Method for manufacturing colourless fluorescent ink anti-counterfeiting printing product

A production method and technology of fluorescent ink, applied to the printing, printing, and printing process of producing special varieties of printed matter, can solve the problems of single yellow-green, single image color, etc., and achieve the effect of improving the anti-counterfeiting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of colorless fluorescent ink anti-counterfeiting printed matter of the present invention comprises the following steps:

[0028] A. Load a color image suitable for printing into the computer, such as figure 1 shown;

[0029] B. Open the image with Photoshop software and convert it to RGB mode, so that more ink particles are attached to the bright part of the image, while the dark part of the image is the opposite;

[0030] C. Invert the RGB mode image; such as figure 2 As shown, prepare for subsequent printing;

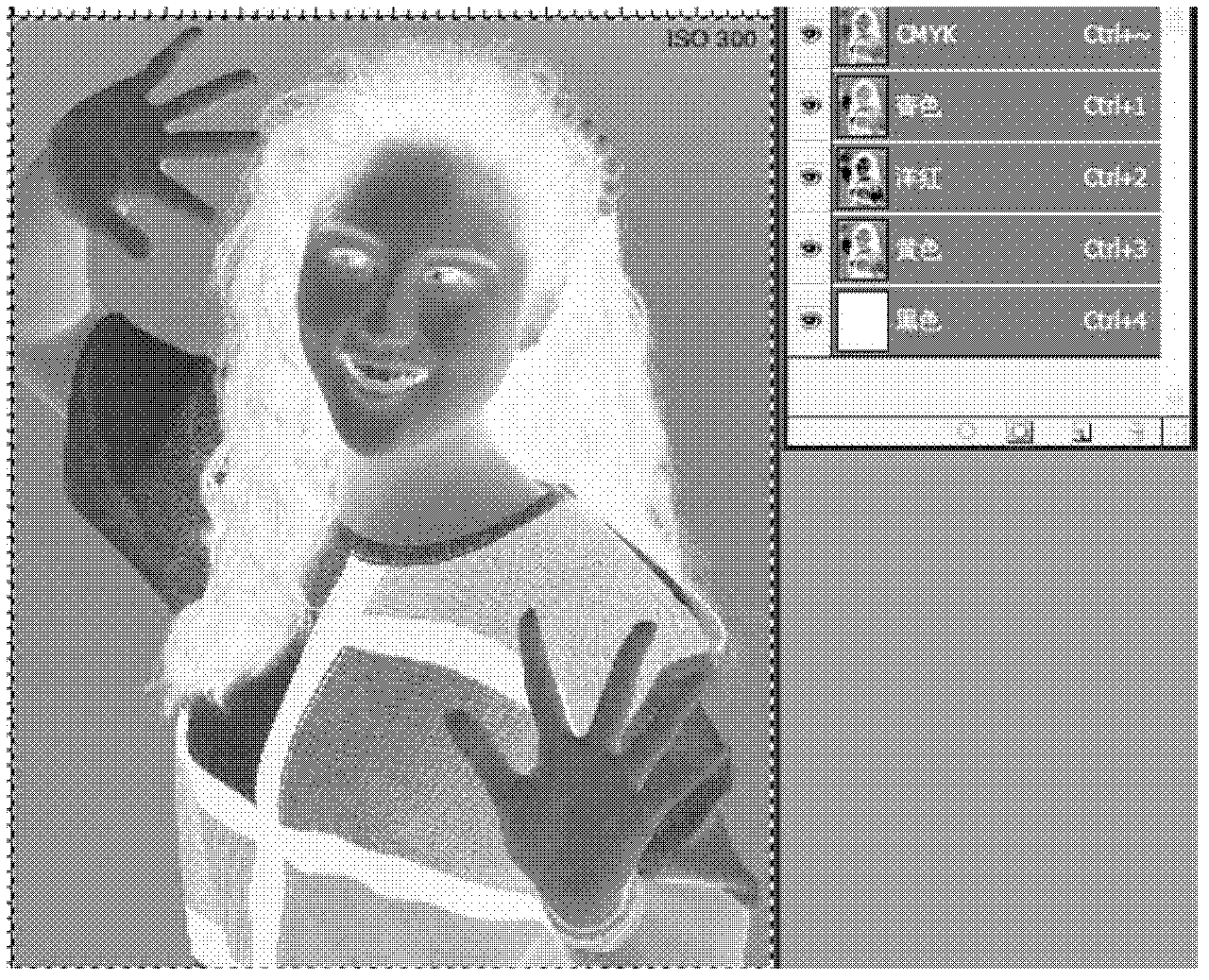

[0031] D. Create a new file in CMYK mode with the same image size and resolution as the selected file; because the RGB mode in the above steps is not a printing mode, it is necessary to create a file in CMYK mode;

[0032] E. Open the two files of step C and step D, and copy the image information of the R, G, and B channels of step C to the M, Y, and C channels of step D of the newly created file (four-color channels are optional)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com