Patents

Literature

2468results about "Grain husking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processes for recovery of corn germ and optionally corn coarse fiber (pericarp)

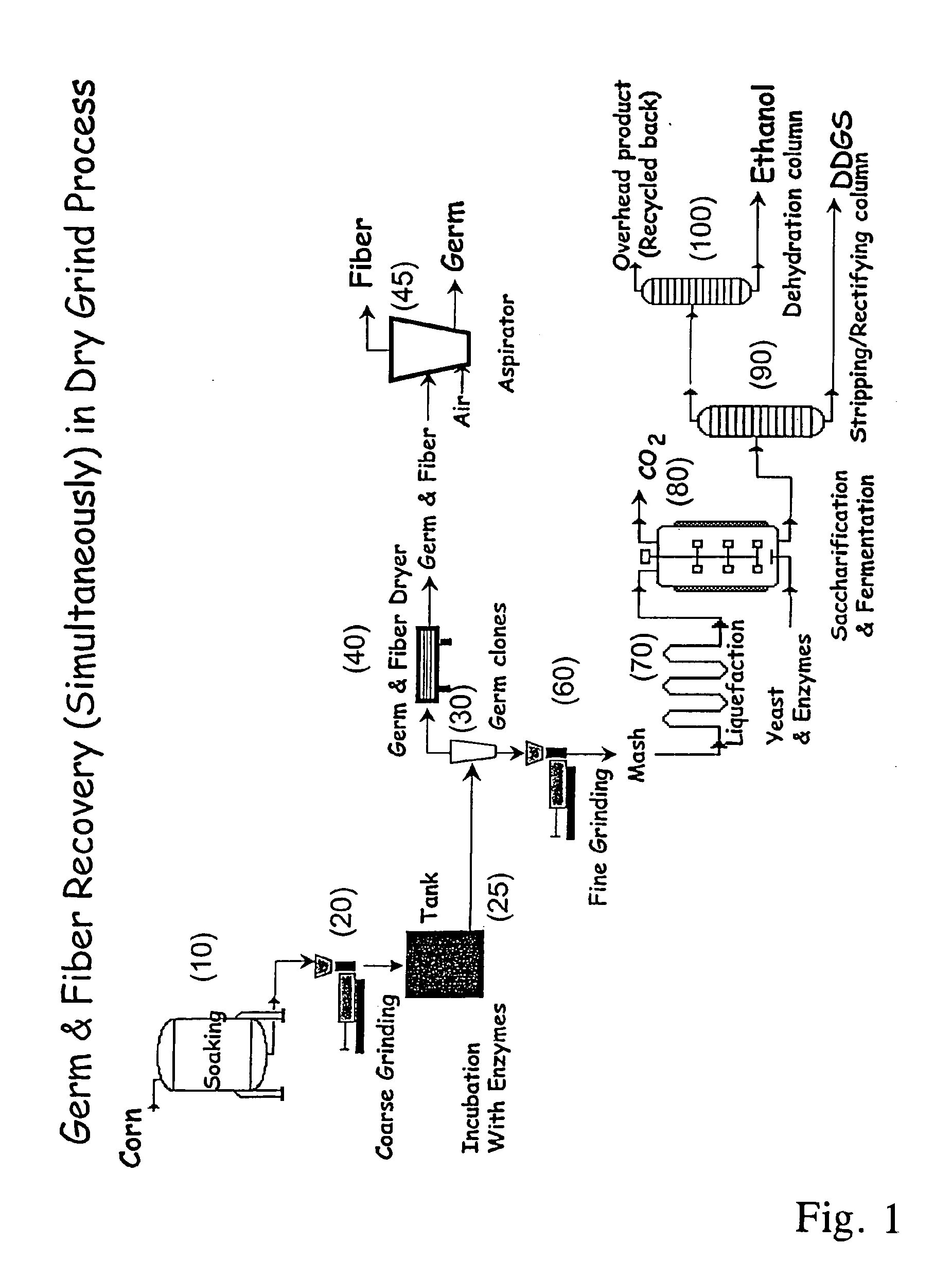

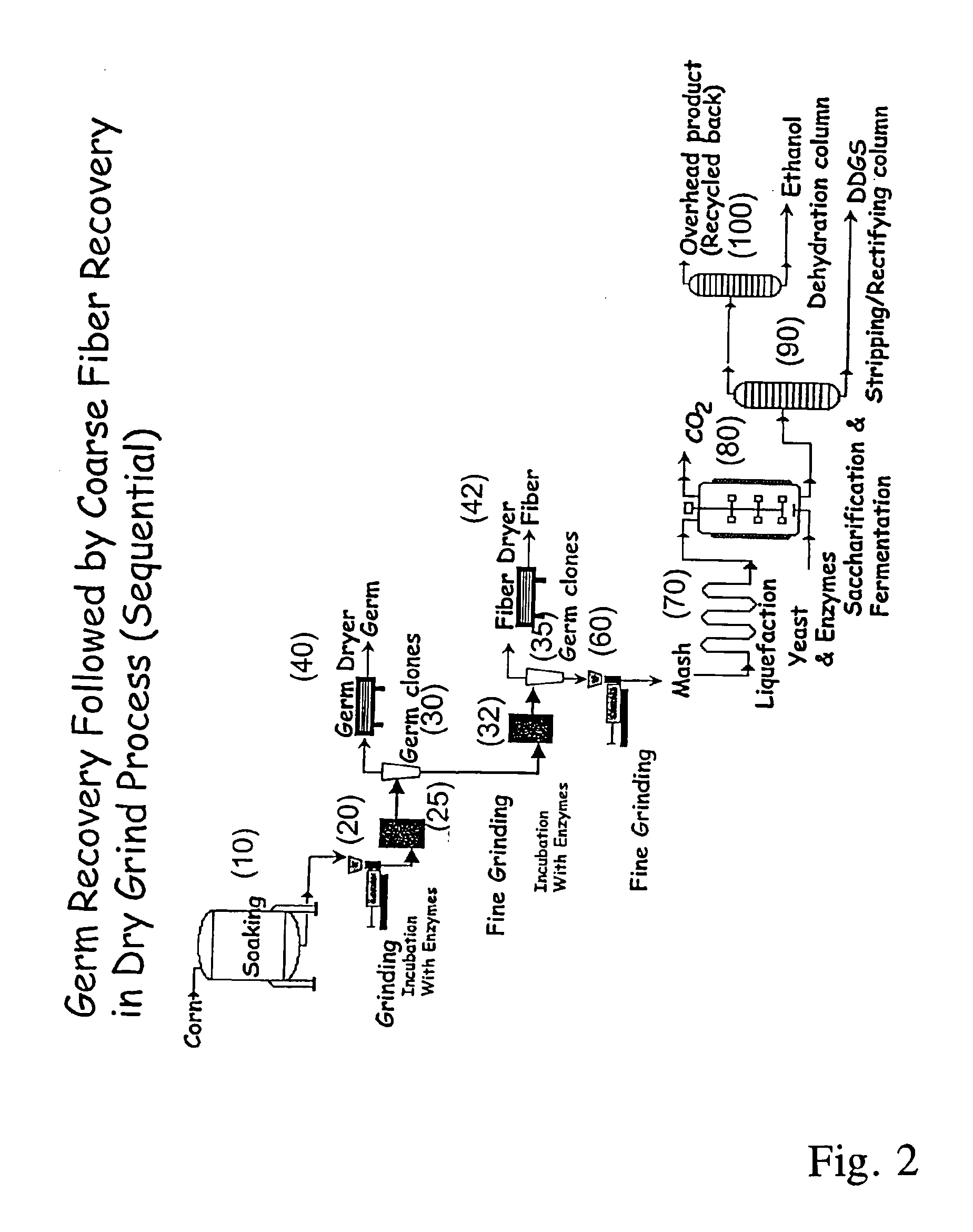

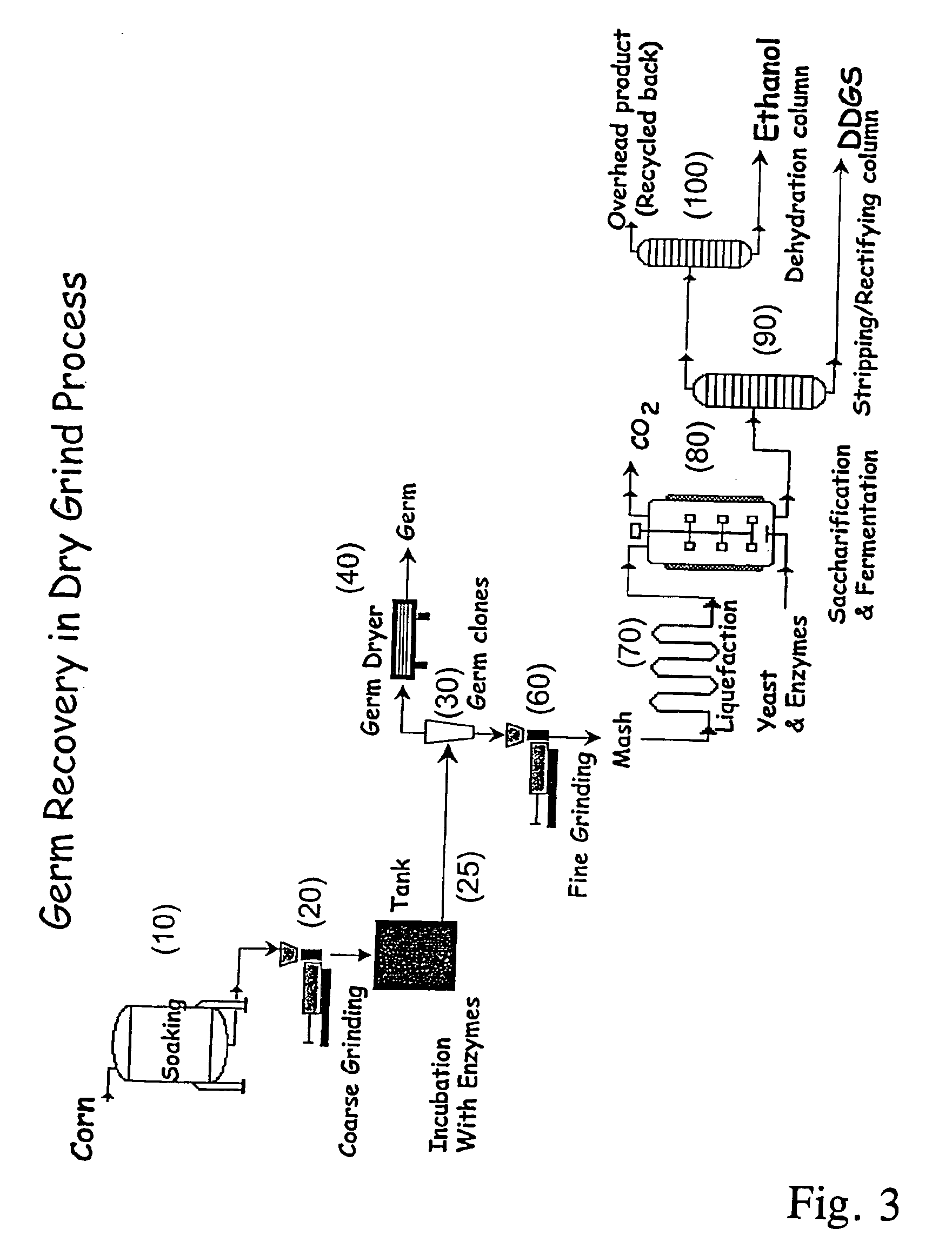

A process for recovering corn germ and corn coarse fiber from corn in a dry grind process, involving soaking corn kernels in water to produce soaked corn kernels, grinding the soaked corn kernels to produce a ground corn slurry, and incubating the ground corn slurry with at least one enzyme (amylase(s), protease(s), cell wall degrading enzyme(s), or mixtures thereof, and optionally other enzyme(s)) to increase the specific gravity of the slurry to about 10-about 16 Baume so that the corn germ and corn coarse fiber floats to the top of the slurry, recovering the corn germ and the corn coarse fiber, and optionally producing ethanol from the slurry no longer containing the corn germ and corn coarse fiber. The process does not involve the addition of starch, a salt, a sugar syrup, or mixtures thereof to the slurry.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

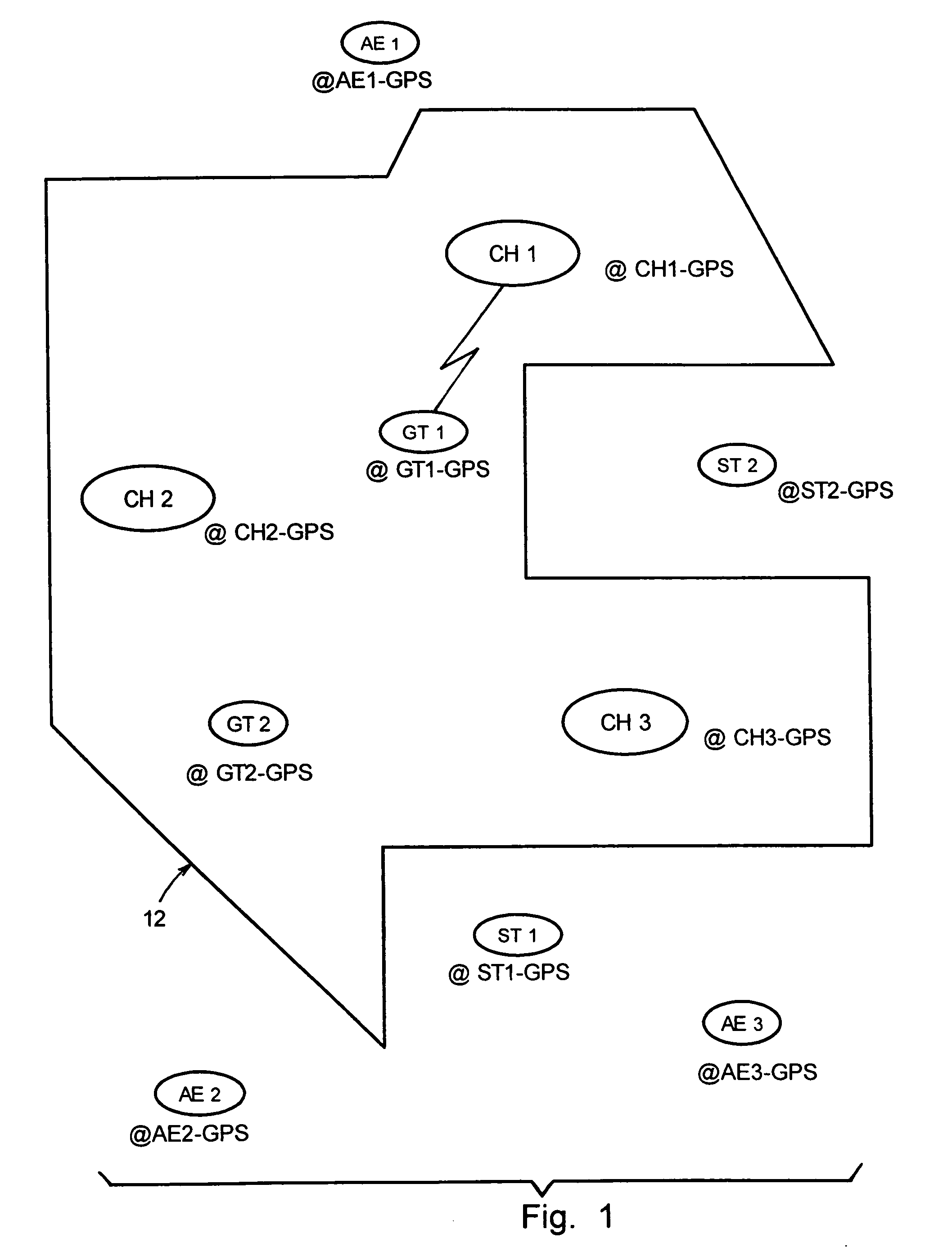

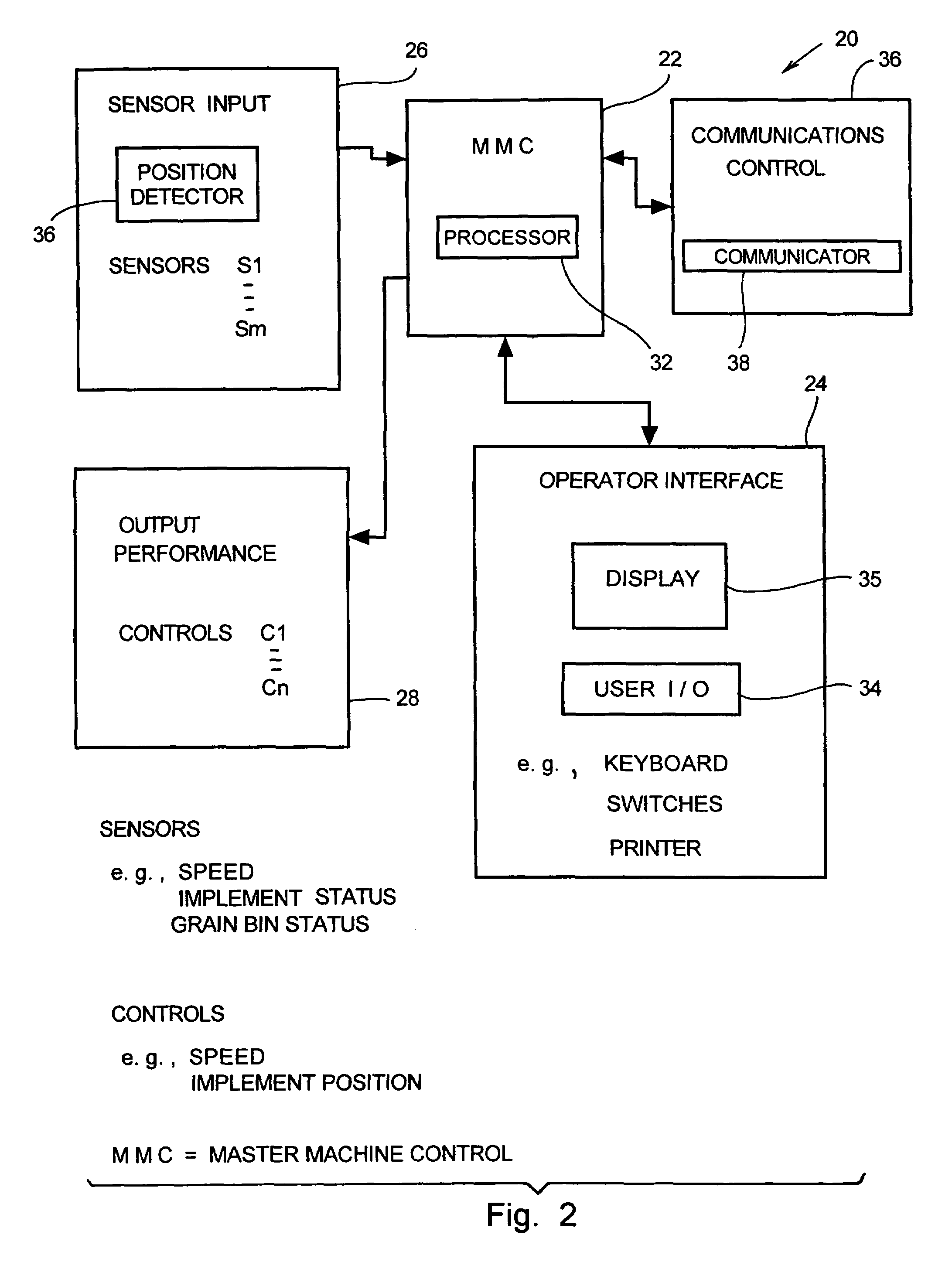

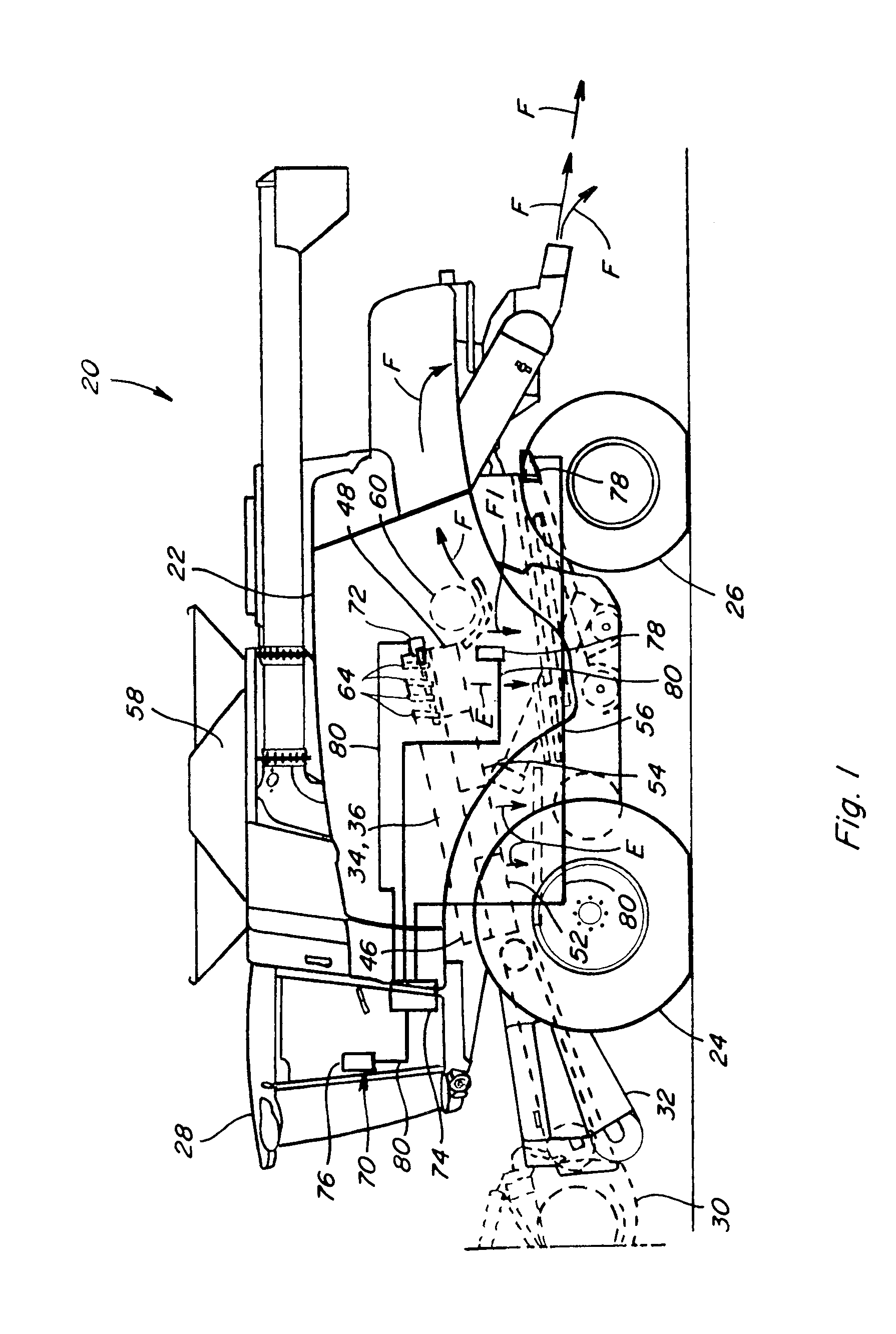

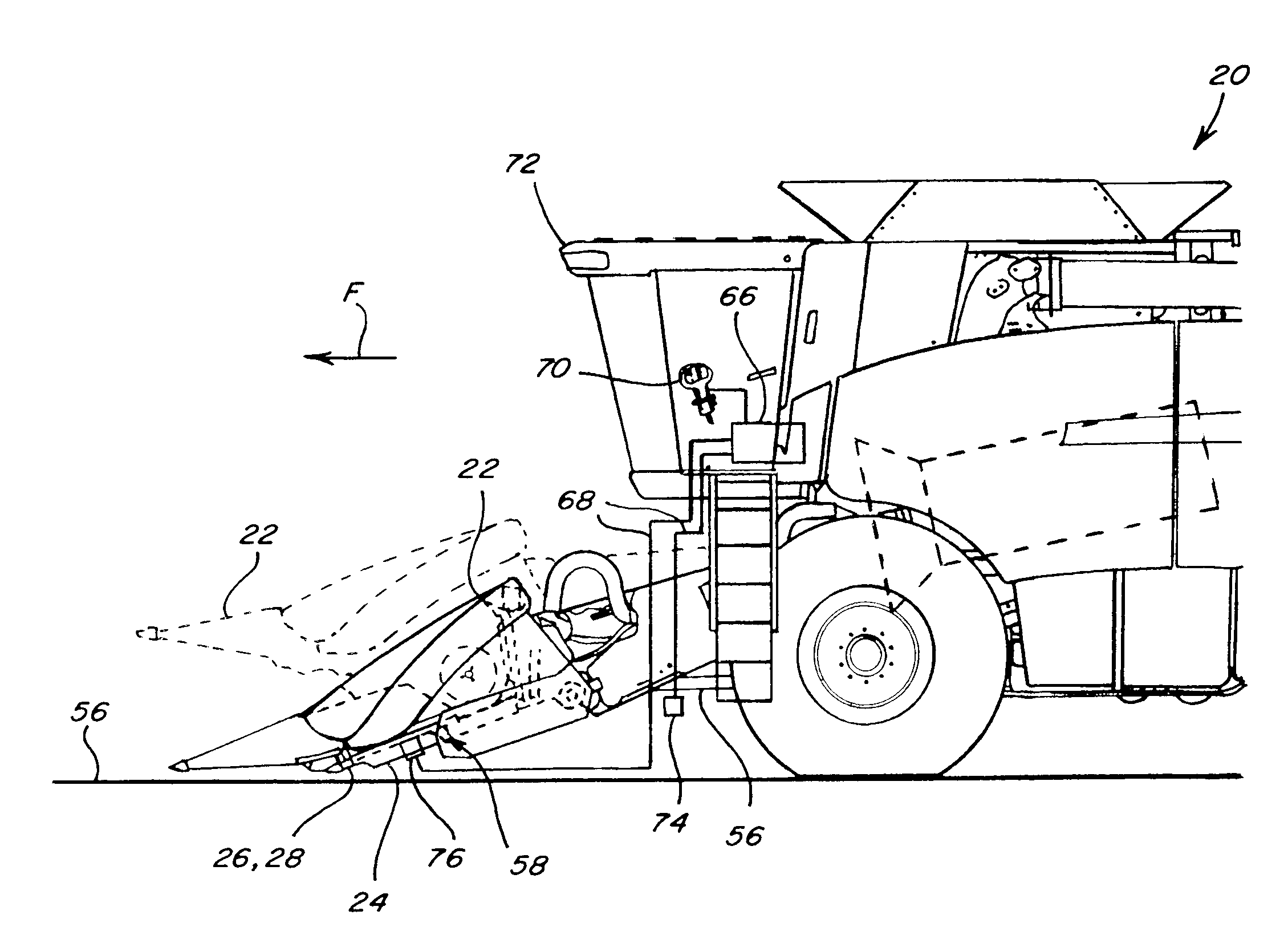

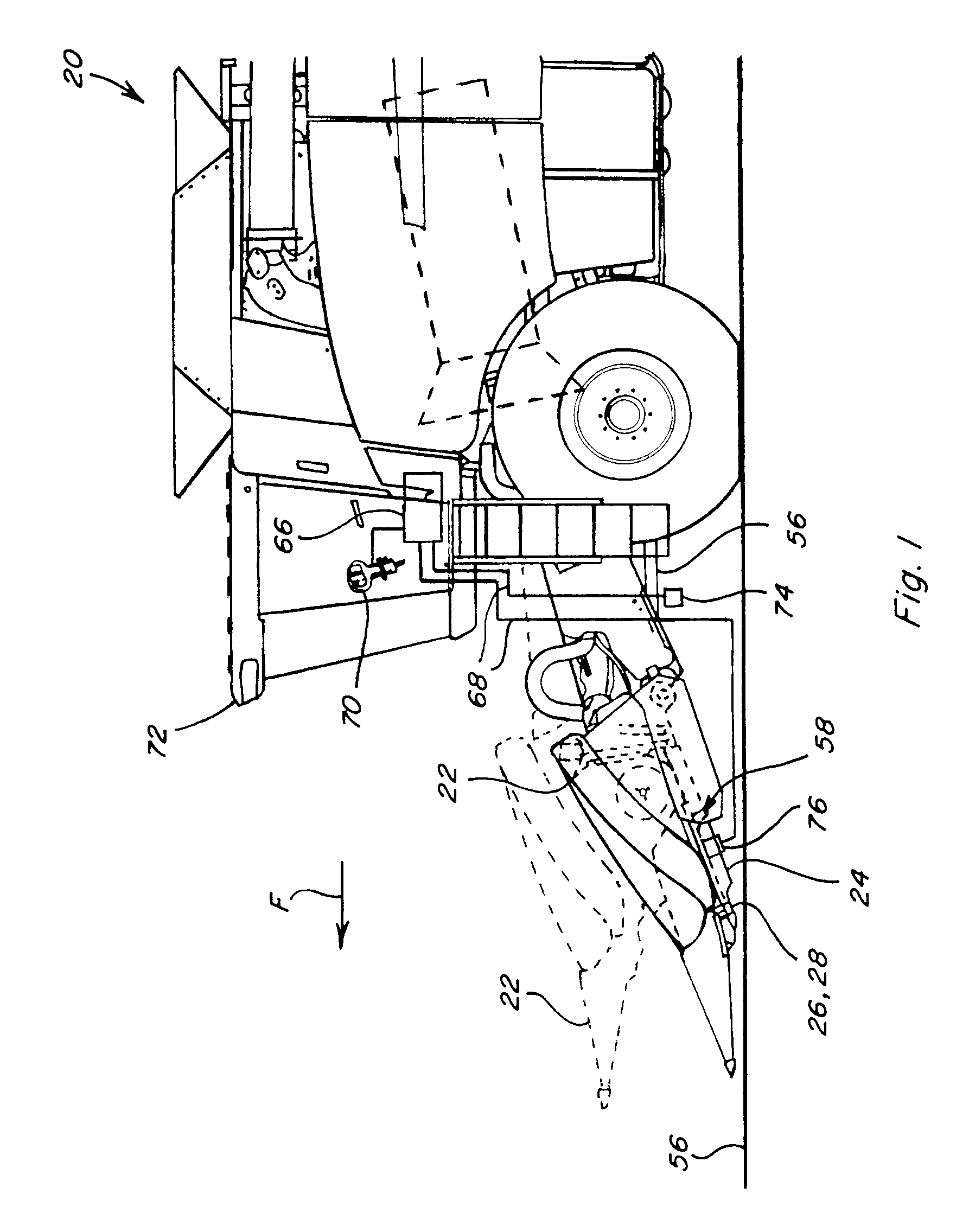

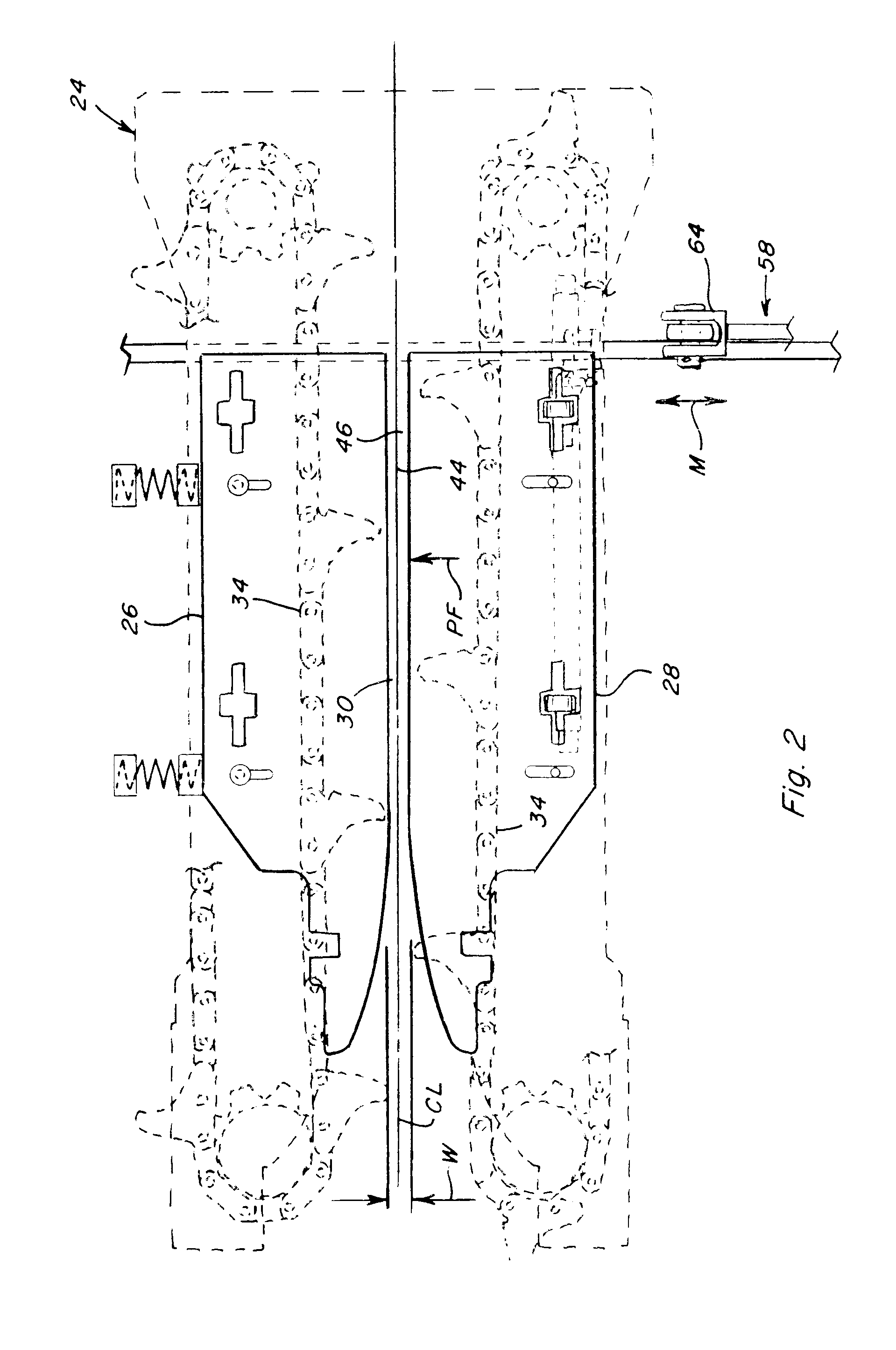

System and method employing short range communications for interactively coordinating unloading operations between a harvester and a grain transport

ActiveUS8145393B2Effectively and advantageously communicateWide of informationAnalogue computers for vehiclesGrain huskingTelecommunications linkOperational system

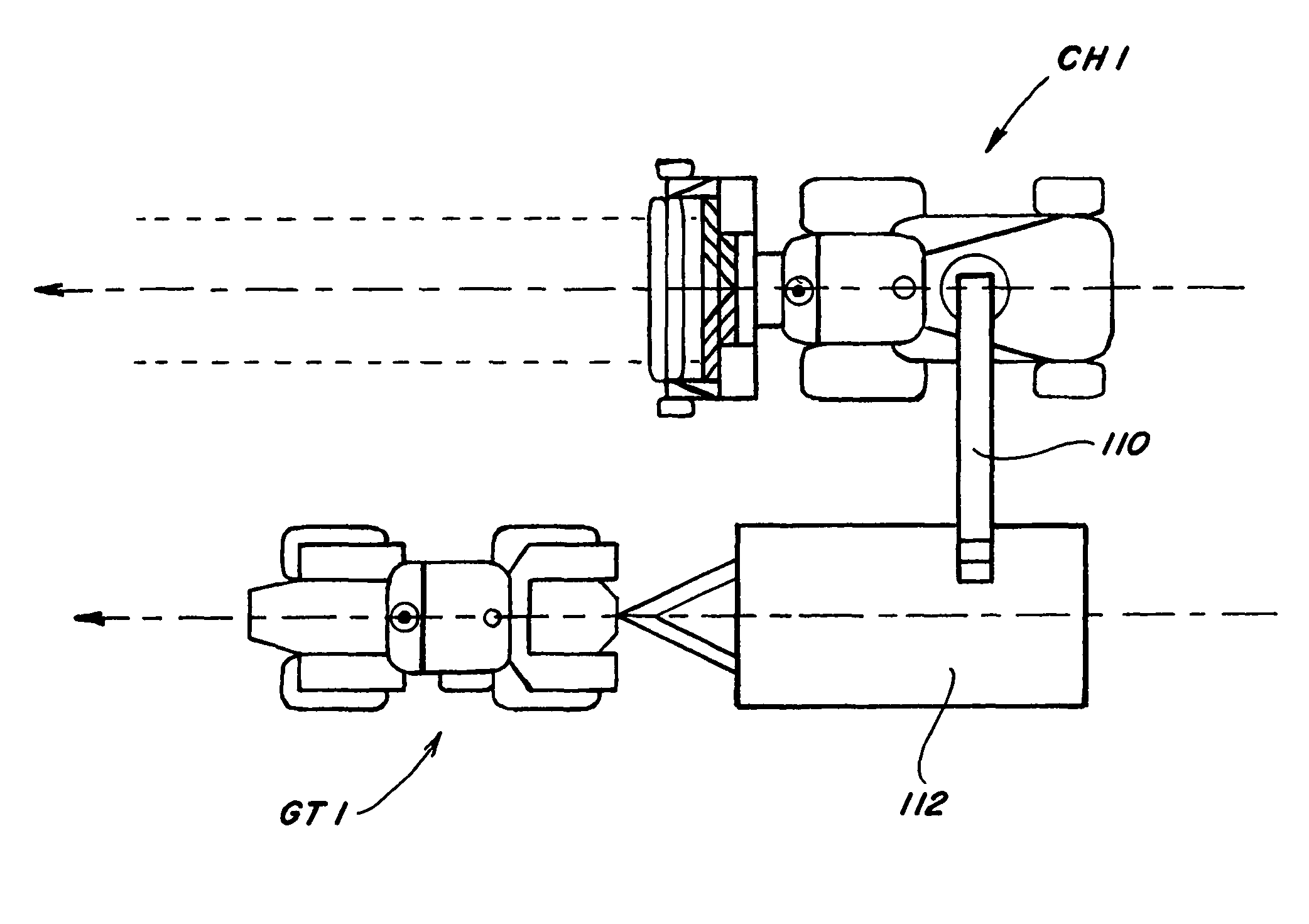

A system, and method of use thereof, that employs short distance communications signals, thereby limiting and localizing the dissemination area for such signals, for interactively coordinating crop material transfer operations between a harvester and a grain transport, including the automated conduct of an unloading operation, including commencement of the actual unloading of the grain through continuation of such unloading to termination of such unloading, which system and method of the present invention employs operating systems in the harvester and grain transport that so operate to become electronically linked to one another to thereafter operate in unison with one another to effect and control the conduct of the crop material transfer operation between the harvester and grain transport, with each of such operating systems having associated therewith a short range communications system for the transmission and receipt at close range of electronic data signals, such operating systems, when appropriately electronically linked to one another, being operable in conjunction with one another to exchange information, to maintain a communications link therebetween, and to automatedly coordinate and effect various activities of the harvester and grain transport as a crop material transfer operation is effected and proceeds.

Owner:BLUE LEAF I P INC

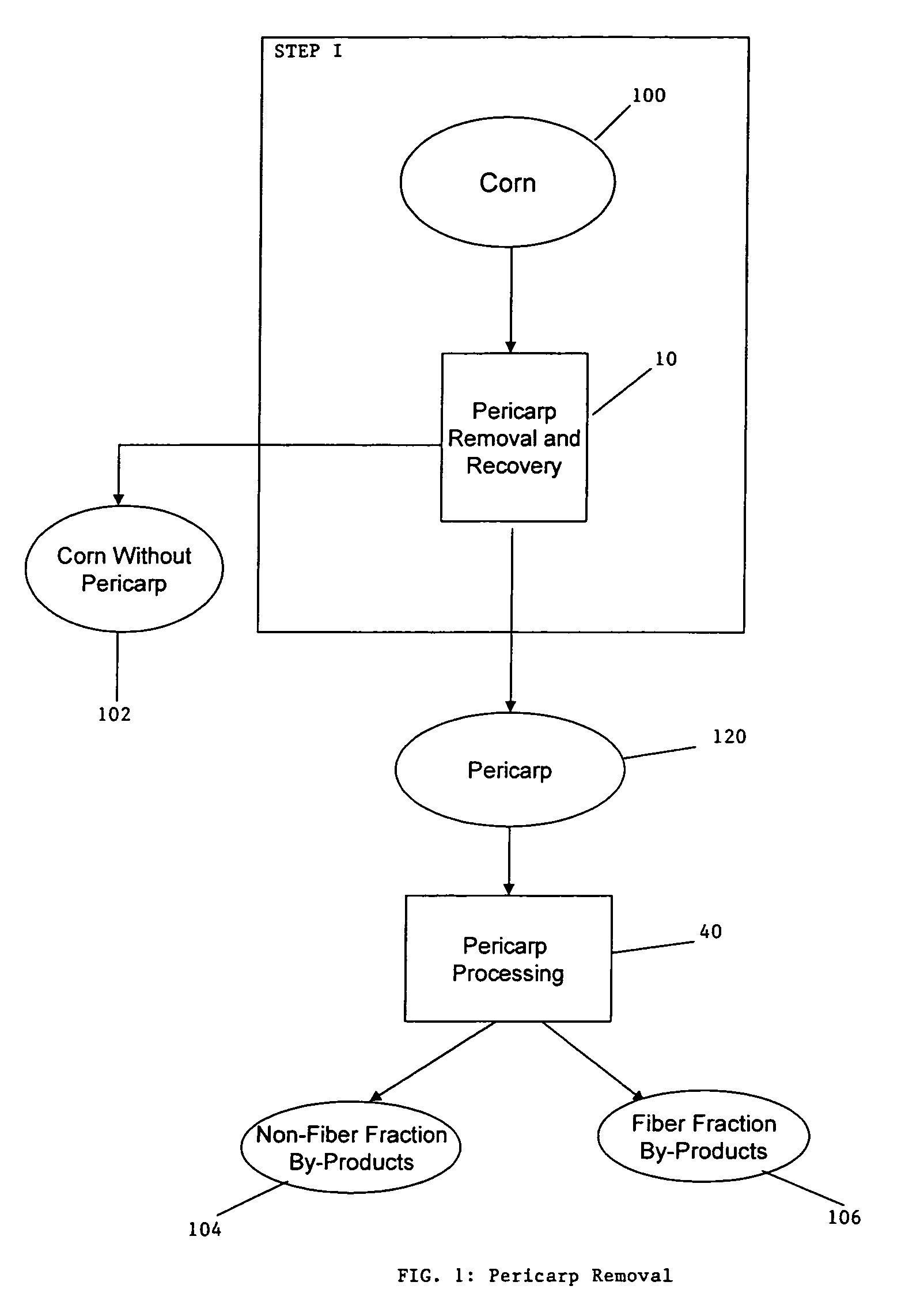

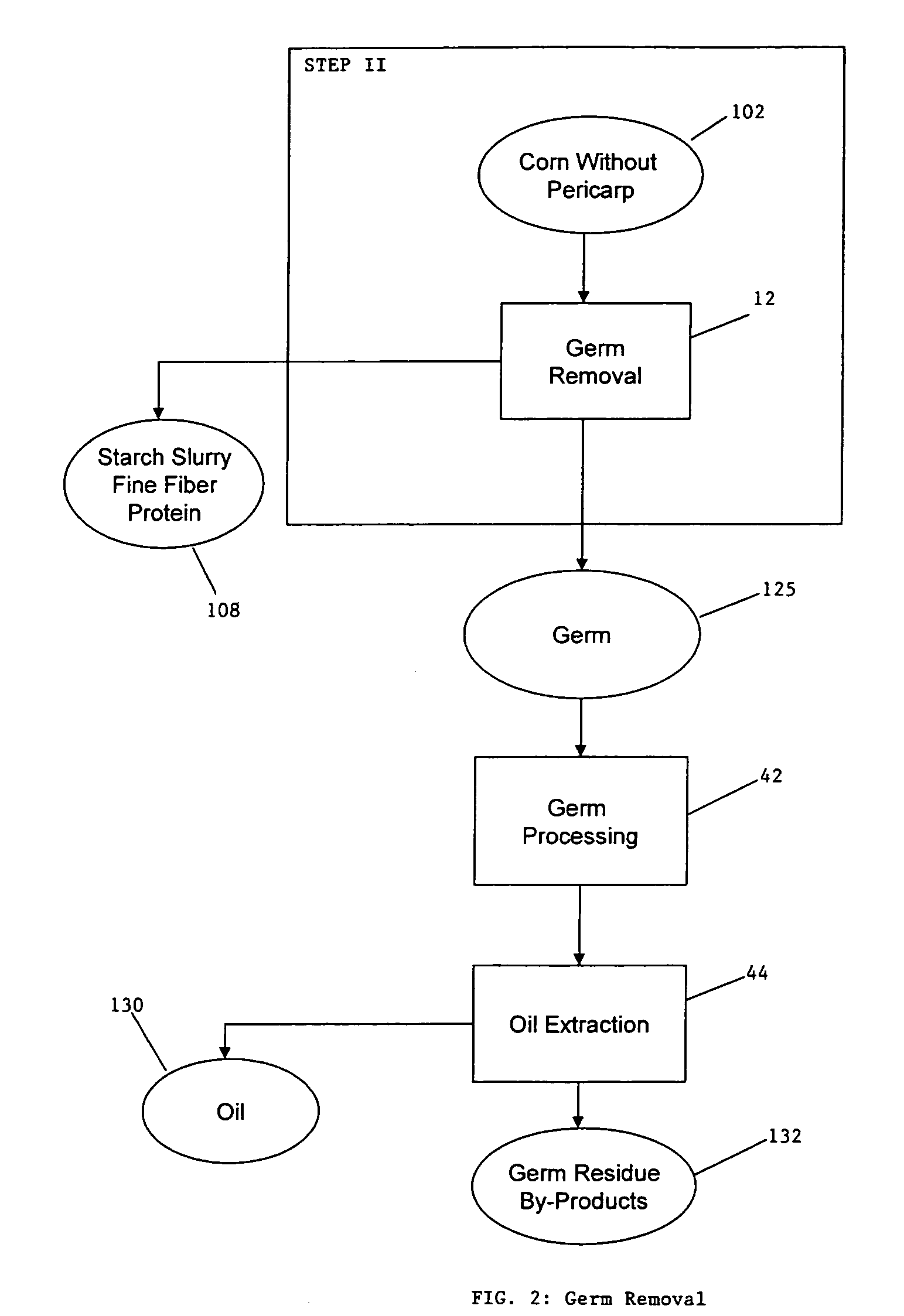

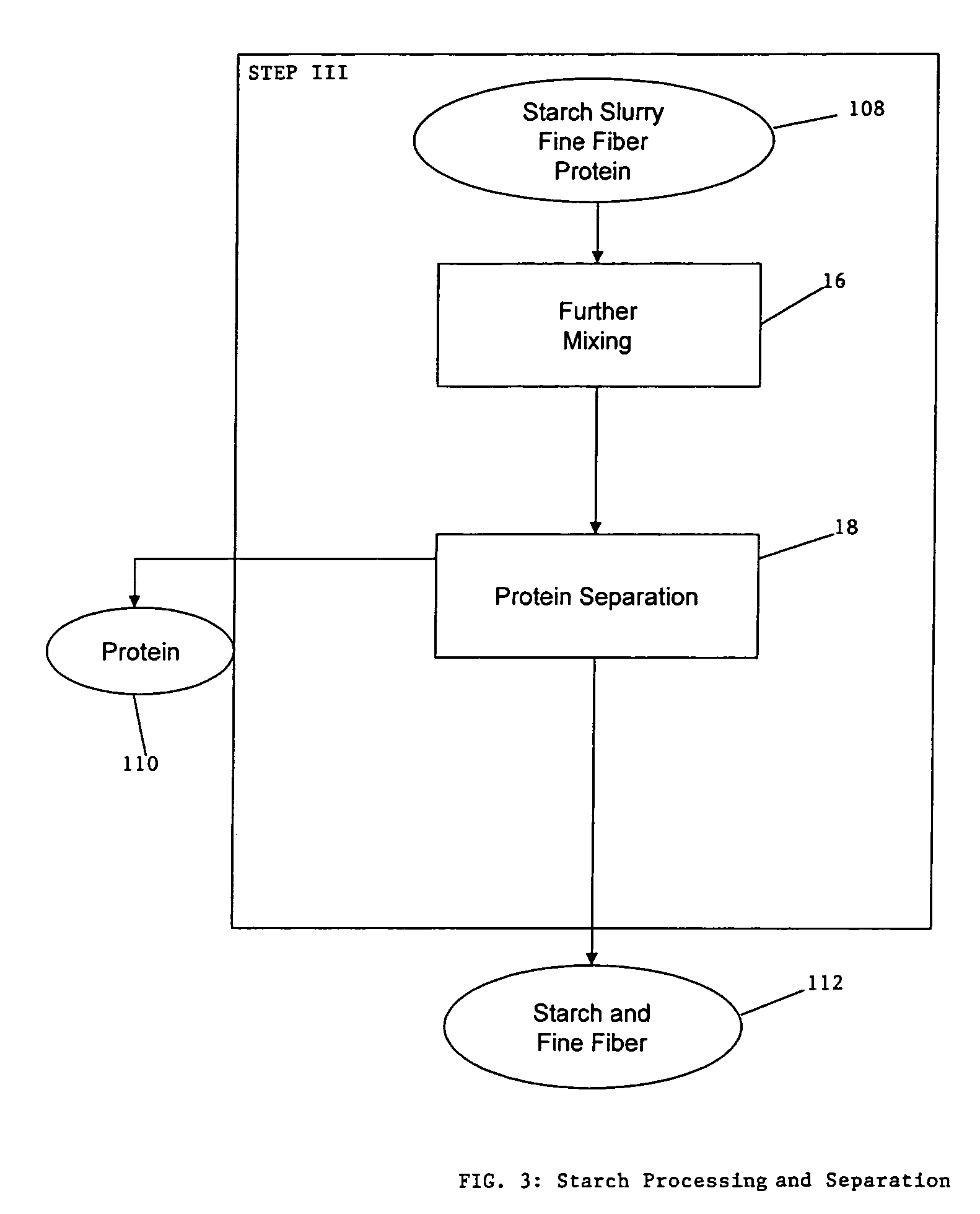

Process for the production of animal feed and ethanol and novel animal feed

A method for the production of ethanol and a modified animal feed is provided. The method replaces the starch in known corn-based animal feed with biomass fiber treated to make it more digestible by animals. The process includes wherein the pericarp and germ are removed from the corn kernel and processed for by-products. The starch and protein are also removed and separated. The starch is then fermented and distilled to ethanol and stillage. The bioavailable modified animal feed comprises the pericarp and germ removed from corn kernels and optionally by-products of the pericarp and germ processing, and lignocellulosic materials. The modified animal feed may optionally include energy materials such as animal and vegetable fats, vegetable soapstocks, or glycerin, and combinations thereof.

Owner:ARCHER DANIELS MIDLAND CO

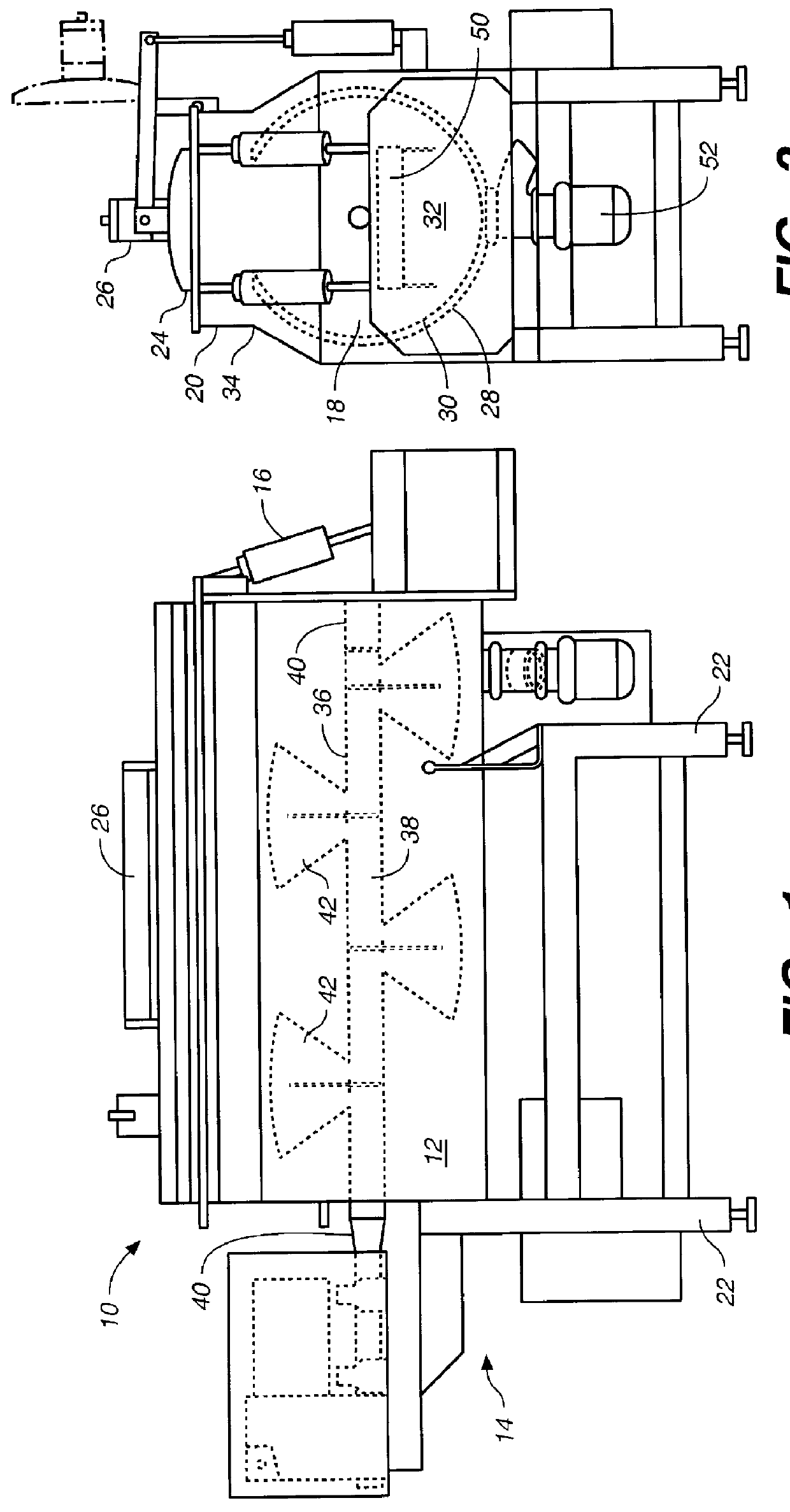

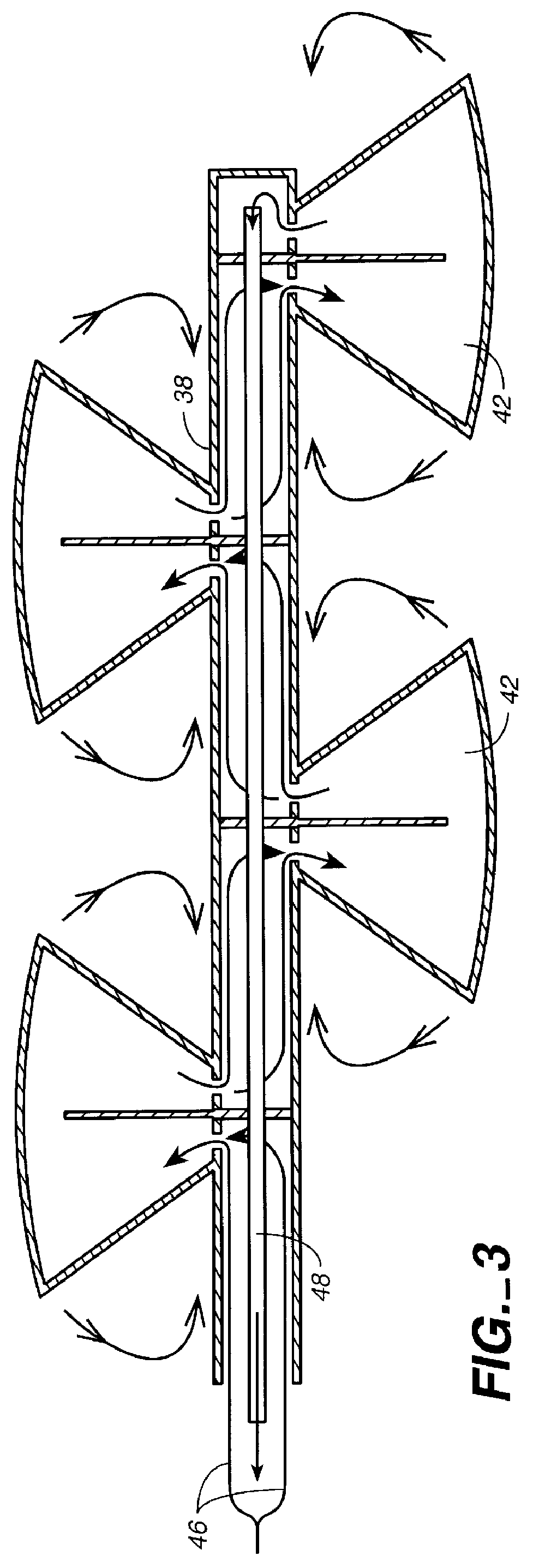

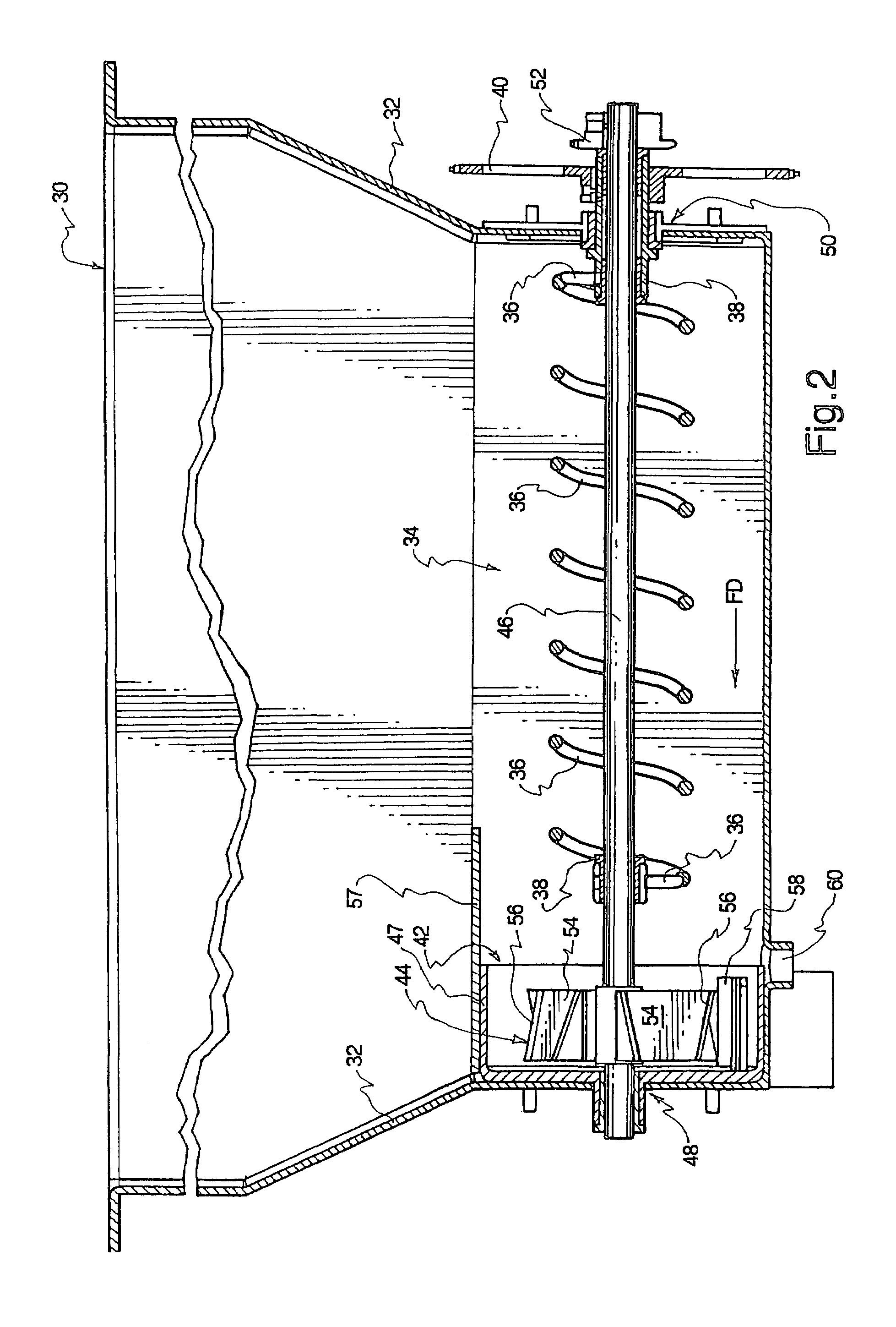

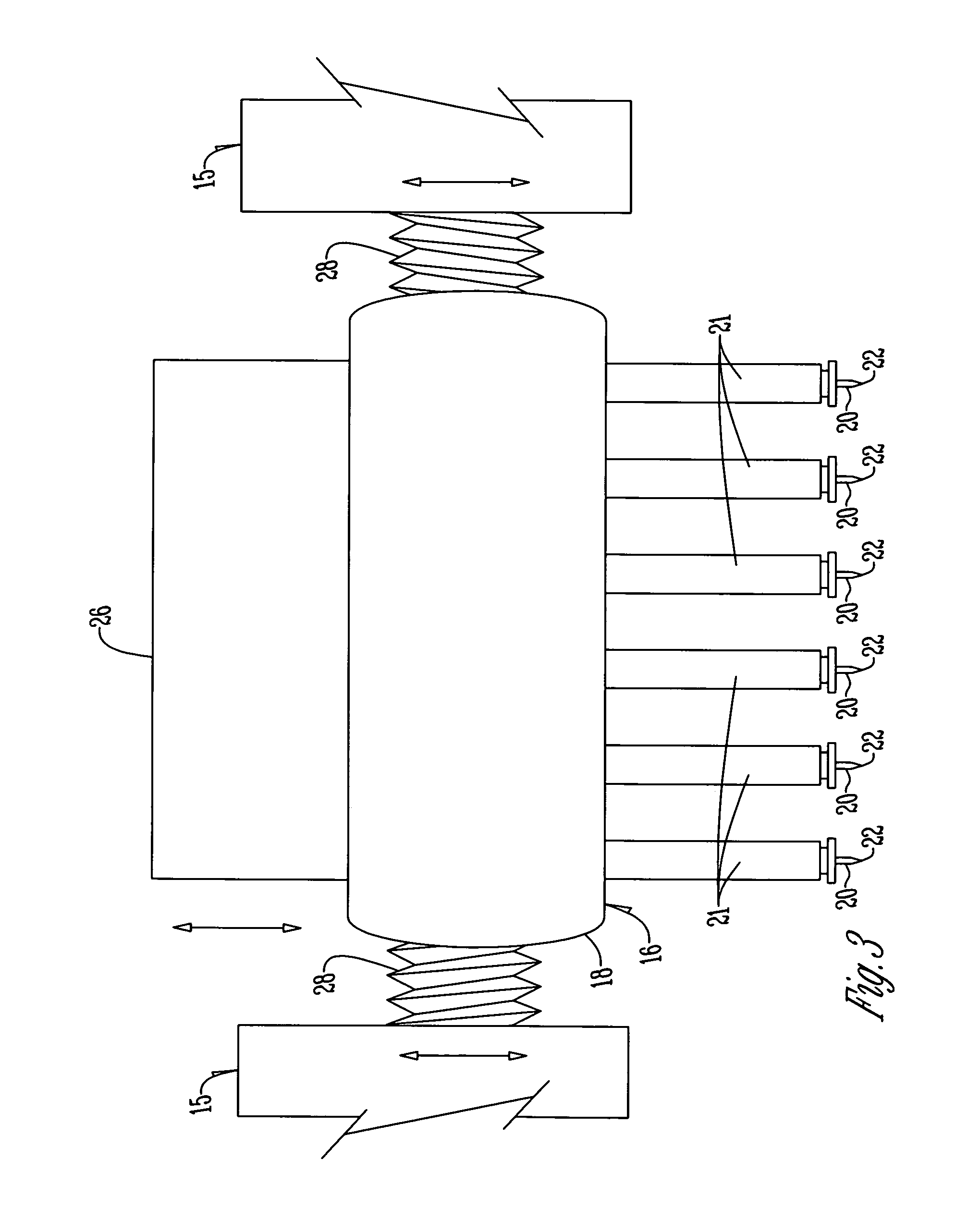

Apparatus for marinating meat products

A vacuum meat marinating machine for products requiring a short vacuum massage cycle, comprising a substantially horizontal cylindrical vessel having a large opening at the top for rapid loading of product, said opening covered by a sealed vacuum cover during operation, and further having a hollow outer wall comprising a jacket for the circulation of liquid refrigerant. A paddle agitator is located within the vessel, having a hollow shaft running longitudinally within the vessel. Affixed at an angle to the shaft are a plurality of hollow triangular-shaped paddles, which paddles push product horizontally during operation. Liquid refrigerant circulates through the hollow wall of the vessel, as well as the hollow agitator shaft and paddles. The agitator shaft is connected to a reversible motor that periodically reverses the direction of rotation, thereby maximizing heat exchange between product and liquid refrigerant.

Owner:HORN DARRELL +1

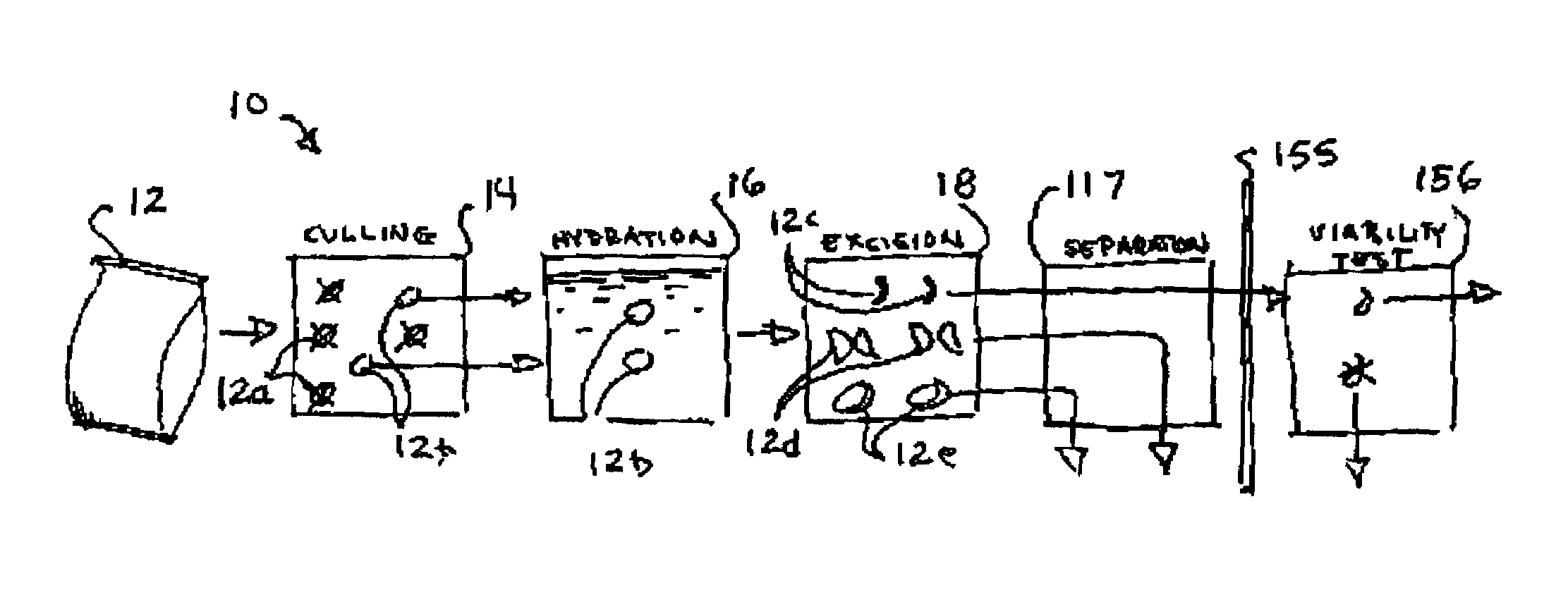

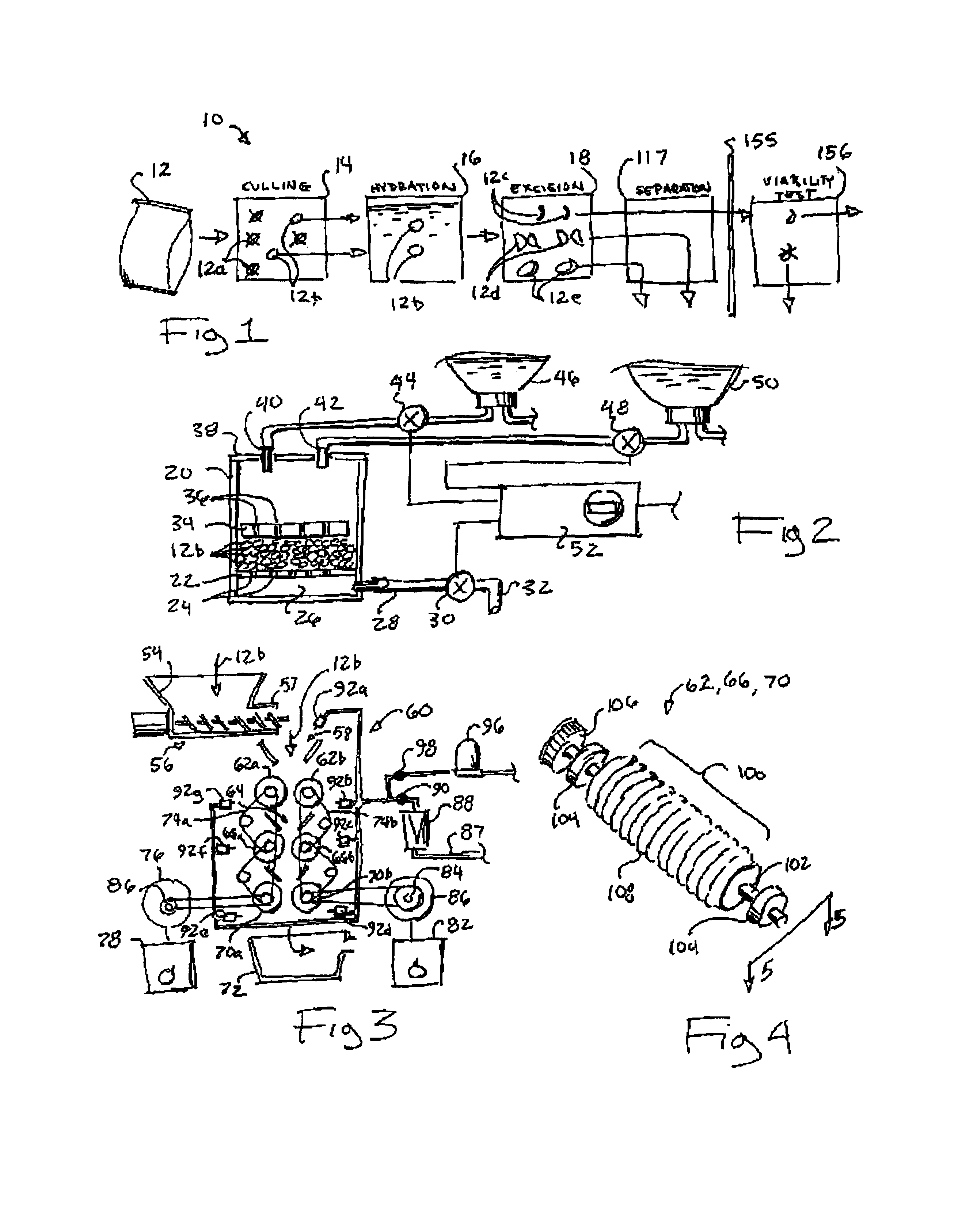

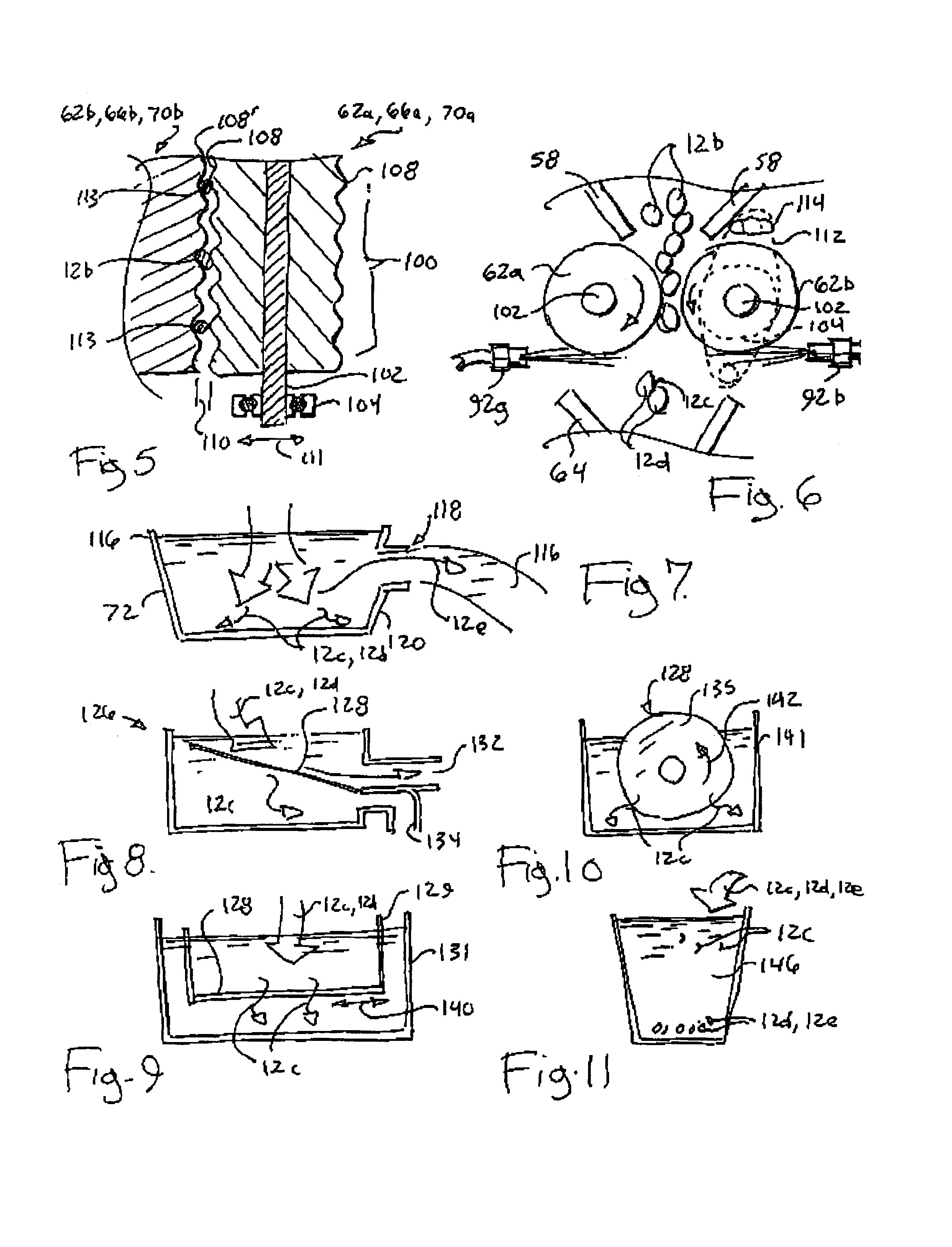

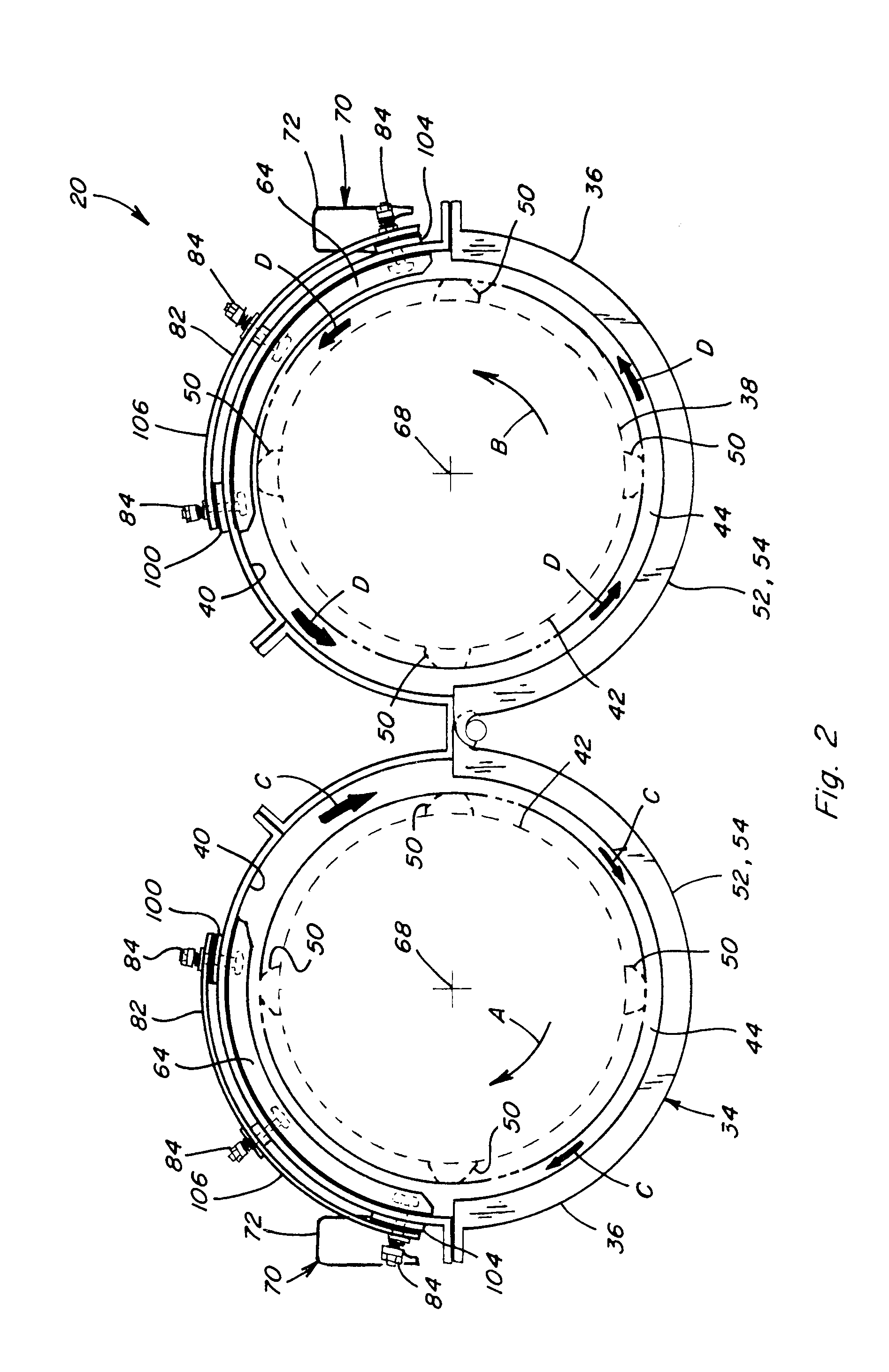

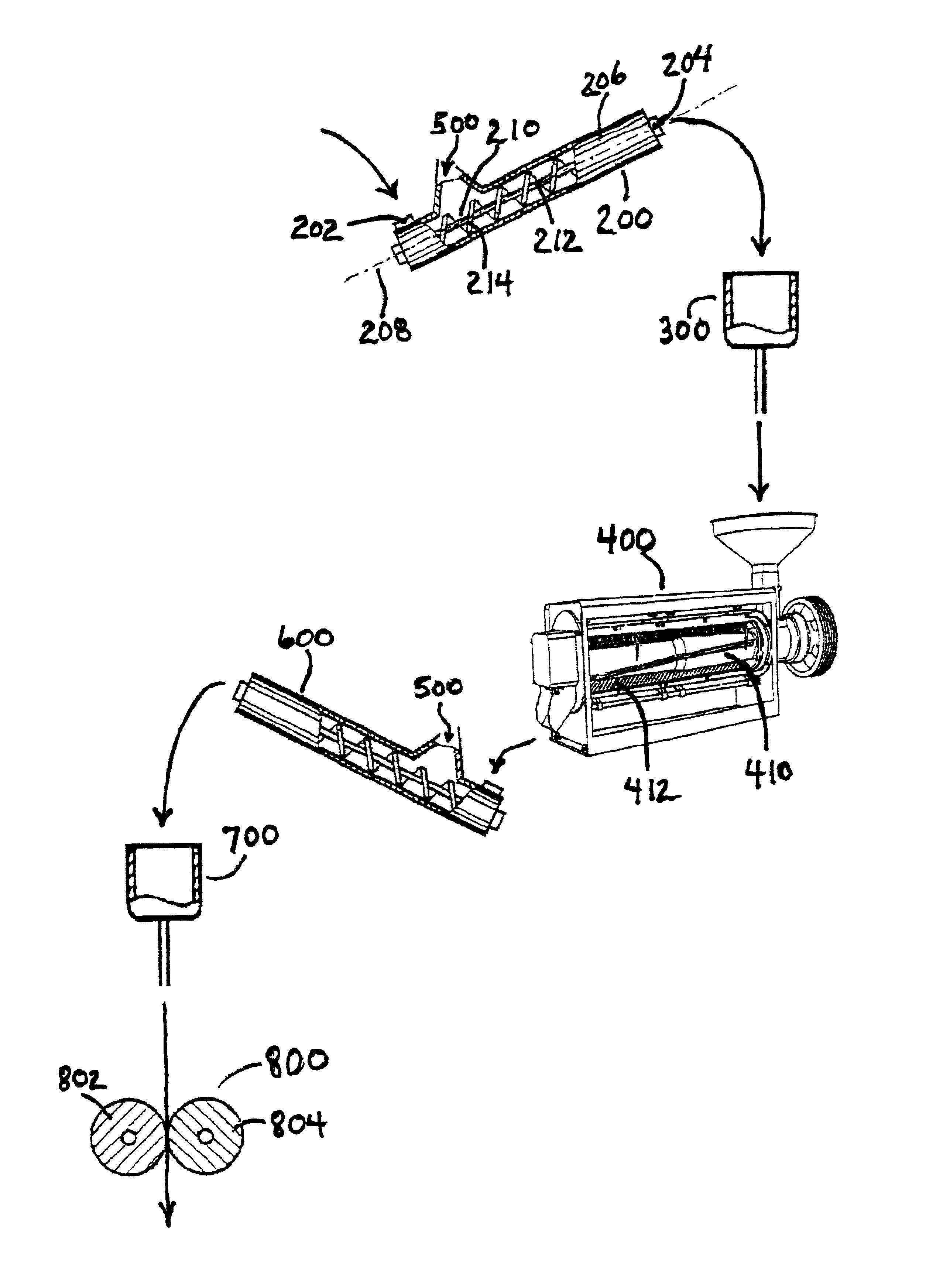

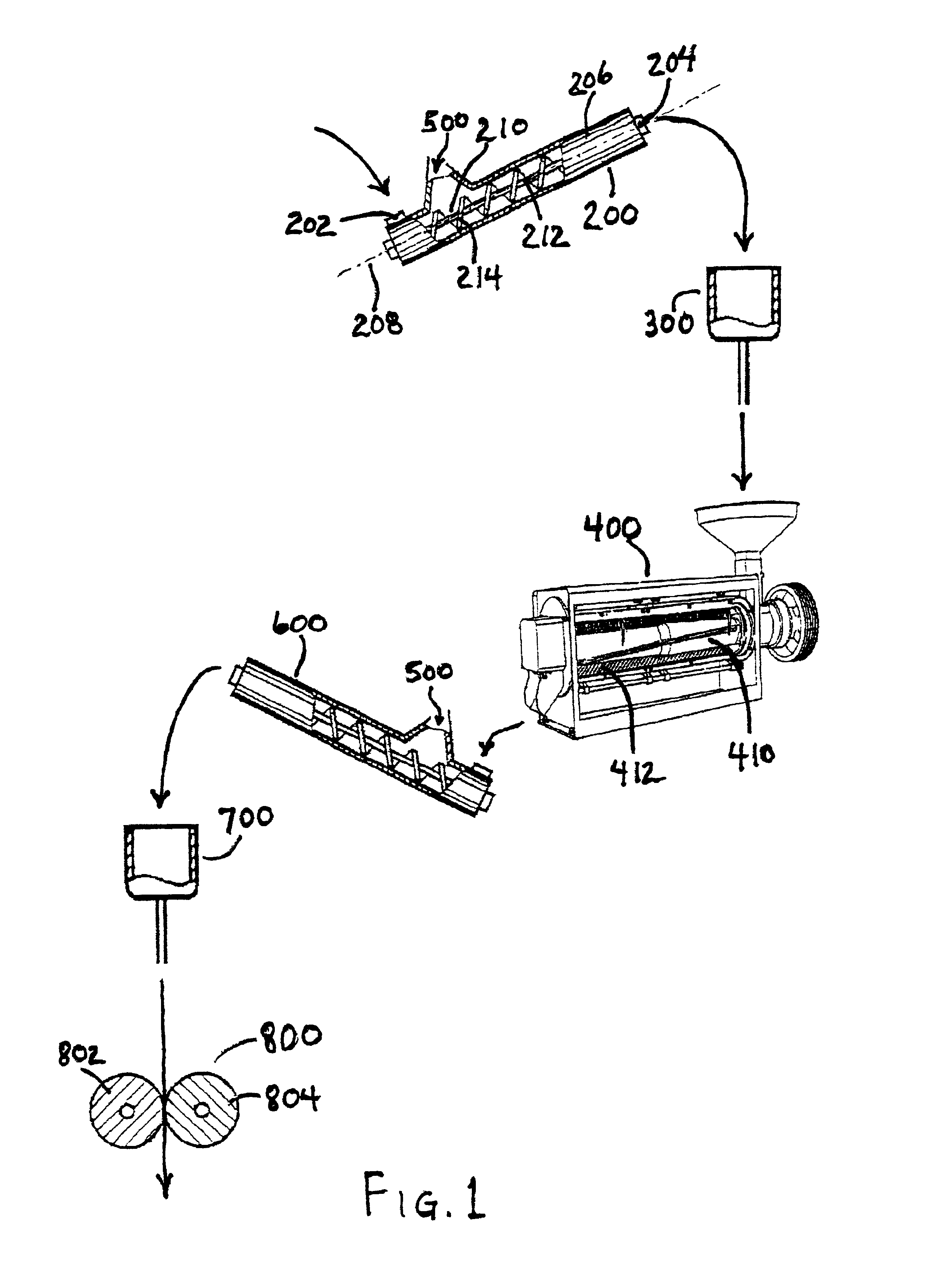

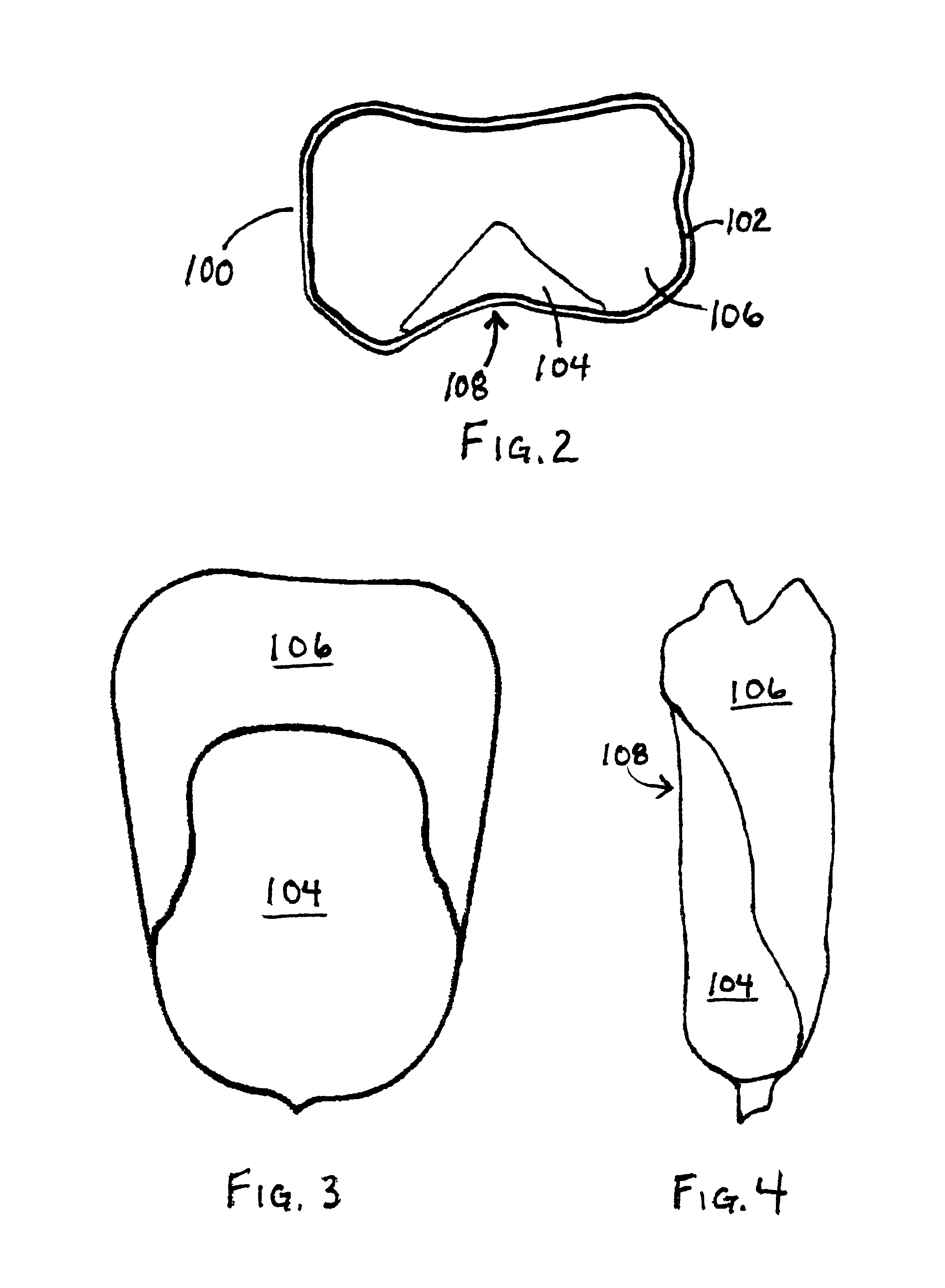

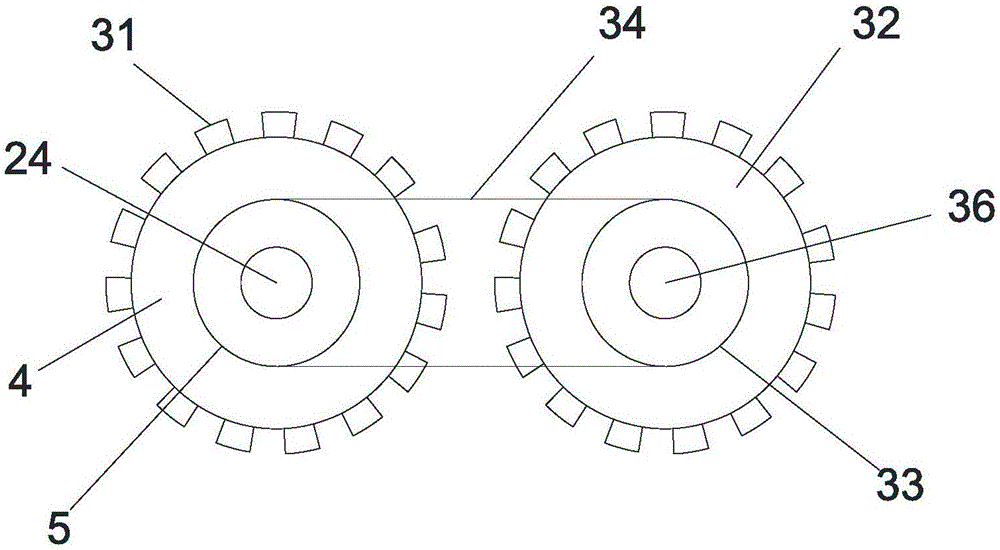

Method and apparatus for preparation of genetically transformable plant tissue

A process of mechanical separation of embryos from seeds for genetic transplantation employs counter-rotating cylinders together with one or more culling, hydration, separation, and viability testing steps to provide high-throughput of viable, transplantable tissue.

Owner:MONSANTO TECH LLC

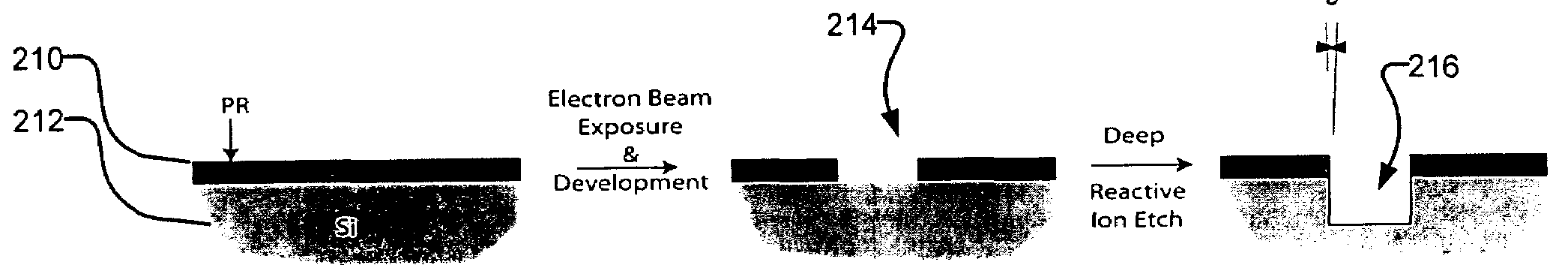

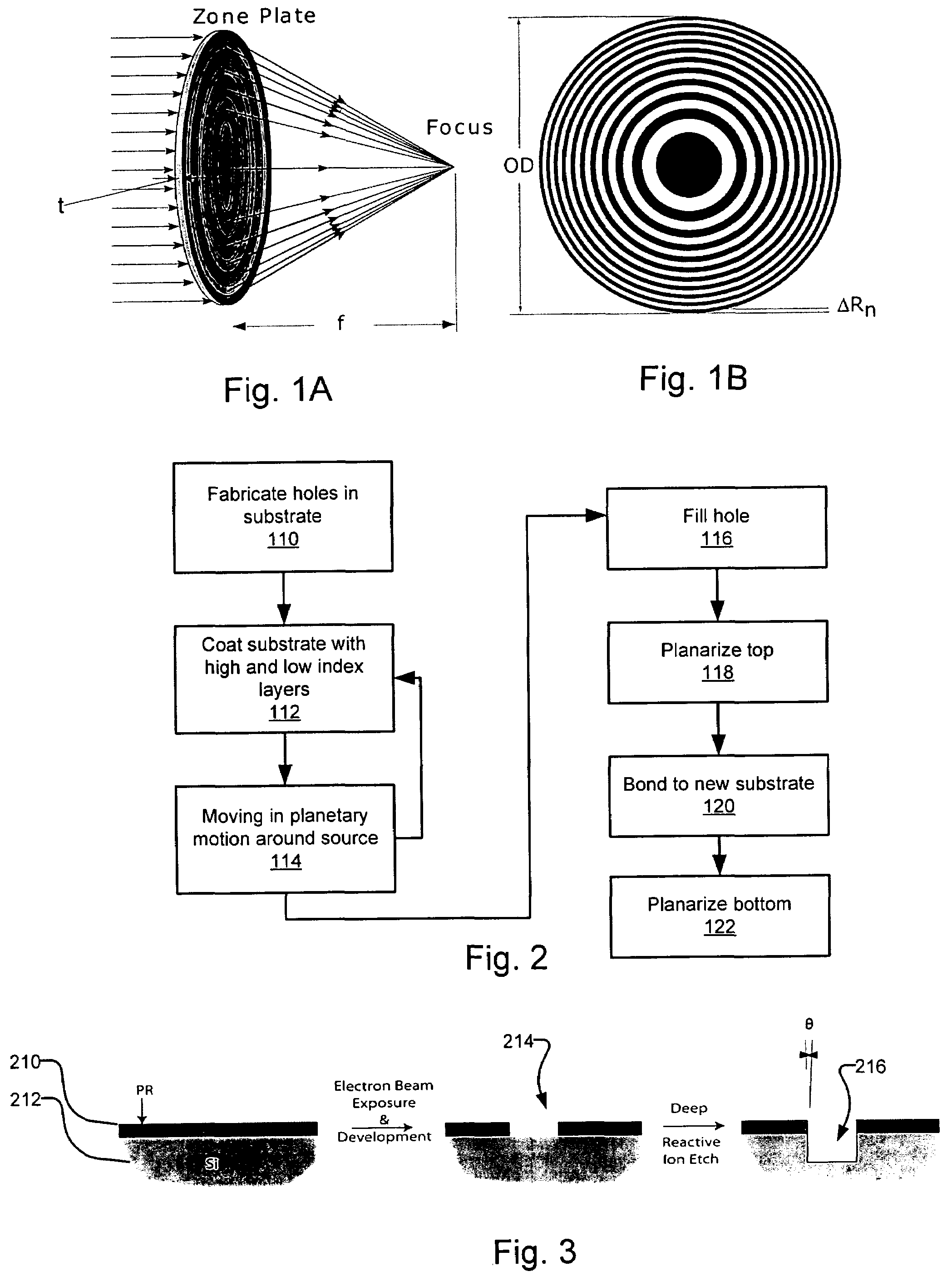

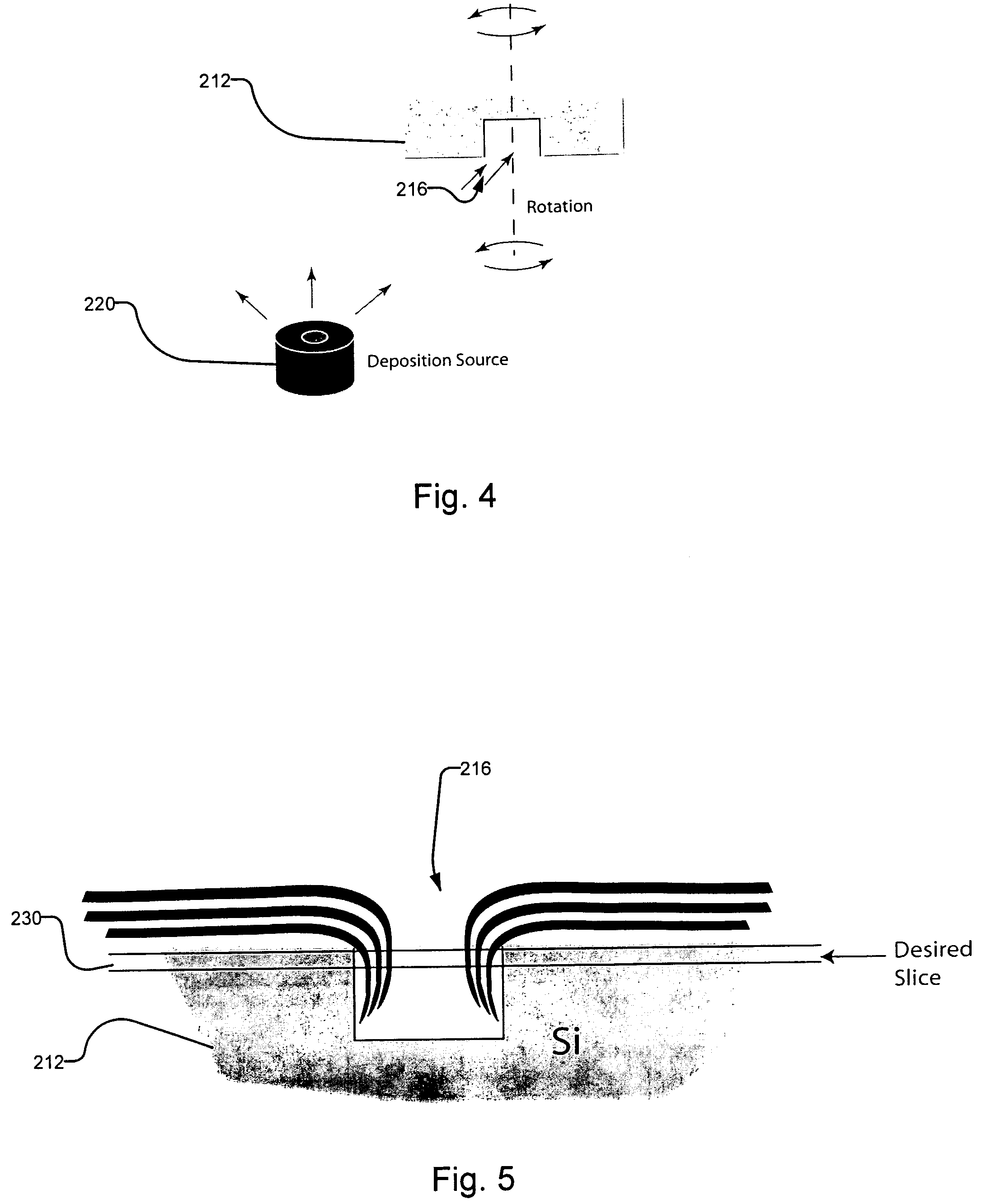

Fast x-ray lenses and fabrication method therefor

A fabrication process for zone plate lenses is based on controlled thin layer deposition for fabricating structures as small as 2 nanometers (nm) in width, and potentially smaller. The substrate for deposition will take the form of a precision hole, fabricated in a substrate, such as silicon by electron beam lithography and subsequent reactive ion etching. A controlled layer deposition is then used to form the required zone plate structure. A subsequent thinning process is used to section the hole and produce a zone plate with the required layer thicknesses.

Owner:CARL ZEISS X RAY MICROSCOPY

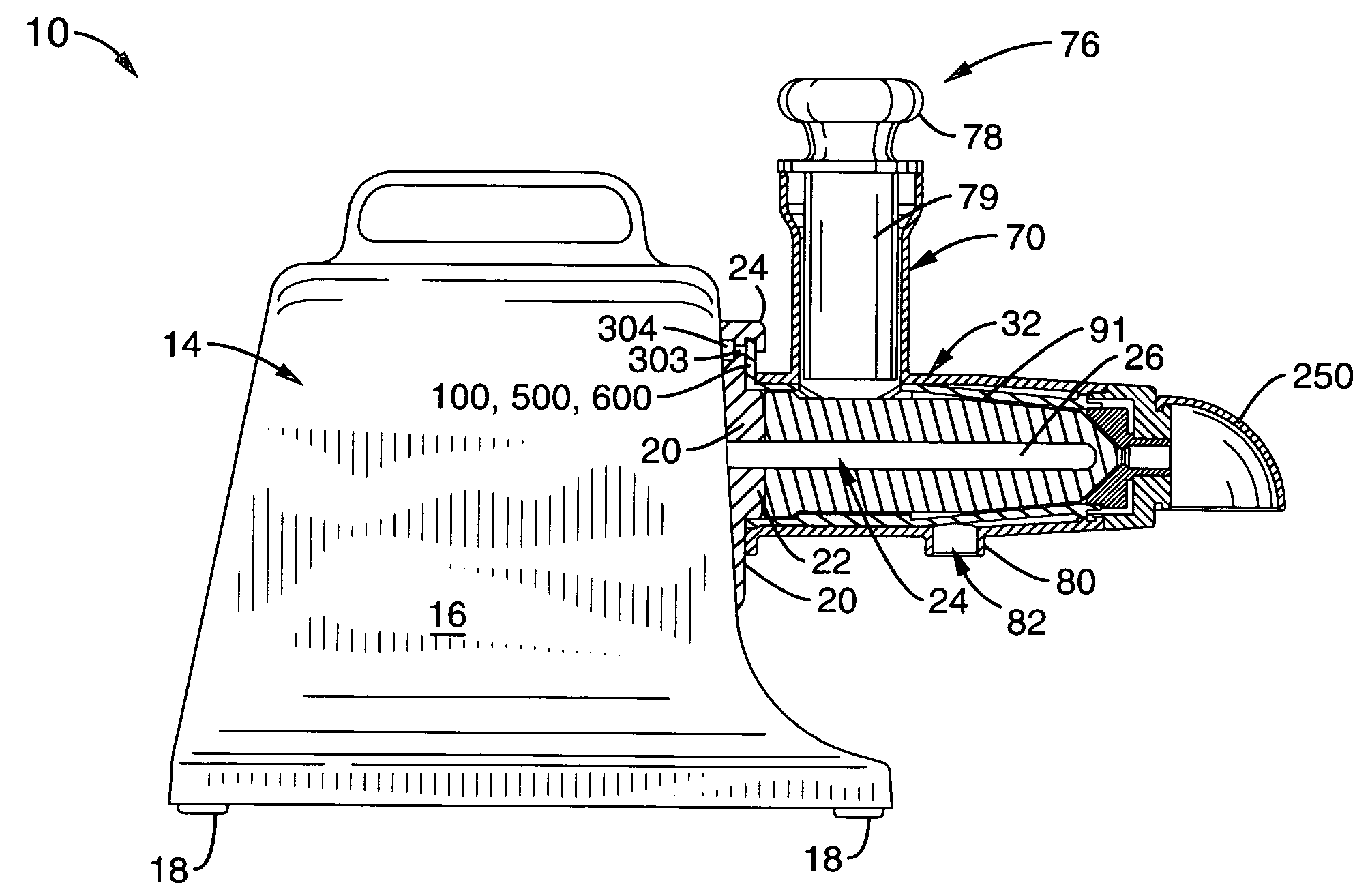

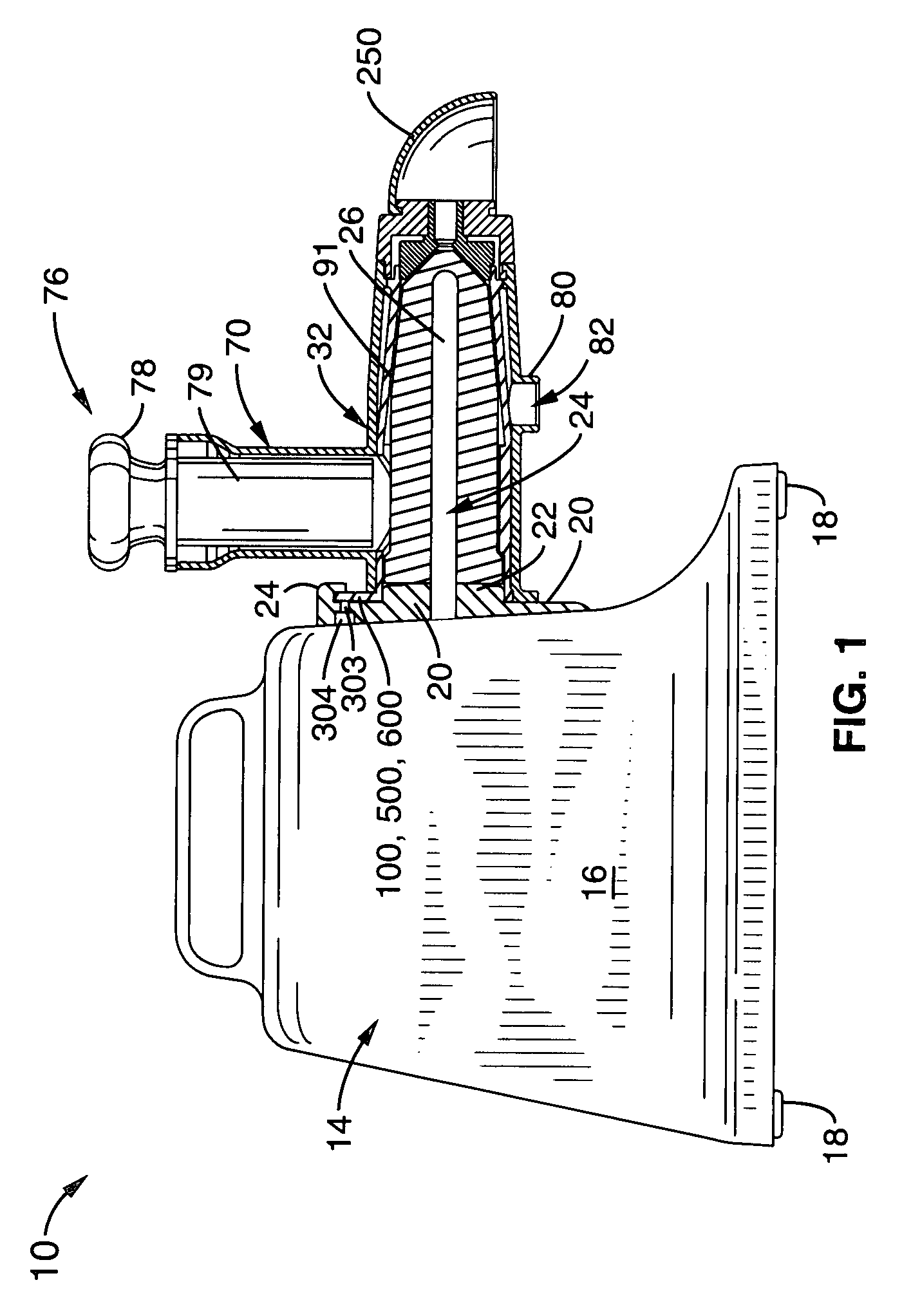

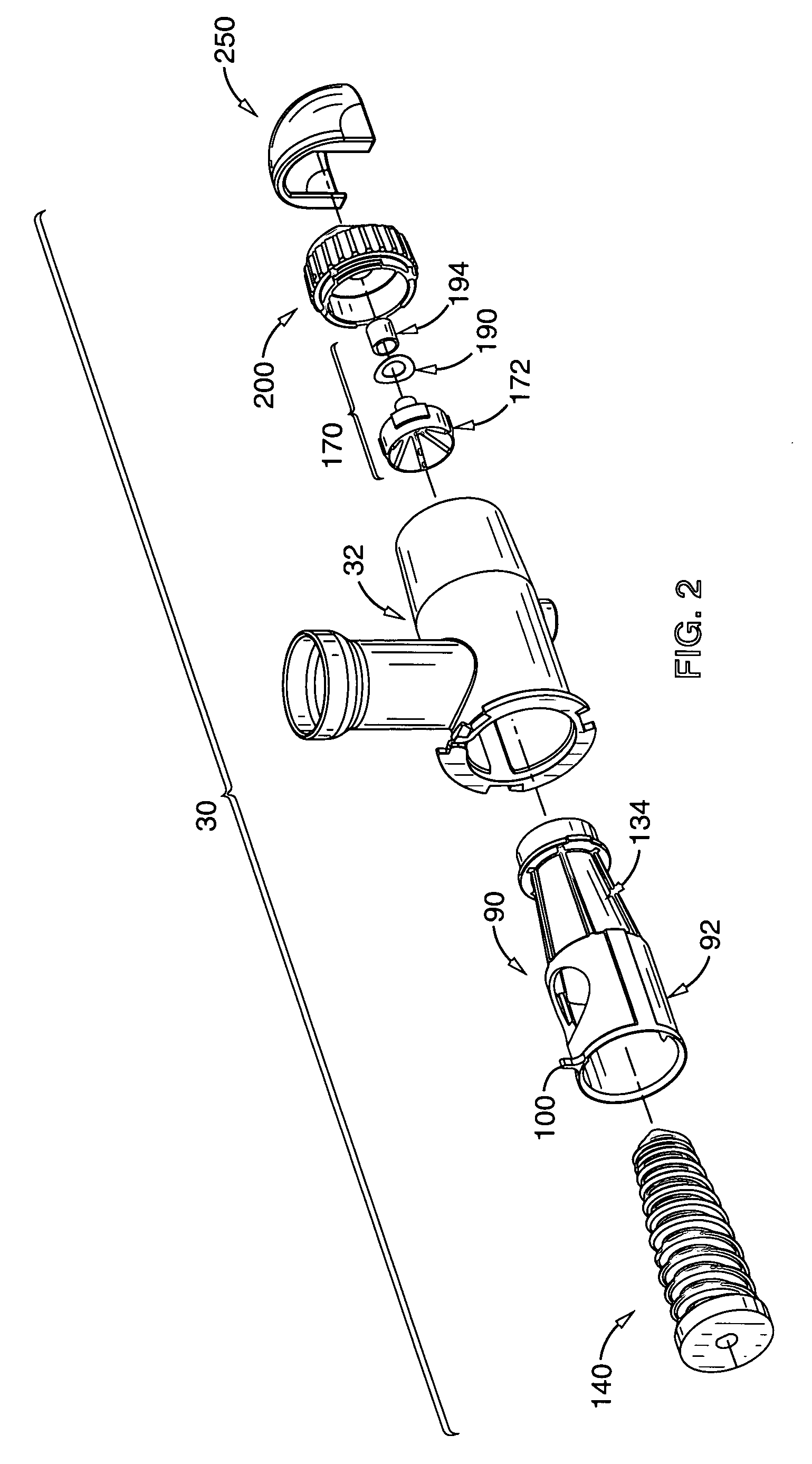

Juicer with alternate cutters

ActiveUS20090064875A1Easily and quickly and efficiently juiceSimple processGrain huskingAutomatic control devicesMinced foodEngineering

A juicer device comprised of a motor disposed within a housing and having an output shaft projecting away from the housing; at least two alternate cutters each individually detachably connectable to the output shaft; a plurality of alternate inserts wherein a selected one of the plurality of alternate inserts circumscribes a selected one of the at least two alternate cutters detachably connected to the output shaft; and a body circumscribing the selected one of the plurality of alternate inserts wherein the body and the selected one of the plurality of alternate inserts include openings for feeding food to the selected one of the at least two alternate cutters detachably connected to the output shaft and openings for receiving juice, homogenized food, or shredded food therefrom upon actuation of the motor under the control of a safety system.

Owner:TROVINGER RUSSELL T

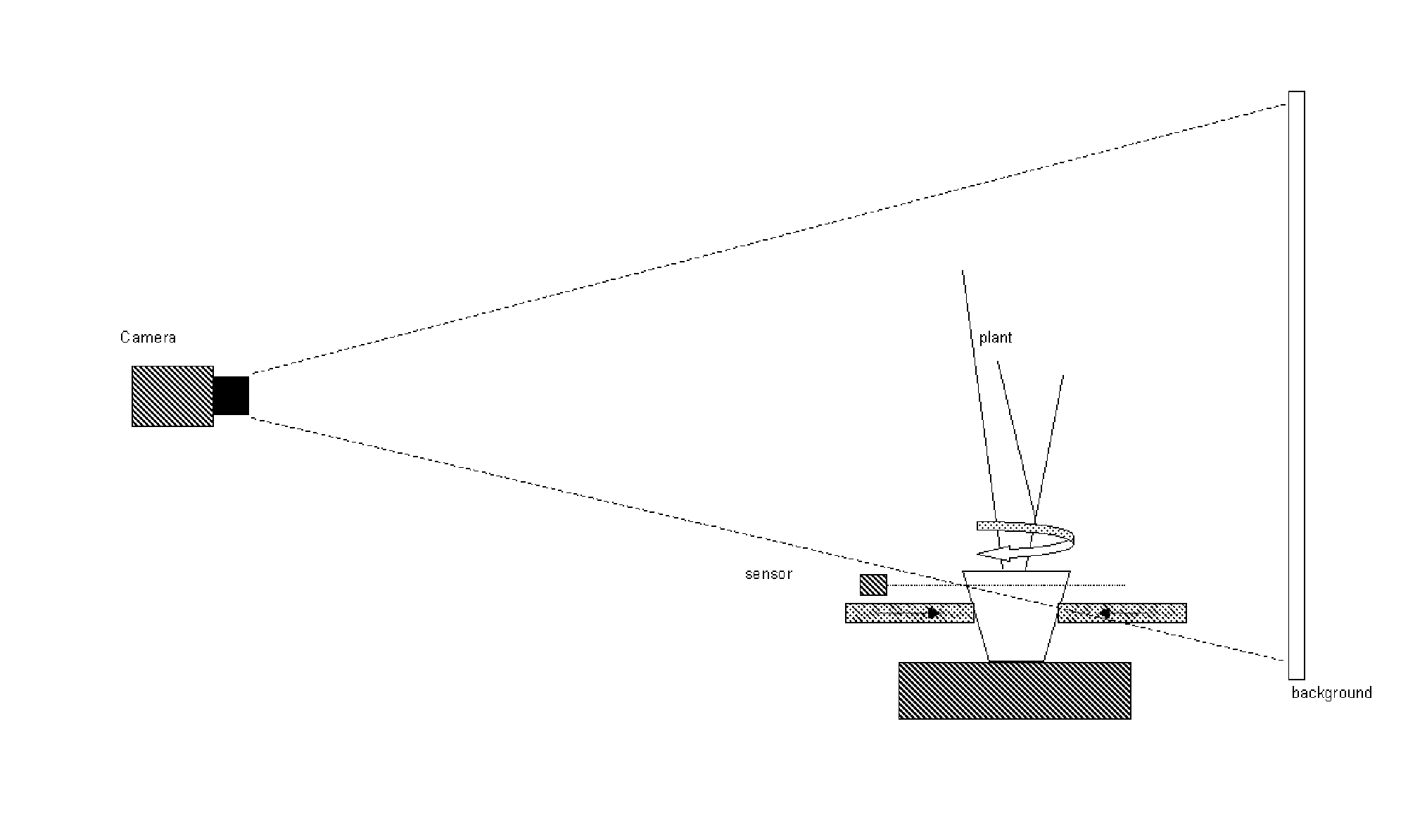

Method for improved plant breeding

InactiveUS20110167721A1Quick analysisAvoid prolonged exposureGrain huskingGrain polishingGenotypeBreeding program

The invention relates generally to an improved plant breeding system. More particularly, this invention relates to a method for automated, high throughput analysis of plant phenotype and plant genotype in a breeding program.

Owner:BASF PLANT SCI

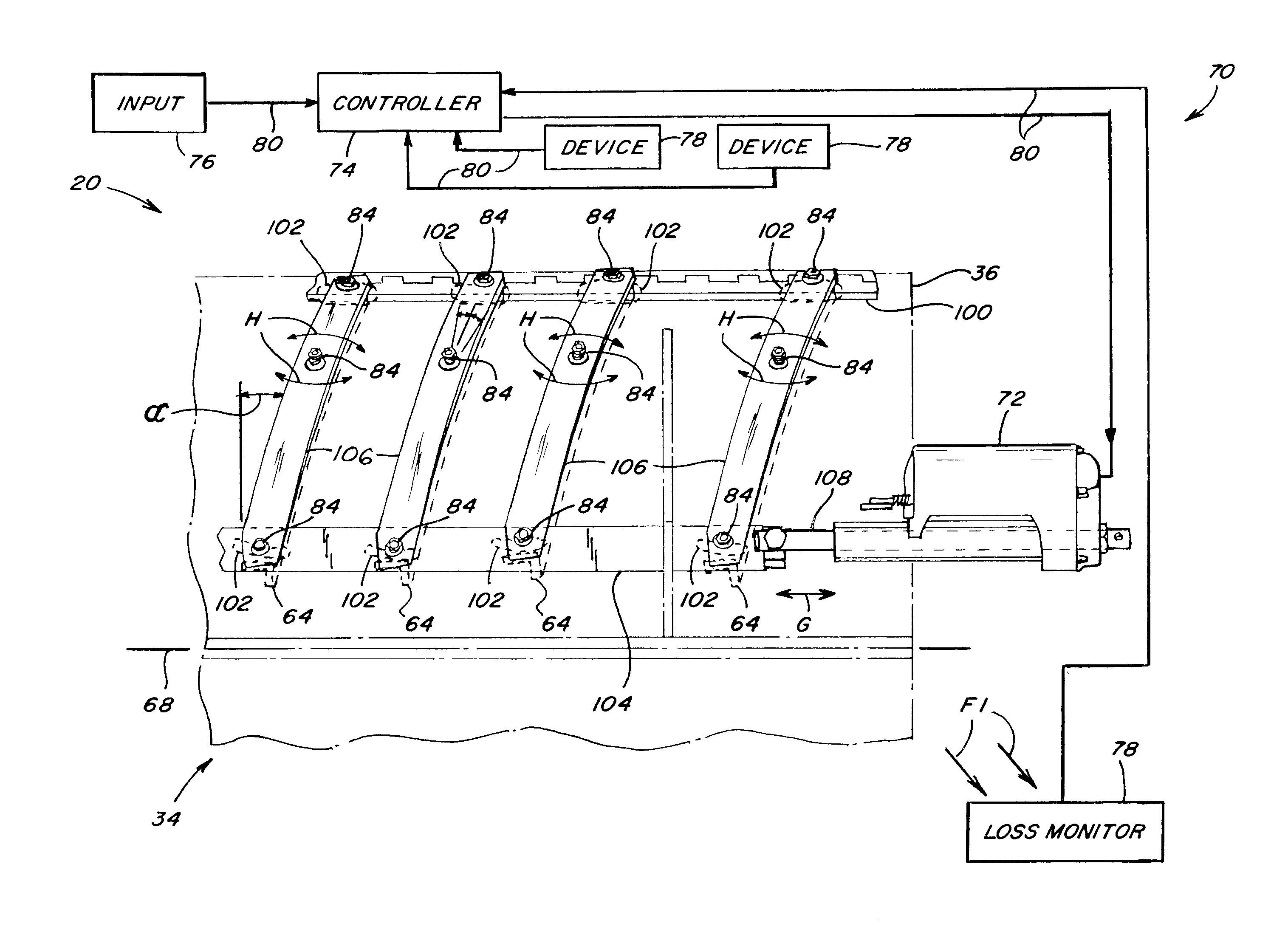

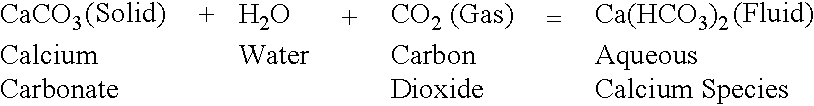

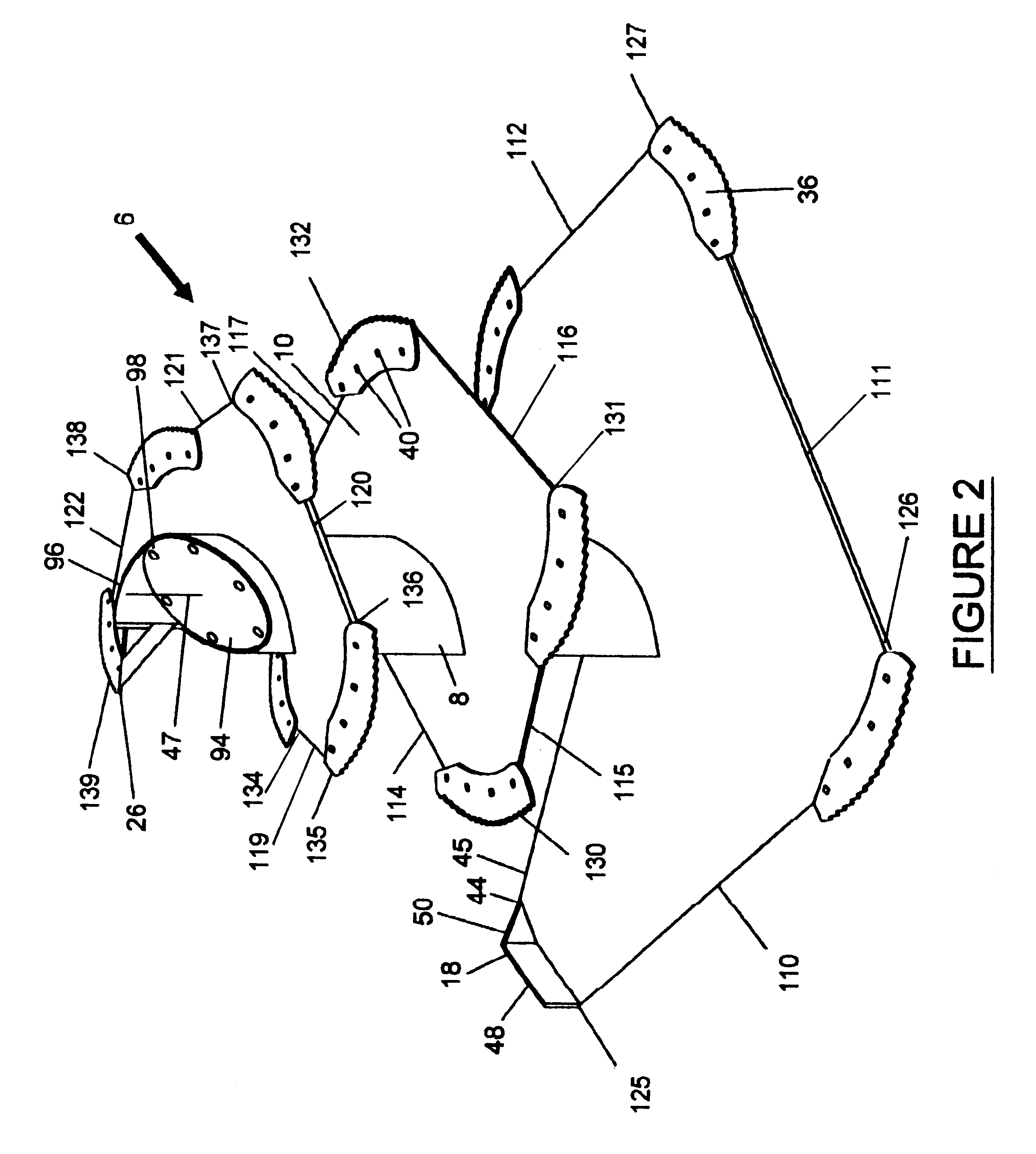

Remote control adjustable threshing cage vane system and method

InactiveUS20110320087A1None provide advantageImprove performanceVehicle testingGrain huskingRemote controlActuator

A system and method for remote control of an adjustable threshing cage vane, including while the threshing system is operating, for improving threshing performance and other operating parameters, utilizes an actuator in connection with the at least one vane and remotely controllable for adjustably varying the position thereof, e.g, pitch angle, within the cage for altering the path of the flow of the crop material therethrough. The remote control can be via an automatic controller to provide control responsive to one or more monitored operating parameters, such as grain loss, grain flow, ground speed, and / or throughput, as well as inputted commands.

Owner:CNH IND AMERICA LLC

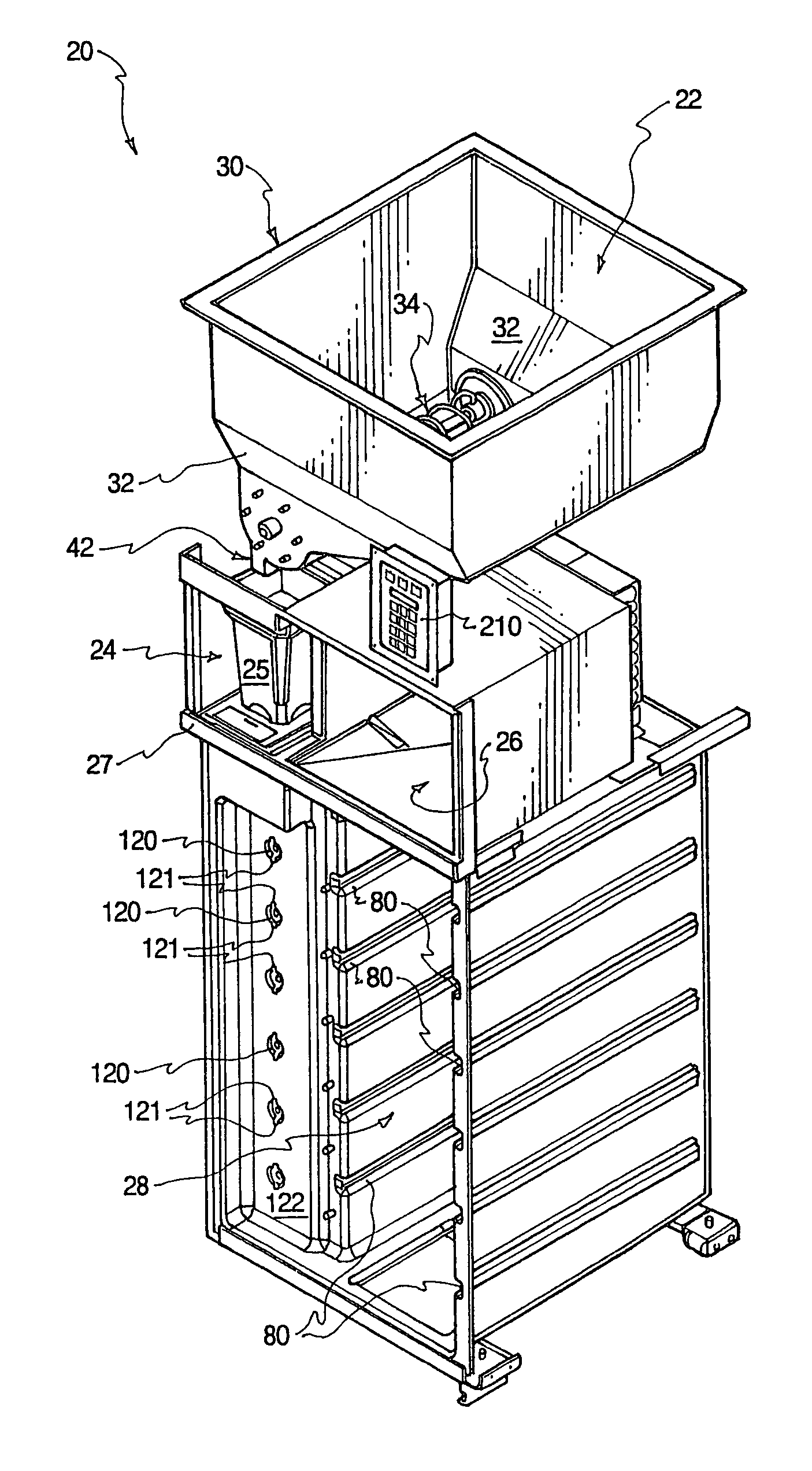

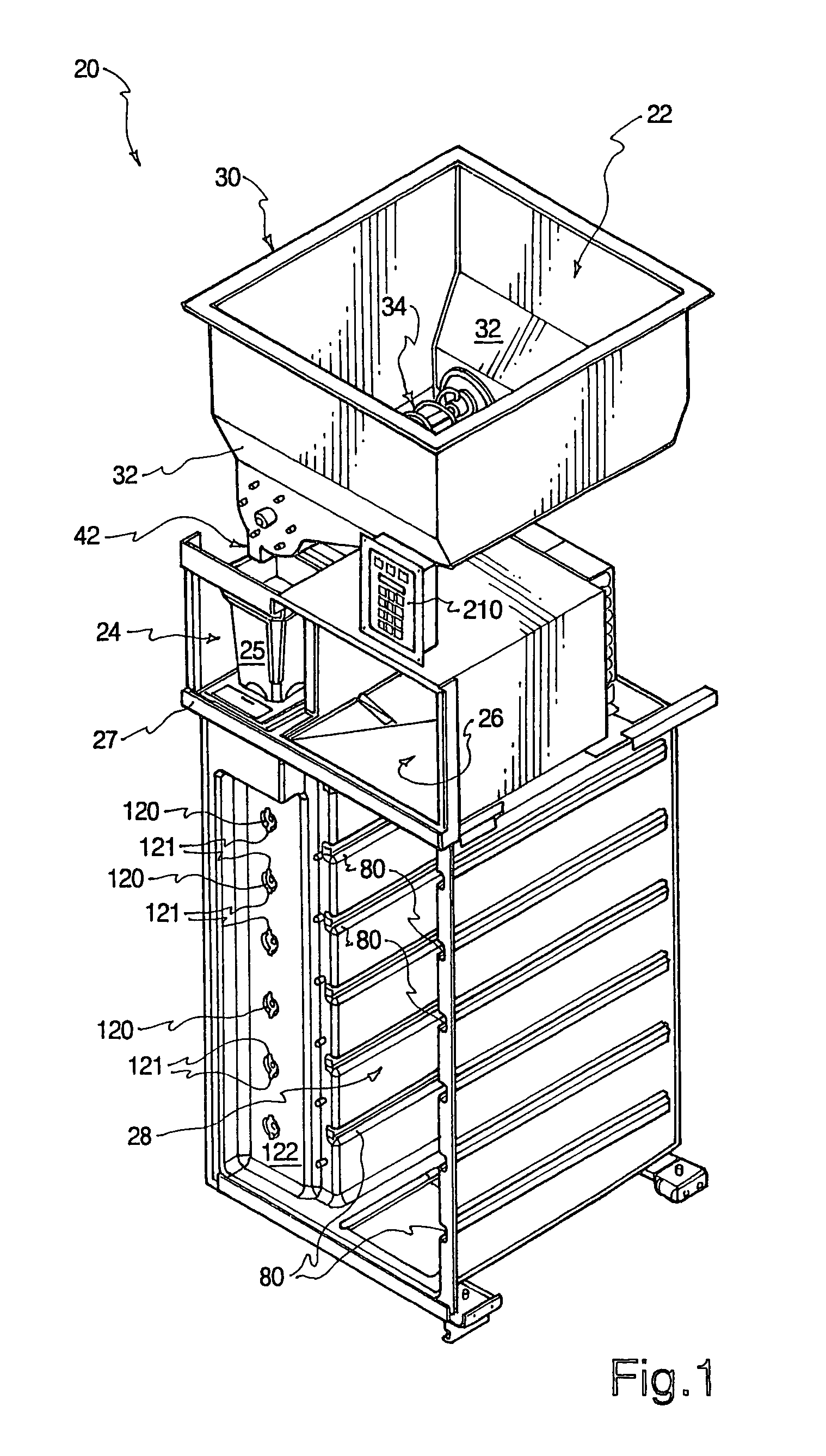

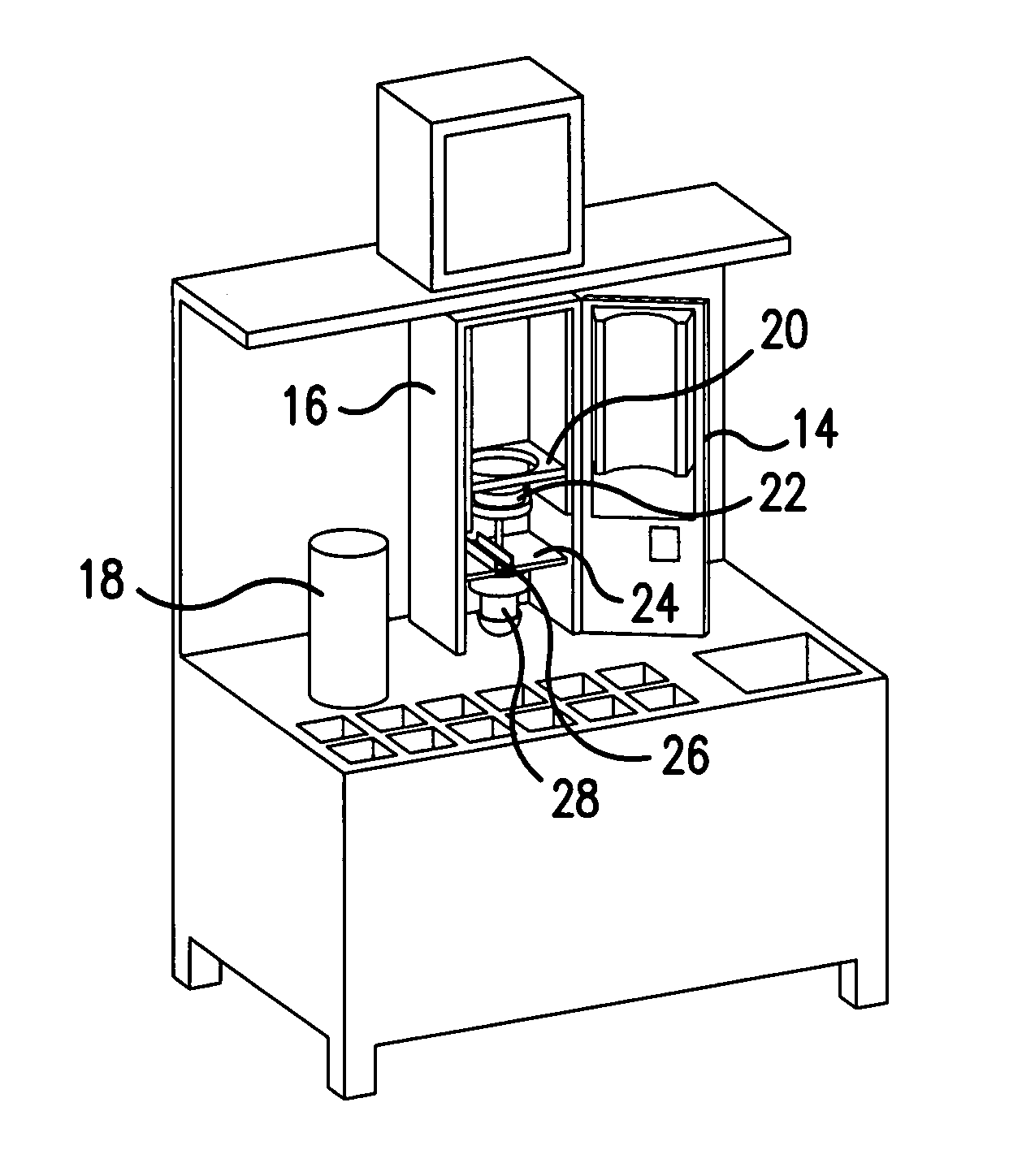

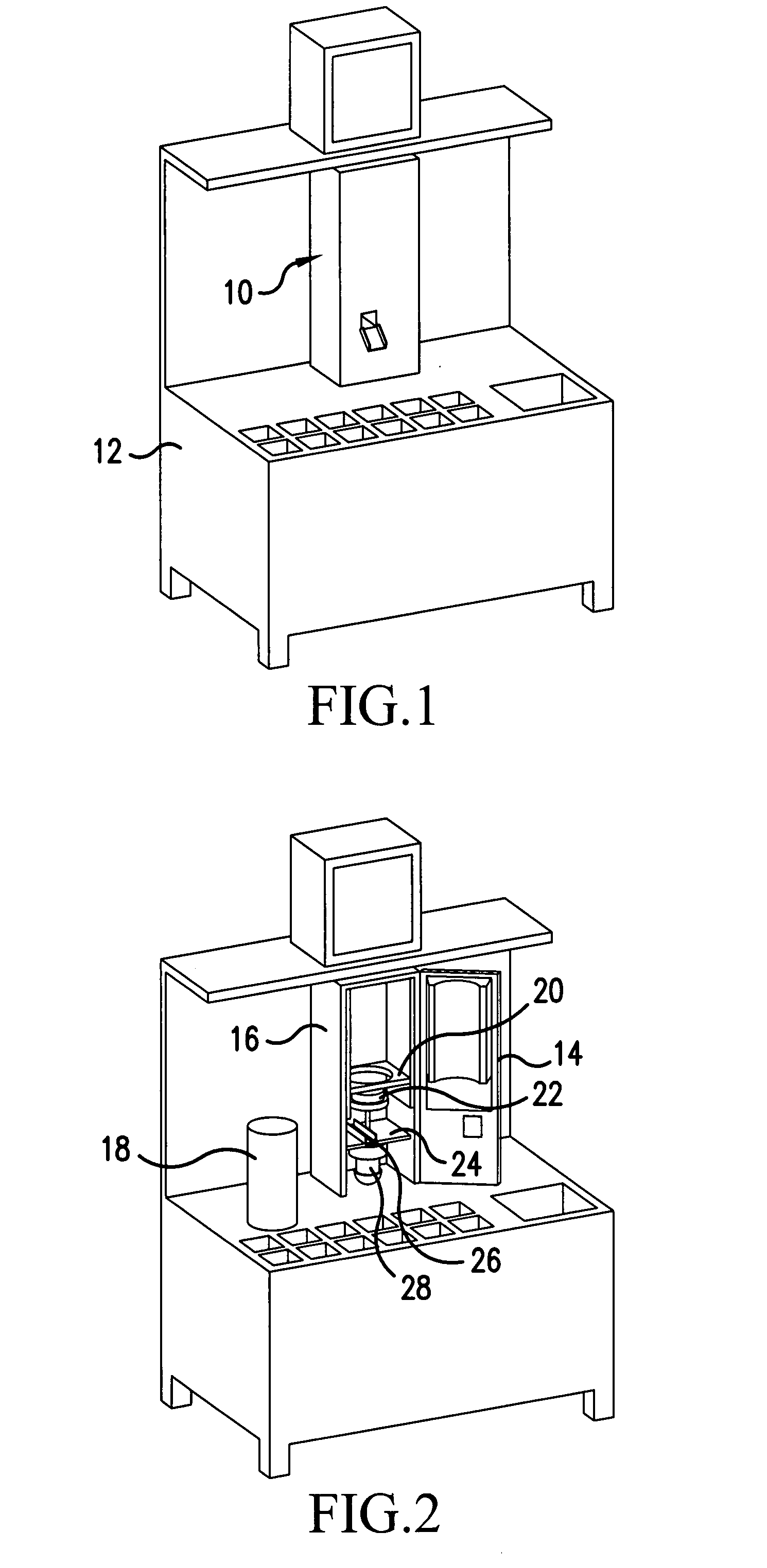

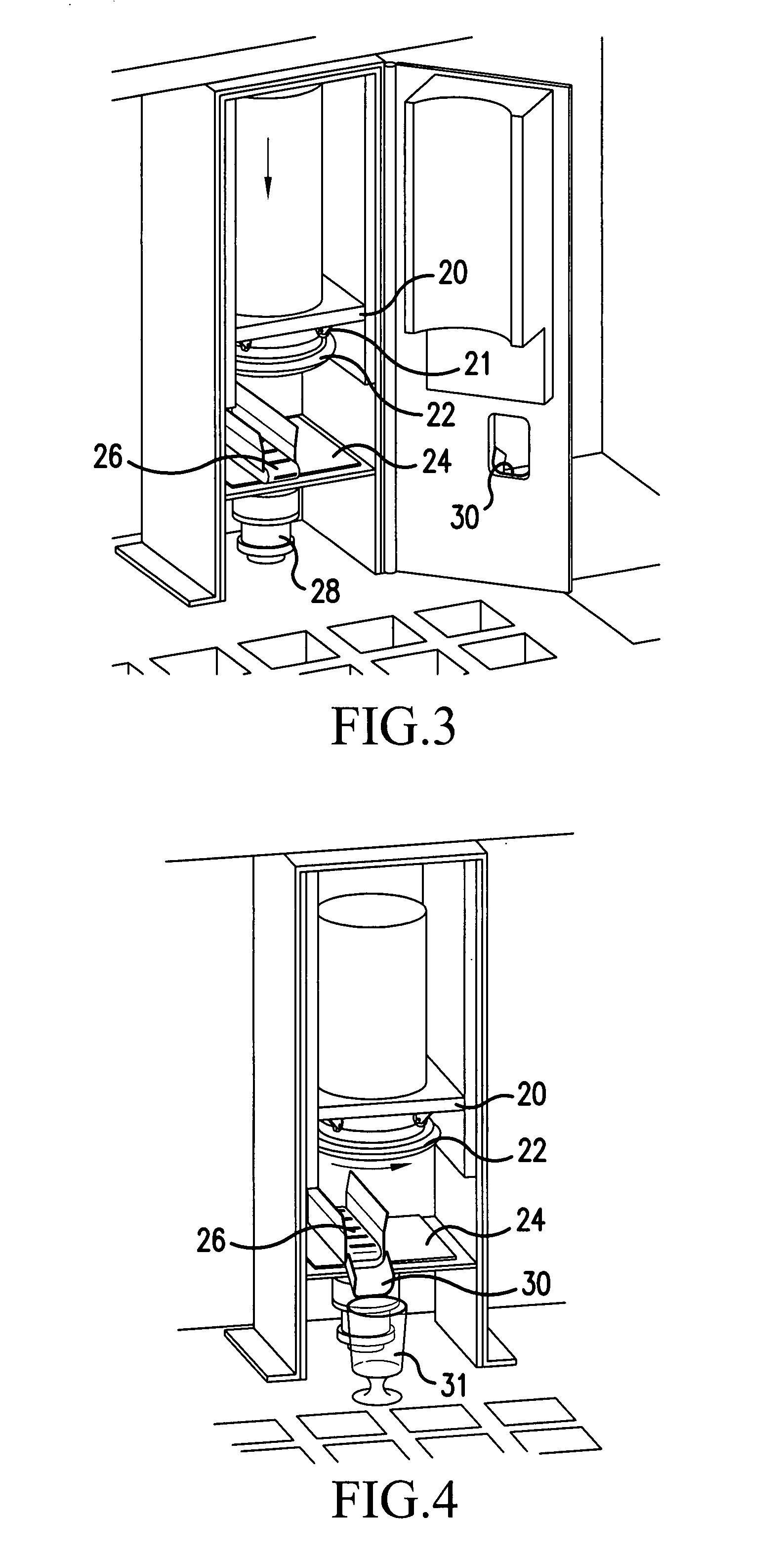

Blending station apparatus and method

InactiveUS7207506B1Less timeImproved taste and texture consistencyGrain huskingGrain polishingAdditive ingredientFood storage

A blending station apparatus and method includes a foodstuffs storage location where a plurality of individual foodstuffs storage containers are held, a control panel for inputting information into the blending station so that the beverage size and one or more of the various types of foodstuffs, as well as other ingredients such as ice, water, supplements, etc., can be selected to make a drink, a blending container to hold the various ingredients, a mixing location for blending the ingredients to achieve a uniform drink consistency, and a cleaning location to clean the blending container after the blended contents have been dispensed into a container for consumption.

Owner:BLENDTEC

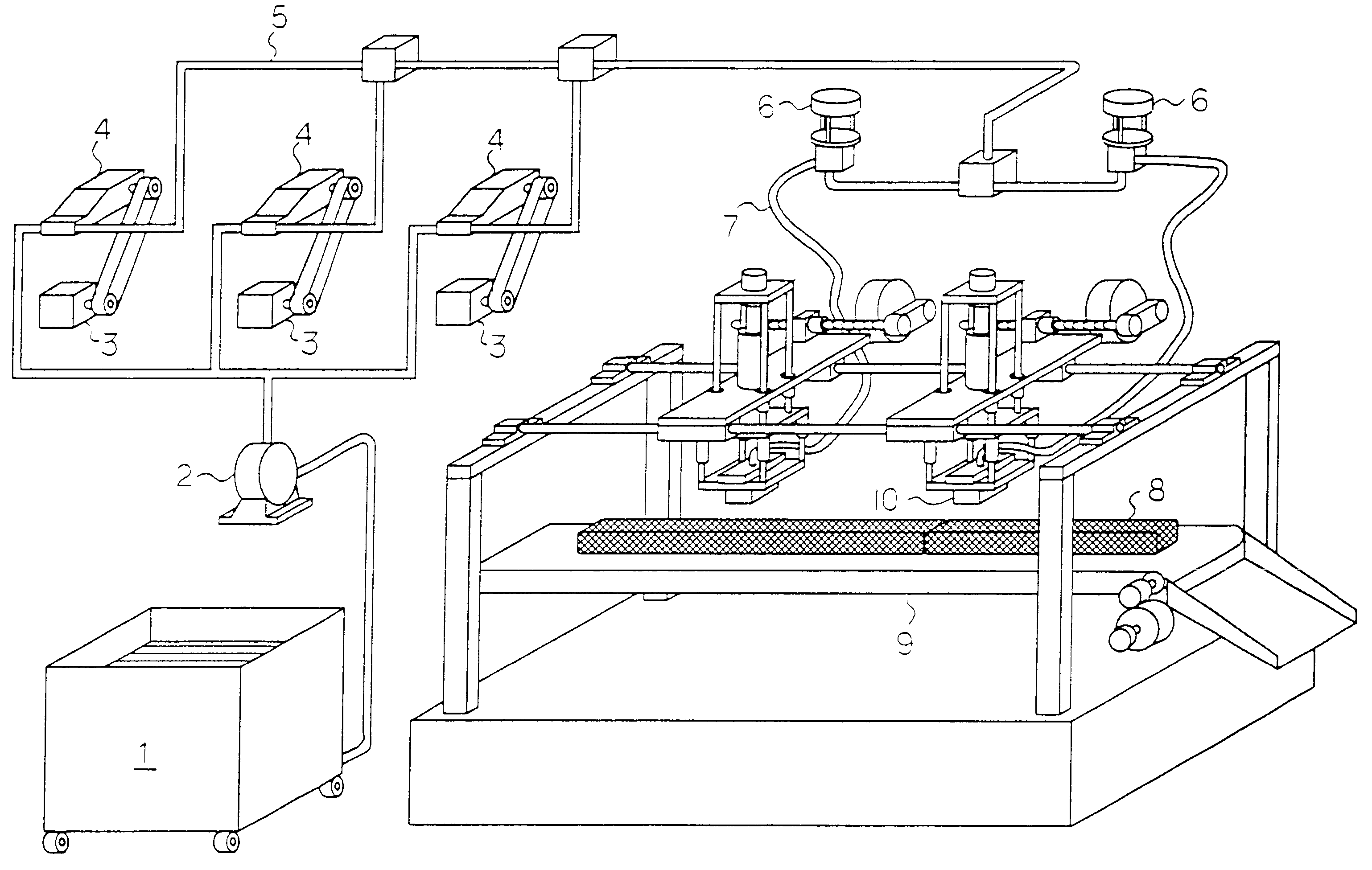

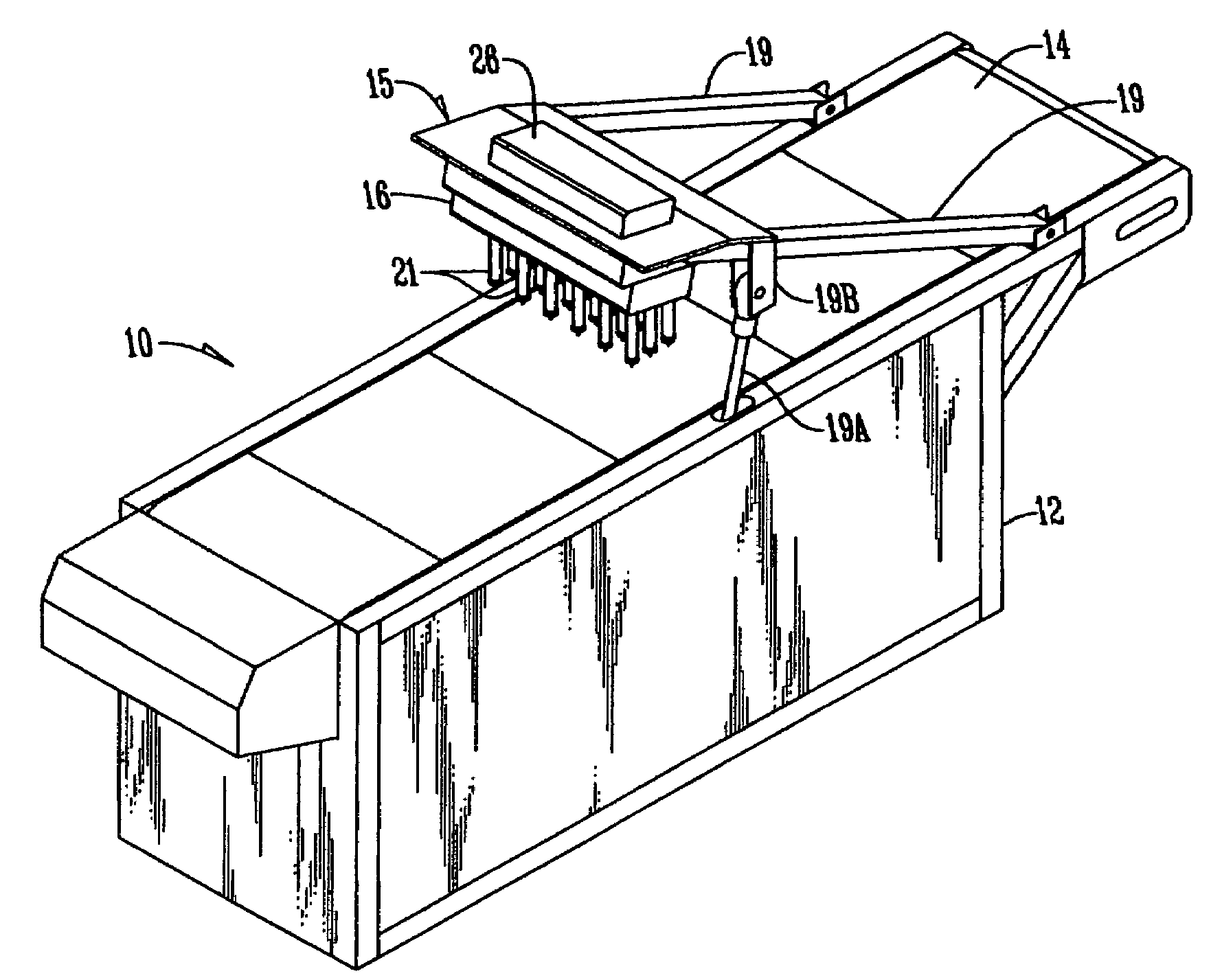

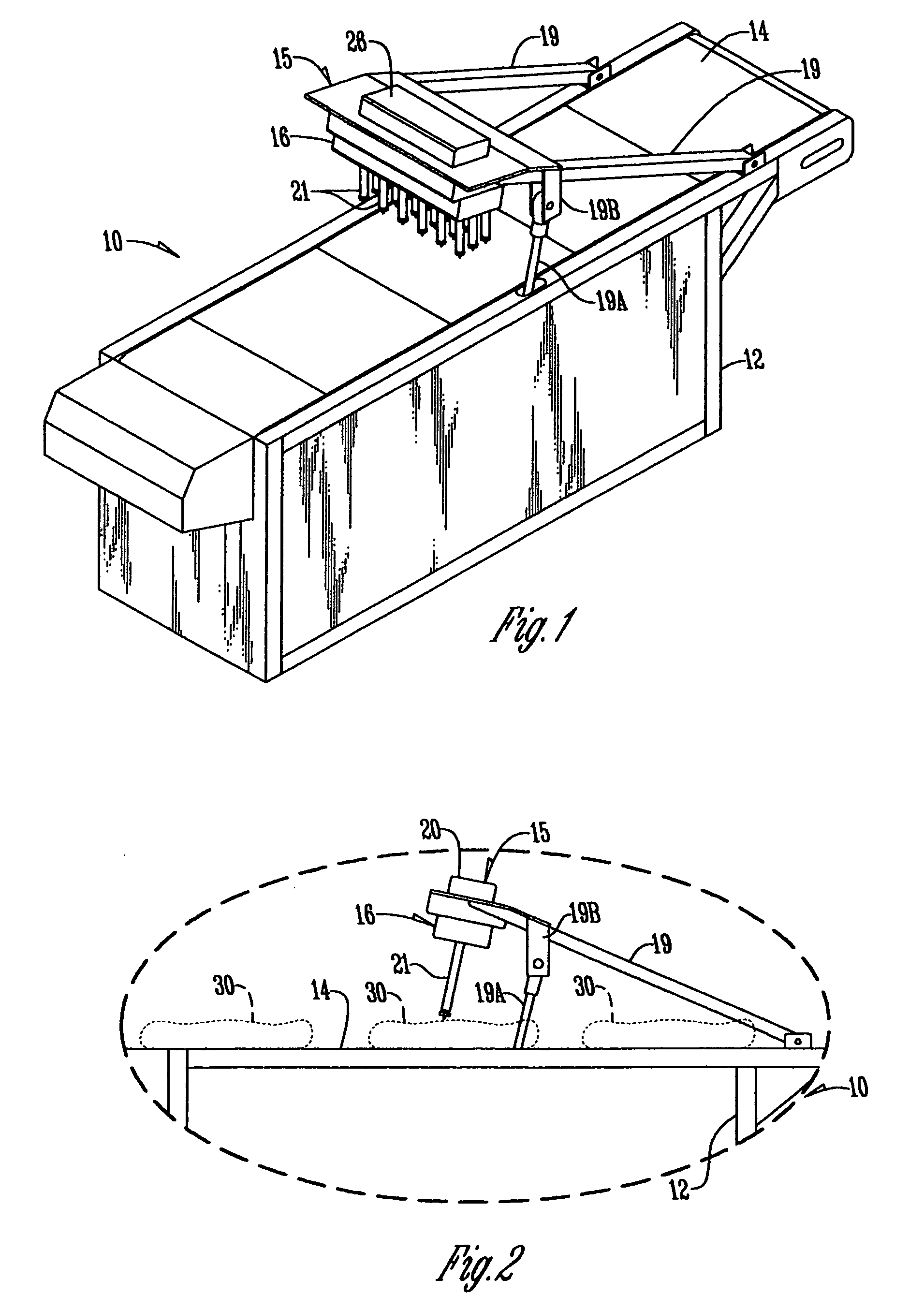

Continuous high-speed pickle injector

InactiveUS6386099B1Improve productivityIncrease speedGrain huskingGrain polishingSaline waterInjection pressure

A continuous high-speed pickle injector is provided with improved productivity that can inject a liquid substance such as brine for curing, seasoning or the like into a block of meat such as pork, beef, livestock meat and the like continuously, and disperse the liquid substance uniformly. A pickle injector which can inject a liquid substance such as brine for curing and the like into a block of meat being conveyed continuously while gradually raising the injection pressure from 0 or a low pressure includes two or more injecting sections being able to repeat an injecting operation, that is, from the start to the completion of the injection of a liquid substance. The two or more injecting sections inject a liquid substance while moving at a speed synchronized with the conveying speed of a block of meat continuously being conveyed during the operation of injection. The timing of the injecting operation for each injecting section is controlled.

Owner:PRIMA MEAT PACKERS LTD

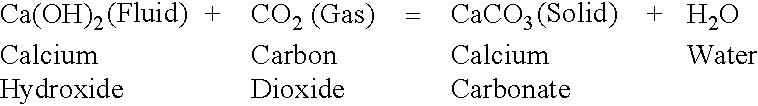

Method for stabilizing and reducing permeability of geologic or waste materials

InactiveUS6648551B1Improves Structural IntegrityReduce penetrationGrain huskingGrain polishingGas phaseWater insoluble

Methods for inducing the precipitation of substantially water insoluble mineral carbonates in pores, spaces and fractures by conveying a carbon-dioxide (ie. CO2) bearing gaseous phase or an oxidised-carbon-bearing aqueous phase into spaces where reaction with an existing or introduced fluid phase of appropriate composition occurs, or by conveying a fluid of appropriate composition into spaces where reaction of the fluid components with a fluid delivery medium occurs, or by conveying a fluid of appropriate composition into spaces under controlled physical conditions such that unassisted reaction of the fluid components occurs. The present invention also provides a method of reducing the permeability or improving the structural integrity of natural or man-made aggregates of mineral or waste materials comprising the introduction of carbon dioxide or a soluble carbonate species into the aggregate to react with a chemical compound capable of reacting with the carbon dioxide or soluble carbonate species to form a substantially insoluble carbonate within pores, spaces or fractures in the aggregate in broadly controllable geometric distributions, wherein an appropriate chemical compound capable of reacting with the carbon dioxide or soluble carbonate species to form a substantially insoluble carbonate may need to be introduced to the aggregate if not already present in suitable concentrations wherein the carbon dioxide or soluble carbonate species need not be introduced to the aggregate if already present in suitable concentrations. The present invention also provides a method of reducing the permeability or improving the structural integrity of natural or man-made aggregates of mineral or waste materials comprising the introduction of one or more reactive materials to react to form a substantially insoluble carbonate within pores, spaces or fractures.

Owner:EARTH SYST

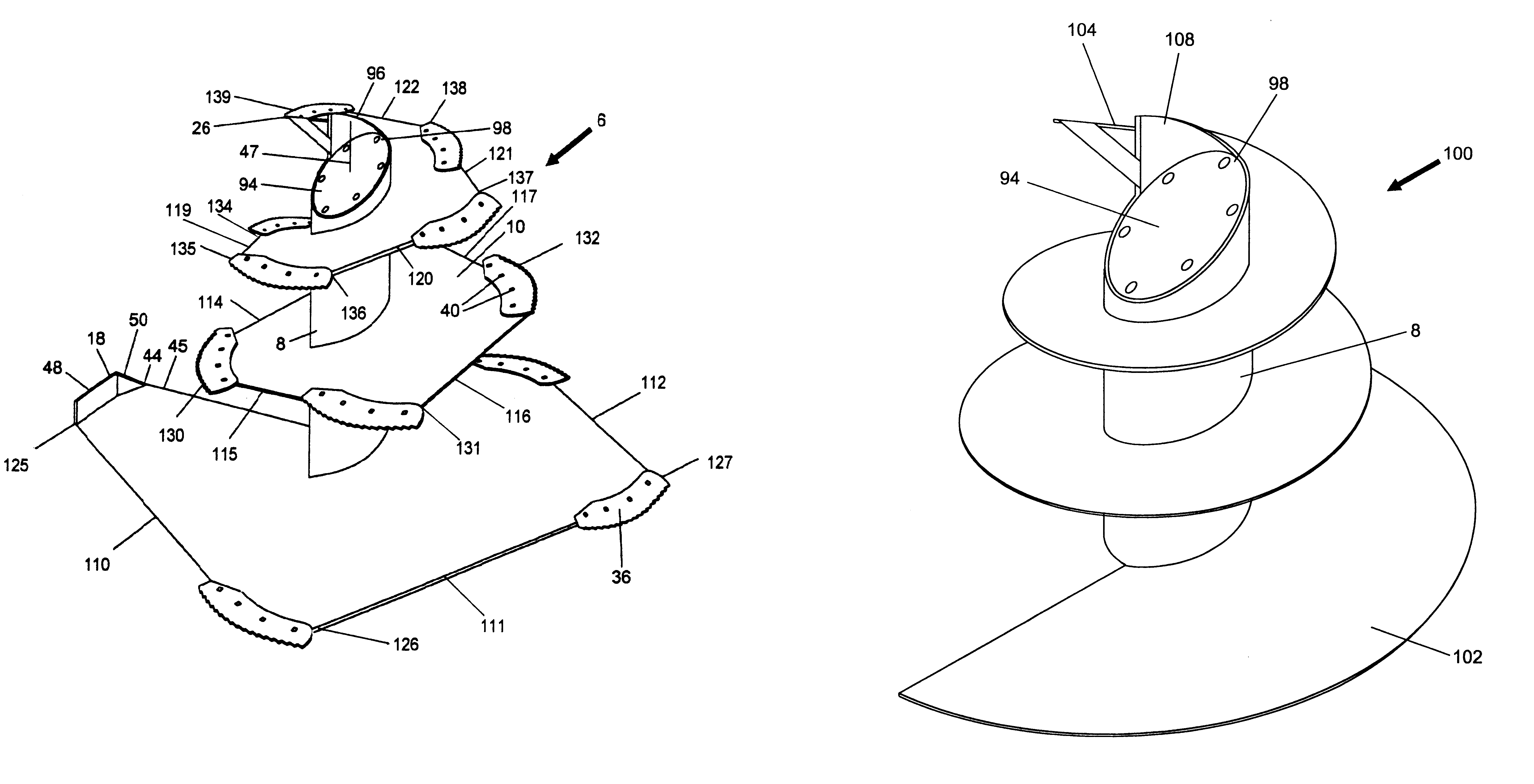

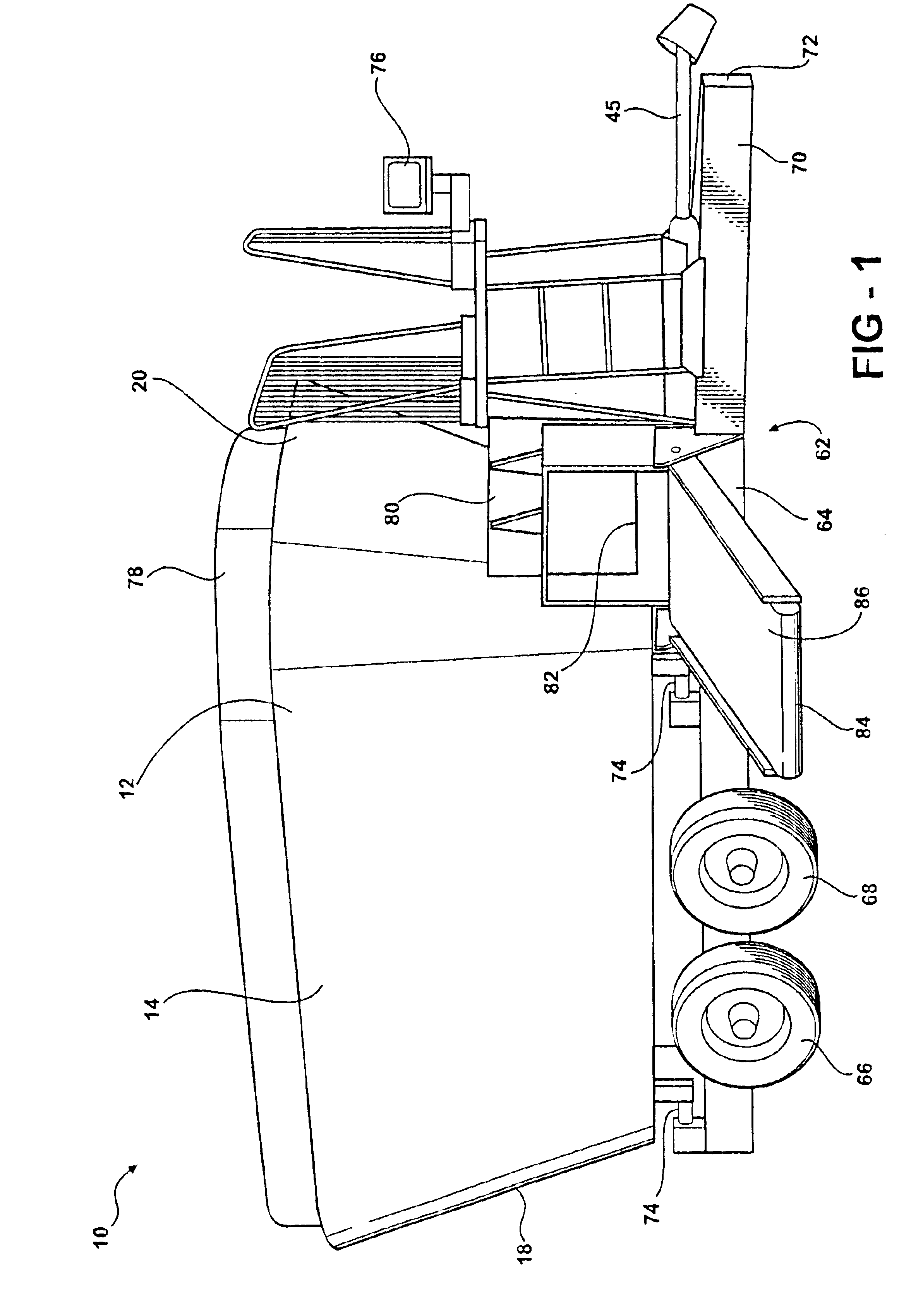

Vertical feed mixer with auger having center post with sloped top

A vertical feed mixer has an auger with a center post that has an inclined upper surface that is substantially flat. Flights of varying shapes can be used. The upper part of the flight extends above the upper surface. The inclined upper surface increases the versatility and efficiency of the mixer since feed bales are unlikely to block the mixer.

Owner:JAY LOR INT INC

Corn degermination process

InactiveUS6936294B2Increase productionYield maximizationGrain huskingGrain polishingSurface velocityEngineering

Owner:SATAKE USA INC

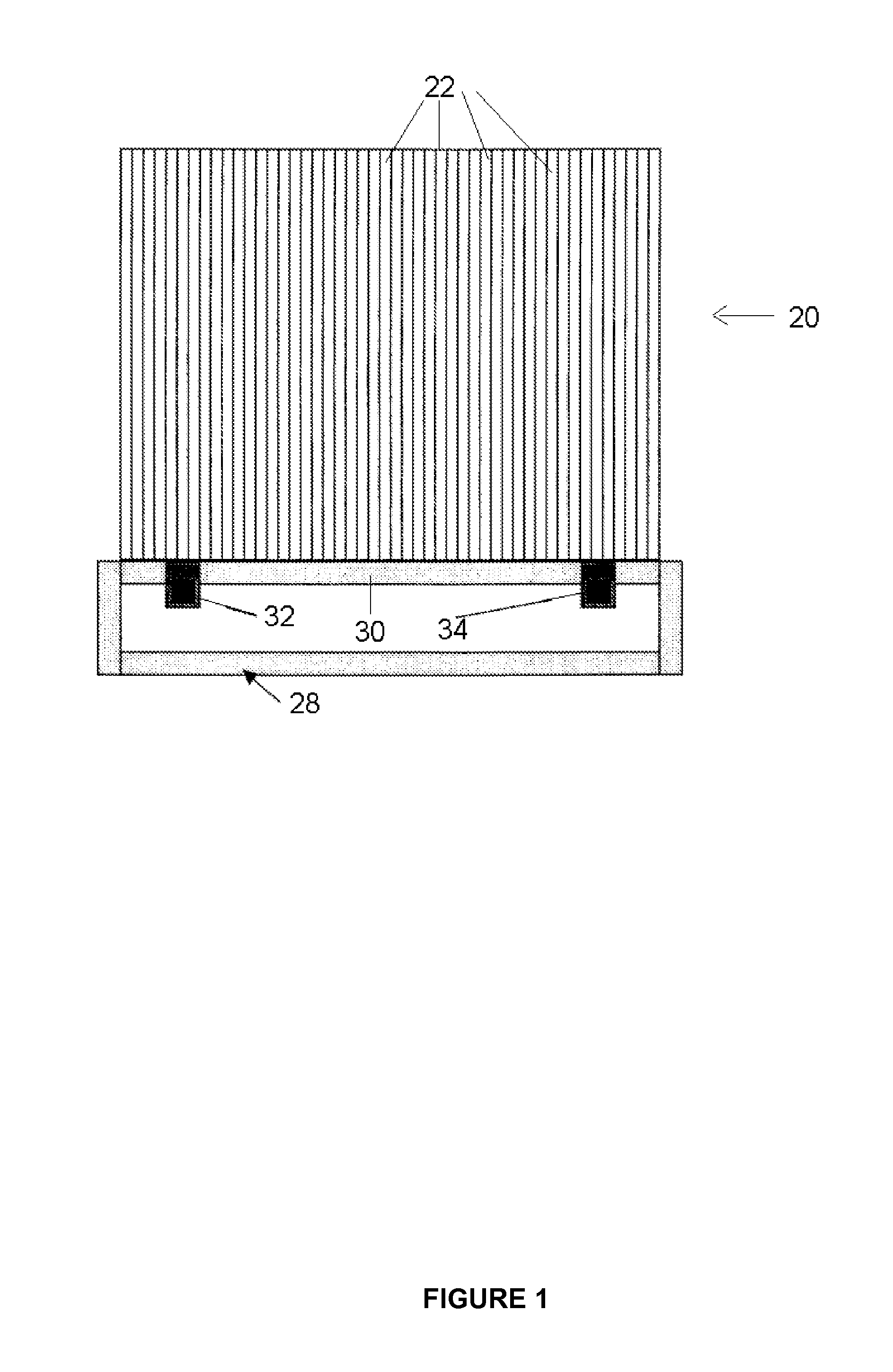

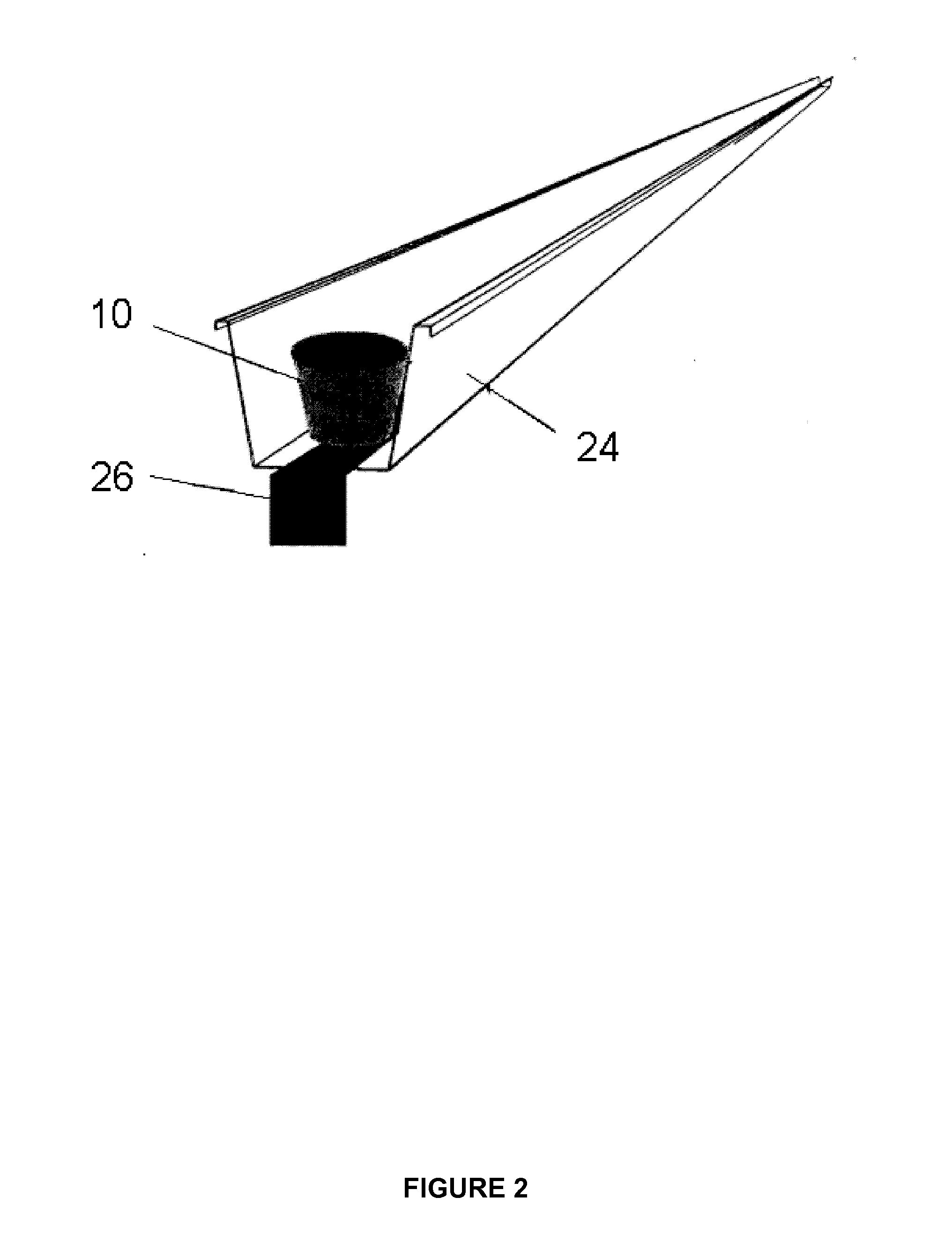

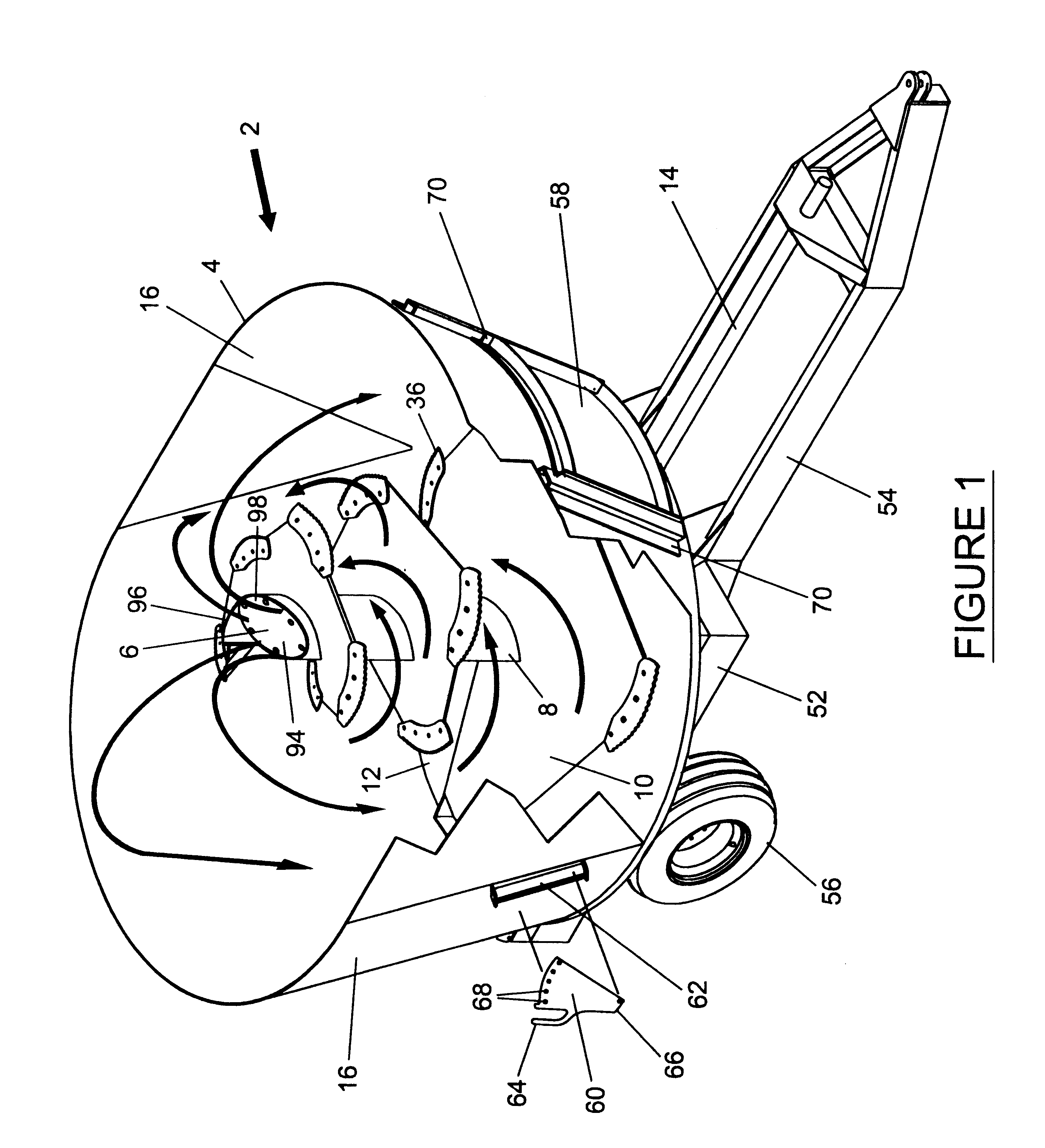

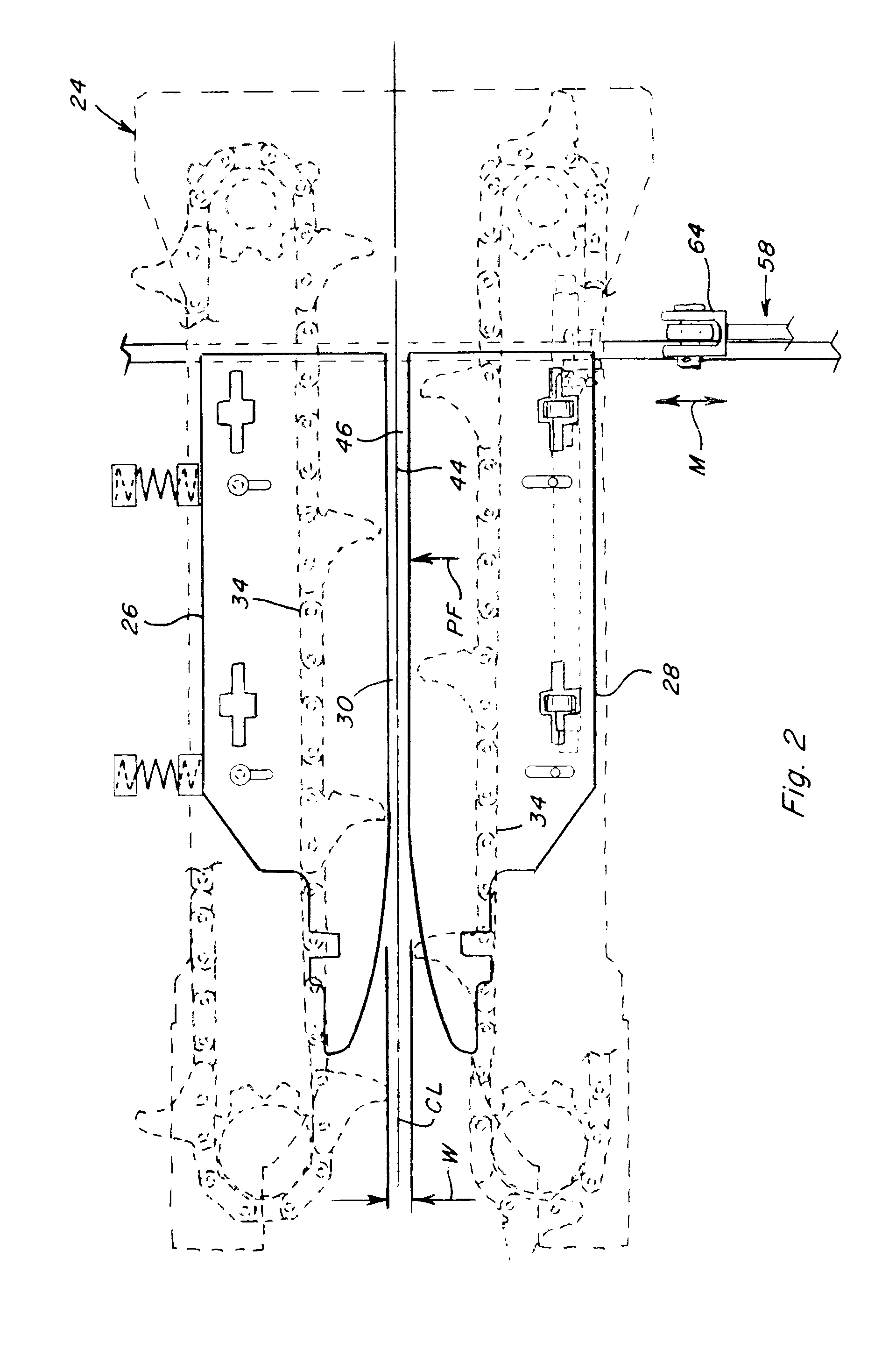

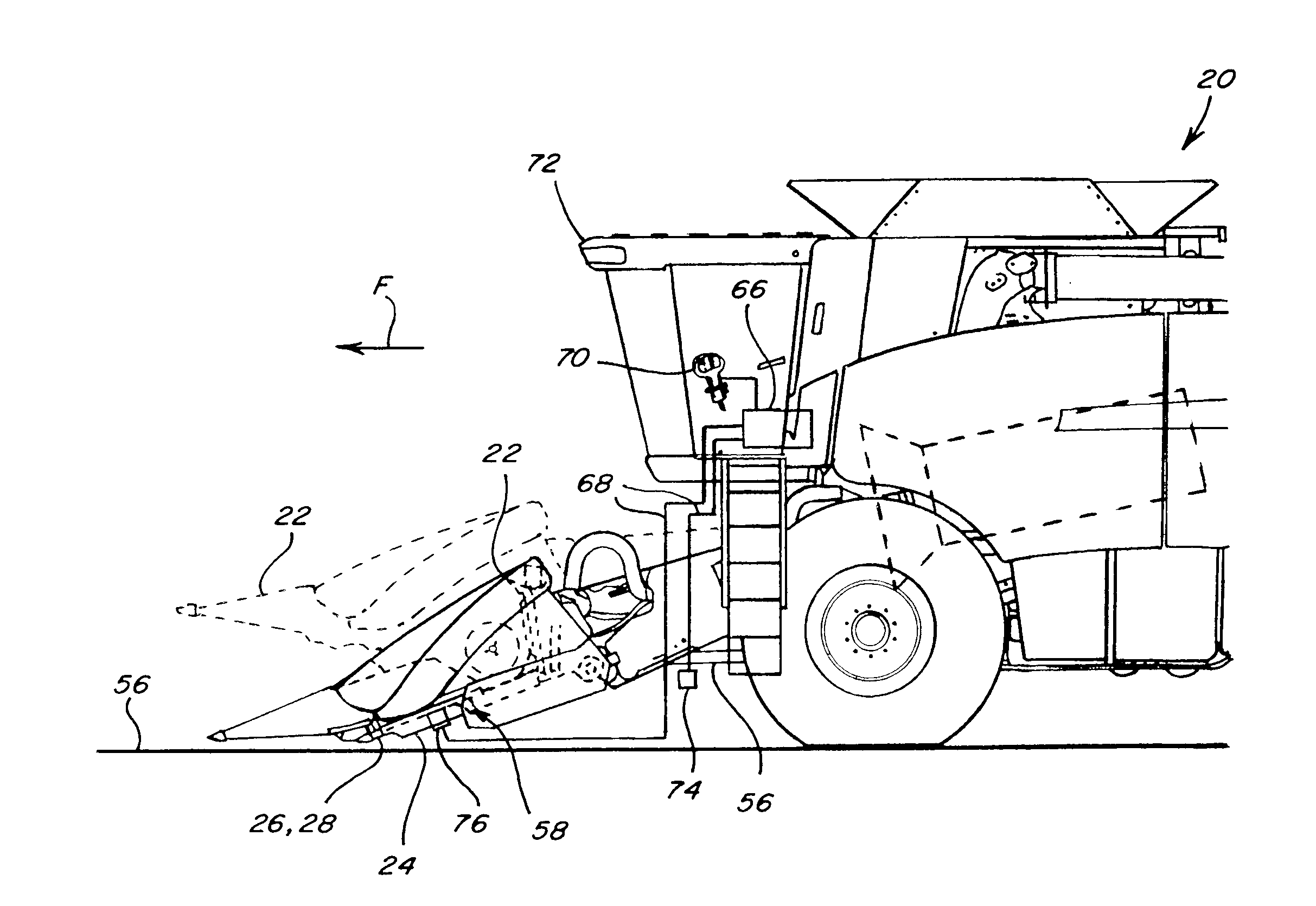

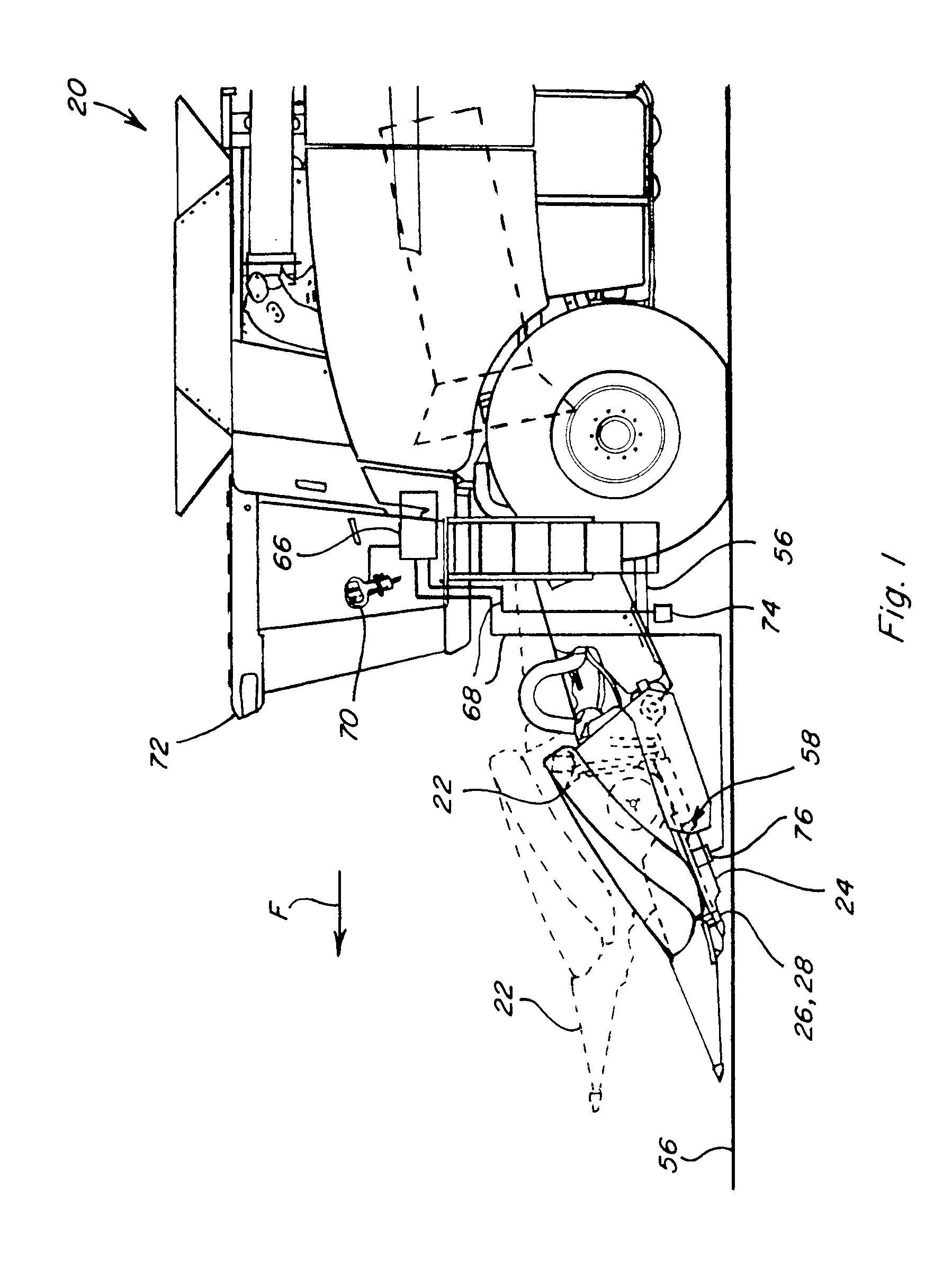

System and method for automatically controlling deck plate position on a corn header

ActiveUS8224534B2Overcomes shortcomingIncrease widthVehicle testingGrain huskingAutomatic controlEngineering

The system and method automatically controls the position of at least one deck plate of a harvesting unit of a corn header so as to increase the width of a stalk receiving channel or reduce pinching forces between the plates when entering a stand of corn to facilitate alignment with the corn rows, and to change the position after a suitable time period or other condition or event, to narrow the channel width and / or increase pinching force, to reduce kernel loss while also monitoring forces exerted against the plates by the stalks and responsively adjusting the plate position for maintaining a desired force on the stalks or width.

Owner:BLUE LEAF I P INC

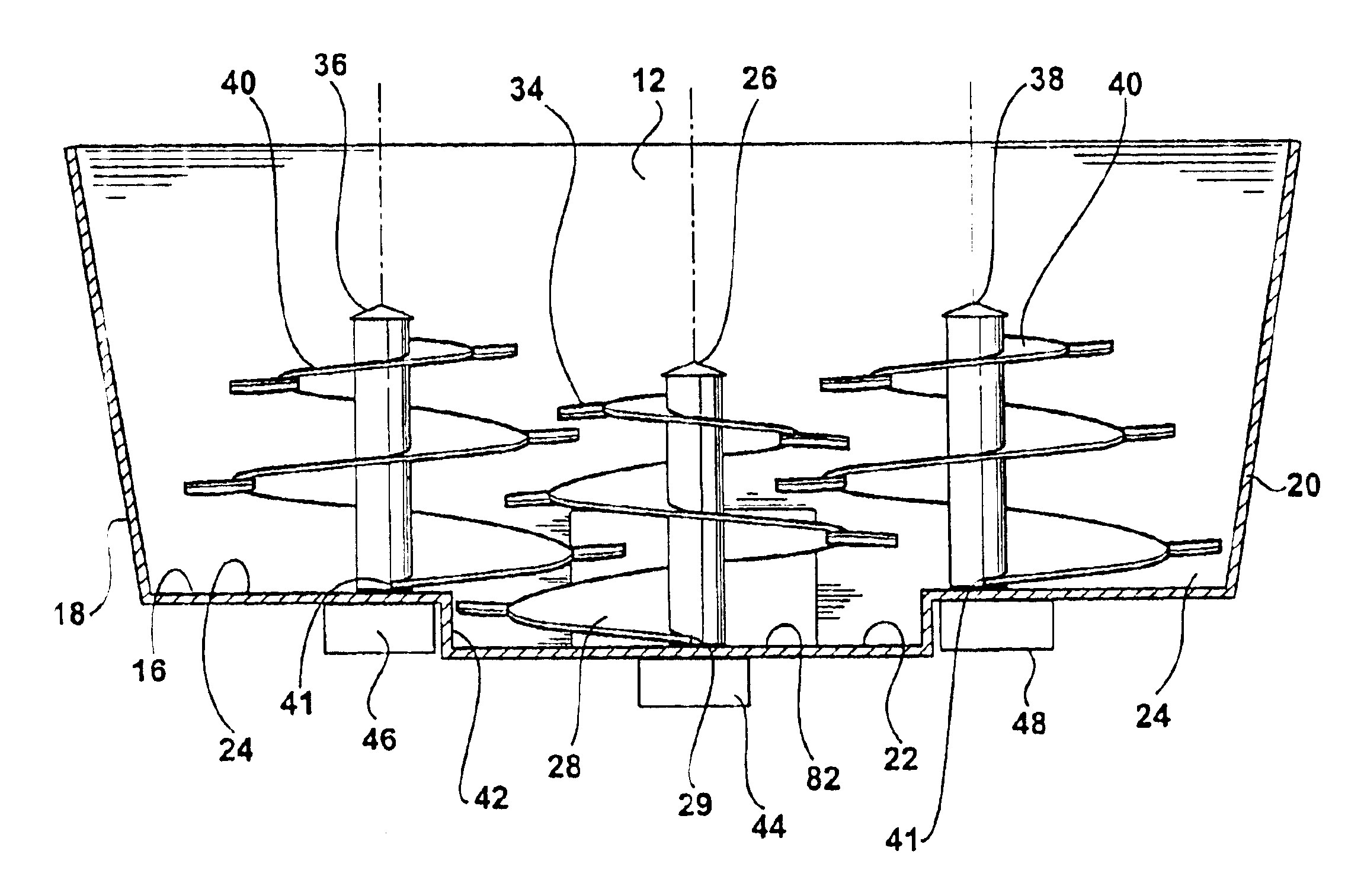

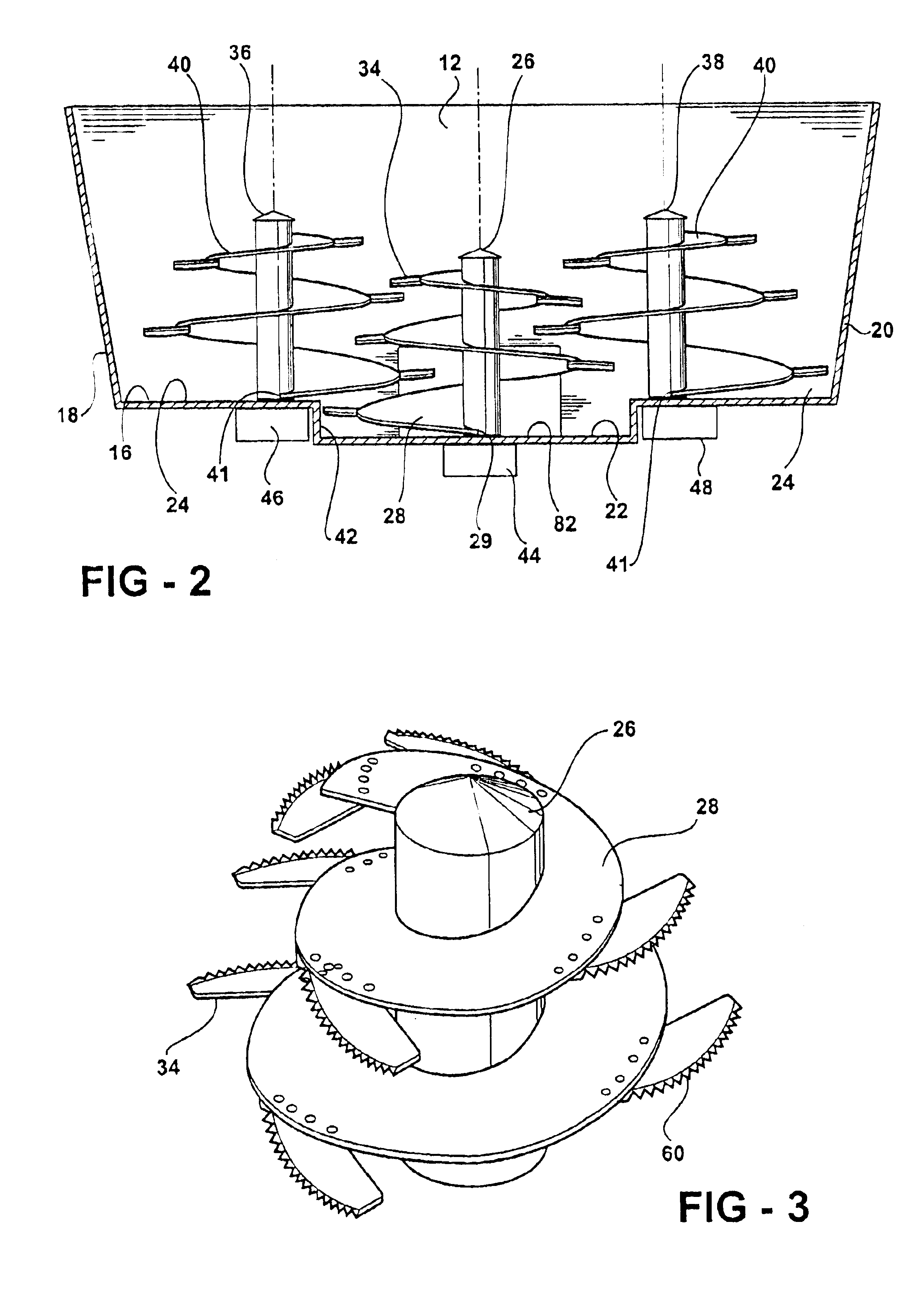

Multiple vertical auger cutter mixer

The cutter mixer has a mixer tub with side walls and a floor. The floor includes a primary floor portion at a lower elevation. At least one secondary floor is positioned vertically above the primary floor portion. A primary vertical spindle is journaled in the center of the primary floor. A secondary vertical spindle is journaled on the secondary floor. Auger flighting is attached to the primary spindle. Auger flighting is also attached to the secondary spindle. The flighting decreases in width from the bottom to the top of each spindle. The bottom of the flighting on the primary spindle sweeps over substantially all the primary floor. The flighting on the secondary spindle overlaps the flighting on the primary spindle and sweeps fodder from the secondary floor to the primary floor. The augers are driven to cut and mix fodder and discharge fodder from the primary floor.

Owner:NEW DIRECTION EQUIP

Rubber composition and method for producing the same

InactiveUS6207723B1Save amountEasy to recycleGrain huskingGrain polishingShear stressPolymer science

The present invention provides a rubber composition containing a reclaimed rubber and a method for producing the same. A rubber molded article having excellent rubber properties can be obtained and the recycling of a used rubber product can be promoted by the present invention.A rubber composition of the present invention is a blend comprising a claimed rubber obtained by applying a heat and a shear stress to a vulcanized rubber, a non-vulcanized virgin rubber or / and a thermoplastic resin, wherein the reclaimed rubber contains 40% by weight or more of a residual toluene-insoluble gel component and the network chain density of the rubber in the gel component is 1 / 20 to 1 / 4 based on the network chain density of the rubber of the vulcanized rubber.

Owner:TOYOTA CENT RES & DEV LAB INC +2

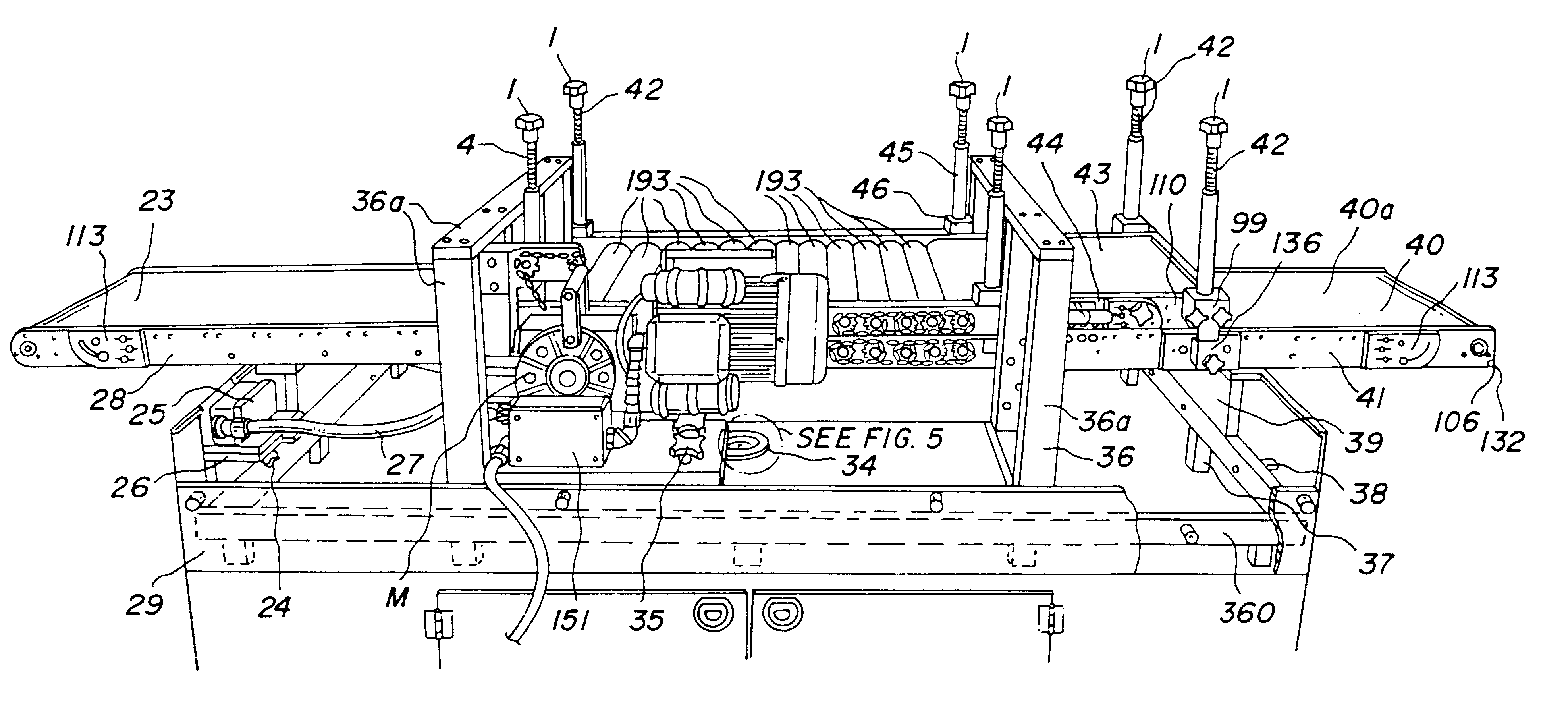

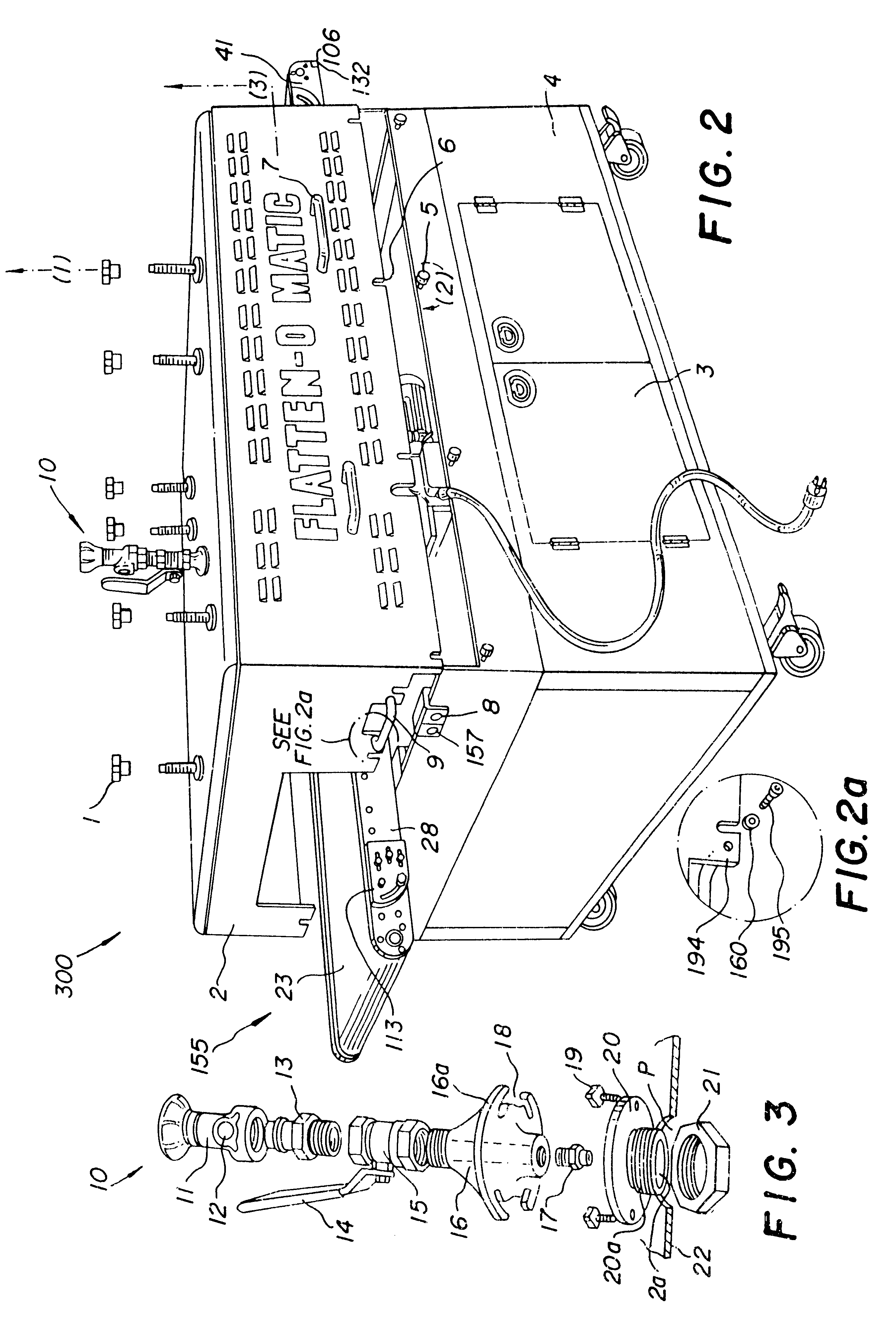

Apparatus for marinating, tenderizing, strip cutting cube cutting and progressively flattening meat

InactiveUS6601499B1Avoid stickingIncrease volumeGrain huskingGrain polishingEngineeringConveyor belt

An apparatus for flattening pieces of meat without piercing nor shredding the meat including a first roller set, each roller in the first roller set having non-sharpened outer edges; a second roller set, each roller in the second roller set having non-sharpened outer edges, the first roller set directly opposing and being spaced and fully separated from the second roller set, the first and second roller sets together having a product in-feed end into which meat pieces are drawn and having a product out-feed end at which flattened meat pieces are expelled from between the first and second roller sets; an adjustment mechanism for adjusting the spacing between the first roller set and the second roller set, where meat passing between the first and second roller sets is substantially flattened but not pierced nor shredded; and an in-feed conveyor belt assembly at the in-feed end including an in-feed conveyor belt and a rolling mechanism for rolling the in-feed conveyor belt in a direction to advance meat pieces placed on the in-feed conveyor belt to the in-feed end.

Owner:BIFULCO PHIL

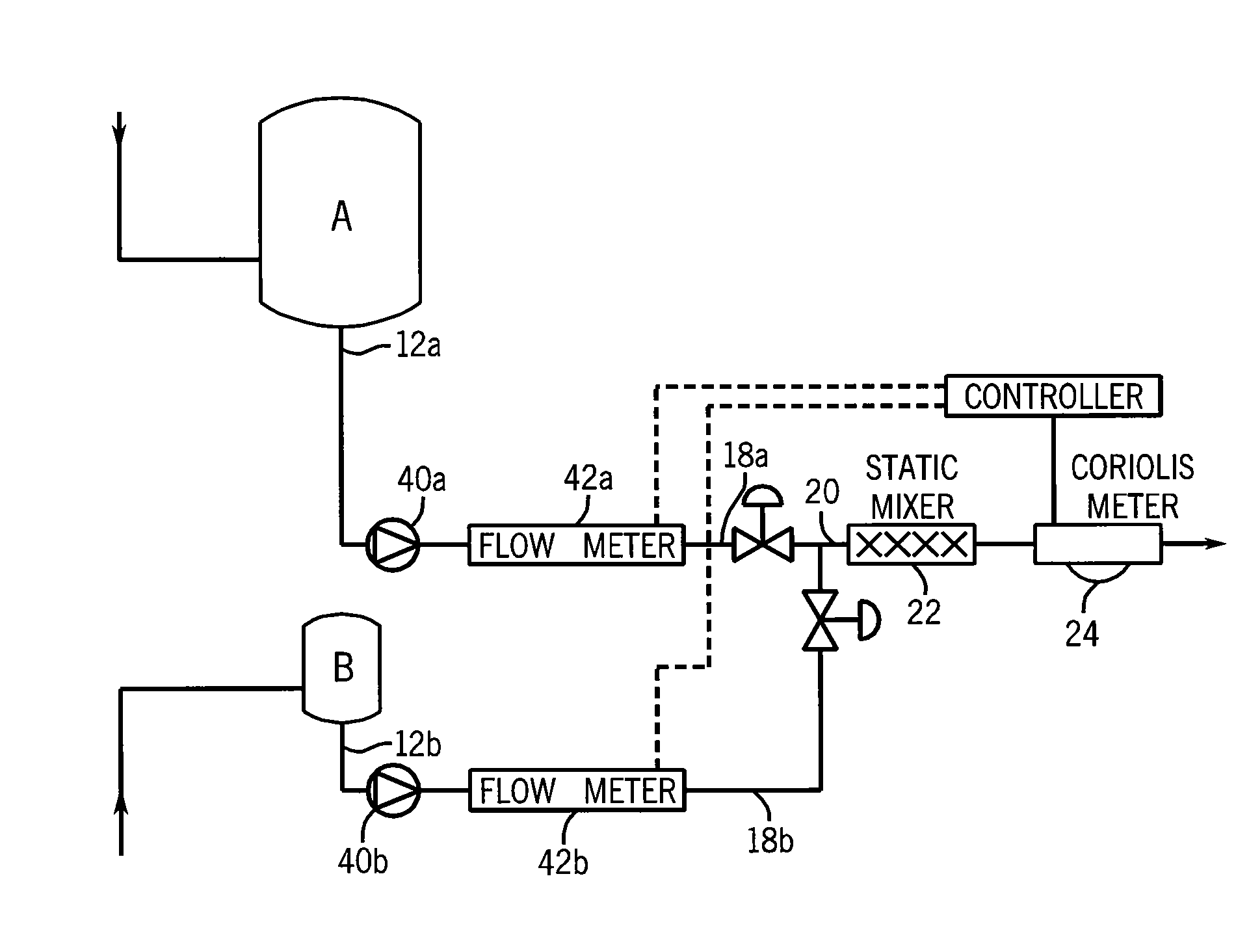

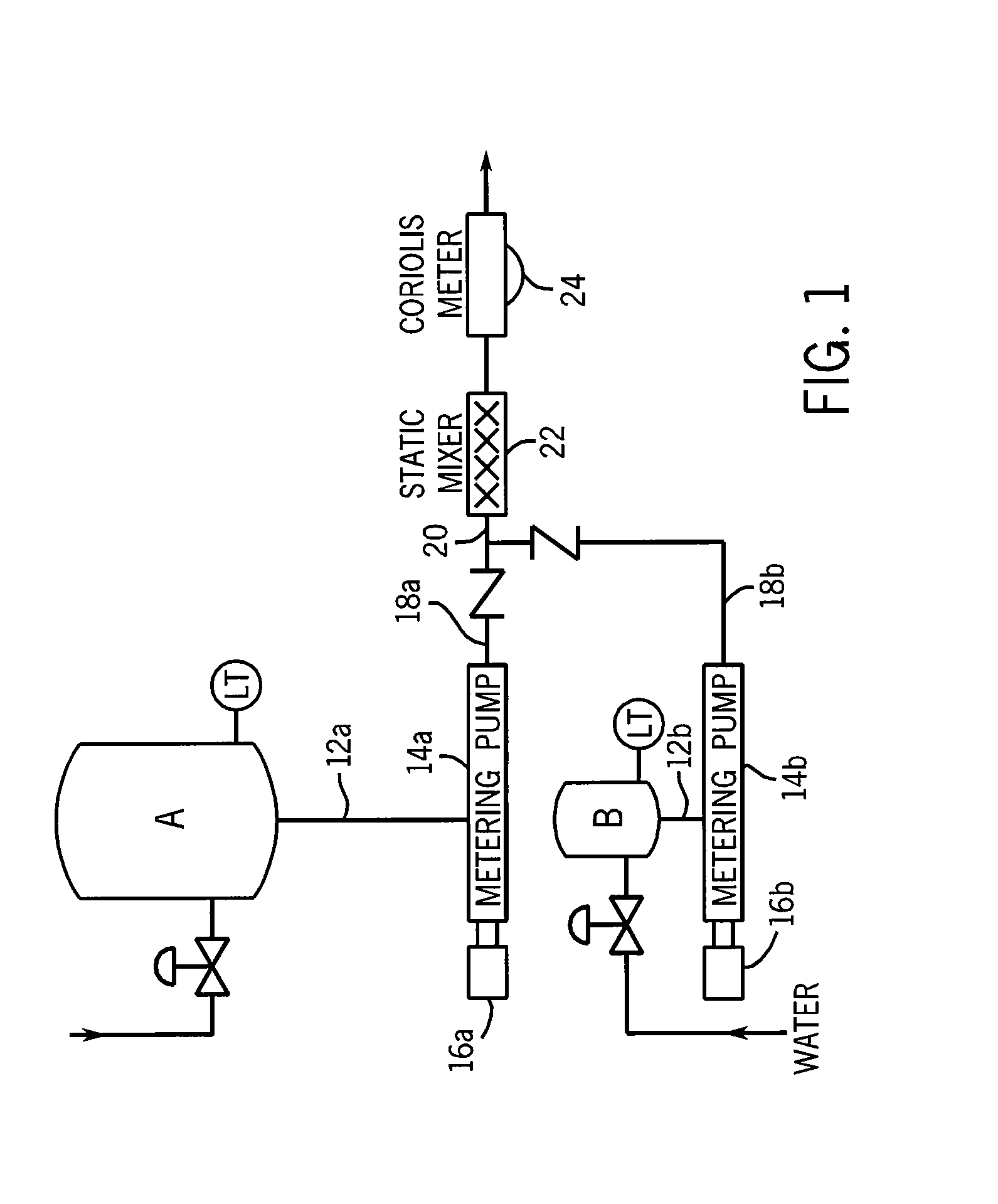

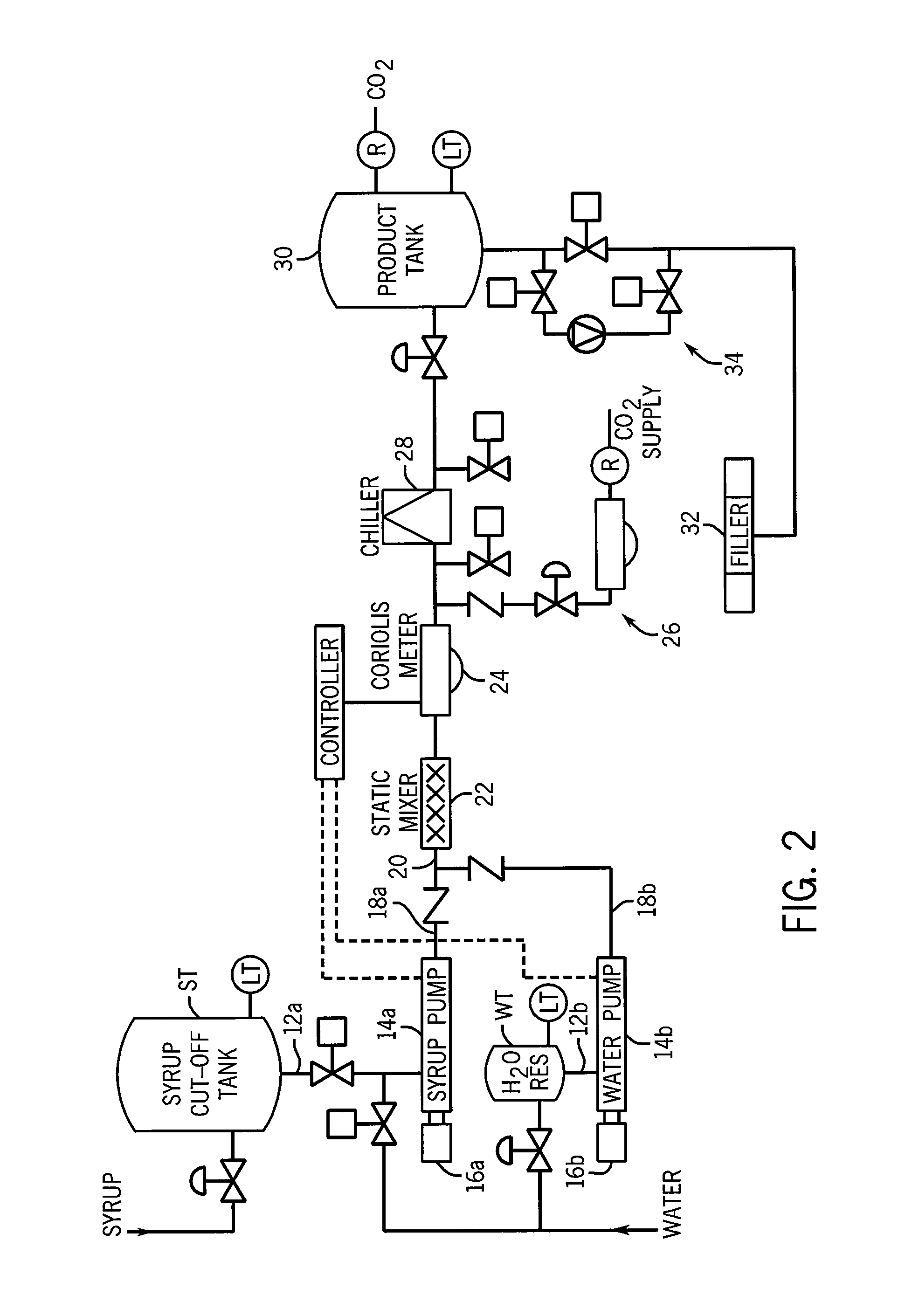

Blending System

InactiveUS20100031825A1Increase in sizeReduce product inventoryGrain huskingGrain polishingHybrid systemProcess engineering

A blending system includes a first liquid supply arrangement for providing a first liquid component, a second liquid supply arrangement for providing a second liquid component, a mixing arrangement for mixing the first and the second liquid components to form a blending liquid, and a mass flow measuring device for determining the mass flow of the blended liquid at a location downstream of the mixing arrangement. The blending system further includes a control arrangement for controlling the first and the second liquid supply arrangements in response to the mass flow measuring device. The mass flow measuring device may also measure the density and / or volumetric flow of the mixed liquid. The blending system may also be setup without a holding tank.

Owner:TECHNI BLEND

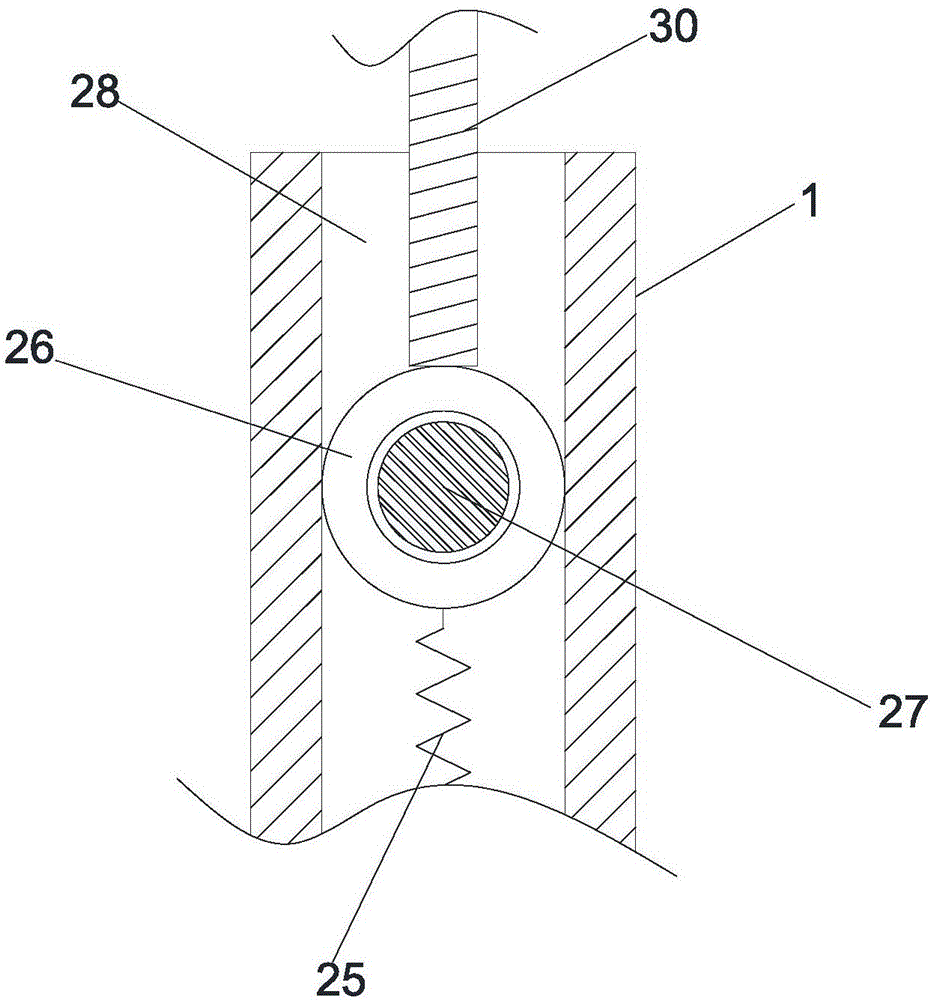

Rice hulling device with screening function

The invention discloses a rice hulling device with a screening function. The device comprises a hulling box; a feeding pipe is fixedly mounted at the top of the hulling box; a limiting plate is arranged on the side wall of the hulling box, and is in vertical threaded connection with a lead screw; a support plate is fixedly mounted on the right side wall of the hulling box; a driving motor is fixedly mounted on the support plate; a driven shaft parallel to a driving shaft is rotationally arranged in the hulling box; and a second driving belt wheel is fixedly mounted on the driving shaft. The device is convenient to hull and screen rice, low in workload and high in efficiency, rotationally hulls the rice through rotation of an adjusting pressure roller, a first hulling rotating roller and a second hulling rotating roller, greatly improves the rice hulling efficiency, and realizes quick hulling of the rice; and the up-down position of the adjusting pressure roller can be adjusted through a rotating lead screw, so that the position adjustment of the adjusting pressure roller and the first hulling rotating roller and the second hulling rotating roller is realized, the hulling extrusion acting force is increased, and the rice hulling is more thorough.

Owner:安徽林胜农业科技有限公司

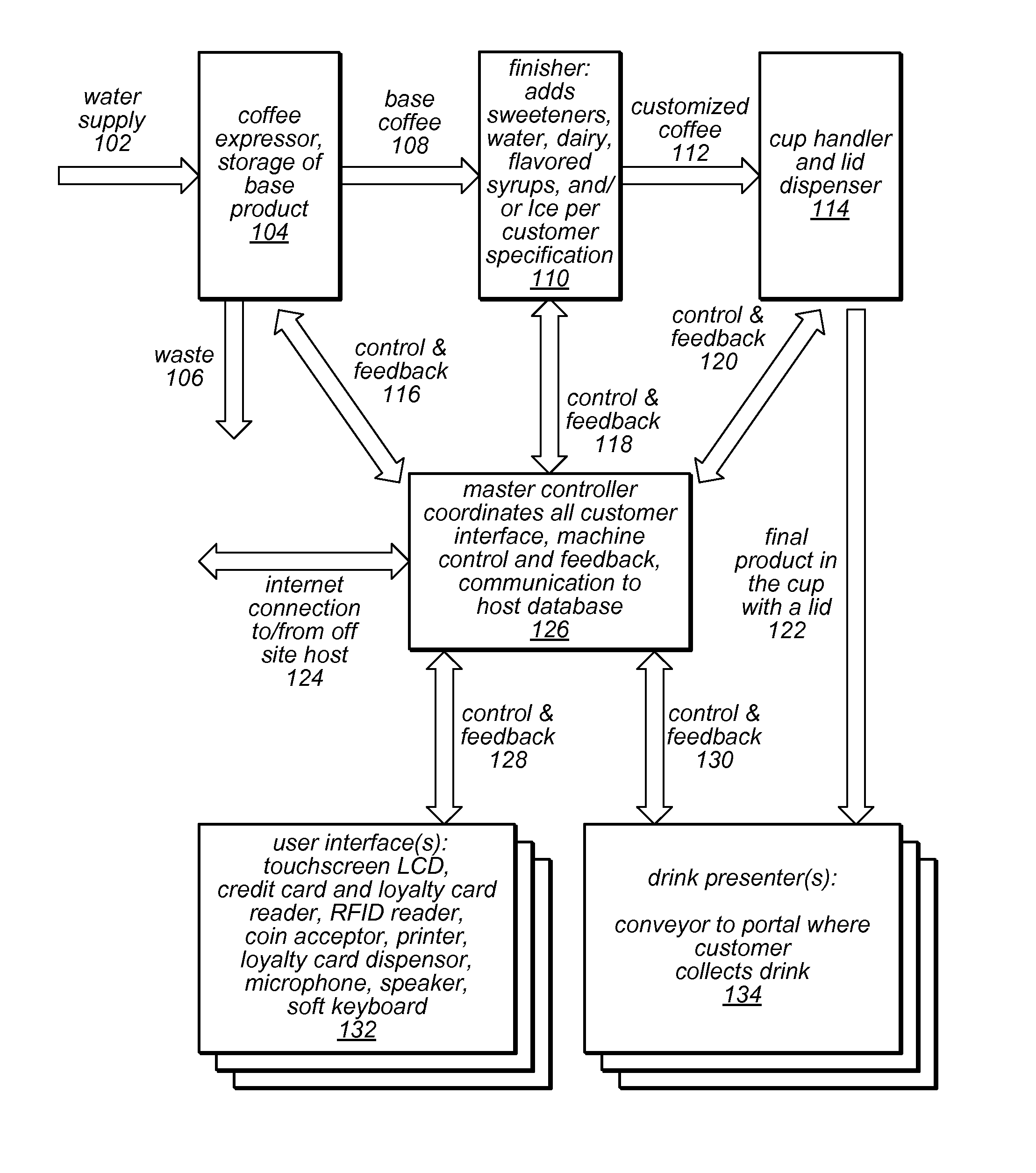

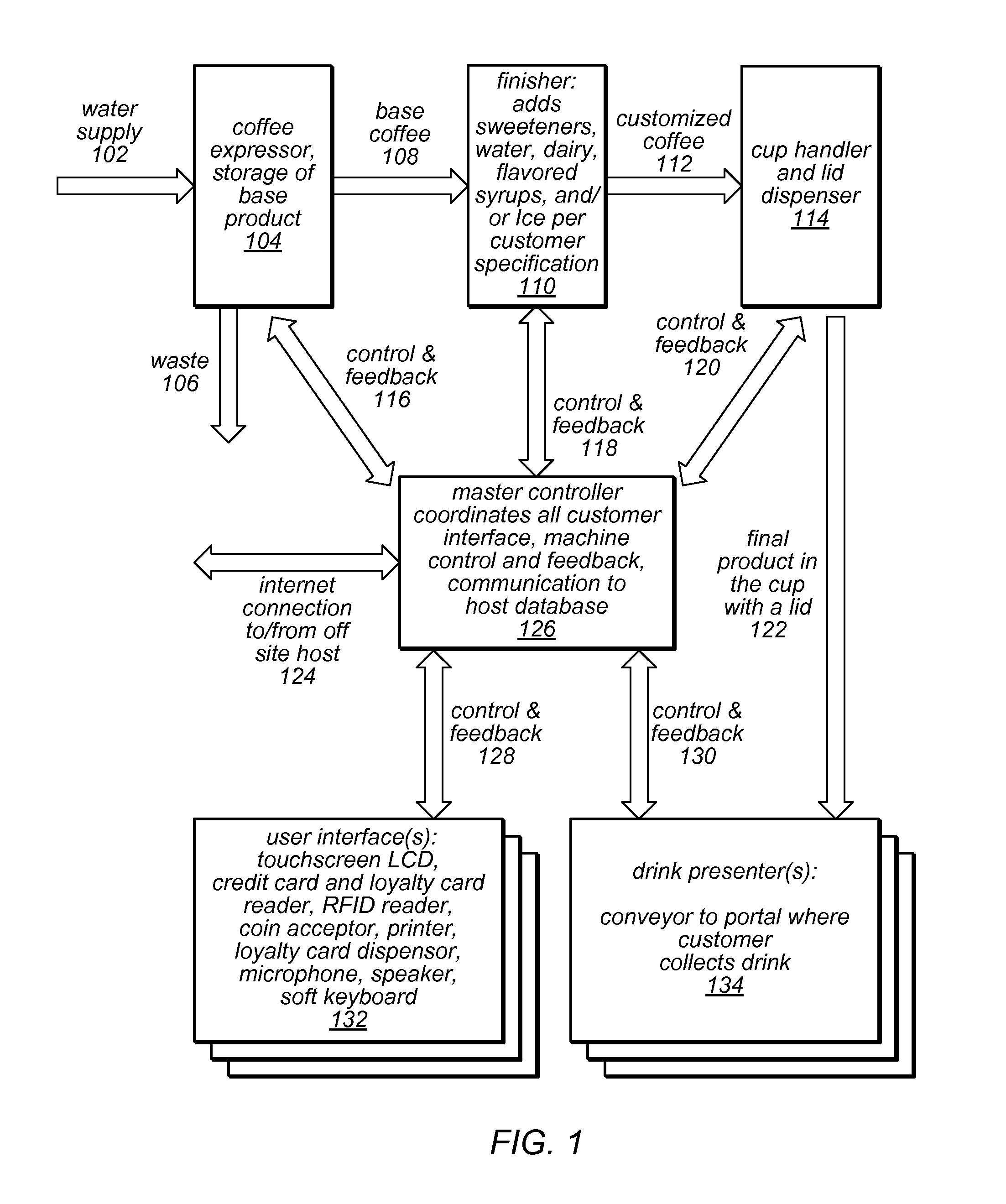

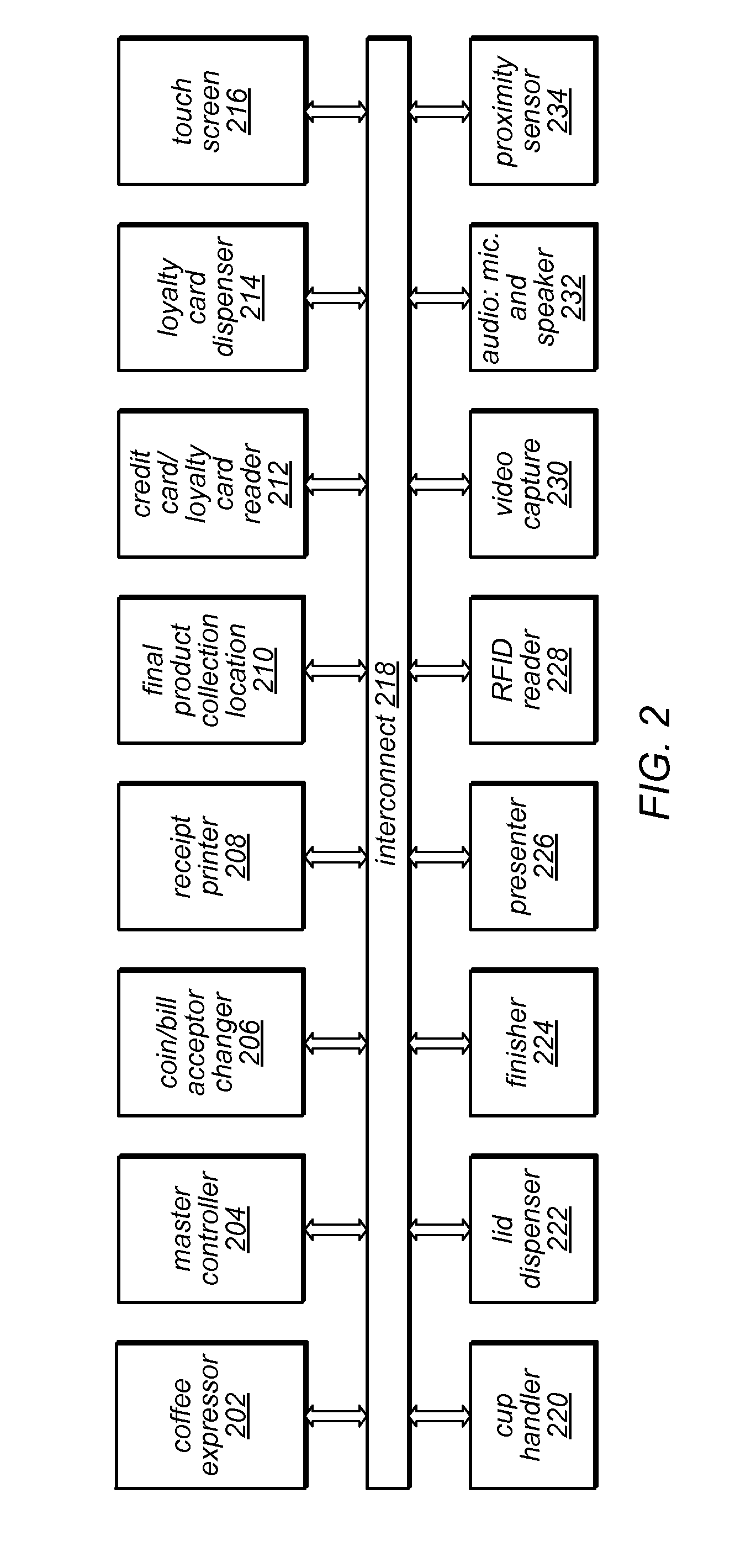

Apparatus and method for brewed and espresso drink generation

An apparatus that generates brewed beverages by performing one or more chemical and / or mechanical processes may receive requests to produce specified brewed beverages. The apparatus may include a master controller that initiates and controls performance of the chemical and / or mechanical processes to produce the specified beverages. The master controller may adaptively apply one or more process accelerators during the performance of one of the chemical or mechanical processes to accelerate the process or to achieve a desired qualitative or quantitative characteristic for a beverage or a component thereof. The adaptive application of one or more process accelerators may be dependent on a multiple-variable process profile developed for the process and / or a specified beverage. For example, the pressure in a steam wand and / or the depth of the wand may be varied during a process to froth milk in order to produce frothed milk having a desired temperature.

Owner:COSTA COFFEE

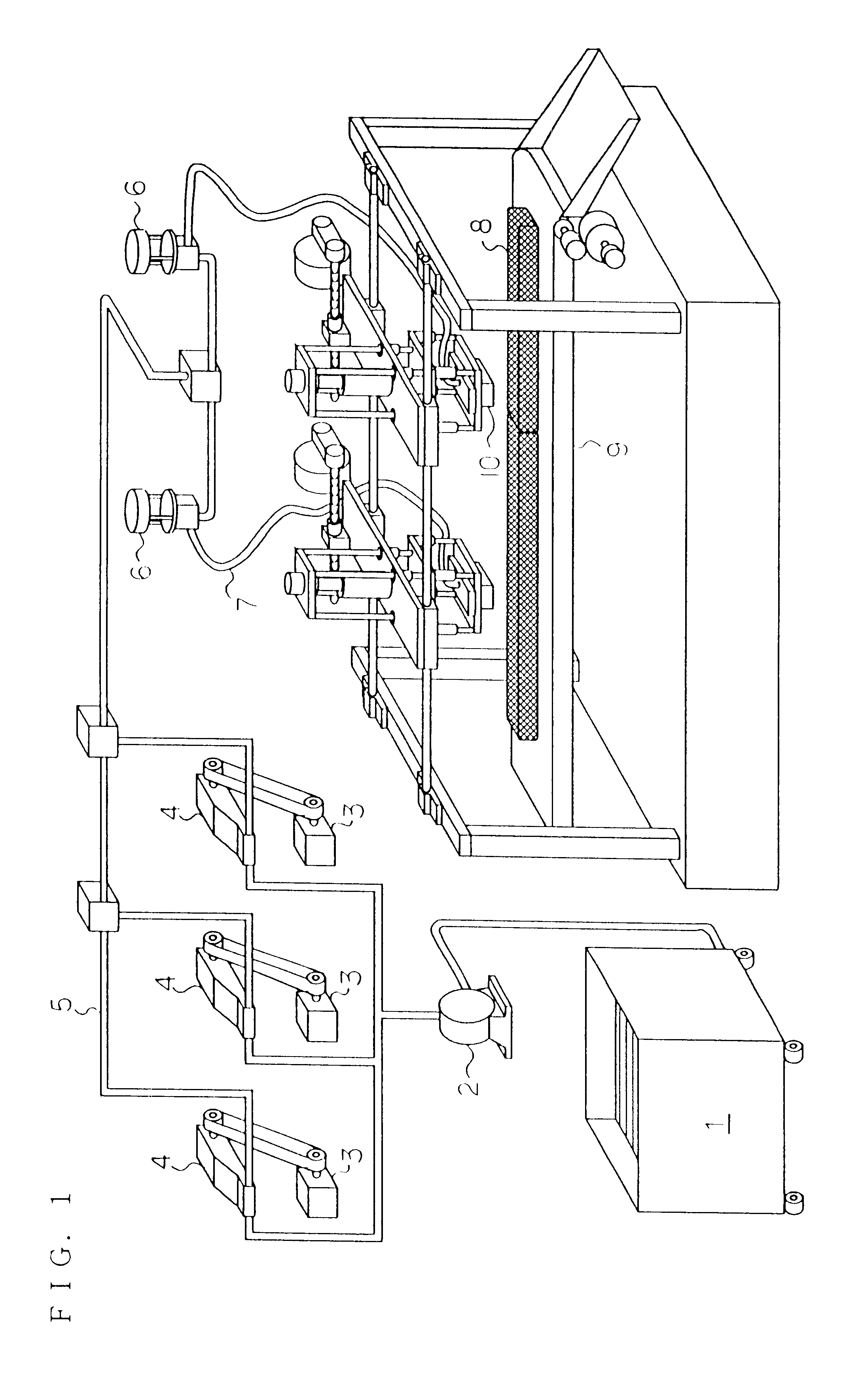

Apparatus for injecting fluid into meat products

InactiveUS7302885B2Easy to disperseIncrease in sizeGrain huskingGrain polishingSyringe needleBiomedical engineering

A method for injecting fluid into meat products comprises taking a plurality of hollow fluid injection needles having sharpened discharge ends, and connecting the needles to a source of pressurized liquid; penetrating the sharpened ends of the needles into the product and thence withdrawing the same while discharging fluid into the product and vibrating the needles for a period of time while they are within the product to enlarge the size of a penetration hole within the product caused by the penetration of the needles to a size greater than the size of the needles to create at least a partial space around the needles to permit fluid from the needles to migrate into the spaces around the needles. The needles have a roughened outside surface.

Owner:STORK TOWNSEND BV

Refined rice processing method

InactiveCN104815714AGuaranteed purityHigh purityGrain huskingGrain polishingBroken riceMoisture measurement

The invention discloses a refined rice processing method. The refined rice processing method comprises the following steps of rice screening, stone removal, magnetic separation and rice shelling, rice-bran separating, secondary shelling, thickness grading, moisture measurement and drying or atomizing, rice milling and white rice grading, rice cooling, polishing, color sorting, secondary white rice grading and moisture content detection, and packaging. The refined rice processing method comprises a plurality of impurity removal steps, and consequently, the purity of rice is guaranteed, the produced rice is high in purity, and the safety and the processing efficiency in the processing process are guaranteed. In the rice shelling and rice milling steps of the refined rice processing method, the material temperature is strictly controlled so that the material can be always kept in a relative low temperature appropriate environment, and the crack ratio and the broken rice rate can be reduced and the complete particle rate can be increased; the original faint scent of rice is maintained. The refined rice processing method is used for solving the problems of surface damage and uneven polishing in the rice polishing process by controlling the polishing water temperature and the dampening amount; as a result, the surfaces of all the rice grains polished can be kept smooth and clean, and the quality guarantee period of the rice can be prolonged.

Owner:ANHUI YOUYUAN FOOD

System and method for automatically controlling deck plate position on a corn header

ActiveUS20120029757A1Overcomes shortcomingIncrease widthVehicle testingGrain huskingAutomatic controlEngineering

The system and method automatically controls the position of at least one deck plate of a harvesting unit of a corn header so as to increase the width of a stalk receiving channel or reduce pinching forces between the plates when entering a stand of corn to facilitate alignment with the corn rows, and to change the position after a suitable time period or other condition or event, to narrow the channel width and / or increase pinching force, to reduce kernel loss while also monitoring forces exerted against the plates by the stalks and responsively adjusting the plate position for maintaining a desired force on the stalks or width.

Owner:BLUE LEAF I P INC

Automatic ice cream scooper

An automatic ice cream scooper. A cylinder of ice cream is placed vertically within a refrigerated container on a slicer having a disc shape. The slicer includes an angled slicing blade for removing ice cream. The slicer is rotated by a motor to remove the ice cream. The slicer has an upstanding edge with the screw thread formed thereon for removing the sidewall of the ice cream container.

Owner:RICHMAN DEBRA S

Rice processing method

The invention discloses a rice processing method. The rice processing method comprises the steps of removing rice impurities to obtain a cleaning workshop section of cleaned grains, shelling the cleaned grains, separating rice hullers and valley workshop section of rice husks and brown rice to obtain a rice grinding workshop section for conducting grinding and polishing treatment on the brown rice, adopting multiple of rice grinding machines to grind the brown rice in the rice grinding workshop section, conducting grading and color selection on rice after the polishing treatment and removing unqualified rice in variegated colors, wherein the multiple of rice grinding machines at least comprise an emery roll rice grinding machine for conducting first rice grinding operation and an iron roll cylinder air blast rice grinding machine for conducting final rice grinding operation. Rice produced by the rice processing method is clean in surface, even in particle size and clean in color. The quality of the rice is improved.

Owner:天津黄庄洼米业有限公司

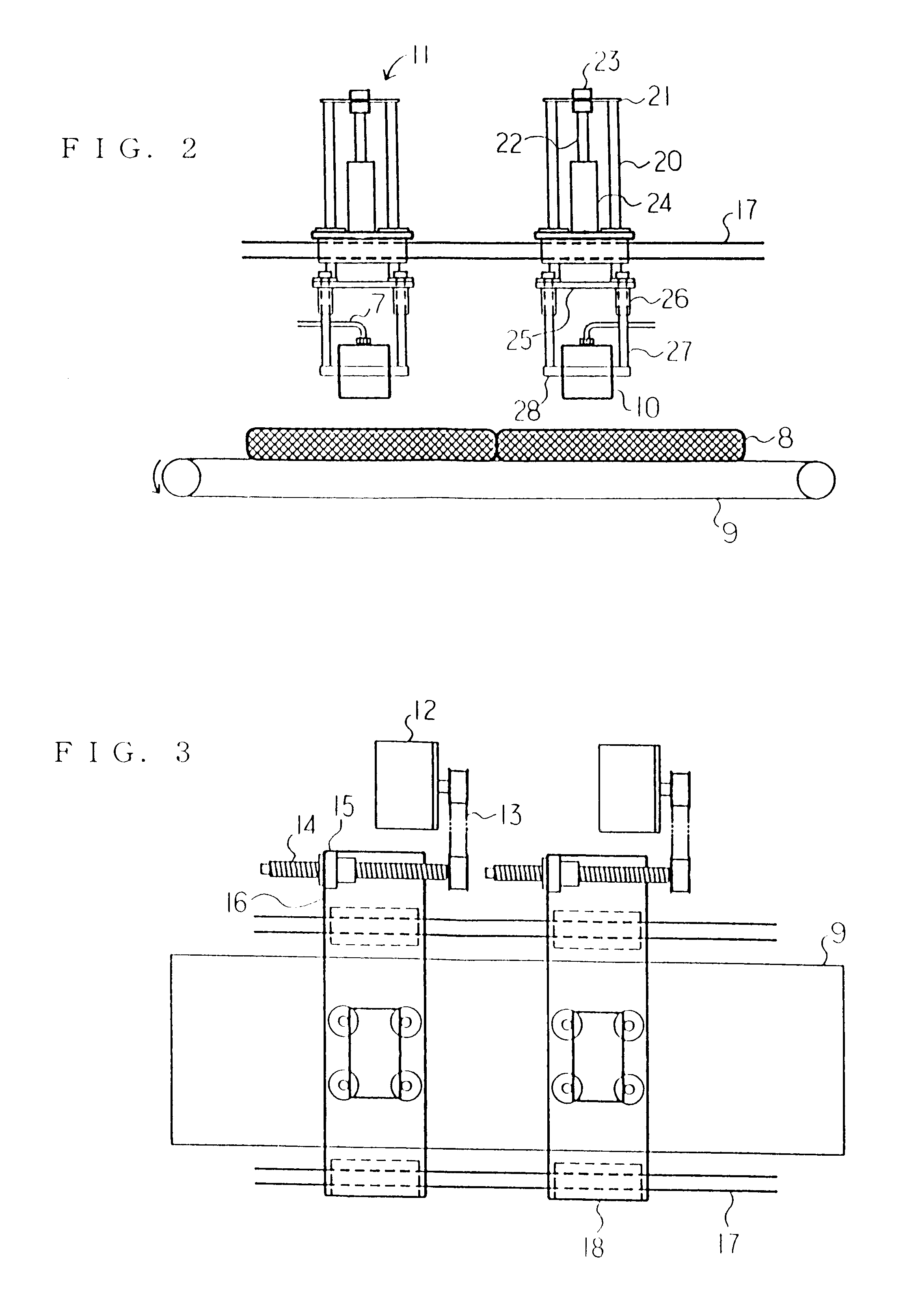

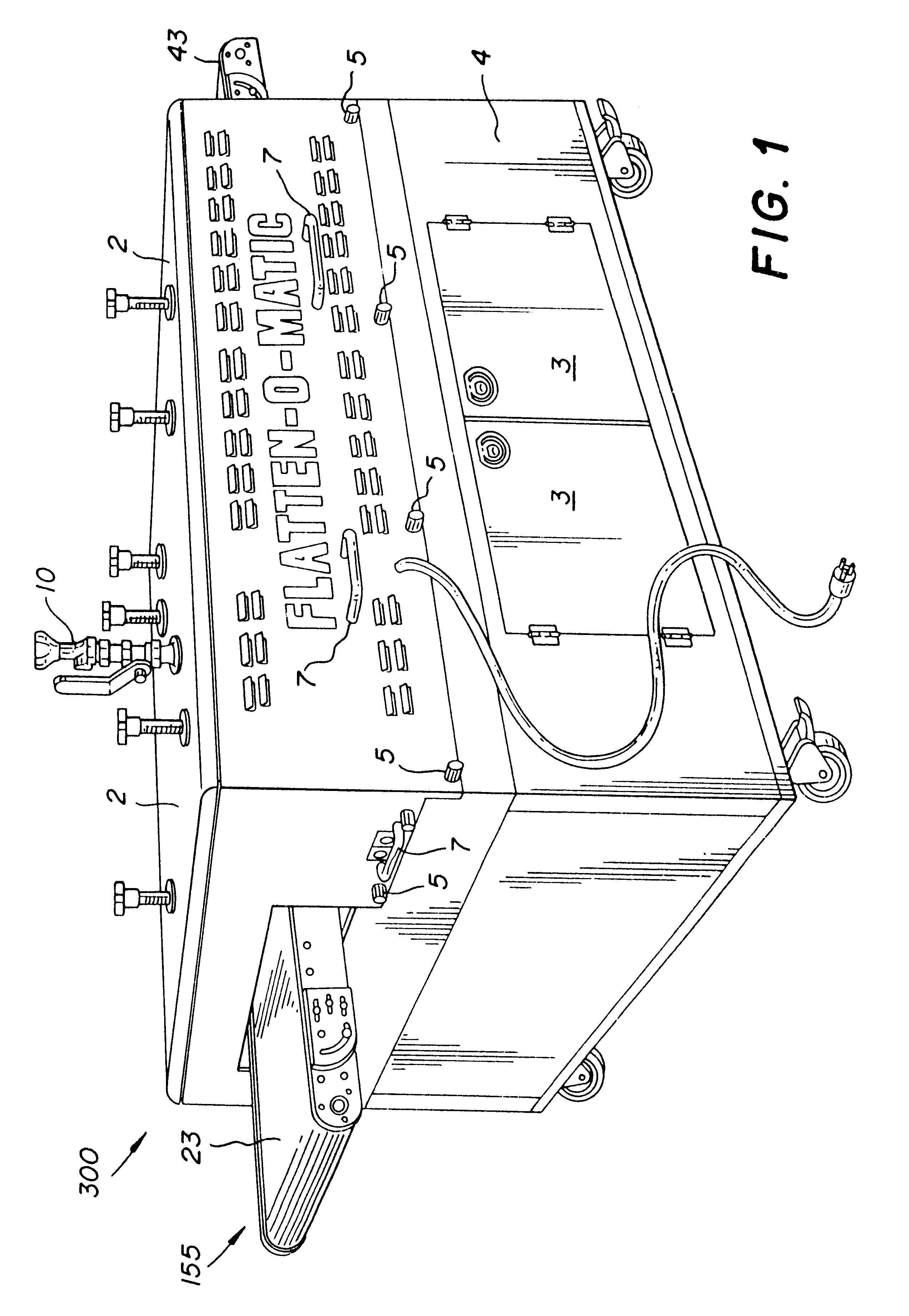

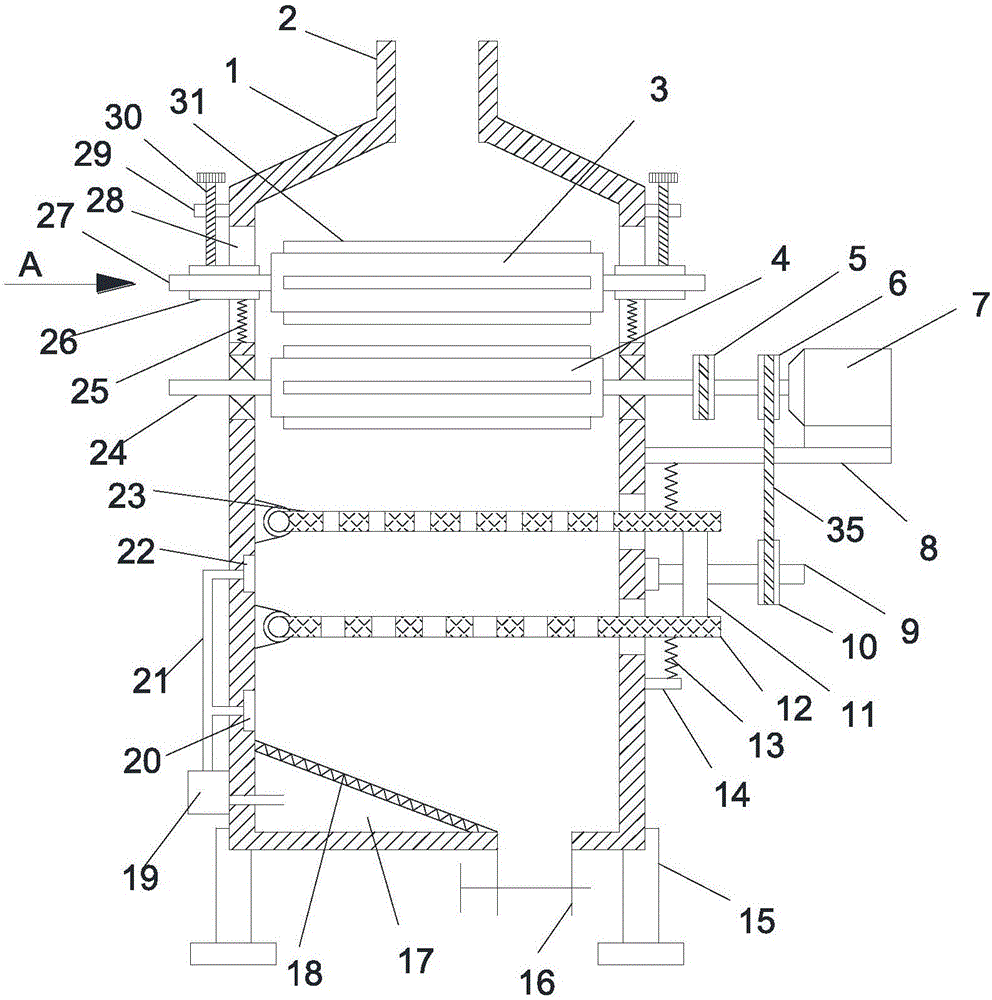

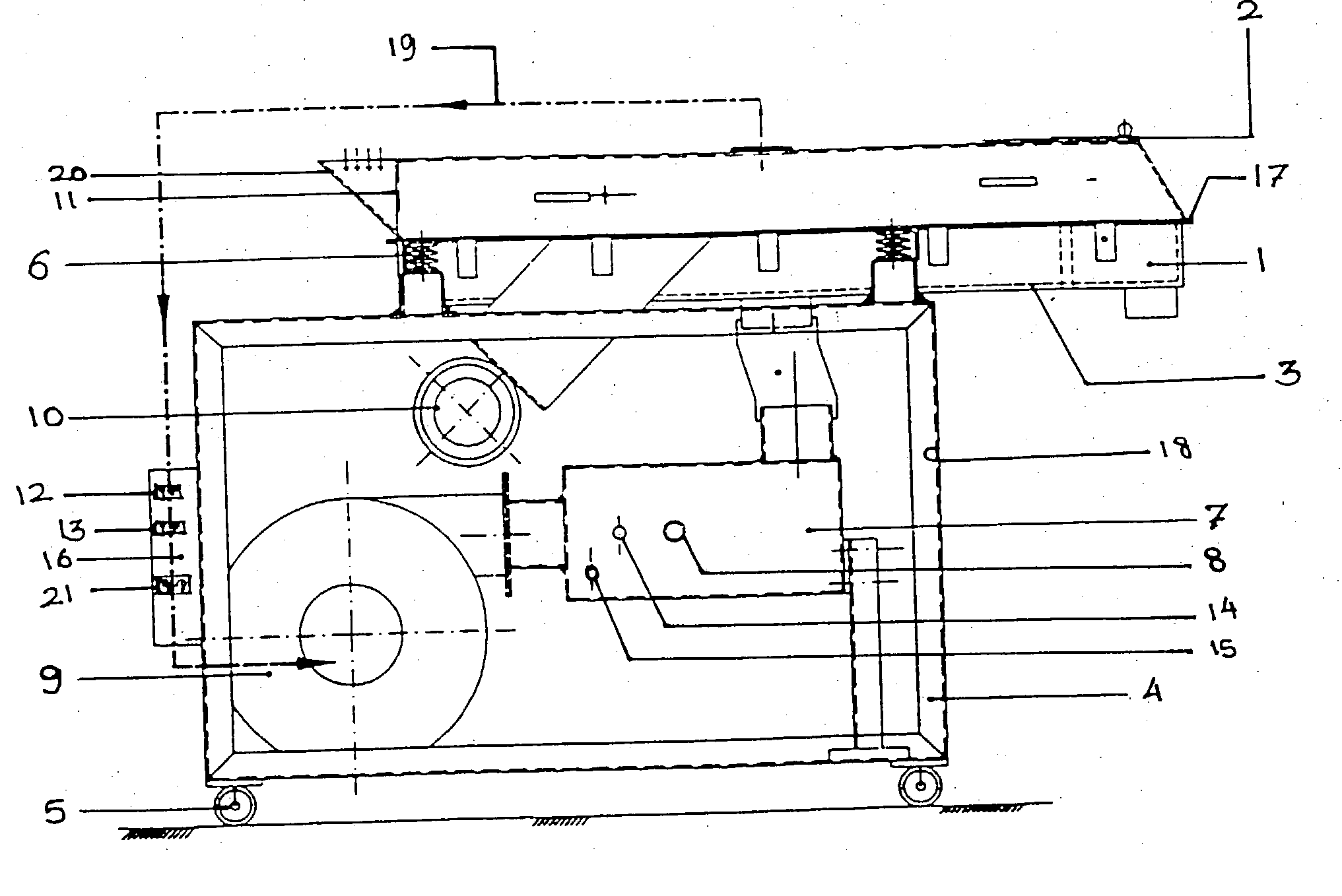

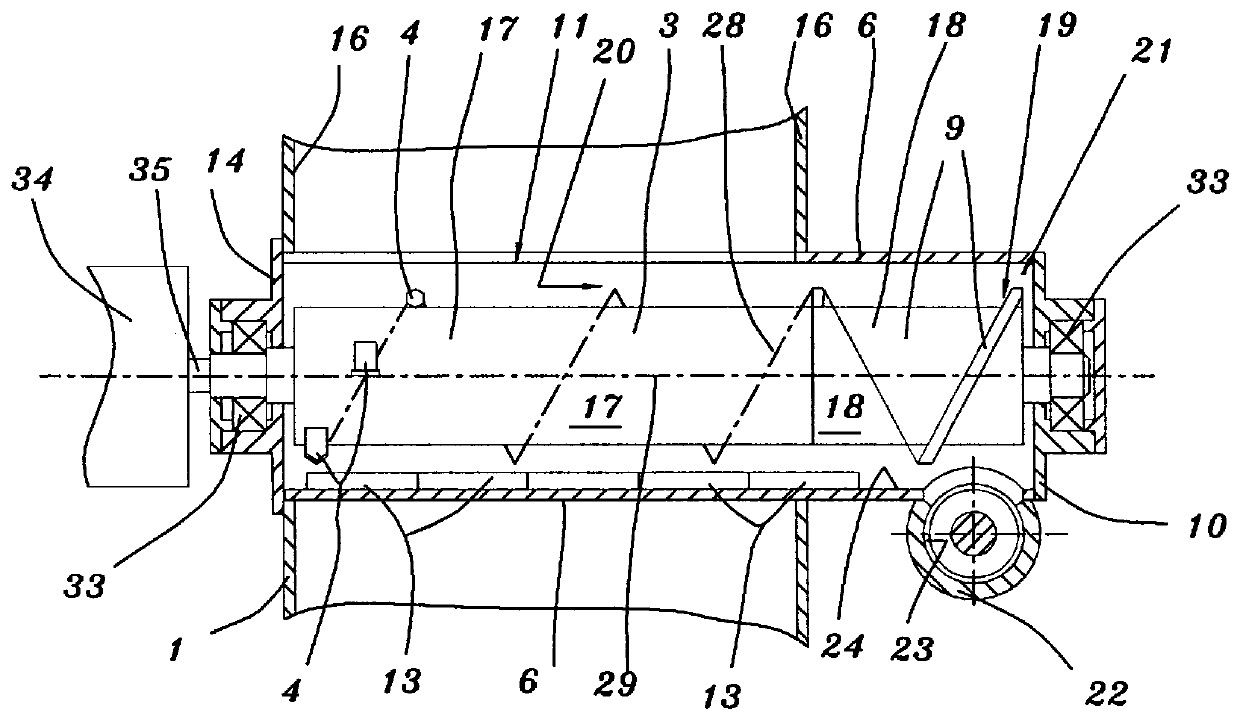

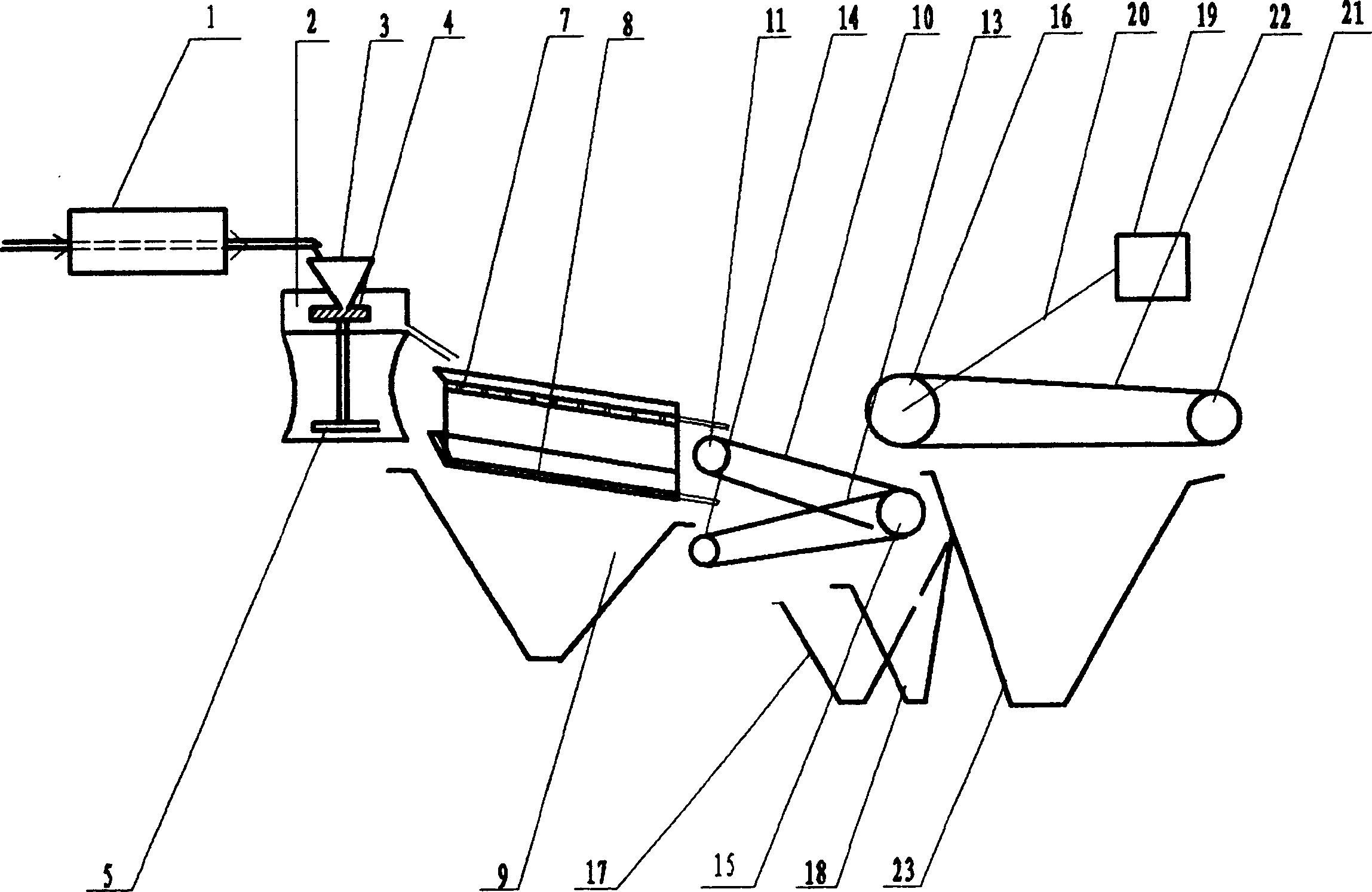

Continuous vibro fluidized bed roaster using flue gas

InactiveUS20040187709A1Reduction in human drudgeryClean and hygienic endGrain huskingGrain polishingCombustion chamberSolenoid valve

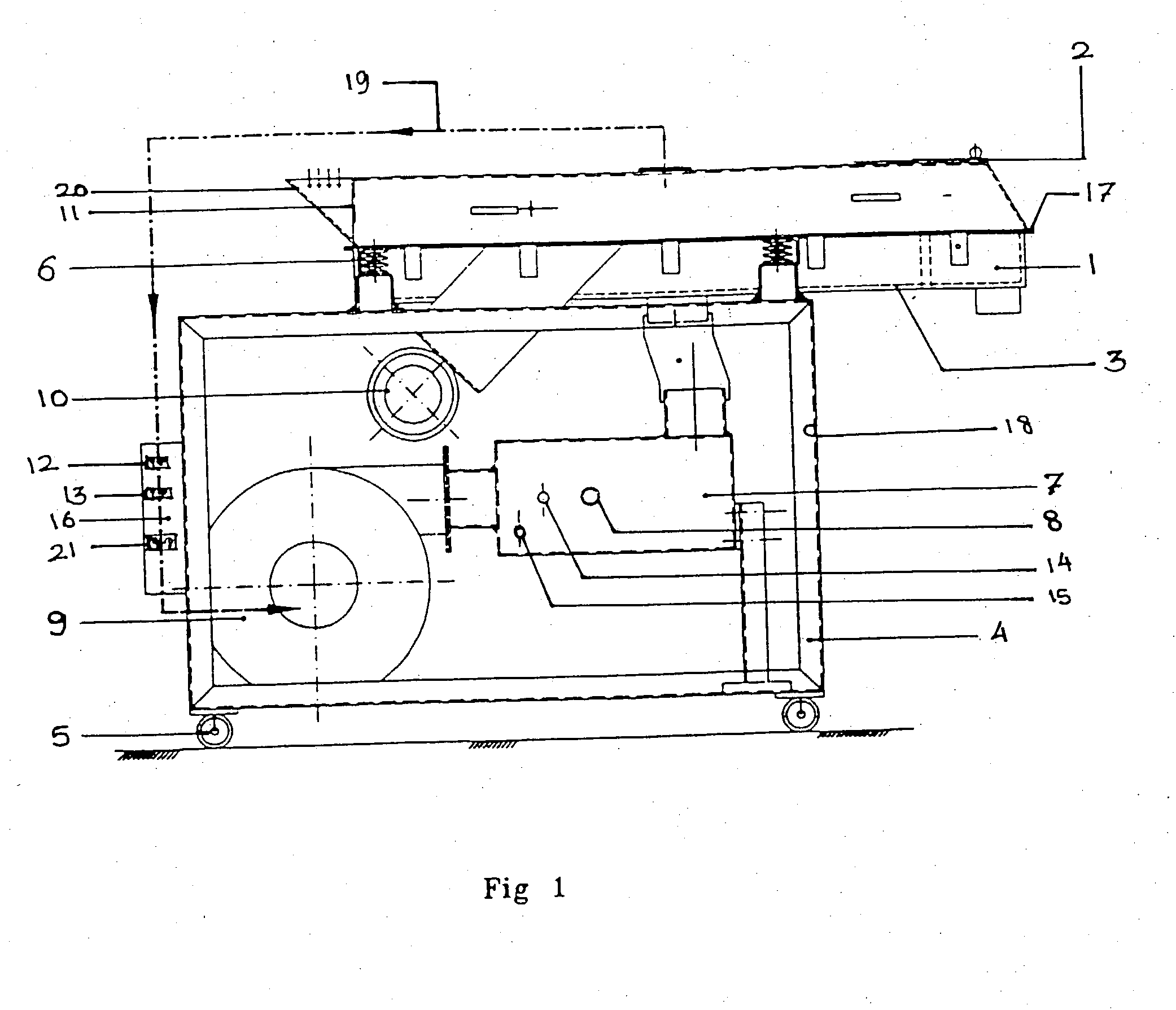

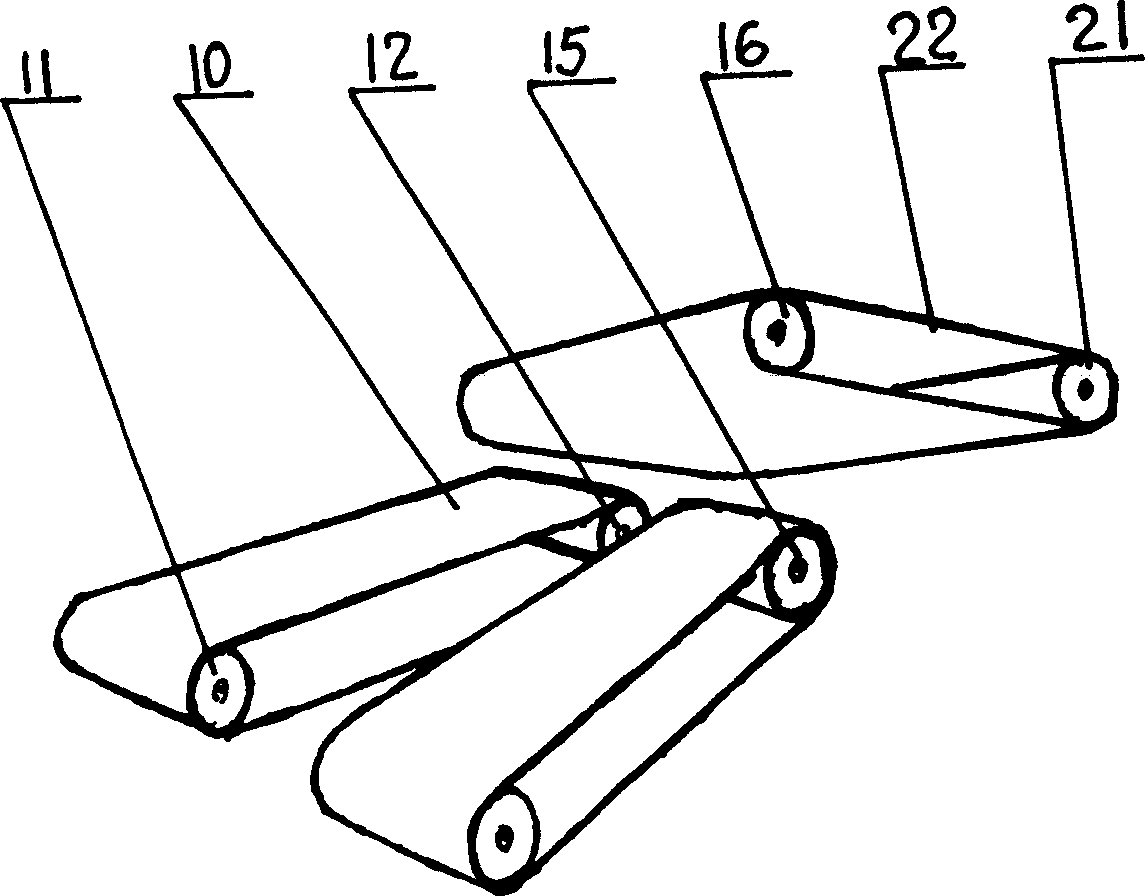

A continuous vibro fluidized bed roaster for roasting cereals, pulses, spices, oil seeds and ready-to-eat snack foods using flue gas, said roaster comprises of a main frame (4) which houses all the parts of the machine, the vibrating deck (1) is mounted on a set of coil springs (6) which is mounted on the main frame through screw fasteners, a perforated sieve (3) and a hood (2) are mounted on the vibrating deck (1) with rubber gasket (17) for sealing the hot air from leakage, a vibratory motor (10) is mounted on the feed end of the vibratory deck for imparting vibrations to the feed material, a vibratory feeder (11) is mounted on the feed side of the vibratory deck (1) for feeding the raw material in to the roaster through a hopper (20). A LPG burner (8) is fastened to the combustion chamber (7) using fasteners, a solenoid valve (14) mounted on the main frame (4) for regulating the LPG supply to the burner and also to close the LPG supply incase of electrical power failure with a signal for flame failure from the photo sensor (15), a blower (9) generates the air needed for the reducing the flue temperature is mounted at the end of the on the vibratory feeder (11) on to the main frame (4), a return duct (19) connects the hood (2) and the suction end of the blower (9), a temperature indicator is (21) is used for measuring the inlet temperature of the hot air admitted in to the roaster, an electrical panel (16) is mounted at the end of the main frame for housing all the required electrical controls and variable speed drive (13) for varying the residence time of travel of the raw material, a rheostat (12) for varying the feed rate of the raw material fed in to the vibrating deck, the roaster is covered by a set of covers (18) on all its sides, the complete machine is mounted on a set of castor wheels (5) for easy movement of the roaster to the required place, the materials of construction of the roaster are preferably of stainless steel but this shall not restrict the use of other materials as well.

Owner:COUNCIL OF SCI & IND RES

Engine fuel injection control system

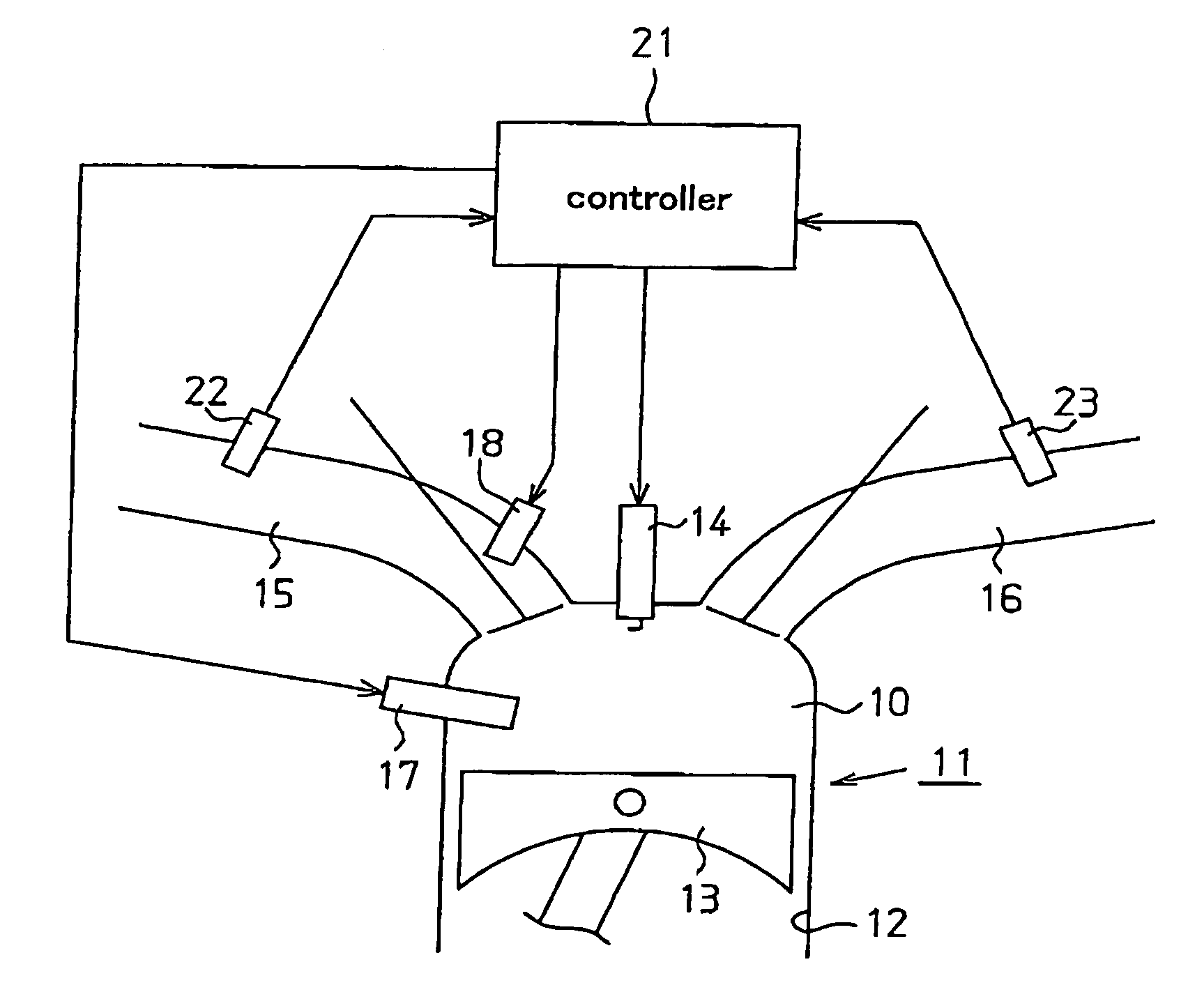

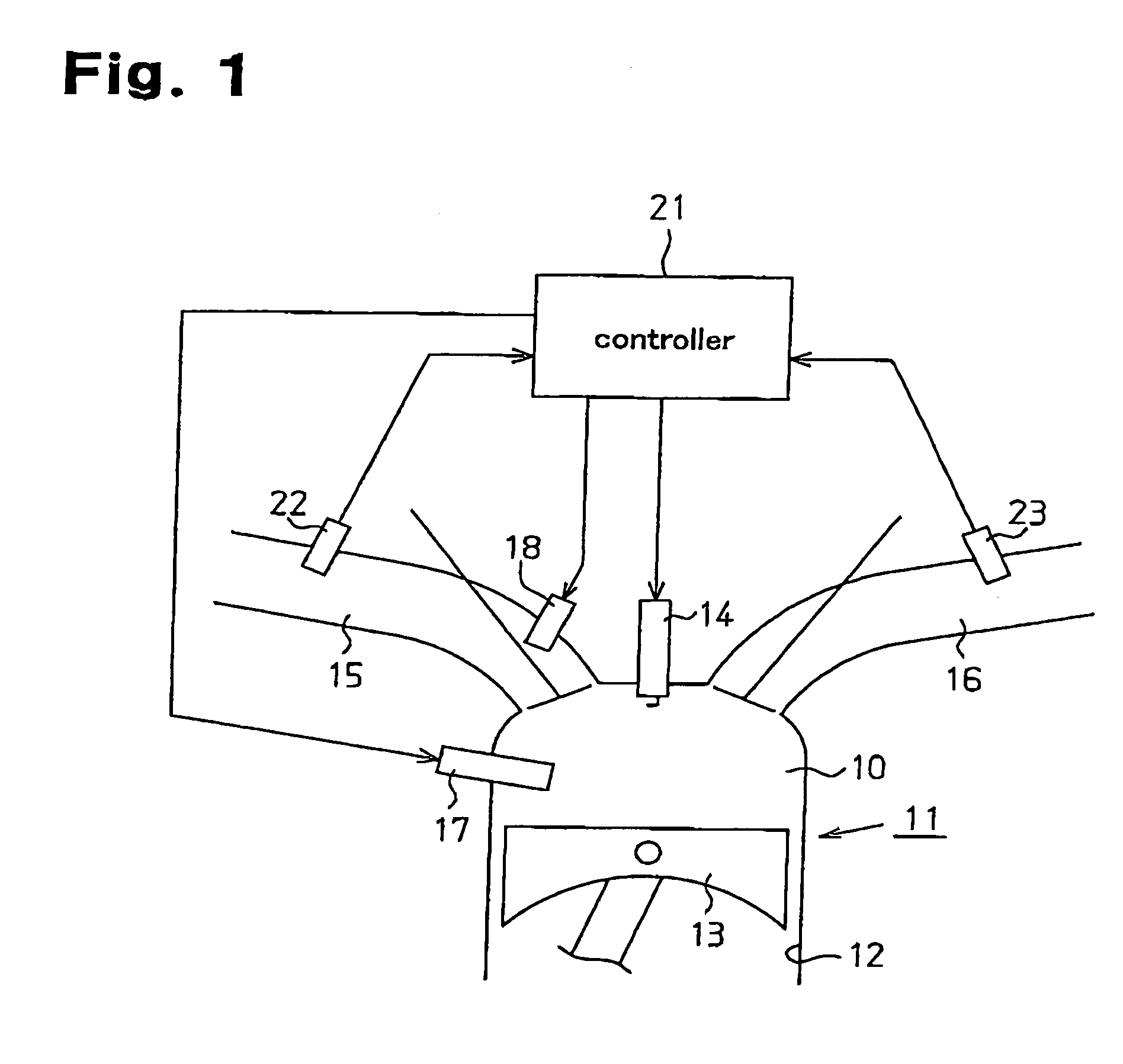

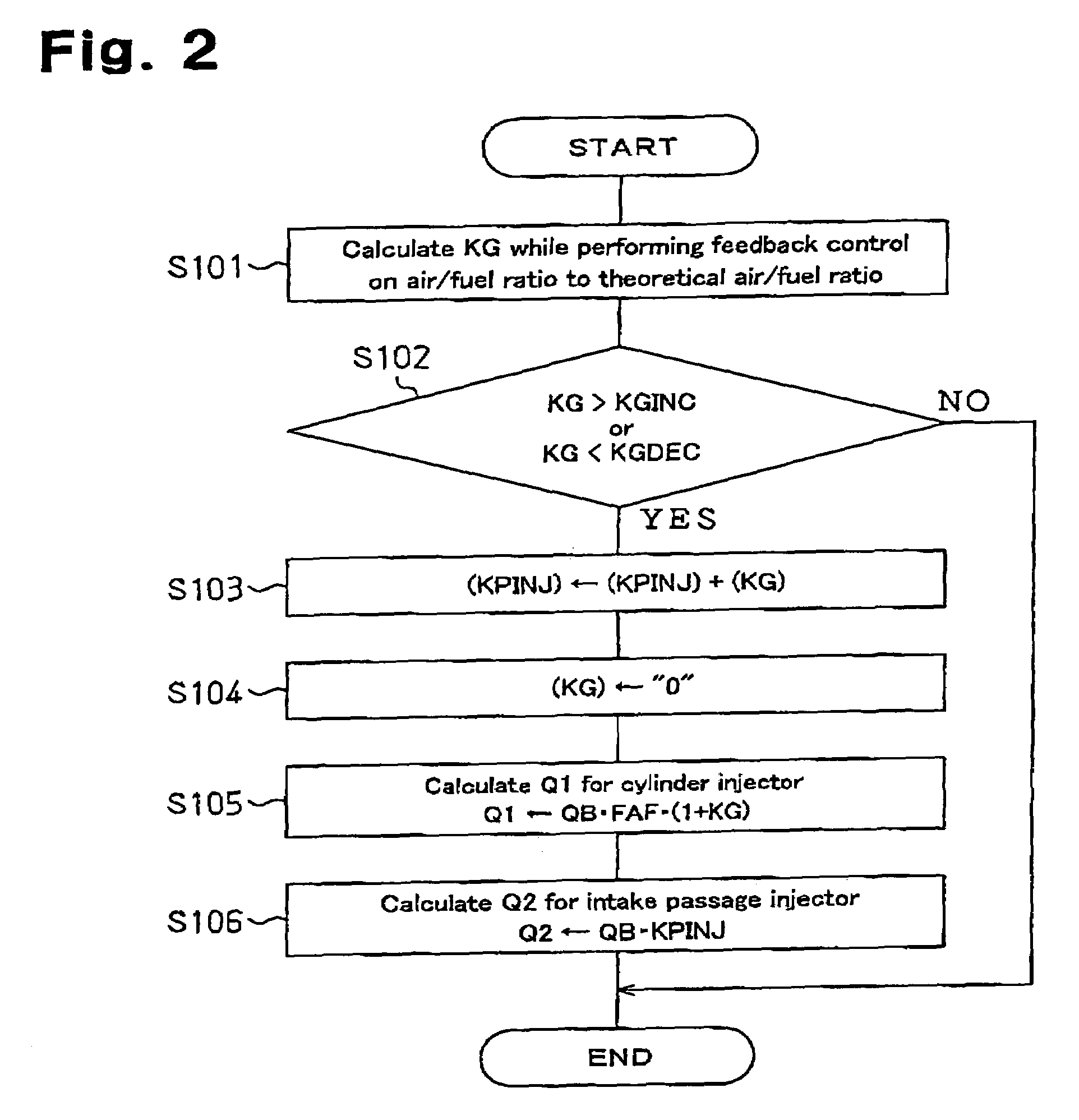

InactiveUS6988490B2Reduce fuel injectionSuppress deterioration in combustion stateGrain huskingGrain polishingCombustion chamberControl system

A system for controlling fuel injection in an engine. The engine includes an intake passage, an intake passage injector, a cylinder having a combustion chamber, and a cylinder injector for injecting a target amount of fuel into the combustion chamber. The system includes a controller for controlling the intake passage and cylinder injectors to permit fuel injection, each with an injection ratio, while said engine operates in a condition in which said engine permits fuel injection from said cylinder injector, a sensor for sensing the amount of fuel injected from the cylinder injector, a detector for detecting the difference between the target injection amount and the amount of fuel injected and an adjuster for adjusting the injection ratio based on the result of the detection by the detector so that the intake passage injector performs fuel injection together with the fuel injection performed by the cylinder injector.

Owner:TOYOTA JIDOSHA KK

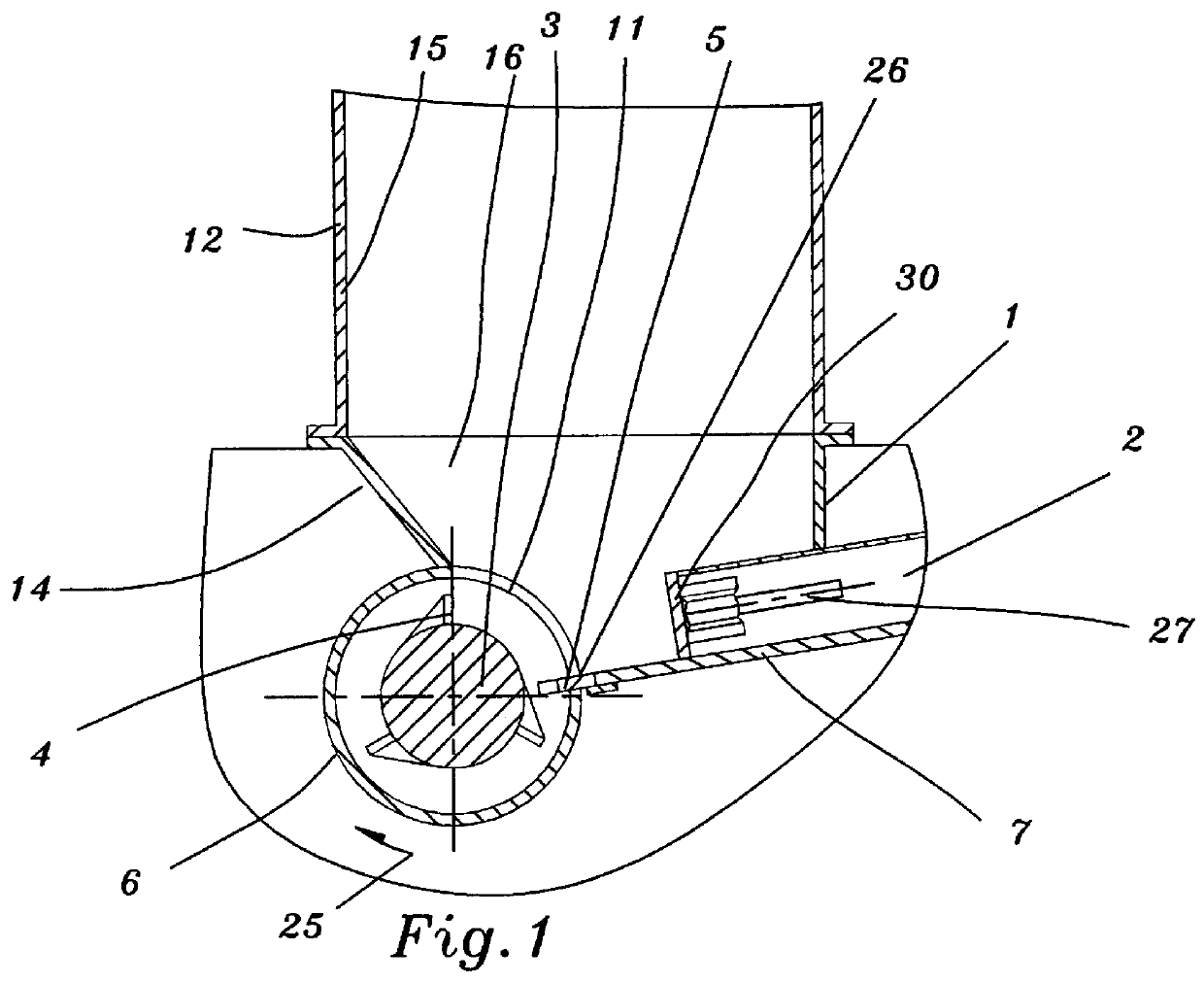

Processing device for crushing, conveying and plastifying thermoplastic synthetic material

InactiveUS6126100AIncrease costImprove processingGrain huskingGrain polishingHelical lineSynthetic materials

A unit for processing thermoplastic synthetic material comprising a machine housing (1) with a delivery cone (12) in whose feed shaft (14) a driven slider (30) presses synthetic material which is to be processed and which is located on a base plate (7) through a feed inlet (11) of a conveyor tube (6) against a processing drum (3) which is placed perpendicularly in the conveyor tube (6) in relation to the direction of the movement of the slider (30). The slider (30) extends over the entire length of the feed inlet (11) which itself extends over the entire blade supporting section (17) of the processing drum (3). Blades (4) are placed thereon in a helical line and operate in conjunction with a fixed counter blade (5) which is fastened to the opening edge (25) of the feed inlet (11). The blades (4) and the associated screw conveyor (9) convey disintegrated synthetic material in axial direction (20) though the conveyor tube (6) towards an outlet (10), which leads downwards into the screw tube (22) of the extruder screw (8) through which the synthetic material is delivered.

Owner:MANFRED DOBERSBERGER +1

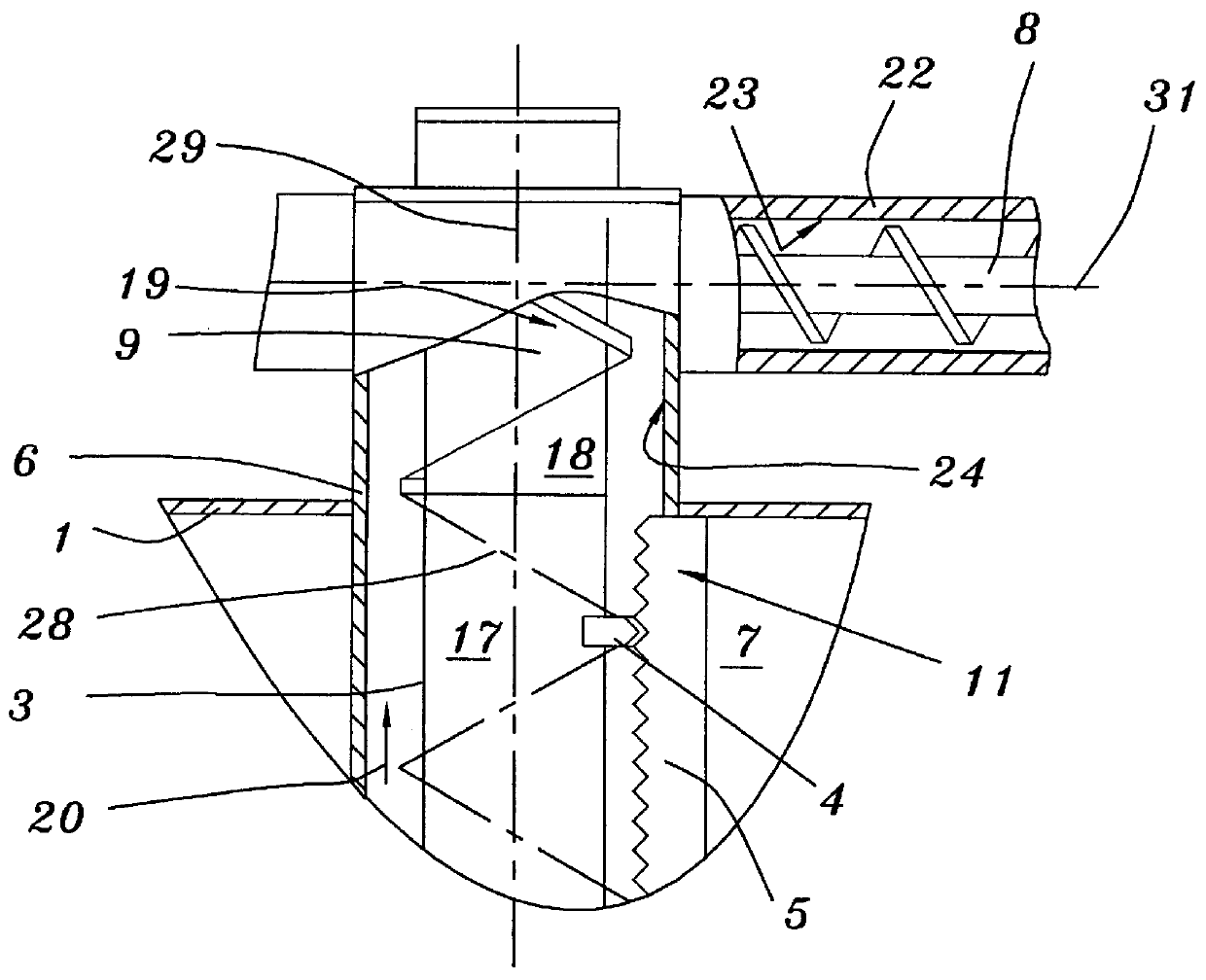

Method and device for dehulling separation of flax seed

InactiveCN1883808AReduce processing timeThorough peelingSievingGrain huskingDecortication procedureMoisture

Disclosed is a method for flax seeds decortication and separation, comprising dehydrading flax seeds to a moisture percentage of 2-4%; feeding same into a rotary centrifugal decortication machine continuously, decorticating the flax seeds to form a mixture of shells and kernels; and separating the shells and kernels mixture through an electrostatic field. An apparatus realizing said method comprises a centrifugal decortication machine, screen means mounted on the discharge side of the centrifugal decortication machine, a convey belt mounted on the discharge side of the screen, and electrostatic absorption means mounted over the discharge terminal of the convey belt front part. The method is provided with continuously industrialization production for large amounts of product, complete seperation of shells and kernels, and high production efficiency to shorten the art time from the flax seeds feeding, decorticating to discharging by 80%, decrease full cost by 50%, and produce no environmental waste materials.

Owner:大同市宏致亚麻科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com