Patents

Literature

369 results about "Mechanical Processes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The mechanical process is the positing of what is contained in the Notion of mechanism, and therefore, in the first instance, of a contradiction. 1. It follows from the Notion just indicated that the interaction of objects takes the form of the positing of the identical relation of the objects.

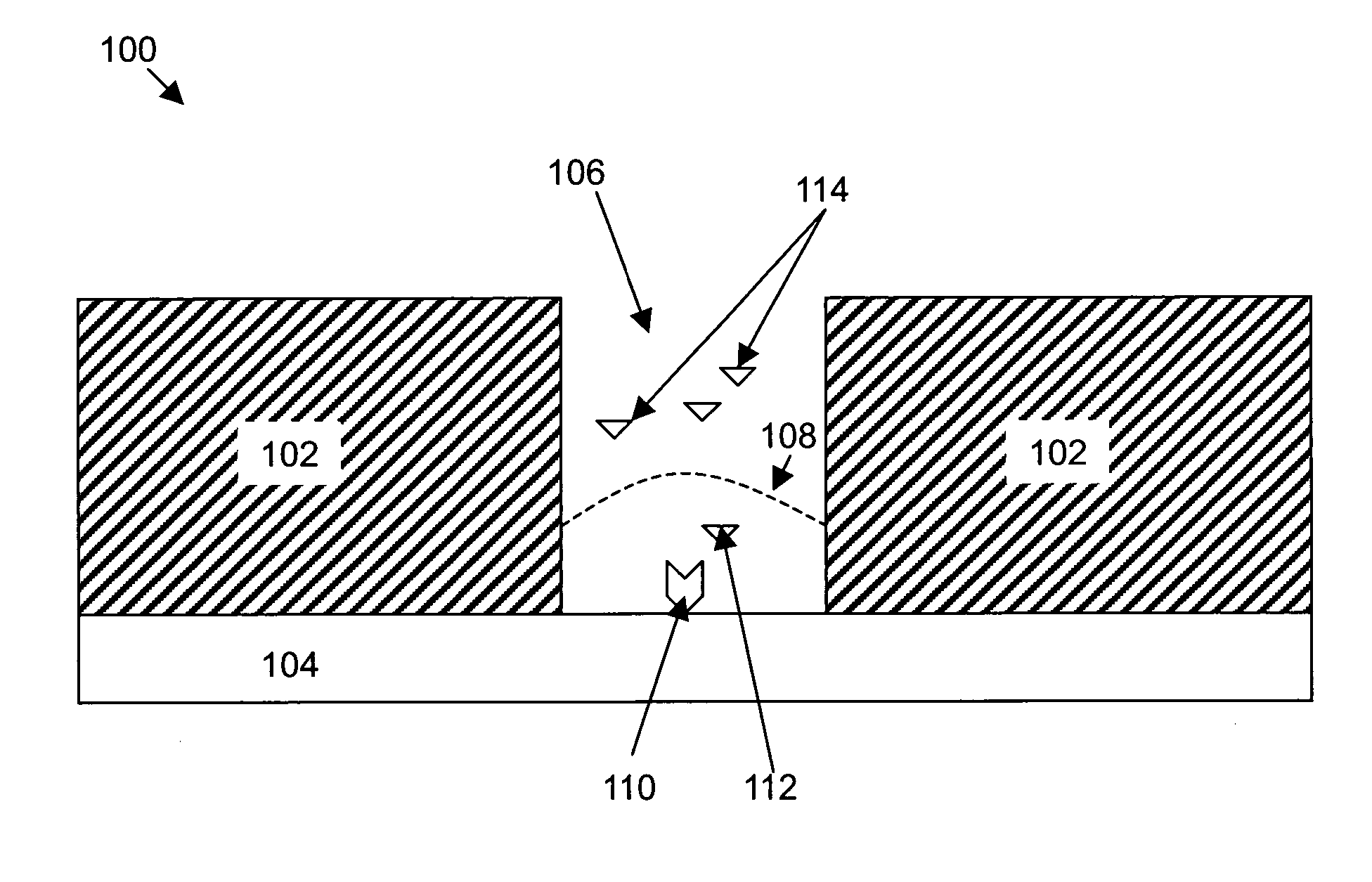

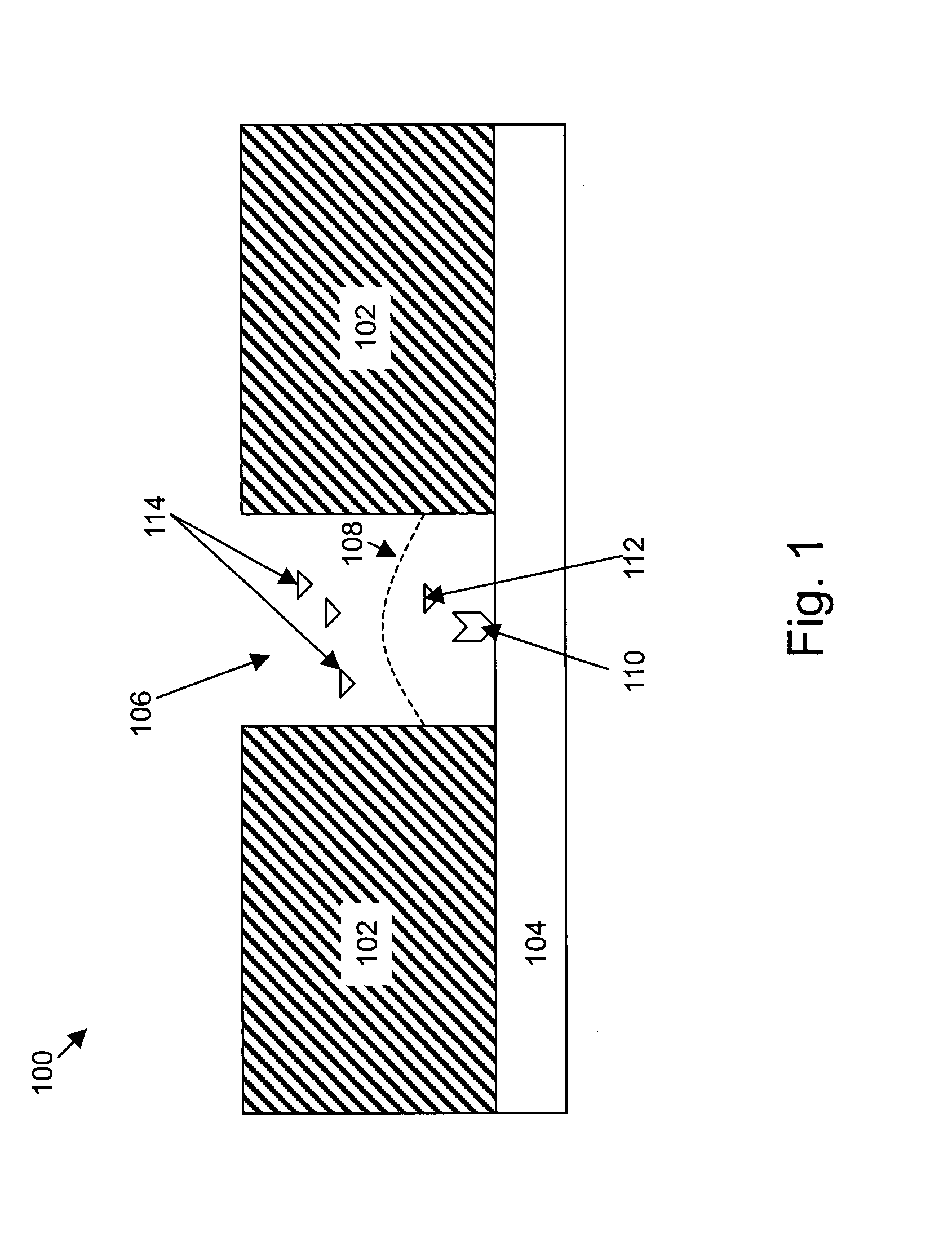

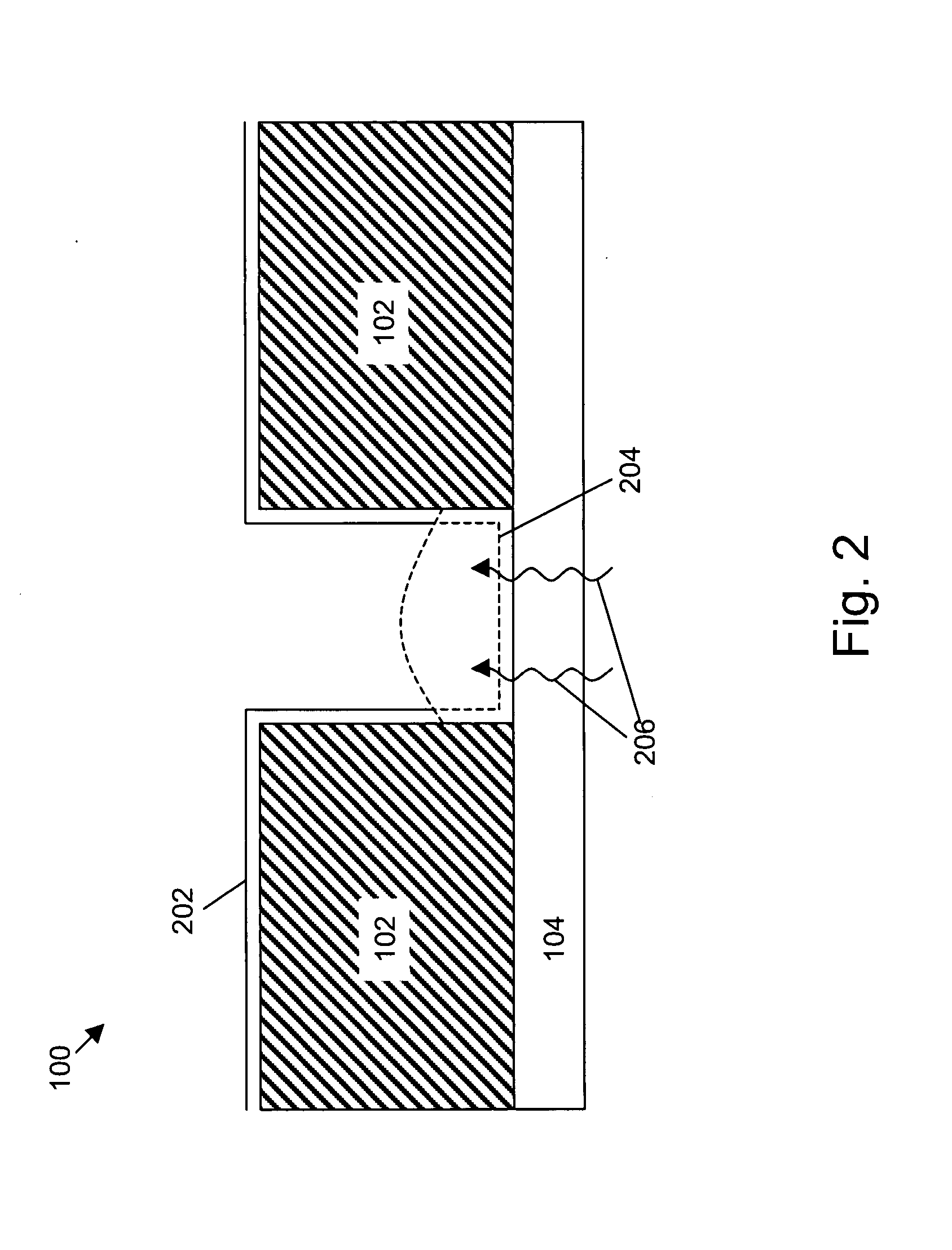

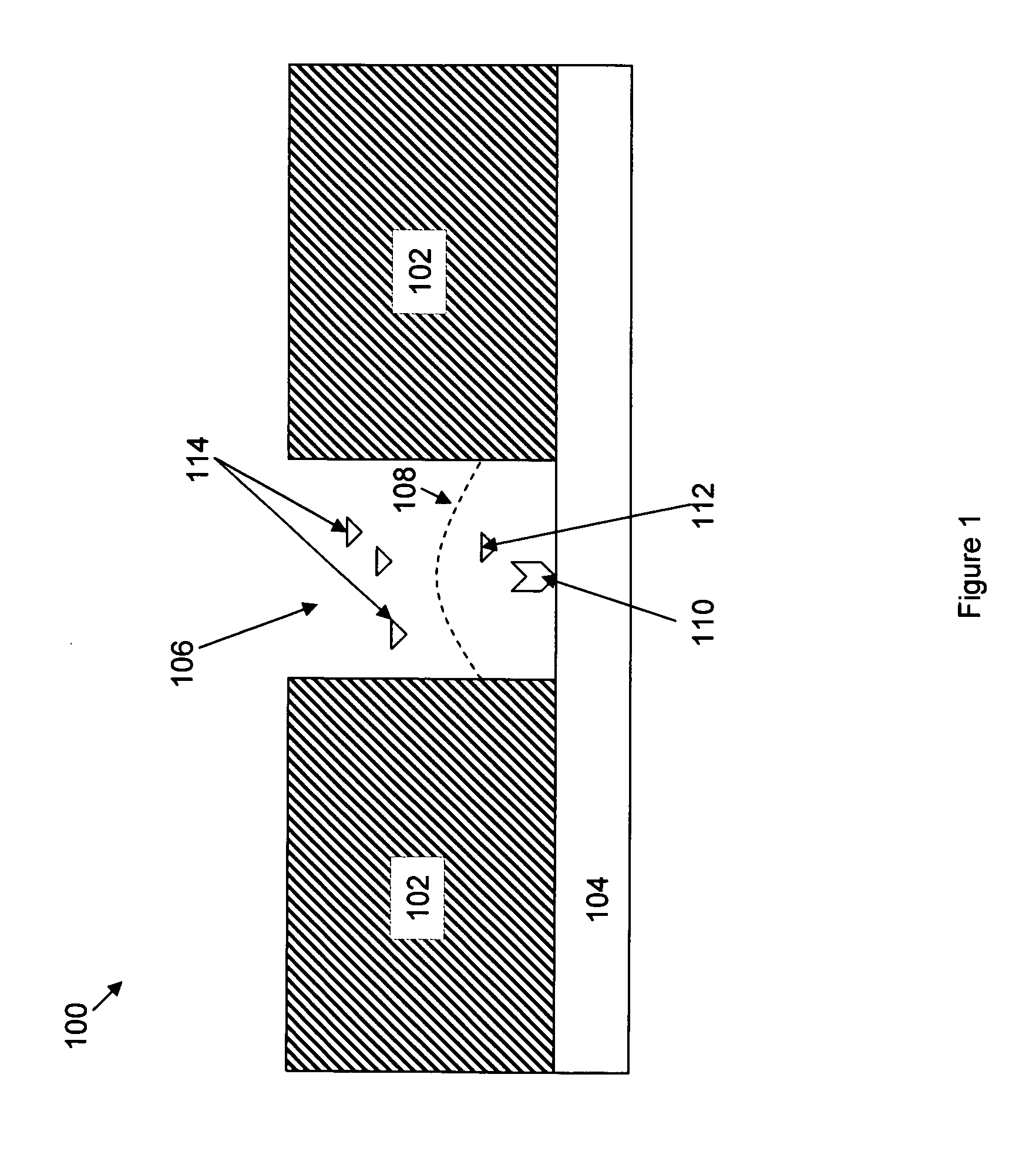

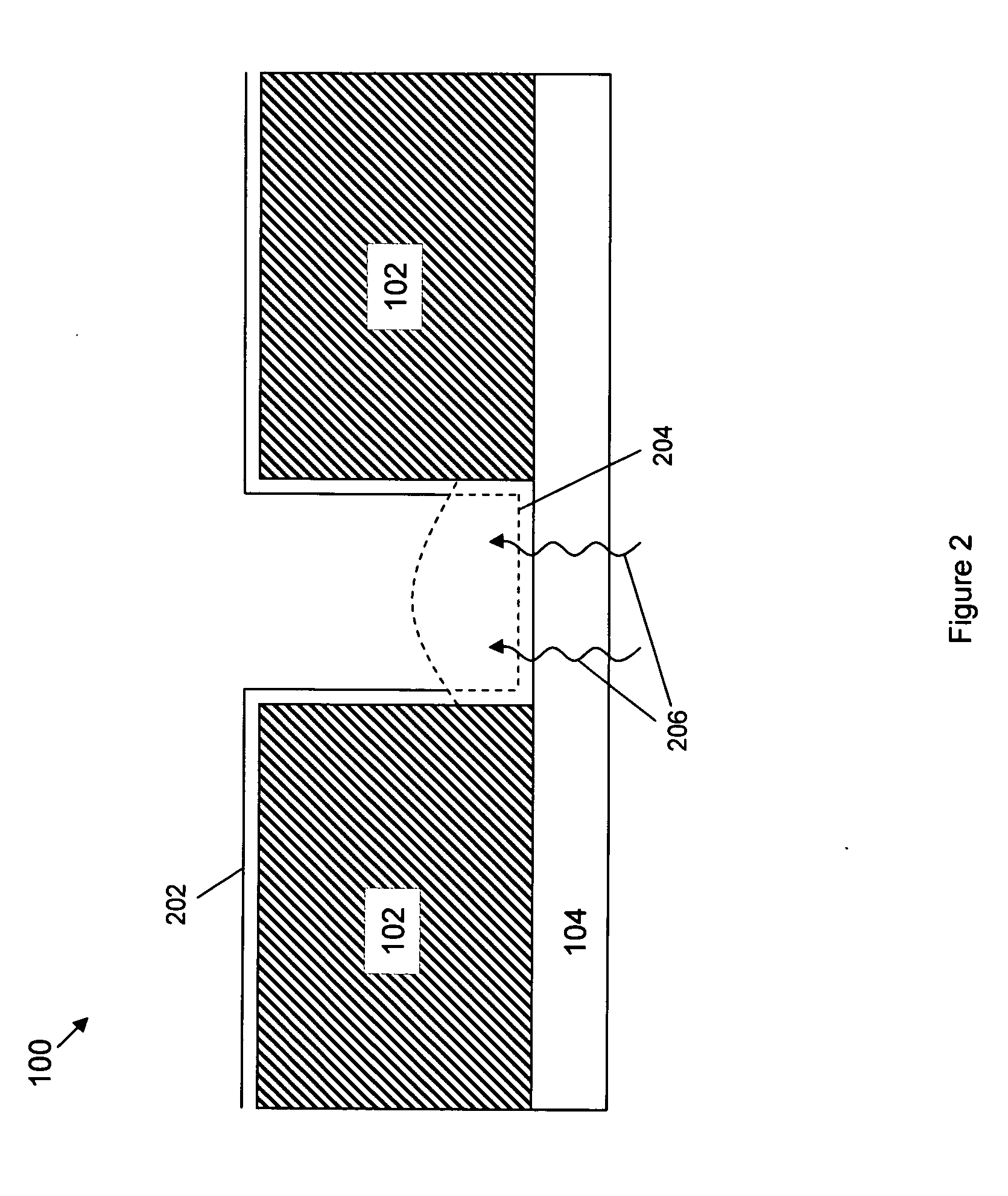

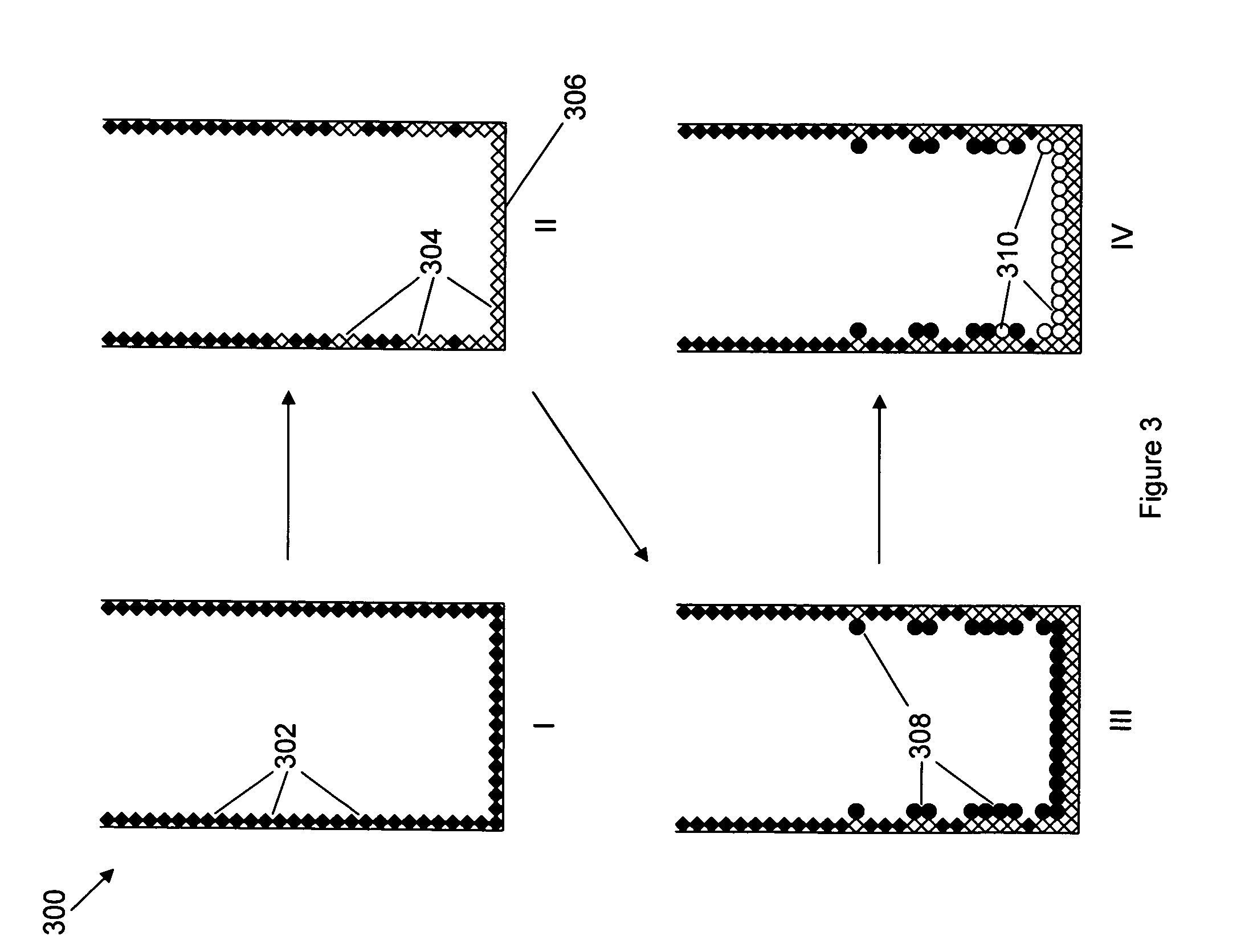

Articles having localized molecules disposed thereon and methods of producing same

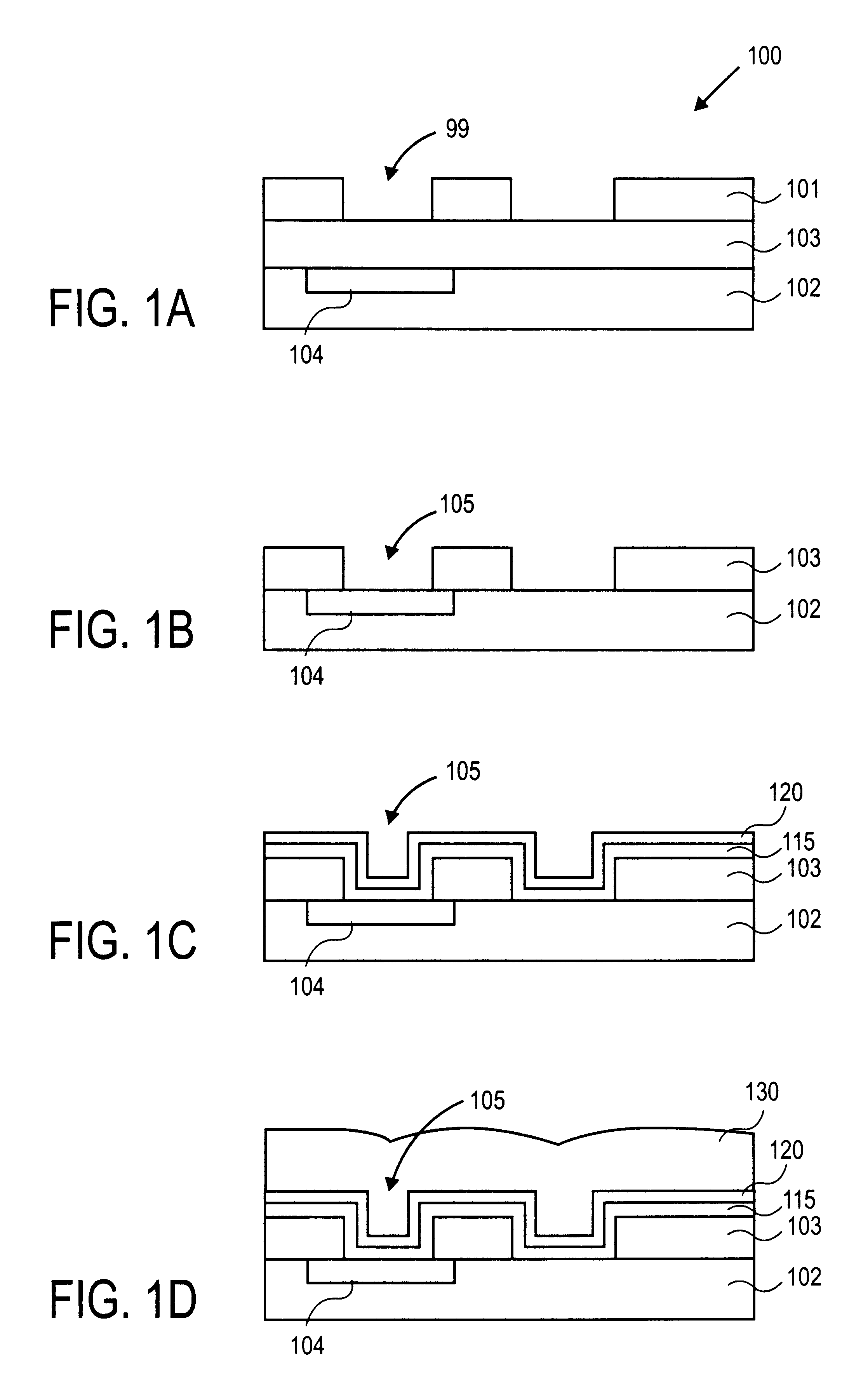

ActiveUS20080032301A1Prevent intra-observation region diffusionMaterial nanotechnologySequential/parallel process reactionsChemical groupsBiological activation

Methods of producing substrates having selected active chemical regions by employing elements of the substrates in assisting the localization of active chemical groups in desired regions of the substrate. The methods may include optical, chemical and / or mechanical processes for the deposition, removal, activation and / or deactivation of chemical groups in selected regions of the substrate to provide selective active regions of the substrate.

Owner:PACIFIC BIOSCIENCES

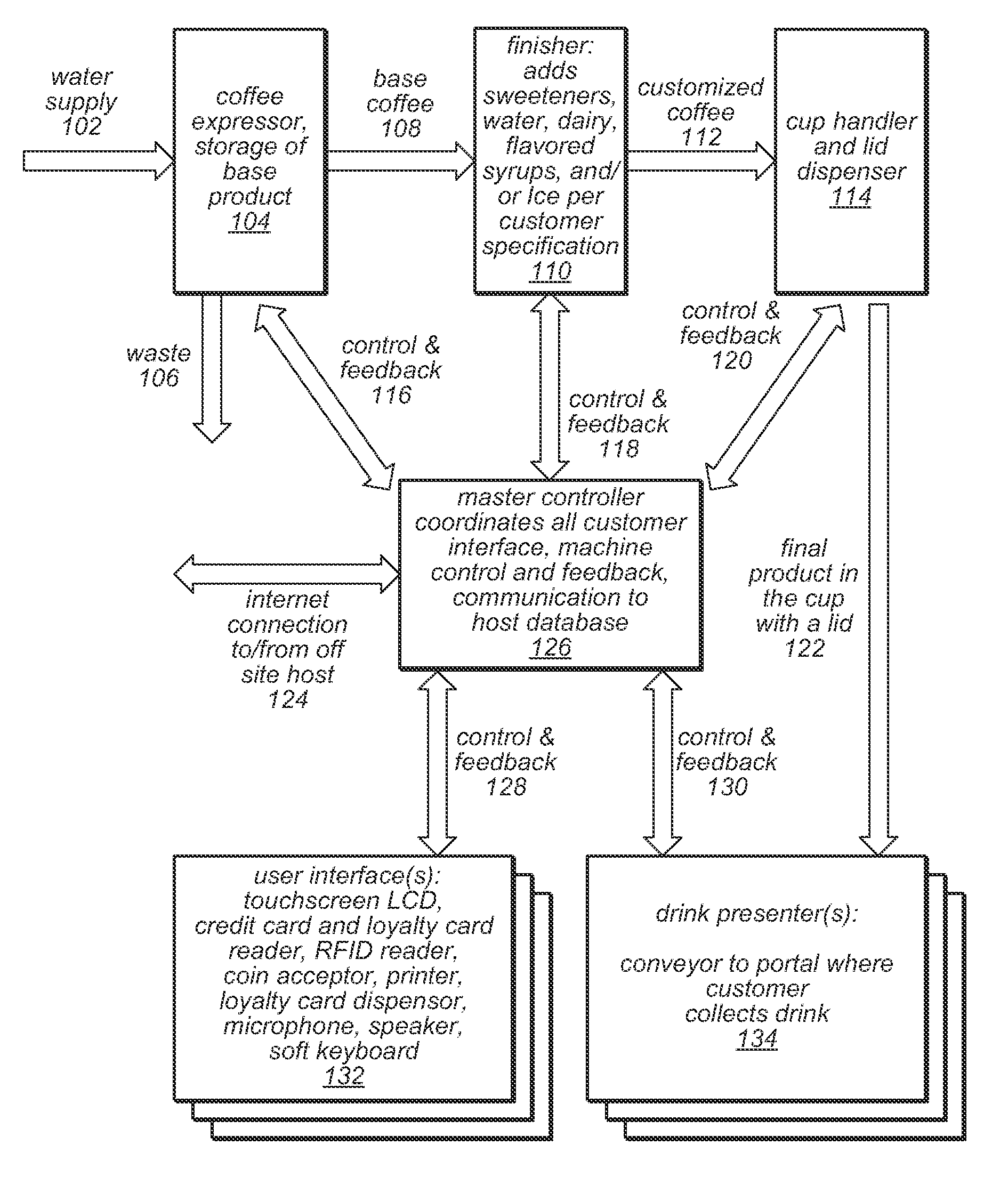

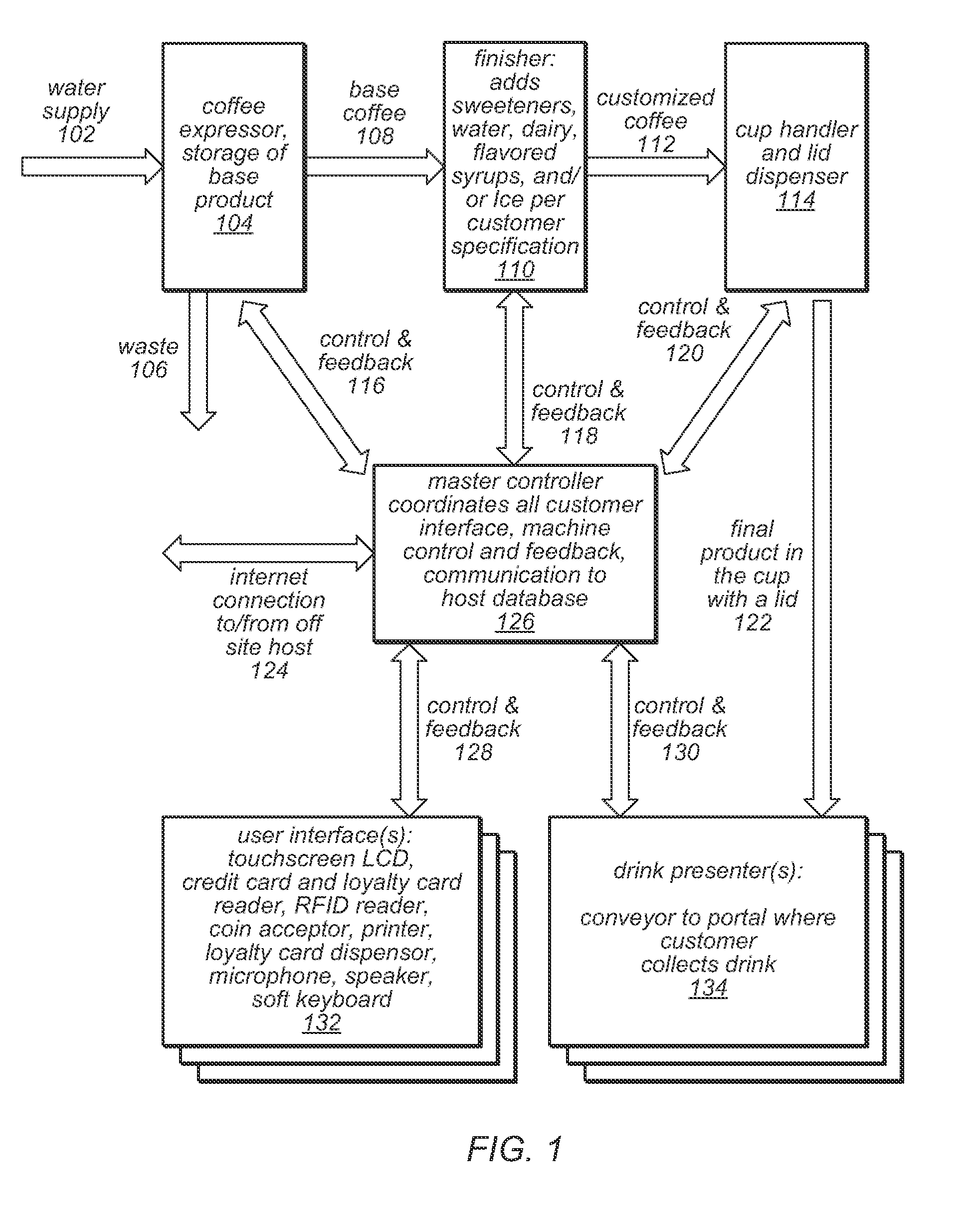

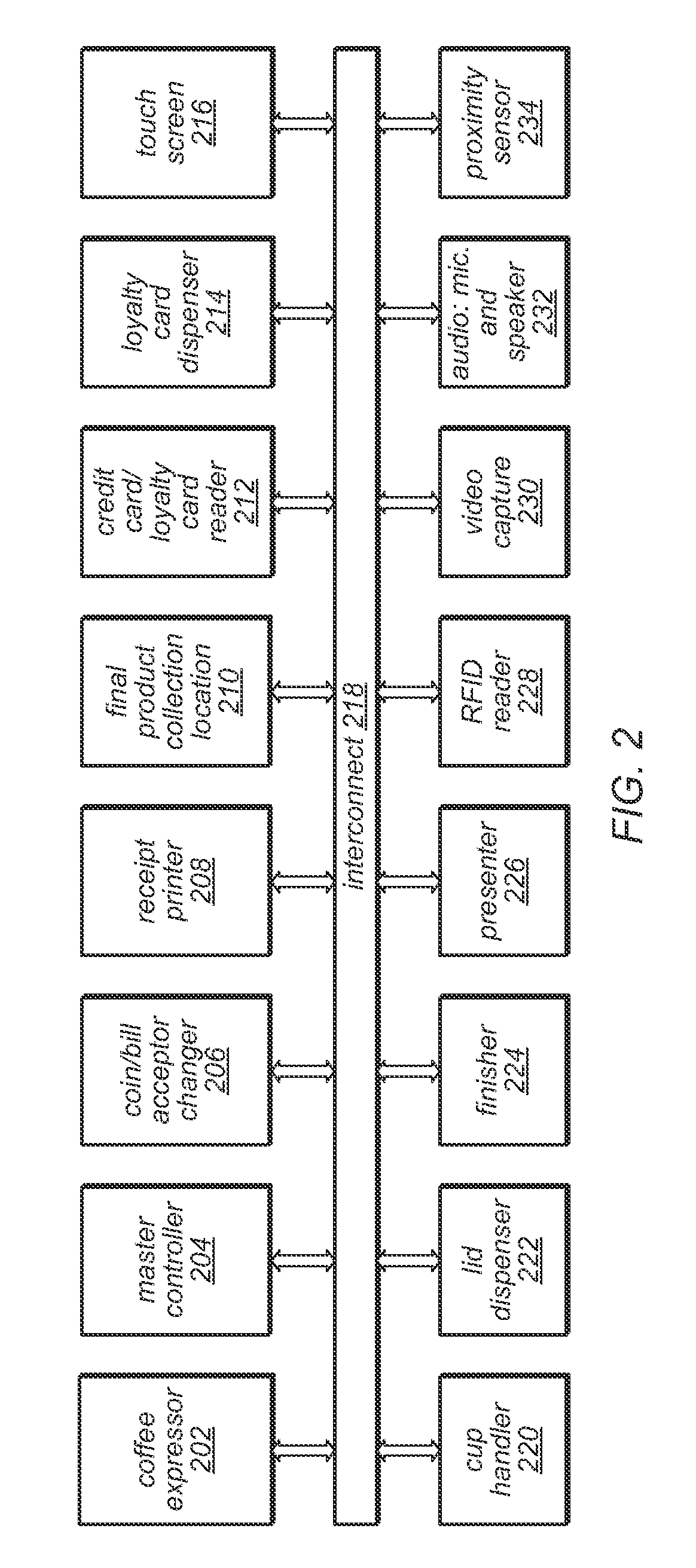

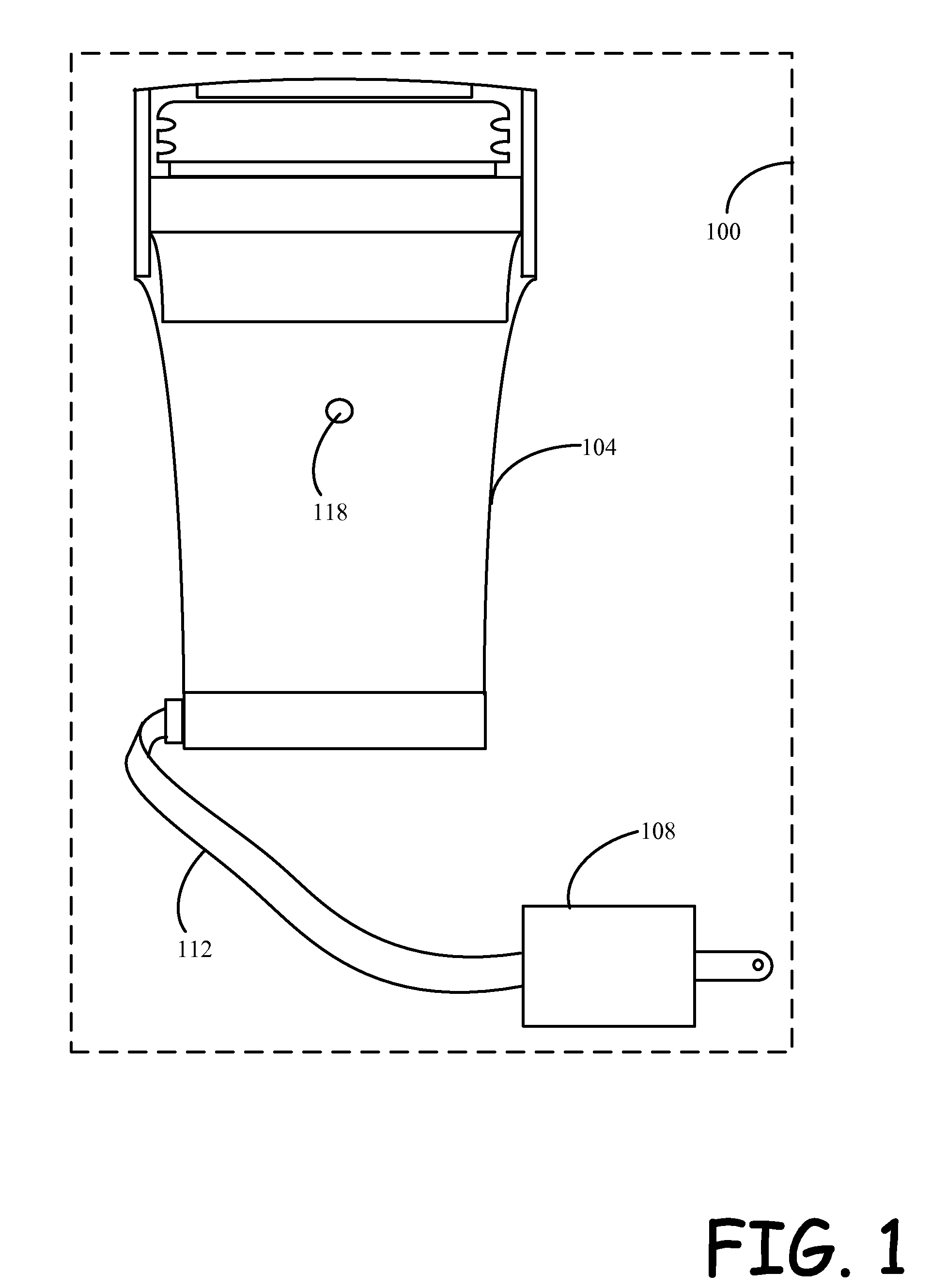

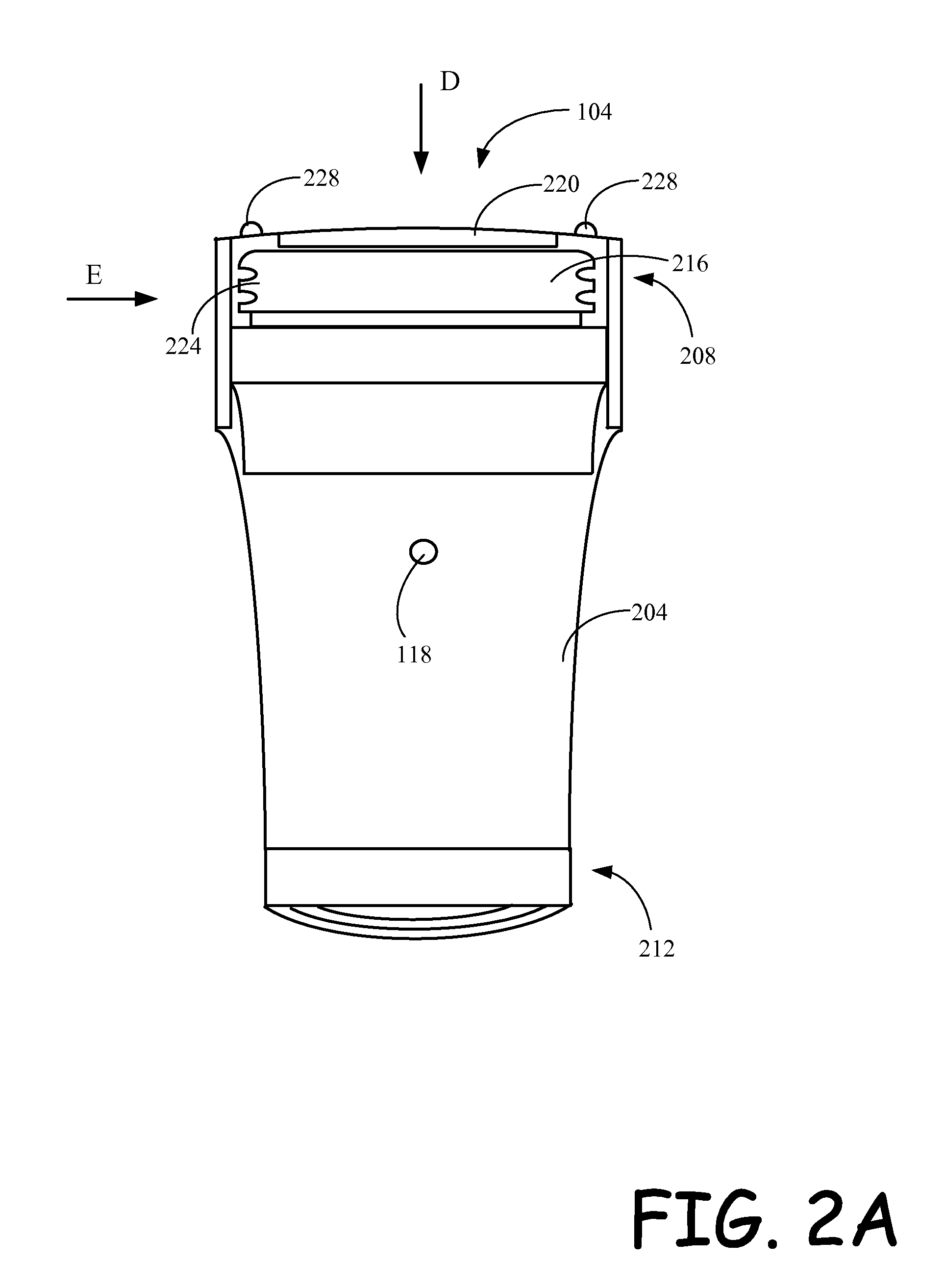

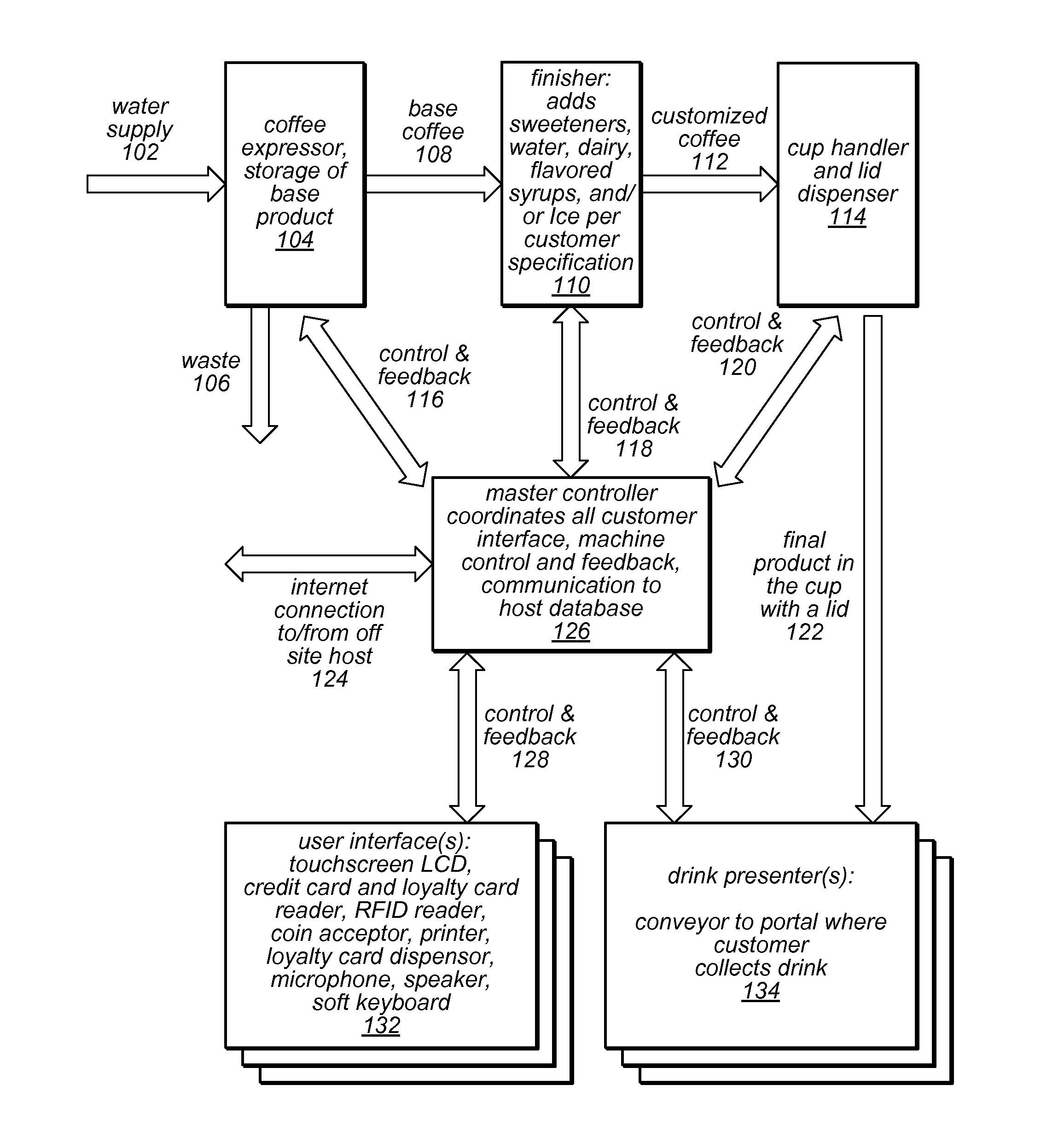

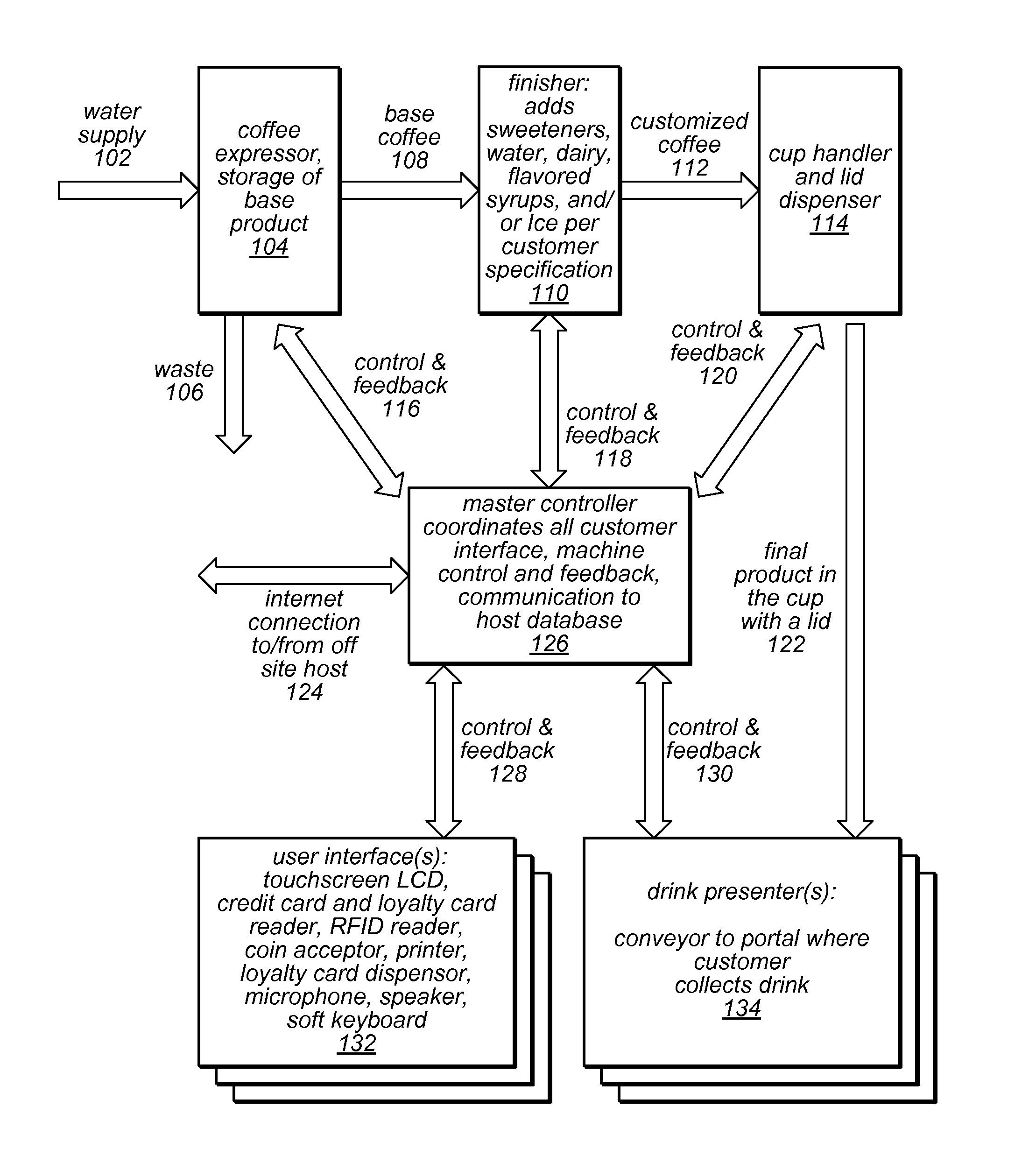

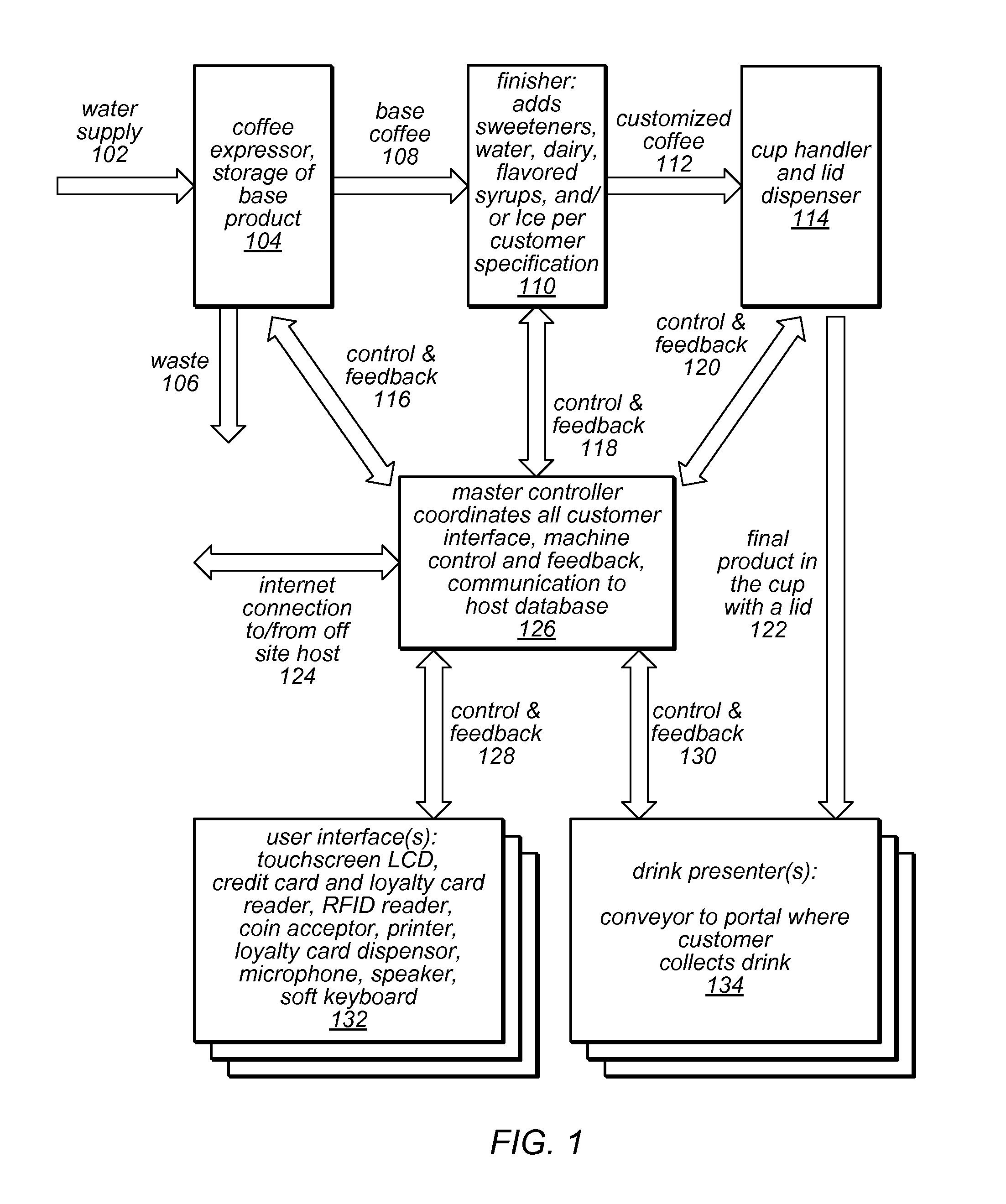

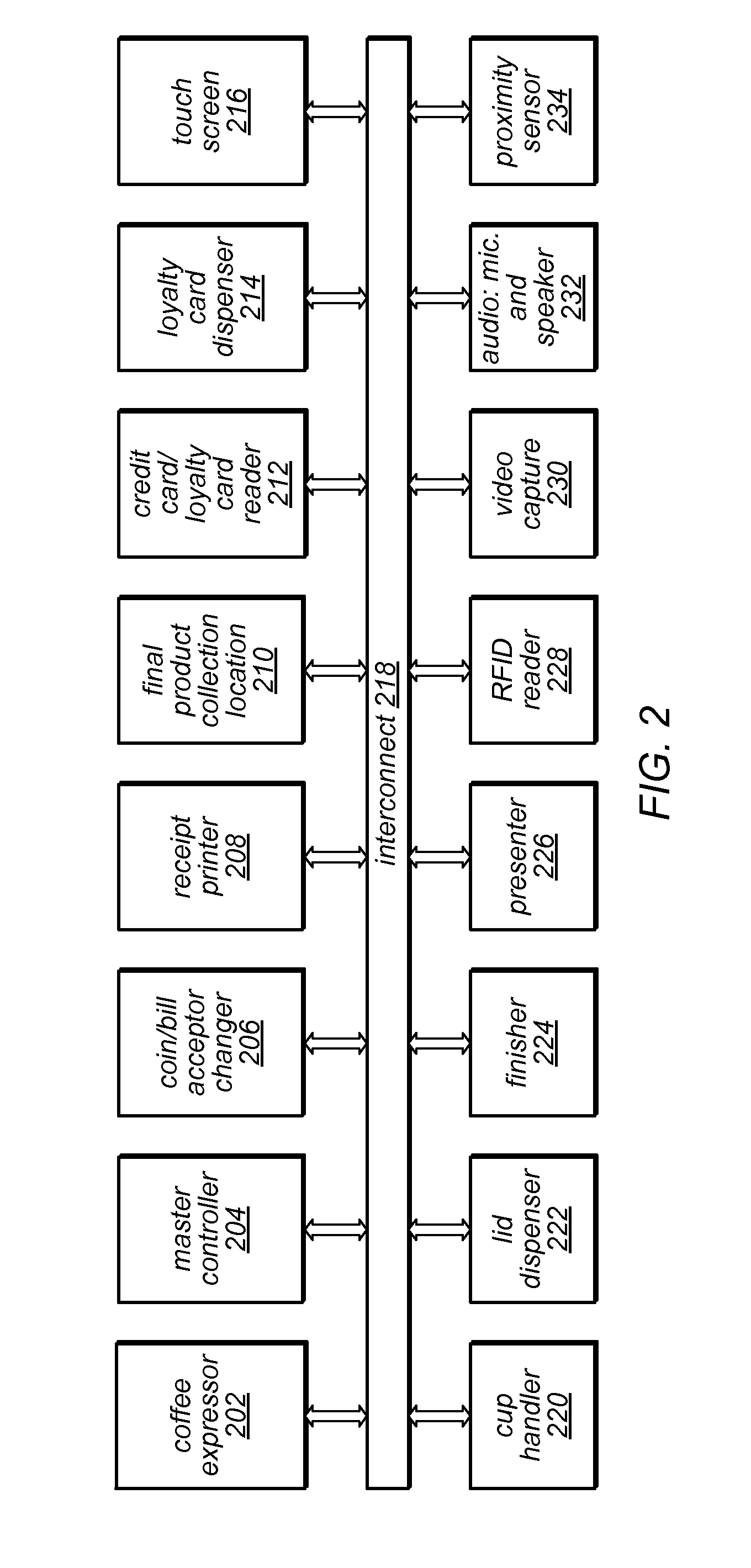

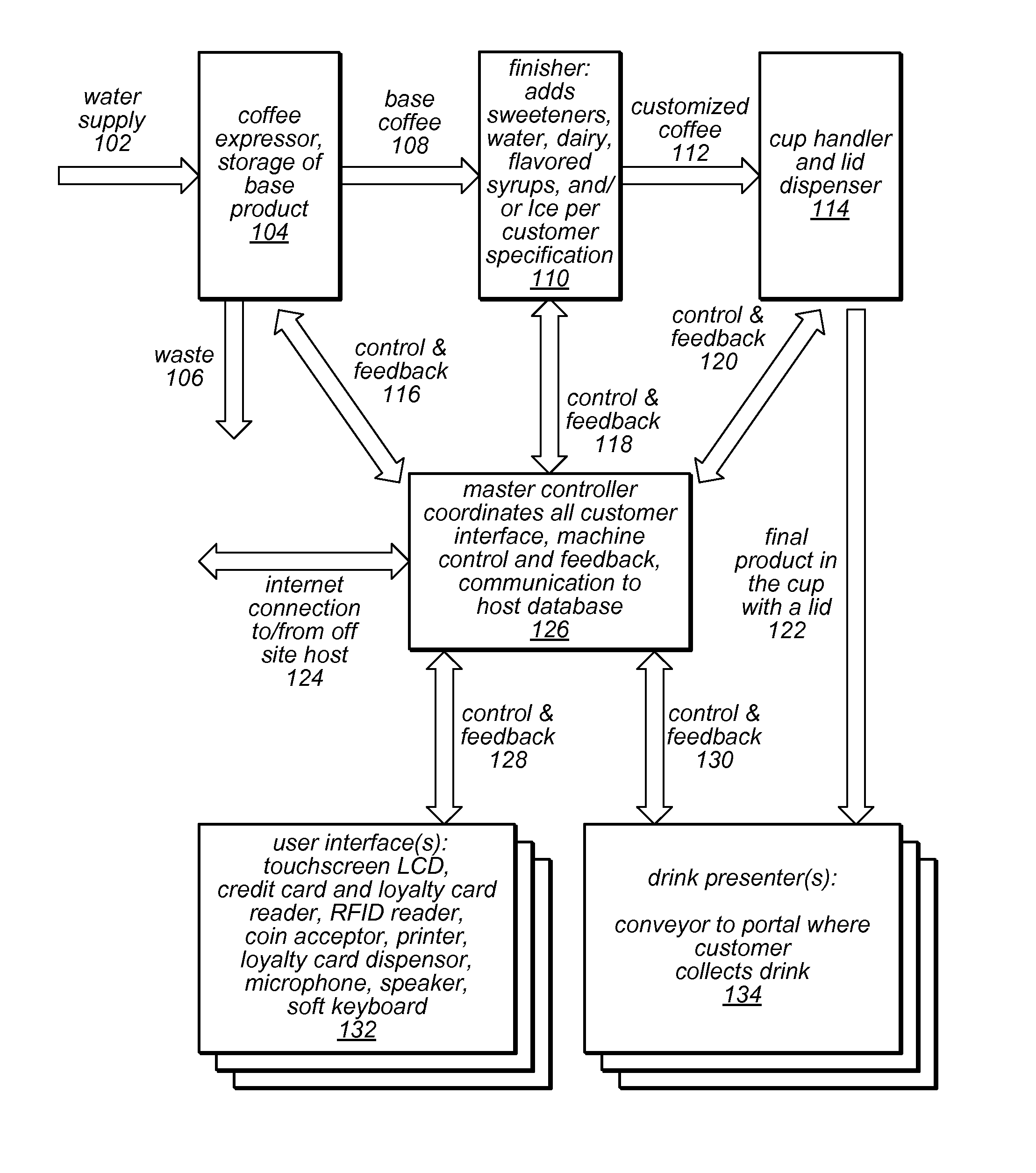

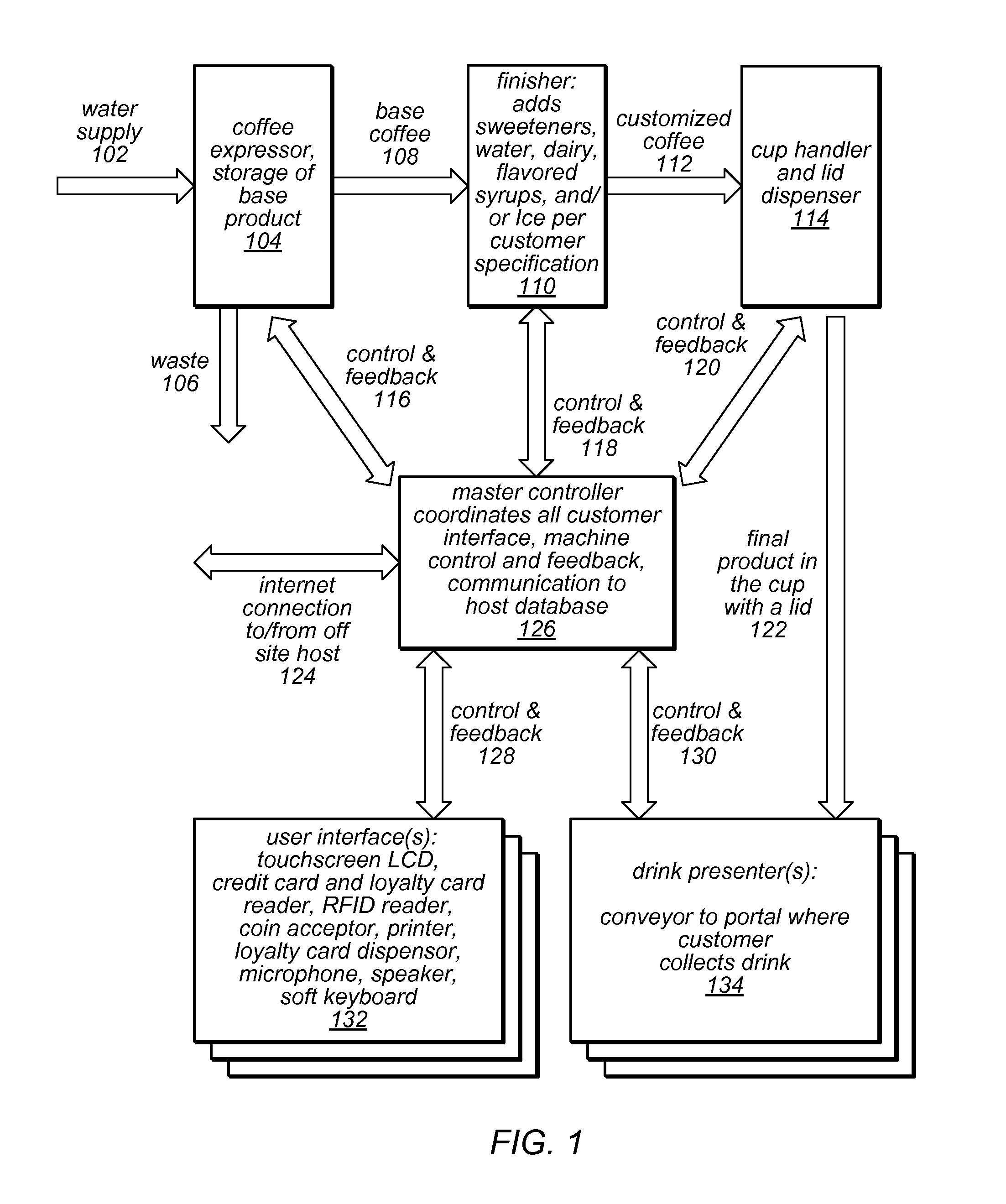

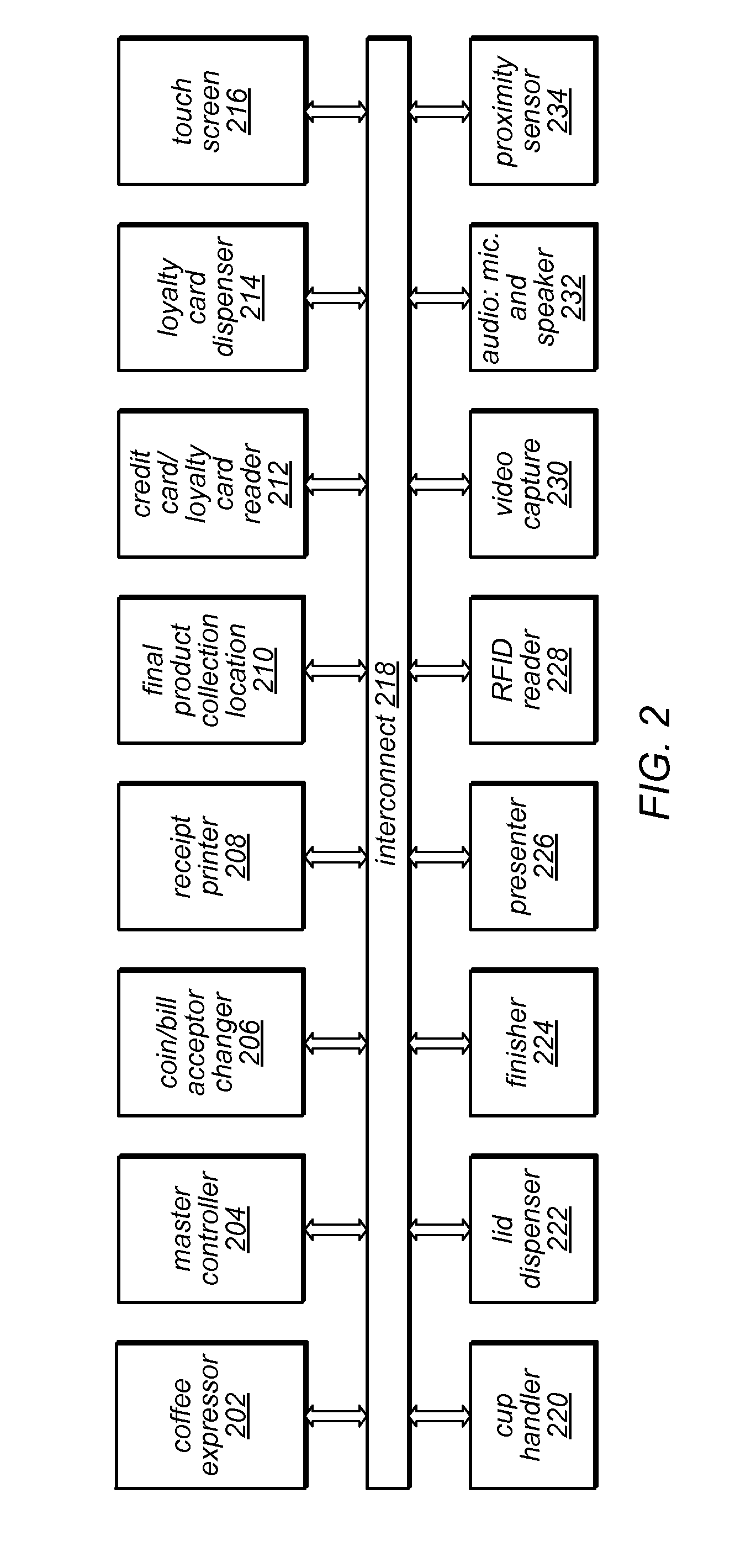

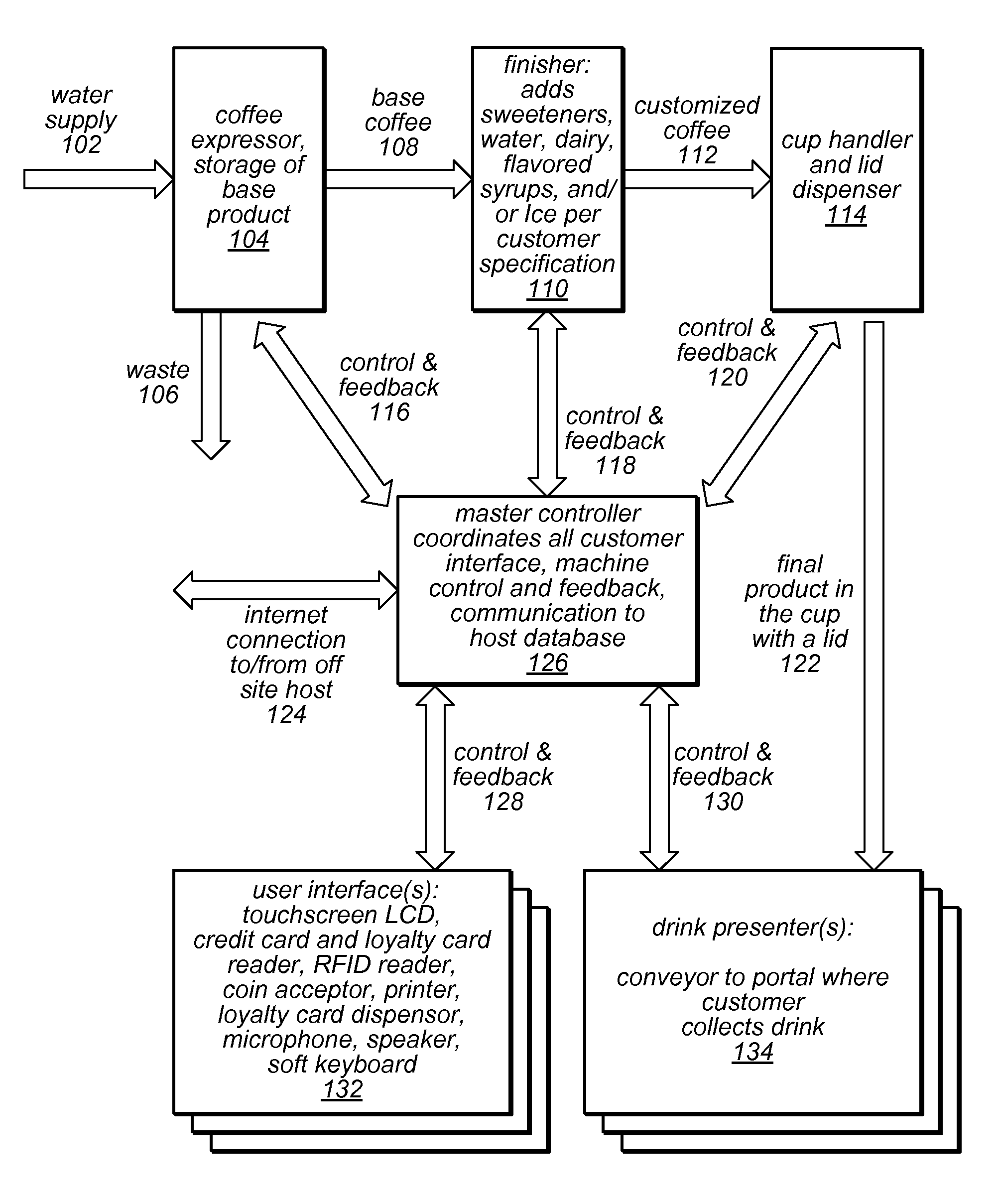

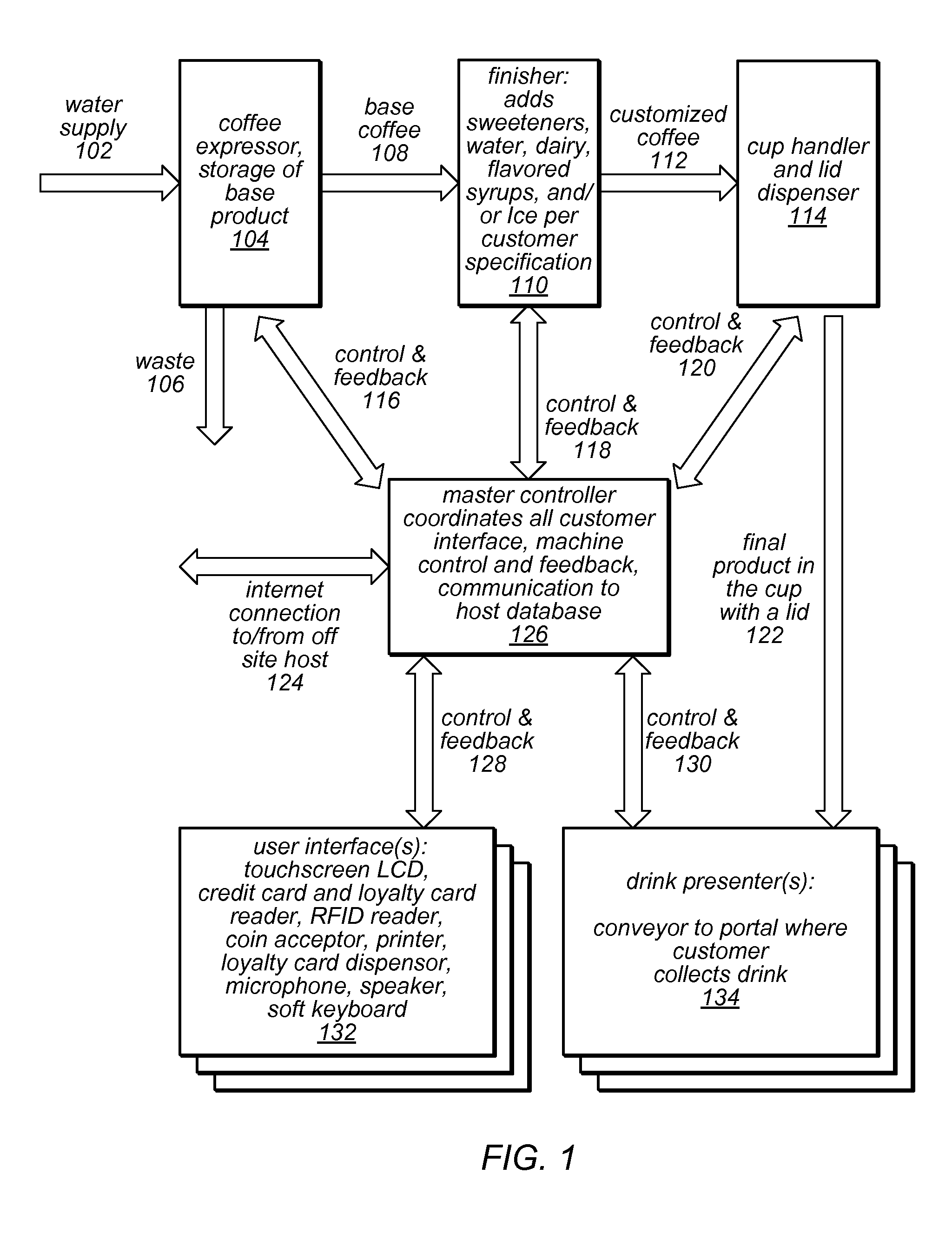

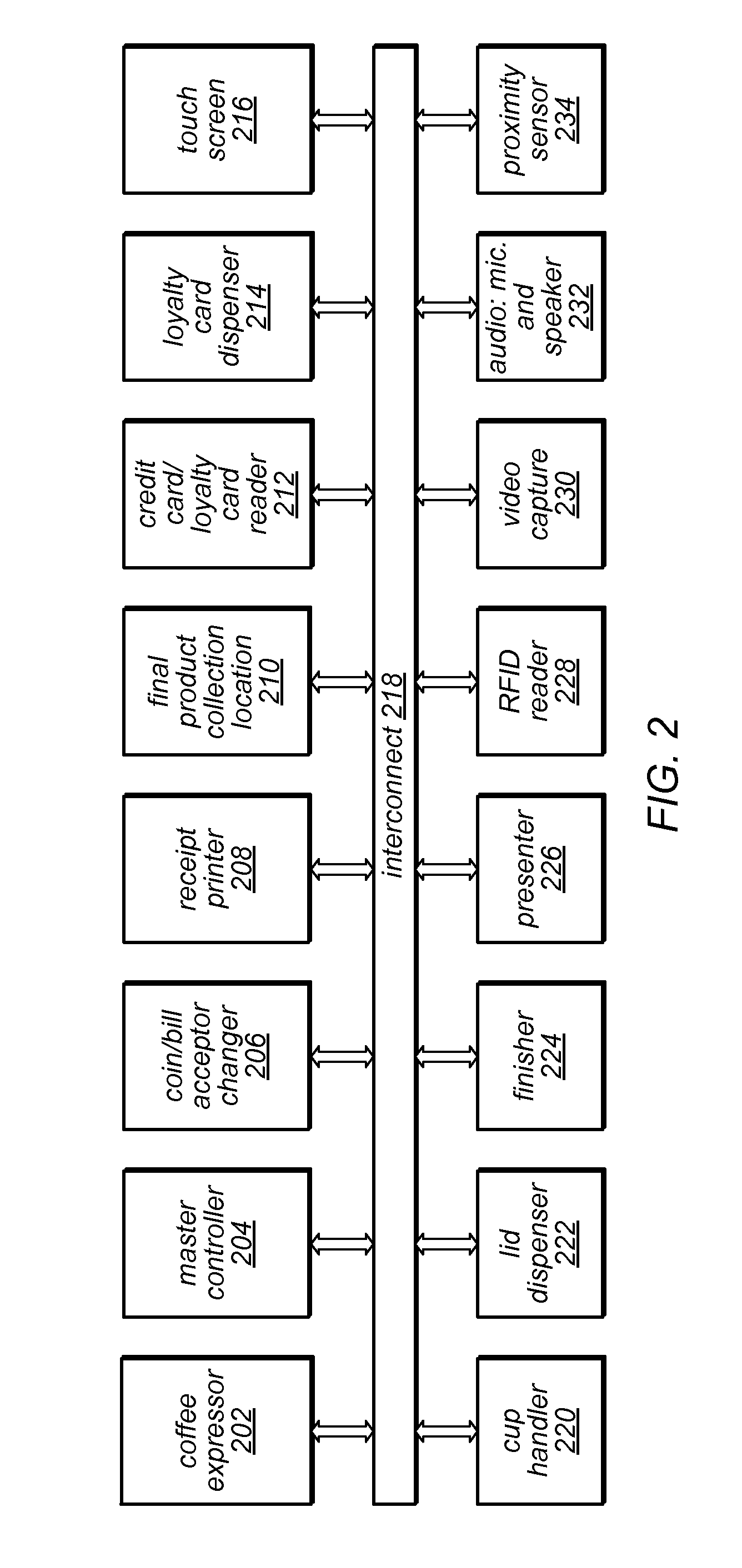

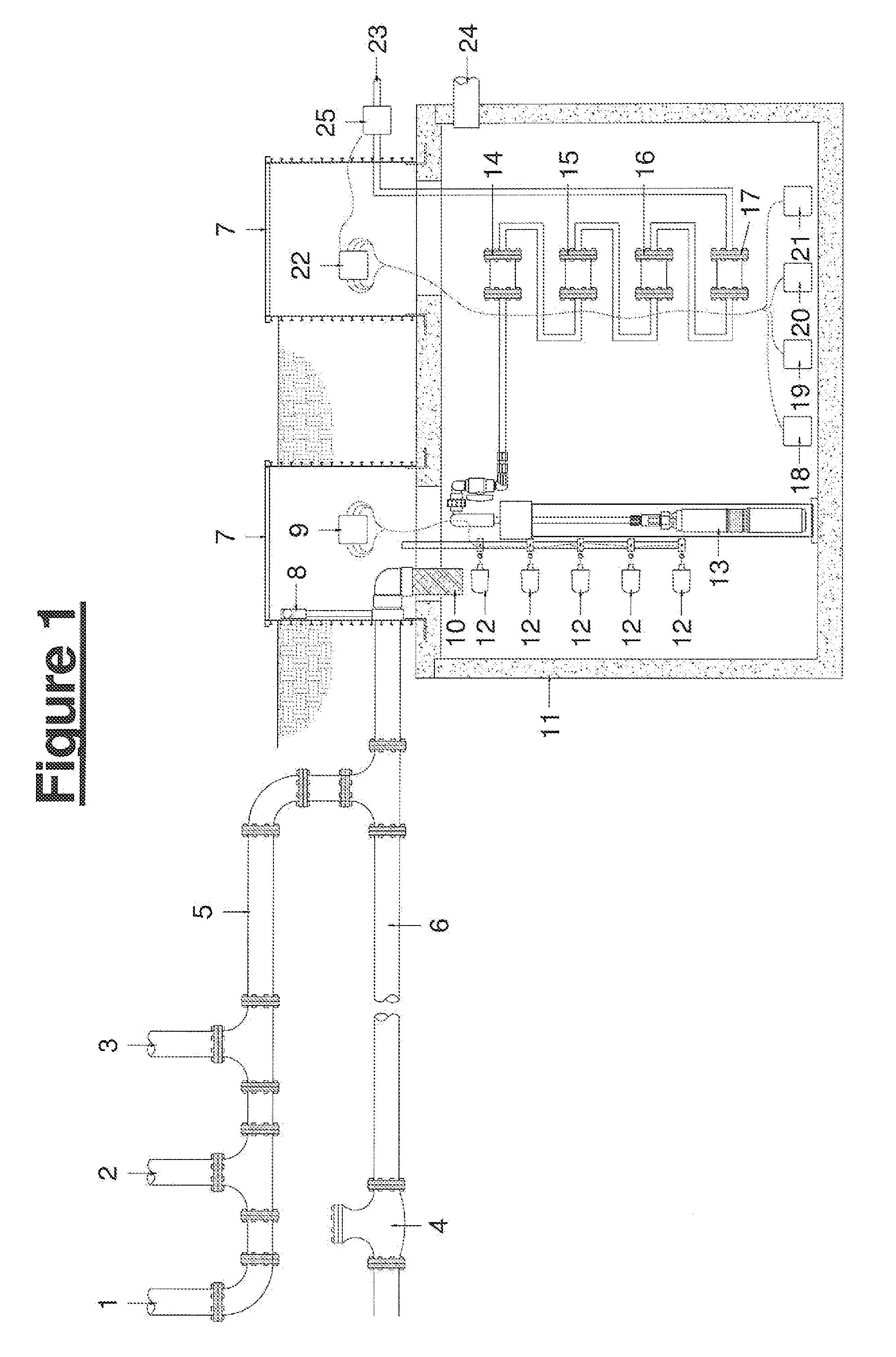

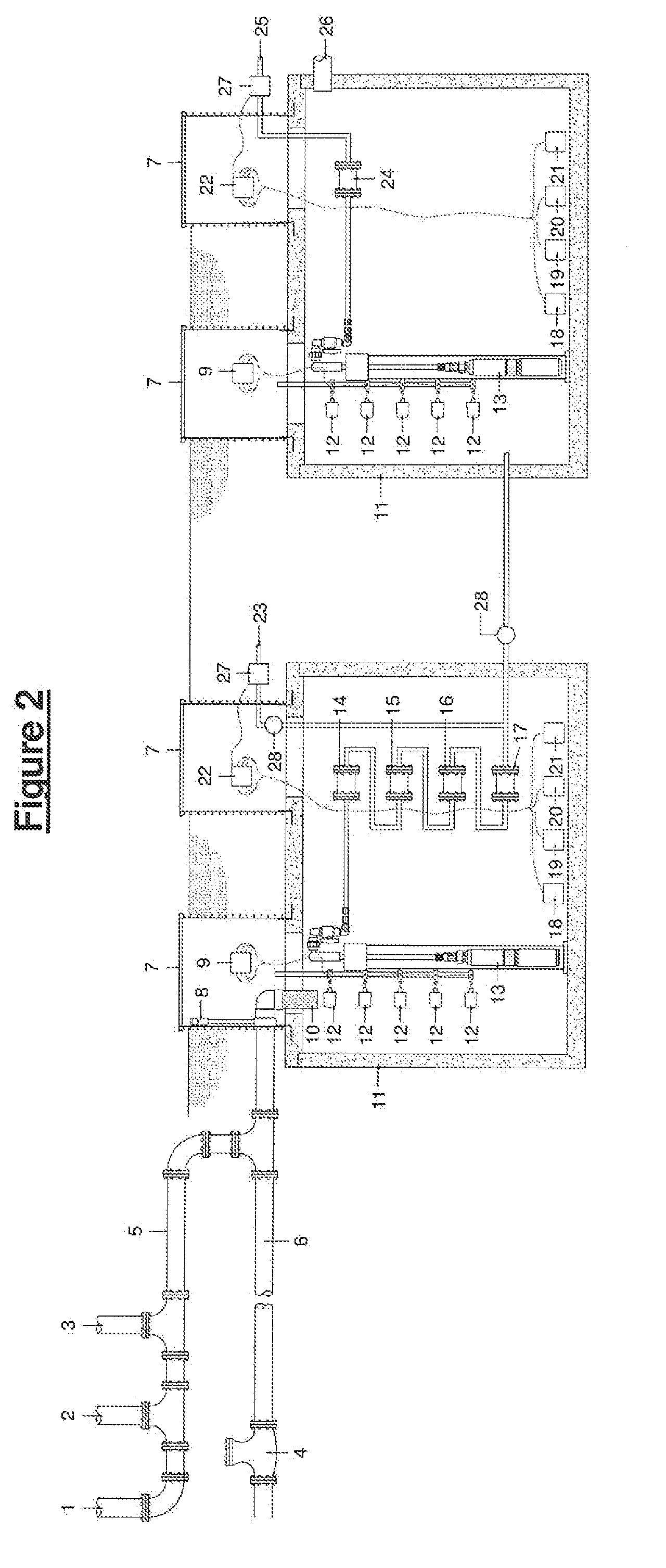

Apparatus and Method for Brewed and Espresso Drink Generation

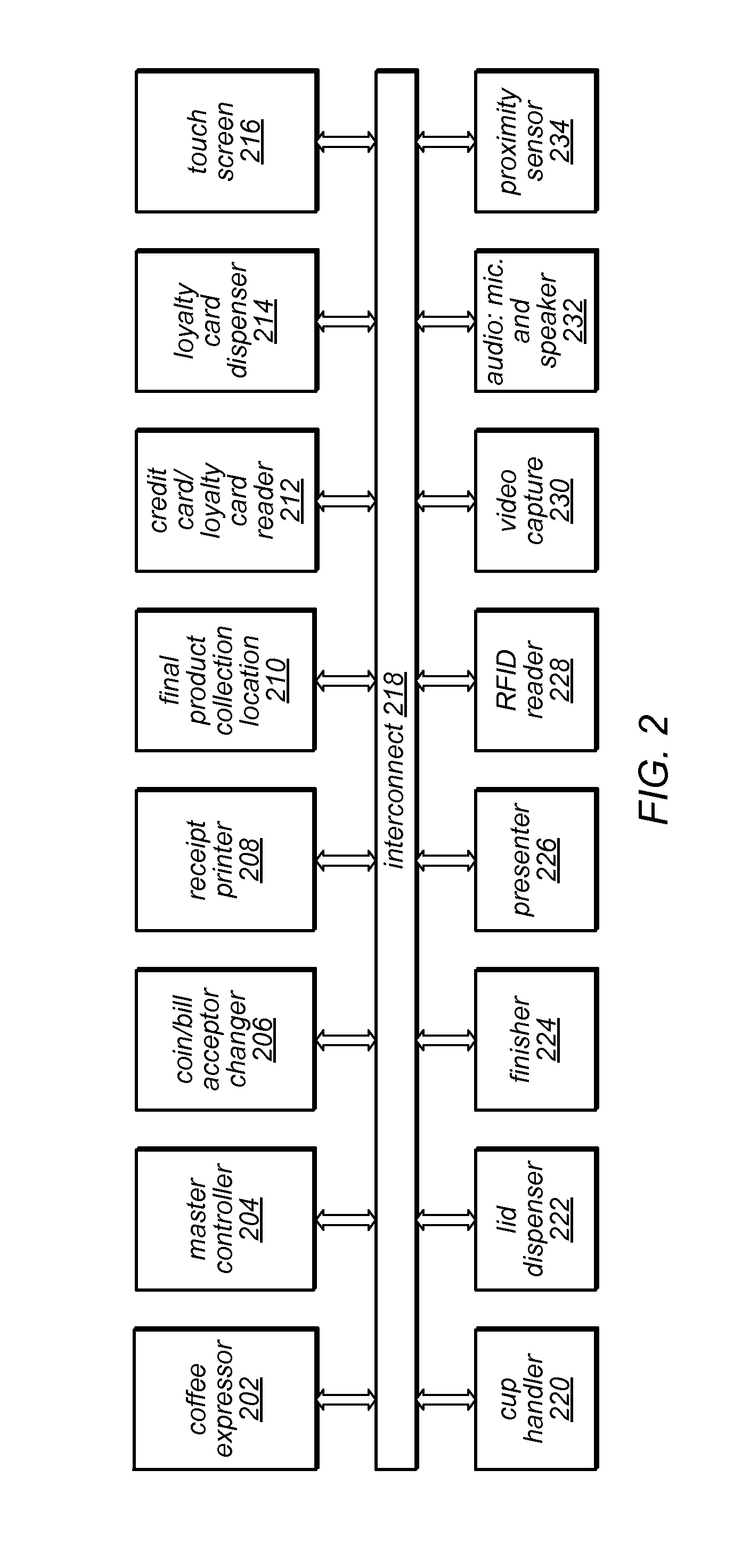

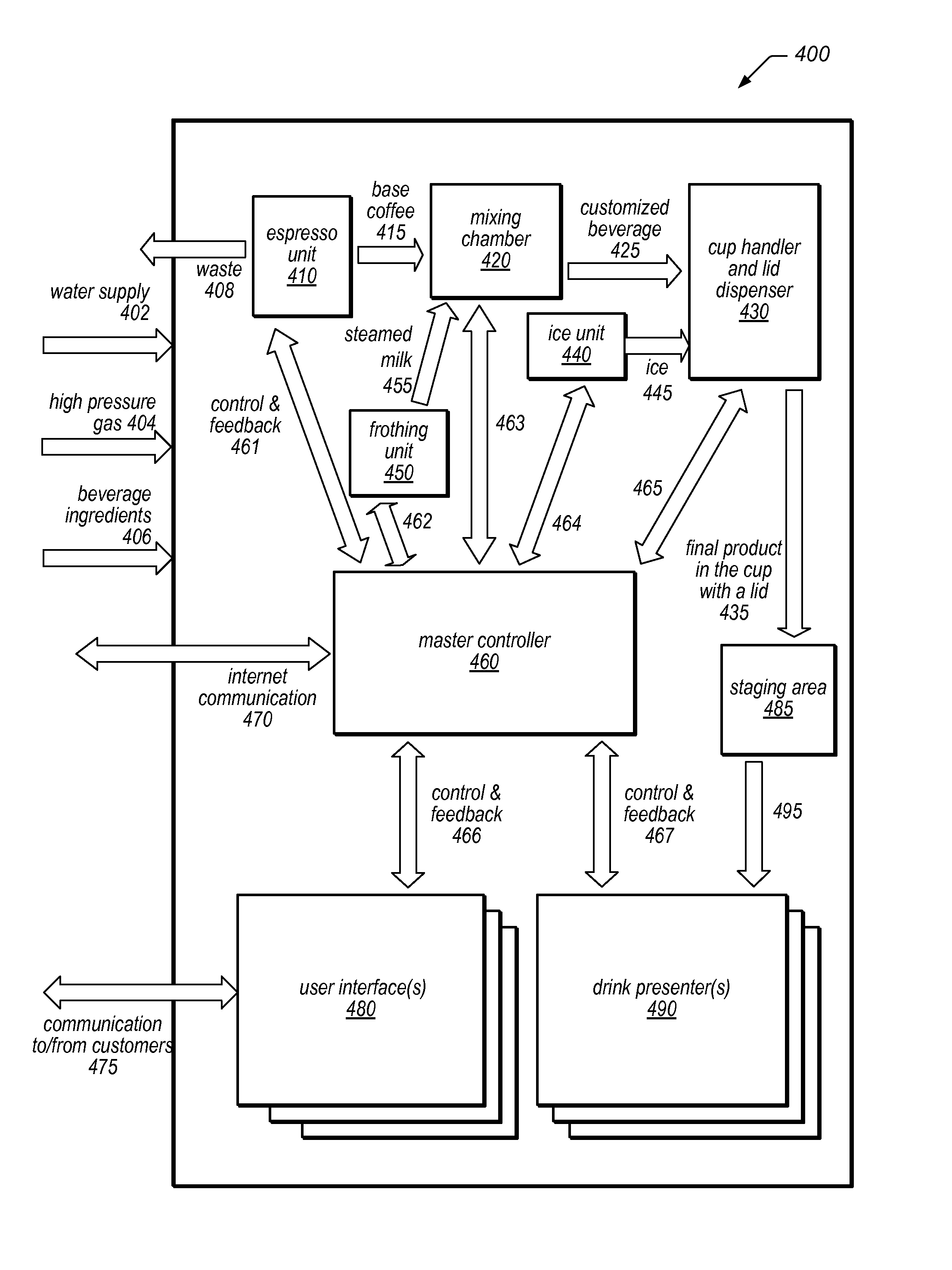

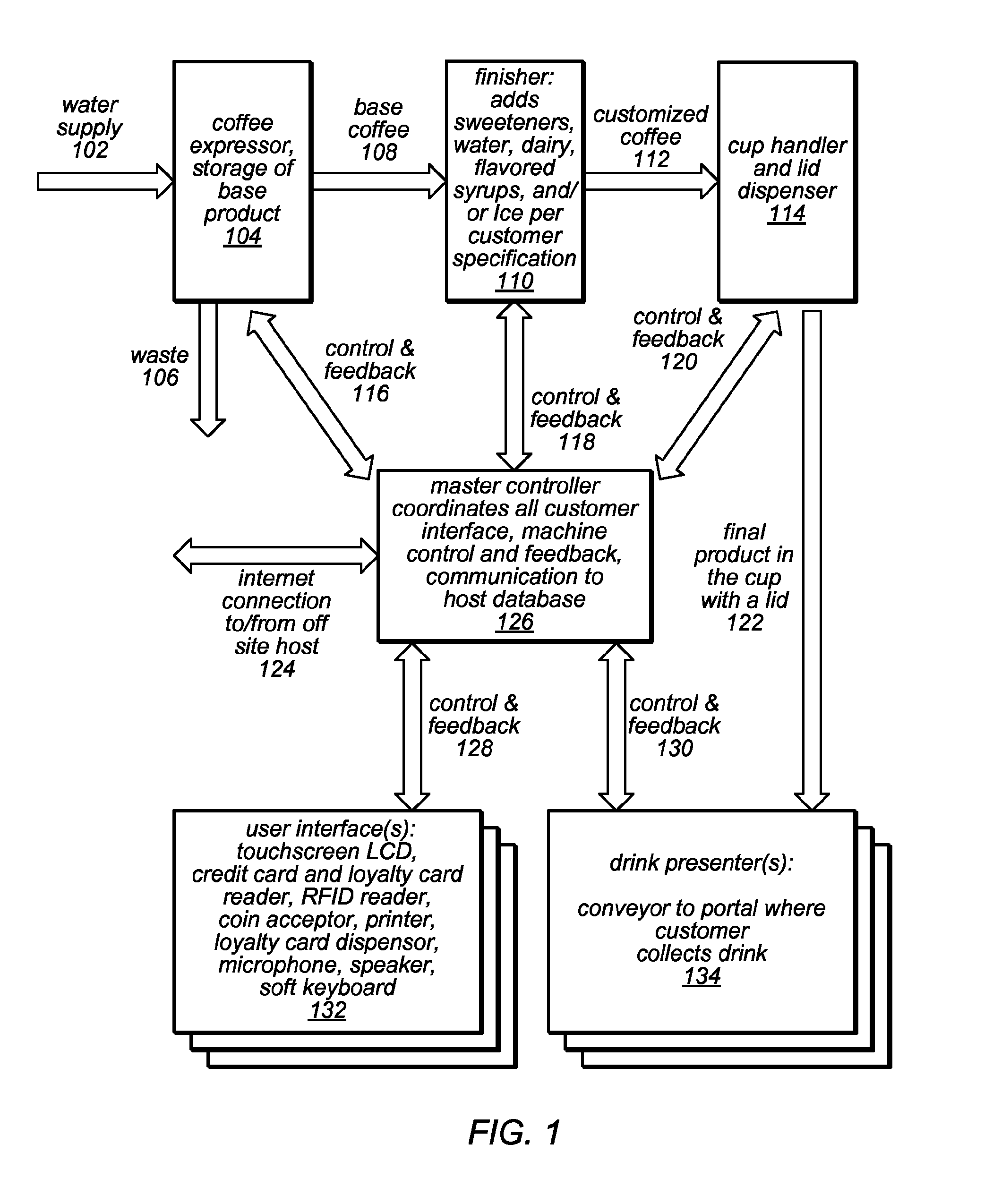

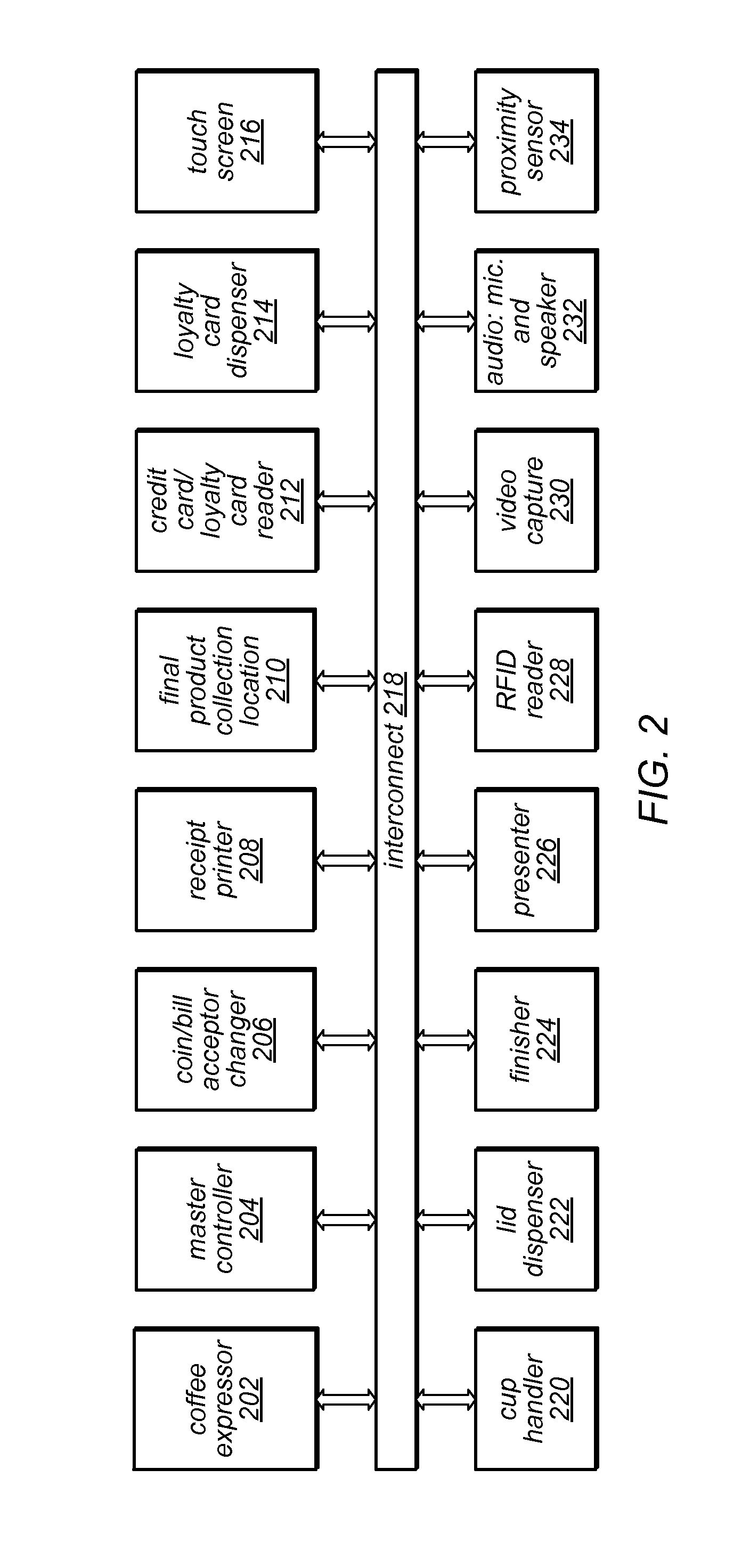

An apparatus that generates brewed beverages by performing one or more chemical and / or mechanical processes may receive requests to produce specified brewed beverages. The apparatus may include a master controller that initiates and controls performance of the chemical and / or mechanical processes to produce the specified beverages. The master controller may adaptively apply one or more process accelerators during the performance of one of the chemical or mechanical processes to accelerate the process or to achieve a desired qualitative or quantitative characteristic for a beverage or a component thereof. The adaptive application of one or more process accelerators may be dependent on a multiple-variable process profile developed for the process and / or a specified beverage. For example, the pressure in a steam wand and / or the depth of the wand may be varied during a process to froth milk in order to produce frothed milk having a desired temperature.

Owner:COSTA COFFEE

Articles having localized molecules disposed thereon and methods of producing same

ActiveUS20070238679A1Prevent intra-observation region diffusionMaterial nanotechnologySequential/parallel process reactionsChemical groupsOrganic chemistry

Methods of producing substrates having selected active chemical regions by employing elements of the substrates in assisting the localization of active chemical groups in desired regions of the substrate. The methods may include optical, chemical and / or mechanical processes for the deposition, removal, activation and / or deactivation of chemical groups in selected regions of the substrate to provide selective active regions of the substrate.

Owner:PACIFIC BIOSCIENCES

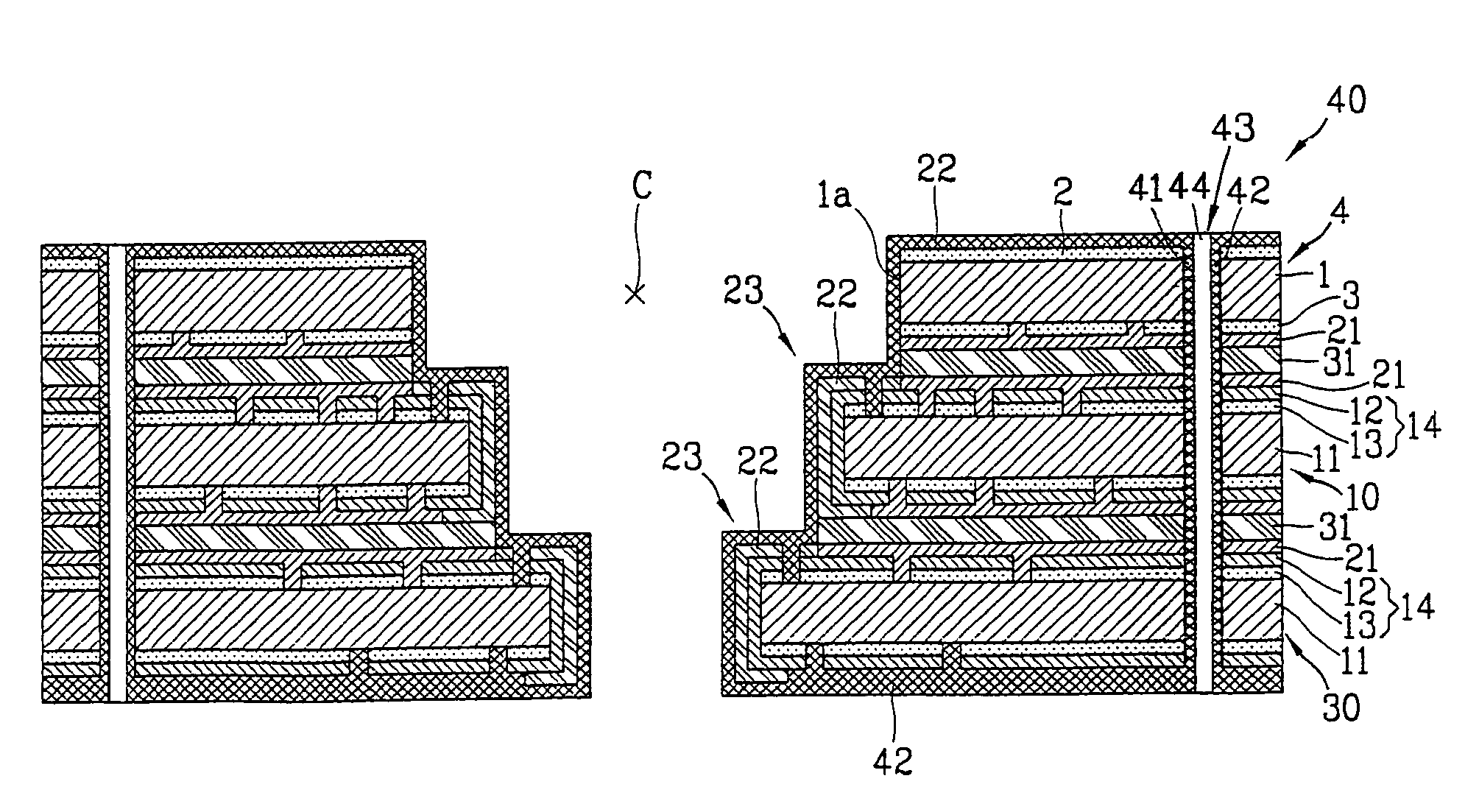

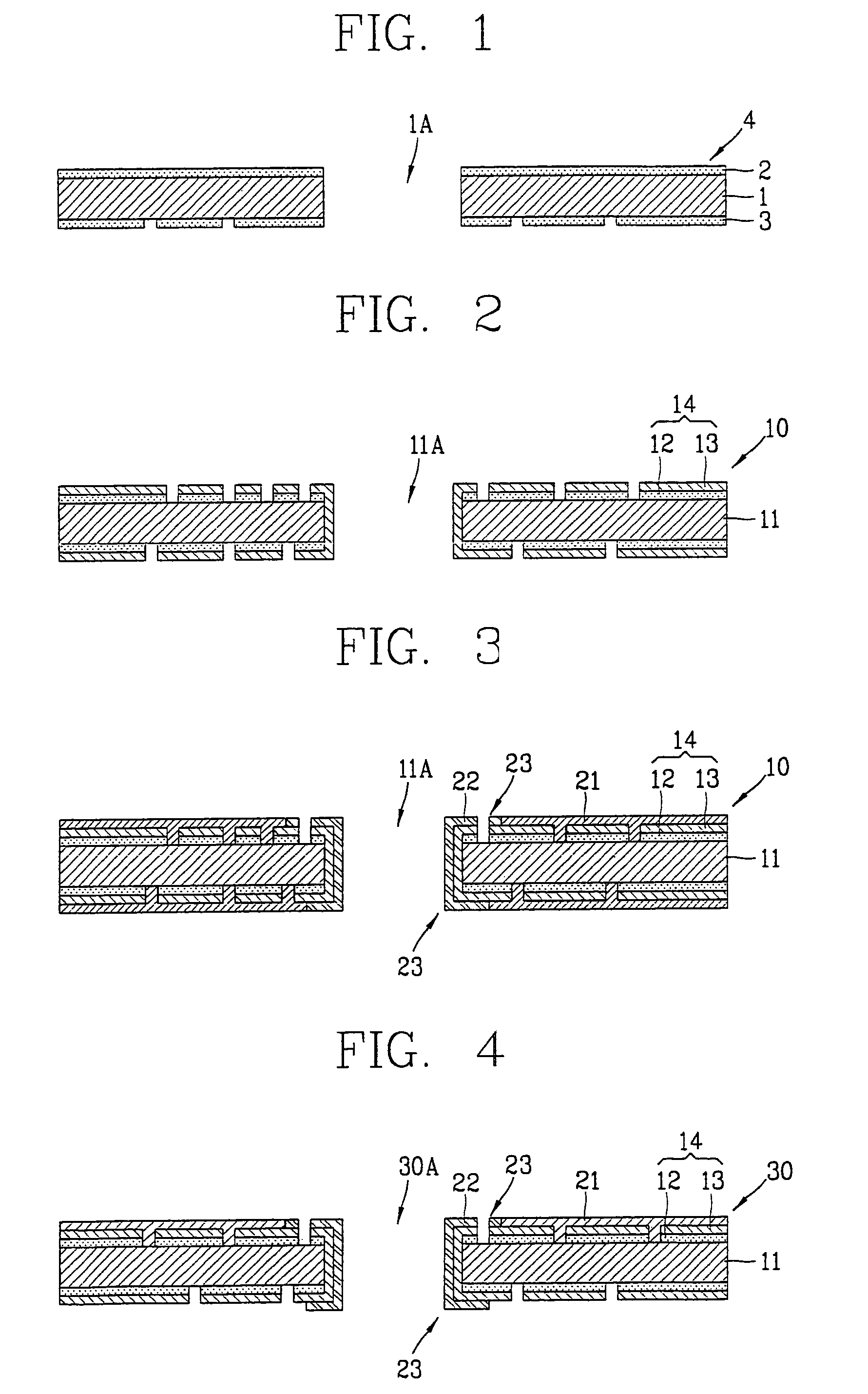

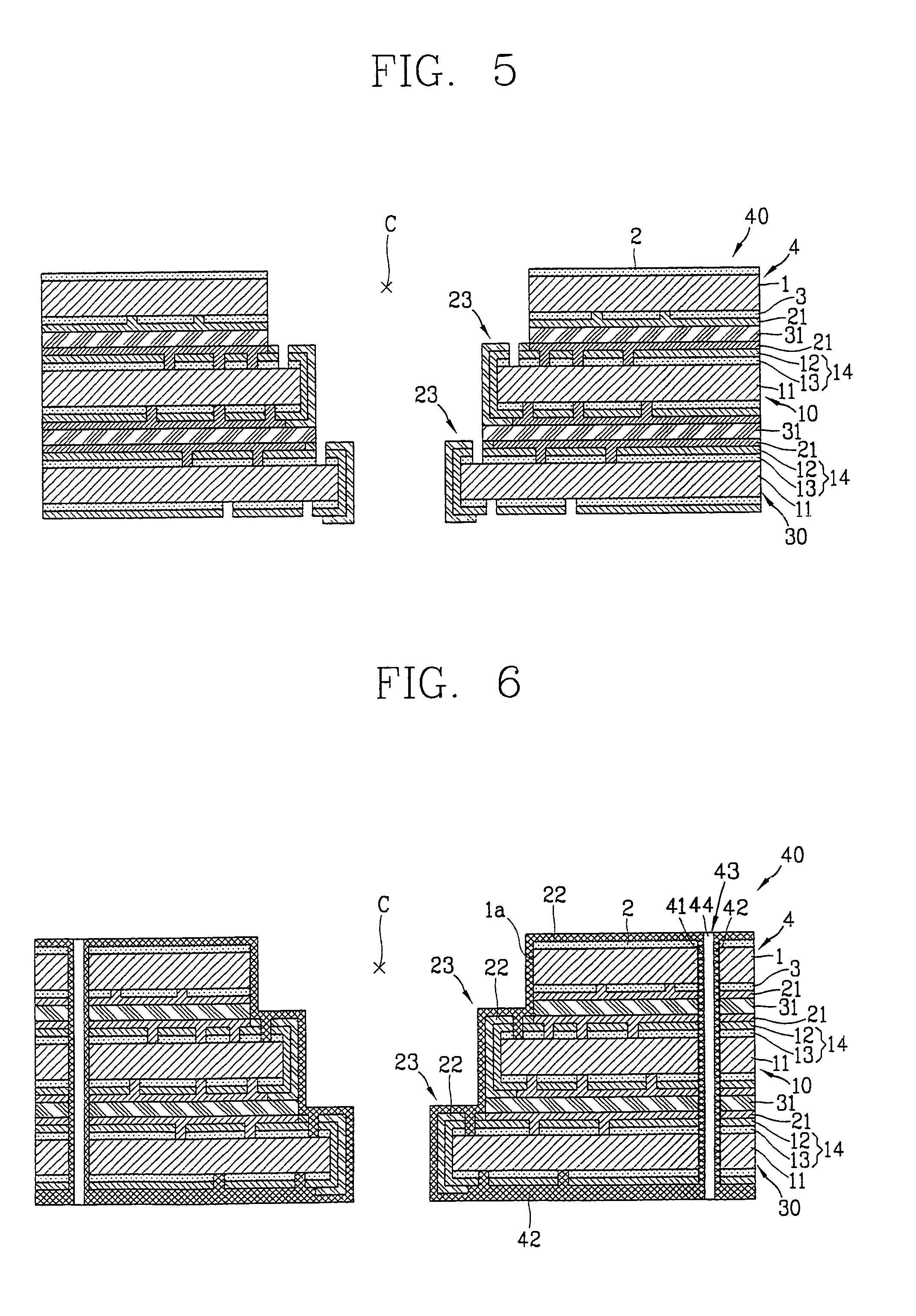

Method for fabricating semiconductor package and semiconductor package

InactiveUS7049178B2Semiconductor/solid-state device detailsSolid-state devicesCopper platingSemiconductor chip

A method of fabricating a semiconductor package is disclosed in which a first Ni—Au plating is formed on a bonding pad for connection with a semiconductor chip, without a mechanical process or a masking operation. The method applies a copper plating on a through bore and the bonding pad, where the copper plated layer formed on the bonding pad is selectively removed, and then a second Ni—Au plating is formed on the bonding pad and a ball pad.

Owner:LG ELECTRONICS INC +1

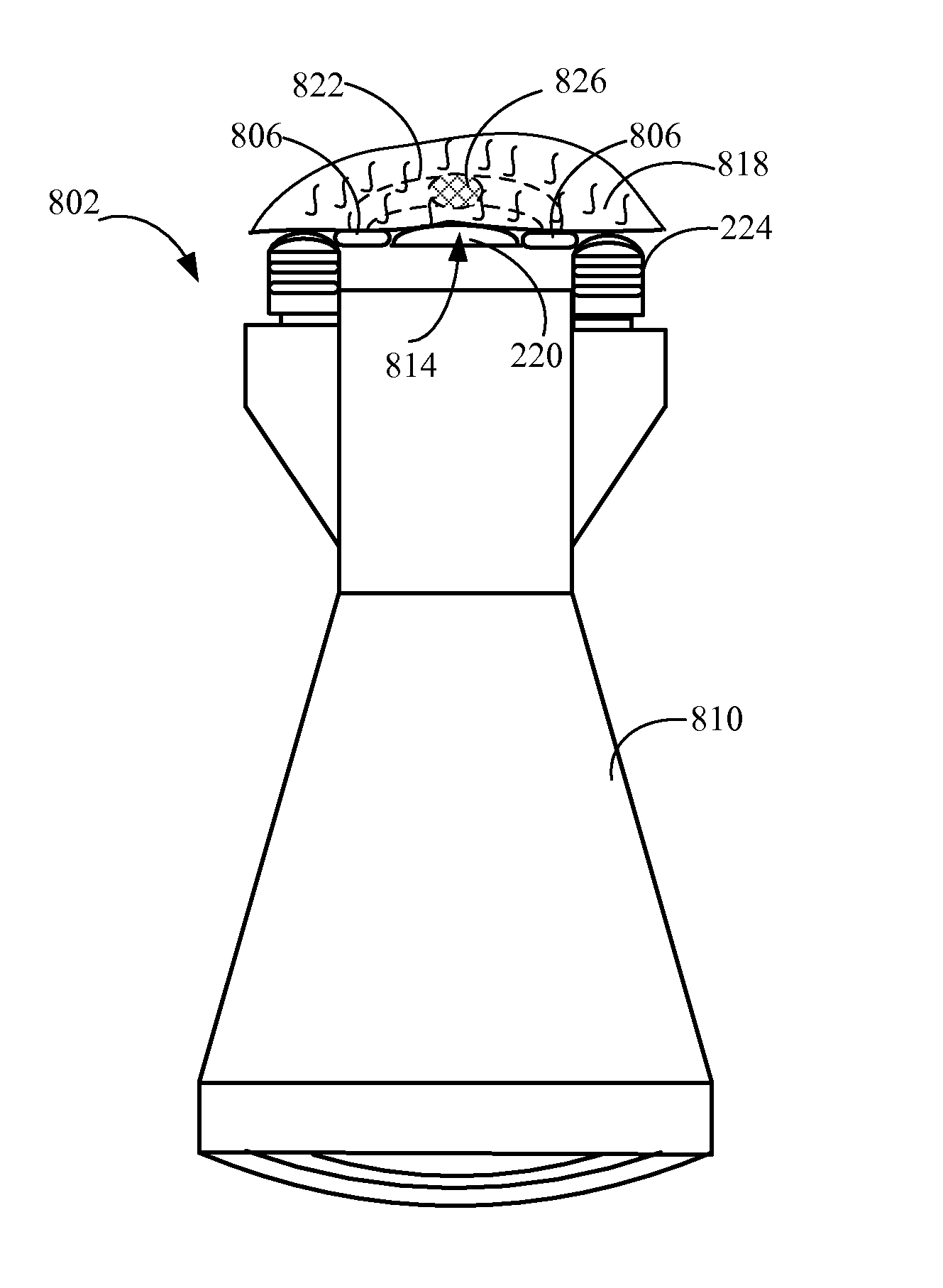

Hair removal apparatus for personal use and the method of using same

Hair or partial hair removal system and hair growth deterrent that includes mechanical process for cutting, plucking or shaving hair follicles, along with pre and / or post skin treatment techniques. The skin treatment techniques can include the application of energy to the skin surface before, after and / or during the application of the mechanical process. Such techniques include the application of heat and / or energy from illumination sources and / or RF emitters. Further skin treatment techniques include the application of solutions before, after and / or during the mechanical process and / or the application of heat and / or energy. Overall, the system operates to treat an area of skin to facilitate the removal of all or a portion of hair, retard further growth, and recovery of skin surface.

Owner:SYNERON MEDICAL LTD

Method of forming a raised contact for a substrate

InactiveUS6596640B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectrical conductorCompound (substance)

Owner:INTEL CORP

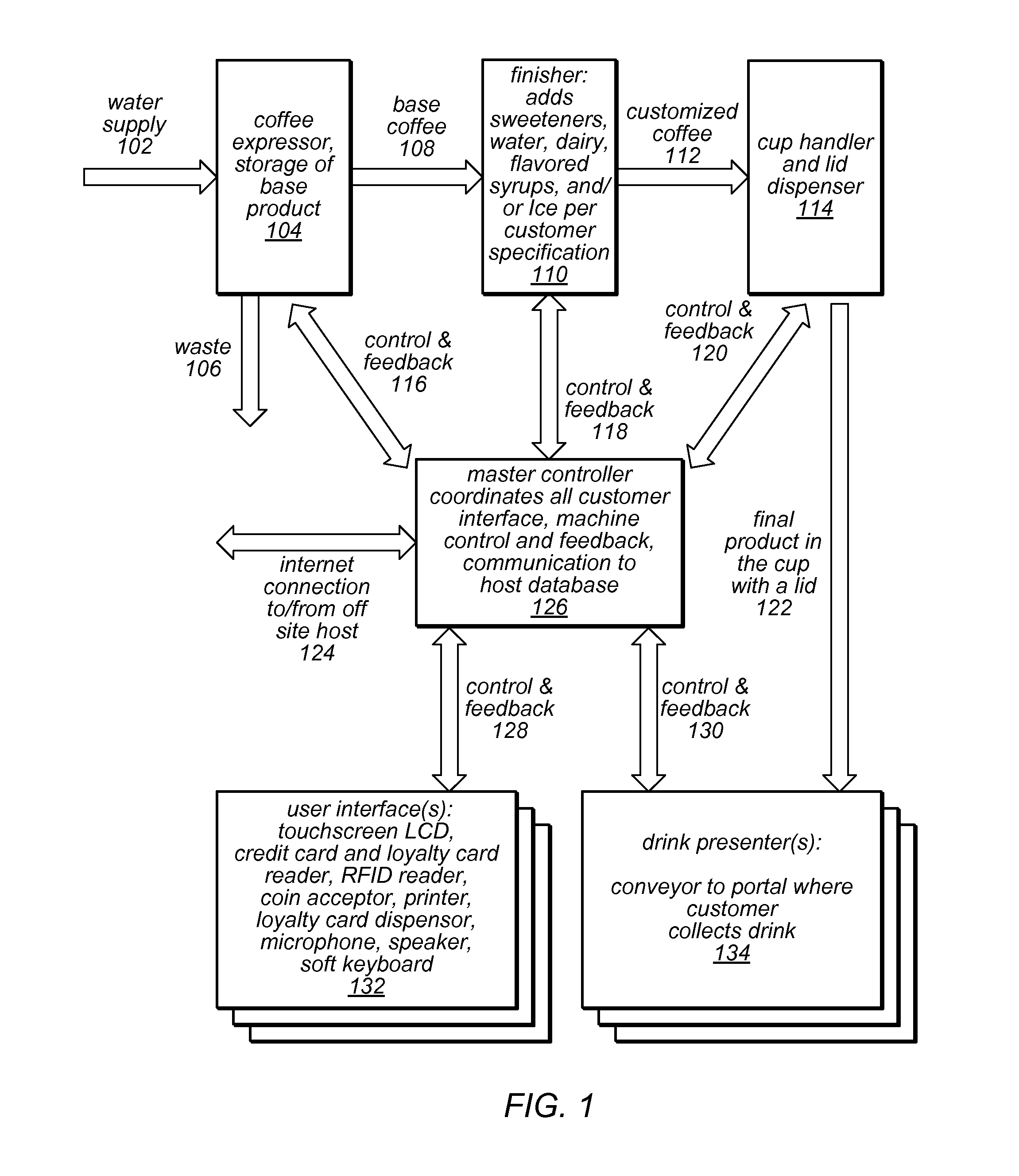

System and Method for Managing the Generation of Brewed Beverages Using Shared Resources

A system that generates brewed beverages may receive requests to produce specified brewed beverages. The system may include a scheduler that initiates and controls the performance of one or more chemical or mechanical processes to produce the beverages. While one chemical or mechanical process for producing a beverage is being performed, other processes may be performed for production of the beverage or another beverage. The scheduler may determine the time at which to perform each process, the time at which a beverage should be presented, the resources to be used to perform the processes, or the time at which to perform a cleaning process, dependent on an actual or expected demand for beverages, or dependent on a target time for beverage retrieval. Shared resources may be applied to the production of beverages for high priority orders, while partially completed beverages for lower priority orders are staged for subsequent advancement.

System and method for managing the generation of brewed beverages using shared resources

A system that generates brewed beverages may receive requests to produce specified brewed beverages. The system may include a scheduler that initiates and controls the performance of one or more chemical or mechanical processes to produce the beverages. While one chemical or mechanical process for producing a beverage is being performed, other processes may be performed for production of the beverage or another beverage. The scheduler may determine the time at which to perform each process, the time at which a beverage should be presented, the resources to be used to perform the processes, or the time at which to perform a cleaning process, dependent on an actual or expected demand for beverages, or dependent on a target time for beverage retrieval. Shared resources may be applied to the production of beverages for high priority orders, while partially completed beverages for lower priority orders are staged for subsequent advancement.

Owner:COSTA COFFEE

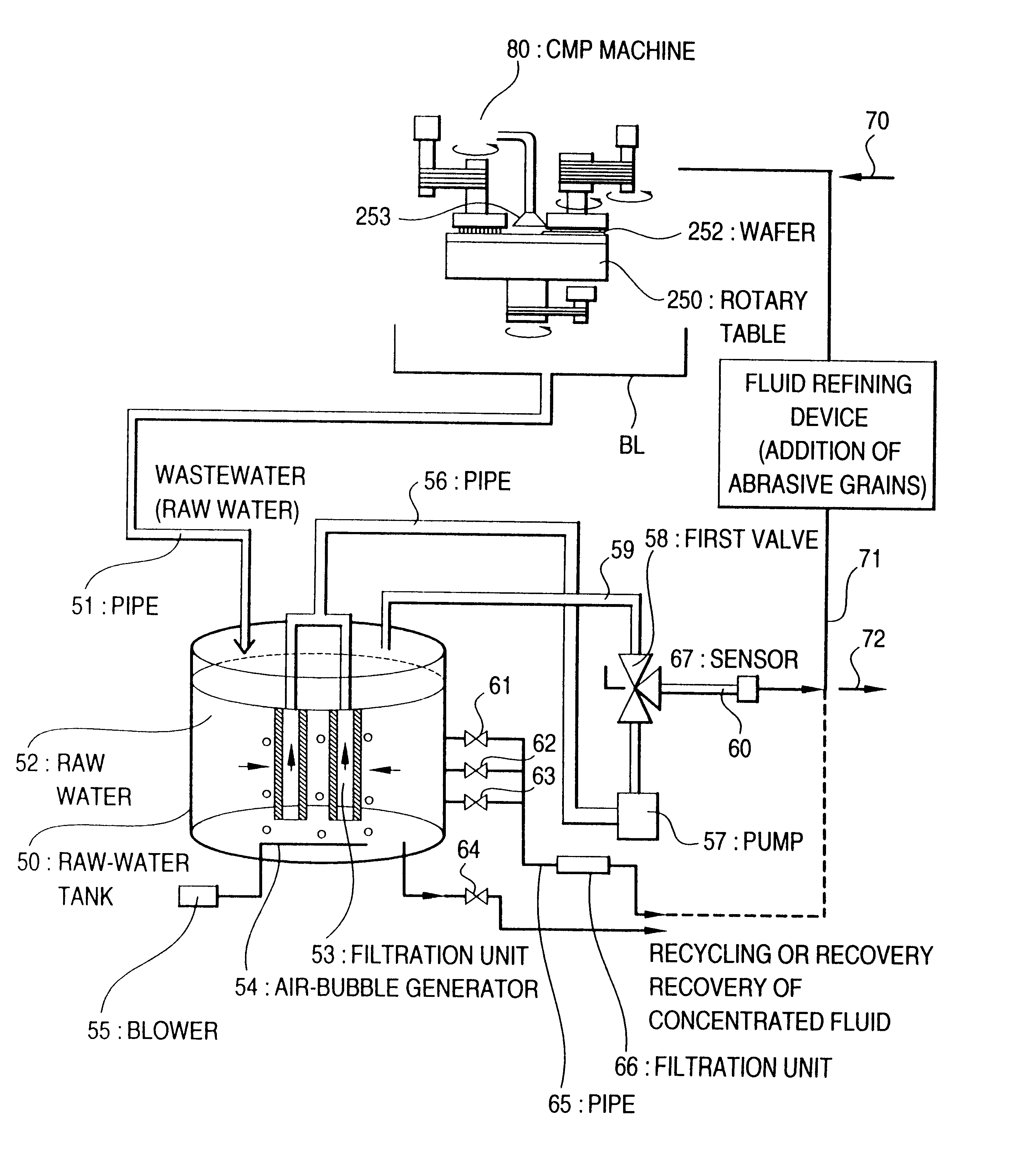

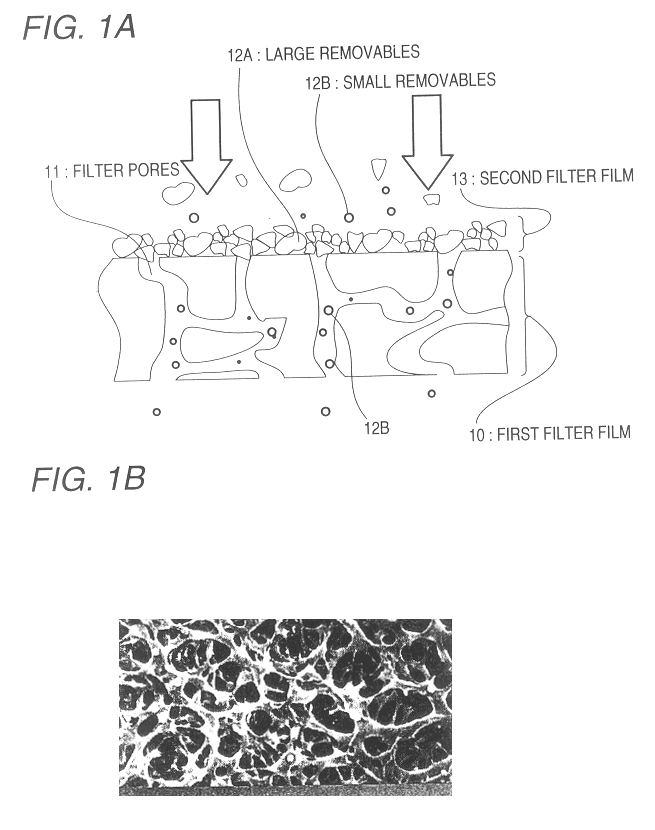

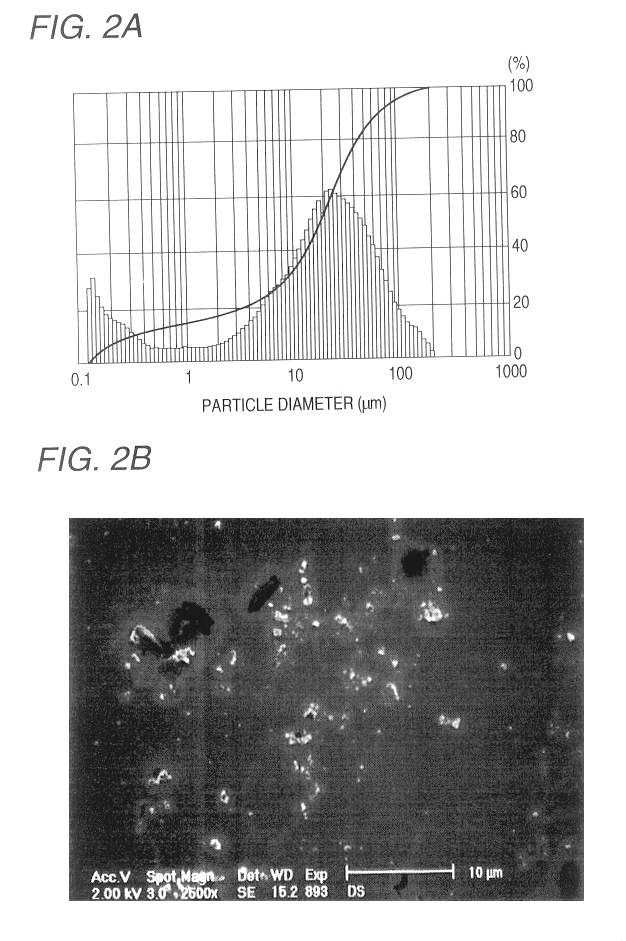

Method of filtering a fluid

InactiveUS6461524B1UltrafiltrationSemiconductor/solid-state device manufacturingFiltrationAcoustic wave

A fluid is filtered by first preparing a filter which includes a base filter and solid substances provided on the base filter, such that the solid substances differ from objects within the fluid to be filtered that are removed by the filter. The objects of filtration are filtered by supplying the fluid to the filter. During filtration, a force is applied to the filter to move the solid substances and objects deposited on the filter. The application of such force thus allows continuous filtration through the filter. The force can take the form of application of rising bubbles, a mechanical vibration or sonic waves to the filter. The filtration method is useful in processing fluid waste from mechanical processes, such as CMP steps.

Owner:PANASONIC CORP

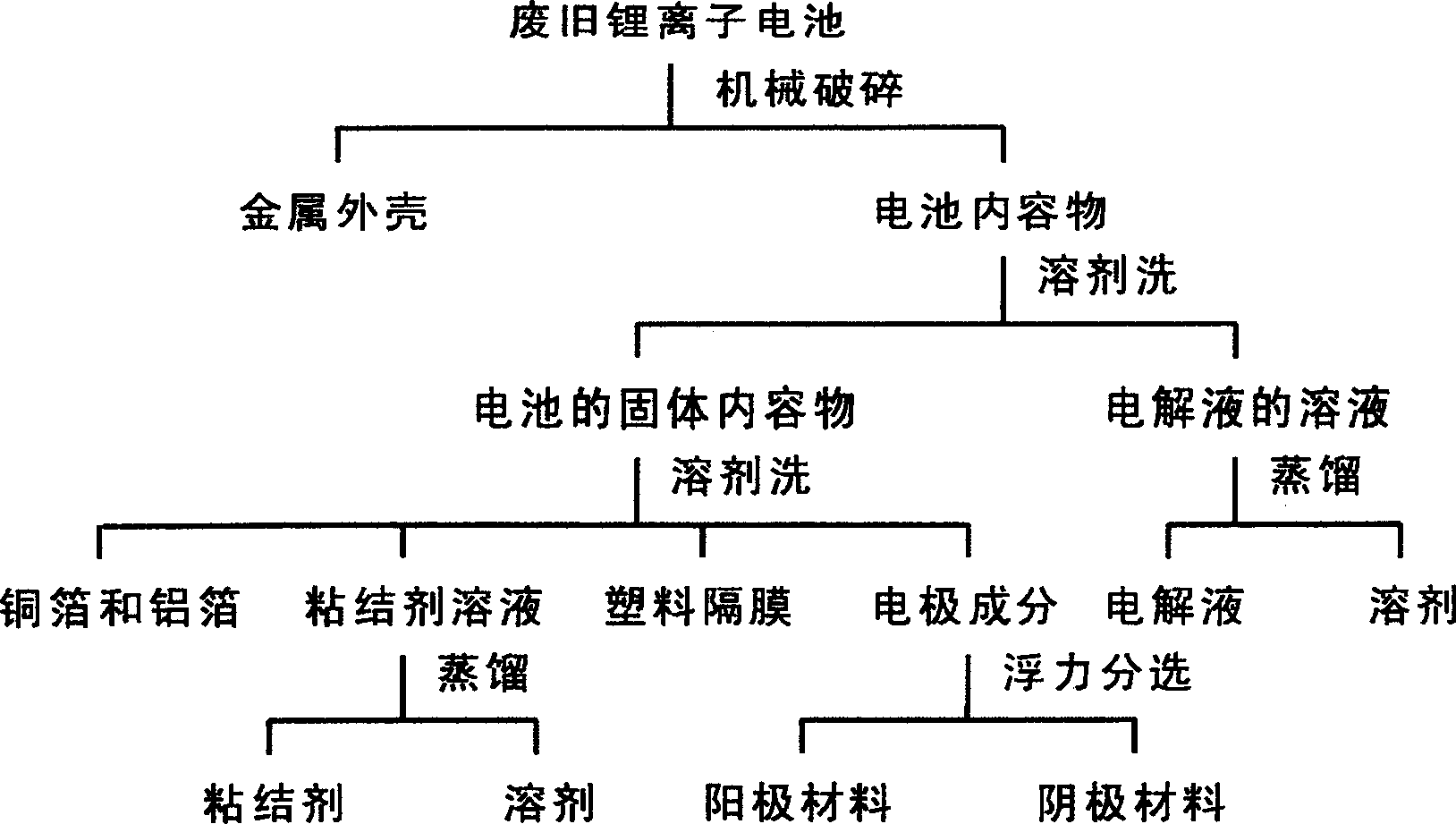

Resource separation of waste lithium ion battery

InactiveCN1819326AReserve availabilityLow added valueReclaiming serviceable partsWaste accumulators reclaimingAdhesiveCopper foil

The invention can make separation for all kinds of components in wasted Li-ion battery such as: case, electrolyte, anode material, cathode material, adhesive, copper foil, and aluminum foil. The process includes: breaking wasted batteries by mechanical process; separating metal case from others; washing out electrolyte using organic solvent, and filtering it from remaining solid; processing the remaining component where the electrolytes are removed using organic solvent to make all electrode active component eluted from current collector, and separated from diaphragm, copper foil, and aluminum foil. The solvent and adhesive can be reused.

Owner:SOUTHEAST UNIV

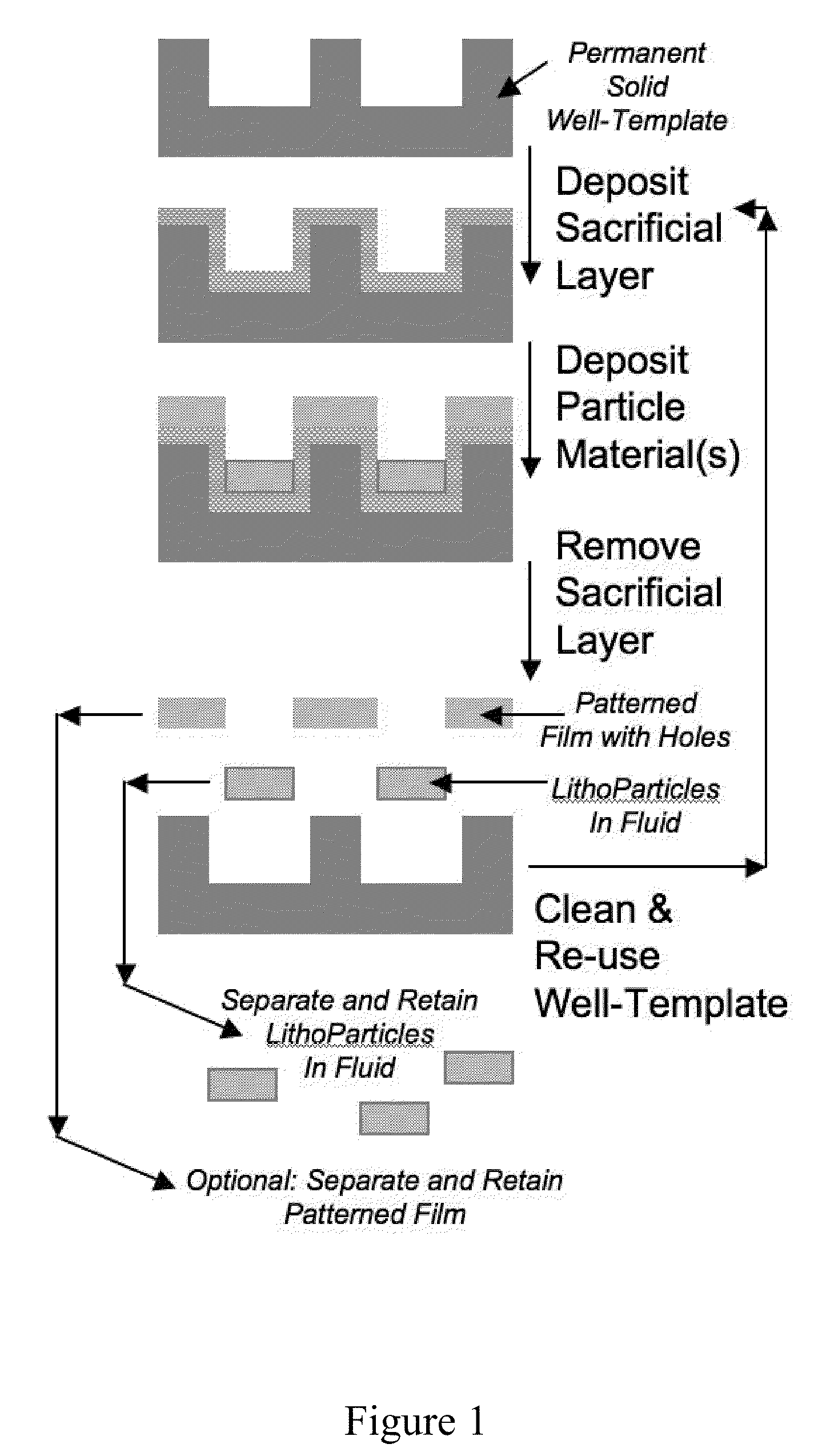

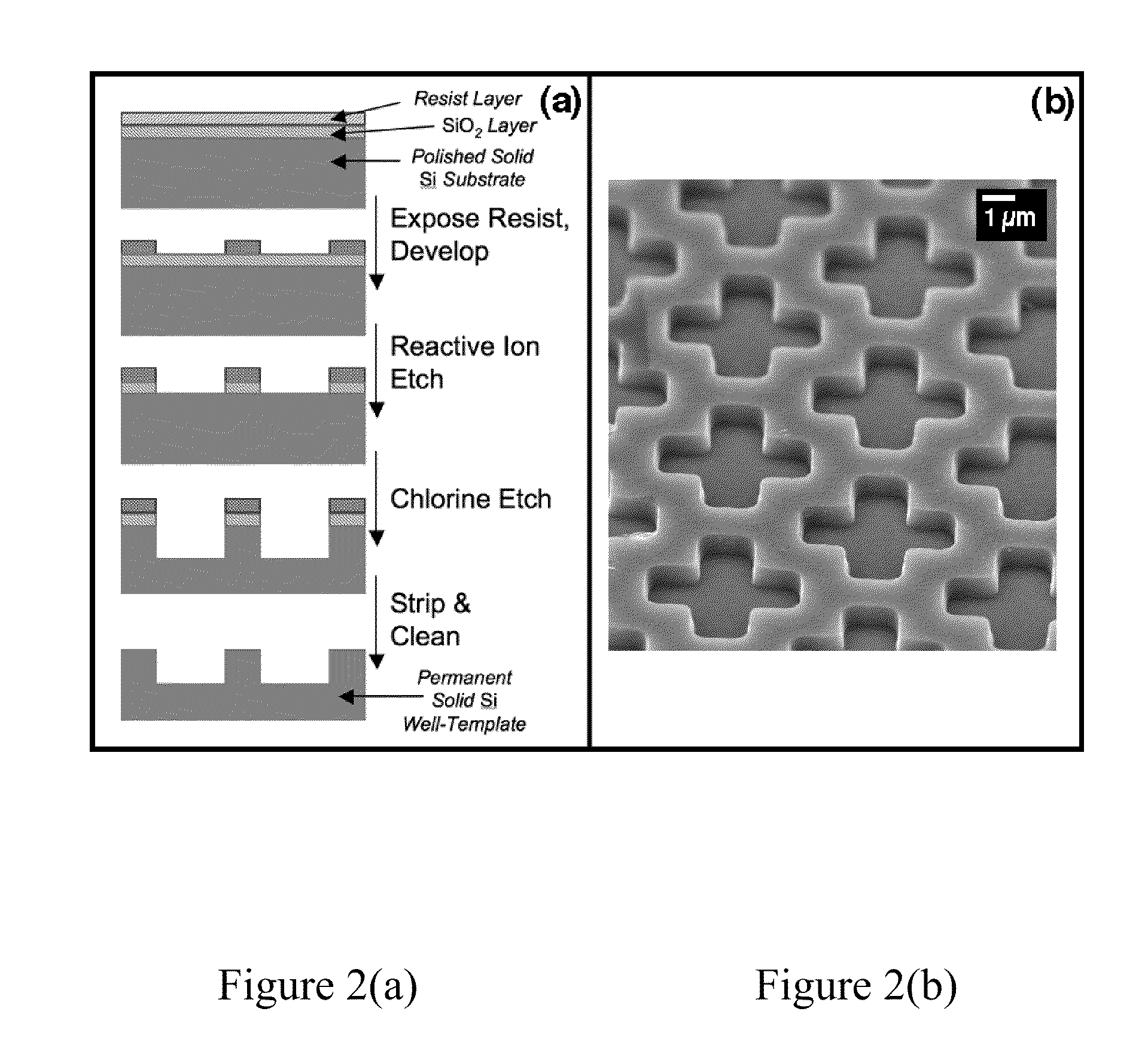

Mechanical process for creating particles in fluid

InactiveUS20100021985A1Impart propertyNanomagnetismLiquid surface applicatorsSurface geometryMaterials science

A method of producing at least one of microscopic and submicroscopic particles includes providing a template that has a plurality of discrete surface portions, each discrete surface portion having a surface geometry selected to impart a desired geometrical property to a particle while being produced; depositing a constituent material of the at least one of microscopic and submicroscopic particles being produced onto the plurality of discrete surface portions of the template to form at least portions of the particles; separating the at least one of microscopic and submicroscopic particles comprising the constituent material from the template into a fluid material, the particles being separate from each other at respective discrete surface portions of the template; and processing the template for subsequent use in producing additional at least one of microscopic and submicroscopic particles. A multi-component composition includes a first material component in which particles can be dispersed, and a plurality of particles dispersed in the first material component. The plurality of particles is produced by methods according to embodiments of the current invention.

Owner:RGT UNIV OF CALIFORNIA

Apparatus and Method for Brewed and Espresso Drink Generation

An apparatus that generates brewed beverages by performing one or more chemical and / or mechanical processes may receive requests to produce specified brewed beverages. The apparatus may include a master controller that initiates and controls performance of the chemical and / or mechanical processes to produce the specified beverages. The master controller may adaptively apply one or more process accelerators during the performance of one of the chemical or mechanical processes to accelerate the process or to achieve a desired qualitative or quantitative characteristic for a beverage or a component thereof. The adaptive application of one or more process accelerators may be dependent on a multiple-variable process profile developed for the process and / or a specified beverage. For example, the pressure in a steam wand and / or the depth of the wand may be varied during a process to froth milk in order to produce frothed milk having a desired temperature.

Owner:COSTA COFFEE

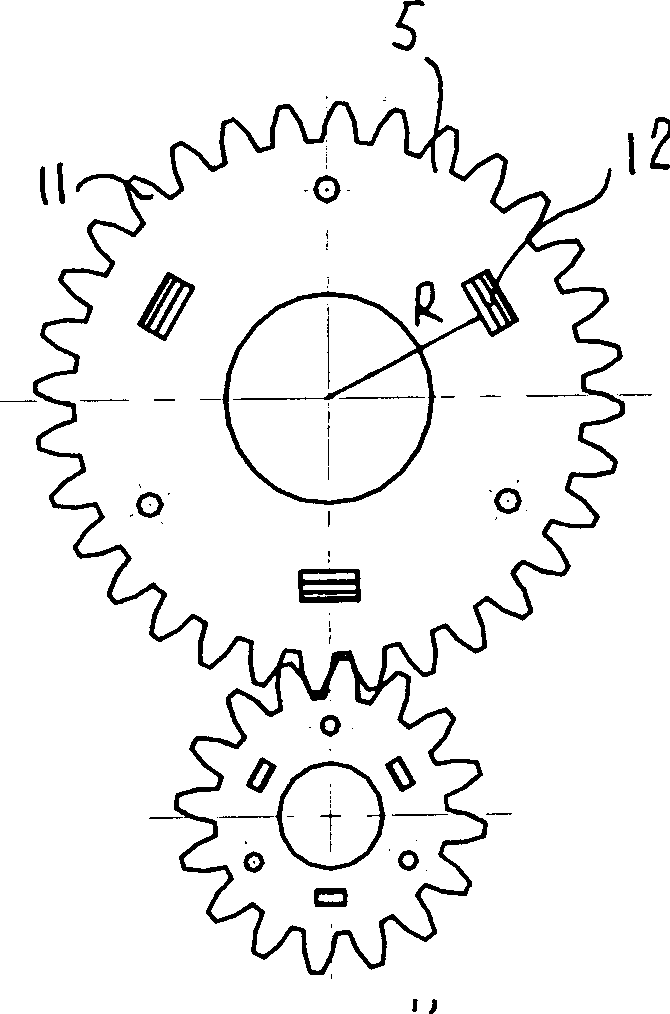

Gear and its production method

InactiveCN1412456AReduce processing costsFacilitate transmissionPortable liftingGearing elementsState of artWhole body

The present invention relates to a gear and its production method. Said gear is made up by using several toothed sheets with identical tooth outline and superimposing them in the mode of aligning tooth profile or alternating them in a certain order, and fixedly connecting them. Its production method includes the following steps: punching thin sheet into toothed sheet, suporimposing toothed sheetsand connecting them together by mechanical process or adhesive process in the mode of aligning their tooth profile and alternating them according to a certain order to form a whole body gear.

Owner:赵永彬 +1

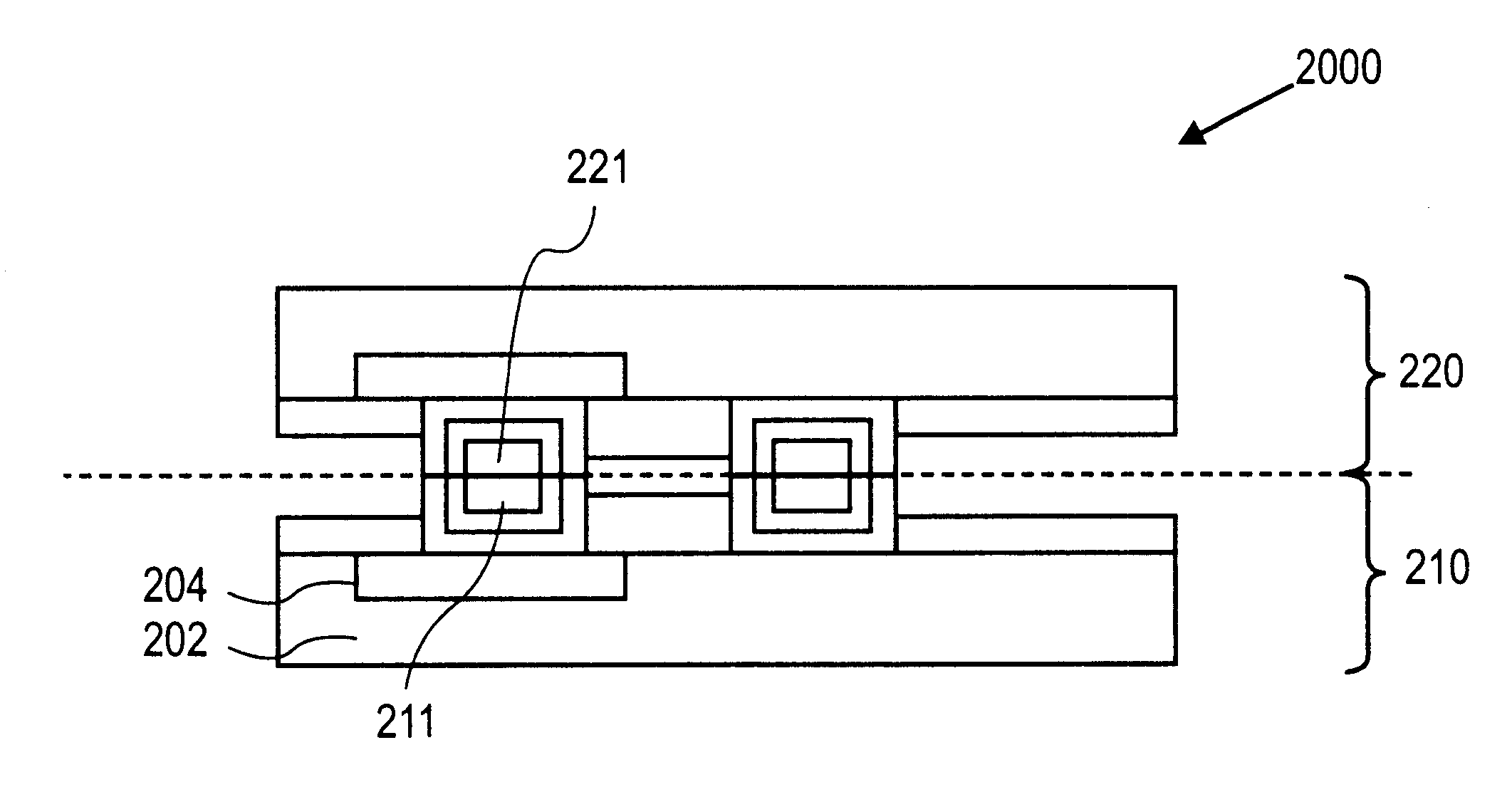

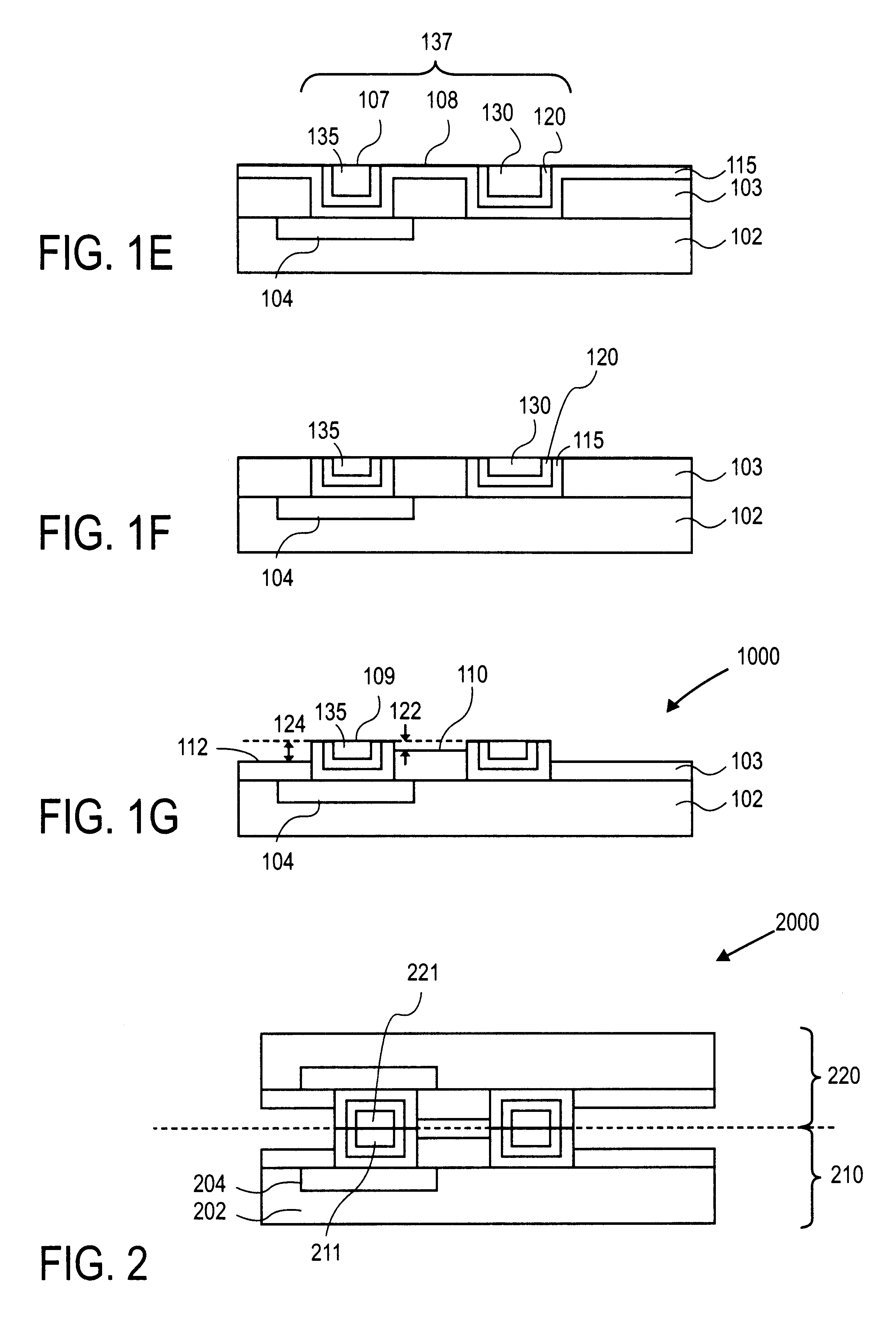

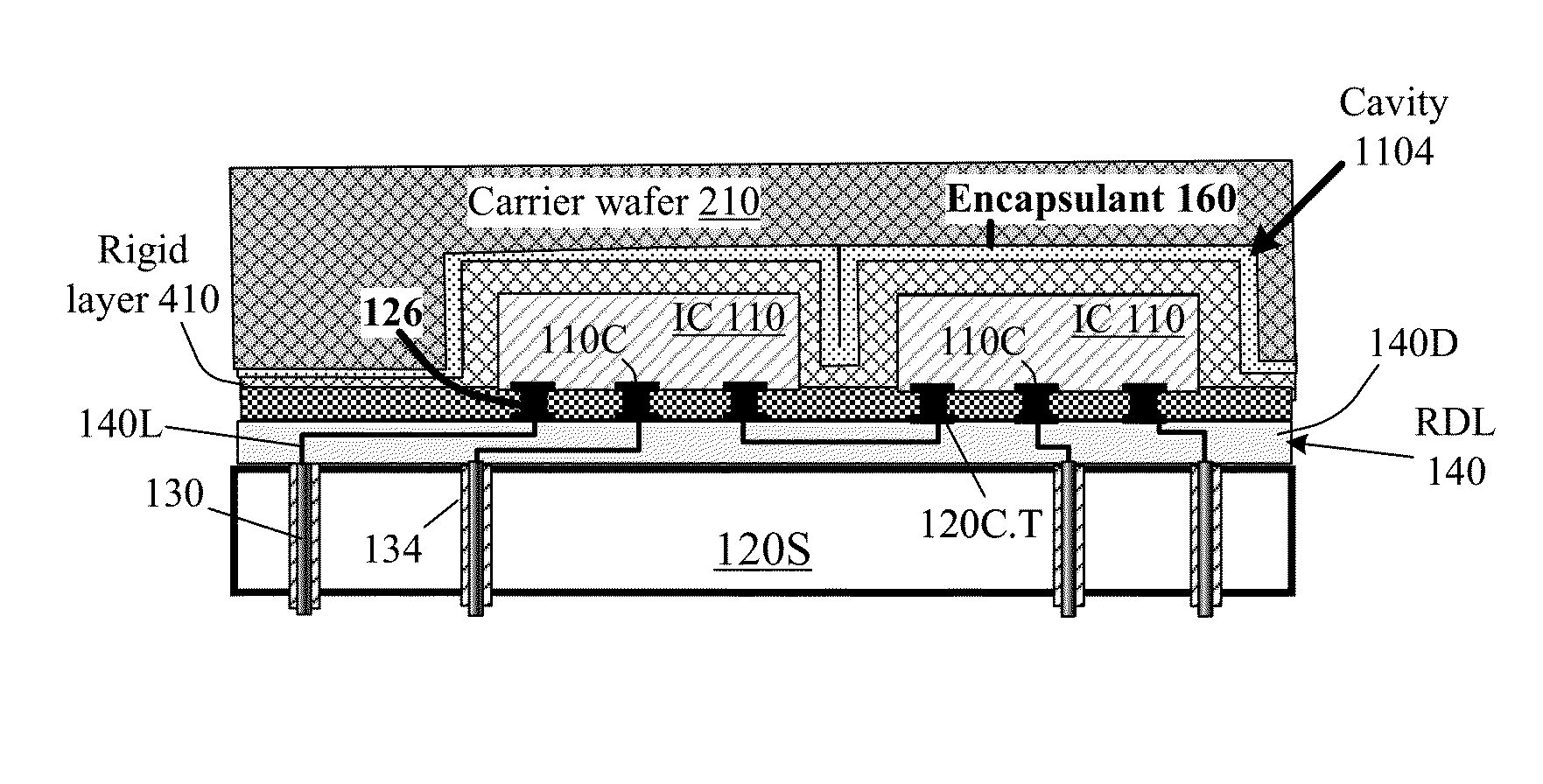

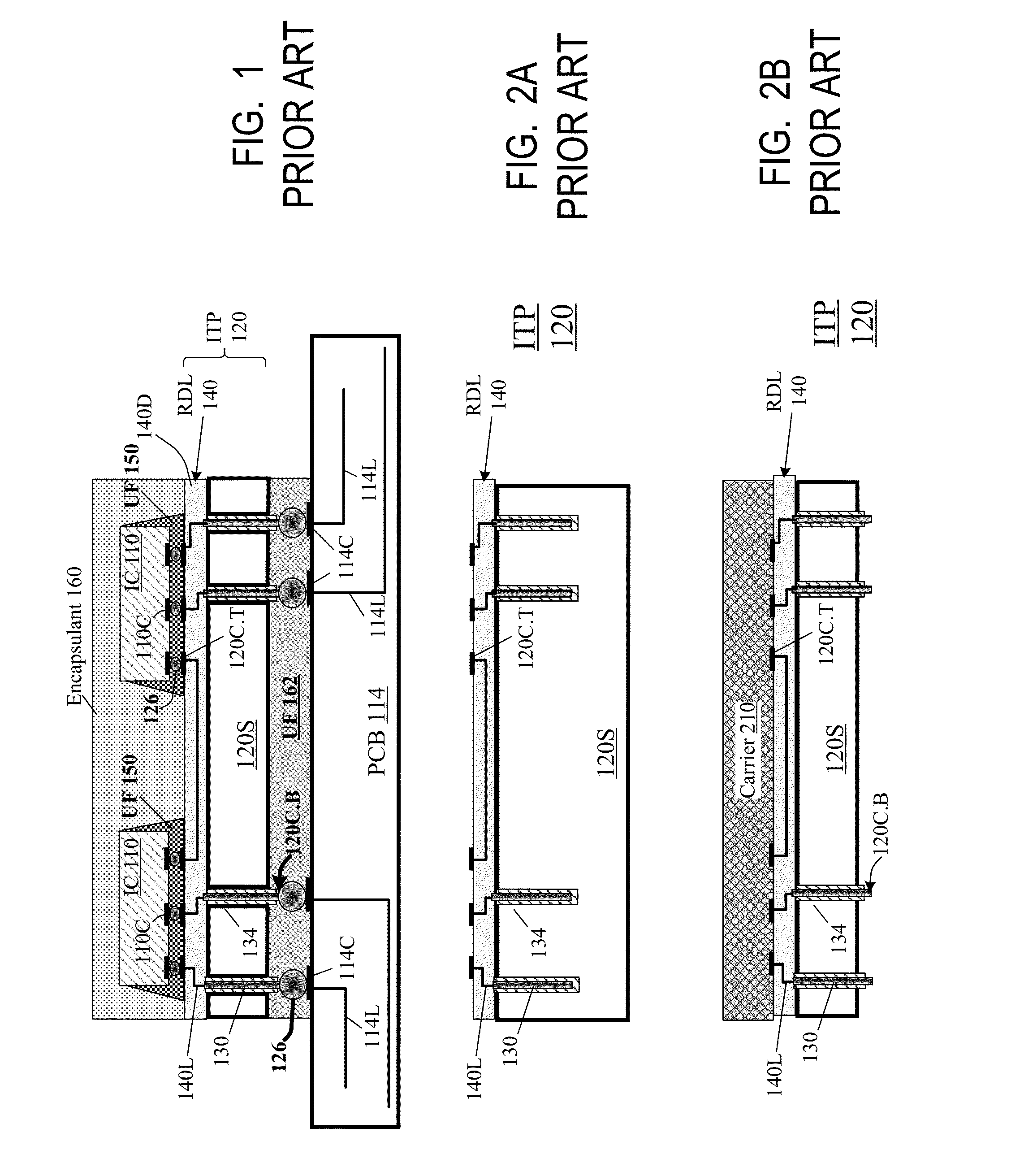

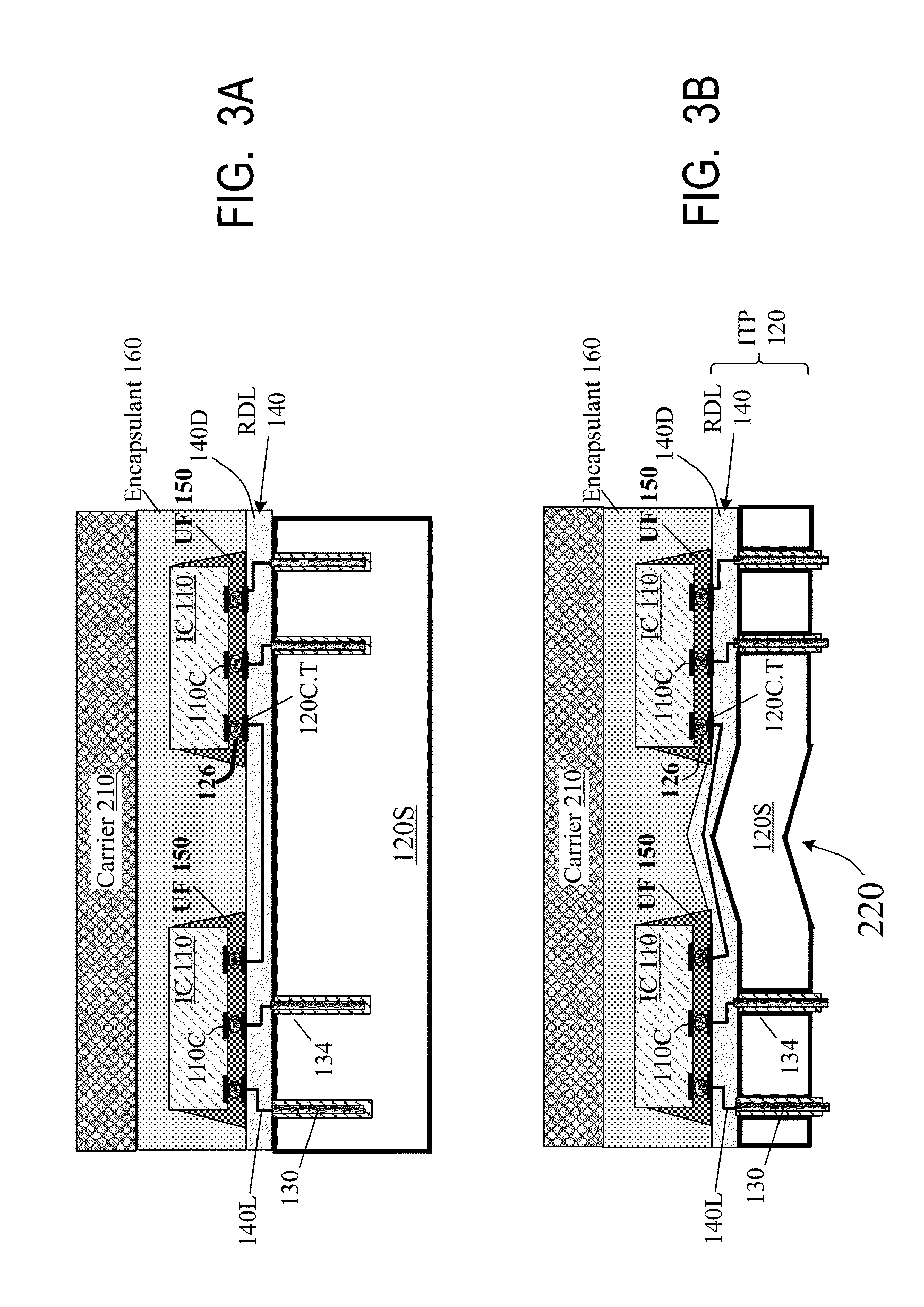

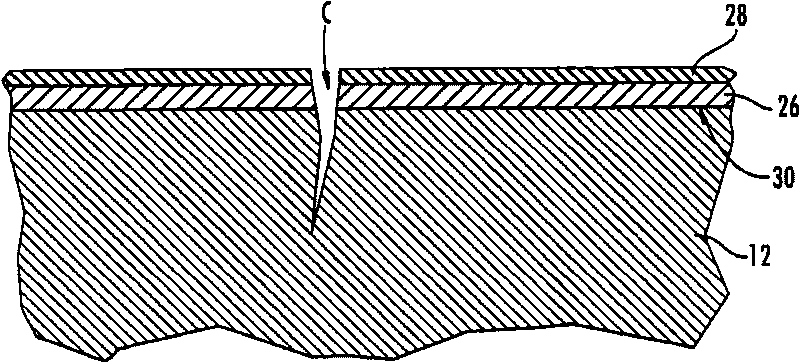

Integrated circuit assemblies with rigid layers used for protection against mechanical thinning and for other purposes, and methods of fabricating such assemblies

ActiveUS20160163650A1Organic polymer CTEs can be loweredImprove rigiditySemiconductor/solid-state device detailsSolid-state devicesInterposerEngineering

Die (110) and / or undiced wafers and / or multichip modules (MCMs) are attached on top of an interposer (120) or some other structure (e.g. another integrated circuit) and are covered by an encapsulant (160). Then the interposer is thinned from below. Before encapsulation, a layer (410) more rigid than the encapsulant is formed on the interposer around the die to reduce or eliminate interposer dishing between the die when the interposer is thinned by a mechanical process (e.g. CMP). Other features are also provided.

Owner:INVENSAS CORP

Apparatus and method for brewed and espresso drink generation

An apparatus that generates brewed beverages by performing one or more chemical and / or mechanical processes may receive requests to produce specified brewed beverages. The apparatus may include a master controller that initiates and controls performance of the chemical and / or mechanical processes to produce the specified beverages. The master controller may adaptively apply one or more process accelerators during the performance of one of the chemical or mechanical processes to accelerate the process or to achieve a desired qualitative or quantitative characteristic for a beverage or a component thereof. The adaptive application of one or more process accelerators may be dependent on a multiple-variable process profile developed for the process and / or a specified beverage. For example, the pressure in a steam wand and / or the depth of the wand may be varied during a process to froth milk in order to produce frothed milk having a desired temperature.

Owner:COSTA COFFEE

Disk type brake lining of cars and its preparing method

InactiveCN1431408AStable coefficient of frictionModerate thermal conductivityFriction liningFiberBrake lining

The percentage of each component weight for a vehicle disk brake gasket is: carbon fiber 0-16; steel fiber 5-25; organic fiber 0.5-8, mineral fiber 3-20; friction performance adjuster 37-60; COPNA resin 4-16; phenolic resin 0-8. Its preparation applies a dry technology to weigh, mix and stir matters in certain proportion then to be dried and moulded by chill-pressure, heat-pressure and after heatprocess mechanical process, polish, spraying paint, and packaging to become product with the advantage of no noise, no vibration, no scuffing the opposite side when braking.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

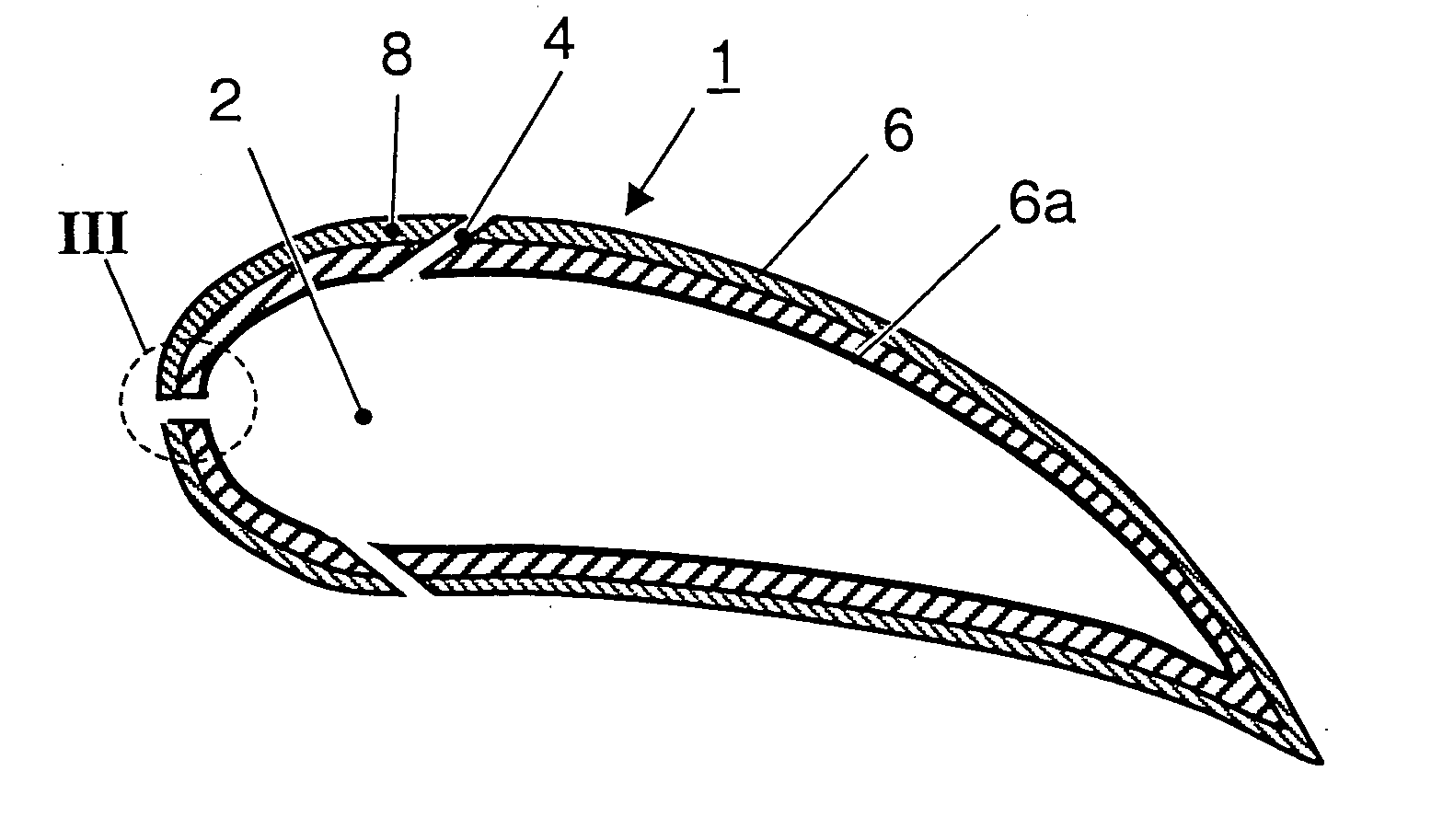

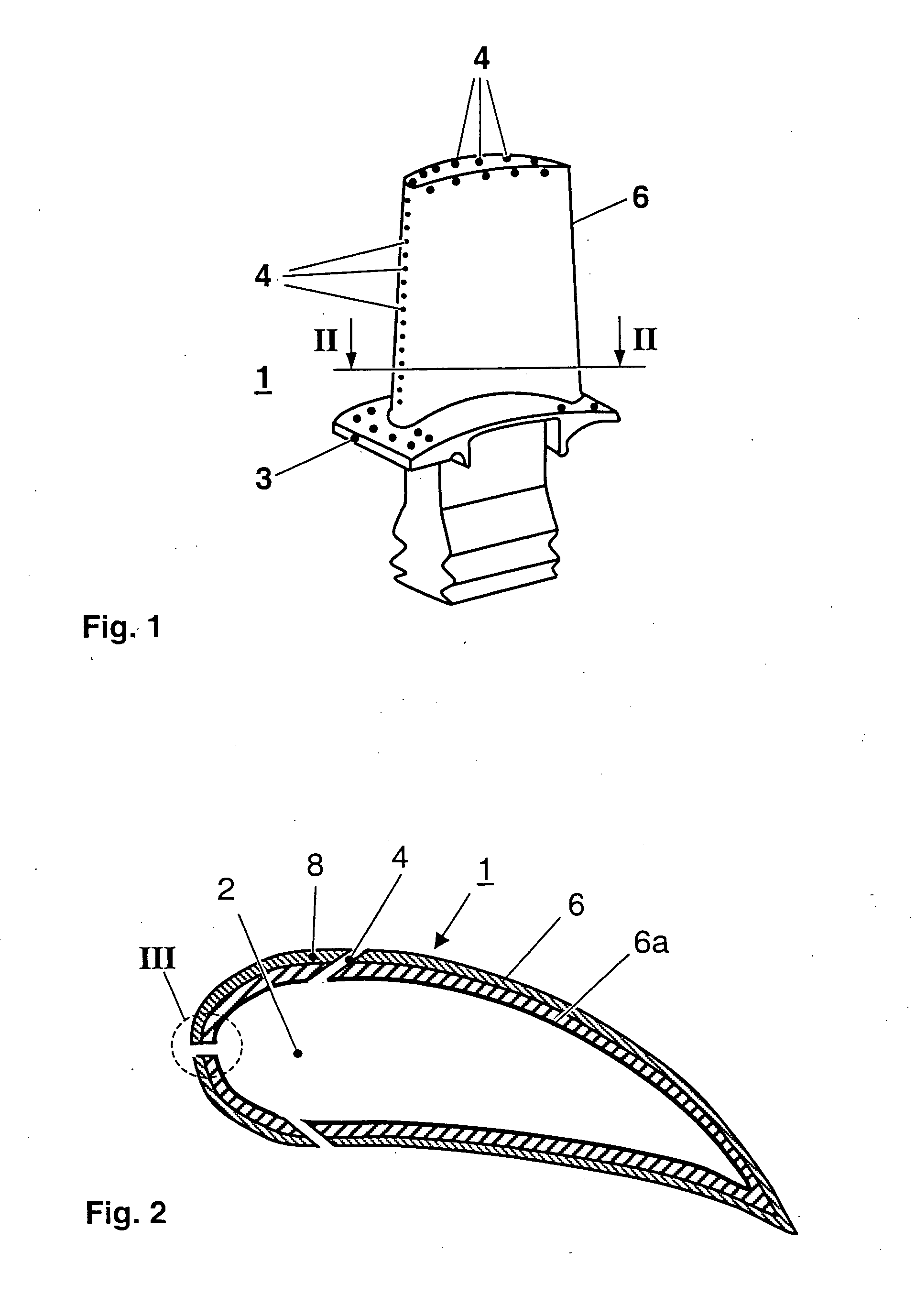

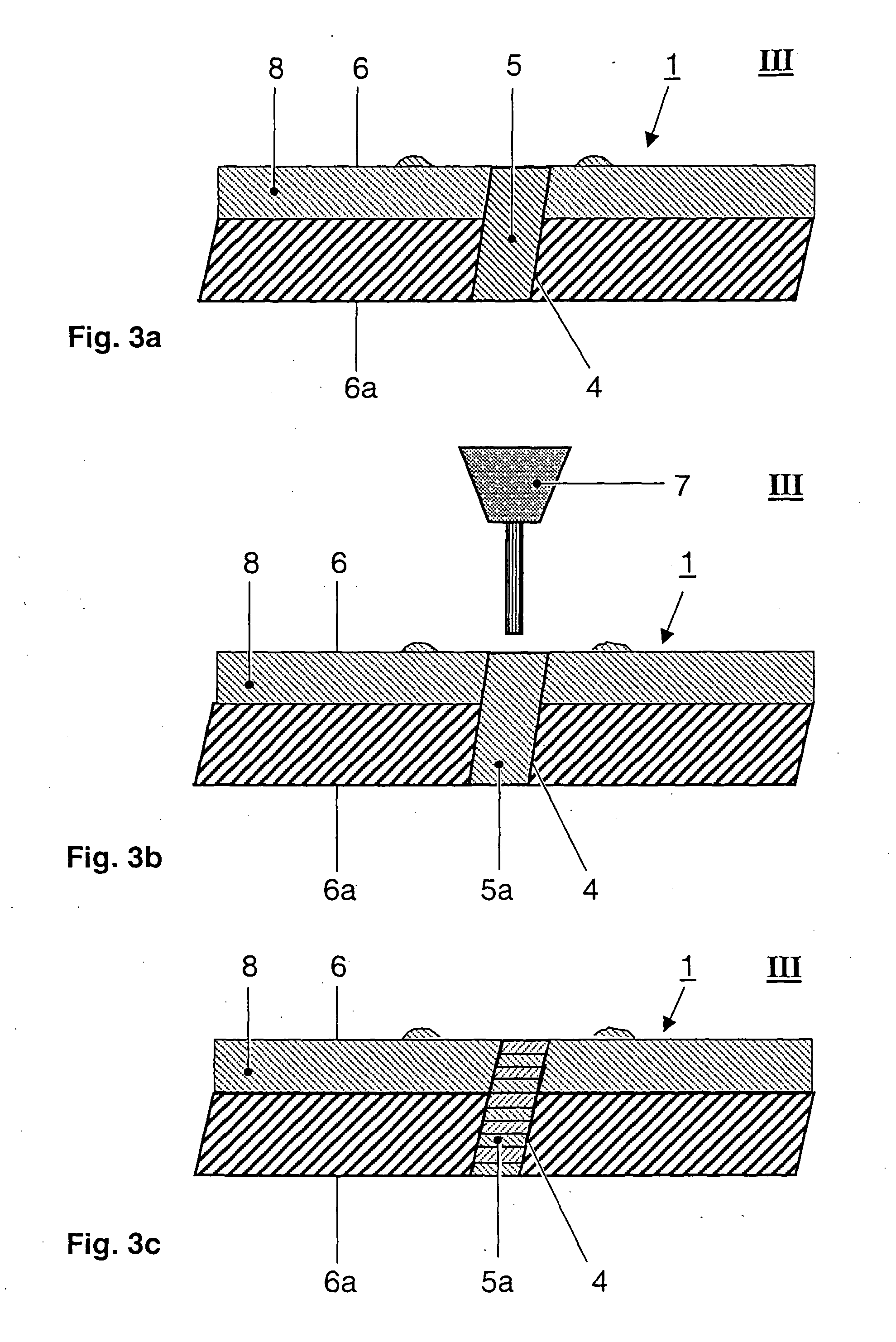

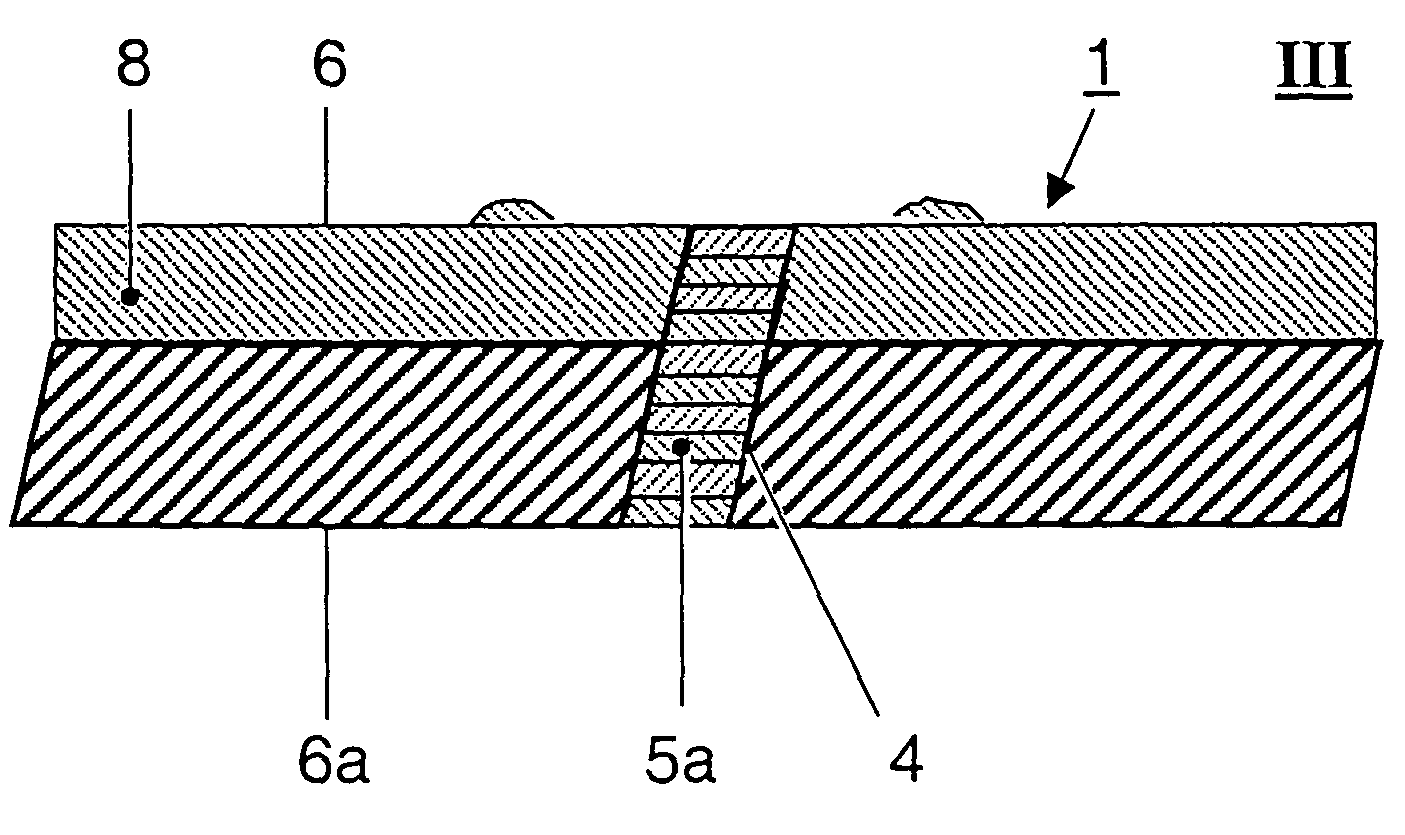

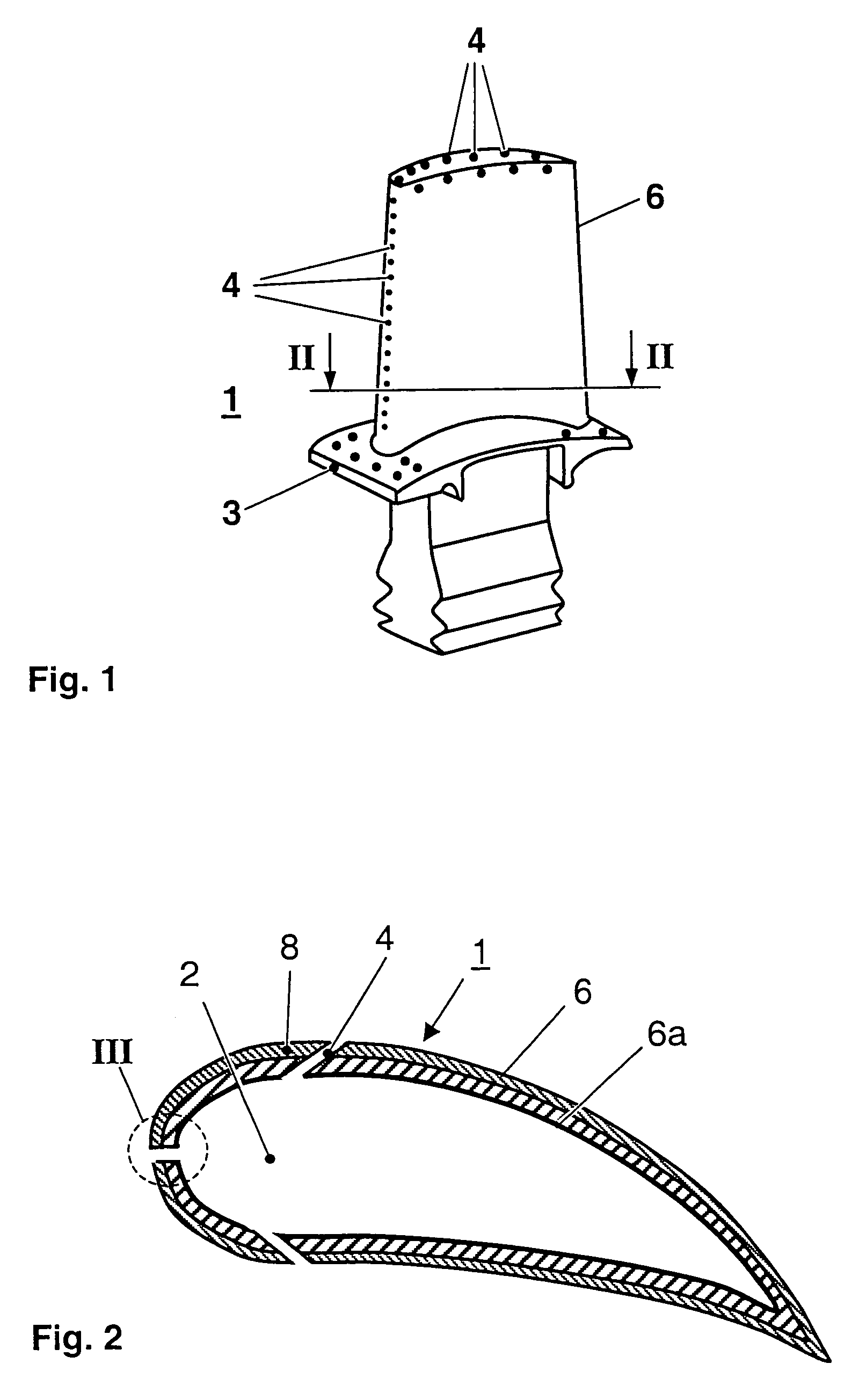

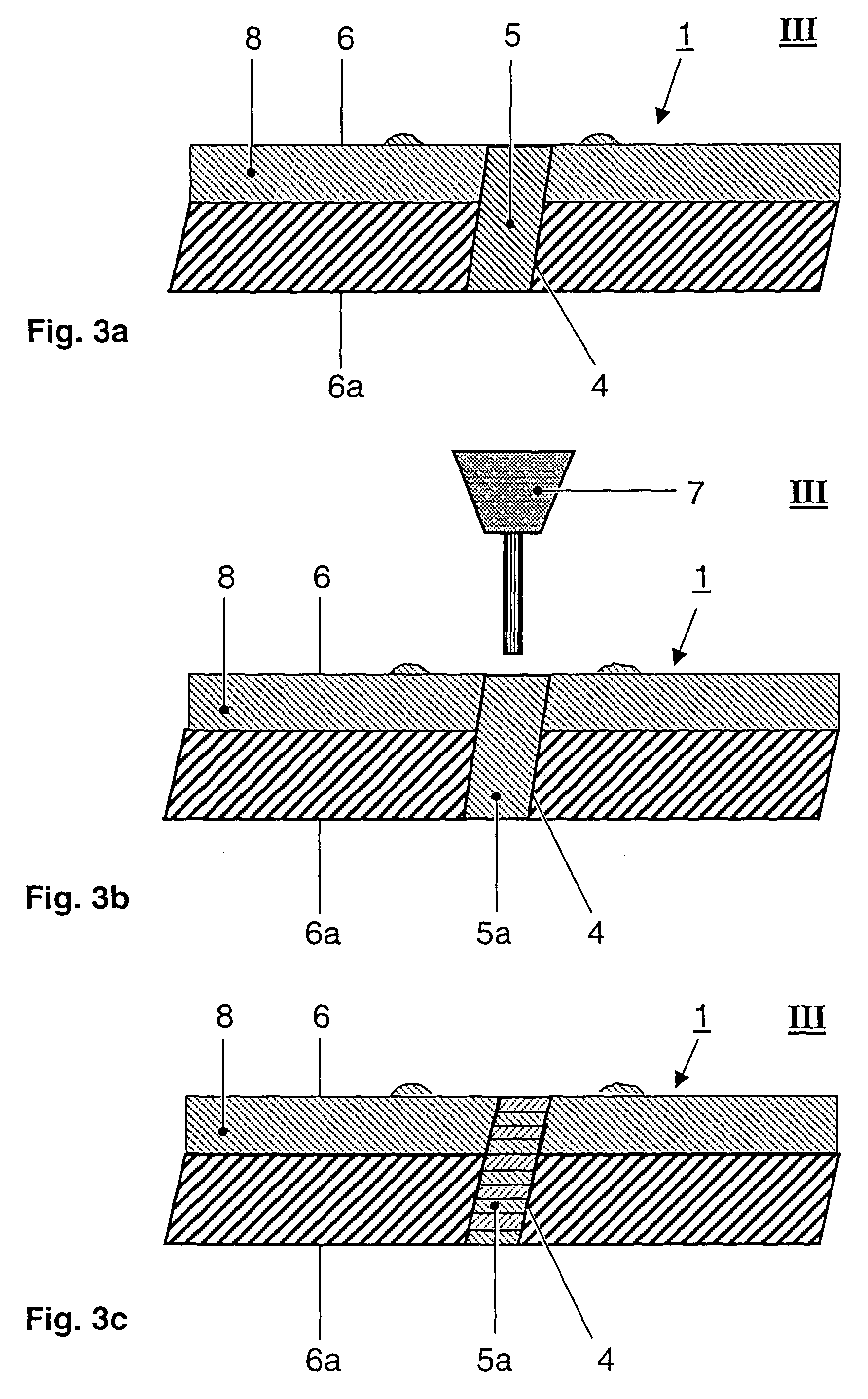

Method of protecting a local area of a component

InactiveUS20050100672A1Good chemical resistanceIncrease thermal resistanceMolten spray coatingVacuum evaporation coatingBiomedical engineeringMechanical Processes

It is disclosed a method of protecting a local area of components (1) from the effects of thermochemical or mechanical processes carried out on the surface (6) of the component. A masking material (5) containing at least one filler material is applied to the local area so that the local area is protected by the masking material (5). This is at least partially polymerized on the local area. Subsequently the thermochemical or physical processes on the surface (6) of the component (1) are carried out after which the polymerized masking material (5) is removed from the local area of the component (1).

Owner:ANSALDO ENERGIA IP UK LTD

System and Method for Managing the Generation of Brewed Beverages Using Shared Resources

A system that generates brewed beverages may receive requests to produce specified brewed beverages. The system may include a scheduler that initiates and controls the performance of one or more chemical or mechanical processes to produce the beverages. While one chemical or mechanical process for producing a beverage is being performed, other processes may be performed for production of the beverage or another beverage. The scheduler may determine the time at which to perform each process, the time at which a beverage should be presented, the resources to be used to perform the processes, or the time at which to perform a cleaning process, dependent on an actual or expected demand for beverages, or dependent on a target time for beverage retrieval. Shared resources may be applied to the production of beverages for high priority orders, while partially completed beverages for lower priority orders are staged for subsequent advancement.

Owner:COSTA COFFEE

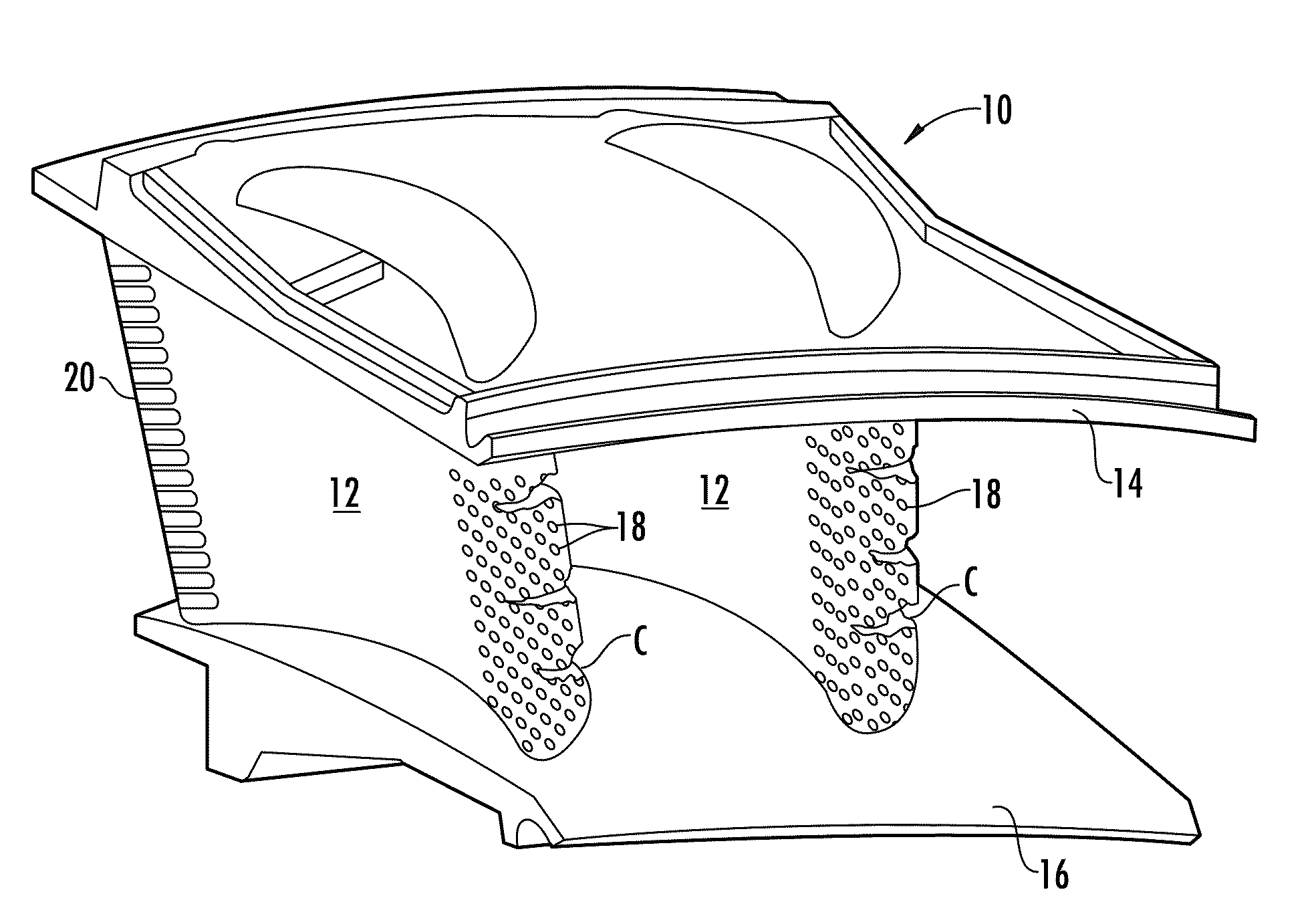

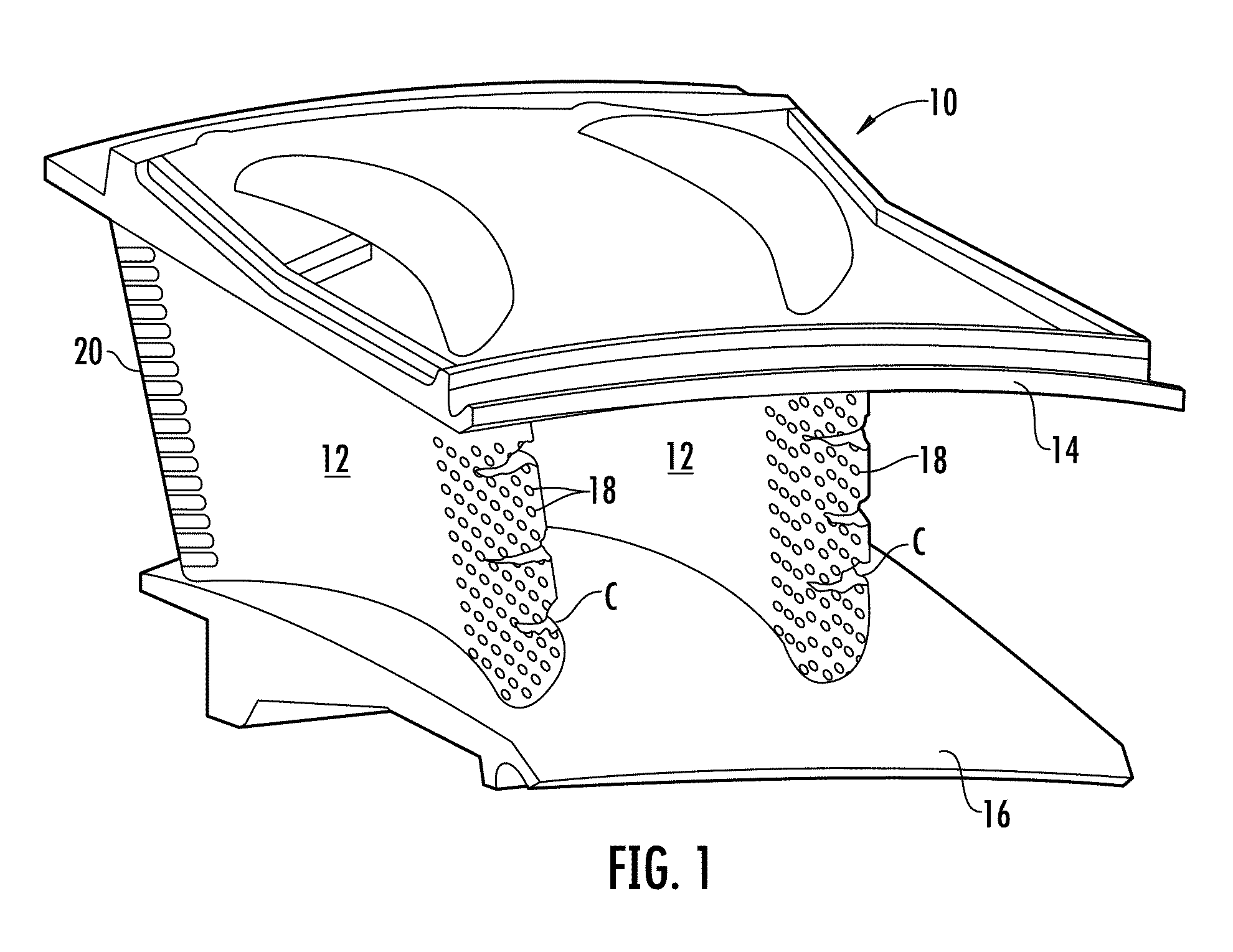

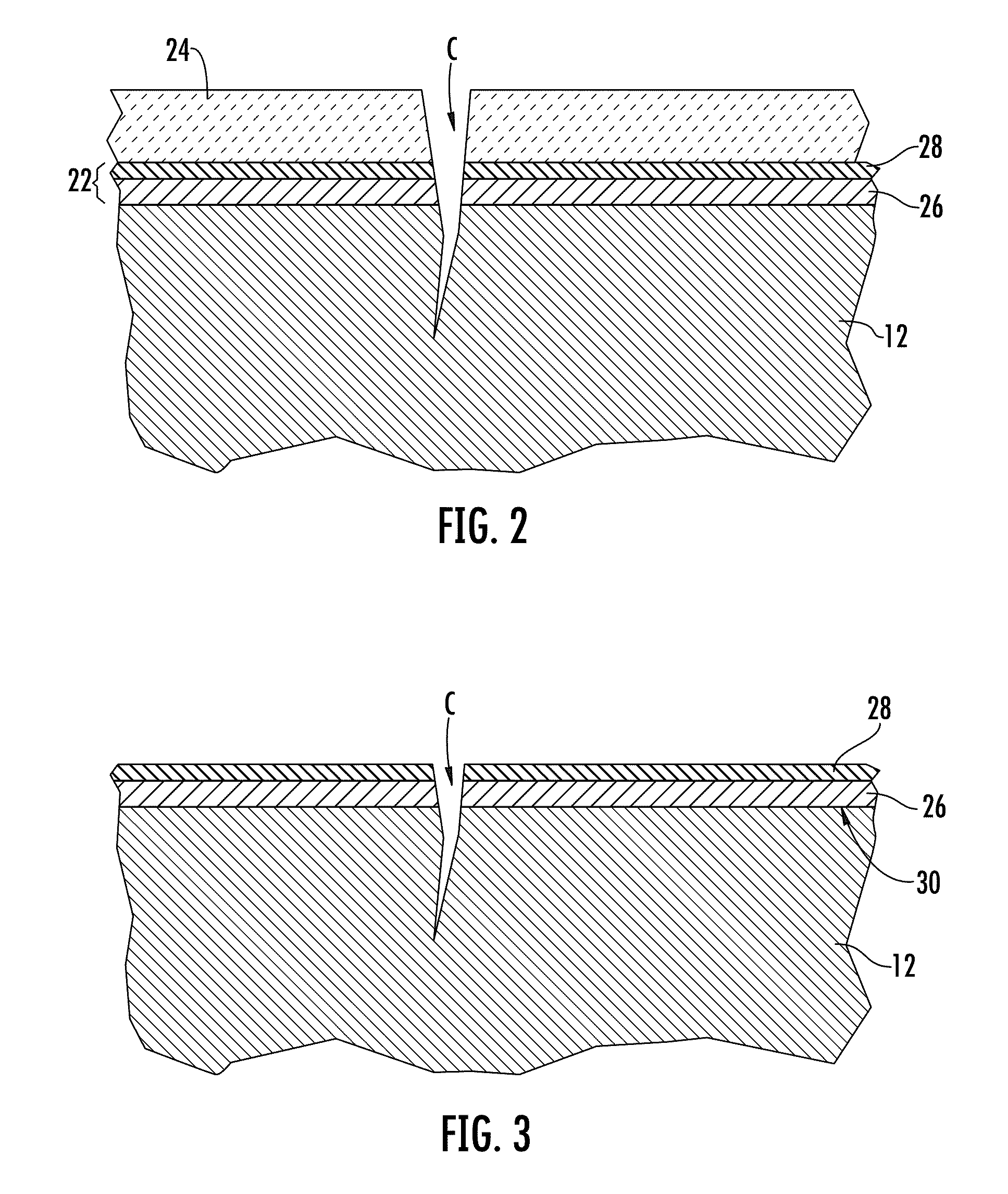

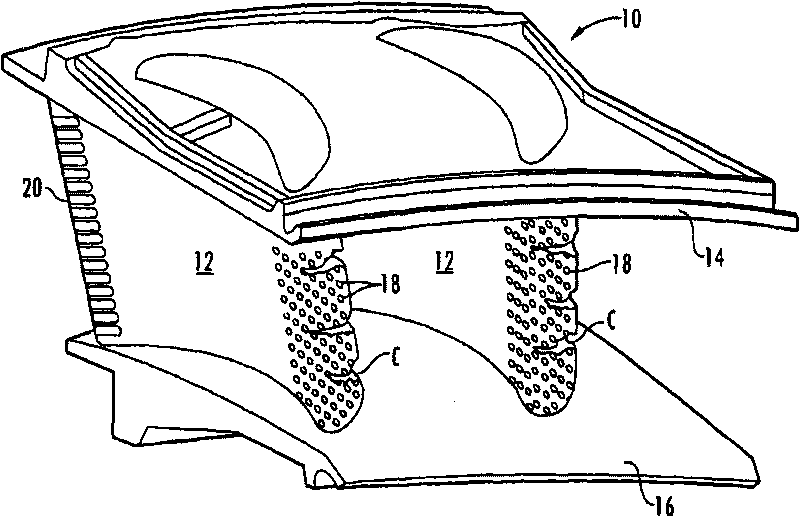

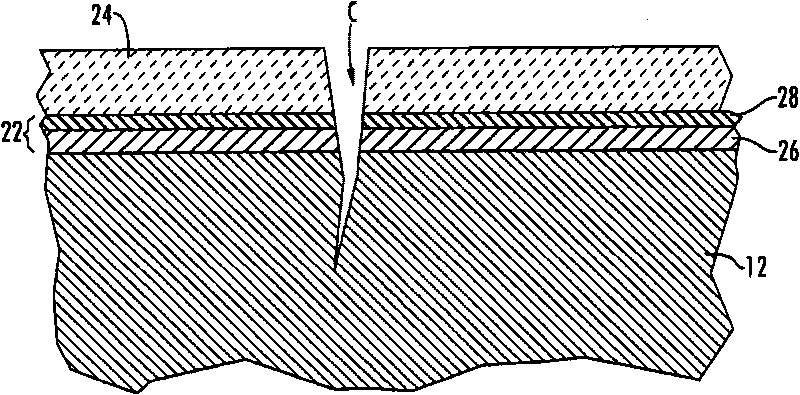

Repair method for tbc coated turbine components

A method is provided for repairing a metallic turbine component which includes a thermal barrier coating system including a metallic bond coat and a ceramic top coat. The method includes: (a) removing the top coat using a mechanical process; (b) partially stripping the metallic bond coat from the component, such that substantially no material of the component is removed; (c) repairing at least one defect in the turbine component; (d) applying a new metallic bond coat to the turbine component; and (e) applying a new ceramic top coat over the metallic bond coat.

Owner:GENERAL ELECTRIC CO

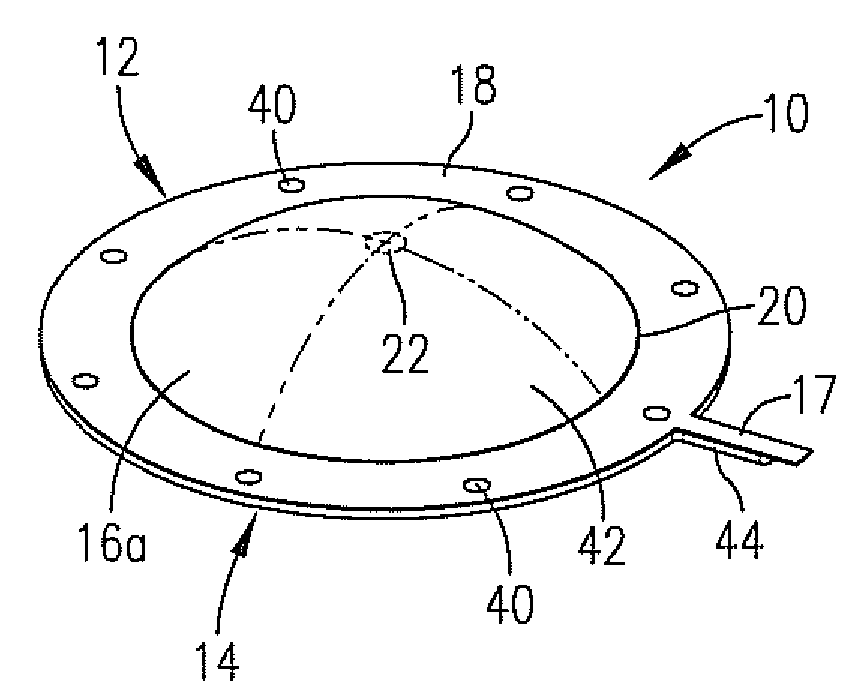

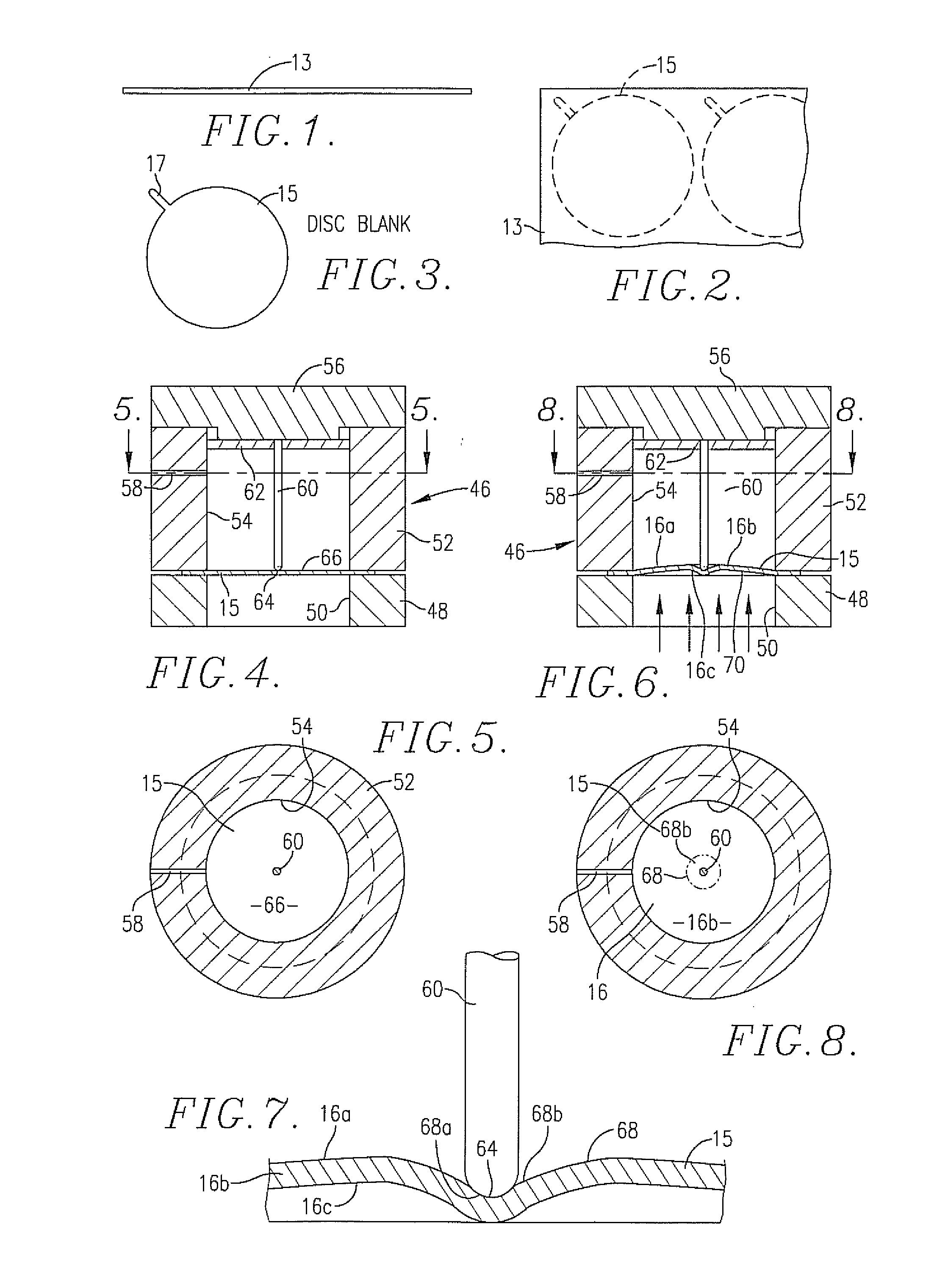

Rupture disc with machined line of opening

ActiveUS20090302035A1Uniform grain structureLarge containersEqualizing valvesMilling cutterGrain structure

A reverse acting rupture disc and methods of forming the same are provided. Generally, the rupture disc comprises a bulged portion and a circumscribing flange area surrounding the bulged portion. The bulged portion includes a mechanically formed line-of-opening recess comprising a singular channel. In certain embodiments, the mechanical process by which the recess is formed utilizes a high-speed mill which removes a portion of metal from the bulged portion of the disc without disrupting the substantially uniform metallic grain structure of the metal adjacent the channel.

Owner:FIKE CORP

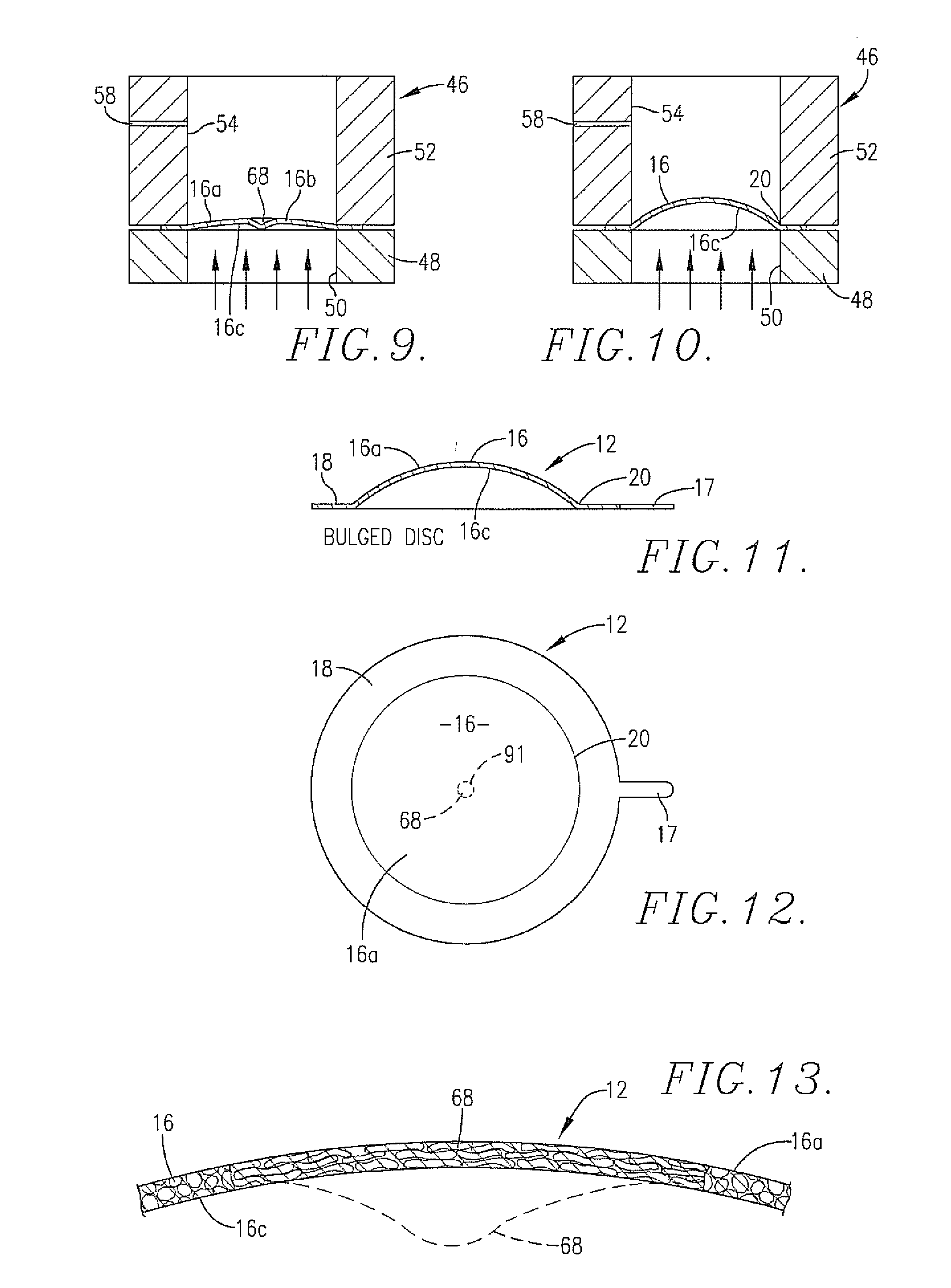

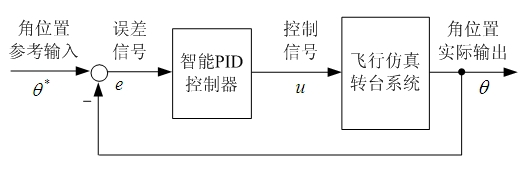

Flight simulation turntable control system and method using intelligent pid controller

InactiveCN102279564ASimple structureImprove performanceAdaptive controlGuidance systemProportion integration differentiation

The invention discloses an intelligent PID (Proportion Integration Differentiation) controller, which comprises a first controller, a second controller and a third controller. The invention further discloses a flight simulation rotating table control system applying the intelligent PID controller. The flight simulation rotating table control system comprises an intelligent PID controller and a flight simulation rotating table system, wherein the output end of the intelligent PID controller is connected with the input end of the flight simulation rotating table system. The control system can be used for setting parameters of the PID controller through online adjustment, so that the adverse effects of nonlinear and uncertain interference factors such as mechanical friction, mechanical resonance, sensor accuracy, mechanical process level and the like existing in a rotating table servo system on tracking control are eliminated, the servo tracking accuracy is enhanced, the confidence levelof a flight control semi-physical simulation system is raised, and the research accuracies or performances of a flying vehicle control system and a guidance system are enhanced. The invention furtherdiscloses a flight simulation rotating table control method.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

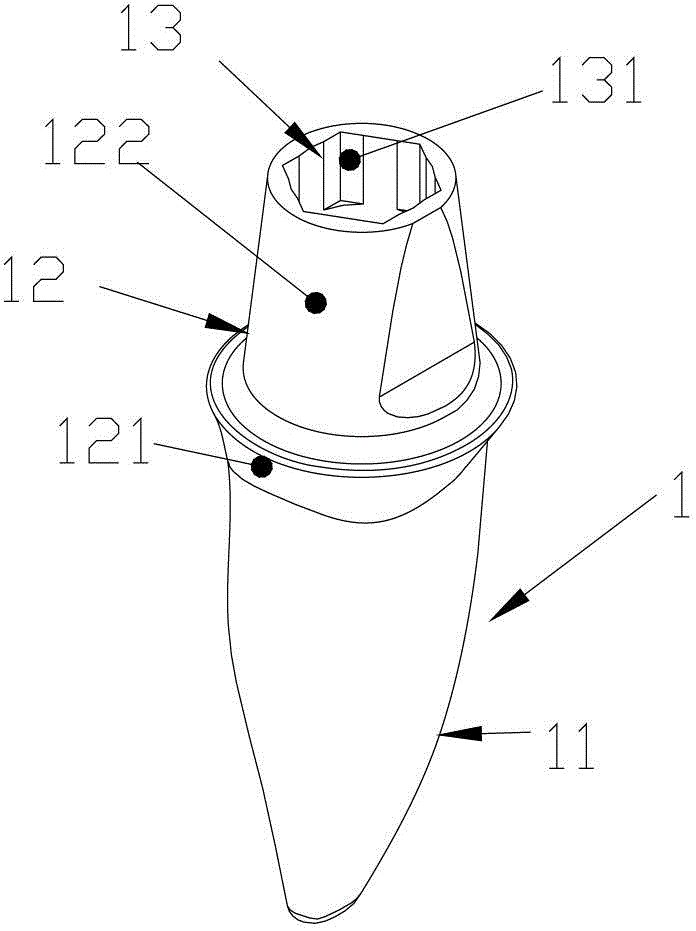

Dental implant and 3D printing preparation method thereof

ActiveCN104055592AOpen design formOpen typeDental implantsDental prostheticsProcess efficiencyProcessing cost

The invention provides a dental implant including a dental implant body and an abutment part, wherein the abutment part is arranged on the dental implant body, and the abutment part is formed integrally with the dental implant body. The invention also provides a 3D printing preparation method of the dental implant. The 3D printing preparation method disclosed by the invention can overcome shortages of an individuated dental implant manufactured by a conventional mechanical processing technology, effectively solves the processing technology problems of a complex dental implant structure, at the same time, makes the design form and type of the dental implant more open, improves the processing efficiency, greatly reduces the processing cost, and reduces the post-treatment process. The requirement on the equipment accuracy is not as high as mechanical-processed equipment, the roughness degree of an outer surface is controllable, and surface sandblasting treatment procedures are reduced. An integrally-formed structure of the dental implant provided by the invention can avoid the micro leakage problem of a traditional two-section connection. The dental implant provided by the invention is more beneficial for immediate implantation, reduces bone loss, reduces the operation process, and allows a operation to become a minimally invasive operation or even a noninvasive operation.

Owner:广东健齿生物科技有限公司

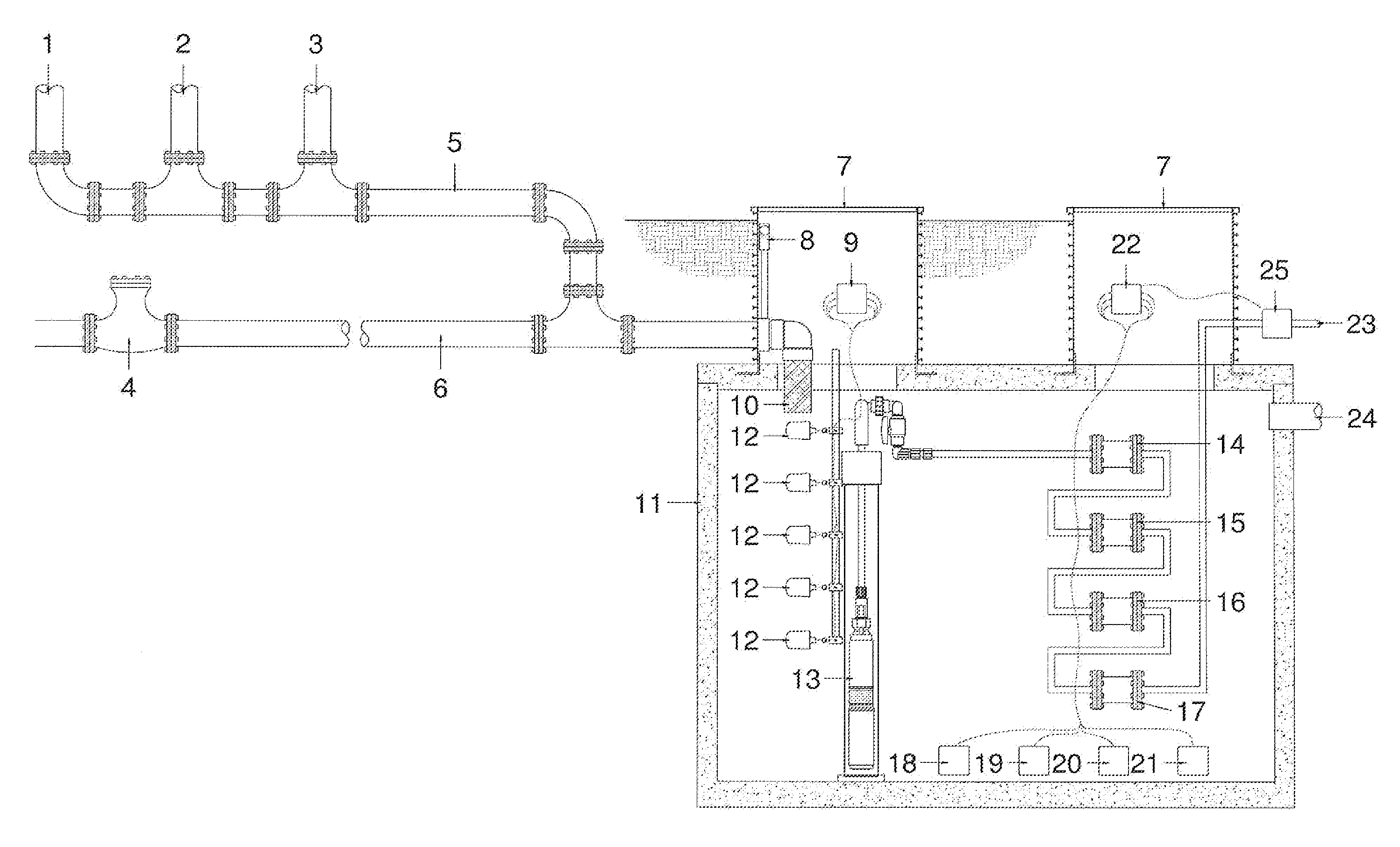

Process for Rain Water, HVAC Condensate and Refrigeration Blowdown/Bleed Blowdown/Bleed Water Recovery, Water Quality Monitoring, Real Time Water Treatment and Utilization of Recovered Water

InactiveUS20110017678A1Easy to useEfficient use of waterProgramme controlSemi-permeable membranesFiltrationWater quality

The present invention includes capturing water from rain, HVAC condensate and refrigeration blowdown / bleed blowdown that is recycled and reutilized in integrated mechanical processes. Water is monitored for volume, flow rate, and contaminants; and automatically cleaned through filtration and / or chemical and / or biological treatment techniques to meet acceptable health and safety standards for engineered end uses. The process components are integrated into an engineered system that includes: 1) water collection from air conditioning and refrigeration units and rain water; 2) custom design, engineering and implementation of a real time and / or scheduled water monitoring for water volume and water quality; 3) custom design, engineering and implementation of a real time and / or scheduled water treatment system to ensure water quality standards are met with respect to the end use of the recovered water; and 4) utilization of the recovered water by an engineered water distribution system.

Owner:ANDERSON DENNIS M +1

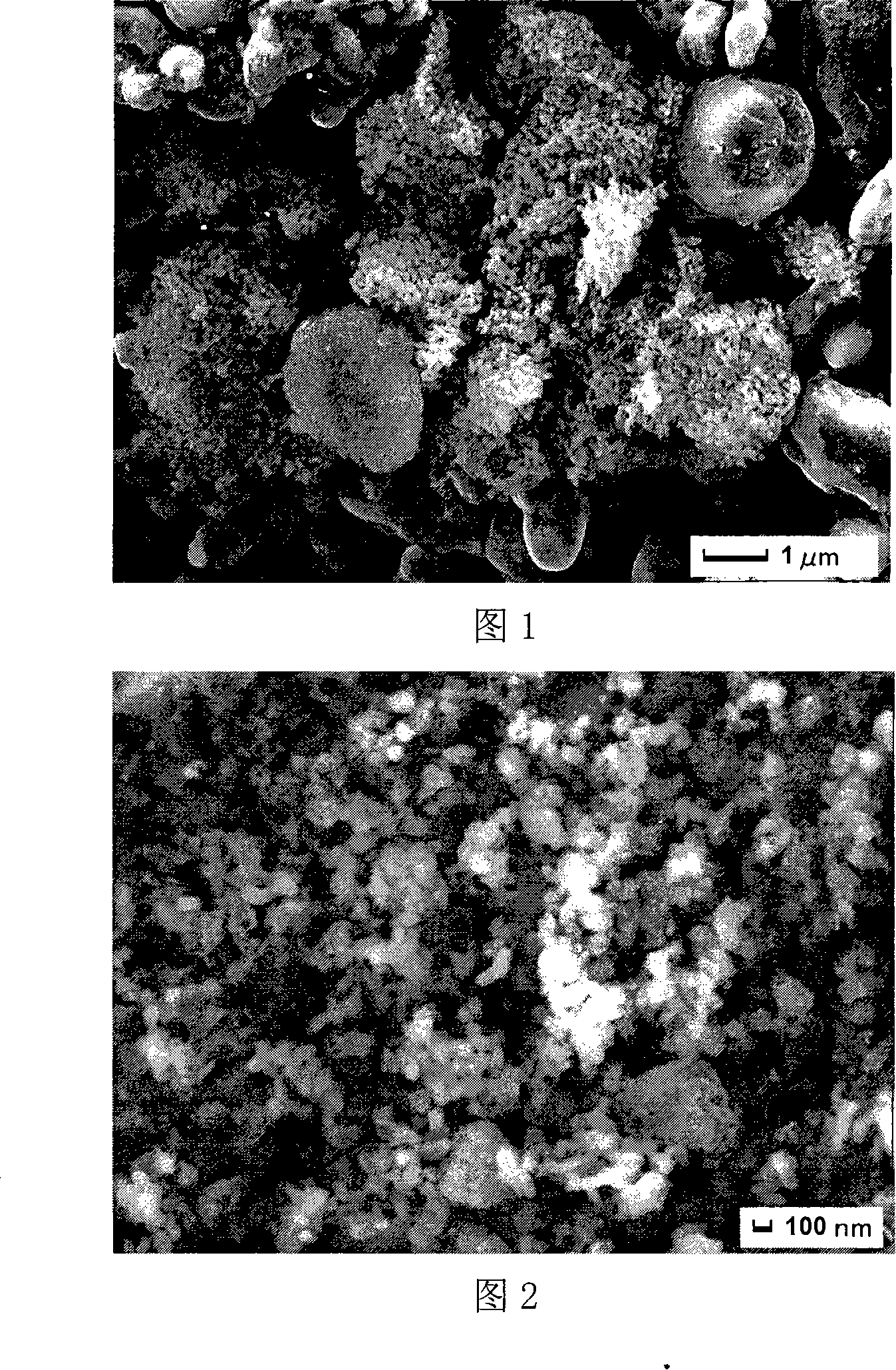

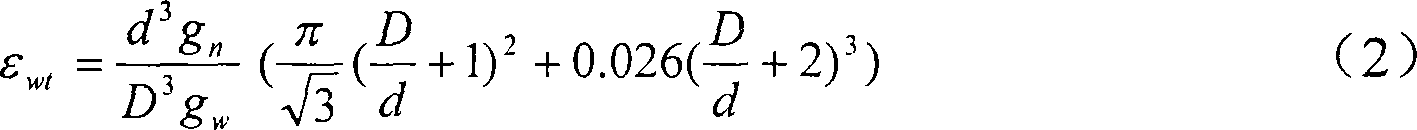

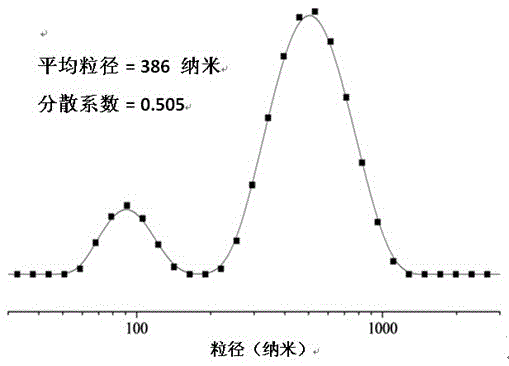

Mechanical process of preparing composite nanometer ceramic and micron metal powder

The present invention discloses mechanical process of preparing composite nanometer ceramic / micron metal powder. The composite nanometer ceramic / micron metal powder is prepared with marketable micron and nanometer powder as material, and through establishing the theoretical model of the weight ratio between the micron powder and the nanometer powder, preparing stable suspension of nanometer ceramic powder, mixing the nanometer suspension and the micron powder, and mechanical compounding. The process has simplicity, short treating time, easy control, continuous production and other features, and is suitable for engineering application.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

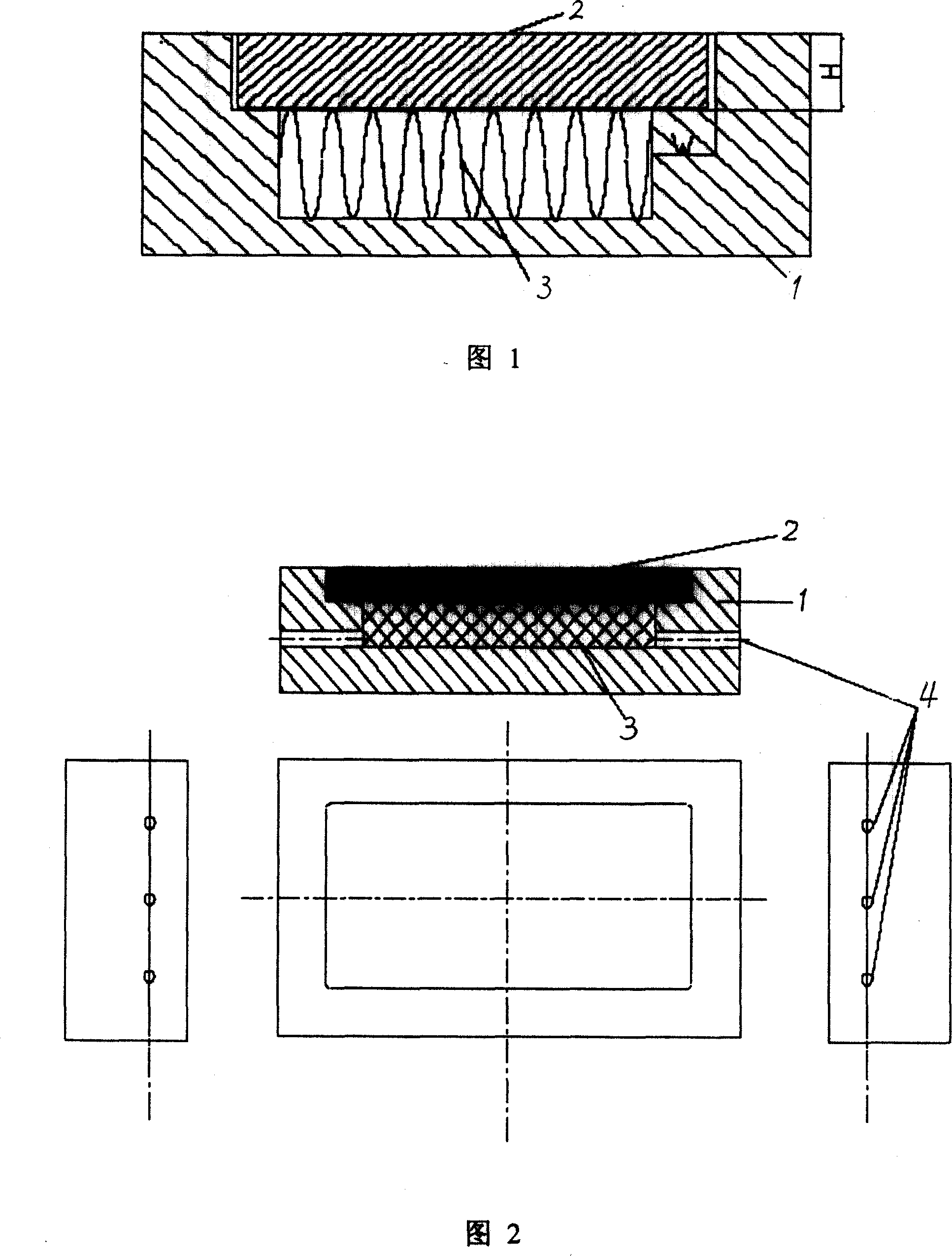

Air cold plate sealing forming technology of aluminum alloy

InactiveCN101007381AGuaranteed tightness requirementsLeakage and scrap rate is highWelding/cutting media/materialsMilling equipment detailsCold plateNitrogen gas

A aluminum alloy air-cooled freezing-plate sealing shaping process includes the following steps: 1. processing the appearance of freezing-plate, dissipating heat fins and cover plate parts according to structure design, the structure design of freezing-plate is flush type cavity structure, the two ends of freezing-plate shell is equipped with 2-3 soldering fabrication holes with diameter of 2-3mm; 2. welding the dissipating heat fins and freezing-plate shell, cover plate through the soldering method in nitrogen protection furnace; 3. milling out printed circuit board slots on the freezing-plate shell; welding the cover plate and shell vertical soldering seam through stirring friction welding; 5. mechanical processing the appearance and two end ventilators of freezing-plate according to the drawings requirements, processing the soldering fabrication holes into two end ventilators. The aluminum alloy freezing-plate using the art method of combination of soldering and stirring friction welding in the invention increases the resistant finely processed capacity of brazing seam surface, ensures the hermeticity requirement after finely process aluminum alloy freezing-plate and increases the welding yield rate of electronic structure cabinet.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

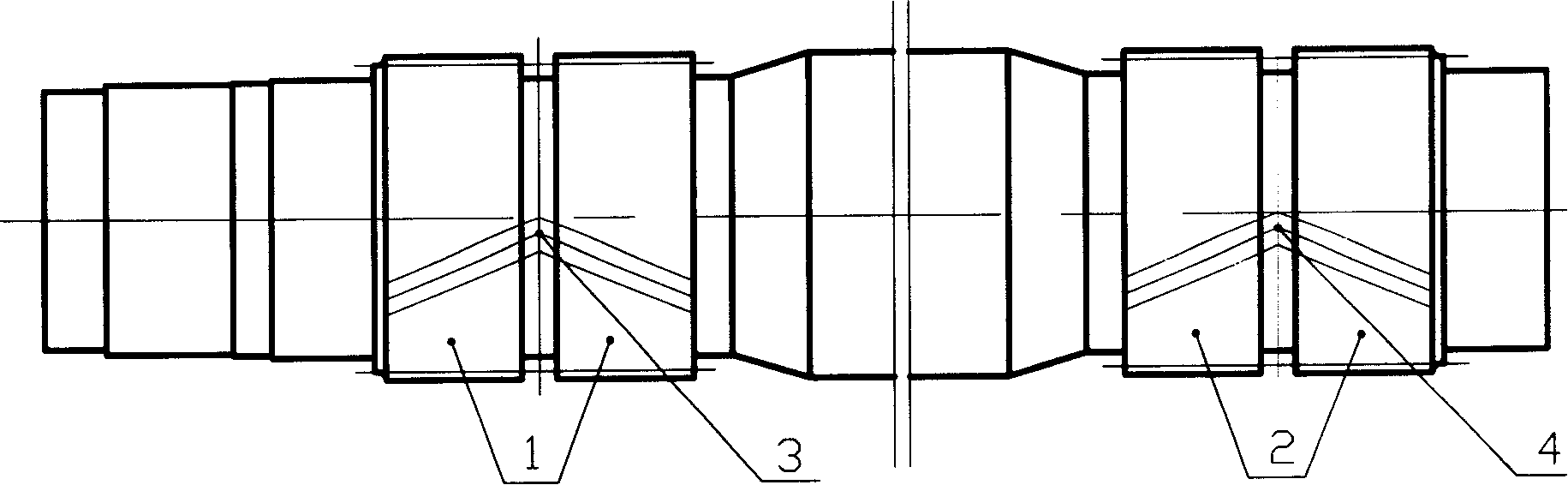

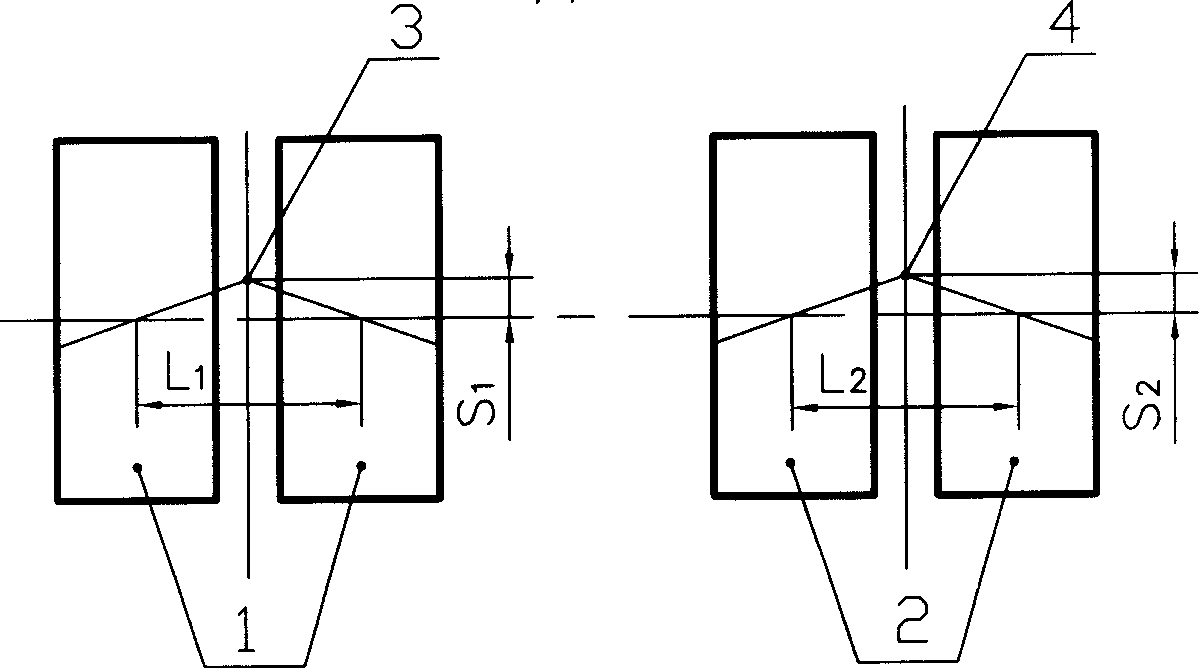

Double herringbone gear in-phase processing method

ActiveCN1876300AHigh precision in phaseEasy to operateGear teethGraduated cylinderAgricultural engineering

The invention discloses a method for preparing double cross gear, belonging to mechanical process technology. Said double cross gear is formed with left-and-right involutes helicoids, the cross gear center is the cross point of left gear central line and the right one; if the two cross gear is the same phase, the cross gear center 3 on graduated cylinder gear 1 and cross center 4 on gear 2 are at the same bus wire; and if projected on gear graduated circumference, the two cross gear center 3 and 4 are at the same circumferential position; and if the cross gear center 3 and 4 are at different phase, the cross gear 1 and 2 are at the same phase, then s1 equals to s2, and the center distance of left gear and right gear of two cross gears are equal, 11=12; clamping double cross gear blank on digital control milling machine for preparation.

Owner:CHINA FIRST HEAVY IND

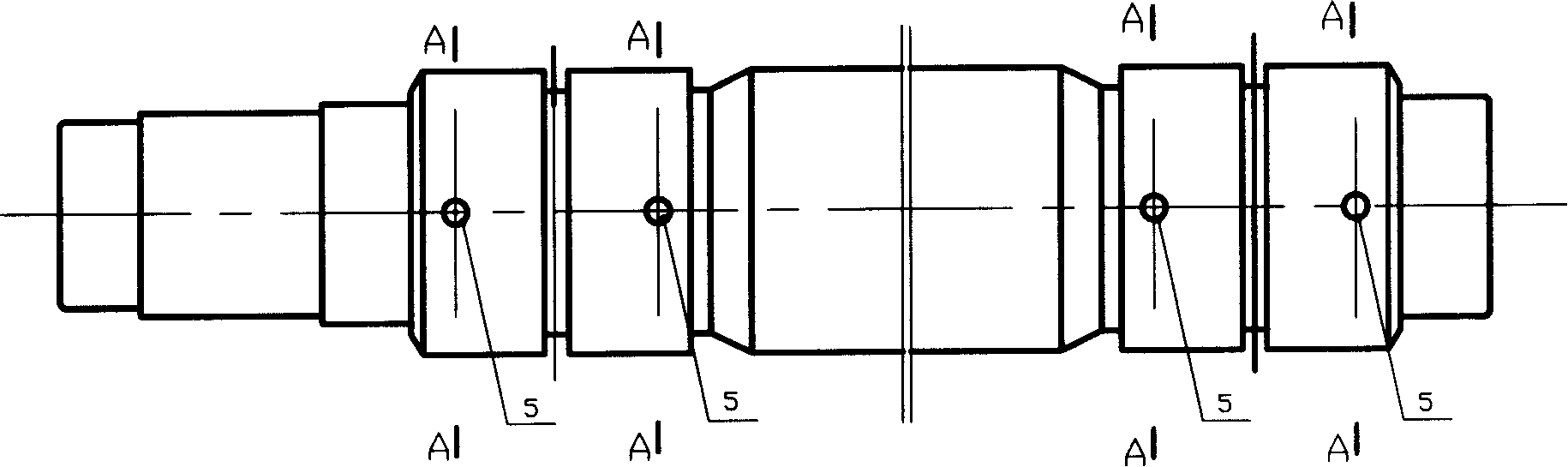

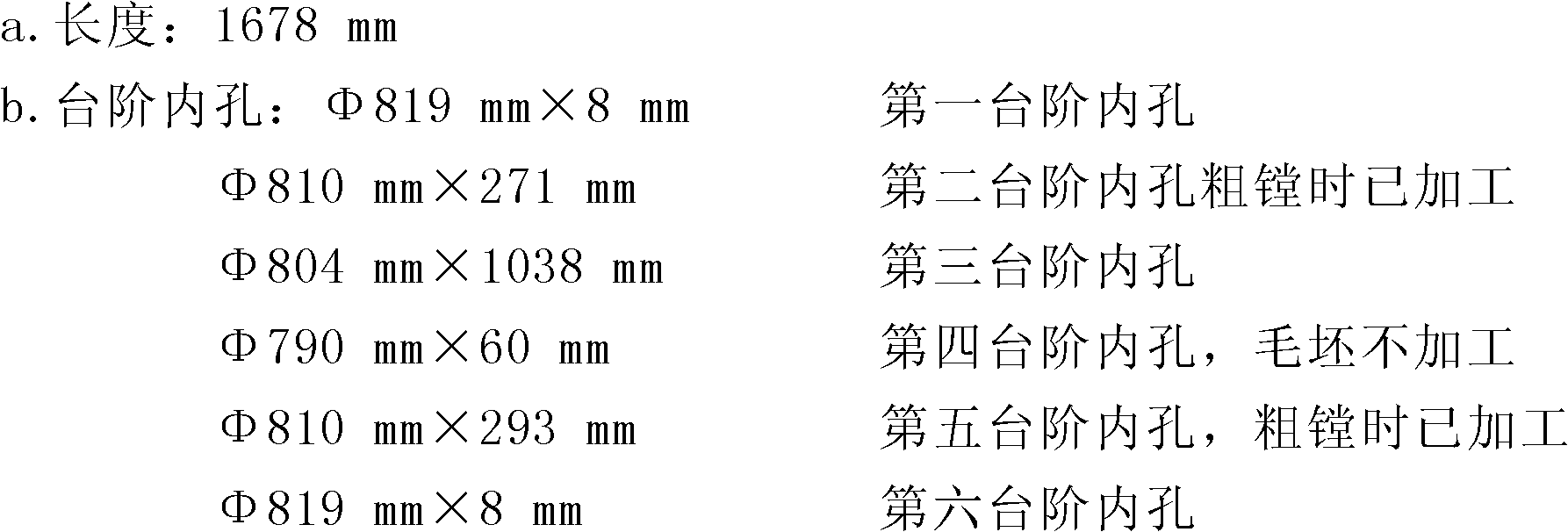

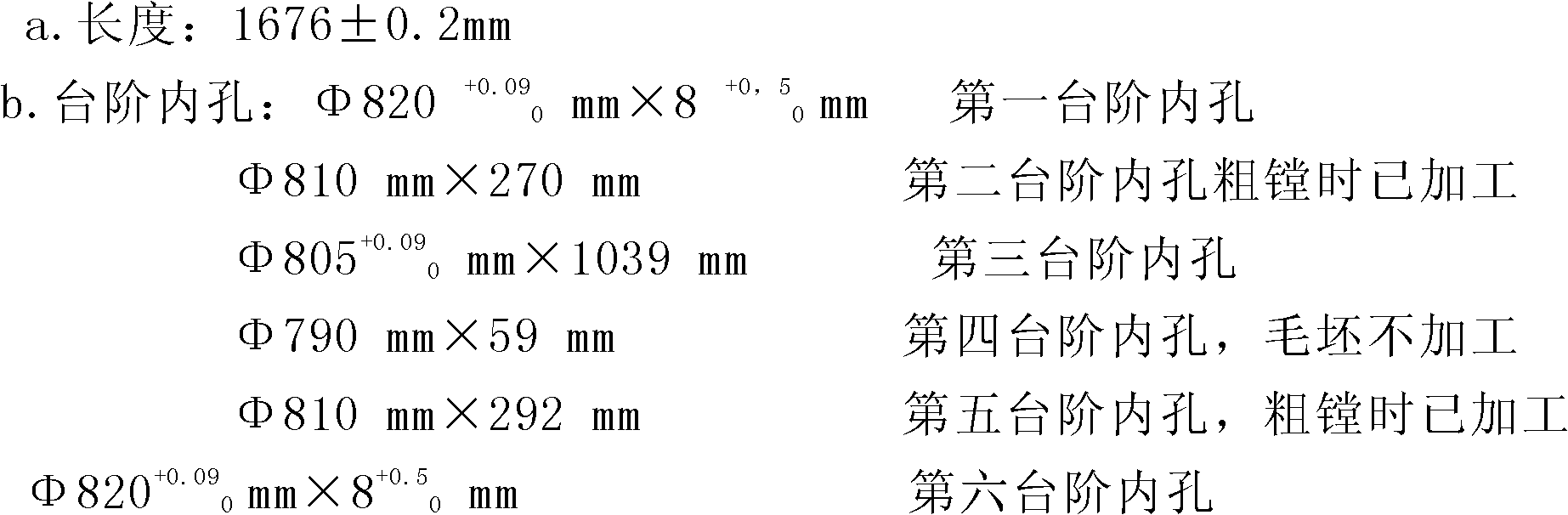

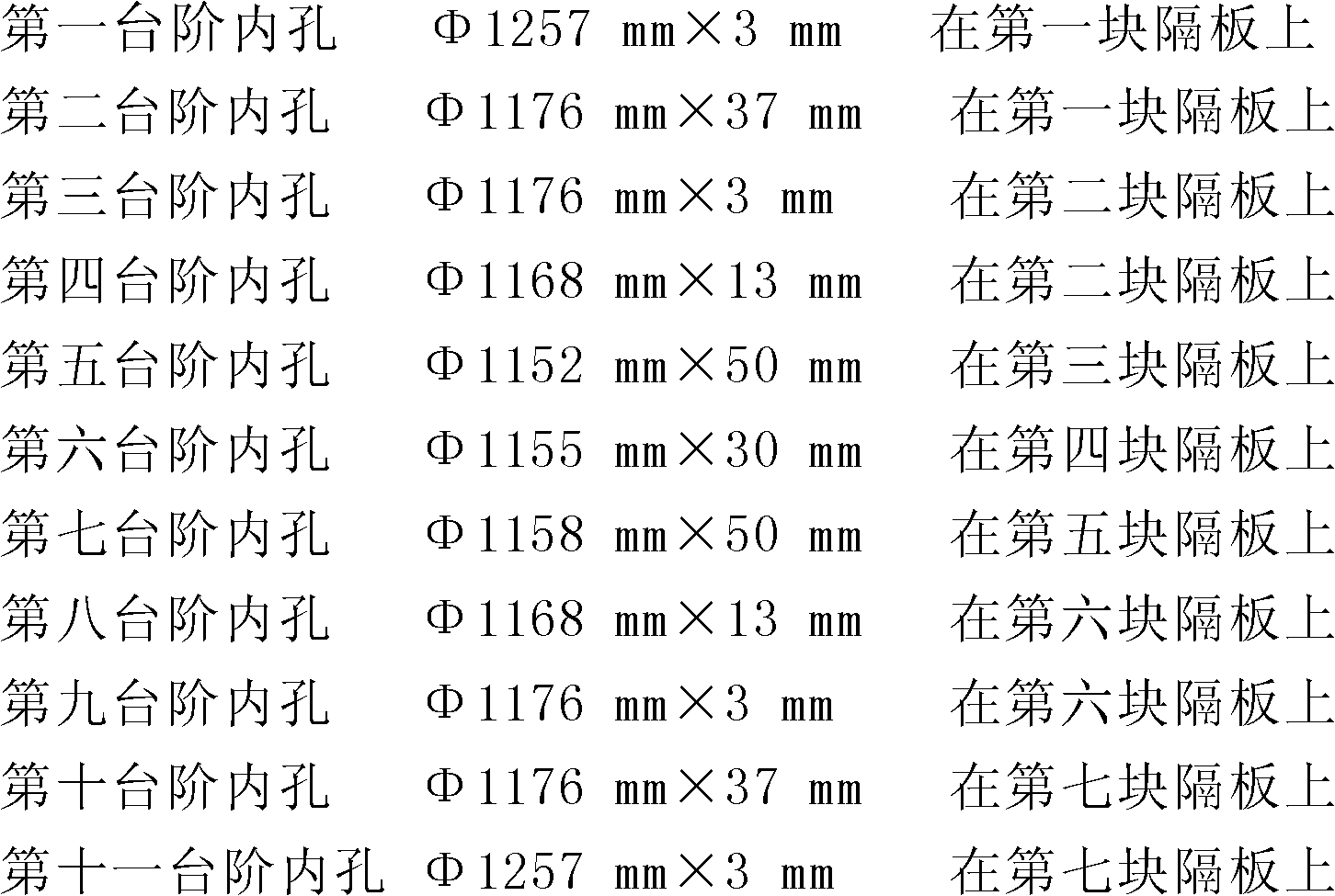

Process for fabricating wind-driven generator base

InactiveCN102581549AGuaranteed coaxialityReduce processing timeMilling equipment detailsWind drivenEngineering

The invention relates to a mechanical process for fabricating a wind-driven generator base, belonging to the technical field of mechanical process. The fabrication process mainly comprises the steps of milling a footing; roughly boring internal step-shaped holes of the base, each step and the planes of two ends; finely boring internal holes of the base as well as each step and the planes of two ends; after the processing is finished, releasing tightening screws and clamp screws; and hoisting the base down onto a wooden frame. According to the fabrication process provided by the invention, the planes of two ends and each internal step-shaped hole are mechanically processed in a state of once clamping, thus the axiality of the internal step-shaped holes at each part on the base can be guaranteed, the processing time is reduced, the precision requirement in base design is met.

Owner:无锡圣贝尔机电有限公司

Method of protecting a local area of a component

InactiveUS7083824B2Increase resistanceEasy to wearMolten spray coatingVacuum evaporation coatingFilling materialsBiomedical engineering

It is disclosed a method of protecting a local area of components (1) from the effects of thermochemical or mechanical processes carried out on the surface (6) of the component. A masking material (5) containing at least one filler material is applied to the local area so that the local area is protected by the masking material (5). This is at least partially polymerized on the local area. Subsequently the thermochemical or physical processes on the surface (6) of the component (1) are carried out after which the polymerized masking material (5) is removed from the local area of the component (1).

Owner:ANSALDO ENERGIA IP UK LTD

Repair method for tbc coated turbine components

The present invention provides repair method for TBC coated turbine components, concretely provides a method for repairing a metallic turbine component which includes a thermal barrier coating system including a metallic bond coat (22) and a ceramic top coat (22). The method includes: (a) removing the top coat (24) using a mechanical process; (b) partially stripping the metallic bond coat (22) from the component, such that substantially no material of the component is removed; (c) repairing at least one defect in the turbine component; (d) applying a new metallic bond coat (26', 28') to the turbine component; and (e) applying a new ceramic top coat (24) over the metallic bond coat(26', 28').

Owner:GENERAL ELECTRIC CO

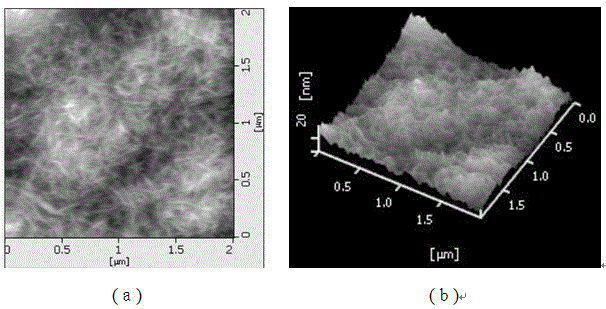

Method for preparing renewable nano-celluloses

InactiveCN105568730AReduce manufacturing costIncrease productivityPulp properties modificationEnvironmental resistanceCatalytic oxidation

The invention relates to a method for preparing renewable nano-celluloses. The method includes pre-treating paper pulp by the aid of mechanical processes and then carrying out catalytic oxidation treatment on the paper pulp by the aid of TEMPO / NaClO / NaBr systems; ultrasonically smashing the paper pulp and carrying out high-pressure homogenization treatment on the paper pulp to obtain nano-cellulose suspension; treating the nano-cellulose suspension by the aid of semi-baking / semi-natural static drying processes to obtain the renewable nano-celluloses. The method has the advantages that the renewable nano-celluloses can be synthesized by the aid of the method with combinations of the mechanical processes and chemical processes, accordingly, the production cost of the nano-celluloses can be greatly reduced, the production efficiency can be improved, the yield can reach 95% at least, the surfaces of the nano-celluloses can be modified, and the renewable nano-celluloses are excellent in mechanical property and heat resistance; the renewable nano-celluloses are made of the paper pulp, TEMPO and the like, water is used as a solvent, main raw materials can be recycled, toxic reagents and medicines are omitted in integral production procedures, accordingly, environments can be protected, and energy can be saved; the renewable nano-celluloses can be produced in an environment-friendly manner, the method is easy and convenient to implement and free of environmental pollution and has a broad application prospect, the renewable nano-celluloses are high in preparation yield and low in cost, and the like.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com