Patents

Literature

10383 results about "Screen filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A screen filter is a type of [filtration of water] using a rigid or flexible screen to separate sand and other fine particles out of water for irrigation or industrial applications. These are generally not recommended for filtering out organic matter such as algae, since these types of contaminants can be extruded into spaghetti-like strings through the filter if enough pressure drop occurs across the filter surface. Typical screen materials include stainless steel (mesh), polypropylene, nylon and polyester.

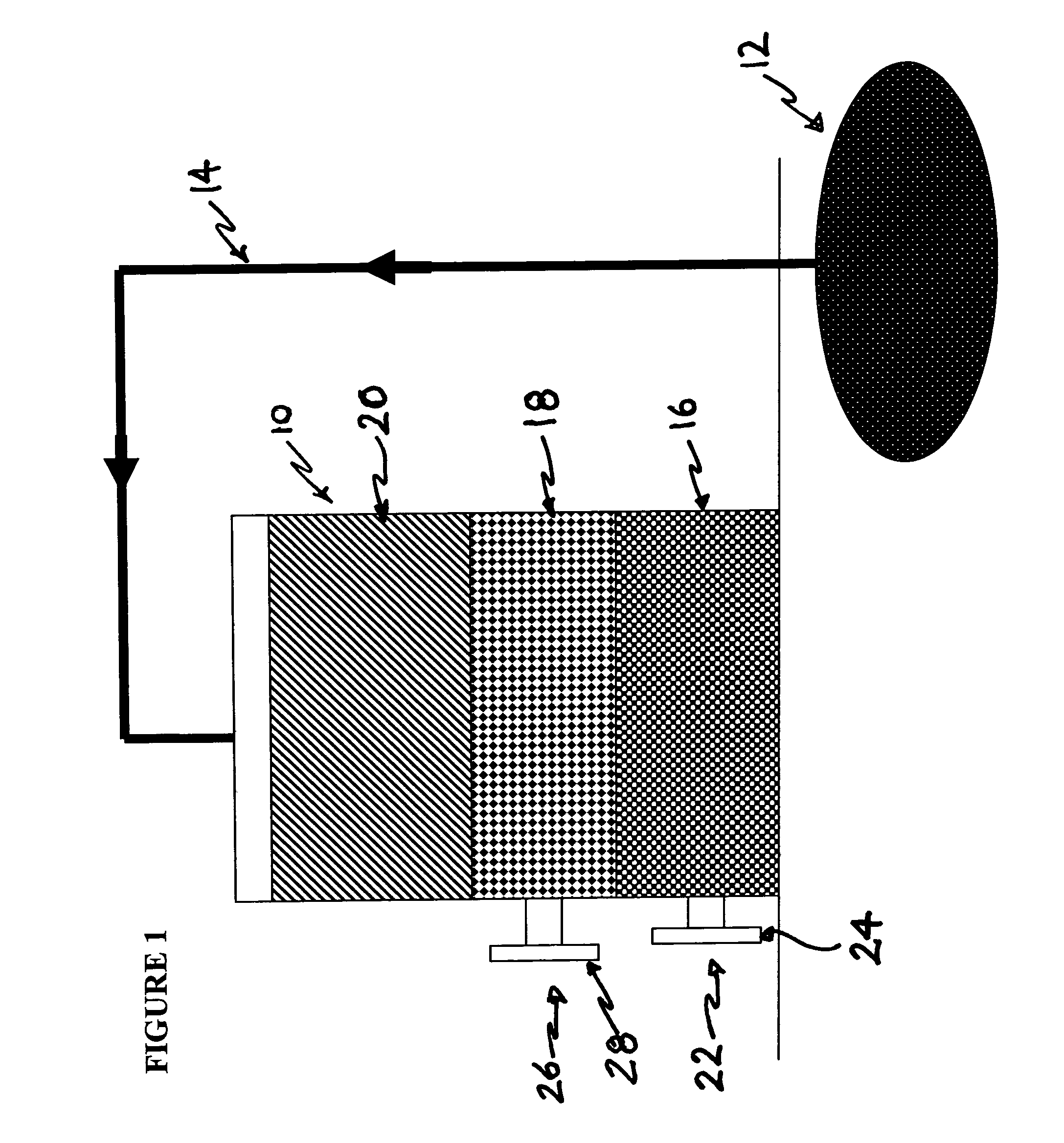

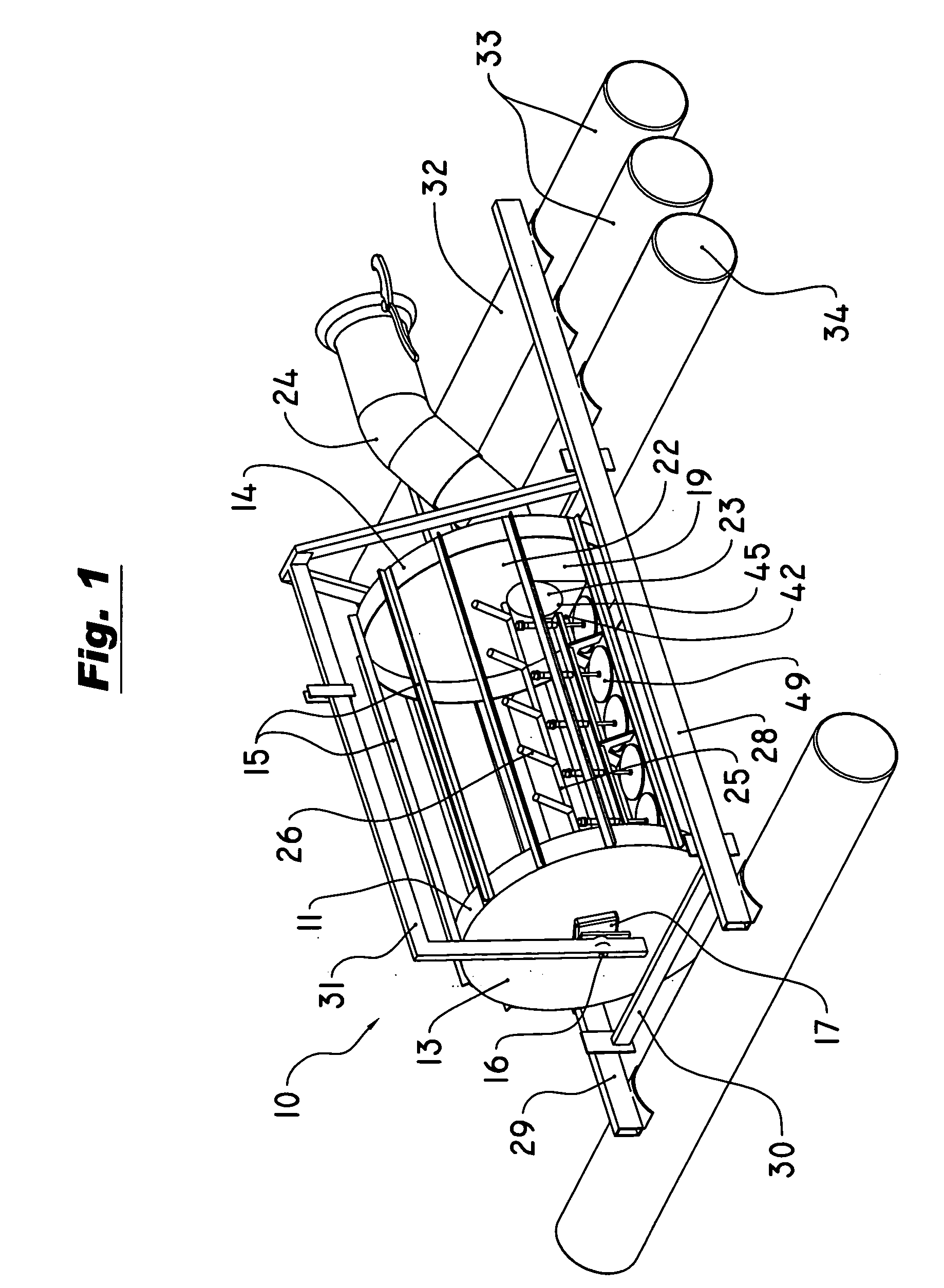

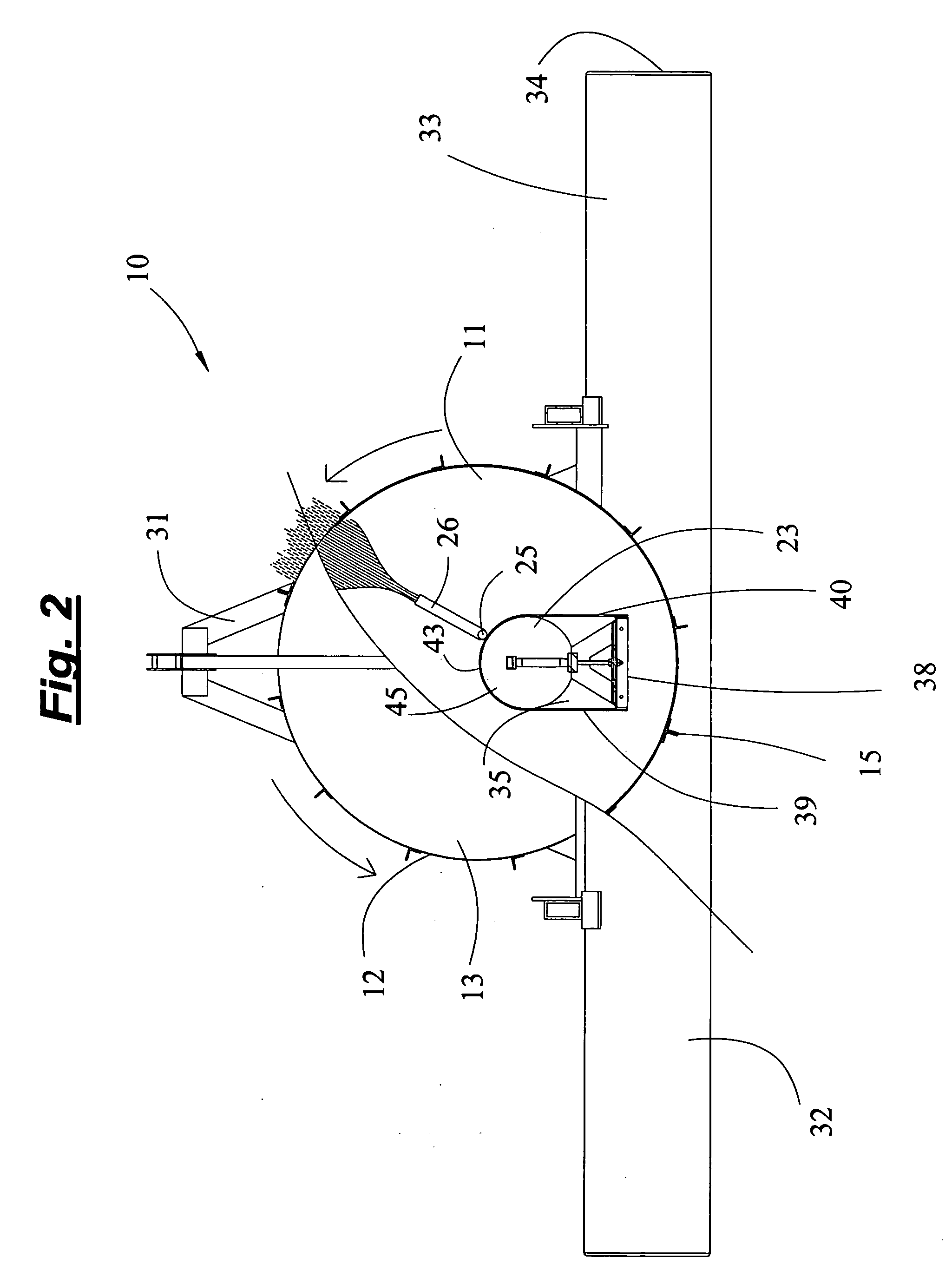

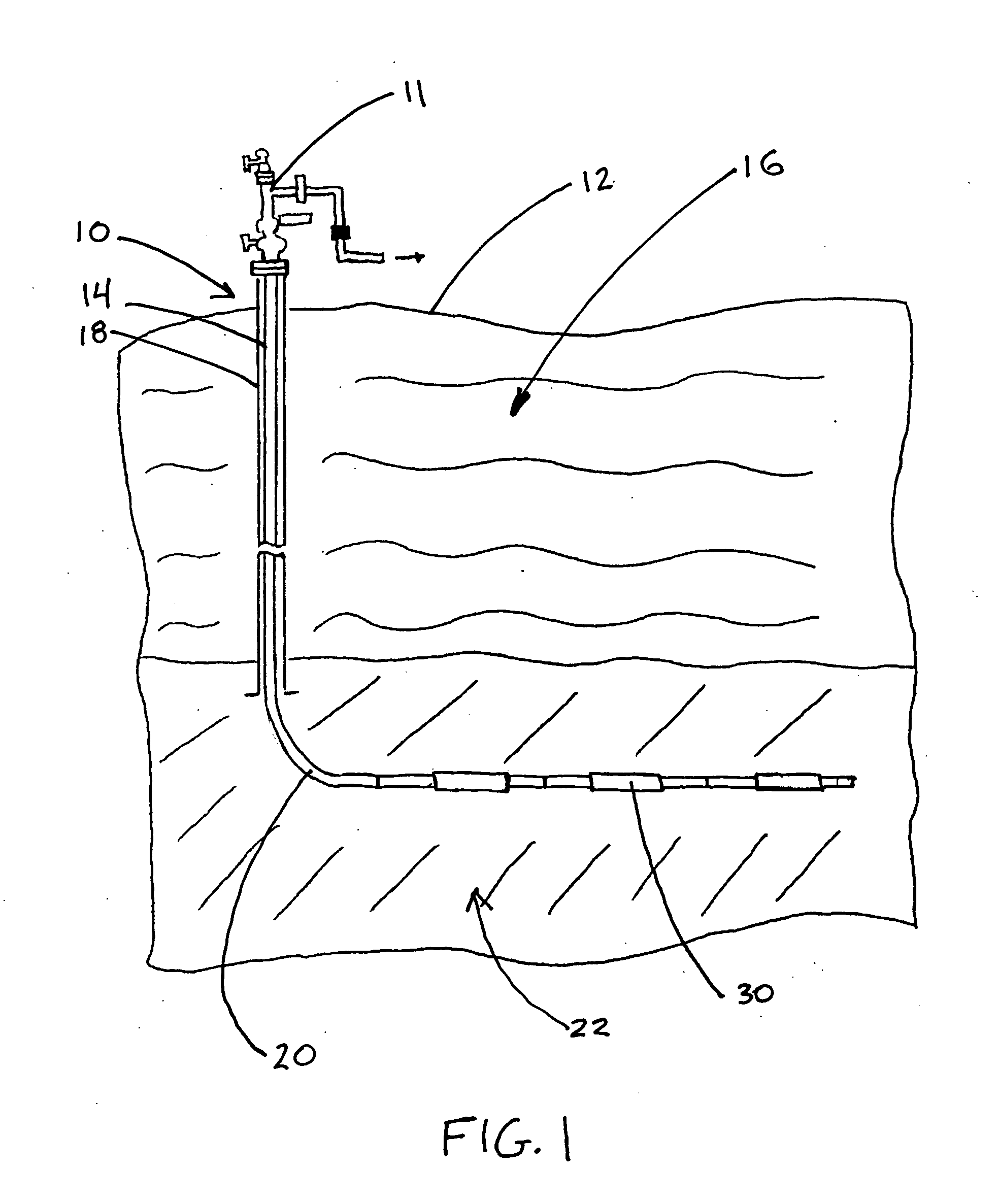

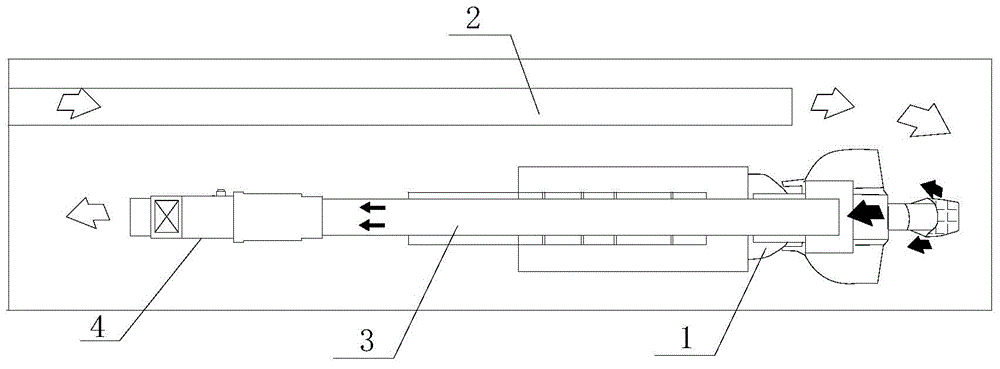

Trailer mounted mobile apparatus for dewatering and recovering formation sand

InactiveUS7240681B2Prevent leakageElectrostatic cleaningMultistage water/sewage treatmentDrive wheelHigh pressure water

An apparatus for removing formation sand from an oil storage tank. The apparatus is mounted to a truck towable trailer so that it may be transported to remote sites. Mounted to the truck towable trailer is a container adapted to accept and dewater a sand-water slurry pumped from the oil storage tank. The slurry is formed by injecting high pressure water from a water reservoir mounted to the truck towable trailer into the approximate centre of mass of the formation sand by way of a pipe having a nozzle generating a spherical spray pattern within the slurry. The pipe is forced into the slurry by way of a two counter-rotating drive wheels in frictional contact with the pipe. Included in the apparatus is a bifurcated conduit adapted for attachment to the storage tank drain port adapted for the injection of high pressure through one branch of the conduit and withdrawal of slurry from the other branch and into the container by way of a slurry pump. The dewatering of the slurry takes place by a plurality of screen filters mounted to the bottom, side and front inside walls of the container. Oil and water extracted from the slurry is recycled back into the storage tank for later removal and treatment. All pumps and conduits are mounted to the truck towable trailer so that the apparatus is self-contained.

Owner:SAIK LARRY

Shower head

Owner:JING MEI IND HLDG LTD

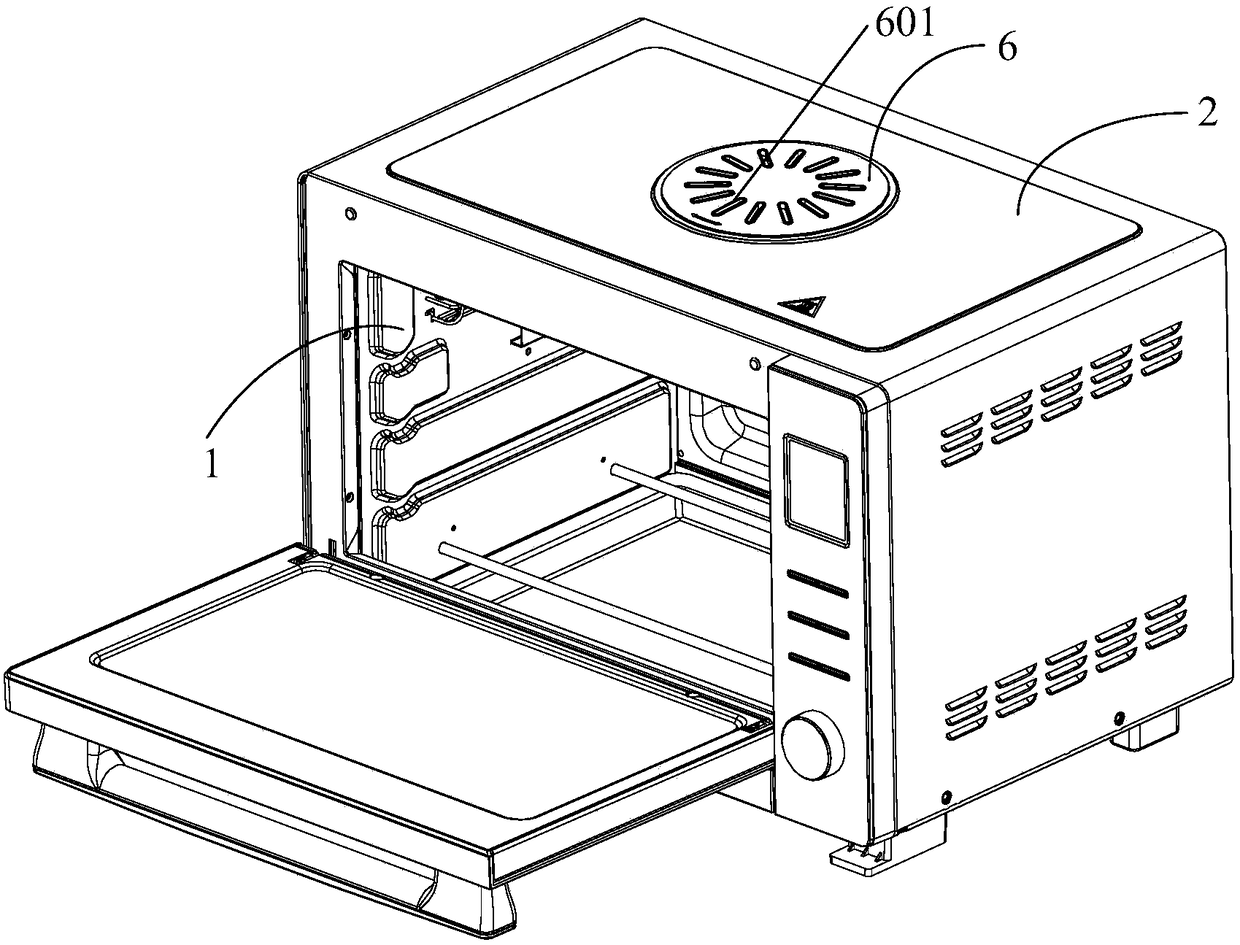

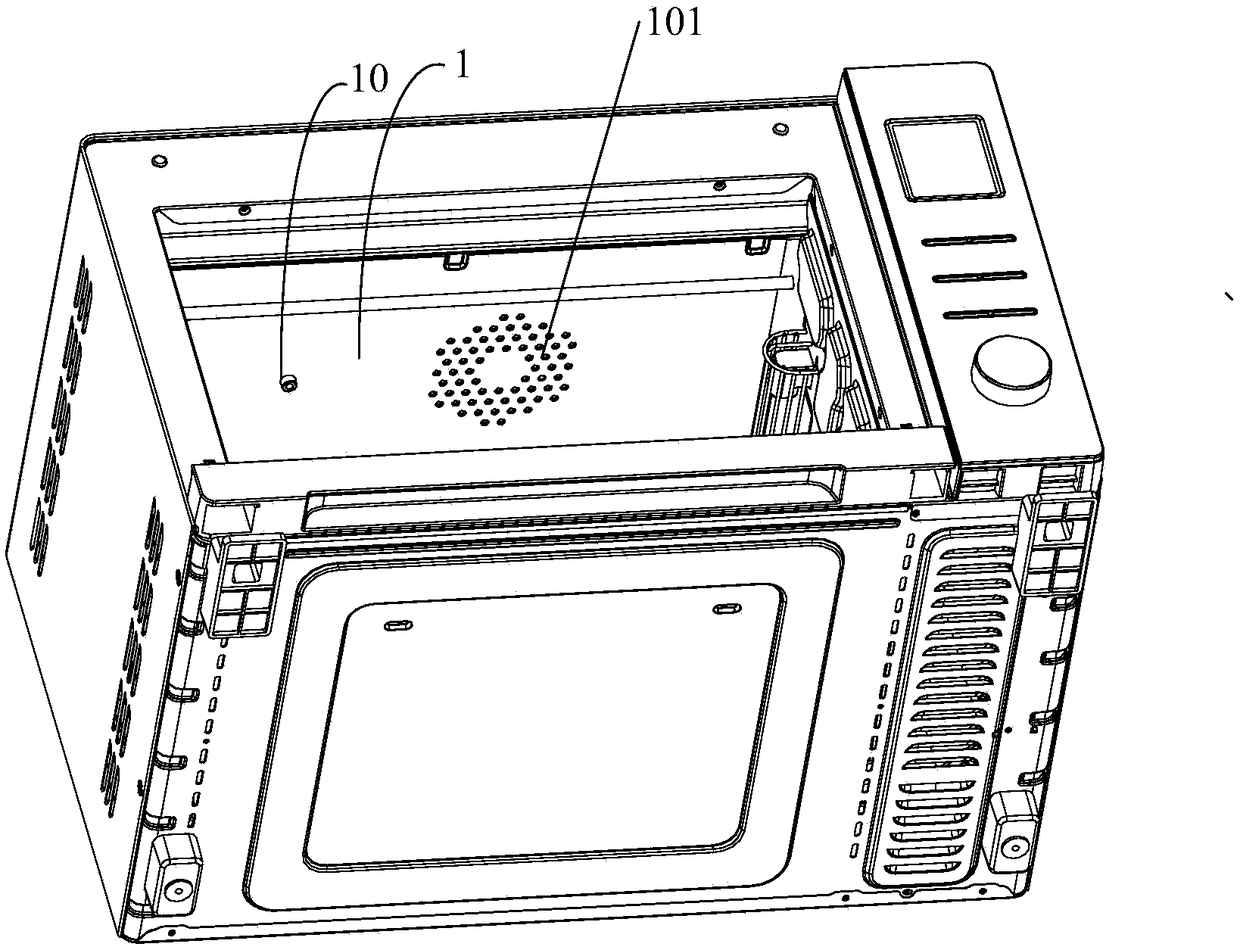

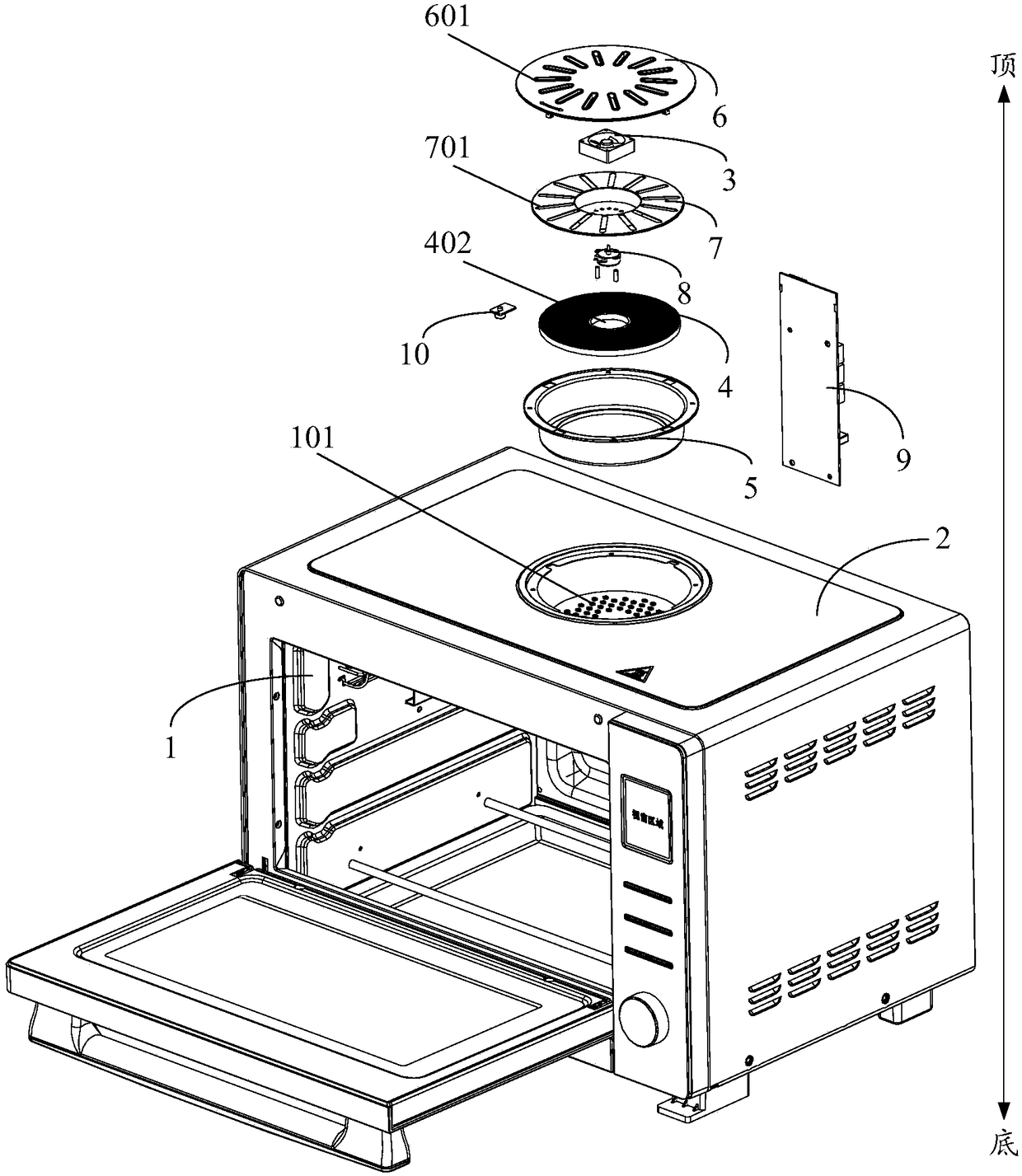

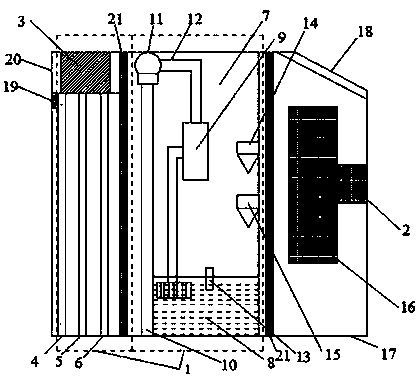

Electric oven and oil fume odor purification device control method

ActiveCN108497942ACompact structureSmall footprintDomestic stoves or rangesLighting and heating apparatusCavity wallScreen filter

The invention provides an electric oven and an oil fume odor purification device control method. The electric oven comprises a cavity and an oil fume odor purification device which comprises a draughtfan and a filter screen used for filtering oil fume and odor, an exhaust port is formed in the cavity wall of the cavity, the filter screen is installed at the exhaust port, and the draught fan is installed near the filter screen and used for discharging the oil fume in the cavity out of the cavity from the exhaust port and makes the oil fume flow through the filter screen. According to the screen, the oil fume odor purification device of the electric oven comprises the draught fan and the filter screen, the filter screen is installed at the exhaust port of the cavity, in the food heating process of the electric oven, the draught fan works to make gas in the cavity pass through the exhaust port and the filter screen, the filter screen filters out the oil fume and odor in the gas, and filtered gas enters a room and cannot pollute indoor air, so that bad feeling cannot be brought to a user, and the degree of satisfaction of the user on products can be improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

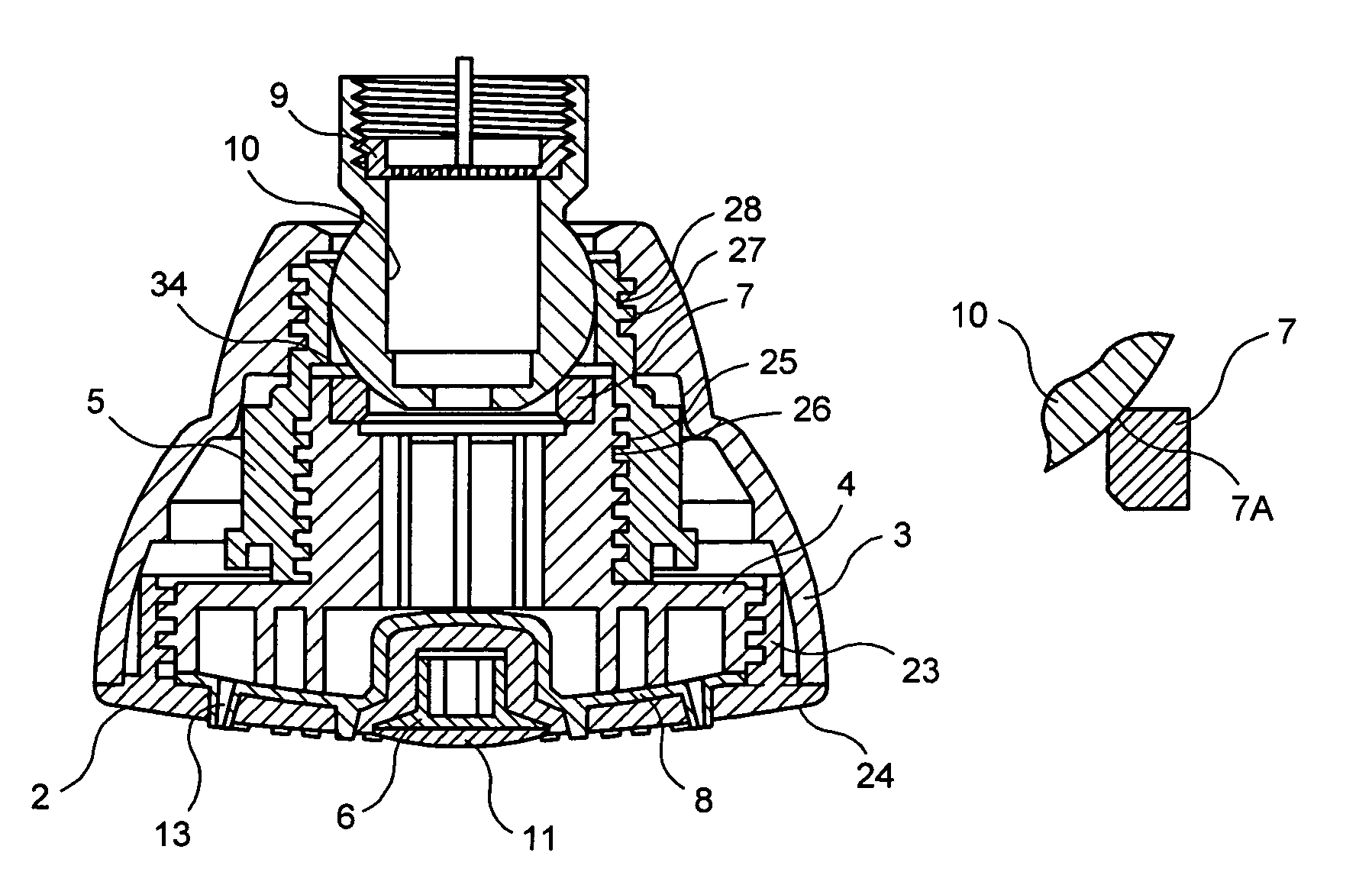

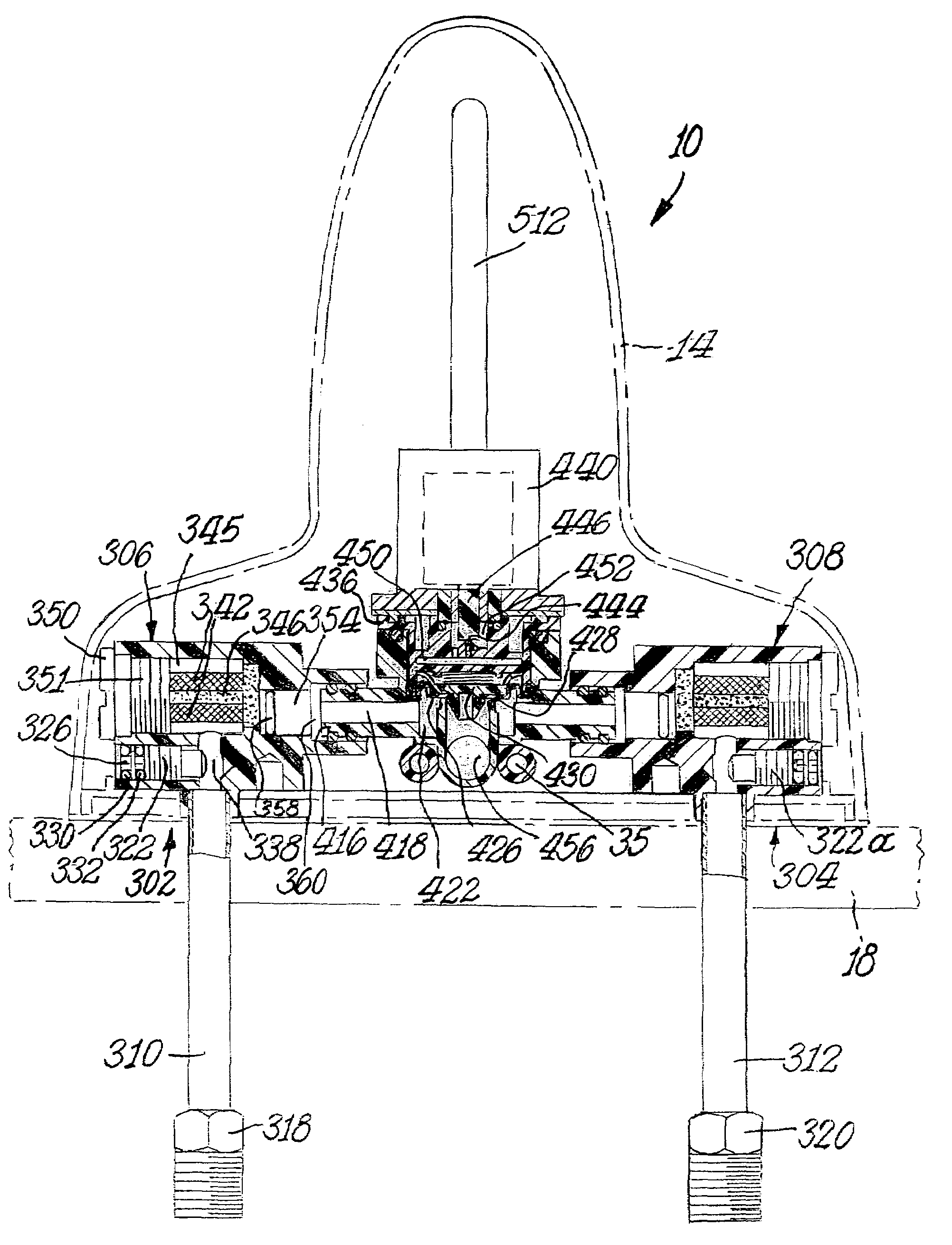

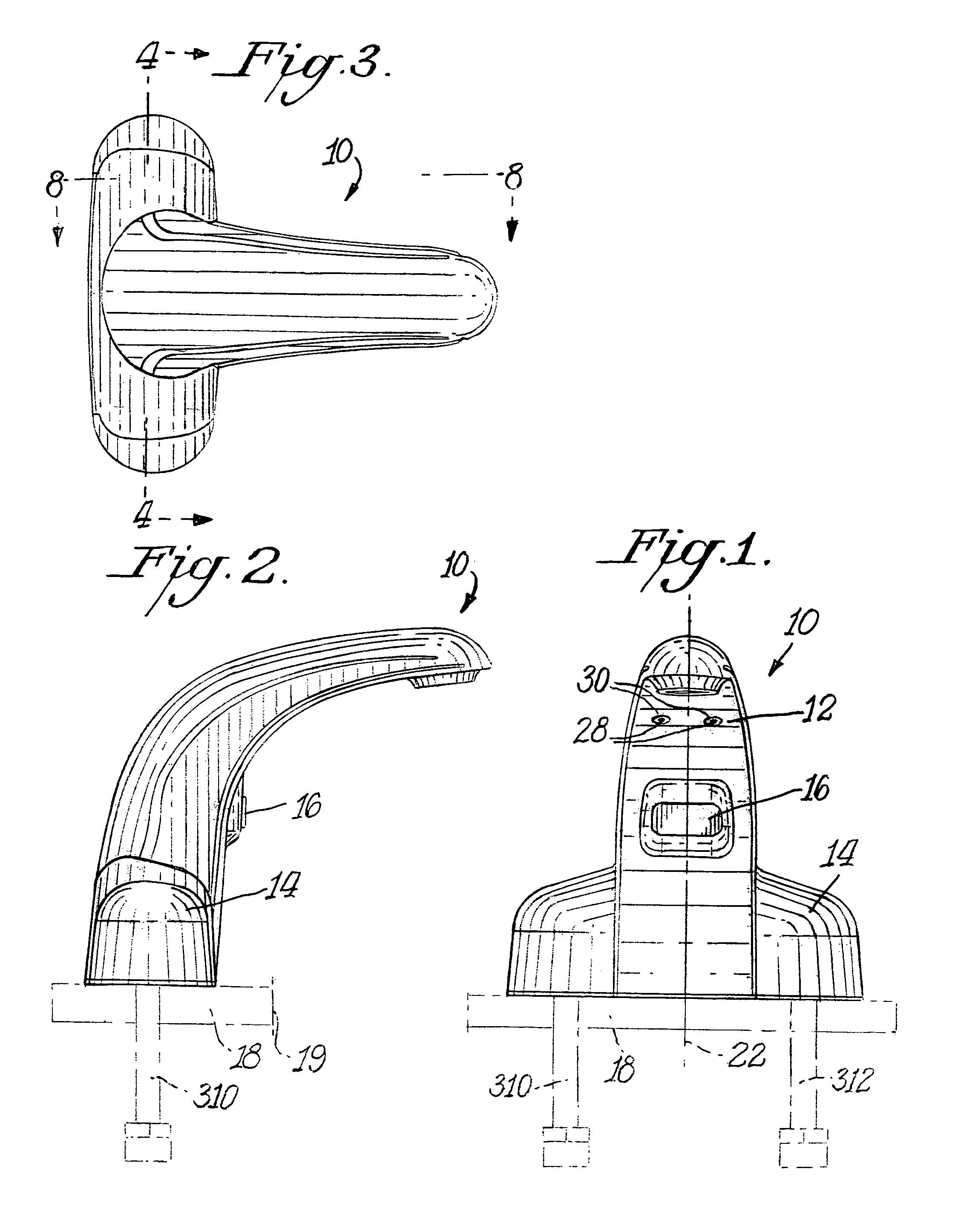

Above deck modular faucet assembly

ActiveUS7445024B2Easy maintenanceLow costServomotor componentsTemperatue controlParticulatesLine tubing

A faucet is provided comprising in-service separable parts that can be removed from the faucet without having to remove the entire housing. The faucet includes a main support housing, bolts, brackets and nuts to secure the main support body to a sink surface, two water inlets for connecting hot and cold incoming water lines. A flow control assembly is provided at each inlet to regulate the hot and cold water introduced into a mixing chamber. The valve housing includes an independent adjustable mixing valve for regulating the flow of water, an inline screen filter for removing particulate matter from the water stream, and a check valve for preventing water from returning back to the water source. Upon passing through the check valve and into water mixing housing inlets, the water is mixed in a mixing chamber. From the mixing chamber the water is regulated by a solenoid. When sink users place their hands, or other objects in front of the sensor the solenoid is activated. This permits water to flow into the faucet head portion and ultimately to the user.

Owner:SPEAKMAN

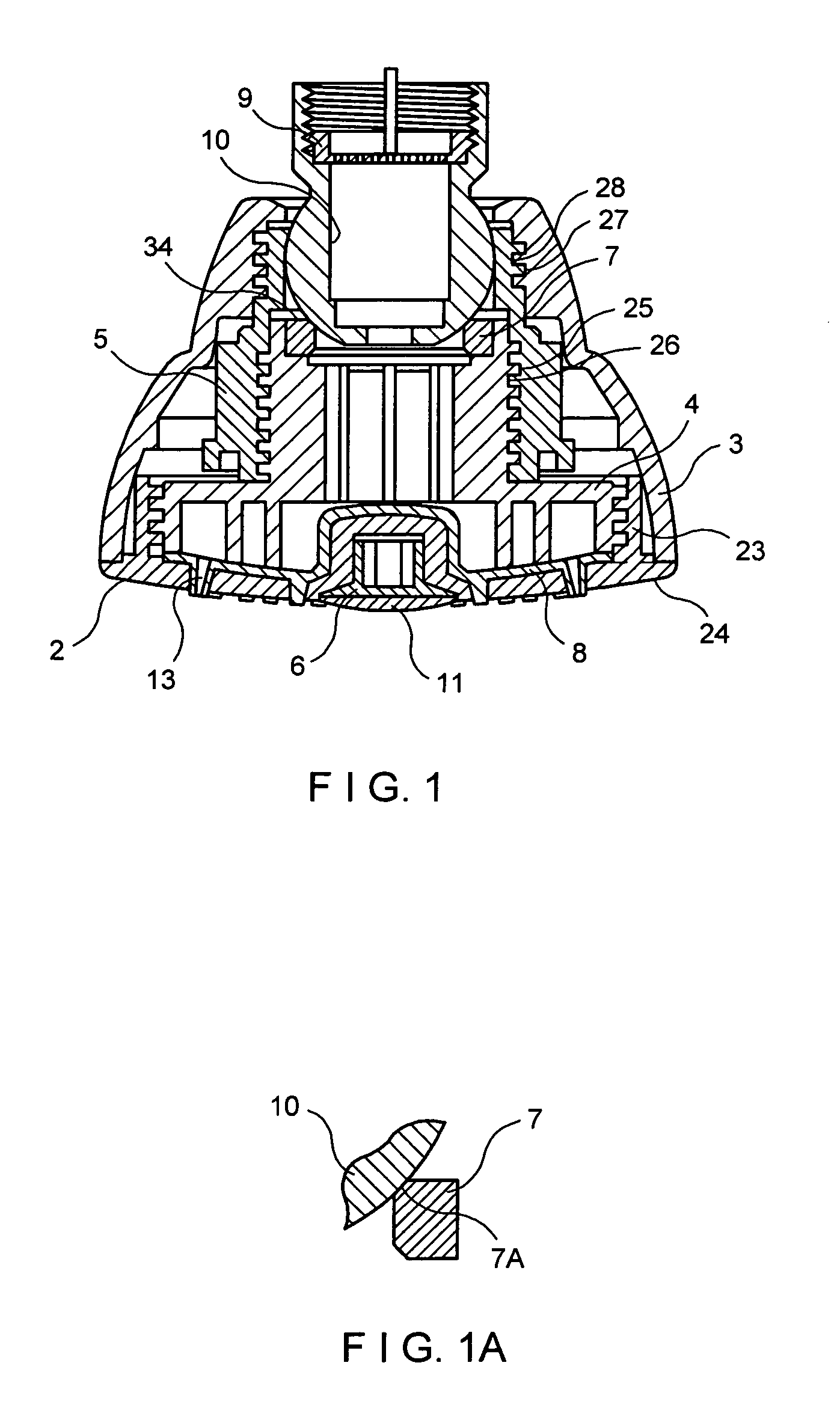

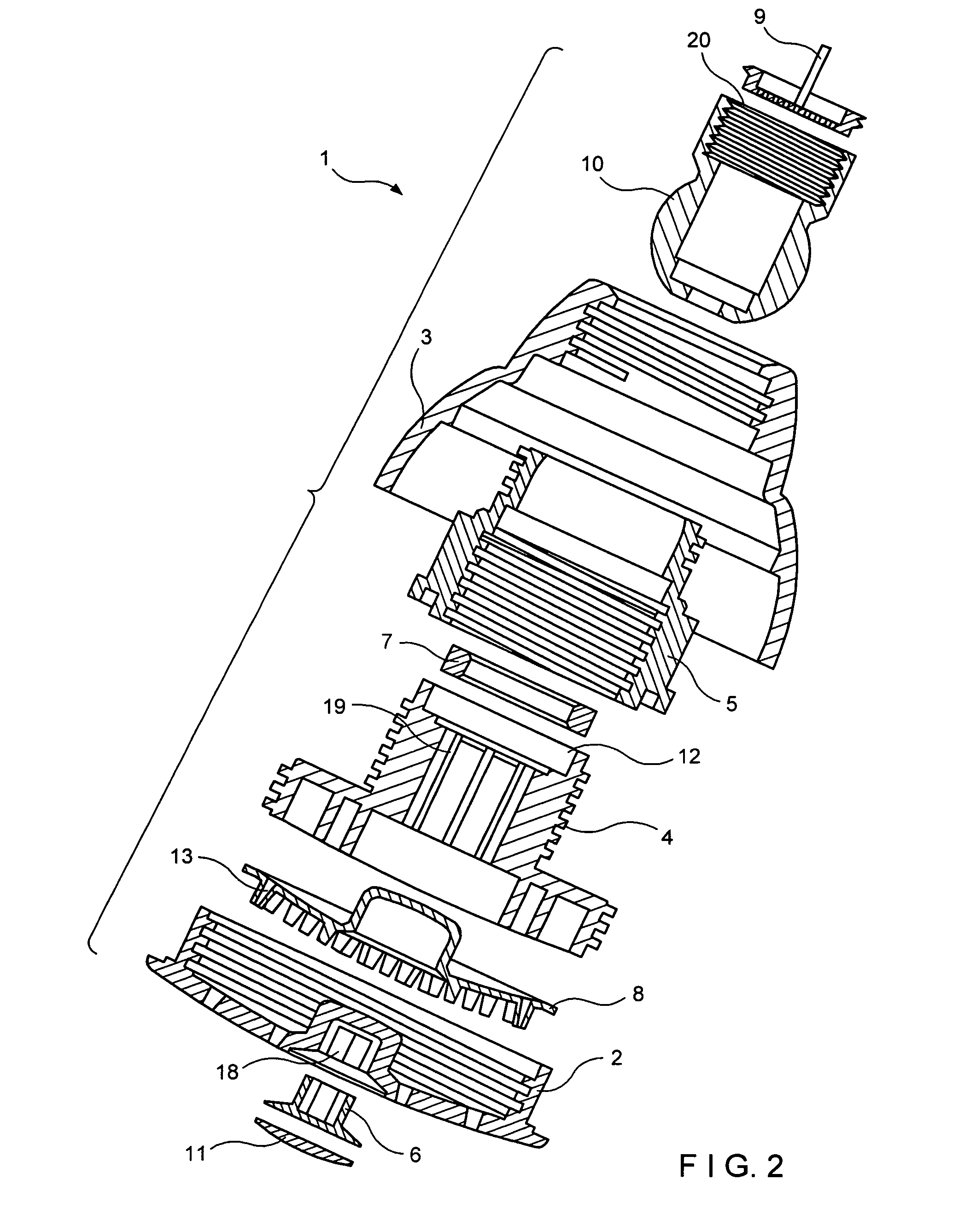

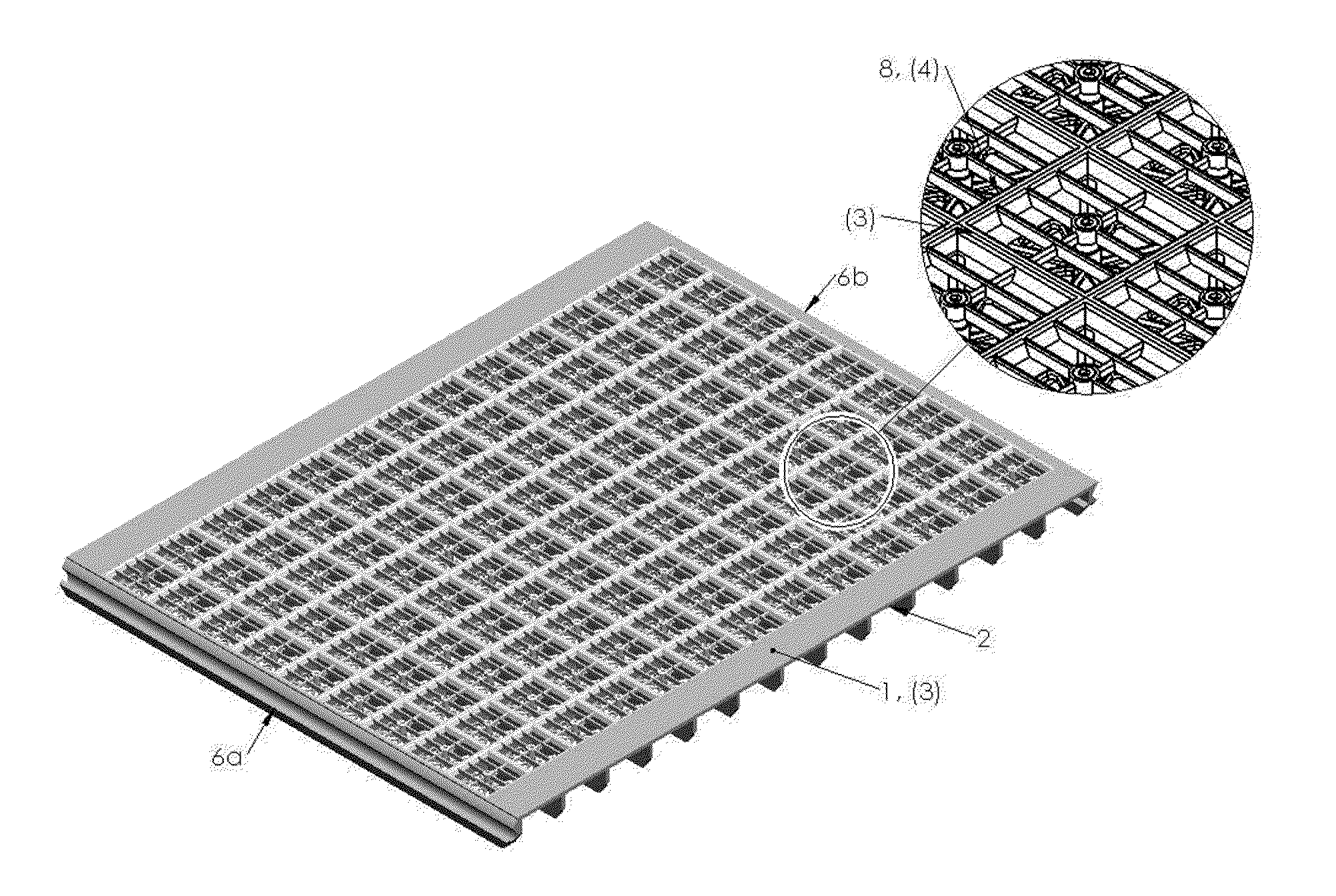

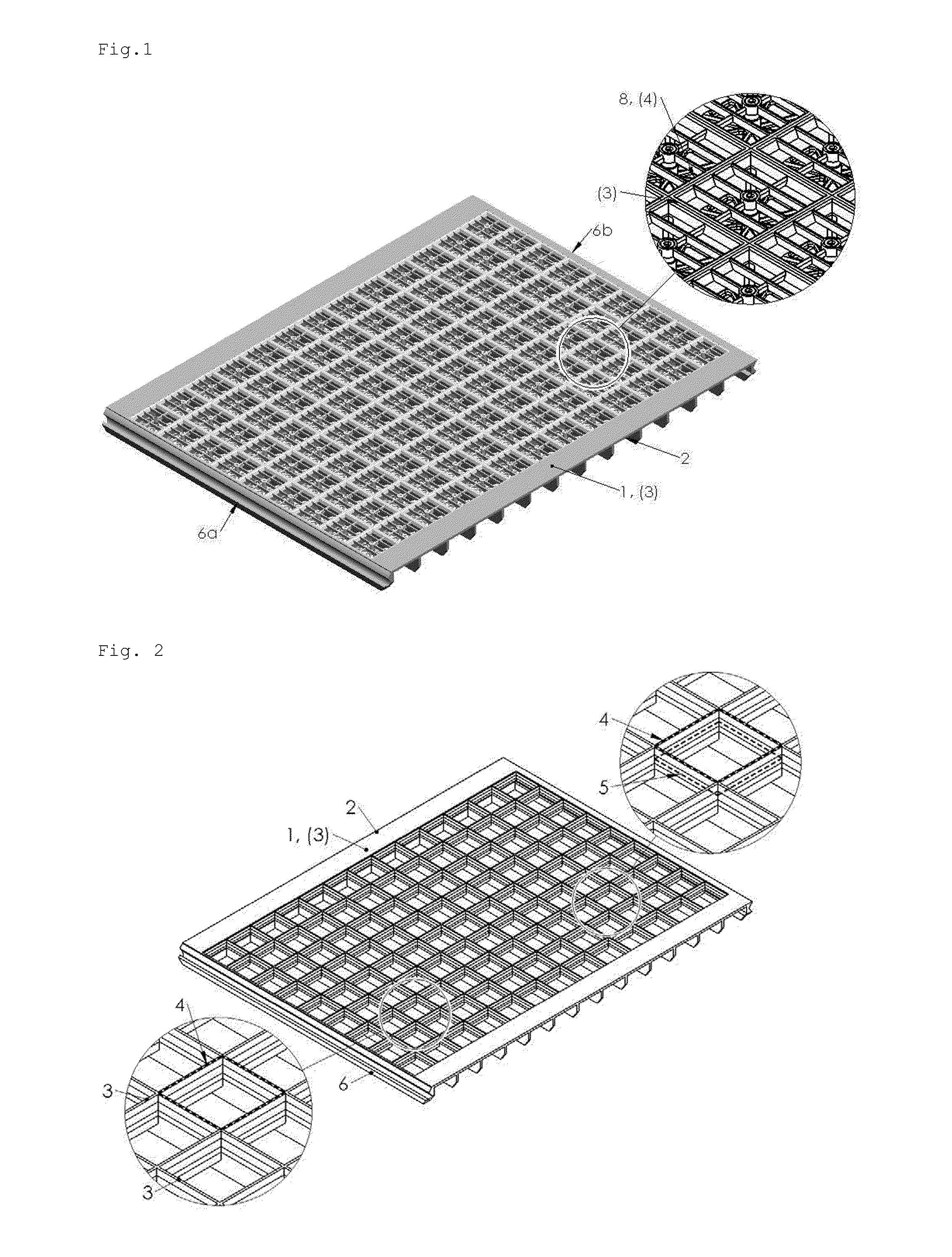

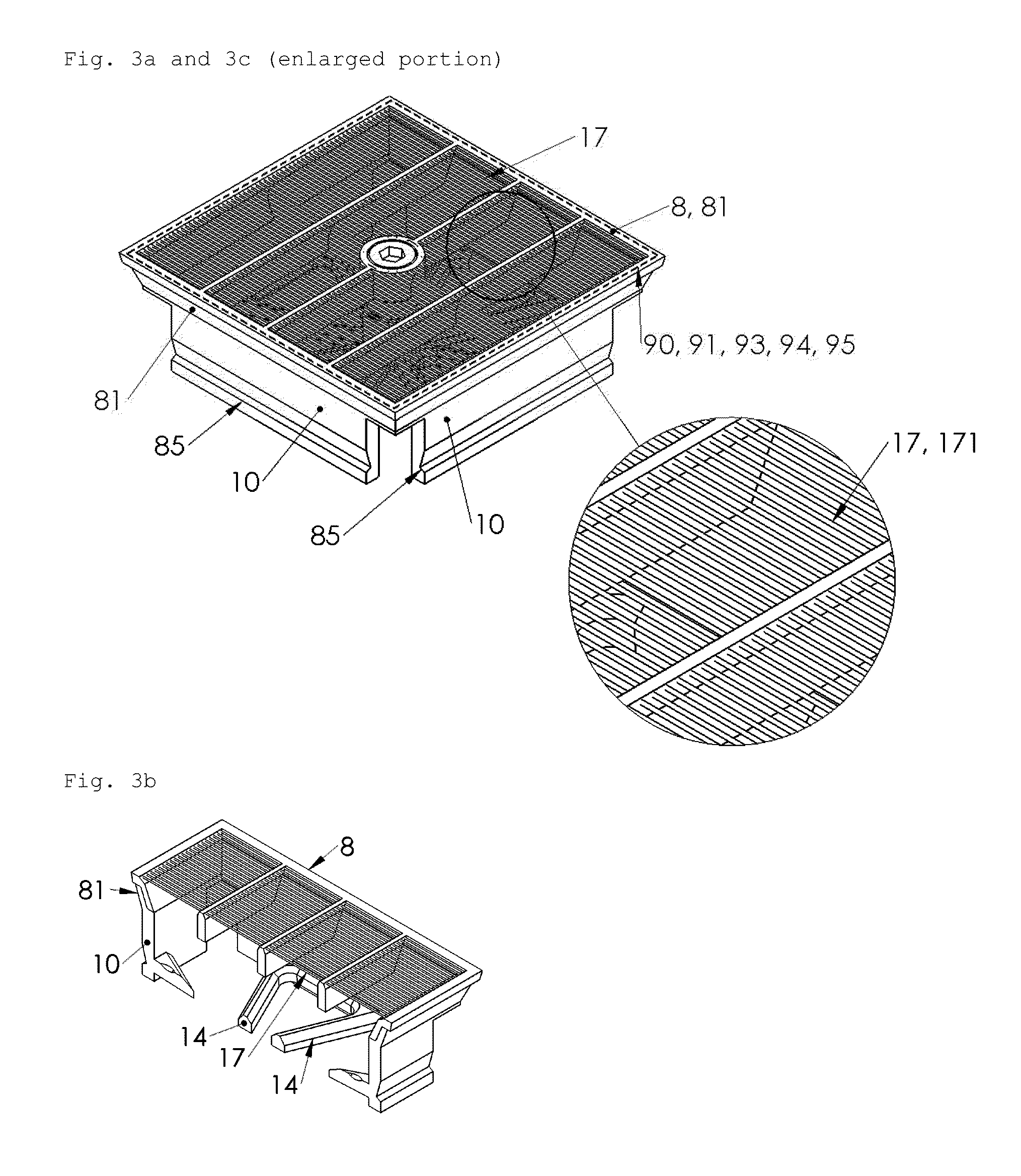

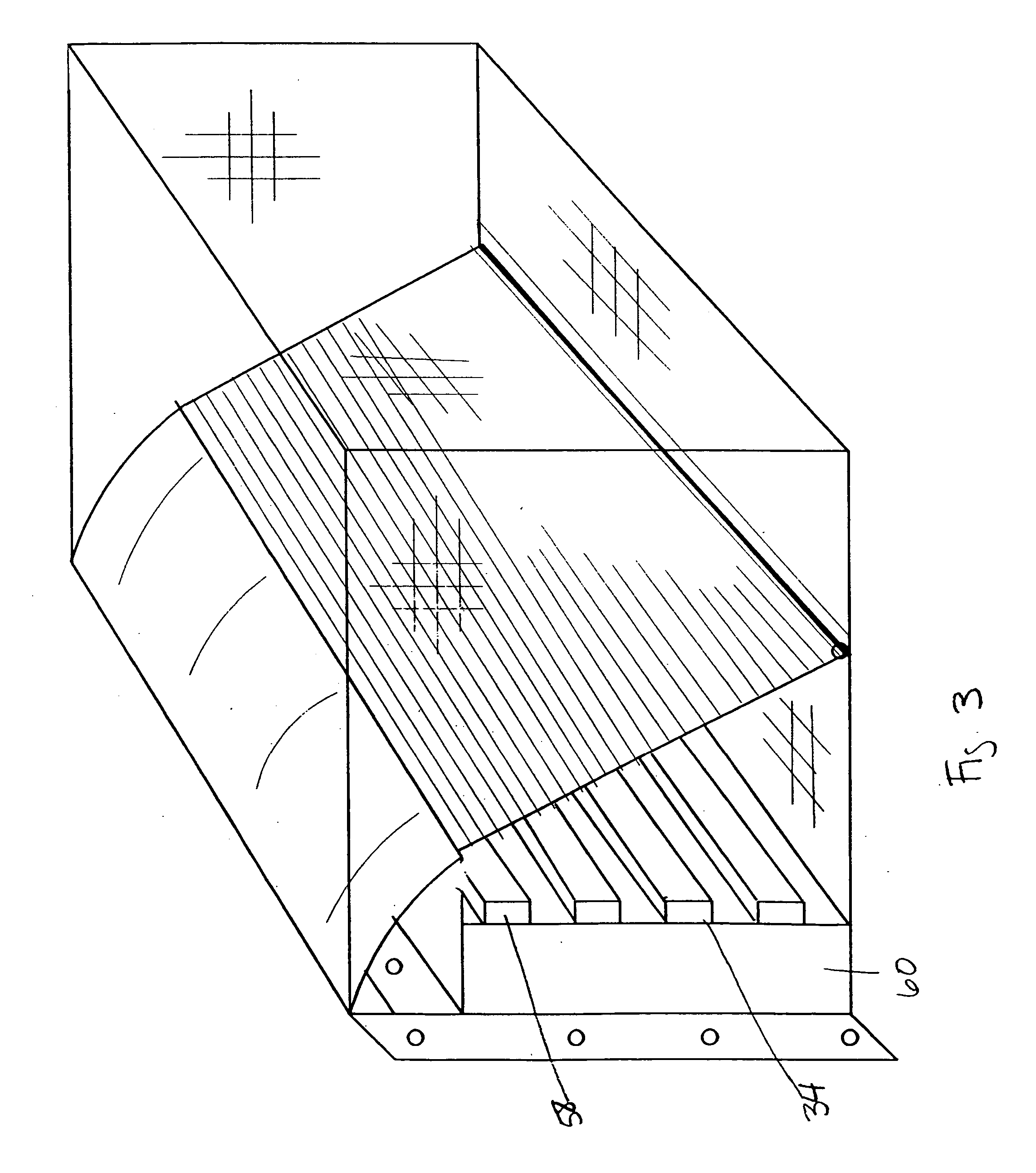

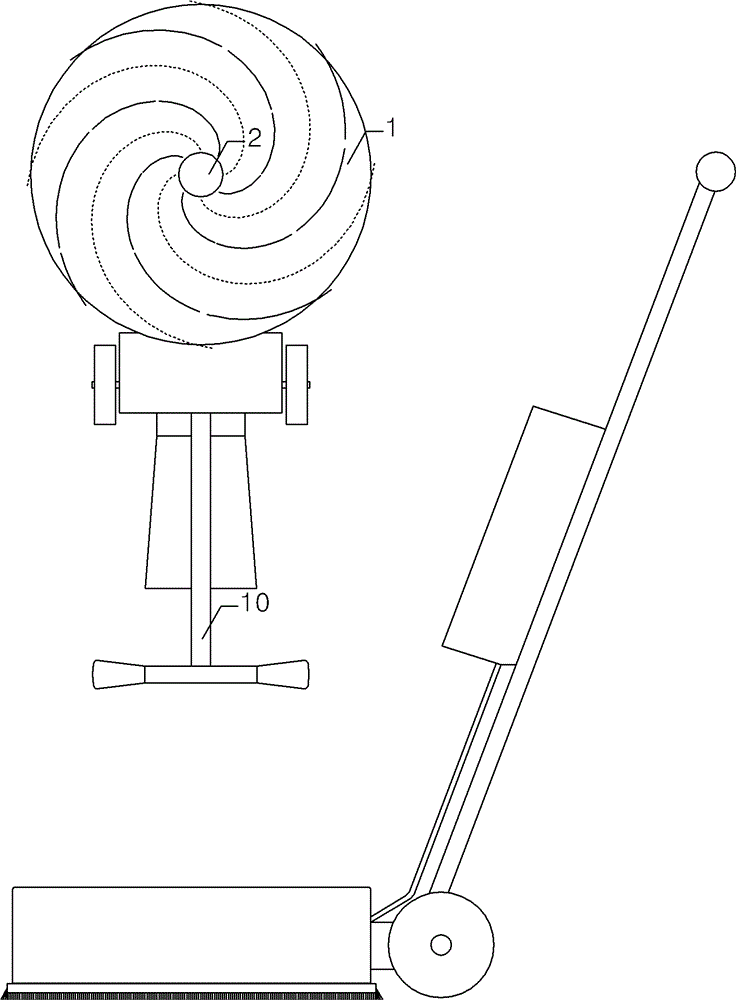

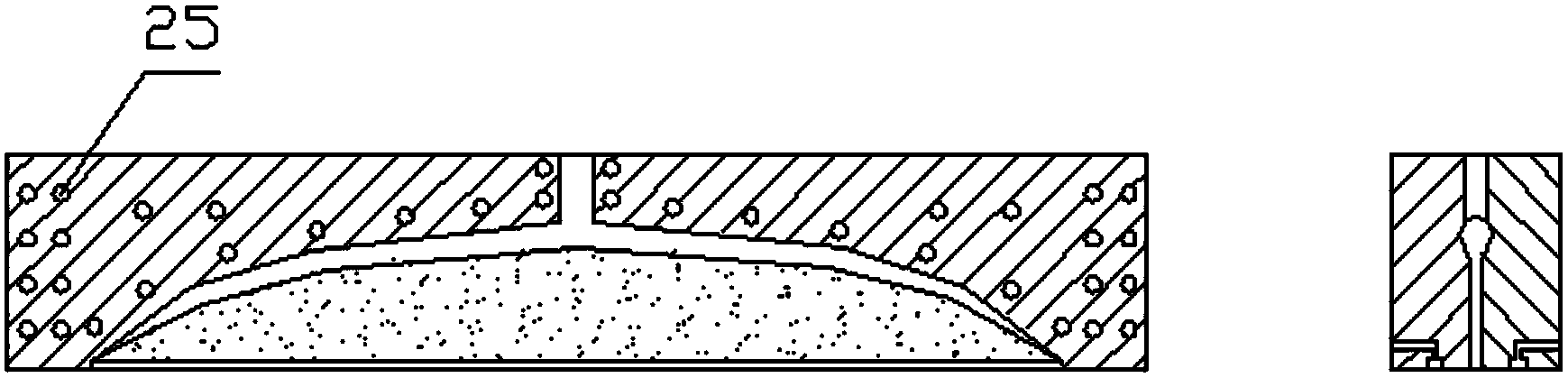

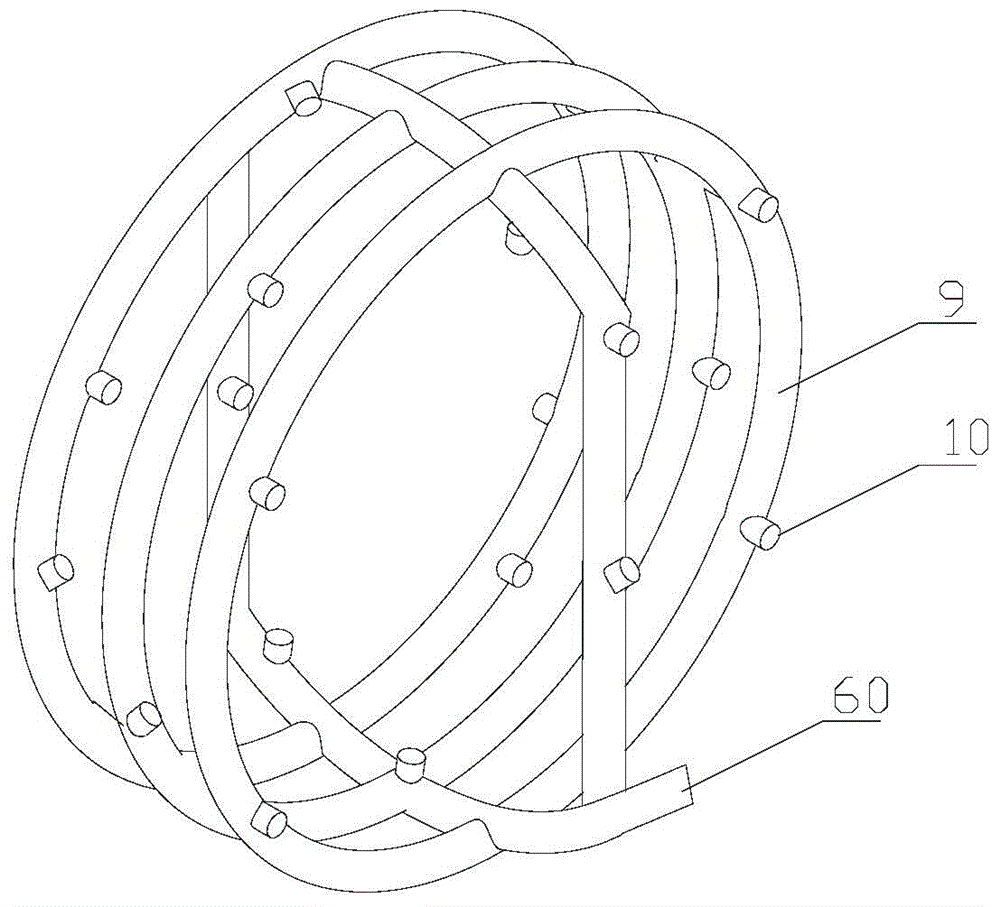

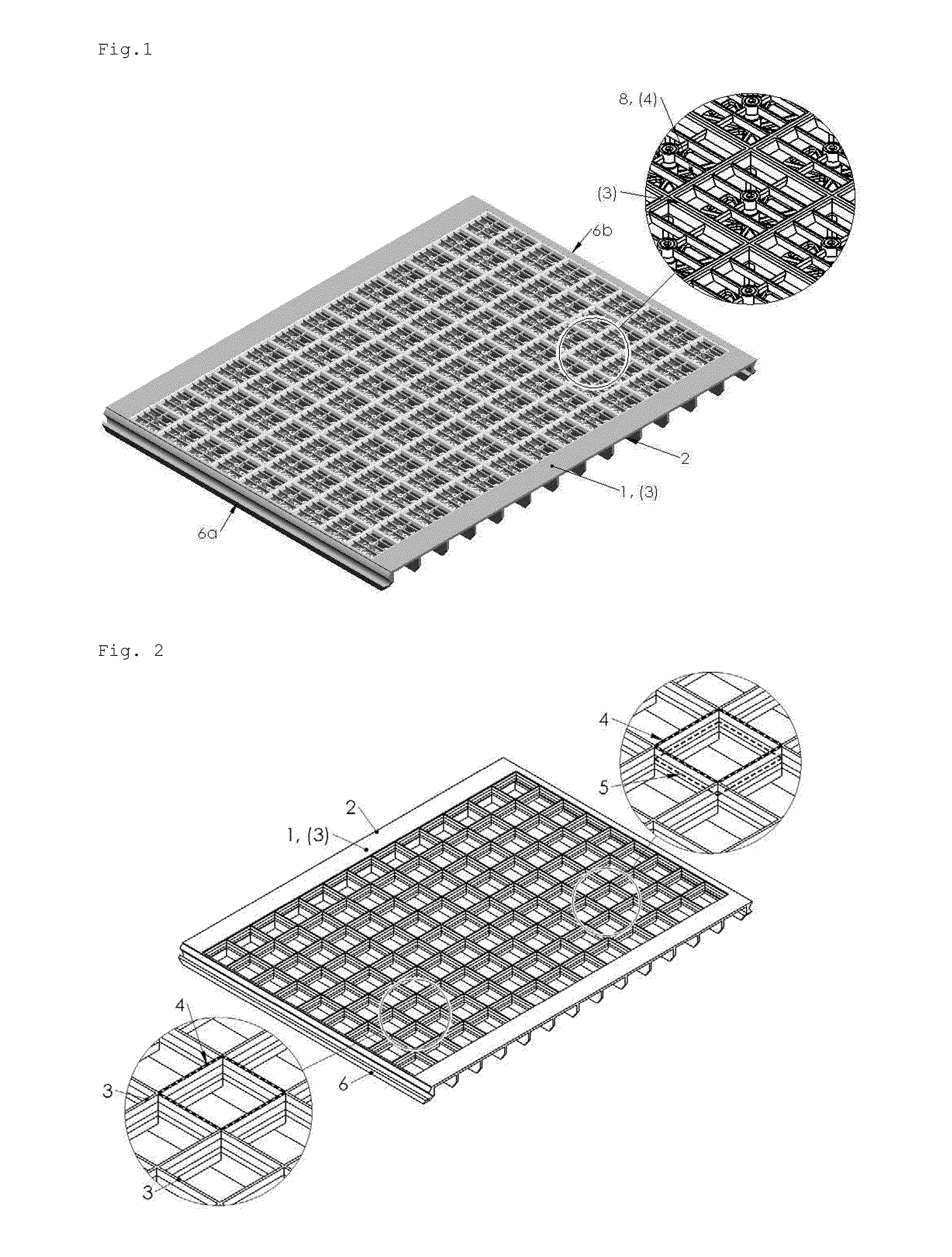

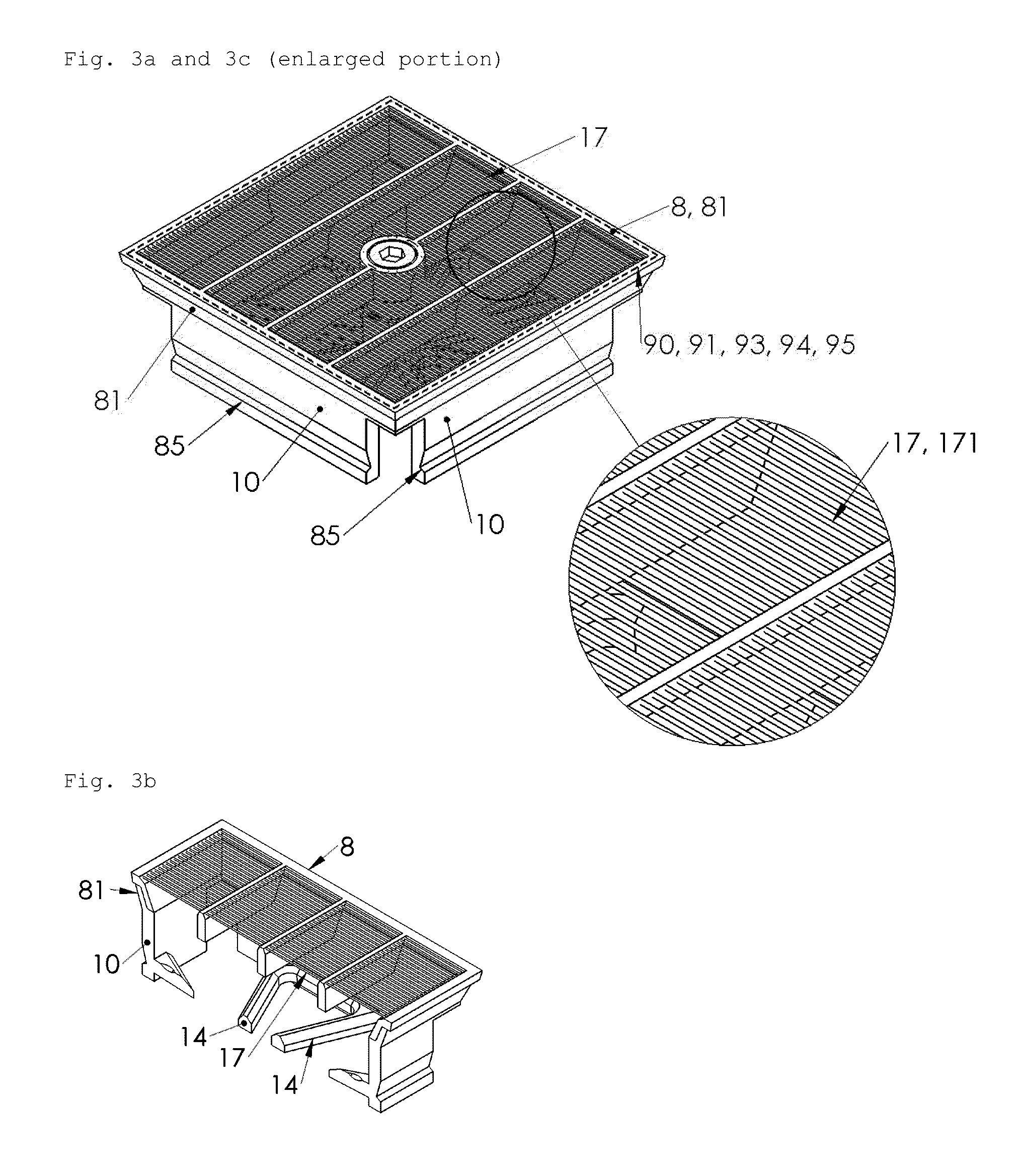

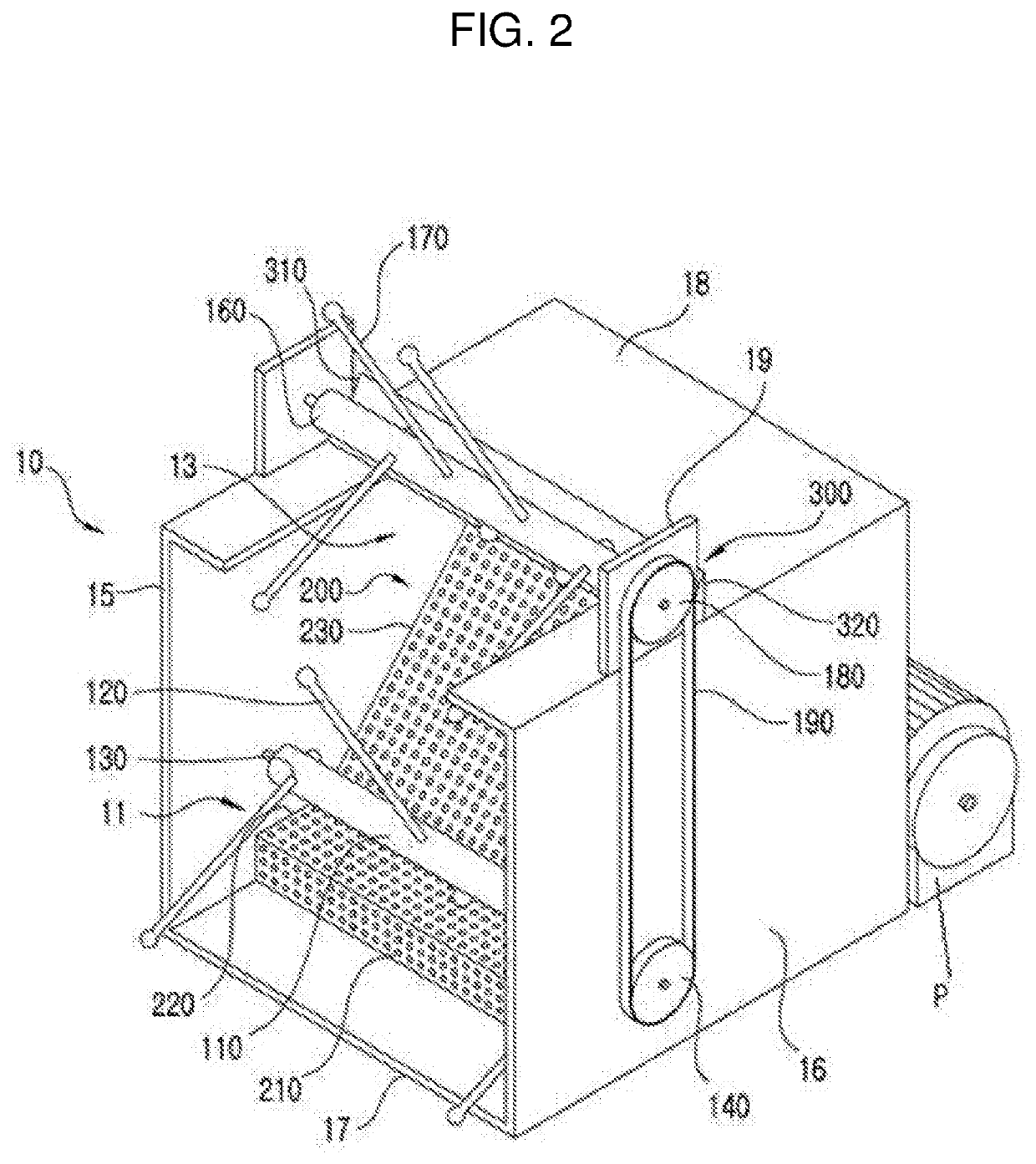

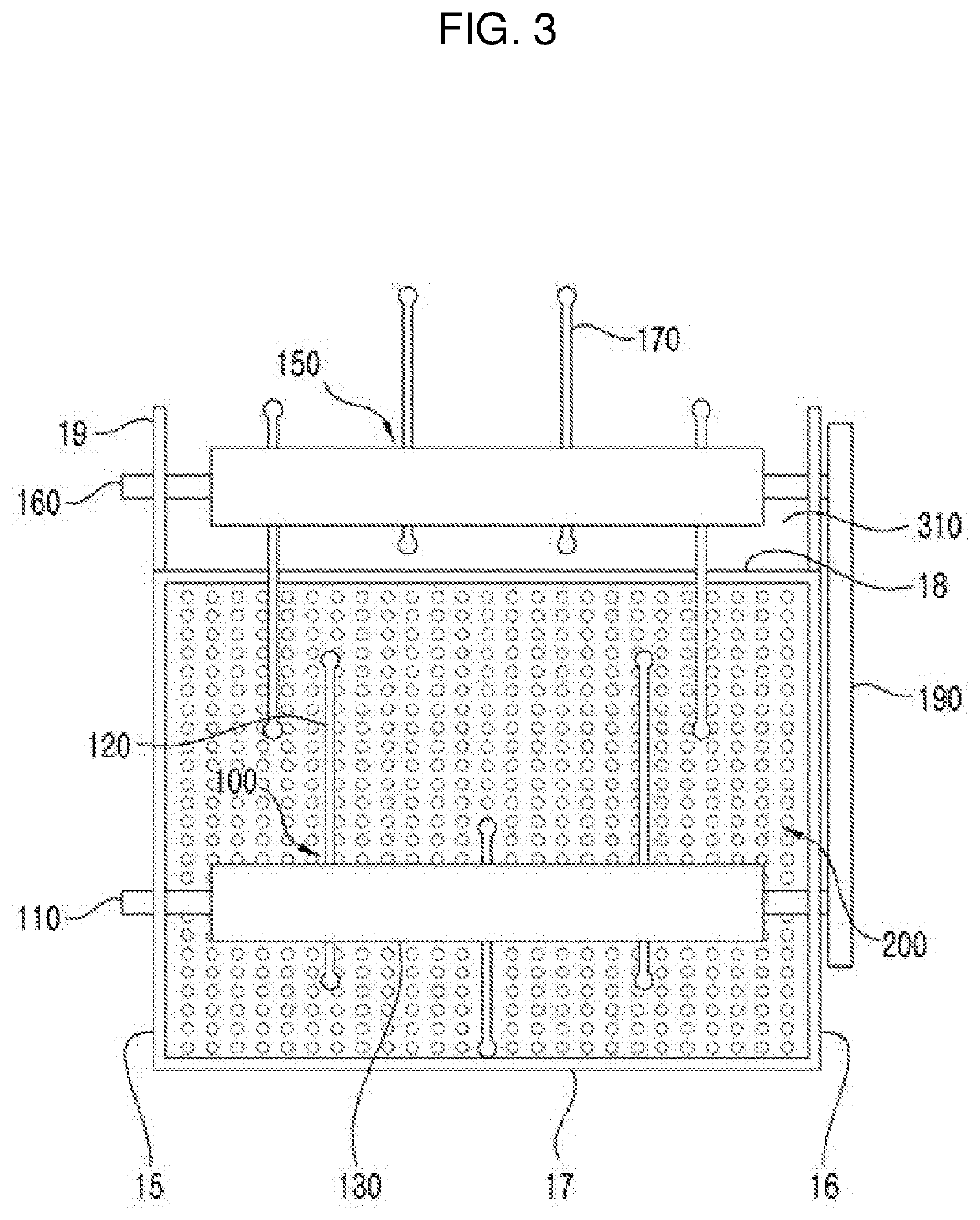

Shaker screen filter for a drilling fluid shaker

ActiveUS20110094950A1Shorten the timeReduce frictionSievingSnap-action fastenersLocking mechanismEngineering

An improved shaker screen filter for a well fluid shale shaker includes a main frame arranged for being arranged in the well fluid shale shaker for screening, preferably under vibration, of drilling mud, wherein the mainframe is subdivided into a plurality of smaller cell frames, one or more cell plug filters with one or more layers of screen cloths on top of at least one support cloth or support layer, wherein each of the cell plug filter includes a cell plug filter frame arranged to be held in each of the cell corresponding frames of the main frame, wherein at least one of the cell plug filter frame includes a locking mechanism arranged for locking the cell plug filter frame, upon desire, in a preferred position in the cell frame, correspondingly releasing the cell plug filter frame from the cell frame.

Owner:OPTIPRO

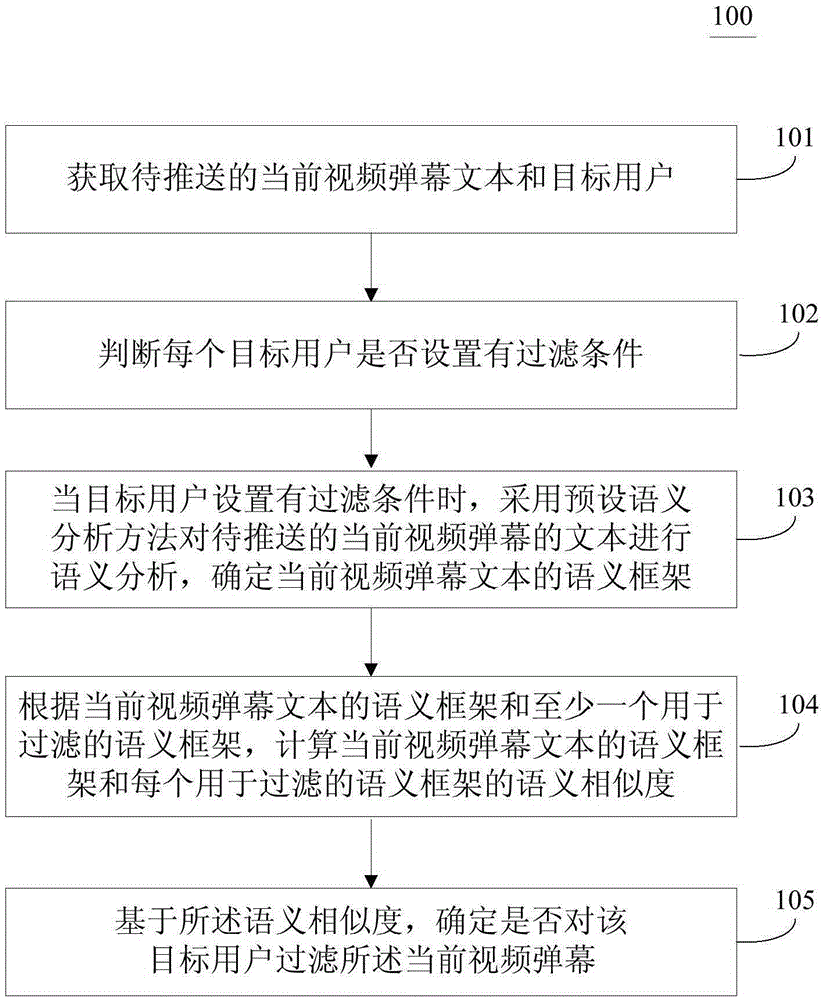

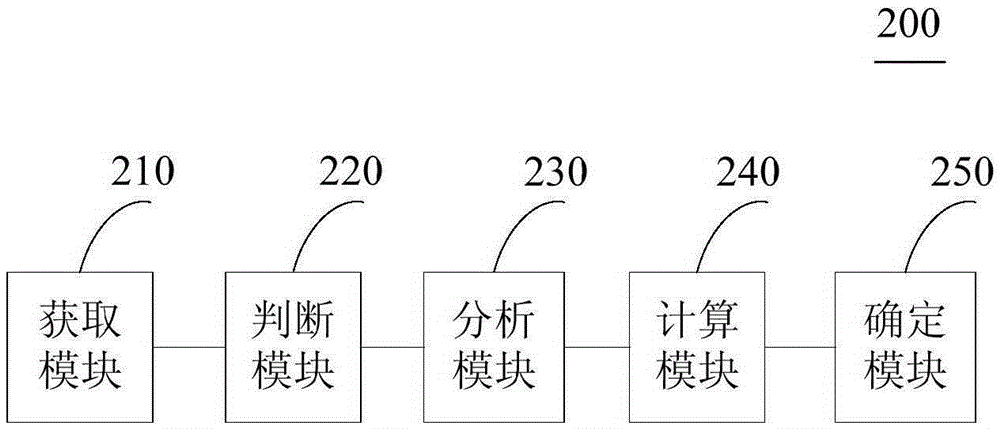

Video bullet screen filtering method and device

ActiveCN105357586AImprove filtration efficiencyEasy to operateSemantic analysisSelective content distributionComputer graphics (images)Ophthalmology

The embodiment of the invention provides a video bullet screen filtering method and device. One specific embodiment of the method comprises the following steps: acquiring a current video bullet screen text to be pushed and target users; judging whether the target users already set filtering conditions or not; when the target users already set the filtering conditions, performing semantic analysis on the current video bullet screen text to be pushed through a preset semantic analysis method, and determining a semantic frame of the current video bullet screen text; calculating semantic similarities between the semantic frame of the current video bullet screen text and semantic frames for filtering according to the semantic frame of the current video bullet screen text and at least one semantic frame for filtering; and determining whether to filter the current video bullet screen or not for the target users on the basis of the semantic similarities. Through the embodiment, user operations can be simplified, and the video bullet screen filtering efficiency is increased.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

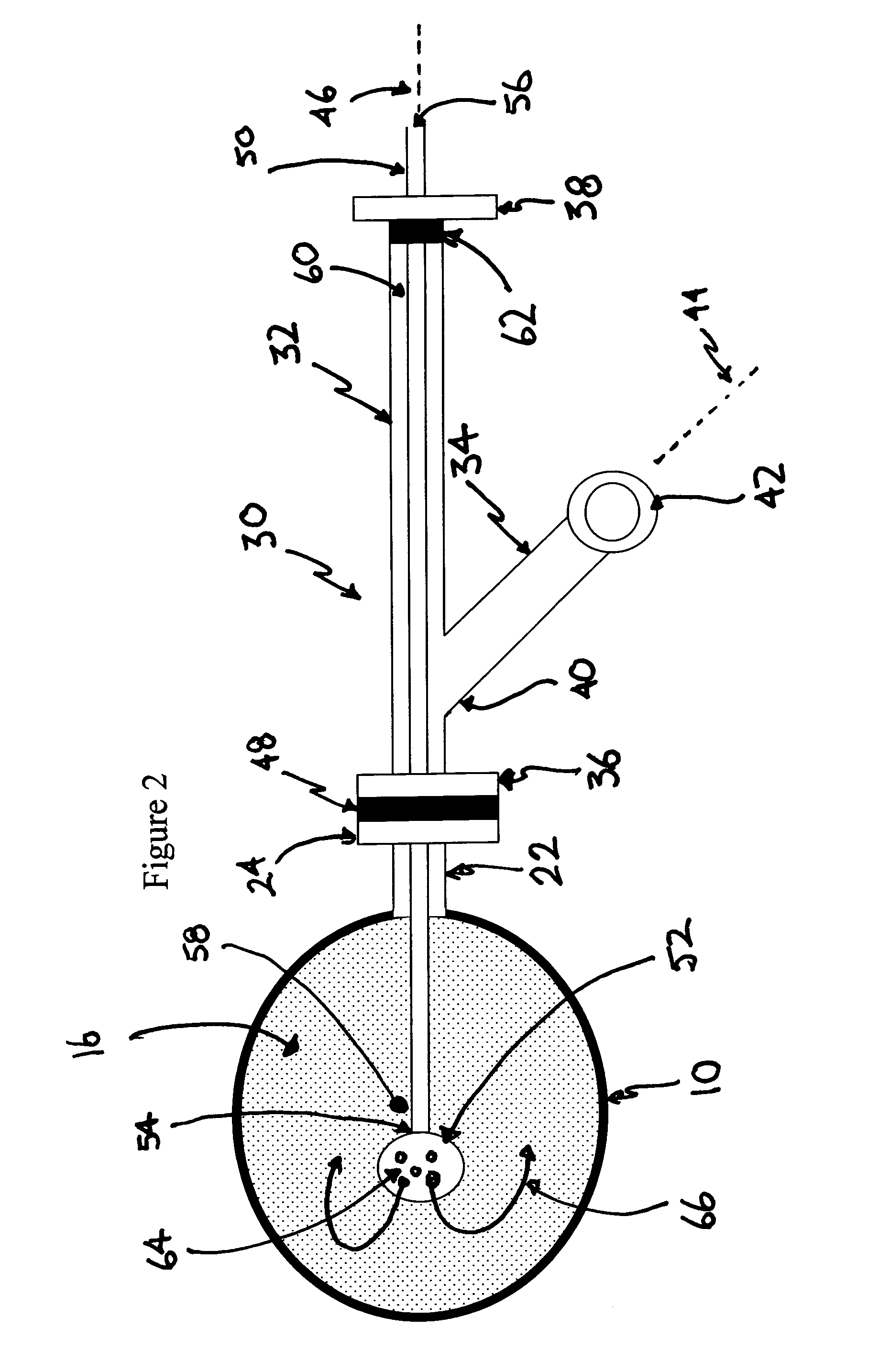

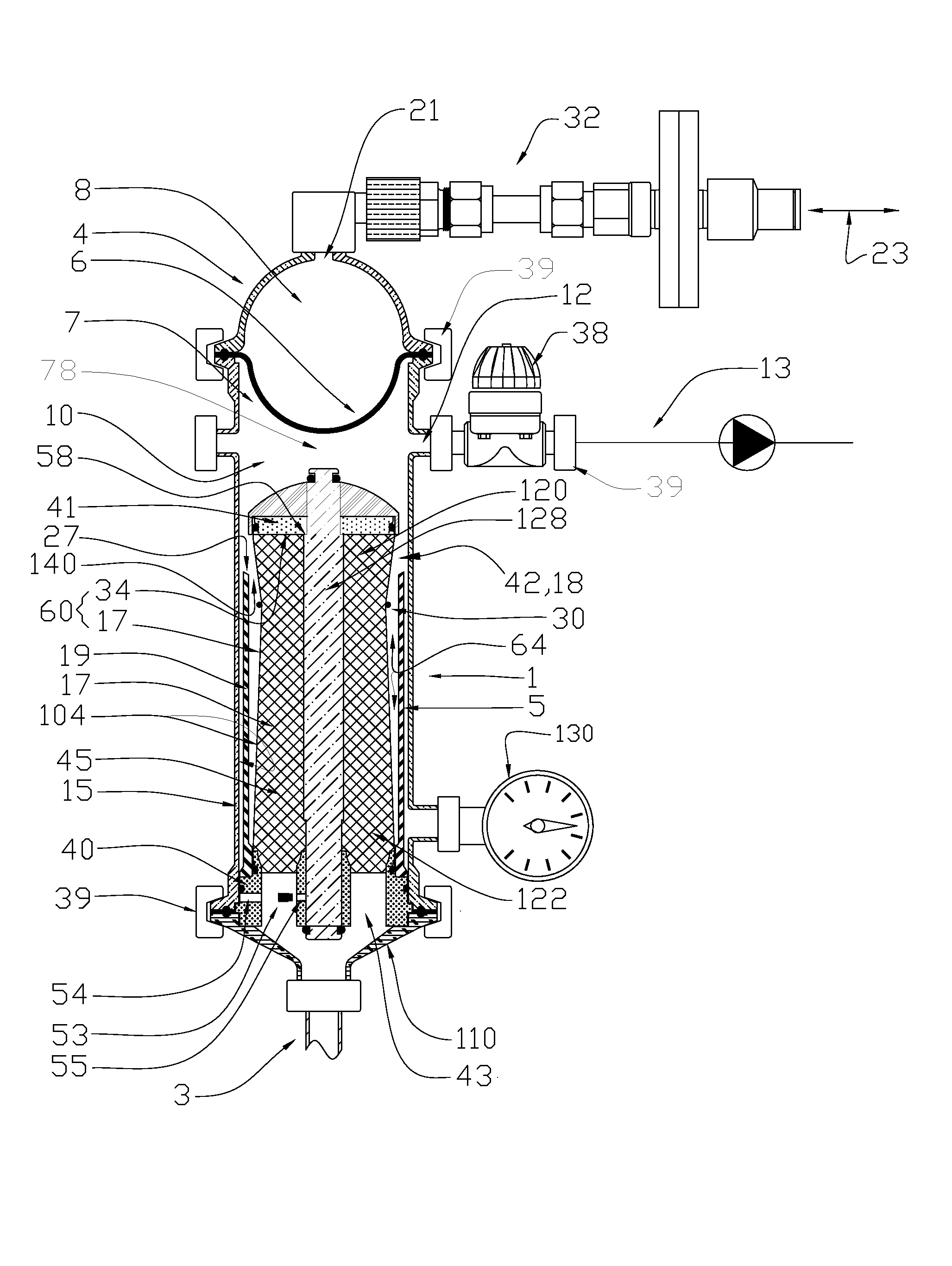

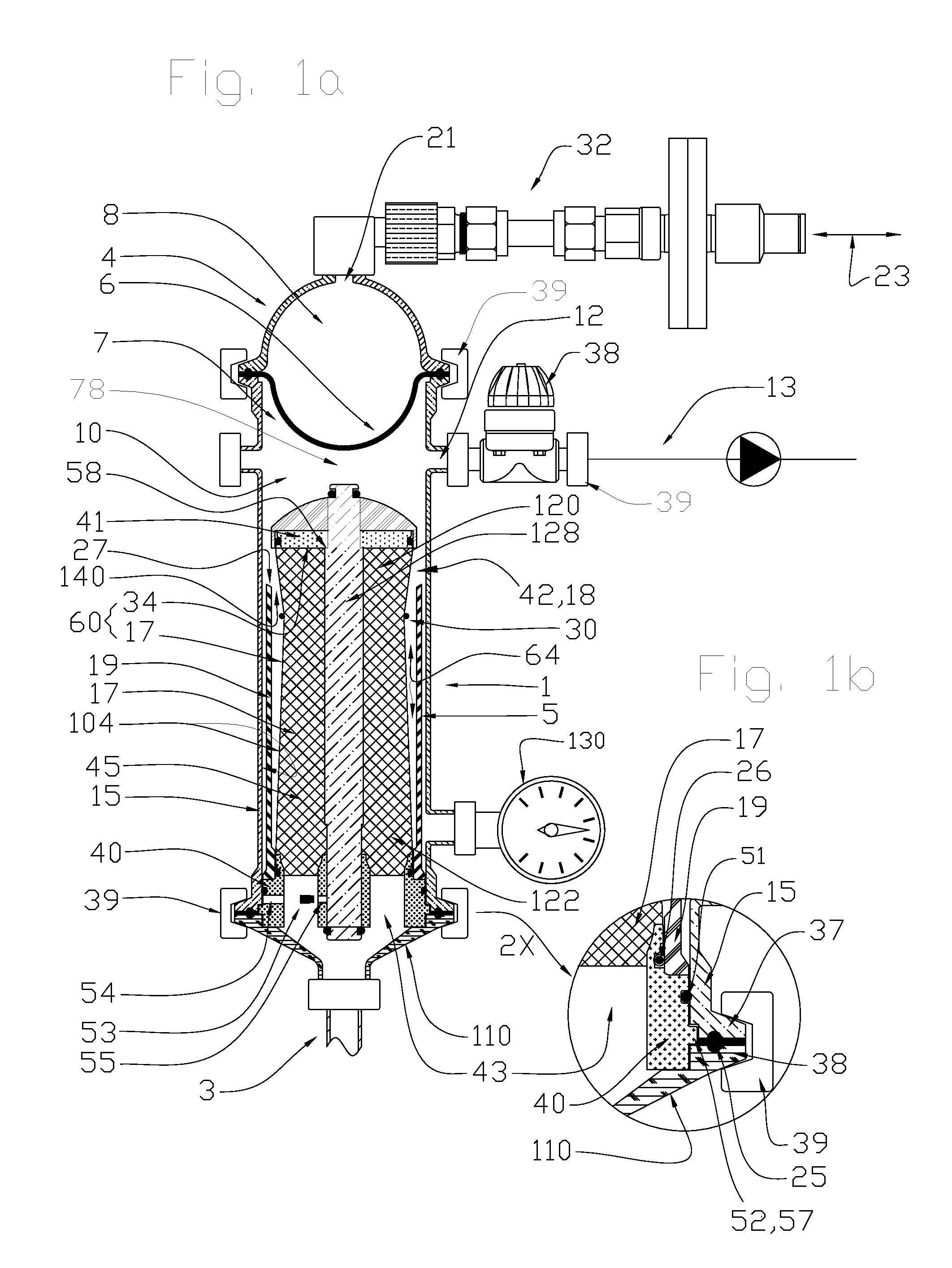

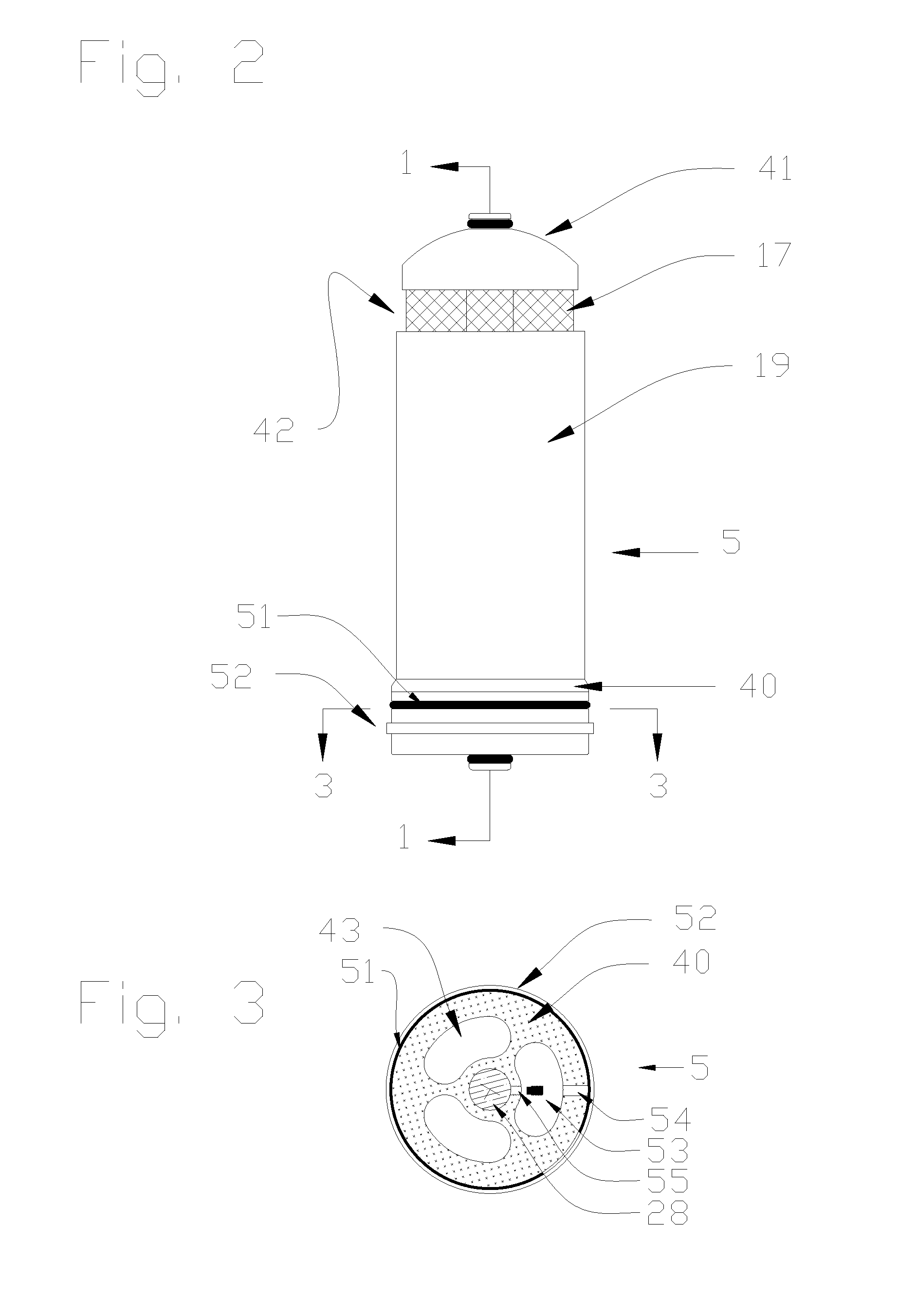

Screen Filter Module for Alternating Flow Filtration

ActiveUS20100078395A1Avoid clogging the filterSemi-permeable membranesBiomass after-treatmentParticulatesFiltration

Improved screen filter modules, related compartmentalized filtration modules, and related filtration processes, suitable for filtering fluid to eliminate suspended particulate matter, such as living cells or microcarriers anchoring living cells, or to separate particulate matter based on size. The improvement is the presence of a barrier that channels redirected filtrate to the portion of the filter most susceptible to clogging by the particulate matter and induces flow patterns that act against clogging.

Owner:REPLIGEN CORP

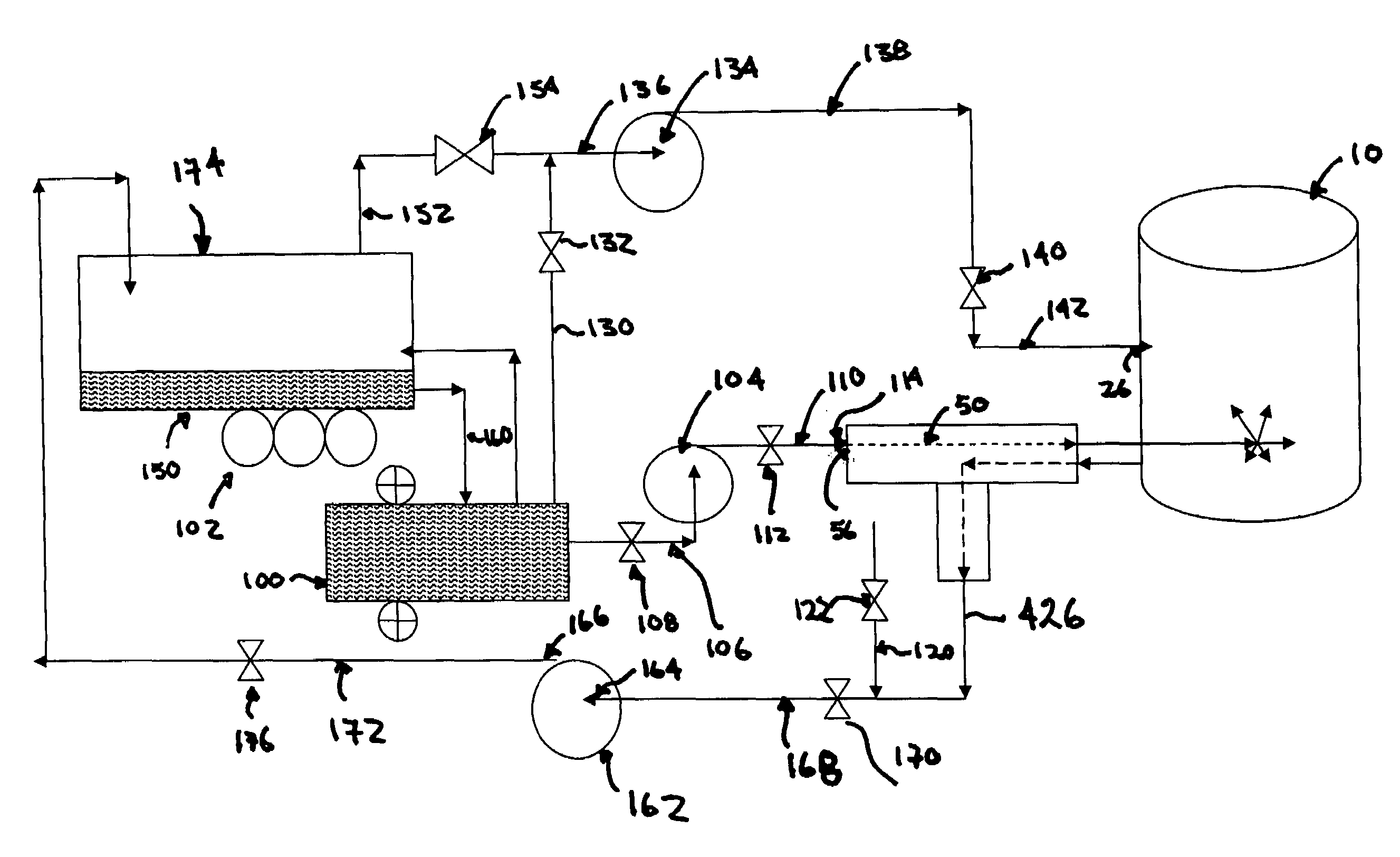

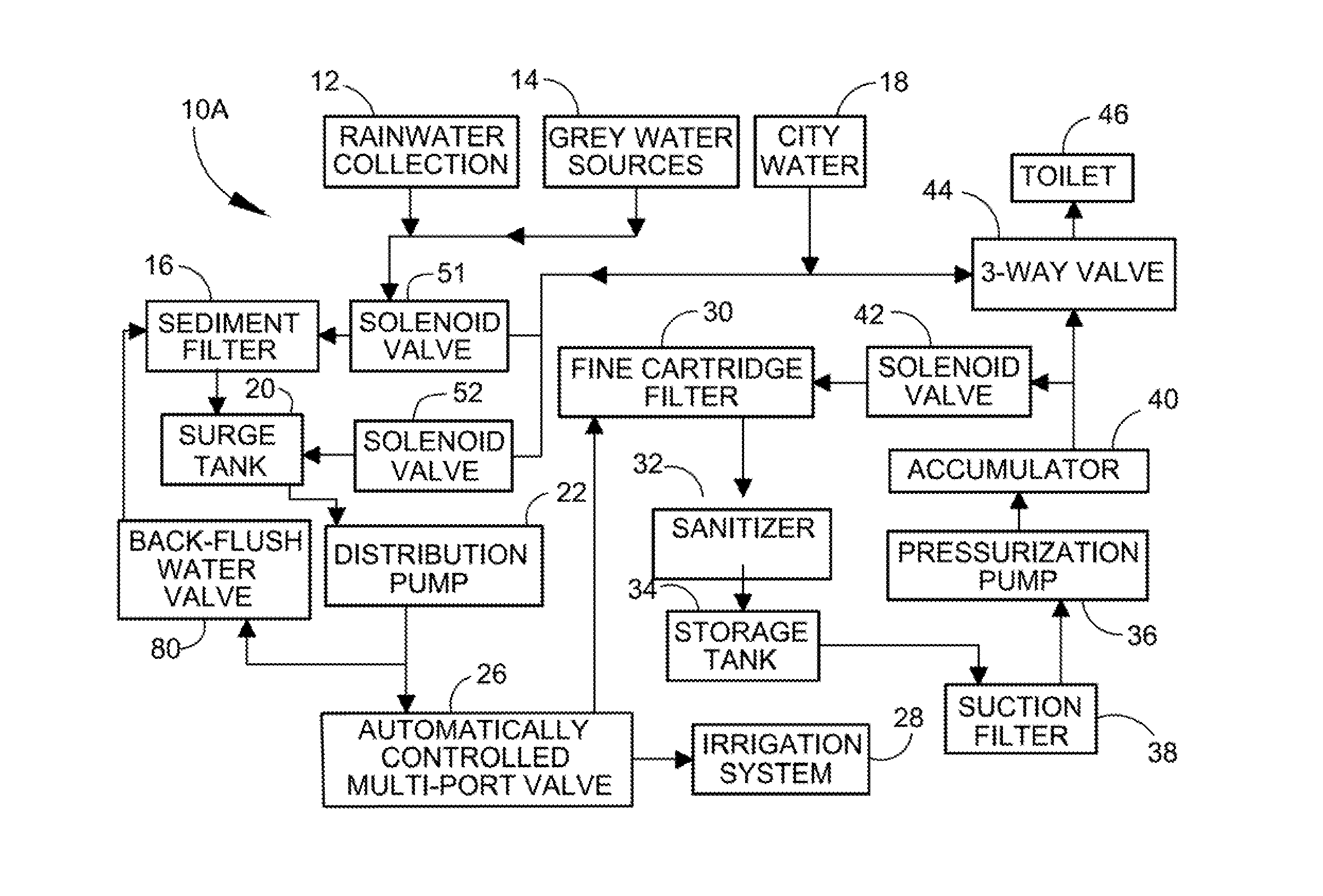

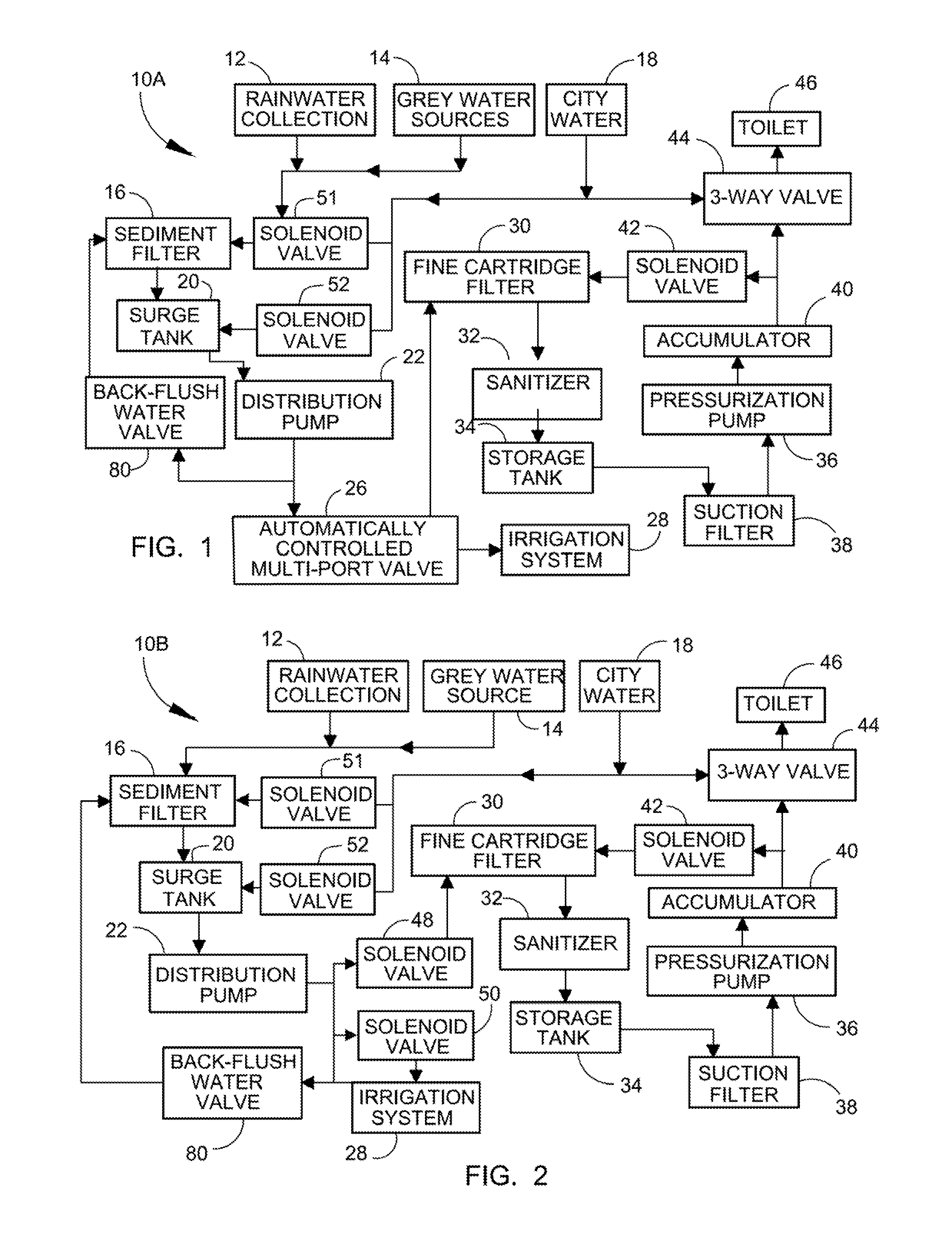

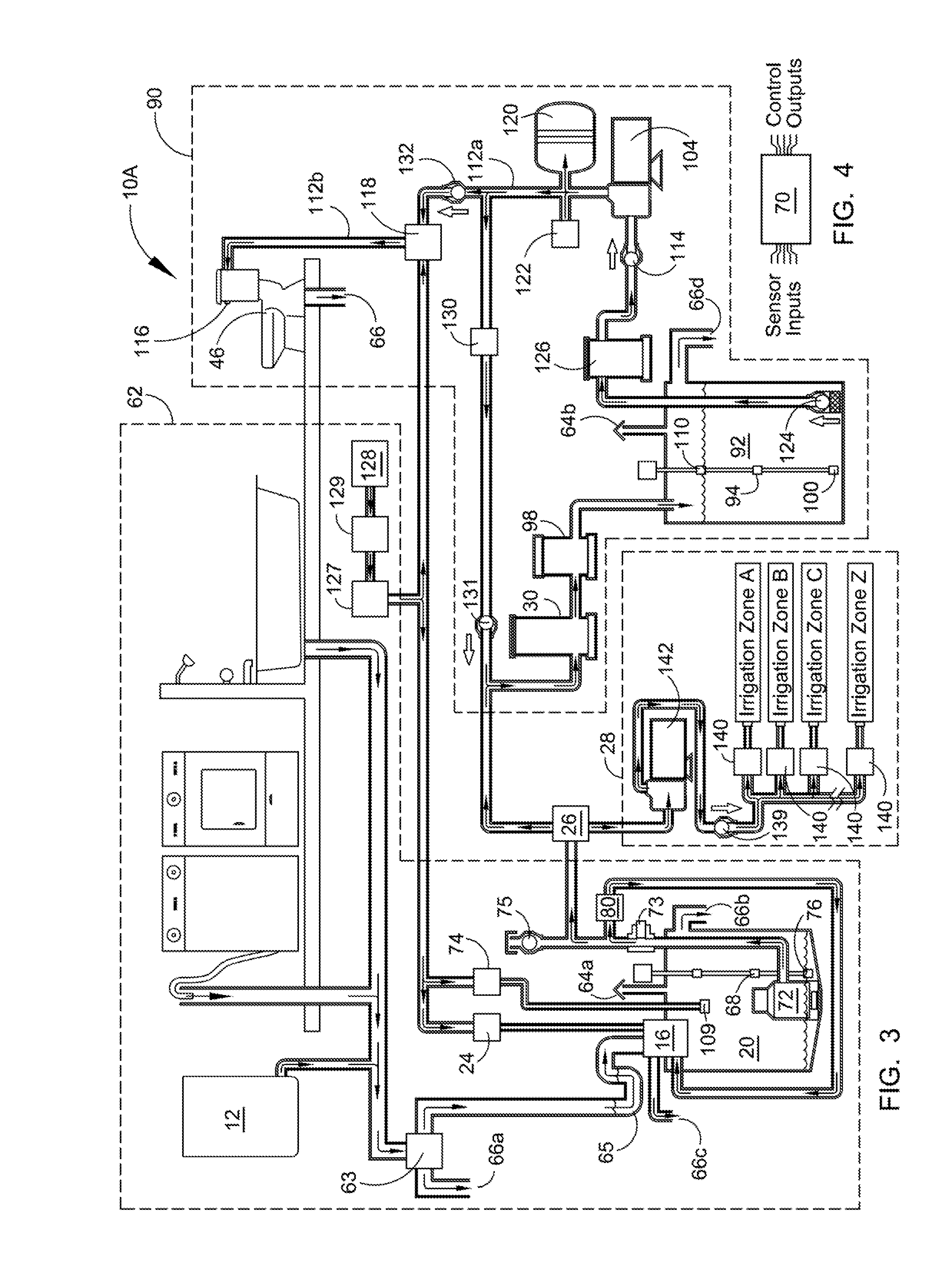

Grey water processing and distribution system

InactiveUS20120199220A1Relieve pressureReduce in quantityWater treatment parameter controlValve arrangementsWater sourceLandscaping

The Grey Water Processing and Distribution System is a self-contained fully functional grey water collection, processing and dispersing system that runs on grey water collected from internal grey water sources and supplies filtered water to the house's landscaping irrigation system as well as filtered and sanitized flush water to the house's toilets and washing machine for usage and requires standard local power. It incorporates a unique self-cleaning fine screen filter system. The central digital control unit monitors and runs the various system components and manages the house's landscaping irrigation system. The digital control unit also makes sure that the toilets are never without flush water and protects the irrigation system against under and over watering. The internal and external plumbing also allows for the system to be completely bypassed in the event of power failure or the introduction of undesirable contaminants into the grey water source stream.

Owner:ADVANCED GREY WATER RECYCLING SYST

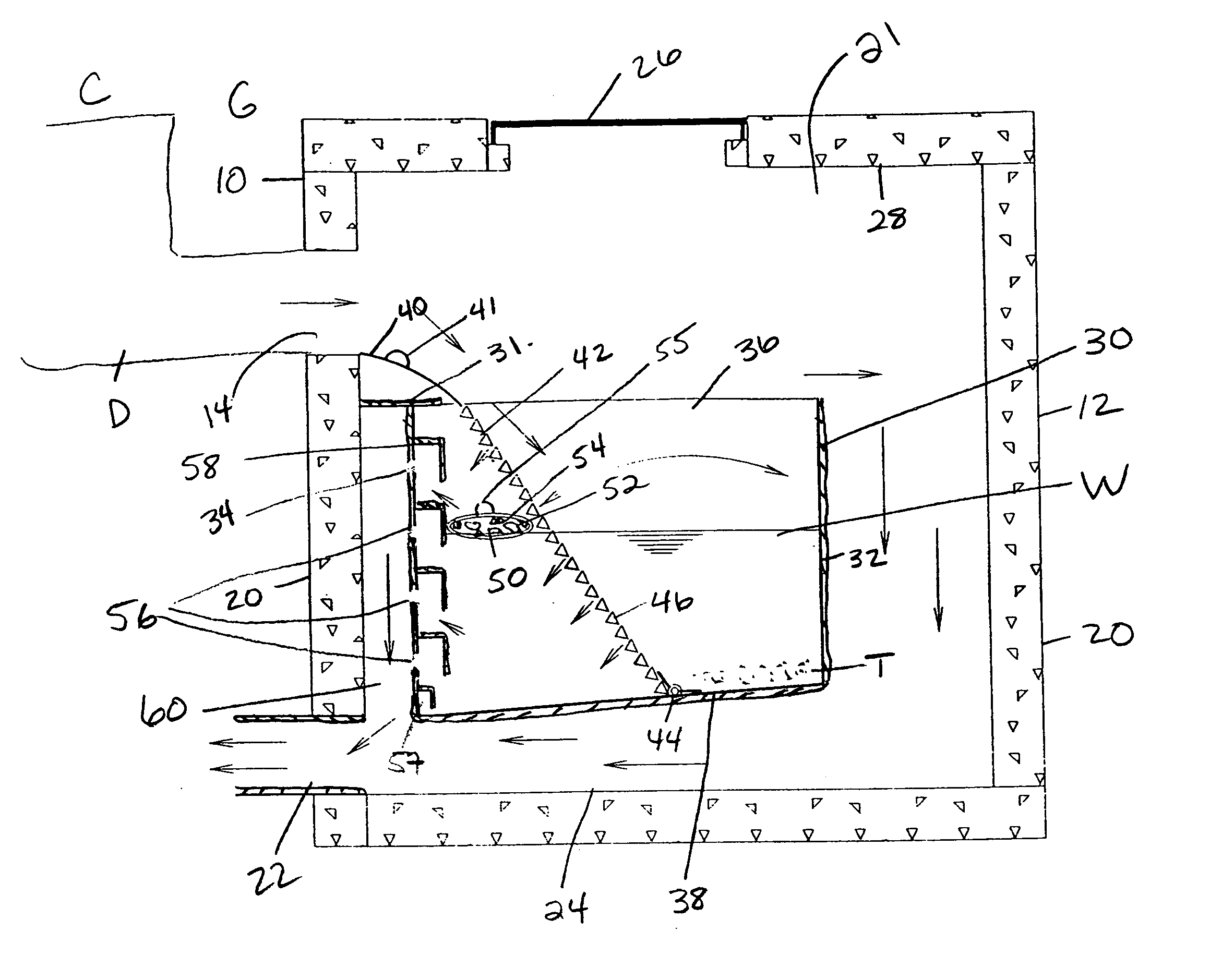

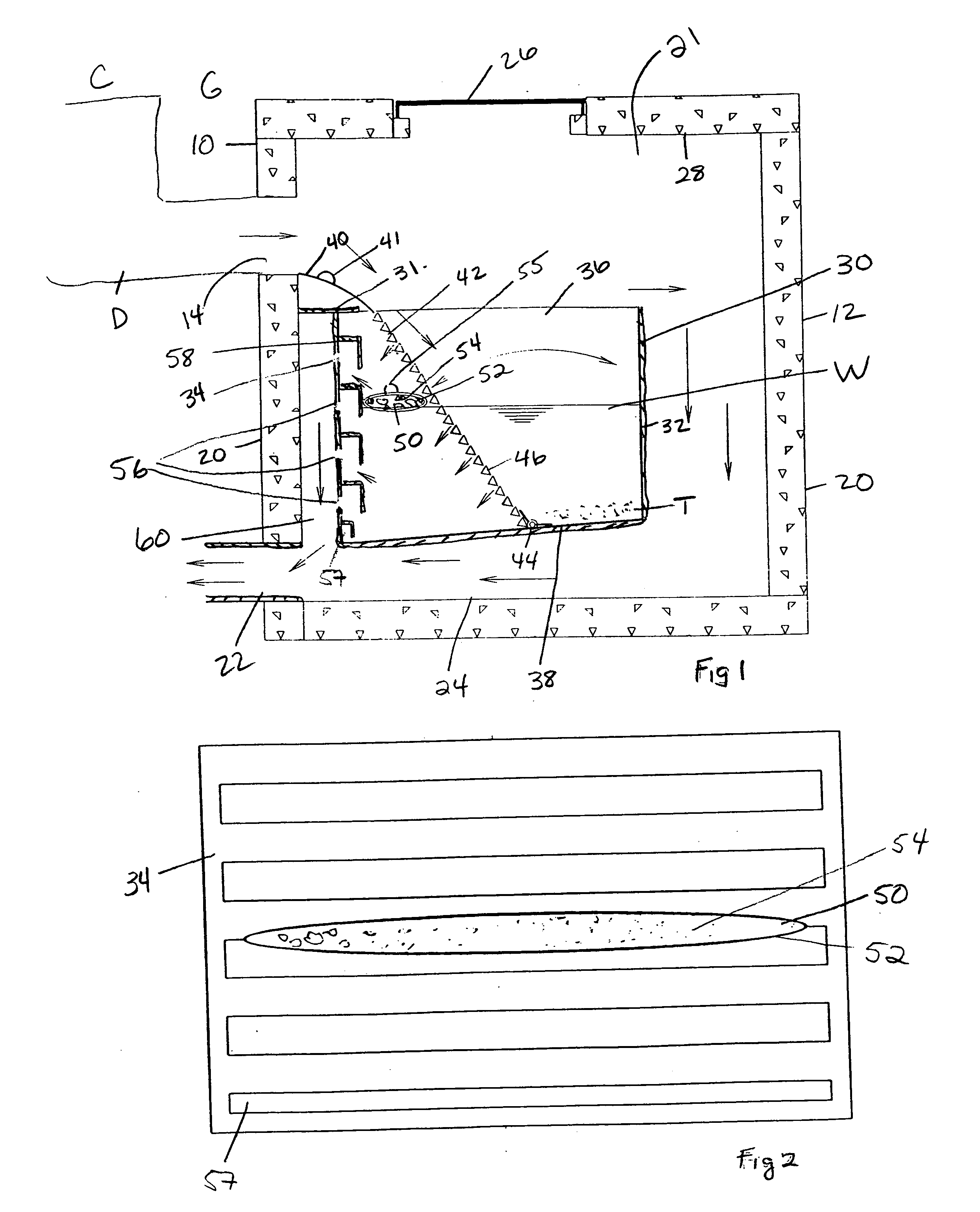

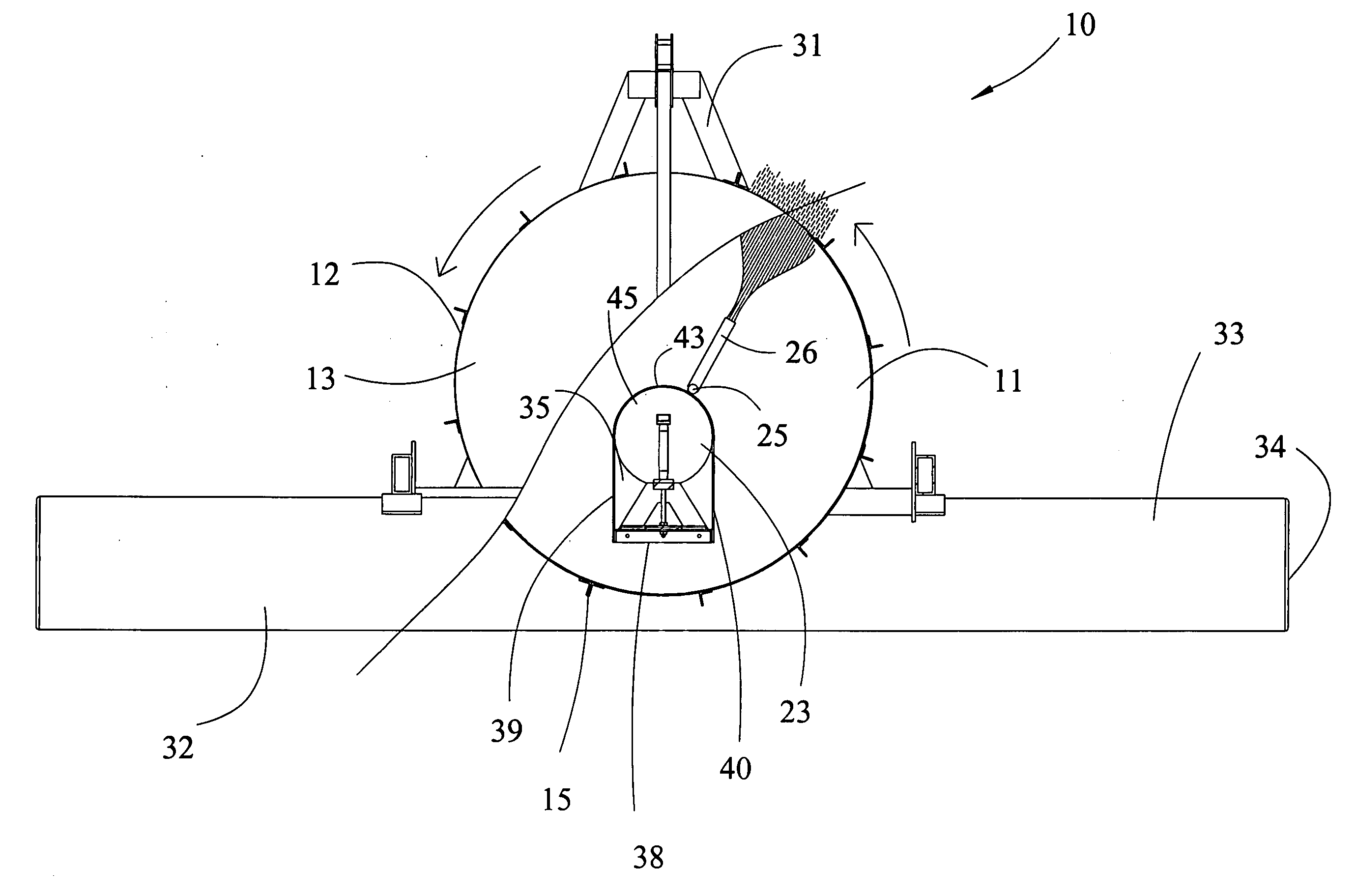

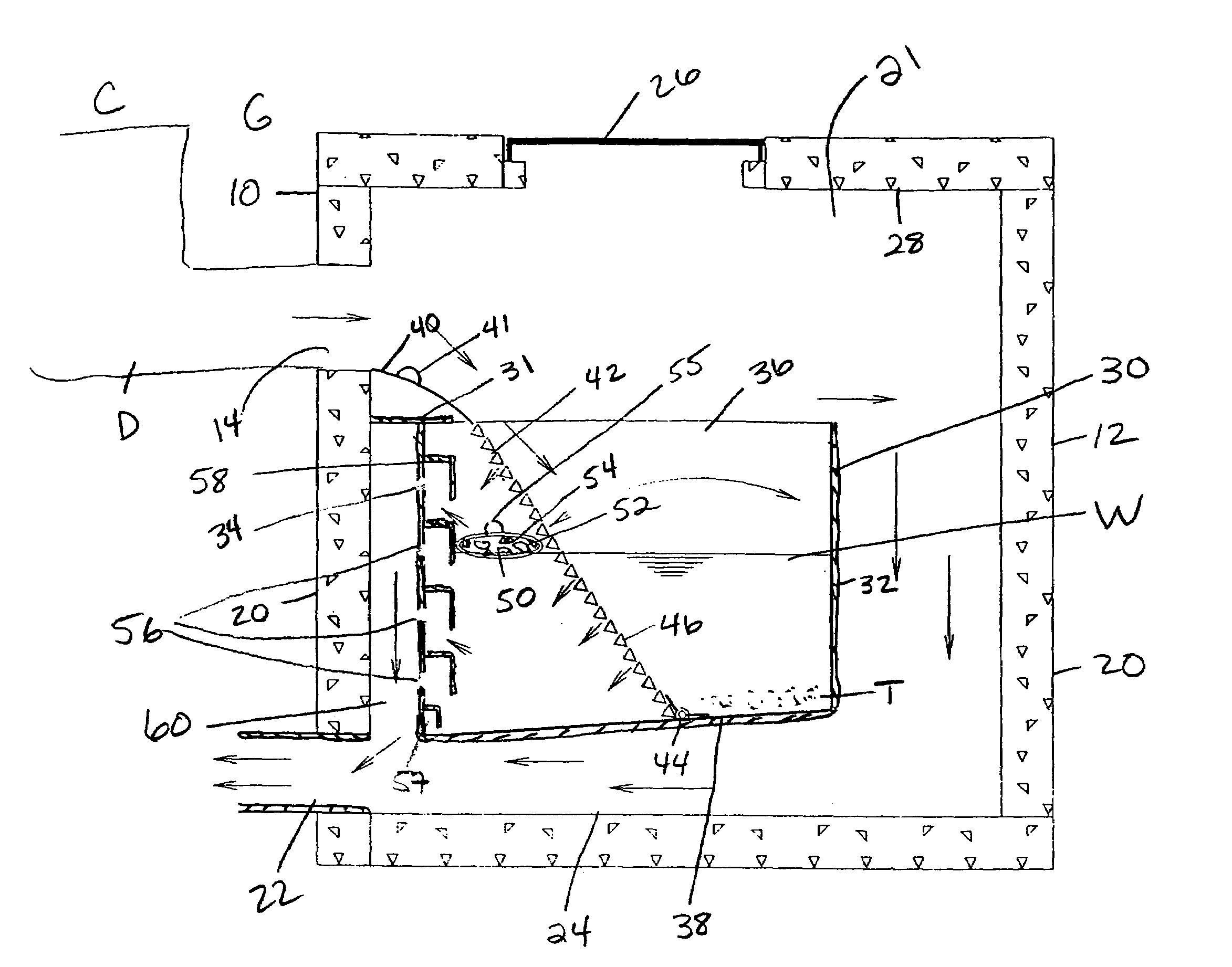

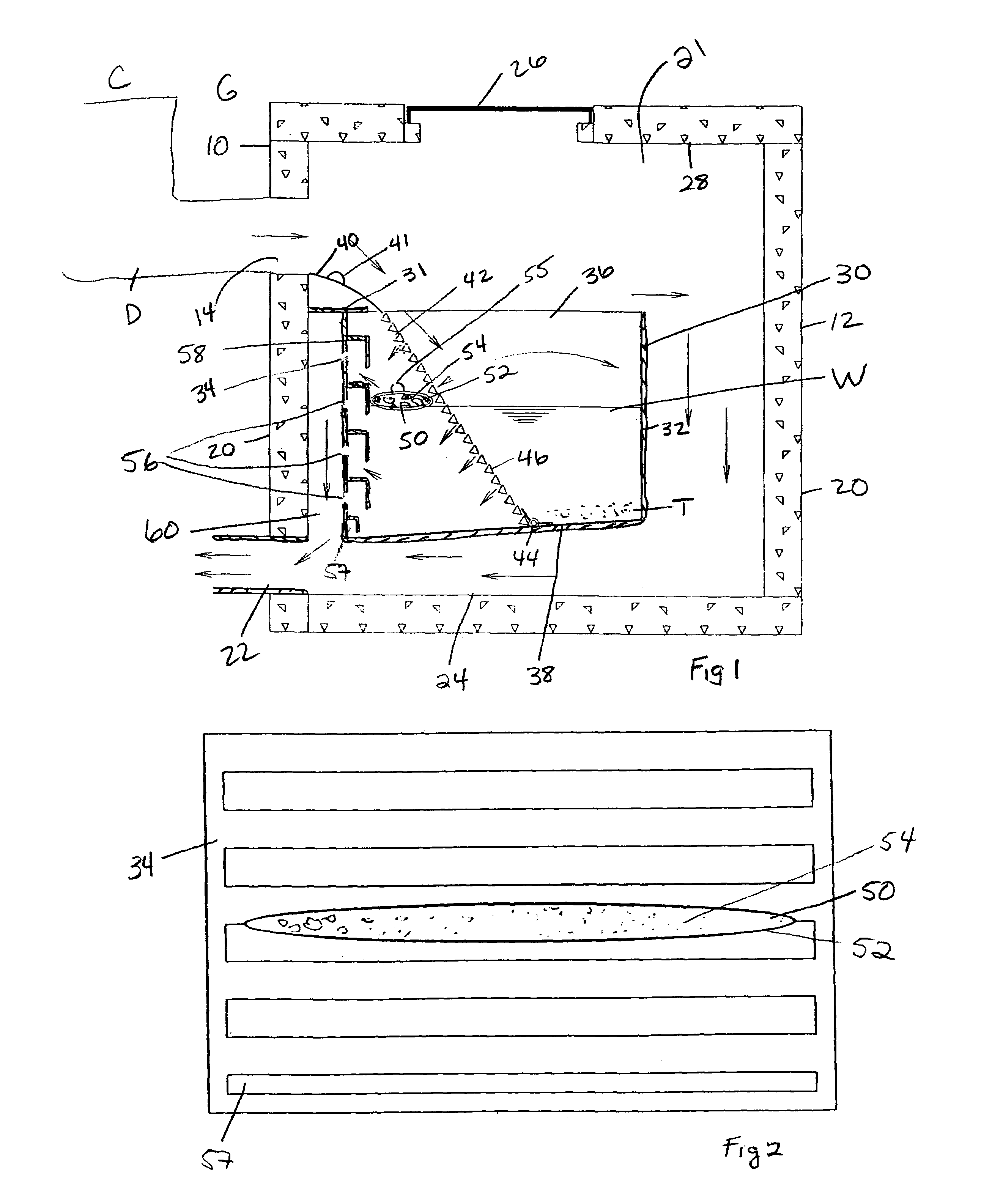

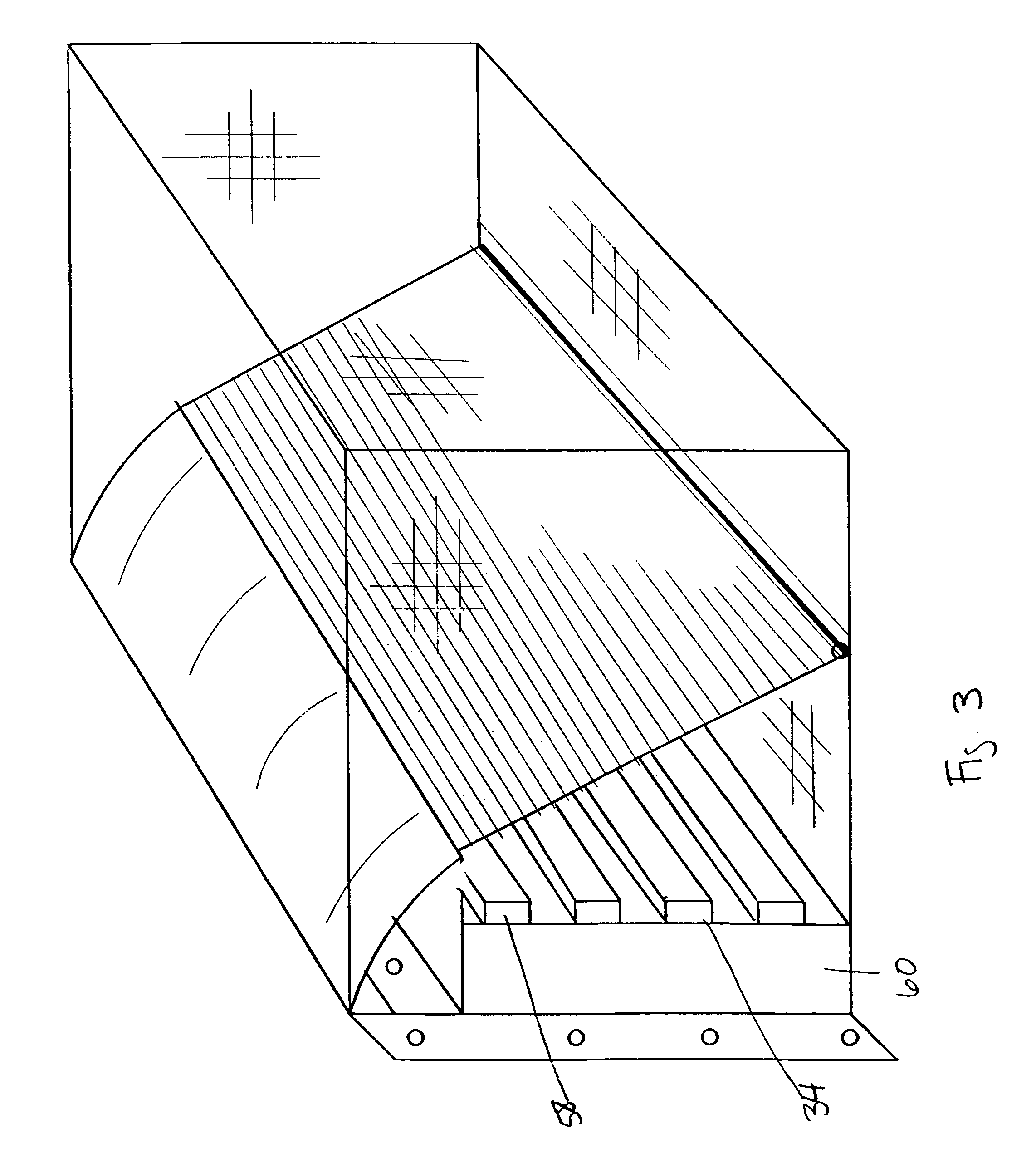

Method and apparatus for separating oil and debris from water run-off

ActiveUS20050072738A1Highly efficient debrisHighly efficient particulate filtrationFatty/oily/floating substances removal devicesSewerage structuresUrban waterStorm drain

A method and apparatus for separating oil and debris from urban water run-off, the apparatus being made up of a chamber which is mounted in a storm drain system and has an inner basin with a tilted wire wedge wire screen filter in the path of flow of the run-off, an organic absorber floats on the water as it is collected in the basin, and a discharge plate has a series of slots which are sized to regulate the flow rate of discharge of the water from the basin for removal through an outlet at the lower end of the chamber. The method and apparatus are conformable for use with existing storm drain systems along curbs or gutters as well as parking lots, runways and the like.

Owner:ESMOND STEVE E +1

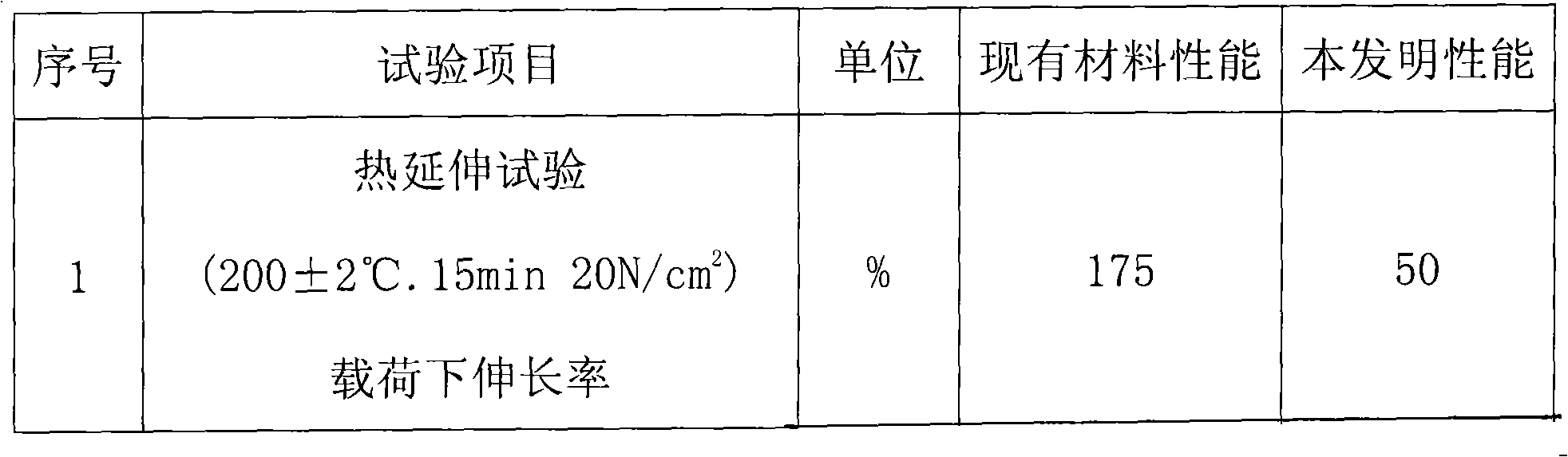

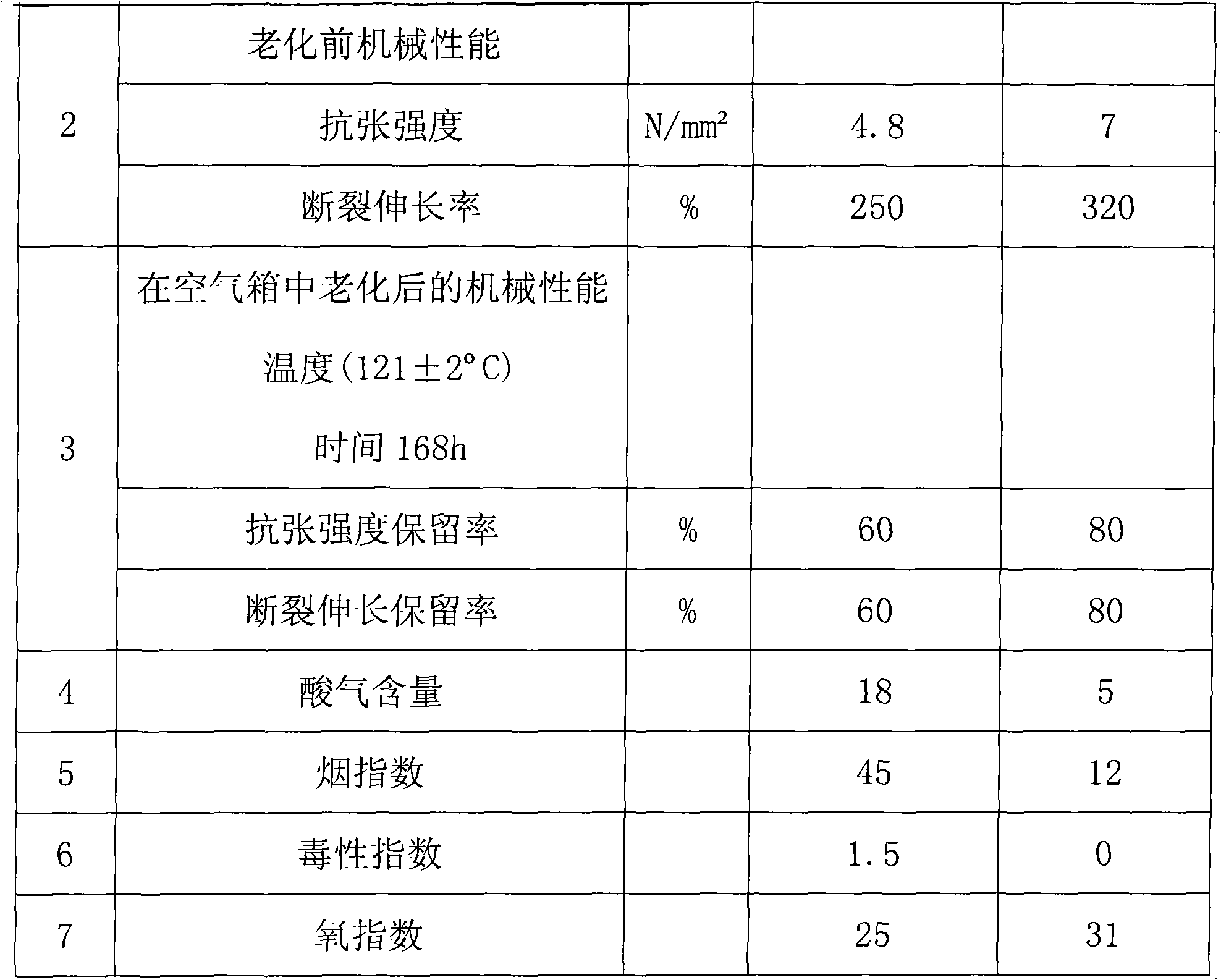

Ethylene propylene rubber insulation material for longitudinal high-voltage watertight cable of ships and warships and production method thereof

InactiveCN101831115AMeet the needs of useGuaranteed flexibilityRubber insulatorsParaffin waxPolymer science

The invention discloses an ethylene propylene rubber insulation material for longitudinal high-voltage watertight cables of ships and warships and a production method thereof. The method comprises the following steps: adding the ethylen e-propylene-diene mischpolymere, age resister and fire retardant into a banbury for banburying for 3.5min; adding argil, white carbon black and paraffin wax for continued banburying for 2min; adding active agent, and discharging after banburying for 1.5min; filtering the rubber compound with a three-layer filter screen (namely a 60 mesh filter screen, a 60 mesh filter screen and a 80 mesh filter screen) on a rubber filter; and beating into cornucopla on a double-roller mill, adding vulcanizer and co-crosslinker, then beating into cornucopla for 7 times, grinding and slicing after finishing the steps, and then cooling, wherein the materials are as follows in parts by weight: 100 parts of ethylen e-propylene-diene mischpolymere, 1-5 parts of vulcanizer, 1-4 parts of age resister, 15-70 parts of fire retardant, 0.5-10 parts of active agent, 10-20 parts of argil and 2-4 parts of paraffin. The prepared insulation material has the characteristics of low smoke, no halogen, fire resistance, high machinery strengthen, and high insulation resistance, good flexibility, elasticity and viscosity, and can be used for the ships and warships.

Owner:嘉兴君宏光学有限公司

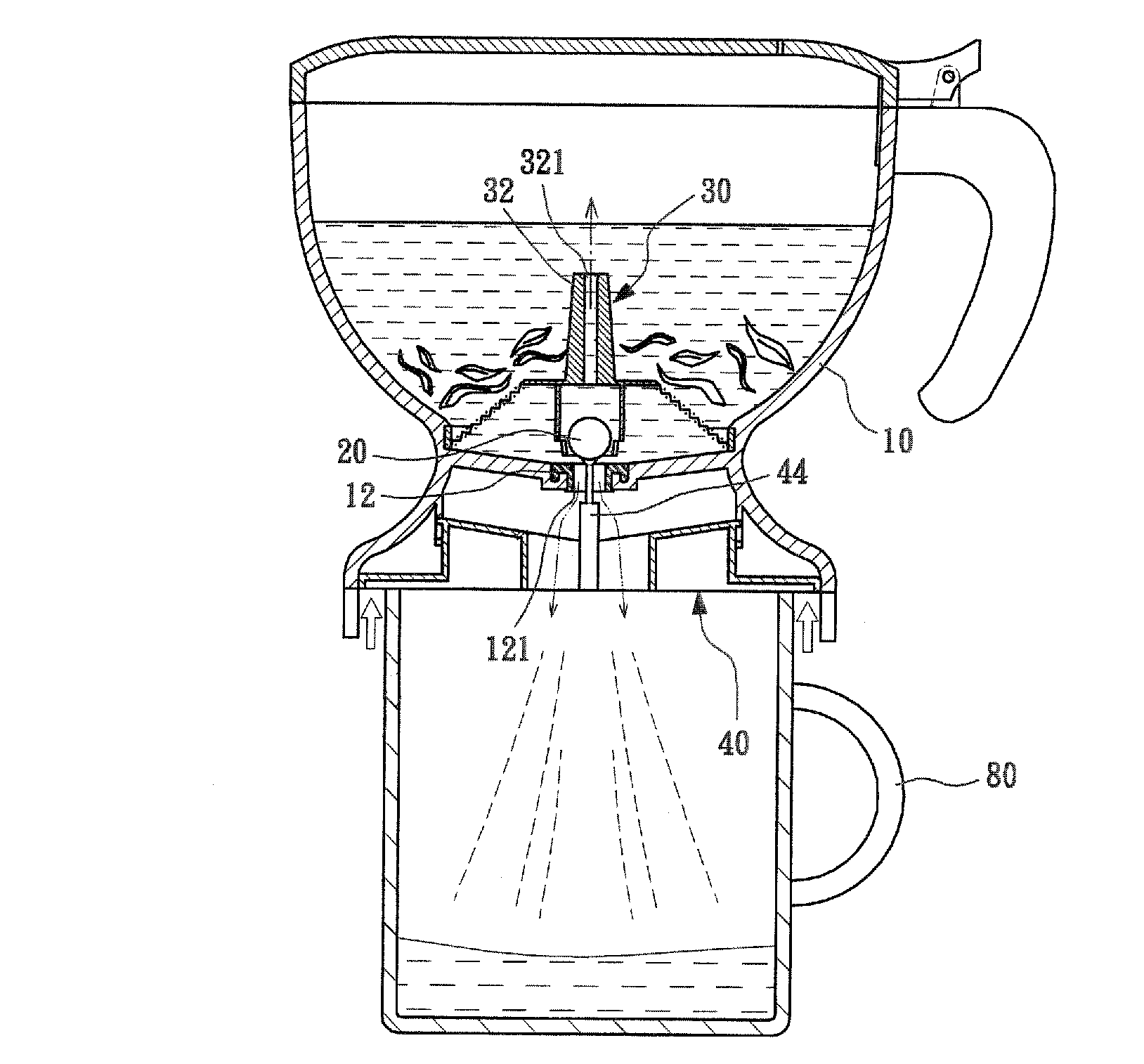

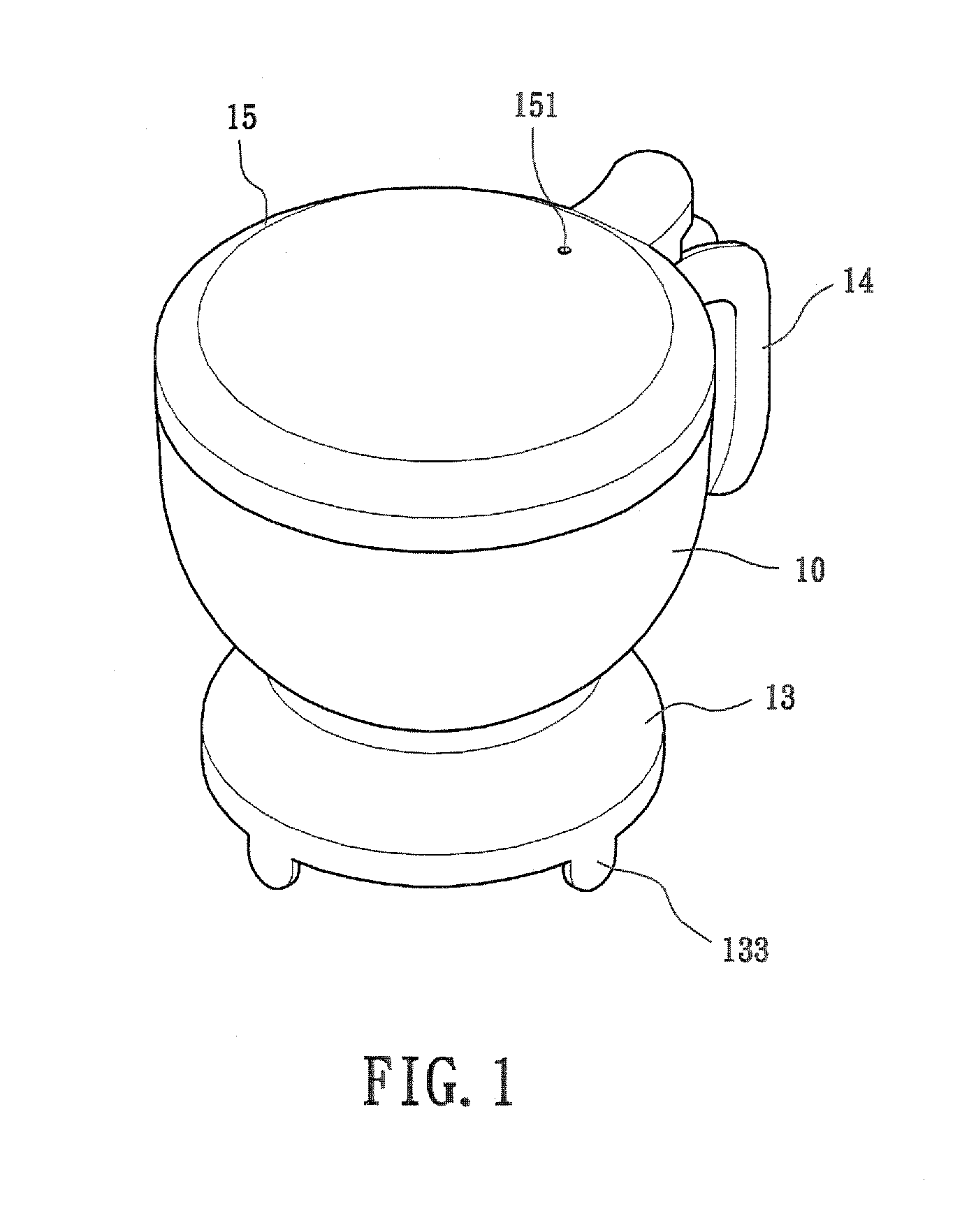

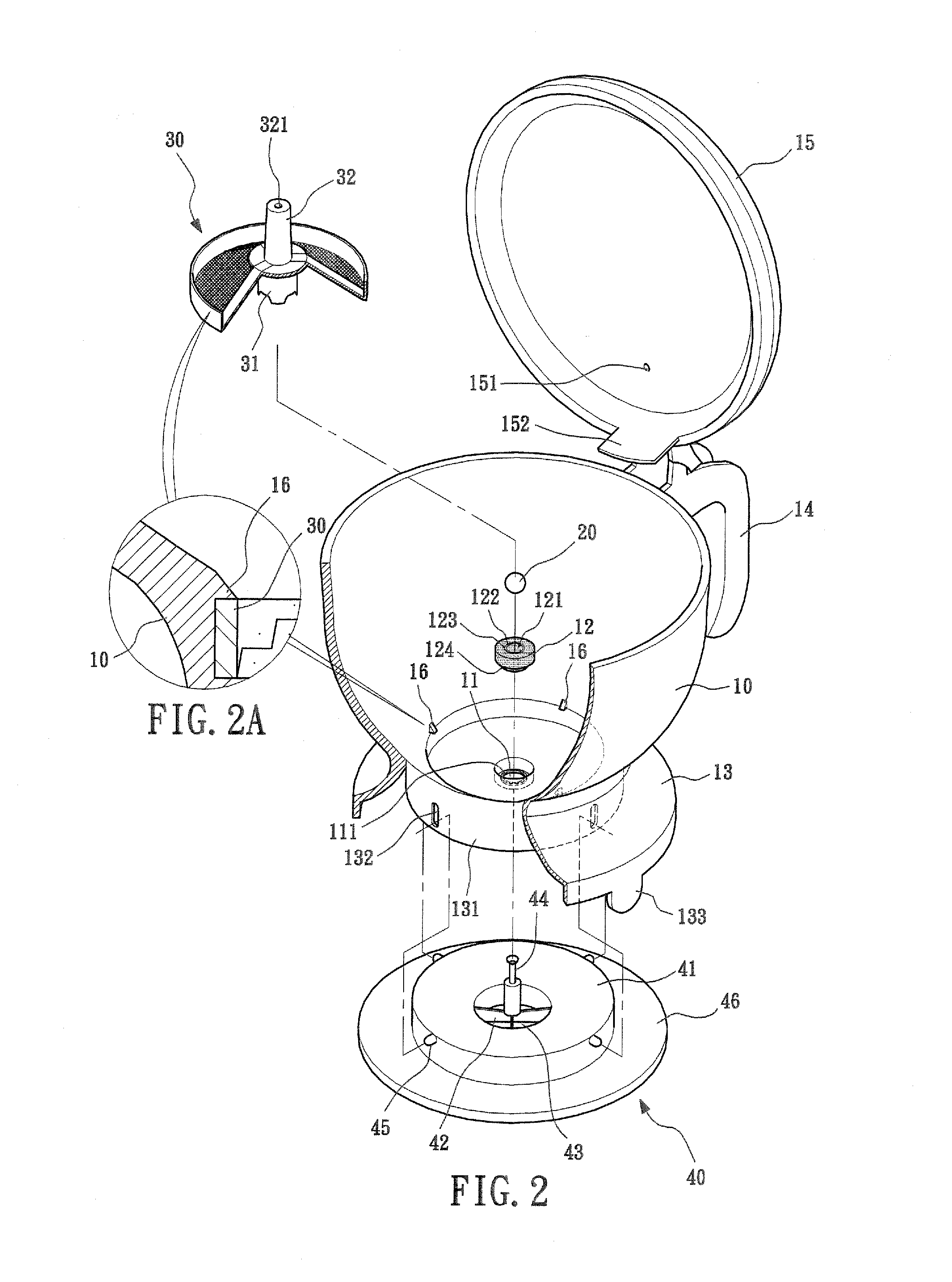

Safety and guide type brewing kettle

InactiveUS20100212509A1Facilitates assembling/disassemblingEasy to cleanBeverage vesselsWater bottleMechanical engineering

A safety and guide type brewing kettle includes a kettle body, a water stopper, a screen filter, and a retention disk. The kettle body has a cove that forms a flow guide plate for guiding liquid droplets formed on the cover into the kettle body. The kettle body has a bottom forming a through bore that receives therein a plug, which forms a through hole and an engagement section. The water stopper is arranged to block the through hole for eliminating undesired leaking. The kettle body has a lower circumference forming a projecting wall that forms legs to enclose and stably hold the kettle body. The kettle body forms at least one locking section, which engages an upper side of the screen filter. The screen filter forms a grip section that facilitates assembling / disassembling and cleaning. The screen filter forms a positioning section for positioning the water stopper.

Owner:TIEN JUNG JUNG

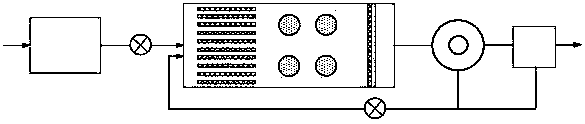

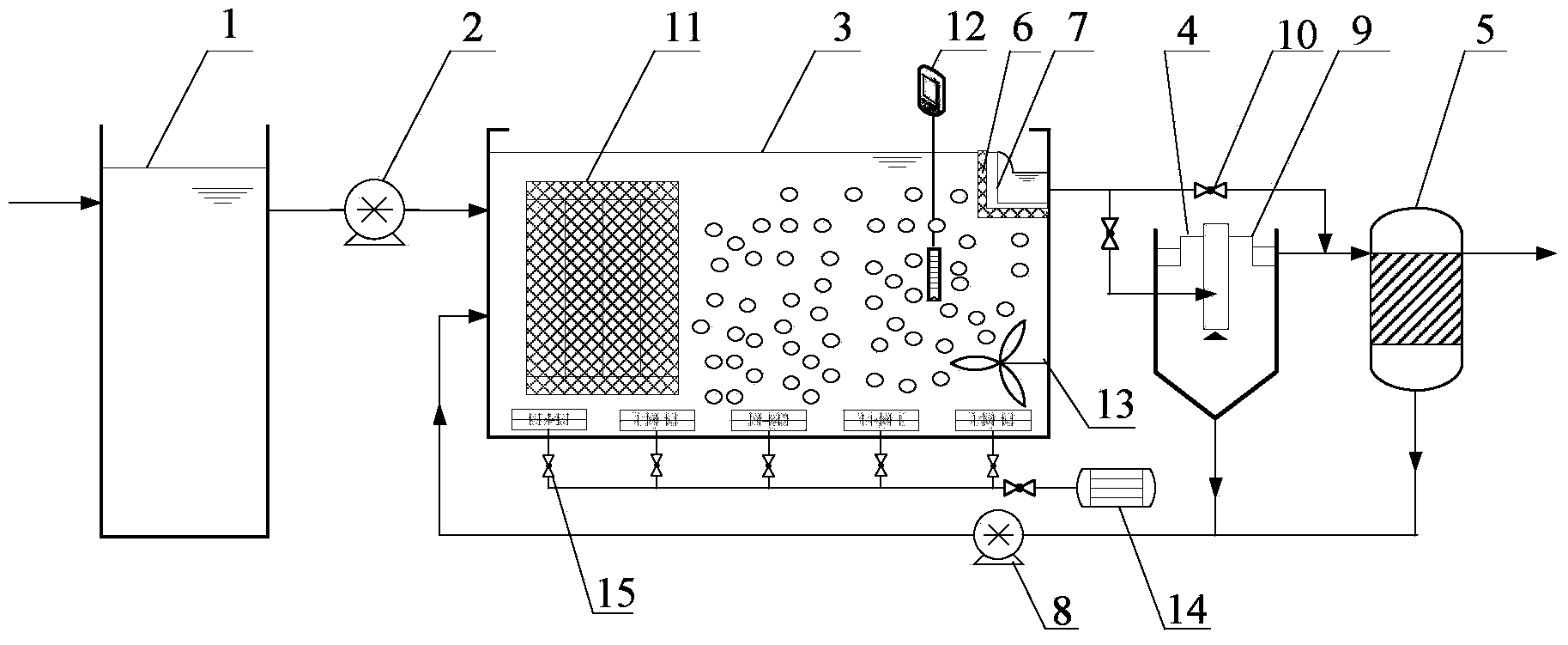

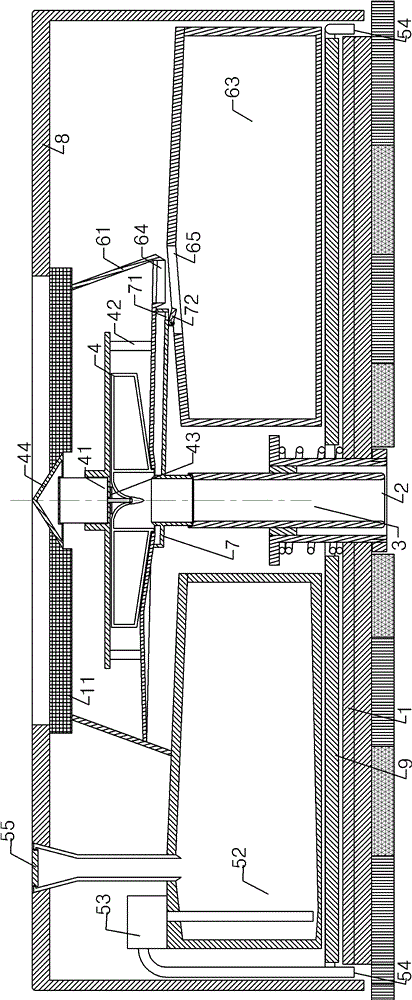

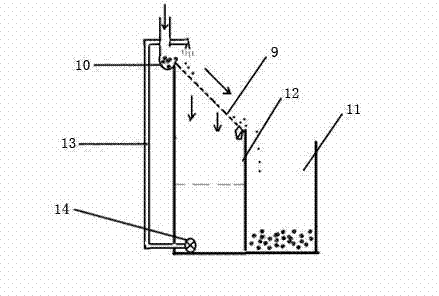

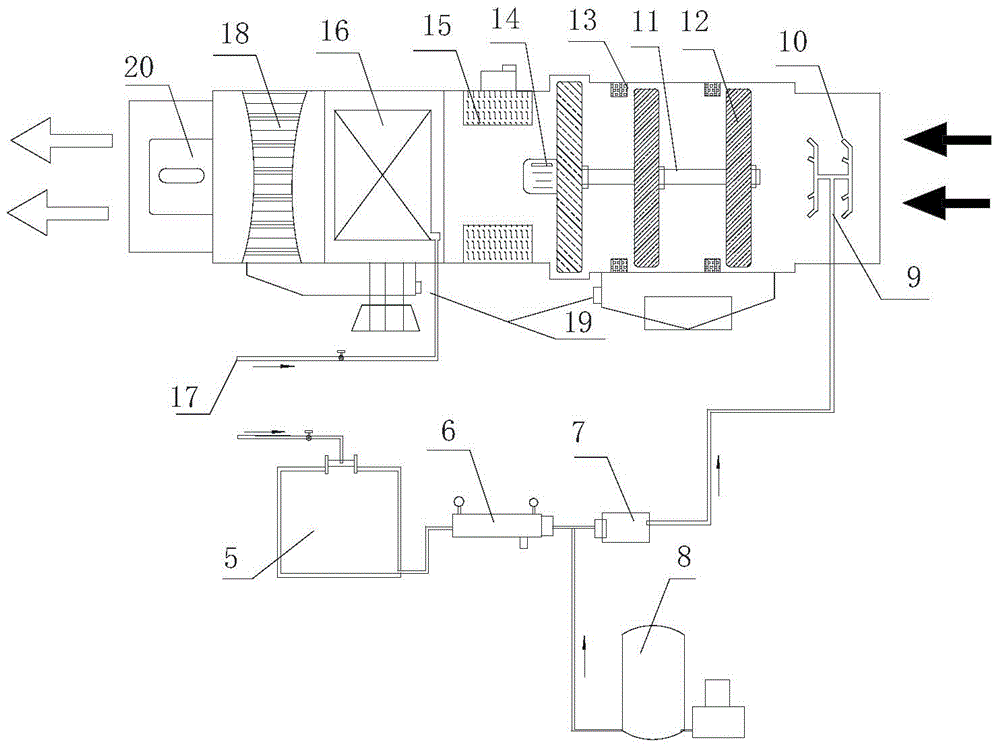

Continuous flow biological denitrification method based on granular sludge, and apparatus

ActiveCN103663725AStart fastReduce startTreatment with anaerobic digestion processesFiltrationSludge

The present invention discloses a continuous flow shortcut nitrification-anaerobic ammonium oxidation biological denitrification method based on granular sludge, and an apparatus. The method comprises: 1) carrying out sludge inoculation culture, and carrying out an active sludge adaptation period; 2) starting a shortcut nitrification-anaerobic ammonium oxidation reaction; 3) performing an anaerobic ammonium oxidation granular sludge formation and growth period; and 4) performing a stable operation period of a granular sludge continuous flow system. The apparatus comprises a water inlet tank, a bioreactor, a sedimentation tank and a hydraulic screen filter, wherein the water inlet tank, the bioreactor, the sedimentation tank and the hydraulic screen filter are sequentially communicated, the influent of the water inlet tank is communicated with high ammonia nitrogen wastewater, the effluent is communicated with the bioreactor, the concentrated sludge on the bottom of the sedimentation tank is communicated with the bioreactor through a sludge reflux pump, a fixation filler, a stirrer, a filtration screen and an aeration head communicated with an air compressor are arranged inside an anoxic reactor, the sedimentation tank is provided with a clear overflow port communicated with the hydraulic screen filter through a pipeline, the effluent of the hydraulic screen filter is the final effluent, and the retained granular sludge refluxes to the bioreactor.

Owner:BEIJING JIAOTONG UNIV

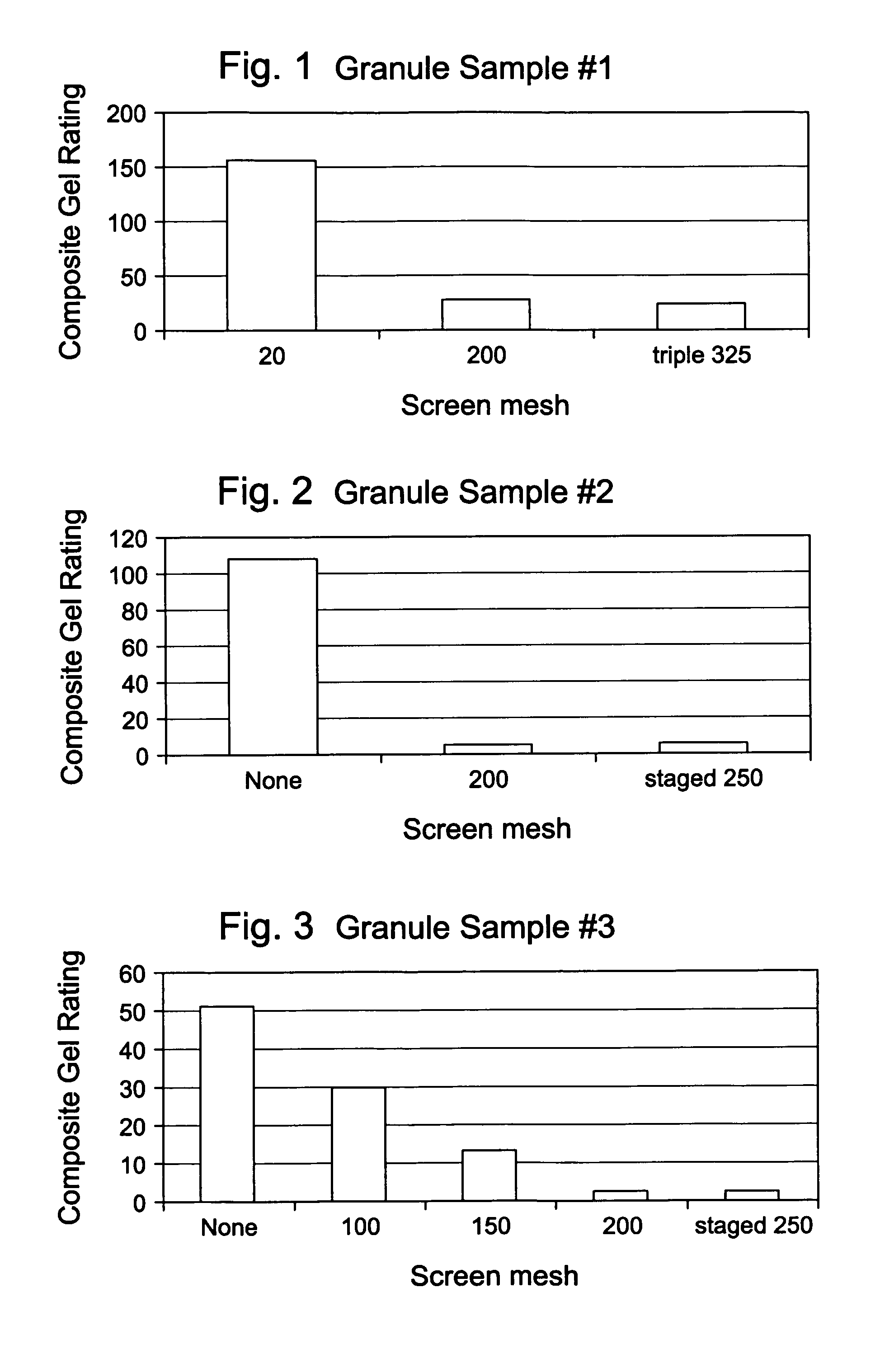

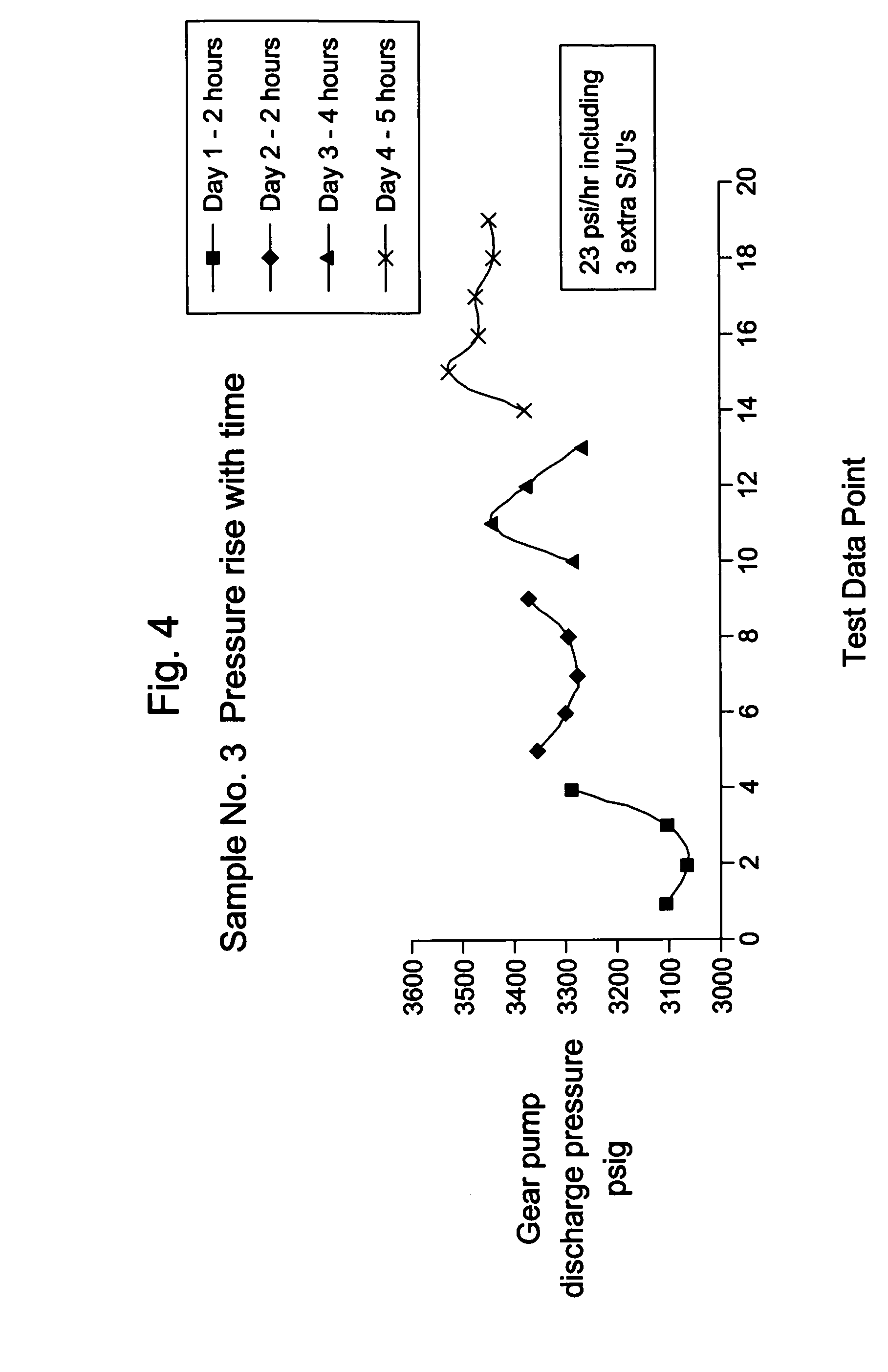

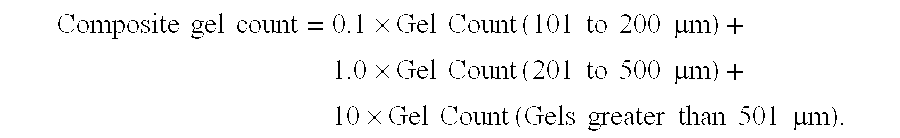

Method of reducing gels in polyolefins

A process of producing a polyolefin, in one embodiment a polyethylene, and in a preferred embodiment a bimodal polyethylene comprising a high molecular weight component and a low molecular weight component, the process comprising providing a polyolefin having an I21 value of from 2 to 100 g / 10 min and a density of from 0.91 to 0.97 g / cm3; followed by forming a melt of the polyolefin and passing the polyolefin through one or more active screen filter(s) having a mesh size of from 70 to 200 micron at a mass flux of from 5 to 100 lbs / hr / square inch; and isolating the polyolefin having passed through the screen filter.

Owner:UNIVATION TECH LLC

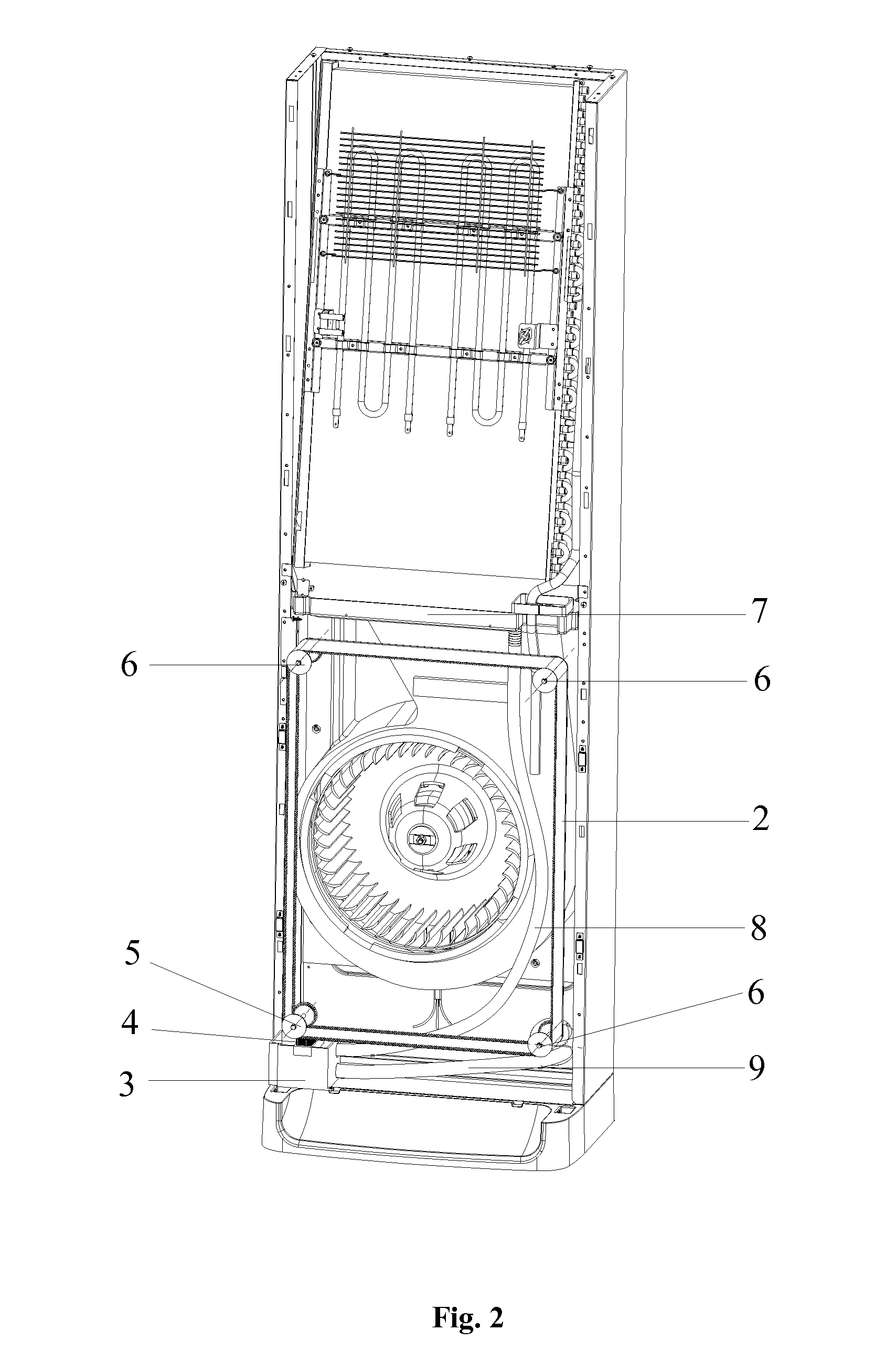

Floor scrubber with drying function

Disclosed is a floor scrubber with a drying function. A chassis of the floor scrubber is provided with at least one scrubbing disc, each scrubbing disc is provided with a suction port in the middle, at least one of bristles, scrubbing pieces or strips is arranged on the scrubbing discs in a centripetal rotating manner, and the suction ports are directly communicated with an impeller throat through a suction passage. The floor scrubber comprises a watering mechanism composed of a clean water tank, a water pump and sprayers, and a sewage collection mechanism composed of a sewage collection trough and a sewage tank, wherein the sewage collection trough is arranged in the periphery of the impeller. The watering mechanism is in charge of watering, the scrubbing discs are in charge of scrubbing and driving sewage to the suction ports in the middle, the impeller generates negative pressure to suck the sewage in, the sewage collection mechanism is used for collecting sewage sprayed by the impeller. Airflow with the sewage does not need to pass a filter screen before entering the impeller, and the sewage discharged by the impeller is discharged without passing a narrow passage.

Owner:SUZHOU SUXIANG ROBOT INTELLIGENT EQUIP CO LTD

Self-cleaning screen with check valve for use in shallow water pumping

A self-cleaning screen for shallow water pumping includes a rotatable drum made of mesh material for removing debris from water passing into the drum, and a suction chamber within the drum for feeding water to a suction pipe connected to a centrifugal pump. Inlet openings are arranged across a bottom side of the suction chamber. A check valve assembly is provided to prevent water from back flowing through the inlet openings, to thereby maintain a prime in the suction pipe when the pump is off. The check valve assembly includes valve members that are slidably mounted above the inlet openings for movement between closed and open positions. The valve members move upwardly from their closed positions to their open positions upon movement of water through the inlet openings into the suction chamber, and return to their closed positions by force of gravity when water stops flowing into the suction chamber.

Owner:WIETHAM ROBERT J

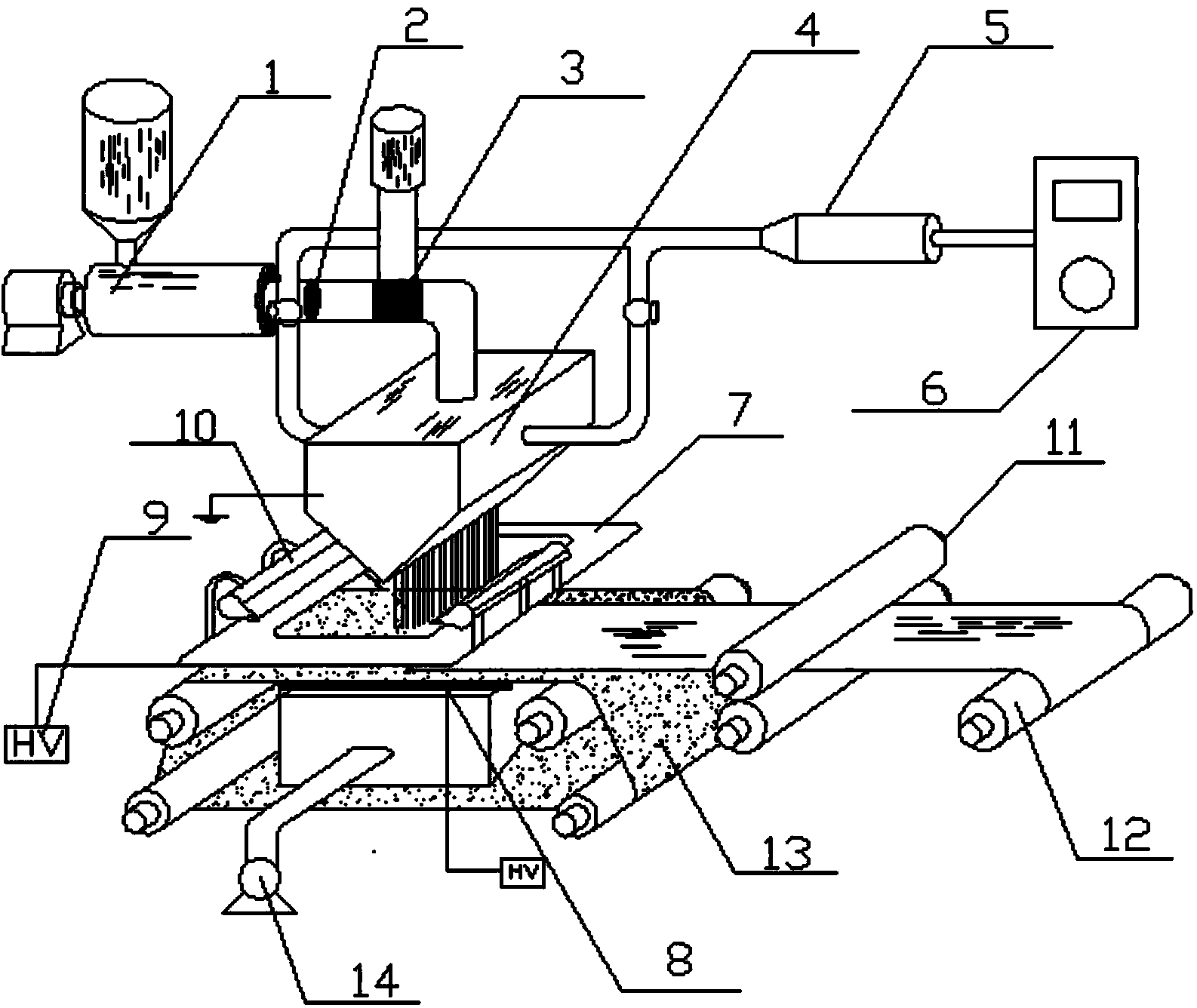

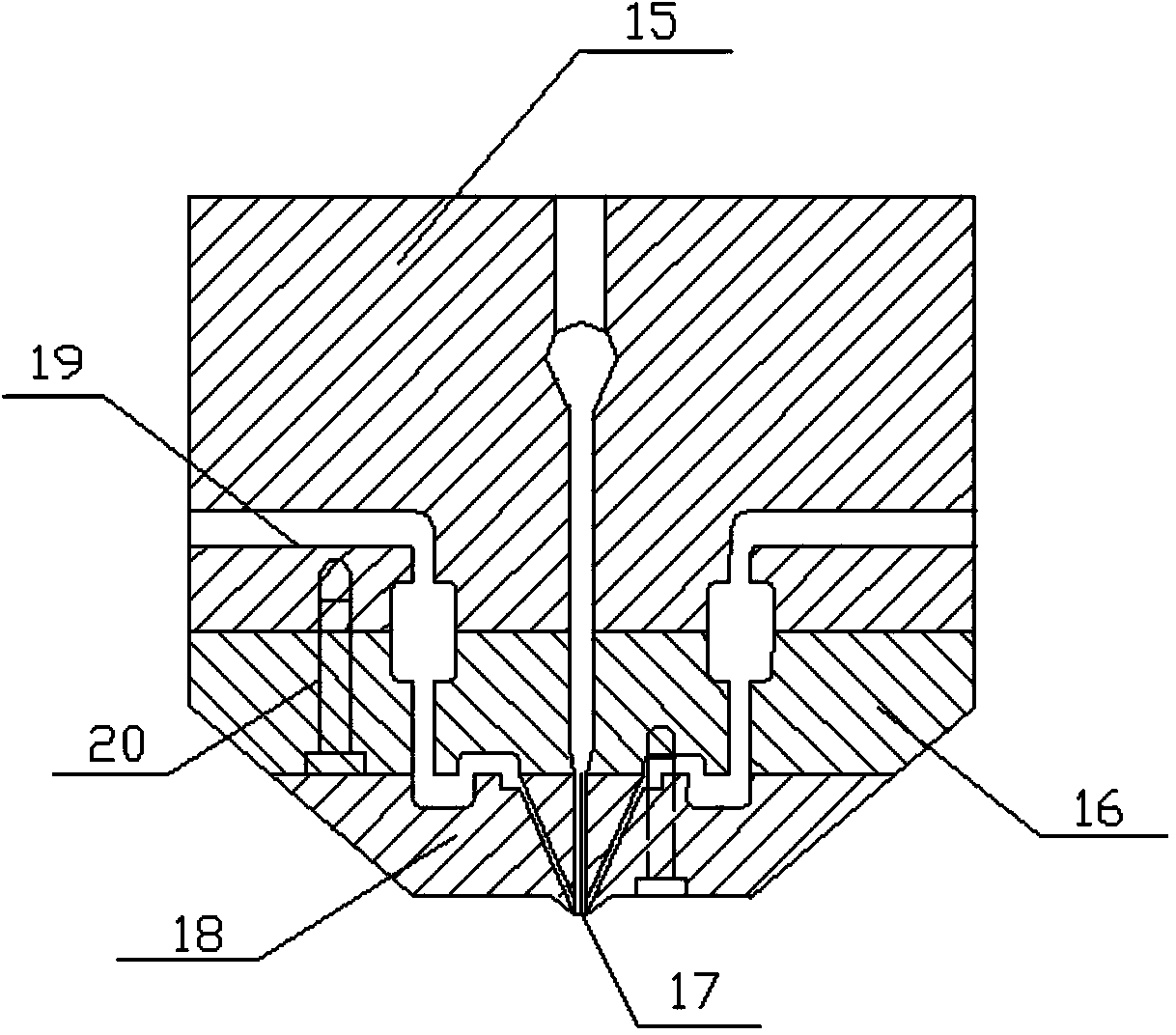

Differential melt electro-blowing spinning device and technology for preparing nanofibers in batches

ActiveCN103451754ARealize industrial productionRealize batch preparationFilament/thread formingNon-woven fabricsFiberSpinning

The invention discloses a differential melt electro-blowing spinning device and technology for preparing nanofibers in batches, and belongs to the field of electrostatic spinning. The device mainly comprises an extruder, a filter screen, a melt metering pump, a spinning manifold, an airflow heating device, an air compressor, an upper plate electrode, a lower plate electrode, a high-voltage electrostatic generator, a guide air knife, a hot rolling device, a receiving device, a screen spreading belt and an air draft system. An outlet of the extruder is connected with the filter screen, and the melt metering pump is connected between the filter screen and the spinning manifold through a flange. Airflow is divided into two portions through a flow divider to be connected to the spinning manifold; after melt is divided and guided in flow through the spinning manifold, a thin uniform-flowing melt layer is obtained at the lower end of a wavy flow guide plate; under the high-voltage electrostatic action, the melt layer forms a plurality of Taylor cones in a self-organization manner, the Taylor cones are stretched and split continuously under the conditions of high-speed airflow and high-voltage electrostatics, and superfine fibers are formed at the receiving end of the screen spreading belt by means of curing. By the aid of the device and technology, difficulties of high viscosity of polymers, low yield, complicated devices and the like are overcome, and industrial production of differential melt electro-blowing spinning can be achieved.

Owner:BEIJING UNIV OF CHEM TECH

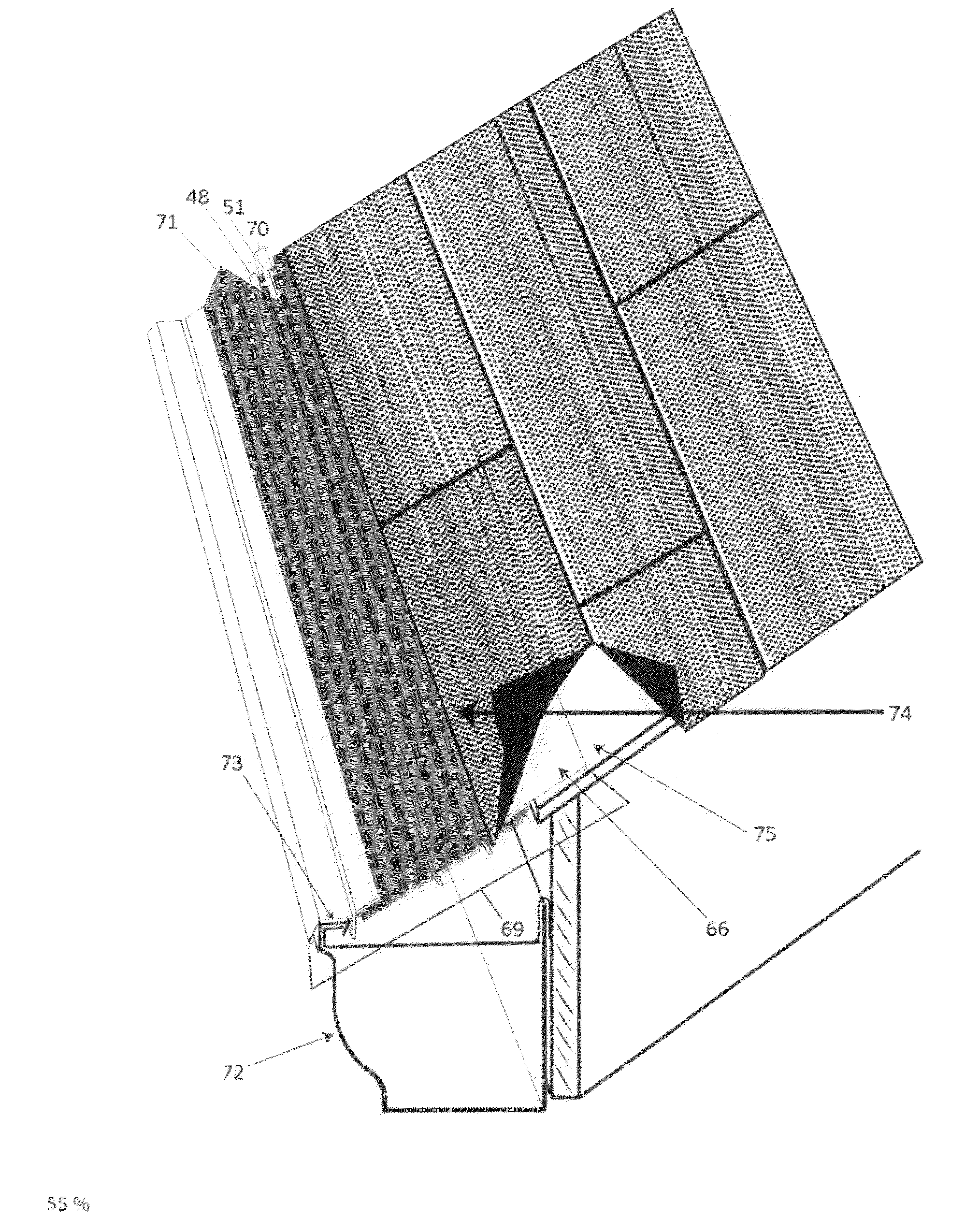

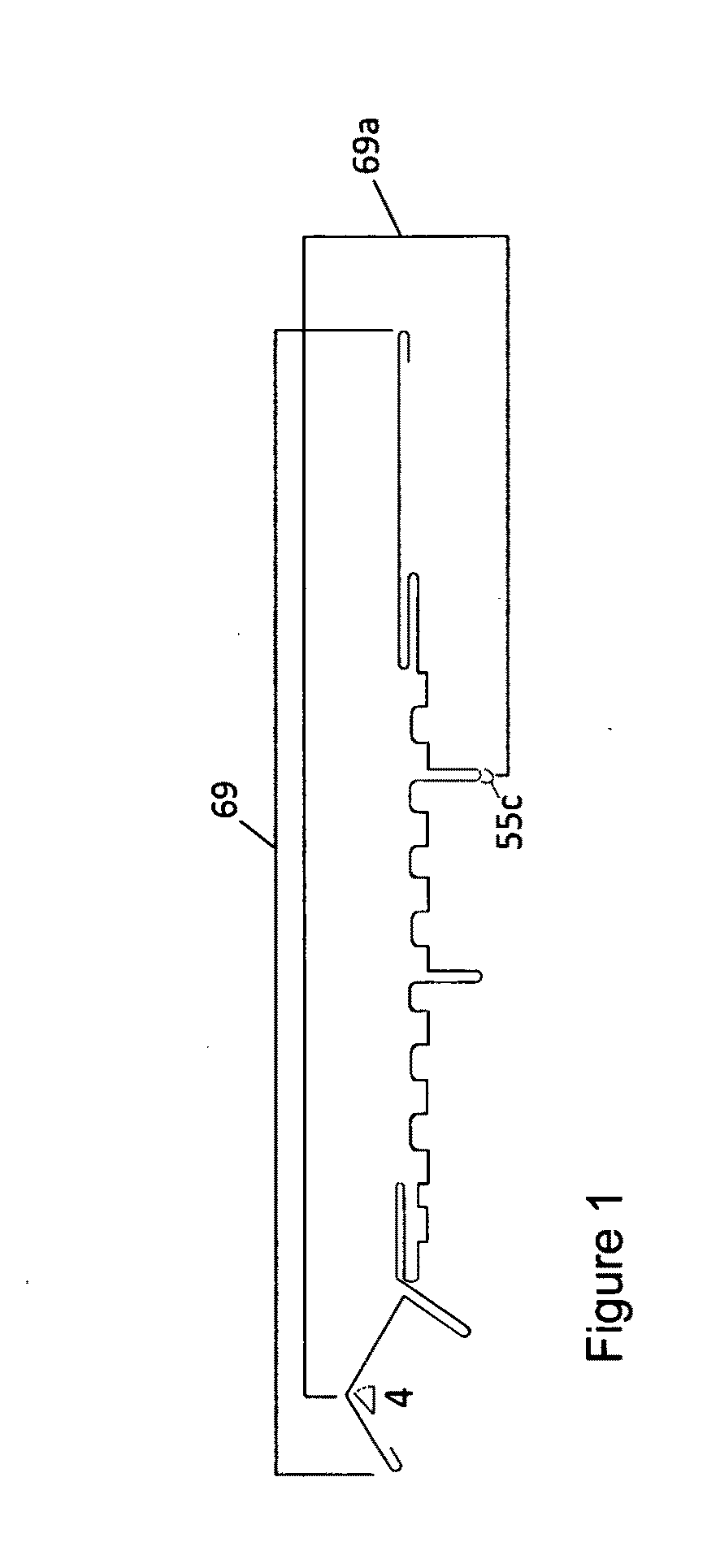

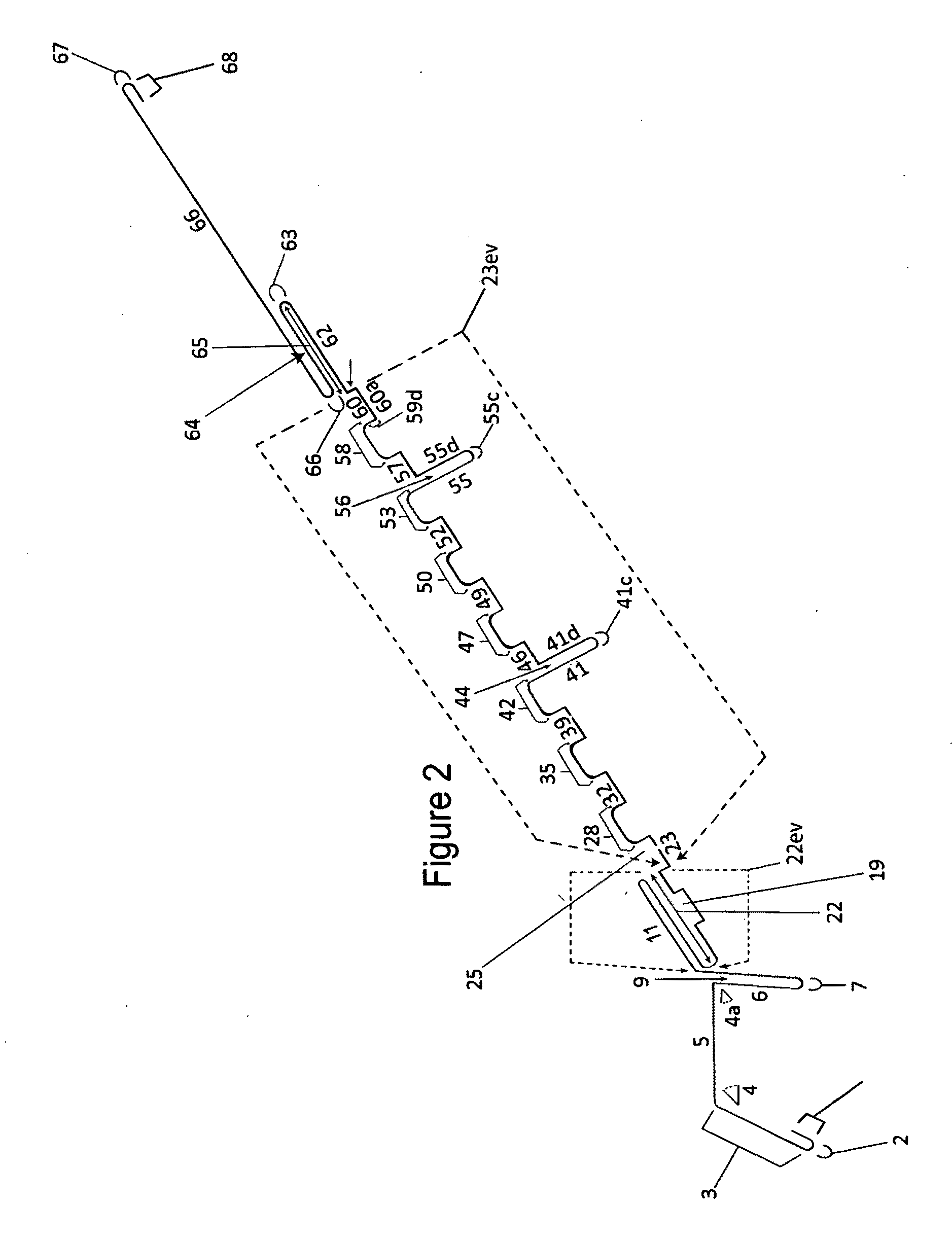

Self cleaning shield

A gutter shield device comprising a first body portion and a second body portion laterally bordering an intermediate body portion that includes a perforated plane out of which arises upward protruding elements that contact the undersurface of a micro-mesh or screen filter comprised of eighty or more threads per inch. The gutter shield includes on the bottom of it's perforated plane at least one downwardly extending element to interdict and redirect downward any forward flowing water present on the underside of the perforated plane.

Owner:MGP MFG

Water spray-type air purifier

InactiveCN103851703AImprove purification effectEnergeticLighting and heating apparatusUsing liquid separation agentHEPAParticulates

Owner:SHANGHAI JINGYUAN ENVIRONMENTAL PROTECTION EQUIP

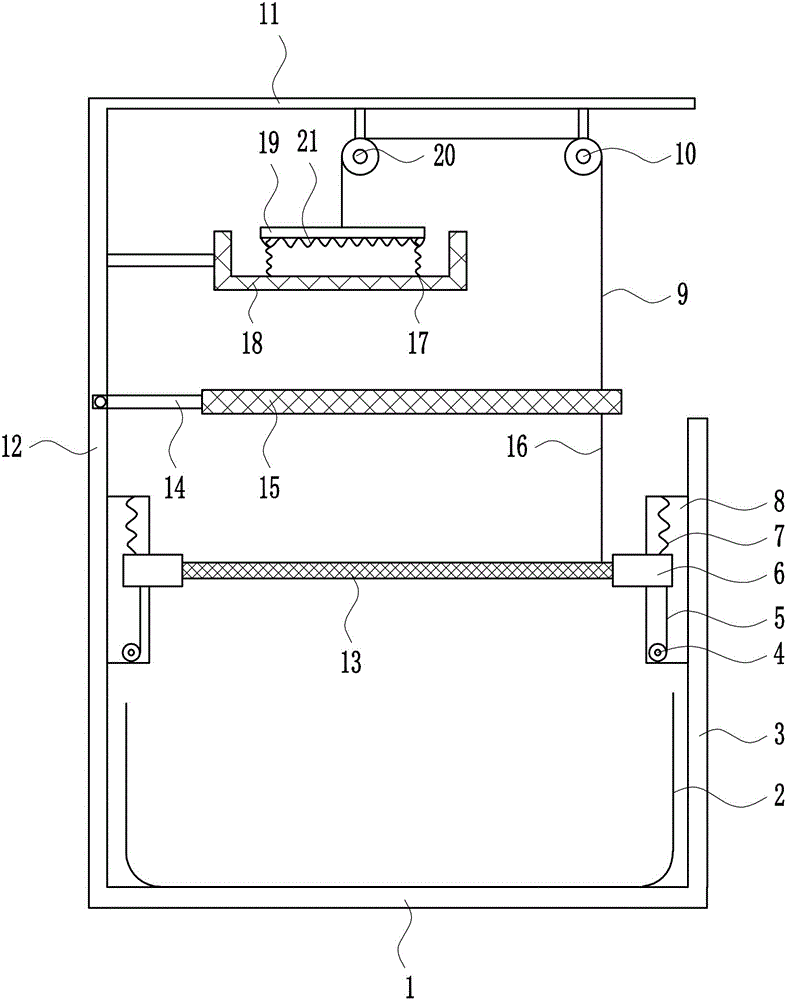

Agricultural soil block crushing device

The invention relates to a crushing device, in particular to an agricultural soil block crushing device. The agricultural soil block crushing device is capable of achieving crushing easily, convenient to operate and high in crushing speed. The agricultural soil block crushing device comprises a bottom plate, a collection box, a right frame, electric wheels, pulling ropes, sliding blocks, springs I, sliding rails, a steel wire rope II, a rolling wheel I, a top plate, a left frame, a filter screen III, a connecting rod, a filter screen II, a steel wire rope I, springs II, a filter screen I, a pressing block and a rolling wheel II. The left frame, the collection box and the right frame are arranged at the top of the bottom plate from left to right in sequence. The top plate is arranged at the top of the right side of the left frame. The rolling wheel II and the rolling wheel I are sequentially arranged at the bottom of the top plate from left to right. The filter screen I is connected to the upper portion of the right side of the left frame. By the adoption of the agricultural soil block crushing device, the effects that crushing is easy, operation is convenient and the crushing speed is high are achieved, and soil blocks can be crushed rapidly.

Owner:奉节县仙鑫蜜蜂养殖有限公司

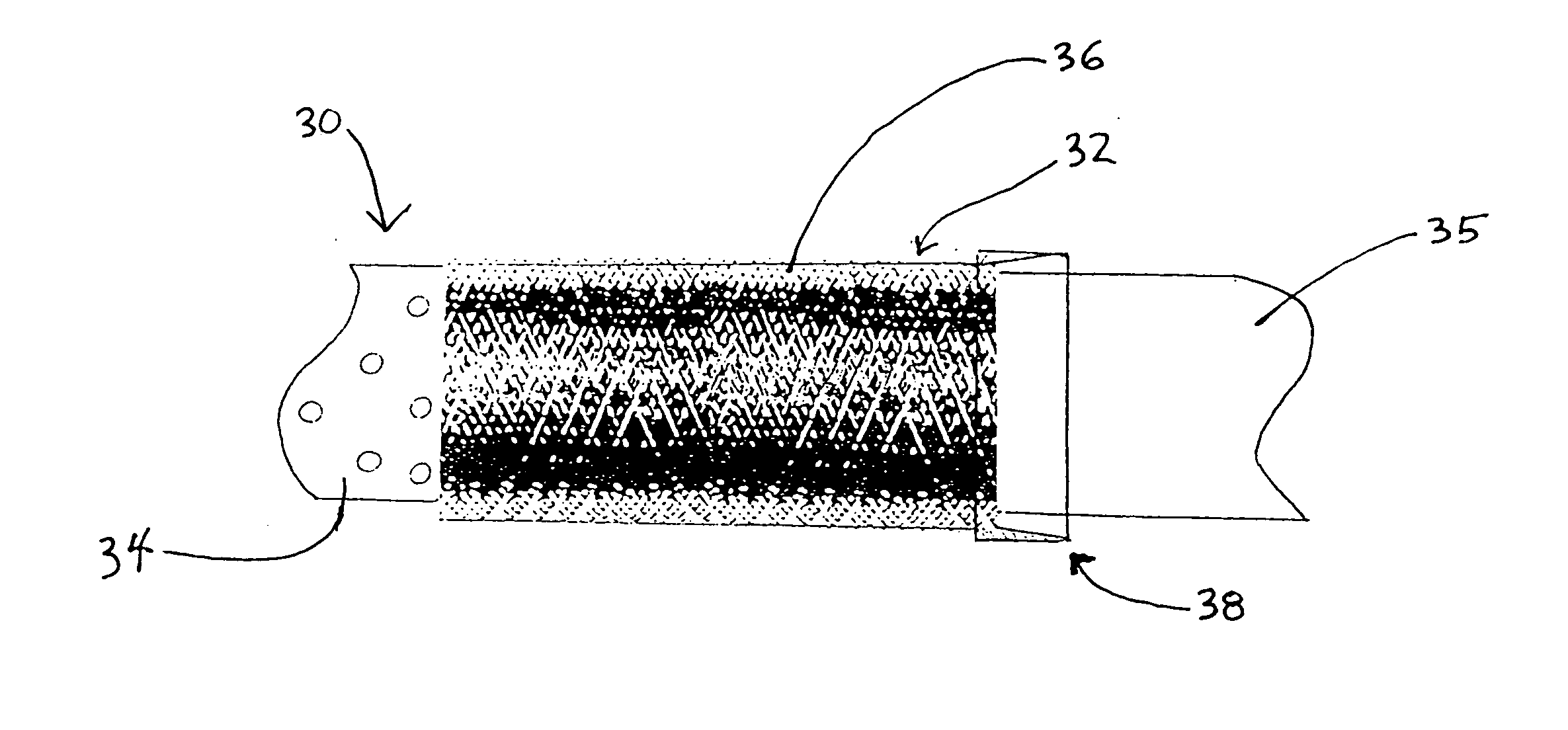

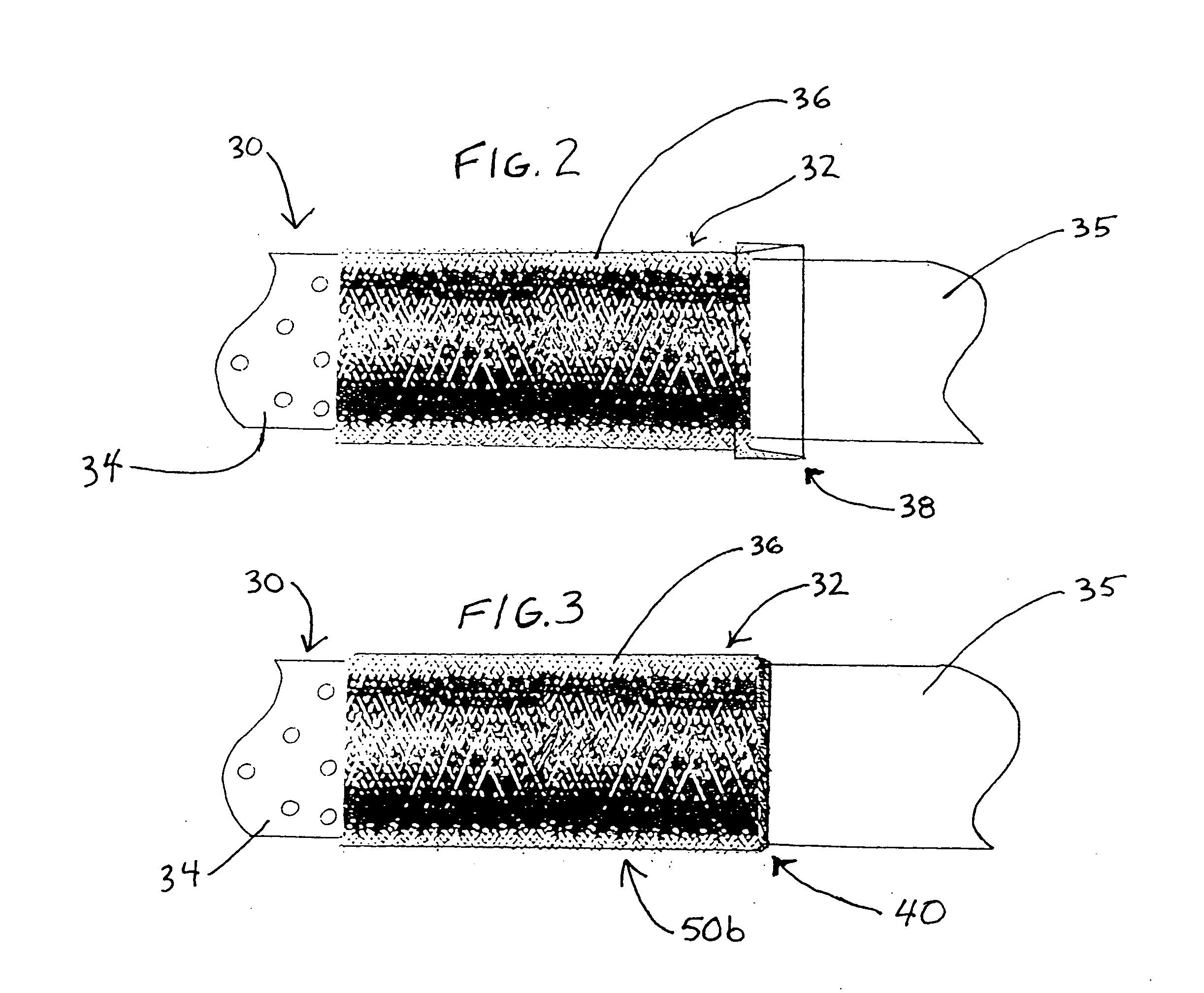

Seamless woven wire sintered well screen

InactiveUS20050126779A1Reliable exclusionFluid removalDrinking water installationMaterials scienceMetal

Owner:CAVINS

Polyurethane based water-based ink and method for preparing same

The invention discloses potyurethane-based water-soluble ink. The ink consists of the following compositions in percentage by mass: 50 to 58 percent of water-soluble potyurethane emulsion, 38 to 46 percent of water-soluble color sizing, 1 to 1.5 percent of wetting agent, 1 to 2 percent of surface active agent and 1.5 to 2 percent of defoaming agent; the total mass is 100 percent. The invention also discloses a method for making the potyurethane-based water-soluble ink; firstly, water-soluble potyurethane emulsion, water-soluble color sizing, wetting agent, surface active agent and defoaming agent with 100 percent of the total mass are weighed according to the mass percentage; secondly, the total weighed compositions are mixed and stirred for 1 to 1.5 hour; finally, the total compositions are filtered by a filter screen with 120 meshes, thereby obtaining the ink. The water-soluble ink can solve the disadvantages of imperfect water resistance, poor glossiness and other performances of the prior water-soluble ink, has good water resistance, wearing resistance and glossiness, strong adhesive force, simple process and convenient facture and can meet the need of high-grade water-soluble printing.

Owner:XIAN UNIV OF TECH

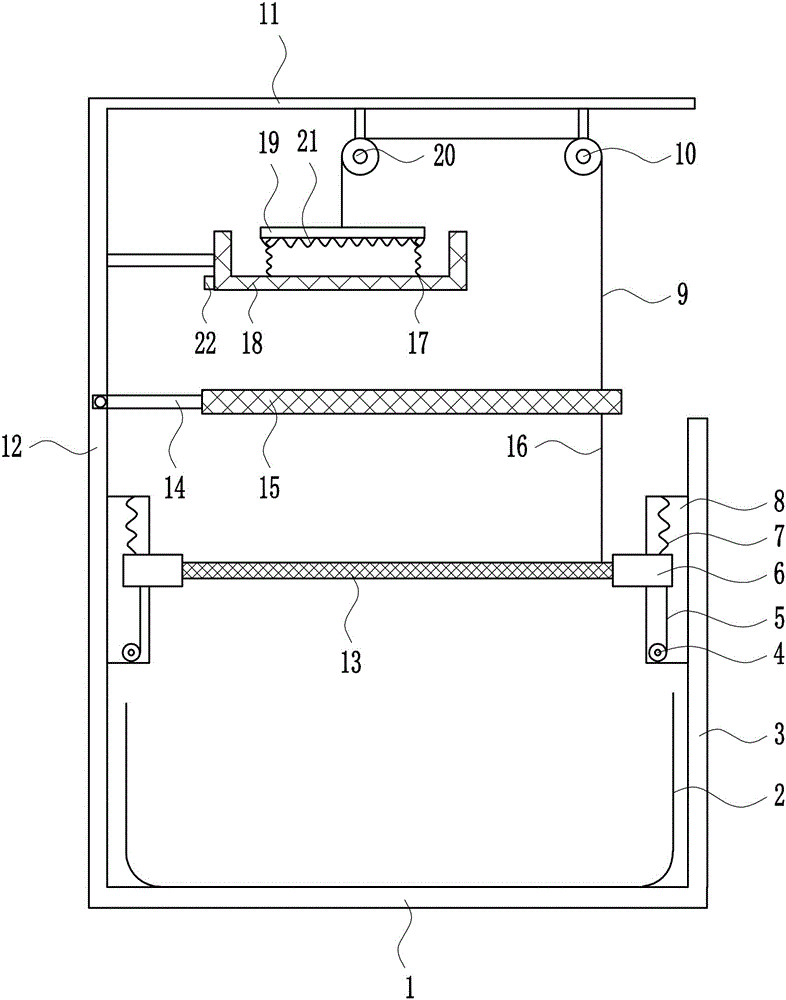

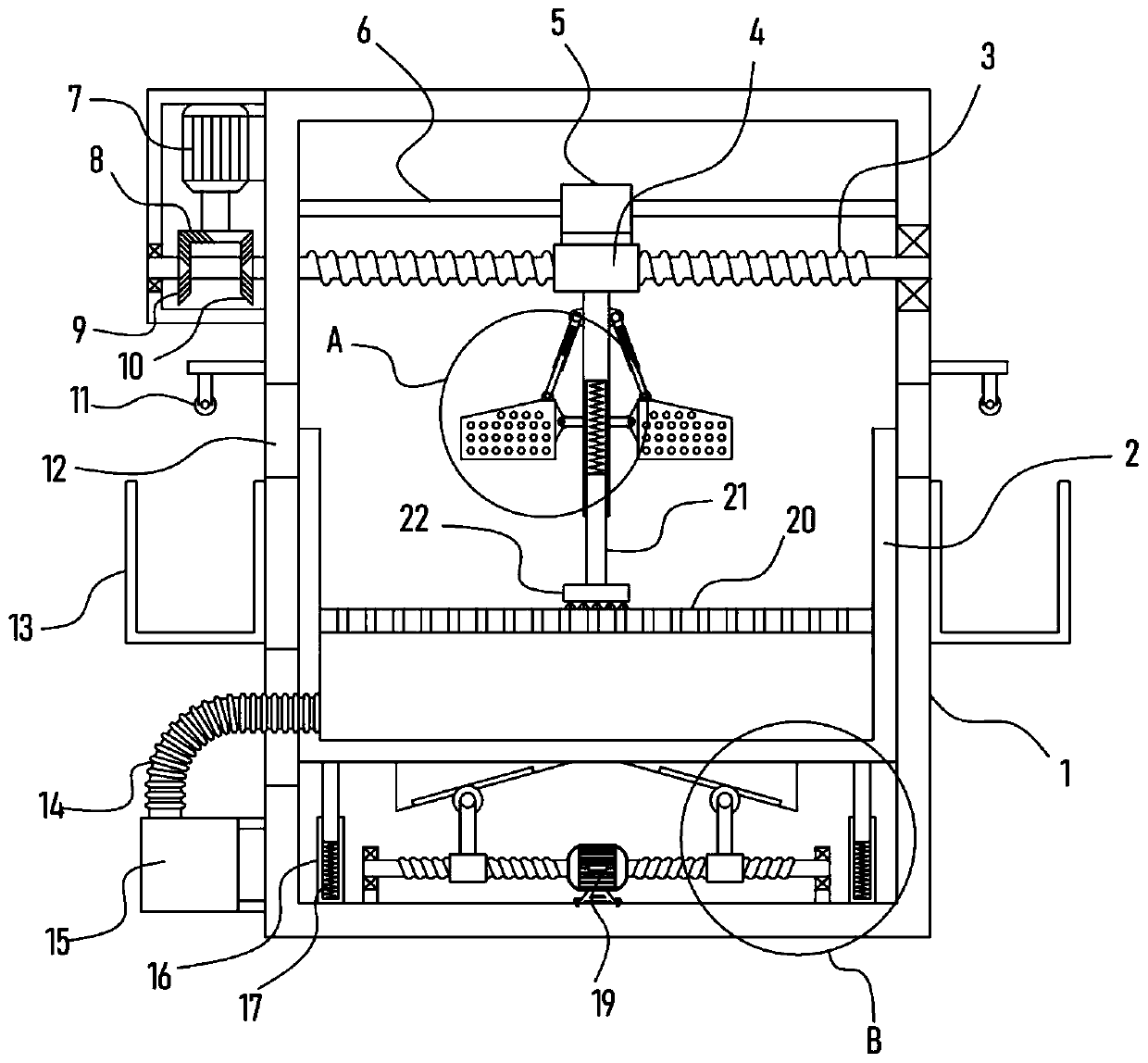

Filtering and impurity removing device for sewage treatment

InactiveCN111203014AEasy to cleanGuaranteed usuallyStationary filtering element filtersScraping - actionElectric machinery

The invention discloses a filtering and impurity removing device for sewage treatment. The invention relates to the technical field of sewage treatment. The device comprises a supporting frame, a threaded rod is rotationally installed on the supporting frame, a reversing mechanism used for driving the threaded rod to rotate clockwise and anticlockwise alternately is arranged on the supporting frame, a double-shaft motor is fixed to the bottom in the supporting frame, and a lifting mechanism used for driving a water tank to adjust the vertical height is connected to the double-shaft motor in adriving mode. The reversing mechanism can drive the threaded rod to alternately rotate clockwise and anticlockwise, and the threaded rod drives a threaded sleeve block to enable a scraping mechanism to collect and filter floating objects on the surface of sewage in the water tank. Arranged pushing wheels can push a mesh basket, so that the mesh basket rotates to pour floating objects in the mesh basket into a collecting tank, and a rapid cleaning effect for the floating objects is achieved. An arranged cleaning mechanism can conduct transverse back-and-forth scraping action on a filter screen,it is guaranteed that meshes in the filter screen are not blocked, and the efficient filtering effect of the filter screen on insoluble impurities in sewage is improved.

Owner:徐卫

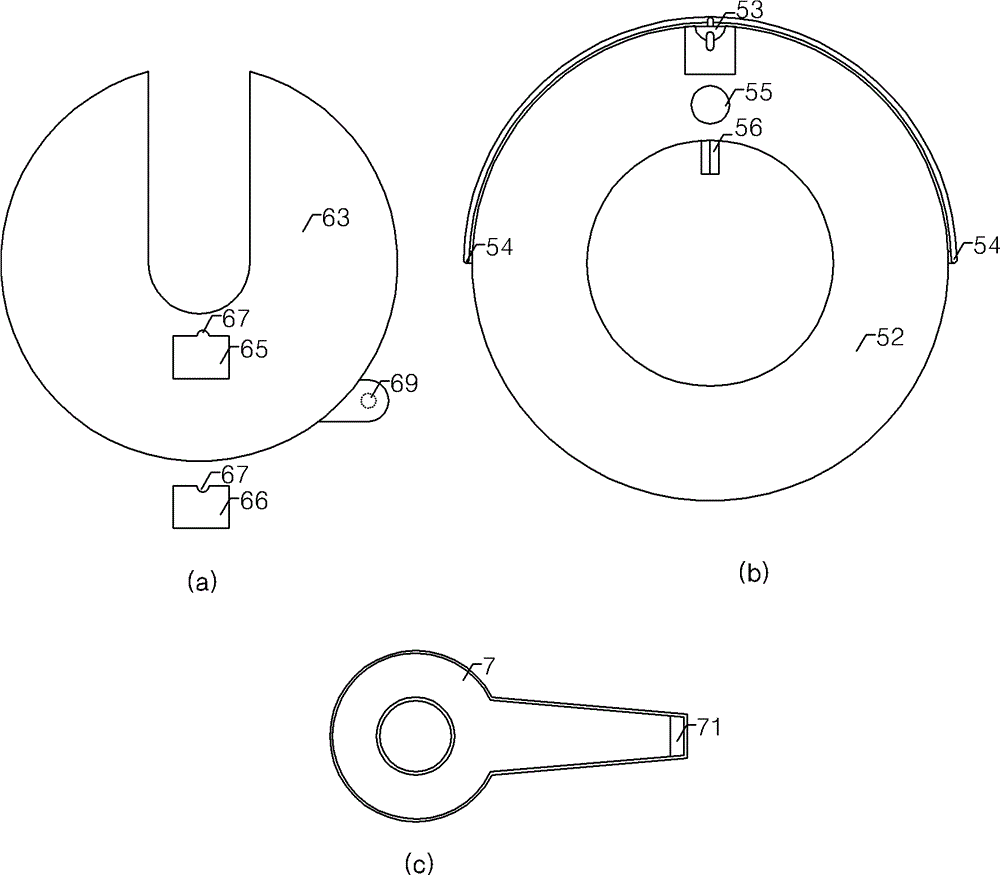

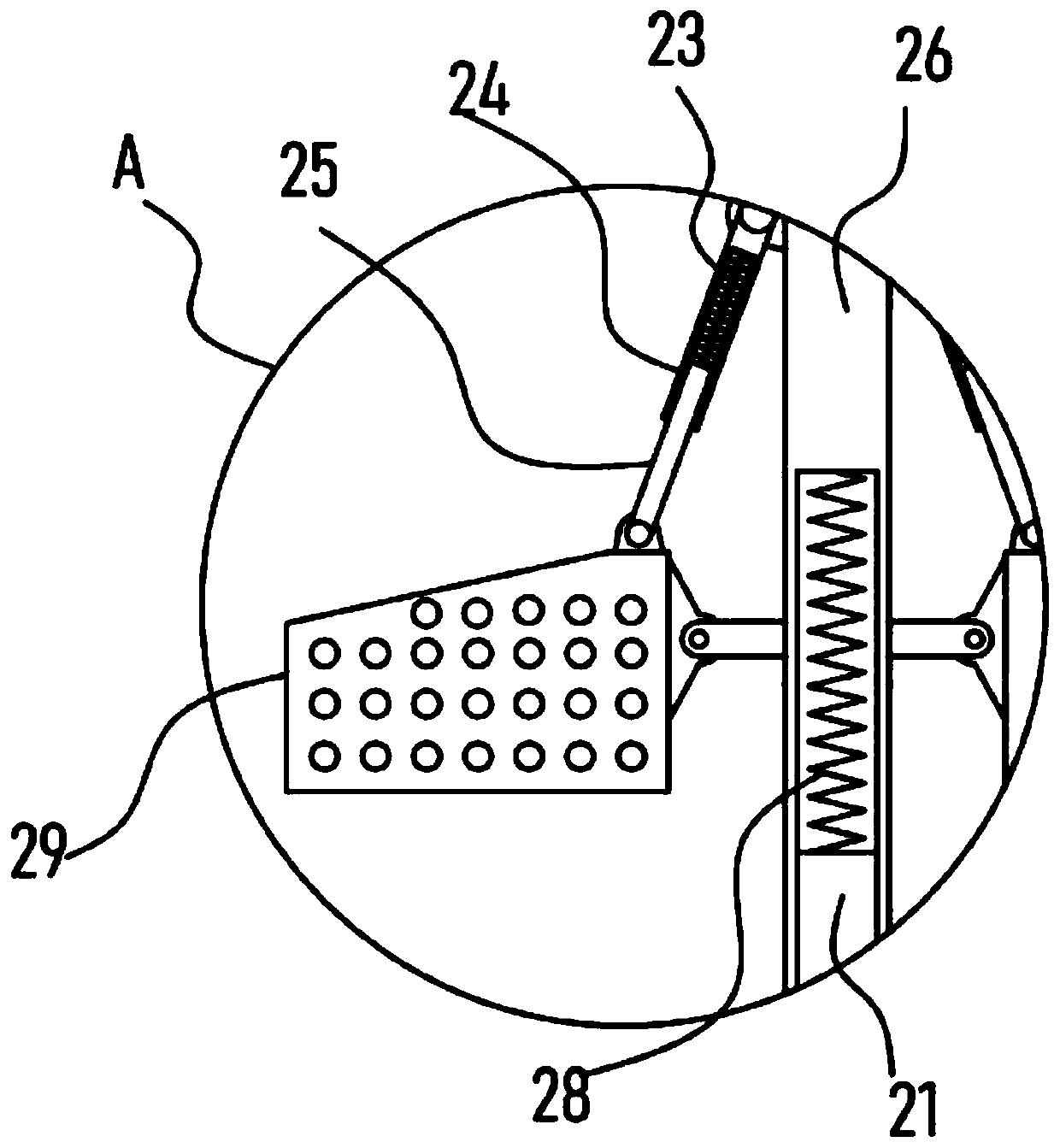

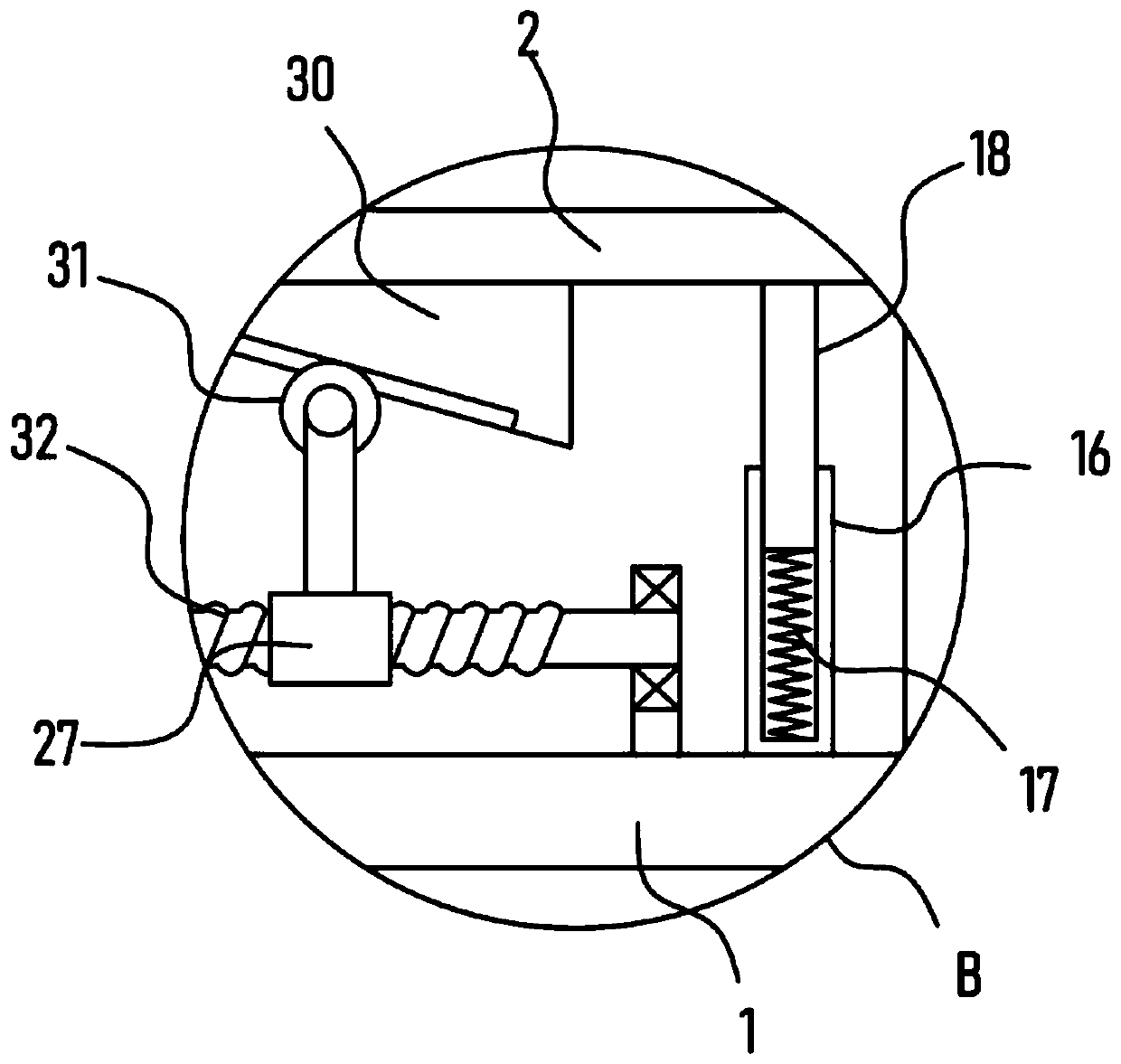

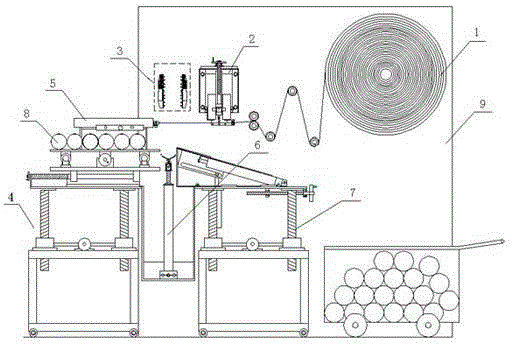

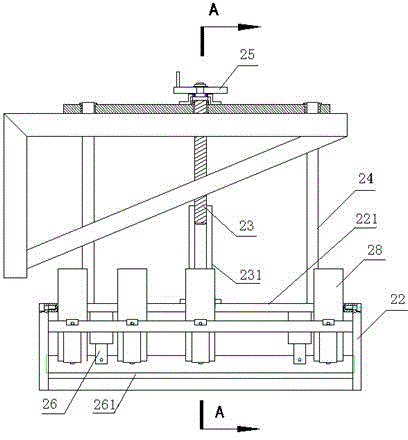

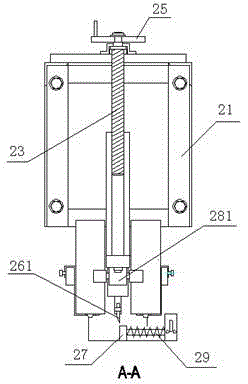

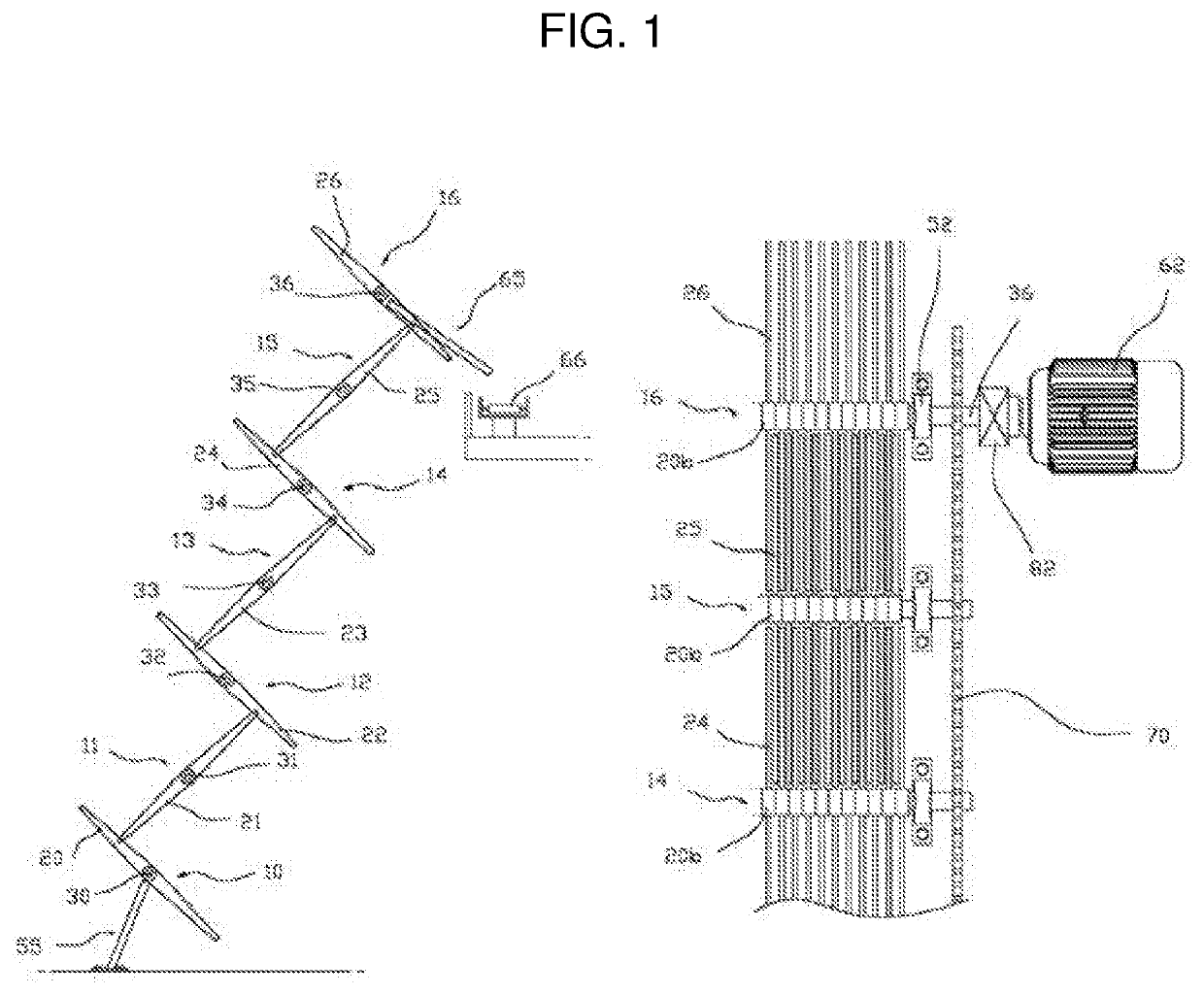

Full-automatic filter element winding machine

ActiveCN104925558AAchieve clampingSolve the thickness of the wallWebs handlingWinding machineAdhesive

The invention relates to a full-automatic filter element winding machine which comprises a filter element paper unreeling mechanism, an adhesive-dispensing cutting mechanism, a clamping drive mechanism, a three-dimensional lifting platform, a filter screen jacking mechanism, an oblique jacking and discharging mechanism and a central control cabinet. A filter paper clamping traction device adjusts the filter element paper position corresponding to the inlet point adhesive-dispensing cutting mechanism and performs filter element paper traction. An adhesive-dispensing of the adhesive-dispensing cutting mechanism performs adhesive dispensing on filter element paper, and the filter element paper is cut off through the cutting device after winding is completed. The filter screen jacking mechanism lifts a filter element screen to the clamping drive mechanism. The clamping drive mechanism is used for clamping the filter element screen and drives the filter element screen to rotate and to be wounded with the filter element paper. The filter element screen completing winding through the clamping drive mechanism drops to the oblique jacking and discharging mechanism and is moved out of a winding machine through the oblique jacking and discharging mechanism. The full-automatic filter element winding machine has a full-automatic multi-azimuth adjusting function, completely replaces manual operation to wind the filter paper on the filter element screen, production efficiency and product quality are improved, and production cost is reduced.

Owner:珠海圣菲玛滤清器有限公司

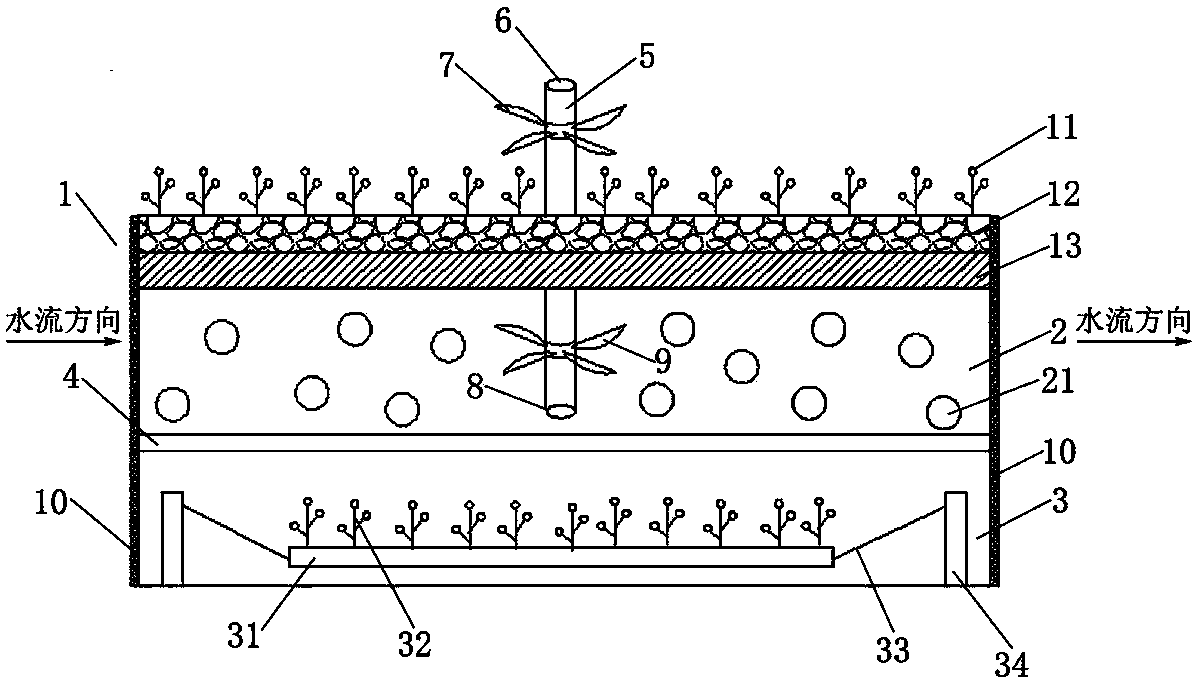

Multi-step water body ecological purification system and construction method thereof

ActiveCN103864220APrevent eutrophicationIncrease dissolved oxygenTreatment with aerobic and anaerobic processesEnergy based wastewater treatmentMicroorganismOutfall

The invention discloses a multi-step water body ecological purification system. The system comprises a concrete bed body, wherein the concrete bed body comprises three regions from top to bottom, respectively a floating bed region, a microorganism region and a sedimentation bed region; a ventilating pipe is arranged in the floating bed region; a vent and a windmill are arranged at the upper end of the ventilating pipe; the windmill is fixedly arranged below and close to the vent; an aeration opening and a stirrer are arranged at the lower end of the ventilating pipe; the stirrer is fixedly arranged above the aeration opening; the lower end of the ventilating pipe deeply extends into the microorganism region; a water inlet and a water outlet are respectively formed in the left and right sides of the concrete bed body; and detachable filter screens are respectively arranged at the water inlet and the water outlet. The invention also discloses a construction method of the multi-step water body ecological purification system. The multi-step water body ecological purification system disclosed by the invention is rapid in purification speed, good in purification effect, easy to maintain and manage and low in cost.

Owner:JIANGSU SHANSHUI ENVIRONMENT CONSTR GRP

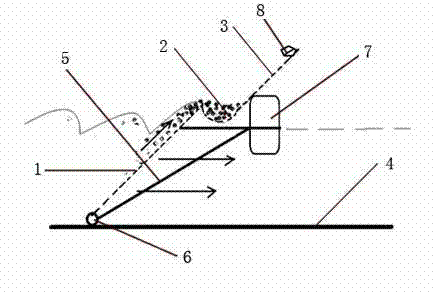

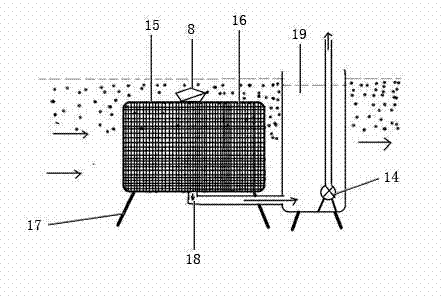

Method for filtering and separating suspended maters from water and filtering device used in method

ActiveCN102824781AIncrease concentrationRaise the upper limit of sizeStationary filtering element filtersSoil scienceCross-flow filtration

The invention relates to a method for filtering and separating suspended maters from water and a filtering device used in the method. According to the concrete technology, a filter screen of the filtering device is directly arranged in water flow in a water flow channel; the included angle a is formed between the filtering surface of the filter screen and the water flow direction of the surface of the filtering surface, wherein the included angle a can be an acute angle between 0 and 70 DEG or an obtuse angle between 110 DEG C and180 DEG; and the filter screen of the device and different water flow channels form different cross flow filtering systems. The method and device provided by the invention can be widely applied to lake blue-green algae, sewer liquid dung, sewage treatment plants and vegetable drug extraction.

Owner:郑向东

Wet-type dust-capturing wind current cooling device

ActiveCN104474819ACompact structureReduce volumeCombination devicesTemperature controlWorking environment

The invention provides a wet-type dust-capturing wind current cooling device mounted at a head-on rear position of a mining working face mining machine, connected with an outlet end of a polluted wind pumping canister and comprising a cover shell, and a spray dedusting device, a cyclone centrifugal dedusting device, a dust screen filtering device, an air cooling type heat exchanger and a baffle plate demister which are connected in order inside the cover shell; positions of the cover shell walls below the cyclone centrifugal dedusting device and the baffle plate demister are respectively provided with drainage pipe ports. Fully-mechanized excavating working face dust capturing and wind current cooling works are combined together, with a treatment mode of firstly dust capturing and then wind current cooling, polluted wind is firstly subjected to multi-stage dust capturing treatment and then is demisted and cooled, the working face wind current temperature is controlled in a suitable temperature, a safe and comfortable working environment of the down-hole working face is ensured, and the problems of high temperature and high dust of the mine mining working face are better solved.

Owner:SHANDONG UNIV OF SCI & TECH

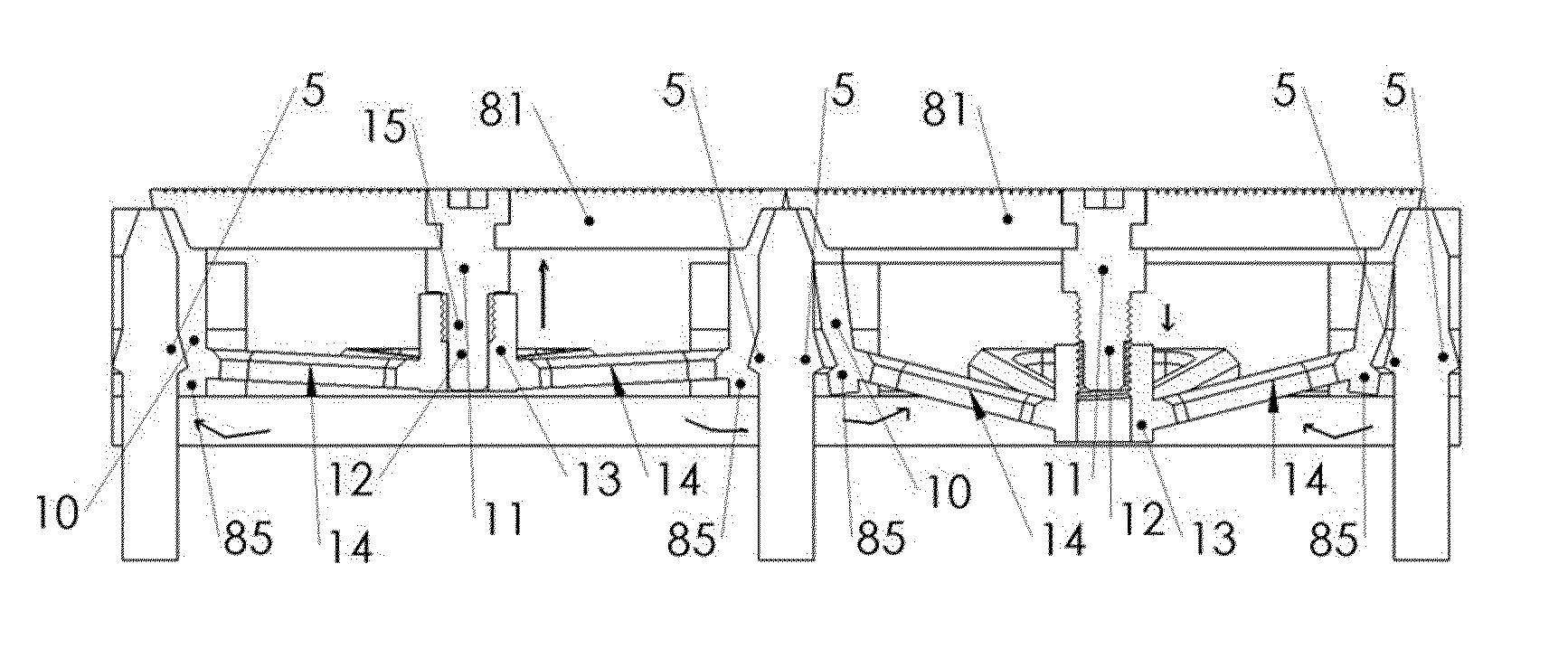

Shaker screen filter for a drilling fluid shaker

ActiveUS9180493B2Shorten the timeReduce frictionSievingSnap-action fastenersLocking mechanismEngineering

An improved shaker screen filter for a well fluid shale shaker includes a main frame arranged for being arranged in the well fluid shale shaker for screening, preferably under vibration, of drilling mud, wherein the mainframe is subdivided into a plurality of smaller cell frames, one or more cell plug filters with one or more layers of screen cloths on top of at least one support cloth or support layer, wherein each of the cell plug filter includes a cell plug filter frame arranged to be held in each of the cell corresponding frames of the main frame, wherein at least one of the cell plug filter frame includes a locking mechanism arranged for locking the cell plug filter frame, upon desire, in a preferred position in the cell frame, correspondingly releasing the cell plug filter frame from the cell frame.

Owner:OPTIPRO

Non-powered drain pump screen device

ActiveUS20200139272A1Efficient removalEasy constructionSewerage structuresSpecific water treatment objectivesImpellerWater flow

A non-powered drain pump screen device is disposed in a river, a stream, a waterway, or a place in which a significant amount soil is carried by a water flow. Upper and lower impellers are provided with upper and lower blades. The lower blades prevent reentry of impurities while rotating due to resistance to a flow of fluid in a non-powered manner. The upper impellers are rotated in a non-powered manner, so that the upper blades filter impurities. The non-powered drain pump screen device is disposed in a waterway to remove impurities at low maintenance costs.

Owner:2H SANEOP INC

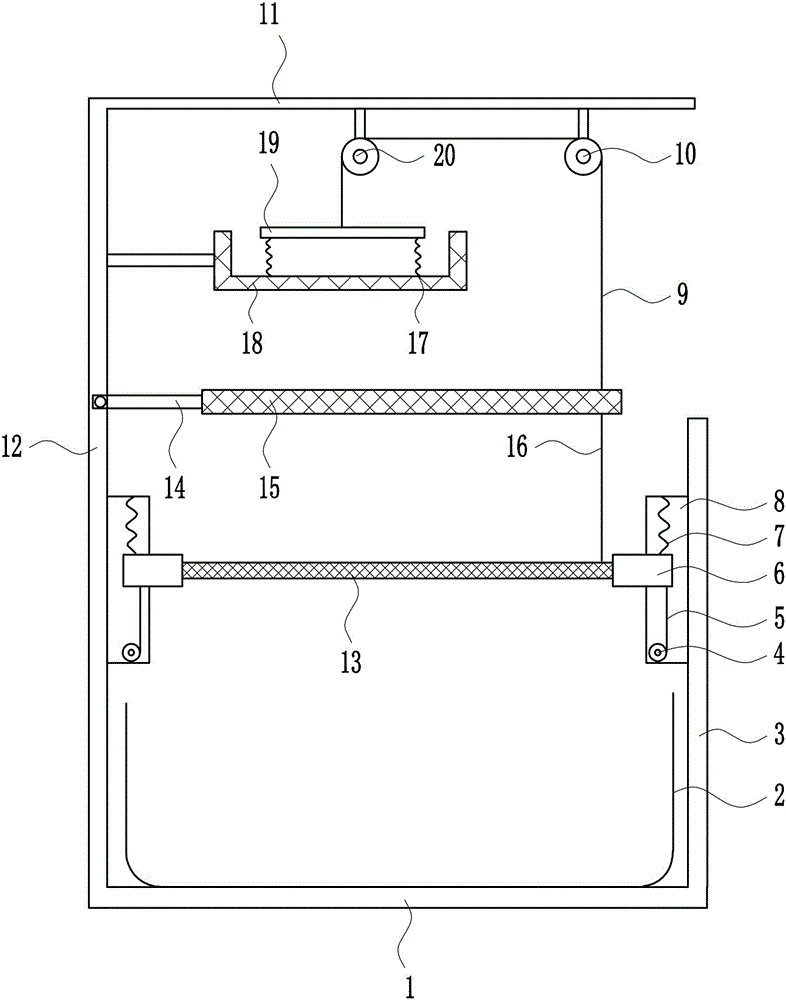

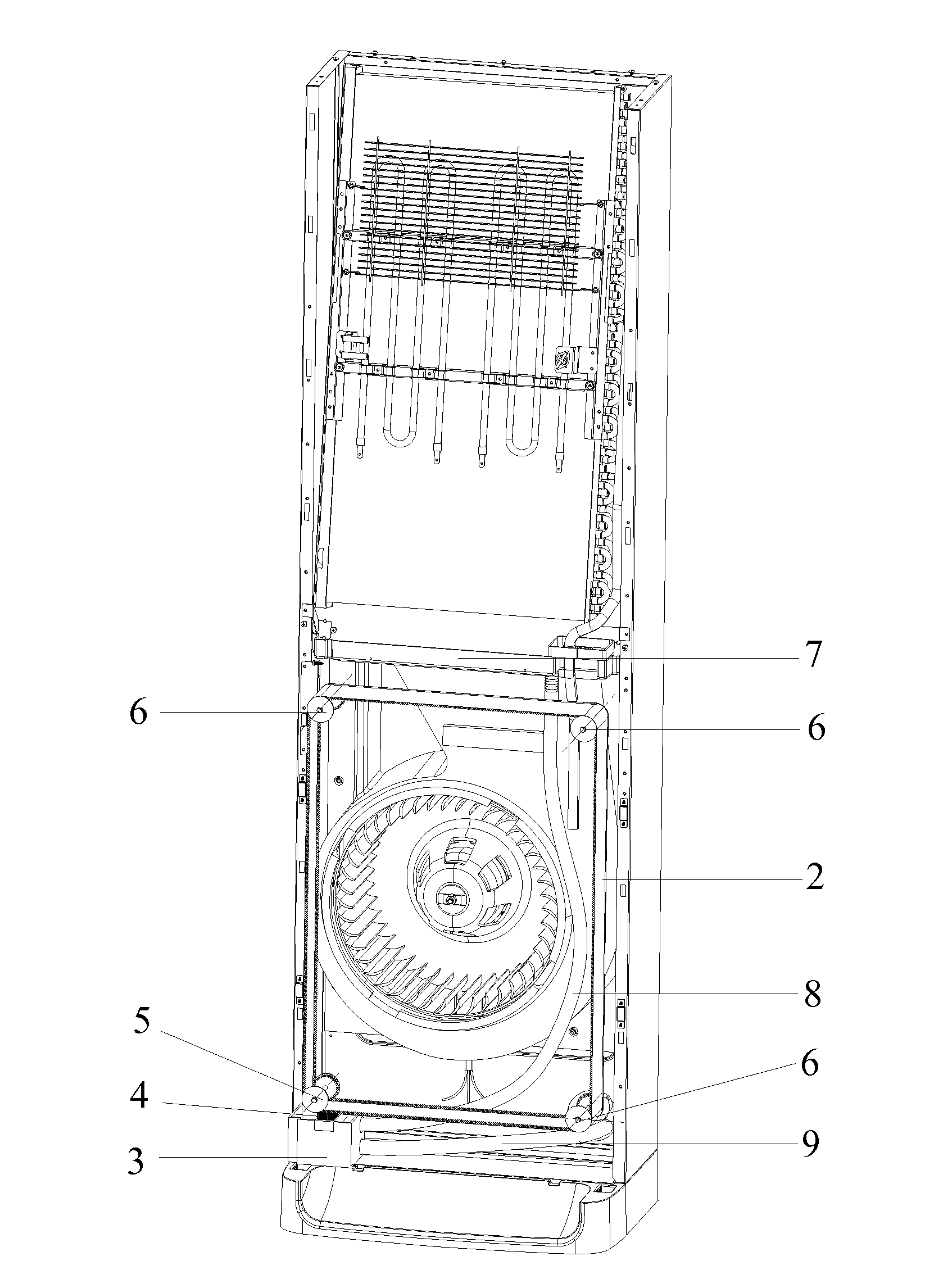

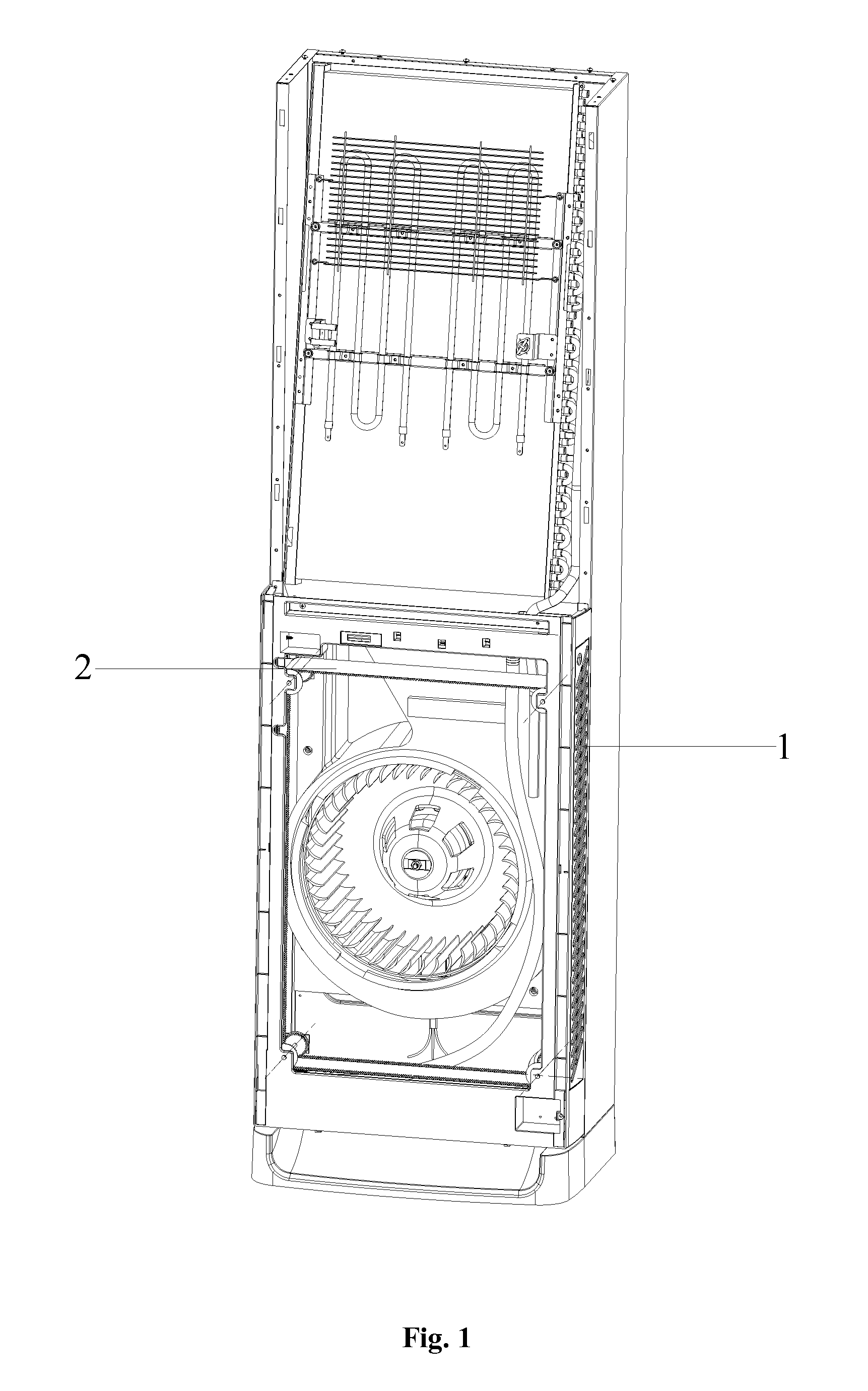

Automatic dust-removing and cleaning device for filter net of air-conditioner

InactiveUS20150114232A1Avoid troubleAvoid mismatchCombination devicesMechanical apparatusGear wheelDust control

Disclosed is an automatic dust-removing and cleaning device for a filter net of an air-conditioner which has a filter net (2) with an end to end sealing ring structure. The filter net (2) comprises a net frame (21) provided with gear sockets (211), and a mesh (22). A driving gear (5) is installed at one corner of an air inlet frame (1) of the air conditioner and meshed with the gear sockets (211) of the net frame (21). Driven gears (6) are installed at the other three corners of the air inlet frame (1) of the air conditioner and meshed with the gear sockets (211) of the net frame (21). A drive mechanism (12) drives the driving gear (5) to rotate. A dust-collecting box (3) is installed at the bottom of the air inlet frame (1) of the air conditioner and provided with a water inlet and a water outlet. The water inlet is connected to a water inlet pipe (8) and the water outlet is connected to a water outlet pipe (9). A dust removing brush (4) is installed on the dust-collecting box (3), located below the filter net (2) and in contact with the filter net (2) simultaneously.

Owner:GUANGDONG CHIGO AIR CONDITIONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com