Optical film, polarizing plate, liquid crystal panel, and image display apparatus

一种光学膜、偏振片的技术,应用在光学、光学元件、偏振元件等方向,能够解决有白浊感、制造成本高、得不到表面光泽感等问题,达到降低制造成本、降低白浊感的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

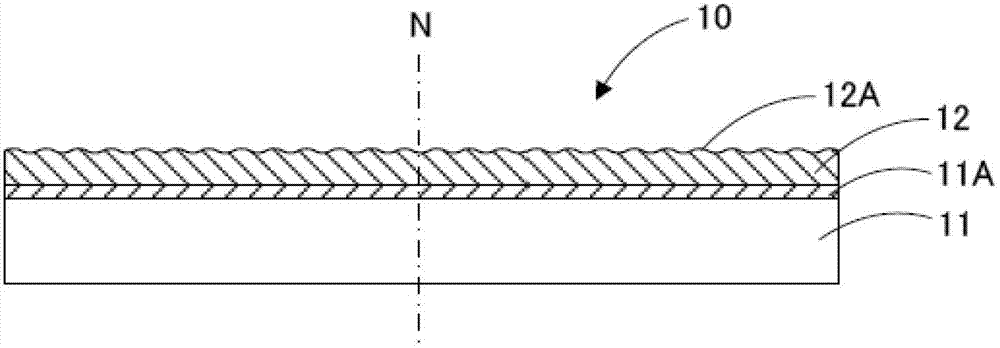

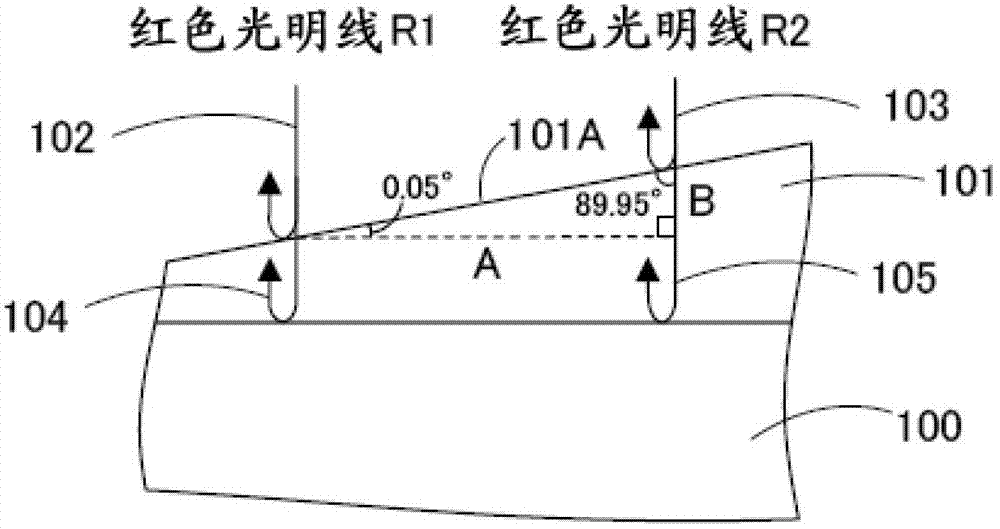

[0026] Hereinafter, the optical film according to the first embodiment of the present invention will be described with reference to the drawings. figure 1 is a schematic configuration diagram of an optical film according to this embodiment, figure 2 This is a diagram for explaining at what pitch red light rays are generated when the surface angle of the concave-convex surface is 0.05°.

[0027] "Optical Film"

[0028] Such as figure 1 As shown, the optical film 10 includes at least a translucent substrate 11 and a functional layer 12 provided on the translucent substrate 11 . Preferably near the interface of the functional layer 12 in the light-transmitting substrate 11, such as figure 1 As shown, a mixed region 11A in which components of a binder resin to be described later are mixed in the light-transmitting base material 11 and the functional layer 12 is formed. In addition, in this specification, terms such as "sheet", "film", and "plate" do not differ from each other...

no. 2 Embodiment approach

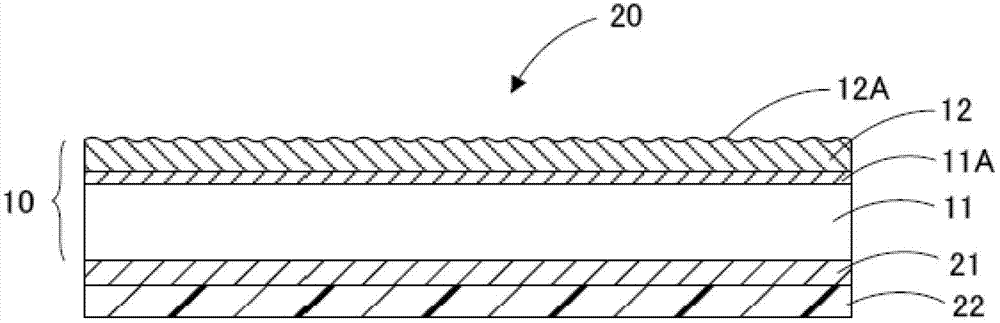

[0164] Hereinafter, the optical film according to the second embodiment of the present invention will be described with reference to the drawings. Figure 6 It is a schematic configuration diagram of the optical film according to this embodiment.

[0165] "Optical Film"

[0166] Such as Figure 6 As shown, the optical film 50 includes at least a translucent substrate 51 and a functional layer 52 provided on the translucent substrate 51 . Since the translucent base material 51 is the same substance as the translucent base material 11 described in the first embodiment, description thereof will be omitted in this embodiment. In addition, in the vicinity of the interface between the light-transmitting substrate 51 and the functional layer 52 (near the interface with the hard coat layer 53 described later), it is preferable that Figure 5 As shown, a mixed region 51A in which components of the binder resin of the translucent base material 52 and the hard coat layer 53 are mixed ...

Embodiment 1

[0272] A 60-μm-thick triacetyl cellulose resin film (manufactured by Fuji Film Co., Ltd., TD60UL) was prepared as a light-transmitting substrate, and the composition 1 for a hard coat layer was coated on one side of the triacetyl cellulose resin film to form a coating film. Next, dry air at 70° C. was circulated at a flow rate of 0.2 m / s for 15 seconds on the formed coating film, and then dried at a flow rate of 10 m / s at 70° C. for 30 seconds to make the coating film The solvent in the solvent is evaporated, and the cumulative light intensity becomes 100mJ / cm in a nitrogen atmosphere (oxygen concentration below 200ppm) 2 The coating film was cured by irradiating ultraviolet rays in the same manner as above to form a hard coat layer with a thickness of 4 μm (at the time of curing), and the optical film according to Example 1 was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com