Patents

Literature

106results about How to "Enhance the three-dimensional sense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing color double-face symmetrical pattern jacquard

InactiveCN101104972AGood visual effectEnhance the three-dimensional sensePattern making devicesLayered structureContinuous production

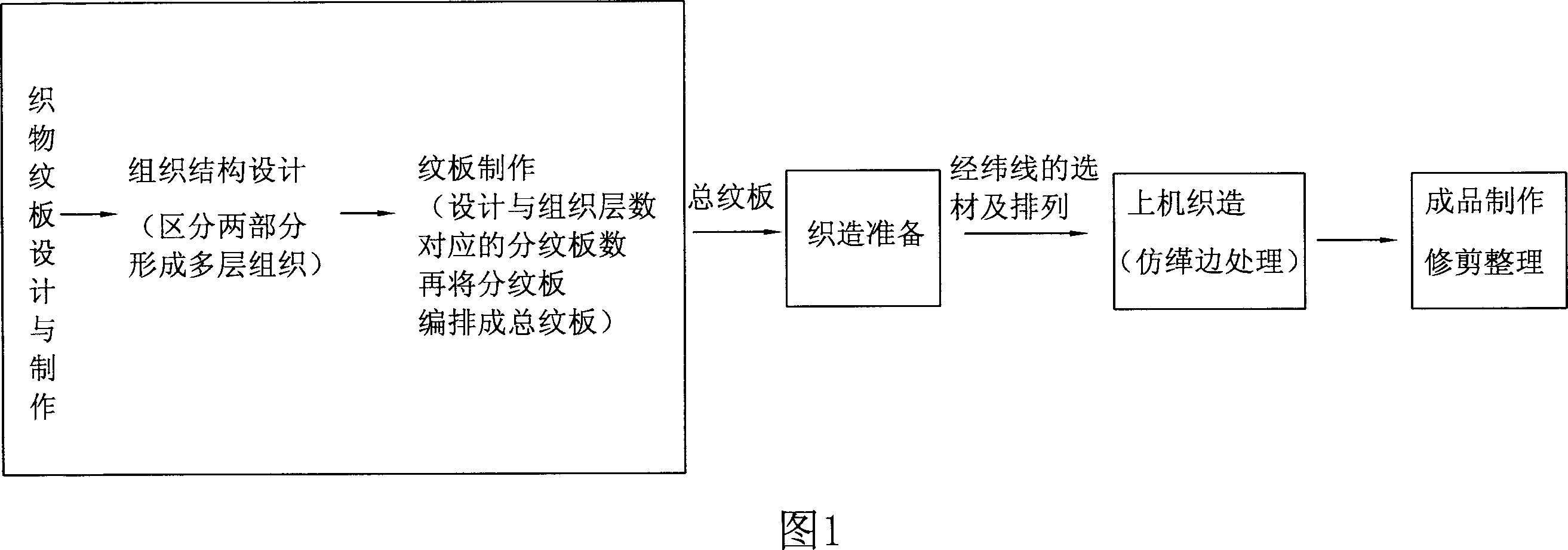

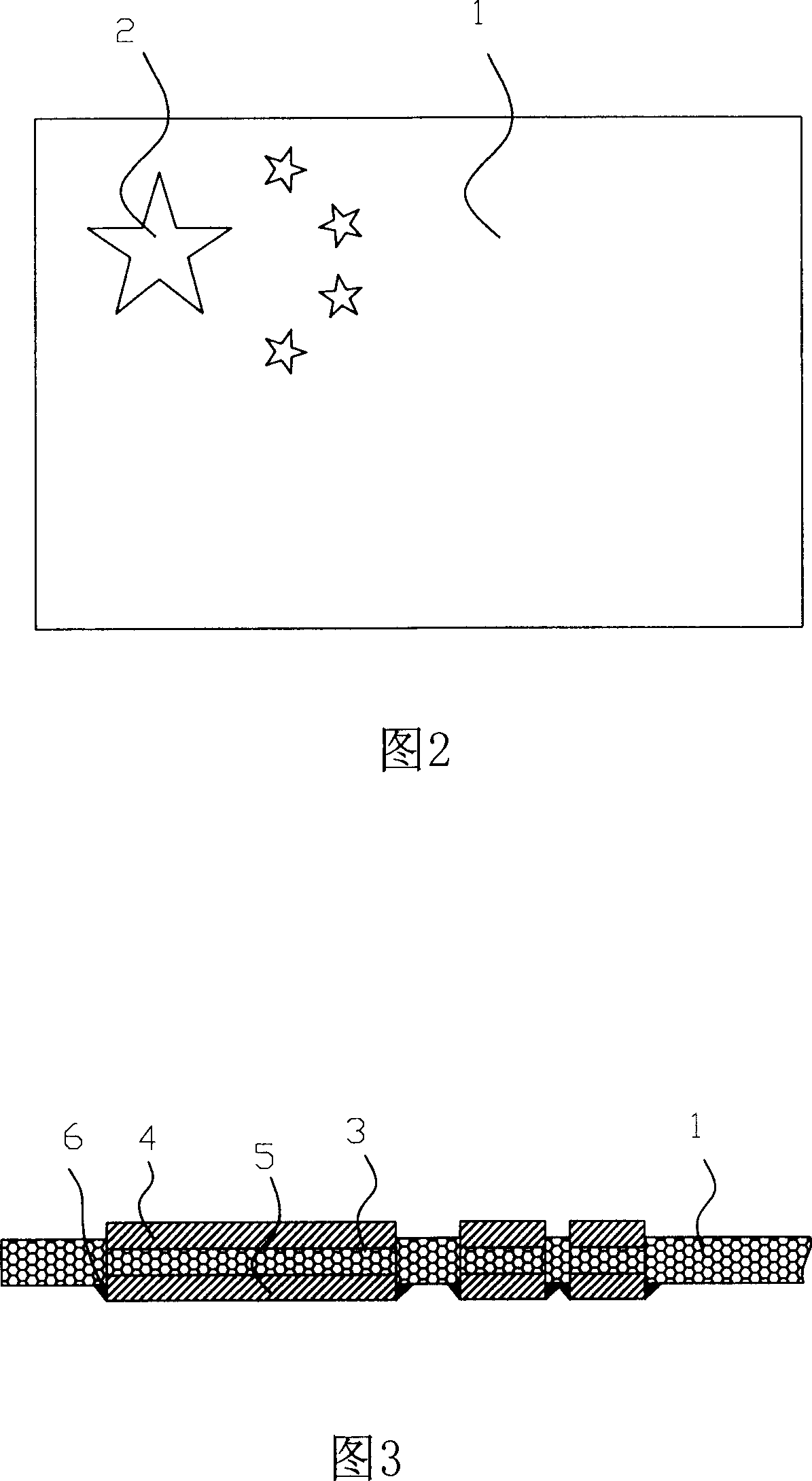

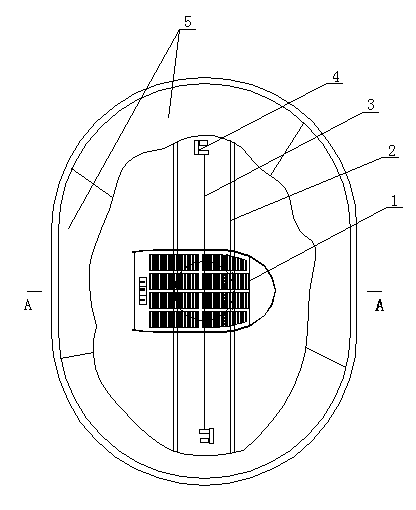

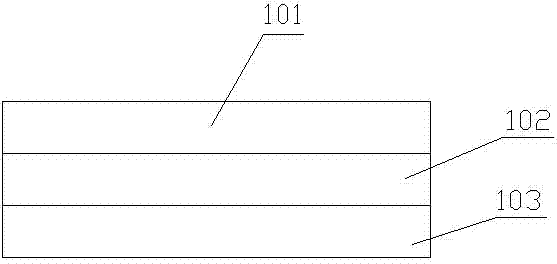

The invention relates to a production method of jacquard fabric with colored symmetrical patterns on double surfaces. The production method comprises the following steps: (I) design and production of fabric pattern card; (II) weaving preparation; (III) machine weaving; and (IV) finishing. The step of design and production of fabric pattern card comprises (1) inputting a target image of jacquard fabric to be woven to a computer; (2) adjusting the input image and setting parameters; (3) distinguishing the pattern part and the basic part of the target image, wherein the pattern part is symmetrically overlaid on the surface of basic part, so that the basic part has single-layer structure and the pattern part has three-layer structure; and (4) making pattern card and inputting an electronic jacquard machine. The invention has the advantages that the produced fabric has multi-layered structure in the pattern part alone; the pattern has two or more colors on double surfaces and is symmetric, thin and soft; and the fabric is integrally woven in one process, facilitating the batch and continuous production.

Owner:李加林

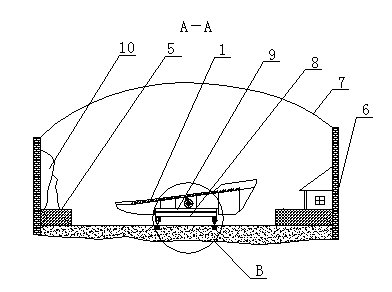

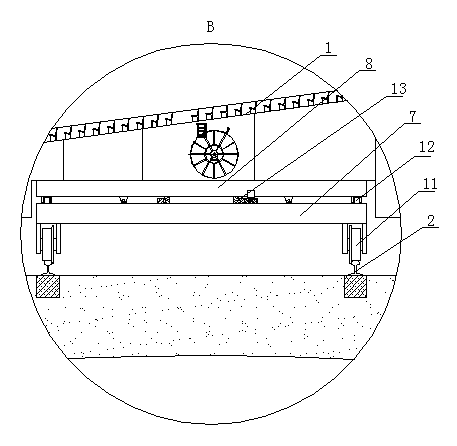

Large-sized live-action performance theatre

InactiveCN103061546AEnhance the three-dimensional senseEasy to operateStage arrangementsGrandstandsSound systemEngineering

The invention provides a large-sized live-action performance theatre and relates to a theatre structure for performing. The large-sized live-action performance theatre comprises a theatre, performing stages and a grandstand, wherein the top face of the grandstand is an inclined plane with low front and high back; the inclined plane is provided with seats which are arrayed into a row; and the theatre is internally provided with a lamplight system including a stage lamp, an illumination lamp and the like, and a sound system. The large-sized live-action performance theatre is characterized in that at least three performing places are arranged on the periphery of the theatre; each performing place is provided with a large-sized live-action background landscape prop for one performance and the performing stage; the grandstand can rotate horizontally for 360 degrees and can do straight-line movement in the horizontal direction; and the grandstand and the performing stages are mutually matched and arranged at the center of the theatre and can rotate and move in front of any one performing place. One performance is finished before the grandstand is moved and rotated to be in front of any one performing place; when a program is changed, the grandstand is rotated and moved and performing background and props do not need to be manually exchanged; and the operation is simple and the waste is saved, so that the large-sized live-action performance theatre is applicable to a large-sized live-action performance with the background and props, which are not easy to replace.

Owner:SHANDONG HUAXIA GROUP

Processing method of surface-engraved multicolor aluminum profile

InactiveCN102358099AEnhance the three-dimensional senseColoring firmDecorative surface effectsMetallurgyMetal

The invention discloses a processing method of a surface-engraved multicolor aluminum profile, which can be used for engraving convex and concave floral designs on the surface of the aluminum profile and applying multiple colors of paint so as to achieve the advantages of strong third dimension and good decoration effect. The processing method comprises the following steps of: 1, engraving the surface of the aluminum profile; 2, primarily coloring; and 3, secondarily coloring comprising the procedures of (1), scribing engraving patterns on scribing paper, (2), adhering the scribing paper, (3), blending metal patient, (4), spraying the patient,(5), complementing color, and (6), washing.

Owner:张萌

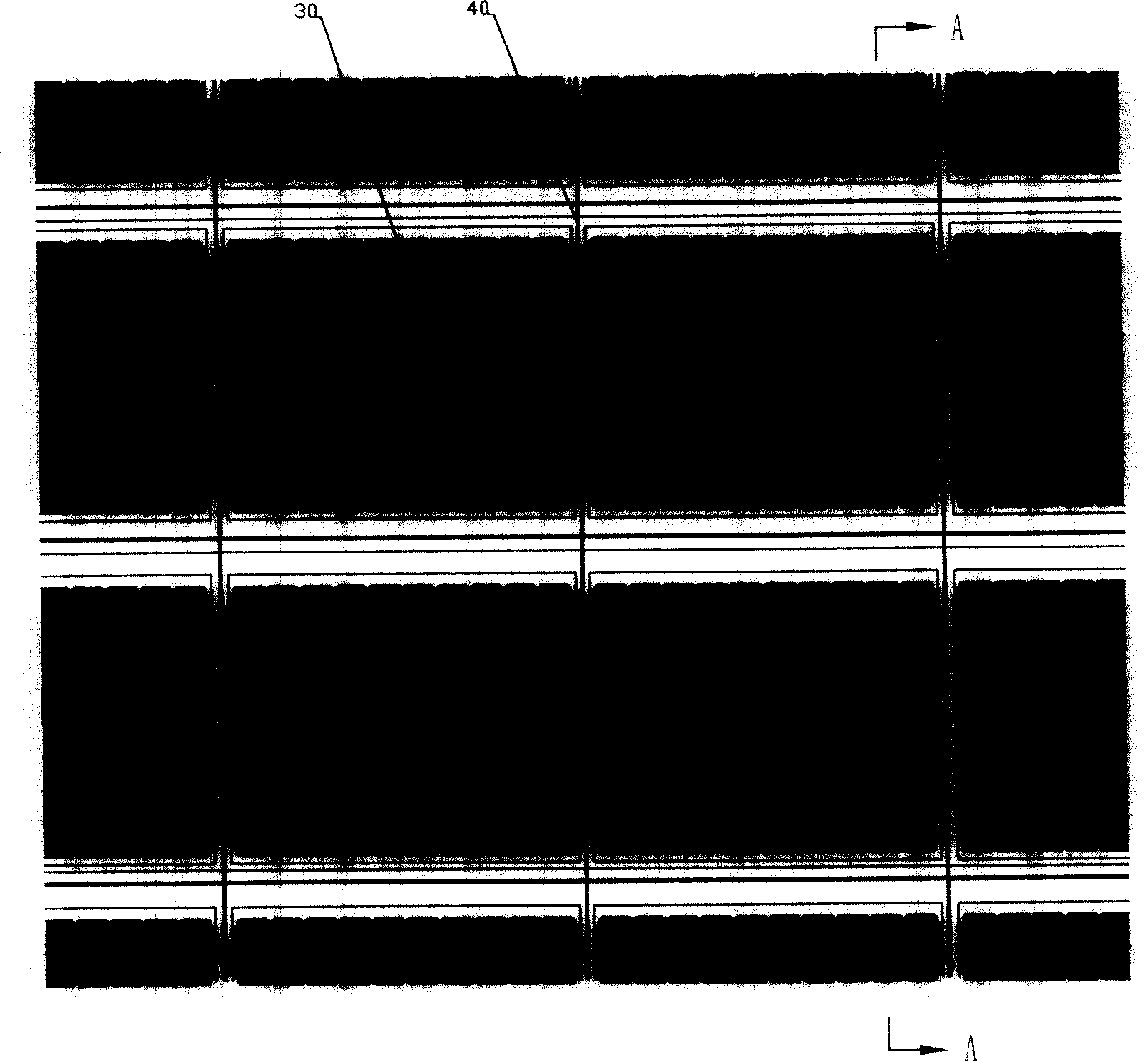

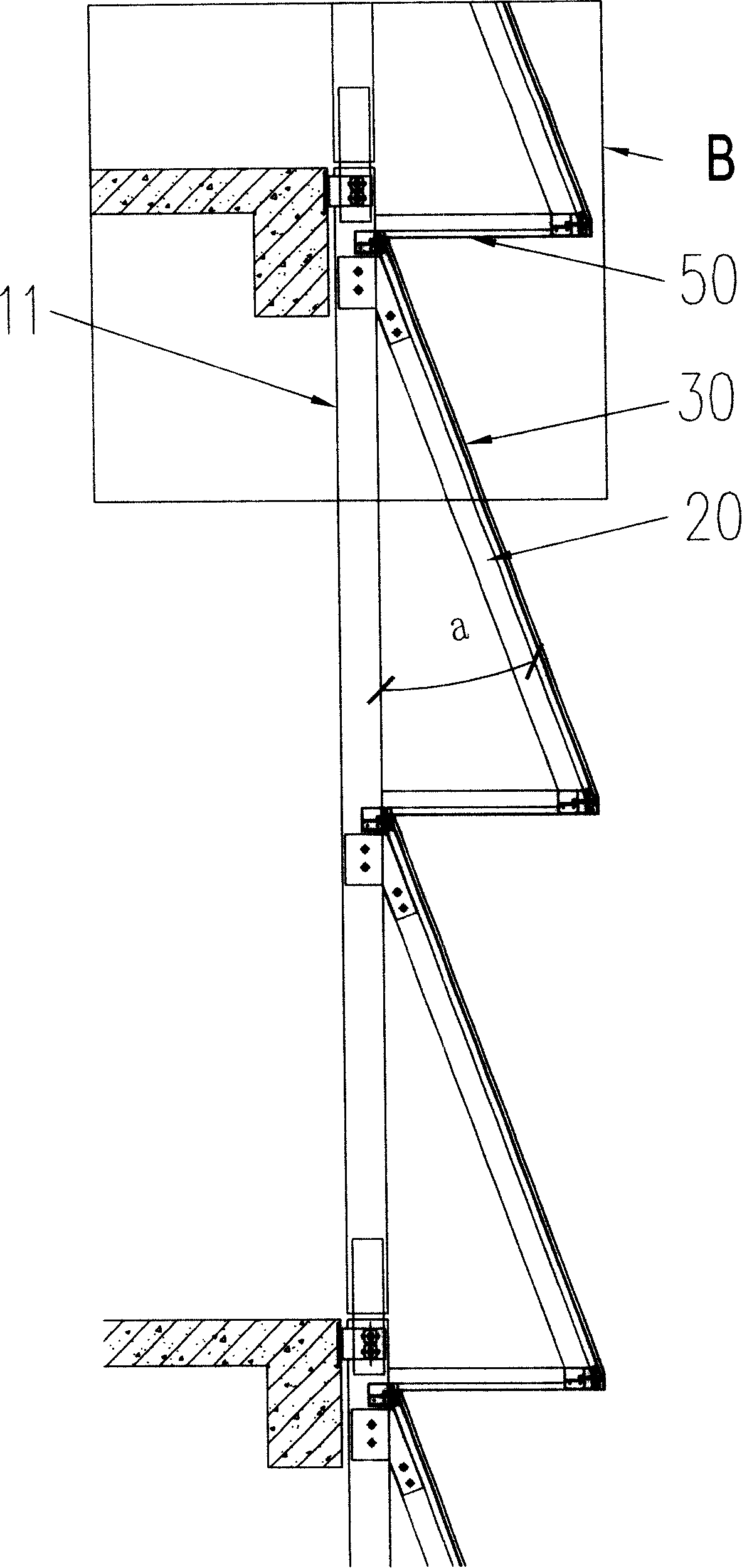

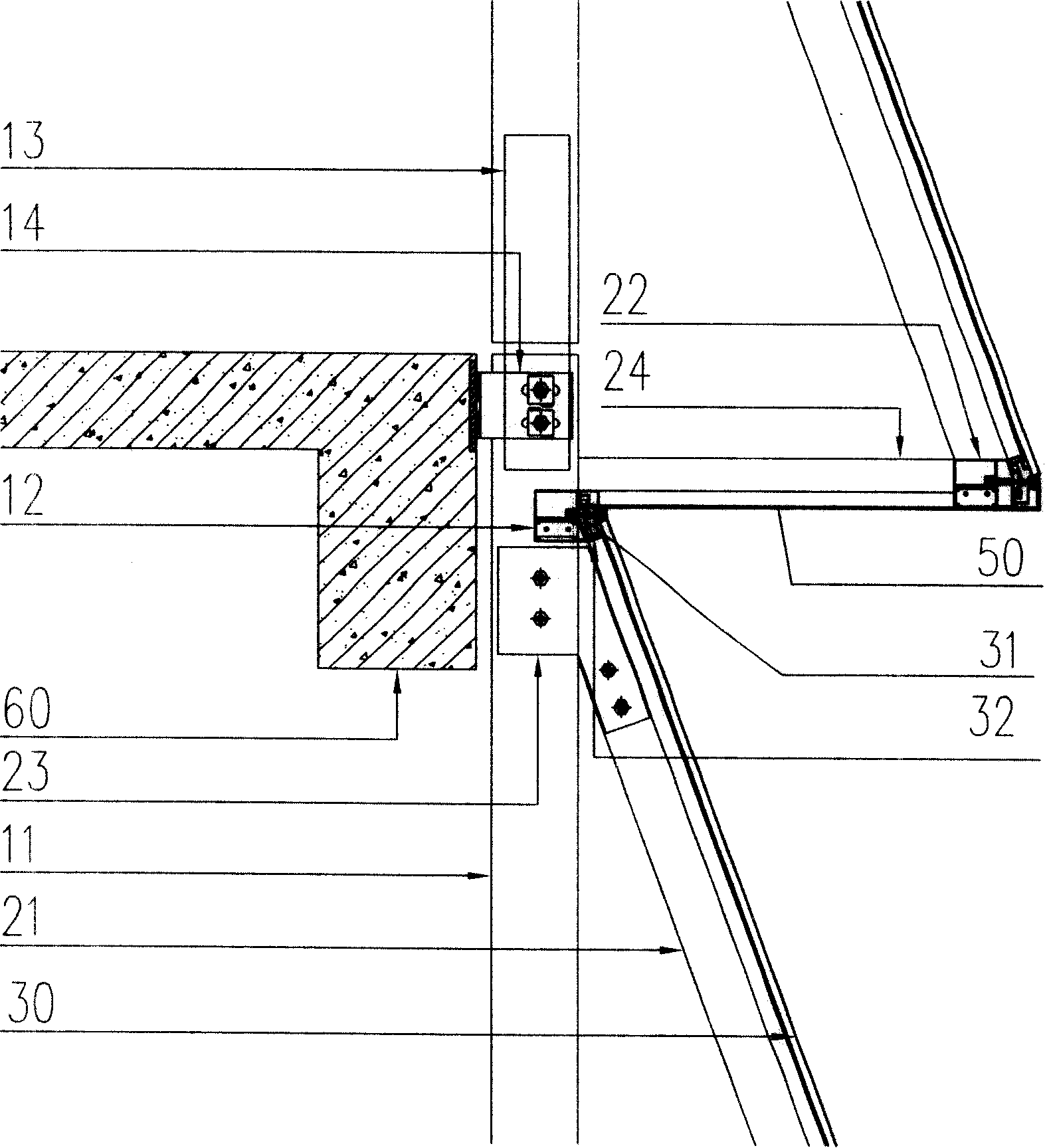

Photoelectric curtain wall of laminated structure

ActiveCN101210444AImprove lighting efficiencyEnhance the three-dimensional senseWallsLamellar structureEngineering

The invention relates to a layered photoelectric curtain wall, which comprises a key keel, a spliced solar photoelectric panel, and a sub-keel forming an included angle Alpha with the key keel. The solar photoelectric panel is fixedly mounted on the outer side of the sub-keel and forms an included angle Alpha with the vertical plane where the key keel is positioned. The light-capturing angle of the solar photoelectric panel can be adjusted by the sub-keel added to the key keel of the curtail wall, thus fitting the angle of sunlight in different regions, enhancing the light-capturing efficiency for solar photoelectric batteries, as well as diversifying the shapes of the curtain wall and increasing the three-dimensional appeal of the curtain wall.

Owner:CHENGDU FANGDA BUILDING TECH CO LTD

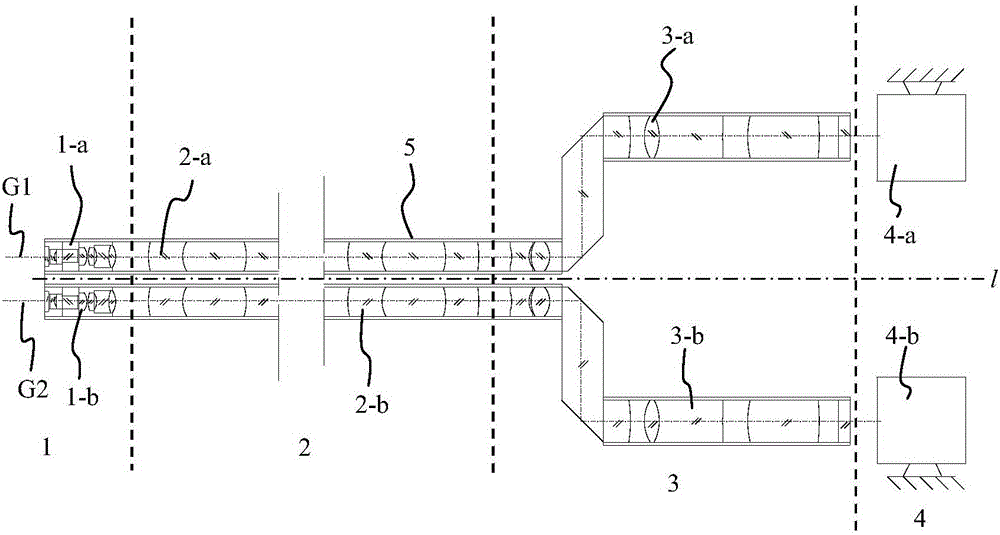

Dual-path 3D laparoscope and dual-path 3D laparoscopic system

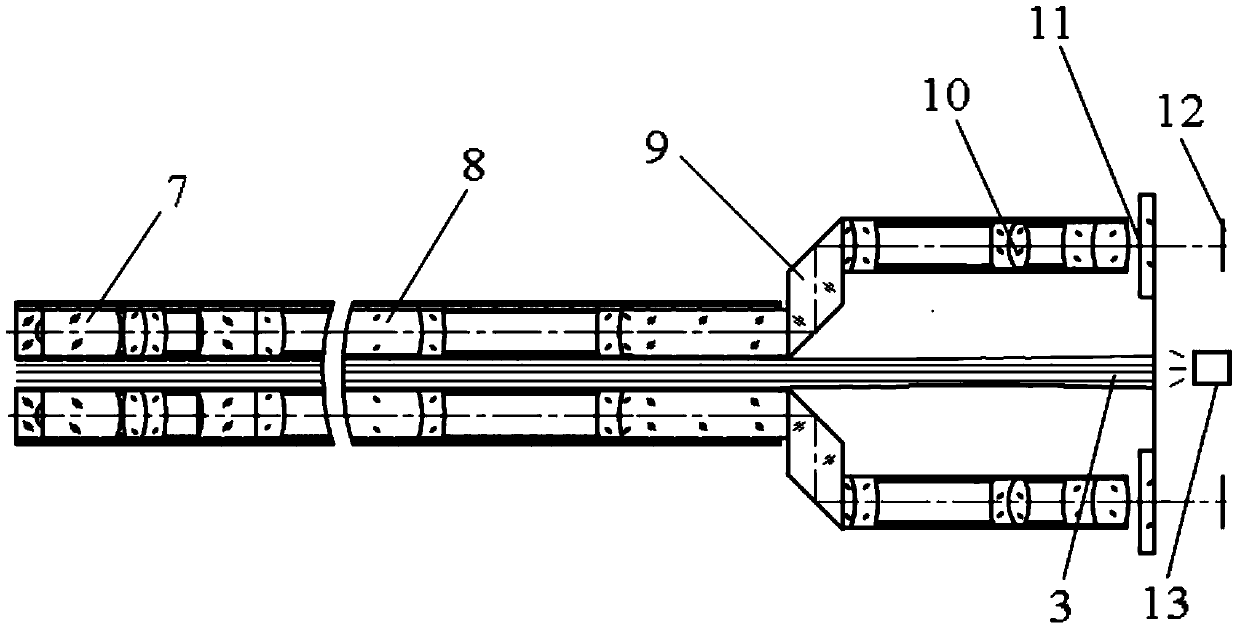

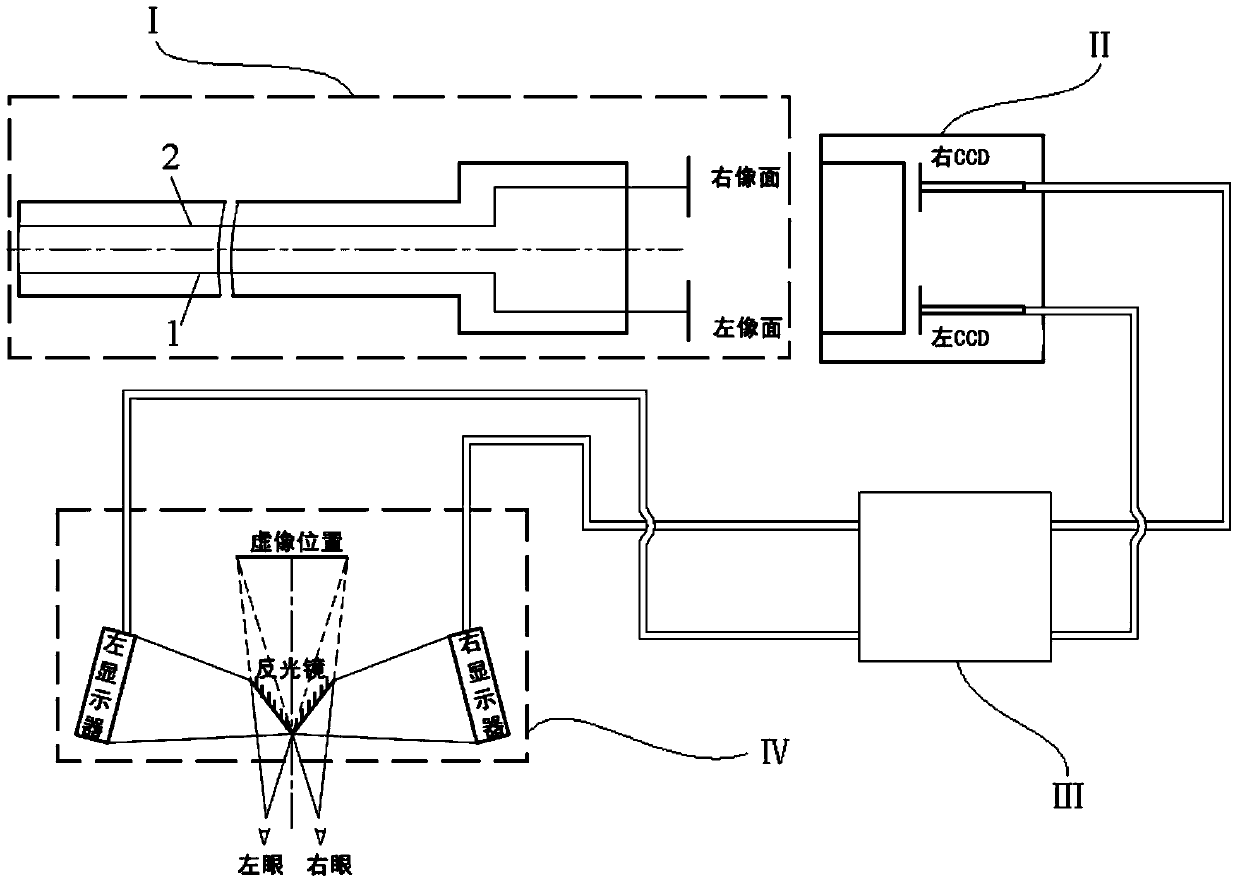

The invention relates to a dual-path 3D laparoscope and a dual-path 3D laparoscopic system, relates to the field of laparoscopes and laparoscopic systems, and solves the problems that presently, foreign 3D laparoscopes are high in cost and domestic 3D laparoscopes do not meet the using standards. The dual-path 3D laparoscope comprises a left light path, a right light path, an upper lighting fiber, a lower lighting fiber, and an outer tube; the left light path and the right light path composed of the full-same structures are formed by sequentially arranging a front objective, a middle image transmission rod lens, a rhombic prism, a rear objective, protective glass and an imaging face in an inner tube. The dual-path 3D laparoscopic system is composed of the dual-path 3D laparoscope, a dual-path CCD camera, an image data processor, and a multi-path precision 3D display. Depth of field of the dual-path 3D laparoscope is 10-180mm, operating length of the outer tube is 330mm, and the depth of field and the operating length both meet the international general requirement of traditional laparoscope for the smallest length; the dual-path 3D laparoscopic system is low in cost and convenient to use.

Owner:JIANGSU KEQIN PHOTOELECTRIC SCI & TECH

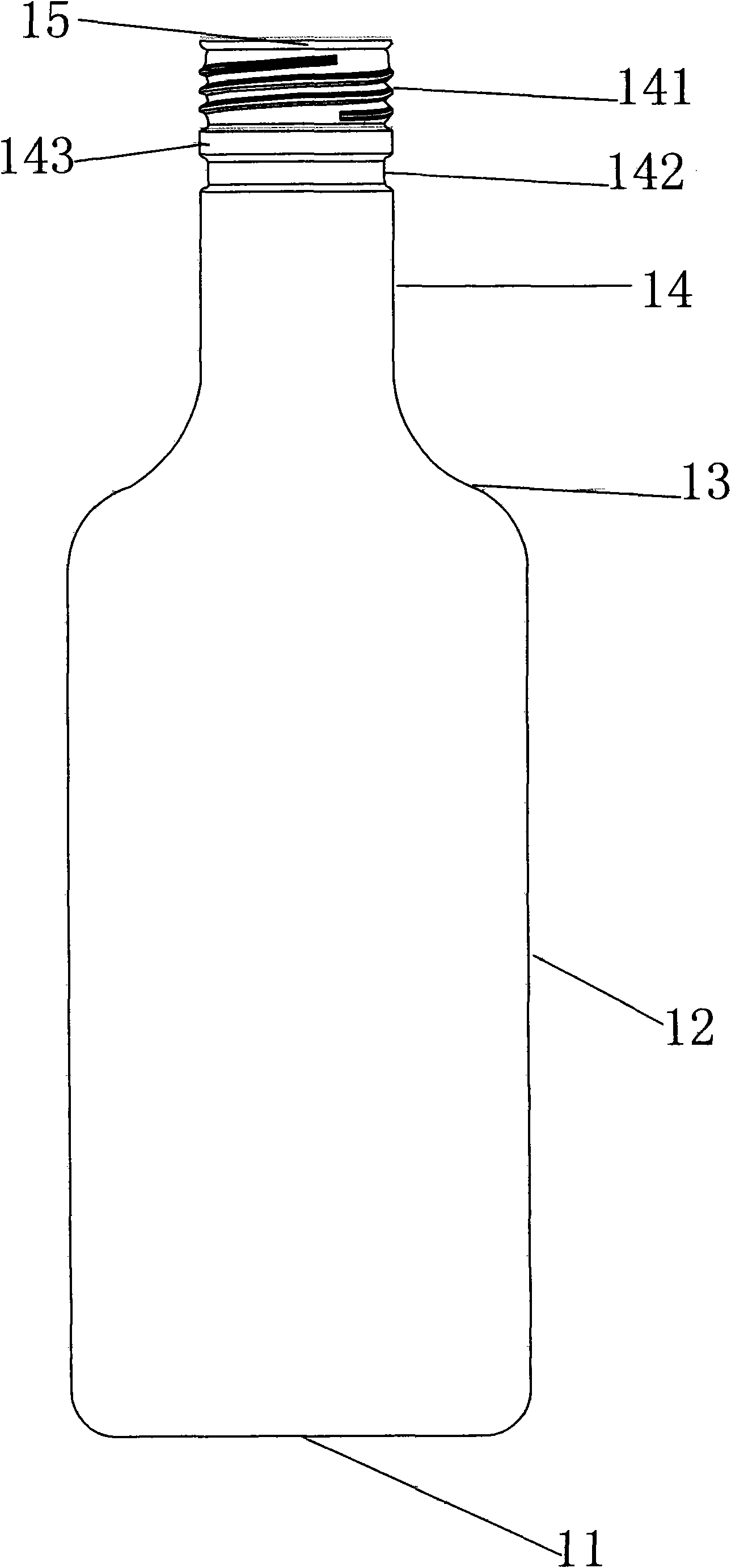

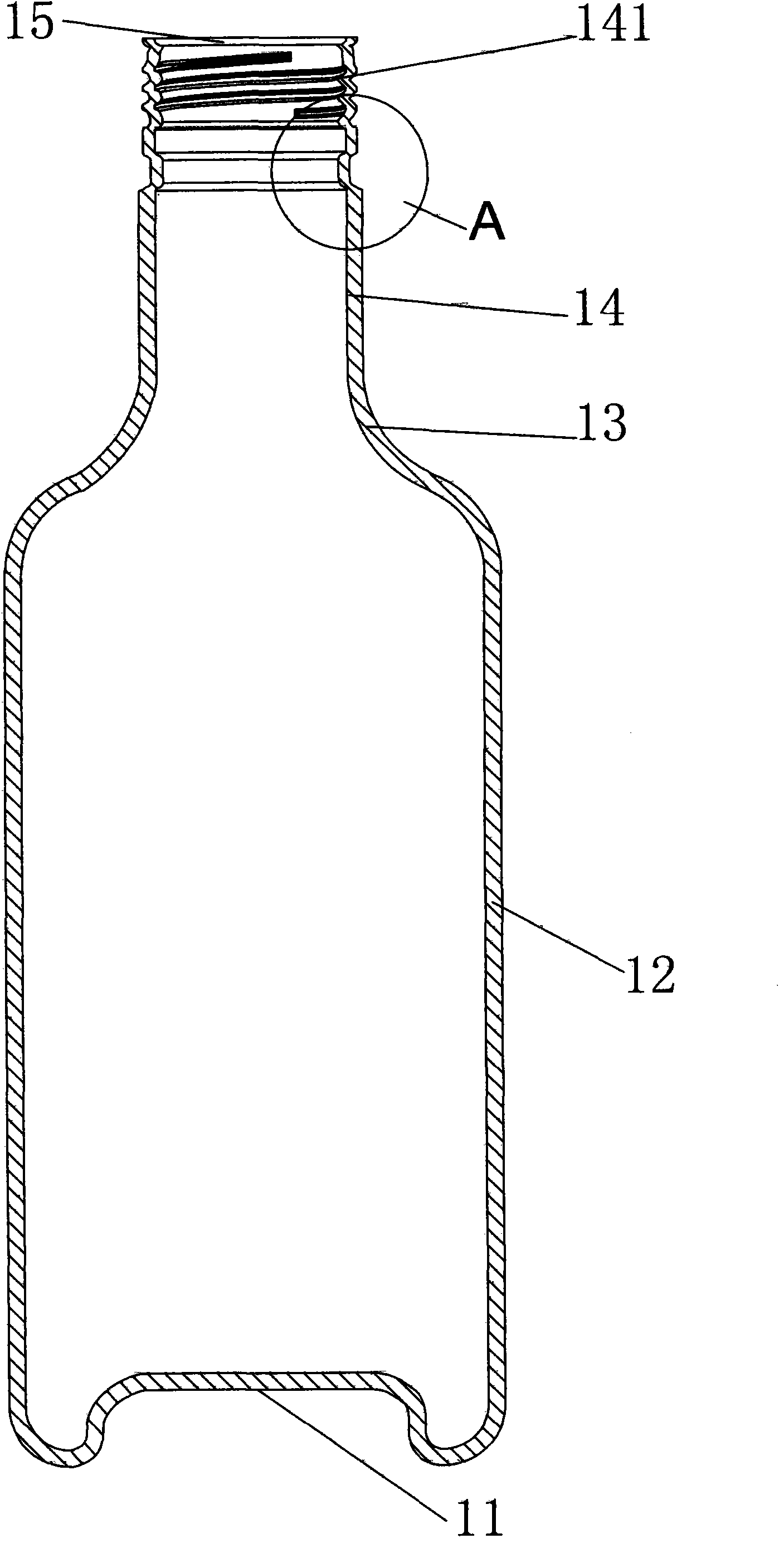

Aluminum screw packaging tin and manufacturing method thereof

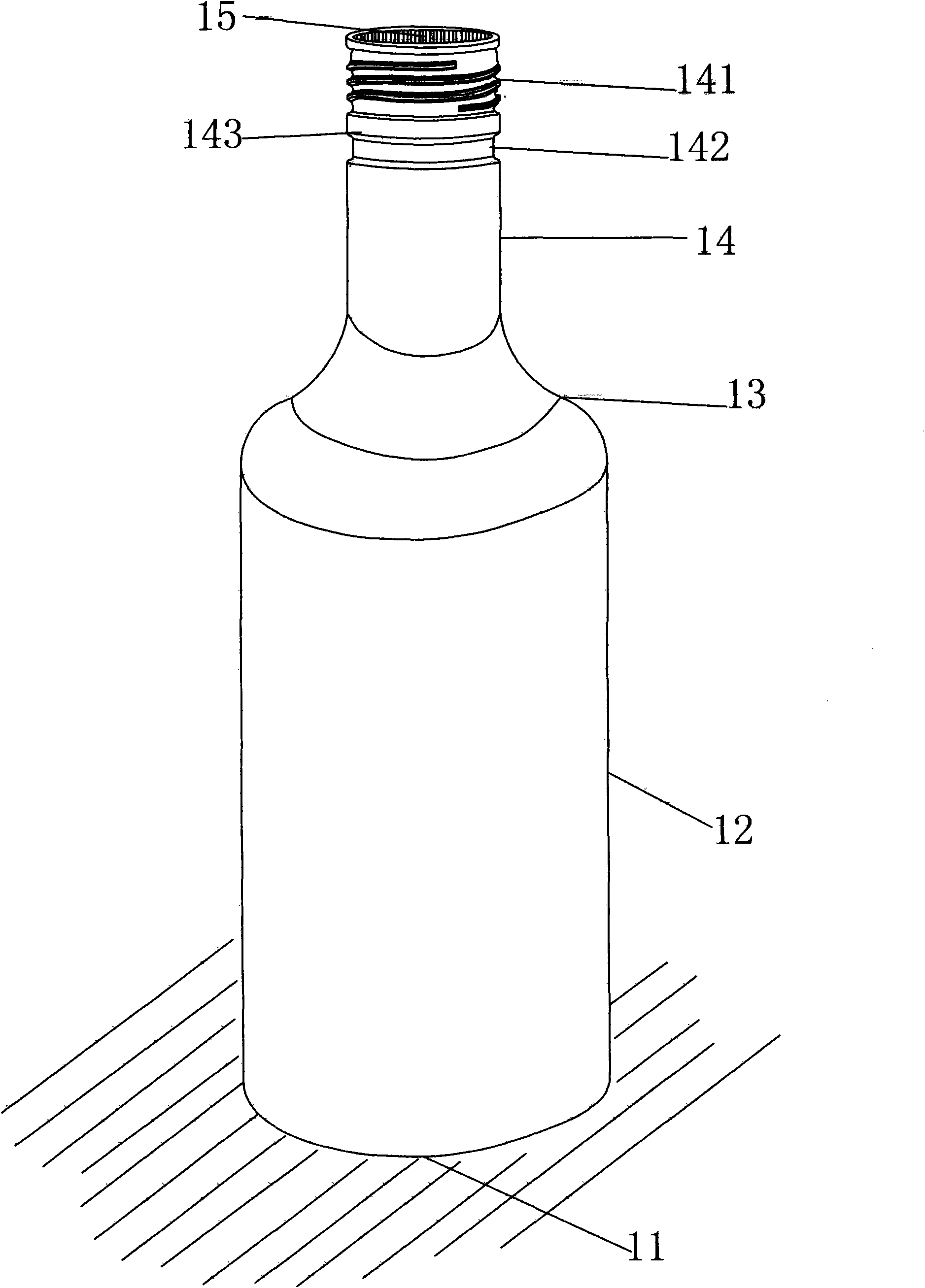

InactiveCN101830303AGood anti-counterfeiting effectEnhance the three-dimensional senseJarsHollow articlesThin walledTin

The invention discloses an aluminum screw packaging tin, which comprises a tin bottom, a tin body, a tin shoulder, a tin neck and a tin mouth, wherein an external thread is arranged on the outer wall of the tin neck, an annular groove is arranged below the external thread in the outer wall of the tin neck, and a convex ring is formed between the annular groove and the external thread. The invention also discloses a manufacturing method of the aluminum screw packaging tin, which comprises the following steps: roasting an aluminum sheet; stamping; trimming; cleaning; carrying out protective treatment; retracting to form the tin neck; and shaping the tin neck: rolling an external thread on the outer wall of the tin neck close to the screw, and then indenting an annular groove below the external thread in the outer wall of the tin neck to form an annular convex edge between the annular groove and the external thread. The invention has advantages of beautiful integral appearance, good visual effect, thin wall, low manufacturing cost, good forgery prevention effect, high added value, high grade and the like, and can fixedly lock the threaded cover locking mouth ring connected with the tin mouth.

Owner:GUANGDONG EURO ASIA PACKAGING

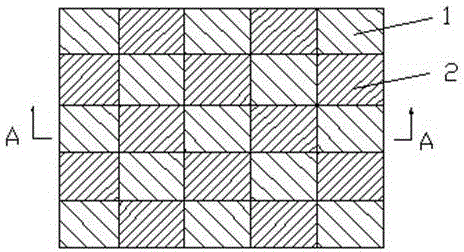

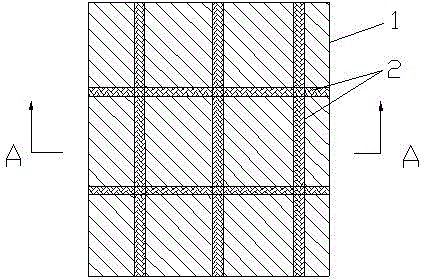

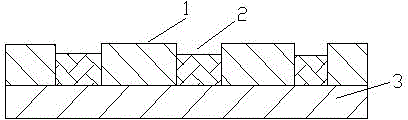

Elastic checked fabric

InactiveCN103820940AEnhance the three-dimensional senseIncrease warmthWarp knittingPolyesterConvex structure

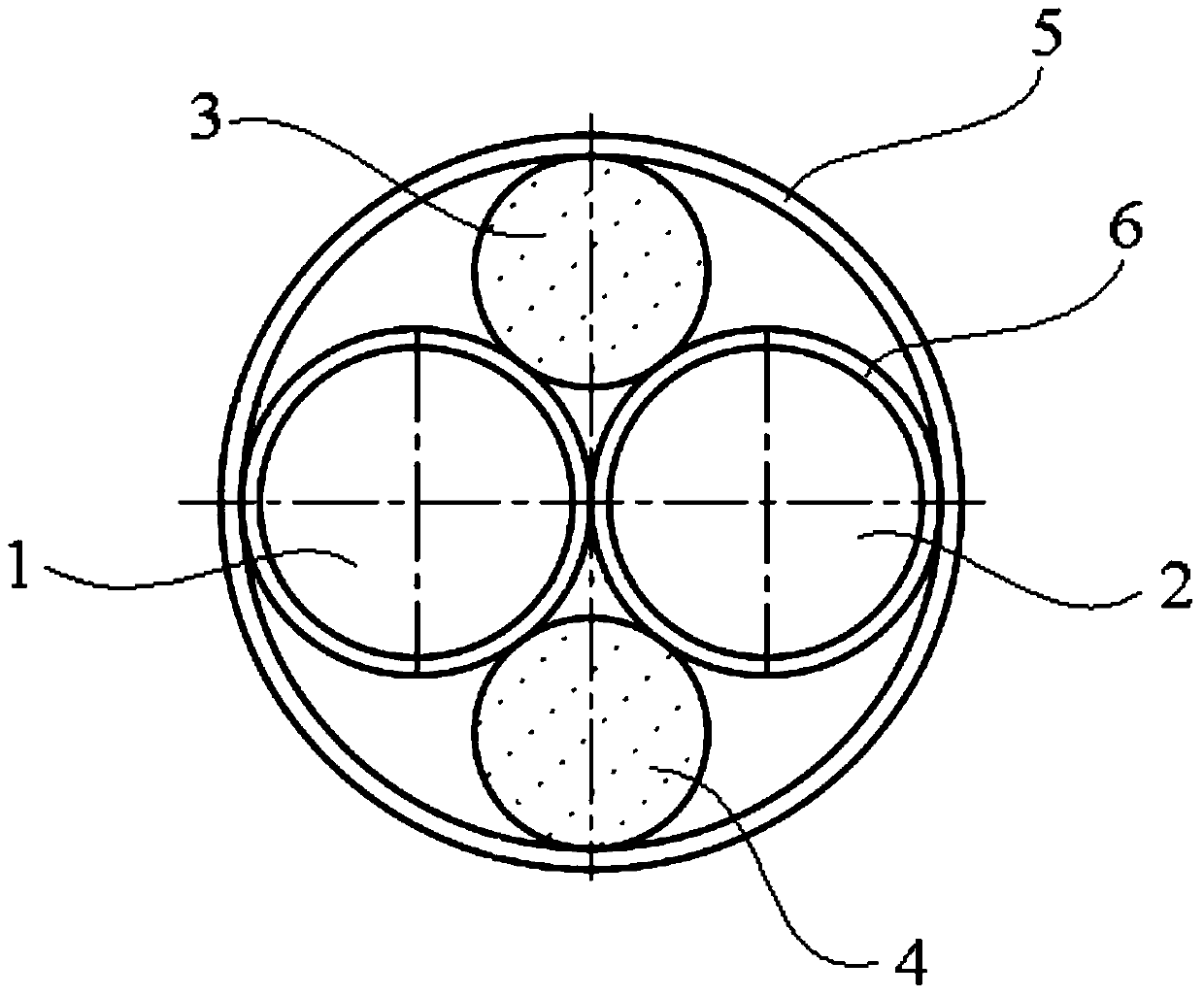

The invention relates to elastic checked fabric, and belongs to the field of textile fabric. The elastic checked fabric comprises a fabric body (1). A plurality of rectangular checks (2) arranged on the fabric body (1) are in staggered arrangement and are embedded in a plane where the fabric body (1) is located. The checks (2) and the fabric body (1) are connected with each other to be integrated as a concave-convex structure. A jacquard layer (3) is arranged on the reverse sides of the fabric body (1) and the checks (2). The fabric body (1) is made of warp knitting fabric. The yarn laying rule is set as 1-0 / 2-3. Surface yarns are made of 75D / 36 T400 fully-stretched polyester fiber filaments, and base yarns are made of FDY 84D / 36F polyester filaments. The cross sections of the T400 hollow fully-stretched polyester fiber filaments are cross-shaped. By the concave-convex structure of the elastic checked fabric, third dimension of the elastic checked fabric is enhanced; by the jacquard layer arranged on the reverse sides of the fabric body and the checks, heat insulation performance of the elastic checked fabric is improved.

Owner:杨洁

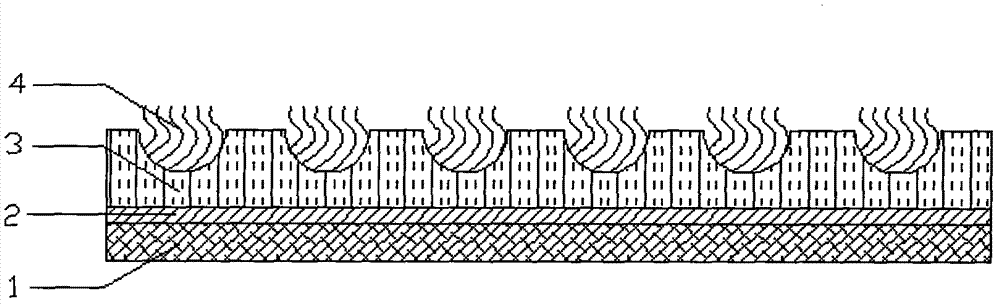

Valley floor flocking wallpaper

InactiveCN103088706AEnhance the three-dimensional senseGood moisture absorptionCovering/liningsSpecial paperNatural fiberEngineering

The invention relates to a valley floor flocking wallpaper which comprises a bottom layer (1), an adhesive layer (2) and a surface layer (3), wherein the bottom layer (1), the adhesive layer (2) and the surface layer (3) are arranged from bottom to top. The valley floor flocking wallpaper is characterized in that a plurality of sunken valleys are arranged on an external surface of the surface layer (3) at intervals, and fuzz (4) which is a natural fiber or an artificial fiber is arranged in valley floors. According to the invention, since the fuzz layer is adhered on the bottom layer through the adhesive layer, stereoscopic impression of the wallpaper is enhanced; and the fuzz layer has the characteristics of good moisture absorption performance and good sound insulation and heat insulation effects, so the valley floor flocking wallpaper is more suitable for household usage as a whole.

Owner:孟莉莉

Method of making patterns on the surface of metal

InactiveCN1810523AEnhance the three-dimensional senseImprove aestheticsDecorative surface effectsSpecial ornamental structuresPrint-throughContour line

One simple method of making stereo patterns on the surface of metal is disclosed. The technological scheme is that the stereo pattern making process includes the following steps: 1. carving outer contour of the patterns with carving tool; 2. carving all the contour lines with carving tool; and 3. forming scratches and dense points inside the contour lines with carving tool. The stereo pattern making process also includes the steps of designing patterns on paper and over printing through adhering the paper with patterns onto the surface of metal.

Owner:宗维

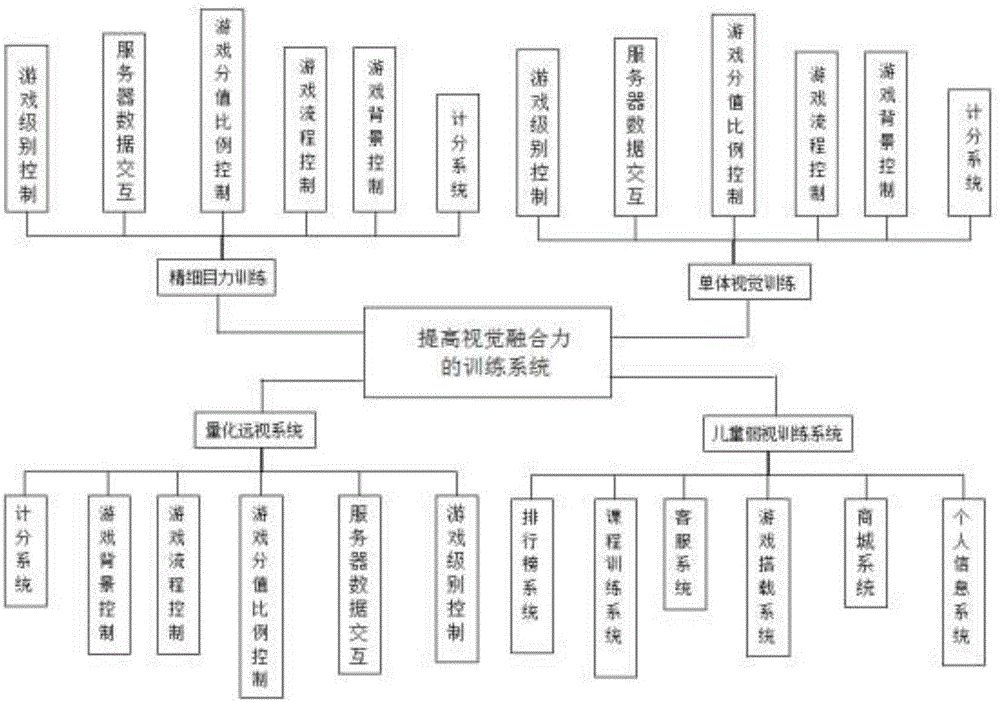

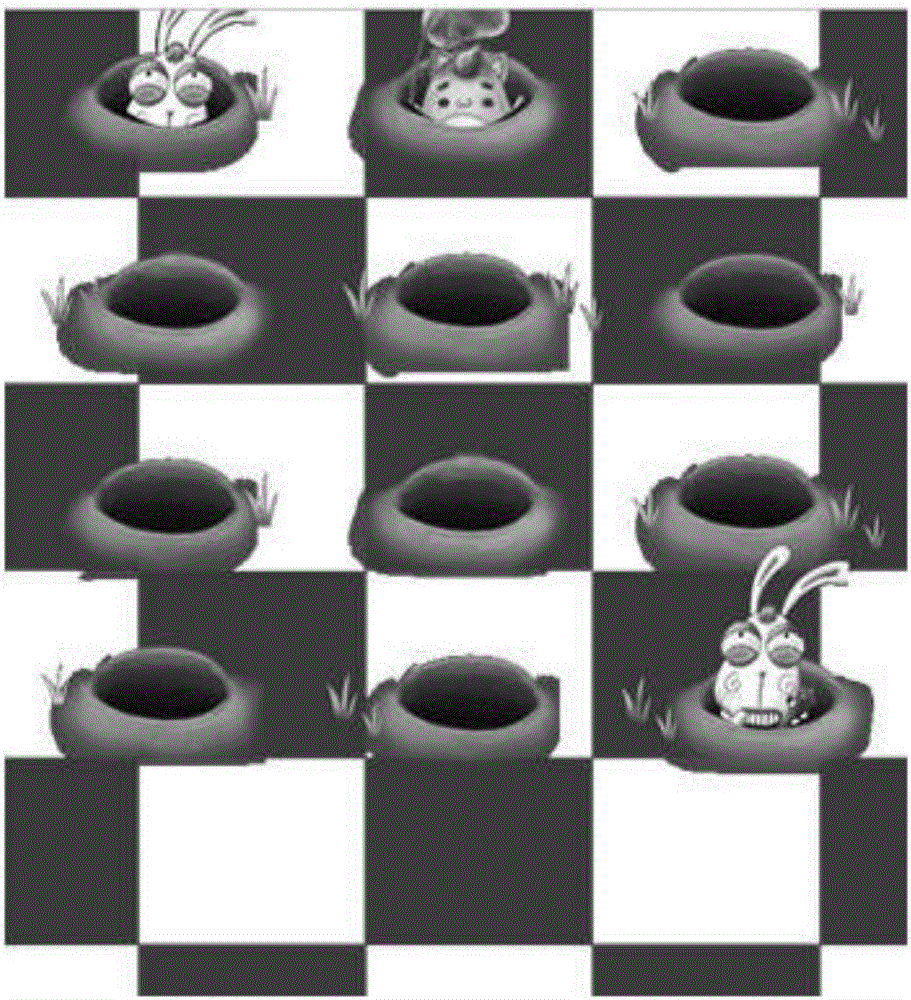

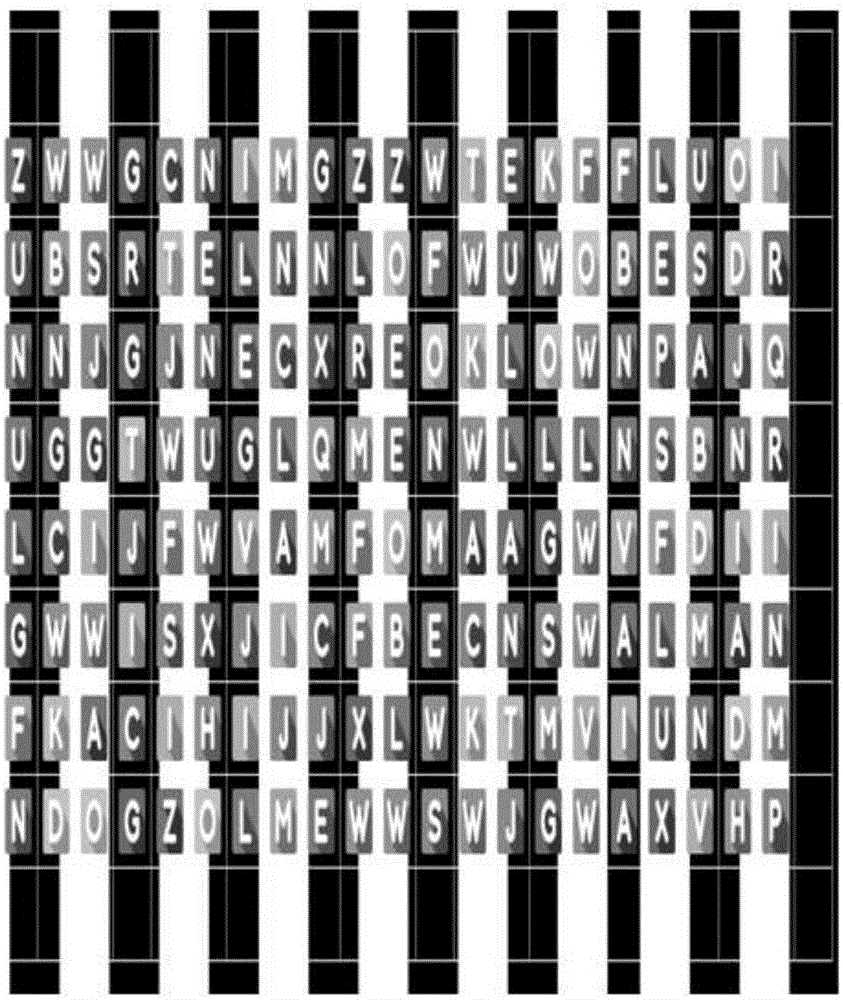

Training system capable of improving vision definition and acuity

InactiveCN106726389ATraining acuityRapid identificationData processing applicationsEye exercisersComputer scienceVisual perception

The invention provides a training system capable of improving vision definition and acuity. The system comprises a fine eyesight training system, a stereoscopic vision training system, a quantitative hyperopia training system and a child amblyopia training system. The stereoscopic vision training system is stereoscopic game training software with keeping of constant-speed movement of an airplane as the characteristic, flying stone is avoided through continuous interference of the head-on flying stone, it is guaranteed that the airplane moves forwards to attract the focus of children, and stimulus is reinforced to promote generation of the stereoscopic sense. Fine eyesight training is based on color impact and dynamic switching, the characteristics of animals, letters and fruits are combined, different training games are formed, the child is taught through training, the training initiative of the children is efficiently mobilized, and the object viewing acuity and definition of the children are improved. According to quantitative hyperopia training, sighting mark sizes in a visual chart are used for copying a batch of number, animal and fruit mixed sighting marks, by means of a manual or automatic mode, different pictures are shown randomly to be distinguished by the children, and the confidence for the children to distinguish objects can be enhanced psychologically.

Owner:上海思明堂生物科技股份有限公司

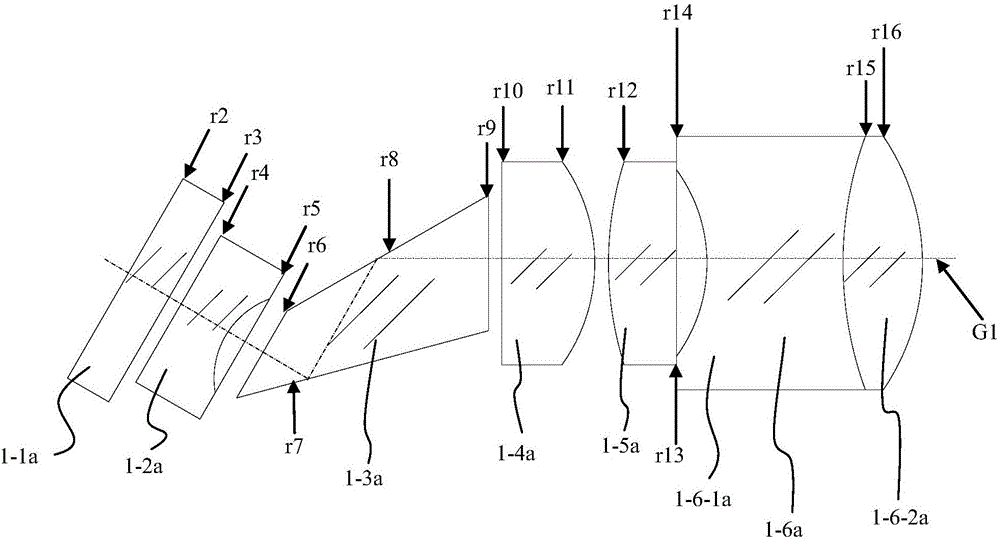

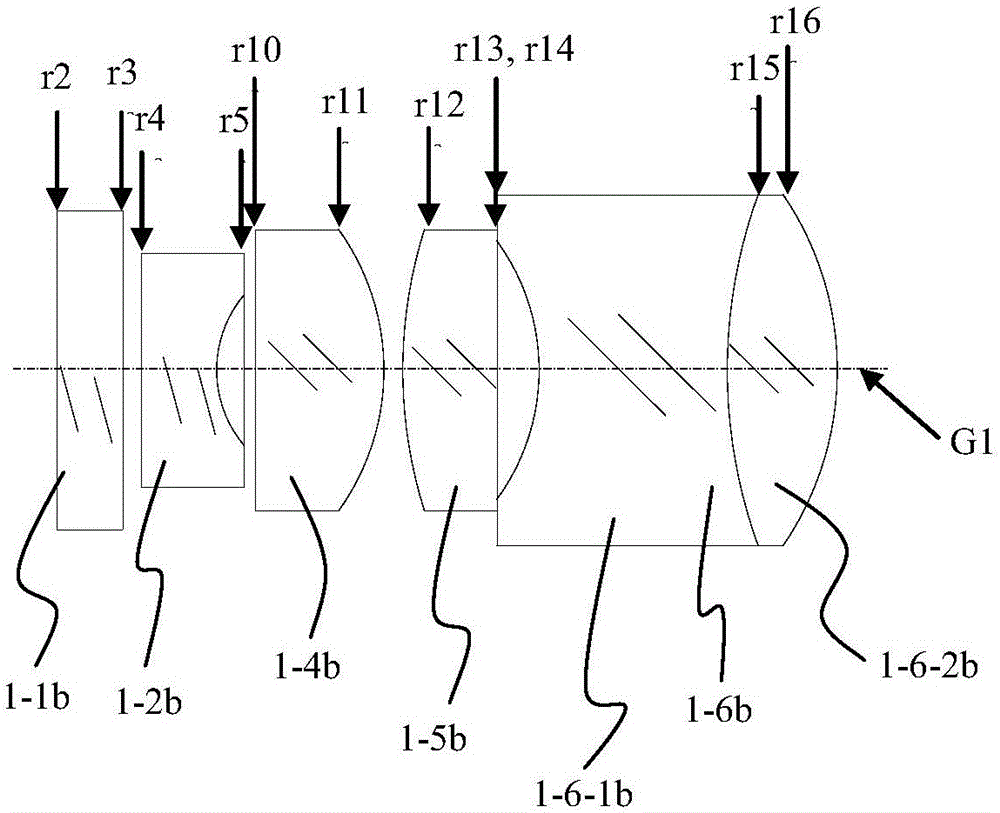

Three-dimensional endoscope optical system

The invention discloses a three-dimensional endoscope optical system. The three-dimensional endoscope optical system comprises left and right optical systems symmetrically arranged along the central axis of an endoscope tube, and each of the left and right optical systems comprises an imaging part, an image transmitting component, an image rotating component and a camera module from the object side to the imaging side; the imaging part is used for capturing the scene, and the focal length is smaller than 2mm. The system satisfies the following conditions: (1) the focal length is smaller than 5mm; (2) the depth of scene is greater than 20mm and smaller than 200mm; (3) the field angle is greater than 70 degrees and smaller than 80 degrees; (4) the working length of the endoscope body is greater than 380mm and smaller than 390mm; and (5) the parallax error is greater than 5.2mm and smaller than 5.5mm.

Owner:TIANJIN UNIV

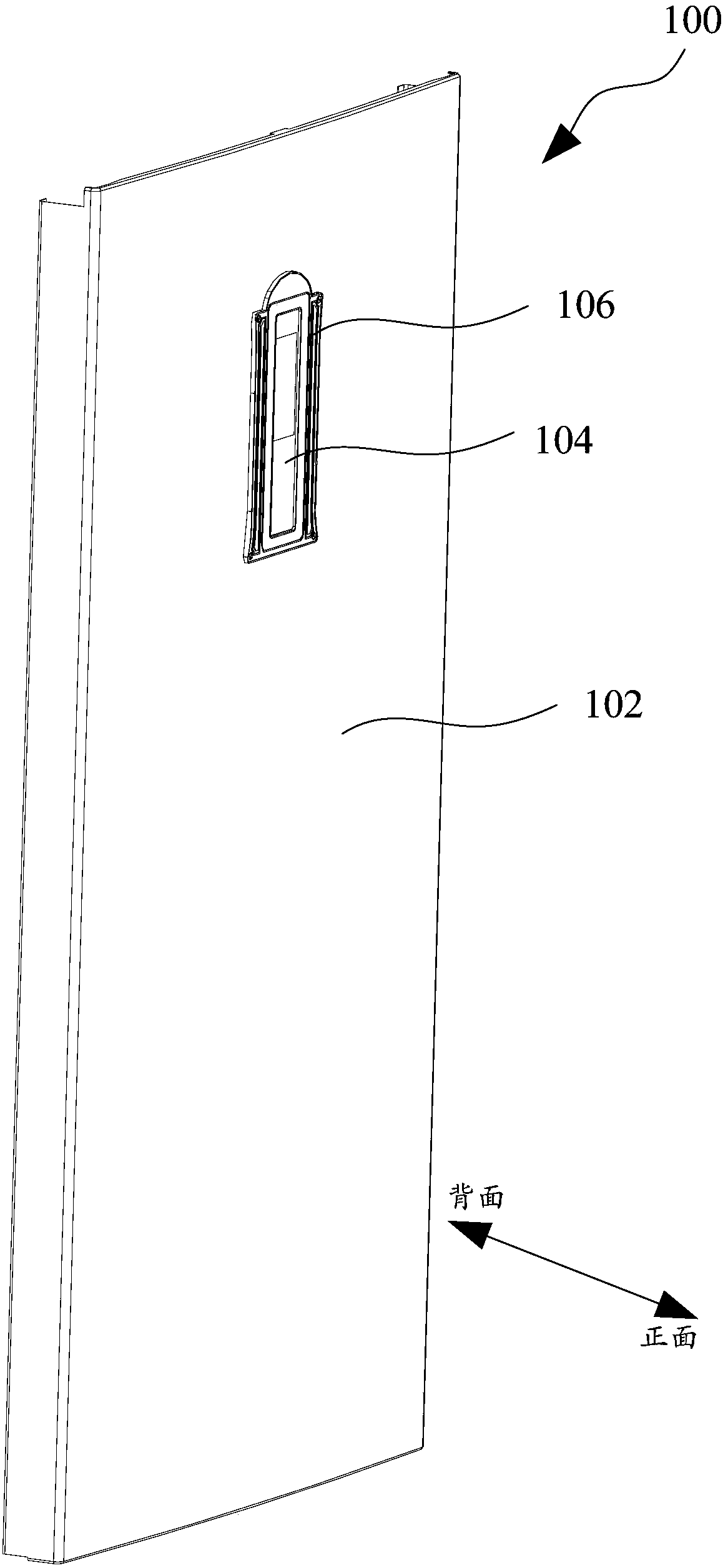

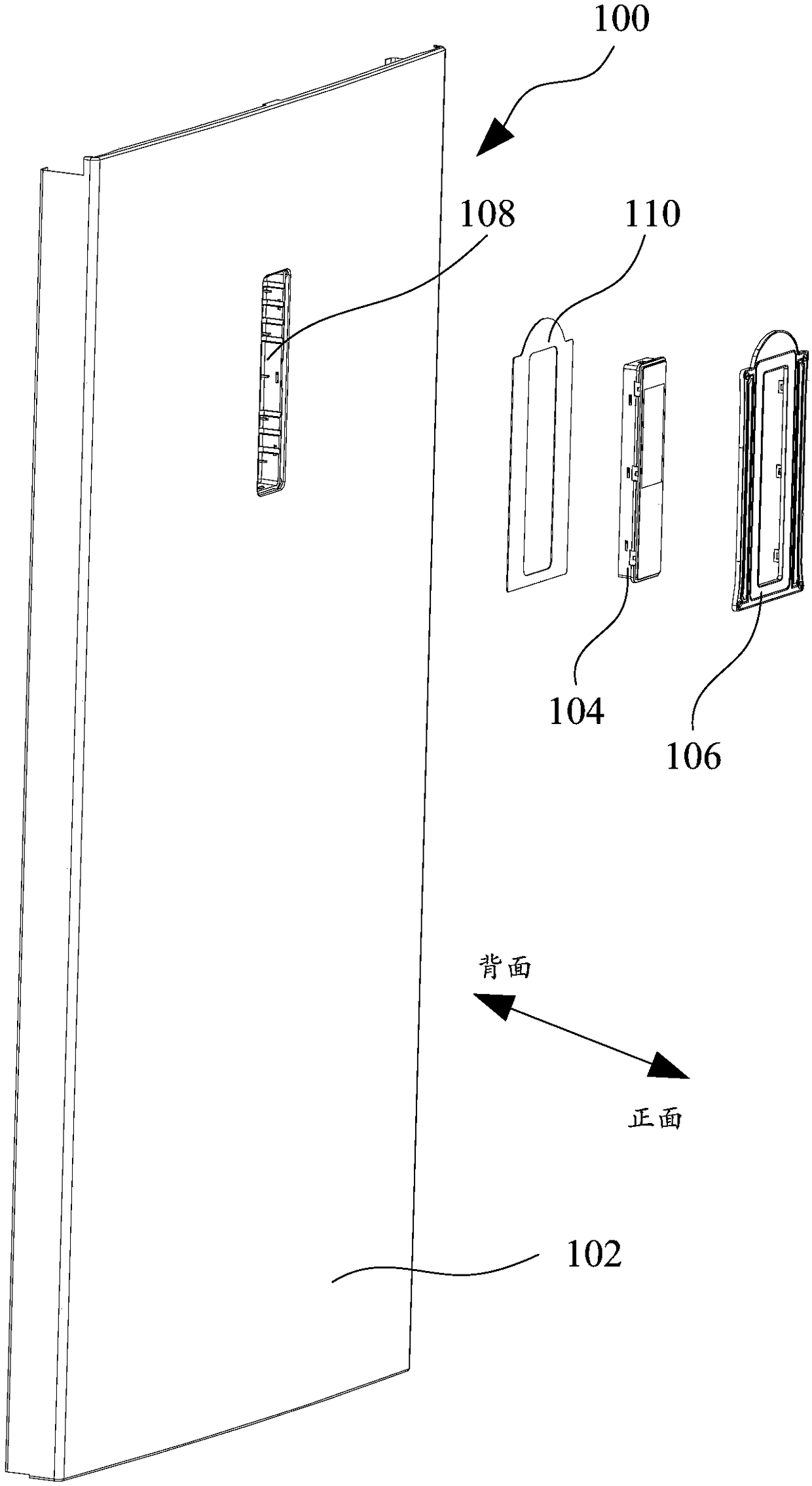

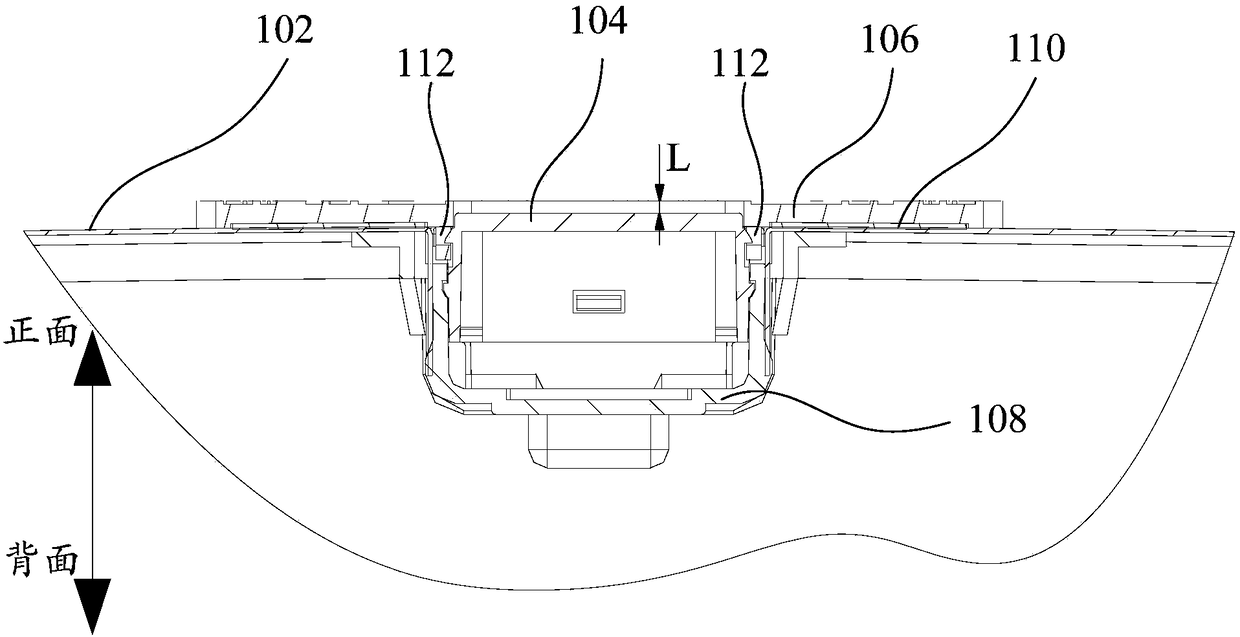

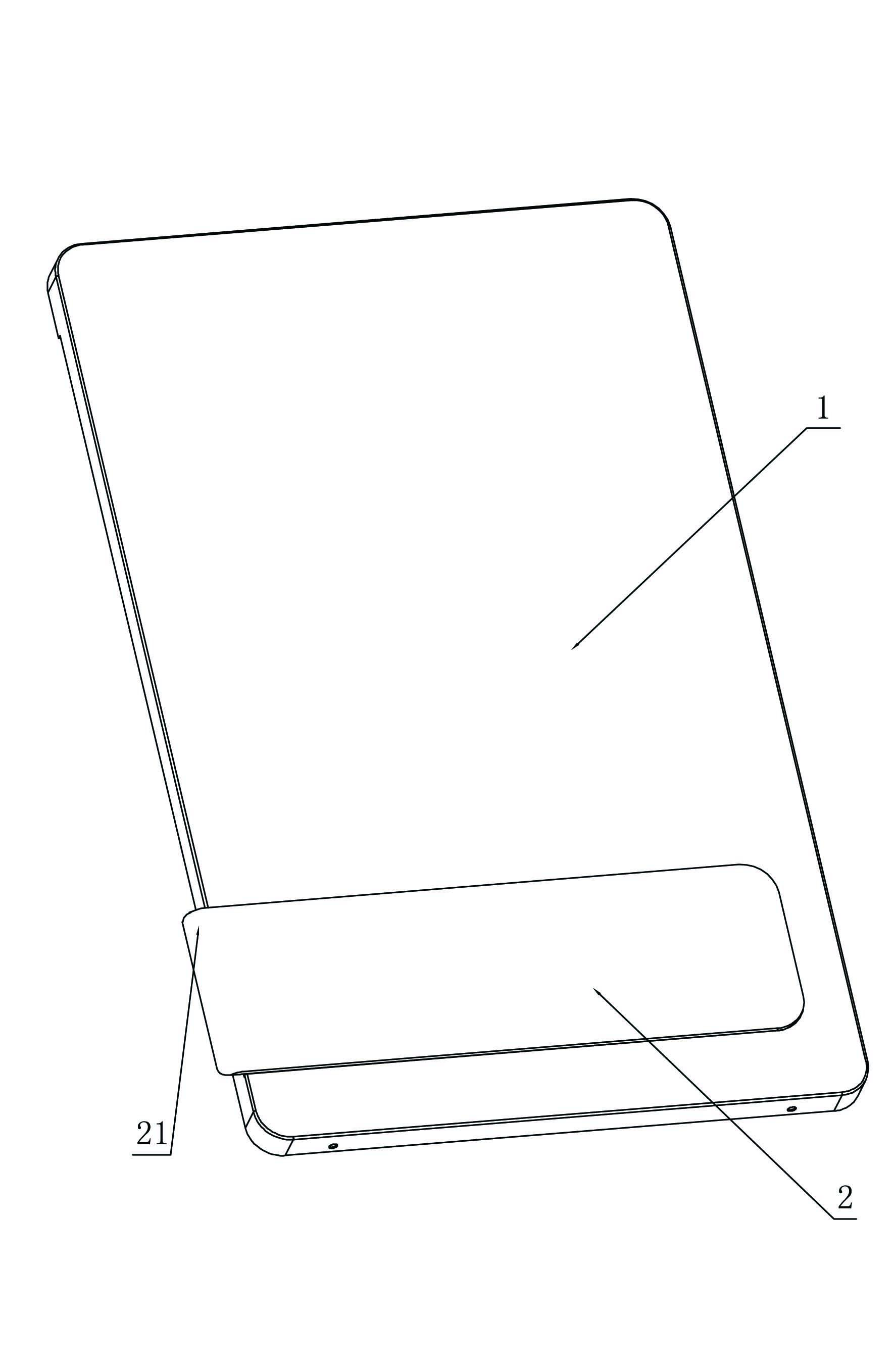

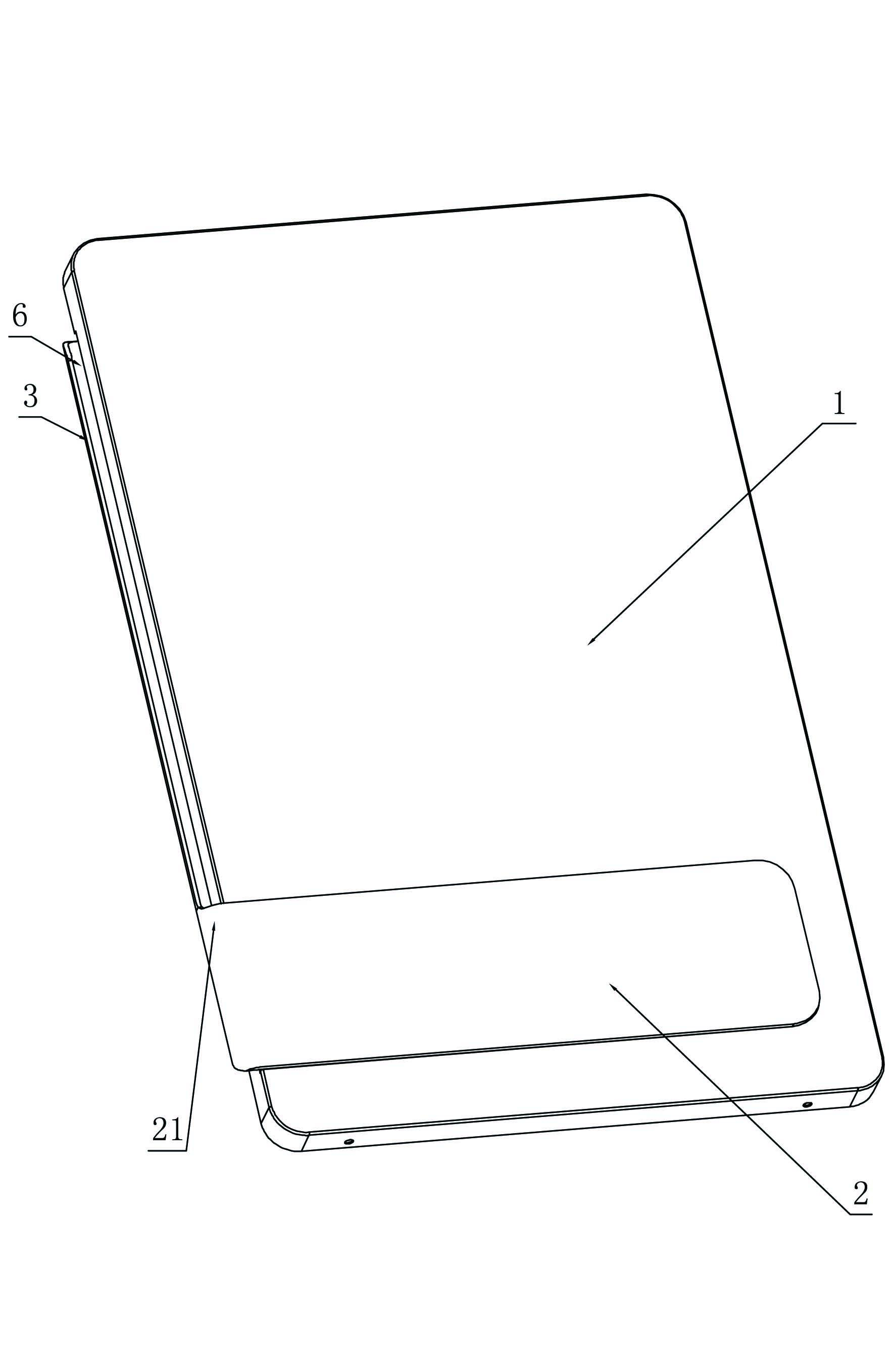

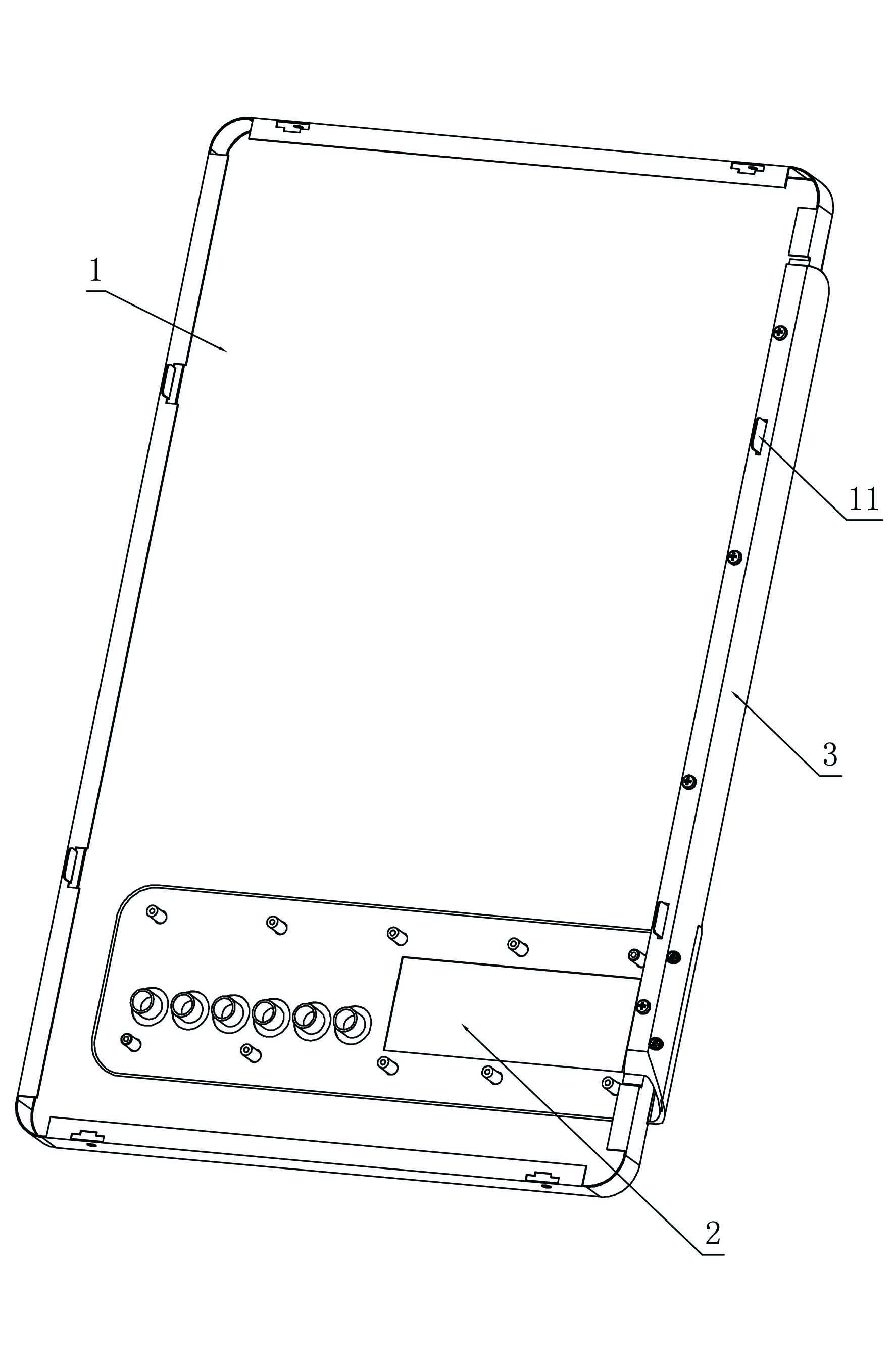

Display control installation structure and refrigerator

InactiveCN108072232AEnhance the three-dimensional senseReduce processing costsDomestic cooling apparatusLighting and heating apparatusEngineeringEconomic benefits

The invention discloses a display control installation structure and a refrigerator. The display control installation structure comprises a door shell, a display control installation box and a frame,wherein the door shell is provided with an installation mouth, the front face of the display control installation box forms a display view window, the display view window is arranged inside the installation mouth in a sleeved manner and protrudes from the front face of the door shell, the hollow portion of the frame is matched with the outline of the display view window, the display view window isembedded in the hollow portion of the frame, and the back face of the frame is in fit with the front face of the door shell. By means of the display control installation structure and the refrigerator, the gap between the display view window and the door shell can be shielded, third dimension is increased, meanwhile, the reduction of machining cost of the door shell is facilitated, the assembly difficulty of the display control installation box and the door shell is lowered, and the display control installation structure and the refrigerator have certain economic benefits.

Owner:GUANGZHOU MIDEA HUALING REFRIGERATOR

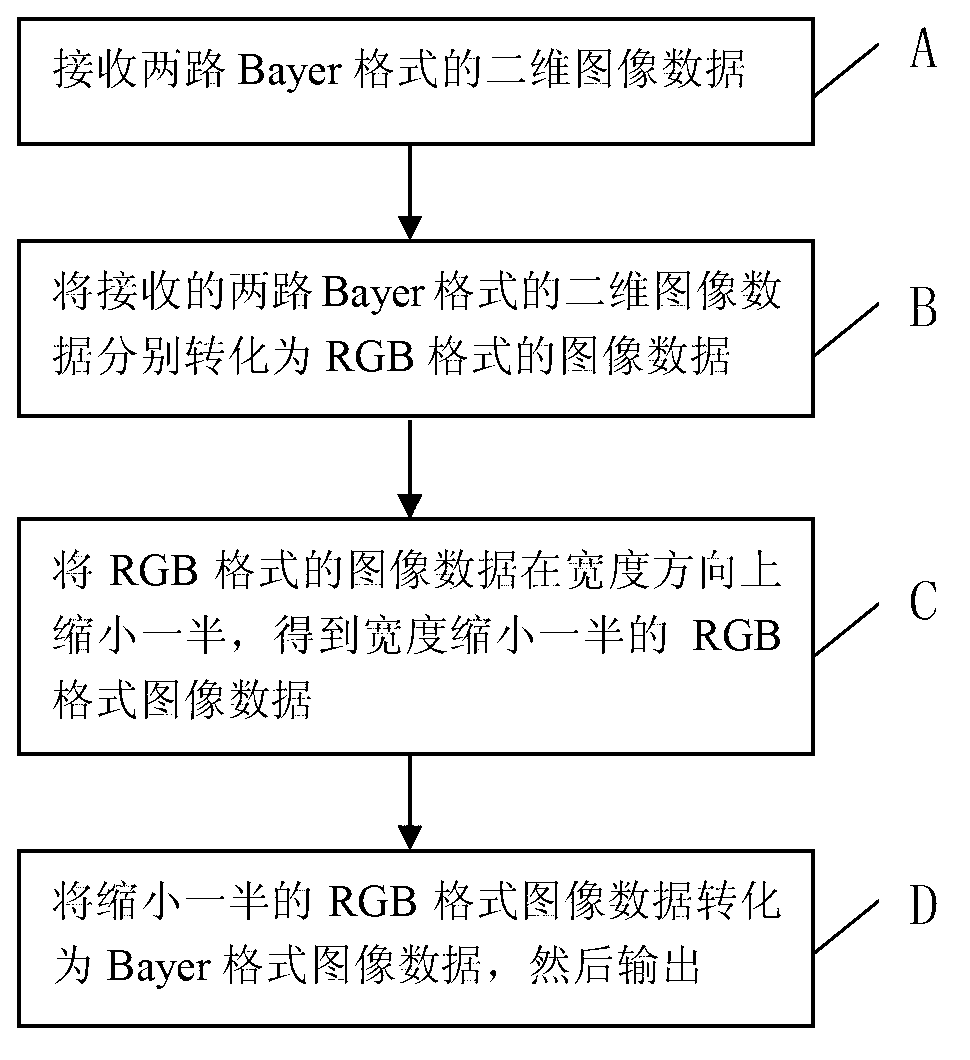

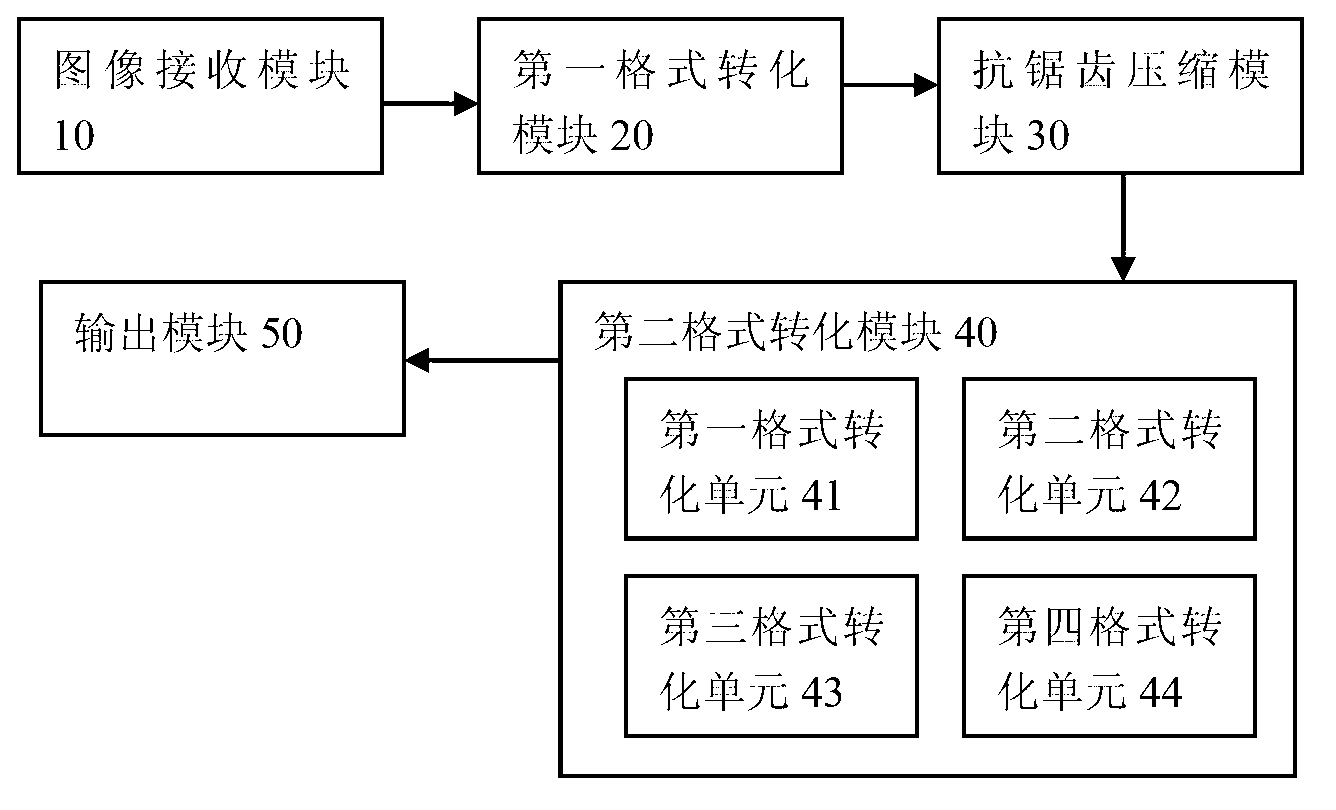

Anti-aliasing method and anti-aliasing device in image compression

ActiveCN102857781AReduce aliasingEnhance the three-dimensional senseColor signal processing circuitsTelevision systemsAnti-aliasingImage compression

The invention discloses an anti-aliasing method in image compression. The method includes the following steps: A. receiving two ways of Bayer format two-dimension image data; B. Respectively converting the received two ways of Bayer format two-dimension image data into RGB format image data; C. reducing the RGB format image data by one half in the width direction to obtain RGB format image data with width reduced by one half; and D. converting the RGB format image data which are reduced by one half into Bayer format image data and outputing the Bayer format image data. An anti-aliasing device in image compression is further disclosed. The anti-aliasing method and the anti-aliasing device in image compression can weaken the aliasing phenomena at the boundary position of scenes and improve image three-dimension performance and observation comfortableness of users.

Owner:INLIFE HANDNET CO LTD

Manufacturing method of mirror frame containing 3D gypsum and clay figure inside

ActiveCN106314003AGood viewingEnhance the three-dimensional senseOrnamental structuresCeramic shaping apparatusGypsumCalcium

The invention provides a manufacturing method of a mirror frame containing a 3D gypsum and clay figure inside. The manufacturing method mainly comprises the following steps: carrying out clay modeling to form a plastic male mold, and carrying out model renovation for the first time to obtain an original female mold; correcting a cavity of the original female mold and casting by using calcium plaster to obtain an original rigid male mold to repair the mold; carrying out model renovation for the second time on the original rigid male mold to obtain a shaping female mold; casting by using calcium plaster to obtain a gypsum and clay figure; and placing the gypsum and clay figure on a boss, and enclosing the gypsum and clay figure integrally by using a first substrate and a second substrate to form the mirror frame. In the manufacturing method of the mirror frame containing the 3D gypsum and clay figure inside, by a two-time model renovation process and the characteristic that the original rigid male mold is stable in size, the finally prepared gypsum and clay figure is stable and uniform in size, and meanwhile, the gypsum and clay figure is encapsulated in the mirror frame which contains a background image and a foreground image, so that the mirror frame has high ornamental value; and the gypsum and clay figure is fixed on the boss, so that third-dimension effect of the gypsum and clay figure is improved.

Owner:无锡市惠山泥人厂有限责任公司

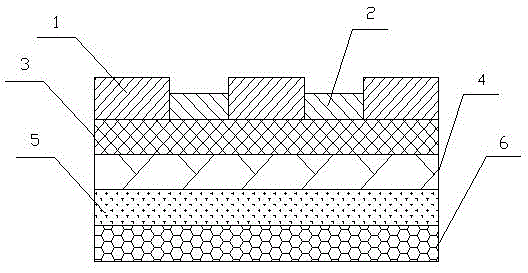

Waterproof, anti-bacterial and anti-radiation plaid shell fabric

InactiveCN105082653AEnhance the three-dimensional senseIncrease warmthSynthetic resin layered productsClothingsAnti bacterialConvex structure

The invention relates to waterproof, anti-bacterial and anti-radiation plaid shell fabric which comprises a shell fabric body (1). The shell fabric is characterized in that the shell fabric body (1) is provided with a plurality of plaids (2), the plaids (2) are rectangular, are arranged in a staggered mode and are inlaid in a plane where the shell fabric body (1) is located, the plaids (2) and the shell fabric body (1) are connected into one to form a concave-convex structure, a jacquard layer (3) is arranged on the back of the shell fabric body (1) and the backs of the plaids (2), a waterproof layer (4) is arranged on the back of the jacquard layer (3), an anti-radiation shell fabric layer (5) is arranged on the back of the waterproof layer (4), and an anti-bacterial layer (6) is arranged on the back of the anti-radiation shell fabric layer (5). By means of the related concave-convex structure of the plaid shell fabric, the stereoscopic impression of the plaid shell fabric is enhanced; meanwhile, as the jacquard layer is arranged on the back of the shell fabric body and the backs of the plaids, the heat preserving property of the plaid shell fabric is enhanced.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

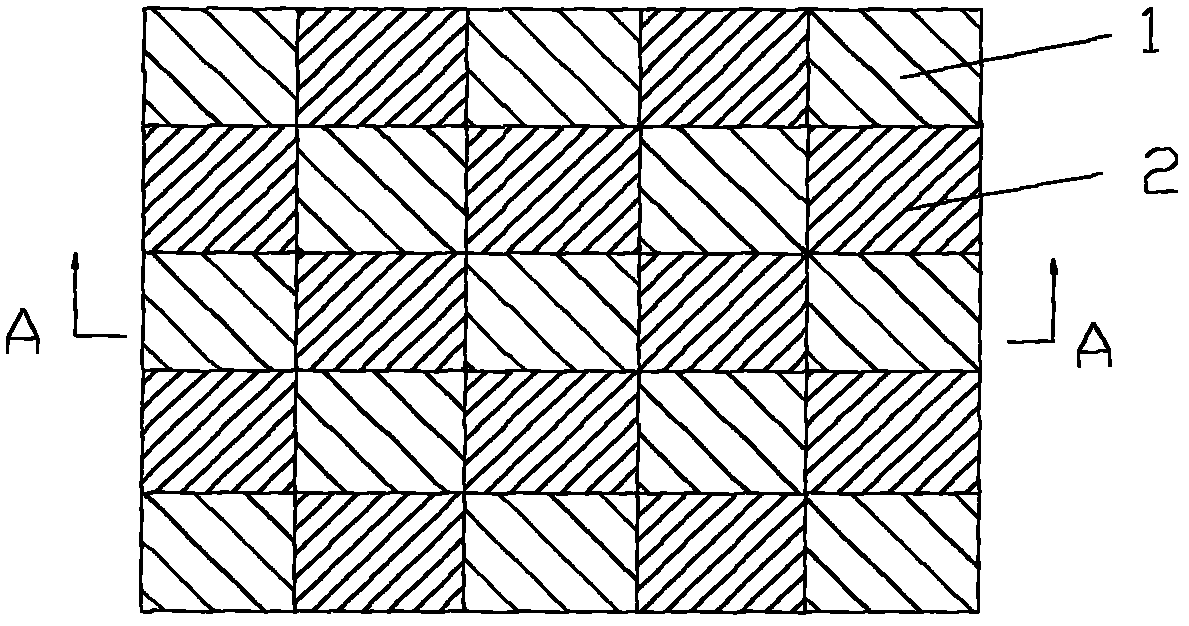

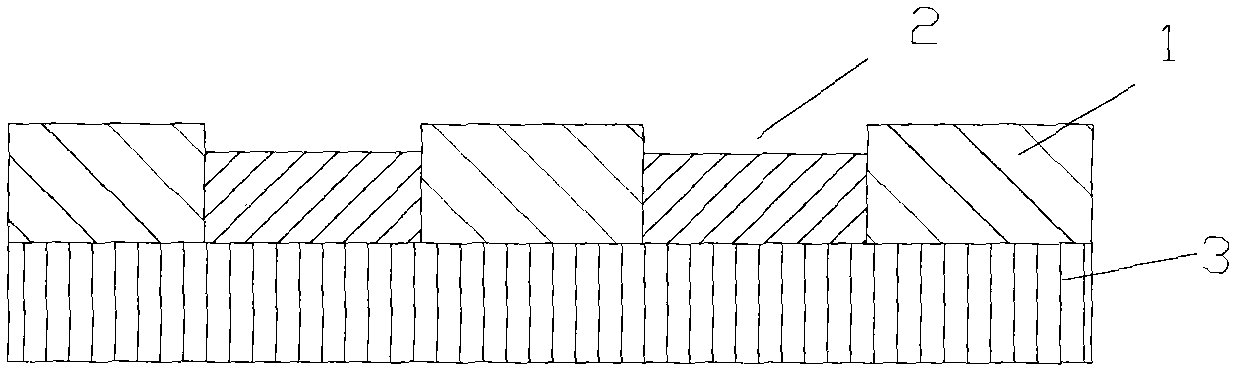

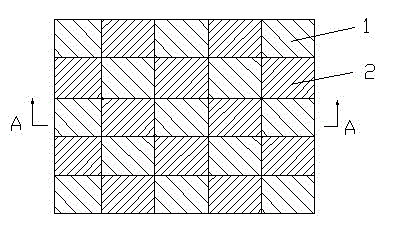

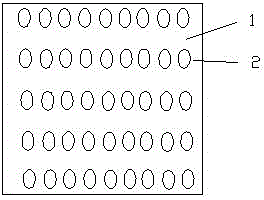

Latticed fabric embedded with metal wires

InactiveCN102794939AEnhance the three-dimensional senseIncrease warmthTextile decorationMetal layered productsEngineeringConvex structure

The invention relates to a latticed fabric embedded with metal wires, and belongs to the field of textile fabrics. The latticed fabric comprises a fabric body (1), wherein a plurality of lattices (2) are formed on the fabric body (1), form a rectangle, are staggered from one another and are embedded on the plane where the fabric body (1) is positioned; the lattices (2) are connected with the fabric body (1) to form a whole, so that a concavo-convex structure is formed; jacquard layers (3) are arranged at the backs of the fabric body (1) and the lattices (2); the metal wires (4) are embedded in the jacquard layers (3); and the metal wires (4) are arranged in the jacquard layers (3) in the horizontal direction and the longitudinal direction. Due to the concavo-convex structure of the latticed fabric, the stereoscopic sensation of the latticed fabric is enhanced; and furthermore, the jacquard layers are arranged at the backs of the fabric body and the lattices, so that the heat retention property of the latticed fabric is enhanced.

Owner:徐立生

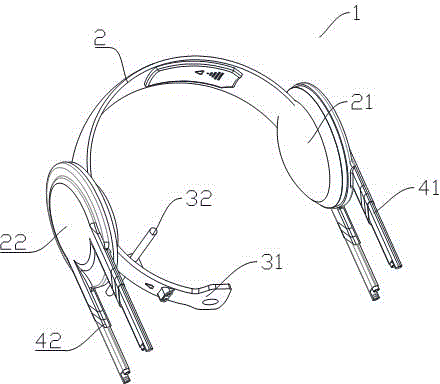

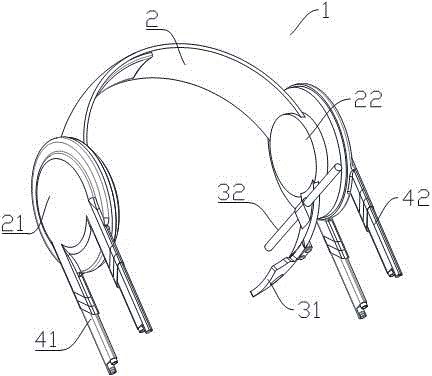

Wireless earphone

InactiveCN104936062AEnhance the three-dimensional senseAdd dimensionEarpiece/earphone attachmentsEngineeringHeadphones

The invention discloses a wireless earphone which comprises a connection portion. The two ends of the connection portion are provided with a first reception earphone body and a second reception earphone body respectively, the second reception earphone body is provided with a microphone, the microphone is provided with a signal antenna, the first reception earphone body is provided with a pair of first reception antennas, the second reception earphone body is provided with a pair of second reception antennas, signals of the first reception antennas are independent from signals of the second reception antennas, and the signal antenna is telescopic. The wireless earphone is provided with the two earphone bodies, the signal reception antennas of the two earphone bodies are independent, play signals of each earphone body are independent, and thus, the stereo perception of the sound of the earphone is greatly improved.

Owner:张素平

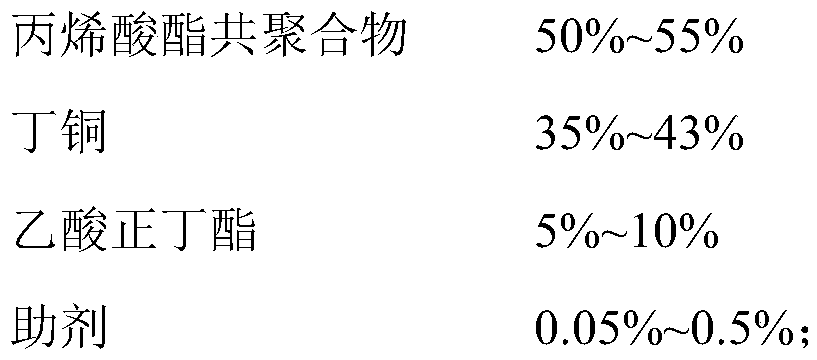

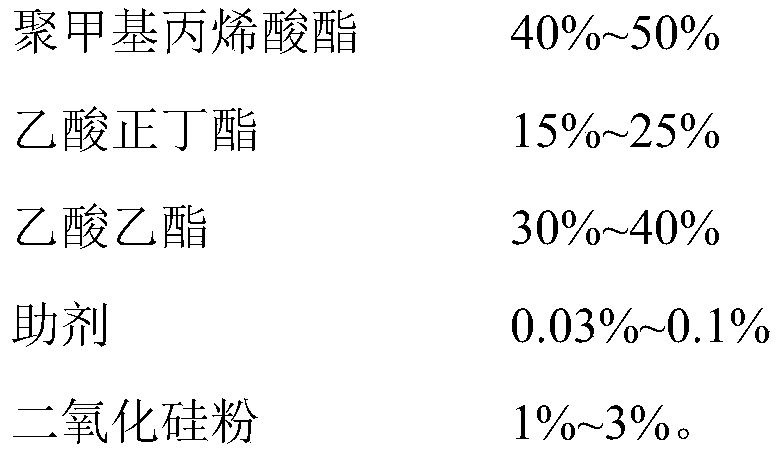

Cold ironing membrane for digital printing machine and preparation process of cold ironing membrane

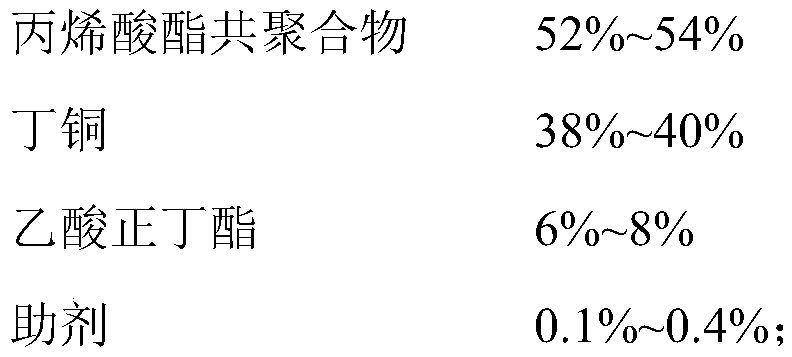

InactiveCN110684225AEnhance the three-dimensional senseWide range of applicationsCoatingsInk transfer from master sheetDigital printingN-Butyl acetate

The invention relates to the technical field of cold ironing membranes and in particular relates to a cold ironing membrane for a digital printing machine and a preparation process of the cold ironingmembrane. The cold ironing membrane for the digital printing machine comprises a PET (polyethylene terephthalate) gold ironing substrate, a separation layer, a mold pressing laser information layer and a UV (ultraviolet) medium layer which are arranged in sequence, wherein the separation layer comprises aqueous acrylic acid, water and ethanol; the mold pressing laser information layer comprises an acrylate polymer, butanone, butyl acetate and an aid; and the UV medium layer comprises polymethacrylate, butyl acetate, ethyl acetate, an aid and silica powder. Due to properties of thermoplasticity and thermal setting of the acrylate copolymer, the mold pressing laser information layer is large in imitation difficulty, bright in lens and empaistic effect and good in three-dimensional property;in addition, the membrane can be applied to two process of first peeling and setting later and first setting and peeling later, is wide in application range and in addition has the advantages of being good in anti-fake performance and is not easy imitate; and the preparation process has the characteristics of being simple in process, low in production cost and applicable to large-scale production.

Owner:DONGGUAN K LASER TECH

Blistered shirt luminous fabric

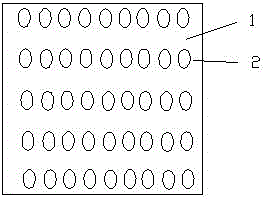

InactiveCN106313708AFluffy surfaceEnhance the three-dimensional senseLayered productsTextile decorationEngineeringTextile

The invention relates to a fabric, in particular to a blistered shirt luminous fabric which comprises a shirt fabric body (1), wherein a plurality rows of blisters (2) are formed in the outer surface of the shirt fabric body (1); the blisters (2) are elliptic and protrude outside the fabric body (1); the fabric body (1) is made of a textile; the textile comprises a textile body and a luminous wire material; the luminous wire material is fixedly arranged on the textile body in a knitted or embroidery manner, and form objects on the textile body. By adopting the blistered shirt luminous fabric, sweat can be isolated from skin, and the breathability and the cool feeling can be achieved.

Owner:王凤华

Hollow and solid line alternative porous fabric clothing

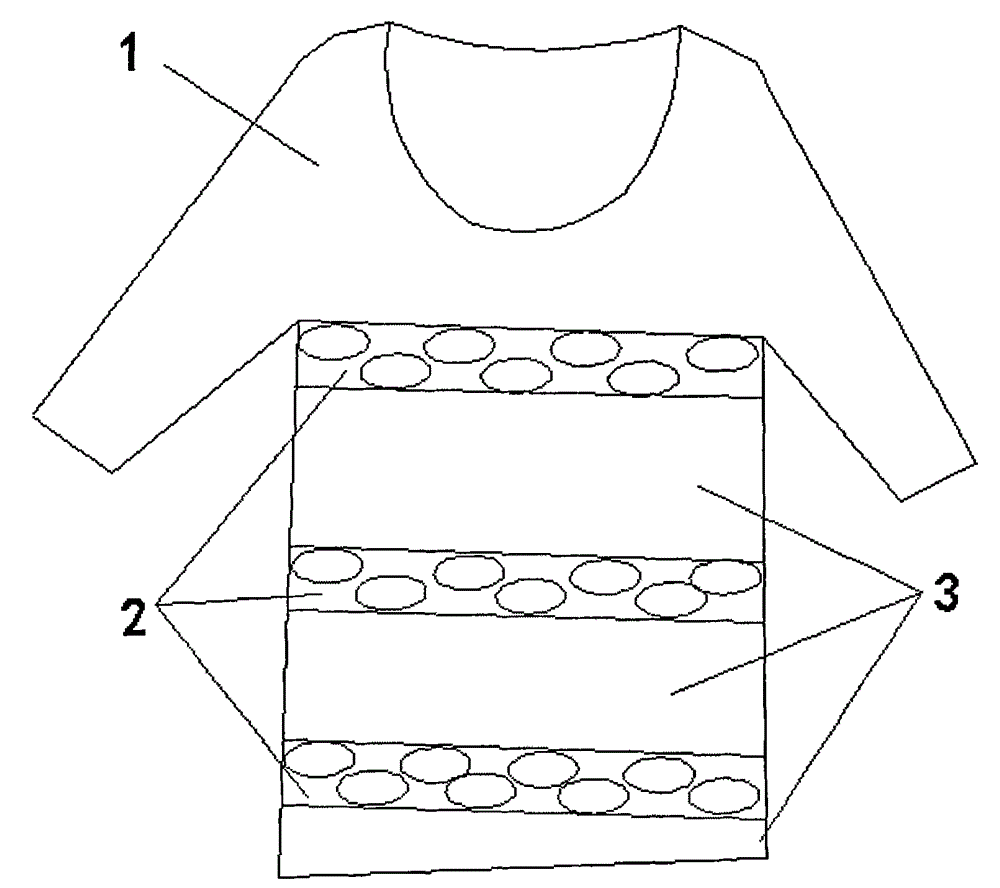

InactiveCN104413702AEnhance the three-dimensional senseAdd layersMulti-ply fabricsProtective garmentEngineeringFiber

The invention relates to hollow and solid line alternative porous fabric clothing. The clothing comprises a clothing body (1), three hollow belts (2) are arranged on the front body of the clothing body, and a solid line belt (3) is arranged between every two hollow belts (2). The fabric used by the clothing body (1) comprises a surface and a lining. The surface is densely distributed circular vertical rings woven through chemical fiber monofilaments, the lining is in an orderly net structure with gaps, and the surface and the lining are woven together. The lining comprises a plurality of weft groups and a plurality of warps. Certain distance is formed between the adjacent weft groups, each weft group comprises a plurality of wefts, the central wefts of the weft groups are woven with the surface circular vertical rings, and the two wefts of the two edges of each weft group are woven to form a plurality of bundling holes. By means of the clothing, the clothing artistry is increased, and the clothing fashionability is increased; the fabric used by the clothing has the advantages of being not prone to loosening and fast in weaving speed.

Owner:訾建平

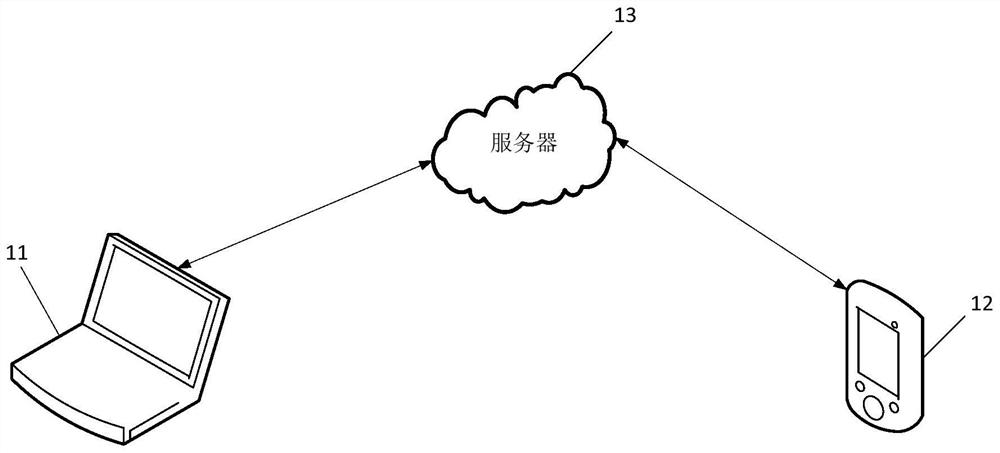

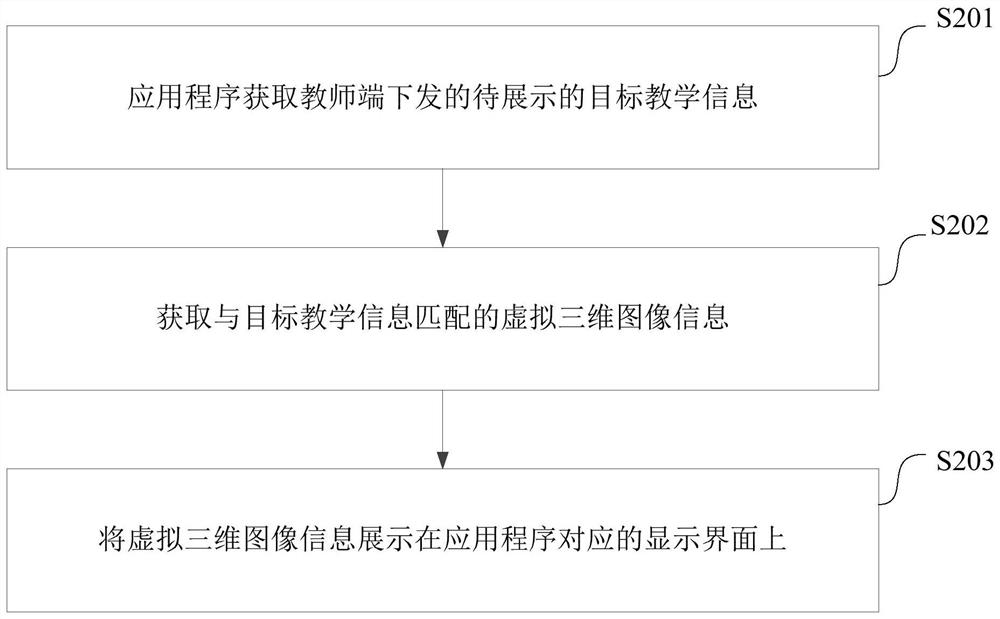

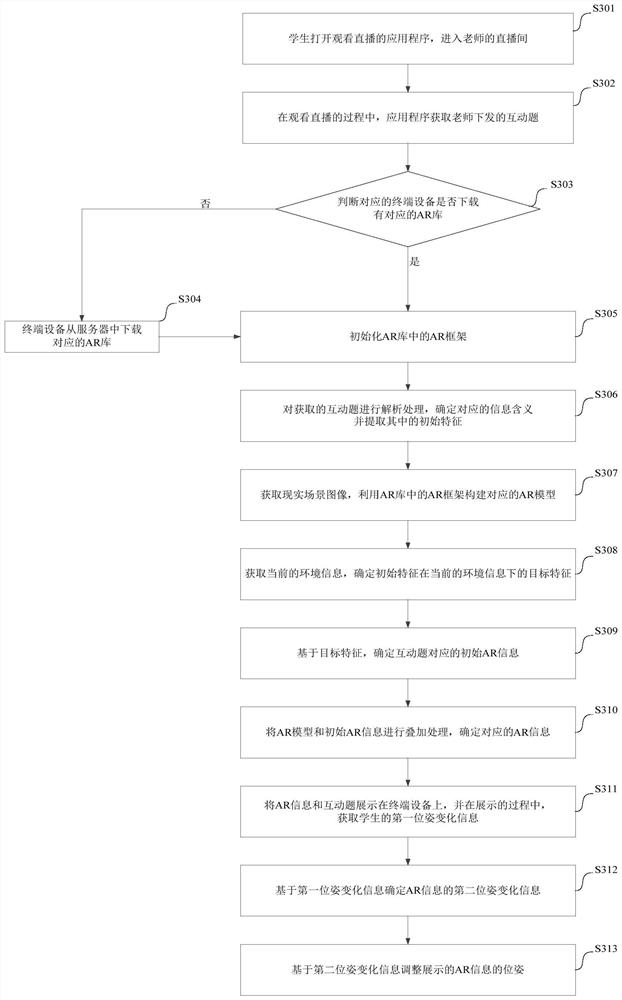

Teaching information display method and device, computer equipment and storage medium

PendingCN112530219AEnhance the three-dimensional senseEasy to understand and acceptExecution for user interfacesElectrical appliancesComputer equipmentVirtual image

The invention provides a teaching information display method and device, computer equipment and a storage medium, and the method comprises the steps: enabling an application program to obtain to-be-displayed target teaching information issued by a teacher end; acquiring virtual three-dimensional image information matched with the target teaching information; and displaying the virtual three-dimensional image information on a display interface corresponding to the application program. By utilizing a virtual image technology, the obtained two-dimensional static target teaching information is converted into a three-dimensional dynamic virtual image to be displayed, so that the stereoscopic impression of the displayed target teaching information is enhanced, and the displayed target teaching information can be understood and accepted conveniently; and students can understand the obtained target teaching information through the displayed virtual image, so that difficulty in understanding the target teaching information is reduced, the target teaching information is favorably answered, and the learning enthusiasm of the students is improved.

Owner:北京高途云集教育科技有限公司

Bubble shirt good-dimensional-stability fabric with temperature-sensitive fabric layer

InactiveCN104939334AEnhance the three-dimensional senseBig spaceLayered productsWoven fabricsYarnEngineering

The invention relates to fabric, in particular to bubble shirt good-dimensional-stability fabric with a temperature-sensitive fabric layer. The bubble shirt good-dimensional-stability fabric comprises a shirt fabric body (1), a plurality of rows of bubbles (2) are arranged on the outer surface of the shirt fabric body (1), the bubbles (2) are elliptic and protrude out of the fabric body (1), the fabric body (1) is made of textile, the textile is formed by interweaving warp and weft, every two pieces of warp are arranged above every two pieces of weft, the warp is 50D / 72F dacron low stretch yarn, the weft is 5D / 36F dacron low stretch yarn, and the warp and the weft are of a twill weave structure. By means of the fabric, sweat is not attached to the skin, and breathability and the cool sense are increased. The dimensional stability of the fabric is good.

Owner:JIANGSU HEJIA TEXTILE

Stereoscopic ceramic paste-on-paste pate-surpate and preparation process thereof

InactiveCN107555942AEnhance the three-dimensional senseEnhance visual effect and appreciationCeramic materials productionClaywaresCeramic glazeMagnesium

A stereoscopic ceramic paste-on-paste pate-surpate comprises a blank body, and further comprises a ground coat, paste-on-paste pate-surpate patterns, a protection glaze and an emboss material which are sequentially arranged on the blank body, wherein the blank body comprises the following raw materials in parts by weight: 18-25 parts of potash feldspar, 20-30 parts of illite, 48-56 parts of wasteglass, 5-8 parts of lepidolite, 8-12 parts of diopside, 3-5 parts of ball clay, 1-3 parts of molybdenum powder, 2-6 parts of glass dust, 1-3 parts of calcium nitride, 5-8 parts of magnesium carbonateand 1-3 parts of lanthanum oxide; the protection glaze comprises the following chemical components by mass percent: 46-54% of SiO2, 18-23% of Al2O3, 5-8% of K2O, 3.2-4.6% of Fe2O3, 8-12% of MgO, 3-4.7% of V2O5, 4.3-5.2% of MnO and 1.2-1.8% of BeO2; the emboss material comprises one or more of frit dry grains, flash grains and an emboss glaze.

Owner:CERAMICS SCI & TECH RES INST QUANZHOU +1

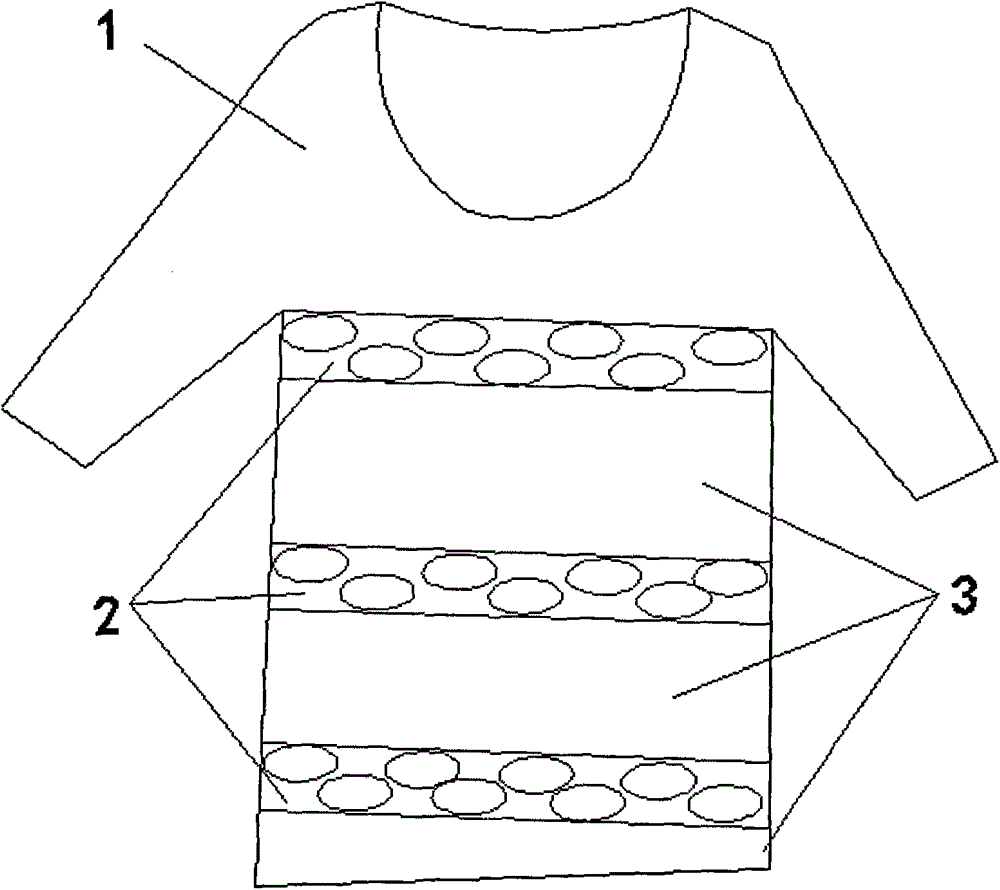

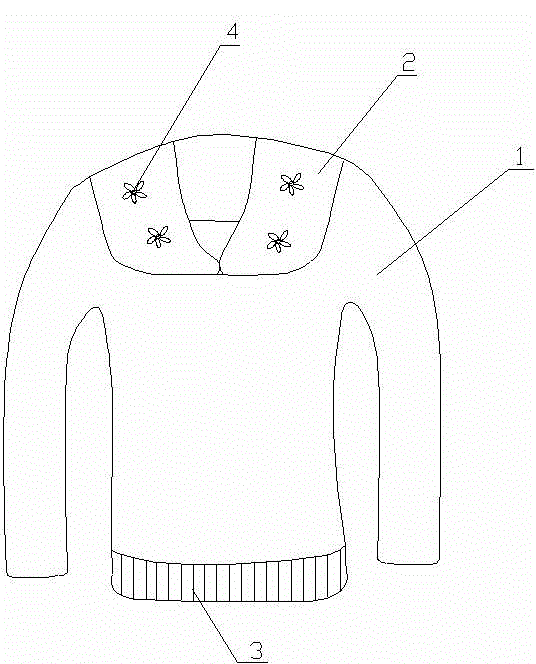

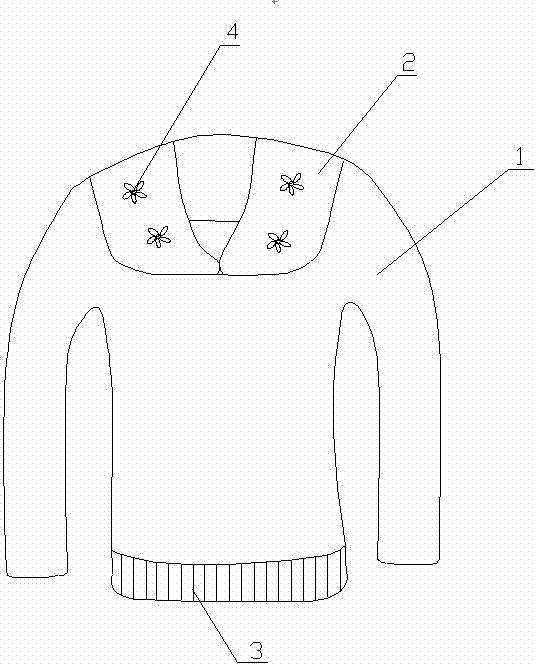

Positionable women's healthful jacket with high warm-keeping ability on shoulders

InactiveCN105077653AEnhance the three-dimensional sensePlay a thermal insulation effectGarmentsCushionEngineering

The invention relates to a positionable women's healthful jacket with high warm-keeping ability on shoulders. A cashmere sweater comprises a clothes body (1), wherein shoulder warm-keeping cushions (2) are respectively arranged on shoulders of the clothes body (1) and are made of cashmere; each shoulder warm-keeping cushion (2) is provided with a plurality of decorating pieces (4); each decorating piece (4) is provided with a plurality of sequins; and strip-shaped projections are vertically arranged at the position of the lower hem (3) of the clothes body (1). By the positionable women's healthful jacket with high warm-keeping ability on shoulders, the shoulders of a wearer can be warmed effectively.

Owner:王凤华

Connecting structure for control panel and panel shell of gas stove

ActiveCN102620435AEnhance the three-dimensional senseGuaranteed flatnessFluid heatersEngineeringElectrical and Electronics engineering

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

High flame-retardant fabric-made garment keeping warmth for shoulders

InactiveCN104273682AEnhance the three-dimensional sensePlay a thermal insulation effectGarment special featuresNatural mineral layered productsThermal insulationCushion

The invention relates to a high flame-retardant fabric-made garment keeping warmth for shoulders. The garment comprises a garment body (1). Shoulder portions of the garment body (1) are provided with thermal insulation cushion pads (2) which are made of cashmere. A plurality of ornaments (4) are arranged on each thermal insulation cushion pads (2), each ornament (4) is composed of a plurality of sequins. A lower hem (3) of the garment body (1) is provided with strip-shaped protrusions vertically arranged. The high flame-retardant fabric-made garment is effective in thermal insulation for shoulders.

Owner:WUXI BALAS LIGHTING ELECTRONICS

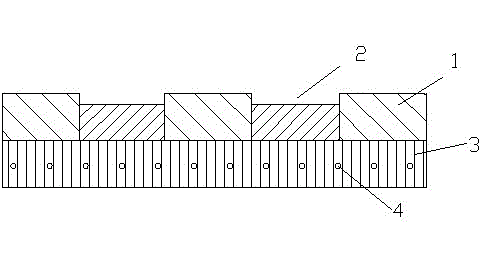

Mosquito-repelling pit artificial leather

InactiveCN104947436AIncrease frictionEnhance the three-dimensional senseLayered productsTextiles and paperDust mitesEngineering

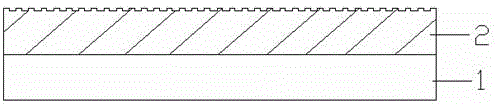

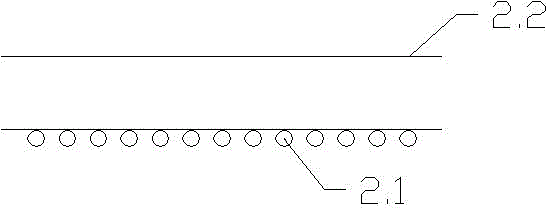

The invention relates to a mosquito-repelling pit artificial leather. The mosquito-repelling pit artificial leather for repelling the mosquito comprises a base layer (1) and a plastic surface layer (2) which are bonded with each other. Regular pits are arranged on the surface of the plastic surface layer (2). The plastic surface layer (2) comprises an inner-layer small scale-shaped knitting layer (2.1) and an outer-layer mosquito-defending protecting layer (2.2). According to the mosquito-repelling pit artificial leather, the regular pits are arranged on the surface of the plastic surface layer, so that the effect of enlarging the friction can be achieved, and the stereoscopic impression of the artificial leather can further be increased; a mosquito-defending addition agent is a non-poisonous product and is coated on the surface of the plastic surface layer, and excellent effect of repelling winged insects like the mosquito and fly or crawler like ant, dust mite, cockroach and the like is achieved.

Owner:JIANGSU HUAHONG RUBBER & PLASTIC

Hollow-out and solid pattern alternated hook-and-loop-fastener fabric clothes

InactiveCN104432795AEnhance the three-dimensional senseAdd layersProtective garmentSpecial outerwear garmentsFastenerYarn

The invention relates to a piece of hollow-out and solid pattern alternated hook-and-loop-fastener fabric clothes. The piece of hollow-out and solid pattern alternated hook-and-loop-fastener fabric clothes comprises a clothes body (1), wherein three hollow-out bands (2) are arranged on the front body of the clothes body, and solid pattern bands (3) are arranged among the hollow-out bands (2). The fabric adopted for the clothes body (1) comprises a loop-portion fabric and a hook-portion fabric, wherein the loop-portion fabric is formed by weaving ultrafine fiber through composite spinning and is subjected to splitting treatment to be restored to more fine fiber so as to form loops, and the hook-portion fabric is formed by weaving short-fiber or long-fiber yarns and is subjected to hairiness treatment so as to form hooks capable of correspondingly hooking the loop-portion fabric. The artistry and fashionability of the clothes are improved. The piece of hollow-out and solid pattern alternated hook-and-loop-fastener fabric clothes is good in stereoscopic impression.

Owner:卞平芳

Stripe brushed luminous fabric lining provided with anti-radiation fabric layer

InactiveCN106313709AEnhance the three-dimensional senseImprove thermal performanceLayered productsCoatingsThermal insulationConvex structure

The invention relates to a stripe brushed luminous fabric lining provided with an anti-radiation fabric layer. The stripe brushed luminous fabric lining comprises a lining body (1), wherein a plurality of stripes (2) are arranged on the lining body (1), the stripes (2) are horizontally and vertically crossed and distributed, the stripes (2) are inlaid on a plane where the lining body (1) is located and are connected with the lining body (1) into a whole, so as to form a concave-convex structure, brushed layers (3) are arranged on the back of the stripes (2) and the lining body (1), the lining body (1) is made from a fabric, the fabric comprises a fabric body and luminescent threads, the luminescent threads are fixedly arranged on the fabric body in a knitting or embroidery manner, and a modeling body is formed on the fabric body. The strip brushed luminous fabric lining provided with the anti-radiation fabric layer has the advantages that the concave-convex structure enhances three-dimensional sense of the lining, and the brushed layer of the back of the lining enhances the thermal insulation property of the lining.

Owner:黄文平

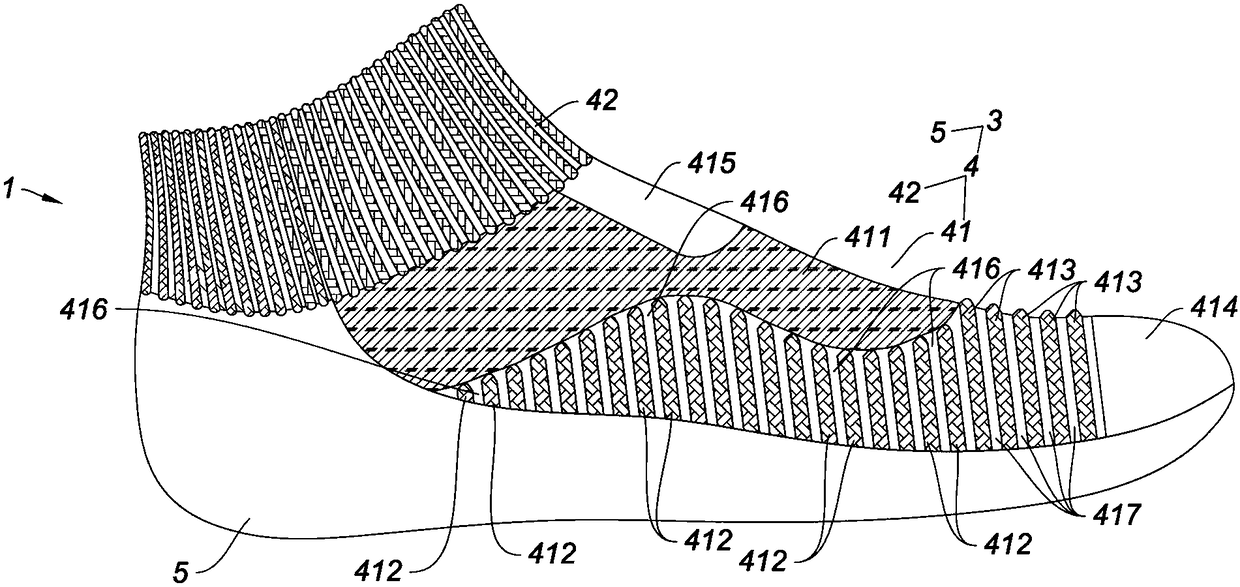

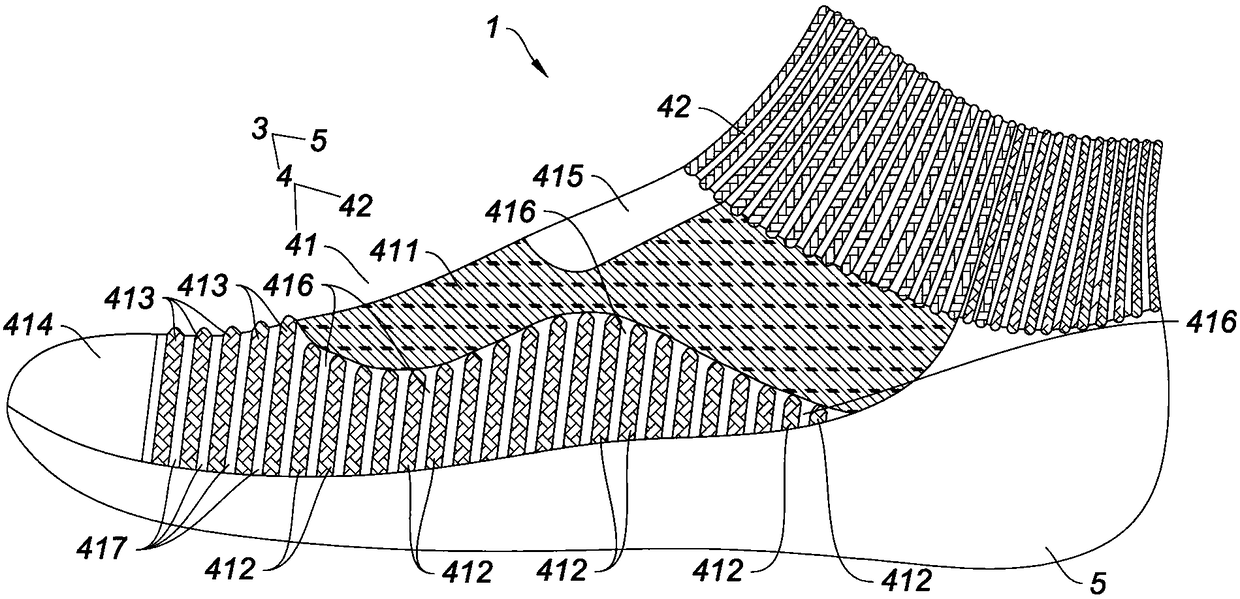

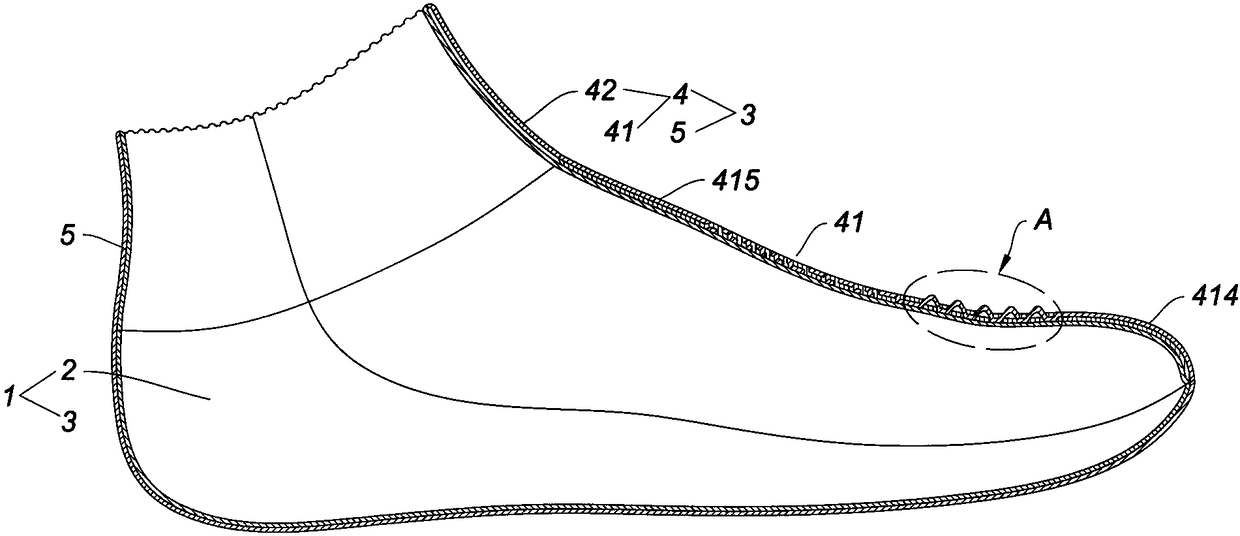

Sock shoe high in stereoscopic sensation

PendingCN108577019AClear outlineEnhance the three-dimensional senseUpperBootlegsBiomedical engineering

The invention relates to a sock shoe high in stereoscopic sensation. The sock shoe comprises a sock shoe body which comprises an inner sock shoe sleeve and an outer sock shoe sleeve which are formed through integral knitting, and the inner sock shoe sleeve is turned into the outer sock shoe sleeve and connected with the outer sock shoe sleeve; the outer sock shoe sleeve comprises a sock surface patch and a sock bottom patch, the sock surface patch comprises a sock surface part and a top surface part, and is characterized in that a jacquard pattern knitting area is formed on the surface of thesock surface part through knitting, first jacquard knitted fabrics arranged in the length direction of the sock shoe body are formed on the two sides of the surface of the sock surface part respectively through knitting, the first jacquard knitted fabrics protrude out of the surface of the sock surface part, and the upper ends of the first jacquard knitted fabrics are located on edge contours of the jacquard pattern knitting area respectively. The sock shoe has the advantages that the structure is simple, design is reasonable, the patterns and the sock shoe body are integrally formed, the stereoscopic sensation is high, and the requirements of users pursuing individuality can be met.

Owner:HESHAN JINGFUNG KNITTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com