Forming method for stereoscopic pattern of plastic rubber member

A technology of three-dimensional pattern and forming method, which is applied in the direction of coating, etc., and can solve the problem of not being able to print three-dimensional patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

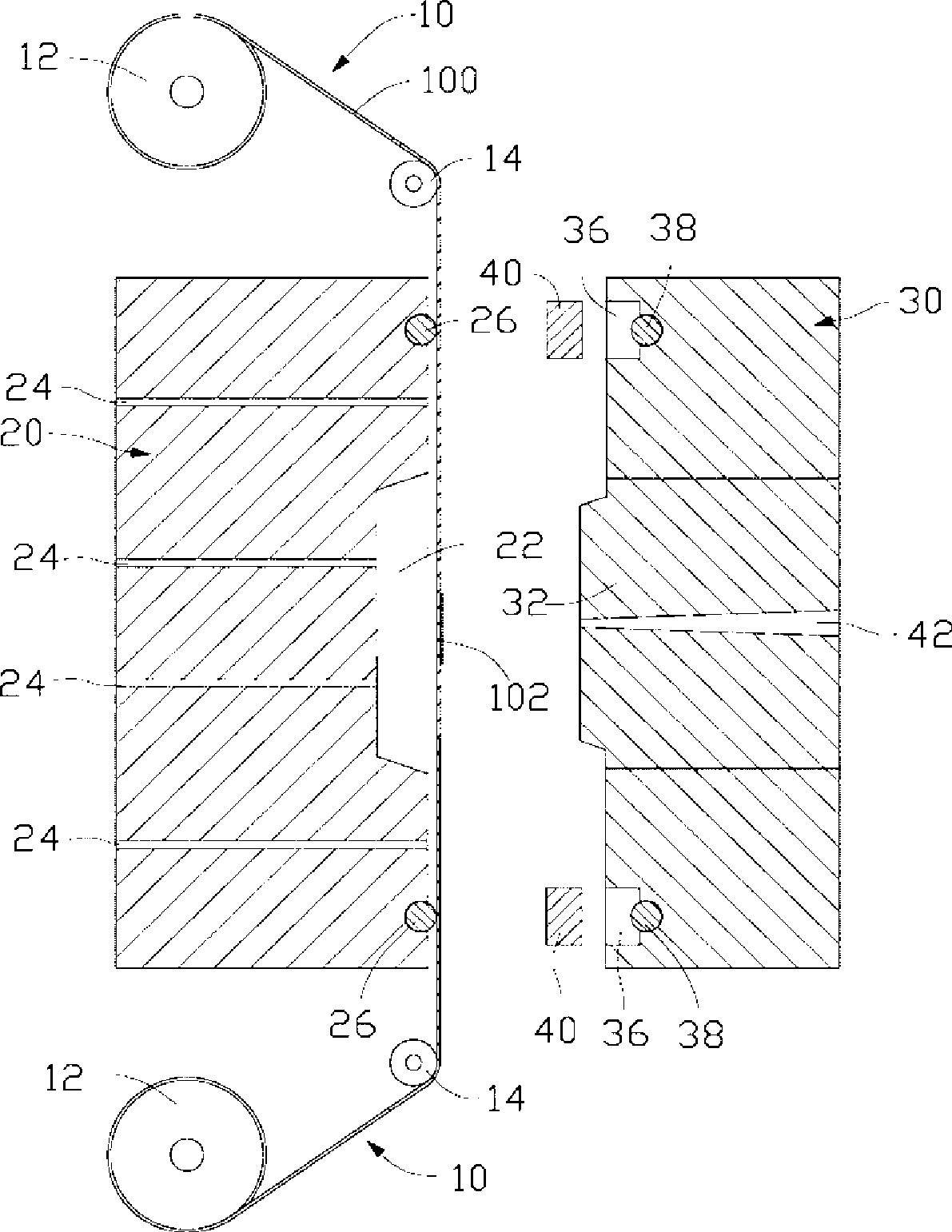

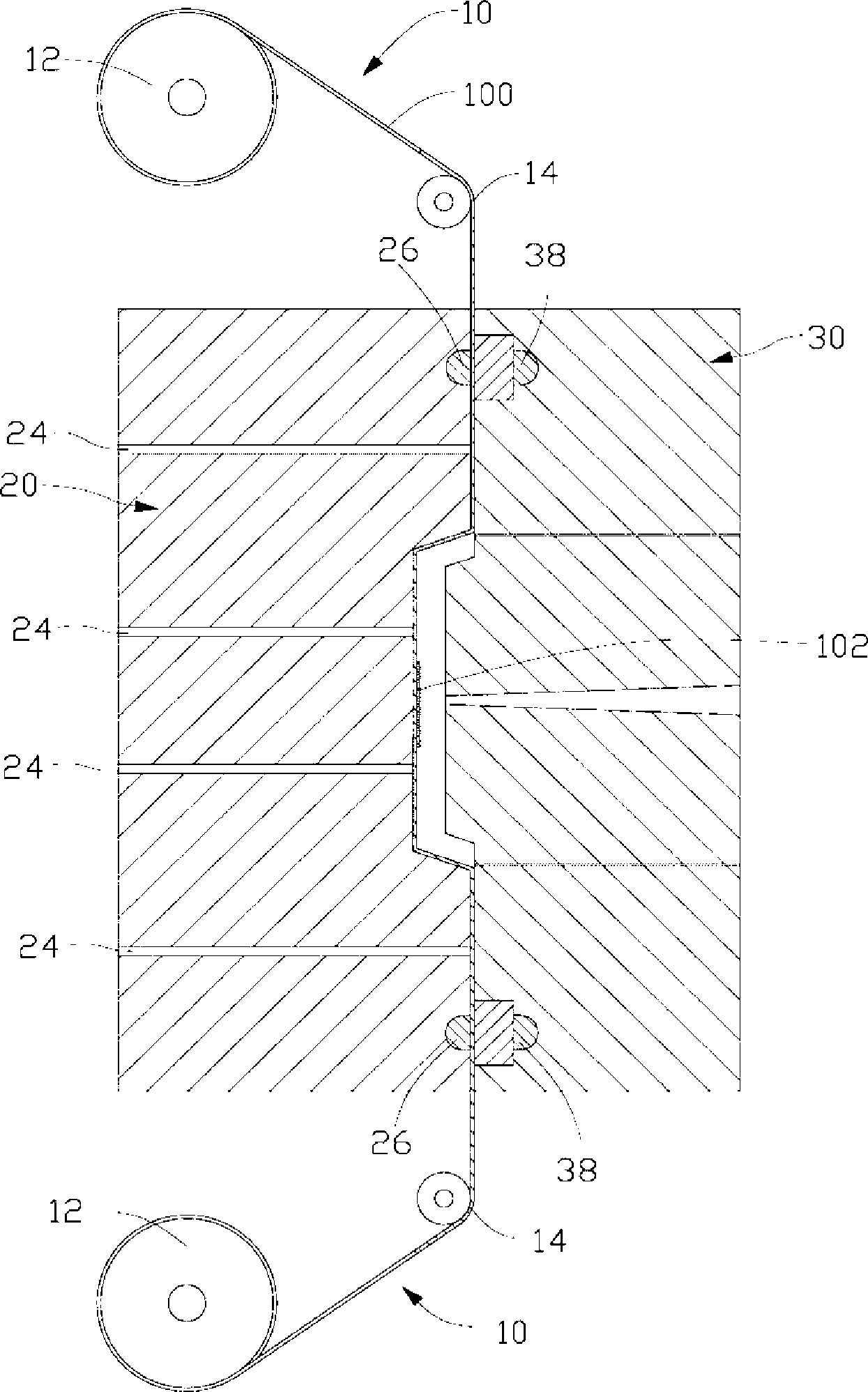

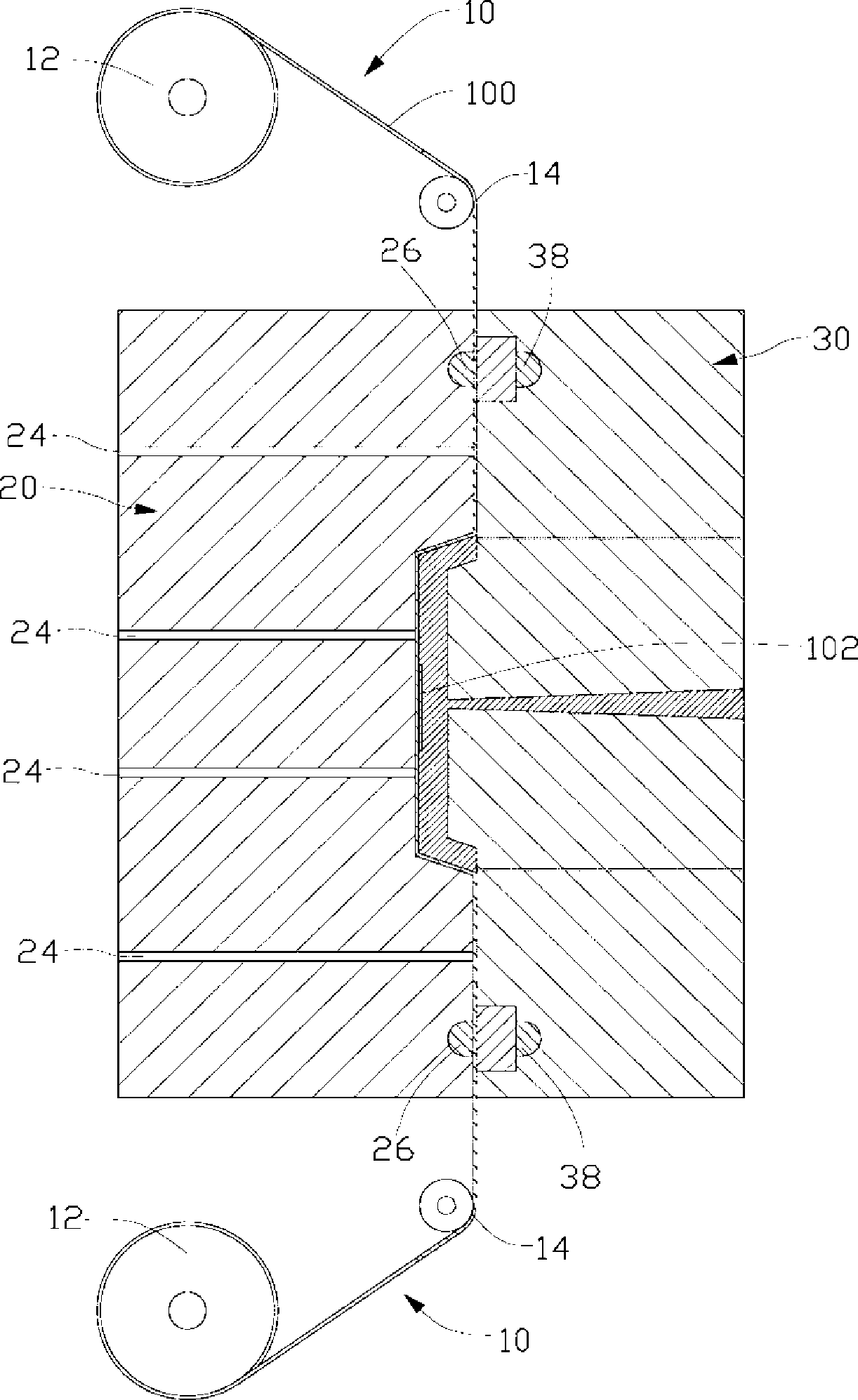

[0016] Such as figure 1 As shown, the molding equipment used for the preferred embodiment of the molding method for implementing the three-dimensional pattern of plastic parts of the present invention includes a film feeding device 10, a die of a female mold 20 and a male mold 30, and a pair of pressing Box 40.

[0017] The mold feeding device 10 includes a pair of film conveying wheels 12 and a pair of guiding wheels 14 . The pair of film conveying wheels 12 are respectively arranged upstream and downstream of the mold for pulling the film 100 . The guide wheels 14 are used to guide the conveying direction of the film 100 . The film 100 includes a substrate and a transfer layer 102 disposed on the substrate. The substrate is generally made of polymer materials such as polycarbonate (PC) and polybutylene terephthalate (PBT). The transfer layer 102 is printed with a three-dimensional ink layer or engraved with a three-dimensional pattern on the side away from the substrate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com