Patents

Literature

163results about How to "Reduce whiteness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

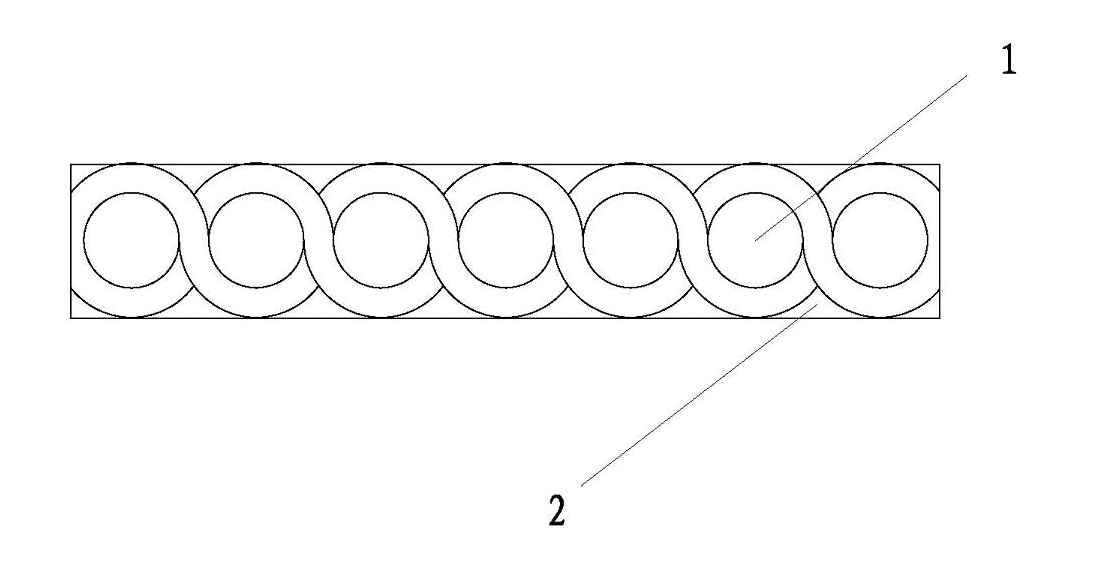

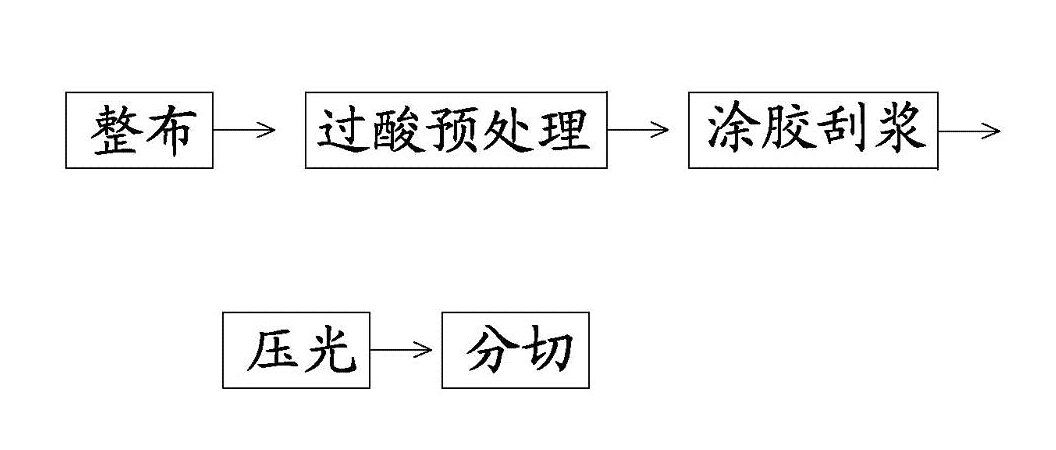

Environment-friendly non-fraying printed label tape and manufacturing method thereof

The invention relates to an environment-friendly non-fraying printed label tape and a manufacturing method thereof, belonging to the technical field of label tape manufacturing. The environment-friendly non-fraying printed label tape comprises a substrate layer and a colloid layer, the thickness of the substrate layer is within 150-170 microns, and the thickness of the colloid layer is within 20-30 microns; and the colloid layer is a synthetic resin scraping layer. The manufacturing method of the environment-friendly non-fraying printed label tape sequentially comprises the steps of cloth arranging, gelatinizing and scraping, calendering and cutting, wherein the gelatinizing and scraping step is as follows: gelatinizing a piece of grey cloth, in which the gelatinizing quantity is controlled within 20-40g / m<2>, and scraping the grey cloth by a scraping machine after gelatinizing, wherein the gelatinizing formula is as follows: 80-89wt% of synthetic resin, 10-15wt% of water and 1-5wt% of thickening agent. In the invention, the manufacturing method needs low production cost; and the product has the technical effect of non-fraying and meets the 0eko-tex standard100.

Owner:HUZHOU SINY LABEL MATERIAL

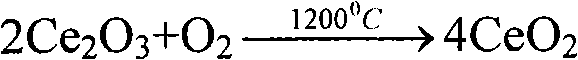

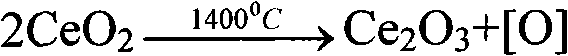

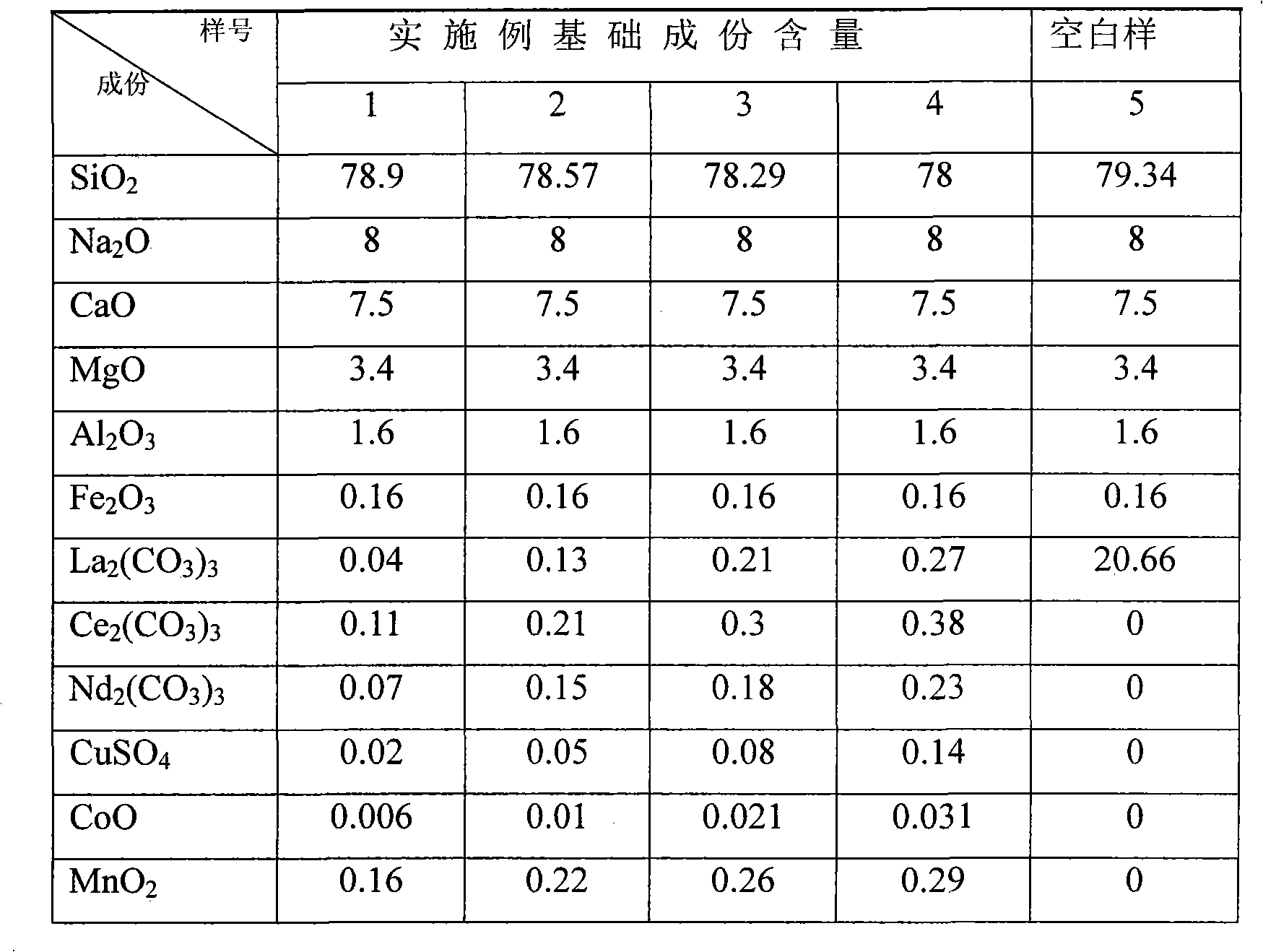

Ultra-white glass

The invention relates to ultra-white glass, belonging to the preparation field of glass. The preparation method of the ultra-white glass is as follows: La2(CO3)3, Ce2(CO3)3, Nd2(CO3)3, MnO2, CoO and CuSO4 are added in common float glass to perform compound clarification and decoloring, wherein under the combined action of chemical decoloring and physical decoloring, the thickness of the molten glass is 4mm, the visible light transmittance is more than 94.5% under the wavelength of 380-780nm, the whiteness is less than 0.082, the flexural strength is more than 380MPa and the microhardness is more than 8320MPa. The ultra-white glass has the advantages of higher visible light transmittance, low whiteness, high flexural strength and higher microhardness; and the quality of the white float glass can be obviously increased. The ultra-white glass can be widely used in the fields such as building glass, photovoltaic technology, experimental apparatus and the like.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

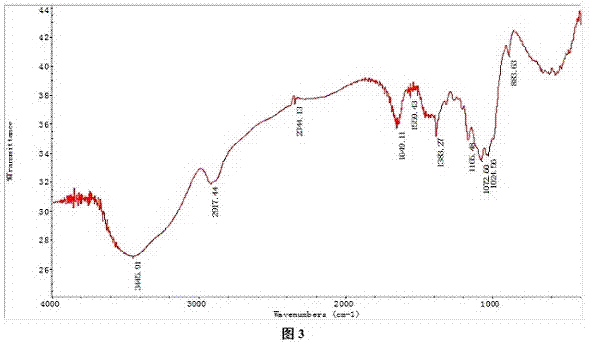

Technique for producing low viscosity octenylsuccinate starch by oxidation process

The invention discloses a technique for producing octenyl succinate starch ester with low viscosity by an oxidation method, which comprises steps as follows: waxy rice starch and water are prepared to be starch milk in a reaction vessel, then the starch milk is heated to 34 DEG C to 38 DEG C, and a sodium hydroxide solution is added for adjusting the PH value between 9.3 and 9.7; sodium hypochlorite is added to carry out oxidation reaction, and the PH value and the reaction temperature are kept; sodium pyrosulfite is added to carry out reduction reaction, and a hydrochloride solution is added in the reaction process to adjust the PH value of the starch milk between 8.5 and 9.0, and the temperature is cooled to 28 DEG C to 31 DEG C, and then octenyl succinic anhydride with 2 percent to 3 percent of the total mass of absolute dry starch is added to carry out esterification reaction; and after the esterification reaction, the hydrochloride solution is added to neutralize the PH value of the starch milk between 5.5 and 6.5, and the finished product can be obtained by washing and drying the neutralized starch milk. By adopting the technique for producing the octenyl succinate starch ester with low viscosity by the oxidation method, the product is high in esterification reaction efficiency, good in emulsifying properties and high in product quality.

Owner:诸城兴贸玉米开发有限公司

Particulate metal oxide

InactiveUS20050069706A1Easily redispersibleEvenly dispersedMaterial nanotechnologyCosmetic preparationsUv protectionPhosphate

A particulate metal oxide having a coating layer comprising phosphate wherein the mean length of the primary particles is in the range from 50 to 90 nm, and the mean width of the primary particles is in the range from 5 to 20 nm. The metal oxide is particularly suitable for forming aqueous dispersions. The metal oxide and aqueous dispersions thereof can be used in a sunscreen product that exhibits both effective UV protection and improved transparency.

Owner:CRODA INT PLC

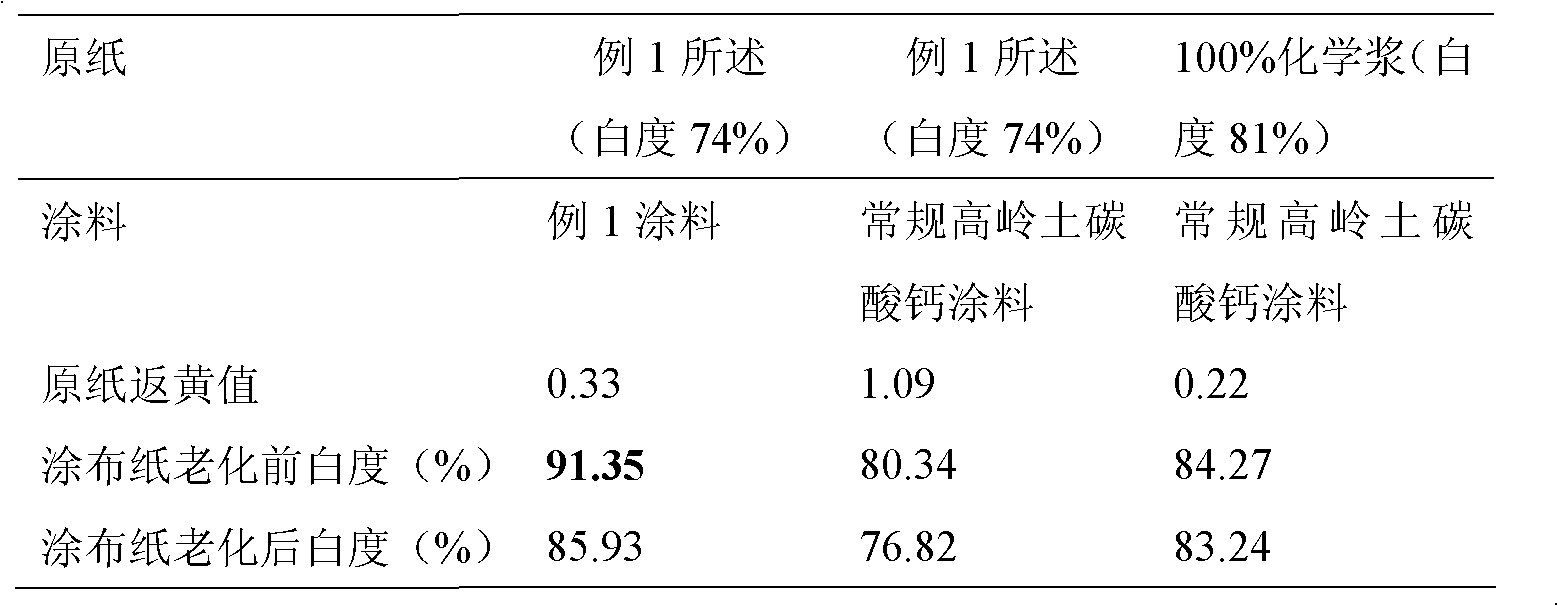

High-whiteness coated paper coated by using raw paper with medium whiteness, coating method and coating

InactiveCN102199897AReduce whitenessFulfil requirementsCoatings with pigmentsReinforcing agents additionCardboardManufacturing technology

The invention relates to high-whiteness coated paper coated by using raw paper with medium whiteness, a coating method and a coating. The coating method is mainly characterized by greatly reducing the whiteness of the raw paper for producing conventional high-grade coated paper such as copper plate paper and coated white cardboards. The coating mode is a common single-side or double-side two-layer (double-coating) or multi-layer coating mode in a papermaking plant. By using the mechanical property of the raw paper, the printing property of coatings and the synergetic whitening effect between the coatings, yellowing of the raw paper is inhibited, and the whiteness of the coated paper is improved to over 86 percent so as to meet the requirements of national standards on the high-grade copper plate paper. The raw paper of the high-grade coated paper can be made by using various kinds of environment-friendly and resource-saving pulp of medium whiteness more widely, and is favorable for promoting the development of the low-carbon manufacturing technology of the pulping papermaking industry. The newly invented coated paper can substitute the traditional high-grade paper such as the copper plate paper, the coated white cardboards and the like in the fields of printing and packing.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

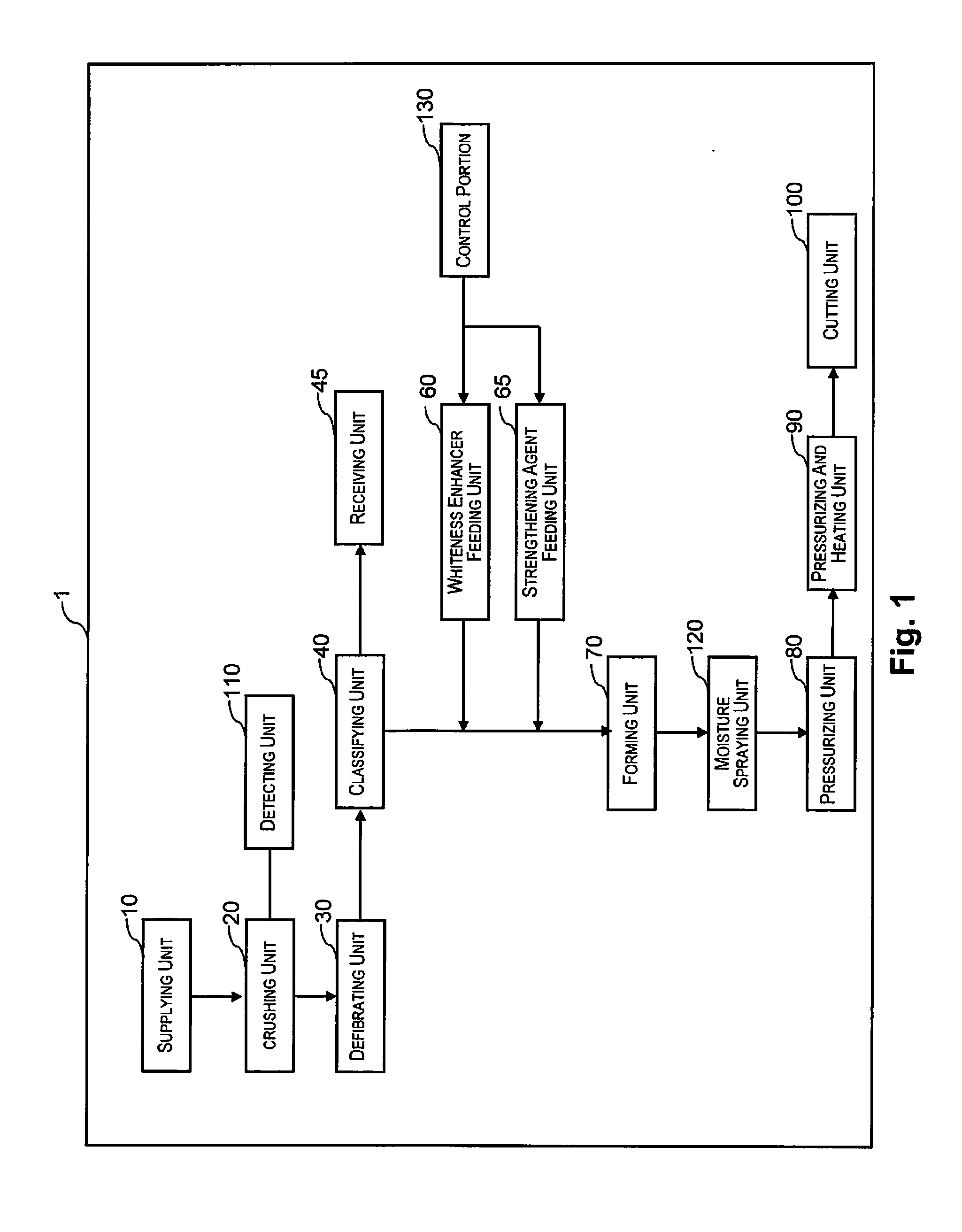

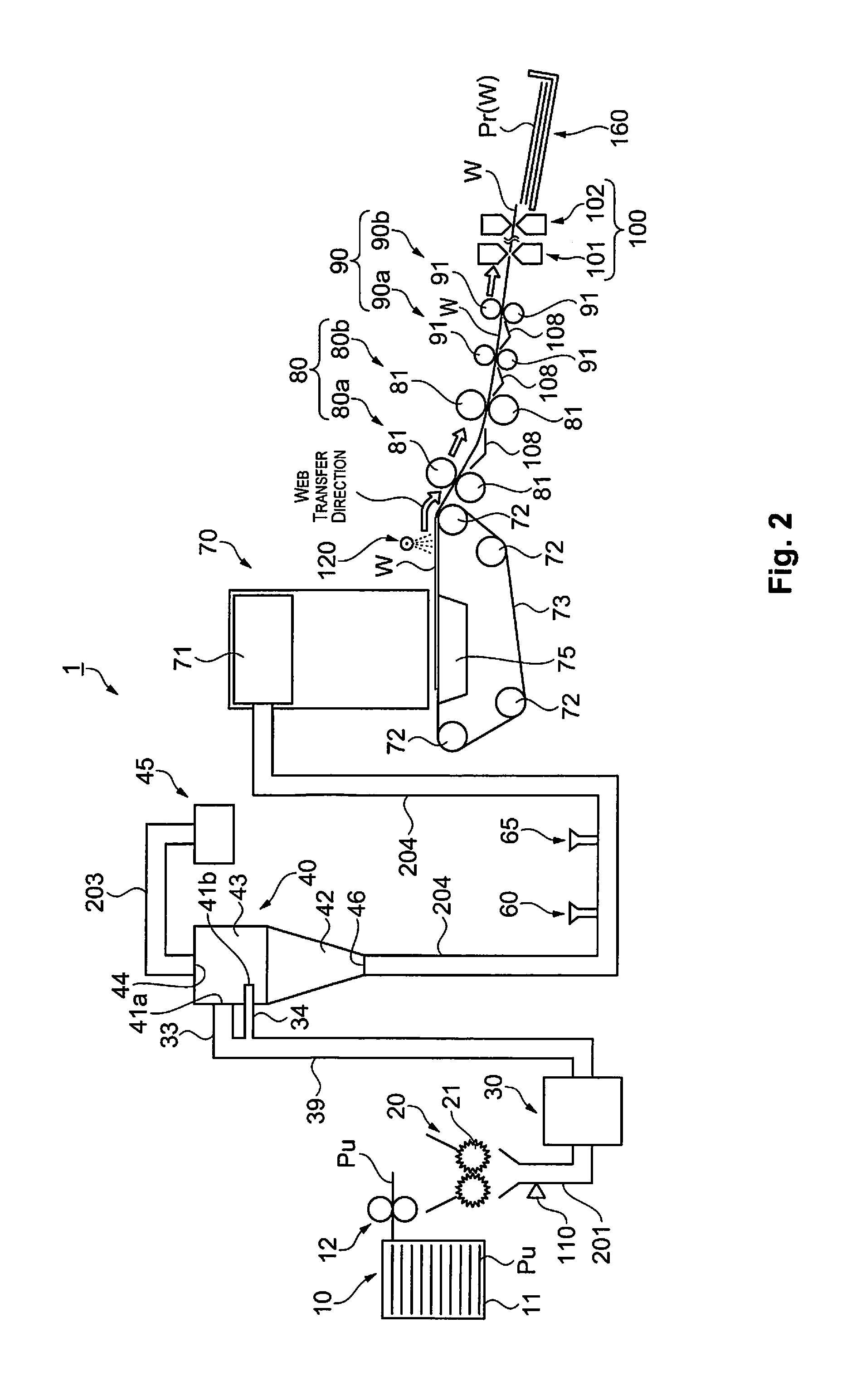

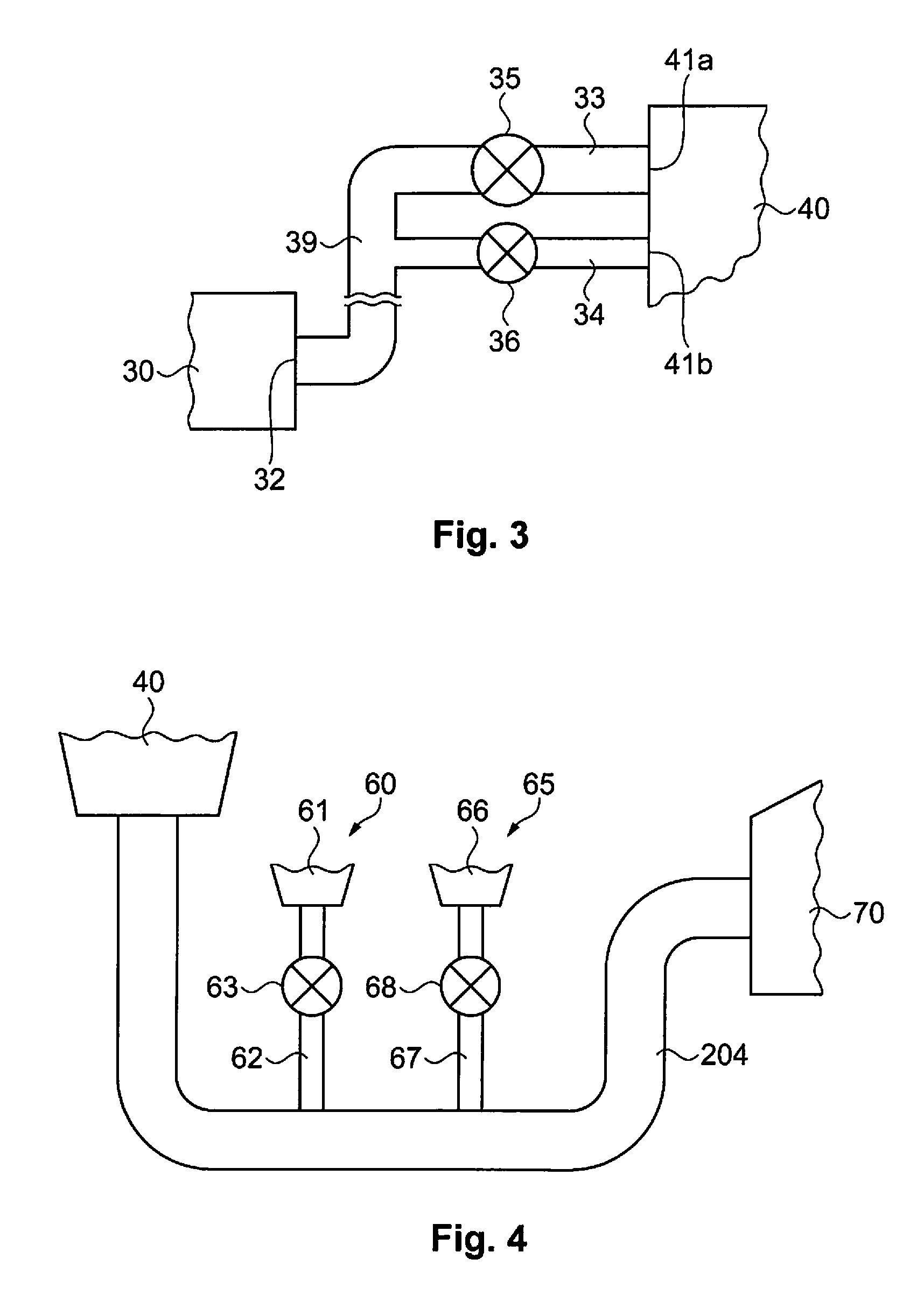

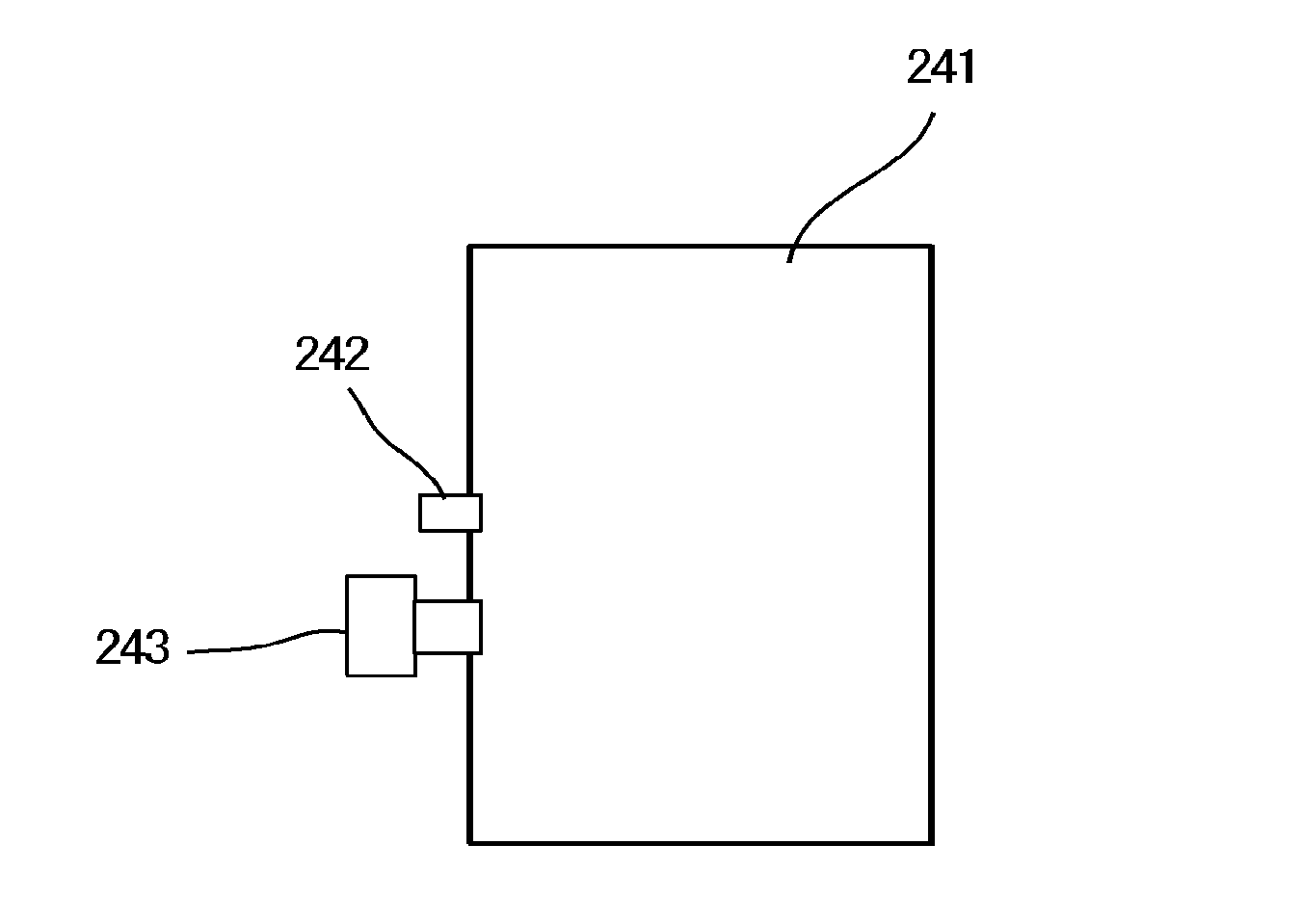

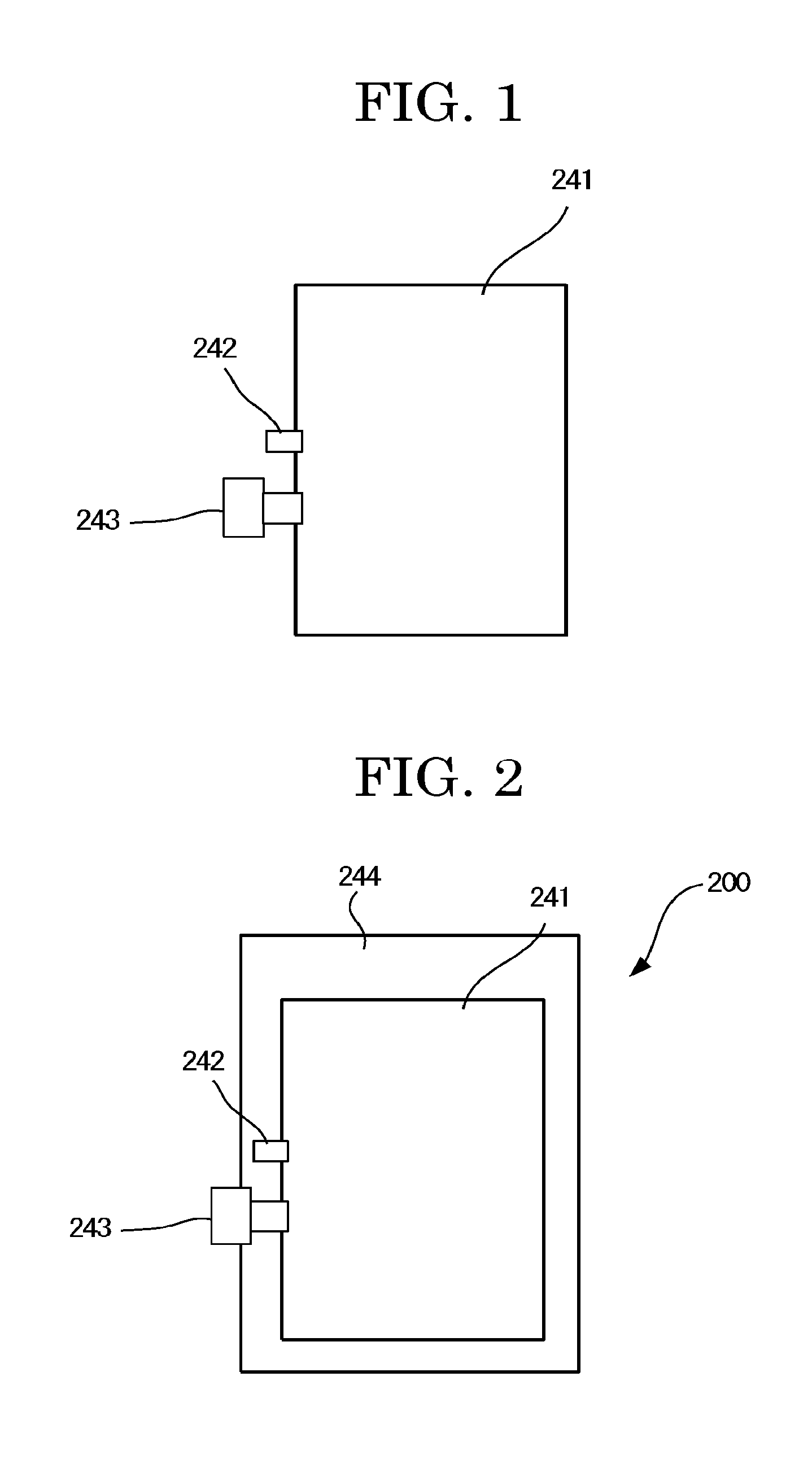

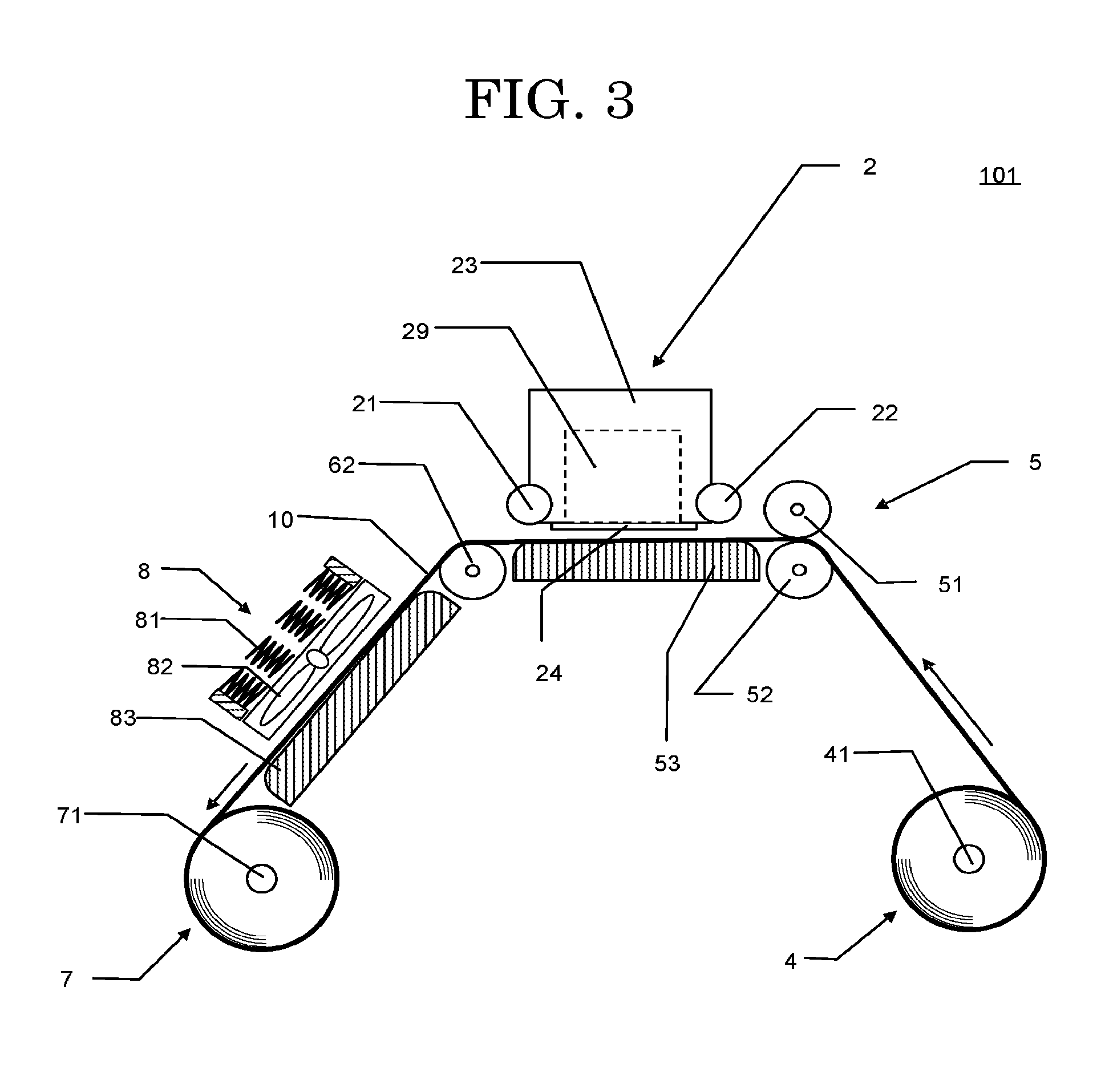

Sheet manufacturing apparatus and method for manufacturing sheet

ActiveUS20140290884A1Low sheet strengthHigh whitenessPaper recyclingWaste paper working-upFiberManufactured apparatus

A present sheet manufacturing apparatus, which manufactures a sheet including defibrated material and whiteness enhancer, is provided with a defibrating unit configured to defibrate a stock material that includes fibers, a whiteness enhancer feeding unit configured to feed the whiteness enhancer to the defibrated material defibrated in the defibrating unit. A feeding amount of the whiteness enhancer is changed based on whiteness information of the stock material or the defibrated material.

Owner:SEIKO EPSON CORP

Hydrophobic polymer carrier based liquid tooth whitening composition

InactiveUS20050069502A1Enhance whitening efficacyHigher available concentrationCosmetic preparationsToilet preparationsWhitening AgentsWater soluble

A tooth whitening system comprising a tooth whitening composition comprising a whitening agent and a hydrophobic polymer carrier. The tooth whitening composition is preferably substantially non-water soluble. The tooth whitening composition is applied to the surface of a tooth to be whitened in a mammal to effect whitening on the tooth surface. Methods of whitening a surface of a tooth are also provided.

Owner:COLGATE PALMOLIVE CO

Method for improving antibacterial property of wool by bio-enzymatic method

InactiveCN101565894AHigh catalytic efficiencyReduce dosageBiochemical fibre treatmentYarnPre treatment

The invention provides a method for improving antibacterial property of wool by a bio-enzymatic method, which belongs to the field of textile biotechnology. The method utilizes the catalysis of transglutaminase (MTG) to graft some natural compounds which contain primary amine groups and have antibacterial property onto wool to improve the antibacterial property of the wool. The method comprises the following process flows: wool pretreatment, treatment with an MTG-containing antibacterial finishing agent, washing and drying. Wool yarn or fabric treated by the method not only has improvement on the antibacterial property but also correspondingly has improvement on some other properties and particularly has great improvement in low-temperature dyeing property. Meanwhile, the method improves the strength of the wool yarn or the fabric, thereby playing a role in restoring strength. The strength-restoring function is an outstanding advantage of the method compared with other antibacterial finishing agents or antibacterial finishing processes. In addition, compared with chemical finishing, the treatment process of the method is free from pollution, healthier and friendlier to environment by adopting a bio-enzyme technique.

Owner:JIANGNAN UNIV

Method for improving wool fire-retardancy with biological enzyme

InactiveCN101509193AConform to modern green environmental protection requirementsMild reaction conditionsBiochemical fibre treatmentAnimal fibresYarnBiotechnology

A method for improving flame retardance of wool by bioenzyme treatment is disclosed, belonging to the field of textile biotechnology. The invention utilizes a catalytic action of transglutaminase (MTG) to graft a type of compounds containing primary amino groups and a large number of phosphorus elements onto the wool so as to improve the flame retardance of the wool, the technological procedures comprise: pretreatment, treatment with a phosphoric finishing agent containing the MTG, water rinsing and drying. Wool yarns and fabrics treated by the inventive technology can not only be improved in the flame retardance, but also be enhanced in some other performances to a certain extent, in particularly the strength of the wool yarns and the fabrics is enhanced to play a role of powerful repair, which is outstandingly superior to other flame-retardant finishing agents or flame-retardant finishing technologies. In addition, in contrast to chemical finishing, the invention is healthier and more environmentally-friendly due to the employment of bioenzyme technique and the pollution-free treatment technology.

Owner:JIANGNAN UNIV

Rapid temporary tooth whitening composition

InactiveUS20050069501A1Reduce whitenessPoor oral hygieneCosmetic preparationsImpression capsParticulatesAdhesive materials

A composition for the rapid, temporary whitening of teeth comprising an adhesive material and whitening particulates.

Owner:COLGATE PALMOLIVE CO

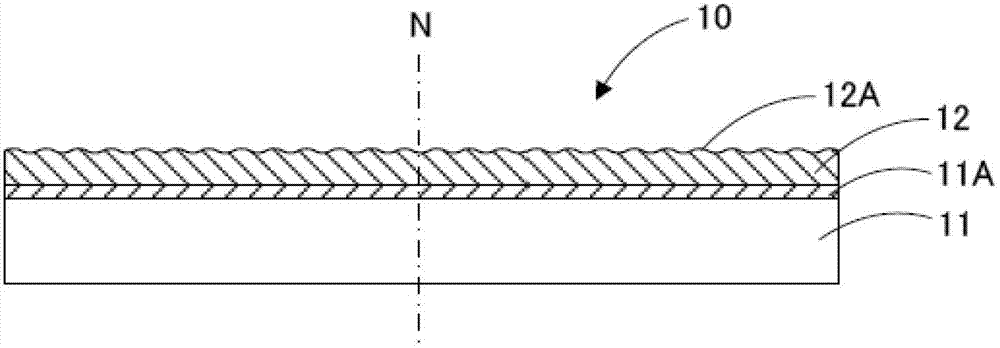

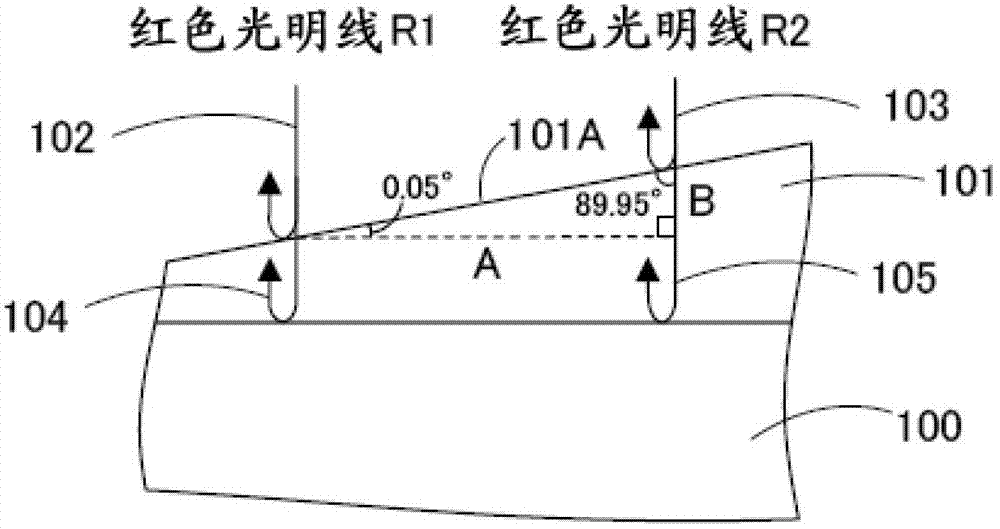

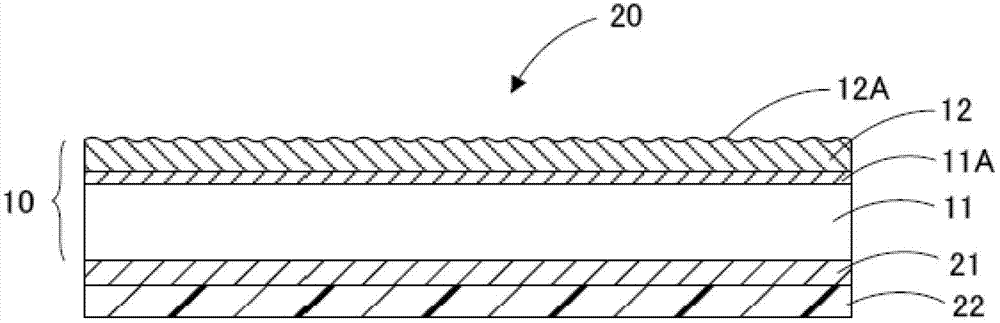

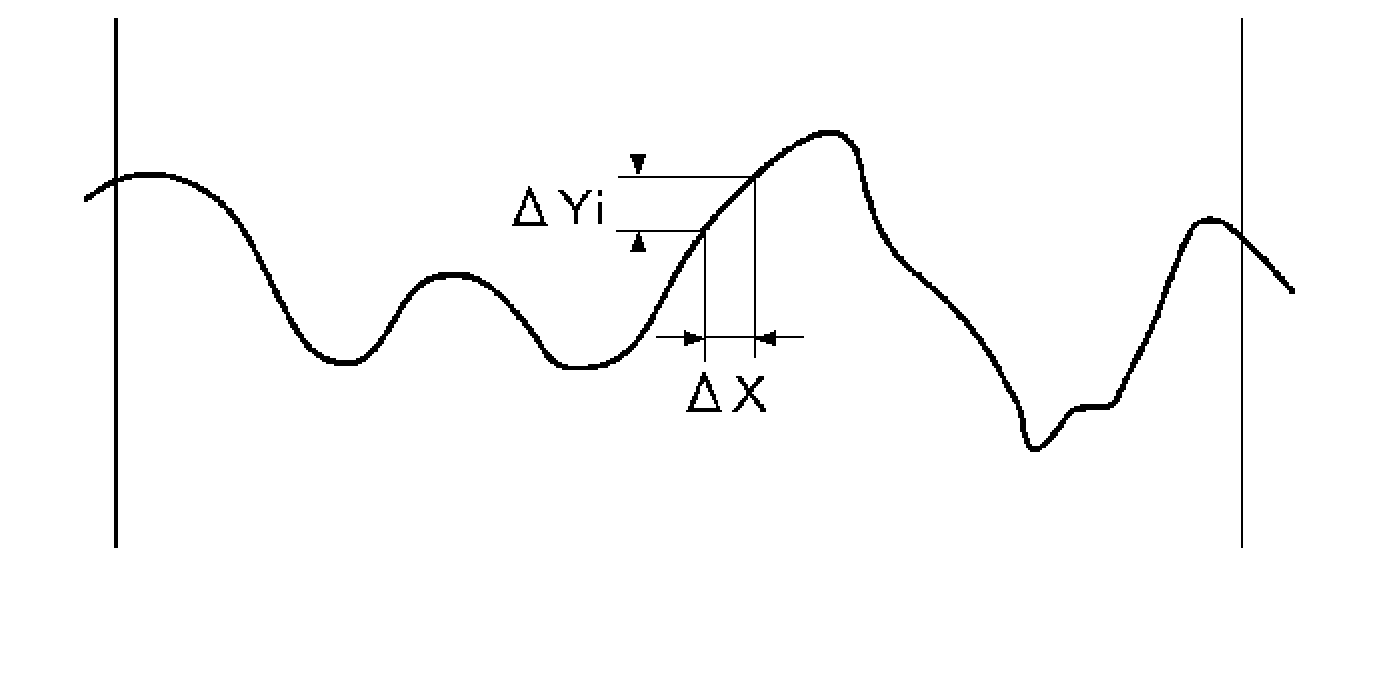

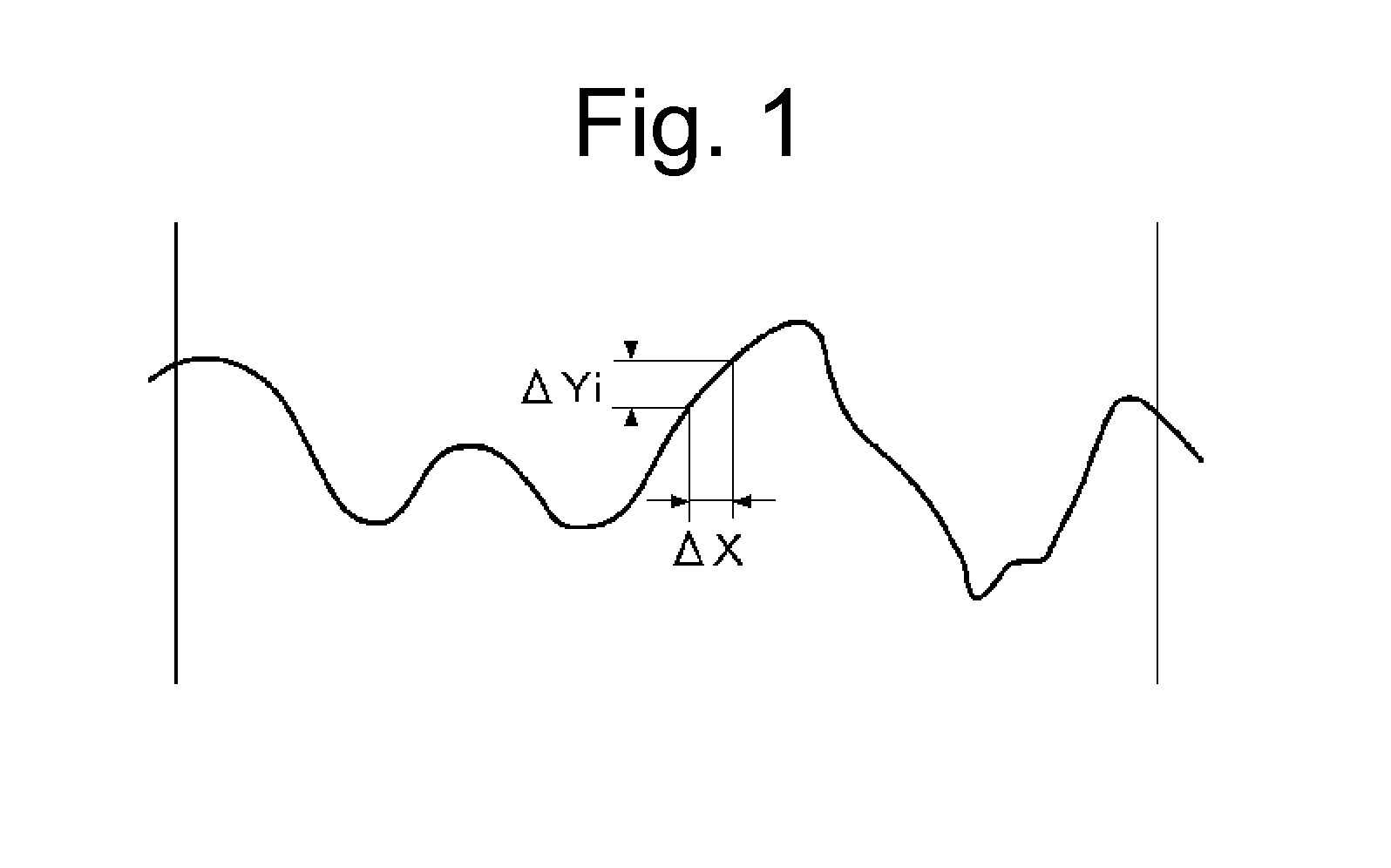

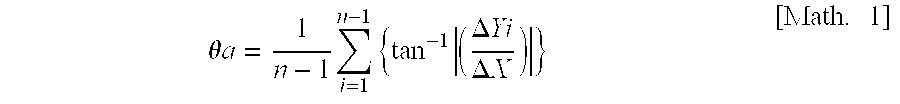

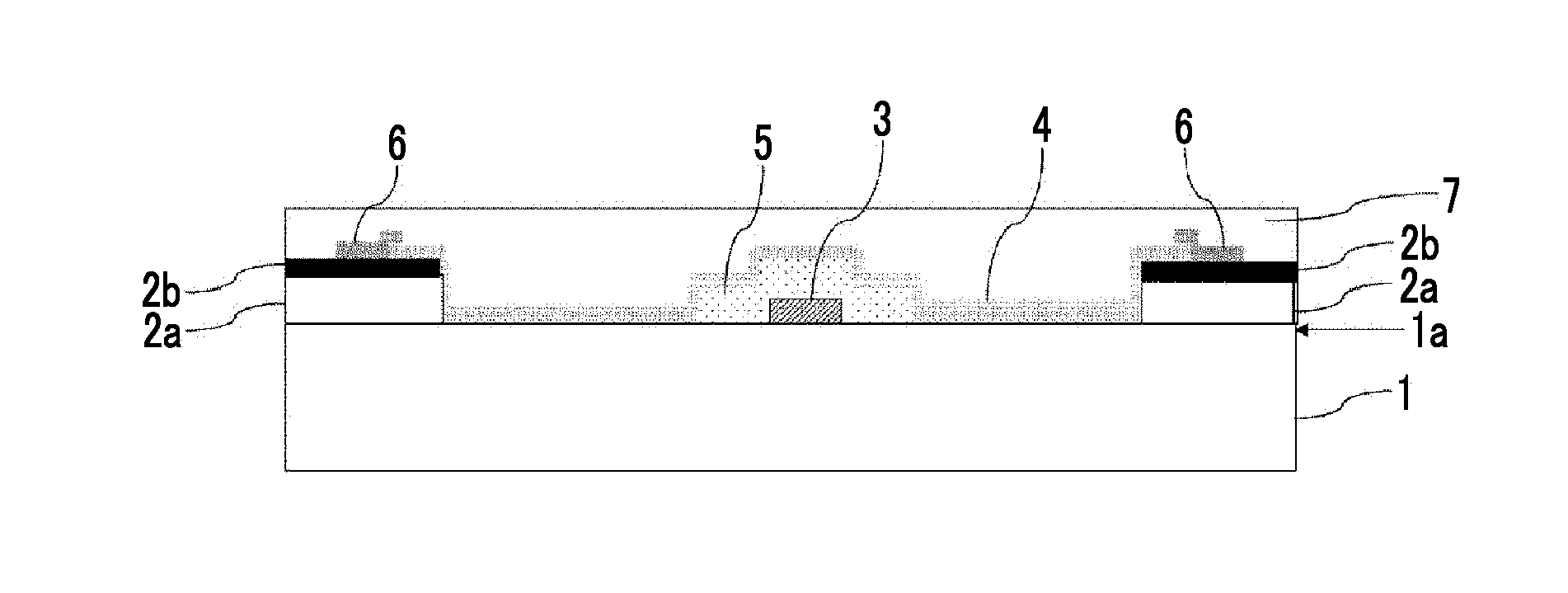

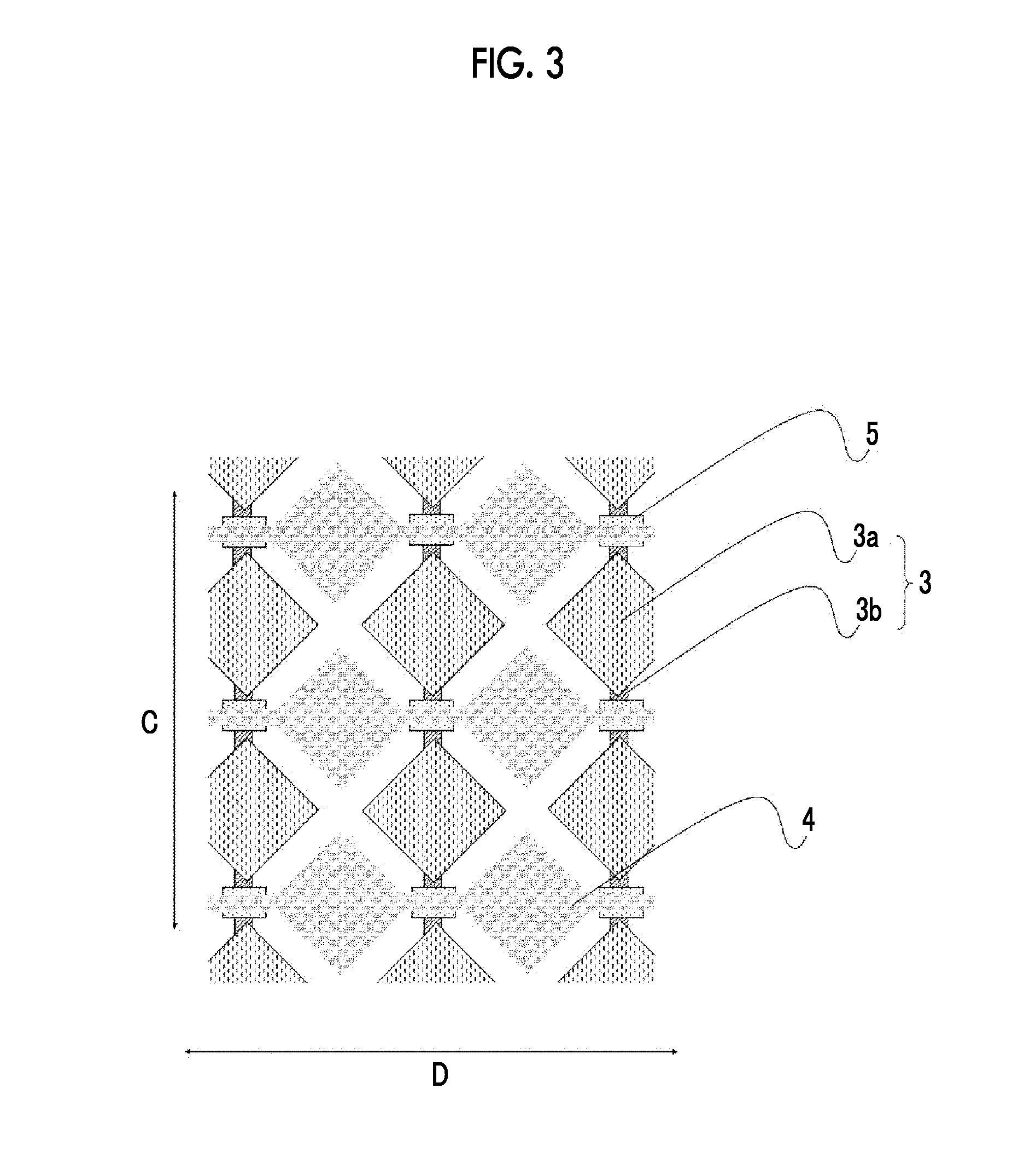

Optical film, polarizing plate, liquid crystal panel, and image display apparatus

ActiveCN103308959AReduce whitenessReduce manufacturing costDiffusing elementsPolarising elementsLiquid-crystal displayFilm plane

An optical film (10), a polarizing plate, a liquid crystal panel, and an image display apparatus, wherein interference fringes can be made to be invisible, and cloudiness can be reduced. In accordance with one aspect of the present invention, there is provided an optical film including a light transmissive substrate (11); and a functional layer (12) disposed on the light transmissive substrate (11), wherein the functional layer (12) has a concavo-convex surface (12A) forming a surface of the optical film (10); assuming that a slope angle of the concavo-convex surface (12A) with respect to a film plane of the optical film in a cross section along a direction normal to the film plane is a surface angle, a rate of a region in which the surface angle is 0.05 DEG or more is 50% or more in the concavo-convex surface; and the root mean square slope R delta q of a roughness curve on the concavo-convex surface is 0.003 or less.

Owner:DAI NIPPON PRINTING CO LTD

White ink, ink set, ink cartridge, inkjet recording apparatus, inkjet recording method, and recording method

ActiveUS20160152845A1Suppressing reduction in degree of whitenessReduce whitenessInksPrintingAlkaneOrganic solvent

Provided is a white ink, including water, a water-soluble organic solvent, and a colorant including hollow resin particles, wherein the water-soluble organic solvent includes at least one of a monohydric alcohol having a boiling point of 240° C. or lower and a diol having a boiling point of 240° C. or lower, having at least one hydroxyl group bonded to an alkane chain at a site other than terminals of the alkane chain, and having 4 to 6 carbon atoms, and a content of the at least one of the monohydric alcohol and the diol is equal to or greater than 75.0% by mass of a total amount of the water-soluble organic solvent.

Owner:RICOH KK

Method for preparing soluble kelp cellulose

ActiveCN102787519AEnzymolysis temperature is lowMild conditions for enzymatic hydrolysisPaper material treatmentFood preparationDietary fiberCellulase

The invention discloses a method for preparing soluble kelp cellulose. The method includes the steps: firstly, preparing kelp dietary fibers from kelp residues by means of flocculation, decalcifying, bleaching, washing and the like; secondly, performing steam explosion to obtain insoluble kelp cellulose, then adding low-temperature cellulase into the insoluble kelp cellulose, and performing enzymolysis in water bath at the temperature of 25 DEG C-35 DEG C to obtain the soluble kelp cellulose with the content of 90.14+ / -1.09wt% and the yield of 50-60%. When the soluble kelp cellulose is prepared, the low-temperature cellulase is used, enzymolysis is performed at the normal temperature, enzymolysis conditions are moderate, only macromolecules are sensitive to the cellulose, and macromolecules in kelp are easily decomposed while micromolecules are relatively stable and not easily further decomposed, so that the obtained soluble kelp cellulose is uniform in molecular weight and high in yield, cellulose content, water-holding capacity and expansibility. Moreover, the enzymolysis temperature is low, so that production energy consumption and operability are reduced.

Owner:QINGDAO HENGSHENG BIOLOGICAL PHARMA TECH DEV

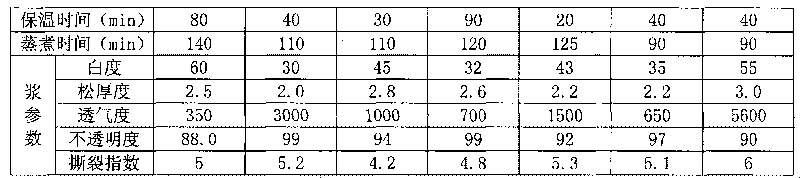

High-air-permeability mixed pulp and household paper made thereof

ActiveCN101760987AEasy to useReduce consumptionNatural cellulose pulp/paperPulping with inorganic basesFiberChemistry

The invention relates to high-air-permeability mixed pulp, which contains high-air-permeability straw pulp. The mixed pulp contains 10-100 percent of high-air-permeability straw pulp and 0-90 percent of other pulp by weight percent. Preferably, the weight percent of the high-air-permeability straw pulp is 30-97 percent and the weight percent of other pulp is 3-70 percent. More preferably, the weight percent of the high-air-permeability straw pulp is 51-95 percent and the weight percent of other pulp is 5-49 percent. The most preferably, the weight percent of the high-air-permeability straw pulp is 71-93 percent and the weight percent of other pulp is 7-29 percent. The other pulp is one or more of wood pulp, bamboo pulp, cotton pulp and secondary fiber. Preferably, the wood pulp and the bamboo pulp are selected. The mixed pulp has the advantages that the drainage capacity is good, the high-speed paper machine can be used during papermaking and the production efficiency is further improved.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Oxygenase-bath alkali-free desizing process for polyester/cotton high-count and high-density fabric

InactiveCN102011298AQuality improvementFeel goodDry-cleaning apparatus for textilesBleaching apparatusPolyesterAlkali free

The invention relates to an oxygenase-bath alkali-free desizing process for a polyester / cotton high-count and high-density fabric. The process sequentially comprises the following steps of: sewing and singeing the fabric; washing the fabric with three-grid hot water; washing the fabric with two-grid coldwater; padding oxidation bleaching working solution; steaming at the temperature of 102 DEG C for 50 minutes; washing the fabric with four-grid hot water; drying; and shaping, wherein in the step of padding oxidation bleaching working solution, the formula of the oxidation bleaching working solution comprises 10g / L of high-efficient scouring agent HS-120B, 65g / L of 288 dispersing agent, 5g / L of scouring enzyme 188, 5g / L of wax regent WR, 10g / L of hydrogen peroxide stabilizing agent P and 14.0 to 15.0g / L of hydrogen peroxide (wherein the concentration is 33 percent). Compared with the prior art, the desized fabric has greatly improved quality, namely the handfeel is plump; the fabric surface loss ratio is low; the fabric surface whiteness is good; and the fabric has no cotton, multiple nodes and no alkaline spots.

Owner:HUAFANG

Preparation method of zirconium silicate wrapped ceramic pigment

The invention discloses a preparation method of zirconium silicate wrapped ceramic pigment. In the method, after preparation of a raw material solution and preparation of a precursor suspension, the precursor suspension is dried so as to obtain the precursor powder, and consequentially, the wrapped ceramic pigment is obtained through roasting. In the method, by optimization of formula and control on pigment granularity, the whiteness of the ZrSiO4 wrapping layer is reduced effectively, and the color generation effect of the ceramic pigment is improved; by the obtained high-density wrapping layer, the effective wrapping efficiency and stability of the ceramic pigment are improved, and thus, the color source is protected effectively.

Owner:广西恒特新材料科技有限责任公司

Preparation method of white, low-fat and odorless silkworm pupa protein

ActiveCN103288946AReduce quality degradation and other problemsSimplify subsequent separation processesPeptide preparation methodsAnimals/human peptidesSolventEnergy consumption

The invention provides a preparation method of white, low-fat and odorless silkworm pupa protein. The preparation method comprises the following steps of: with mechanically taken-off silkworm pupa as the raw material for production, preprocessing the silkworm pupa; filtering silkworm pupa skin; preparing rough silkworm pupa protein; adding ethanol to preprocess the silkworm pupa protein in a decolorizing and deoiling manner; adding a non-polar solvent and natural zeolite to process the silkworm pupa protein in the decolorizing and deoiling manner again; and then drying and crushing to obtain the finished silkworm pupa protein. According to the preparation method, the conventional method of extracting the raw material of silkworm pupa protein, extracting the silkworm pupa protein firstly and extracting the silkworm pupa oil secondly is changed, and the steps of heating and drying the raw silkworm pupa for extracting the silkworm pupa oil are avoided, so that the energy consumption is reduced, and the cost is reduced; a polar solvent and a non-polar solvent are adopted and used for extracting the silkworm pupa oil, respectively; the odor and the silkworm pupa oil in the silkworm pupa protein can be effectively removed by virtue of the physical absorption and deodorization effects of the natural zeolite, and the quality of the silkworm pupa oil also can be improved by distributive extracting.

Owner:GUANGXI UNIV

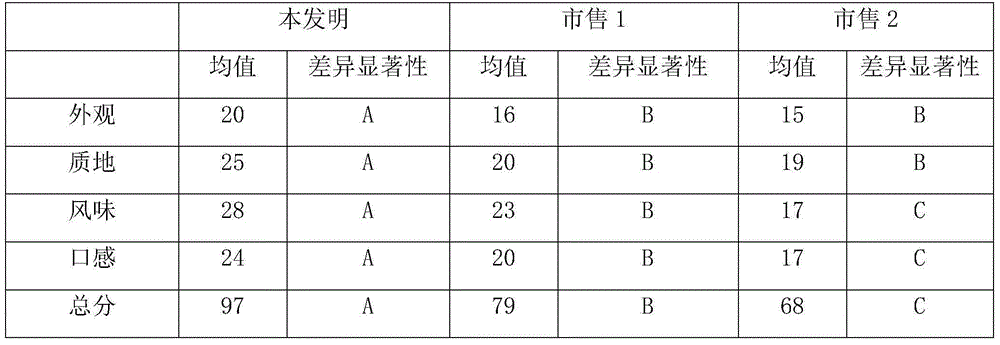

Compound type yoghurt stabilizer and preparation method thereof

PendingCN105211674AImprove survival rateHigh content of live bacteriaMilk preparationFood preparationTremellaGlutaminase

The invention discloses a compound type yoghurt stabilizer and a preparation method thereof, which belong to the technical field of yoghurt stabilizer preparation. The compound type yoghurt stabilizer is prepared by taking modified dietary fibers with high water holding capacity, expansibility, thickening property and adsorptivity as well as abundant grid structure as main raw materials, scientifically compounding a plant extract and protein hydrolysate which contain high-content natural antifreeze peptides, Chinse herbal medicinal extracts with cold and heat stress resistance, sodium carboxymethylcellulose, pectin, tremella polysaccharide, transglutaminase and other food raw materials and refining; the prepared compound type yoghurt stabilizer has the advantages that the quality problems about low viscosity, rough texture, poor mouthfeel, whey separating and the like in the late-stage storage process of yoghurt are solved; in addition, the viable content of lactic acid bacteria in the yoghurt is obviously improved, and the shelf life is prolonged to over twenty-one days; besides, the yoghurt is good in solidifying state, and is suitable for long-distance transportation.

Owner:NINGXIA HAIDA BIOTECH DEV

Particulate metal oxide

InactiveUS20030223940A1Reduce whitenessGood dispersibilityCosmetic preparationsMaterial nanotechnologyUv protectionUltraviolet

A particulate metal oxide having a mean length of the primary particles in the range from 50 to 90 nm, the mean width of the primary particles in the range from 5 to 20 nm, and the median volume particle diameter of the secondary particles is less than 45 nm. The metal oxide can be used in a sunscreen product that exhibits both effective UV protection and improved transparency.

Owner:CRODA INT PLC

Methods For Smoothing Wrinkles and Skin Texture Imperfections

InactiveUS20130195783A1Excellent initial and lasting contractionReduce whitenessBiocideCosmetic preparationsWrinkle skinSodium Bentonite

Owner:PROCTER & GAMBLE CO

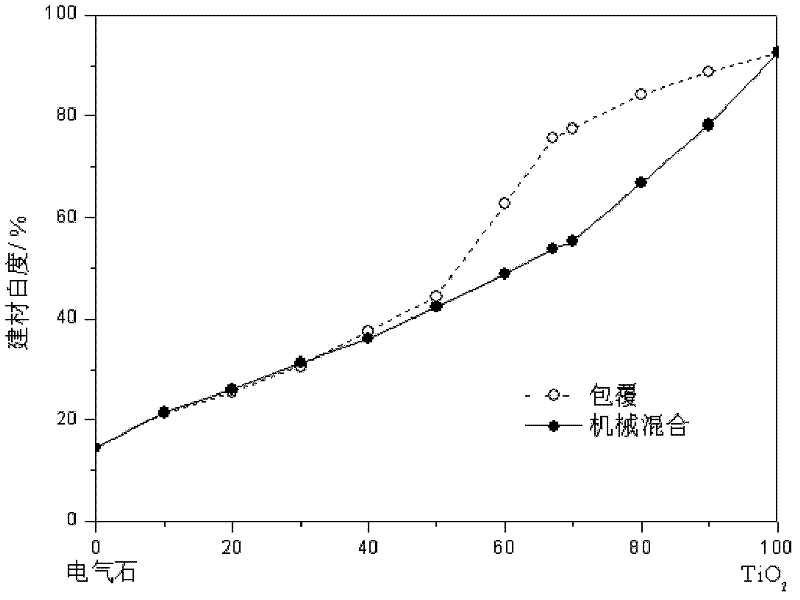

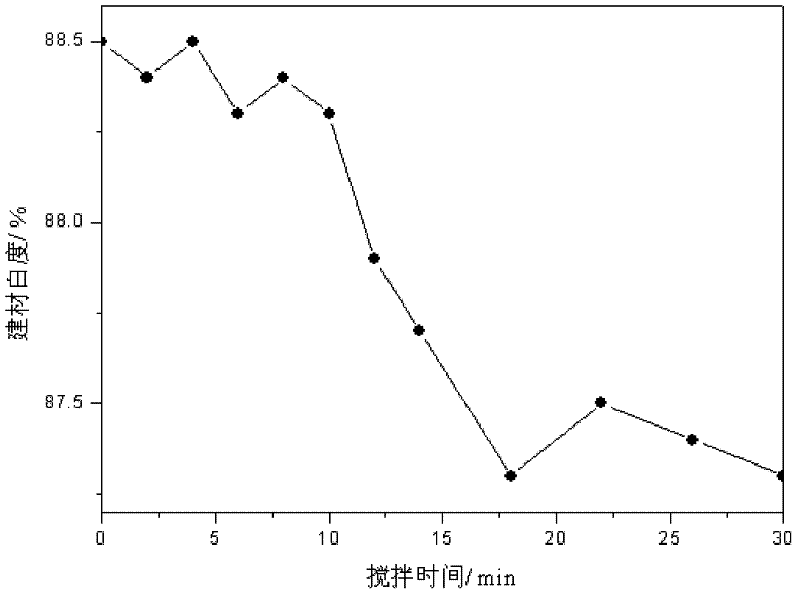

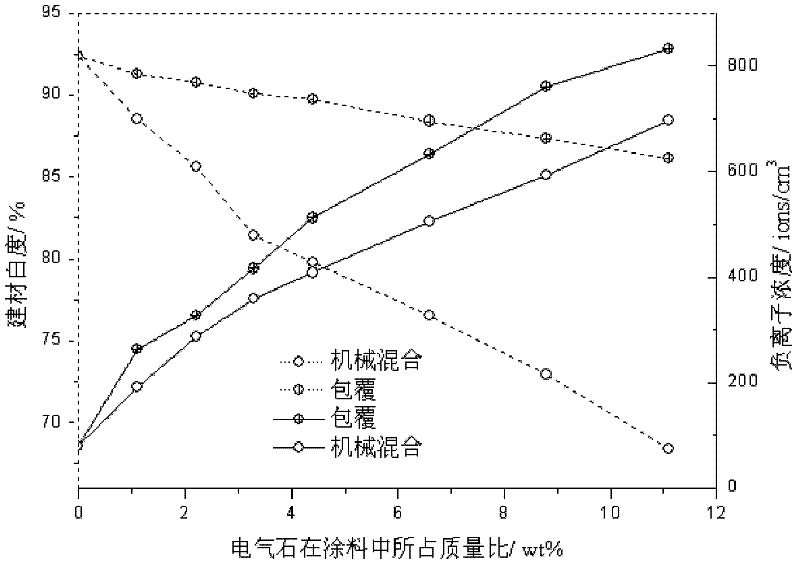

High whiteness tourmaline negative ion powder and coating process

InactiveCN102391690AStrong ability to release negative ionsThoroughly adsorb and crack harmful gases such as formaldehydeCoatingsPigment treatment with macromolecular organic compoundsWater basedPhysical chemistry

The invention relates to tourmaline negative ion powder with high performance and a coating process. The tourmaline negative ion powder comprises tourmaline, a coupling agent and a coating agent, wherein the occupied weight ratio of the tourmaline is 25-35%, the occupied weight ratio of the coupling agent is 1-3%, and the occupied weight ratio of the coating agent is 62-74%. The tourmaline negative ion powder is obtained by coating, whitening and modifying the tourmaline and can be used as stuffing powder for preparing a functional coating; and the tourmaline negative ion powder is directly doped in a water-based coating or is combined with a film forming material, pigment, an addition agent, a solvent agent and the like to prepare the functional coating. After forming the coating, the tourmaline negative ion powder can release lots of negative ions for long time, adsorbs and degrades indoor harmful gases, settle dust in the air and effectively improves indoor housing environments.

Owner:JIANGXI UNIV OF SCI & TECH +1

Particulate metal oxide

InactiveUS7220305B2Reduce whitenessGood dispersibilityCosmetic preparationsMaterial nanotechnologyUv protectionPhysical chemistry

A particulate metal oxide having the mean length of the primary particles in the range from 50 to 90 nm, the mean width of the primary particles in the range from 5 to 20 nm, and the median volume particle diameter of the secondary particles is less than 45 nm. The metal oxide can be used in a sunscreen product that exhibits both effective UV protection and improved transparency.

Owner:CRODA INT PLC

Neutral rosin sizing agent and its prepn

The rosin sizing agent consists of main components including modified rosin, tall oil, stearic acid, pine gum and paraffin; and supplementary material including polyethenoxy ether sulfo succinate, abietate, polymer dispersant and disinfectant. It is prepared through low pressure process with relatively high controllability and production quality stability. The sizing agent has high compatibility with calcium carbonate stuffing, high sizing effect, low production cost and less mildew produced in storage. The sizing agent is suitable for use in producing high-grade paper and paper card.

Owner:上海埃格环保科技有限公司

Antiglare hard coat film

ActiveUS20140254020A1High transparencySuppression of of imageDiffusing elementsCoatingsMaterials scienceOptical comb

An antiglare hard coat film formed by providing an antiglare hard coat layer containing fine particles and a resin on a transparent film. When an average value of height in an evaluation region on a surface of the antiglare hard coat film is set at zero (0), a maximum cross sectional height represented by a difference between a height maximum value in the evaluation region and a height minimum value in the evaluation region is from 1.0 to 3.0 μm, and an average inclination angle of unevenness on the surface of the antiglare hard coat film is 1 degree or less. The total value of the transmissive clarity measured through four optical combs using a transmissive clarity measuring device according to JIS K 7105-1981 is 280% or more, and the value of the transmissive clarity measured through each optical comb is 70% or more, respectively.

Owner:NIPPON PAPER IND CO LTD

High-yield natural-color wood pulp production method

The invention discloses a high-yield natural-color wood pulp production method which comprises the following steps; boiling a wood material as a raw material by using a sulfate cooking process so as to obtain unbleached pulp, wherein the alkali amount is 15-18%, the sulfidity is 26-30%, the boiling temperature is 140-155 DEG C, and the kappa number of the unbleached pulp is 40-80; and performing oxygen delignification treatment on the unbleached pulp to remove 40-60% of lignin so as to obtain oxygen delignification pulp, wherein the alkali amount is 1-4%, the initial oxygen pressure is 0.2-0.8MPa, the temperature is less than 100 DEG C, and the kappa number of the oxygen delignification pulp is 20-35. By adopting the method, under mild reaction conditions, the use quantity of boiling chemicals is reduced, after the raw material is prepared into the pulp, the whiteness is relatively low, the Kappa number is relatively high, and the loss of carbohydrate is small, after the oxygen delignification treatment is performed, 40-60% of lignin is removed, then natural-color wood pulp which is superior to that of a conventional pulp preparing production process is obtained, the pulp yield is increased, the possibility of water closed cycle in a workshop is increased, and the production cost is greatly lowered.

Owner:CHINA LIGHT IND INT ENG CO LTD

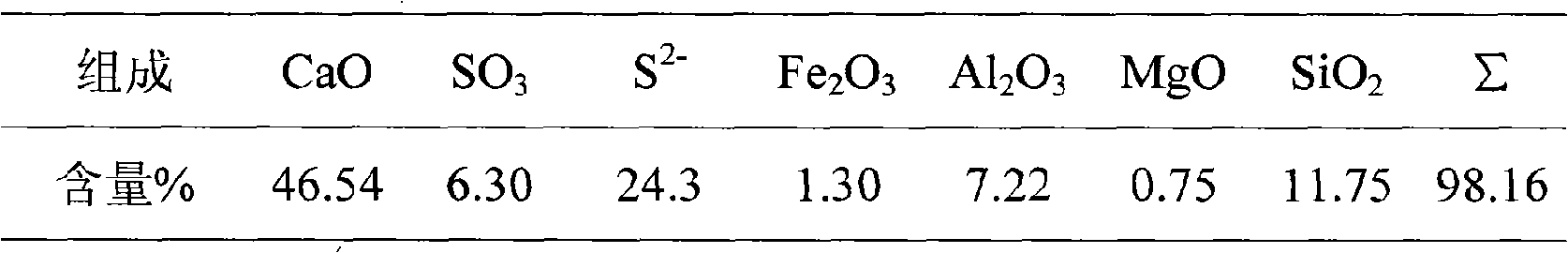

Method for producing light calcium carbonate and coproducing hydrogen sulfide by using crude calcium sulfide

InactiveCN101538060AReduce whitenessHigh solid impurity contentCalcium/strontium/barium carbonatesHydrogen sulfidesCALCIUM HYDROXIDE SOLUTIONCalcium sulfide

The invention relates to a method for producing light calcium carbonate and coproducing hydrogen sulfide by using crude calcium sulfide, belonging to the technical field of chemical production. The method comprises the steps of: pulverizing the crude calcium sulfide, and dissolving out the pulverized crude calcium sulfide by using saturated hydrogen sulfide solution at room temperature to obtain sulfur calcium hydroxide solution; removing other impurities in the crude calcium sulfide by filtering and washing, and introducing CO2 into clear solution to generate precipitation of light calcium carbonate and continuously generate hydrogen sulfide gas; preparing the saturated hydrogen sulfide solution by using part of the generated hydrogen sulfide gas, and delivering the rest of the hydrogen sulfide gas to a gas holder for storage; filtering and washing feed liquid generated from carbonatation reaction to obtain light calcium carbonate solid; introducing the hydrogen sulfide gas into the filtrate to prepare the saturated hydrogen sulfide solution, and returning to the previous step to dissolving out the crude calcium sulfide for recycling; and drying, crashing and packaging the light calcium carbonate to obtain a finished product of light calcium carbonate. The light calcium carbonate product has less impurity and high whiteness compared with that produced by the traditional method, and the byproduct hydrogen sulfide can be used as raw material of other chemical products.

Owner:GUIZHOU XIYANG FERTILIZER IND

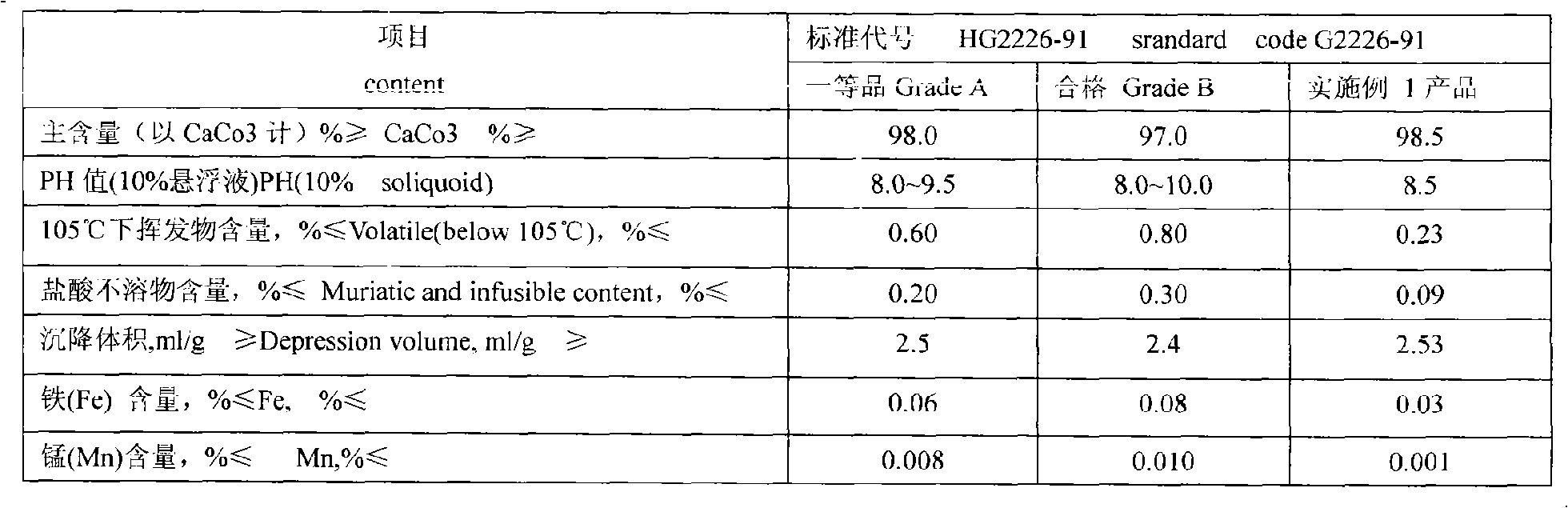

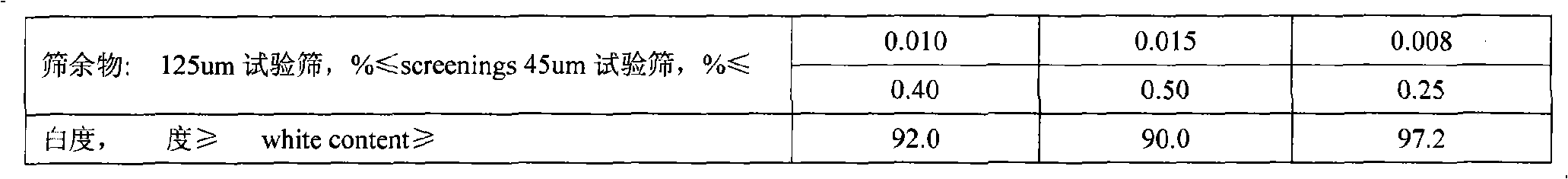

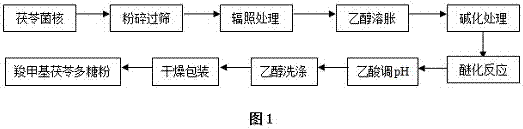

Carboxymethyl pachymaran with suitable substitution degree and preparation method thereof

InactiveCN106995499AColor deepeningReduce whitenessDough treatmentBakery productsSolubilityReaction temperature

The invention relates to carboxymethyl pachymaran with suitable substitution degree and a preparation method thereof, and belongs to the technical field of polymer polysaccharide preparation. The mthod comprises the steps that during the carboxymethylation modification process of pachymaran, an irradiation process is used, the proportion of reaction media is changed, and reaction temperature is regulated, thereby enhancing the efficiency of the carboxymethylation of pachymaran and the utilization rate of a raw material and an auxiliary material significantly, reducing the reaction time, and reducing the cost. The carboxymethyl pachymaran with substitution degree of about 0.7 can be obtained by the preparation method of the invention, and the product has the properties of higher antioxidant biological activity, white color and good solubility. Proved by the animal safety and toxicology evaluation test, the carboxymethyl pachymaran is classified into the safe and non-toxic level so as to be able to apply to the fields of foods, health products, feed additives and cosmetics and the like.

Owner:武汉润歌生物科技有限公司

Method and device for producing nano calcium carbonate by microwave drying

ActiveCN104229850AFast heatingAchieve heating effectCalcium/strontium/barium carbonatesMaterial nanotechnologyHeating timeMicrowave

The invention discloses a method for producing nano calcium carbonate by microwave drying. The method is carried out according to the following steps: (1) preparing Ca(OH)2 raw refined slurry; (2) preparing boiled calcium carbonate slurry; (3) preparing an activated calcium carbonate filter cake; (4) pelletizing; (5) carrying out microwave drying; and (6) crushing and sieving to prepare a nano calcium carbonate product. A device for producing nano calcium carbonate by microwave drying comprises a pelletizer, a feeding hopper, a conveyor belt, a transmission mechanism, a tunnel type microwave drying box, a microwave generator, a discharge hopper and a moisture removal mechanism. The method and the device are adopted to produce nano calcium carbonate, so that time of drying operation in a production process of the nano calcium carbonate can be greatly shortened, the energy consumption is lowered, the agglomeration of the nano calcium carbonate is weakened and the dispersion is improved, and thus, the quality of the nano calcium carbonate is improved; the prepared nano calcium carbonate has the advantages of small grain size, low agglomeration strength, a great specific surface area, small hardness and good dispersion; and moreover, the heating time is short, so that the whiteness of the nano calcium carbonate can be improved.

Owner:FUJIAN HONGFENG NANO TECH

Transfer film, manufacturing method of capacitive input device, capacitive input device, and image display device including the same

ActiveUS20150092123A1Good adhesivenessIncrease brightnessSynthetic resin layered productsElectronic switchingCapacitanceDisplay device

Owner:FUJIFILM CORP

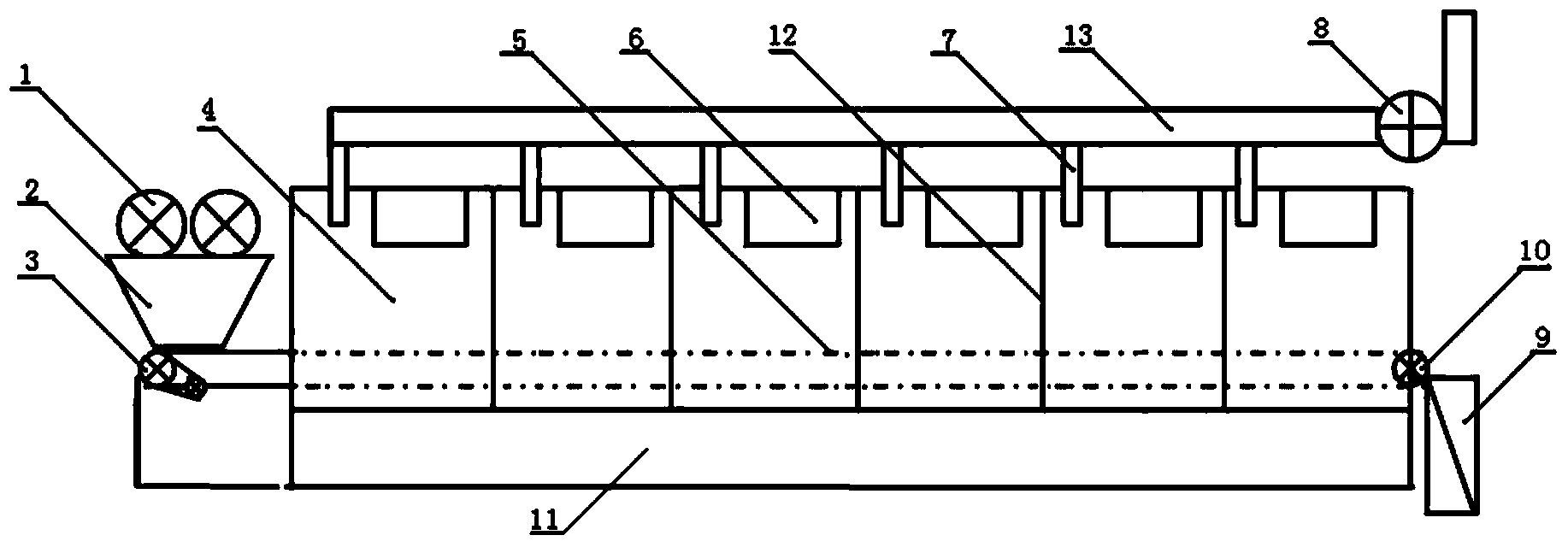

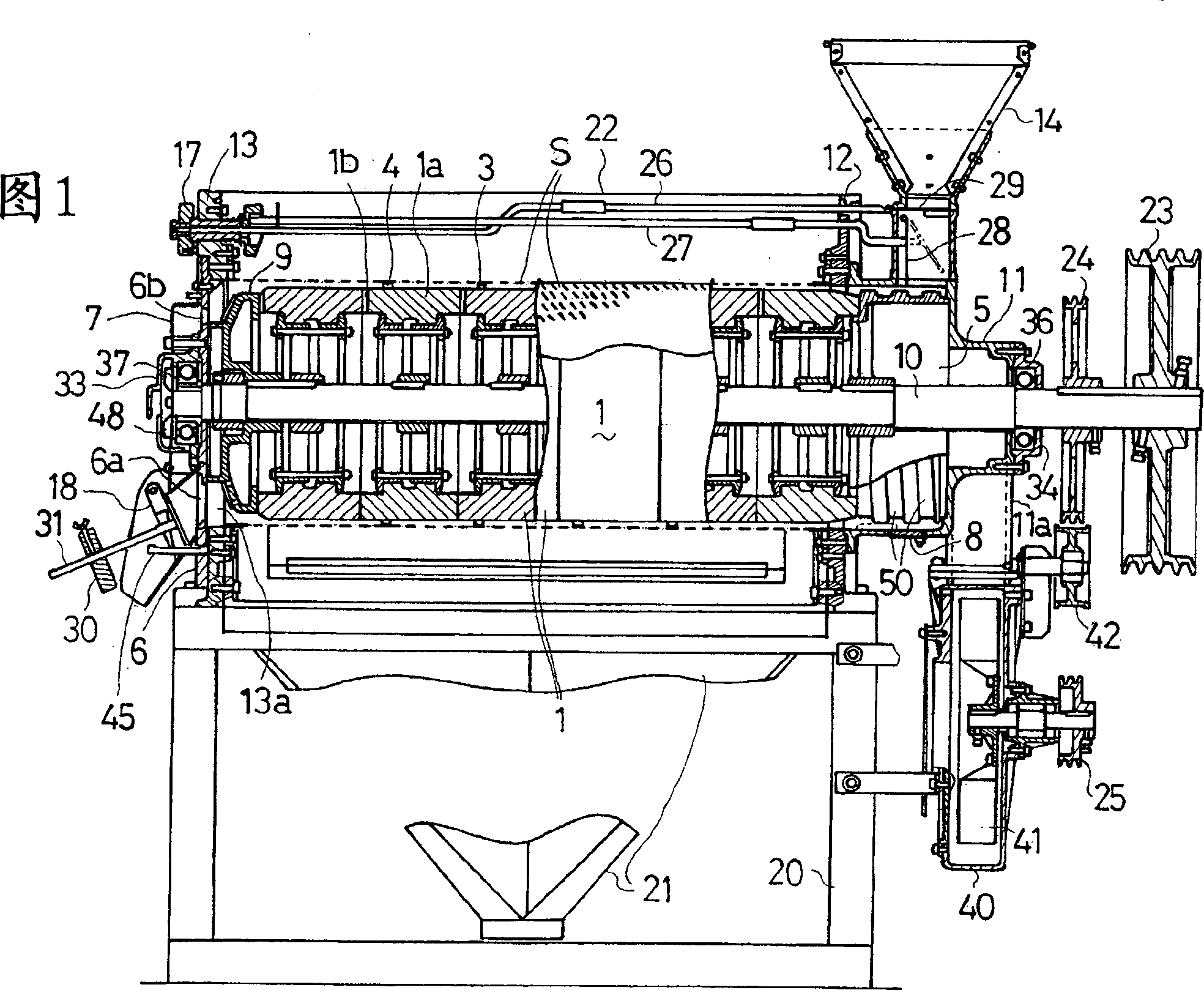

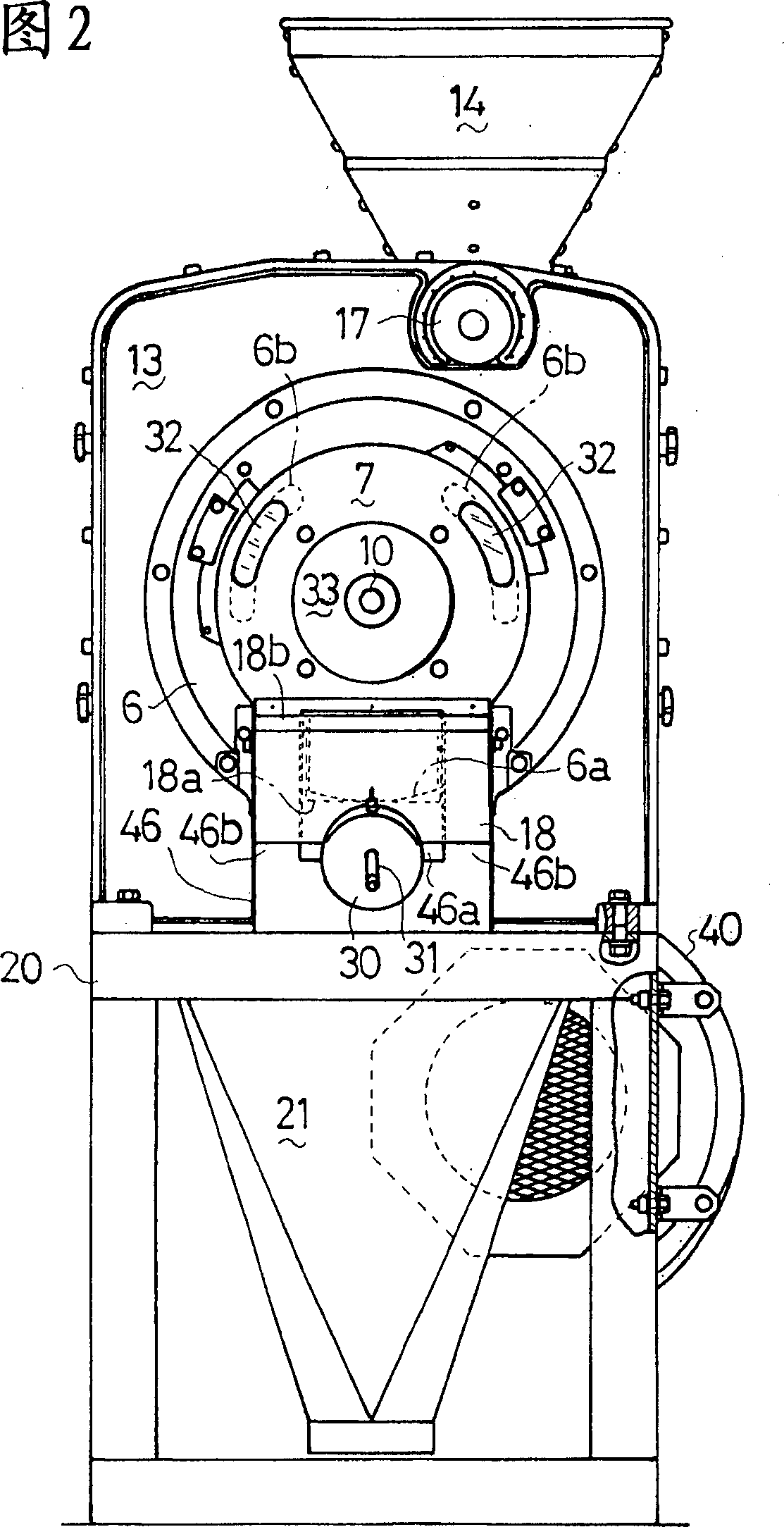

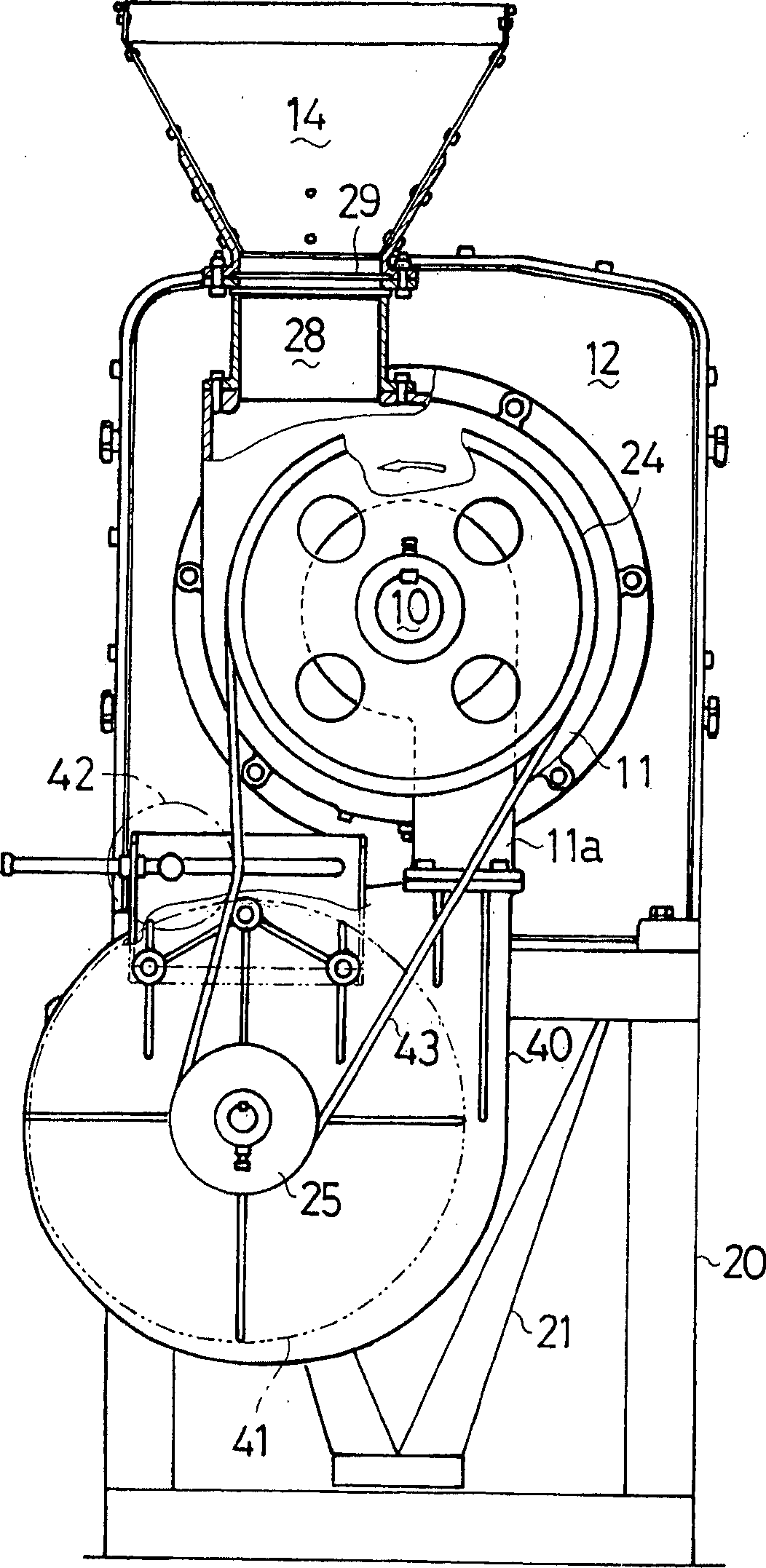

Horizontal grinding type rice milling machine

Owner:SEIREI IND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com