Automatic board unloader for electroplating device

A kind of electroplating equipment and automatic technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of rising labor costs, scratches and deformation of the board surface, low board efficiency, etc., to improve product quality, improve efficiency, and reduce labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

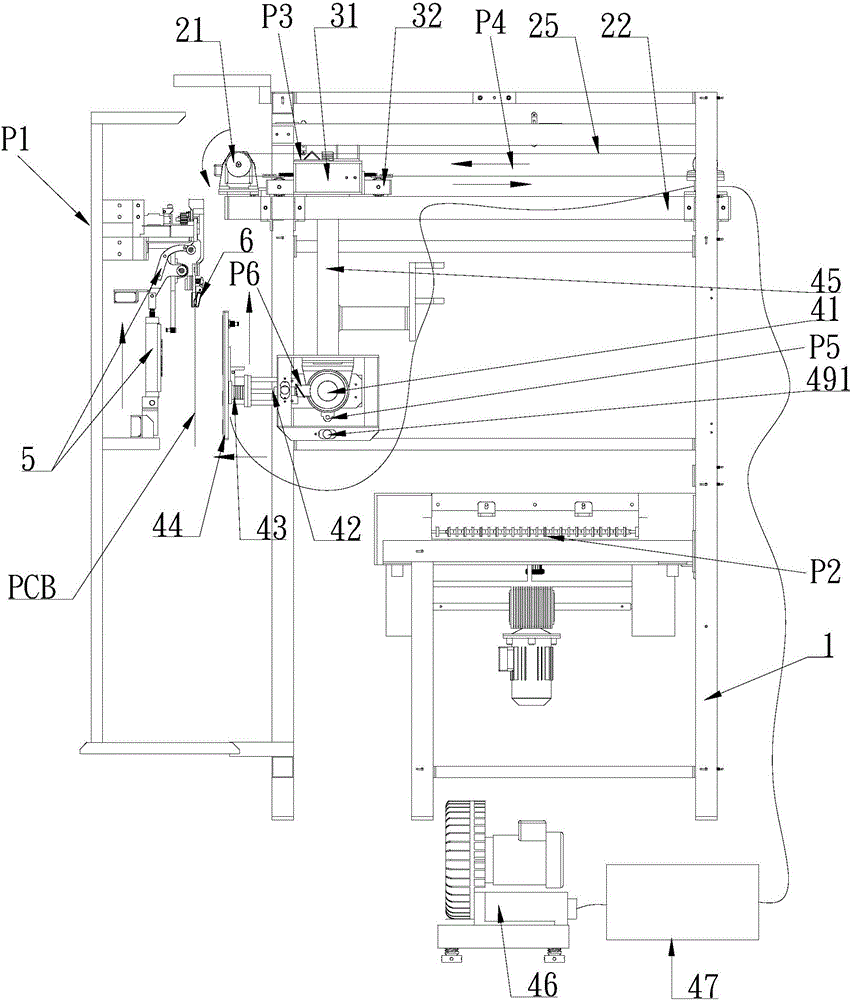

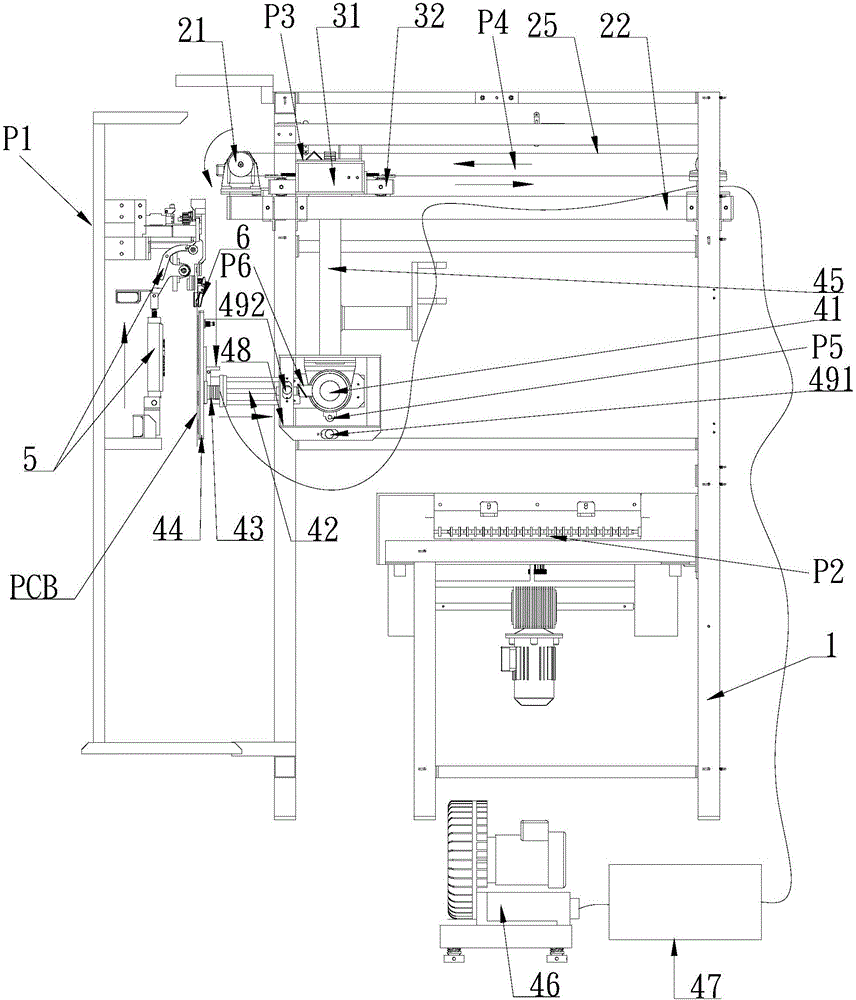

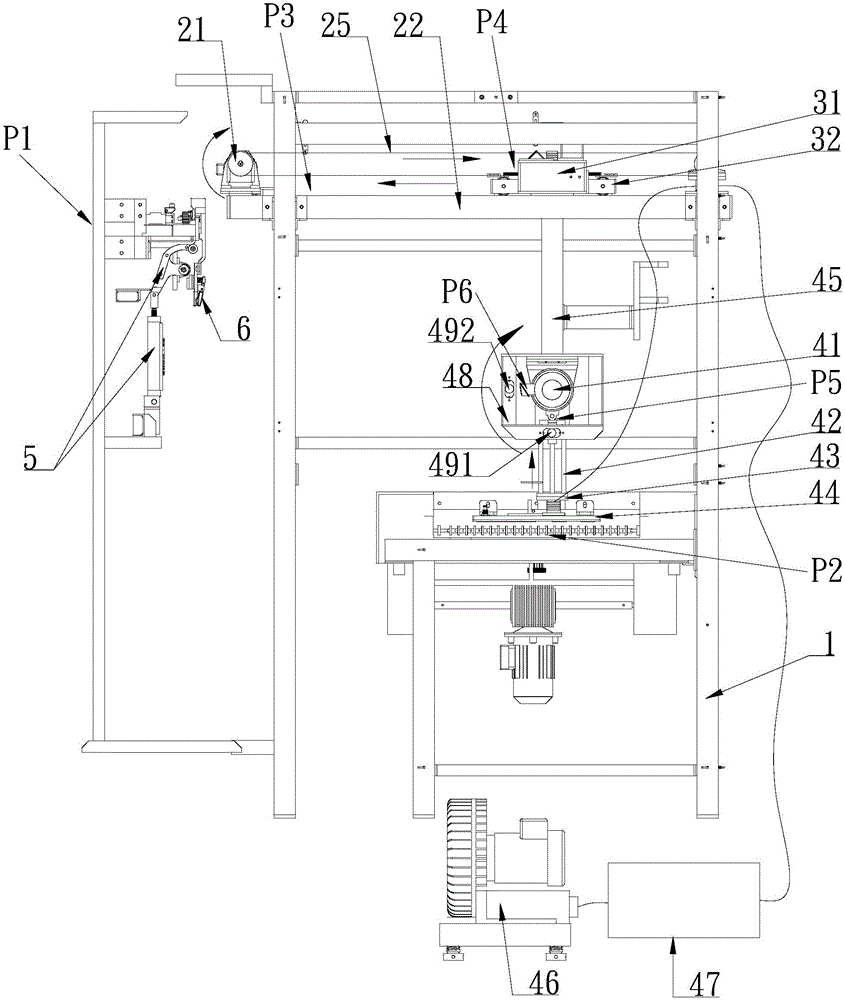

[0051] Such as Figure 3 to Figure 14 As shown, the electroplating equipment automatic unloading machine of the present invention, the electroplating equipment applicable to it can transport the electroplated PCB boards one by one to the lower board position P1 and then stop, so as to wait for the PCB board to be taken away and sent to the electroplating The processing equipment carries out the next step process, wherein, the electroplating equipment is clamped on the upper edge of the PCB board by the clamp 6 to transport the PCB board, and the PCB board staying at the lower board position P1 is located in the vertical plane, and the post-plating processing equipment is on the PCB board. The transfer surface for the next step is located in the horizontal plane.

[0052] see image 3 and Figure 4 The electroplating equipment automatic unloading machine of the present invention is provided with a frame 1 and a linear drive device 2 installed on the frame 1, a transfer device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com