Anti-counterfeiting ink having specific spectral line features and preparation method of ink

An anti-counterfeiting ink and spectral line technology, applied in the field of ink, can solve the problems of low anti-counterfeiting strength, easy imitation of anti-counterfeiting ink, poor confidentiality, etc., and achieve the effects of high anti-counterfeiting strength, easy promotion and strong concealment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

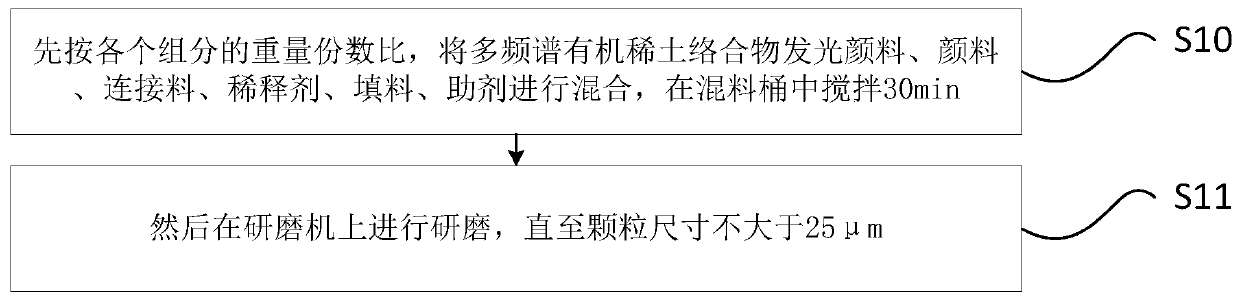

[0054] Such as figure 1 Shown, a kind of preparation method of the anti-counterfeiting ink with specific spectral line feature, comprises:

[0055] Step S10: First, mix the multi-spectrum organic rare earth complex luminescent pigment, pigment, binder, diluent, filler, and auxiliary agent according to the weight ratio of each component, and stir in the mixing tank for 30 minutes;

[0056] Step S11: Grinding on a grinder until the particle size is not greater than 25 μm, an anti-counterfeit ink with specific spectral line characteristics can be prepared; wherein, the weight ratio of each component refers to:

[0057]

Embodiment 1

[0059] A kind of anti-counterfeiting ink (offset printing colorless) with specific spectral line characteristics has the following components and component ratios:

[0060]

[0061]

[0062] The preparation method is as follows:

[0063] First, mix the multi-spectrum organic rare earth complex luminescent pigments, pigments, binders, diluents, fillers, and additives according to the weight ratio of the above-mentioned components, and stir in the mixing tank for 30 minutes; Grinding on a grinding machine (grinding time greater than 24 hours) until the particle size is not greater than 25 μm, the anti-counterfeiting ink with specific spectral line characteristics can be prepared.

Embodiment 2

[0065] A kind of anti-counterfeiting ink (water-based gravure golden light red) with specific spectral line features has the following components and component ratios:

[0066]

[0067] The preparation method is as follows:

[0068] First, mix the multi-spectrum organic rare earth complex luminescent pigments, pigments, binders, diluents, fillers, and additives according to the weight and number ratios of the above components, and stir in the mixing tank for 30 minutes; then mix them on the ball mill Grinding (ball milling time greater than 24 hours) until the particle size is not greater than 25 μm can produce anti-counterfeiting ink with specific spectral line characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com