Anti-scouring concrete repairing device

A concrete and anti-abrasion technology, applied in clay preparation devices, unloading devices, cement mixing devices, etc., can solve the problems of deep cracks that are difficult to fill, leakage of slurry, low efficiency, etc., to improve the effect of slurry replenishment, The effect of solving slurry leakage and reducing the amount of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

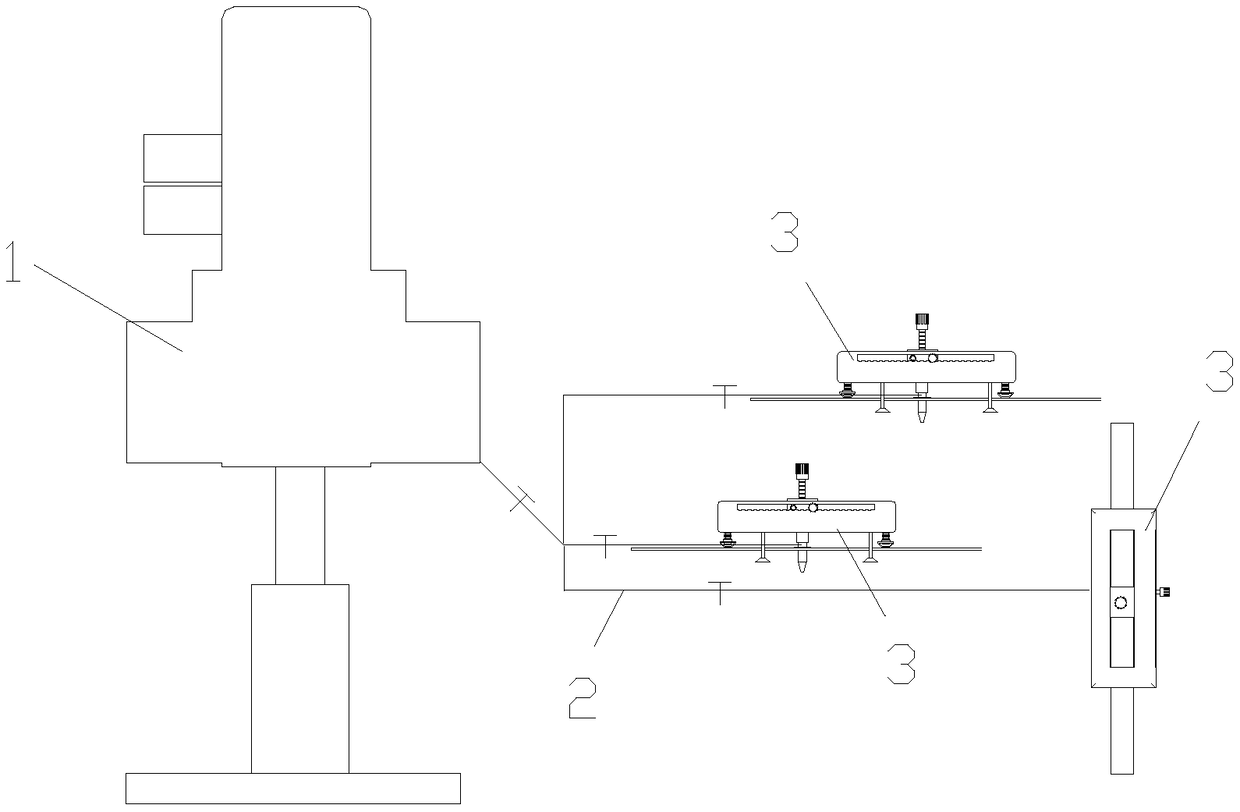

[0058] Such as figure 1 As shown, the present invention discloses an anti-scouring concrete repair device, which includes a mixing device 1 and a grouting machine 3. The mixing device 1 is used to stir the concrete slurry, and the concrete slurry is injected through the grouting machine 3. into concrete cracks. The mixing and stirring device 1 can work in a cycle according to the order of batching first and then discharging, and multiple pipelines 2 are communicated between the mixing and stirring device 1 and the slurry replenishing machine 3 .

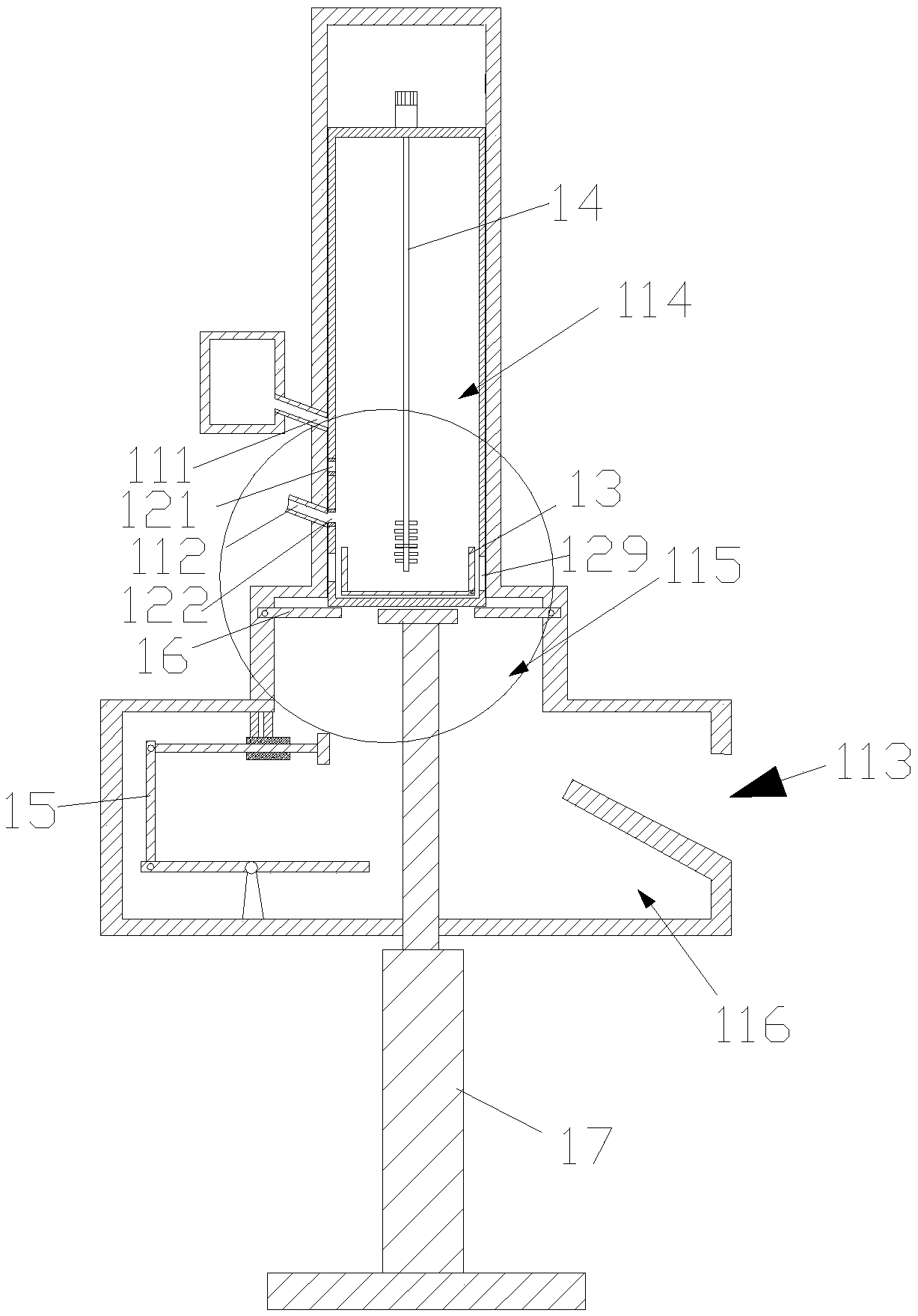

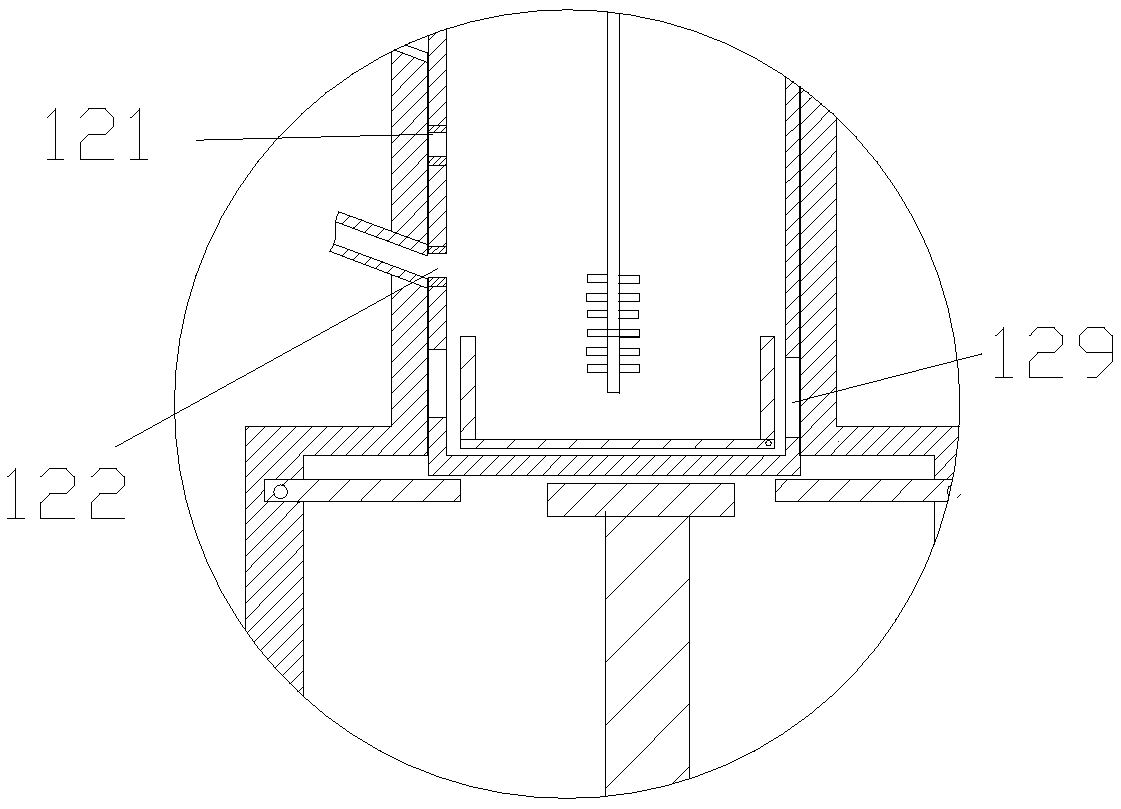

[0059] Such as Figure 2-4 As shown, the mixing and stirring device 1 includes a housing 11 , a built-in frame 12 , a mixing bin 13 , a stirring member 14 , a lever-type driving pusher assembly 15 , a baffle assembly 16 , and an elastic support member 17 .

[0060]The casing 11 is separated from top to bottom with a feed inlet 111, a water inlet 112, and a discharge outlet 113. The inner cavity of the casing 11 includes a passage c...

Embodiment 2

[0078] Such as Figure 2-4 As shown, the difference of this embodiment compared with the above-mentioned embodiments is that the baffle plate assembly 16 includes a first baffle plate 161 and a second baffle plate 162 which are mirror-symmetrical, the hinged end of the first baffle plate 161, and the hinged end of the second baffle plate 162 The hinge ends are respectively hinged on both sides of the baffle installation cavity 115 . The length of the gap between the free end of the first baffle 161 and the free end of the second baffle 162 in a natural state is shorter than the length of the bottom of the housing 11 . The hinged end of each baffle is hinged to the inner wall of the baffle installation cavity 115 via a second torsion spring (not shown in the figure). The second torsion spring is assembled to the free end of the baffle in a horizontal state. When the free end of the baffle is in a horizontal state, the hinged end of the baffle can be attracted to the inner wal...

Embodiment 3

[0082] Such as Figure 8 As shown, the difference between the present embodiment and the above-mentioned embodiment is that the lever-type transmission pusher assembly 15 includes a lever 151, a transmission rod 152, a sleeve 153, and a push rod 154, and one end of the lever 151 is hinged to the lower end of the transmission rod 152, The upper end of the transmission rod 152 is hinged with one end of the push rod 154 , and the other end of the push rod 154 passes through the sleeve 153 so as to be in contact with or connected to the sliding push plate 133 . The other end of the lever 151 can be in contact with the bottom of the housing 11 .

[0083]When housing 11 descends to its contact with the other end of lever 151, the other end of lever 151 descends, and one end of lever 151 rotates upwards, drives drive rod 152 to rotate, and drives push rod 154 to push sliding push plate 133.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com