Patents

Literature

55 results about "Product Labeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Use of written, printed, or graphic materials upon or accompanying a product or its container or wrapper. It includes purpose, effect, description, directions, hazards, warnings, and other relevant information.

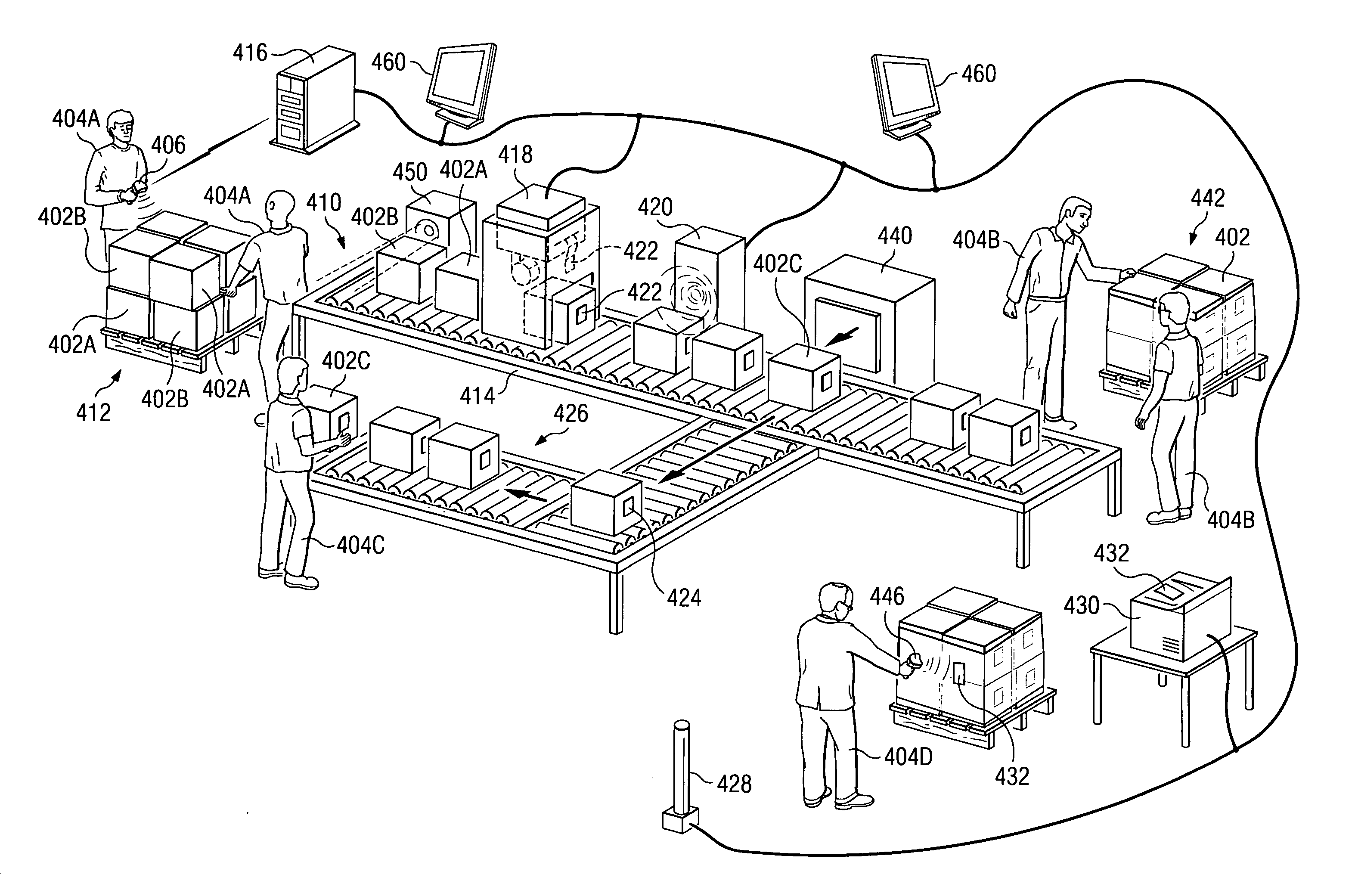

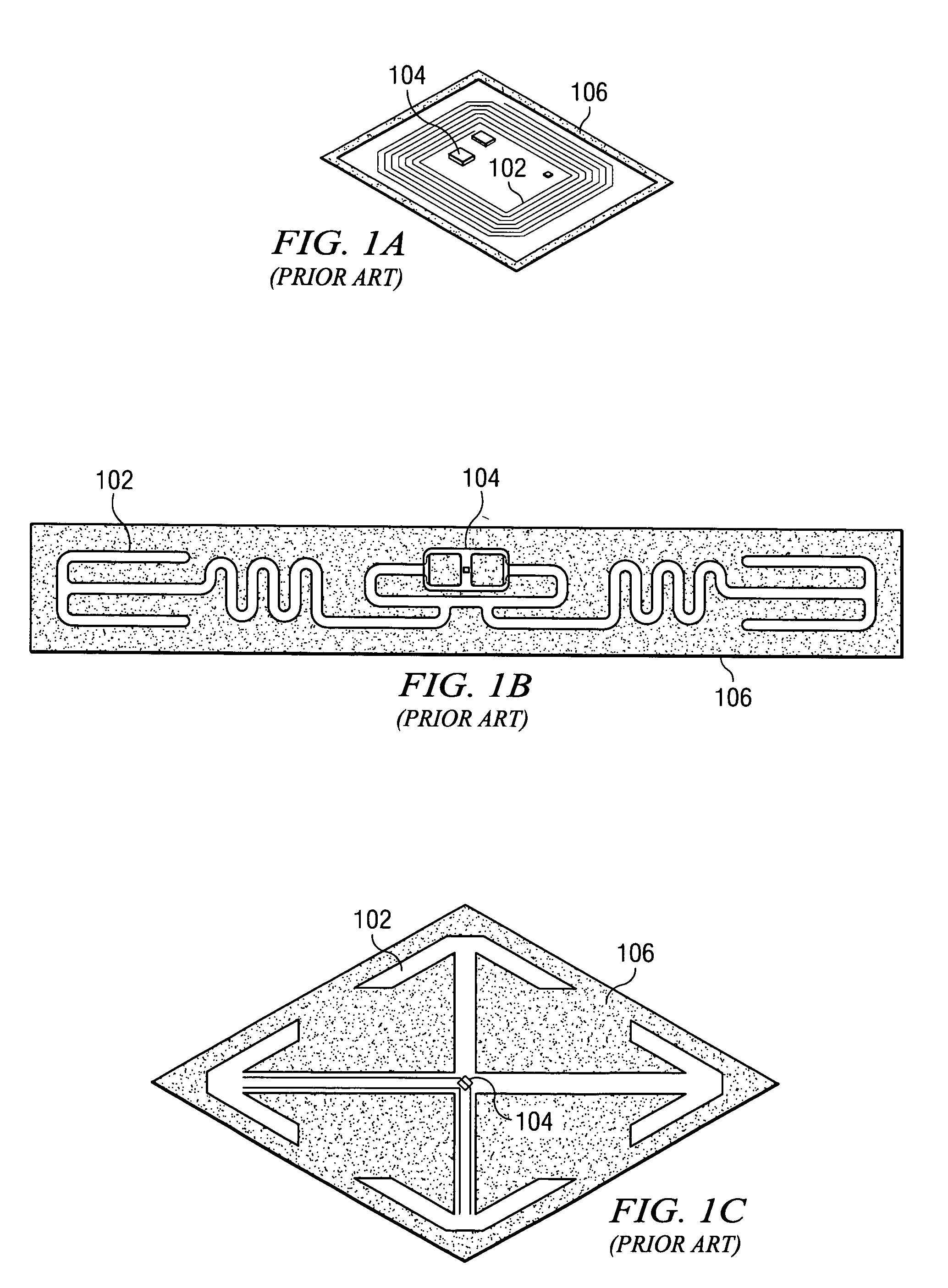

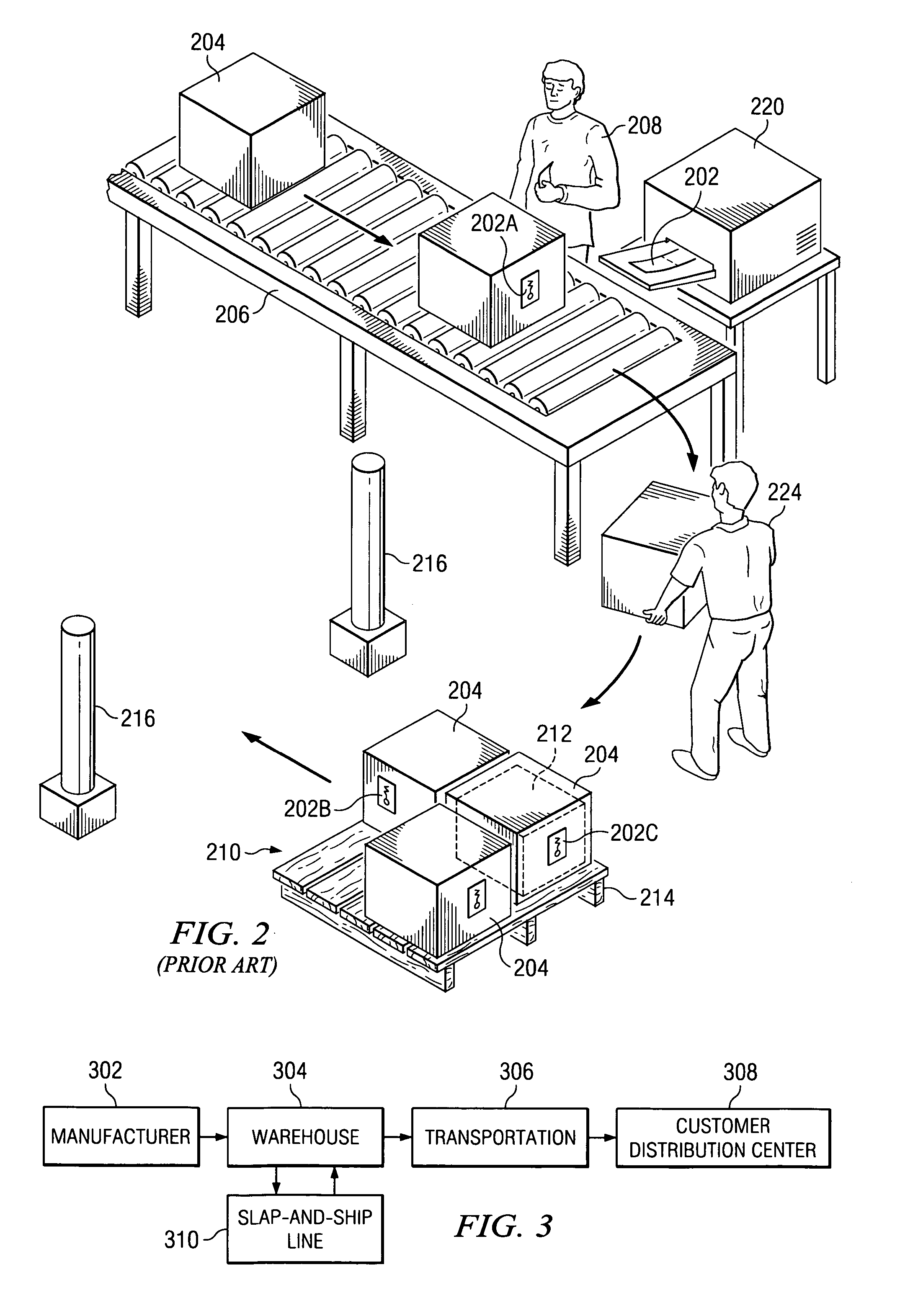

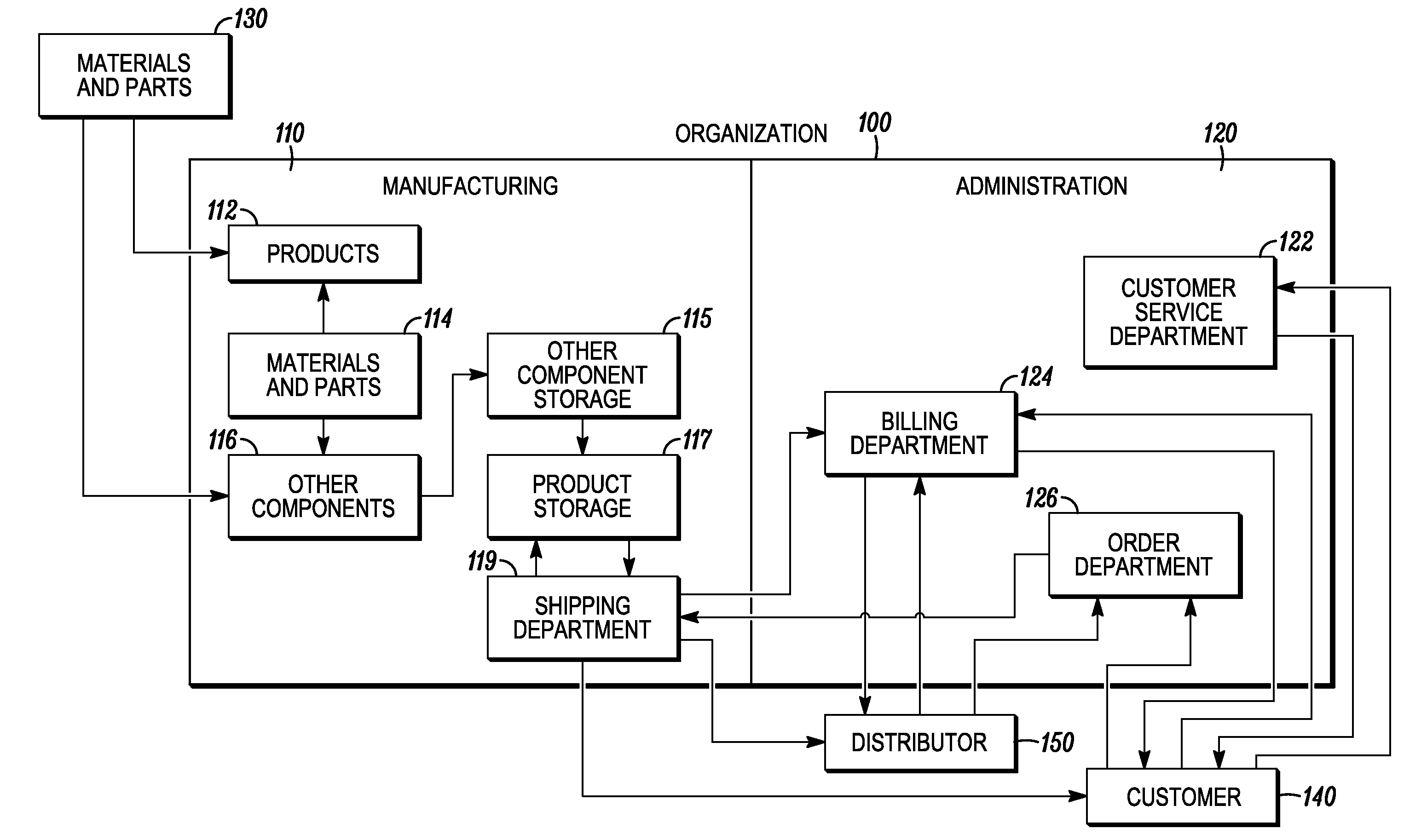

Method for slap-and-ship RFID labeling

ActiveUS20070126578A1Function can be ensuredEasy to placeDigital data processing detailsCo-operative working arrangementsCrateEmbedded system

A method for applying at least one RFID product tag to each of a plurality of products and to a product-containing container. Each product, case, or box is first unloaded from a container (e.g. pallet, tote, crate) or passed directly from manufacturing onto a conveyor whereon each item receives at least one RFID tag. Each RFID tag is then verified. Multiple items are then re-stacked in a container. An RFID tag is applied to the container and then the RFID tags are verified again before the container is shipped. Serialized numbers corresponding to products and containers are assigned and tracked. EPC data is stored on, or associated with, each RFID tag. RFID tags are verified to detect faulty placement and non-functionality. Non-functioning and poorly placed RFID tags are replaced before passing verification. The slap-and-ship line can handle execute-and-record methods and synchronized execution methods of handling product and associated data.

Owner:FRITO LAY NORTH AMERICA INC

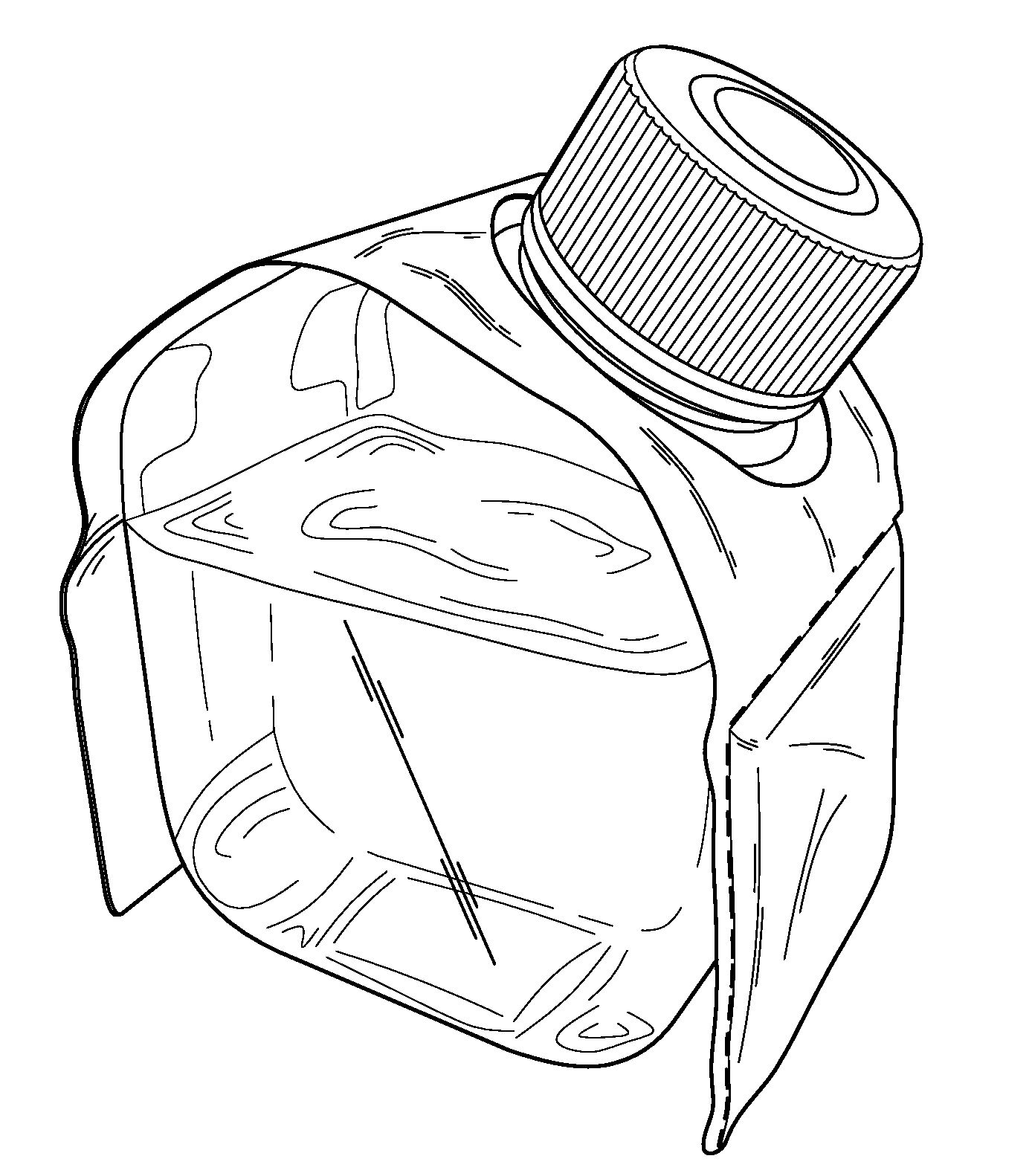

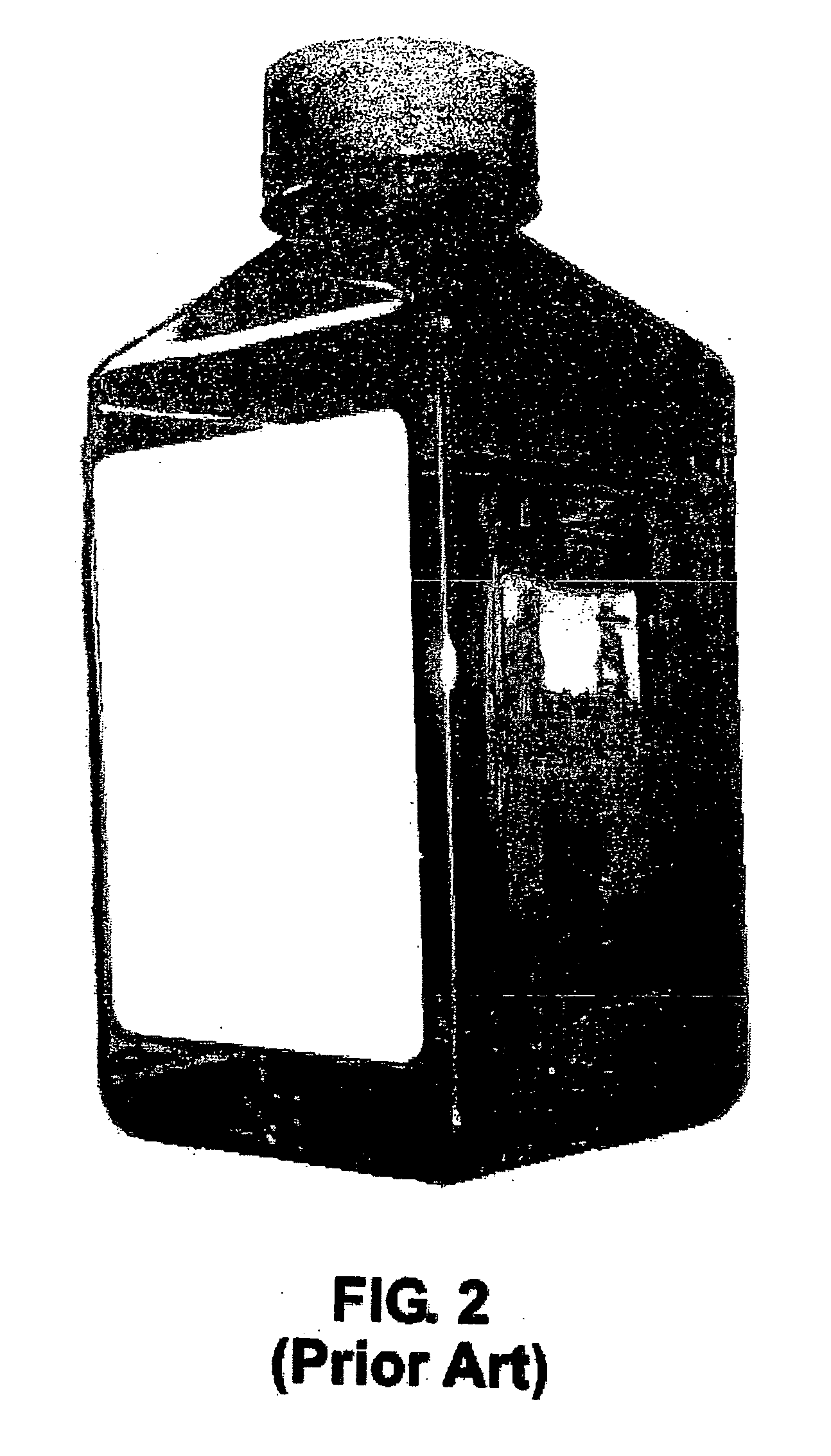

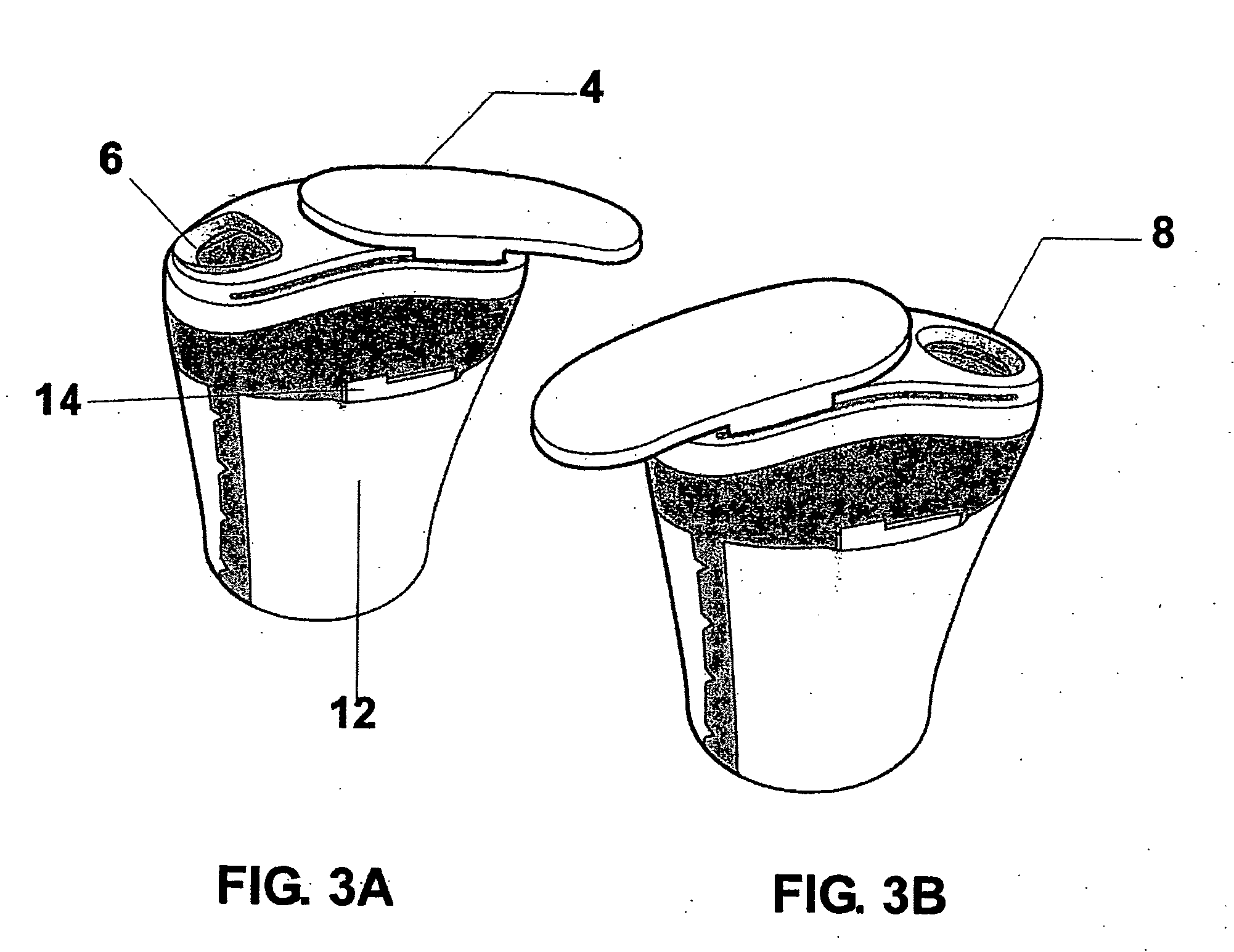

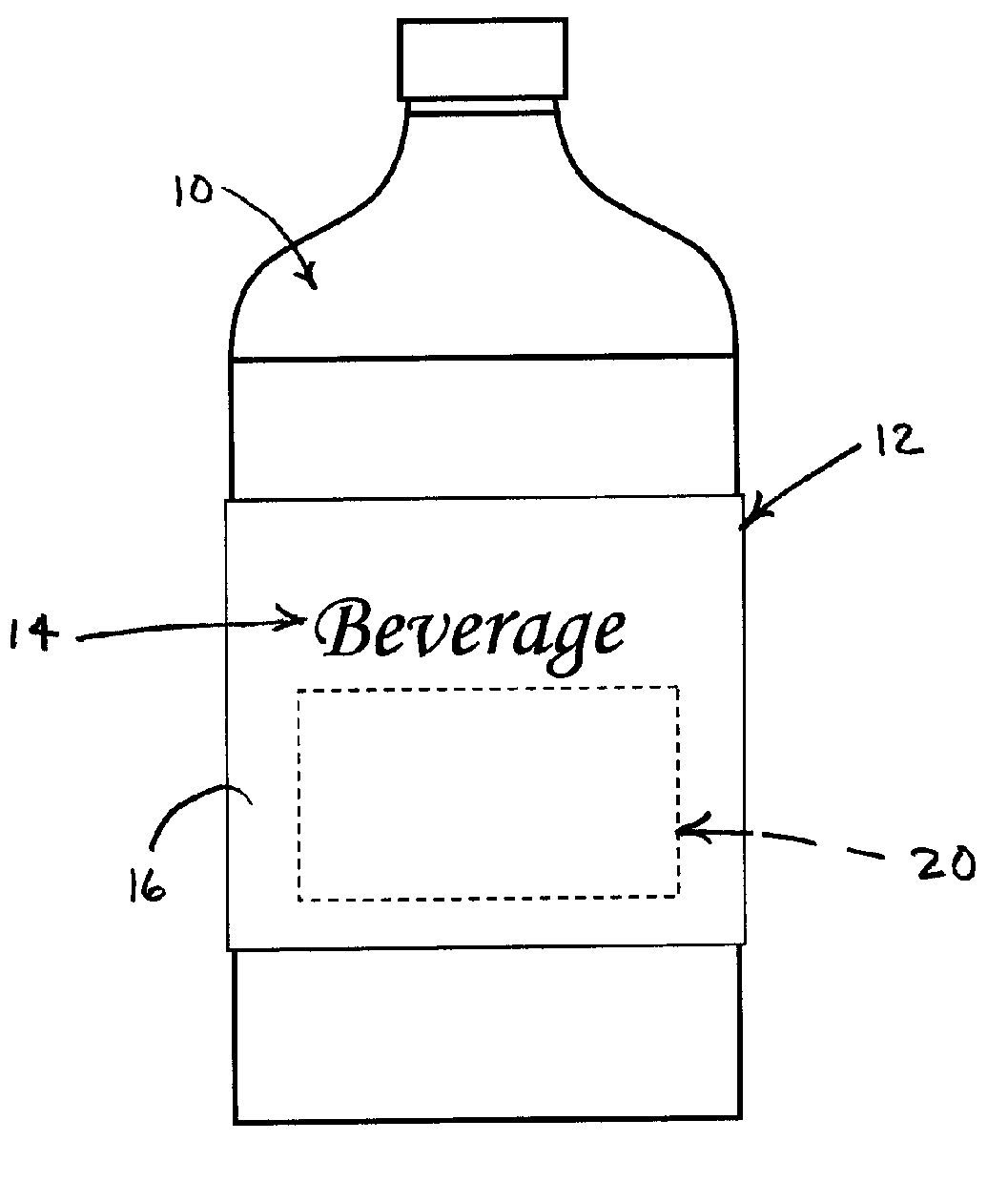

Labels, containers, system and method for providing reagents

InactiveUS20100059533A1Avoid trafficStop the flowContainer decorationsLevel indicationsAlphanumericLaboratory facility

The invention relates to systems and methods for marketing and using products such as liquid materials, especially liquid reagents for use in microbiological and cellular biological laboratory settings include the use of unique color and simple numeric or alphanumeric identifiers to quickly and easily identify any product from a catalog list of products. Methods of marketing, advertising and producing such products are also disclosed. Particular embodiments include products, product packaging and product labeling. The invention also relates to collars and sleeves for containers, flexible stabilizers for containers, as well as related methods of use.

Owner:LIFE TECH CORP

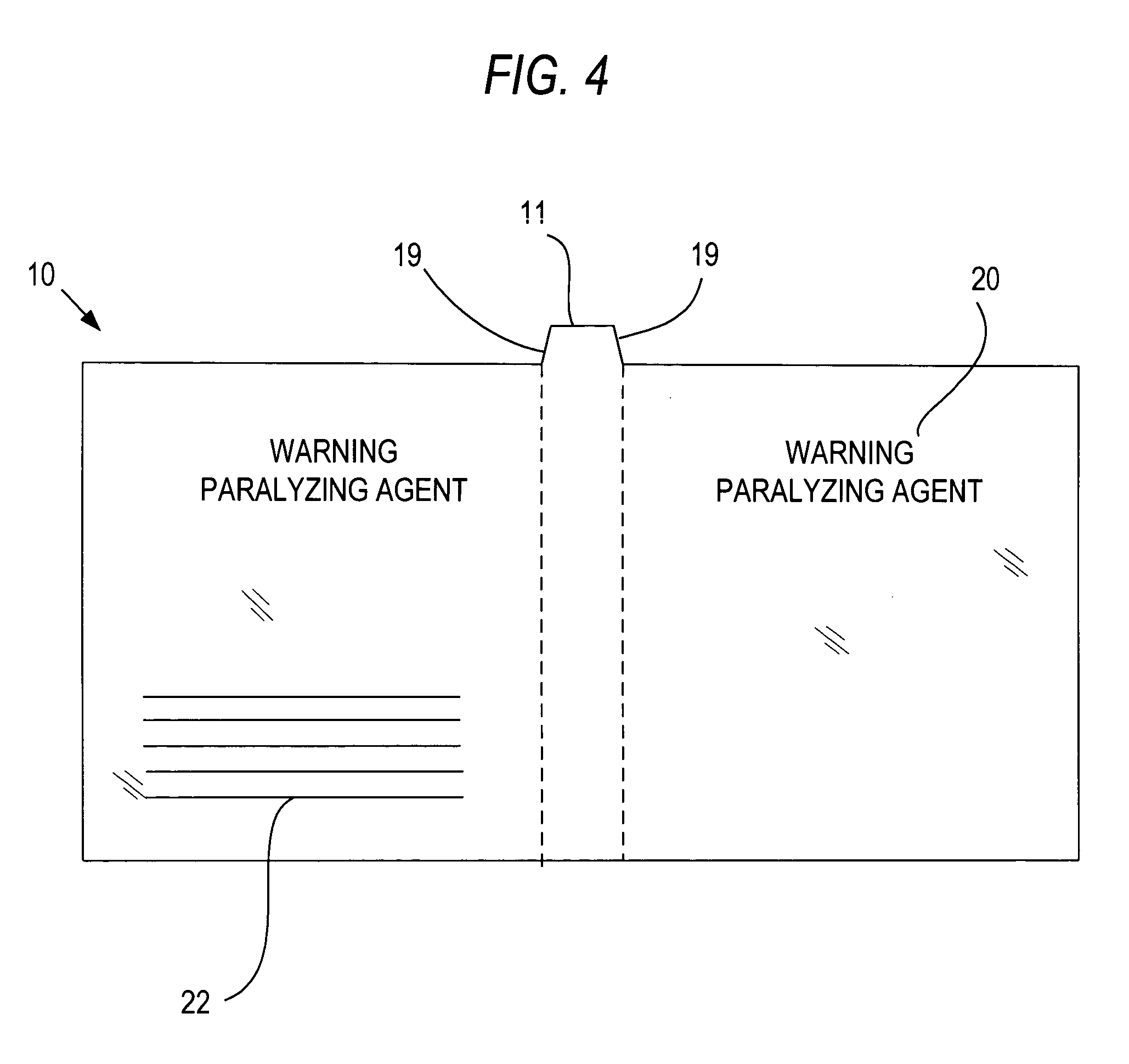

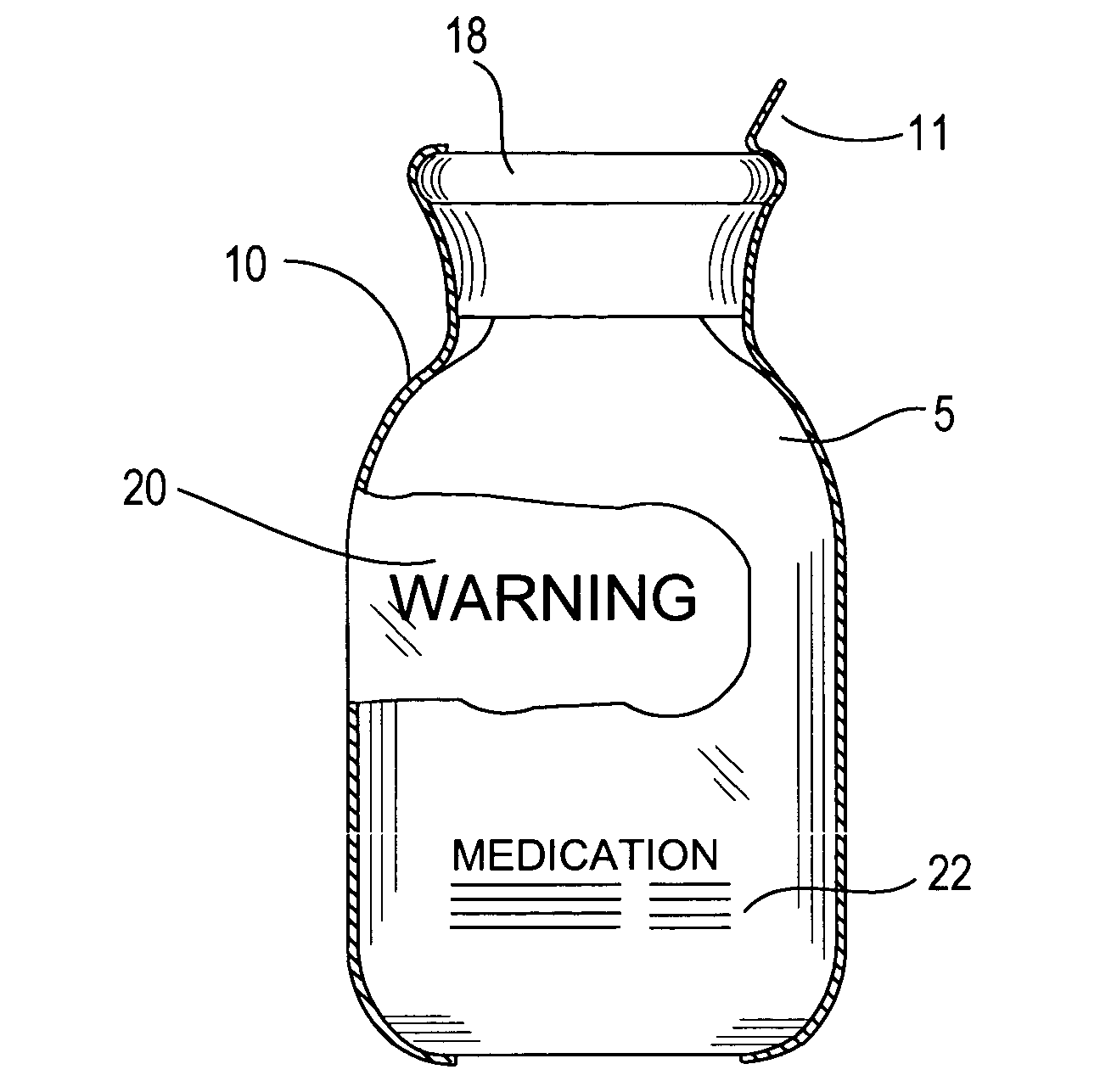

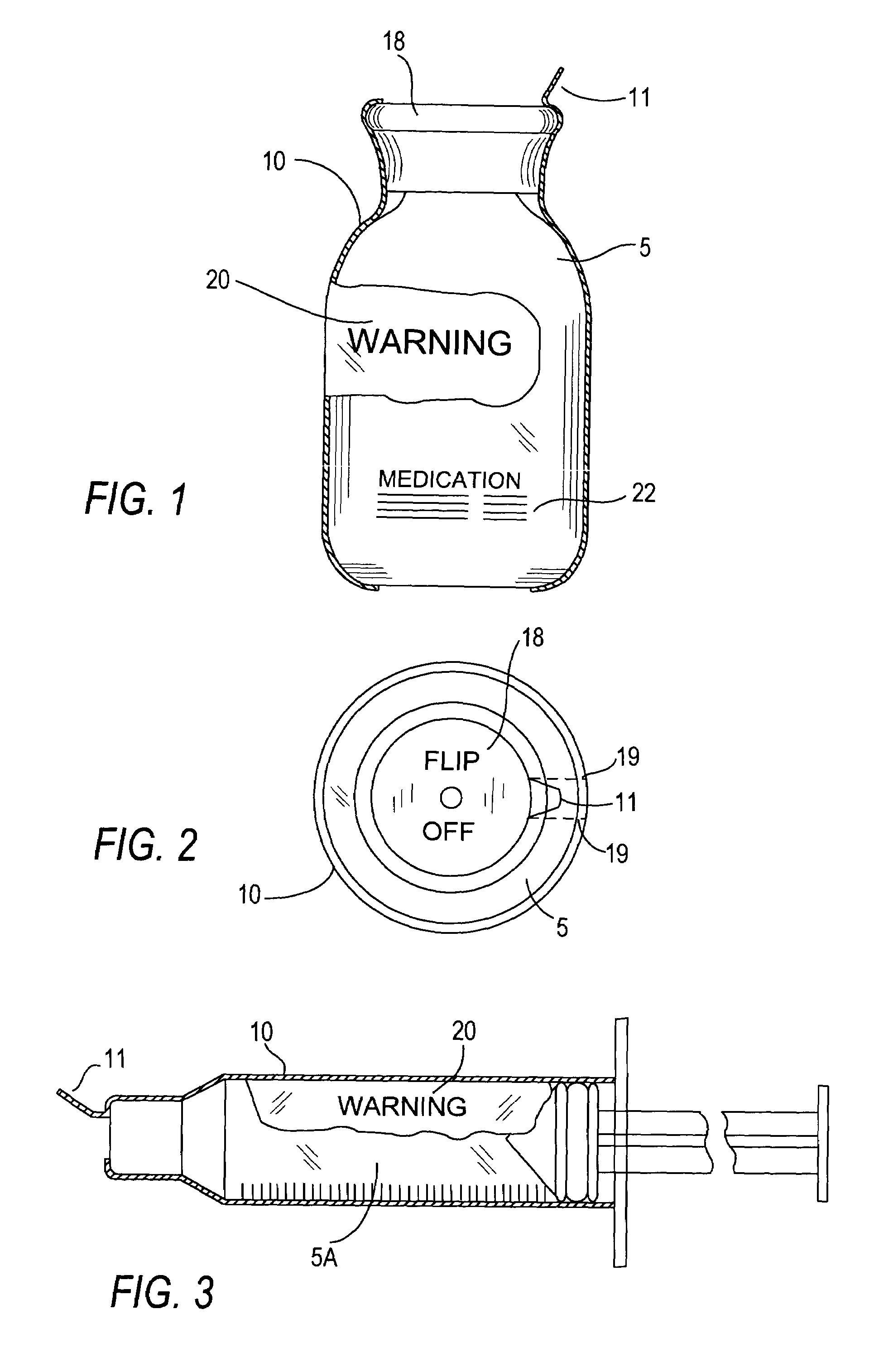

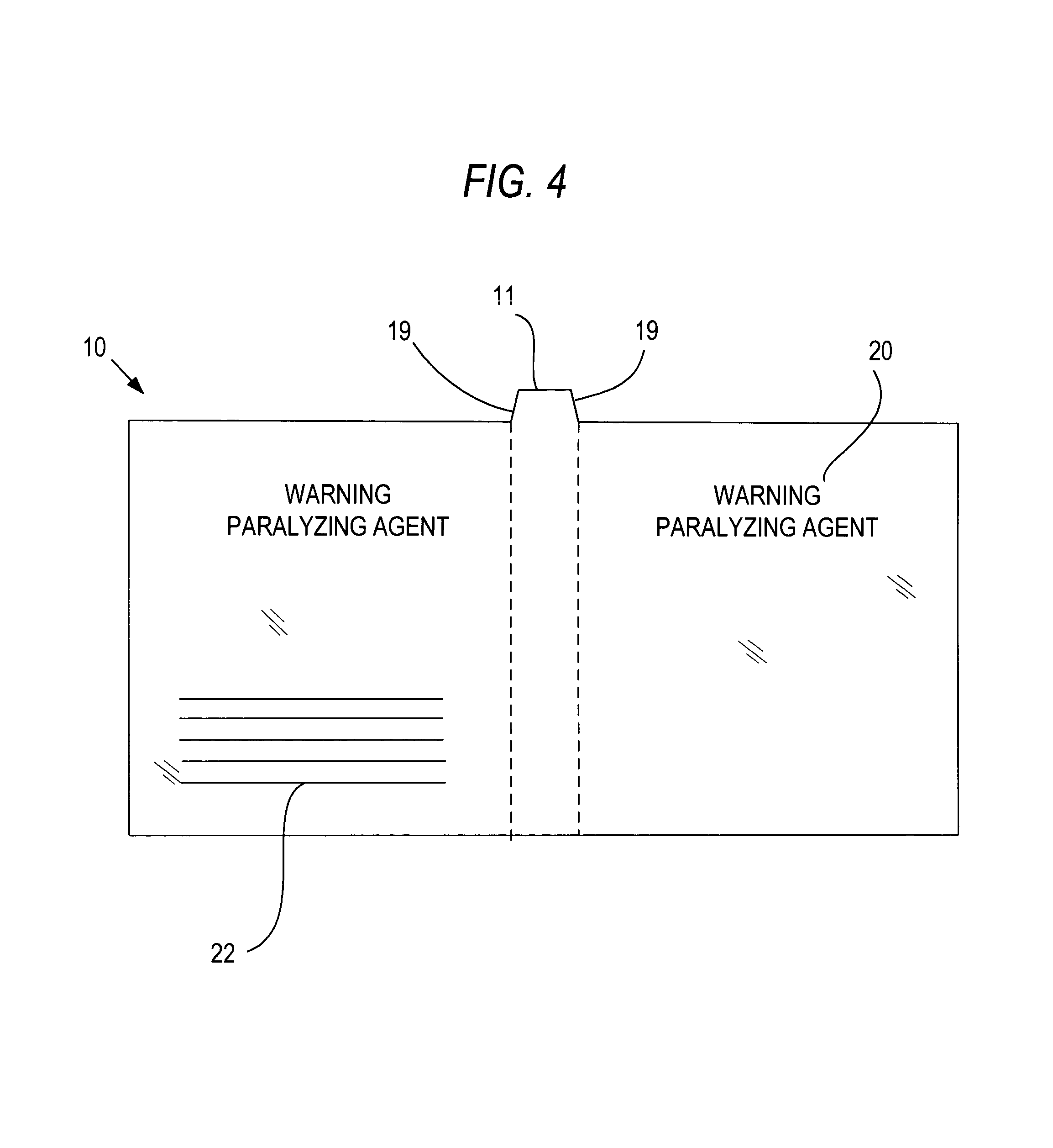

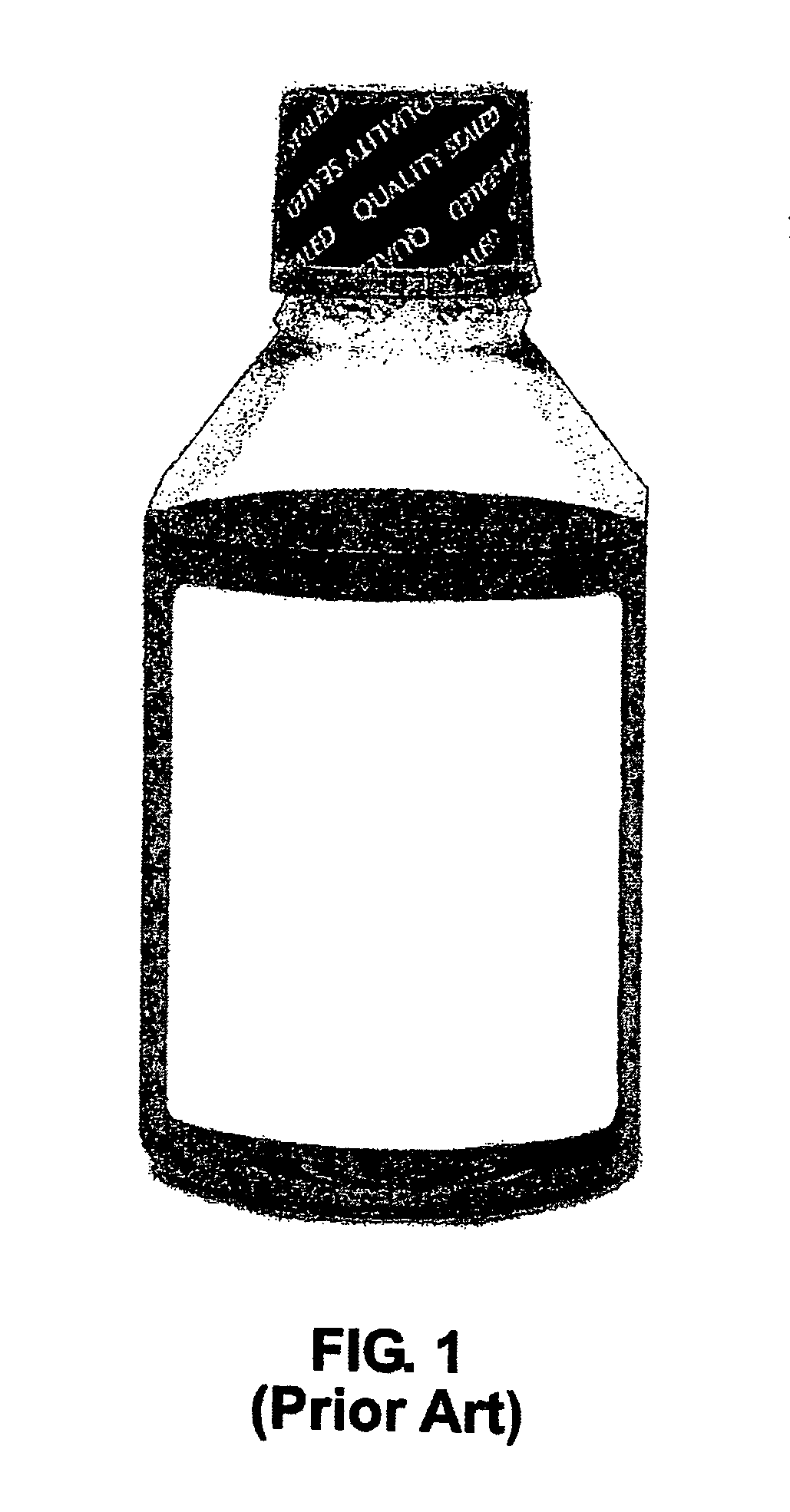

Alert medication safety seal system and method

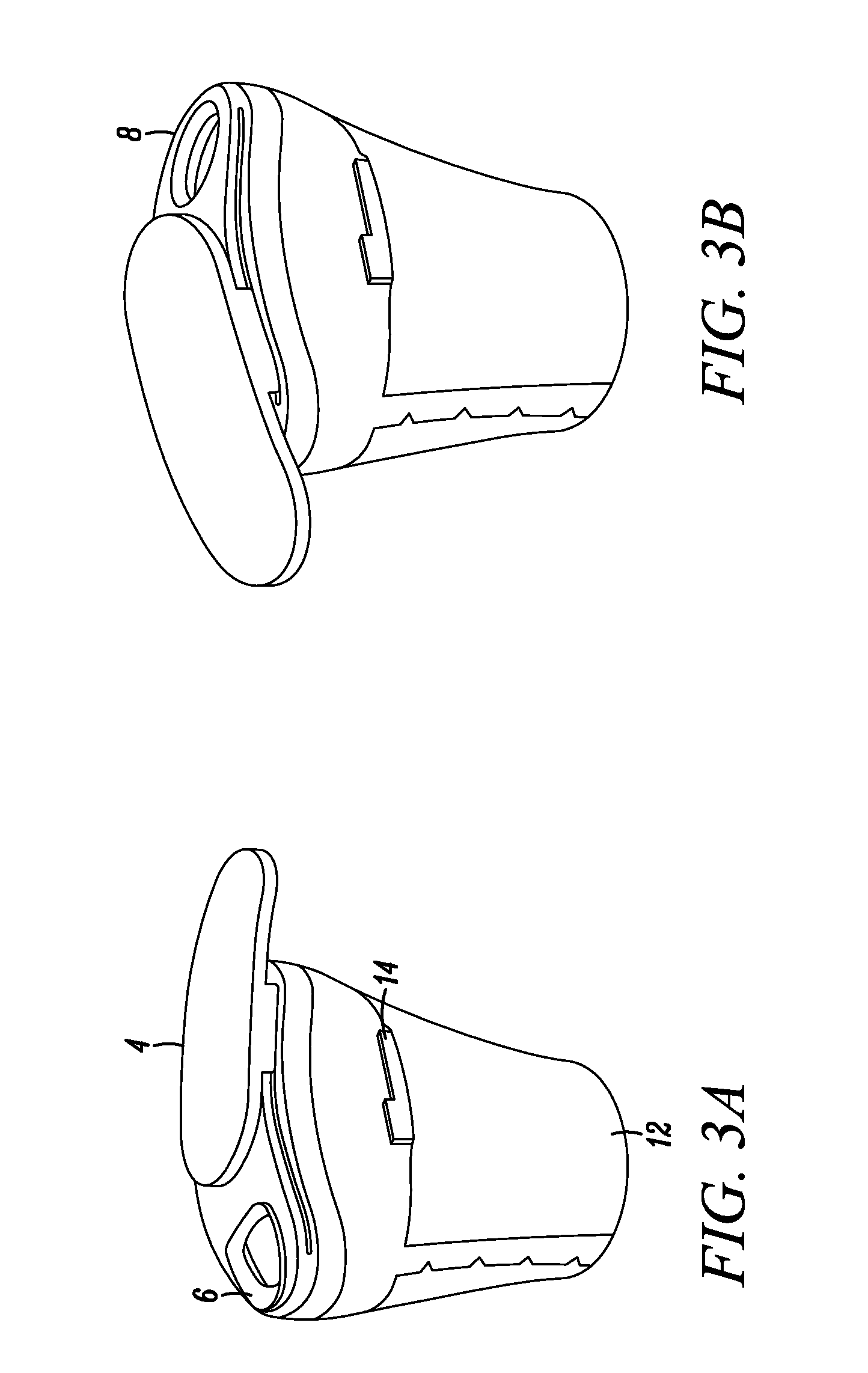

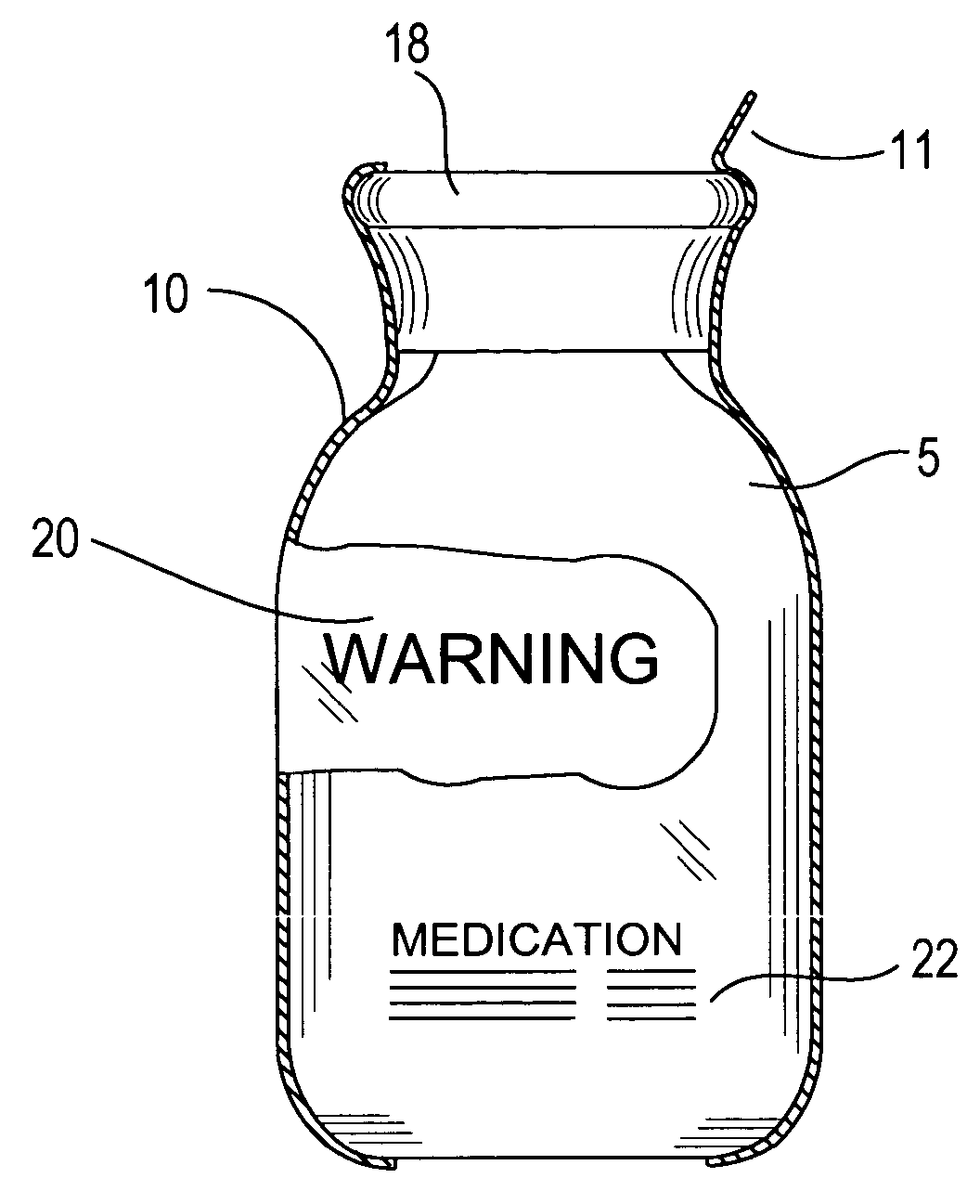

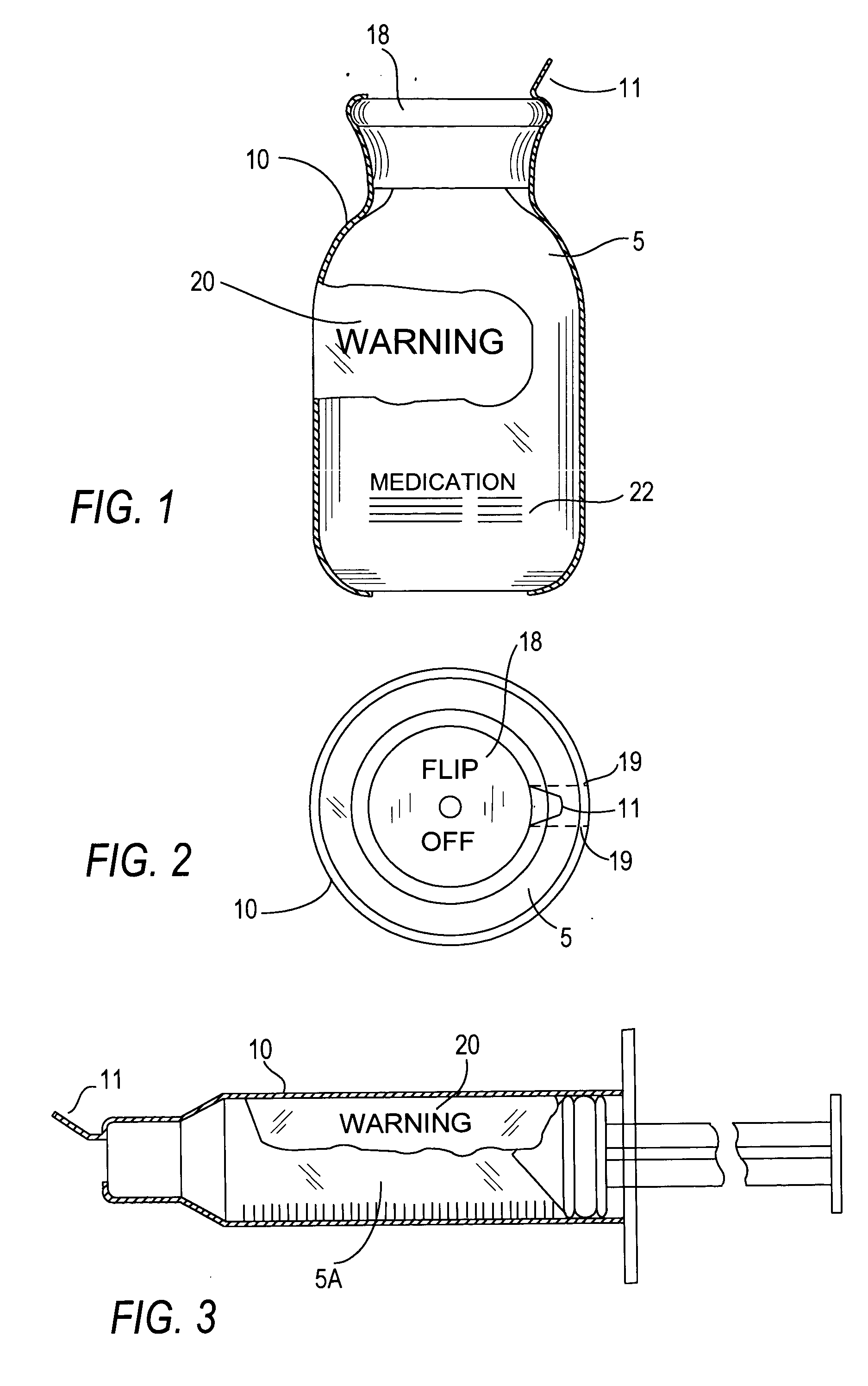

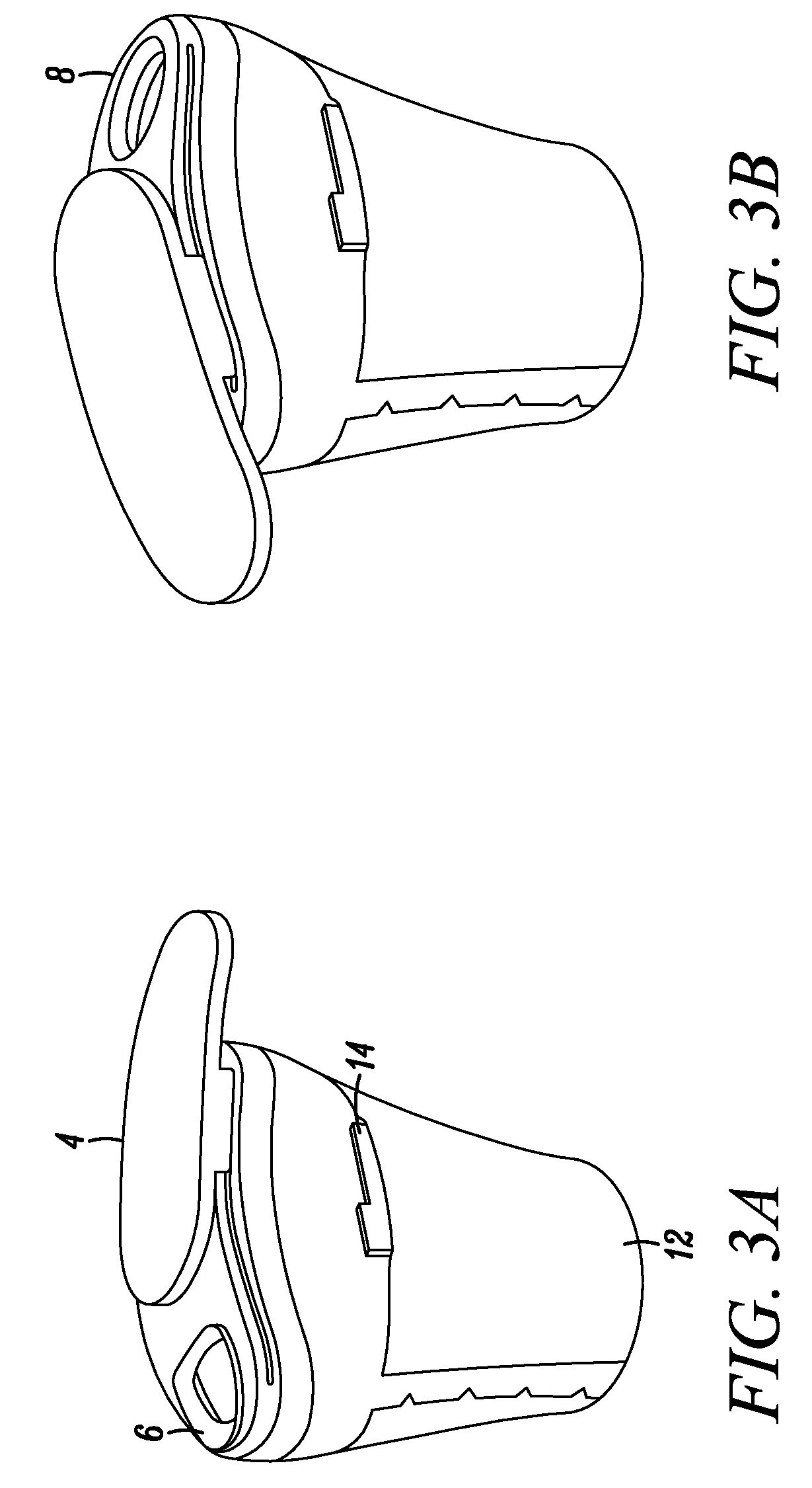

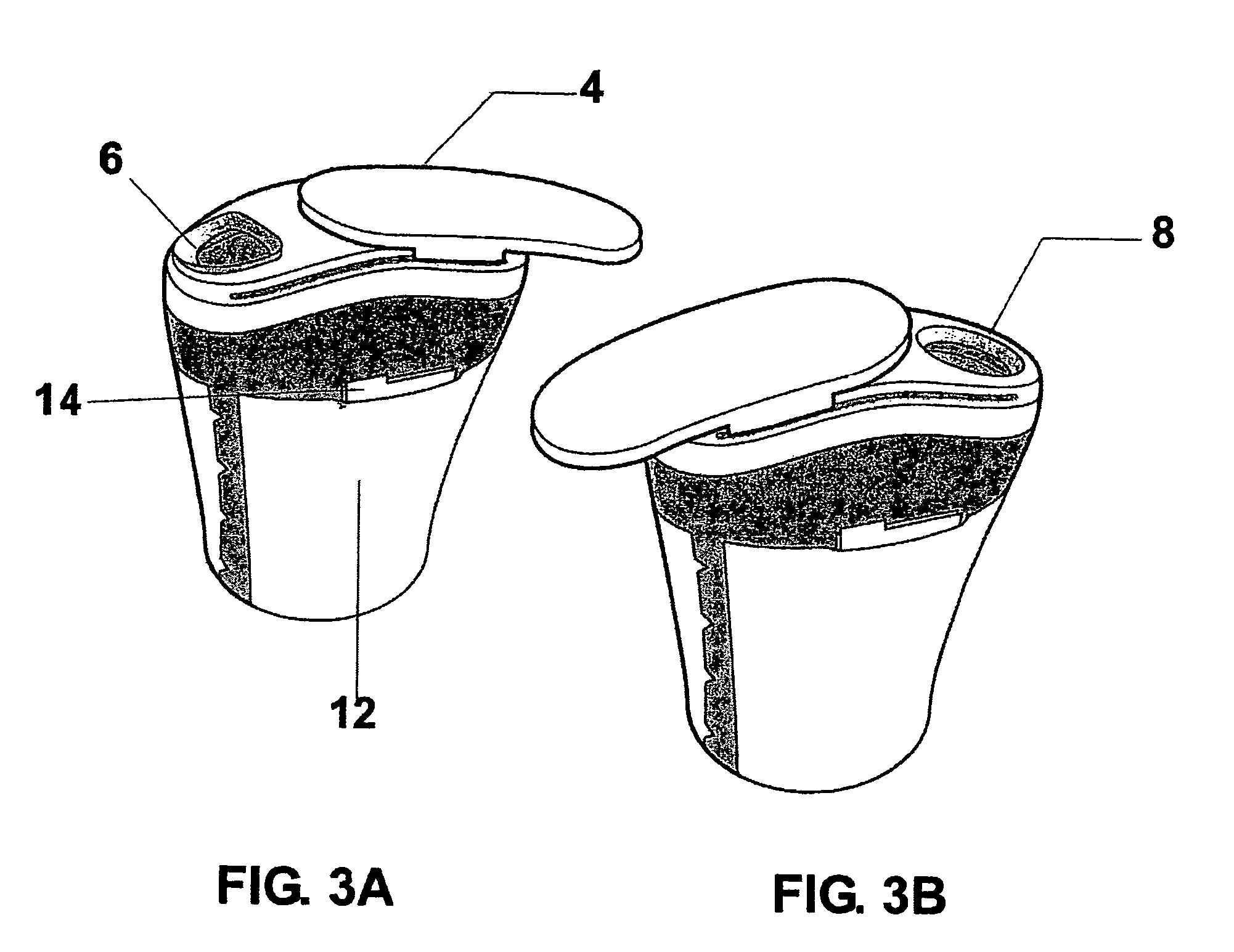

The present invention provides for method and system in which a heat-shrinkable plastic cover is placed over an individual conventional medicine container. The cover is heat shrunk around the container to form a tight-fitting seal which covers the majority of the original medication container. The seal must be opened in order to gain entry into an individual medication container just prior to the use or the administration of the product in the container. The seal includes an easy-open mechanism, such as a pull-tab or perforated tear strip. The purpose of the seal is to distinguish high-alert medications and requires an additional safety step in the medication administration process by requiring the removal of an additional cover which entirely encloses the container. The non-adhesive nature of the seal is significant in that the removal of the seal does not damage the original product labeling or leave unwanted residue on the medication container. The seal includes an integrated warning statement directed to point-of-use, high-alert medication preparations for the person preparing the medication for use. The level of repackaging would distinguish categories of high-alert medications, alerting users as to the classification of the medication. Application of the seal offers the user visual cues and “tactile awareness” different from the look and feel of the original container to distinguish high-alert medications from other medications.

Owner:PAOLETTI RICHARD D

Labels, containers, system and method for providing reagents

ActiveUS20070077655A1Avoid trafficStop the flowStampsBioreactor/fermenter combinationsAlphanumericReagent

The invention relates to systems and methods for marketing and using products such as liquid materials, especially liquid reagents for use in microbiological and cellular biological laboratory settings include the use of unique color and simple numeric or alphanumeric identifiers to quickly and easily identify any product from a catalog list of products. Methods of marketing, advertising and producing such products are also disclosed. Particular embodiments include products, product packaging and product labeling. The invention also relates to collars and sleeves for containers, as well as related methods of use.

Owner:LIFE TECH CORP

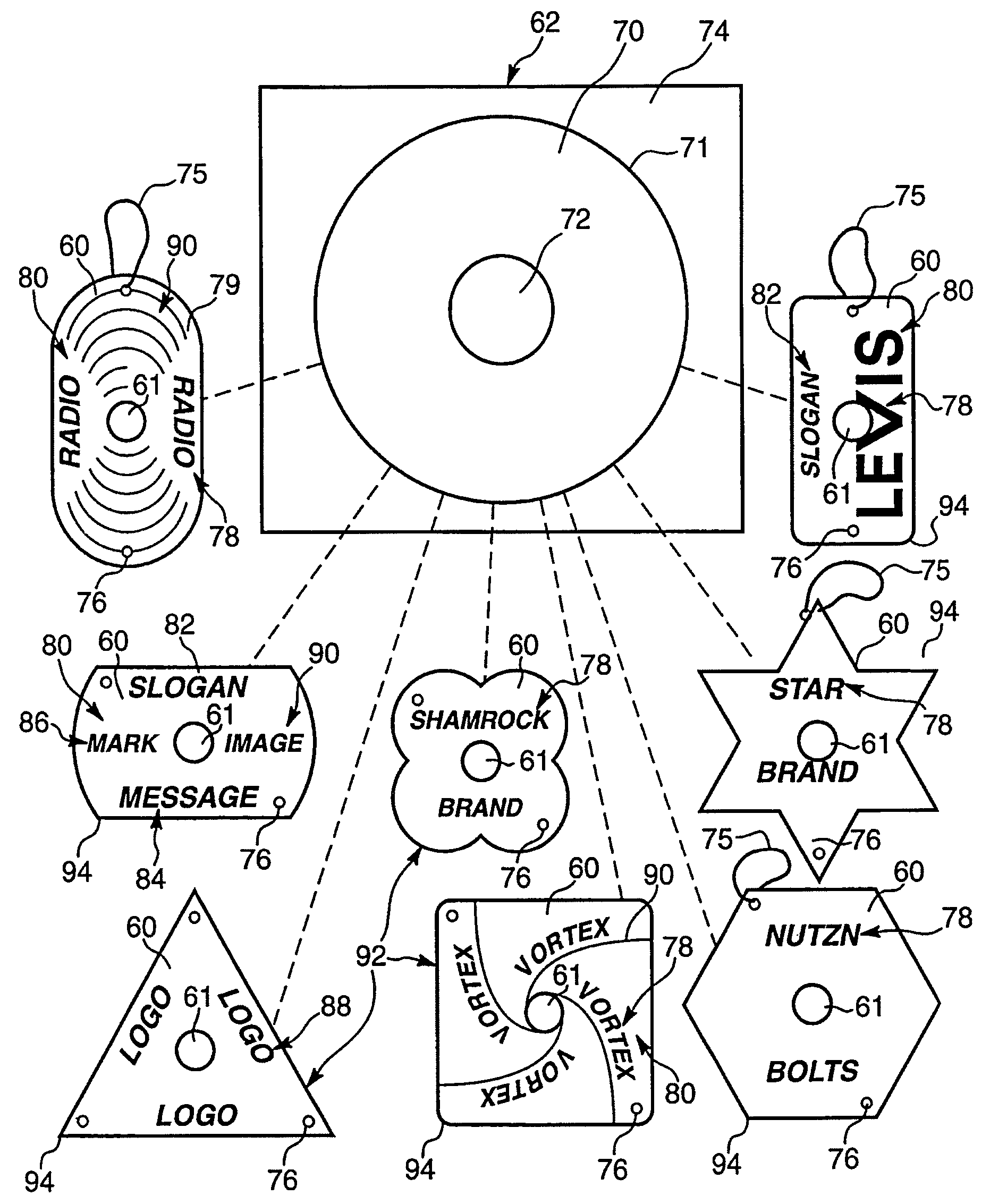

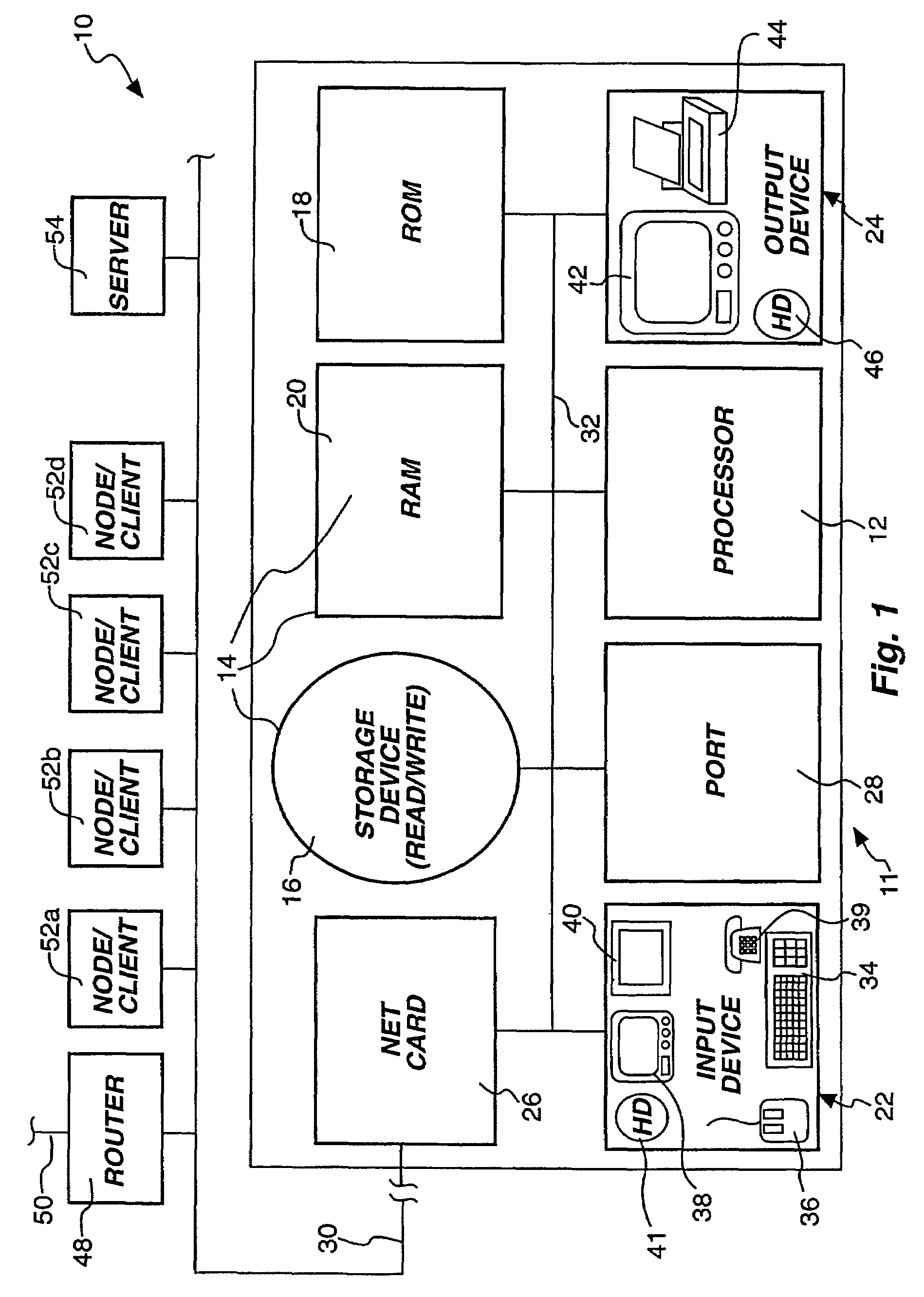

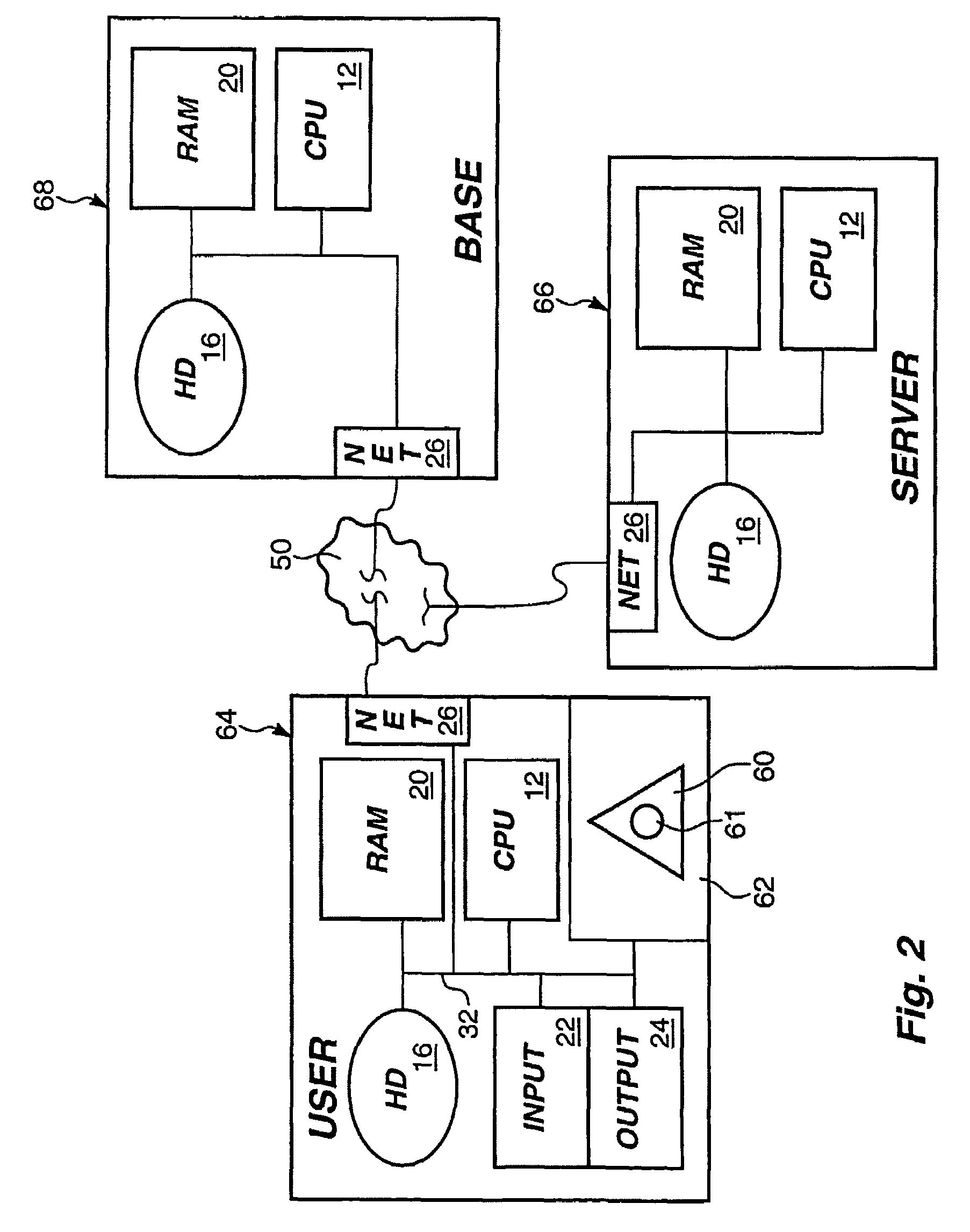

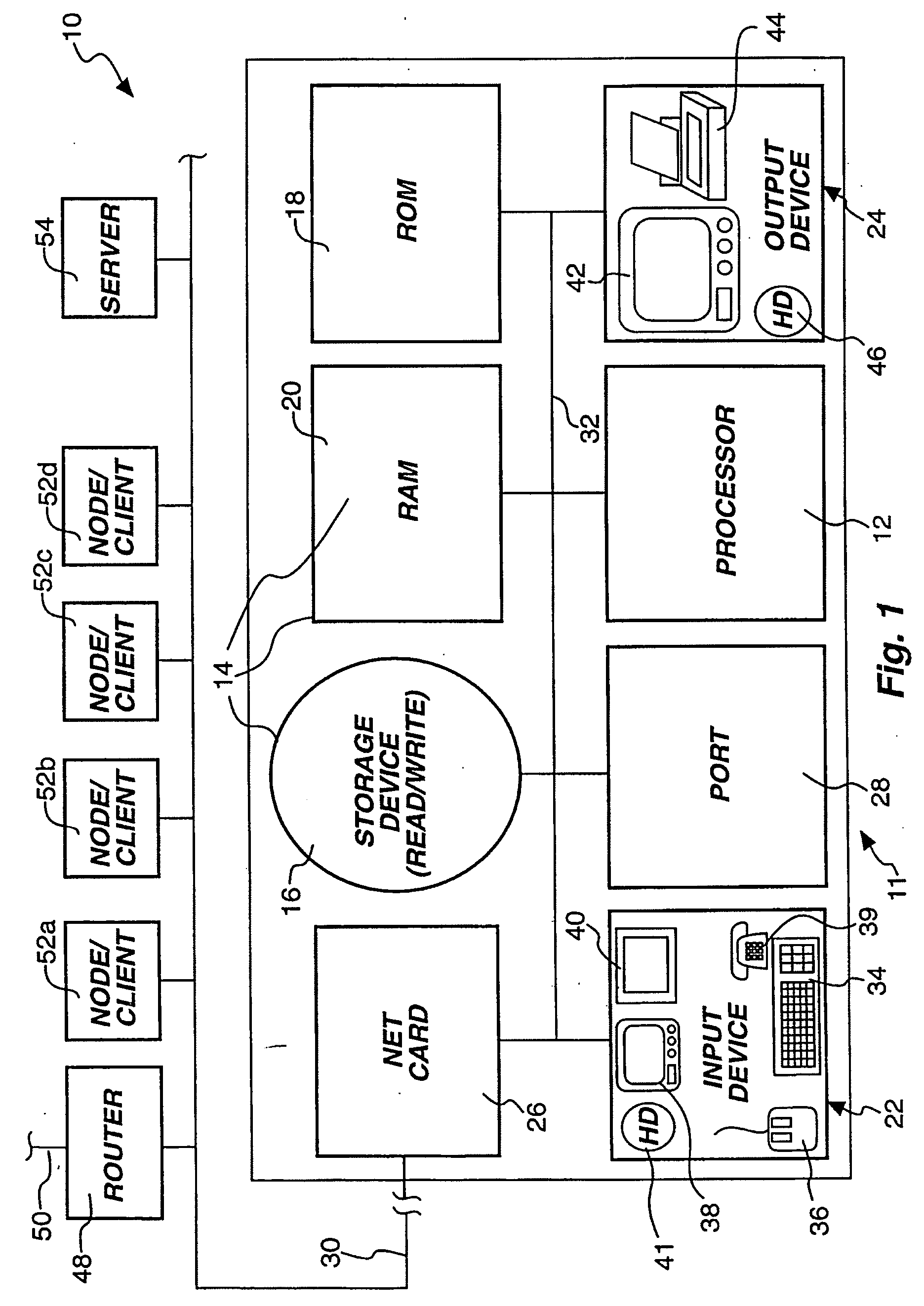

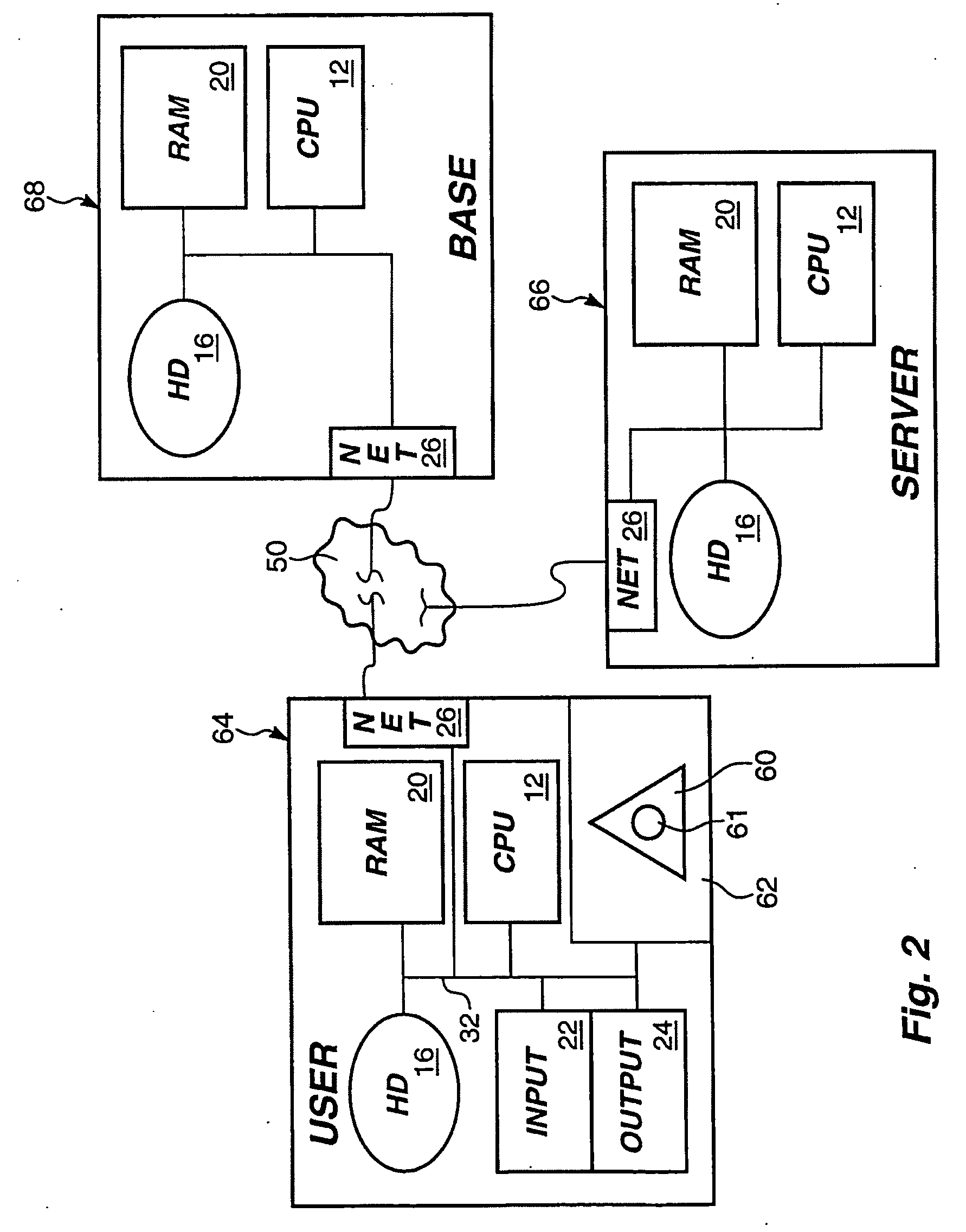

Computer readable hang tag and product

A user-computer-readable medium provides all or part of a product labeling system for engaging purchasers. Executables, data, or both are recorded in the medium embodied in a tag or other product labeling structure, in order to deliver to a consumer or purchaser engaging presentations of products, information, or registration templates. As a result, purchasers may receive launchers, browsers, viewers, e-mail systems, facsimile centers, players, or interface brokers for the foregoing, if organically installed already on a workstation of a purchaser. Software may provide catalog presentations, user registration templates, communications, linkers, or engines, and the like. Operation modules and profile builders may provide information over ready links implemented by software on the medium. In certain embodiments, entertainment, games, skill tests, and the like, recorded in the medium as a tag or label may execute to engage a purchaser and provide purchaser profiling information, product purchasing information, and the like to a vendor, while providing additional product information, warranty registrations, applications, entertainment, or the like, to a purchaser.

Owner:ETAGZ

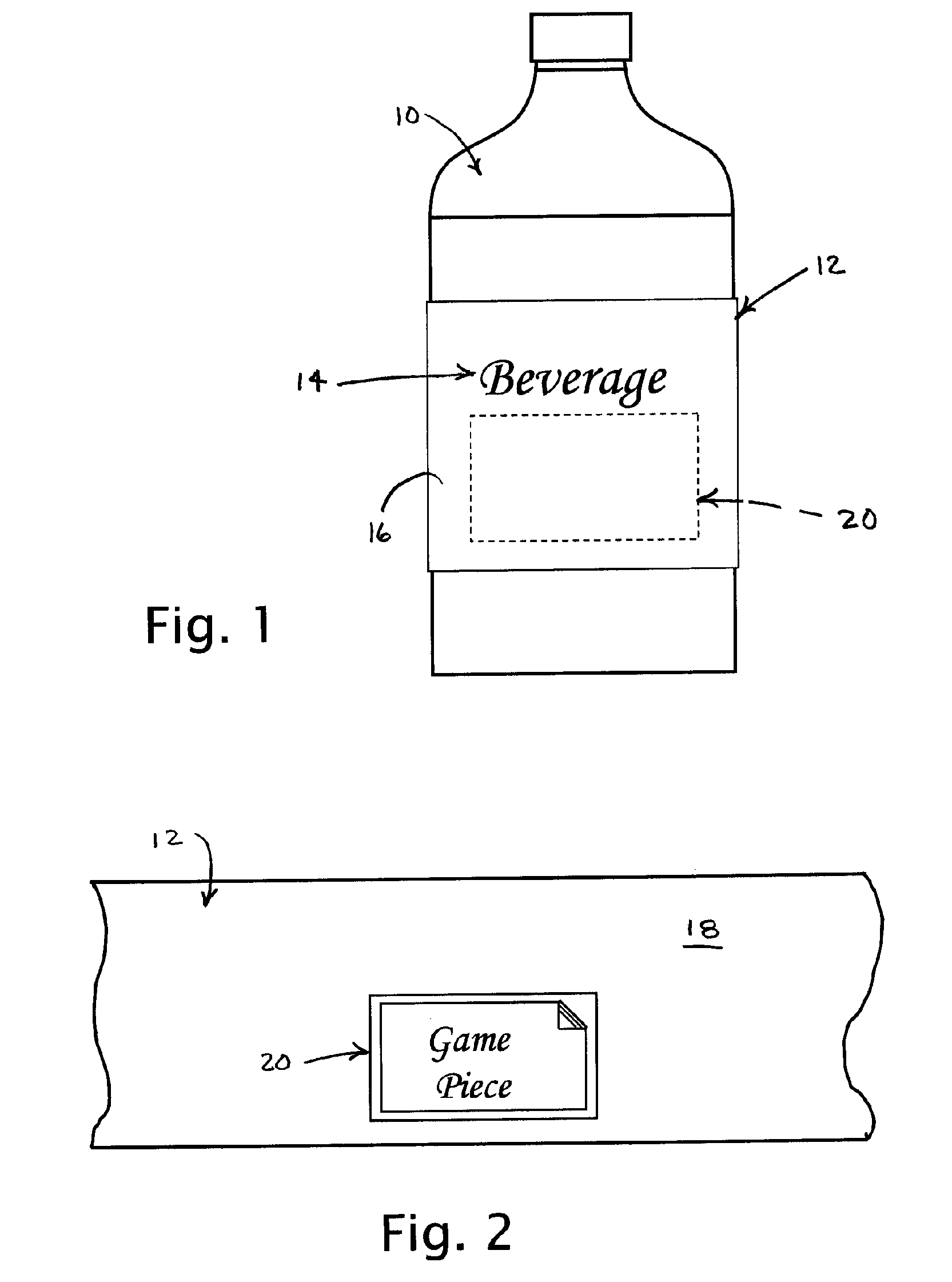

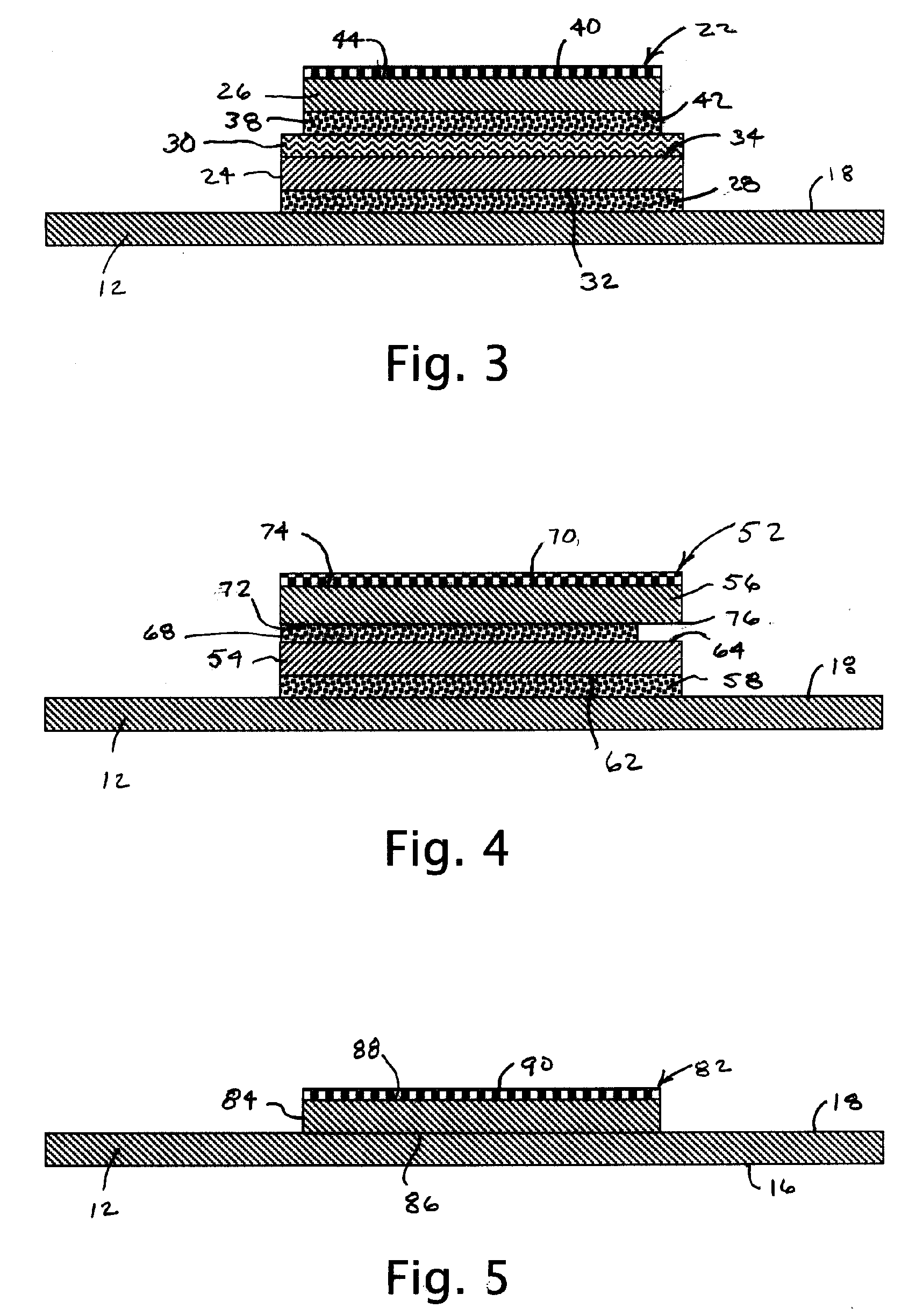

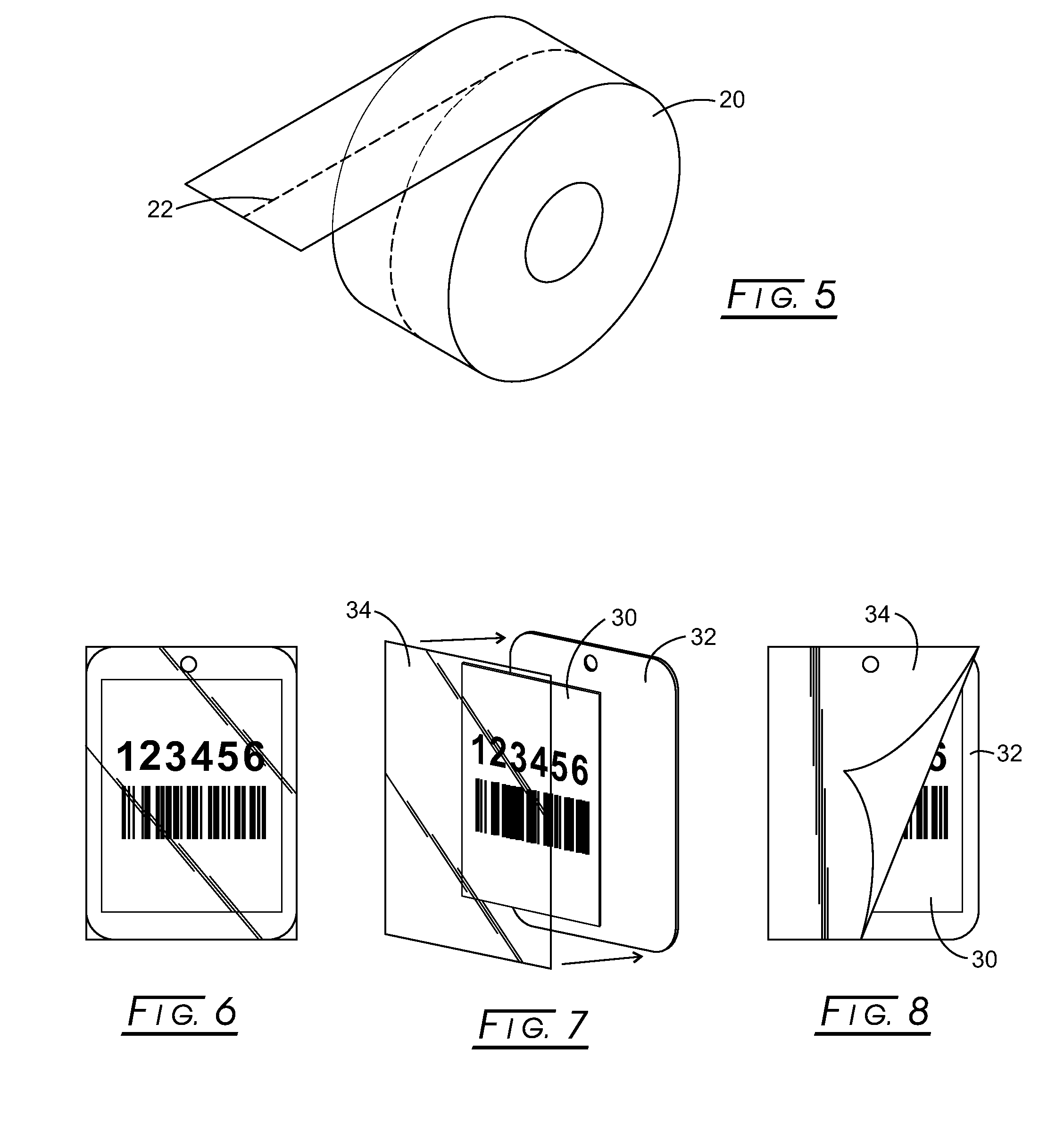

Product Labeling System with Overwrapped Printed Article

A product labeling system for overwrapping printed articles on products includes a web having product-labeling information being visible at an outer surface of the web. A succession of base substrates is positioned along the continuous length of the web, and a permanent adhesive bonds the base substrates to an inner surface of the web. Printable substrates are mounted on the succession of base substrates and are held in place by a temporary adhesive. Successive lengths of the web are separated into discrete sections and wrapped around products such that the product labeling information remains visible on the outside of the products and the printable substrates are located between the wrapped web sections and the products.

Owner:WS PACKAGING GROUP

Labels, containers, system and method for providing reagents

The invention relates to systems and methods for marketing and using products such as liquid materials, especially liquid reagents for use in microbiological and cellular biological laboratory settings include the use of unique color and simple numeric or alphanumeric identifiers to quickly and easily identify any product from a catalog list of products. Methods of marketing, advertising and producing such products are also disclosed. Particular embodiments include products, product packaging and product labeling. The invention also relates to collars and sleeves for containers, as well as related methods of use.

Owner:LIFE TECH CORP

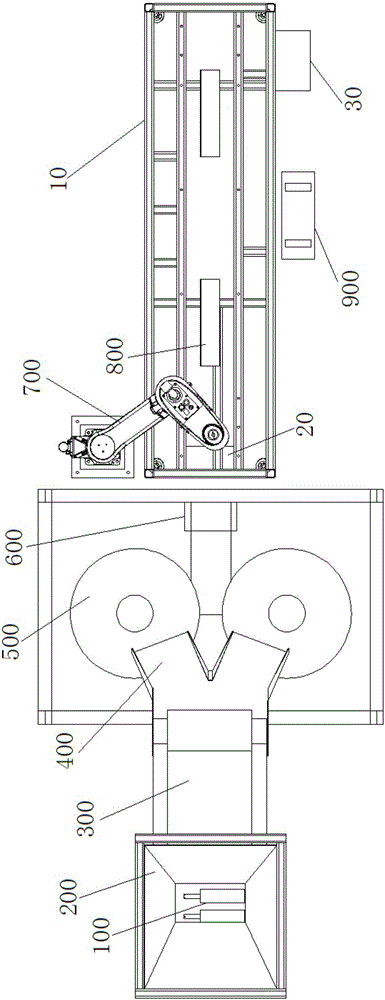

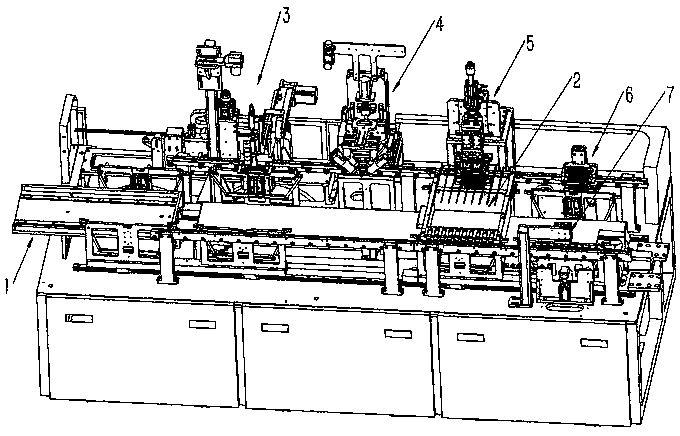

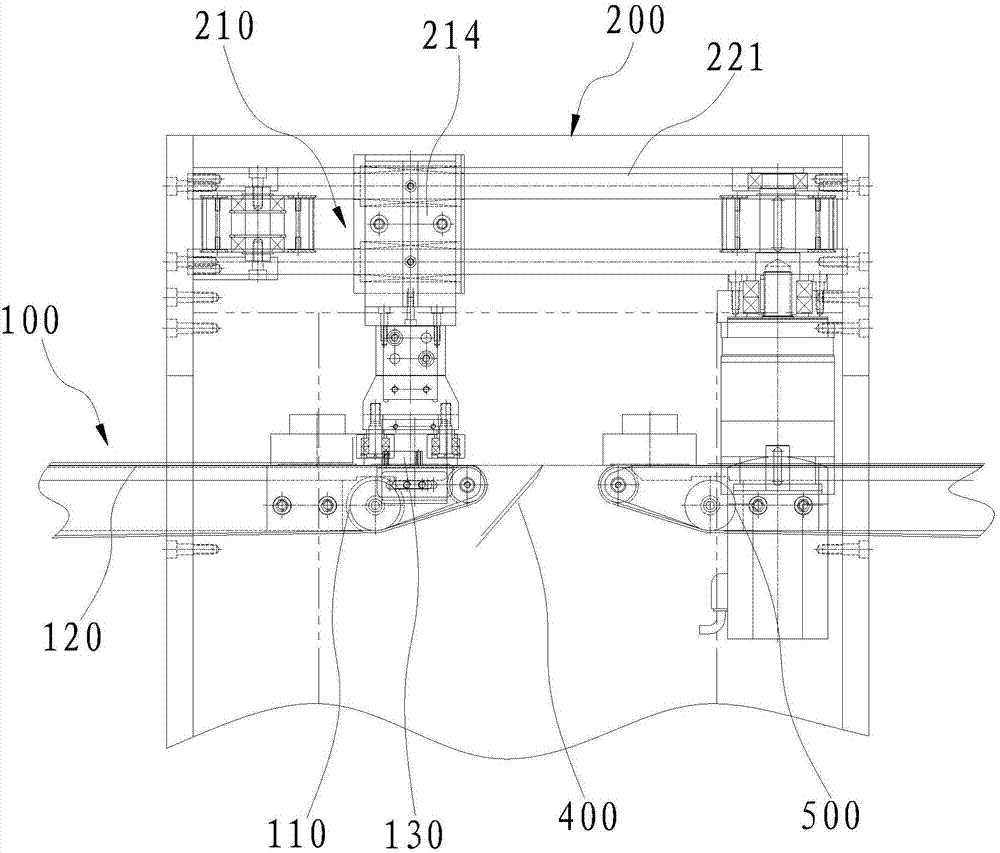

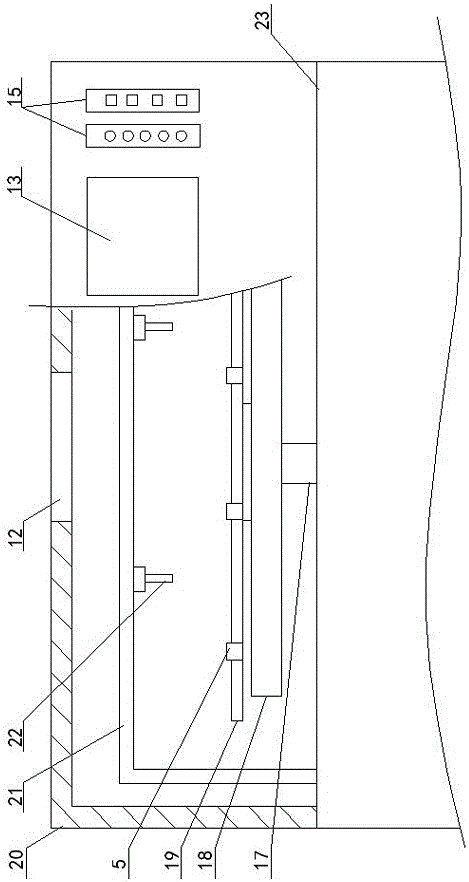

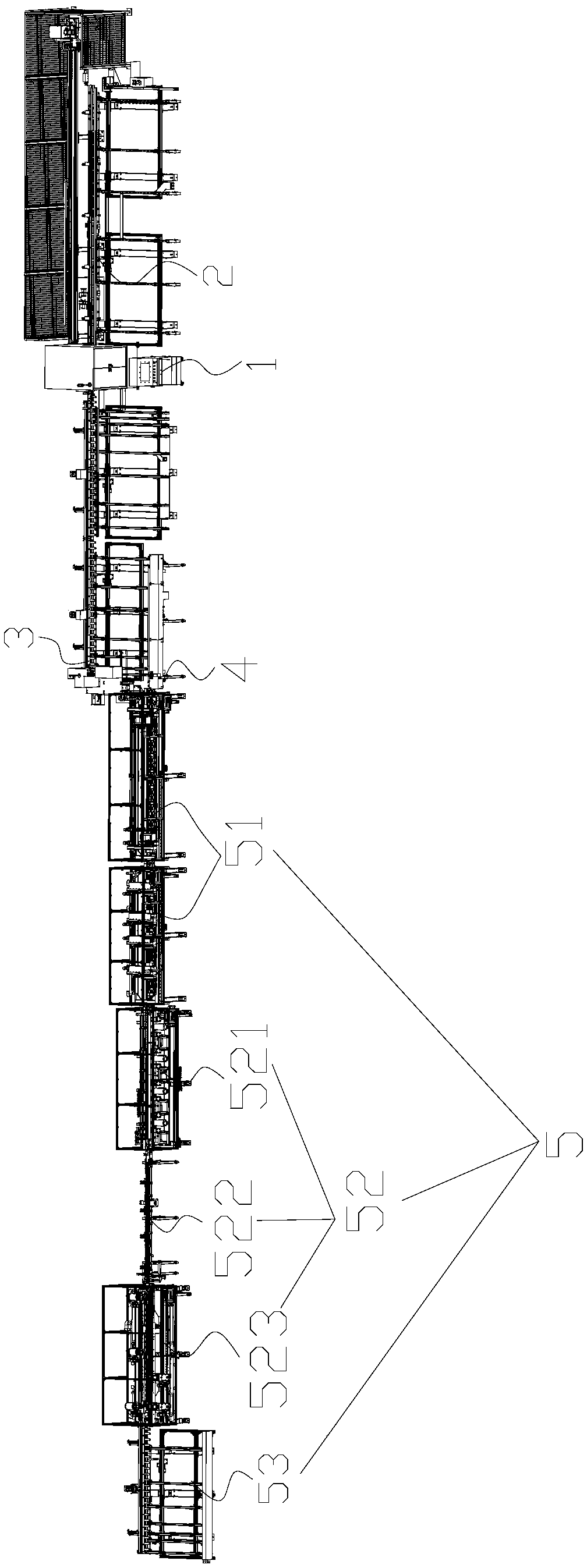

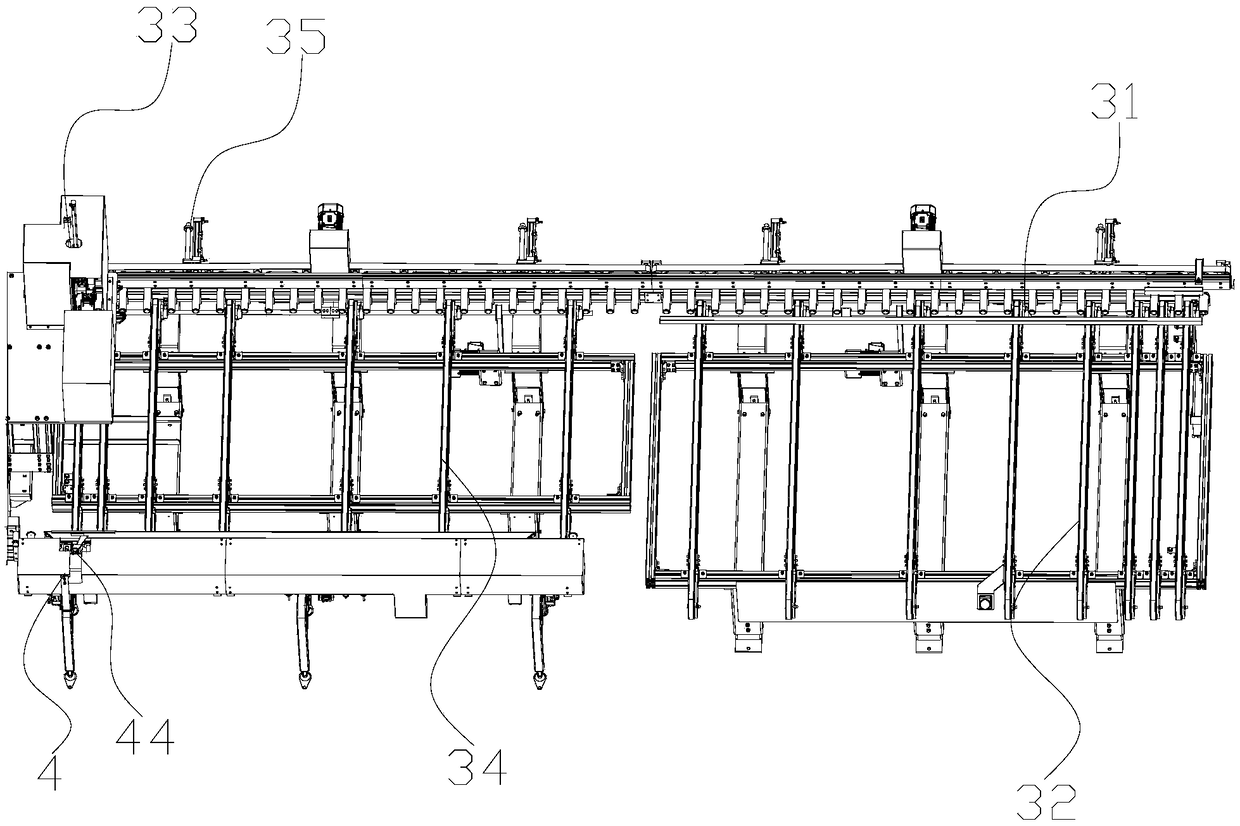

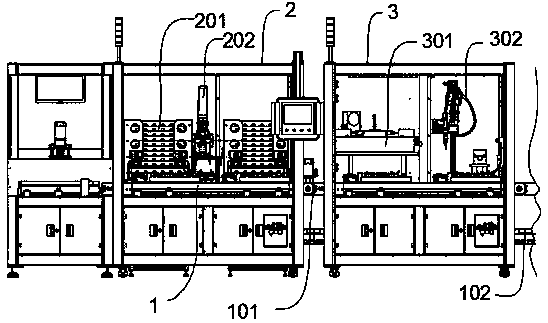

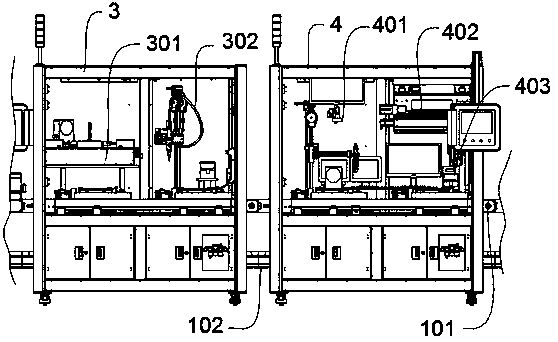

Automatic product labeling production line

InactiveCN106043872AImprove efficiencyImprove processing qualityConveyor partsLabelling machinesProduction lineEngineering

The invention discloses an automatic product labeling production line, which comprises a feeding funnel, a feeding belt, a material distribution chute, a vibrating plate assembly, a robot and a labeling conveying line arranged in sequence; The bottom end of the belt is located below the outlet at the bottom of the feeding funnel; the top of the feeding belt is located above the distribution chute; the distribution chute is Y-shaped and contains two outlets; corresponding to each distribution chute A vibrating plate assembly is respectively set under the discharge port of the trough; the two vibrating plate assemblies transmit the material to the receiving platform, and the sensor for detecting the presence or absence of material is set on the receiving platform; the robot will undertake the material on the platform It is sucked into the jig for placing materials that is transported along the labeling conveying line; above the labeling conveying line, there is also a pressing wheel mechanism for completely pressing the material into the jig; the side of the labeling conveying line is equipped with a useful Labeling mechanism for labeling.

Owner:深圳市凯之成智能装备有限公司

Alert medication safety seal system and method

The present invention provides for method and system in which a heat-shrinkable plastic cover is placed over an individual conventional medicine container. The cover is heat shrunk around the container to form a tight-fitting seal which covers the majority of the original medication container. The seal must be opened in order to gain entry into an individual medication container just prior to the use or the administration of the product in the container. The seal includes an easy-open mechanism, such as a pull-tab or perforated tear strip. The purpose of the seal is to distinguish high-alert medications and requires an additional safety step in the medication administration process by requiring the removal of an additional cover which entirely encloses the container. The non-adhesive nature of the seal is significant in that the removal of the seal does not damage the original product labeling or leave unwanted residue on the medication container. The seal includes an integrated warning statement directed to point-of-use, high-alert medication preparations for the person preparing the medication for use. The level of repackaging would distinguish categories of high-alert medications, alerting users as to the classification of the medication. Application of the seal offers the user visual cues and “tactile awareness” different from the look and feel of the original container to distinguish high-alert medications from other medications.

Owner:PAOLETTI RICHARD D

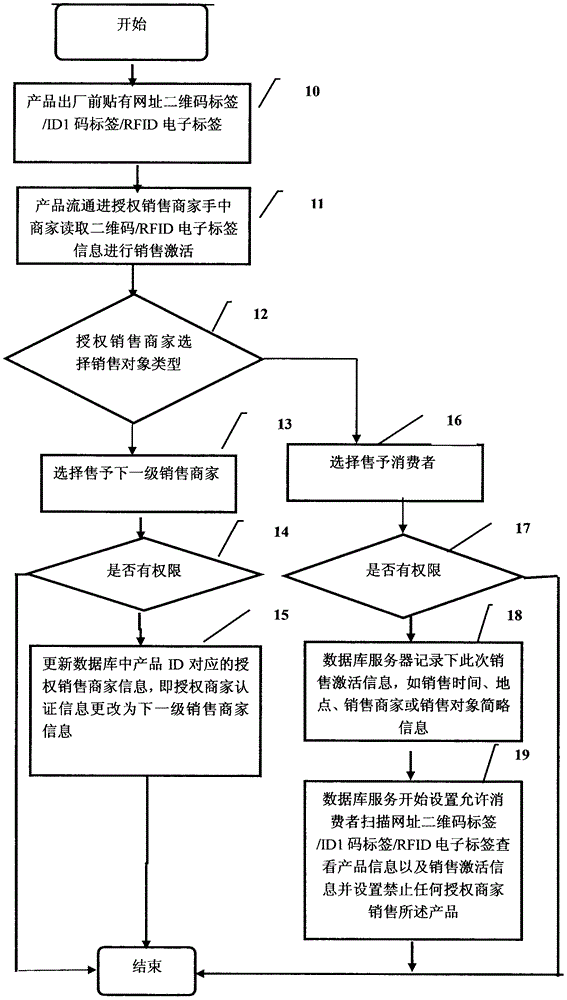

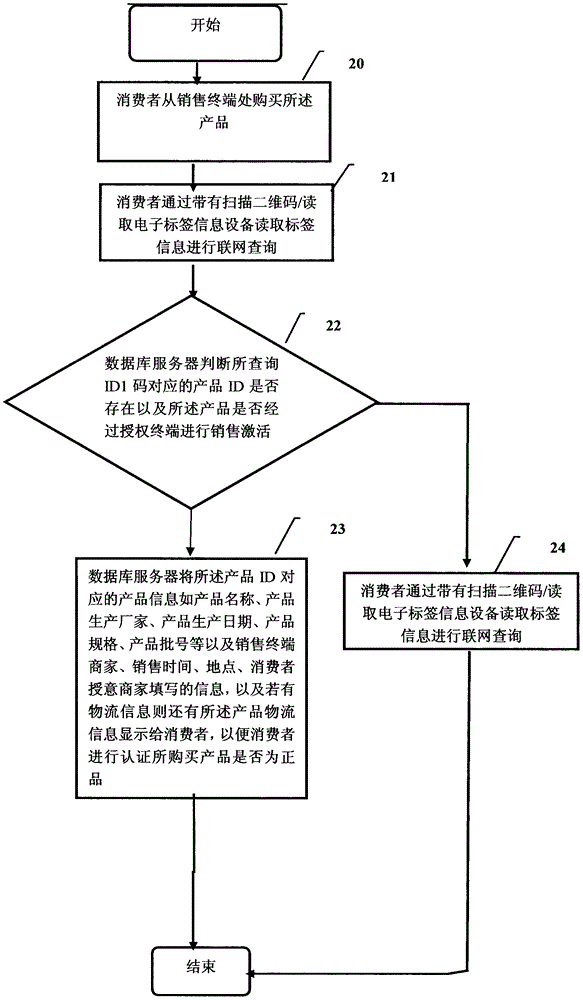

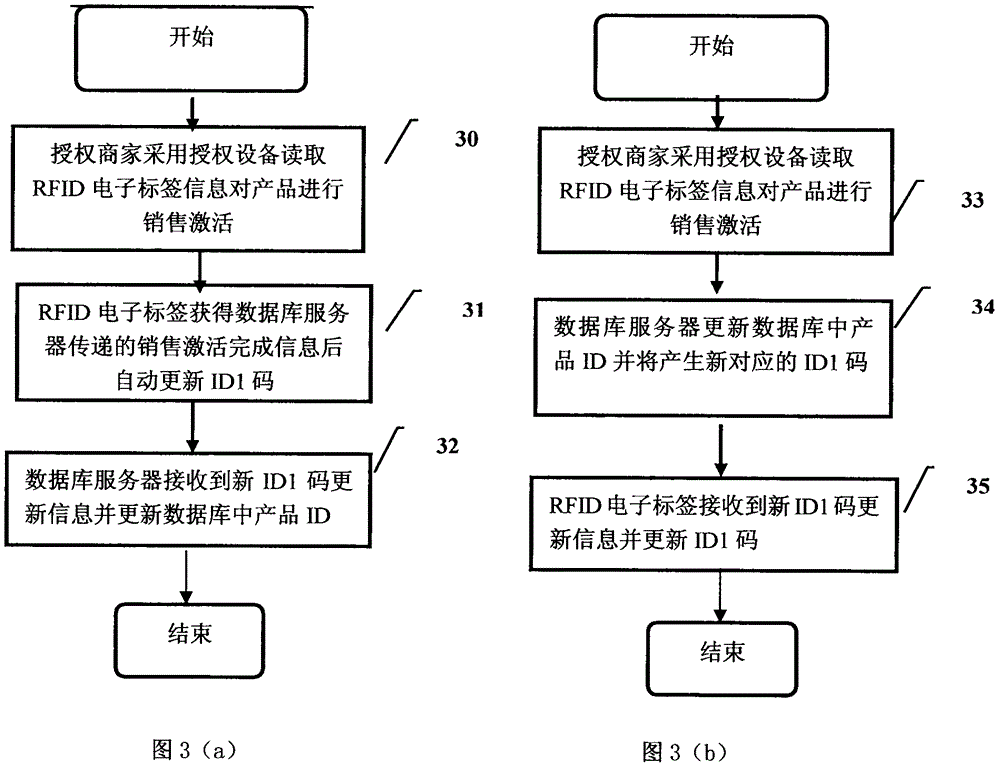

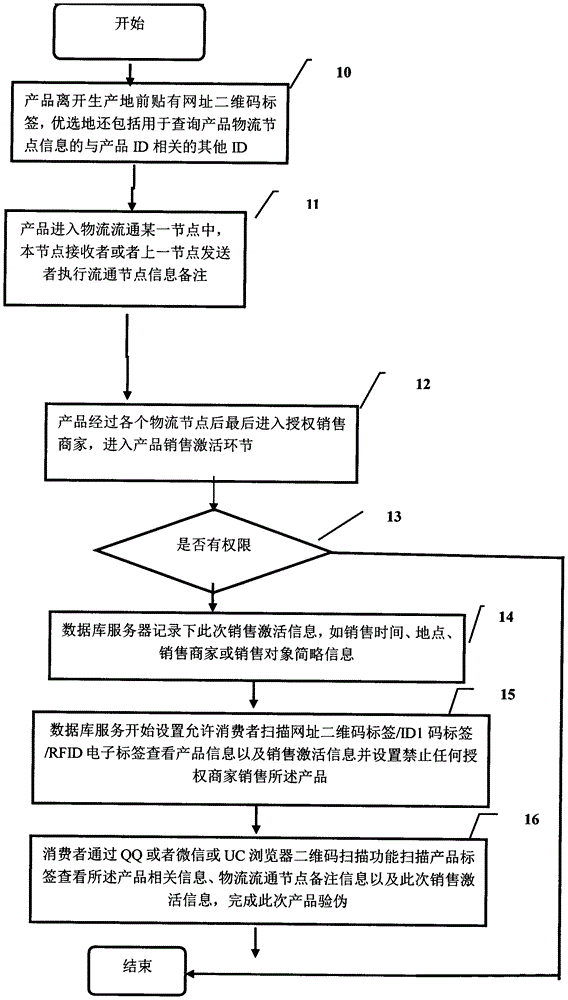

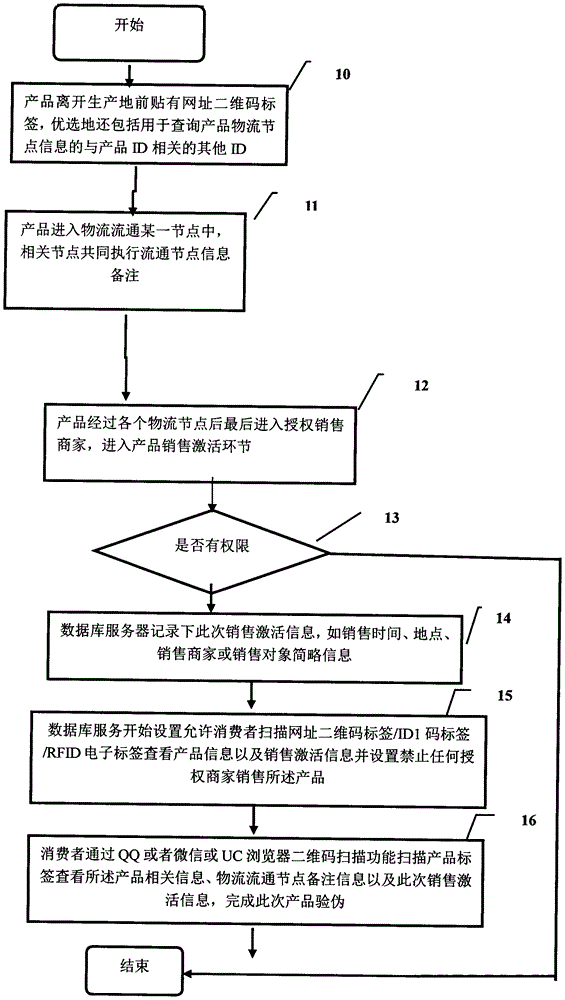

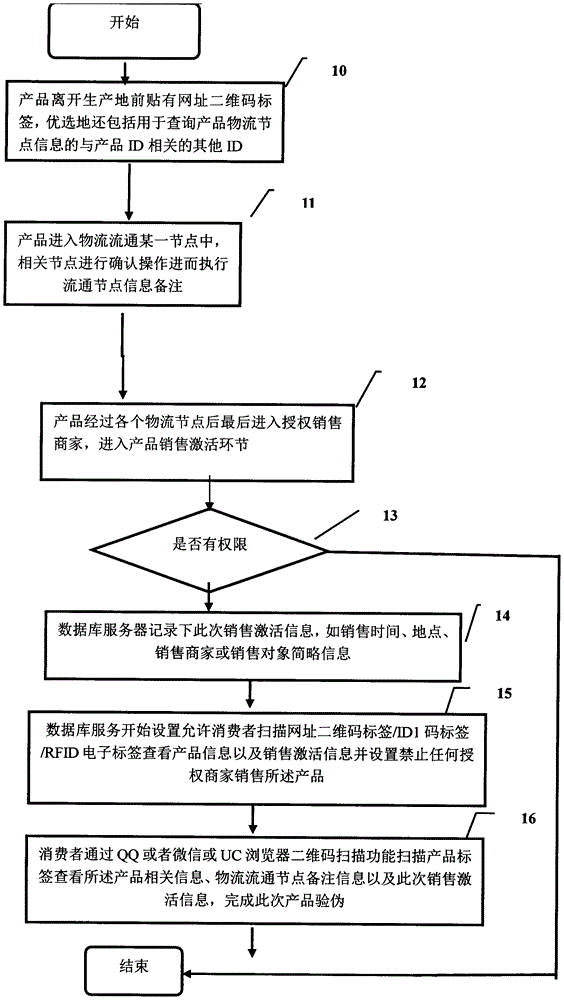

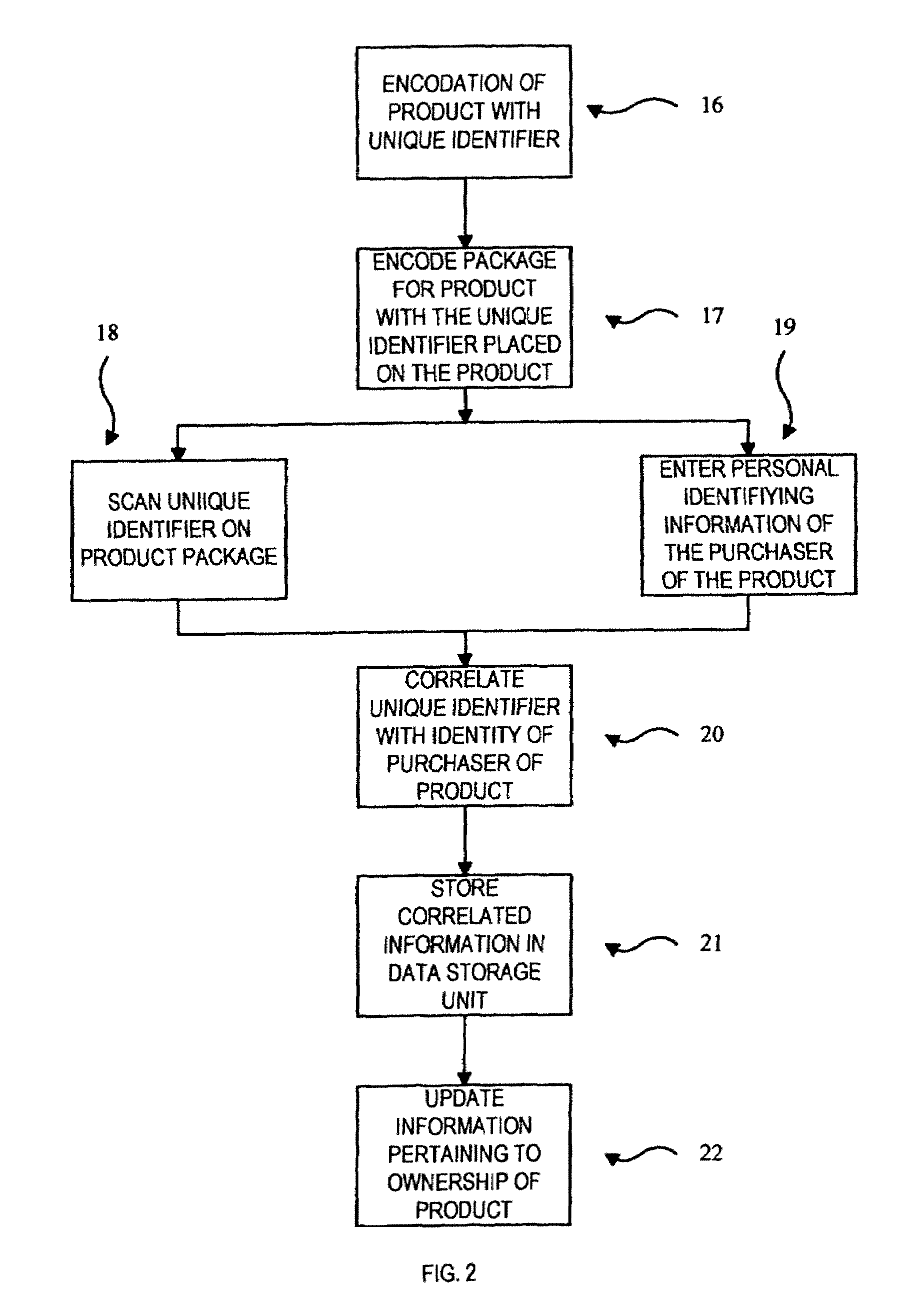

Product anti-counterfeiting method

ActiveCN105894304ACo-operative working arrangementsCommerceProduct traceabilityBiological activation

The invention provides a product anti-counterfeiting method, which comprises the following steps: a) a product is accompanied by a two-dimensional code / an RFID electronic tag before leaving the factory; b) a seller carries out sale activation by scanning or reading the product tag information when selling the product; and c) a consumer can check product information and sale activation information by checking the tag after purchasing the product. The method truly realizes product traceability and an anti-counterfeiting function, and prevents the problem that the tags are utilized again; and a very popular smart phone serves as a checking tool, so that difficulty in checking and recognizing authenticity of the product of the user is reduced, and the system construction cost is extremely low.

Owner:黄世纬

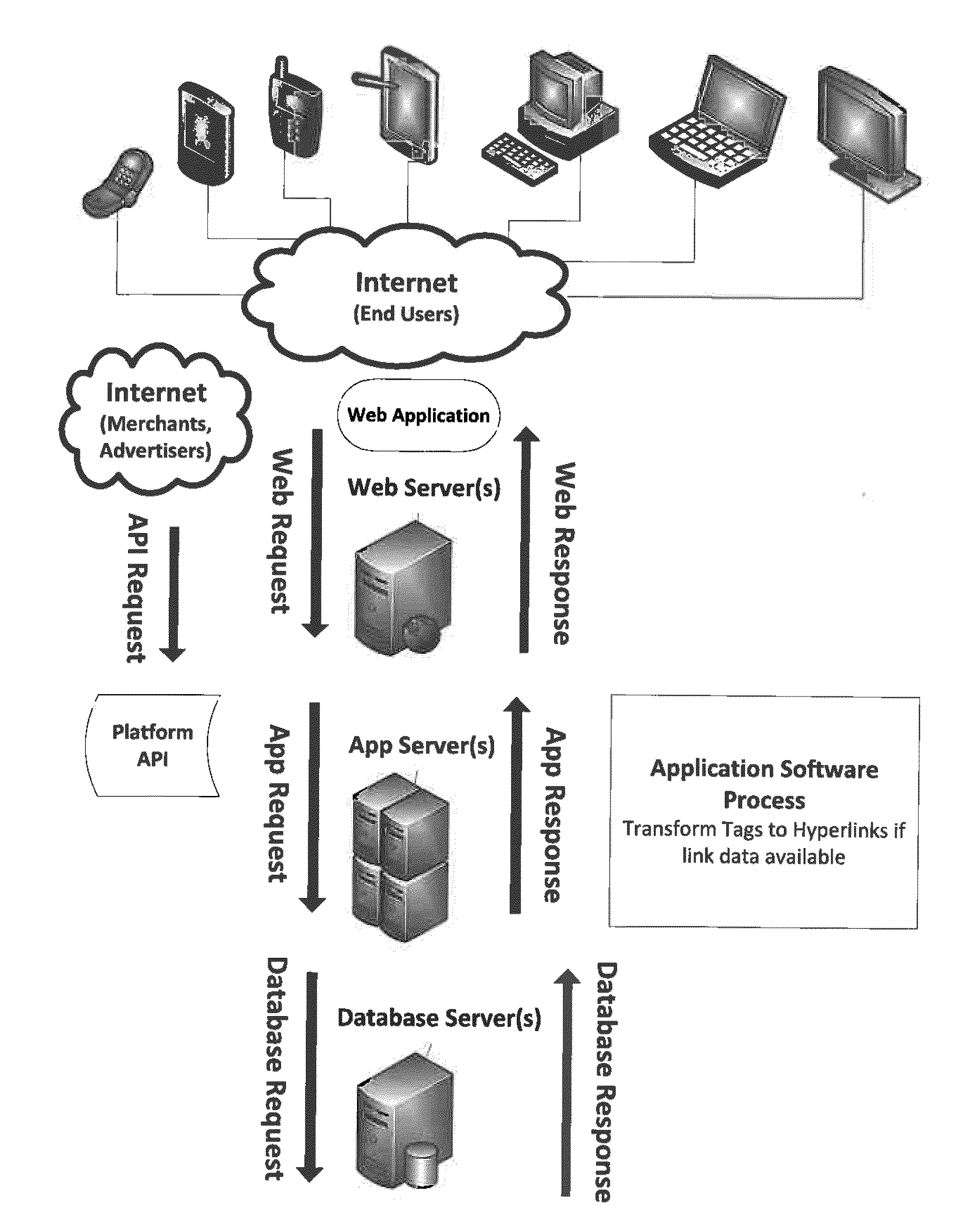

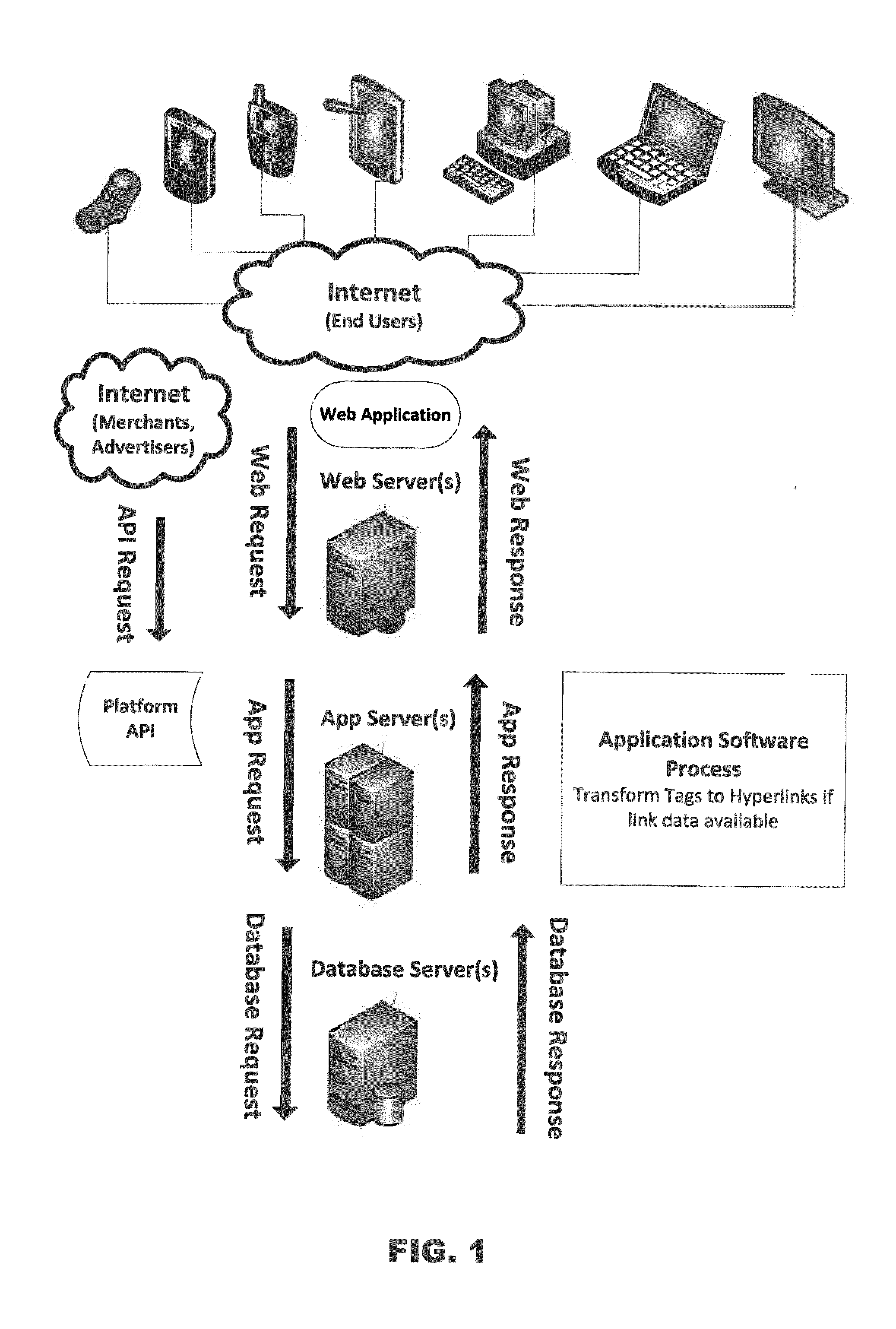

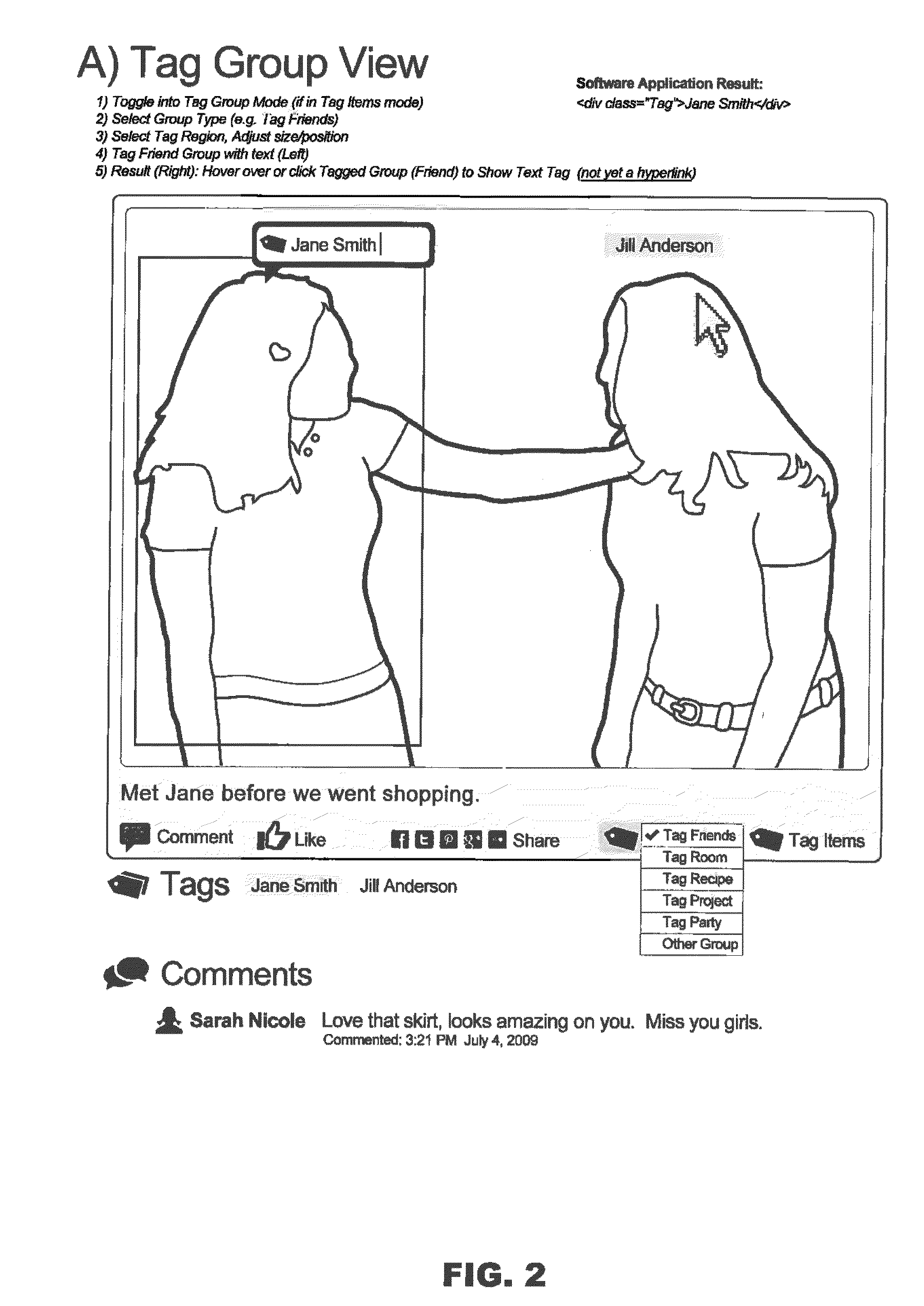

System and method for transforming photo tags of products into a linkable advertisement or purchase page

A system includes a plurality of servers to process and serve a social web application and advertising platform. The platform is capable of transforming tags of products in identifiable regions of a socially shared photo into a linkable advertisement and / or hyperlink to a purchase page for the products. Transforming the shared photo itself into a multi-faceted advertisement, creates direct relevance, desire, works within the confines of screen real estate limitations, saves manual research and communication and provides a direct path to complete the purchase.

Owner:MCMILLION JOHN BENJAMIN

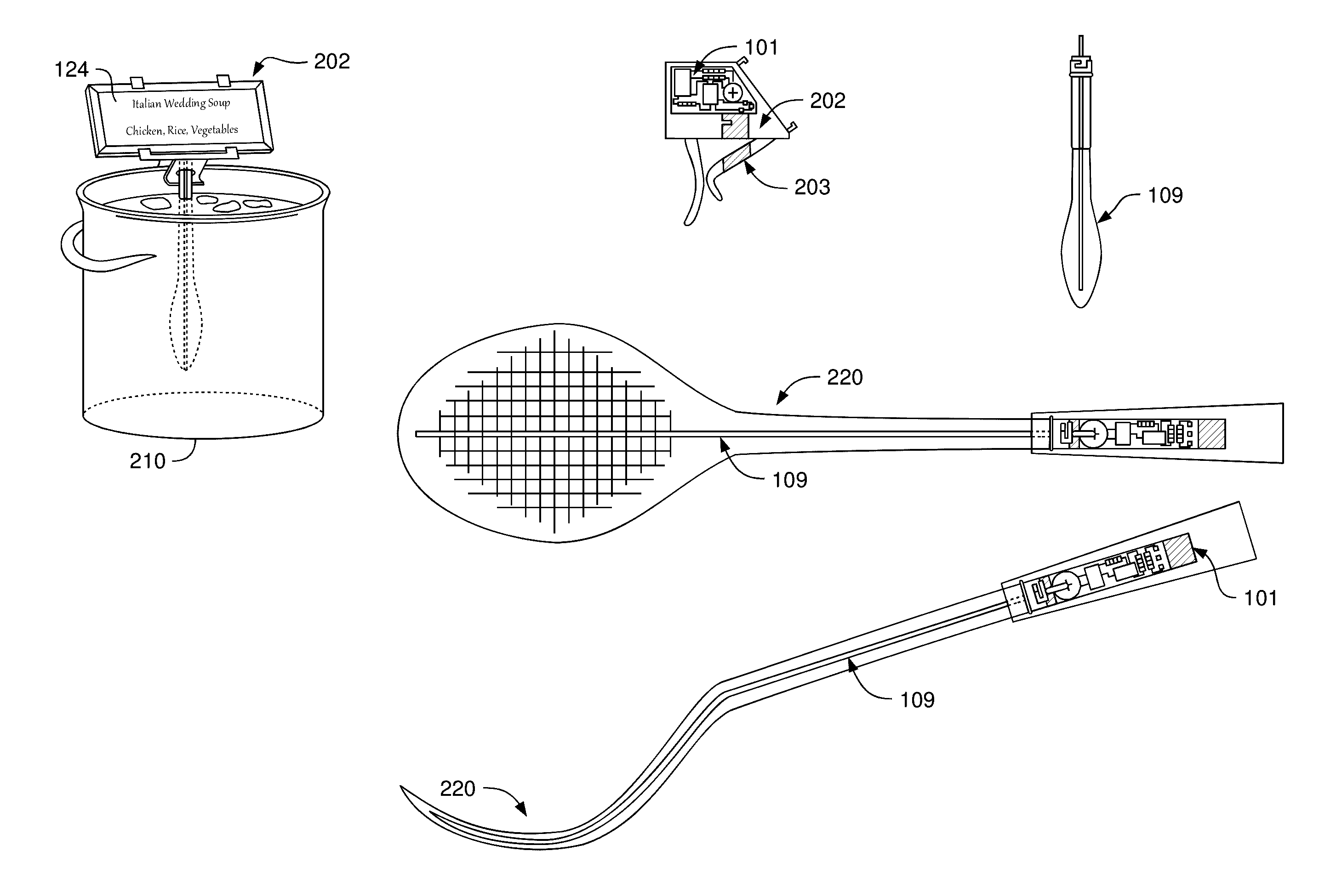

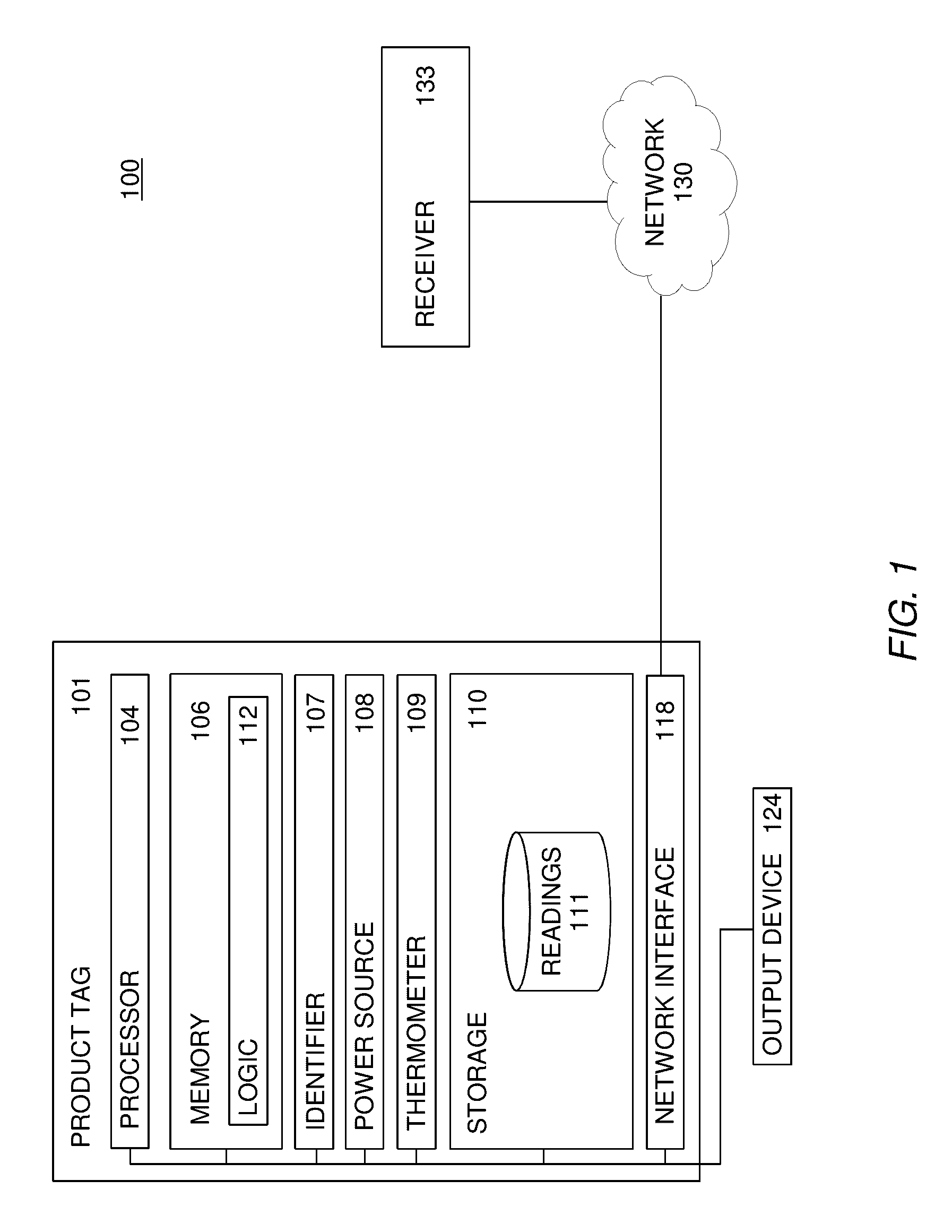

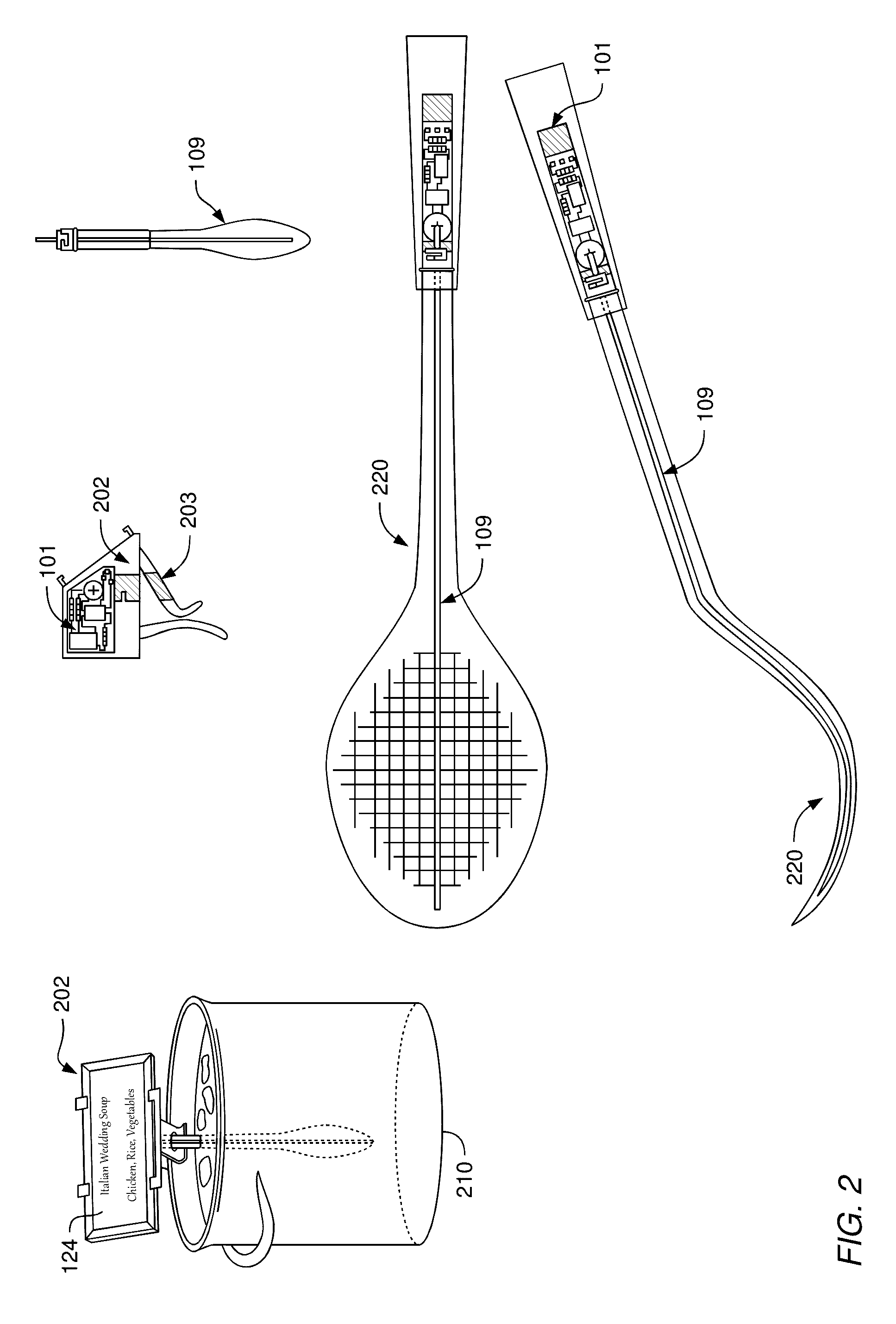

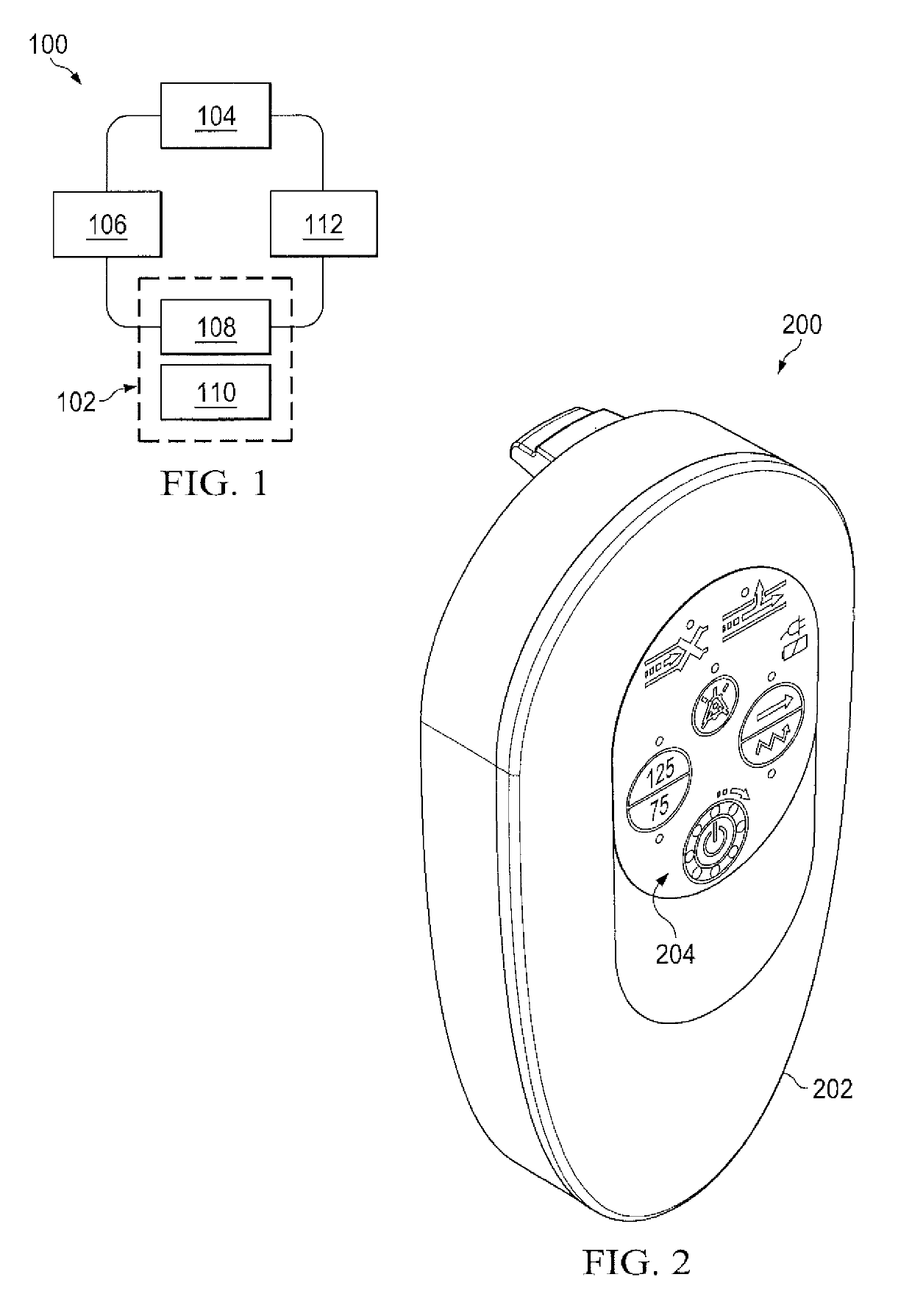

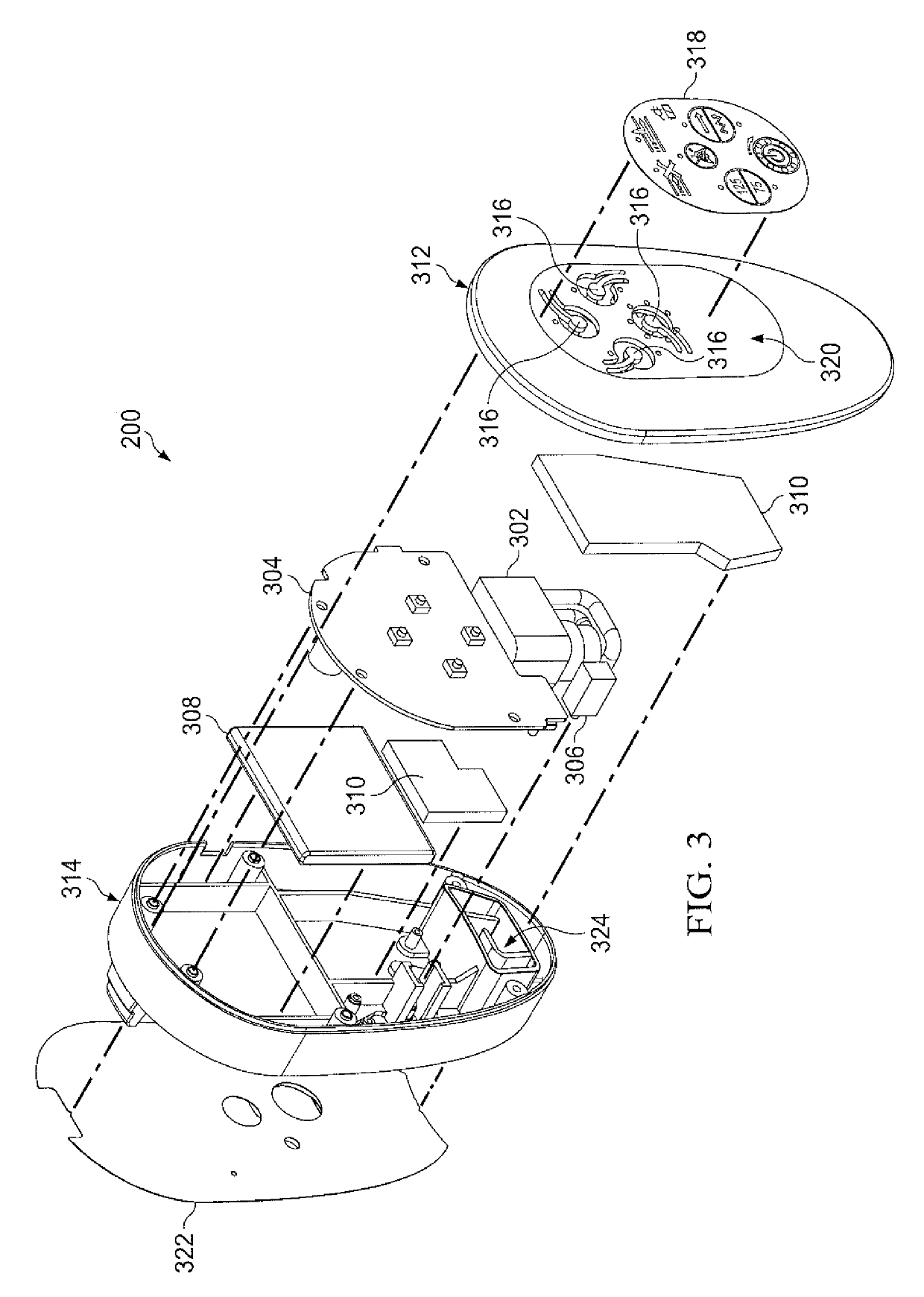

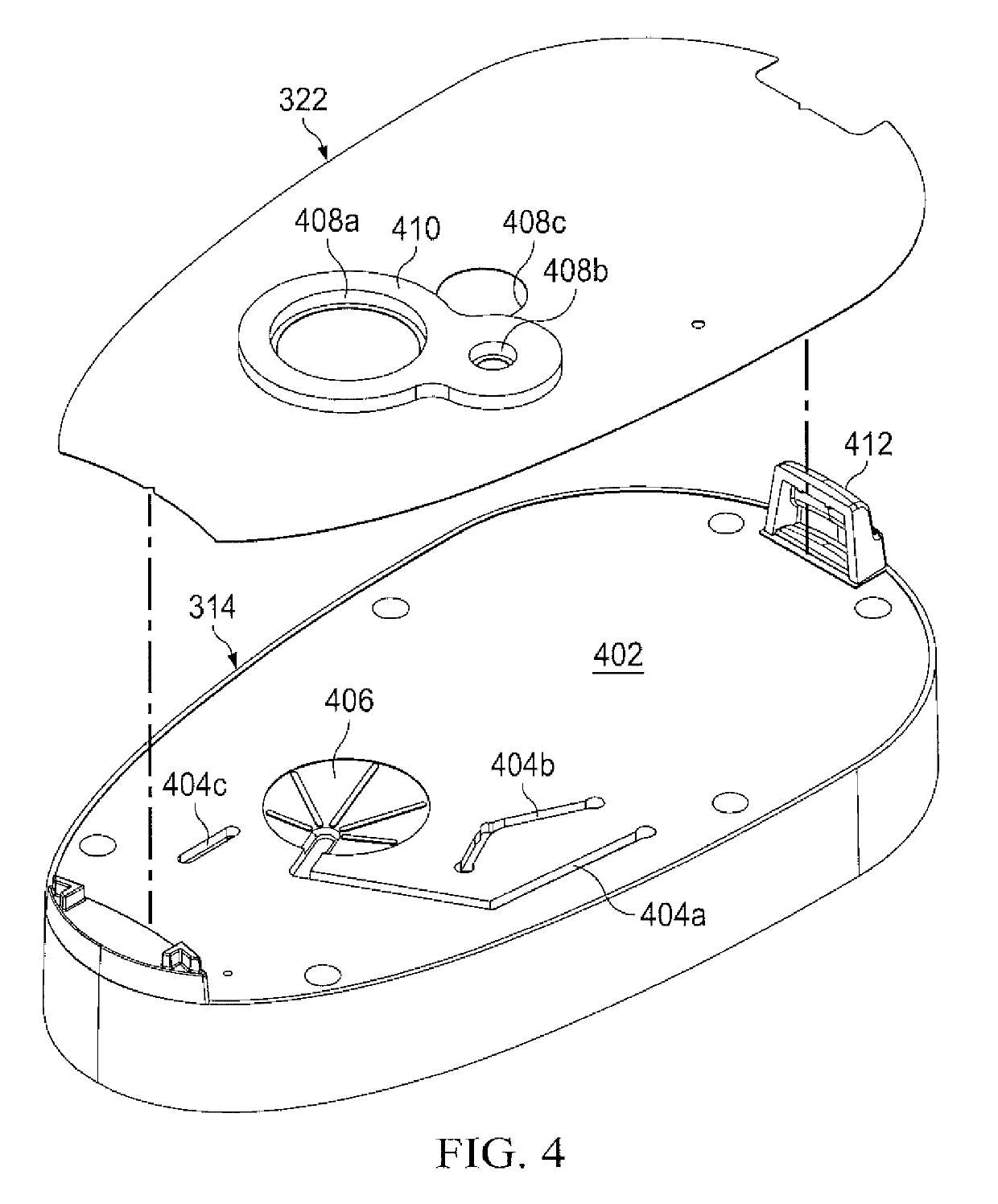

Monitoring food products

ActiveUS9477962B2Improve food safetyThermometer detailsThermometers using mean/integrated valuesGuidelineFood safety

Owner:DISNEY ENTERPRISES INC

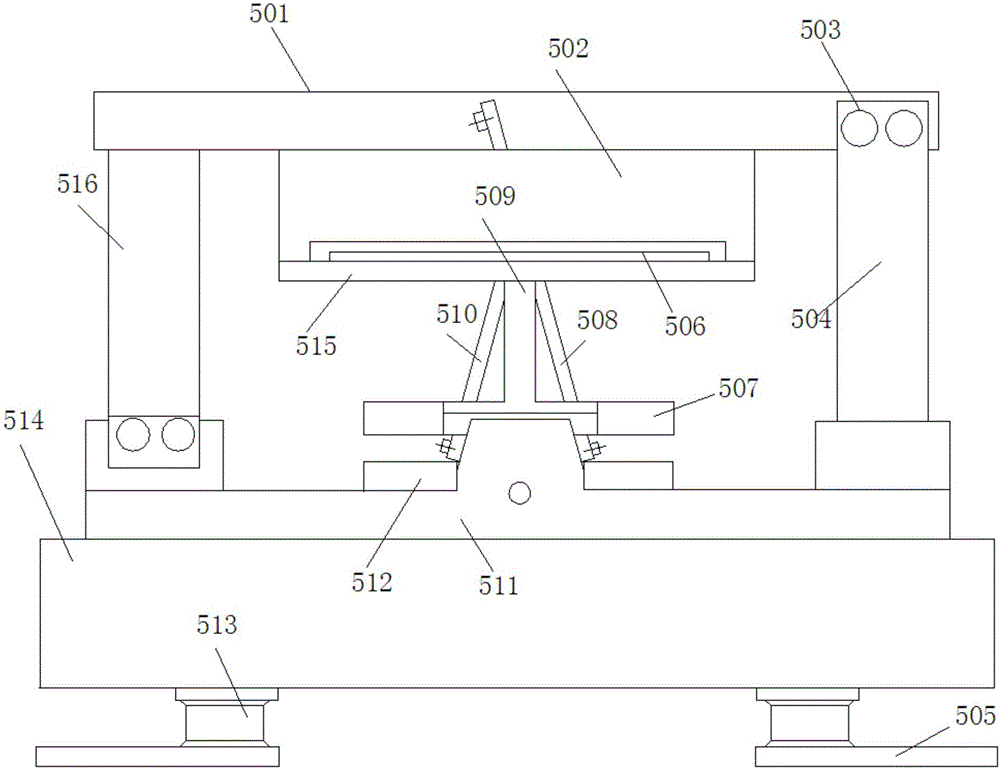

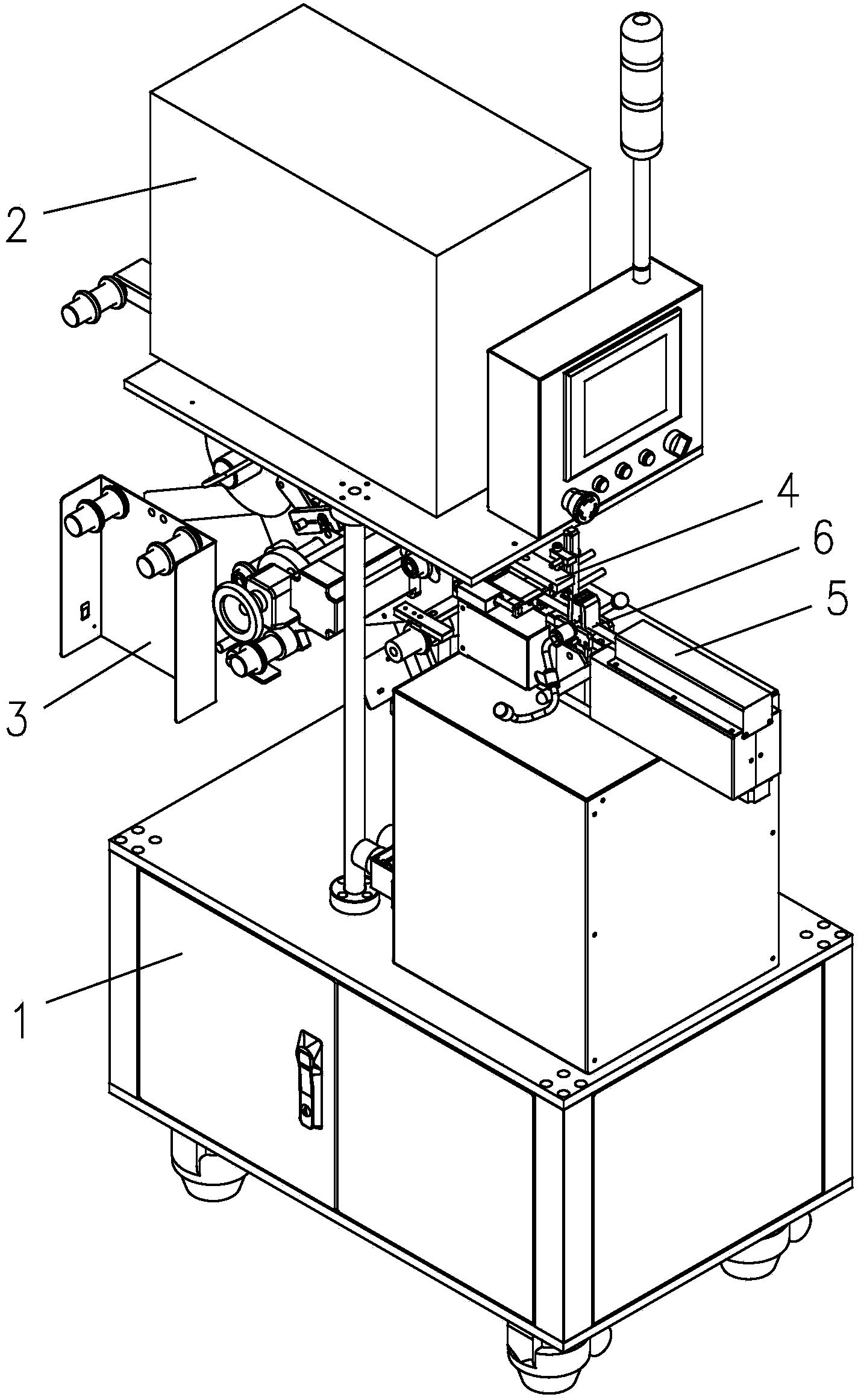

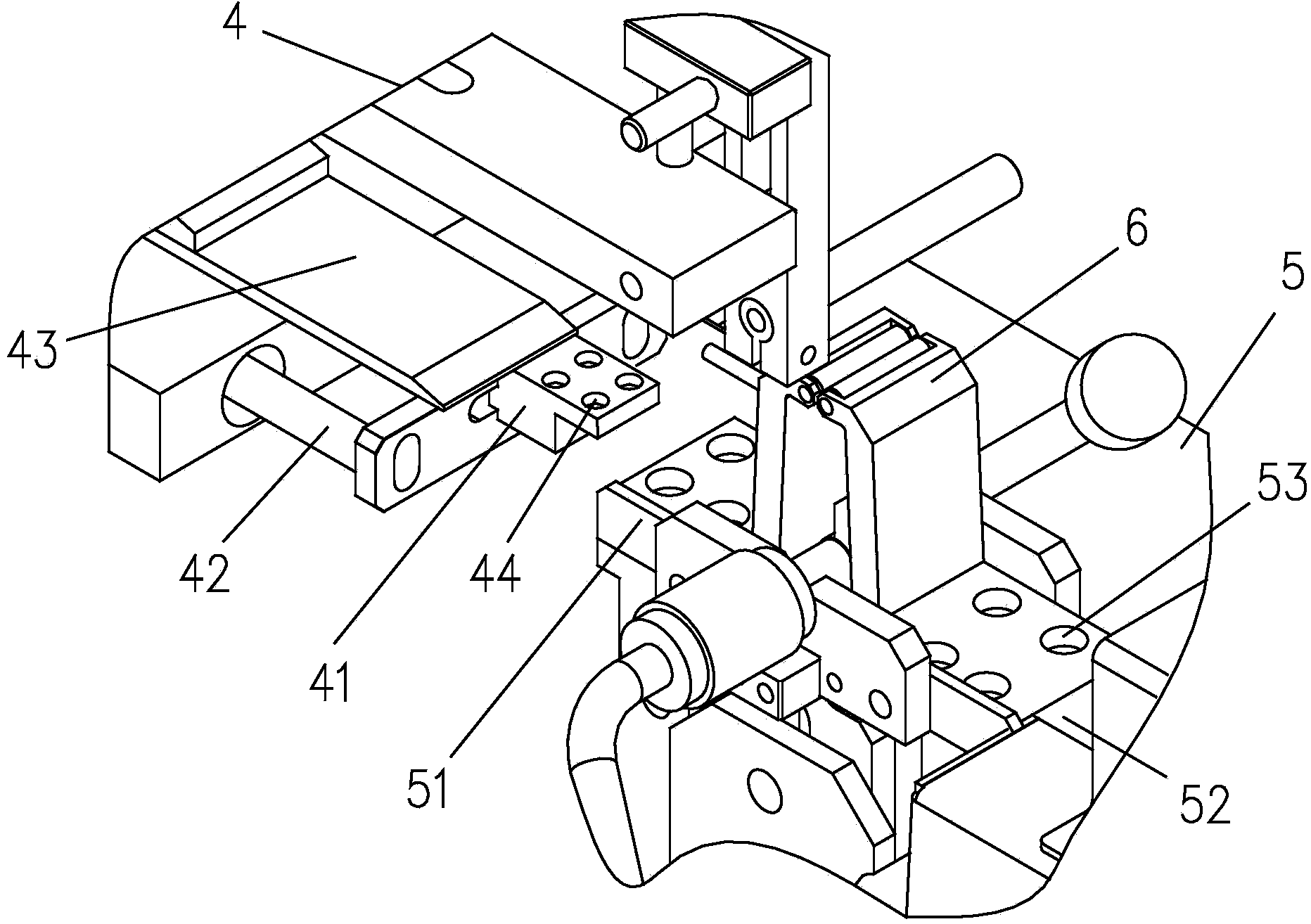

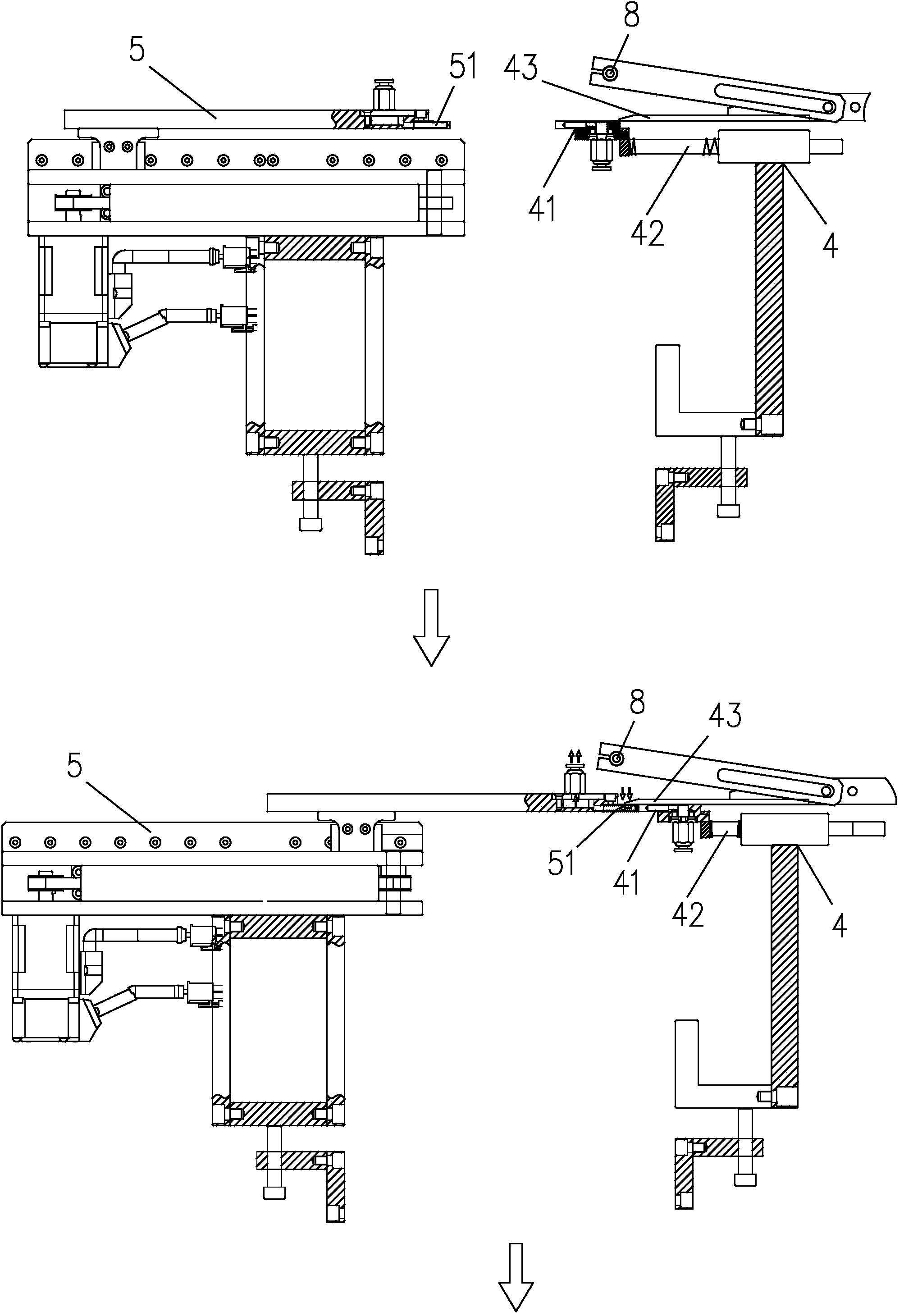

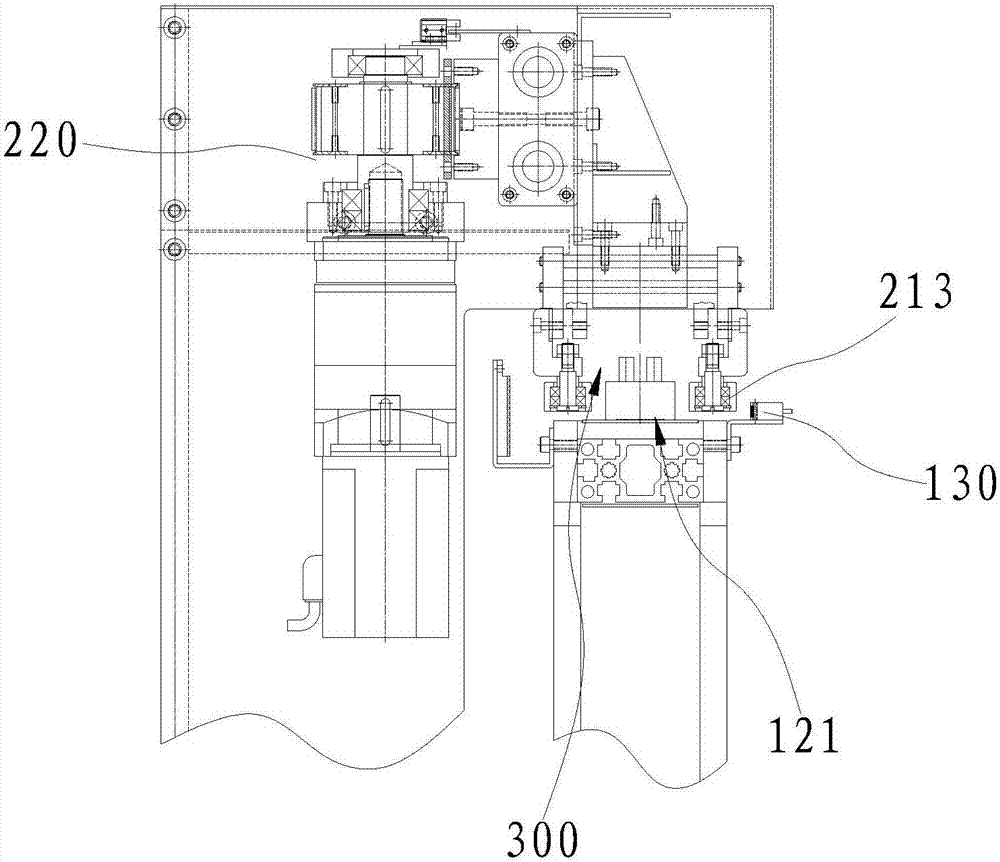

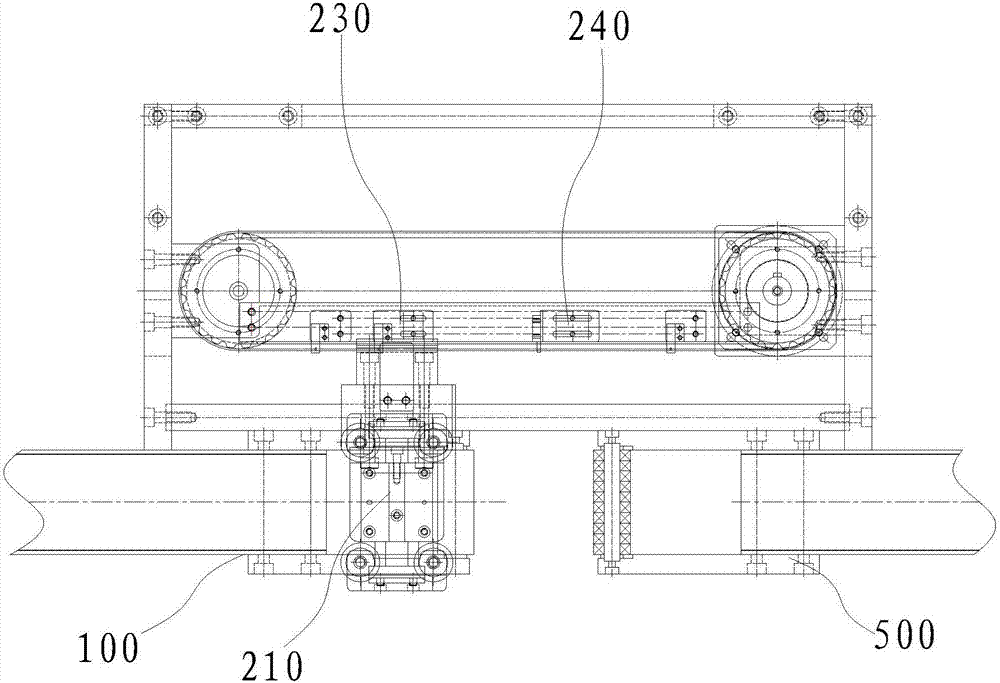

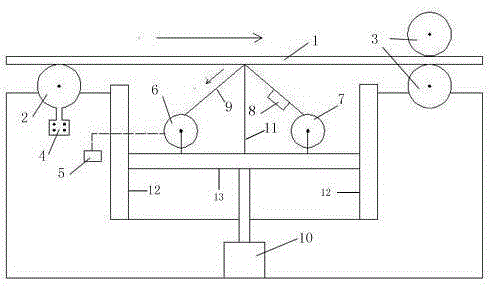

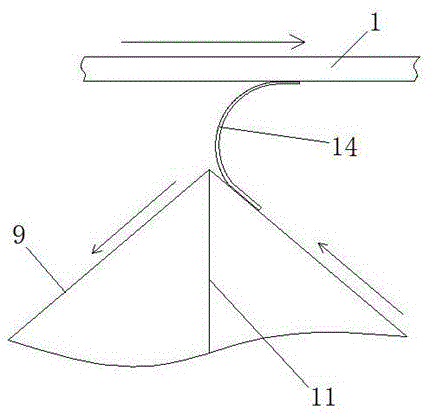

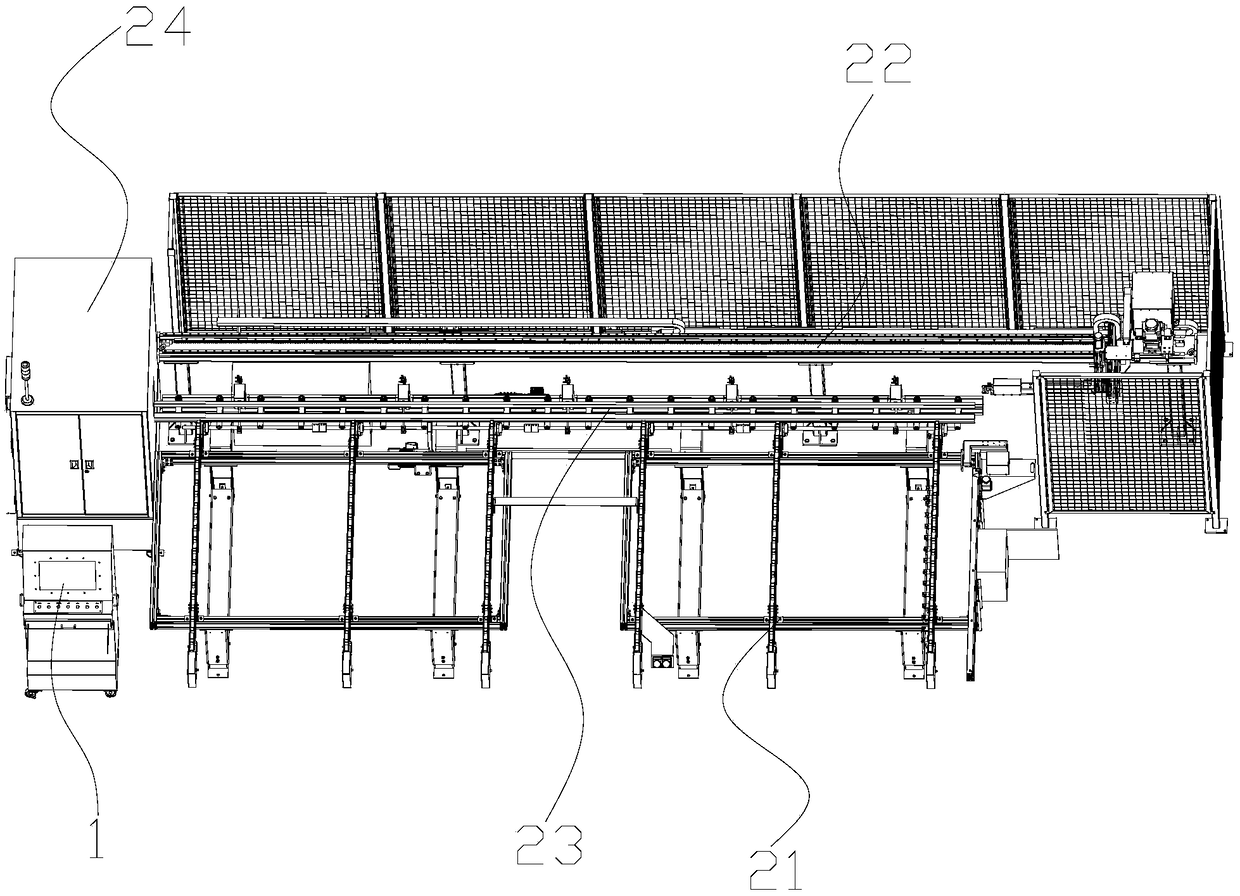

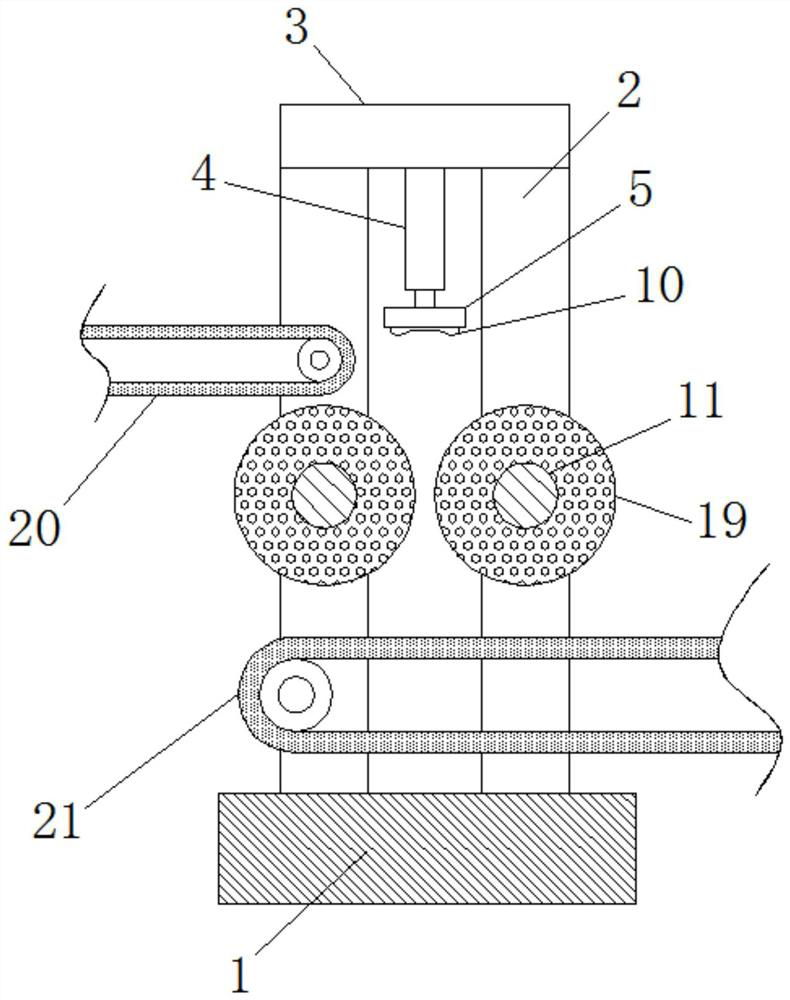

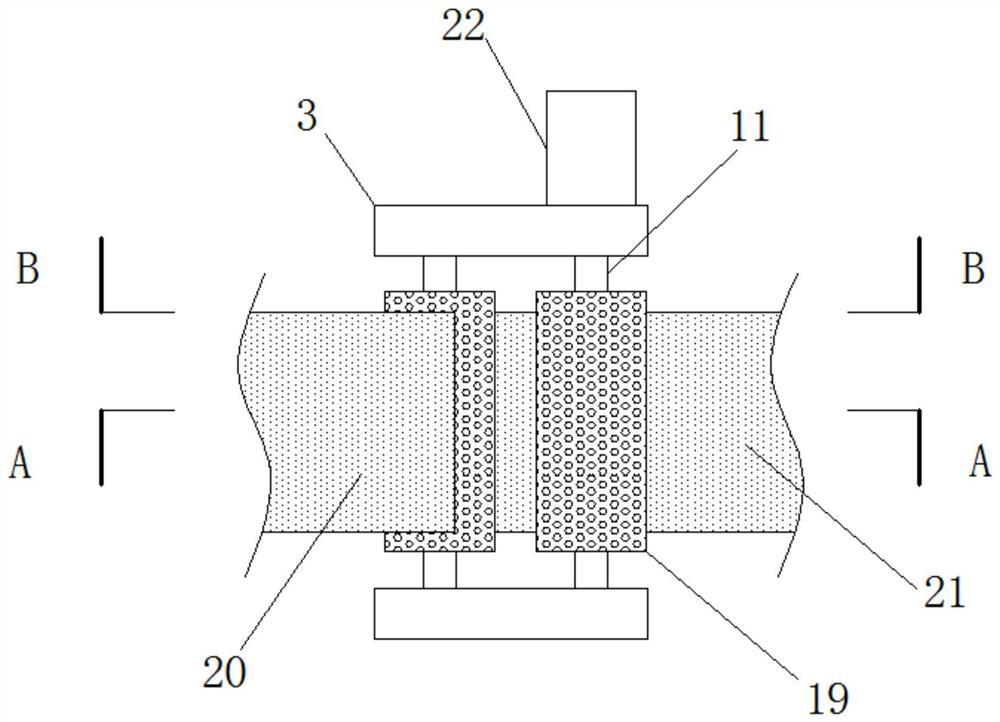

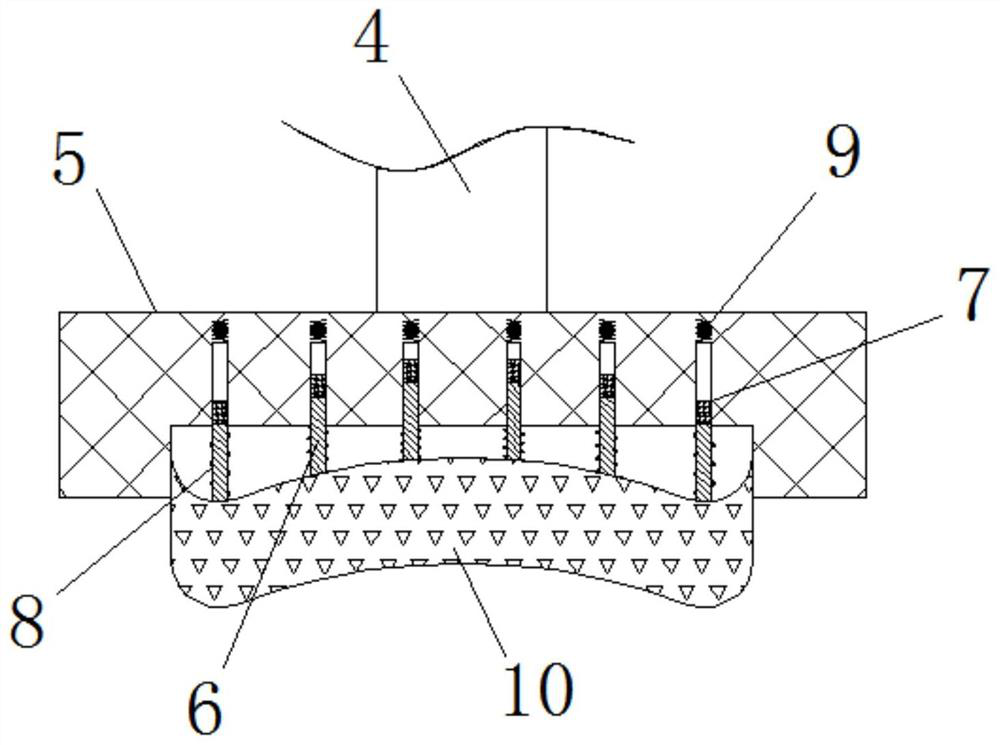

Automatic labeling machine and labeling method for product labeling

ActiveCN103662228AGuaranteed to straightenAccurate locationLabelling machinesEngineeringProduct Labeling

The invention discloses an automatic labeling machine and labeling method for product labeling. The automatic labeling machine comprises a rack, a printer and a buffer pocket, a label fixing device, a label taking device and a labeling device which are arranged between the rack and the printer, wherein the buffer pocket is located under the printer; the label fixing device is located between the buffer pocket and the label taking device; a gap is formed between the label fixing device and the label taking device; and the labeling device is located above the gap between the label fixing device and the label taking device. During labeling, a label is fixed and straightened by the label taking device and the label fixing device and bonded by the labeling device. The automatic labeling machine has the benefits as follows: the label fixing device cooperates with the label taking device, so that the label is straightened and accurate in position, corrugation is avoided during labeling, and the label is positioned accurately. The distance between the label fixing device and the label taking device is changeable, so that the machine is applicable to labeling of objects with different sizes, particularly to labeling of long and thin objects. No requirement is applied to the printer, and any printer is applicable. The machine is small in size, low in cost and high in yield and product pass percent.

Owner:SHANGHAI LAWARE PACKAGING MACHINERY

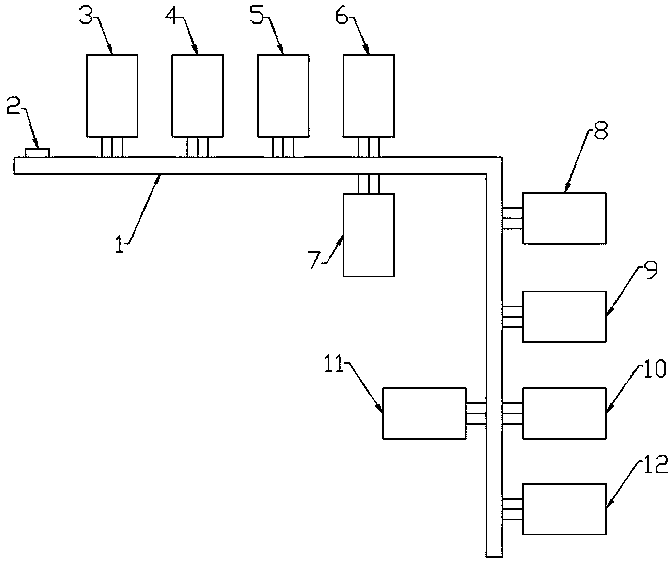

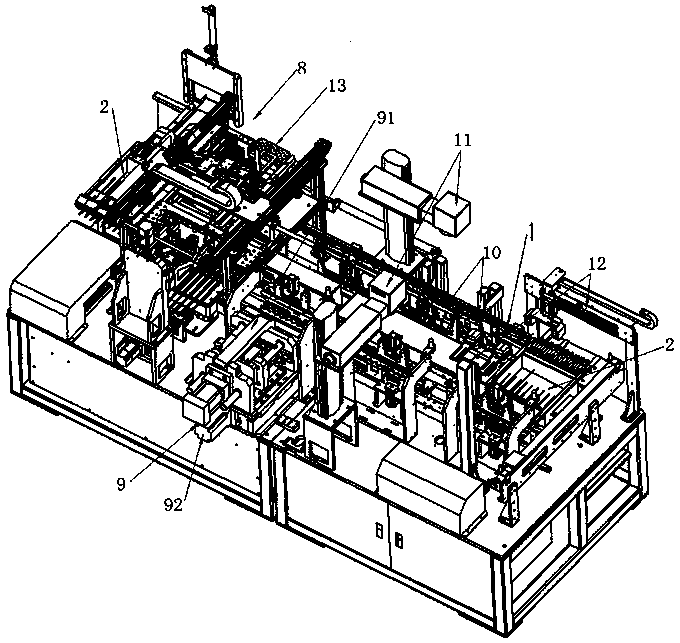

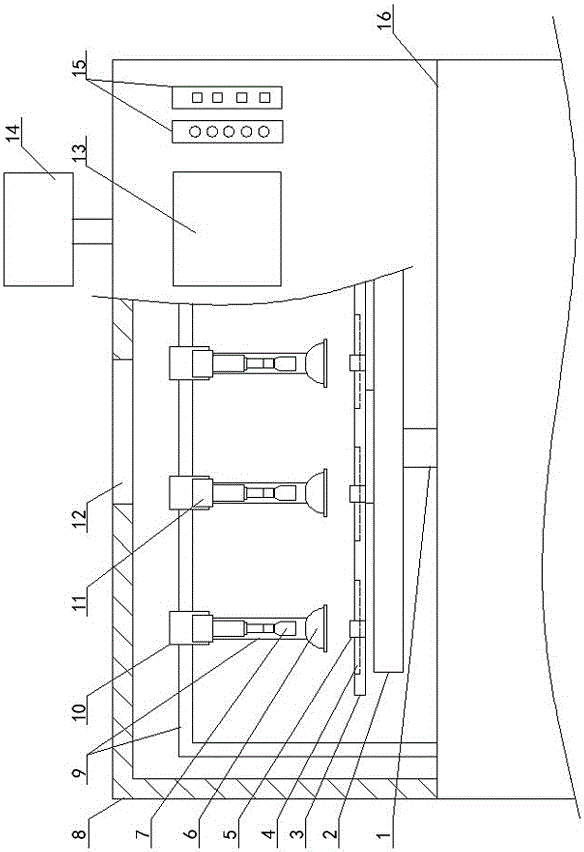

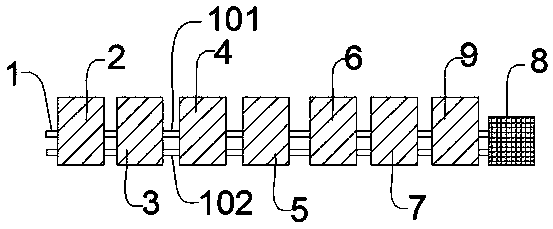

Automatic continuous production line for electronic detonators

PendingCN108827092ARealize continuous automatic productionIncrease productivityAmmunition fuzesTotal factory controlDetonatorIndustrial engineering

The invention discloses an automatic continuous production line for electronic detonators, which includes: a mold transport mechanism (1), a transportation mold (2), a fuse head stamping, testing anddemolding integrated device (3), a full-automatic welding device (4), a pressing and air-cooling device (5), an electric parameter detection system (6), an auto-assembling work station (8), an auto-bayonet device (9), an electric parameter detection and writing system (10), and a vision detection device (12), a reject product labeling apparatus (7) and a laser encoder (11). All of the units are connected to a computer controller that controls cooperation thereof. Through the computer controller, the cooperation among the units is controlled, so that the production line avoids manual assistanceoperation beside every unit. The production line achieves automatic continuous production of the electronic detonators and not only increases production efficiency and quality of the electronic detonators but also reduces the risk that an operator is directly contacted with the explosive hazardous articles.

Owner:GUIZHOU PANJIANG CIVIL EXPLOSIVE

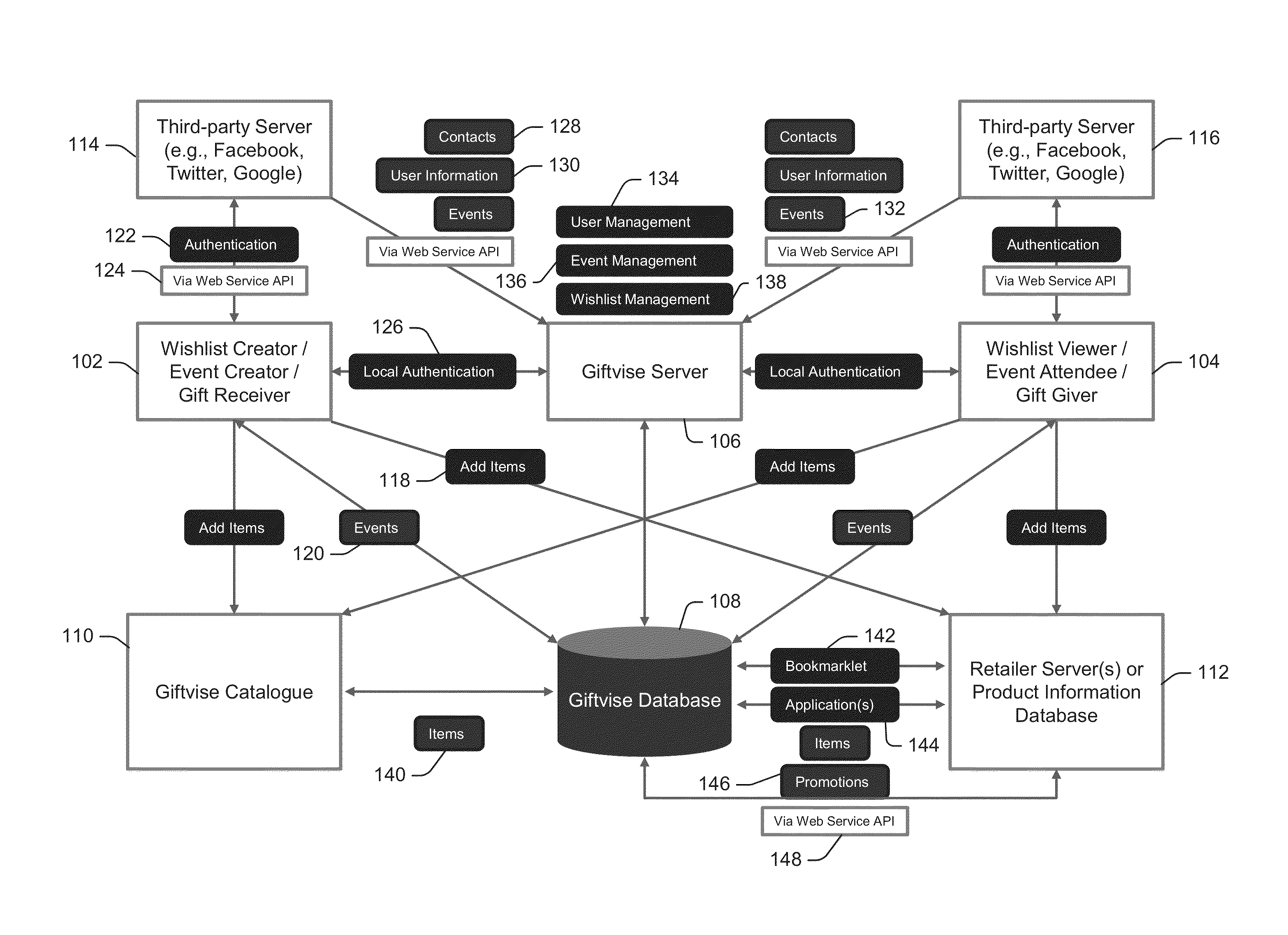

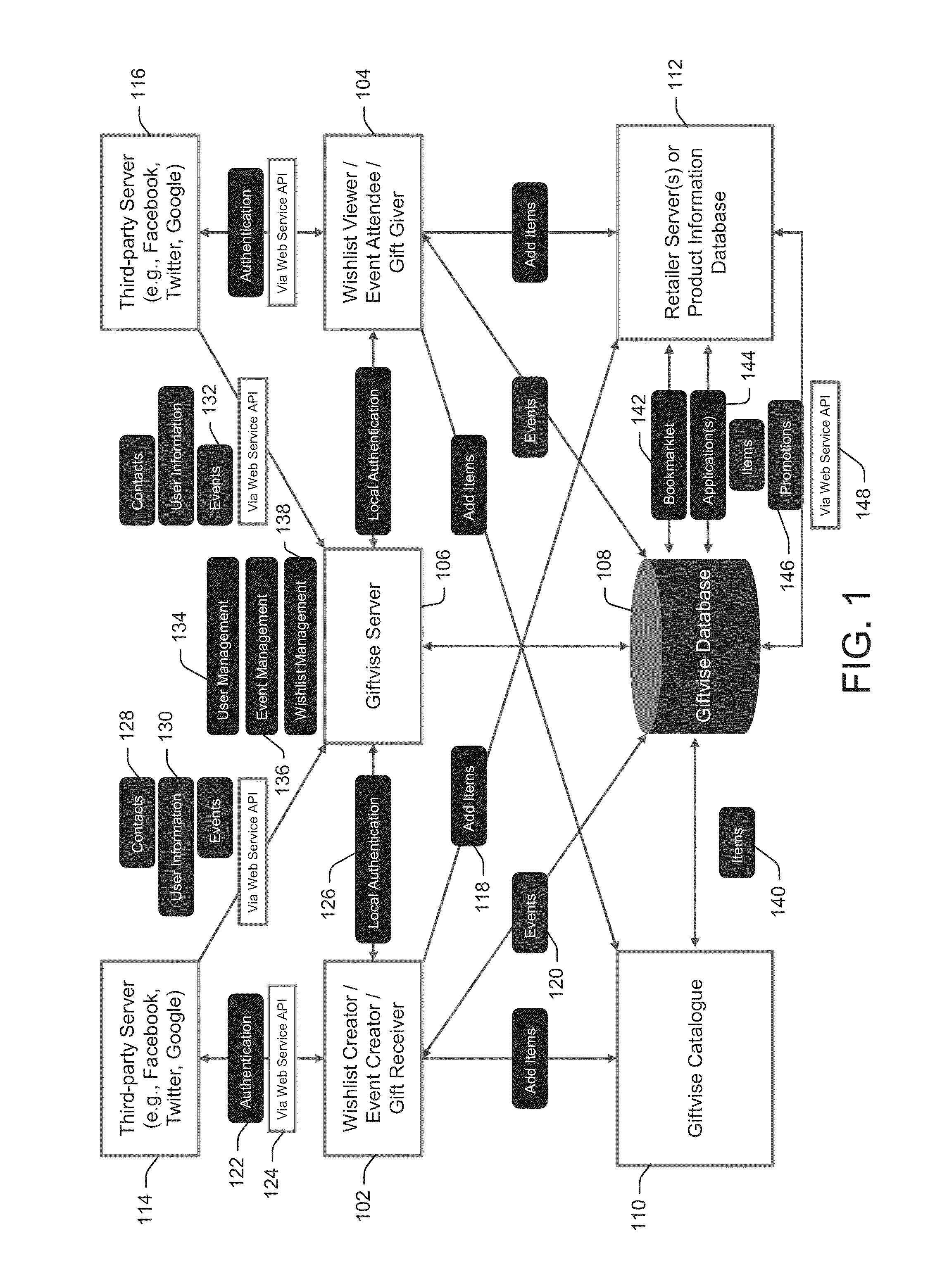

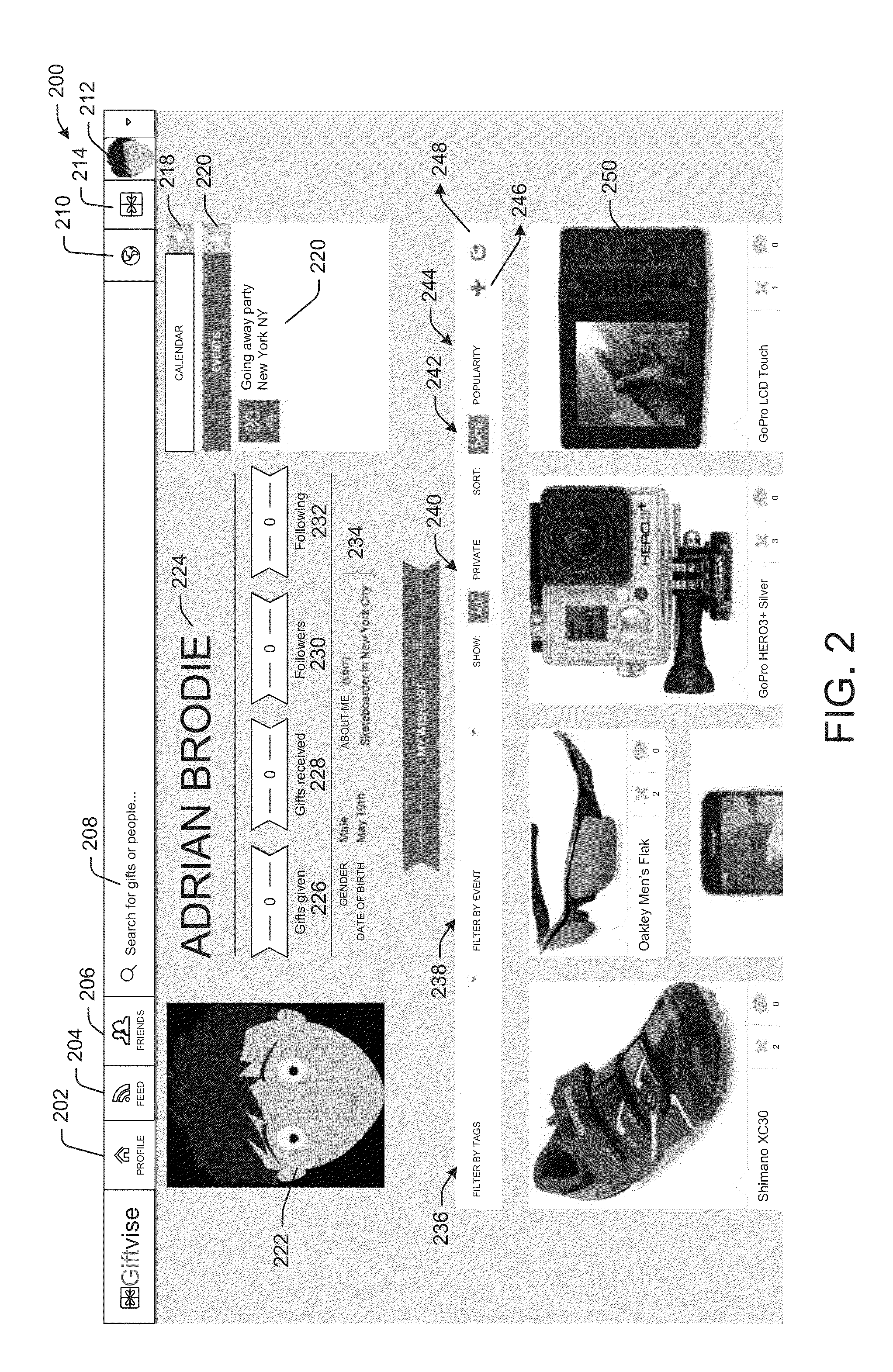

Systems and methods for event-based gift giving and receiving

InactiveUS20150039464A1Easy to giveEasy to manageBuying/selling/leasing transactionsThird partyGift giving

Online, event-based gift giving and receiving systems and methods eliminate the redundancy of creating a separate registry or wishlist with the same products listed for each life event by using event-based product tags. One or more example embodiments include setting privacy for event-based product tags, setting privacy for each product on a wishlist, filtering wishlists by event-based product tags, searching for event-based product tags, selectively sharing and displaying products for groups, indicating the unavailability of reserved products and automatically re-listing reserved products not received within a determined time period, using event-based product tags with events imported from external sources, providing third party event hosting using event-based product tags, connecting users who received the same gift, and providing product attribute change notifications, among other things.

Owner:GIFTVISE

Product-tracing and anti-counterfeiting method

InactiveCN106157056ACommerceSensing by electromagnetic radiationLogistics managementBiological activation

A product traceability and anti-counterfeiting method, comprising the following steps: a. A two-dimensional code label is attached to the product before it is produced; b. When the product passes through the logistics node, an authorized device is used to register the logistics node; c. The authorized merchant passes the scan when selling the product Read the product label information to activate product sales; d. After consuming and purchasing the product, check the product information and sales activation information by querying the above label. The invention truly realizes product traceability and anti-counterfeiting functions and truly eliminates opportunities for label reuse. Since the query tool uses a very common smart phone, it reduces the difficulty for consumers to query and identify product authenticity, and the system construction cost is extremely low.

Owner:黄世纬

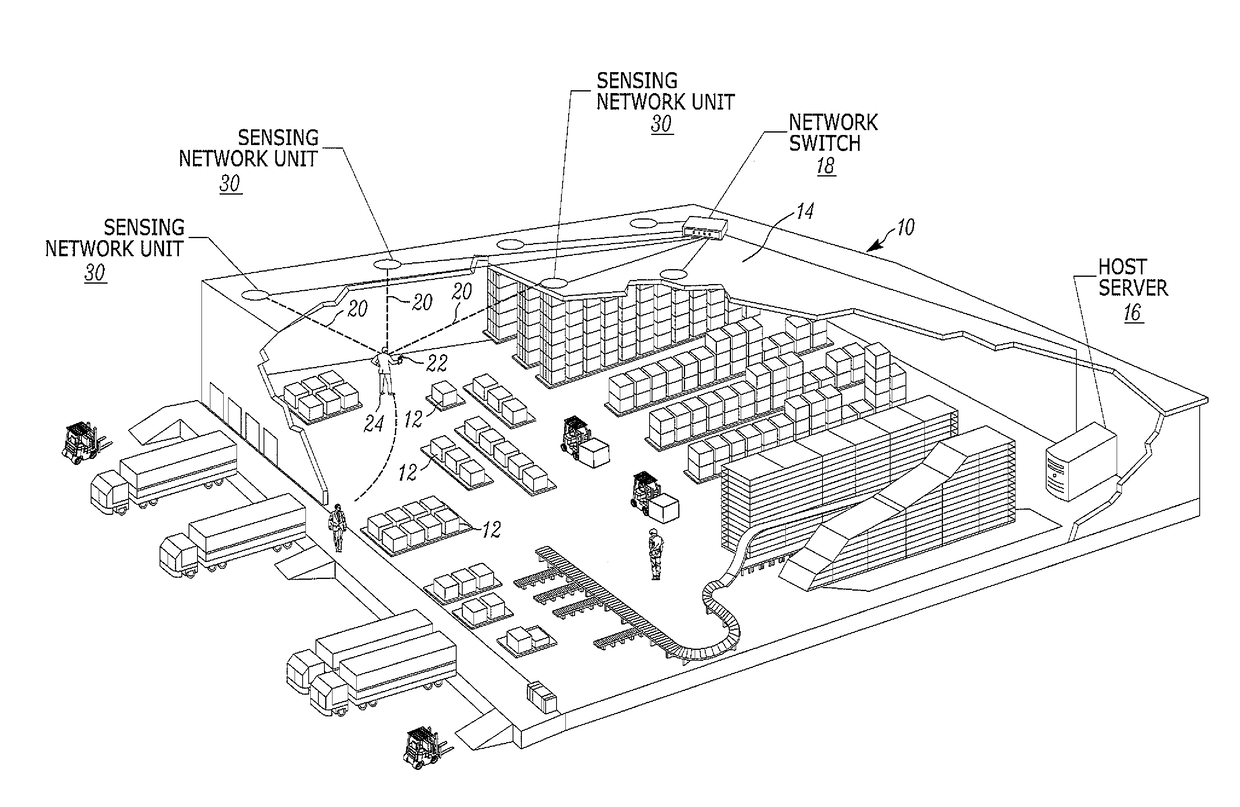

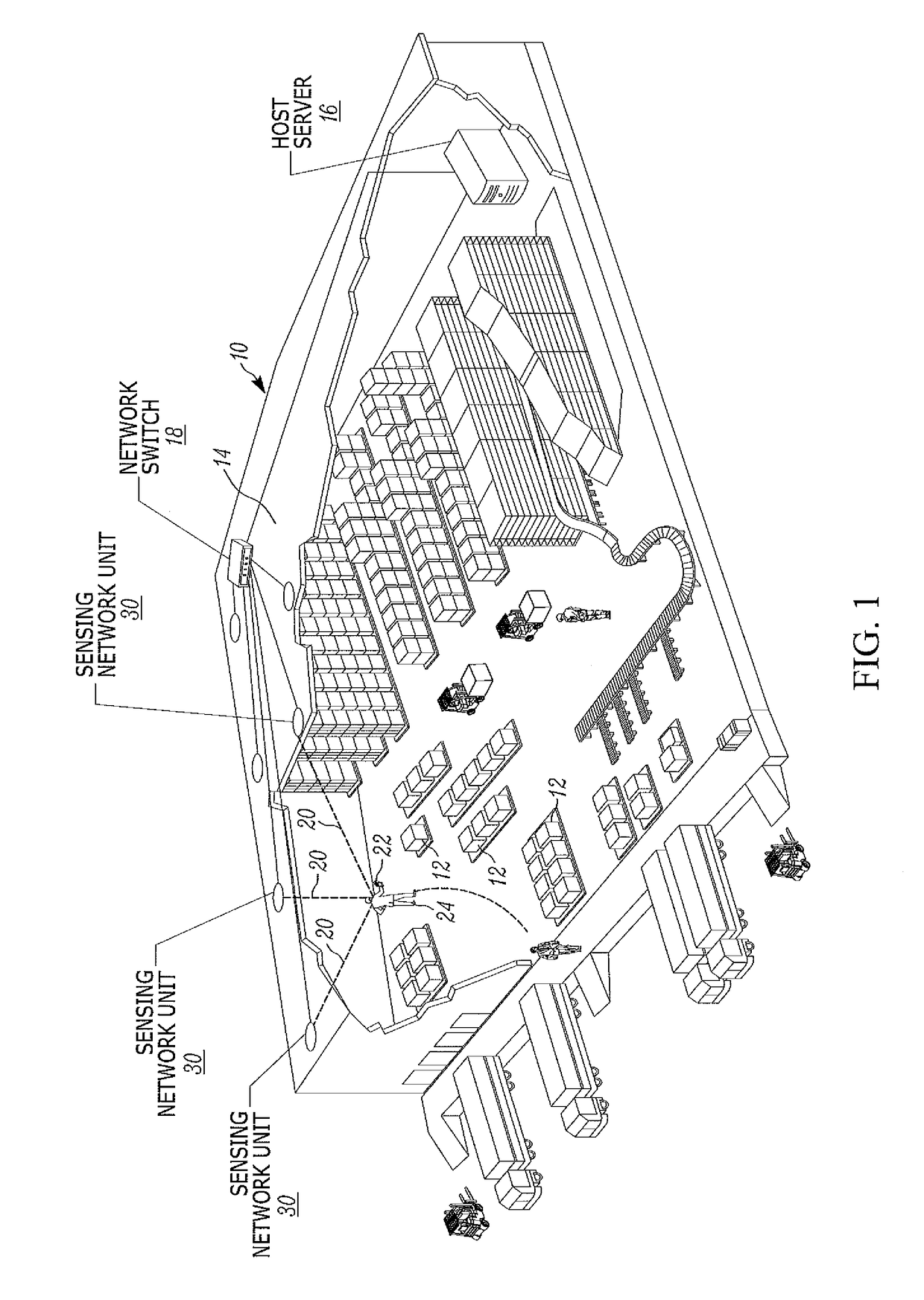

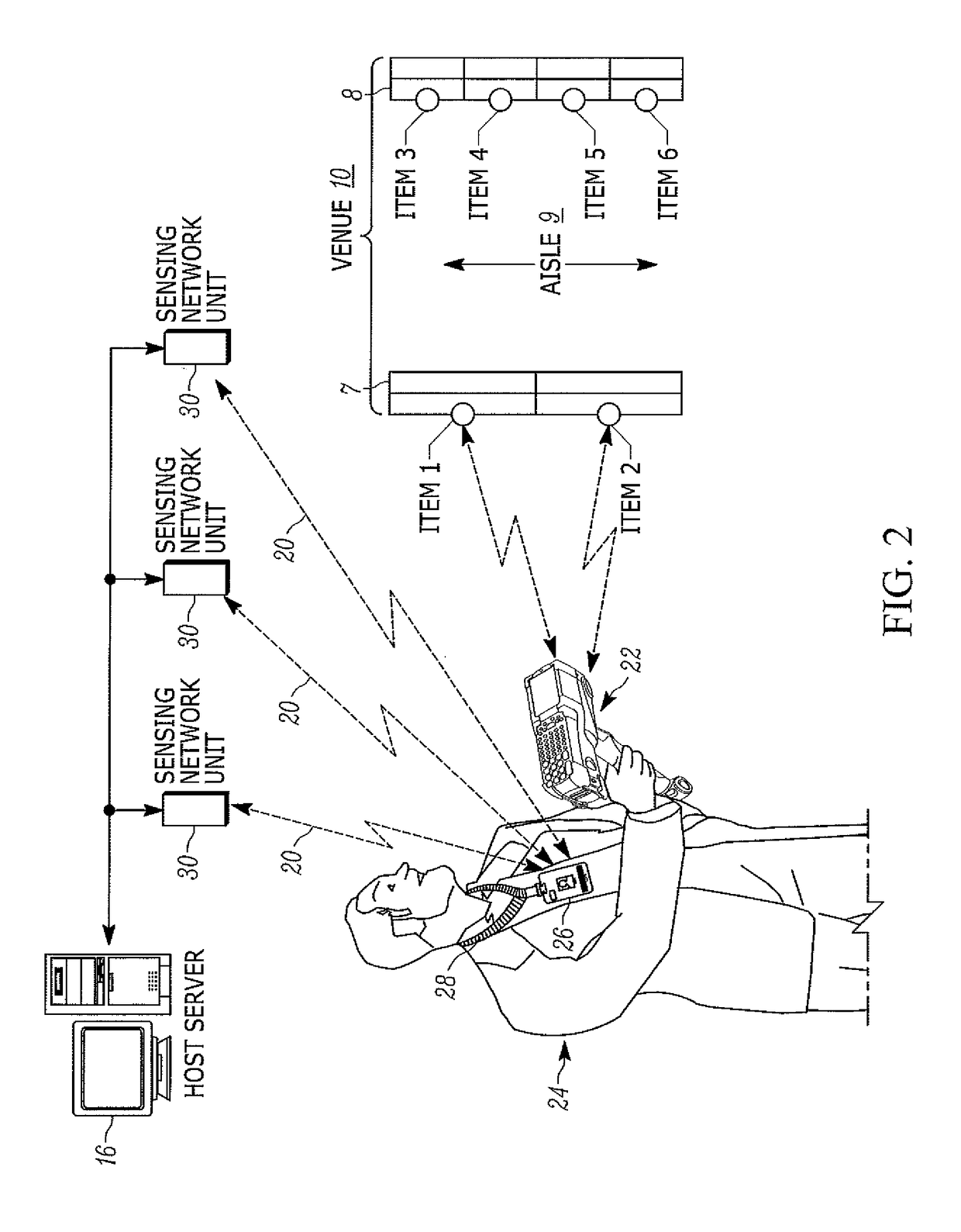

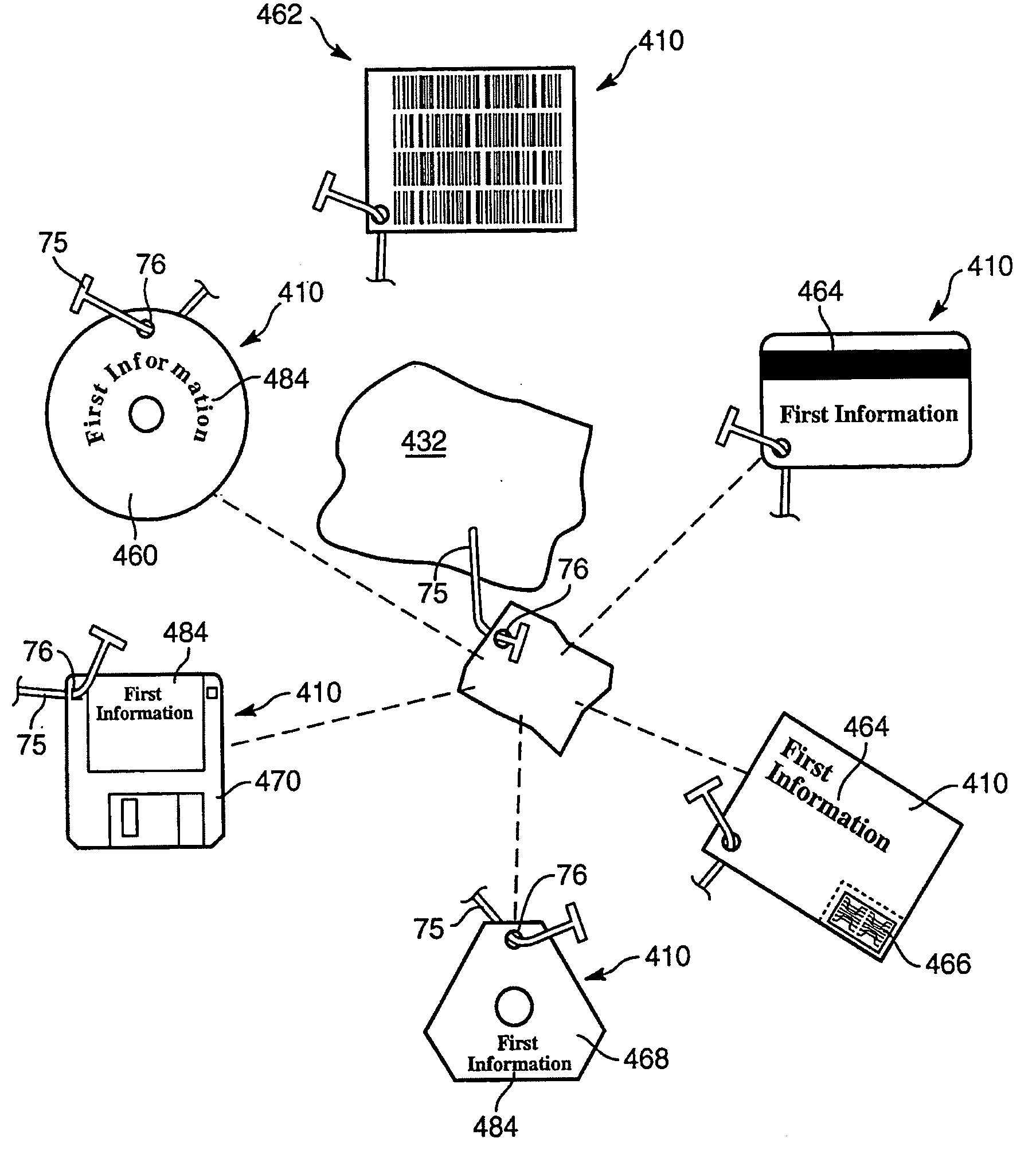

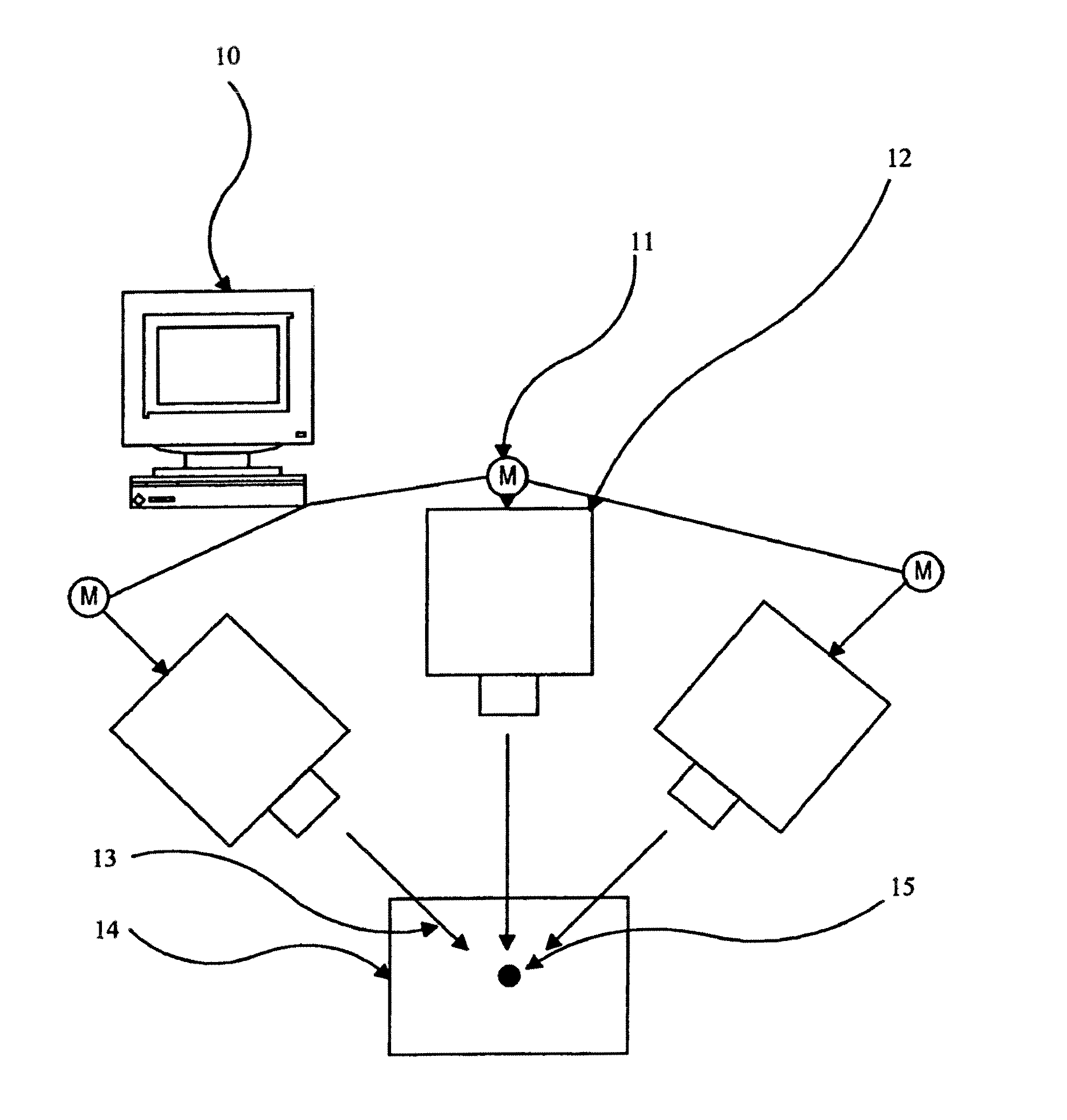

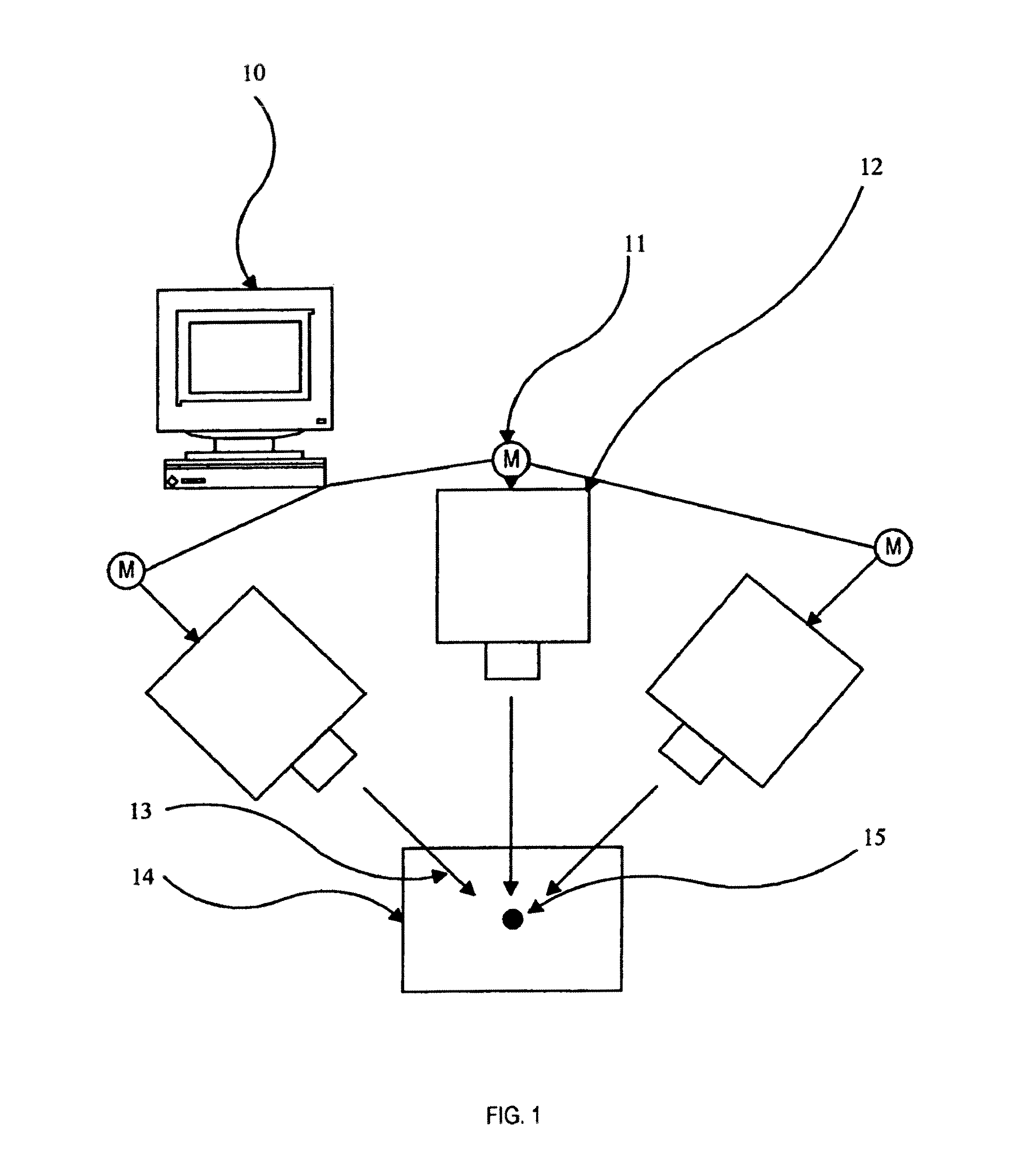

Arrangement for, and method of, locating product tags by locating users who are operating mobile readers for reading the product tags

ActiveUS20170249584A1Co-operative working arrangementsWireless commuication servicesWorld Wide WebProduct Labeling

A user moves about a venue, and operates a mobile reader to read a product tag in a read zone of the mobile reader. An identifier, such as a user identity badge, is associated with the user to identify the user. A sensing system is deployed in the venue for sensing the location of the identifier. A host server associates the mobile reader with the identifier of the user operating the mobile reader, and determines a location of the product tag in the venue based on the read zone and the location of the identifier.

Owner:ZEBRA TECH CORP

Method for making color-changing anti-counterfeiting digital identifier

ActiveCN102208044AHigh anti-counterfeiting strengthPattern printingRecord carriers used with machinesColor changesComputer vision

The invention discloses a method for making a color-changing anti-counterfeiting digital identifier. The method comprises the following steps of: (1) selecting k different colors to form a color sequence C, generating a group of random digital sequence A with n-bit length, and processing the random digital sequence A according to a first algorithm to acquire a binary sequence B; (2) processing all digits in the binary sequence B and the random digital sequence A according to a second algorithm to acquire corresponding binary sequences respectively, performing modulus operation on the acquiredbinary sequences respectively to acquire color sequence factors of all the digits in A, and taking corresponding colors from the color sequence C; and (3) sequentially printing the corresponding colors of all the digits in A to a product tag or an anti-counterfeiting identifier. According to the invention, color information visible for a customer is added in the traditional digital anti-counterfeiting, so that the anti-counterfeiting strength of the digital anti-counterfeiting can be effectively improved; and the information is difficultly decoded by a fabricator because the fabricator needs to own not only digits but also colors corresponding to all the digits, but the digits per se do not contain the color information.

Owner:江苏南大数码科技有限公司

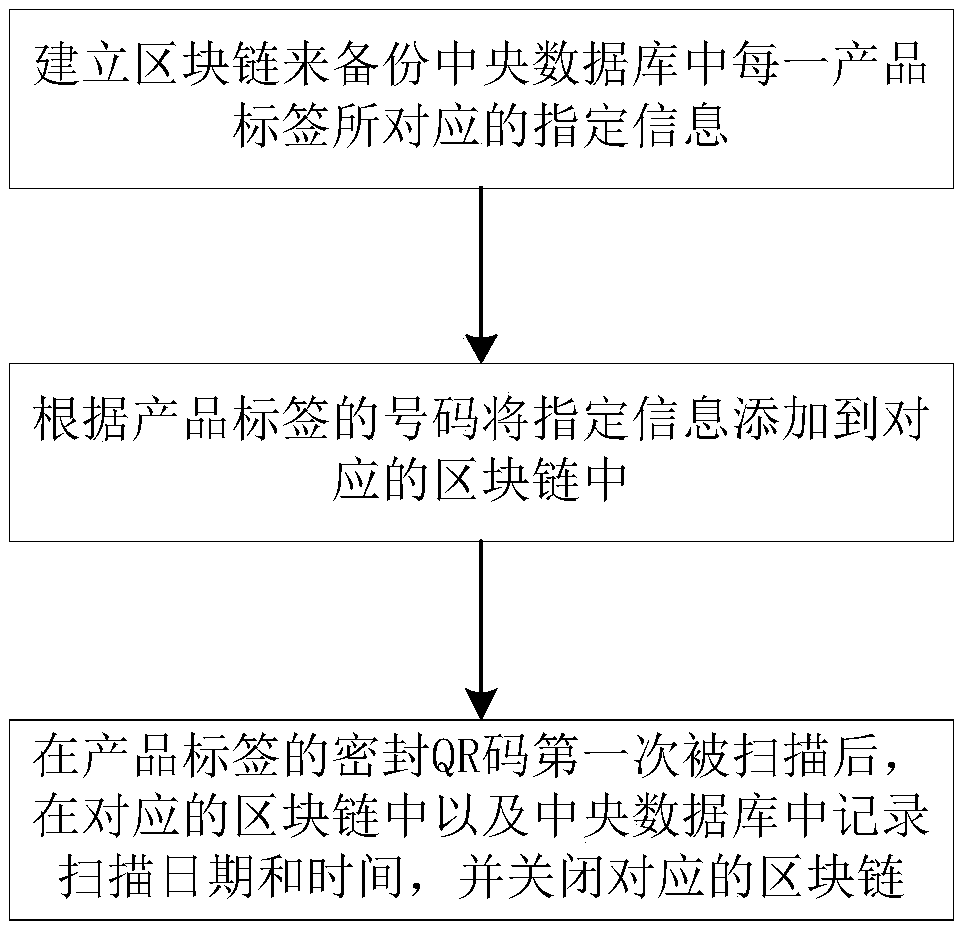

Block chain-based information query method and system

InactiveCN108710924APrevent tamperingData SecurityCo-operative working arrangementsCommerceCentral databaseComputer science

The invention provides a block chain-based information query method and system. The method comprises the steps that block chains are built to backup designated information corresponding to each product tag in a central database; the designated information is added into the corresponding block chains according to numbers of the product tags; and after a seal QR code of one product tag is scanned for the first time, the scanning date and time are recorded in the corresponding block chain and the central database, and the corresponding block chain is closed. According to the method and system, the block chains are combined with the product tags, and whether or not products are used, open or invalid can be queried; the condition that some block chain and tag are used in other products is prevented; and the condition that anyone or even the central database tampers data is prevented, information addition is unidirectional, operation is finished after the seal tag is scanned, and therefore the data is more secure and more reliable.

Owner:林清华

Computer readable hang tag and product

A user-computer-readable medium provides all or part of a product labeling system for engaging purchasers. Executables, data, or both are recorded in the medium embodied in a tag or other product labeling structure, in order to deliver to a consumer or purchaser engaging presentations of products, information, or registration templates. As a result, purchasers may receive launchers, browsers, viewers, e-mail systems, facsimile centers, players, or interface brokers for the foregoing, if organically installed already on a workstation of a purchaser. Software may provide catalog presentations, user registration templates, communications, linkers, or engines, and the like. Operation modules and profile builders may provide information over ready links implemented by software on the medium. In certain embodiments, entertainment, games, skill tests, and the like, recorded in the medium as a tag or label may execute to engage a purchaser and provide purchaser profiling information, product purchasing information, and the like to a vendor, while providing additional product information, warranty registrations, applications, entertainment, or the like, to a purchaser.

Owner:ETAGZ

Therapy apparatus with integrated fluid conductors and noise attenuation

ActiveUS10478536B2Prevent tamperingMedical devicesIntravenous devicesElectrical conductorControl system

In one example embodiment, an apparatus may include a panel with integrated fluid channels, wherein the panel and the fluid channel consist only of surfaces that can be manufactured with a straight-pull mold. A port may also be integrated into the panel to facilitate coupling the fluid channel to pneumatic components in an assembly. A seal may be secured to the panel over the fluid channel to form an integrated fluid conductor. The seal is preferably an adhesive label that can also be used for product labeling. Such an apparatus may be used in a control unit of a therapy system, employing several integrated fluid conductors. A method of manufacturing may include molding a panel, wherein the mold forms a channel integral to the panel. The panel and the channel preferably consist of surfaces that can be molded with a straight-pull mold.

Owner:3M INNOVATIVE PROPERTIES CO

Substrate labeling system

InactiveUS7740280B1Easy to storeOther printing matterElectric discharge tubesHigh energyProduct Labeling

In an embodiment, there is disclosed a product labeling system comprising: a first high energy electromagnetic or particle wave generator, at least one second high energy electromagnetic of particle wave generator; and a controller operatively configured to direct wave produced by said first generator and the wave produced by said second generator onto a portion of the subsurface of the product to mark the product at said subsurface without generating any substantial disruption of the surface of said product.

Owner:MOORE STEVEN J

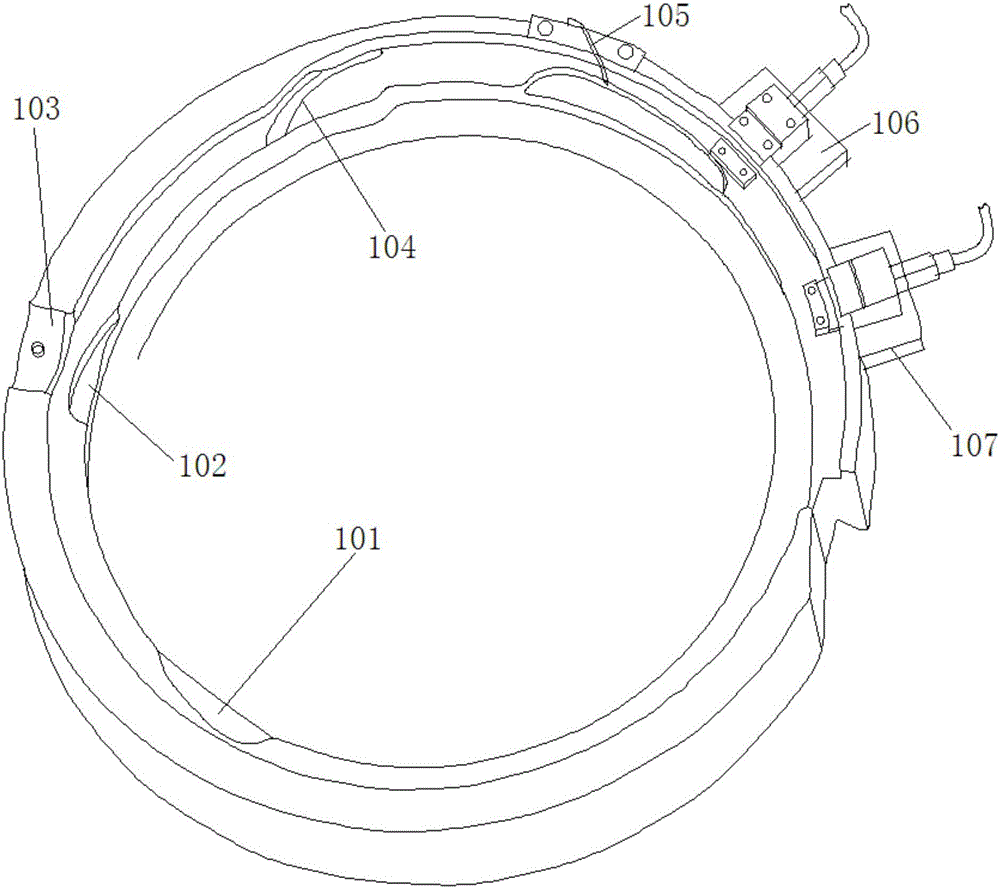

Bottom surface labeling machine

The invention discloses a bottom surface labeling machine which comprises a controller, a first conveying mechanism used for inputting a to-be-labeled product and a positioning and clamping device, wherein the first conveying mechanism is electrically connected with the controller; the positioning and clamping device comprises a material clamping mechanism arranged above the first conveying mechanism and is electrically connected with the controller, the material clamping mechanism comprises a drive part, a fixed seat in drive connection with the drive part and at least three material clamping and correcting fingers arranged on the fixed seat; the at least three material clamping and correcting fingers can rotate relative to the fixed seat, are arranged in a surrounding manner to form a material clamping chamber and can be relatively-close to or far away from one another. Thus, through the characteristic that the material clamping and correcting fingers can rotate relative to the fixed seat, the bottom surface labeling machine can better adapt to clamping, positioning and pose correction of irregularly-shaped products, so that the poses of the irregularly-shaped products are adjusted to be aligned with the height of a labeling station, the product labeling precision is greatly improved, and the higher product production quality is ensured.

Owner:GUANGZHOU SHELL CONNING MECHANICAL EQUIP CO LTD

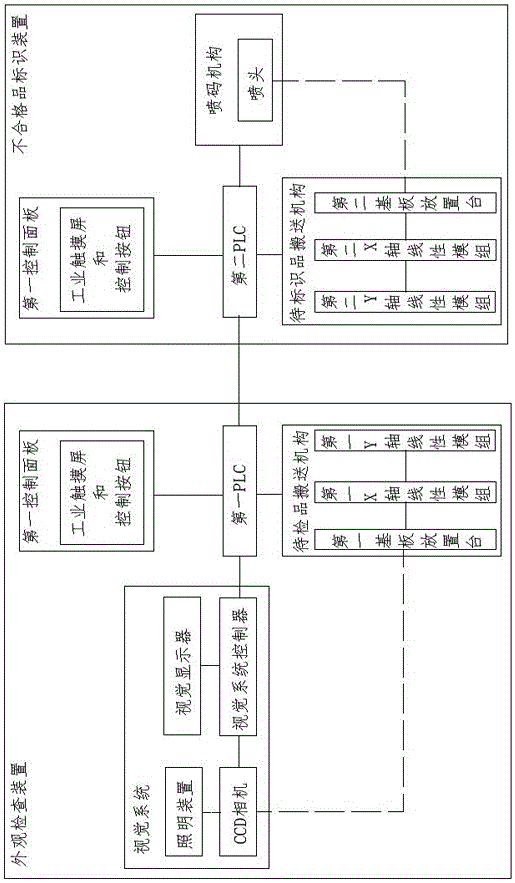

A lens appearance inspecting system

PendingCN106248696ALabor savingImprove inspection efficiencyMaterial analysis by optical meansSystem controllerMechanical engineering

A lens appearance inspecting system includes an appearance inspecting device and an unqualified-product labeling device. The appearance inspecting device comprises an inspection cabinet, a visual system and a first PLC. The inspection cabinet is provided with a first control panel. A visual system controller and the first control panel are connected to the first PLC. An operating table, a support, photographic devices, a walking mechanism for products to be inspected, and a walking driving element for the products to be inspected are disposed in the inspection cabinet. The walking driving element for the products to be inspected is connected to the first PLC. The unqualified-product labeling device comprises a labeling cabinet, a second PLC and an ink-jet printer. The labeling cabinet is provided with a second control panel connected to the second PLC. The ink-jet printer is connected to an electromagnetic valve. The electromagnetic valve is connected to the second PLC. An object table, a spray head mounting rack, spray heads of the ink-jet printer, a walking mechanism for products to be labeled, and a walking driving element for the products to be labeled are disposed in the labeling cabinet. The walking driving element for the products to be labeled is connected to the second PLC. The first PLC and the second PLC are in communication connection. The lens appearance inspecting system increases the inspection efficiency and product stability.

Owner:连云港中蓝光电科技有限公司

Automatic labeling machine

The invention discloses an automatic labeling machine for labeling products. The machine includes a delivery device, a labeling device, a driving device and a control device. The delivery device includes a transfer roller equipped with an encoder, and a pressing roller; the labeling device comprises a coiling roller, an unwinding roller and a label conveyor belt; the control device includes a PLC controller, and transmits an instruction to the labeling device in receiving a signal from the encoder; the labeling device moves up and down under the action of the driving device for product labeling; and the whole system adopts a back labeling method, so as to make the label more time-saving and convenient.

Owner:JIAXING YUNMU ENVIRONMENTAL PROTECTION TECH CO LTD +1

Labels, containers, system and method for providing reagents

The invention relates to systems and methods for marketing and using products such as liquid materials, especially liquid reagents for use in microbiological and cellular biological laboratory settings include the use of unique color and simple numeric or alphanumeric identifiers to quickly and easily identify any product from a catalog list of products. Methods of marketing, advertising and producing such products are also disclosed. Particular embodiments include products, product packaging and product labeling. The invention also relates to collars and sleeves for containers, as well as related methods of use.

Owner:LIFE TECH CORP

Invisible Window Intelligent Production Line

ActiveCN108890400AProduction is accurate and stableHigh degree of automationMetal working apparatusProcessing InstructionProduction line

The invention discloses an invisible window intelligent production line, comprising: a parameter generating device generates a corresponding bill of materials according to an order and raw material cutting parameters and label parameters corresponding to the bill of materials; The raw material cutting device is connected with the parameter generating device and cuts the raw material according to the raw material cutting parameters of the parameter generating device; The product labeling device is connected with the parameter generating device and labels the raw material cut by the raw materialcutting device according to the label parameters of the parameter generating device; The tag recognition device scans the tag and generates a corresponding machining instruction according to the tag.A processing device connected to the label recognition device and processing the raw material cut by the raw material cutting device according to the processing instruction. The invisible window intelligent production line provided by the invention can be continuously and automatically produced, has high automation degree, avoids excessive manual operation, reduces labor intensity of human beings, and improves production efficiency.

Owner:GUANGDONG XG INTELLIGENT SYST CO LTD

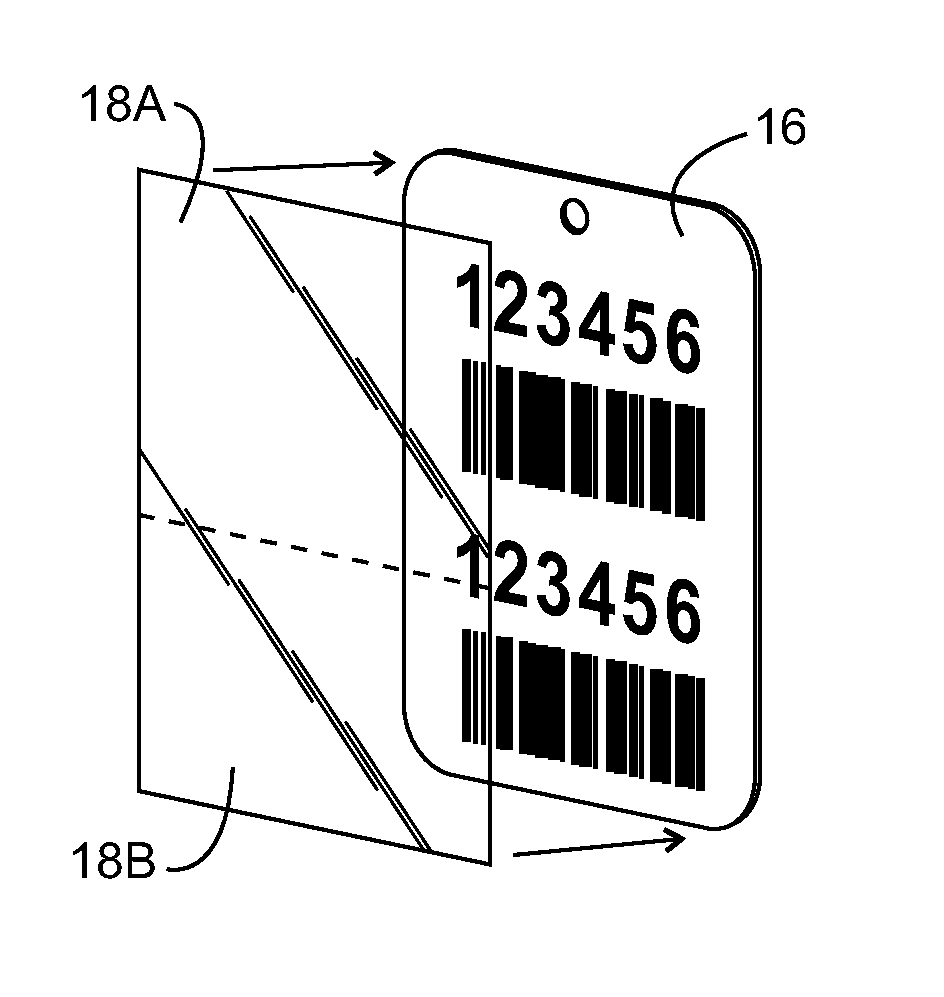

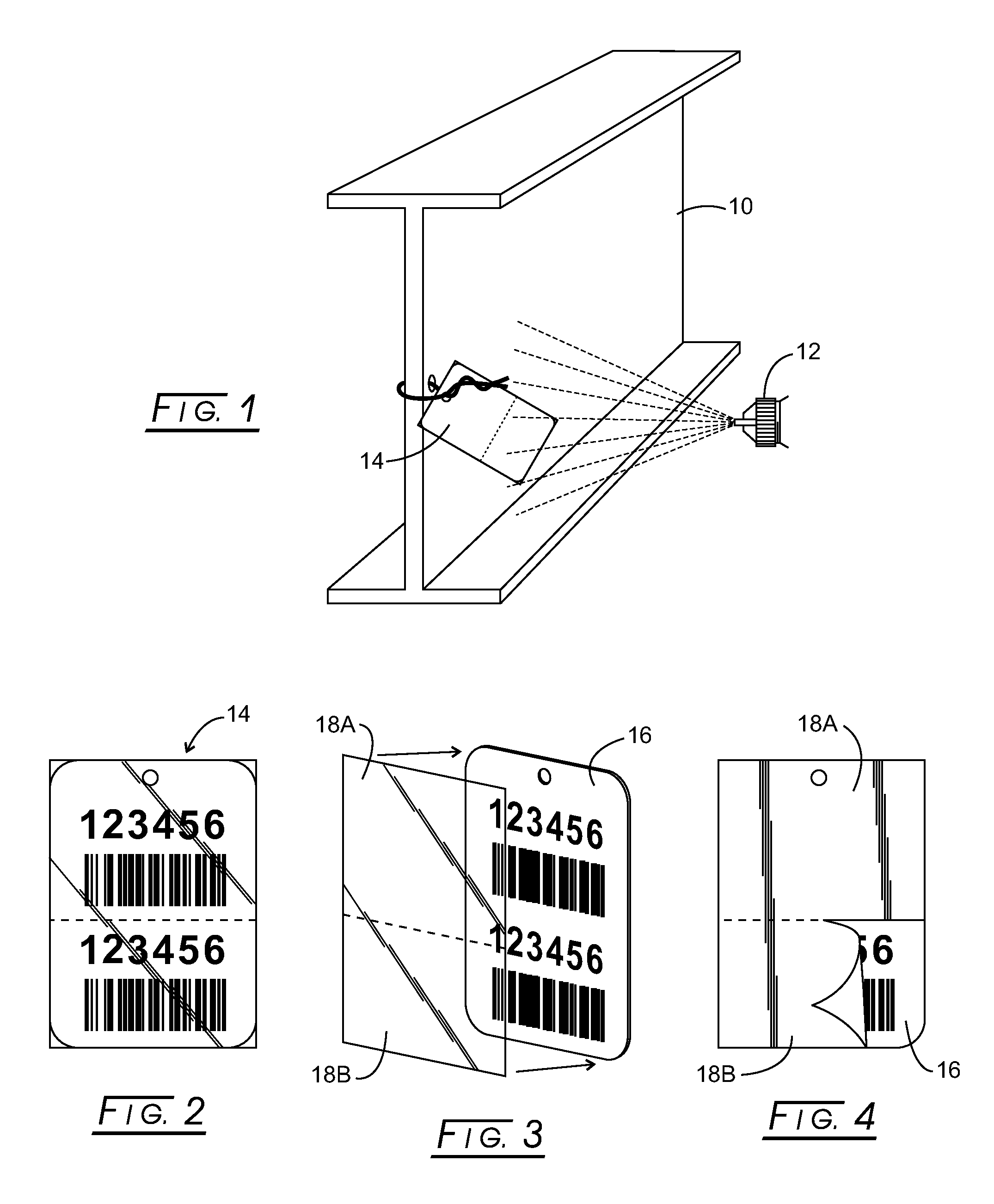

Identification Method and Tag for Painted Substrates

InactiveUS20150170551A1Extension of timeStampsLamination ancillary operationsProduct LabelingProduct identification

A product identifying tag has a front surface and a back surface. Multiple readable product identification indicia are printed on one or more of the tag front surface or the tag back surface. A transparent overlay covers each of the multiple readable product tag product identification indicia. Each overlay is separately removable from each of the multiple readable product tag product identification indicia. Alternatively, there may be only one set of product identifying indicia and a first adhesively coated transparent overlay covers the product identification indicia while a second adhesively coated transparent film overlays the first adhesively coated transparent overlay.

Owner:INFOSIGHT CORP

Note code printing equipment for processing and producing cylindrical art products

InactiveCN112277452AFit tightlySolve the strength problemRotary pressesSoft layerProcess engineering

The invention relates to the technical field of art product production, and discloses note code printing equipment for processing and producing cylindrical art products. The note code printing equipment comprises a base, wherein a coil corresponding to a magnetic block is arranged on the upper side of the interior of a code printing seat, the lower end of a sliding rod is connected with a pressingsoft layer, a variable resistor is connected to the upper portion of the inner side of a fixing column on the right side, the upper portion of a swing rod is connected with a magnetic ball, and the outer side end of a third spring is connected with a soft magnetic strip. The soft magnetic strip is driven to be recessed through a concave point on an art product bottle extrusion rubber layer, the recess of the soft magnetic strip adsorbs the magnetic ball to be close to the soft magnetic strip, a metal block in the middle of the swing rod slides on the variable resistor, the current of the coilconnected with the variable resistor in series is changed, the magnetic field generated by the coil pushes the magnetic block to move, and the magnetic block controls the curvature of the lower arc surface of the pressing soft layer through the sliding rod. According to the note code printing equipment, the problems that an existing art product labeling work is high in strength, creases are easily caused, and capability of automatically adapting to the radian of a round bottle cannot be achieved are solved.

Owner:王早花

Intelligent equipment production line for electric automobile charging pile

PendingCN110480334AStable productionImprove product qualityAssembly machinesProduction lineAssembly line

The invention discloses an intelligent equipment production line for an electric automobile charging pile. The intelligent equipment production line comprises a multiple-chain assembly line, wherein aplurality of work stations are sequentially arranged on the multiple-chain assembly line, and the work stations on the multiple-chain assembly line are sequentially presented as a loading station, asealing ring assembling work station, a control box upper cover assembling work station, a control box assembling work station, a product labeling work station, a detection work station and a turnoverwork station; and the multiple-chain assembly line comprises a multi-speed chain line body and a conveying belt line body, wherein the multi-speed chain line body is located below the working surfaceof the work stations, a plurality of tools are arranged on the multi-speed chain line body and used for placing workpieces, and the conveying belt line body is used for conveying the workpieces and tools from the turnover work station to the feeding work station. According to the intelligent equipment production line for the electric automobile charging pile, the problems that quality inspectionis complicated and efficiency in product production is low due to that fact that large personnel error conditions and obvious assembly errors exist on manual assembly in an existing charging gun production process can be solved.

Owner:中科摩通(常州)智能制造股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com