Residual oil hydrodemetallization catalyst and preparation method thereof

A technology for hydrodemetallization and residue hydrogenation, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., and can solve the problem that the reaction molecules stay in the pores for a short time. , the stability needs to be further improved, the carrier utilization rate is reduced, etc., to achieve the effect of promoting penetration and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

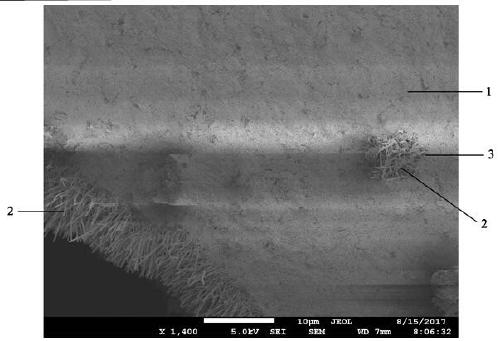

Image

Examples

Embodiment 1

[0054] (1) Weigh 100 grams of activated carbon particles with a particle size of 6 µm, and impregnate them with active component impregnation solution I with a concentration of molybdenum oxide of 3.30g / 100ml and a concentration of nickel oxide of 0.56g / 100ml. The modified physical pore expander was obtained by drying for 4 hours.

[0055] (2) Weigh 200 grams of pseudo-boehmite (self-made by aluminum sulfate method), 23.5 grams of modified physical pore-enlarging agent in step (1), 0.4 grams of squash powder, 1.9 grams of ammonium heptamolybdate, 2.95 grams of nickel nitrate hexahydrate gram, the above-mentioned physical mixing is uniform, adding an appropriate amount of acetic acid aqueous solution with a mass concentration of 1.5% and kneading, extruding and molding, drying the molded product at 100°C for 6 hours, and roasting the dried product at 600°C for 5 hours in an air atmosphere to obtain a modified Alumina support SI.

[0056] (3) Weigh 100 grams of modified alumina...

Embodiment 2

[0060] Same as Example 1, except that step (1) the particle size of activated carbon is 5 microns, the concentration of molybdenum oxide in the active component impregnation solution I is 3.55g / 100mL, and the concentration of nickel oxide is 0.45g / 100mL; step (2) modified physical expansion The addition of pore agent is 27 grams, the addition of ammonium heptamolybdate is 1.76 grams, and the nickel nitrate hexahydrate is 2.82 grams; the concentration of the ammonium bicarbonate solution in step (3) is 17.5%, and the addition of the solution is 1150 grams. The temperature is 90°C, the treatment time is 2 hours, the heat treatment temperature is 145°C, and the treatment time is 7 hours to prepare the modified alumina carrier SII-2 step (4) MoO in the active component impregnation solution II 3 The hydrodemetallization catalyst Cat2 was prepared with a concentration of 4.7g / 100mL and a NiO concentration of 2.75g / 100mL. The content of molybdenum oxide in the catalyst was 5.65wt%, a...

Embodiment 3

[0063] Same as Example 1, except step (1) the particle size of activated carbon is 9 microns, the concentration of molybdenum oxide in the active component impregnation solution I is 2.15g / 100mL, and the concentration of nickel oxide is 0.71g / 100mL; step (2) modified physical expansion The addition amount of the pore agent is 30.8 grams, the addition amount of ammonium heptamolybdate is 2.24 grams, and the nickel nitrate hexahydrate is 2.41 grams; the concentration of the ammonium bicarbonate solution in step (3) is 16.5%, the solution addition amount is 980 grams, and the heat treatment temperature is 125 ℃, the treatment time is 8 hours, and the modified alumina support SII-3 is prepared. Step (4) MoO in the active component impregnation solution II 3 The hydrodemetallization catalyst Cat3 was prepared with a concentration of 4.95g / 100mL and a NiO concentration of 3.15g / 100mL. The content of molybdenum oxide in the catalyst was 5.34wt%, and the content of nickel oxide was 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com