Patents

Literature

47results about How to "Guaranteed tightness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

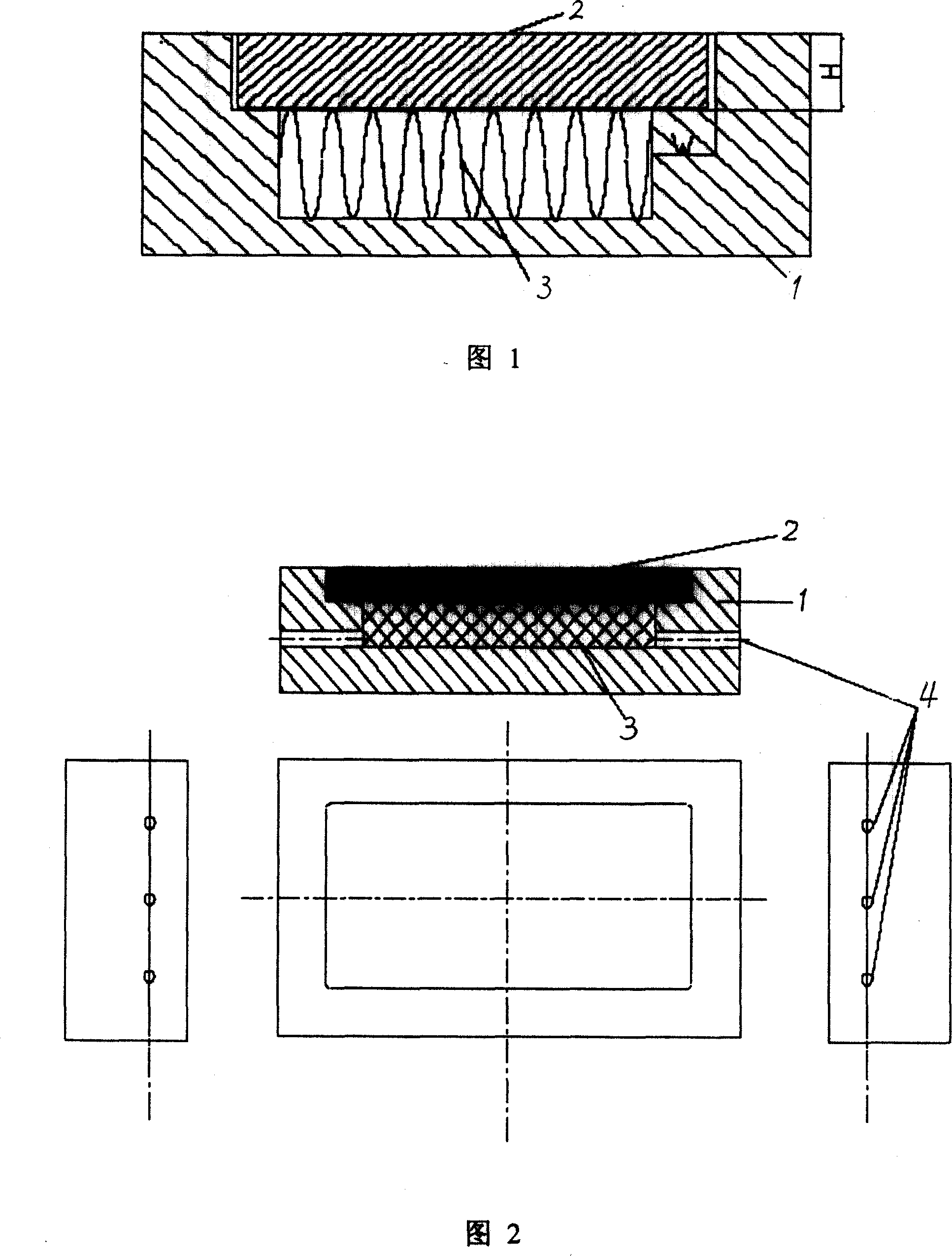

Air cold plate sealing forming technology of aluminum alloy

InactiveCN101007381AGuaranteed tightness requirementsLeakage and scrap rate is highWelding/cutting media/materialsMilling equipment detailsCold plateNitrogen gas

A aluminum alloy air-cooled freezing-plate sealing shaping process includes the following steps: 1. processing the appearance of freezing-plate, dissipating heat fins and cover plate parts according to structure design, the structure design of freezing-plate is flush type cavity structure, the two ends of freezing-plate shell is equipped with 2-3 soldering fabrication holes with diameter of 2-3mm; 2. welding the dissipating heat fins and freezing-plate shell, cover plate through the soldering method in nitrogen protection furnace; 3. milling out printed circuit board slots on the freezing-plate shell; welding the cover plate and shell vertical soldering seam through stirring friction welding; 5. mechanical processing the appearance and two end ventilators of freezing-plate according to the drawings requirements, processing the soldering fabrication holes into two end ventilators. The aluminum alloy freezing-plate using the art method of combination of soldering and stirring friction welding in the invention increases the resistant finely processed capacity of brazing seam surface, ensures the hermeticity requirement after finely process aluminum alloy freezing-plate and increases the welding yield rate of electronic structure cabinet.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

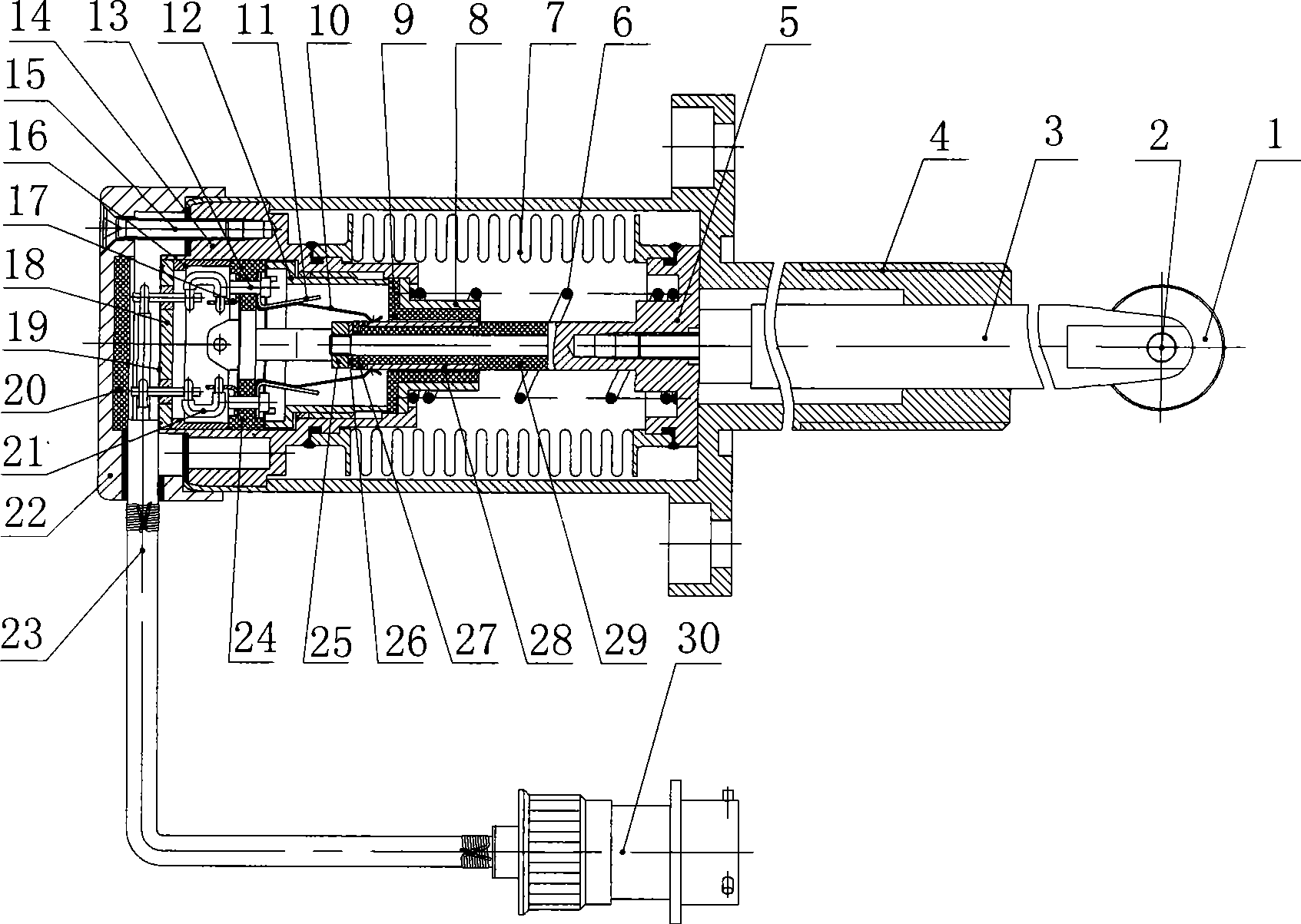

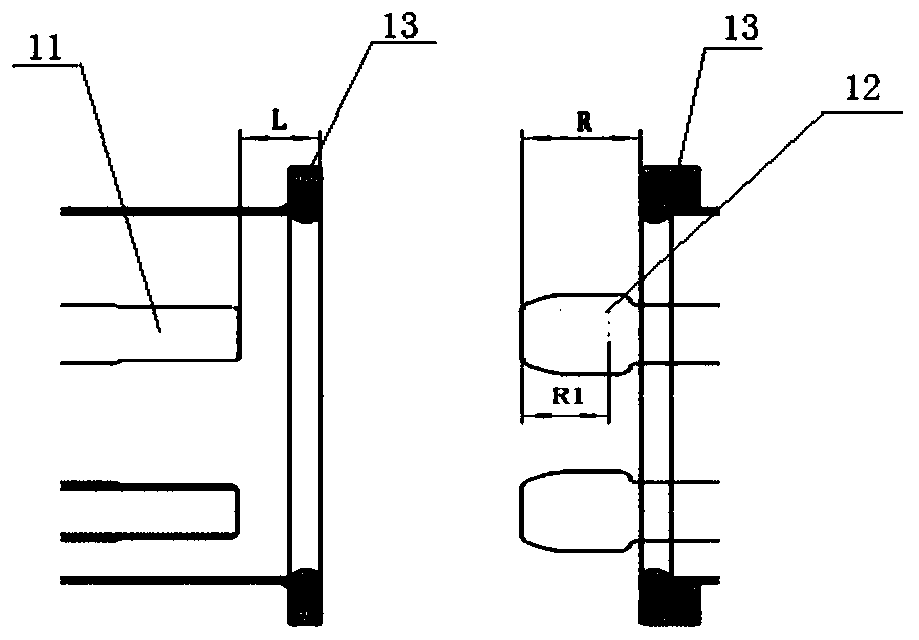

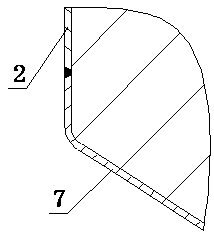

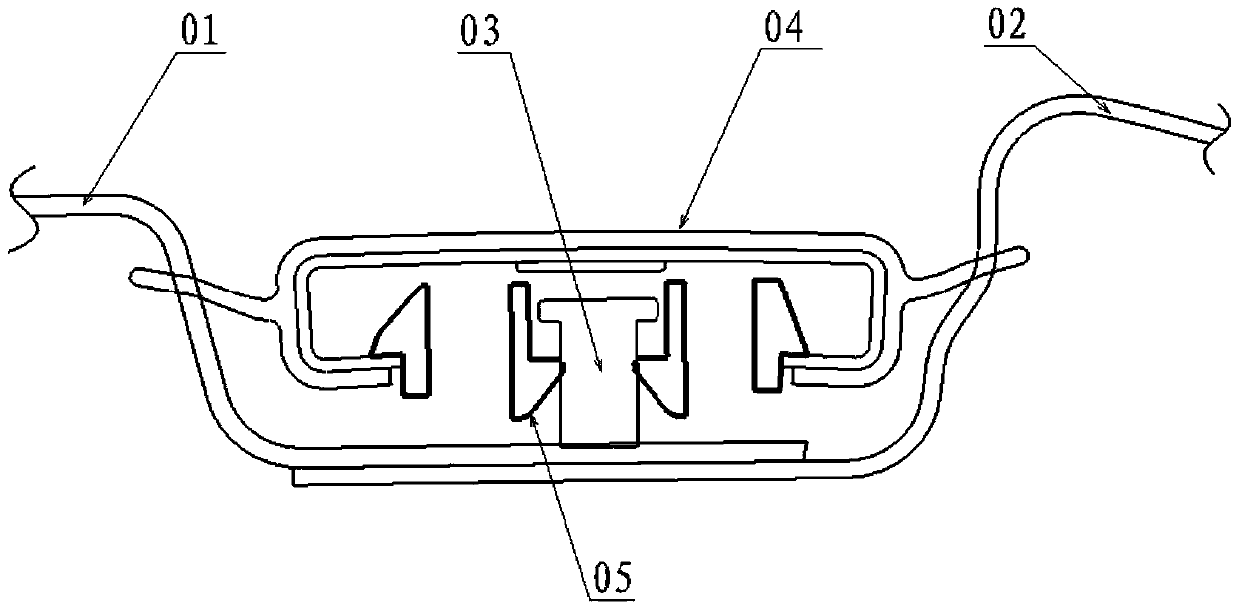

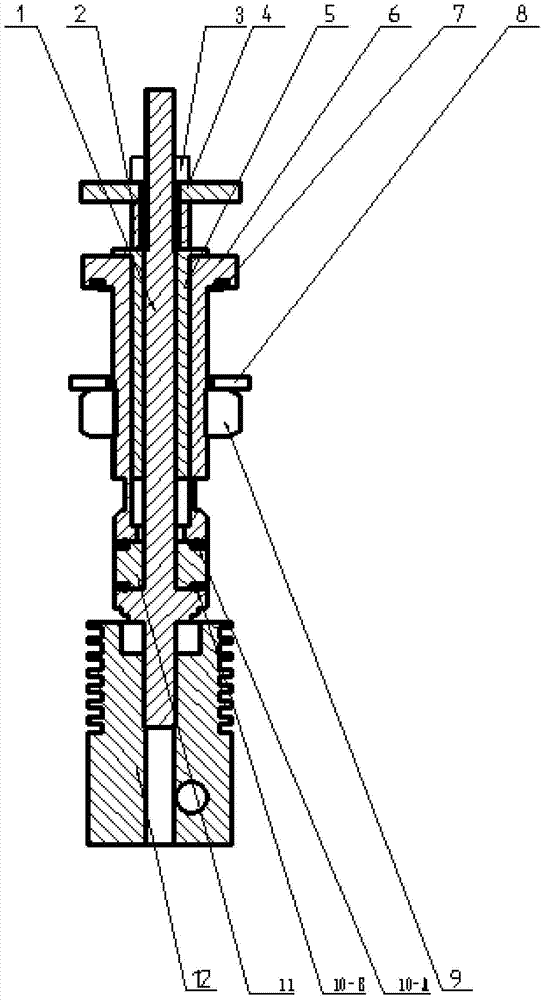

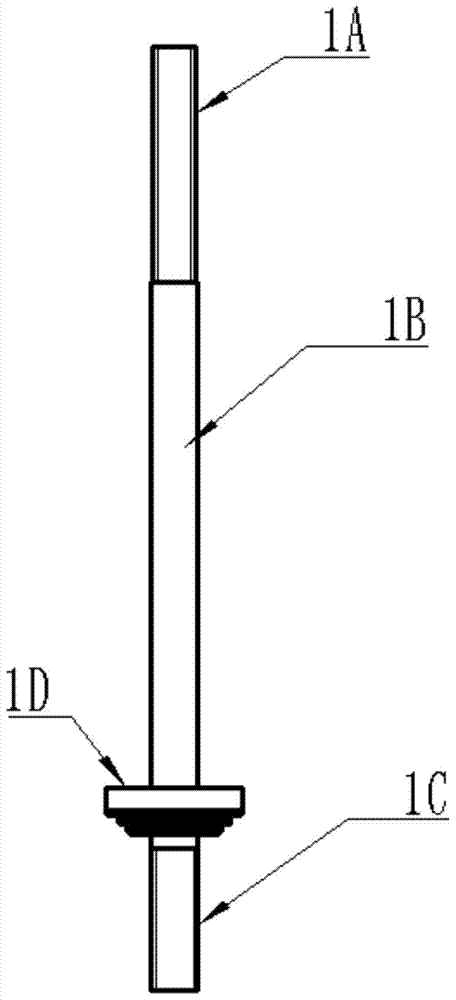

Sealed travel switch

InactiveCN101419874AGuaranteed tightness requirementsSolve the sealing problemElectric switchesEngineeringTower

The invention discloses a seal stroke switch which consists of a tower-form contact system of a seal structure, a pedestal combination, an outer hood, an axle and a guide wheel. One end of a push cylinder and one end of the periphery of a base are respectively manufactured into an interface form suitable for welding; the left end and the right end of a welding sylphon bellows are respectively fused together with the push cylinder and the base by welding, so as to form the seal shell of the stroke switch; L-shaped contact sheets and supporting sheets are overlapped together and are riveted in the annular step hole of the pedestal by rivets; every two mutually symmetrical contact sheets form a contact quadrangle and a tower-form contact system; the middle of the pedestal is provided with a through hole; the pedestal combination and a glass isolator are sintered together by the induction terminal of a basic board; one end of the pedestal combination is welded with a connection terminal and the other end is welded with the induction terminal of the pedestal combination, thus improving the seal performance and the reliability of the stroke switch.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

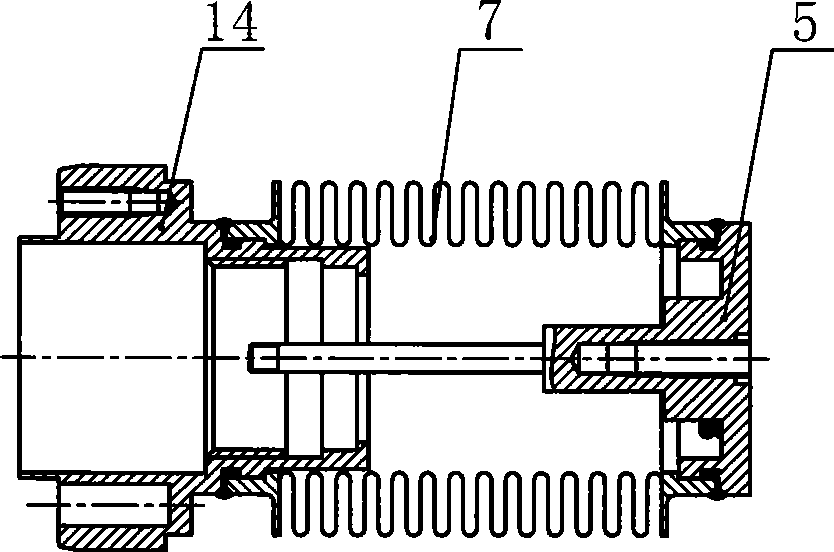

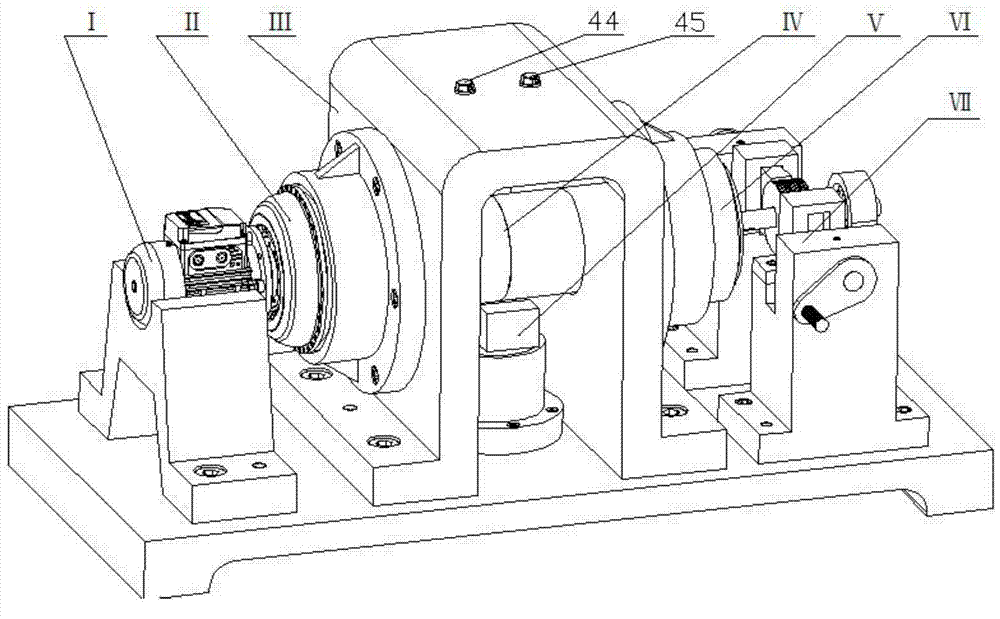

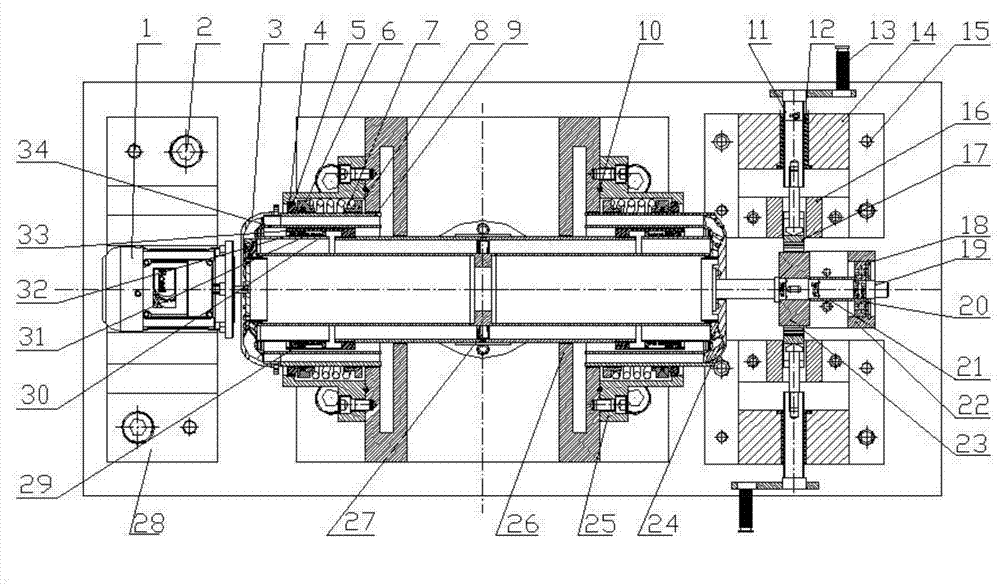

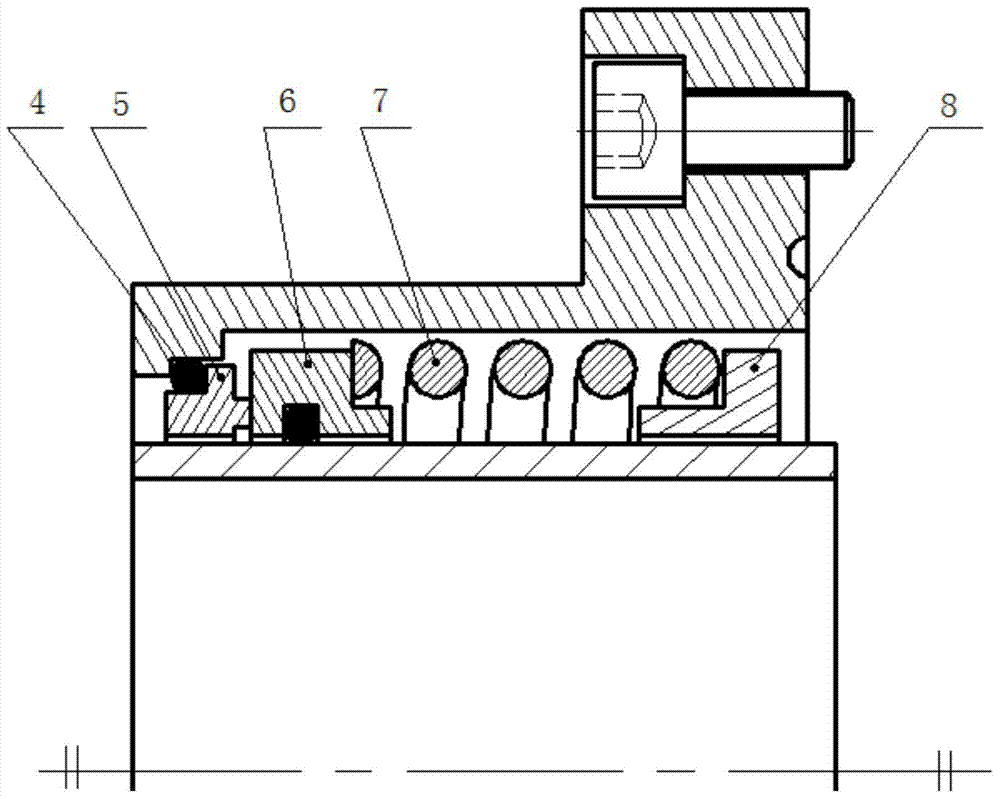

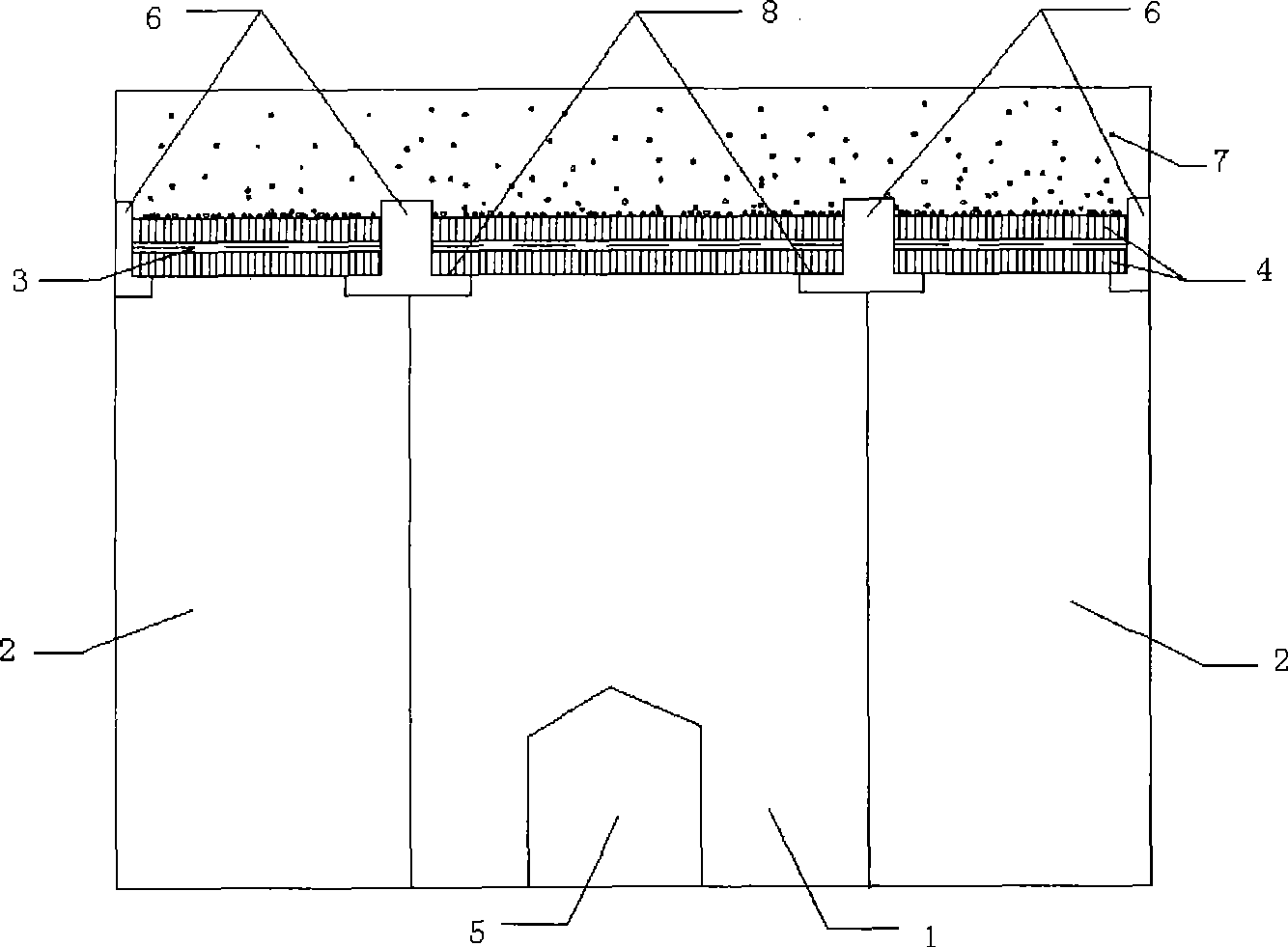

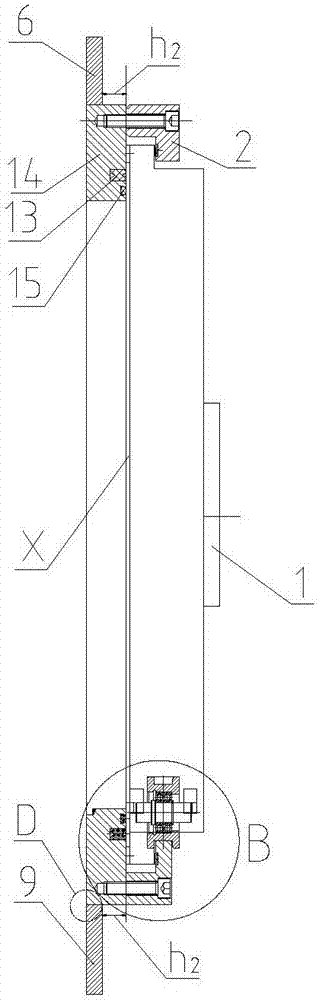

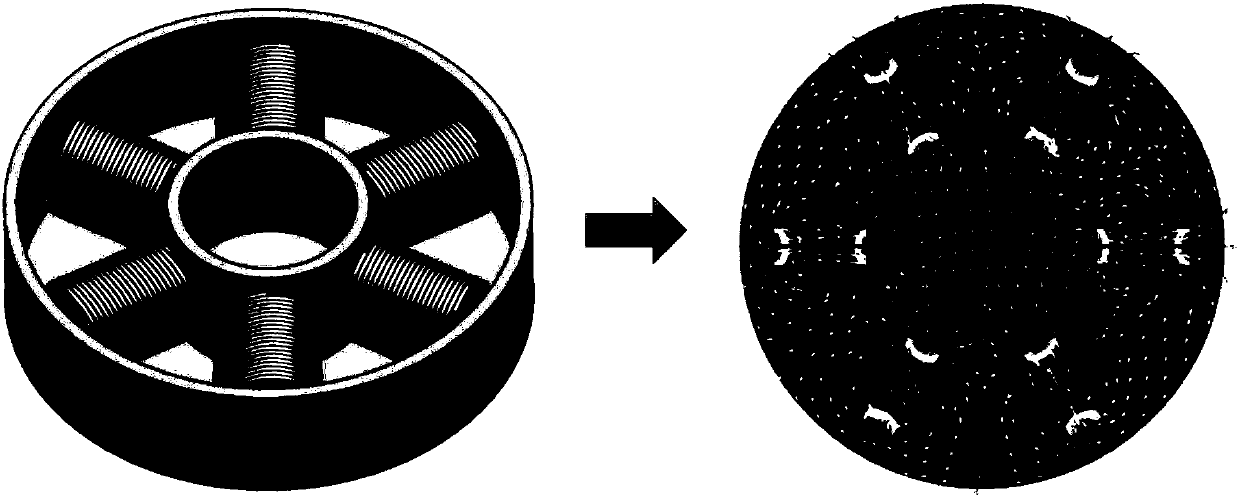

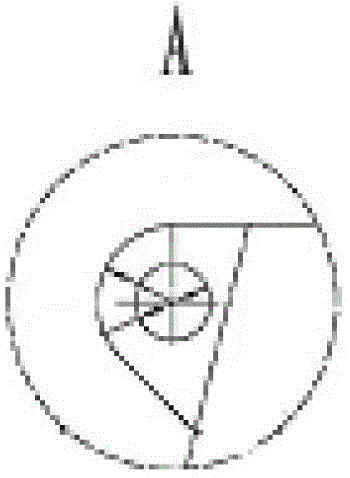

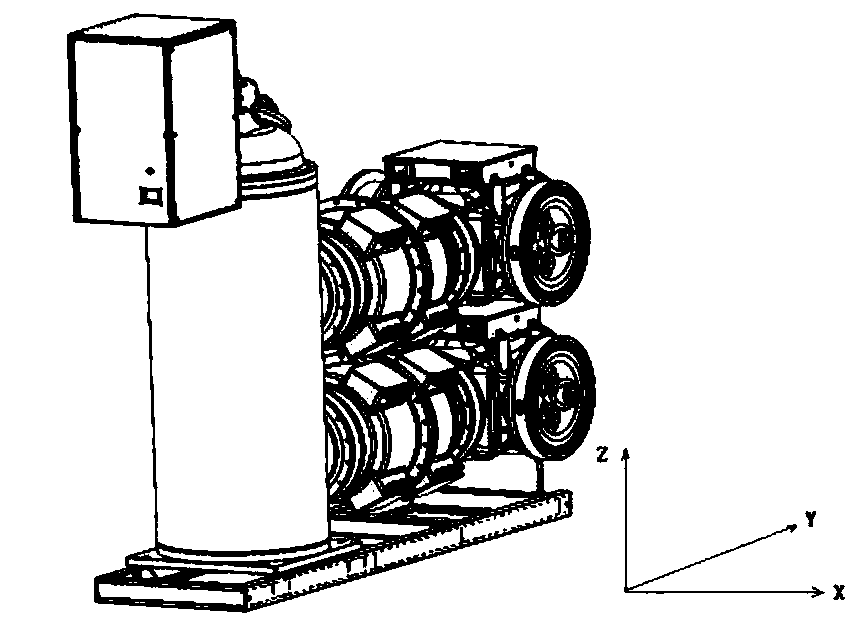

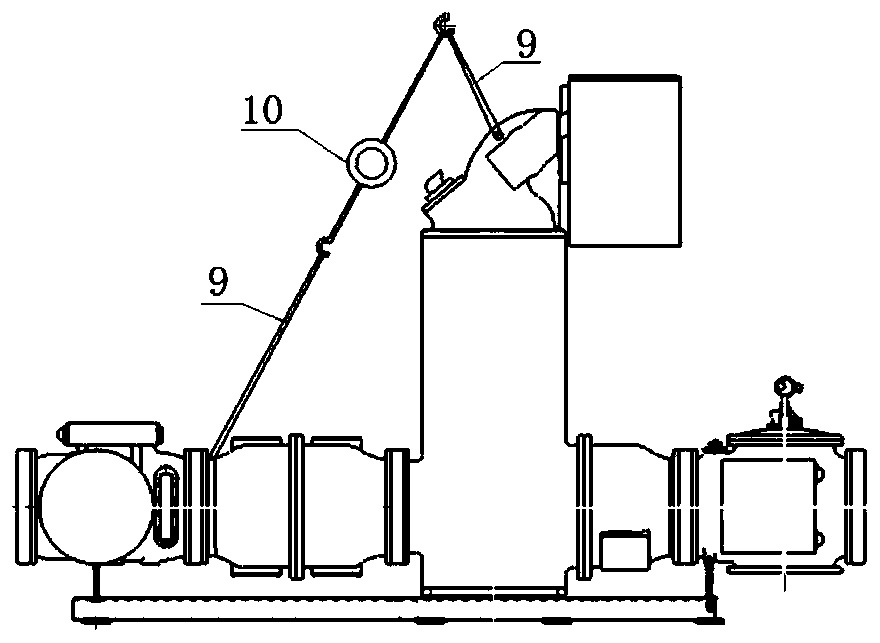

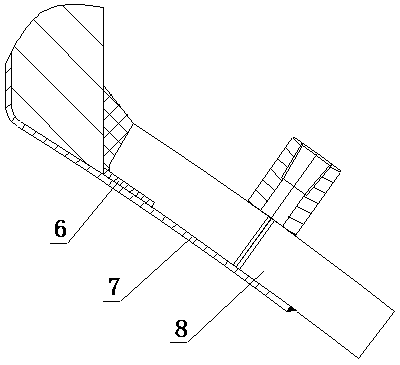

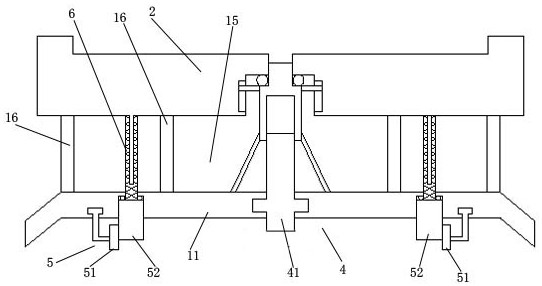

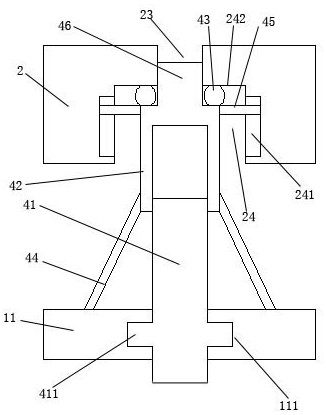

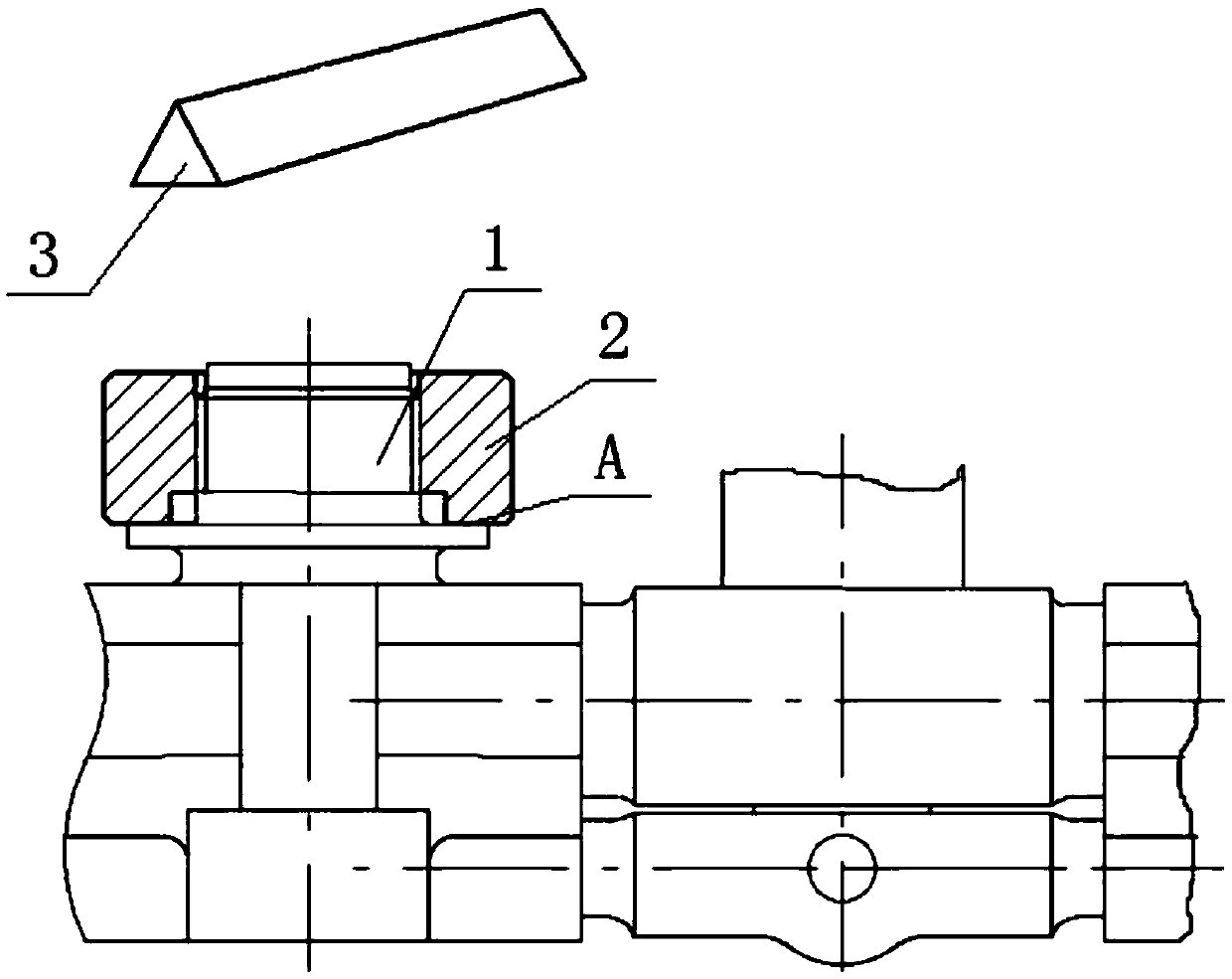

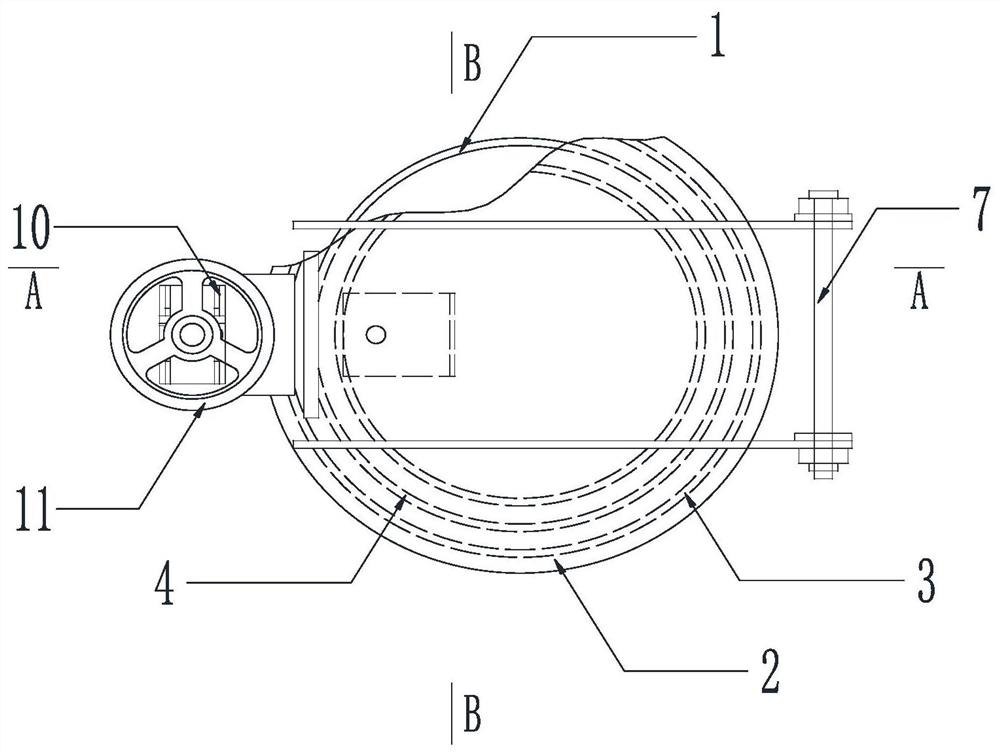

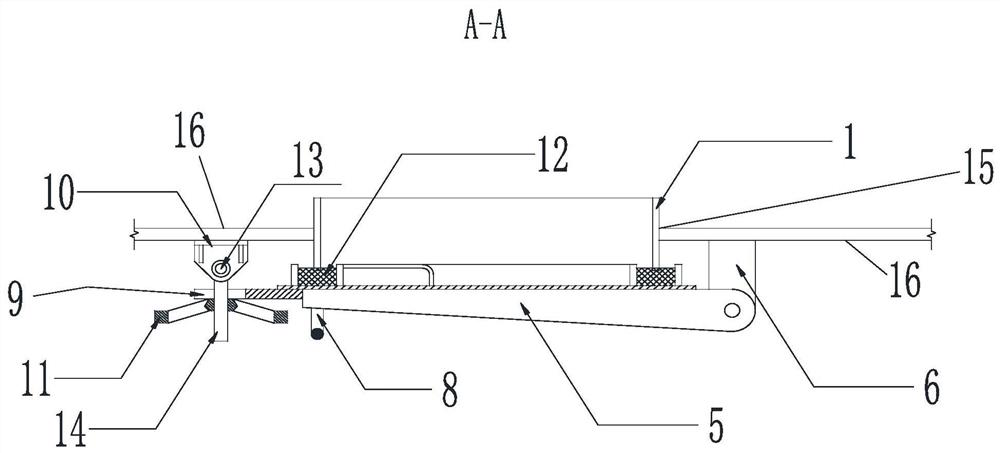

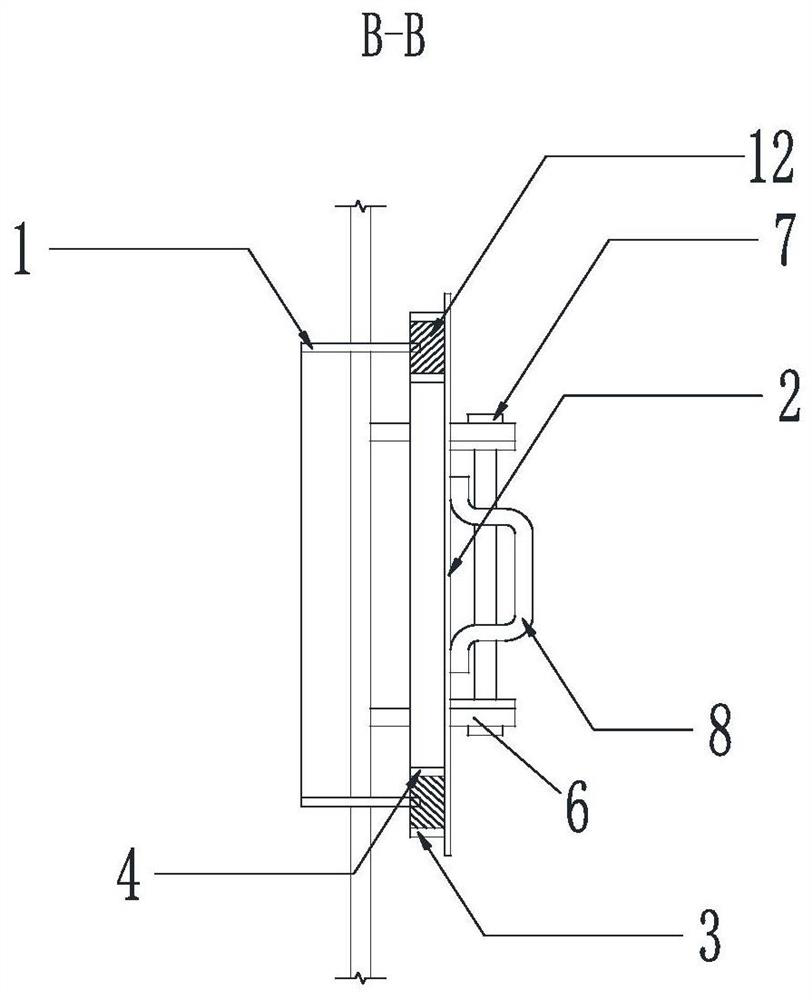

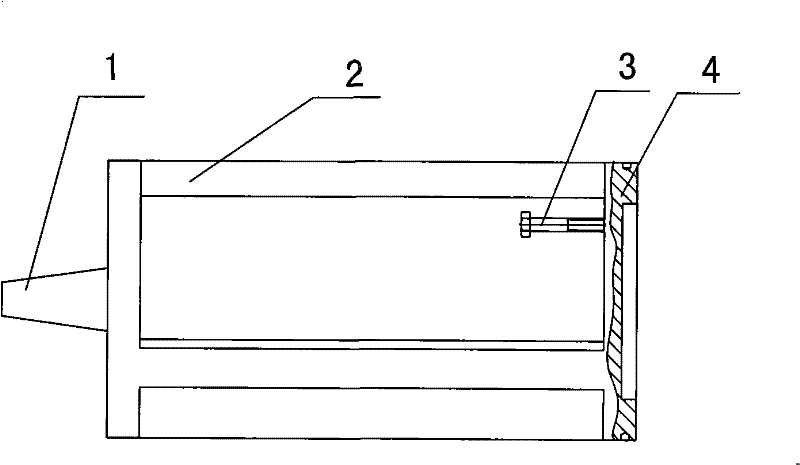

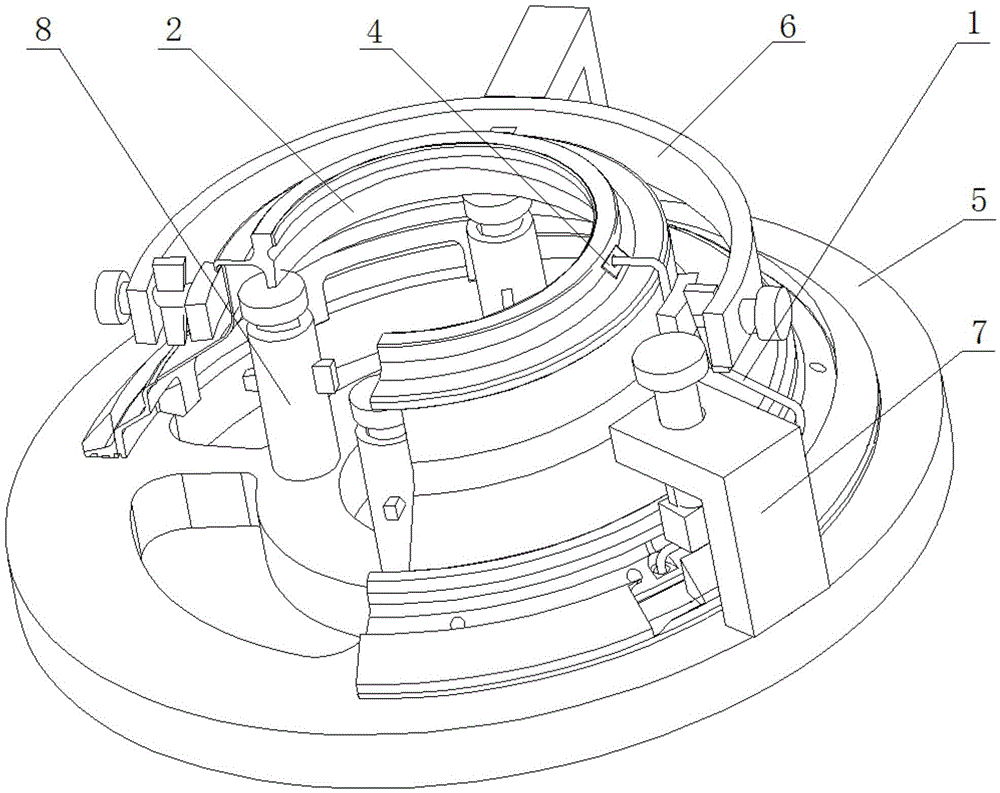

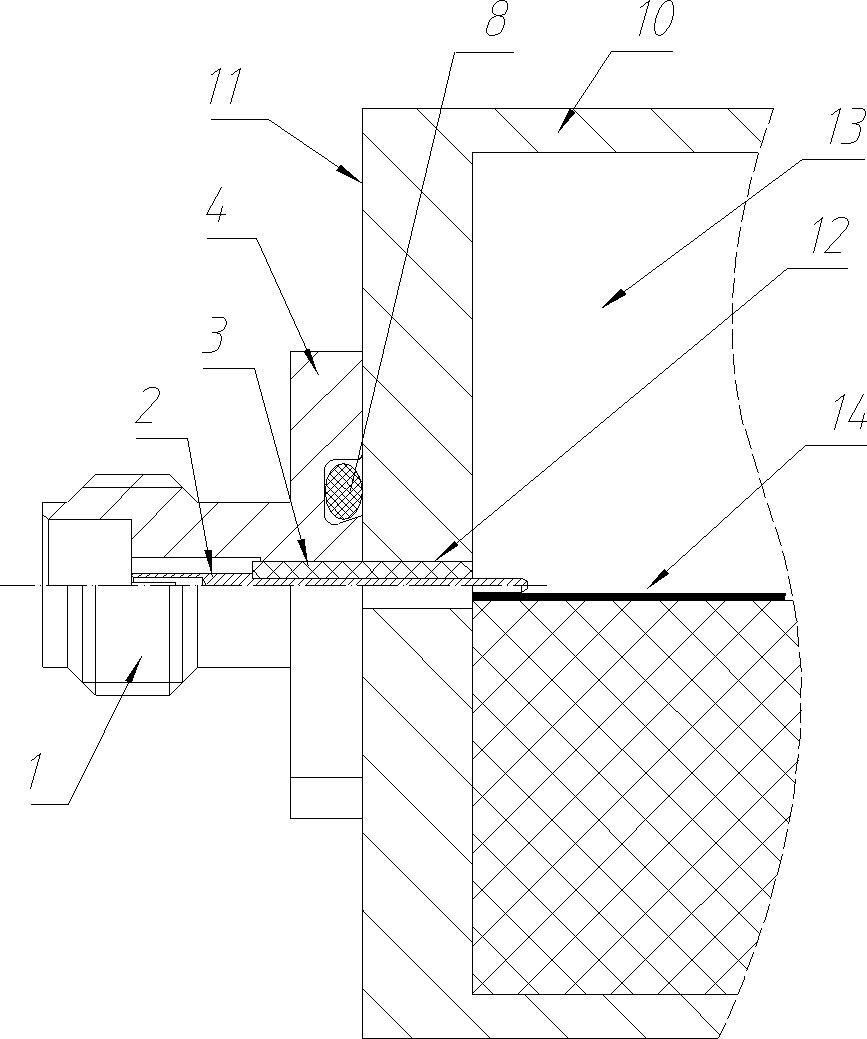

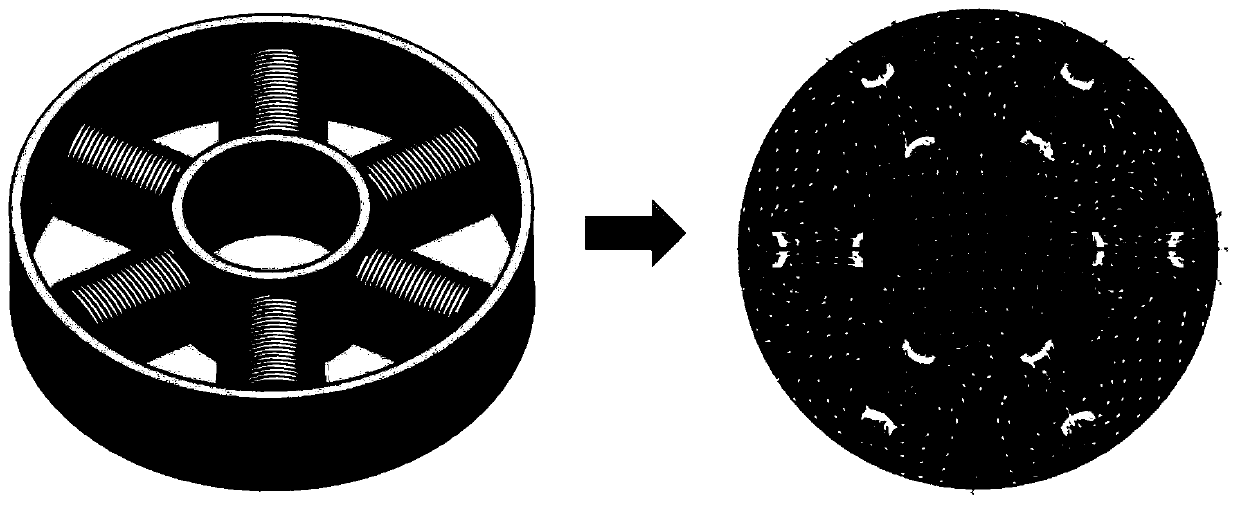

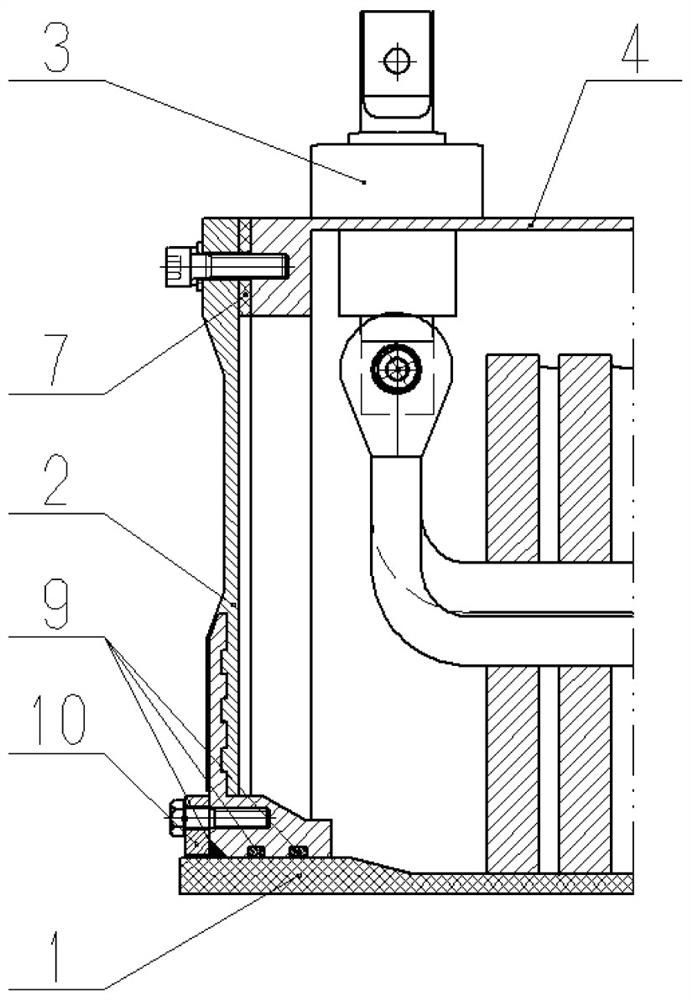

Discrete-point test device for internal flow field of hydraulic torque converter

InactiveCN104122068ARealize visualizationReduced wear on connectionsHydrodynamic testingDoppler velocityParticle imaging

The invention discloses a discrete-point test device for the internal flow field of a hydraulic torque converter. The discrete-point test device comprises a drive module, a pump wheel flowing module, a gantry-type pipeline flowing module, a guide wheel flowing module, a guide wheel support module, a turbine flowing module and a simulated load module, wherein the drive module is used for driving a pump wheel in the pump wheel flowing module to rotate as a whole, a working liquid flows to arrive at the turbine flowing module through the gantry-type pipeline flowing module, and then drives the turbine of the turbine flowing module to rotate, and a power is output to the simulated load module; the working liquid flows out from a turbine outlet and enters the blade area of the guide wheel of the guide wheel support module through a guide wheel inner ring-outer ring connection element; and then the working liquid enters the pump wheel flowing module again, so as to form a sealed circulation flowing channel. The discrete-point test device disclosed by the invention breaks through the closure and compactness limits of the own structure of the hydraulic torque converter, and is capable of being combined with a particle imaging velocity measurement technology and a laser Doppler velocity measurement technology to obtain the distribution condition of the internal flow field of the hydraulic torque converter.

Owner:JILIN UNIV

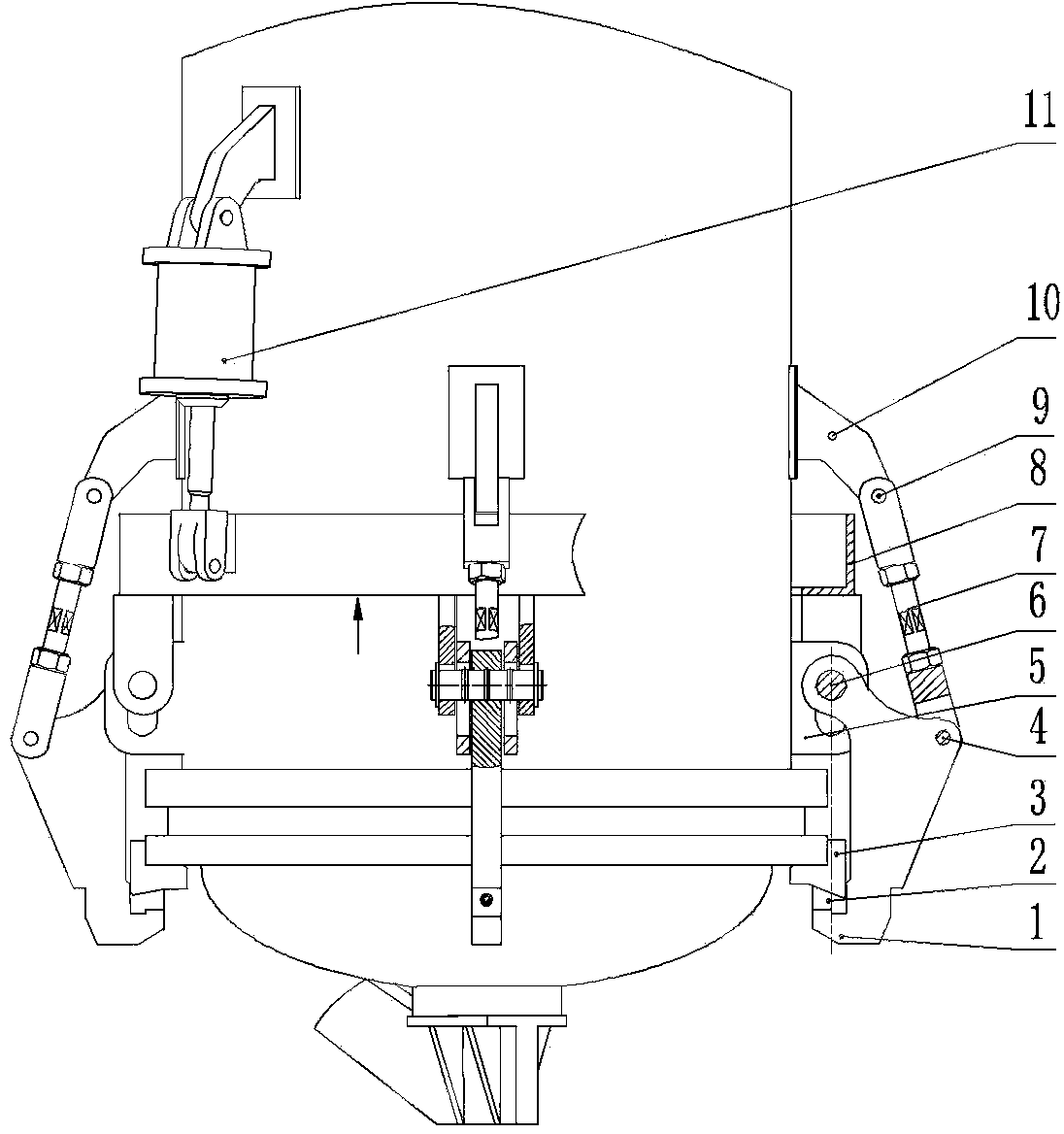

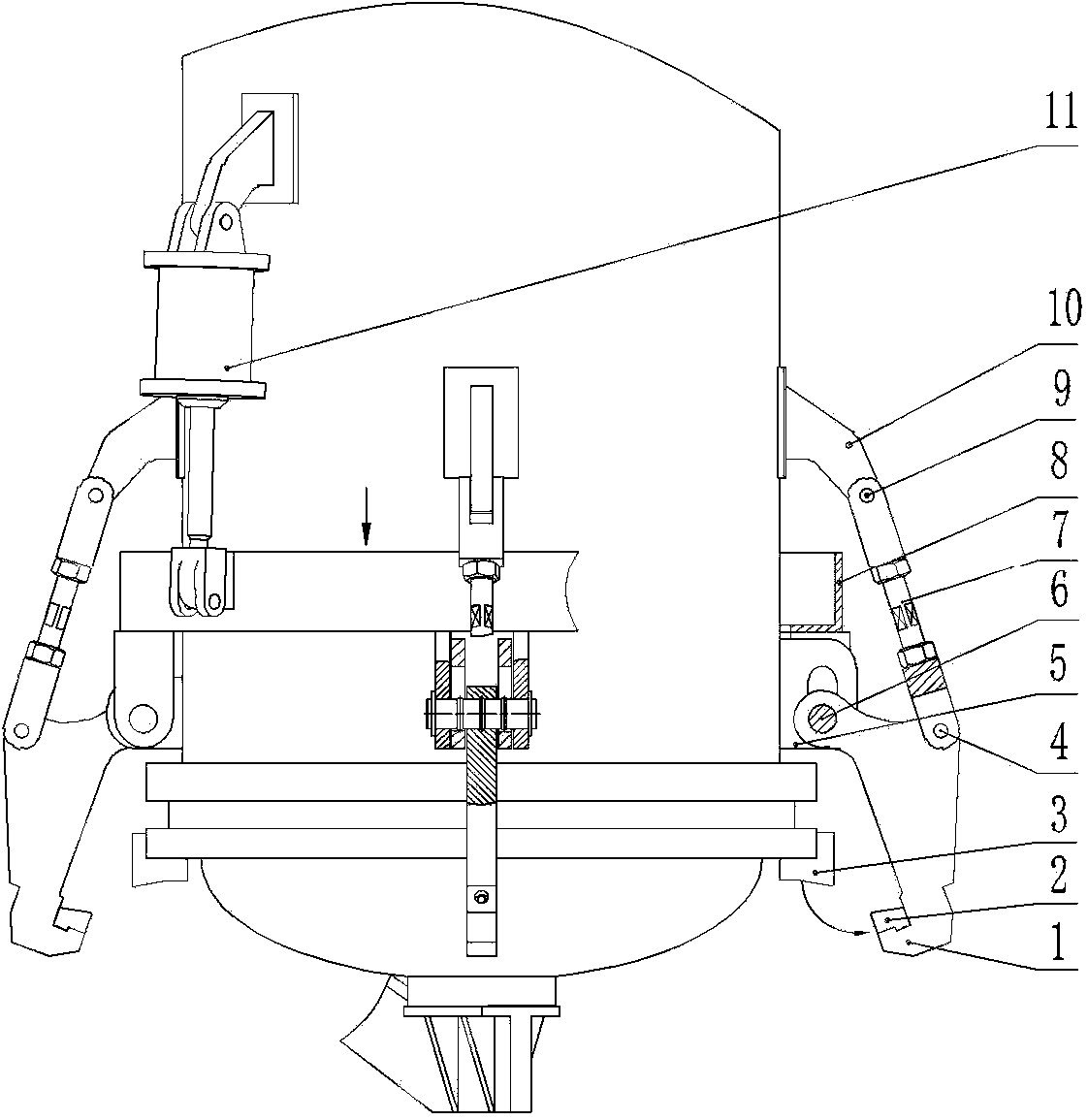

Safety linkage locking device for quick valve of pressure vessel

InactiveCN103742644AMaintain structural featuresEnsure security requirementsPressure vesselsHead (vessel)Structural engineering

The invention provides a safety linkage locking device for a quick valve of a pressure vessel. The safety linkage locking device comprises a locking hook, inclined iron, inclined face pad iron, a first hinge pin, a second hinge pin, a pull rod, a sliding ring, a third hinge pin, a fixing lifting lug and an air cylinder or oil cylinder. The sliding ring is driven by the air cylinder or the oil cylinder. The locking hook comprises the hook head end, the hook tail end and a bending rod connecting the hook head end and the hook tail end. The inclined iron is fixedly arranged at the hook head end. The inclined face pad iron is installed on a flange of the pressure vessel. The inclined face pad iron is matched with the inclined iron and the locking hook to form a hook mechanism. The hook tail end is connected with the sliding ring through the second hinge pin. The bending rod is connected with one end of the pull rod through the first hinge pin, and the other end of the pull rod is connected with the fixing lifting lug through the third hinge pin. The safety linkage locking device lowers the requirement for the processing and manufacturing precision of parts in the processing, manufacturing, debugging and using processes and is convenient to operate, and the linkage locking performance is stable and reliable.

Owner:ZHEJIANG DONGOU FILTERING MASCH MFG CO LTD

Method for controlling solution crystal growth rate

InactiveCN101503818AControl growth rateSolve the leakFrom normal temperature solutionsLiquid stateWater vapor

The invention discloses a method for controlling the growth rate of a solution crystal. The method adopts a three-layer structure consists of a stainless steel screen, a drainage type microporous filter membrane and a stainless steel screen as a sealing member on a top cover of a crystallizer, and makes use of the air permeable and watertight function of the sealing member to control the growth rate of the crystal through a solution evaporation method. As the method uses the three-layer structure which consists of the stainless steel screen, the drainage type microporous filter membrane and the stainless steel screen on the top cover of the crystallizer to seal the crystallizer, vapor of a solvent can pass through the drainage type microporous filter membrane, while liquidized water cannot pass through the filter membrane. Therefore, the problem of the leakage of a growth liquid is solved, and simultaneously the growth rate of the crystal is controlled through the control on the solution temperature, the sectional area of a seed crystal, the aperture size and area size of the microporous filter membrane, and the dosage of an adsorbent. Furthermore, the requirements on the sealing performance of the crystallizer are also met. A single crystal with better crystallization quality is obtained through the setting of the seed crystal area, the growth temperature, the evaporate aperture and area of the microporous filter membrane, and the dosage of the adsorbent.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

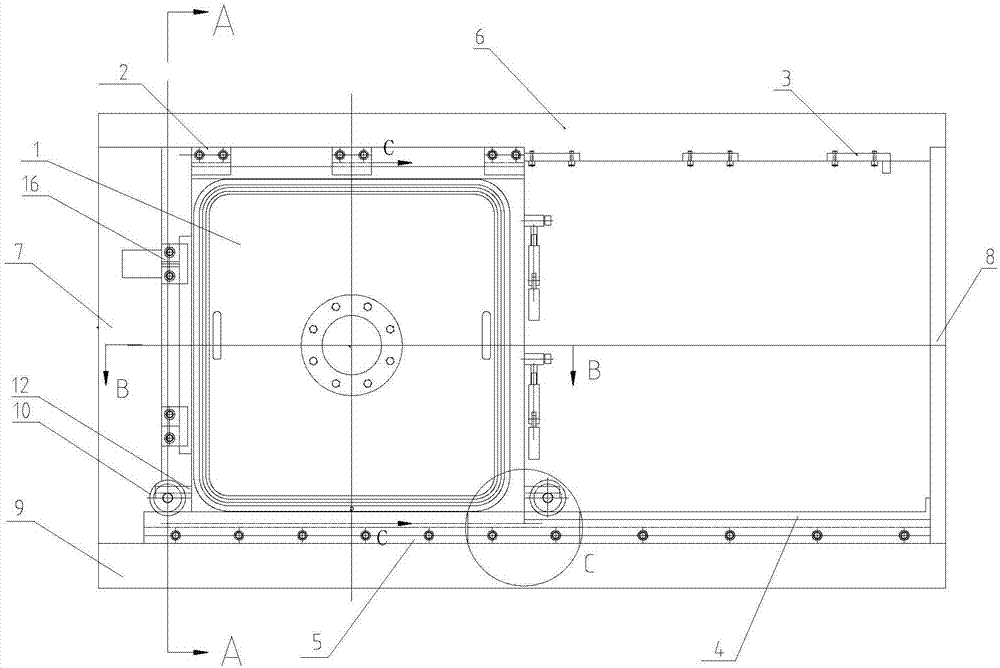

Translation door of sealing equipment

PendingCN107956377ASimple preparation processReduce processing stepsDrying chambers/containersWing arrangementsEngineeringLeft half

The invention provides a translation door of sealing equipment. The translation door comprises a box frame of the sealing equipment, a butt joint upper base plate, a butt joint lower base plate, a butt joint left base plate and a butt joint right base plate which are fixedly connected to the box frame in sequence; the distances of the outer surfaces of the base plates and the outer surface of thebox frame all keep identical; a lower baffle is horizontally and fixedly connected to the longitudinal left half section of the butt joint lower base plate, a lower guide rail is horizontally and fixedly connected to the longitudinal right half section of the butt joint lower base plate, the right end of the lower baffle is horizontally and fixedly connected with the left end of the lower guide rail, and the top face of the lower baffle and the top face of the lower guide rail are arranged on the same horizontal plane; a translation door body is movably arranged above the lower baffle and thelower guide rail; the moving range of the translation door body is limited in a rectangular frame enclosed by the base plates; an upper sliding mechanism is arranged at the top of the translation doorbody, and a lower rolling mechanism is arranged at the bottom of the translation door body. The translation door of the sealing equipment moves linearly, is prevented from being displaced inwards andoutwards and deformed due to external force and is easy to open and close, and the risk of leakage is avoided.

Owner:上海东富龙制药设备制造有限公司

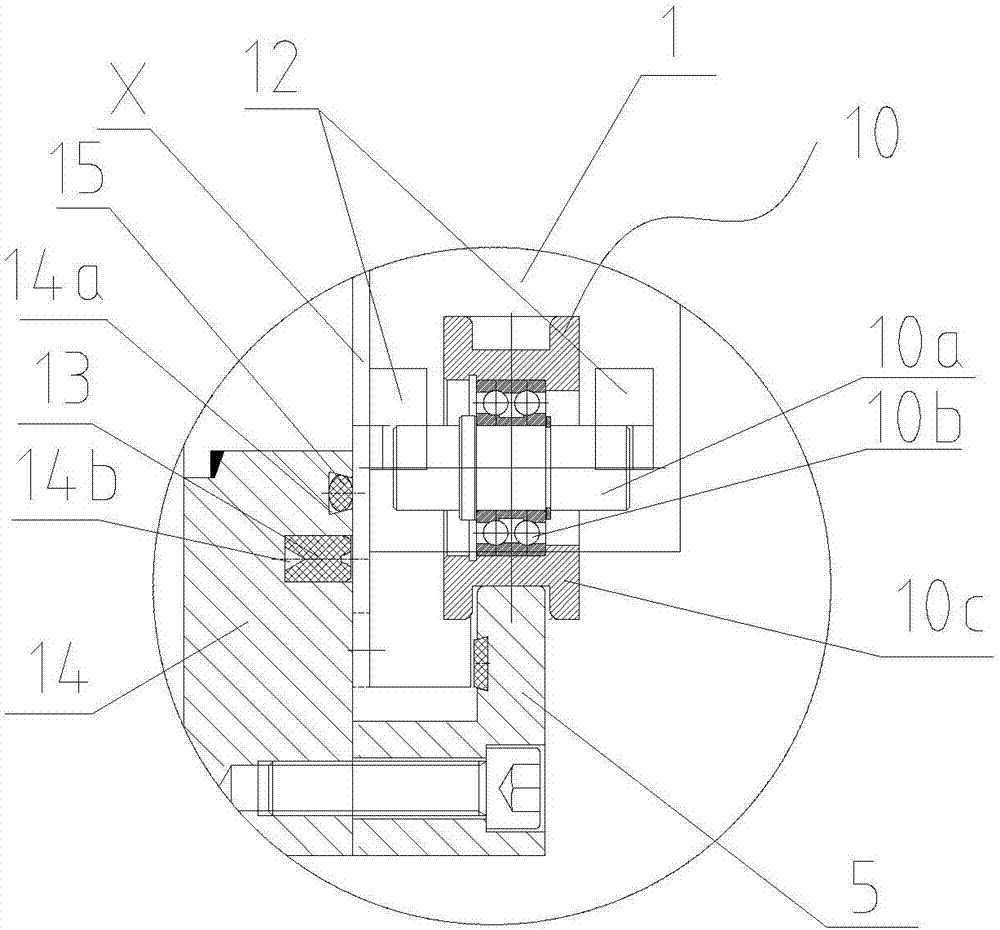

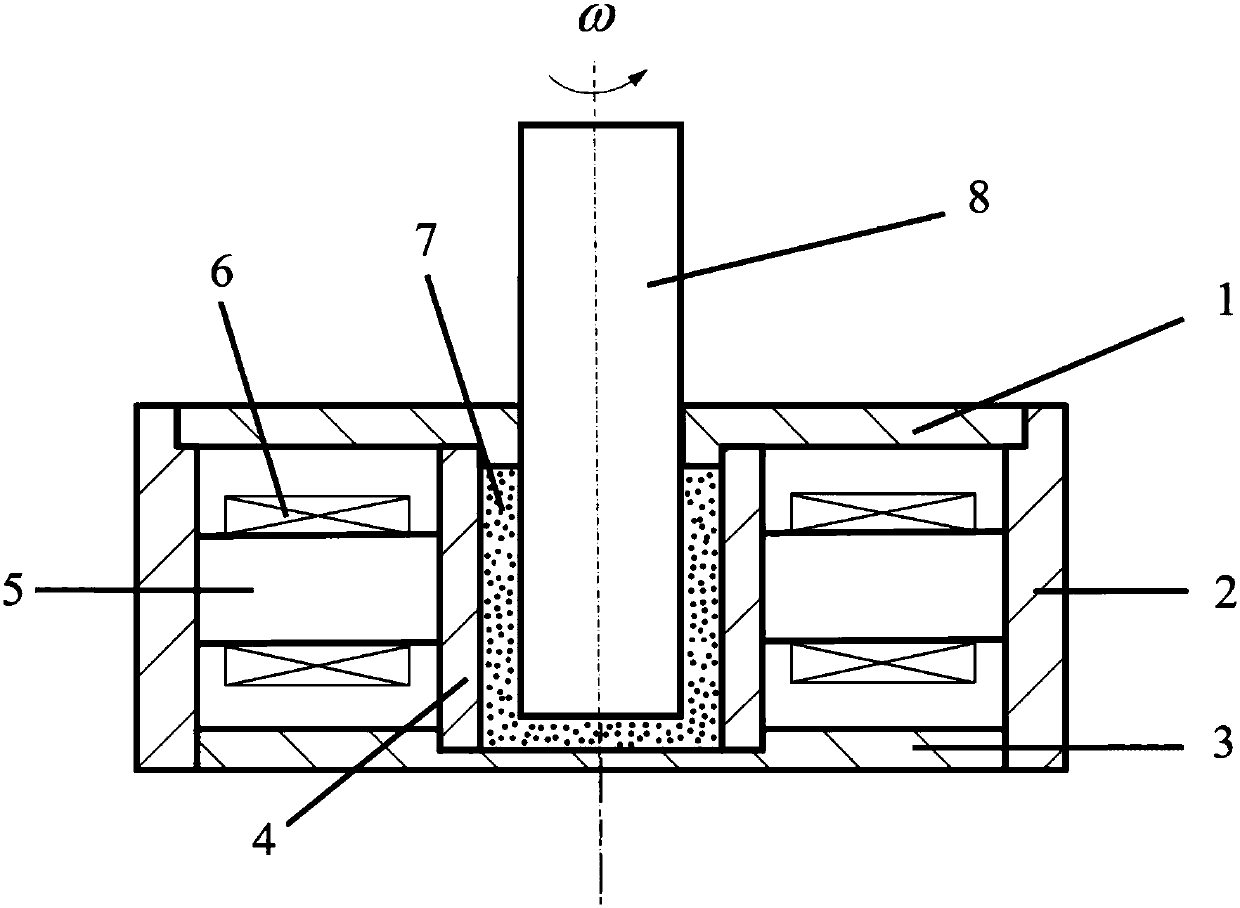

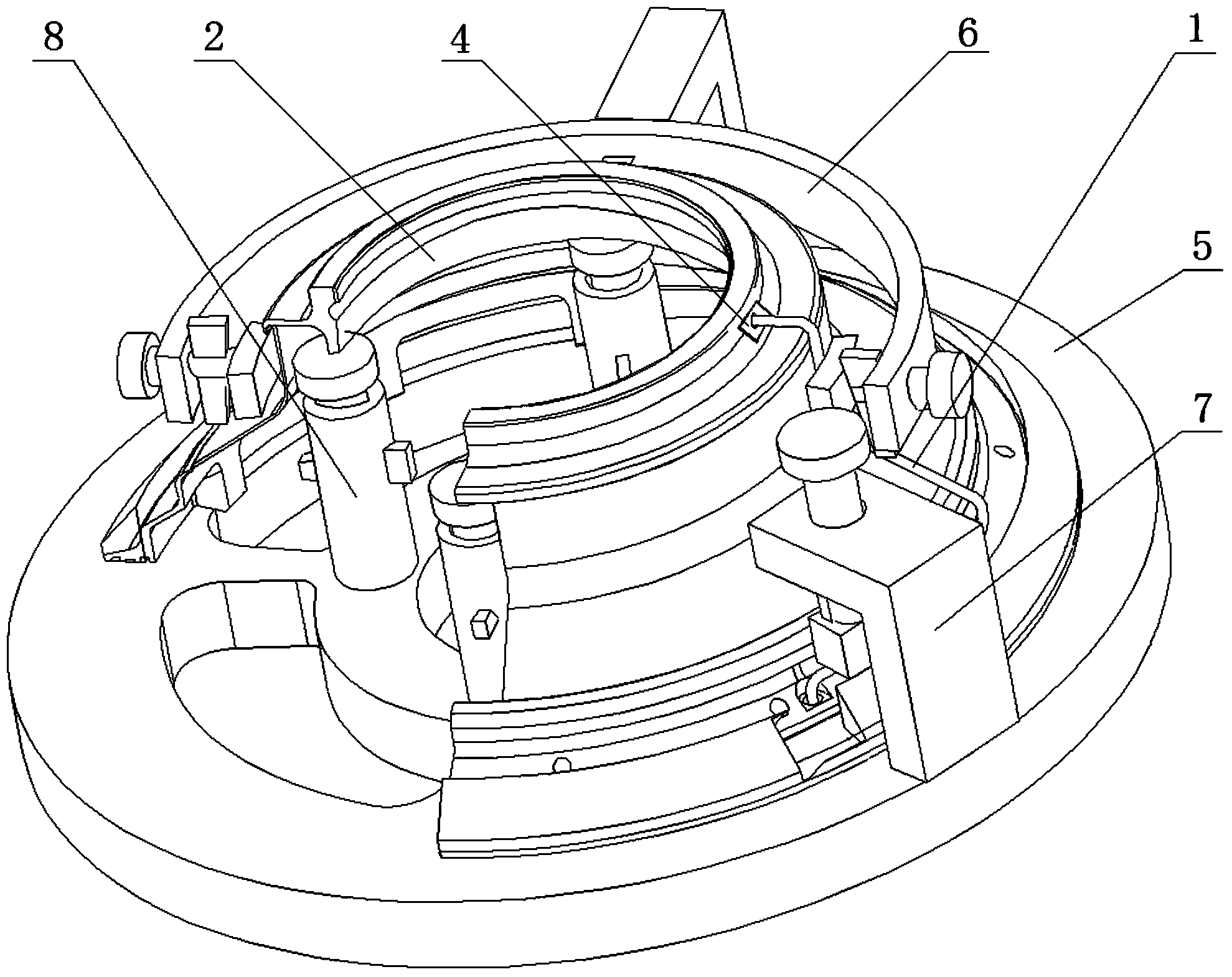

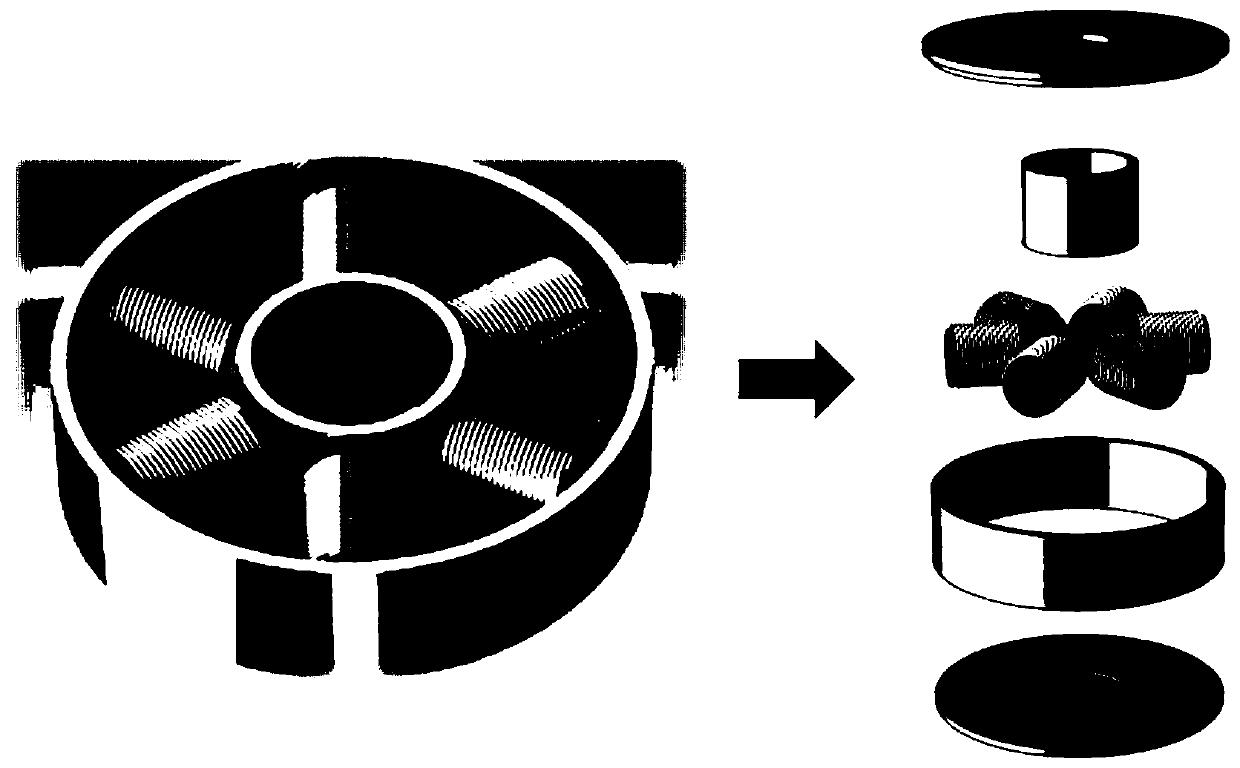

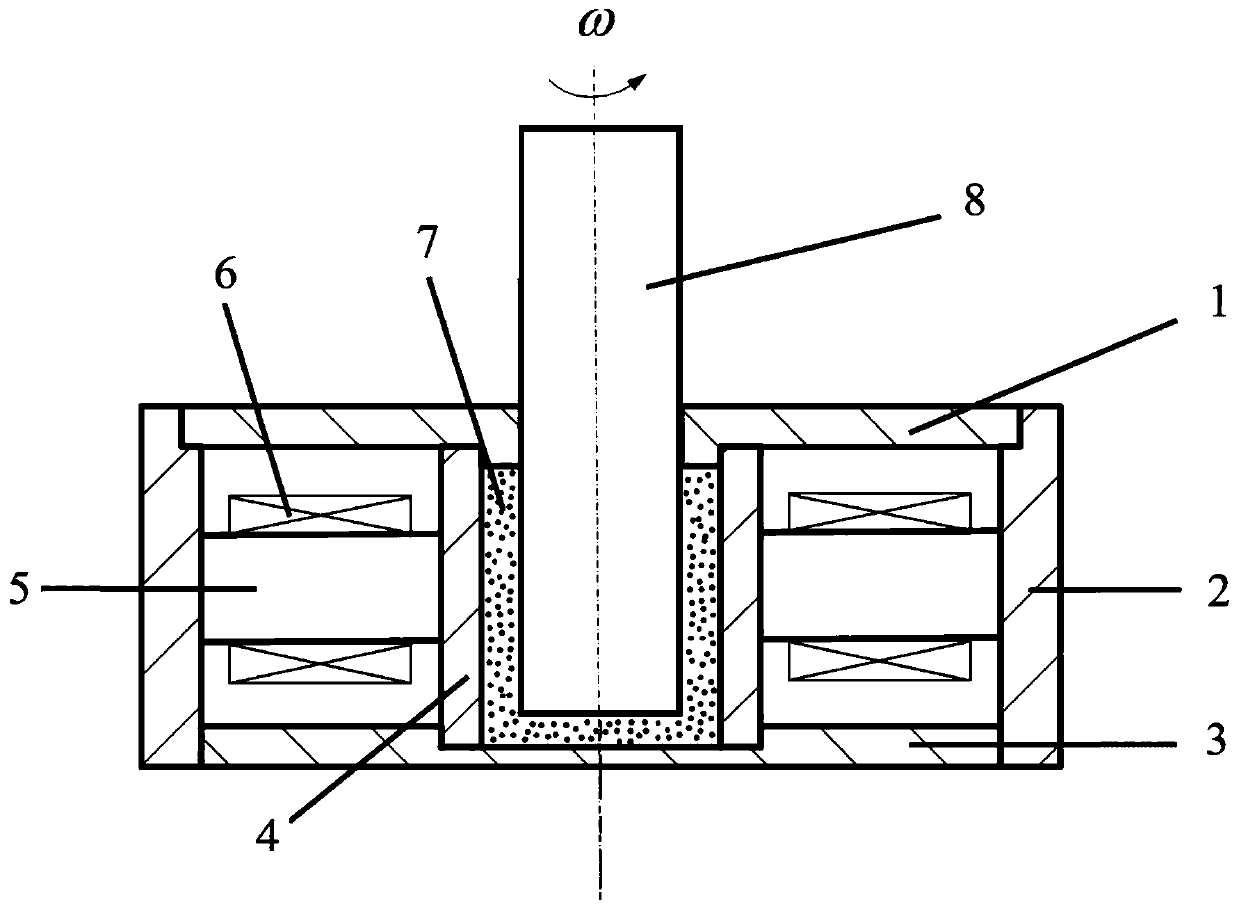

Magnetorheological material-based high-efficiency rotating speed control device

ActiveCN107612441AHigh directnessImprove energy conversion efficiencyElectric generator controlParticle chainsEngineering

The invention discloses a magnetorheological material-based high-efficiency rotating speed control device, and belongs to the field of rotating speed control of Fuze turbine generators. The magnetorheological material-based high-efficiency rotating speed control device comprises an upper cover, an inner cylinder, a housing, a bottom, excitation coils, magnetic cores and a magnetorheological material, wherein the upper cover, the inner cylinder, the housing and the bottom form a substrate; a peripheral device comprises a turbine generator; the excitation coils are arranged between the inner cylinder and the housing and are vertical to a rotating shaft of the generator, so that the magnetic particle chaining direction in the magnetorheological material is vertical to the rotating shaft of the generator; magnetic core positioning slots are formed in the inner side of the housing and the outer side of the inner cylinder separately, circular grooves are adopted by the positioning slots andthe connection line of circle centers of each pair of positioning slots horizontally passes through the axis of the rotating shaft; and the diameters of the magnetic cores are matched with those of the corresponding grooves and the magnetic cores pass through the inside of the corresponding excitation coils through the matched positioning slots. According to the magnetorheological material-based high-efficiency rotating speed control device, improvement of the energy conversion efficiency of the magnetorheological material is achieved by combining the magnetic characteristics of the magnetorheological material.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

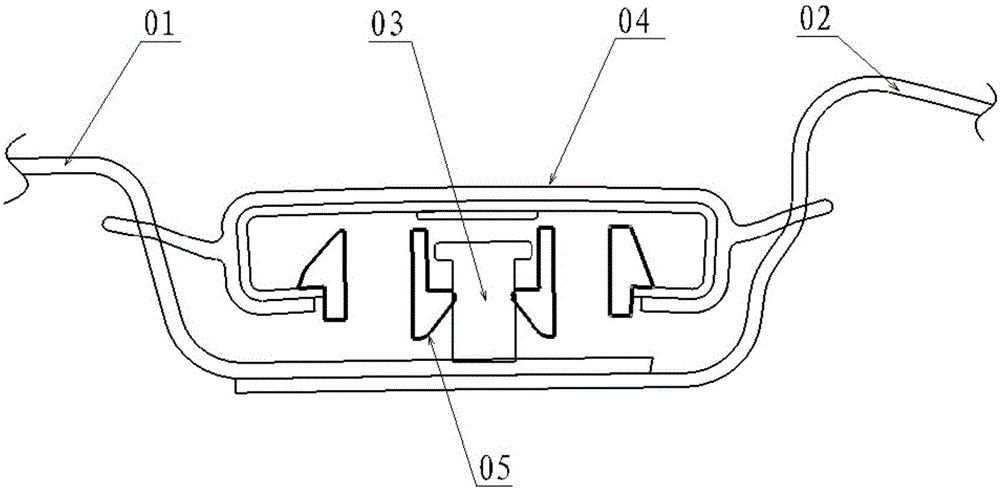

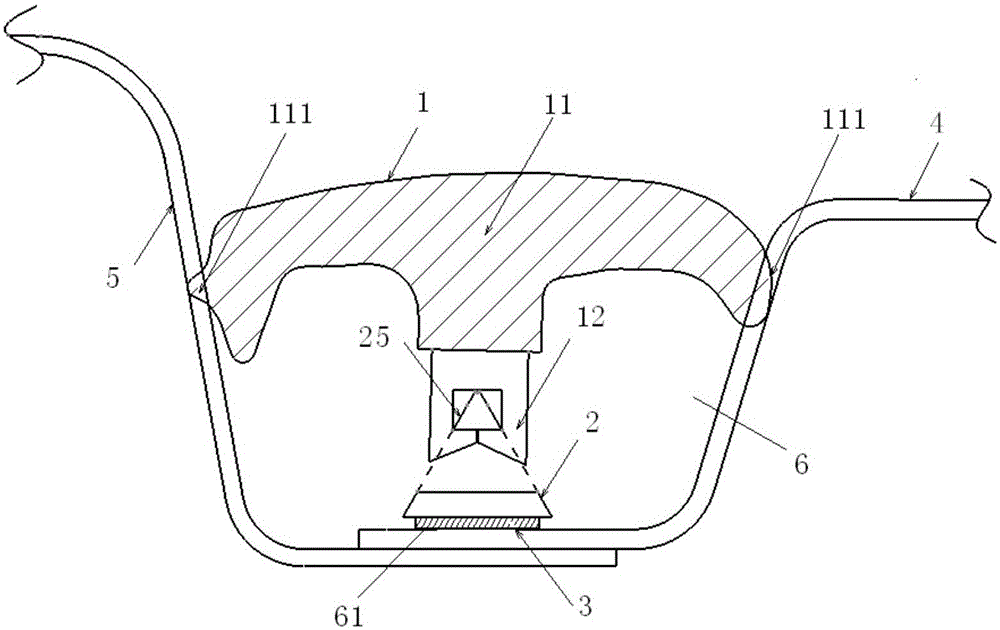

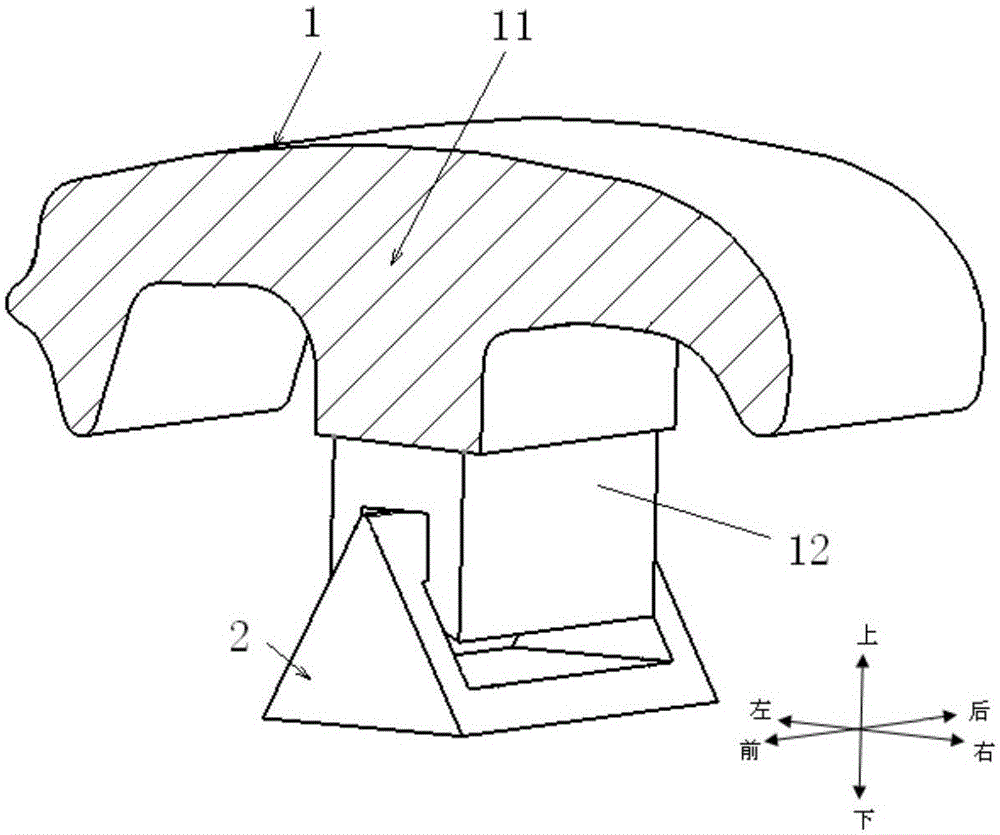

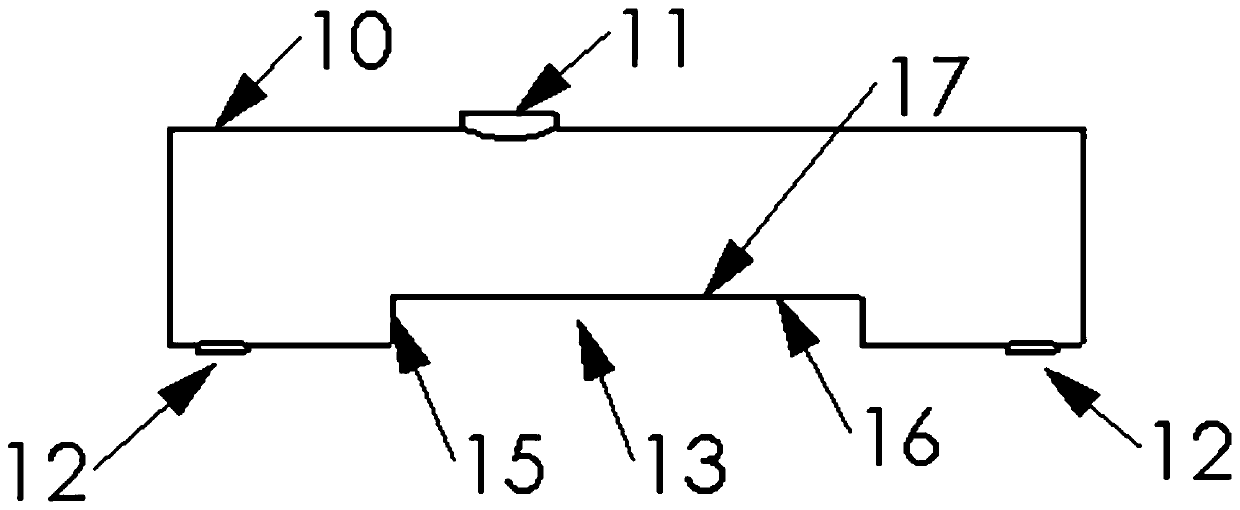

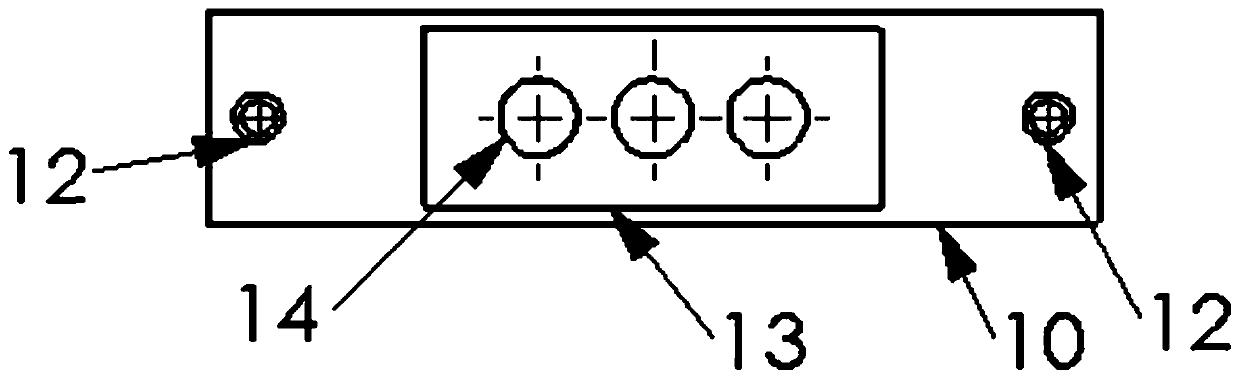

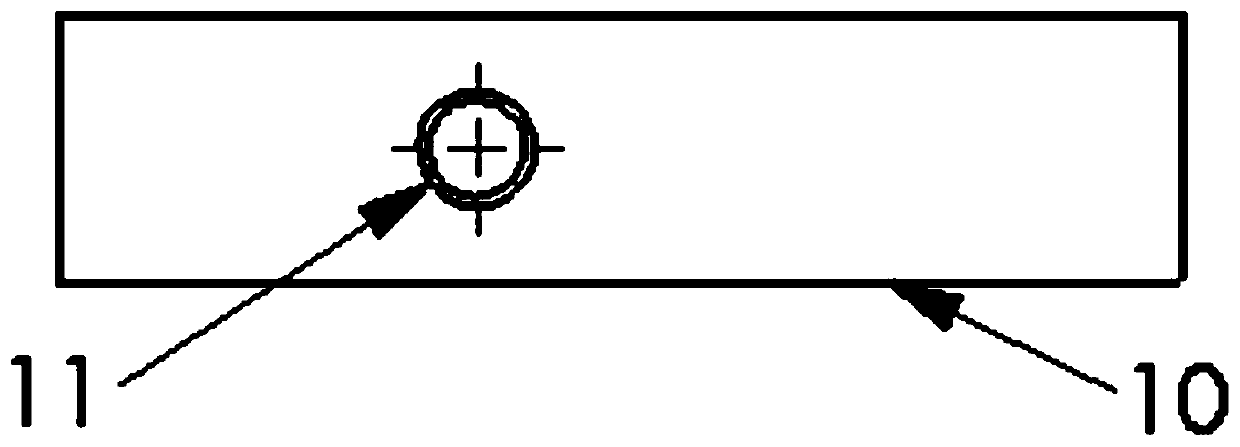

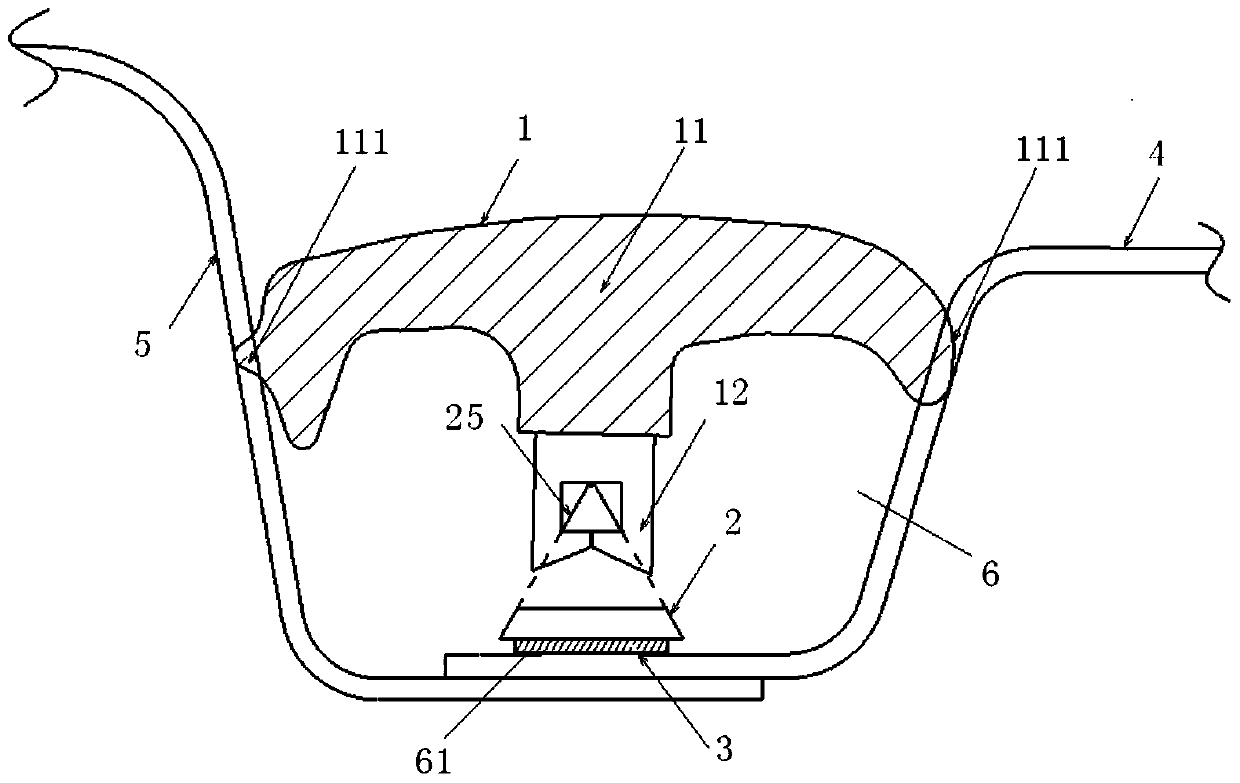

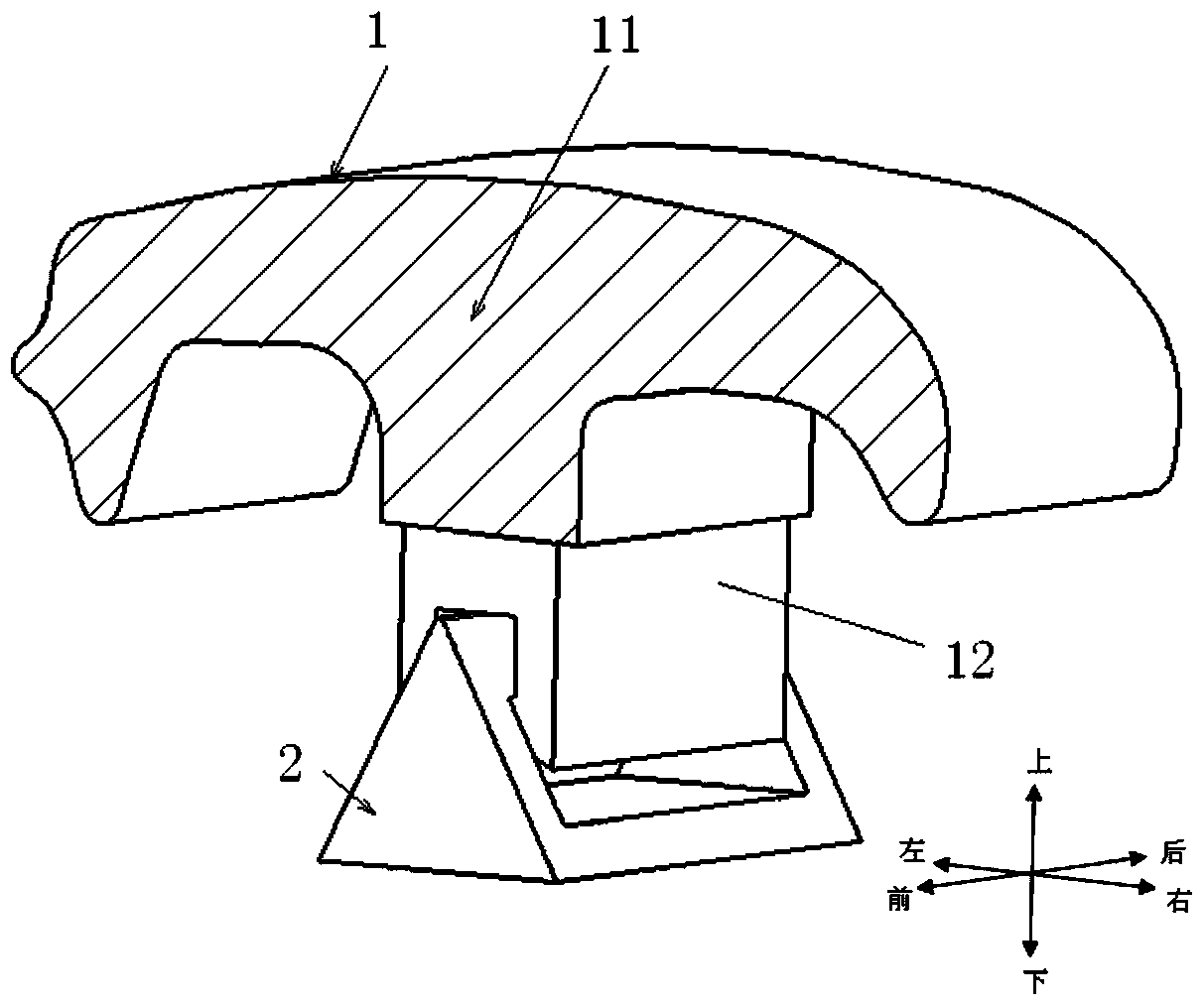

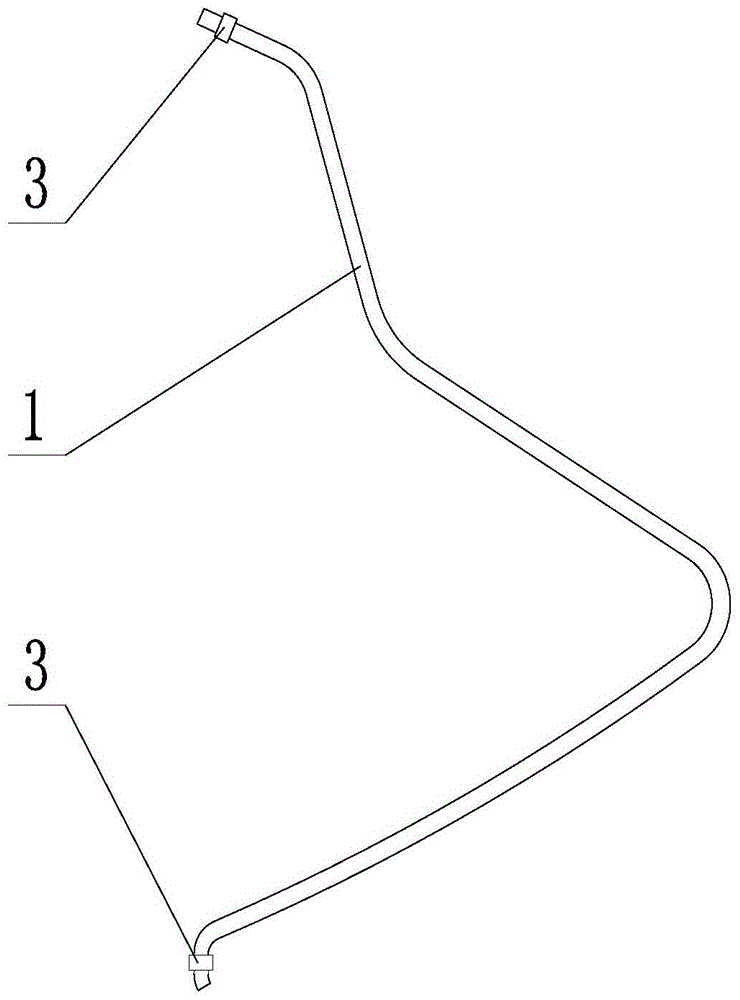

Installing structure of automobile top cover decoration strip

The invention discloses an installing structure of an automobile top cover decoration strip. The installing structure comprises the top cover decoration strip and a groove formed by overlapping a side wall and a top cover. The installing structure further comprises a clamping base adhering to the bottom wall of the groove. The top cover decoration strip comprises a decoration strip body, an elastic buckle body is connected to the middle of the lower portion of the decoration strip body and matched with the clamping base in a clamped mode, and lip sides are arranged on the left and right sides of the decoration strip body respectively and are in interference fit with the two side walls of the groove respectively. The installing structure is reliable in connection, not prone to warping and beneficial to sealing, and installing precision is easy to control.

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES

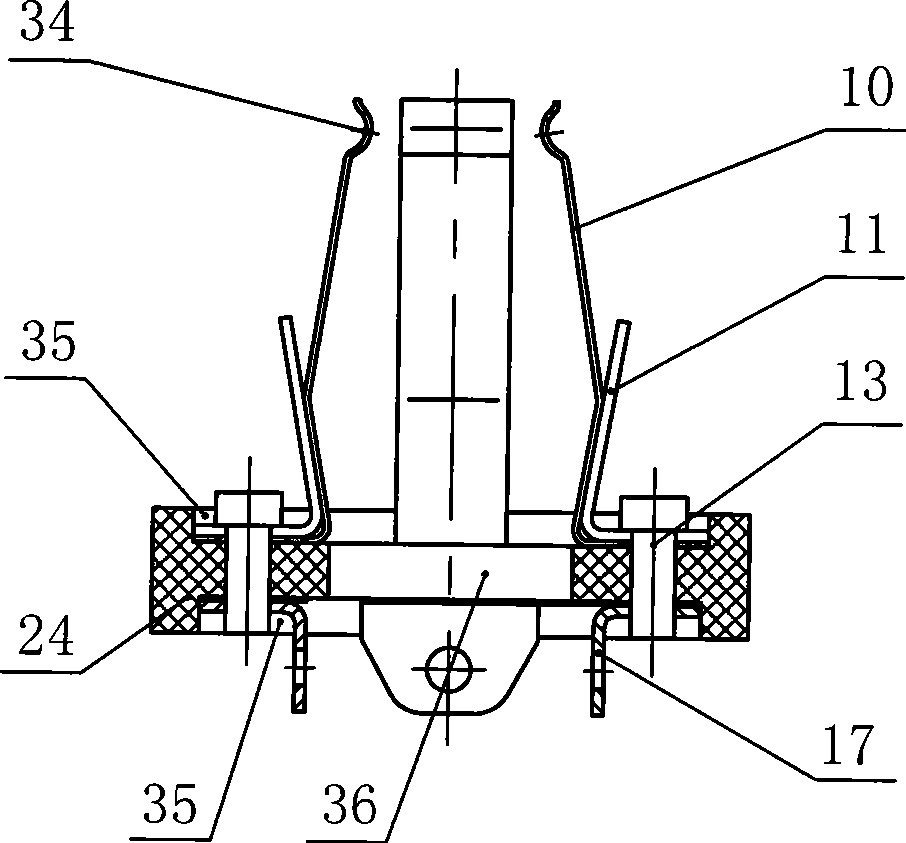

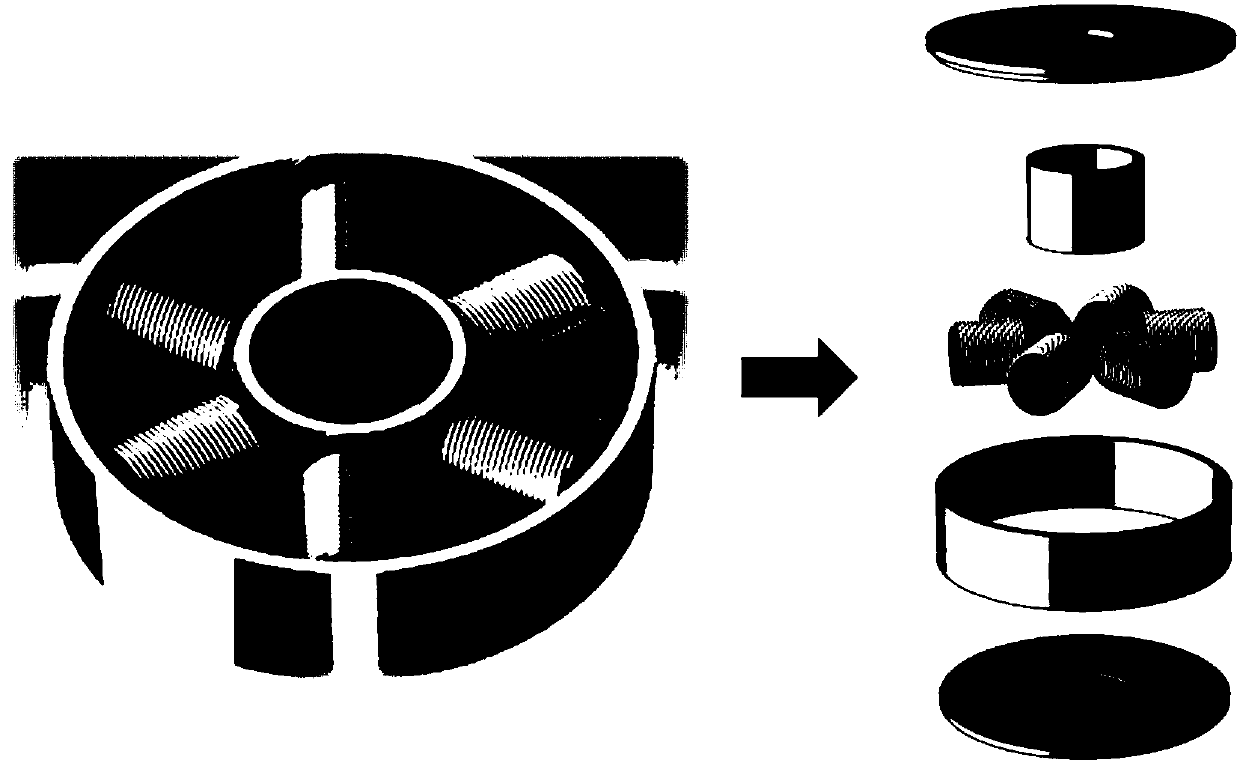

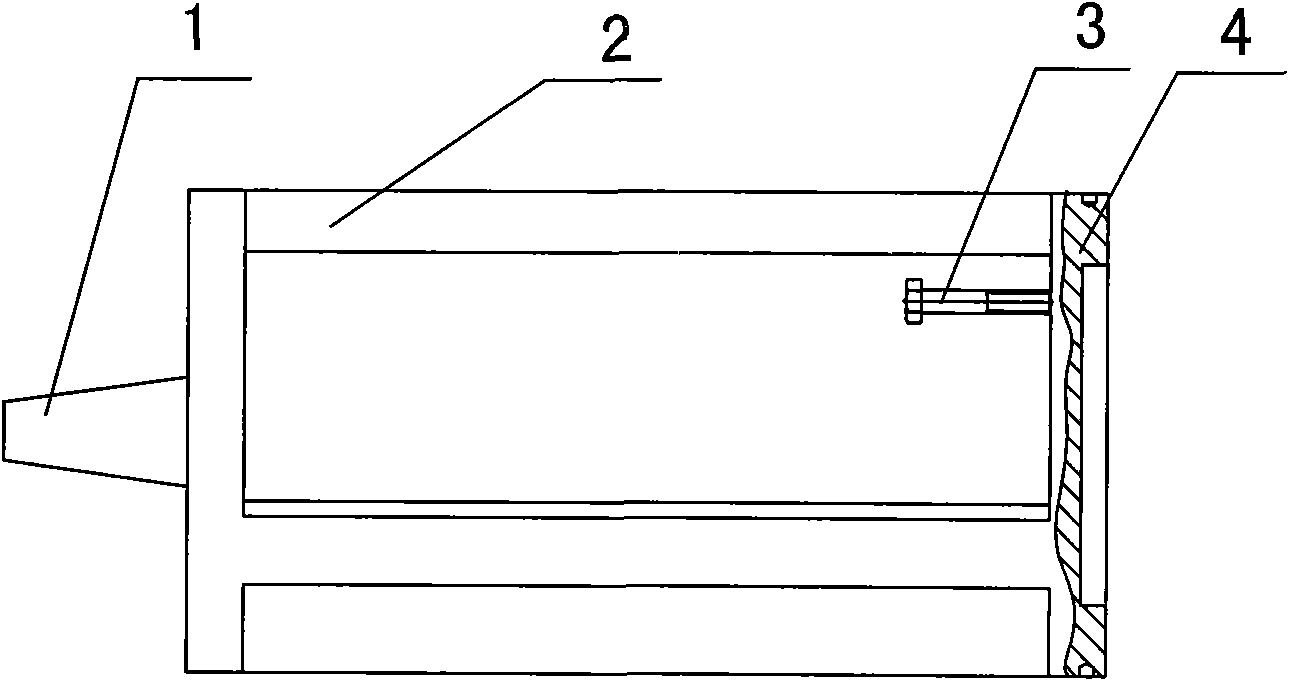

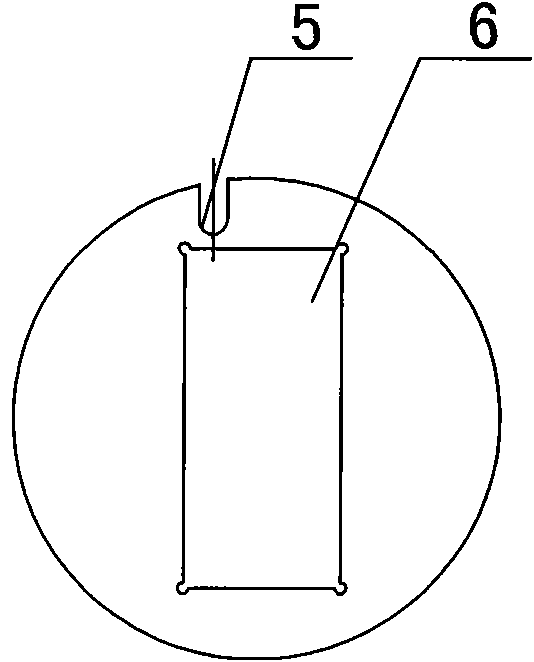

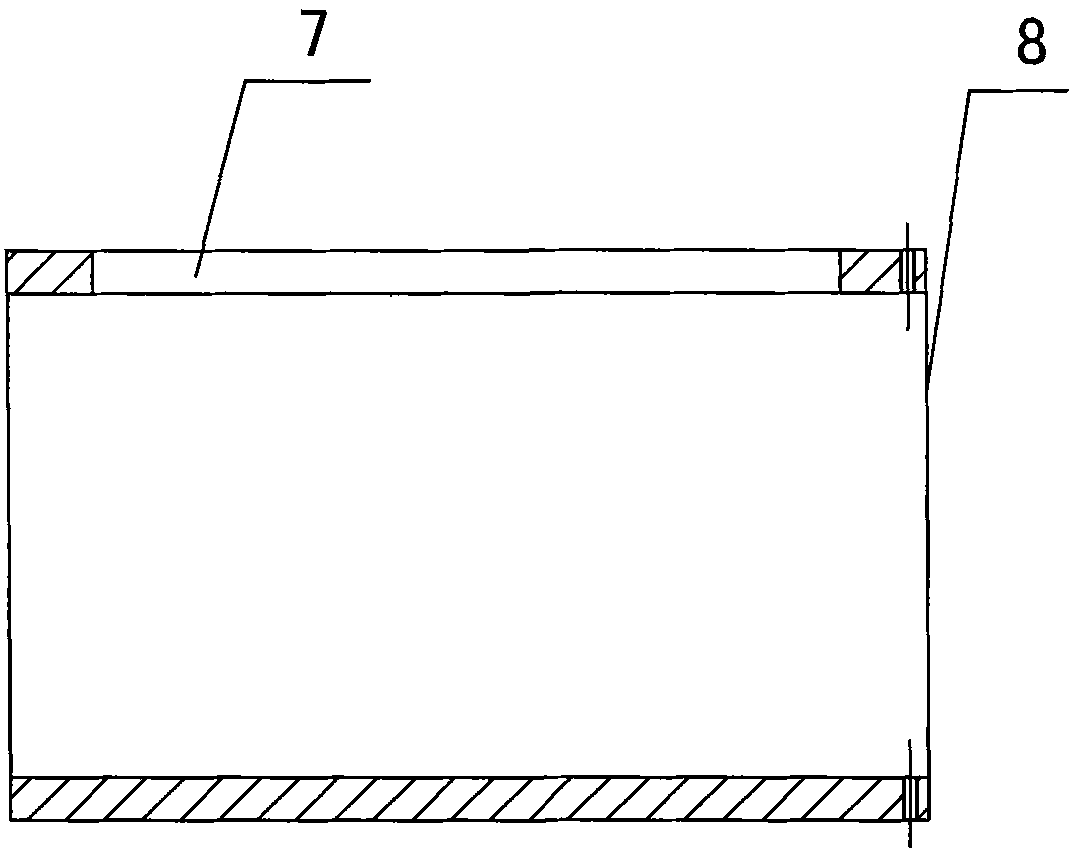

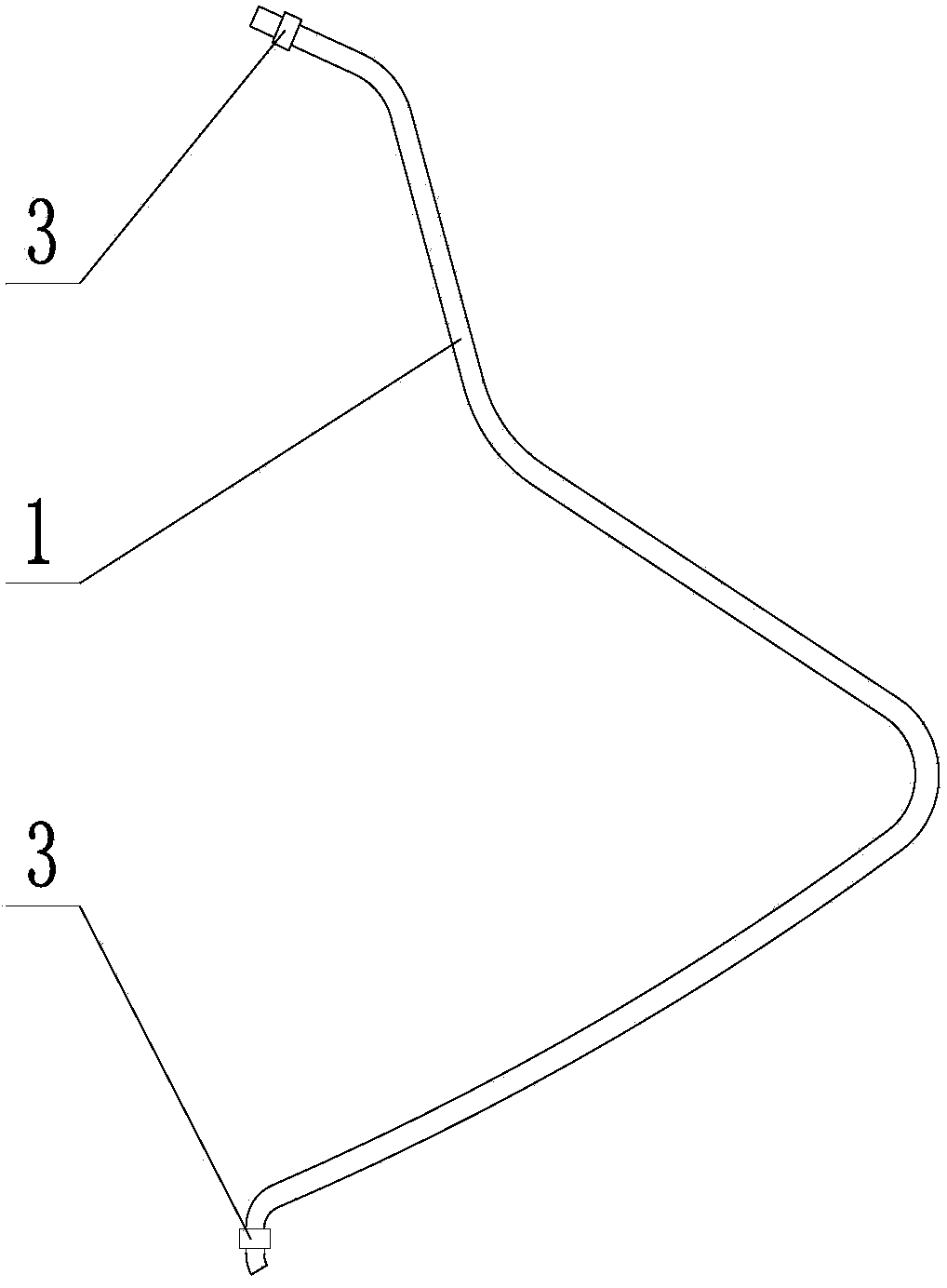

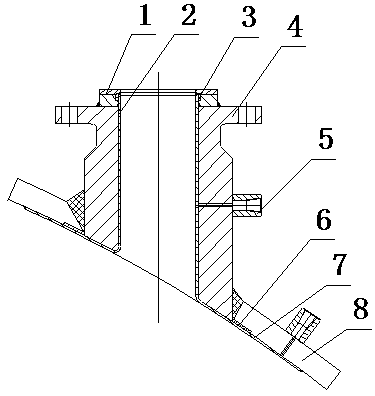

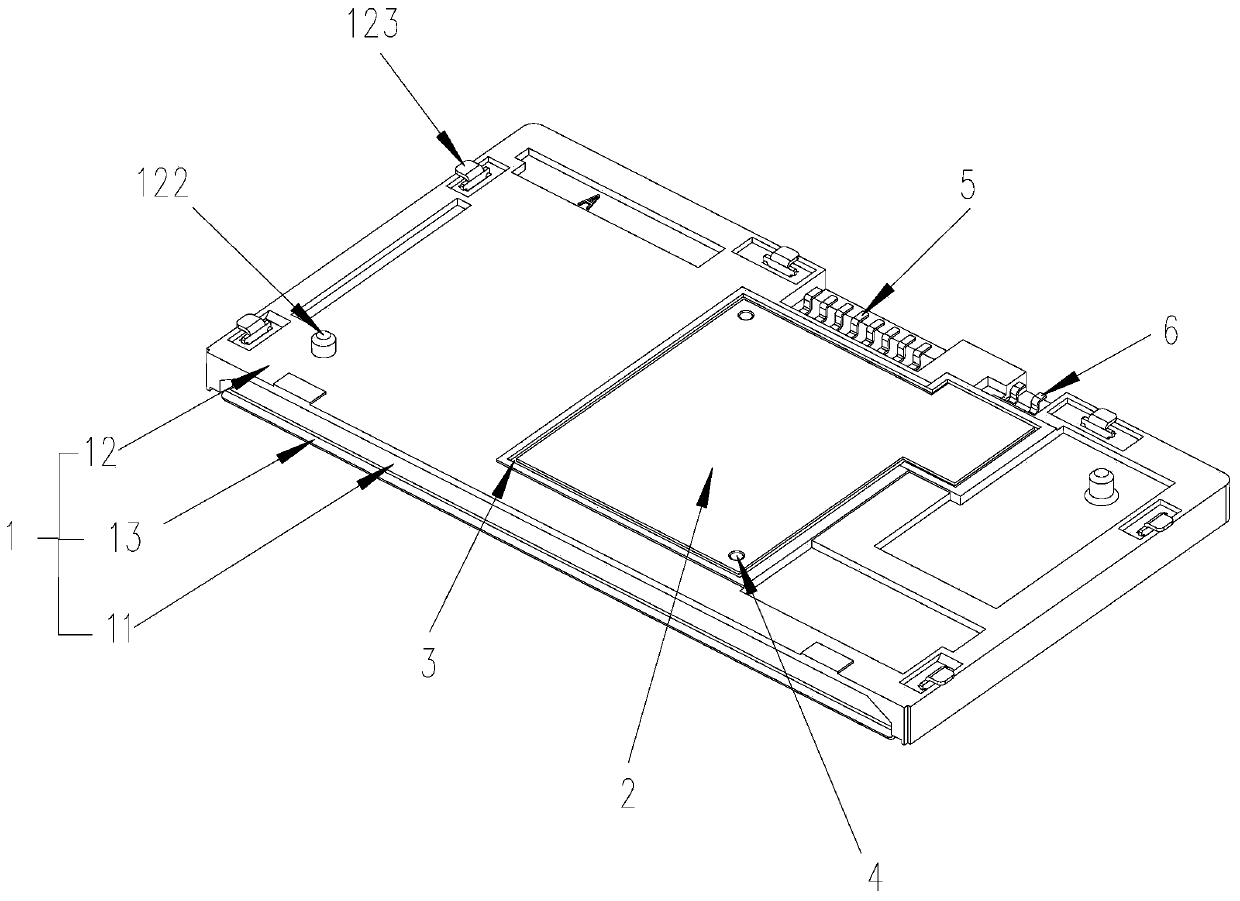

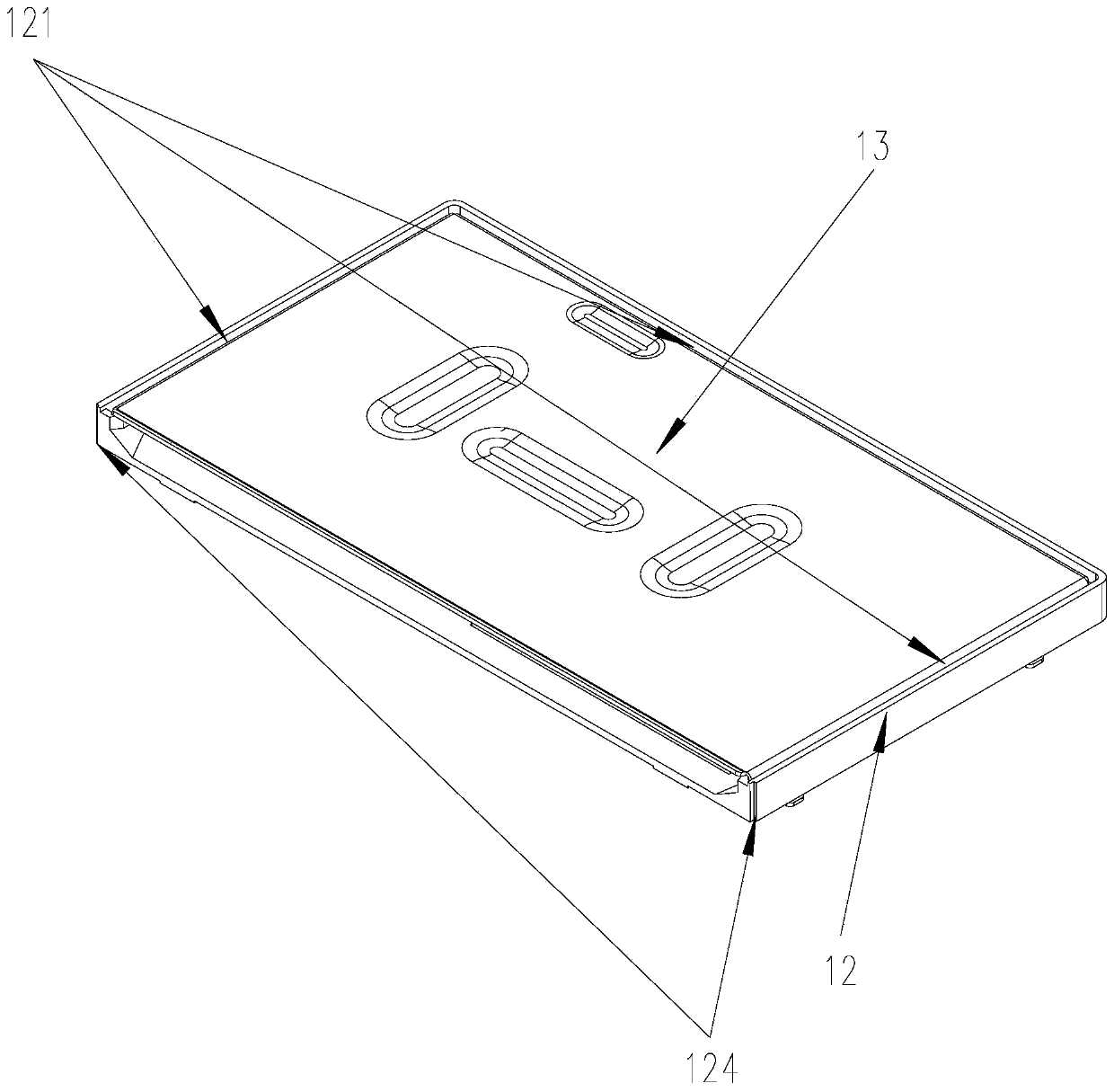

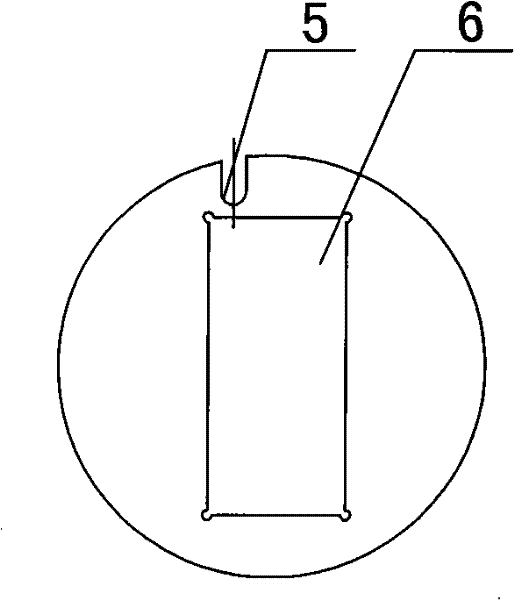

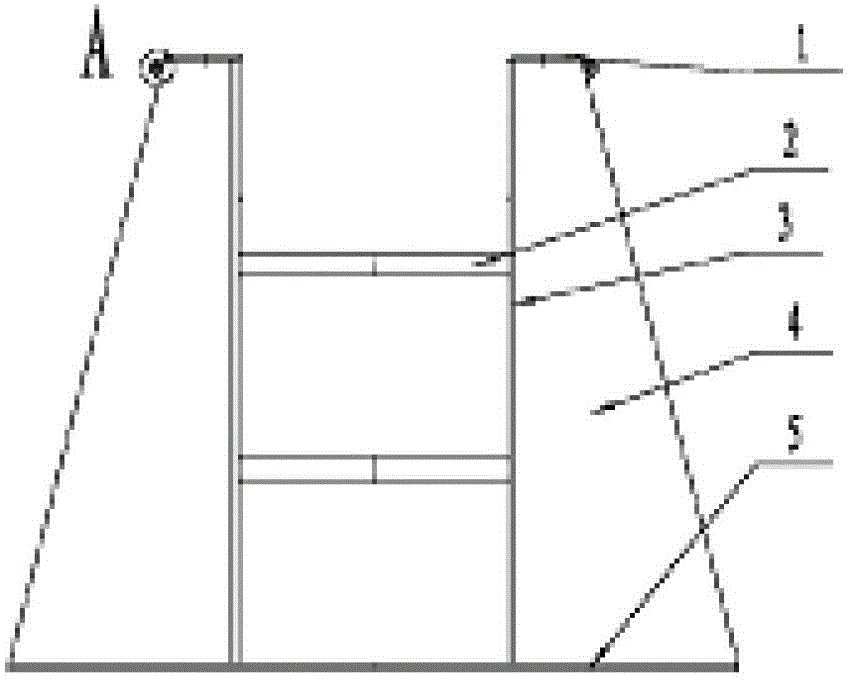

Split type stator coil winding method and winding mold device

ActiveCN101783553AImprove performance and stabilitySave wiring materialManufacturing dynamo-electric machinesNumerical controlWinding machine

The invention relates to a split type stator coil winding method and a winding mold device, which belong to the manufacture field of an alternating current servo permasyn motor and can be widely applied to industrial automation and military equipment, such as numerical control machines, processing centers, robots, printing machinery, textile machinery, medical machinery, petroleum, chemical engineering, metallurgy, radar antennae and the like. The invention is characterized in that a winding mold device which consists of a winding mold and a winding mold plate matched with the winding mold; sheathing an outer sleeve barrel (8) of the winding mold on a mold core bracket (2); fixing the mold core bracket (2) of the winding mold and the first group of split type stator core teeth on a winding machine; arranging one end of the split type stator core on the mold plate of the winding mold, and pushing tightly by the other end of the winding machine; and directly winding the windings on the first group of split type stator core. The invention has the advantages of large output power, small volume, good low-speed property, strong overloading capability, stable rotation speed and the like.

Owner:SHANDONG SHANBO ELECTRIC MACHINE GROUP

Brazing method of hermetically sealed seat component

ActiveCN104353921AGuaranteed tightness requirementsHigh positioning accuracyWelding/cutting media/materialsWelding/soldering/cutting articlesManufacturing technologyPass rate

The invention relates to a brazing method of a hermetically sealed seat component and belongs to the technical field of manufacture of aircraft engine parts. The hermetically sealed seat component comprises a seat body and a guide pipe, wherein the seat body is made of titanium alloy materials; the guide pipe is made of stainless steel materials. As the welding is hard to perform by adopting a traditional fusion welding method, and the selection of solders, the setting of brazing process parameters, the brazing position sealing requirements, the assembling and the positioning of the seat sealing component in the brazing process and other aspects can be involved when the brazing method is adopted, a set of feasible brazing method is urgently needed to meet the production demands of the hermetically sealed seat component. The brazing method has the benefits that the invention overcomes the technical problems encountered by the hermetically sealed seat component in the brazing process and provides the solder with good weldability; meanwhile, the brazing process parameters are provided, the sealing requirements after brazing at brazing positions are ensured, the positioning precision during brazing is high, and smooth and continuous brazing seams can be obtained; the brazing method has the characteristics of strong maneuverability, high production efficiency and high brazing pass rate.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

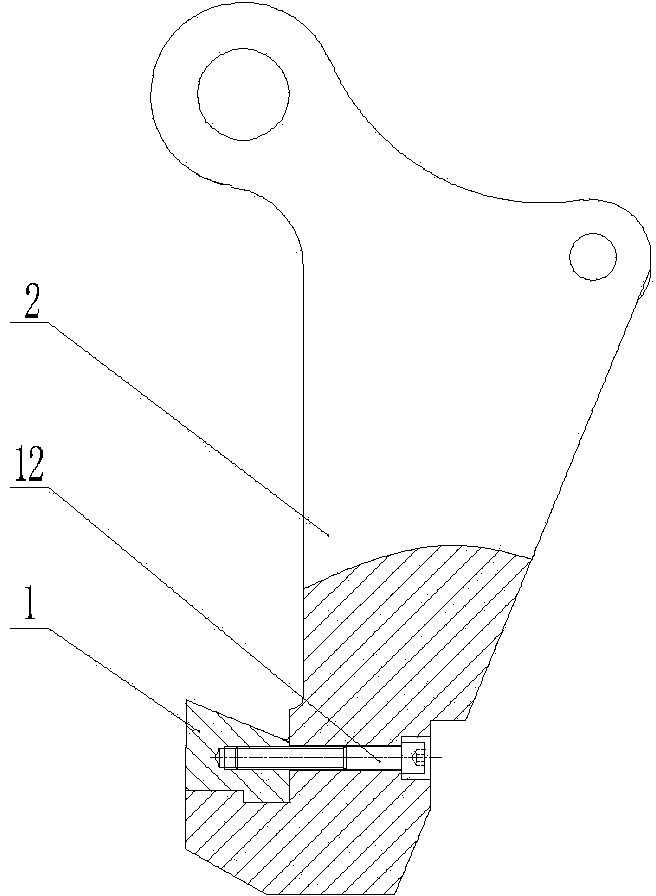

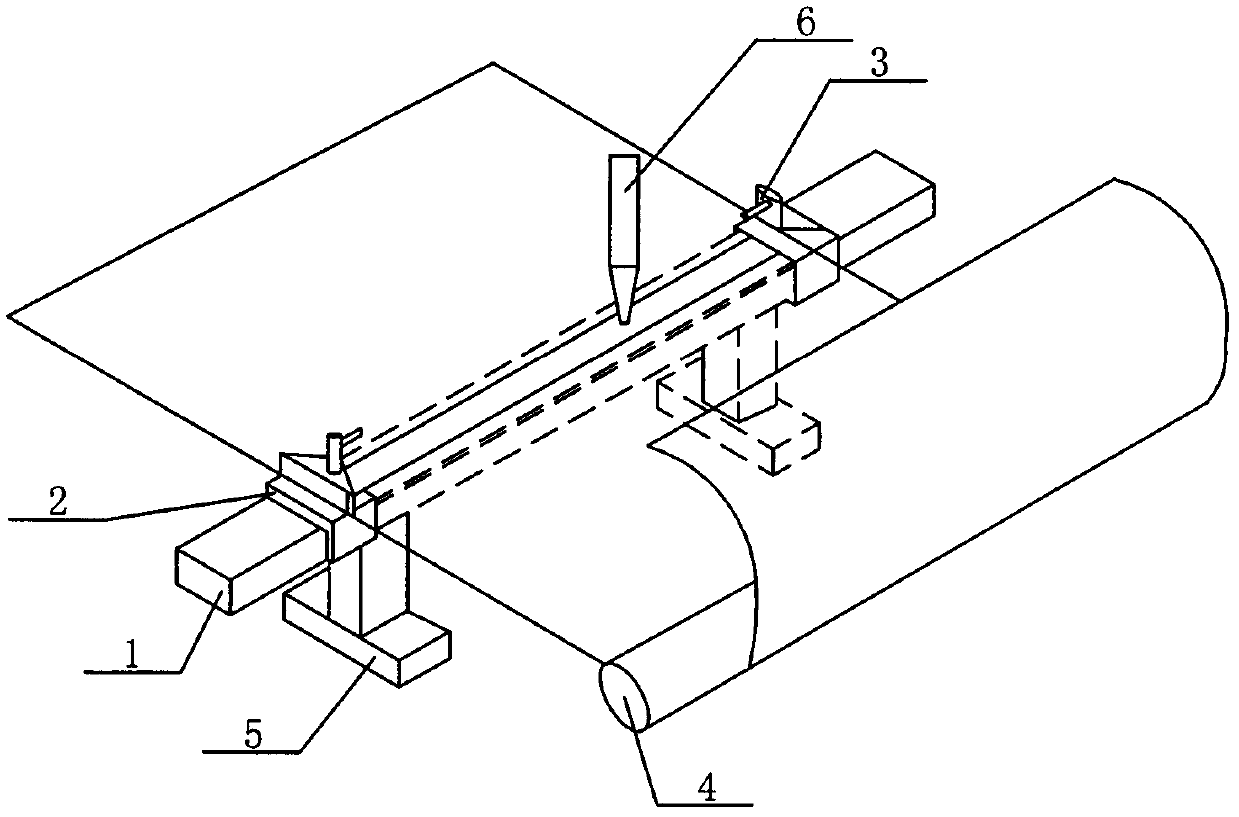

Special bracket for integrally hoisting marine main engine cylinder body and air cooler and method for integrally hoisting marine main engine cylinder body and air cooler

ActiveCN103145024AGuaranteed tightness requirementsAvoid enteringLoad-engaging elementsMarine engineeringSlipway

The invention discloses a method for integrally hoisting a marine main engine cylinder body and an air cooler. The method includes: (1), when a main engine is disassembled, the cylinder body and an air cooler assembly are placed on a special bracket; (2), oil seal is carried out on the lower flat surface of the main engine cylinder body to be ready for being transported ; (3), integrally, the main engine cylinder body and the air cooler assembly together with the special bracket are hoisted on a flat car; (4), after transported to a slipway, the oil seal of the lower flat surface of the main engine cylinder body is removed and the lower flat surface of the main engine cylinder body is cleaned on the flat car; and (5), the cylinder body and the air cooler assembly are hoisted on a main engine rack to be assembled. The invention further provides the special bracket used for the method. By utilization the special bracket, the whole hoisting and shipping of a main engine are achieved, the processes of disassembling and assembling the cylinder body and the air cooler assembly are saved, the utilization efficiency of a hoisting device is improved, meanwhile the assembling quality of the main engine is guaranteed, the labor intensity of workers is relieved, and safety potential hazards of site work are reduced.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Method for installing booster stations for wind power and photovoltaic power generation systems

PendingCN110474248AReduce installation accumulation errorsGuaranteed tightnessMulti-purpose toolsSwitchgearElectricityElectrical conductor

The invention relates to a method for installing the booster stations for wind power and photovoltaic power generation systems. According to the method, a foundation adjustment method and an initial spacer in-place method are adopted; the highest point of metal embedded parts is found out; an initial spacer installation foundation height is adjusted through gaskets; other spacer foundation heightsare pre-adjusted according to the initial spacer installation foundation height; a bus-bar connection spacer is adopted as an initial spacer to be installed; and after the bus-bar connection spacer is installed, other spacer on two sides of the bus-bar connection spacer are installed. With the method adopted, the accumulated error of the installation of a GIS can be reduced, and the sealing degree of the GIS is ensured; after the spacers are in butt joint with one another, the insertion depths of contacts are calculated; the insertion depths of conductors and contact seats are confirmed, andtherefore, requirements for the sealing degree of the GIS and the safety of a plug are satisfied; the rapid pressing and separation of flanges between the spacers can be facilitated through a multifunctional clamp, and therefore, damage to equipment contacts during the separation of the flanges is avoided; and the multifunctional clamp has a cable shearing function and a cable head crimping function, so that the multifunctional clamp can be used in other electrical construction.

Owner:CHINA THIRD METALLURGICAL GRP

Titanium-steel composite adapter tube and equipment for adopting titanium-steel composite adapter tube

InactiveCN108426102AAchieve smooth transitionAvoid stress concentrationRigid pipesNon-disconnectible pipe-jointsPetrochemicalWeld seam

The invention relates to a titanium-steel composite adapter tube, and further relates to equipment for adopting the composite adapter tube. The composite adapter tube comprises a steel adapter tube body, a titanium bushing and a titanium bowl-shaped angle joint ring, wherein the bushing is sleeved in an adapter tube body, the bowl-shaped angle joint ring comprises an angle joint ring tube part, which is laminated with an inner wall of the adapter tube body, and an angle joint ring loop part, which is laminated with an end face of the bottom end of the adapter tube body; the composite adapter tube is adopted by the equipment, the bottom end of the composite adapter tube is welded on a hole wall of an adapter tube hole of an equipment body, the angle joint ring loop part of the bowl-shaped angle joint ring stretches to an inner side of an inner wall of the equipment body around the adapter tube hole and is laminated with the inner wall of the equipment body. The titanium-steel compositeadapter tube can be used for reducing or eliminating a phenomenon that the stress at a welding position between an adapter tube titanium bushing and a titanium backing ring of the equipment body is excessively concentrated, the cracks of welding seams are reduced or avoided, and the titanium-steel composite adapter tube can be widely applied to titanium-steel composite board petrochemical equipment with an external adapter tube and a flange.

Owner:CHINA KUNLUN CONTRACTING & ENG

Waterproof card holder and payment device

PendingCN110718031AAvoid enteringEasy to installCash registersHermetically-sealed casingsElectrical and Electronics engineeringMechanical engineering

The invention relates to a waterproof card holder and a payment device. A card insertion port for inserting an IC card is formed in one side wall of the waterproof card holder, and the rest side wallsof the waterproof card holder are sealed; and in addition to the card insertion port, the other portions of the waterproof card holder are of sealed structures, thereby effectively preventing liquidor water mist from entering the card insertion port and passing through the waterproof card holder to enter equipment provided with the waterproof card holder such as a POS machine.

Owner:BEIJING TECH MAGNETIC RECORD MAKING

Extended driving type electroplating liquid resetting mechanism

ActiveCN113445113AImprove convenienceImprove fluencyCellsElectrophoretic coatingsGear wheelControl engineering

The invention discloses an extended driving type electroplating liquid resetting mechanism. The mechanism comprises an extended driving mechanism. A driving structure of a liquid drainage start-stop mechanism is extended, the operation convenience and smoothness are improved, an inner threaded sleeve is driven to transversely move through rotation of the outer end of a power screw, so that a movable toothed plate is driven to be slidably clamped on a limiting rod, in this way, a rotating gear is driven to rotate through engaged connection, the purpose of driving a start-stop screw is achieved, therefore, by means of extension of the power screw, driving convenience is improved, a worker does not need to stretch into the lower portion of a bottom cabin for adjustment, in addition, a lap joint block is movably installed on an installation groove in a supporting plate, and disassembly is convenient.

Owner:JIANGSU AOGUANG ELECTRONICS

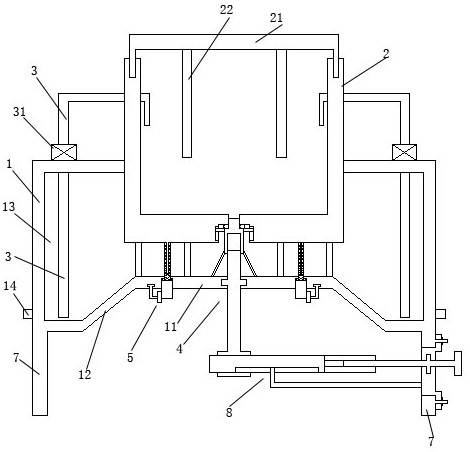

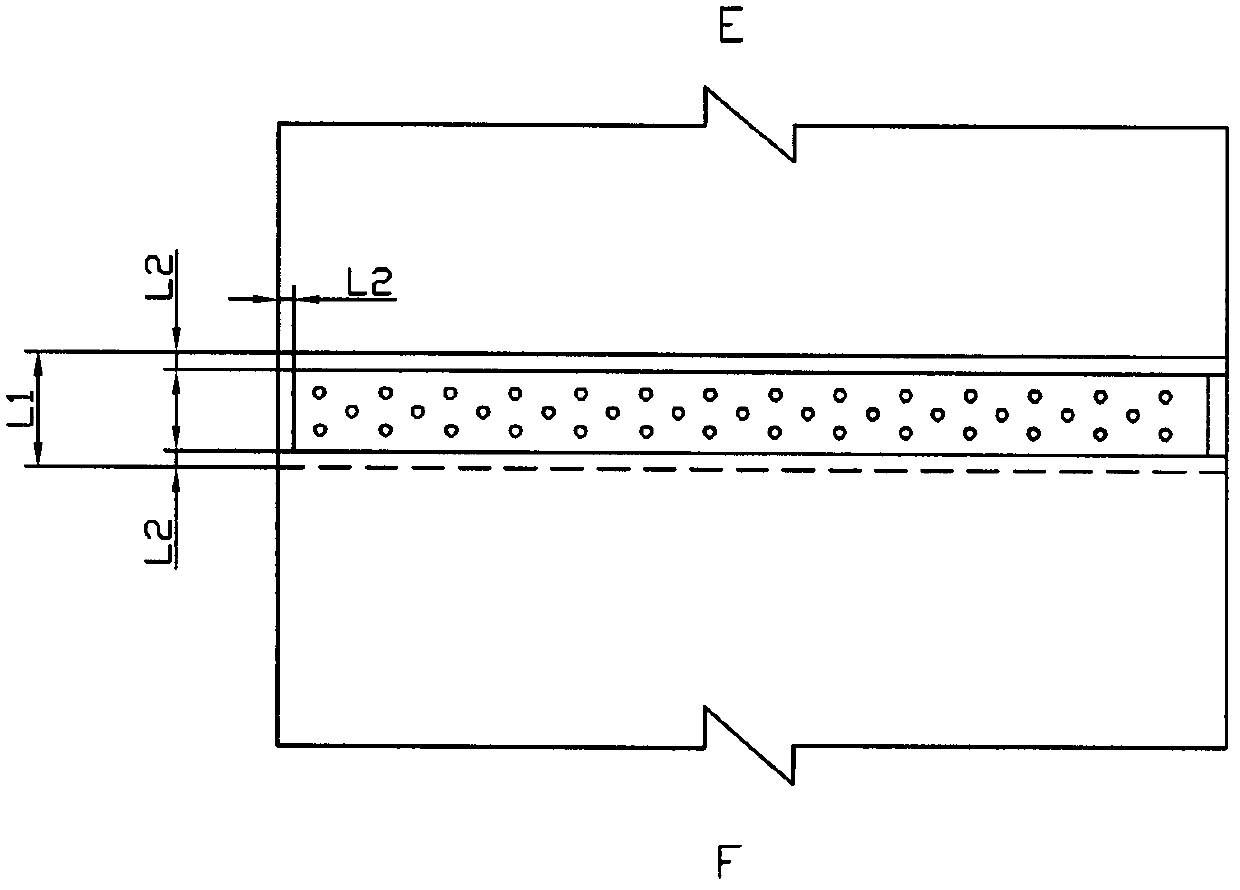

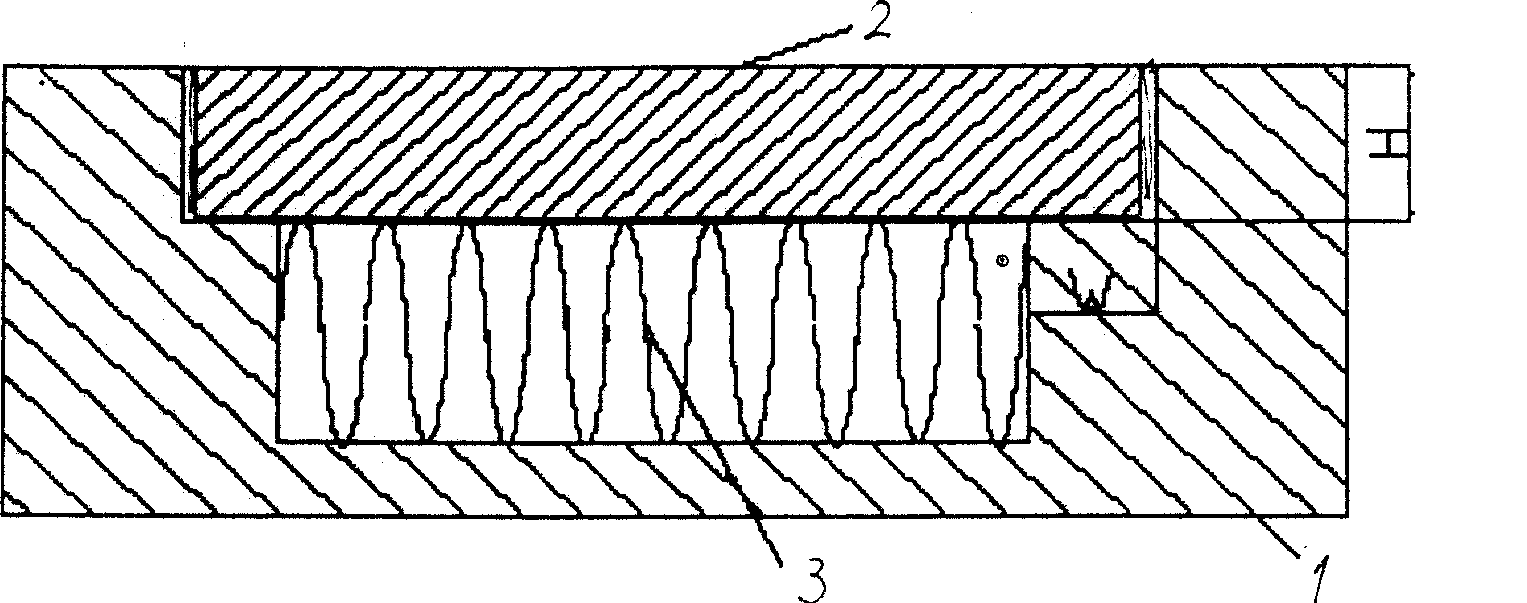

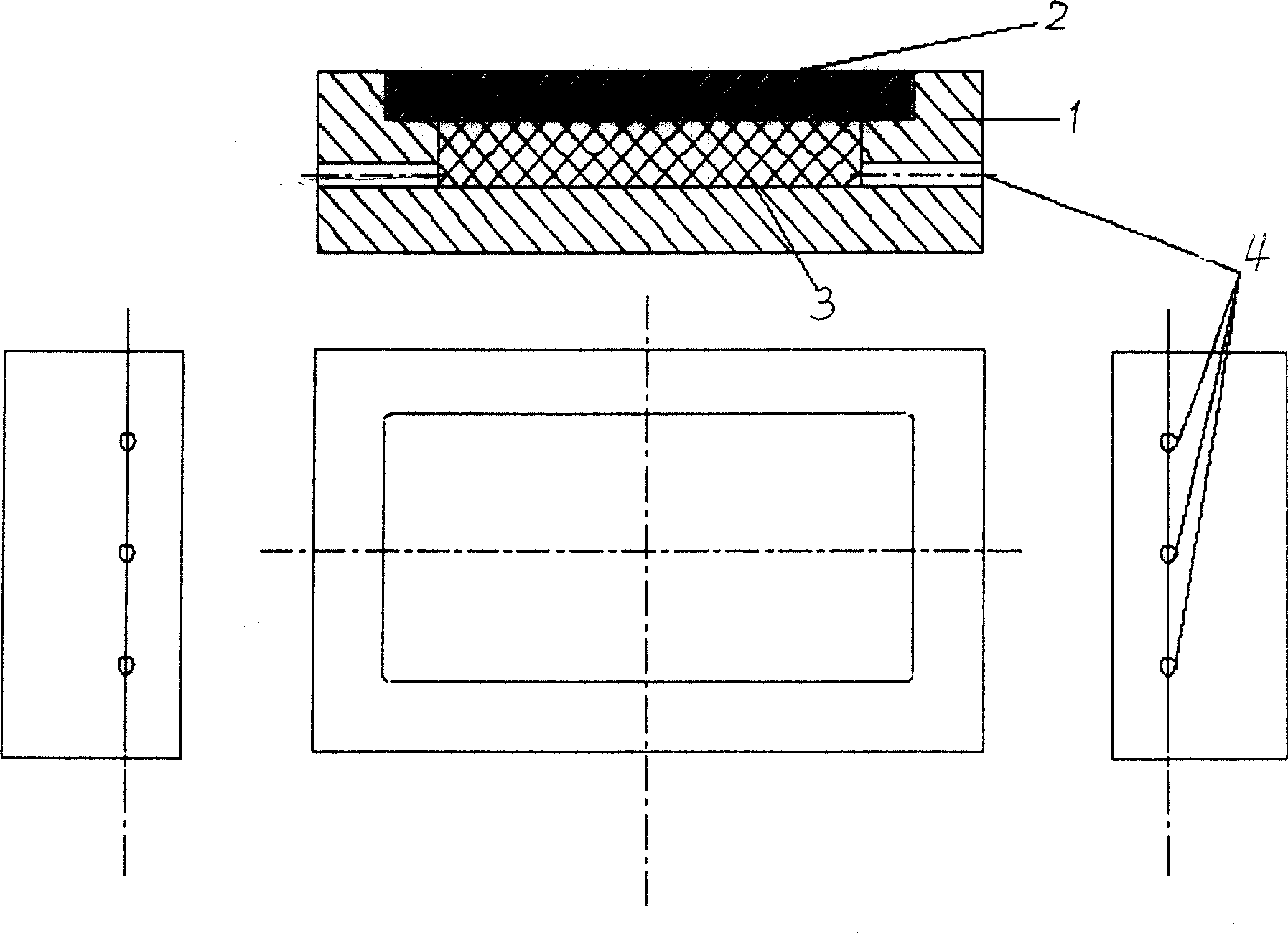

Closed-loop polyester film conveyor belt connecting device of drier and connecting method thereof

InactiveCN103302852AGuaranteed connection strengthGuaranteed tightness requirementsPolyesterDrive shaft

The invention discloses a closed-loop polyester film conveyor belt connecting device of a drier and a connecting method thereof, and relates to the technical field of drying of continuous low temperature films. An adjusting base (2) is slidingly arranged on a welding platform (1), a compressing device (3) is connected on the adjusting base (2) through a thread, a driving shaft (4) is arranged on one side of the welding platform (1), two bases (5) are fixedly arranged on the lower parts at both ends of the welding platform (1), and a high frequency plastic welder (6) is moveably arranged on the upper part of the welding platform (1). With the adoption of the high frequency plastic welder matched with a certain welding method, the connecting strength, the sealing performance and the leveling demand of the conveyer belt are ensured. A conveyer belt welding tool is adopted, so that the linearity of the pulley welded is ensured. Meanwhile, the method can realize field installation, and the structure of equipment is simplified.

Owner:常州朗诣节能技术有限公司

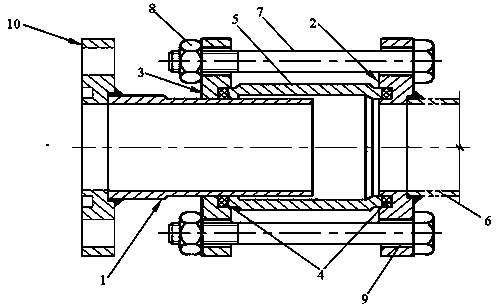

Vacuum pipeline length compensation device

ActiveCN103867825AGuaranteed tightness requirementsSimple structureAdjustable jointsLength changeFlange

The invention discloses a vacuum pipeline length compensation device which comprises a pipe connector, a concave flange and a compensator flange. Annular grooves surrounding central through holes are formed on end faces of opposite sides of the concave flange and the compensator flange. The end face of the other side of the concave flange is connected with a pipeline. Sealing gaskets are arranged in the annular groove of the concave flange and the annular groove of the compensator flange. A flange is welded at one end of the pipe connector, and the other end of the pipe connector extends into the central through hole of the compensator flange. One end of a sleeve is arranged outside the pipe connector in a sleeved mode and is inserted into the annular groove of the compensator flange. The other end of the sleeve is inserted into the annular groove of the concave flange. The two ends of the sleeve both compress the sealing gaskets in the annular grooves. Bolts respectively penetrate through an installation hole of the concave flange and an installation hole, corresponding to the installation hole of the concave flange, of the compensator flange and are fastened by nuts. The vacuum pipeline length compensation device solves the problem of installation difficulty caused by connecting pipe length changes due to pipeline processing errors at technological pipeline installation time so as to ensure the sealing requirements of connecting positions.

Owner:中国原子能工业有限公司

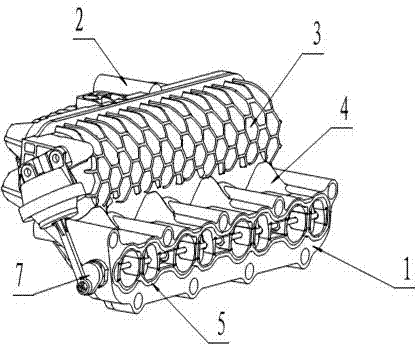

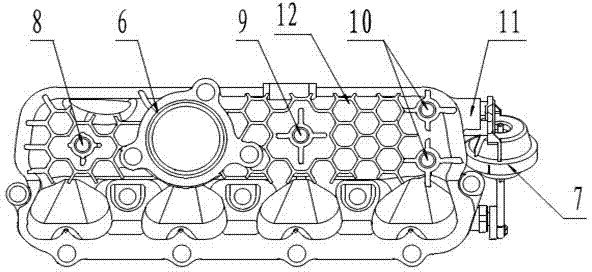

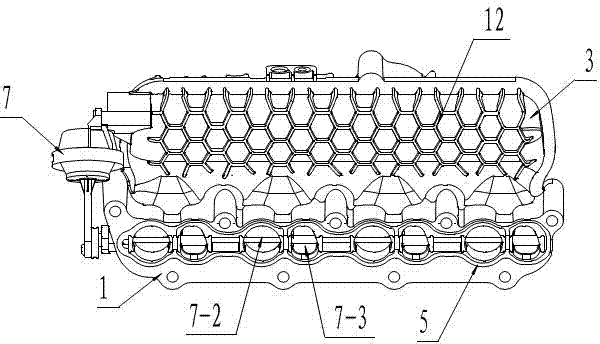

Engine intake manifold

ActiveCN102953877AReduce intake resistanceImprove sound qualityInternal combustion piston enginesCombustion-air/fuel-air treatmentCylinder headAir filter

An engine intake manifold is used for matching the intake swirl to an engine under different operating conditions in order to enhance the comprehensive performance of the engine. The engine intake manifold comprises an inlet end flange, a pressure-stabilizing cavity, intake branches, an outlet end flange and an intake swirl regulation mechanism, the front end surface of the inlet end flange is connected with an intake connecting pipe behind an air filter of an engine, the rear end of the inlet end flange is connected with the air inlet of the pressure-stabilizing cavity, the pressure-stabilizing cavity is of a two-piece type butt joint structure, the group of intake branches are arranged on the sidewall opposite to the air inlet of the pressure-stabilizing cavity, the rear ends of the intake branches are connected with the outlet end flange, the axes of the intake branches make the included angle of 135 degrees with the axis of the outlet end flange, and the outlet end flange is connected with the intake passage of the cylinder head of the engine. The structure of the engine intake manifold is simple, and is compactly arranged, and the engine intake manifold can meet the requirement of the lightweight design of automobile engines, reasonably guide intake flow and improve the power performance, economic performance and emission indexes of engines.

Owner:GREAT WALL MOTOR CO LTD

Stainless steel four-way reversing valve main valve with integrated valve seat for air conditioner and machining method

ActiveCN111473146AReduce processing complexitySolve the deformationValve housingsEngineeringStructural engineering

The invention discloses a stainless steel four-way reversing valve main valve with an integrated valve seat for an air conditioner and a machining method, and relates to the field of reversing valves.At present, the problems that cost is high, the machining process is complex, welding positions are not firm, and a valve port face is prone to deformation after long-time use exist. The stainless steel four-way reversing valve main valve comprises a connecting seat fixed to a valve body, a middle section of the valve body is concaved inwards to form a valve seat, and the left side face and the right side face of the valve seat are disconnected with the valve body to form arched edges; the concave valve seat forms a protruding platform in an inner cavity of the valve body, the top face of theplatform is a valve port face matched with a sliding block in the valve body, the connecting seat is embedded in the concave valve seat, the left side face and the right side face of the connecting seat seal a notch formed after the valve seat and the valve body are disconnected, the wall thickness of the valve body is d, and d is larger than or equal to 0.8 mm and smaller than or equal to 1.7 mm. According to the technical scheme, the left side face and the right side face of the valve seat are disconnected with the valve body, stress generated by large deformation during stamping is avoided, and the yield and production efficiency are improved; the process complexity is reduced; the total cost is reduced; and the wall thickness of the valve body can be selected in a larger range to meetdifferent requirements.

Owner:浙江南宏金属科技有限公司

Grinding method for ring-shaped part

ActiveCN105500178AControl altitudeEnsure consistencyLapping machinesWork carriersEngineeringStructural shapes

The invention discloses a grinding method for a ring-shaped part. The grinding method comprises the following steps: designing an auxiliary tool according to a structural shape of a to-be-grinded ring-shaped part, wherein height of the auxiliary tool is matching height required by the grinded ring-shaped part; selecting a unified positioning datum plane on the ring-shaped part; fixedly mounting the auxiliary tool to the ring-shaped part in a threaded connection mode; after the lower surface of the auxiliary tool clings to the datum plane of the part, coating a layer of thin inkpad on the upper surface of the auxiliary tool, coating a layer of grinding paste on a to-be-grinded surface of the ring-shaped part; and grinding the to-be-grinded surface until the auxiliary tool starts contact the inkpad by adopting a grinding tool. The height of the part grinded by the method disclosed by the invention can be effectively controlled, so that the height consistency of the grinded part is guaranteed. Gap requirements and tightness requirements of the assembled part are guaranteed, so that the accuracy and the adjustability of a follow-up test of the part are guaranteed.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

The installation structure of the decorative strip on the roof of the car

The invention discloses an installing structure of an automobile top cover decoration strip. The installing structure comprises the top cover decoration strip and a groove formed by overlapping a side wall and a top cover. The installing structure further comprises a clamping base adhering to the bottom wall of the groove. The top cover decoration strip comprises a decoration strip body, an elastic buckle body is connected to the middle of the lower portion of the decoration strip body and matched with the clamping base in a clamped mode, and lip sides are arranged on the left and right sides of the decoration strip body respectively and are in interference fit with the two side walls of the groove respectively. The installing structure is reliable in connection, not prone to warping and beneficial to sealing, and installing precision is easy to control.

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES

Watertight access door structure of steel box arch bridge

PendingCN112921836AEasy to pass throughGuaranteed tightness requirementsBridge structural detailsBridge erection/assemblyArchitectural engineeringStructural engineering

The invention relates to the field of bridge structures, in particular to a watertight access door structure of a steel box arch bridge, which can ensure the sealing performance while ensuring the convenience of opening and closing, and the structure comprises an access hole arranged at the bottom of a steel box girder, a manhole stiffening ring fixedly arranged along the access hole and a manhole cover plate in closed fit with the manhole stiffening ring, the manhole cover plate is rotationally connected with a cover plate connecting piece fixedly arranged on the steel box girder, the manhole cover plate is in closed fit with the manhole stiffening ring through a cover plate sealing mechanism arranged on the steel box girder, and a sealing ring structure matched with the edge of the manhole stiffening ring is arranged on the surface of the side, facing the manhole stiffening ring, of the manhole cover plate. The sealing ring structure is tightly attached to the edge of the manhole stiffening ring in a sealed mode. According to the invention, the sealing ring structure matched with the edge of the manhole stiffening ring is arranged on the surface of the side, facing the manhole stiffening ring, of the manhole cover plate, and therefore the sealing performance requirement is met. The watertight access door structure is particularly suitable for a steel box bridge structure of a bridge.

Owner:CHINA 19TH METALLURGICAL CORP

Split type stator coil winding method and winding mold device

ActiveCN101783553BImproved hand winding methodSave materialManufacturing dynamo-electric machinesNumerical controlStator coil

The invention relates to a split type stator coil winding method and a winding mold device, which belong to the manufacture field of an alternating current servo permasyn motor and can be widely applied to industrial automation and military equipment, such as numerical control machines, processing centers, robots, printing machinery, textile machinery, medical machinery, petroleum, chemical engineering, metallurgy, radar antennae and the like. The invention is characterized in that a winding mold device which consists of a winding mold and a winding mold plate matched with the winding mold; sheathing an outer sleeve barrel (8) of the winding mold on a mold core bracket (2); fixing the mold core bracket (2) of the winding mold and the first group of split type stator core teeth on a winding machine; arranging one end of the split type stator core on the mold plate of the winding mold, and pushing tightly by the other end of the winding machine; and directly winding the windings on the first group of split type stator core. The invention has the advantages of large output power, small volume, good low-speed property, strong overloading capability, stable rotation speed and the like.

Owner:SHANDONG SHANBO ELECTRIC MACHINE GROUP

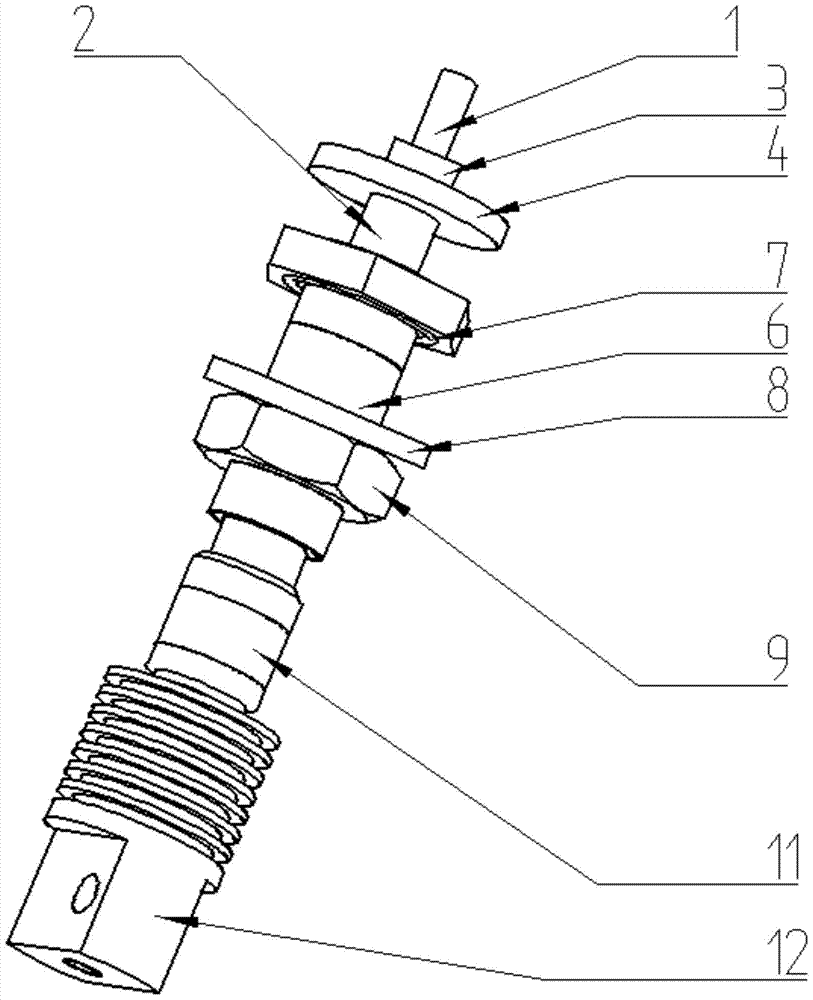

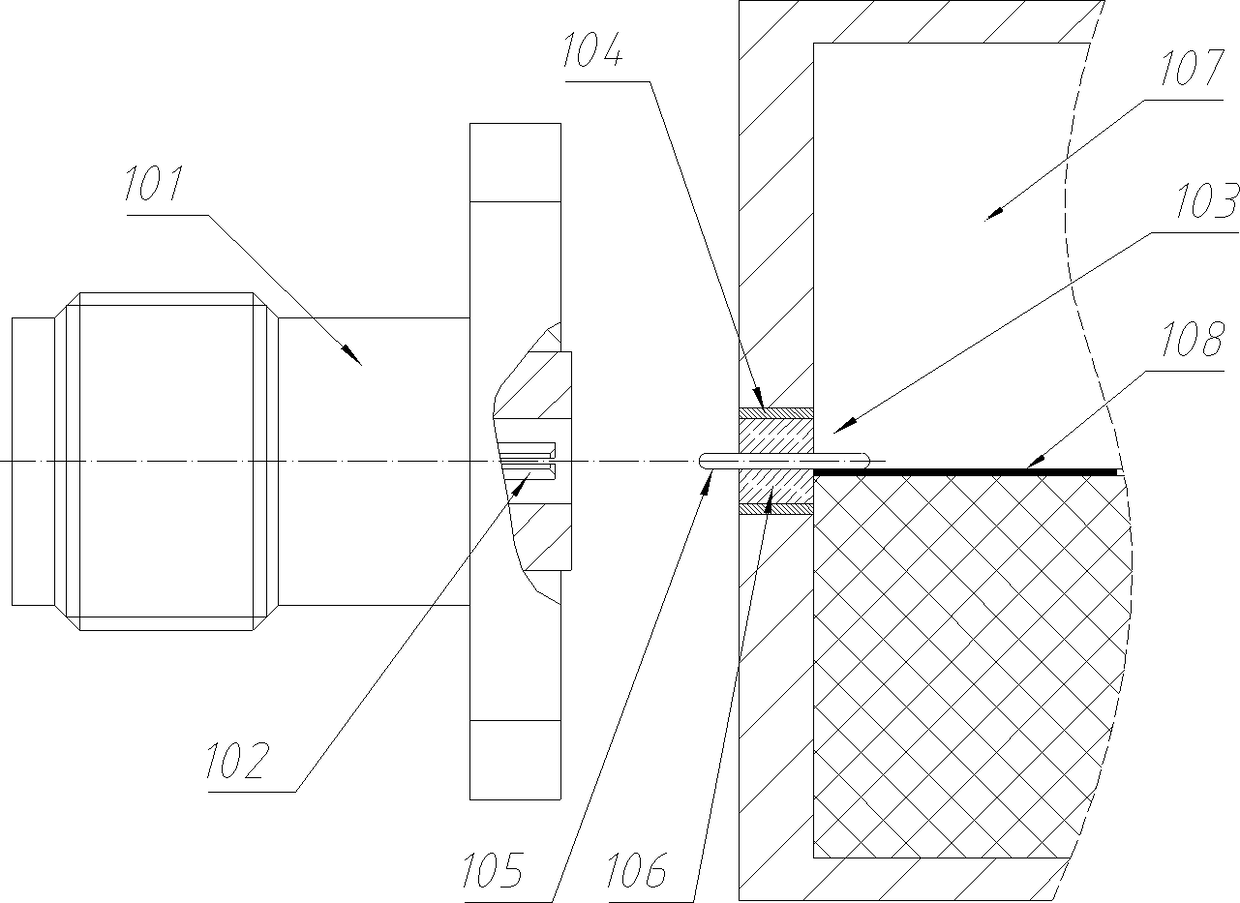

An insulated and sealed electrode assembly

ActiveCN105490058BGuaranteed tightnessReduce volumeSecuring/insulating coupling contact membersElectrical connectionEngineering

The invention discloses an insulated sealing electrode component, and belongs to an electrical connection component. The insulated sealing electrode component is applied to a to-be-sealed conductive material cavity, and solves the problems that an existing electrode insulated sealing device is relatively large in size, relatively complicated in structure and poor in sealing effect and cannot bear a high temperature. The insulated sealing electrode component comprises a copper bar, an upper sleeve, an upper-end retaining nut, a separate washer, an inner sleeve, an outer sleeve, a base sealing ring, a retaining washer, a lower-end retaining nut and a lower sleeve, wherein the outer sleeve is connected to an equipment cavity base through the retaining washer and the lower-end retaining nut when the insulated sealing electrode component is used, so that the insulativity between an electrode and an equipment cavity connected with the electrode is ensured when the electrode carries out normal conducting work; the air-tightness of the connected part can be ensured; and the overall safety of equipment is ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

Air cold plate sealing forming technology of aluminum alloy

InactiveCN100491058CGuaranteed tightness requirementsLeakage and scrap rate is highWelding/cutting media/materialsMilling equipment detailsCold plateNitrogen gas

A aluminum alloy air-cooled freezing-plate sealing shaping process includes the following steps: 1. processing the appearance of freezing-plate, dissipating heat fins and cover plate parts according to structure design, the structure design of freezing-plate is flush type cavity structure, the two ends of freezing-plate shell is equipped with 2-3 soldering fabrication holes with diameter of 2-3mm; 2. welding the dissipating heat fins and freezing-plate shell, cover plate through the soldering method in nitrogen protection furnace; 3. milling out printed circuit board slots on the freezing-plate shell; welding the cover plate and shell vertical soldering seam through stirring friction welding; 5. mechanical processing the appearance and two end ventilators of freezing-plate according to the drawings requirements, processing the soldering fabrication holes into two end ventilators. The aluminum alloy freezing-plate using the art method of combination of soldering and stirring friction welding in the invention increases the resistant finely processed capacity of brazing seam surface, ensures the hermeticity requirement after finely process aluminum alloy freezing-plate and increases the welding yield rate of electronic structure cabinet.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

A kind of brazing method of sealing seat assembly

ActiveCN104353921BGuaranteed tightness requirementsHigh positioning accuracyWelding/cutting media/materialsWelding/soldering/cutting articlesPass rateFusion welding

The invention relates to a brazing method of a hermetically sealed seat component and belongs to the technical field of manufacture of aircraft engine parts. The hermetically sealed seat component comprises a seat body and a guide pipe, wherein the seat body is made of titanium alloy materials; the guide pipe is made of stainless steel materials. As the welding is hard to perform by adopting a traditional fusion welding method, and the selection of solders, the setting of brazing process parameters, the brazing position sealing requirements, the assembling and the positioning of the seat sealing component in the brazing process and other aspects can be involved when the brazing method is adopted, a set of feasible brazing method is urgently needed to meet the production demands of the hermetically sealed seat component. The brazing method has the benefits that the invention overcomes the technical problems encountered by the hermetically sealed seat component in the brazing process and provides the solder with good weldability; meanwhile, the brazing process parameters are provided, the sealing requirements after brazing at brazing positions are ensured, the positioning precision during brazing is high, and smooth and continuous brazing seams can be obtained; the brazing method has the characteristics of strong maneuverability, high production efficiency and high brazing pass rate.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

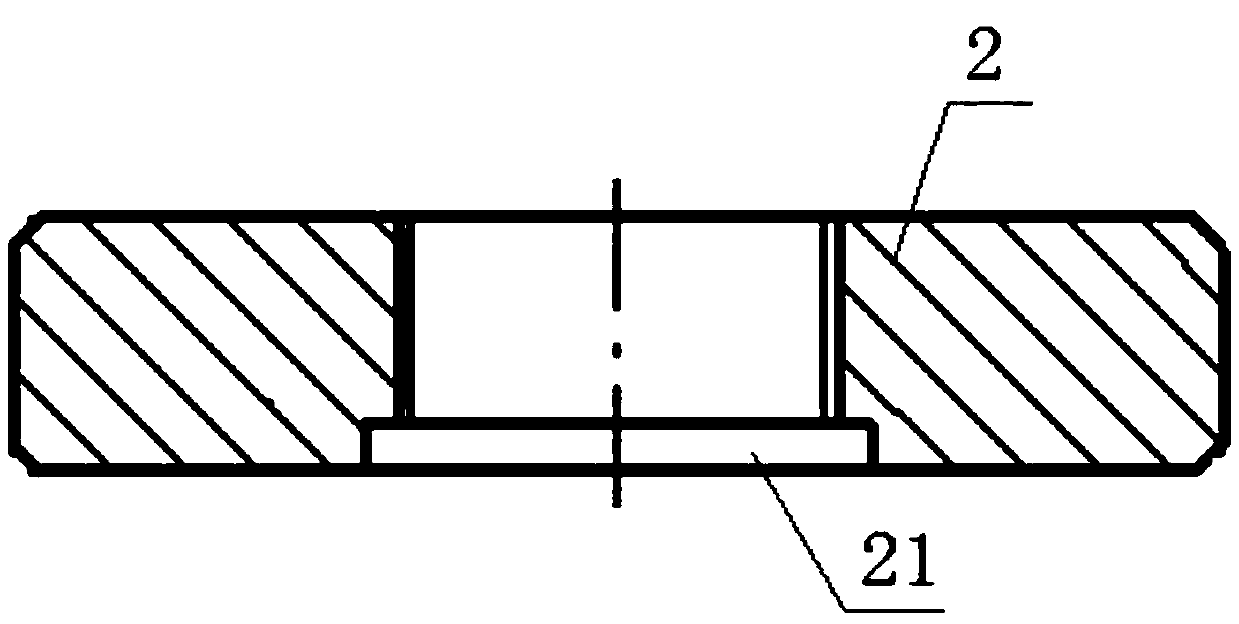

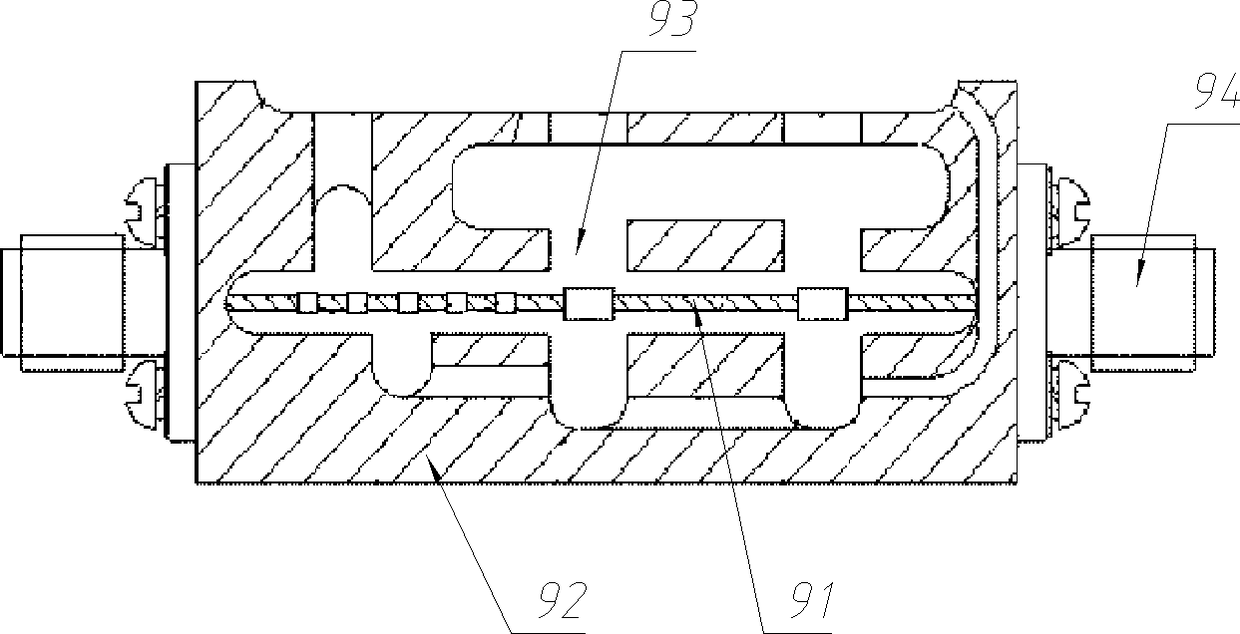

Coaxial rotating microstrip sealed connector

InactiveCN109309315AGuaranteed tightness requirementsLow costCouplings bases/casesTwo-part coupling devicesElectrical conductorAdhesive

The invention relates to a sealing structure of a coaxial rotating microstrip connector, and provides a coaxial rotating microstrip sealed connector. The coaxial rotating microstrip sealing connectorincludes a connector body, an inner conductor, and an insulator disposed between the connector body and the inner conductor. The insulator is made of a plastic material, and the inner conductor is embedded in the insulator, and the connector body and the insulator, as well as the insulator and the inner conductor are sealed and fixed by an adhesive. Compared with the prior art adopting the sintered glass process, the coaxial rotating microstrip sealing connector of the invention has the advantages of low cost and convenient manufacture while ensuring the sealing performance requirement. Compared with the prior art in which the microstrip adapter needs to be provided, the connector in the invention has an integral structure and a simple structure. The assembly of the connector is not required when assembling the microstrip housing, which is convenient to use.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Special bracket for integrally hoisting marine main engine cylinder body and air cooler and method for integrally hoisting marine main engine cylinder body and air cooler

ActiveCN103145024BGuaranteed tightness requirementsAvoid enteringLoad-engaging elementsMarine engineeringMechanical engineering

The invention discloses a method for integrally hoisting a marine main engine cylinder body and an air cooler. The method includes: (1), when a main engine is disassembled, the cylinder body and an air cooler assembly are placed on a special bracket; (2), oil seal is carried out on the lower flat surface of the main engine cylinder body to be ready for being transported ; (3), integrally, the main engine cylinder body and the air cooler assembly together with the special bracket are hoisted on a flat car; (4), after transported to a slipway, the oil seal of the lower flat surface of the main engine cylinder body is removed and the lower flat surface of the main engine cylinder body is cleaned on the flat car; and (5), the cylinder body and the air cooler assembly are hoisted on a main engine rack to be assembled. The invention further provides the special bracket used for the method. By utilization the special bracket, the whole hoisting and shipping of a main engine are achieved, the processes of disassembling and assembling the cylinder body and the air cooler assembly are saved, the utilization efficiency of a hoisting device is improved, meanwhile the assembling quality of the main engine is guaranteed, the labor intensity of workers is relieved, and safety potential hazards of site work are reduced.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

A high-efficiency rotational speed control device based on magnetorheological materials

ActiveCN107612441BHigh directnessImprove energy conversion efficiencyElectric generator controlEngineeringMagnetic characteristic

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

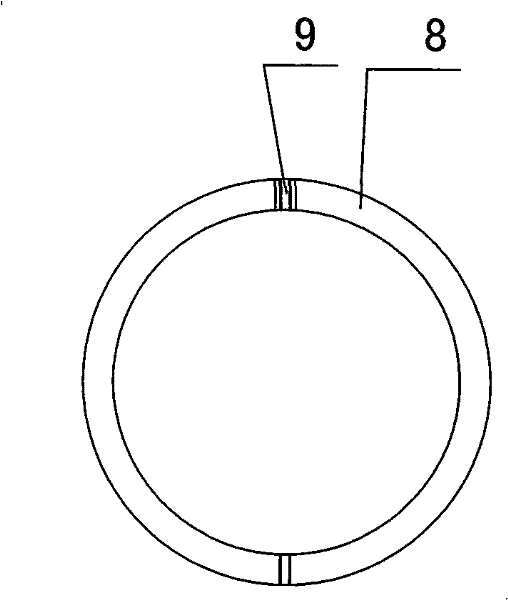

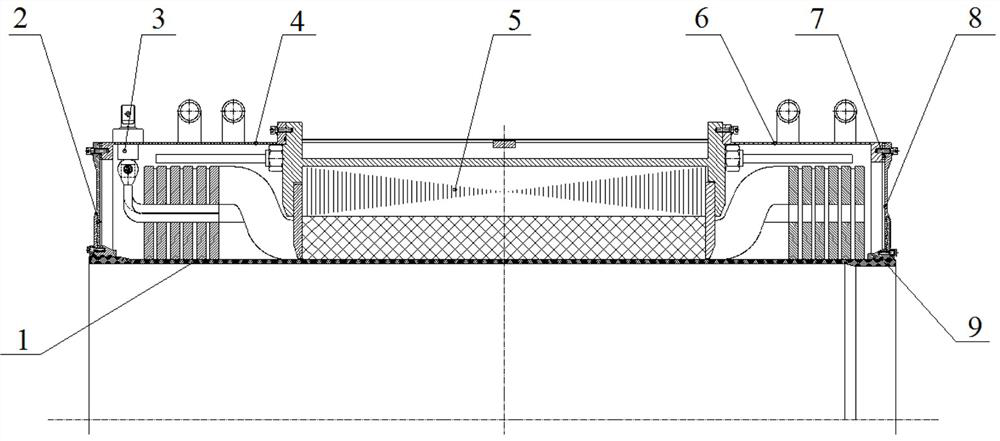

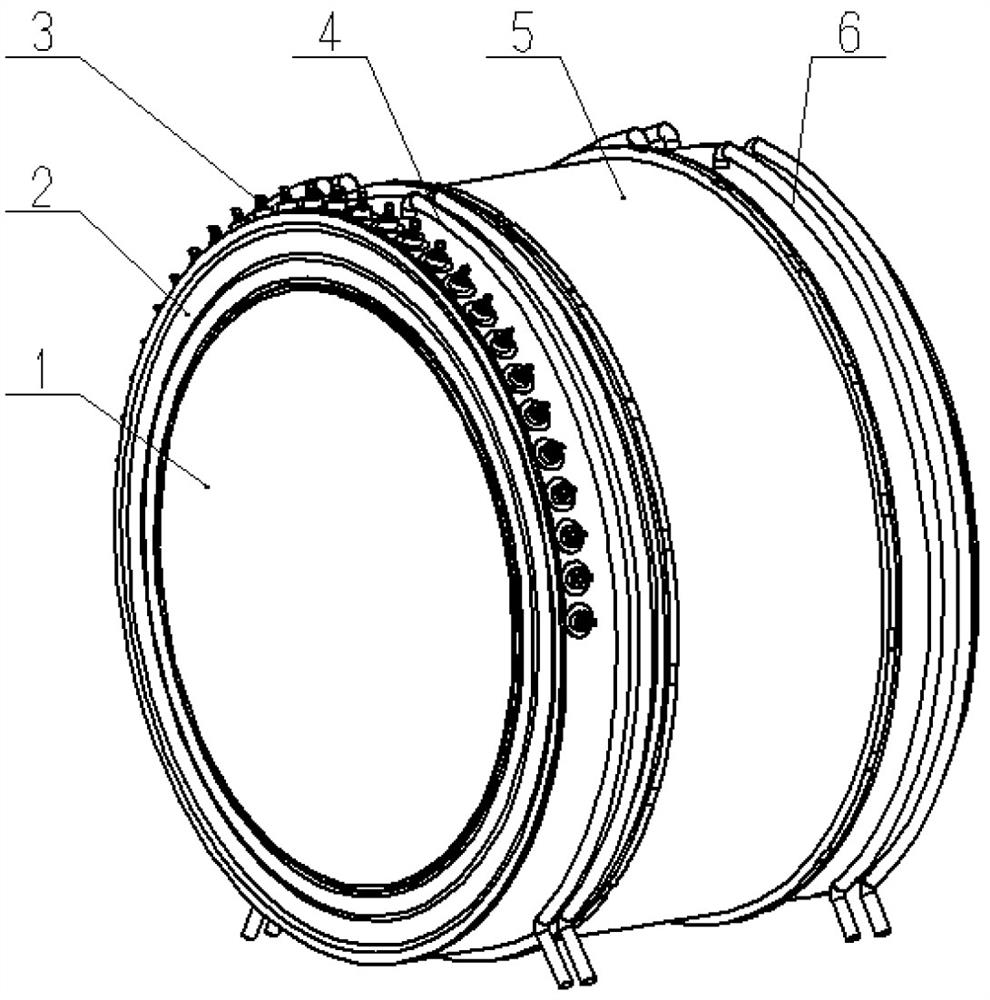

High-temperature superconducting motor liquid cooling air gap armature stator structure and assembling method

PendingCN114204723AImprove carrying capacityImprove sealingMagnetic circuit stationary partsManufacturing dynamo-electric machinesMarine propulsionSuperconducting electric machine

The invention relates to a high-temperature superconducting motor liquid cooling air gap armature stator structure which is composed of a cylinder, a leading-out terminal end plate, a sealing binding post, a leading-out terminal end cap, a stator armature, a non-leading-out terminal end cap, a rubber cushion plate, a non-leading-out terminal end plate and a sealing ring. The leading-out end cap and the non-leading-out end cap outside the cylinder are respectively in sealed connection with the end face of the stator armature through sealing rings, and the leading-out end plate and the non-leading-out end plate are respectively of an annular structure embedded with a metal flange and are respectively in sealed connection with the cylinder through sealing rings and pressing plates; the invention further discloses an assembling method. The stator temperature rise can be effectively controlled, and the reliability of the motor can be improved, so that the requirements of high heat load, compact structure, high torque density and the like of the motor are met, and the high-temperature superconducting motor or the high-temperature superconducting direct-driven wind driven generator for ship propulsion has the requirements of high power, low rotating speed, compact structure, high torque density, low operating cost and the like.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com