Organic hollow superfine fibre composition and preparation and application thereof

A technology of ultra-fine fiber and composition, which is applied in the manufacture of hollow filaments, fiber chemical characteristics, rayon manufacture, etc., to achieve the effects of convenient preparation, large specific surface area and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

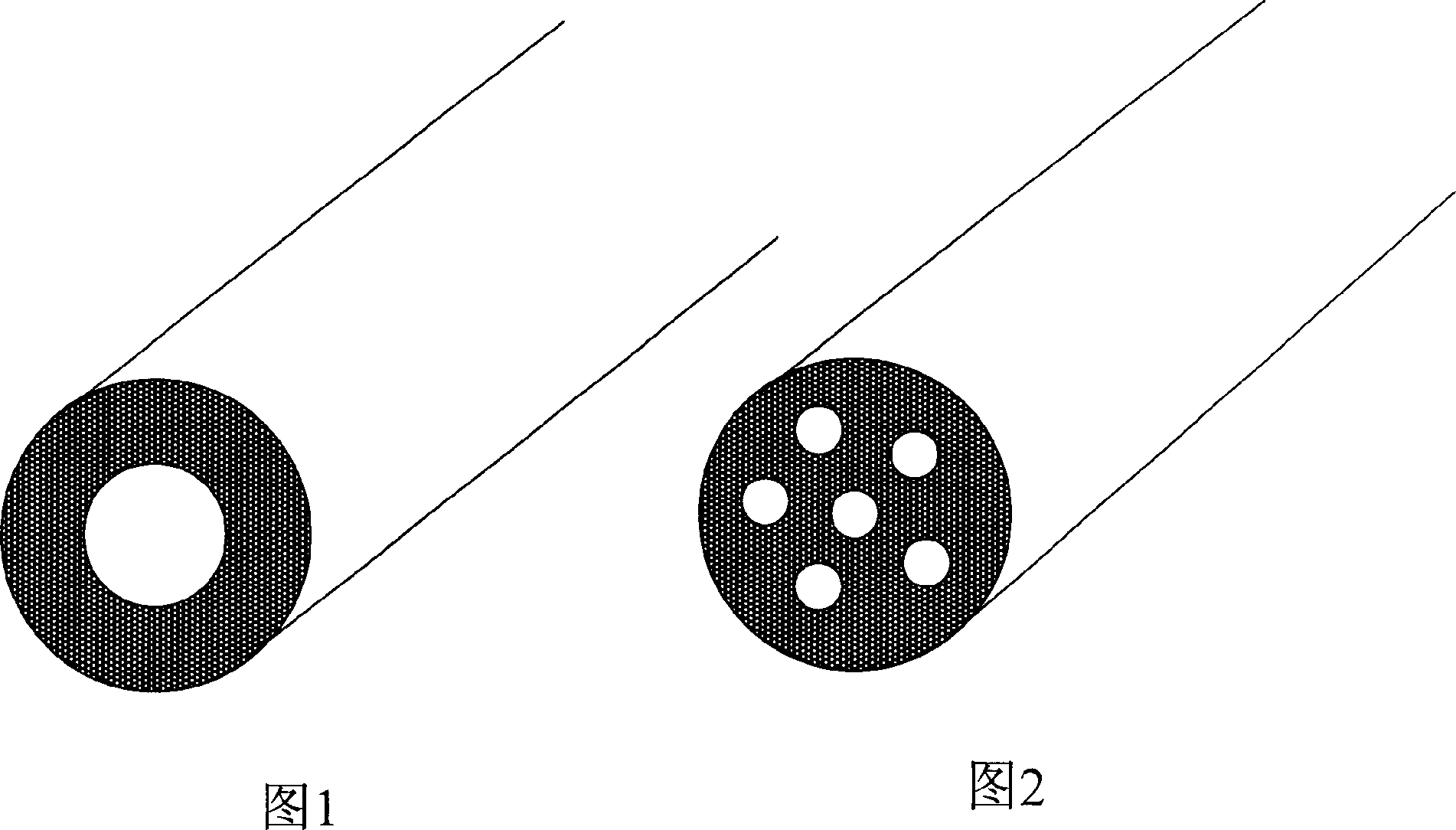

[0038] The preparation of the organic hollow microfiber composition is mainly carried out in five ways:

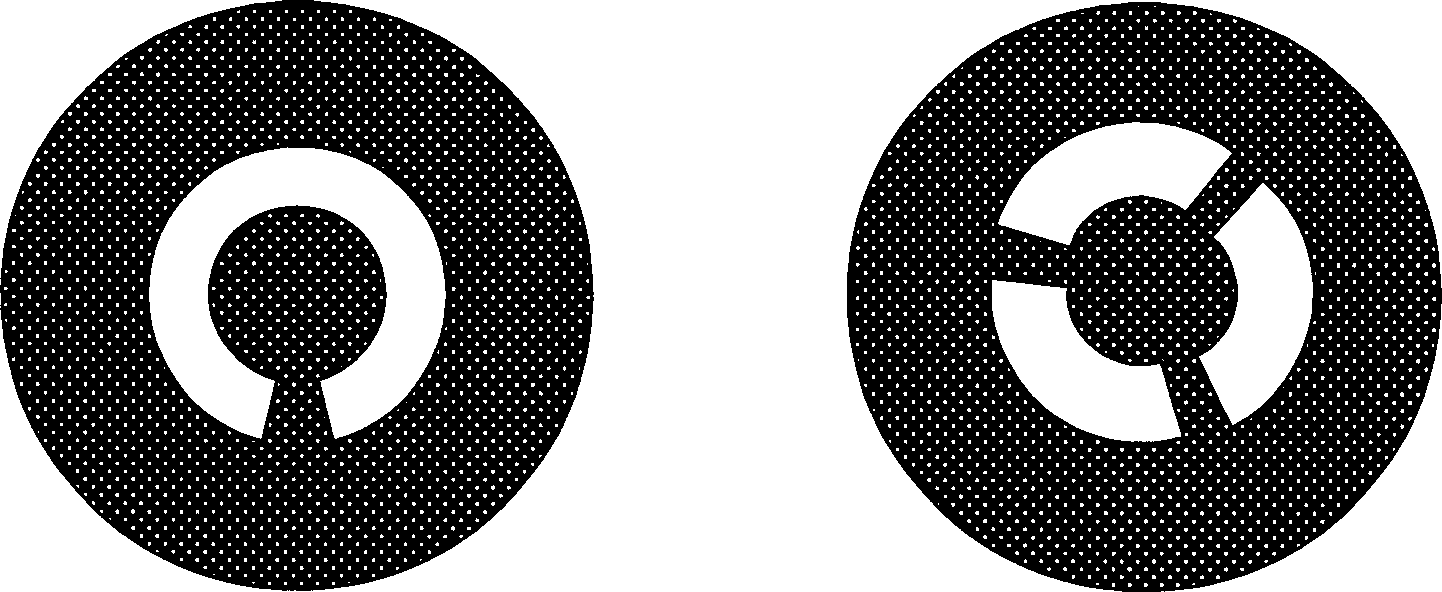

[0039] (1) Through the arc slit spinneret ( image 3 ), double ring spinneret ( Figure 4 ) and double-ring sleeve-shaped spinneret ( Figure 5 ) are directly prepared by jet stream. The jet stream can be charged or uncharged. When the jet stream is charged, its voltage range is between plus and minus 50,000 volts, and the electric field can be a DC positive electric field, a DC negative electric field, or an alternating electric field. The spray pressure applied is between 1 atmosphere and 5000 atmospheres.

[0040] (2) Form a core-shell structure 6b with different fluidization capabilities by chemical reaction on the surface of the prepared ultrafine fiber 6a, and then make the core by controlling one or more conditions in temperature, pressure, solvent, electric field, and magnetic field. The layer ultrafine fibers are fluidized to remove the core layer ultrafine fibe...

Embodiment 1

[0046] Firstly, a 10% chitosan acetic acid solution containing 1% silver-loaded zeolite with a particle size of 50 nanometers was prepared, and then the solution was electrospun through a double-ring nozzle. The outer diameter of the double ring nozzle is 0.8mm and the inner diameter is 0.5mm, and the gap width is 0.12mm. A built-in electrode in the inner and outer tubes of the double-ring nozzle is connected to the positive pole of the DC high-voltage positive power supply. The outer tube is connected to chitosan acetic acid solution, the inner tube is connected to ammonia gas, and the collector is connected to the negative electrode. The distance between the double-ring nozzle and the opposite electrode is 20 cm, a voltage of 15,000 volts is applied between the two electrodes, the flow rate of the outer ring is 1 ml / hour, and the flow rate of the inner ring is 1 ml / min. Outside the double-shaped nozzle, ammonia gas is charged with the same charge at a speed of 5 m / min to tre...

Embodiment 2

[0048] Dissolve polyethylene PET in a mixed solvent of methylene chloride and 1,2,2-trichloroethane at a weight ratio of 1:1 to make a spinning stock solution with a concentration of 10%, and then heat it at 250 degrees, Spinning is carried out through a C-shaped nozzle under the condition of 8MPa. The C-shaped nozzle has an outer diameter of 0.8 mm, an inner diameter of 0.6 mm, a slit width of 0.1 mm, and a gap width of 0.1 mm. After the spinning stock solution is sprayed out from the spinneret hole, it enters the water vapor airflow moving in the same direction at 5 m / s, and the mixed solvent is vaporized instantly to obtain PET hollow ultrafine fibers. The organic medium fiber can be used as a separation membrane for separating pure water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Slit width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com