Patents

Literature

668results about How to "Achieve fastening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

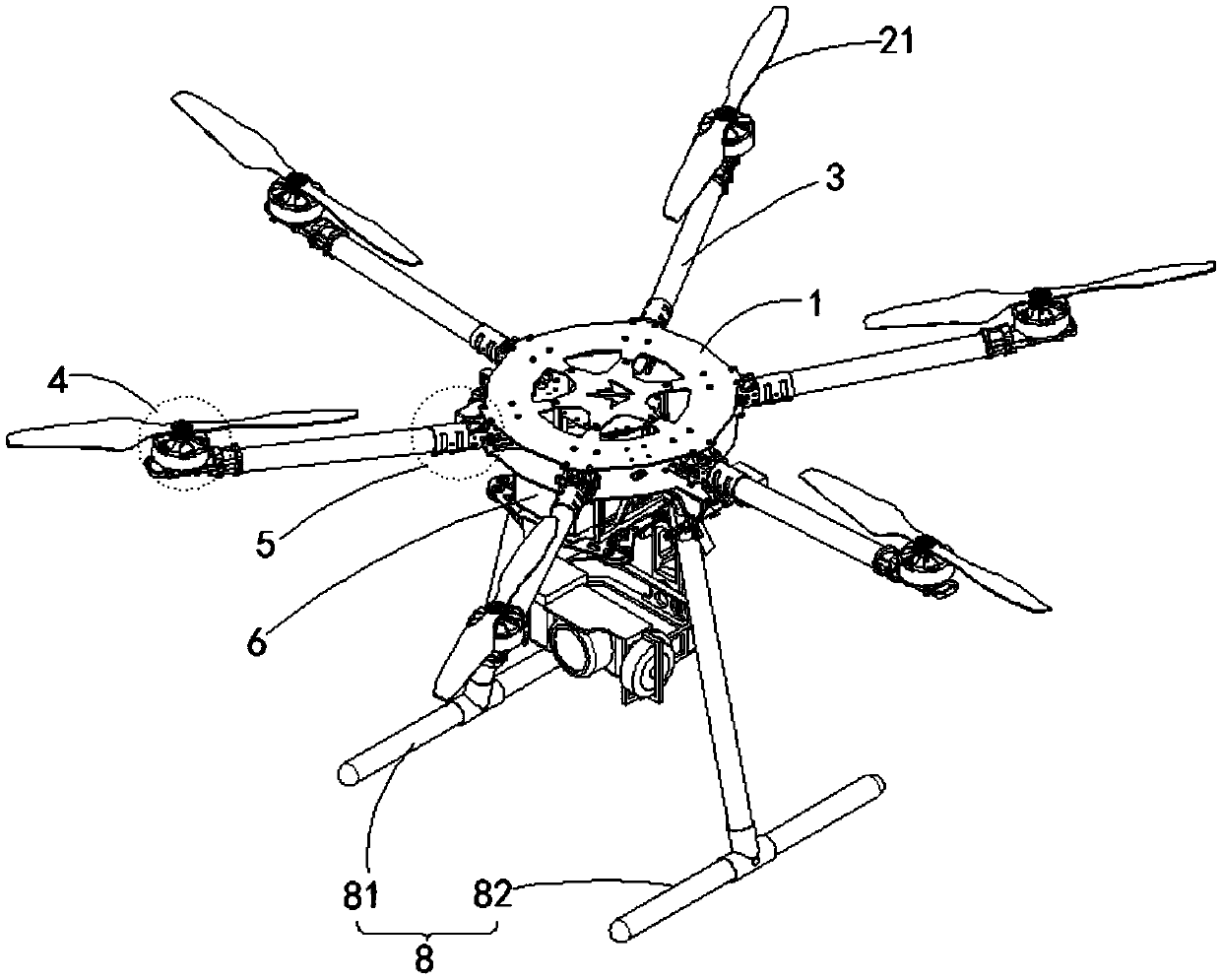

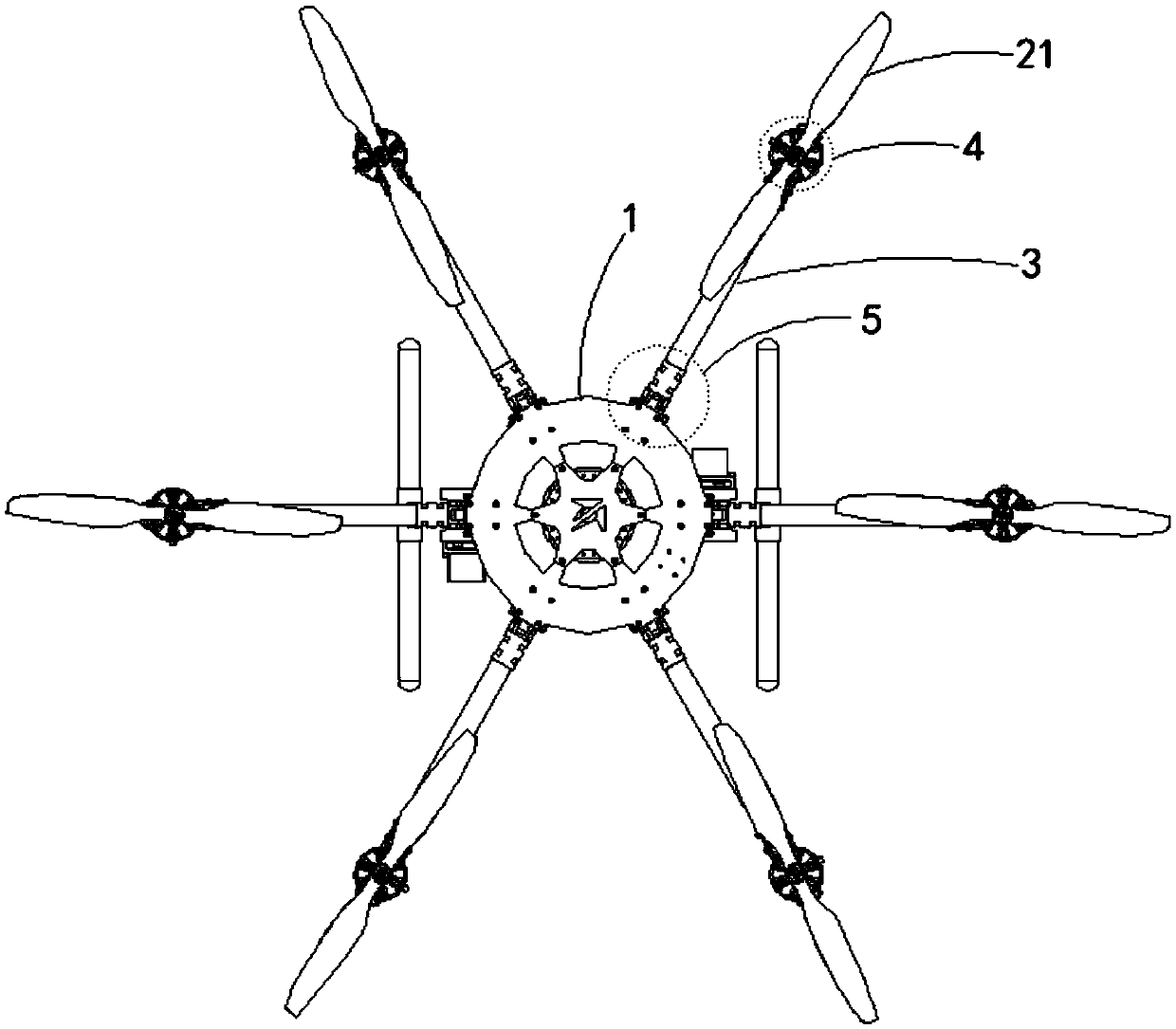

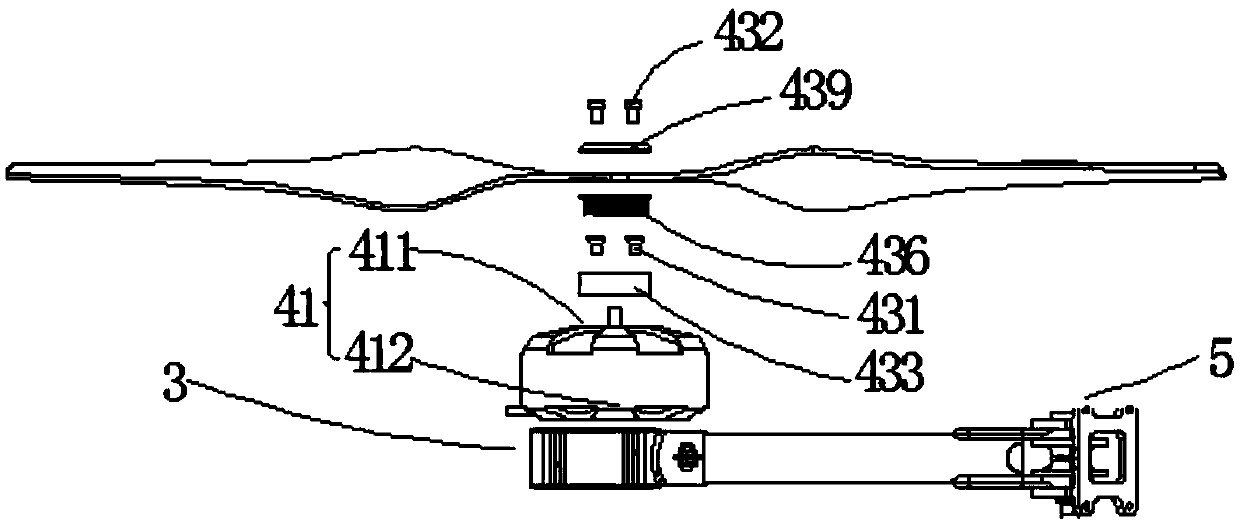

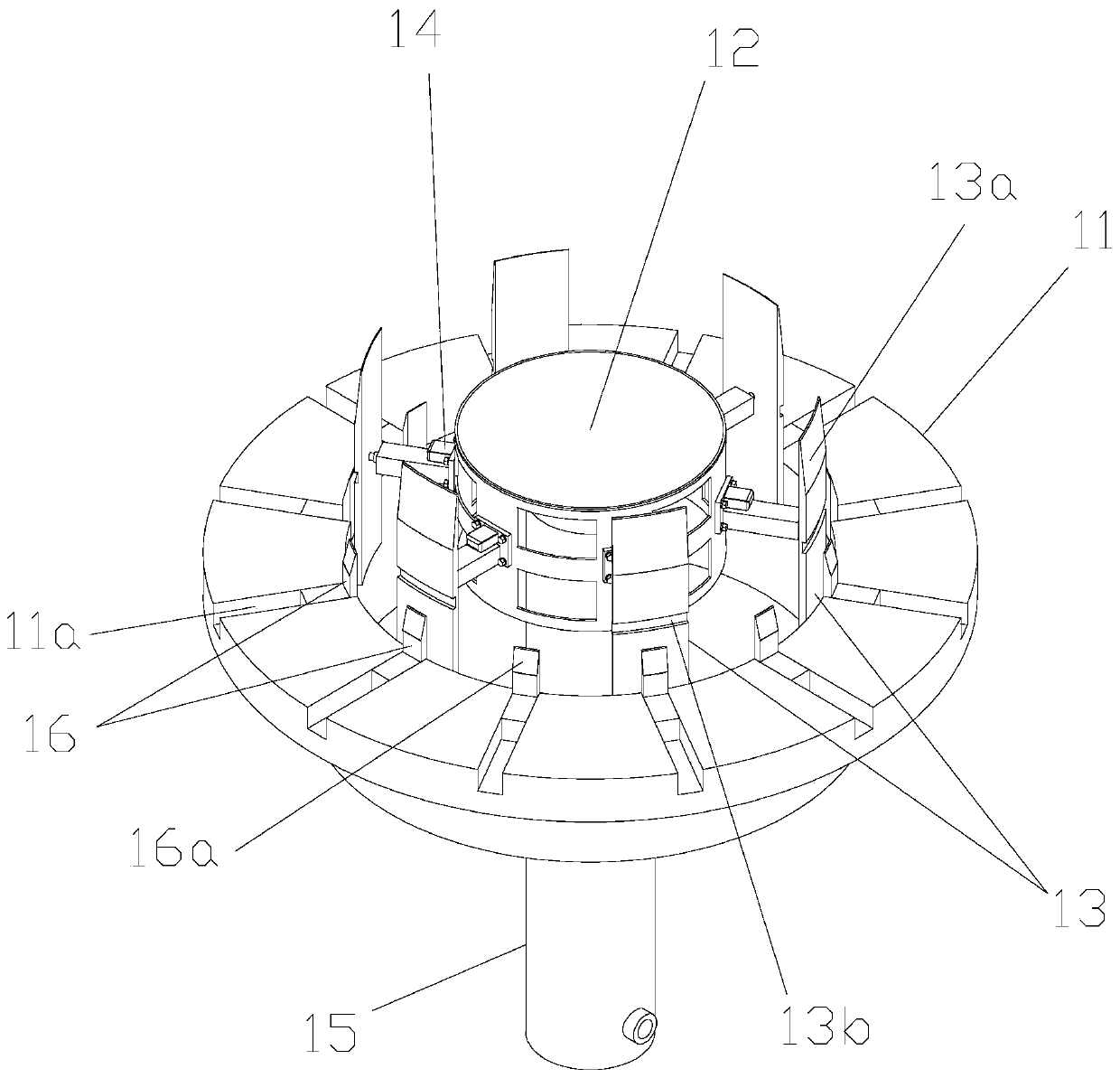

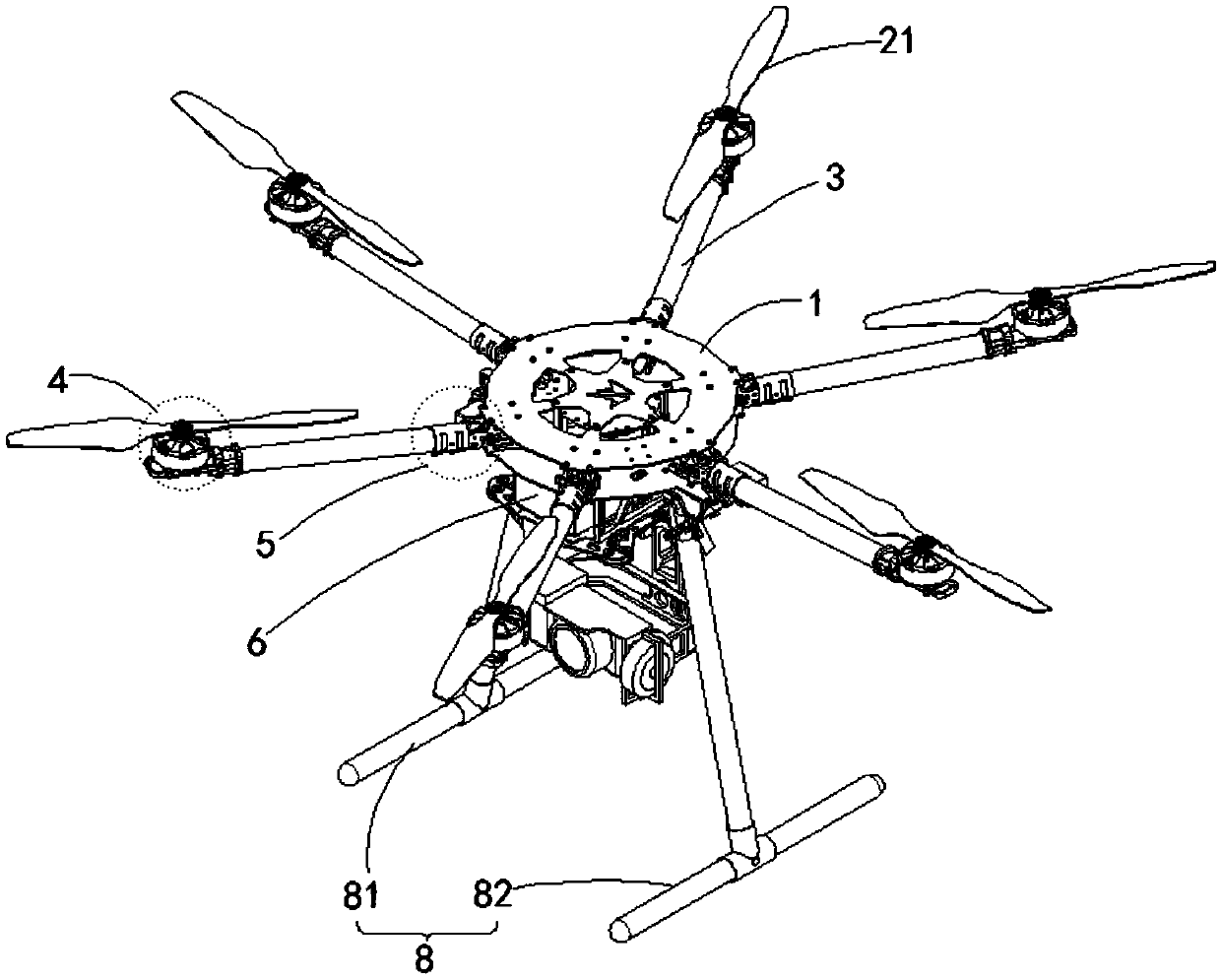

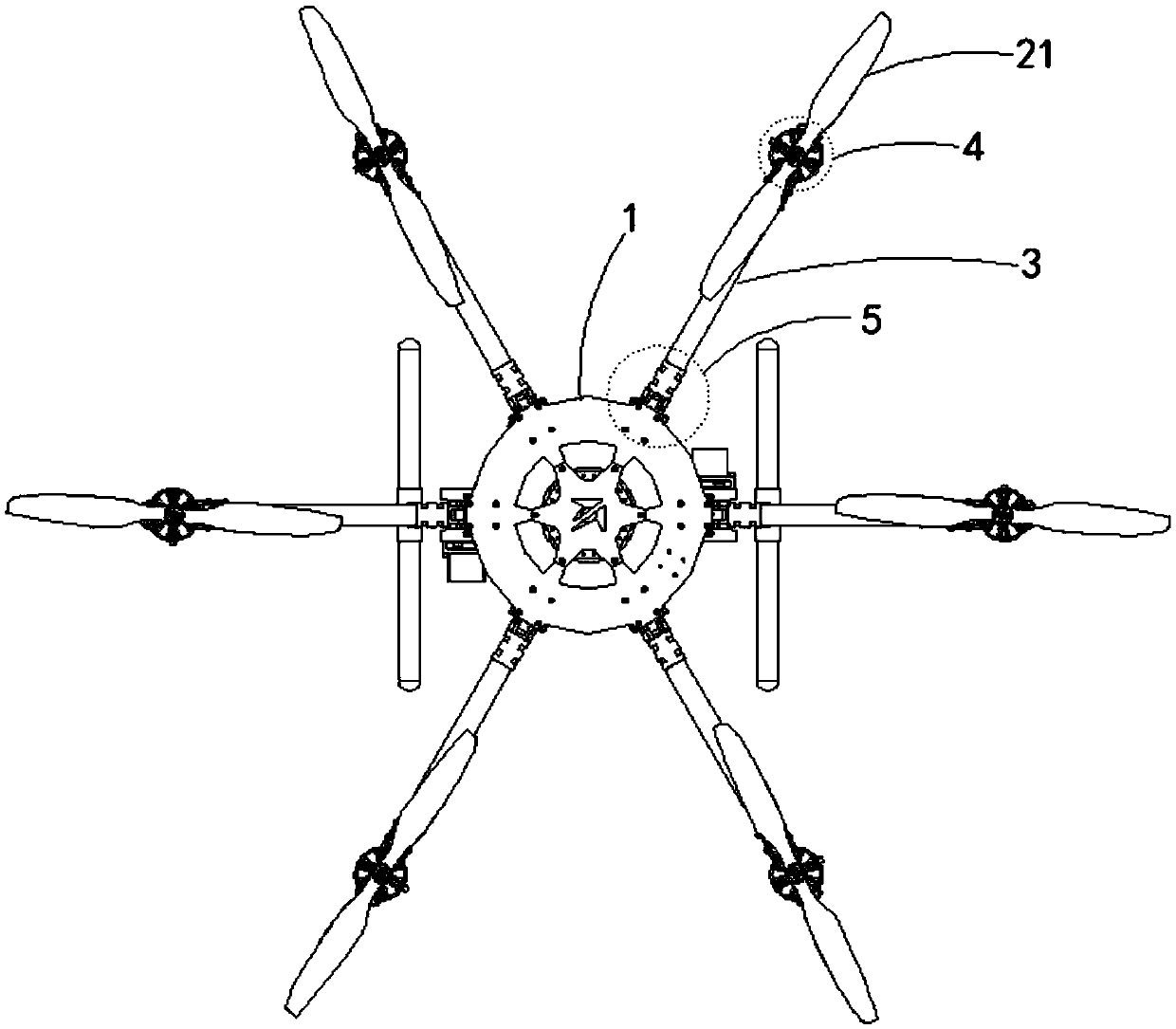

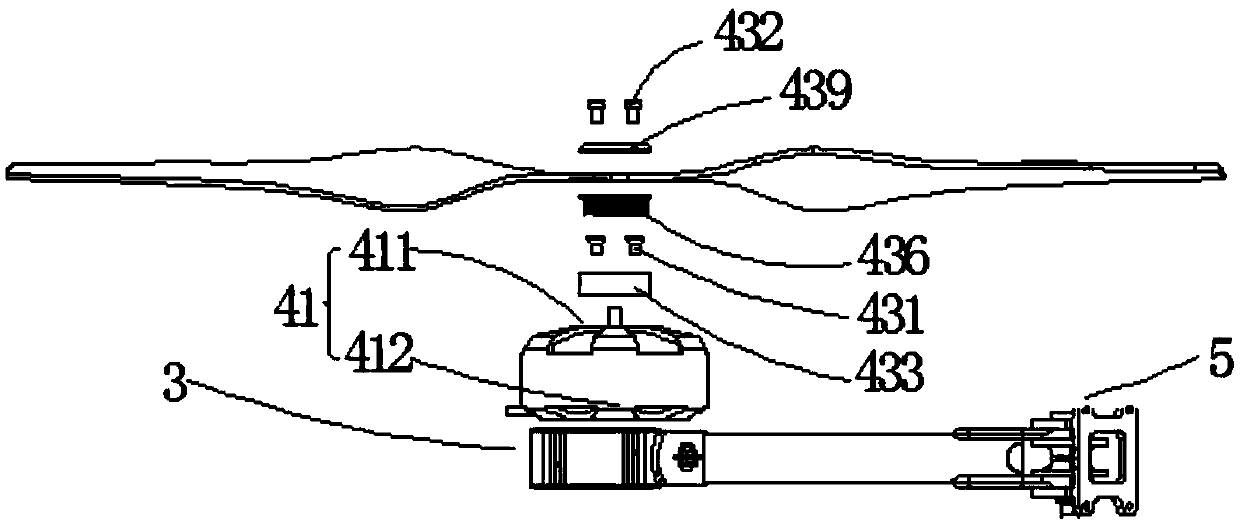

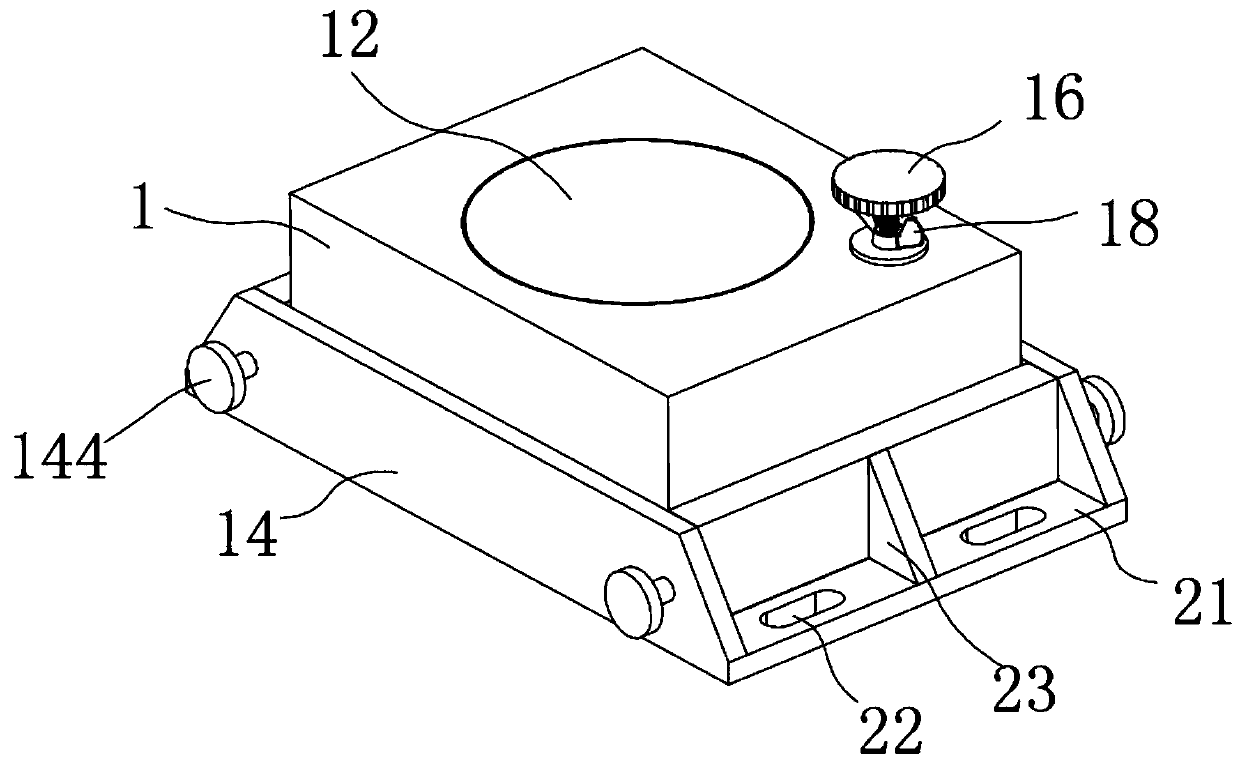

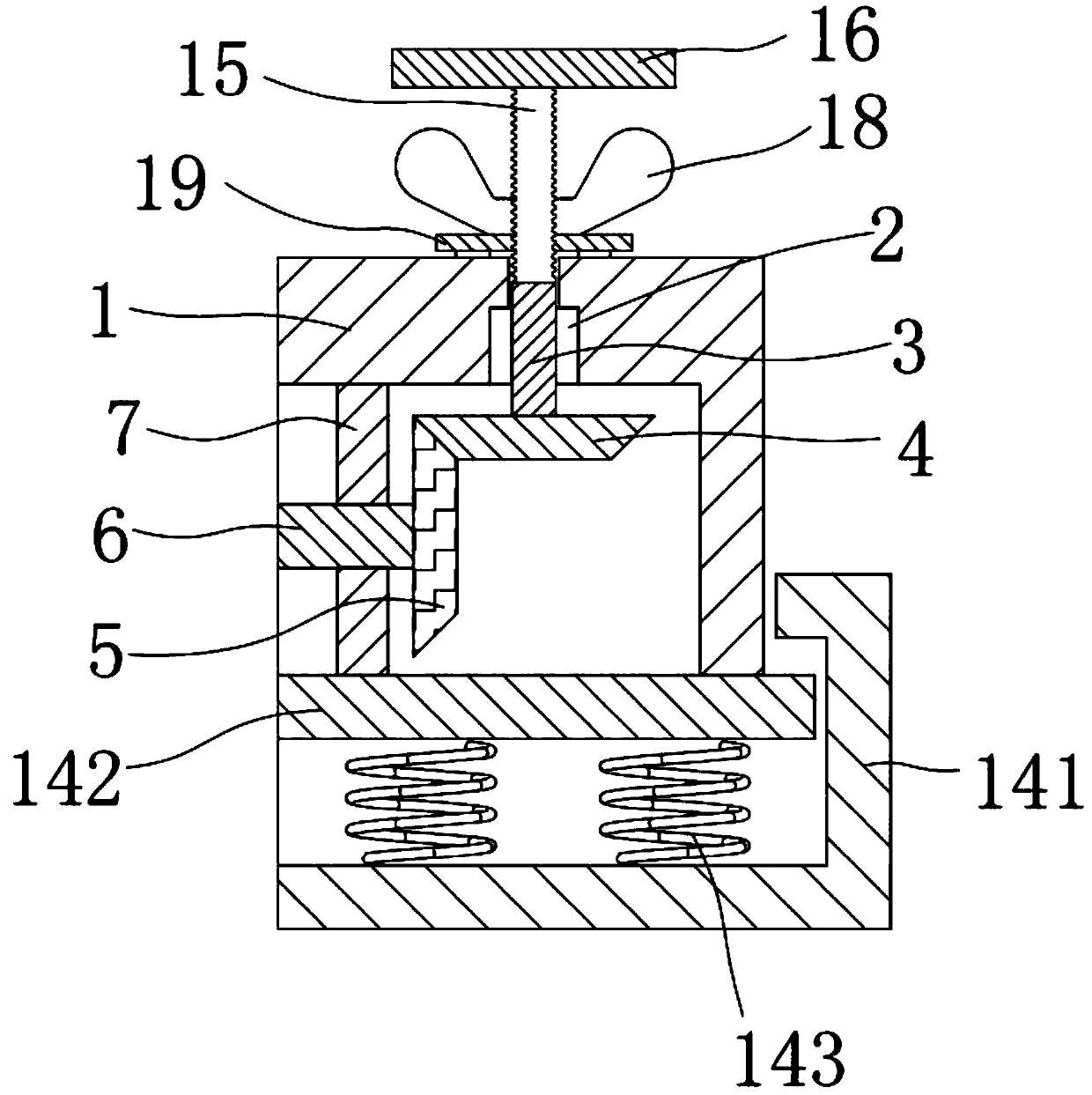

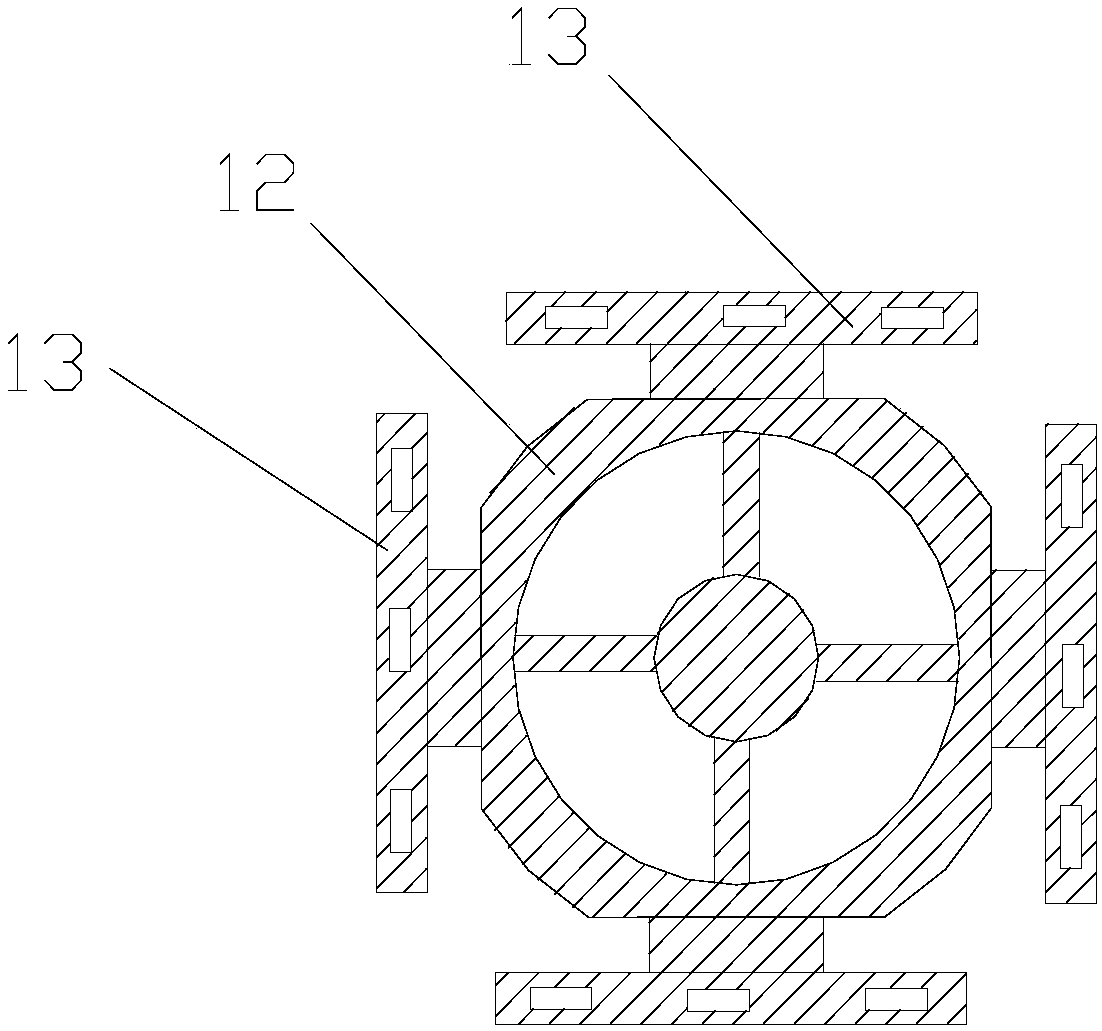

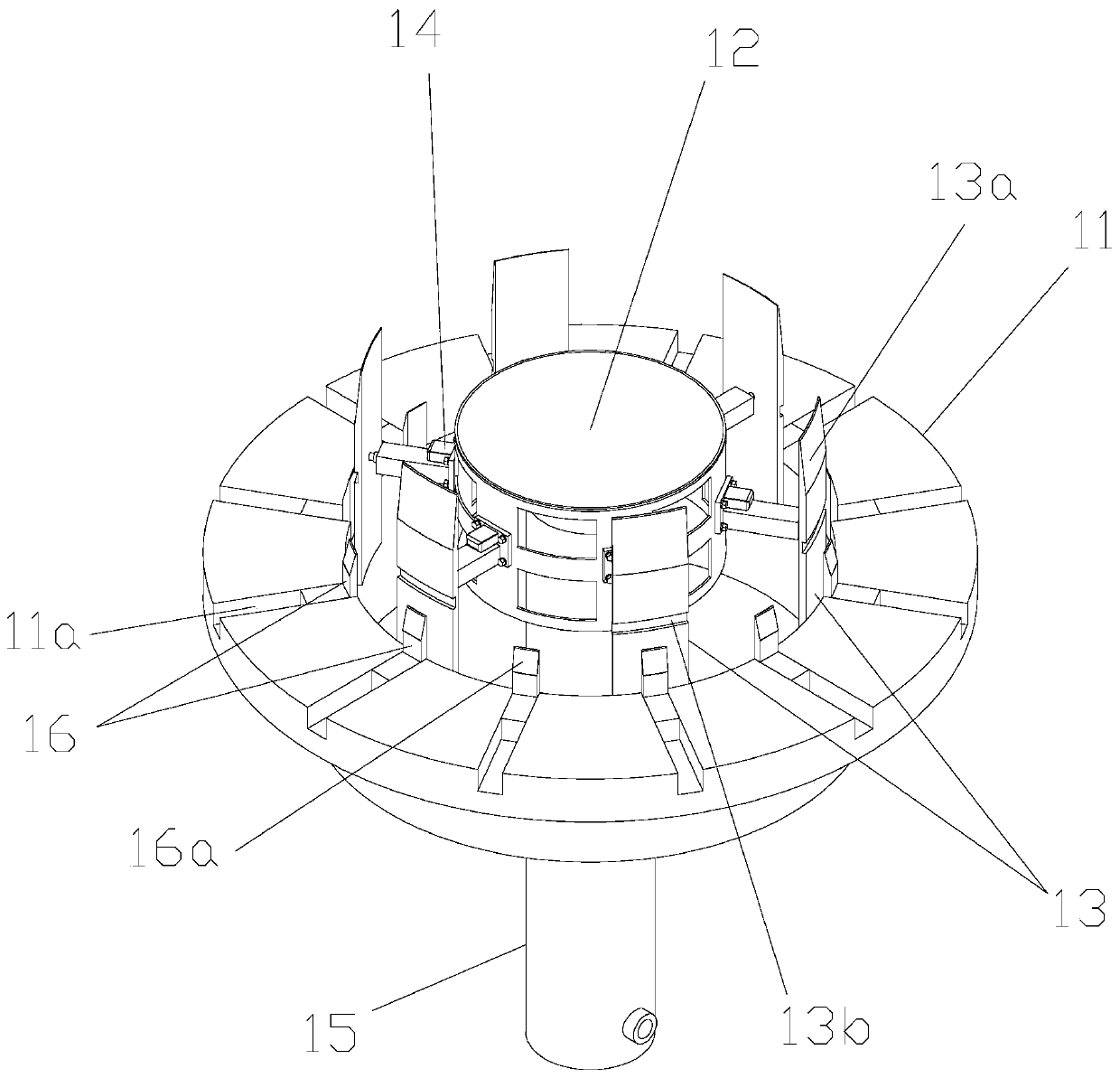

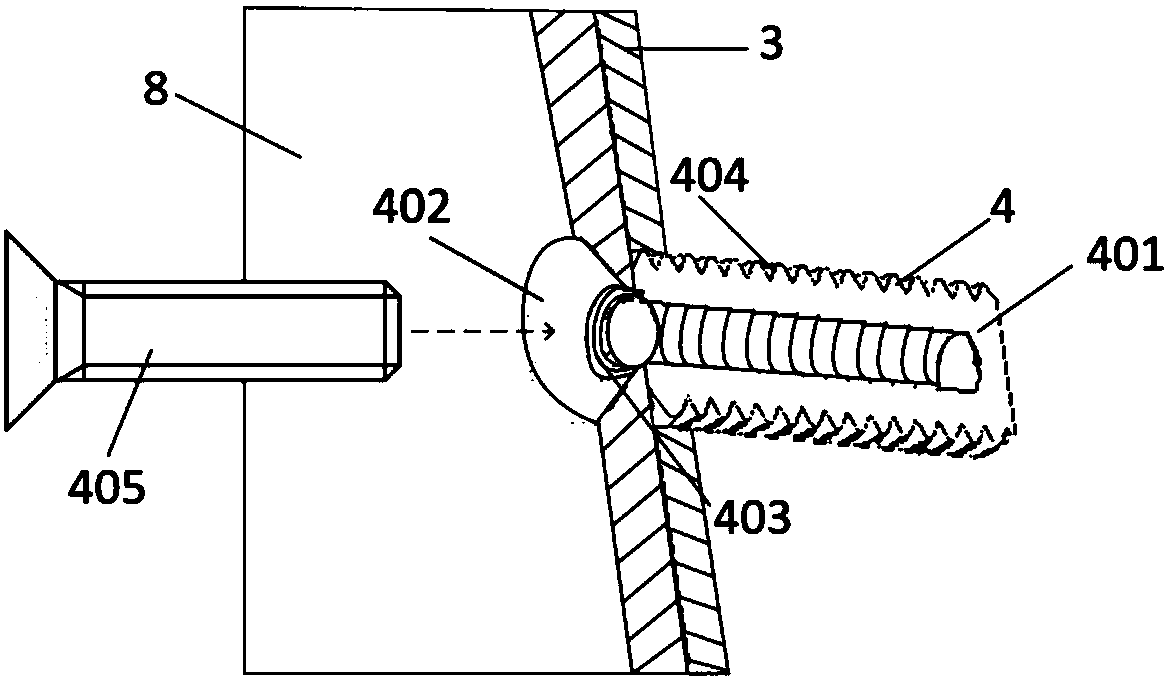

Multi-rotor structure applied in unmanned aerial vehicle

InactiveCN105366041AAchieve fasteningAchieve separationRemote controlled aircraftRotocraftEngineeringScrew thread

Owner:EWATT TECH CO LTD

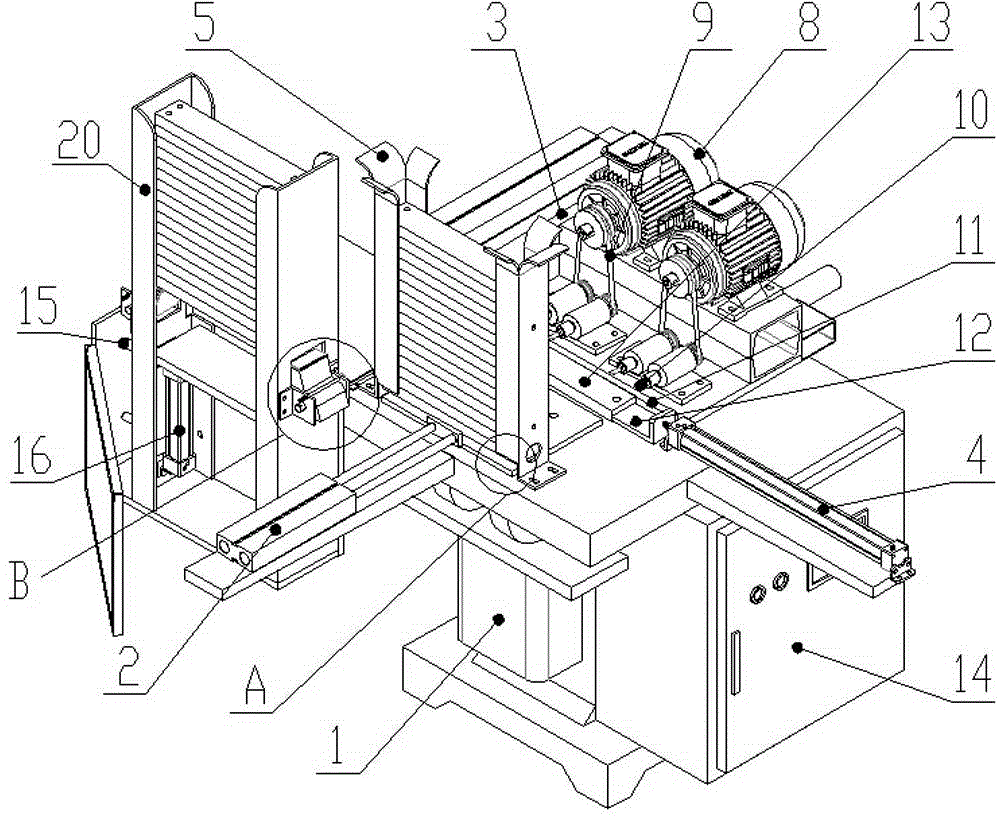

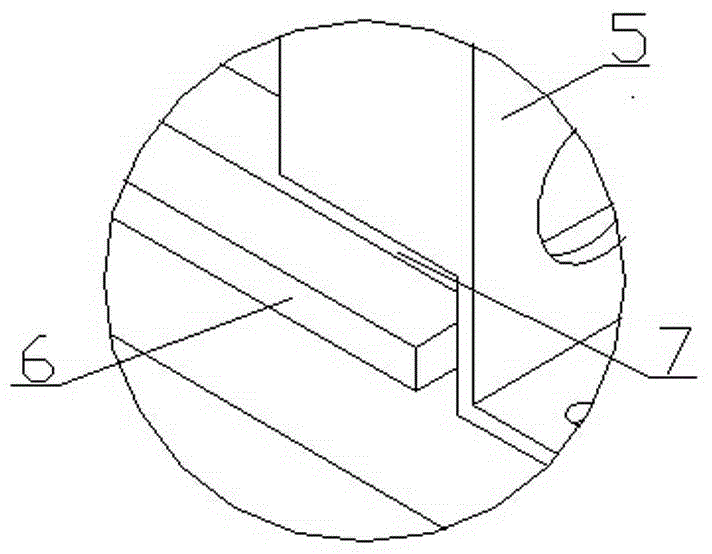

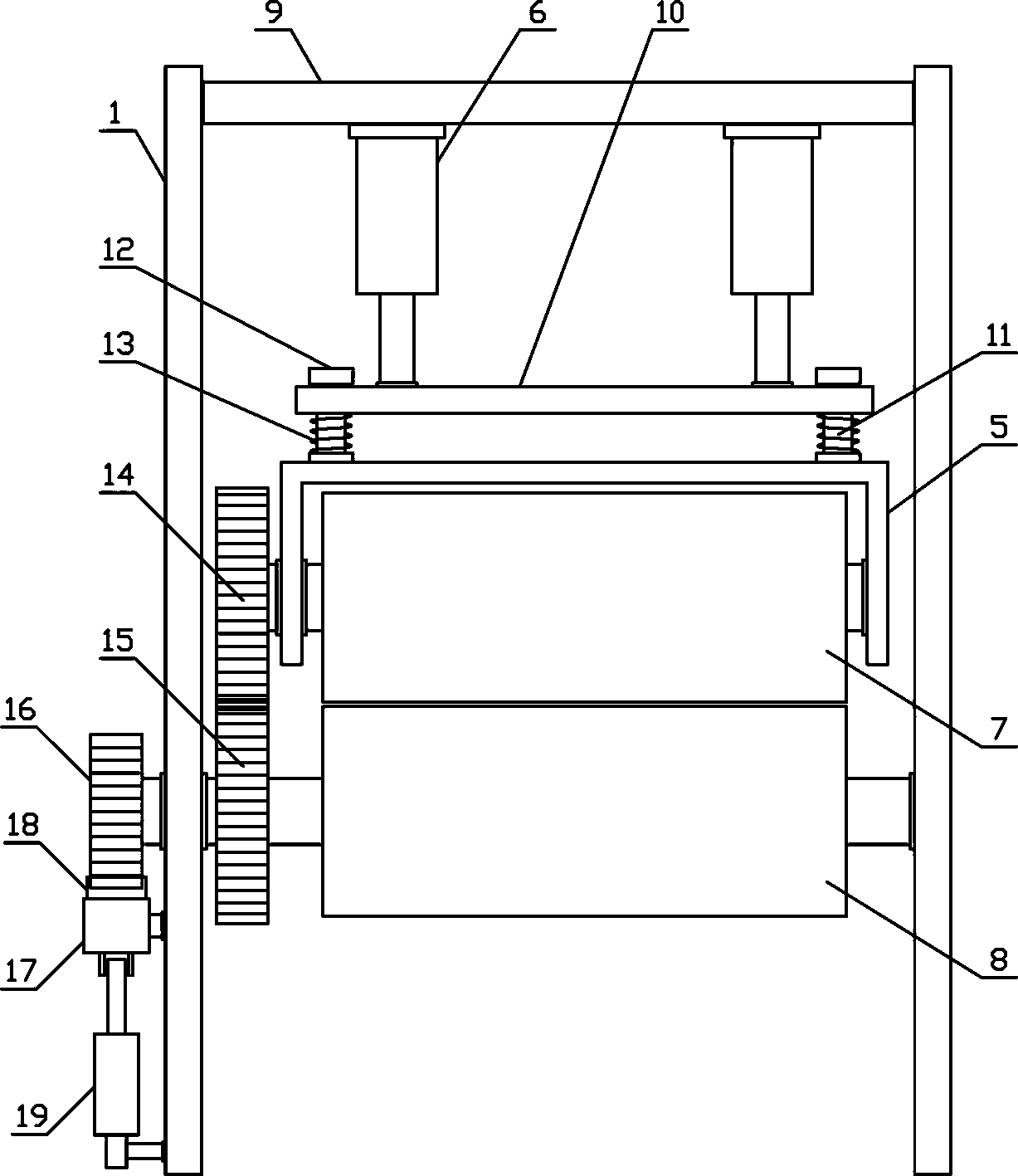

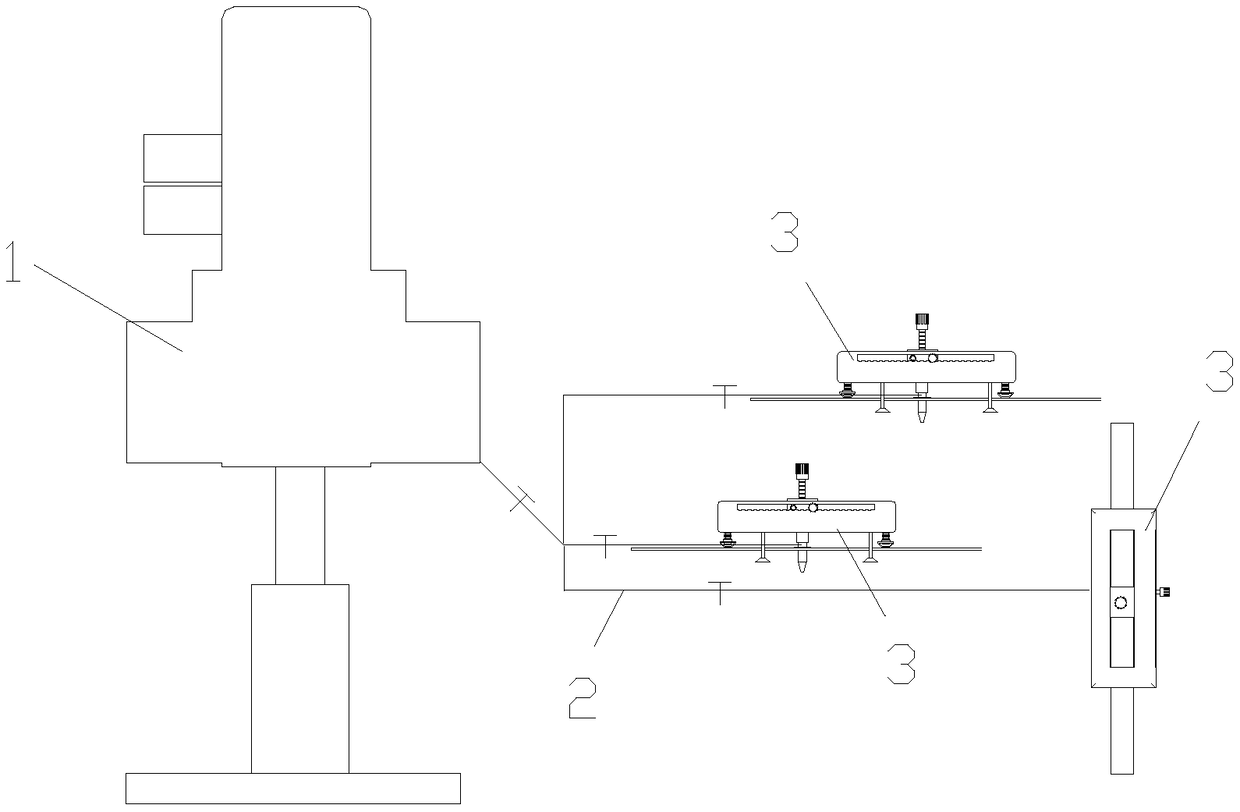

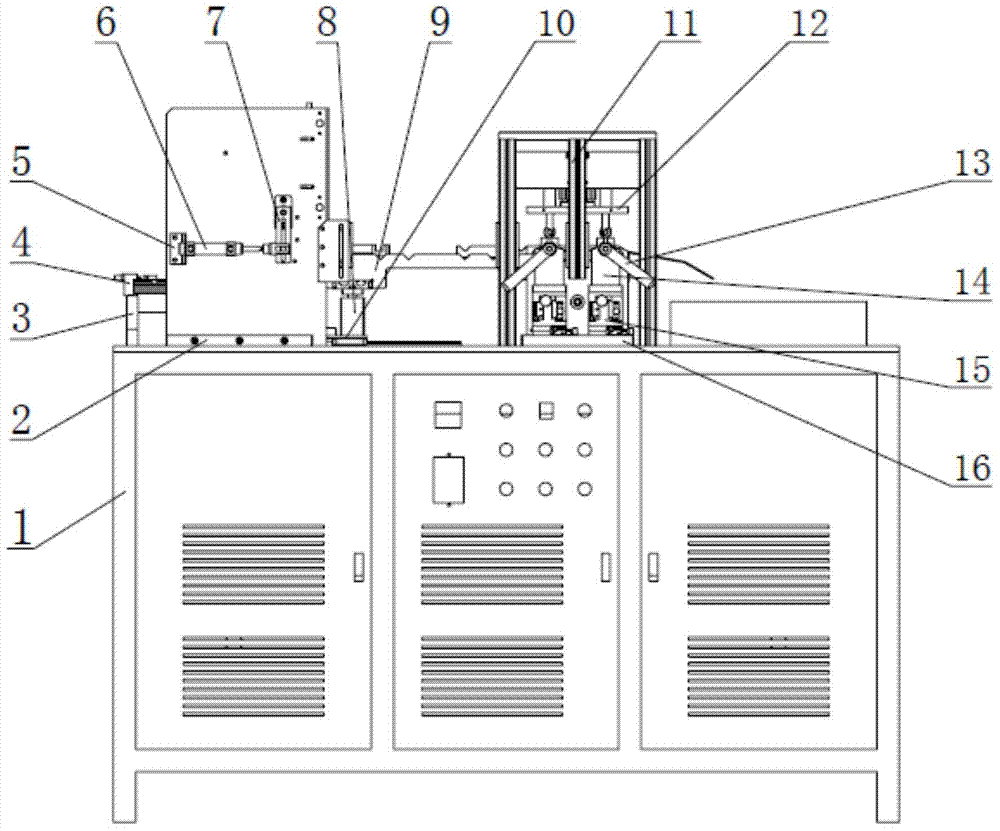

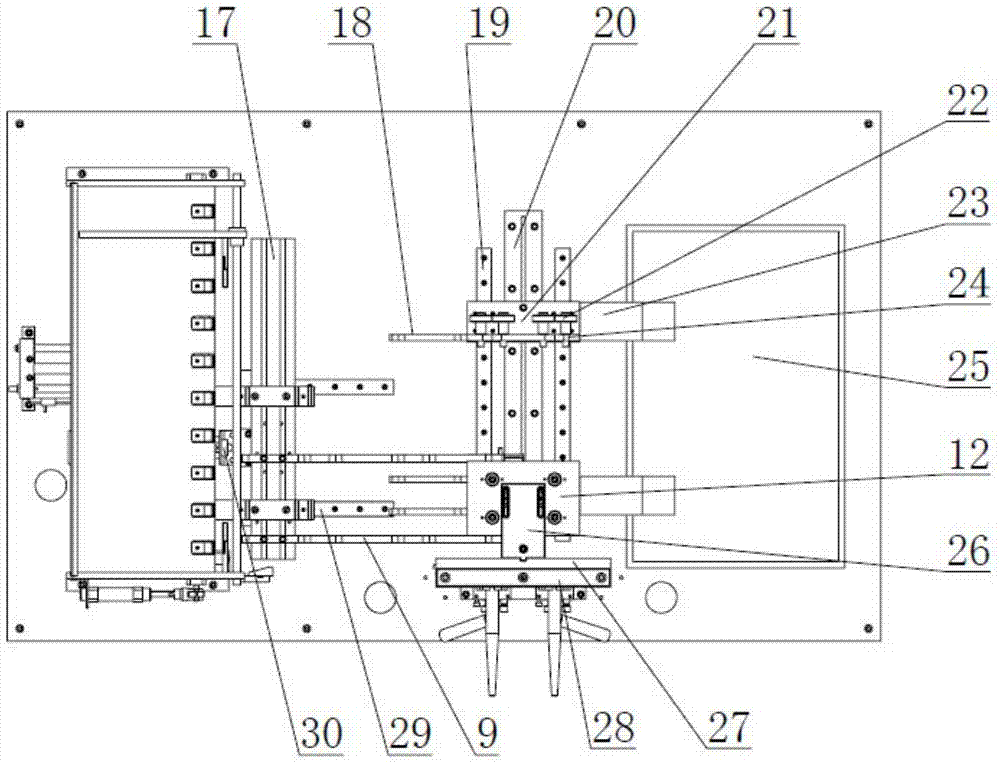

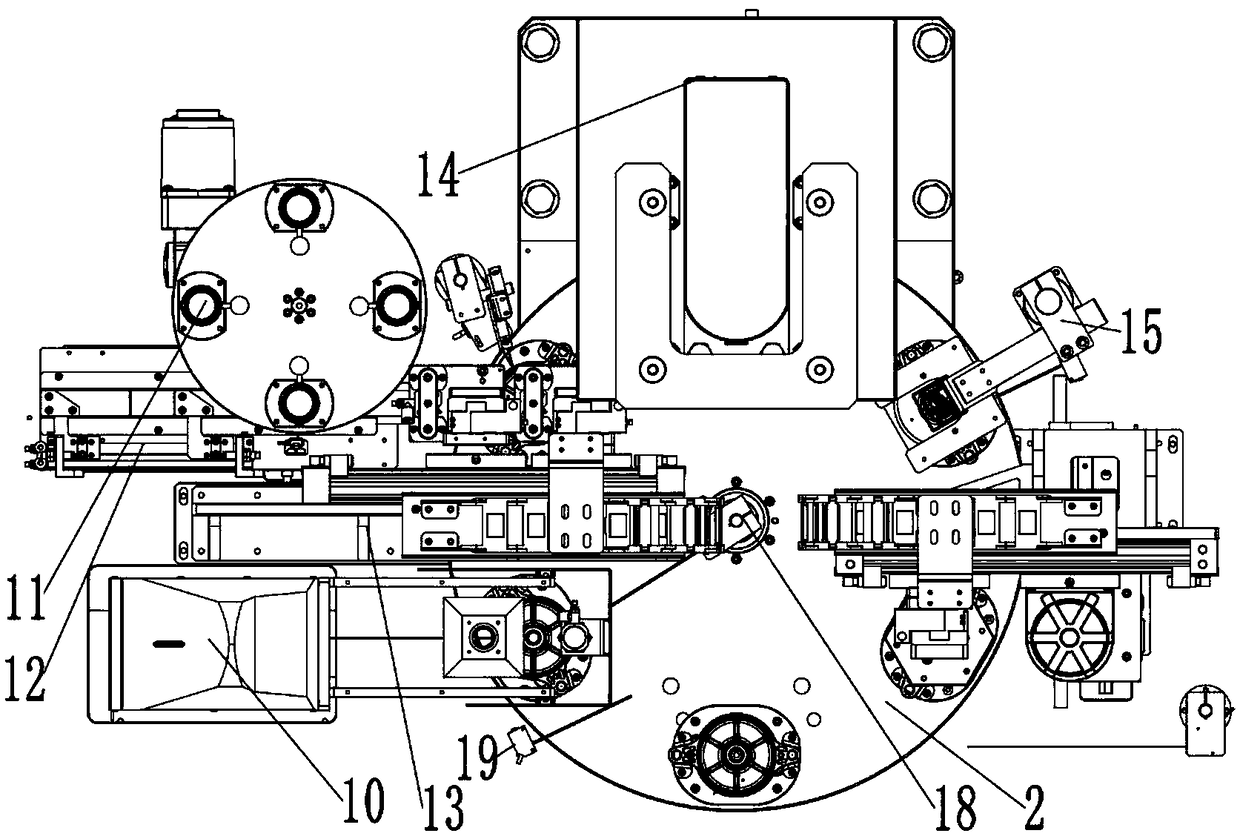

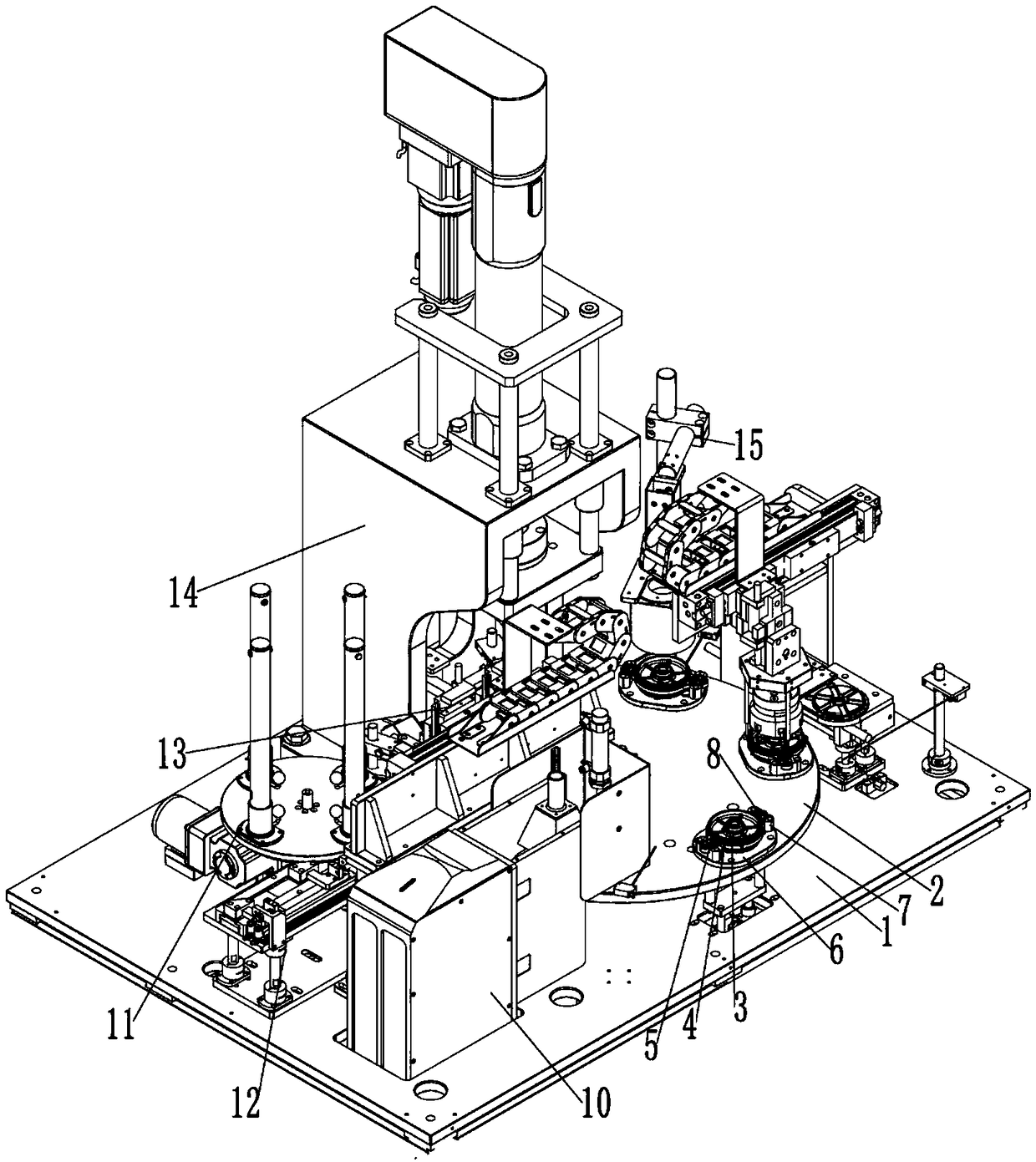

Full-automatic effective drilling machine for furniture panel

ActiveCN104875243AReduce labor intensityShorten the timeStationary drilling machinesEngineeringUltimate tensile strength

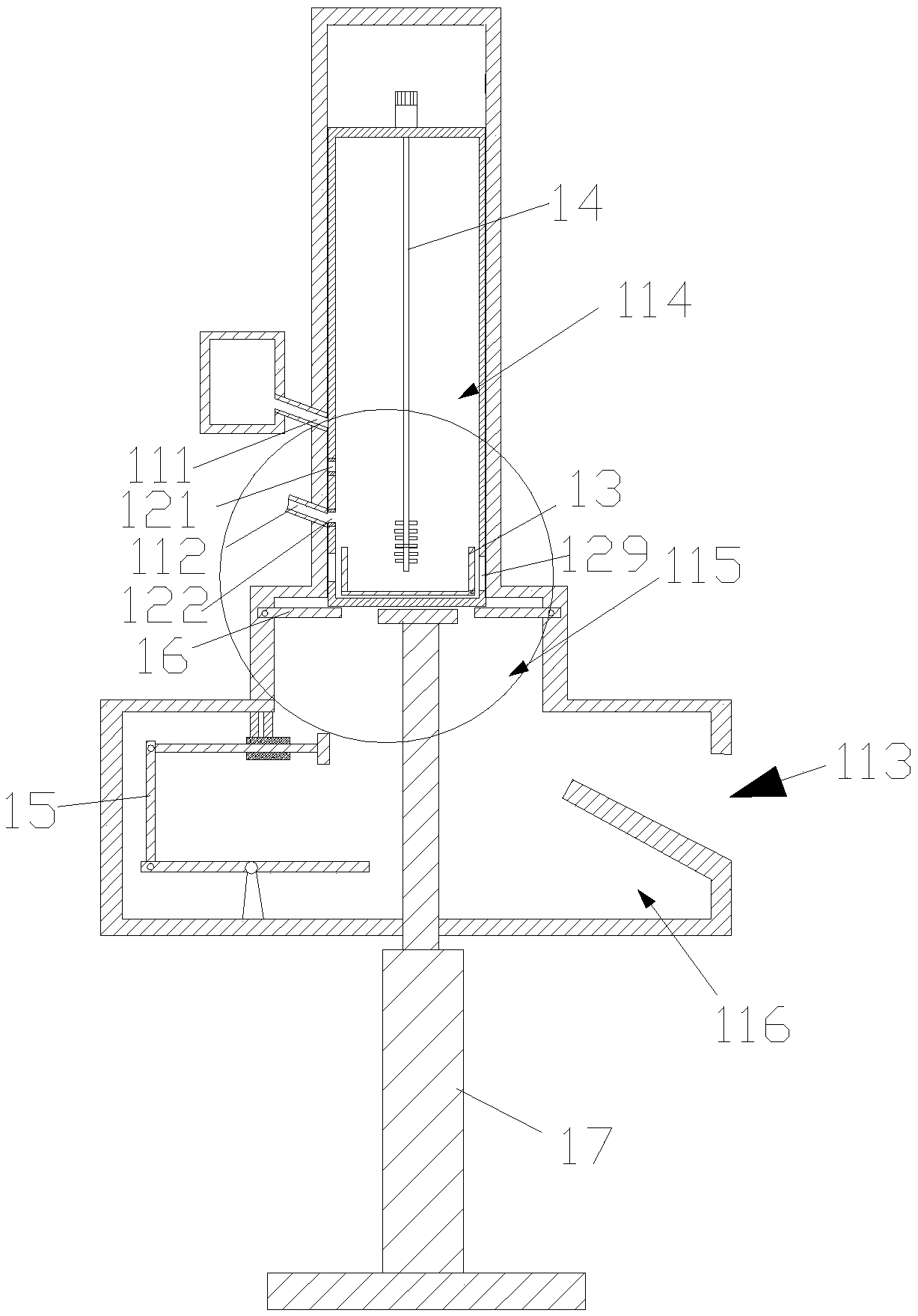

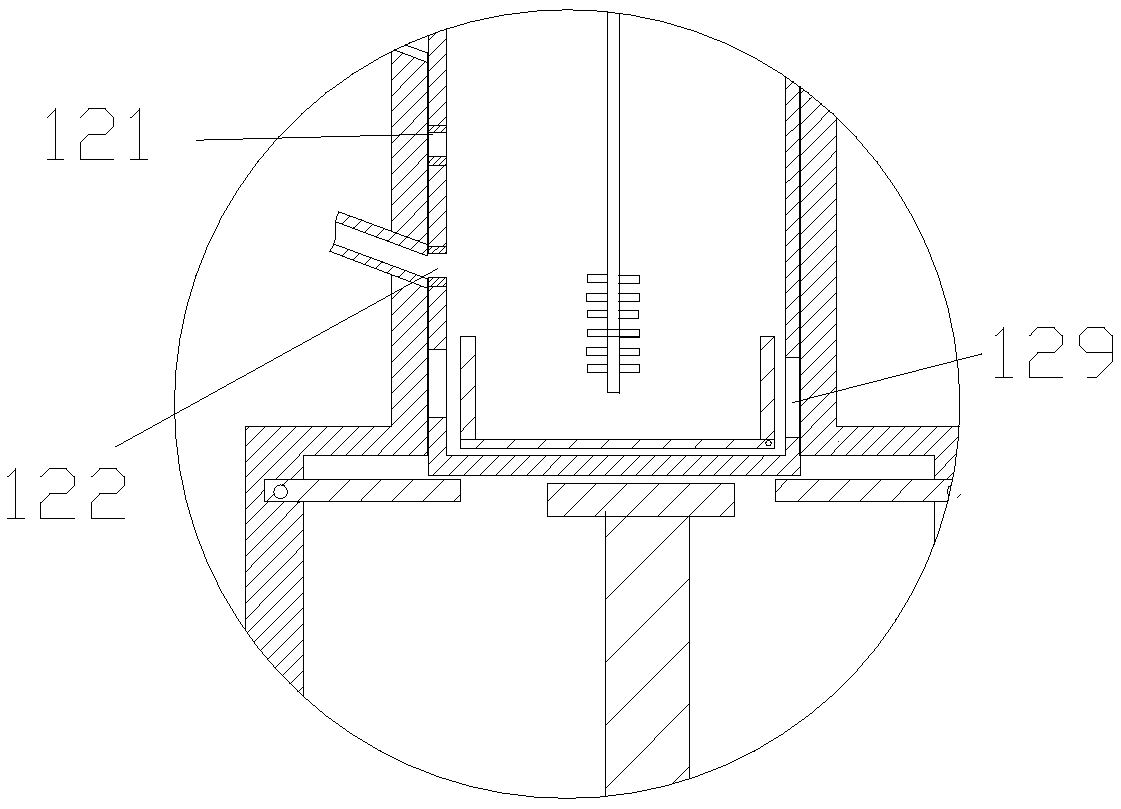

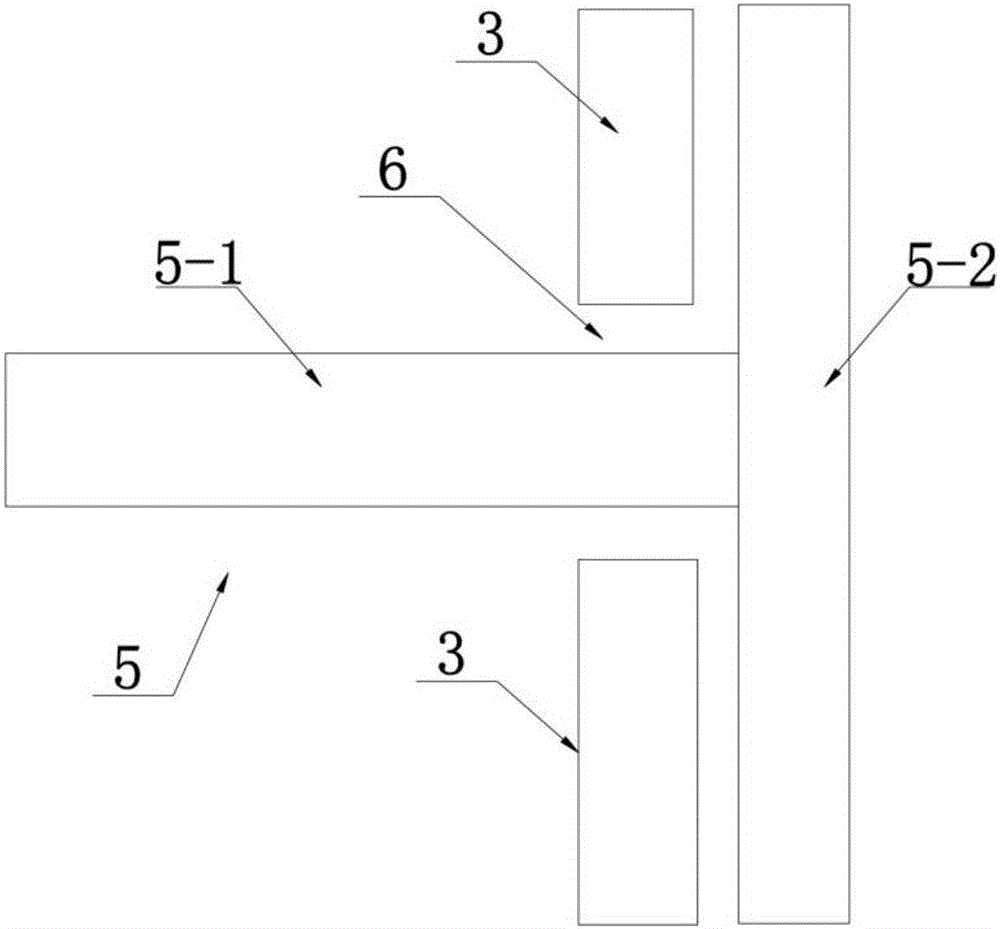

The invention belongs to the technical field of panel processing and discloses a full-automatic effective drilling machine for a furniture panel. The full-automatic effective drilling machine for the furniture panel is used for solving the problems that an existing panel drilling device is large in labor intensity and low in production efficiency due to discontinuous production. The full-automatic effective drilling machine for the furniture panel comprises a main stand, the main stand is provided with a feed cabin for holding a workpiece to be processed, the main stand before the feed cabin is provided with a push cylinder for pushing the workpiece to be processed, the main stand behind the feed cabin is provided with a drilling device for drilling the lateral surface of the workpiece to be processed, and the main stand at one side of the feed cabin is provided with a transverse push cylinder for pushing out the processed workpiece; the main stand at the other side of the feed cabin is provided with a storage device for recycling the processed workpiece, and the transverse push cylinder and storage device are respectively located at two sides of the feed cabin.

Owner:QUANYOU FURNITURE

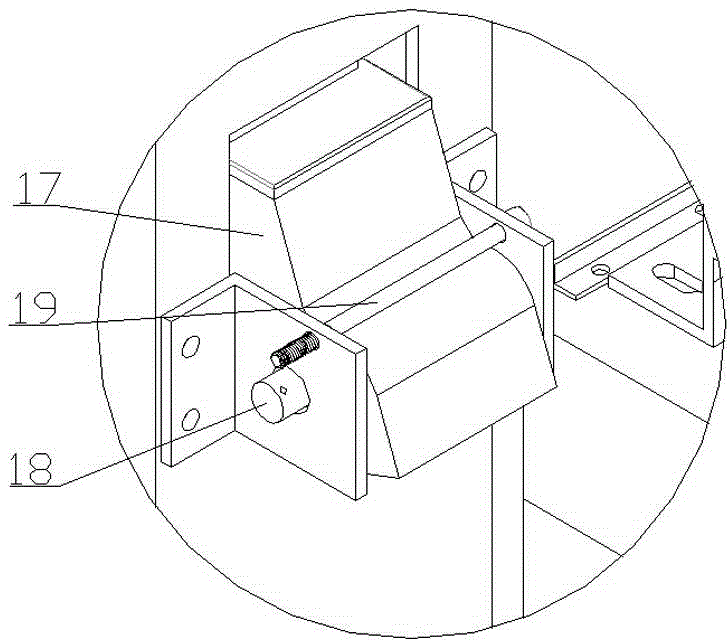

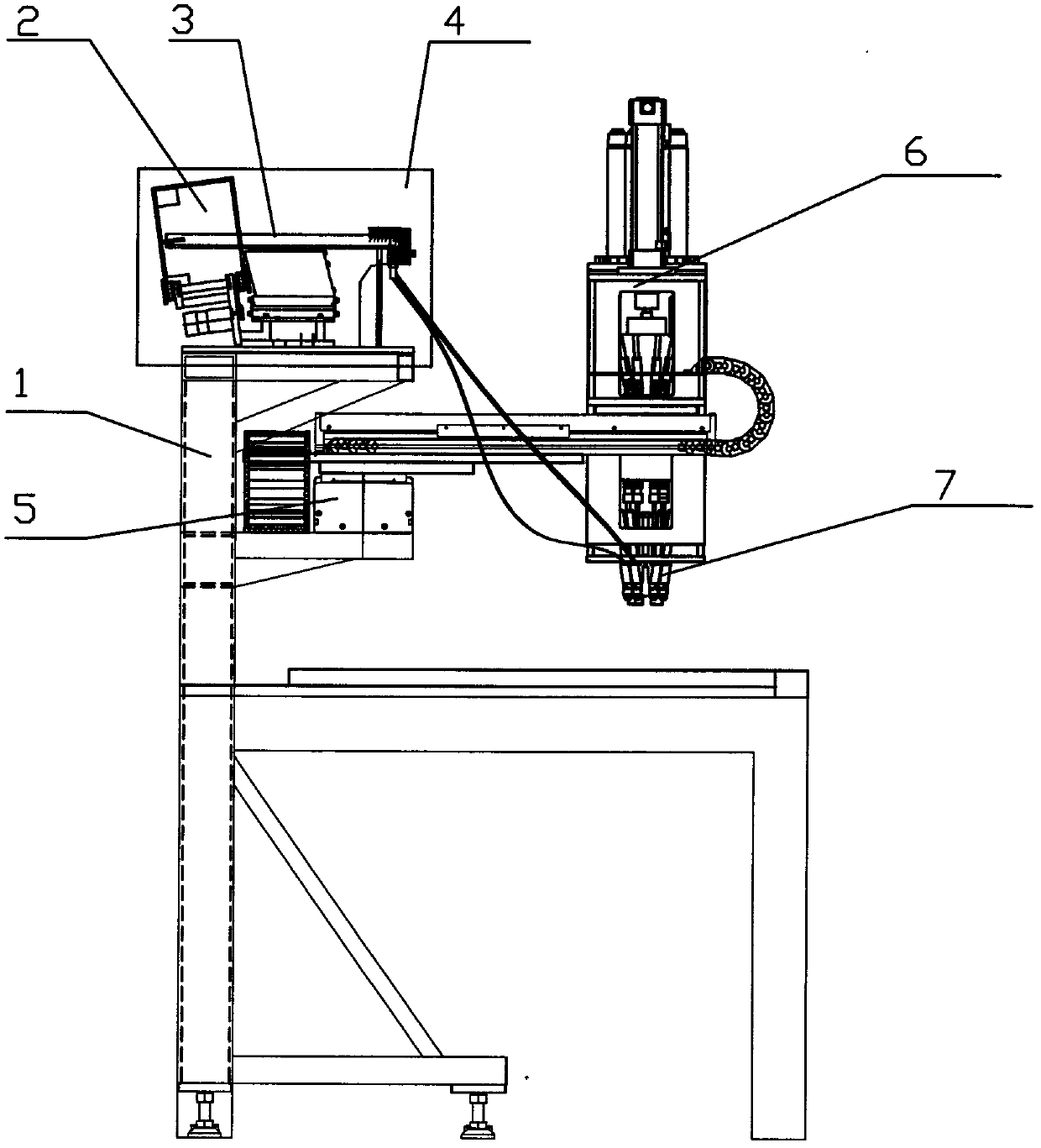

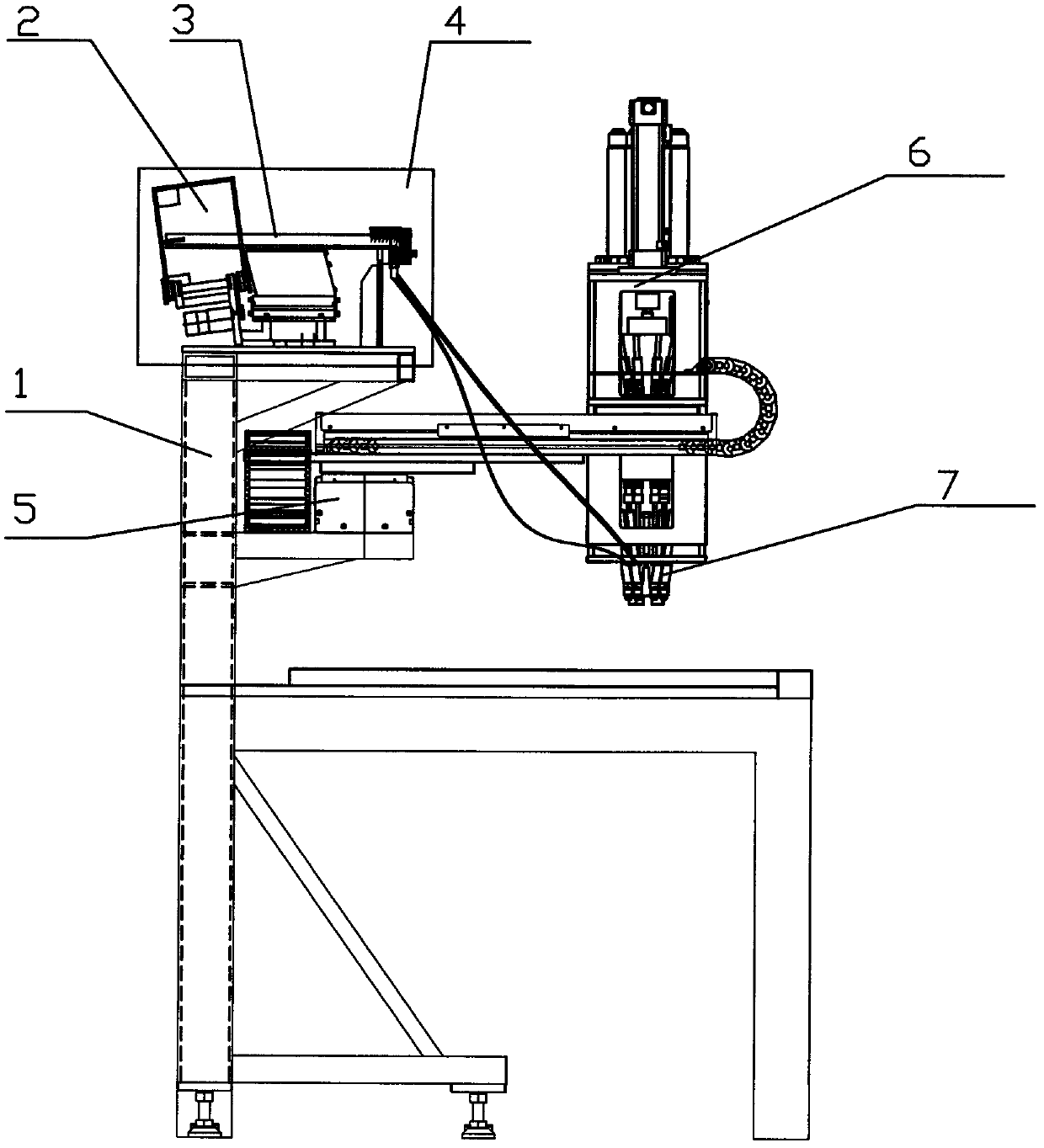

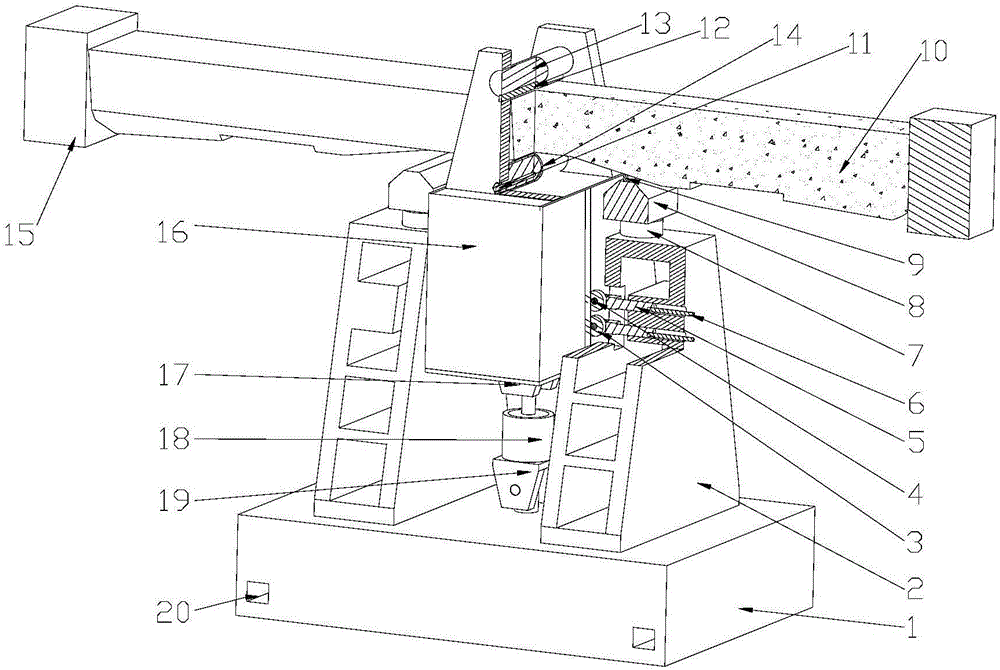

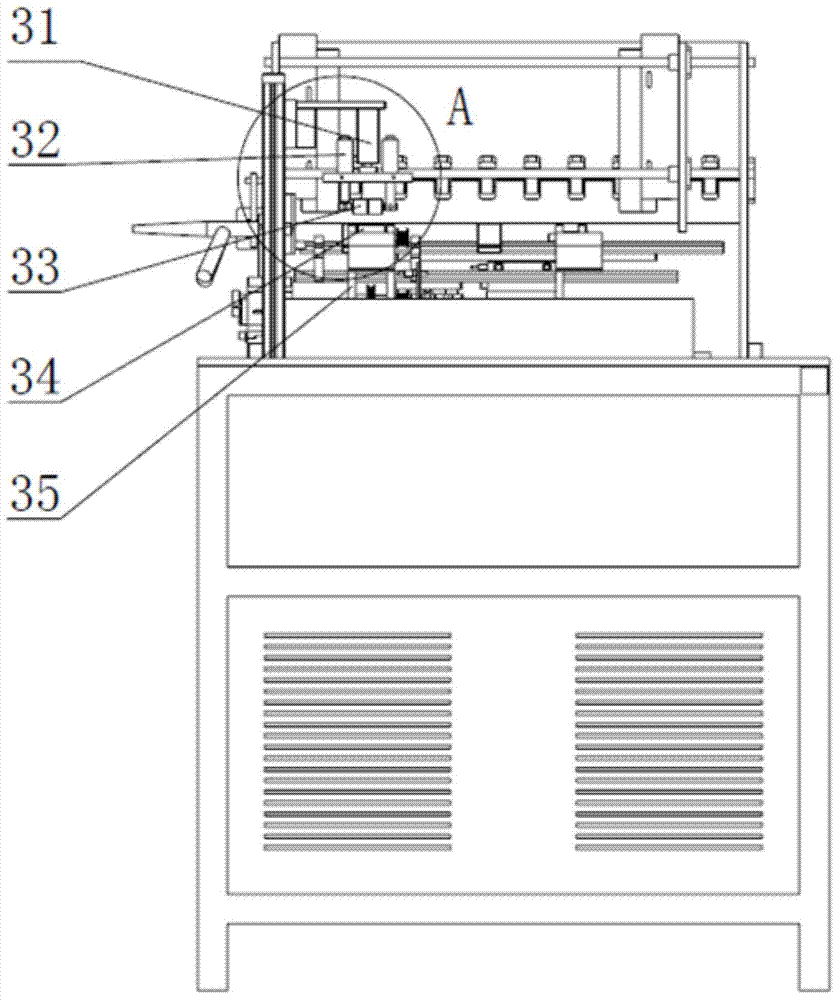

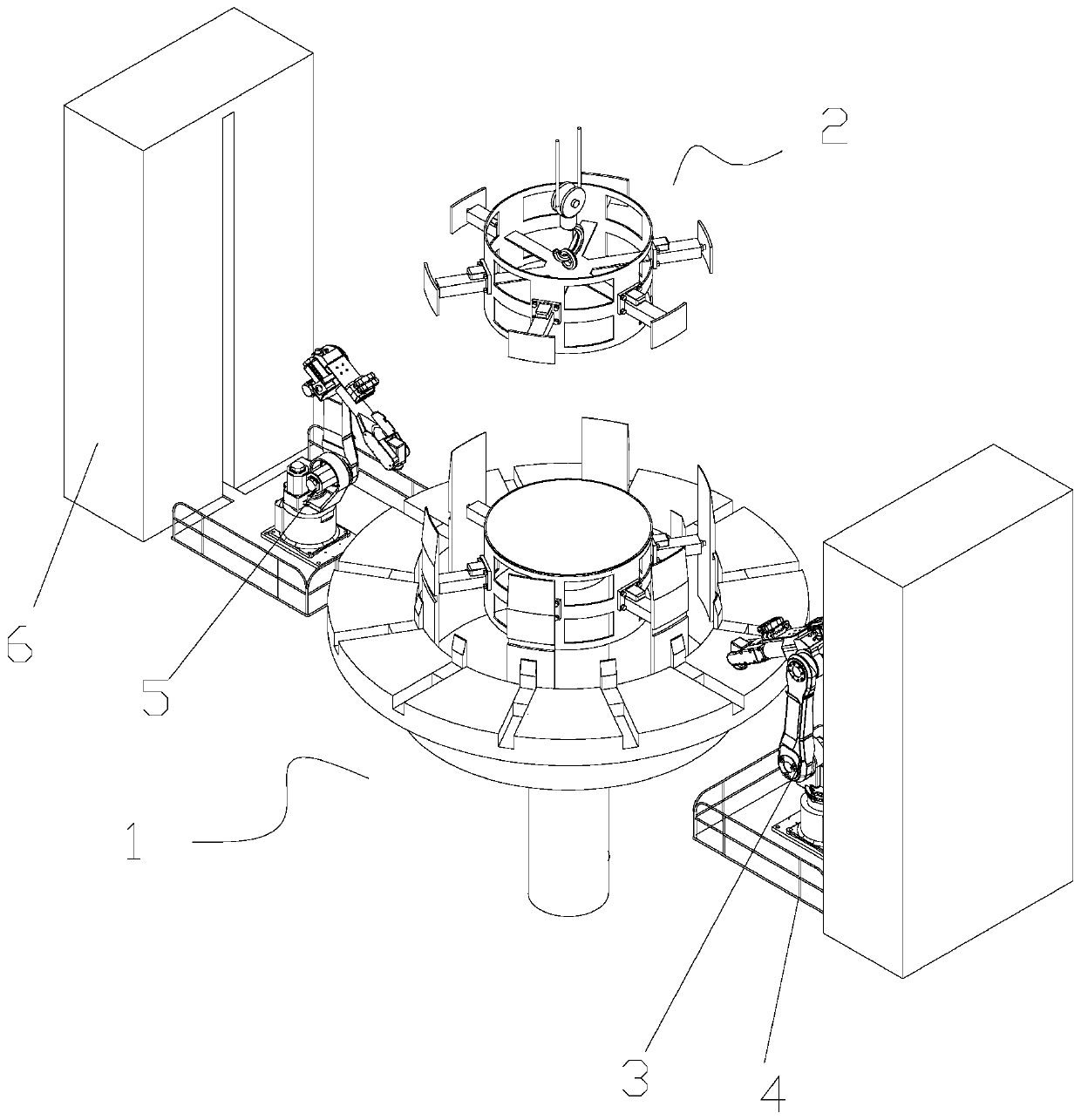

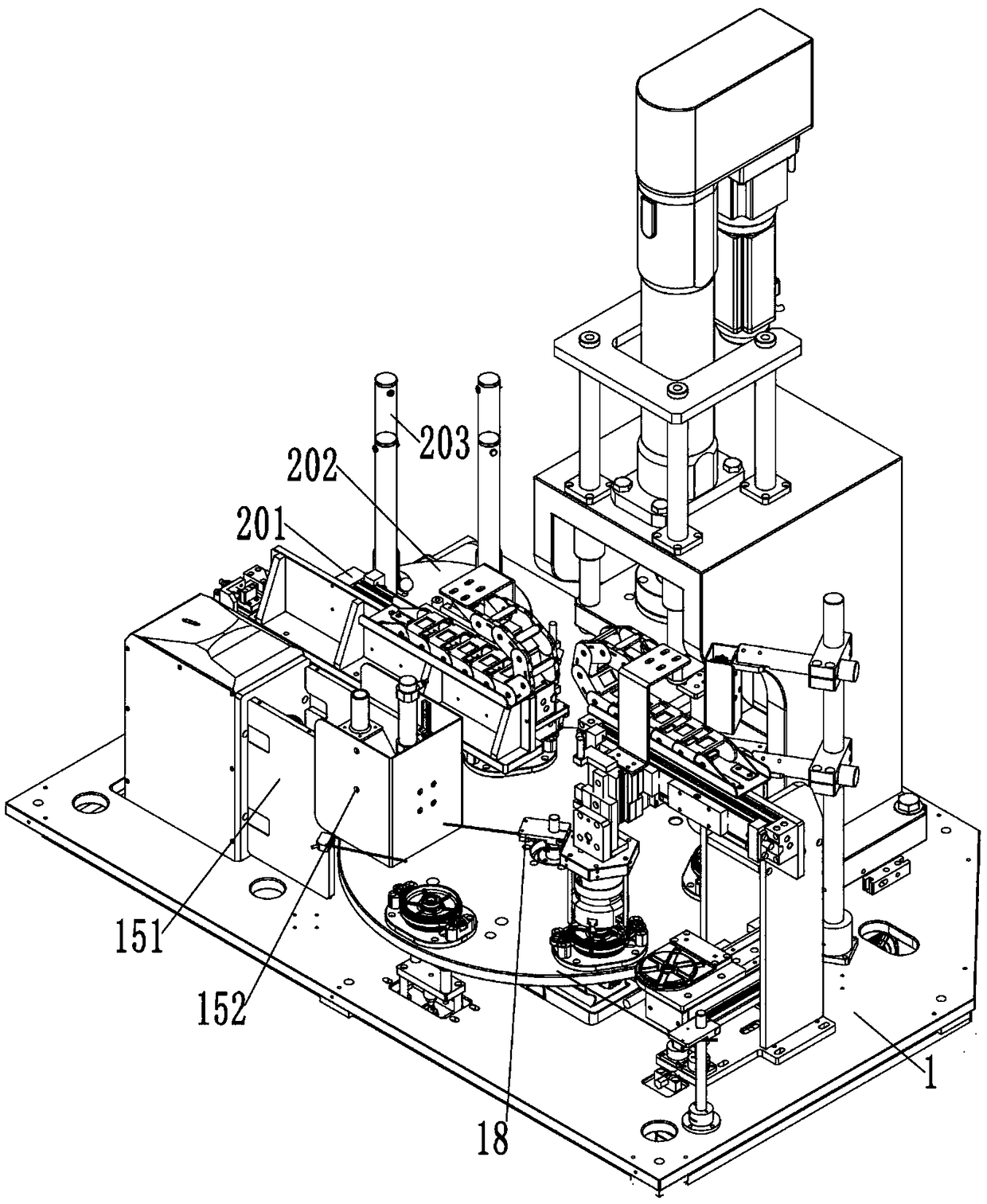

Multi-shaft blowing distribution type high-speed intelligent automatic bolt-fastening and assembling machine

ActiveCN102179692AAchieve fasteningWork flexibly and reliablyMetal working apparatusEngineeringMechanical engineering

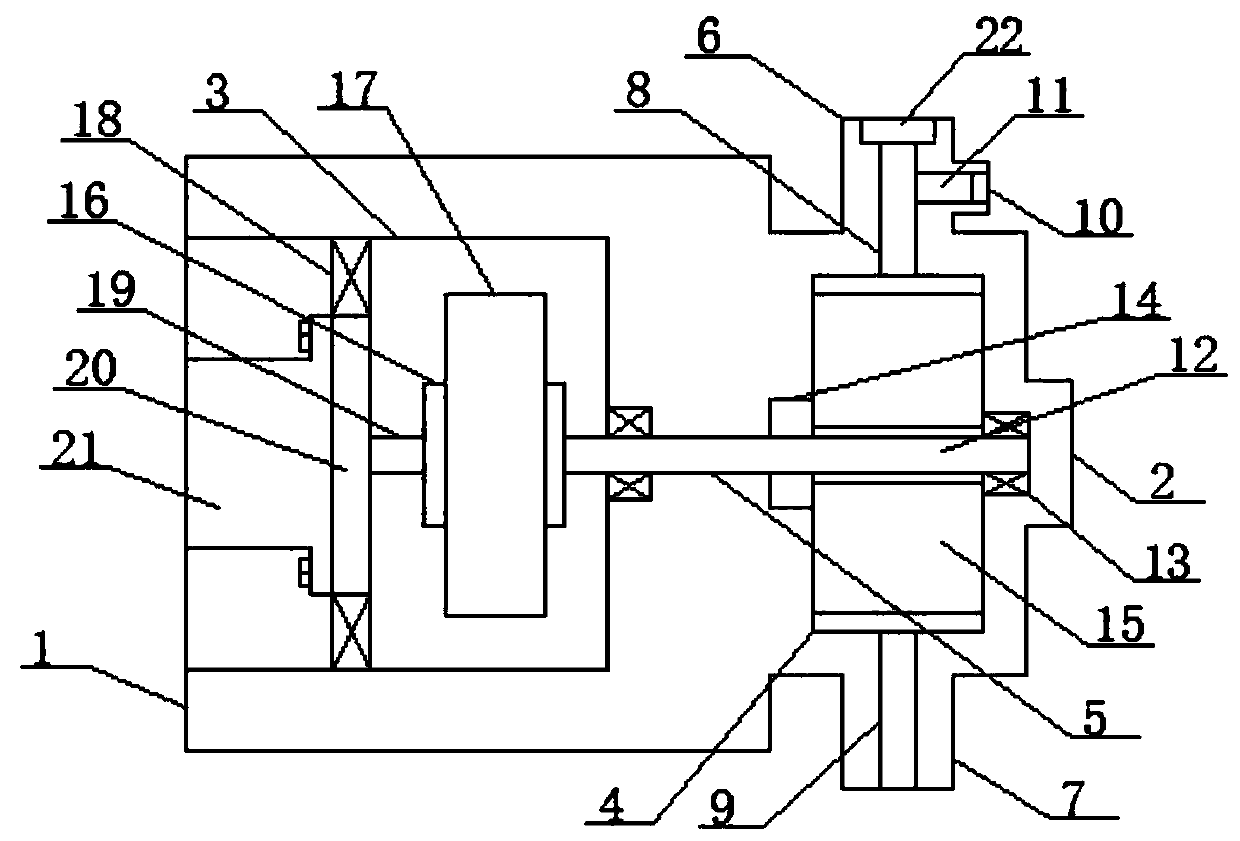

The invention relates to a multi-shaft blowing distribution type high-speed intelligent automatic bolt-fastening and assembling machine, which is characterized in that a multi-shaft blowing type bolt feeding device of the assembling machine comprises a bolt array device, a bolt distributing mechanism and a bolt blowing mechanism; the bolt array device is used for masterly realizing the operation of bolt array feeding in the combined feeding manner of a rotary charging barrel and a straight vibrator; the bolt distributing mechanism is used for distributing the bolt from one feeding mechanism to a plurality of pipes; the bolt blowing mechanism is used for finishing the operation of blowing the bolt from a material channel port of the bolt distributing mechanism to a bolt fastening assembling mechanism; the bolt fastening assembling mechanism is arranged on a robot; the bolt fastening assembling mechanism sends out the bolts under the action of a nailing machine; and a screwdriver is used for fastening the bolts, thereby fastening and assembling the bolts. The assembling machine can be used for automatically fastening and assembling eight bolts on one hinge of a foldable door at one time. One foldable door is provided with three hinges, so the assembling machine can be used for automatically fastening and assembling twenty four bolts in one period. By using the assembling machine, the working efficiency is increased while the labor intensity is reduced.

Owner:DALIAN YUN MING AUTOMATION TECH

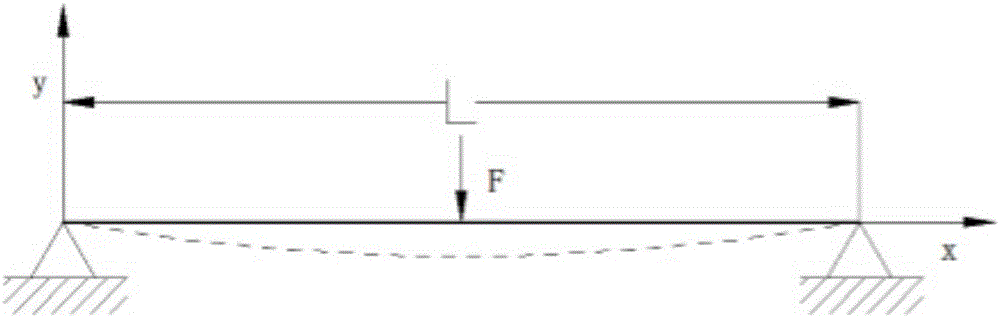

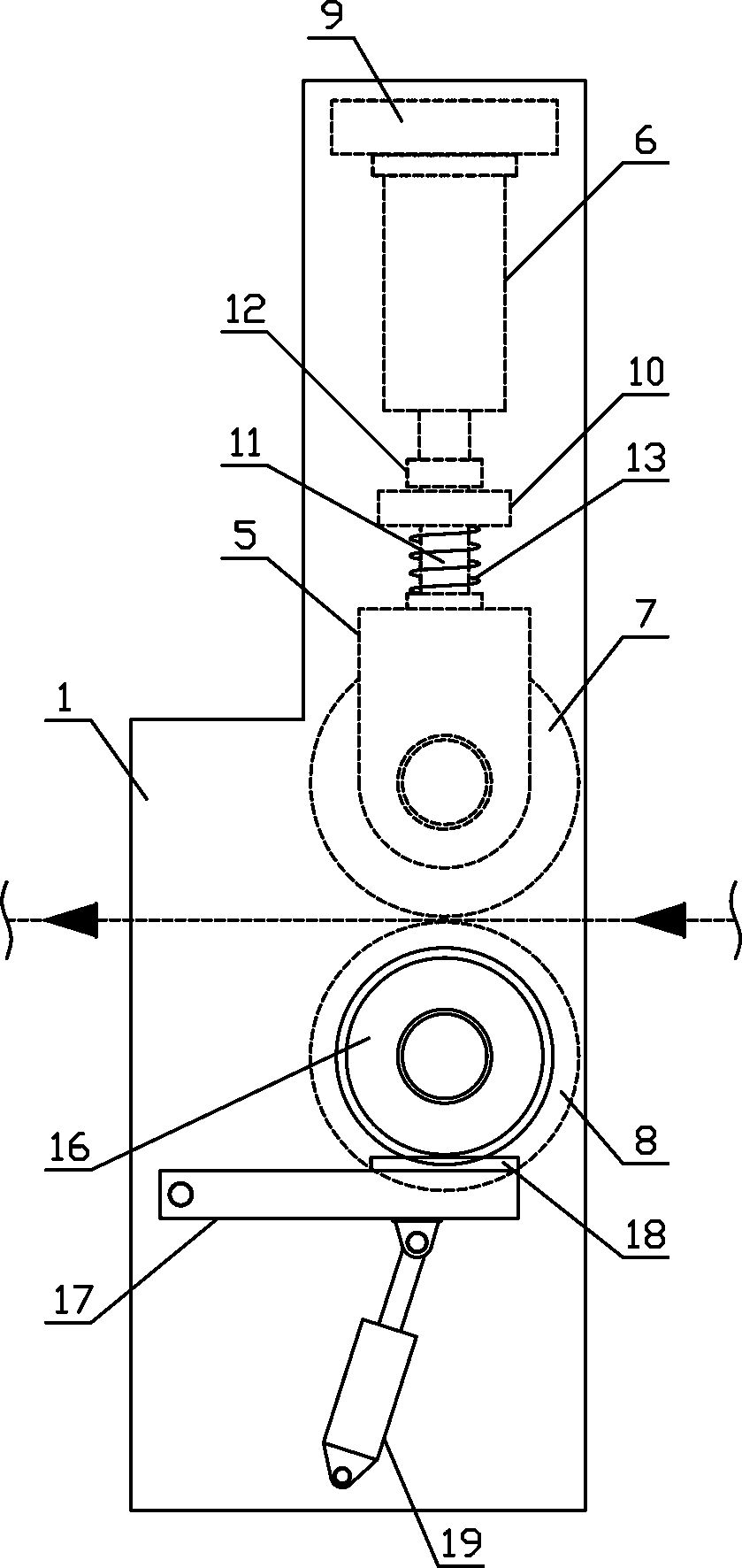

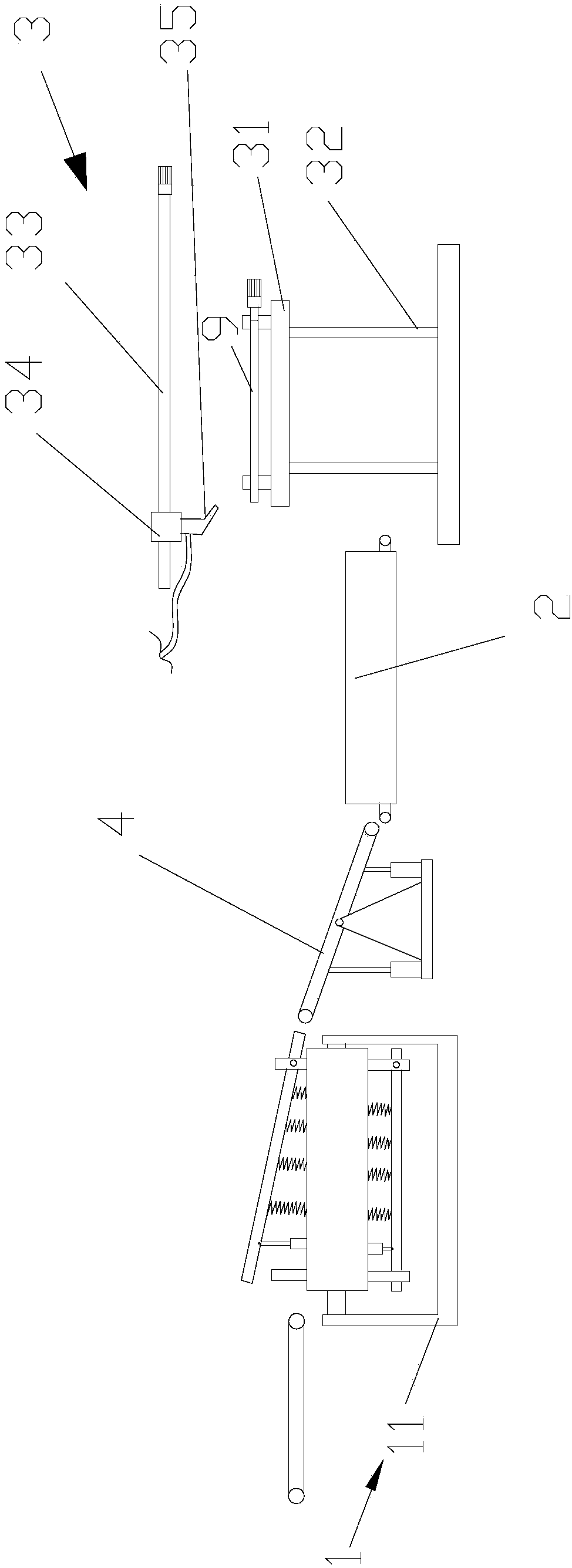

Resonance bending fatigue test machine for railway sleepers and application of resonance bending fatigue test machine

InactiveCN106248509ANo secondary disturbing vibrations should occurGuarantee normal implementationMaterial strength using repeated/pulsating forcesControl systemResonance

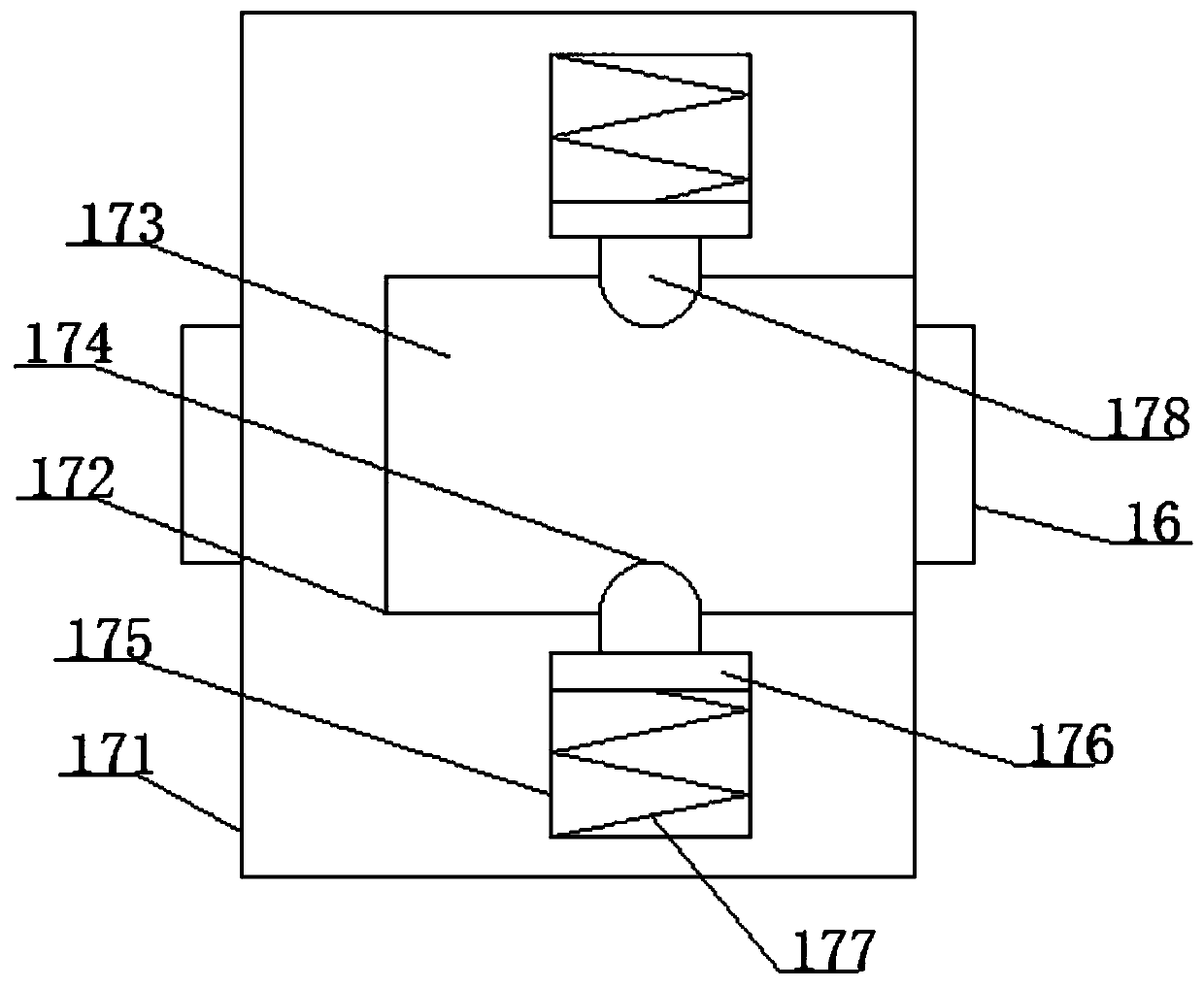

The invention discloses a resonance bending fatigue test machine for railway sleepers and application of the resonance bending fatigue test machine, and belongs to the technical field of test machines. The resonance bending fatigue test machine for the railway sleepers comprises a base, two side upright columns, a vibration exciter, a constant-force hydraulic loading system and a control system. The two side upright columns are symmetrically arranged on the upper end surface of the base, force measuring sensors, support blocks and small support plates A are sequentially arranged on the upper end surfaces of the two side upright columns, and a railway sleeper can be supported by the two side upright columns; the vibration exciter is arranged between the two side upright columns, the lower end of the vibration exciter is supported on the upper end surface of the base by a constant-force hydraulic loading mechanism, the upper end of the vibration exciter is fastened and connected with the tested railway sleeper by a fastening support mechanism, and load applied by the vibration exciter acts on a loading location for the tested railway sleeper; force can be loaded on the tested railway sleeper by the constant-force hydraulic loading system via the vibration exciter, and the constant-force hydraulic loading system and the vibration exciter can work under the control of the control system. The resonance bending fatigue test machine and the application have the advantages that test frequencies can be increased by the fatigue test machine on the basis of resonance principles, the test cycle can be shortened, and accordingly the test cost can be saved to a great extent.

Owner:JILIN UNIV

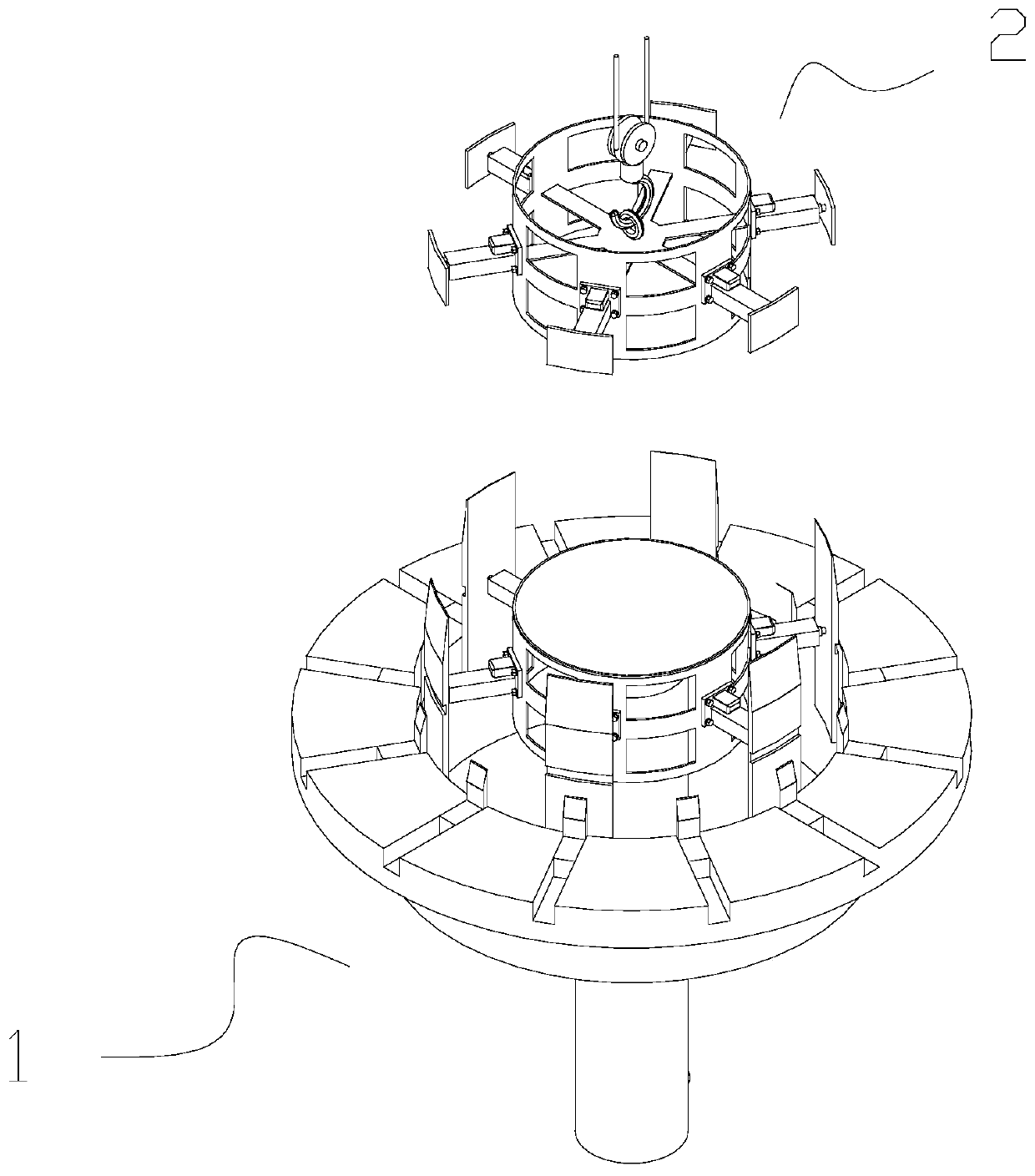

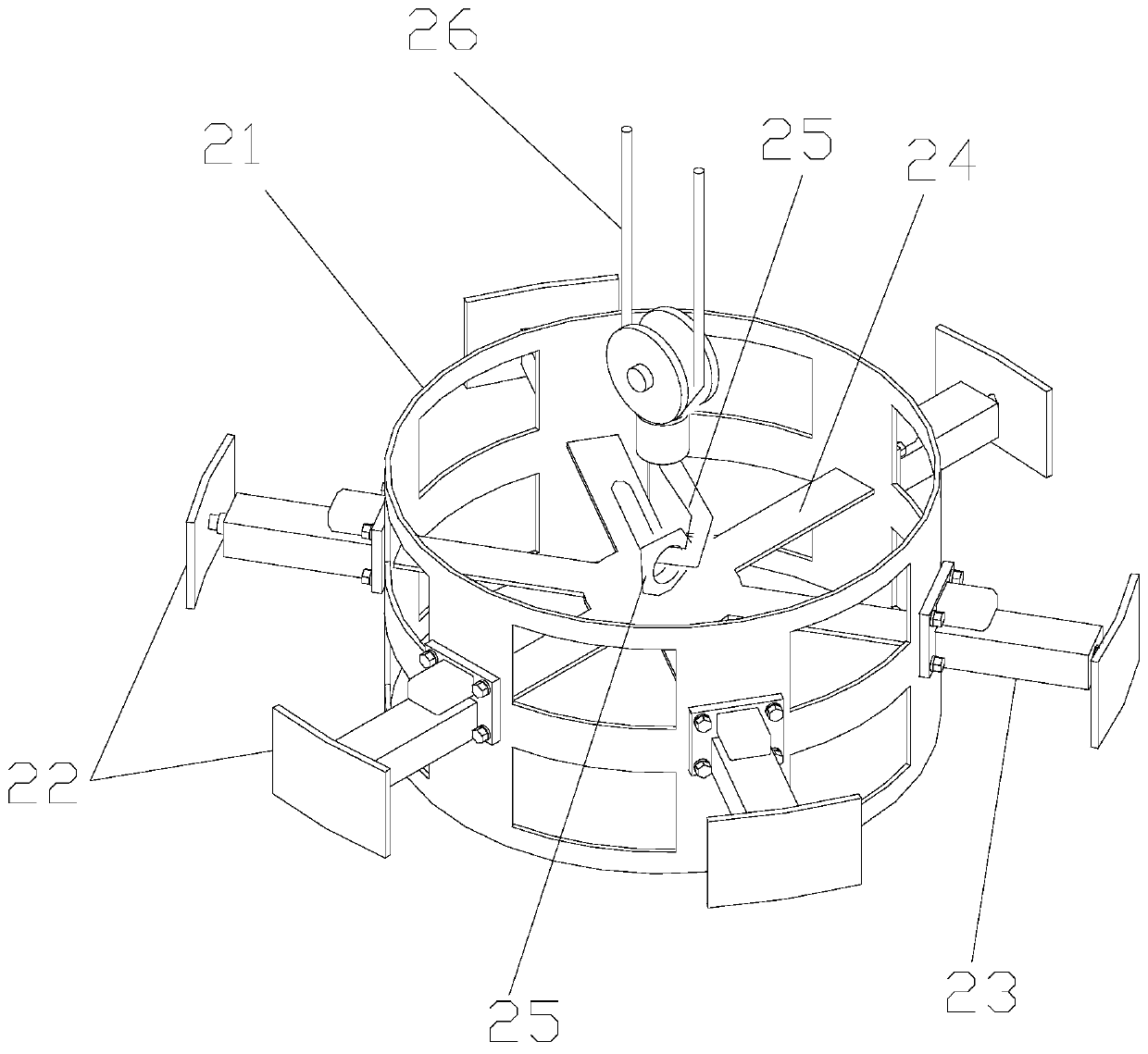

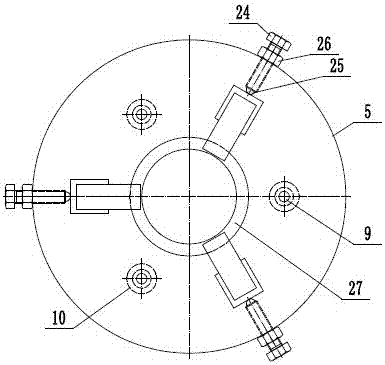

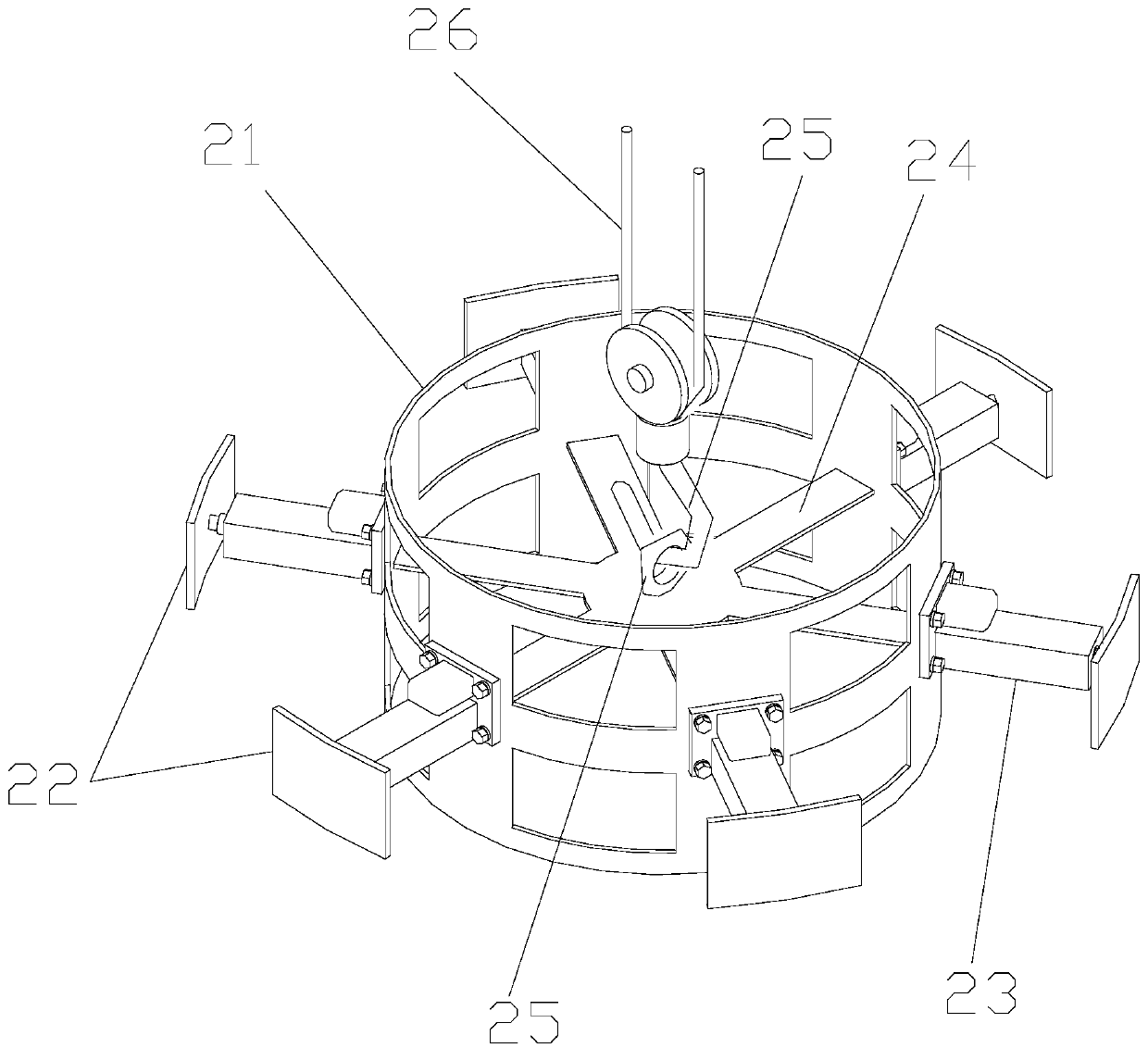

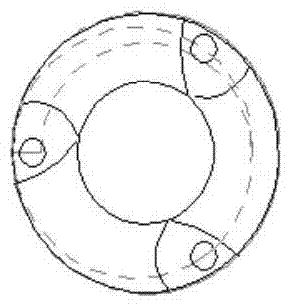

Thin-walled barrel welding assisting tool

InactiveCN109822190ASmall amount of deformationAchieve fasteningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention discloses a thin-walled barrel welding assisting tool. The thin-walled barrel welding assisting tool comprises an inner support assembly and an inner support lifting appliance; the innersupport assembly comprises a bottom platform, a supporting frame I, and a plurality of supporting plates I which are uniformly distributed in the circumferential direction of the supporting frame I;the supporting plates I are connected with drivers I arranged on the supporting frame I, and driven by the drivers I to synchronously move in the radial direction, and one side surfaces of the supporting plates I are closely attached to the inner wall surface of a barrel section; the supporting frame I is arranged on a vertical lifting mechanism; the inner support lifting appliance comprises a supporting frame II and a plurality of supporting plates II which are uniformly distributed in the circumferential direction of the supporting frame II; the supporting plates II are connected with drivers II arranged on the supporting frame II, and driven by the drivers II to synchronously move in the radial direction, and one side surfaces of the supporting plates II are closely attached to the inner wall surface of the barrel section; and the supporting frame II is arranged on a lifting moving mechanism so that the barrel section can be lifted and conveyed to the bottom platform. According to the thin-walled barrel welding assisting tool, the influence of the gravity factor on welding deformation can be eliminated, girth welding station automation is advantageously achieved, and the assembling quality and efficiency are improved.

Owner:QINGDAO UNIV OF SCI & TECH

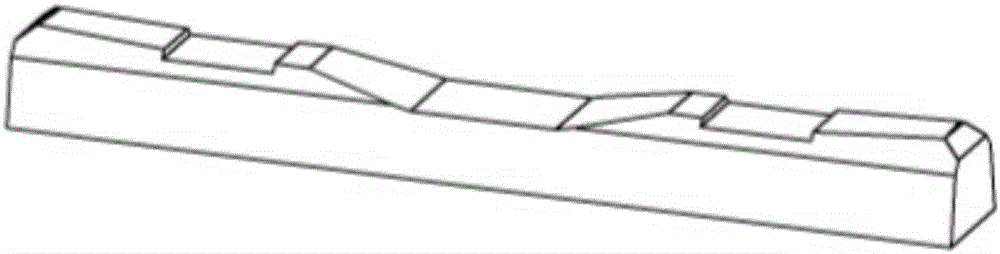

Yarn conveying and pulling mechanism

PendingCN108584532AStable and even stretchingEfficient heatingFilament handlingTextiles and paperYarnHeat conducting

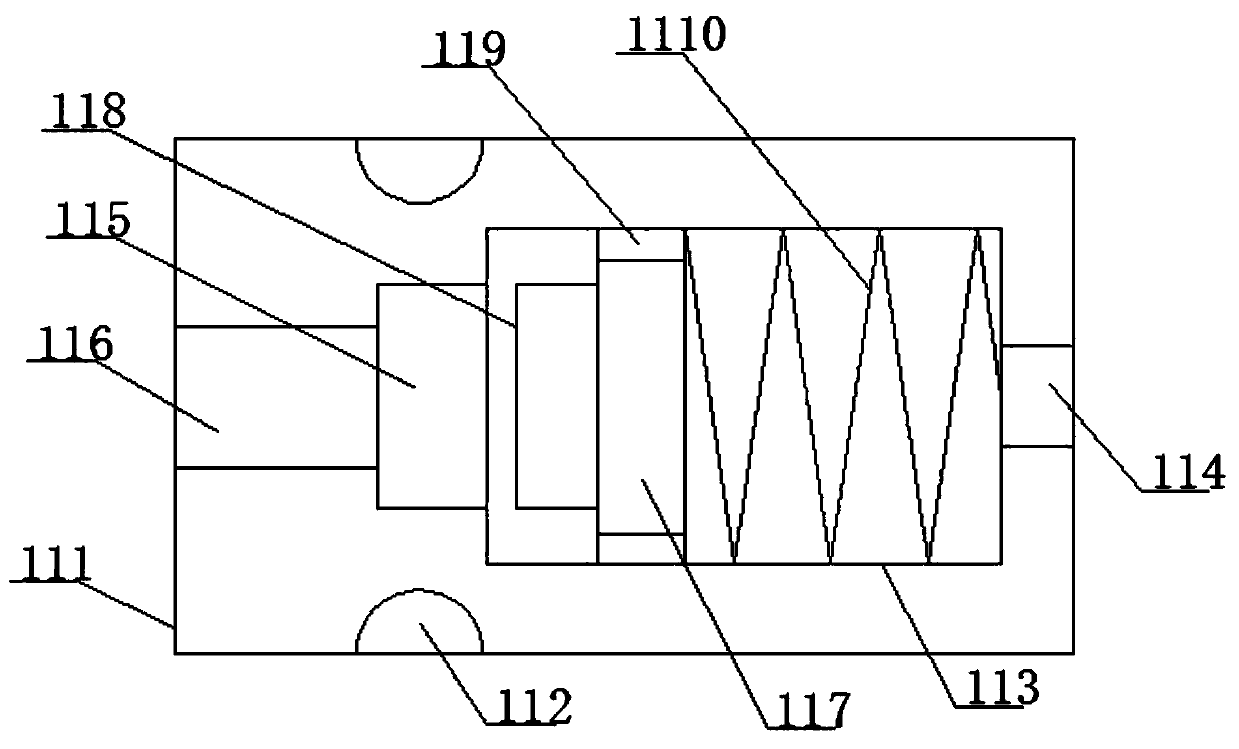

The invention discloses a yarn conveying and pulling mechanism, and belongs to the field of textile processing mechanical equipment. According to the yarn conveying and pulling mechanism, a yarn feeding mechanism, a pulling mechanism and a yarn guide mechanism are arranged on a fixing support in sequence in the horizontal direction. A lower yarn bearing guide roller is connected with the portion,located on the lower side of an upper yarn press guide roller, of the fixing support in a horizontal rotation mode. A shaping rotating drum is connected to the portion, located between a front yarn guide roller and a rear yarn guide roller, of the fixing support in a horizontal rotation mode, and a heat-conducting oil pipe is arranged at the shaft ends of the two sides of the shaping rotating drumin a communicating mode. Pulling guide plates are arranged in pulling guide grooves in a sliding mode in the circular arc direction, and the pulling guide grooves are formed in the two sides of the shaping rotating drum. One end of one pulling rotating roller and the same end of the other pulling rotating roller are connected to the pulling guide plates on the two sides of the fixing support in arotating mode correspondingly. A yarn discharging guide roller is connected to the portion, located on one side of an adjusting support, of the fixing support in a horizontal rotation mode. The yarnconveying and pulling mechanism is reasonable in structural design, can efficiently and accurately convey yarn, and can conduct stable pulling shaping on the yarn section by section in the conveying process, the degree of automation of yarn processing is improved, and the requirements of production and usage are met.

Owner:嘉兴市华益股份有限公司

Multi-rotor unmanned aerial vehicle

The invention discloses a multi-rotor unmanned aerial vehicle, which belongs to the technical field of unmanned aerial vehicle. The multi-rotor unmanned aerial vehicle includes a fuselage, first rotors, rotor shafts, rotating connecting pieces, folding assemblies and a sliding assembly. Each rotating connecting piece comprises a first motor and a first dismounting screw thread group; and the first rotor is detachably connected to the first motor through the first dismounting screw group, so that the installation or dismounting between the first rotor and the first motor can be realized by rotating the first rotor. The multi-rotor unmanned aerial vehicle has the characteristics of fastness, convenience and high working efficiency.

Owner:EWATT TECH CO LTD

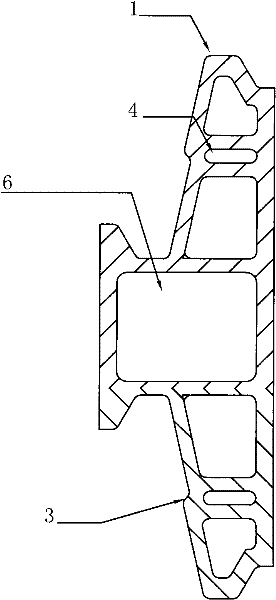

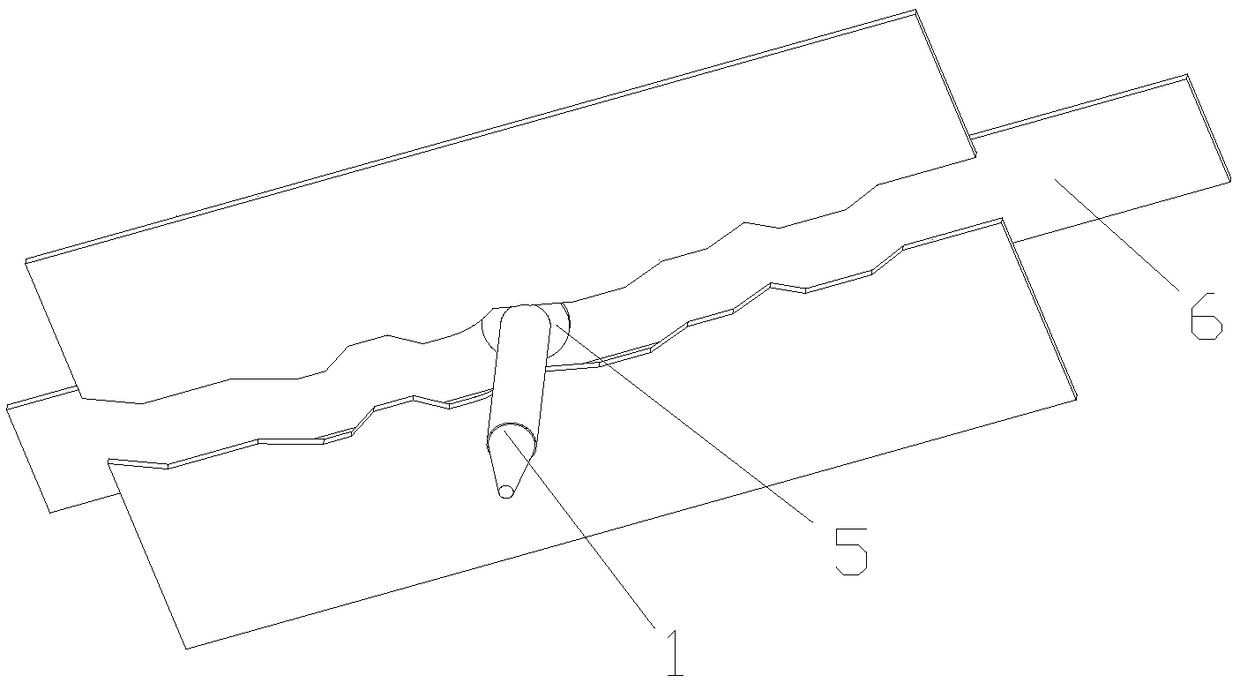

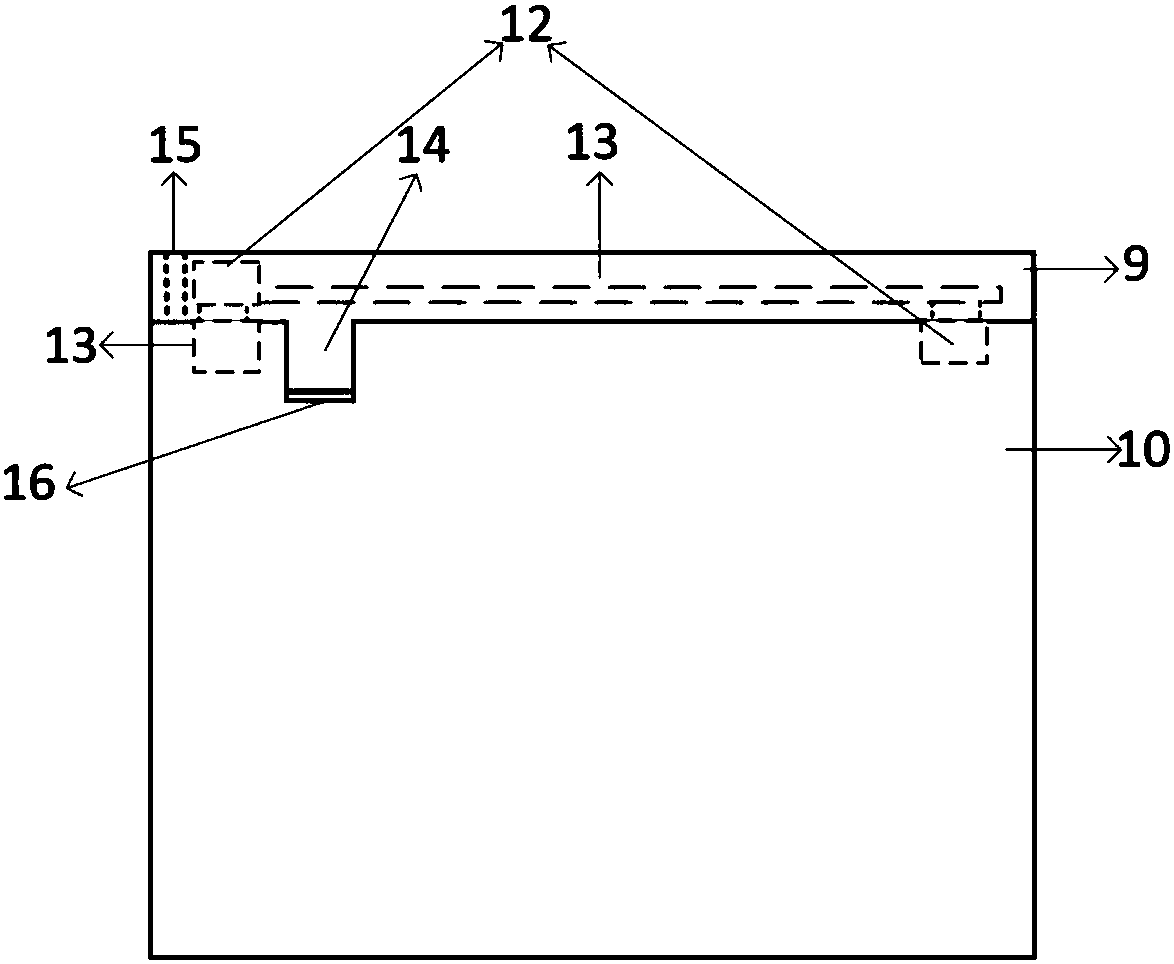

Precision building template system

ActiveCN102330493AImprove bindingAchieve matingAuxillary members of forms/shuttering/falseworksForming/stuttering elementsSlurryEngineering

The invention discloses a spliceable precision building template system which is provided with two panels and reinforced ribs for connecting the two panels, wherein connecting heads (9) are formed on the splicing sides spliced with adjacent templates; seen from the cross section of the template, each connecting head (9) comprises a chuck (1) protruding towards the adjacent template, a clamping groove (2) and a connecting mechanism (4); the clamping groove (2) is inwards concaved relative to the protruding direction of the chuck (1); the connecting heads (9) of the adjacent templates are combined together by using the connecting mechanism (4); and the chuck (1) is suitably embedded into the clamping groove (2); and outer surfaces of the panels at two sides of the adjacent templates are positioned on the same plane at the same side. The building template with the structure can be freely spliced; after splicing, a joint is tight and favorable integrity is achieved; and after grouting, the probability of slurry leakage is low.

Owner:王亚运

Anti-scouring concrete repairing device

ActiveCN109016145ARealize quantitative stirring and mixingReduce generationDischarging apparatusBuilding repairsEngineeringSlurry

The invention discloses an anti-scouring concrete repairing device. The anti-scouring concrete repairing device comprises a mixing and stirring device and a slurry supplement pipe. The mixing and stirring device is used for stirring concrete slurry, and the concrete slurry is injected into concrete cracks through the slurry supplement pipe. The anti-scouring concrete repairing device is characterized in that the mixing and stirring device can cyclically work to prepare materials first and then to discharge the materials, and a plurality of pipelines arranged between the mixing and stirring device and the slurry supplement pipe. The anti-scouring concrete repairing device has the advantages that the cracks are fully filled, the probability of slurry leakage is lowered, the surface flatnessis high after reinforcement, and a grouting pipe can slide in the cracks to achieve slurry supplement; the mounting stability of a support is high, and a wall is not likely to be damaged, or the adhesion strength of a plate body is high; intermittent material supplement and quantitative stirring are conducted, so that raw material waste is reduced, the cracks are fully filled, the probability of slurry leakage is lowered, the surface flatness is high after reinforcement, the grouting pipe can slide in the cracks to achieve slurry supplementation; and the mounting stability of the support is high, and the wall is not likely to be damaged, or the adhesion strength of the plate body is high.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

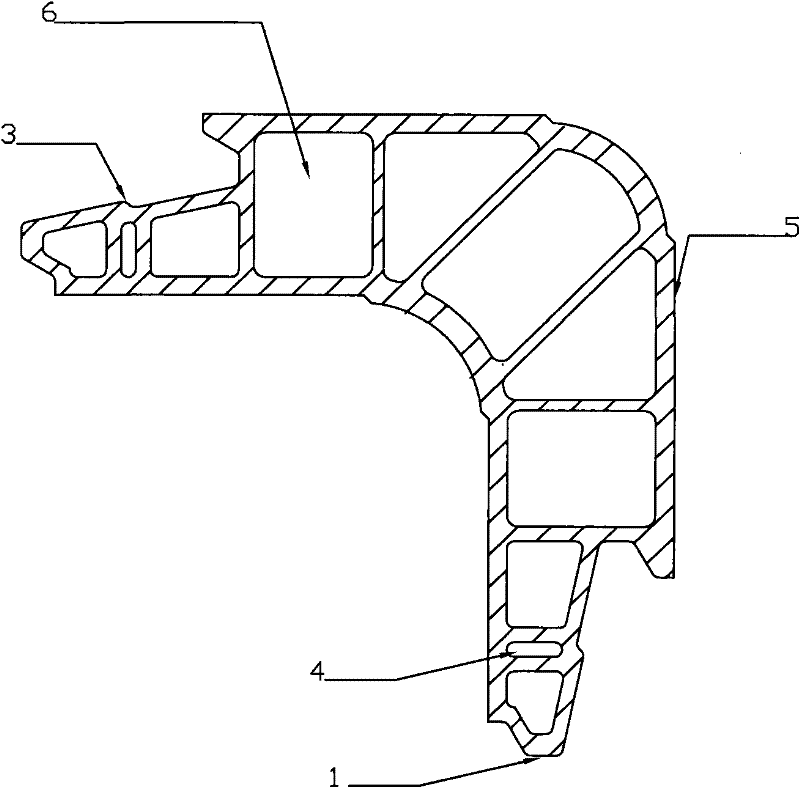

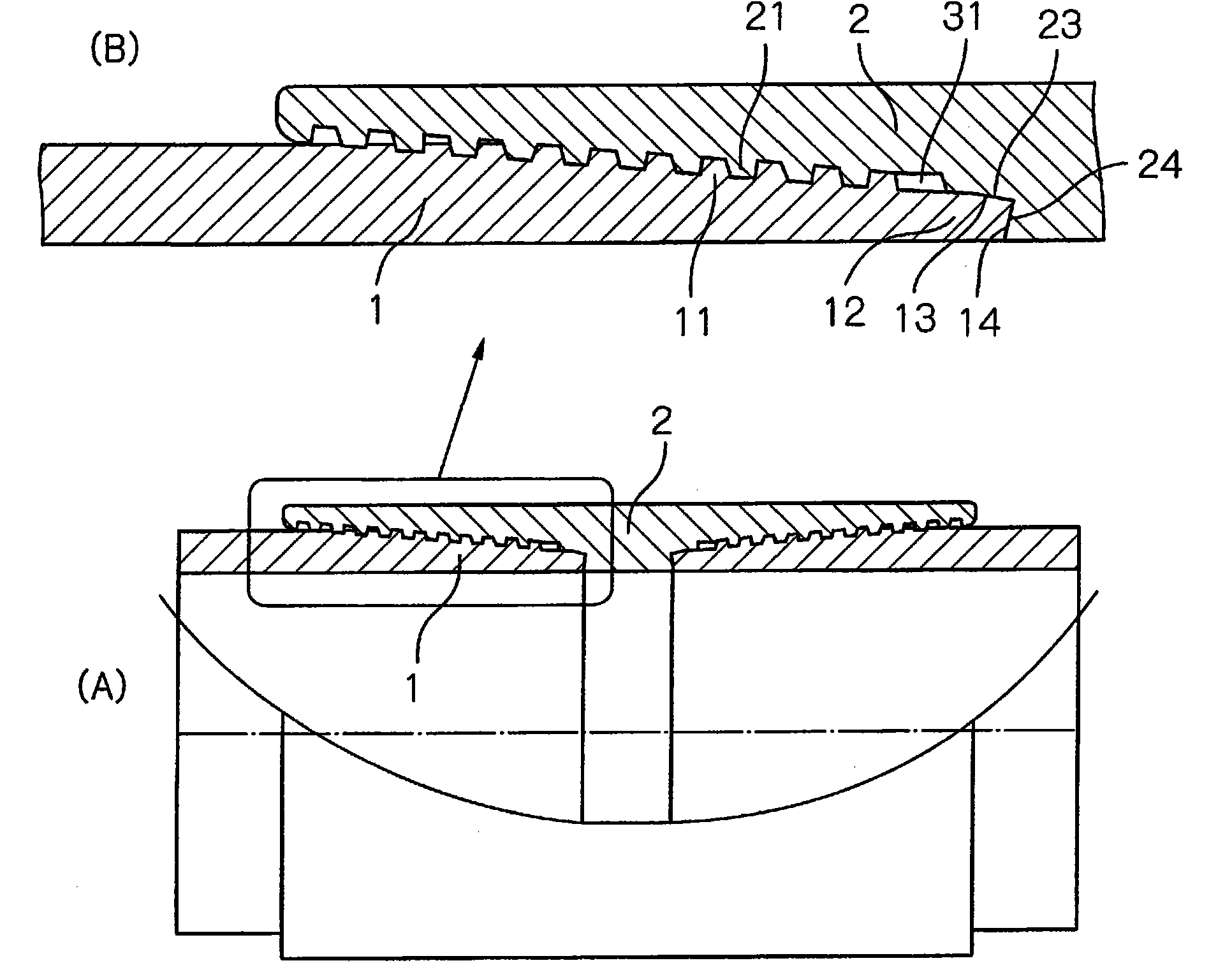

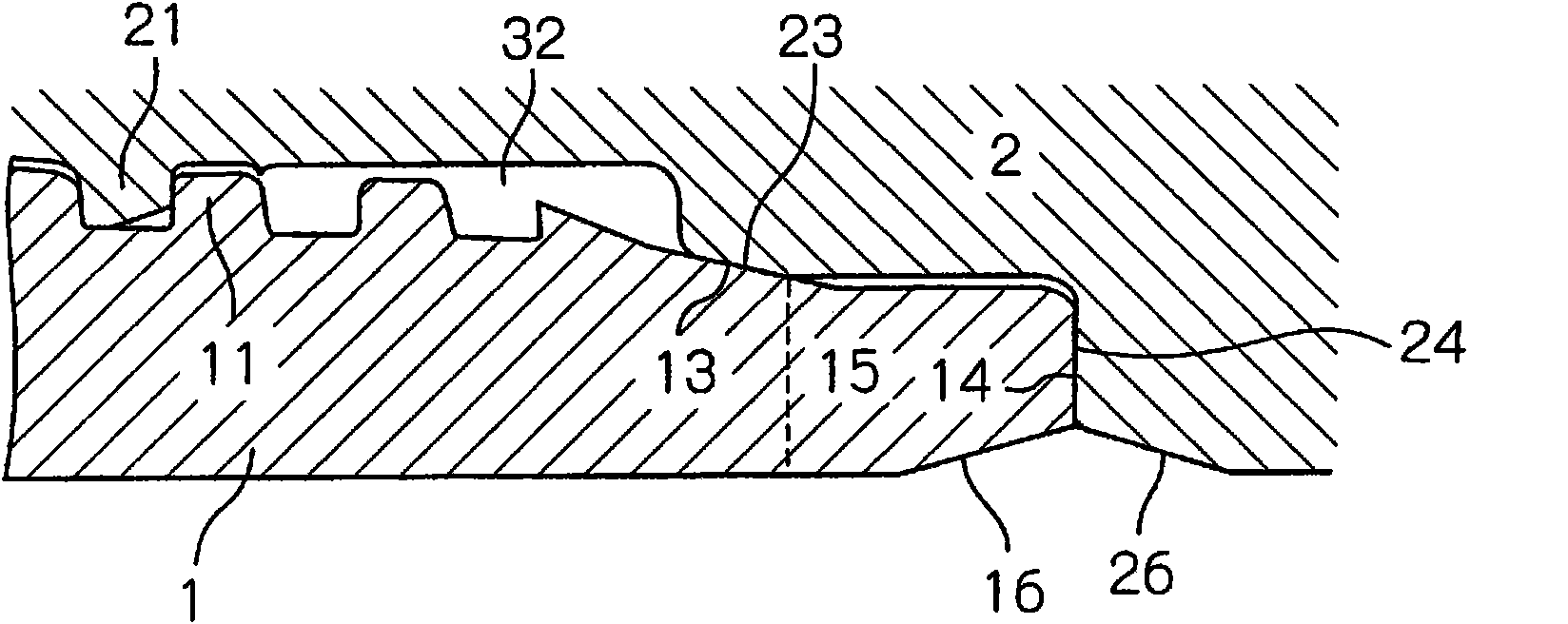

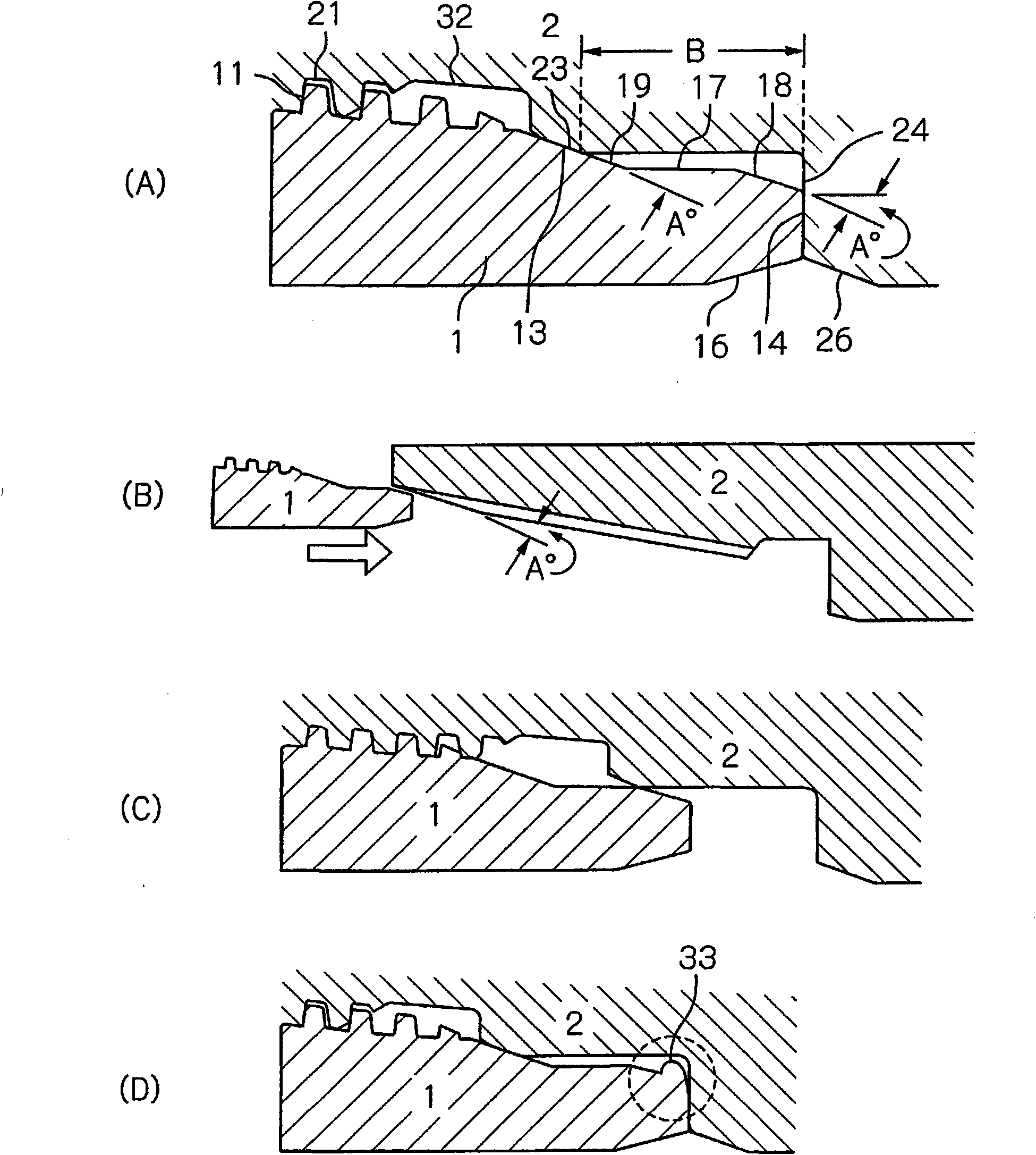

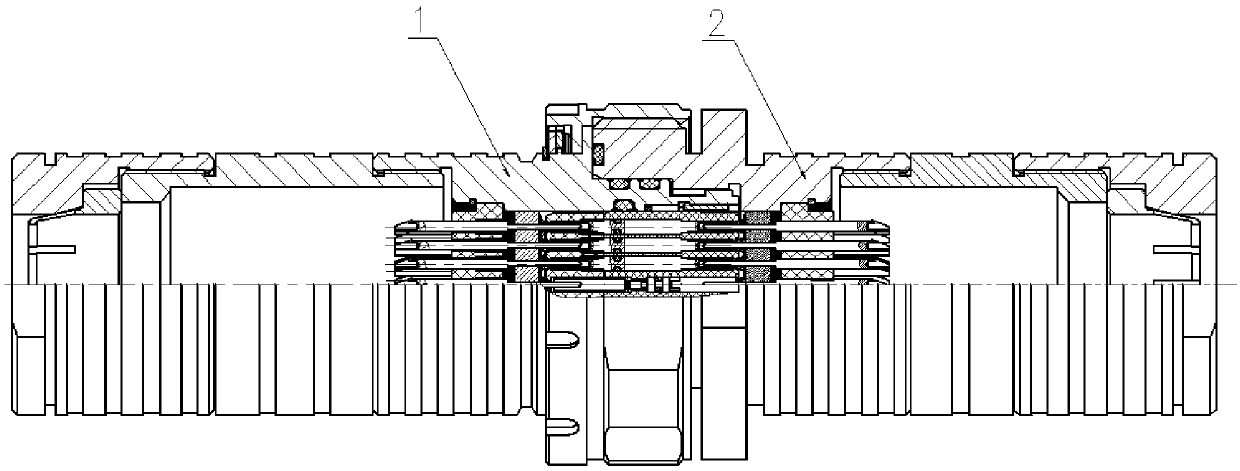

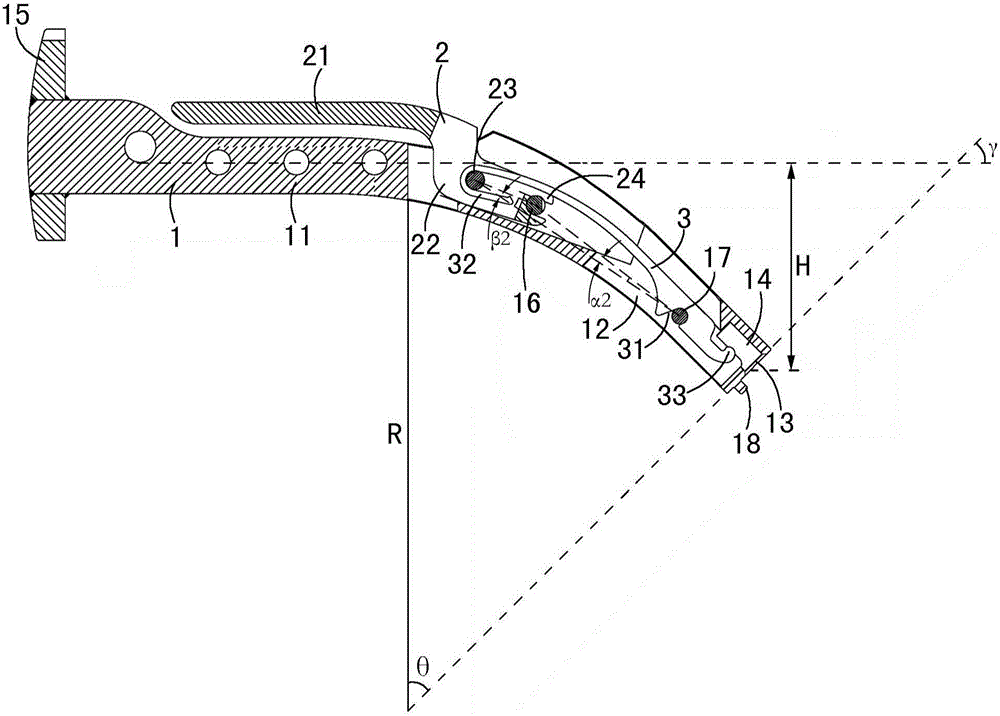

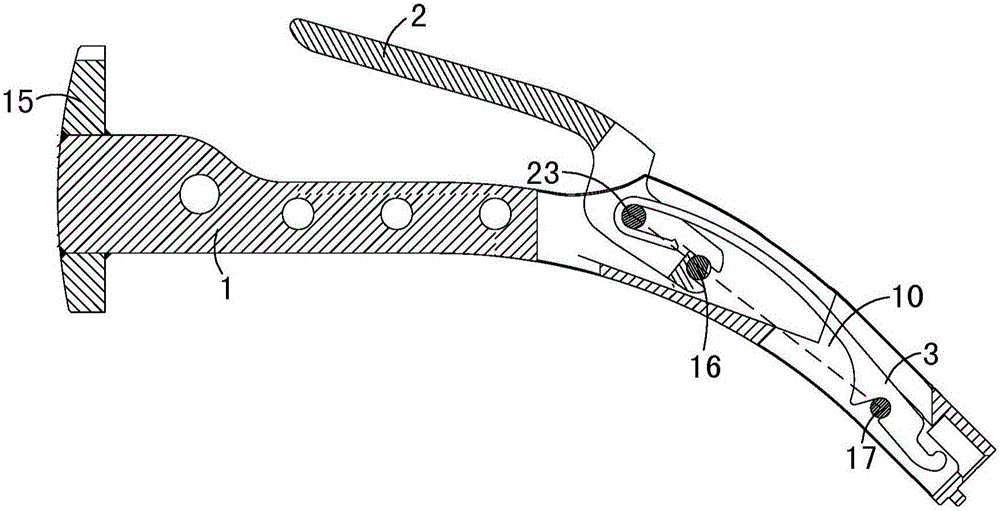

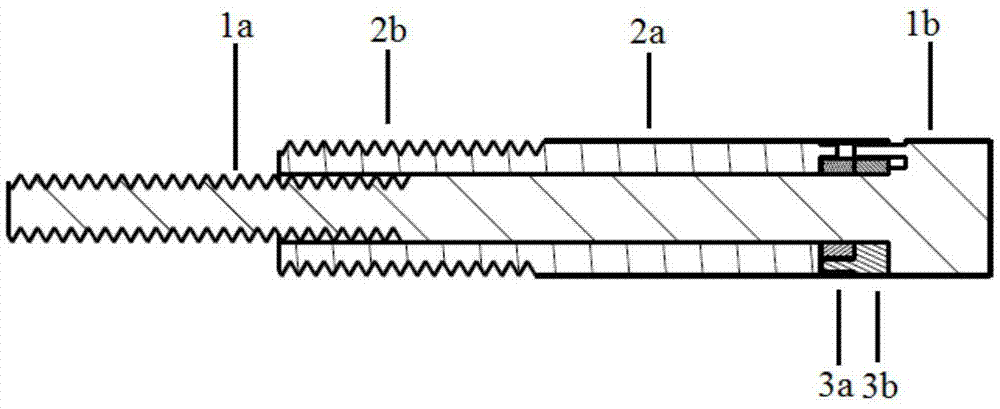

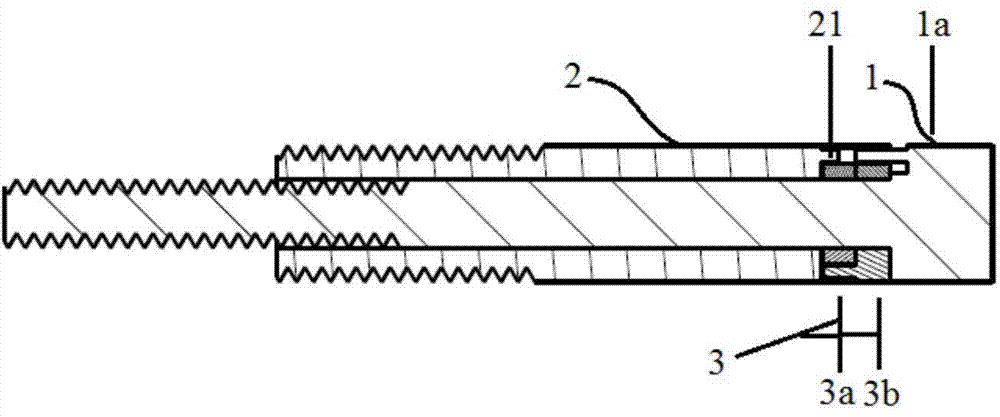

Screw-threaded joint for steel pipe

ActiveCN101883944AImprove rigidityImprove sealingDrilling rodsDrilling casingsEngineeringAir tightness

A screw-threaded joint for a steel pipe includes a pin (1) and a box (2). The pin (1) has a tapered male screw thread (11), a tapered seal surface (13), and an end shoulder surface (14), while the box (2) has, in a corresponding manner, a tapered female screw thread (21), a tapered seal surface (23), and a shoulder surface (24). The pin (1) and the box (2) can be easily fastened together, and the screw-threaded joint has improved tightness at seal surfaces. The pin and the box have a contactless region (B) between the seal surfaces (13, 23) and the shoulder surfaces (14, 24), and the peripheral surfaces of the pin and the box do not make contact with each other in the contactless region (B). At least that portion of pin which is in the contactless region and adjacent the front end of the pin is a tapered surface portion (18) having substantially the same inclination angle as the tapered seal surface (13). Also, that portion of the box which is in the contactless region is substantially a circular cylindrical surface.

Owner:NIPPON STEEL CORP +1

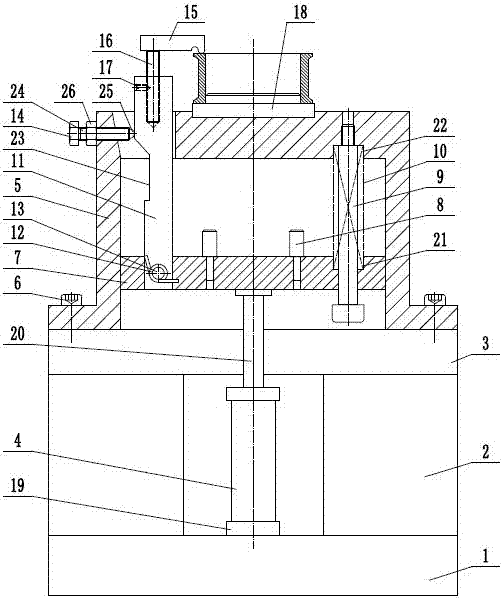

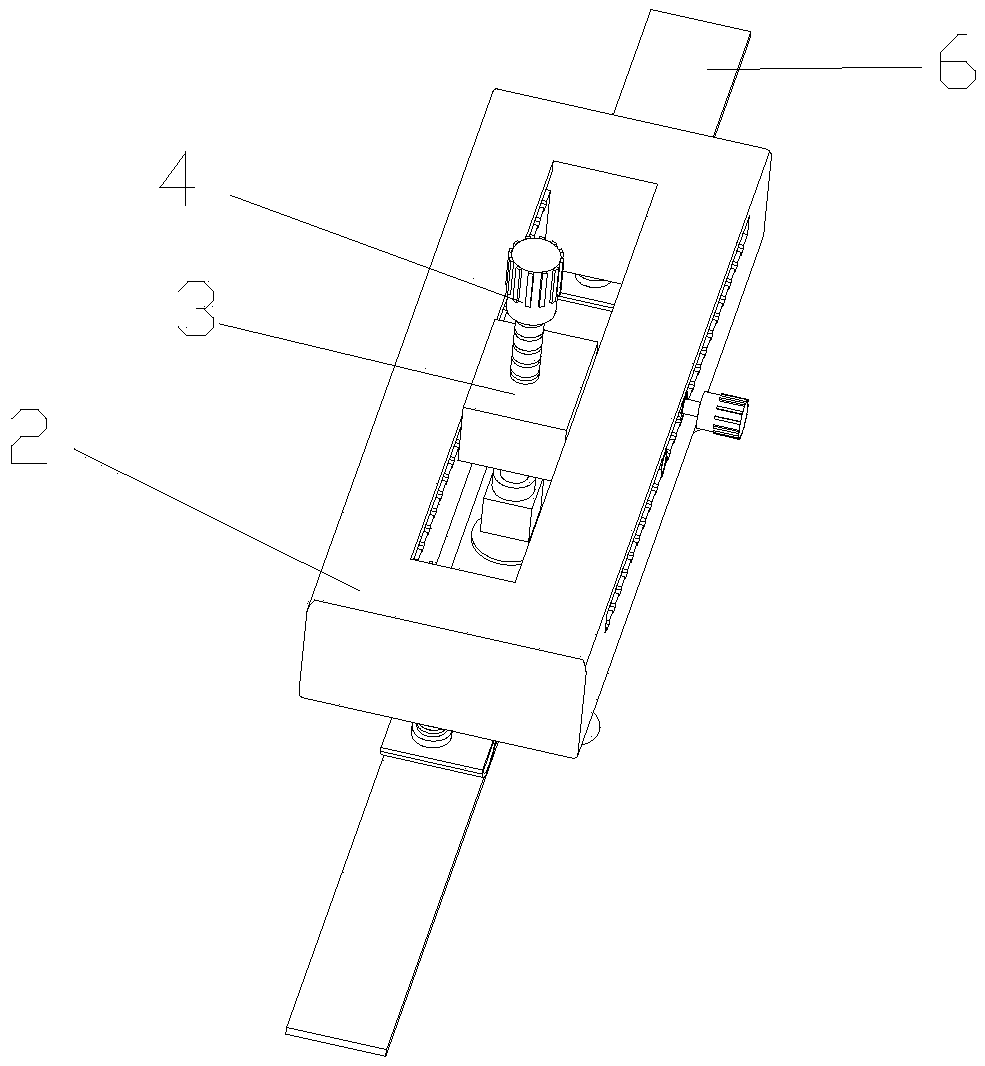

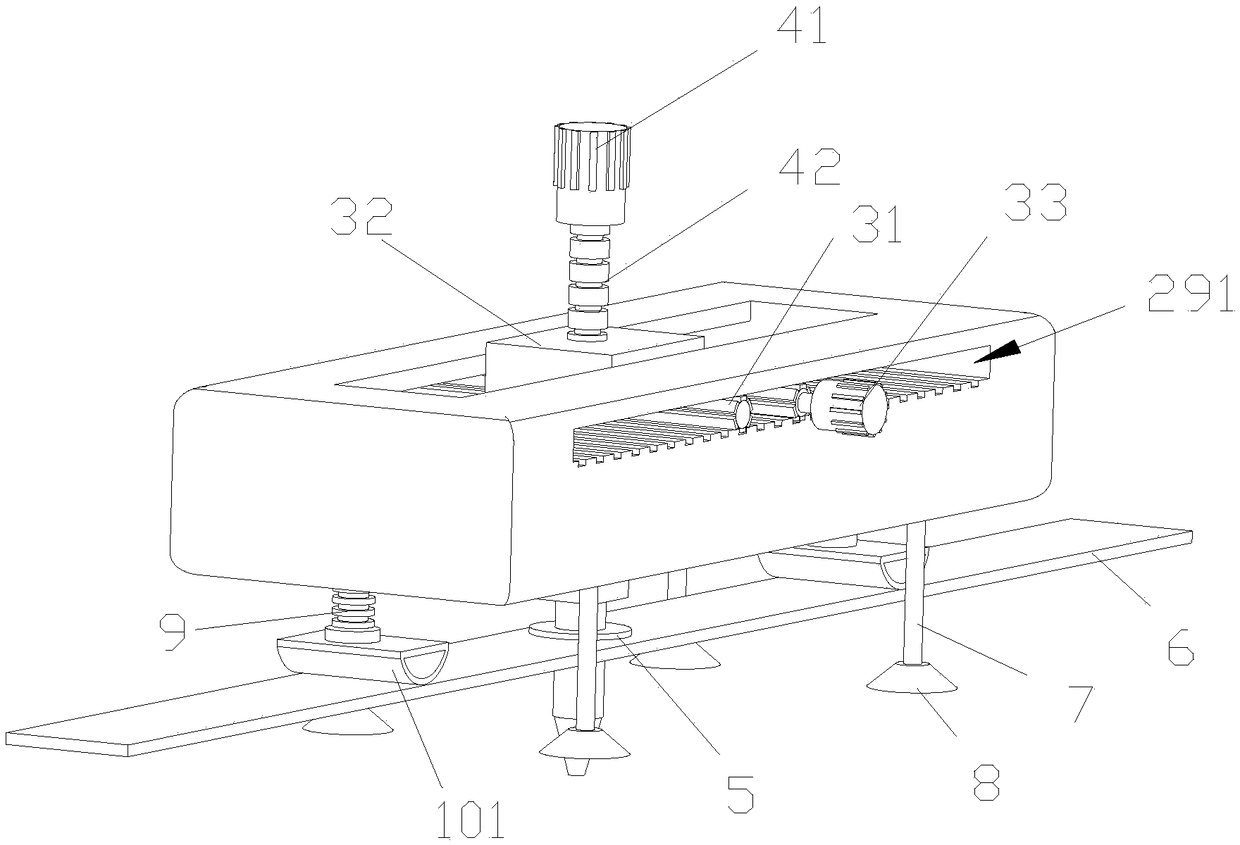

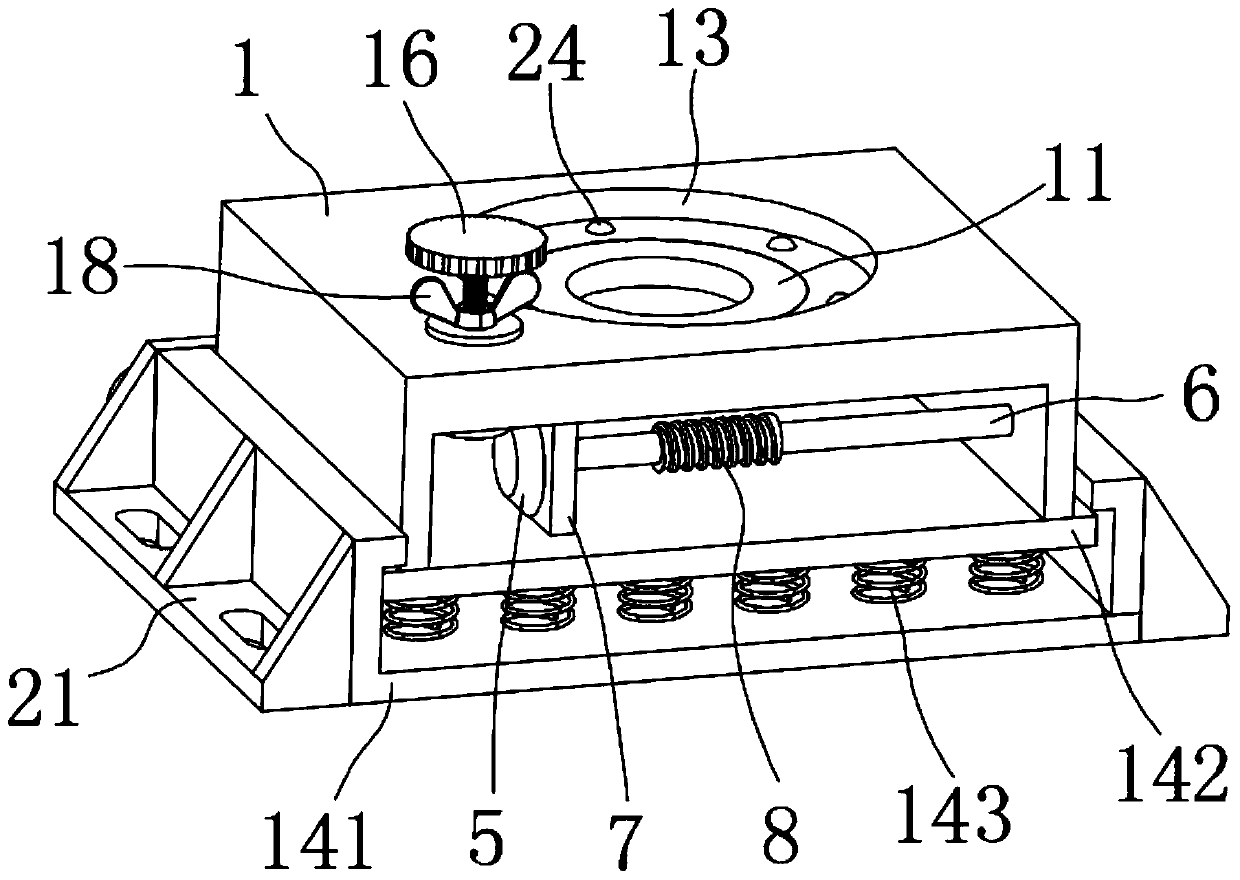

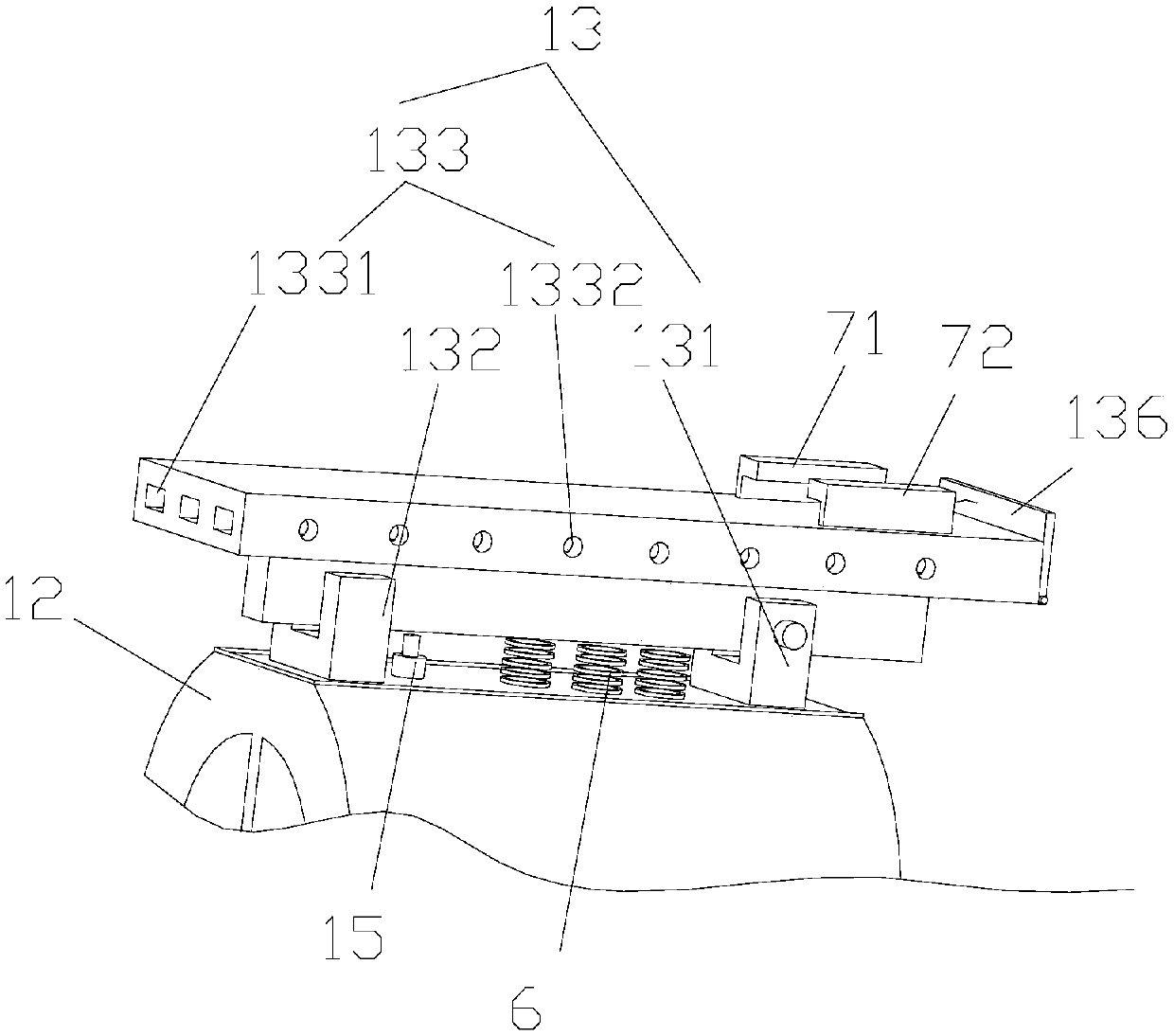

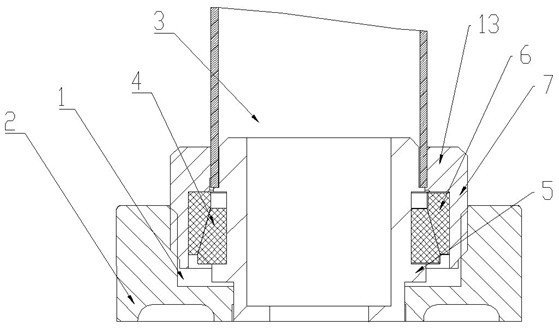

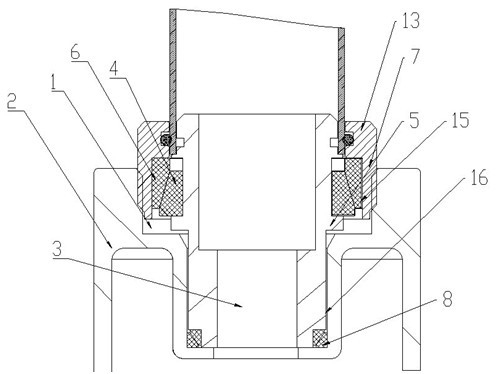

Hub clamping device

The invention provides a hub clamping device and belongs to the technical field of automobile parts. The hub clamping device comprises support plates, guide rods, pull rods, a guide assembly and clamping jaws. The three guide rods are uniformly arranged. The support plates are arranged on a bearing seat and the guide rods in an up-down sliding manner. The upper end of a compression spring is attached to an upper spring bearing groove. The lower end of the compression spring is attached to a lower spring bearing groove. The three pull rods are arranged and uniformly arranged. The pull rods and the guide rods are arranged in a staggered manner. The lower ends of the pull rods are hinged to the support plates through pull rod pin shafts. Torsional springs and the pull rod pin shafts are concentrically arranged. The lower ends of clamping jaw connecting rods are connected to the upper ends of the pull rods in a threaded manner. The clamping jaws are fixed to the upper ends of the clamping jaw connecting rods. Guide steel balls of the guide assembly are arranged on the right sides of guide bolts in a rolling manner. A hub centering bearing seat is mounted on the upper side of the bearing seat. The upper ends of the support plates are further provided with limiting pins. By the adoption of the hub clamping device, hubs can be centered and clamped quickly, the feeding and discharging space of the hubs is large, and feeding and discharging of the hubs are facilitated.

Owner:江苏优智享智能制造有限公司

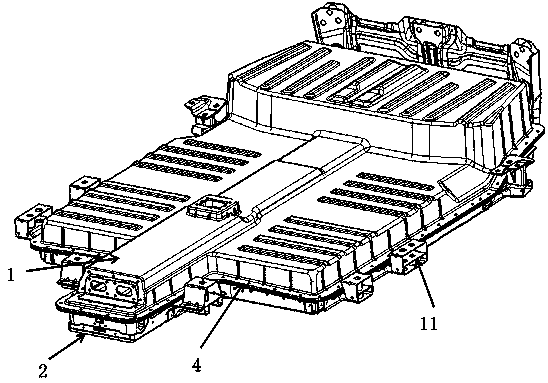

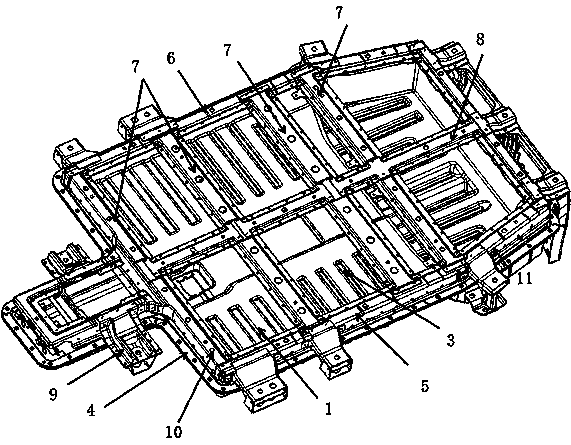

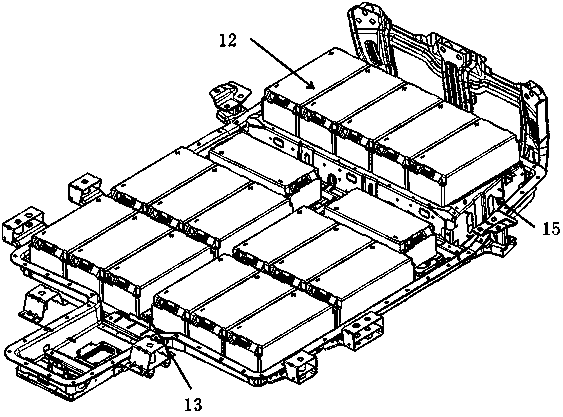

New energy vehicle battery pack assembly and new energy vehicle

ActiveCN108749548AReasonable structure layoutGood strength and rigidityElectric propulsion mountingCell component detailsAutomotive batteryElectrical battery

The invention relates to a new energy vehicle battery pack assembly and a new energy vehicle. The battery pack assembly comprises an upper housing, a lower housing and a battery module; the inner sidefaces of the upper and lower housings are provided with symmetric framework structures; battery modules are fixedly arranged in the framework structures of the inner side faces of the upper and lowerhousings. According to the new energy vehicle battery pack assembly and the new energy vehicle, the battery pack assembly is simple and compact in structure, high in safety performance, strong in loading capacity, convenient to the install and dismantle and high in universality, the fastening of the battery modules can be achieved, the requirements of the installation reliability of the battery modules are met to greatly improve the vibration resistance and anti-impacting performance of the battery modules and the battery pack assembly, the overall structure of the battery pack assembly is simple, the processing and the assembling are convenient and easy, the rigid strength is high, the battery pack assembly is easy to process and produce, the barycenter and stability of a vehicle body are not affected, and a light-weight designing concept is thoroughly presented.

Owner:CHERY AUTOMOBILE CO LTD

Automatic slurry filling device for concrete crack defect with high adhesion strength

The invention discloses an automatic slurry filling device for a concrete crack defect with high adhesion strength, which comprises a slurry filling pipe, wherein the concrete slurry is injected intothe concrete crack through the slurry filling pipe; and also comprises a machine frame, an electric sliding element, an electric lifting element, a rubber sleeve, a trowel, a first supporting rod, a first sucking disc, a second supporting rod and a abutted element; the electric sliding element is in sliding fit with the machine frame, the electric lifting element is arranged on the electric sliding element, the lifting end of the electric lifting element is connected with the slurry filling pipe, and the trowel is sleeved at the periphery of the slurry filling pipe through the rubber sleeve. The first sucking disc is arranged on the end part of the first supporting rod; the connecting end of the abutted element is slidably mounted on the end part of the second supporting rod, and the abutted end of the abutted element can be contacted with the trowel. The device has the advantages that the crack can be fully filled, the slurry leakage condition is reduced, the flatness of the surface after filling the slurry is high, the slurry filling pipe can achieve sliding and grouting in the crack, and the installation stability of a bracket is high, no damage is caused on a wall body or the adhesion strength of a plate body is high.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

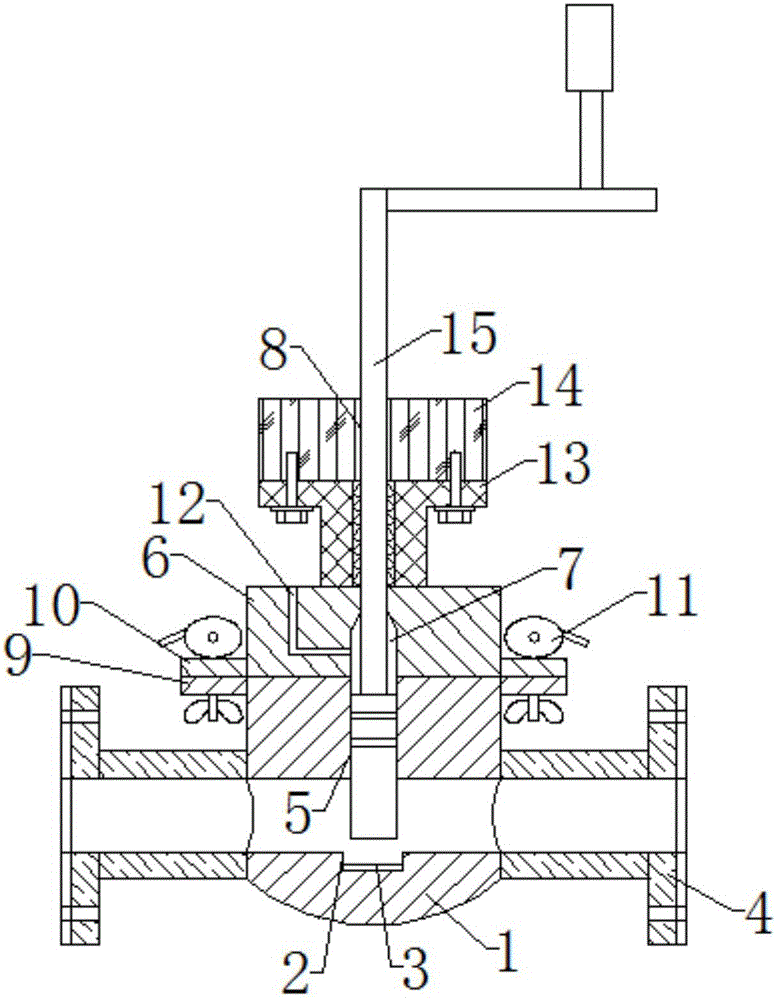

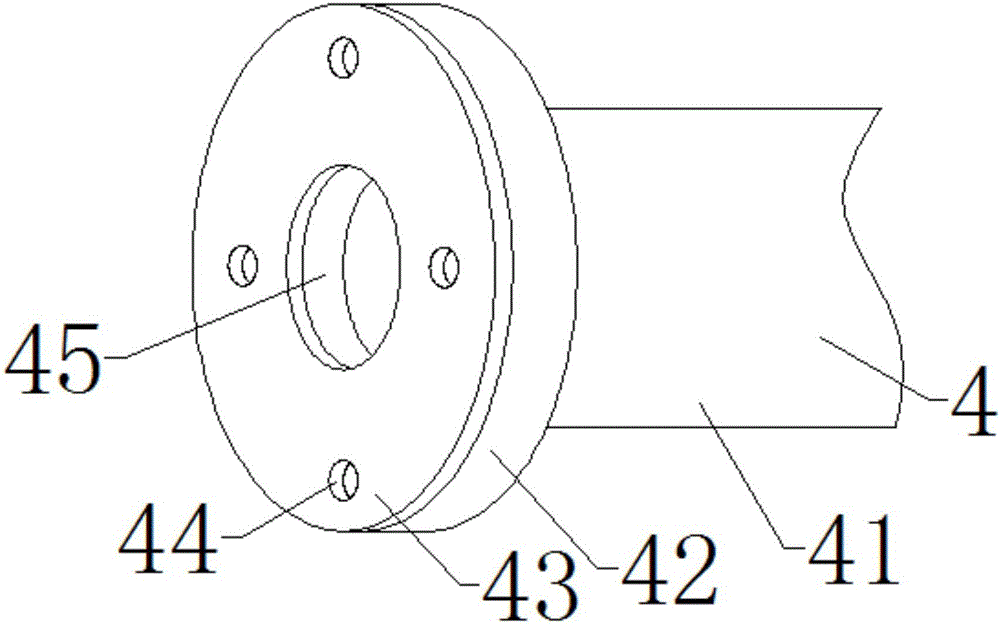

Connecting flange valve for water collecting pipe and concealed draining pipe

InactiveCN106321871AEasy to openEasy to getOperating means/releasing devices for valvesSlide valveFriction reductionEngineering

The invention discloses a connecting flange valve for a water collecting pipe and a concealed draining pipe in the technical field of valves. The connecting flange valve comprises a valve seat. A groove is formed in the bottom of an inner cavity of the valve seat. A rubber gasket is arranged on the inner wall of the groove. Flange plates are arranged on the left wall and the right wall of the valve seat correspondingly. A sliding groove is formed in the middle of the top of the valve seat and communicates with the inner cavity of the valve seat. According to the connecting flange valve for the water collecting pipe and the concealed draining pipe, the groove is formed in the bottom of the inner cavity of the valve seat, and the rubber gasket is arranged on the inner wall of the groove, so that the leakproofness during baffle closing is improved, and a water blocking effect is effectively achieved; due to the fact that a sliding cavity with the size the same as that of the sliding groove is formed in the bottom of a valve deck, due to the sliding cavity, a baffle can conveniently enter the sliding cavity when opened, and the inner cavity of the valve seat can be completely opened; and an oil hole is formed in the top of the valve deck, the right end of the oil hole communicates with the sliding cavity, lubricating oil can be injected from the oil hole when friction between the baffle and the sliding groove is relatively large, and therefore friction is reduced.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

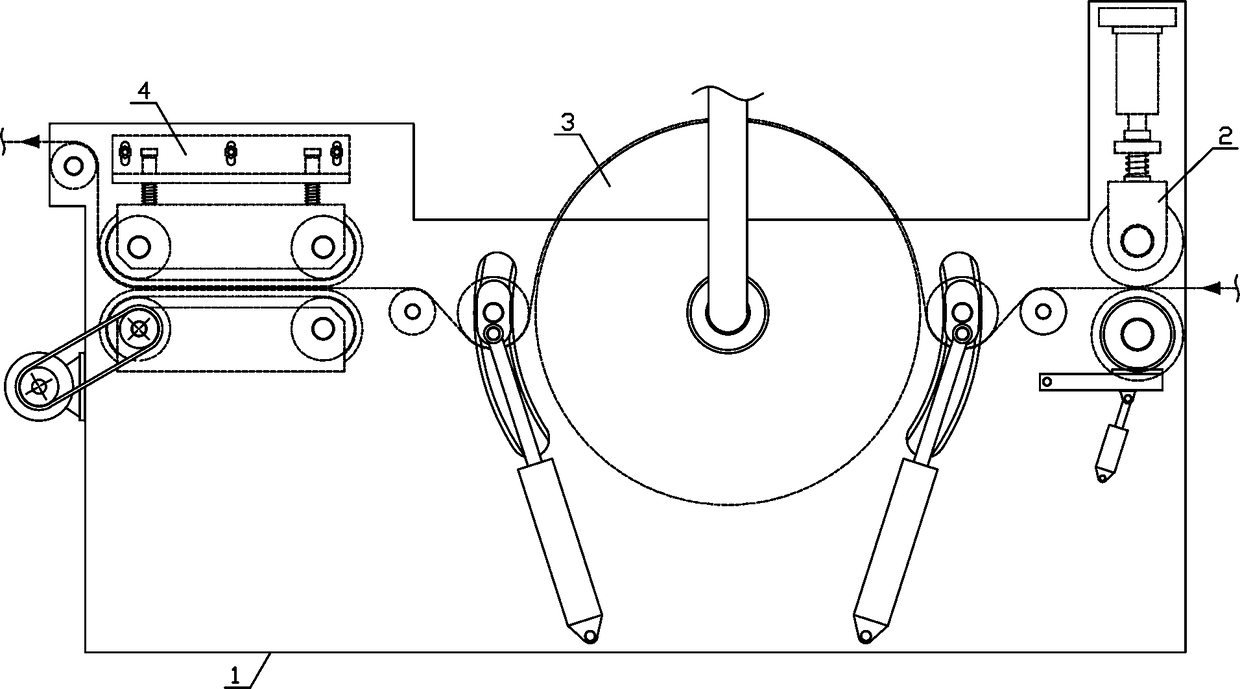

Double-welding-gun automatic heat pipe welder

ActiveCN104842043AEfficient weldingGuaranteed welding requirementsElectrode holder supportersHeat exchange apparatusDouble tubeMain branch

The invention discloses a double-welding-gun automatic heat pipe welder. The welder comprises a machine frame, an automatic double-pipe discharging device, an automatic double-pipe feeding device, a double-argon-arc-welding-gun adjusting device, an automatic double-pipe welding device and an automatic double-pipe falling device and a PLC, wherein an outer branch pipe sliding table and a rubber wheel sliding table of the automatic double-pipe feeding device are installed on two linear guide rails through a pair of sliding blocks arranged in parallel respectively, an auxiliary branch pipe fixing plate is arranged on one side of the outer branch pipe sliding table, and two rubber wheel side plates are arranged on the two sides of the rubber wheel sliding table respectively; multiple parallel V-shaped grooves are formed in two main branch pipe plates and three auxiliary branch pipe plates respectively in pairs, and the distance between two V-shaped grooves in each pair is equal to the distance between two material claw block clamping grooves. By the adoption of the welder, two heat pipes are welded at a time, the whole processes include conveying, feeding, welding and falling, two heat pipes are welded at the same time, efficient welding can be achieved, and various welding requirements can be met.

Owner:SOUTH CHINA UNIV OF TECH

New energy automobile engine mounting adjusting bracket convenient to adjust angle

InactiveCN109720187AAchieve regulationSimple structureJet propulsion mountingInternal combustion mountingNew energyAgricultural engineering

The invention discloses a new energy automobile engine mounting adjusting bracket convenient to adjust angle. The new energy automobile engine mounting adjusting bracket convenient to adjust angle comprises a mounting box; a first bearing is arranged at the top end of the mounting box; a first rotating shaft is fixed on the first bearing; a first bevel gear is fixed on the first rotating shaft; asecond bevel gear is connected to the first bevel gear in a transmission manner; the second bevel gear is fixed on a second rotating shaft; a worm is fixed in the middle of the second rotating shaft;a worm wheel is connected to one side of the worm in a transmission manner; the worm wheel is fixed on a connecting shaft; an engine mounting platform is fixed at the end part of one end, far away from the worm wheel, of the connecting shaft; the engine mounting platform is positioned in a groove; the groove is formed in the middle of the top end of the mounting box; and a shock absorbing mechanism is arranged at the lower end of the mounting box. Through adoption of the new energy automobile engine mounting adjusting bracket convenient to adjust angle, angle adjusting is realized during engine mounting, the structure is simple, the operation is easy, the adjusting is convenient, the angle adjusting accuracy is high, a shock absorbing effect on an engine is realized, and the service life is prolonged.

Owner:李程魏

Aluminium sectional material spraying system and spraying method thereof

ActiveCN107649325AScattered spatial locationAdd storage pointsPretreated surfacesCoatingsMaterials scienceAluminium

The invention discloses an aluminium sectional material spraying system which comprises a cleaning / oxidizing tank, a drying box and a spraying device, wherein the cleaning / oxidizing tank is used for carrying out cleaning and oxidizing treatment on the surface of aluminium sectional material; the drying box is used for drying the aluminium sectional material after cleaning and oxidizing treatment;the spraying device is used for spraying the dried aluminium sectional material; and the aluminium sectional material spraying system further comprises a rotating type conveying mechanism. The invention further discloses an aluminium sectional material spraying method by adopting the aluminium sectional material spraying system. The aluminium sectional material spraying system has the advantages of high cleaning efficiency and spraying uniformity.

Owner:奋安铝业股份有限公司

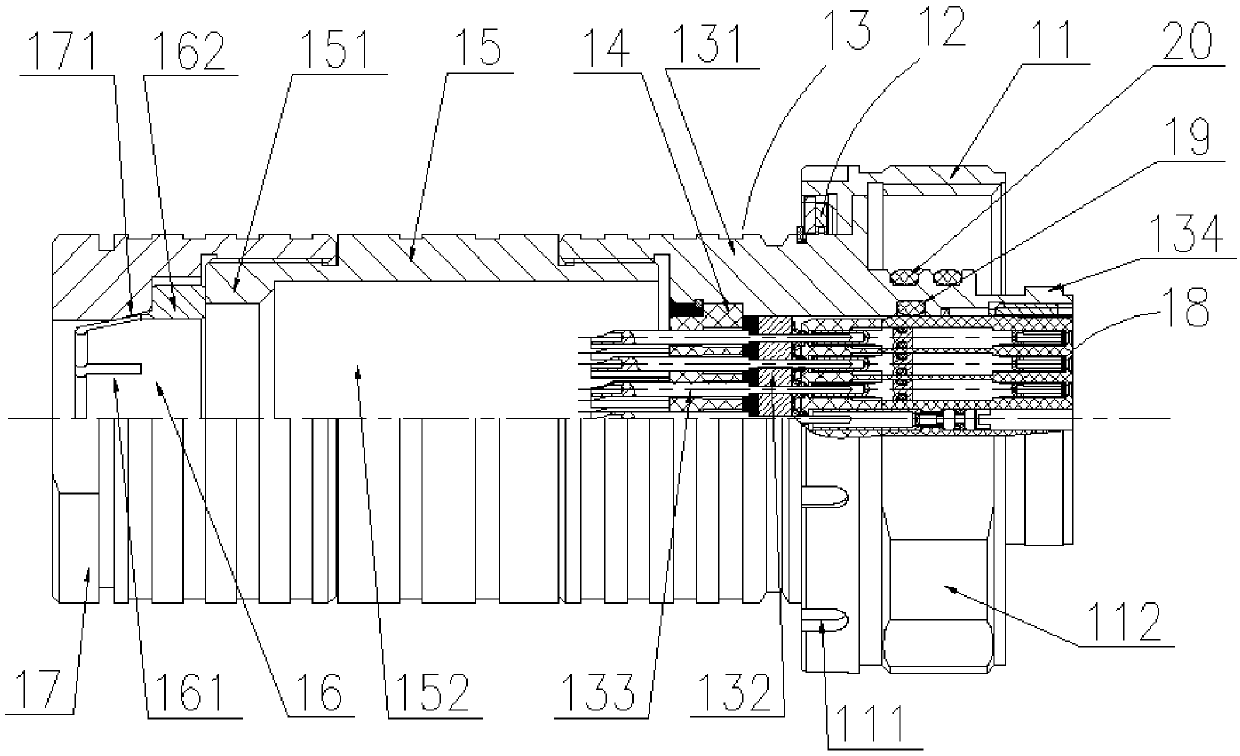

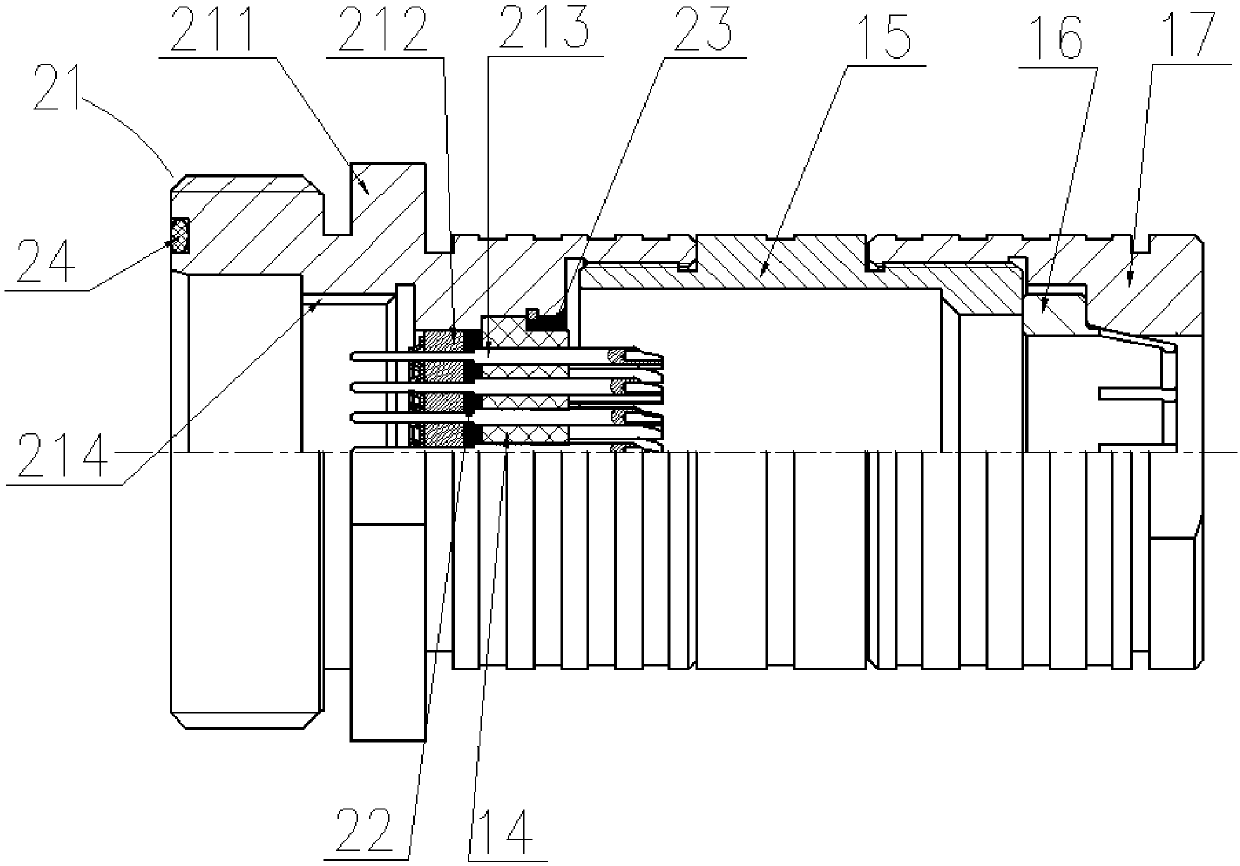

Circular underwater sealing electric connector capable of being plugged in blind manner

PendingCN109560420ASelf-sealingImprove maintainabilityEngagement/disengagement of coupling partsRelieving strain on wire connectionElectricityUnderwater

The invention relates to a circular underwater sealing electric connector capable of being plugged in a blind manner. The electric connector comprises a plug and a socket, wherein the plug comprises aconnecting nut, an anti-loose mechanism and a plug sealing-connecting assembly; and the socket comprises a socket sealing-connecting assembly. The circular underwater sealing electric connector capable of being plugged in the blind manner provided by the invention has the advantages that due to the fact that the plug and the socket are both sealed by sintering and forming a glass sintering layerand a contact part, and a sealing jack insulation assembly is arranged at the plugging end of the plug, so that the internal structure of the jack insulation assembly can realize self-sealing, and theoutside of the jack insulation assembly is sealed with the plug shell; when water enters the plugging end plane of the plug, the sealing structure of the jack insulation assembly plays an isolating role, so that short circuit in the plug caused by water entrance to the internal structure of the plug can be avoided; and after water entrance, the electric connector can be used as normal by only performing a simple operation on the plug, so that high product maintainability and high reliability are achieved, and the electric connector is suitable for application occasions with high-reliability sealing requirements.

Owner:杭州航天电子技术有限公司

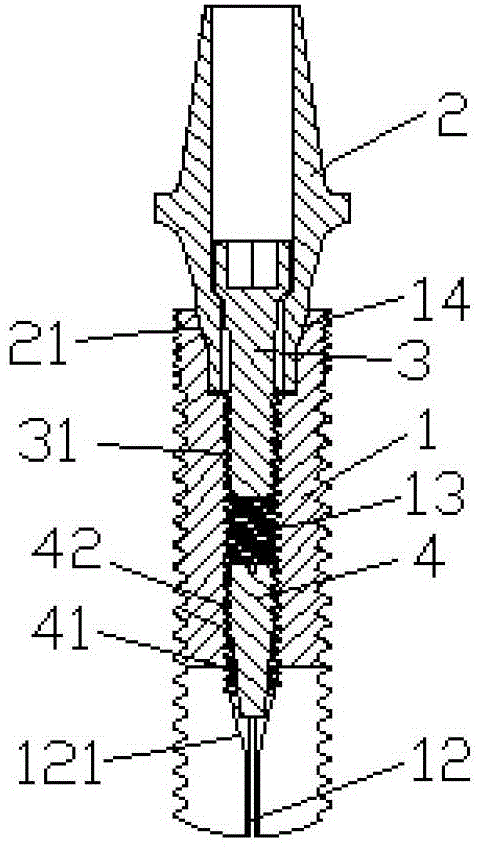

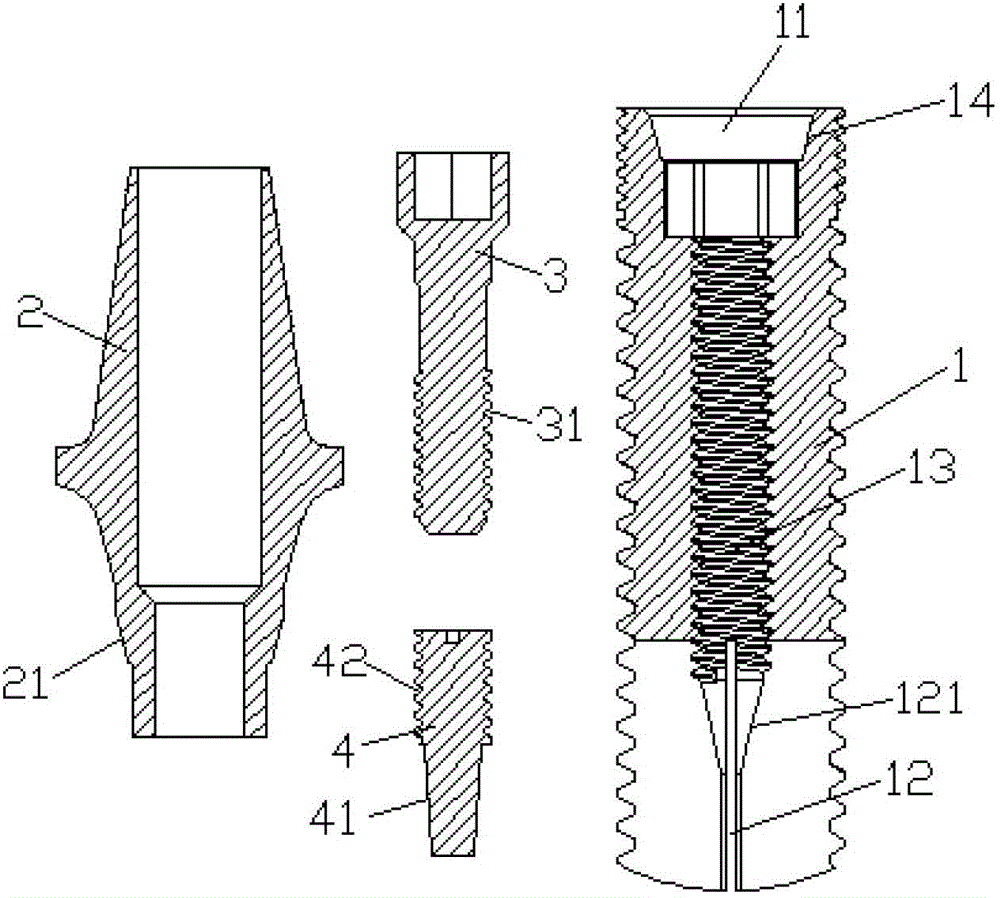

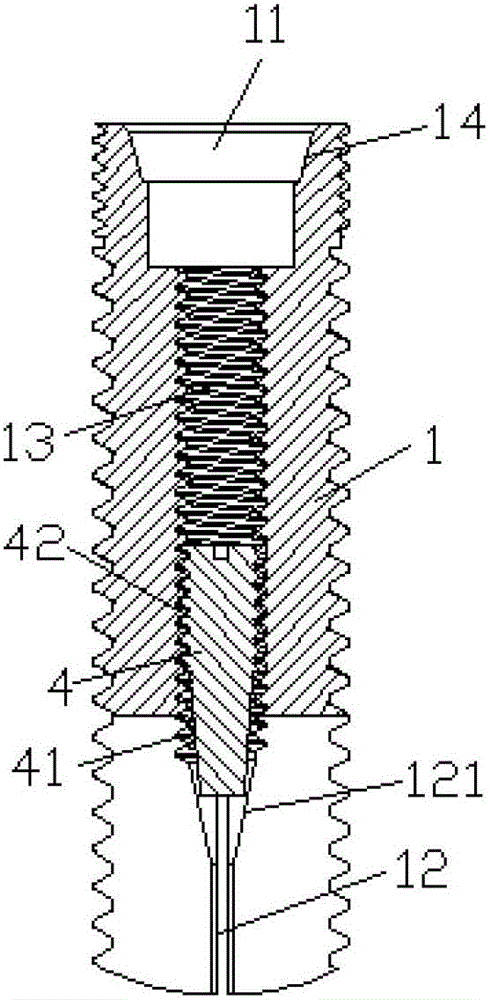

Two-section implant with spontaneous expansion function

InactiveCN104055590AImprove initial stabilityIncrease success rateDental implantsMissed toothTooth Supporting Structures

The invention discloses a two-section implant with a spontaneous expansion function. The two-section implant is applied to restoration of teeth in dental implanting surgeries. The two-section implant comprises an implant body, an abutment, a connecting screw and an expansion screw, wherein the implant body is connected with the abutment through the connecting screw and is provided with an opening and a notch groove; the expansion screw is screwed into the implant body from the opening, and a wedged slope is utilized for promoting the expansion of the notch groove to generate a tensile force so as to make fastened. The expansion screw with a thread and a taper is screwed into the implant body, and the wedged slope is utilized for promoting the expansion of the notch groove so as to generate the tensile force, so that a fastening effect is achieved, the early-stage stability of the dental implant is improved, and a missing tooth can be restored immediately; and when the appearance of the implant is in the shape of an imitation human tooth root, the damage on bones of patients can be more minimized to a greatest degree on the premise of ensuring the early-stage stability.

Owner:广东健齿生物科技有限公司

Thin-walled cylinder girth welding device

ActiveCN109822191ASmall amount of deformationAchieve fasteningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThin walled cylinder

The invention discloses a thin-walled cylinder girth welding device. The device comprises an arc welding machine, a grinding machine, an inner supporting tooling and an inner supporting lifting device. The arc welding machine and the grinding machine are arranged on the left and right sides of the inner supporting tooling correspondingly. The inner supporting tooling comprises a bottom platform, asupporting frame I and a plurality of supporting plates I uniformly distributed in the circumferential direction of the supporting frame I. The supporting plates I are connected with drivers I arranged on the supporting frame I and move synchronously in the radial direction under the effect of the drivers I, and one side surfaces of the supporting plates I are tightly attached to the inner wall surface of a cylinder section. The supporting frame I is arranged on a vertical lifting mechanism. The inner supporting lifting device comprises a supporting frame II and a plurality of supporting plates II uniformly distributed in the circumferential direction of the supporting frame II. The supporting plates II are connected with drivers II arranged on the supporting frame II and move synchronously in the radial direction under the effect of the drivers II, and one side surfaces of the supporting plates II are tightly attached to the inner wall surface of the cylinder section. By means of thethin-walled cylinder girth welding device, influences of the gravity factor on welding deformation can be eliminated, girth welding station automation can be achieved easily, and the assembling quality and efficiency are improved.

Owner:义乌市思淇工业设计有限公司

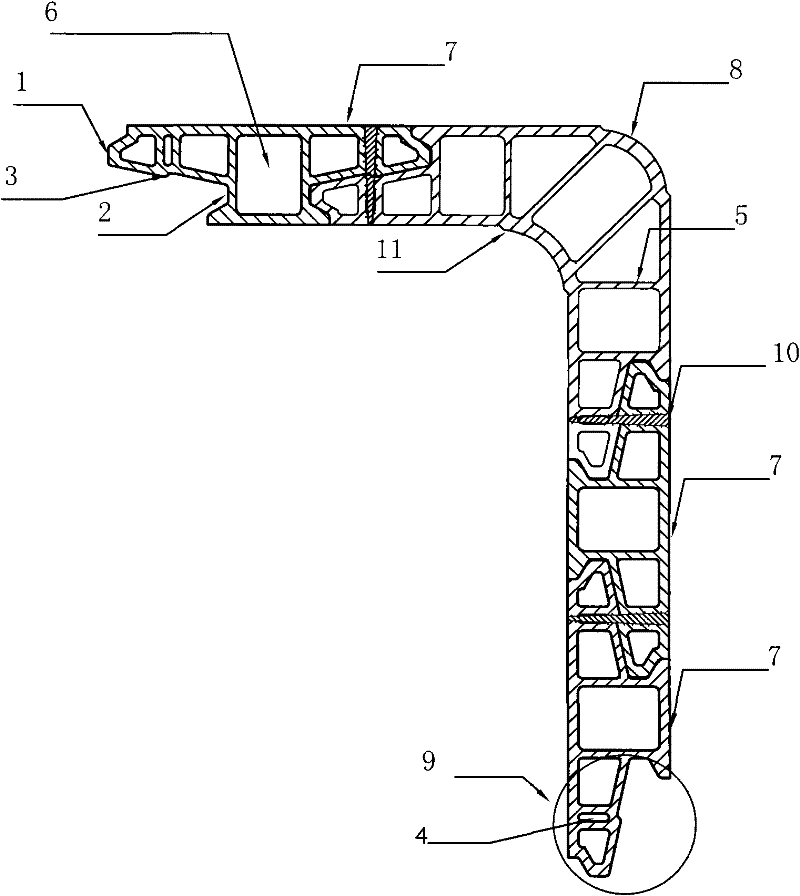

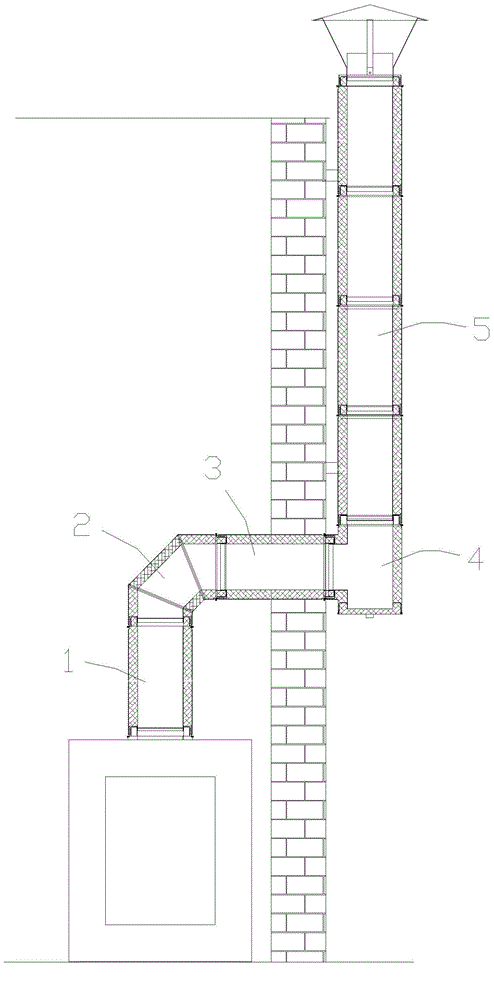

Spiral double-layer heat-preservation metal purging system

A spiral double-layer heat-preservation metal purging system, relates to the field of a chimney of a fireplace, and comprises an indoor vertical section, an indoor and outdoor communicating section and an outdoor vertical section; the indoor vertical section and the indoor and outdoor communicating section are connected by a 90-degrees one-way connector, the indoor and outdoor communicating section and the outdoor vertical section are connected by a 90-degrees two-way connector; the indoor vertical section, the indoor and outdoor communicating section and the outdoor vertical section all are connected by straight pipe connectors; entirely closed ring-shaped end closures are welded on the ends of all the straight pipe connectors, the 90-degrees one-way connector and the 90-degrees two-way connector; inner screws or outer screws are machined on the ring-shaped end closures; the connector of each section of the purging system is fastened by threaded tight connection. The purging system is simple in structure, the purging system is fastened by threaded tight connection, so the rain or steam is prevented completely from entering the heat-preservation cotton of the purging system, meanwhile, the mounting materials like hoops are saved, and the mounting efficiency is improved by more than three times than that of the purging system with hoops.

Owner:安徽沃木采暖科技有限公司

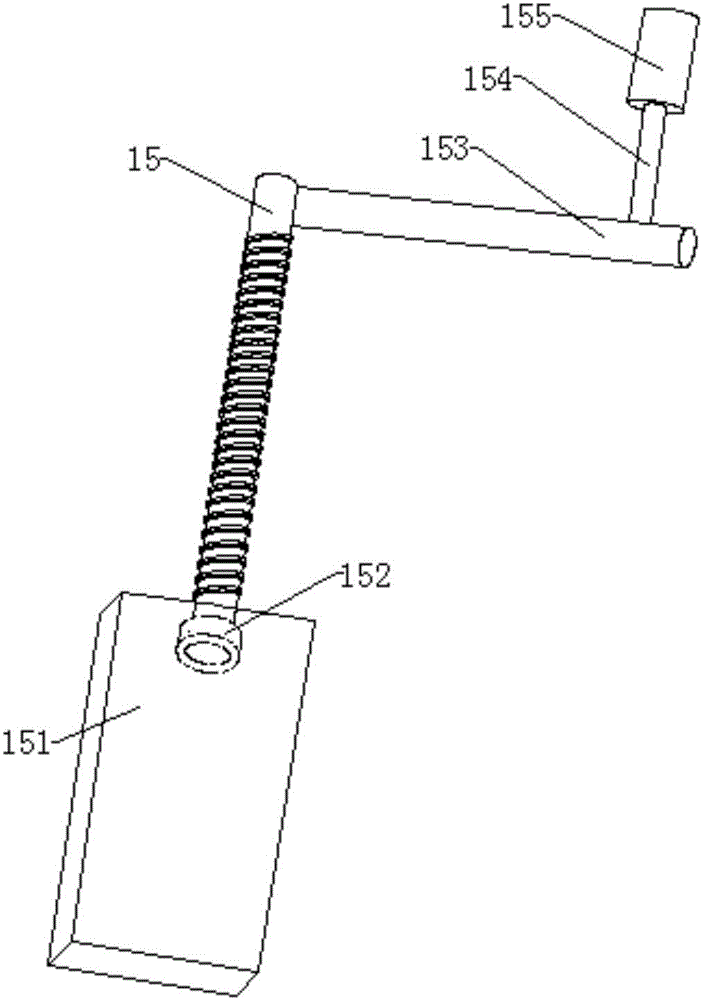

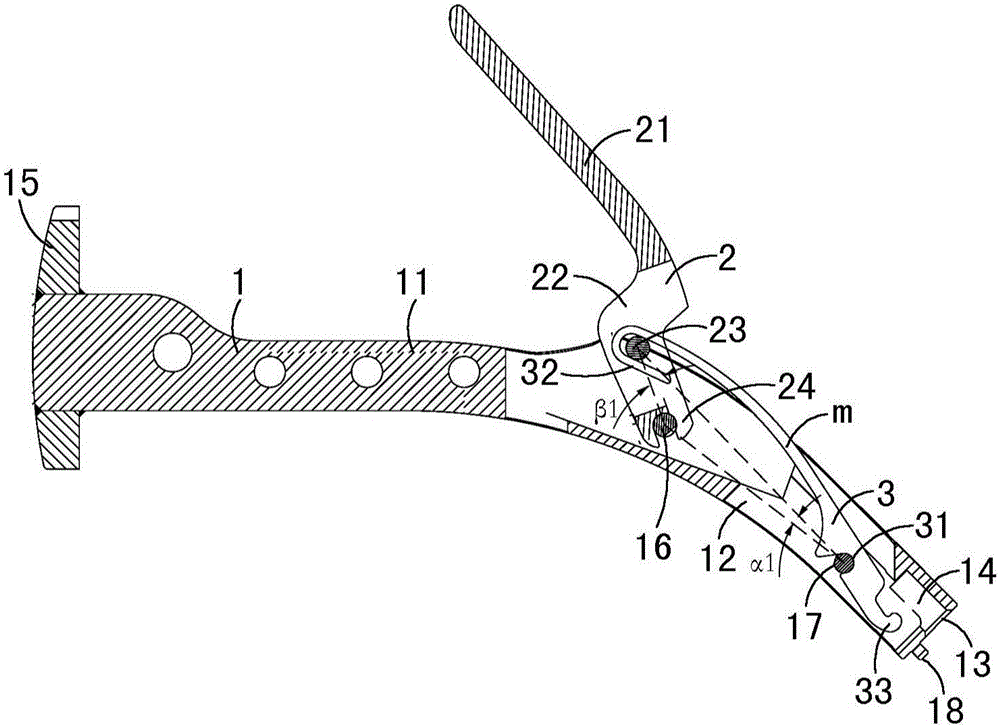

Medullary cavity file handle

ActiveCN106551735AAchieve fasteningEasy to splitSurgeryJoint implantsBone marrow cavityComputer science

The invention discloses a medullary cavity file handle. The medullary cavity file handle comprises a pedestal, a handgrip and a plate spring, wherein the pedestal comprises a front-segment matrix and a rear-segment matrix, and the front-segment matrix is provided with an operation cavity; the operation cavity is arranged to penetrate the front end surface of the front-segment matrix, and a medullary cavity file insertion groove is formed on the front end surface; the operation cavity is internally fixedly provided with a first shaft rod and a second shaft rod; one end of the handgrip is installed in the operation cavity and is in pivoted connection with the first shaft rod, the other end of the handgrip extends out of the operation cavity, and a third shaft rod is fixedly arranged on the handgrip; the plate spring is simultaneously in pivoted connection with the second shaft rod and the third shaft rod; and a locking structure is formed at the front end of the plate spring. According to the invention, the plate spring is drawn through the handgrip, the locking structure on the plate spring realizes fastening on a file, locking and separation are quite convenient, besides, the pedestal, the handgrip and the plate spring are conveniently split for disinfection and packaging, and the operation safety is improved.

Owner:BEIJING NATON TECH GRP CO LTD

Abrasion-proof rotation structure

The invention discloses an abrasion-proof rotation structure. The abrasion-proof rotation structure is provided with a tightening cap, wherein the tightening cap is provided with a thread suitable to be screwed into a screwed hole; an outer elastic gasket is arranged between the tightening cap and an inner elastic gasket; a contact surface between the outer elastic gasket and the inner elastic gasket is in force fit; the contact surface is gradually expanded along the direction of the tightening cap which is screwed into the screwed hole. When the abrasion-proof rotation structure is practically used and when a clearance between the inner elastic gasket and the outer elastic gasket or between the inner elastic gasket and a rotating shaft exists due to abrasion, the tightening cap is screwed up clockwise or anticlockwise along the direction of the thread on the outer wall of the tightening cap; the tightening cap is extruded to the direction of the front section of the rotating shaft along the thread; meanwhile, the outer elastic gasket downwards moves to extrude the inner elastic gasket so as to solve the problem that a fixing device in the prior art can not be normally used after abrasion.

Owner:GUANGZHOU SEAGULL KITCHEN & BATH PROD

Wind-driven type large-scale nut fastening device with controllable performance

ActiveCN110091163AAvoid damageTo achieve the twist effectMetal working apparatusWind drivenCoil spring

Owner:海盐瑞扬新材料股份有限公司

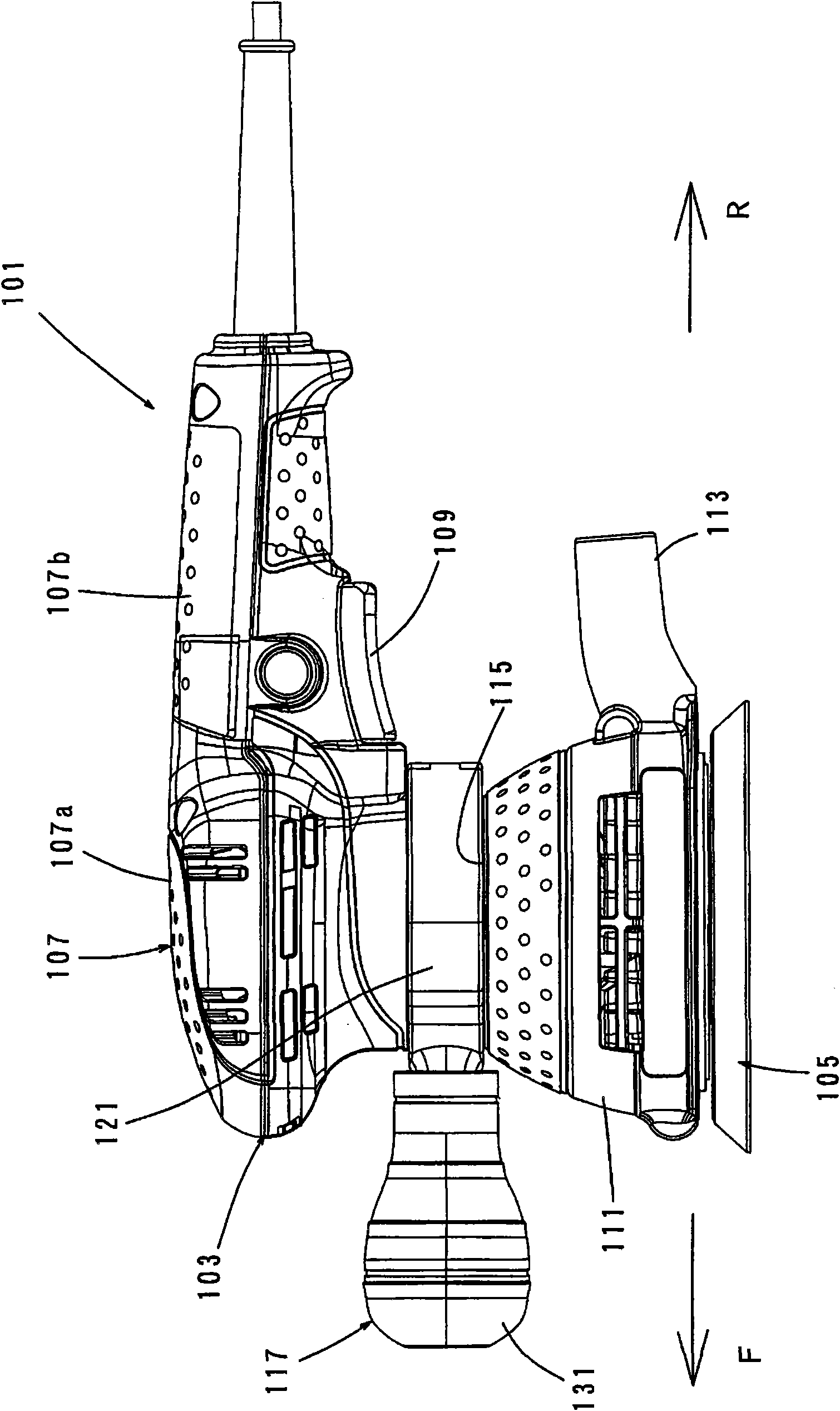

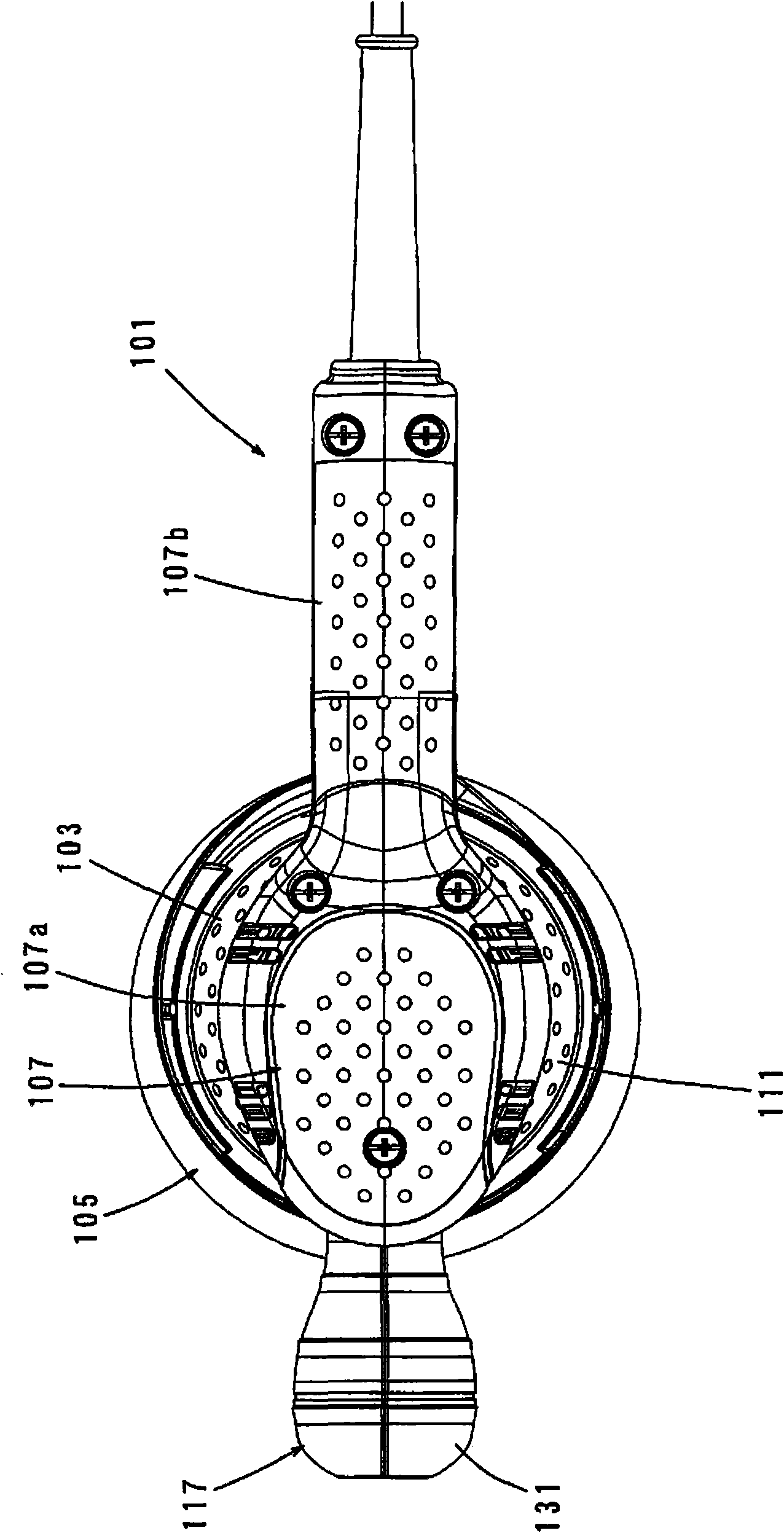

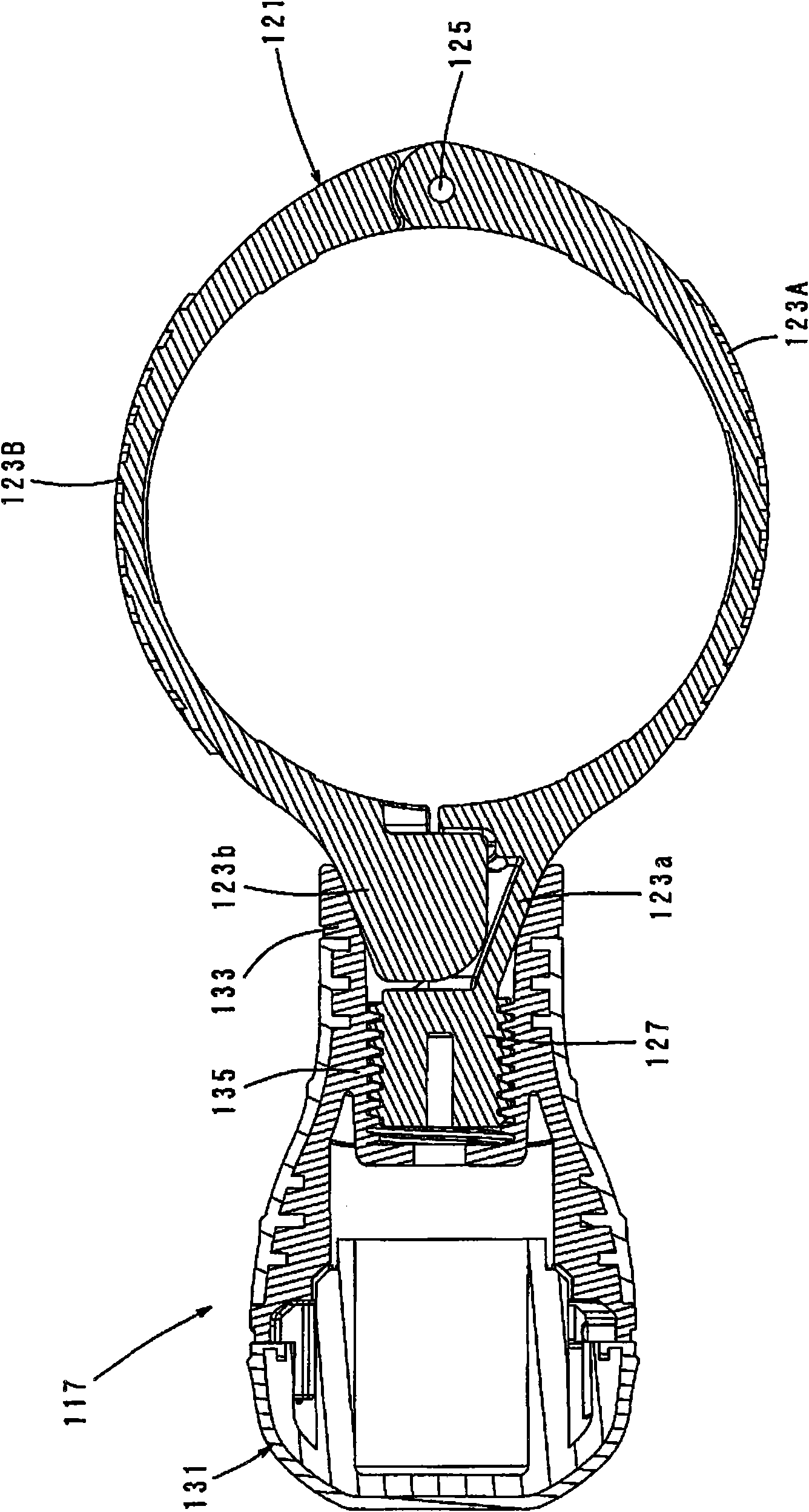

Sander

InactiveCN101941172AImprove work efficiencyEasy to transformGrinding machine componentsPortable grinding machinesSanderEngineering

It is an object of the invention to improve usability of a sander. The sander includes a rotary working surface (105), a driving mechanism that is disposed above the rotary working surface (105) in a direction of the rotation axis of the rotary working surface (105) and rotationally drives the rotary working surface (105), a cylindrical housing (103) that houses the driving mechanism, and a movable handle (117) that is mounted on a surface of a cylindrical part of the cylindrical housing (103). The movable handle (117) can be turned around the central axis of the cylindrical housing (103) and can be fixed at an arbitrary position in a circumferential direction of the cylindrical housing (103).

Owner:MAKITA CORP

Rotary type unfolding bolt fastener for single-side installation of component

InactiveCN104329351ARealize single-sided operationOptimize the extraction processScrewsScrew threadScrew cap

The invention discloses a rotary type unfolding bolt fastener for single-side installation of a component. The rotary type unfolding bolt fastener is provided with a screw rod and a sleeve cylinder, the end part of the screw rod is spaced with three convex rotary shafts at the intervals of 120 degrees, the sleeve cylinder is matched with the screw rod, and is spaced with three convex rotary shafts at the intervals of 120 degrees which are matched with rotary sheets, the tail section of the screw rod is provided with threads which are matched with a screw cap, the middle section of the screw rod is provided with a polished rod, and the front end of the screw rod is provided with a support head; the support head is spaced with the rotary shafts at the intervals of 120 degrees and the six rotary unfolding type rotary sheets in two layers, each layer is provided with three rotary sheets, and the rotary sheets are matched with the rotary shafts on the sleeve cylinder; when the rotary sheets are unfolded, the diameter of the support part of the part, protruding out of the sleeve cylinder, of each rotary sheet is greater than the outer diameter of the sleeve cylinder and the diameter of the tail part, so as to realize the support function; when the fastener is installed, the screwing of the screw cap is locked by an inner screw rod, so the six rotary sheets are unfolded, and the single-side tightening is realized. The rotary type unfolding bolt fastener has the advantages that the installation of a bolt is completed at one side, and the single-side operation of the bolt is completed.

Owner:SOUTHEAST UNIV

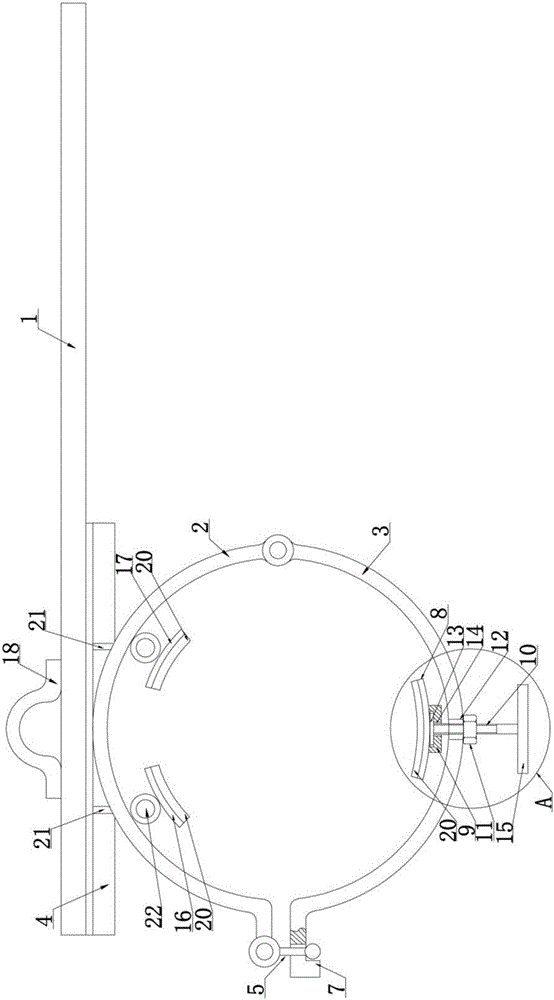

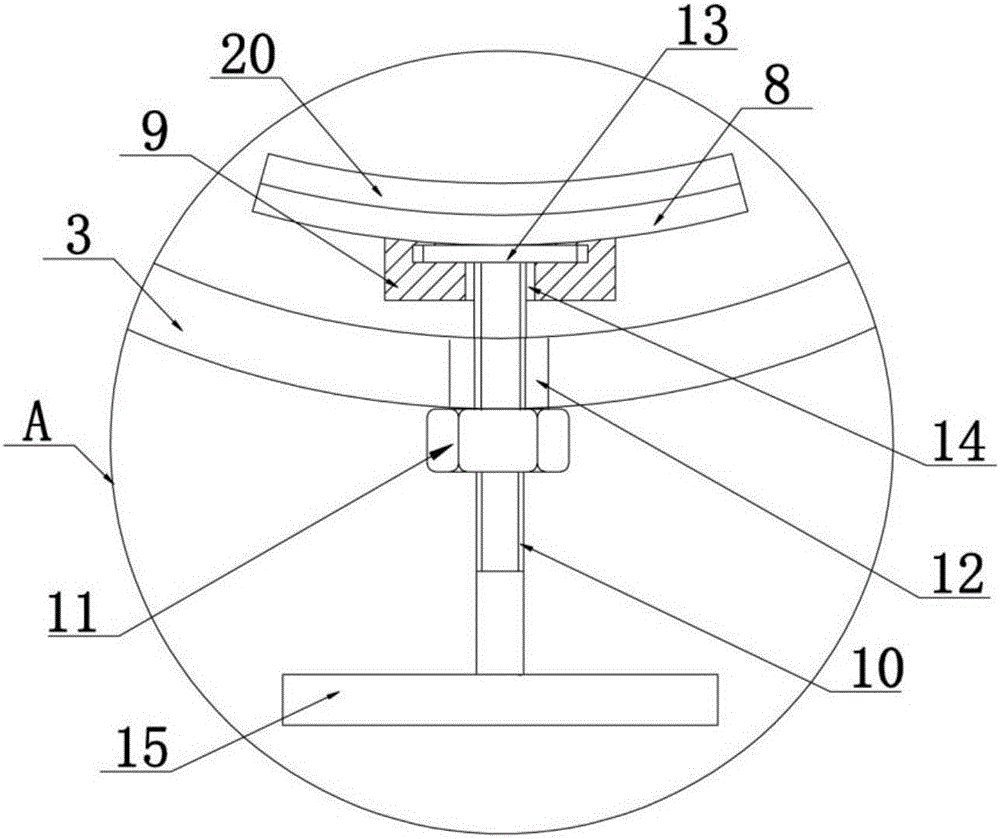

Pole correcting device and pole correcting method for adjusting directions of electric poles and cross arms

The invention discloses a pole correcting device and a pole correcting method for adjusting the directions of electric poles and cross arms. The pole correcting device comprises a main operating handle and a hoop assembly. The hoop assembly comprises a fixed hoop and a movable hoop, the fixed hoop is fixed onto the main operating handle, is hinged to one end of the movable hoop and is connected with the other end of the movable hoop by a locking mechanism, the locking mechanism comprises a T-shaped pole, a bayonet and a clamp hook, a transverse pole of the T-shaped pole is hinged to the fixed hoop, a vertical pole of the T-shaped pole is fittingly locked with the clamp hook, and a fastening mechanism is arranged in the middle of the movable hoop and comprises a first bent plate, a concave block, a screw, a nut and a mounting hole. The pole correcting method includes steps of 1, assembling accessories; 2, mounting the pole correcting device; 3, correcting the poles; 4, detaching the pole correcting device. The pole correcting device and the pole correcting method have the advantages that the pole correcting method can be applied to repositioning and turning the electric poles in pole erecting procedures, the pole correcting device is easy to operate and convenient to mount and is safe and reliable, and operation conditions can be improved for workers; labor can be saved, the labor intensity can be relieved for the workers, and the electric pole and cross arm adjusting efficiency can be improved.

Owner:国网山东省电力公司招远市供电公司

Rear cover assembly of intelligent bearing storage gearbox

ActiveCN108714742APlay the role of process transfer connectionAvoid problems requiring level adjustmentsMetal working apparatusLaser beam welding apparatusDrive motorEngineering

The invention relates to a rear cover assembly of an intelligent bearing storage gearbox. The rear cover assembly comprises a base, a rotating station device arranged on the base, a protection cover externally covering the base, and a gearbox rear cover assembly center arranged on the base and corresponding to the rotating station device; the rotating station device comprises a station driving motor, a station rotating disc, rotating stations, mould parts, U-shaped clamping bases and V-shaped positioning grooves, wherein the station driving motor is arranged on the base, the station rotating disc is in transmission connection with the station driving motor and is rotationally arranged on the base, the rotating stations are distributed on the station rotating disc according to working procedures, the mould parts each are arranged at the corresponding rotating station and are used for fixing the lower end surface of a gearbox cover, the U-shaped clamping bases are arranged on the symmetric two sides of the upper end faces of the mould parts, and the V-shaped positioning grooves are formed in the U-shaped clamping bases and are used for fixing lugs on the two sides of the gearbox cover; and the rotating station device plays a role in working procedure transfer connection. The rear cover assembly is reasonable in design, compact in structure and convenient to use.

Owner:上善智城(苏州)信息科技有限公司

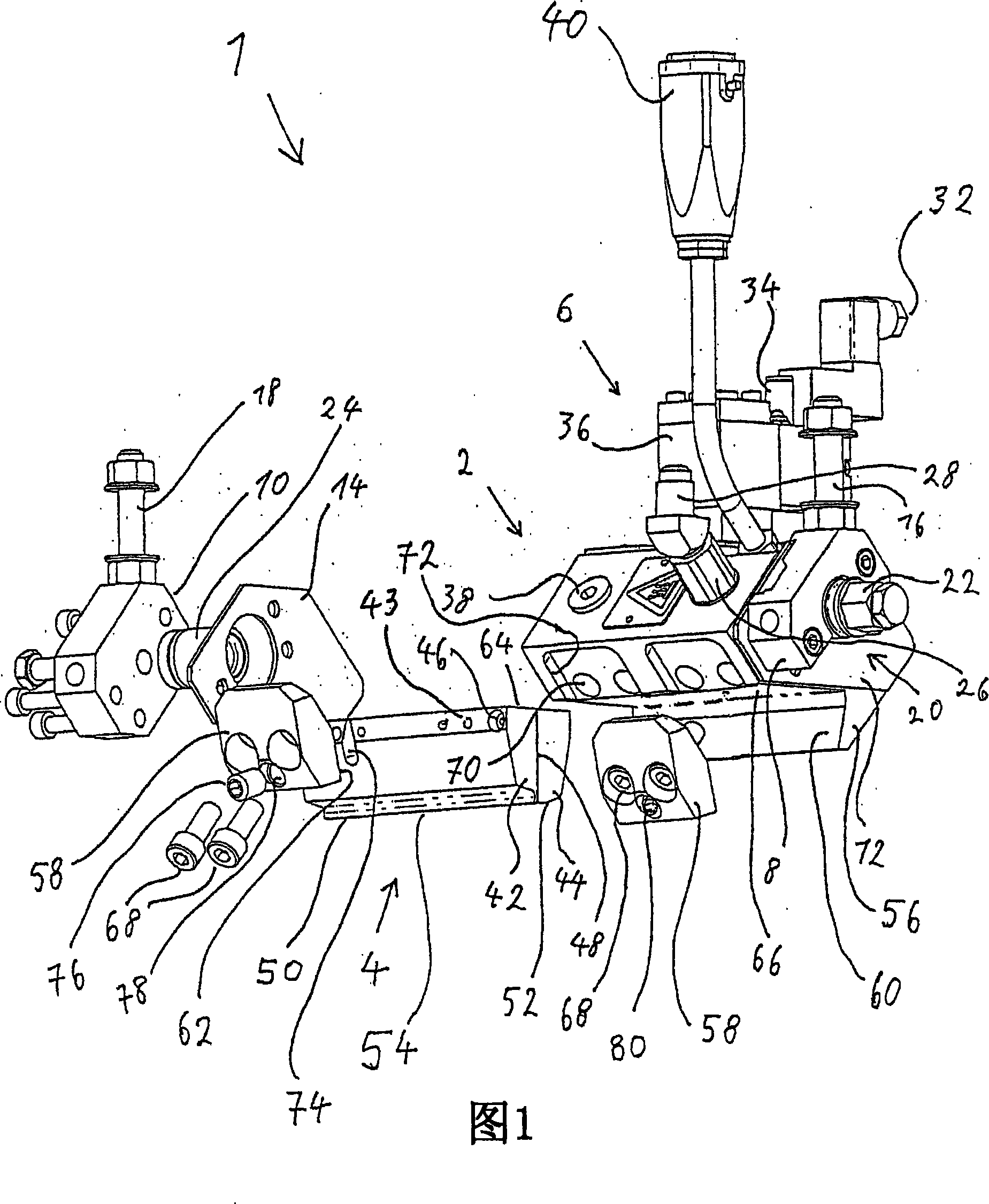

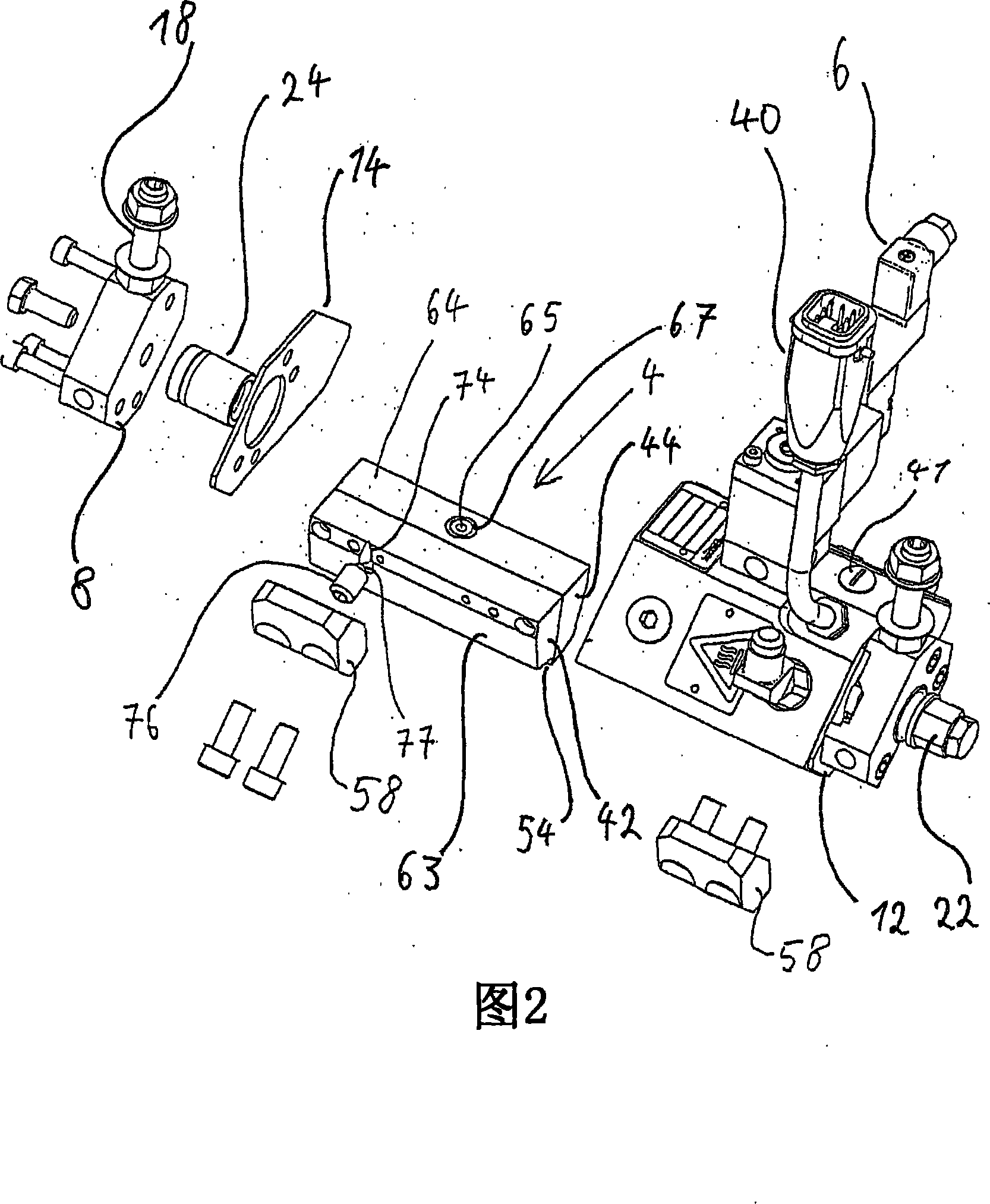

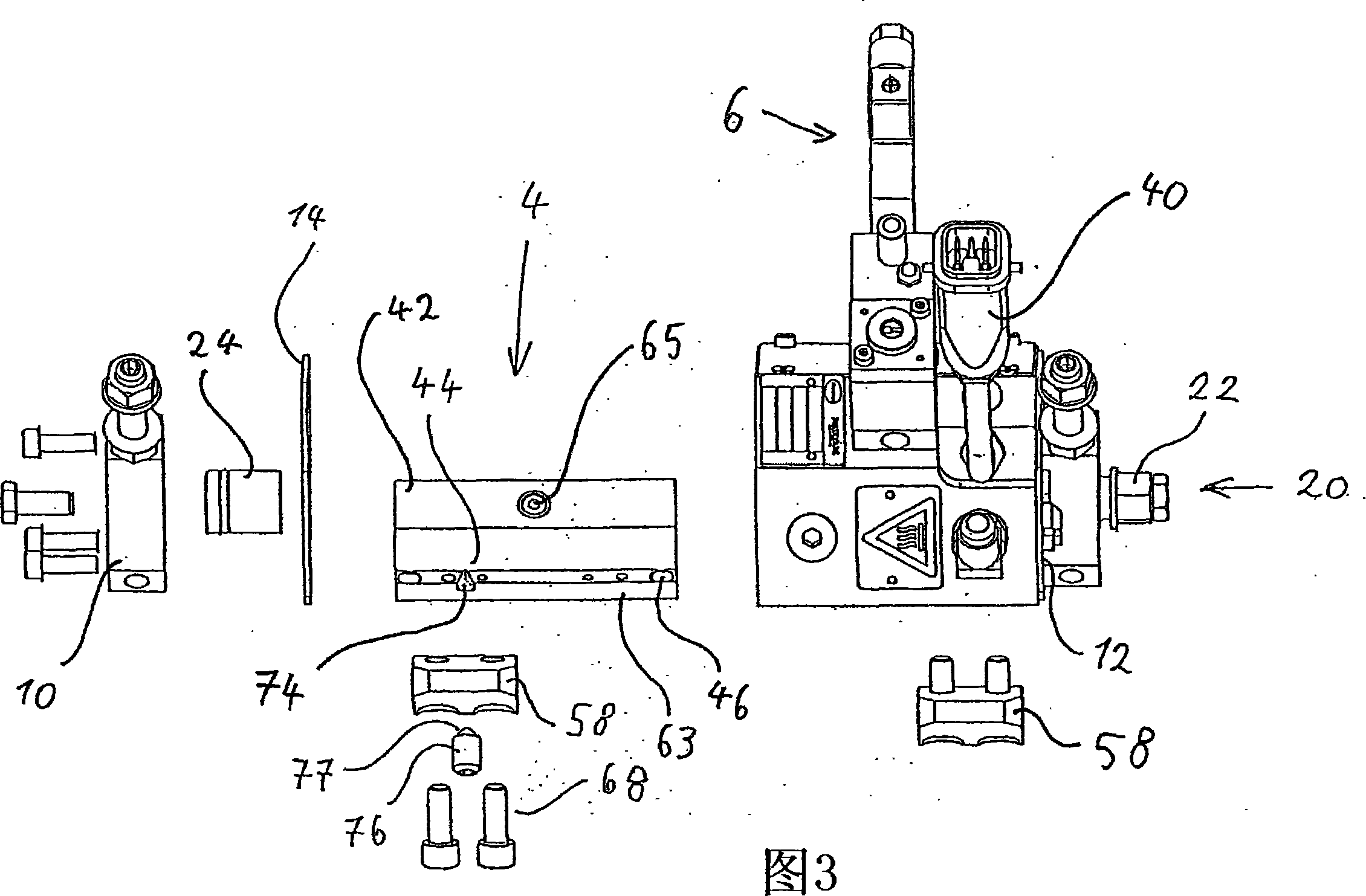

Coating device for coating liquid material

ActiveCN101185923AAchieve fasteningConvenient stopLiquid surface applicatorsSpraying apparatusLiquid stateHot-melt adhesive

The invention refers to an Applicator apparatus for the surface application of liquid material, in particular hot melt adhesive, comprising a main body, and a nozzle arrangeme having at least one slot applicator nozzle for the delivery of the liquid material. According to the invention a clamping device for fixing the nozzle arrangement to the main body is comprised.

Owner:NORDSON CORP

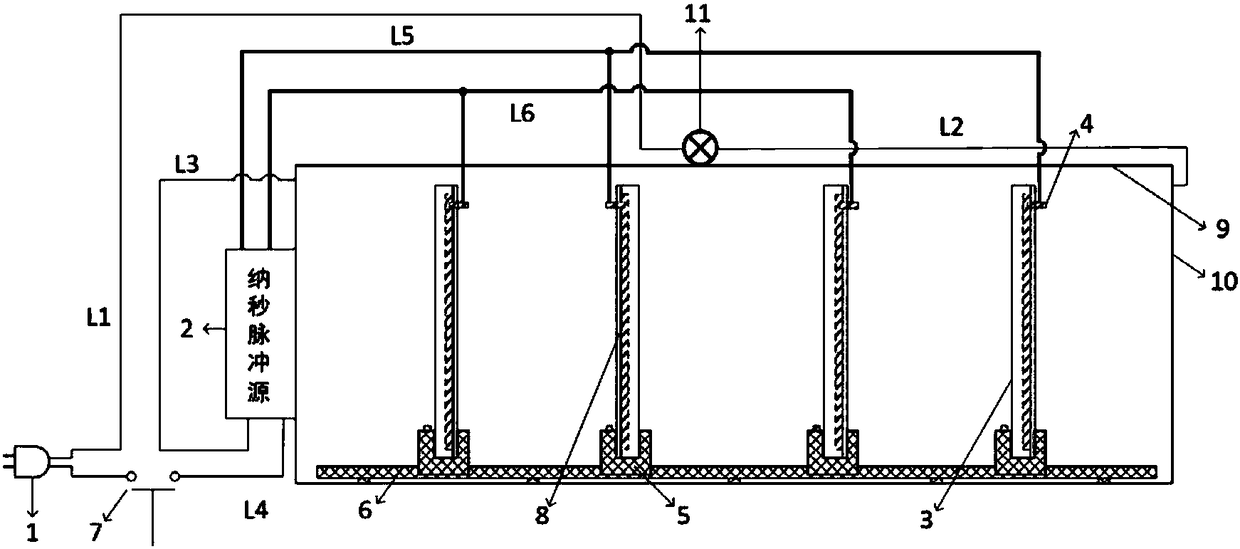

Fruit and vegetable preservation device based on nanosecond pulse low-voltage electric field

ActiveCN108271856AFlexible arrangementEnsure safetyFruits/vegetable preservation by irradiation/electric treatmentFood electrical treatmentDevice formLow voltage

The invention discloses a fruit and vegetable preservation device based on a nanosecond pulse low-voltage electric field. The fruit and vegetable preservation device comprises a treatment chamber anda nanosecond pulse electric field generating device, wherein the treatment chamber comprises a closed cavity, a box body with an open top and an upper cover arranged at the open top of the box body, the upper cover contains a copper sheet protecting path, the box body matches with the upper cover by virtue of a positioning assembly, and an electromagnetic device, the copper sheet protecting path and a work indicating lamp form a safety protection device together; and the nanosecond pulse electric field generating device comprises a nanosecond pulse power with adjustable parameters and a multichannel dual electrode sealed in an insulating barrier, and the multichannel dual electrode is connected with an electrode outgoing post. The electric field generating device forms a nanosecond pulse electric field in the box body, and fruits and vegetables are put in the nanosecond pulse electric field for performing electric field treatment, thereby achieving an enzyme inactivating effect by changing the inherent electric fields of the fruits and vegetables, inhibiting the respiratory action of the fruits and vegetables and achieving a good cold sterilization effect. The fruit and vegetable preservation device based on the nanosecond pulse low-voltage electric field has a convenient operation method, is pollution-free and suitable for preserving various perishable fruits and vegetables and has very high application value.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com