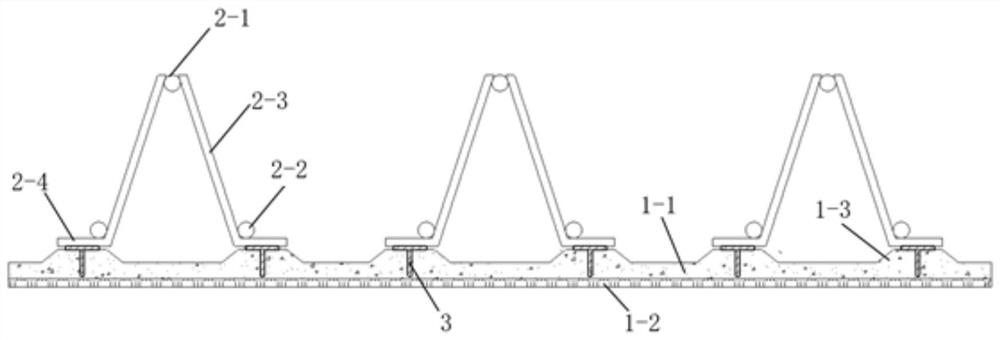

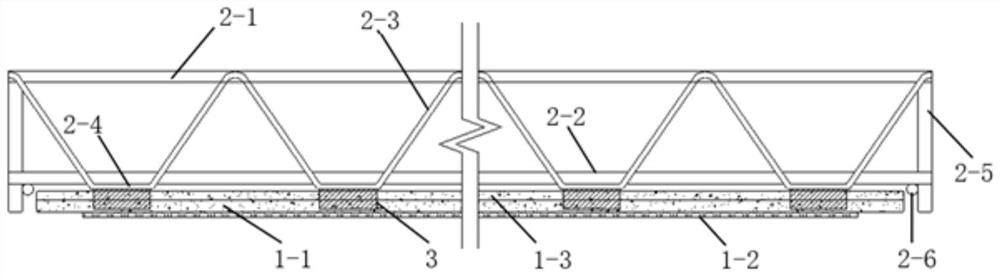

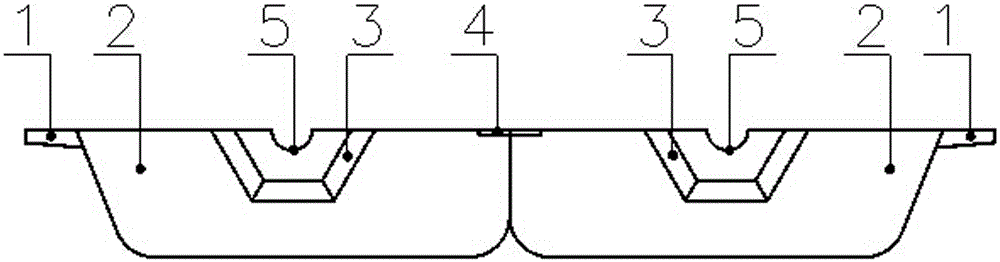

Novel steel bar truss composite floor slab

PendingCN113374168AImprove adhesionReduce thicknessConstruction materialFloorsFloor slabStructural engineering

The invention discloses a novel steel bar truss composite floor slab. The novel steel bar truss composite floor slab comprises a necking type profiled steel sheet, a concrete prefabricated layer and a steel bar truss, wherein the steel bar truss comprises an upper chord steel bar, a lower chord steel bar and a truss abdomen supporting steel bar; the truss abdomen supporting steel bar is welded on the upper chord steel bar and the lower chord steel bar to form the steel bar truss; and the steel bar truss is welded on the necking type profiled steel sheet through the lower chord steel bar. According to the novel steel bar truss composite floor slab, the necking type profiled steel sheet is adopted so that the binding power between the profiled steel sheet and lower-layer concrete is improved and the thickness of the prefabricated layer is reduced; the novel steel bar truss composite floor slab is combined with the suitable steel bar truss and the strength of the upper chord steel bar and the lower chord steel bar of the steel bar truss is sufficiently utilized; transverse steel bars are paved on site and bidirectional plate reinforcement is easily realized; furthermore, the concrete below the necking type profiled steel sheet can be used as a protection layer of the lower chord steel bar and the profiled steel sheet; the effect of the profiled steel sheet is effectively utilized and the strength and rigidity of a prefabricated part are enhanced; and the problems of beauty, fireproof spraying and anticorrosion maintenance do not need to be considered.

Owner:南通装配式建筑与智能结构研究院 +1

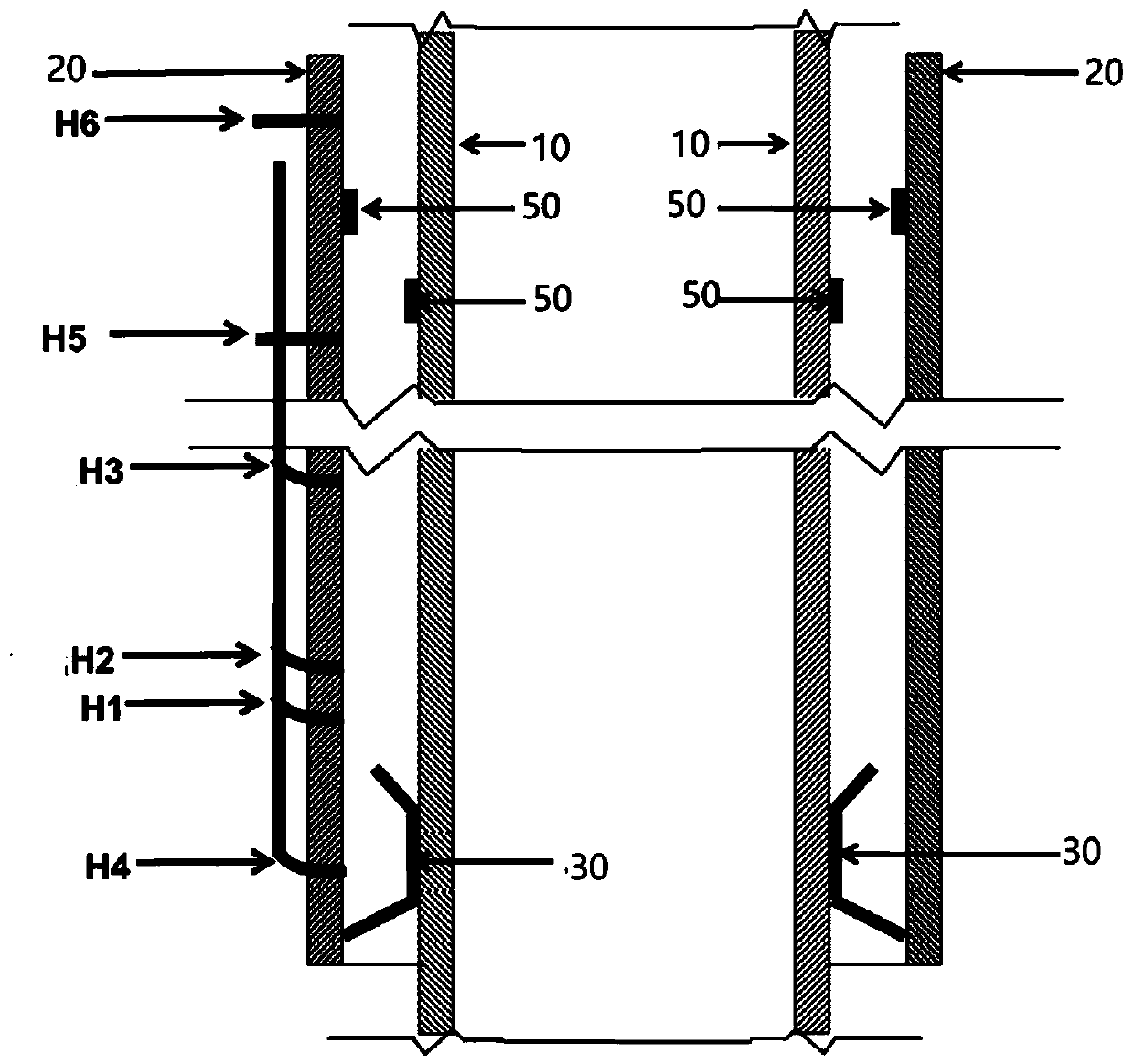

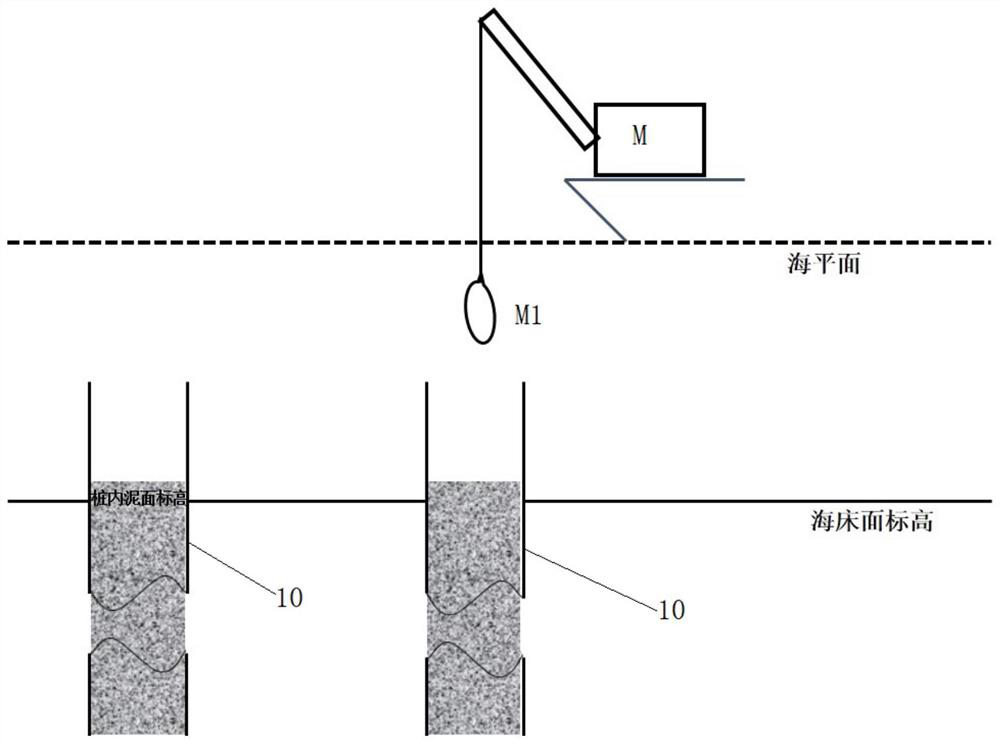

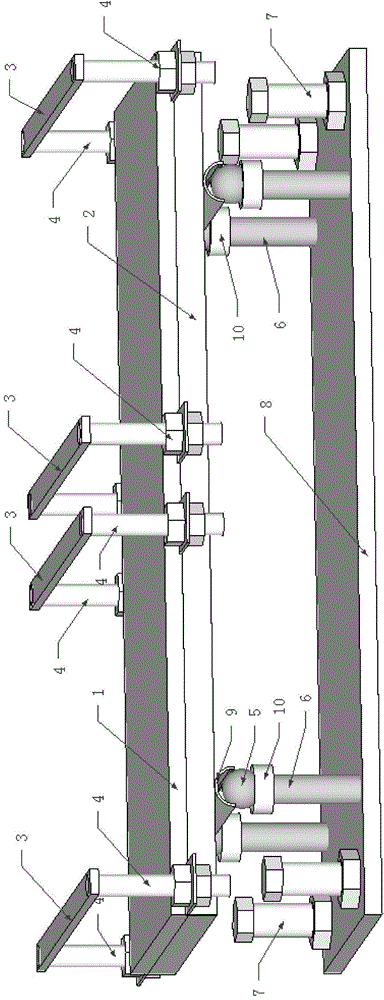

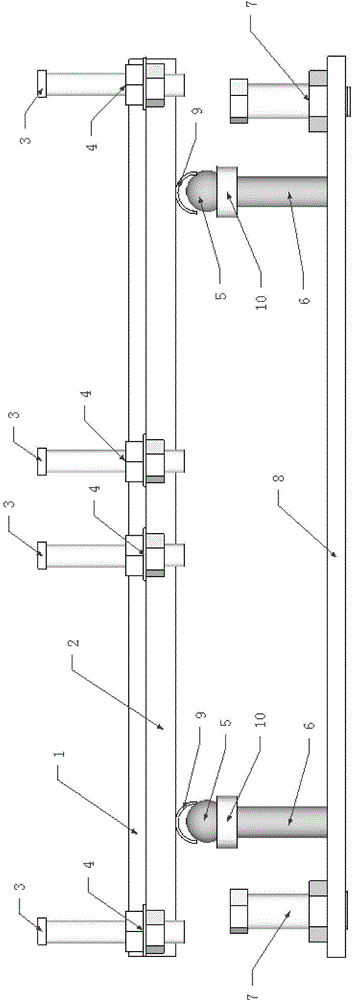

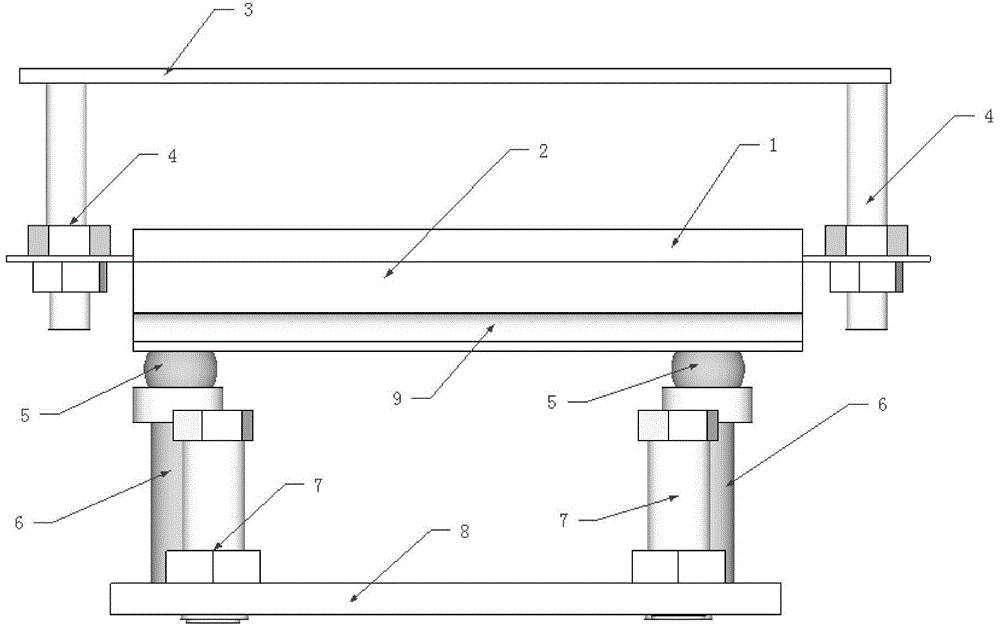

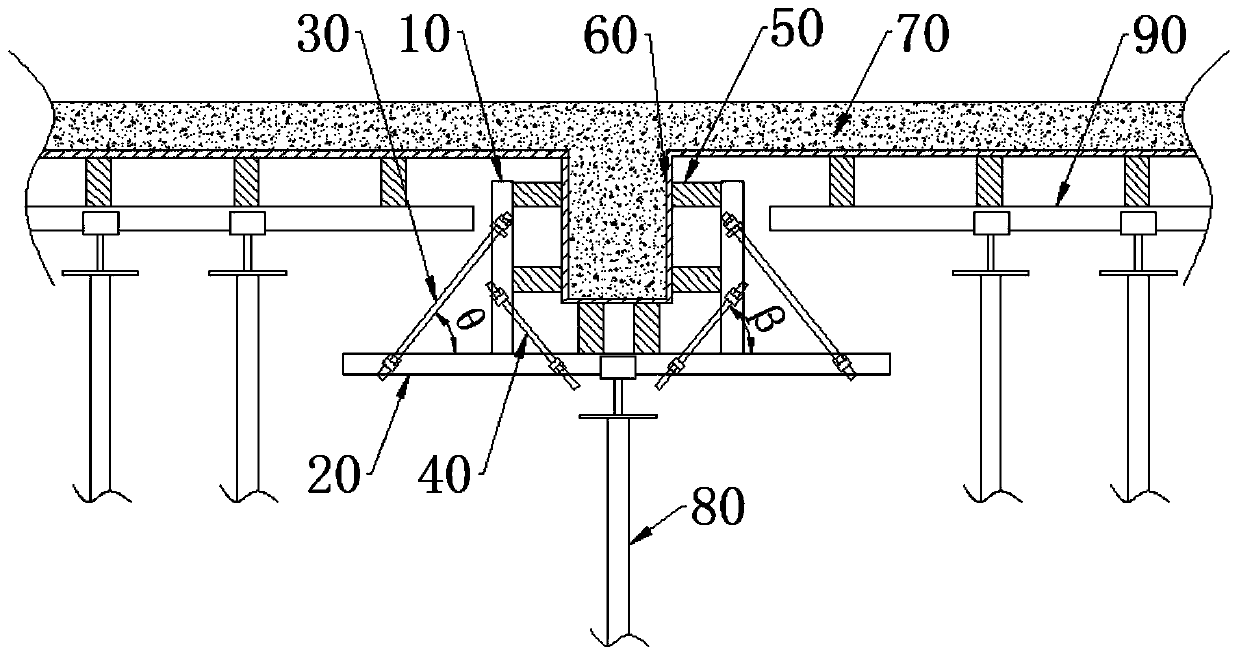

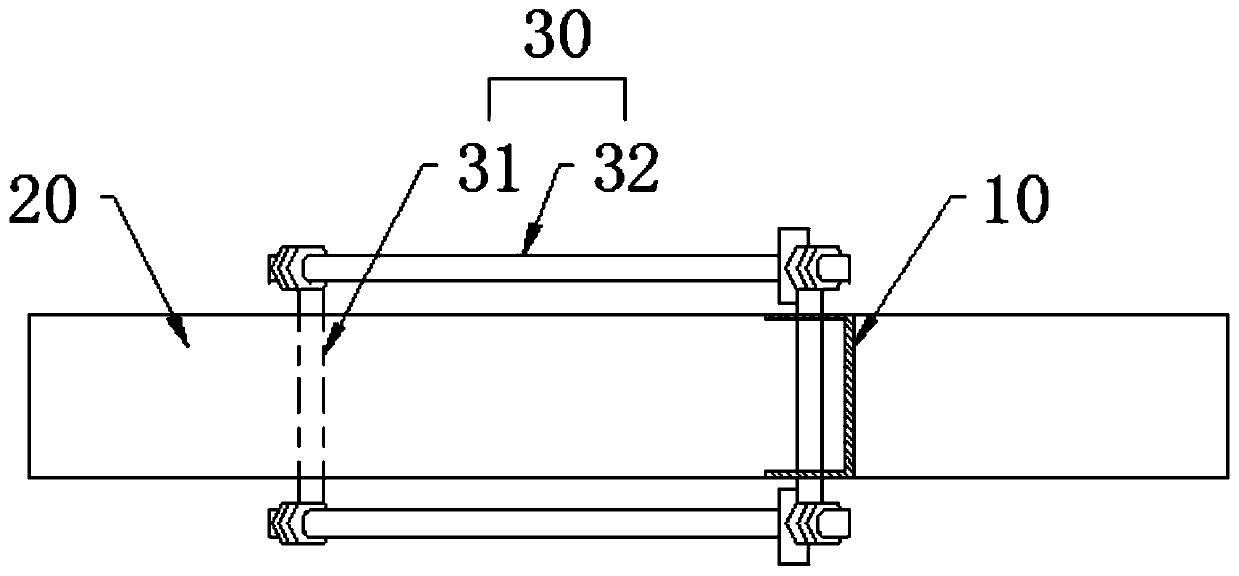

Pile-first method jacket foundation in-pile slurry leakage prevention construction system and construction method

PendingCN112647533AReduce risk of leakageGuarantee the quality of grouting connectionArtificial islandsUnderwater structuresArchitectural engineeringSlurry

The invention discloses a pile-first method jacket foundation in-pile slurry leakage prevention construction system and a construction method. The construction system comprises a steel pipe pile and a jacket, the jacket is inserted into the steel pipe pile, and an annular grouting space for pouring grouting materials is formed between the steel pipe pile and the jacket; and a gravel filling layer is further filled above the mud surface elevation in the steel pipe pile. The construction method comprises the steps that the steel pipe pile is piled to the designed elevation; the filling amount of gravels or gallets in the steel pipe pile is determined; the jacket is mounted; the jacket is leveled and locked; and the grouting materials are poured into the annular grouting space. Aiming at the construction of a pile-first method jacket foundation, in particular to a jacket structure of which a grouting connection section is above the mud surface elevation and the pile diameter is relatively large, the pile-first method jacket foundation in-pile slurry leakage prevention construction system has the characteristics of simple construction method, low equipment requirement, saving of offshore construction time, reduction of grouting material loss rate and construction cost and the like, and a powerful guarantee is provided for ensuring the connecting quality of the jacket and the steel pipe pile.

Owner:CCCC SHANGHAI THIRD HARBOR SCI RES INST CO LTD +2

Workbench for manufacturing pressure grouting mold

ActiveCN104875280AGuaranteed flatnessEnsure normal dischargeAuxillary shaping apparatusEngineeringLower face

The invention discloses a workbench for manufacturing a pressure grouting mold, and belongs to the technical field of domestic ceramics. The workbench comprises a work face plate, a frame, a lower face plate and a horizontal frame mechanism, the frame is fixed to the lower surface of the work face plate, the lower face plate is arranged under the work face plate, the horizontal frame mechanism is divided into two groups by four horizontal frame components which are evenly distributed on the work face plate in the longitudinal direction, each horizontal frame component comprises a horizontal frame and a first adjusting bolt, and the two ends of the horizontal frames are connected with the positions, below the two sides of the work face plate, of the frame through the first adjusting bolts. Two supporting plates with sliding grooves are arranged on a longitudinal beam below the frame, supporting legs are arranged under the two ends of the sliding groove of each supporting plate, the bottom ends of the supporting legs are fixed to the lower face plate, balls are fixedly arranged at the top ends of the supporting legs, and the balls are in contact with the sliding sleeves corresponding to the top ends of the supporting legs. The phenomena of mold cracking, grout runout and the like in the pressure grouting process are avoided, the obtained plaster mold is high in strength and flatness, operation is easy and convenient, and production efficiency is high.

Owner:南通莱特伟特汽配科技有限公司

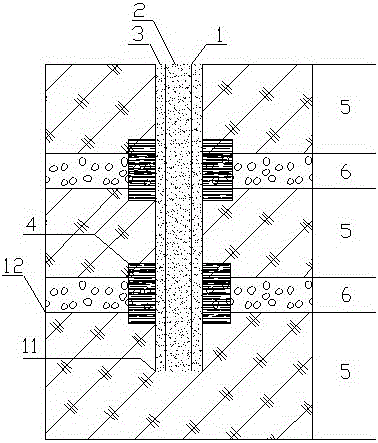

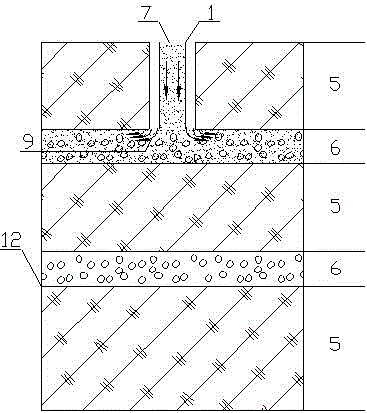

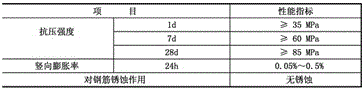

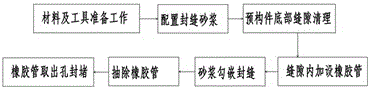

Separate bin grouting method

InactiveCN106121240ASolve the problem of slurry leakageEnsure safety and qualityBuilding material handlingFloor slabSlurry

The invention relates to a separate bin grouting method. The separate bin grouting method includes the following steps that firstly, CGMJM-VI high-strength slurry is poured into a stirring cylinder; secondly, before pointing, the surface of a component and the surface of concrete should be cleaned up; thirdly, one end of a rubber hose with the diameter being 20 mm is gradually crammed into a seam in the bottom of the component along the outer side of the seam of the bottom of the prefabricated component; fourthly, the component and the concrete floor slab surface are wetted firstly before the cording seam is pointed through pointing trowels; fifthly, the rubber hose crammed into the seam of the bottom of the prefabricated component is pulled out slowly from the other end after the cording seam pointing is completed; and sixthly, after the rubber hose is pulled out, a taking-out opening is blocked tightly with a small ball of cording seam mortar. The separate bin grounding method is a construction process for rebar sleeve connection grouting component bottom seam blocking and has the beneficial effects that construction operation is easy, convenient and fast, and energy saving and environment protection are achieved.

Owner:SHENYANG XRJ CONSTR ENG CO LTD

Concrete beam form supporting device and construction process thereof

PendingCN110593559ASimple structureEasy to controlForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksConcrete beamsBuilding construction

Owner:TIANJIN 20 CONSTR

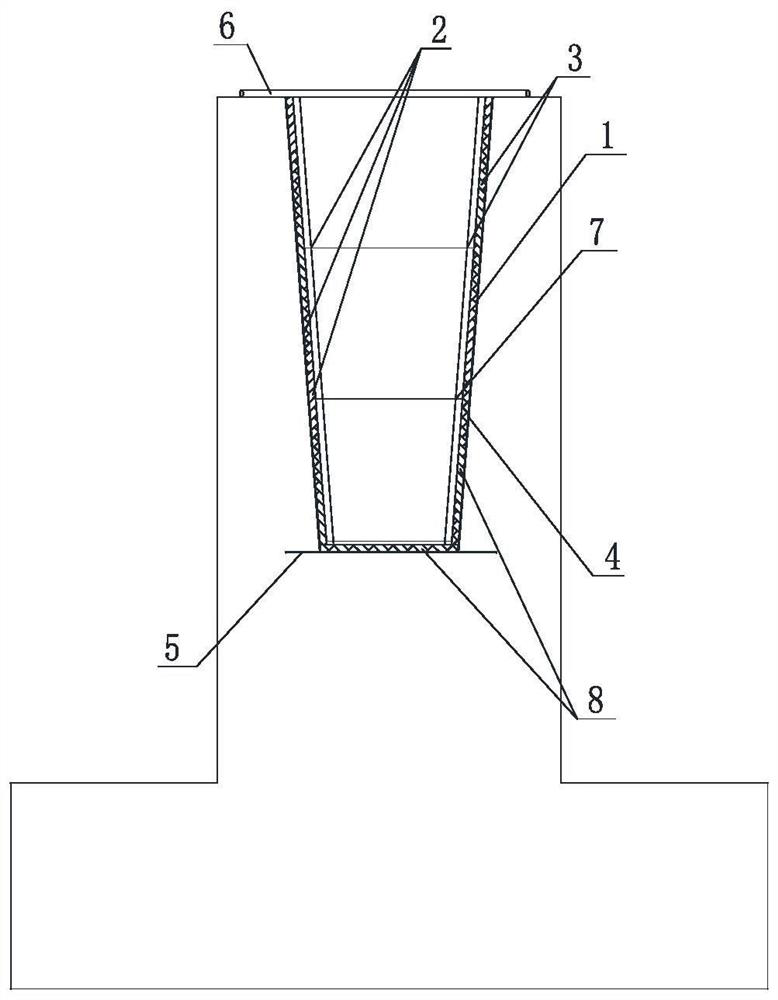

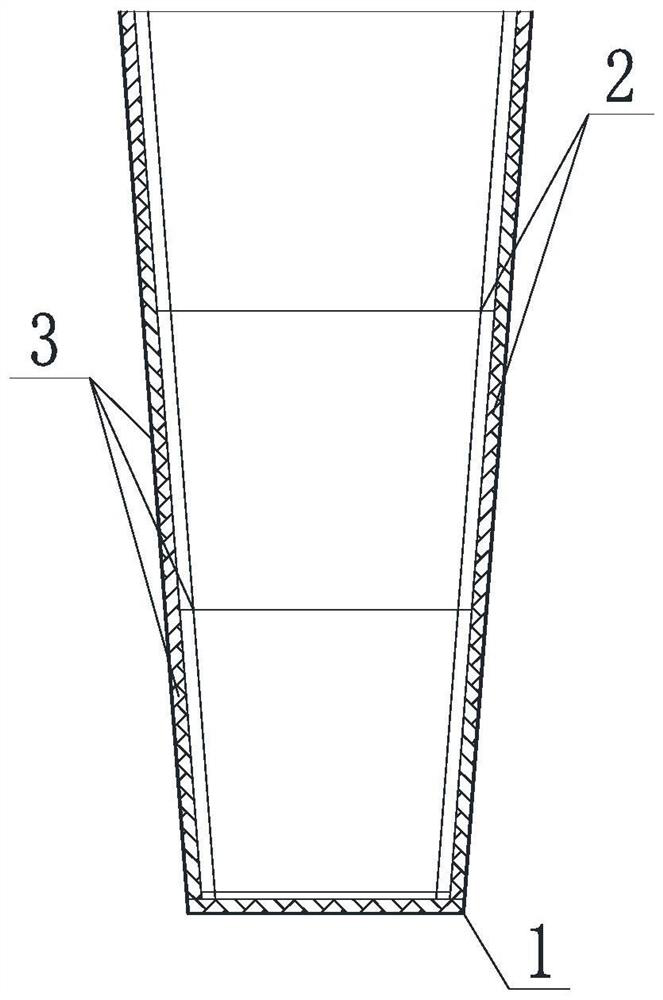

Formwork system for inverted circular truncated cone-shaped cup opening of column foundation of steel structure factory building and construction method

InactiveCN113073676AGuarantee the pouring qualitySolve problems that cannot be removedFoundation engineeringForms/shuttering/falseworksManufacturing technologyProcess equipment

The invention discloses a formwork system for an inverted circular truncated cone-shaped cup opening of a column foundation of a steel structure factory building and a construction method, and belongs to the technical field of design and manufacturing of building engineering construction process equipment. The formwork system for the inverted circular truncated cone-shaped cup opening of the column foundation of the steel structure factory building and the construction method are convenient in construction and capable of effectively guaranteeing the pouring quality of the inverted circular truncated cone-shaped cup opening of the column foundation. The formwork system at least comprises an inner mold blank body comprising a flexible template and a supporting framework, and the flexible template coats the bottom side wall surface and the outer side wall surface of the supporting framework; and in a forming process of the inverted circular truncated cone-shaped cup opening of the column foundation, the inverted circular truncated cone-shaped cup opening is formed by space arranged by an inner mold blank body fixedly supported on a column foundation binding steel bar after a column foundation outer mold is erected. The construction method comprises the steps of designing and manufacturing the formwork system; binding the column foundation steel bar and erecting the column foundation outer mold; installing the inner mold blank body and pouring concrete; dismantling the formwork system after the concrete is initially set and crystallized; and cleaning the formwork system for repeated use next time.

Owner:CHINA 19TH METALLURGICAL CORP

Building automatic formwork connecting system and precise positioning system thereof

PendingCN108952156AReduce labor intensityImprove work efficiencyAuxillary members of forms/shuttering/falseworksEngineeringPositioning system

The invention relates to the technical field of building devices, in particular to a building automatic formwork connecting system which comprises a central frame, a second formwork, a first formworkand at least two connecting rod assemblies. One end of the first connecting rod assembly is hinged to the central frame, and the other end of the first connecting rod assembly is hinged to the back side of the first formwork. One end of the second connecting rod assembly is hinged to the central frame, and the other end of the second connecting rod assembly is hinged to the back side of the secondformwork. The top end of the central frame is provided with at least two drivers with telescopic rods. The first driver is hinged to the top end of the central frame. The telescopic rod of the firstdriver is hinged to the first connecting rod assembly. In the formwork connecting state, the side face of the first formwork and the opposite side face of the second formwork are connected; compared with the prior art, by using the drivers as the power source, the work efficiency is improved, and the labor intensity of workers is relieved. The invention further provides a building automatic formwork connecting precise positioning system. By means of the system, the seamless connection between the formworks can be realized.

Owner:SHENZHEN EXCELLENCE INDZATION INTELLIGENT CONSTR DEV CO LTD

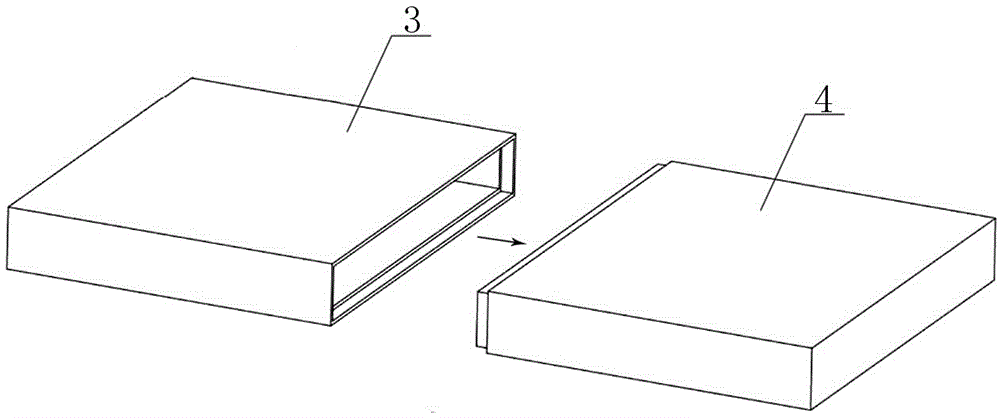

Material-saving type modular plastic formwork and construction method thereof

ActiveCN105735633AIncrease usageExtended service lifeForming/stuttering elementsArchitectural engineeringQuality control

Disclosed are a material-saving type modular plastic formwork and a construction method thereof. The formwork comprises a panel. The outer side of the panel is sleeved with a surface skin which is a hollow sealed box body formed by connecting at least two parts in an inserting mode. According to the material-saving type modular plastic formwork and the construction method thereof, according to the functional needs in the application process of the formwork, the formwork is designed to be the panel part and the surface skin part, wherein the surface skin is a wearing part and is responsible for concrete forming quality control and protecting the panel, and the panel is a long-term used part and provides strong support for the formwork. The surface skin and the panel are supplementary to each other so that the number of times of service of the formwork can be increased by a large margin, the service life of the formwork can be prolonged by a large margin, and the problem of resource waste existing in the plastic formwork industry is solved. The surface skin is easy to repair and replace, can be repaired after damaged, and can be recycled and machined to be a new surface skin again if damaged badly, so that the environmental protection and energy saving effects are achieved, the number of times of service of the formwork can be increased by a large margin, and the service life of the formwork can be prolonged by a large margin. The material-saving type modular plastic formwork and the construction method thereof can be widely applied to a concrete pouring formwork system.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

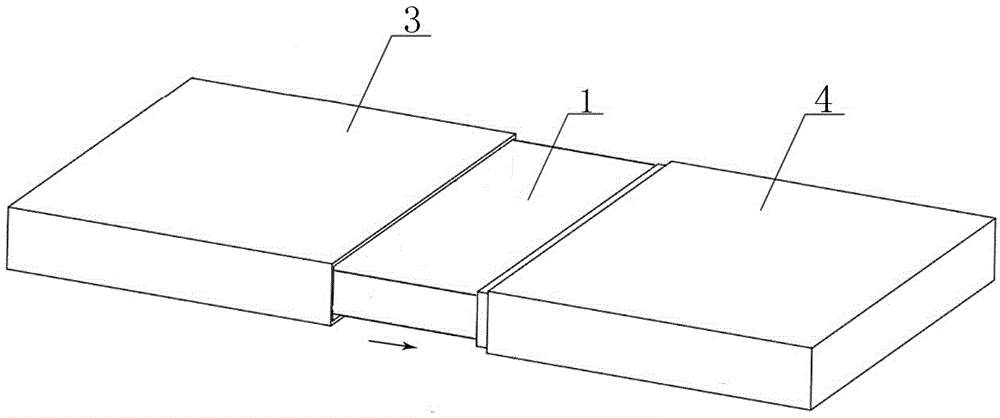

Ball mill feeding apparatus

The invention discloses a ball mill feeding apparatus. The ball mill feeding apparatus comprises a feeding pipe, a supporting base, a feeding hopper, a sealing flange and a feeding bushing, wherein the feeding pipe is fixed on the supporting base, the front end of the feeding pipe stretches into a feeding opening of a ball mill, a returning screw is arranged in the sealing flange, the spiral direction of the returning screw is consistent with the feeding direction, one end of the sealing flange is fixed on the feeding bushing, the other end of the sealing flange is provided with an inclined anti-abrasion rubber plate, the feeding pipe is provided with angular sealing rubber, the anti-abrasion rubber plate tightly contacts the angular sealing rubber, a rotating shaft is arranged in the feeding pipe in a penetrating manner, the rotating shaft is provided with screw blades, the top of the feeding pipe is provided with the feeding hopper, the end part of the rotating shaft is provided with a reducer, one end of the reducer is connected with the rotating shaft by virtue of a coupler, and the other end of the reducer is connected with an electromotor output shaft. By adopting the ball mill feeding apparatus, abrasion to a sealing part is alleviated, the sealing effect is good, the installation is convenient, the adjustment is simple, and the blockage of the feeding pipe can be effectively prevented.

Owner:江苏博拓新型建筑材料股份有限公司

Method for forming pile foundation in karst area

ActiveCN114108675AImprove compactnessSolve the shortcomings of easy to collapse holesBulkheads/pilesWave detectionKarst

The invention provides a pile forming method for a pile foundation in a karst area. The method comprises the steps that the positions and the number of karst caves are comprehensively determined according to advanced drilling, pipe wave detection and the drilling process of a rotary drilling machine; in the drilling process of the rotary drilling machine, a special drill bit is used at the position of the karst cave to press pile core soil and gravel into the karst cave, and the compactness of filler in the karst cave is increased; a thickened double-layer reinforced composite membrane is installed outside a reinforcement cage according to data of the specific position of a karst cave, then the reinforcement cage is hoisted into a pile hole, a composite bag is filled with concrete before grouting so that the concrete can block the karst cave, and grouting is conducted after the concrete in the composite membrane reaches certain strength to form a pile foundation. The construction difficulty of a pile foundation in a karst area can be reduced, the defect that semi-filling and non-filling type karst caves are prone to hole collapse is overcome, the later-period karst cave processing procedure is reduced, the problem of slurry leakage in the pile body grouting process is solved, and the composite membrane is low in manufacturing cost and convenient to use.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Production method and die of prefabricated supporting sleeve used in cooperation with split bolt

The invention discloses a production die of a prefabricated supporting sleeve used in cooperation with a split bolt. The production die is formed by connecting two same die assemblies through a hinge side by side. The die comprises a die body, a plurality of shape setting die plates located in the die body and communicated with one another, and a fixing pipe groove. Each shape setting die plate is composed of a middle and two ends. Each end is of a frustum-shaped amplification head structure with the shape same as that of the corresponding middle. Each frustum-shaped amplification head structure is composed of a cone body and an end column body. Die releasing agents are painted to the interior of the die, concrete or pebble mortar with the weight of pebbles gradually decreased is poured, a PVC thin-walled pipe is pressed into the pipe groove, the die is closed, after the die removing strength is achieved, the die is opened, the prefabricated supporting sleeve is taken out, the PVC thin-walled pipe is cut off along the end of the prefabricated supporting sleeve, and the prefabricated supporting sleeve is manufactured. The die is simple in structure, convenient to operate and easy to master. A method is high in construction speed, the prefabricated supporting sleeve can be prefabricated on a construction site, mass production can also be performed in a prefabrication factory, and the concrete slurry leakage problem is effectively solved.

Owner:JIANGSU NANTONG SANJIAN CONSTRUCTION GROUP CO LTD

Leaking stoppage method for abutted seam of fabricated building precast beam and precast composite floor

The invention relates to a fabricated building. A leaking stoppage method for an abutted seam of a fabricated building precast beam and a precast composite floor comprises the steps that the precast beam and the precast composite floor are mounted, bolt holes are formed in the positions close to the precast beam, and bolts are pre-buried; a leaking stoppage component is mounted and is a rigid L-shaped component, the two outer side faces of the leaking stoppage component are flexible waterproof material faces, through holes corresponding to the bolt holes are formed in the attaching positions of the flexible waterproof material faces and the precast composite floor, the flexible waterproof material faces on the outer side of the component are matched with the bottom of the composite floor with certain extrusion force through manual adjusting to complete vertical compaction, and then through transverse horizontal adjusting, the flexible waterproof material faces of a blocked seam of thecomponent are matched with the precast beam to achieve transverse compaction; and the component is screwed at the bolt holes in the precast composite floor through the bolts to be fixed, and then mounting is completed. On-site construction is facilitated, the hidden danger that rubber strips are impacted and then fall off is avoided, and the safety and stability of the blocked seam are greatly improved. The time of solidification shaping needed by sealing the rubber strips is avoided.

Owner:CHINA MCC20 GRP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com