Thin-walled barrel welding assisting tool

A technology of auxiliary tooling and thin-walled cylinders, applied in welding/cutting auxiliary equipment, auxiliary devices, welding equipment, etc., can solve the problems that the cylinder’s self-weight deformation cannot be completely eliminated, the positioning accuracy cannot be guaranteed, and the cylinder’s force is uneven.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

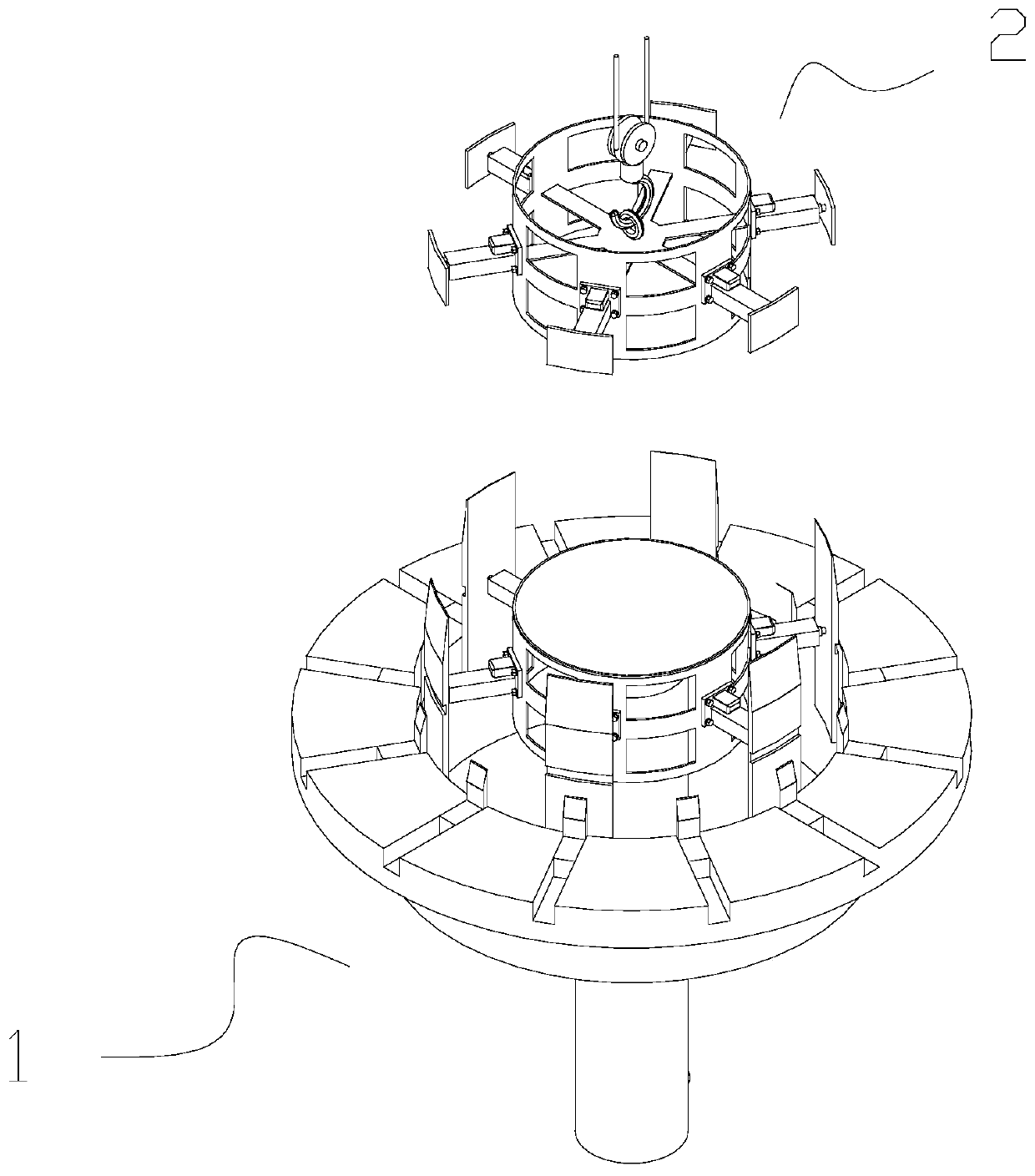

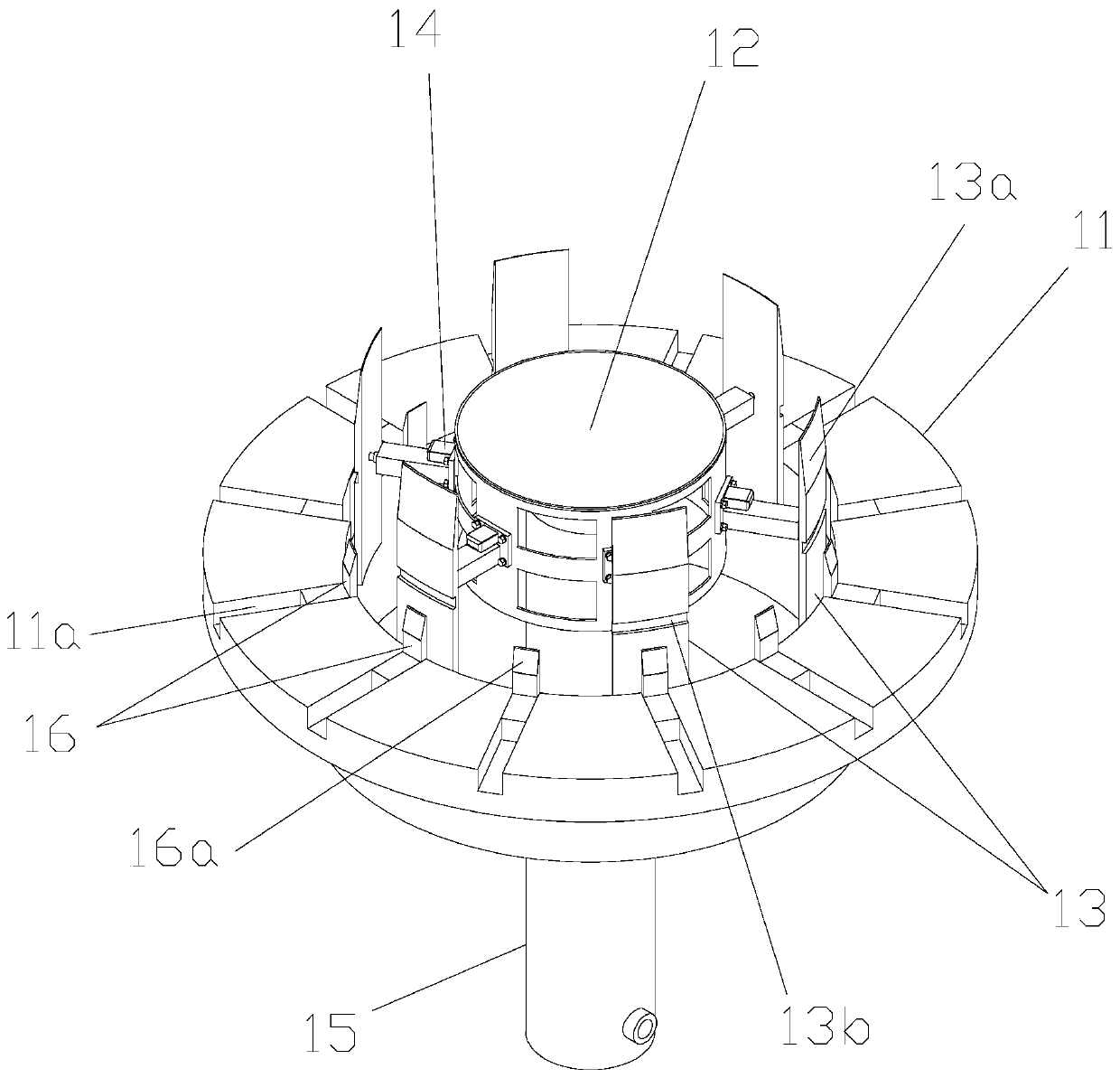

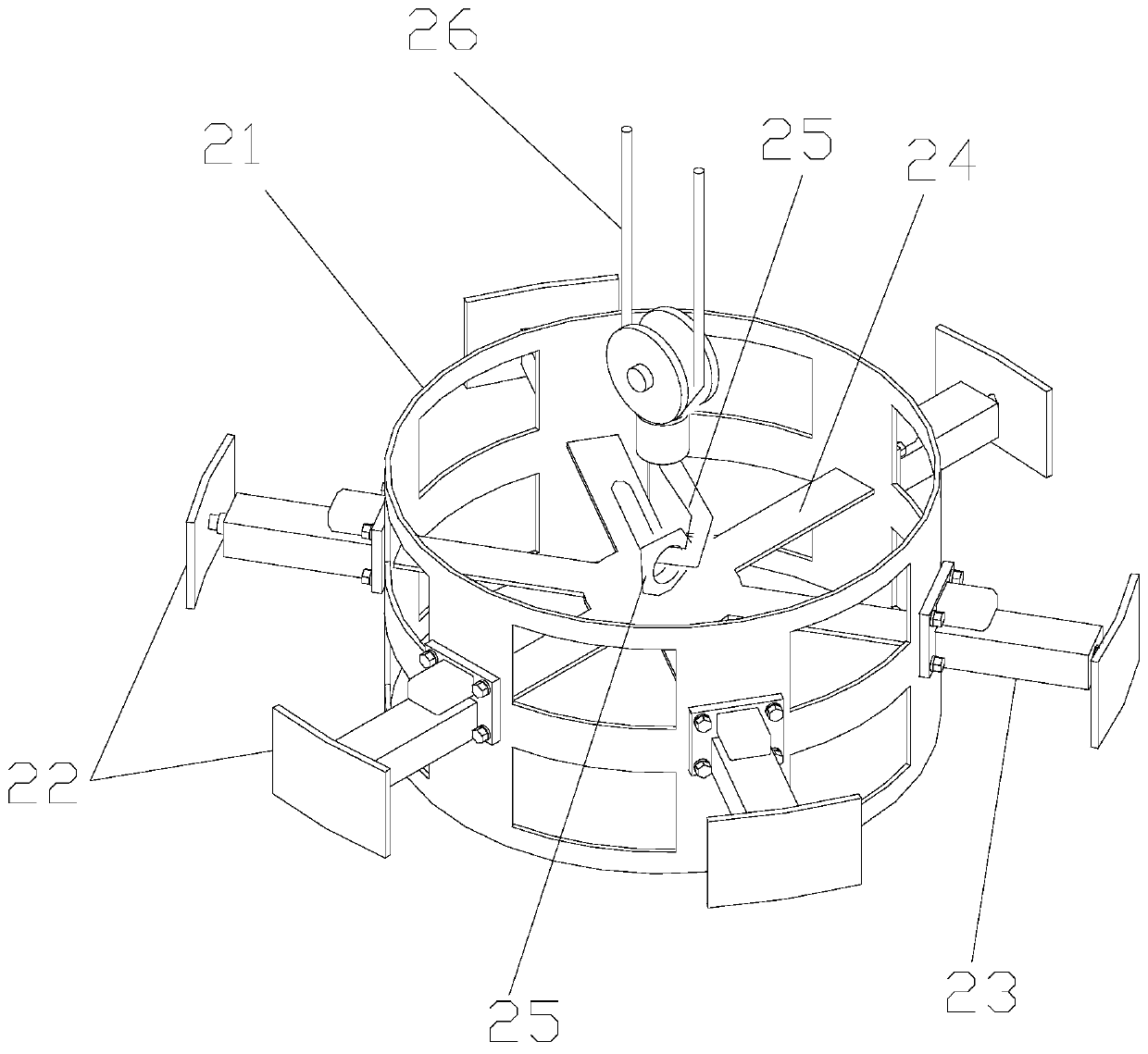

[0021] Such as Figure 1 to Figure 3 As shown: a thin-walled cylindrical welding auxiliary tooling of this embodiment, including an inner support assembly 1 for positioning and tightening the cylindrical section and an inner support hanger 2 for hoisting the cylindrical section to the inner support assembly 1; when in use It is also used in conjunction with an arc welding machine capable of welding the upper and lower cylinder joints and a grinding machine capable of grinding the circumferential seam. The arc welding machine and the grinding machine are respectively arranged on the left and right sides of the inner support assembly 1 . The cylinder section is the cylinder section, and the multi-section cylinder sections are welded in sequence to form the required cylinder; the thin-walled cylinder can be, for example, a stainless steel tank, and its material can mainly be 304 stainless steel, with a plate thickness of 3mm, which has its own restraint Small, small thermal condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com