Patents

Literature

195results about How to "Improve material properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

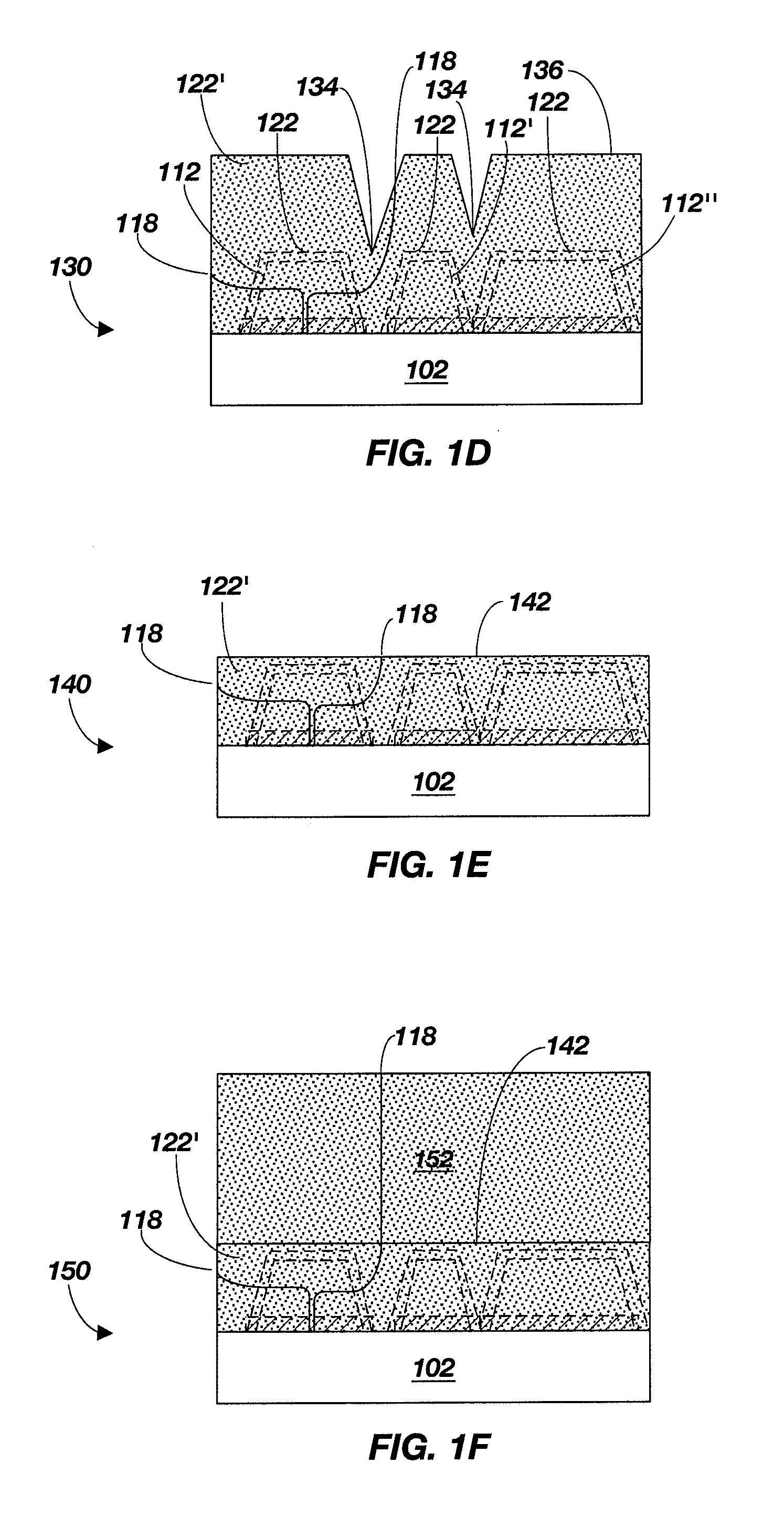

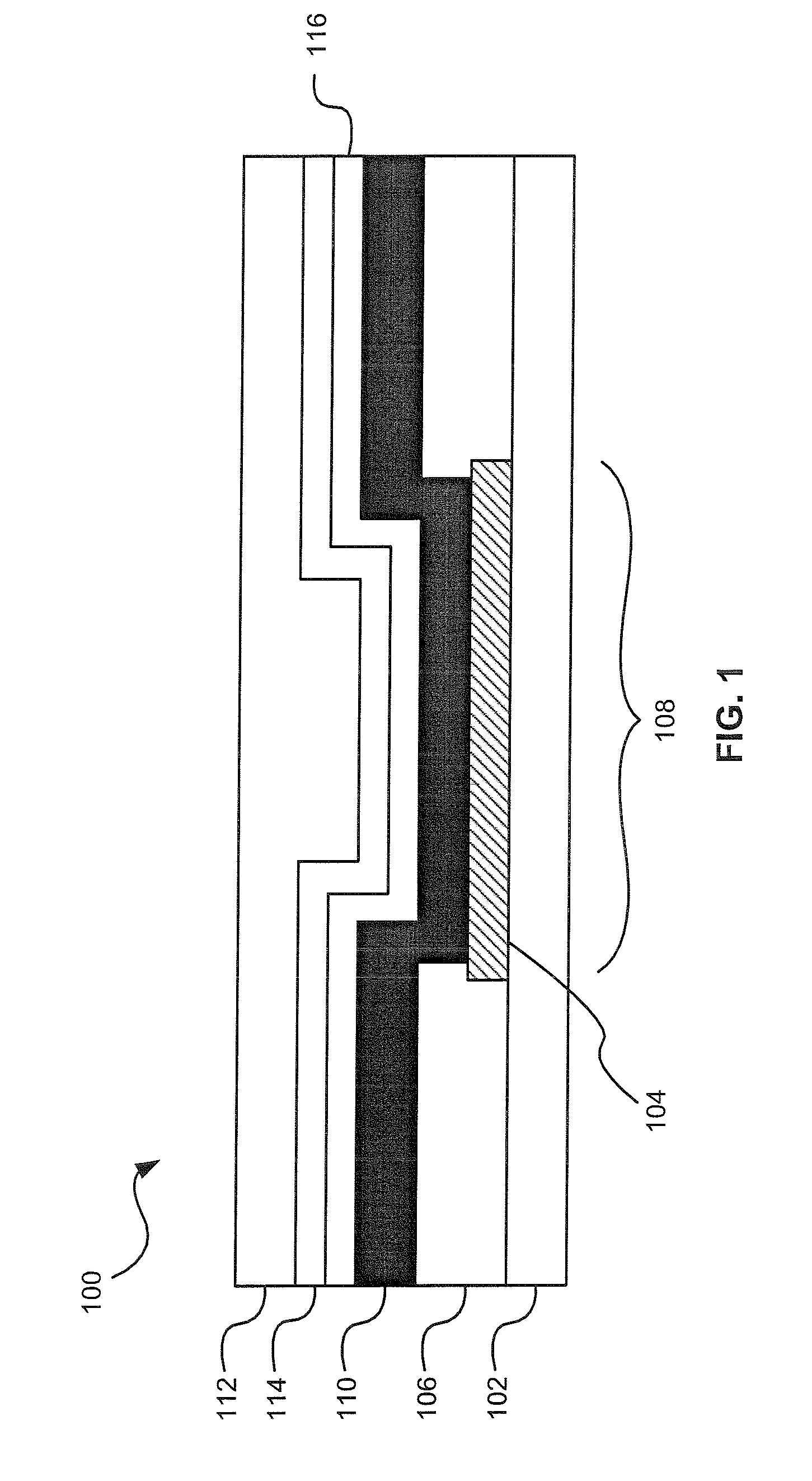

Method of forming crystallographically stabilized doped hafnium zirconium based films

ActiveUS20080233288A1Improve material propertiesImprove material performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingRare-earth elementDopant

A method is provided for forming doped hafnium zirconium based films by atomic layer deposition (ALD) or plasma enhanced ALD (PEALD). The method includes disposing a substrate in a process chamber and exposing the substrate to a gas pulse containing a hafnium precursor, a gas pulse containing a zirconium precursor, and a gas pulse containing one or more dopant elements. The dopant elements may be selected from Group II, Group XIII, silicon, and rare earth elements of the Periodic Table. Sequentially after each precursor and dopant gas pulse, the substrate is exposed to a gas pulse containing an oxygen-containing gas, a nitrogen-containing gas, or an oxygen- and nitrogen-containing gas. In alternative embodiments, the hafnium and zirconium precursors may be pulsed together, and either or both may be pulsed with the dopant elements. The sequential exposing steps may be repeated to deposit a doped hafnium zirconium based film with a predetermined thickness.

Owner:TOKYO ELECTRON LTD

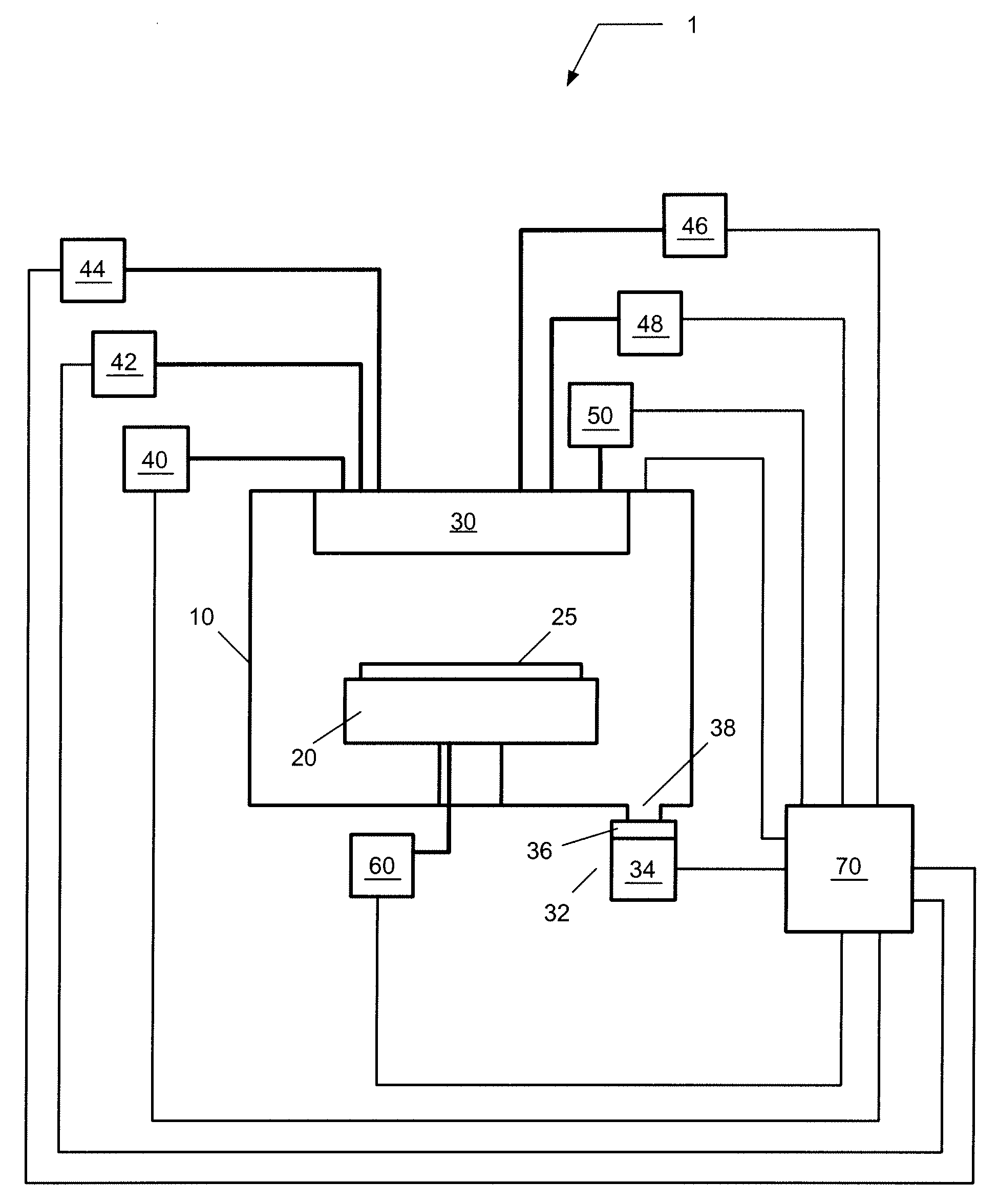

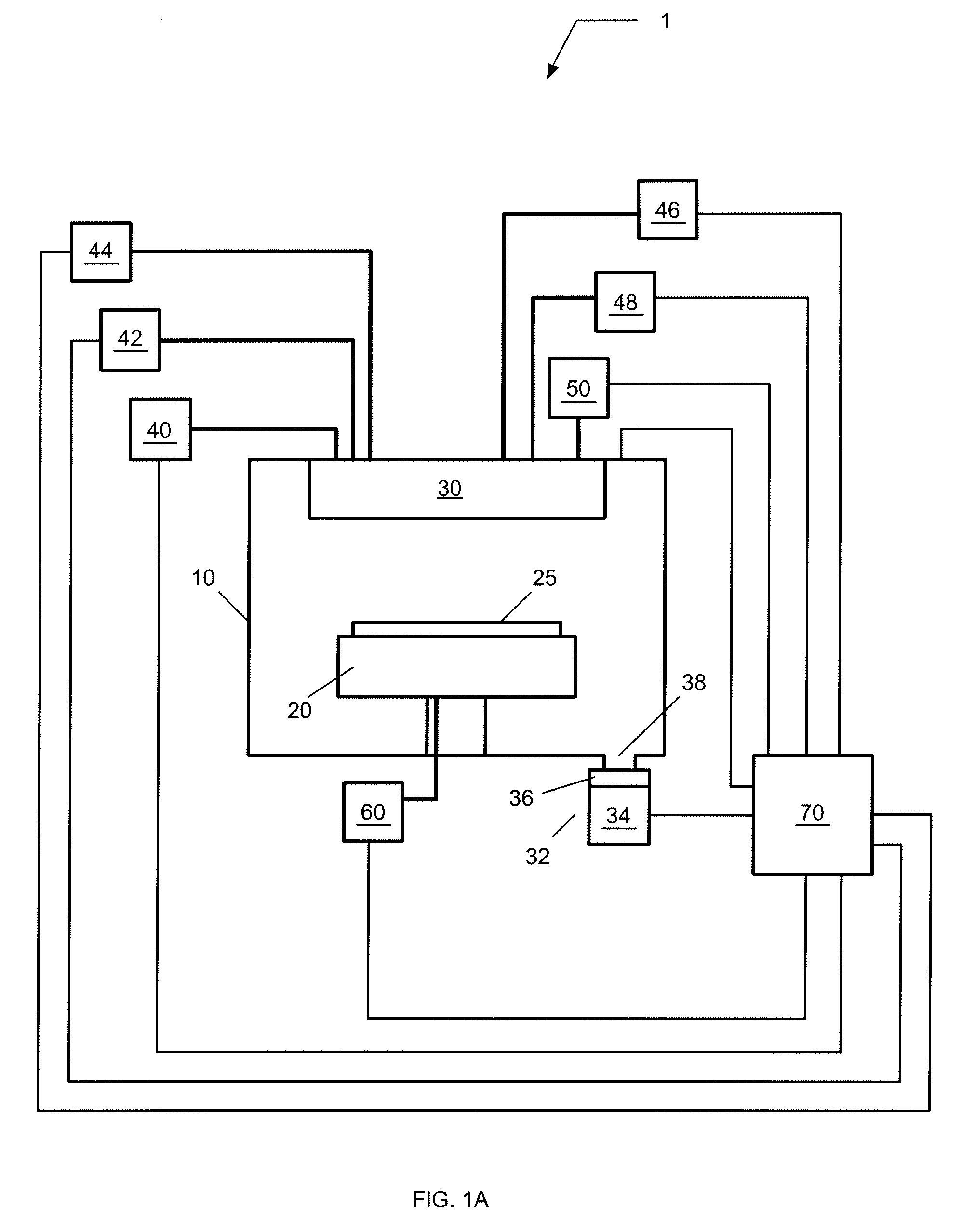

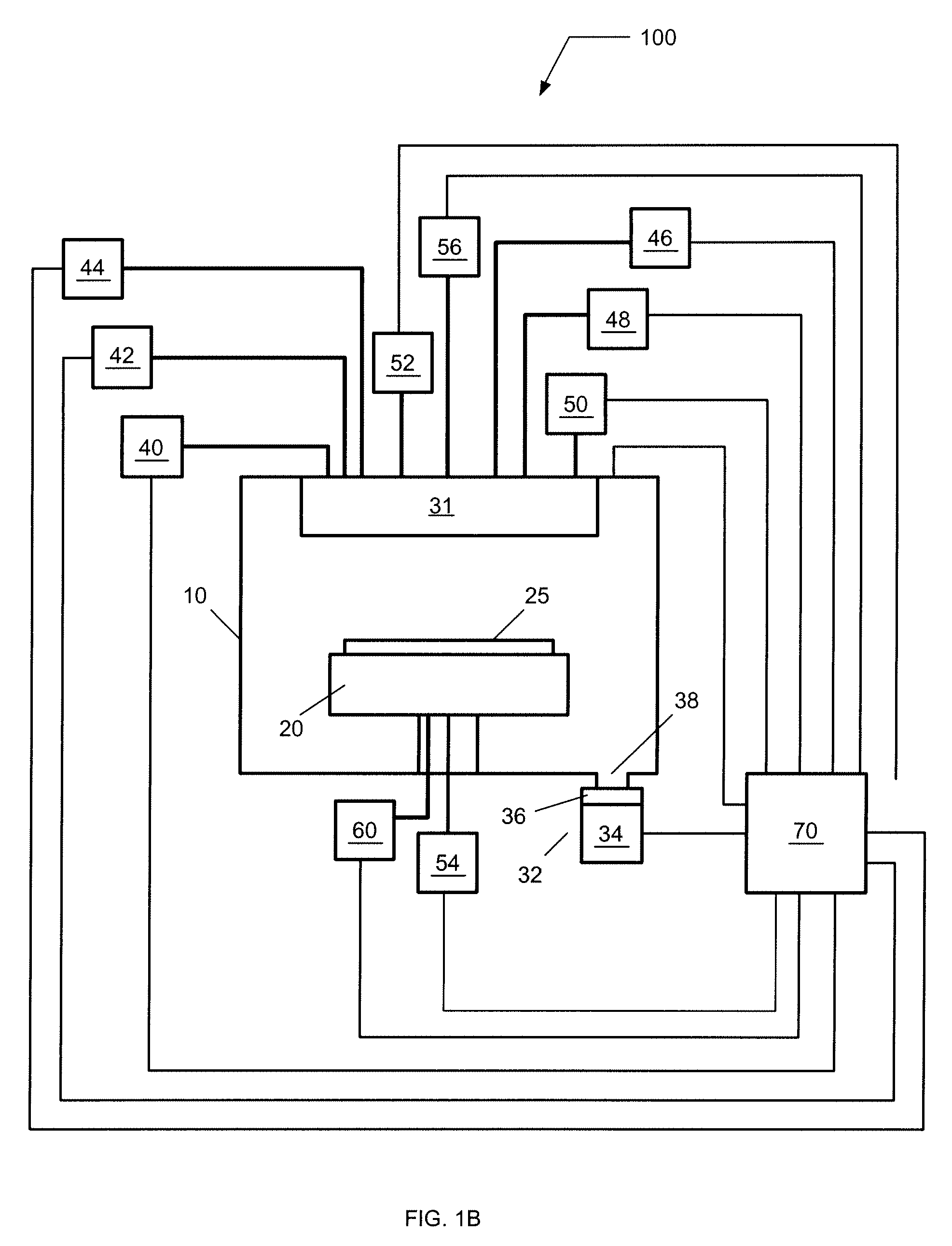

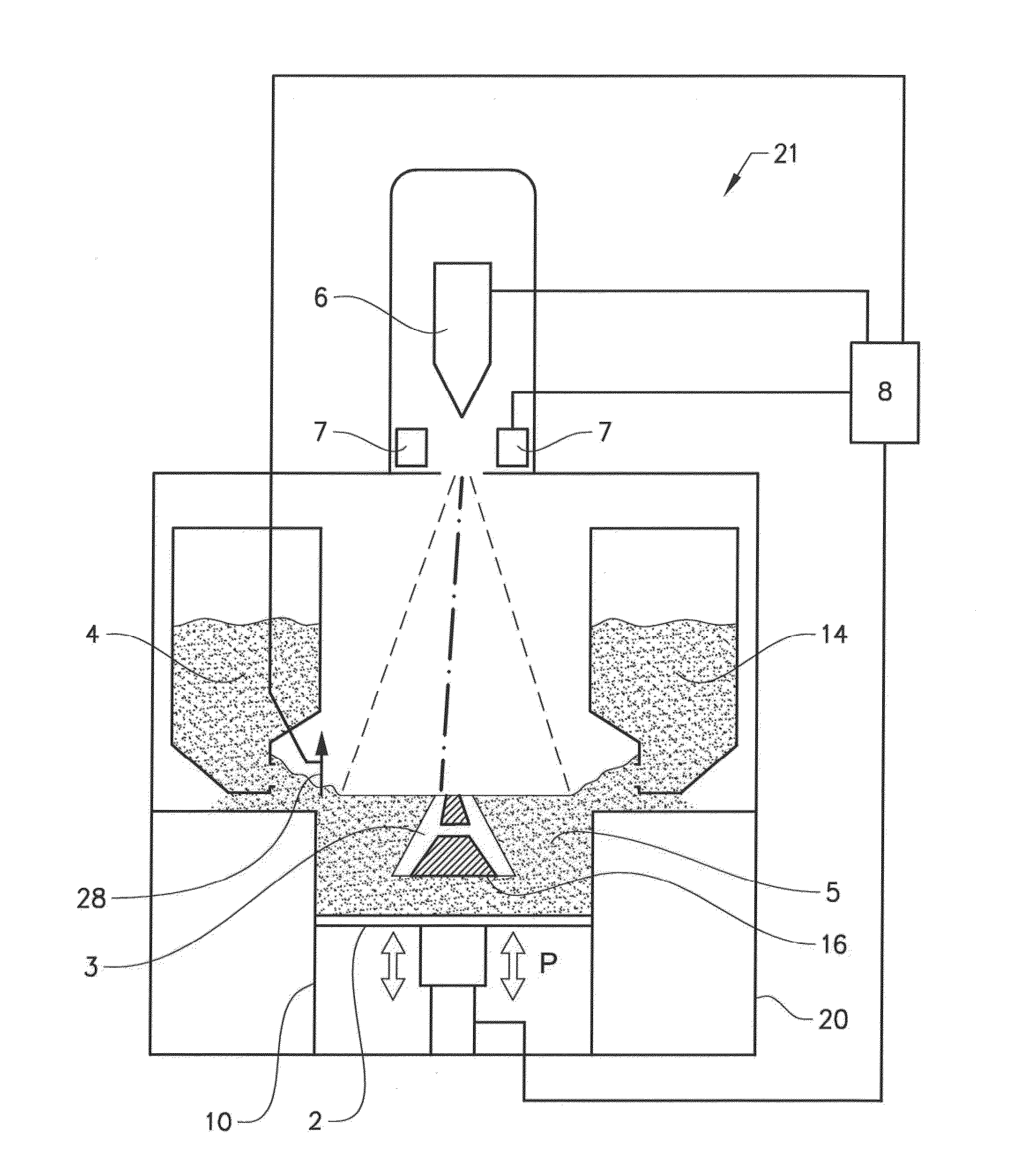

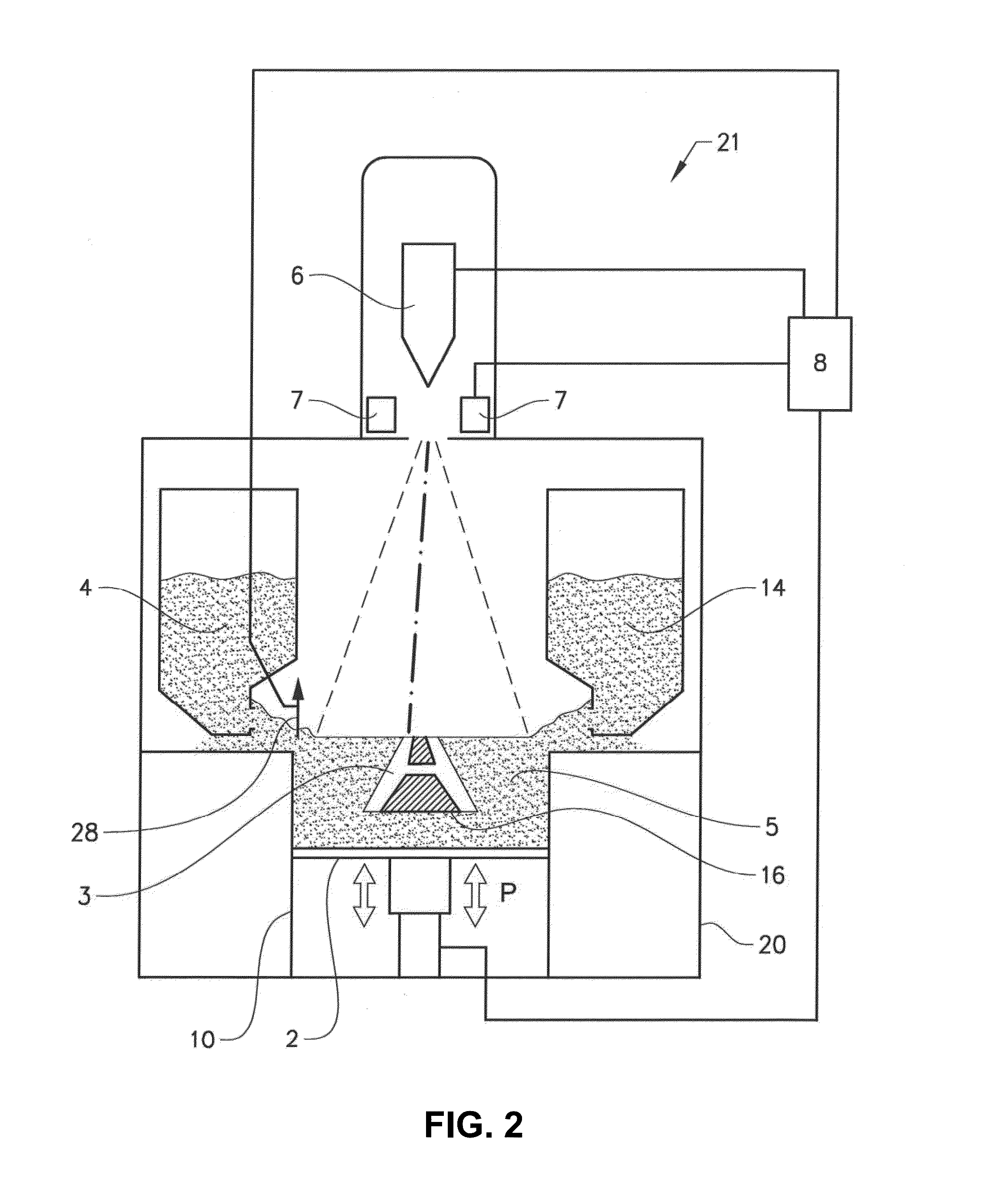

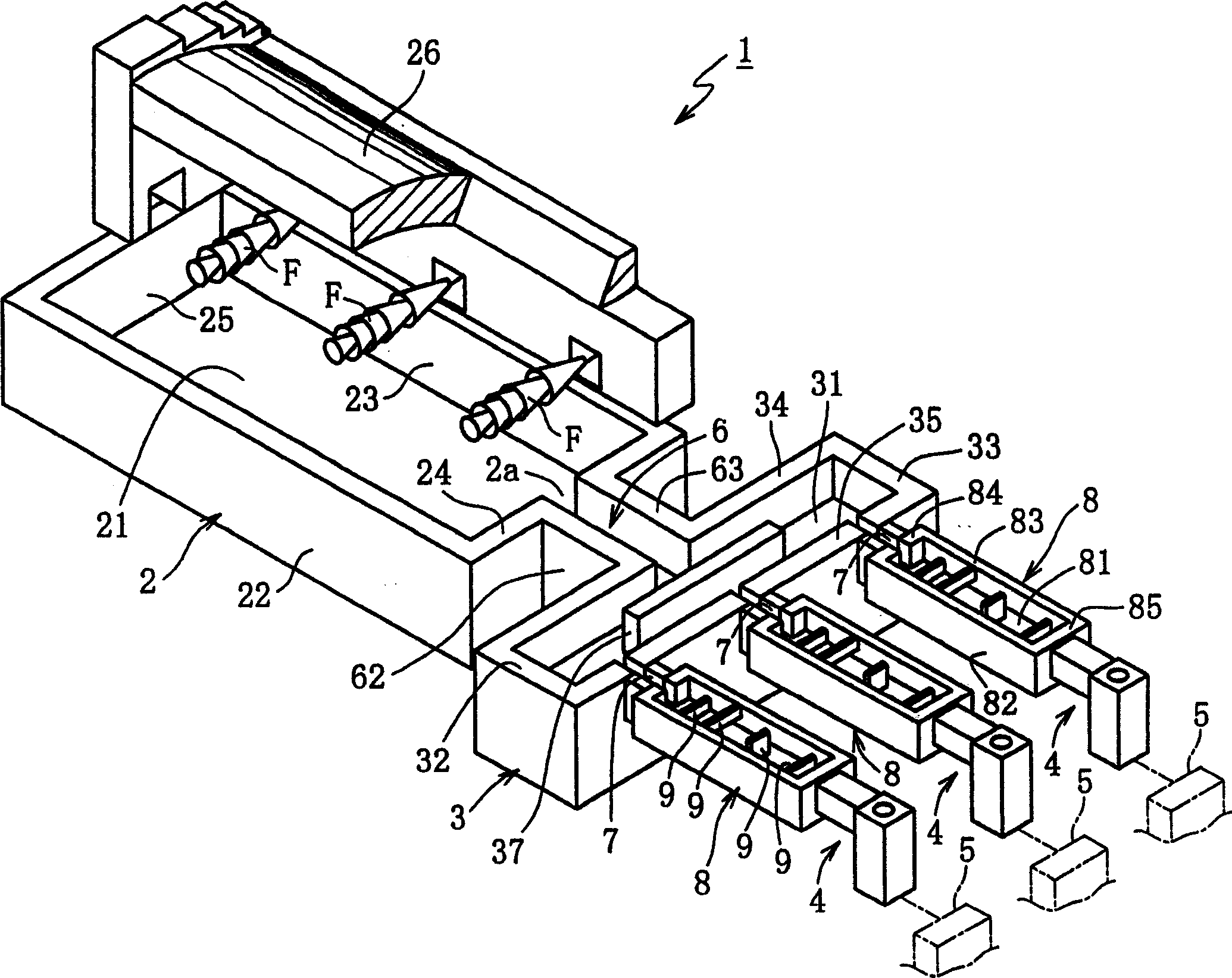

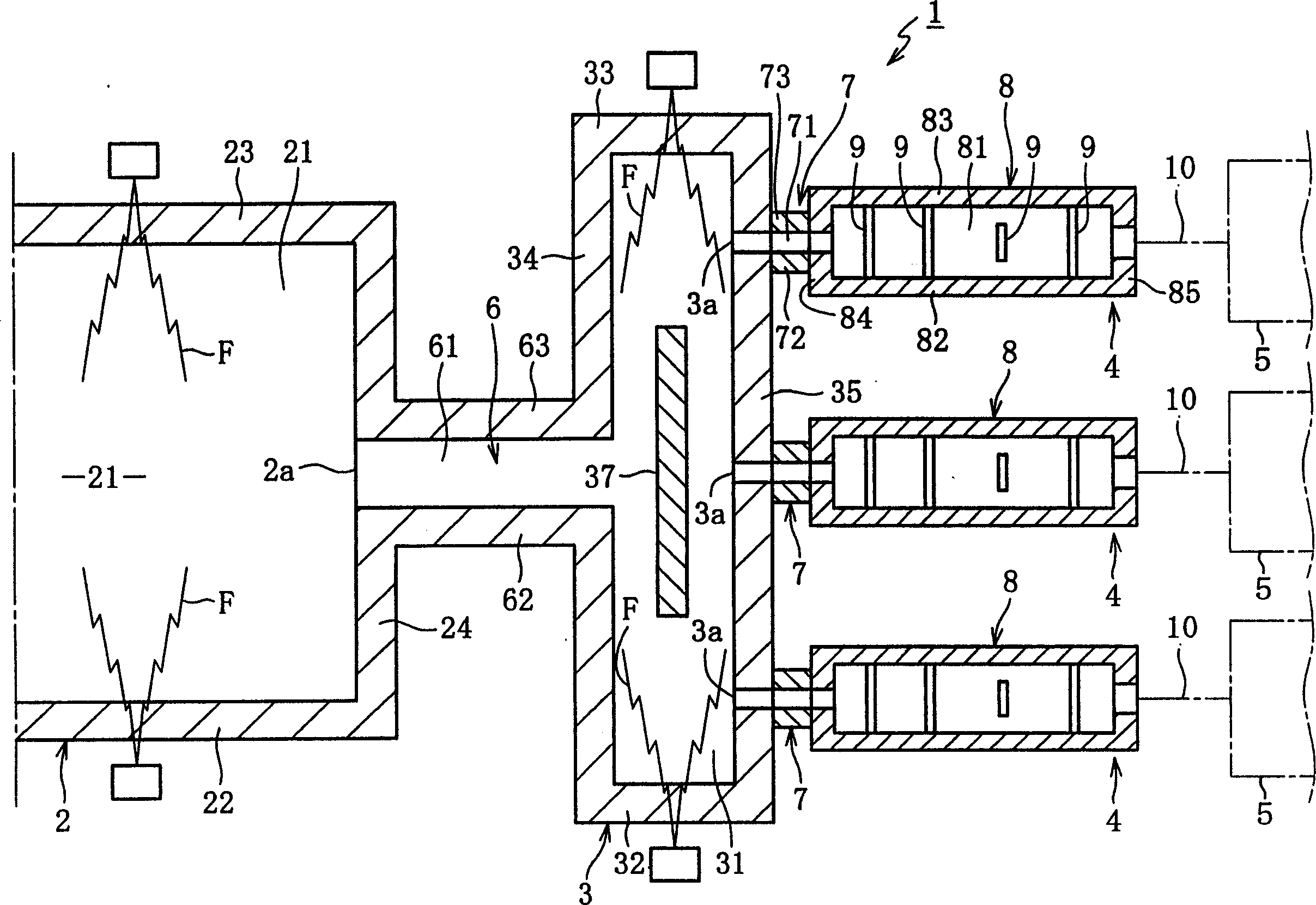

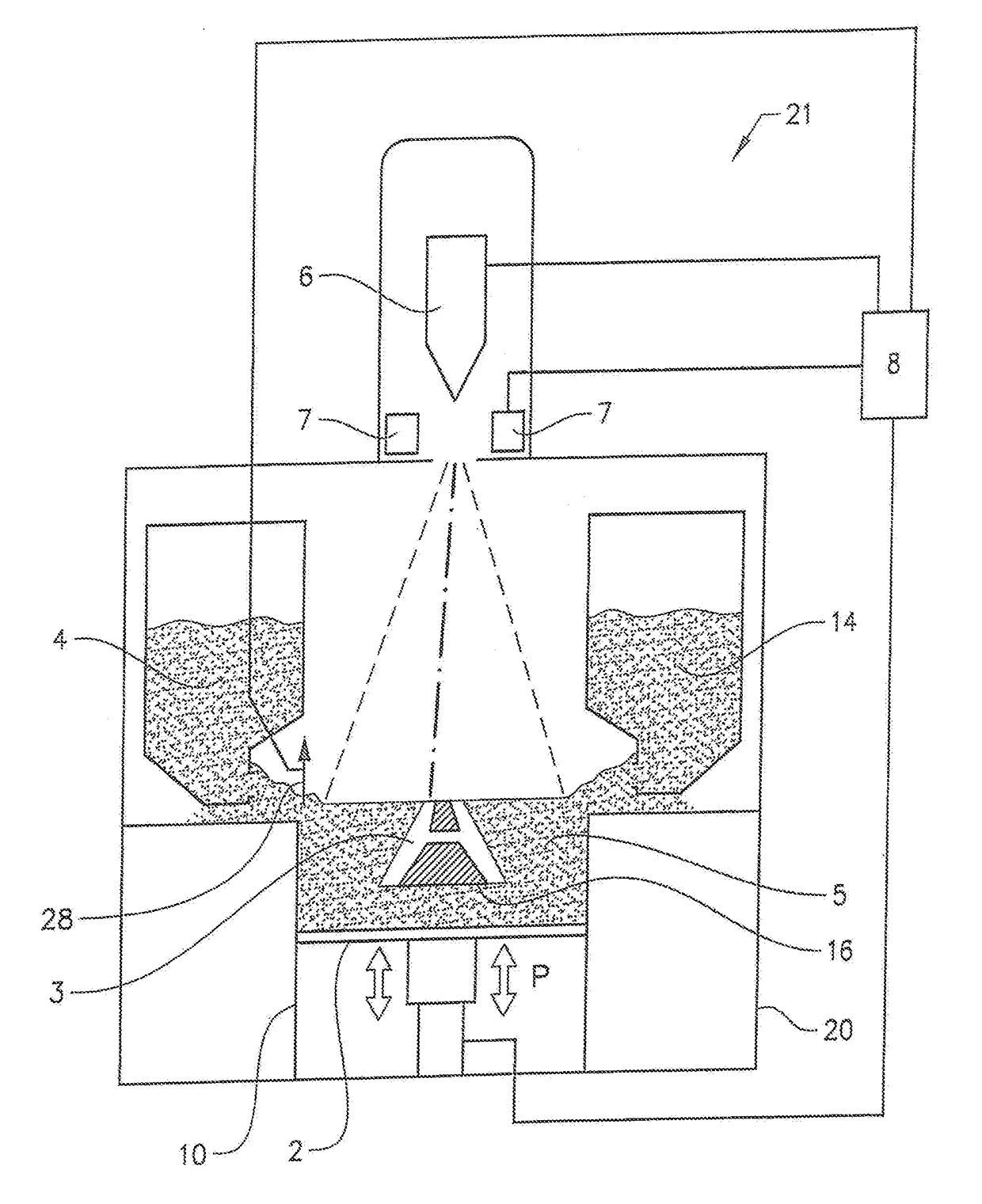

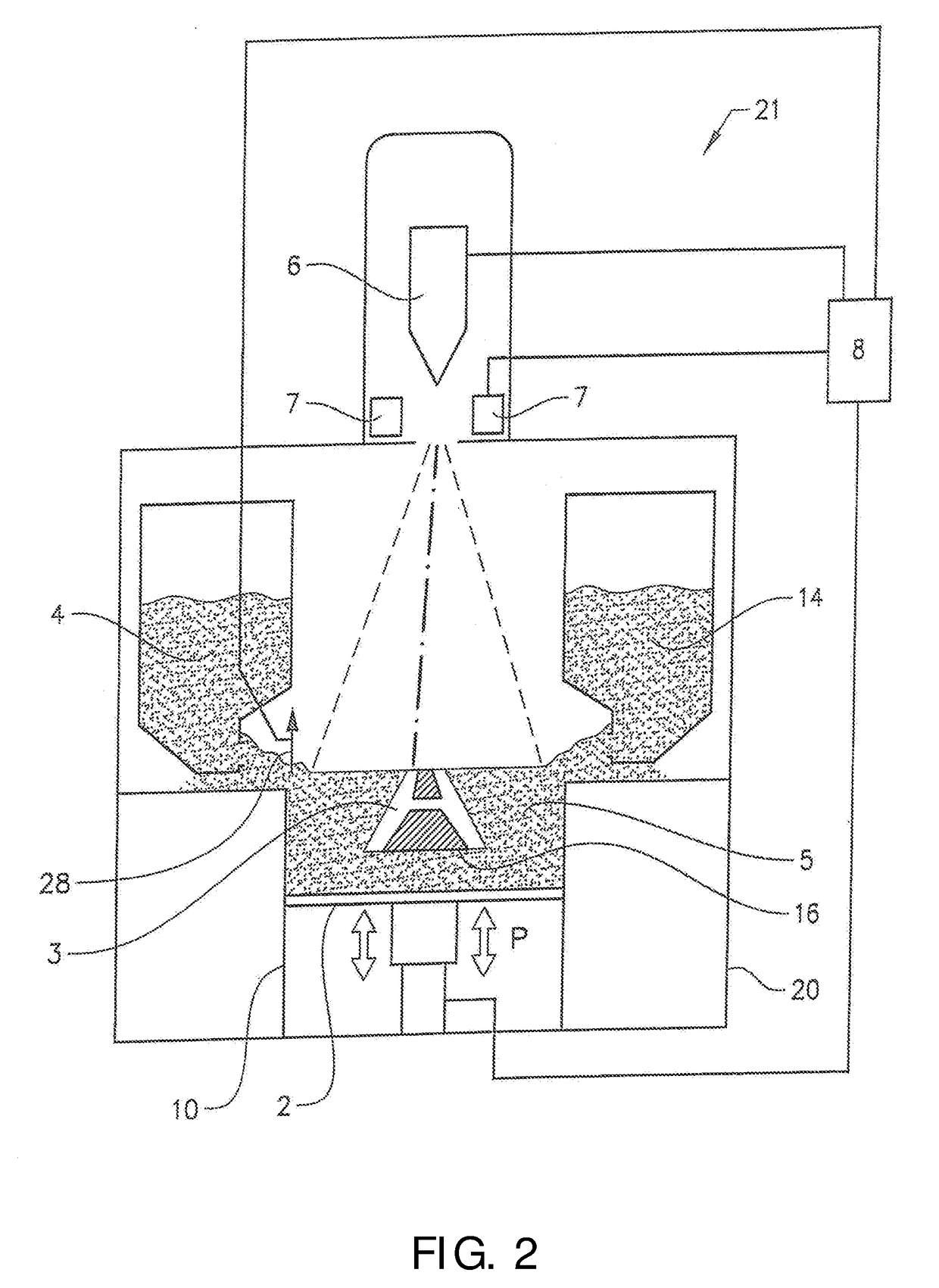

Additive manufacturing of three-dimensional articles

ActiveUS20150165525A1Improve material characteristicImprove material propertiesAdditive manufacturing apparatusArc welding apparatusBeam sourcePower flow

The present invention relates to a method for forming a three-dimensional article through successively depositing individual layers of powder material that are fused together so as to form the article, said method comprising the steps of: providing at least one electron beam source emitting an electron beam for heating and / or fusing said powder material. Controlling the electron beam source in a first mode when said formation of said three dimensional article is in a first process step. Controlling said electron beam in a second mode when said formation of said three dimensional article is in a second process step, wherein in said first mode an electron beam current from said electron beam source is controlled in a feed-forward mode and in said second mode said electron beam current is controlled in a feed-back mode.

Owner:ARCAM AB

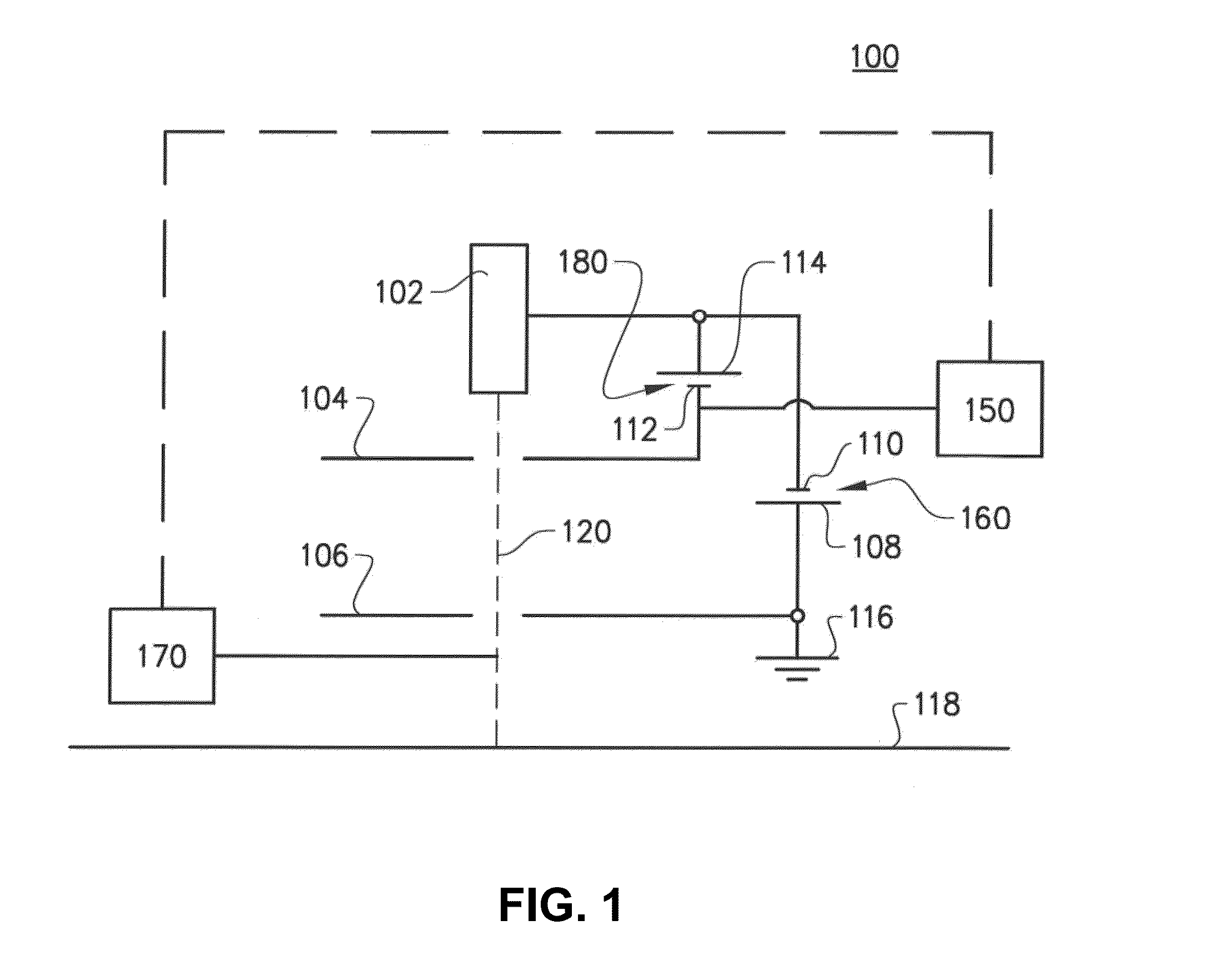

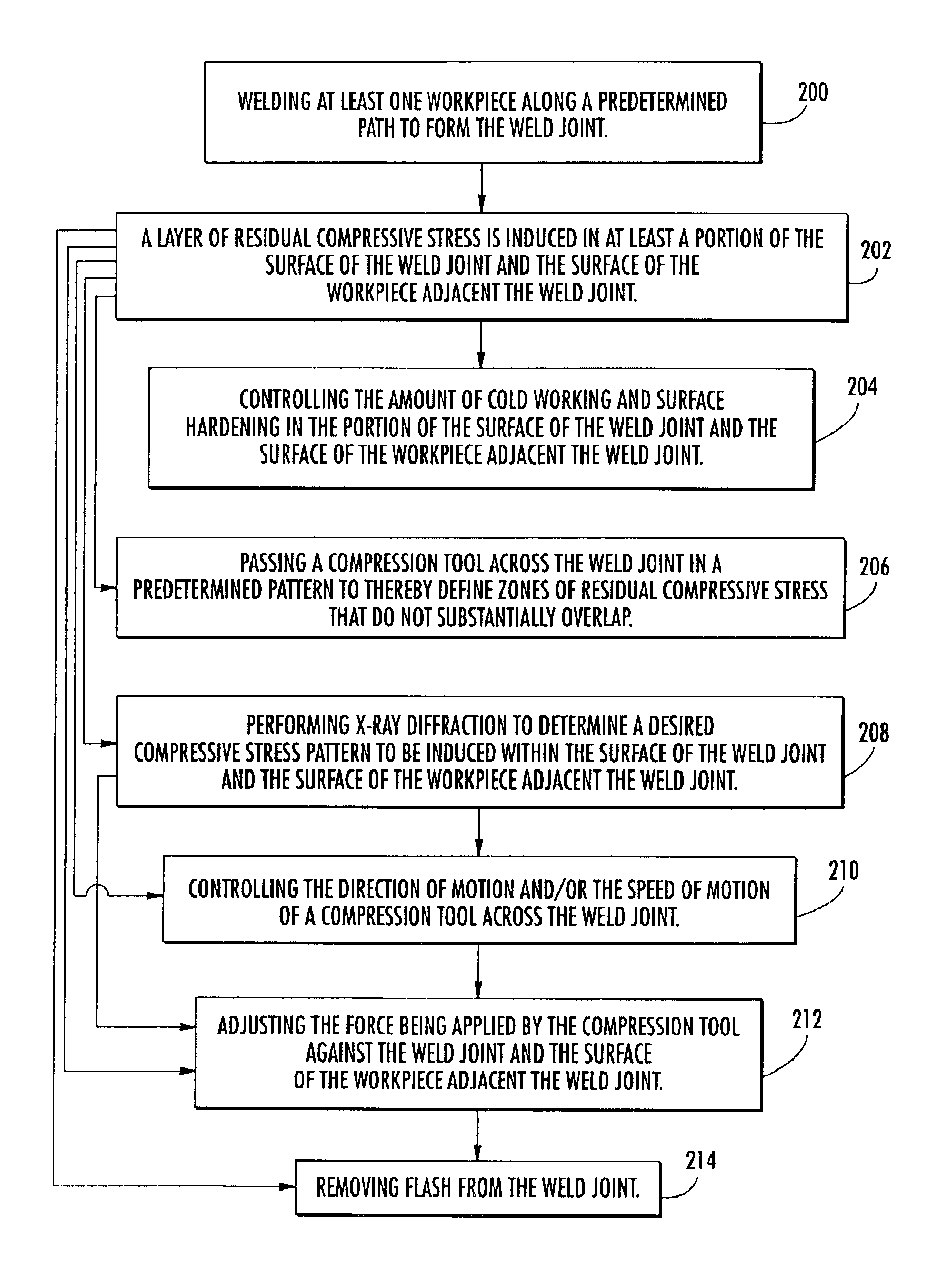

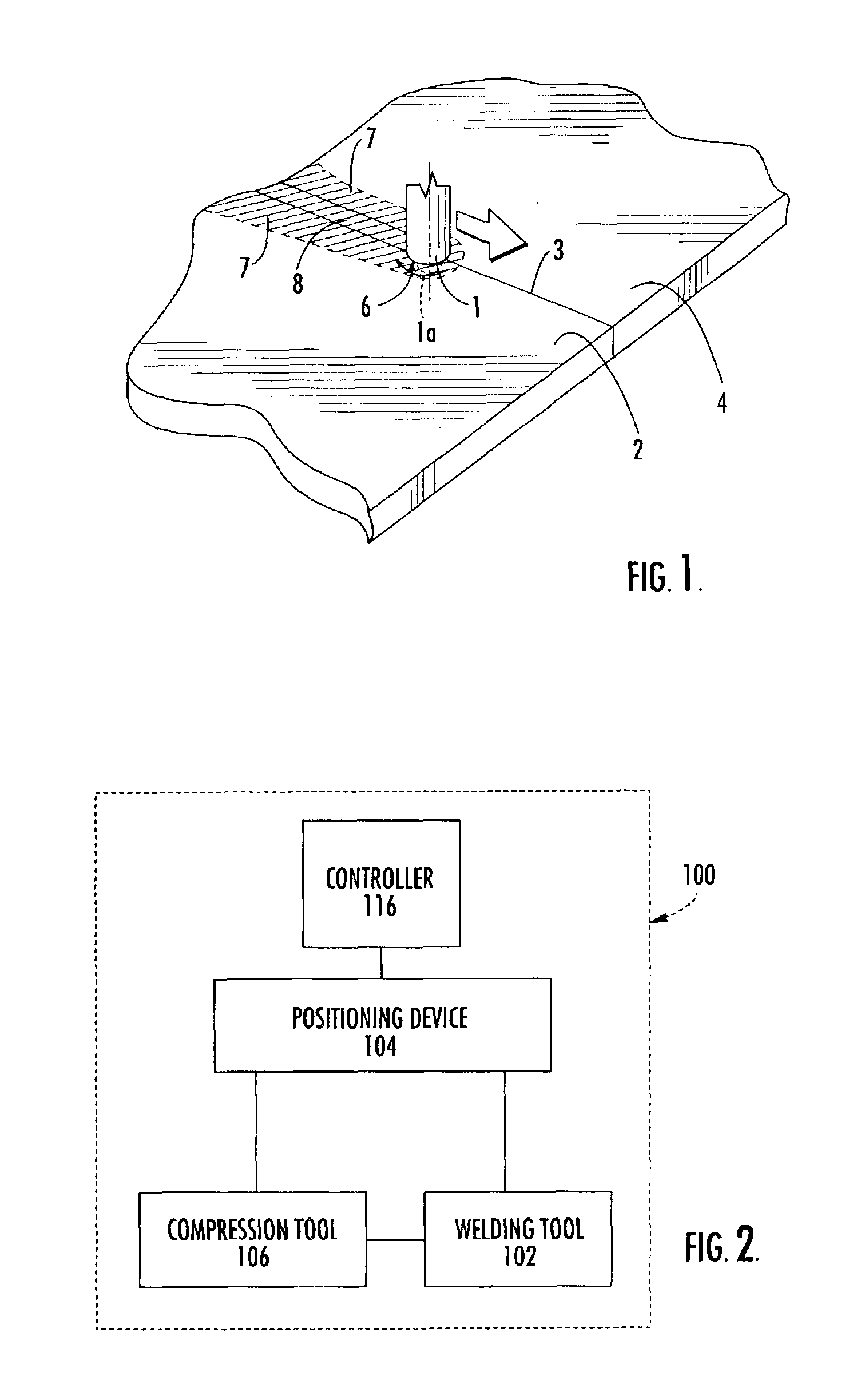

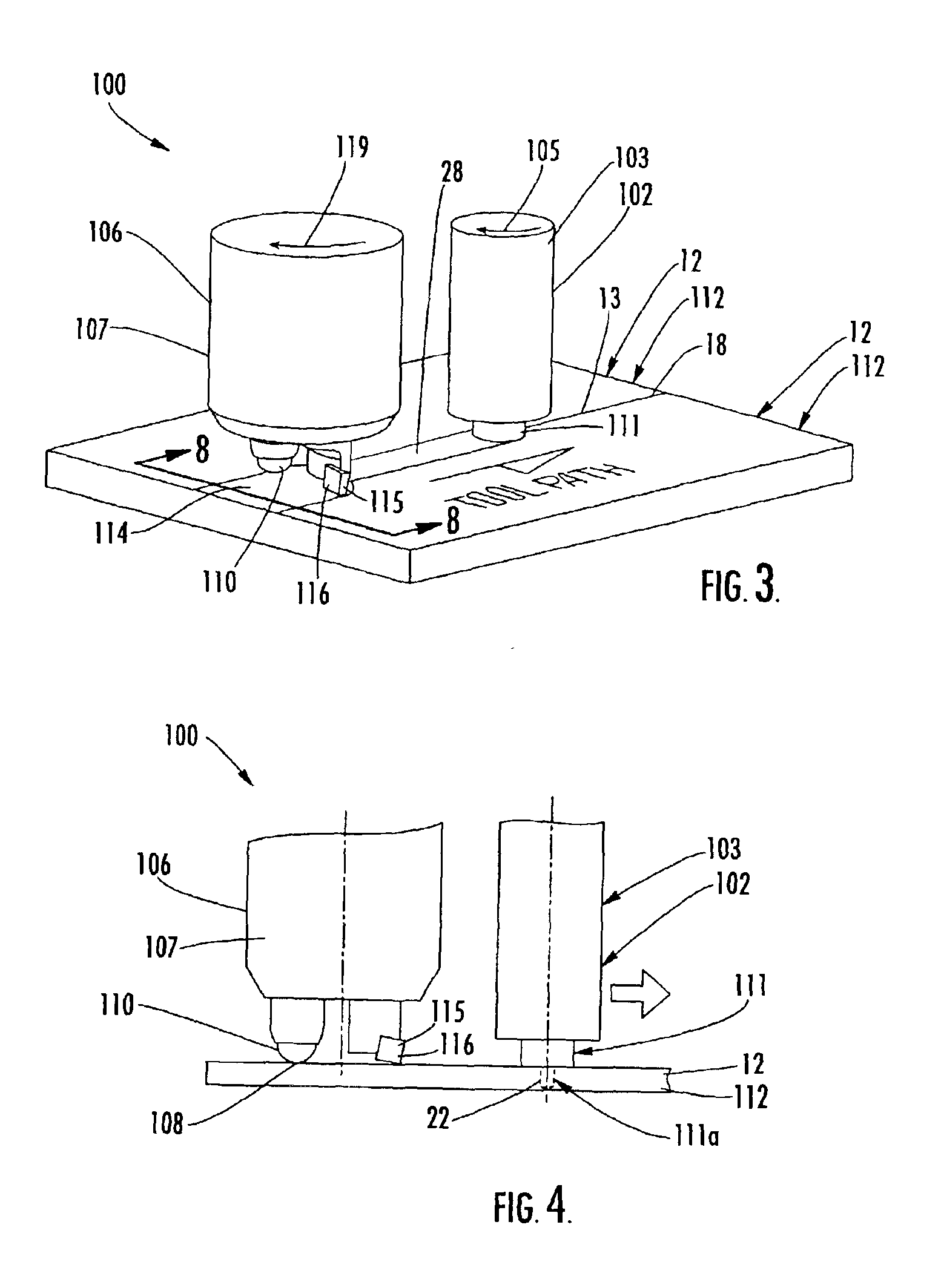

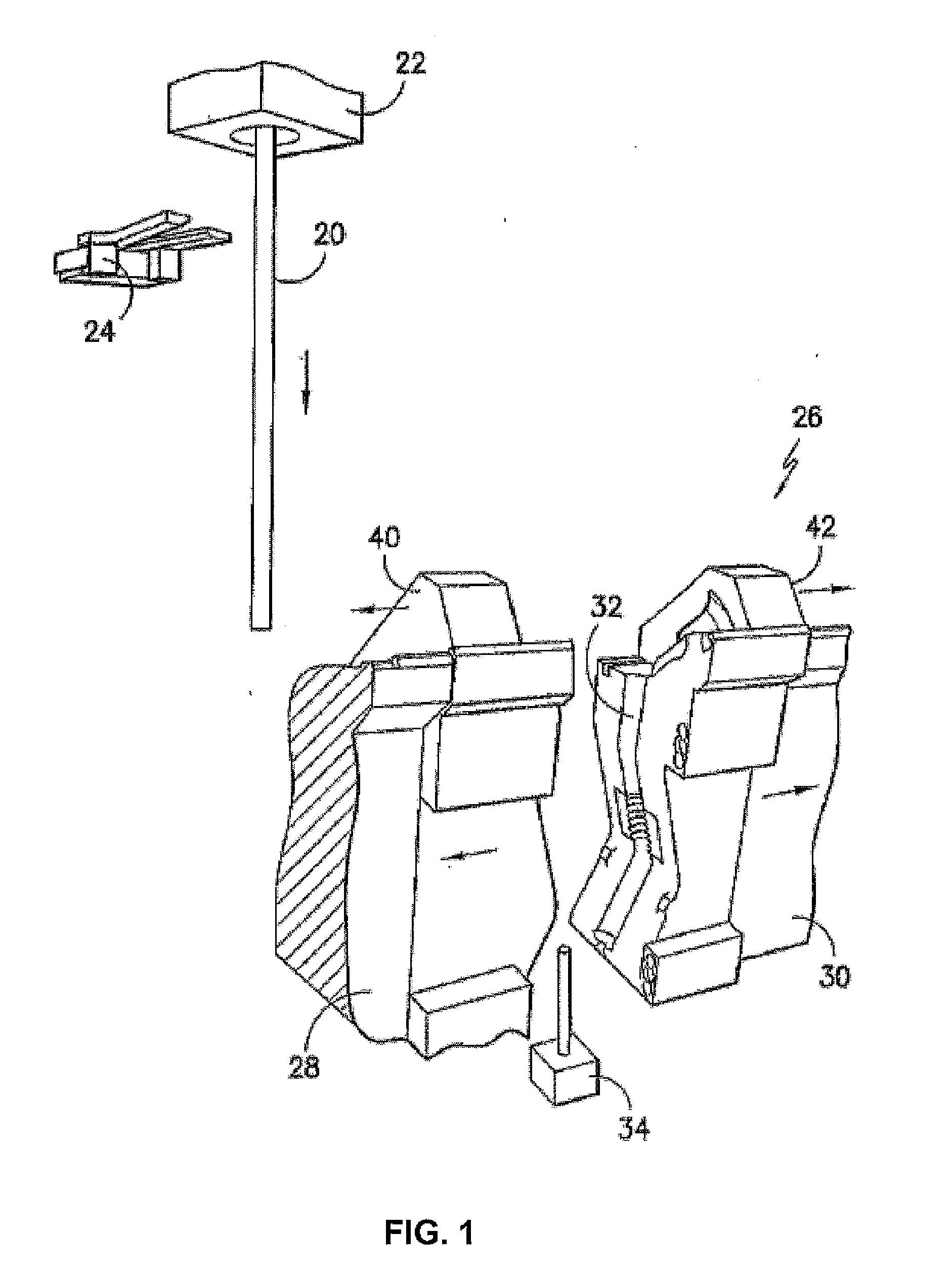

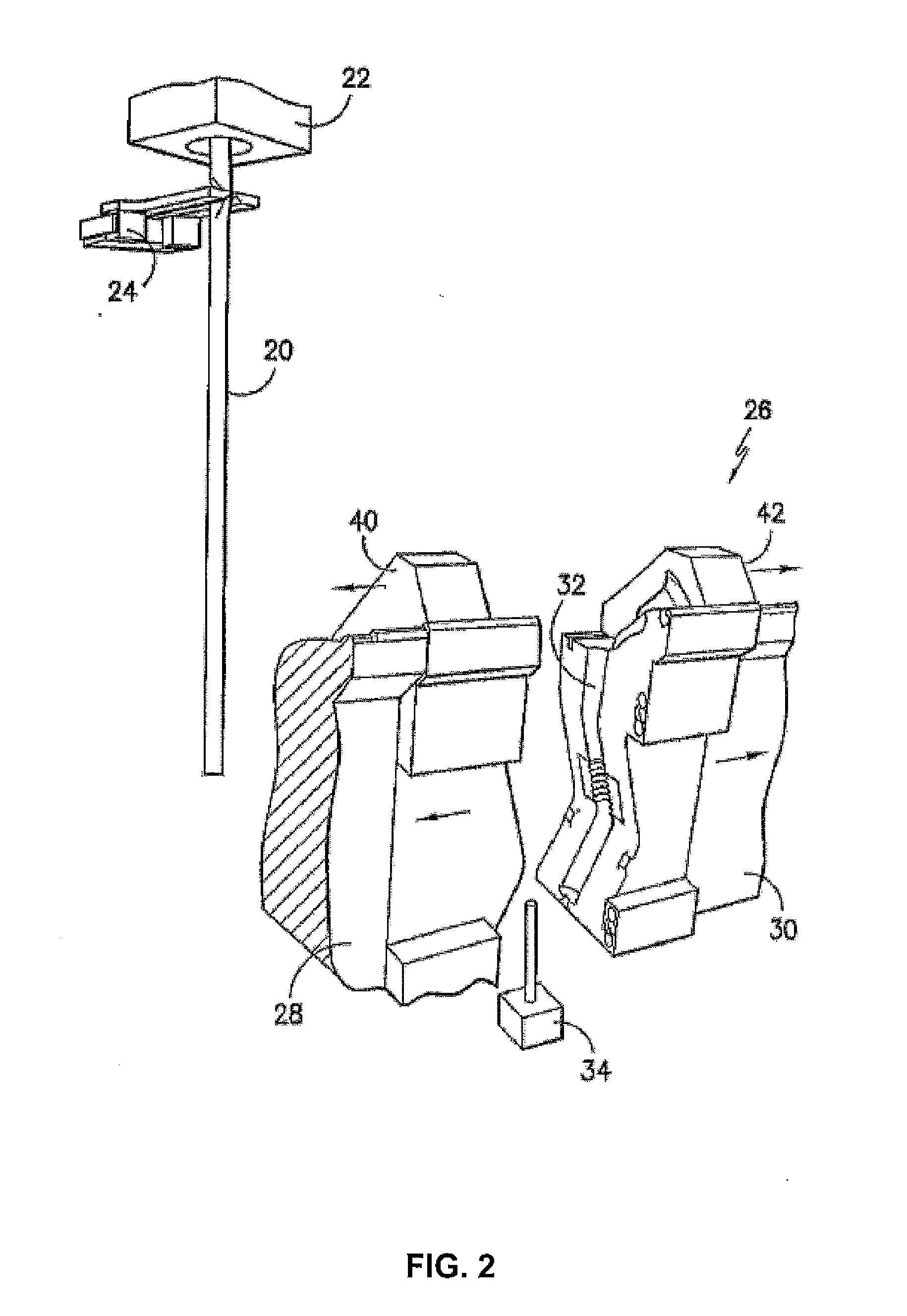

Apparatus and method for forming weld joints having compressive residual stress patterns

InactiveUS6926970B2Improve material propertiesHigh surface finishWelding/cutting auxillary devicesBurnishing machinesUltimate tensile strengthMechanical engineering

The welding apparatus and associated method are provided. The welding apparatus includes a welding tool for forming a weld joint along the surface of at least one workpiece. The welding apparatus also includes a compression tool for selectively inducing a layer of residual compressive stress in at least a portion of the surface of the weld joint and the surface of the at least one workpiece to thereby improve the material properties of the workpiece, including corrosion resistance and fatigue strength.

Owner:SURFACE TECH HLDG +1

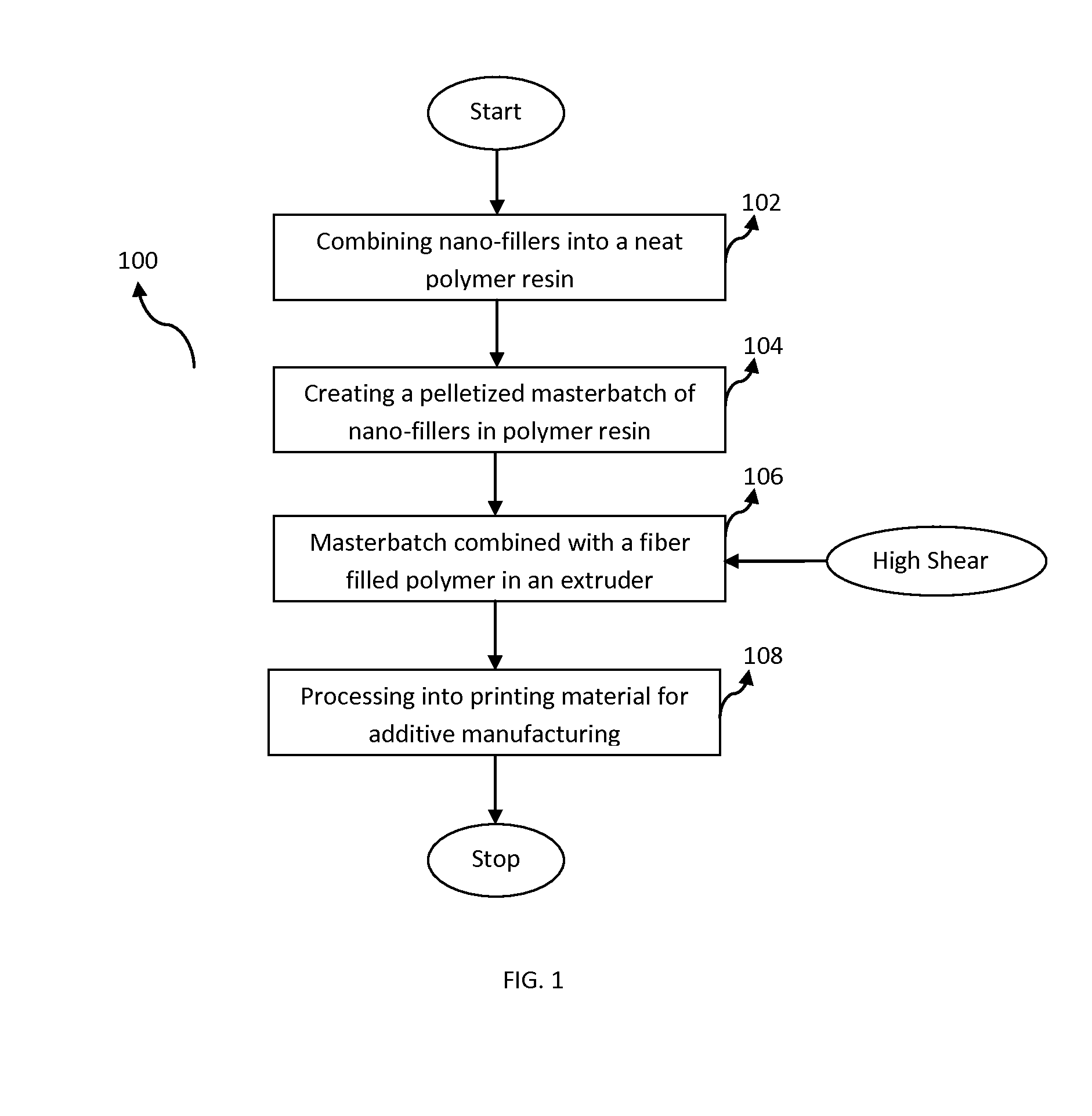

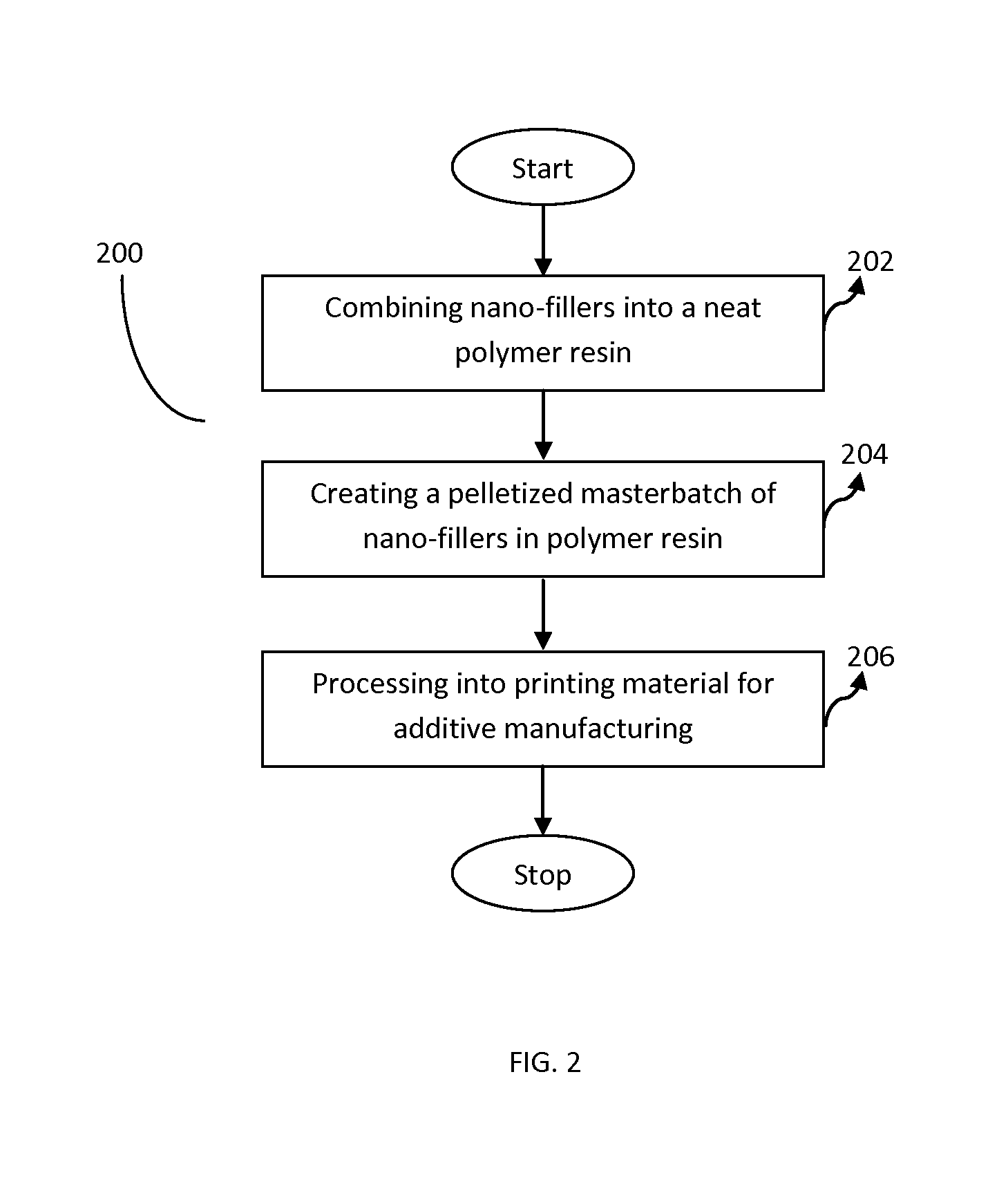

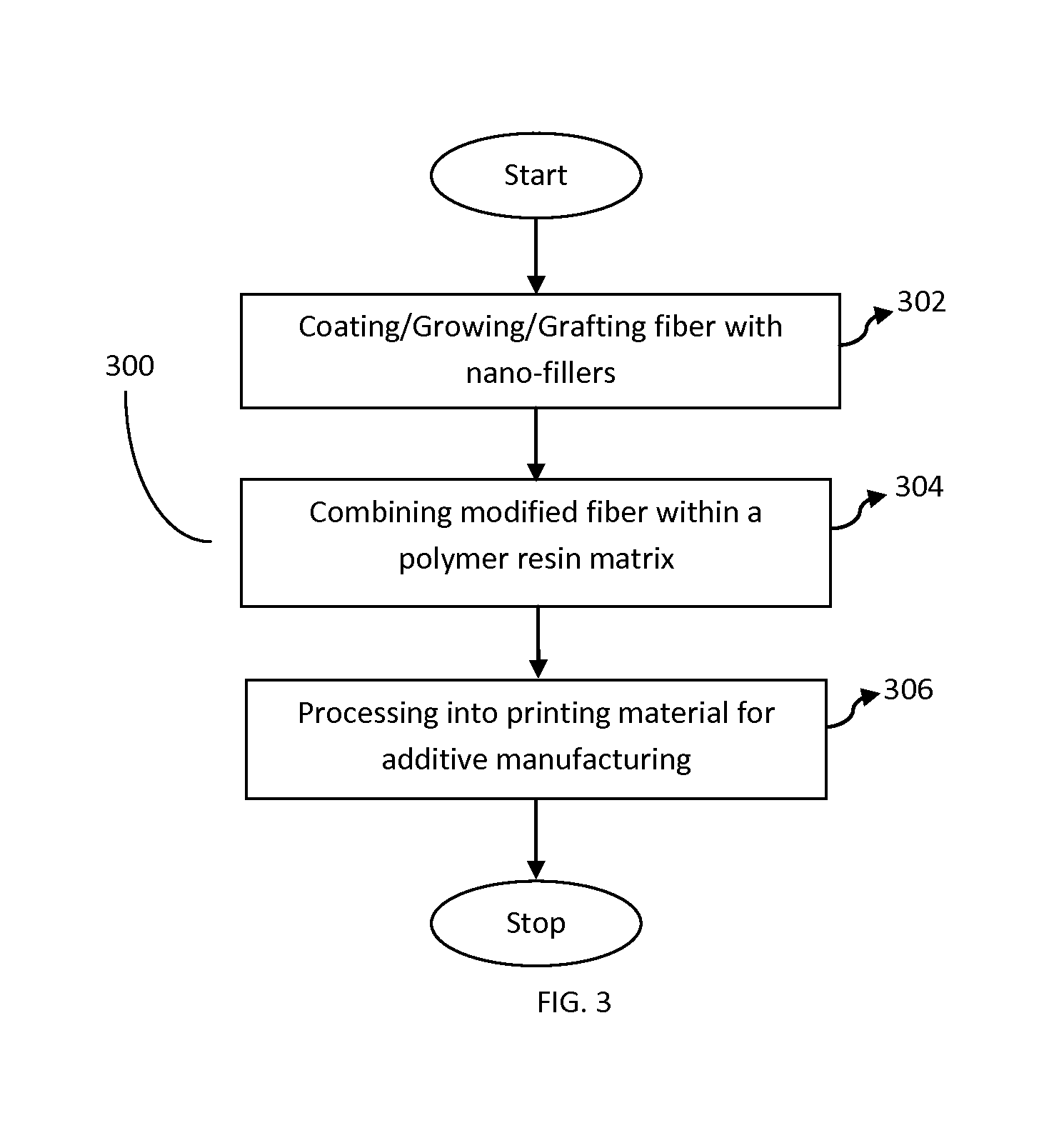

Method to manufacture polymer composite materials with nano-fillers for use in addtive manufacturing to improve material properties

ActiveUS20160297935A1Improved propertyImprove material propertiesAdditive manufacturing apparatusCarbon nanotubeAdvanced manufacturing

Methods for producing 3D printing composite polymer materials for use in additive manufacturing processes are provided. The methods result in enhancing the material properties of the printing material by providing a uniform and smooth surface finish of the printing material and the nozzle extrudate for additive manufacturing processes, such as Fused Filament Fabrication. The method includes implementing impregnation techniques for combining carbon nanotubes or other nano-fillers, a polymer resin and a fiber material to produce a polymer material that can be processed into a printing material. Further, the method may include combining the carbon nanotubes or other nano-fillers and the polymer resin to form a masterbatch that may be further combined with the fiber material through an extrusion process. The method results in a printing material with enhanced material properties and smooth surface finish for the printing material and resulting nozzle extrudate for Fused Filament Fabrication.

Owner:AREVO INC

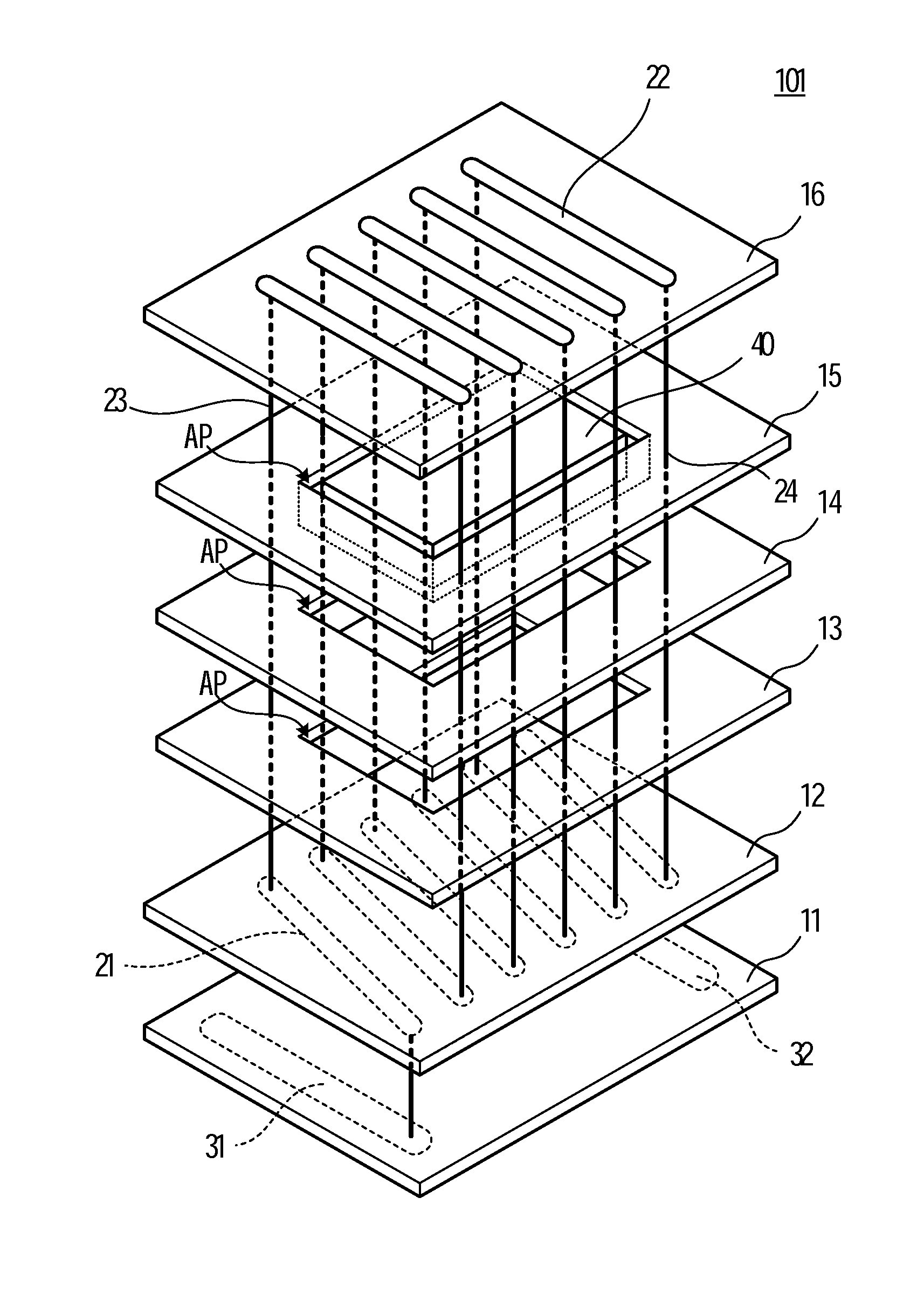

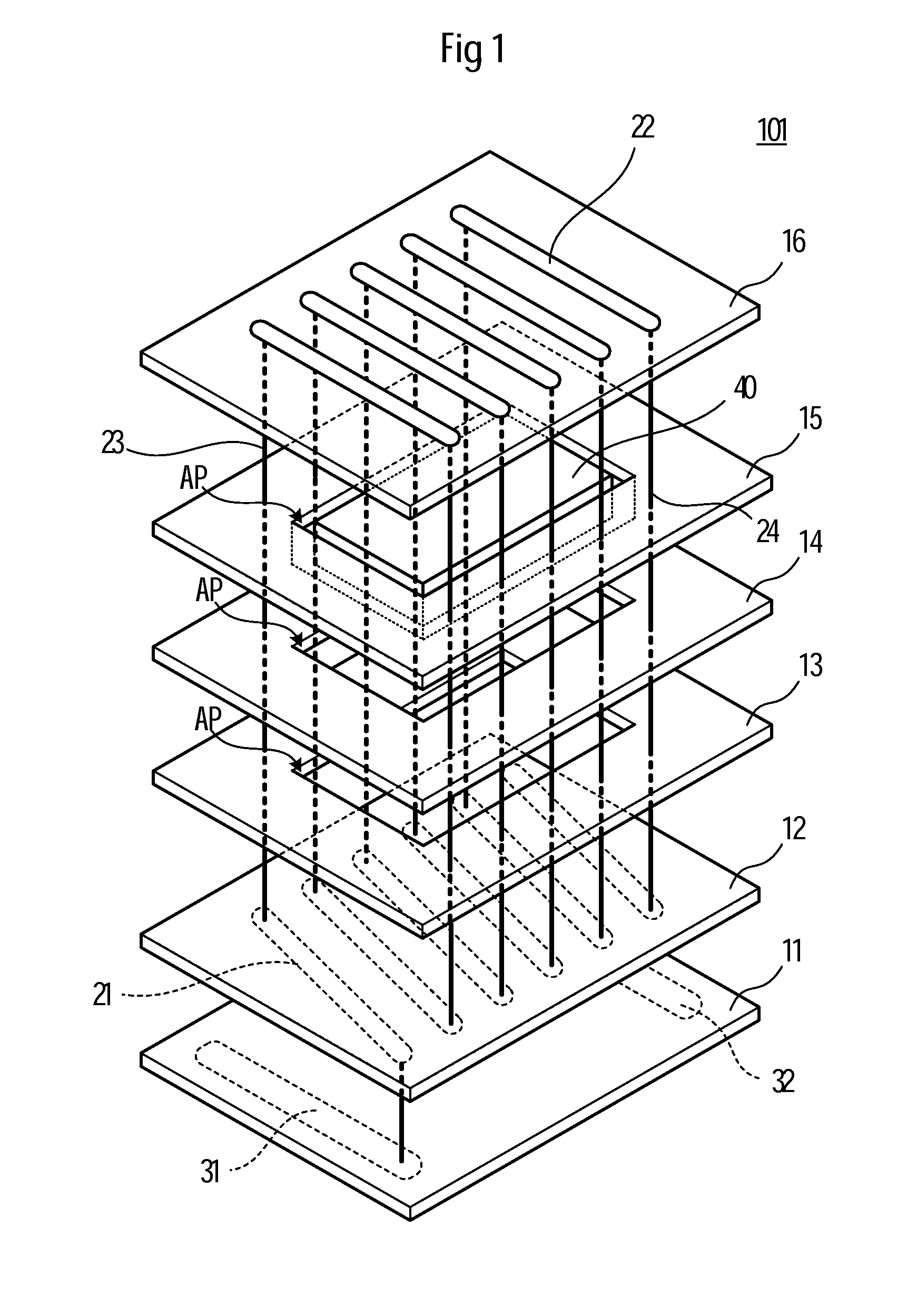

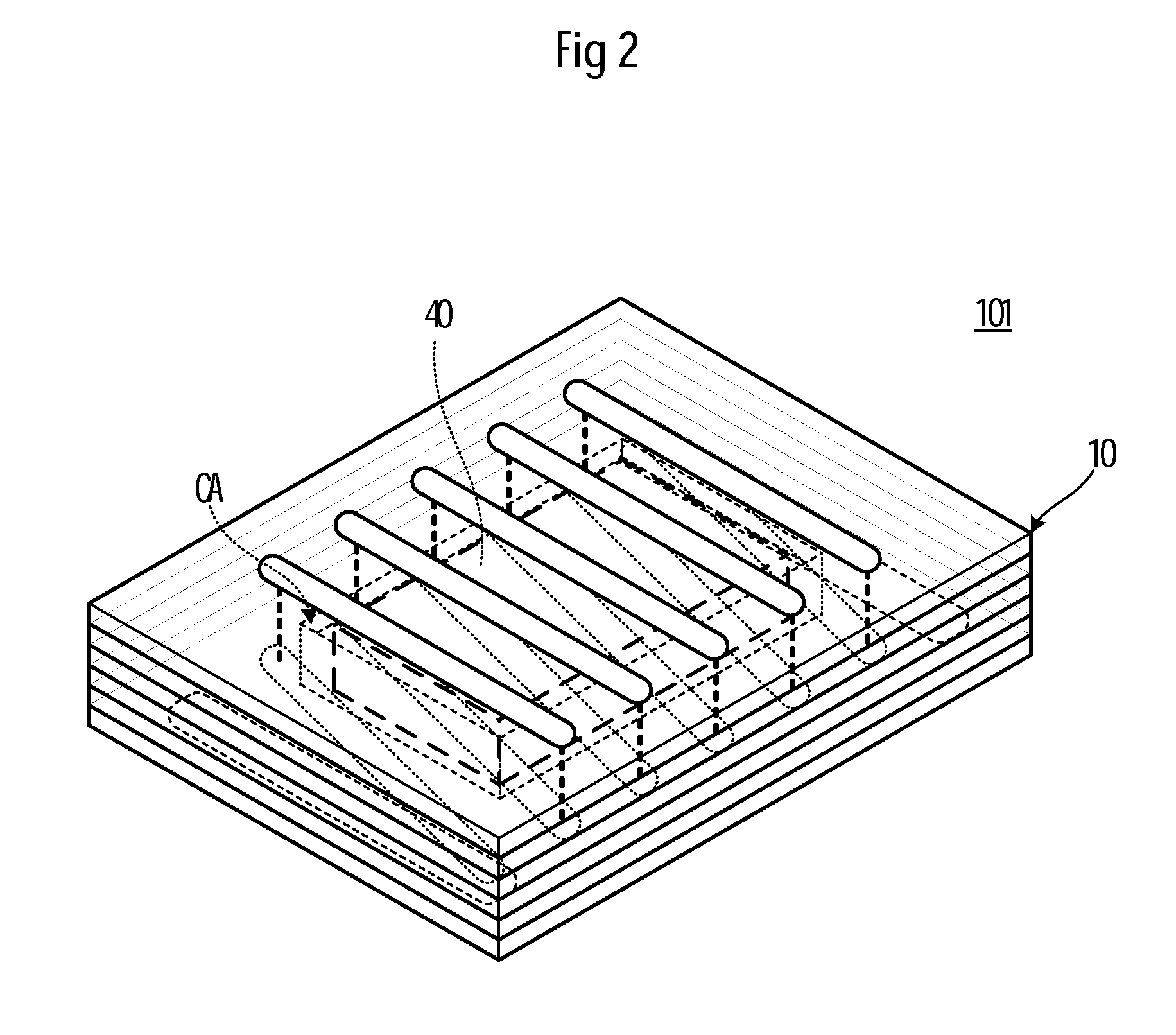

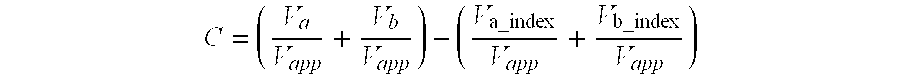

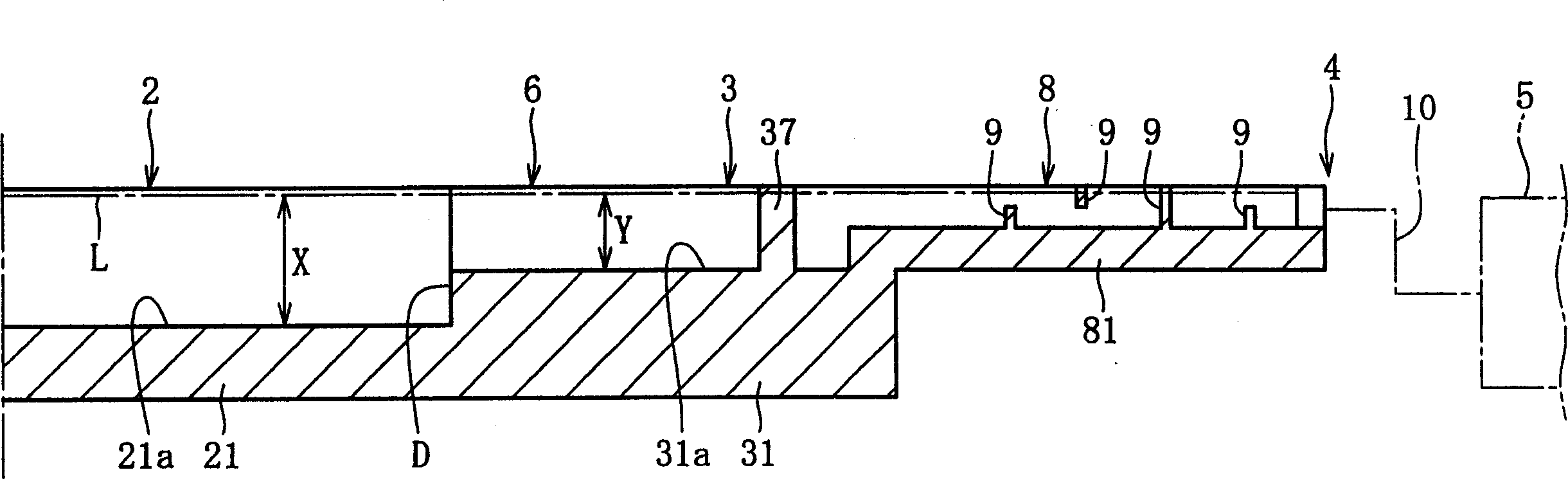

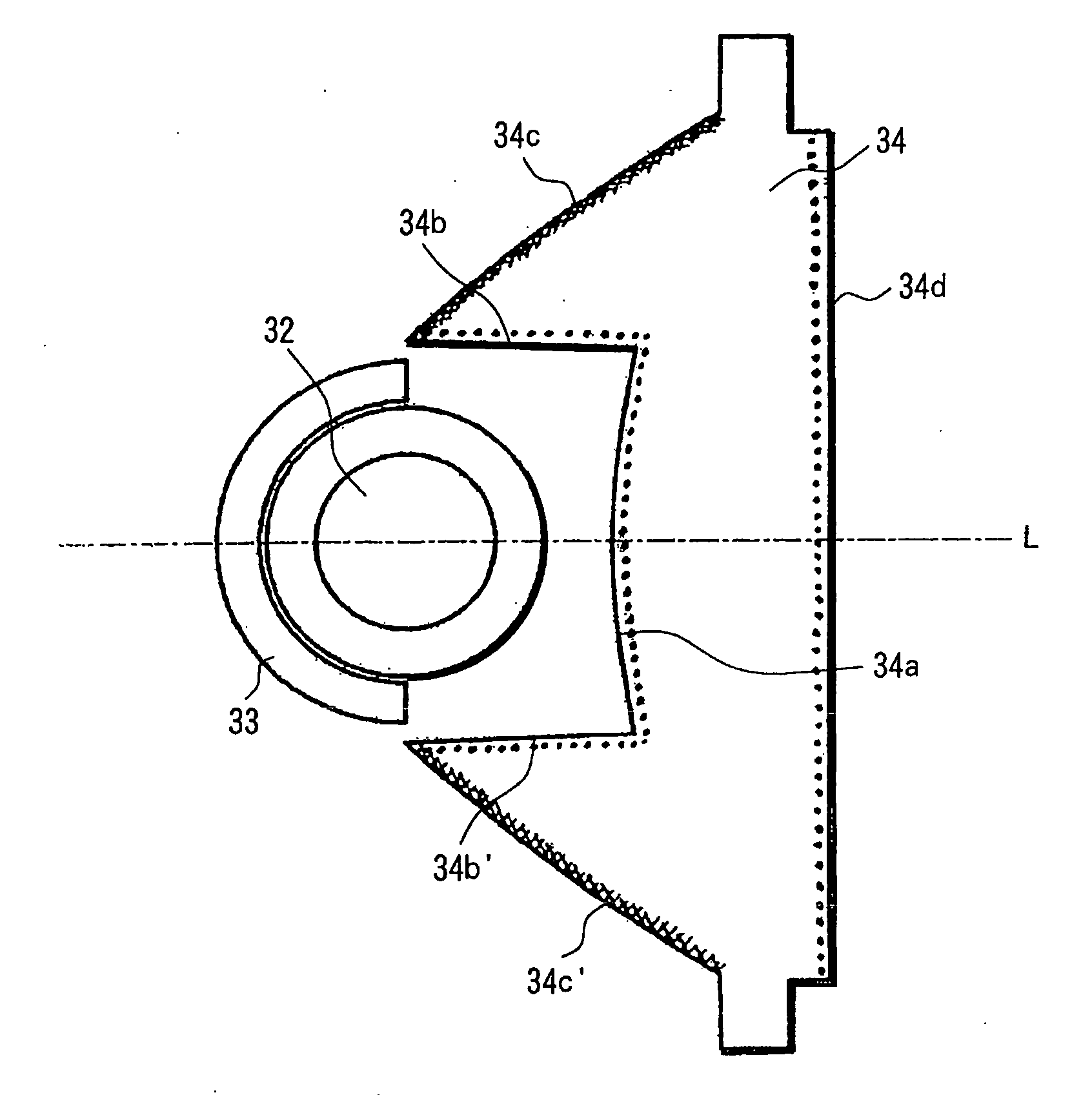

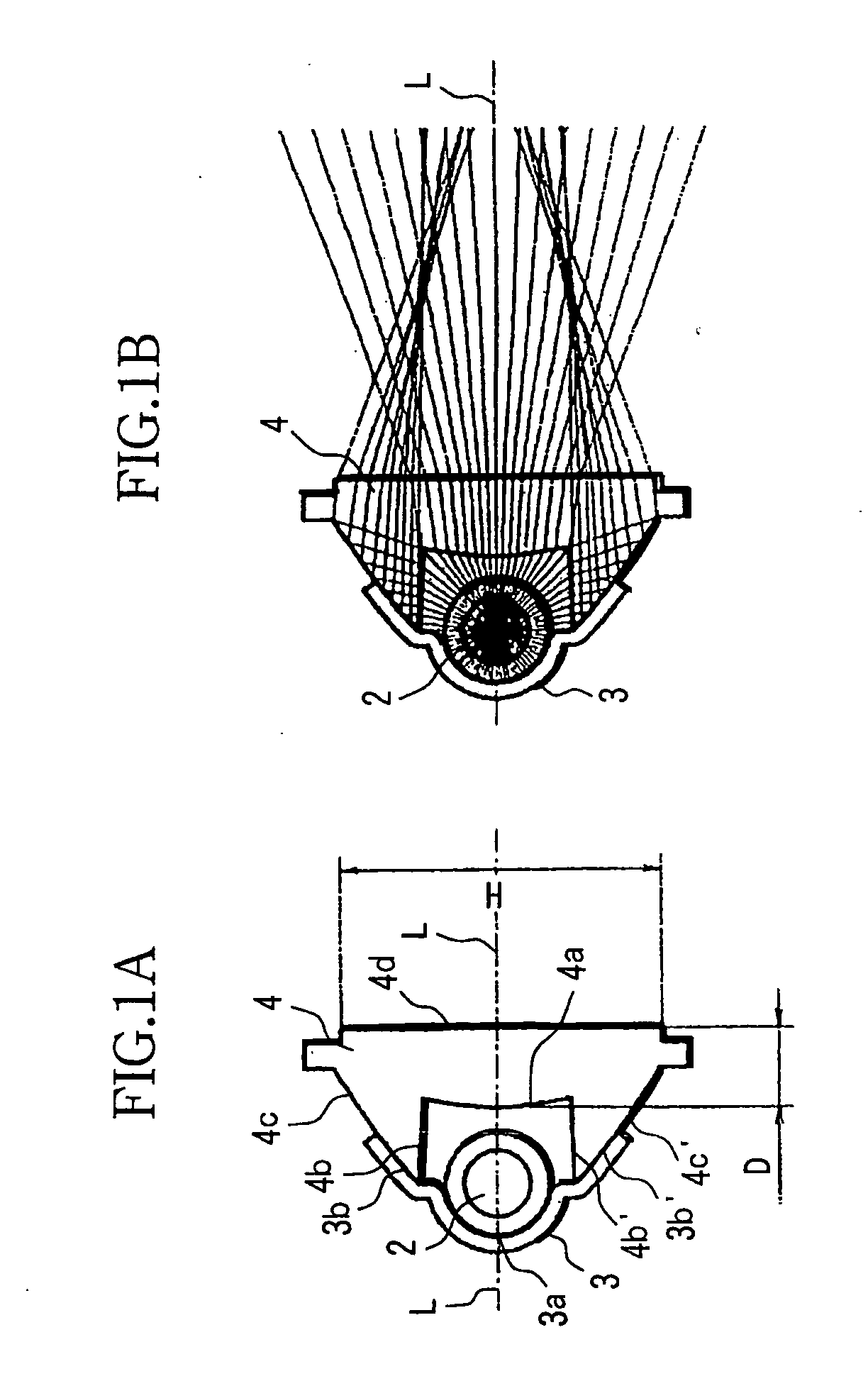

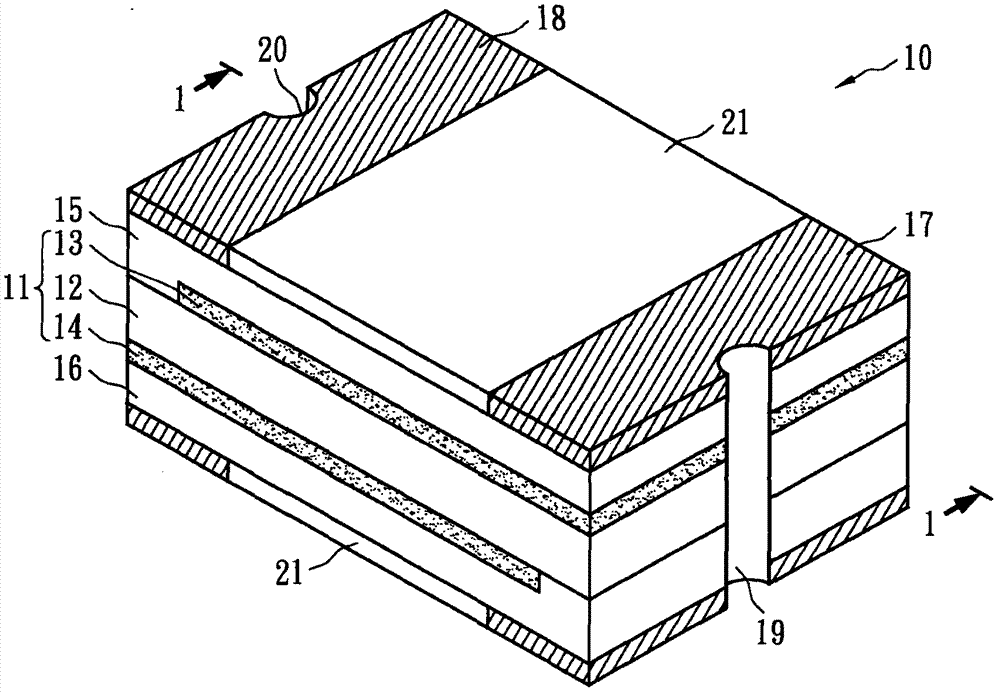

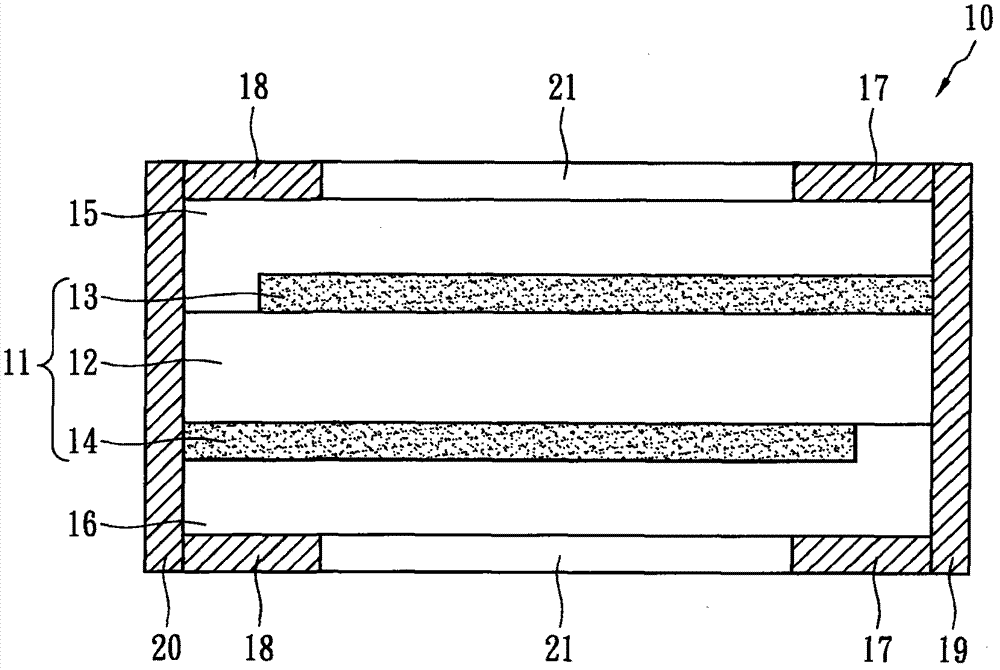

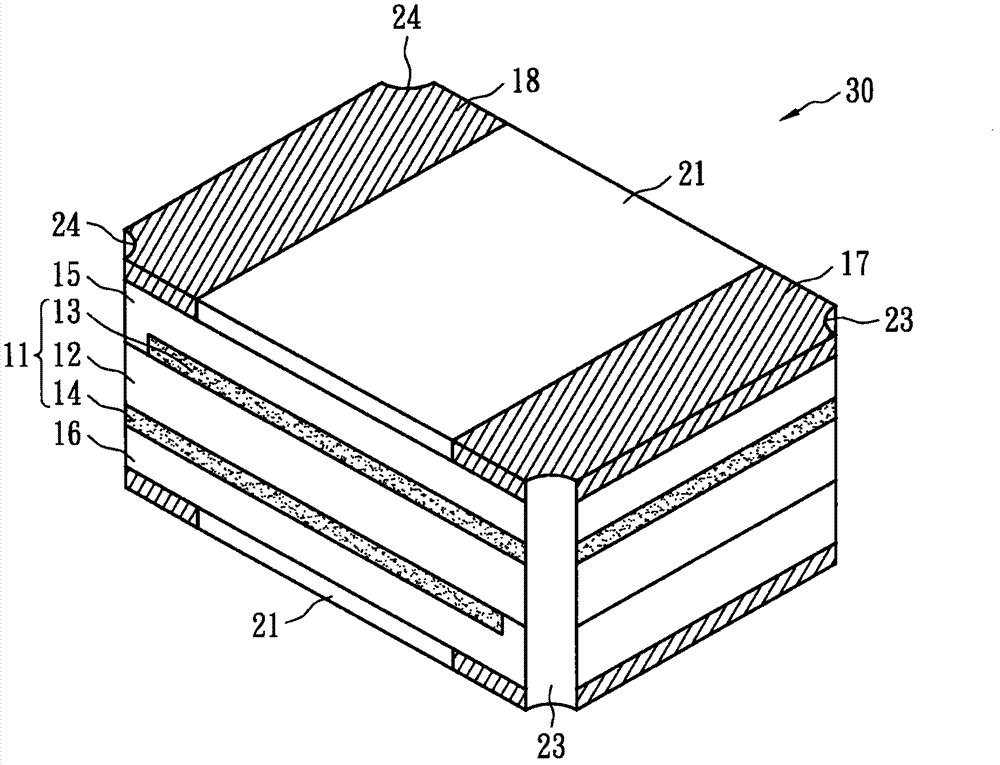

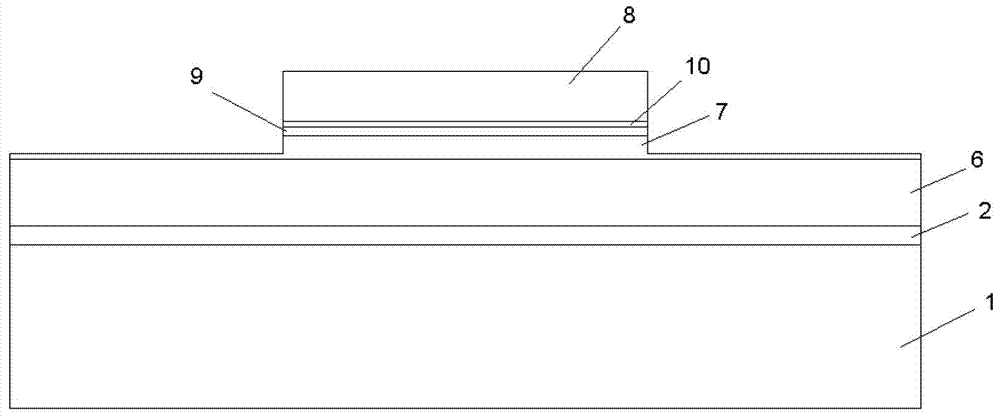

Antenna device, wireless communication device, and method of manufacturing antenna device

ActiveUS20140043196A1Low loss characteristicIncrease in maximum communicable distanceLoop antennas with ferromagnetic coreSolid-state devicesElectrical conductorCommunication device

Owner:MURATA MFG CO LTD

Resistive nanocomposite compositions

InactiveUS6617377B2Increased mechanical and wear and electrical and thermal propertyImprove material performanceNanotechPrinted electric component incorporationScreen printingOrganic solvent

A resistive composition for screen printing onto a substrate. The resistive composition, based on total composition has a) 5-30 wt. % of polymer resin, b) greater than 0 up to and including 10 wt. % of thermosetting resin, c) 10-30 wt. % conductive particles selected from the group consisting of carbon black, graphite and mixtures thereof and d) 0.025-20 wt. % carbon nanoparticles, wherein all of (a), (b), (c) and (d) are dispersed in a 60-80 wt. % organic solvent.

Owner:CTS CORP ELKHART

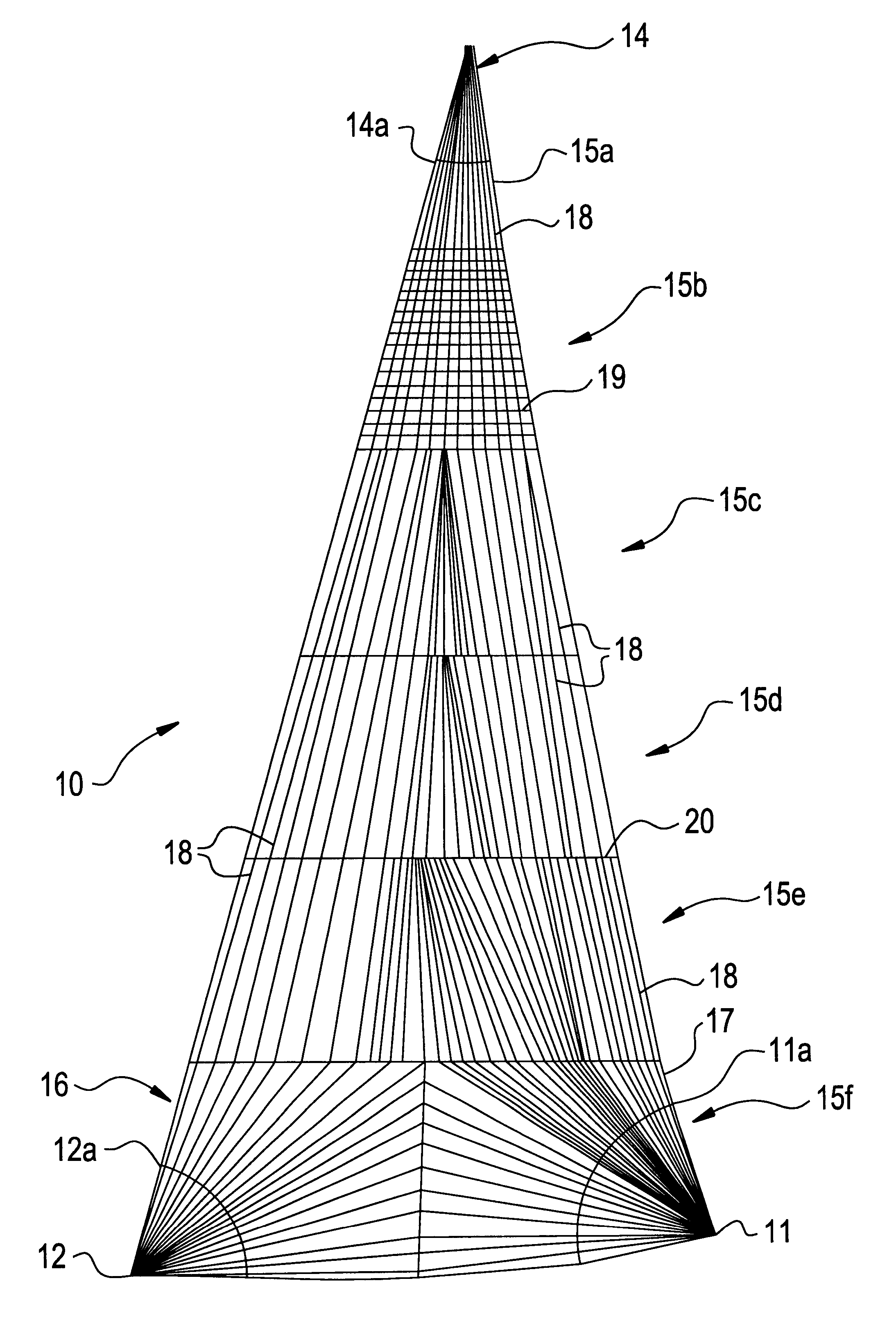

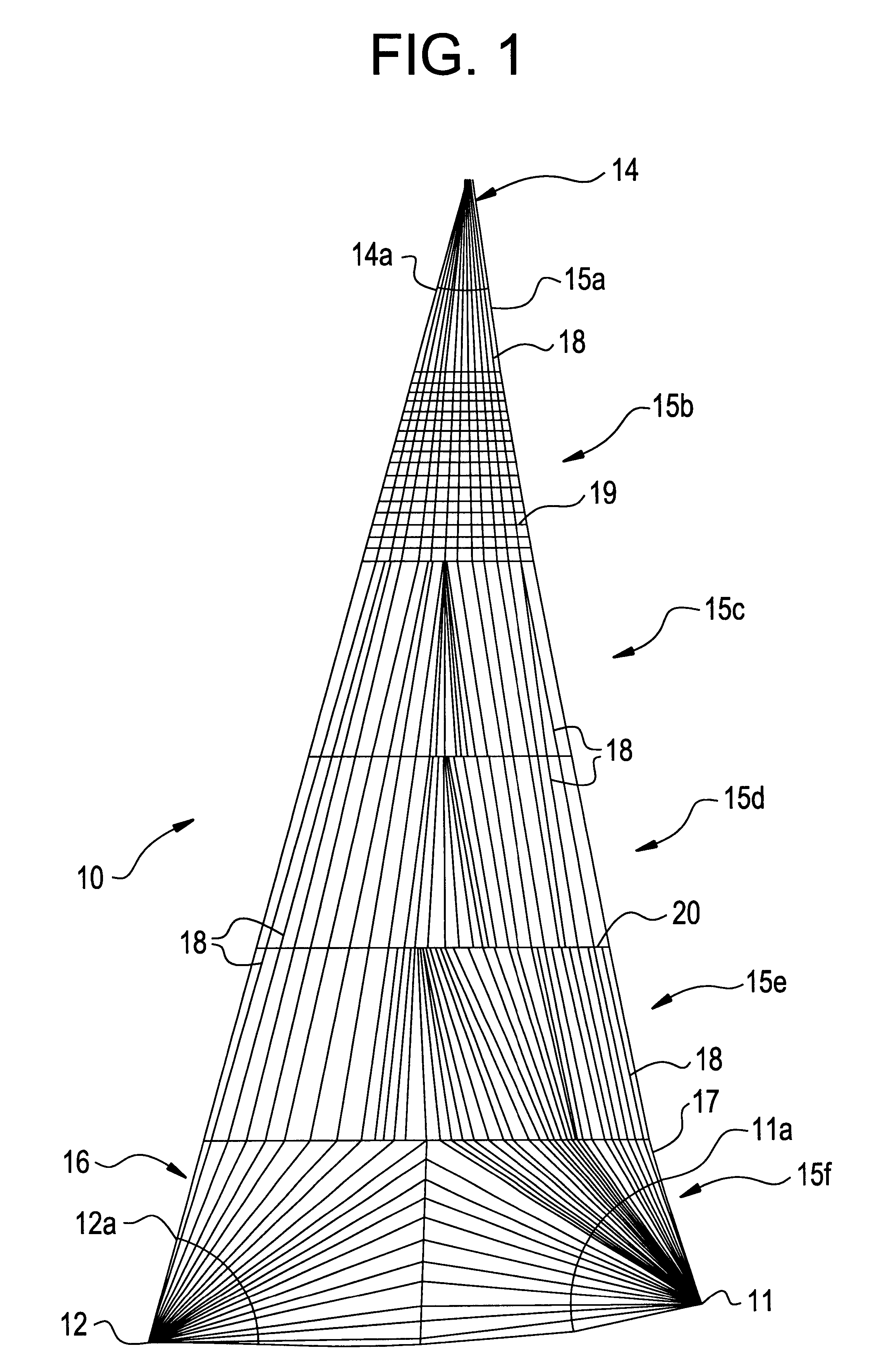

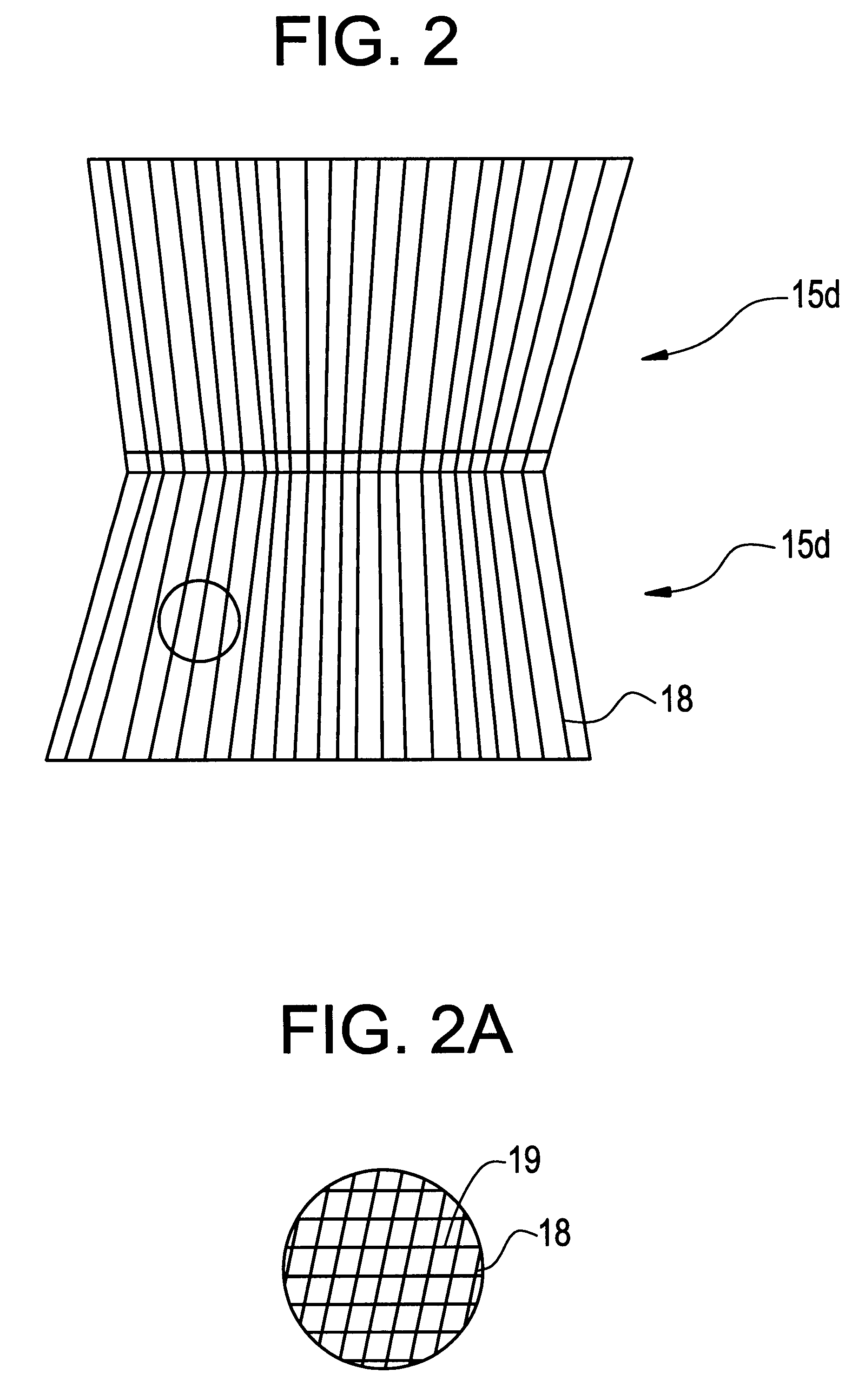

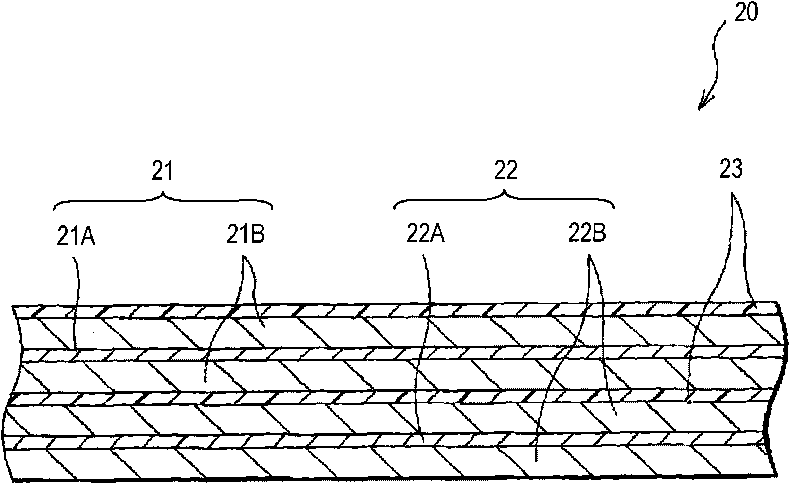

Sail of woven material and method of manufacture

InactiveUS6257160B1More material propertyImprove material performanceWoven fabricsNon-woven fabricsYarnEngineering

Fiber oriented sails made of woven panels of scrim type weave wherein warp yarns in the panels follow primary load paths in a sail and a method for making woven panels and sails.

Owner:KEIRE FRED AIVARS

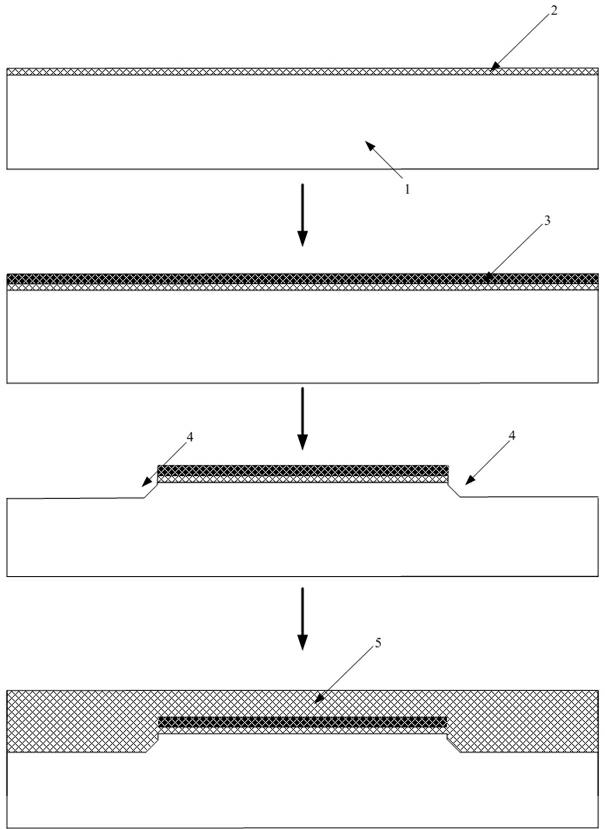

Laminating base plate for boring and preparing method thereof

ActiveCN103950057APrevent warping abnormalitiesGuaranteed flatnessNon-fibrous pulp additionPaper/cardboardPulp and paper industryKraft paper

The invention discloses a laminating base plate for boring and a preparing method thereof. The preparing method comprises the step that the laminating base plate for boring is formed by laminating and pressing surface paper and inside paper, wherein the surface paper is formed by soaking wood pulp paper with phenolic resin and the inside paper is formed by soaking brown paper soaked with urea resin or modified urea resin. The surface paper used by the base plate for boring and having well waterproofness can prevent the warping abnormity of the base plate caused by the temperature and humidity change of the environment and the flatness of the base plate is ensured; in addition, chip removal is not affected due to heating and adhesion in the small-aperture boring process of the base plate and the hole wall quality of a boring hole is improved. The attribution of the material of the base plate is superior to that of the urea resin and is close to that of a phenolic aldehyde base plate, and the cost of the base plate is lower than that of the phenolic aldehyde base plate, so the laminating base plate for boring has higher competitiveness.

Owner:SHENZHEN NEWCCESS IND

Blow Molded Thermoplastic Composition

ActiveUS20130273287A1Improve material propertiesSynthetic resin layered productsUnderstructuresFiberVulcanization

Components formed of blow molded thermoplastic compositions are described. The blow molded thermoplastic compositions exhibit high strength and flexibility. Methods for forming the thermoplastic compositions are also described. Formation methods include dynamic vulcanization of a composition that includes an impact modifier dispersed throughout a polyarylene sulfide. A crosslinking agent is combined with the other components of the composition following dispersal of the impact modifier. The crosslinking agent reacts with the impact modifier to form crosslinks within and among the polymer chains of the impact modifier. The compositions can exhibit excellent physical characteristics at extreme temperatures and can be used to form, e.g., tubular member such as pipes and hoses and fibers.

Owner:TICONA LLC

Self-healing dental composites and related methods

ActiveUS20080300340A1Reduce Shrinkage ProblemsIncrease polymerization rateImpression capsDentistry preparationsSelf-healingMicrosphere

Dental restorative composites having self-healing capabilities to repair discontinuities in the composite are provided. Dental restorative composites according to the present invention include a microsphere that encapsulates a monomer. When a fracture occurs, the microsphere is ruptured and the monomer fills the fracture. Depending on the monomer present in the microsphere, it is polymerized by a polymerization initiator or by an olefin metathesis catalyst present in the dental restorative composite. Self-healing dental restorative composites provide increased resistance to fracturing, and thus remain substantially intact for a longer period of time, preserving the remedial integrity of the dental repair or reconstruction.

Owner:PREMIER DENTAL PRODS

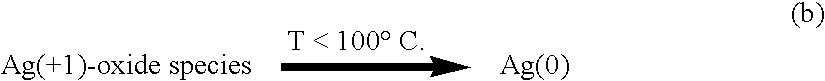

Process for manufacture of silver-based particles and electrical contact materials

ActiveUS20070234851A1Improve material propertiesMaterial nanotechnologyTransportation and packagingMaterials scienceInorganic oxide

The invention is directed to a process for manufacture of fine precious metal containing particles, specifically silver-based particles and silver-based contact materials via an intermediate silver(+1)-oxide species. The process comprises in a first step the formation of a thermally instable silver (+1)-oxide species by adding a base to an aqueous silver salt solution comprising an organic dispersing agent. Due to the presence of the organic dispersing agent, the resulting silver (+1)-oxide species is thermally instable, thus the species is decomposing to metallic silver at temperature lower than 100° C. The process optionally may comprise the addition of a powdered compound selected from the group of inorganic oxides, metals, and carbon-based compounds. Furthermore the process may contain additional separating and drying steps. The process is versatile, cost efficient and environmentally friendly and is used for the manufacture of silver-based particles and electrical contact materials. Silver nanoparticles made according to the process are characterized by a narrow particle size distribution. Electrical contact materials manufactured according to the process reveal improved contact welding properties.

Owner:NOBEL NOBLE ELEMENTS LLC

TiAl intermetallic compound-based alloy

This invention relates to a TiAl intermetallic compound-based alloy exhibiting excellent heat resistance, oxidation resistance and resonance resistance and having a cast structure composed of fine equiaxed grains. Specifically, it relates to a TiAl intermetallic compound-based alloy comprising of 45 to 48 atomic percent of Al, 5 to 9 atomic percent of Nb, 1 to 2 atomic percent of Cr, 0.2 to 0.5 atomic percent of Si, 0.3 to 2 atomic percent of Ni, 0.01 to 0.05 atomic percent of Y, and the balance being Ti and incidental impurities, the alloy exhibiting excellent heat resistance, oxidation resistance and resonance resistance and having a cast structure formed of fine equiaxed grains.

Owner:MITSUBISHI HEAVY IND LTD

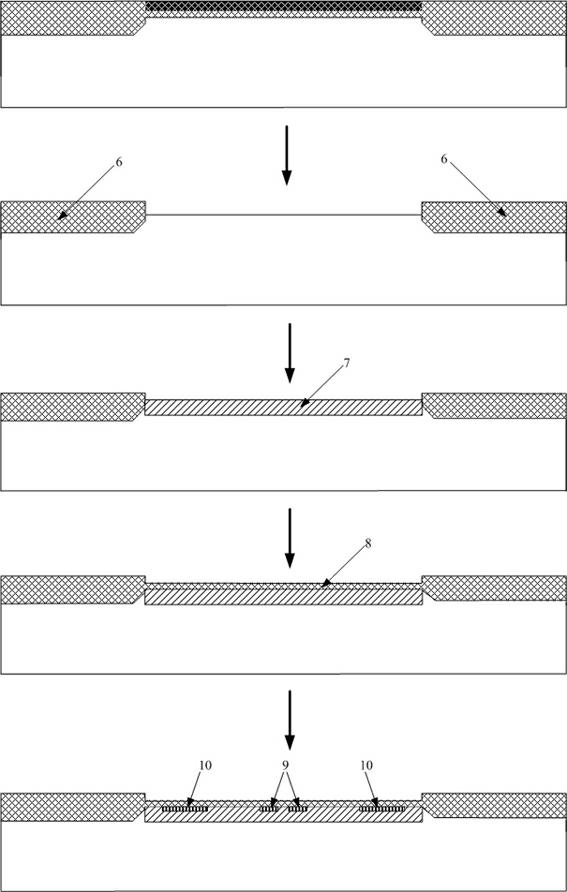

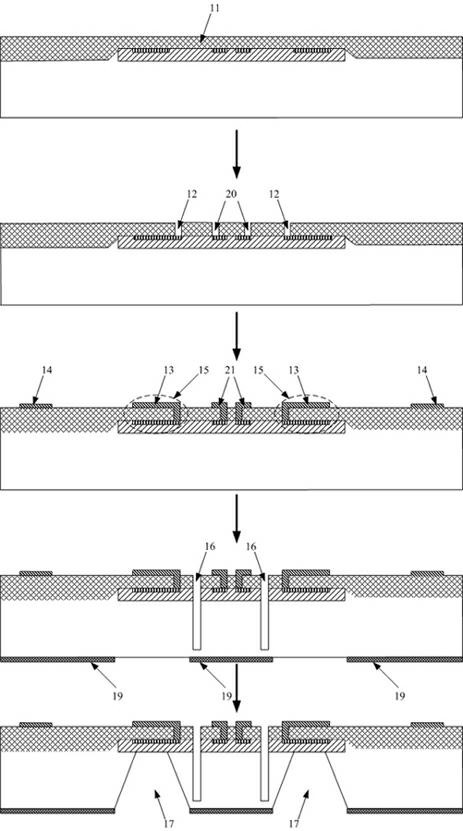

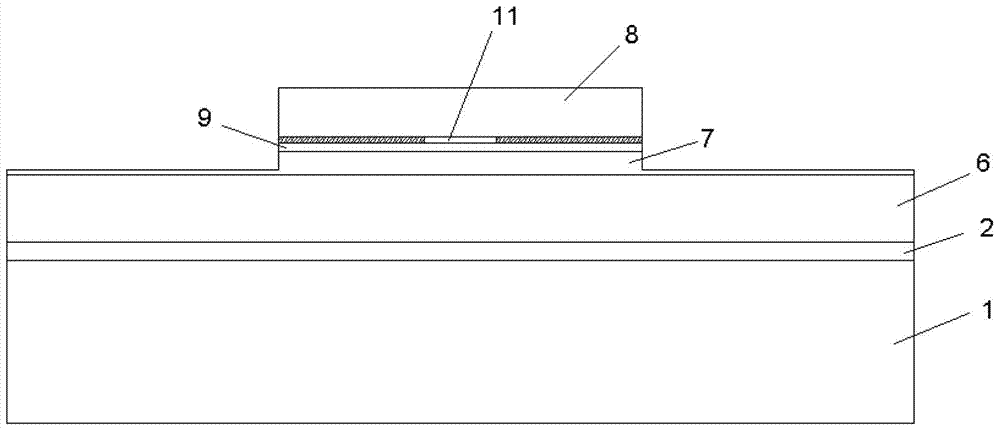

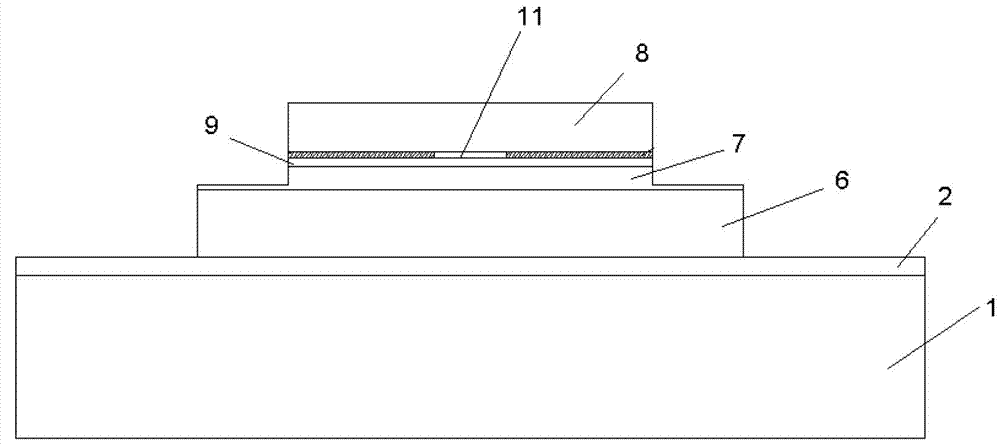

Heat-type wind-speed and wind-direction sensor with heat insulation structure and preparation method thereof

InactiveCN102095888AEnsure consistencyImprove consistencySemiconductor/solid-state device detailsSolid-state devicesBonding processHeat capacity

The invention discloses a heat-type wind-speed and wind-direction sensor with a heat insulation structure, comprising a silicon chip and a ceramic substrate, wherein the silicon chip is positioned above the ceramic substrate; four heating elements and four heat-sensing temperature-measuring elements are symmetrically distributed on the four edges of the upper surface of the silicon chip; a heat insulating groove is arranged between each heating element and each heat-sensing temperature-measuring element; heat insulating cavities are arranged below the heat-sensing temperature-measuring elements at the back of the silicon chip; and a ceramic gold-plating layer and a silicon gold-plating layer are arranged between the silicon chip and the ceramic substrate and are connected by adopting a gold-gold bonding process so as to be used for the heat connection between the silicon chip and the ceramic substrate. In the whole preparation process of the sensor, a standard CMOS (complementary metal-oxide-semiconductor) process is used, the after-treatment process is simple, and the prepared heat-insulating groove and the heat insulating cavities can be used for increasing the sensitivity of the chip effectively, reducing the heat conduction loss of the chip and the heat capacity of the sensor, and reducing the response time of the sensor.

Owner:SOUTHEAST UNIV

Biological-enzyme inner-wall environment-friendly coating

The invention relates to an environment-friendly coating, in particular to a biological-enzyme inner-wall environment-friendly coating which can be used for decorating the surfaces of indoor wall surfaces, ceilings, gypsum boards, and the like and can clear indoor formaldehyde, release anions and purify indoor air by biological enzymes. The preparation technology of the biological-enzyme inner-wall environment-friendly coating comprises the following steps: firstly, sequentially adding a dispersant, a wetting agent, a foam suppressor, a thickening agent and a mildewproof algaecide at a low speed; sequentially adding titanium pigment, a pH regulator, coarse whiting, calcined kaolin, talcum powder and anion fungi at a medium speed; and sequentially adding latex, a film-forming additive, an anti-freezing agent, a preservative, a foam suppressor, a flatting agent, 40 percent of biological-enzyme solution and H2O at a low speed and filtering and packaging after detecting to be qualified. The biological-enzyme inner-wall environment-friendly coating has the advantages of clearing the indoor formaldehyde, releasing the anions and purifying the air.

Owner:SKSHU PAINT

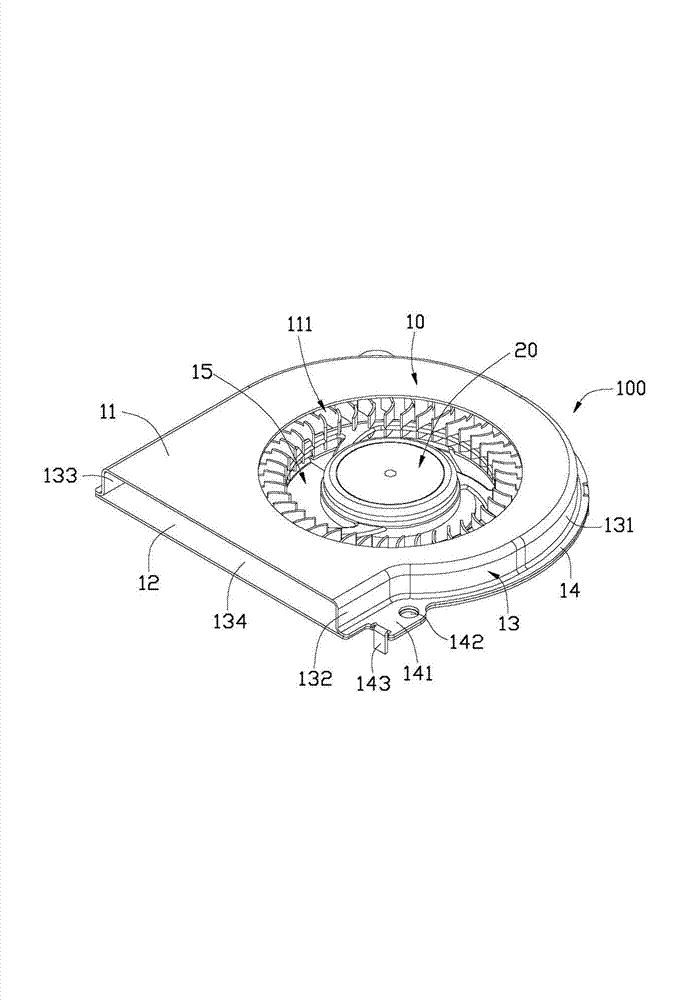

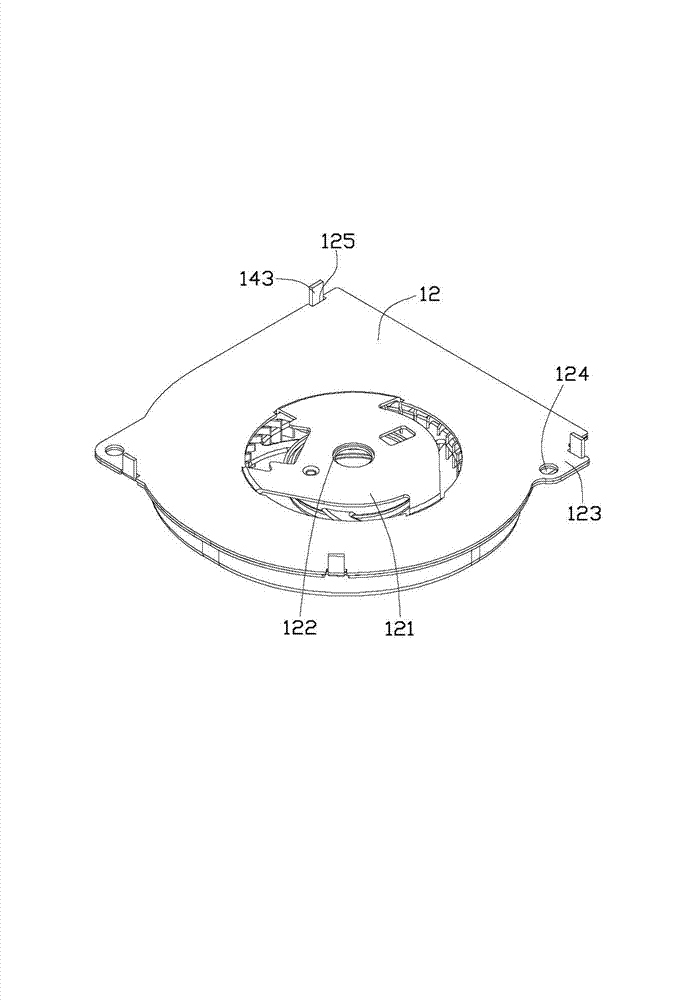

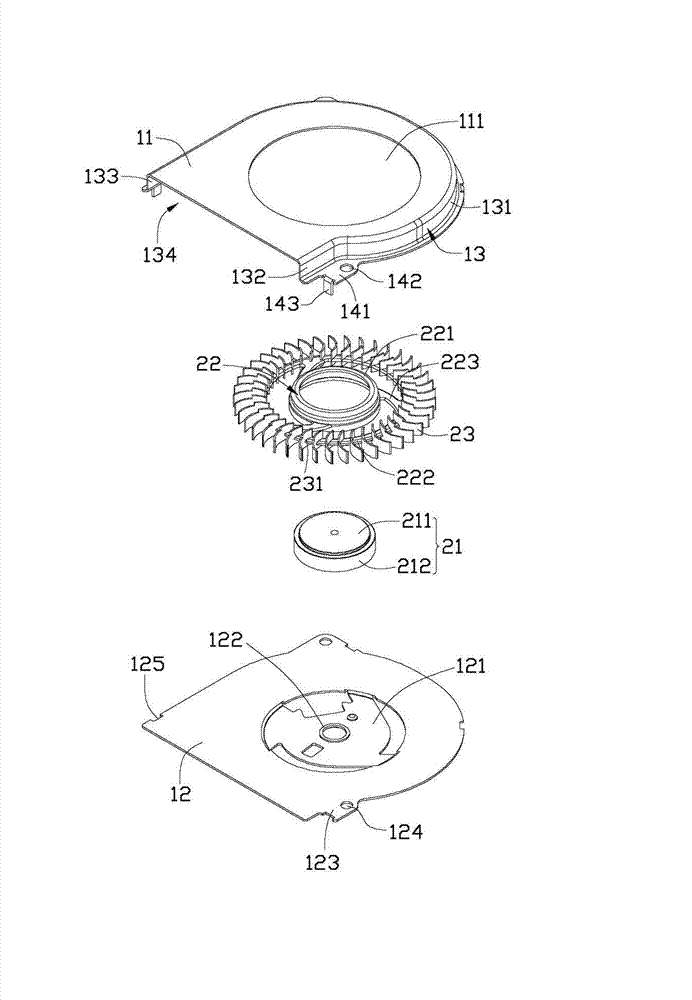

Thin fan

A thin fan comprises a fan frame and a blade assembly accommodated in the fan frame. The fan assembly comprises a hub, a blade ring structure around the hub and a plurality of blades clamped on the blade ring structure, and the blades are made of magnesium and aluminum alloy. The thickness of the fan is reduced greatly as compared with that of the prior art, so that the thin fan has larger air intake space and high in airflow and cooling effect of the thin fan is guaranteed. Besides, since the blades of the fan are thinned, the integral size of the blades is reduced, and weight of the blades is lower than that of existing plastic blades. Further, due to excellent performance of the magnesium and aluminum alloy blades, stress of the blades is improved, the blades are not easy to deform. In addition, since interference between the blades and a top cover is avoided, stability of the thin fan is improved.

Owner:FURUI PRECISE COMPONENT (KUNSHAN) CO LTD +1

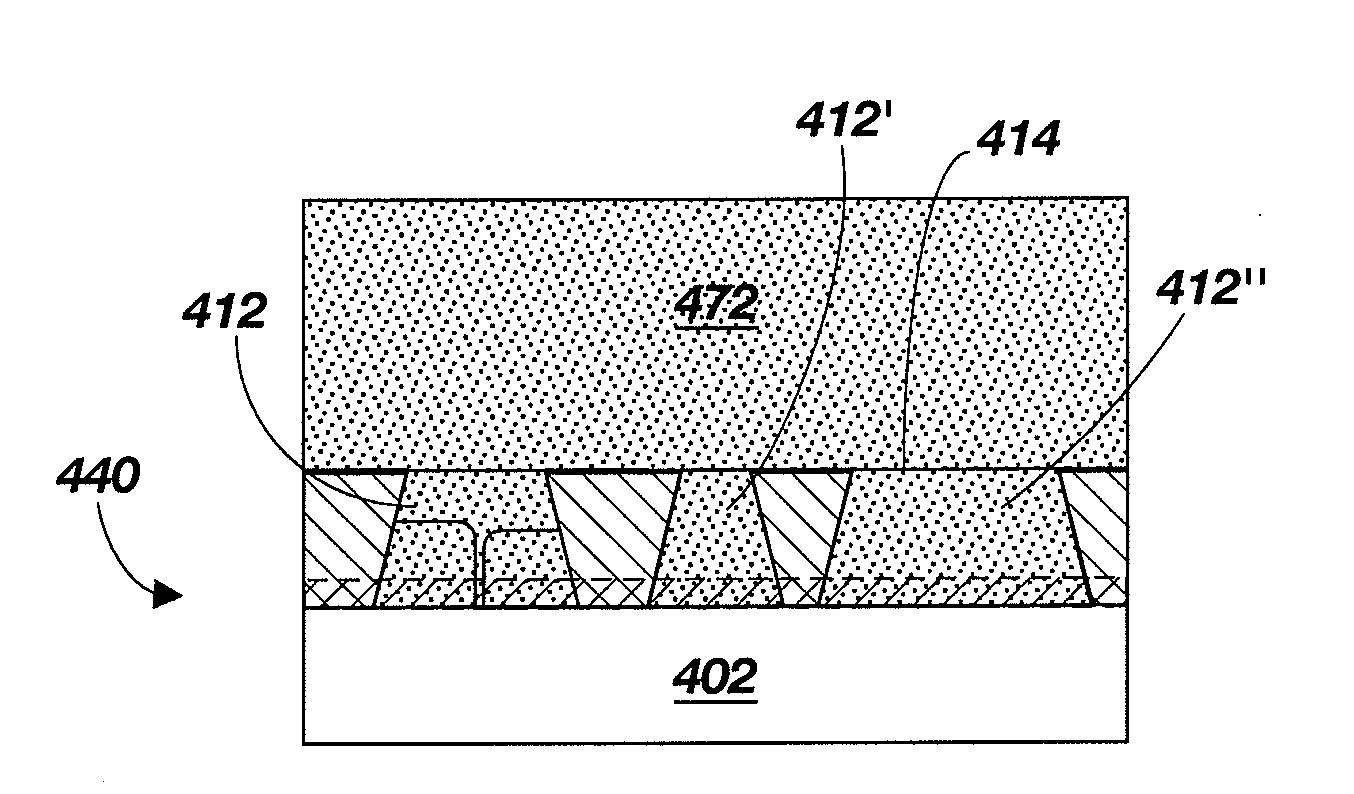

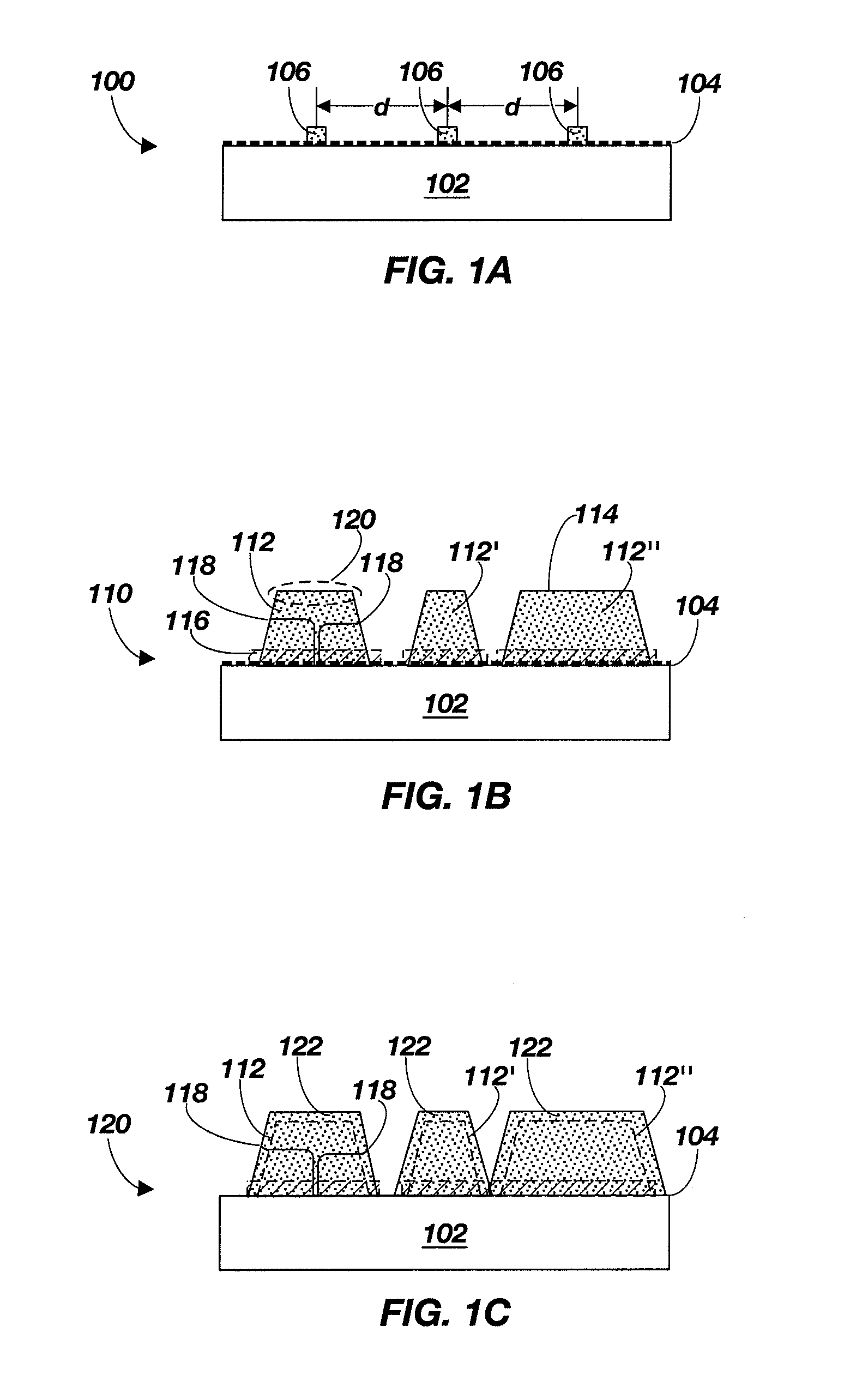

Epitaxial methods and structures for forming semiconductor materials

InactiveUS20100187568A1Low densityLower Level RequirementsSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsMaterials science

Methods and structures for producing semiconductor materials, substrates and devices with improved characteristics are disclosed. Structures and methods for forming reduced strain structures include forming a plurality of substantially strain-relaxed island structures and utilizing such island structures for subsequent further growth of strain-relaxed substantial continuous layers of semiconductor material.

Owner:SOITEC SA

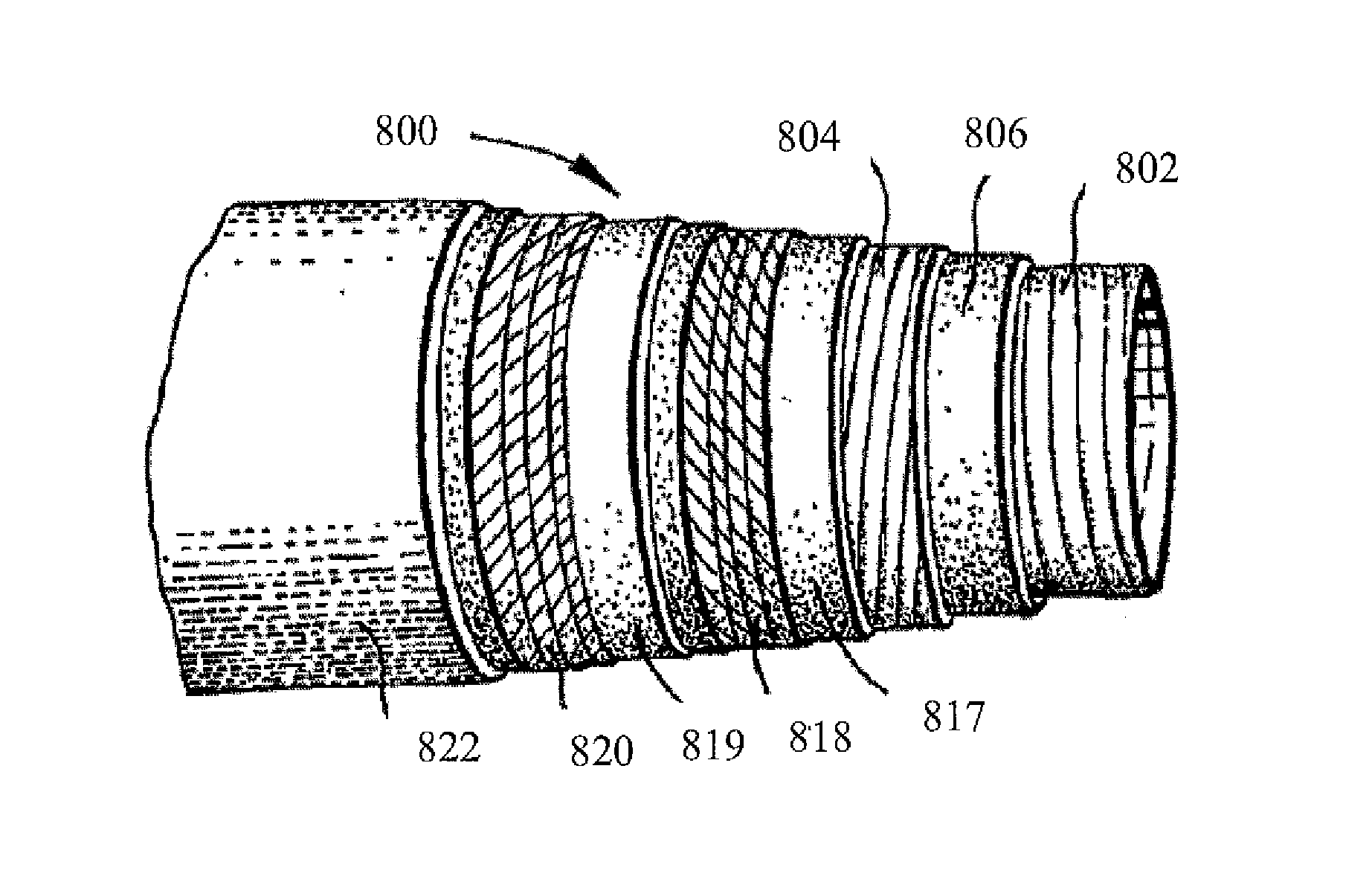

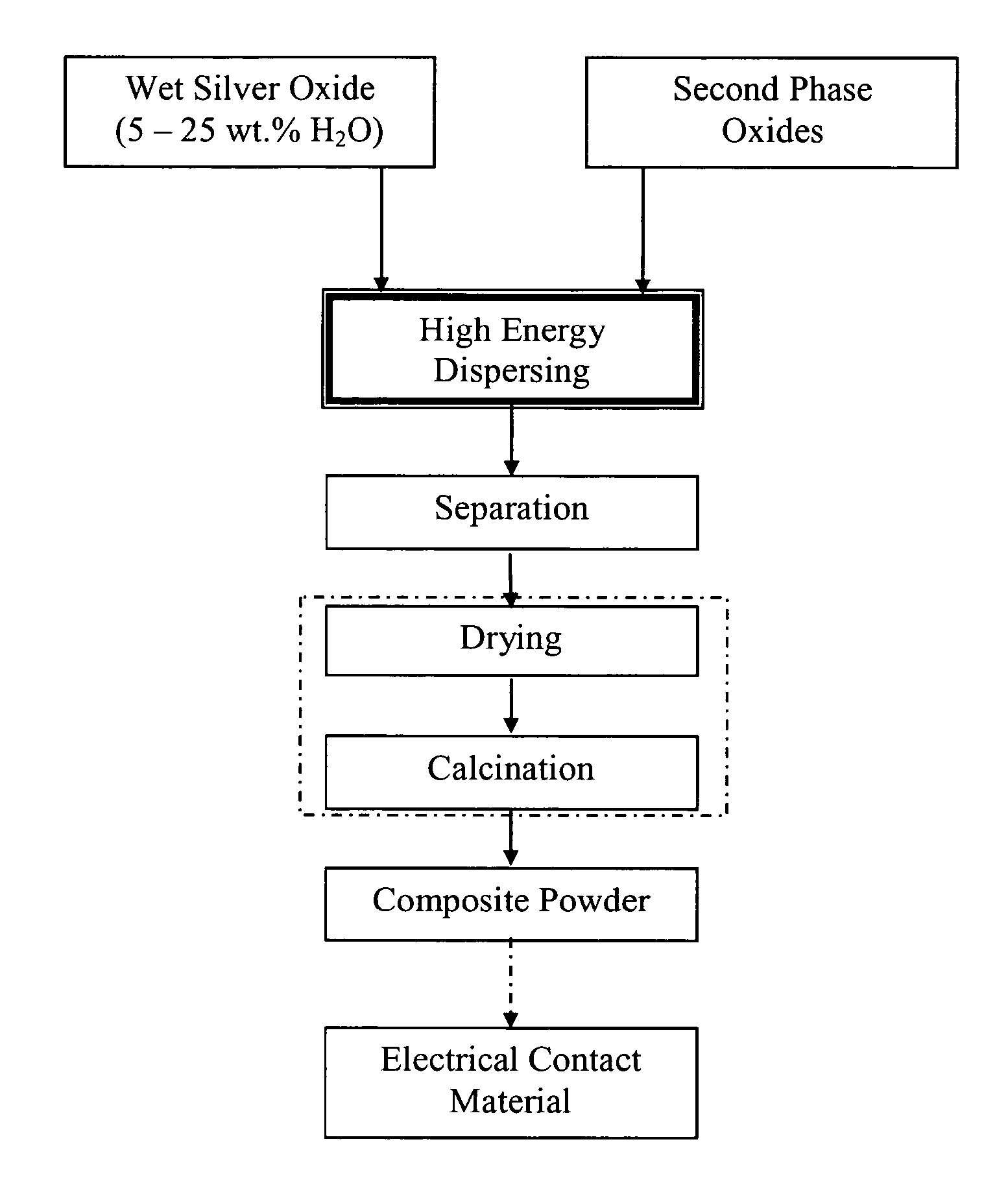

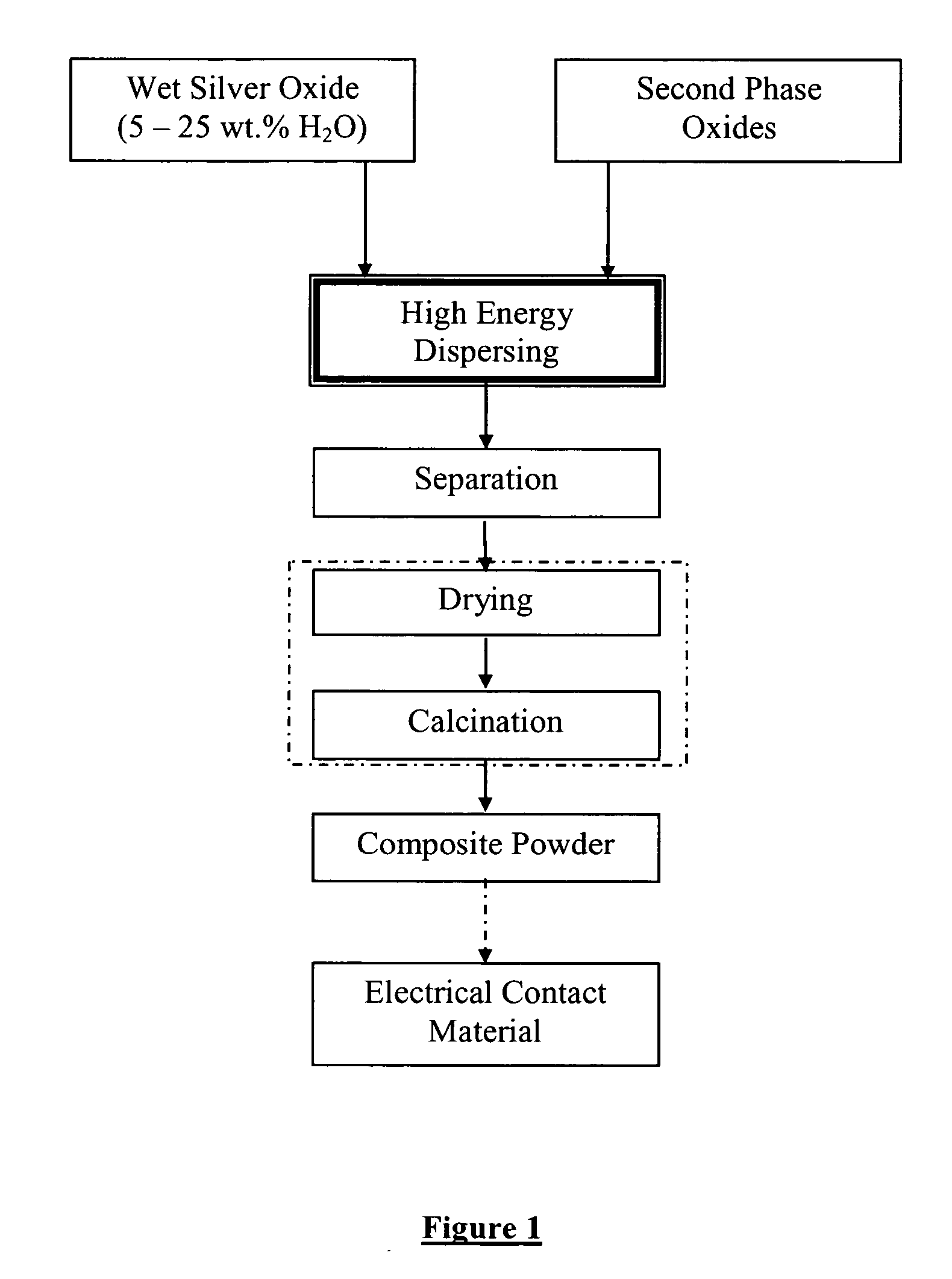

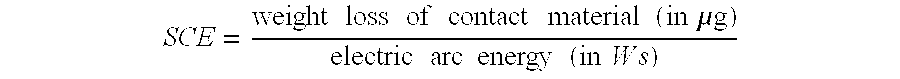

Process for manufacture of silver-based composite powders for electrical contact materials and composite powders so produced

InactiveUS20070228334A1Improve manufacturingImprove material propertiesConductive materialGold compoundsHigh energySilver oxide

The present invention relates to a method for manufacture of silver-based composite powders for electrical contact materials. The invention relates also to electrical contact materials made from such composite powders. The process comprises a high energy dispersing process of wet silver oxide (Ag2O) with additional second oxide components in aqueous suspension. The high energy dispersing process can be conducted by high shear mixing or by high energy milling. Preferably high speed dispersing units working at rotating speeds in the range of 5,000 to 30,000 rpm or high energy mills such as attritor mills are used. The new process is versatile, economical and offers access to a broad spectrum of contact materials. The silver-based composite powders made according to the new process yield contact materials with a highly dispersed microstructures and superior material characteristics.

Owner:UMICORE AG & CO KG

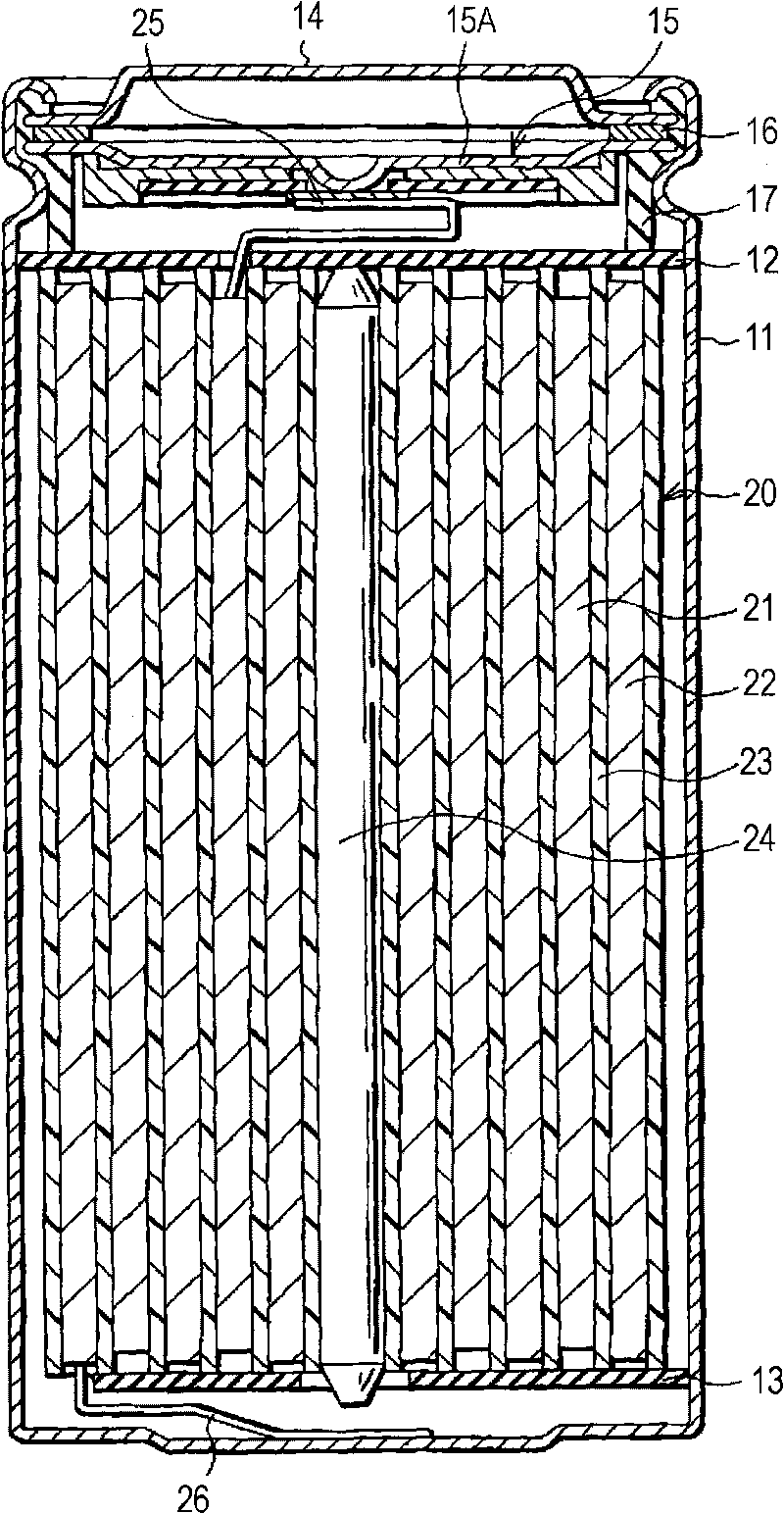

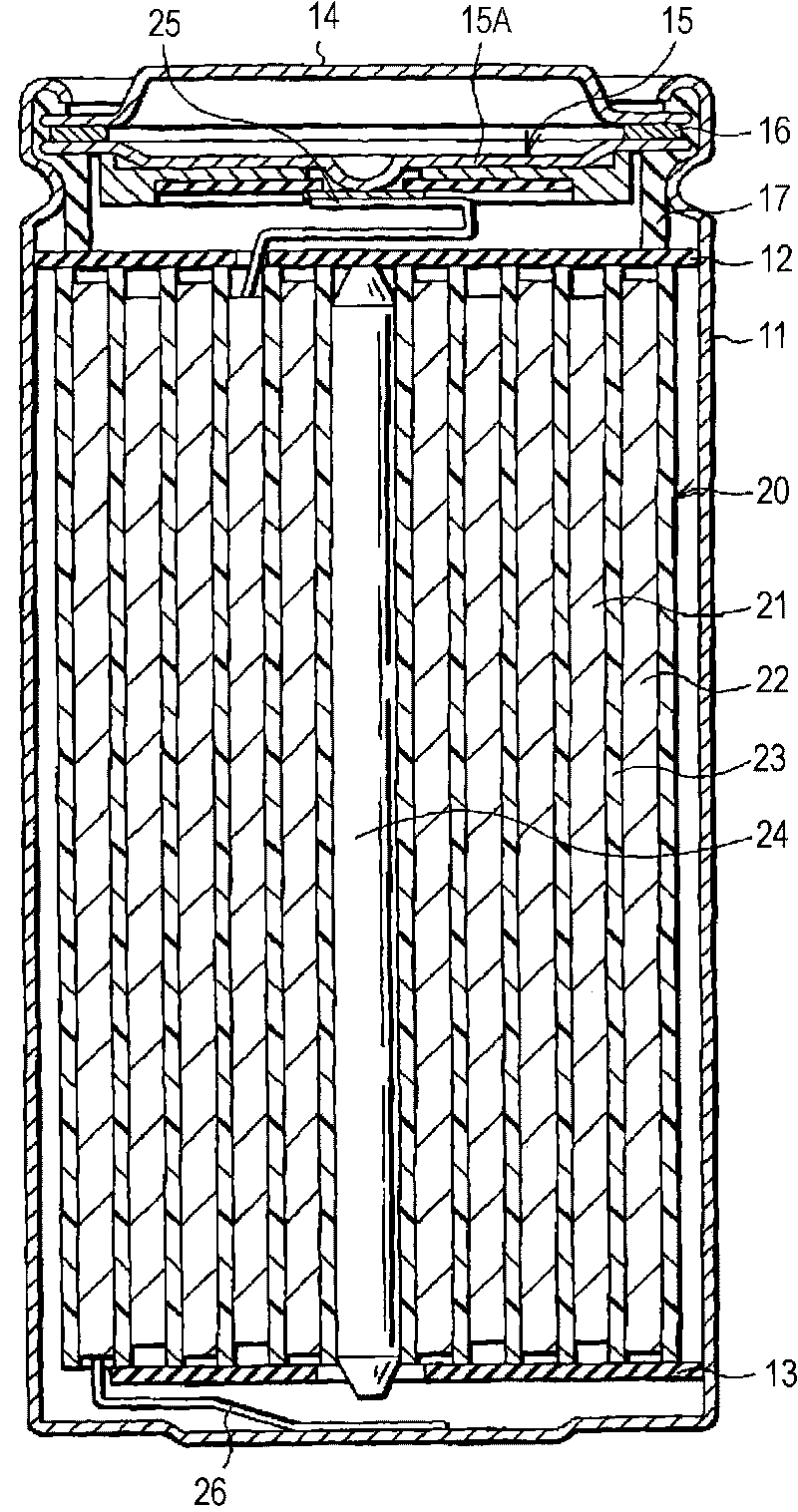

Nonaqueous electrolyte secondary battery

InactiveCN101740807AMaterial properties are stableImprove material propertiesNon-aqueous electrolyte accumulatorsActive material electrodesMaterials scienceElectrolyte

A negative electrode mixture is provided and includes: a negative electrode active material containing a carbon based material; a binder containing at least a polyacrylonitrile based resin; and a polymer capable of suppressing an intermolecular interaction between cyano groups and imparting a steric hindrance.

Owner:SONY CORP

Recyclate Blends

ActiveUS20160108233A1Improve material performanceIncrease loadProductsReagentsPolyesterPolymer science

Compositions comprising recyclate blends of polymer recyclate and polyester additives are described. In certain embodiments, the polyester additive is a PHA such as a poly-3-hydroxybutyrate-co-4-hydroxybutyrate copolymer having a weight percent 4-hydroxybutyrate of 8.5-45%. In other embodiments the PHA is mixed with the recyclate polymer at concentrations of 10-50% by weight of the recyclate blend. Methods of making the compositions of the invention are also described. The invention also includes articles made from the recyclate blends.

Owner:CJ CHEILJEDANG CORP

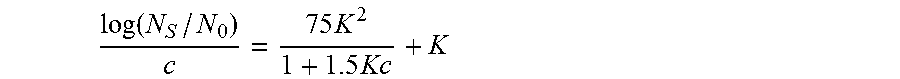

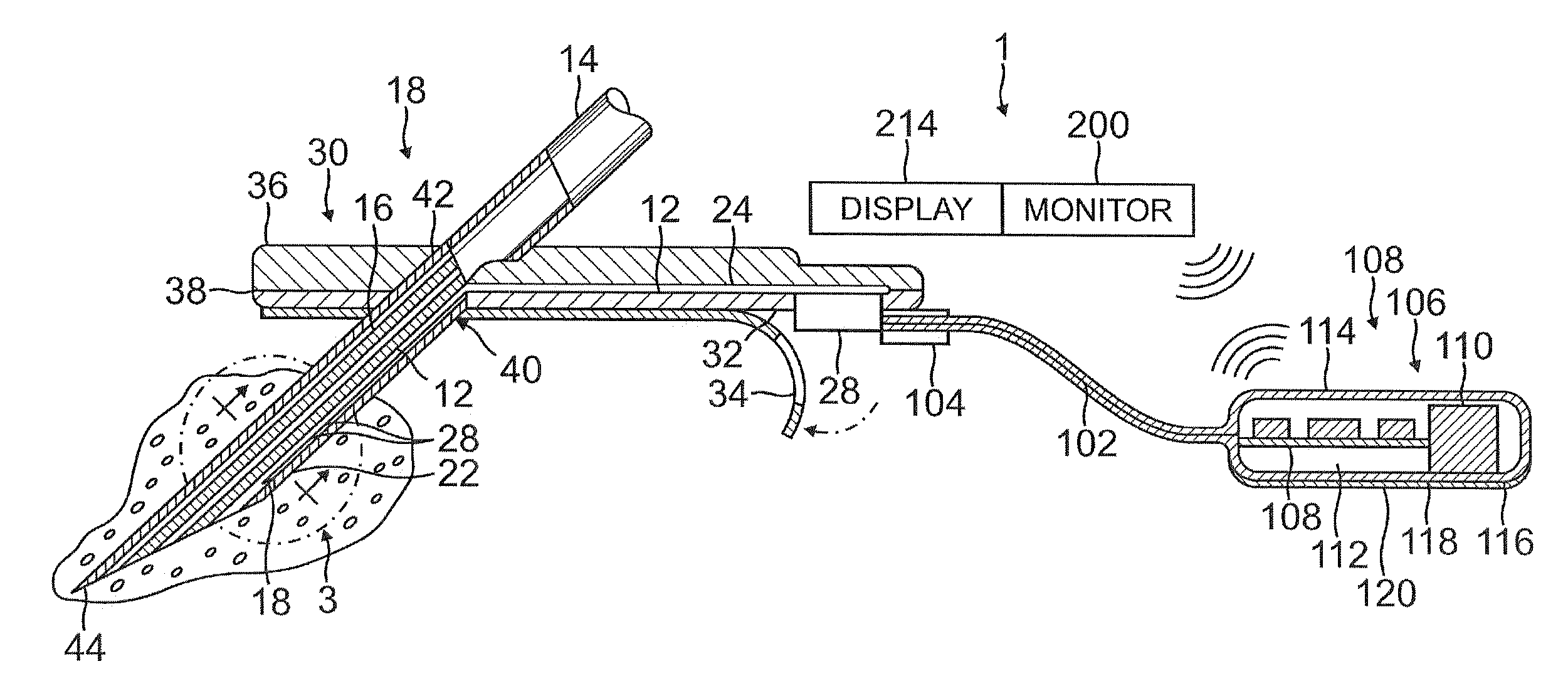

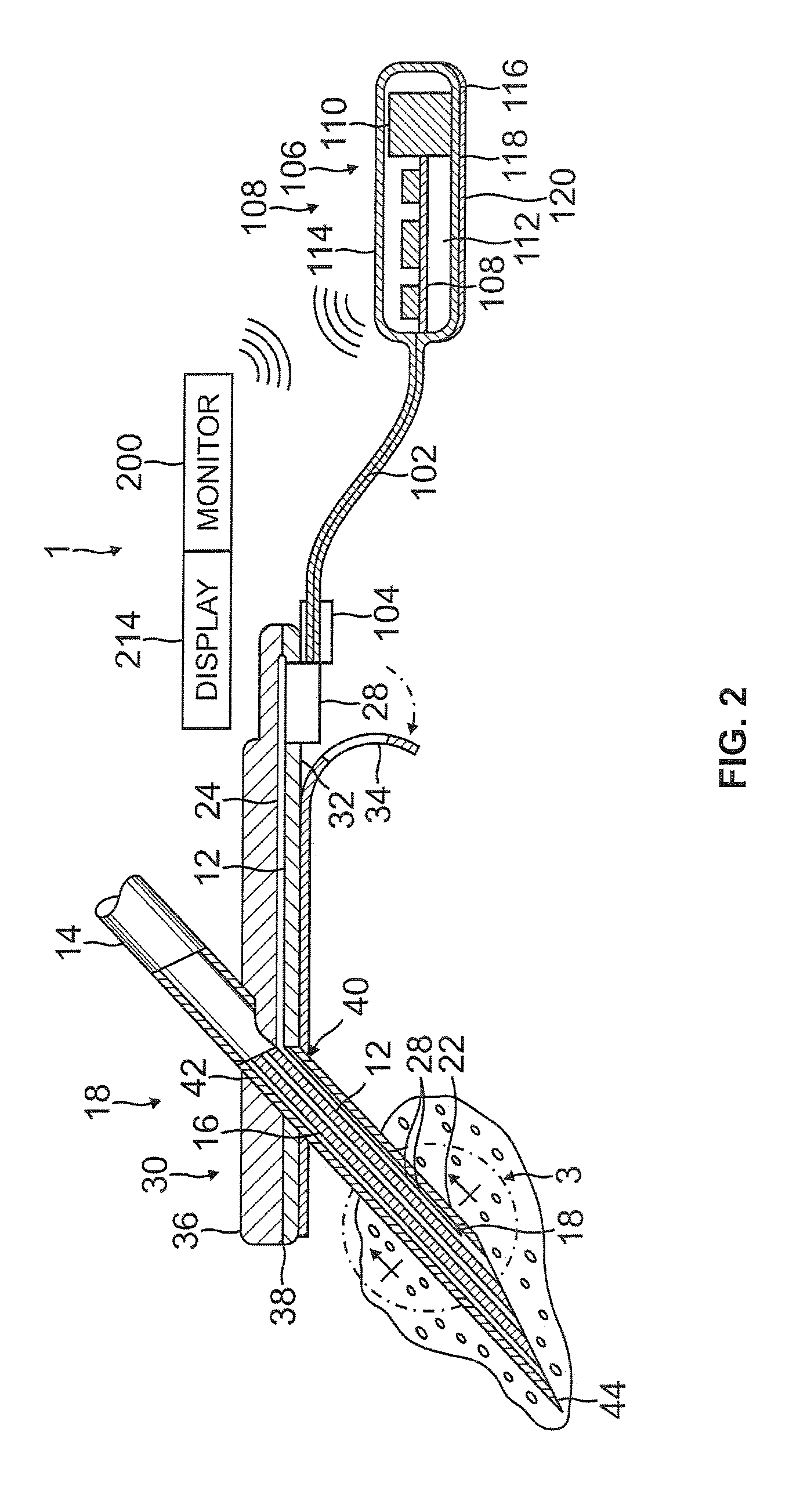

Enzyme matrices for use with ethylene oxide sterilization

InactiveUS20150122647A1Function increaseImprove material propertiesImmobilised enzymesBioreactor/fermenter combinationsGlucose sensorsPyridinium

The invention pertains to analyte sensors designed to include layered compositions that provide these sensors with enhanced functional and / or material properties including, for example, resistance to damage caused by ethylene oxide during sterilization processes. Embodiments of the invention include polyvinyl alcohol N-methyl-4(4′-formylstyryl)pyridinium (SbQ) polymer materials and methods for employing such materials during the ethylene oxide sterilization of glucose sensors.

Owner:MEDTRONIC MIMIMED INC

Molten glass supply device, glass formed product, and method of producing the glass formed product

ActiveCN1524811AAvoid deterioration in qualityEasy to useForehearthsGlass furnace apparatusPoiseMolten glass

Owner:NIPPON ELECTRIC GLASS CO LTD

Open-porous metal foam body and a method for fabricating the same

ActiveUS20140004259A1Improve material propertiesStable to oxidationLiquid surface applicatorsElectrolytic coatingsMetal foamMaterials science

Disclosed are an open-porous metal foam and a method for manufacturing the same. An open-porous metal foam according to an exemplary embodiment of the present invention is made of an iron-based alloy including 15 wt % or more of chrome and 5 wt % or more of aluminum. The open-porous metal foam is a semi-product that is formed of iron or the iron-based alloy that does not include chrome and aluminum or includes a smaller amount of chrome and aluminum in the powder when manufacturing, and the surface and the open pore thereof are uniformly coated with the powder of the iron-chrome-aluminum alloy and the organic binding agent. When heat treatment is performed under a reduction atmosphere, sintering is performed. In this case, the metal foam body that is formed of the iron-chrome-aluminum alloy is obtained by compensating concentrations of alloy elements between the semi-product and the powder by diffusion, and a content of chrome and aluminum in the metal foam is smaller than a content of chrome and aluminum included in a starting alloy of the used powder.

Owner:ALANTUM CORP +1

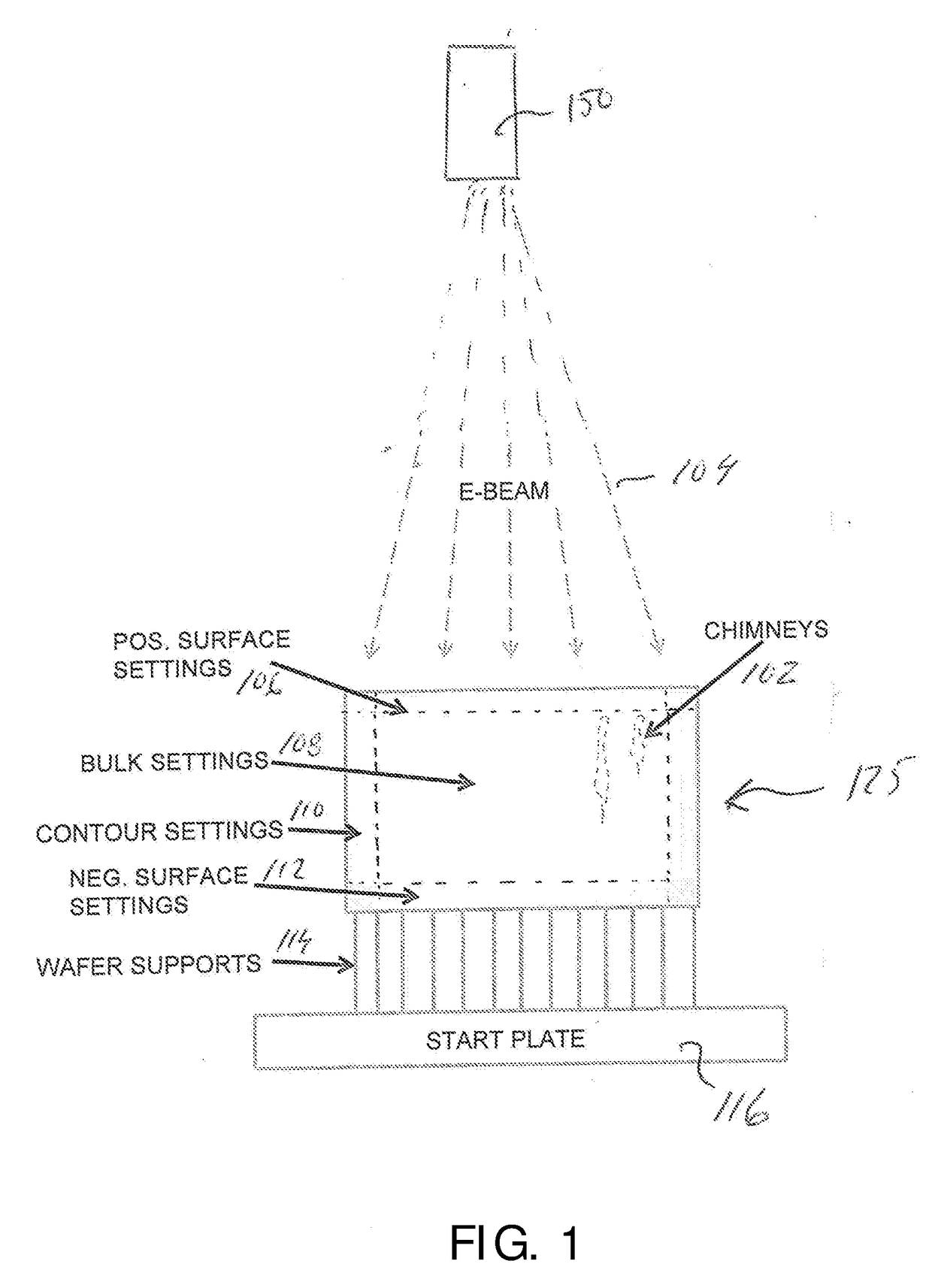

Additive manufacturing of three-dimensional articles

PendingUS20180147655A1Sufficient powerEliminate stomataAdditive manufacturing apparatusIncreasing energy efficiencyPorosityBeam source

Provided is a method for forming a three-dimensional article through successively depositing individual layers of powder material that are fused together so as to form the article in a vacuum chamber, said method comprising the steps of: providing at least one electron beam source emitting an electron beam for at least one of heating or fusing said powder material in said vacuum chamber, applying a first set of beam parameters for formation of a fused bulk material of said three-dimensional article, where said bulk material has a predetermined microstructure, applying a second set of beam parameters for formation of a top portion of said three-dimensional article, wherein said second set of beam parameters is applied a predetermined number of layers prior to reaching a top surface of said three-dimensional article for encapsulating chimney porosities into said bulk material. Associated apparatus and computer program product are also provided.

Owner:ARCAM AB

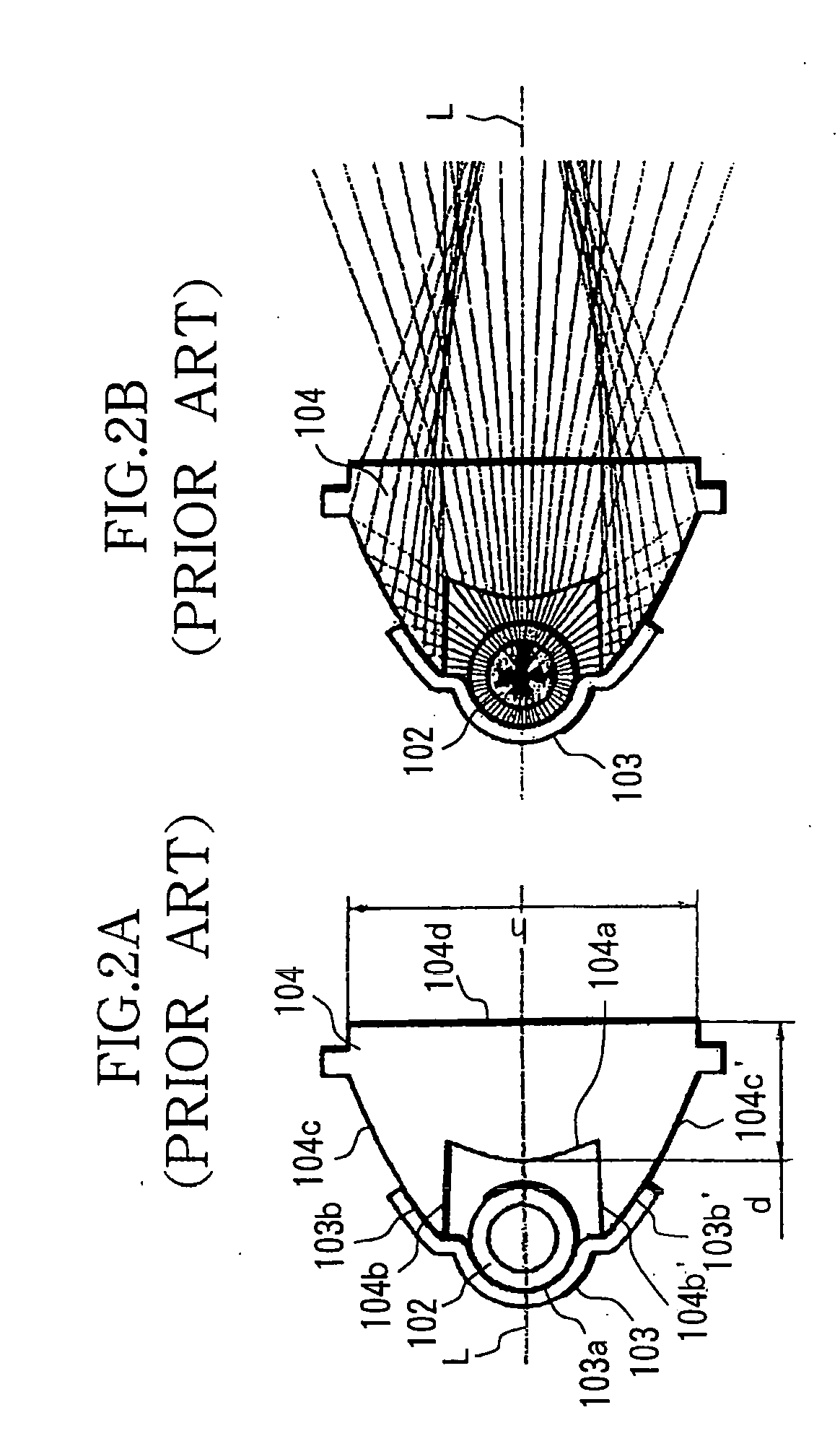

Illumination optical system and image-taking apparatus

InactiveUS20050117318A1Improve material propertiesMechanical apparatusDiffusing elementsMiniaturizationIrradiation

An illumination optical system is disclosed, which can achieve miniaturization by improving the characteristics of the material of the optical member. The illumination optical system according to the present invention includes a light source and an optical member disposed in a direction of irradiation of light from the light source. The optical member is made of a particle-containing material with particles having a particle size smaller than 1 μm contained in a base material made of a resin material.

Owner:CANON KK

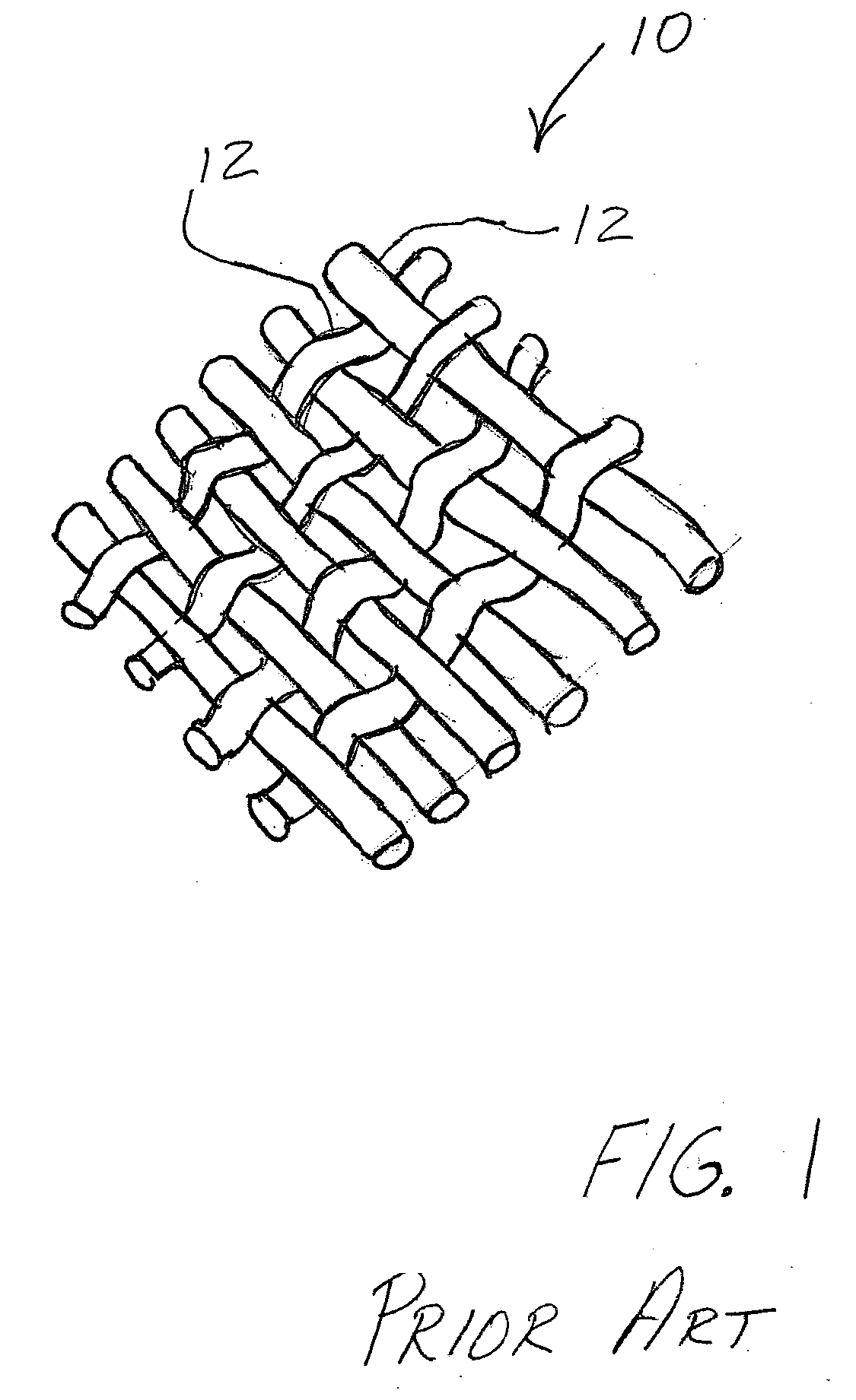

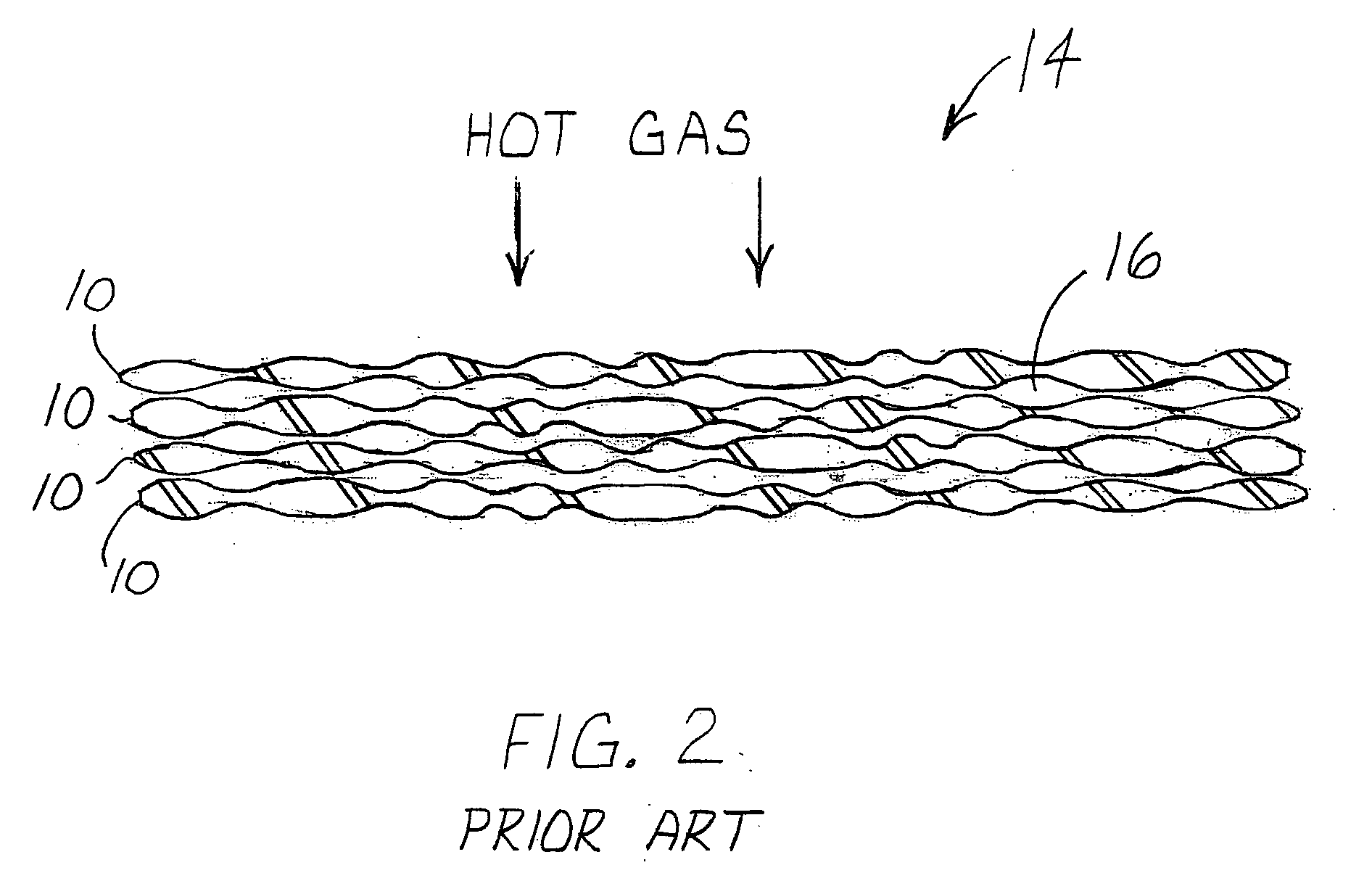

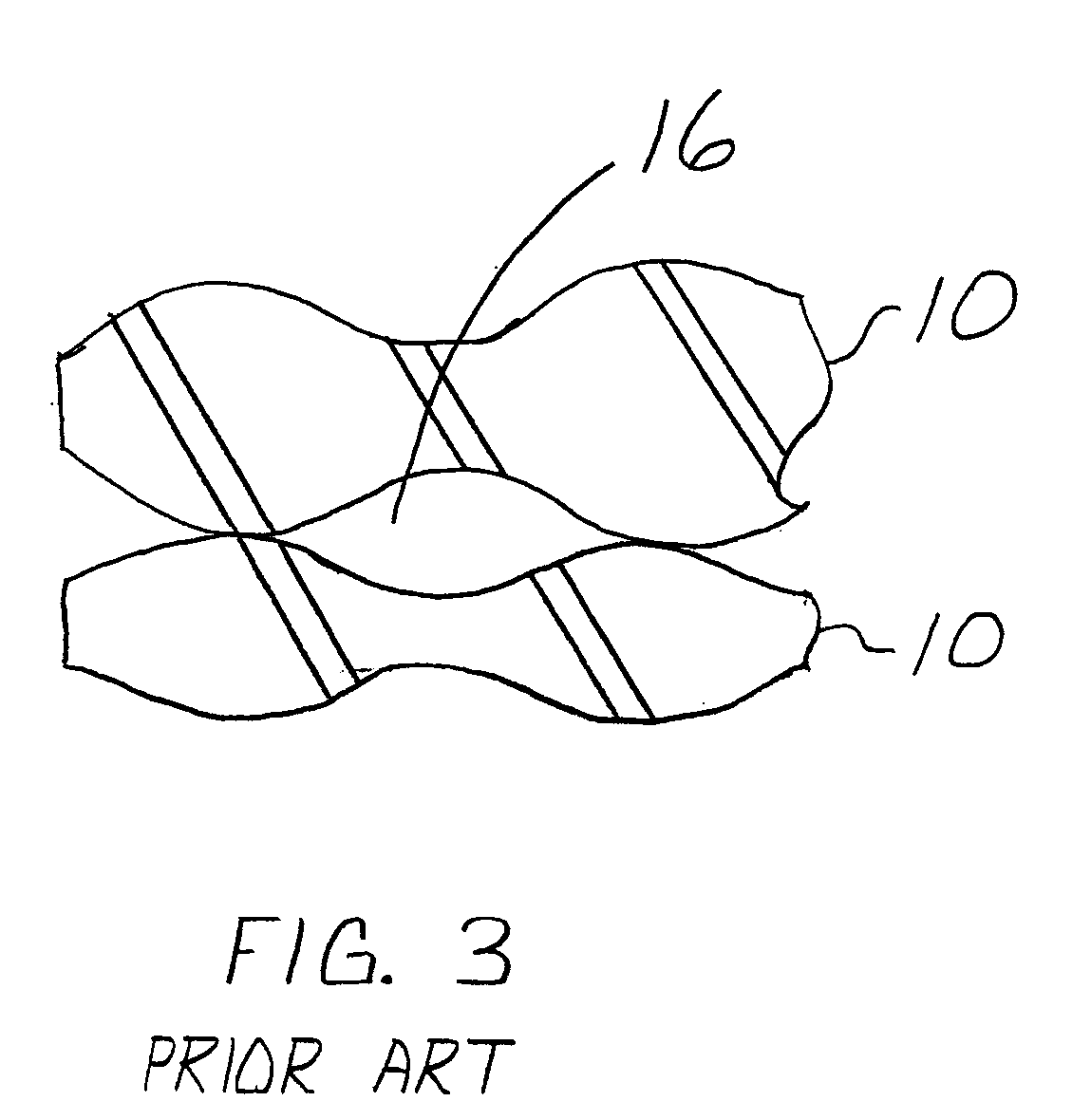

Thermo-mechanical property enhancement plies for CVI/SiC ceramic matrix composite laminates

InactiveUS20050186878A1Reduce inter laminar porosityReduce porosityAnimal housingCeramic layered productsCeramic matrix compositeMetallurgy

A ceramic matrix composite laminate includes at least two directional, continuous ceramic fiber preform lamina each being formed of interwoven or braided fibers. A layer of non-woven mat includes a plurality of chopped ceramic fibers mixed with a bonding agent. The non-woven mat layer is interposed between adjacent directional, continuous ceramic fiber preform lamina to substantially eliminate inter-laminar gaps formed between the adjacent directional, continuous ceramic fiber preform lamina. The additional chopped fiber content improves the interlaminar mechanical and thermo-mechanical material properties of resulting ceramic matrix composite laminate.

Owner:GENERAL ELECTRIC CO

Surface tack thermistor element

InactiveCN103247399AImprove material propertiesImprove thermal efficiencyNegative temperature coefficient thermistorsPositive temperature coefficient thermistorsResistive elementThermistor

The invention discloses a surface tack thermistor element, which comprises a resistor element, a first electrode, a second electrode and at least a thermally conductive insulating layer. The resistor element comprises a first conductive member, a second conductive member and high-molecular material layers, wherein the high-molecular material layers are laminated between the first conductive member and the second conductive member and have characteristics of positive temperature coefficient or negative temperature coefficient. The high-molecular material layers and the first and second conductive members extend together along a first direction to form a laminated structure. The first electrode is electrically connected with the first conductive member. The second electrode is electrically connected with the second conductive member and is electrically isolated from the first electrode. Heat conductivity of the first and second electrodes is at least 50W / mK. The thermally conductive insulating layer contains a high-molecular insulated substrate and a thermally conductive filling material and is arranged between the first electrode and the second electrode. Heat conductivity of the thermally conductive insulating layer is within 1.2W / mK-13W / mK.

Owner:POLYTRONICS TECH

Semi-conductor surface emitting laser and production method and applications thereof

ActiveCN103208741ALower core layerHigh heat dissipation coefficientLaser detailsSemiconductor lasersBenzeneCapacitance

The invention relates to a semi-conductor surface emitting laser and a production method and applications thereof. An active layer utilizes a strain five quantum well; a lower DBR (Distributed Bragg Reflector) layer utilizes a binary N type AlAs / GaAs pair; an upper DBR layer utilizes a DBR of a general ternary N type Al0.92Ga0.08 As / Al0.12Ga0.88As; a plurality of pairs under the active layer utilize a same structure; the top utilizes a high thermal conductive ALN (Aluminium Nitride) layer; copper layers are arranged and covered on bilateral sides of the platform surface and above the platform; the size of an oxidation hole is 18 micron; and the capacitance of components are reduced through a BCB (p-bis benzene) layer. The production method of the semi-conductor surface emitting laser has the advantages of improving an integral heat dissipation level by improving processes, effectively solving the heat dissipation problem of a large power surface emitting laser, improving an stage of the power of the surface emitting laser, enabling the surface emitting laser to be improved in material character, improving the service life and working reliability of the surface emitting laser and achieving free space communication within 1-3 km.

Owner:WUHAN TELECOMM DEVICES

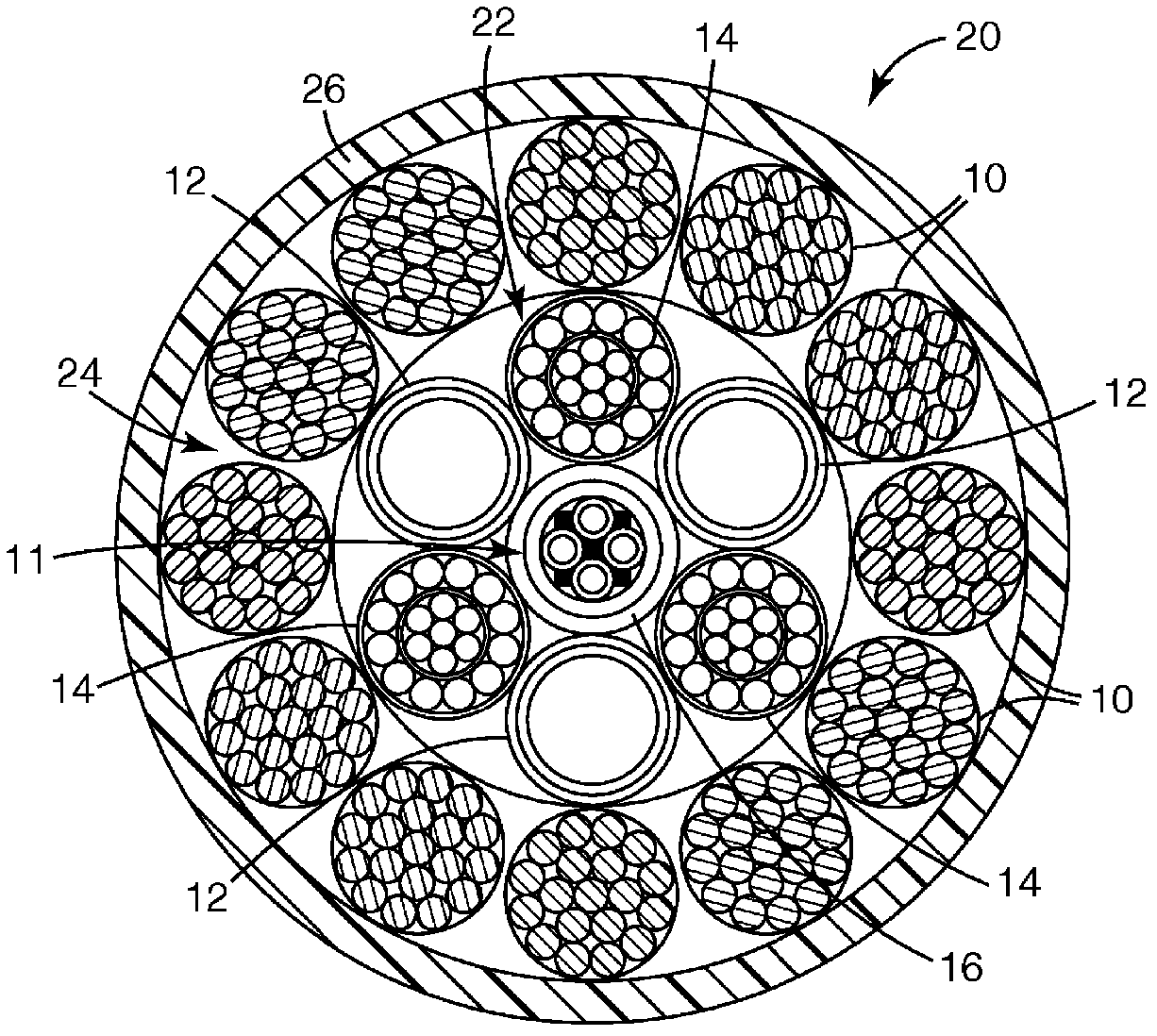

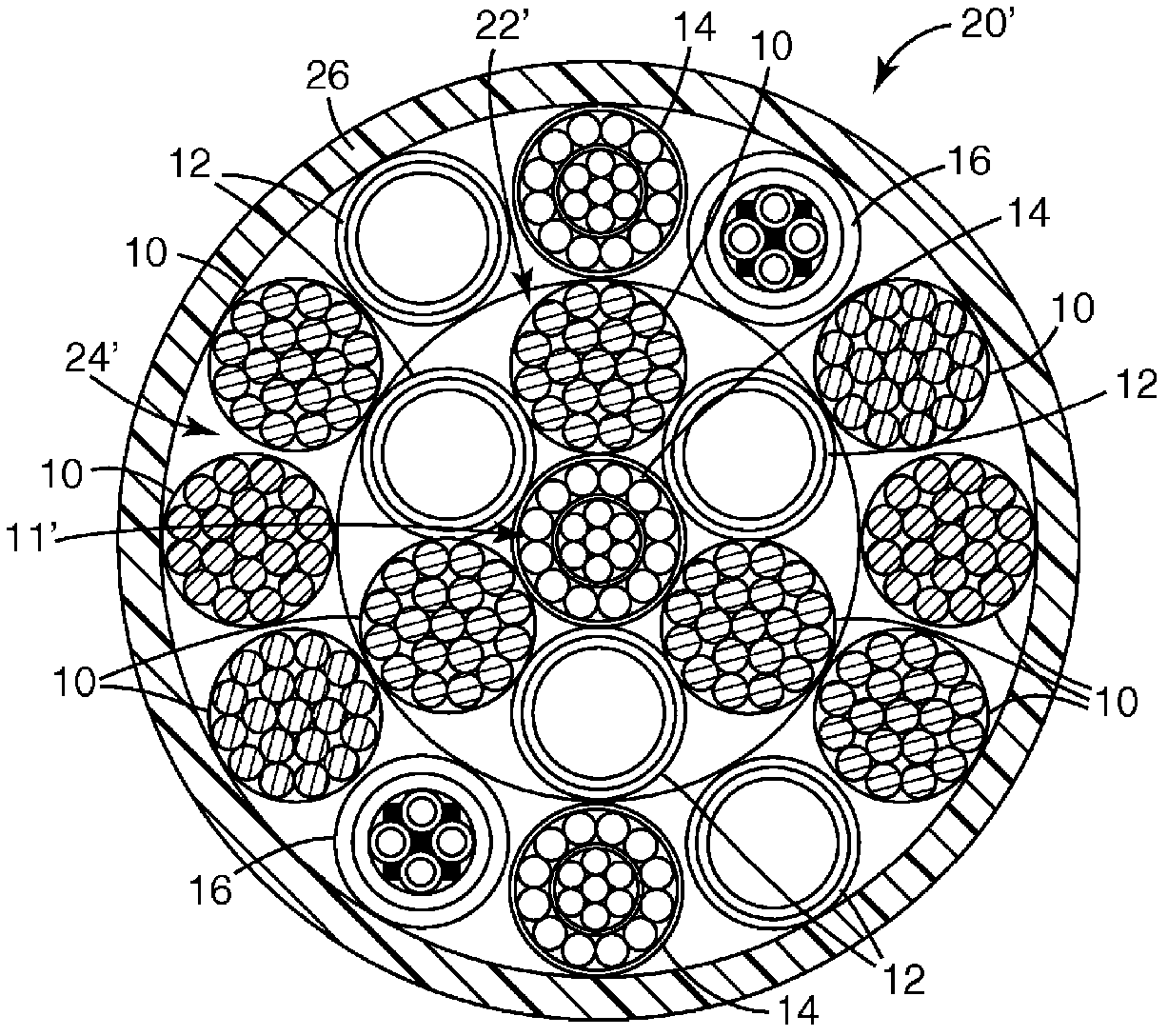

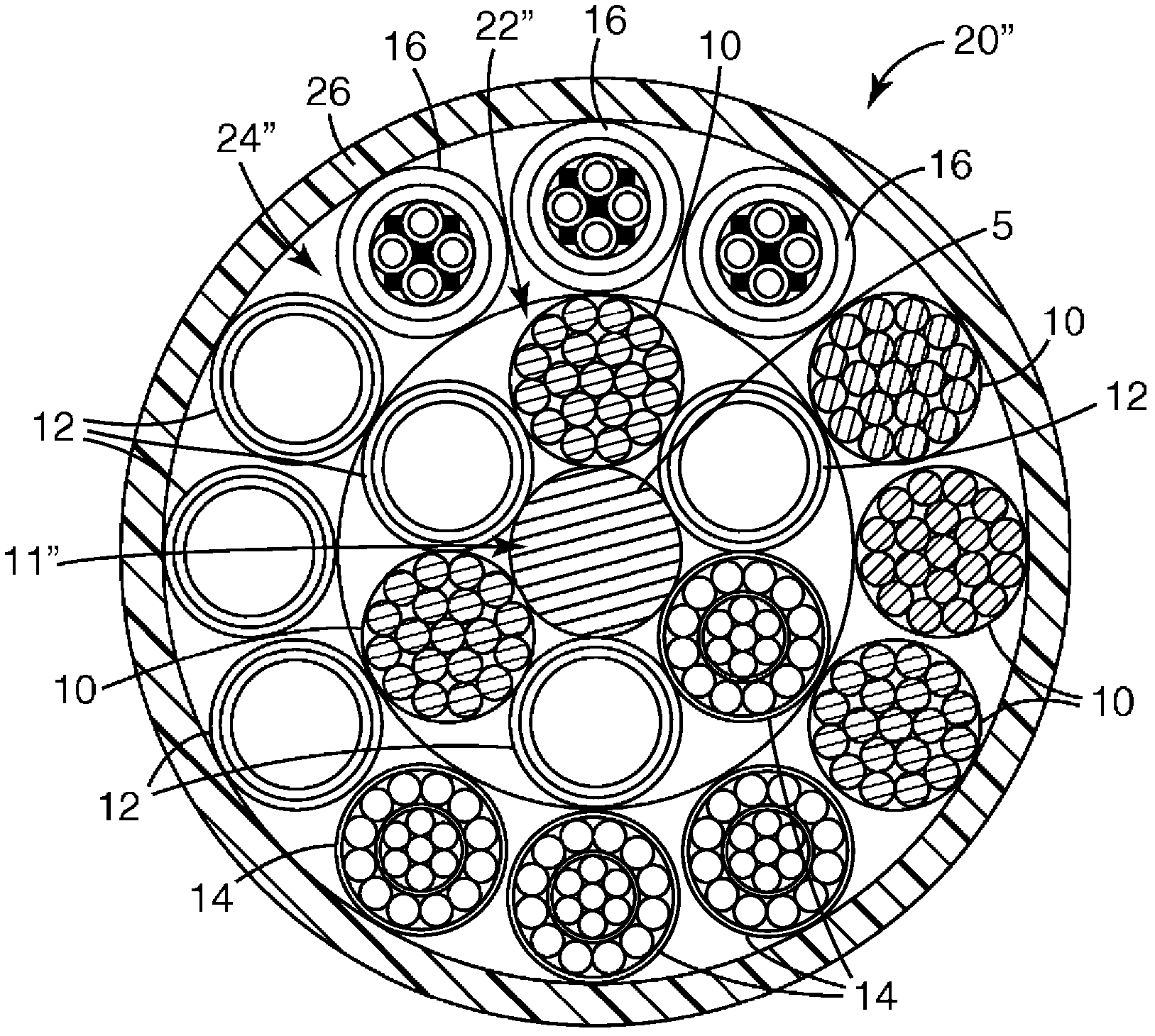

Submersible Composite Cable And Methods

InactiveCN102483973AIncrease working depthIncrease workloadNon-insulated conductorsPlastic/resin/waxes insulatorsElectric power transmissionFluid transport

Embodiments of submersible composite cables include a non-composite electrically conductive core cable, a multiplicity of composite cables, including a multiplicity of composite wires, around the core cable, and an insulative sheath surrounding the composite cables. Other embodiments include an electrically conductive core cable; a multiplicity of elements selected from fluid transport, electrical power transmission, electrical signal transmission, light transmission, weight elements, buoyancy elements, filler elements, or armor elements, arranged around the core cable in at least one cylindrical layer defined about a center longitudinal axis of the core cable when viewed in a radial cross section; a multiplicity of composite wires surrounding the elements in at least one cylindrical layer about the center longitudinal axis; and an insulative sheath surrounding the composite wires. The composite wires may be metal matrix or polymer composite wires. Methods of making and using submersible composite cables are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

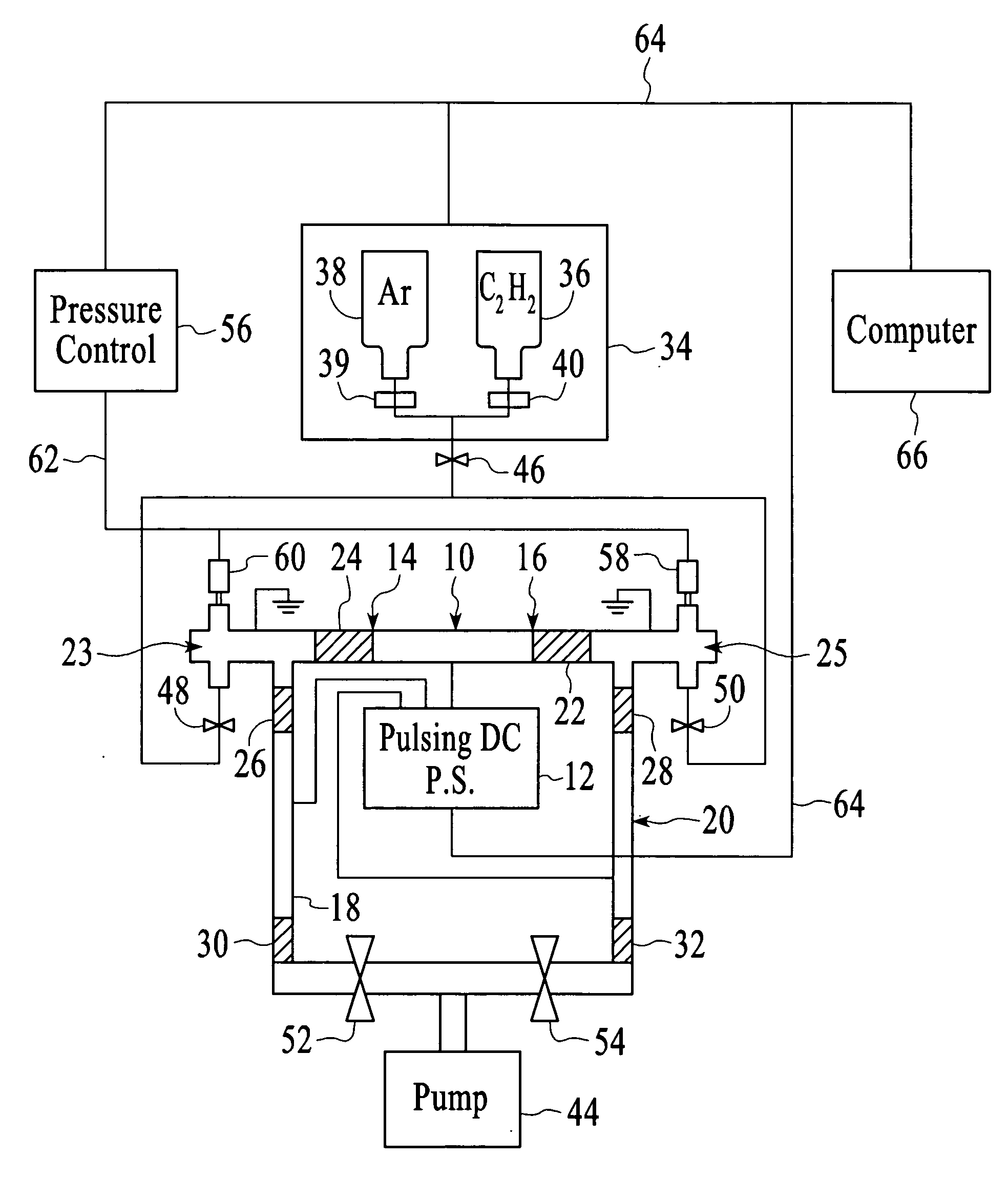

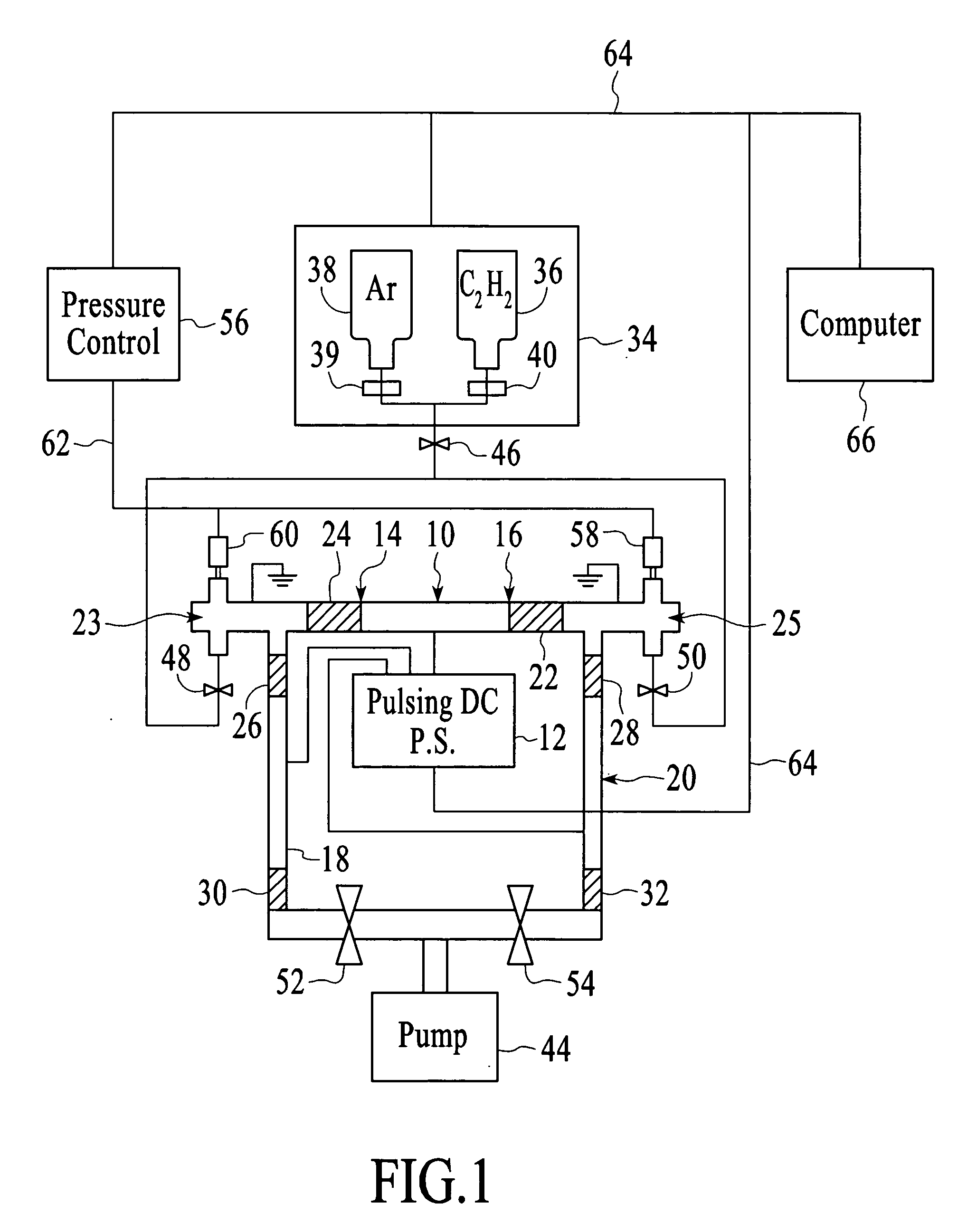

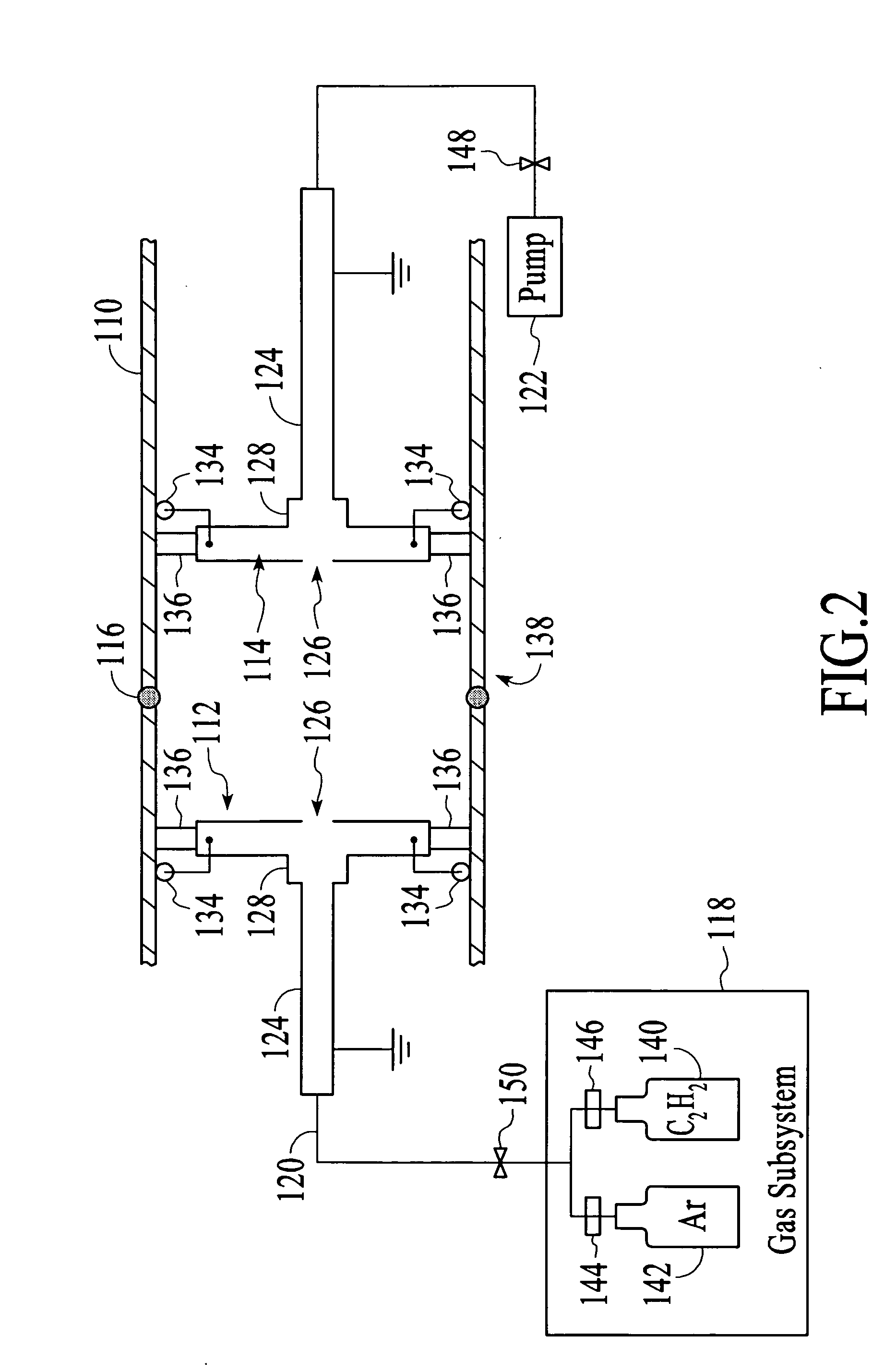

Plasma enhanced bonding for improving adhesion and corrosion resistance of deposited films

ActiveUS20090017222A1Reduce the possibilityGood chemical resistanceChemical vapor deposition coatingPlasma techniqueDiamond-like carbonHigh energy

Plasma Enhanced Bonding (PEB) during a coating process is used to improve both adhesion and corrosion resistance of the resulting coating. New interfacial compounds may be formed, offering the increased resistance to corrosion, as well as enhanced bonding to the workpiece being coated and any subsequently formed layer, such as diamond-like carbon. In one embodiment, the PEB processing is employed during coating of at least one interior surface of the workpiece, which may be a pipe. In a first step, a thin film is deposited. Then, the film is exposed to a high energy etch-back plasma. This two-step cycle of depositing a film and then providing bombardment of the film may be repeated a number of times. Typically, the deposition step of the cycle is much shorter than the bombardment step.

Owner:AGM CONTAINER CONTROLS

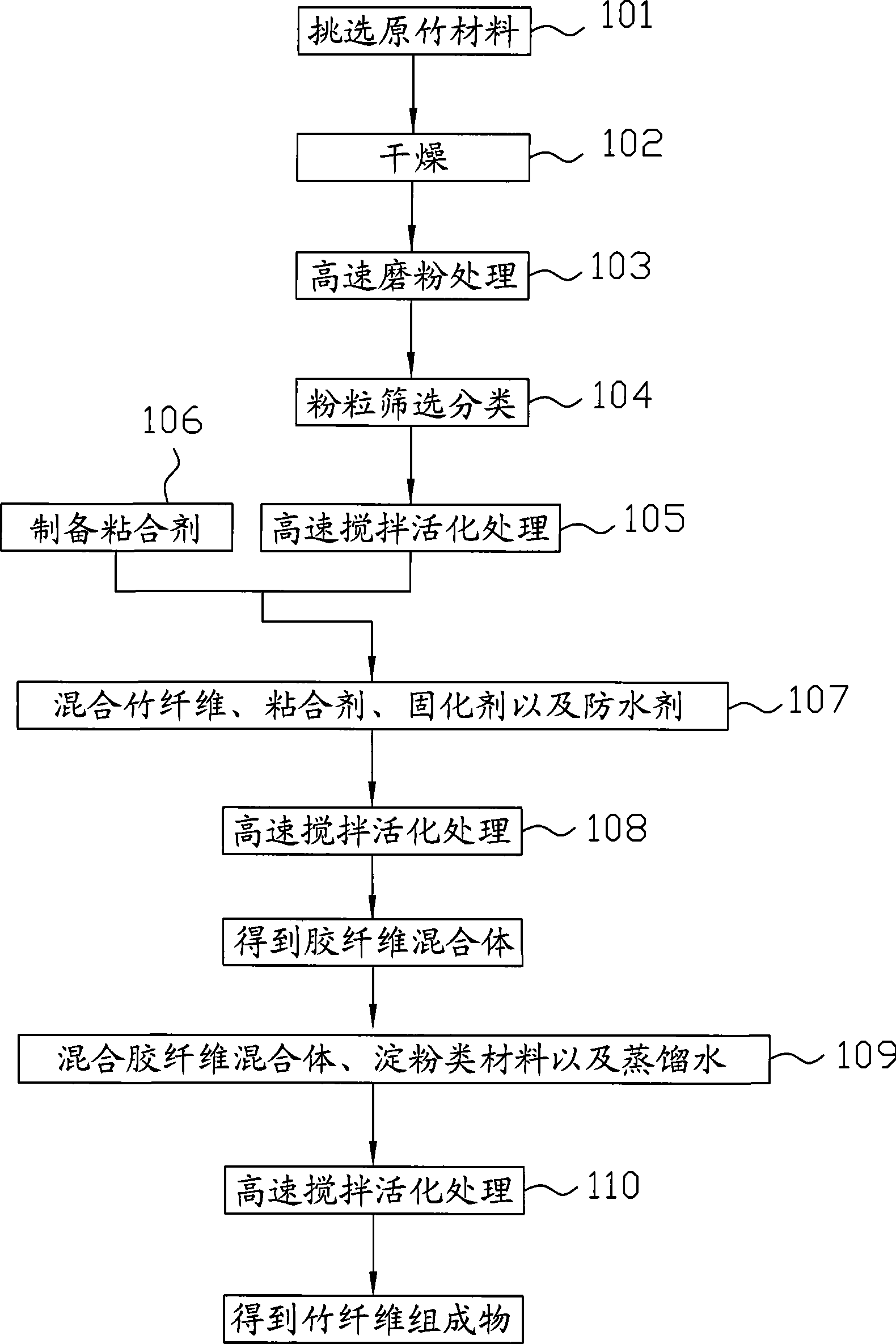

Bamboo fibre composition and method for producing the same

InactiveCN101451318AGood and stable material propertiesNot easy to carbonize blackWater-repelling agents additionReinforcing agents additionProduct processingFibre composition

The invention relates to a bamboo fiber composition and a manufacturing method thereof. The bamboo fiber composition comprises the following components: 35 to 55 weight percent of bamboo fiber, 25 to 50 weight percent of bonding agent, 0.4 to 0.7 weight percent of curing agent, 0.4 to 0.8 weight percent of waterproof agent, 12 to 18 weight percent of starch material and 2 to 4 weight percent of water. The manufacturing method comprises the following steps: mixing bamboo raw materials with the water and stirring the mixture at a high speed to obtain a bamboo fiber; and mixing a proper proportion of the bamboo fiber, the bonding agent, the curing agent, the waterproof agent, the starch material with the water; and stirring the mixture at a high speed to obtain the bamboo fiber composition. In the steps, high-speed stirring treatment is performed to activate the material property of the bamboo fiber composition, so that the material property is good and stable, and the material has even color and luster; in addition, the activation treatment makes the composition of the bamboo fiber composition even, and endows the bamboo fiber composition with good flowability in the finished product processing process.

Owner:吴瑞良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com