Flexible guardrail of mining dump truck

A technology for mining dump trucks and flexible guardrails, which is applied in vehicle components, vehicle safety arrangements, pedestrian/occupant safety arrangements, etc. Installation accuracy is difficult to guarantee and other problems, to achieve the effect of improving safety and attendance, reducing welding workload, and improving production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following description illustrates specific embodiments of the invention sufficiently to enable those skilled in the art to practice and reproduce it.

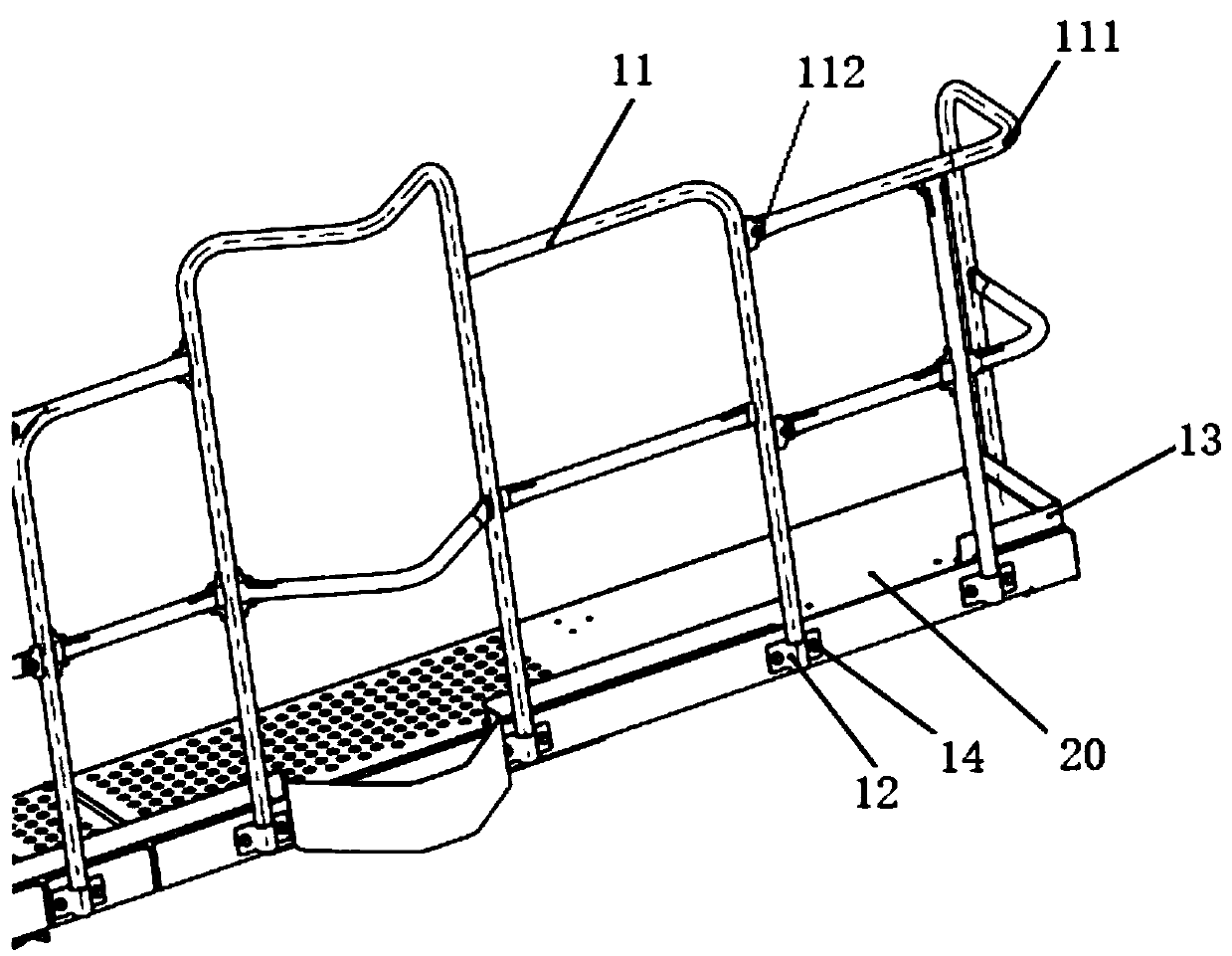

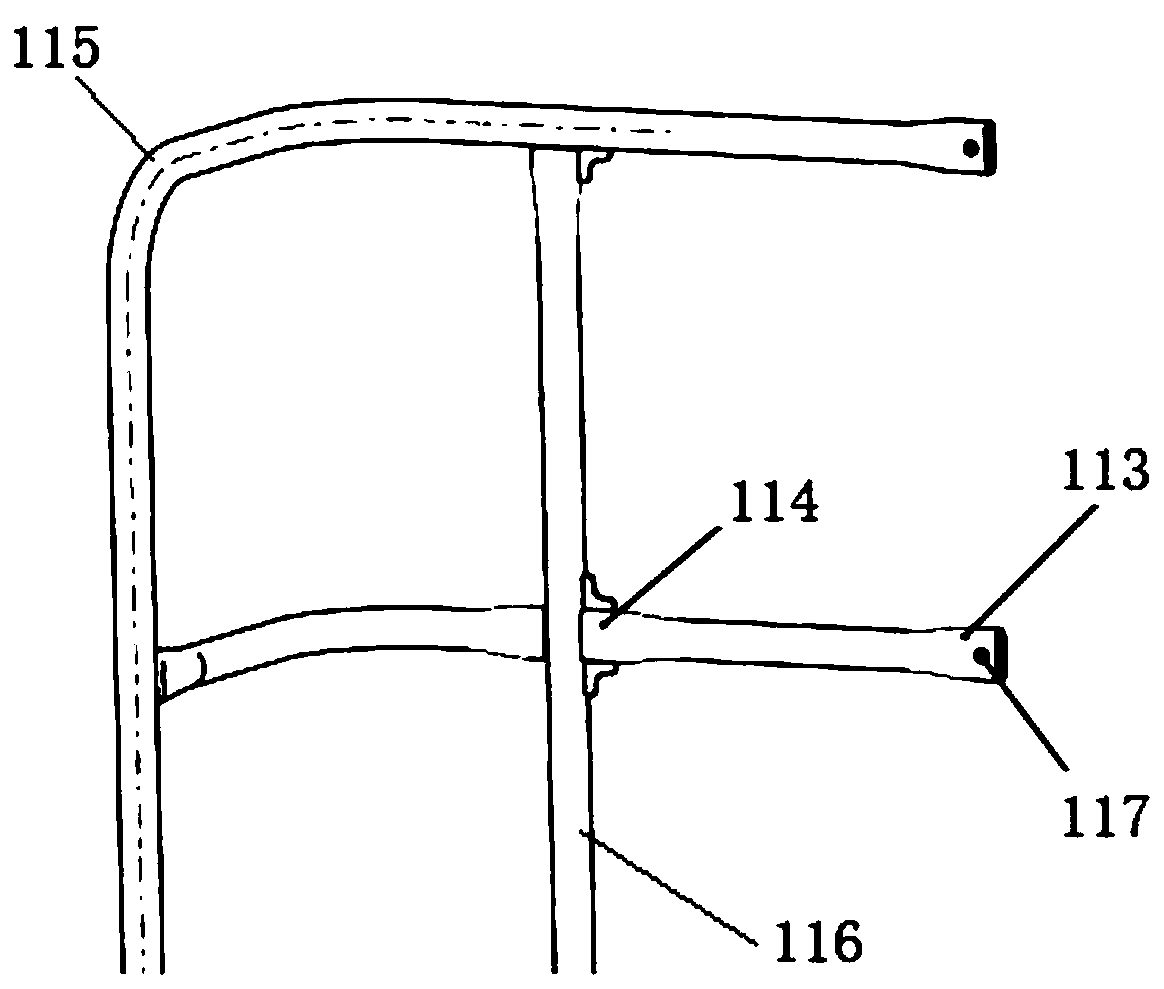

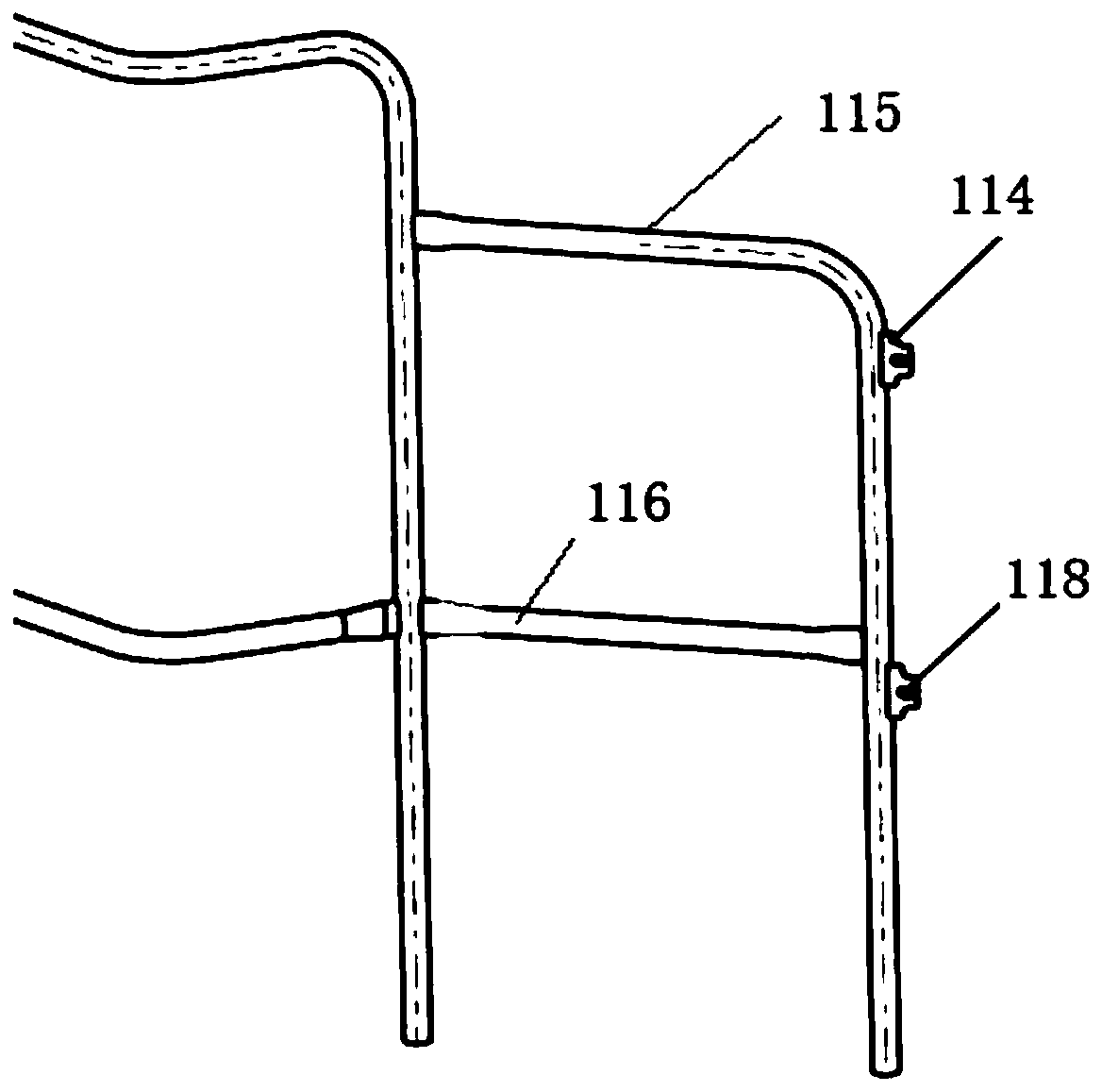

[0022] Such as figure 1 Shown is a schematic structural view of the mine dump truck flexible guardrail in the present invention.

[0023] A flexible guardrail for a mining dump truck includes: a guardrail assembly 11 , a guardrail pressure plate 12 , a skirting board 13 and mounting bolts 14 .

[0024] The guardrail assembly 11 includes: a plurality of guardrail split bodies 111 and connecting bolts 112 , and the plurality of guardrail split bodies 111 are connected through the connecting bolts 112 .

[0025] The bottom end of the guardrail assembly 11 is installed on the platform assembly 20 through the guardrail pressure plate 12 and the mounting bolt 14; the arc section 121 of the guardrail pressure plate 12 is pressed on the bottom end of the guardrail assembly 11. There is a certain gap between the end face of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com