Automobile transmission gear heat treatment method

A technology of automobile gearbox and heat treatment method, which is applied in the field of heat treatment, which can solve the problems of reducing the fatigue resistance of gears, long heat treatment production cycle, and shortened service life, so as to achieve small grain growth tendency, reduce out-of-smelting links, and reduce deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

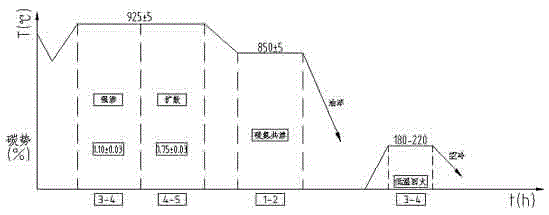

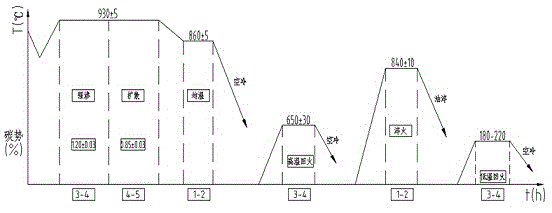

[0037] The present invention discloses a heat treatment method for automobile gearbox gears. Due to the large volume of automobile gearbox gears, it is generally figure 2 The single carburizing and quenching process shown is heat-treated to form a deep carburized layer on the surface of the gear to improve the wear resistance and fatigue resistance of the gear. However, due to the defects in the above-mentioned process, the applicant through long-term experiments And research, a heat treatment method that can perfectly combine carburizing process an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com