Gas-liquid separation device and gas-liquid separation method

A technology of gas-liquid separation device and turntable, which is applied in the direction of separation method, combined device, and dispersed particle separation, etc., which can solve the problems of mixed liquid, unsatisfactory separation effect, failure to take into account the separation effect and separation speed, and achieve the goal of maintaining cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

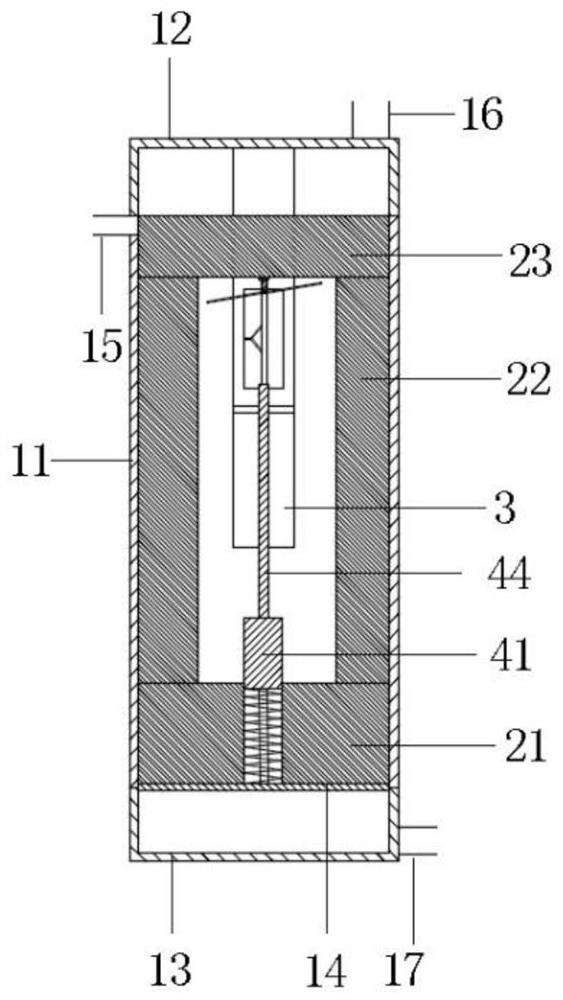

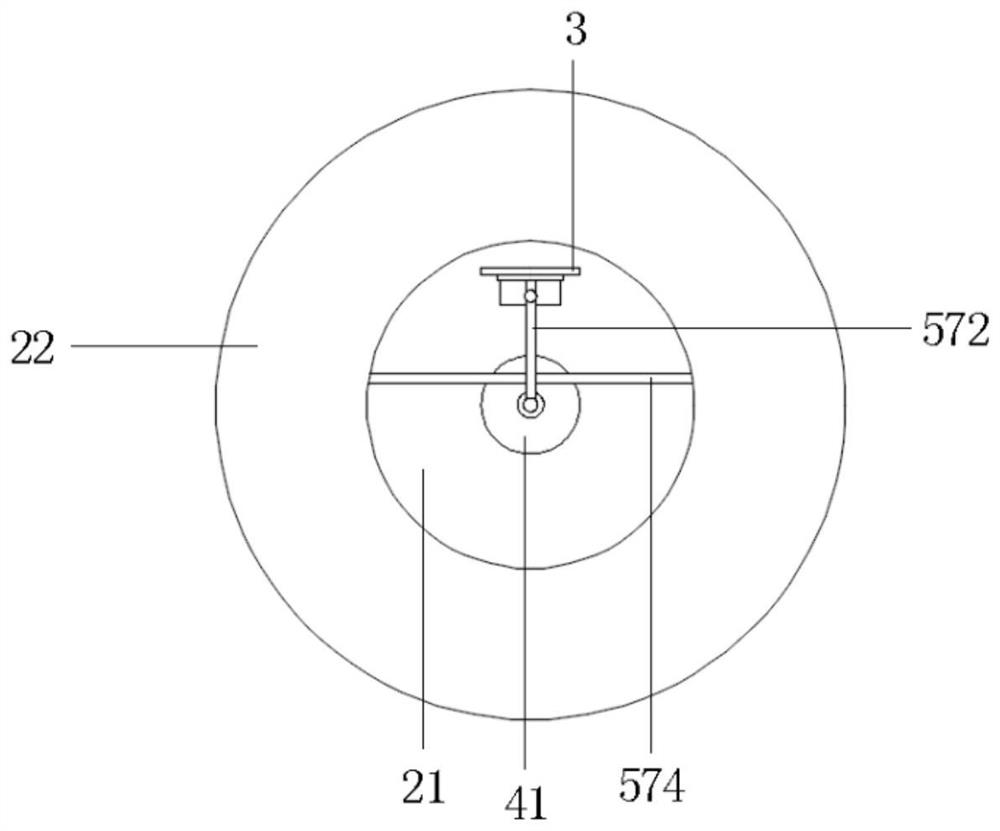

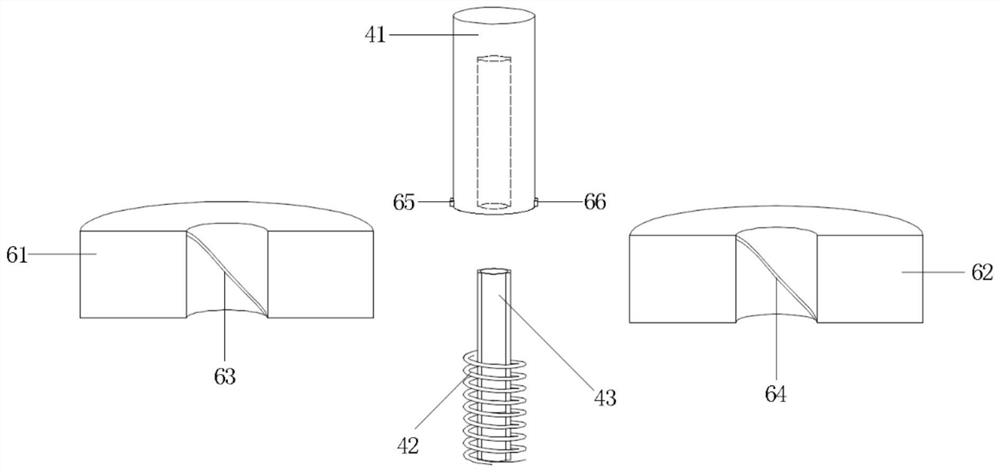

[0029] A gas-liquid separation device, such as Figure 1 to Figure 6 , including a cylinder 11, a filter element, a drive assembly and a rotating assembly; the upper end of the cylinder 11 is fixedly connected with an upper end cover 12, the lower end of the cylinder 11 is fixedly connected with a lower end cover 13 through a filter screen 14, and the cylinder 11 is close to the upper end cover 12 Part is provided with an air inlet pipe 15, the upper end cover 12 is provided with an air outlet pipe 16, and the lower end cover 13 is provided with a liquid outlet pipe 17, and the gas-liquid mixture enters from the air inlet pipe 15 and is separated inside the cylinder 11. In the process, the liquid will fall under the action of gravity, and finally be discharged from the liquid outlet pipe 17, the gas net will rise, and finally be discharged from the air outlet pipe 16; in this embodiment, the cylinder body 11 is a hollow cylinder, the upper end cover 12 and The lower end cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com