Extended driving type electroplating liquid resetting mechanism

A driving type, electroplating liquid technology, applied in electrophoretic plating, electrolytic coating, electrolytic process, etc., can solve the problems of cumbersome cleaning methods, cumbersome and inefficient processing, etc., achieve ingenious structure design, convenient operation, improve convenience and smoothness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

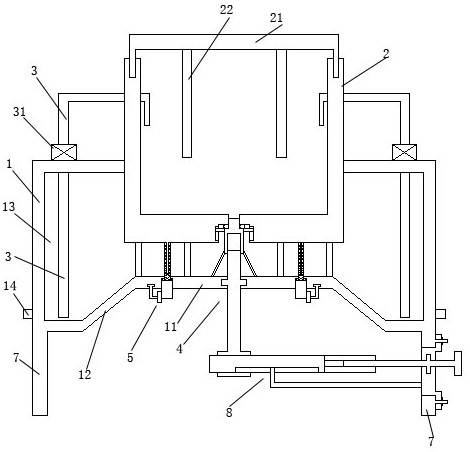

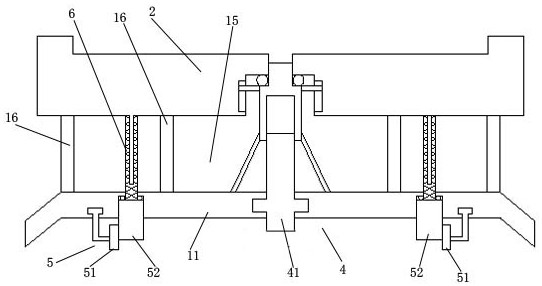

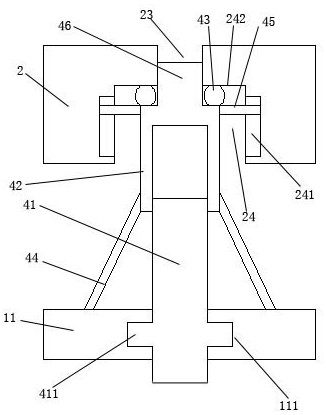

[0026] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] Such as Figures 1 to 7As shown, an epitaxially driven electroplating solution reset mechanism includes a support plate 7, a bottom cabin 1, an electroplating tank 2, an annular filter 6, a liquid discharge opening and closing mechanism 4, a liquid suction pipe 3, and an epitaxial driving mechanism 8; A support plate 7 is respectively installed on both sides of the lower end of the bottom cabin body 1; the electroplating tank 2 is inserted and fixedly connected from the middle of the upper end of the bottom cabin body 1; There is a flow gap 15 between them; the inside of the bottom cabin 1 is provided with an annular liquid accumulation chamber 13; a suction pipe 3 is respectively installed on both sides of the annular liquid accumulation chamber 13; the liquid suction pipe 3 can be provided with Liquid suction pump 31; the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com