Patents

Literature

282results about How to "Won't wrinkle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

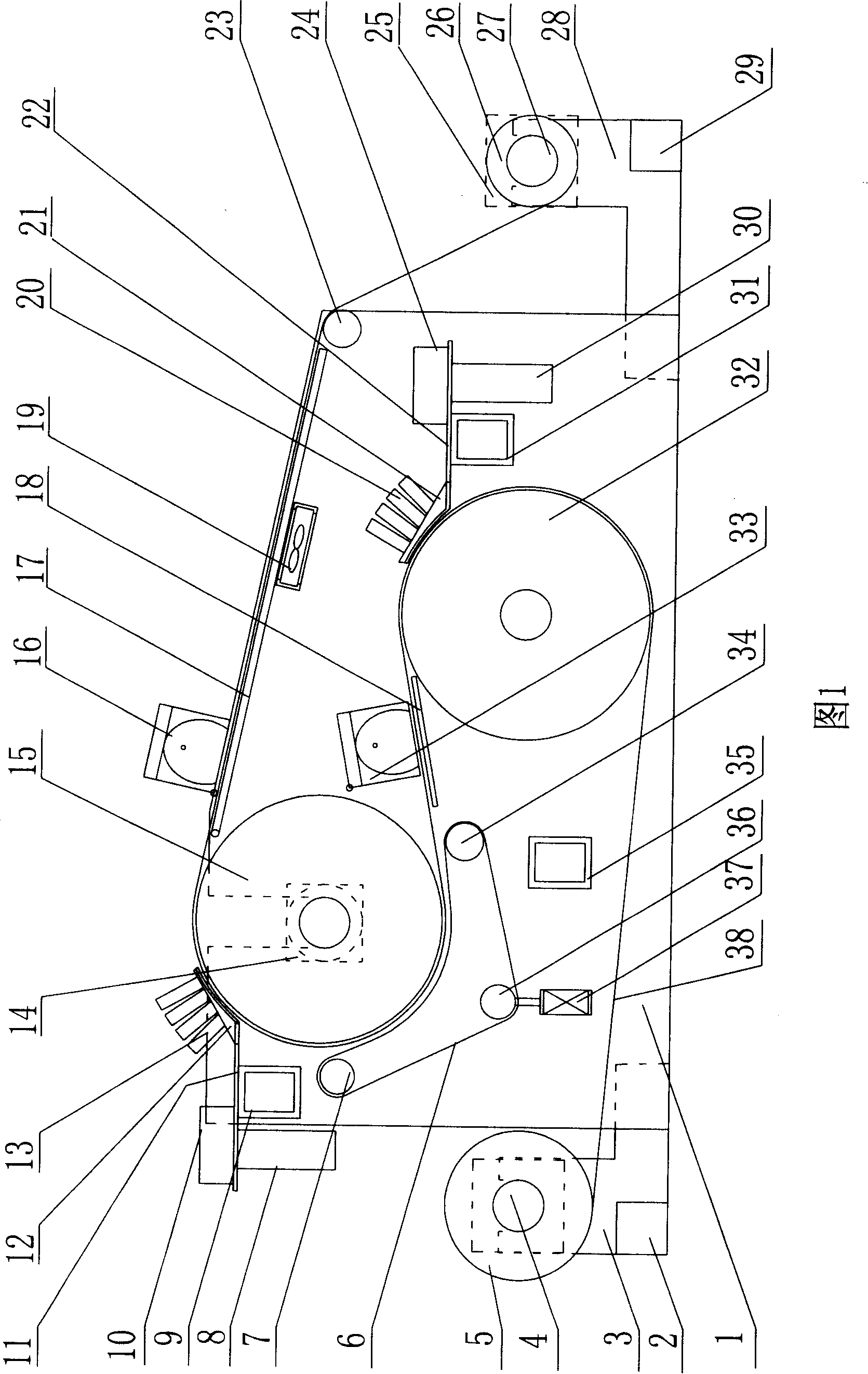

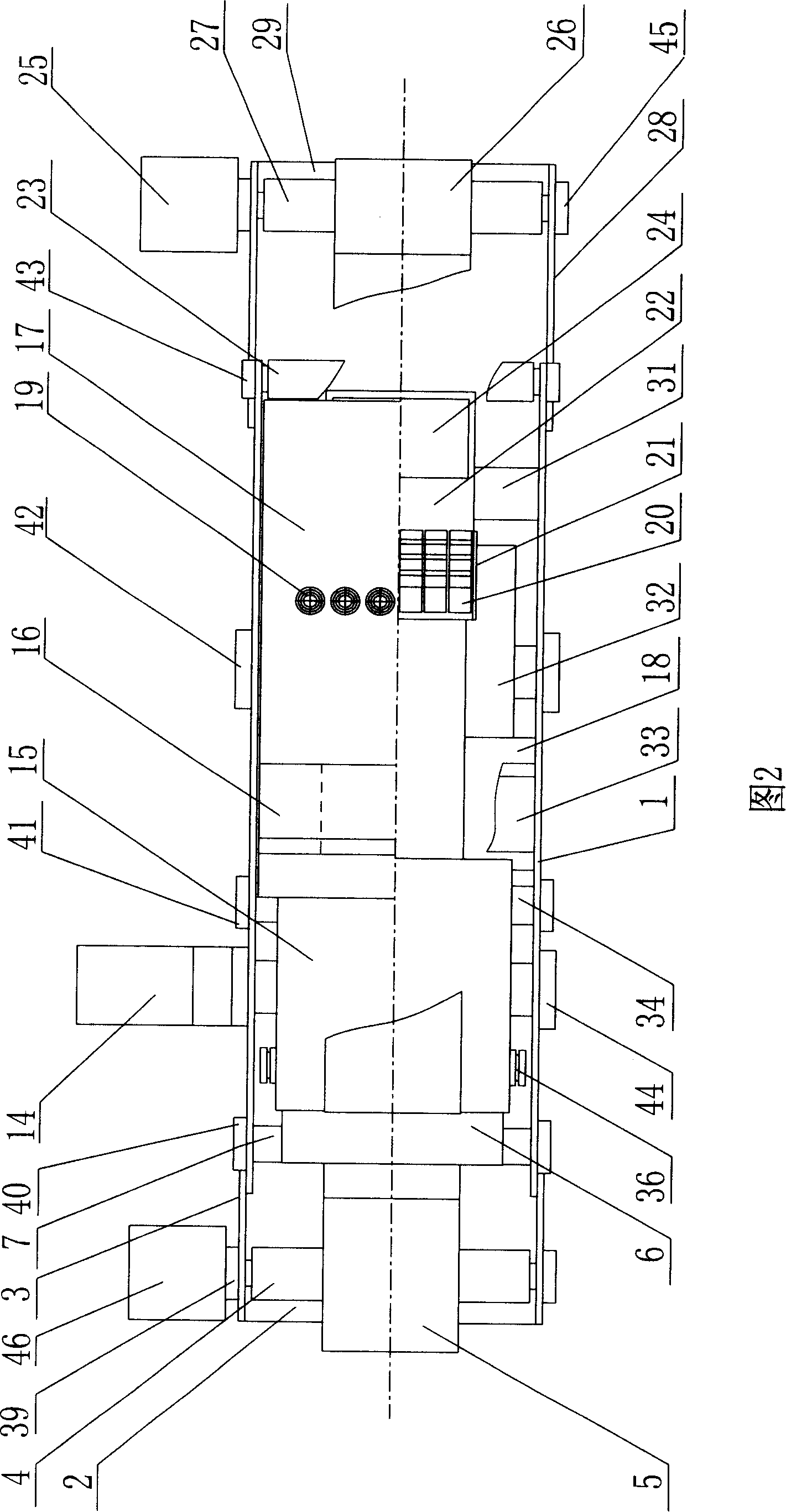

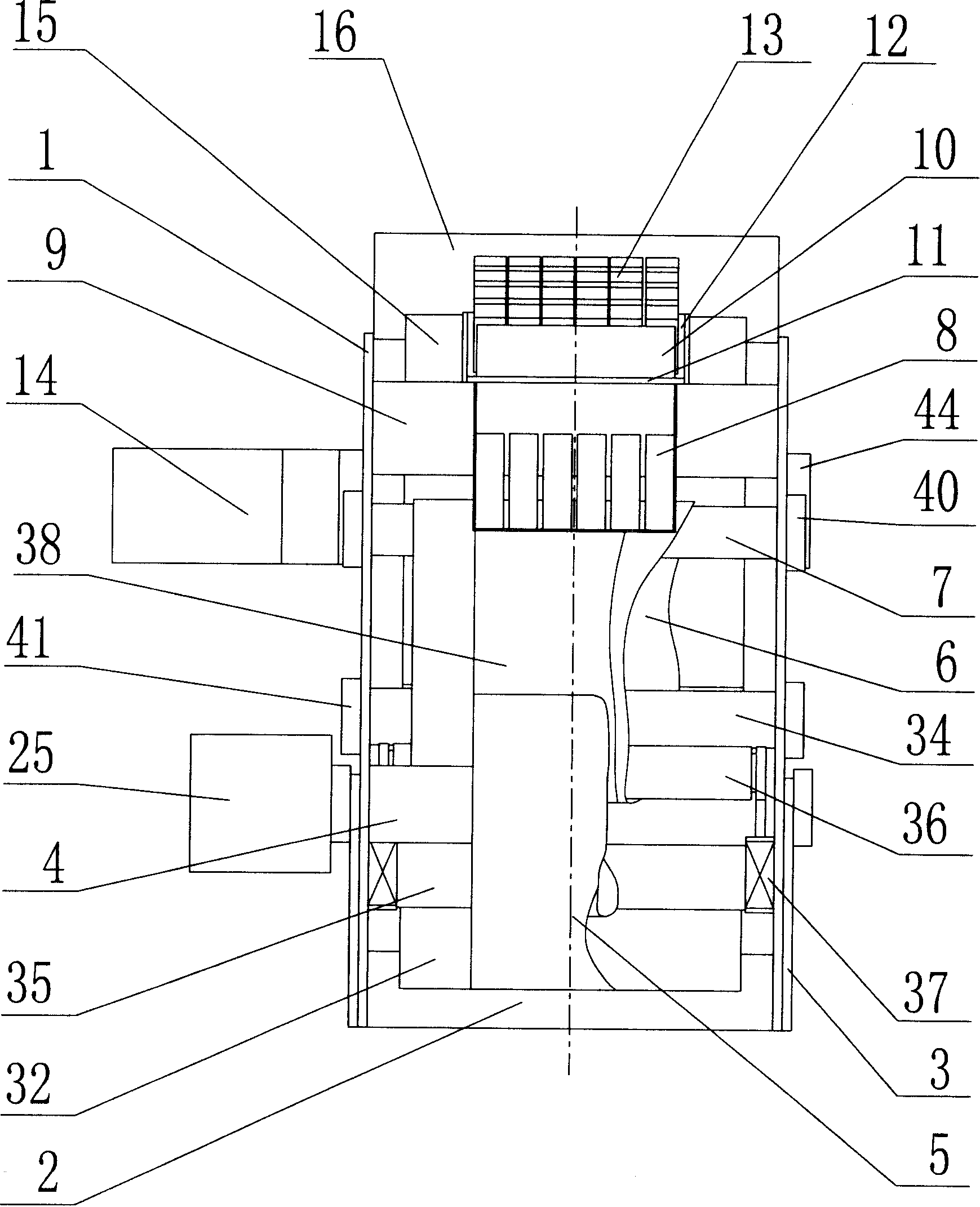

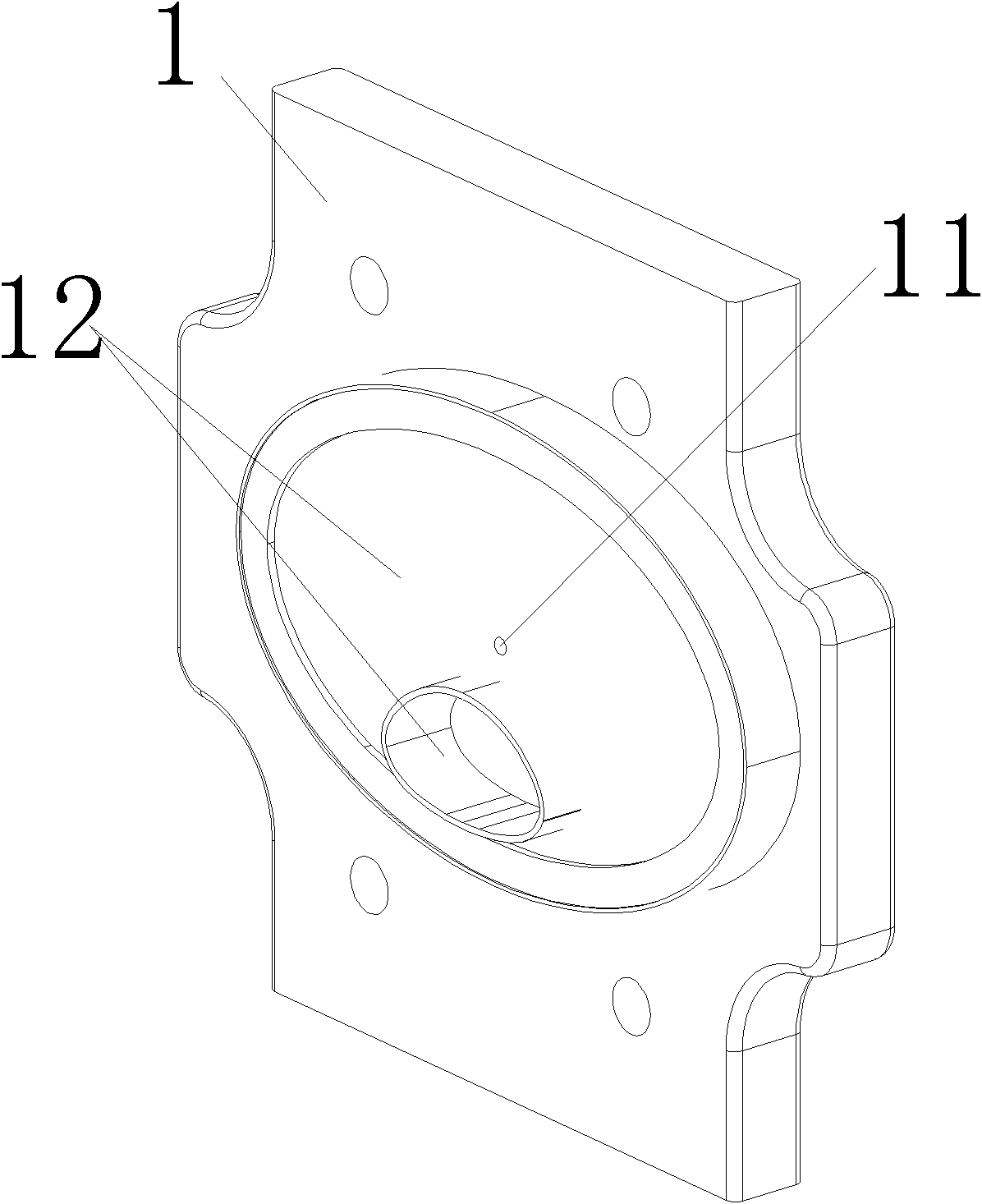

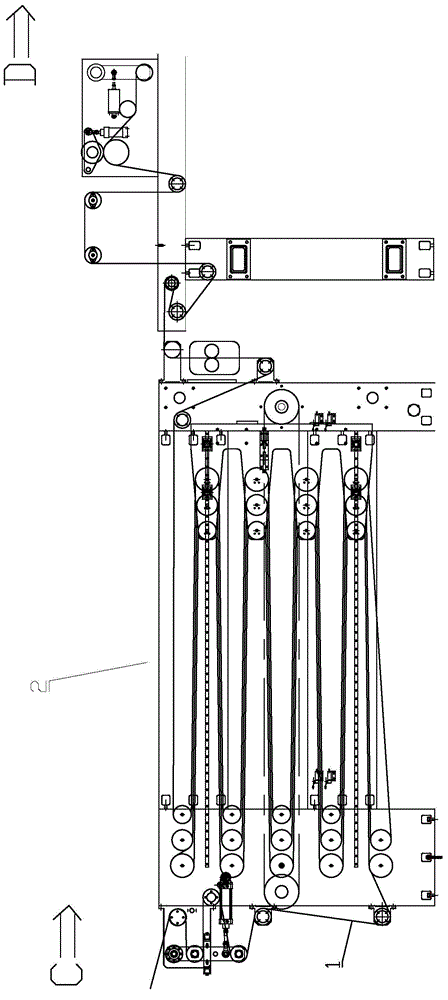

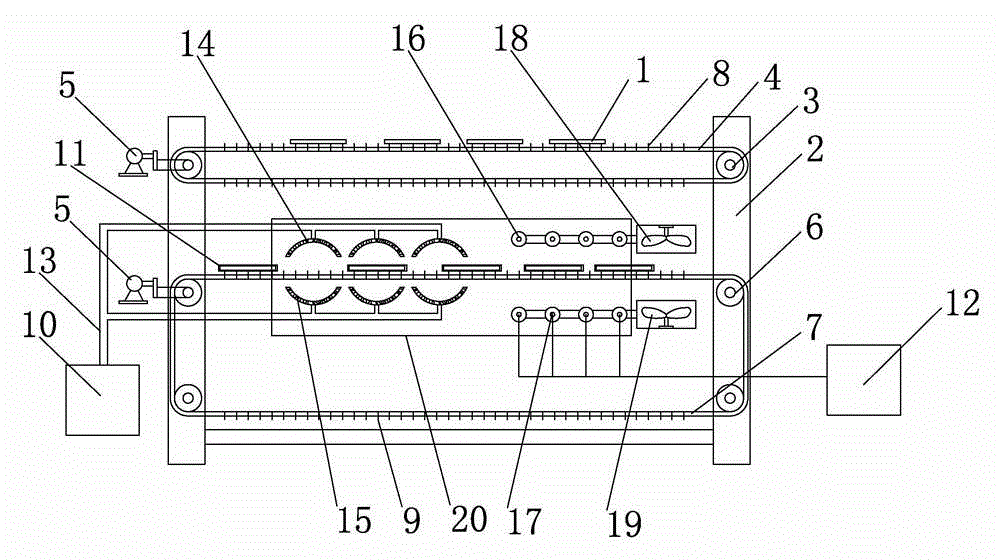

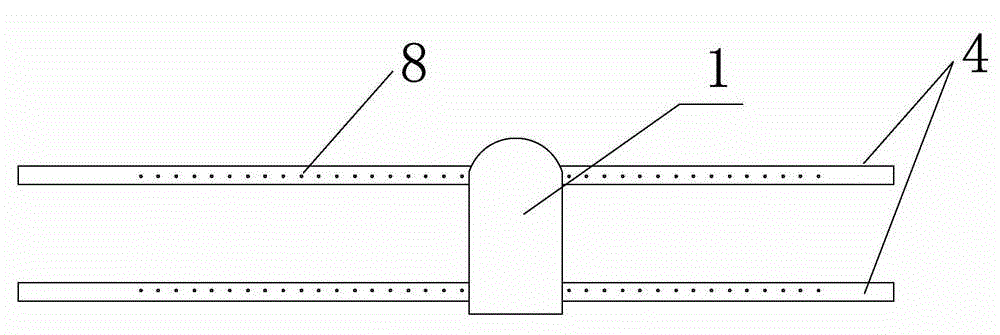

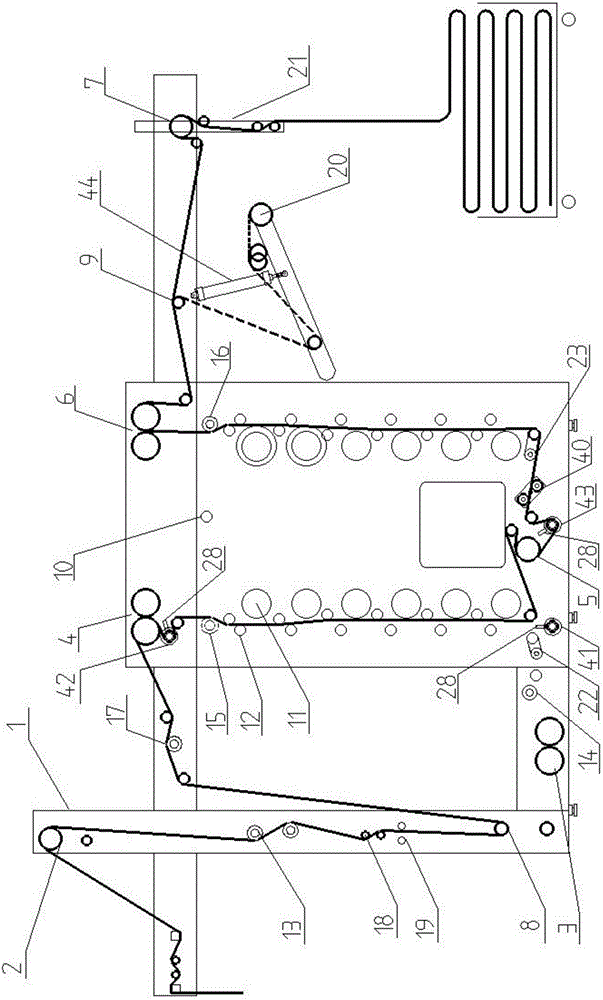

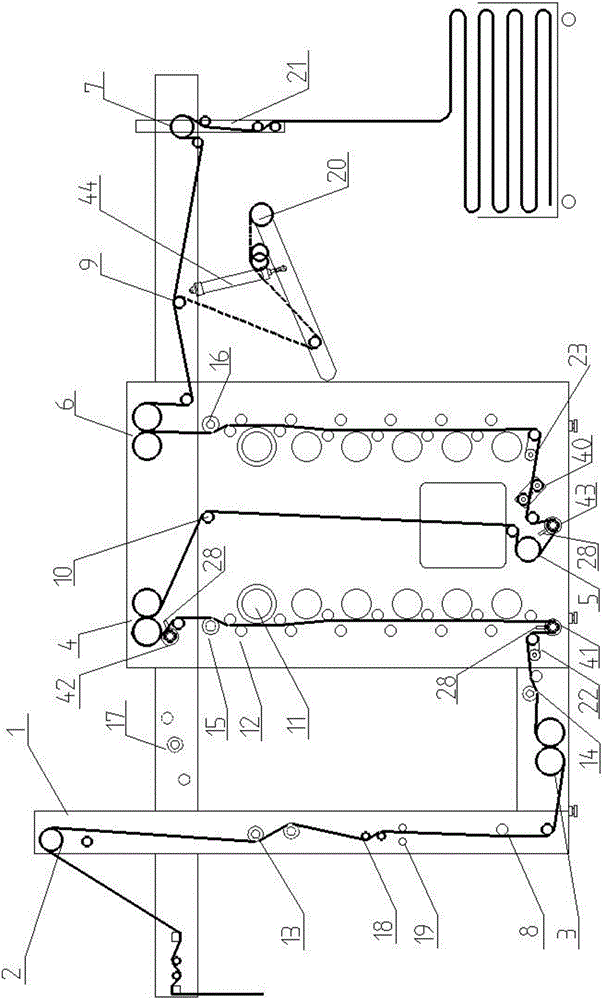

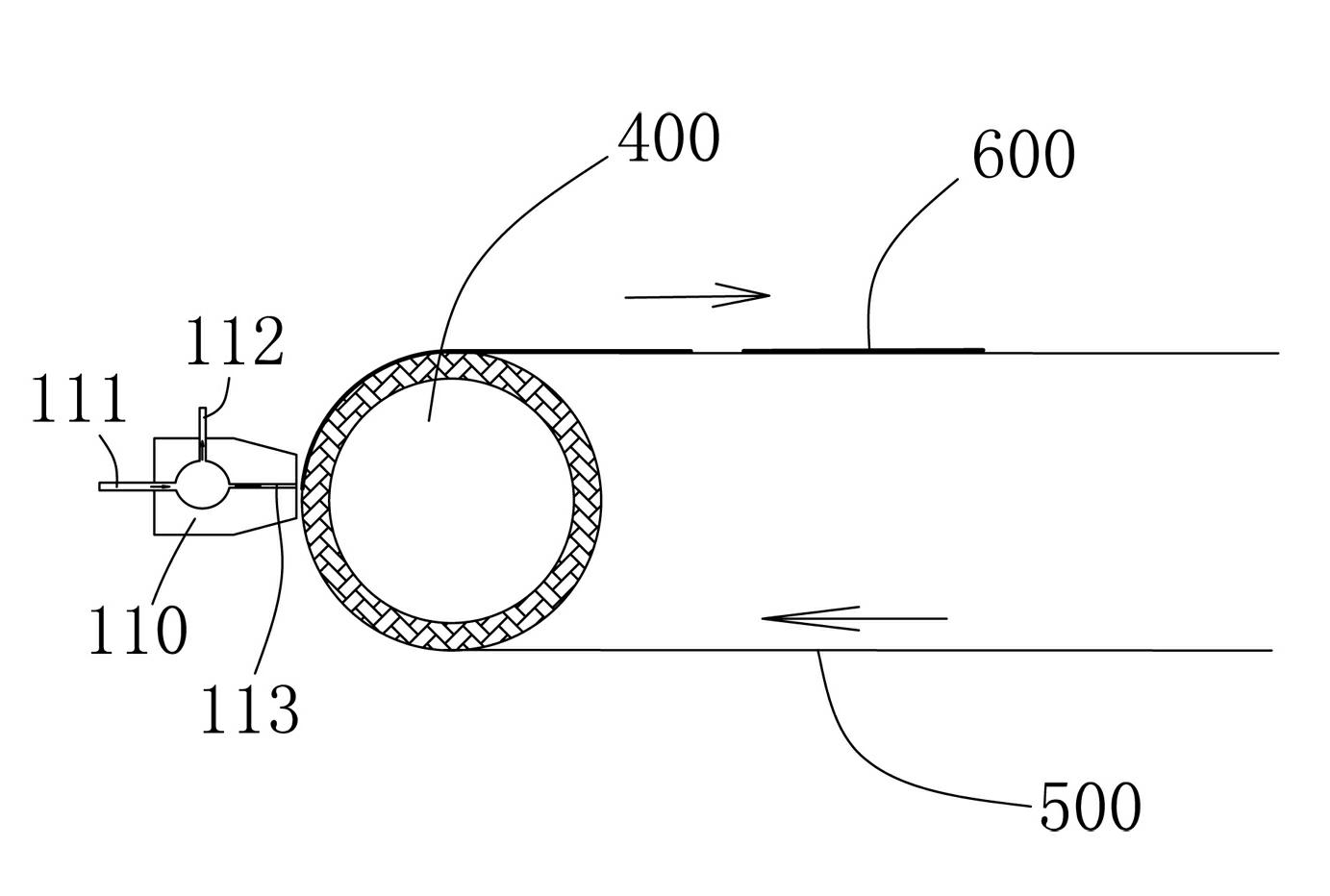

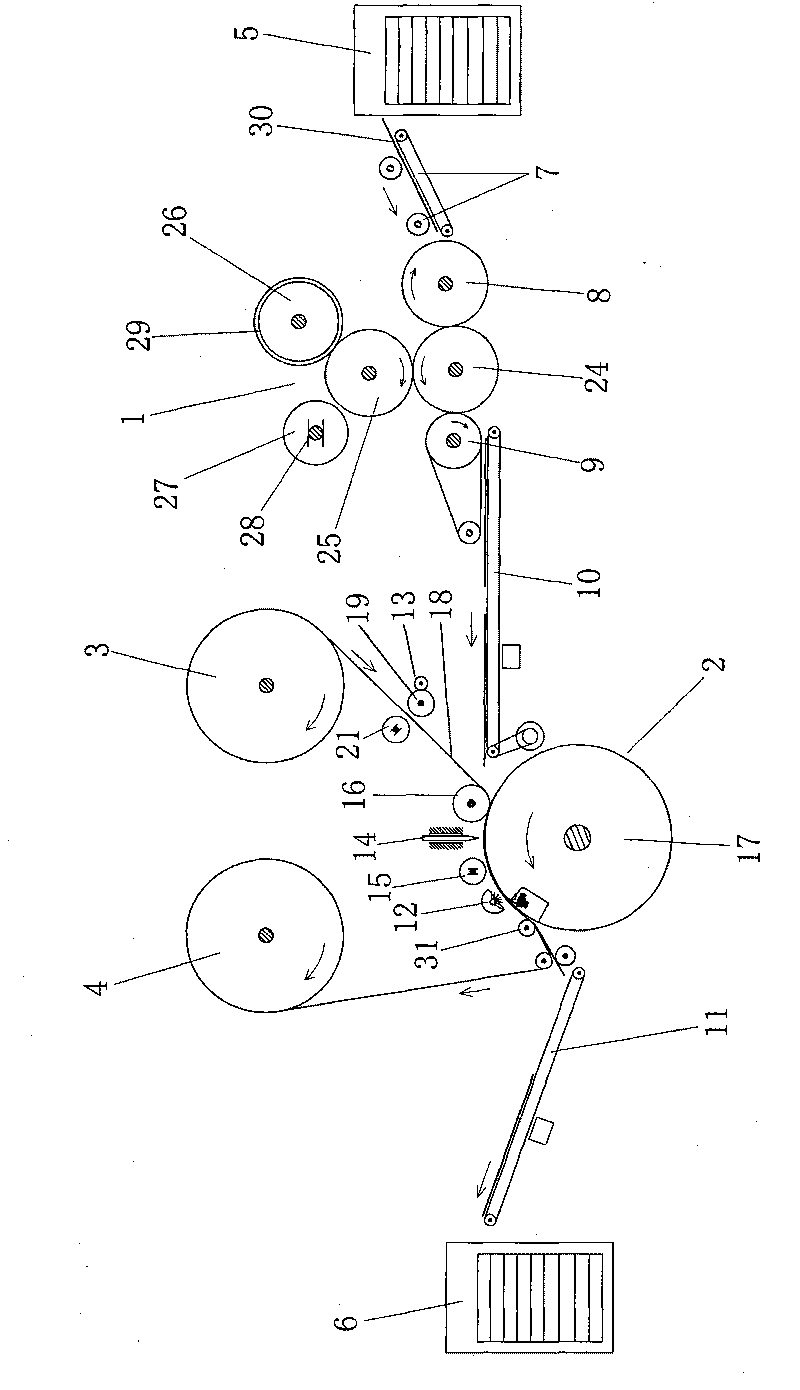

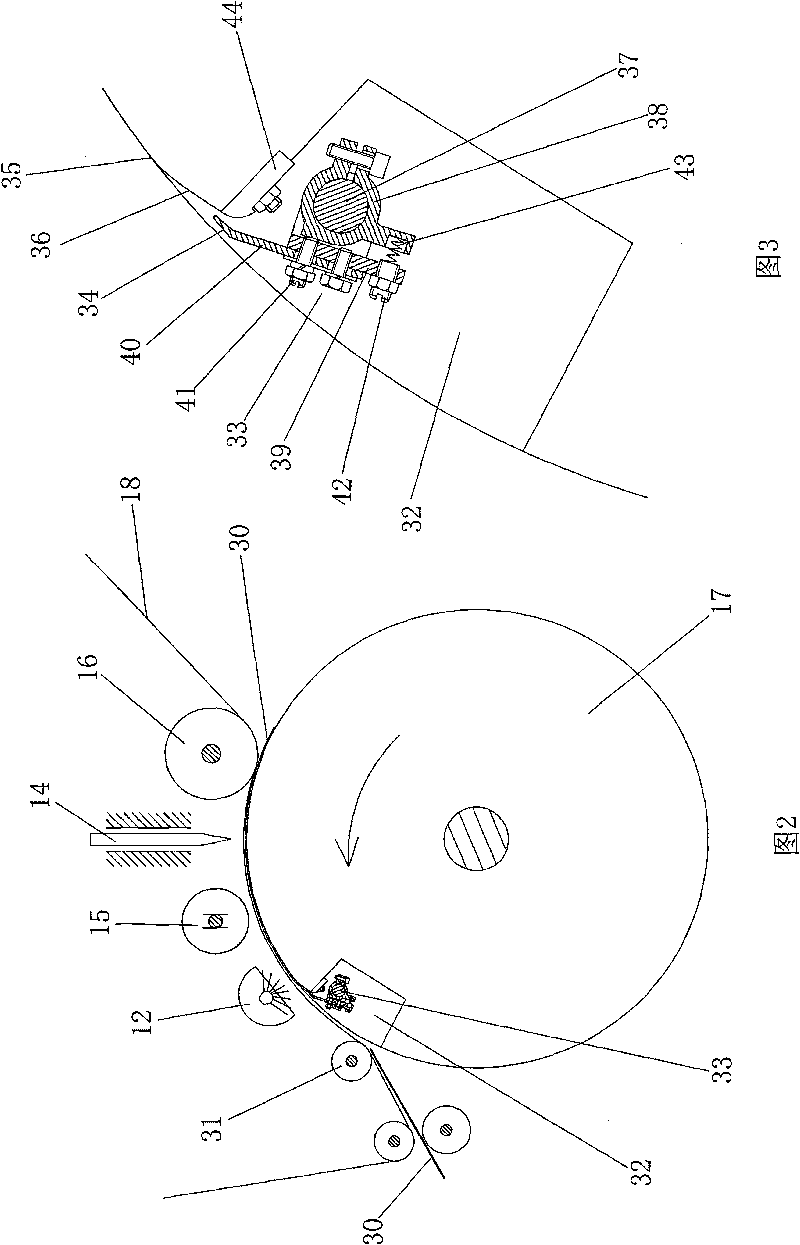

Synchronous double-side digital printer

InactiveCN101164791AWon't wrinkleImprove printing accuracyTypewritersOther printing apparatusDigital printingDigital ink

The present invention relates to a printing machine. In the concrete, it relates to a printing machine capable of making personalized synchronous double-sided digital ink jet on the flexible rolled materials, such as paper, plastics and fabrics, etc. Said printing machine includes wall boards and feeding device, receiving device and guide device which are mounted on the wall boards, between wall boards, a front face printing drum and a back face printing drum are placed. The spray-printing material on the feeding device can be winded on the back face printing drum by adopting rubbing contact mode, and the back-printing face of back-printed spray-printing material can be winded on the front face printing drum by adopting rubbing contact mode, then the double-face printed spray-printing material can be passed through the described guide device and can be winded on the receiving end of receiving device.

Owner:梁健

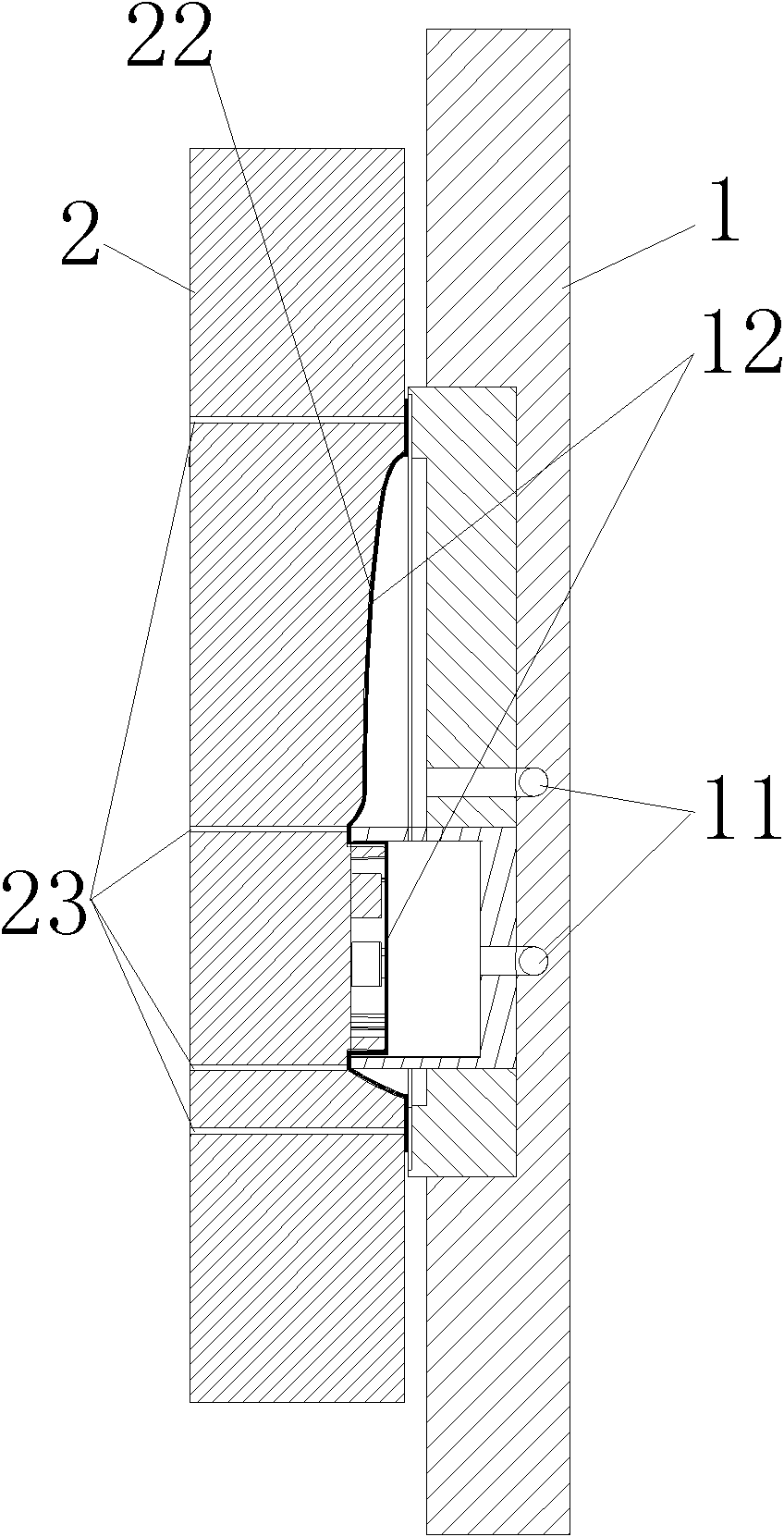

In-mould film lamination process for plastic product and forming mould thereof

The invention discloses an in-mould film lamination process for a plastic product and a forming mould for the in-mould film lamination process. The invention provides the in-mould film lamination process for the plastic product, which can simultaneously finish injection moulding and film lamination operation of the plastic product in a one-time forming process; and the invention also provides theforming mould for the in-mould film lamination process. The in-mould film lamination process for the plastic product comprises the following steps of: arranging a film forming module on the forming die, forming a film on a female mould of the forming mould through the film forming module before injection moulding, and then performing injection moulding so that the film lamination and the injection moulding are finished at the same time and the film has good attachment on an injection moulding part. In order to ensure smooth implementation of the in-mould film lamination process, the inventionalso provides the forming mould comprising the film forming module, a film cutter module and a movable slipway for mounting the film forming module and the film cutter module.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

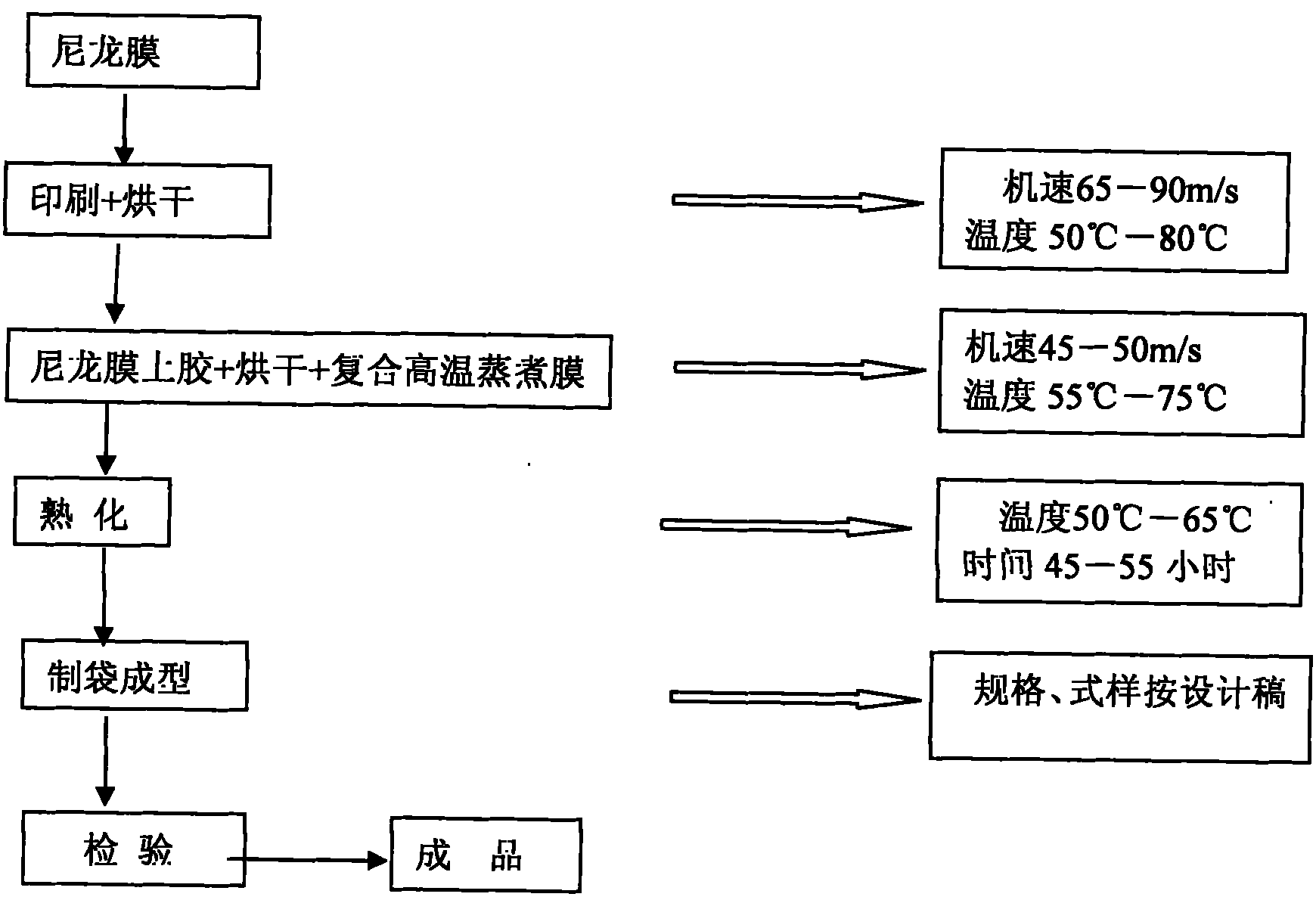

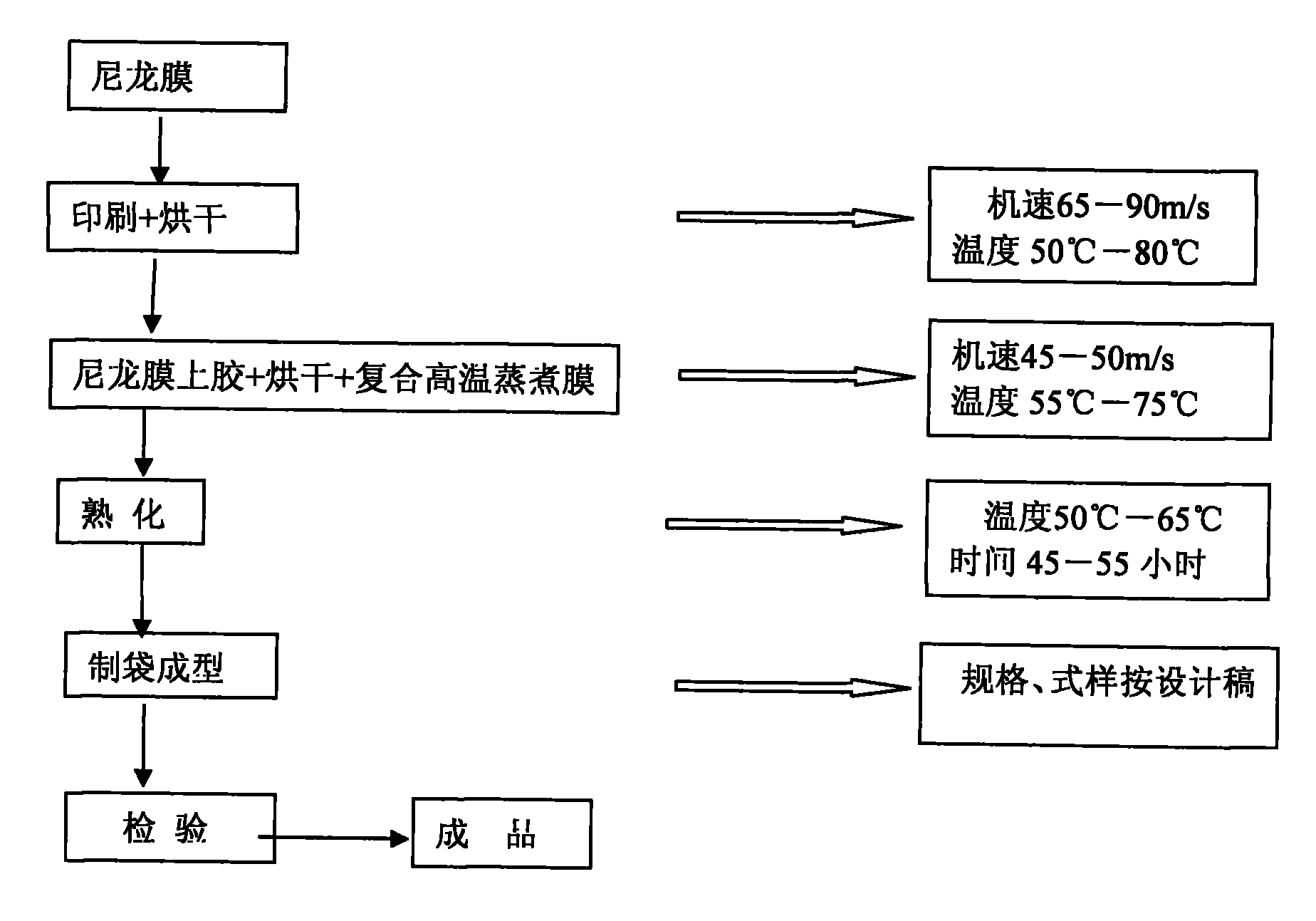

Manufacturing method of vacuum cooking and packaging bag for food

InactiveCN101837855AIncrease air flowImprove toughness and strengthLamination ancillary operationsBagsCompound aEngineering

The invention relates to a manufacturing method of a vacuum cooking and packaging bag for food, which comprises the following steps: selecting and proportioning raw materials and controlling the process flow; compounding a BOPA with an RCPP; firstly, delivering the printed BOPA into a compounding process; and proportioning a polyurethane glue and a solvent by weight; stirring uniformly and gluing on the BOPA; and manufacturing and forming a bag by heating in a drying tunnel, aging at constant temperature and heat sealing. After the food is packaged in vacuum, the vacuum package can resist high-temperature cooking and sterilizing at 135 DEG C for 30 minutes, and the packaging bag can not loose or leak air, can ensure the quality of the food and prolong the preservation and quality guarantee period of the food.

Owner:赵秀雄

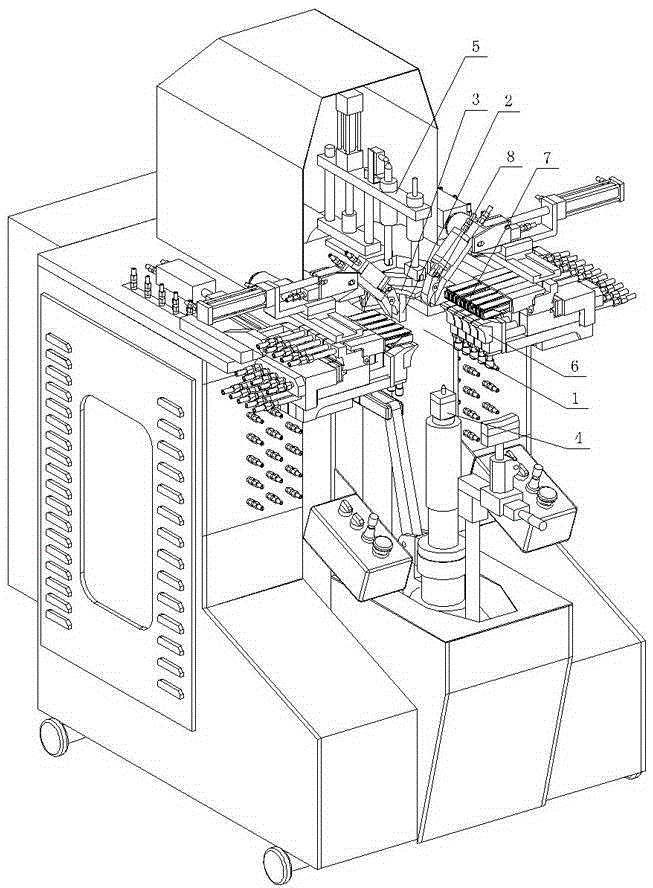

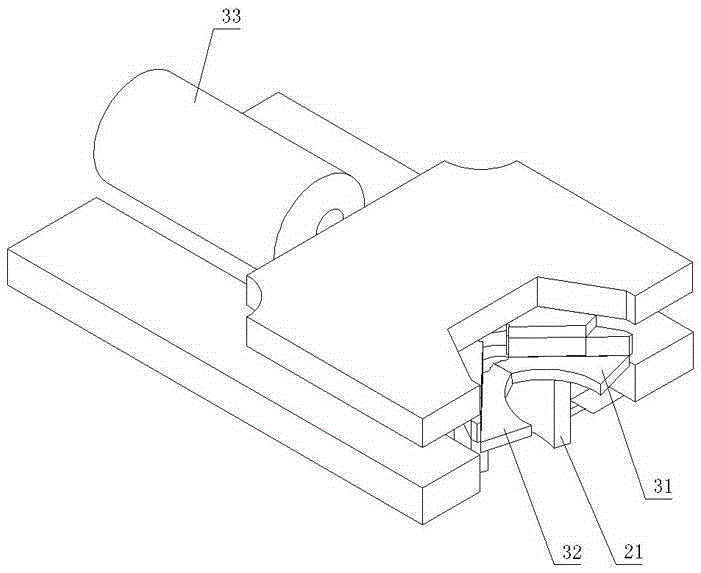

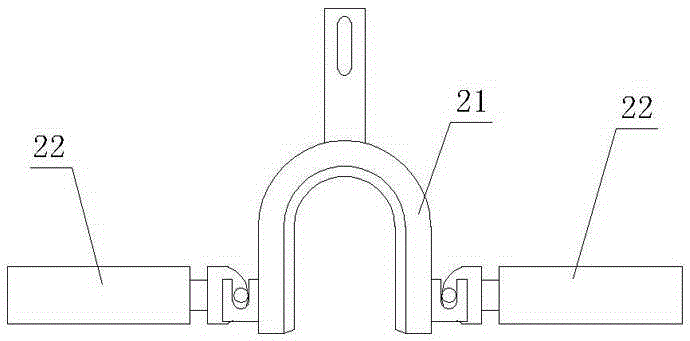

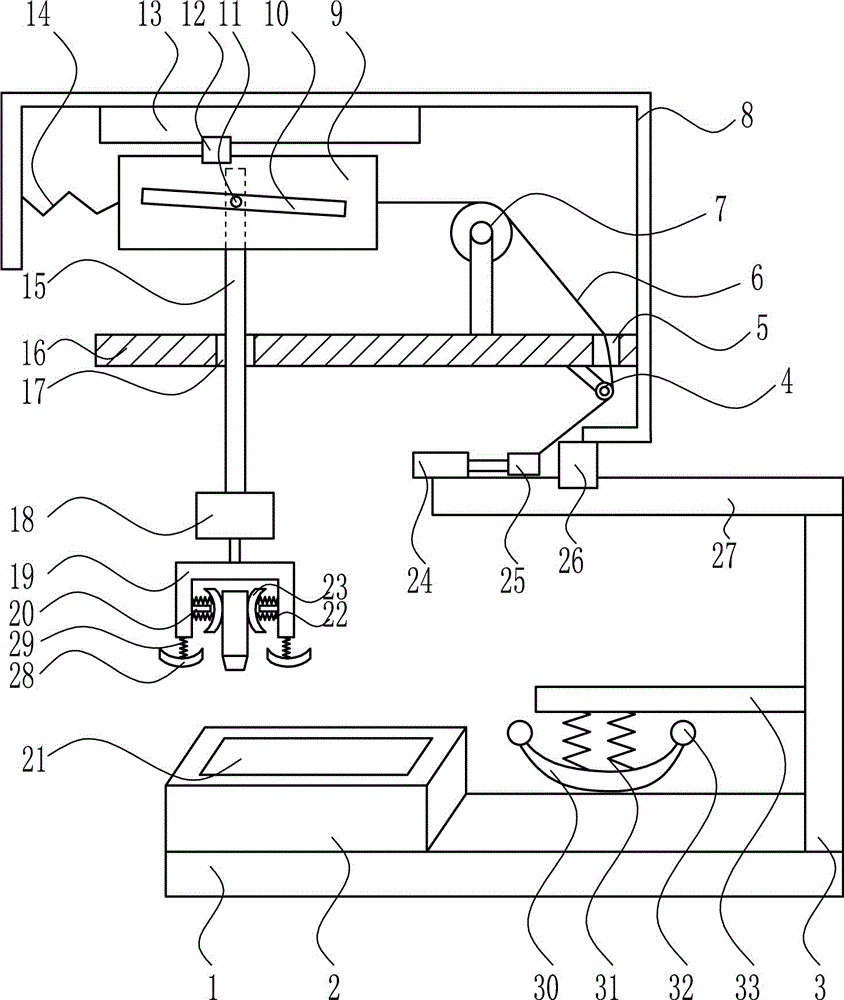

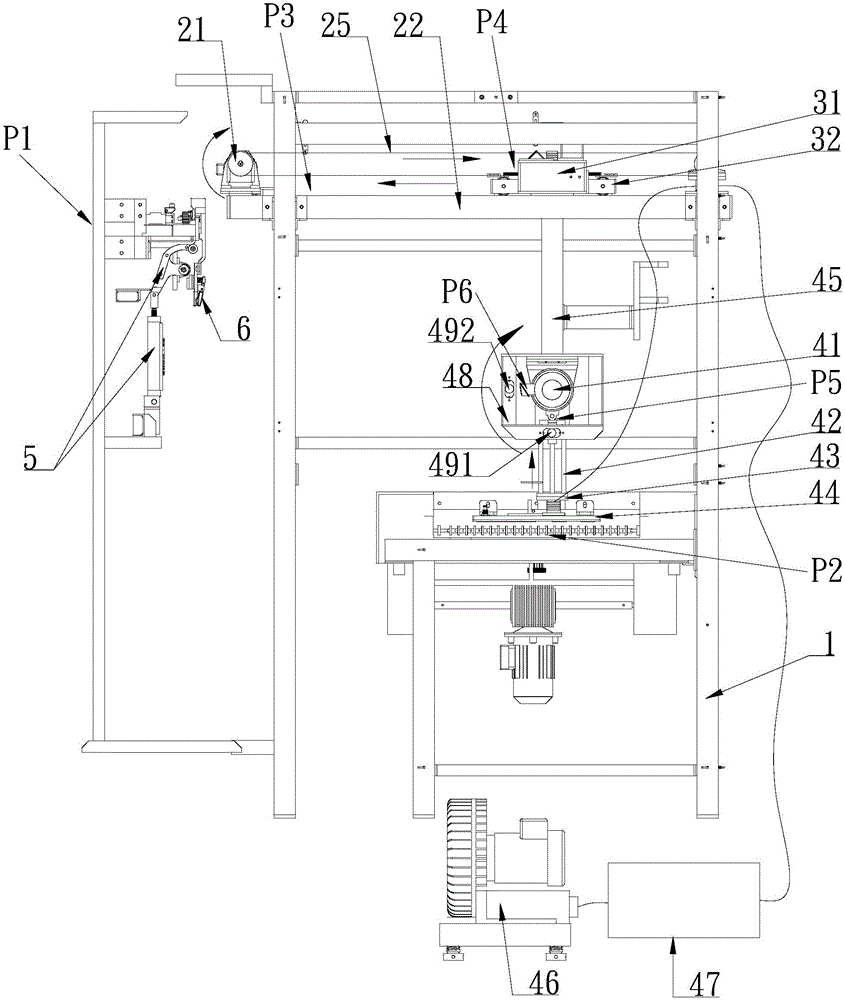

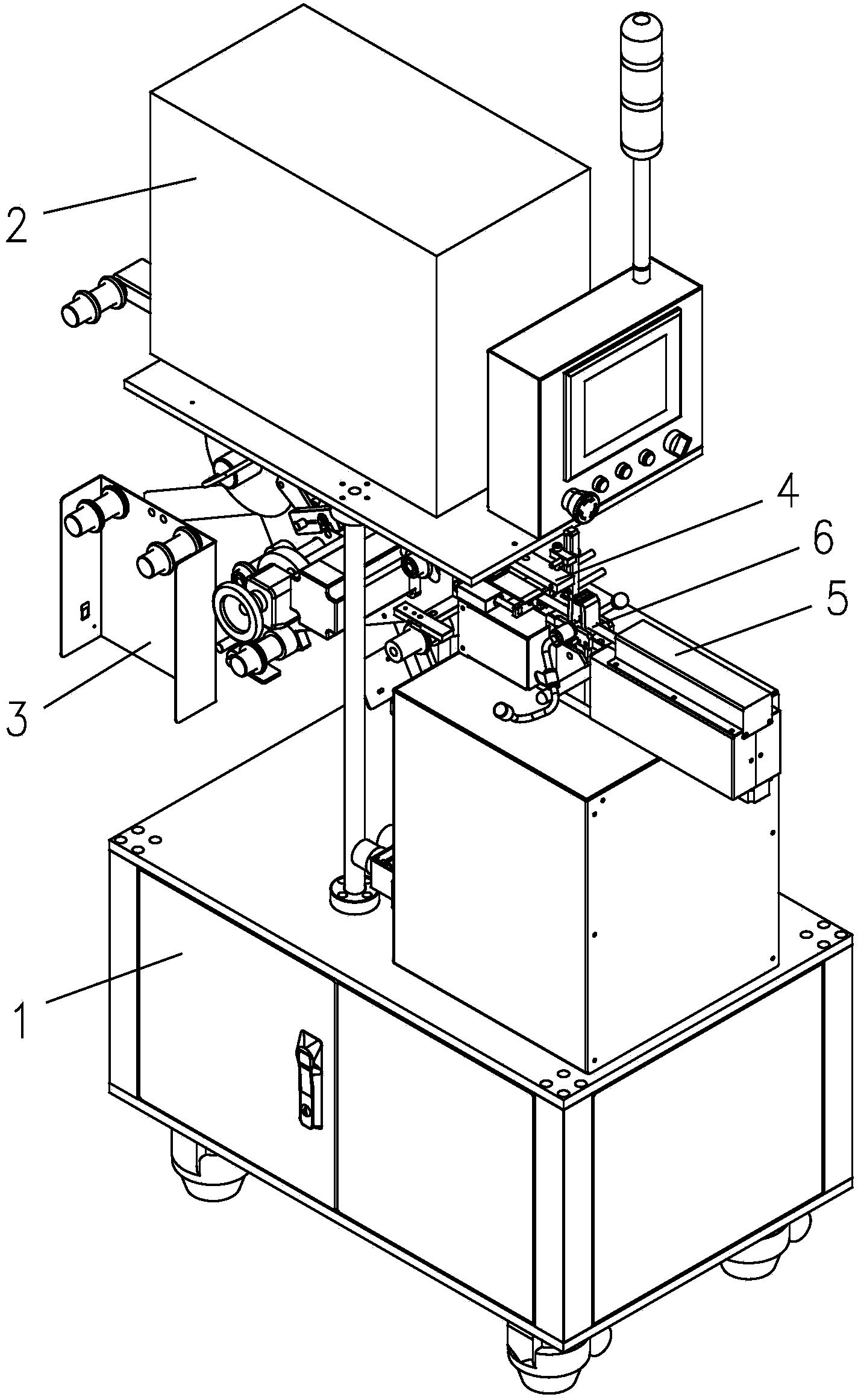

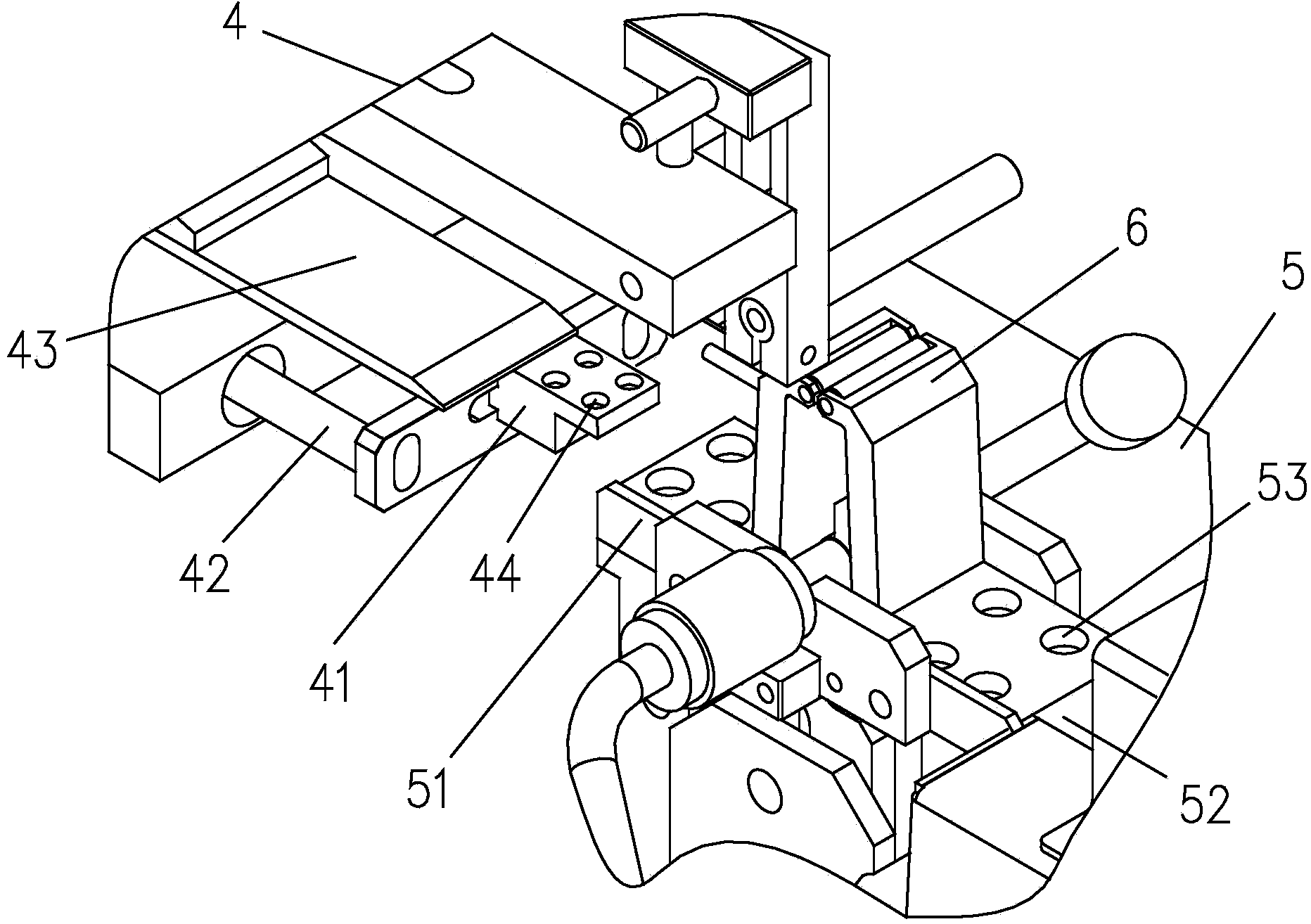

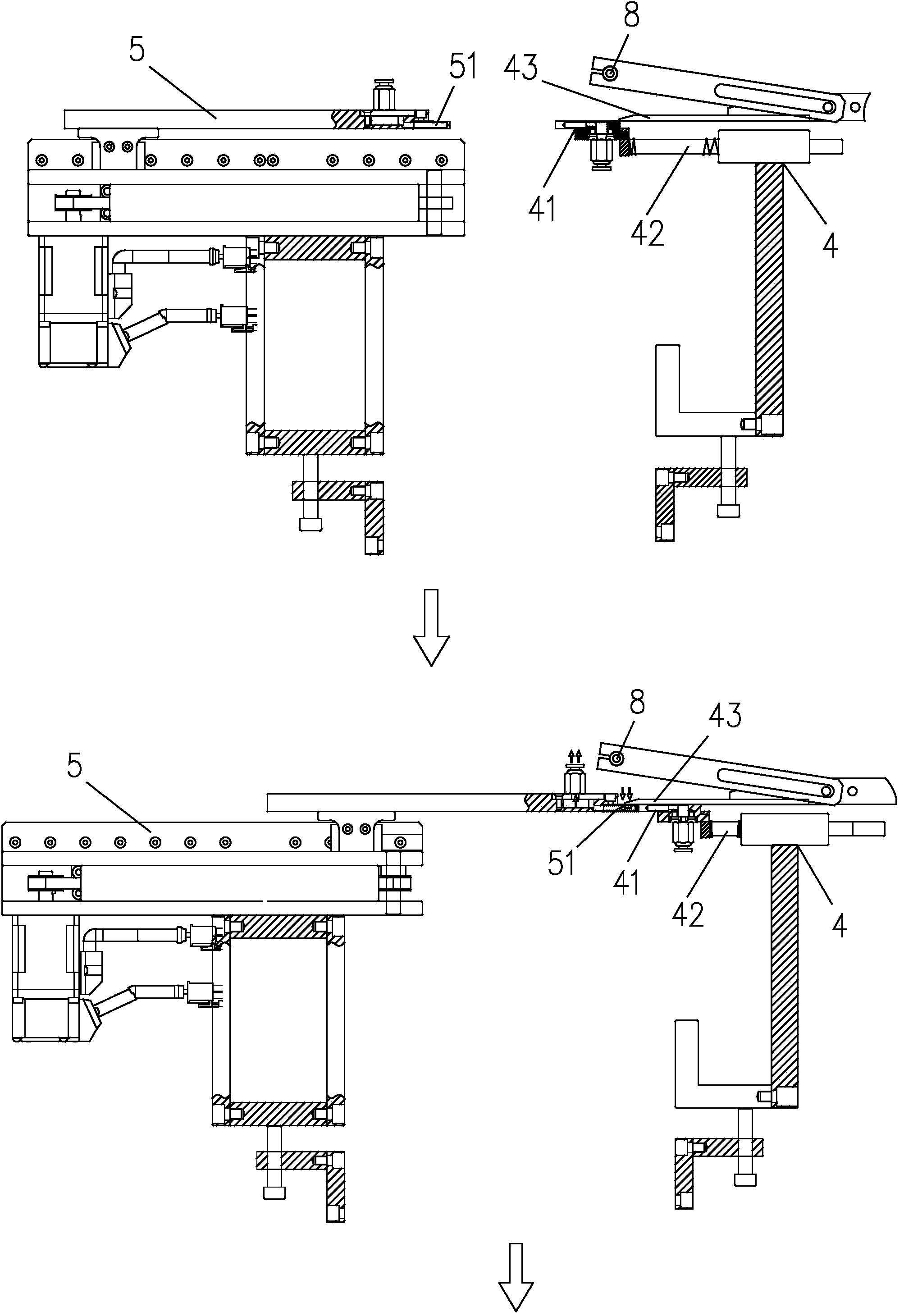

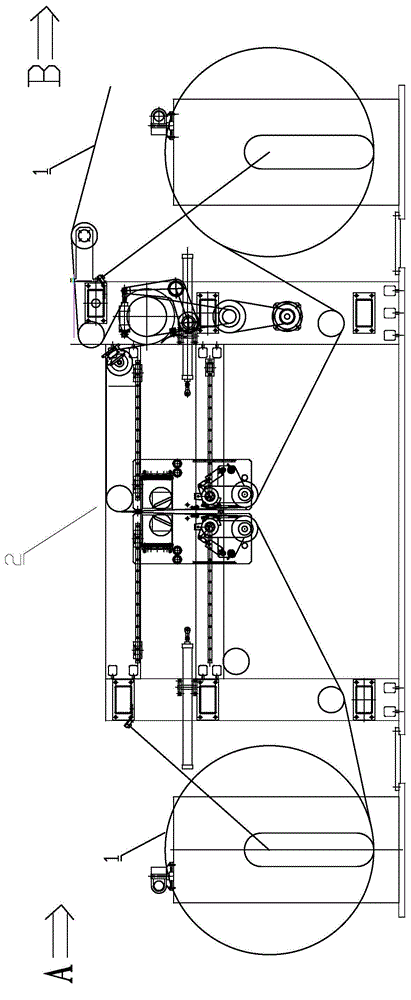

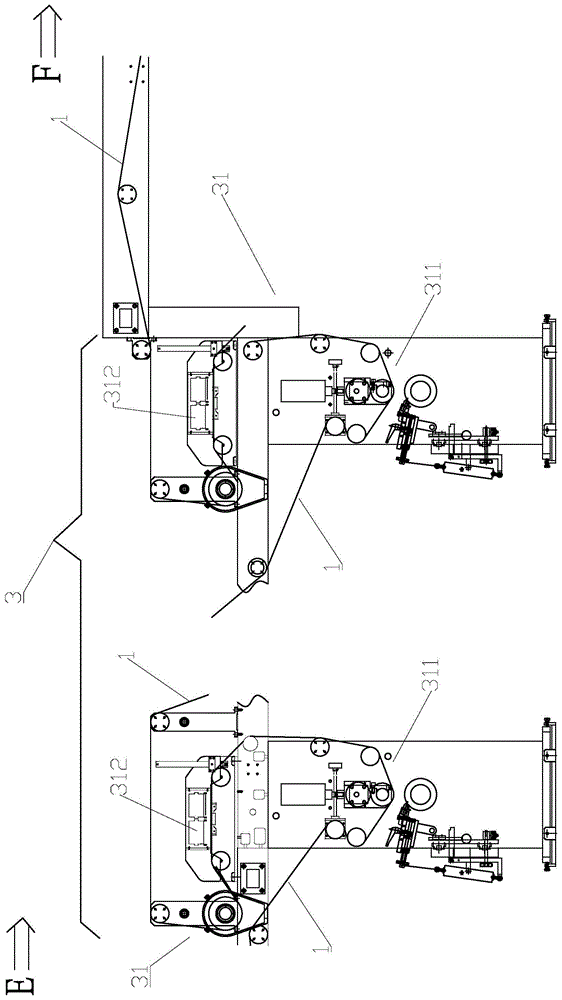

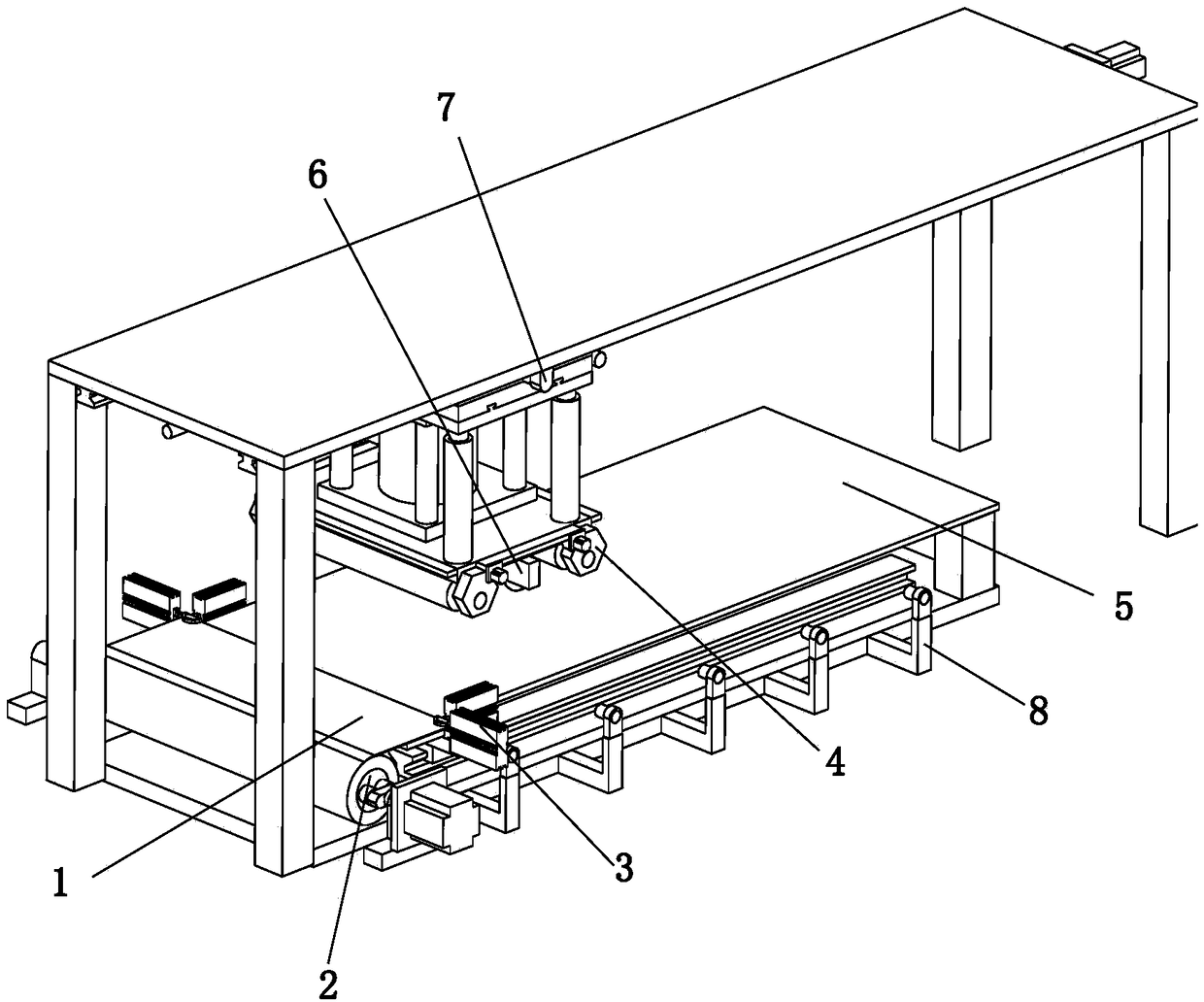

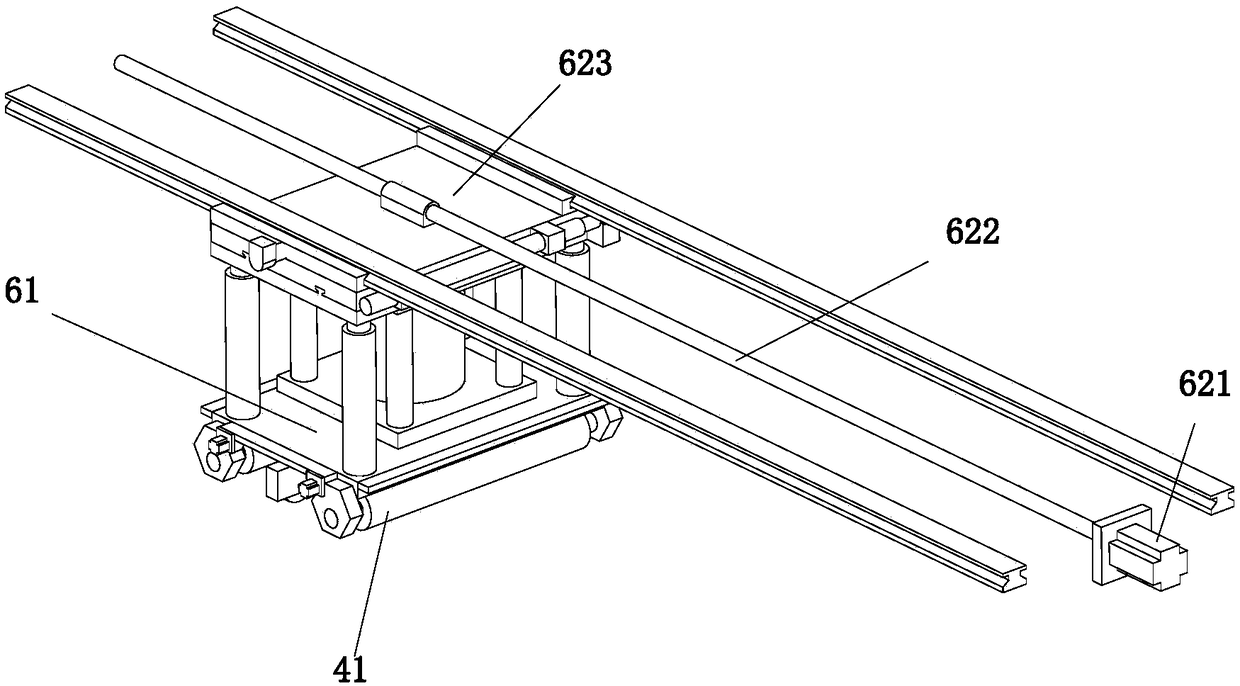

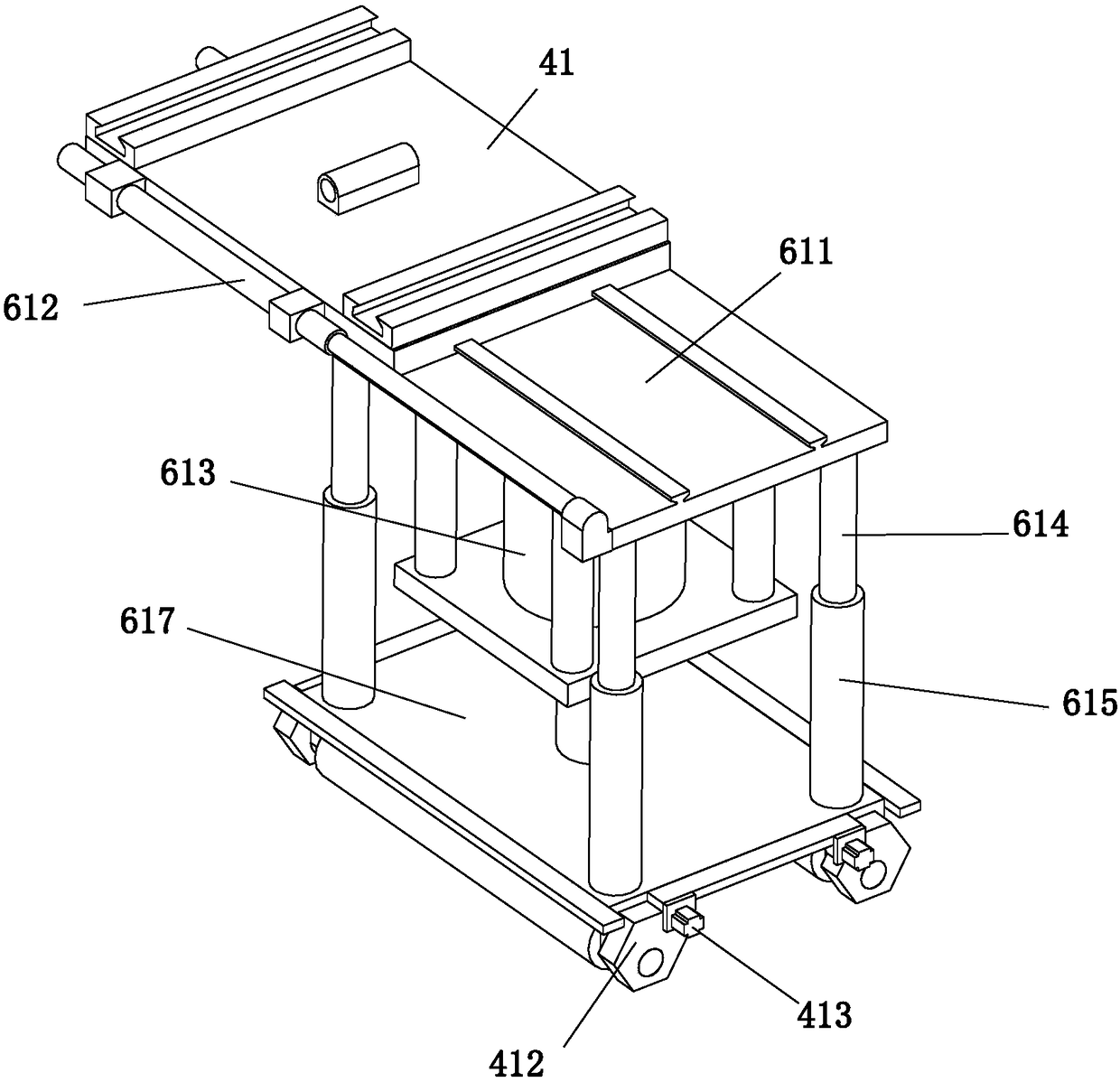

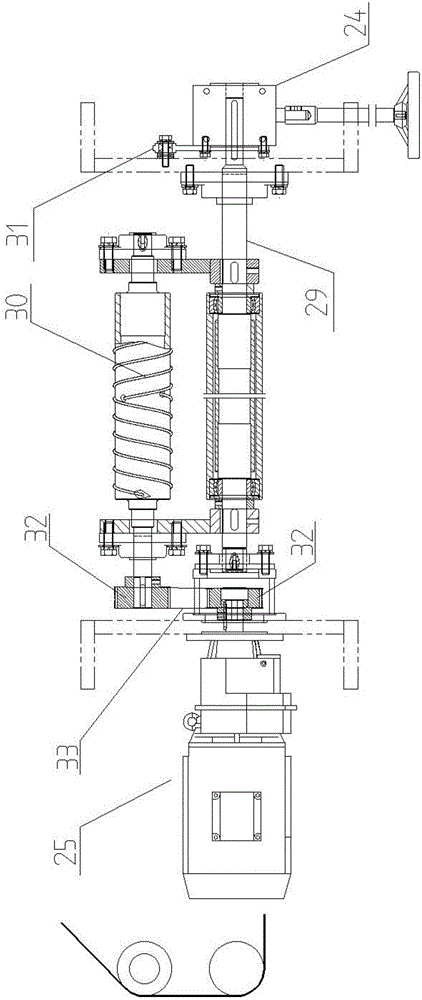

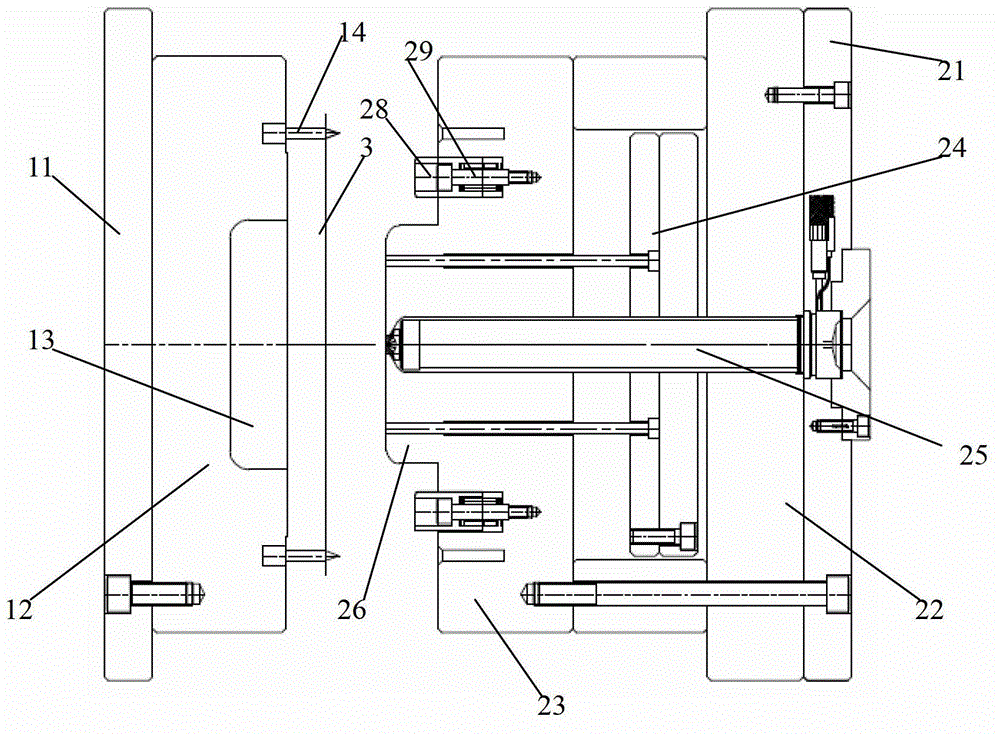

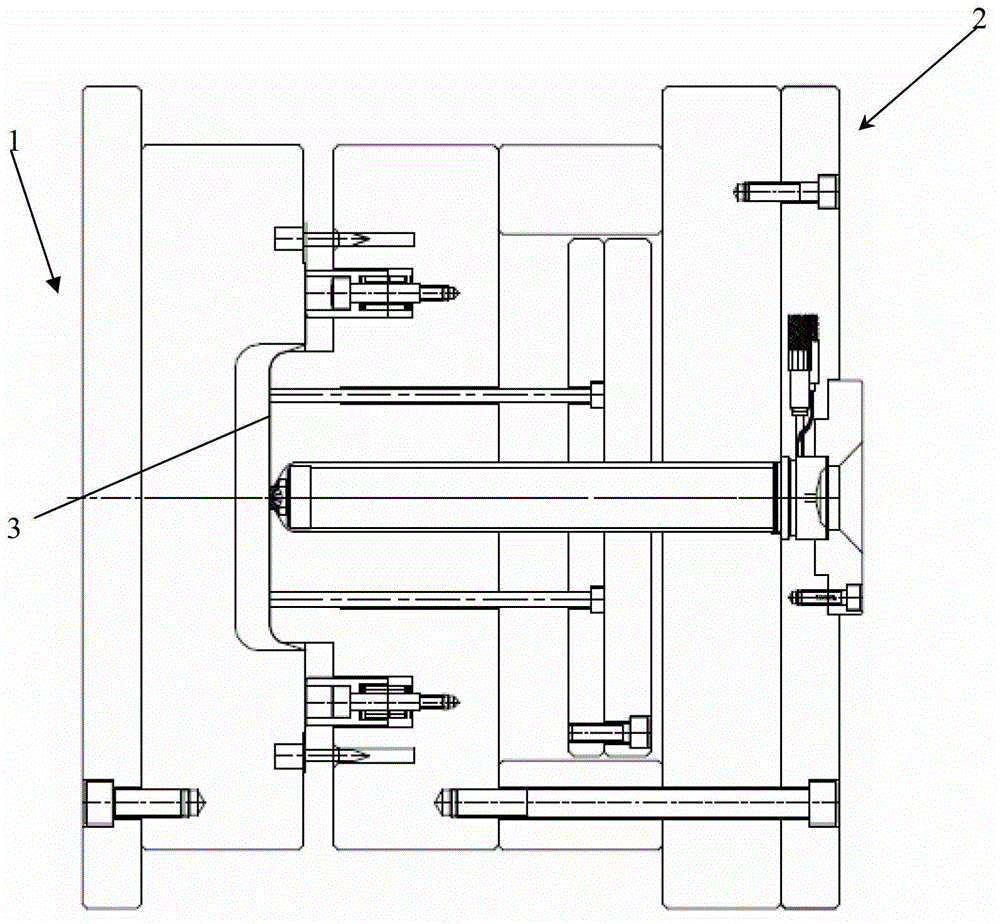

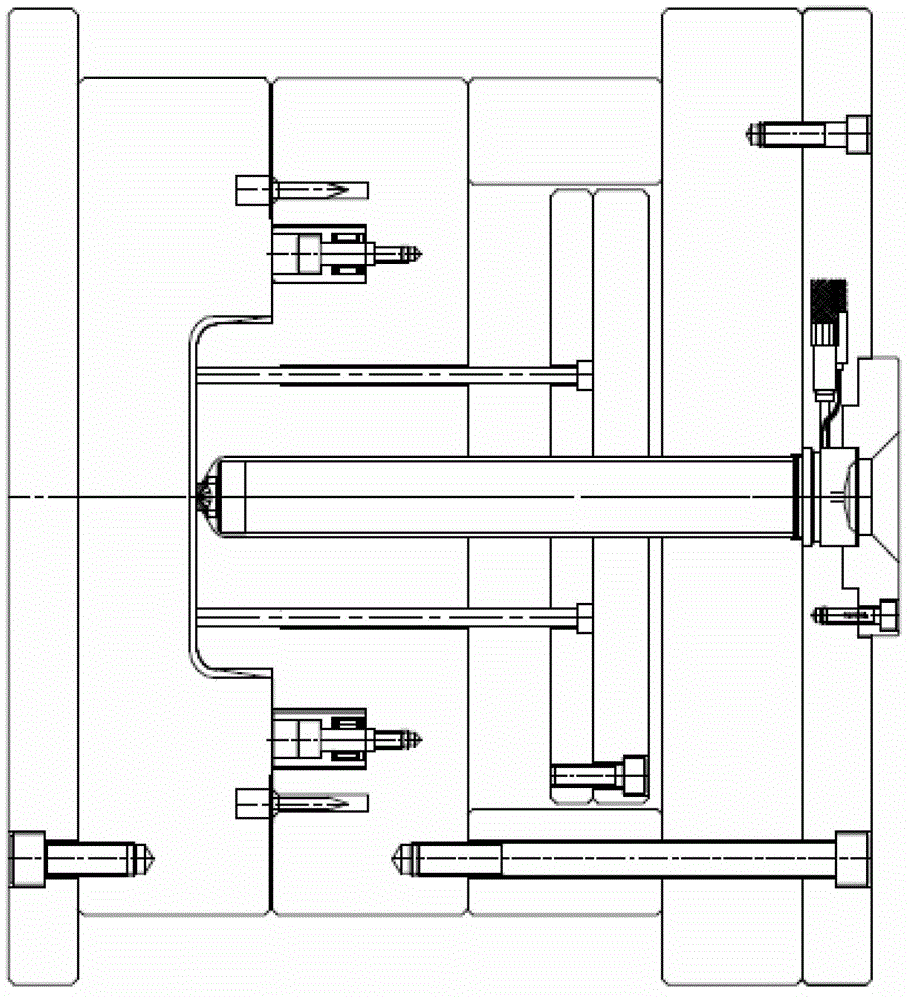

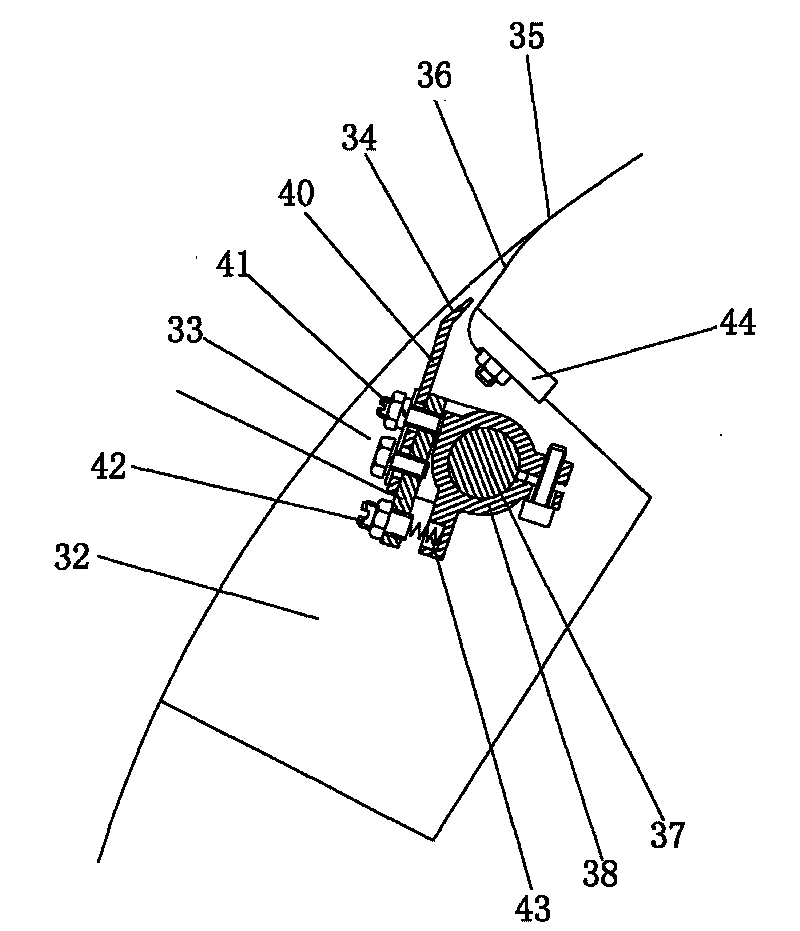

Shoe side part and heel part integrated lasting machine

The invention discloses a shoe side part and heel part integrated lasting machine. The machine comprises a lasting station. A shoe tree embedded in the shoe upper surface is reversely arranged with the head of the shoe tree facing outwards during lasting. The machine is characterized in that a shoe tree accommodating space is formed in front of the lasting station, a shoe tree heel holding component is arranged behind the lasting station, a rear wiper component is arranged above the shoe tree heel holding component, a shoe tree lifting component is arranged below the lasting station, a shoe tree pressing component is arranged on the lasting station, shoe tree side holding components are arranged on the left side and right side of the lasting station, side wiper components are arranged above the shoe tree side holding components, and side part lasting and pulling components are arranged above the side wiper components. The side part and heel part lasting procedures adopted in the traditional shoe making process are combined and achieved with one device, manual work is effectively replaced, and lasting quality and production efficiency are improved; meanwhile, the device is simple in structure and convenient to operate.

Owner:RUIAN HONGDA LEATHER & PLASTIC MACHINERY FACTORY

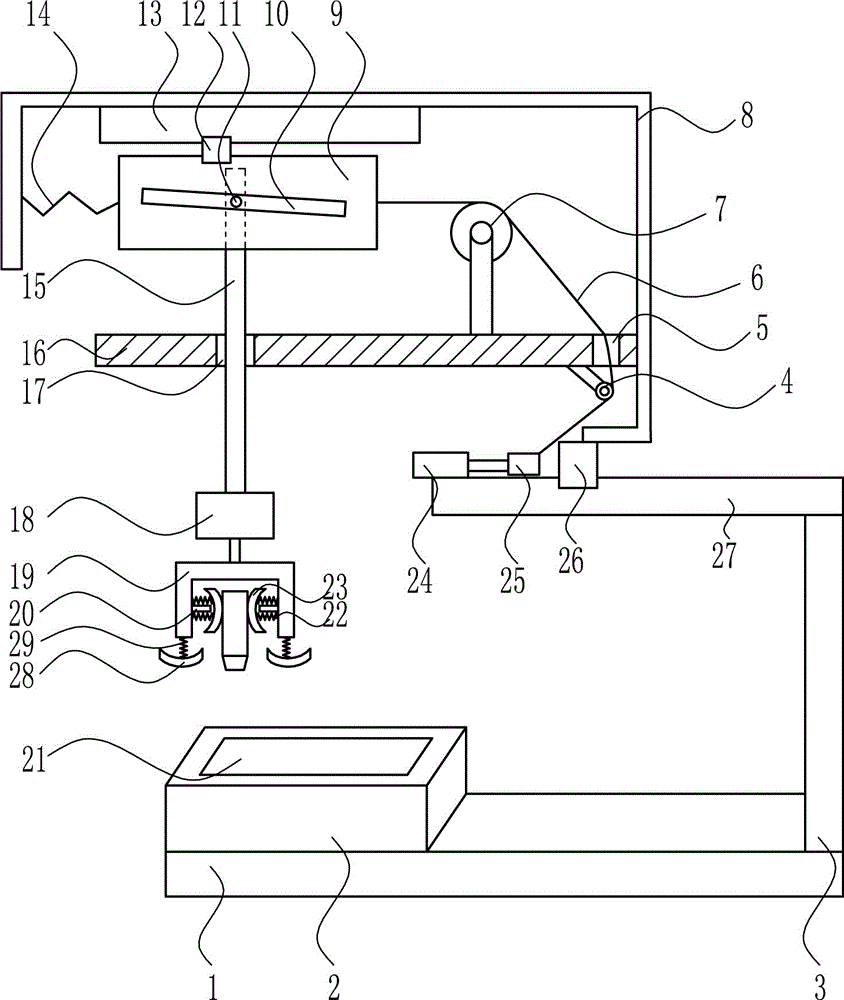

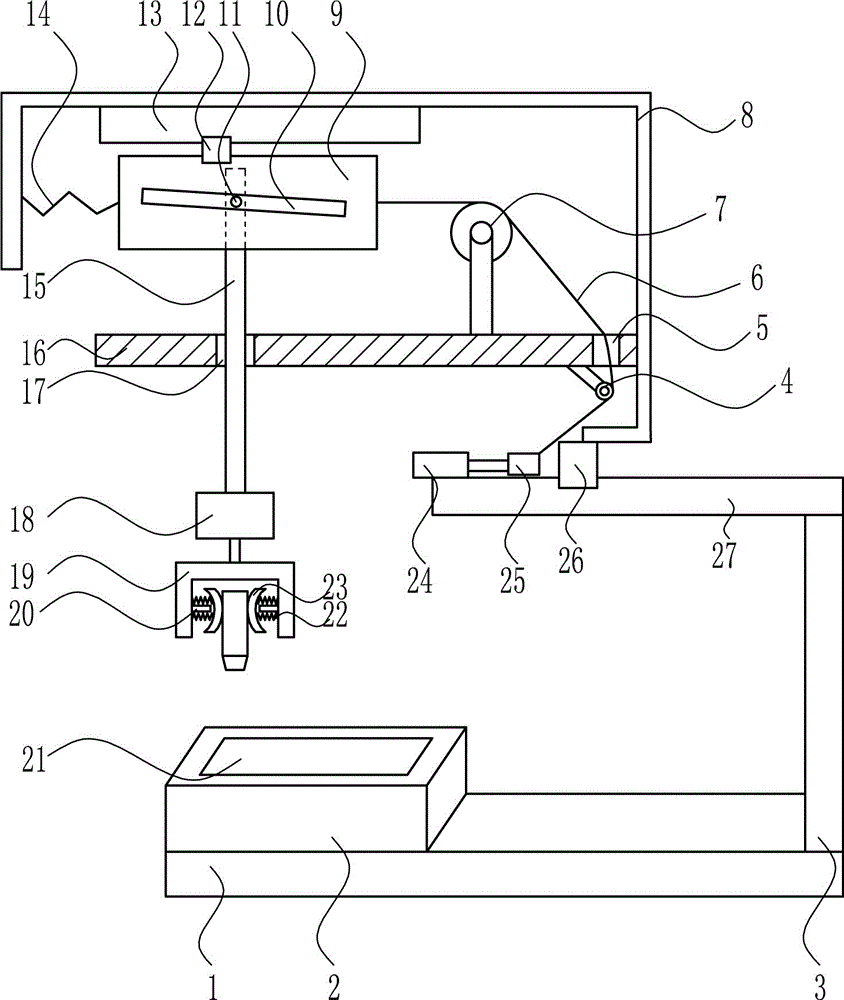

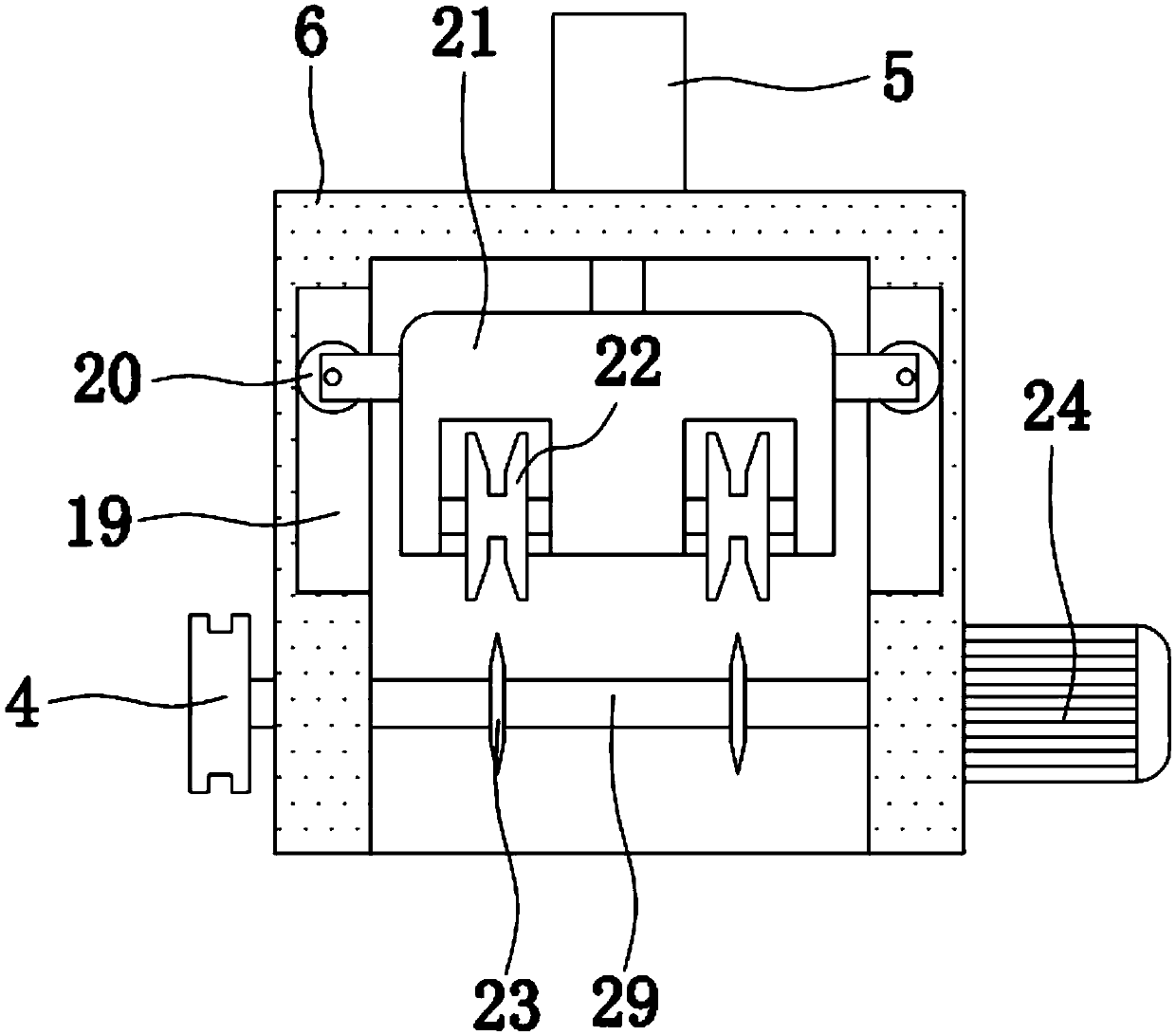

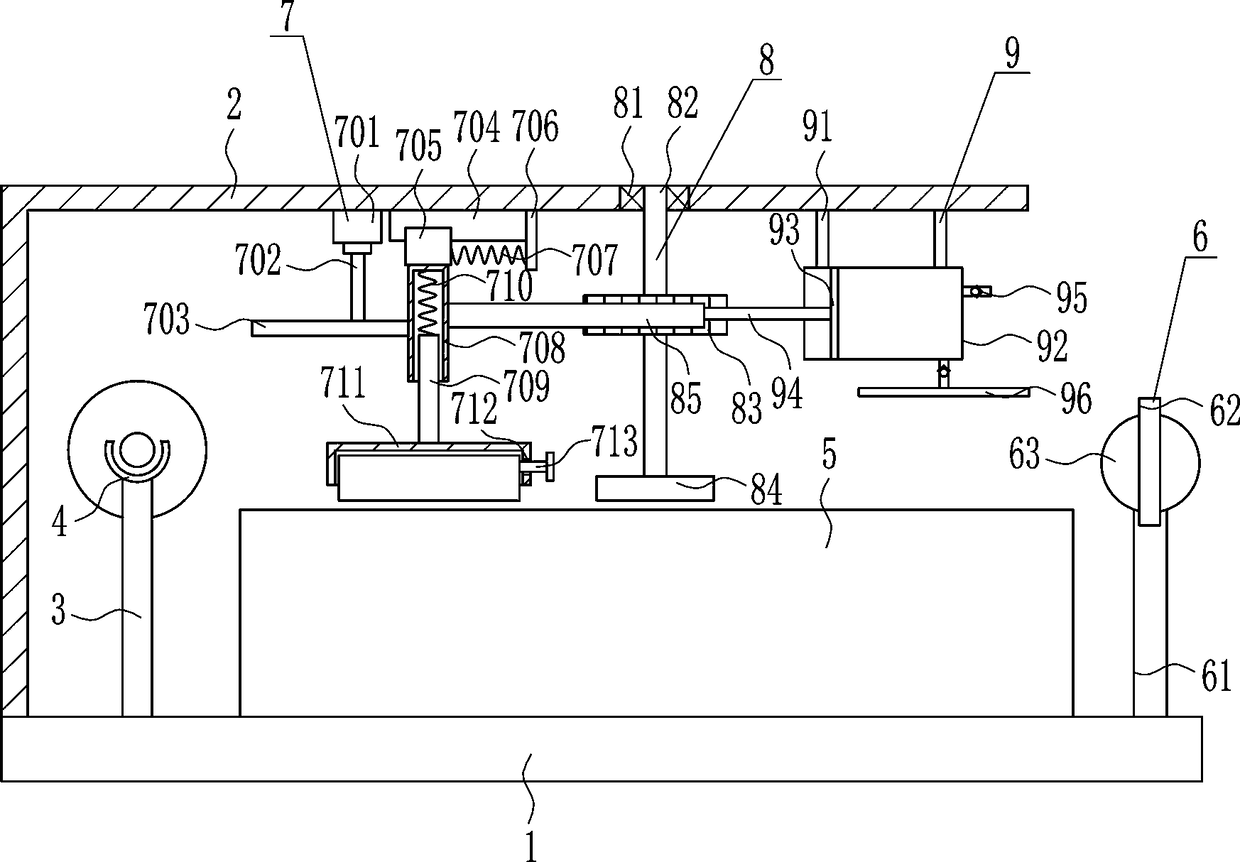

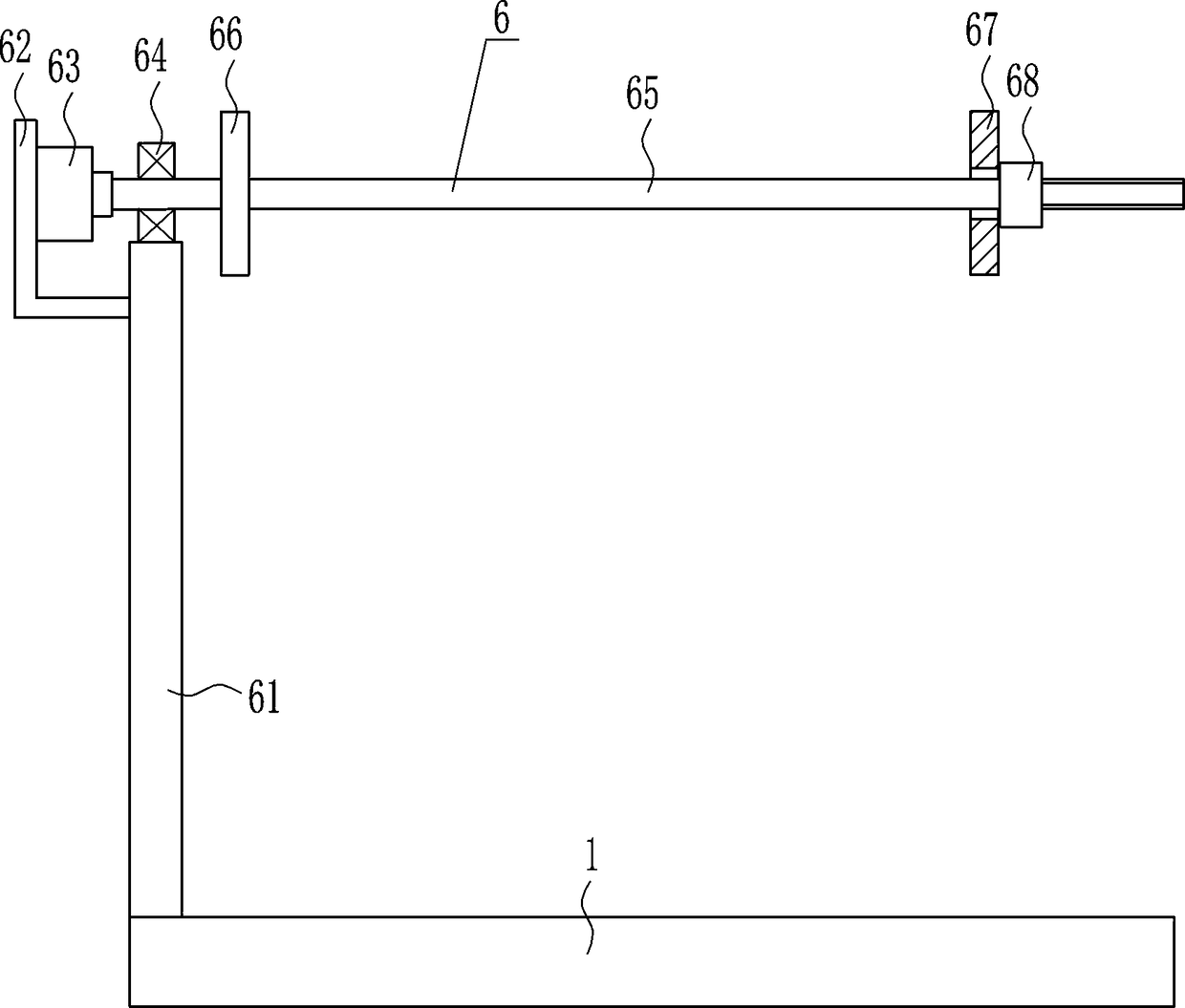

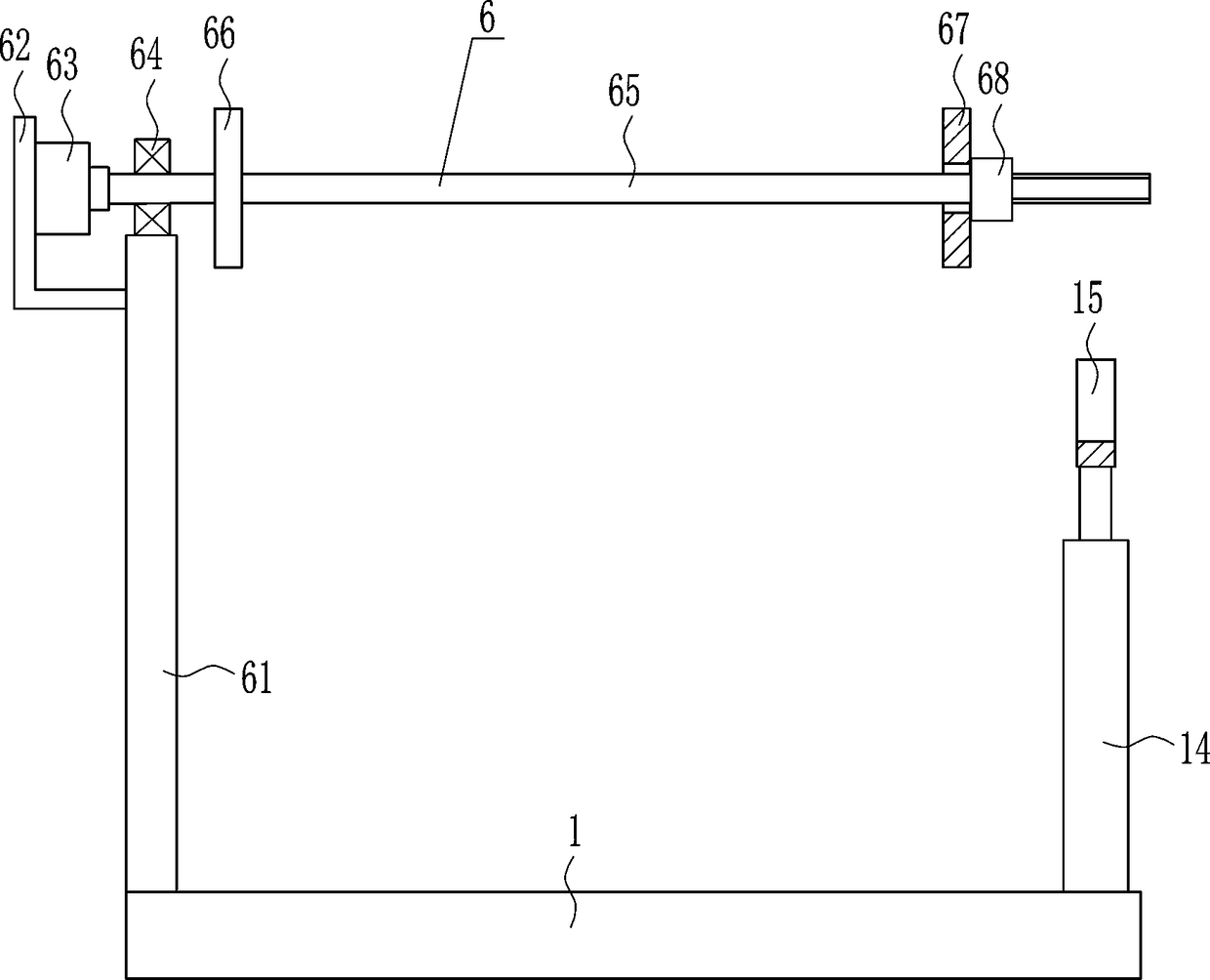

Glue coating device for teaching of accounting

ActiveCN106076736AWon't wrinkleReduce laborLiquid surface applicatorsCoatingsEngineeringIndustrial engineering

The invention relates to a glue coating device, in particular to a glue coating device for teaching of accounting. The glue coating device for teaching of accounting aims at achieving the technical purposes that the labor amount is small, smearing is uniform and the work efficiency is high. In order to achieve the above technical purposes, the glue coating device for teaching of accounting comprises a base, a placement block, a support, a small guiding wheel, a pulling wire, a large guiding wheel, an n-shaped frame, a movable block, a sliding shaft, a second sliding block, a second sliding rail, a first spring, a lifting rod, a guiding plate, a motor, a small groove body, a fixing rod, second springs, rubber pressing blocks, an electric push rod, a connection block, a first sliding block and a first sliding rail; and the placement block is arranged at the left end of the top of the bottom plate and is provided with a groove. The glue coating device for teaching of accounting achieves the effects the labor amount is small, smearing is uniform, and the work efficiency is high; and the smearing performance is optimized, paper subjected to smearing can be pressed immediately, the operation time is shortened, and the paper cannot be ruffled.

Owner:威海神舟信息技术研究院有限公司

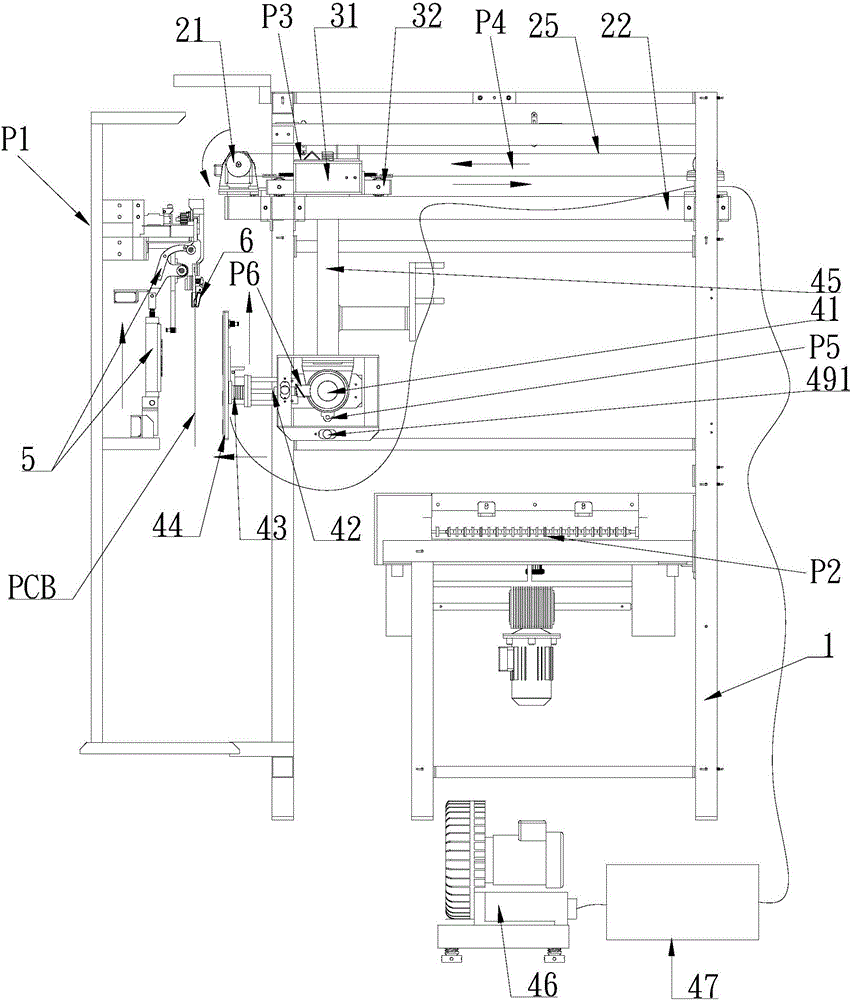

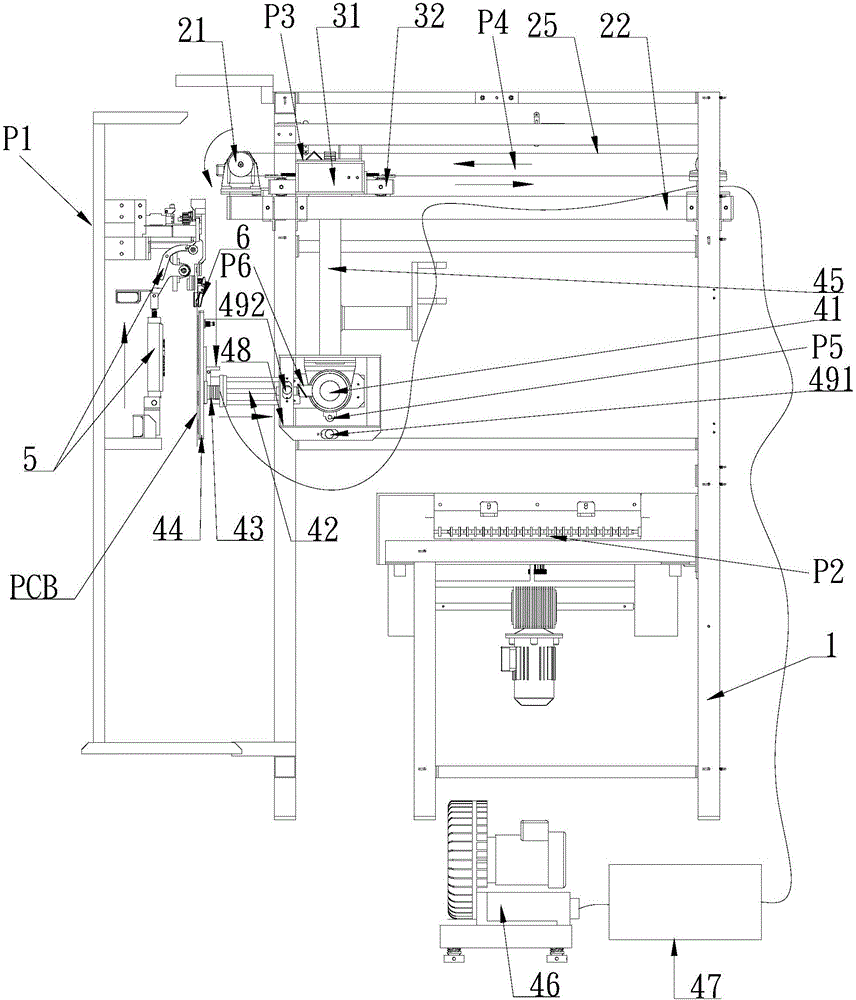

Automatic board unloader for electroplating device

ActiveCN106087015AImprove production and processing efficiencySave human effortElectrolysis componentsSensory controlEngineering

The invention discloses an automatic board unloader for an electroplating device. The automatic board unloader comprises a rack, a linear driving device, a transfer device, a suction cup device, an inductive control device and a board unloading sensory control device, wherein the linear driving device, the transfer device, the suction cup device, the inductive control device and the board unloading sensory control device are installed on the rack. The linear driving device can drive the transfer device to make linear movement between a taking position close to a board unloading position and a discharging position close to a board loading position. The suction cup device is provided with a rotary motor, a first cylinder, a second cylinder, a suction cup and a suction cup driving mechanism. According to the automatic board unloader for the electroplating device, a PCB which stops at the board unloading position can be automatically taken down from a clamp of the electroplating device and sent to the board loading position of a conveying face of an electroplating post treatment device; full-automatic operation can be conducted without manpower; and accordingly, the PCB production and processing efficiency is improved, manpower is reduced, and the cost is lowered.

Owner:GREAT CHIEFTAIN ELECTRONICS MACHINERY

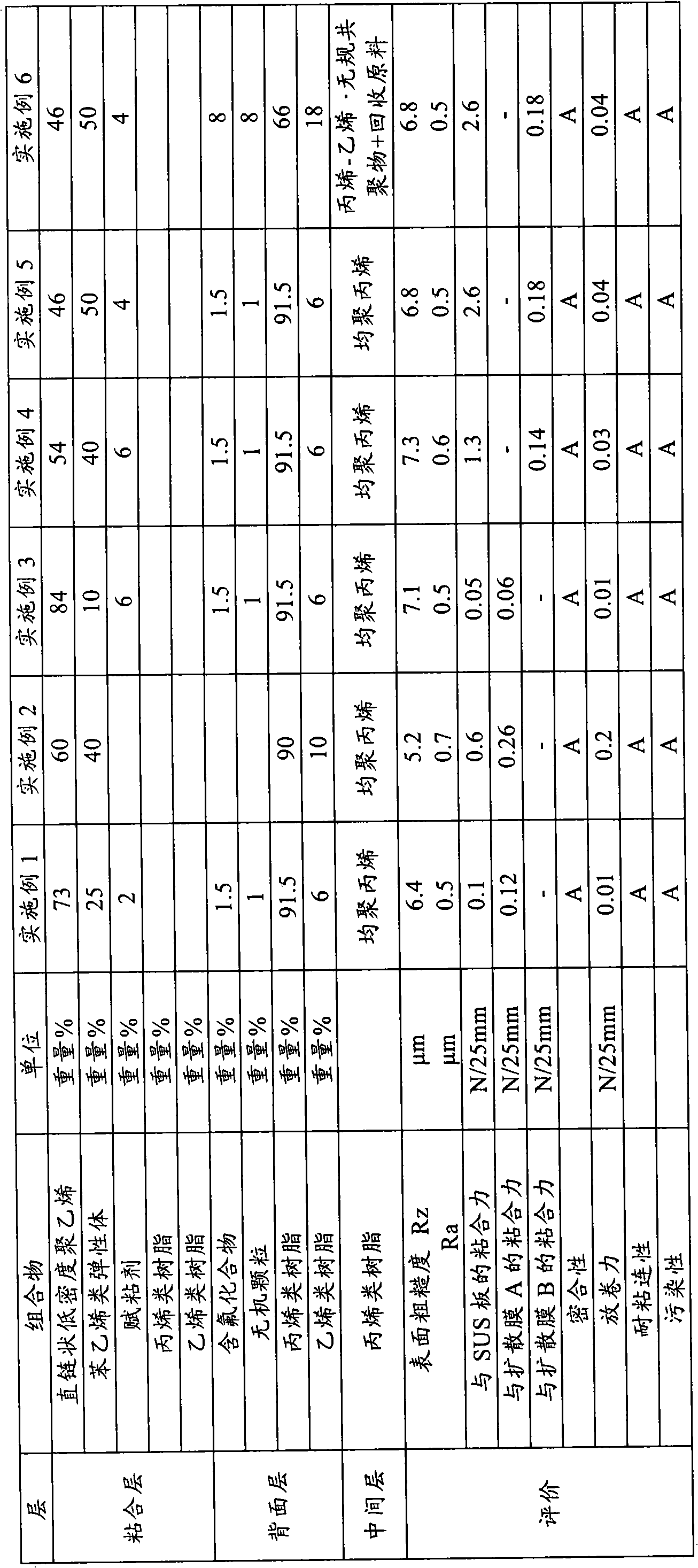

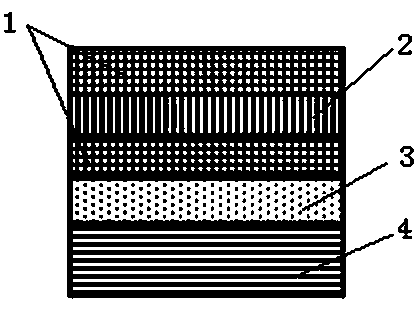

Surface protective film

ActiveCN102834263AProper adhesive propertiesEasy to slideFlexible coversWrappersLow-density polyethyleneElastomer

The present invention provides a surface protective film which has proper adhesion property even for an adherend having a rough surface, which is excellent in sliding property of a back surface and is excellent also in anti-blocking property and unwinding characteristic (unwinding tension is reduced, no wrinkle or damage occurs even upon the attaching to the adherend, and the easy and high-speed attachment is made possibly). The surface protective film of the present invention comprising a three-layer composite form consists of an adhesive layer, a middle layer and a back surface layer, wherein the adhesive layer consists of a straight chain-form low density polyethylene 35 to 90 wt.%, a styrenic elastomer 5 to 50 wt.% and a tackfier <= 15wt.%, the middle layer consists mainly of a propylenic resin and the back surface layer is composed mainly of a propylenic resin constituting the middle layer and / or different propylenic resin, and the back surface layer has a surface roughness of >= 3 [mu] m by a ten-point mean roughness(Rz).

Owner:TORAY ADVANCED FILM CO LTD

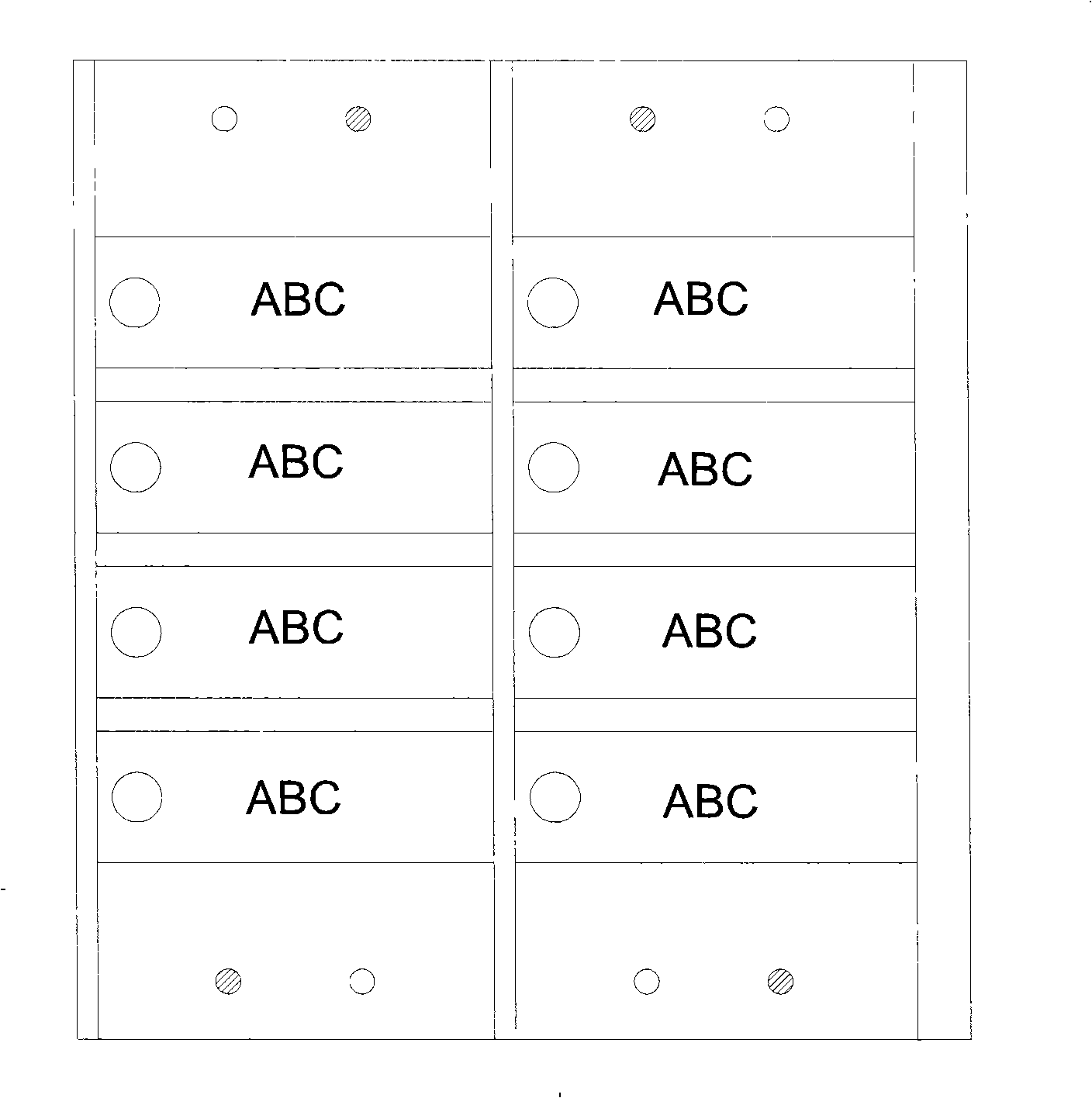

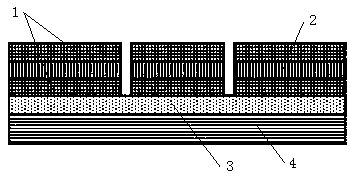

Manufacturing technique of label in mold

ActiveCN101332641AStretch smoothlyWon't wrinkleMetal working apparatusState of artThree dimensional shape

The invention discloses a manufacture process for labels in dies, comprising the steps as follows: a) printing the justification sheets such as patterns of products, justification positioning hole and a unit positioning hole; b) punching corresponding justification positioning hole on the sheets; c) die-cutting the unit positioning hole and the label shape required to be formed by a die cutter; d) forming a label with a certain three-dimensional shapes on a forming die; e) processing the final product by the injection molding. The manufacture process of the invention has the beneficial effects of overcoming the defects in the prior art such as large consumption of leftover material, easily appeared pressing marks on the edges, rupture and colour difference appearing on the curved surface, low efficiency, and the like, changes the type of the prior art that a label is singly positioned, realizes the effects that a plurality of labels commonly use the positioning hole and a plurality of labels are formed once, improves the performance of the product and reduces the production cost.

Owner:BYD CO LTD

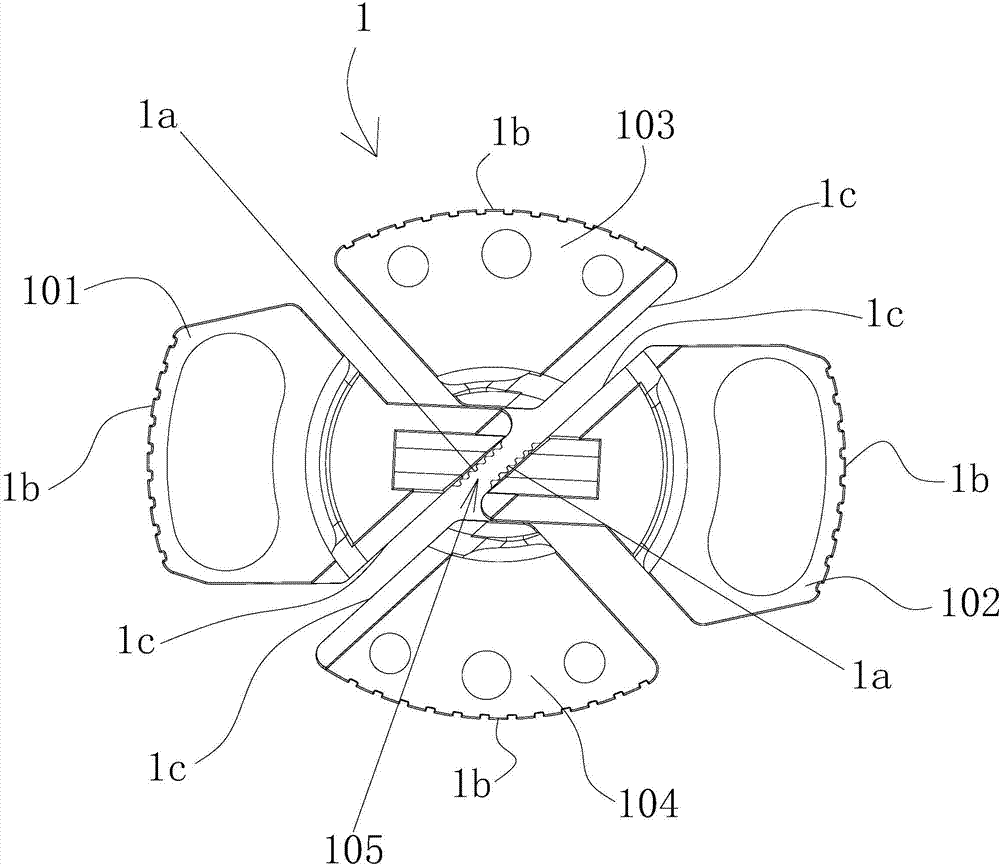

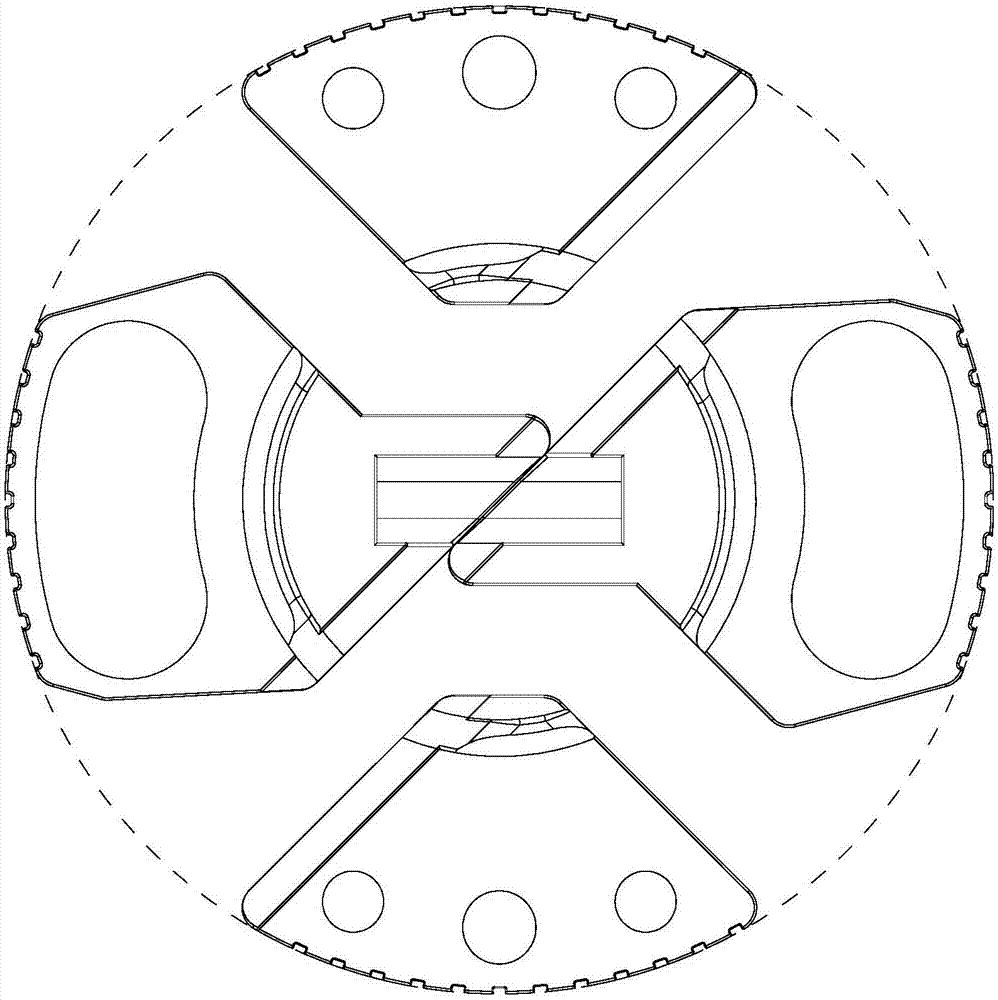

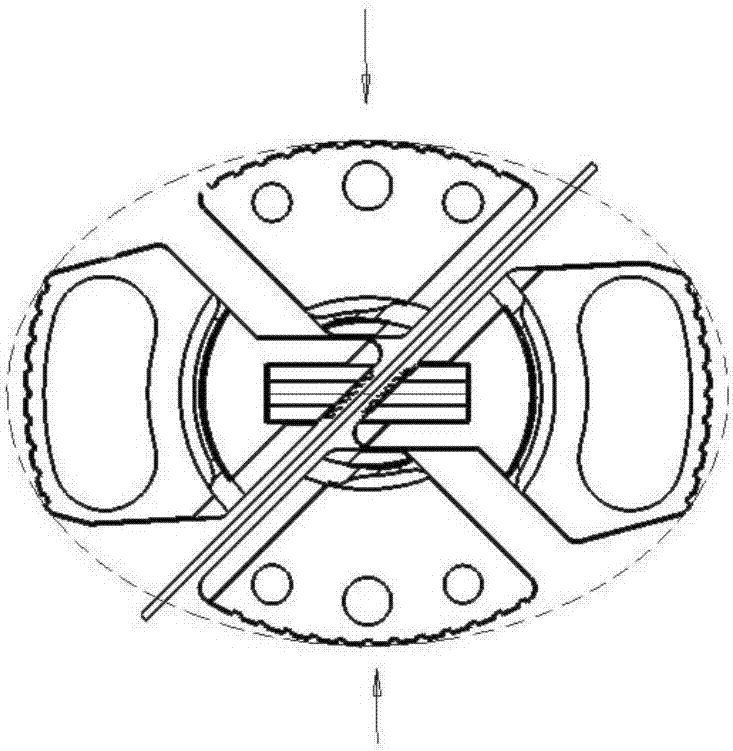

Rolling needle

PendingCN106981688ADoes not cause jitterReduce tension fluctuationsFinal product manufactureSecondary cells manufacturePole pieceTooth position

The invention discloses a rolling needle. The rolling needle comprises a left needle body and a right needle body in parallel arrangement on the left side and the right side, an upper needle body and a lower needle body in parallel arrangement up and down, a clamping gap formed between the left needle body and the right needle body, a left-right needle body displacement driving device for driving the left needle body and the right needle body to move away from each other or close to each other along the left-right direction, and an up-down needle body displacement driving device for driving the upper needle body and the lower needle body to move away from each other or close to each other along the up-down direction; clamping teeth positioned at the position of the clamping gap are arranged on the left needle body and the right needle body respectively; and circular arc-shaped outer surfaces, with the same semi-diameter, which correspond to one another are arranged on the left needle body, the right needle body, the upper needle body and the lower needle body respectively. The rolling needle has a circular outer contour, a membrane and pole pieces are wound according to the circular outer contour respectively during winding, the tension fluctuation is low, too great vibration cannot be caused for the pole pieces, and the production efficiency is greatly improved.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

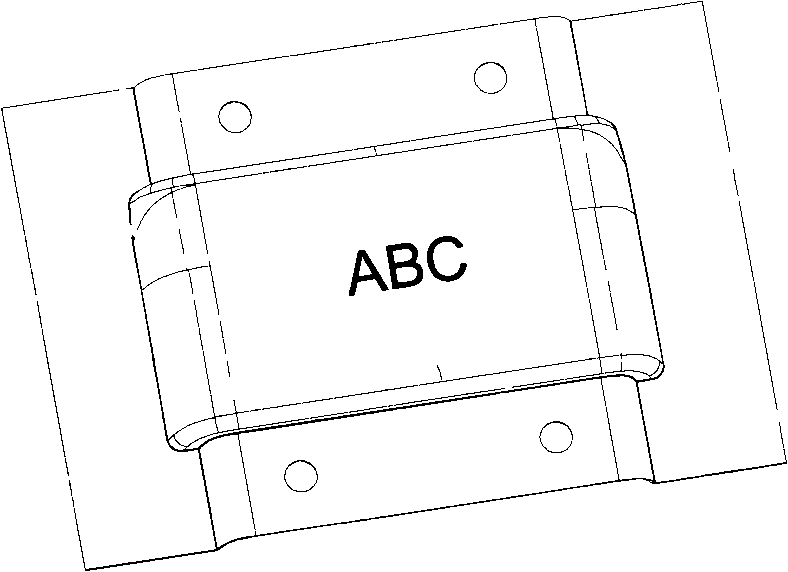

Automatic labeling machine and labeling method for product labeling

ActiveCN103662228AGuaranteed to straightenAccurate locationLabelling machinesEngineeringProduct Labeling

The invention discloses an automatic labeling machine and labeling method for product labeling. The automatic labeling machine comprises a rack, a printer and a buffer pocket, a label fixing device, a label taking device and a labeling device which are arranged between the rack and the printer, wherein the buffer pocket is located under the printer; the label fixing device is located between the buffer pocket and the label taking device; a gap is formed between the label fixing device and the label taking device; and the labeling device is located above the gap between the label fixing device and the label taking device. During labeling, a label is fixed and straightened by the label taking device and the label fixing device and bonded by the labeling device. The automatic labeling machine has the benefits as follows: the label fixing device cooperates with the label taking device, so that the label is straightened and accurate in position, corrugation is avoided during labeling, and the label is positioned accurately. The distance between the label fixing device and the label taking device is changeable, so that the machine is applicable to labeling of objects with different sizes, particularly to labeling of long and thin objects. No requirement is applied to the printer, and any printer is applicable. The machine is small in size, low in cost and high in yield and product pass percent.

Owner:SHANGHAI LAWARE PACKAGING MACHINERY

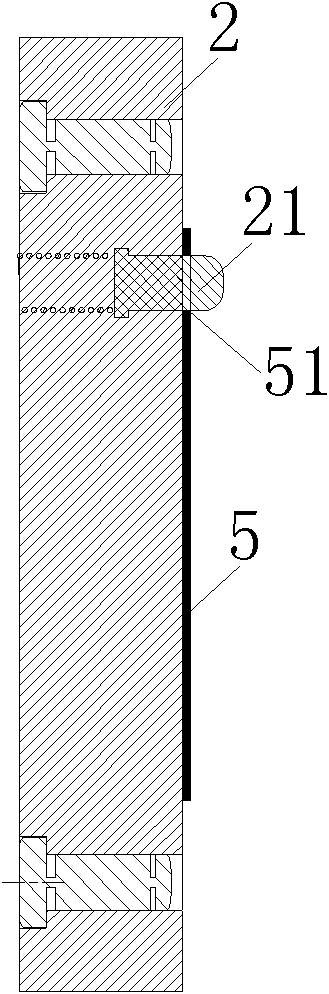

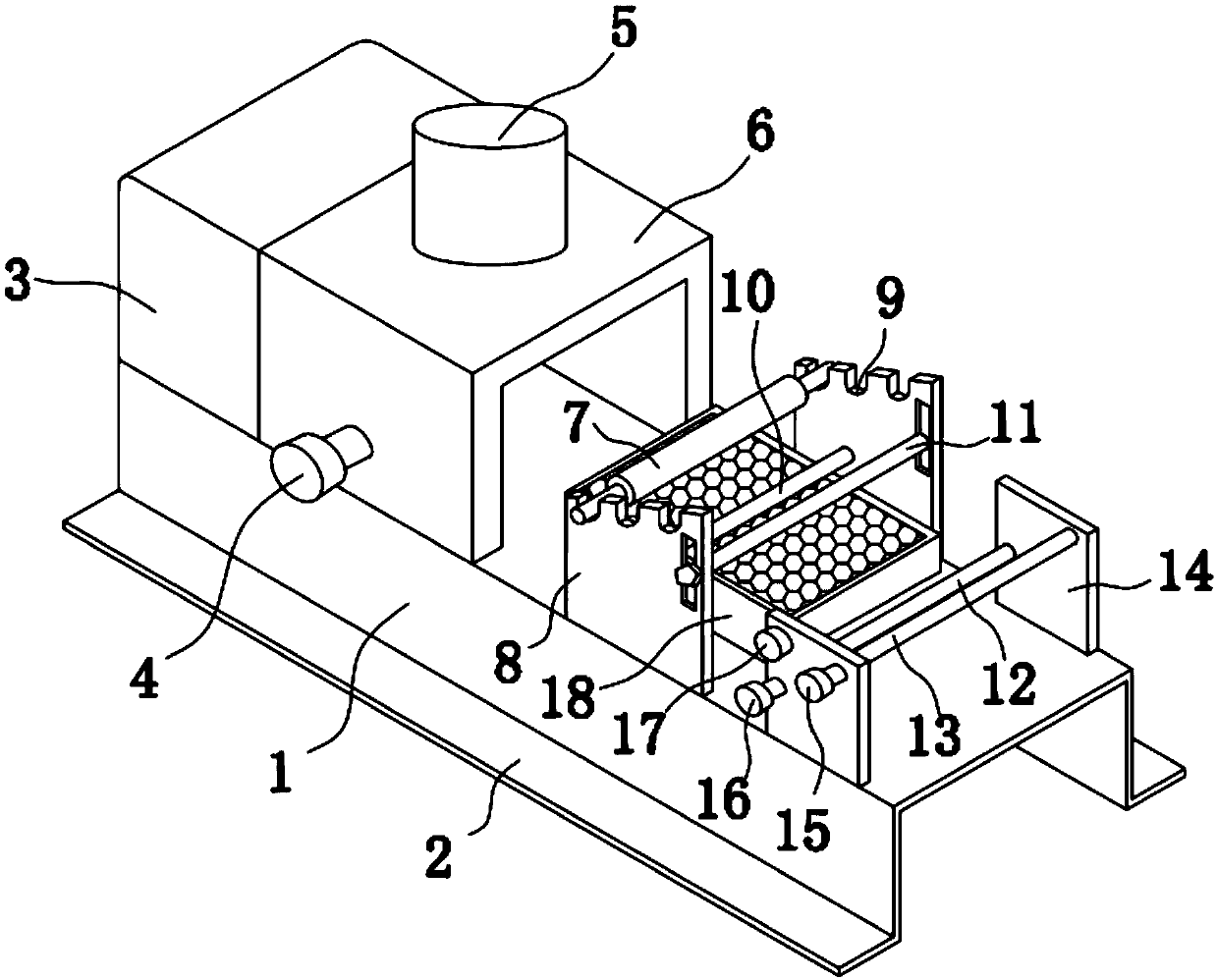

Automatic slitting and winding structure for digital printing machine

ActiveCN108675030AImprove cutting effectWon't wrinkleSevering textilesRotary pressesDigital printingAutomatic testing

The invention discloses an automatic slitting and winding structure for a digital printing machine. The automatic slitting and winding structure comprises a base. A digital jet printer, a slitting box, first vertical plates and second vertical plates are sequentially arranged at the upper end of the base from the rear to the front. A servo motor is mounted on the right side wall of the slitting box. A rotating shaft at the output end of the servo motor penetrates into the slitting box. The tail end of the rotating shaft extends out of the left side wall of the slitting box and is connected with a driving pulley. Slitting blades are arranged at the end, located in the slitting box, of the rotating box. A first guiding rod is connected to the portion between the middle portions of the firstvertical plates. A second guiding rod is connected to the portion between the front sides of the first vertical plates. A heating resistance wire heats air inside a drying box, and the heated air is blown to cloth passing through the first guiding rod and the second guiding rod through a gas permeable mesh plate by means of a fan, and the printed cloth is dried. Guide wheels press the cloth, and the cloth does not wrinkle, so that the slitting blades have a better slitting effect on the cloth.

Owner:湖南天闻新华印务有限公司

LED UV cold light source full-gravure solvent-free printing technological method

InactiveCN104786684APrinting environmental protectionRealize printingOther printing apparatusPrinting after-treatmentColor printingPrinting ink

The invention discloses an LED UV cold light source full-gravure solvent-free printing technological method. The method includes the following steps that first, a printed material is conveyed forwards; second, the printed material is conveyed to a multi-color printing machine set which comprises a plurality of printing units, and each printing unit comprises a UV printing machine using UV ink for printing and an LED UV cold light source used for drying the printed material. The printed material is conveyed into the position between a gravure printing rubber roller and a gravure printing plate roller of the corresponding UV printing machine, a UV ink supply device supplies ink to the gravure printing plate roller, patterns on the gravure printing plate roller are transferred to the surface of the printed material in the rotating process of the gravure printing rubber roller and the gravure printing plate roller, and then the patterns on the surface of the printed material are cured by the corresponding LED UV cold light source; third, the printed material continues to be conveyed to the next printing unit, and another color is printed; fourth, the third step is repeated according to the category number of needed colors; fifth, the printed material subjected to the fourth step is cut into finished products.

Owner:ZHONGSHAN SOTECH PRINTING MACHINERY CO LTD +1

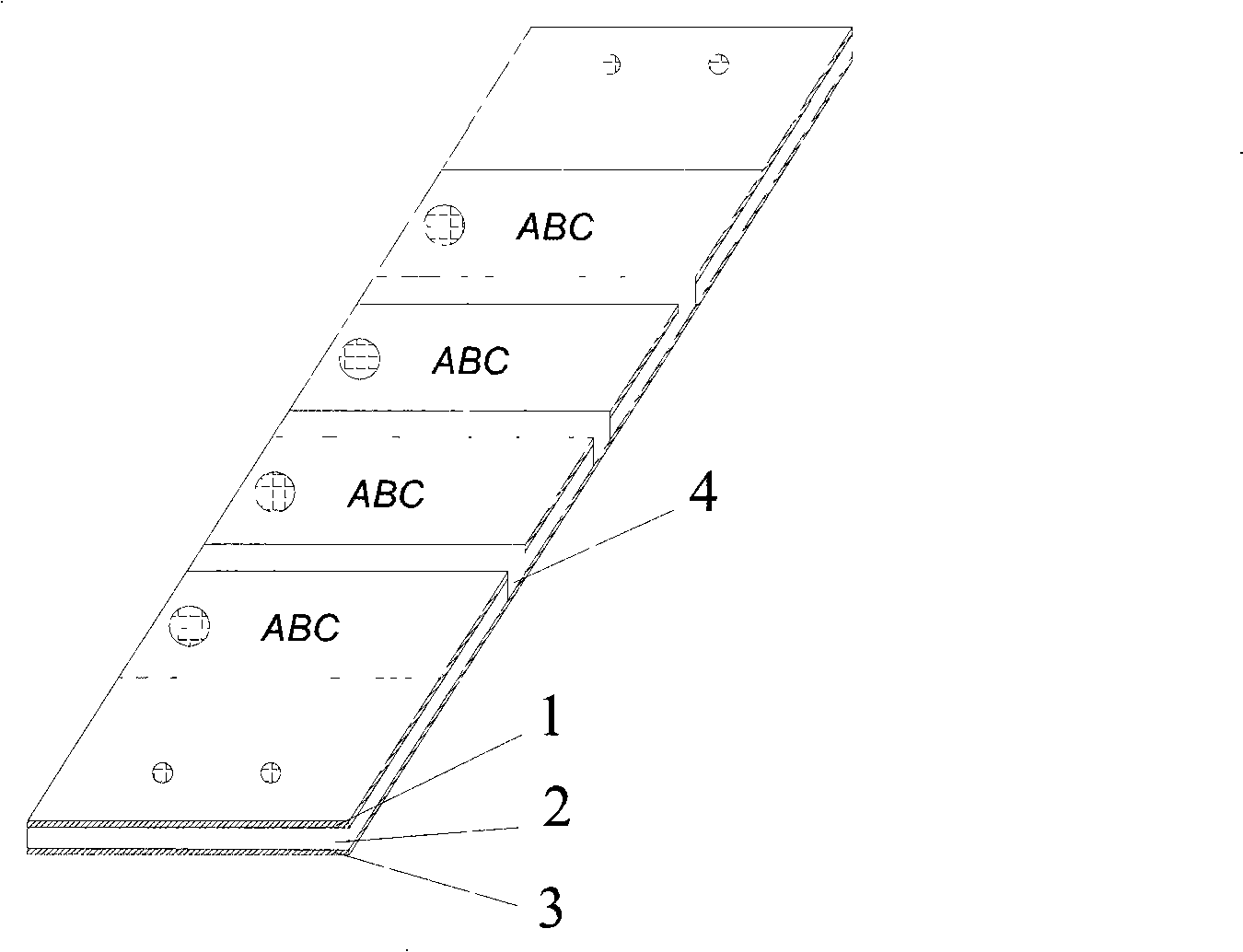

Method for drilling rolled flexible printed circuit board

InactiveCN103732010AWon't wrinkleSave laser processing timePrinted element electric connection formationCopper foilEngineering

The invention discloses a method for drilling a rolled flexible printed circuit board. The method comprises the following steps of 1 bonding a bearing film on one side of a rolled raw material; 2 using a laser machining machine to perform hole drilling on the rolled raw material bonded with the bearing film; 3 tearing off the bearing film and obtaining the flexible printed circuit board with holes. In the machining process by adopting the method, all of through holes can be directly subjected to shape cutting, residual copper foil materials are left on the bearing film 4 for saving the laser machining time, residues after laser machining can be directly stripped and removed with the bearing film 4. In addition, the flexible printed circuit board is required to move with a laser machine platform at high speed, copper foils are not draped, the production efficiency is improved, the cost is reduced, and the production quality is ensured.

Owner:杨秀英

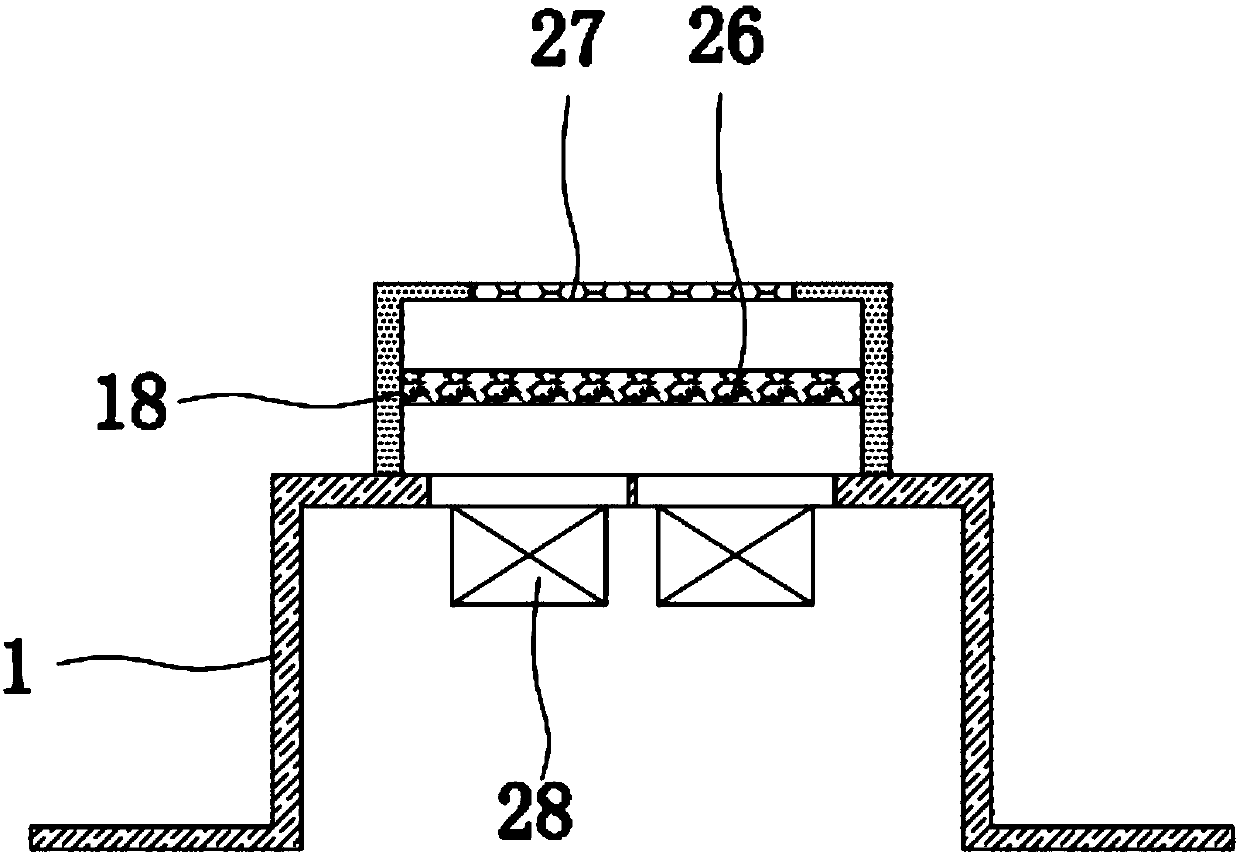

Automatic assembly line equipment for steam finish-ironing and shaping

ActiveCN104452241AWon't wrinkleWill not change shapeIroning apparatusTextiles and paperEngineeringAssembly line

The invention relates to automatic assembly line equipment for steam finish-ironing and shaping. The automatic assembly line equipment mainly comprises a machine frame. An upper layer conveying line is arranged on the machine frame, a group of upper layer supporting needles are fixedly connected to an upper layer chain, a lower layer conveying line is arranged on the machine frame, and a group of lower layer supporting needles are fixedly connected to a lower layer chain. The lower layer chain penetrates through a sealed steam drying box, a steam processing section formed by upper steam spraying pipes and lower steam spraying pipes is arranged in the steam drying box, and a drying shaping processing section formed by upper heating tubes and lower heating tubes is arranged in the steam drying box. The automatic assembly line equipment for steam finish-ironing and shaping has the advantages that the equipment is operated in an assembly line mode, labor is saved, and efficiency is improved. The temperature and the speed can be adjusted; blown out steam can be adjusted; the steam spraying pipes are concave, and the steam can be blown to a cap in all directions. The cap can be quickly cooled down through fans at the rear portion of the equipment, and the product is integrally formed (without deforming). Meanwhile, after finish ironing of the cap quickly cooled down, the cap cannot be creased and deform no matter how hard a user rubs the cap.

Owner:桐庐手套总厂

Working method of cutting device for phosphor copper net

ActiveCN108213283AWon't wrinkleRealize automatic spreadingMetal-working apparatusPhosphorPulp and paper industry

The invention relates to the field of cutting equipment, in particular to a working method of a cutting device for a phosphor copper net. The cutting device comprises a roller assembly, a spreading device, a flattening device, a cutting platform, a cutting device and a control device. The roller assembly comprises a driving roller and a driving assembly, and the spreading device comprises a clamping mechanism and a first moving assembly; the flattening device comprises two flattening mechanisms, and the cutting device comprises a cutting mechanism and a second moving assembly; and the controldevice comprises a controller and a sensor assembly. The working method of the cutting device has the beneficial effects that the phosphorus copper net can be quickly spread on the cutting platform byadopting the spreading device, a large amount of manpower is saved, two flattening rollers are used for flattening the phosphorus copper net, and redundant parts are prevented from being cut off, sothat workers can be prevented from being stabbed, and manpower occupied by the cutting process can be saved; and it is guaranteed that the phosphor copper net is not wrinkled in the cutting process, automatic spreading, flattening and cutting of the phosphor copper net are realized in the whole process, and the cutting efficiency of the phosphor copper net is improved.

Owner:广东金大湾新材料有限公司

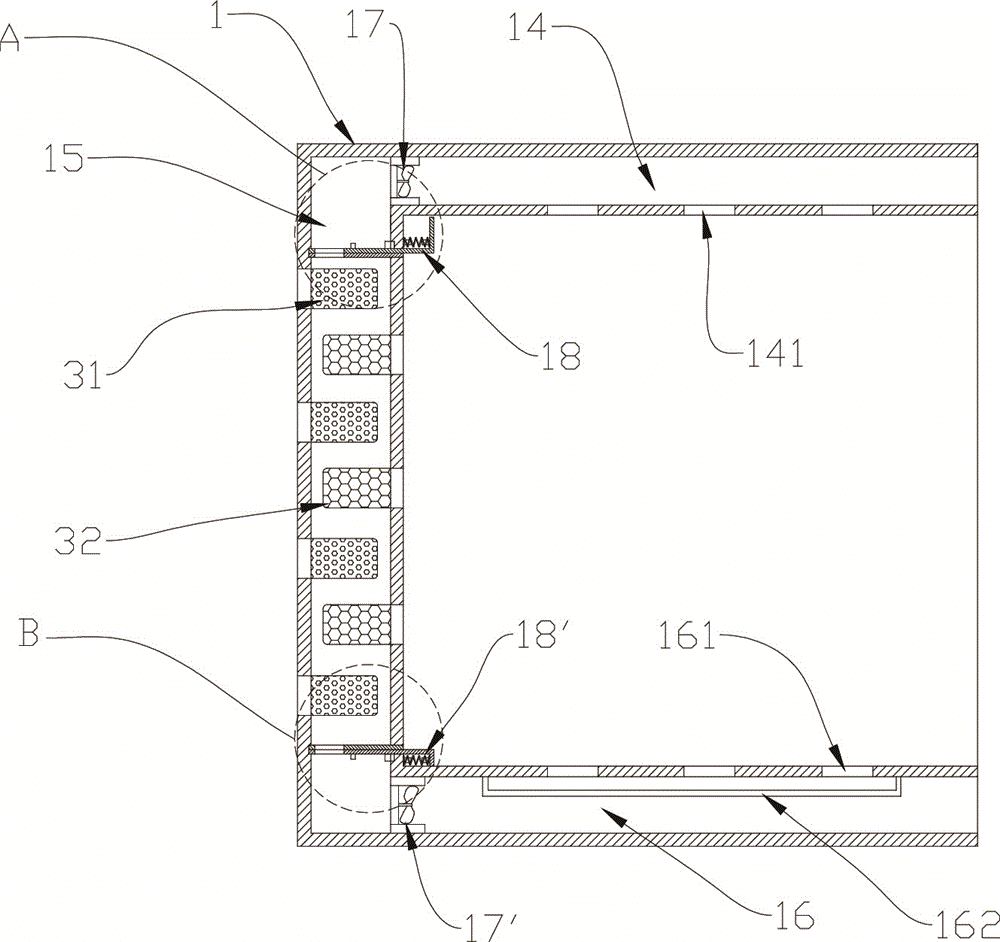

Vertical single-/double-surface napping machine

ActiveCN106835588ATension real-time monitoringRealize automatic controlRougheningProgrammable logic controllerAgricultural engineering

The invention discloses a vertical single- / double-surface napping machine, which comprises a frame, wherein the frame is provided with a cloth feeding mechanism and a cloth discharging mechanism; front and rear napping mechanisms are arranged between the cloth feeding mechanism and the cloth discharging mechanism; each napping mechanism consists of six napping roller components. The single-surface or double-surface napping operation on a textile can be completed through adjusting a cloth threading route; traction roller components and tension roller components are arranged; adjustable single cloth spreading mechanisms and an integral rotary swing double cloth spreading mechanism are arranged, and the textile is sufficiently spread in an advancement process, and cannot crinkle; a PLC (Programmable Logic Controller) system is arranged, and the PCL system automatically regulates and controls the running speed of a raising machine according to a received feedback signal of a tension sensor; single-surface napping and double-surface napping functions are integrated by the vertical single- / double-surface napping machine; further, the vertical single- / double-surface napping machine has the advantages of being high in degree of automation, high in efficiency and good in napping effect.

Owner:JIANGSU YINGYOU TEXTILE MACHINERY

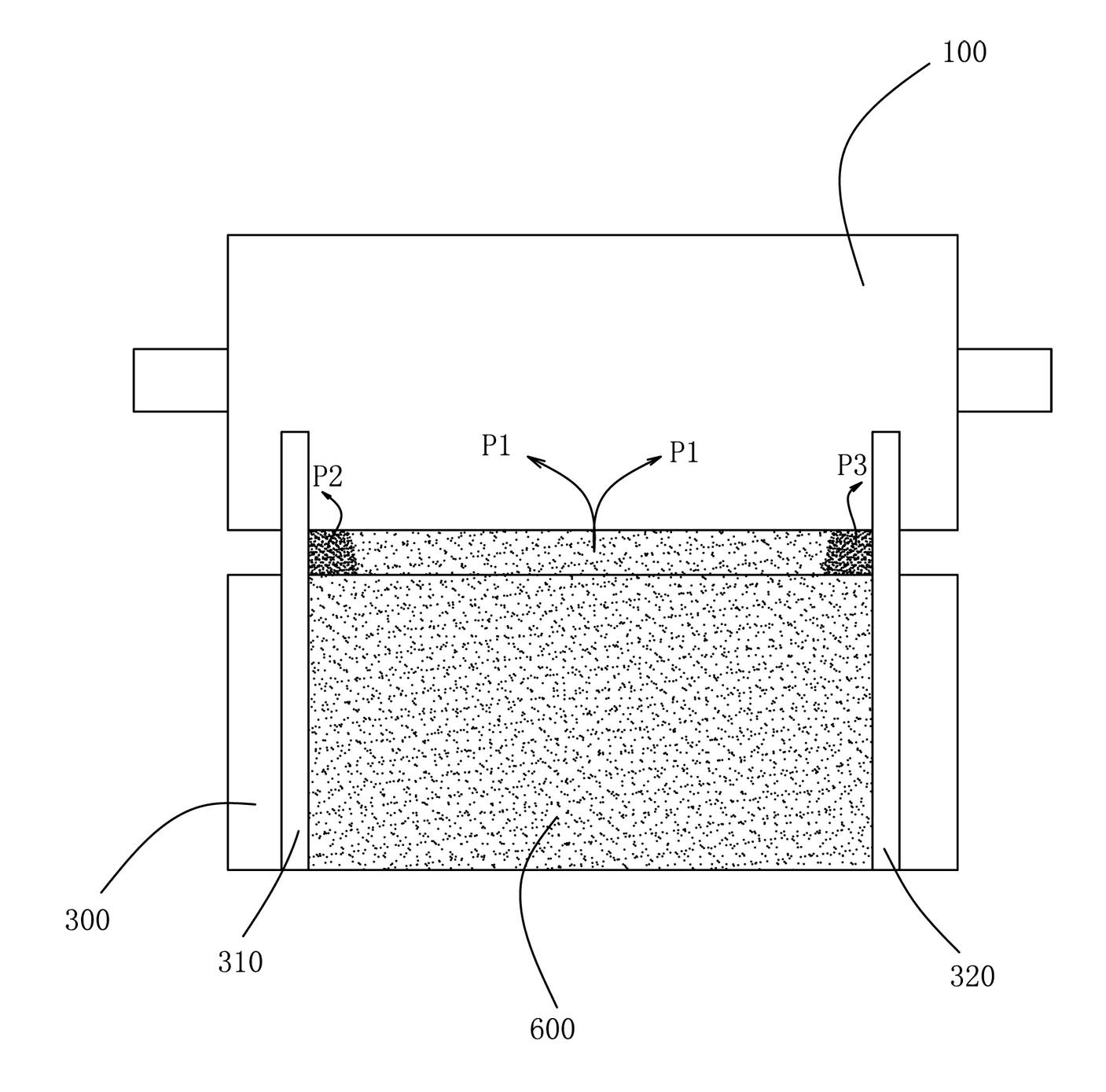

Low pressure injection mold and injection method

The invention discloses a low pressure injection mold, which comprises a fixed mold and a moving mold, wherein the moving mold comprises a base plate, a cavity fixedly formed on the base plate, and a plurality of cloth hanging pins arranged at the periphery of the cavity; the outer sides of the cloth hanging pins are provided with blade structures, so that a fabric is cut apart when strained; the fixed mold comprises a panel, a hot runner plate fixedly connected with the panel, a core fixedly connected with the hot runner plate, an ejection mechanism and a hot nozzle; the periphery of a lug of the core is provided with through holes corresponding to the cloth hanging pins to avoid interference; and the periphery of the lug is provided with a plurality of cloth pressing mechanisms. The invention also discloses an injection method. The mold is inversely mounted, the cavity is taken as the moving mold, the core is taken as the fixed mold, and glue feed and ejection are carried out on the same fixed mold side of the mold; meanwhile, the locating pins are provided with blades, so that the fabric can be cut apart when strained, and cannot be deformed because the fabric is strained too much.

Owner:TIANJIN SILVER BASSIS TECH CO LTD

Cotton cloth embroidery anti-deformation processing technology

InactiveCN105040300AComplete embroideryNot offlineEmbroidering machines apparatusCotton clothHot melt

The invention relates to a cotton cloth embroidery anti-deformation processing technology. the technology comprises the following steps: (1) subjecting cotton cloth to a preshrinking treatment; (2) fixedly arranged a layer of hot melt glue on the backside of the processed cotton cloth; (3) artificially embroidering required patterns on the front side of the cotton cloth, knotting the thread residues, and after embroidery, removing the hot melt glue that face the blank area on the front side of the cotton cloth; (4) pressing and heating the residual hot melt glue, drying in the air, and cooling. In the provided technology, the patterns and hot melt glue are adhered together, the adhesion is quickly, the operation is simple, the completeness of embroidery on the cotton cloth can be guaranteed, moreover, the phenomenon of loose thread is avoided, after washing, the cotton cloth does not shrink or deform, the cotton cloth cannot be wrinkled easily, the overall cotton cloth is flat, and the technology has a good application prospect therefore.

Owner:苏州尊赢会展服务有限公司

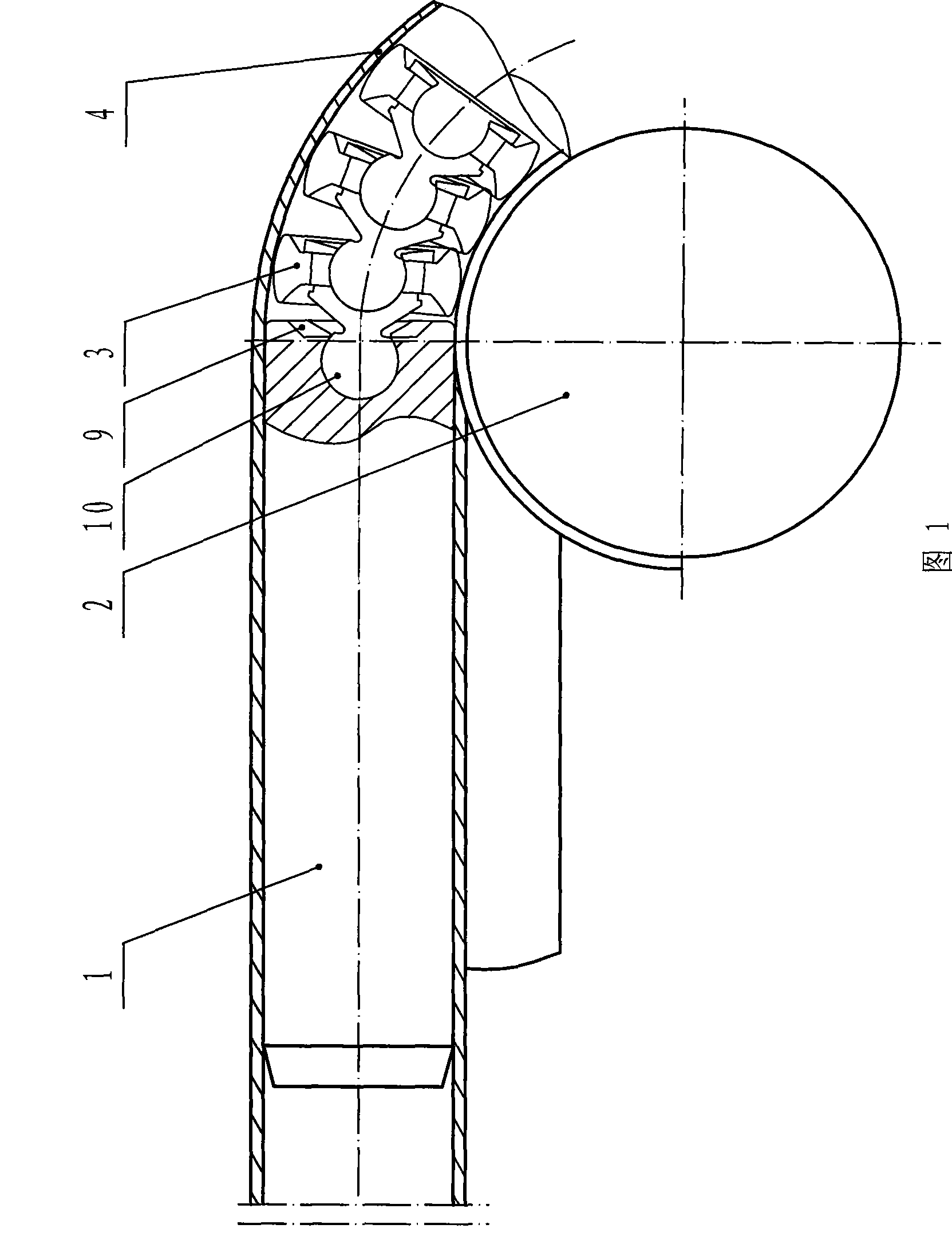

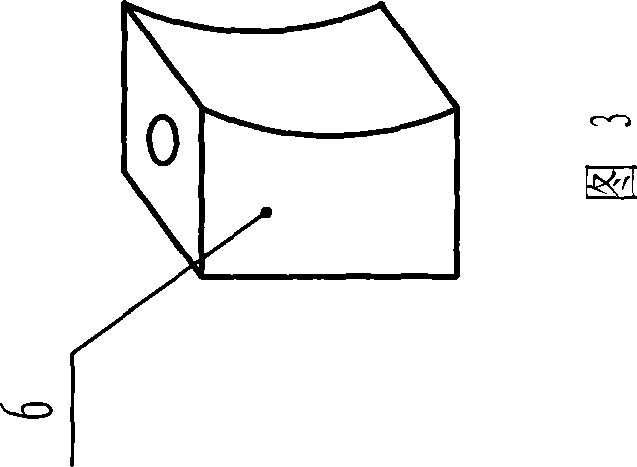

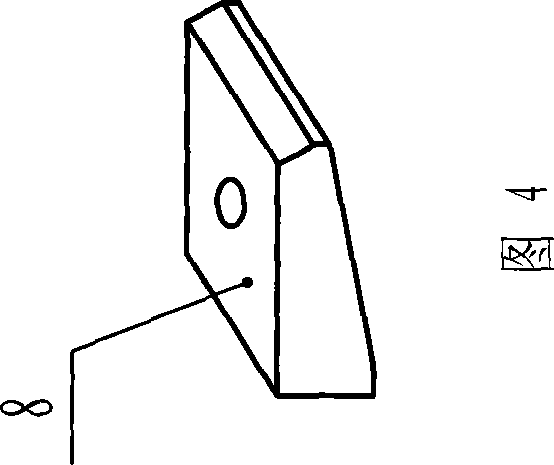

Flexible core of flexible tube terminal mould

The invention discloses a flexible core stud for a flexible pipe end die, which belongs to the technical field of manufacturing a die for a wound form pipe bending machine. The flexible core comprises a straight core stud and a universal core stud, which are connected via a press plate. The universal core stud is comprising a spherical core stud, a middle internal connector, a middle external ring and a lower connector, wherein the middle internal connector and the lower connector are fitted over the spherical core stud via screws at the lower end of the spherical core stud, and the middle external ring is fitted over the middle internal connector. The flexible core stud can be widely used in dies of various wound form pipe bending machines.

Owner:长治钢铁(集团)锻压机械制造有限公司

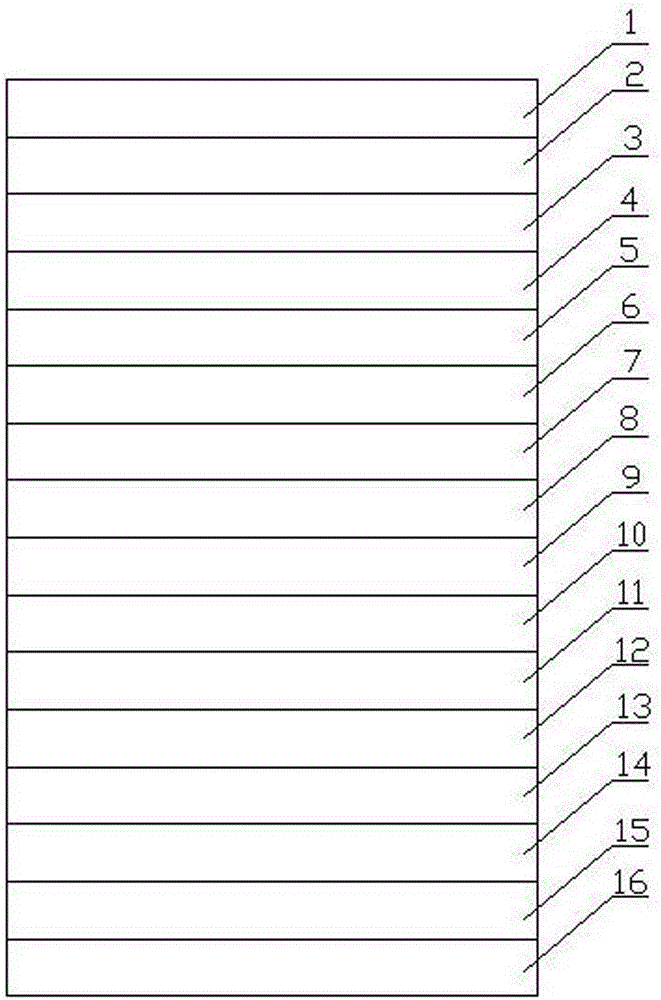

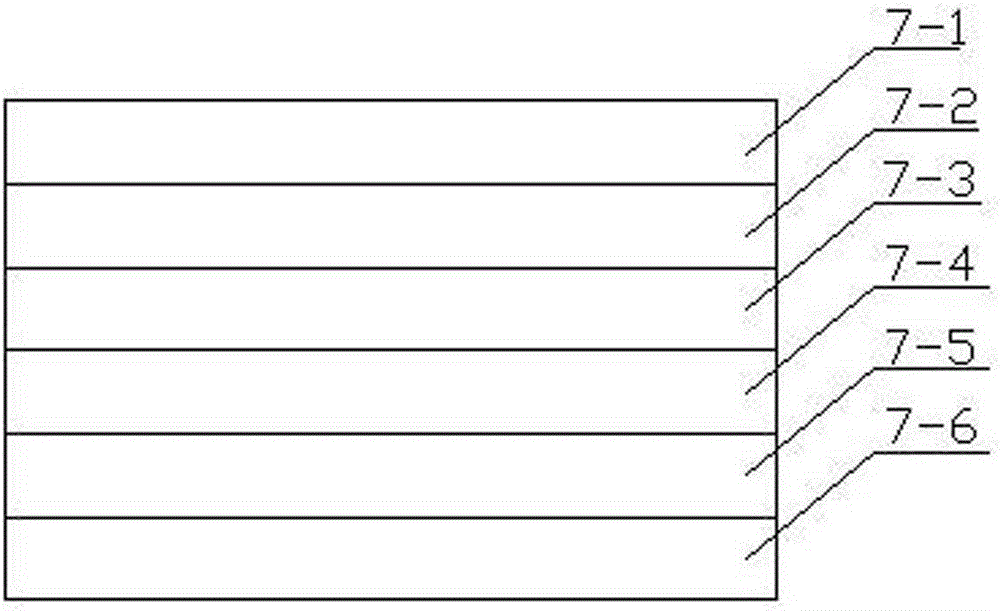

Uncovering type anti-shifting digital anti-counterfeiting mark paster and manufacturing method thereof

InactiveCN105321423AImprove anti-counterfeiting functionPlay an anti-counterfeiting roleStampsIdentification meansWater basedBiochemical engineering

The invention discloses an uncovering type anti-shifting digital anti-counterfeiting mark paster and a manufacturing method thereof. The uncovering type anti-shifting digital anti-counterfeiting mark paster comprises a black ink layer, a backing paper layer, a second glue layer, a white ink layer, a second data printing layer, a second water-based polishing oil layer, a silicone oil separation layer, an uncovering layer, a first glue layer, a paper layer, a surface printing layer, a first water-based polishing oil layer, a first data printing layer, an oil-based polishing oil layer, a covering layer and a caption layer which are compounded in sequence. The paster is characterized in that the paper layer is provided with a safety line and comprises a first paper layer, a printing layer, an aluminum layer, a fluorescent layer, a PET layer and a second paper layer which are sequentially compounded together. According to the uncovering type anti-shifting digital anti-counterfeiting mark paster, the uncovering layer can be completely uncovered, a large amount of anti-counterfeiting information is provided, and the anti-counterfeiting effect is achieved. The uncovering type anti-shifting digital anti-counterfeiting mark paster is particularly suitable for top-grade wine, top-grade cigarettes and the like.

Owner:无锡新光印防伪技术有限公司

Coating process for pearlescent paper

InactiveCN105398242AWon't fall offIncrease brightnessInksOther printing apparatusEnvironmental resistanceWater based

The invention discloses a coating process for pearlescent paper. The coating process comprises the following steps: the step of preparing pearlescent printing ink: firstly, pearl powder of 500-1000 grams and water-based polishing oil of 15-20 grams are mixed, and then the mixed pearlescent printing ink is enabled to be in a still standing state, and the still standing time is 12 hours; the step of coating: the pearlescent printing ink is transferred onto paper by using a coating device; and the step of drying and curing: the transferred paper is conveyed into a drying unit for drying and curing, and three ultraviolet lamps and one infrared lamps are turned on during drying. According to the coating process for the pearlescent paper, the mixed pearlescent printing ink has high brightness and high adhesive force, so that the pearl ink bonding film surface of a printed product can be enabled to be smooth and not to wrinkle; the process stability is high; during use, pearls cannot fall off; the subsequent adaptability is excellent; requirements of consumers and production are met better; and furthermore, in the manufacturing and use processes of the pearlescent paper, the environment is not polluted, no harm is caused to the human health, and the national requirements of environmental protection are met.

Owner:豪门印刷(上海)有限公司

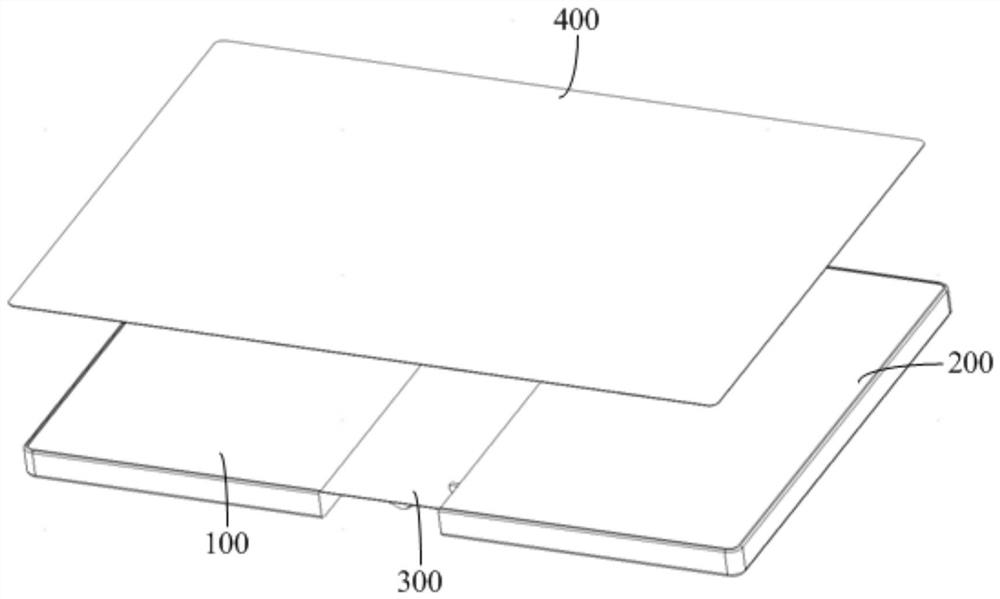

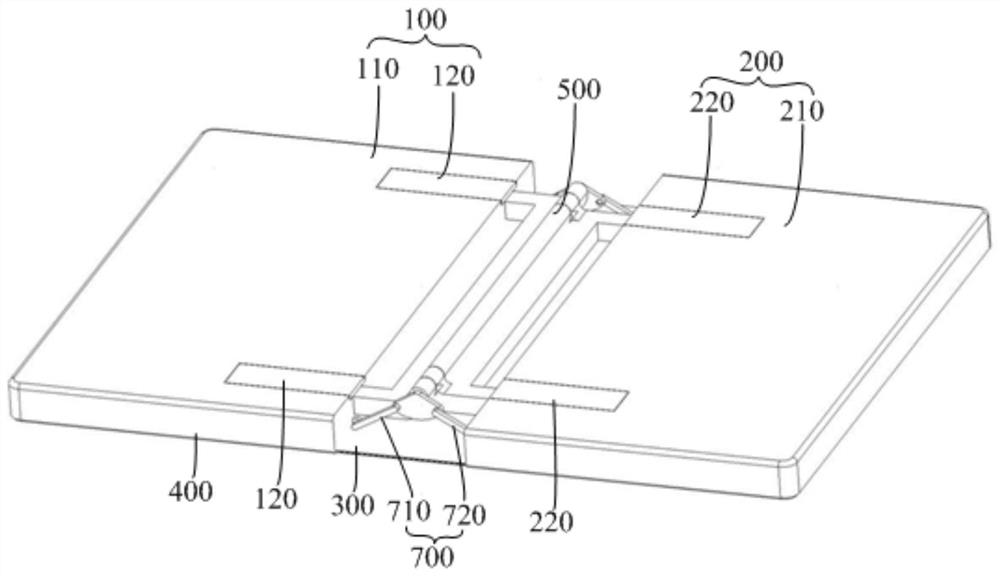

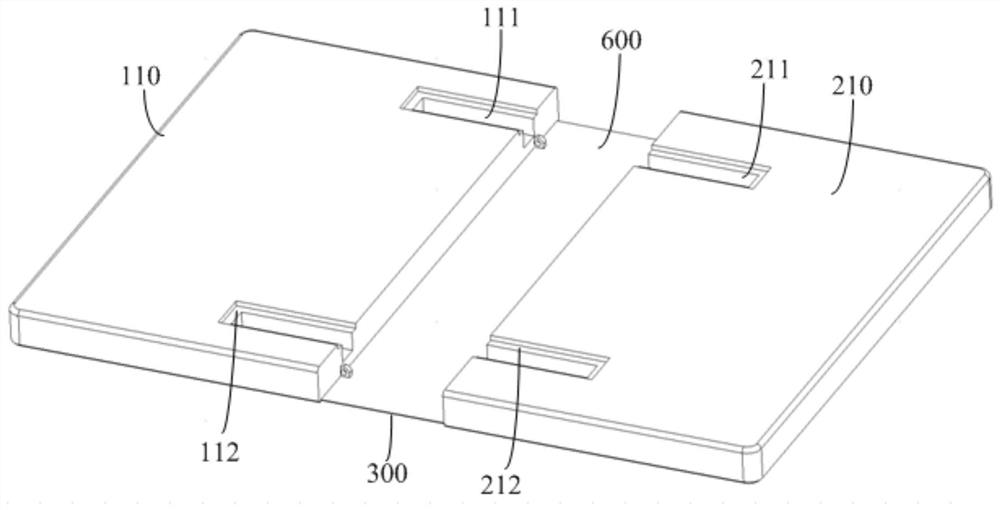

Electronic device

ActiveCN111901461AEasy to openWon't wrinkleDigital data processing detailsTelephone set constructionsEngineeringMechanical engineering

The application discloses an electronic device. The device comprises a first folding part, a second folding part, a connecting part, a flexible screen, a rotating shaft assembly and a connecting rod assembly, the first folding part is rotationally connected with the second folding part through the connecting part, and the first folding part, the second folding part and the connecting part form a supporting structure; the rotating shaft assembly comprises a rotating shaft, in the unfolding or folding process of the electronic device, the first folding part and / or the second folding part rotate / rotates relative to the rotating shaft. When the electronic device is in a folded state, the flexible screen is located on the outer side of the electronic device, and the first part, located on the first folding part, of the flexible screen and the second part, located on the second folding part, of the flexible screen are arranged back to back; the connecting rod assembly comprises a first connecting rod and a second connecting rod, first ends of the first connecting rod and the second connecting rod are rotationally connected with the rotating shaft assembly, and second ends of the first connecting rod and the second connecting rod are connected with the first folding part and the second folding part. According to the scheme, the problem that the electronic device is prone to wrinklingin the unfolding process in the background art can be solved.

Owner:VIVO MOBILE COMM CO LTD

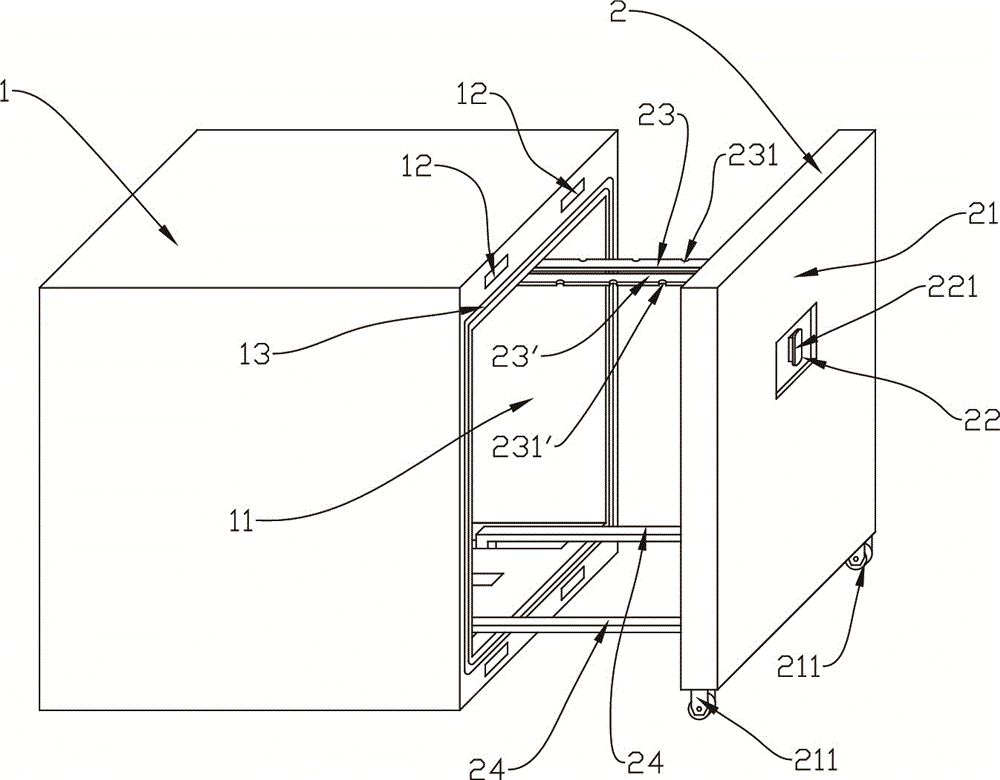

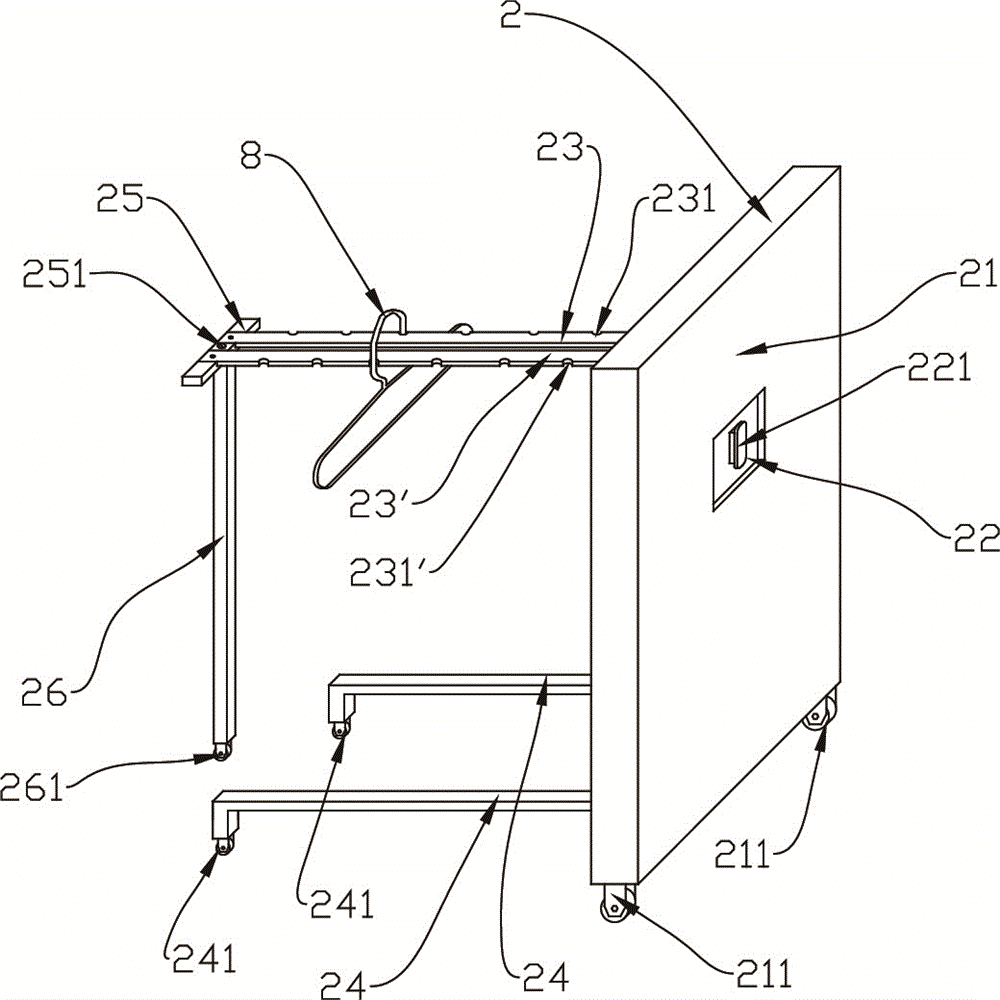

Drying equipment

The invention provides drying equipment which comprises a shell and a sliding plate rack. An opening is formed in one face of the shell. The sliding plate rack comprises a movable plate capable of being matched with the opening in a sealed mode. A clothes hanging rod and a supporting rod are arranged on one side, facing the opening, of the movable plate. A hollow layer is arranged in the shell. A fan is arranged in the hollow layer. The hollow layer and an inner cavity of the shell are communicated through an air inlet and an air outlet. A drying agent box used for containing drying agents and an adsorbing agent box used for containing absorbing agents are arranged in the hollow layer. An electric heating device and a closing mechanism are arranged in the hollow layer. The closing mechanism seals the drying agent box and the adsorbing box after being closed. The closing mechanism keeps an opening state when the sliding plate rack and the shell are sealed, enables a circuit of the fan and a circuit of the electric heating device to be connected, keeps the closing state when the sliding plate rack and the shell are separated, and enables the circuit of the fan and the circuit of the electric heating device to be disconnected. The drying equipment prevents clothes from winkling in the drying process, prevents smells on the clothes from being dispersed, and saves energy sources.

Owner:ZHEJIANG BUSINESS TECH INST

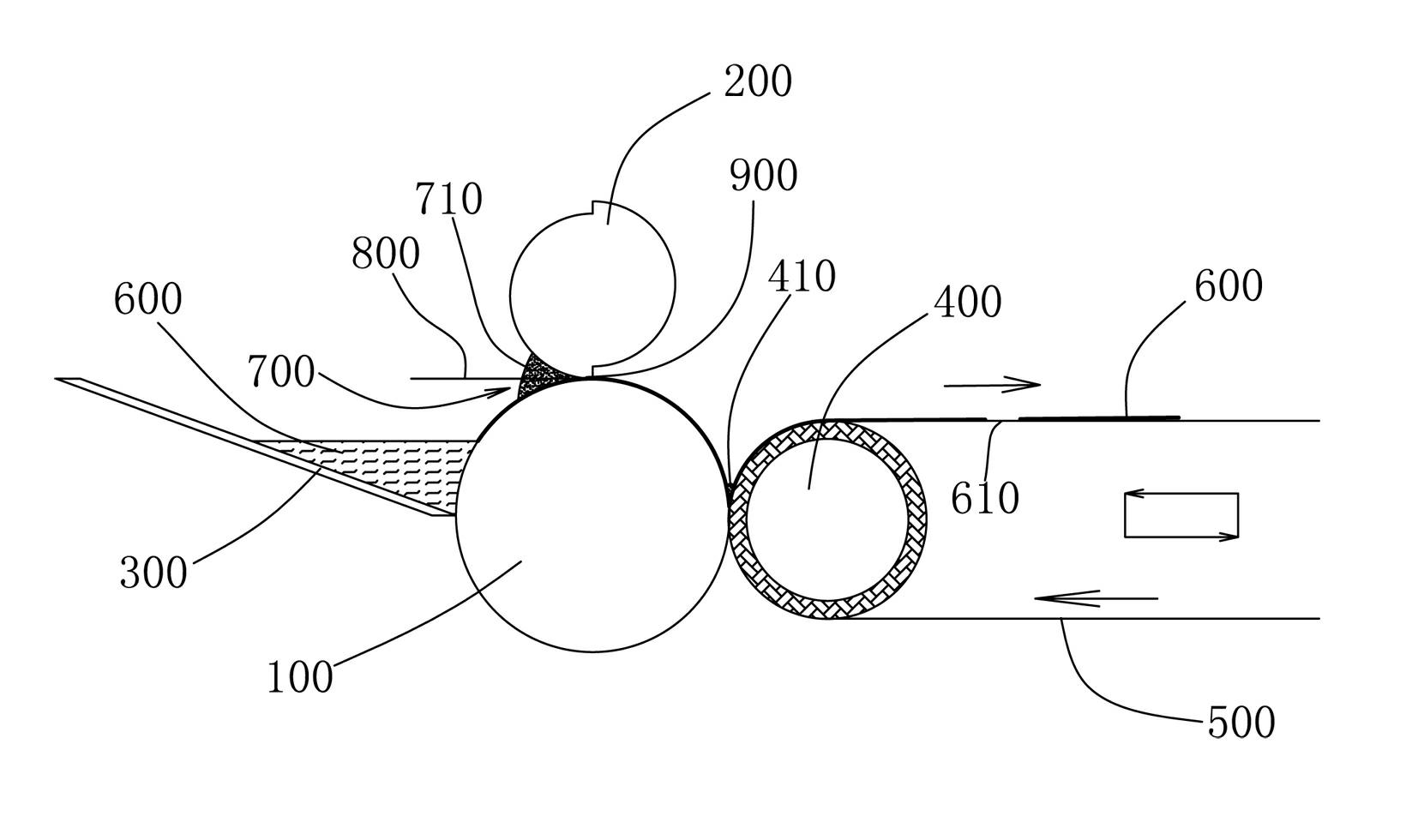

Interval type coating machine head

ActiveCN102357441AImprove uniformityHigh precisionLiquid surface applicatorsCoatingsPole pieceSlurry

An interval type coating machine head comprises a drive roll and a hopper located at one side of the drive roll and feeding the drive roll, an upper knife edge located above the drive roll, arranged along a same direction of the axial direction of the drive roll and used for evenly distributed slurry, a back roll used for delivering pole pieces and a reciprocate driving device used for driving the back roll and the drive roll to be in interval contact. The upper knife edge is a plate-type upper knife edge which comprises a three-dimensional hanging body, and a plate-type blade is arranged on the lower bottom face of the three-dimensional hanging body which is in a same plane with a coating line of the coating machine head. The interval type coating machine head is high in uniformity of coating piece thickness and accuracy, free of limitation of mounting position and height, capable of removing accumulated material pressure between included angles. Rotational speed of a feeding roll can be freely controlled, feeding amount on the curved surface of the drive roll is even and unanimous, the feeding roll has good stirring effect, the slurry can be avoided depositing in the hopper, andinfluences on the pole piece of dry materials are avoided. Two edges of the pole piece can not wrinkle.

Owner:SHENZHEN XINYUREN TECH

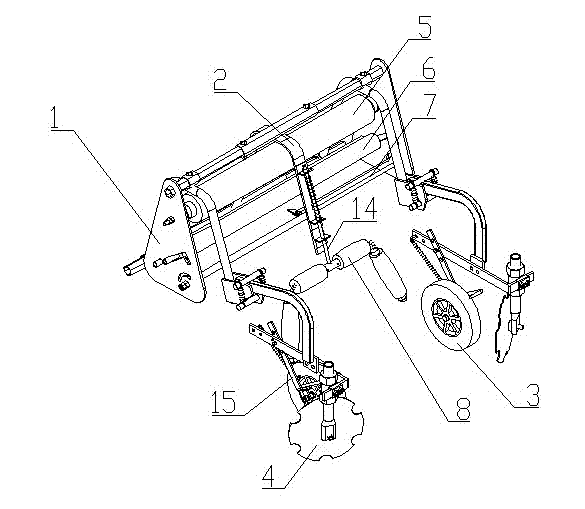

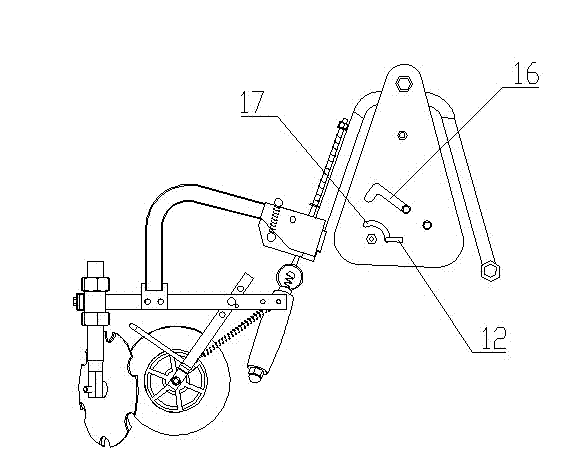

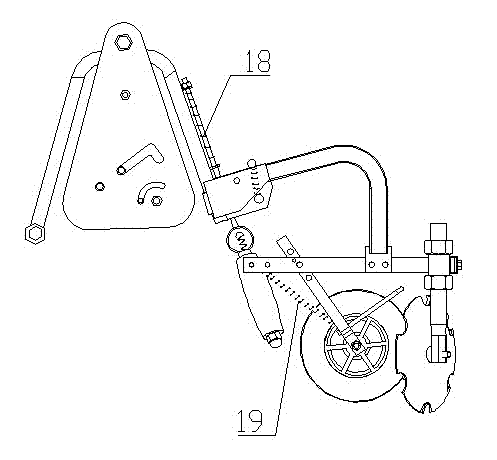

Mulch applicator special for tobacco field

ActiveCN103081762AFree and smooth rotationWon't wrinklePlant protective coveringsEarth surfaceControllability

The invention relates to the field of agricultural machinery, in particular to a mulch applicator special for a tobacco field. The effect that thin film which is cut off do not flutters in wind can be ensured through the fact that a film cutting knife device is arranged on the slant down portion of a film roller, flatness of the thin film and controllability of machine film cutting can be ensured through the fact that film clamping pair rollers are arranged between the film roller and the film cutting knife device, and the thin film can be pressed to a ridge shape and attached to the top and two sides of ridge walls through the fact that a ridge shaping device is arranged on a front rack of film pressing wheels, and thus subsequent film pressing wheels work and earth up knife work are facilitated. Shape copying along ups and downs of the ground can be achieved through the combination of fixing rods of compression springs arranged on the ridge shaping device and the rack, the thin film is enabled to be attached to the ridge walls, and the reliability of film pressing of the film pressing wheels and the continuity of sequence earth up are ensured. The mulch applicator special for the tobacco field is not only reasonable in design and ingenious in conception, but also thoroughly resolves the defects of loose film-drawing, discontinuous earth up, bad sealing coverage, insufficient sealing earth, unachievable machine cutting and the like, and improves the efficiency of film covering work significantly.

Owner:洛阳卓格哈斯机械有限公司

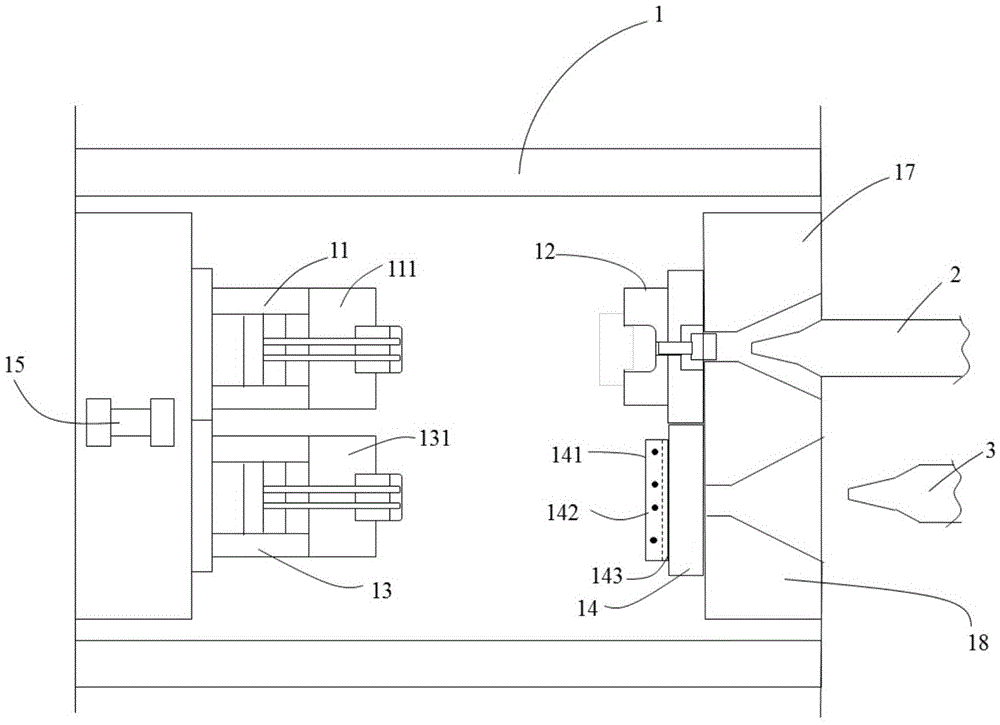

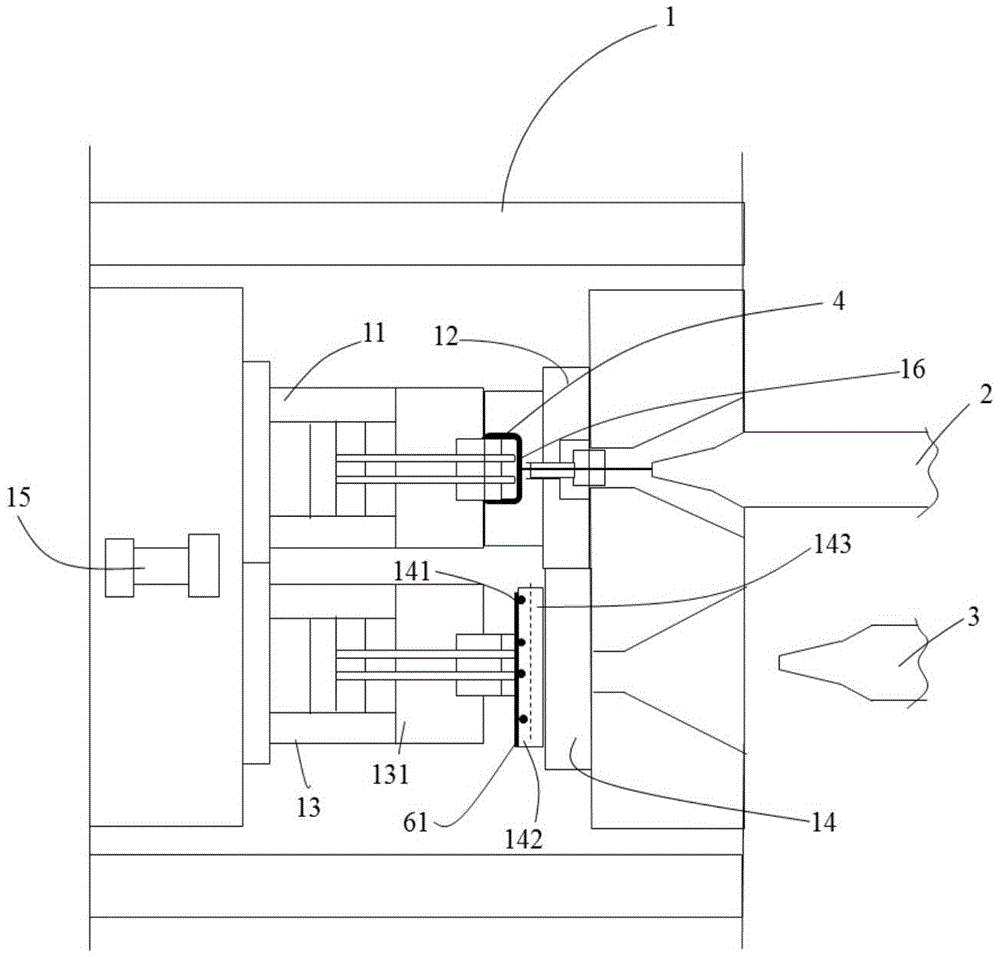

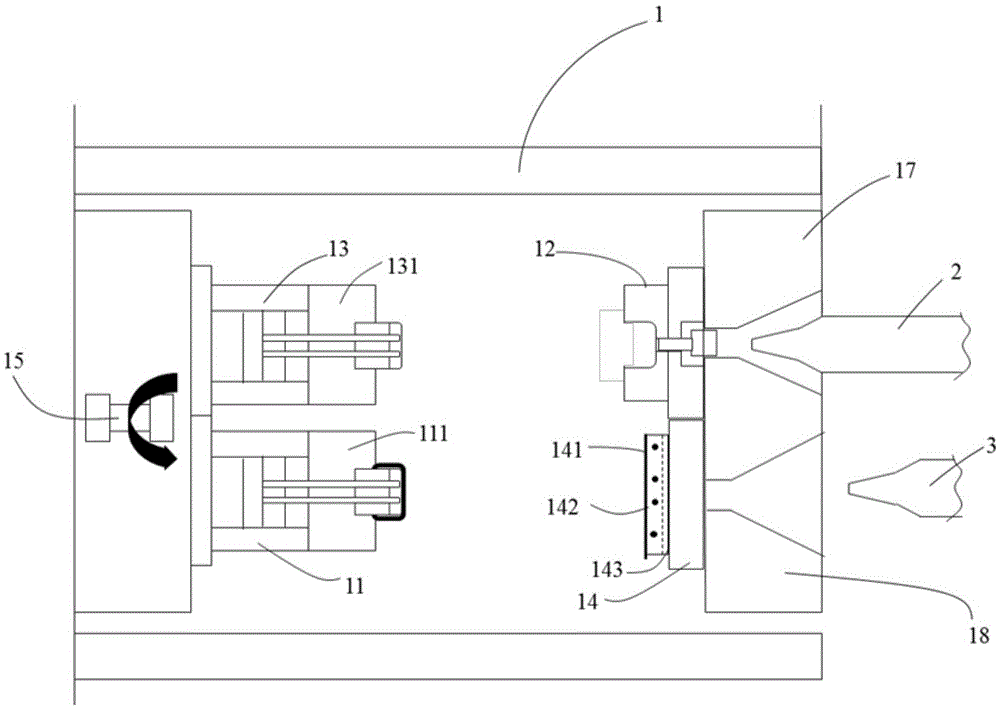

Injection moulding machine and surface decoration mould used by same

The invention provides a surface decoration mould, which comprises an injection male mould provided with a vacuum air channel, a first female mould, wherein the first female mould and the male mould form a first mould cavity, a raw material is injected into the first mould cavity to form a primary product; a decoration male mould provided with a vacuum air channel, a second female mould, which can be moved and closed with the decoration male mould, wherein the surface (inner surface), which is contacted with the decoration male mould, of the second female mould is attached with a film, and the second female mould is provided with a plastic air channel and a heater; and a rotation disc, which is connected to the injection male mould and the decoration male mould through shafts. By rotating the rotation disc, the injection male mould on the primary side can be turned to the secondary side and the decoration male mould is turned to the primary side.

Owner:FAR EAST UNIVERSITY

Printing and dyeing process of polyester-cotton blended fabric

The invention relates to the technical field of printing and dyeing of fabric, in particular to a printing and dyeing process of polyester-cotton blended fabric. The printing and dyeing process specifically includes preprocessing, preliminary processing, dyeing and post-processing. The printing and dyeing process has the advantages that the printing and dyeing process is simple and easy to operate and even in dyeing, the dyed fabric is smooth and free of rags and burrs, the adhesive power of dye is enhanced greatly by ethanol fixation, fading after long-term soaking and rubbing is avoided, cloth wrinkles and shrinkage cannot be caused by the printing and dyeing, and breaking and pilling of cotton fibers and polyester fibers are avoided during the printing and dyeing.

Owner:JIAXING FUSHENGDA DYEING & FINISHING

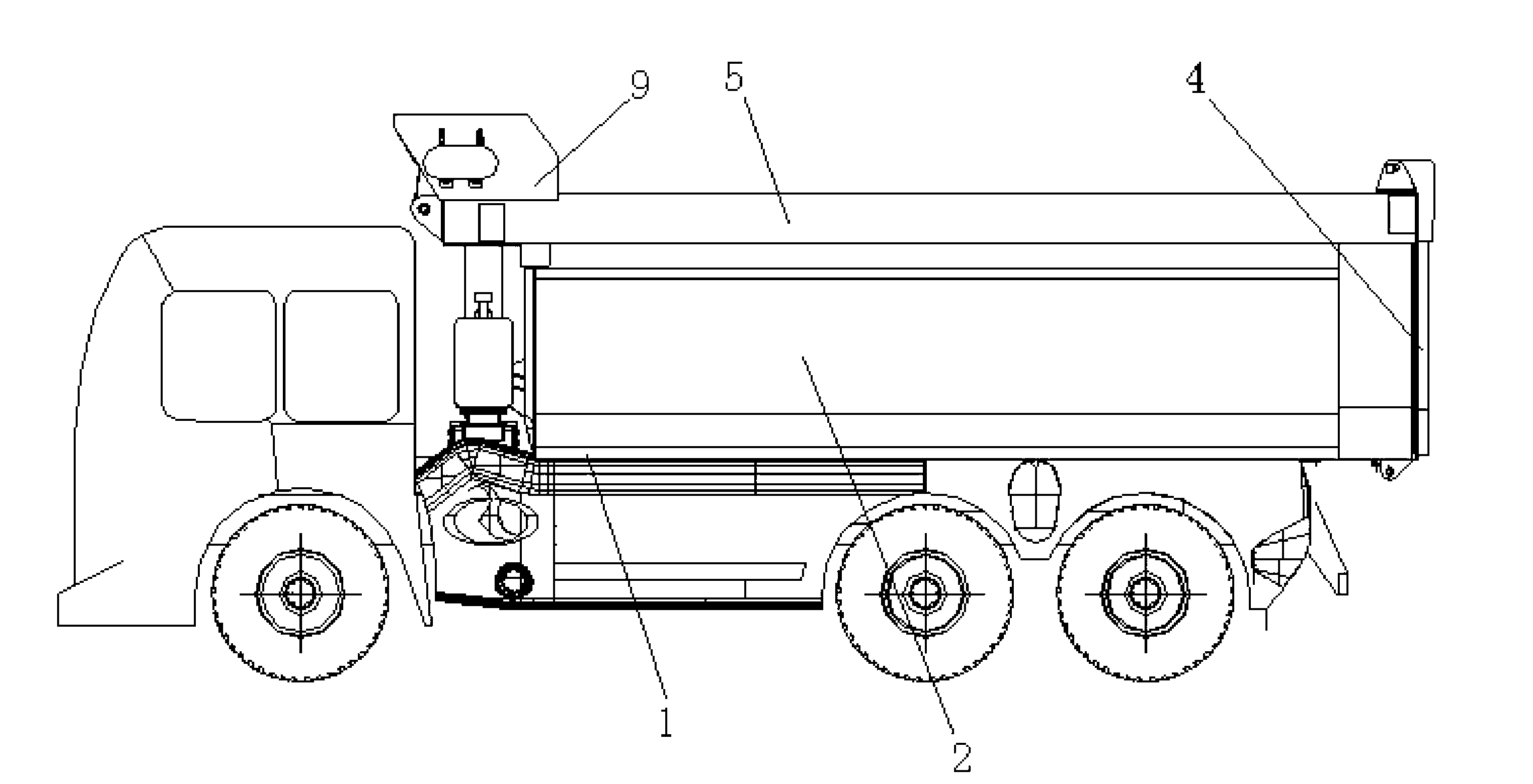

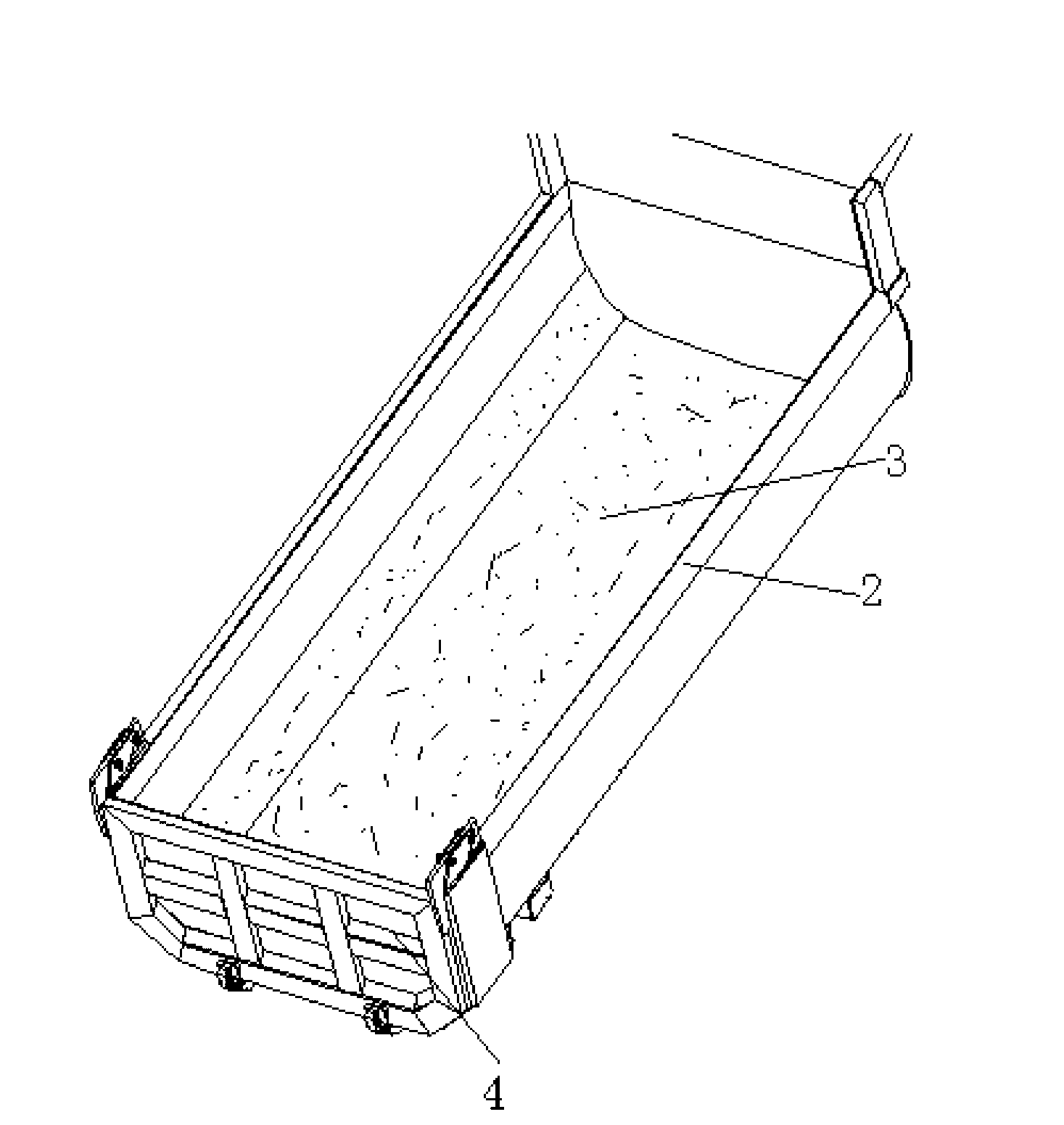

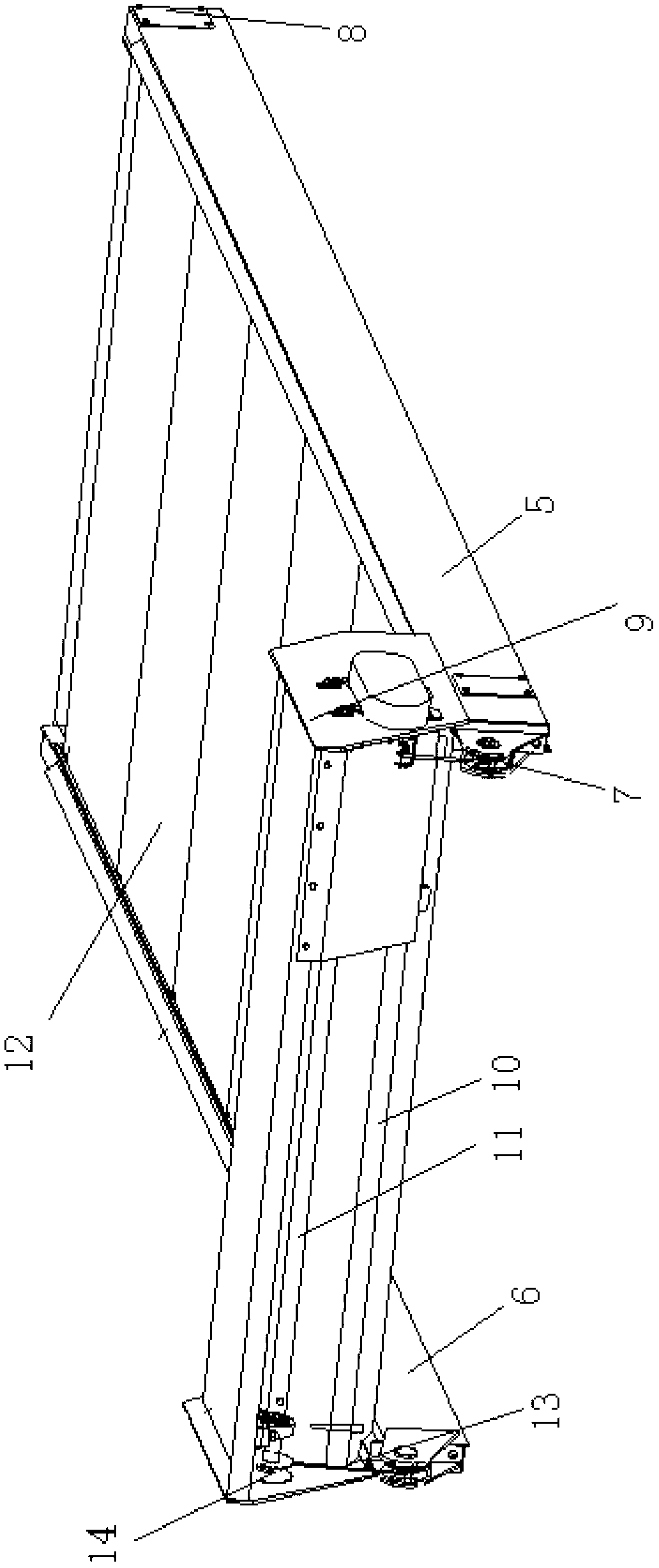

Residue soil dump vehicle with built-in horizontal-pushing environment-friendly top cover system

The invention discloses a residue soil dump vehicle with built-in horizontal-pushing environment-friendly top cover system. The residue soil dump vehicle with the built-in horizontal-pushing environment-friendly top cover system comprises a U-shaped car which mounted on the vehicle body, wear-resistant boards or polymer composite material boards are laid inside the U-shaped car, the upper ends of both sides of the U-shaped car are provided with a left guide rail beam and a right guide rail beam respectively, the front end and the back end of each of the guide rail beam are provided with a front moving wheel assembly and a rear moving wheel assembly respectively, the upper end portions of the front ends of the left guide rail beam and the right guide rail beam are provided with a waterproof cloth box, the inside of each waterproof cloth box is provided with a waterproof cloth reeler assembly and a rope wheel mechanism, a waterproof cloth assembly can penetrate the rear end of the waterproof cloth box and moves on the left guide rail beam and the right guide rail beam, and the reeling operation and the unreeling operation of the waterproof cloth assembly can be synchronously driven by the waterproof cloth reeler assembly and the rope wheel mechanism. When the residue soil dump vehicle with the built-in horizontal-pushing environment-friendly top cover system is in use, no material accumulation occurs outside the car and no material spilling occurs during transportation, so that rapid unloading and convenient cleaning are both achieved. Meanwhile, the residue soil dump vehicle with the built-in horizontal-pushing environment-friendly top cover system can be operated by operated by one person, thereby being time-saving, labor-saving, easy to place and stable in the reeling and unreeling operation, avoiding wrinkling and guaranteeing the service life of the waterproof cloth.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

Multi-purpose pressing mechanism for single-piece printing material surface treatment equipment

InactiveCN101746114ANo jitterImprove processing qualityTransfer printingLaminationEngineeringAir bubble

Owner:李飚

Leather waxing device for leather shoe production

ActiveCN108315510AImprove waxing effectWon't wrinkleLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingEngineeringWaxing

The invention relates to a waxing device, in particular relates to a leather waxing device for leather shoe production and aims to solve the technical problem of providing the leather waxing device for time shortening and waxing for leather shoe production. To solve the technical problem, the invention provides the leather waxing device which comprises a bottom plate, a 7-shaped plate, first support rods, first arc-shaped clamping blocks, a waxing table, and the like, wherein the 7-shaped plate is mounted on the left side of the top of the bottom plate; the first support rods are mounted on the left side and the right side of the top of the bottom plate; the first support rods are positioned inside the 7-shaped plates; the first arc-shaped clamping blocks are mounted at the tops of the twofirst support rods; the waxing table is mounted in the middle of the top of the bottom plate; a coiling mechanism is arranged on the right side of the top of the bottom plate; the coiling mechanism is positioned on the right side of the waxing table. By adopting the leather waxing device, leather can be collected through the coiling mechanism, the leather can be waxed through the waxing mechanism, and the effects of time saving and sufficient and uniform waxing can be achieved.

Owner:嘉兴市南湖区余新振涛五金喷涂厂(普通合伙)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com