Differential melt electro-blowing spinning device and technology for preparing nanofibers in batches

A nanofiber, melt differentiation technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of increasing equipment cost and maintenance cost, and achieve the effect of overcoming high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

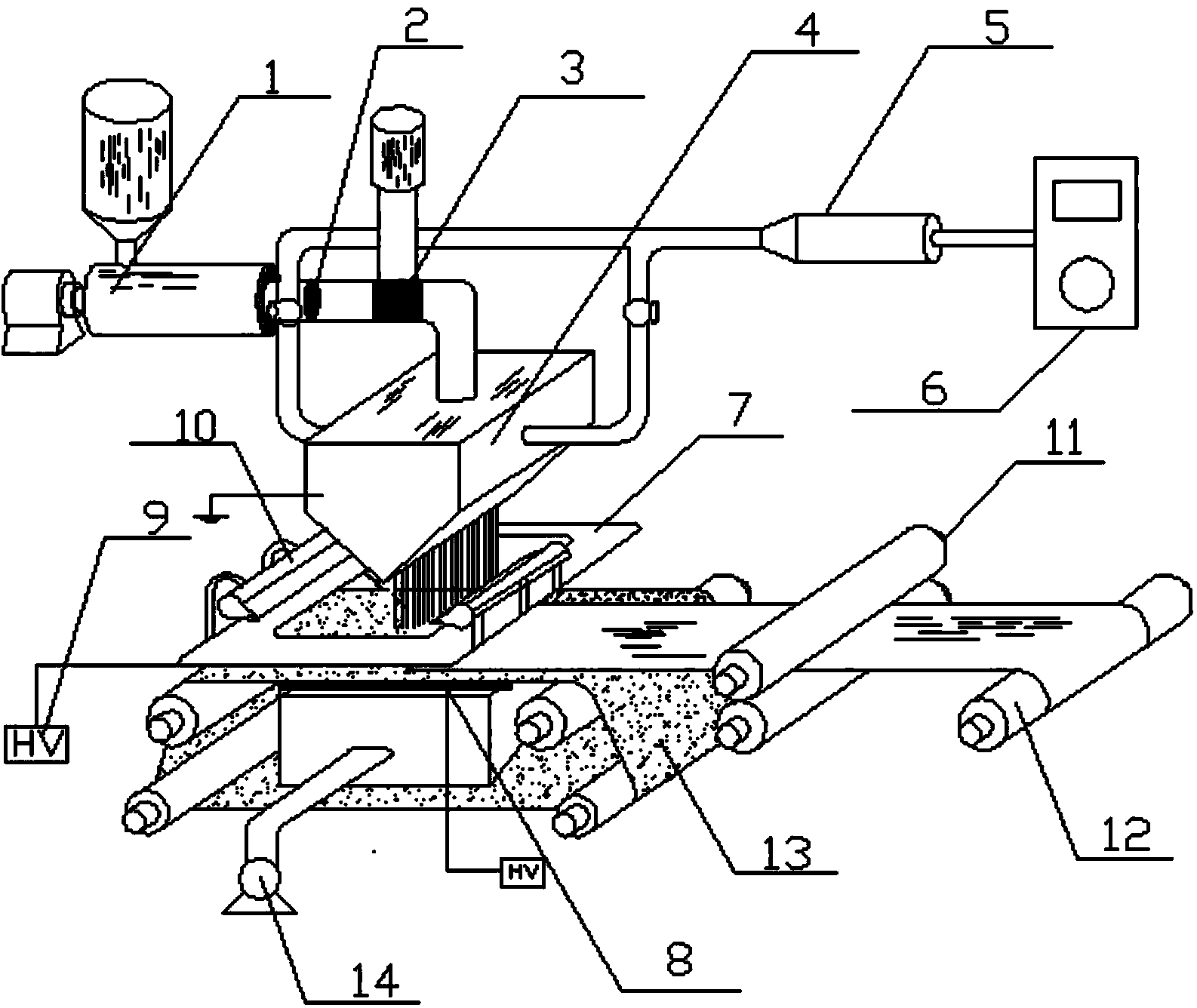

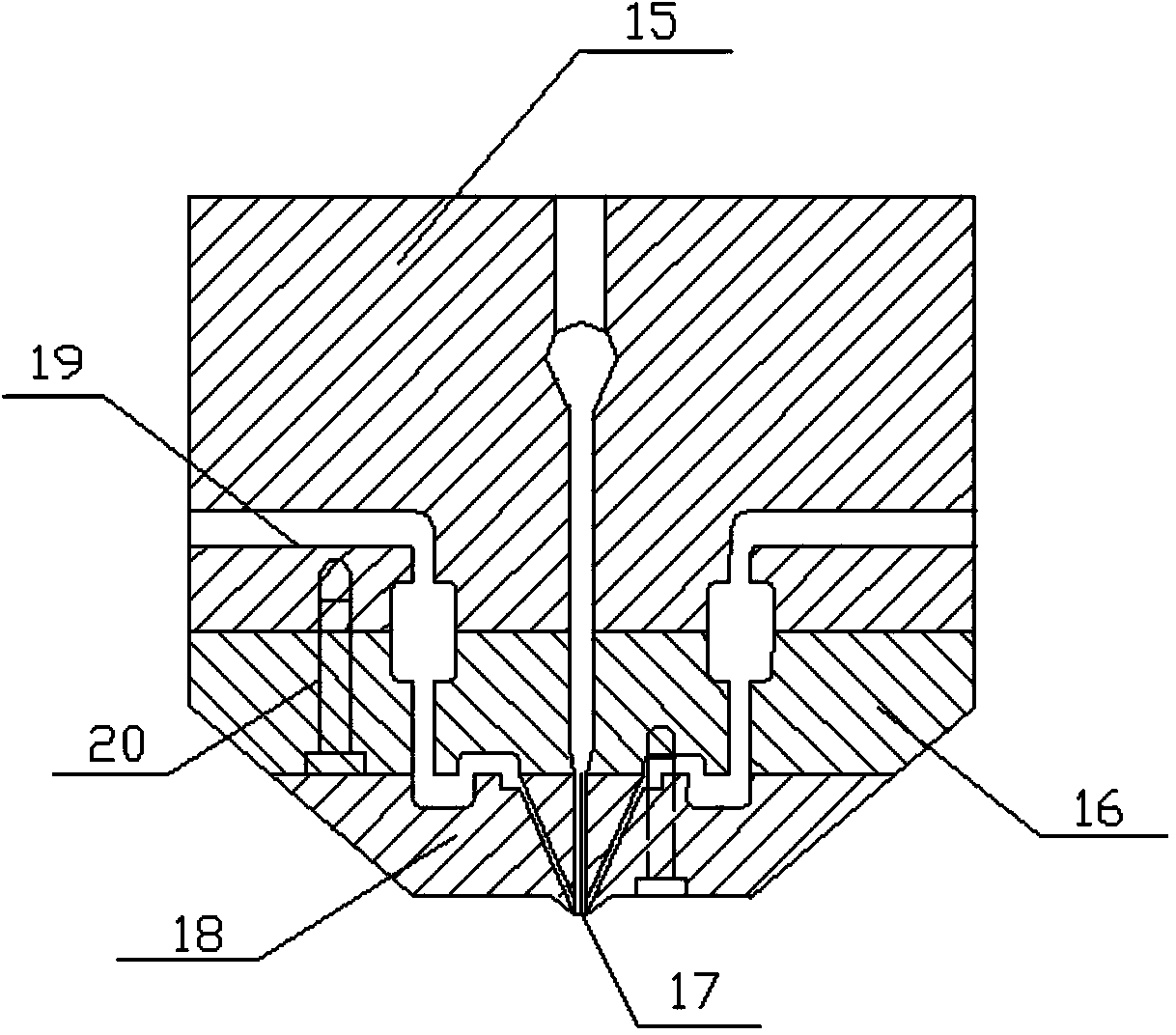

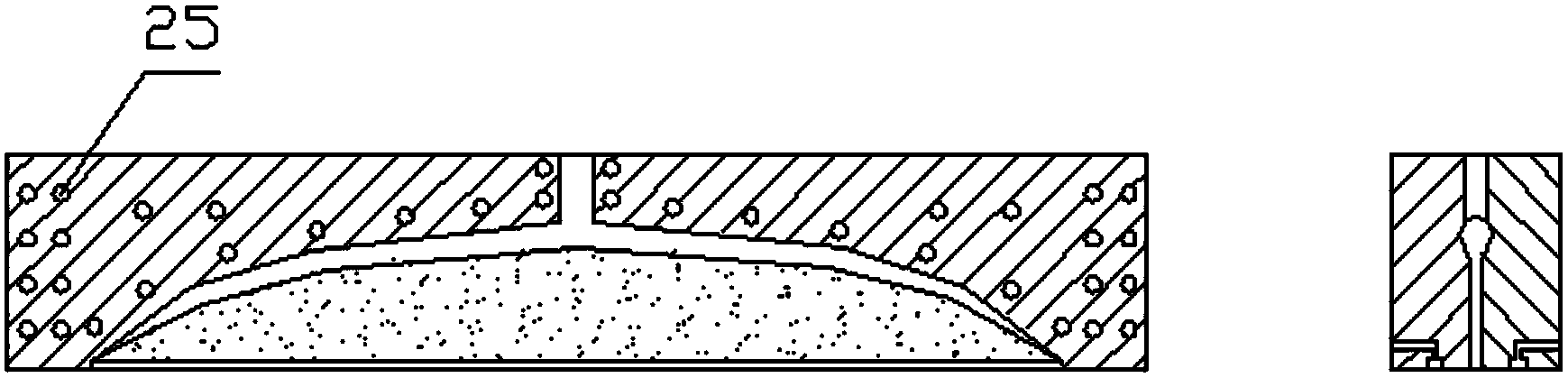

[0023] The present invention is a melt differential electrospray spinning device for preparing nanofibers in batches, such as Figure 1-7 As shown in the schematic diagram, the spinning device mainly includes an extruder 1, a filter screen 2, a melt metering pump 3, a spinning box 4, an airflow heating device 5, an air compressor 6, an upper electrode plate 7, and a lower electrode plate 8 , high-voltage electrostatic generator 9, guide air knife 10, hot rolling device 11, winding roller 12, netting belt 13 and exhaust system 14, the outlet of extruder 1 is connected to filter screen 2, filter screen 2 and spinning box 4 The inlet is connected to the melt metering pump 3 through the flange, and the outlet of the air compressor 6 is connected to the airflow heating device 5, and then divided into two pipes through the flow diversion device, connected to the spinning box 4, and placed under the spinning box 4 The upper electrode plate 7, the lower electrode plate 8 is placed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com