Patents

Literature

111 results about "Fibre composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical Composition of Natural Fiber: Every fiber consists of some chemical elements. Such as cotton contains cellulose, protein, pectin etc. Wool contains keratin, dirt, suint etc. Chemical composition of natural fibers are given below:

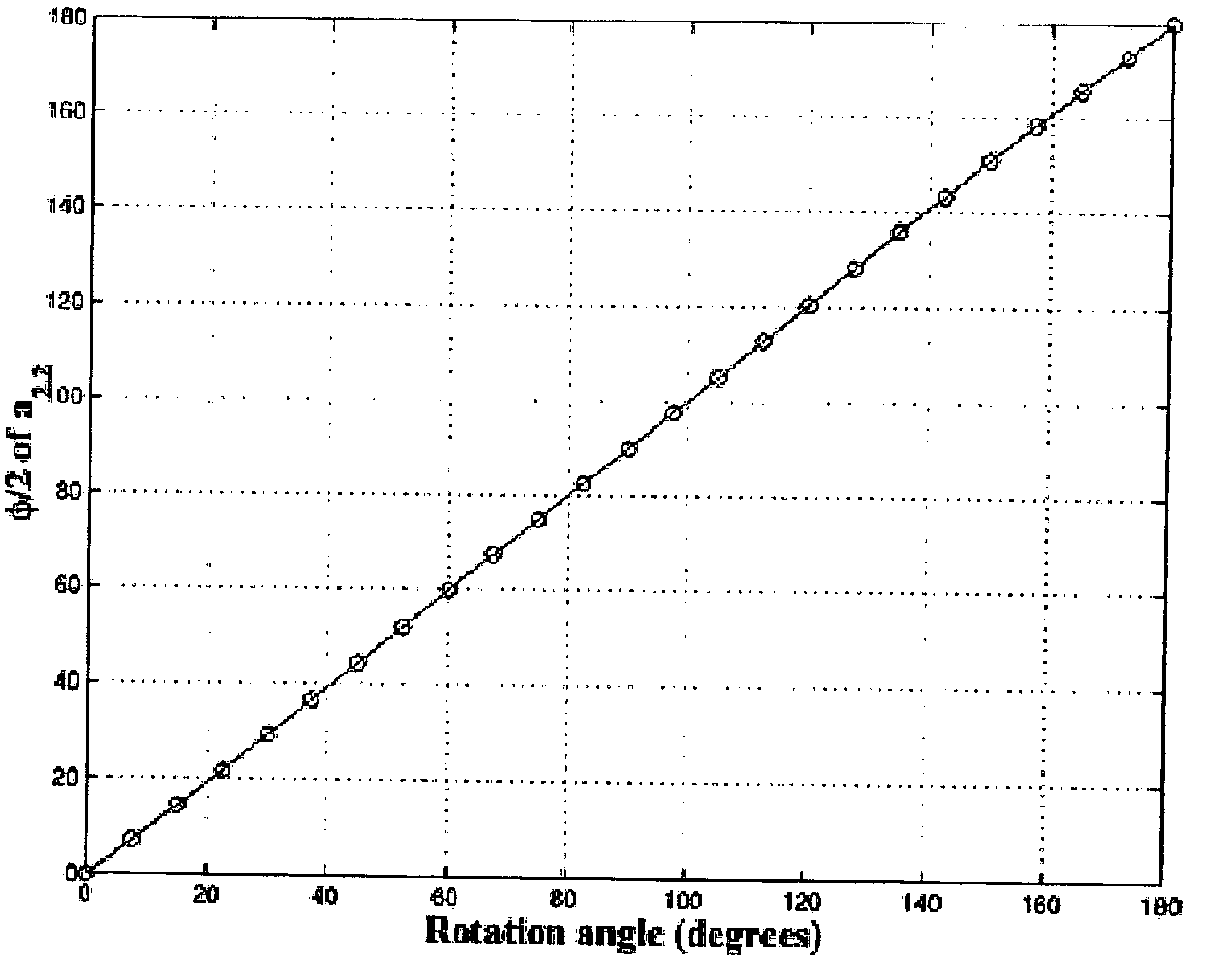

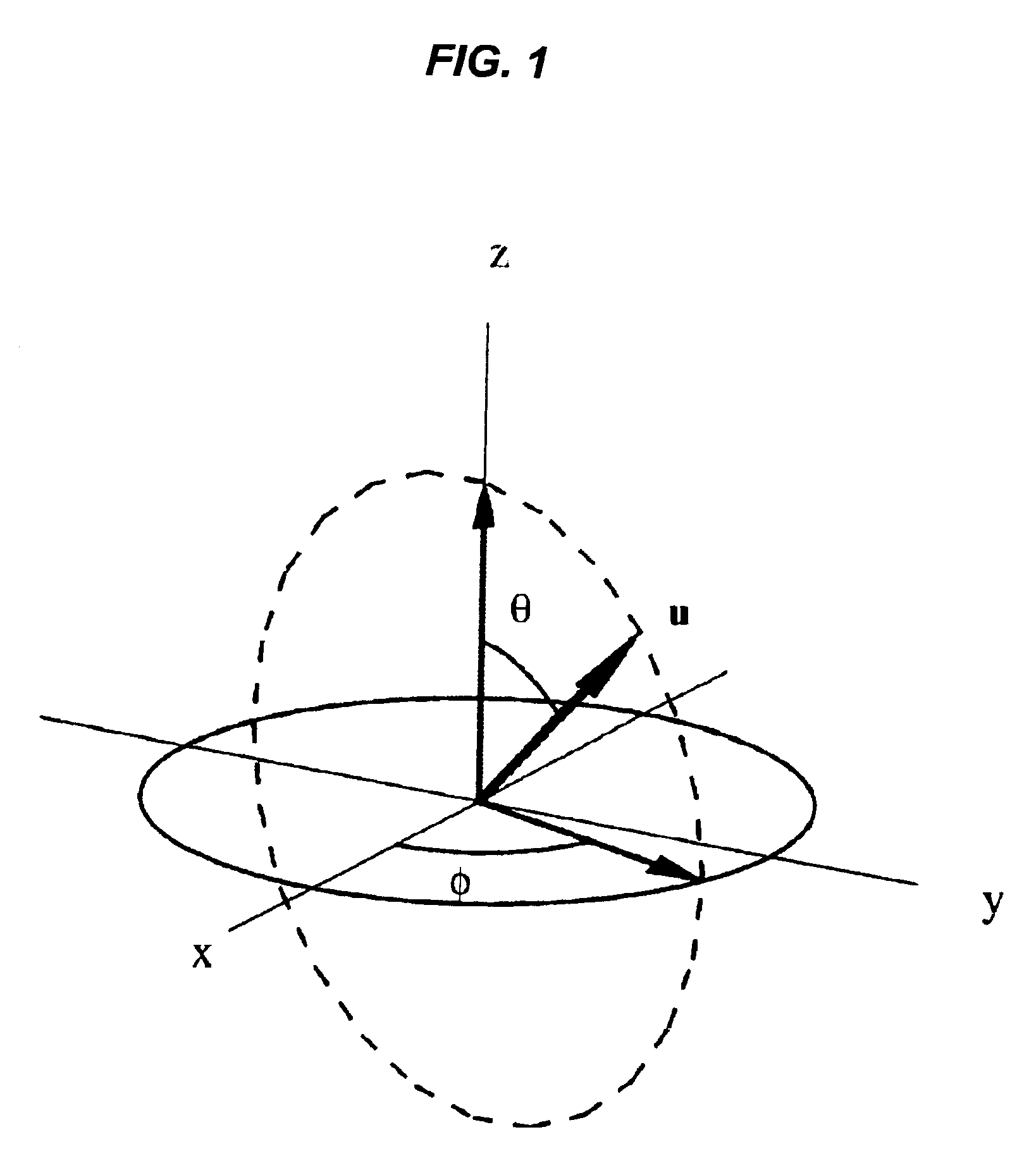

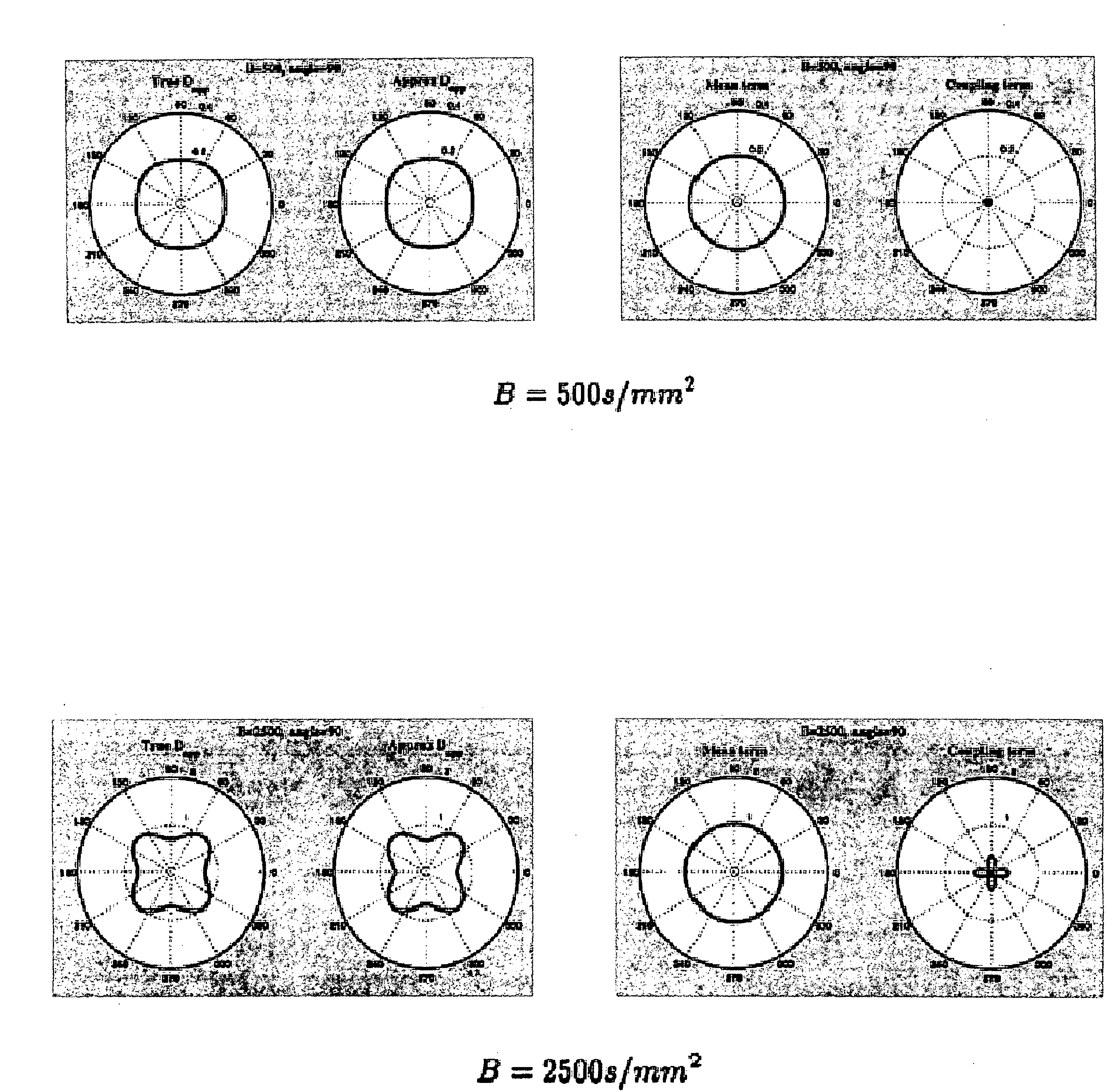

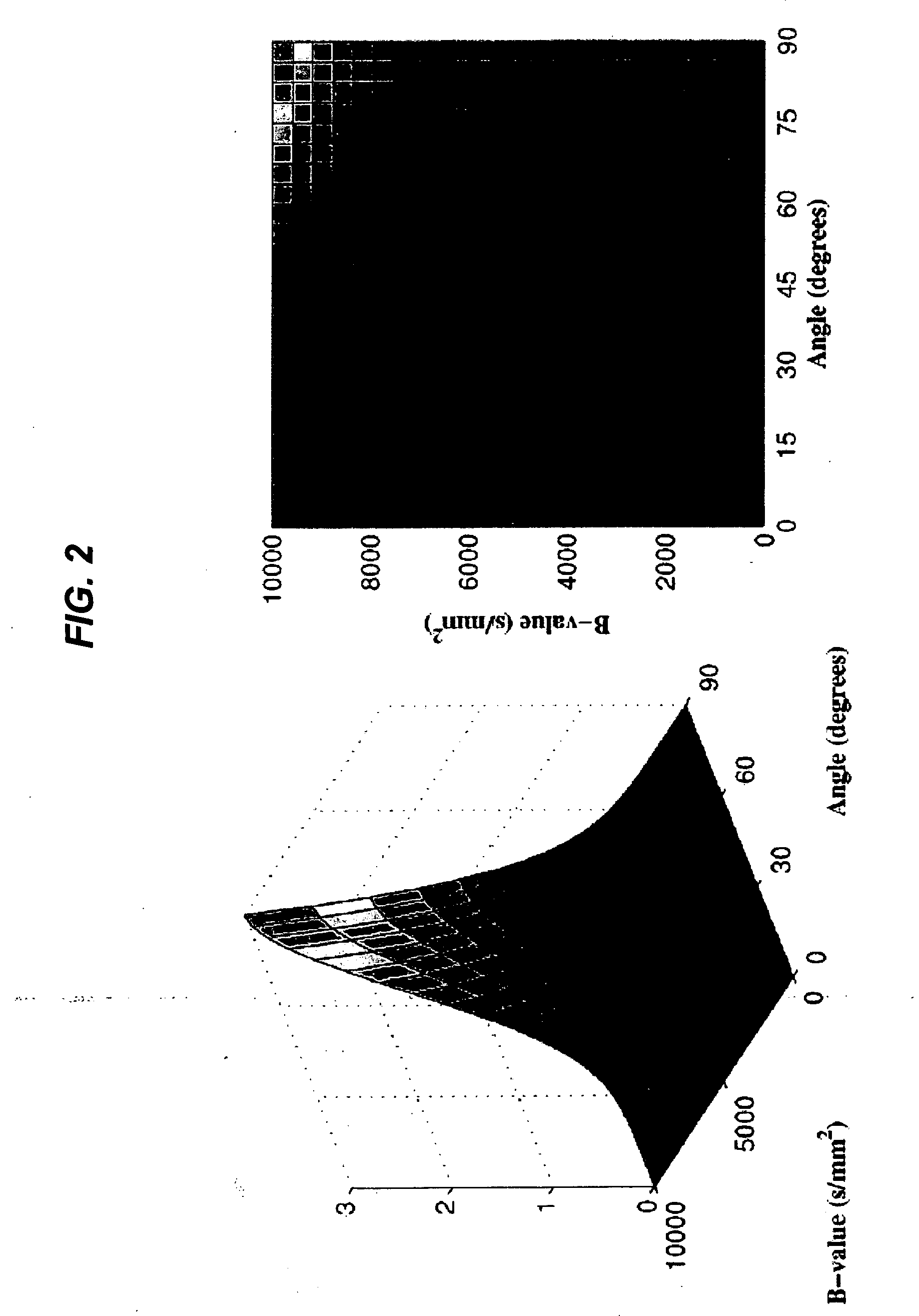

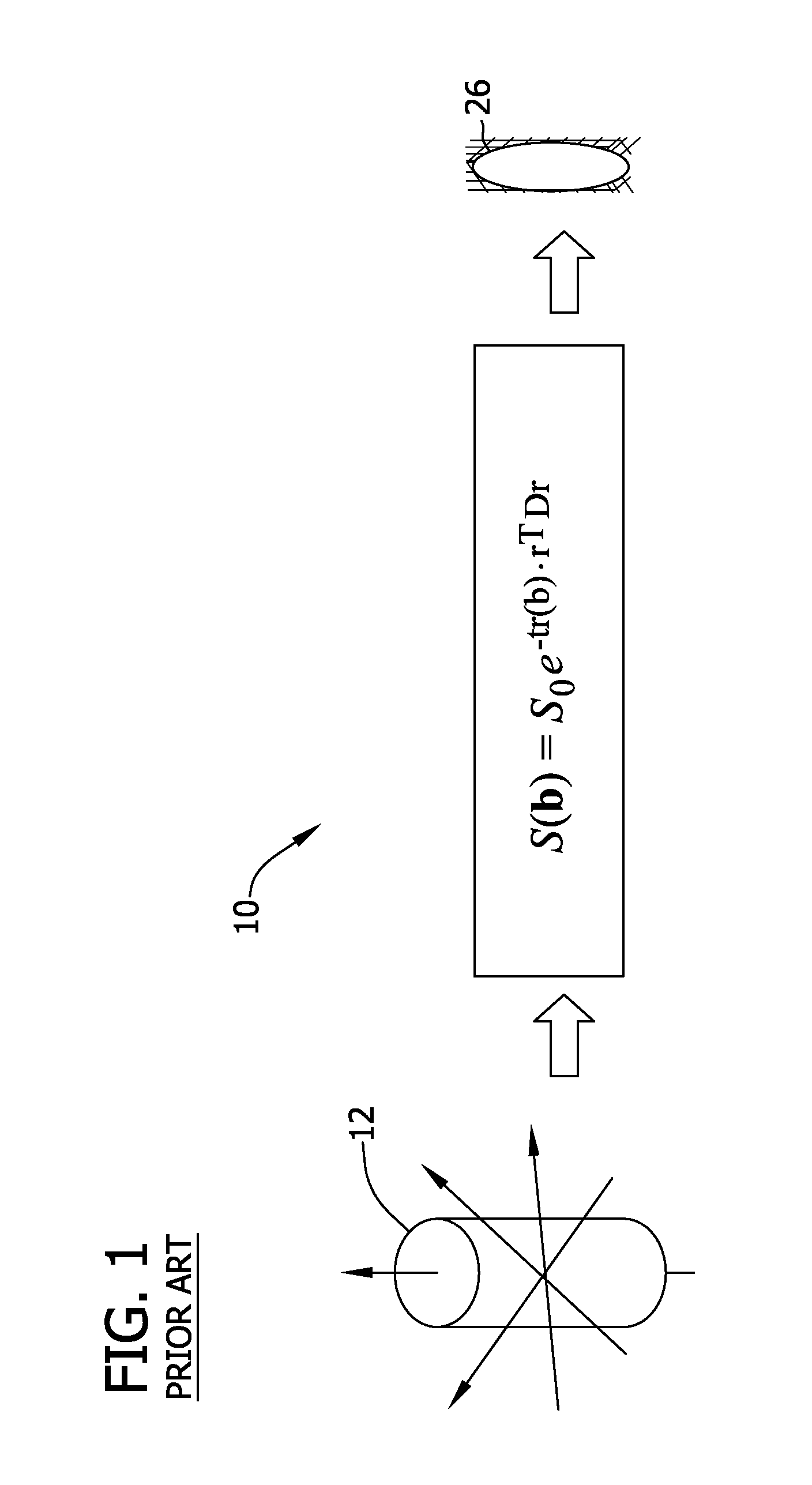

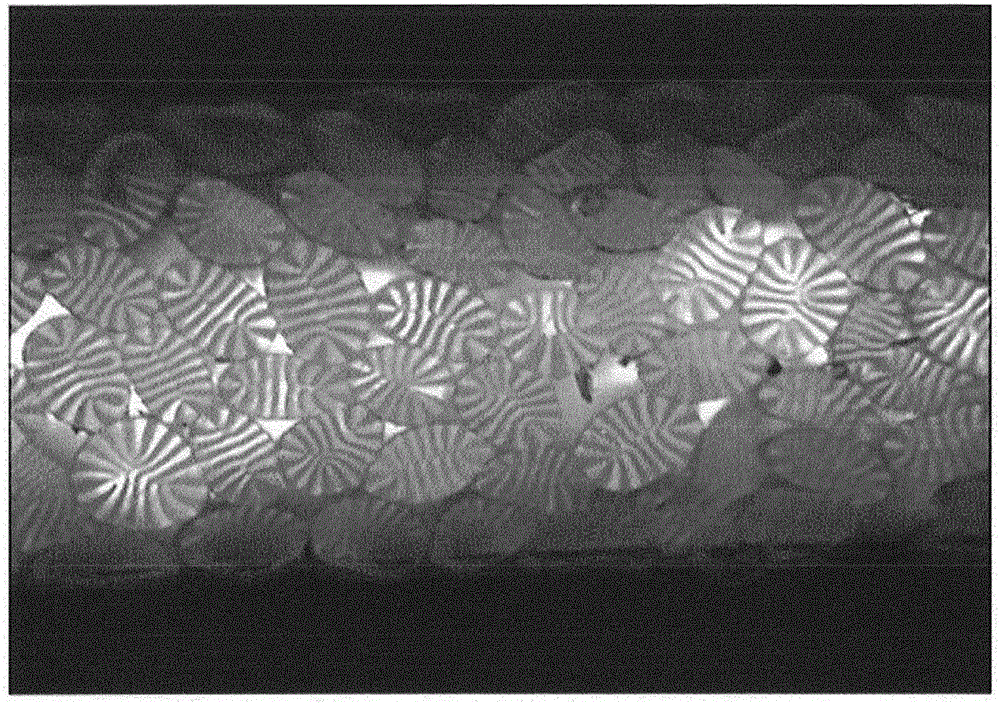

Method for analyzing MRI diffusion data

A new transform is disclosed, applying methods of group theory, with which the composition of a voxel of three channels comprising isotropic, single fiber and multiple fiber components can be determined, as well as the magnitude and orientation of the diffusion field. Asymmetries produced by experimental artifacts fall into channels distinct from the fiber channels, allowing their separation and a subsequent reduction in noise from the reconstructed fibers.

Owner:U S GOVERNMENT REPRESENTED BY THE DEPT OF VETERANS AFFAIRS +1

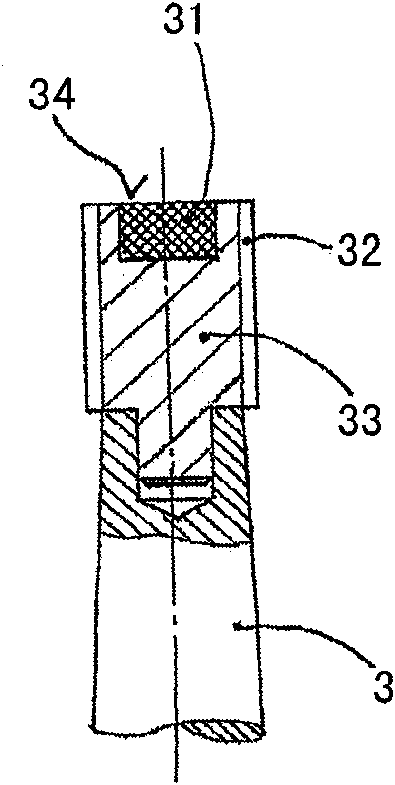

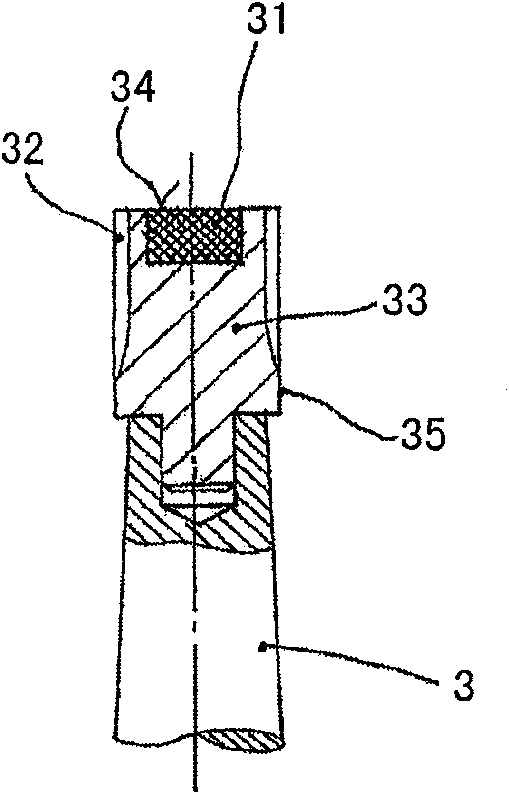

Spontaneously degradable fibers and goods made thereof

InactiveUS6844062B2Easy to splitGood bulkinessSynthetic resin layered productsFilament/thread formingYarnPolyester

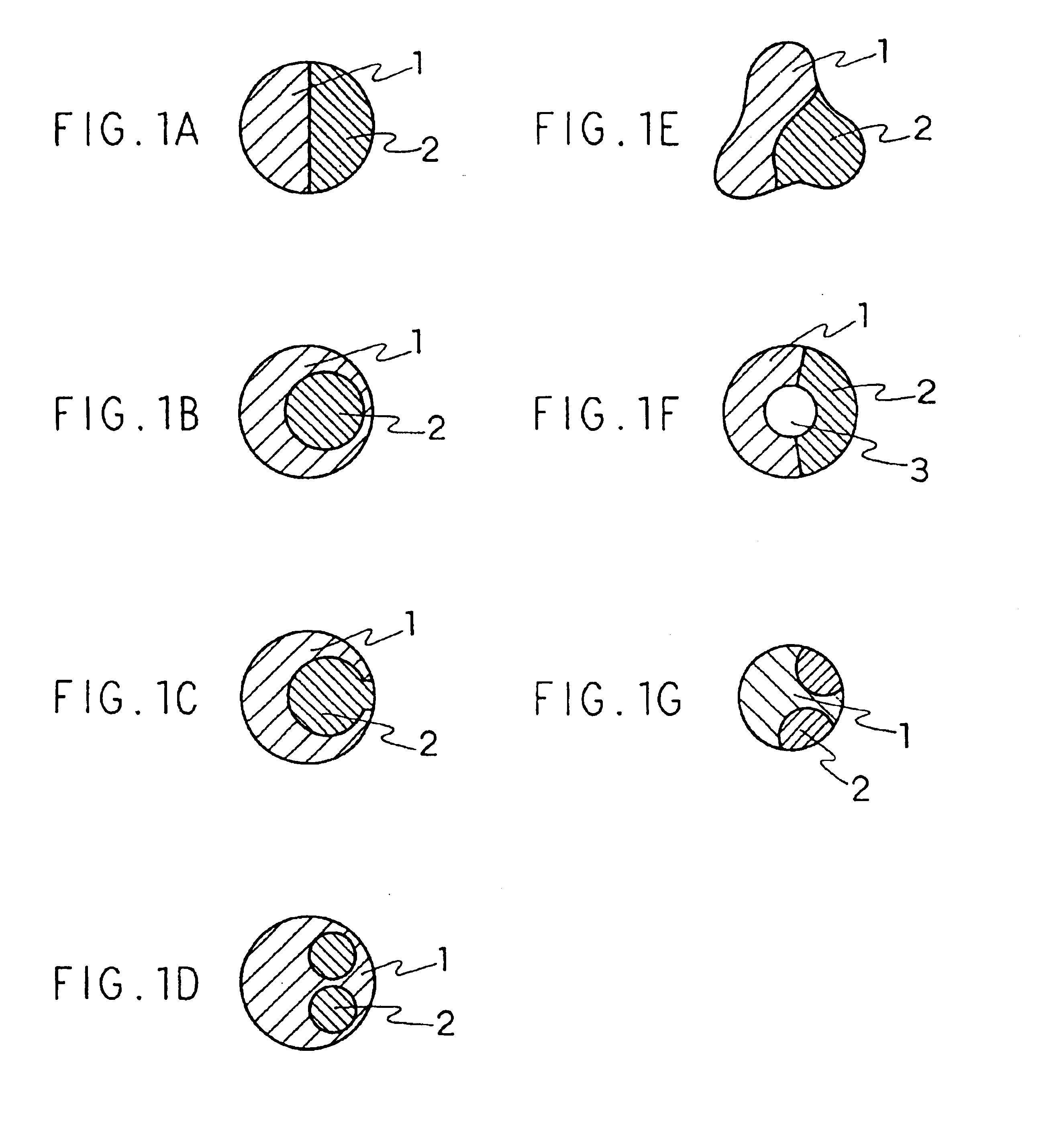

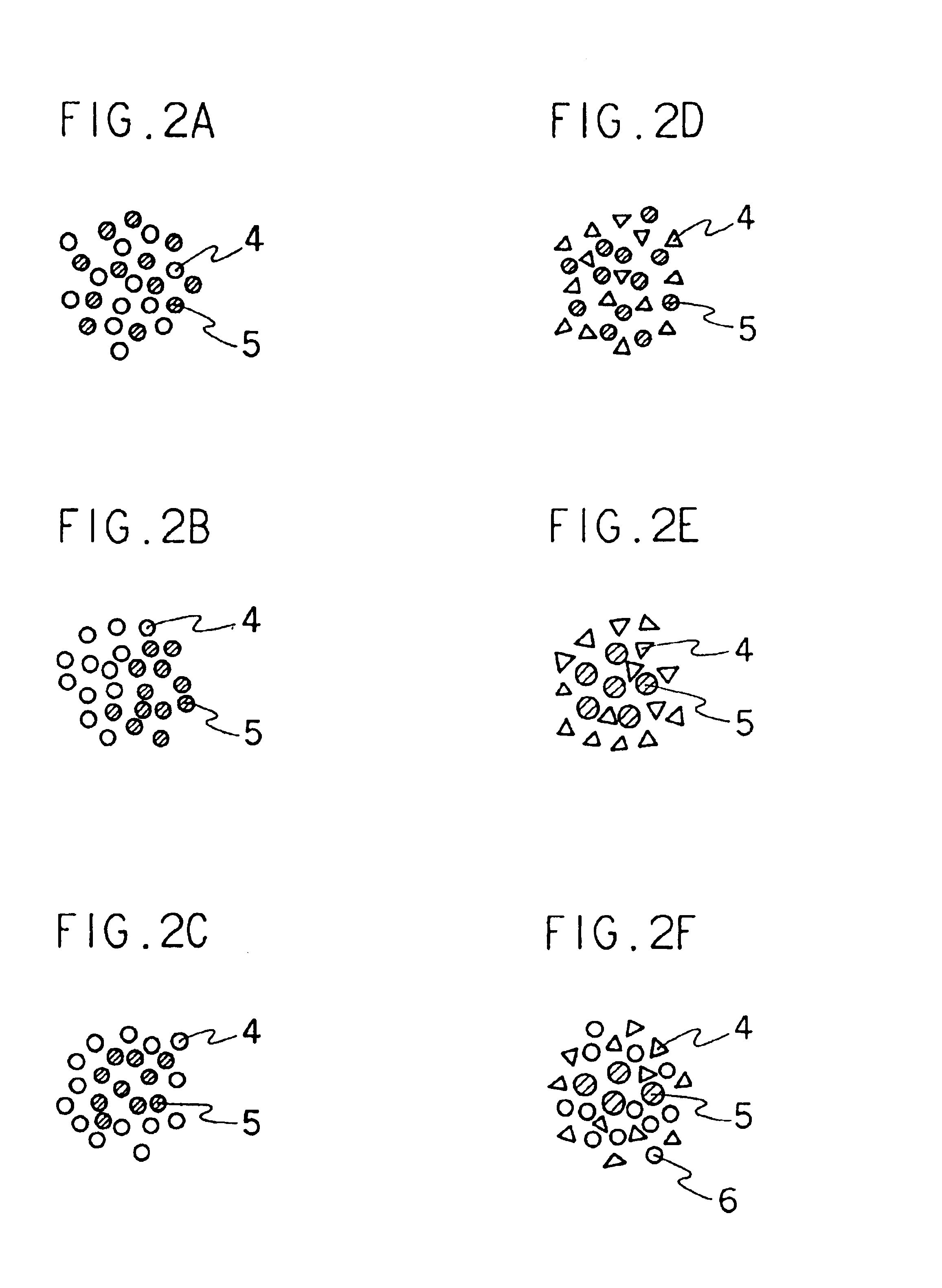

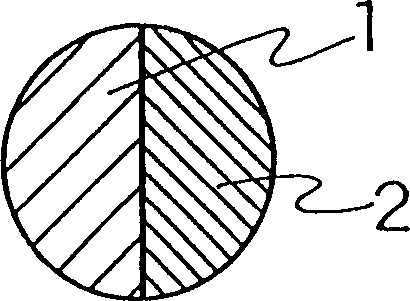

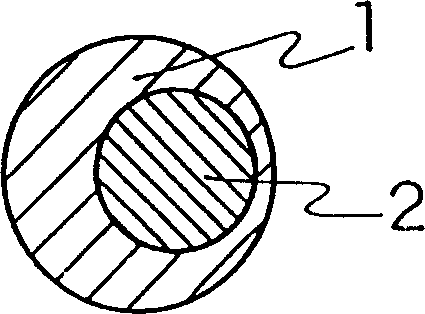

A spontaneously degradable fiber excellent in bulkiness, softness, stretchability and feeling, which comprises (A) a low heat-shrinkable fiber component comprising a high crystalline aliphatic polyester and (B) a high heat-shrinkable fiber component comprising an aliphatic polyester, e.g., a low crystalline or non-crystalline aliphatic polyester, and a block copolymer or a mixture the main component of which is an aliphatic polyester and which comprises a high-melting component and a low-melting component. Further, fibers excellent in self-crimpability or self-adhesion property and dividable fibers are obtained by suitably combining the fiber components (A) and (B) to form conjugated fibers or composite yarns.

Owner:TORAY IND INC

Method for analyzing MRI diffusion data

A new transform is disclosed, applying methods of group theory, with which the composition of a voxel of three channels comprising isotropic, single fiber and multiple fiber components can be determined, as well as the magnitude and orientation of the diffusion field. Asymmetries produced by experimental artifacts fall into channels distinct from the fiber channels, allowing their separation and a subsequent reduction in noise from the reconstructed fibers.

Owner:U S GOVERNMENT REPRESENTED BY THE DEPT OF VETERANS AFFAIRS +1

Process for producing a fibre compositions

InactiveUS20070143932A1Eliminate the problemGood componentSpecial paperPaper after-treatmentPolymer scienceFibre composition

The present invention relates to fibre compositions. In particular, the present invention concerns a process for producing a fibre composition comprising a lignocellulosic fibre material and a synthetic, electrically conductive polymer formed by polymerized monomers. The invention provides for good adhesion between the fibre matrix and the polymer, because the monomer is polymerized directly on the fibre. The conductivity of the polymer is improved and the electrical properties and conductivity levels of the modified fibre can be adjusted by changing the amounts of the electrically conductive polymer.

Owner:VALTION TEKNILLINEN TUTKIMUSKESKUS

Paper made from collagen fiber and its processing method

InactiveCN101050602ARaise the gradeImprove flame retardant performancePaper/cardboardRaw material divisionPlant fibrePapermaking

The present invention discloses a kind of paper made of collagen fiber and its processing method. The paper made of collagen fiber includes fiber component and non-fiber component; said fiber component is formed from 10-100 wt% of collagen fiber and 0-90 wt% of other fiber for making paper. Its processing method mainly includes the following steps: screening raw materials, liquid defibrination, cleaning, rinsing, and opening by using liquor, dewatering and drying, opening and removing impurity, carding, pulping and papermaking.

Owner:张立文

Antimicrobial compositions and fibres incorporating the same

InactiveUS20120082711A1Reduces difficulty and disadvantagePreventing the growth of a broad spectrum of bacteriaBiocideInorganic active ingredientsMasterbatchMechanism of action

The present application defines an antimicrobial composition comprising (a) at least two antimicrobial agents having different antimicrobial mechanisms of action and being present in amounts that together provide a synergistic antimicrobial effect or (b) an antimicrobial agent and a surface modifying agent, an antimicrobial masterbatch comprising antimicrobial composition (a) or (b) and a polymer carrier, an antimicrobial fibre composition comprising the antimicrobial masterbatch and a fibre substrate, an antimicrobial fibre comprising a fibre body or a fibre surface having the antimicrobial fibre composition, and a process for producing antimicrobial fibres.

Owner:NOVEKO

Wool, pearl fibre, modal, viscose blended yarn and method of processing the same

The invention relates to blended yarn which contains wool, pearl fiber, modal fibre and viscose, and a machining method thereof. The blended yarn is composed of wool, pearl fiber, modal fibre and viscose with the mass ratio as the following: wool 10-15%, pearl fiber 20-30%, modal fibre 30-35% and viscose 25-30%. The blended yarn can be in pure white, bleached to be white, gray, apricot, pinkish purple, or in other colors. The performance index meets the requirements that the single yarn rupture strength is 12.5-19.5cN / tex, the CV value of single yarn rupture strength is less than or equal to 6.0% and the CV value of yarn evenness variation coefficient is less than or equal to 15%. The processing method includes the following steps: dyeing according to the tinctorial pattern of a matching card (used for producing colored yarn), manually mixing the cotton and baling; grabbing the cotton through a disc, blending and opening the cotton, opening the cotton through carding pins, feeding cotton in the vibrating mode, single beater scutching, combing the cotton, drawing, roving, spinning, winding and packing.

Owner:江阴市茂达棉纺厂有限公司

Cellulosic fibre composition

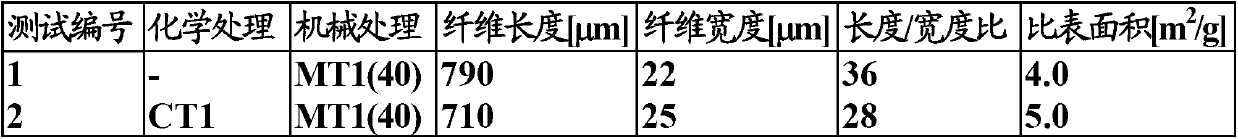

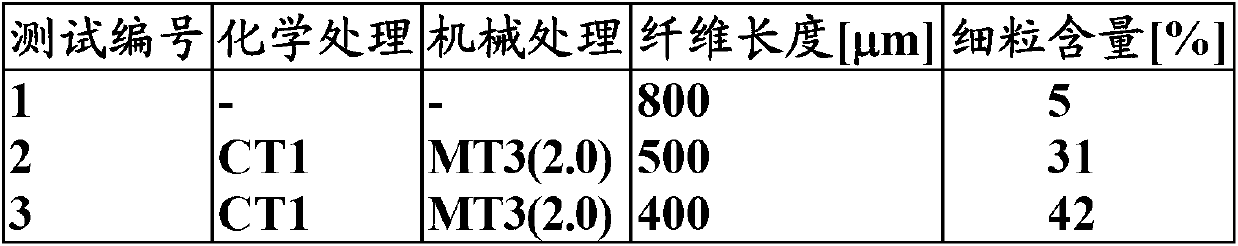

InactiveCN102971462AEasy to prepareWithout significant loss of qualityWood working apparatusPaper/cardboardChemical treatmentNitroxyl radicals

The invention relates to a composition comprising cellulosic fibres having an average degree of substitution of anionic groups of from 0.001 to 0.25, and DEG a length weighted mean fibre length up to 1,100 [mu]m and a length weighted mean fibre width over 10 [mu]m, or DEG a length weighted mean fibre length up to 1,100 [mu]m, and wherein at least 50 % by weight of the cellulosic material is insoluble in water, or DEG a length weighted mean fibre length / width ratio up to 30, or DEG a length weighted mean fibre width over 35 [mu]m. The invention also relates to a composition comprising cellulosic fibres having a specific surface area of at least 1.5 m2 / g, a length weighted mean fibre length / width ratio up to 30, and a dry solids content of at least 5 % by weight, based on the weight of the composition, or up to 30 % by weight, based on the total weight of the cellulosic fibres, of cellulosic fibres with a length weighted mean fibre length up to 100 [mu]m. Method of producing a composition comprising cellulosic fibres which comprises subjecting cellulosic fibres to chemical treatment and mechanical treatment, wherein the chemical treatment comprises treating cellulosic fibres with (i) at least one agent containing a carboxyl group, optionally substituted, (ii) at least one oxidant and at least one transition metal, or (iii) at least one nitroxyl radical, and the mechanical treatment comprises subjecting cellulosic fibres to extrusion with a twin-screw extruder or a planetary roller extruder. The invention also relates to a method of producing a composition comprising cellulosic fibres which comprises subjecting cellulosic fibres having an average degree of substitution of anionic groups of from 0.001 to 0.25 to extrusion. The invention also relates to a composition comprising cellulosic fibres obtainable by the methods, a process for producing a cellulosic pulp mixture which comprises mixing the composition with cellulosic pulp, a cellulosic pulp mixture obtainable by the process, and the use of the composition and cellulosic pulp mixture as an additive in the production of paper and board, processes for producing paper and board in which the composition or cellulosic pulp mixture is used, paper and board obtainable by the processes, and various uses of the paper and board.

Owner:AKZO NOBEL CHEM INT BV

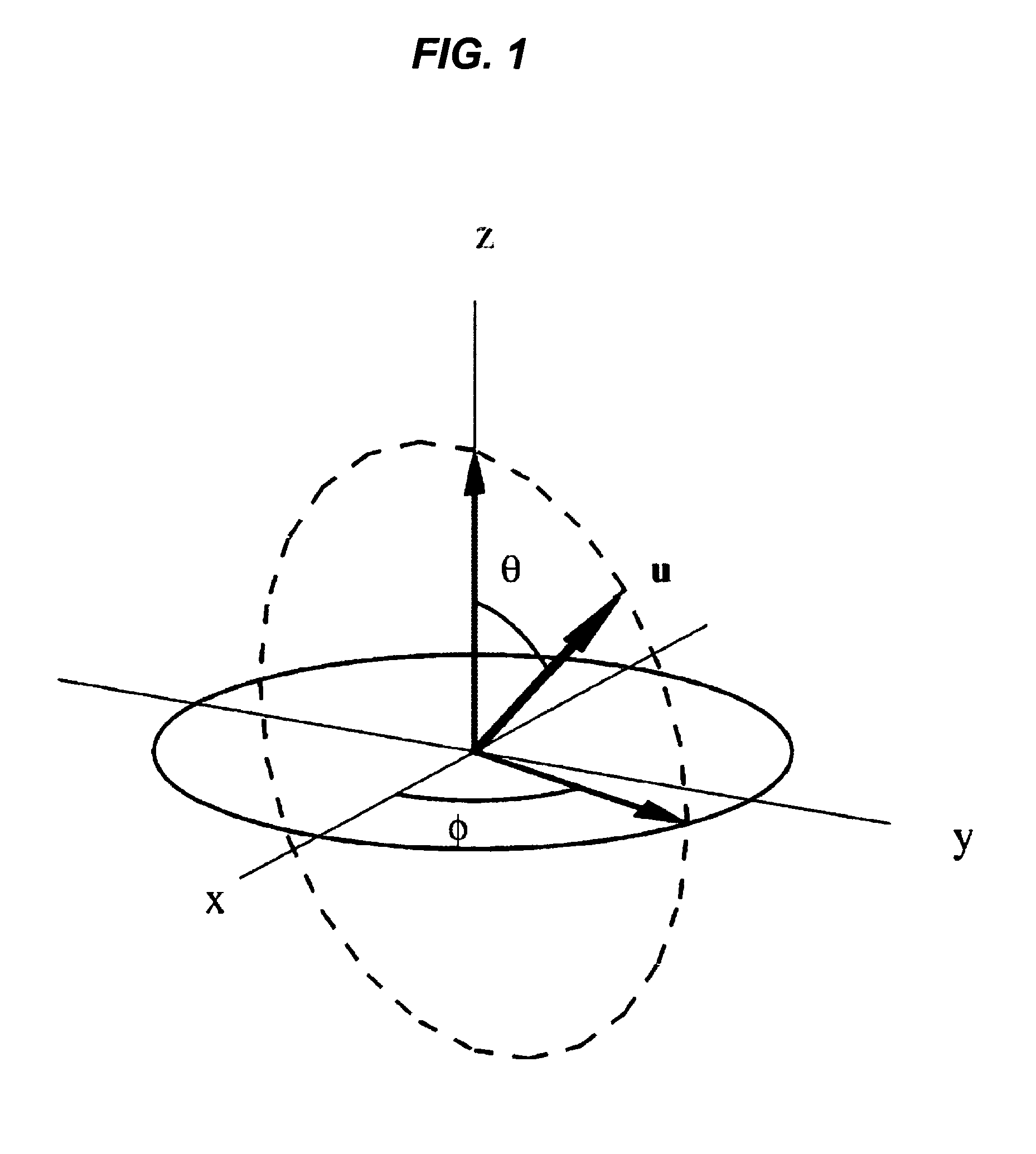

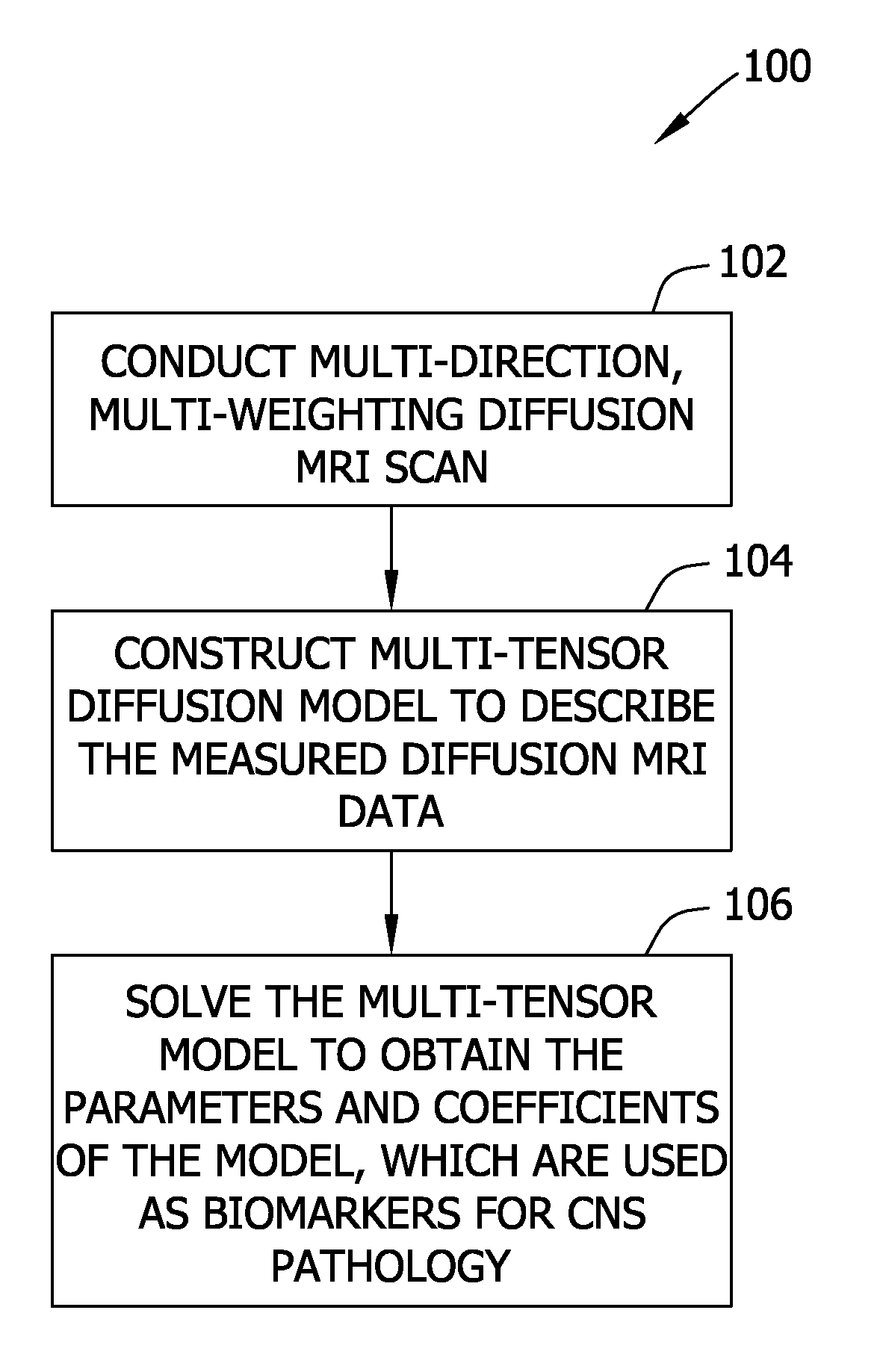

Diagnosis Of Central Nervous System White Matter Pathology Using Diffusion MRI

Determining diffusivity of multiple diffusion components within a tissue using diffusion magnetic resonance data representing a volume of the tissue. A plurality of candidate fibers having a direction is defined within the volume. A possibility coefficient is calculated by a processor for each candidate fiber of the plurality of candidate fibers based on the magnetic resonance data and the direction of the candidate fiber. The possibility coefficient represents a likelihood that the candidate fiber exists in the volume. Candidate fibers associated with a possibility coefficient greater than a threshold value are selected by the processor to create one or more probable fibers. For each probable fiber of the one or more probable fibers, an axial diffusivity indicating a diffusion of water in the direction of the probable fiber and a radial diffusivity indicating a diffusion of water perpendicular to the direction of the probable fiber are calculated by the processor. The diffusivity of isotropic diffusion component and the volume ratios of each fiber component and isotropic components are calculated.

Owner:WASHINGTON UNIV IN SAINT LOUIS

Intumescent Fireproofing Systems and Methods

InactiveUS20130331489A1Eliminate the potential for VOC releaseImprove performanceCoatingsEthyl groupFibre composition

Water-based intumescent fireproofing formulations are provided that exhibit excellent fireproofing properties while simultaneously significantly reducing and / or eliminating the potential for VOC release and exhibiting excellent hangability properties. The intumescent fireproofing formulation includes a coalescent that significantly reduces and / or eliminates the potential for VOC release and fiber constituents, e.g., fibers of greater than 0.2 mm in length. Exemplary coalescents have a boiling point of at least 180° C. and include bis(2-ethylhexanoate)triethyleneglycol, 2,2,4-trimethyl-1,3-pentanediolmono(2-methylproponate) and 2,2,4-trimethyl-1,3-pentanedioldi(2-methylpropanoate). Intumescent fireproofing formulations are also provided that include clay to further improve performance.

Owner:US MINERAL PRODS

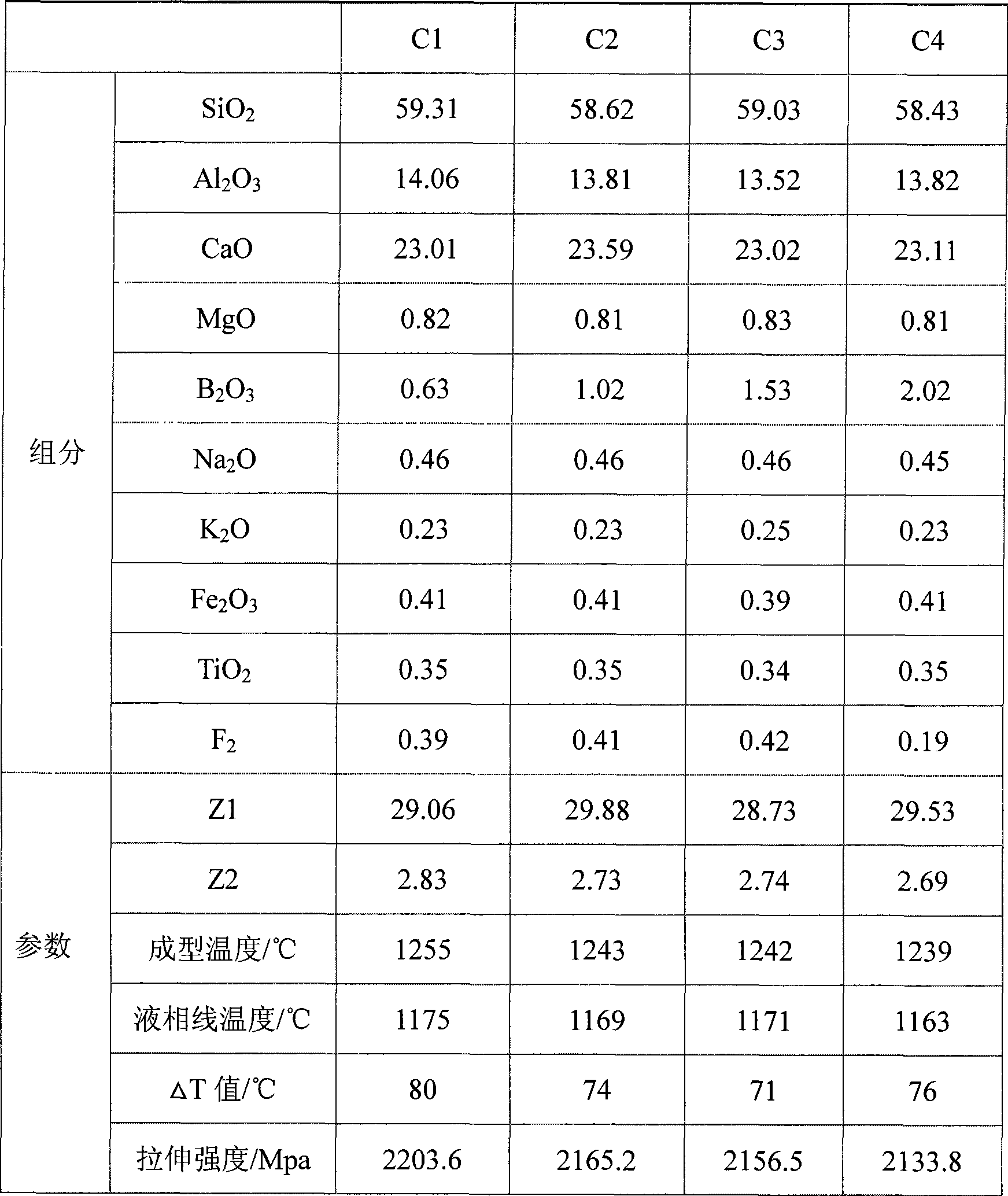

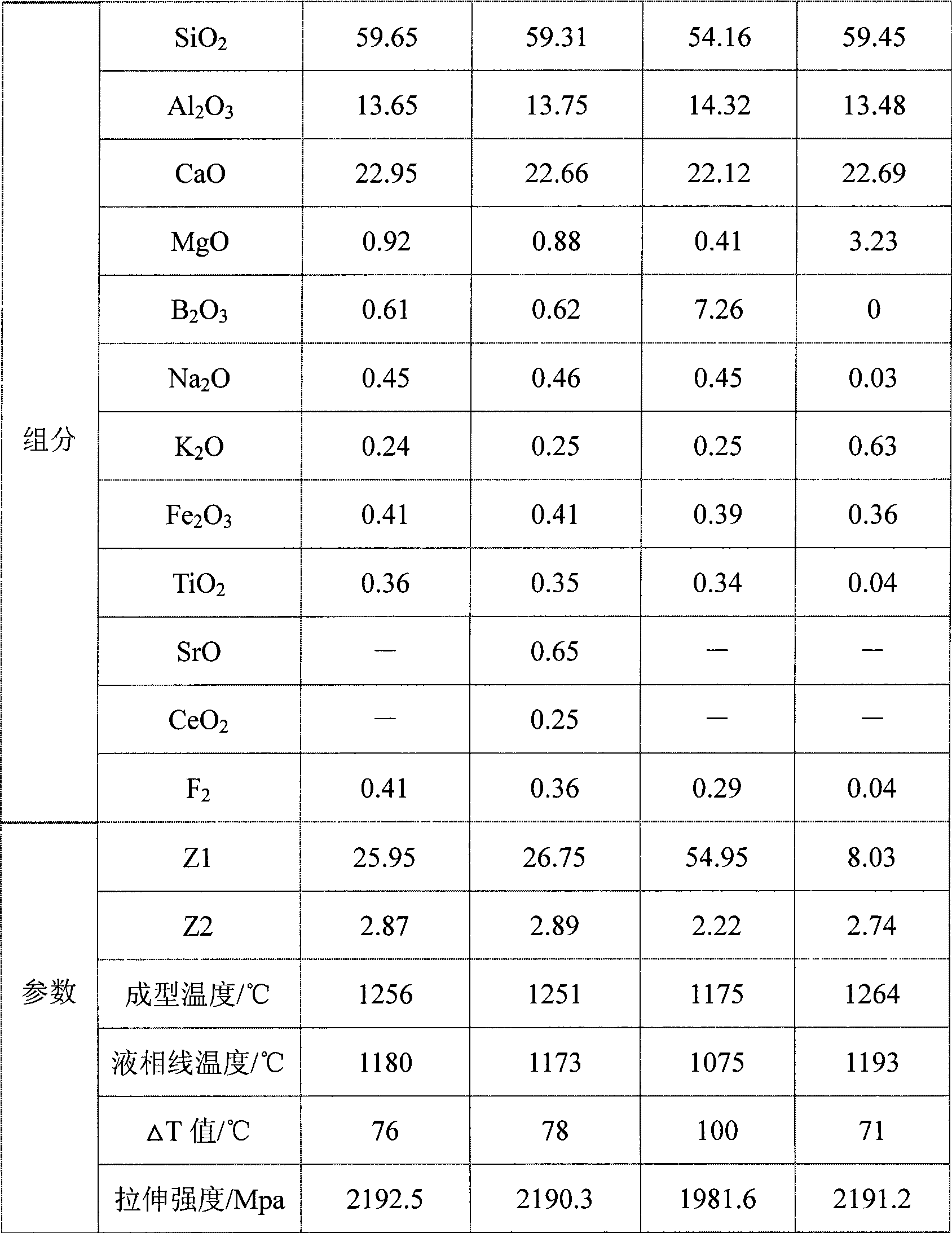

Novel glass fibre composition

The invention relates to a glass fiber composition. The composition comprises the following compositions in percentage by weight: 58 to 65 percent of SiO2, 20 TO 26 percent of CaO, 9 to 17 percent of Al2O3, 0.5 to 1 percent of MgO, 0 to 5 percent of B2O3, 0 to 1 percent of F2, 0.1 to 1 percent of TiO2, 0 to 0.8 percent of K2O and Na2O, 0.1 to 0.5 percent of Fe2O3, and 0 to 0.6 percent of SO3. The glass fiber composition uses SiO2-Al2O3-CaO three-element system as basis, introduces MgO and B2O3 with low content, and reasonably designs the gross weight of alkaline metal oxides and the proportional relationship between the MgO and the CaO, not only contributes to the improvement of the mechanical strength, the high temperature resistance and the chemical stability of the glass, but also has excellent drawing performance; furthermore, the glass fiber composition has low cost in raw materials, and meets the requirement of environmental protection.

Owner:JUSHI GRP CO

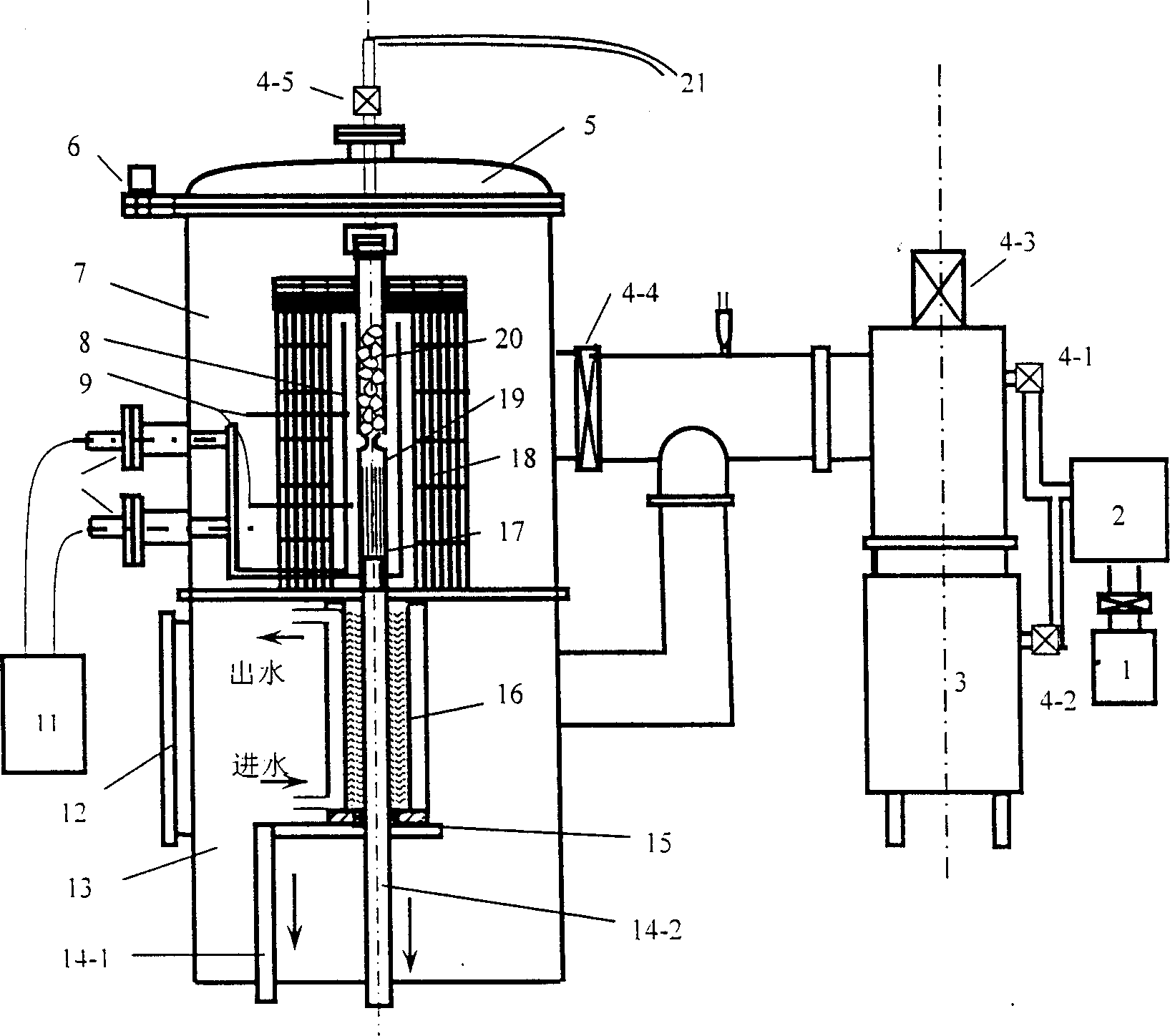

Method of preparing large non crystal/fiber composite material and tis equipment

A process and equipment for preparing great non-crystal / fibre composition block is disclosed. Its equipment features that its heater is composed of a Mo layer and 6 reflecting layers, the mould made of quartz glass or graphite is arranged in said heater and is pneumatically drawn by a drawing mechanism under it, a cooling water tank is under the mould, and a dual-wall design is used for flowing cooling water between two walls and holding Ga-In or Ga-In-Sn alloy in the center. Its advantages are high control capability, less pollution to molten body and low cost.

Owner:UNIV OF SCI & TECH BEIJING

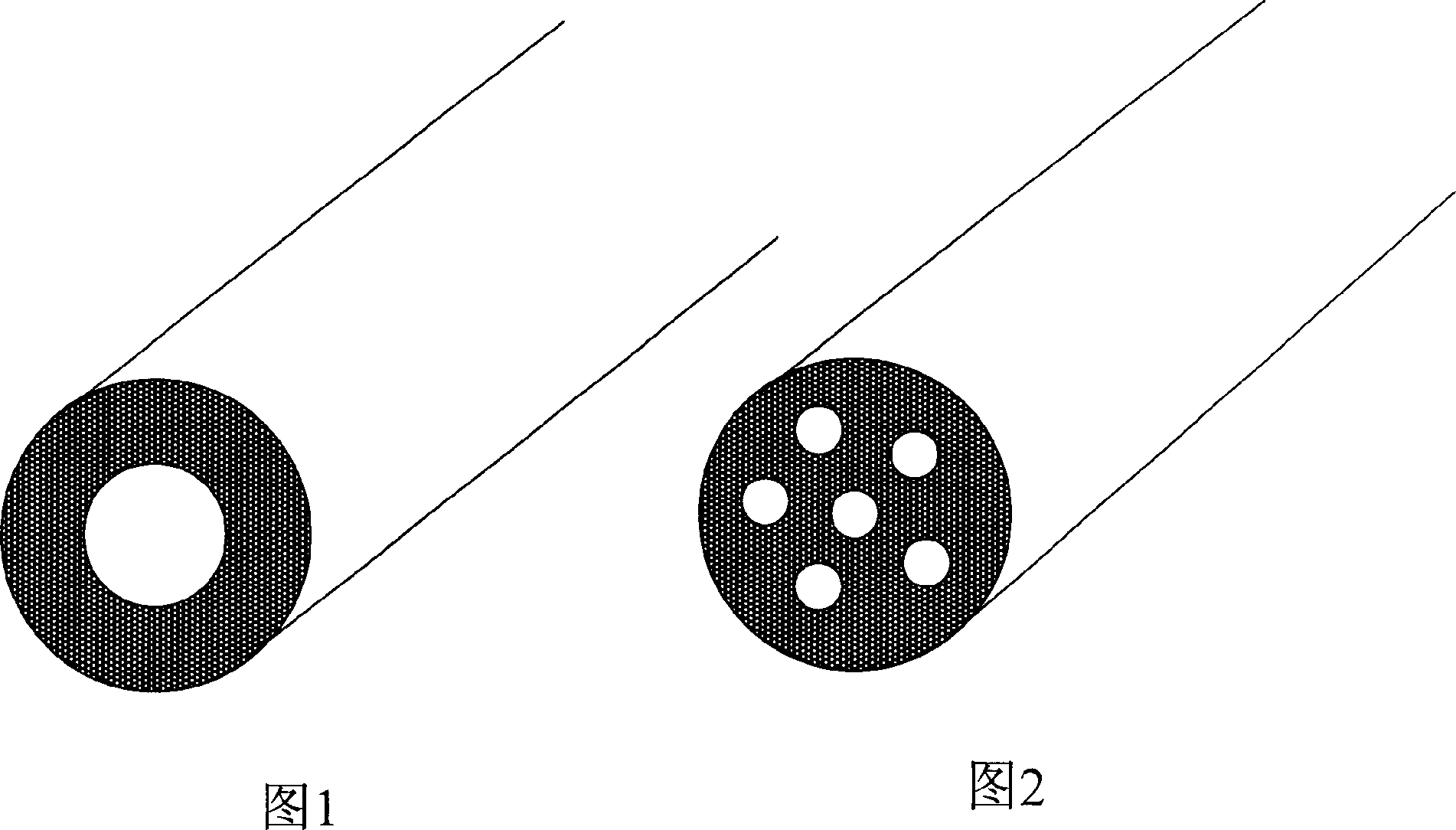

Organic hollow superfine fibre composition and preparation and application thereof

InactiveCN1793445AOvercome areaOvercome costsHollow filament manufactureFibre compositionPrice ratio

The invention discloses organic hollow superfine fiber composite preparing and application. It adopts direct weaving or match-plate victim method to manufacture organic hollow superfine fiber with 15 nm-20 nm inside diameter and 50 nm-500 nm outside diameter. It can be applied to separating, protecting, antibacterial, catalyzing, sensing, decorating, structure support, biological consistent, conducting, repairing, and intelligence responding fields, and etc. It can greatly increase the material whole performance and reduce cost. It has the advantages of convenient manufacturing, low cost, and high quality price ratio.

Owner:张爱华

Cellulose fibre composition

Owner:ZEO IP

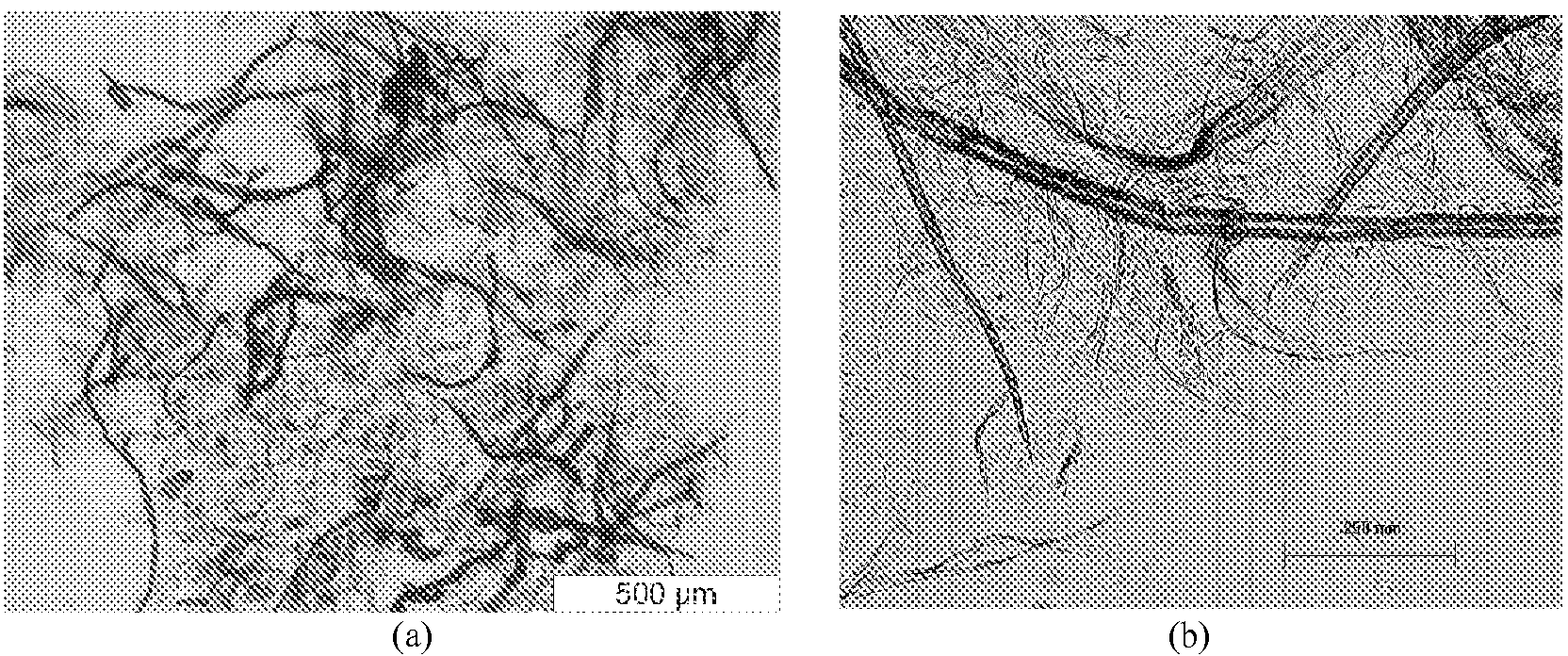

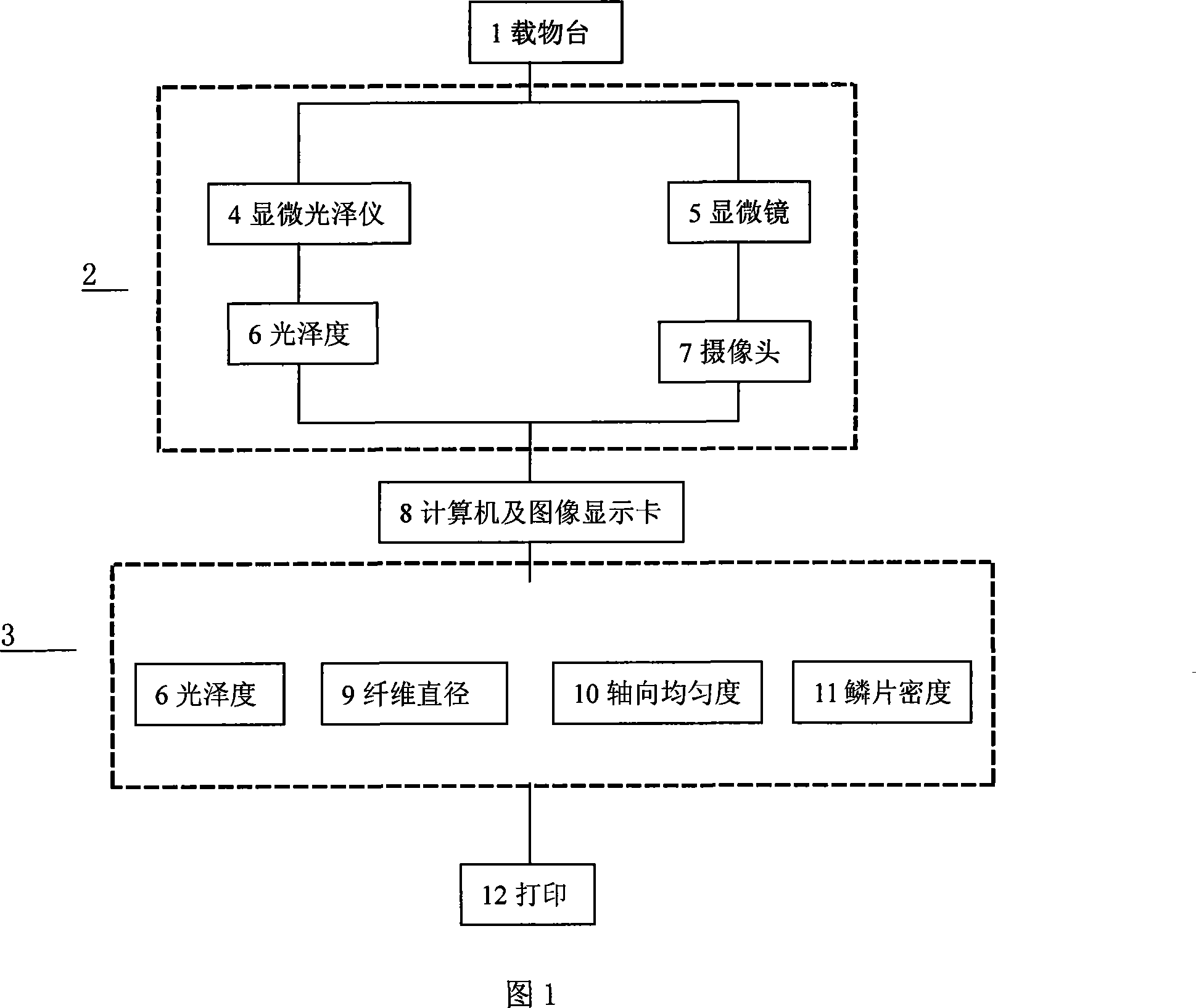

Cashmere fibre, fleece fibre blended spinning quantitative determination instrument and method

InactiveCN101178396AFully automatic and precise actionAccurate calculationScattering properties measurementsTextile testingContinuous measurementInformation processing

The invention relates to a quantitative detection instrument and method for cashmere fiber and wool fiber blending. A micro-gloss meter, a microscope and a digital camera are mounted on a three-dimensional displacement automatic control stage. The stage realizes automatic and precise action and can be positioned The fiber photographed by the microscope corresponds to the fiber photometry measured by the micro-gloss meter; the micro-gloss meter can accurately measure the gloss of each fiber; the computer and image processing system adopts advanced image processing technology to accurately measure, Calculate the fiber diameter and scale density; the information processing system comprehensively evaluates the data collected about fiber diameter, gloss, fiber axial uniformity and scale density, and accurately judges the fiber composition. The invention adopts high-resolution image real-time capture, two-dimensional workbench automatic feed, automatic continuous rapid measurement, improves work efficiency, has high degree of automation and intelligence, simple operation, and changes the differences in test results caused by human factors.

Owner:DONGHUA UNIV +1

Chemical corrosion-resistant blended fabric

InactiveCN104055253AGood chemical resistanceImprove high temperature resistanceProtective garmentSpecial outerwear garmentsChemical safetyTemperature resistance

The invention discloses a chemical corrosion-resistant blended fabric. The chemical corrosion-resistant blended fabric is formed by blending and weaving four types of fabric fibers of Teflon fibers, polyphenylene sulfide fibers, chlorine-containing fibers and aromatic polyamide fibers; the chemical corrosion-resistant blended fabric is formed by the components in percentage by weight of 35-39% of Teflon fibers, 20-24% polyphenylene sulfide fibers, 18-22% chlorine-containing fibers and 15-27% of aromatic polyamide fibers. The fabric is formed by blending and weaving the four types of fabric fibers of Teflon fibers, polyphenylene sulfide fibers, chlorine-containing fibers and aromatic polyamide fibers, and has excellent chemical corrosion resistance, flaming retardance and high temperature resistance and is high in chemical safety protection level and the woven fabric is high in strength and abrasion-resistant.

Owner:ZHANGJIAGANG CITY YANGSHE TOWN XINMIYANG KNITTINGMILL

High modulus glass fibre composition, and glass fibre and composite material thereof

A high-modulus glass fiber composition, and a glass fiber and a composite material therefrom. The glass fiber composition comprises the following components in weight percentage: SiO2 55.7 to 58.9%, Al2O3 15 to 19.9%, Y2O3 0.1 to 4.3%, La2O3 less than or equal to 1.5%, CeO2 less than or equal to 1.2%, CaO 6 to 10%, MgO 9.05 to 9.95%, SrO less than or equal to 2%, Li2O+Na2O+K2O less than or equal to 0.99%, Li2O less than or equal to 0.65%, Fe2O3 less than 1%, TiO2 0.1 to 1.5%; wherein, the range of the weight percentage ratio C1=Y2O3 / (Y2O3+La2O3+CeO2) is greater than 0.6. The composition can greatly improve the elastic modulus of glass, significantly reduce liquidus temperature and forming temperature of the glass, greatly reduce the crystallization rate of molten glass and bubble amount under the same conditions, and therefore is more suitable for large-scale tank furnace production of high-modulus fiberglass with low bubble amount.

Owner:JUSHI GRP CO

Spontaneously degradable fibers and goods made thereof

InactiveCN1560339AFilament/thread formingConjugated synthetic polymer artificial filamentsYarnPolyester

Owner:TORAY IND INC

Inorganic fibre compositions

Owner:THE MORGAN CRUCIBLE CO PLC

Preparation method for high-toughness and wear-resistant cement fiber board

The invention relates to a preparation method for a high-toughness and wear-resistant cement fiber board, belonging to the technical field of preparation of building materials. The preparation methodprovided by the invention has the following steps: subjecting rice straw and rice leaves used as raw materials to a reaction, carrying out filtering so as to obtain filter residue, then soaking the filter residue with acetic acid, carrying out ultrasonic oscillation, adding magnesium chloride so as to prepare a mixed solution, mixing the mixed solution, glucose and rice husks, carrying out fermentation and high-temperature treatment, then mixing a high-temperature treatment product, cement and water, and carrying out hot pressing, drying and discharging so as to obtain the high-toughness and wear-resistant cement fiber board. According to the invention, all organic fiber components in the rice straw and the rice leaves are separated; meanwhile, through introduction of magnesium ions, strength and toughness of plant fiber are improved; fiber components of the rice straw and the rice leaves are partially hydrolyzed to generate a saccharide compound and organic carboxylic acid, so the bonding effect among all components in a cement fiber board is improved; and through high-temperature treatment, the fiber is partially carbonized, so mechanical strength and toughness of the cement fiber board are further improved, and good application prospect is achieved.

Owner:常州通和建筑工程有限公司

Ramie knitted fabric

InactiveCN102443955AMaintain good performanceGuaranteed performanceWeft knittingYarnYarnWrinkle skin

The invention discloses a ramie knitted fabric, comprising ramie blended yarns formed by blending ramie fibres and other fibres according to a certain ratio, wherein the other fibres comprise one or two of terylene fibres, tencel fibres, corn fibres and chinlon fibres; the ratio of the blending percentages by weight of the ramie fibres to the other fibres is 20-35%: 65-80%; and the specification of the ramie blended yarns is 20-42 yarns / 2, and the twist coefficient is 560-700. Fibre ingredients with a good toughness such as corn fibres, tencel fibres and terylene fibres are variously combined, matched and blended with ramie fibres in the invention via the method aforementioned, so as to weaken the rigidity of the blended yarns and enhance the feasibility of the yarns for knitted fabric ramie; and the service ability problems such as strong prickle sensation and bad wrinkle resistance of a fabric are improved in a precondition of ensuring the various excellent performances of ramie.

Owner:SUZHOU CHUANGYU WEAVING

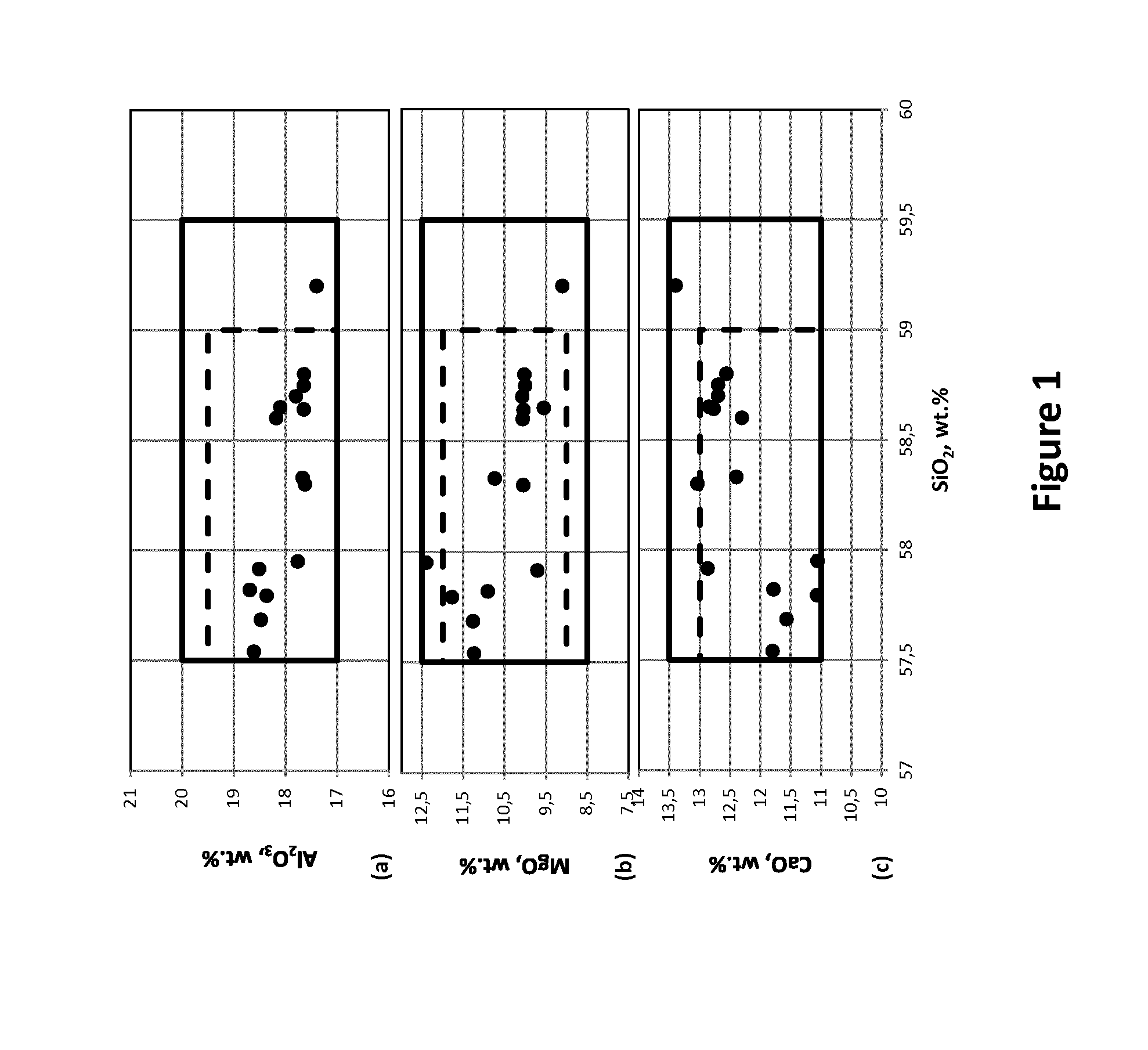

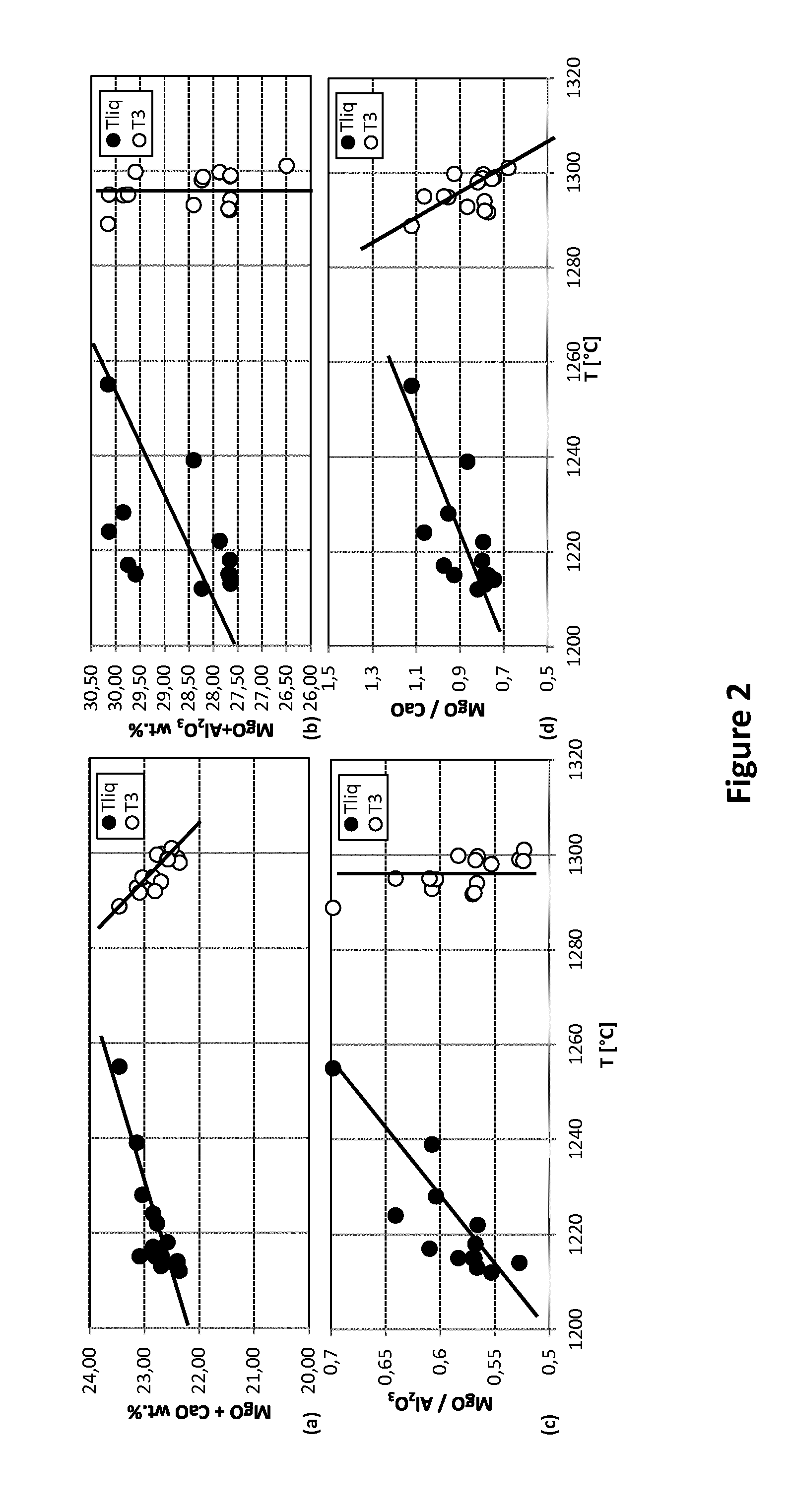

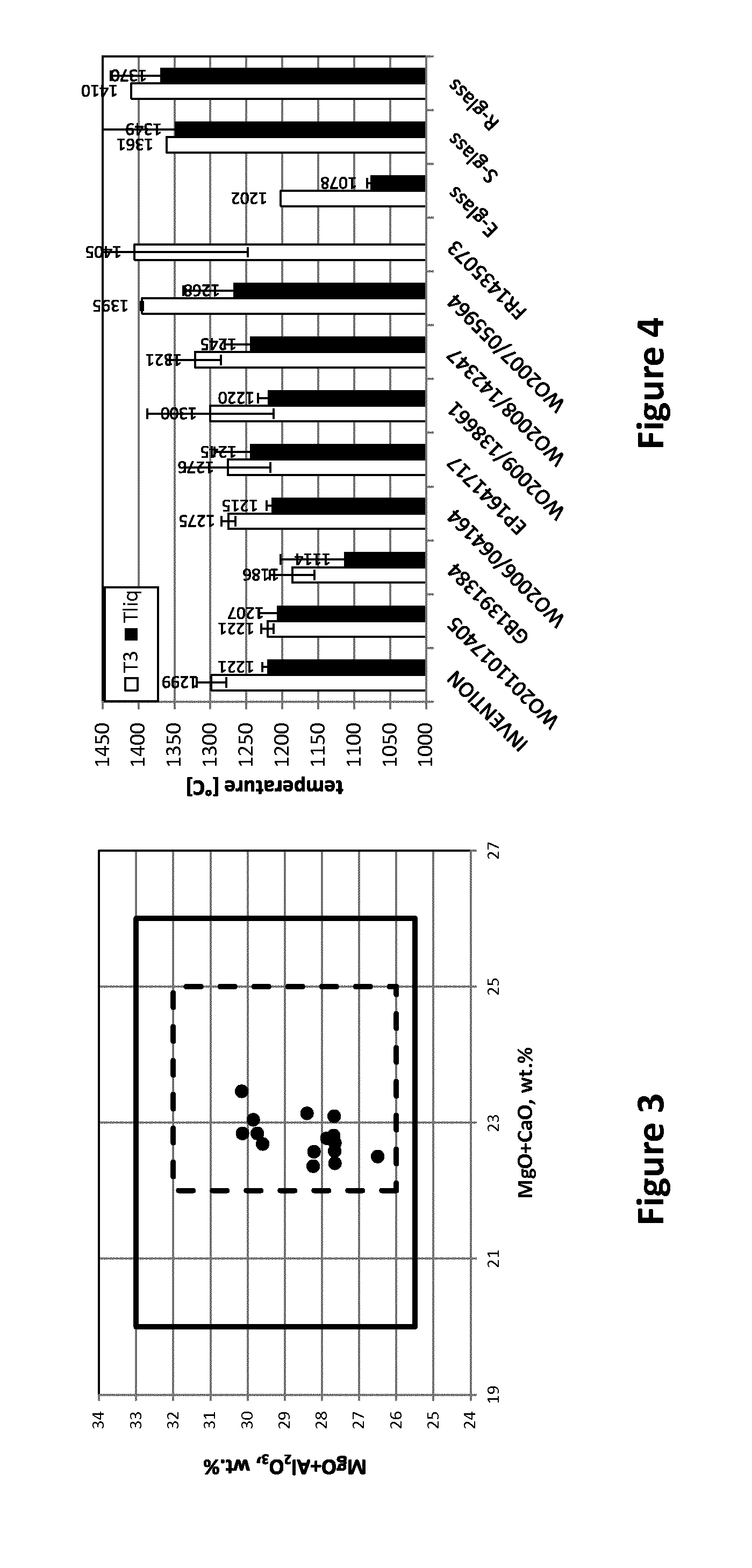

Glass fibre composition and composite material reinforced therewith

The present invention concerns glass fibre composition comprising the following oxides: Si02: 57.5-59.5 wt. % AI2O3: 17.0-20.0 wt. % CaO: 11.0-13.5 wt. % MgO: 8.5-12.5 wt. % wherein the sum of Na2O, K2O, and TiO2 is at least 0.1 wt. % and Li2O≦2.0 wt. %, all amounts being expressed in weight % with respect to the total weight of the composition. It also concerns composite materials reinforced with such fibres, used in applications such as wind(a) mill blades, pressure vessels, components in the automotive, machinery, aerospace applications and such products produced therewith, and wherein the temperature difference, ΔT, defined as the difference between the temperature, T3, at which the composition has a viscosity of 103 Poise and the liquidus temperature, Tliq, is at least 50° C.

Owner:3B FIBERGLASS

High performance glass fibre composition, and glass fibre and composite material thereof

The present invention provides a glass fibre composition, a glass fibre and a composite material therefrom. The glass fibre composition comprises the following components expressed as percentage by weight: 53-64% SiO2, greater than 19% and lower than 25% Al2O3, 0.05-7% Y2O3+La2O3+Gd2O3, not greater than 1% Li2O+Na2O+K2O, 10-24% CaO+MgO+SrO, 1.5-12% CaO, lower than 2% TiO2, lower than 1.5% Fe2O3. Said composition can not only significantly improve the elastic modulus and chemical stability of the glass, but also overcome the technical problems in the manufacture of traditional high-performance glasses including high risk of crystallization, fining difficulty of molten glass and production efficiency difficulty with refractory-lined furnaces, significantly reduce the liquidus and forming temperatures and greatly reduce the crystallization rate under the same conditions, thus making it particularly suitable for production of high-performance glass fibre with excellent chemical stability in refractory-lined furnaces.

Owner:JUSHI GRP CO

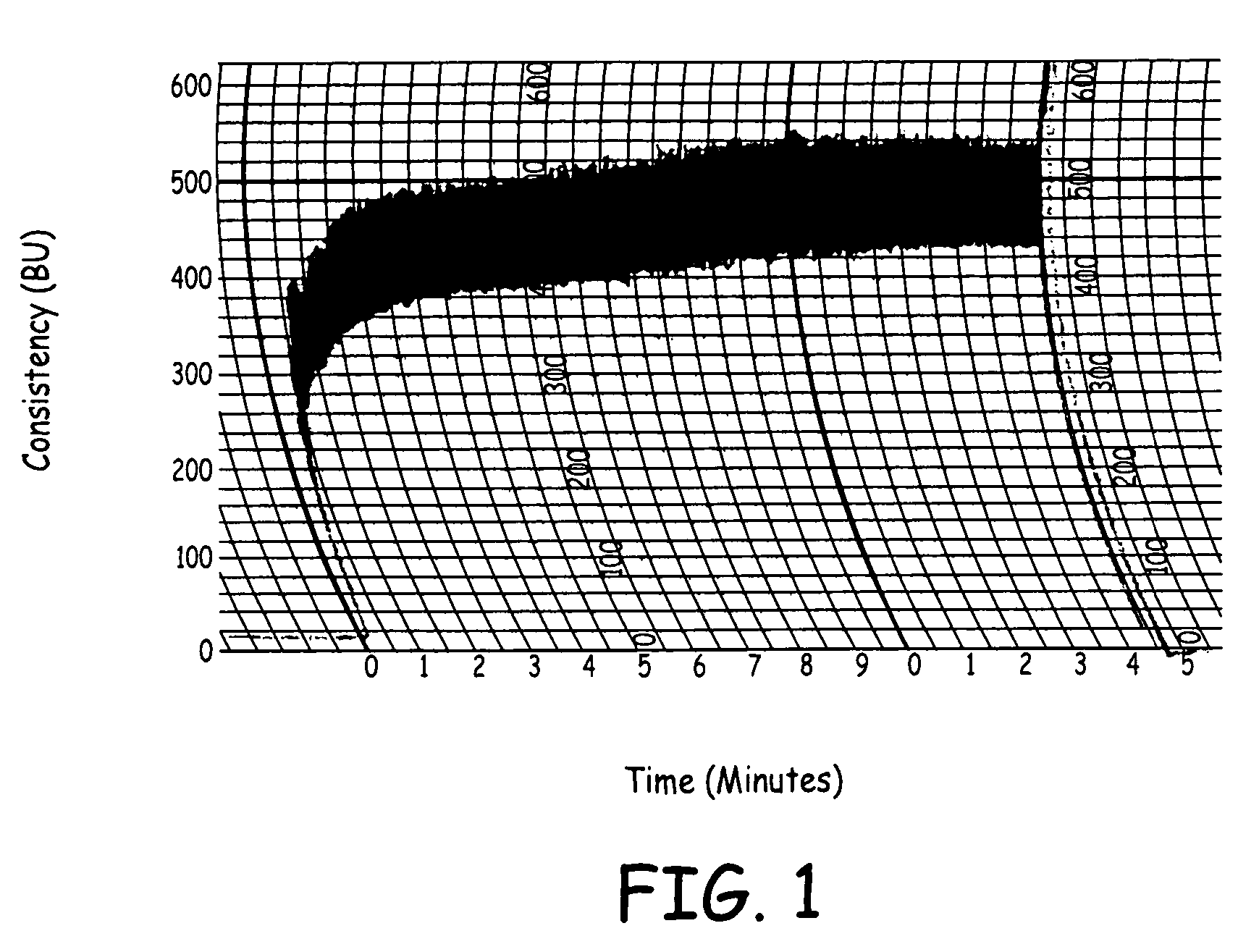

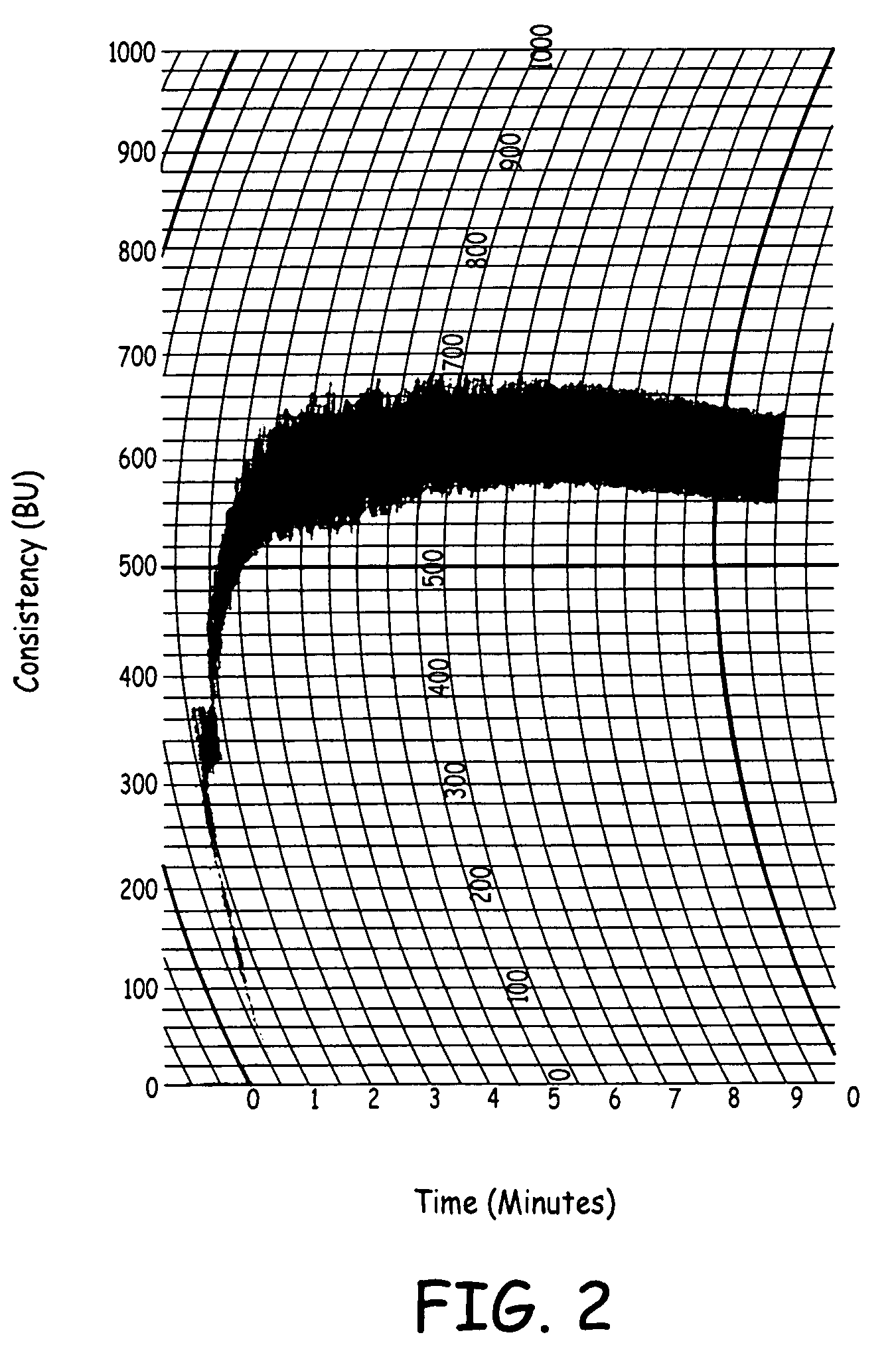

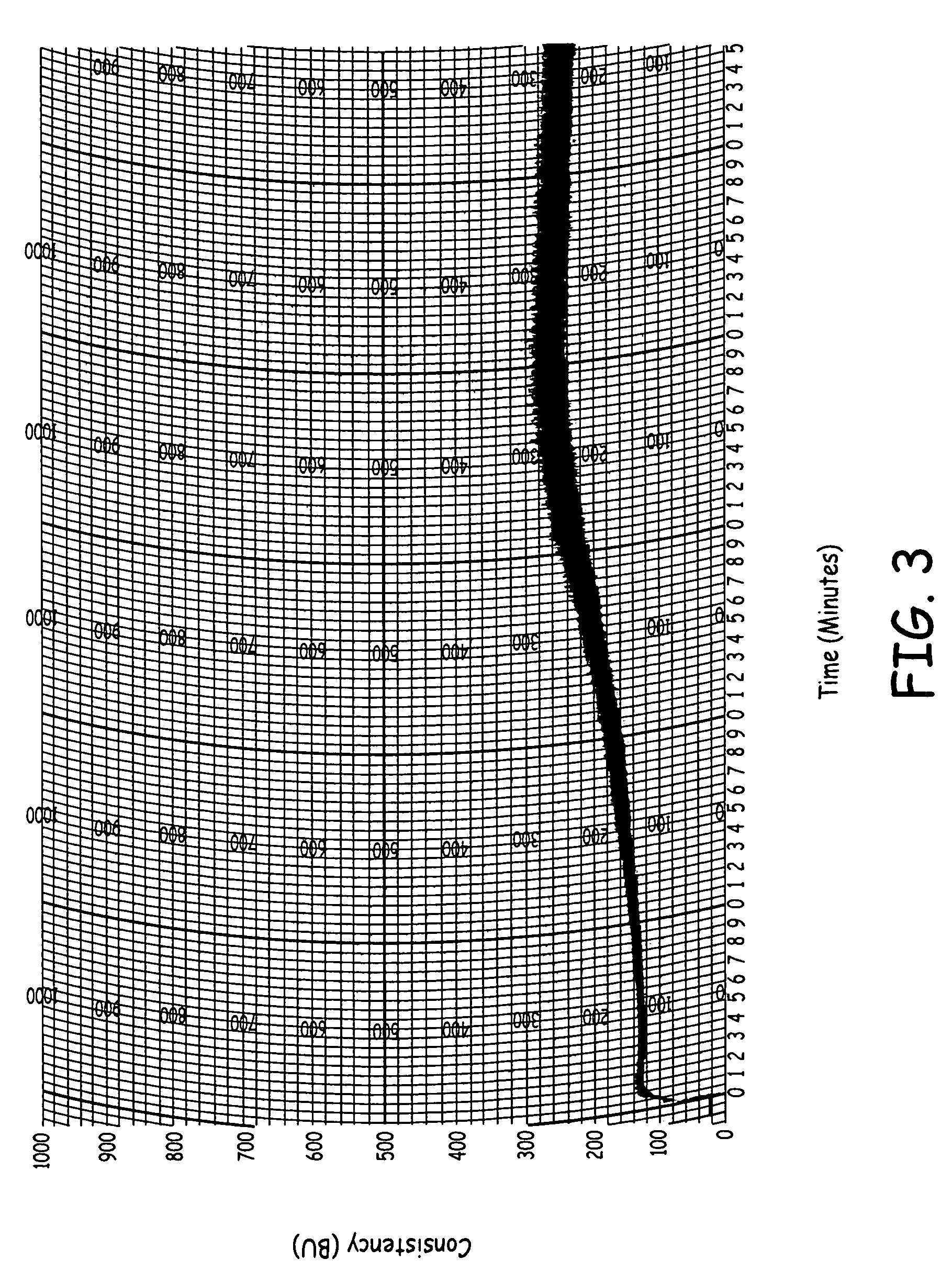

Rheologically balanced high fiber ingredient for food products

ActiveUS8354134B2Improve the level ofHigh in fiberDough treatmentBaking mixturesAdditive ingredientReady to use

The present invention is a high fiber blend which includes a stiffening agent and a plasiticizing agent. The blend replaces part of the flour in a dough without substantially affecting the dough's rheological properties. High fiber food products can then be made from the dough, using conventional commercial manufacturing equipment and processes. The blend can be used to produce food products that meet FDA requirements for fiber-related health claims. The present invention is also a method of making the high fiber blend. This method involves measuring a rheological property of the stiffening agent and the plasticizing agent. The stiffening agent and plasticizing agent are then combined, in amounts that will allow the resulting blend to provide a high level of fiber to a food product without substantially affecting the rheological properties of the dough.

Owner:CARGILL INC

Novel moisture-absorbing and breathable blend fabric

InactiveCN104207387ASoft and comfortable to wearWith health careTextiles and paperProtective garmentKapok fiberMoisture

The invention discloses a novel moisture-absorbing and breathable blend fabric. The novel moisture-absorbing and breathable blend fabric is blended and woven of Coolmax fibers, Shengfeng pearl fibers, bamboo charcoal fibers and kapok fibers. The novel moisture-absorbing and breathable blend fabric comprises the following fabric fiber components in percentage by weight: 25-29 percent of Coolmax fibers, 17-21 percent of Shengfeng pearl fibers, 20-24 percent of bamboo charcoal fibers and 26-38 percent of kapok fibers. The novel moisture-absorbing and breathable blend fabric is blended and woven of the Coolmax fibers, the Shengfeng pearl fibers, the bamboo charcoal fibers and the kapok fibers; the woven fabric is soft, comfortable, moisture-absorbing and breathable to wear and has the characteristics of health care, beauty maintaining and skin care.

Owner:刘喜

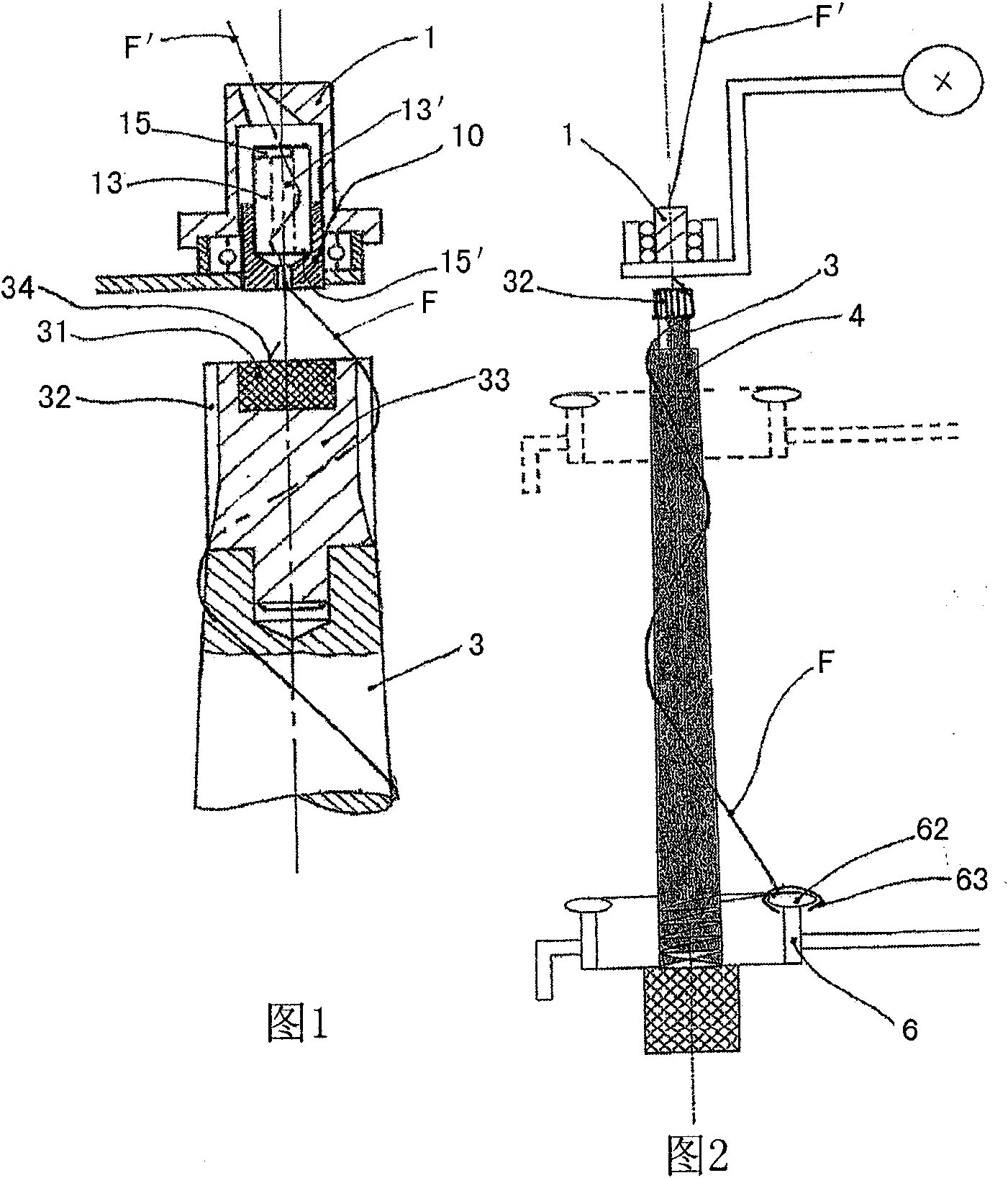

Method and apparatus for spinning staple fibres on ring-spinning machines

Owner:DITF DEUT INST FUR TEXTIL UND FASERFORSCHUNG DENKENDORF

Microfiber nonwoven composite

ActiveCN106029967ALong-lasting washing stabilityIncreased durabilityLayered productsBed linenNonwoven fabricFibre composition

The invention relates to a microfiber nonwoven composite, comprising a first and a second fiber component arranged in form of alternating layers, wherein at least a first layer A comprises the first fiber component in form of composite filaments melt-spun and deposited as a nonwoven fabric which are at least partially slit and solidified to form elementary filaments having an average titer of less than 0.1 dtex, preferably between 0.03 dtex and 0.06 dtex, at least one layer B is arranged over layer A, wherein the layer B comprises the second fiber component in form of fibers deposited and solidified as a nonwoven fabric having an average titer of from 0.1 to 3 dtex, and at least one second layer A is arranged on layer B.

Owner:CARL FREUDENBERG KG

High modulus glass fibre composition, and glass fibre and composite material thereof

The present invention provides a high-modulus glass fiber composition, a glass fiber and a composite material therefrom. The glass fiber composition comprises the following components expressed as percentage by weight: 55-64% SiO2, 13-24% Al2O3, 0.1-6% Y2O3, 3.4-10.9% CaO, 8-14% MgO, lower than 22% CaO+MgO+SrO, lower than 2% Li2O+Na2O+K2O, lower than 2% TiO2, lower than 1.5% Fe2O3, 0-1.2% La2O3, wherein the range of the weight percentage ratio C1=(Li2O+Na2O+K2O) / (Y2O3+La2O3) is greater than 0.26. Said composition can significantly increase the glass elastic modulus, effectively inhibit the crystallization tendency of glass, decrease the liquidus temperature, secure a desirable temperature range (ΔT) for fiber formation and enhance the fining of molten glass, thus making it particularly suitable for production of high-modulus glass fiber with refractory-lined furnaces.

Owner:JUSHI GRP CO

Glass fiber composition, glass fiber and composite material therefrom

ActiveUS20180230039A1Improve mechanical propertiesLower crystallization temperatureGlass productionGlass fiberRefractive index

The present invention provides a glass fiber composition, glass fiber and composite material therefrom. The glass fiber composition comprises the following components expressed as percentage by weight: 58-63% SiO2, 13-17% Al2O3, 6-11.8% CaO, 7-11% MgO, 3.05-8% SrO, 0.1-2% Na2O+K2O+Li2O, 0.1-1% Fe2O3, 0-1% CeO2 and 0-2% TiO2, wherein a weight percentage ratio C1=(MgO+SrO) / CaO is greater than 1. Said composition greatly improves the refractive index of glass, significantly shields against harmful rays for humans and further reduces glass crystallization risk and production costs, thereby making it more suitable for large-scale production with refractory-lined furnaces.

Owner:JUSHI GRP CO

Adhesive-free polyimide copper-clad plate, and manufacturing method and application thereof

The invention relates to a manufacturing method of an adhesive-free polyimide copper-clad plate. The manufacturing method comprises the following steps: S1: blending short fibers or fiber powder in a DMT solution containing 12%-23% of polyamide acid according to weight percentage, and stirring and blending uniformly; S2: uniformly coating the mixture on a copper foil and heating to remove a solvent in the DMF solution, wherein the heating temperature is 150-250 DEG C; S3: continuing to heat to 300-450 DEG C to achieve imidization of the polyamide acid, forming the polyimide and firmly adhering the polyimide on the copper foil, so as to obtain the adhesive-free polyimide copper-clad plate. The fiber component is added into the polyimide, the costs for manufacturing the copper-clad plate and a circuit board are lowered, the strengths of the copper-clad plate and the circuit board are improved, the expansion and the shrinkage are small, the size is stable, and the quality stability of the copper-clad plate and the circuit board is improved. In addition, no adhesive is used, the materials used are saved, the manufacturing process is reduced, and the production cost is lowered.

Owner:王定锋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com