Electronic product metal shell formed with antenna slot and preparation method of electronic product metal shell

A technology for electronic products and metal shells, which is applied to the metal shells of electronic products with antenna slots and its preparation field, which can solve the problems of affecting the cleanliness and continuity of the appearance, destroying the metal texture, and destroying the overall structure, so as to maintain Neatness and continuity, clean and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In a second aspect, the present invention provides a method for preparing a metal casing of an electronic product formed with an antenna slot, the method comprising the following steps:

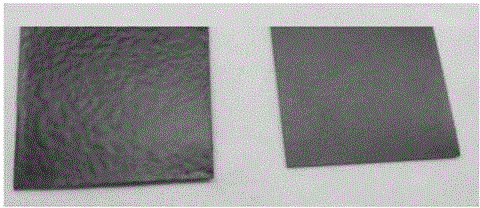

[0028] (1) The metal layer is subjected to hard anodic oxidation treatment and ink spraying treatment in sequence to form a hard anodic oxidation layer and an ink layer respectively;

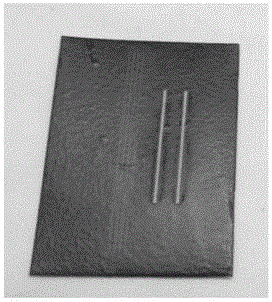

[0029] (2) An antenna groove is formed on the back side of the product obtained through step (1), so that the antenna groove penetrates the back ink layer, the back hard anodized layer and the metal layer of the product in the thickness direction, and makes the front hard The inner side of the quality anodized layer is exposed;

[0030] (3) Remove the ink layer and fill the antenna groove with non-conductive material.

[0031] In the method of the present invention, the method for the hard anodic oxidation treatment is not particularly limited, and may be various hard anodic oxidation treatment methods ...

Embodiment 1

[0058] This embodiment is used to illustrate the mobile phone aluminum alloy casing formed with the antenna slot and the preparation method thereof according to the present invention.

[0059] (1) Alkaline etching treatment: Cut the 5-series aluminum material with a thickness of 0.5mm in the aluminum alloy layer 1 into aluminum alloy sheets of 5cm*3.5cm. Alkaline etching in the solution for 1.5min, then wash twice with deionized water;

[0060] (2) Light-emitting treatment: at 25°C, put the aluminum alloy sheet obtained in step (1) into light-emitting liquid (based on 1L of light-emitting liquid, the amount of 65% by weight concentrated nitric acid is 300ml) for 2 minutes, and then deionized water Wash 2 times;

[0061] (3) Oxidation treatment: put the aluminum alloy sheet obtained in step (2) into an oxidation tank, wherein, at 10° C., adopt a forward square wave pulse with a duty cycle of 80%, a frequency of 800 Hz, and a current density of 5 A / dm 2 , the aluminum alloy ...

Embodiment 2

[0071] This embodiment is used to illustrate the mobile phone aluminum alloy casing formed with the antenna slot and the preparation method thereof according to the present invention.

[0072] (1) Alkaline etching treatment: Cut the 5-series aluminum material with a thickness of 0.5mm in the aluminum alloy layer 1 into aluminum alloy sheets of 5cm*3.5cm. Alkaline etching in the solution for 2 minutes, and then washed twice with deionized water;

[0073] (2) Light-emitting treatment: at 20°C, put the aluminum alloy sheet obtained in step (1) into light-emitting liquid (based on 1L of light-emitting liquid, the amount of 65% by weight concentrated nitric acid is 400ml) for 1min, and then rinse with deionized water Wash 2 times;

[0074] (3) Oxidation treatment: put the aluminum alloy sheet obtained in step (2) into an oxidation tank, wherein, at 5°C, use a forward square wave pulse with a duty cycle of 50%, a frequency of 500Hz, and a current density of 2A / dm 2 , the aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com