Patents

Literature

92 results about "Solid pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

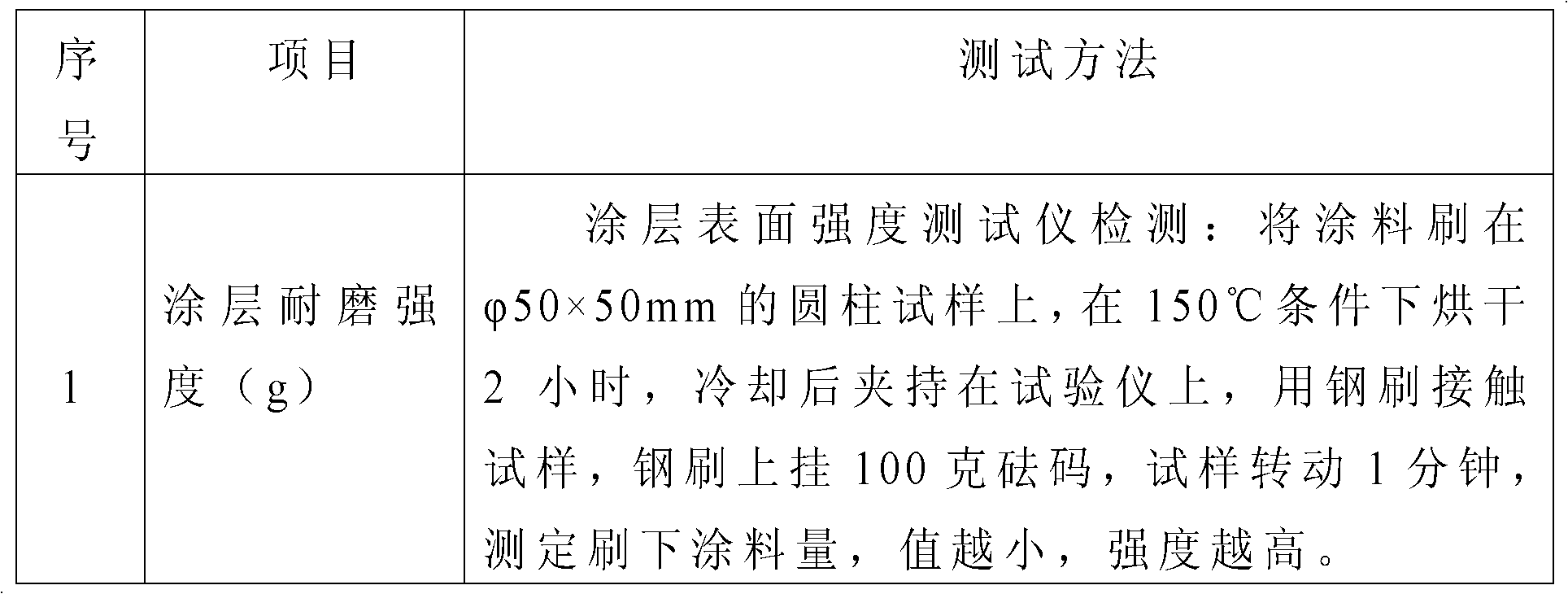

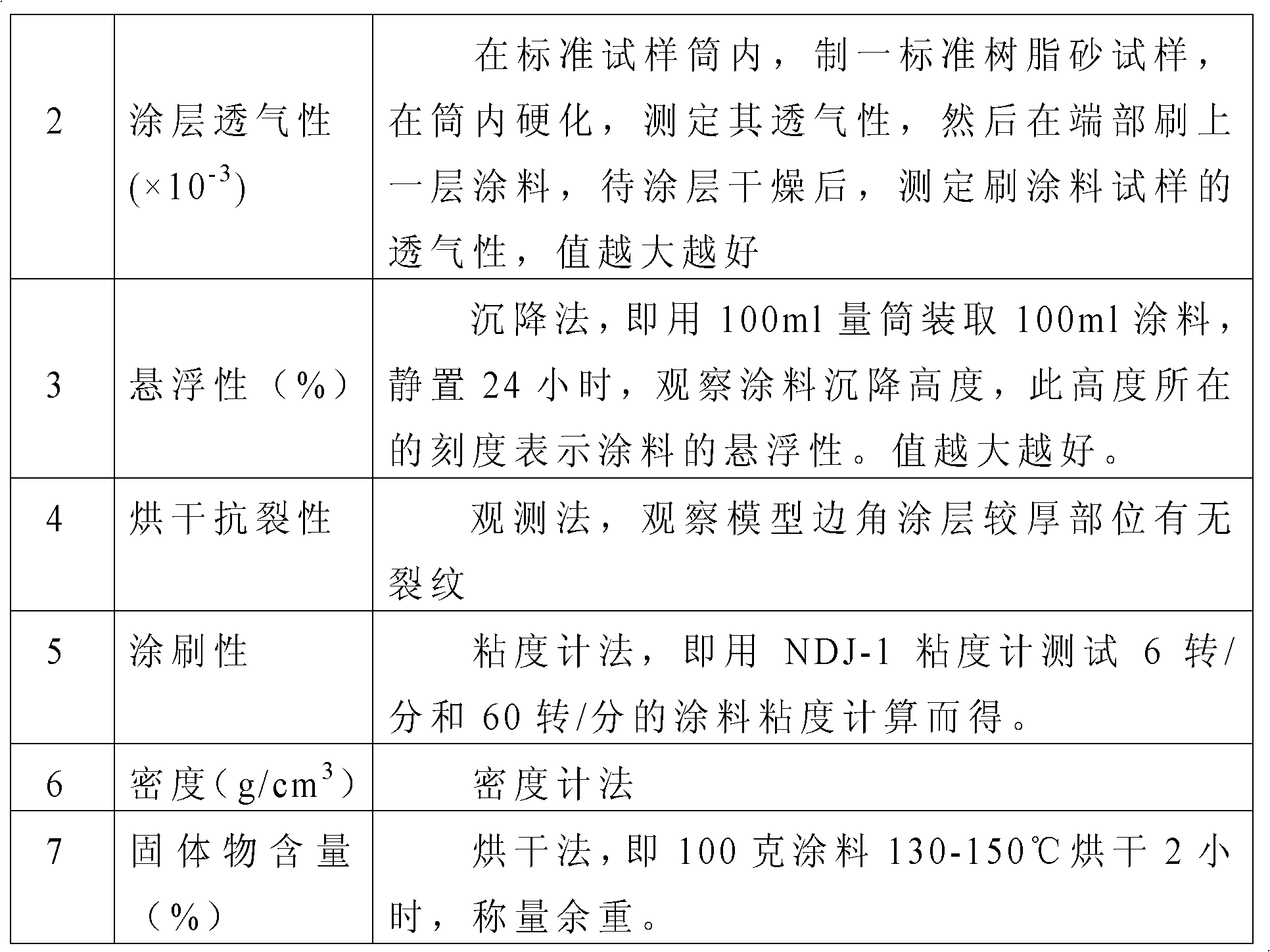

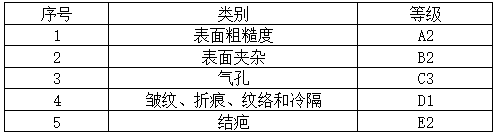

Solid pattern casting special paint and preparation method thereof

InactiveCN102049464AHigh strengthImprove integrityFoundry mouldsFoundry coresGraphiteSuspending Agents

The invention discloses a solid pattern casting special paint and a preparation method thereof. The mass percentages of various constituents in the paint are: 30-40% of bauxite chamotte, 20-30% of flaky graphite powder, 6.3-8.5% of bonder, 1-2% of iron oxide red powder, 4-6% of suspending agent, 0.8-1.5% of water reducing agent and 20-30% of water. The preparation method comprises the steps: mixing the various components of the solid pattern casting special paint according to the mass percentages and loading the constituents into a ball mill; adding 50-80 ceramic balls with a diameter of 30-50 mm into the ball mill; and mixing and stirring the materials evenly to obtain the paint. Practices show that the paint has strong abrasion performance, high adhesiveness, good air permeability and fast-dry performance both in low and high temperature environments; the paint can satisfy the production requirement of large casting production; the preparation method disclosed by the invention is simple; and the cost is low.

Owner:DONGFENG MOTOR CO LTD

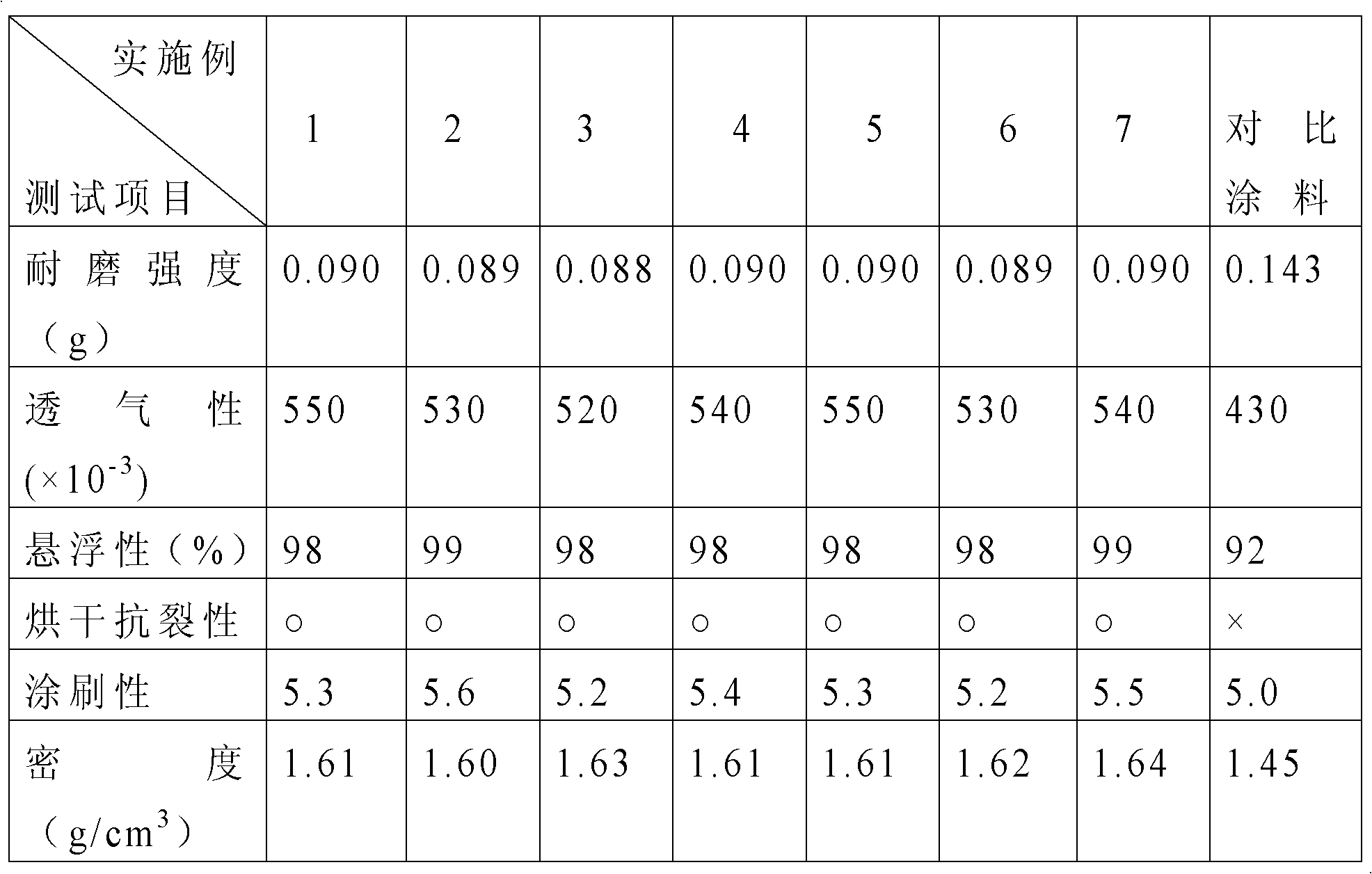

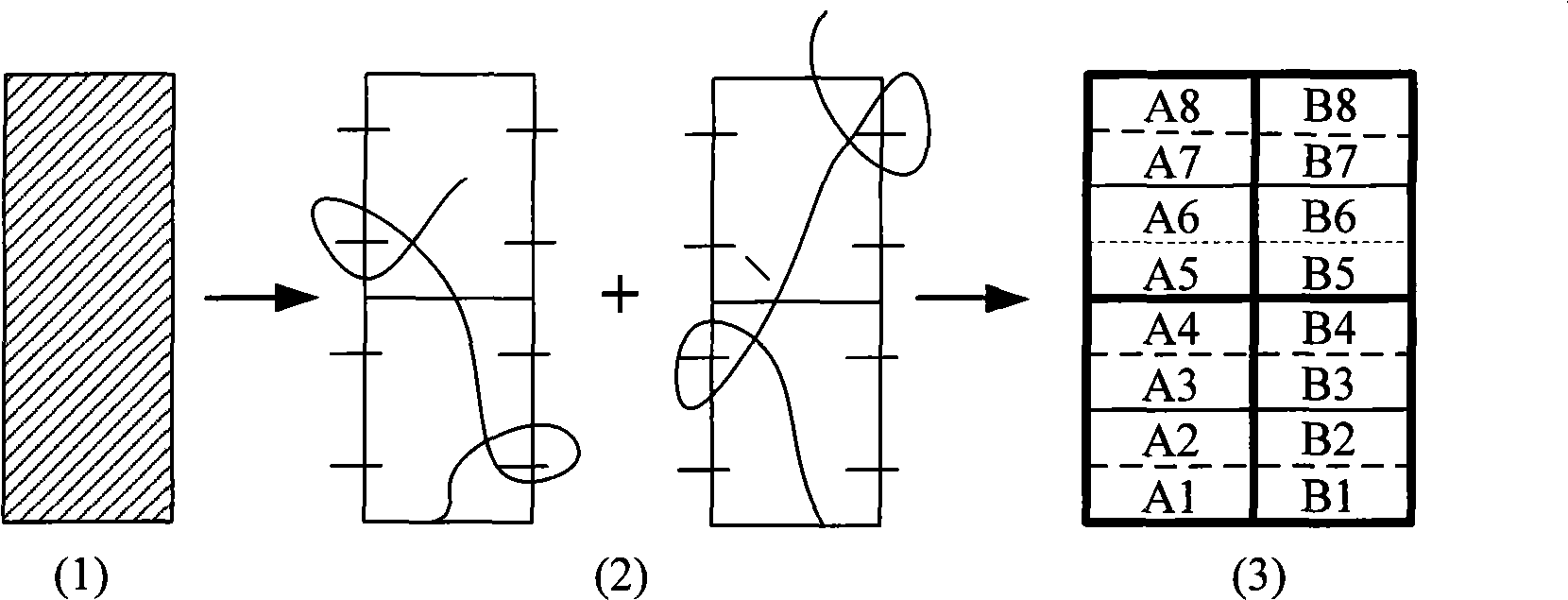

A warp knitting method for double-color jacquard seamless fabric

The invention discloses a warp knitting method for double-color jacquard seamless fabric. The concrete process is as follows: first, determining basic knitting process; each of front and back needle bed uses one ground guide bar for knitting base cloth and two jacquard guide bar for knitting main jacquard pattern and connection tissue for front and back sheet; second, determining overlap of main pattern formed by jacquard comb and corresponding motion information of jacquard needle, combines corresponding basic motion information of jacquard needle; finally, determining overlap of edge of front and back sheets and motion information of jacquard needle by adopting superposition method. The invention adopts special machine configuration and specific process, knits double-color seamless fabric, completes warp knitting jacquard seamless fabric with concurrent structural effect and color effect. The seamless fabric of the inventive method has a solid pattern and outstanding layers, rich color, variable structural effect, massive thickness, thereby largely promoting market competitive force of seamless fabric.

Owner:JIANGNAN UNIV

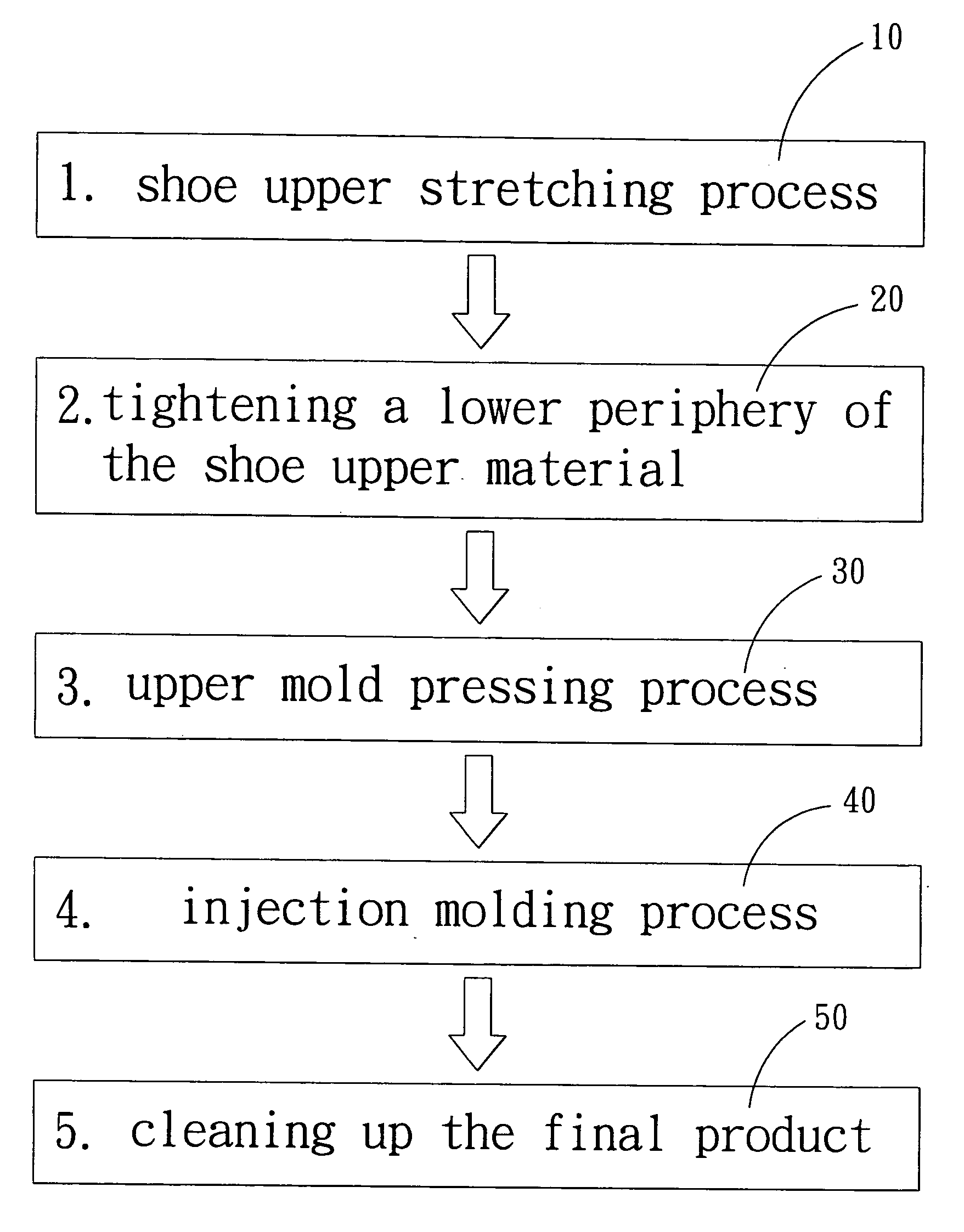

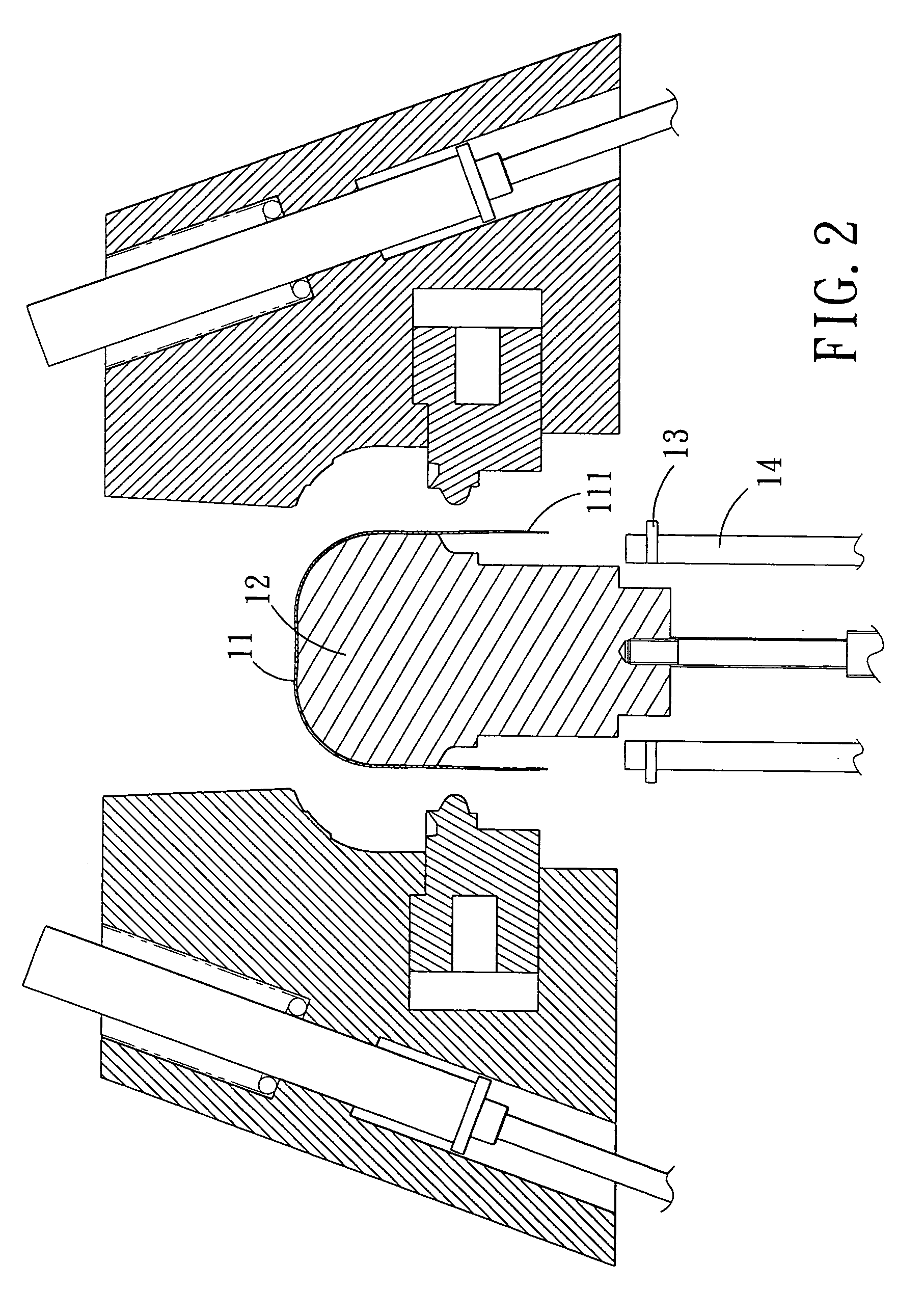

Method for injection molding a solid pattern onto a shoe upper

The invention relates to a method for injection molding a solid pattern onto a shoe upper, which is capable of molding solid pattern on a shoe upper, and generally including the following steps: 1. shoe upper stretching process 2. tightening a lower periphery of the shoe upper material 3. upper mold pressing process 4. injection molding process 5. cleaning up the final product.

Owner:YANG DENG RENG

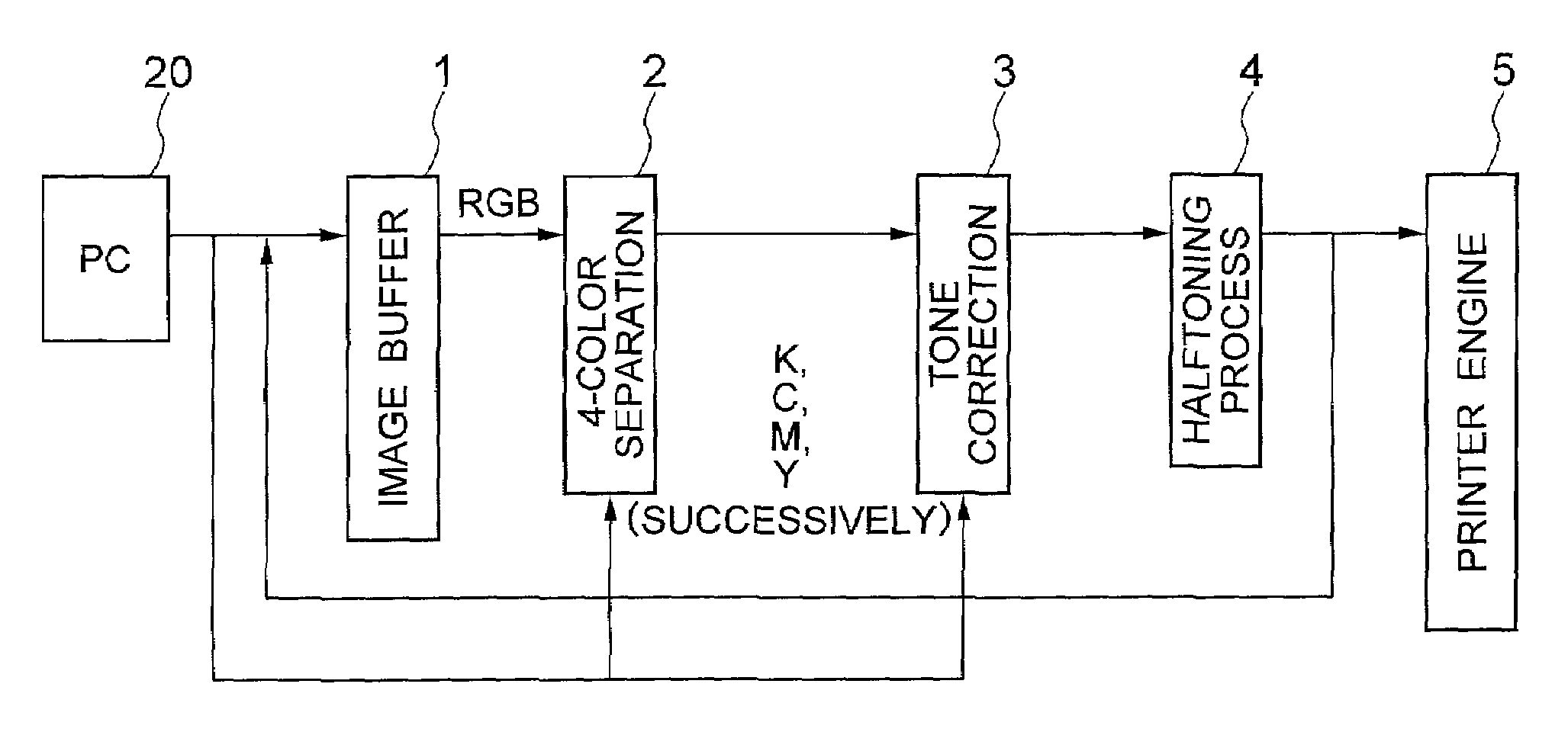

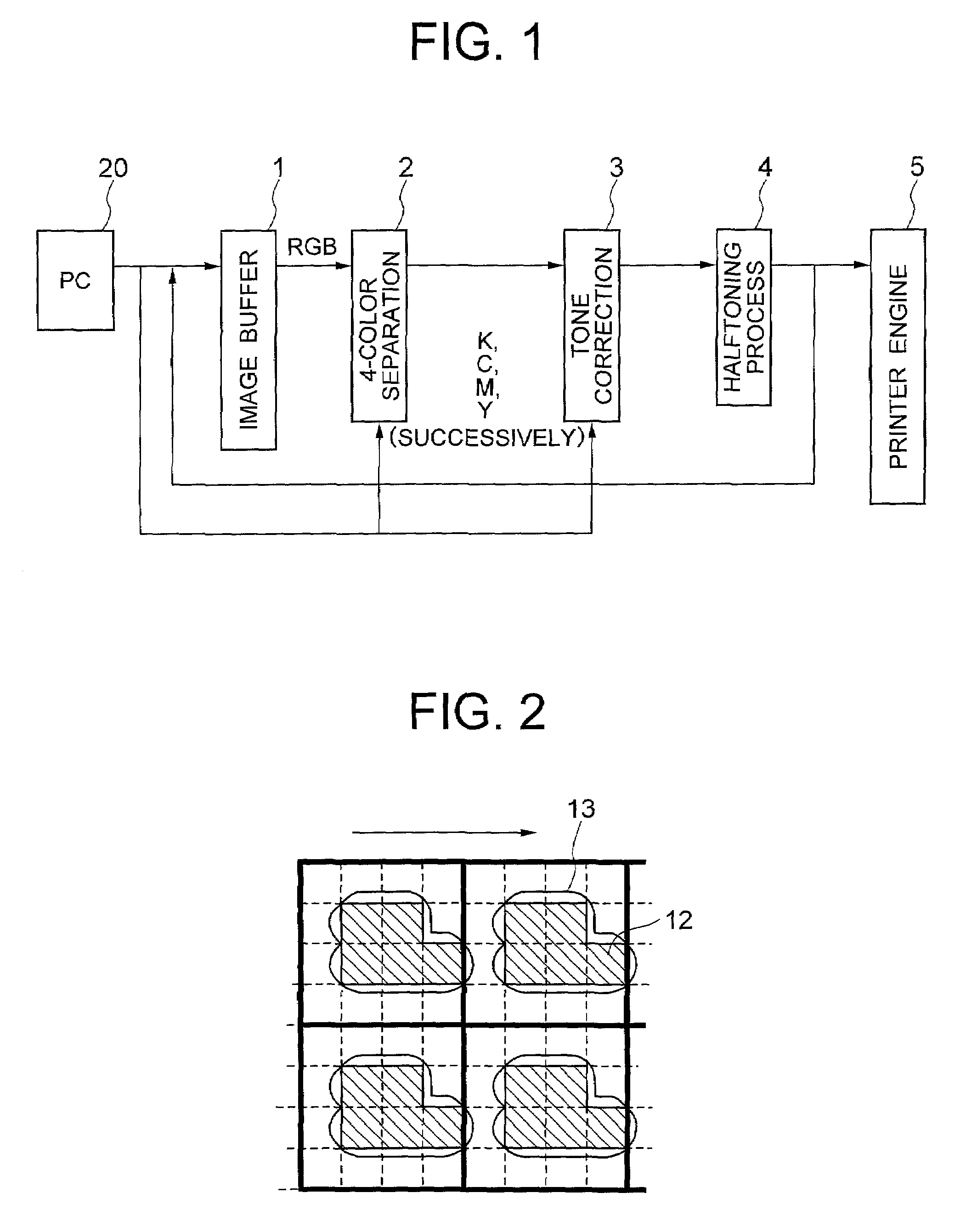

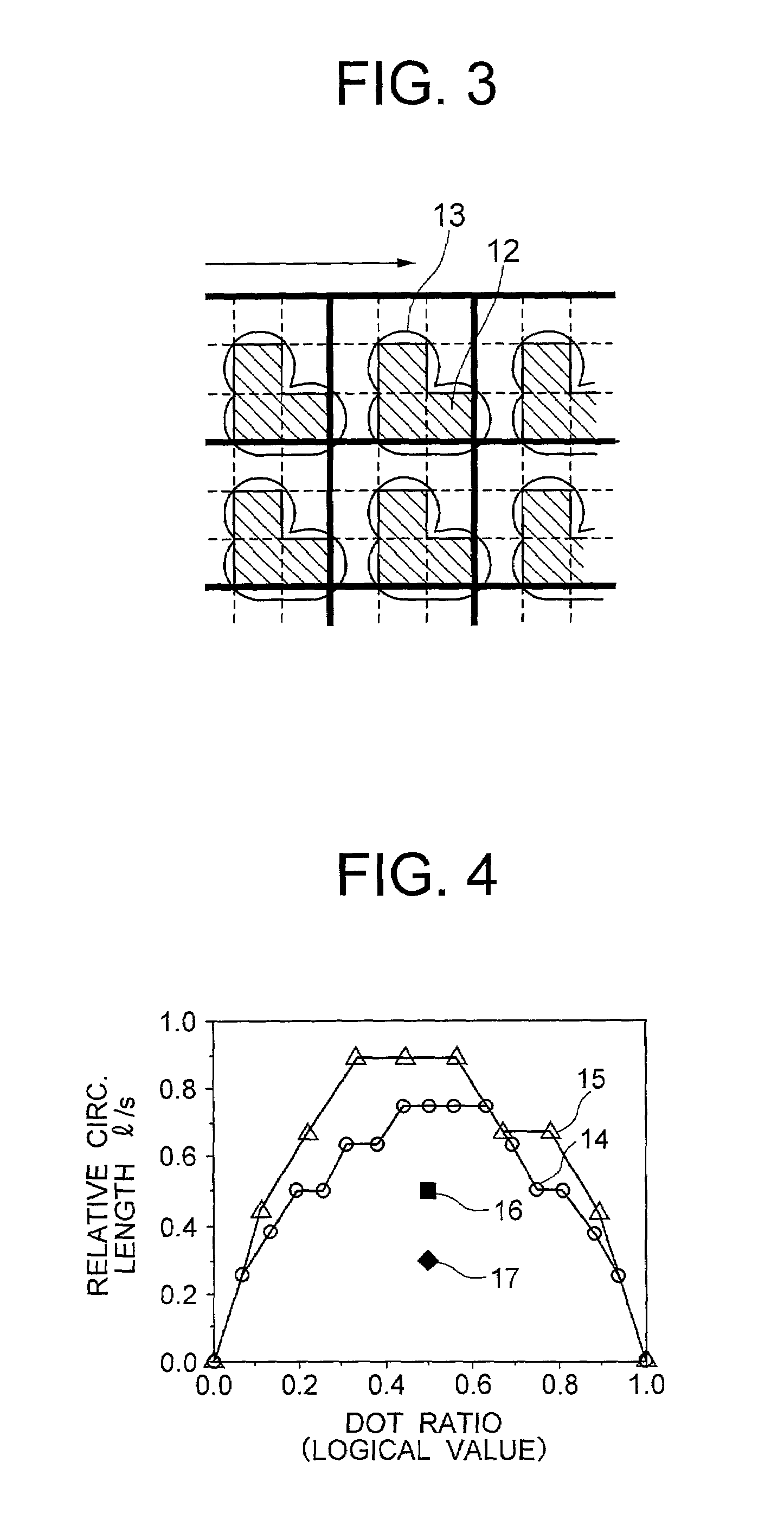

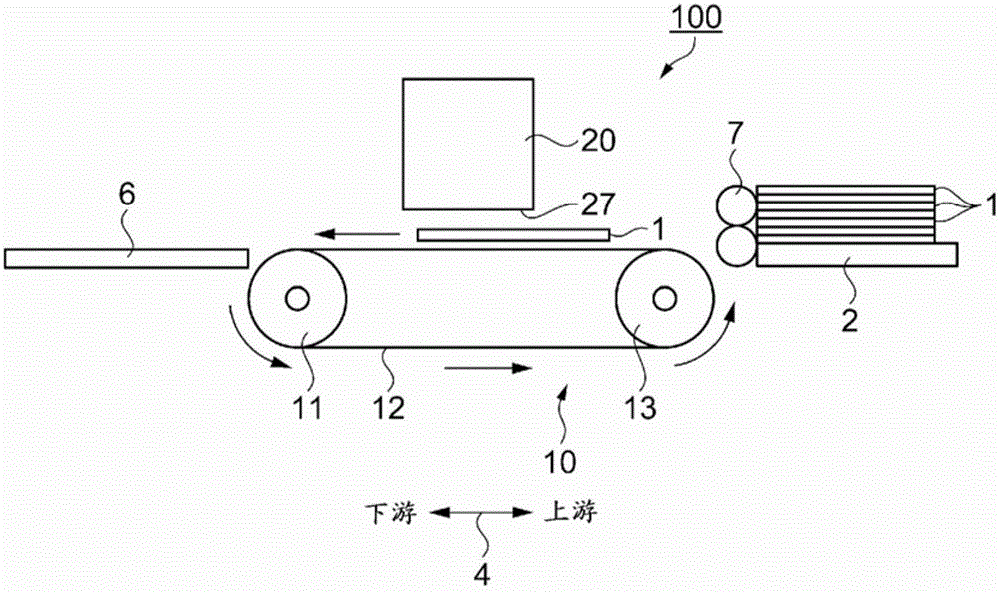

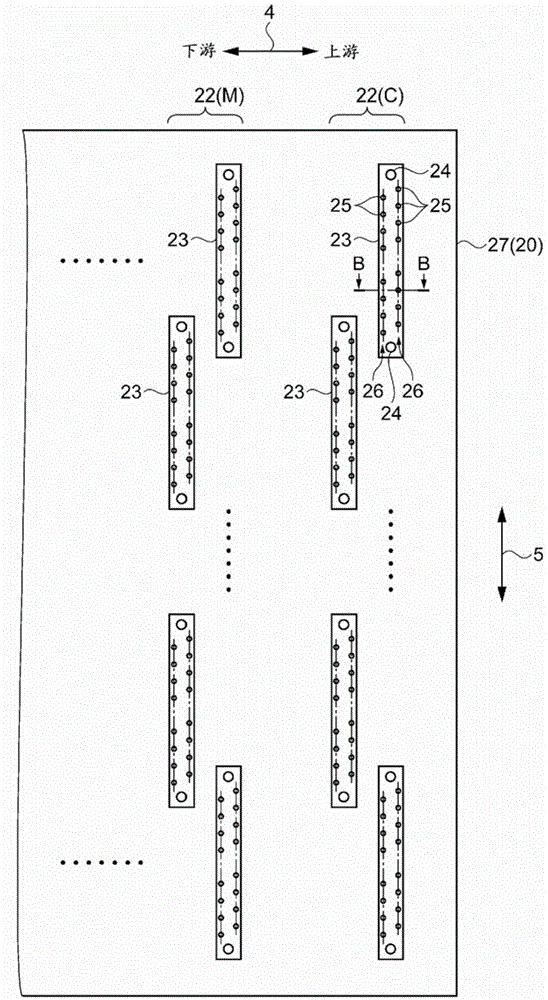

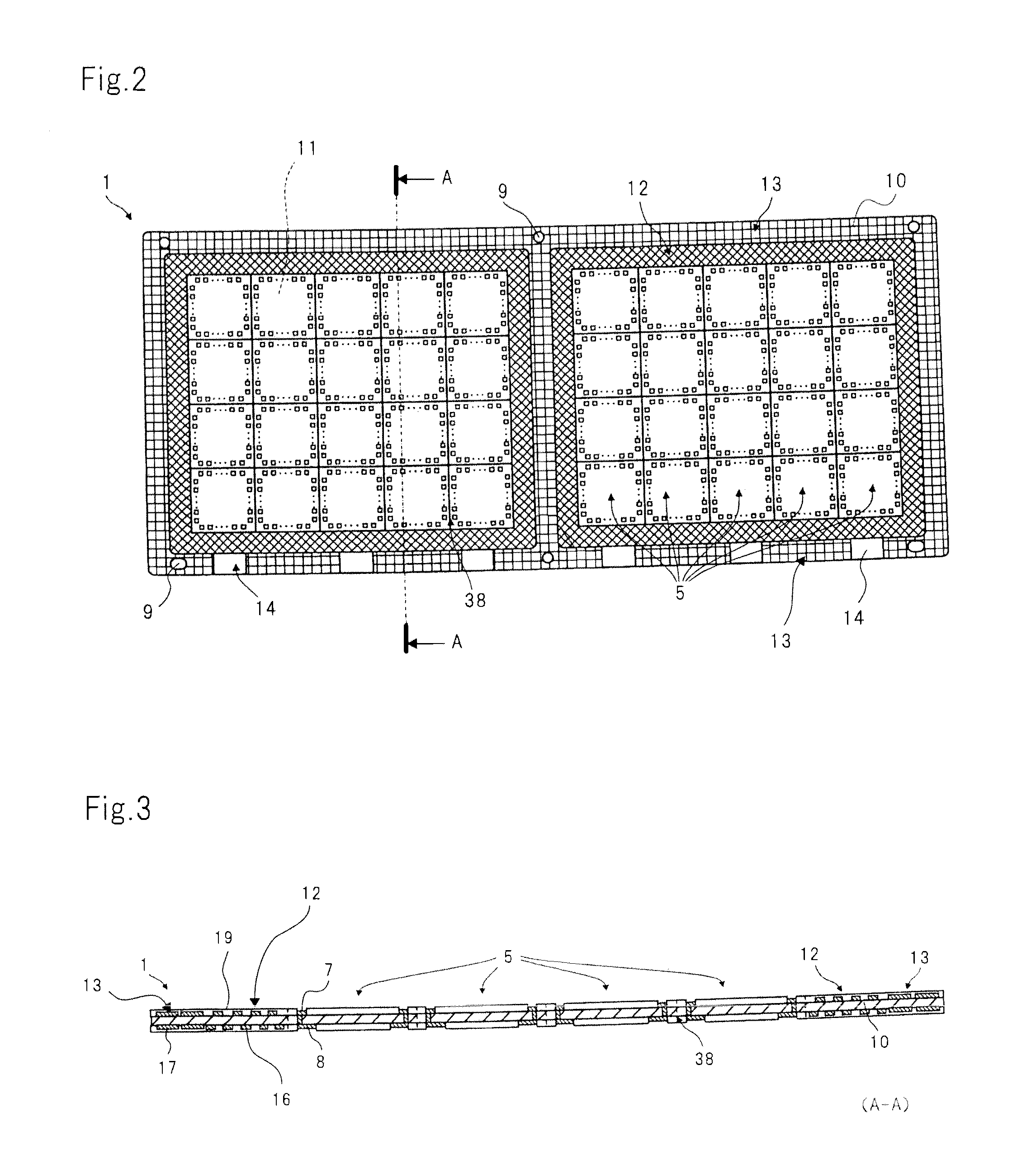

Image output device and test chart for the same

InactiveUS7130076B2High precision calibrationEasy to copyImage enhancementDigitally marking record carriersImage resolutionOutput device

In an image output device a test chart 18 including tests charts 6 of each color is used, and a tone correction table is calculated. The test charts 6 are patterned in a checkered pattern, each including continuous areas 10 in which the tones increase in steps and reference areas 11 for comparison with the continuous areas 10. The reference areas 11 are formed of white ground of paper in a highlight proof part 7, a solid pattern with a maximum density in a shadow proof part 8, and halftone dot-concentrated or line screens with a lower resolution than in the continuous areas in a middle proof part 9. Tone correction values are calculated from characteristic values of the highlight, shadow and middle parts, obtained from visual data of the test chart 18.

Owner:RICOH PRINTING SYST

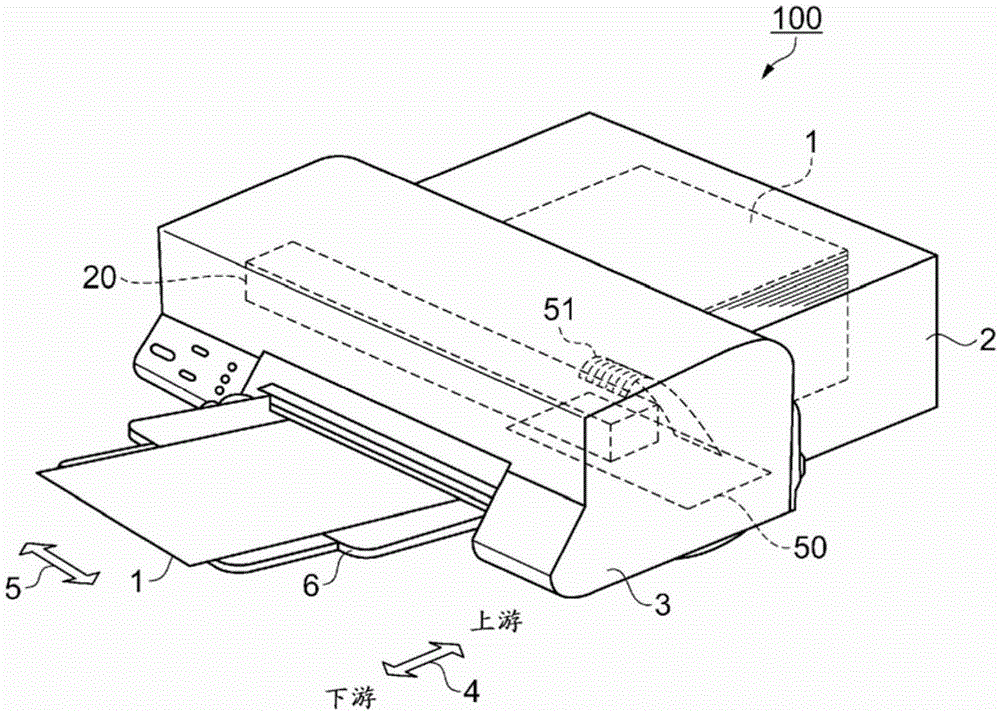

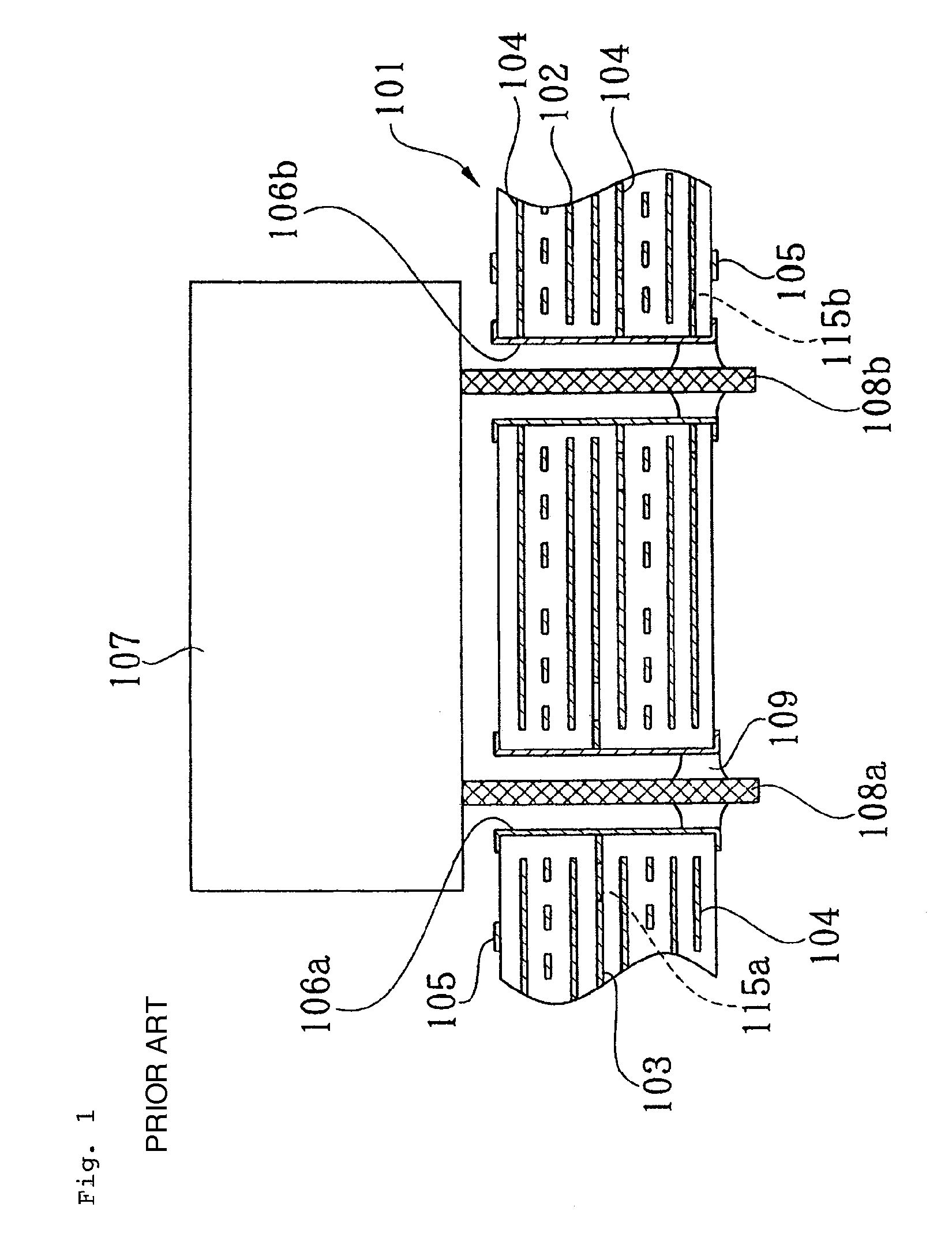

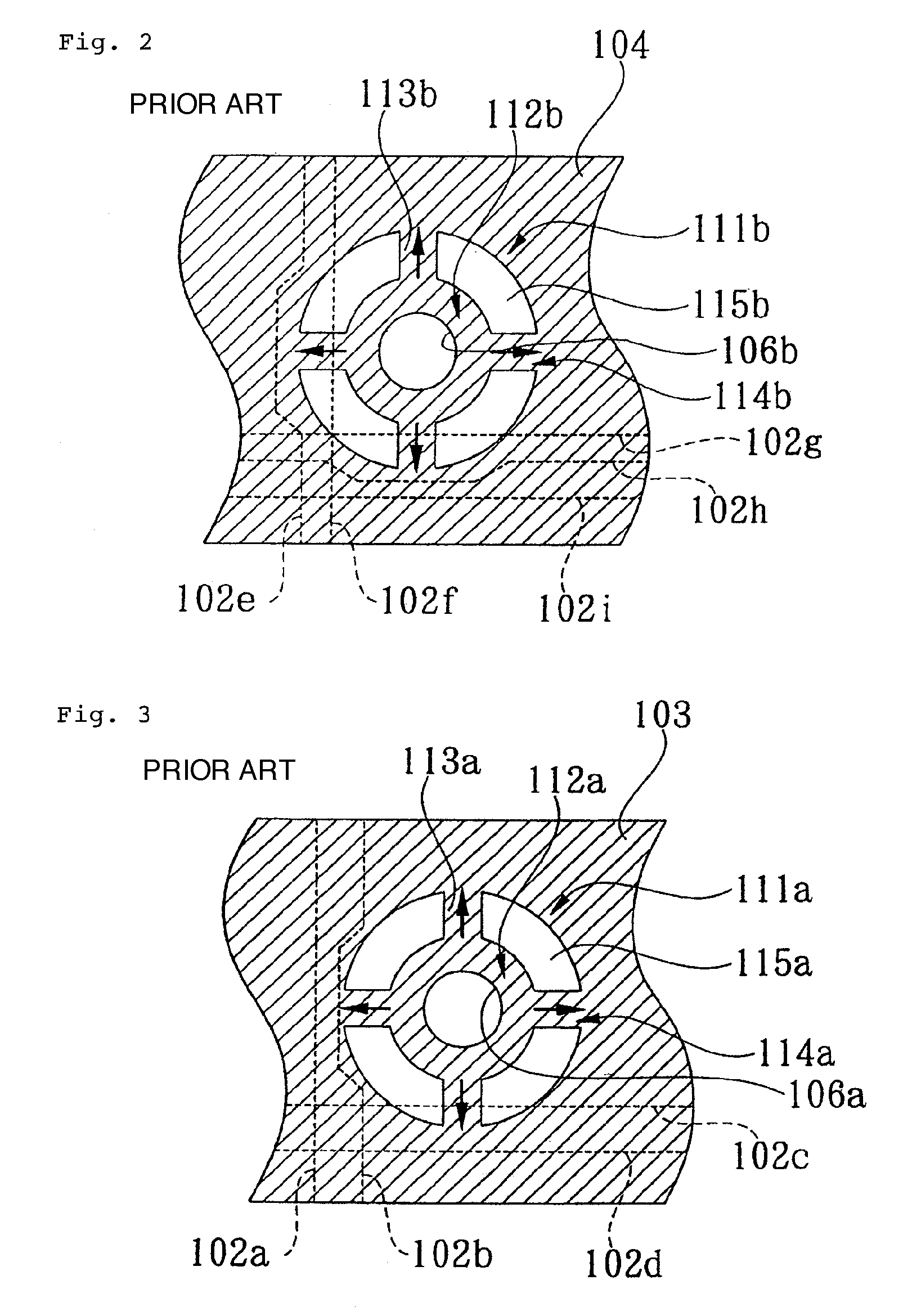

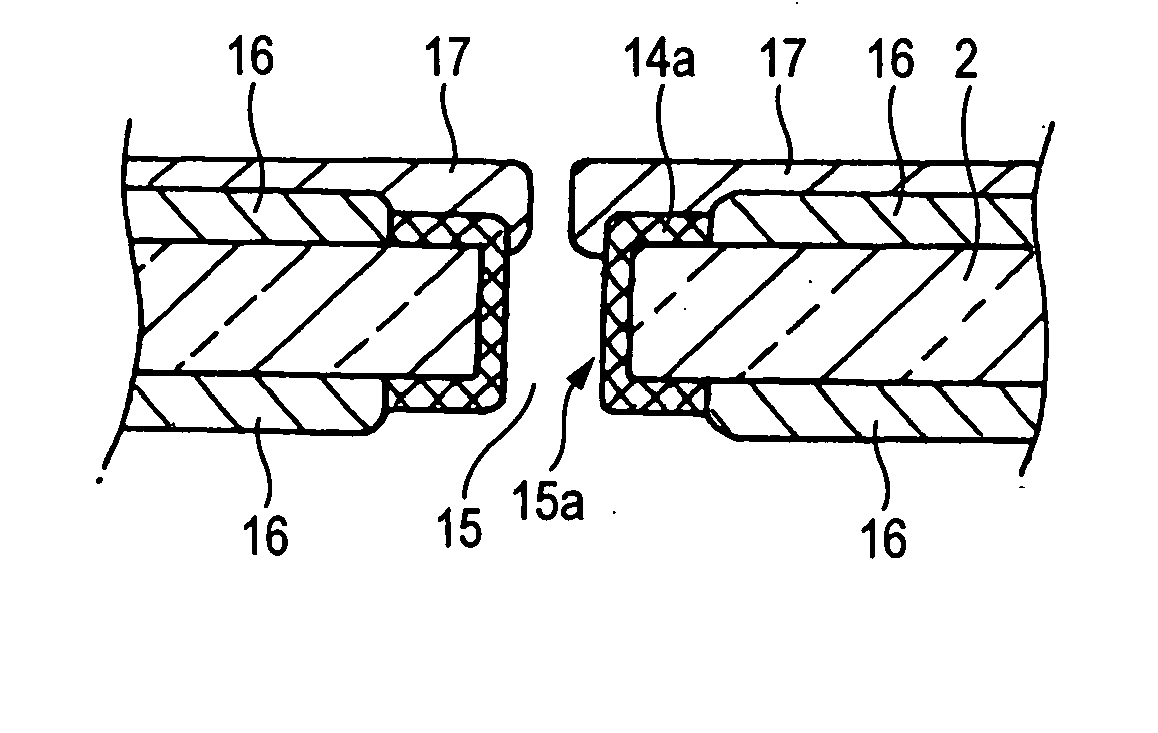

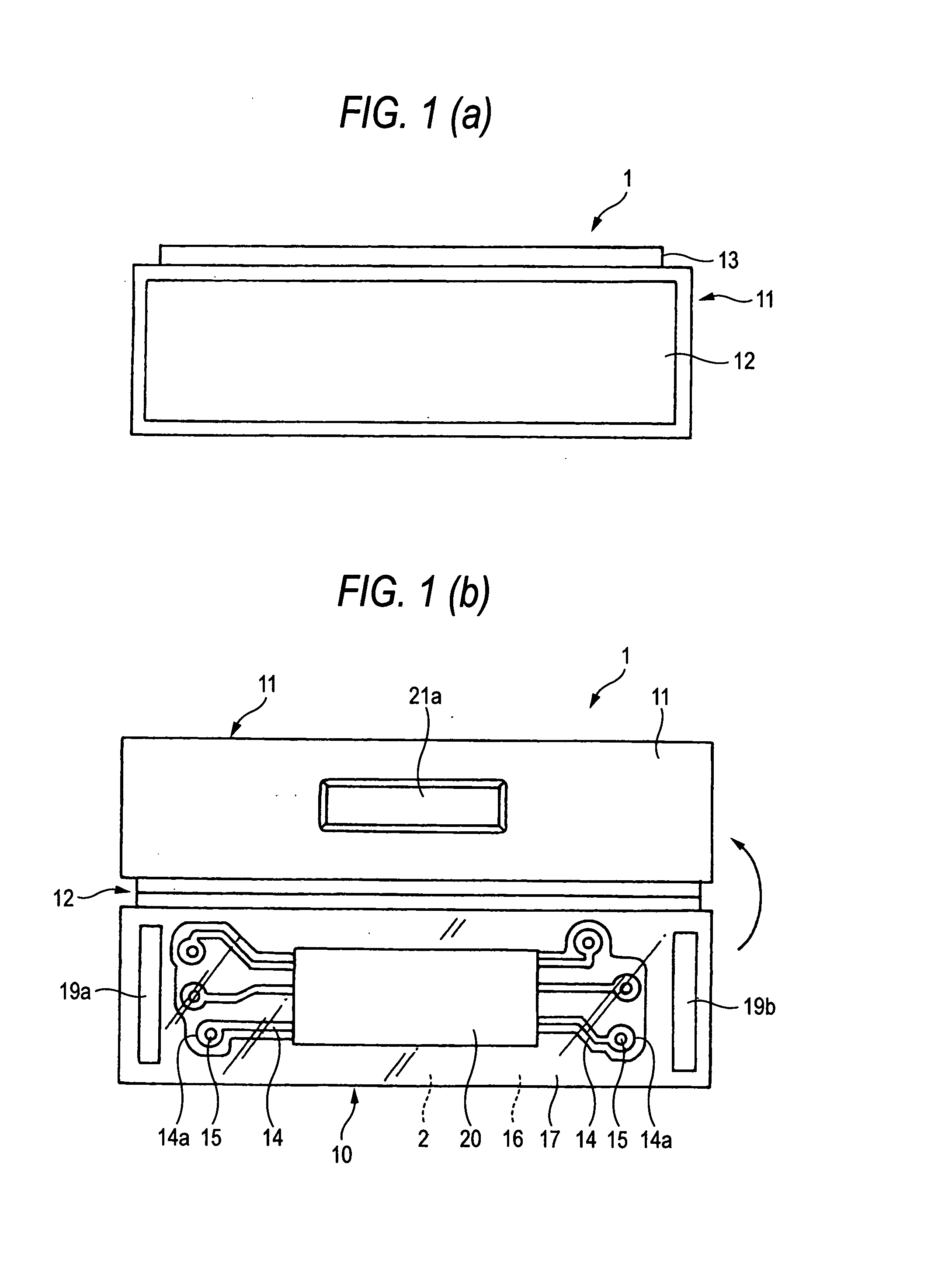

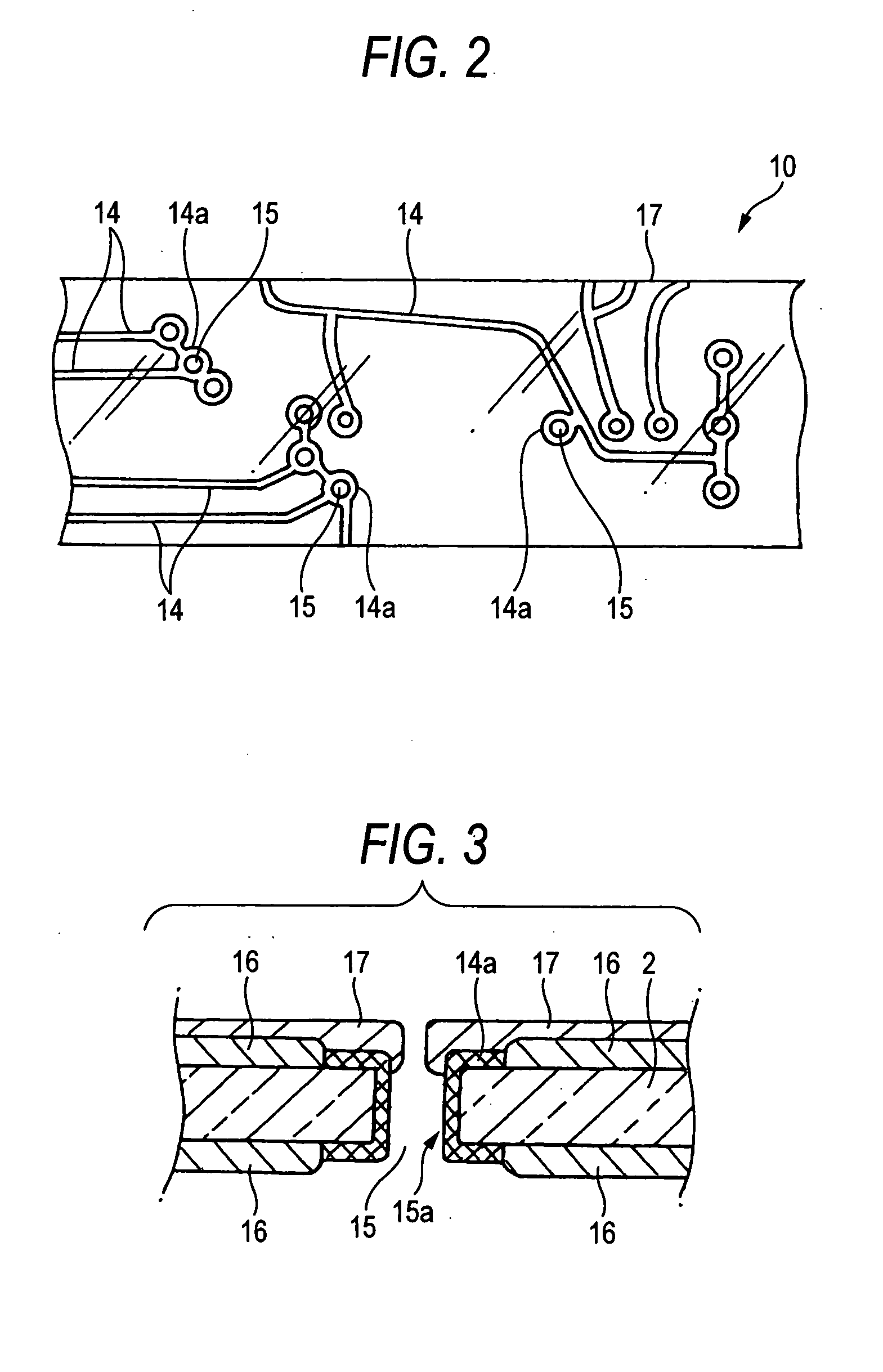

Liquid ejecting apparatus, print head unit, and drive substrate

A plurality of THs are formed in the main substrate (drive substrate) in a region in which switching transistors are disposed. In addition, a solid pattern obtained by expanding an interconnection pattern at the periphery of the transistors is formed to surround the transistors. In addition, a solid pattern for heat dissipation is also formed on a rear surface to add a heat dissipation structure for a frame. According to this, it is possible to provide a liquid ejecting apparatus which has a simple configuration and which realizes operation stability without using a dedicated heat dissipation component.

Owner:SEIKO EPSON CORP

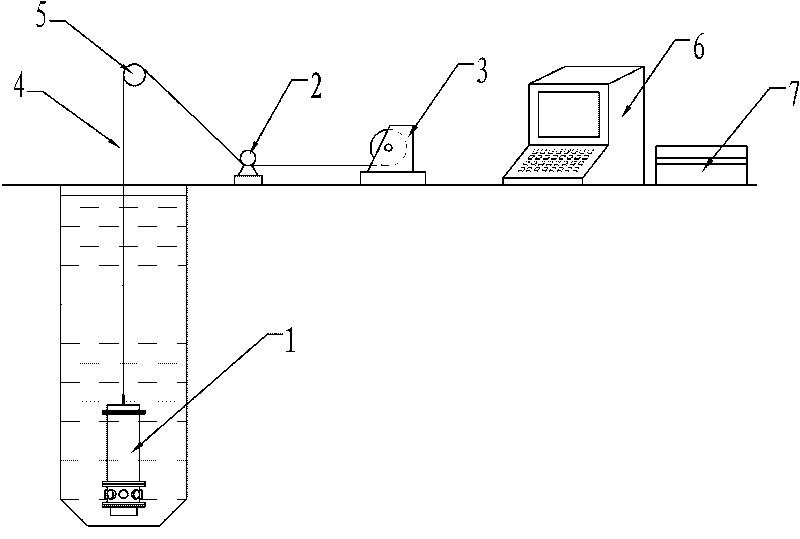

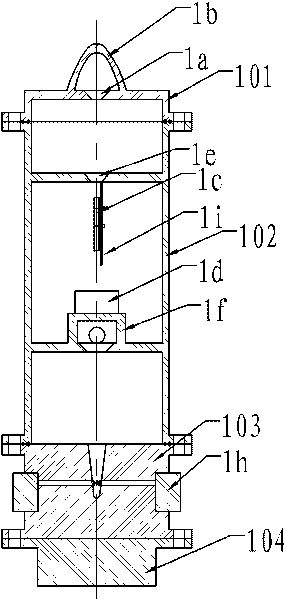

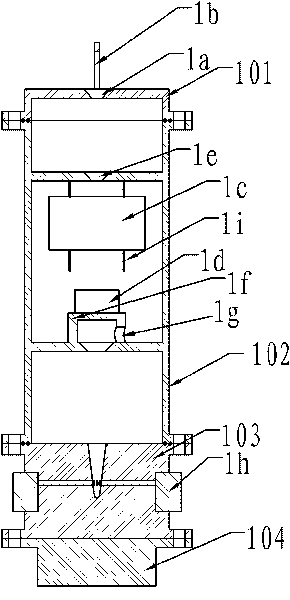

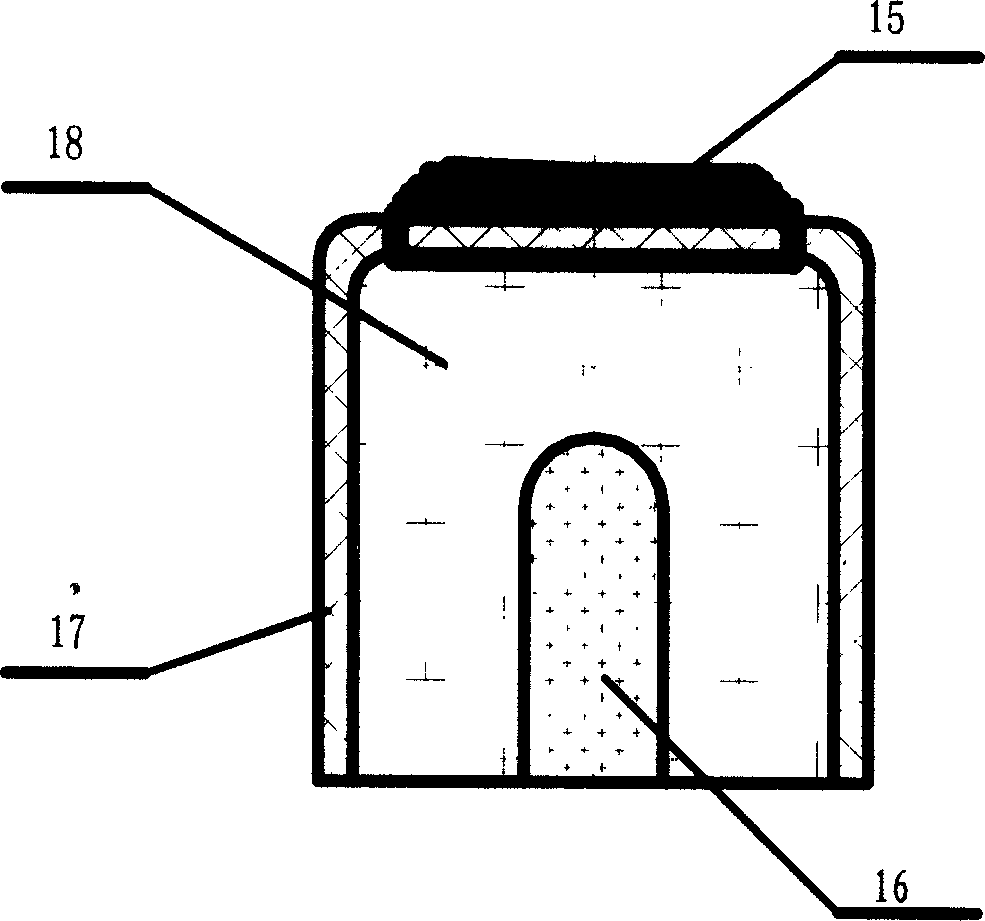

Ultrasonic logging system using self-orienting device of ultrasonic logging instrument

ActiveCN101761330AImproved orientation accuracyImprove reliabilitySurveyConstructionsEngineeringWorkstation

The invention provides an ultrasonic logging system using a self-orienting device of an ultrasonic logging instrument. The system comprises a down-hole meter which is connected with a depth gauge and a logging winch by an armoured cable bypassing a pulley, wherein the logging winch is connected with a ground workstation; the depth gauge is arranged for measuring the laid down depth of the down-hole meter; a main device of the down-hole meter is fixed with an optical fiber top inside so as to measure the self-orienting direction of the down-hole meter; an energy converter device is provided with a plurality of uniformly distributed energy converters; the energy converter sends an ultrasonic wave and receives an echo aperture of a measuring well; and the ground workstation performs the single-step linear prediction interpolation on the orienting direction data of the optical fiber top, performs the linear interpolation on the depth of the depth gauge, performs the linear interpolation on the aperture value measured by the energy converter, and calculates and acquires a solid pattern and a parameter of a rockshaft. The invention provides an ultrasonic logging system using a self-orienting device of an ultrasonic logging instrument which promotes the self-orienting precision of the ultrasonic logging instrument and widens the measuring scope of the down-hole meter.

Owner:SHANDONG UNIV OF SCI & TECH

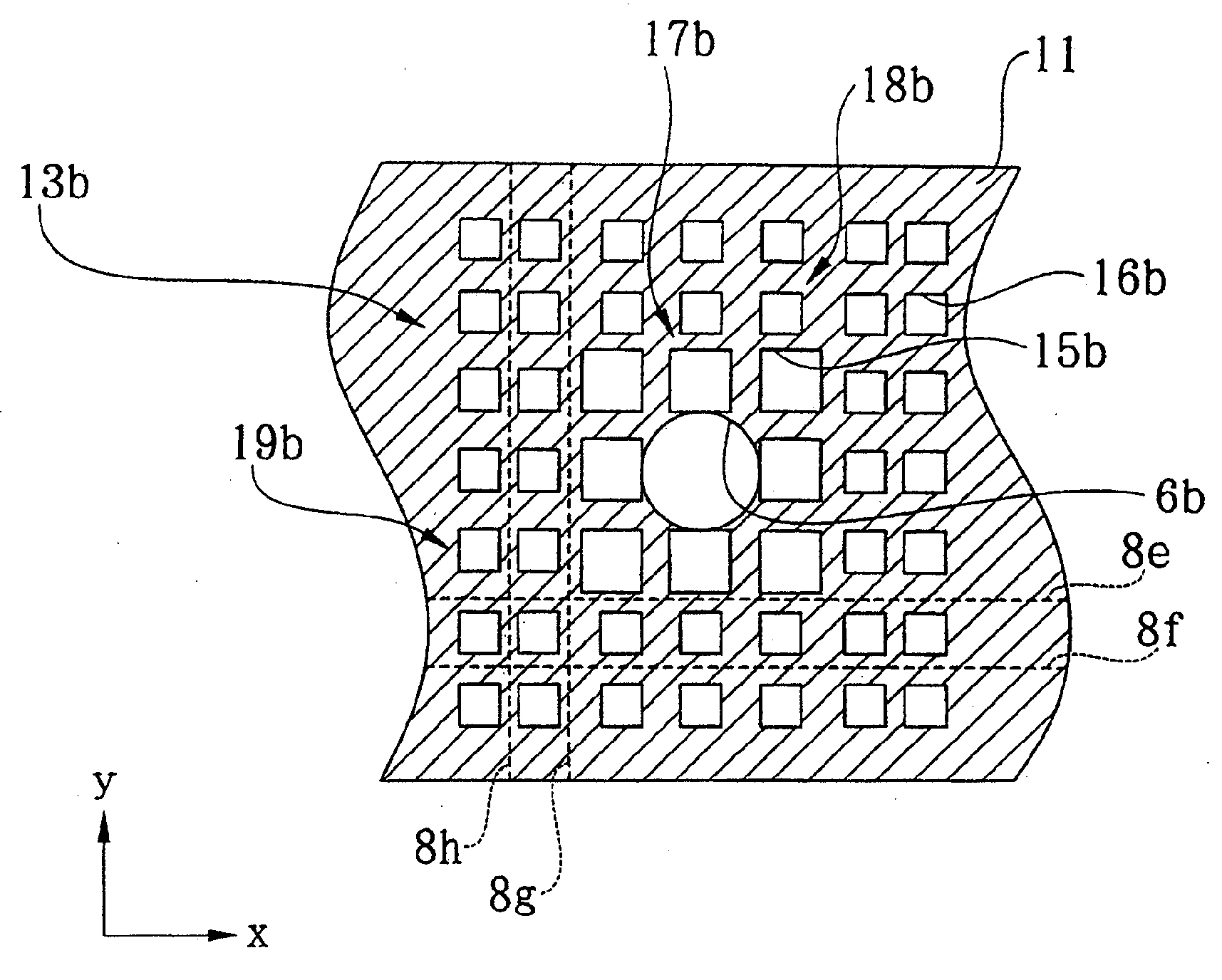

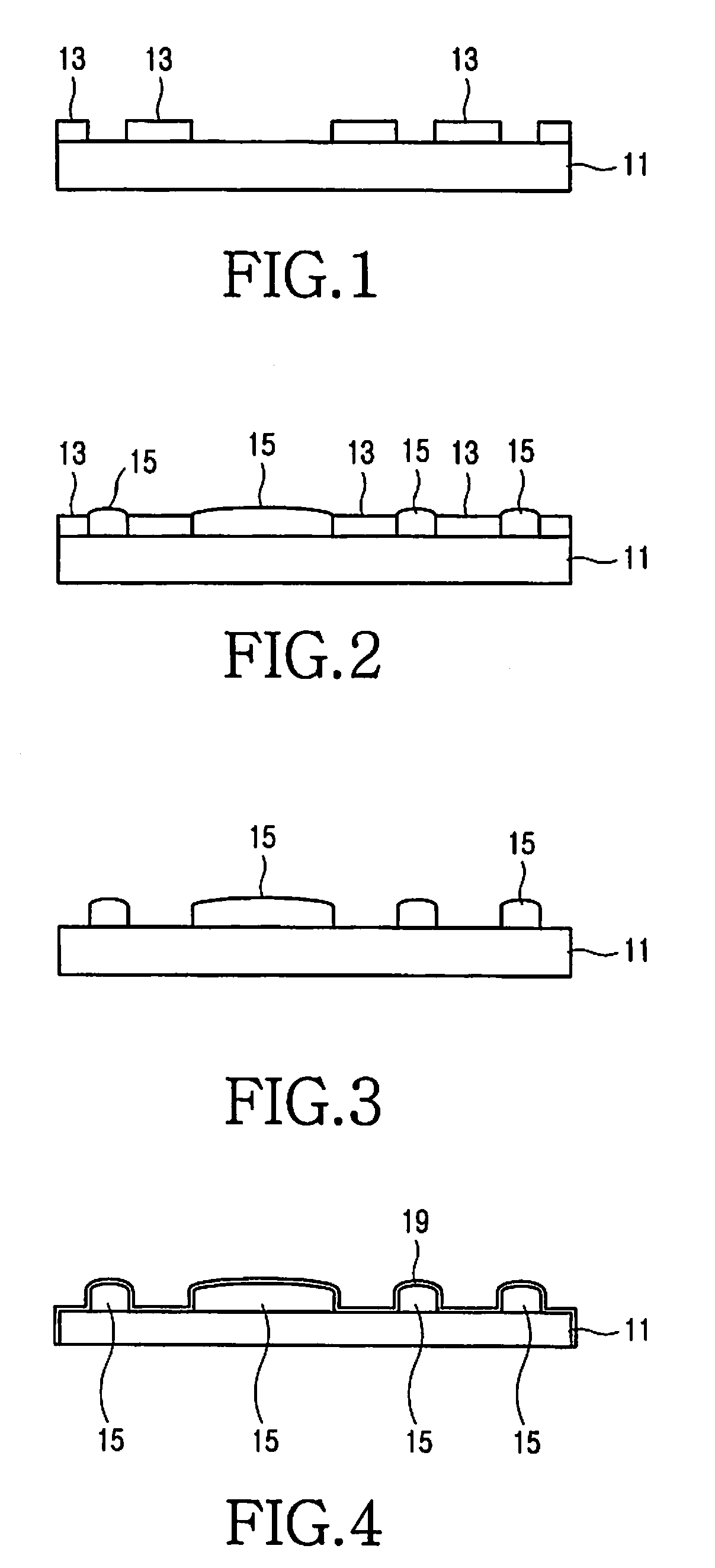

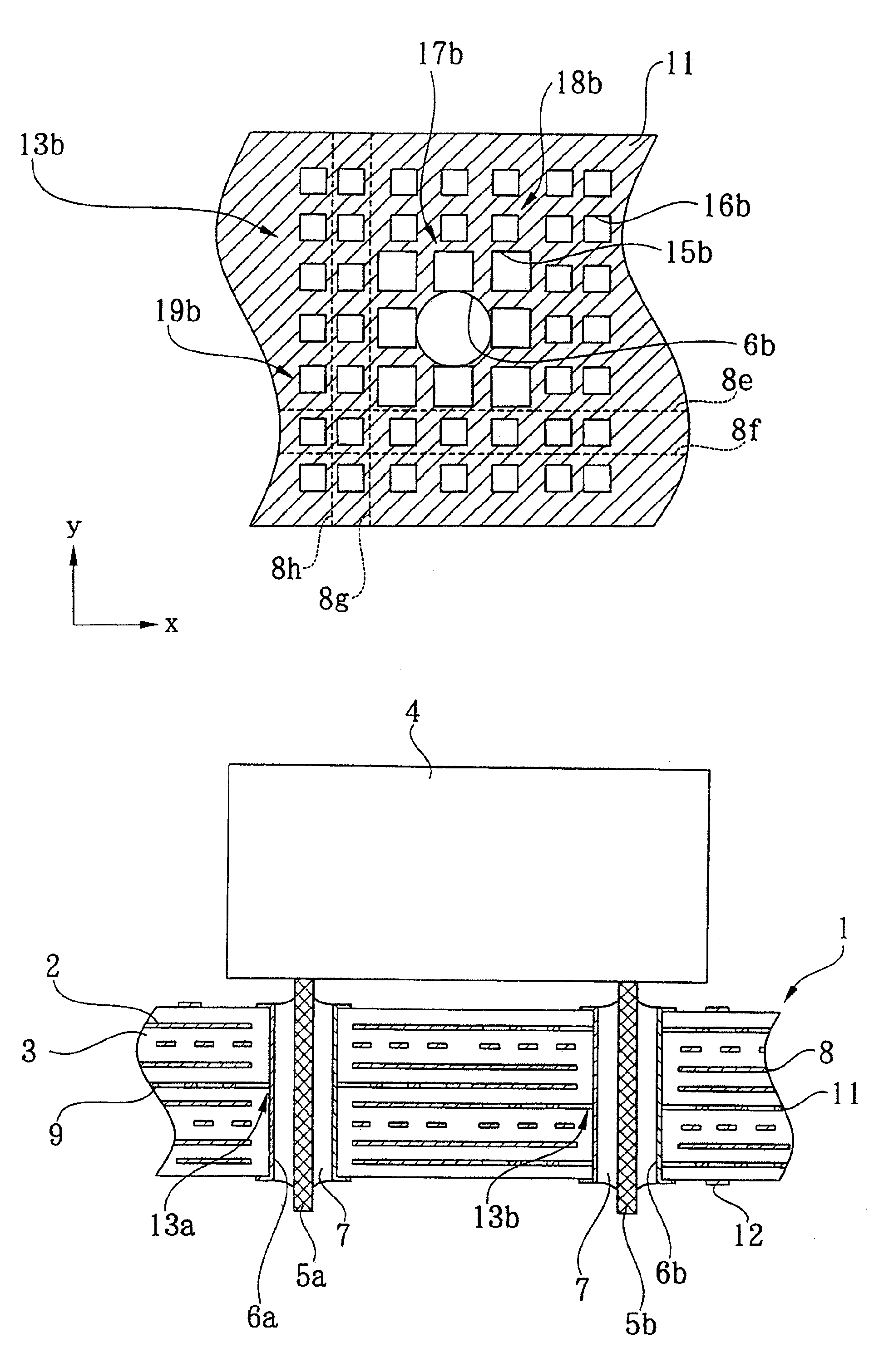

Printed wiring board

InactiveUS20090183899A1Increasing the thicknessDifficult to solderPrinted electric component incorporationPrinted circuit aspectsEngineeringCopper foil

When soldering is performed, heat transferred from through hole 6b is caused to bypass a mesh-like copper foil region between non-copper-foil regions and thus the transfer of heat to a solid pattern region around thermal land 13b is delayed. Signal wirings 8e, 8f and signal wirings 8g, 8 are formed along the arrangement directions of non-copper-foil regions 15b, 16b respectively keeping a predetermined spacing between them and disposed to overlap copper foil regions, thus ensuring a current return path by means of opposing ground layer 11.

Owner:NEC CORP

Production method of color-based glass with solid pattern

The invention provides a method for producing a kind of glass with a bottom-colored embossed pattern, comprising following steps: 1) blocking out one side of the transparent plate glass by protective coating and washing, airing; 2) printing the colorful pattern on one side of the plate glass without protective coating by silk screen with predesigned and colorful epoxide resin antisepsis oil, and solidifying; 3) soaking the solidified plate glass for 60-120 minutes in the etching liquid; 4) forming the glass with a bottom-colored embossed pattern while cleaning the glass after etching and removing the protective coating. Above-mentioned etching liquid is composed of 55 wt.% of hydrofluoric acid, 20-31 wt.% of acidic liquid which is 98 wt.%, 48-58 wt.% of water, wherein the acidic liquid is nitric acid or sulphuric acid. The method is simple, less-pollution, colorful and with a strong three-dimension effect.

Owner:李守进

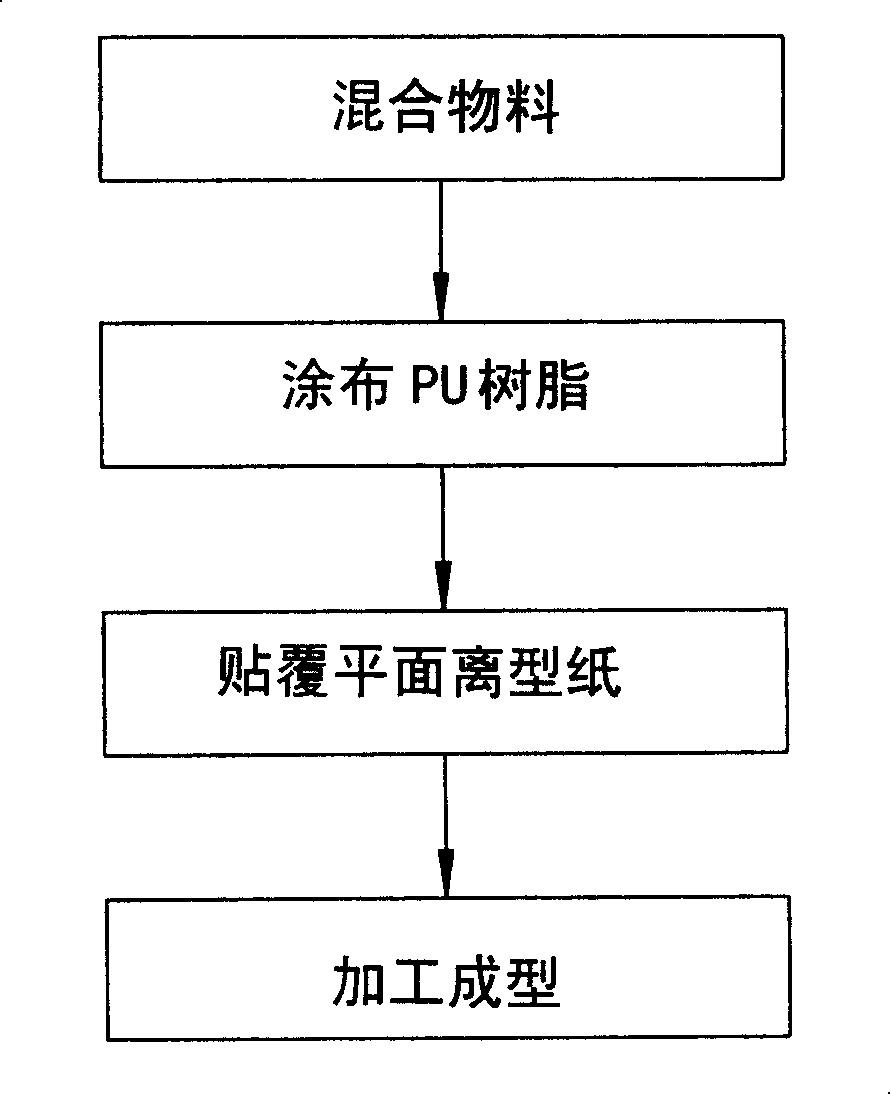

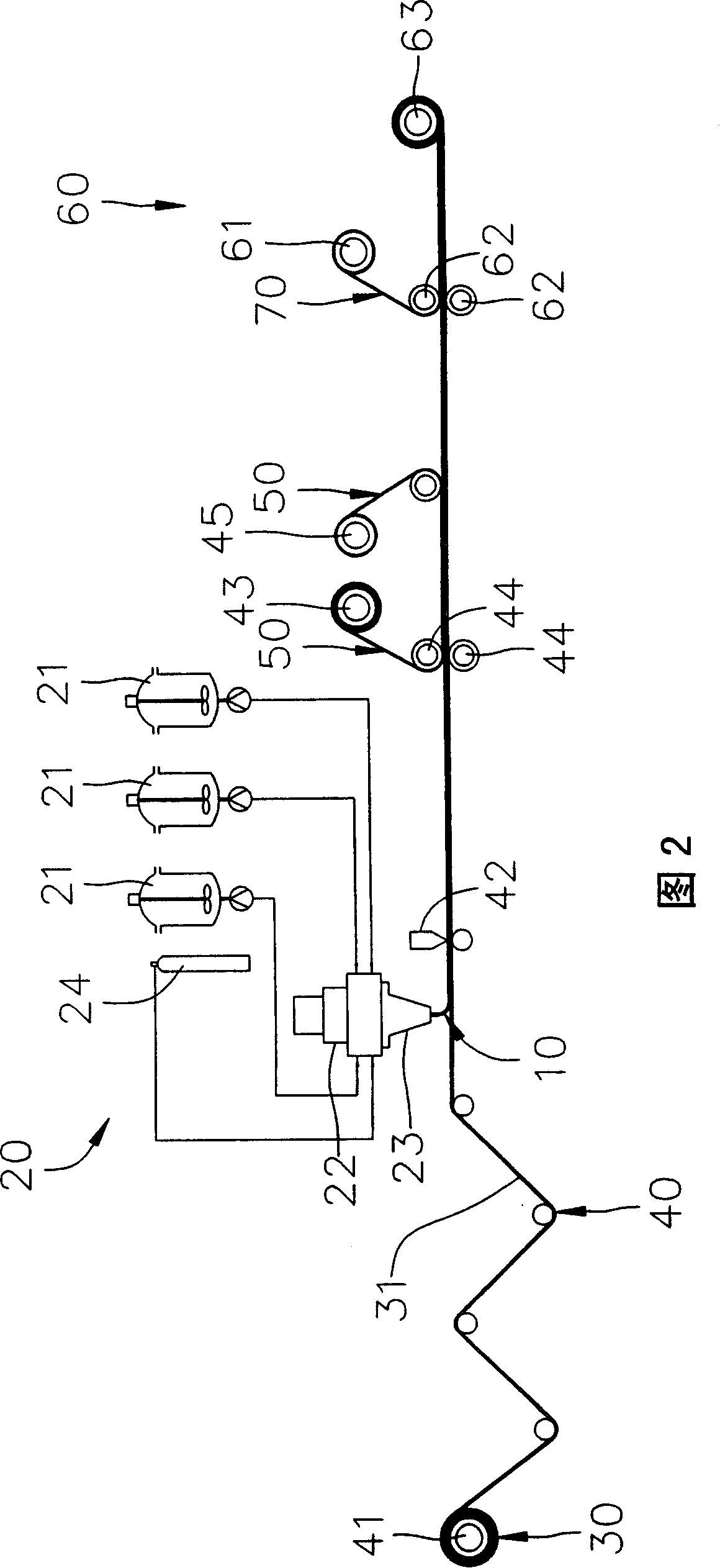

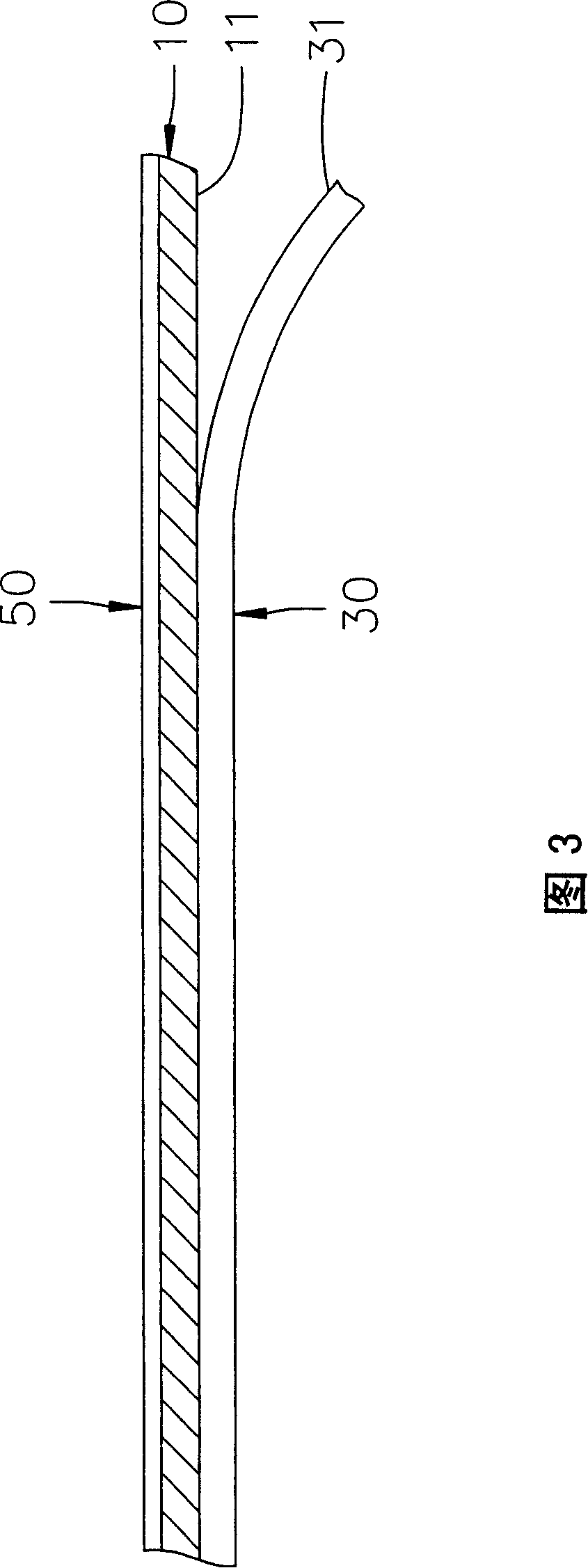

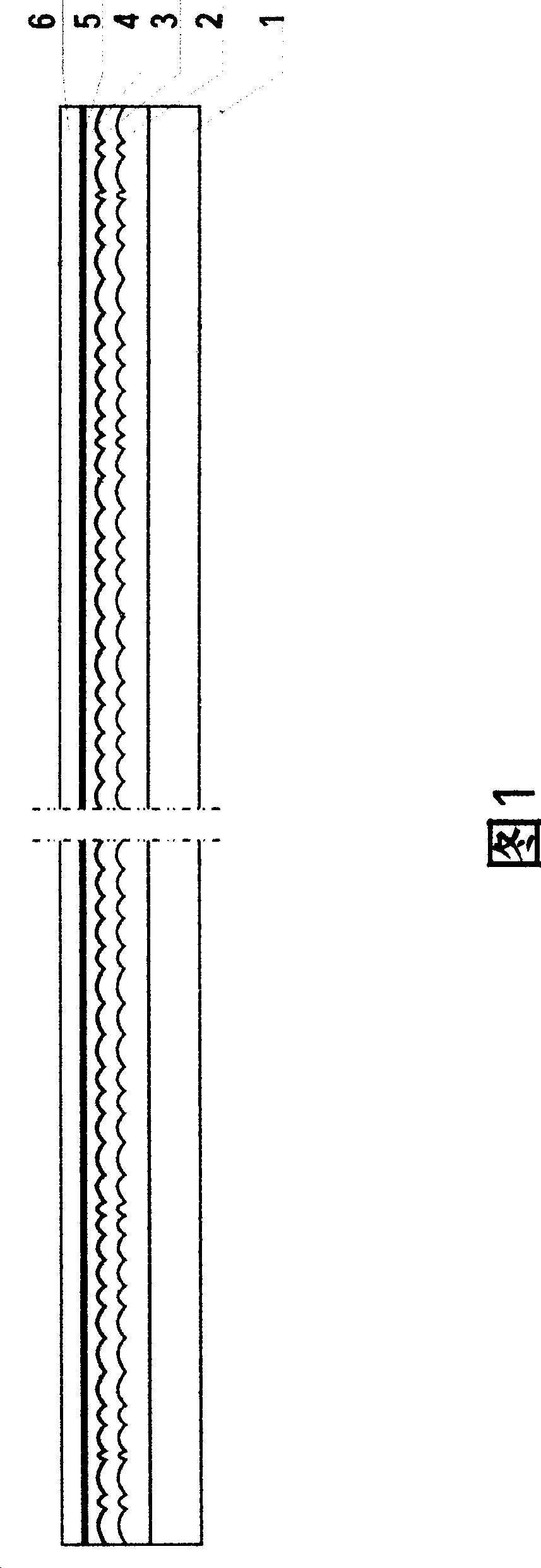

Method for preparing decorative tablet or decorative cloth with solid pattern

InactiveCN101177051ANo pollutionNo public nuisanceLamination ancillary operationsSpecial ornamental structuresPulp and paper industrySolvent

The invention relates to a manufacture method for decorative plate or decorative cloth of three-dimensional patterns, which adopts the steps as follow: a pattern layer of three-dimensional release paper is delivered to a material mixing device containing PU resin material; the PU resin is coated on the pattern layer with predetermined thickness; a planar release paper is adhibited on the other surface of the three-dimensional release paper opposite to the PU resin, and semi-finished products is formed, and then the semi-finished products are delivered to a forming device, and are combined with the base fabric to form a three-dimensional decorative cloth without adding any solvent according to the demand, or put into a forming mold to form a three-dimensional decorative design plate. The invention has an advantages of being a manufacture method for environmental protection and pollution-free.

Owner:PERFECTION MIGHTY IND

Compound film for decoration with tridimensional multicolor pattern

InactiveCN101376317ASave mineral resourcesNo smellSynthetic resin layered productsSpecial ornamental structuresComposite filmMineral Sources

A multilayer composite film with solid multicolor patterns for decorative use comprises a plastic bottom film layer. The technical proposal of the composite film is that a thermal sol layer, a metal deposition layer or a multicolor dyeing film layer with convex and concave solid patterns or solid embossing patterns, transparent double adhesive vinyl, and a transparent film layer with characters or / and patterns are arranged on the plastic bottom film layer in sequence. The invention has the advantages that the composite film adopts metal film composite materials and a multicolor printing and cold mounting process, so as to achieve the sense of metal of metal tags and the rich color change which can not be reached by the metal tags, thereby saving a large amount of mineral resources. The process produces no smell, no pollution or noise, and is more environment-friendly and beautiful compared with the chemical corrosion process for producing the traditional tag, and improves the production efficiency by more than 10 times. The invention particularly adopts the thermal sol layer with a certain thickness. In the invention, the thermal sol layer is not only a bounding layer, but also a framework layer for the metal layer composite material to form the permanent solid pattern.

Owner:赵臣

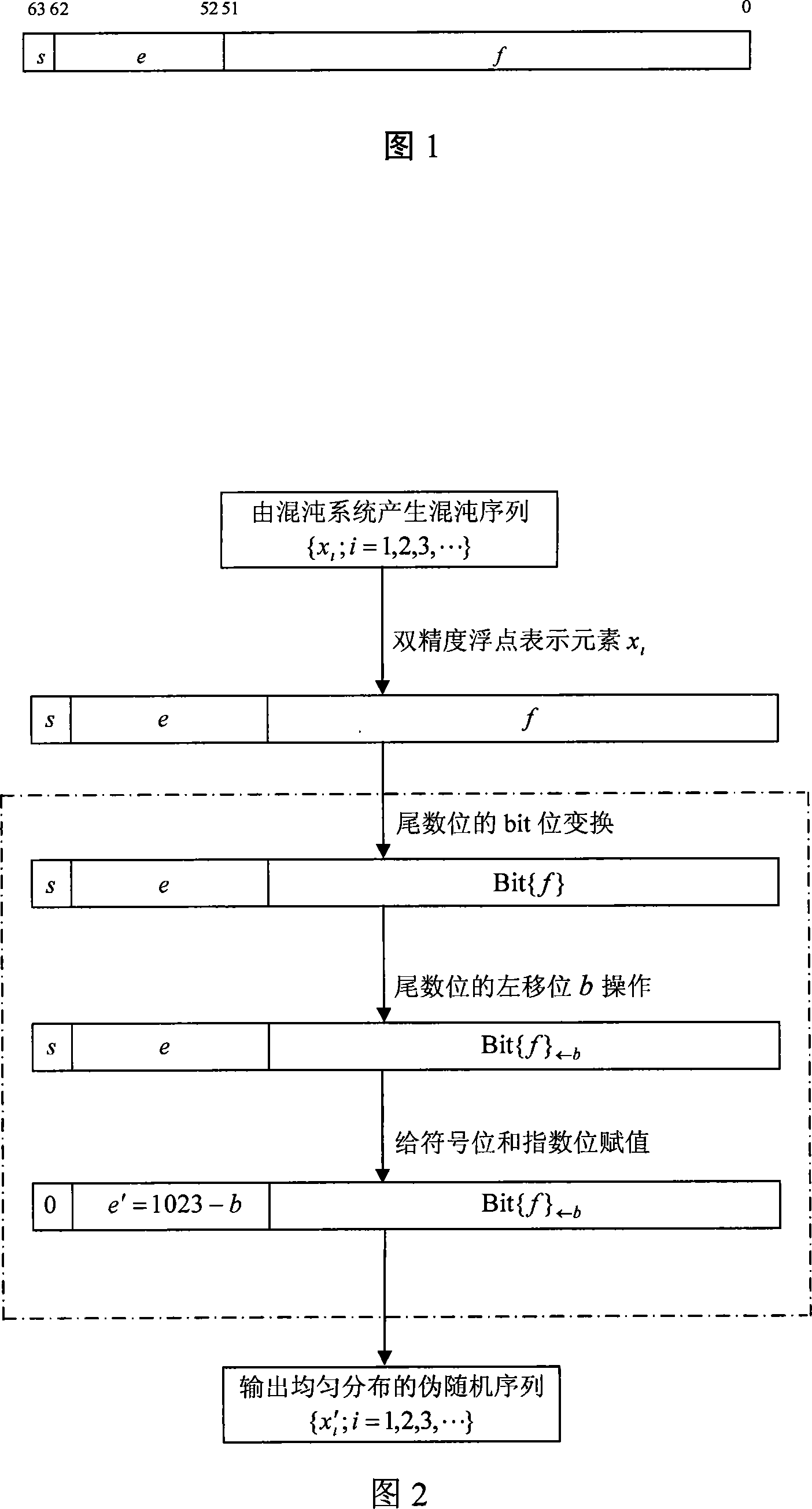

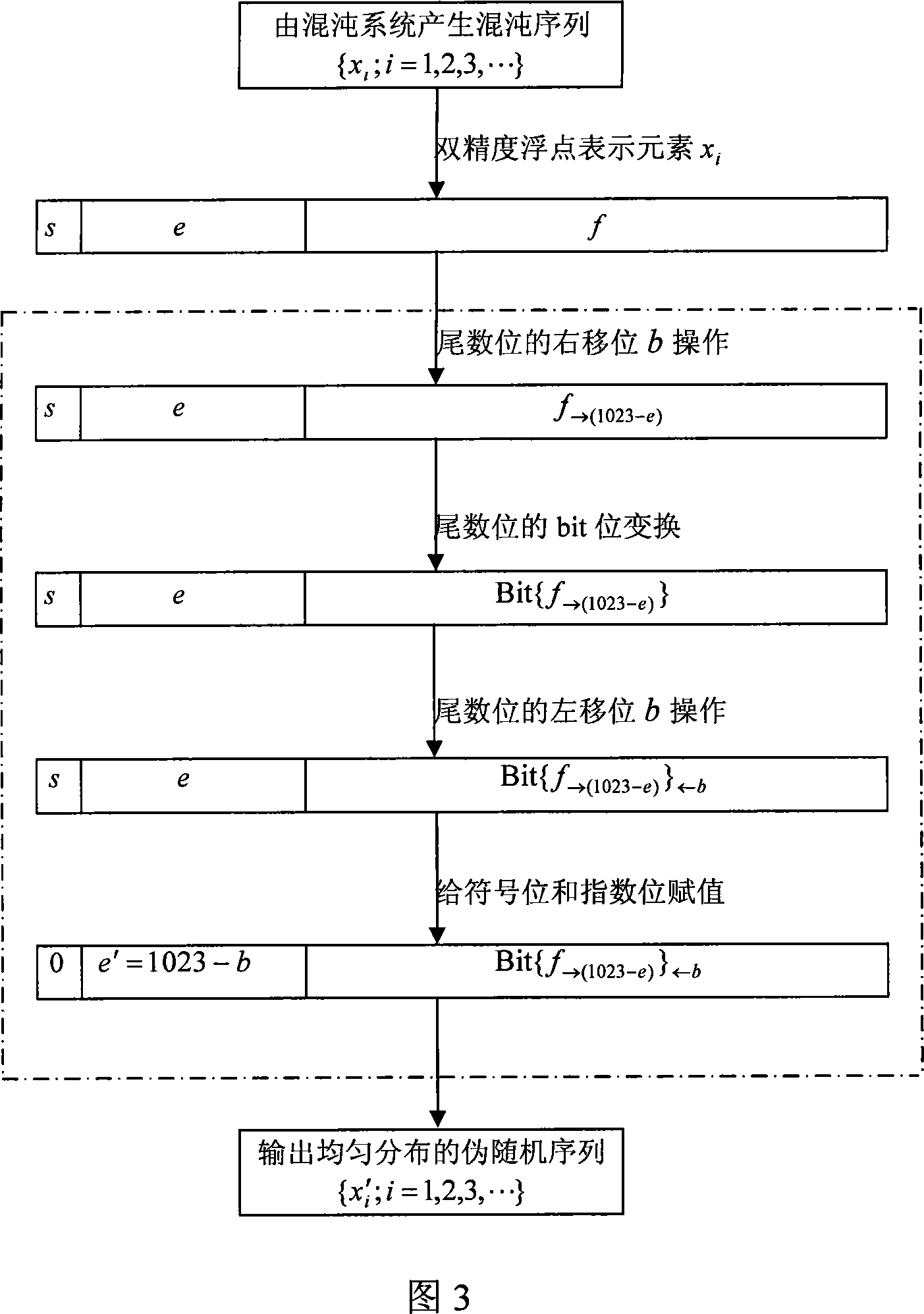

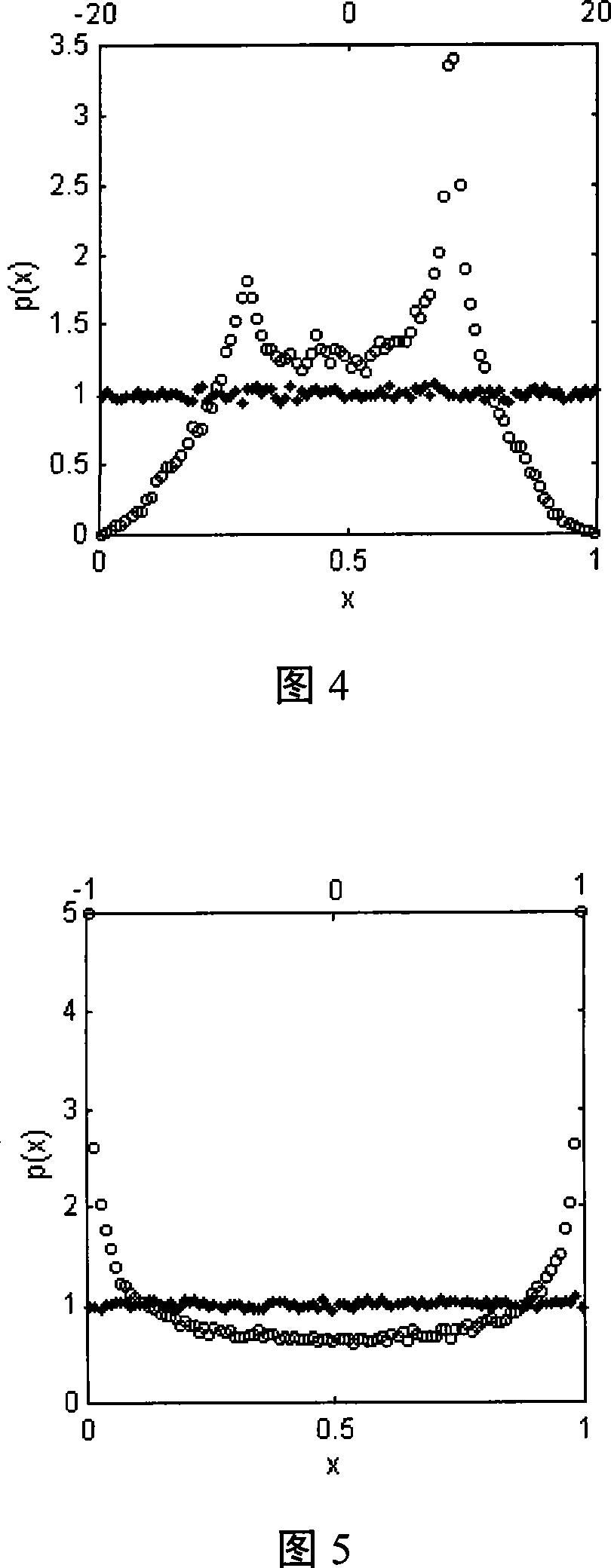

A method to obtain uniform distributed pseudo random sequence in random chaos system

InactiveCN101217360AEvenly distributedEasy to implementSecret communicationSecuring communicationRight shiftSign bit

The invention discloses a pseudo-random sequence even obtaining method from an arbitrary chaotic system. The invention comprises the following steps: for an arbitrary solid pattern chaotic sequence from a chaotic map system or a chaotic differential dynamic system, if the field of definitions of the chaotic sequence is (-1, 1), a real number converter carries on right shift b operations successively to the mantissas of each element in the arbitrary solid pattern chaotic sequence, switches the bit position of mantissa and carries on left shift b operations to the mantissas; the sign bit is endowed with a value '0' and an asynchronous exponential bit is endowed with a value '1023-b' to obtain an even-distributed pseudo-random sequence; or the real number converter switches the position of bit successively of the mantissas of each element in the arbitrary solid pattern chaotic sequence, carries on left shift b operations to the mantissas; the sign bit is endowed with a value '0' and an asynchronous exponential bit is endowed with a value '1023-b' to obtain the even-distributed pseudo-random sequence. The invention can obtain good-homogeneity pseudorandom number from an arbitrary chaotic system, in particular to be convenient for the realization of digital system.

Owner:CENT SOUTH UNIV

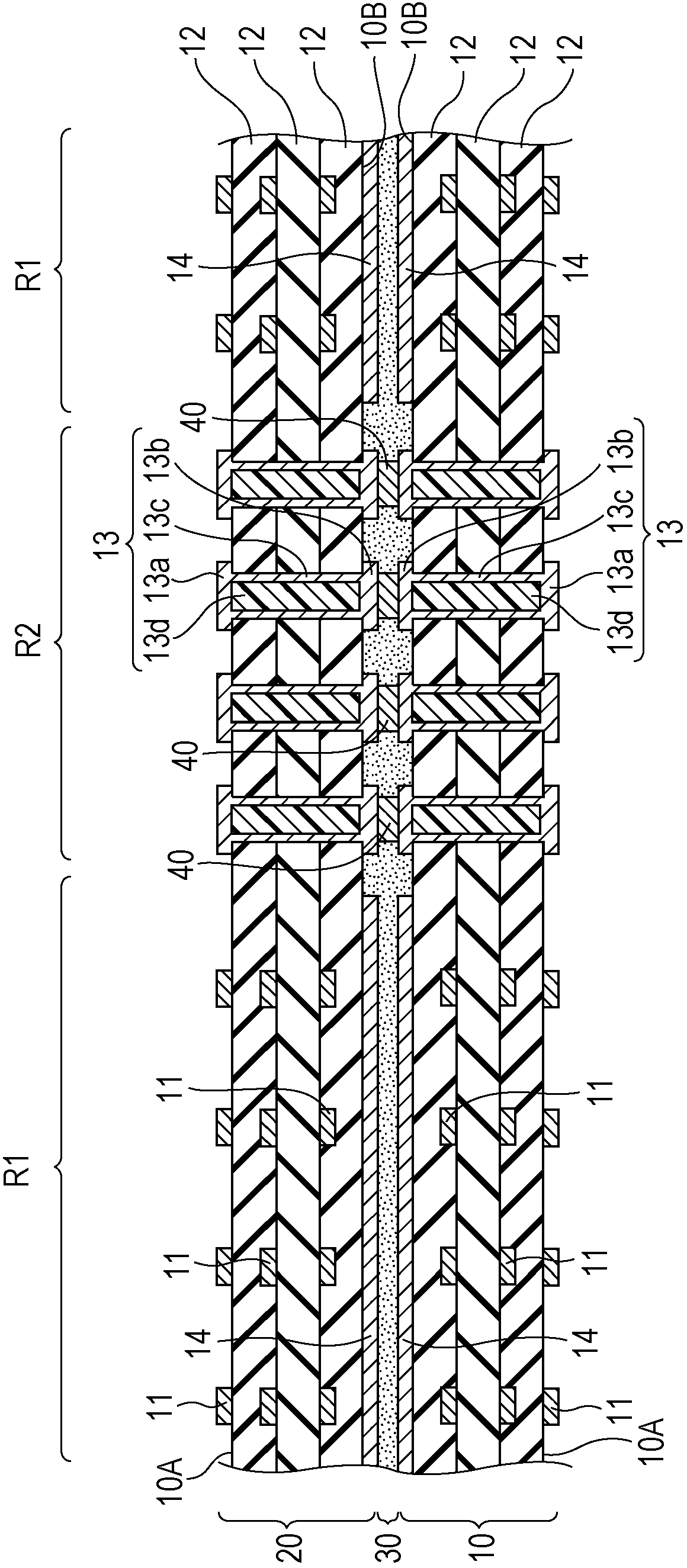

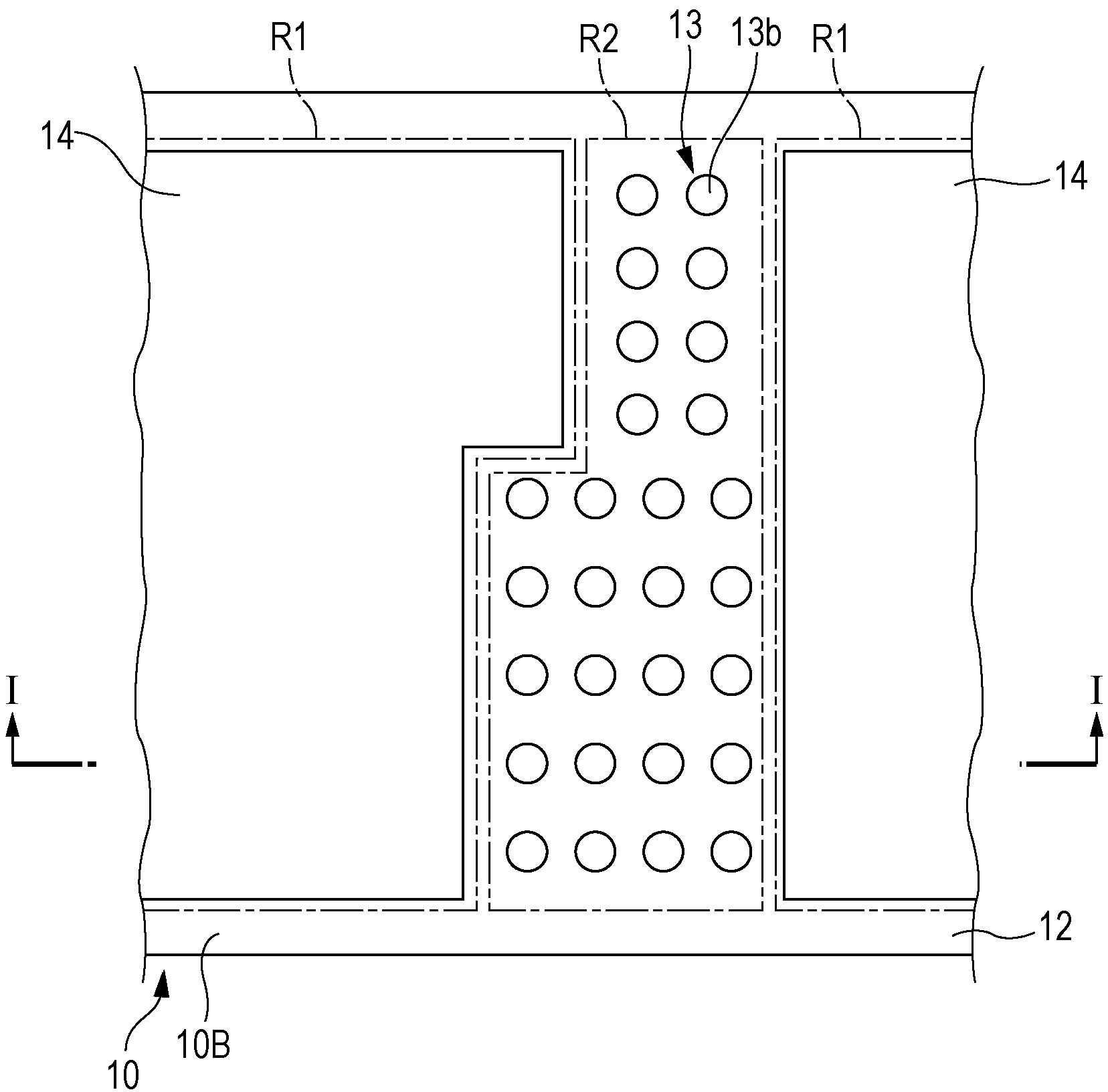

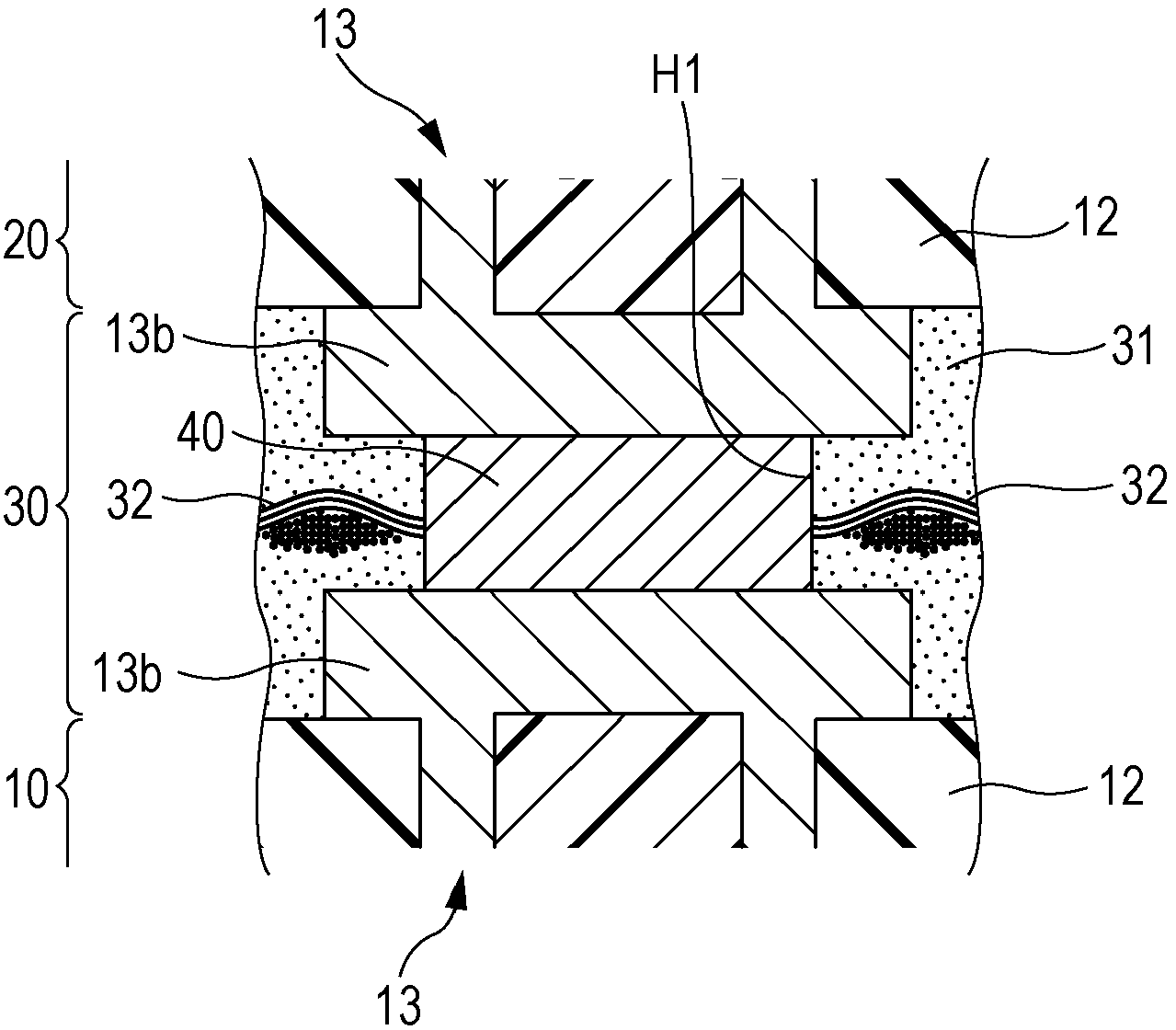

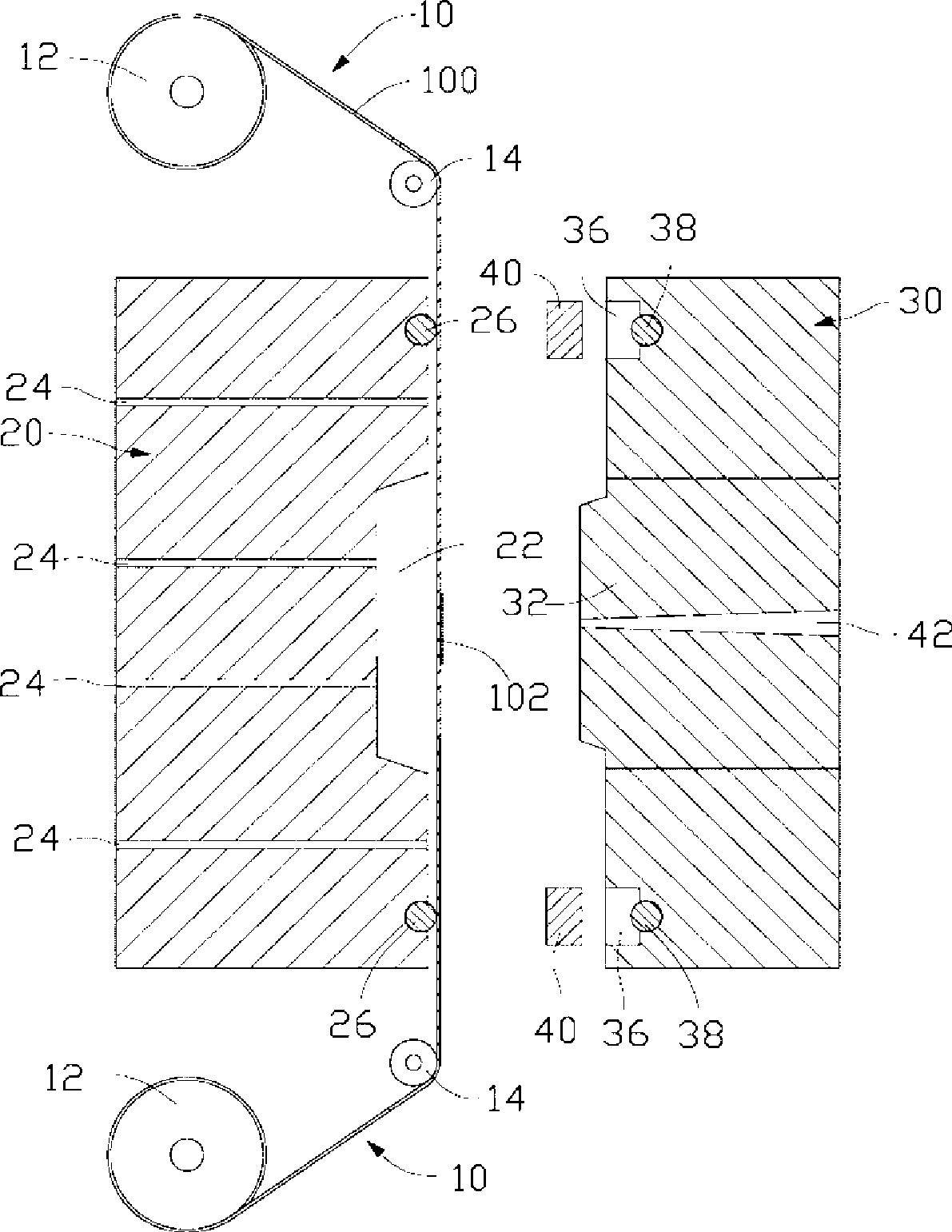

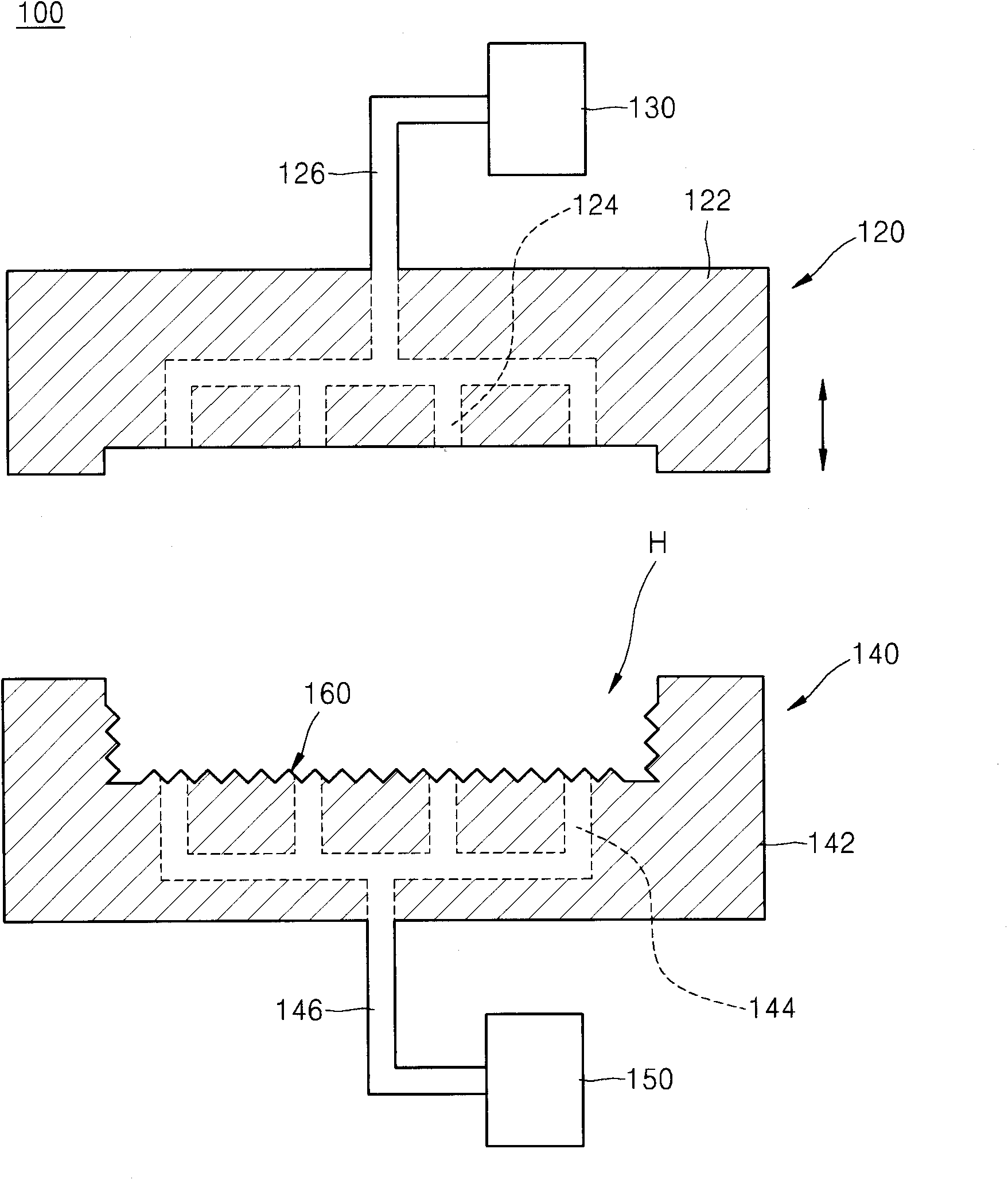

A method of manufacturing a multilayer circuit board and the multilayer circuit board

InactiveCN102843876ASemiconductor/solid-state device detailsPrinted circuit aspectsConductive pasteElectrical and Electronics engineering

A method of manufacturing a multilayer circuit board includes forming a prepreg on a surface of a first circuit board including a first region in which a plated-through hole is formed and a second region in which a solid pattern is formed, the prepreg having a first hole reaching the plated-through hole and a second hole reaching the solid pattern, filling the first hole with a conductive paste, and pressing a second circuit board on the prepreg to laminate the first circuit board and the second circuit board to each other after filling the first hole with the conductive paste.

Owner:FUJITSU LTD

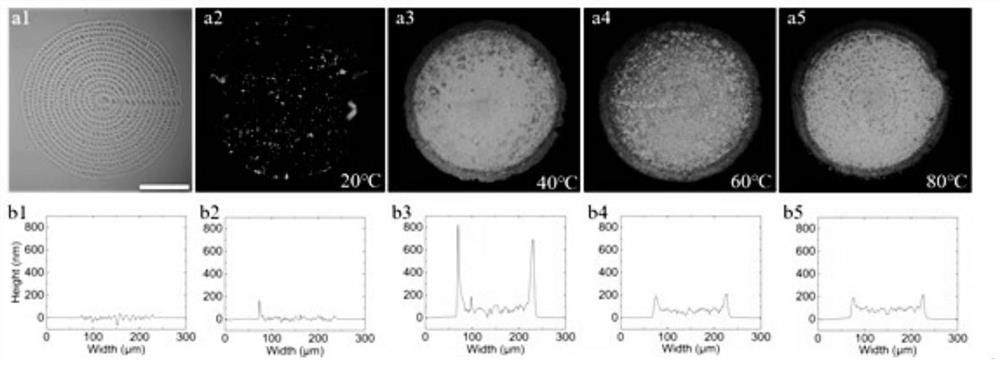

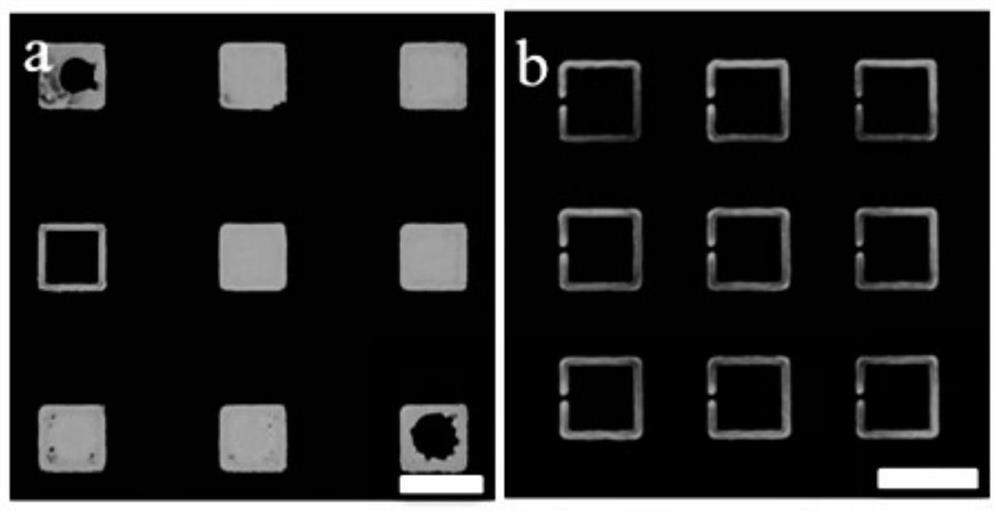

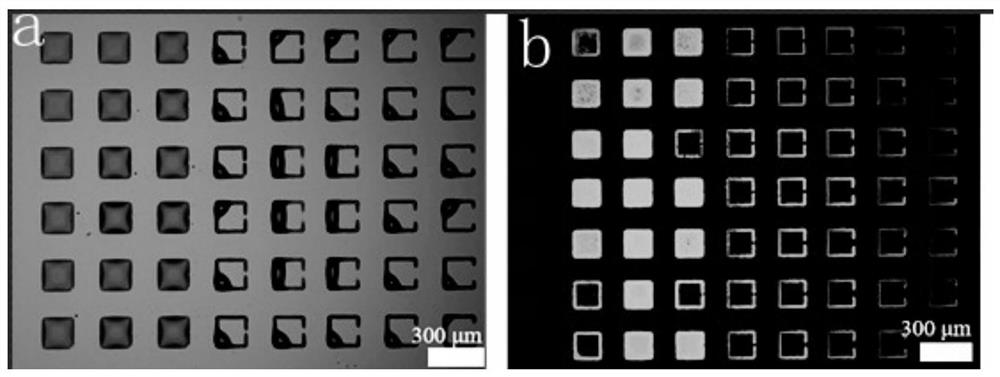

Manufacturing method and application of non-reproducible perovskite fluorescent anti-counterfeit label

ActiveCN112634740AHighly controllable shape profileRaise the potentialStampsIlluminated signsFluorescenceEngineering

The invention relates to a manufacturing method and application of a non-reproducible perovskite fluorescent anti-counterfeiting label; the manufacturing method comprises the following steps: preparing a substrate with a patterned lyophilic and lyophobic array, preparing a precursor droplet array substrate, and heating the substrate to obtain the perovskite fluorescent anti-counterfeiting label. According to the invention, different patterns are obtained by combining the solid patterns and the hollow patterns, and unique pattern morphology textures are obtained by adjusting the temperature. According to the invention, the solid pattern and the hollow pattern can be set, and the solid pattern and the hollow pattern can also be combined, so that anti-counterfeiting patterns set by different shape classification symbols are obtained, and the potential of the anti-counterfeiting label in commercial anti-counterfeiting application is improved. By using the method disclosed by the invention, the crystal films with highly similar shapes can be prepared, but each crystal film has irreproducible textures, and the reflection of the textures in a fluorescence image is unique light and shade distribution. The anti-counterfeit label is low in cost, the verification process is simple and efficient, and the anti-counterfeit label has a good market prospect.

Owner:SHANGHAI UNIV

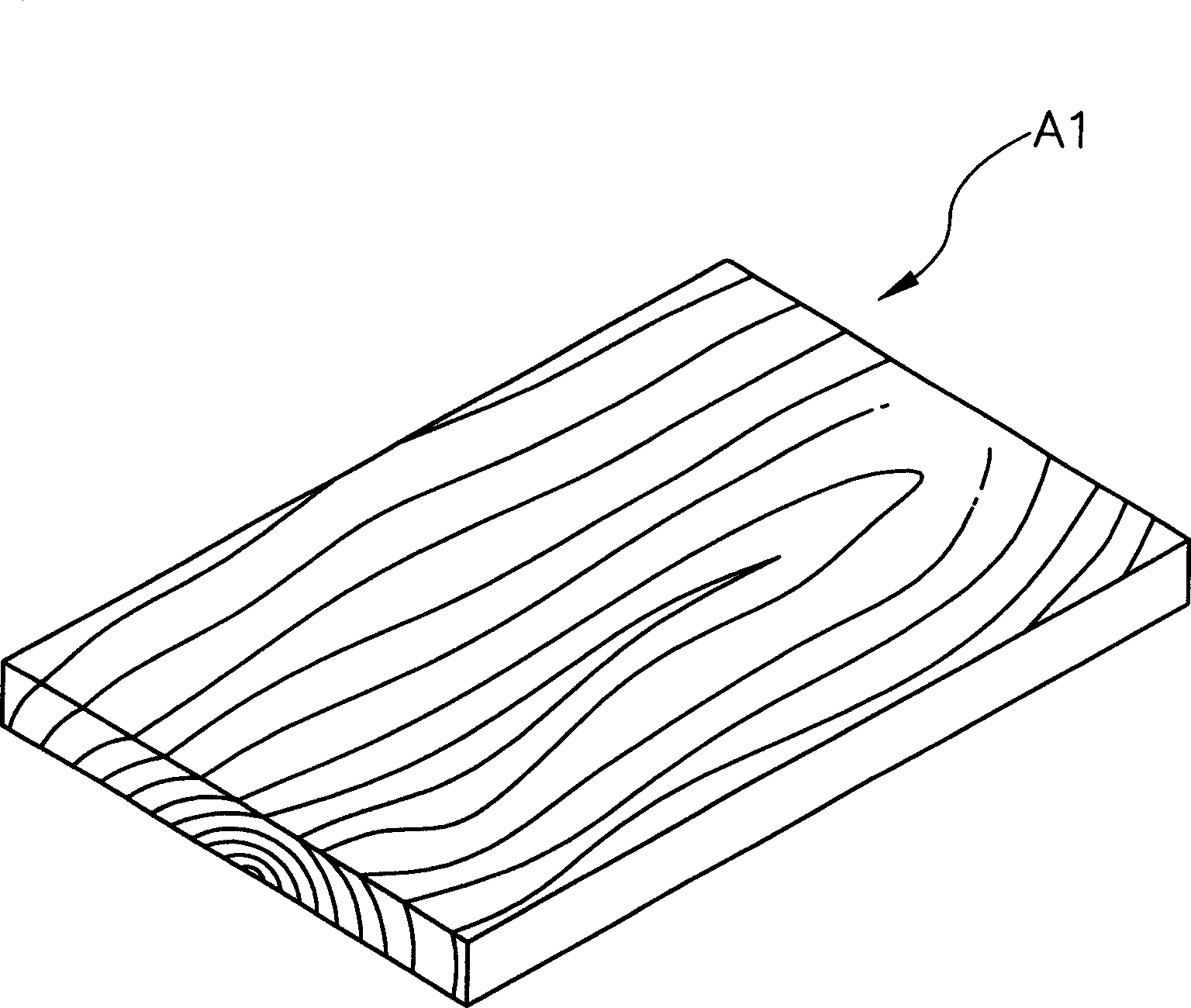

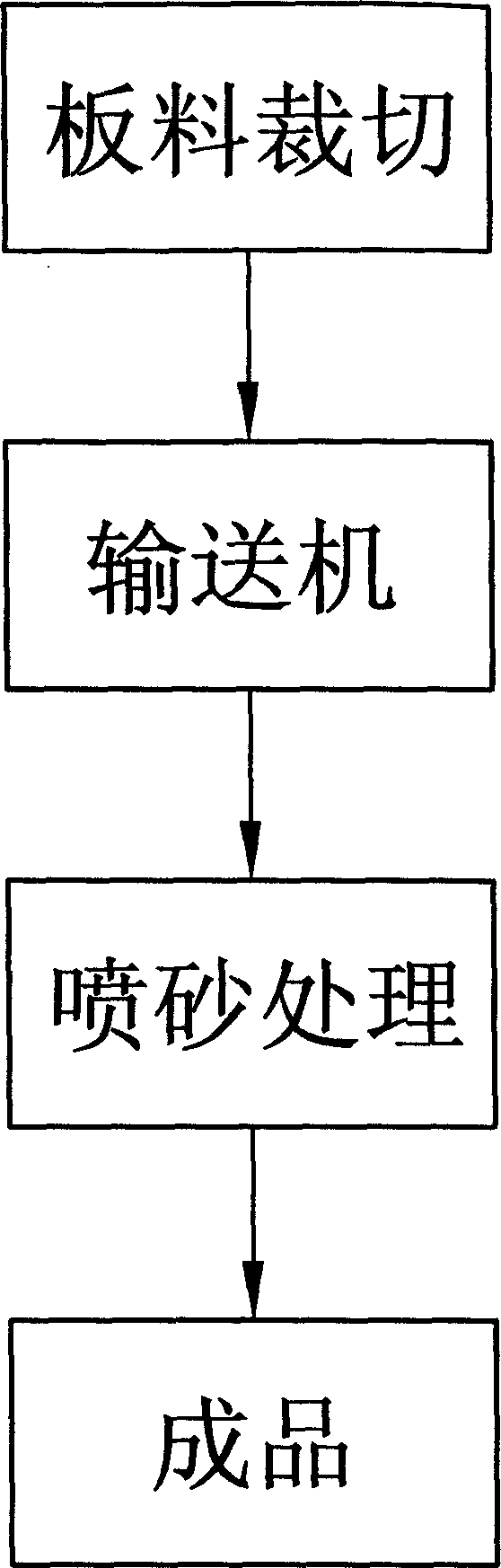

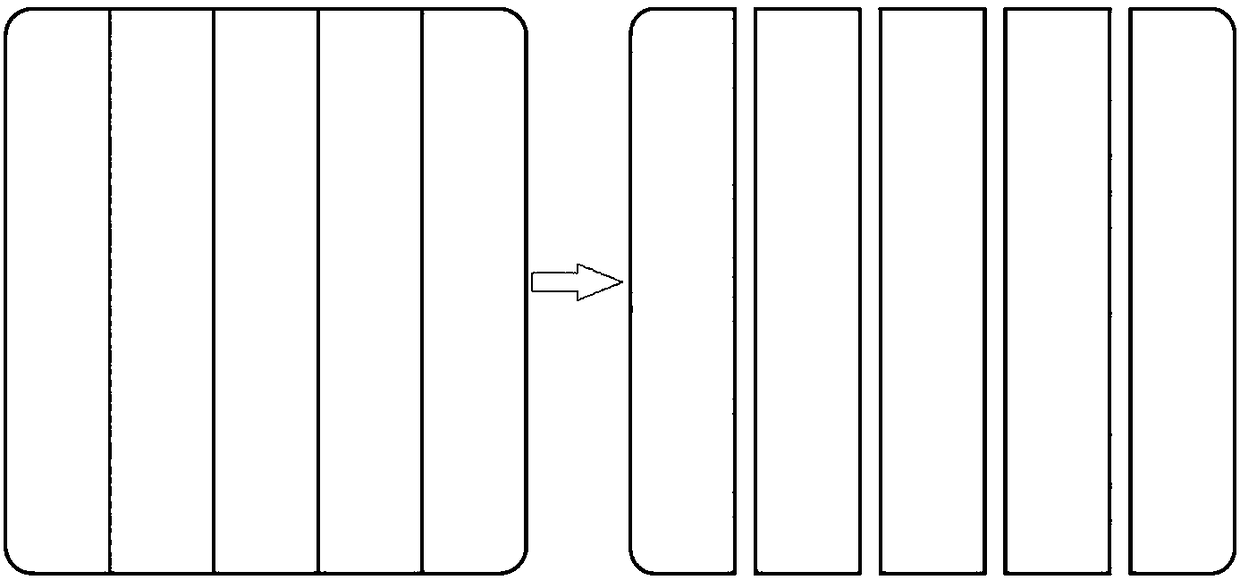

Method and equipment for forming wood pattern by sand blasting

The invention relates to a method for sand-blast wood grain and relative device. Wherein, it arranges the sheet on the transporter; arranges several sand blasters above the transporter; the sand blaster contains steel sand; the sand blaster has nozzle above the sheet to blast sand on the sheet; the invention pressurizes the steel sand to be ejected to the surface of sheet, to remove the soft part to form concave shape; therefore, the invention surface of sheet can form solid pattern according to the growth ring pattern, to be used as decorate sheet.

Owner:田伟宏

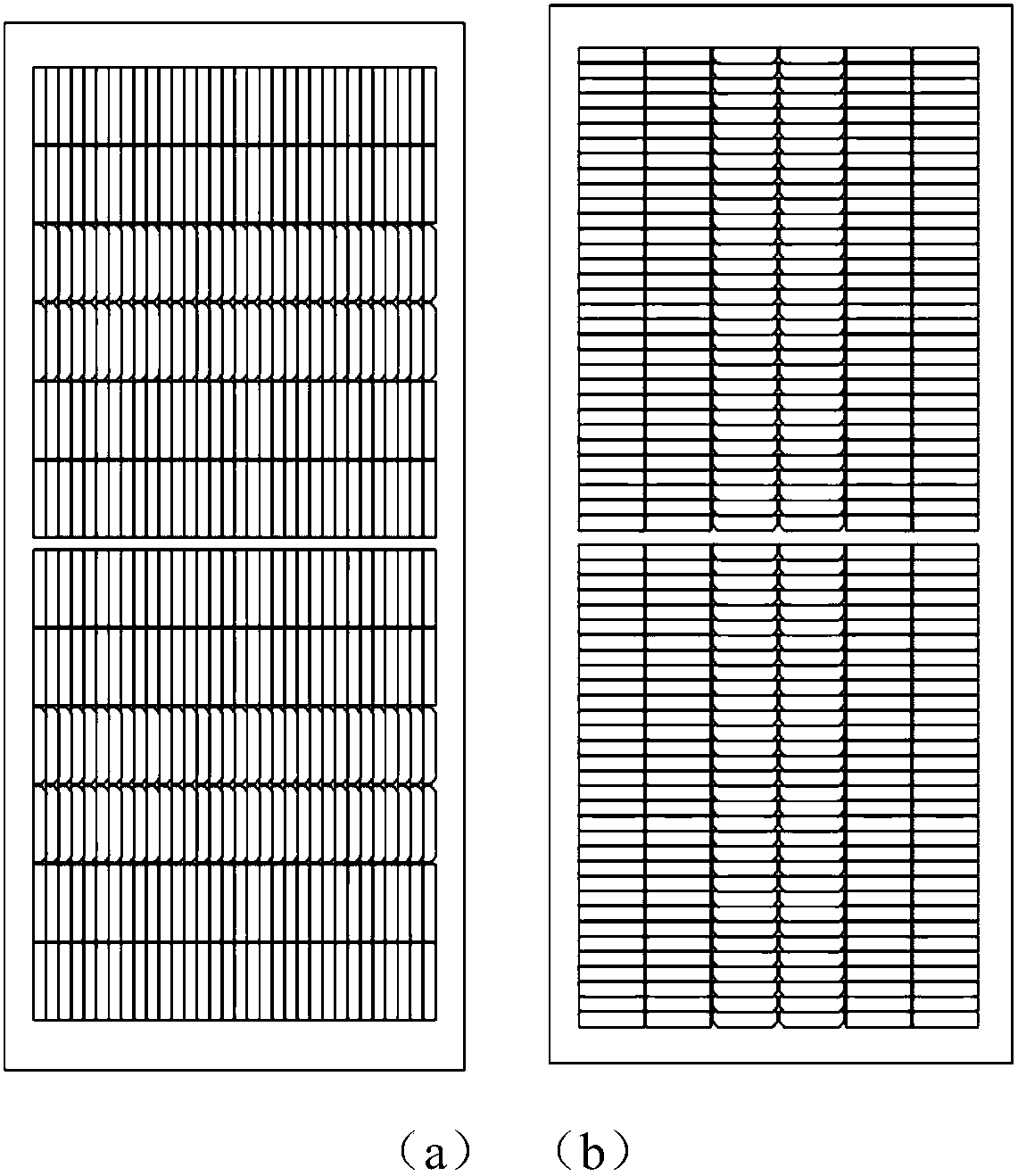

Solar cell grid line structure, solar cell sheet and solar laminate module

PendingCN108538948AElectrical performance impactImprove conductivityPhotovoltaic energy generationSemiconductor devicesConductive pasteElectricity

The invention provides a solar cell grid line structure, a solar cell sheet and a solar lamination module. The grid line structure comprises a plurality of sub grid lines arranged on a silicon wafer and a main grid line perpendicular to the sub grid lines. The main grid line is formed by a grid-like porous structure. When the main grid line is coated with a conductive paste, grid holes are filledwith a part of the conductive paste. Since the materials of the conductive paste and the main grid line have good electrical conductivity, when the above grid lines are sufficiently dense, the use ofa grid pattern instead of a solid pattern does not seriously affect the electrical performance of a module. The deformation of the conductive paste and the diffusion on a cell shell texture covered bysilicon nitride are limited by the grid pattern of the main grid line and are limited in the grid pattern, and thus paste overflow and bleeding are avoided.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

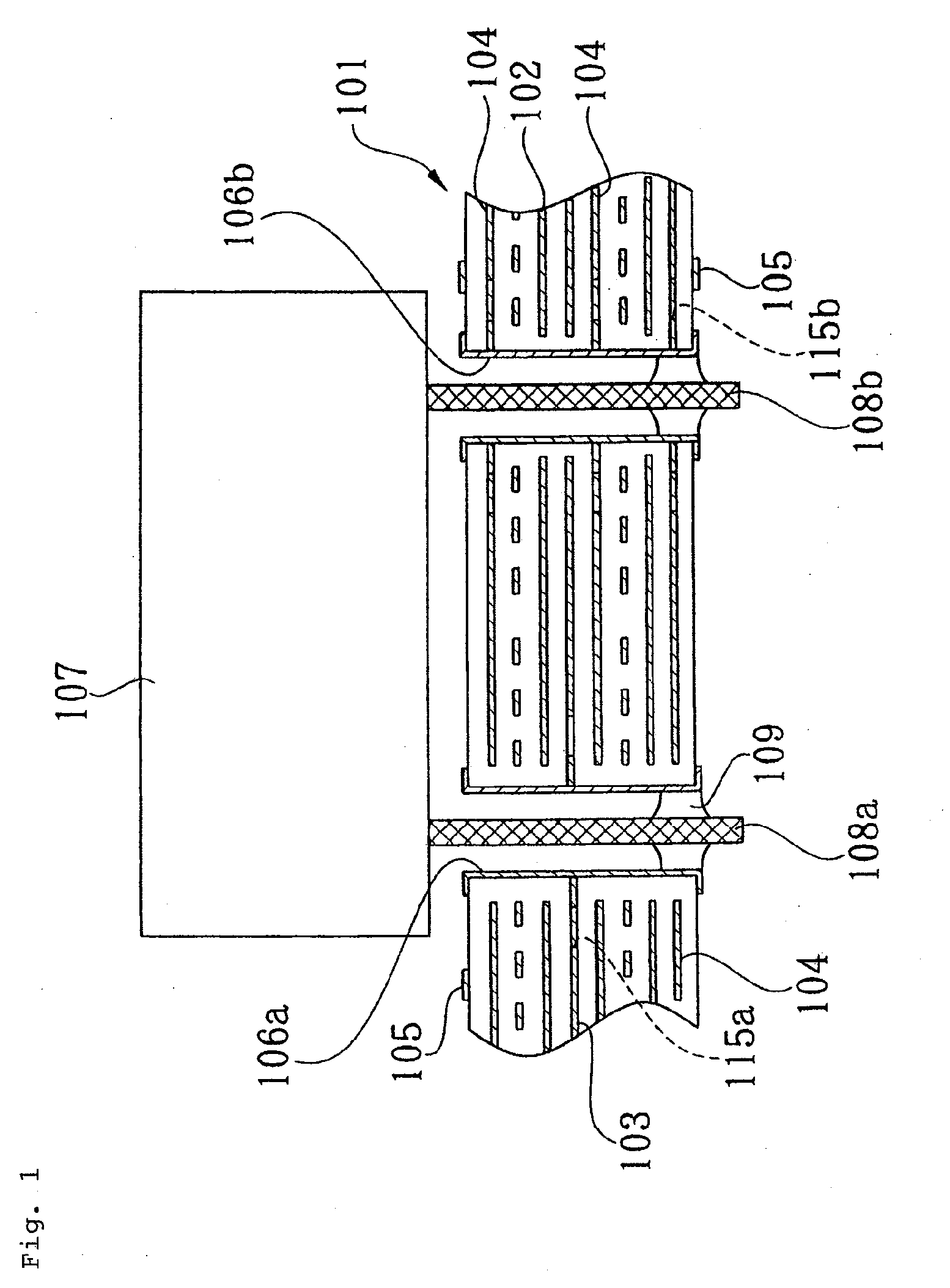

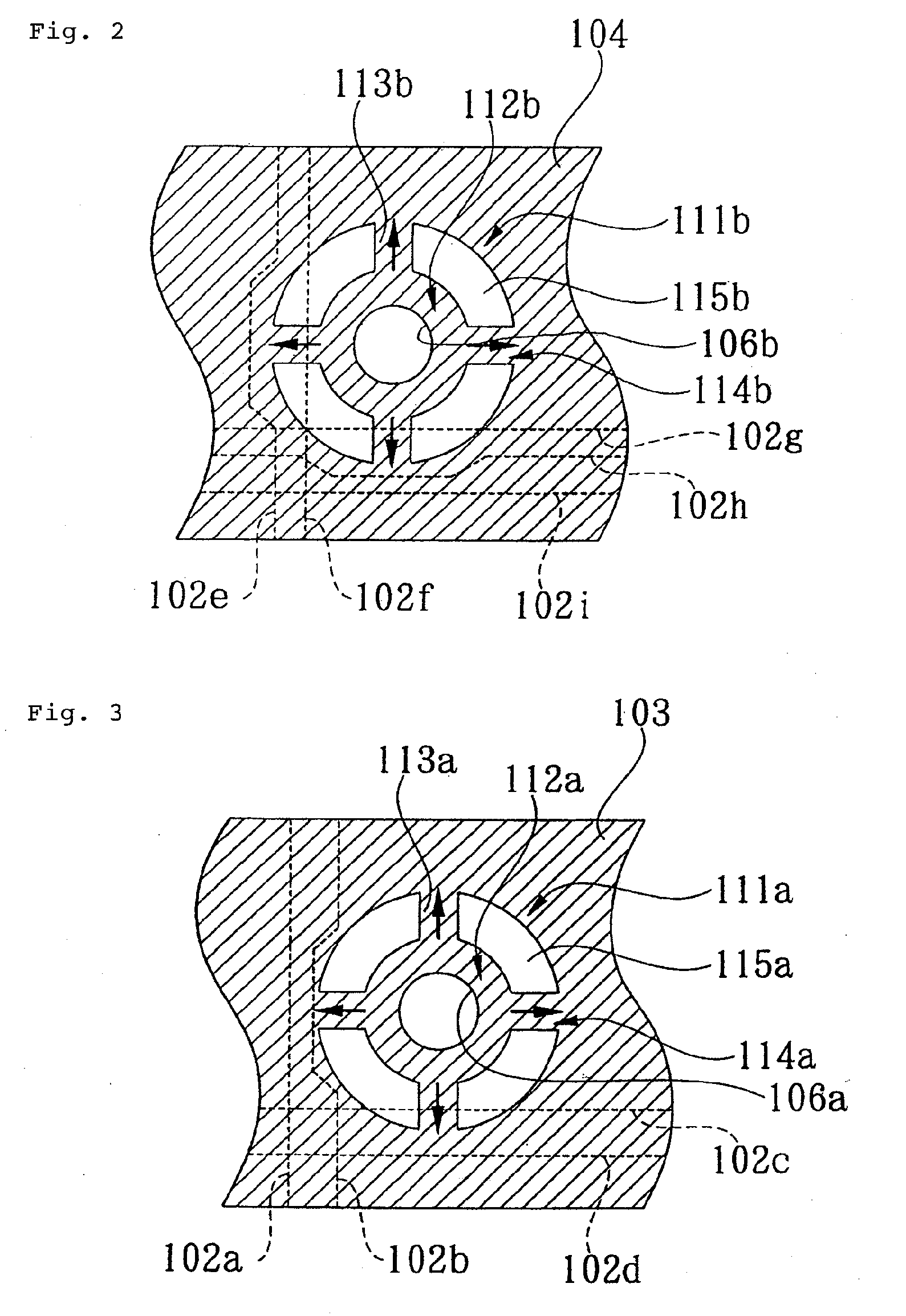

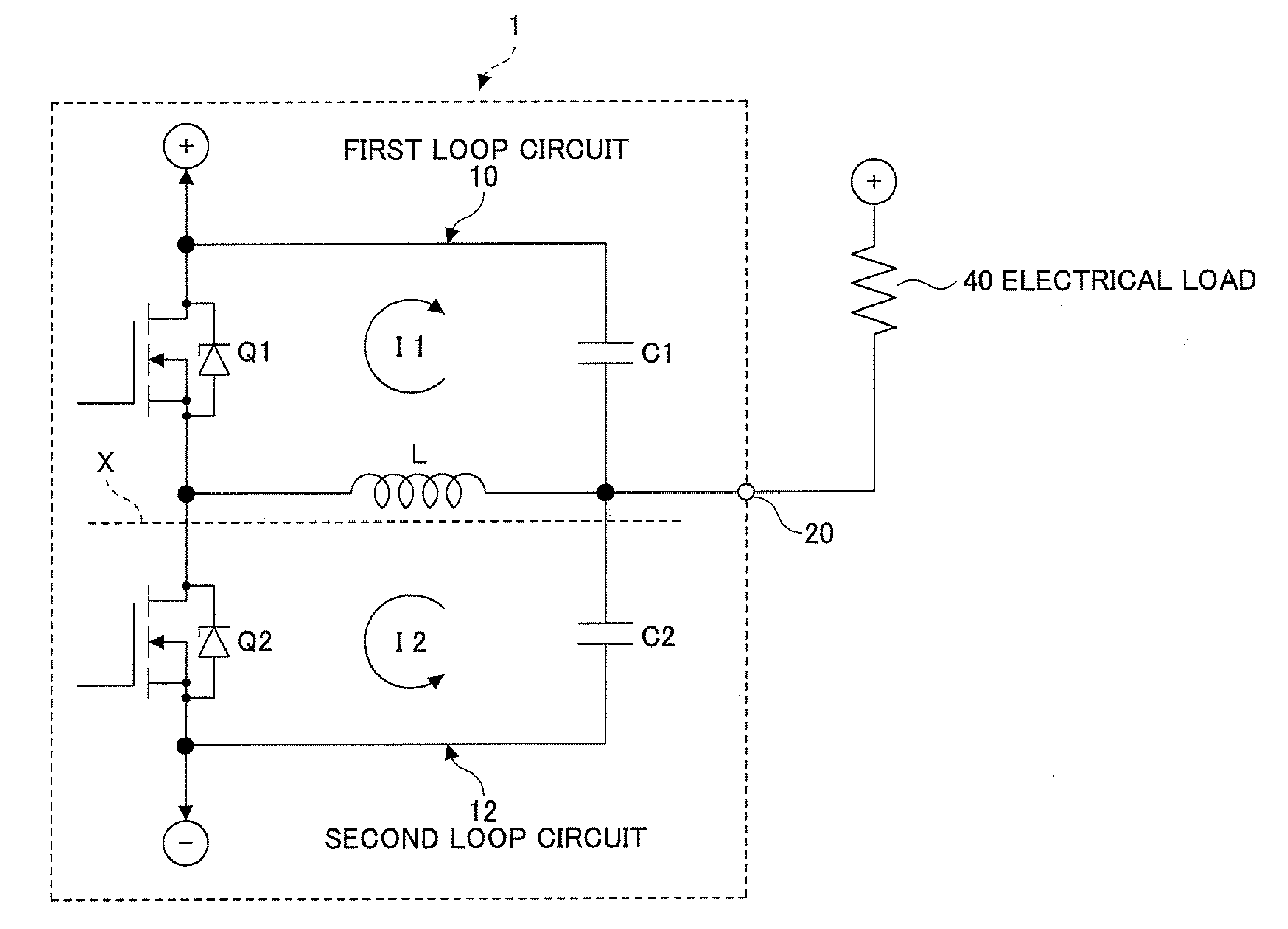

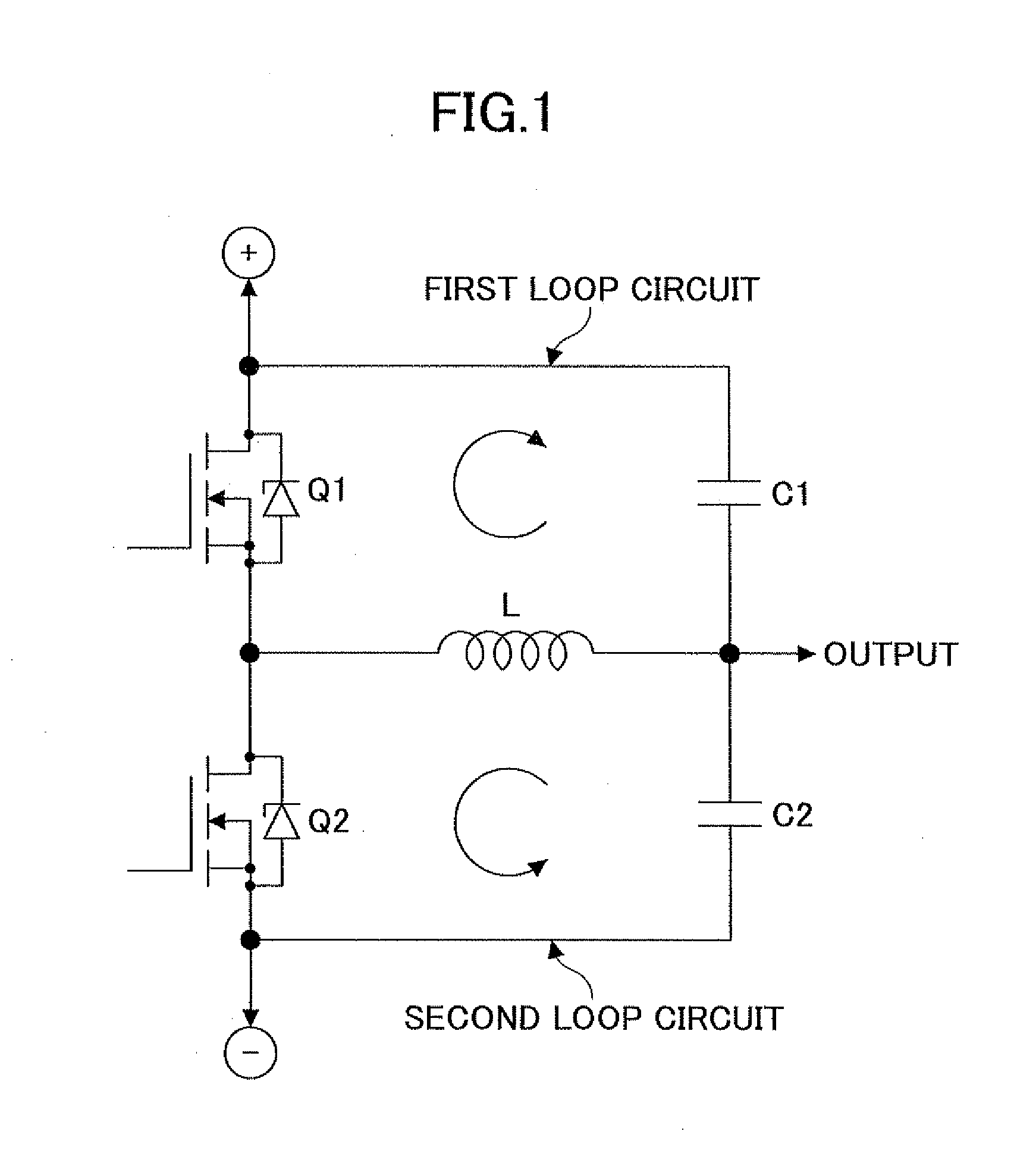

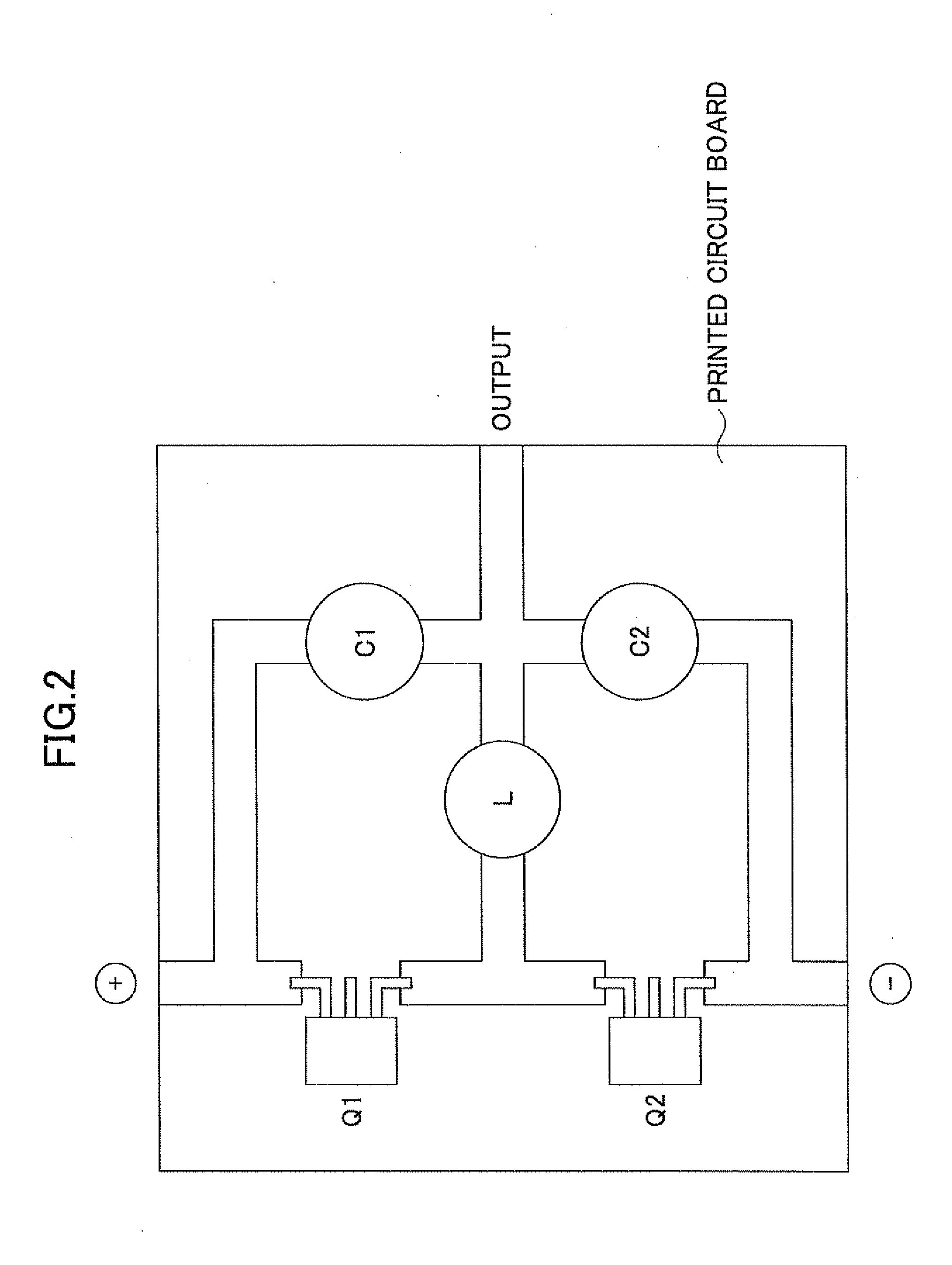

Voltage conversion apparatus and electrical load driving apparatus

ActiveUS20120119723A1Effective coolingReduce noiseDc-dc conversionElectric variable regulationElectricityMetallic materials

A voltage conversion apparatus is disclosed in which a current passes through first and second loop circuits alternately in accordance with ON / OFF operation of a first switching element provided in the first circuit. The direction of a magnetic field through the first loop circuit formed at the ON operation is the same as a direction of a magnetic field through the second loop circuit formed at the OFF operation. The first loop circuit and the second loop circuit are provided on opposite sides of a printed circuit board, respectively, in such a manner that the first loop circuit and the second loop circuit are opposed to each other. A heat sink is provided on a surface of the printed circuit board. A solid pattern of a metal material is provided on an inner layer of the printed circuit board to be connected to the heat sink via a through hole.

Owner:TOYOTA JIDOSHA KK +1

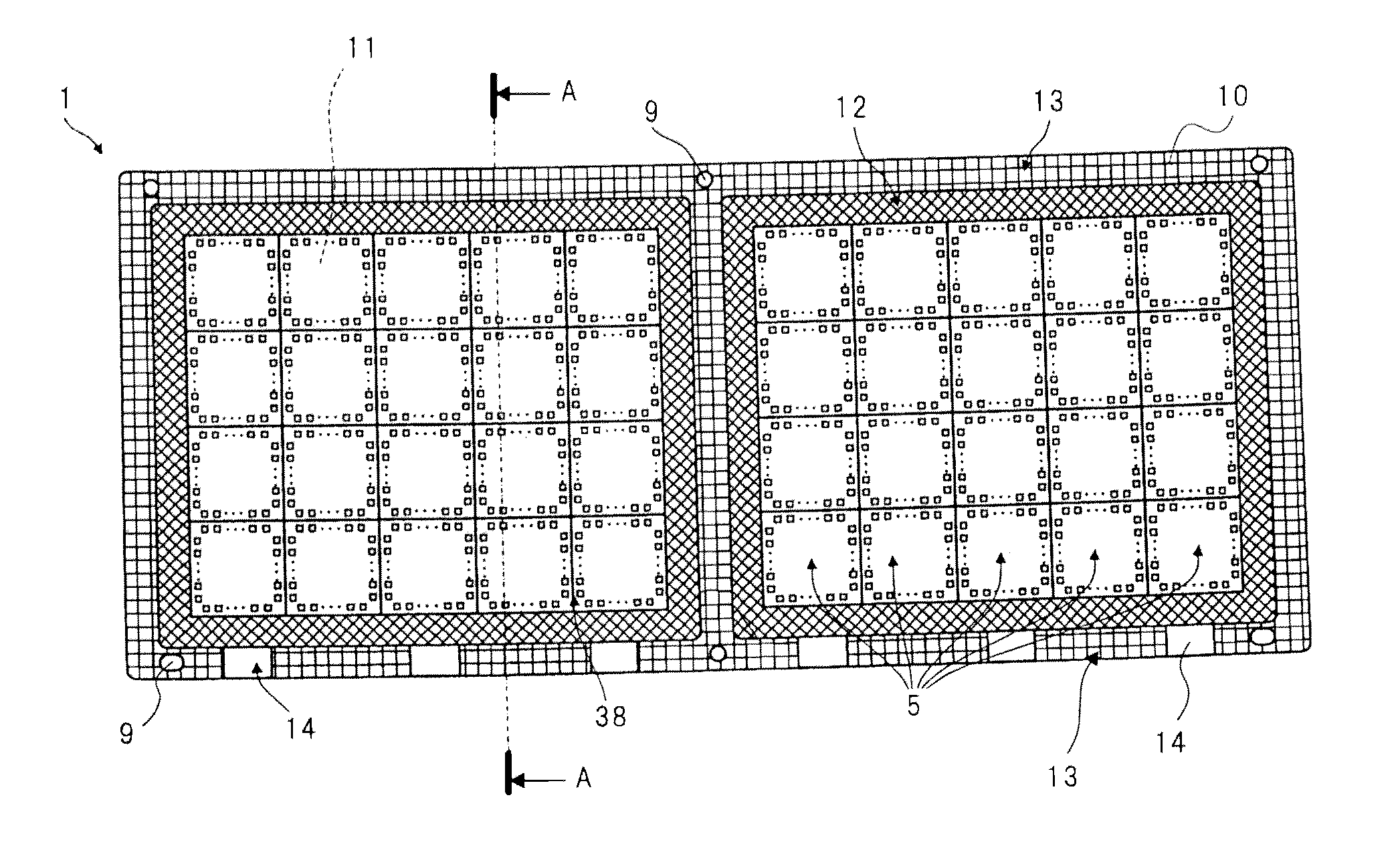

Wiring board and method of manufacturing a semiconductor device

InactiveUS20120048595A1Improve rigidityAvoid it happening againSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipProduct formation

A wiring board of this invention includes a product formation area in which are arranged a plurality of product formation sections on which a semiconductor chip is mounted; a molding area that is provided on an outer circumferential side of the product formation area, and with which a seal portion that covers the semiconductor chips mounted on the product formation sections makes contact; a clamp area that is provided on an outer circumferential side of the molding area, and that is held by a molding die that forms the seal portion; wiring that is provided in the product formation area, and that is electrically connected to the semiconductor chips; a first solid pattern that is provided in the molding area, and in which a plurality of dots are arranged; and a second solid pattern that is provided in the clamp area, and in which a plurality of dots that are larger than the dots of the first solid pattern are arranged.

Owner:LONGITUDE SEMICON S A R L

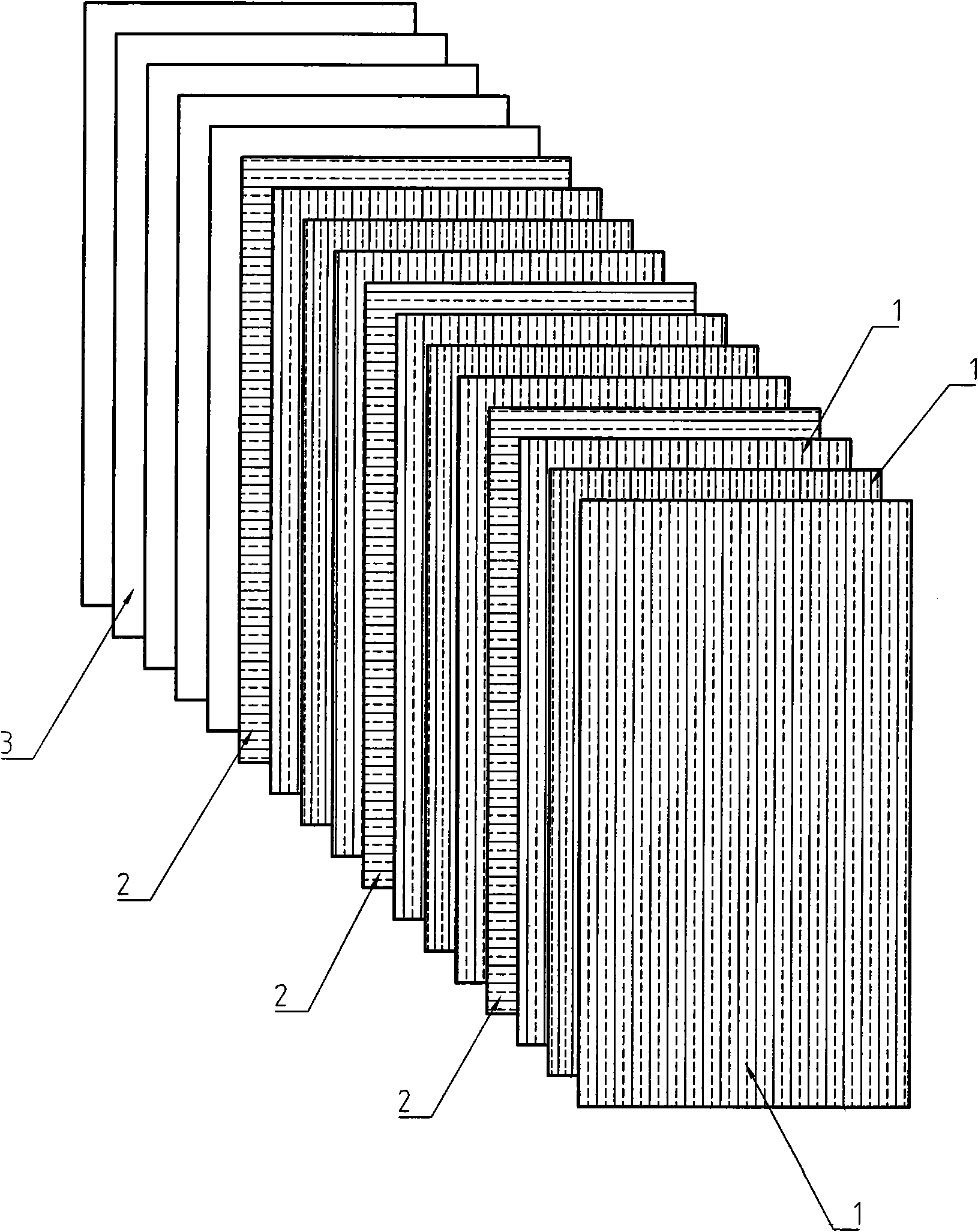

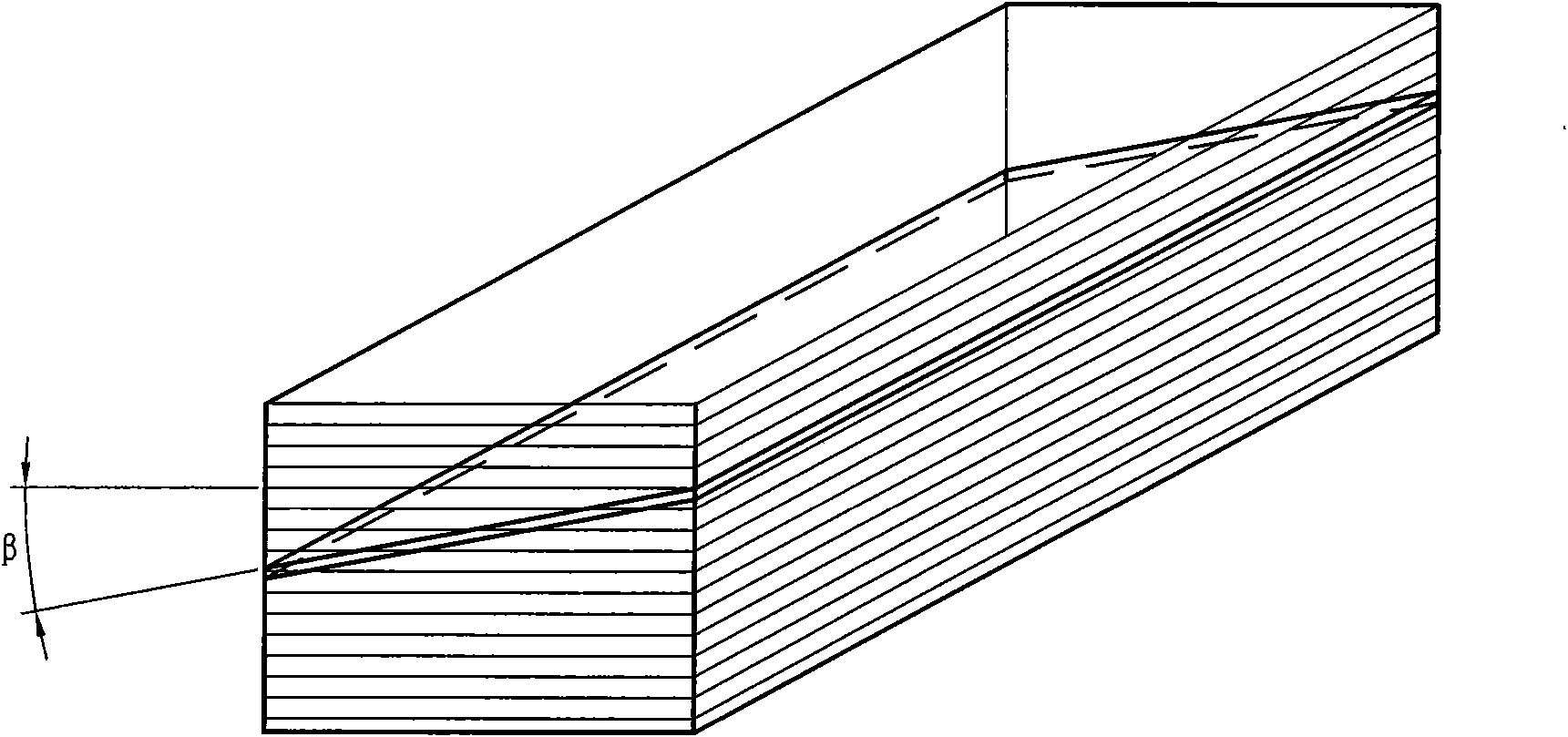

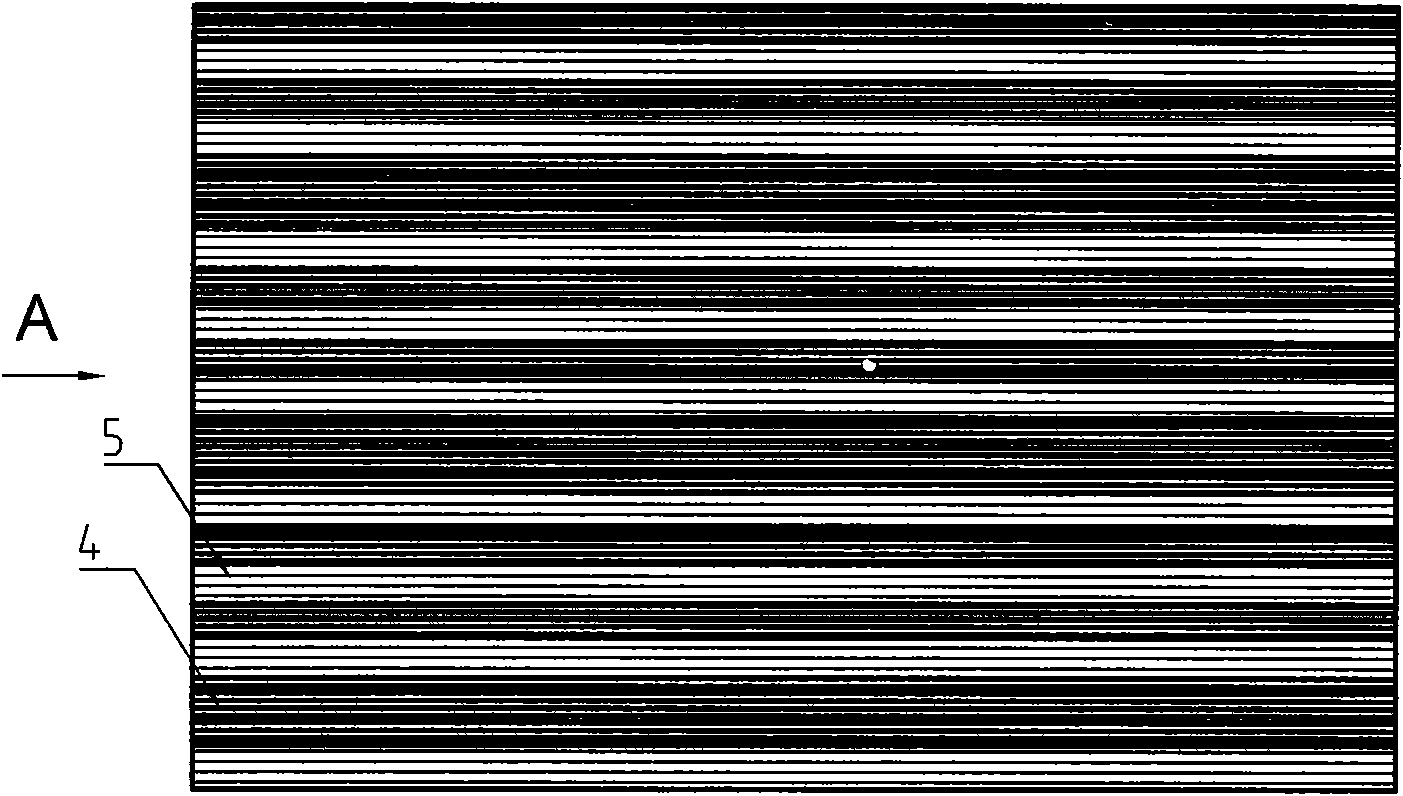

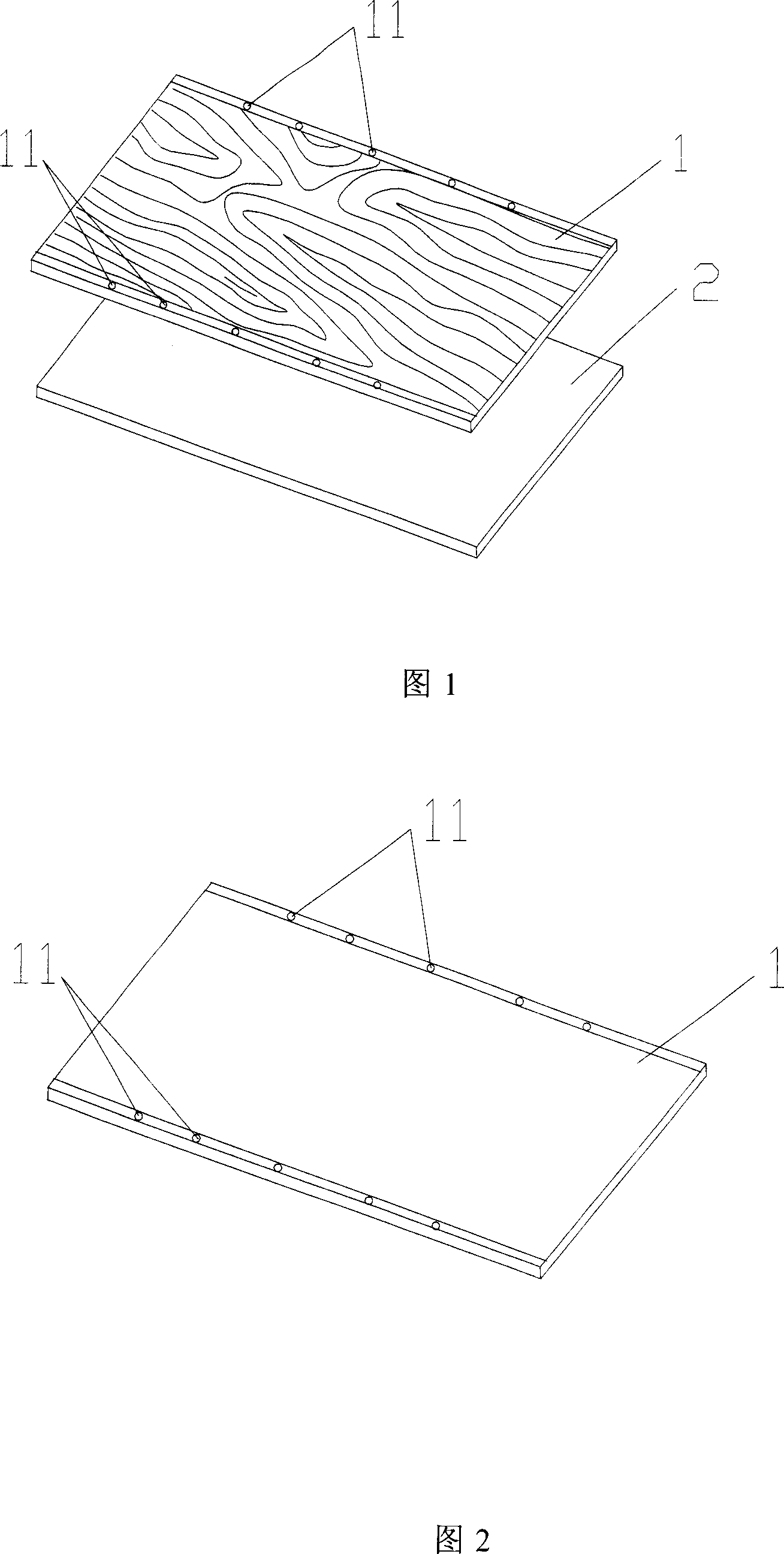

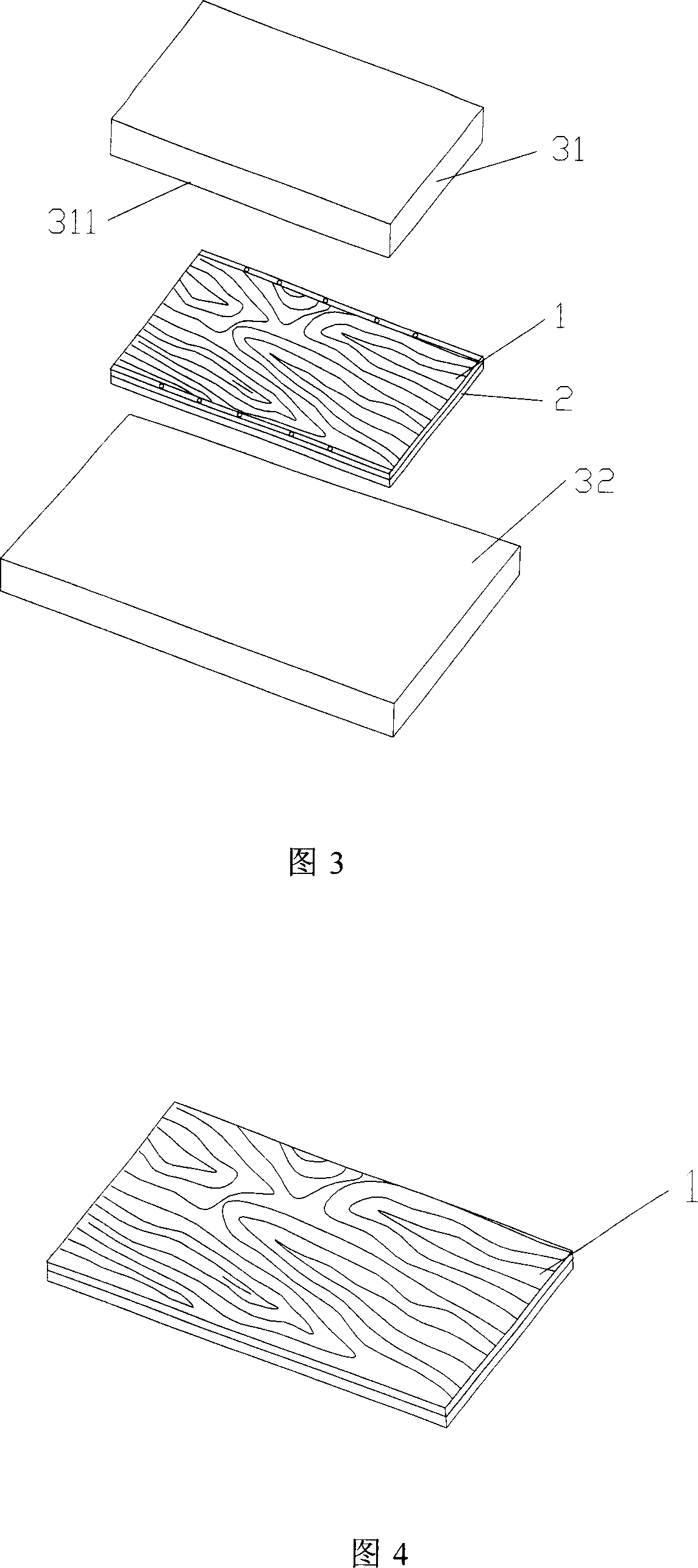

Scrimber art decoration plate and forming method thereof

ActiveCN101633186ANo deformationImprove the artistic effectOther plywood/veneer working apparatusWood veneer joiningWood veneerPulp and paper industry

The invention discloses a scrimber art decoration plate and a forming method thereof. The scriber art decoration plate is formed by adhering and pressing laminated wood veneers, the wood veneers in a carving layer are scrimber wood veneers, and a veneer in the scrimber wood veneers in the carving layer has different colors or different depths of the color. Solid patterns formed due to different colors or different depths of the color can be displayed on the veneer of the carving layer when the scriber art decoration plate is carved, and the more the difference among colors and depths of the color is, the clearer the solid patterns displayed by carving are; in addition, different solid patterns can be displayed by adopting different colors and different carving modes; and the carved solid patterns have strong artistry and good appreciation.

Owner:SHENZHEN SONGBOYU TIMBERING

Plating method

InactiveUS20080124468A1Simple designMolten spray coatingPretreated surfacesEngineeringElectroplating

Disclosed is a plating method which, includes preparing a plating base; printing a plating pattern on a plating surface of the plating base; and plating the plating surface of the plating base. During plating, a plating layer is formed on a portion where the plating pattern is not printed. The method is provided for contributing to diversification of the external appearance of a compact type device such as portable terminals, is capable of printing three-dimensional patterns as well as a trademark and a logo, and is capable of highlighting the metallic texture together with three dimensional solid patterns.

Owner:SAMSUNG ELECTRONICS CO LTD

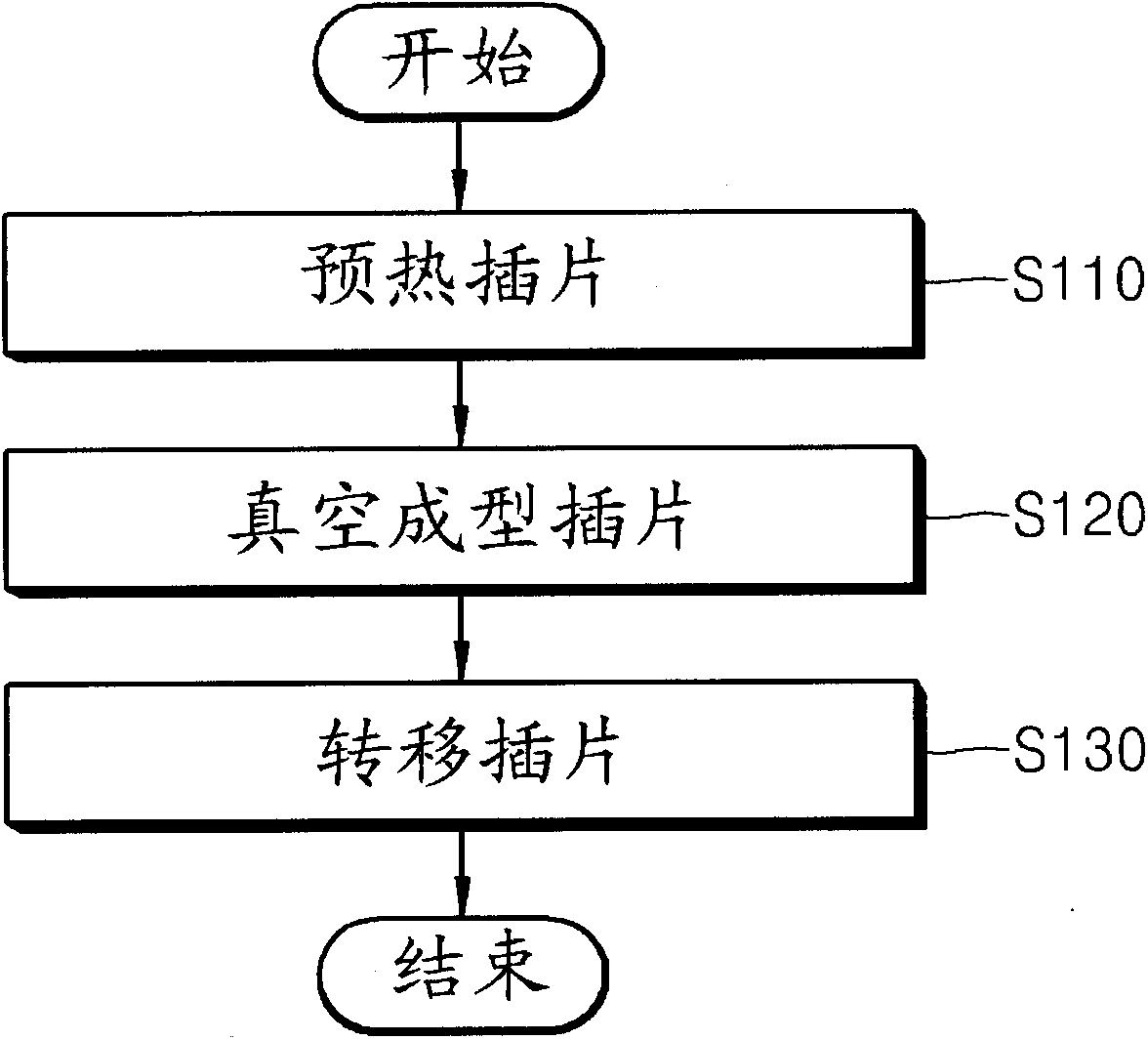

Forming method for stereoscopic pattern of plastic rubber member

The invention provides a forming method of solid patterns of a plastic-rubber part, comprising the steps as follows: a die used for decoration forming in the die is provided; the die is provided with a cavity; a film is provided; the film is provided with a transfer printing layer which is provided with patterns with third dimension; the transfer printing layer is jointed to the position corresponding to the cavity of the die; a forming part is formed by injecting rubber into the cavity of the die; and die-opening is carried out so as to lead the transfer printing layer to be jointed on the surface of the forming part and form the plastic rubber part with third-dimension patterns. The forming method of the solid patterns of the plastic-rubber part is provided with the patterns with third dimension on the transfer printing layer of the film, is finally formed by rubber injection, leads the transfer printing layer to be jointed on the surface of the forming part, and forms the plastic-rubber part with smooth appearance and internal third-dimension patterns. The obtained plastic-rubber part with third-dimension pattern has firm coloring and is not easy to be abraded.

Owner:KANGZHUN ELECTRONICS TECH KUNSHAN +1

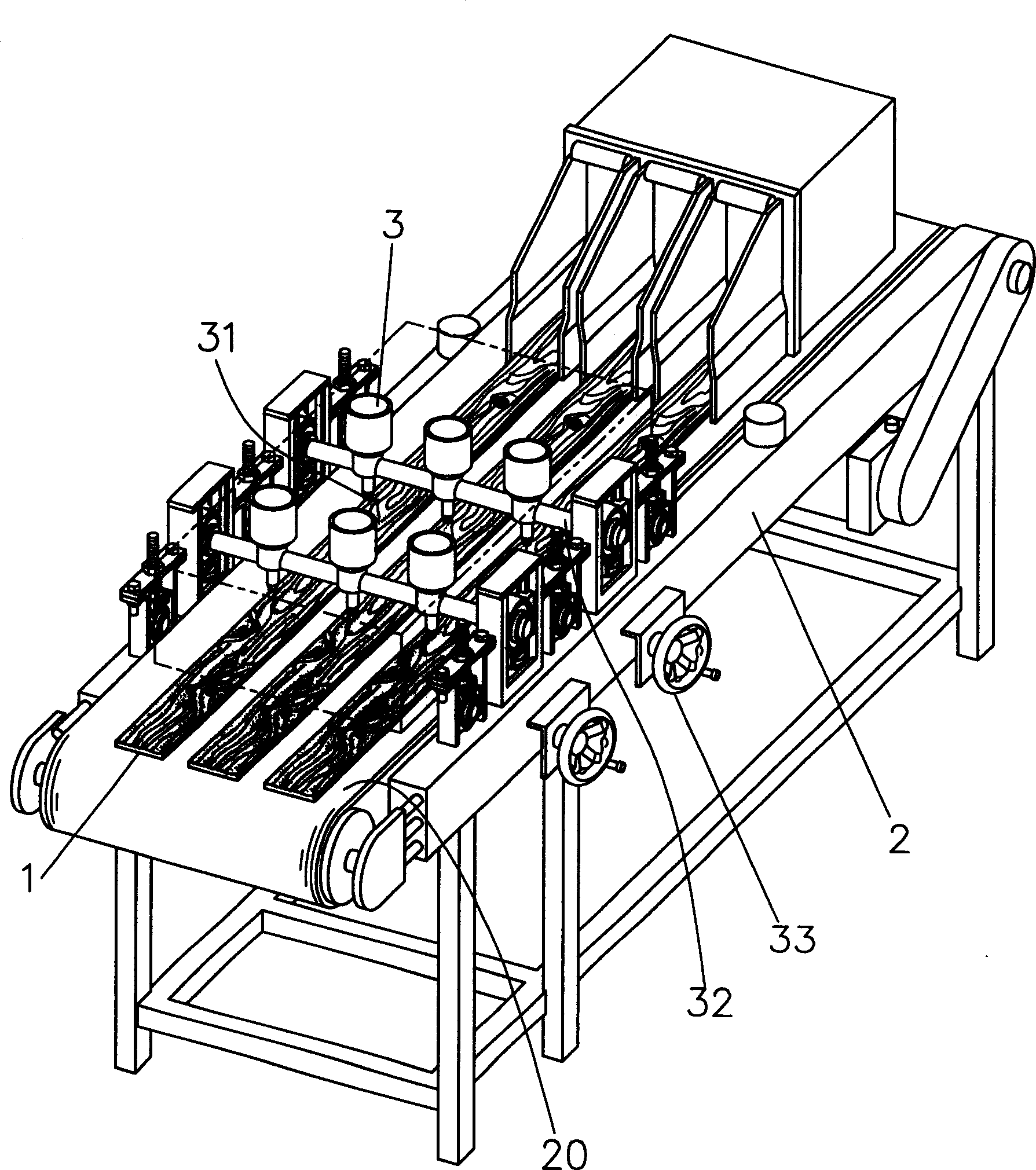

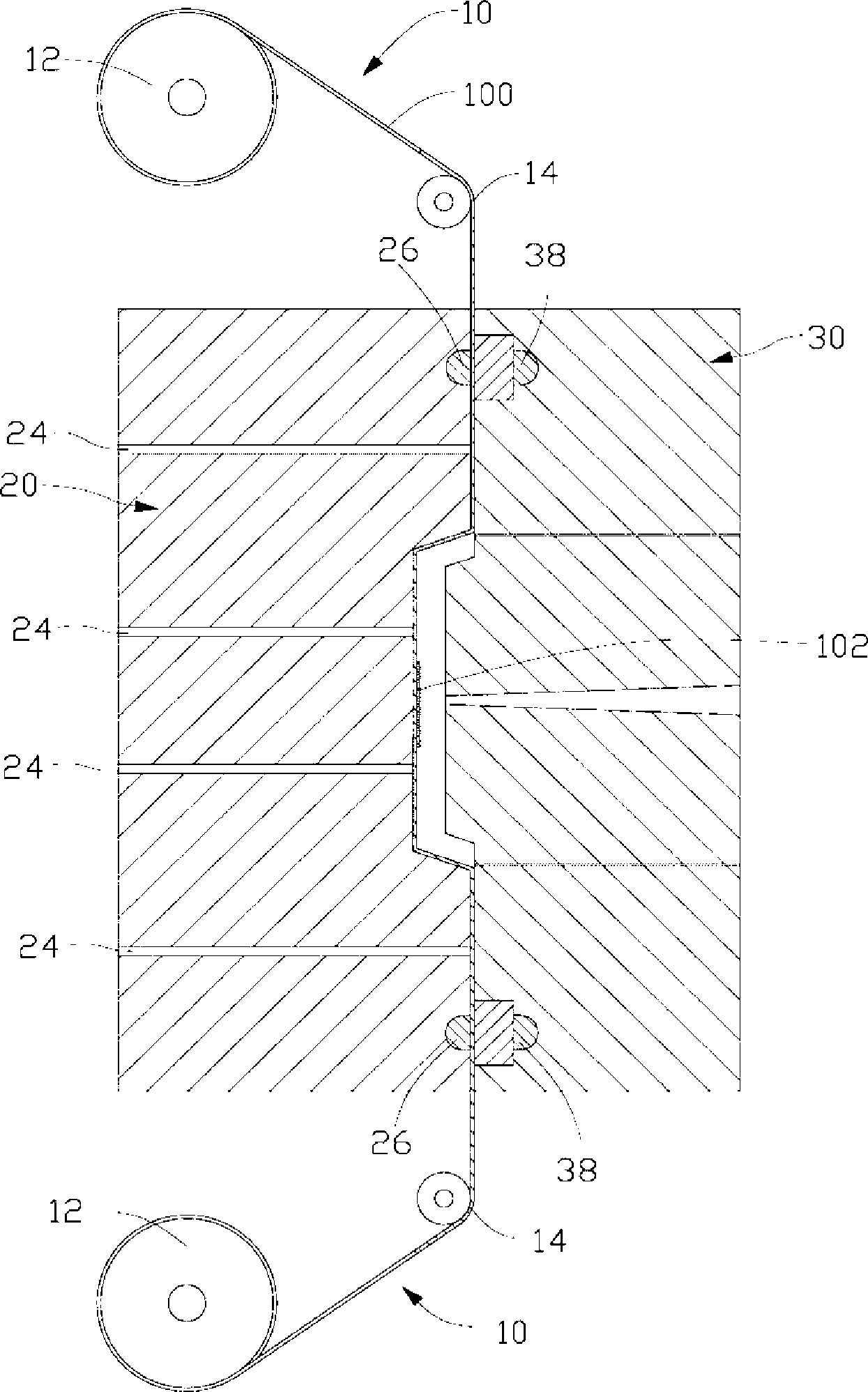

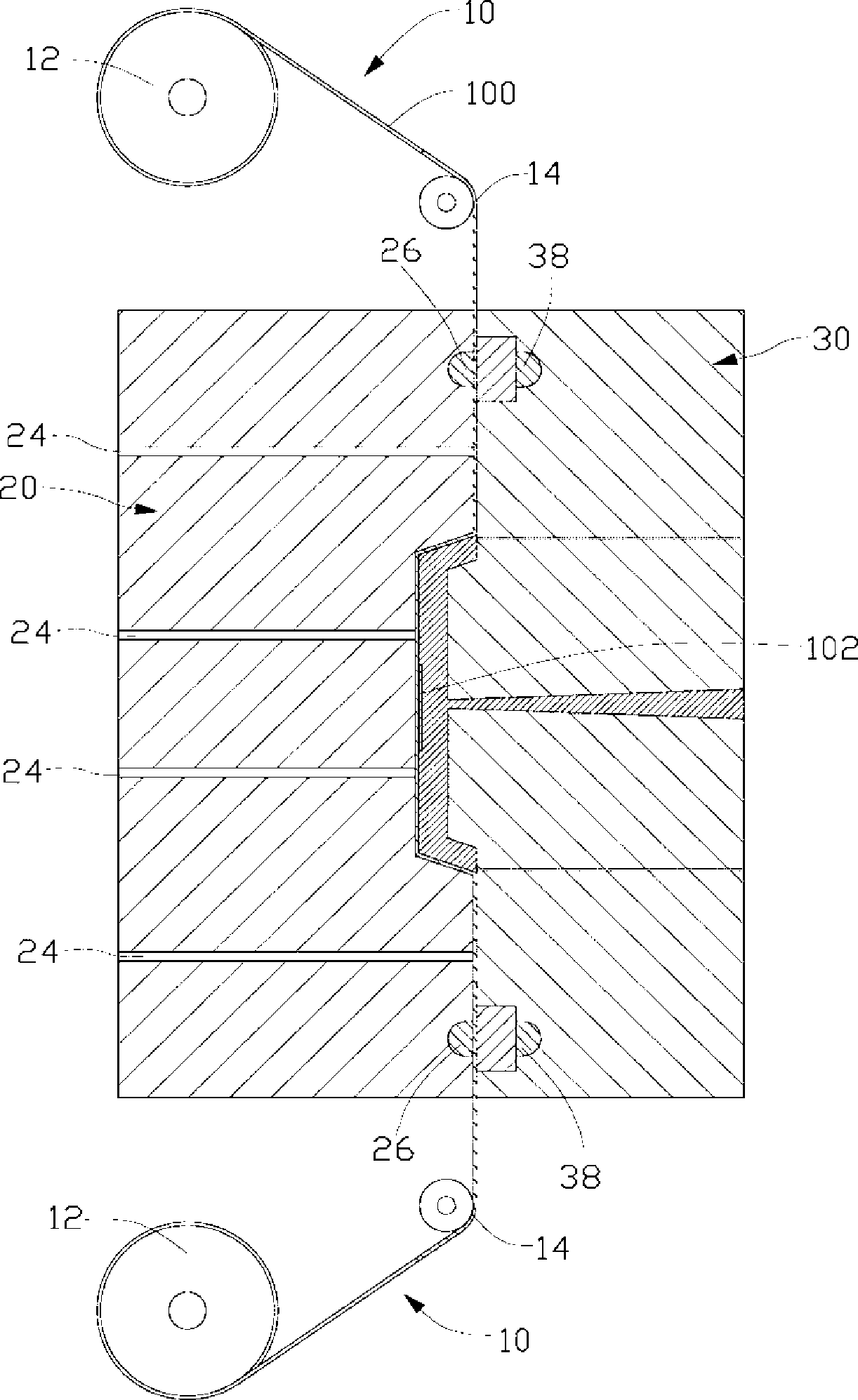

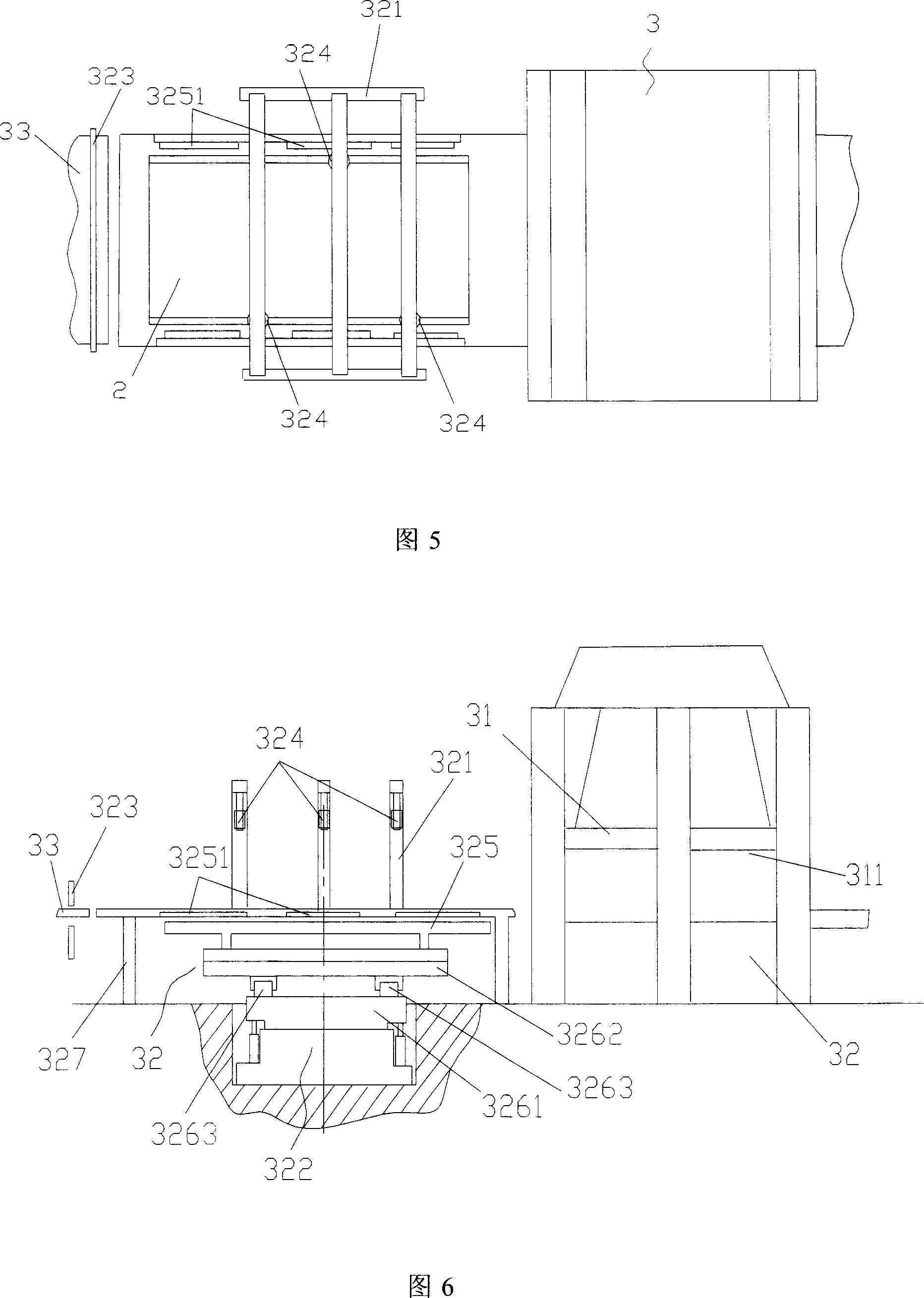

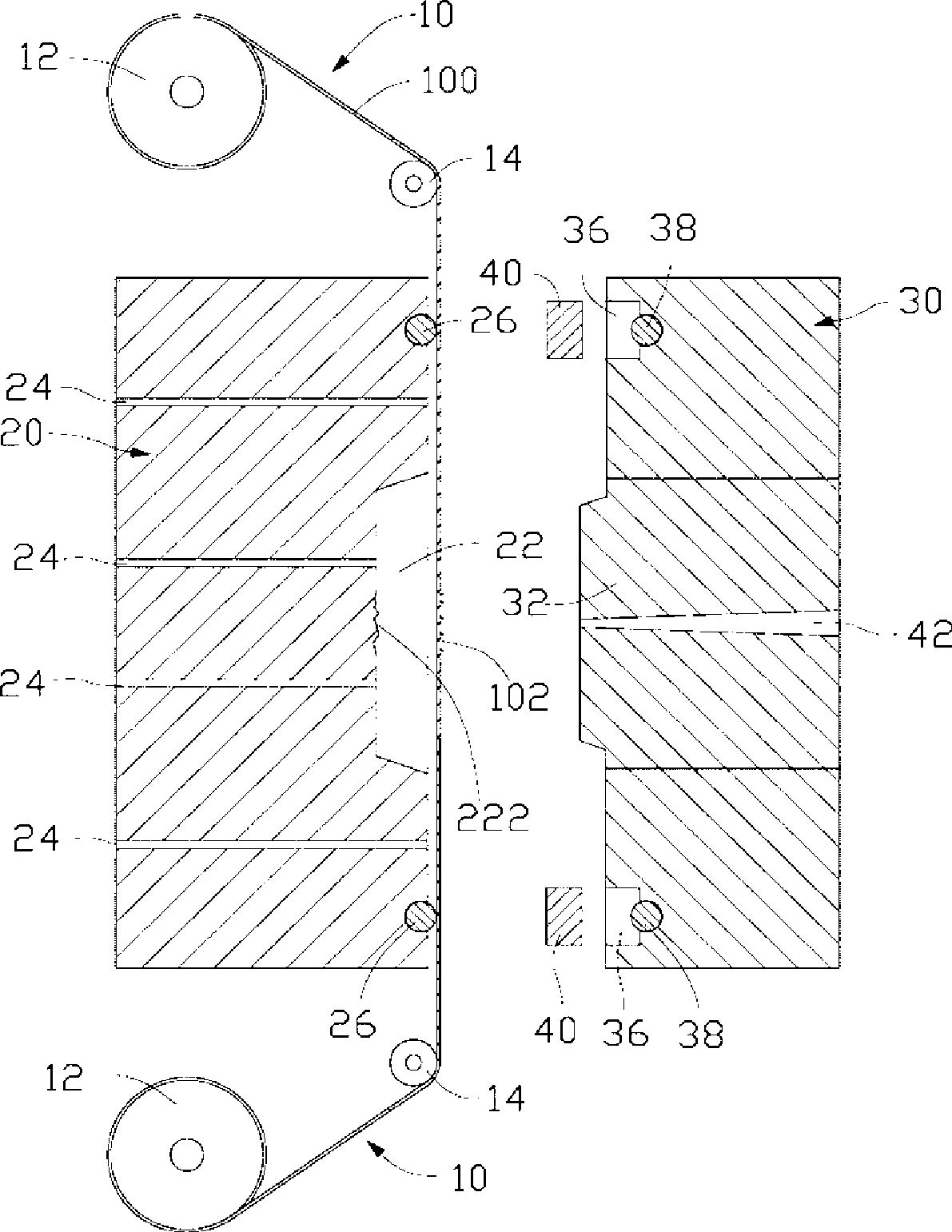

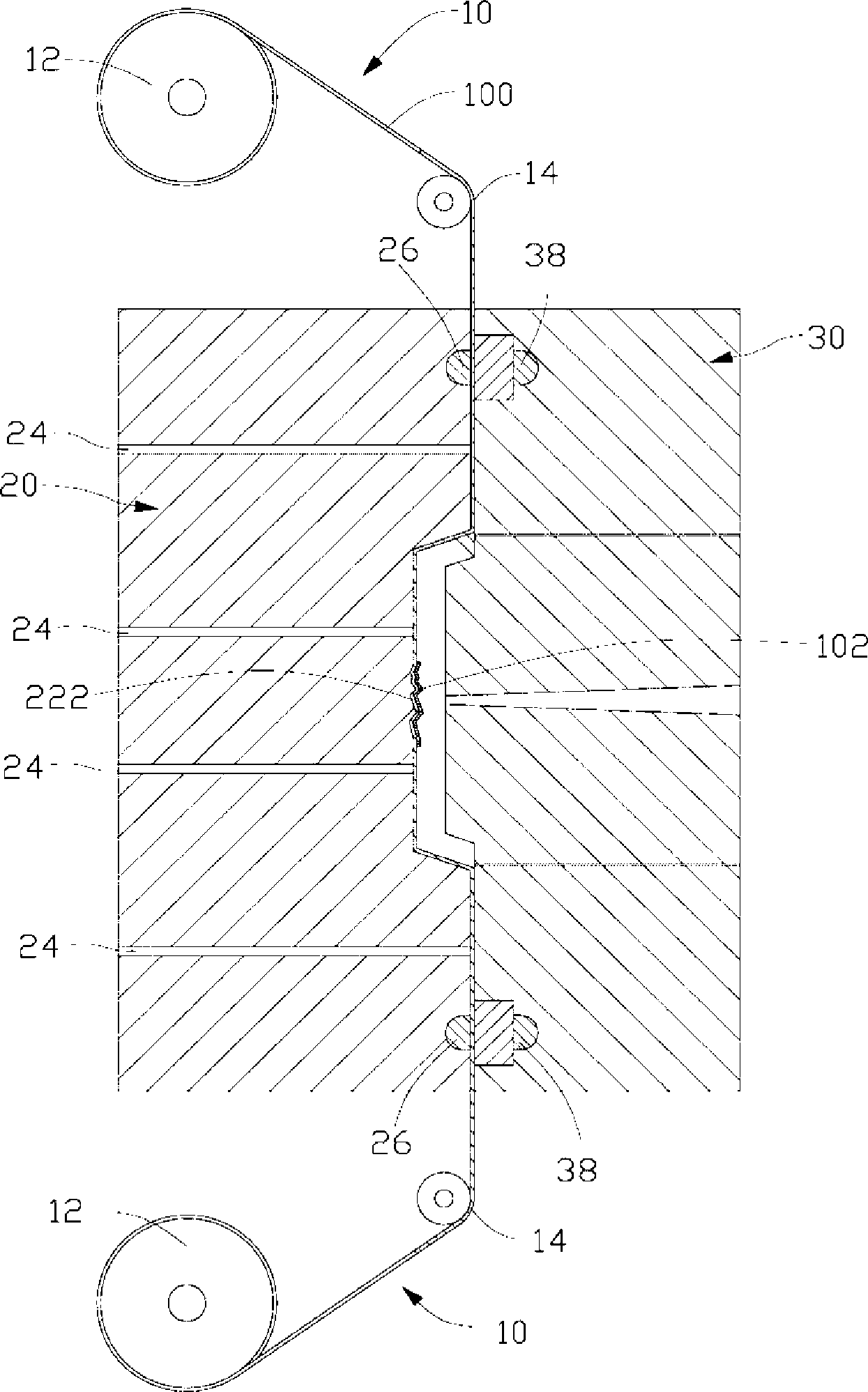

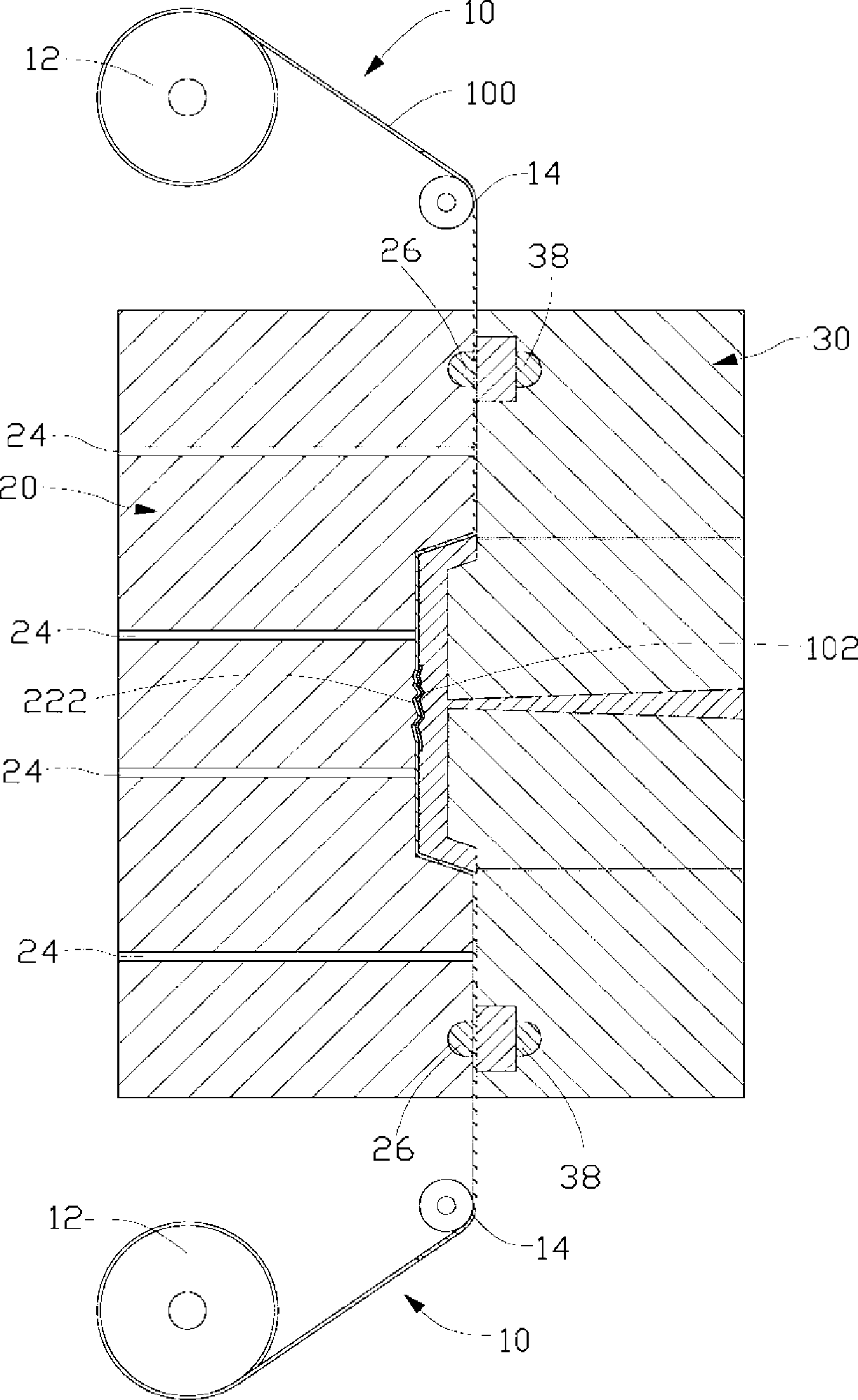

Method for preparation of artificial laminated board and the regulating and transport unit thereof

InactiveCN101112809ARealistic three-dimensional effectUnderstand the purposeLamination plant layoutLaminationPaper basedPulp and paper industry

The invention discloses a manufacture method of a simulation piling plate, and comprises the steps that a lining paper with patterns and lining paper base points is obtained; the lining paper is arranged on a plain plate, an adjusting transmission device and a pressing equipment are obtained; the pressing die working surface of the pressing equipment is provided with the same solid pattern with the pattern on the lining paper; the adjusting transmission device comprises a position adjusting mechanism and an aligning mechanism; the plain plate with the lining paper is arranged on the position adjusting and is adjusted according to the measurement signal of the lining paper base points by the aligning mechanism to ensure the plain plate to obtain exact prearranged position; the plain plate obtaining the exact position is arranged in the pressing equipment; the pressing die with the same solid pattern is adopted to press the plain plate with the lining paper to obtain a product with the pattern on the lining paper exactly coincident with the solid pattern on the pressing die. The invention also provides an adjusting transmission device to implement the manufacture method. The manufacture method of the invention obtains the simulation plate which has realistic solid patterns and can be applied to the fields such as the furniture, etc.

Owner:ACCUMULATE A IND SHANGHAI

Method for molding plastic rubber piece tridimensional pattern and molding equipment using the method

Owner:KANGZHUN ELECTRONICS TECH KUNSHAN +1

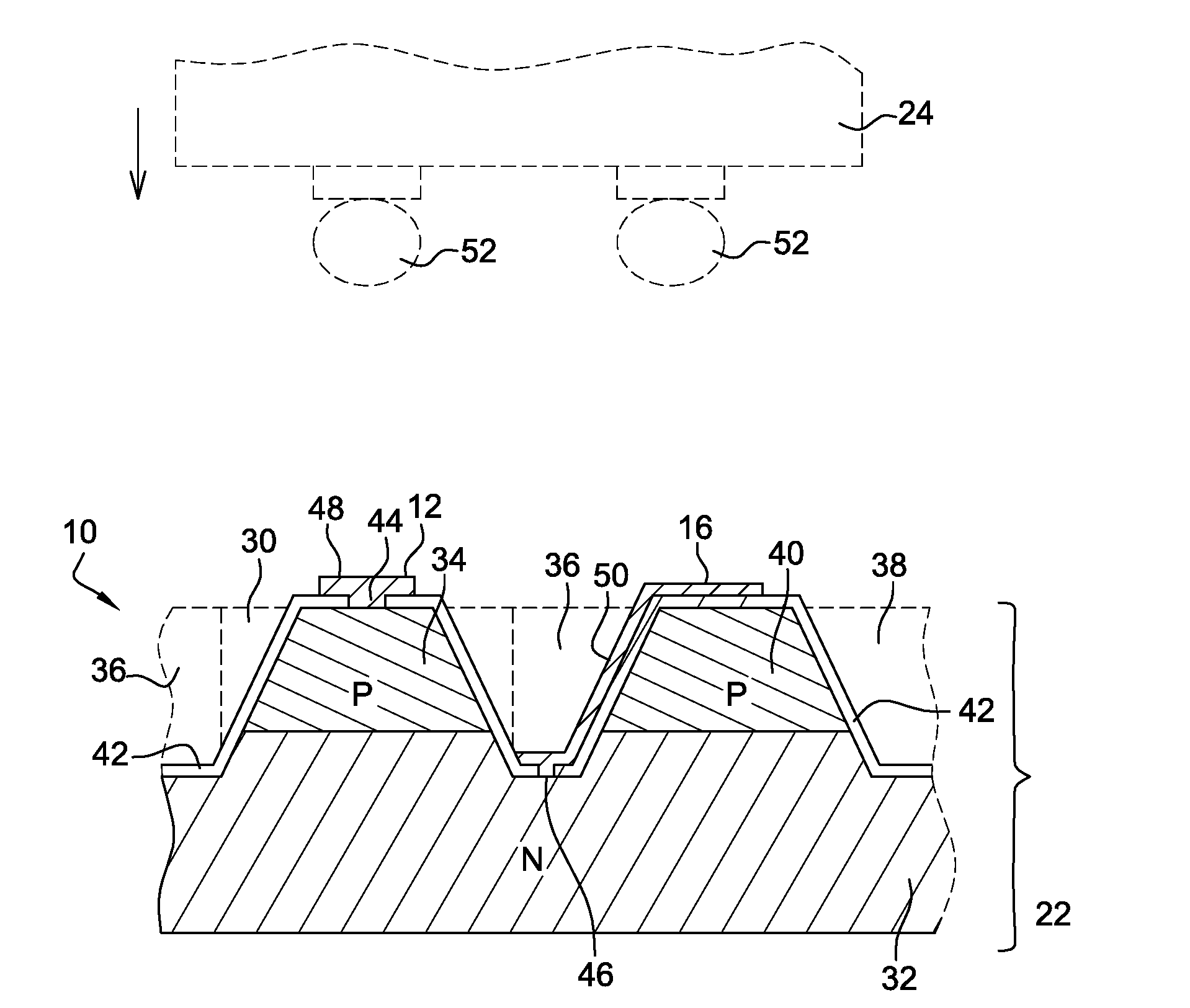

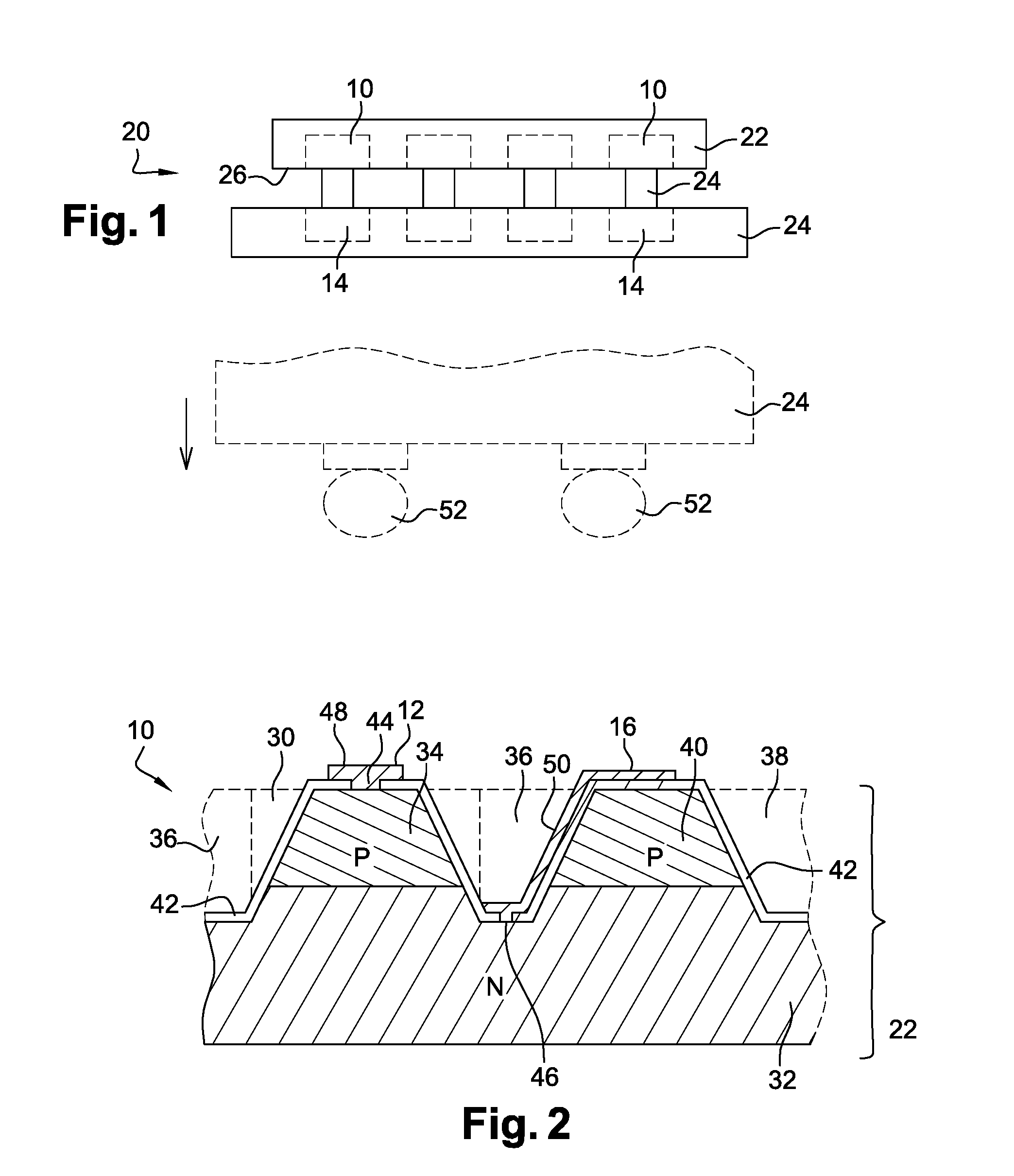

Method of manufacturing a plurality of island-shaped dipoles having self-aligned electrodes

ActiveUS20160380017A1Firmly connectedEasy to manufactureSolid-state devicesSemiconductor/solid-state device manufacturingElectronic componentInert

An electronic component includes a plurality of dipoles, each comprising an island solid with a base, a first electrode arranged at the top of the island and a second electrode arranged on the base. Its manufacturing includes forming, on the base, a layer of a material capable of being etched by means of a predetermined isotropic etching, forming, over the layer of material, solid patterns made of electrically-conductive material and inert to said etching, applying the isotropic etching of the thickness of material between said solid patterns to form islands totally overlooked by said solid patterns, and depositing electrically-conductive material on top of and between the islands to form the first and second electrodes of the dipoles.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

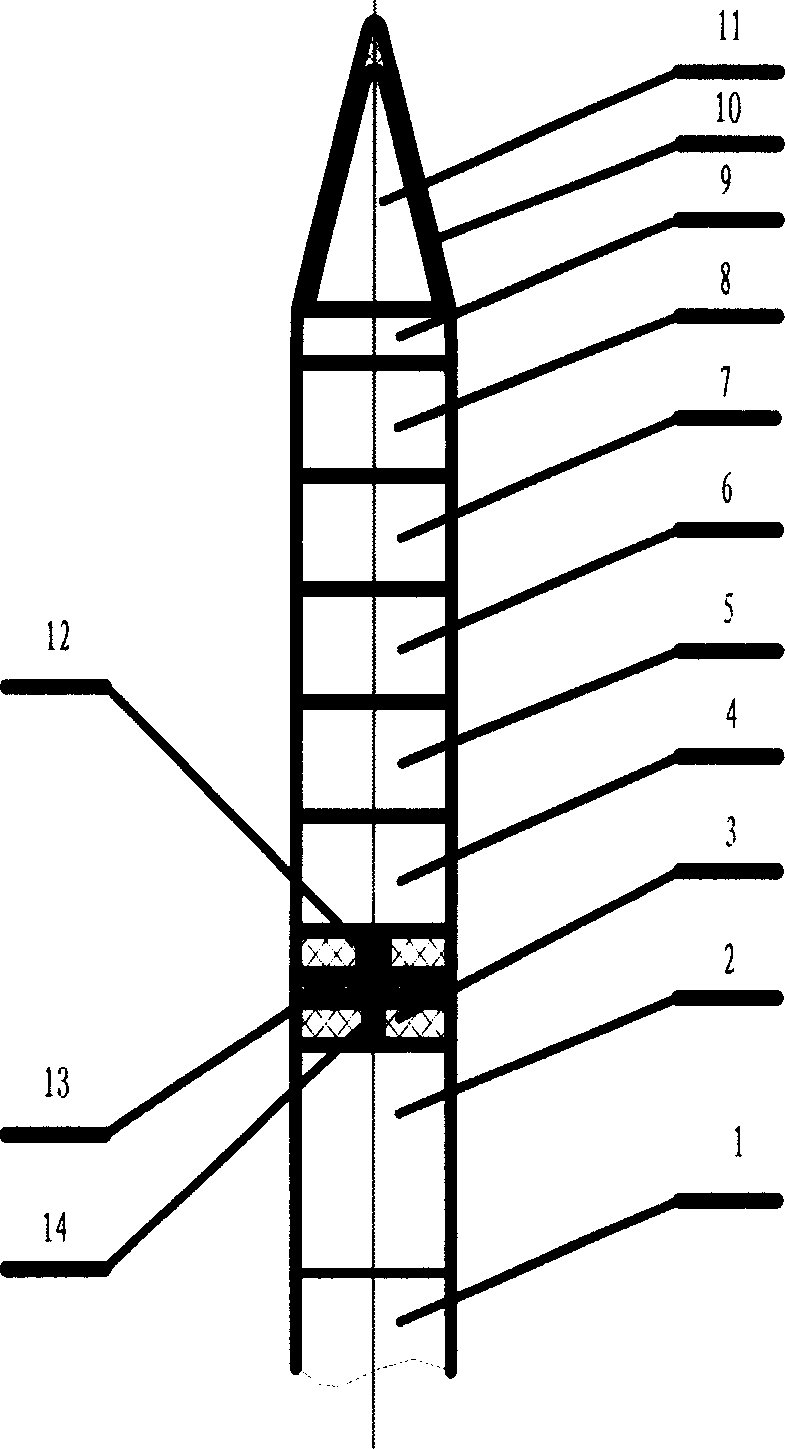

Anti-hail rain-enhancing bomb system

InactiveCN1808048AImprove performanceStrong technical comprehensivenessAmmunition projectilesSelf-propelled projectilesEngineeringDistributor

The invention relates to a shrapnel technique for preventing hail and increasing rain, belonging to the device which can affect the weather to fill the blank of outer nation in said area. The invention comprises the mother bomb distributor and the multiple sub-bomb boxes which are in series and parallel, therefore, the distribution track of mother bomb and track of each sub-bomb can form a spatial solid pattern to enlarge the distribution space, accelerate the diffusion of aerosol, improve the effect of preventing hail and increasing rain, and improve the efficiency of thruster. It has simple structure, lower cost, high efficiency, and better reliability.

Owner:HUAIHAI IND GRP

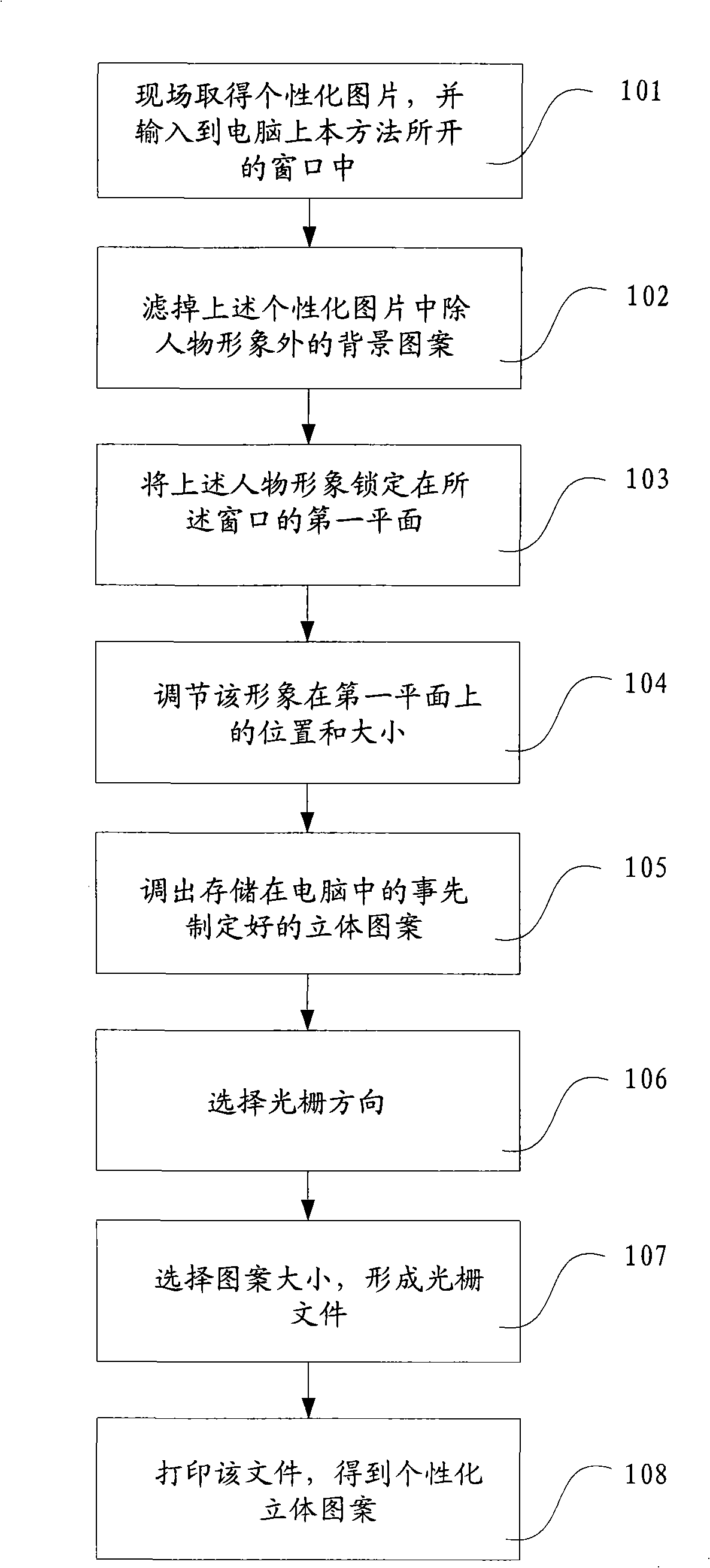

Method for making personalized stereo pattern by computer

InactiveCN101408972AEasy to manufactureImage data processing detailsSteroscopic systemsPersonalizationGrating

The invention relates to a method for manufacturing individual solid patterns by using a computer, comprising the following steps: extracting and inputting individual pictures; placing the individual pictures on a first plane where the focus of the individual solid patterns is; selecting the solid patterns designed in advance and adding the individual solid patterns; selecting the grating direction of the whole picture for generating grating picture files; outputting or storing the grating picture files. The method for manufacturing the individual solid patterns has the following advantages: as the method combines and edits the individual pictures of a user and uses the property of the computer to store a plurality of background and foreground files in advance, thus leading the user to conveniently manufacture the individual solid patterns.

Owner:陈伟明

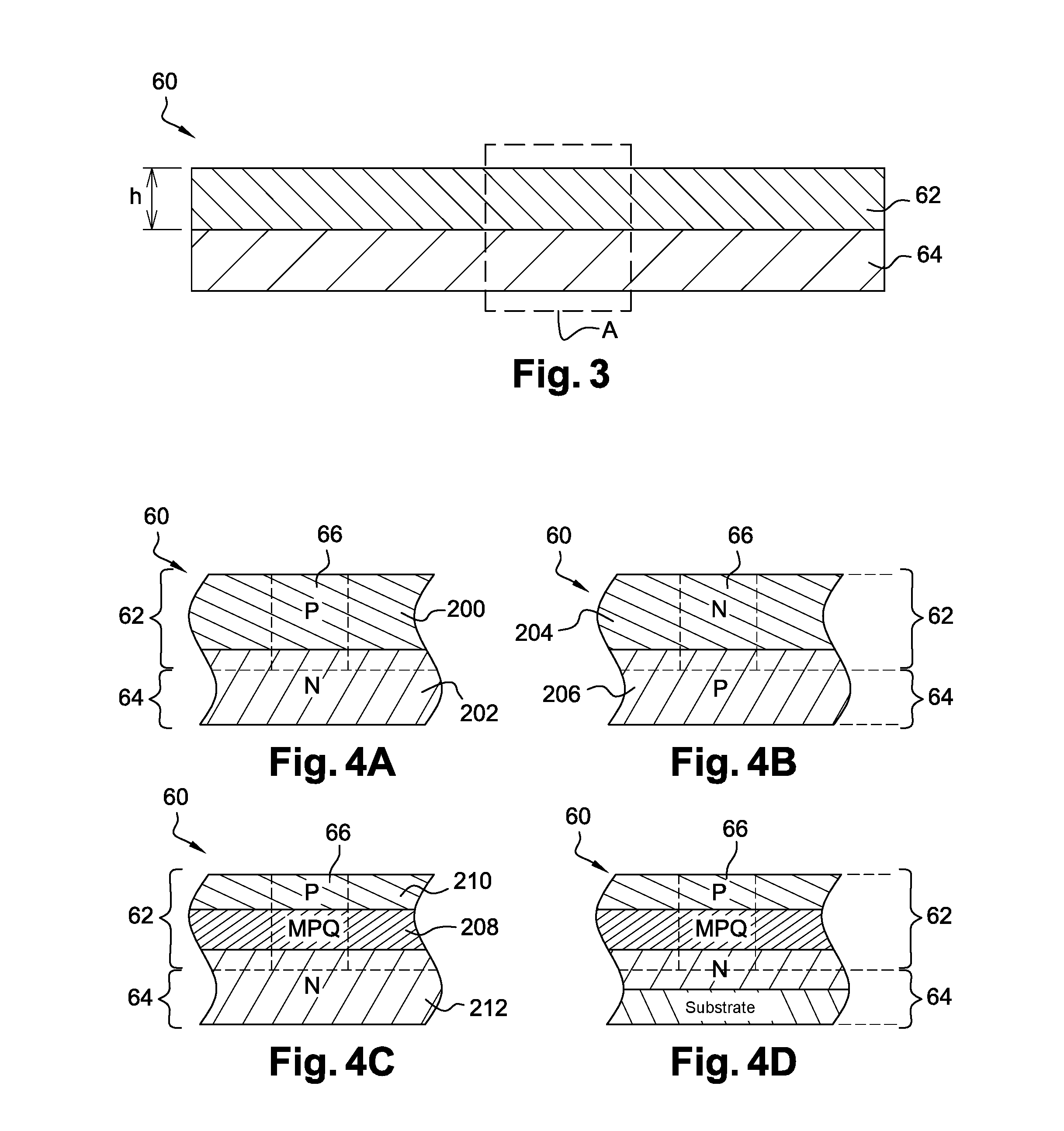

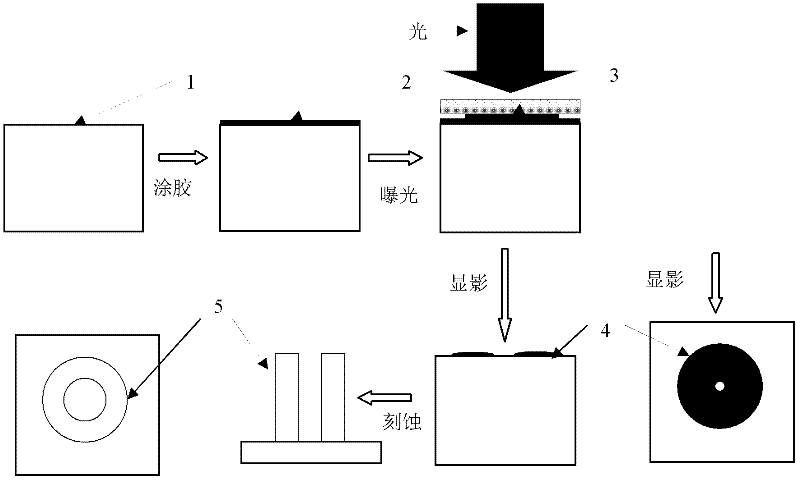

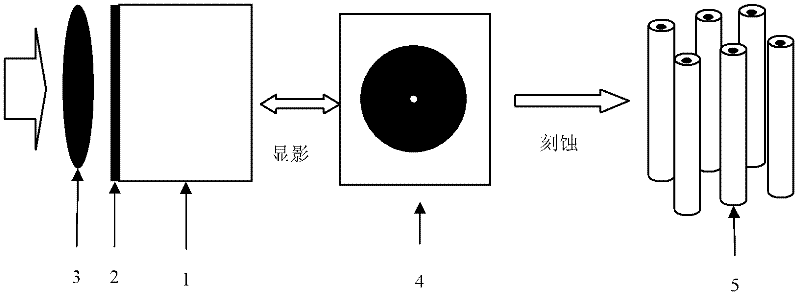

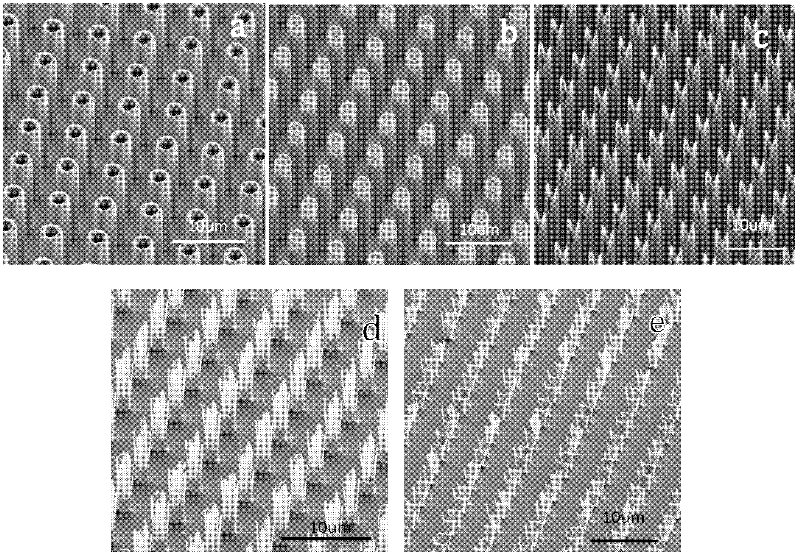

Optical exposing method, and method for applying optical exposure in preparation of silicon material vertical hollow structure

ActiveCN102495526AIncrease Exposure Limit SizeReduce manufacturing costDecorative surface effectsPhotomechanical exposure apparatusMicro nanoPhotonics

The invention provides an optical exposing method used for forming a micro-nano hollow cavity structure. The method comprises steps that: (1) a mask with a mask pattern is selected, wherein the mask pattern is a geometrical solid pattern or an array thereof with which Poisson spots can be formed through illumination; (2) the mask is positioned above a positive photoresist requiring exposure; exposure is carried out; Poisson spots behind pattern shades are exposed as well; (3) developing is carried out, such that a pattern of hollow cavities corresponding to the Poisson spots is obtained on the positive photoresist. With the method, a silicon pipe-shaped structure array with controllable length-to-diameter ratios can be prepared. With the exposing method, a limit size of laboratory photomask exposure is greatly increased; a limitation of interference exposure that only periodical lines and point lattice can be obtained is broken through; cost is greatly reduced; and experiment technologies are enriched. The structure has a wide application prospect in fields of photonic crystals, filtering devices, and radial p-n junction structured solar cells.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

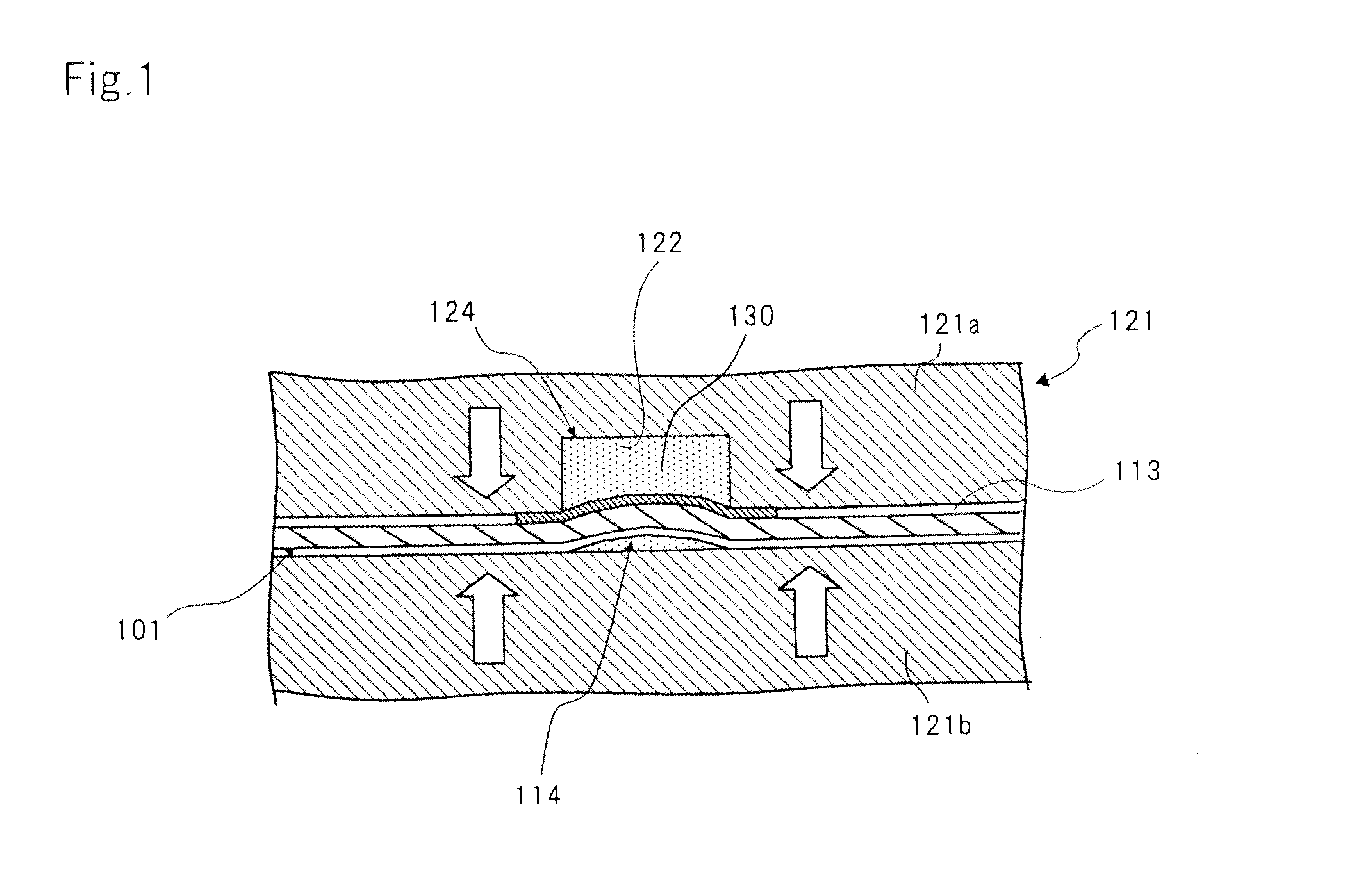

Printed wiring board including a thermal land for supressing heat dissipation

InactiveUS8106303B2Good conditionImprove connection reliabilityPrinted electric component incorporationPrinted circuit aspectsCopper foilEngineering

When soldering is performed, heat transferred from through hole 6b is caused to bypass a mesh-like copper foil region between non-copper-foil regions and thus the transfer of heat to a solid pattern region around thermal land 13b is delayed. Signal wirings 8e, 8f and signal wirings 8g, 8 are formed along the arrangement directions of non-copper-foil regions 15b, 16b respectively keeping a predetermined spacing between them and disposed to overlap copper foil regions, thus ensuring a current return path by means of opposing ground layer 11.

Owner:NEC CORP

Printed board and electronic apparatus

InactiveUS20040262034A1Improve the immunityPrinted circuit aspectsSolid-state devicesResistElectrical conductor

A printed board includes an electrically insulating board, a conductor layer made of an electrically conducting pattern, and at least one of a resist layer and an ink layer, each made of an electrically insulating solid pattern. The electrically insulating board has one surface on which electronic parts will be mounted, and the other surface on which the conductor layer is formed and covered with at least one of the resist layer and the ink layer. An organic EL display device includes the printed board, and a housing having a planar structure. The surface on which the conductor layer of the printed board is covered with at least one of the resist layer and the ink layer, each made of the electronically insulating solid pattern is arranged so as to face a planar portion of the housing having the planar structure.

Owner:TOHOKU PIONEER CORP

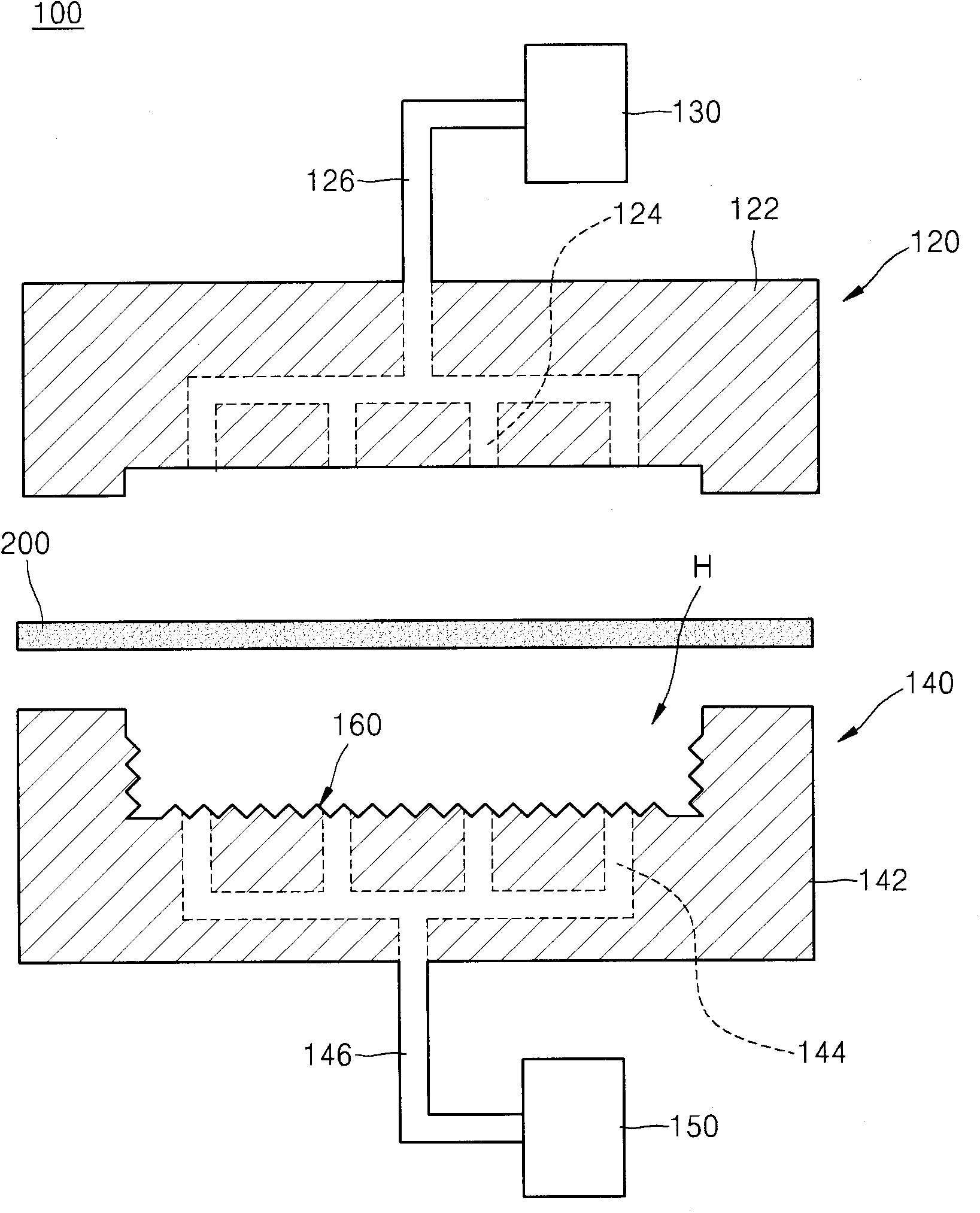

Vacuum mold having a reverse solid pattern, and vacuum-orming method using same

Provided is a vacuum mold having a reverse solid pattern, which enables an insert sheet to be vacuum-formed, and a solid pattern to be transferred onto the insert sheet. The vacuum mold having the reverse solid pattern includes: a lower mold; and a solid pattern disposed on the surface of the lower mold. The insert sheet disposed above the lower mold is adsorbed to the surface of the lower mold by vacuum pressure in order to transfer a pattern of the solid pattern onto the insert sheet.

Owner:LG HAUSYS LTD

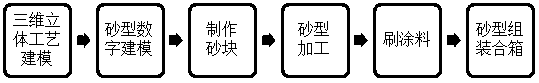

Manufacturing method of casting mold for steel casting molding process

InactiveCN110102711ABlank weight is lightHigh dimensional accuracyFoundry mouldsFoundry coresBrickThermal insulation

The invention discloses a manufacturing method of a casting mold for a steel casting molding process. By applying SolidWorks three-dimensional modeling software and UG (Unigraphics NX) digital modeling software and employing the processing technology of a digital pattern-less casting precision molding machine, corresponding positions of process elements: a gating and riser system, a chilling block, a core iron and a deformability material and the like, included in the steel casting molding process are processed and reserved; then, a steel brick tube, a thermal insulation bush required by a riser, the chilling block, the corn iron and the deformability material are put into a processed sand mold, and are assembled and fixed, and casting is performed to obtain a product. Compared with a traditional production mode of manufacturing a pattern according to a traditional casting molding process and manufacturing the sand mold by utilizing the pattern to form the casting mold, the productionmode of the manufacturing method disclosed by the invention does not need to manufacture a solid pattern and does not need to consider the factors: the drafting angle and the like, so that the dimensional precision of the casting is increased; the billet weight of the casting can be reduced by 3 % to 5 %; and meanwhile, the problem that a traditional pattern for new product development and new process verification is long in manufacturing period and high in cost is solved.

Owner:LANZHOU LS GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com