Horizontal grinding type rice milling machine

A rice milling machine, horizontal technology, applied in grain processing, application, grain pod removal, etc., can solve the problems of parts durability, uneven rice milling, and vibration of the rotating shaft, so as to improve the whiteness, improve the The effect of whitening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

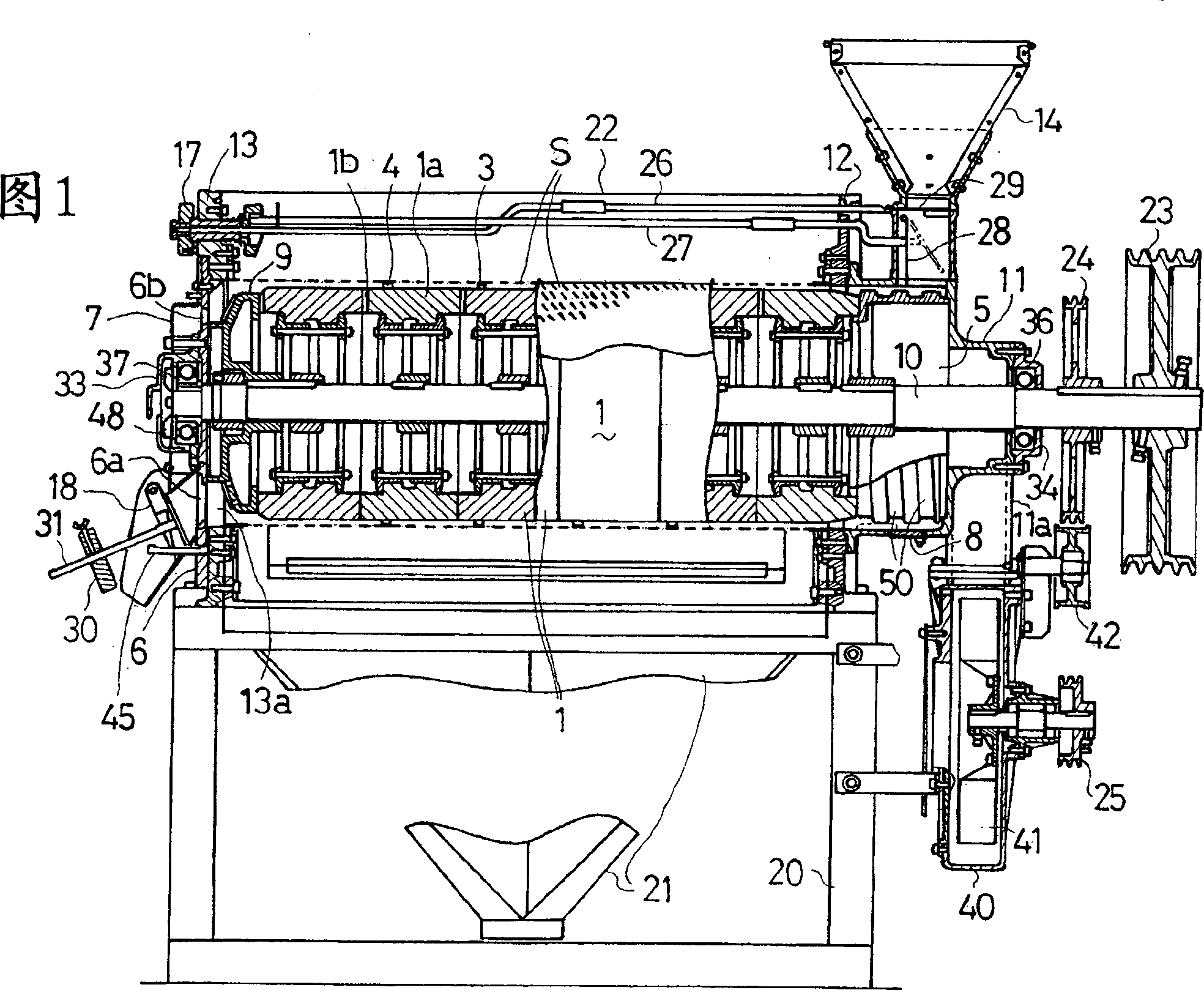

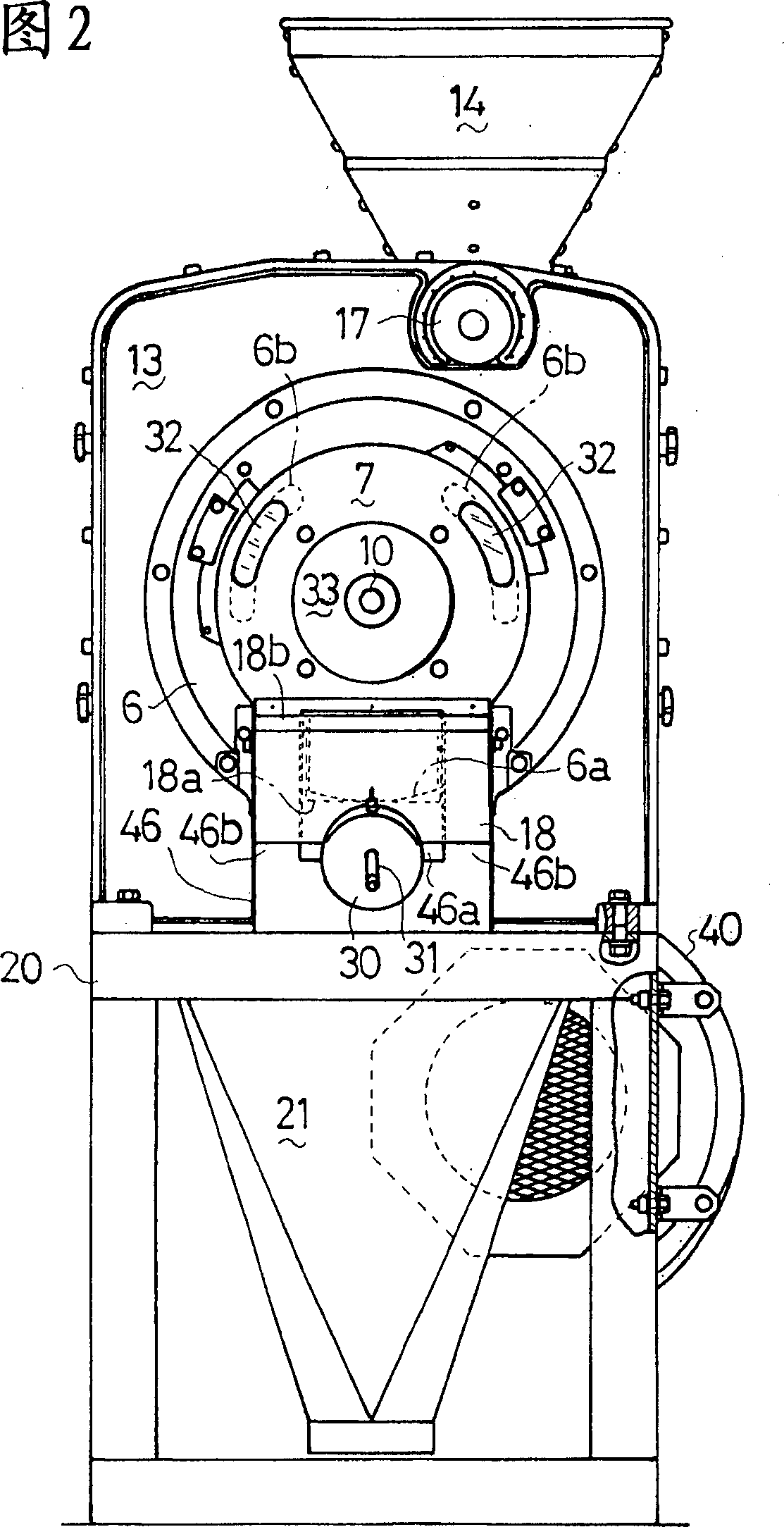

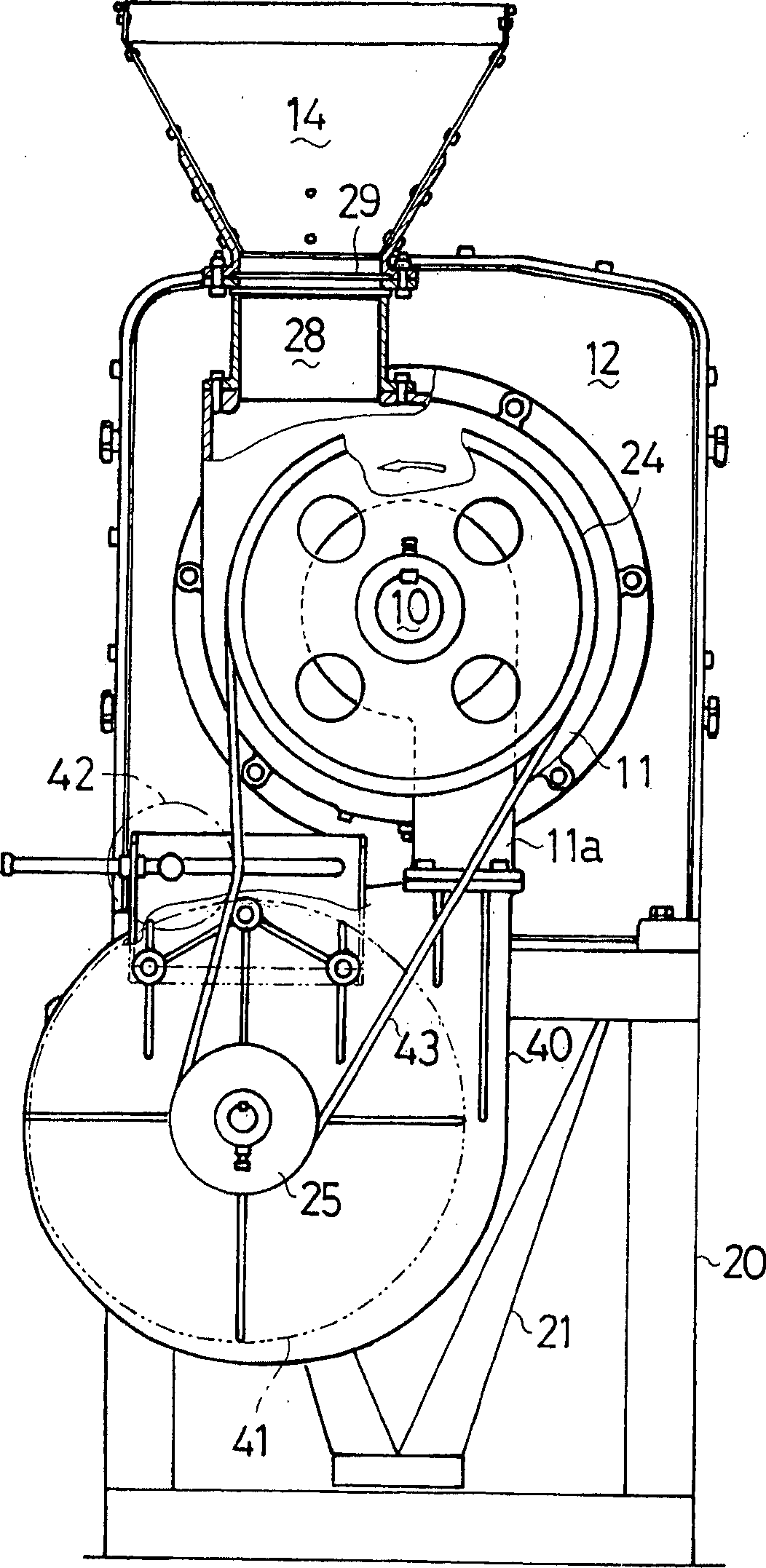

[0053] Below, according to Figure 1~ Figure 4 The overall structure of the horizontal grinding type rice polisher of this invention is demonstrated.

[0054] On the lower supporting frame 20, an inlet-side supporting plate (front plate) 12 and an outlet-side supporting plate (rear plate) 13 are fixedly erected front and rear with a gap between them. A cylindrical rice polishing section cover 22 is provided. In the future, as long as there is no special notice, this machine will use the side of the outlet side support plate 13 (the left side in Figure 1) as the front side, and the side of the inlet side support plate 12 (the right side in Figure 1) as the rear side. illustrate.

[0055] A feed roller casing 11 is fixedly installed on the rear portion of the inlet side support plate 12, and a coarse rice hopper 14 for supplying coarse rice to the polishing rice section is fixedly erected on its upper portion. Inside the coarse rice hopper 14 , an opening and closing gate 29 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com