Omnibearing defect detection equipment

A defect detection, all-round technology, applied in the field of detection, can solve the problems of easy misjudgment and missed judgment, high repeatability and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

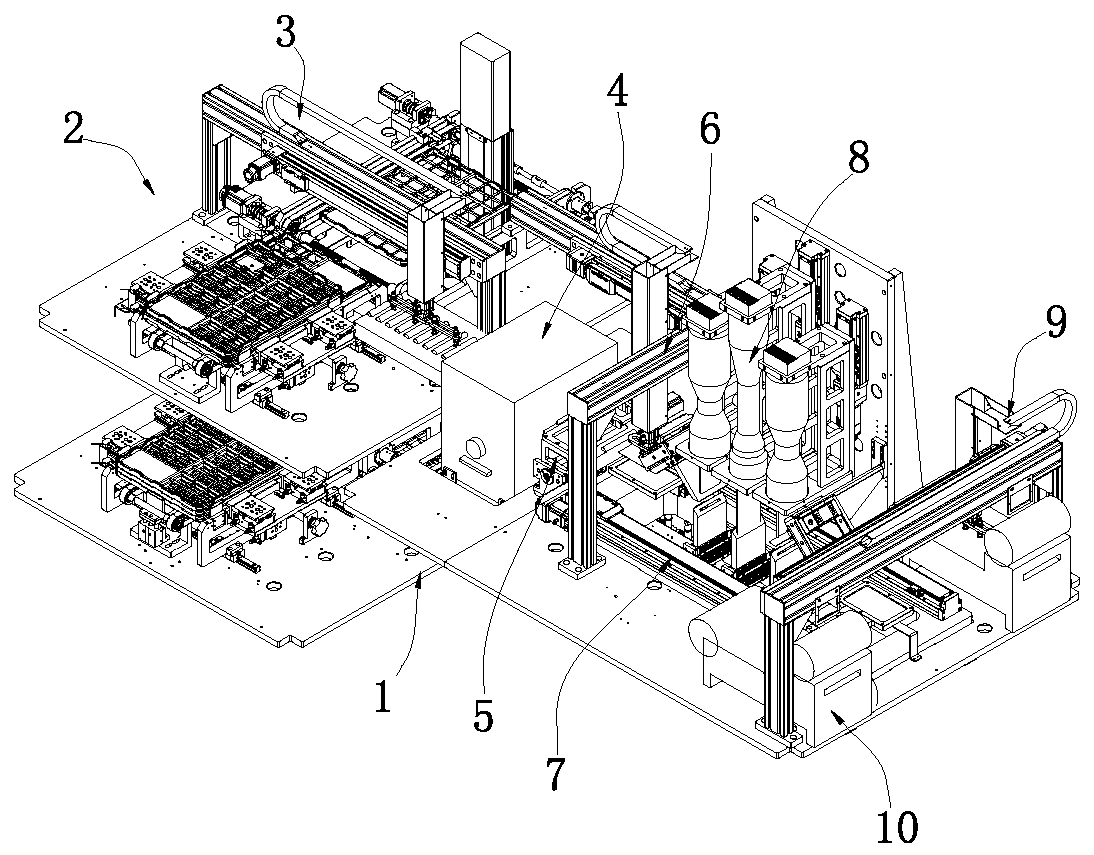

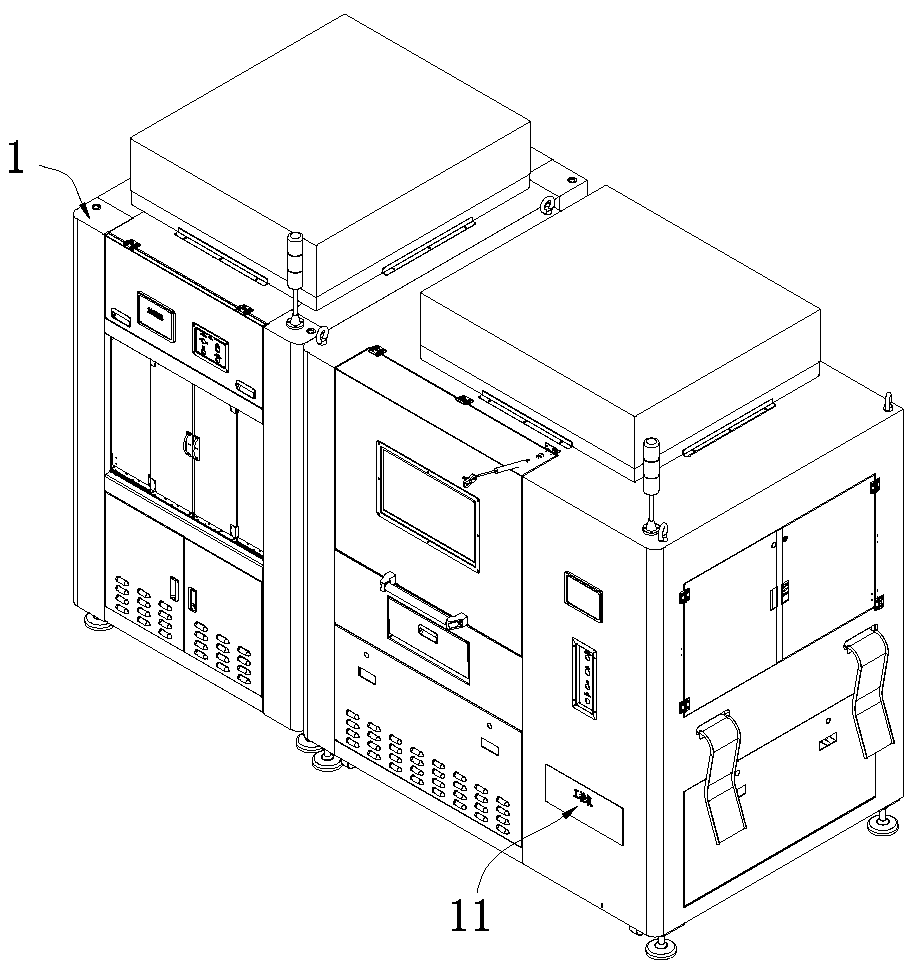

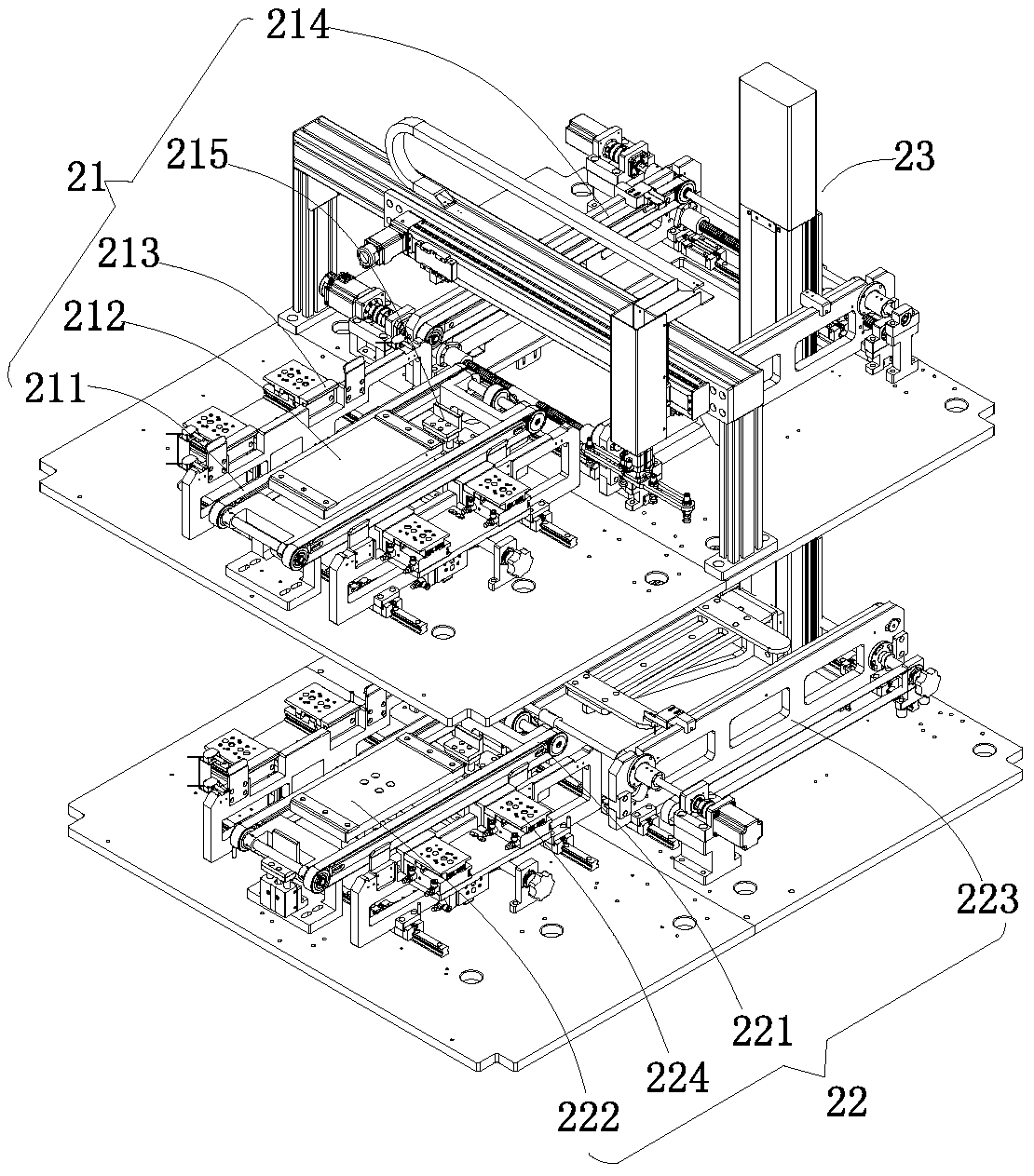

[0044] Example: see Figure 1 to Figure 16 , The embodiment of the present invention provides an omnidirectional defect detection equipment, which includes a frame 1, an AGV online ordering and continuous feeding mechanism 2, a feeding handling manipulator 3, a dust removal mechanism 4, a positioning correction mechanism 5, a transfer manipulator 6, Double-track staggered conveyor line 7, omnidirectional defect detection device 8, sorting manipulator 9 and laminating machine 10. The AGV online ordering continuous feeding mechanism 2, the dust removal mechanism 4, the positioning correction mechanism 5, and the double-track staggered conveying line 7 are arranged in sequence on the frame 1, and the feeding handling manipulator 3 corresponds to the AGV online ordering continuous feeding The connection position of the mechanism 2 and the dust removal mechanism 4 is set on the frame 1, the transfer manipulator 6 corresponding to the connection position of the positioning correction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com