Patents

Literature

174results about How to "High anti-counterfeiting strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bill anti-counterfeit method and device based on texture image characteristics

ActiveCN103761799AGreat practicabilityImage acquisition is simpleCharacter and pattern recognitionData informationComputer graphics (images)

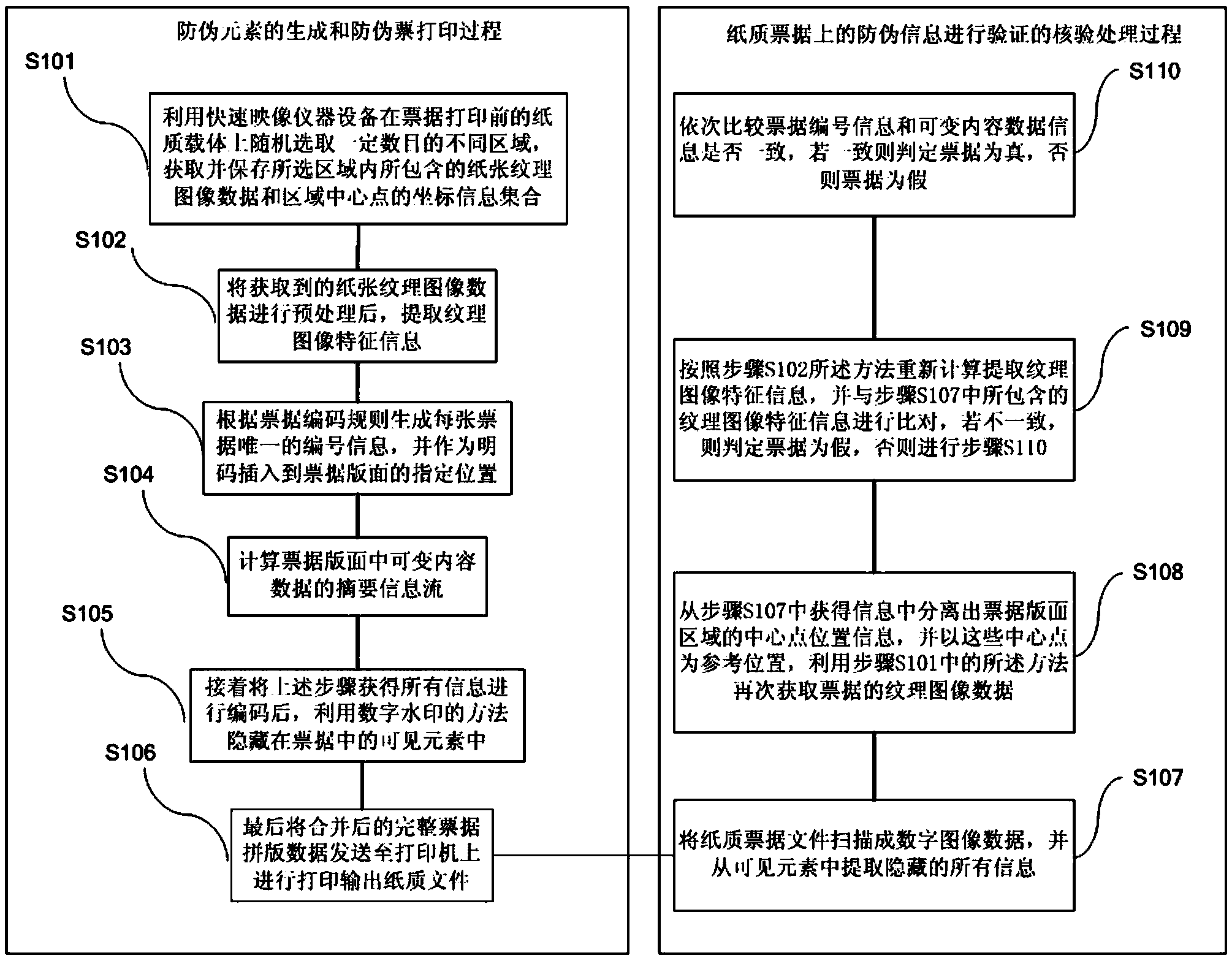

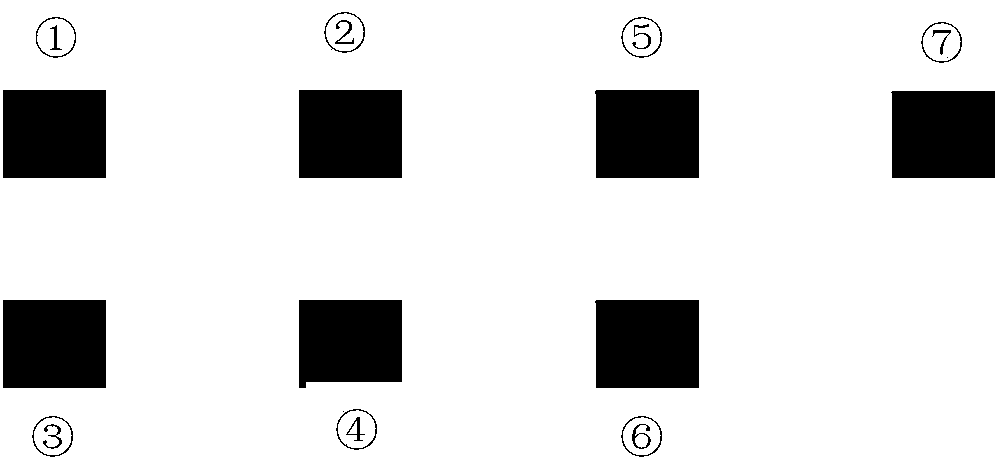

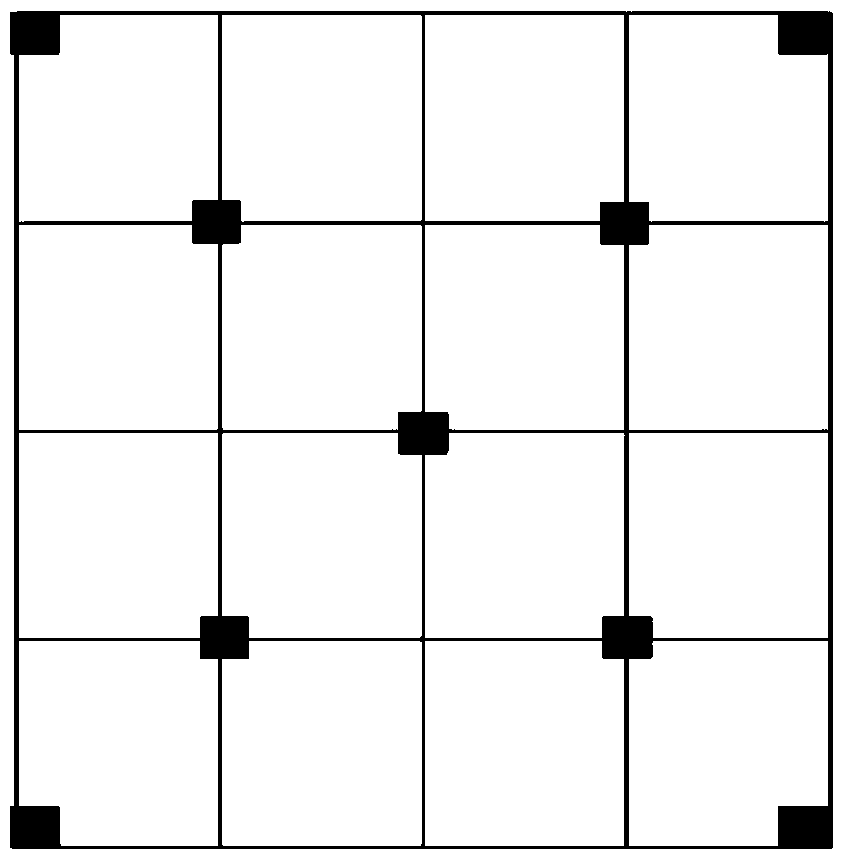

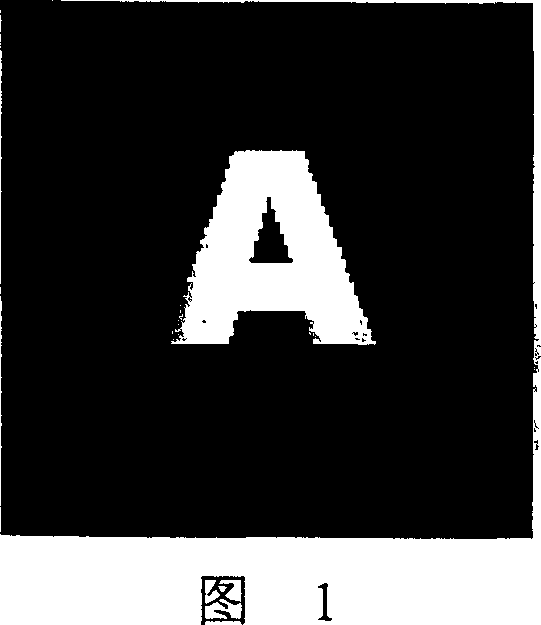

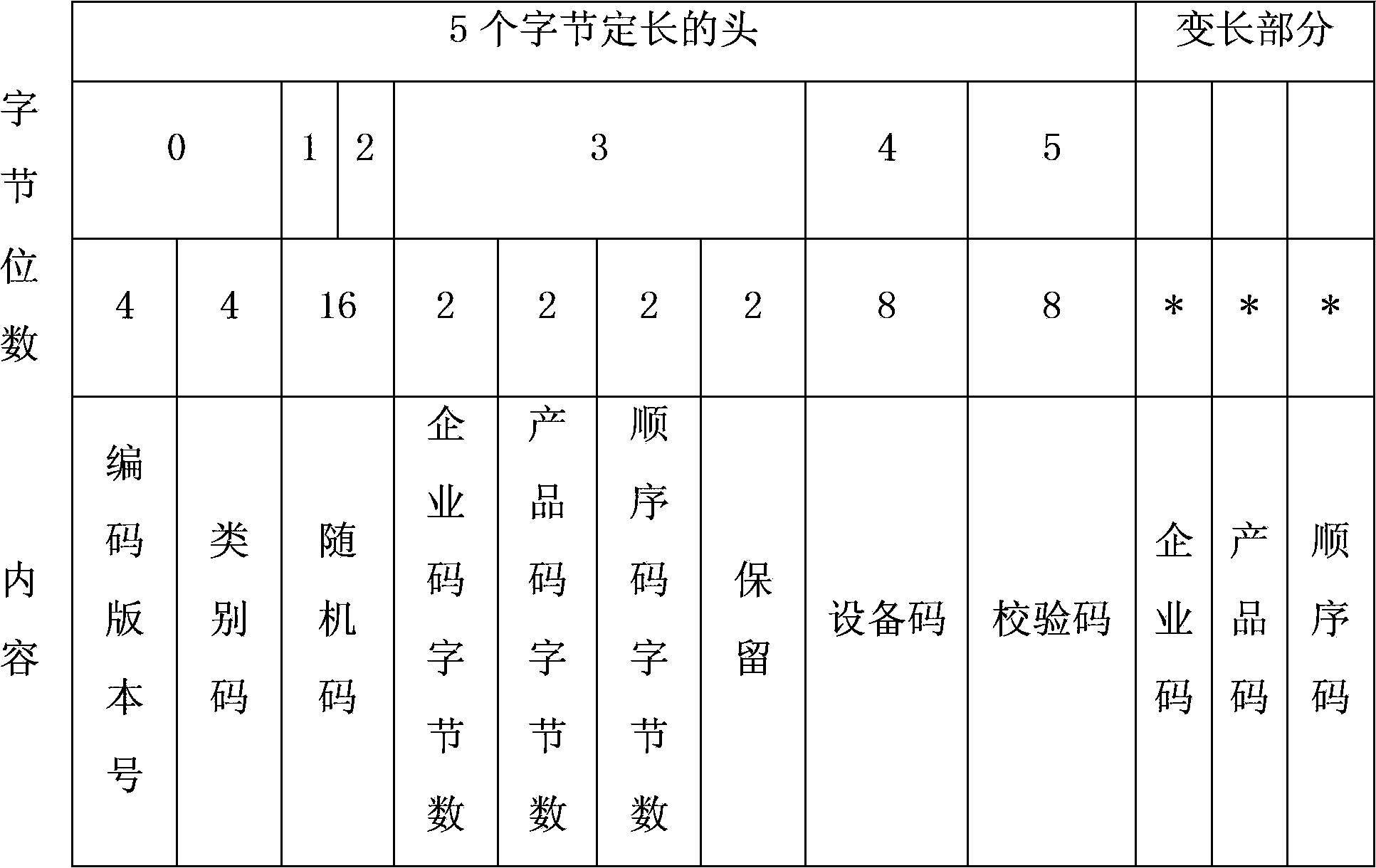

The invention relates to a bill anti-counterfeit method and device based on texture image characteristics. The method comprises the steps of firstly utilizing a rapid image device for selecting a certain number of areas from a paper carrier before a bill is printed, obtaining paper texture image data and area central point position information, extracting texture image characteristic information, generating bill number information, calculating an abstract information flow of variable content data, encoding all the obtained information, hiding the information in visible elements of the bills, and finally printing and outputting the complete bill makeup data. In the verification process, a paper bill file is scanned to digital image data, all hidden information is extracted, and then whether the texture image characteristic information, the bill number information and the variable content data information are consistent or not is obtained in a comparing mode so as to judge bill authenticity. The anti-counterfeit technology meets the requirements of technical exclusivity, technical reliability, identification simplicity, identification uniqueness, anti-counterfeit timeliness and the like.

Owner:李晓妮

Process for preparing phase regulating diffraction light grating encrypted anti-false identifier

InactiveCN1949025ATo achieve the purpose of hiding encrypted informationIncrease the difficulty of counterfeitingOptical elementsOptical diffractionLaser holography

The invention discloses phase modulation diffraction grating enciphered anti-fake mark preparing method. It includes the following steps: selecting out one pattern as enciphered information pattern; transforming to phase modulation diffraction grating pattern; shortening to the size generated optical diffraction as phase modulation diffraction grating making unit; using cameo structure form to make the unit set on the film. The produced enciphered anti-fake mark of the invention can change the enciphered information into optical information which can not be determined by human eye. Thus it needs machine identifying method to detect. This can increase faking difficulty in order to improve anti-fake performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Digital holographic stamped anti-counterfeiting packing bag and production method thereof

ActiveCN103922018ARealize integrationHigh number of security featuresDuplicating/marking methodsBagsHot stampingInformation layer

The invention belongs to the technical field of anti-counterfeiting materials and particularly relates to a digital holographic stamped anti-counterfeiting packing bag and a production method thereof. The digital holographic stamped anti-counterfeiting packing bag comprises a packing bag body and anodized aluminum; the anodized aluminum is composed of a base layer, a transfer layer and a gum layer; the transfer layer is composed of a release layer, an information layer and an aluminized layer. The anodized aluminum is printed on the packaging bag body by hot stamping. The production method includes selecting materials, designing, making a plate and die-pressing, aluminizing, printing and partially aluminizing, coating with a printed layer, tagging, applying gum, gilding, and cutting and hot-sealing. The digital holographic stamped anti-counterfeiting packing bag and the production method thereof have the advantages that holographic anti-counterfeiting packing, print anti-counterfeiting packing and digital anti-counterfeiting packaging are integrated by means of the bidirectional-positioning hot stamping technique, various anti-counterfeiting features are applied to the packing bag according to needs of customers and features of the packing bag, the single anti-counterfeiting means of the original packing bag is broken, unachievable untransferability of anti-counterfeiting labels is achieved, and secondary use of anti-counterfeiting contents is avoided.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

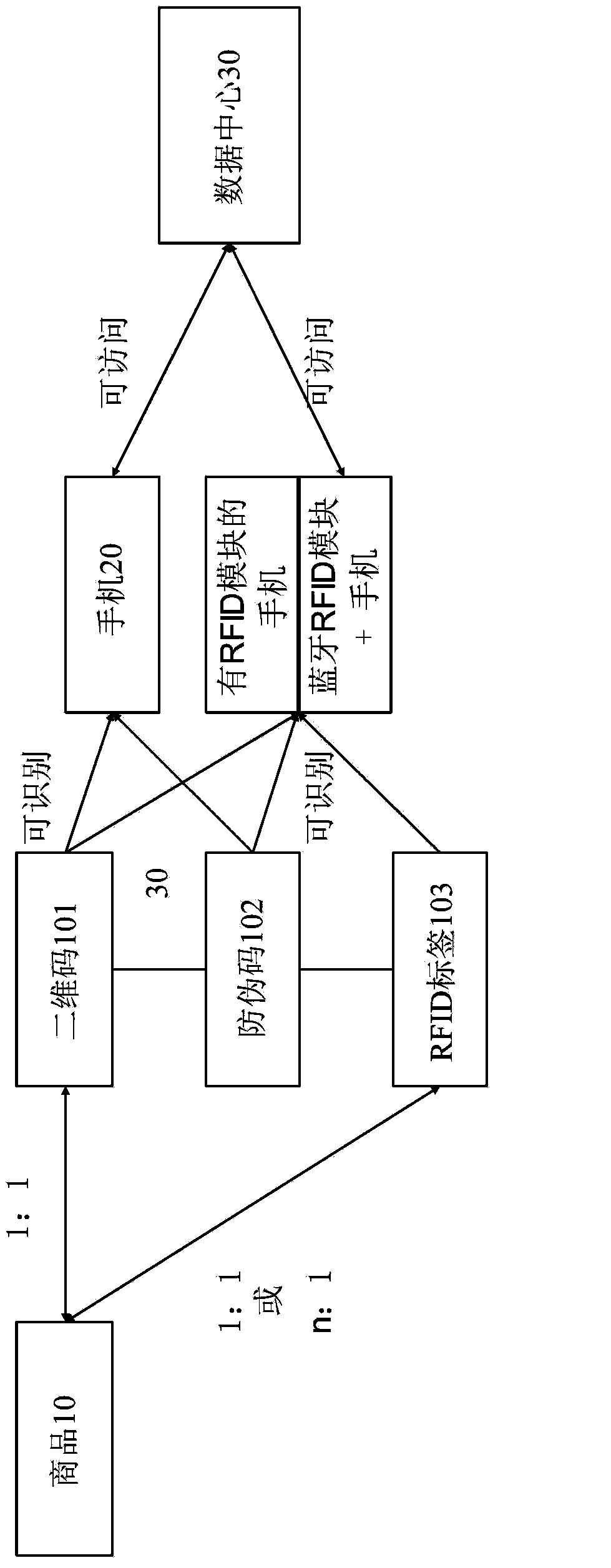

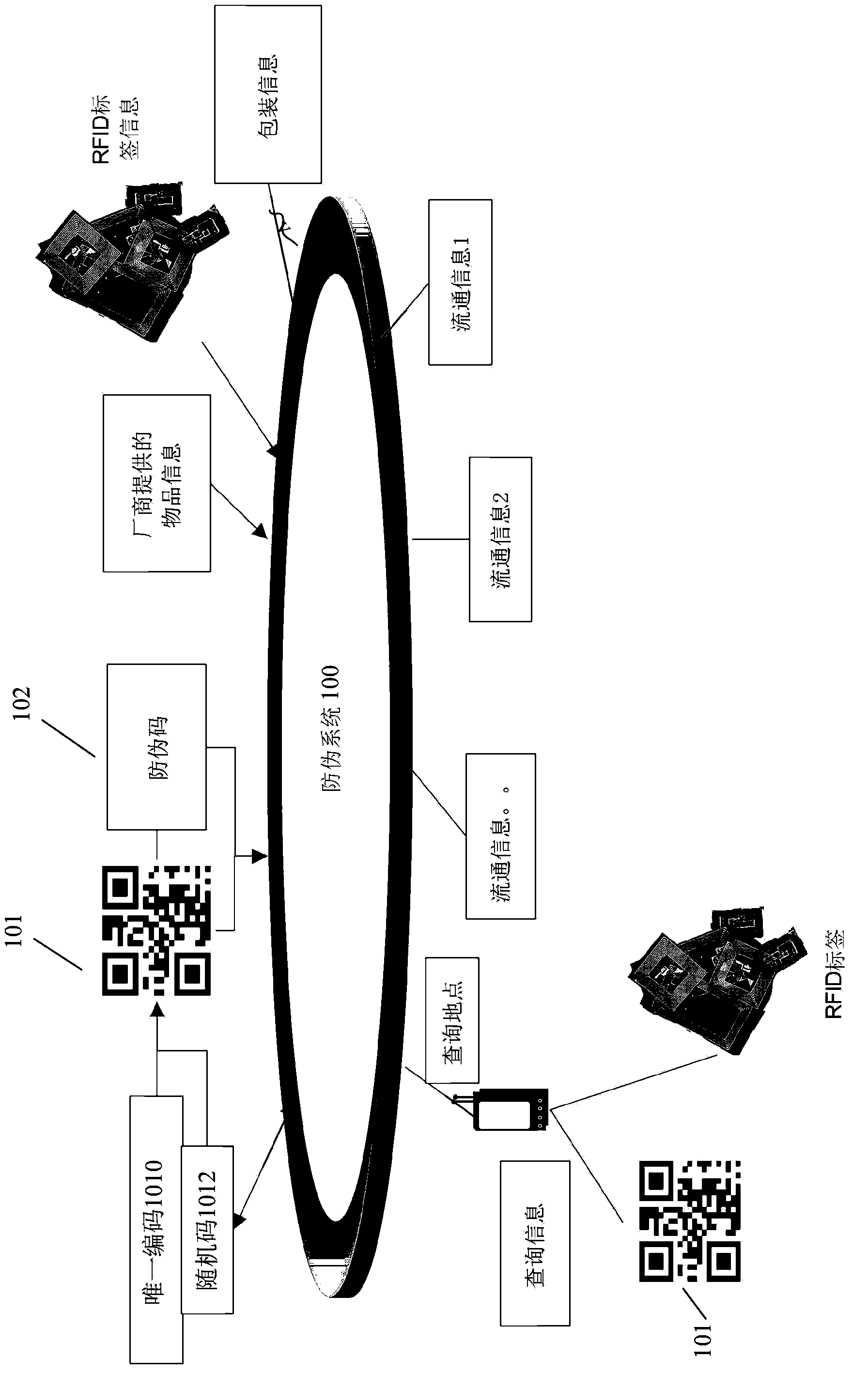

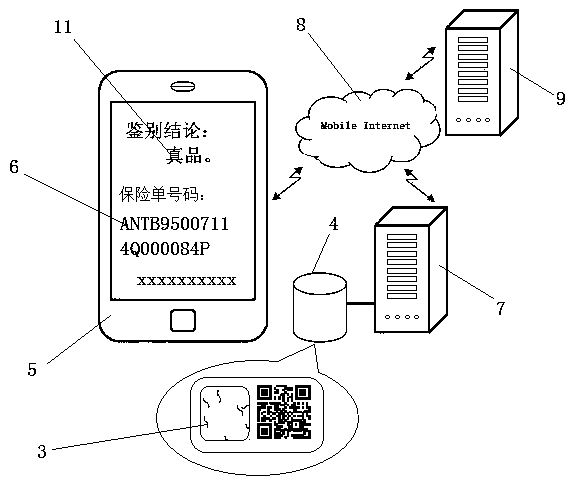

QR code, anti-counterfeiting code, RFID tag and mobile application combined anti-counterfeiting system

InactiveCN103854185AInquiry is simple and fastHigh anti-counterfeiting strengthCommerceRecord carriers used with machinesComputer hardwareData center

The invention discloses a QR code, anti-counterfeiting code, RFID tag and mobile application combined anti-counterfeiting system. According to the system of goods, each goods is provided with a QR code and a corresponding anti-counterfeiting code. The QR code contains a server address and a system unique code of the goods. A mobile terminal of the system is used for logging in a general browser to scan the QR code of the goods, parses the server address to send the system unique code of the goods and inputting the corresponding anti-counterfeiting code of the goods through an interface provided by a server. A server data center of the system receives the system unique code of the goods sent from the mobile terminal, provides an input interface of the anti-counterfeiting code by a webpage mode and receives the system unique code of the goods and the anti-counterfeiting code inputted by the mobile terminal. By the adoption of the system, the defect that a single anti-counterfeiting technology has low anti-counterfeiting strength and is hard to implement is avoided. The system provides enterprises with an anti-counterfeiting system and a method which have advantages of simple and convenient implementation, low operation cost, simple and fast query by consumers and high anti-counterfeiting strength.

Owner:SHANGHAI TY TECH

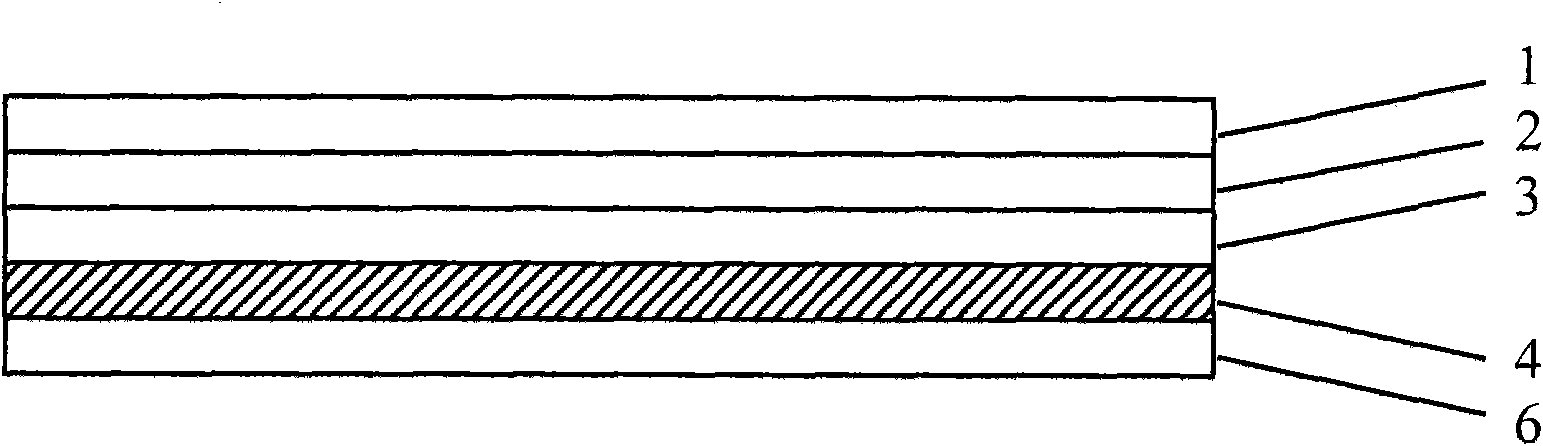

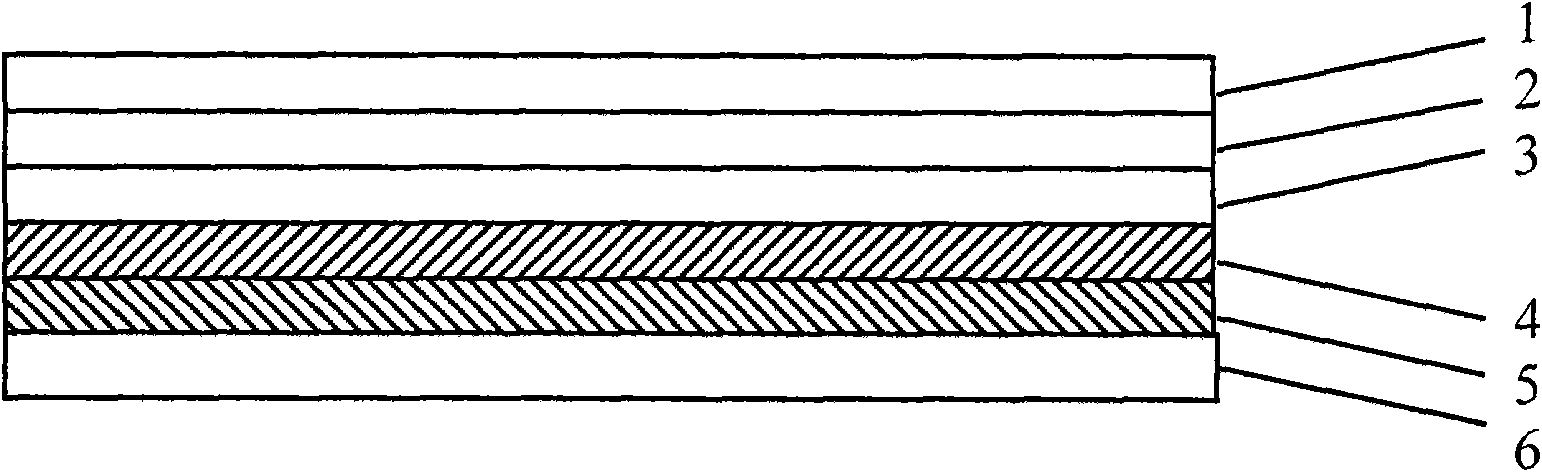

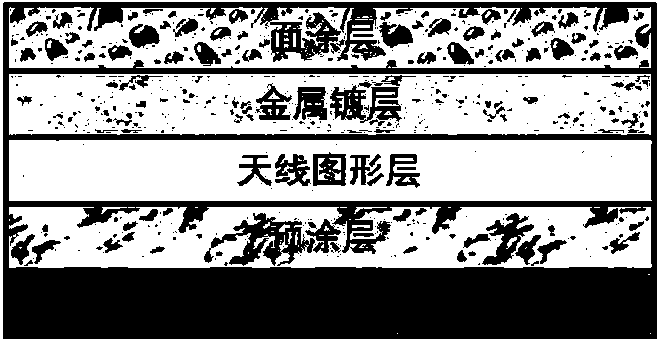

Production method of paper RFID hot stamping label

ActiveCN105893890ALow costEasy to recycleDigital marking by photographic/thermographic registrationHot stampingAntenna substrate

The invention belongs to the technical field of information, and in particular relates to a production method of a paper RFID hot stamping label. A paper substrate is used as an antenna substrate, wherein variable or invariable barcode information or a LOGO pattern is printed on one side of the antenna substrate, the other side of the antenna substrate is subjected to alignment printing to form an electronic label antenna surface, and then the electronic label antenna surface is compounded and compacted with a PET film coated with an isolation layer to obtain an antenna; a chip is bound to the compounded antenna to be manufactured into an electronic label inlay layer; an adhesive film is coated on an inlay surface bound with the chip; then the hot stamping electronic label is cut into a single label or single-row labels by a positioning die, and the single label or the single-row labels are rolled up to obtain a product. The production method of the paper RFID hot stamping label disclosed by the invention realizes a dual-information safety guarantee of visual information and electronic label information, and is environment-friendly and pollution-free, and the prepared electronic label has non-transferability, high anti-counterfeiting strength, fast hot stamping speed and high efficiency.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

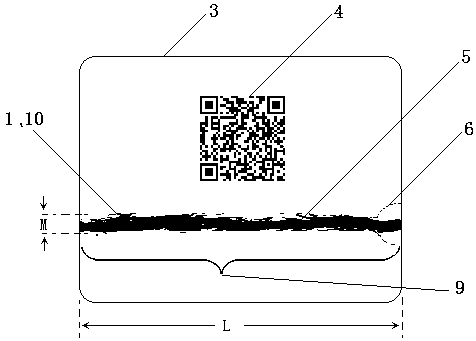

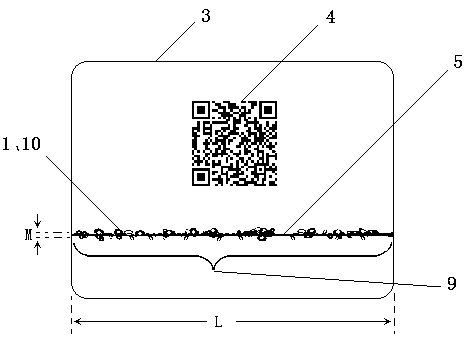

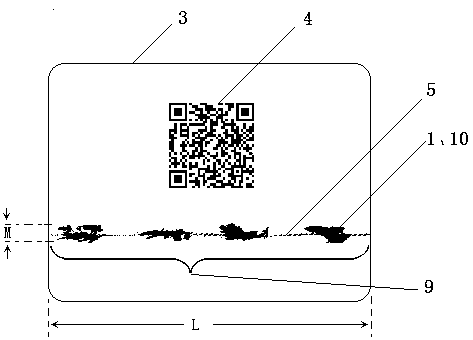

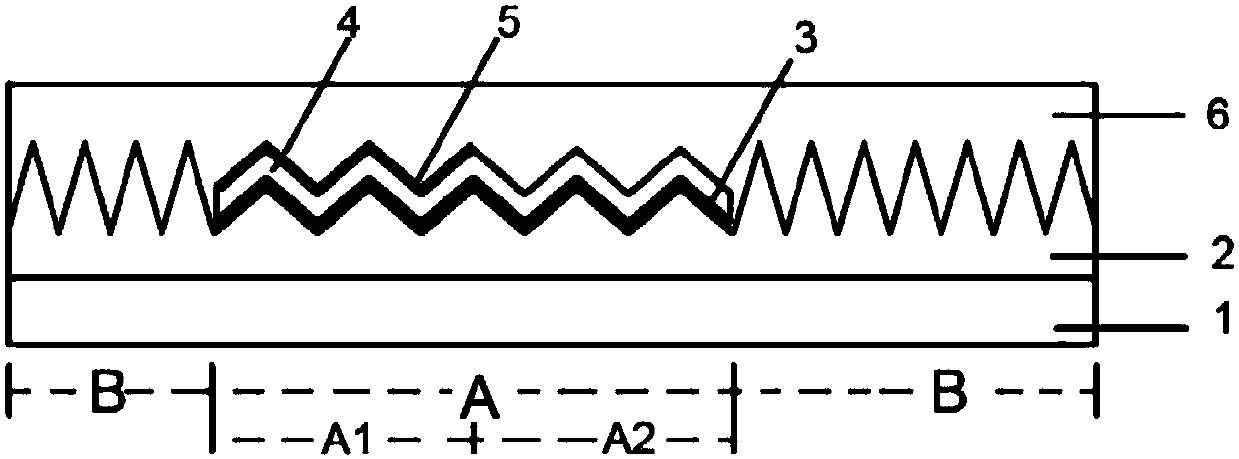

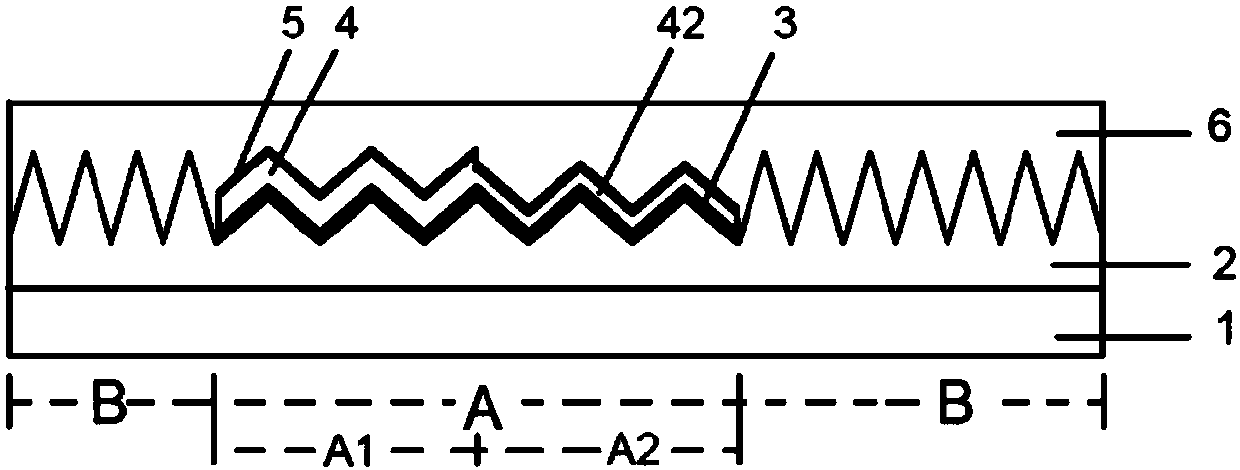

Hand-tear texture anti-counterfeiting method and its product and material

ActiveCN109215493BOvercoming the disadvantages of distinguishing true and false texturesAvoid circulationStampsRecord carriers used with machinesPattern recognitionFiber

A hand-tear texture anti-counterfeit method and a product and a material thereof are provided. Fancy yarn is embedded in printed matters and substrates, fancy yarn and its individual element are squeezed and shaped into a flat texture string. Personality information of flat texture strings is collected and stored as texture information files in the database of anti-counterfeit checking system. Themethod overcomes the drawbacks of needle pick fiber (texture), achieves the purpose of manual texture detection, can facilitate the public to discriminate the true and false texture by hand, avoids the trouble of anti-counterfeit application of needle pick texture, simplifies the production of texture paper, and avoids the residual fibers from polluting the production workshop environment of ordinary white paper.

Owner:HAINAN PAIPAIKAN INFORMATION TECH CO LTD

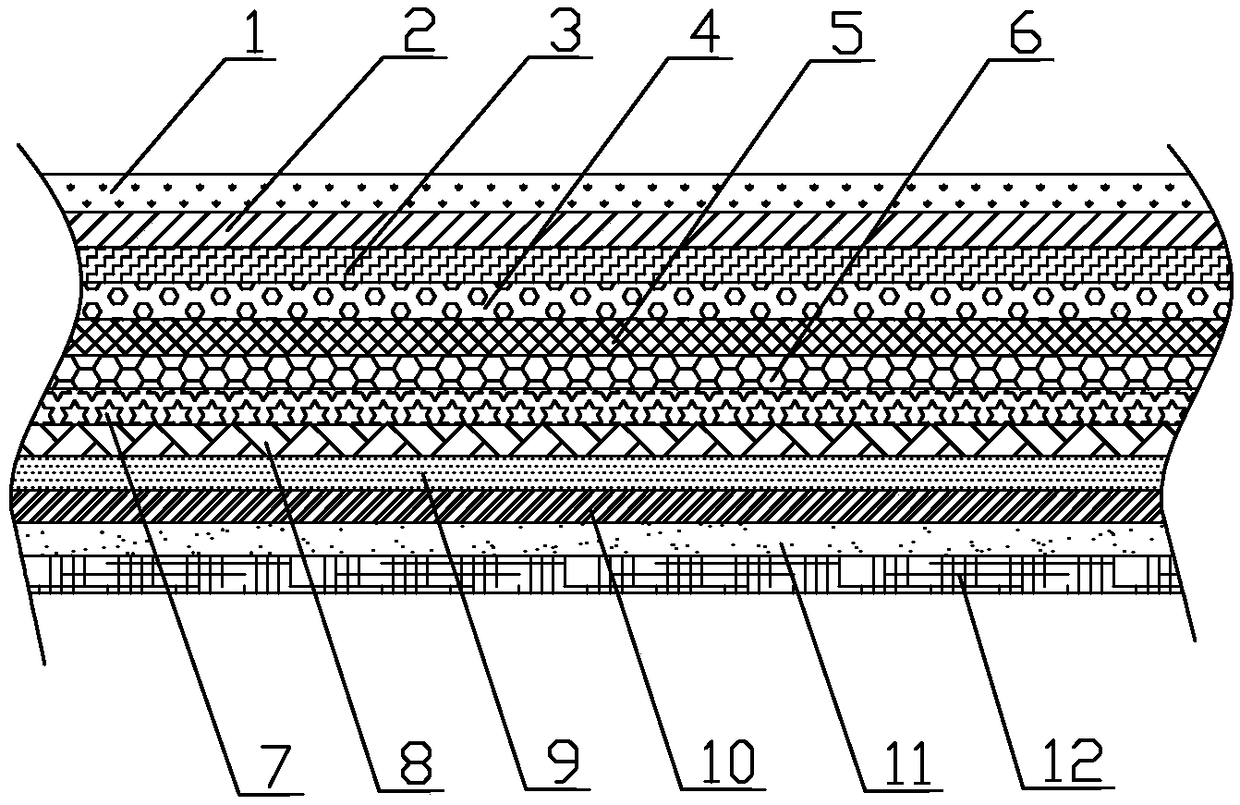

Laser holographic anti-counterfeiting stamping foil containing magnetic encryption information and preparation method thereof

InactiveCN101593459AHigh anti-counterfeiting strengthReduce the temperatureStampsVacuum evaporation coatingInstrumentationMedia layer

The invention provides a laser holographic anti-counterfeiting stamping foil containing magnetic encryption information and a preparation method thereof. A separation layer, an information recording layer and a medium layer are arranged in turn between a plastic carrier film layer and a bonding glue layer. The laser holographic anti-counterfeiting stamping foil is characterized in that a magnetic coat is also arranged between the medium layer and the bonding glue layer; moreover, a magnetic material is not printed on the surface of the stamping foil but coated on the medium layer; thus, the magnetic material cannot cover holographic patterns, and magnetic information writing and reading can be carried out through an instrument; therefore, the stamping foil not only contains holographic anti-counterfeiting information, but also has the function of magnetic encryption information anti-counterfeiting protection to obtain the effect of multiple anti counterfeiting.

Owner:WUHAN HUAGONG IMAGE TECH & DEV

Optical anti-counterfeit element and manufacturing method thereof

The embodiment of the invention provides an optical anti-counterfeit element and a manufacturing method thereof, and belongs to the field of optical counterfeit prevention. The optical anti-counterfeit element comprises a base material, a fluctuation structure layer located on the base material, a reflection layer, a medium layer and an absorption layer. The fluctuation structure layer at least comprises a first area composed of a first microstructure and a second area composed of a second microstructure, wherein the depth-to-width ratio of the first microstructure is smaller than that of thesecond microstructure. The reflection layer is only located on the first area. The medium layer is located above the reflection layer and at least covers a first sub area of the first area. The absorption layer is located above the medium layer, only covers the first sub area of the first area but does not cover a second sub area of the first area. By means of the optical anti-counterfeit elementand the manufacturing method thereof, the anti-counterfeit degree of optical anti-counterfeit products can be greatly improved.

Owner:ZHONGCHAO SPECIAL SECURITY TECH +1

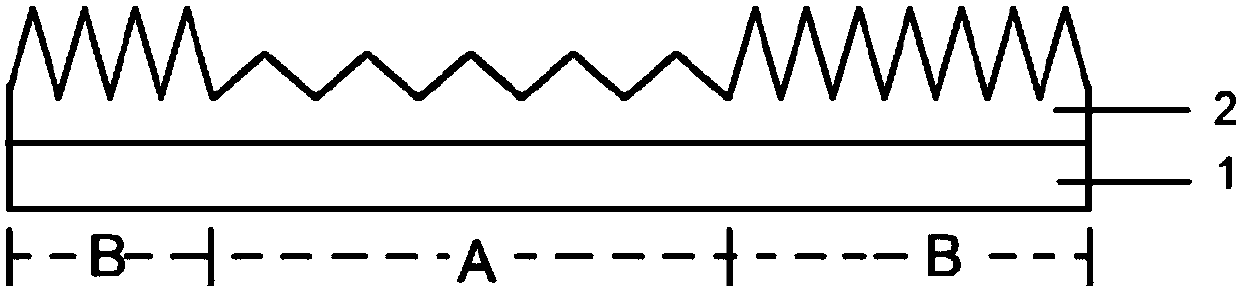

Manufacturing method of metal-directly-plated RFID (radio frequency identification) electronic tag antenna

ActiveCN104347944ALong preparation timeReduce manufacturing costRadiating elements structural formsHot stampingTag antenna

The invention discloses a manufacturing method of a metal-directly-plated RFID (radio frequency identification) electronic tag antenna. The antenna is formed by sequentially arranging a pre-coating layer, an antenna pattern layer, a metal-directly-plated layer and a surface coating layer. The manufacturing method comprises the following steps of pre-coating a base material, designing the antenna, preparing a pattern anilox roller, printing an anilox roller pattern, directly plating metal in vacuum, coating a surface coating and the like. Due to the fact that the antenna is directly formed by melting and evaporating a metal raw material in vacuum at high temperature, and evaporating the metal raw material onto the base material according to the designed antenna pattern, and subsequent manufacturing steps such as aluminum washing or hot stamping are not required, the production process is simplified. The manufacturing method of the metal-directly-plated RFID electronic tag antenna is capable of reducing radio frequency antenna manufacturing cost, environment-friendly, simple in process and high in production efficiency, and the defects of high cost, environment pollution and the like of the current electronic tag antenna manufacturing method are overcome.

Owner:上海顺灏新材料科技股份有限公司

Method for manufacturing colourless fluorescent ink anti-counterfeiting printing product

The invention discloses a method for manufacturing a colourless fluorescent ink anti-counterfeiting printing product. The method comprises the following steps: A. loading a color picture suitable for being printed in a computer; B. opening the picture by using Photoshop software and converting the picture into an RCG mode; C. reversing the picture in the RGB mode; D. creating a file with the size and the resolution the same as those of the image converted by the step A and in the CMYK color mode; E. copying the image information of the file subjected to reversion to an M channel, a Y channel and a C channel of the new file; F. outputting the file of the step E into an M film, a Y film and a C film; G. drying the films into PS formes to be printed; and H. printing the Y forme with green fluorescent ink, printing the M forme with red fluorescent ink, and printing the C forme with blue fluorescent ink. The method has the following beneficial effects: the additive method principle is adopted for printing the printing product, and the colored light principle in the optics is applied in printing, so that a fluorescent image has the color effect with variable continuous tone, and the anti-counterfeiting strength is further improved.

Owner:天津渤海化学股份有限公司

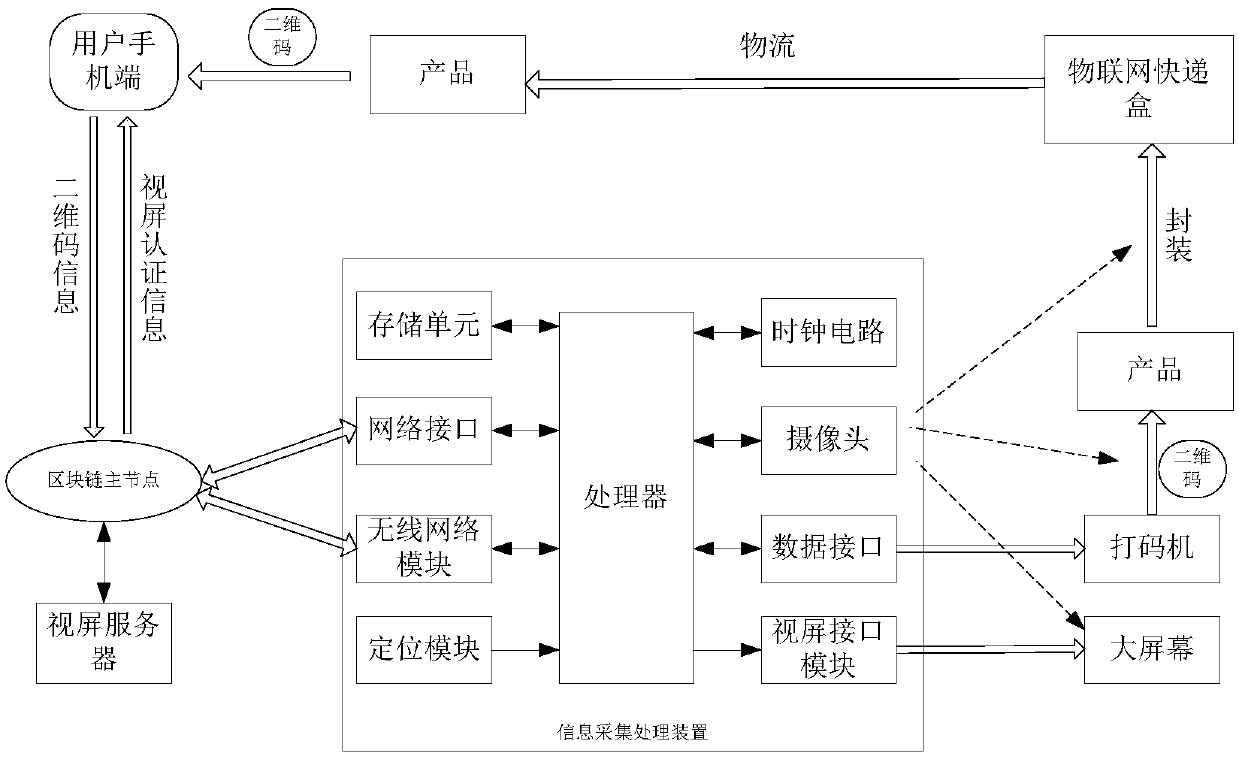

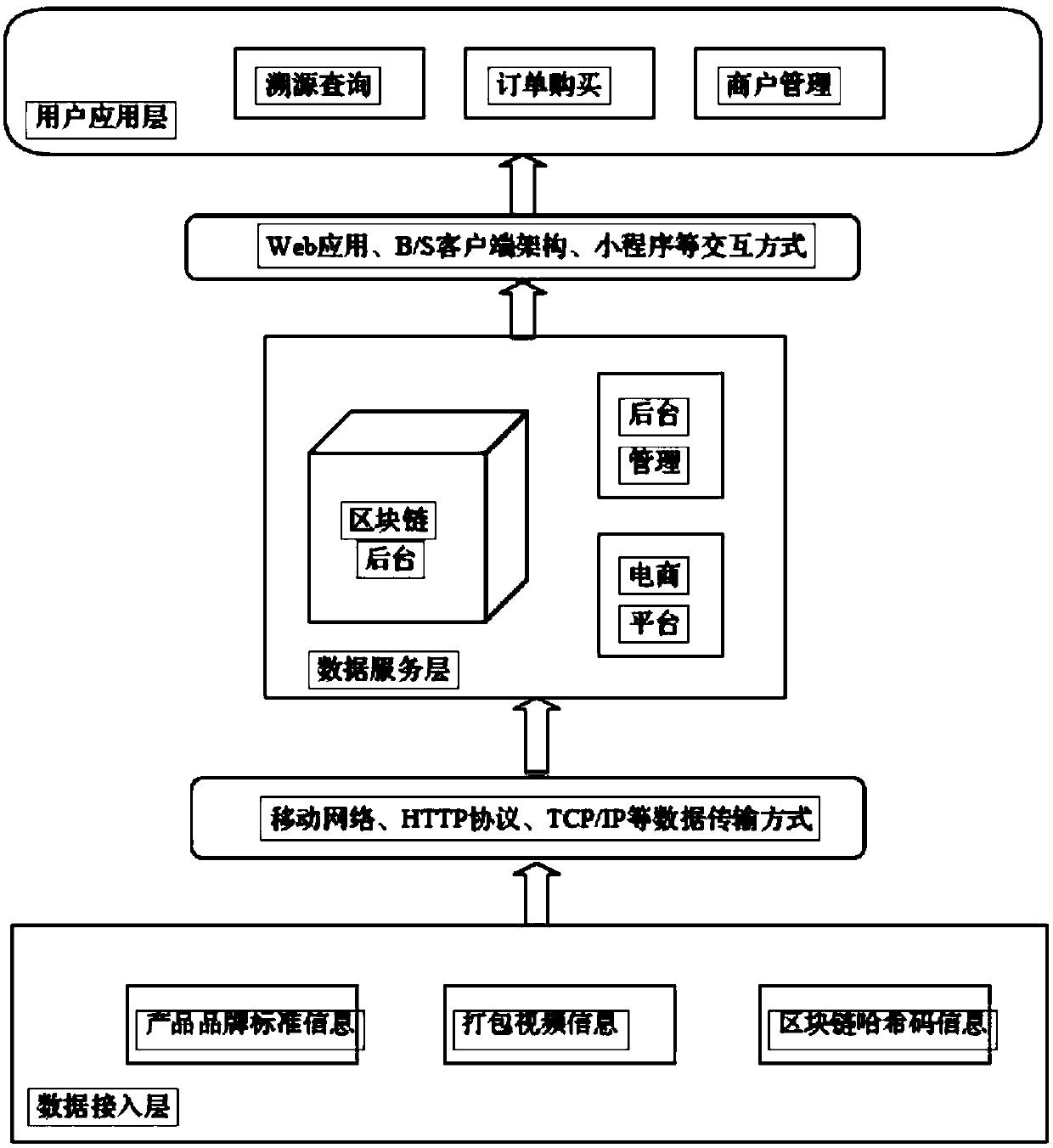

information acquisition and authentication system and method based on Internet of Things and a block chain

PendingCN109657760AEfficient and reliable traceabilityEfficient and reliable proofreadingCo-operative working arrangementsDigital data protectionThe InternetComputer terminal

The invention discloses an information acquisition and authentication system and method based on the Internet of Things and a block chain. the anti-counterfeiting packaging position and the code loading packaging process of the product are acquired through the information acquisition and processing device; position verification is carried out by using the position information; the process video isencrypted and stored through the block chain nodes; A product traceability block chain two-dimensional code printed by an external device serves as a unique information carrier of the identity of each product, an authentication terminal scans the code on the product by adopting the two-dimensional code, and the authenticity is verified by using the scanned two-dimensional code information to be consistent with the code information in the video content; All levels are mutually connected, so that efficient, reliable and low-cost product traceability and proofreading are achieved, and the problems that at present, information anti-counterfeiting is particularly important, however, an anti-counterfeiting system used at present is based on the centralized database technology, data of the anti-counterfeiting system is prone to being tampered, and existing information anti-counterfeiting verification information is single and not tight in verification are solved.

Owner:溧阳市铀链科技有限公司

Heat-sensitive magnetic anti-fake ink

InactiveCN1616562AAdd temperature factorIncrease the difficulty of imitationInksHeat sensitiveElectrical and Electronics engineering

The present invention relates to magnetic ink, and especially a kind of magnetic ink with magnetism varying with temperature. The anti-fake mark printed with the anti-fake ink exhibits certain magnetism under the temperature lower than some specific value and possesses no magnetism under the temperature higher than the specific value. The specific value is designed based on specific requirement within 30-150 deg.c. The heat-sensitive magnetic anti-fake ink may be printed in different printing mode and may be in different colors, black, brown, blue, etc. The present invention raises anti-fake capacity.

Owner:ZHONGBIAO ANTICOUNTERFEIT PRINTING +1

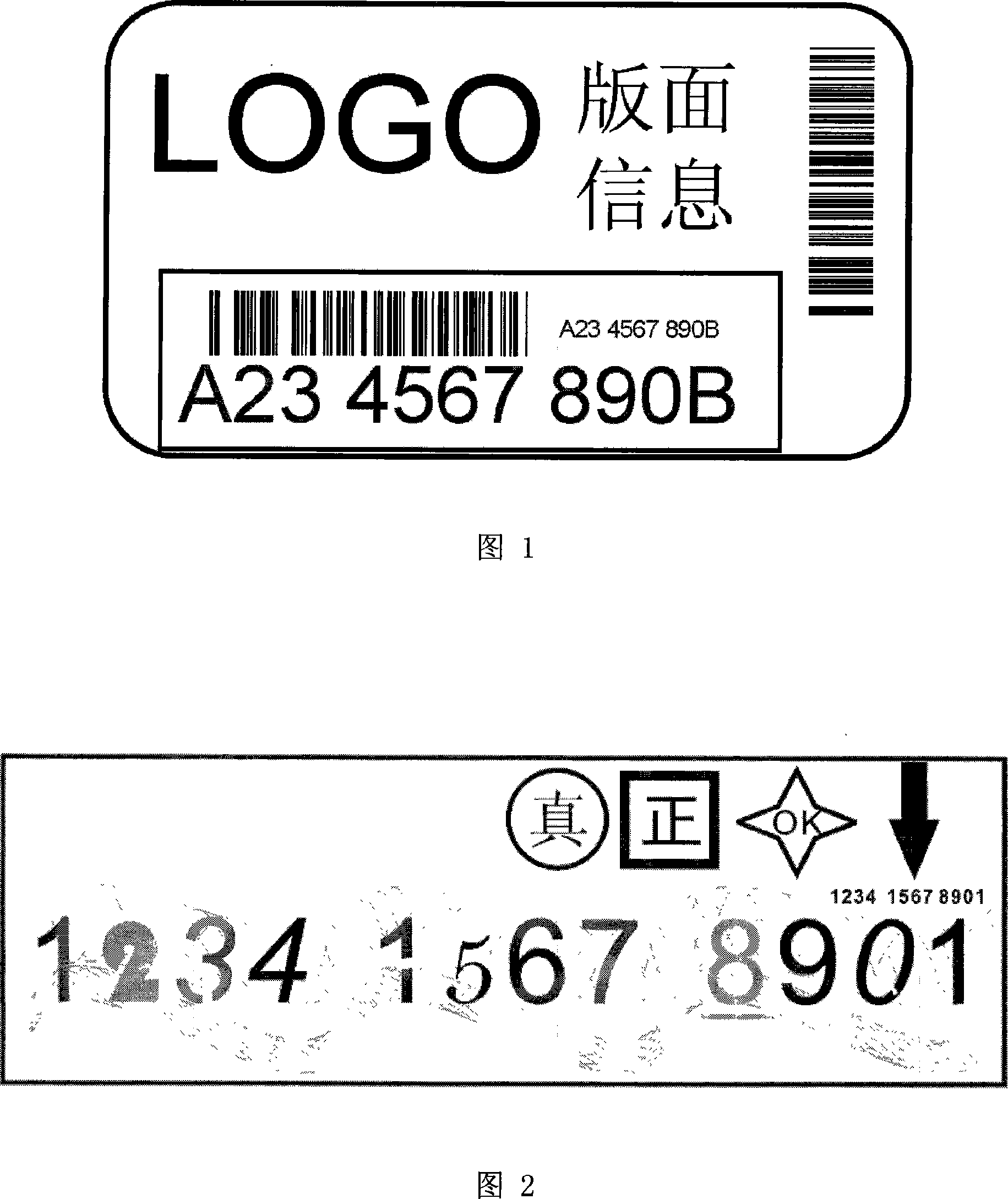

Digital anti-fake printing method

InactiveCN101105837AEasy to identifyThe method of change is intuitive and easy to understandVisual representation by matrix printersVisual representatino by photographic printingComputer number formatSecurity printing

Owner:俞熹

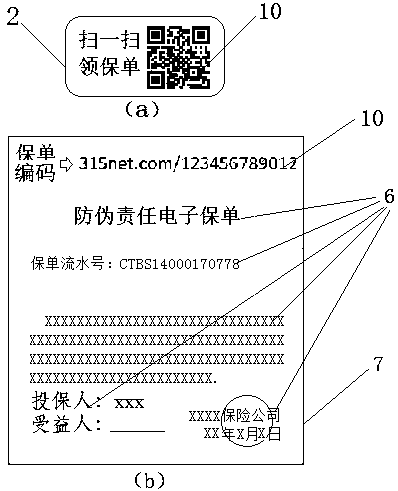

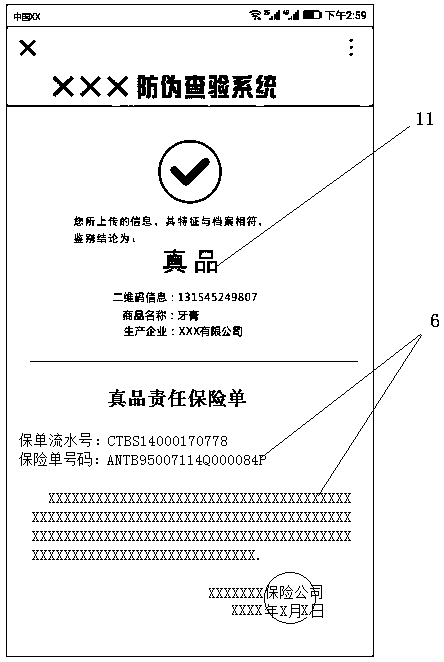

Anti-counterfeiting insurance packaging method for products

InactiveCN111091394ADifficult to counterfeitAnti-counterfeiting inspection rate increasedFinanceCryptography processingInternet privacyEngineering

The invention belongs to the technical field of anti-counterfeiting and printing packaging for products, and particularly relates to an anti-counterfeiting insurance packaging method for products. Themethod comprises the following steps of setting an anti-counterfeiting responsibility electronic insurance policies or products, encoding insurance policies, making code on an insurance policy marker, setting the markers on the product, and saving electronic insurance policies, anti-counterfeiting information and the insurance policy codes in an insurance policy claiming system database; when a consumer claims an electronic insurance policy from an insurance policy claiming system by using a smart phone, enabling the consumer to unconsciously identifies the authenticity of the insurance policies. According to the invention, a very high insurance policy claiming rate is converted into a very high anti-counterfeiting check rate, and the anti-counterfeiting strength is enhanced. The unexpected technical effect is the beneficial technical effect which is dreamy for domestic and overseas anti-counterfeiting technology and insurance technology research and development personnel.

Owner:HAINAN PAIPAIKAN INFORMATION TECH CO LTD

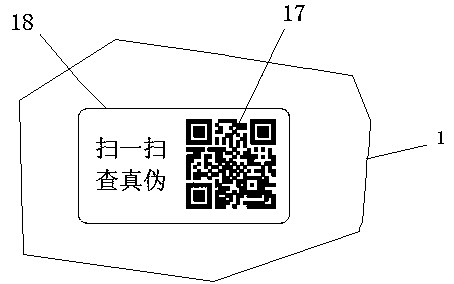

Genuine insurance anti-counterfeiting method and system

ActiveCN109658119AImprove trustBuy/consume with confidenceFinanceCo-operative working arrangementsThird partyHigh effectiveness

The invention discloses a genuine insurance anti-counterfeiting method and system, and the method comprises the steps: presetting genuine responsibility insurance or / and insurance policy information for a commodity, and building record information in an anti-counterfeiting query system database in combination with the anti-counterfeiting feature information in an anti-counterfeiting mark on the commodity; When or after the anti-counterfeiting inquiry system feeds back the identification conclusion information that the inquired commodity is a genuine commodity to the smart phone of the inquirer, activating the insurance policy to enable the insurance policy to take effect; And providing third-party guarantee that the inquired commodity is a genuine commodity by using an insurance one-way inquirer so as to enhance trust of the inquirer on an identification conclusion that the inquired commodity is a genuine commodity. According to the invention, the credibility of an identification conclusion can be enhanced, the anti-counterfeiting query rate is improved, the anti-counterfeiting degree is enhanced, and high commodity sales big data can be obtained with low cost and high efficiency.

Owner:HAINAN JIALI NETWORK

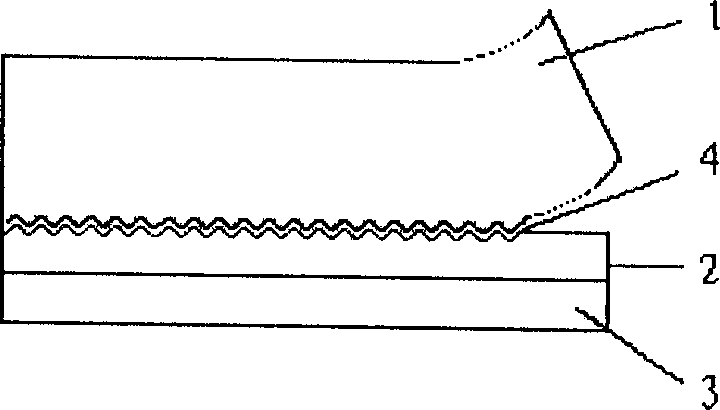

Uncovering type anti-counterfeiting label and preparation method thereof

ActiveCN105469704BPrevent breakage and failureHigh anti-counterfeiting strengthStampsIdentification meansEngineering

The invention belongs to the field of anti-fake marks and particularly relates to an uncovered anti-fake mark and a making method thereof. The anti-fake mark comprises two parts, namely a stripping part and a retaining part. The surface of the retaining part is a transparent layer which is composed of multiple parts. According to the preparation method, the material of the transparent layer is cut and then composited to the lower portion of a cured glue layer. The anti-fake mark is high in anti-fake power and cannot be easily simulated; since the transparent layer is composed of multiple parts, when the anti-fake mark is uncovered, only a part at the edge is uncovered, and the remaining parts are reserved at the retaining part; in this way, pattern information of the retaining part can be protected, and invalidation due to damage is prevented; the making method is scientific, reasonable, simple and easy to implement.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

Encrypted laser holographic anti-fake mark

InactiveCN1392422AHigh anti-counterfeiting strengthIncrease the difficulty of counterfeitingStampsIdentification meansGraphicsHuman eye

The encrypted laser holographic anti-fake mark includes an adhesive layer, an image layer and a plastic substrate and features its image layer of spectral converted relief structure. Between the plastic substrate and the adhesive layer, there may be a reflecting metal layer with also image layer of spectral converted relief structure. The present inventino is one practical technology developed for strengthening the anti-fake effect of anti-fake mark and is one anti-fake mark with hidden anti-fake information. The hidden anti-fake information is detected by machine rather than human eye and this increases the difficulty of imitation and raises the anti-fake effect.

Owner:HUAZHONG UNIV OF SCI & TECH

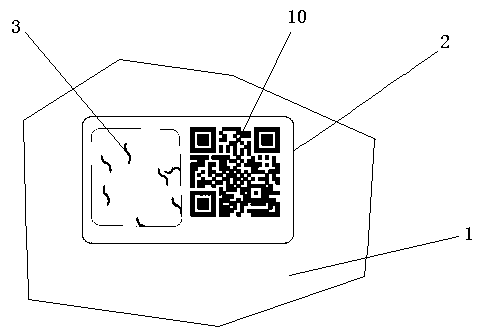

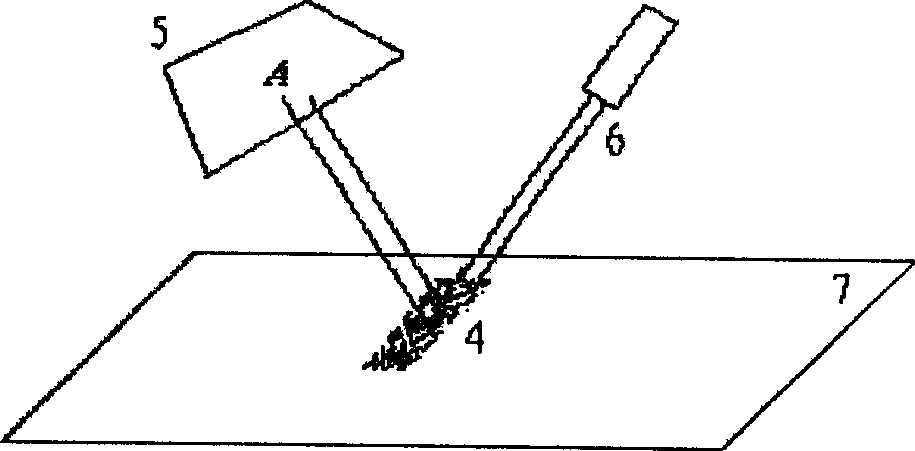

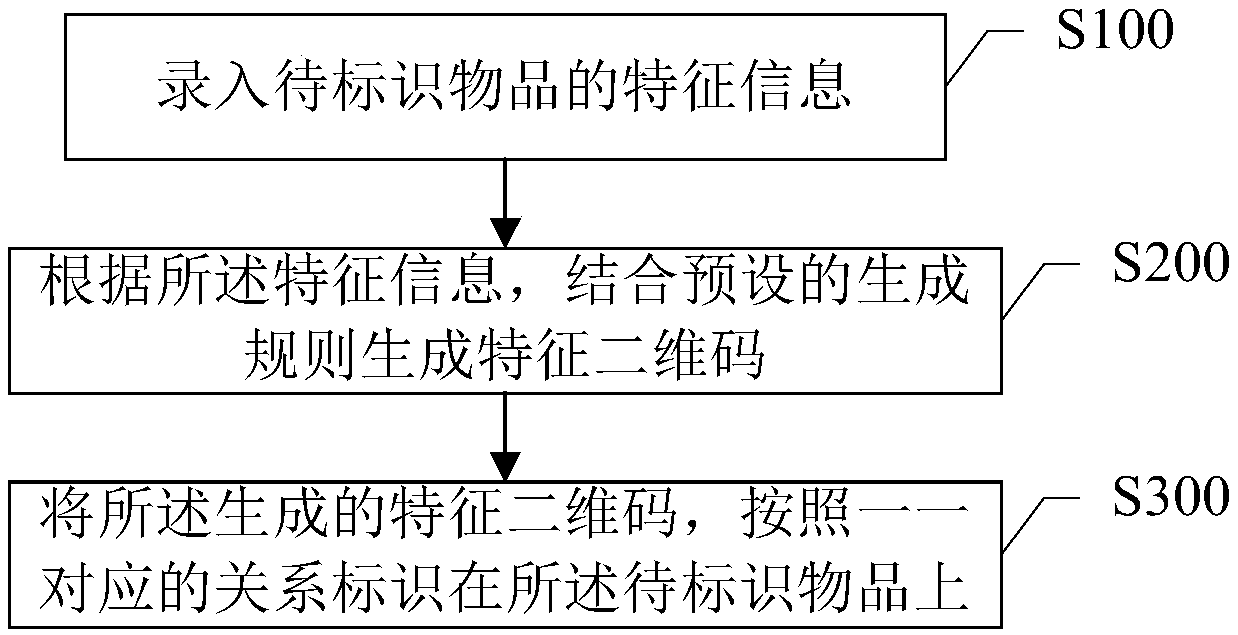

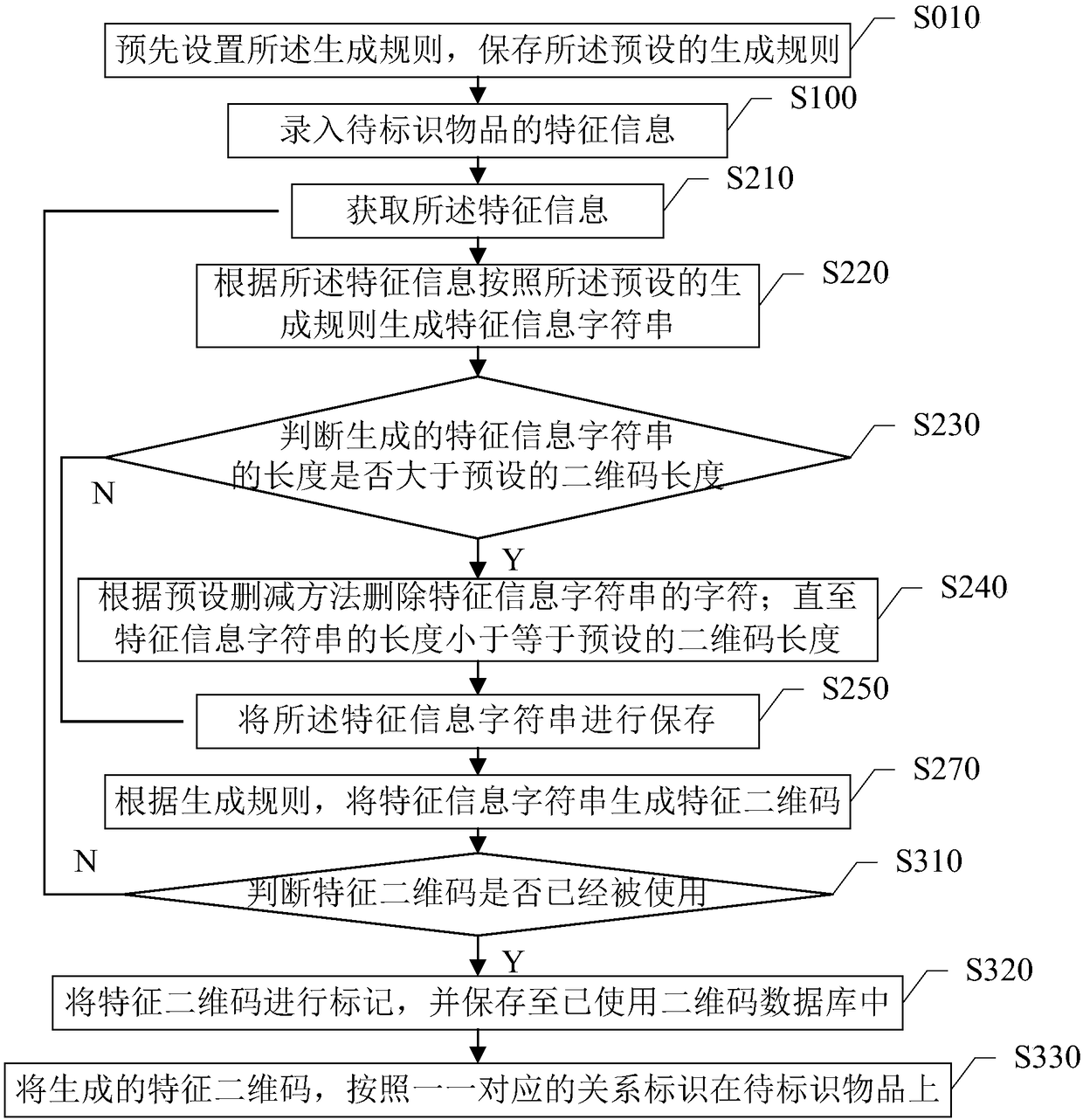

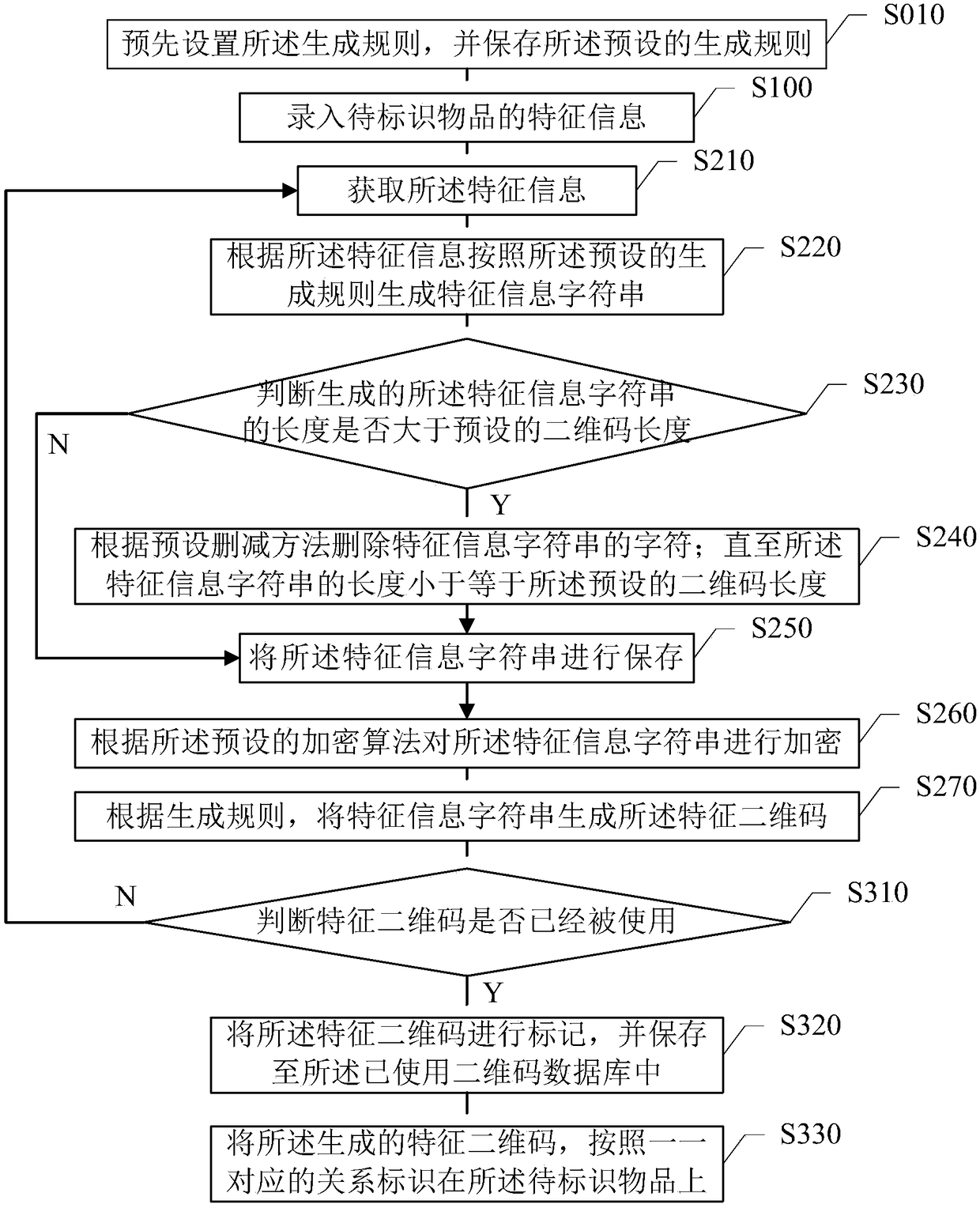

Object marking method and system and object recognition method and system based on two-dimensional codes

ActiveCN108154208AHigh anti-counterfeiting strengthCo-operative working arrangementsCommerceAlgorithmTheoretical computer science

The invention discloses an object marking method and system and an object recognition method and system based on two-dimensional codes. The marking method comprises the steps of S100 inputting characteristic information of objects to be marked; S200 generating characteristic two-dimensional codes by combining preset generation rules according to the characteristic information; and S300 marking thegenerated characteristic two-dimensional codes on the objects to be marked according to a one-to-one correspondence relation. In the invention, the characteristic information of the objects to be marked is obtained through a two-dimensional code generation device, then characteristic two-dimensional codes are generated on the basis of the characteristic information according to the preset generation rules, and the objects to be marked are marked by the generated two-dimensional codes according to a one-to-one correspondence relation. Therefore, repeated marking or missed marking can be avoided. Meanwhile, the characteristic two-dimensional codes can serve as unique identification codes of the objects because the marking is performed in a one-to-one correspondence manner so as to be used for differentiating the uniqueness and peculiarity of the objects.

Owner:SHANGHAI PEOPLENET TECH

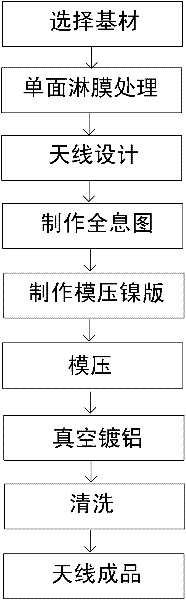

Production method for making hot stamping RFID electronic label

InactiveCN107247987ASimple structureShort processing cycleDuplicating/marking methodsCo-operative working arrangementsProduction lineHot stamping

The invention belongs to the information technology field and particularly relates to a production method for making a hot stamping RFID electronic label. An antenna is compounded on a PET layer, binding with a chip is carried out, a hot melt adhesive film is then compounded or coated, and the hot stamping label is acquired; die cutting of the hot stamping label is carried out, a knife edge of a die cutting cutter is provided with die cutting connection points, after die cutting, the connection points are distributed at periphery of the hot stamping label with intervals, and the label is connected with the PET layer through the connection points; on a label hot stamping machine, hot stamping of the hot stamping label onto a target object surface is carried out through a hot stamping head, under the action of a cooling device, cooling of a hot stamping adhesive film is realized, the PET film layer is pulled through a coiling shaft, the label is disconnected at the connection points, the label is marked on the target object surface, residual materials are removed, and making the hot stamping RFID electronic label is accomplished. The method is advantaged in that the RFID intelligent electronic label can be pasted to the target object surface in a hot stamping mode based on the PET film, the label PET has antennas at one surface or two surfaces, performance and quality are stable, and packaging production line large-scale application is facilitated.

Owner:孙涵

Electronic invoice generation steps and false discrimination method of electronic invoice

The invention discloses electronic invoice generation steps and a false discrimination method of the electronic invoice. The electronic invoice generation steps specifically comprise the following steps: (1) acquiring information that a user accomplishes the payment operation; (2) acquiring an organic invoice format image; (3) receiving input invoice information; (4) performing SHA-1 abstract calculation on binary data of the image so as to obtain abstract result, performing private key calculation on the abstract result so as to obtain signature data, and writing the signature data to the back side of the invoice image FF D9, thereby generating a final electronic invoice. The false discrimination method of the electronic invoice comprises the following steps: (1) reading data between FF D8 and FF D9 of the electronic invoice, and performing SHA-1 abstract calculation; (2) verifying the data of FF D9 of the electronic invoice according to the abstract data acquired in the previous step by using a public key, thereby obtaining the legality result of the data. The purposes that the resource is saved, the cost is reduced, the anti-false grade is increased, and the social development and stability are promoted can be achieved.

Owner:WUXI INST OF ARTS & TECH

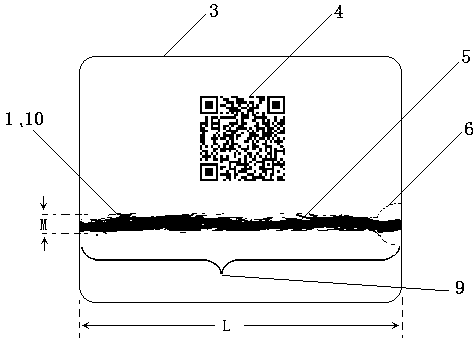

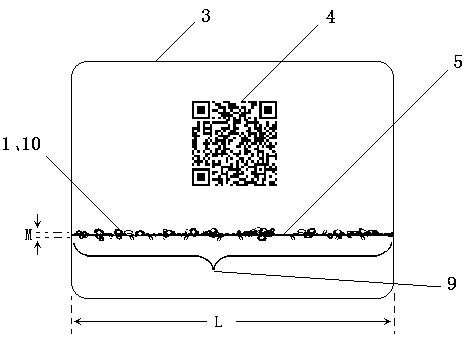

Manufacturing method of anti-fake label

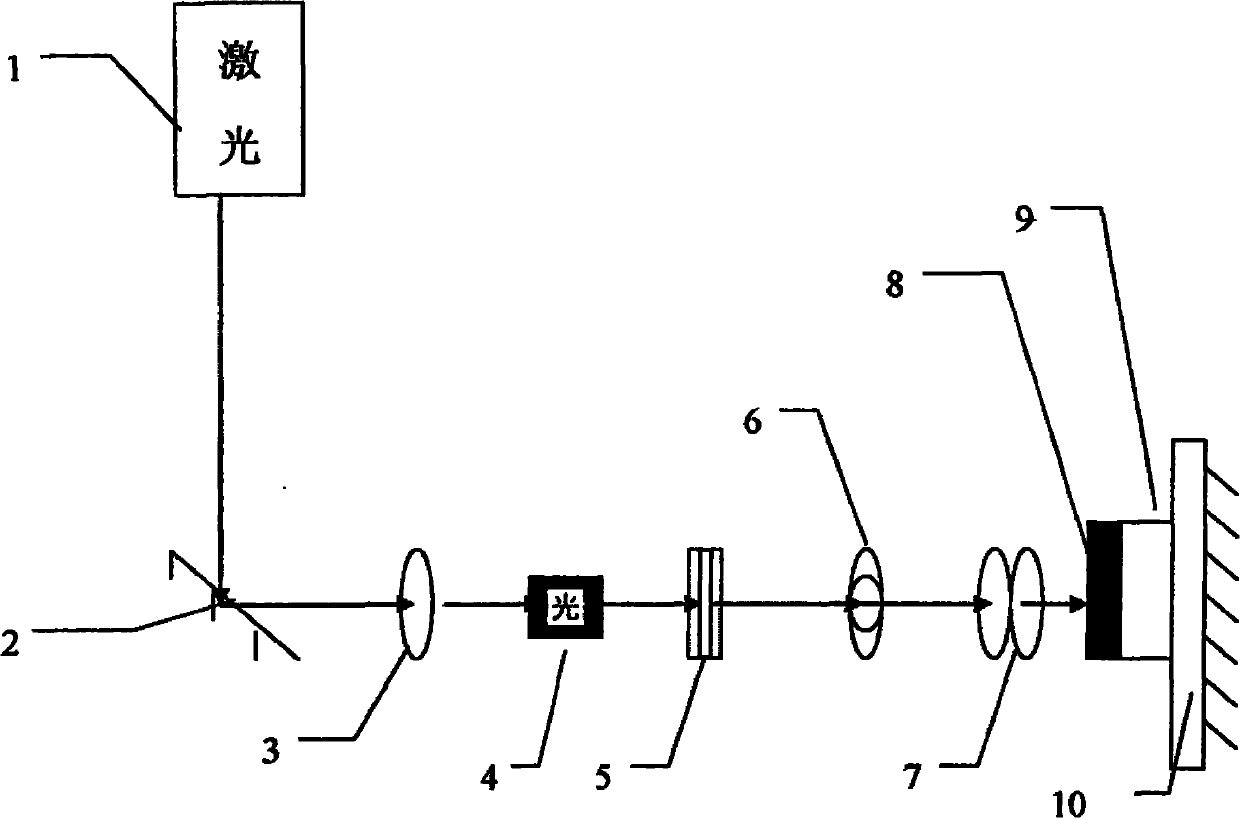

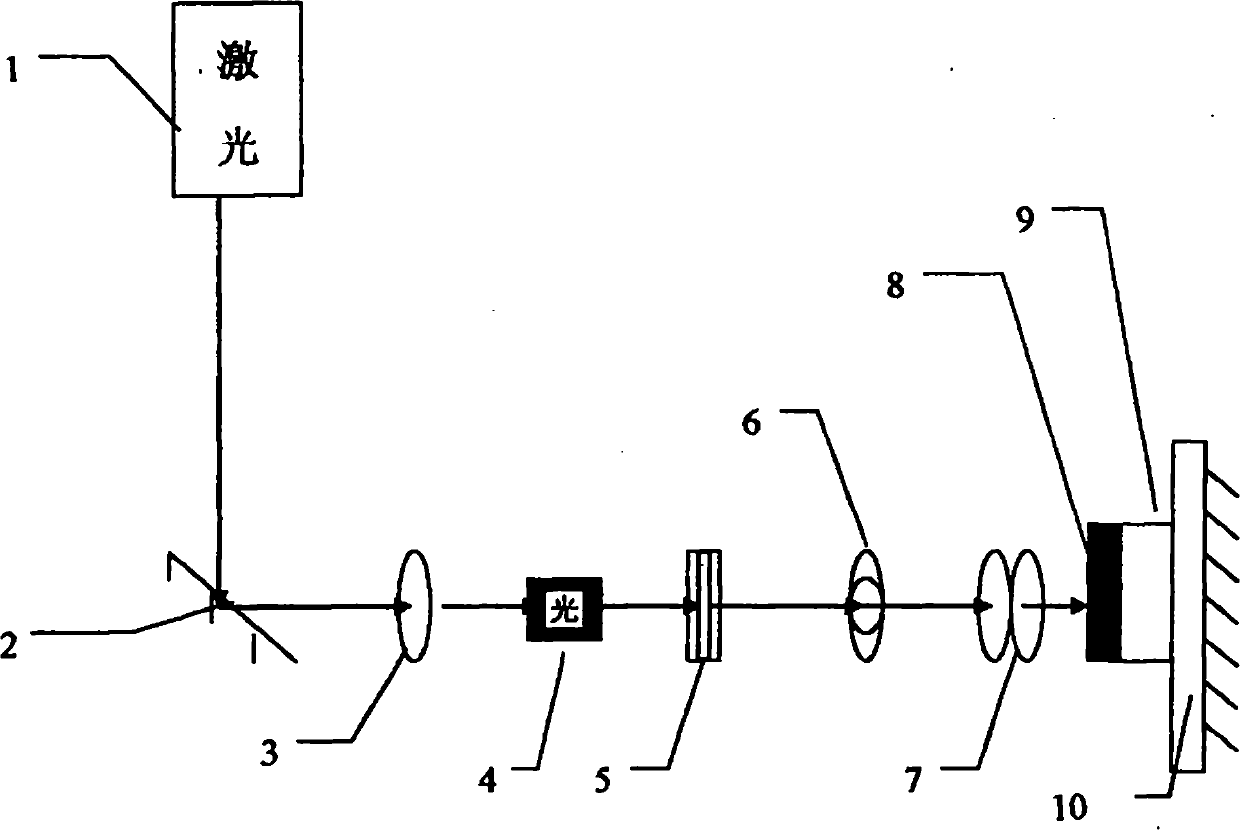

ActiveCN102658740AHigh anti-counterfeiting strengthImprove concealmentPattern printingPrinting inkEngineering

The invention provides a manufacturing method of an anti-fake label. The method comprises the following steps of: microfilming anti-fake information coding to be printed on a medium for plate making, carrying out plate making on an anti-fake pattern to be printed on the medium, printing the anti-fake information coding on a first designated position of the medium by using infrared absorbing printing ink capable of absorbing a wavelength of 720-1200nm, and then printing the anti-fake pattern on a second designated position of the same medium by using infrared laser anti-fake printing ink; or, printing the anti-fake pattern on the second designated position of the medium by using the infrared laser anti-fake printing ink, and then printing the anti-fake information coding on the first designated position of the same medium by using the infrared absorbing printing ink capable of absorbing the wavelength of 720-1200nm. The manufacturing method provided by the invention can be used for invisibly printing the anti-fake information coding and the anti-fake pattern on the same medium so as to be combined into an integrated anti-fake label, so that the printed anti-fake label is invisible for naked eyes of human. In addition, the anti-fake label is well elusive and has strong anti-fake capability, and thus the manufacturing method of the anti-fake label provided by the invention is a big advance in an anti-counterfeit technology.

Owner:广东恒立信息科技有限公司 +1

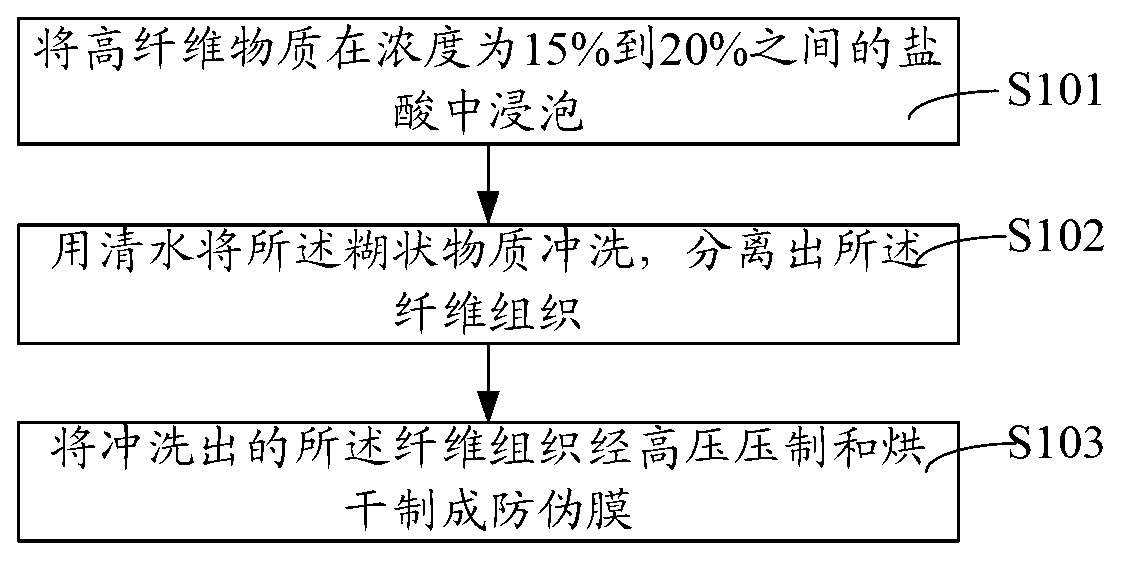

Radiofrequency anti-counterfeiting tag and anti-counterfeiting system

InactiveCN103177280AUniqueness of identityImprove anti-counterfeiting performanceRecord carriers used with machinesImaging processingIdentification device

The invention provides a radiofrequency anti-counterfeiting tag which comprises an anti-counterfeiting film and a radiofrequency tag. The invention further provides a plurality of methods for manufacturing the anti-counterfeiting film. The invention further provides an anti-counterfeiting system which comprises a storage device, a scanning device, an image processing device and an anti-counterfeiting identification device. The storage device is used for storing anti-counterfeiting codes or anti-counterfeiting two-dimensional codes; the scanning device is used for photographing the radiofrequency anti-counterfeiting tag; the image processing device is used for converting photos photographed by the scanning device into image data and processing the image data to obtain two-dimensional codes; and the anti-counterfeiting identification device is used for comparing the two-dimensional codes with the anti-counterfeiting codes or the anti-counterfeiting two-dimensional codes and identifying authenticity of the radiofrequency anti-counterfeiting tag according to a comparison result. The radiofrequency anti-counterfeiting tag and the anti-counterfeiting system have the advantages that an anti-counterfeiting tag which cannot be copied is integrated with the radiofrequency tag and can be subjected to anti-counterfeiting identification, or the radiofrequency tag can be subjected to anti-counterfeiting identification; and when identified, the anti-counterfeiting tag has a unique identity, is high in the anti-counterfeiting performance is good and cannot be copied owing to an anti-counterfeiting technology implemented by means of combining the advanced two-dimensional codes with the property that the anti-counterfeiting film cannot be copied.

Owner:张震历 +1

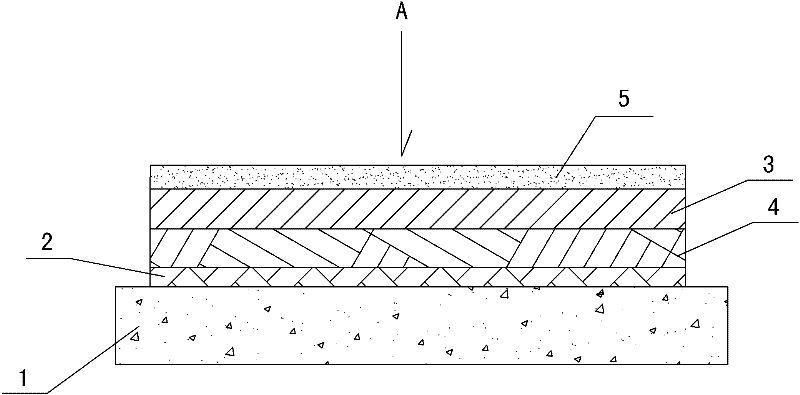

Disposable uncovered holographic electronic tag antenna and its manufacturing method and application

ActiveCN102263316APlay the effect of anti-counterfeiting transferAvoid being used a second timeAntenna supports/mountingsRadiating elements structural formsPolyesterTag antenna

The invention belongs to the technical category of electronic label manufacturing, and specifically relates to a one-time uncovered holographic electronic label antenna and its manufacturing method and application, including a base material layer, and is characterized in that: a coating layer and an antenna hologram are sequentially arranged on the base material layer Layer and aluminized layer; the production method of the present invention includes preparing a substrate layer, preparing an antenna holographic layer, vacuum aluminizing, and cleaning; the application of the product obtained in the present invention in a disposable uncovered holographic electronic tag antenna. The invention uses polyester film, coated paper or fragile paper as a disposable substrate layer, which has the effect of anti-counterfeiting transfer and avoids being used for the second time; the manufacturing process is simplified, so that the holographic antenna can be printed in large quantities and quickly Replication can be used in combination with various printed materials, reducing costs; through the organic combination of holographic anti-counterfeiting and RFID technology, the aesthetics of the product is increased, and the anti-counterfeiting strength is improved.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

Photoetching encrypted anti-counterfeiting method

InactiveCN101907825AHigh anti-counterfeiting strengthRich technical effectsPhotomechanical apparatusDot matrixImage resolution

The invention relates to the technical field of photoetching anti-counterfeiting, in particular to a photoetching encrypted anti-counterfeiting method, and provides the photoetching encrypted anti-counterfeiting method for miniaturizing characters and patterns on pixel points. The method comprises the following steps of: taking a glass sheet of which the surface is subjected to uniform gluing as a substrate, and designing a character aperture, namely designing a single character aperture design sheet of miniaturized characters by using a computer; preparing a film; turning the film, namely exposing, developing and slitting the film so as to obtain a single character aperture sheet; designing an original drawing according to the resolution and character space; introducing the original drawing into a photoetching machine computer on a photoetching machine, substituting original common metal apertures, such as a nickel hole with only aperture function for the single character aperture sheet, and exposing a photoresist dot matrix; developing by using developing solution; and electroforming, namely injecting silver and reprinting to obtain a mother set. By adopting the method for increasing characters and patterns in photoetching pixel points, the characters and patterns can be observed by a high power magnifier only, while human visual inspection is substantially consistent with common photoetching. Therefore, the anti-counterfeiting capability of holographic identifiers is improved, and the plate-making technical effect is enriched.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

Hand-tear texture anti-counterfeit method and product and material thereof

ActiveCN109215493AOvercoming the disadvantages of distinguishing true and false texturesAvoid circulationStampsRecord carriers used with machinesYarnTears

A hand-tear texture anti-counterfeit method and a product and a material thereof are provided. Fancy yarn is embedded in printed matters and substrates, fancy yarn and its individual element are squeezed and shaped into a flat texture string. Personality information of flat texture strings is collected and stored as texture information files in the database of anti-counterfeit checking system. Themethod overcomes the drawbacks of needle pick fiber (texture), achieves the purpose of manual texture detection, can facilitate the public to discriminate the true and false texture by hand, avoids the trouble of anti-counterfeit application of needle pick texture, simplifies the production of texture paper, and avoids the residual fibers from polluting the production workshop environment of ordinary white paper.

Owner:HAINAN PAIPAIKAN INFORMATION TECH CO LTD

Digital holographic anti-counterfeiting glue cap and preparation method thereof

ActiveCN103964058AHigh number of security featuresHigh anti-counterfeiting strengthDuplicating/marking methodsPattern printingPolyvinyl chlorideEngineering

The invention belongs to the technical field of anti-counterfeiting packages and particularly relates to a digital holographic anti-counterfeiting glue cap and a preparation method thereof. The digital holographic anti-counterfeiting glue cap comprises a glue cap and a thermally-printed foil layer, wherein the glue cap, a printing layer, an aqueous priming coat and the thermally-printed foil layer are sequentially connected, and the thermally-printed foil layer is transferred to the glue cap in a cramping manner. The preparation method comprises the steps of material selection, designing, plate-making, mold pressing, printing, aluminum washing, printing layer coating, code printing, coating transfer, slitting, forming. According to the preparation method, digital holographicanti-counterfeiting thermally-printed foil is transferred to a fixed position of the glue cap by virtue of a cramping transfer technique, so that the holographic and digital anti-counterfeiting techniques are integrated; as the number of anti-counterfeiting characteristics is large, the anti-counterfeiting capability is improved; an anti-counterfeiting mark is replaced by virtue of the digital holographic anti-counterfeiting glue cap so as to achieve an untransferable purpose, and a positioning transfer method of the thermally-printed foil on a PVC (Polyvinyl Chloride) material is realized.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

Shading anti-counterfeiting technology

InactiveCN105376456AWith double anti-counterfeiting functionQuality is not affectedPictoral communicationGraphicsCode module

The invention provides a shading anti-counterfeiting technology. Through a copying machine, authenticity identification can be simply performed. Simultaneously, an image sensor can be used to read embedded figure coding information so as to realize an anti-counterfeiting function. In a coding mode which is different from screen coding, a specific size, a specific shape and a group of dot matrixes with a specific direction are not needed; based on a gray value of an image itself, pixel points are sequentially exposed so that a coding module group with a certain rule is formed and information embedding is realized.

Owner:王萍

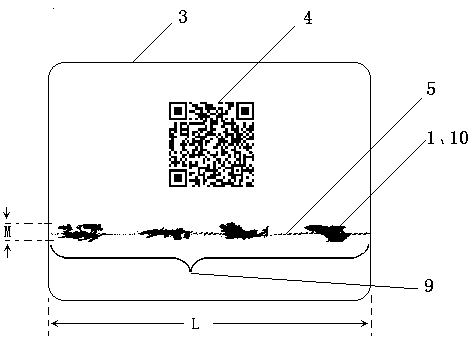

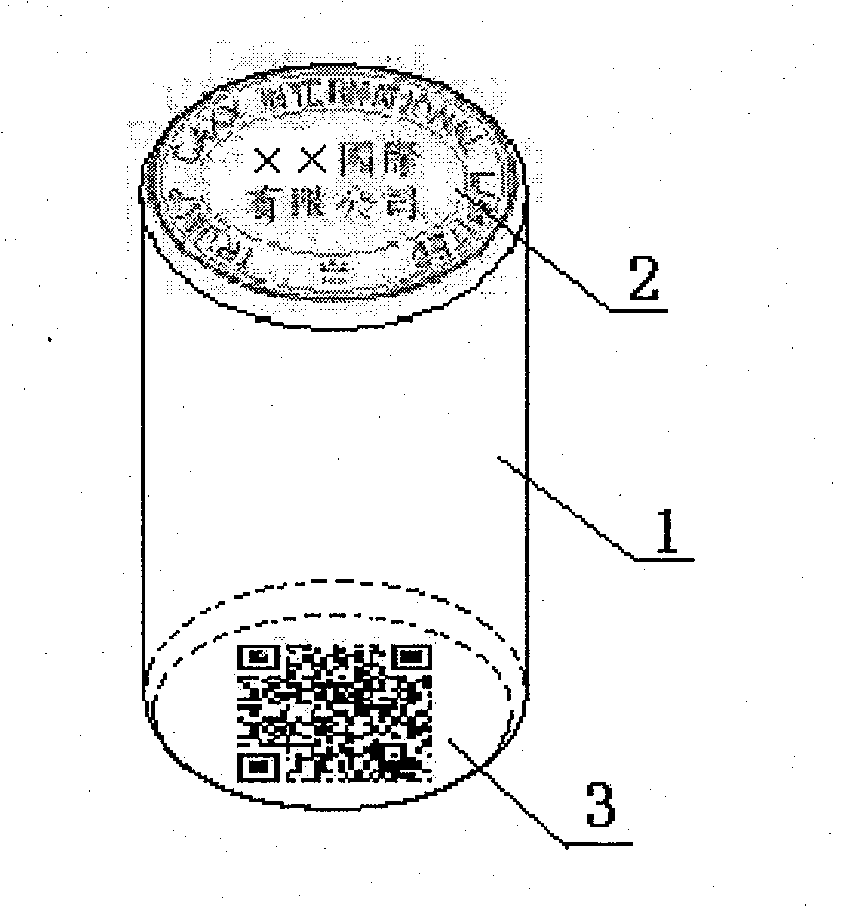

Anti-counterfeiting stamp with two-dimensional code

The invention provides an anti-counterfeiting stamp with a two-dimensional code, which is characterized in that a body of an anti-counterfeiting stamp is provided with an upper stamp face and a lower stamp face; one of the stamp face is a personal and corporate text stamp for identification with naked eyes; and the other stamp face is a two-dimensional code pattern stamp of a computer for machine identification. A two-dimensional code pattern comprises all personal or corporate information so that the two stamps are stamped on a file simultaneously. Therefore, the anti-counterfeiting capability grade can be improved, and the anti-counterfeiting stamp lays the foundation for the machine identification.

Owner:兰州科能机电设备制造有限责任公司

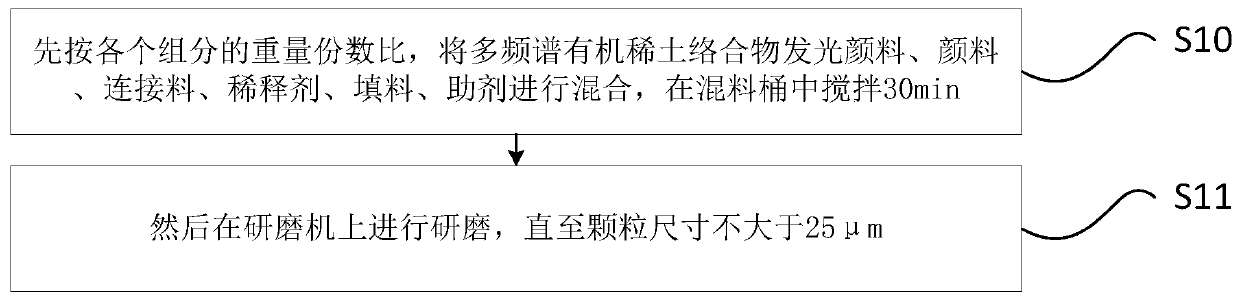

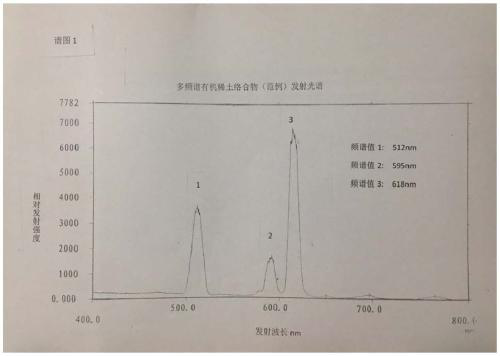

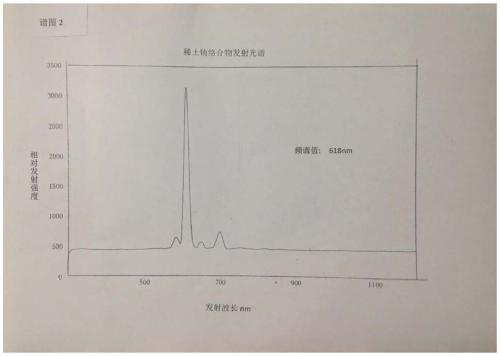

Anti-counterfeiting ink having specific spectral line features and preparation method of ink

The present application provides anti-counterfeiting ink having specific spectral line features and a preparation method of the ink. The ink comprises the following components, in parts by weight: 20-30 parts of a multi-frequency spectrum organic rare earth complex luminescent pigment, 10-15 parts of a pigment, 20-60 parts of a connecting material, 3-5 parts of a diluent, 5-25 parts of a filler and 3-5 parts of an auxiliary agent. The anti-counterfeiting ink with specific spectral line features provided by the invention is nearly colorless, can be used to print various invisible barcodes and figures invisible to naked eyes on various invoices, Hong Kong and Macao passes, passports, banknotes, ID cards, credit cards, lottery tickets and the like, has strong concealment, strong confidentiality and high anti-counterfeiting strength, can effectively prevent copying and counterfeiting, has simple identification operation, quick identification and strong aging resistance, and is convenient for promotion.

Owner:BEIJING JINCHEN CVIC SECURITY PRINTING

Method for making nuclear microporous anti-fake identification

InactiveCN1419224AHigh track etch rateHigh anti-counterfeiting strengthStampsIdentification meansEtchingAdhesive

The invention refers to the manufacturing method for core micro hole anti-false identification, it incldues: it uses heavy or light ion to lighten plastic film; then the film is added into di-methyl acyl amine liquid; it prints patterns on the surface of film with adhesive and carries on chemical etching; cleaning; drying.

Owner:北京清华试金石新技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com