Patents

Literature

221results about How to "Good visual effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

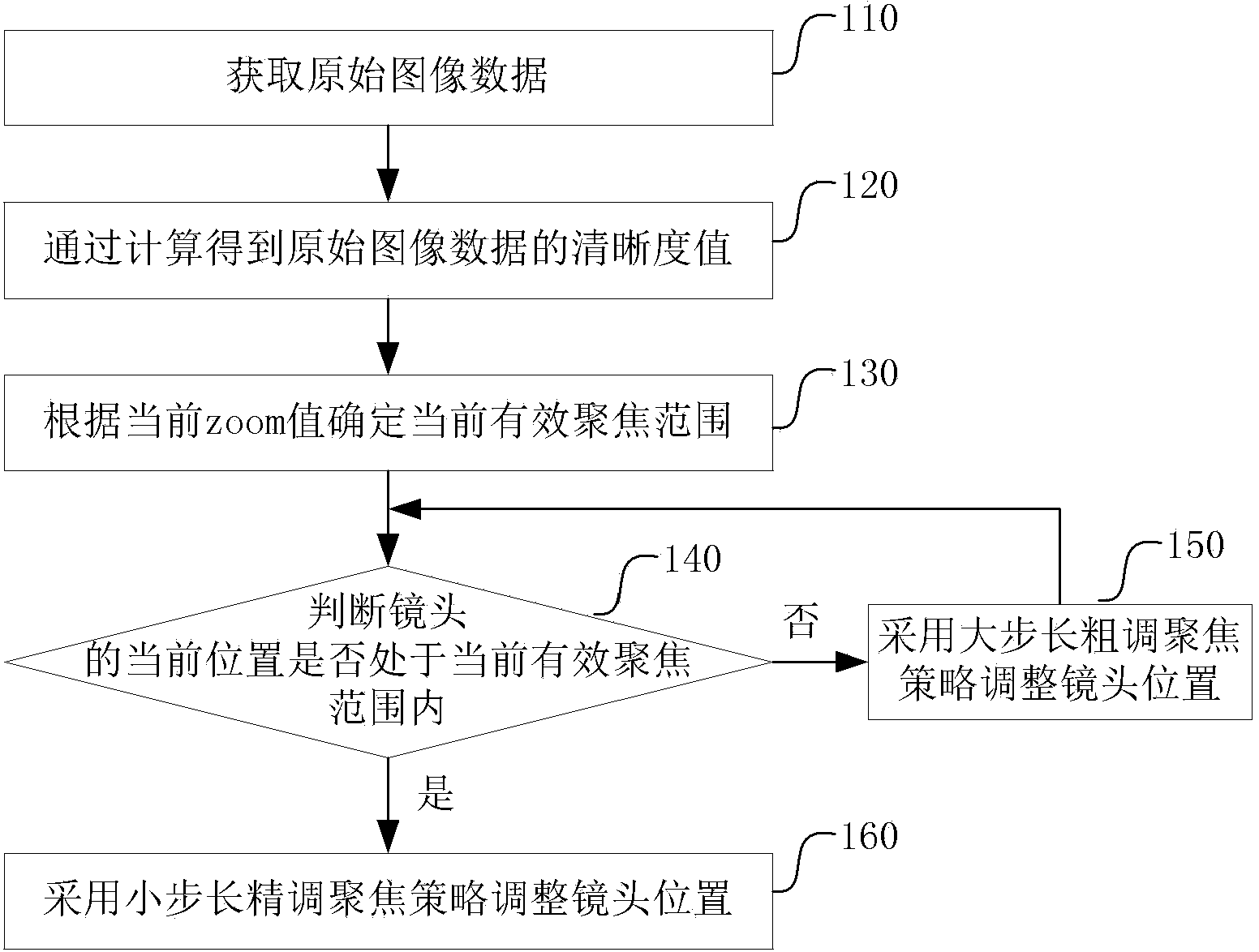

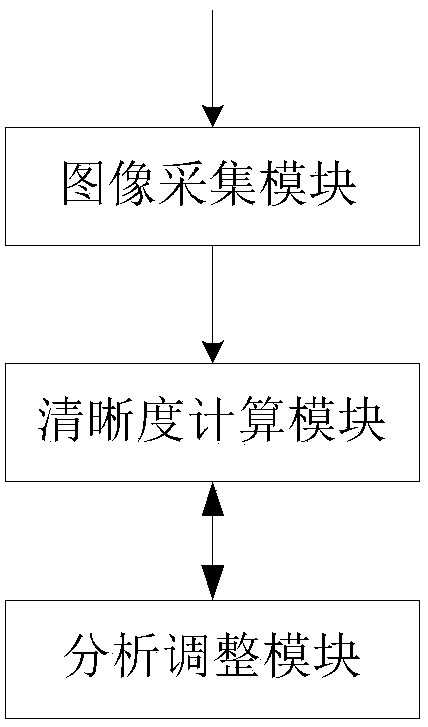

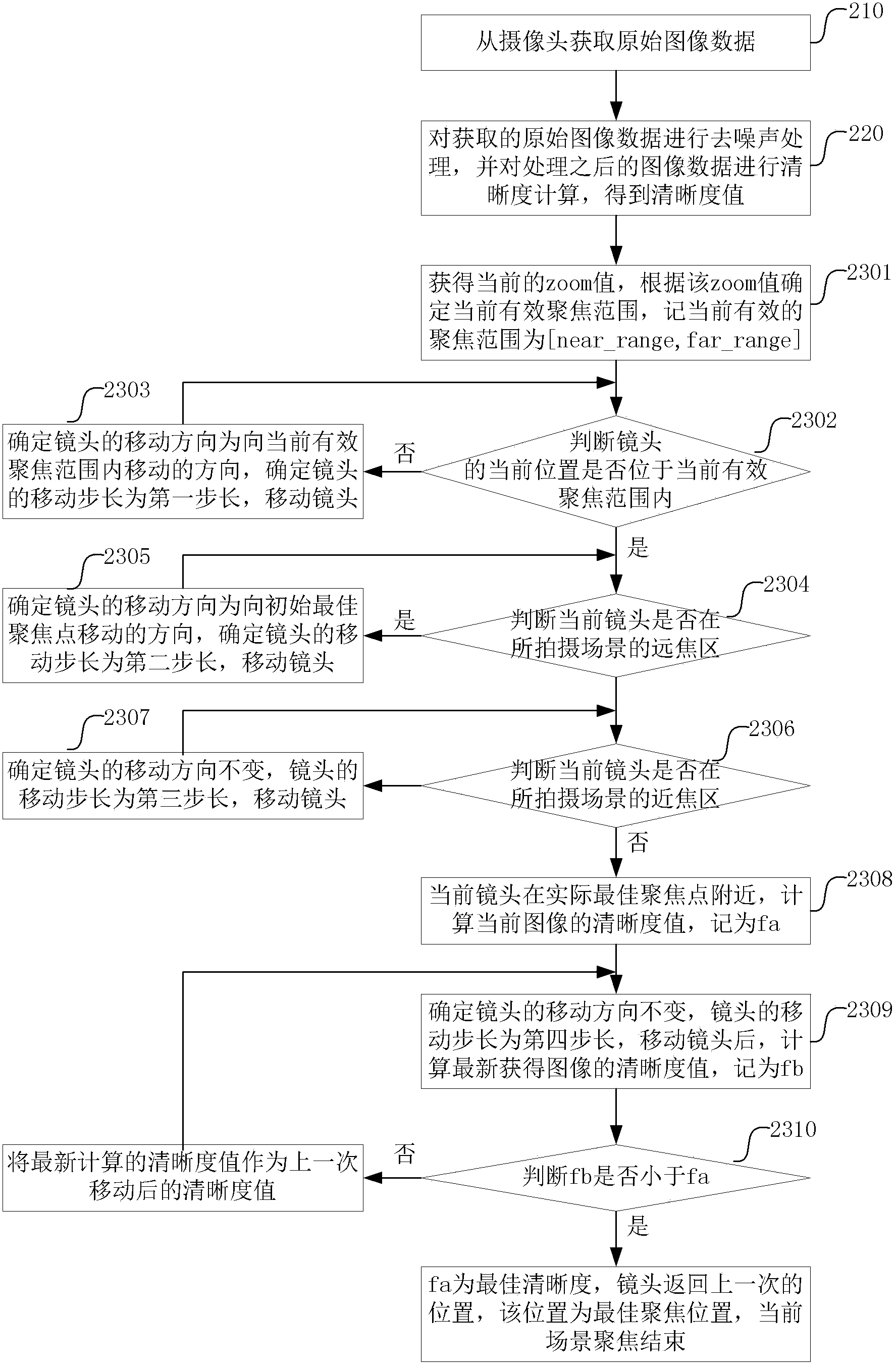

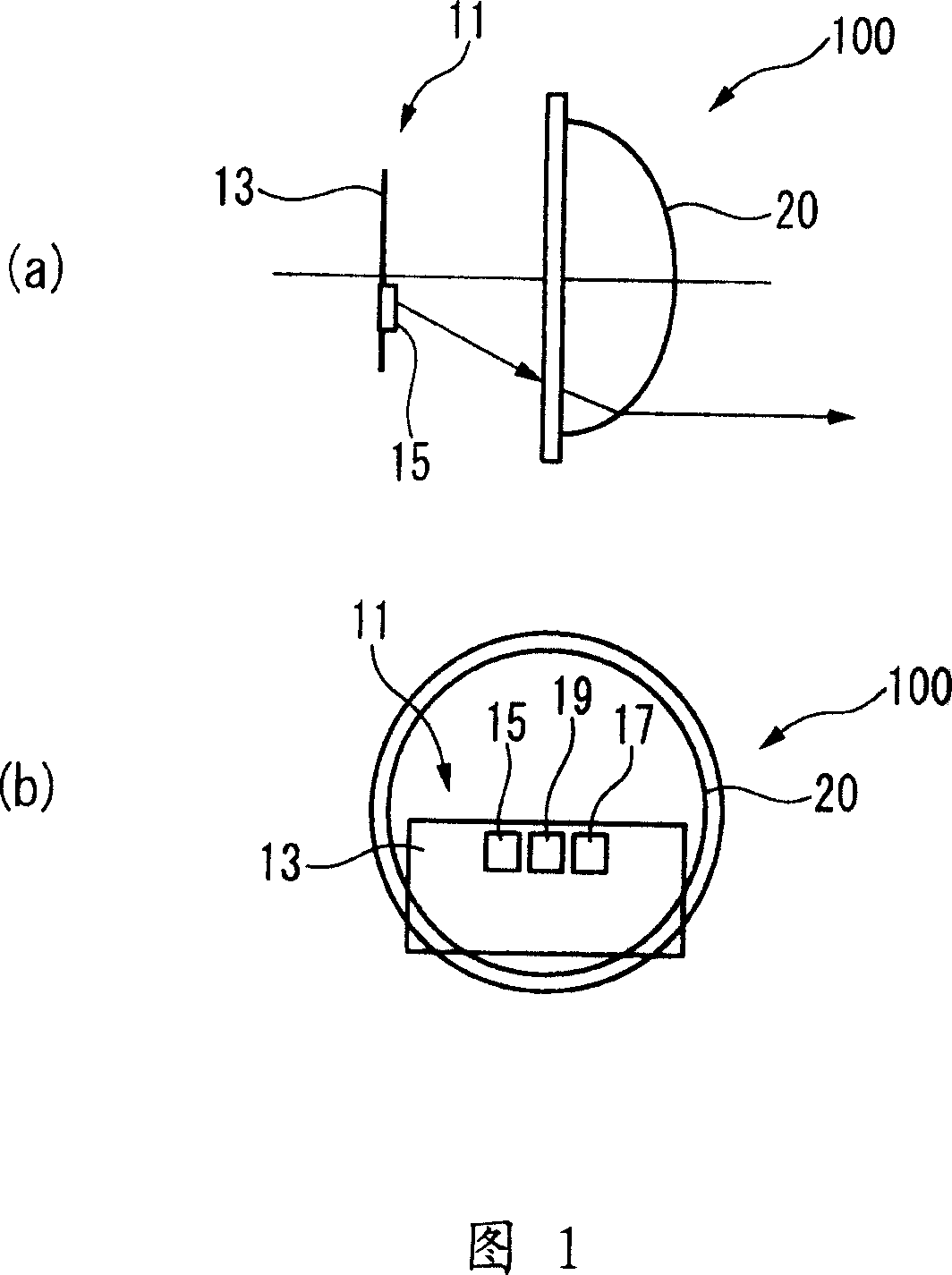

Passive auto-focusing method and device

ActiveCN103513395AIncrease the speed of autofocusGood visual effectTelevision system detailsColor television detailsImaging dataReal-time computing

The invention discloses a passive auto-focusing method and a device so as to solve the problem of slow focusing speed. The method provided by the invention comprises the following steps: original image data is acquired; sharpness is calculated to obtain sharpness value of the original image data; current valid focusing range is determined according to current zoom value, the position of a lens is adjusted by a large-step rough-focusing strategy if the current position of the lens is not within the current valid focusing range, and the position of the lens is adjusted by a small-step fine-focusing strategy when the current position of the lens is within the current valid focusing range; and if the current position of the lens is within the current valid focusing range, the position of the lens is adjusted by a small-step fine-focusing strategy. The large-step rough-focusing strategy is as follows: a first-step shift lens is adopted until the current position of the lens is within the current valid focusing range. The small-step fine-focusing strategy is as follows: a step shift lens with step being less than the first step is used until the calculated sharpness value is the best sharpness value.

Owner:ZTE CORP

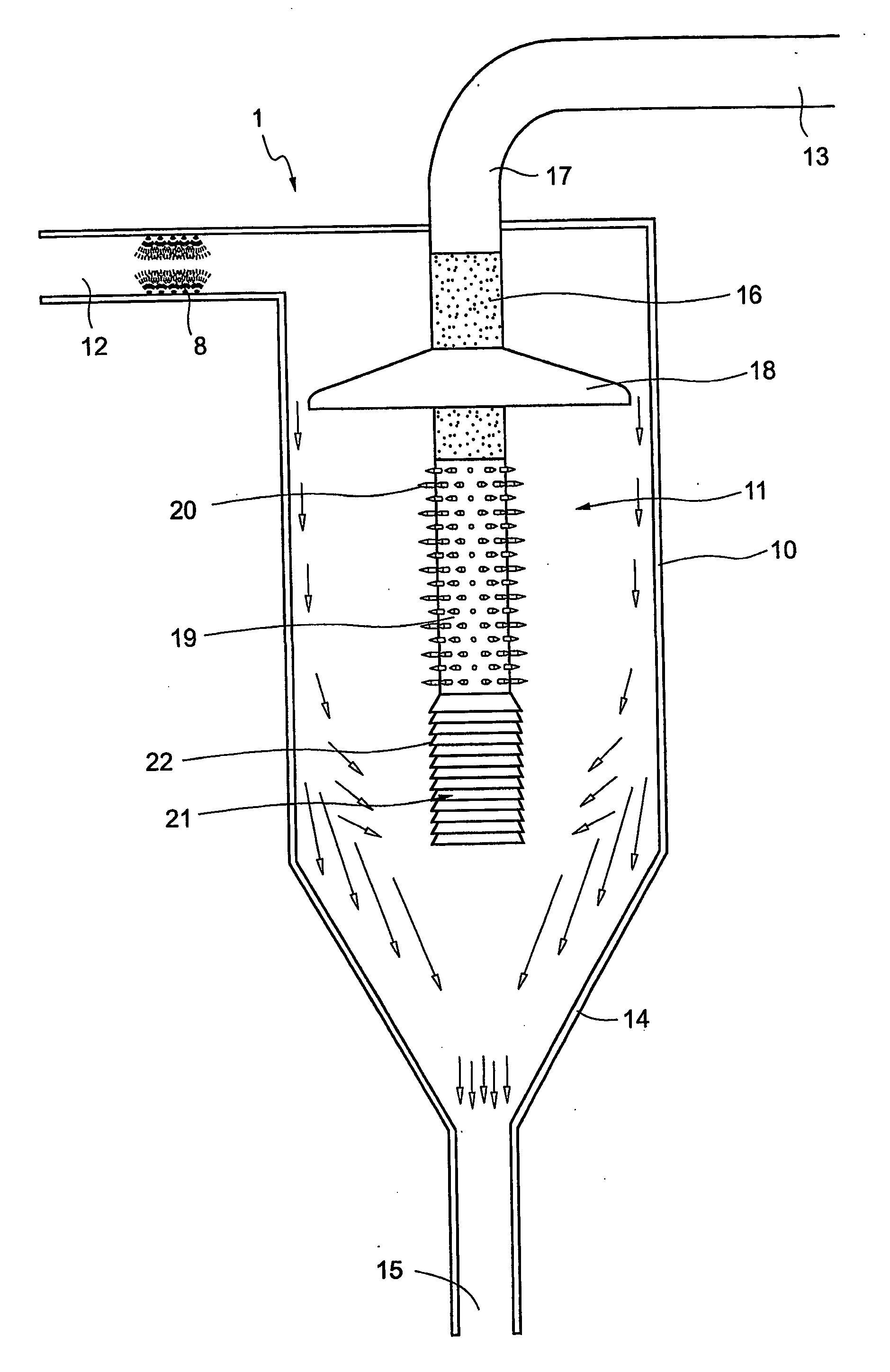

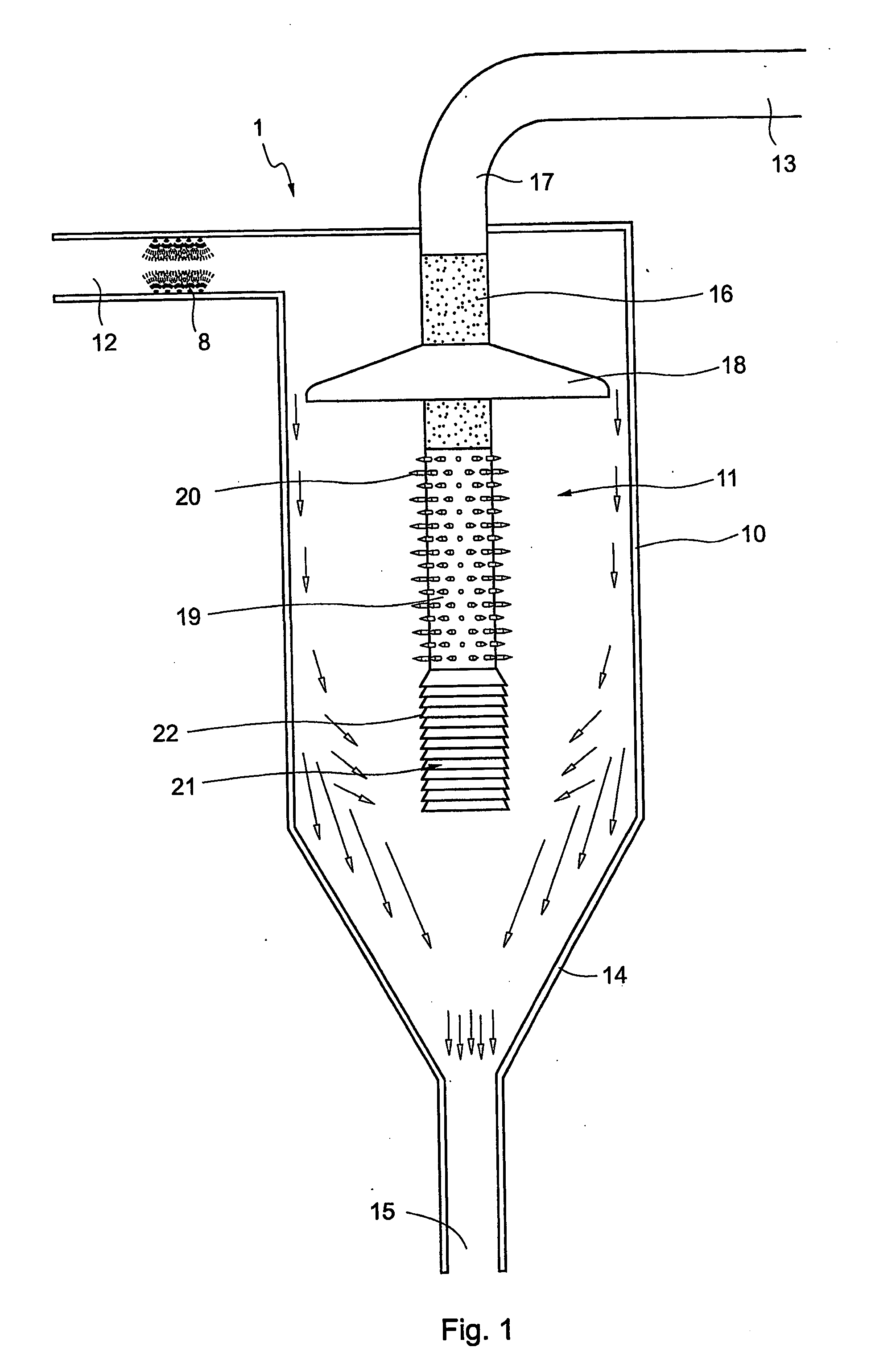

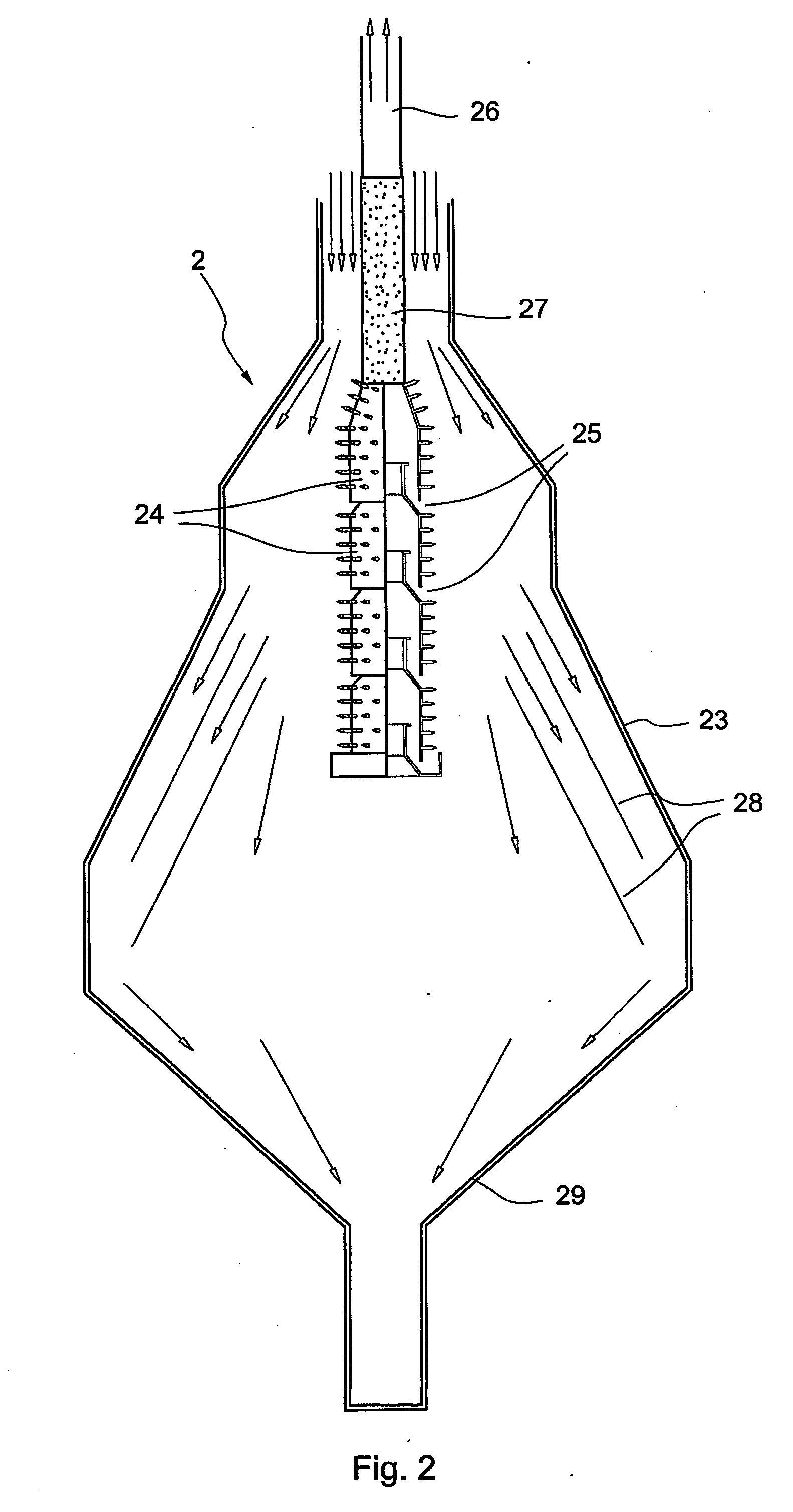

Electrostatic filter

InactiveUS20040025497A1Good visual effectIncrease volumeInternal combustion piston enginesExhaust apparatusElectrode arrayAirflow

An electrostatic filter (1) has a chamber (11) into which a gas stream is introduced. An ioniser (19) in the form of an electrode array (20) is located in the chamber (11) and creates an ionising zone through which the gas stream passes. A charged outlet (21) is located downstream from the ioniser (19). As the gas stream passes through the ionising zone, the unwanted particles therein are charged and urged away from the outlet (21) by the ioniser (19). Charged particles approaching the outlet (21) are also electrostatically repelled therefrom, permitting "clean" gas to be extracted through the outlet.

Owner:HANSOM ENVIRONMENTAL PROD

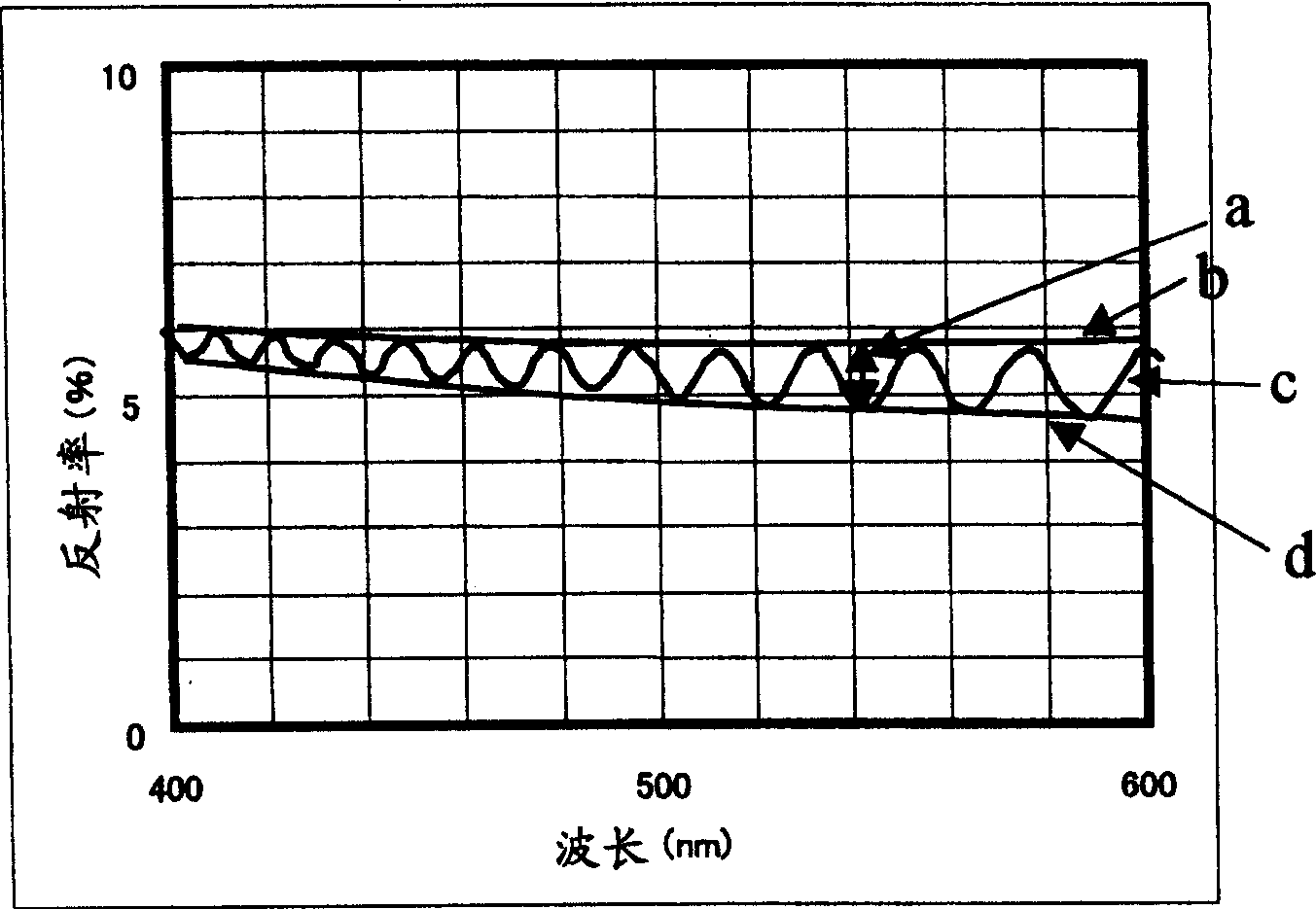

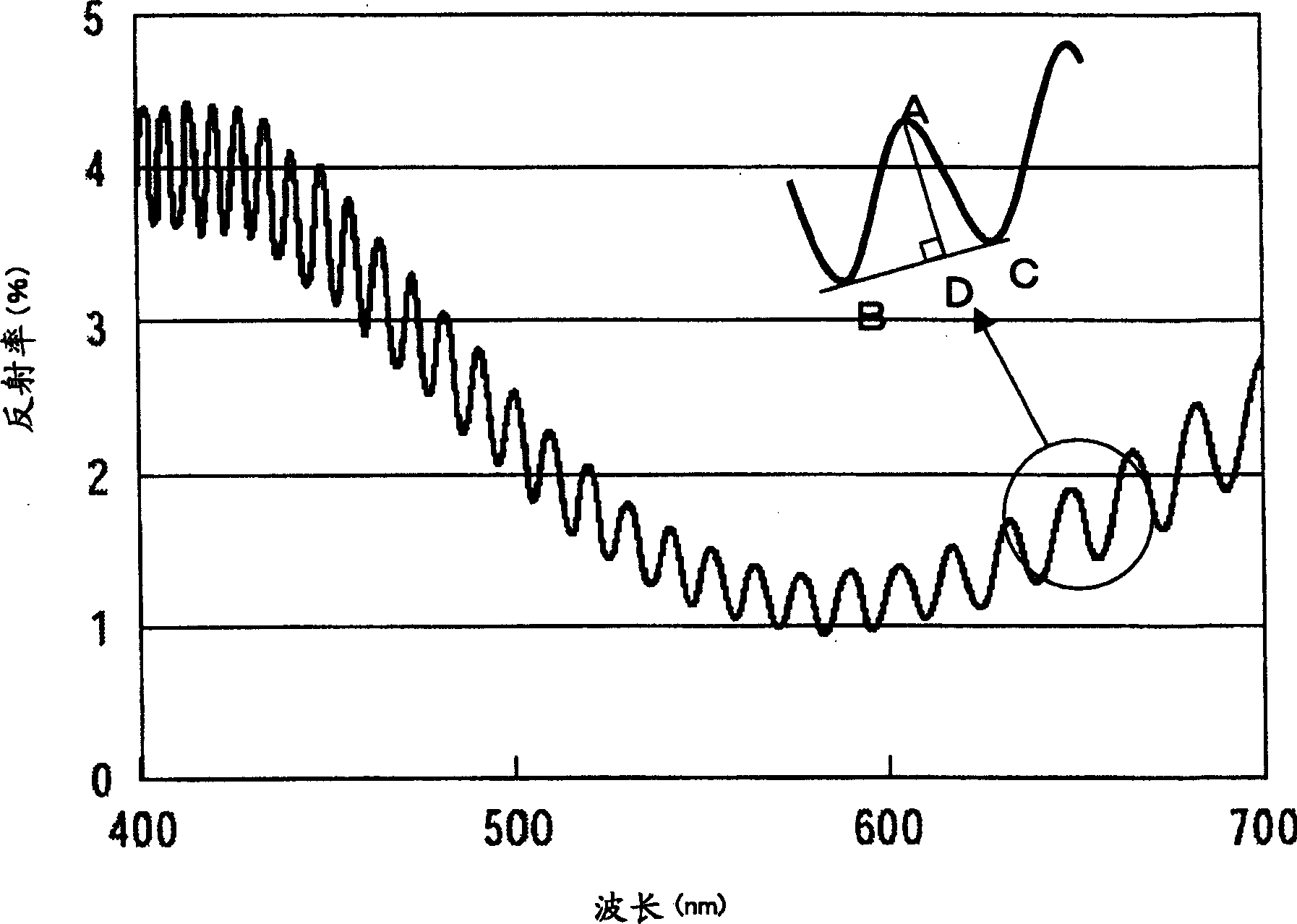

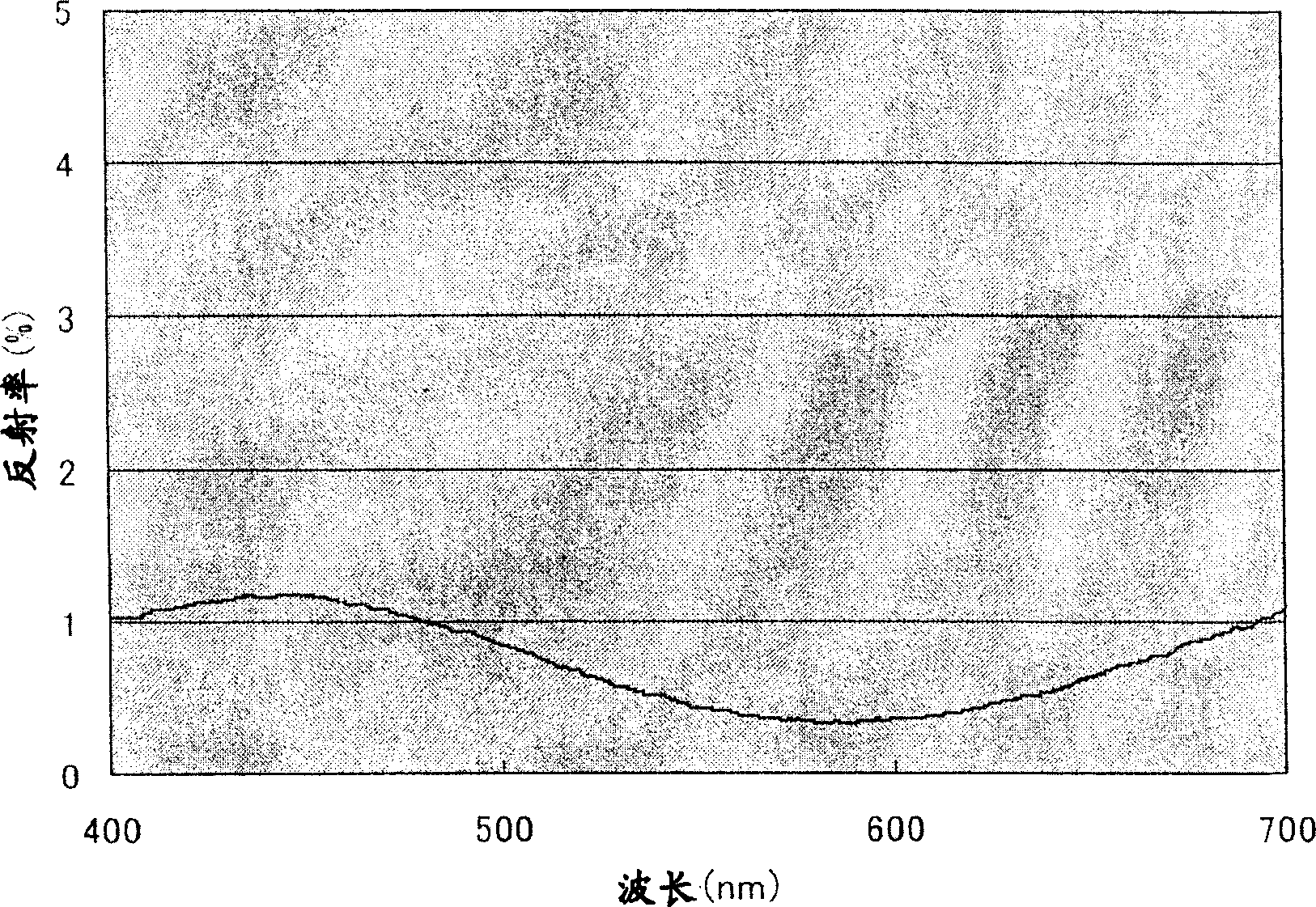

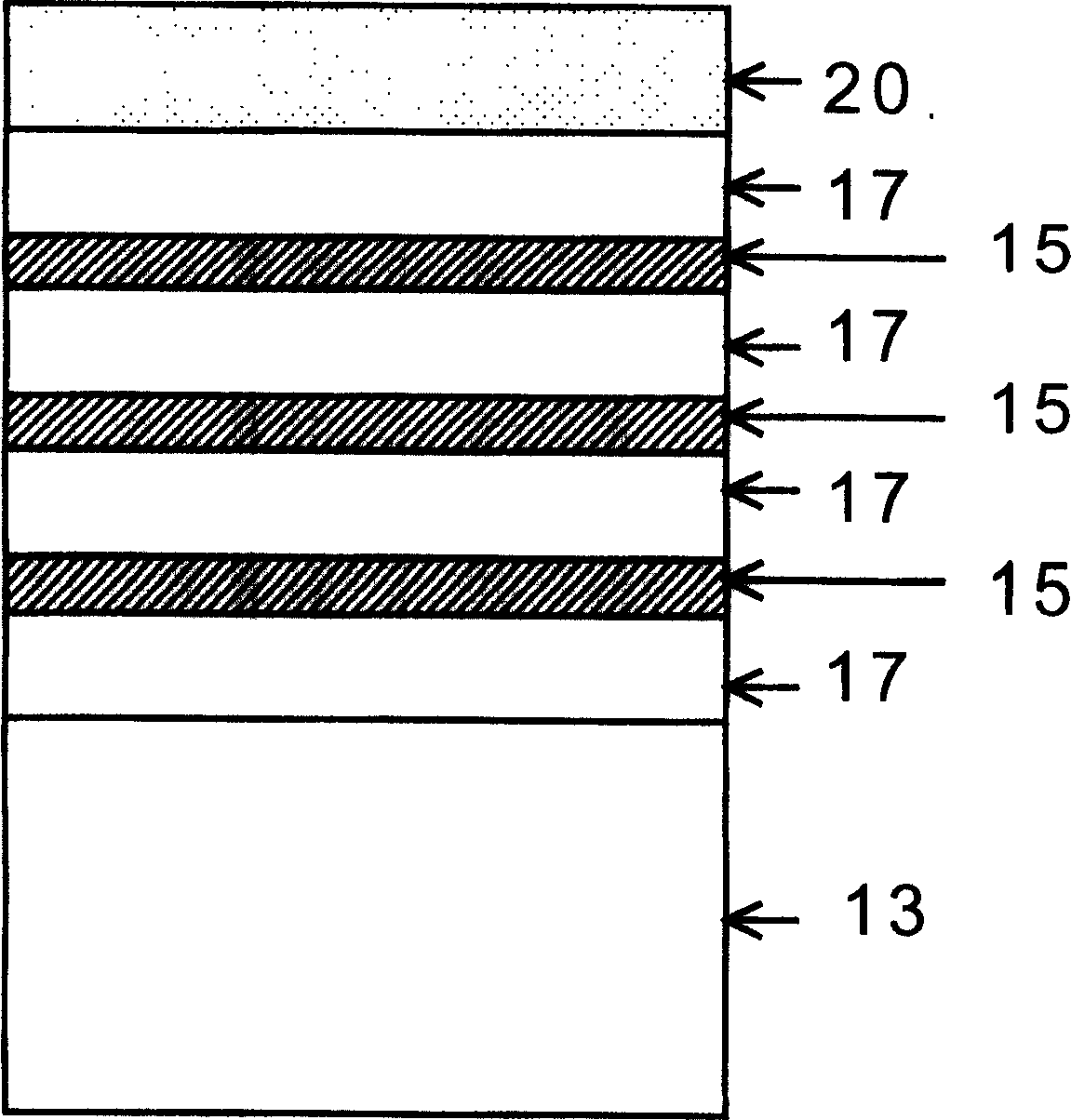

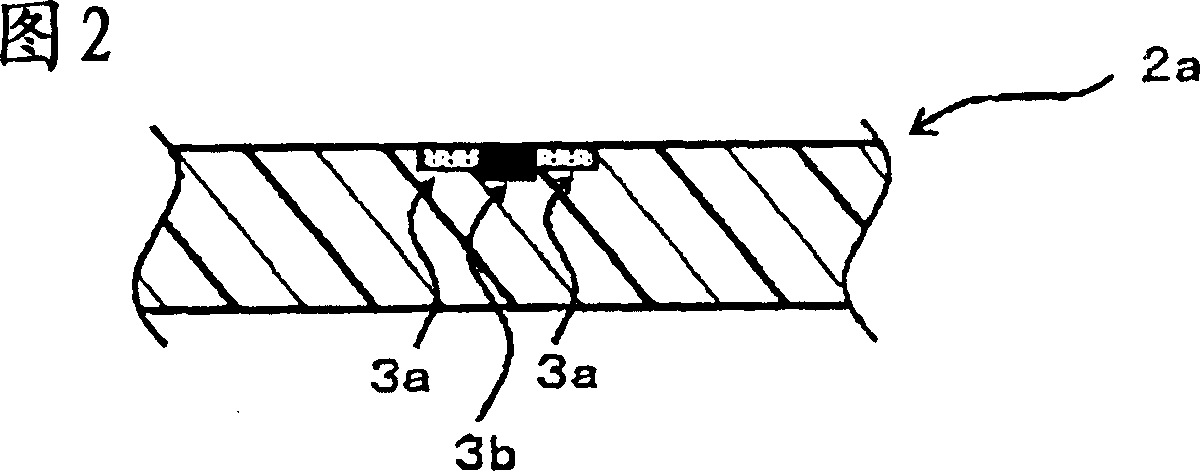

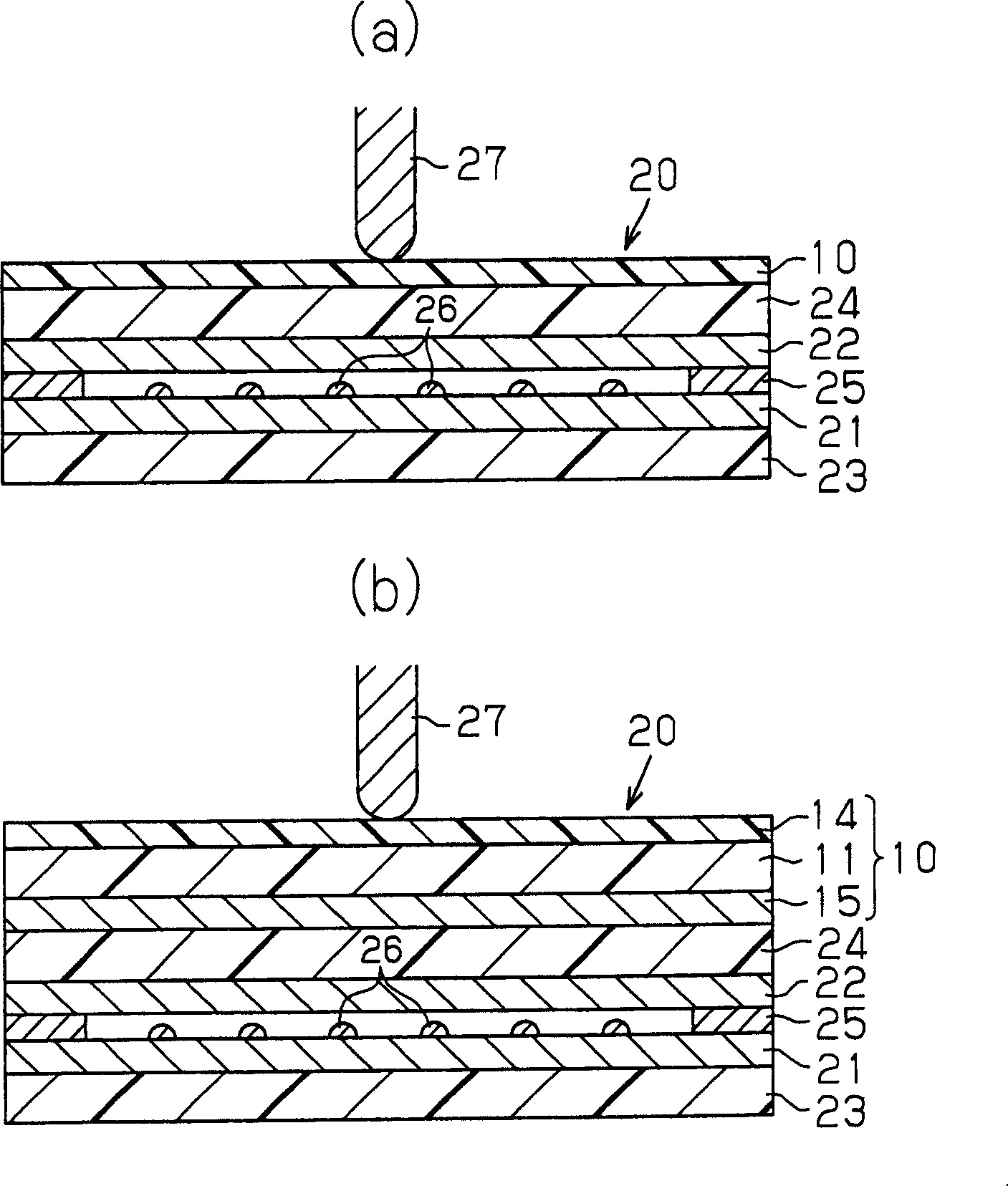

Hardcoat film, antireflection film and equipment for display

InactiveCN1575970AInhibitionGood visual effectSynthetic resin layered productsCoatingsThin membraneEngineering

A hardcoat film comprises a substrate film, and a hardcoat layer laminated on at least one side of the substrate film, wherein a reflectance of the hardcoat layer at a wavelength within 400 to 600 nm has a mean ripple amplitude of 1% or less. The hardcoat film has decreased iris patterns. There is also provided an antireflection film having a low surface reflectance and a neutral tone of color, and an equipment for display including the film.

Owner:TORAY IND INC

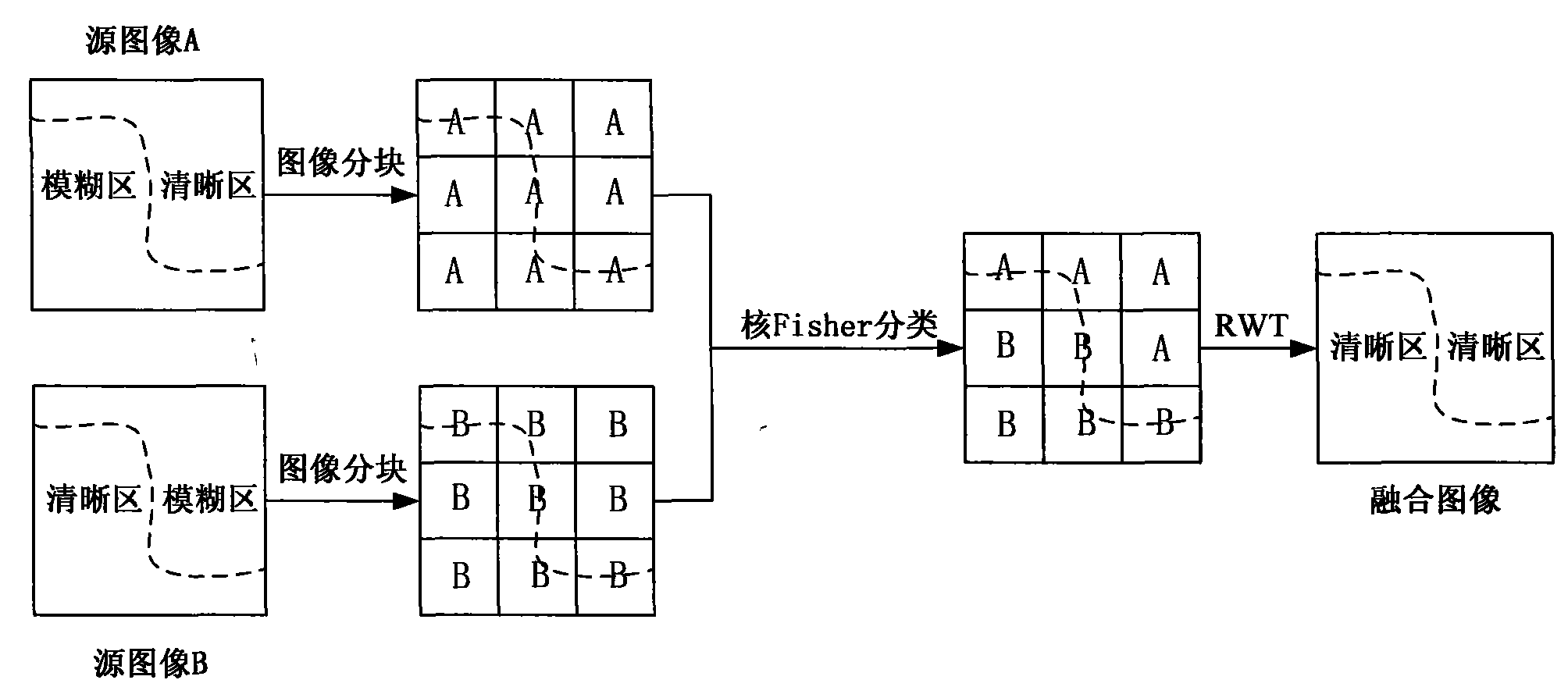

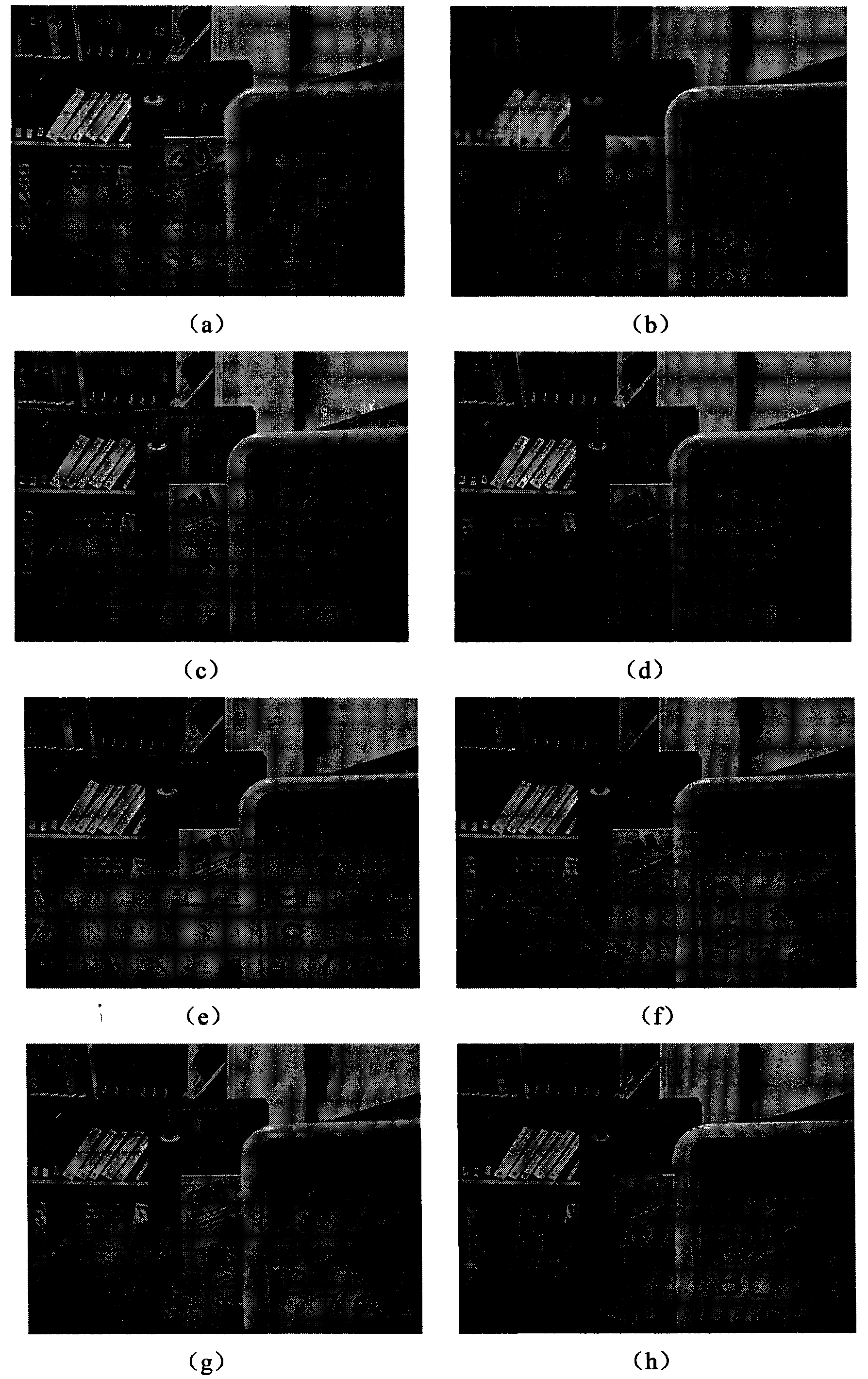

Multi-focusing image fusion method utilizing core Fisher classification and redundant wavelet transformation

InactiveCN101630405AEasy to integrateGood calculation efficiencyImage enhancementCorrelation coefficientSpatial correlation

The invention discloses a multi-focusing image fusion method utilizing core Fisher classification and redundant wavelet transformation. The method comprises the following steps: firstly, carrying out image block segmentation on source images and calculating definition characteristics of each image block; secondly, taking part of areas of the source images as a training sample and obtaining various parameters of a core Fisher classifier after training; thirdly, utilizing the known core Fisher classifier to obtain preliminary fusion images; and finally, utilizing redundant wavelet transformation and space correlation coefficients to carry out fusion processing on the image blocks positioned at the junction of the clear and fuzzy areas of the source images to obtain final fusion images. The invention has better image fusion performance, does not have obvious blocking artifacts and artifacts in fusion results, obtains better compromise between the effective enhancement of the image fusion quality and the reduction of the calculation quantity and can be used in the subsequent image processing and display. When wavelet decomposition layers with less number are adopted, the invention is more suitable for an occasion with higher real-time requirement.

Owner:CHONGQING SURVEY INST

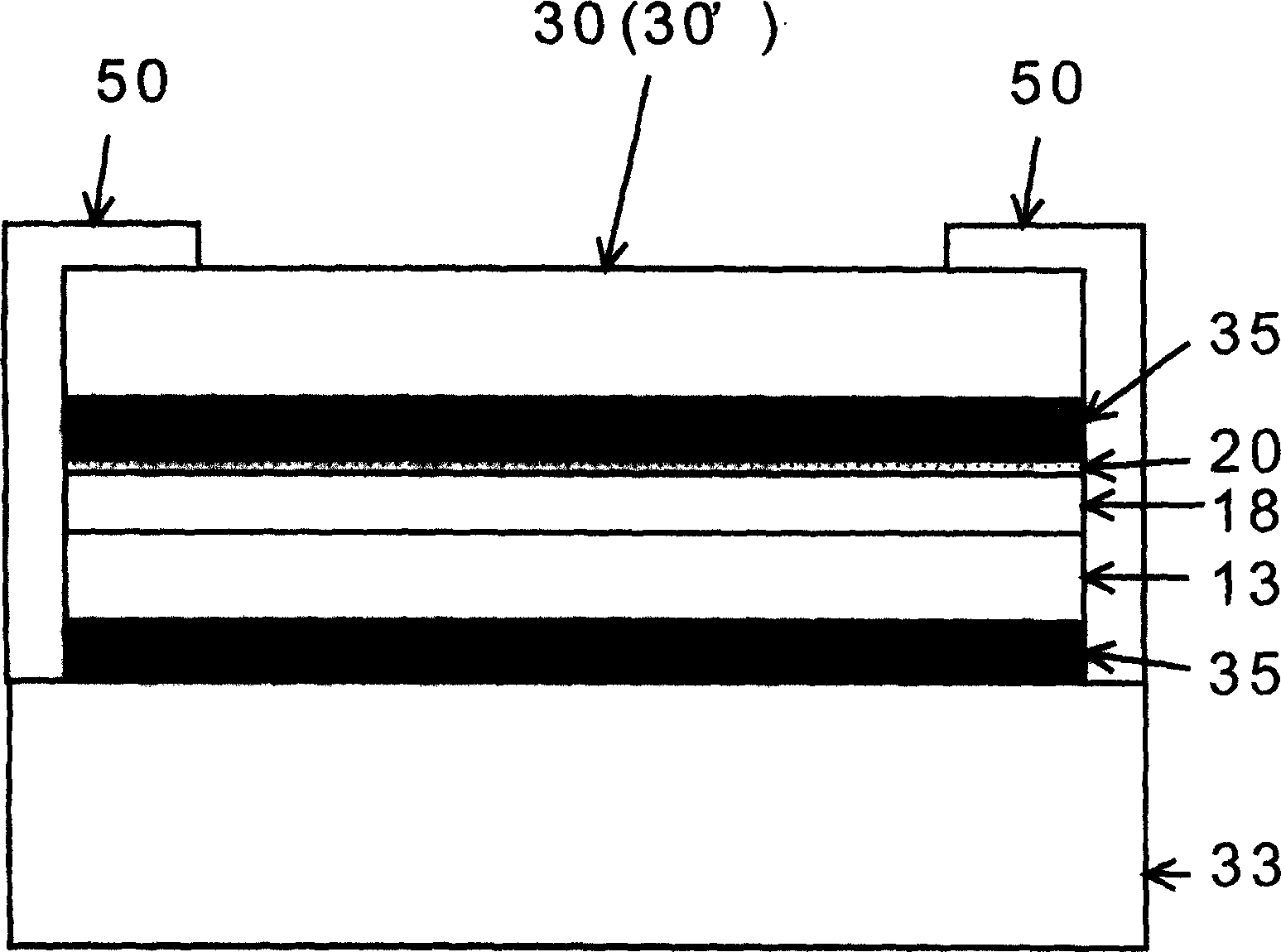

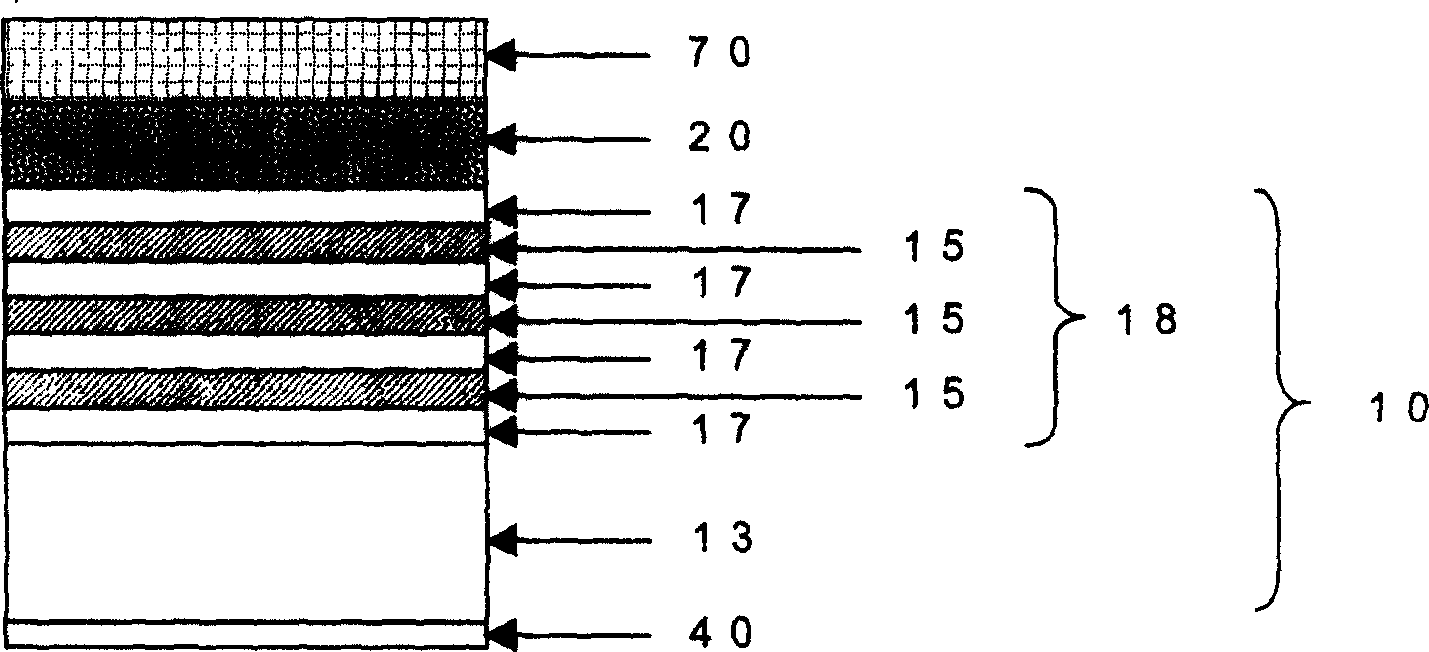

Laminate and filter of display using the same laminate

InactiveCN1576886AImprove conductivityIncrease reflectionOptical filtersCoatingsVisibilityDisplay device

A transparent and conductive laminate that is substantially decreased in reactive defects, and a display filter, a heat-ray reflecting film and an electromagnetic wave-shielding film comprising the laminate are provided. The laminate includes a transparent substrate, a transparent conductive thin-film layer containing silver, and a protective layer containing a binder material and inorganic fine particles, wherein the transparent conductive thin-film layer is in contact with the protective layer. The generation of reflective defects can be outstandingly reduced. Therefore, a laminate superior in electromagnetic wave-shielding ability, heat-ray reflecting ability and visibility for a long period of time and products comprising the laminate can be obtained.

Owner:YAMAMOTO CHEM INC

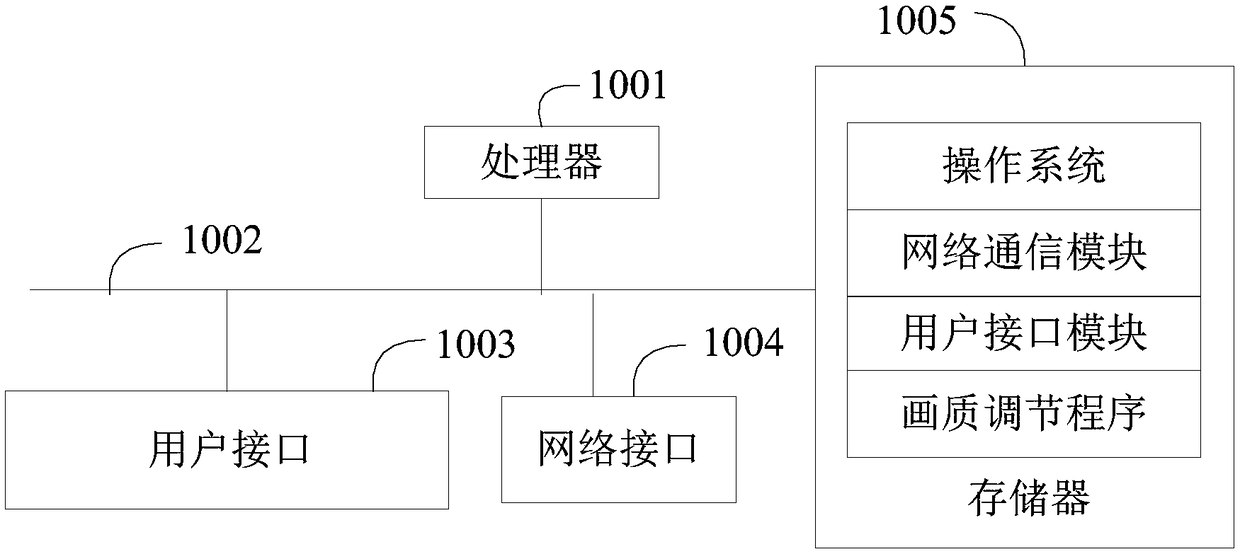

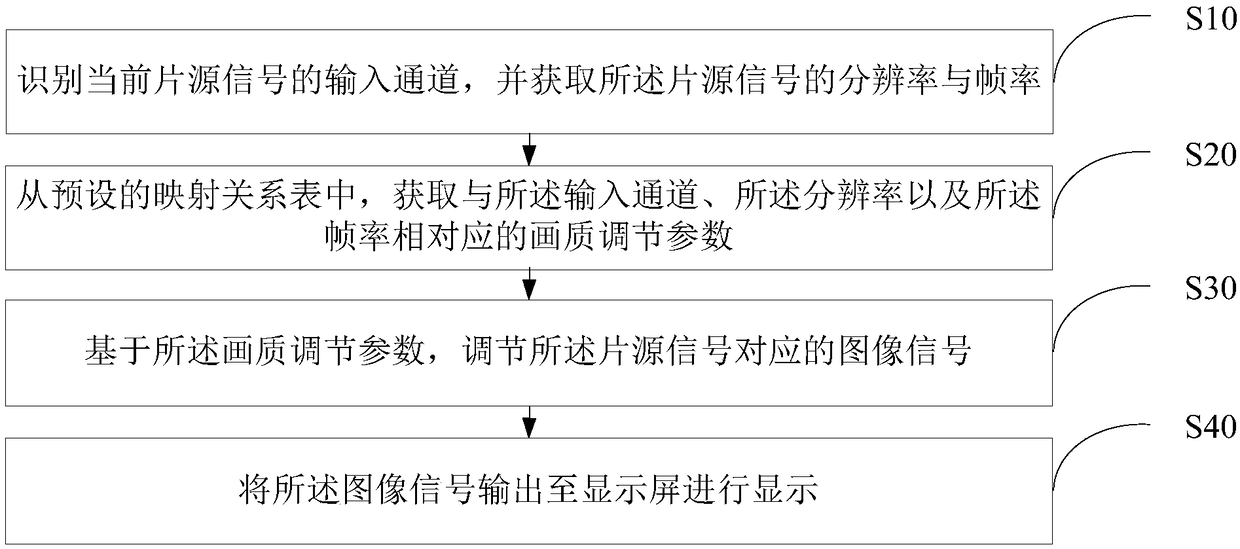

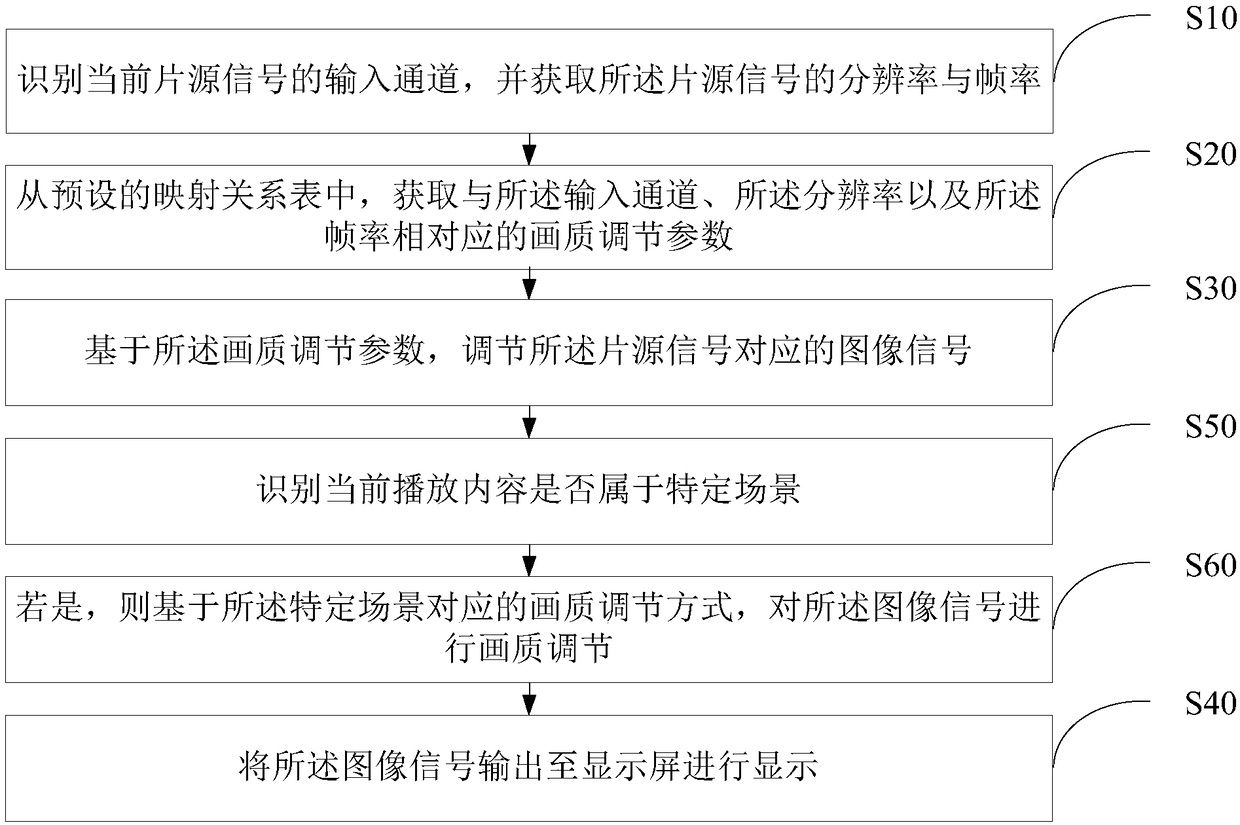

Image quality adjustment method, smart television and memory medium

ActiveCN108810649AGood visual effectImprove visual effectsTelevision system detailsColor television detailsImage resolutionFrame rate

The invention discloses an image quality adjustment method, comprising the following steps of identifying an input channel of a current film source signal, and obtaining resolution and a frame rate ofthe film source signal; obtaining image quality adjustment parameters corresponding to the input channel, the resolution and the frame rate from a preset mapping relationship table; adjusting an image signal corresponding to the film source signal based on the image quality adjustment parameters; and outputting the image signal to a display screen for displaying. The invention also discloses a smart television and a computer readable memory medium. According to the image quality adjustment method, the smart television and the computer readable memory medium, when the television plays film source content of different formats, a superior visual effect can be achieved.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

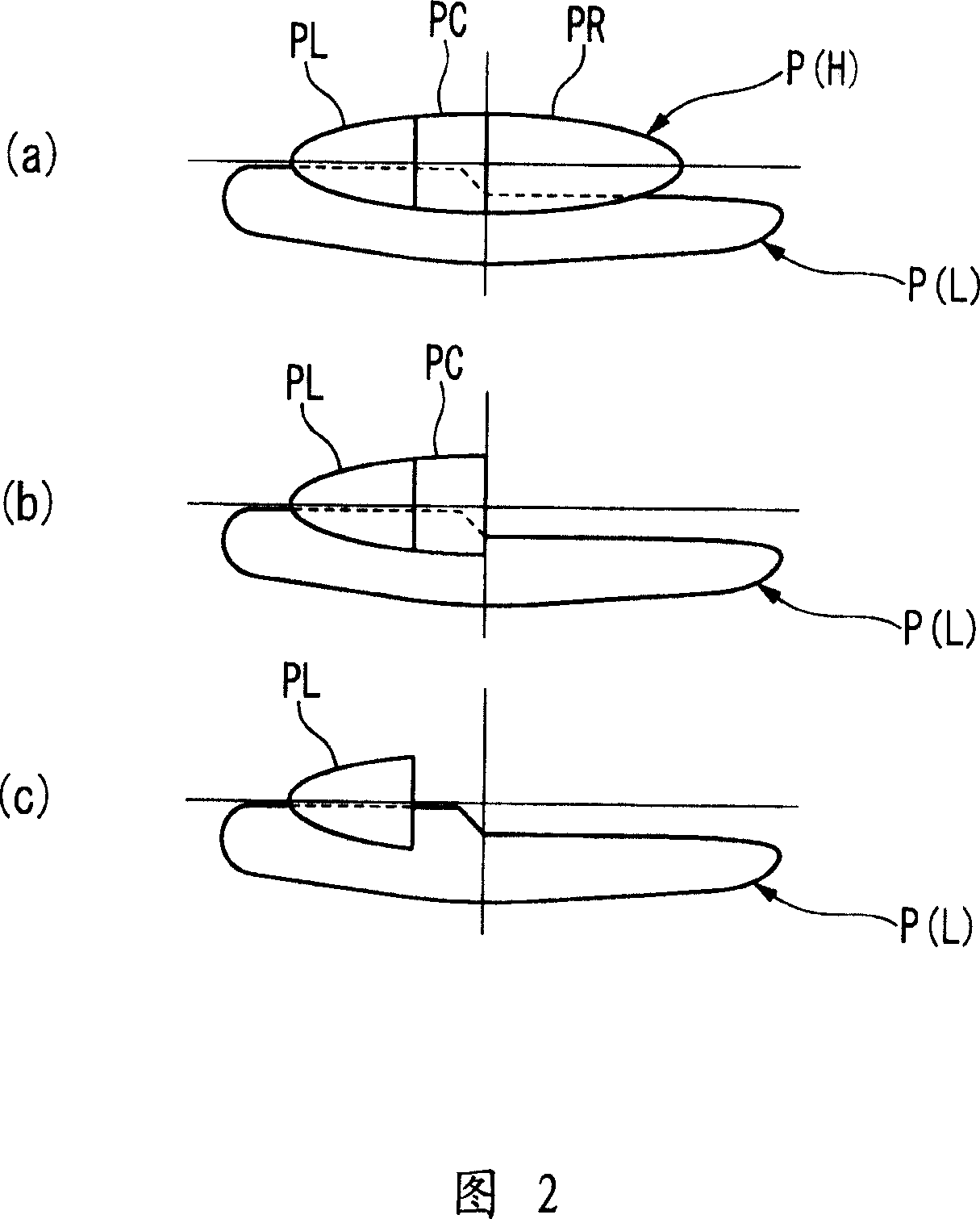

Vehicle lighting device

InactiveCN101008481AGood visual effectReduce glareVehicle headlampsPoint-like light sourceDistribution patternEffect light

A vehicle lighting device includes a light source unit for emitting light for forming a high beam light distribution pattern by projecting forward light from the light source unit. The high beam light distribution pattern has at least two illumination patterns which illuminate areas which are different from each other. A control unit is provided for controlling the at least two illumination patterns to be turned on and off selectively.

Owner:KOITO MFG CO LTD

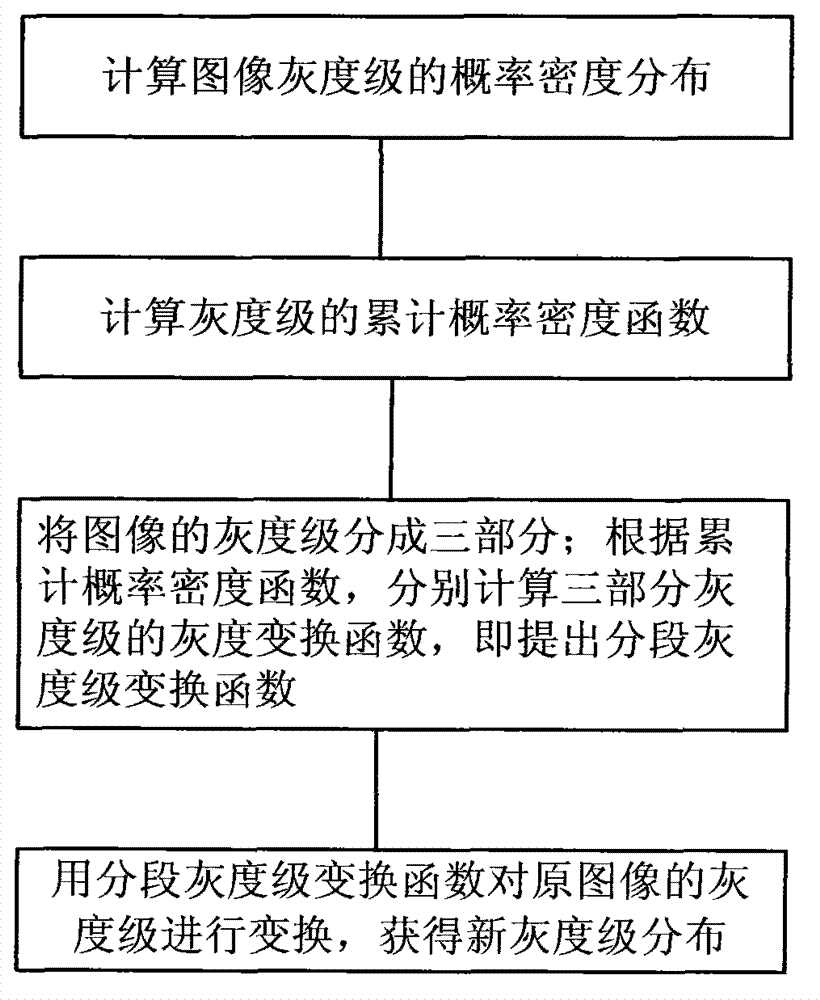

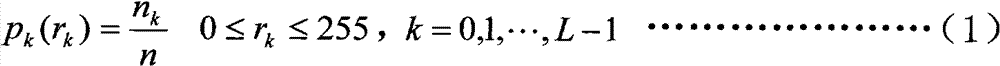

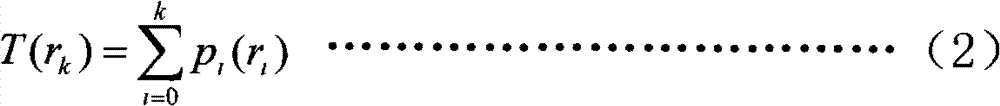

Image nonlinearity enhancement method based on histogram subsection transformation

The invention discloses an image nonlinearity enhancement method based on histogram subsection transformation. The method comprises the following steps of: S1, calculating probability density distribution of image gray levels; S2, calculating accumulated probability density functions of the gray levels; S3, dividing the gray levels of the images into three parts, wherein the first part of gray level range is between 0 and 85, the second part of gray level range is between 86 and 170, and the third part of gray level range is between 171 and 255; respectively calculating gray level transformation functions of the three parts of gray levels according to the accumulated probability density functions, namely proposing sectional gray level transformation functions; and S4, transforming the gray levels of the original images by using the sectional gray level transformation functions to acquire the distribution of new gray levels. By the method, the definition of the image is further improved, the excessive enhancement of the image is avoided, and the image vision effect meets the requirement of an eye vision system.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

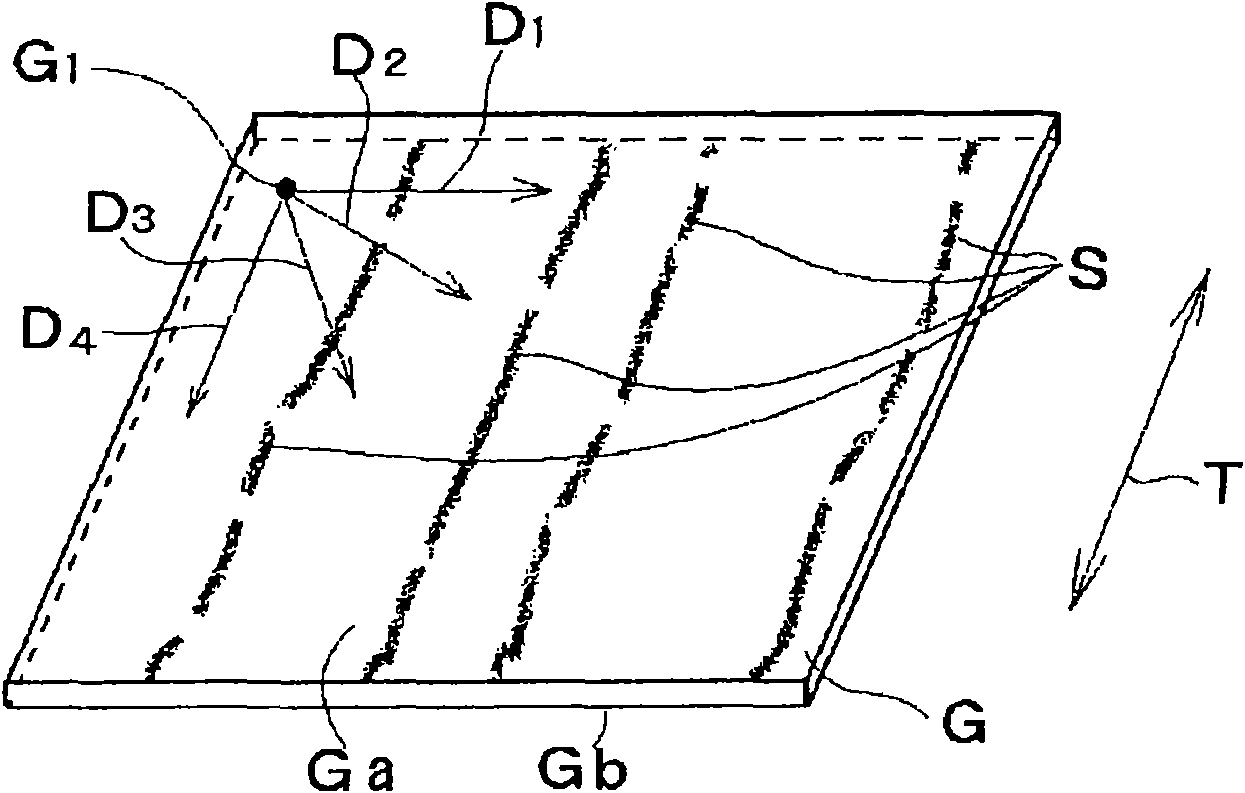

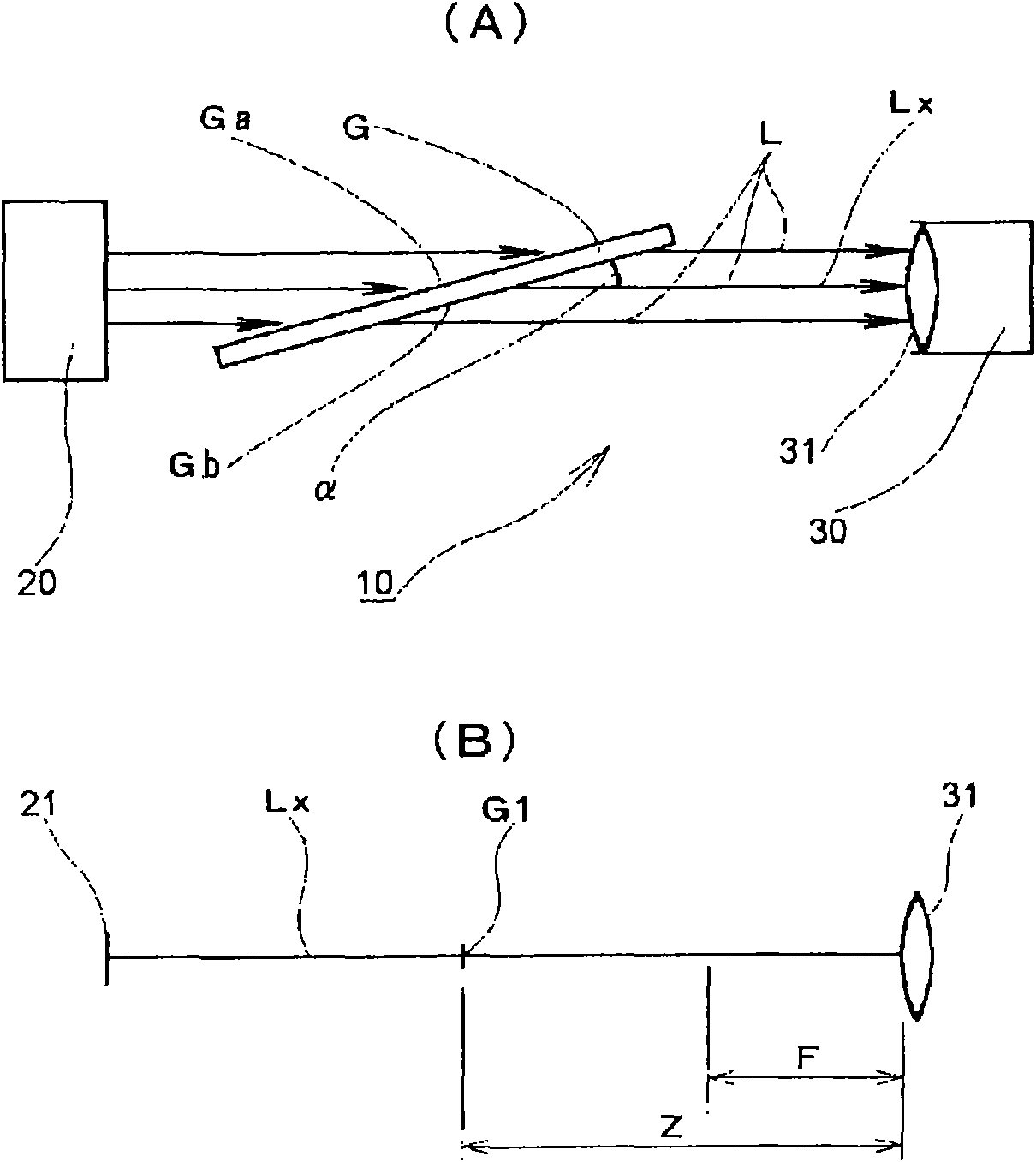

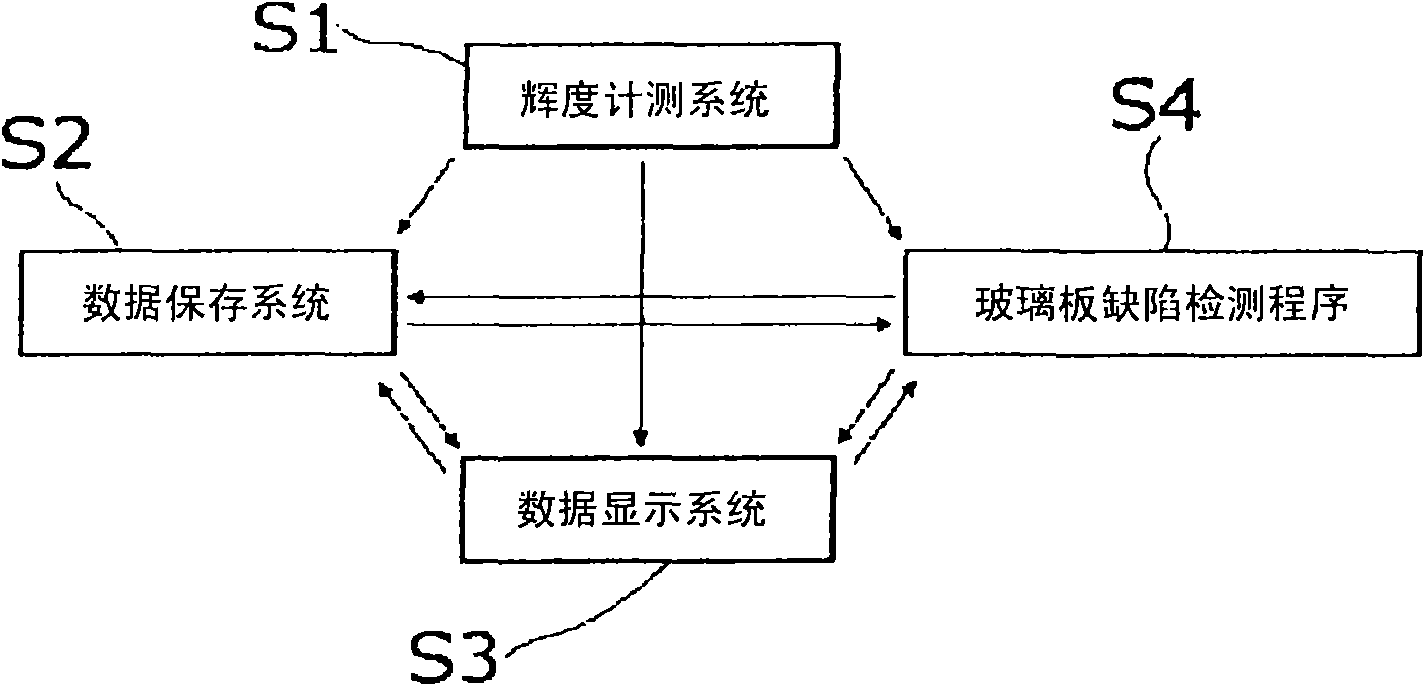

Glass sheet defect detection device, glass sheet manufacturing method, glass sheet, glass sheet quality judging device, and glass sheet inspection method

ActiveCN101558292ADetection defect informationReduce noiseMaterial analysis by optical meansUsing optical meansOptical axisEngineering

Owner:NIPPON ELECTRIC GLASS CO LTD

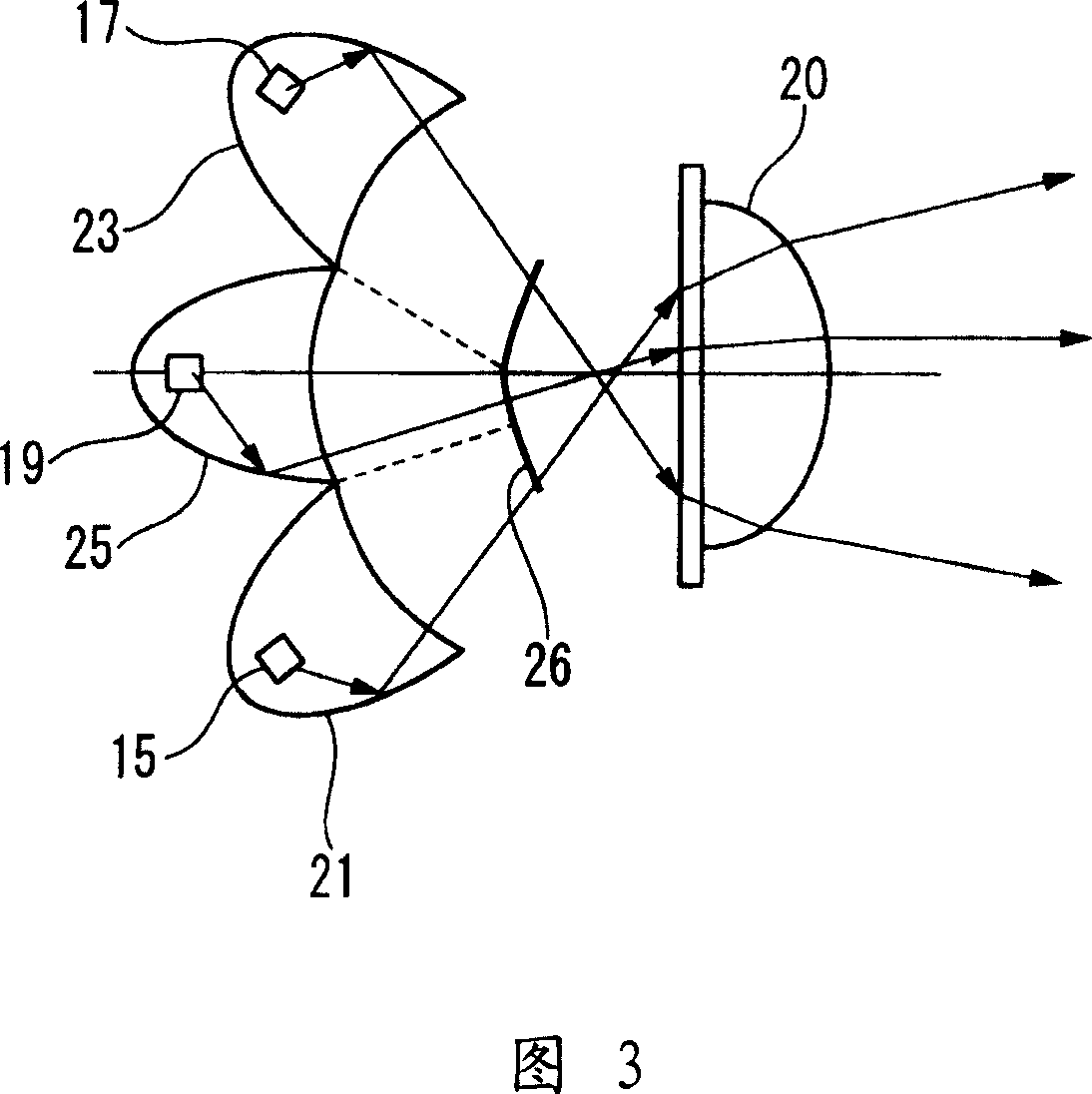

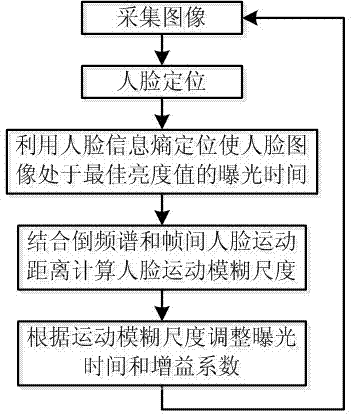

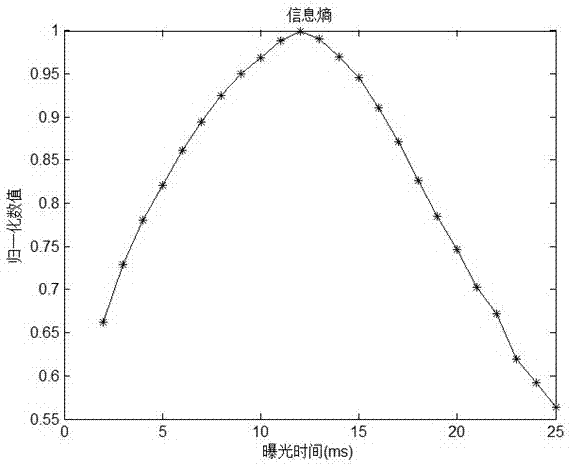

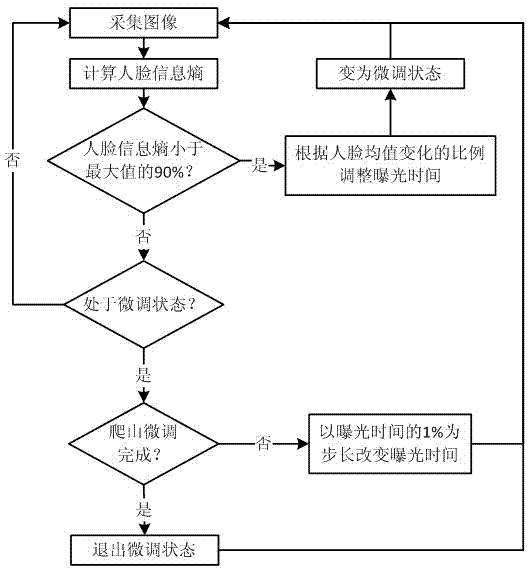

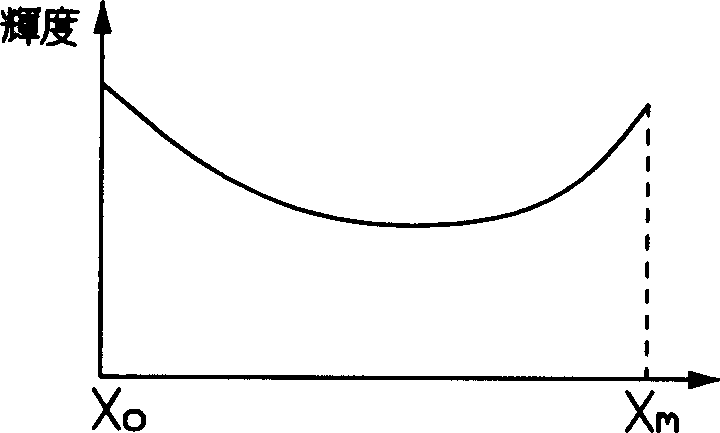

Exposure control method for human face image acquisition system under near-infrared condition

InactiveCN103702015AGood brightnessGood visual effectTelevision system details2D-image generationImage degradationExposure control

The invention discloses an exposure control method for a human face image acquisition system under a near-infrared condition. The method is combined with a human face image information entropy and a human face image motion-blur extent to carry out exposure control, and comprises the following steps: a), using the human face image information entropy as an optimal human face image brightness judgment value, and determining the exposure time for optimal human face brightness through finding the maximum value of the human face image information entropy; b), estimating the human face image motion-blur extent through being combined with cepstrum and the interframe movement distance of a human face; c) adjusting the exposure time according to the human face image motion-blur extent. The exposure control method can be applicable to the human face image acquisition system under the near-infrared condition, can overcome the image degradation phenomenon of the human face image acquisition system due to illumination variation and motion blur effectively, improves the quality of the acquired human face images, and ensures the stability and the accuracy of human face image processing analysis.

Owner:SOUTH CHINA UNIV OF TECH

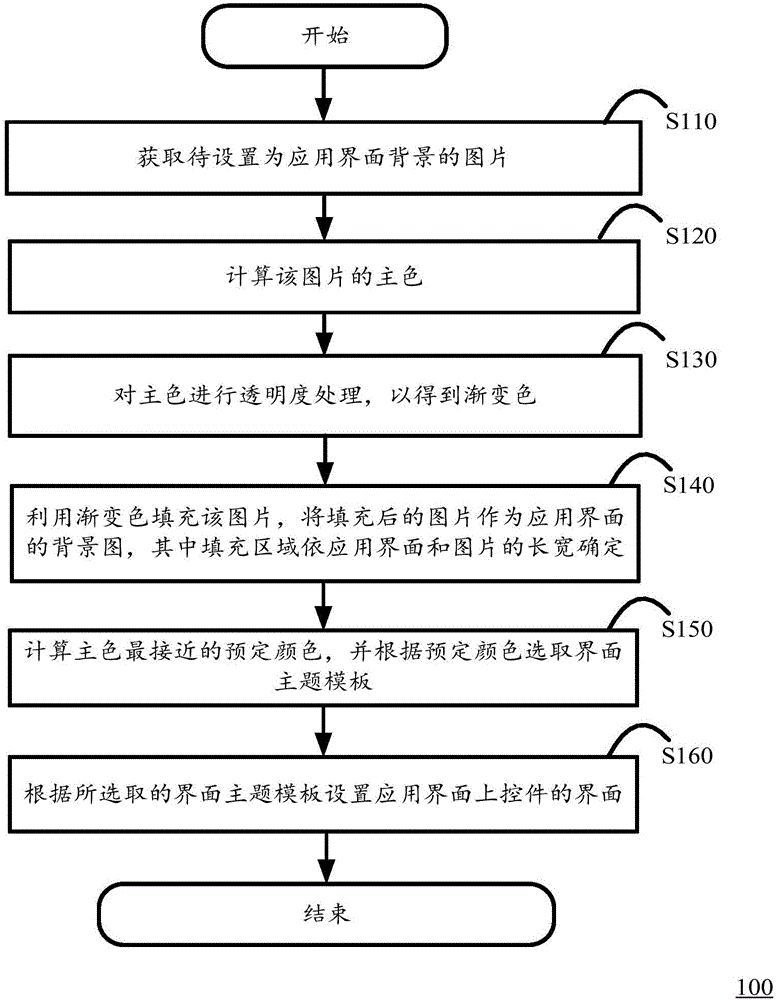

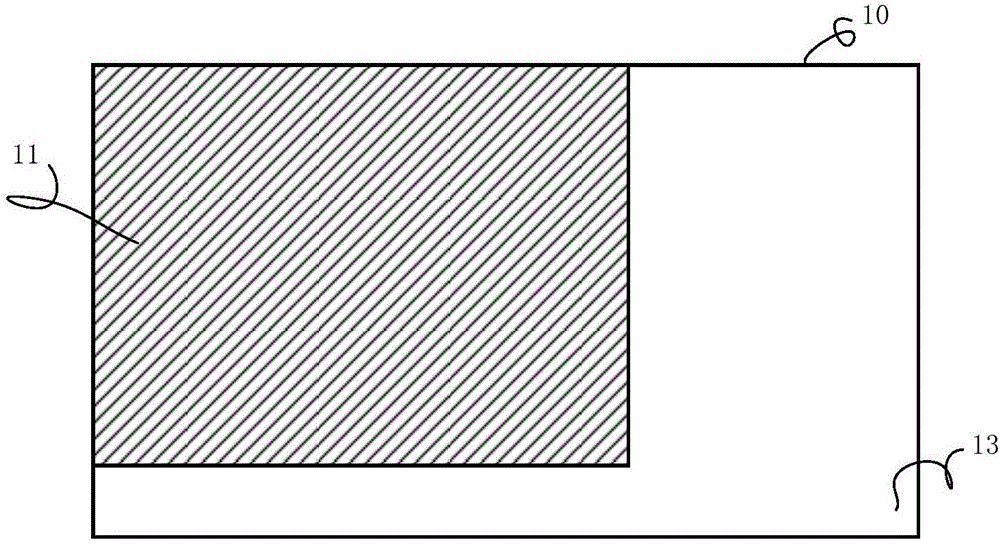

Application interface generating method and device and calculation device

ActiveCN106095447AObvious contrastGood visual effectExecution for user interfacesSkin colorComputer engineering

Owner:武汉深之度科技有限公司

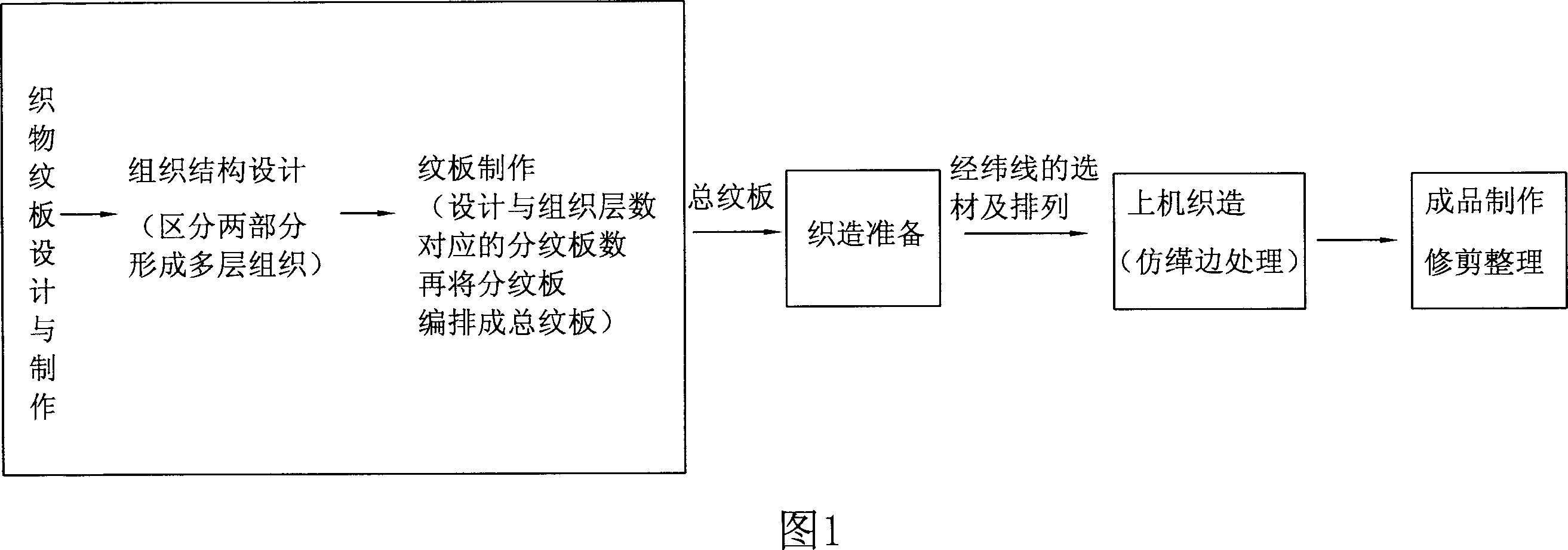

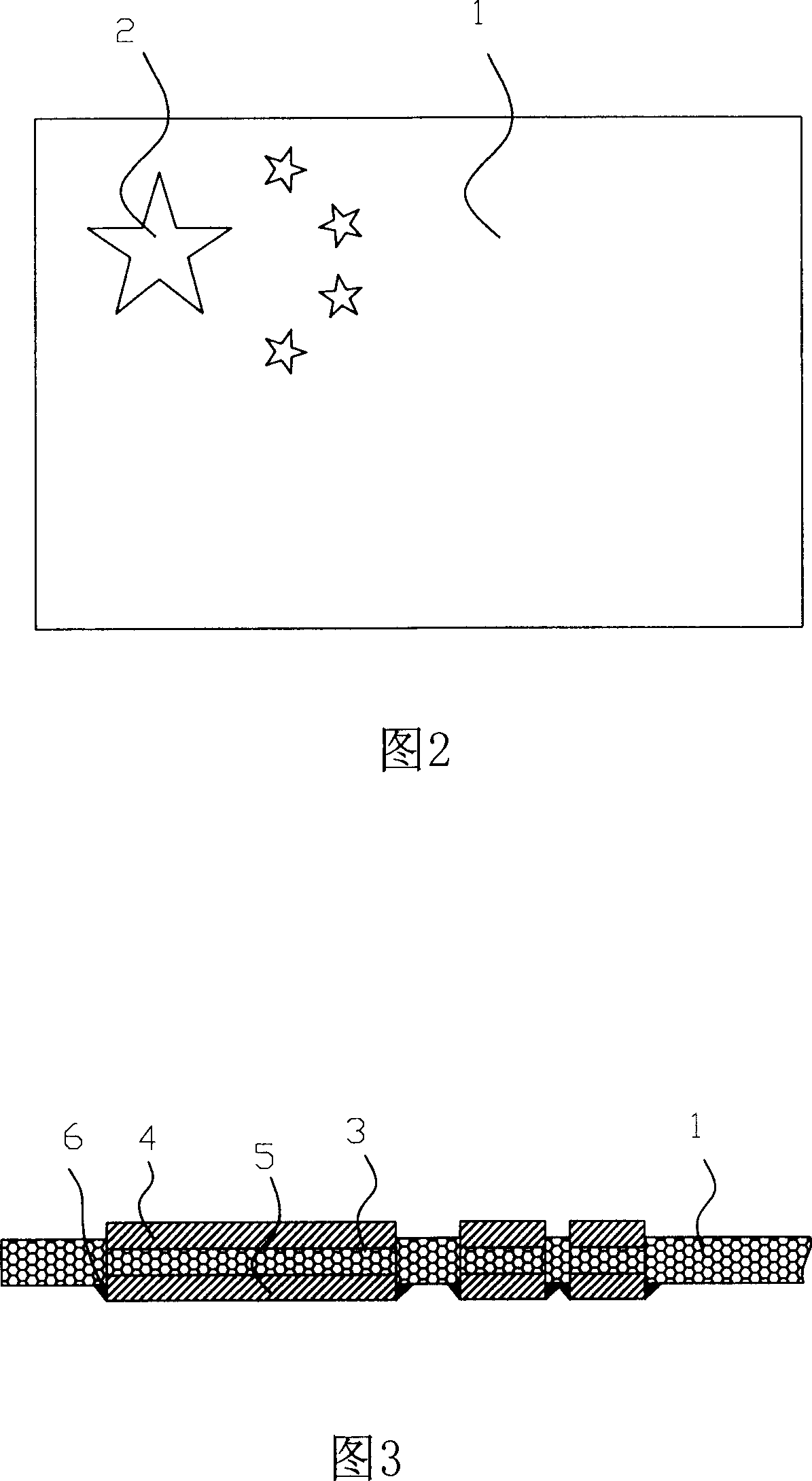

Method for manufacturing color double-face symmetrical pattern jacquard

InactiveCN101104972AGood visual effectEnhance the three-dimensional sensePattern making devicesLayered structureContinuous production

The invention relates to a production method of jacquard fabric with colored symmetrical patterns on double surfaces. The production method comprises the following steps: (I) design and production of fabric pattern card; (II) weaving preparation; (III) machine weaving; and (IV) finishing. The step of design and production of fabric pattern card comprises (1) inputting a target image of jacquard fabric to be woven to a computer; (2) adjusting the input image and setting parameters; (3) distinguishing the pattern part and the basic part of the target image, wherein the pattern part is symmetrically overlaid on the surface of basic part, so that the basic part has single-layer structure and the pattern part has three-layer structure; and (4) making pattern card and inputting an electronic jacquard machine. The invention has the advantages that the produced fabric has multi-layered structure in the pattern part alone; the pattern has two or more colors on double surfaces and is symmetric, thin and soft; and the fabric is integrally woven in one process, facilitating the batch and continuous production.

Owner:李加林

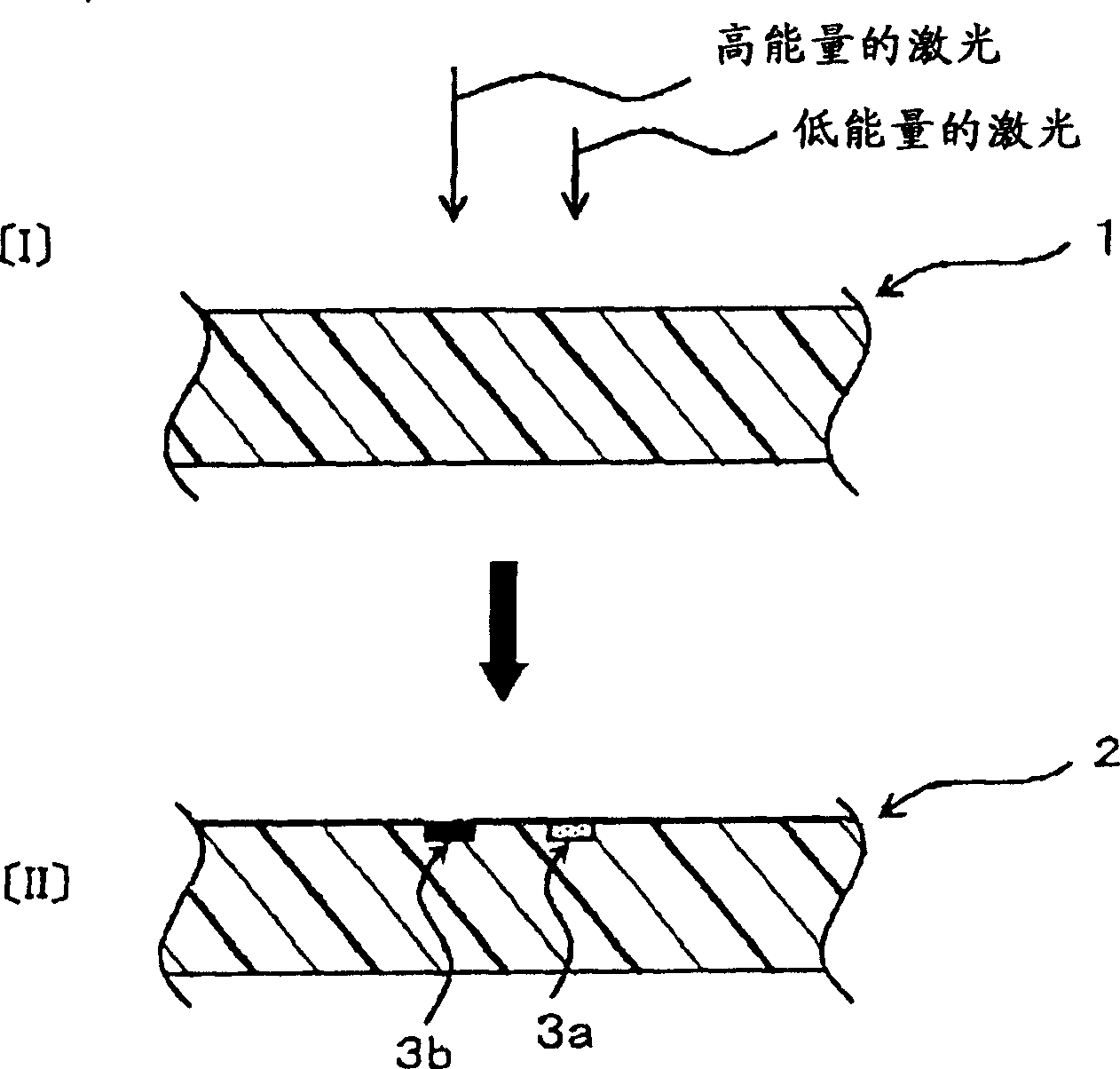

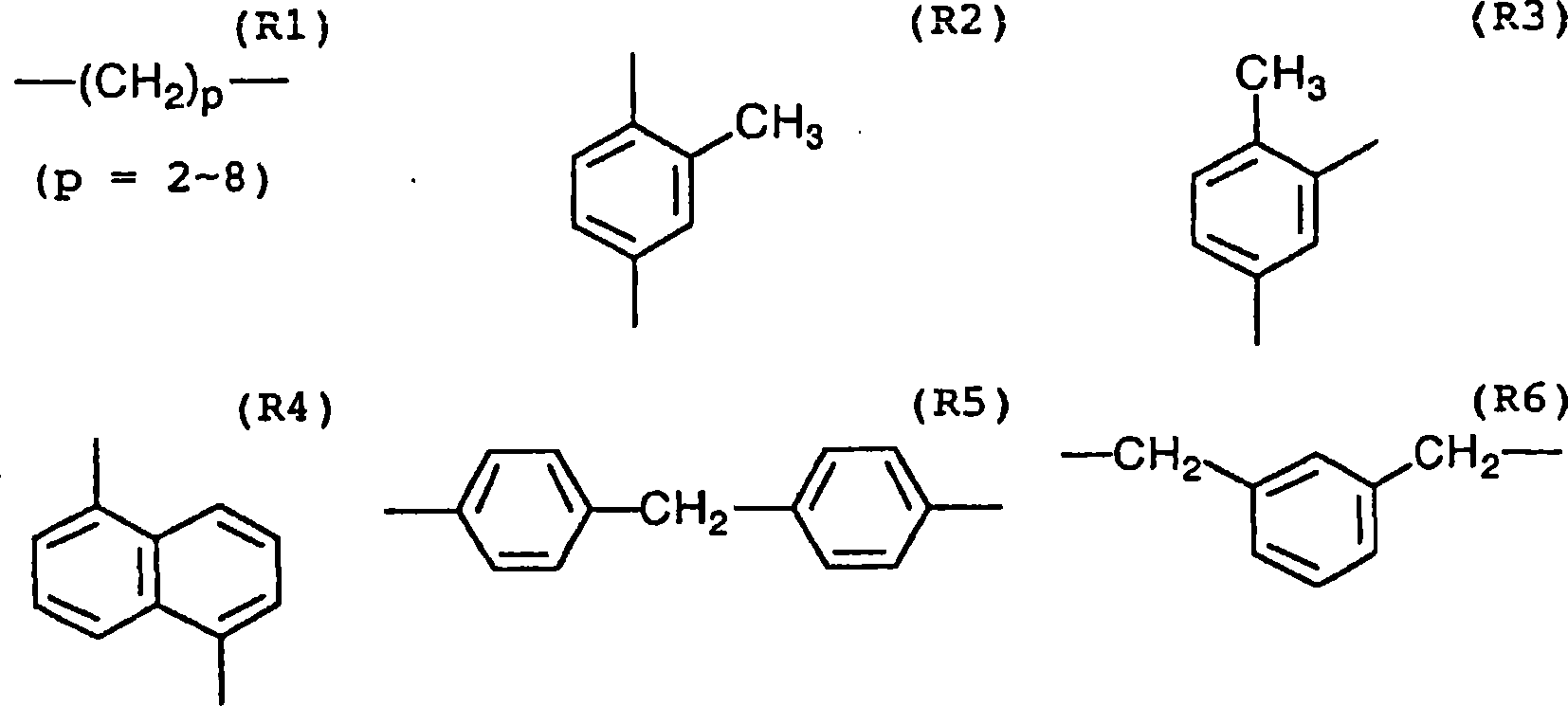

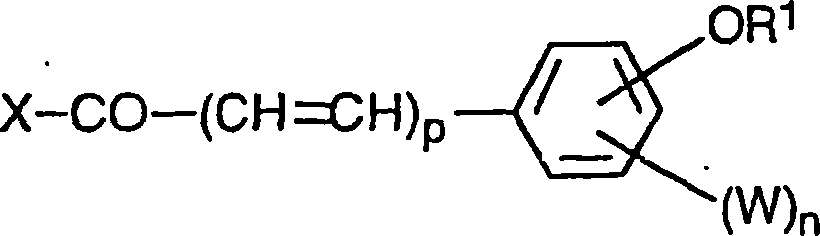

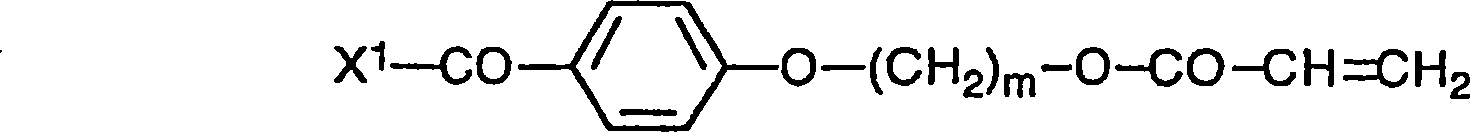

Multi-color coloring laser marking-use chromatic color colorant, multi-color coloring laser marking-use composition and molding containing it, multi-color marking-carrying molding and laser marking me

InactiveCN1910238AAvoid deformationLess prone to wearOrganic dyesThermographyColored whiteBlack substance

Owner:TECHNO POLYMER CO LTD

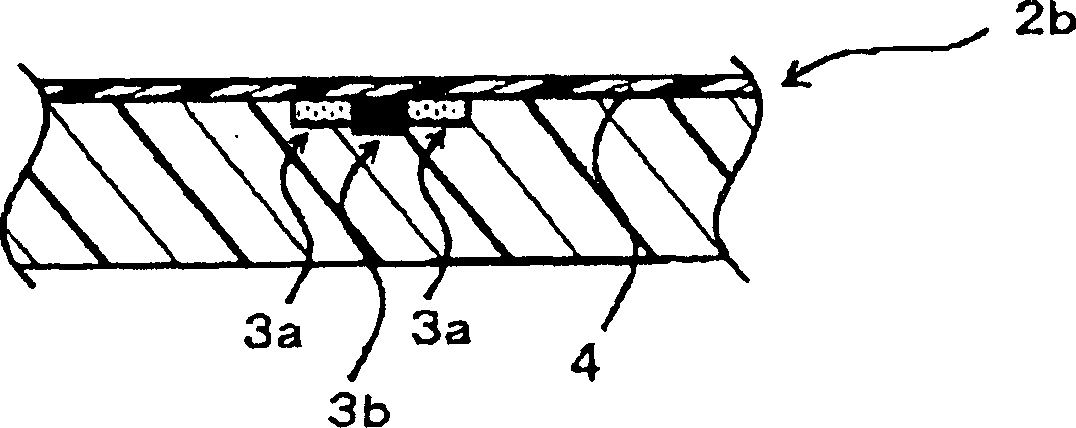

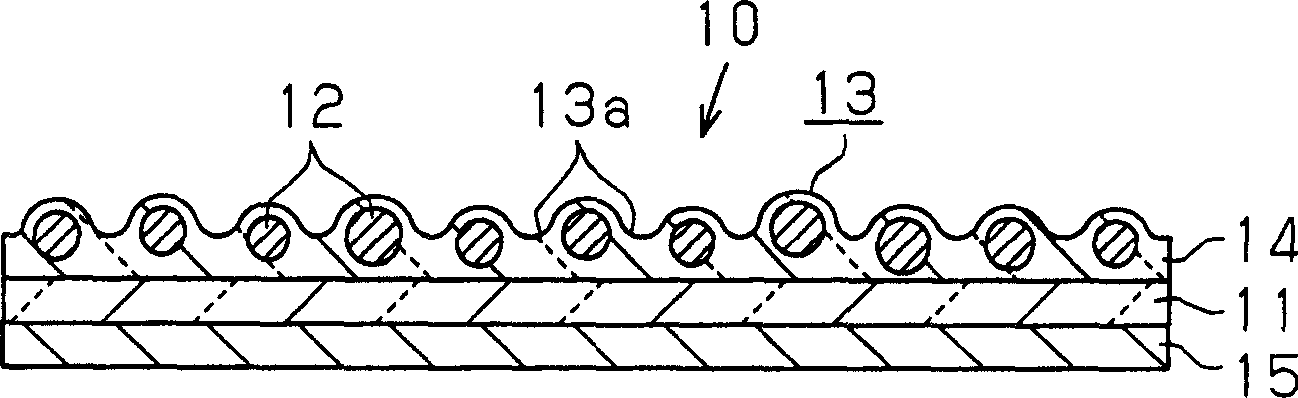

Surface material for display and display with the same

ActiveCN1904646AWith anti-glare functionGood visual effectDiffusing elementsSynthetic resin layered productsDisplay deviceOleic Acid Triglyceride

Provided is a surface material for a display which has an antidazzle layer (14; 14, 16) disposed on the transparent base (11), the antidazzle layer has a resin jog (13) on the surface and it is set at less than 60 deg in the contact angle of a flat film formed of the resin with oleic acid. The invention also relates to a display with the same.

Owner:HIGASHIYAMA FILM

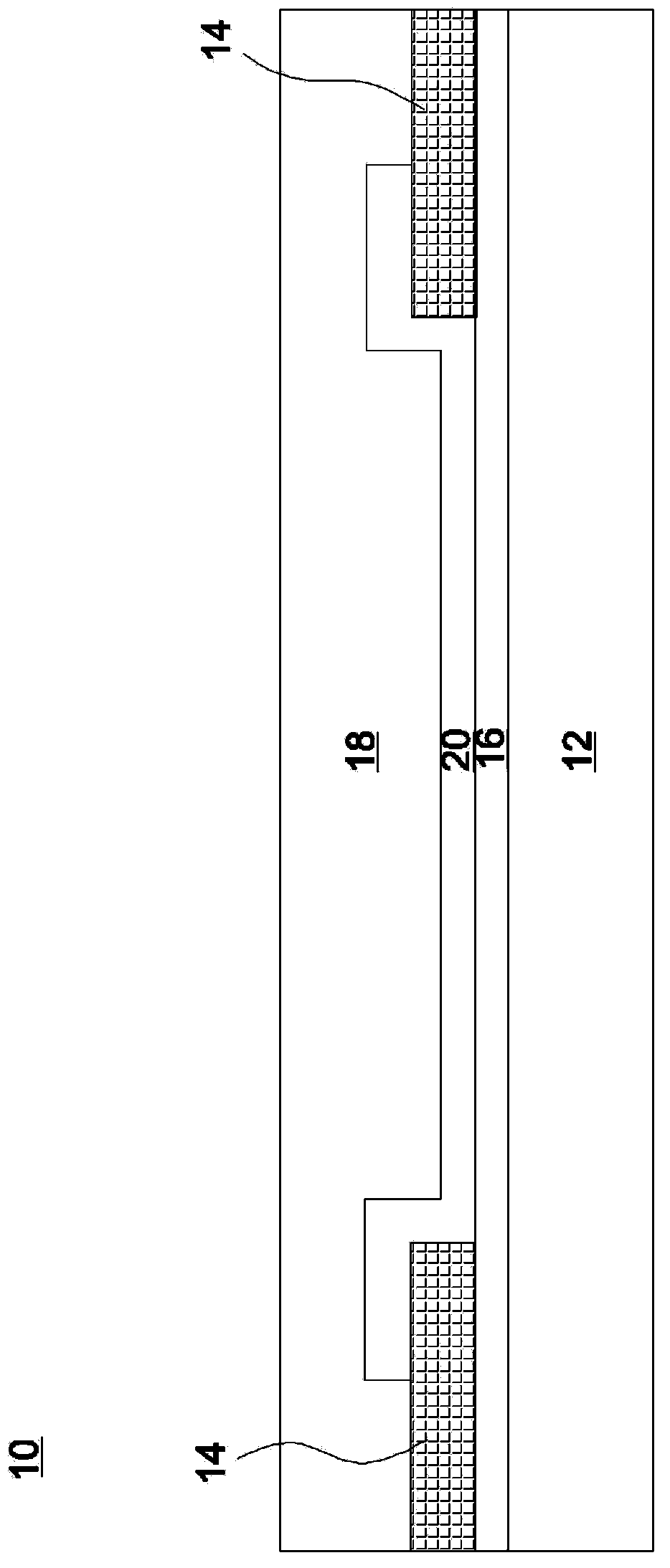

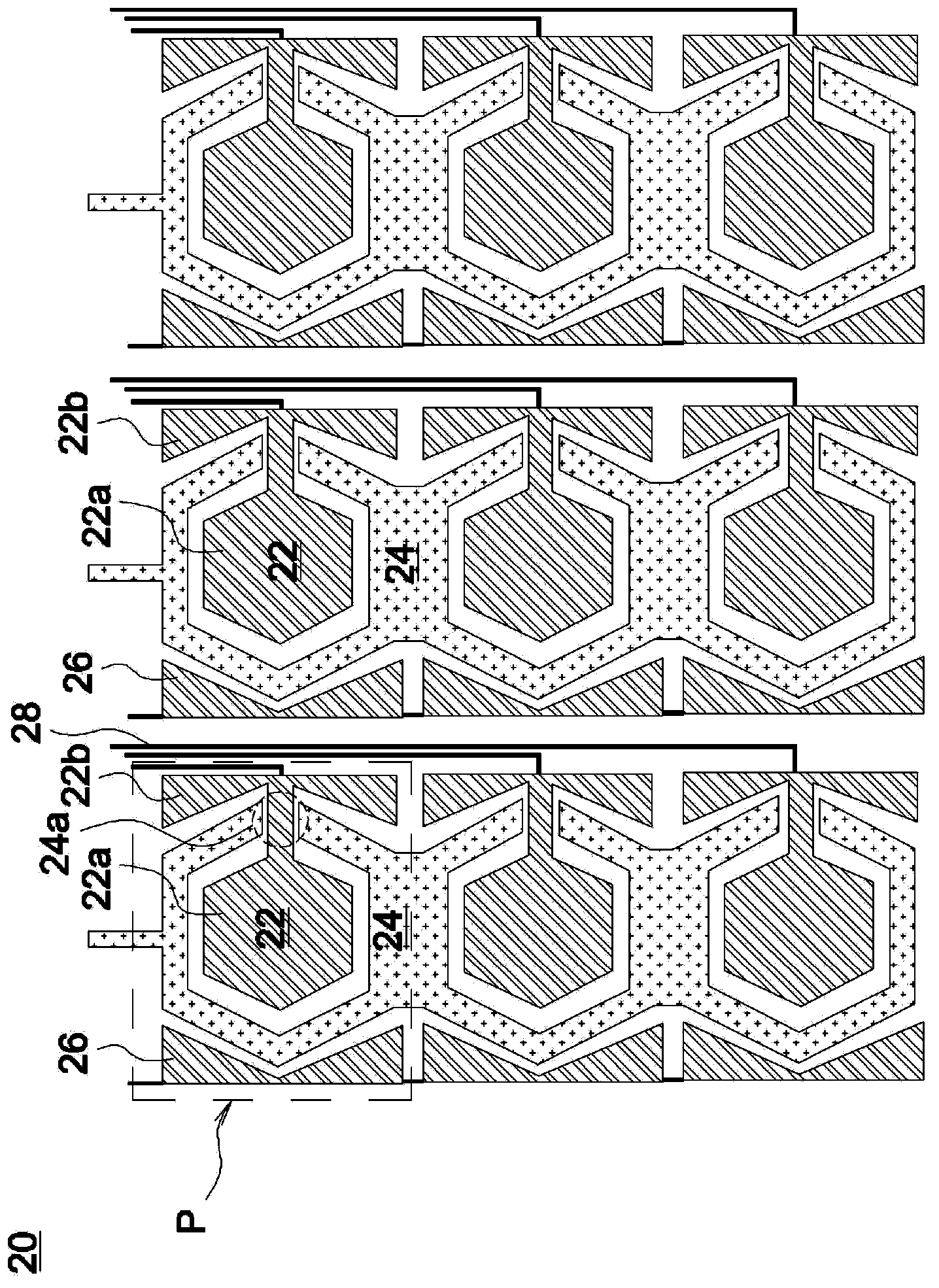

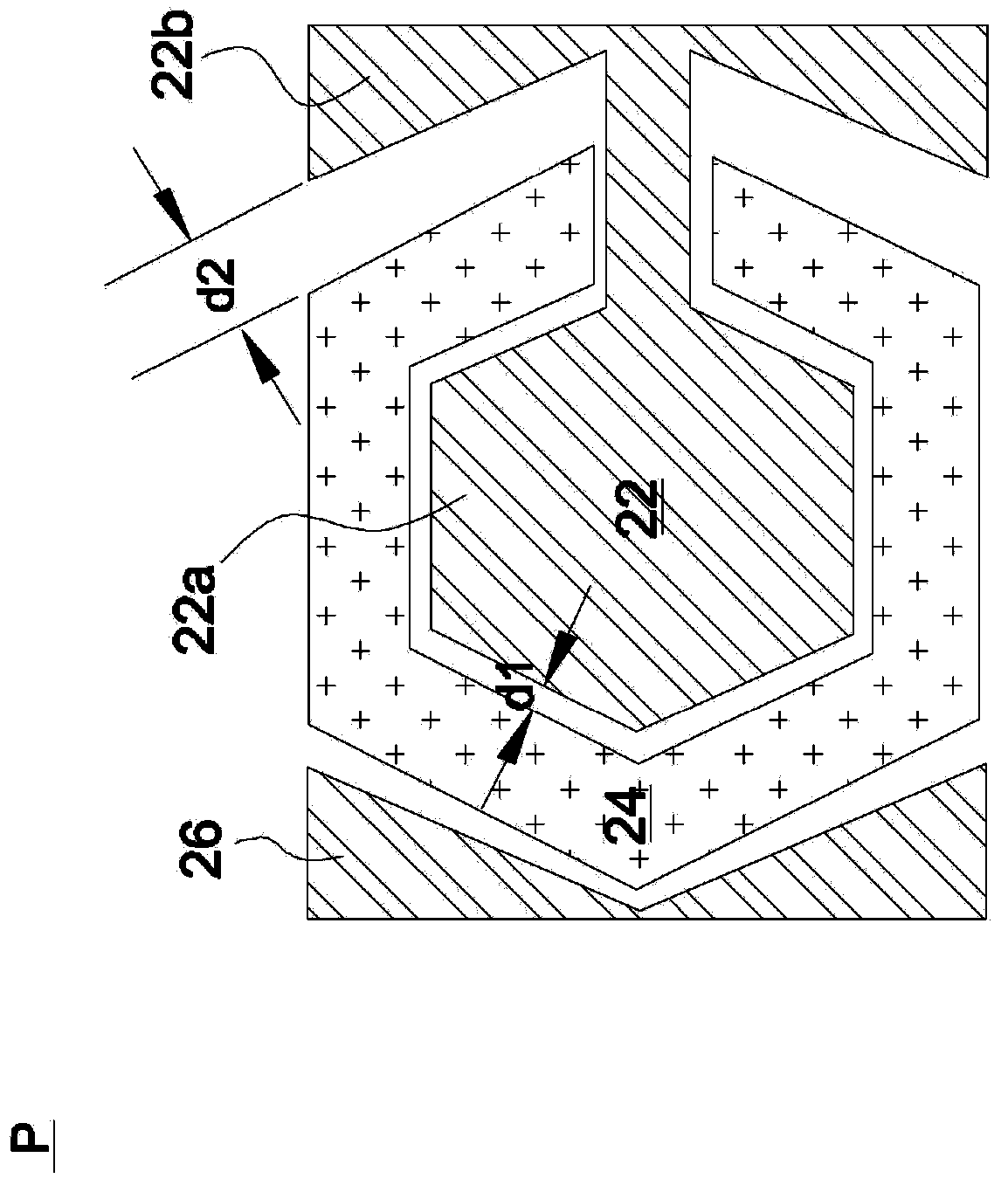

Touch-sensing electrode structure and touch-sensitive device

InactiveCN103455223AIncrease inductive capacitanceIncreased interaction surface available for mutual inductionMeasurement leads/probesInput/output processes for data processingElectric capacityTouch Senses

The invention provides a touch-sensing electrode structure and a touch-sensitive device. The touch-sensing electrode structure has a plurality of electrode units. Each of the electrode units includes at least one first electrode and at least one second electrode. The second electrode is formed in an area not overlapping the first electrode, and the first electrode has a first part and a second part. The second electrode is adjacent to the first part of the first electrode and spaced apart the first part of the first electrode by a first interval, the second part of the first electrode is adjacent to the second electrode and spaced apart the second electrode by a second interval, and a width of the second interval is not equal to a width of the first interval. In this way, the area of the mutually inducted action surface between the first electrode and the second electrode is greatly increased, so that the inducted electric capacity of the touch-sensing electrode structure and the sensitivity of the touch-sensing operation are improved.

Owner:WINTEK CORP

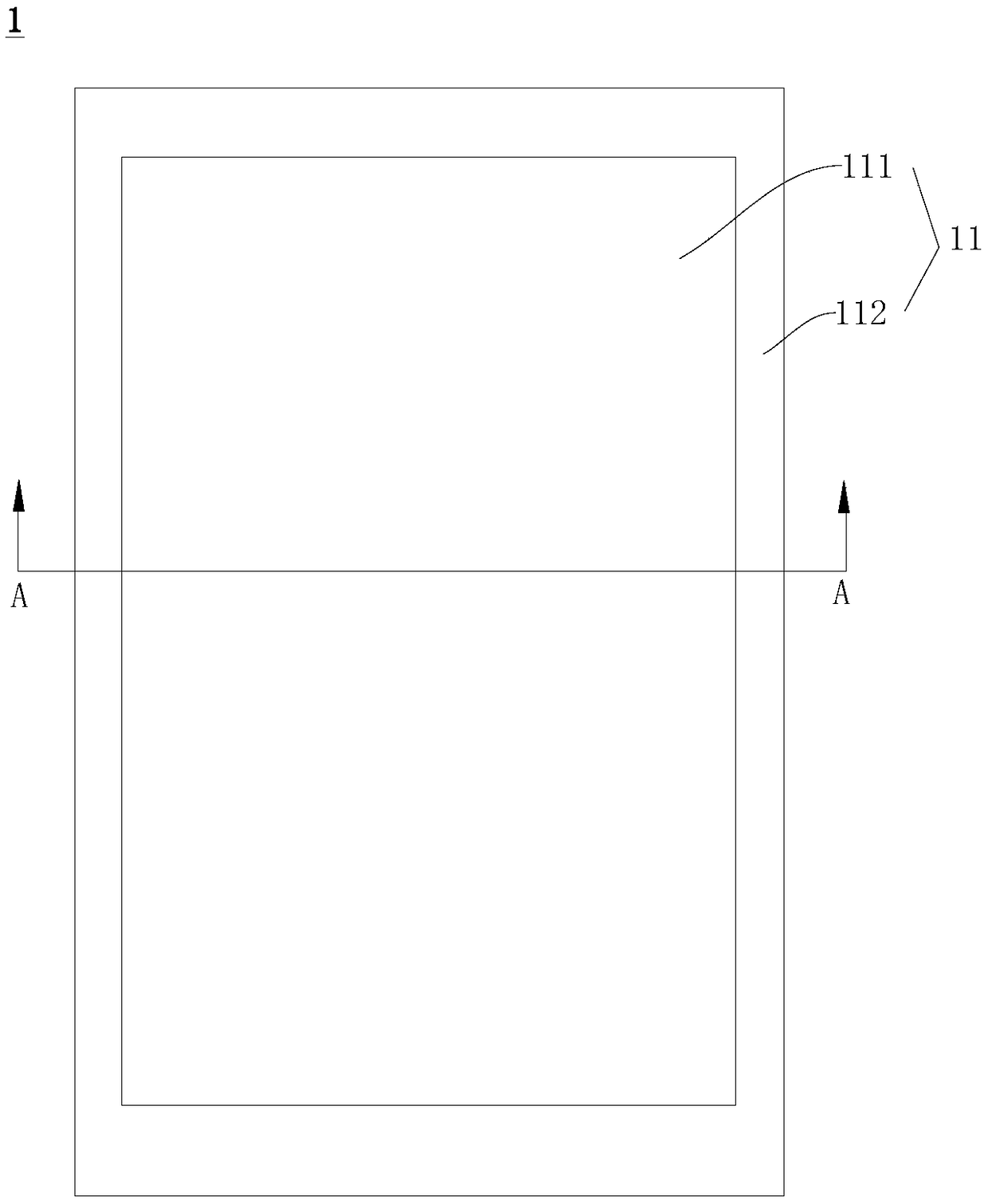

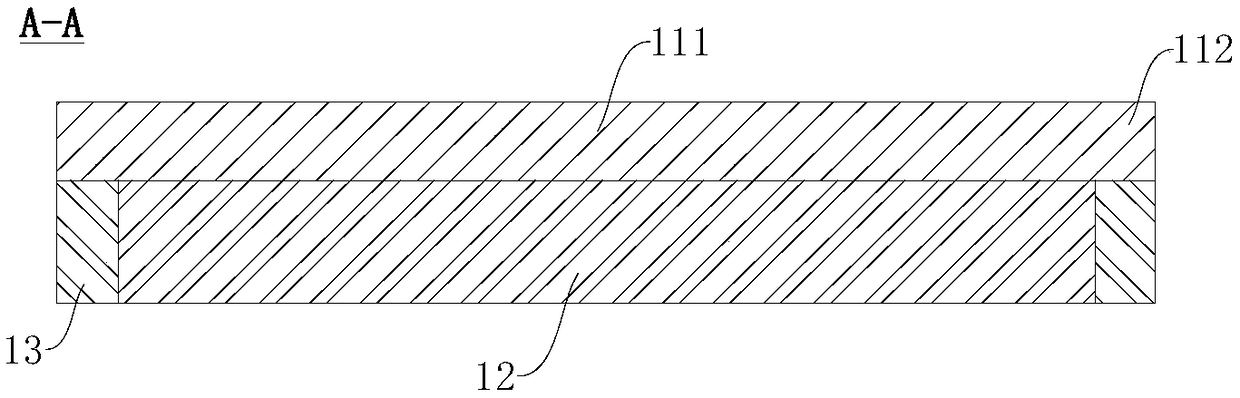

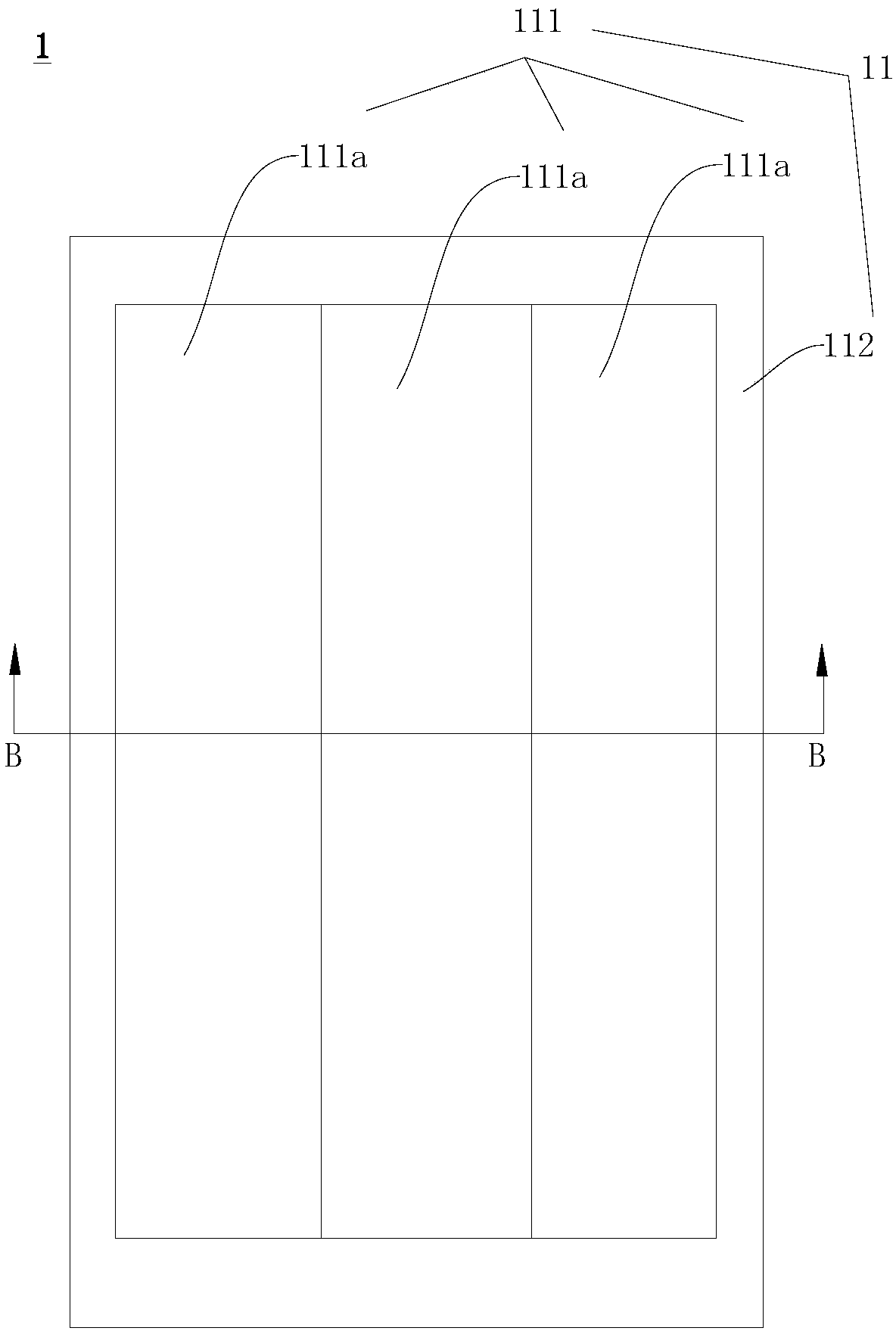

Display screen cover plate of electronic device, electronic device and control method of electronic device

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

Optical compensating sheet, polarizing plate, and liquid crystal display device

ActiveCN101201423AImprove transmittanceIncrease production capacityPolarising elementsFlat articlesLiquid-crystal displayDisplay device

The object of the present invention is to provide an optical compensation sheet for improving the display quality of a liquid crystal display device, a polarizer having the optical compensation sheet, and a liquid crystal display device. The optical compensation sheet is formed by sequentially laminating an alignment film and an optically anisotropic layer on a transparent support containing at least fine particles with an average primary particle diameter of 80 nm or less and a film thickness of 20 μm or more and 80 μm or less, wherein the transparent support is The arithmetic average roughness Ra of the surface irregularities on the side surface of the alignment film based on JISB0601-1994 is 0.0002 μm to 0.1 μm, the ten-point average roughness Rz is 0.0002 μm to 0.3 μm, and the maximum height Ry is 0.002 μm to 0.5 μm , the Re value defined by the formula (I) and (II) of the transparent support is 2nm or more and 200nm or less, and the value of Rth is in the range of 50nm or more and 400nm or less. In the formula, nx is the slow axis direction in the transparent support body ny is the refractive index in the fast axis direction in the plane of the transparent support; nz is the refractive index in the thickness direction of the transparent support; and d is the thickness of the transparent support. (I) Re=(nx-ny)×d (II) Rth={(nx+ny) / 2-nz}×d.

Owner:FUJIFILM CORP

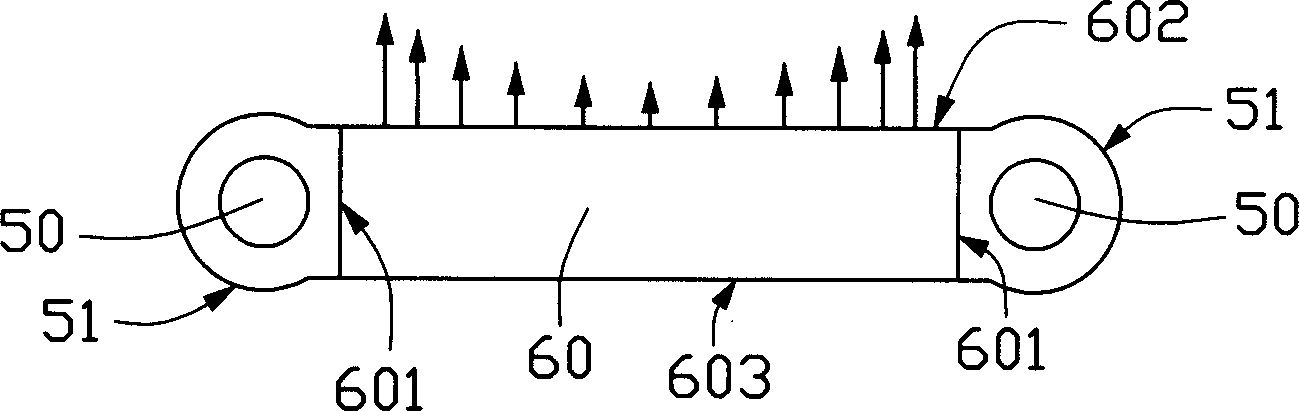

Backlight module and light guiding board

InactiveCN1566999AGood visual effectIncrease center brightnessDiffusing elementsNon-linear opticsOptoelectronicsLight guide

It is an aphototropism module comprises light conductive plate and light source. The light conductive material comprises fluorescent powder material and resin material, wherein; the fluorescent powder is located inside the light conductive plate and decrease from center to circumferential end

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

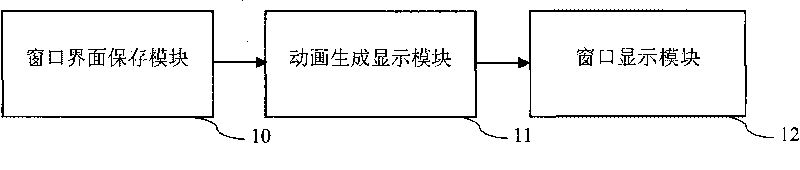

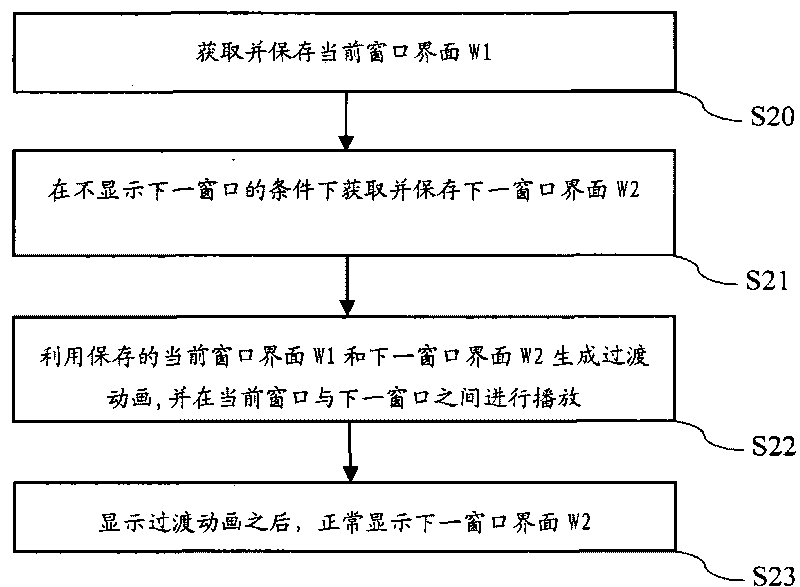

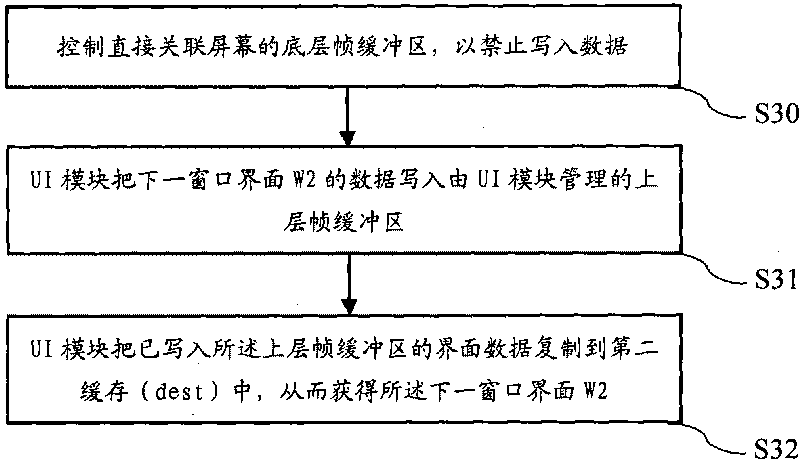

Implementation method for enhancing visual effect of user interfaces of mobile terminal and device thereof

ActiveCN101714088AControl refreshImprove visual effectsProgram initiation/switchingExecution for user interfacesAnimationEnd user

The invention discloses an implementation method for enhancing the visual effect of user interfaces of a mobile phone and a device thereof. The method of the invention comprises the following steps: (A) acquiring and saving the current window interface W1; (B) acquiring and saving the next window interface W2 under the condition that the next window is not displayed; (C) generating a transition cartoon by utilizing the saved current window interface W1 and the saved next window interface W2, and playing the transition cartoon between the current window and the next window; and (D) after the transition cartoon is displayed, normally displaying the next window interface W2. The invention can realize the purpose of farther enhancing the visual effect of the mobile phone in the switching process of the user interfaces under the conditions that the hardware cost and the software cost are not increased, the development difficulty is not increased and the development cycle is not prolonged.

Owner:ZTE CORP

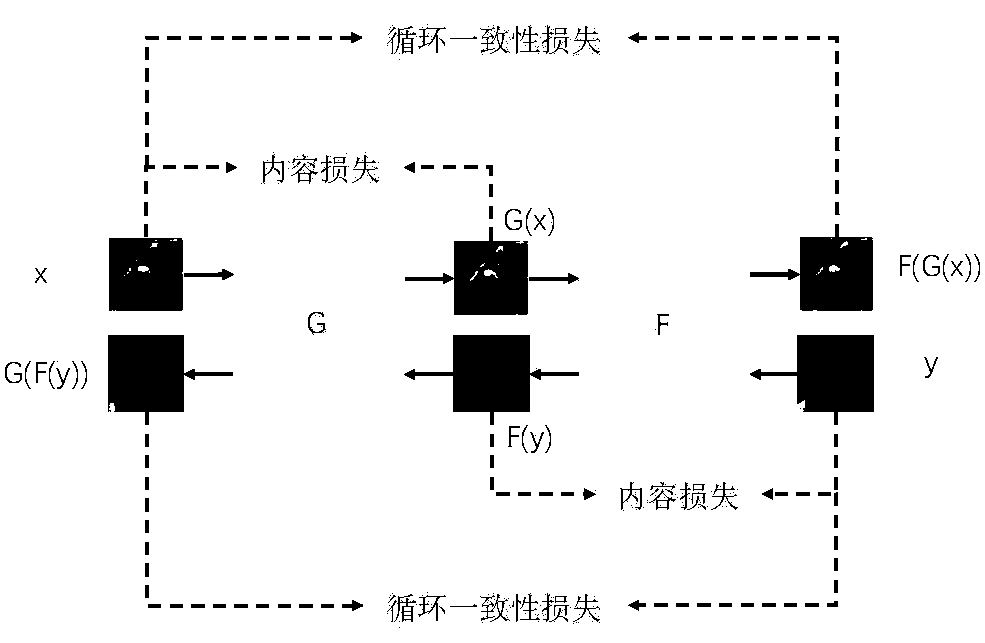

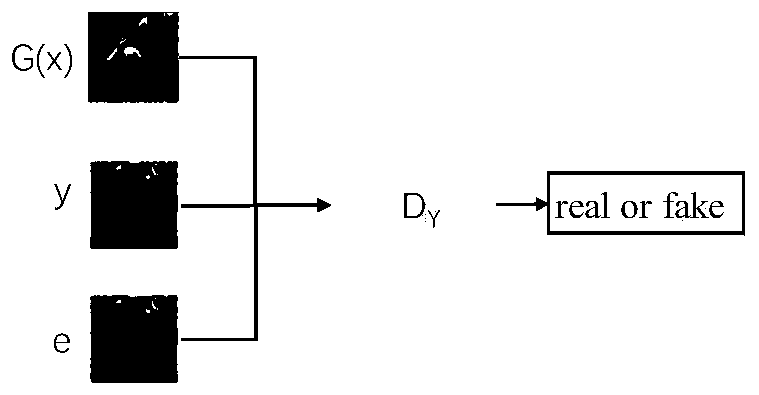

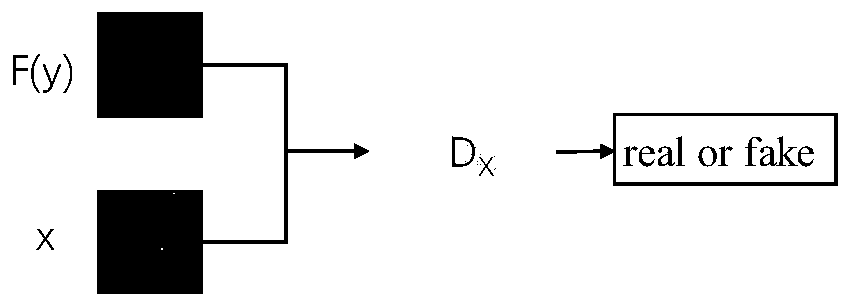

Underwater degraded image enhancement method based on GAN network

PendingCN111260584AGood visual effectWork around limitationsImage enhancementImage analysisImage recoveryNetwork architecture

The invention relates to an underwater degraded image recovery method based on a GAN network. The method is used for solving the problem of underwater degraded image recovery without paired data sets.A network architecture of the method consists of two generator networks and two discriminator networks, two generators are respectively used for converting an underwater degraded image into a clear image and restoring the generated clear image into a degraded image, and the two generators have the same structure and different parameters. The two discriminators respectively determine whether an image generated by the first generator is a clear image and determine whether the image generated by the second generator is a degraded image. First, a training generator is arranged, when the number oftraining times is reached, generator parameters are not changed, a discriminator is trained again, when the discriminator reaches the number of training times, the discriminator parameters are not changed, the generator continues to be trained, the steps are repeated until the loss function is minimized to complete optimization training of the network, and the trained first generator is used forgenerating a clear image of the underwater degraded image.

Owner:BEIJING UNIV OF TECH

Cereal/stone fruit chocolate preparation method

The present invention discloses a preparation method of corn / kernel food chocolate; the steps comprise that the corn / kernel food is peeled off and dehydrated after ripening; the chocolate block is melted and molded with a PE plastic piece mold; the bottom of the dehydrated corn / kernel is stained with chocolate paste and two sides are embedded with molded chocolates; in this way, the molded chocolates are combined at the bottom with the top open to expose the hydrated ripe corn / kernel food. The present invention adopts chocolates to be embedded with hydrated ripe corn / kernel food and the ripe corn / kernel which is dehydrated with low temperature is exposed between the open molded chocolates; in this way, the transparency is good and the visible effect of appearance is good which is beneficial to advancing the color, shape and taste of traditional food and promoting the level of edible fruit and enriching the life of people.

Owner:ZHEJIANG UNIV

Airborne vision enhancement method and device

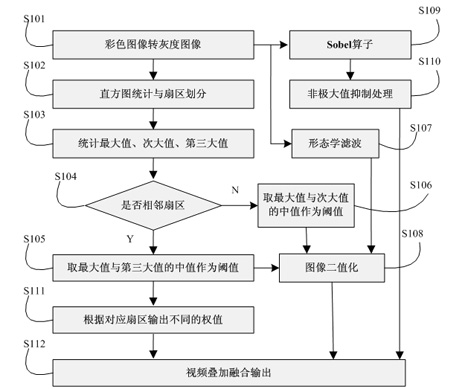

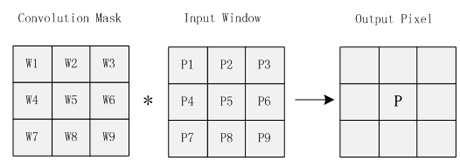

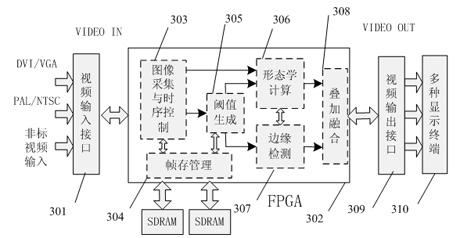

The invention discloses an airborne vision enhancement method and an airborne vision enhancement device. The method comprises the following steps of: performing histogram statistical analysis on an input digital image to generate an adaptive threshold value, and dividing into different sectors according to the characteristics of a histogram to generate different fusion weight coefficients; performing morphological filtering and edge detection calculation according to the characteristics of different images; and performing vision enhancement on a calculation result according to a video superposition and fusion algorithm. The device comprises a threshold value generation module, a morphological calculation module, an edge detection module and a superposition and fusion module. Compared with the conventional vision enhancement method, the airborne vision enhancement method has the advantages that: superposition and fusion calculation can be adaptively performed for different characteristics of an airborne vision; the method is suitable for hardware implementation; and the airborne vision can be effectively enhanced in real time, and a better visual effect is achieved.

Owner:CHINESE AERONAUTICAL RADIO ELECTRONICS RES INST

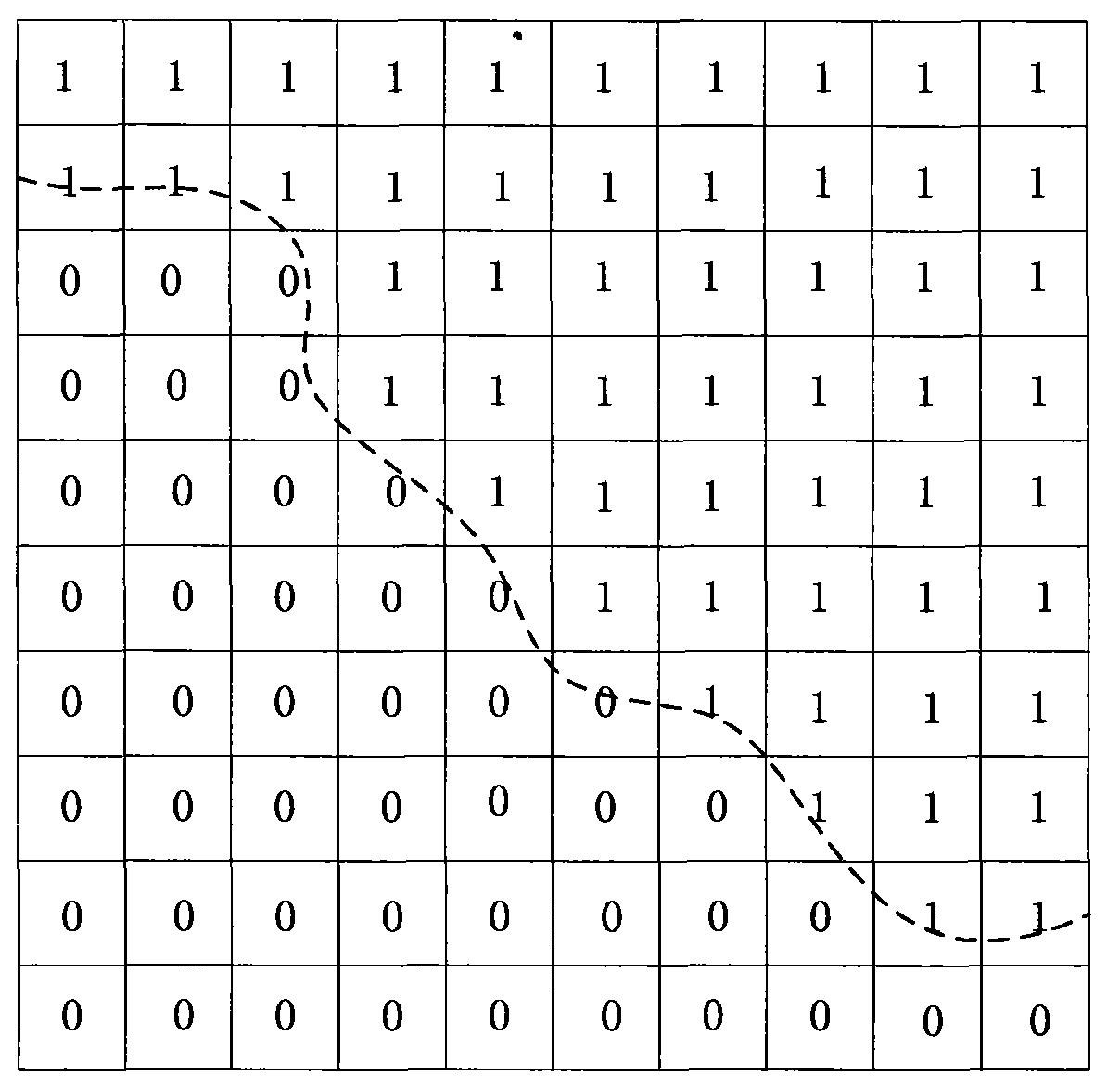

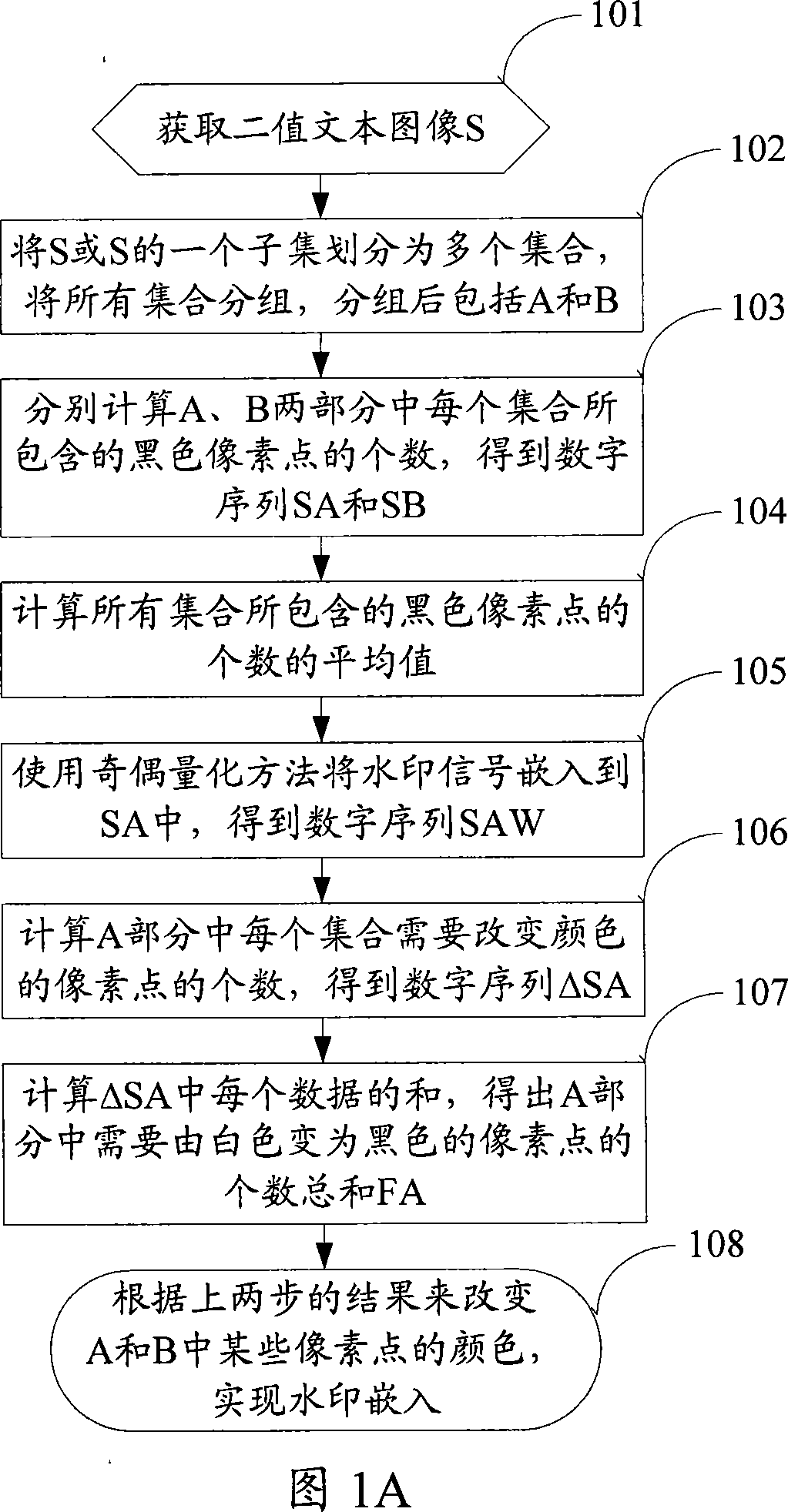

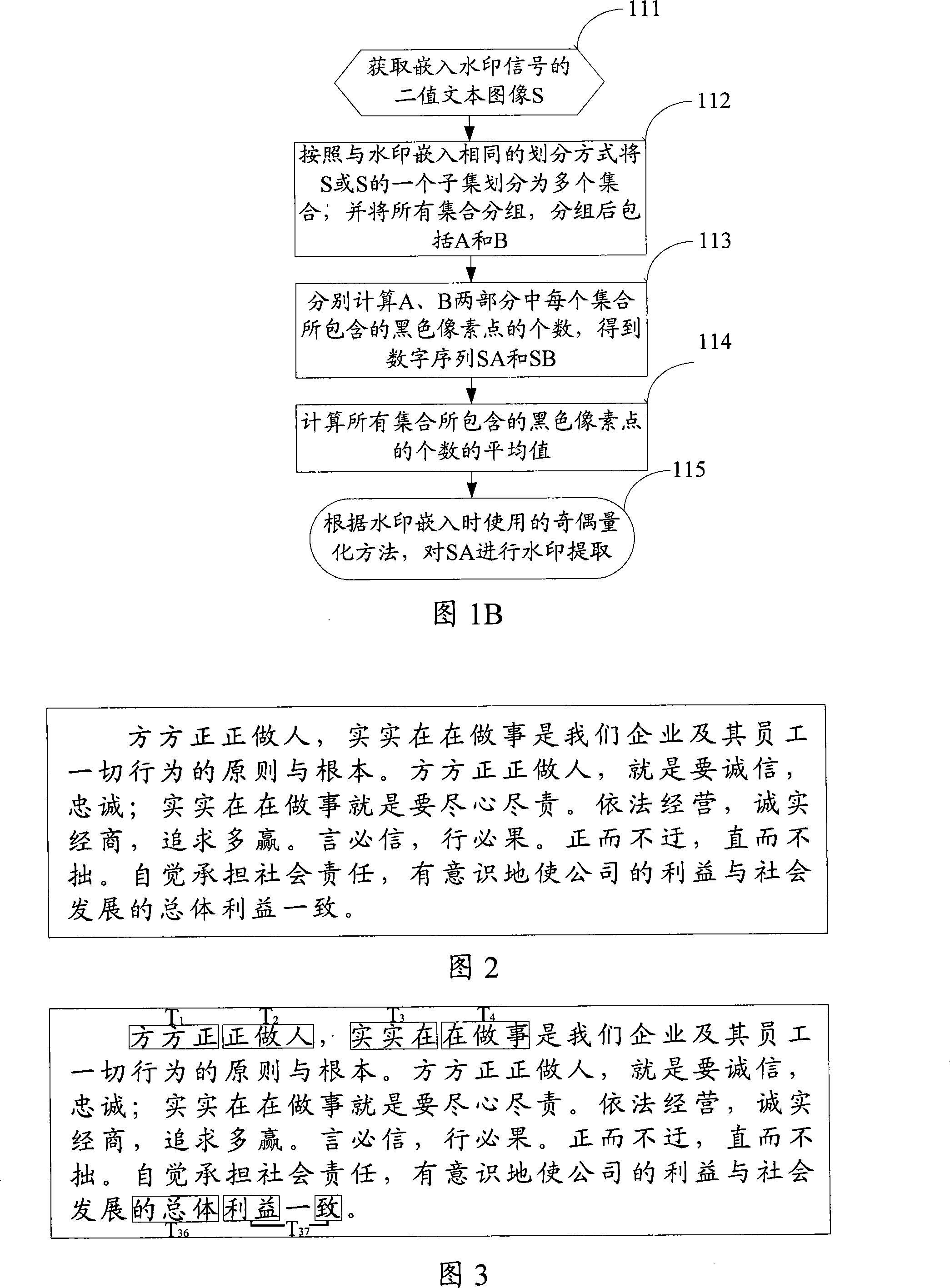

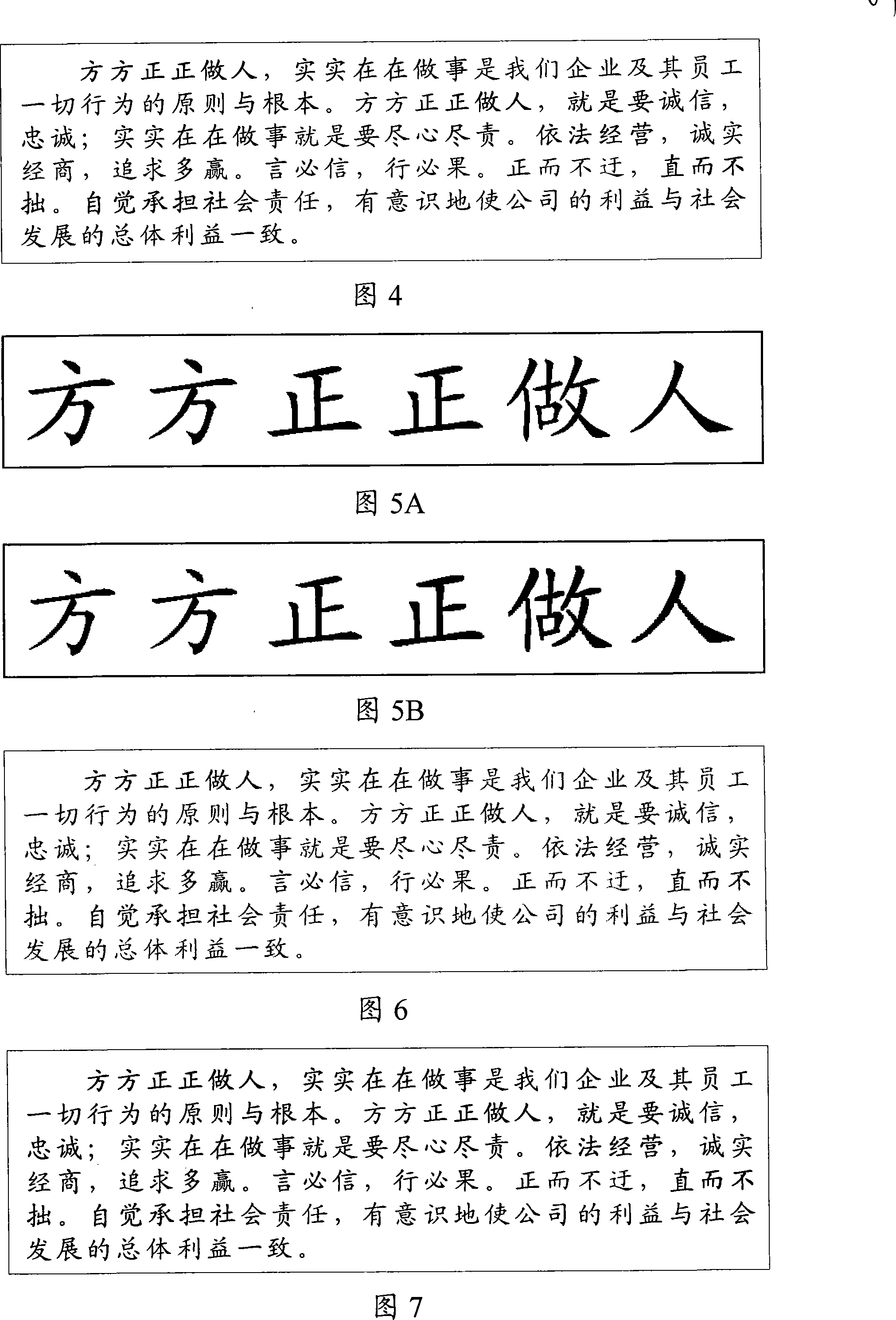

Apparatus and method for abstracting and imbedding digital watermarking in two value text image

ActiveCN101231742AGood visual effectResist print copyingImage data processing detailsEmbedded systemDigital watermarking

The invention discloses a method of embedding watermarks in a binary text image and a device thereof. The method comprises the following steps: the binary text image is divided into an embedded part and an adjustment part partially or entirely; the average of black pixel points contained in each set of the embedded part and the adjustment part is calculated; color change parameters are calculated according to the average and the number of the black pixel points contained in each set of the embedded part; the number of the black pixel points contained in each set of the embedded part and the adjustment part is changed according to the color change parameters. In this way, watermarks are embedded. The invention also discloses a method of extracting watermarks from the binary text image and a device thereof. The image with embedded watermarks looks good, and can better resist the attacks of printing, copy (in particular reduced copy) and scanning. The Original image are not required when watermarks are extracted.

Owner:PEKING UNIV +2

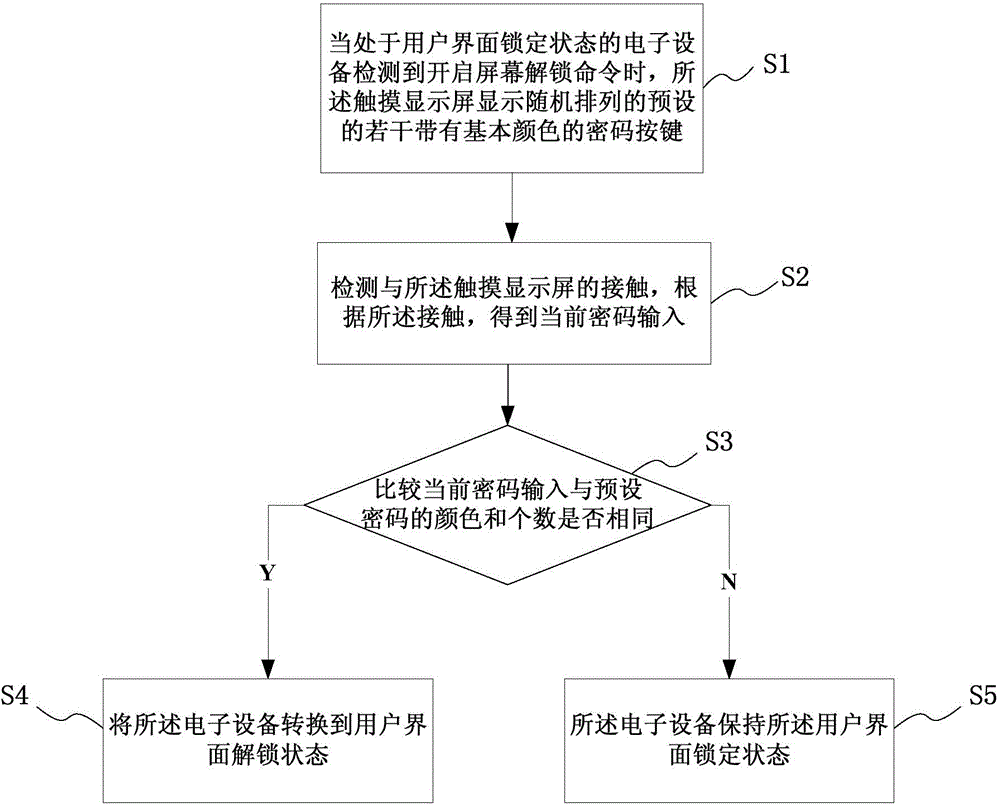

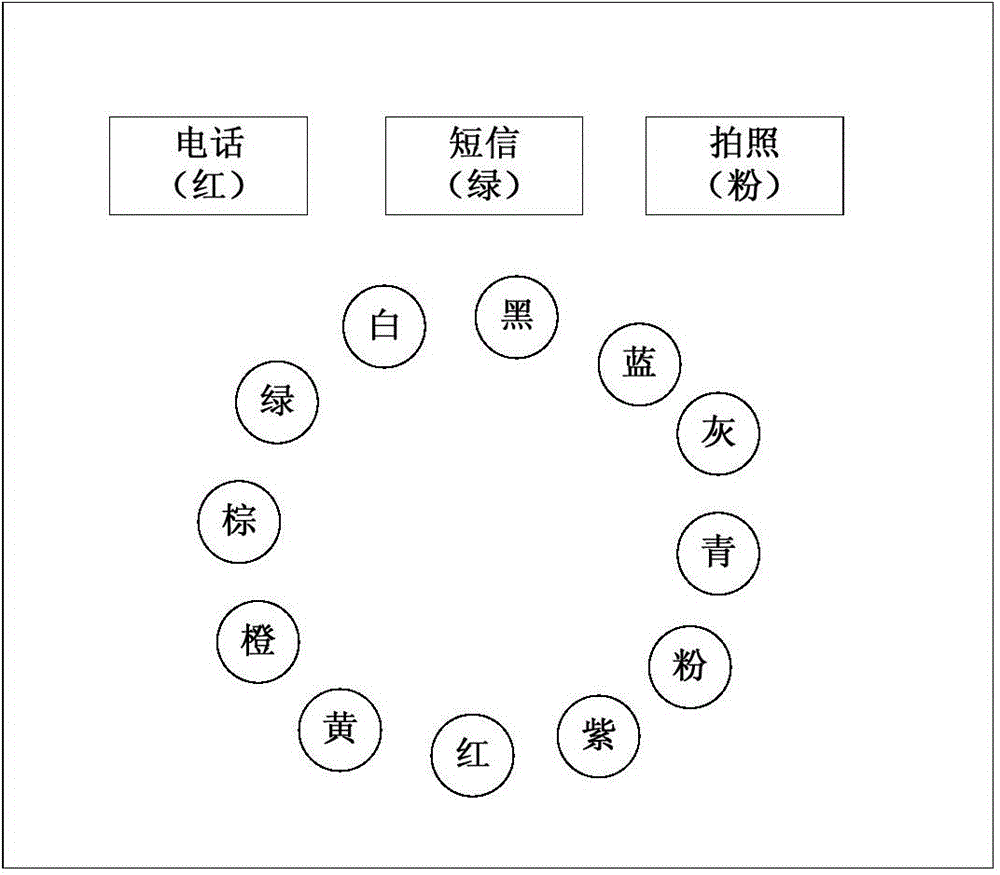

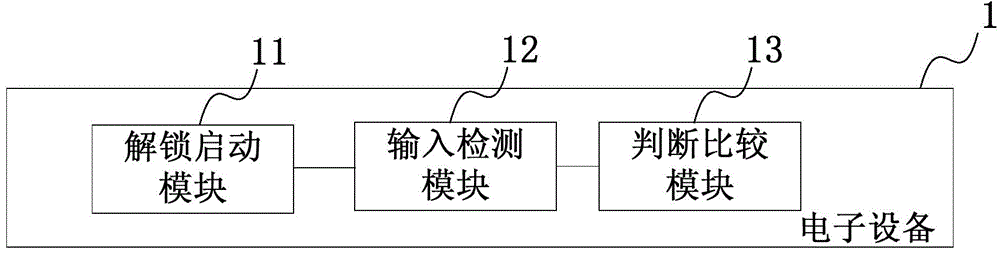

Electronic equipment and unlocking method thereof

InactiveCN104360814ARich pictureGood visual effectInternal/peripheral component protectionInput/output processes for data processingEmbedded systemElectric equipment

The invention provides electronic equipment and an unlocking method thereof. The unlocking method comprises the following steps: when the electronic equipment which is at a user interface locking state detects a screen opening unlocking order, a touch display screen displays a plurality of preset password keys which are randomly arrayed and have basic colors; the contact with the touch display screen is detected and a current password input is obtained according to the contact; whether the colors and quantity of the current password input and a preset password are the same or not is obtained by comparison; if so, the electronic equipment is converted into a user interface unlocking state; if not, the electronic equipment keeps the user interface locking state. According to the unlocking method, an unlocking interface picture is abundant and the visual effect is good; the unlocking is safe and reliable and a phenomenon that the unlocking password is illegally cracked due to the remained trace of unlocking is avoided; a binding procedure can be directly and rapidly accessed and the unlocking method is convenient and intelligent and has better user experiences.

Owner:PHICOMM (SHANGHAI) CO LTD

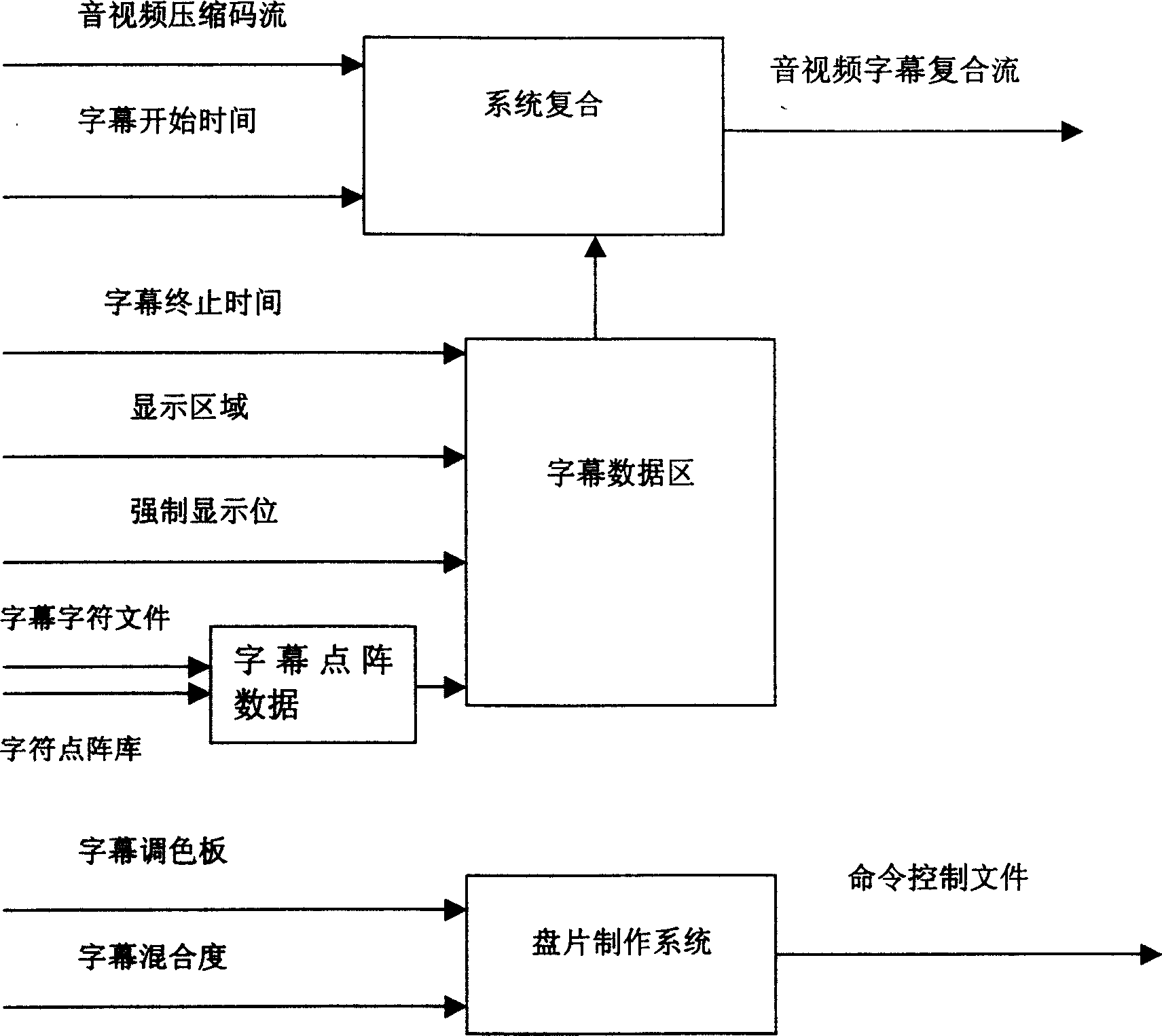

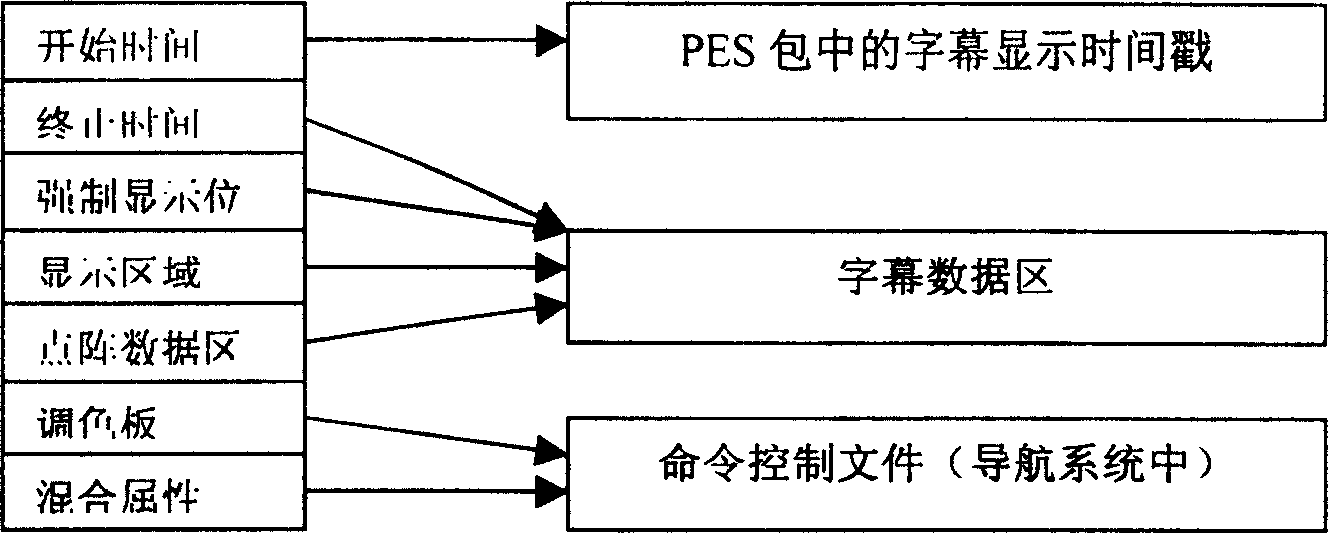

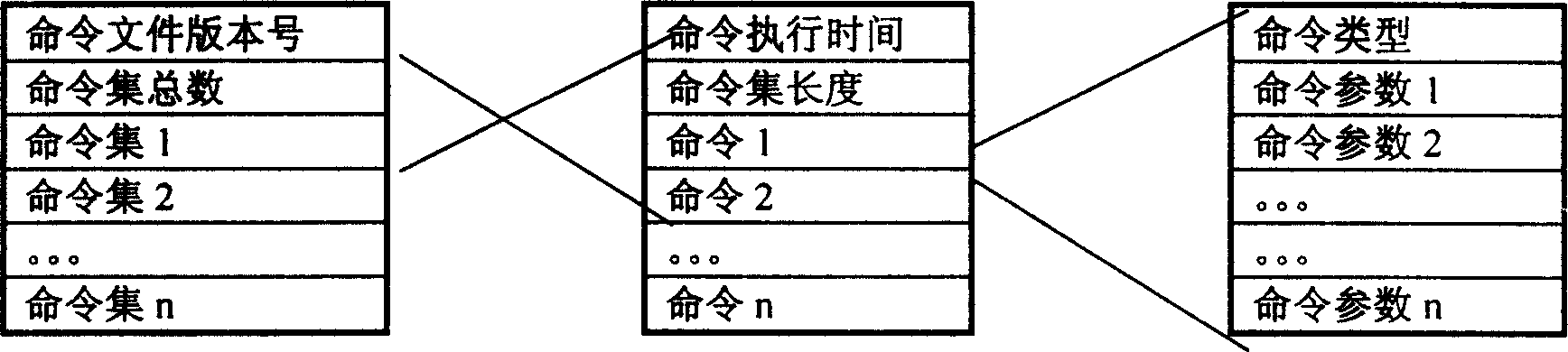

Method of overlaying caption in digital compression video code stream

InactiveCN1561094AEasy to implementGood visual effectTelevision system detailsColor television detailsStart timePilot system

This invention relates to a method for overlapping captions in a digital compression video ASCII stream. The composite ASCII stream is finished by composite process of the system which composites audio, video compressed streams, starting time of captions and a caption data region including caption end time, a display region, a forced display region and a character lattice data composite by its character documents and character lattice base. The command control file in the pilot system is composed of a caption coloring board, and a mixed degree control data generated by a disk generation system.

Owner:AMOLOGIC (SHANGHAI) CO LTD

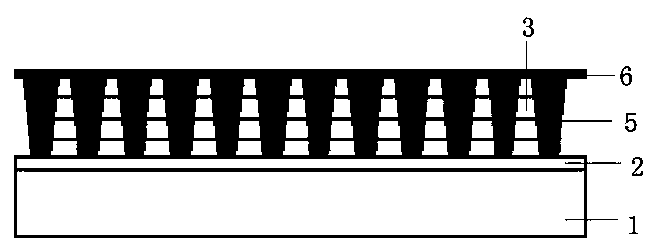

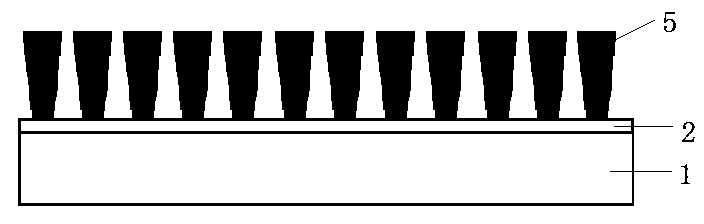

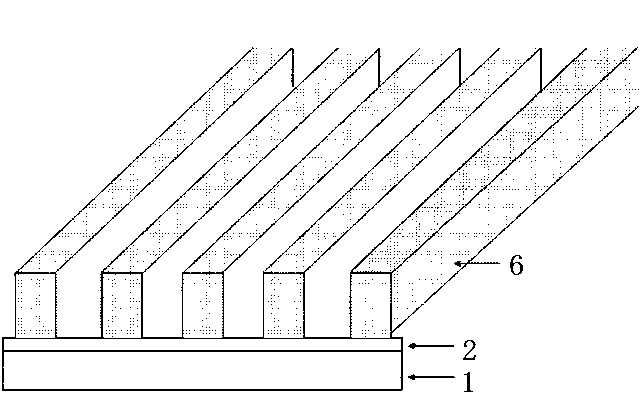

Preparation method of peep-proof membrane

ActiveCN103818074AImprove transmittanceGood visual effectLamination ancillary operationsSynthetic resin layered productsSolventChemistry

The invention discloses a preparation method of a peep-proof membrane, comprising the following steps: 1) coating a PET layer with UV resin for forming so as to prepare a first transparent resin layer which covers the PET layer and several columns of raised units which are uniformly distributed on the first transparent resin layer; 2) carrying out wet-type coating in gaps between the raised units with a black or grey filler; 3) removing a surface layer formed by the black or grey filler on the top of the peep-proof membrane; 4) roasting: a solvent in the filler is volatilized, solid components in the filler are deposited on the bottom of the gaps and a thin layer is adhered to the side surface of the gaps; and 5) second transparent resin is filled between the raised units. Refractive index of the second transparent resin is lower than refractive index of the first transparent resin, and a protection layer is formed on the top of the peep-poof membrane by the second transparent resin. Light transmittance of a viewable area is enhanced. Visual effect is better. User experiment is more comfortable. In addition, the peep-proof function outside the viewable area of the peep-proof membrane provided by the invention is the same with as effects of a traditional peep-proof membrane.

Owner:SUZHOU CHENGBANG DALI MATERIAL TECH

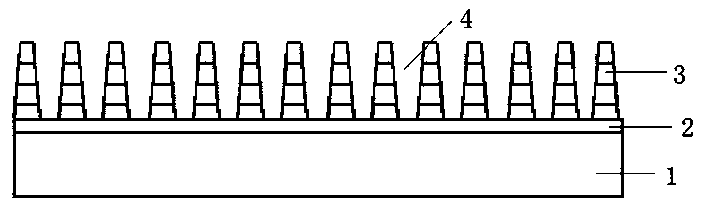

Peep-proof membrane

ActiveCN103818076AImprove transmittanceGood visual effectSynthetic resin layered productsTransmittanceEngineering

The invention discloses a peep-proof membrane which comprises a PET layer at the bottom and a first transparent resin layer arranged on the PET layer. the peep-proof membrane is characterized in that several columns of filling units are uniformly arranged on the first transparent resin layer; each filling unit contains a non-transparent filing part which is positioned at the bottom and is connected with the first transparent resin layer and a second transparent resin part positioned on the top; the top of each non-transparent filling part is provided with a cavity; and the second transparent resin part is plugged in the cavity. In comparison with the structure of a traditional peep-proof membrane, the peep-proof membrane provided by the invention has advantages as follows: light transmittance in a viewable area is increased, visual effect is good, and user experience is more comfortable. However, peep-proof function outside the visual area in the invention is the same as the effect of the traditional peep-proof membrane.

Owner:昆山倬跃蓝天电子科技有限公司

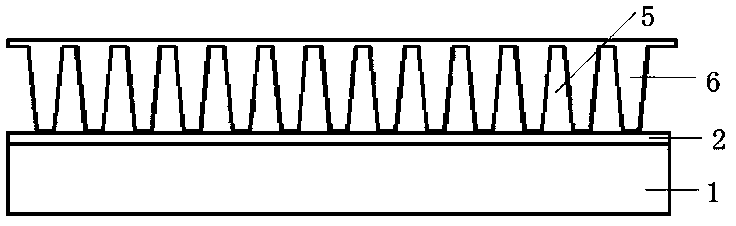

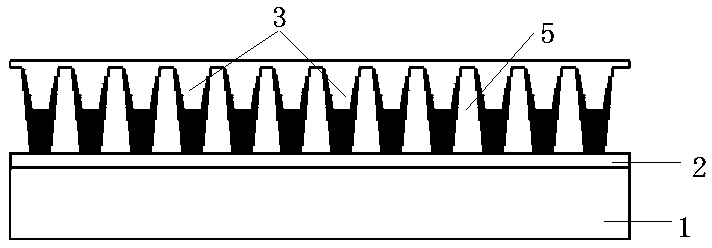

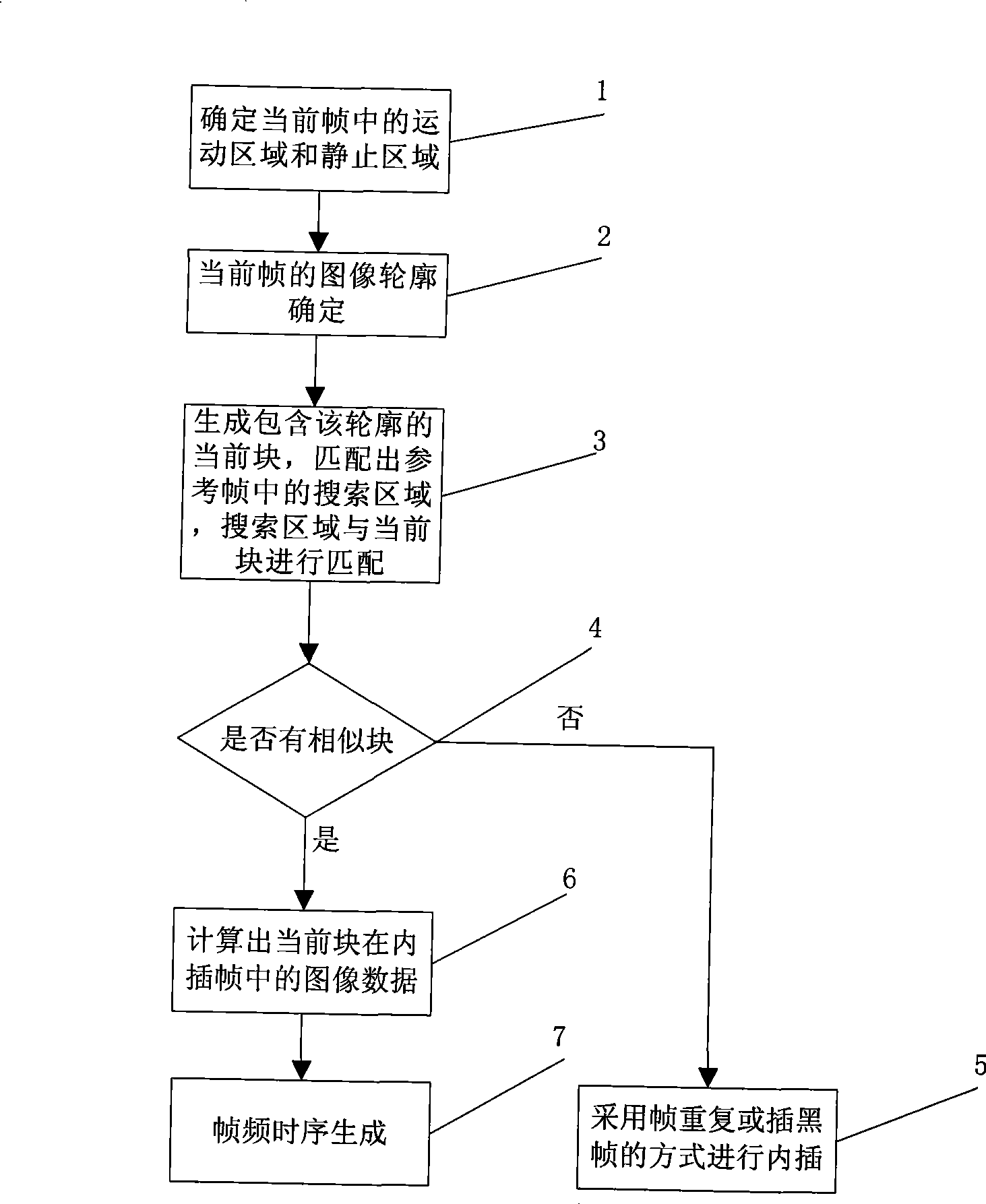

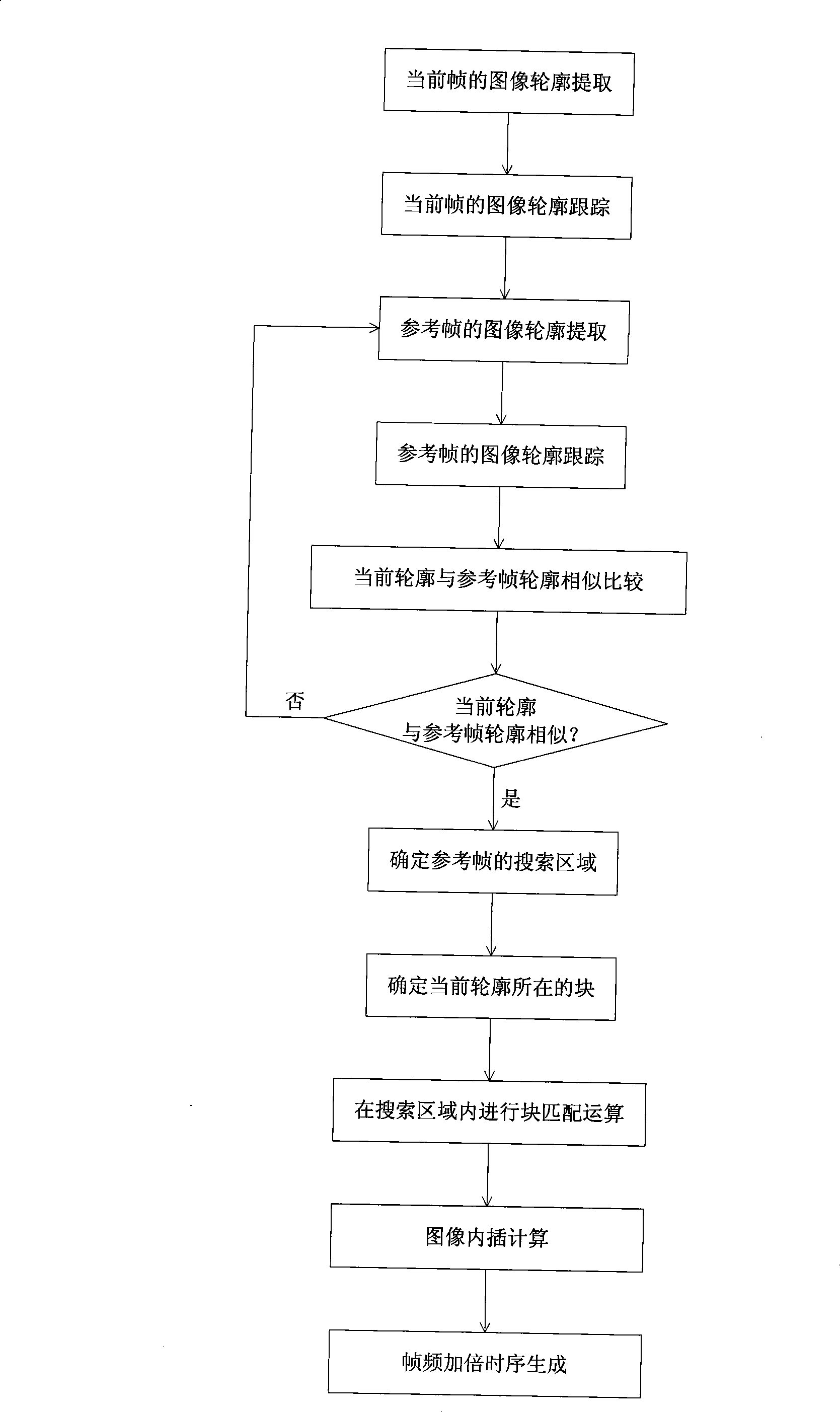

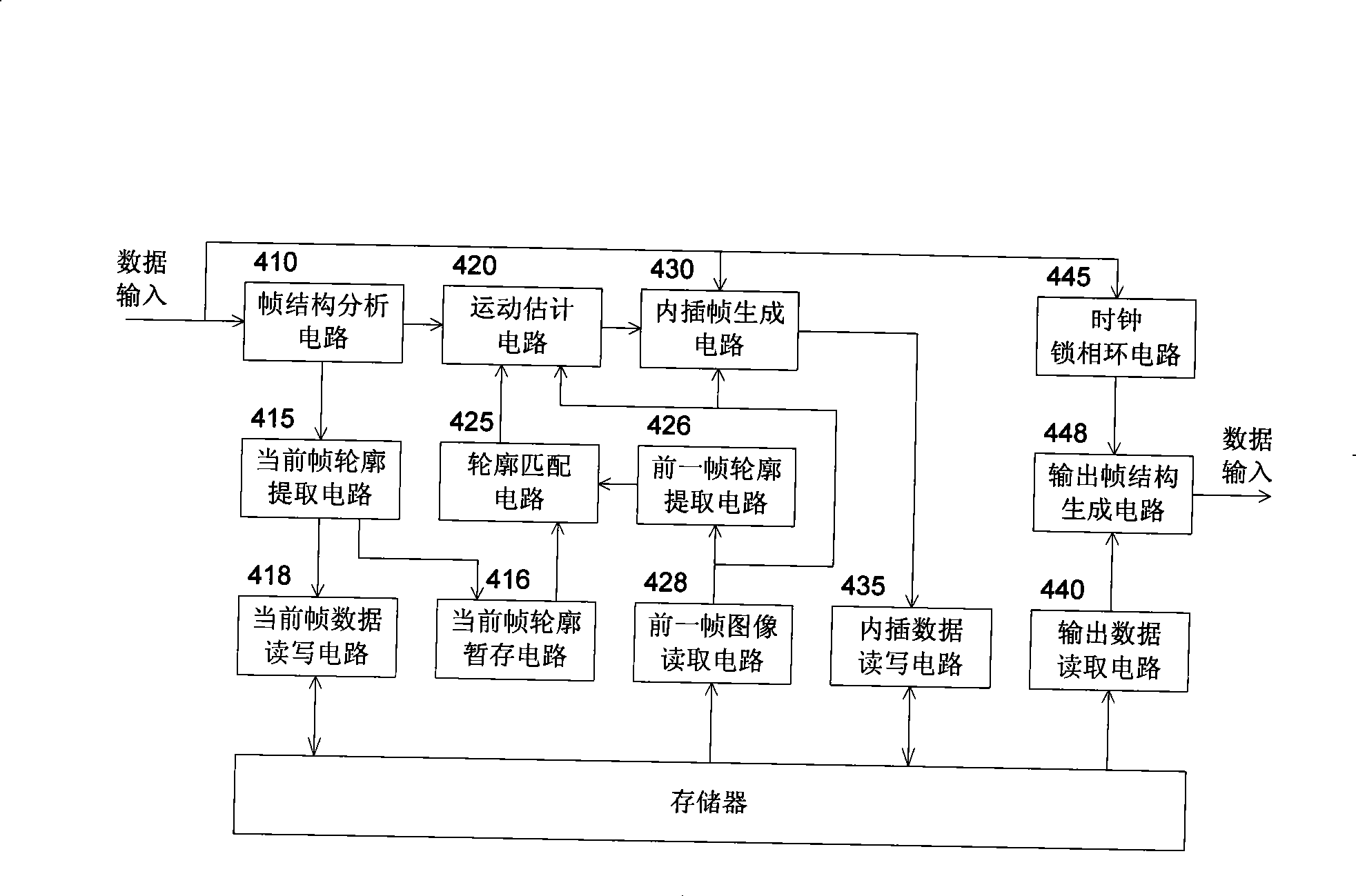

Method for frame frequency doubling based on image profile matching

InactiveCN101399950AGood visual effectRemove motion blurTelevision system detailsColor television detailsFrame timeLiquid crystal

The invention relates to a method for frame frequency doubling method based on image contour matching. The inventive method compares present frame with reference frame, and determines movement area and static area of present frame; edge detection of the movement area is performed to determine present contour of image in movement area; generating present block containing the contour according to determined present contour, matching search area of reference frame, and searching block similar to present block in search area by matching rule; executing interpolation by adopting frame repetition or black frame insertion; calculating image data of present block in interpolation frame; generating frame frequency doubling time sequence and outputting interpolation frame image data of present frame and then image data of present frame in a frame time according to time sequence. The invention processes 50 frame / second and 60frame / second non-interlaced signal based on image contour matching, provides better visual effect at 100Hz / 120 Hz liquid crystal screen, achieves goal for removing movement blurring.

Owner:上海携昌电子科技有限公司

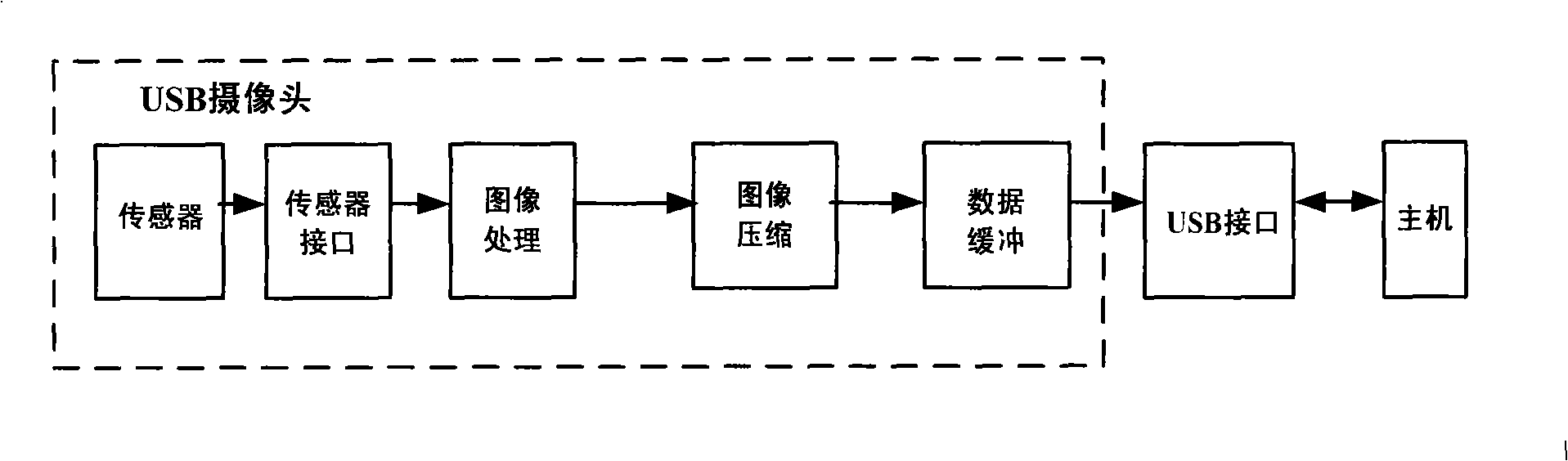

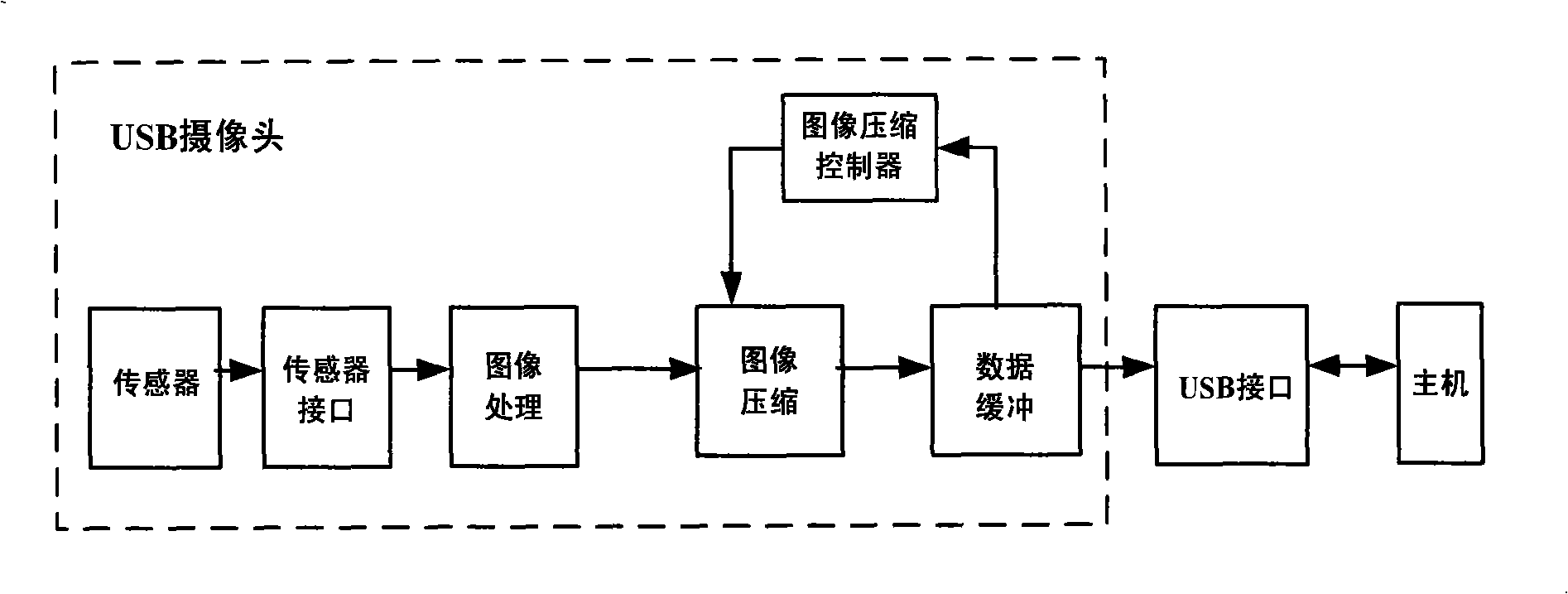

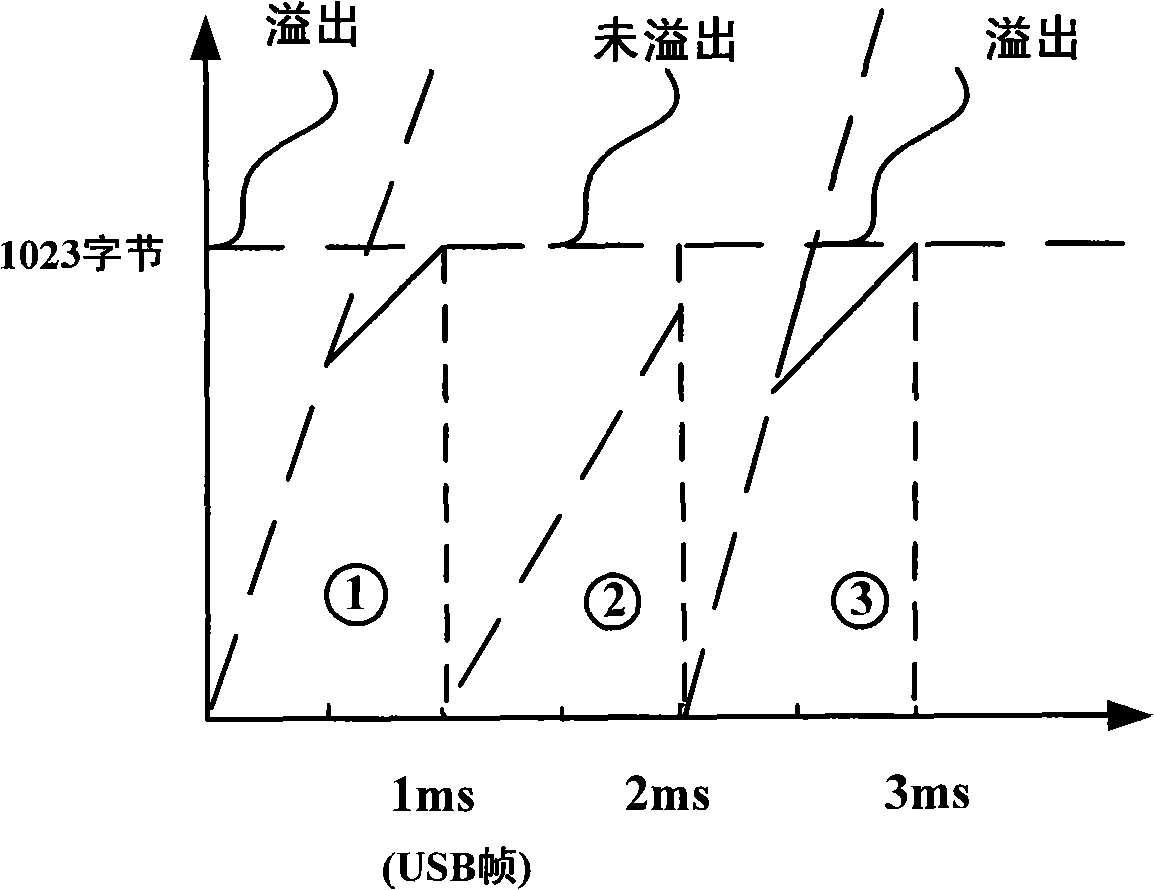

Method and apparatus for real-time image data transmission

InactiveCN101299808AImprove bandwidth utilizationImprove image qualityTelevision system detailsColor television detailsImaging qualityImage transfer

The invention discloses a data transmission method used in the image transmission system and a device, comprising: a device for real-time receiving the image data, wherein the device divides the received image data into a plurality of image blocks to real-time transmit to the host computer through a USB interface, also comprises a buffer area with the capacity MAXP, a buffer, an image compression controller and an image compressor. The image compression controller performs the computation according to the size of the residual capacity of the buffer, and controls the compression format algorism based on the computed result. The device and the method has the advantages of better image quality, high compression SNR, good vision subjective effect and high availability of the USB bandwidth.

Owner:BEIJING SIGMACHIP CO LTD

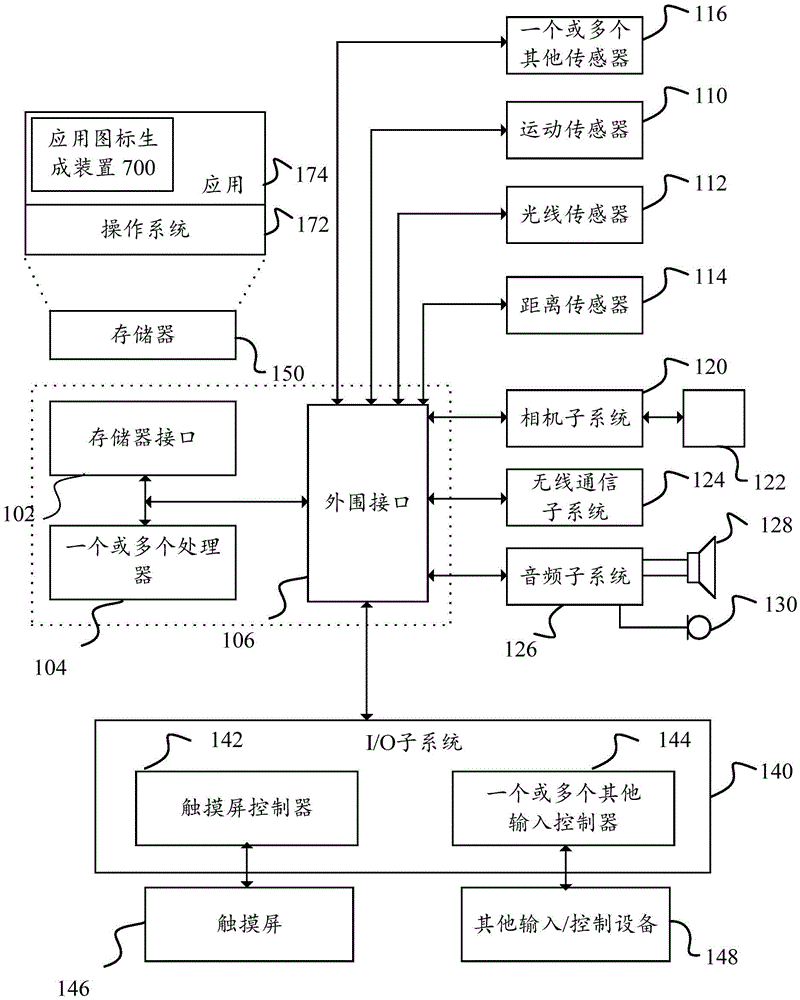

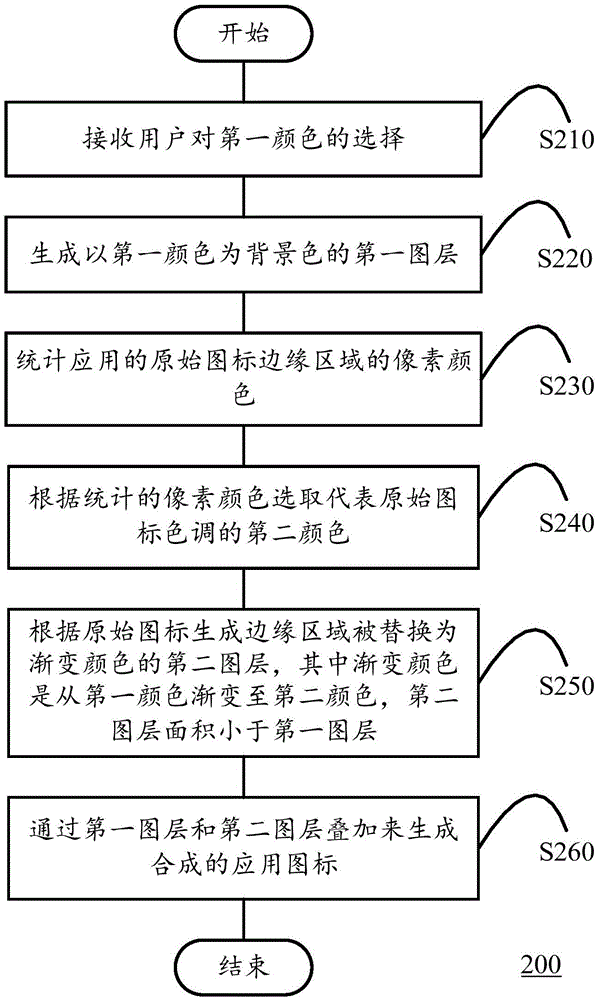

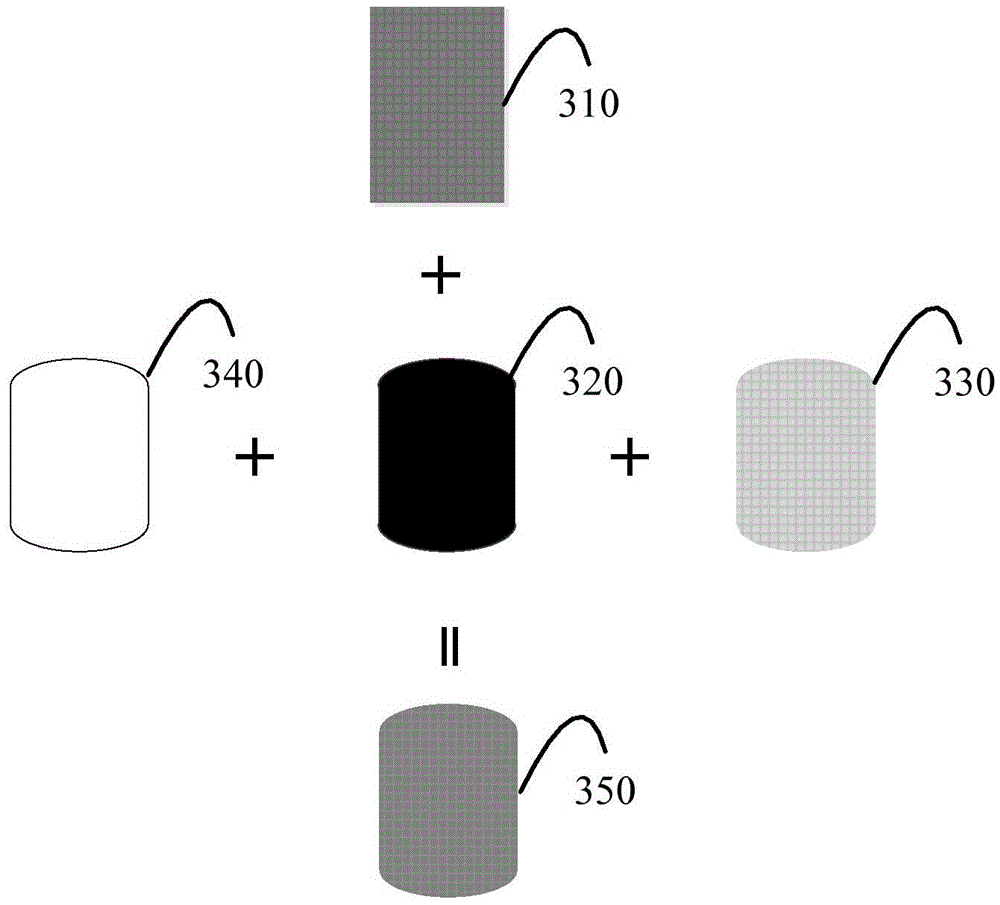

Application icon generation method and device as well as mobile terminal

ActiveCN105653128AReduce varianceEasy to integrateInput/output processes for data processingComputer graphics (images)Change color

The invention discloses an application icon generation method and device as well as a mobile terminal. The application icon generation method is suitable for being executed in the mobile terminal. The method comprises the following steps: receiving a selection of a user for a first color; generating a first image layer taking the first color as background color; carrying out statistics on pixel colors in the marginal area of an original icon of an application; selecting a second color which represents the tone of the original icon according to the pixel colors; generating a second image layer, the marginal area of which is replaced by a gradually changing color, according to the original icon, wherein the gradually changing color gradually changes from the first color to the second color, and the area of the second image layer is less smaller than the area of the first image layer; and finally overlapping the first image layer and the second image layer to generate a synthesized application icon.

Owner:XIAMEN MEITU MOBILE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com