Patents

Literature

5260results about How to "Ingenious structural design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

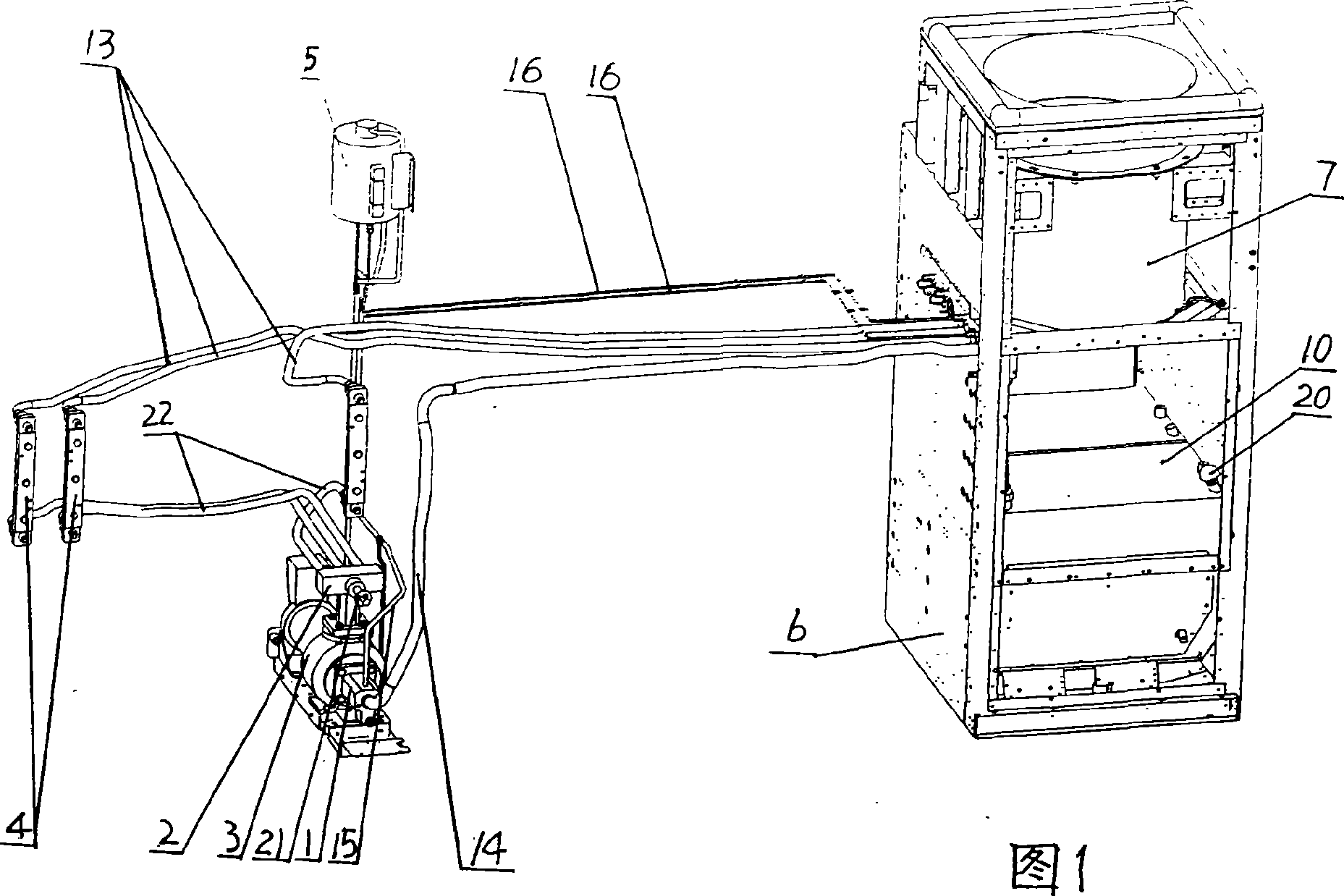

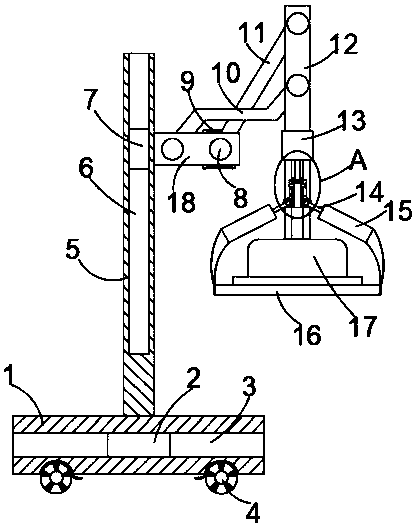

Greenhouse suspended self-propelled target-oriented sprayer system and operation method thereof

InactiveCN102017938AAvoid bodily harmImprove labor efficiencySpraying apparatusInsect catchers and killersSprayerEngineering

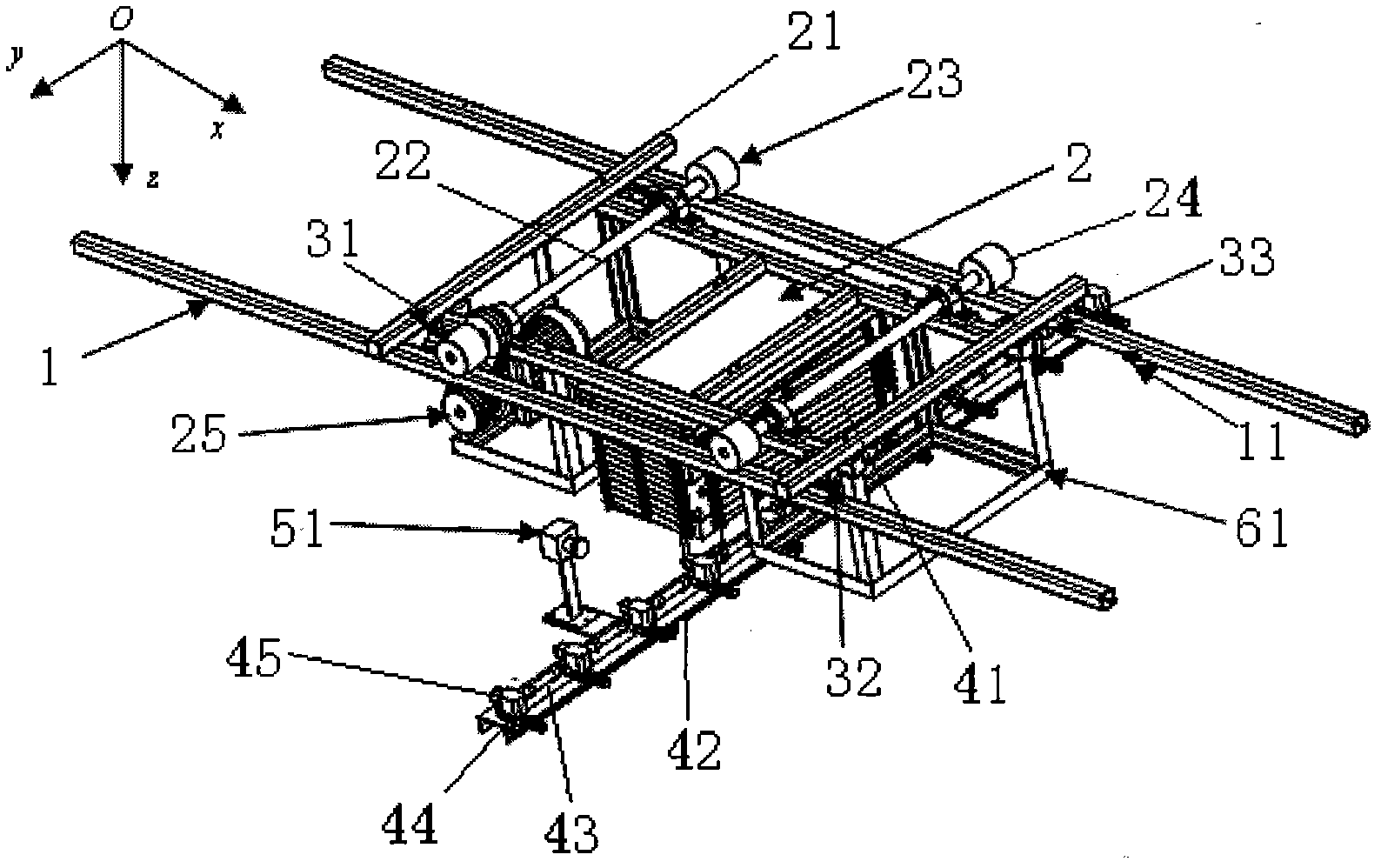

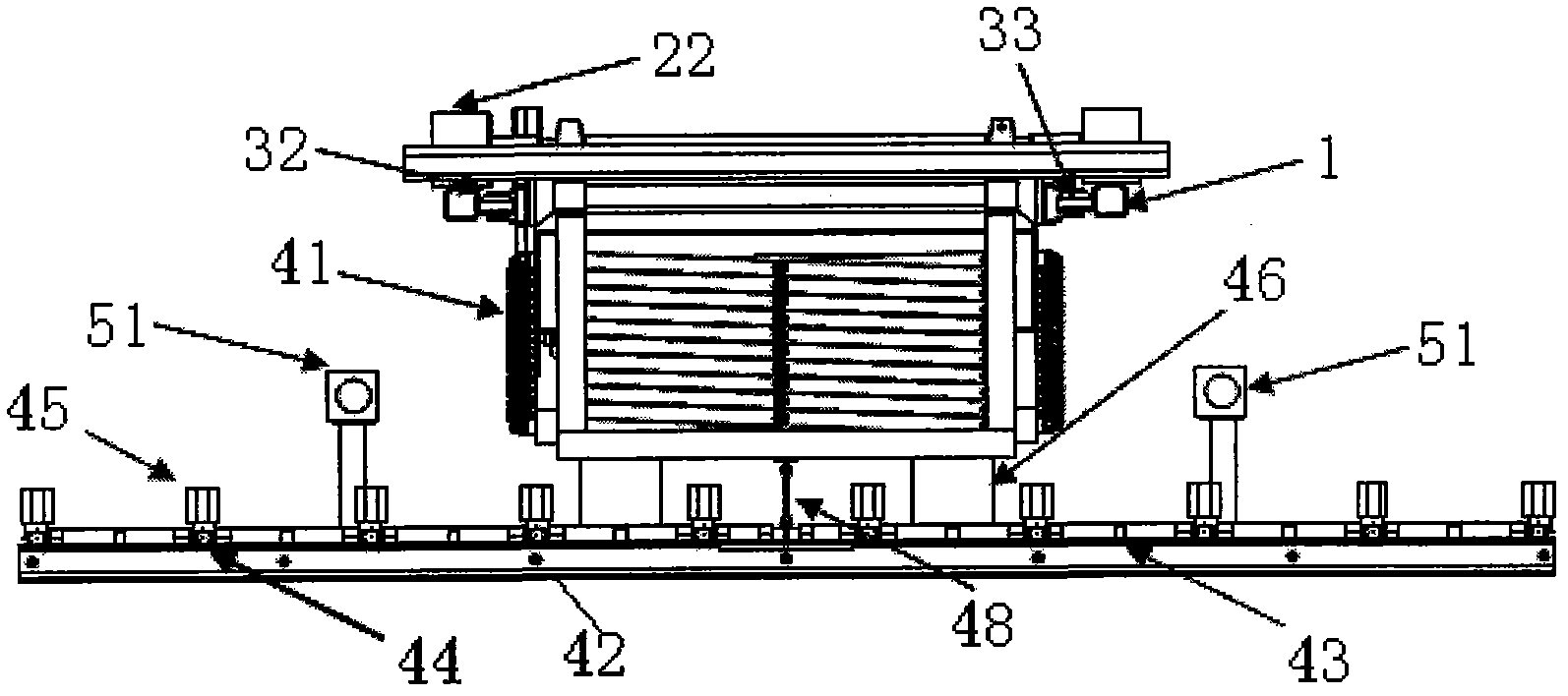

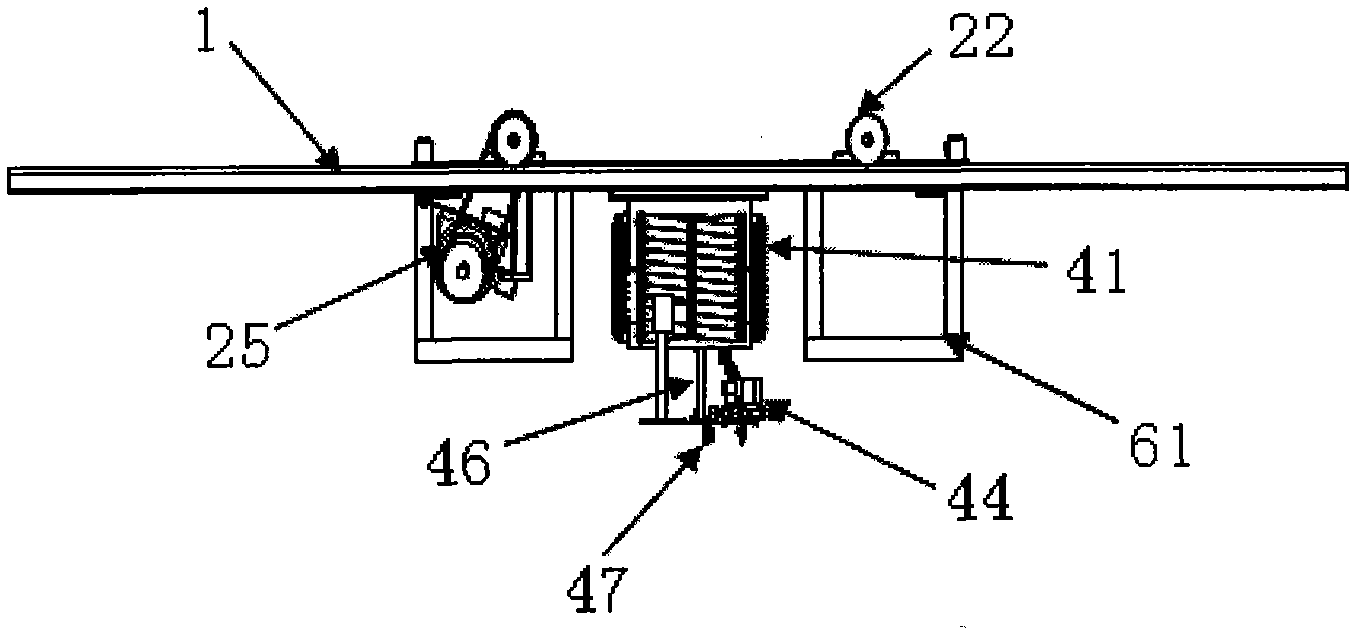

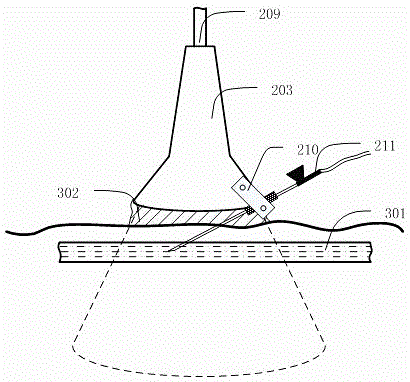

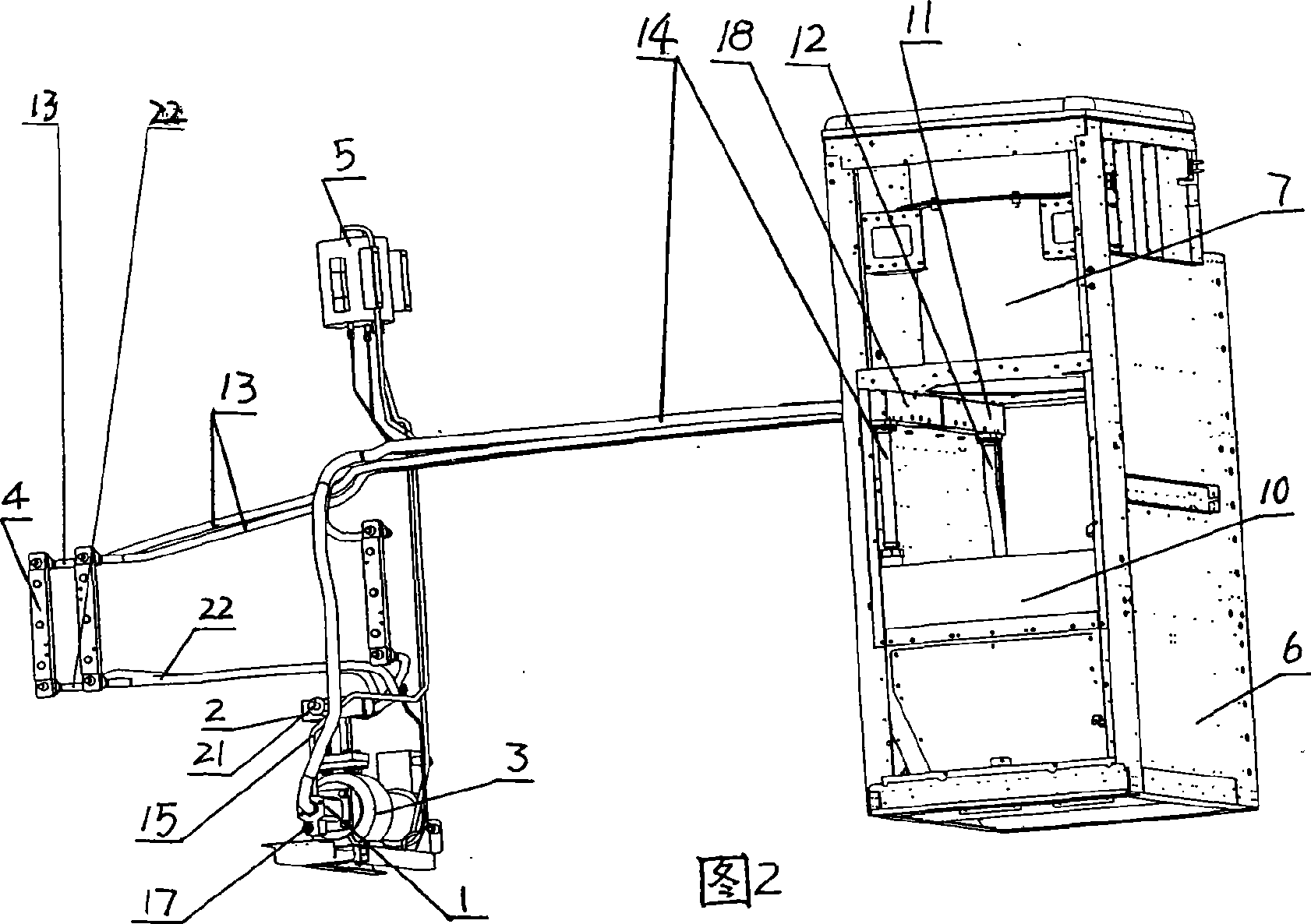

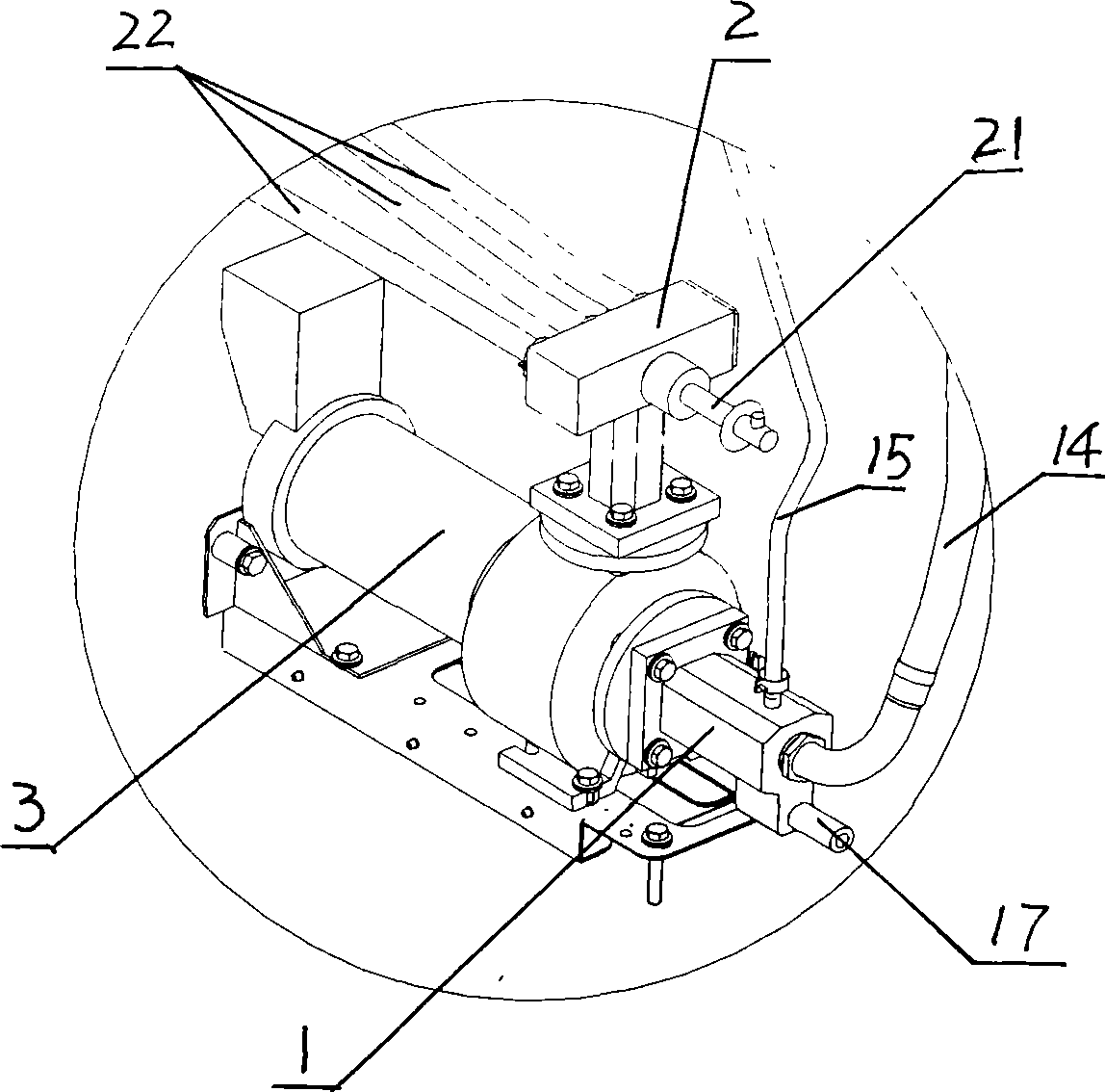

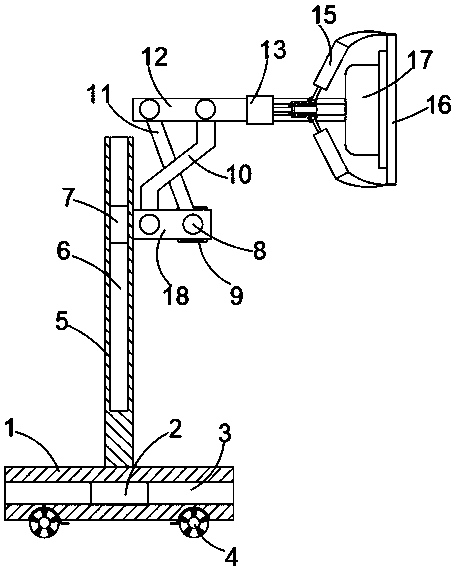

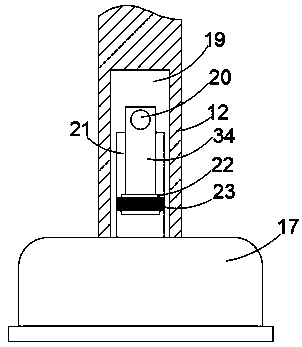

The invention relates to a greenhouse suspended self-propelled target-oriented sprayer system and an operation method thereof. The greenhouse suspended self-propelled target-oriented sprayer system is characterized by comprising a guide way, a self-propelled mobile platform, a hall sensor, a spraying manipulator device, a binocular vision system and a PLC (Programmable Logic Controller), wherein a plurality of magnetic positioning marks are preinstalled on the guide way; the self-propelled mobile platform is arranged on the guide way through a walking mechanism and provided with the hall sensor; the spraying manipulator device comprises a Z direction cross-shear hanger which is arranged on a rack; a spray rod is horizontally arranged below the hanger through a rotary positioning mechanism; a spray pipe is fixedly arranged on the spray rod; a plurality of spray heads are arranged on the spray pipe at intervals and independently controlled by electromagnetic valves; the hanger has the functions of extension and retraction; the binocular vision system comprises two CCD (Charge-Coupled Device) video cameras; the two CCD video cameras are fixedly installed on both ends of the spray rod respectively and connected with an upper computer in which control software is prearranged; and the PLC is electrically connected with the upper computer, the hall sensor, a frequency converter, a drive controller, the electromagnetic valves and the CCD video cameras respectively.

Owner:CHINA AGRI UNIV

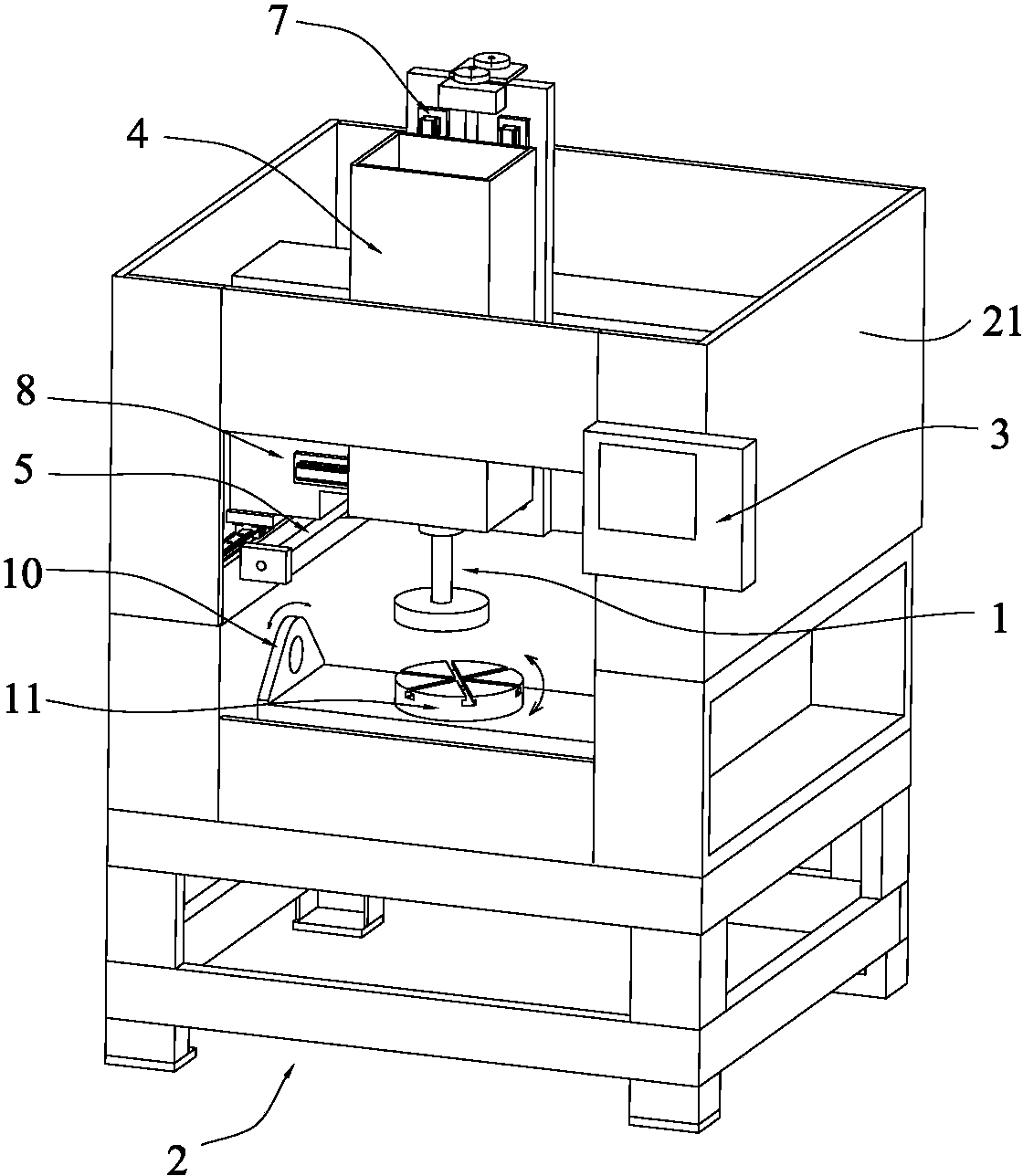

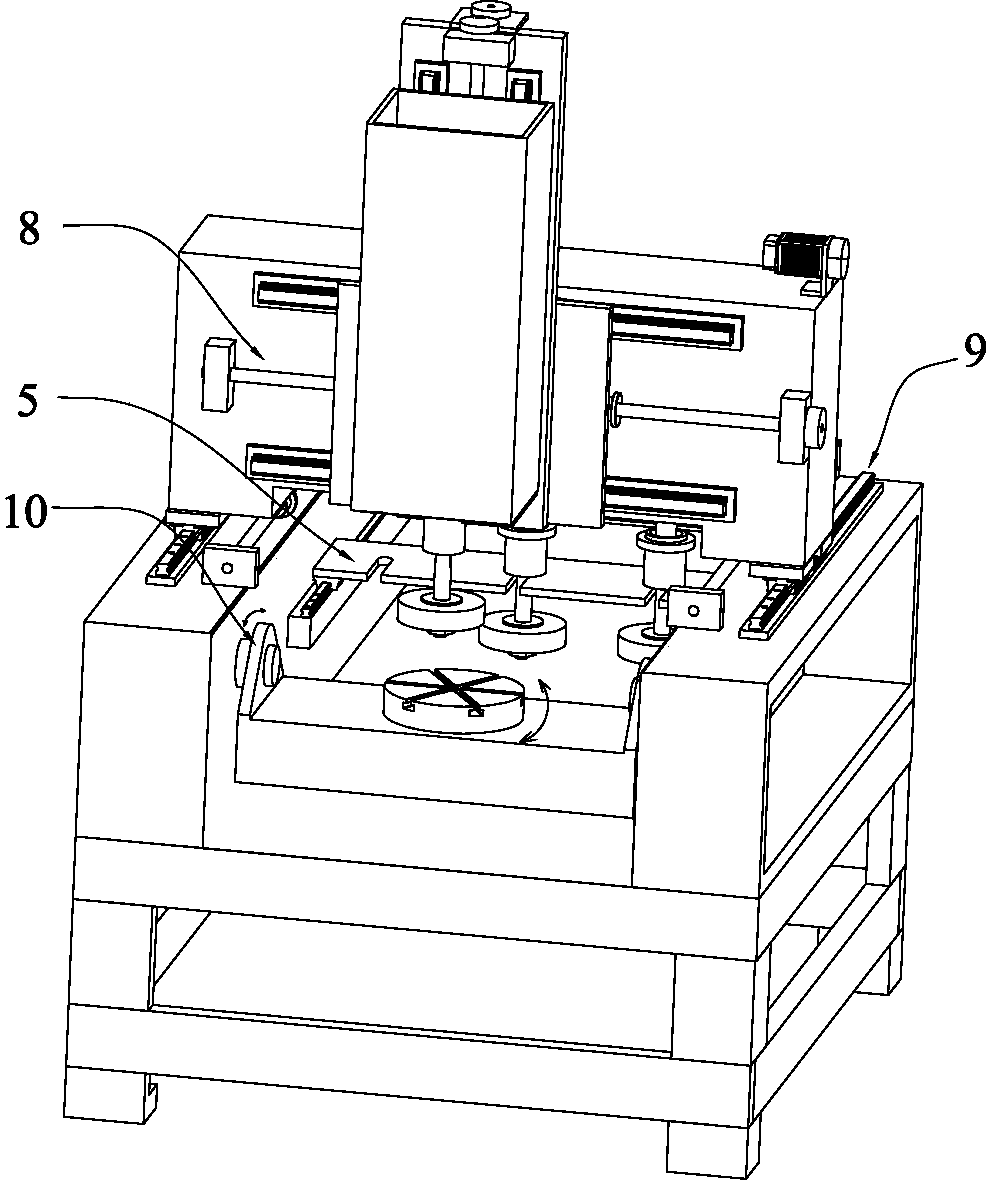

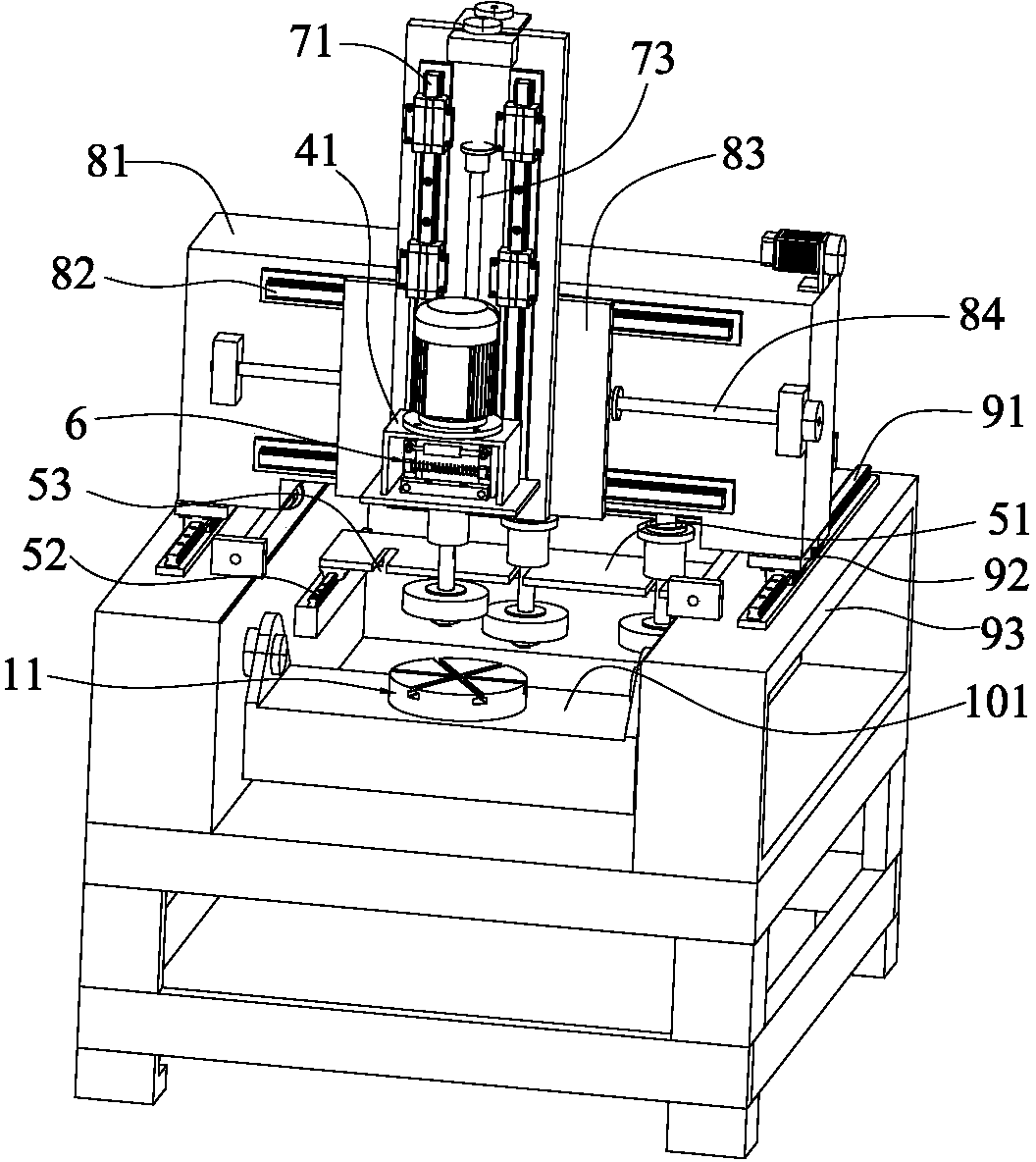

Five-axis numerical control polishing machine capable of changing grinding heads automatically

InactiveCN103465145AAutomatic replacementReduce labor intensityPolishing machinesNumerical controlCurve shape

The invention discloses a five-axis numerical control polishing machine capable of changing grinding heads automatically. The five-axis numerical control polishing machine comprises a plurality of semi-axis grinding heads, a machine body frame, a controller, a polishing head, a grinding head supply mechanism, a spindle clamping device, a Z-axis drive mechanism, an X-axis drive mechanism, a Y-axis drive mechanism, an A-axis rotary workbench and a C-axis rotating mechanism. The polishing head, the grinding head supply mechanism, the spindle clamping device, the Z-axis drive mechanism, the X-axis drive mechanism, the Y-axis drive mechanism, the A-axis rotary workbench and the C-axis rotating mechanism are respectively connected with the controlled and controlled by the same. The five-axis numerical control polishing machine capable of changing grinding heads automatically has the advantages that the polishing machine is ingenious and reasonable in structural design, high in automation level, convenient and fast to operate, high in flexibility by the five-axis linkage structure, and widely applicable; multiple polishing procedures such as rough polishing, fine polishing and mirror polishing can be completed at one-step clamping, clamping time is saved, machining efficiency and precision are increased greatly, polishing effect is guaranteed, work efficiency is increased, labor intensity of workers is lowered, enterprise competitiveness is increased effectively, and polishing of surfaces of complex curve shapes can be achieved.

Owner:东莞市钜铧机械有限公司

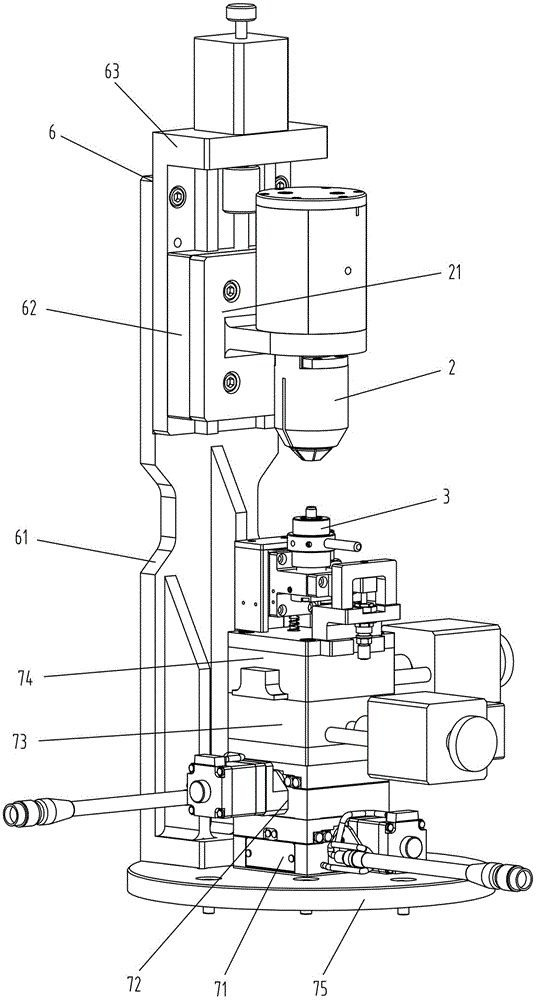

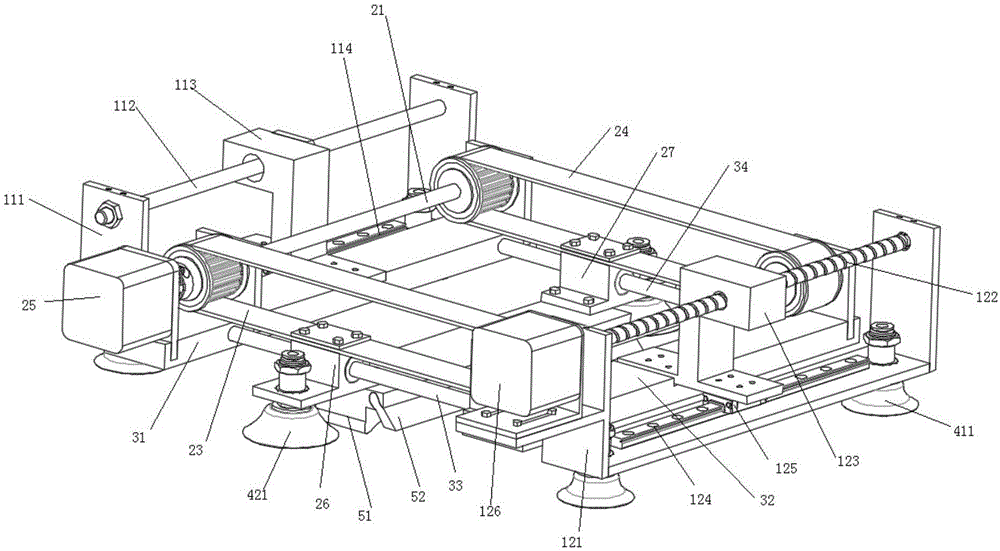

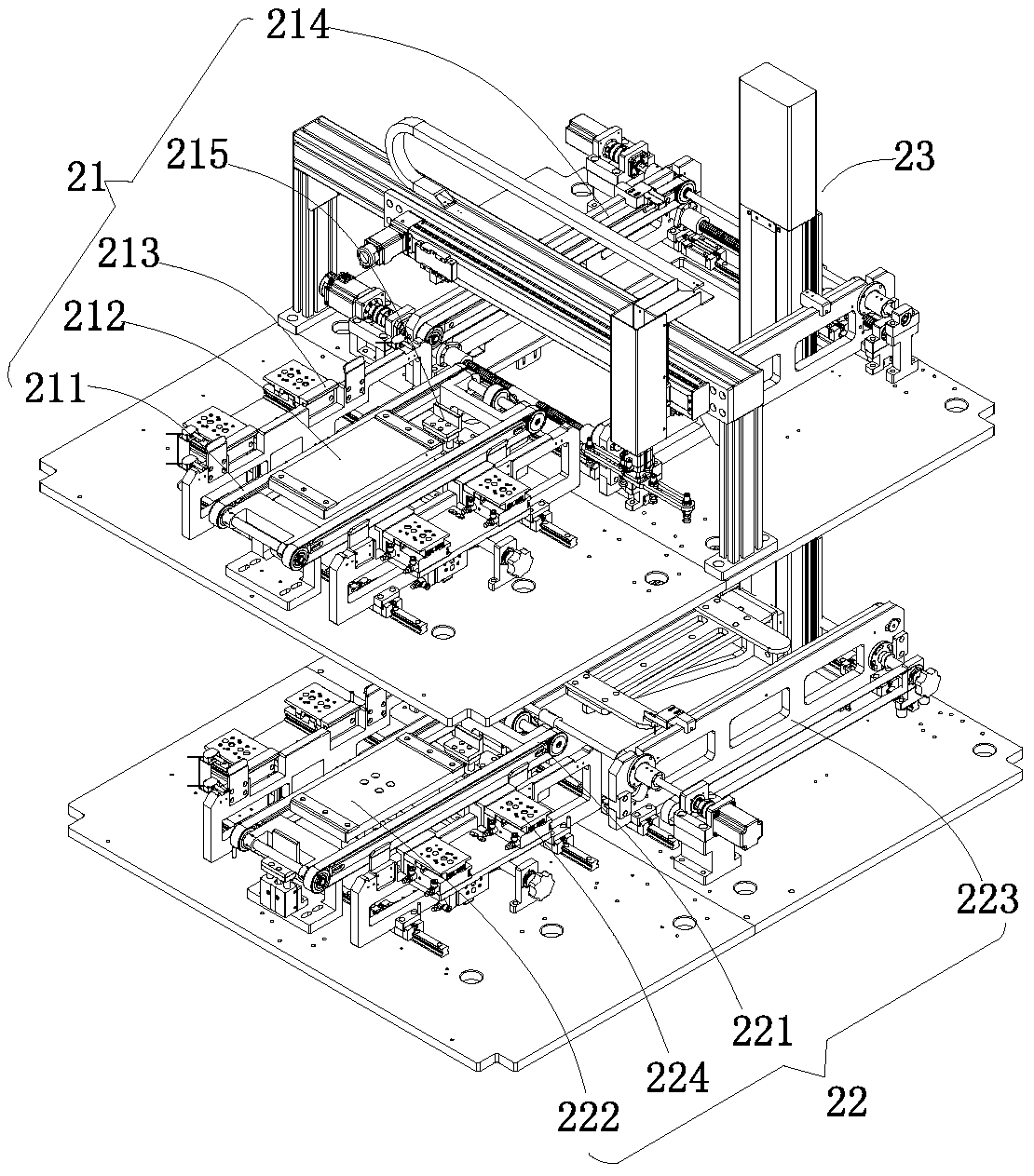

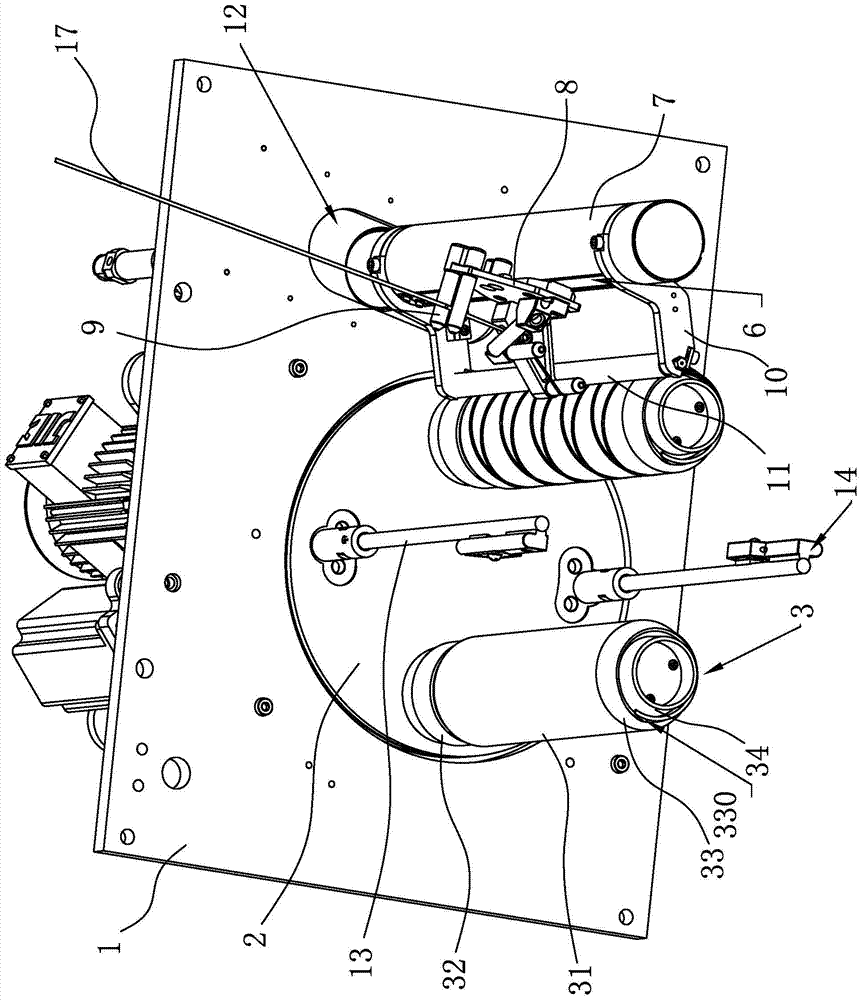

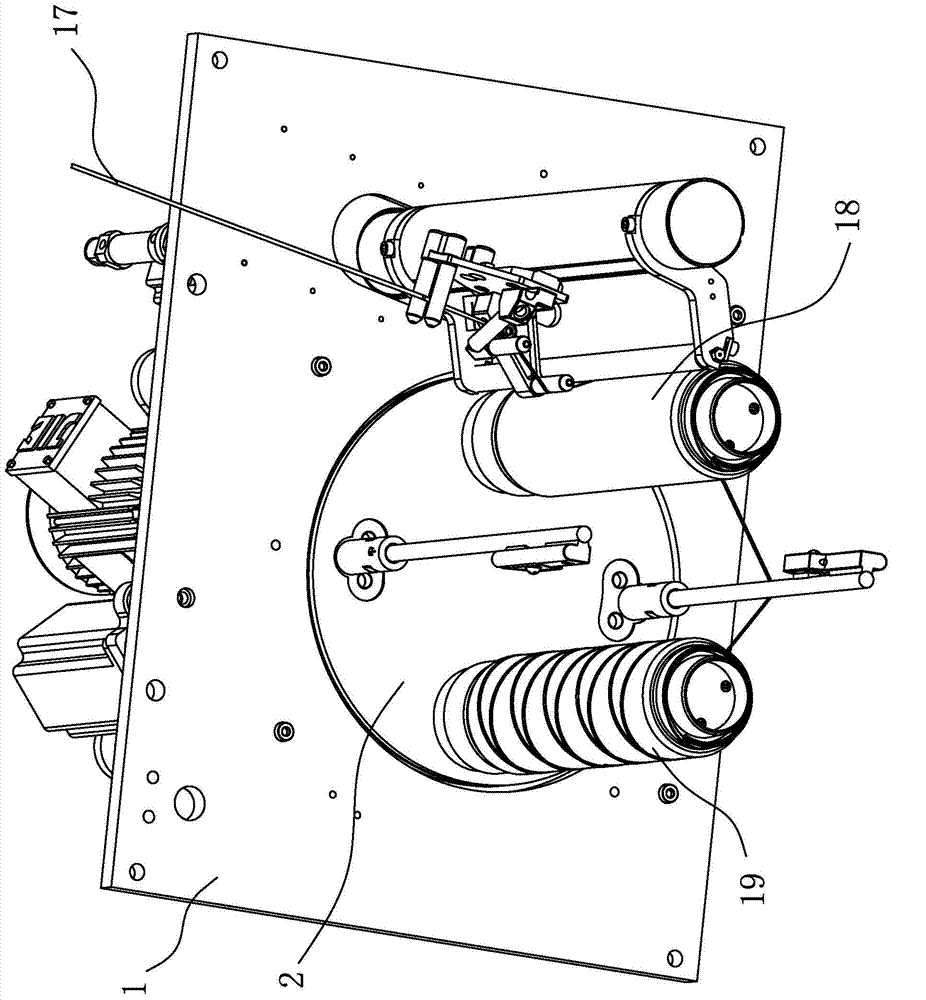

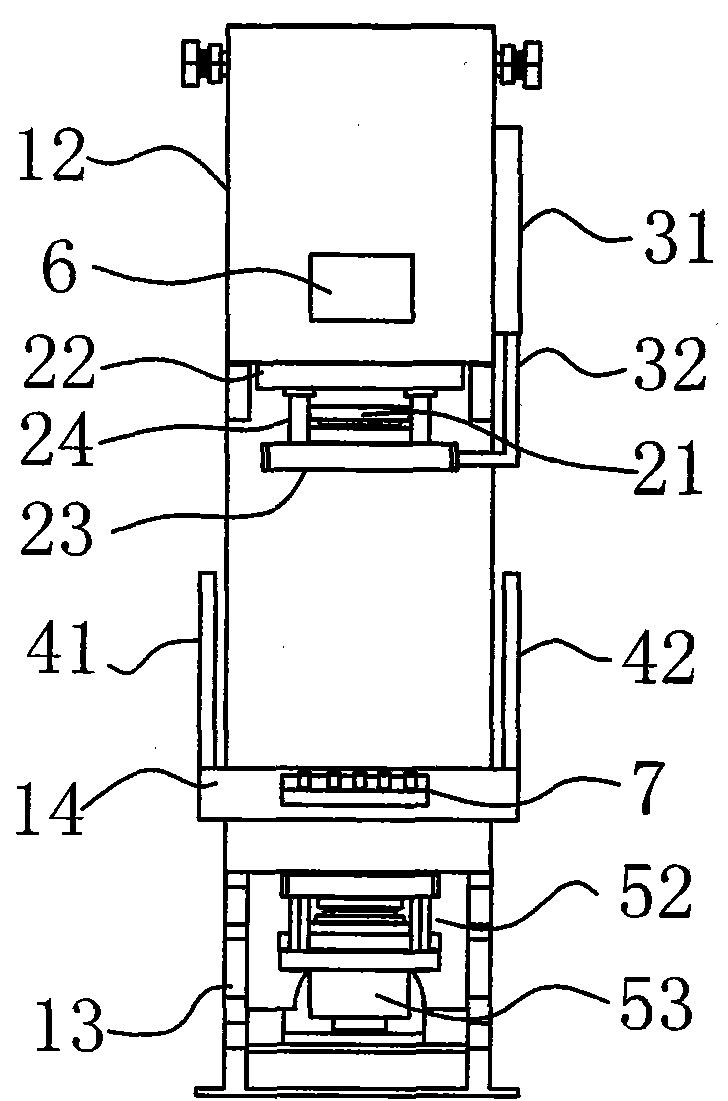

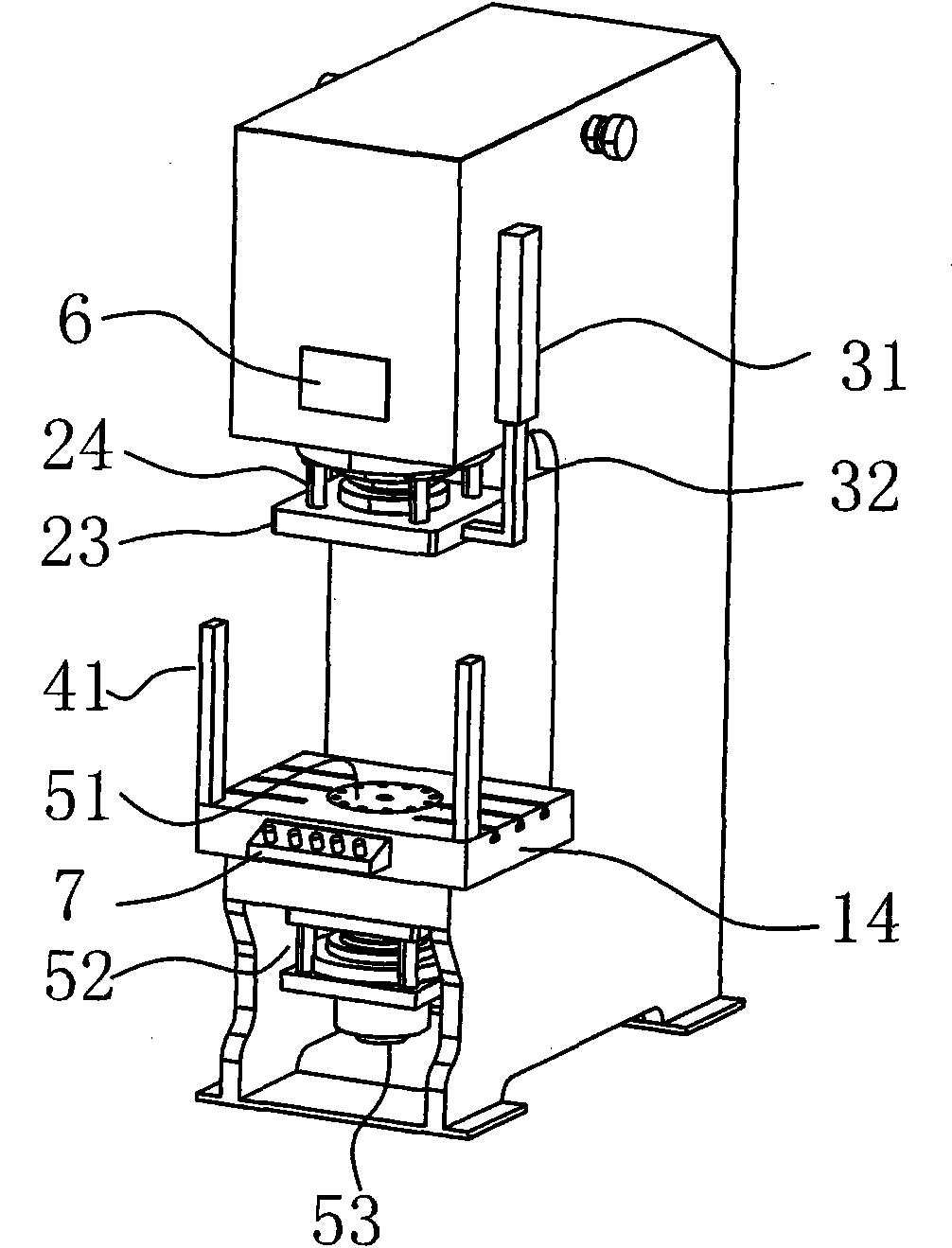

Coupling alignment device and coupling alignment method of coaxial type optoelectronic device

ActiveCN104101966AHigh degree of automationIncrease productivityCoupling light guidesEngineeringMechanical engineering

The invention discloses a coupling alignment device and a coupling alignment method of a coaxial type optoelectronic device. The coupling alignment device comprises a mounting base, an upper clamp and a lower clamp, wherein the upper clamp is arranged on the mounting base through a lifting device; the lower clamp is arranged on the mounting base through an alignment device and can move respectively along an X-axis and a Y-axis and swing respectively around the X-axis and Y-axis under the driving of the alignment device; the lower clamp comprises a base and a clamp component; the base is provided with a bearing component for bearing the clamp component by a constant bearing force and enabling the clamp component to slide up and down; the coupling alignment device further comprises a displacement detection component and a controller. The coupling alignment method comprises the steps of clamping devices, adjusting position of a Z-axis, aligning angles, aligning coarsely, aligning precisely and the like. The coupling alignment device and the coupling alignment method of the coaxial type optoelectronic device have the advantages of rational structure design, adjustment in multiple degrees of freedom, high automation degree, capabilities of greatly improving production efficiency and product quality, and the like.

Owner:CENT SOUTH UNIV

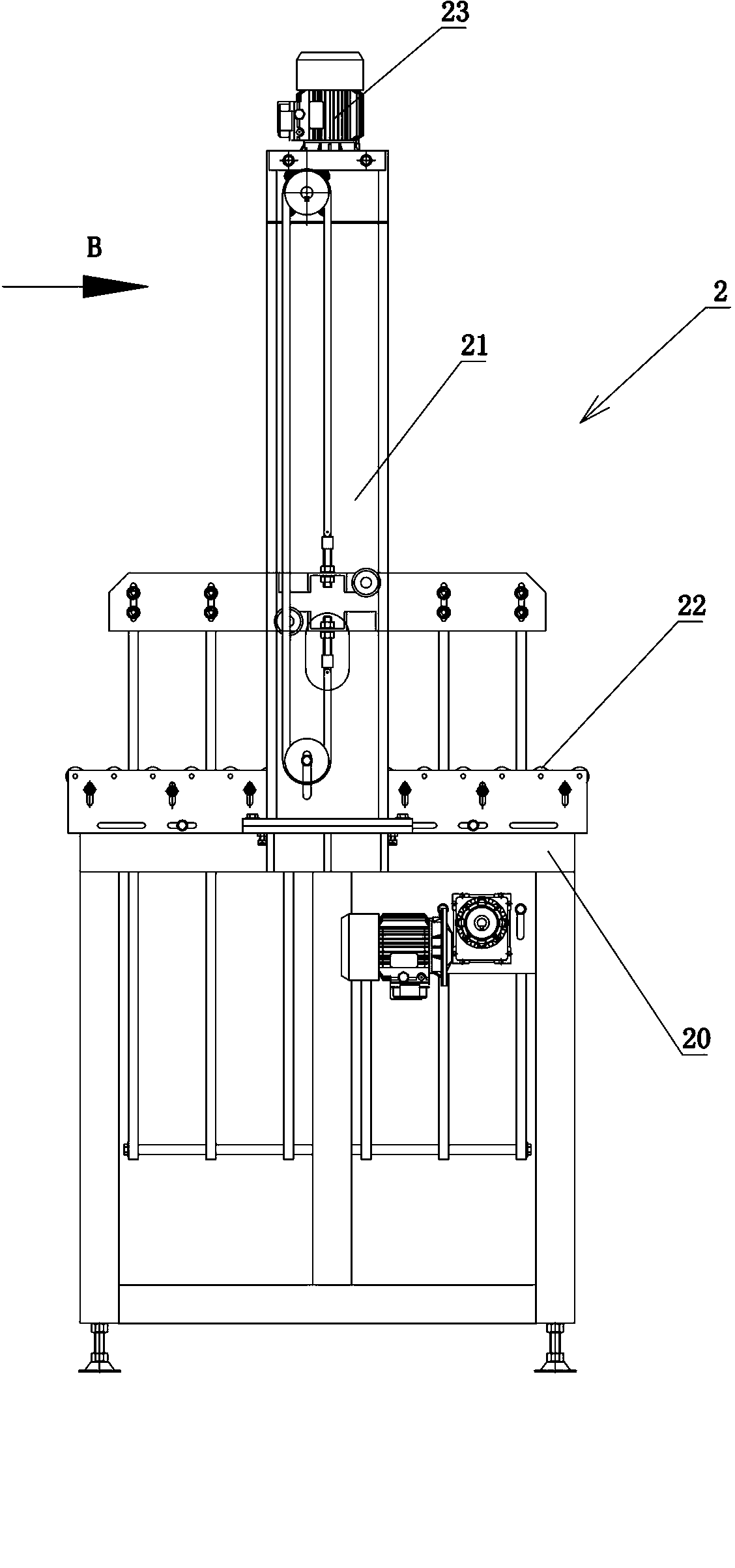

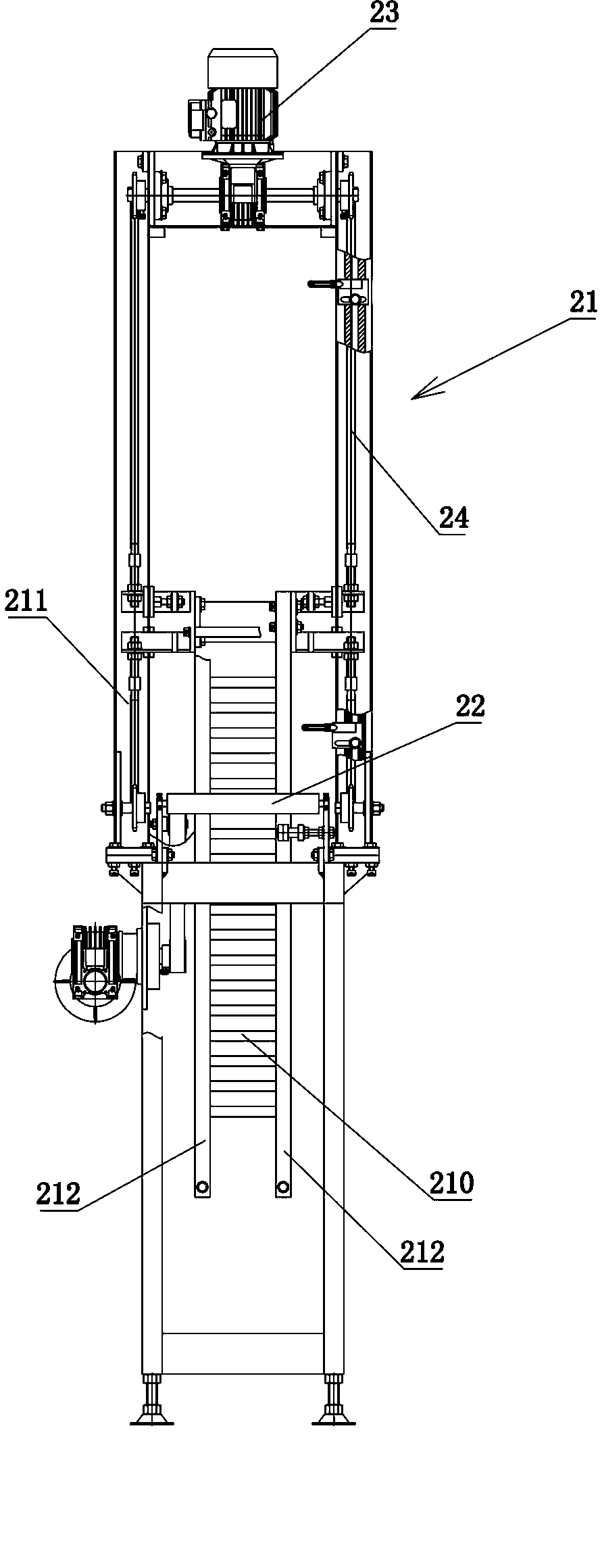

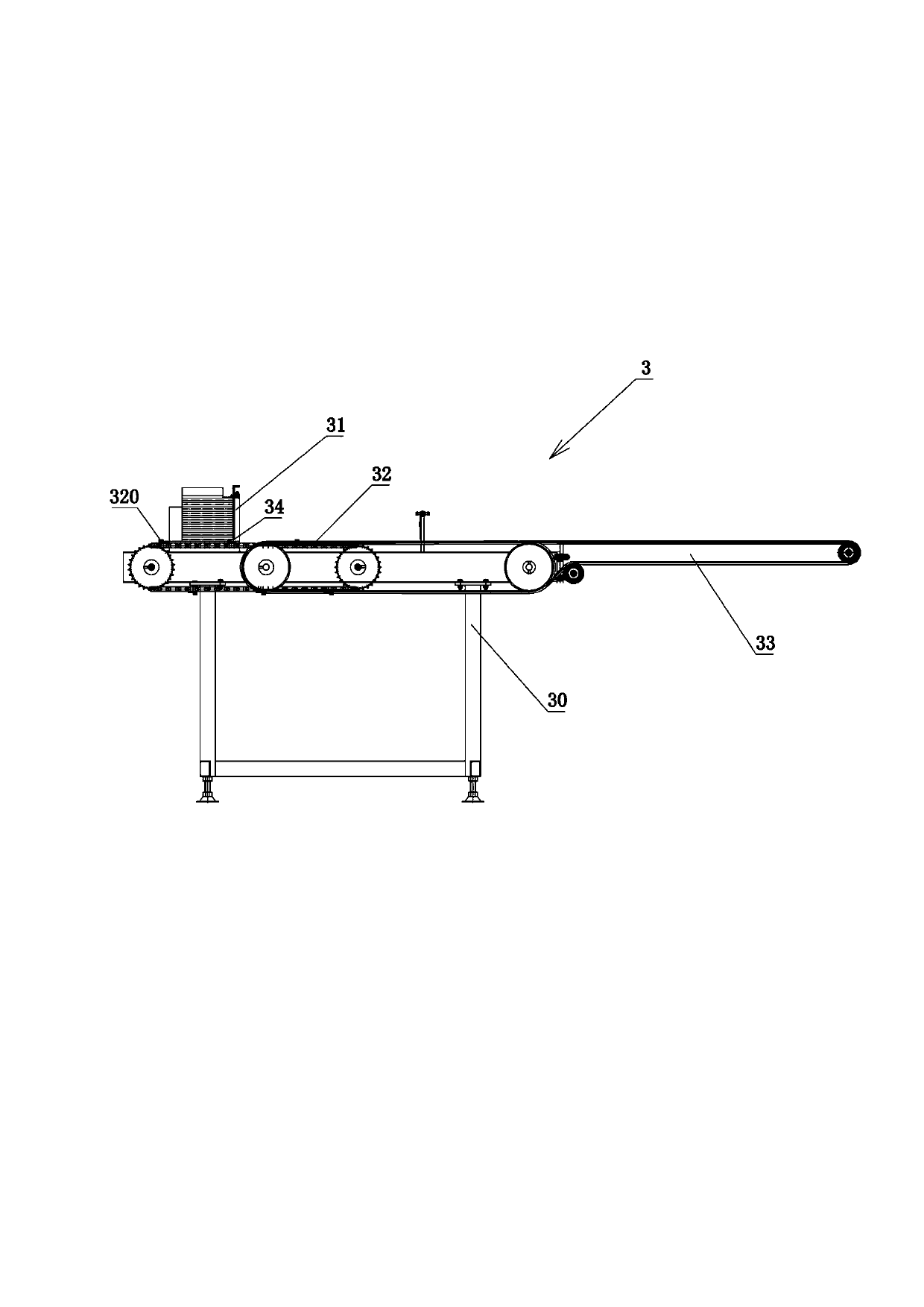

Novel full-automatic middle-small-size tile packaging production line

InactiveCN102730220ASimple structureHigh degree of automationPackaging automatic controlShock-sensitive articlesProduction lineBrick

A novel full-automatic middle-small-size tile packaging production line comprises an initial conveyor platform, a blank storage machine, a tile arranging machine, a tile laminating machine, a box opening, bottom folding and box overturning machine, a bottom and cover sealing machine and a stacker through which the tile passes in sequence, wherein the initial conveyor platform, the blank storage machine, the brick arranging machine, the brick laminating machine, the box opening, bottom folding and box overturning machine, the bottom and cover sealing machine and the stacker are all connected with a terminal control system. Through the initial conveyor platform, the blank storage machine, the brick arranging machine, the brick laminating machine, the box opening, bottom folding and box overturning machine, the bottom and cover sealing machine, the stacker and the like, the packaging production line can realize actions such as ceramic brick conveying, temporary storage, arranging, laminating, boxing, overturning, automatic box sealing and packaging and automatic stacking and delivery. The production line is complete in structure, high in automation degree, low in fault rate, simple and convenient to operate, convenient to maintain, low in manufacturing cost and cheap in price, suitable for packaging of middle-small-size tiles, high in practicability, and efficient and fast, and facilitates wide popularization and use.

Owner:FUJIAN KEJIE ELECTROMECHANICAL

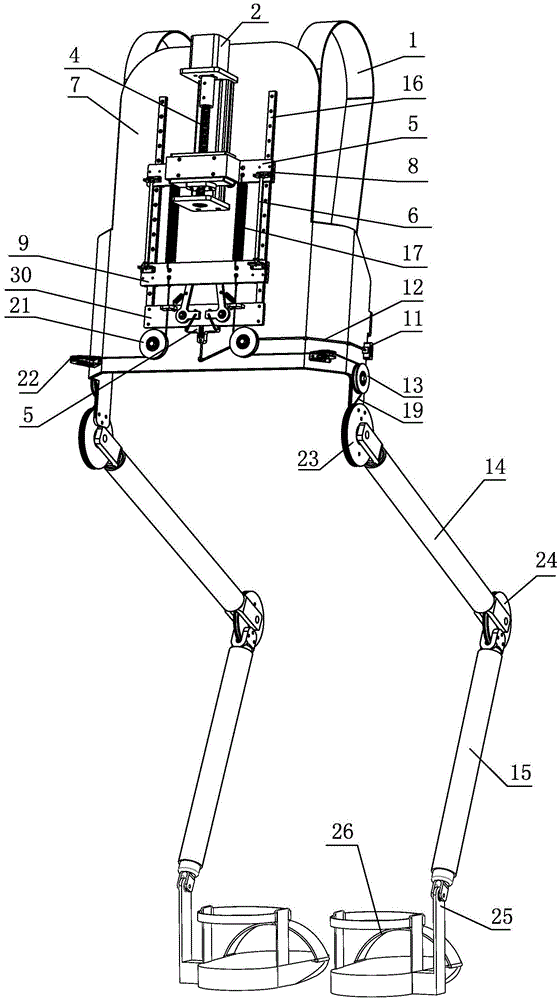

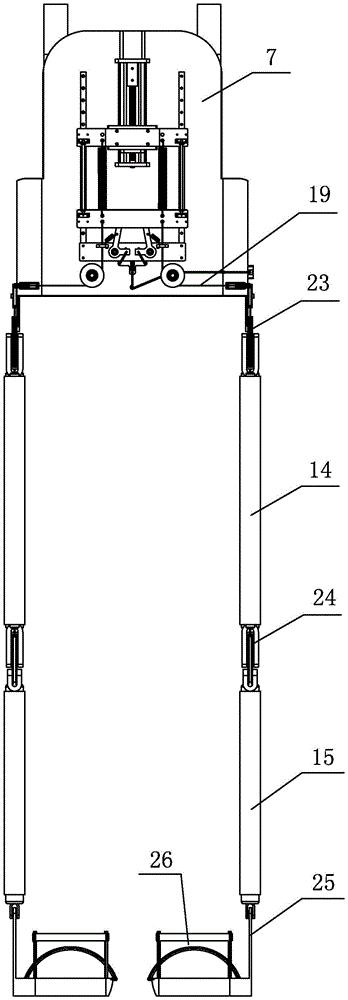

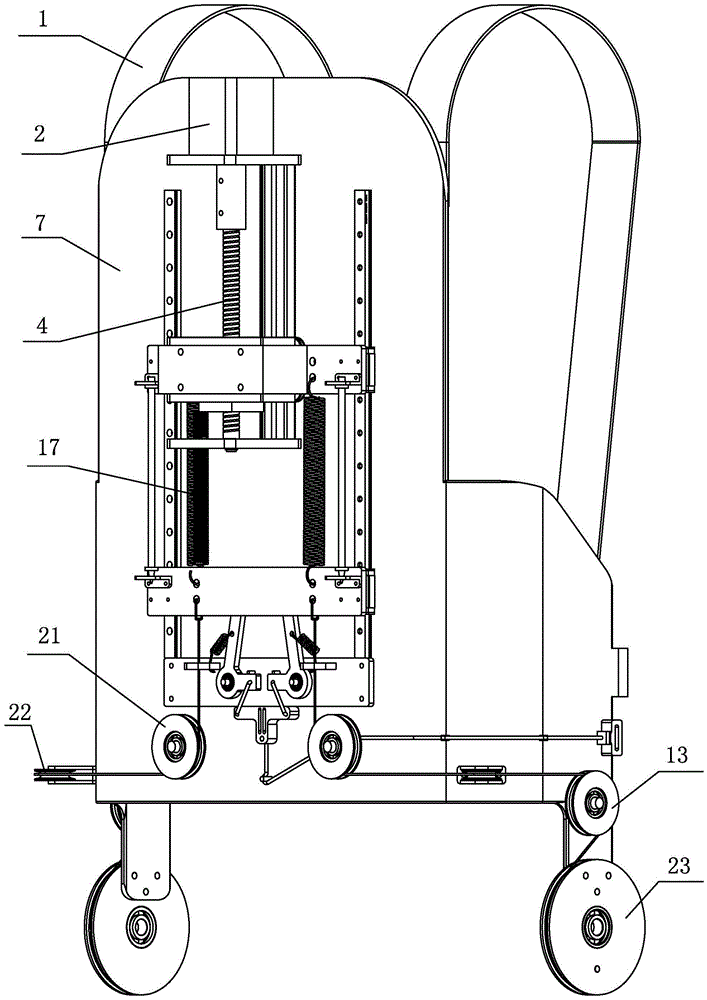

Exoskeleton with function of assisting in jumping through energy storage of springs

ActiveCN105479438AImprove explosive powerIncrease jump heightProgramme-controlled manipulatorThighKnee Joint

The invention discloses an exoskeleton with the function of assisting in jumping through energy storage of springs, relates to an exoskeleton, and solves the problems that a conventional exoskeleton is mainly used for enhancing walking or running, and an exoskeleton used for improving the simple exercise capacity of a human body has not yet been provided. The exoskeleton comprises a left leg, a right leg and a back. Both the left leg and the right leg comprise thighs, calves, feet, hip joints, knee joints and ankle joints. The back is rotationally connected with the thighs through the hip joints. The thighs are rotationally connected with the calves through the knee joints. The calves are rotationally connected with the feet through the ankle joints. The exoskeleton further comprises a driving motor, a lead screw pair, an energy storage spring pulling plate, an energy storage spring releasing plate, a pull ring, a stay cord, a connecting plate, an auxiliary pressure spring mechanism, return poking rods, two hooks, two guide rails, two energy storage springs, two reset springs, two first traction driving steel wire ropes, two second traction driving steel wire ropes, two auxiliary pulleys, two reserving pulleys and two connecting rods. The exoskeleton is used for assisting in walking or jumping.

Owner:HARBIN INST OF TECH

Automatic glass cleaning robot

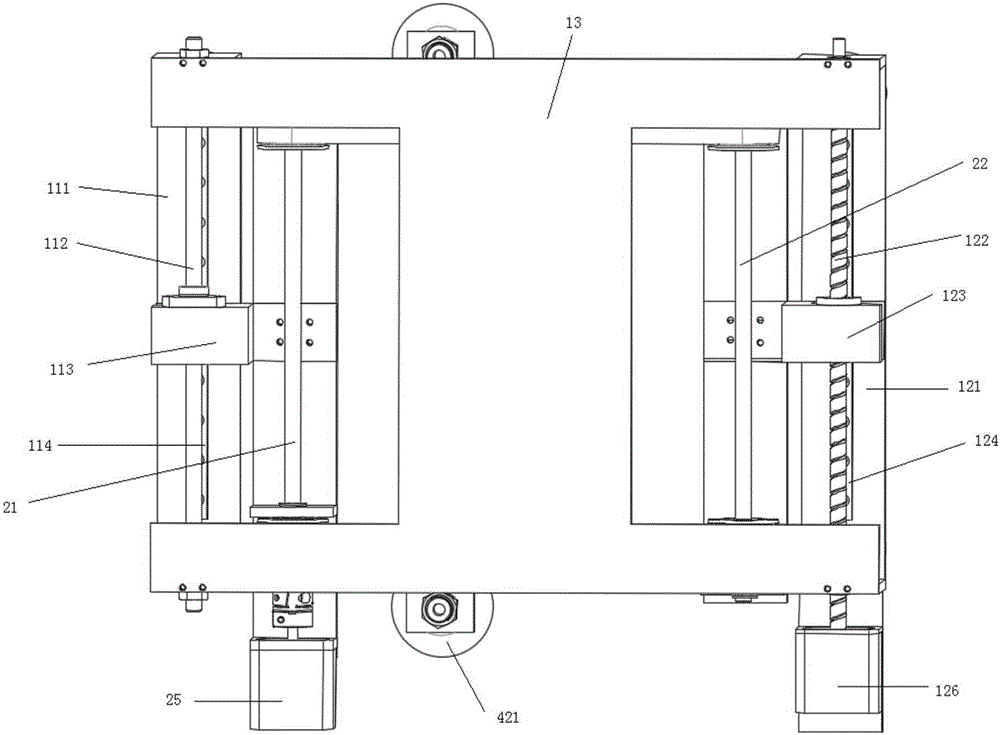

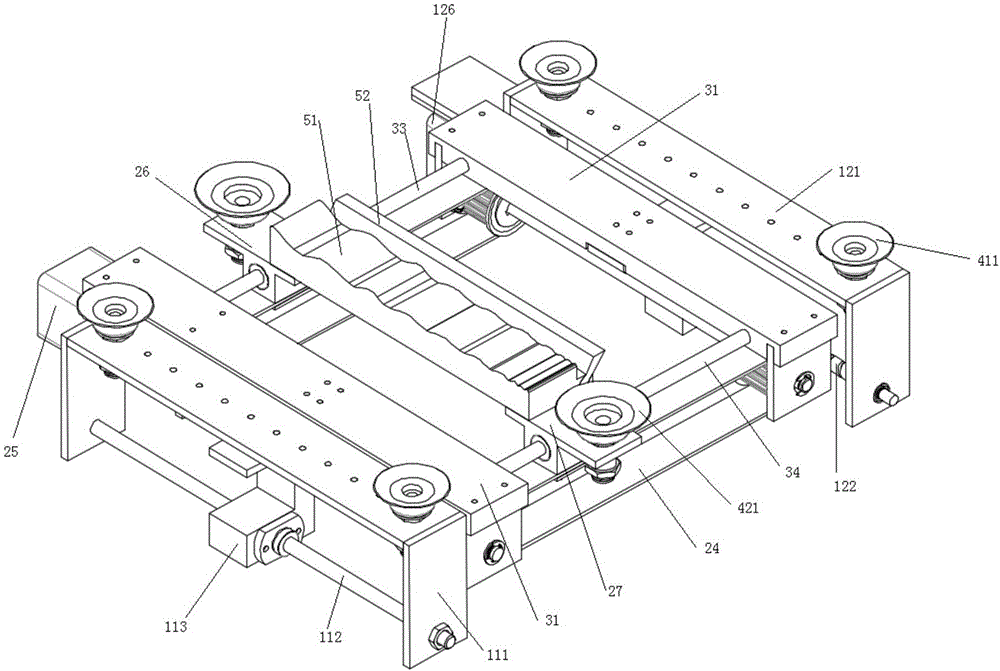

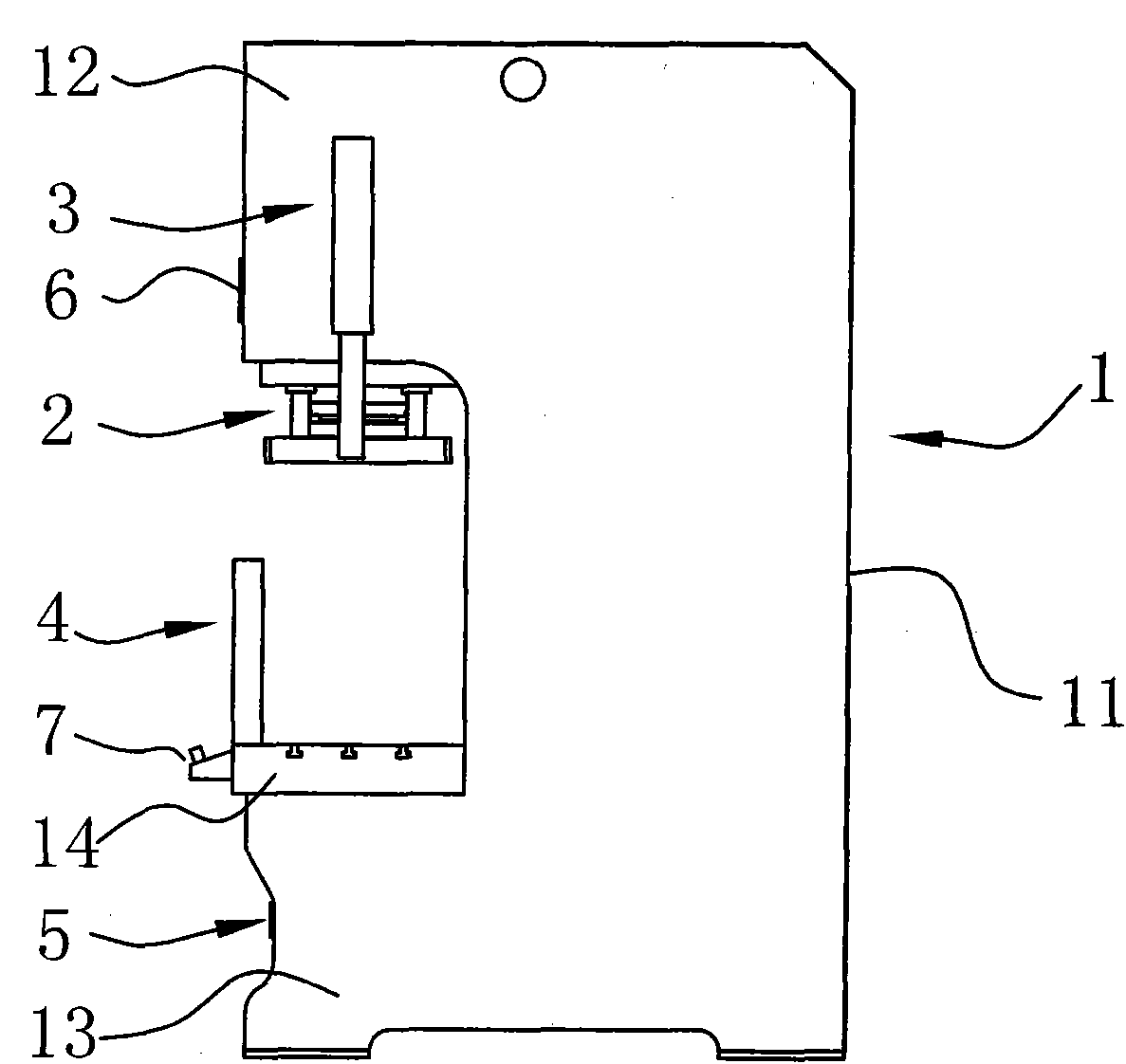

ActiveCN106419722AReduce cleaning costsAchieve freedom of movementCarpet cleanersFloor cleanersAgricultural engineeringRobot

The invention relates to the field of robot invention, and particularly to an automatic glass cleaning robot which comprises an engine base, a first translation mechanism, a second translation mechanism, an adsorption mechanism and a cleaning mechanism, wherein the first translation mechanism and the second translation mechanism are respectively installed on the engine base; the cleaning mechanism is installed on the second translation mechanism; the adsorption mechanism is installed on the first translation mechanism and the second translation mechanism respectively; the first translation mechanism matches the adsorption mechanism to realize the movement of the robot towards a first direction; the second translation mechanism matches the adsorption mechanism to realize the movement of the robot towards a second direction; the second translation mechanism matches the adsorption mechanism and the cleaning mechanism to realize the glass cleaning function of the automatic glass cleaning robot; and the first direction and the second direction are vertical to each other. The automatic glass cleaning robot provided by the invention can realize the free movement of the robot along two vertical directions, the operation is easy and saves both time and labor, the cleaning effect is good, the structure is simple, and the manufacturing cost is low.

Owner:唐山新禾智能科技有限公司

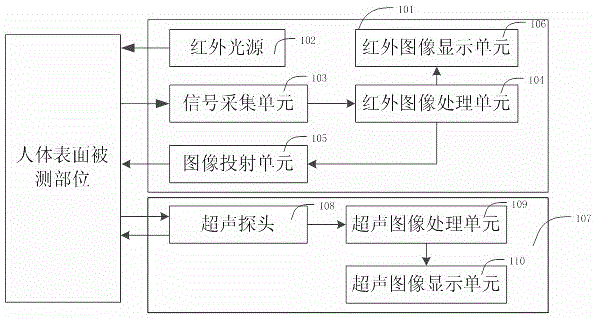

Venipuncture system with infrared guidance and ultrasonic location

ActiveCN105107067ASolve the problem of difficult punctureEasy to findIntravenous devicesVenous vesselBlood vessel

The invention relates to a venipuncture system with infrared guidance and ultrasonic location. The venipuncture system is characterized by comprising an infrared guidance unit and an ultrasonic location unit, wherein the infrared guidance unit comprises an infrared light source, a signal acquisition unit, an infrared image processing unit, an image projection unit and an infrared image display unit; the ultrasonic location unit comprises a high-frequency ultrasonic probe, an ultrasonic image processing unit, an ultrasonic image display unit and a puncture needle connection frame fixed on the ultrasonic probe. According to the system provided by the invention, superficial vein blood vessels can be positioned and displayed through infrared imaging, and the depth of the vein blood vessels also can be identified through the ultrasonic unit under the guidance of an infrared image, so that a needle entering angle and the depth of a puncture needle can be observed in real time, and furthermore, the venipuncture difficulty is reduced and the puncture precision is improved.

Owner:ZD MEDICAL HANGZHOU CO LTD

Patient caring bed with turnover assisting function and turnover assisting method thereof

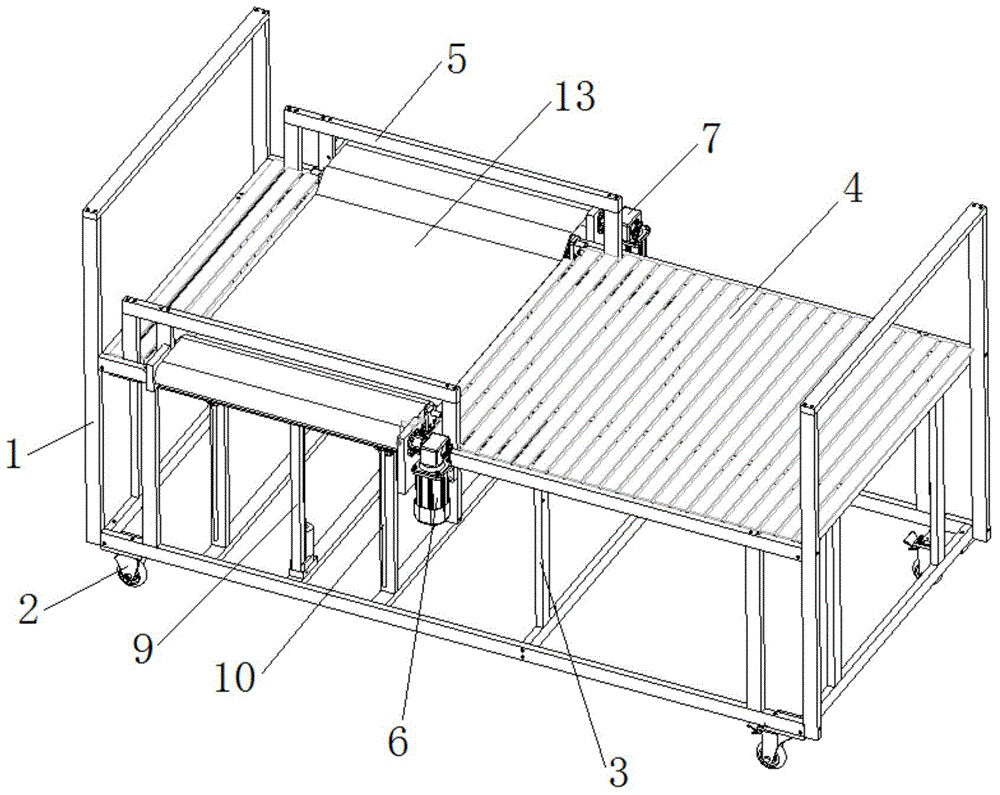

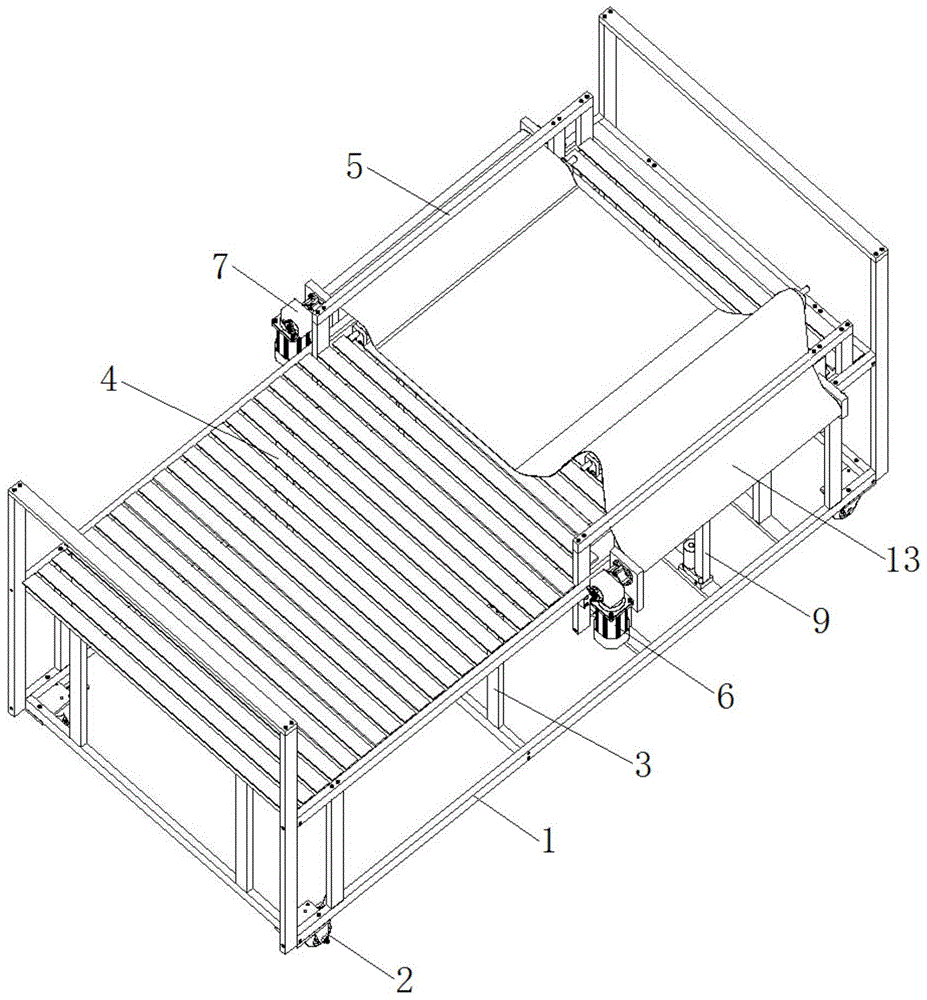

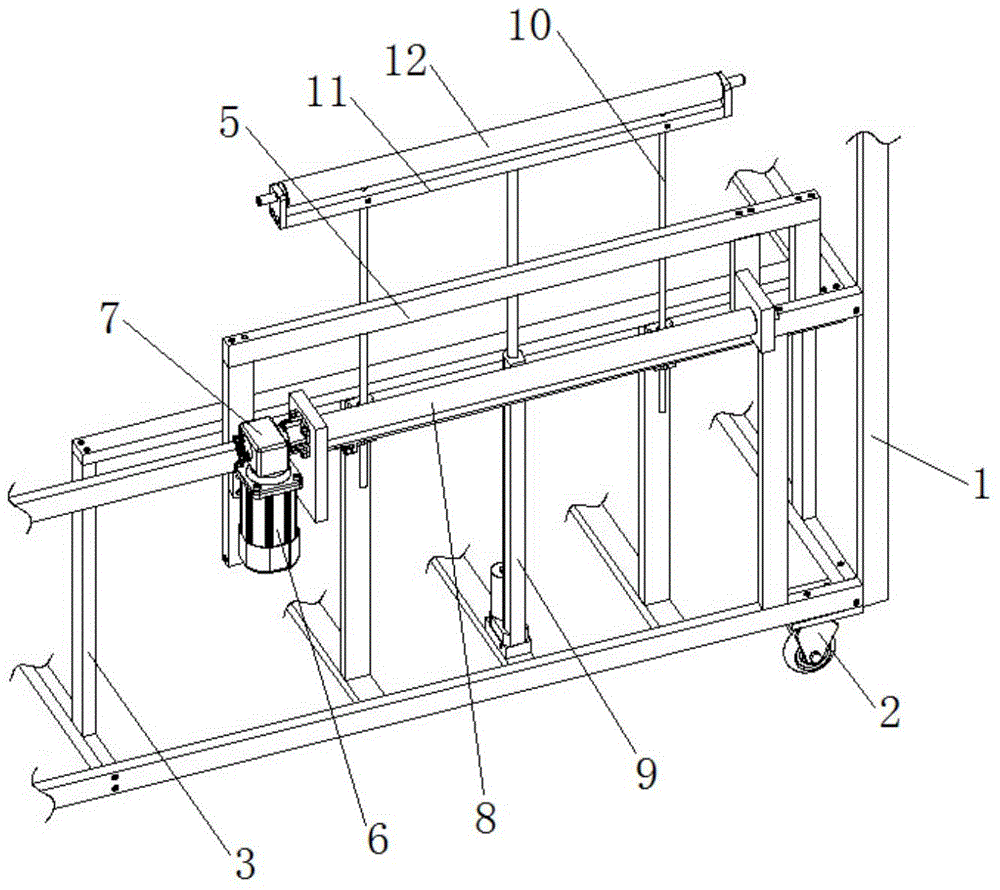

ActiveCN104352315AImprove comfortReduce work intensityNursing bedsEngineeringUltimate tensile strength

The invention discloses a patient caring bed with a turnover assisting function and a turnover assisting method thereof and belongs to the field of caring beds. The patient caring bed comprises a bed body frame, a bed plate, an ejection mechanism and a cloth winding mechanism, wherein the cloth winding mechanism comprises cloth winding rolls, a driving device and turnover cloth; the cloth winding rolls are arranged at the two sides of the caring bed; the driving device is used for driving the cloth winding rolls to rotate; the two ends of the turnover cloth are respectively and fixedly wound on the cloth winding rolls at the two sides; the turnover cloth between the two cloth winding rolls are laid on the bed plate; the ejection mechanism comprises two ejecting rolls positioned under the turnover cloth, an ejecting bracket for installing the ejecting rolls, an electric pushing rod arranged under the ejecting bracket and a guiding device. The invention also discloses the turnover assisting method of the patient caring bed. The patient caring bed and the turnover assisting method disclosed by the invention have the advantages that the inclination of the body of a patient is realized by utilizing the ejection mechanism and the cloth winding mechanism to assist serving staffs to turn over the patient, the turnover action is gentle, the comfort level of the patient is high, and the working intensity of the serving staffs is greatly reduced.

Owner:上海稼多医疗器械有限公司

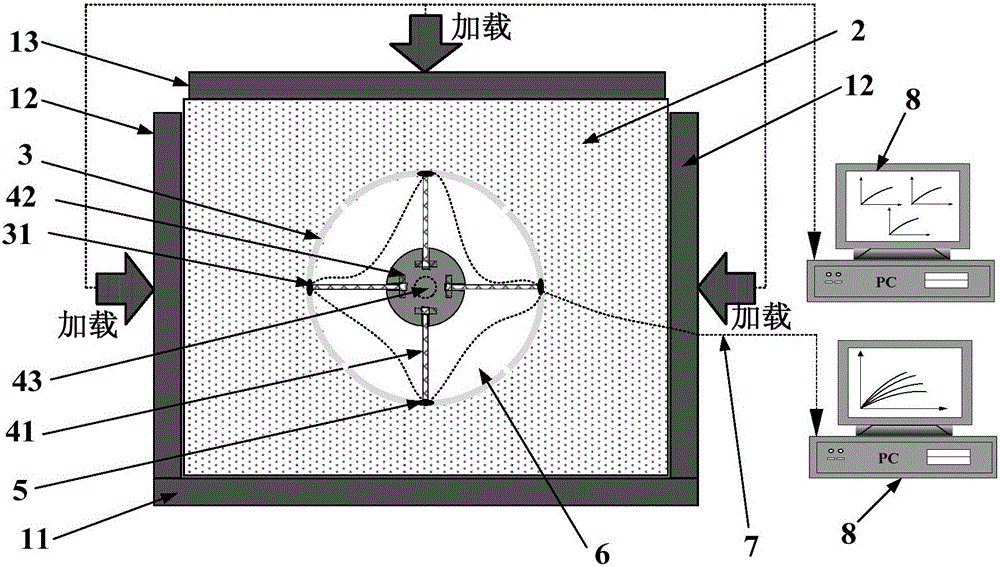

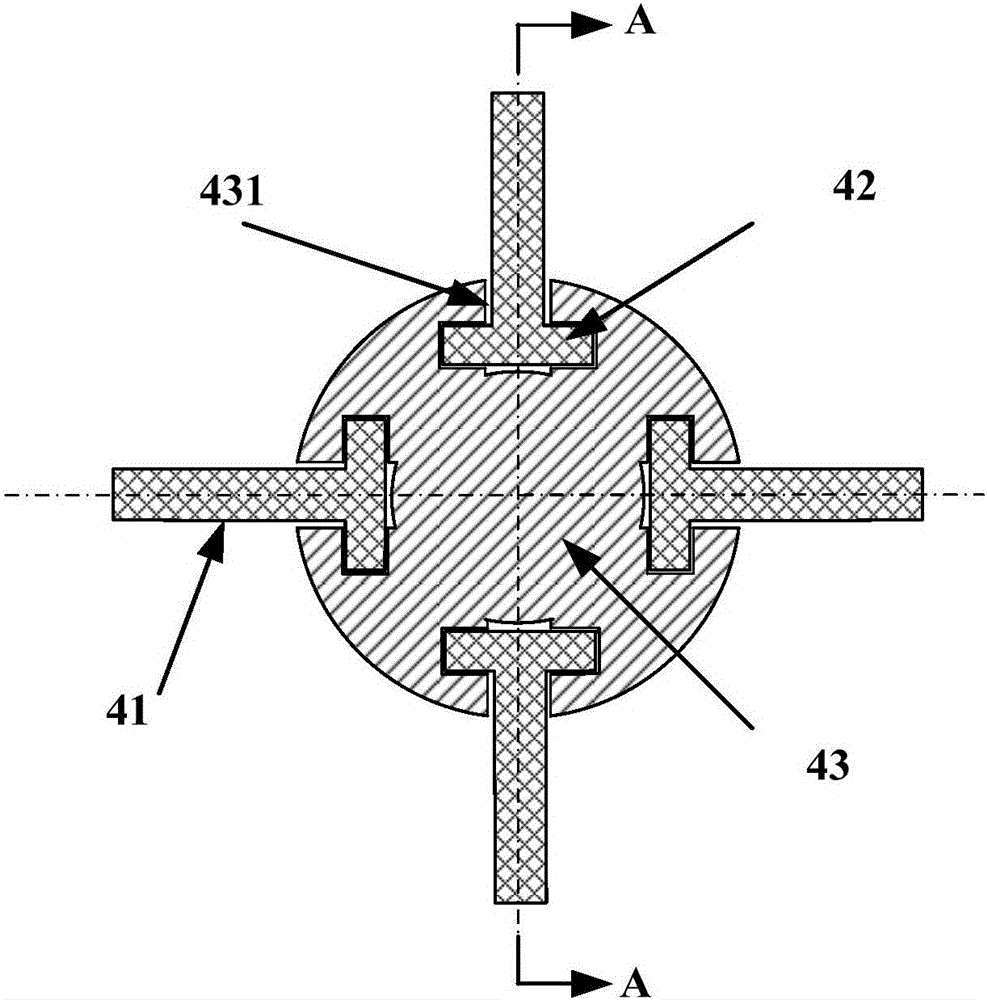

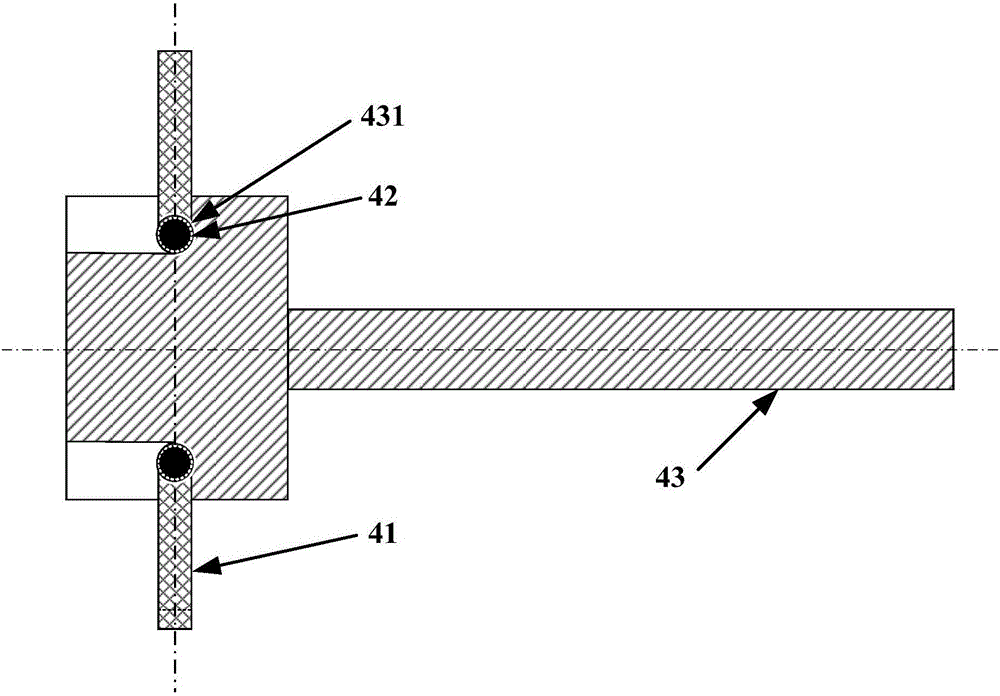

Tunnel excavation unloading simulation testing device and testing method

ActiveCN105931558AIngenious structural designCause additional disturbanceEducational modelsEngineeringSimulation testing

The invention provides a tunnel excavation unloading simulation testing device and testing method. In the tunnel excavation unloading simulation testing device, a lower bearing plate, a side bearing plate, and an upper bearing plate wrap a sample together, a prefabricated tunnel is arranged in the sample, a fixed board is laid along the outer surface of the prefabricated tunnel, a groove is arranged in the fixed board, a pressure sensor is arranged in the groove, the pressure sensor is in signal connection with a computer, one end of the support rod is hinged to one end of an unloading rod, the other end of the support rod is movably connected with the groove, the other end of the support rod is tightly attached to the pressure sensor, a loading end acts on the side bearing plate and the upper bearing plate, and the loading end is in signal connection with the computer. The tunnel excavation unloading simulation testing device can stimulate the tunnel surrounding rock excavation unloading process, generates no obvious additional disturbance to the surrounding rocks, can accurately control the unloading rate and unloading amount of the surrounding rocks, and accurately measures the related mechanic parameters during the unloading.

Owner:SHANDONG UNIV OF SCI & TECH

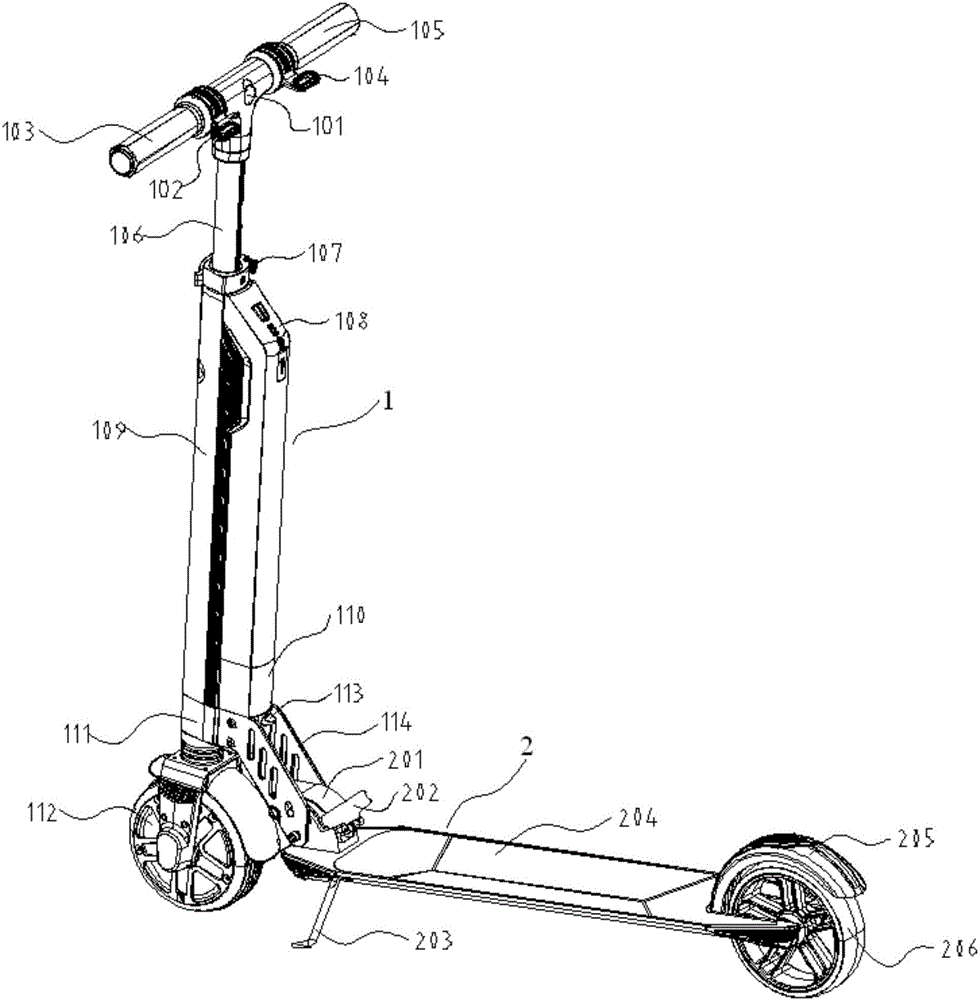

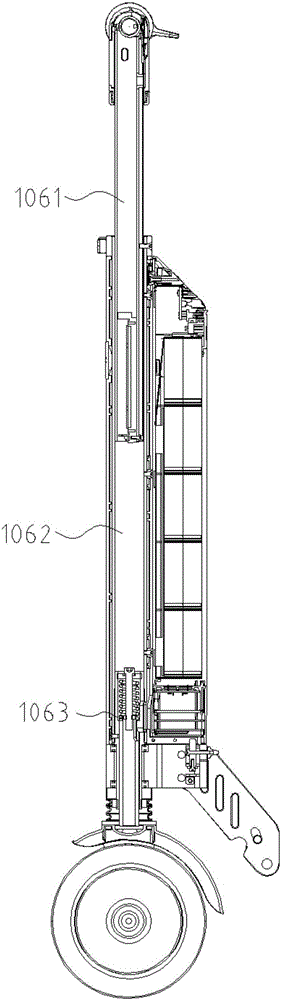

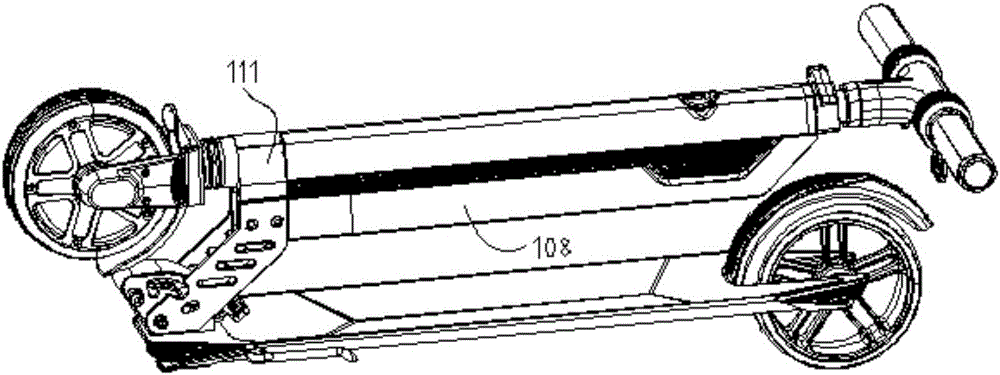

Intelligent folding scooter

ActiveCN105818912AIngenious structural designSimple and stylish structureSteering deviceFoldable cyclesDrive wheelHuman–computer interaction

The invention relates to an intelligent folding scooter which comprises a front scooter body and a rear scooter body. The front scooter body and the rear scooter body are connected in a foldable mode through a front scooter body and rear scooter body connecting piece. The front scooter body comprises handlebars, a handlebar lifting rod and a driving wheel, wherein the handlebars are connected to the two sides of the top end of the handlebar lifting rod through threads, a front wheel fork piece is fixedly arranged at the bottom of the handlebar lifting rod, and the driving wheel is rotationally installed on the front wheel fork piece. The rear scooter body comprises a pedal, a folding device and a rear wheel, wherein the folding device is fixedly installed at the front end of the pedal and provided with a folding footstep, the front scooter body and rear scooter body connecting piece is movably connected to the folding device, a rear wheel installation base is arranged at the rear end of the pedal, the rear wheel is rotationally installed on the rear wheel installation base, a battery locking device and a controller are arranged on the handlebar lifting rod, a detachable and replaceable battery pack is installed on the battery locking device, and the controller is electrically connected with the detachable and replaceable battery pack. The intelligent folding scooter is light and flexible, easy to fold and store, complete in function and good in man-machine interaction performance.

Owner:NANJING KUAILUN INTELLIGENT TECH CO LTD

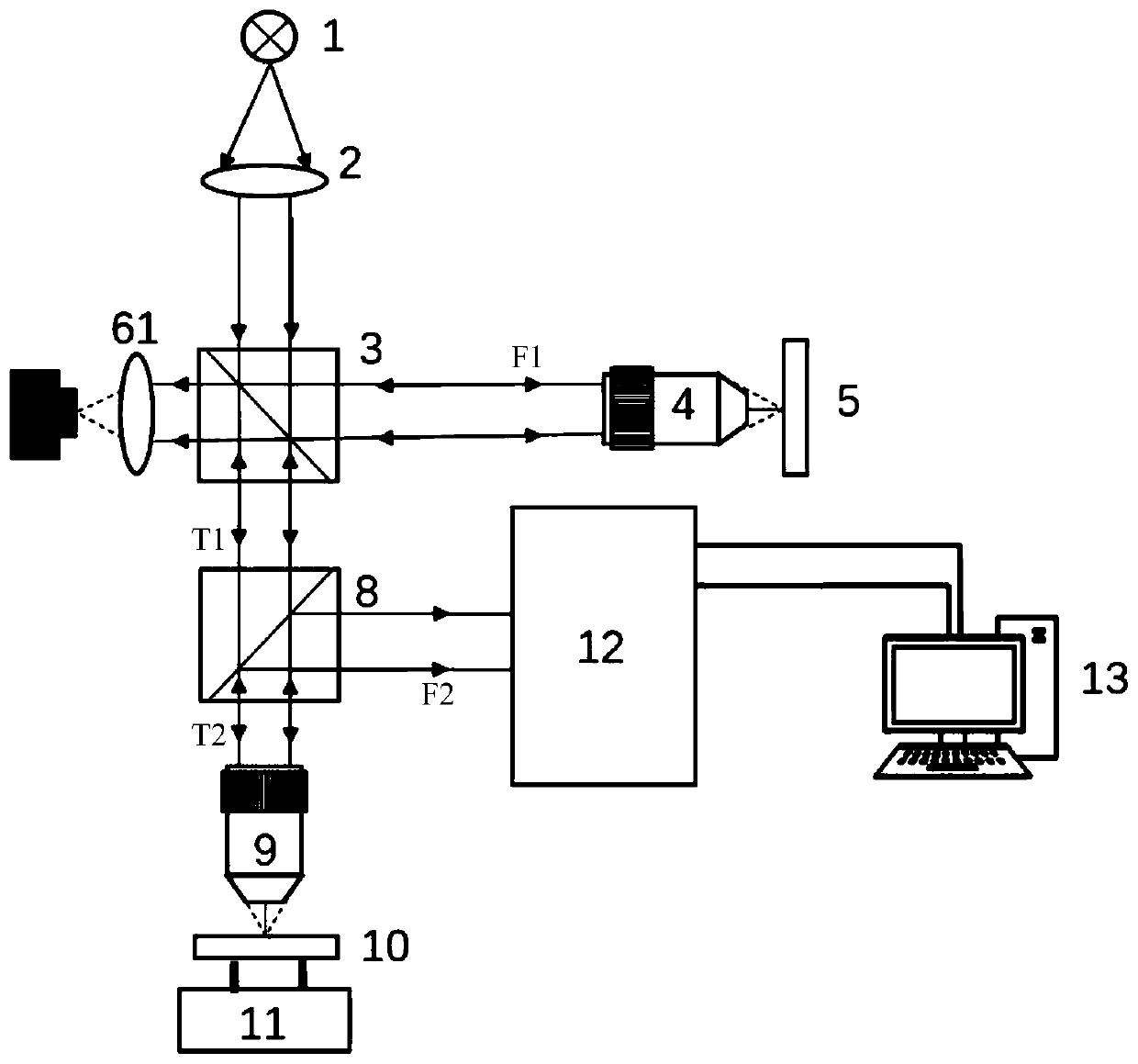

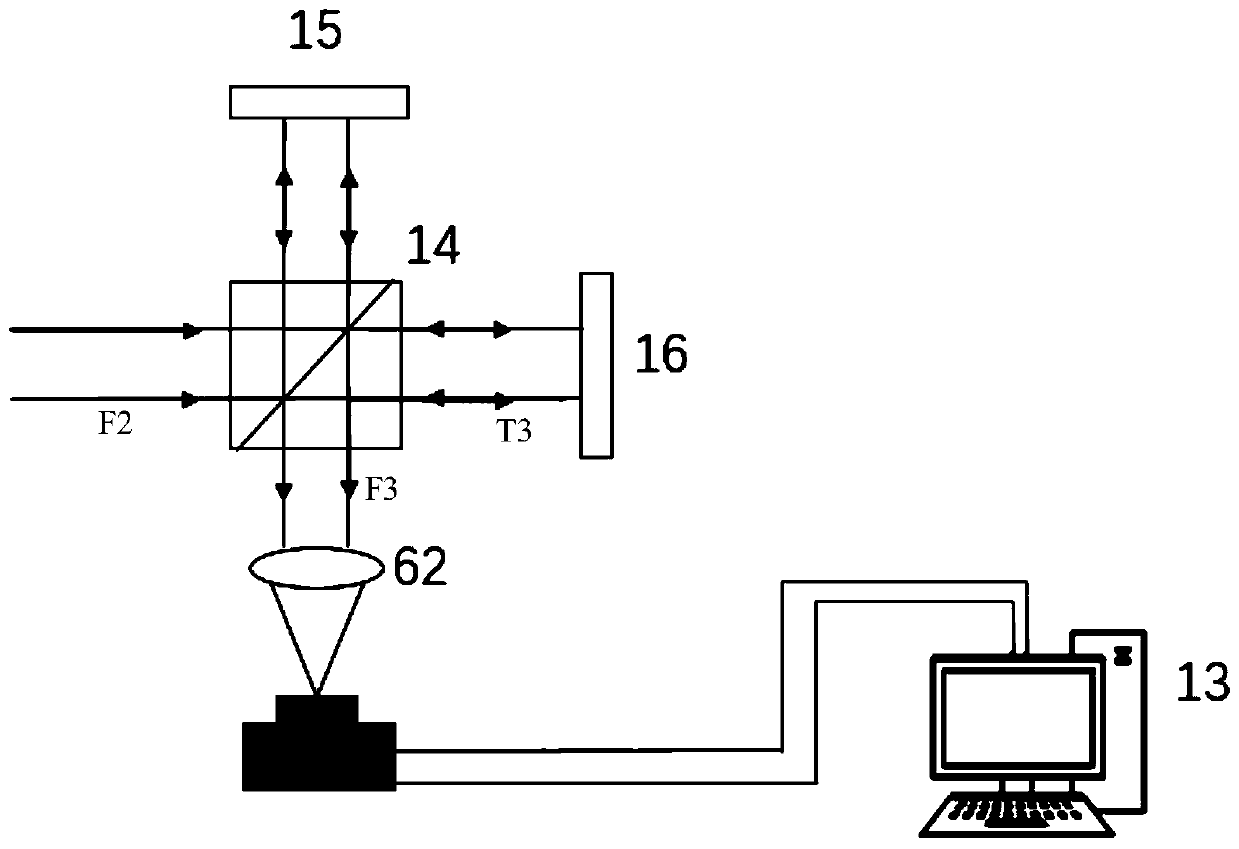

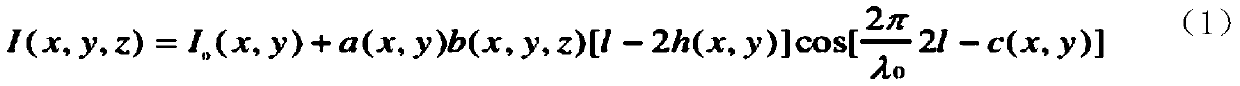

White light microscopic interferometry system and method capable of acquiring spectral information

InactiveCN109781633ARealize multivariate measurementNovel thinkingPhase-affecting property measurementsUsing optical meansBeam splitterCatoptrics

The invention, belonging to the field of precision measurement, relates to a white light microscopic interferometry system and method capable of acquiring spectral information. The system comprises awide spectrum light source, a first beam splitter, a first microscope objective, a second beam splitter, a second microscope objective, a first CCD detector and a spectrum detecting module. Light emitted by the light source is split into reflected light and transmitted light by the beam splitters; the split light passes through a reference optical path and a test optical path; after the interfering on the beam splitters, the processed light is received by the CCD detector to obtain a surface microstructure of a to-be-tested plane; and the beam splitters are added into the test optical path, areflection optical signal containing the spectral information of the to-be-tested plane is introduced into the spectrum detection module to obtain an interference pattern, and Fourier transform calculation is carried out by a PC terminal to obtain spectral information. The employed ideal is novel; and the surface topography detection technology is combined with the Fourier transform spectroscopy principle, so that the surface stereoscopic shape and spectral information of the sample can be obtained simultaneously. Therefore, the multi-element measurement of the object is realized; and the experimental steps and time are saved.

Owner:SHANDONG UNIV

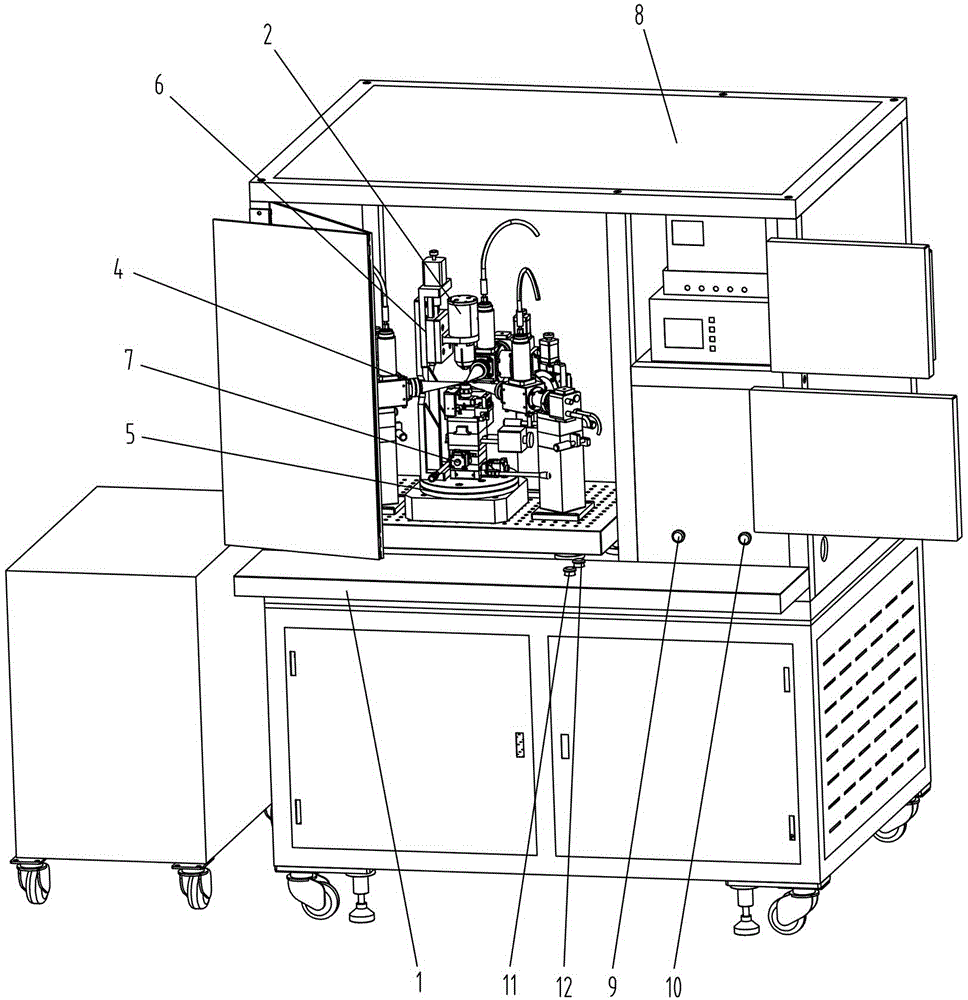

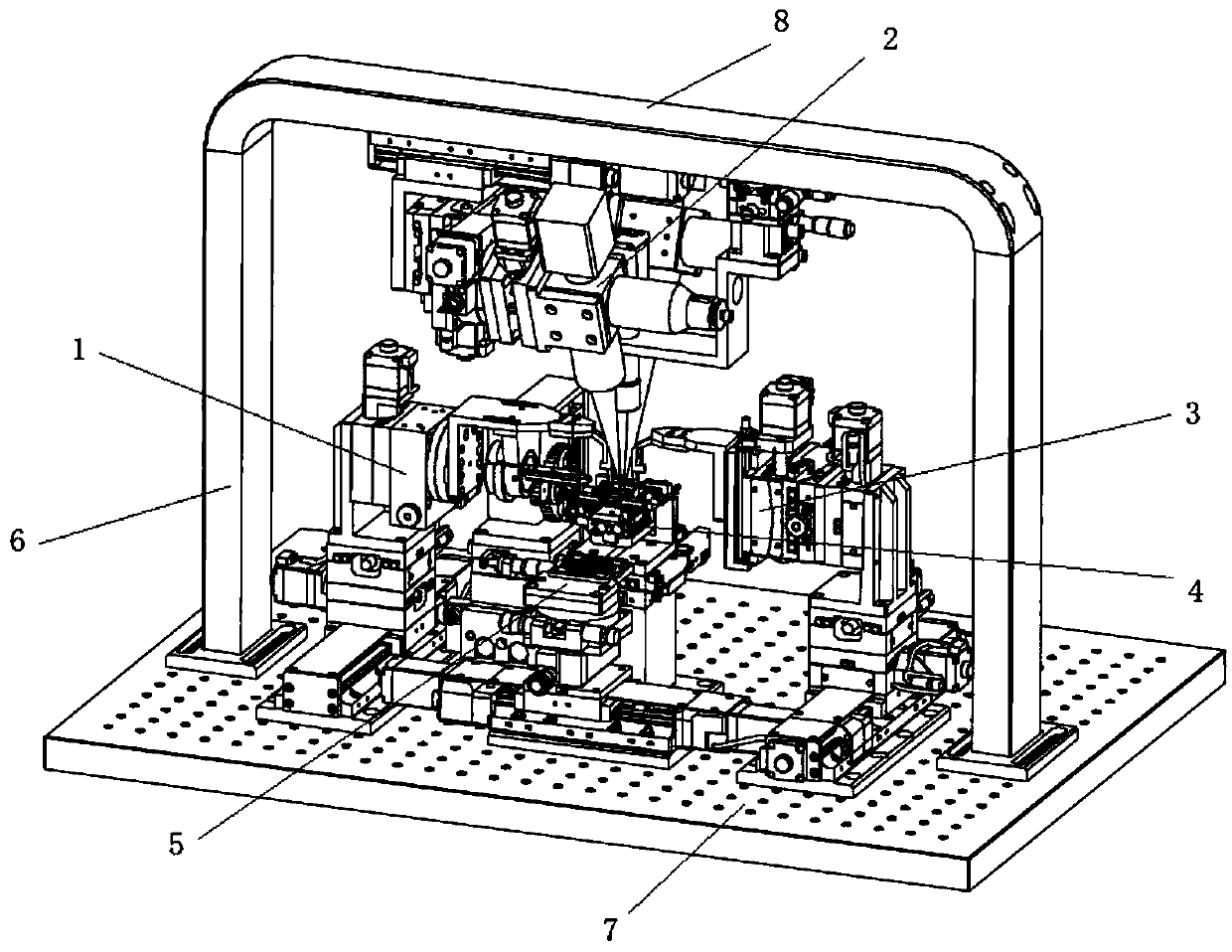

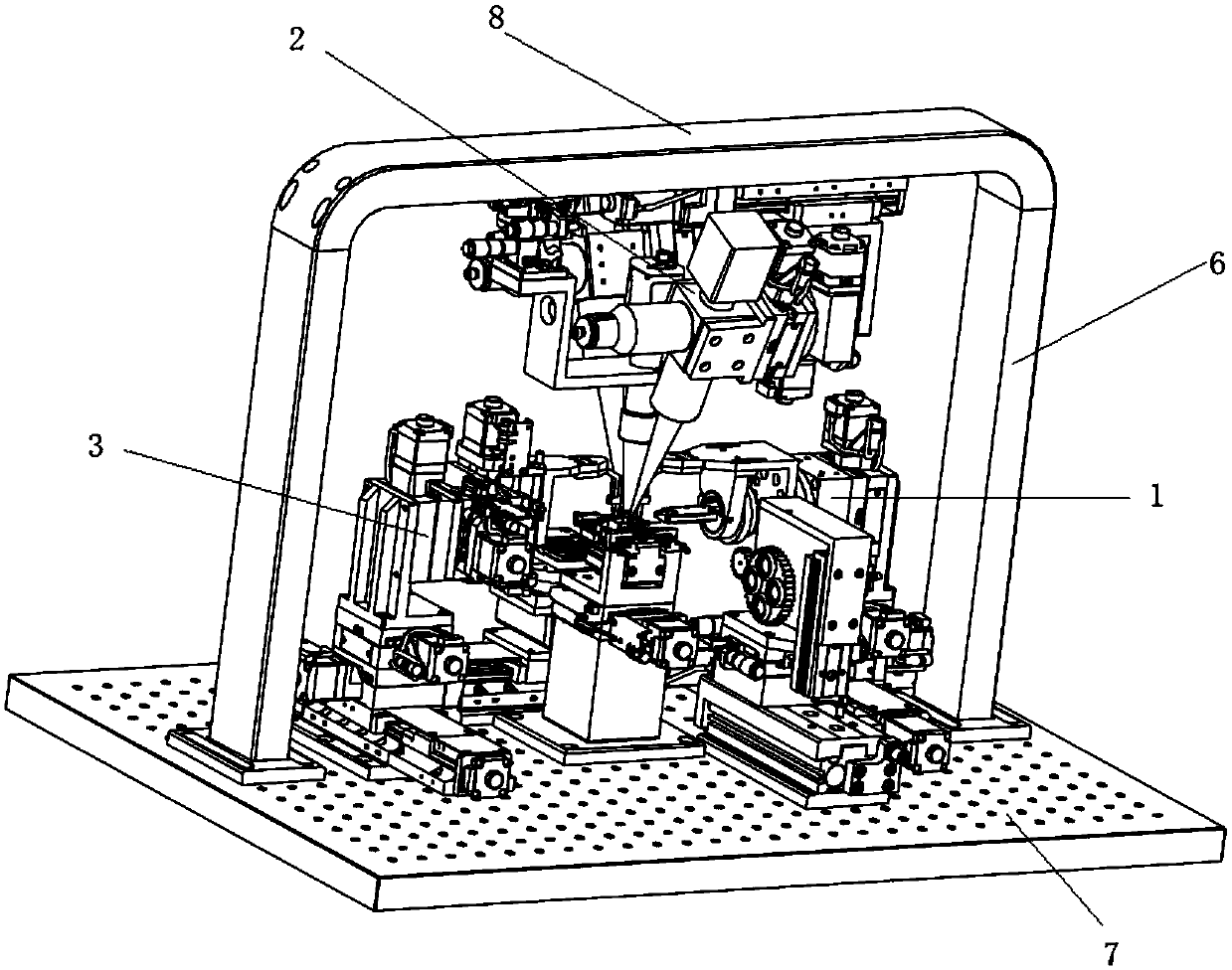

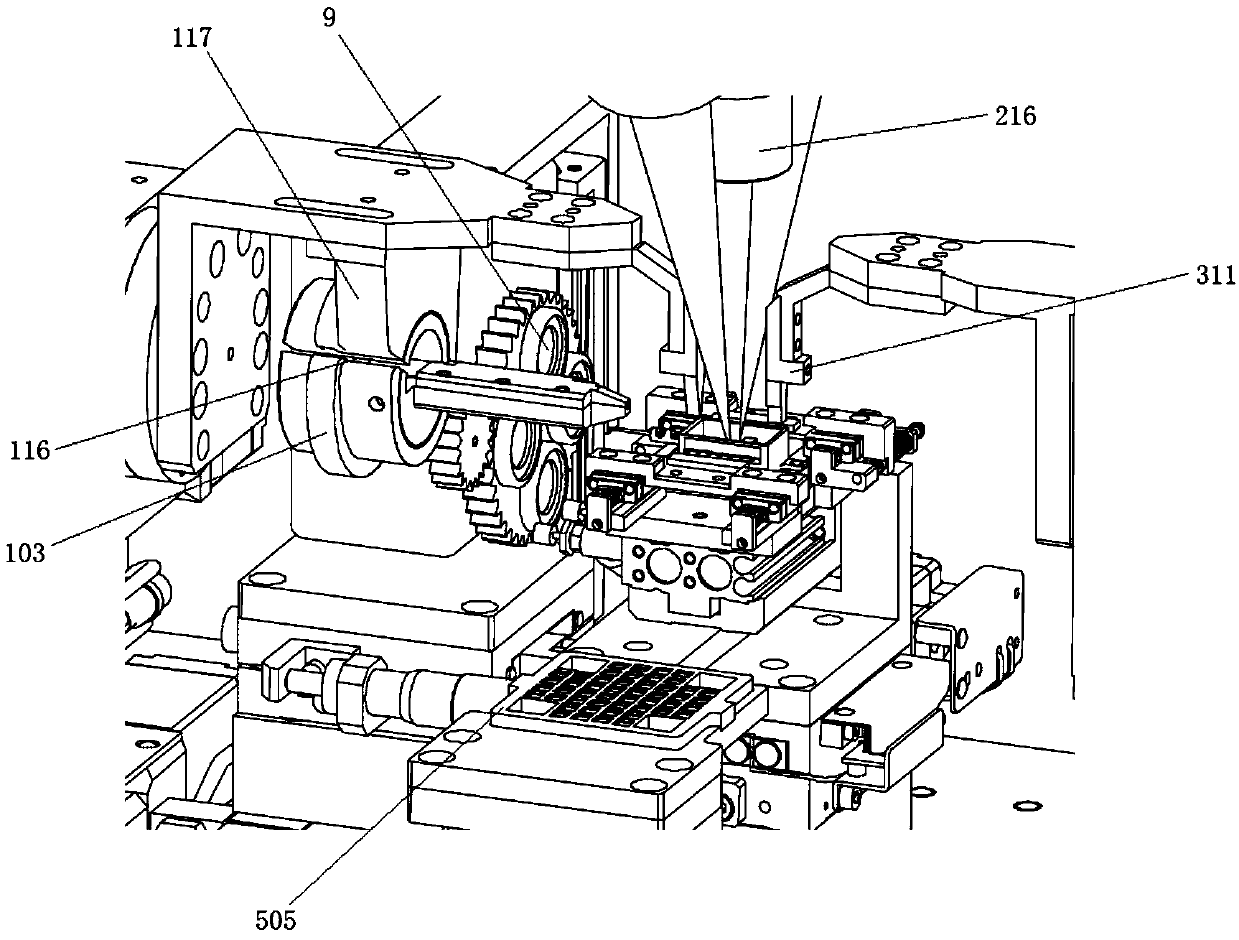

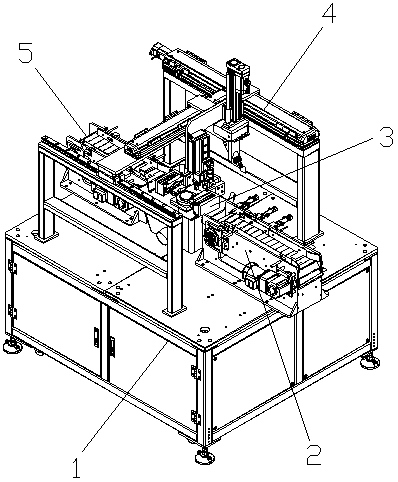

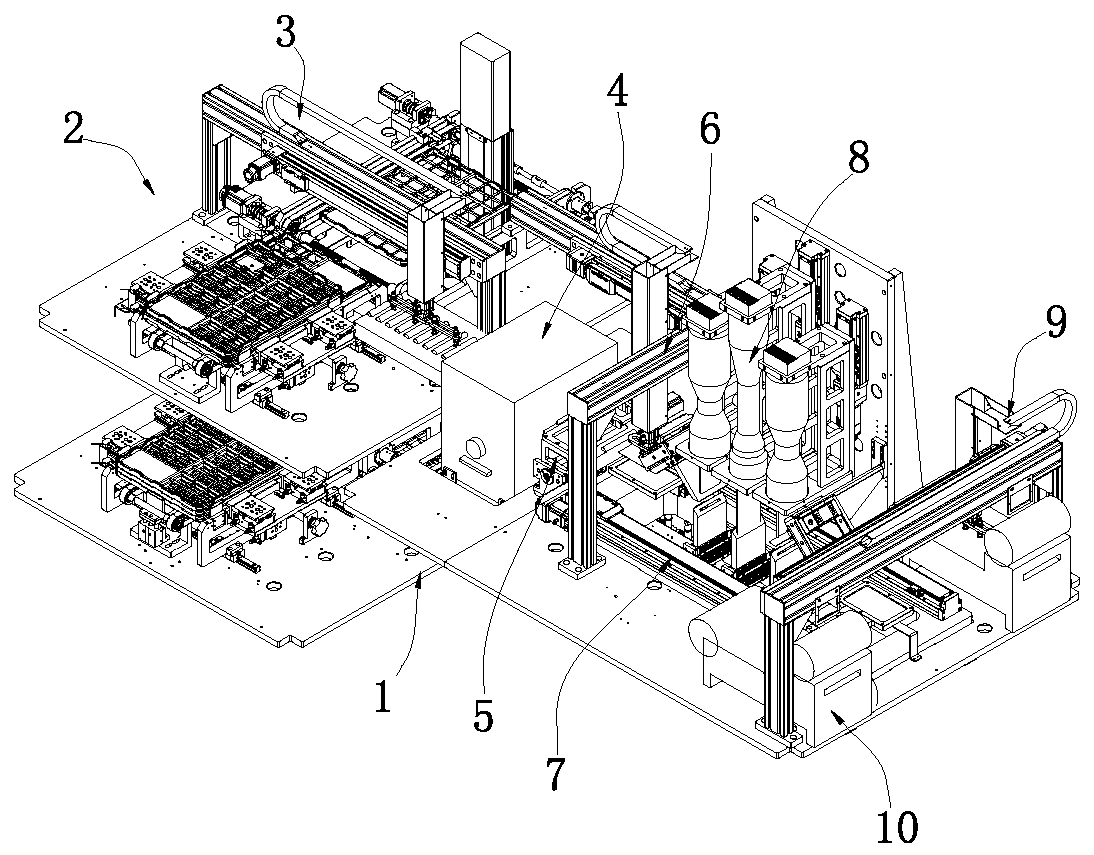

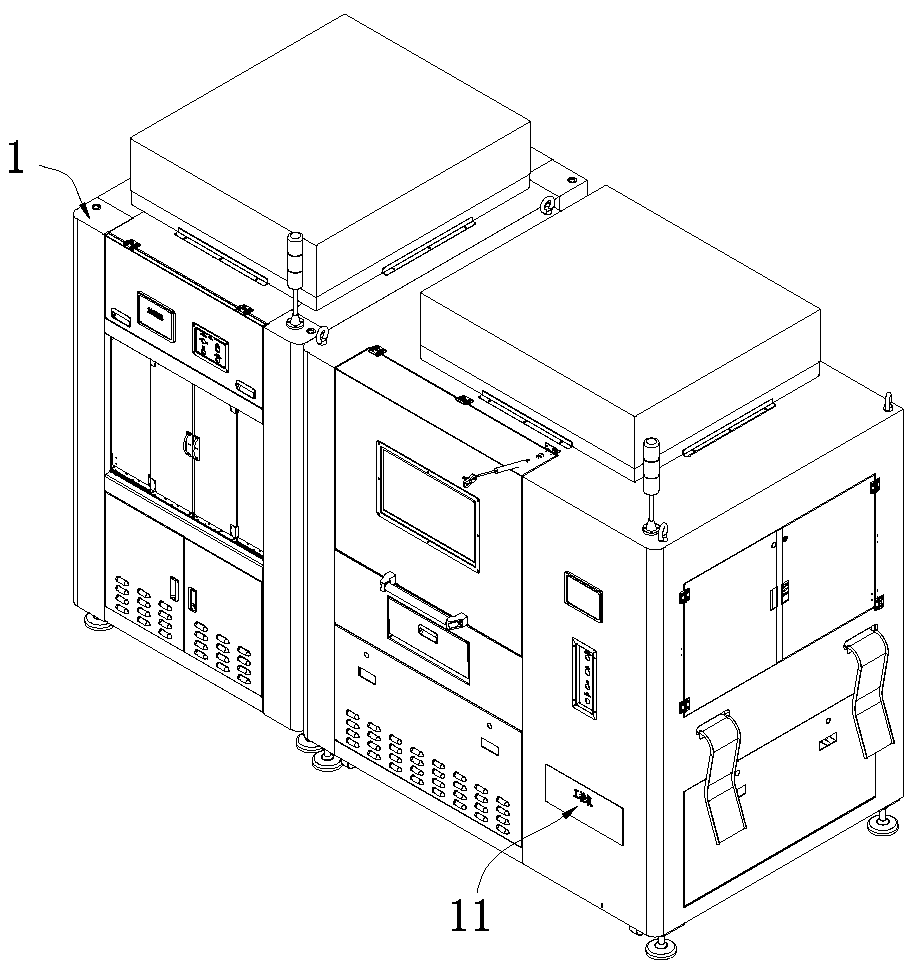

Butterfly-shaped semiconductor laser automatic coupling packaging device

ActiveCN109521536AHigh degree of automationIncrease productivityCoupling light guidesProduction lineCoupling

The invention discloses a butterfly-shaped semiconductor laser automatic coupling packaging device and relates to the automatic coupling packing field of an electronic device. The automatic coupling packaging device includes a column, a cross beam, and a fiber clamp, a lens clamp mechanism, a lower clamp device and a material disc mechanism arranged on a base, and a laser power meter, wherein thefiber clamp, the lens clamp mechanism and a fiber automatic angle adjusting welding device can be adjusted in position to realize accurate coupling and packaging of a butterfly-shaped semiconductor laser. The device is advantaged in that the structure design is reasonable, the whole subsequent operation from coupling, alignment and packaging can be automatically completed, compared with a traditional hand-operated production line, advantages of high automatic degree, simple and convenient operation, high production efficiency, low production cost and stable product quality are achieved.

Owner:CENT SOUTH UNIV

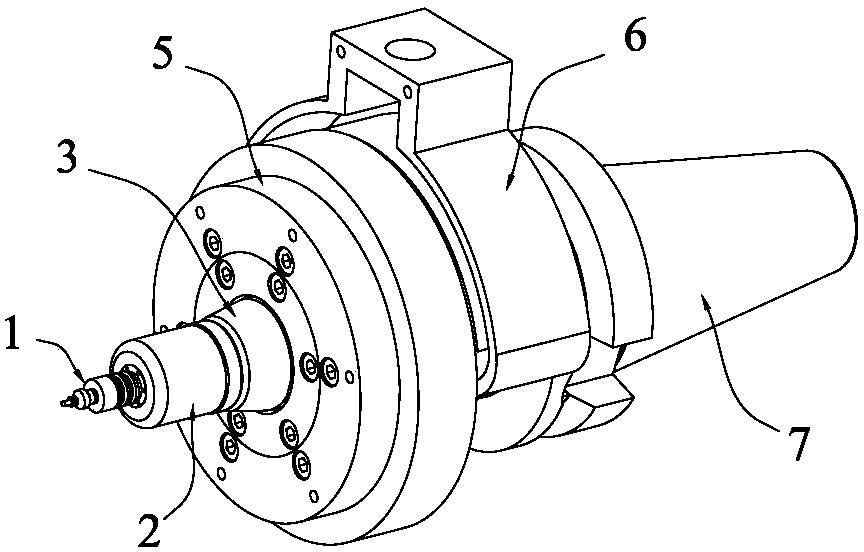

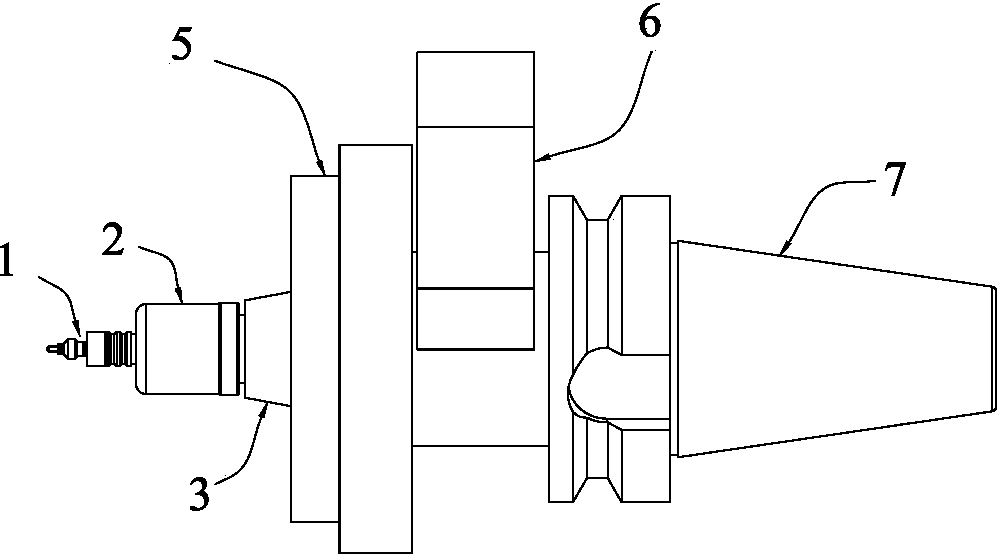

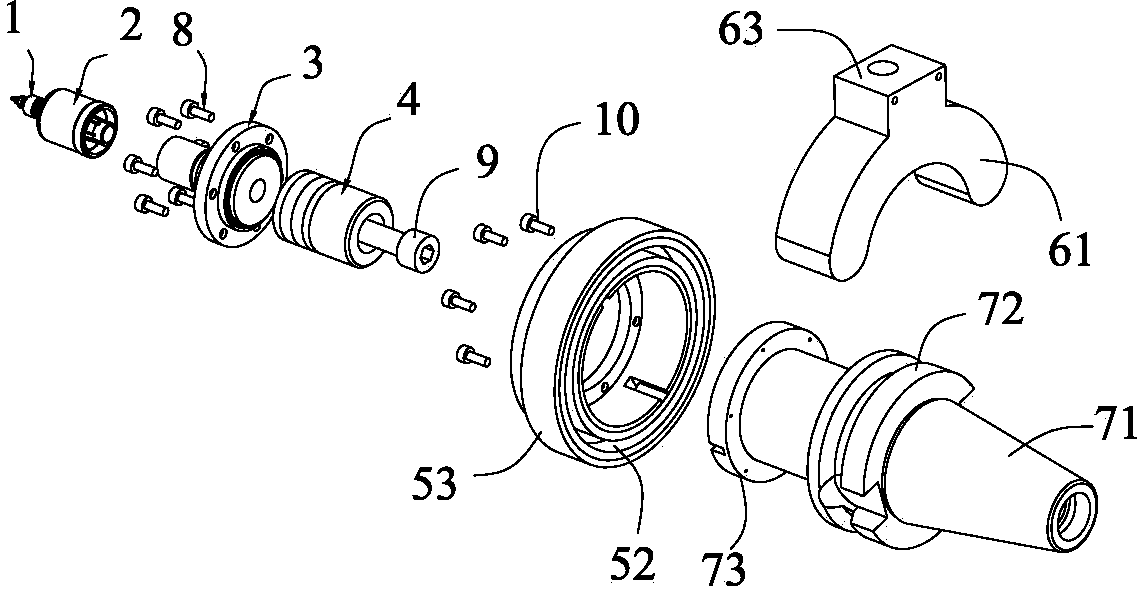

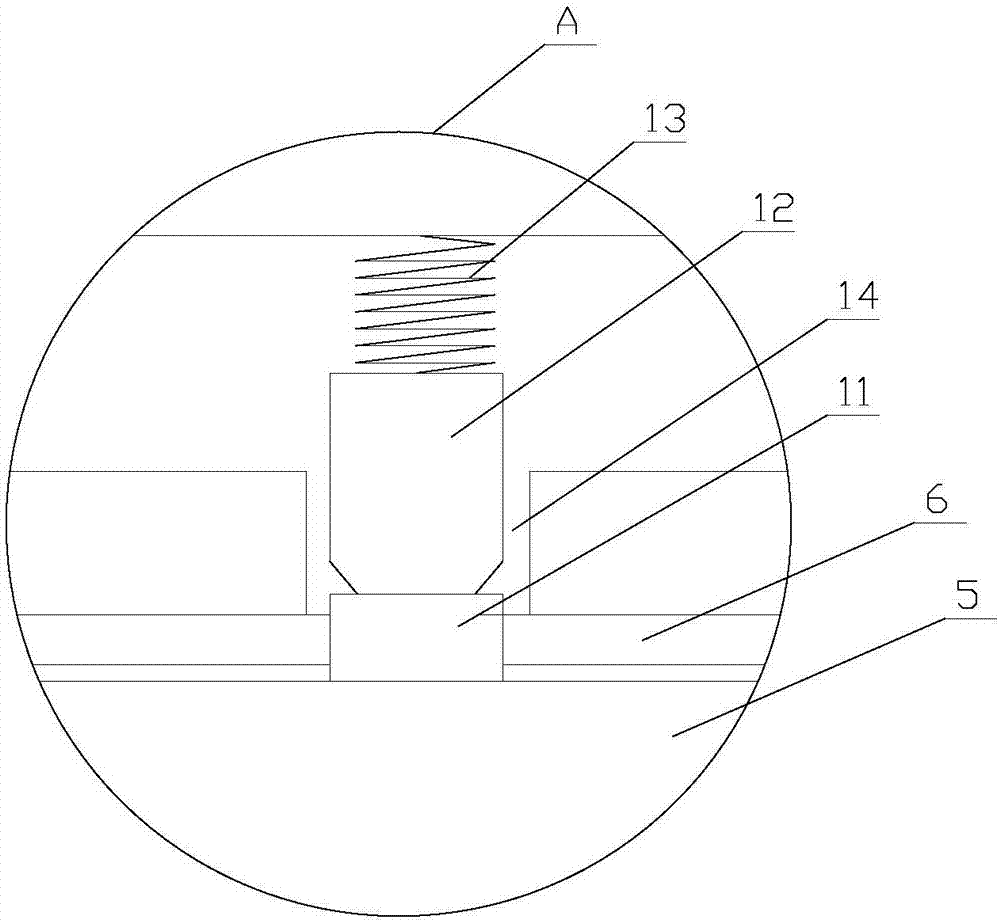

Non-contact energy transmission type ultrasonic machining device

The invention discloses a non-contact energy transmission type ultrasonic machining device. The non-contact energy transmission type ultrasonic machining device comprises a grinding head, an amplitude-change rod, a front cover plate, piezoelectric ceramic, secondary magnetic ring coil, a primary magnetic ring coil and a tool handle. The grinding head, the amplitude-change rod, the front cover plate and the tool handle are sequentially connected, the piezoelectric ceramic is arranged in a concave assembly position of the tool handle, the secondary magnetic ring coil is fixed to the front cover plate, the primary magnetic ring coil is arranged on a mechanical arm of an ultrasonic machine, and gap is formed between the secondary magnetic ring coil and the primary magnetic ring coil. The non-contact energy transmission type ultrasonic machining device is ingenious and reasonable in structural design; because of the non-contact energy transmission structure design, not only is non-contact high-efficiency transmission of electric energy achieved, but also the problem of traditional slip ring abrasion in ultrasonic machining is solved, the heat generation phenomenon caused by contact friction is avoided, the rotation speed of a spindle is increased without limitations, and meanwhile the automatic tool changing requirement of a machining center can be met; moreover, because no exposed conductors exist, electric energy transmission is not influenced by environments, and the non-contact energy transmission type ultrasonic machining device is good in working stability, safe, reliable, capable of keeping work for a long time and high in working efficiency.

Owner:张增英

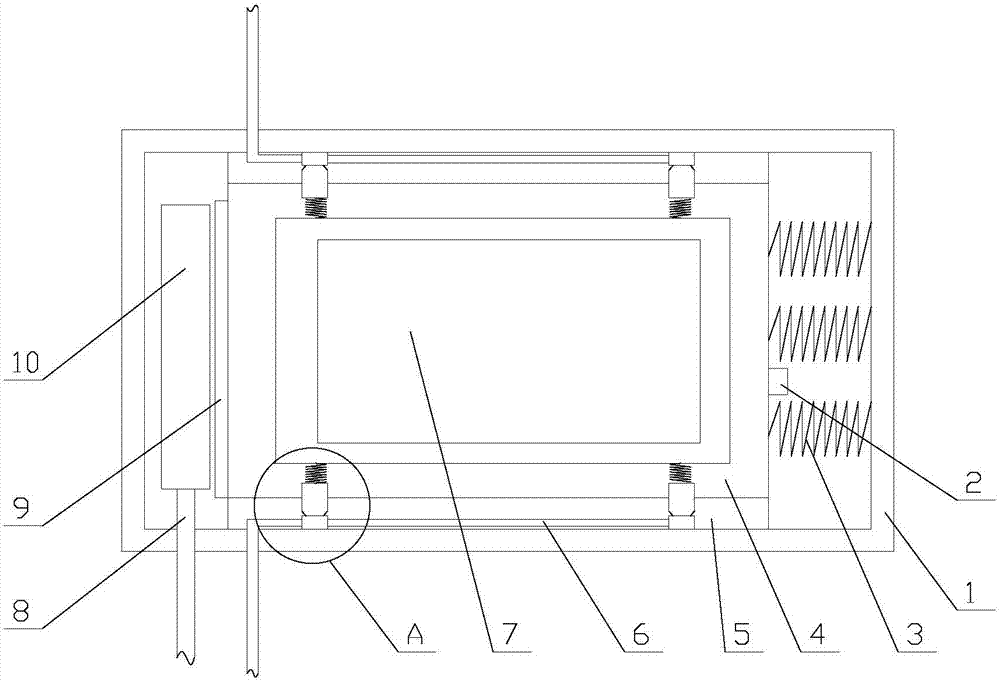

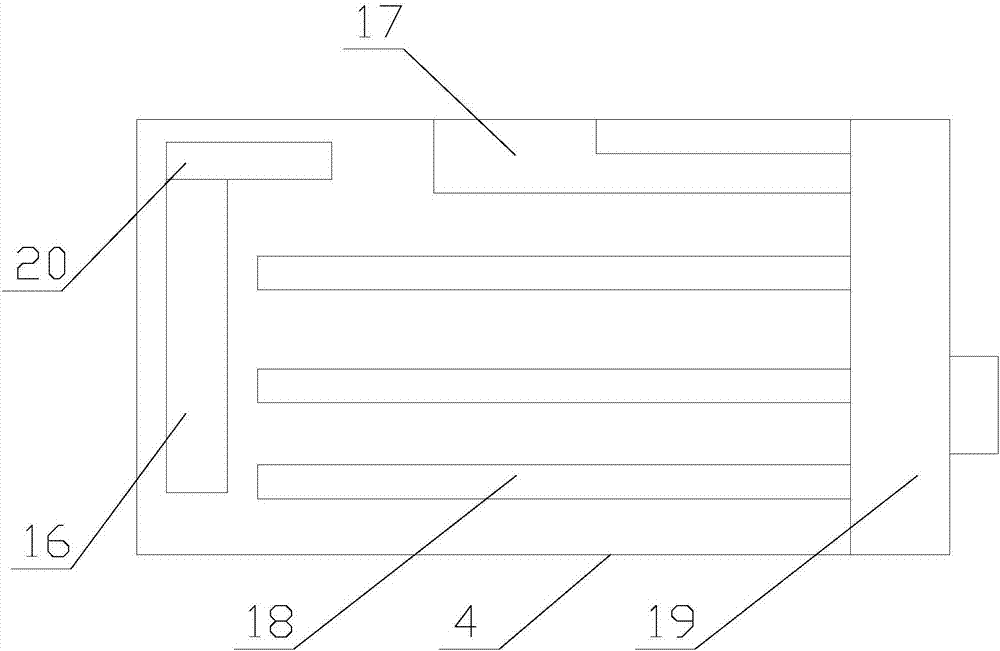

Water cooling device used for current transformator power module

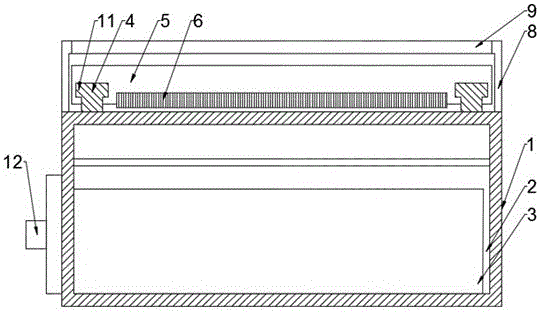

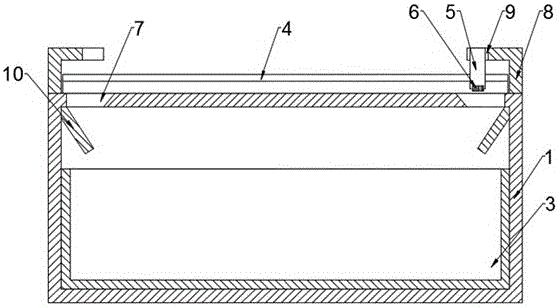

InactiveCN101420168AImprove efficiencyReasonable structural designSemiconductor/solid-state device detailsSolid-state devicesExpansion tankWater pipe

The invention relates to a water cooling device, in particular to a water cooling device which is used for a converter power module and solves the problem that the water cooling of the converter power module is not maturely applied to the existing locomotive AC transmission systems. The water cooling device comprises a heat-exchanging wind-cooling device, a water pump, a power module quick joint, and an expansion water tank; the heat-exchanging wind-cooling device comprises a supporting box body which is internally fixed with a cooling fan and a radiator; the water inlet pipe joint of the radiator is connected with the water outlet of the water pump by the power module quick joint; the water outlet pipe joint of the radiator is connected with the water pump water inlet; the expansion water tank and the water distributor of the water inlet of the water pump are connected with each other by a water pipe; meanwhile, the expansion water tank is connected with the water distributor which is fixed on the supporting box body by pipelines. The water cooling device solves the heat dissipation and cooling problem of the power module in the converter, improves the efficiency of the power module, and can carry out real-time protection by a pressure sensor and a temperature sensor.

Owner:CRRC YONGJI ELECTRIC CO LTD

Workbench for cleaning and recycling waste scraps generated in machine element processing

InactiveCN105965316AIngenious structural designClean up thoroughlyMaintainance and safety accessoriesScrapWaste management

The invention discloses a workbench for cleaning and recycling waste scraps generated in machine element processing. The workbench comprises a workbench body. A scrap removal cavity is formed in the workbench body; a drawer is arranged in the scrap removal cavity; two guide rails are symmetrically arranged on the left end and the right end of a table top of the workbench body; a scraper blade is arranged right above the workbench body; hairbrushes are embedded into the bottom end of the scraper blade; guide slots matched with the guide rails are symmetrically formed on the bottom face of two ends of the scraper blade; two baffle plates are symmetrically arranged on the front end and the rear end of the workbench body and comprise vertical baffle plates and horizontal baffle plates; the cross section of the vertical baffle plates is of a concave structure; grooves are formed at opposite ends of the two horizontal baffle plates; the length of each groove is larger than the length of the scraper blade; the workbench body is provided with scrap removal holes near the baffle plates; guide plates for the scrap removal holes are arranged on the top end of the side wall of the scrap removal cavity, and are slantways arranged. The workbench for cleaning and recycling the waste scraps generated in machine element processing provided by the invention is ingenious in structural design, element waste scraps on the table top of the workbench body are swept to and fro so as to be cleanly and thoroughly swept, and the waste scraps are directly fallen into a scrap removal chamber, so that the personal safety of the cleaning crews is ensured.

Owner:江苏力栋机械科技有限公司

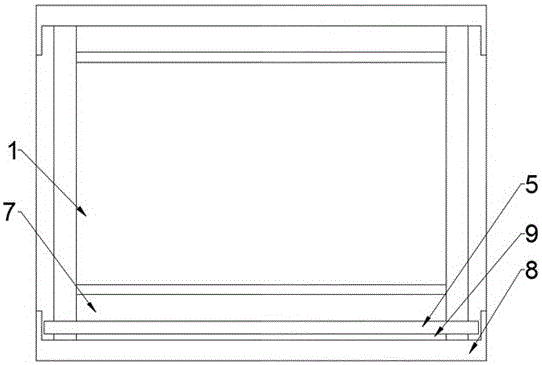

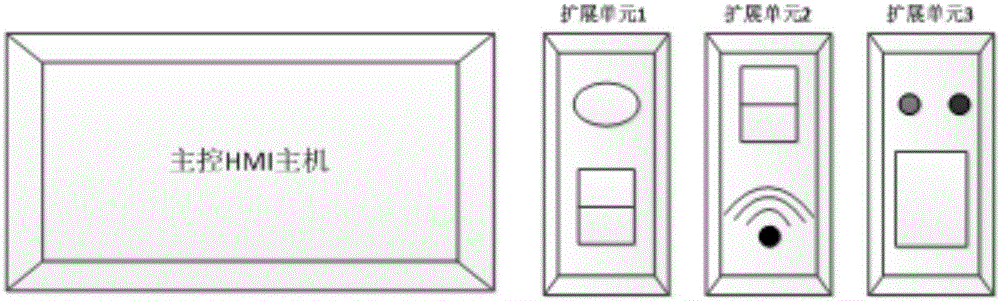

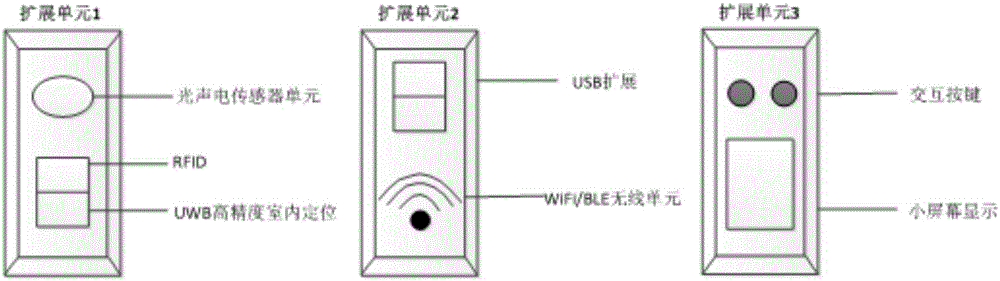

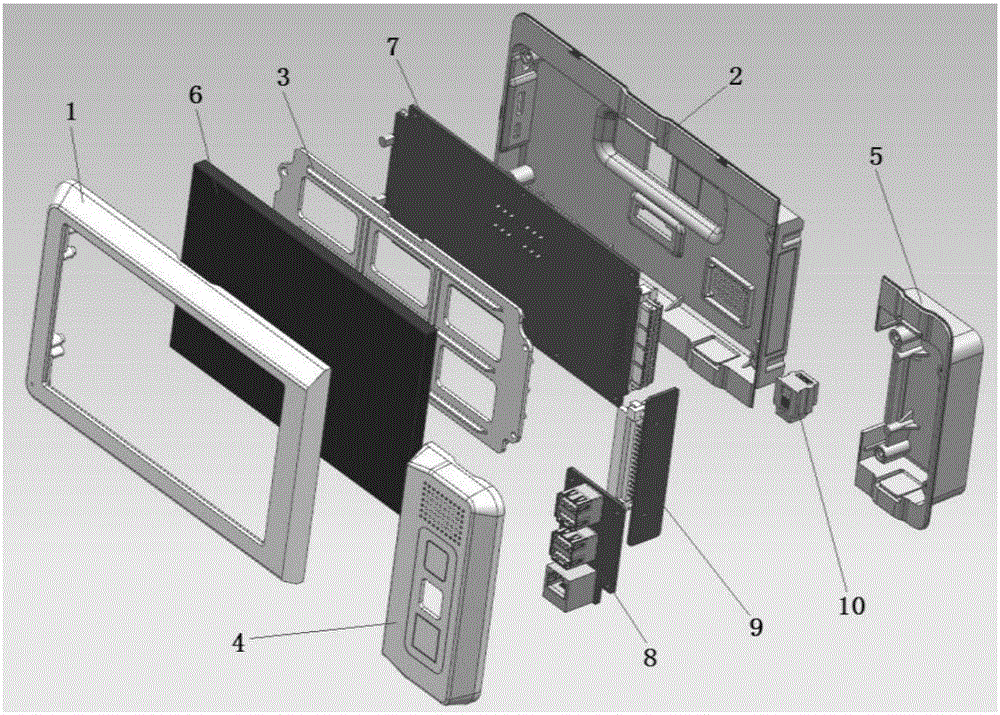

Medical ward intelligent terminal based on internet of things technology

InactiveCN106778020AIngenious structural designEasy to disassemble, assemble, repair and replaceReservationsTelemedicineExtensibilityHuman–machine interface

The invention relates to a medical ward intelligent terminal based on internet of things technology, comprising a bed-head sensing layer, an information transmission layer and an application processing layer; the bed-head sensing layer comprises an intelligent bed-head terminal positioned on a bed-head wall and at least one extension unit electrically connected to the intelligent bed-head terminal, the information transmission layer comprises a wired and / or wireless network interface and a data interaction server, the intelligent bed-head terminal is connected to the data interaction server through a wired network interface, the data interaction server is connected to an existing network of a hospital information system through a wired and / or wireless network interface, and the application processing layer comprises a management and service module running on the intelligent bed-head terminal; the intelligent bed-head terminal comprises a master control HMI (human-machine interface) main unit and a touch interactive screen. The medical ward intelligent terminal has high automatic integrity and high extensibility, is effective in assisting medical staff in providing precise, accurate, elaborate nursing, nursing skill level of medical staff is increased, nursing information and intelligence levels are increased.

Owner:江苏卫岗集团有限公司

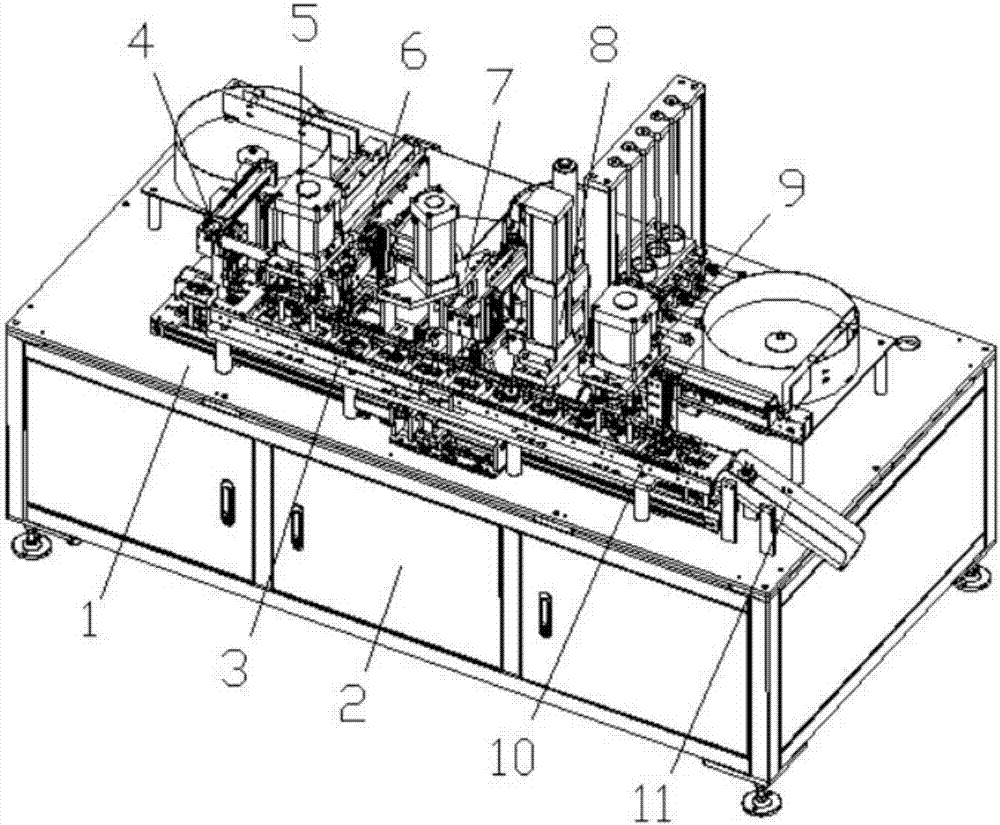

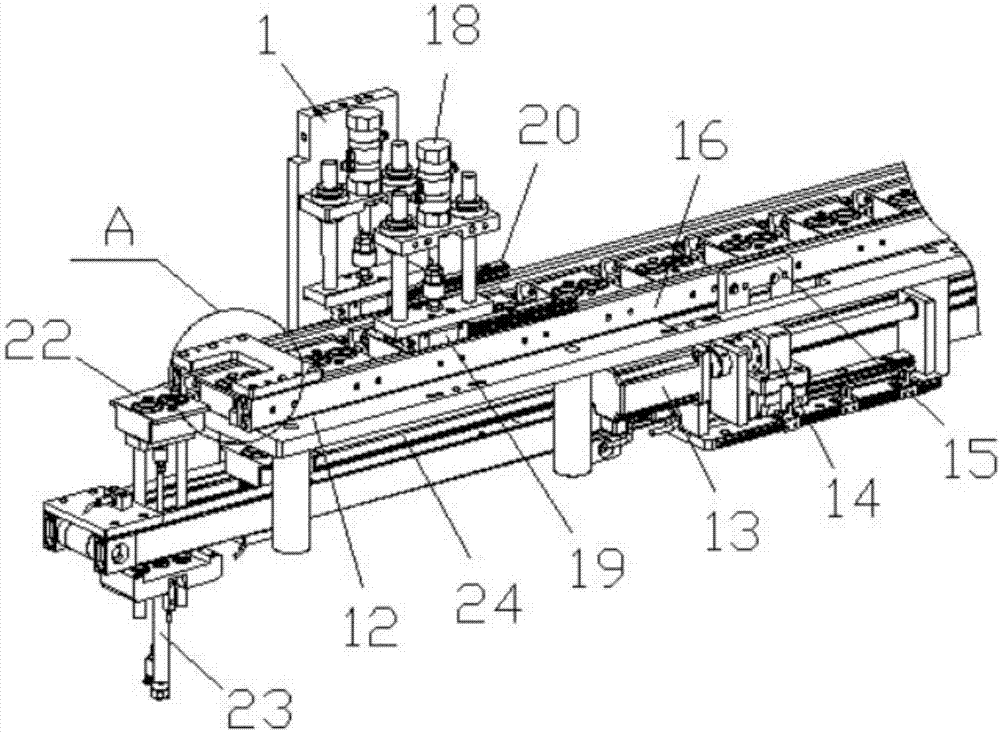

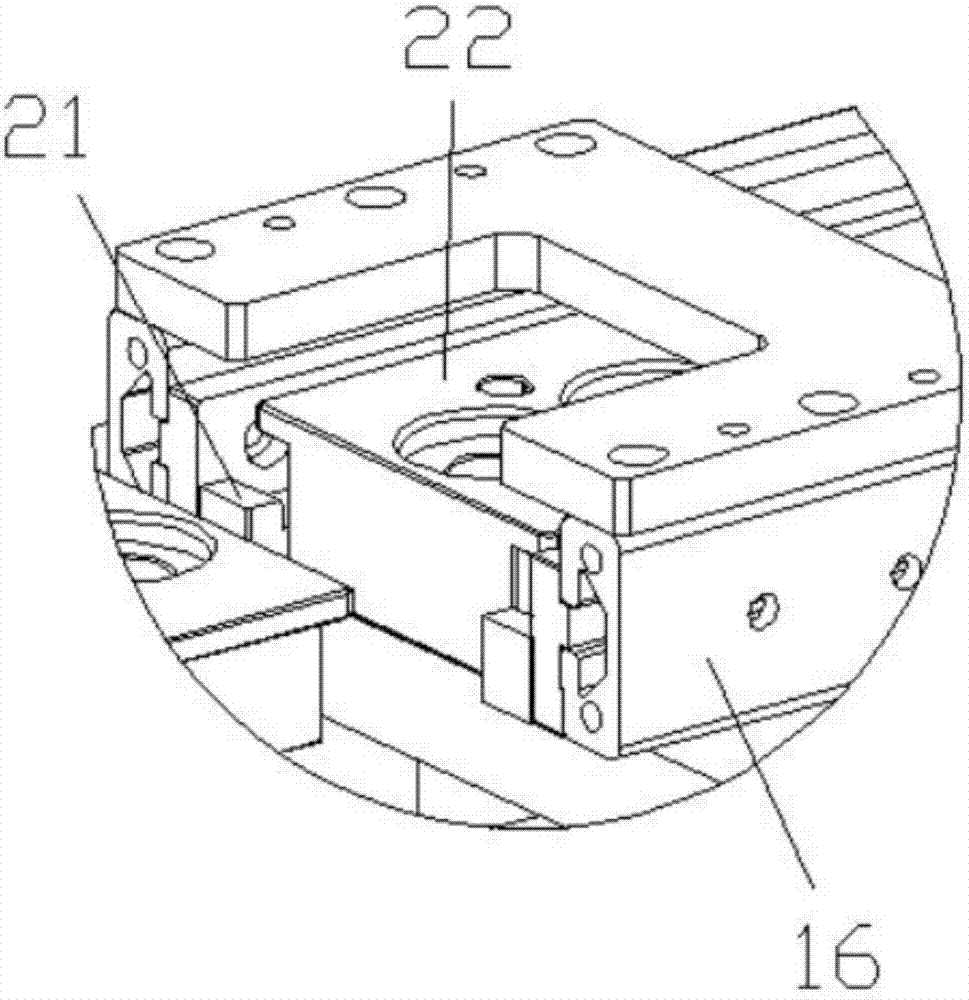

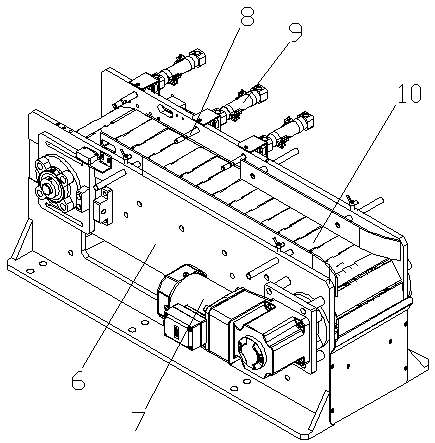

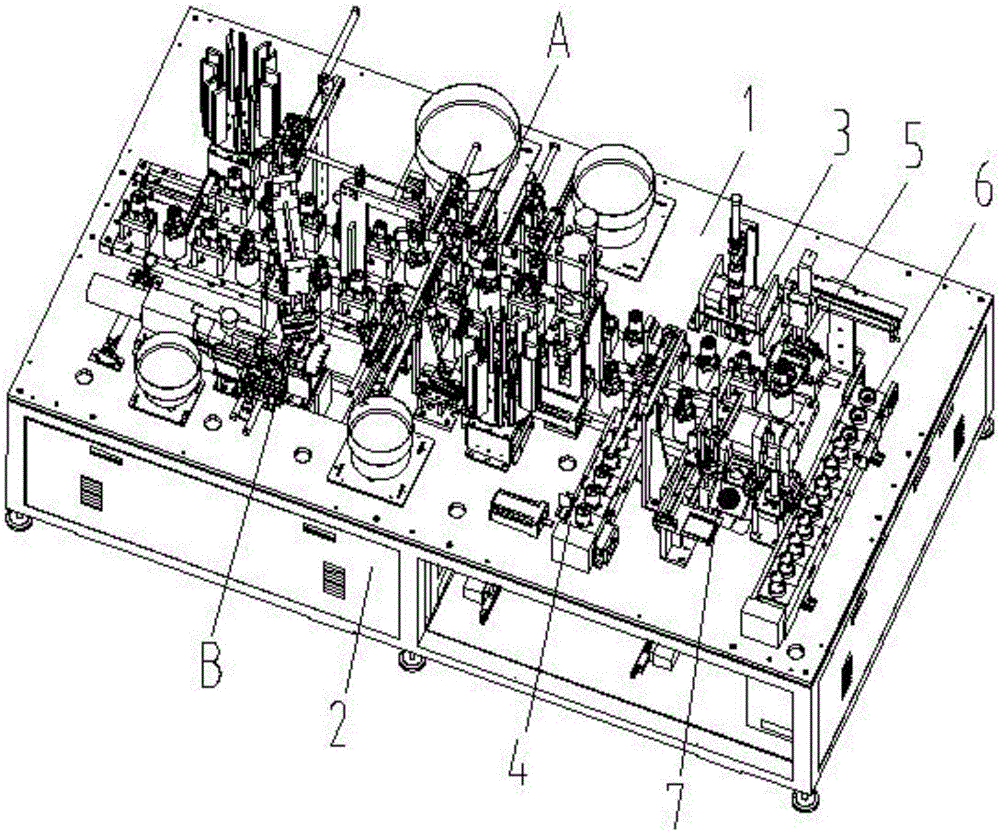

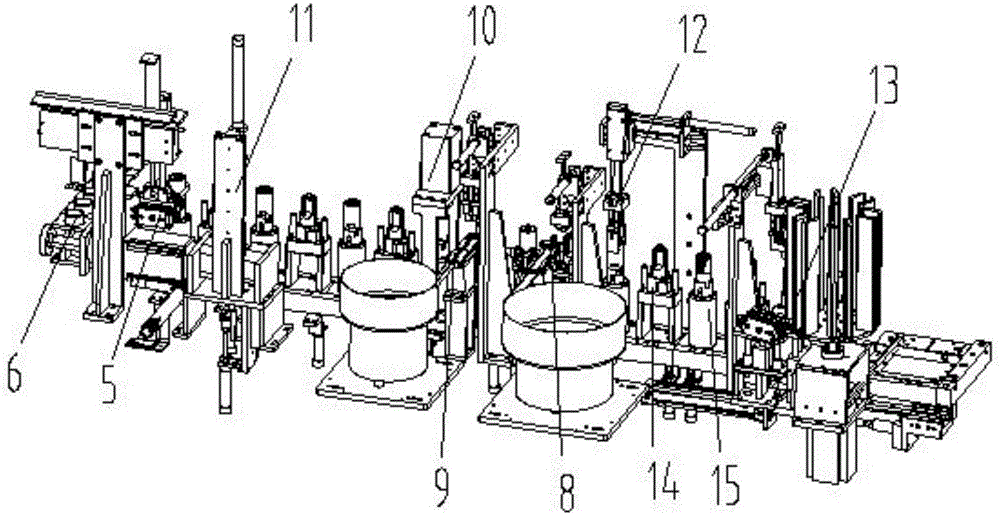

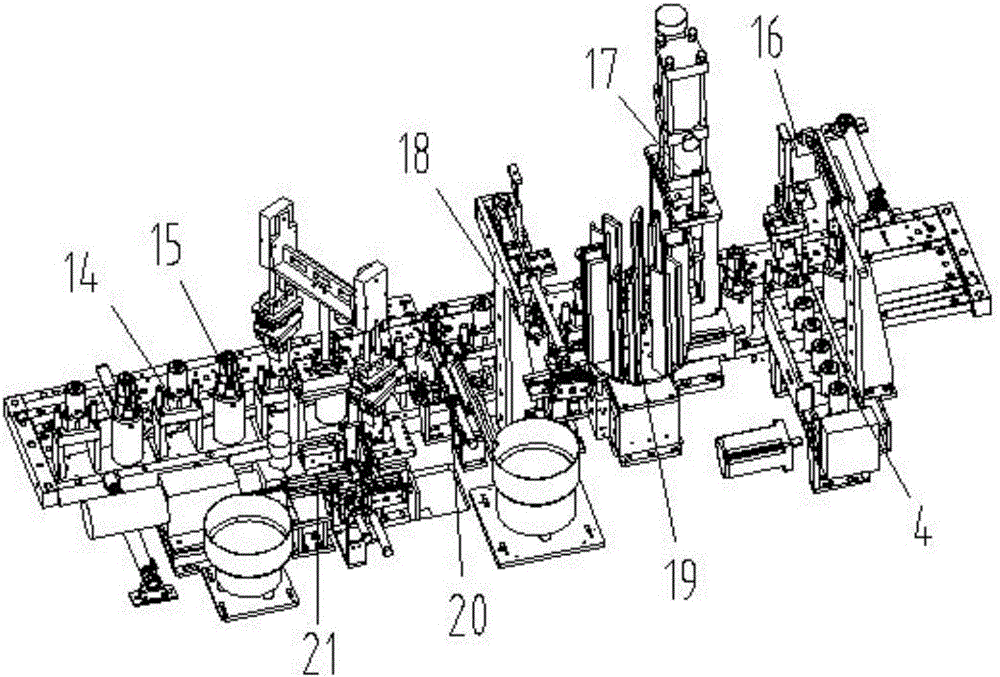

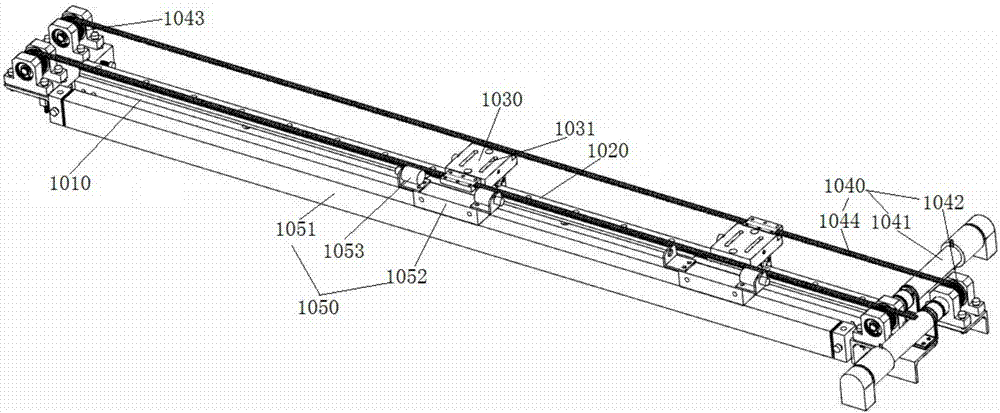

Automatic gear shaft assembling machine

InactiveCN107571008AHigh matching precisionImprove assembly efficiency and yieldAssembly machinesManipulatorBall bearing

The invention relates to an automatic gear shaft assembling machine. The rack is provided with a carrier conveying device. The carrier conveying device comprises a carrier conveying base. Carrier feeding movable air cylinders are arranged on the front side and the rear side of the carrier conveying base and connected with a carrier feeding movable base. The carrier feeding movable base is connected with a carrier feeding movable block. A carrier feeding clamping block matched with a carrier is arranged on the inner side of the carrier feeding movable block. A carrier feeding lifting matched sliding rail is arranged at the upper portion of the carrier feeding movable block and matched with a carrier feeding lifting matched sliding block. The upper portion of the carrier feeding lifting matched sliding block is matched with a carrier feeding lifting air cylinder on the rack. The rack is provided with a ball bearing feeding device, a shaft rod feeding device, an overturning device, a clamping ring feeding device, a gear feeding device, a clamping bearing feeding device and a discharging mechanical arm. According to the automatic gear shaft assembling machine, automatic ball bearing and shaft rod assembling can be achieved, and the assembling efficiency and the yield are greatly improved.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

New energy automobile battery with collision protection function

ActiveCN107146865AReduced speed of hitting the first airbagProtection securityFinal product manufactureBattery isolationLow voltageNew energy

The invention relates to a new energy automobile battery with a collision protection function. The new energy automobile battery comprises a protection shell, a battery box and a collision preventing assembly; the battery box comprises a box top, a battery pack, an air inlet pipe, a distribution box, a battery management module, a high-voltage wiring harness, a low-voltage wiring harness, a cooling fan, air outlet pipes and a base; the collision preventing assembly comprises guiding grooves, limiting units, a first airbag, a first ventilating pipe, a second airbag and a second ventilating pipe; each limiting unit comprises a first spring and a limiting block; when the new energy automobile is in collision, a safety airbag inflates the first airbag and the second airbag, so that the limiting block leaves the corresponding limiting hole; and the battery box slides on the guiding grooves with certain buffering, and then is collision with the first airbag to be detected, so that the rigid collision is greatly lowered, thereby protecting the new energy automobile battery with the collision protection function from being damaged, and ensuring the normal operation of the automobile.

Owner:JILIN UNIV

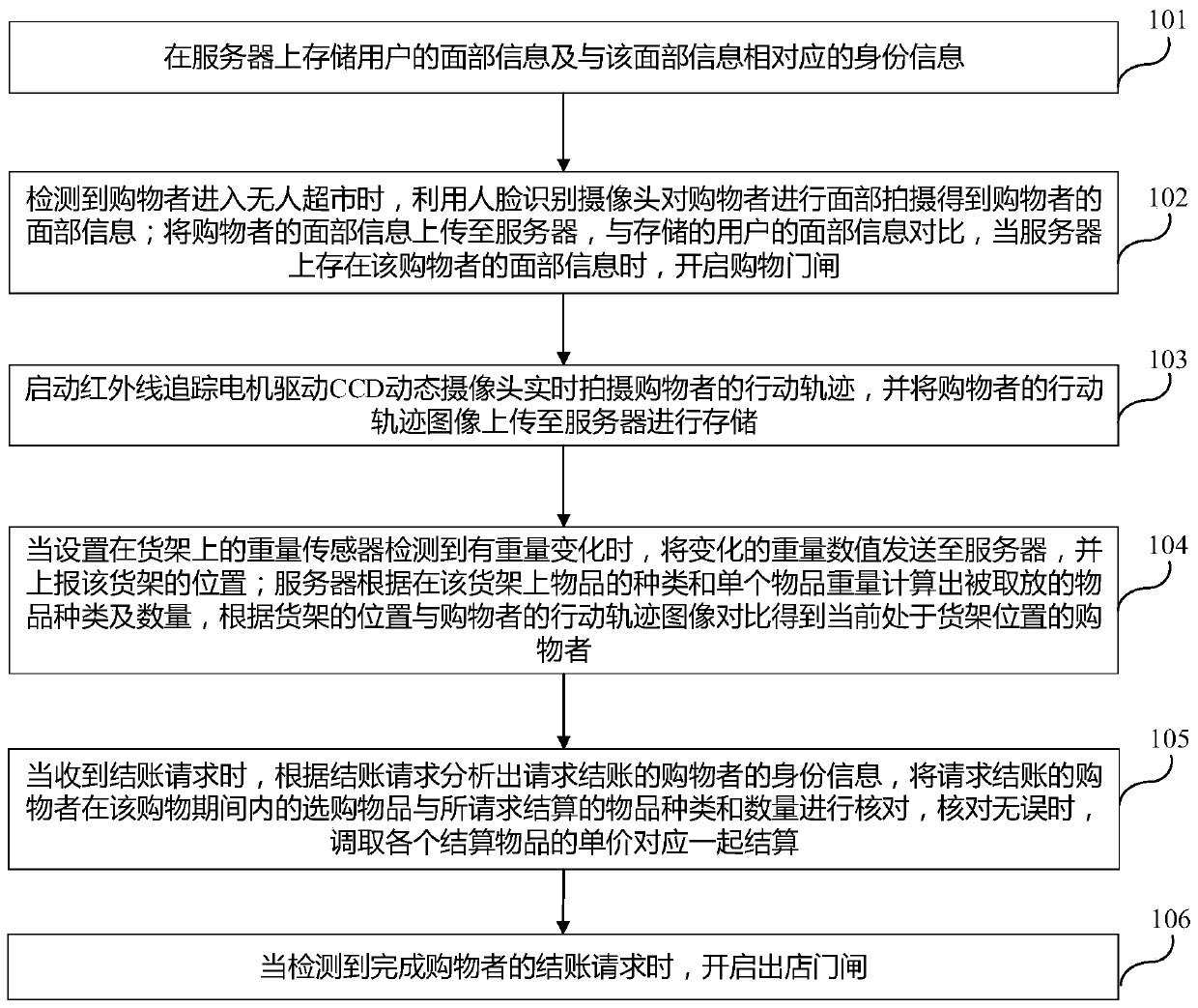

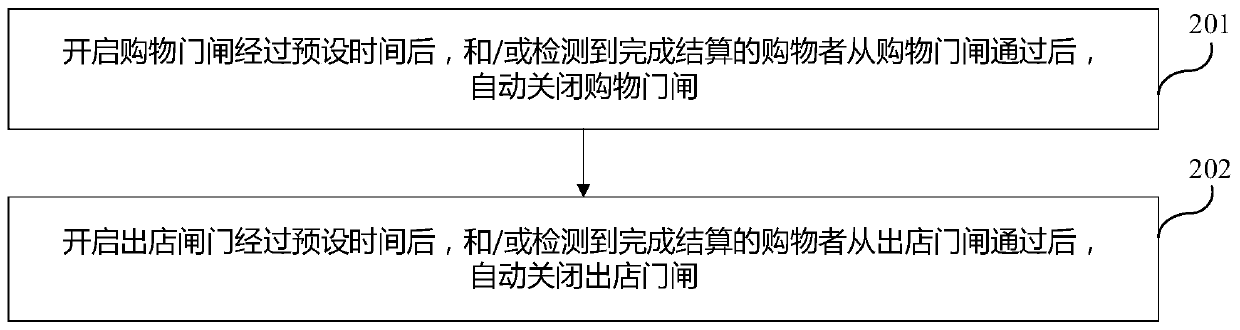

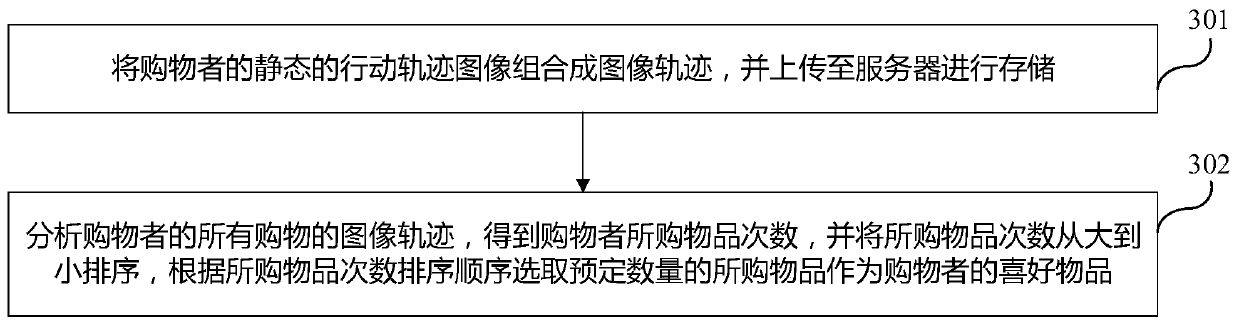

Deep learning system and method based on hyperspectral camera technology

InactiveCN110009836AReasonable designEasy to useCharacter and pattern recognitionCash registersComputer visionChange weight

The invention provides a deep learning system and method based on the hyperspectral camera technology. The method comprises the following steps: storing face information of a user and identity information corresponding to the face information; shooting the face of a shopper by using a face recognition camera to obtain the face information of the shopper; comparing the face information of the shopper with the stored face information of the user, and when the face information of the shopper exists on a server, opening a shopping gate; shooting the action track of the shopper in real time, and uploading an action track image of the shopper to the server for storage; sending a changed weight value to the server, and reporting the position of a shelf; comparing the position of the shelf with the action track image of the shopper to obtain the shopper currently at the position of the shelf; obtaining unit prices of settlement items to be settled together; and when it is detected that a checkout request the shopper is completed, opening an exit door. By adoption of the deep learning system and method provided by the invention, accurate monitoring and management of shopping behaviors in unmanned supermarkets are achieved.

Owner:JIANGXI UNIV OF SCI & TECH

Pneumatic polishing machine with conveniently-adjusted polishing angle

InactiveCN108296937AEasy to holdIngenious structural designGrinding drivesGrinding feed controlDistribution controlPower component

The invention relates to a polishing machine, in particular to a pneumatic polishing machine with the conveniently-adjusted polishing angle. The pneumatic polishing machine comprises a rack, a conveying device and a power distribution control cabinet, the conveying device and the power distribution control cabinet are arranged on the rack, the conveying device is composed of a feeding device and adischarging device, a clamping rotation mechanism is arranged between the feeding device and the discharging device, a feeding mechanism is arranged at the position, above the clamping rotation mechanism, of the rack, and power components in the feeding device, the discharging device, the clamping rotation mechanism and the feeding mechanism are electrically connected with the power distributioncontrol cabinet; and automatic feeding and discharging of workpieces are achieved through the feeding device and the discharging device, the clamping rotation mechanism is used for fixing the workpieces and automatically adjusting the polishing angle during polishing, and polishing in different directions is achieved.

Owner:DONGGUAN UNIV OF TECH

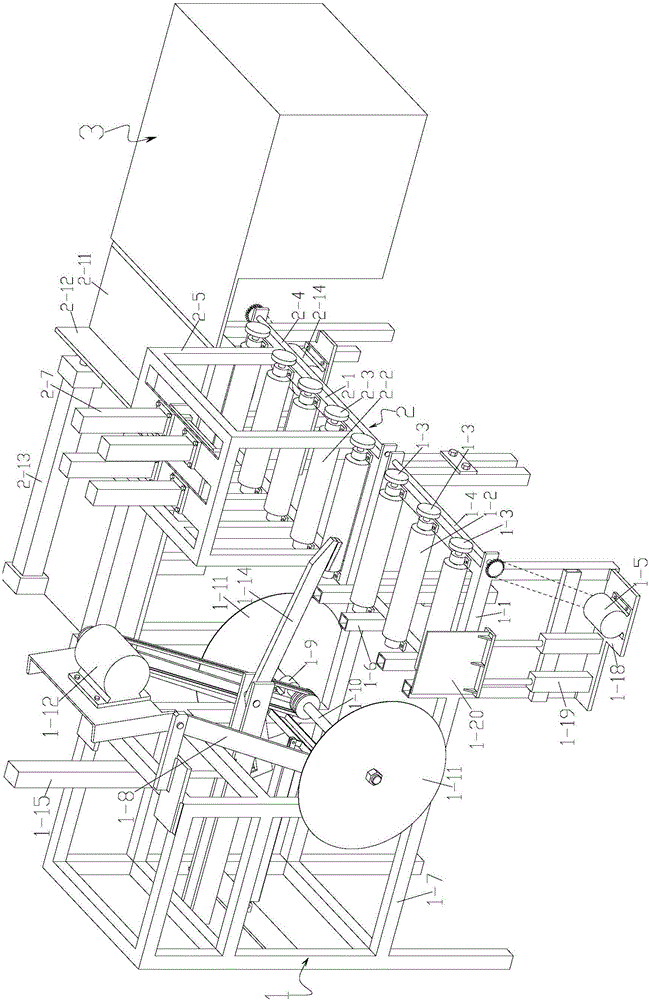

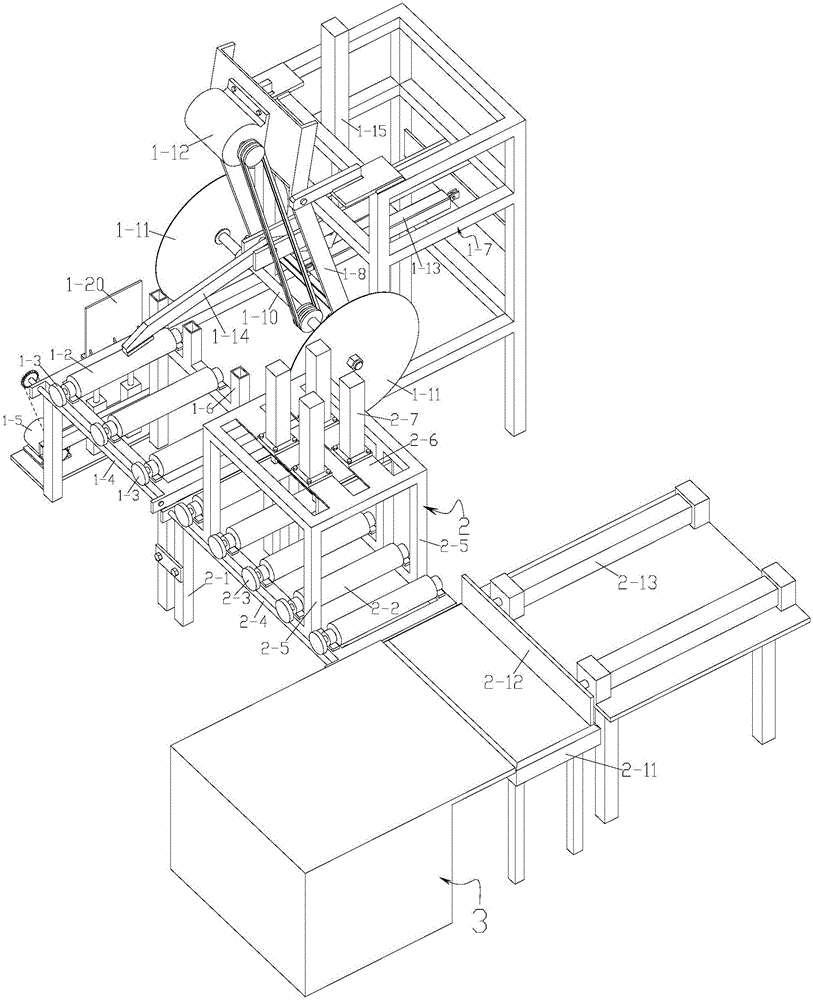

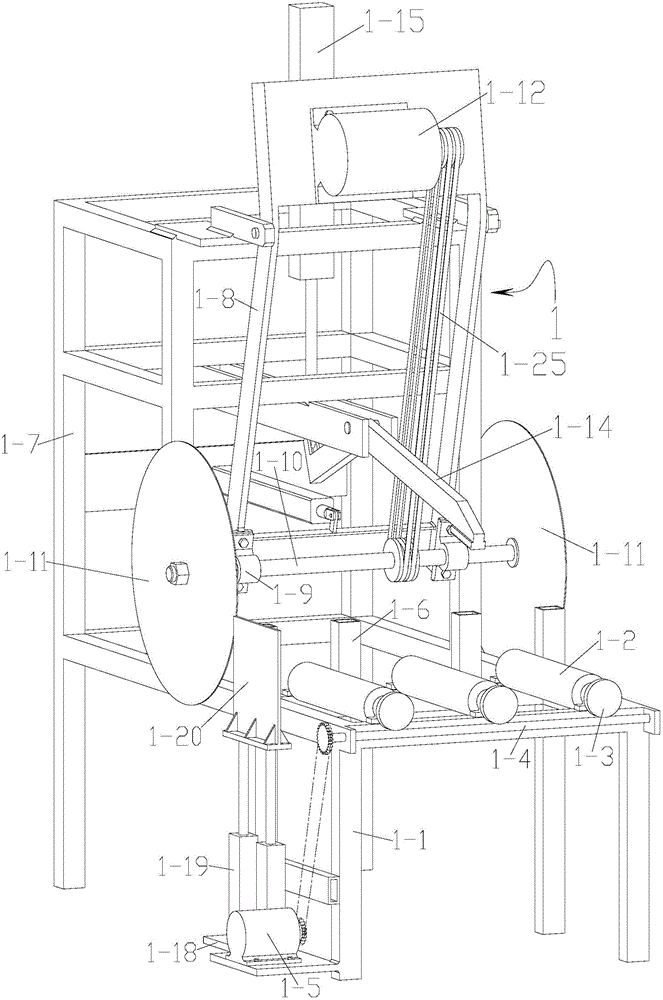

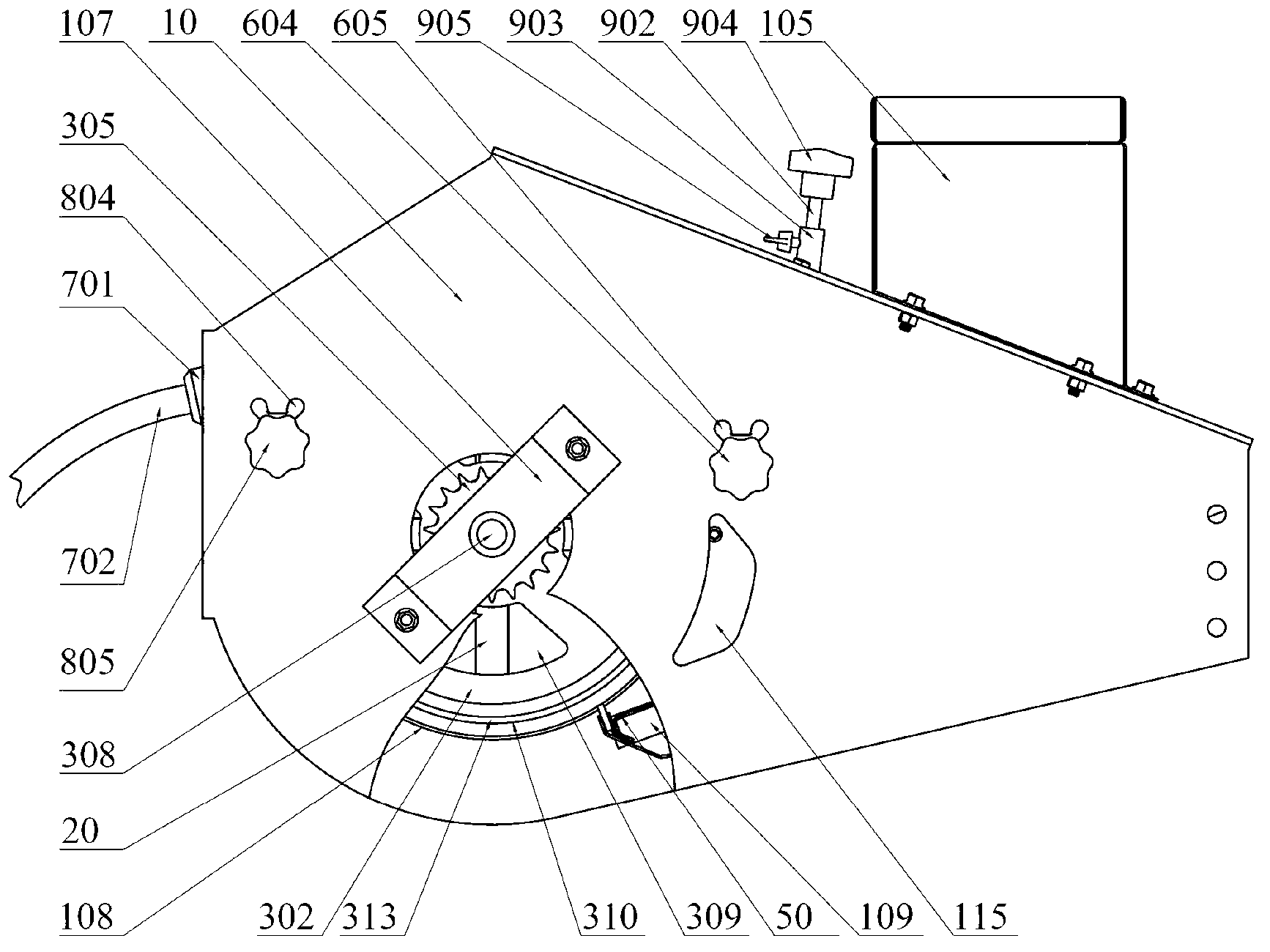

Wood thin-board machining process and wood thin-board automatic machining equipment

ActiveCN105818216AEasy to pushEasy to processFeeding devicesGripping devicesMachining processEngineering

A wood thin-board machining process comprises the following steps: A) clamping a log; B) cutting both ends of the log; C) conveying the cut log; D) machining the cut log. Wood thin-board automatic machining equipment comprises a log clamping and cutting device, a log conveying device and a wood thin-board machining device; a base I disposed on the log clamping and cutting device and a base II disposed on the log conveying device are matched with each other by position, and linked together; a material receiving platform disposed on the log conveying device and a base III disposed on the wood thin-board machining device are matched with each other by position, and linked together. The equipment disclosed by the invention achieves an ingenious and reasonable structure design. The process and equipment disclosed by the invention can greatly improve the efficiency of machining logs into wood thin-board, and are worth popularizing and applying.

Owner:ZHEJIANG DOLO IND

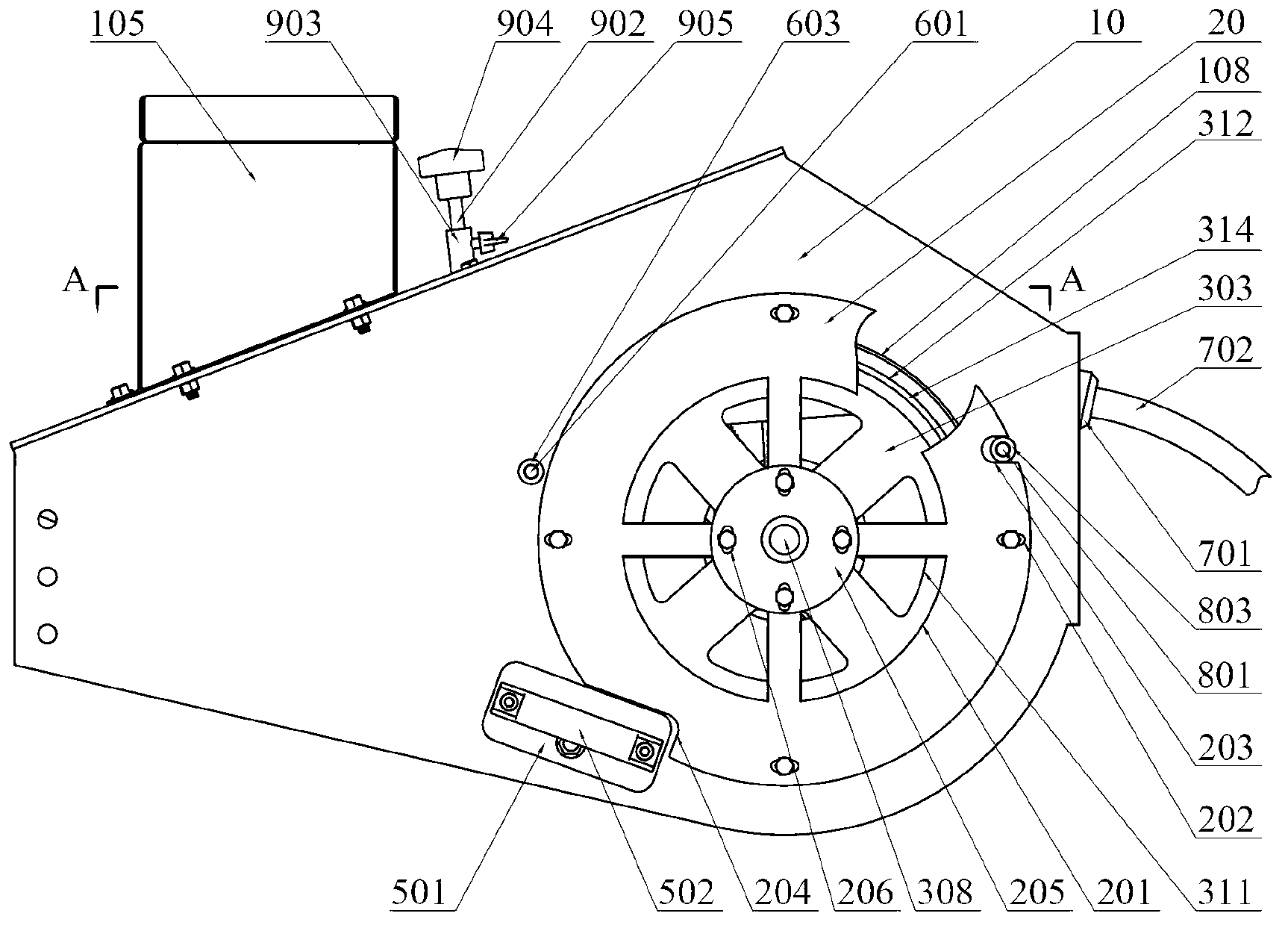

Air power collecting and discharging type precision seed sowing device

InactiveCN103004338AStrong shape adaptabilityReduce vibrationSeed depositing seeder partsRegular seed deposition machinesPositive pressureCritical position

The invention relates to an air power collecting and discharging type precision seed sowing device, which is characterized by comprising a shell, a sealing cover plate, a seed sowing roller, a pressure relief wheel, a seed bed screen, a seed cleaning shifting finger, a seed guiding pipe, an impurity collecting plate and a seed stopping plate, wherein the shell is connected with the sealing cover plate by virtue of bolts, the seed sowing roller is arranged in the shell to form an operation air chamber, an air supply chamber and a seed chamber, the seed chamber is internally provided with an air supply pipe, the seed bed screen is arranged at a critical position of the air supply chamber and the operation air chamber, and the air supply chamber provides air flow for the operation air chamber by virtue of the seed bed screen and the air supply pipe; the seed cleaning shifting finger is arranged in the operation air chamber, is close to the roller in a gap and is in an L shape, a shorter side of the seed cleaning shifting finger is in a right trapezoid shape, and relative position between a bevelled edge of the trapezoid and a seed attaching hole can be adjusted by virtue of a seed cleaning shaft fixedly connected with the shorter side; the pressure relief wheel is arranged inside the seed sowing roller and is close to the interior of the roller by virtue of a tension spring; and the inlet of the seed guiding pipe is close to the roller in the gap and is dead against a contact point of the pressure relief wheel and the roller. The precision seed sowing device realizes centralized precision seed sowing, seed attaching pressure difference and a seed sending air flow are provided by virtue of a positive pressure system, a seed layer is disturbed by utilizing the air flow, and seed filling probability is improved. The precision seed sowing device is applicable to precision seed sowing of large-row-spacing crops such as corn and soybean.

Owner:CHINA AGRI UNIV

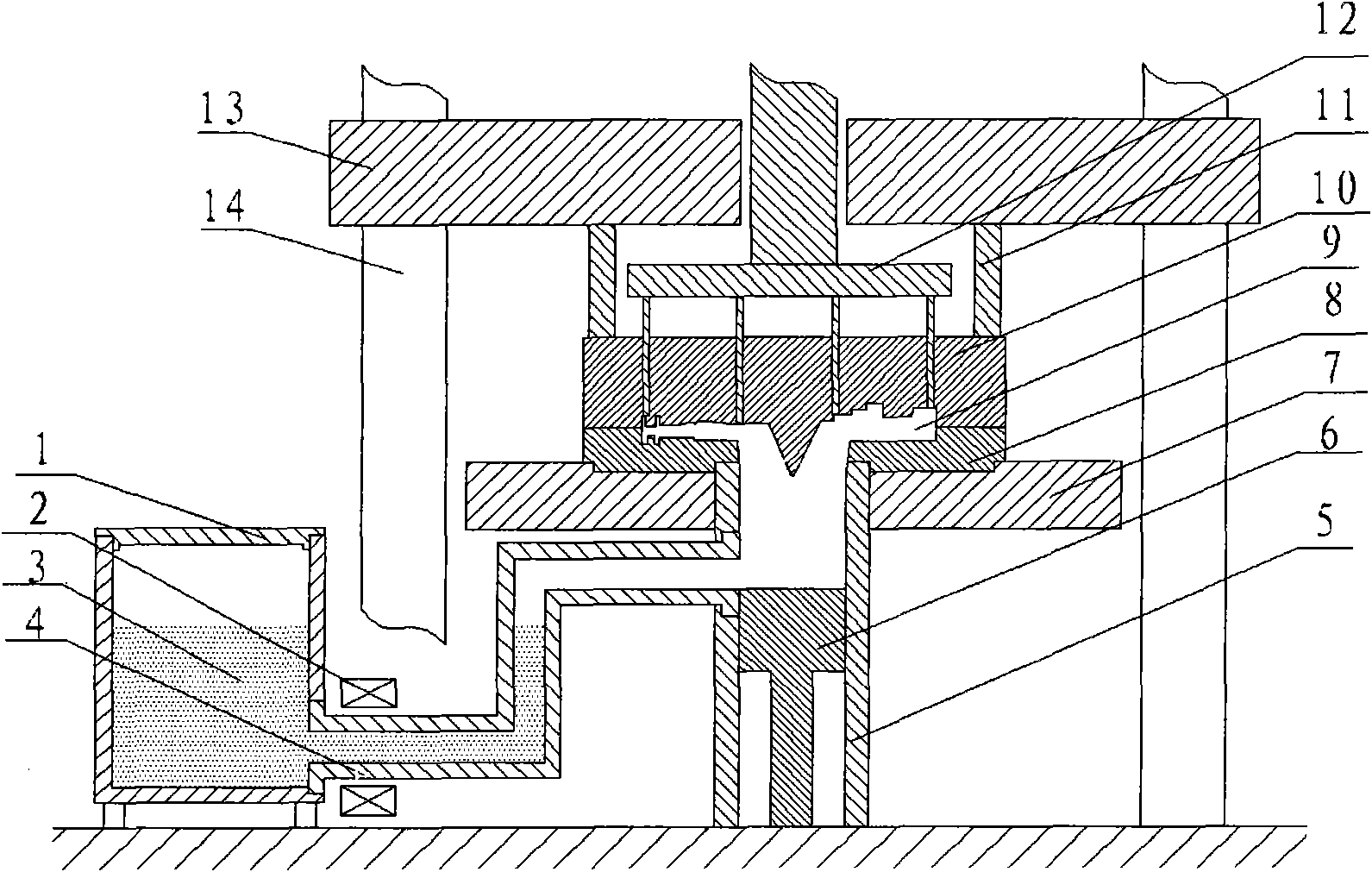

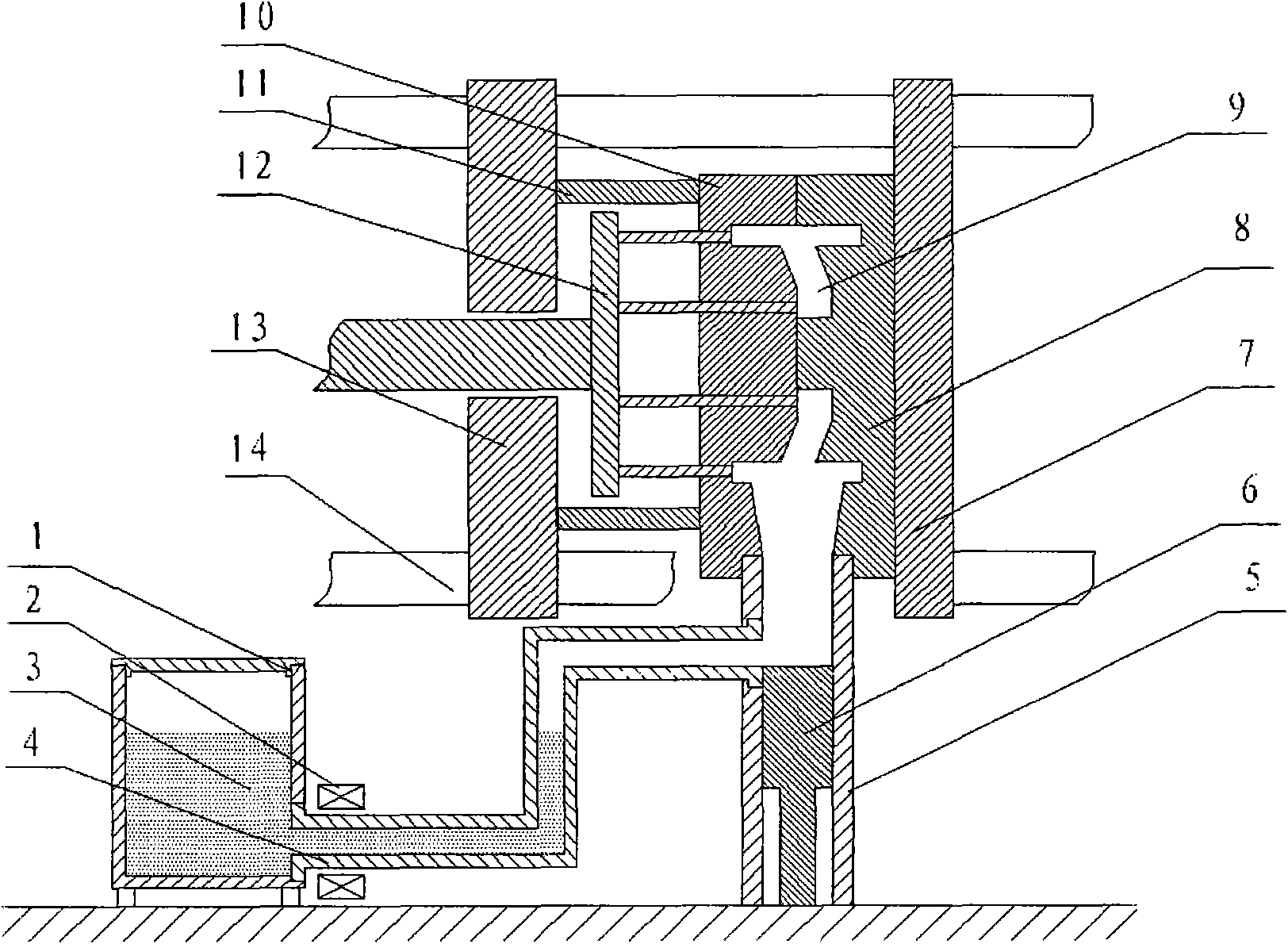

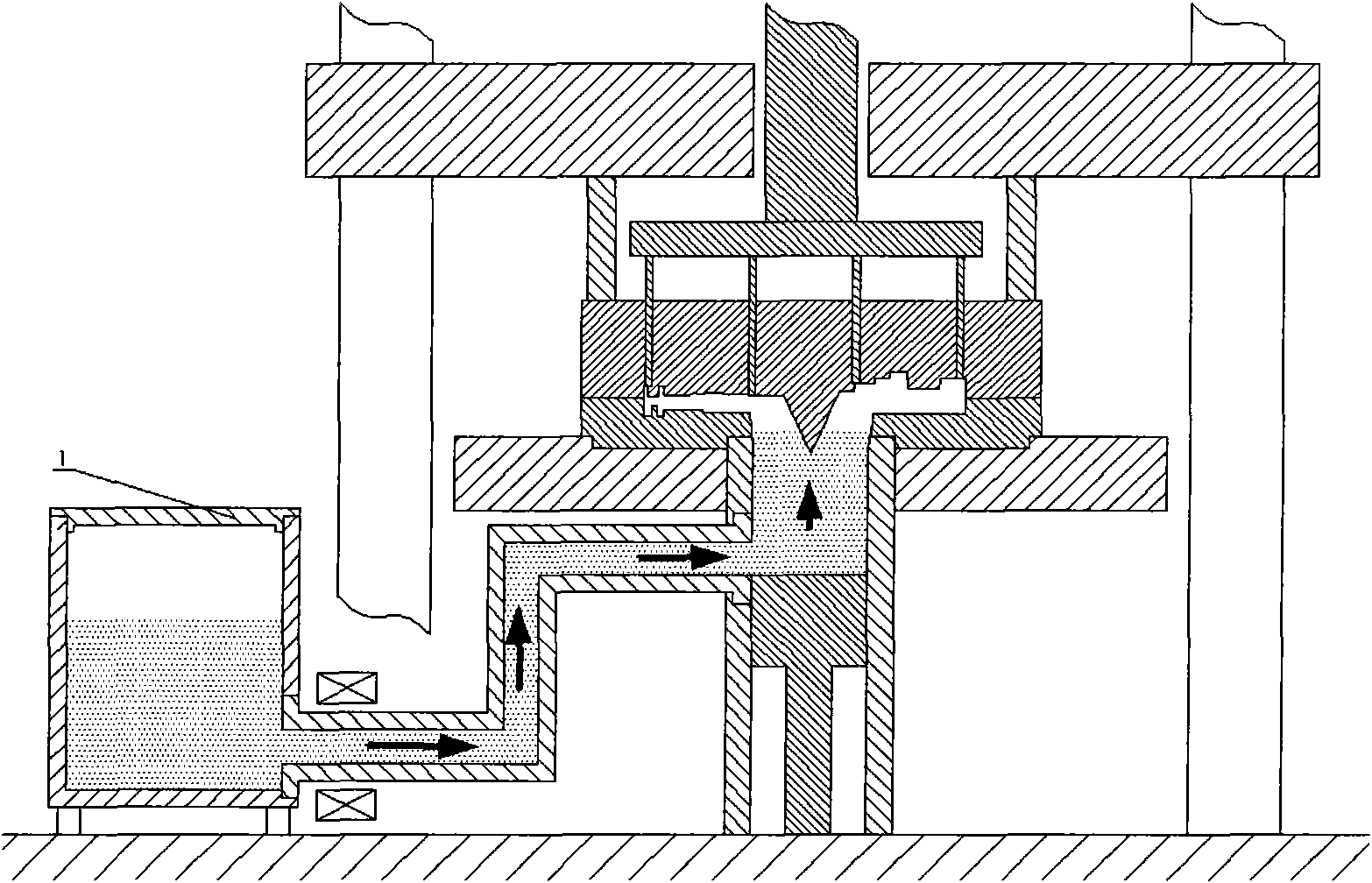

Method for indirect extrusion casting by utilizing filling of electromagnetic force and device thereof

The invention relates to a method for indirect extrusion casting by utilizing the filling of electromagnetic force and a device thereof. In the method, electromagnetic force is utilized to introduce liquid metal into an extrusion chamber to fill part of a mould cavity by a transmission pipeline; when the liquid metal in the mould cavity reaches a preset quantity, the transmission of the liquid metal is stopped; and an extrusion punching head ascends to push the liquid metal to fill the part which is not full in the mould cavity and continuously ascends to extrude and shape the liquid metal, and the liquid metal in the transmission pipeline flows back to a thermal insulation furnace under the function of reverse electromagnetic force. The invention has simple and convenient method, high automatization degree, good stability and skillful structural design of a special device. The liquid metal is transmitted and filled by a sealed transmission pipeline, and oxidation and air suction are reduced; the flow speed and the flow rate are controllable, and the quantification of extrusion casting is realized; at the time of extrusion shaping, the liquid metal in the transmission pipeline flows back, and the production efficiency is enhanced; and the friction and the abrasion of the extrusion punching head and the extrusion chamber are reduced, and the service lives of the extrusion punching head and the extrusion chamber are enhanced.

Owner:SOUTH CHINA UNIV OF TECH

Omnibearing defect detection equipment

PendingCN110000111AHigh degree of automationImprove detection accuracySortingCleaning processes and apparatusProduction lineGlass cover

The invention discloses omnibearing defect detection equipment. The omnibearing defect detection equipment comprises a rack, an AGV online material-calling continuous feeding mechanism, a feeding carrying manipulator, a dust removal mechanism, a positioning and correcting mechanism, a transfer manipulator, a two-track staggered conveying line, an omnibearing defect detection device, a sorting manipulator and a film laminating machine. It is ensured that a production line does not lack of materials through AGV automatic material calling of a client MES system, empty discs used by the equipmentare automatically carried to the customer designated position by an AGV and transferred onto the two-track interlaced conveying line after feeding and dust removal, then the omnibearing defect detection device conducts defect detection, if the requirements are met, the discs are transferred to the film laminating machine for film laminating and shipment by the sorting manipulator, otherwise, NG products are transferred to an unqualified area for scrap disposition, the processes of feeding, dust removal, detection, film laminating and the like on mobile phone glass cover plates are automatically achieved correspondingly, the automation degree is high, the detection accuracy is high, the detection speed is high, the product quality is ensured, and the product pass rate is increased.

Owner:FOLUNGWIN AUTOMATIC EQUIP CO LTD

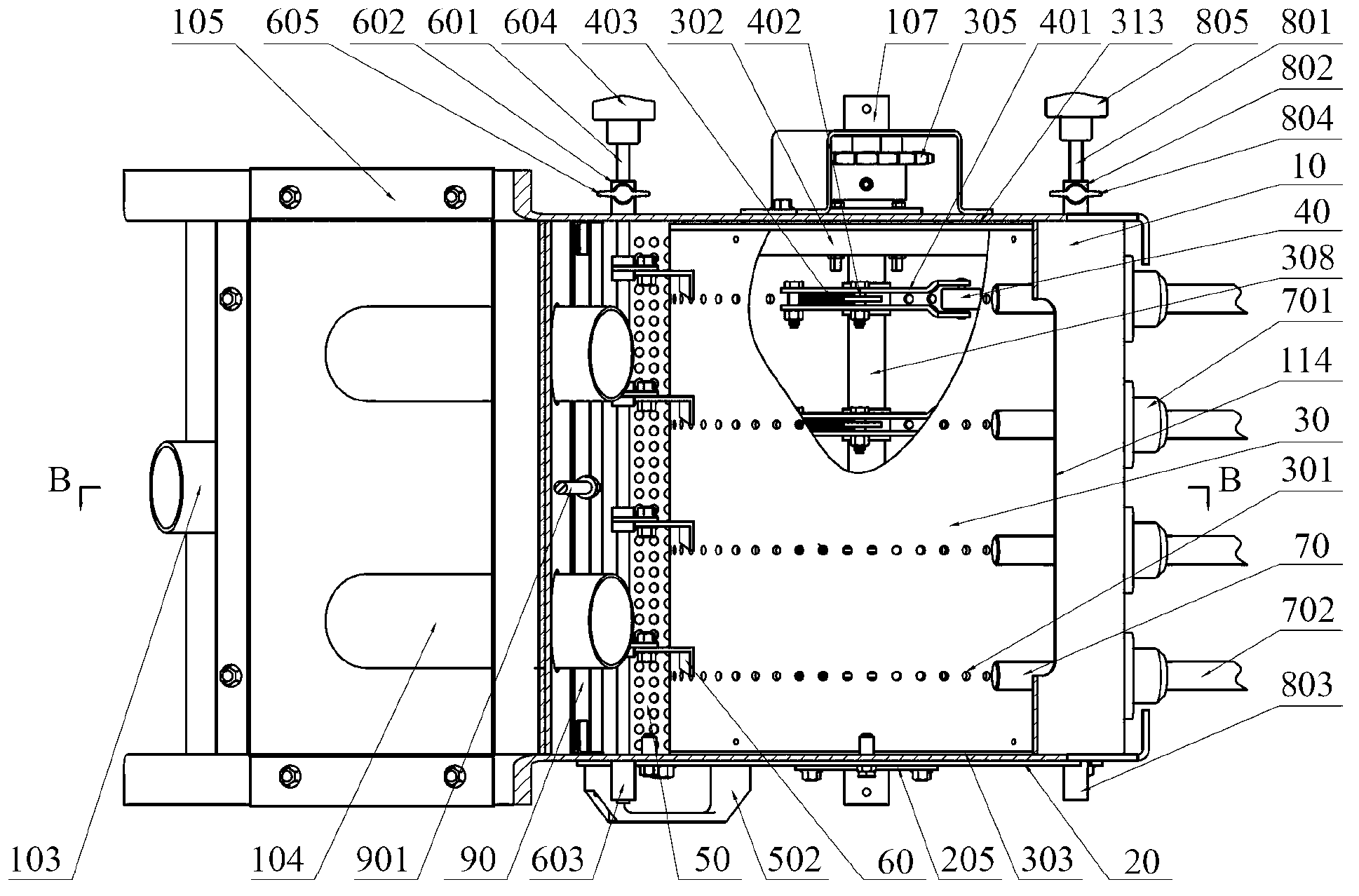

Full-automatic assembly production machine for motor stator

ActiveCN106787494AImprove efficiencySimple structureManufacturing stator/rotor bodiesManipulatorStator

The invention relates to a full-automatic assembly production machine for a motor stator. The full-automatic assembly production machine comprises a frame and a distribution control box, a conveying device is arranged on the frame and comprises two feeding devices, feeding blocks are arranged on the feeding devices, transposition cylinders are arranged at ends of the two feeding devices, shell assembly carriers and magnetic tile assembly carriers are arranged on the feeding blocks, a clamp spring feeding device, an oil bearing feeding device, a shell feeding manipulator, a riveting device, a grounding terminal assembly device, a left magnetic tile feeding device, a magnetic tile spring piece feeding device, a right magnetic tile feeding device, a sleeving manipulator, a compression device, a magnetizer and a turnover discharging device are arranged on the frame, the shell feeding manipulator is matched with a shell conveying belt on the frame, and the turnover discharging device is matched with a discharging conveying belt on the frame. Integrated automatic assembly is realized, and assembly efficiency is greatly improved.

Owner:ANHUI DALAI MOTOR CO LTD

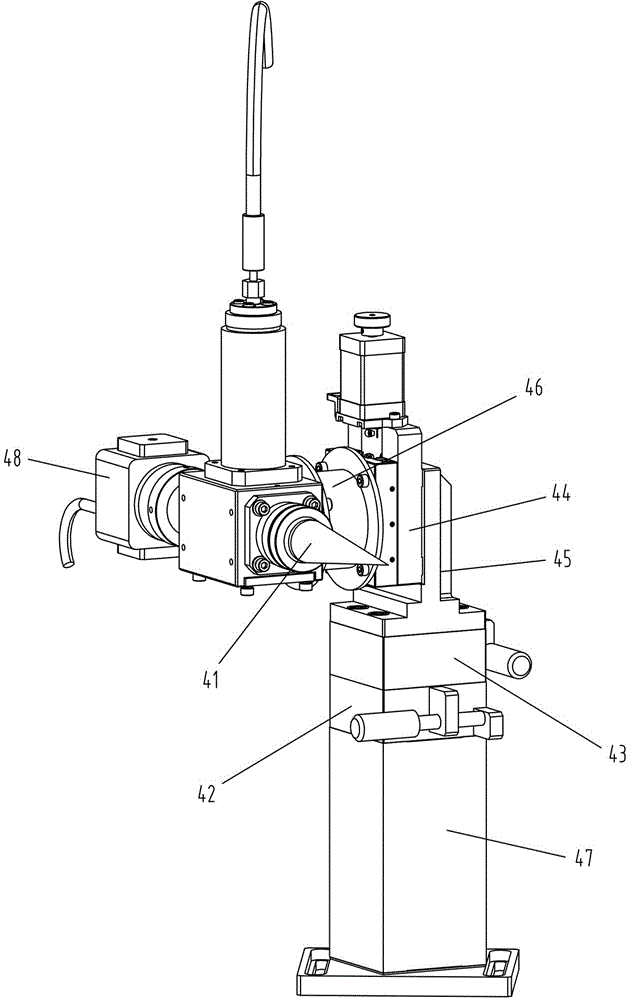

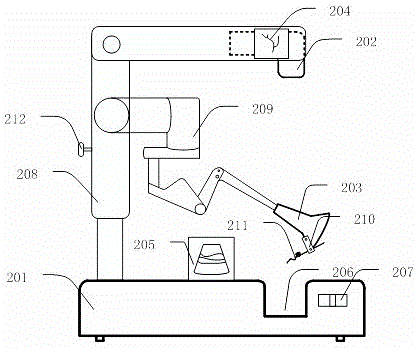

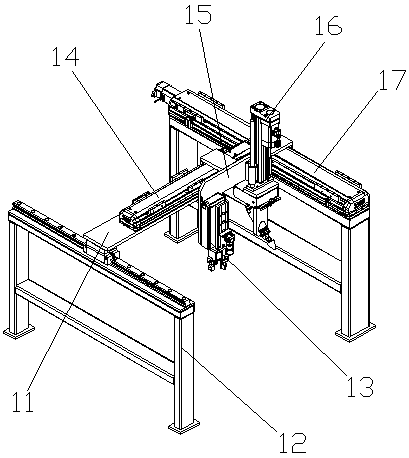

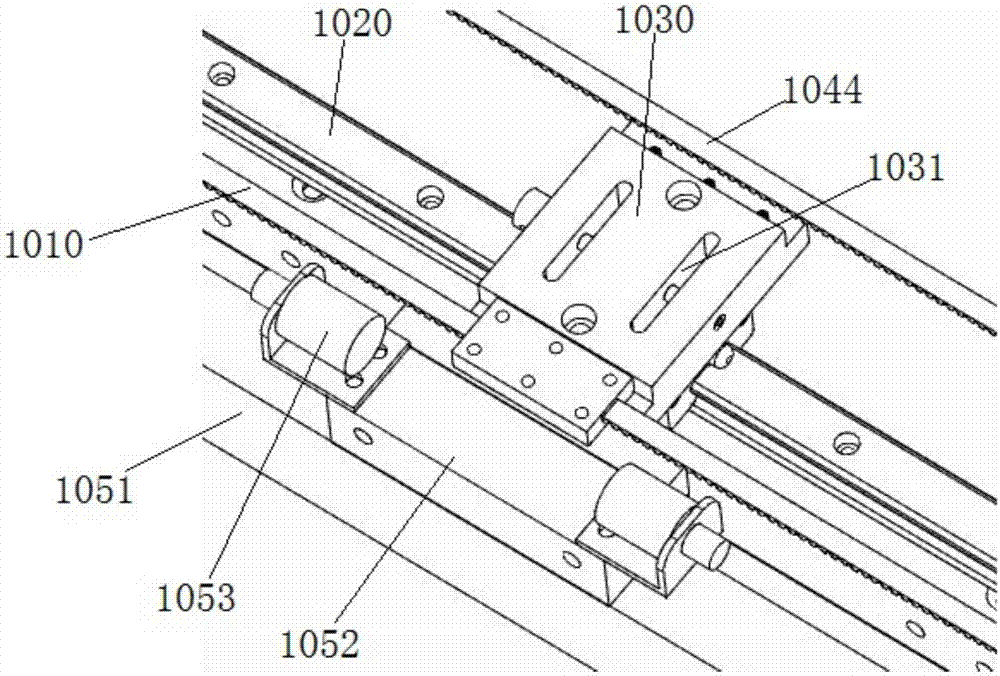

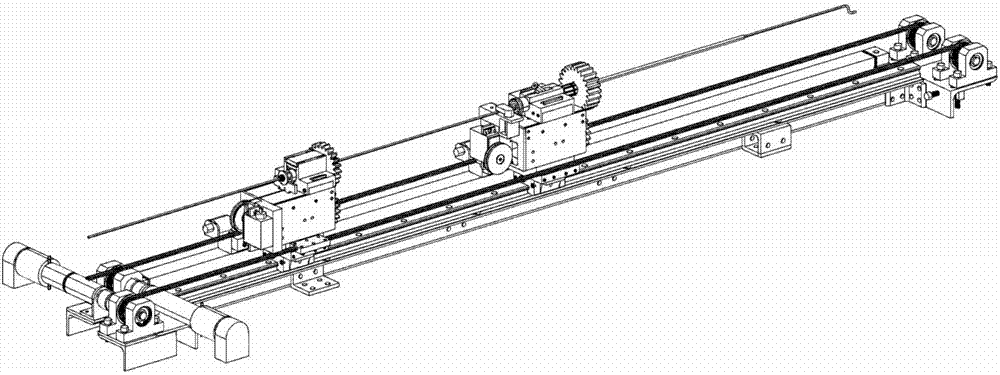

Interventional surgical robot subordinate end and mobile platform and control method of robot subordinate end

ActiveCN107374738AMeet the requirements for collaborative operationHigh transmission precisionDiagnosticsSurgical robotsSurgical robotThree vessels

The invention discloses an interventional surgical robot subordinate end and a mobile platform and a control method of the robot subordinate end and belongs to the technical field of minimally invasive blood vessel interventional operations. The mobile platform comprises a platform main beam, and platform connection blocks are arranged on the platform main beam through a linear guide rail pair D; the platform connection blocks are driven by a platform driving mechanism and used for installing a catheter controller or a guide wire controller. The interventional surgical robot subordinate end comprises the catheter controller, the guide wire controller and the mobile platform; the catheter controller and the guide wire controller are mounted on the two platform connection blocks respectively. According to the interventional surgical robot subordinate end, the catheter controller and the guide wire controller are installed on the mobile platform, and the problem is solved that it is difficult for an existing robot to complete co-operating of a catheter and a guide wire.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

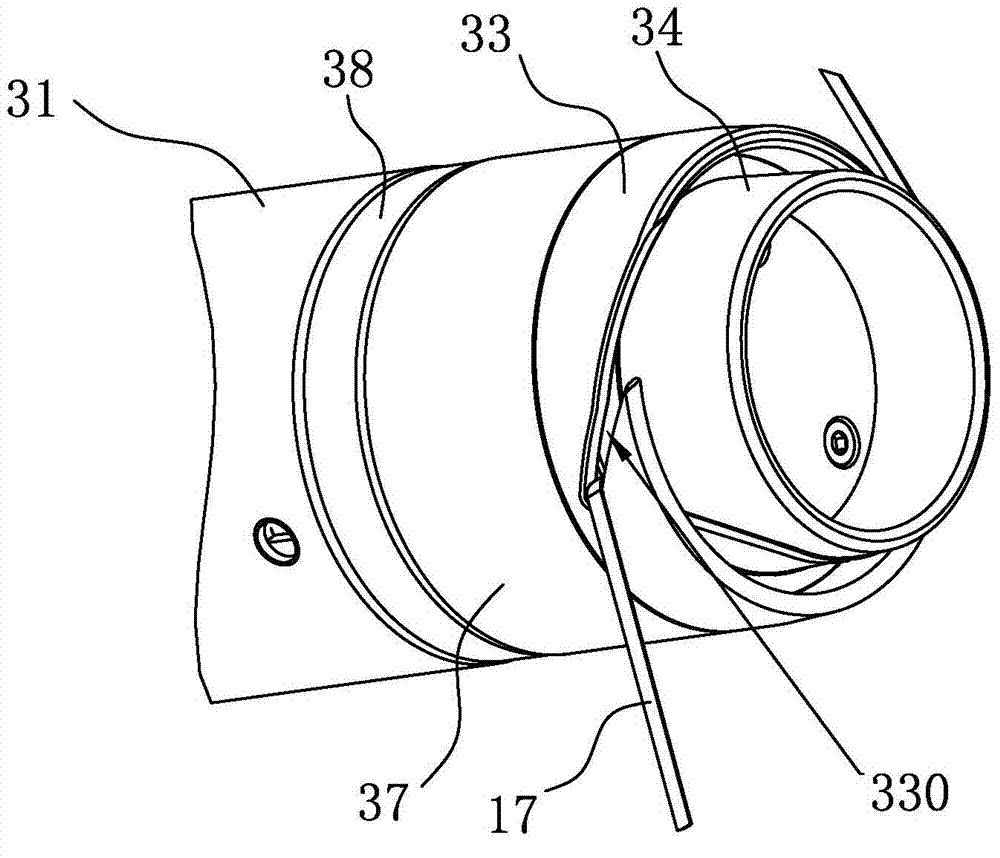

Automatically continuous carbon fiber winding device

ActiveCN104261202AContinuous winding and roll changingIngenious structural designFilament handlingAutomatic controlElectric machinery

The invention relates to an automatically continuous carbon fiber winding device. The automatically continuous carbon fiber winding device is characterized by comprising a base, a guide mechanism arranged on the base, a winding changing seat with winding drum seats, a drum changing driving mechanism for driving the winding changing seat to change the winding drum seats to be alternately arranged correspondingly to the guide mechanism, and a winding driving mechanism for driving the winding drum seats to rotate; at least two winding drum seats and cutting mechanisms arranged correspondingly to every winding drum seats are fixedly connected to the winding changing seat; the guide mechanism, the drum changing driving mechanism and the winding mechanism are all connected with an automatic control system by signals. The automatically continuous carbon fiber winding device has the beneficial effects that the automatic control system controls motors on the various driving mechanism to act so that the winding changing seat automatically changes the winding drum seats, carbon fibers are automatically cut by use of the cutting mechanism while being wound around an empty drum, and after the fibers are cut, the full winding drum can be taken off and then another empty drum is loaded for next changing, and therefore, the purposes of full-automatic efficient continuous winding and drum changing are achieved.

Owner:ZHEJIANG JINGGONG SCI & TECH

Die-casting mold multi-point precise temperature control system and method

The invention relates to a die-casting mold multi-point precise temperature control system and a method. The invention is characterized in that the system comprises a plurality of temperature detectors which are embedded in a mold, each temperature detector is repetitively connected with an analog quantity input module through a compensating lead wire, the analog quantity input modules are connected with a central processing unit, the central processing unit is respectively connected with a human-machine interaction interface and a mold temperature controller, a plurality of oil inlet pipes and a plurality of oil outlet pipes are arranged on the mold temperature controller, and the oil inlet pipes and the oil outlet pipes are respectively communicated with a plurality of flow passages arranged on the mold for forming a cyclic circulation pipeline. The invention has ingenious structural design, can improve the repeatability of the mold temperature control in the die-casting process, can improve the production efficiency, and can be widely used in the temperature control process of the die casting production.

Owner:TSINGHUA UNIV

Servo electrohydraulic composite pressure method and press machine thereof

InactiveCN101927578AImprove performanceReduce energy consumptionPress ramNumerical controlPunch press

The invention discloses a servo electrohydraulic composite pressure method, comprising the following steps: 1) arranging a stander; 2) arranging an upper hydraulic device on the stander, 3) arranging a closed ring servo electrohydraulic control system, wherein the closed ring servo electrohydraulic control system is connected with the upper hydraulic device, and controls the work situation of the upper hydraulic device; the invention further discloses a press machine which implements the method; the method provided by the invention uses a servo electrohydraulic technology to replace the traditional electrohydraulic control technology, which has simple manufacturing, high efficiency, little power consumption and high control precision; the position control precision can reach to 0.01 to 0.02 millimeters; the pressing, the tensioning, the de-molding, the full deciding and other functions can be realized simultaneously, so the method has a comparatively high processing flexibility; the press machine provided by the invention is rational in structure, little in volume, stable in work, high in capacity, little in noise, and wide in application range. The advantages of a mechanical punching machine, a hydraulic punching machine and a numerical control are integrated, so the press machine has the advantages of multi-function, low cost, large pressure tonnage, etc.

Owner:东莞市得力仕机械科技有限公司

Vertical type automatic wall brick-pasting device for building construction

InactiveCN108729631ARealize the lifting effectIngenious structural designBuilding constructionsBrickEngineering

The invention discloses a vertical type automatic wall-tiling device for building construction. The vertical type automatic wall-tiling device comprises a base; a transversely arranged first electricsliding rail is arranged on the side wall of the base; the first electric sliding rail is internally connected with a first sliding block in a sliding way, and the first sliding block is matched withthe first electric sliding rail; the side wall of the upper side of the first sliding block is provided with a vertically arranged support rod; the side wall of the support rod is provided with a vertically arranged second electric sliding rail; the second electric sliding rail is internally connected with a second sliding block in a sliding way, and the second sliding block is matched with the second electric sliding rail; the second sliding block passes through the side wall of the second electric sliding rail and is connected with a transversely arranged connecting block; a drive motor is arranged on the side wall of one side of the connecting block; an output shaft of the drive motor is connected with a first rotating shaft. The vertical type automatic wall-tiling device for building construction can automatically perform a wall-tiling operation, thus saving a great deal of labor force and budget, and improving the tiling efficiency; furthermore, the device is lower in manufacturing cost and suitable for being popularized in the construction industry.

Owner:广东鑫基建设集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com