Patents

Literature

7687results about "Cleaning processes and apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

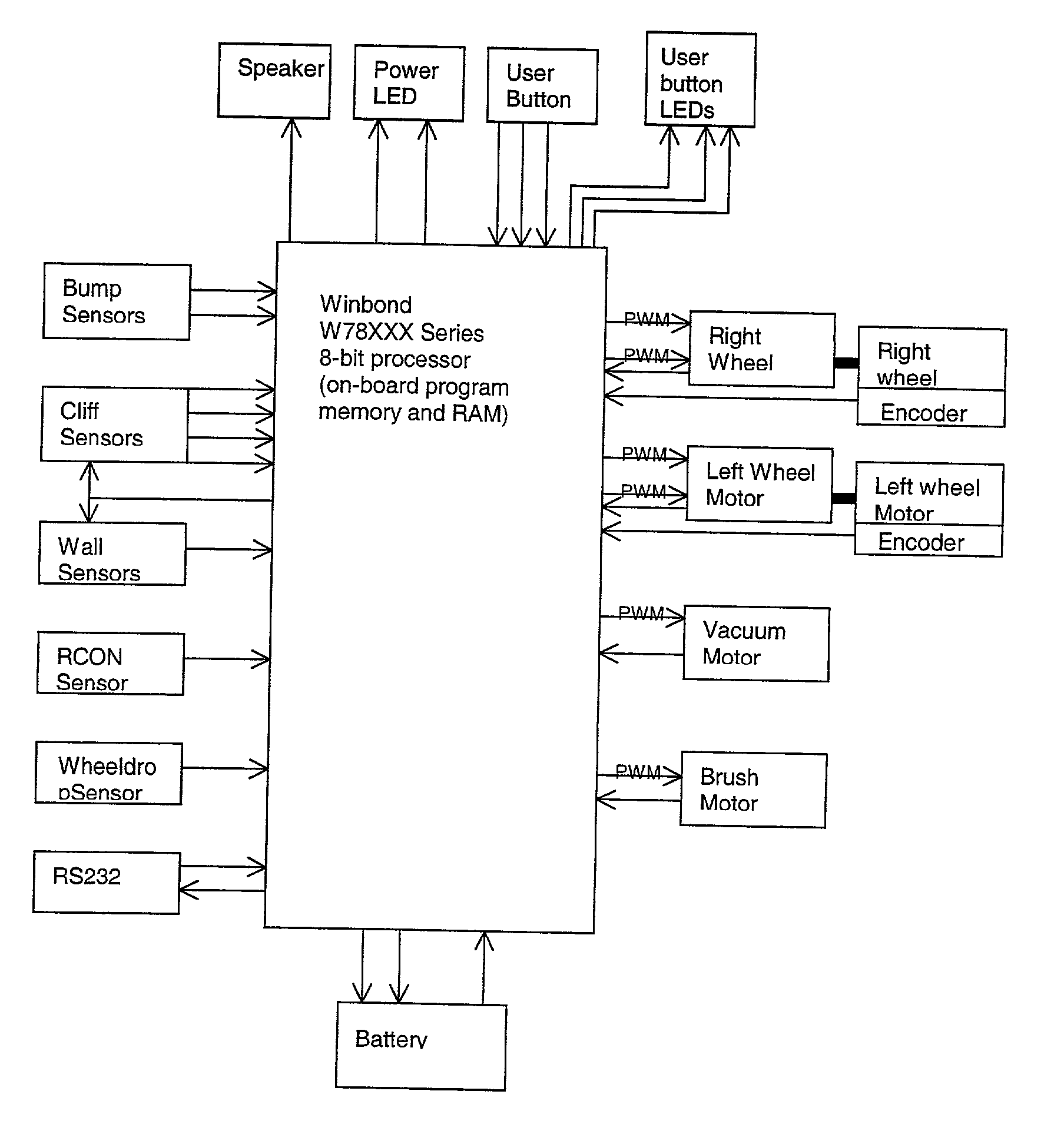

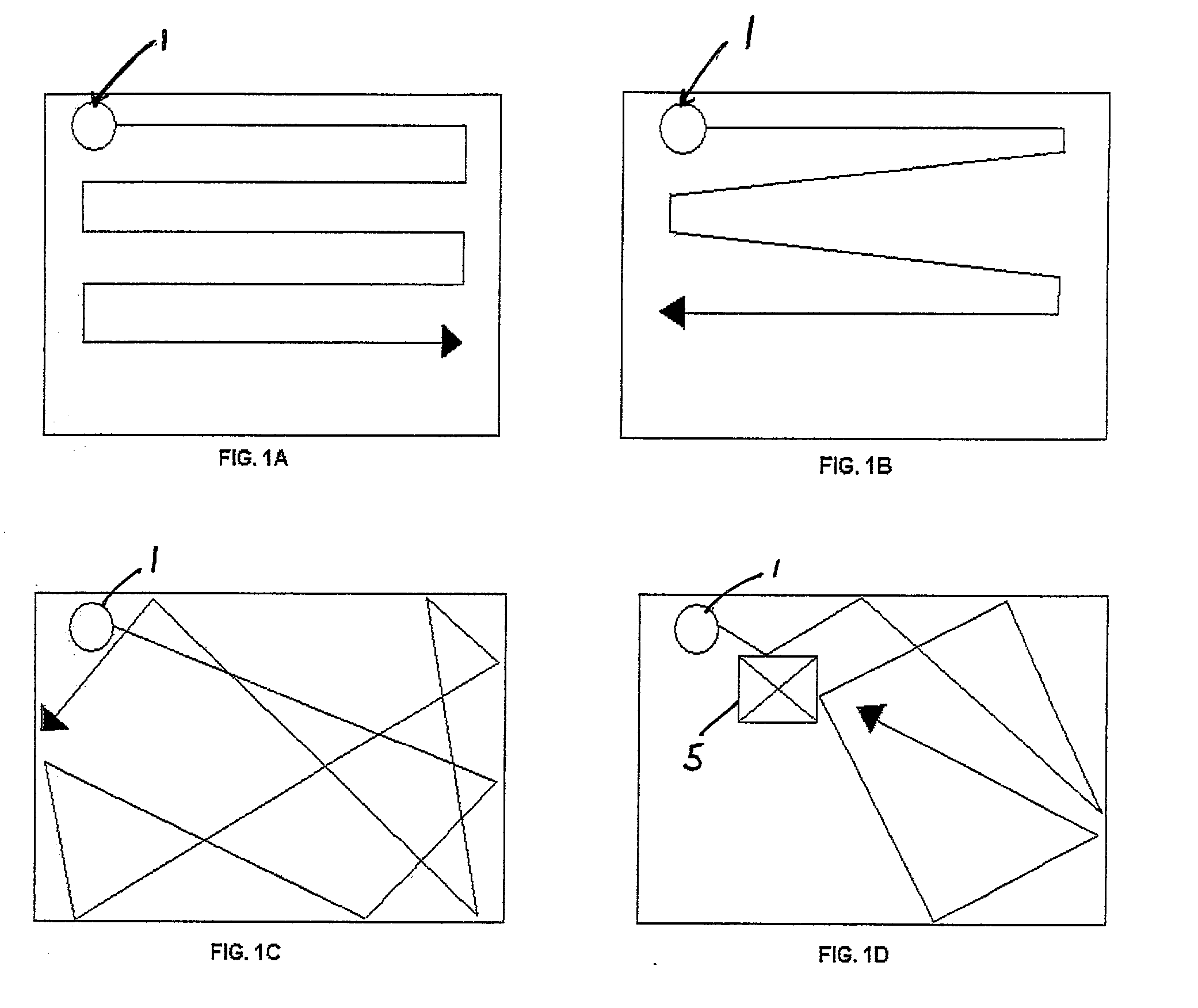

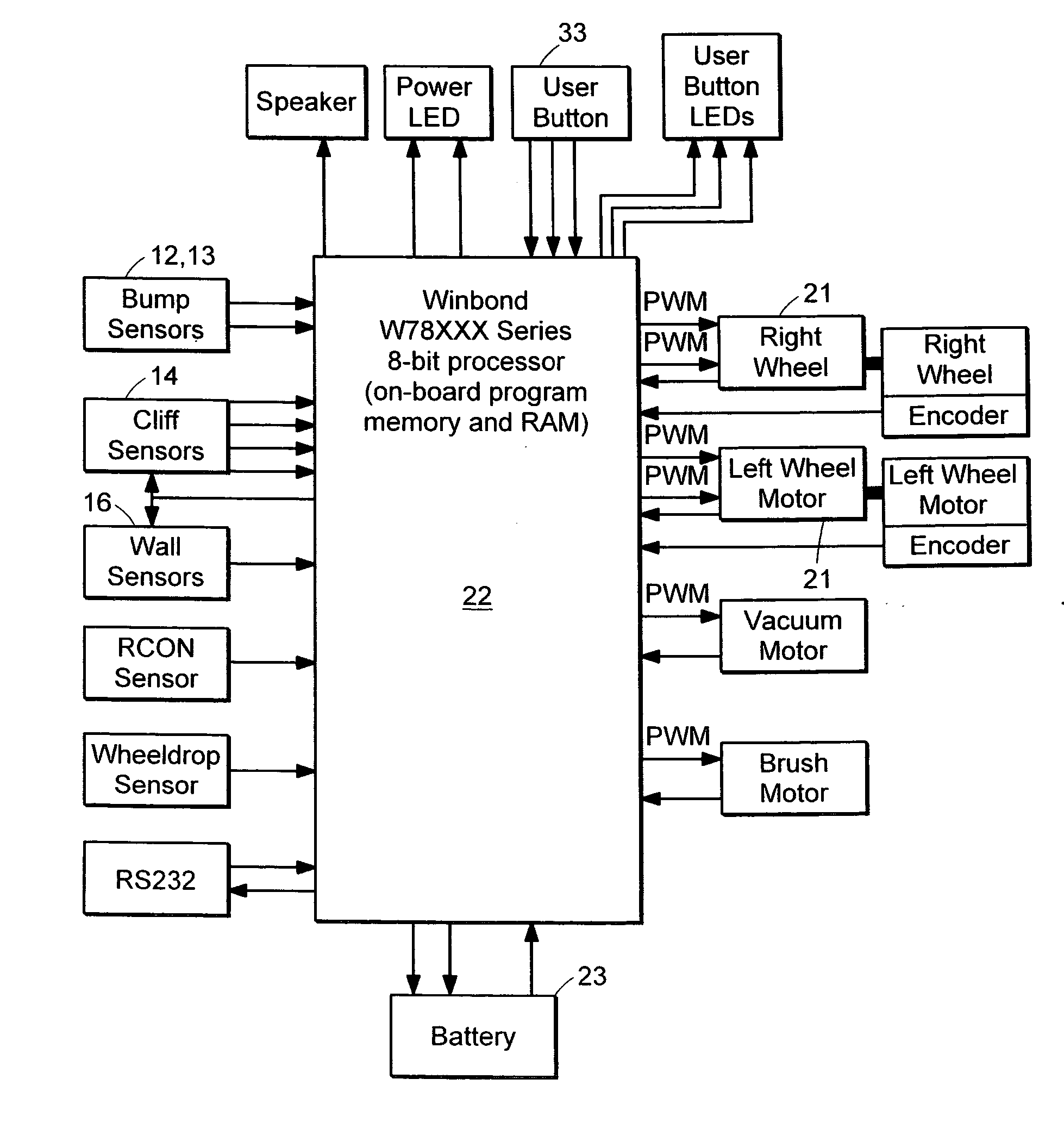

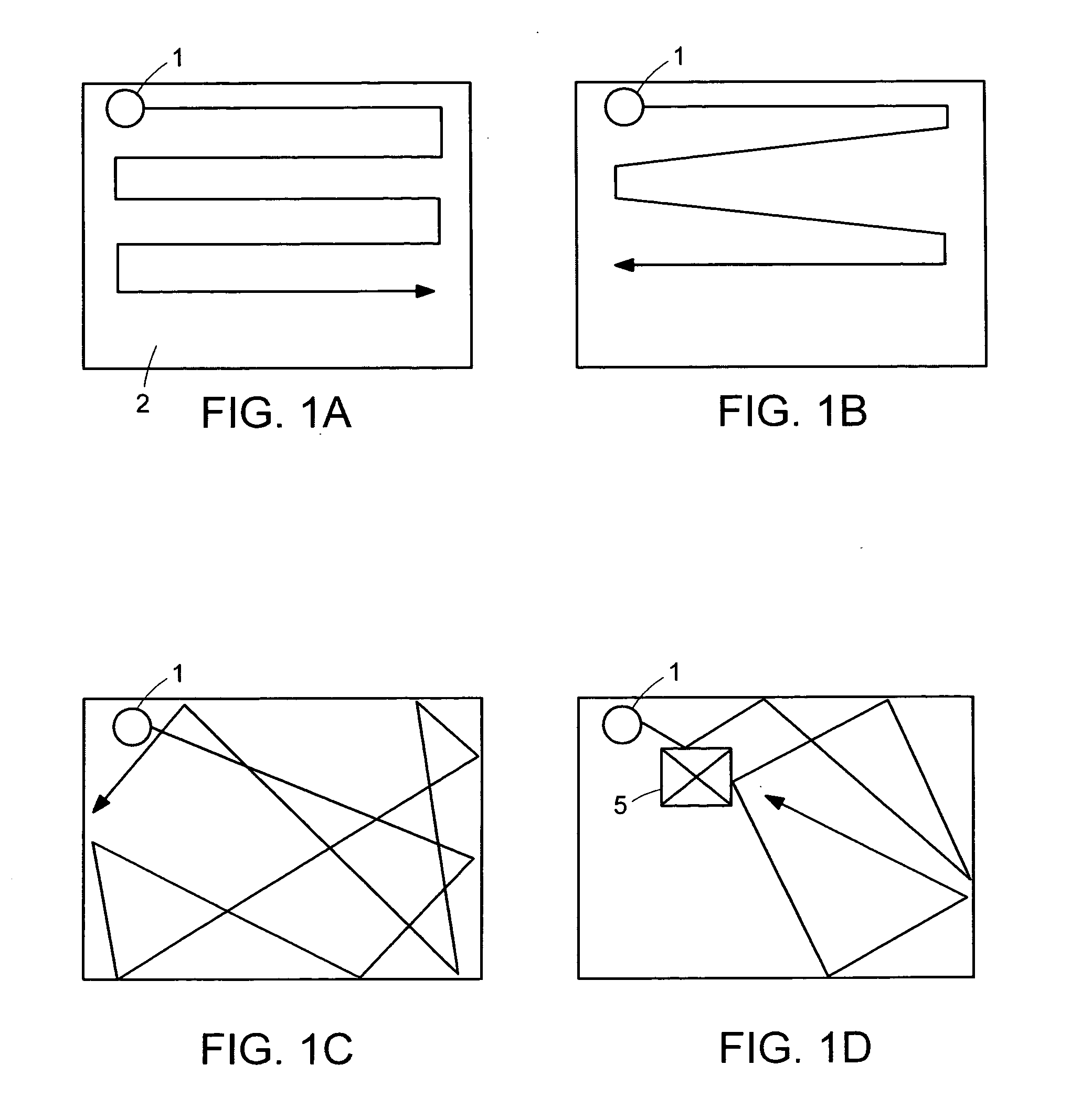

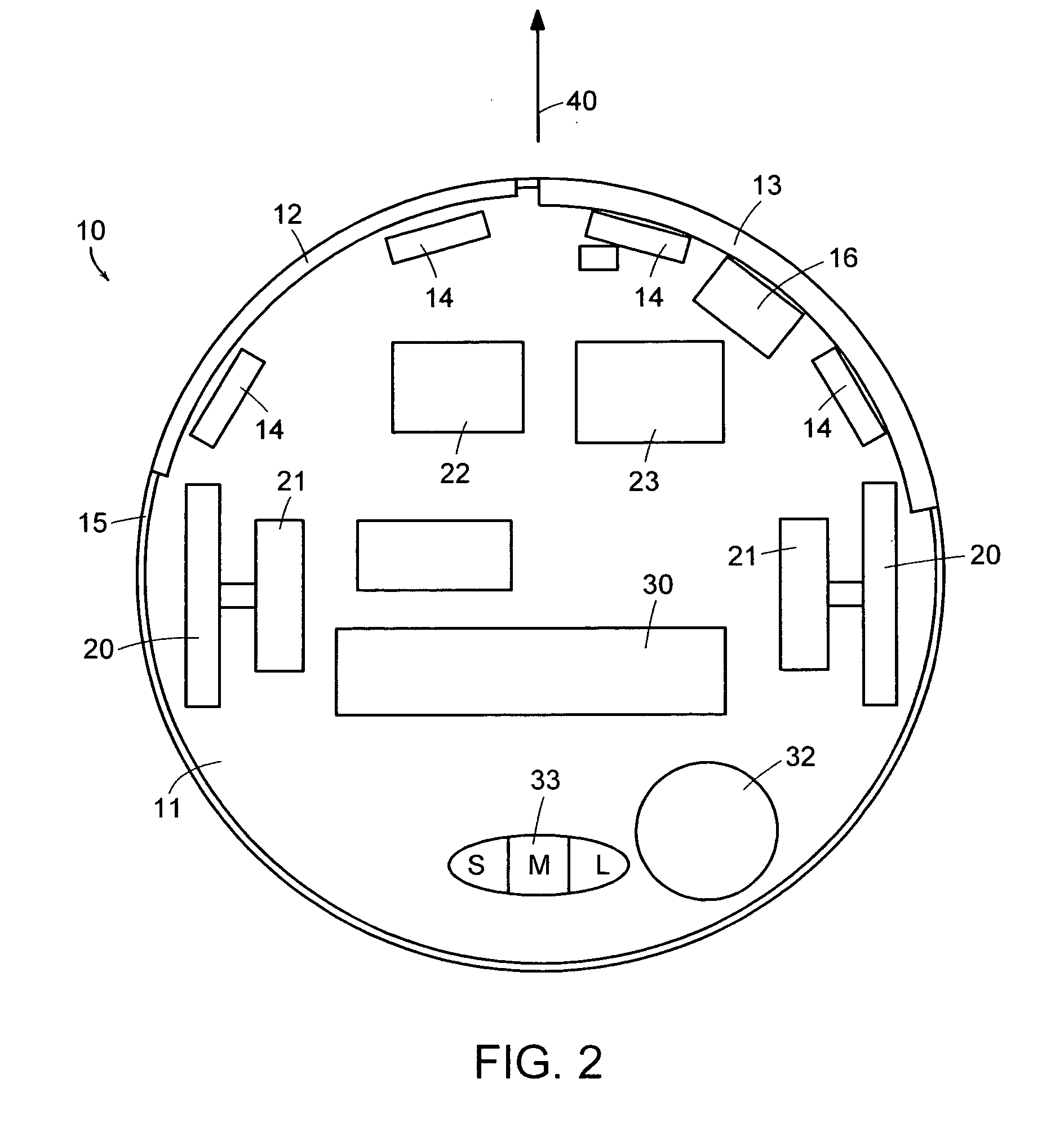

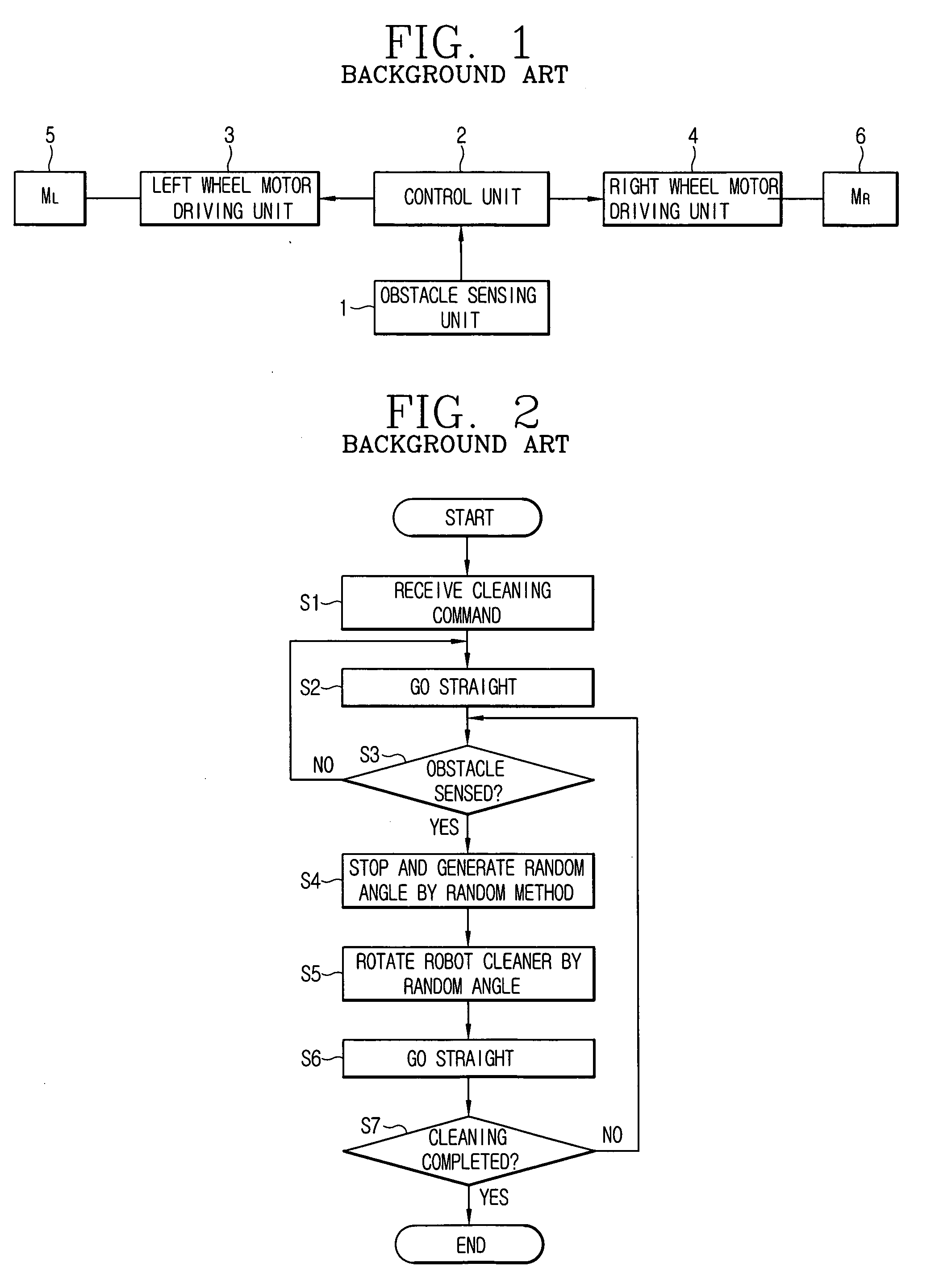

Method and system for multi-mode coverage for an autonomous robot

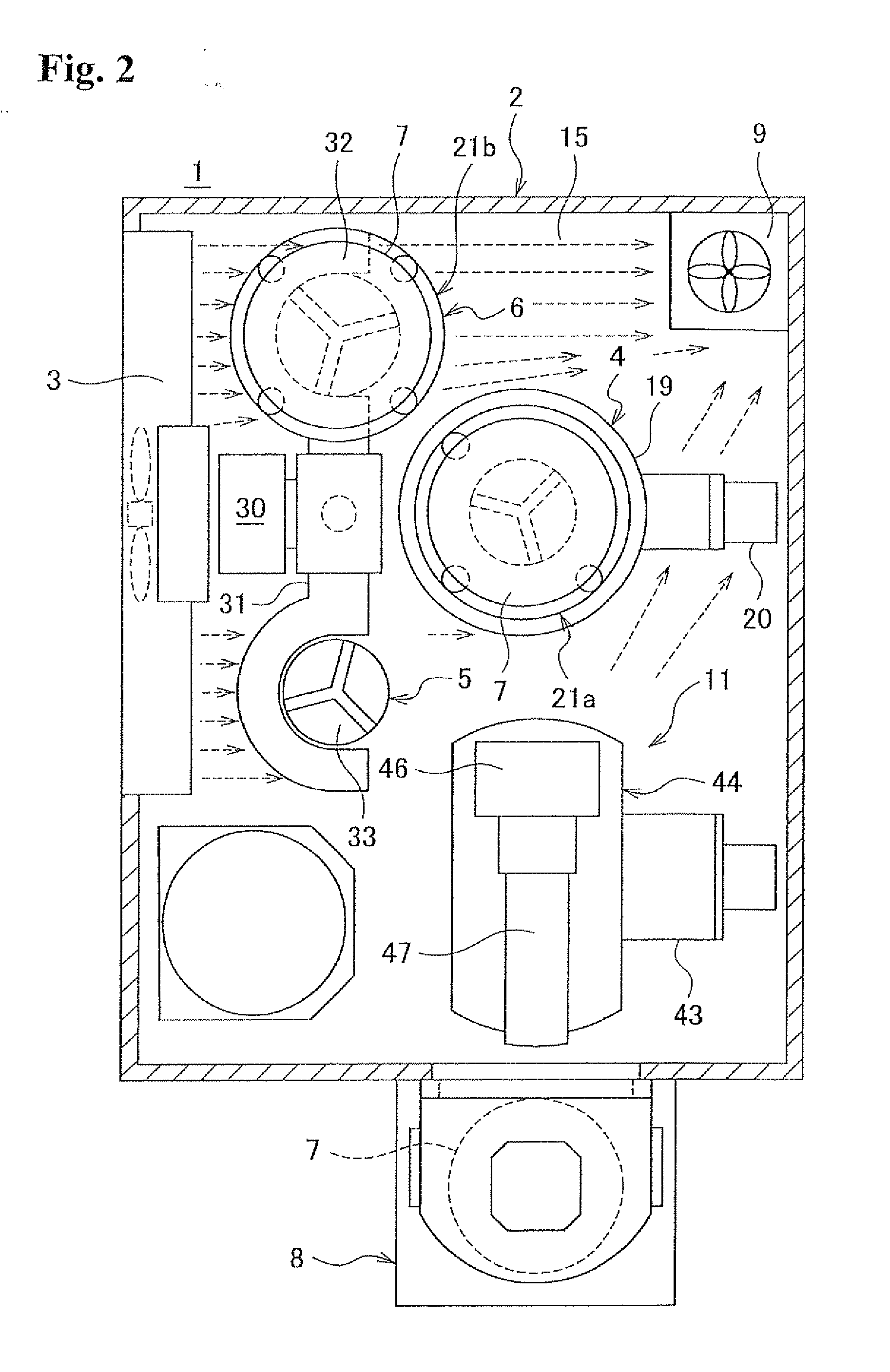

A control system for a mobile robot (10) is provided to Effectively cover a given area by operating in a Plurality of modes, including an obstacle following mode (51) and a random bounce mode (49). In other embodiments, spot coverage, such as spiraling (45), or other modes are also used to increase effectiveness. In addition, a behavior based architecture is used to implement the control system, and various escape behaviors are used to ensure full coverage.

Owner:IROBOT CORP

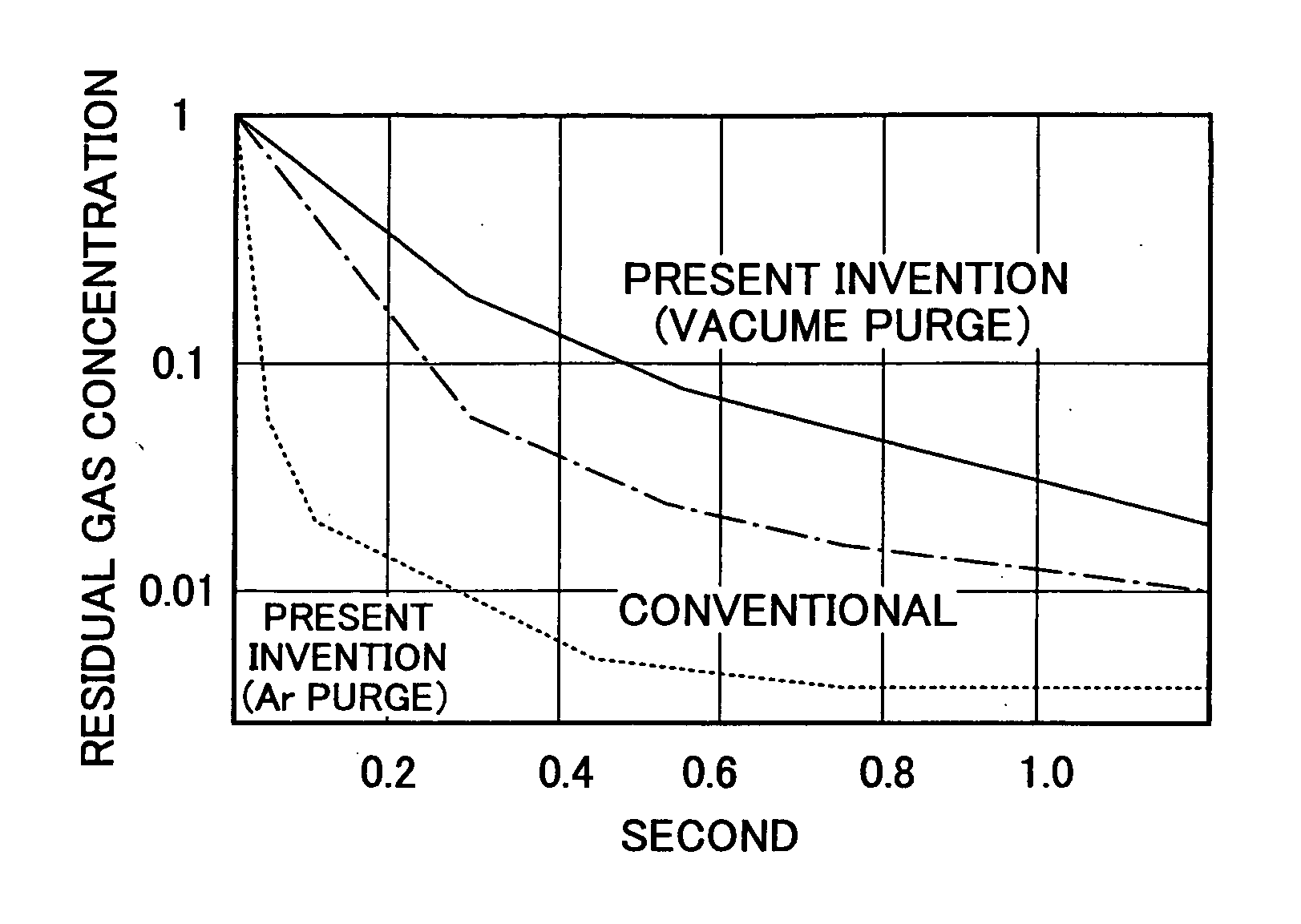

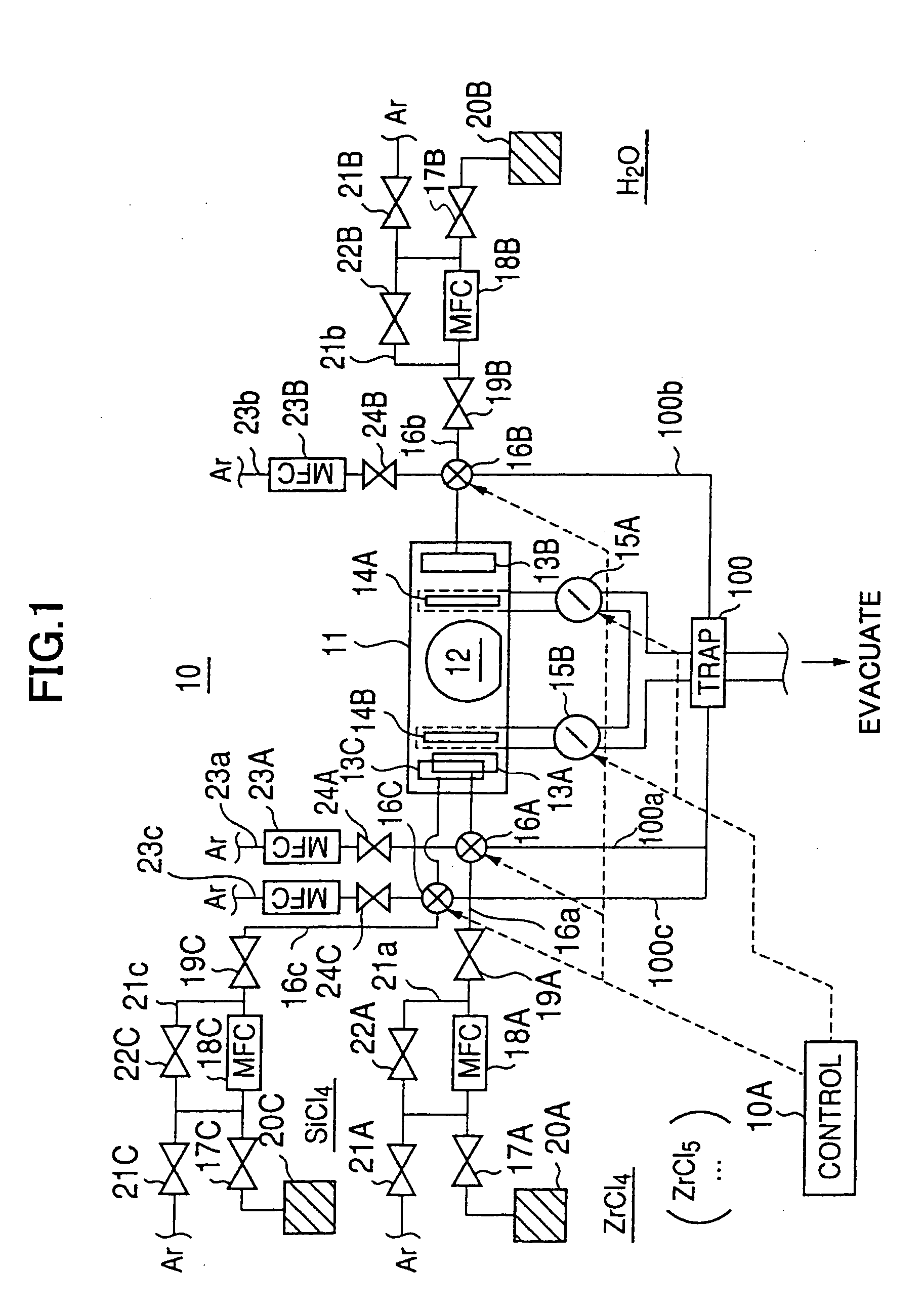

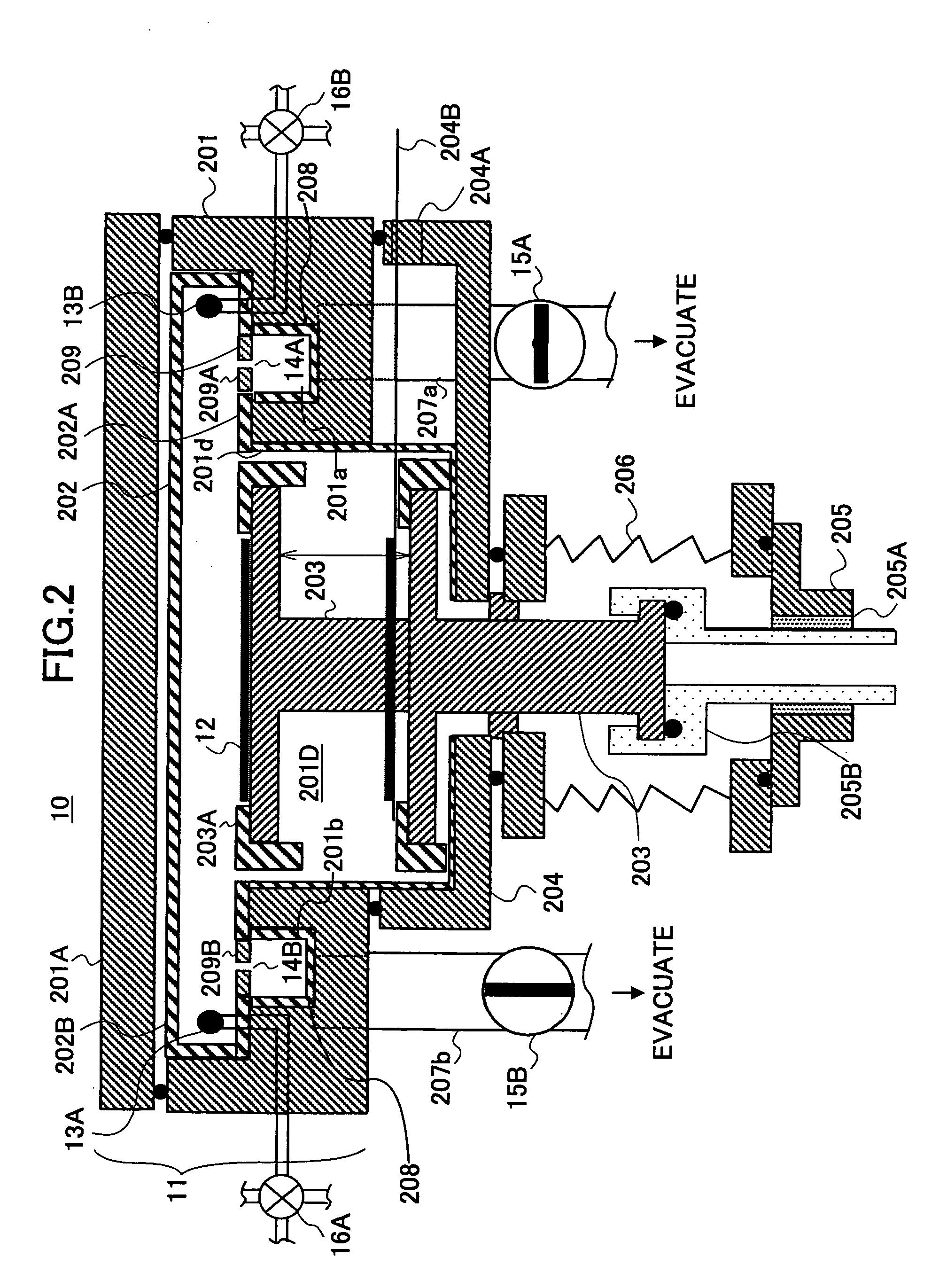

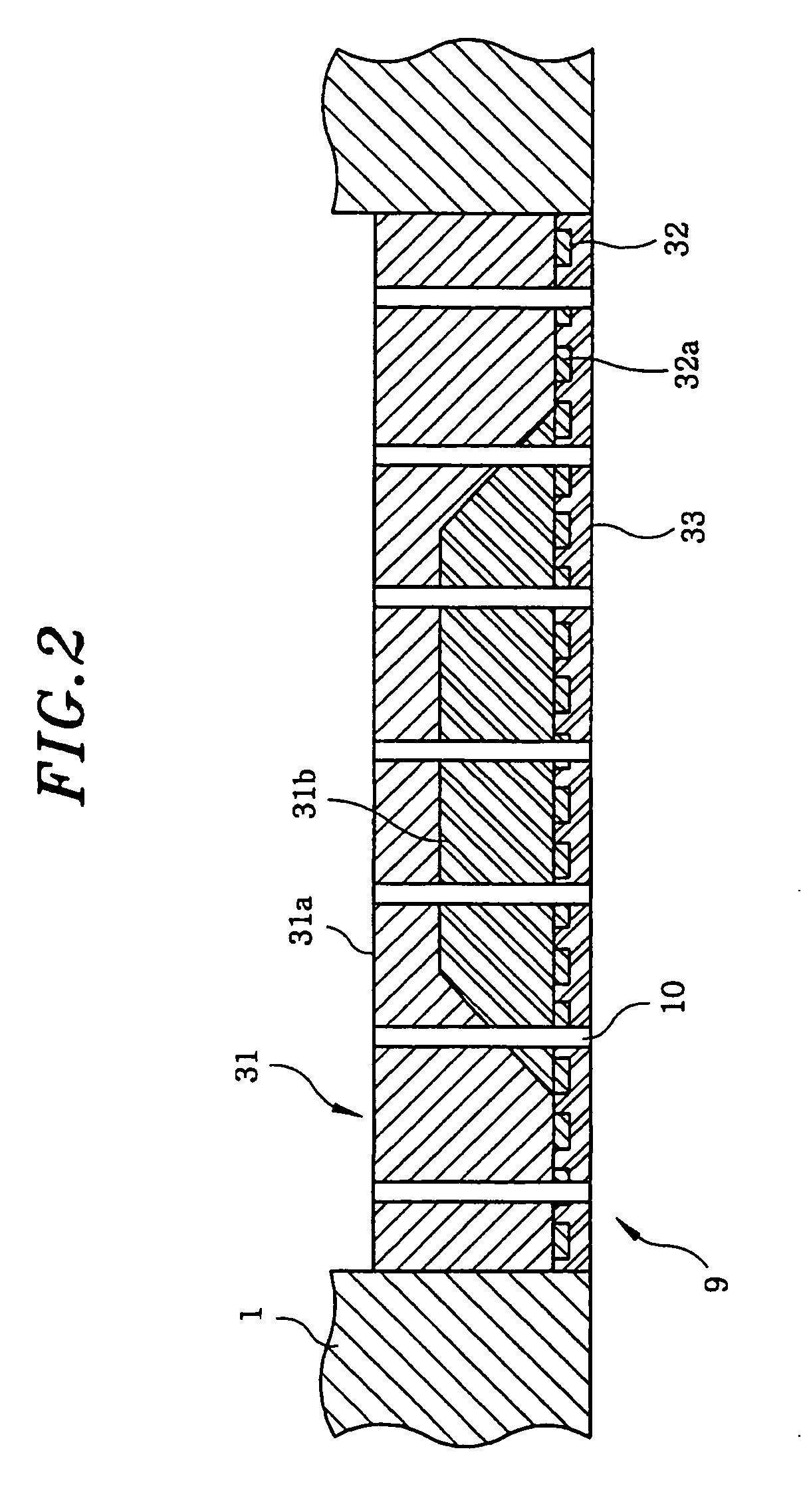

Substrate processing apparatus and substrate processing method, high speed rotary valve, and cleaning method

InactiveUS20050074983A1Increase speedFilm growth efficientlyPlug valvesLiquid surface applicatorsRotary valveEngineering

A substrate processing apparatus includes a processing vessel provided with a stage holding thereon a substrate to be processed and evacuated at an evacuation port, and a source gas supplying system that supplies plural source gases to the processing vessel separately in the form of a laminar flow, wherein the evacuation port has a slit-form shape extending in a direction generally intersecting perpendicularly to a direction of the laminar flow, the evacuation port is engaged with a valve having a valve body formed with a slit-form opening corresponding to the slit-form shape of the evacuation port, the slit-form opening being provided so as to cause a displacement with respect to the evacuation port in a direction generally intersecting perpendicularly to an extending direction of the evacuation port, the valve changing a degree of valve opening thereof via displacement of said slit-form opening.

Owner:TOKYO ELECTRON LTD

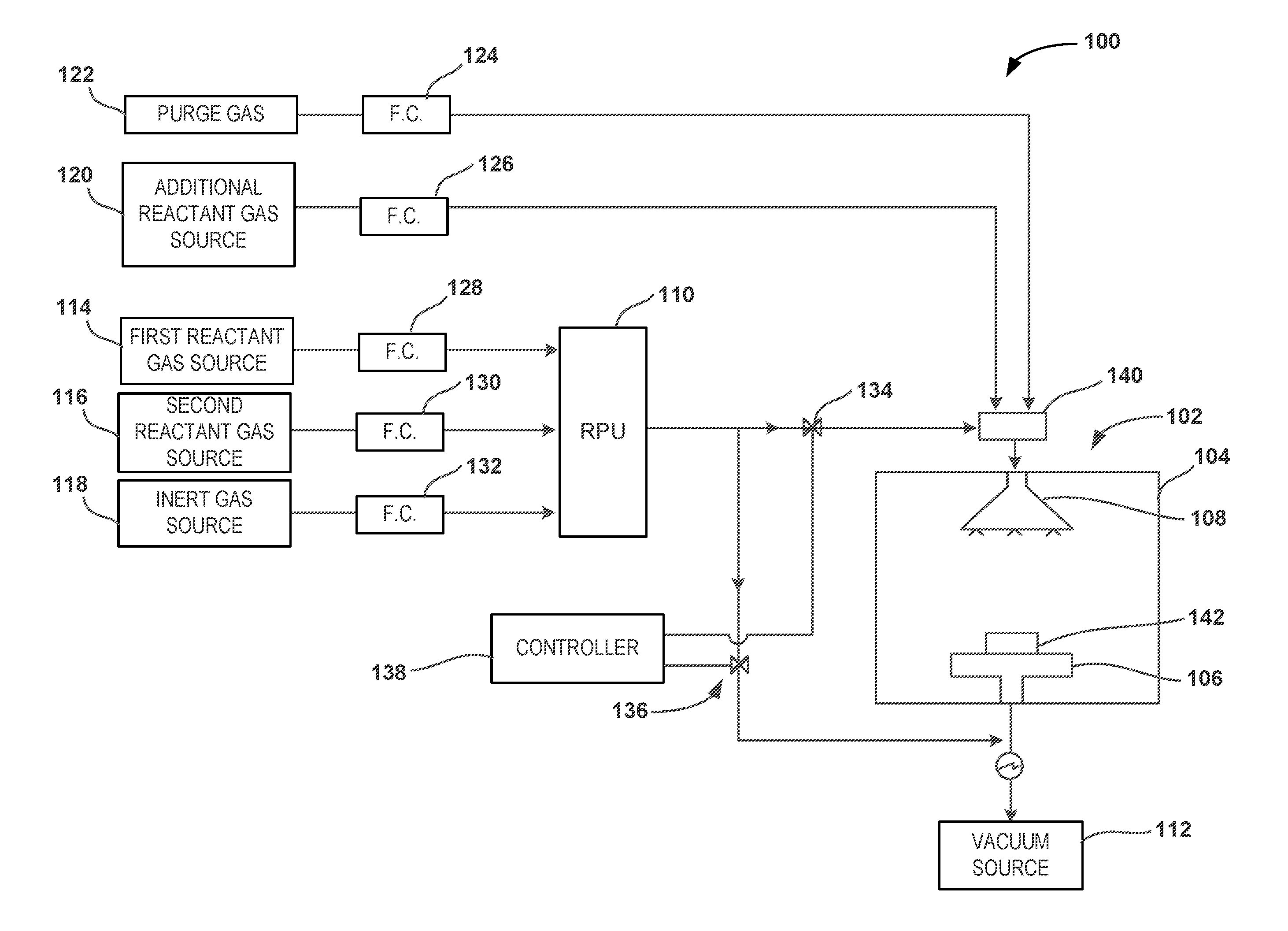

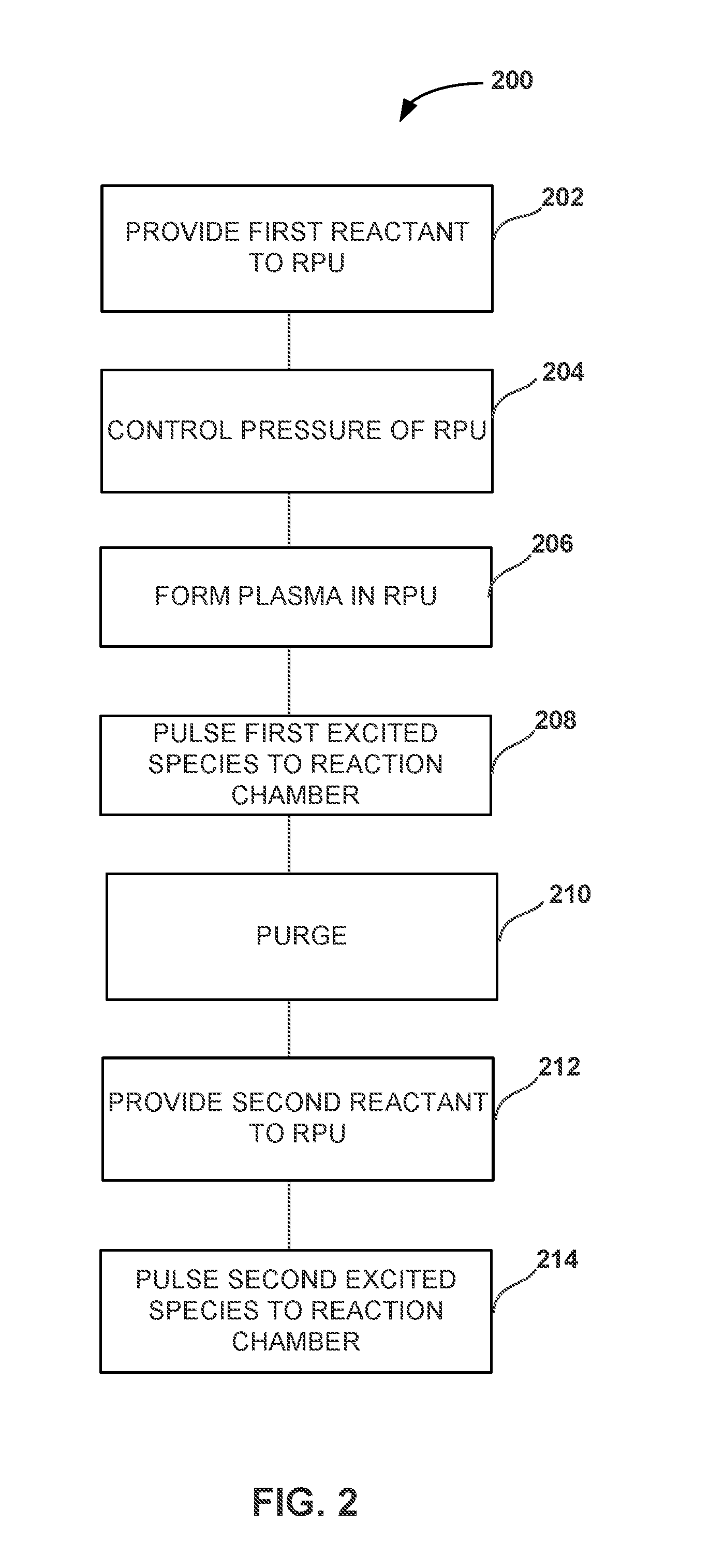

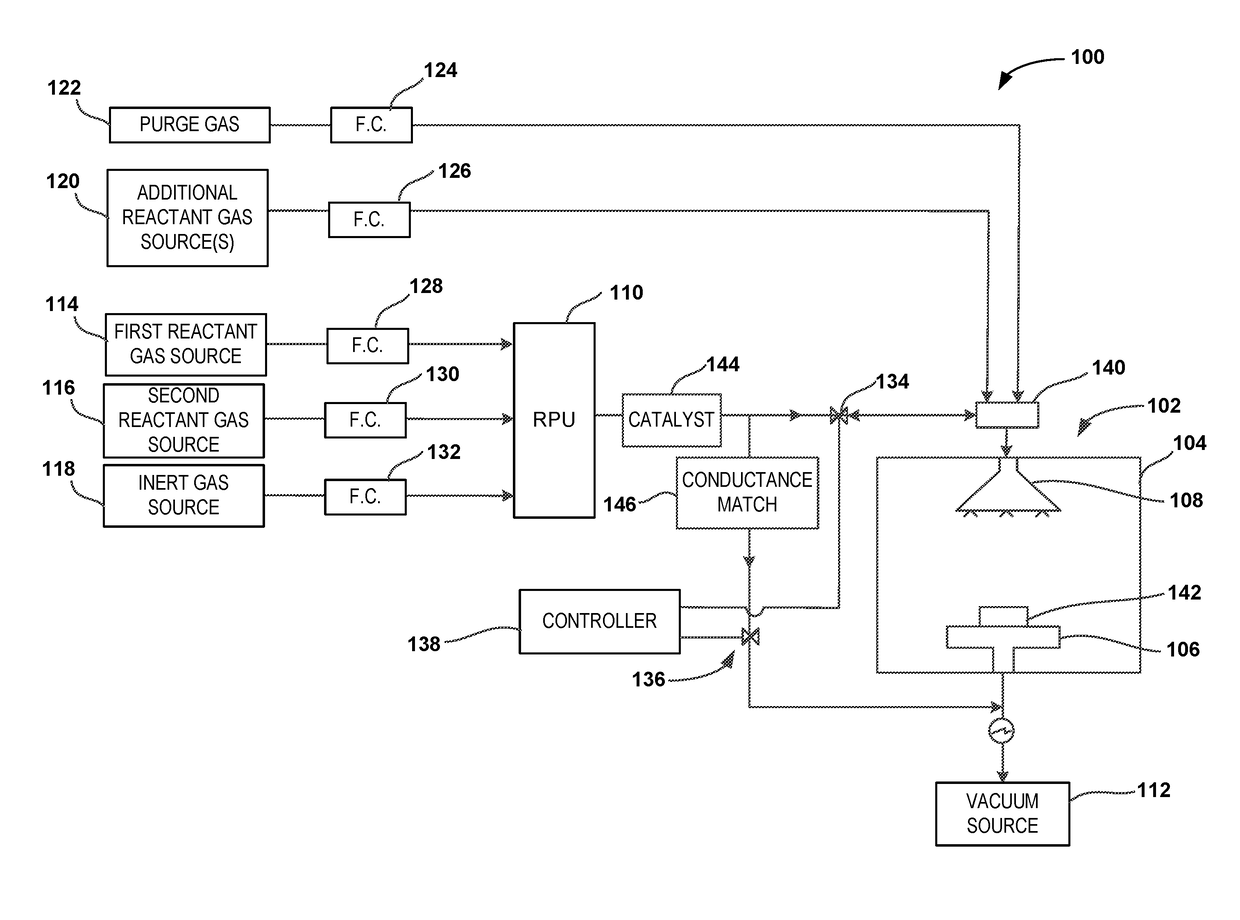

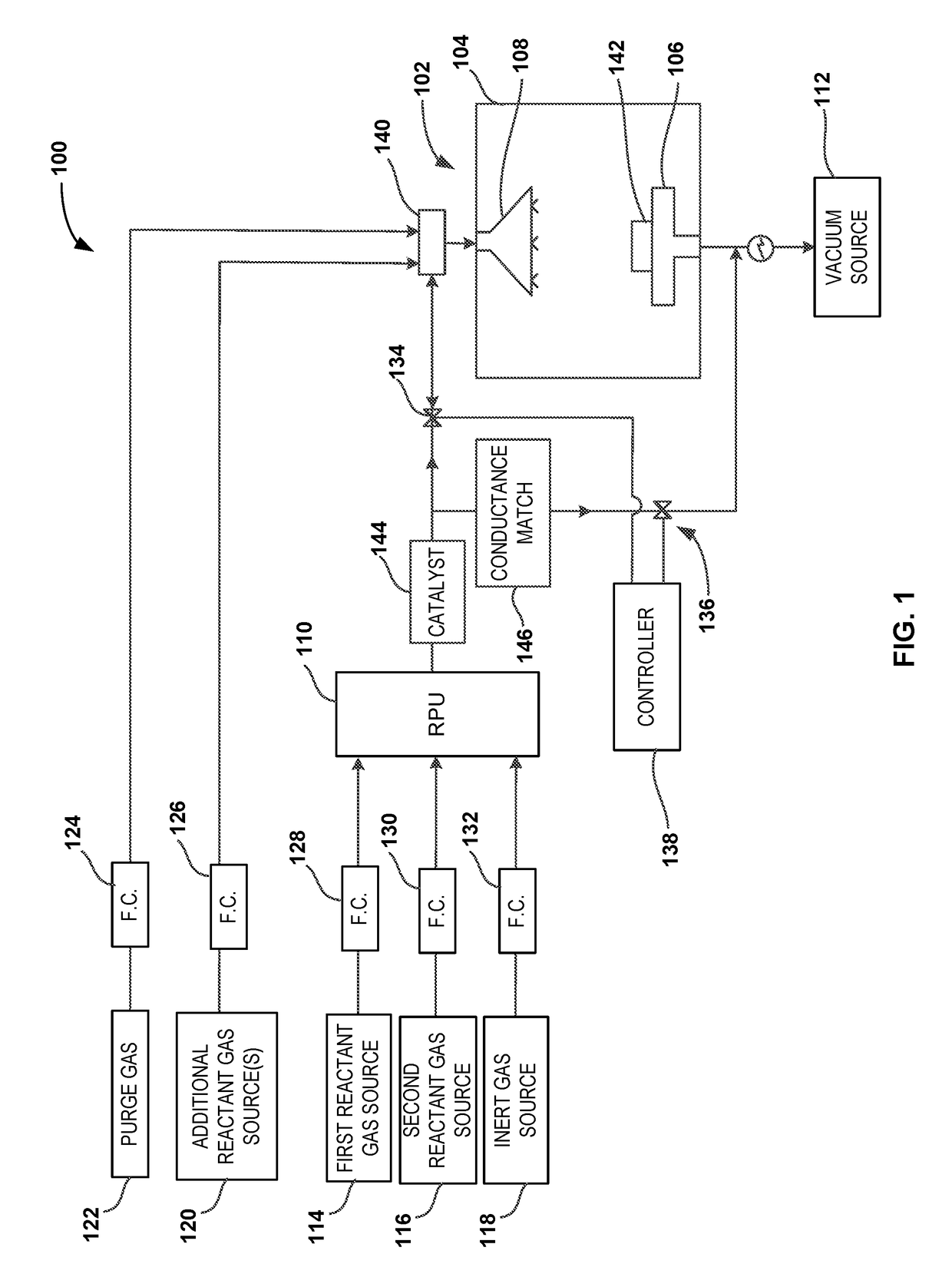

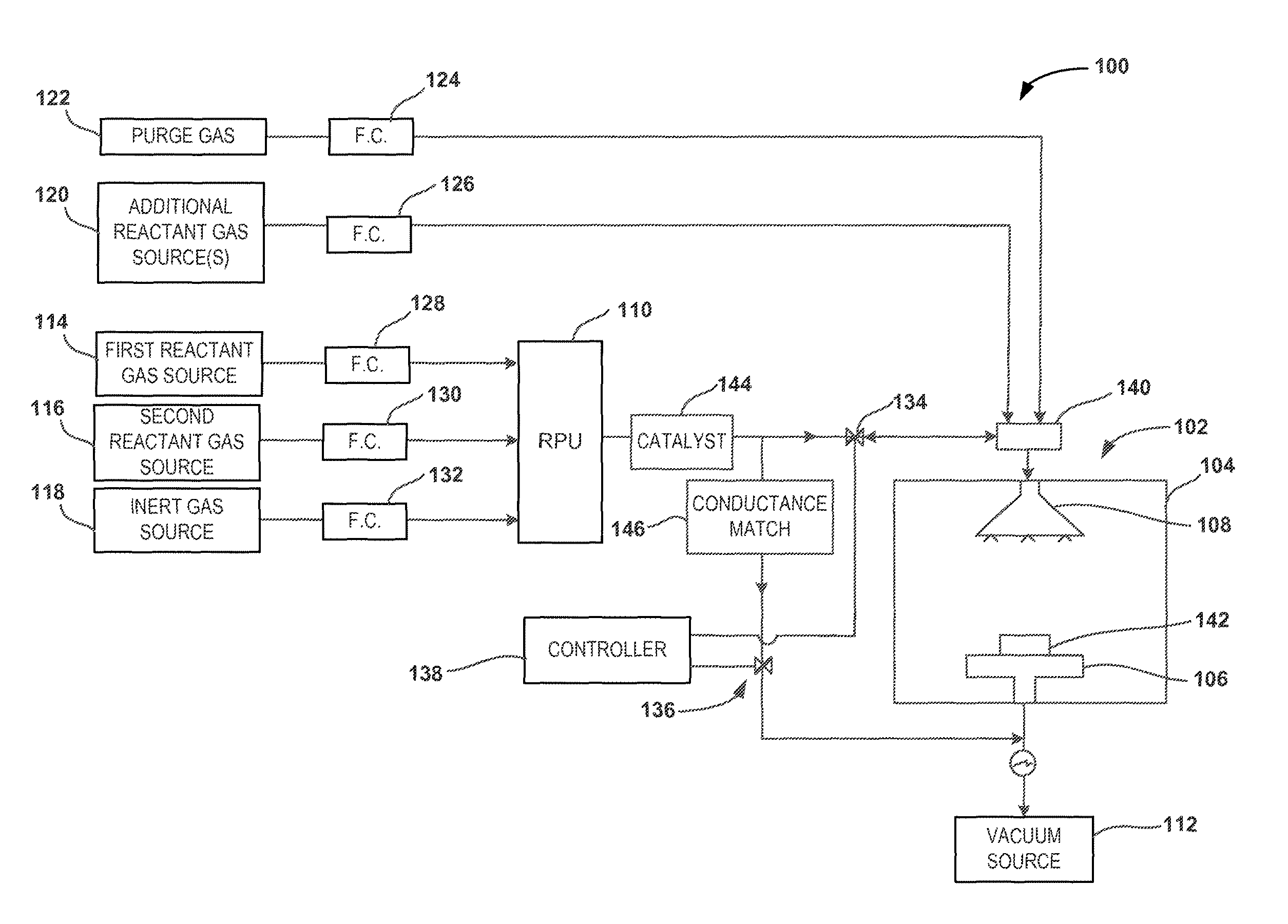

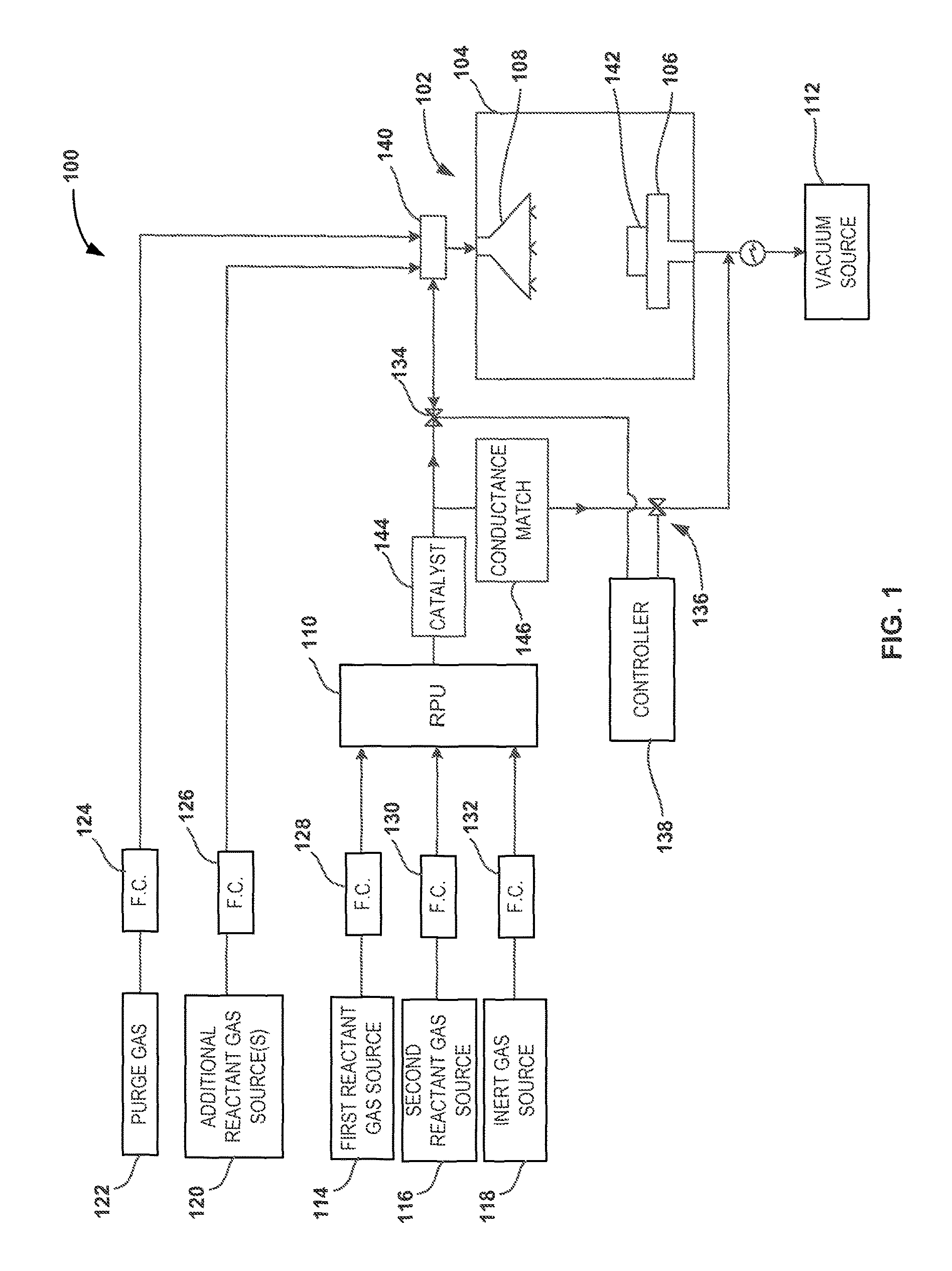

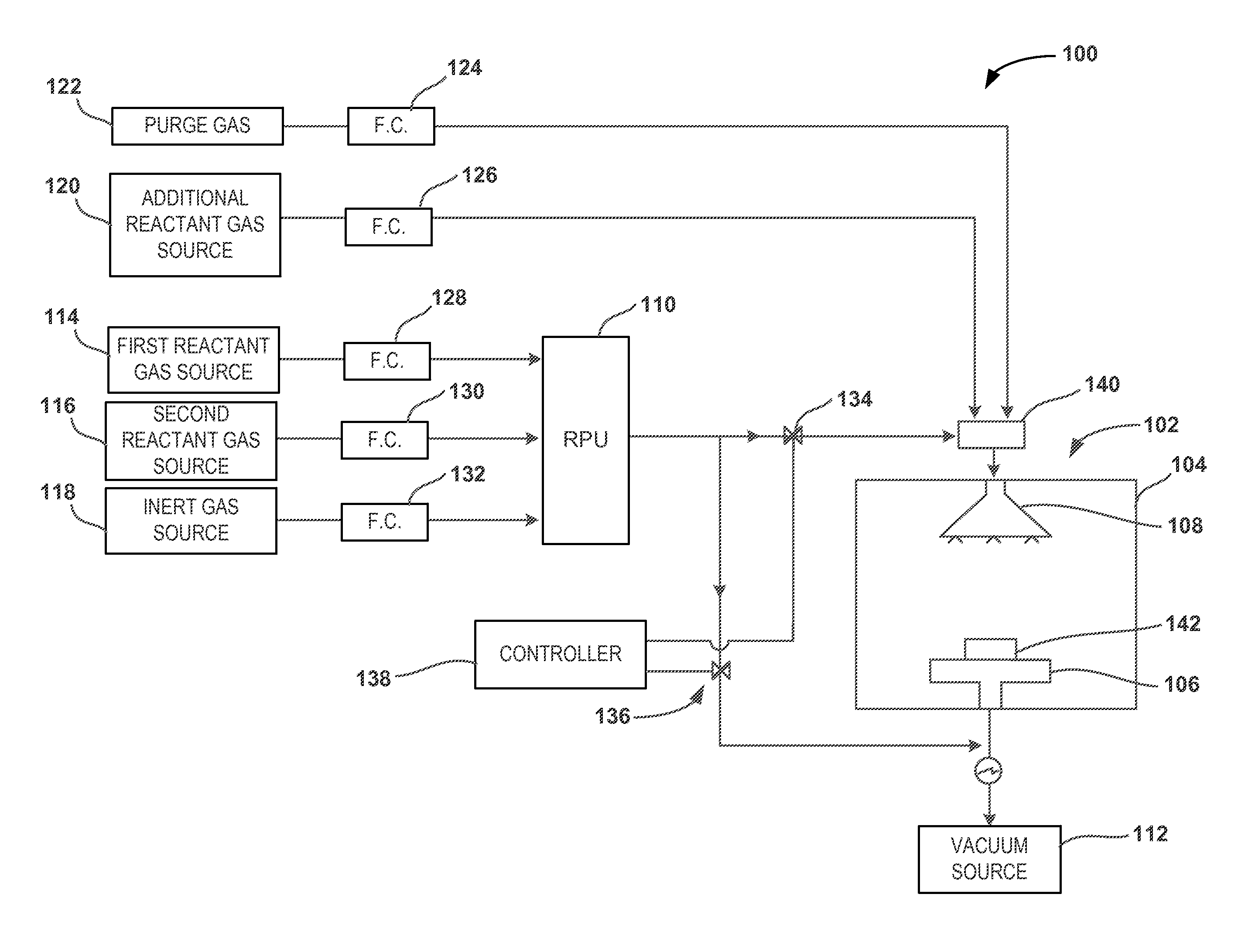

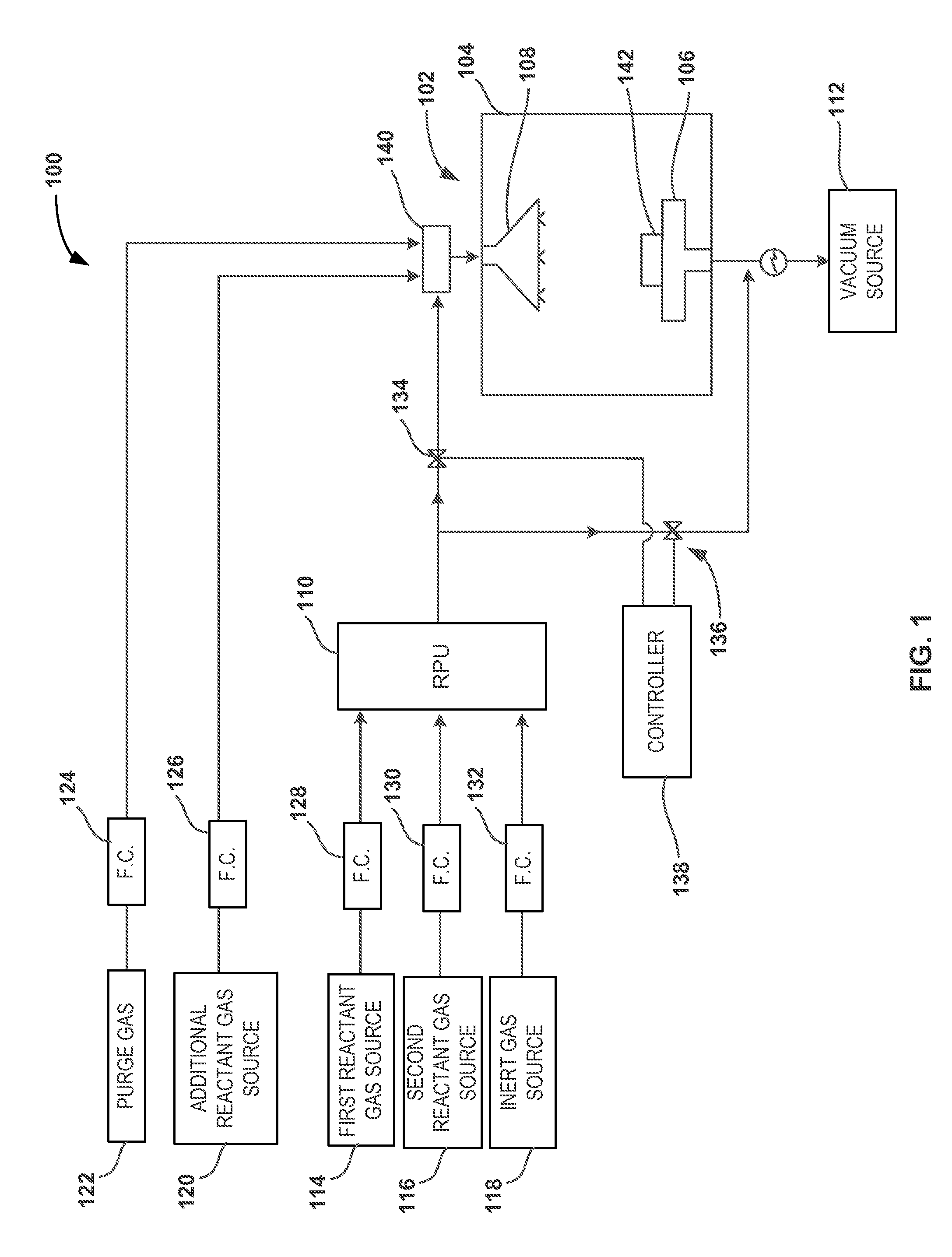

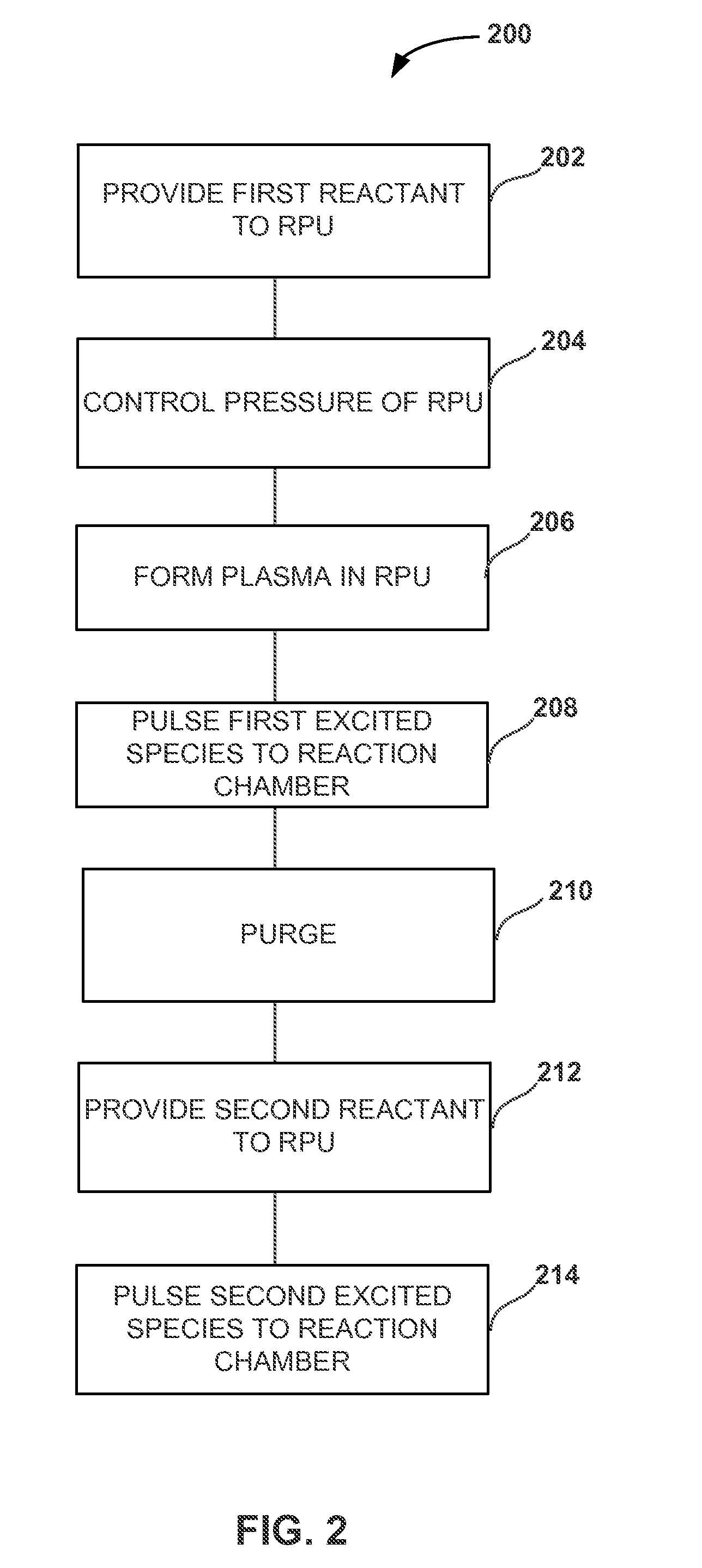

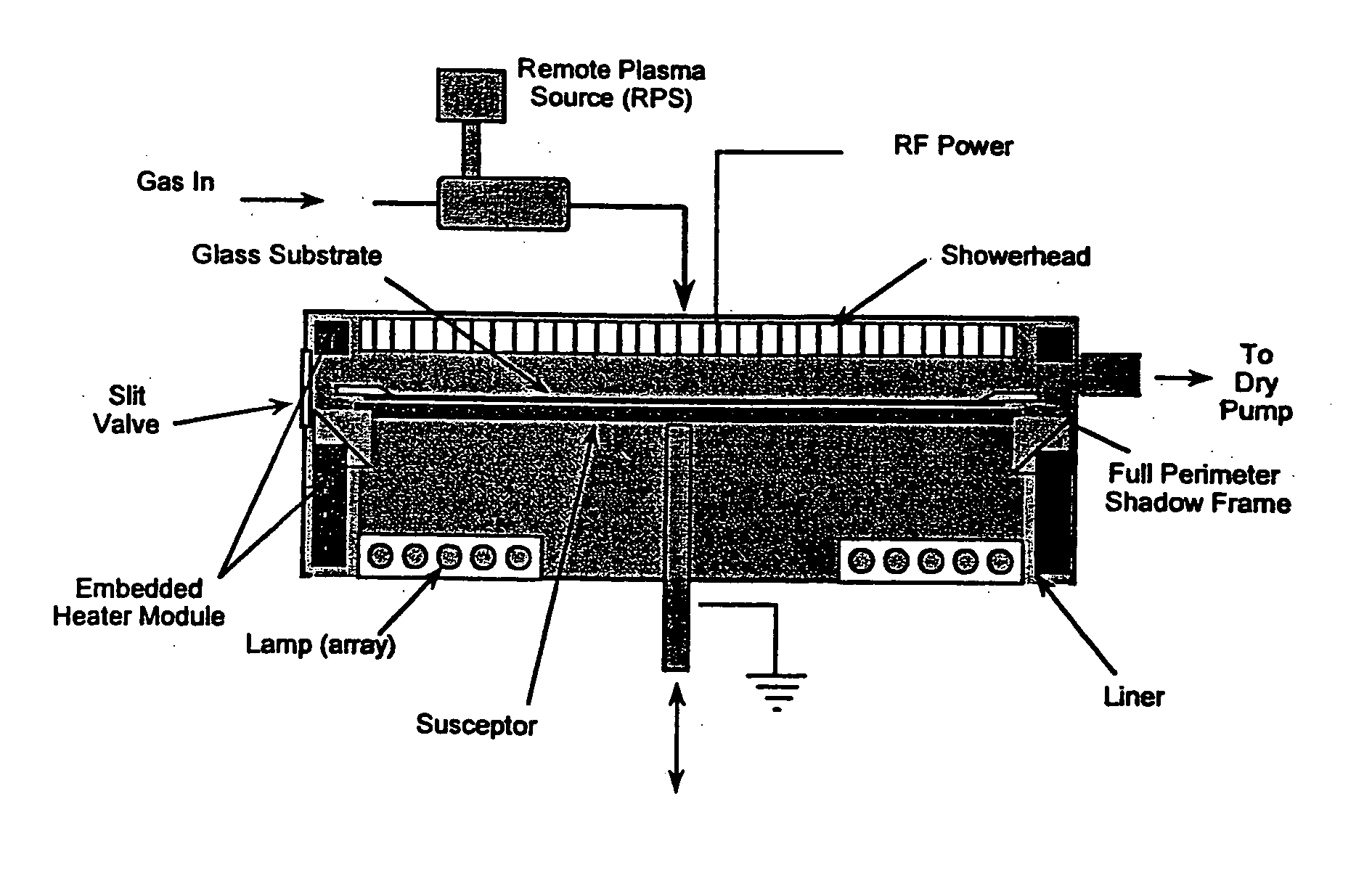

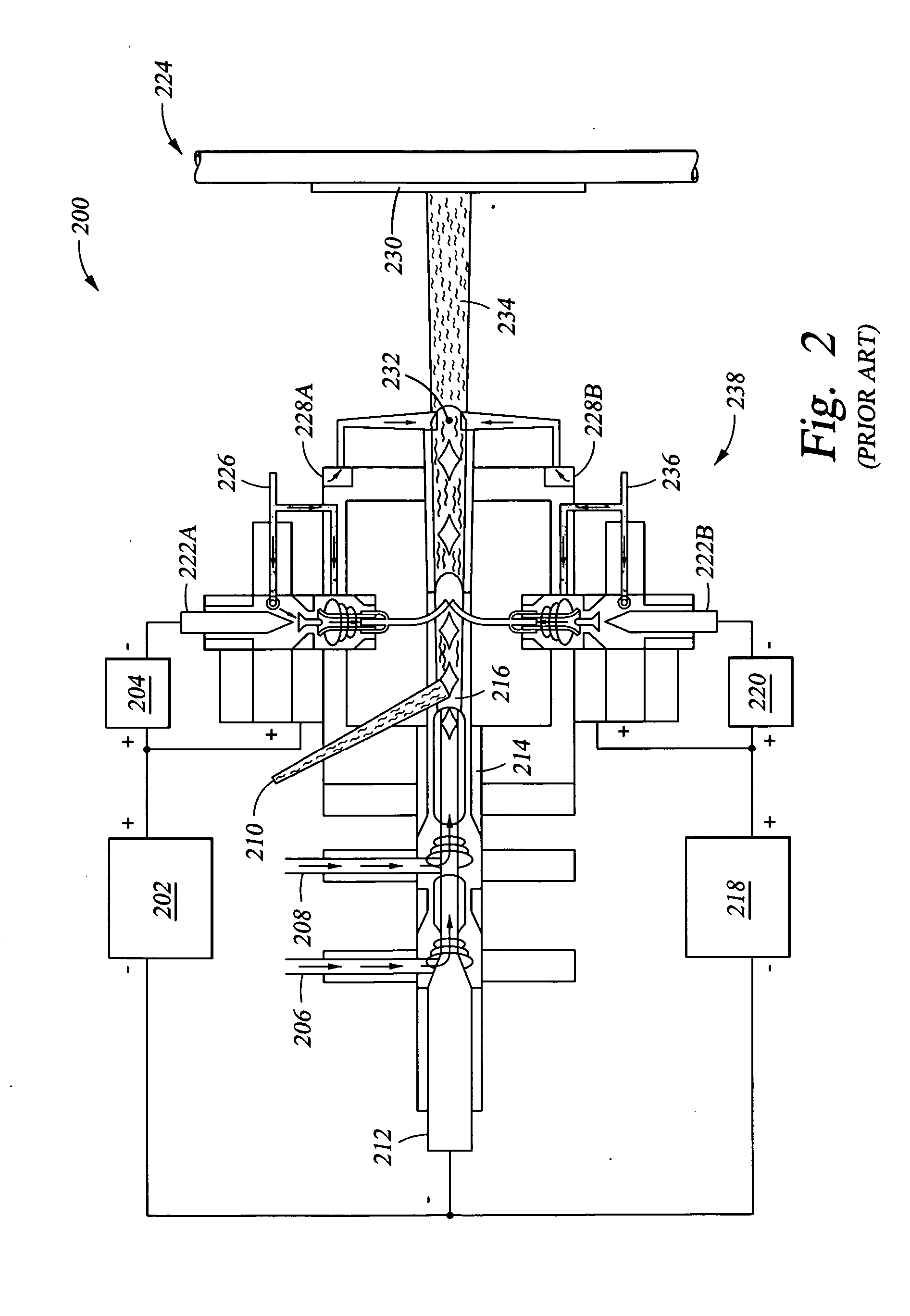

Pulsed remote plasma method and system

ActiveUS20170011889A1Electric discharge tubesChemical vapor deposition coatingRemote plasmaEngineering

A system and method for providing pulsed excited species from a remote plasma unit to a reaction chamber are disclosed. The system includes a pressure control device to control a pressure at the remote plasma unit as reactive species from the remote plasma unit are pulsed to the reaction chamber.

Owner:ASM IP HLDG BV

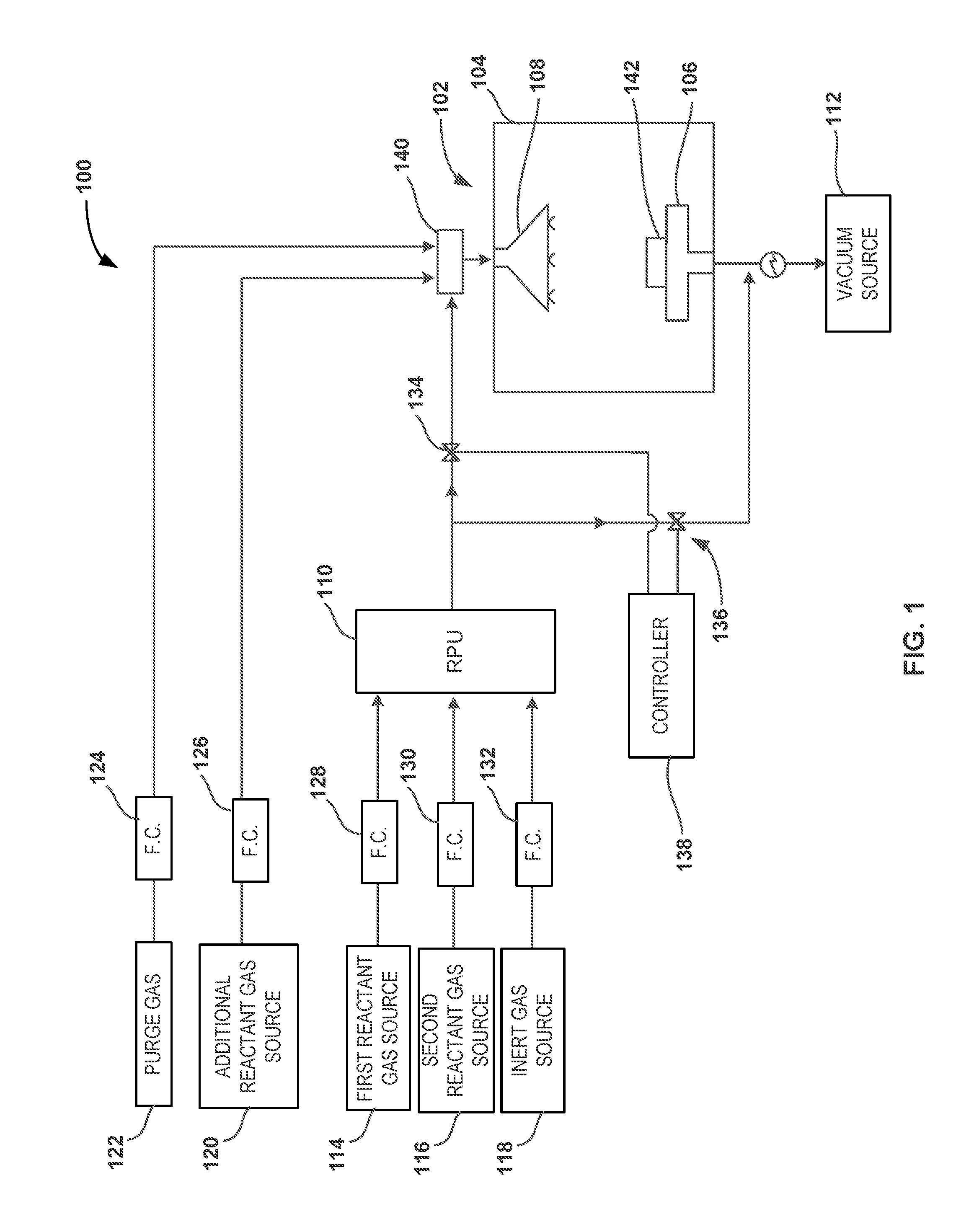

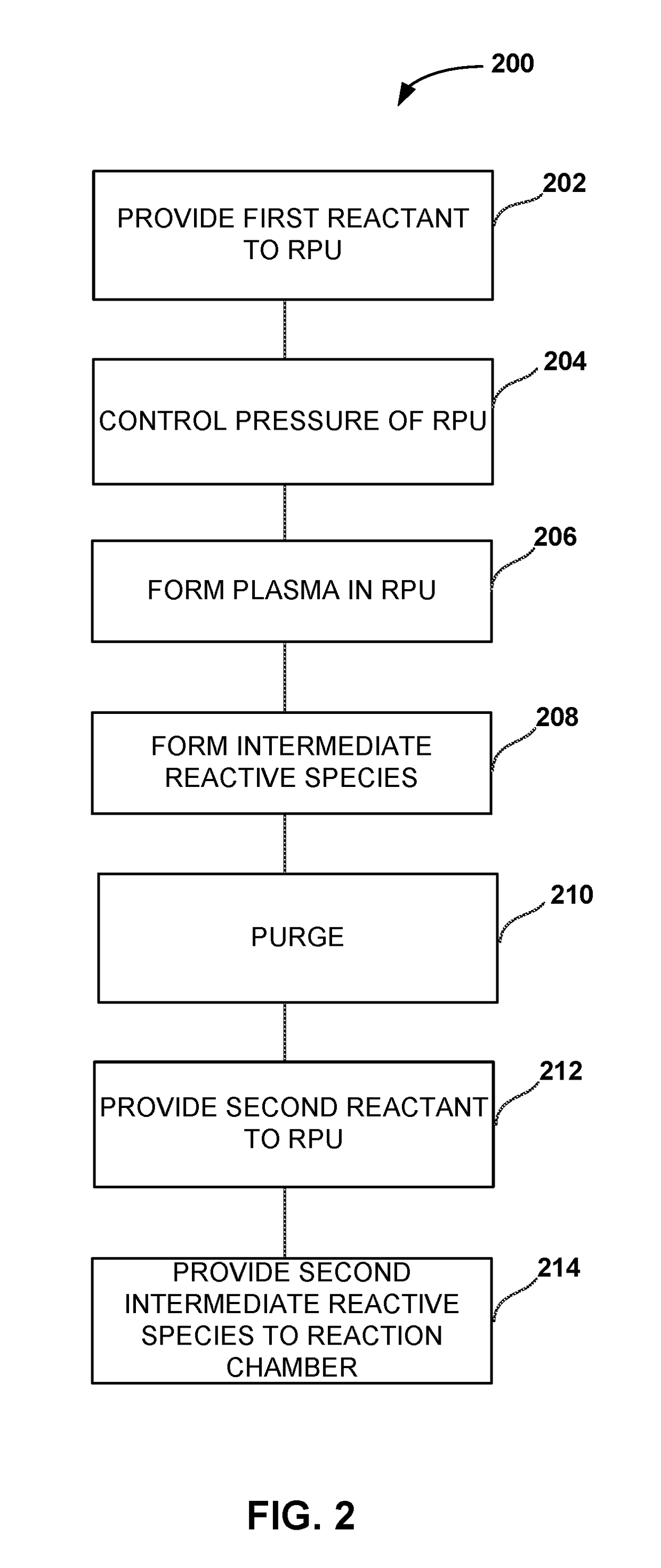

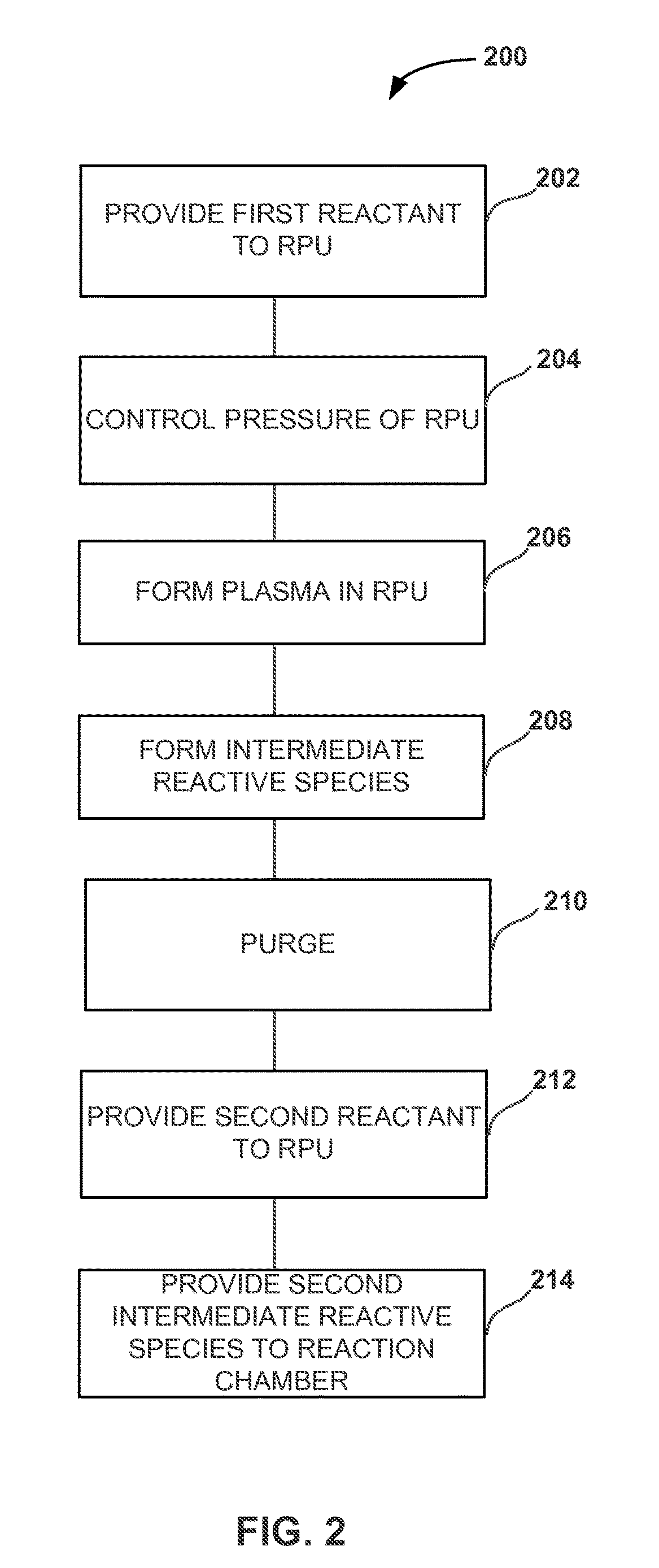

Method and system for in-situ formation of intermediate reactive species

ActiveUS20170154757A1Electric discharge tubesChemical vapor deposition coatingRemote plasmaEngineering

Owner:ASM IP HLDG BV

Method and systems for in-situ formation of intermediate reactive species

ActiveUS9589770B2Electric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaEngineering

A system and method for providing intermediate reactive species from a remote plasma unit to a reaction chamber are disclosed. The system includes a pressure control device to control a pressure at the remote plasma unit as intermediate reactive species from the remote plasma unit are provided to the reaction chamber.

Owner:ASM IP HLDG BV

Pulsed remote plasma method and system

ActiveUS9484191B2Electric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaEngineering

A system and method for providing pulsed excited species from a remote plasma unit to a reaction chamber are disclosed. The system includes a pressure control device to control a pressure at the remote plasma unit as reactive species from the remote plasma unit are pulsed to the reaction chamber.

Owner:ASM IP HLDG BV

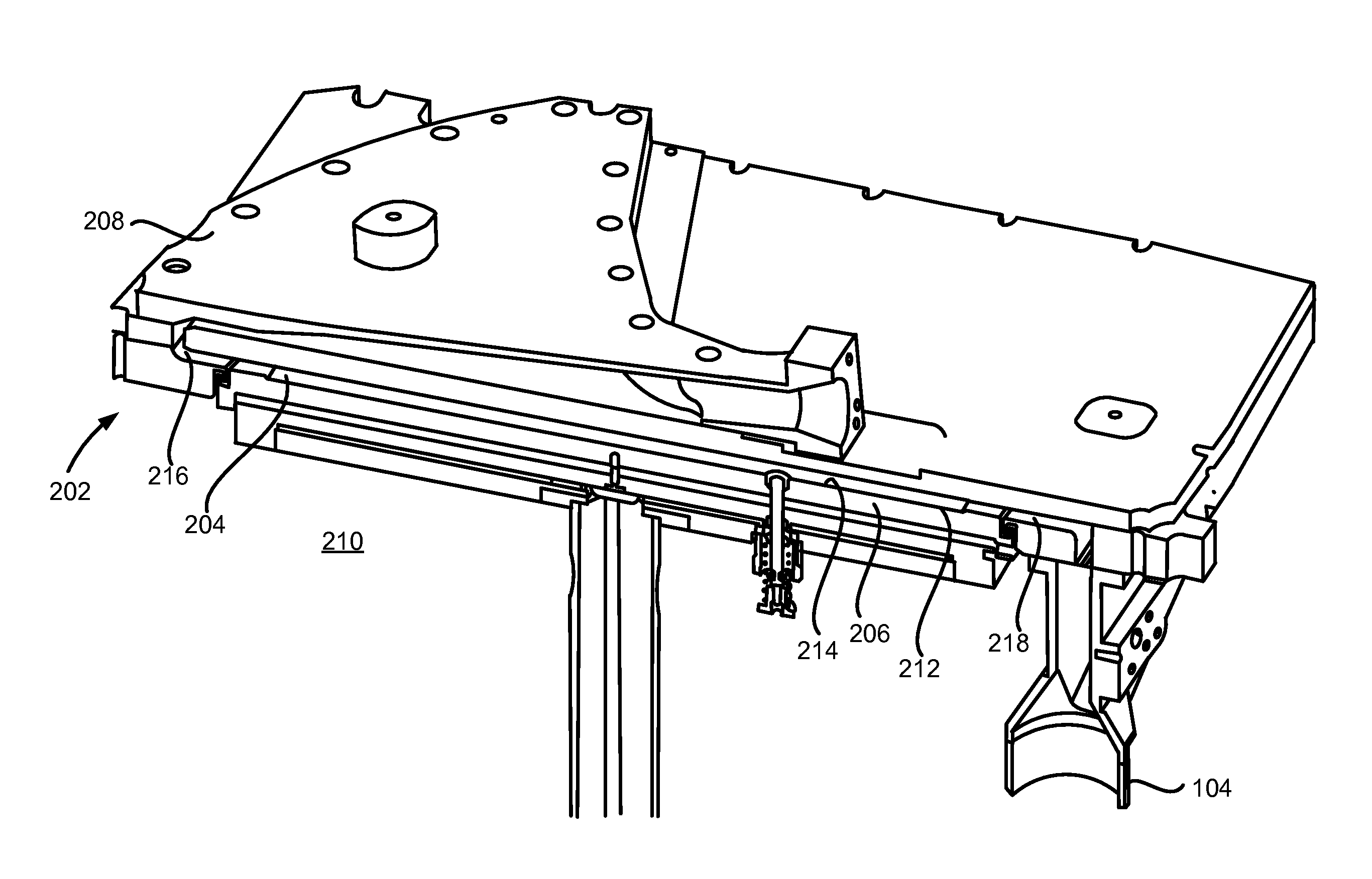

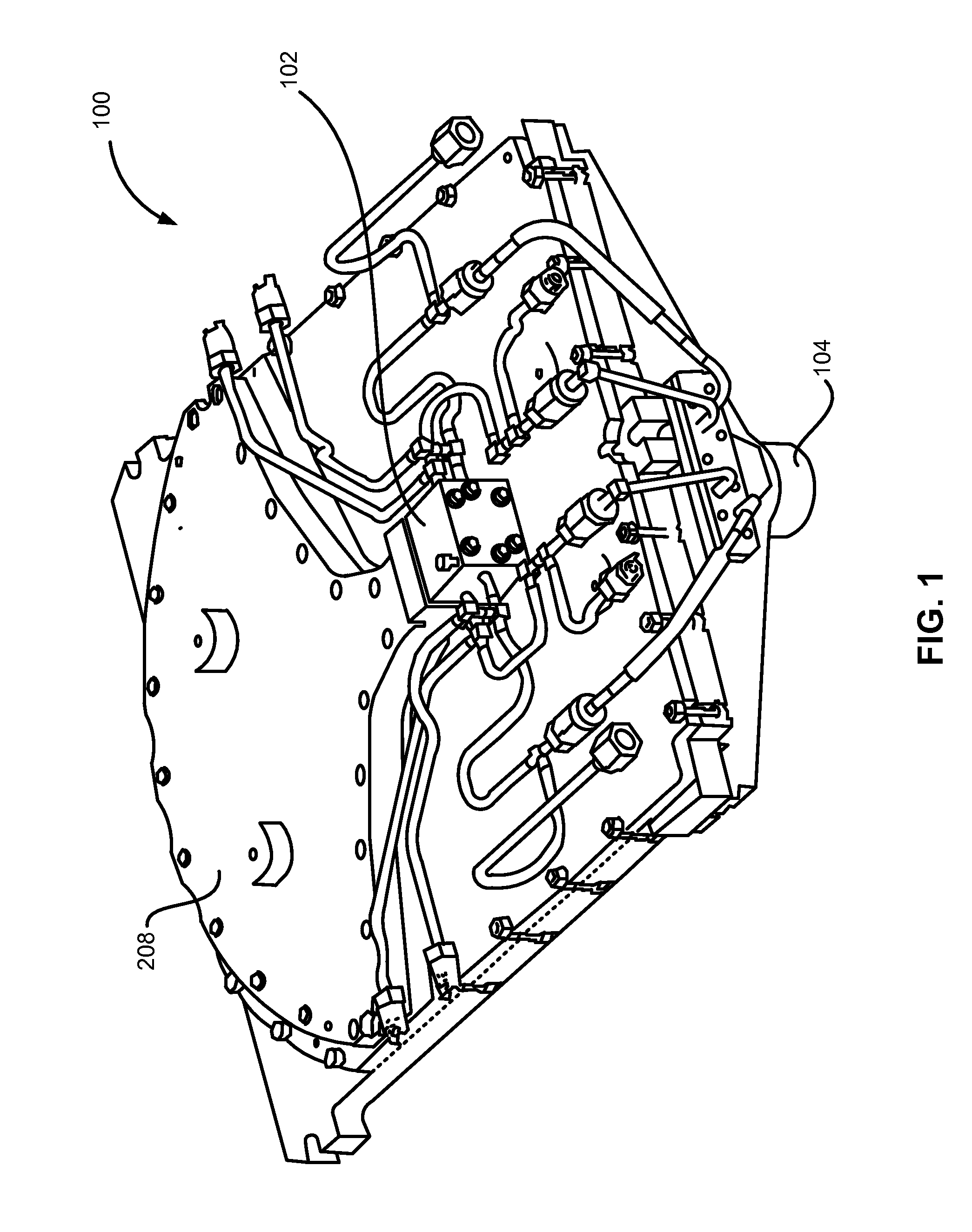

Cross-flow reactor and method

ActiveUS20160268102A1Facilitates consistent spacingElectric discharge tubesLiquid-gas reaction processesGas phaseEngineering

Gas-phase reactors and systems are disclosed. Exemplary reactors include a reaction chamber having a tapered height. Tapering the height of the reactor is thought to reduce a pressure drop along the flow of gasses through the reactor. Exemplary reactors can also include a spacer within a gap to control a flow of gas between a region and a reaction chamber.

Owner:ASM IP HLDG BV

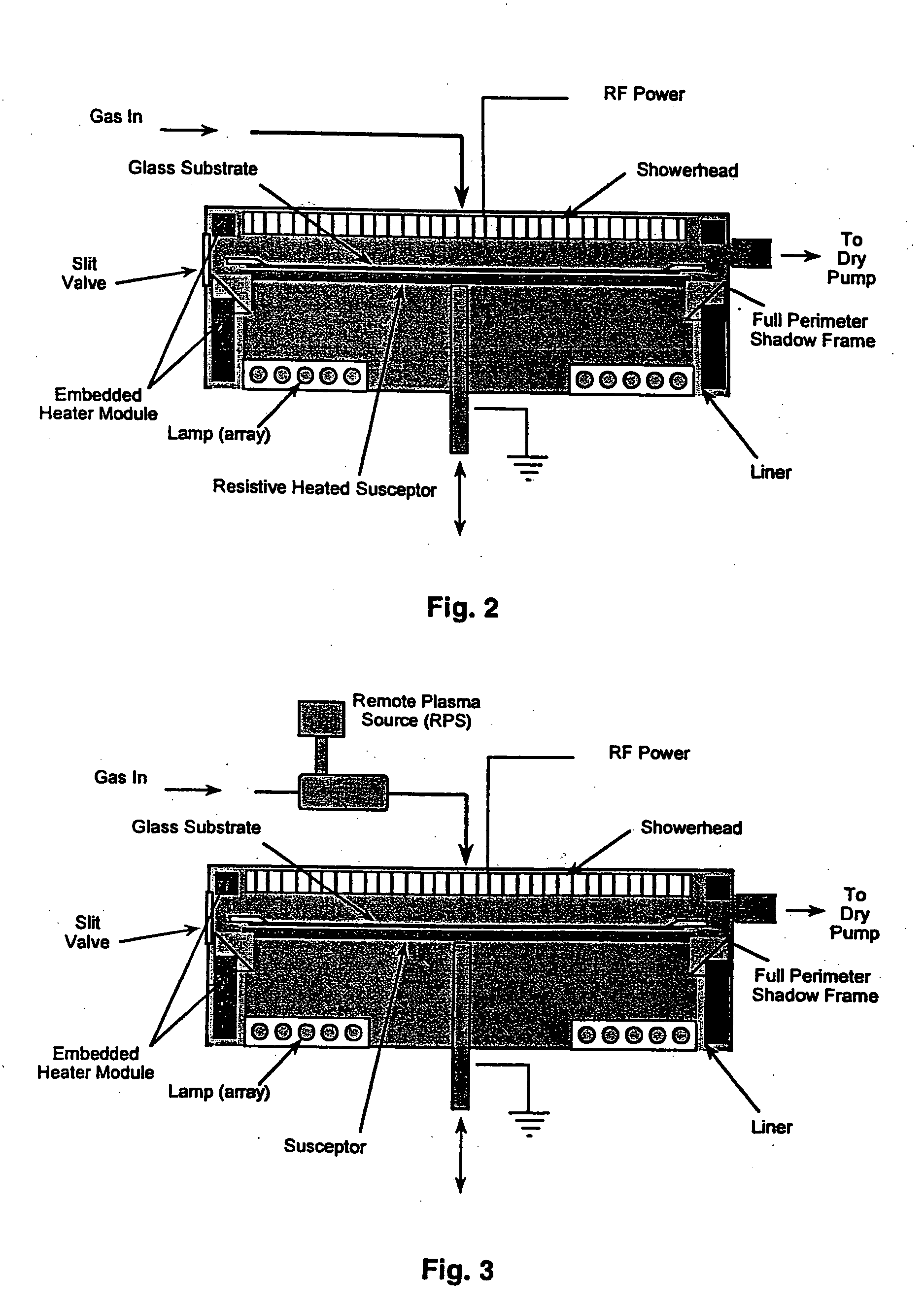

Chamber cleaning via rapid thermal process during a cleaning period

InactiveUS20050109461A1Increase temperatureImprove surface temperature uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringHeat treated

Owner:SUN SHENG

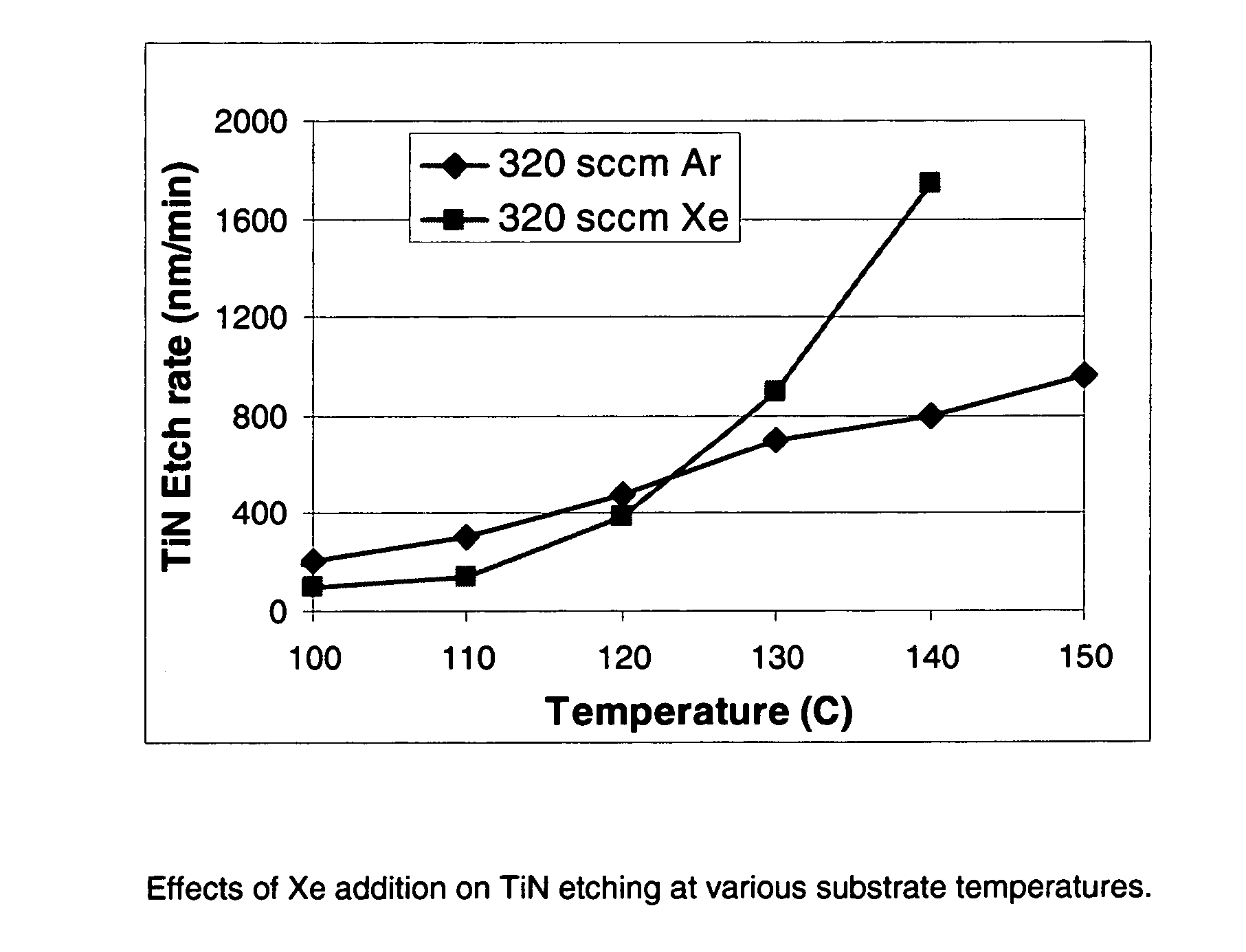

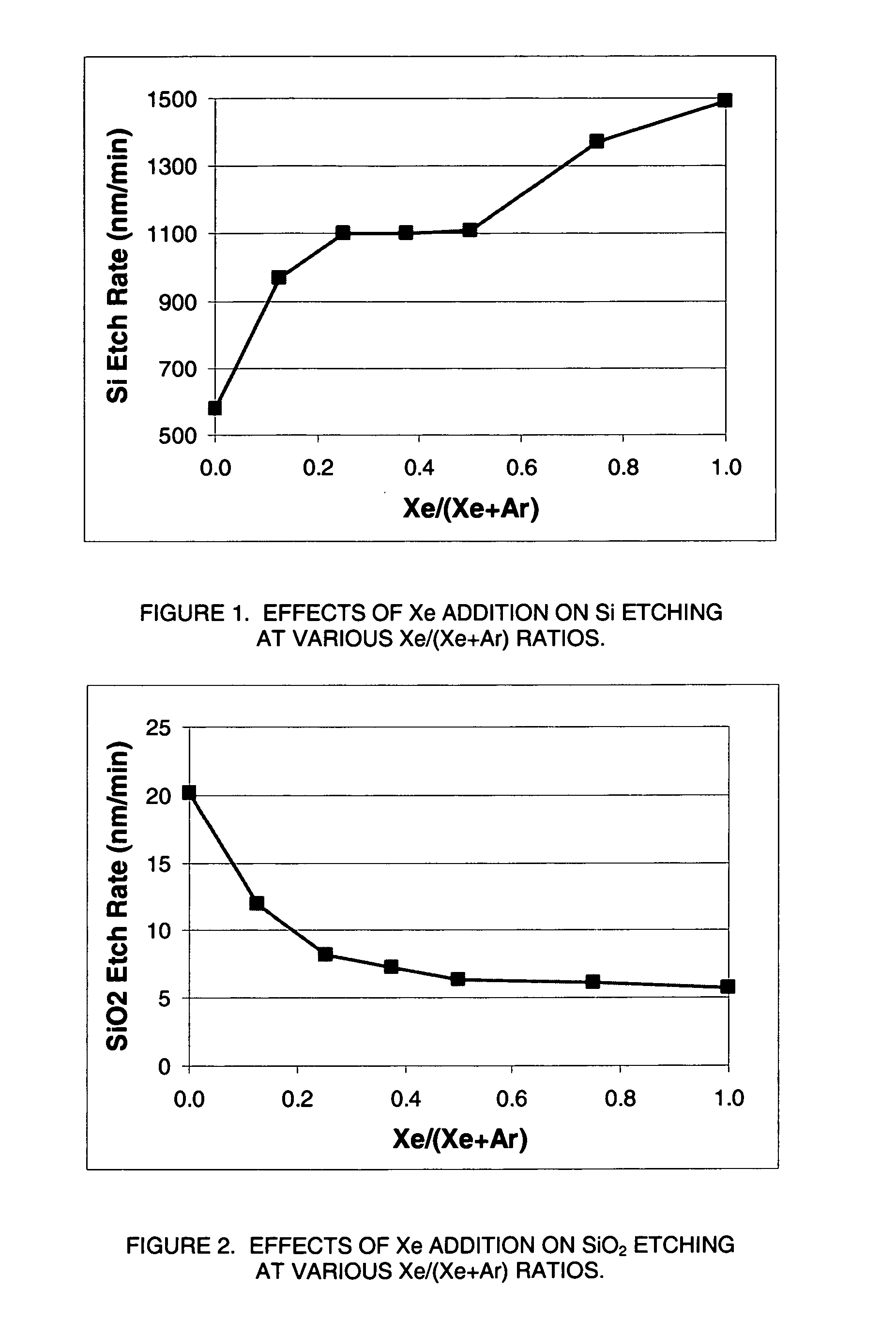

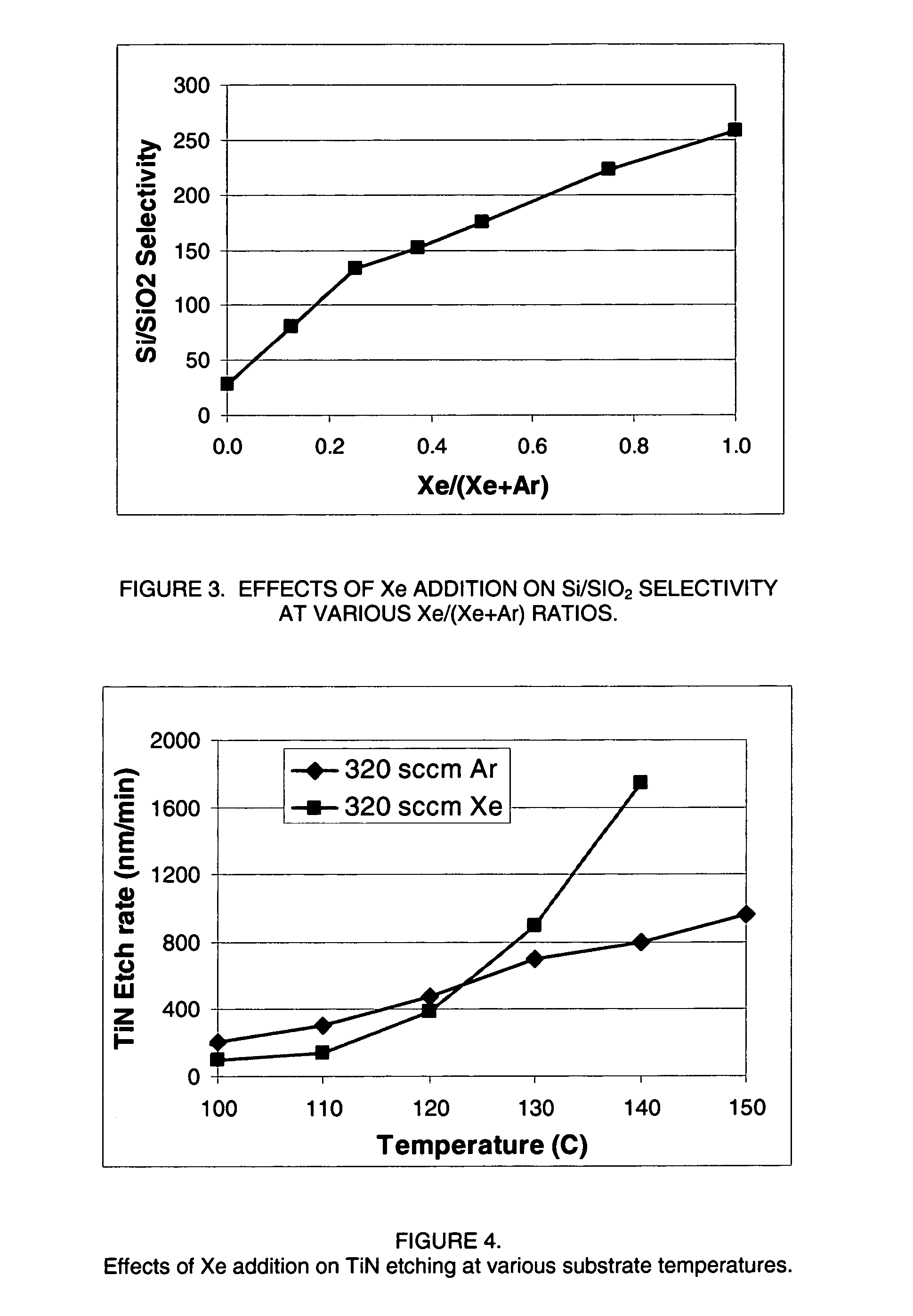

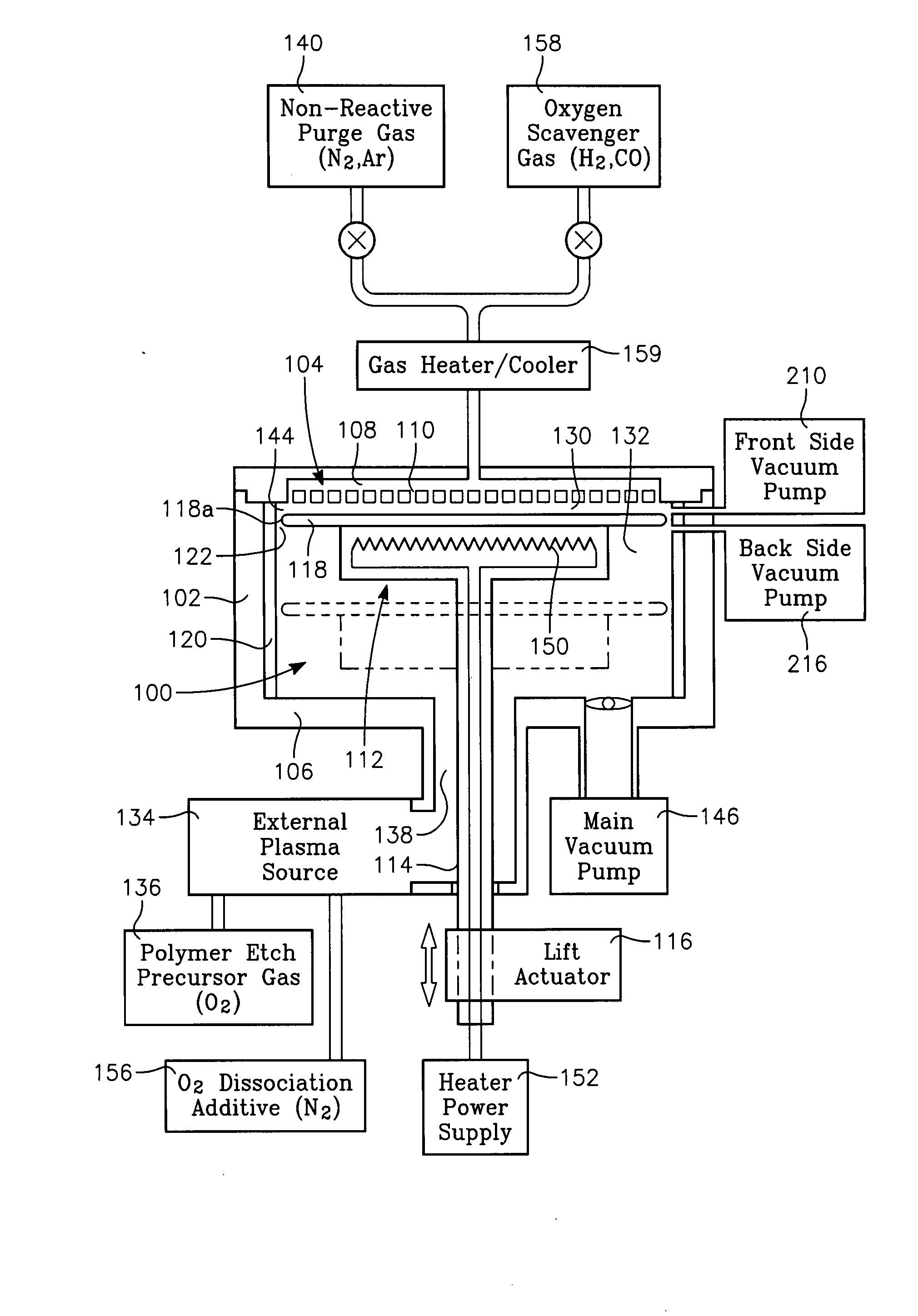

Selective etching of titanium nitride with xenon difluoride

InactiveUS20070117396A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingEtchingTitanium nitride

This invention relates to an improved process for the selective etching of TiN from silicon dioxide (quartz) and SiN surfaces commonly found in semiconductor deposition chambers equipment and tools. In the process, an SiO2 or SiN surface having TiN thereon is contacted with XeF2 in a contact zone to selectively convert the TiN to a volatile species and then the volatile species is removed from the contact zone. XeF2 can be preformed or formed in situ by reaction between Xe and a fluorine compound.

Owner:VERSUM MATERIALS US LLC

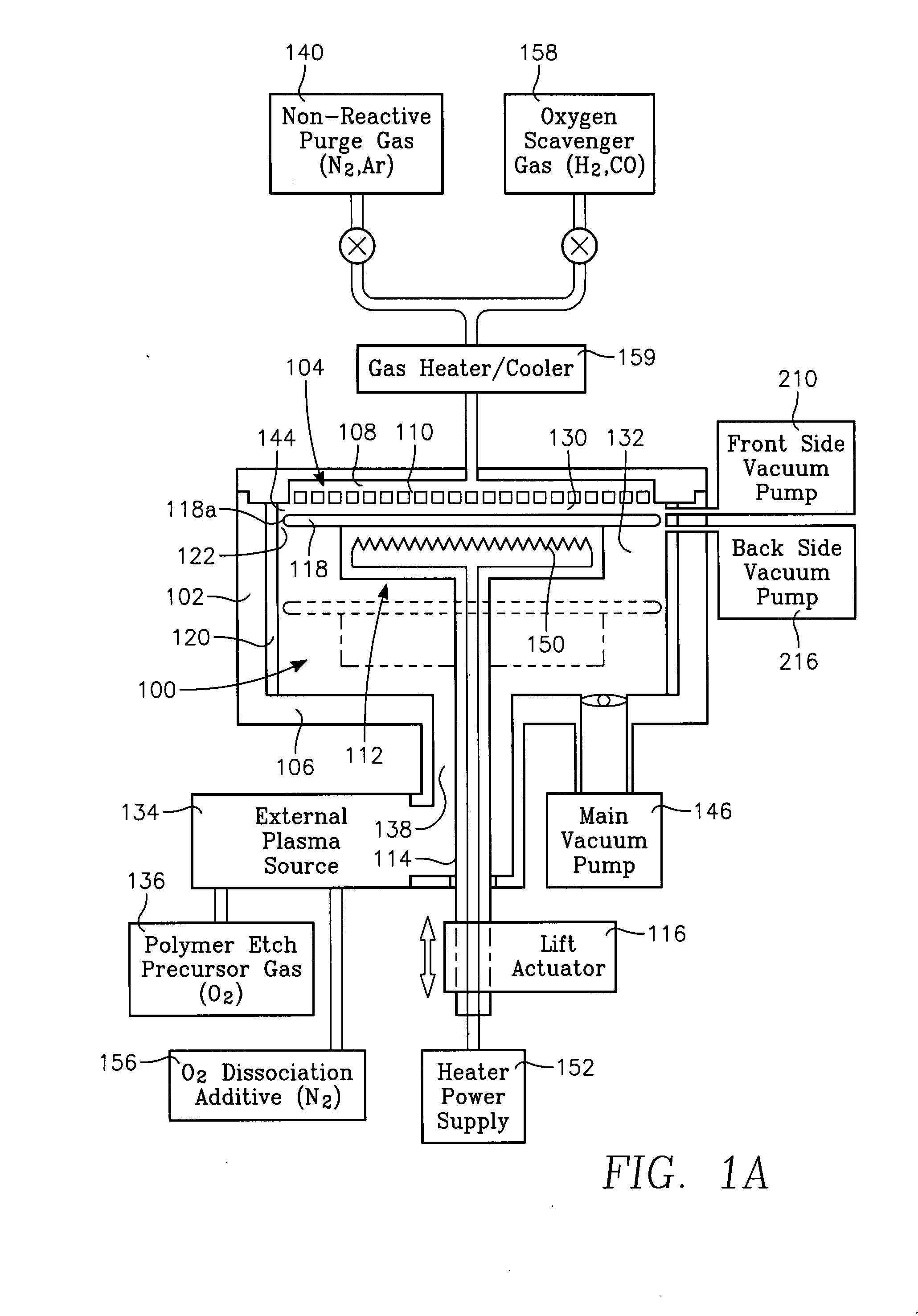

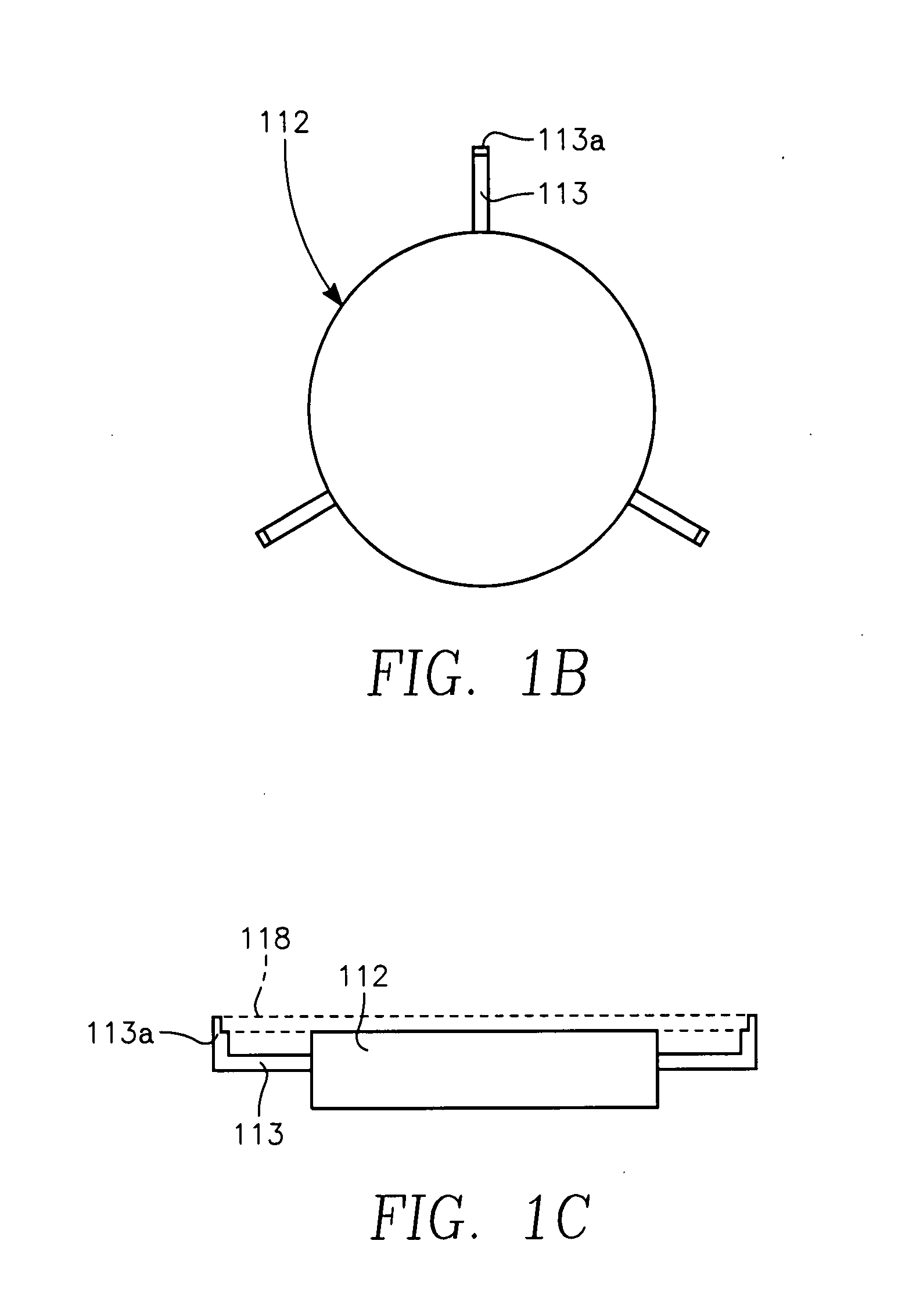

Process for wafer backside polymer removal and wafer front side photoresist removal

A process is provided for removing polymer from a backside of a workpiece and / or photoresist from a front side of the workpiece. For backside polymer removal, the wafer is positioned near the ceiling to above a localized or remote plasma source having a side outlet through the sidewall of the chamber, and backside polymer is removed by rotating the workpiece while flowing plasma by-products from the side outlet to the wafer backside. For front side photoresist removal, the wafer is positioned away from the ceiling and below the side outlet of the localized plasma source, and front side photoresist is remove by rotating the workpiece while flowing plasma by-products from the side outlet to the wafer front side.

Owner:APPLIED MATERIALS INC

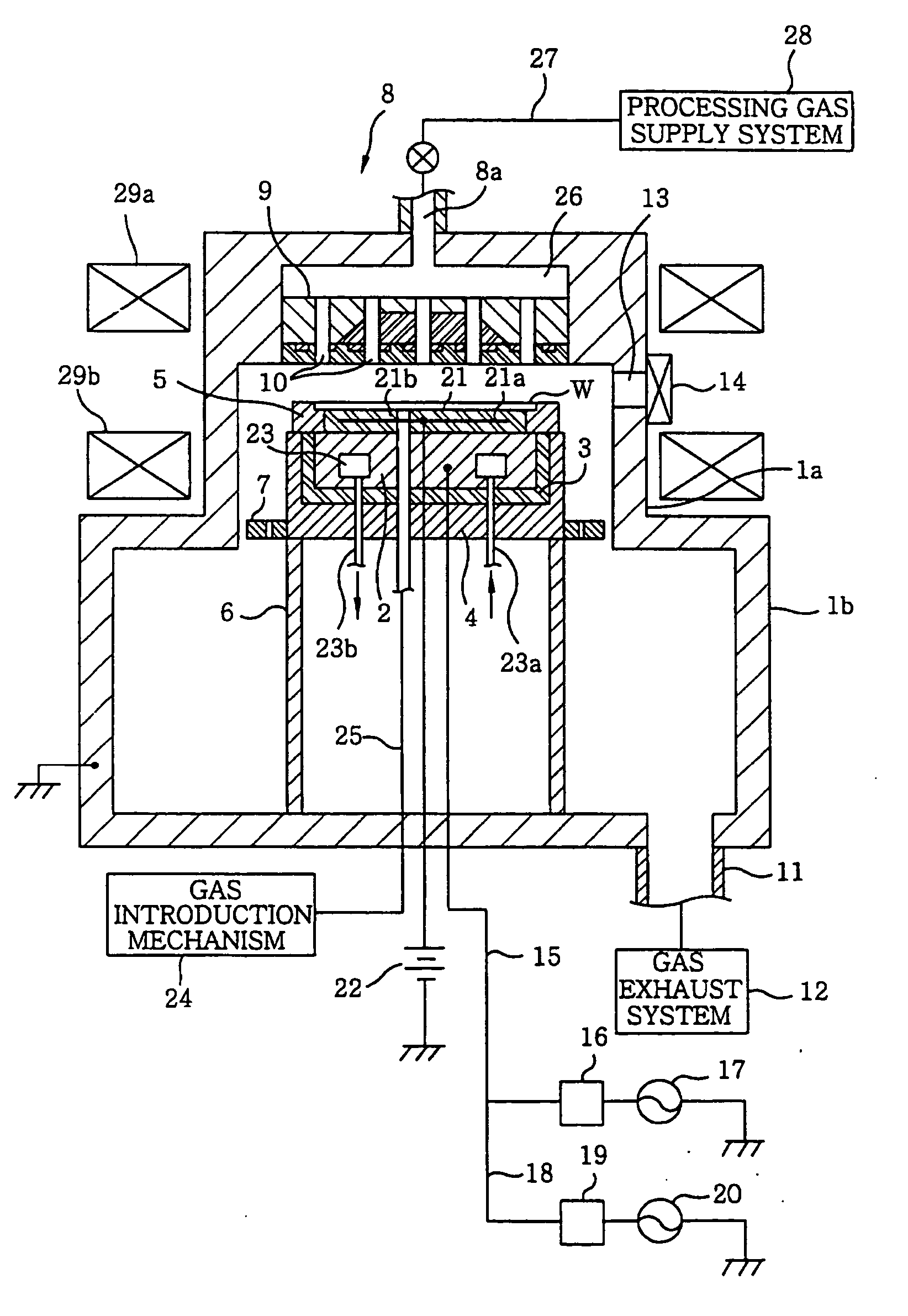

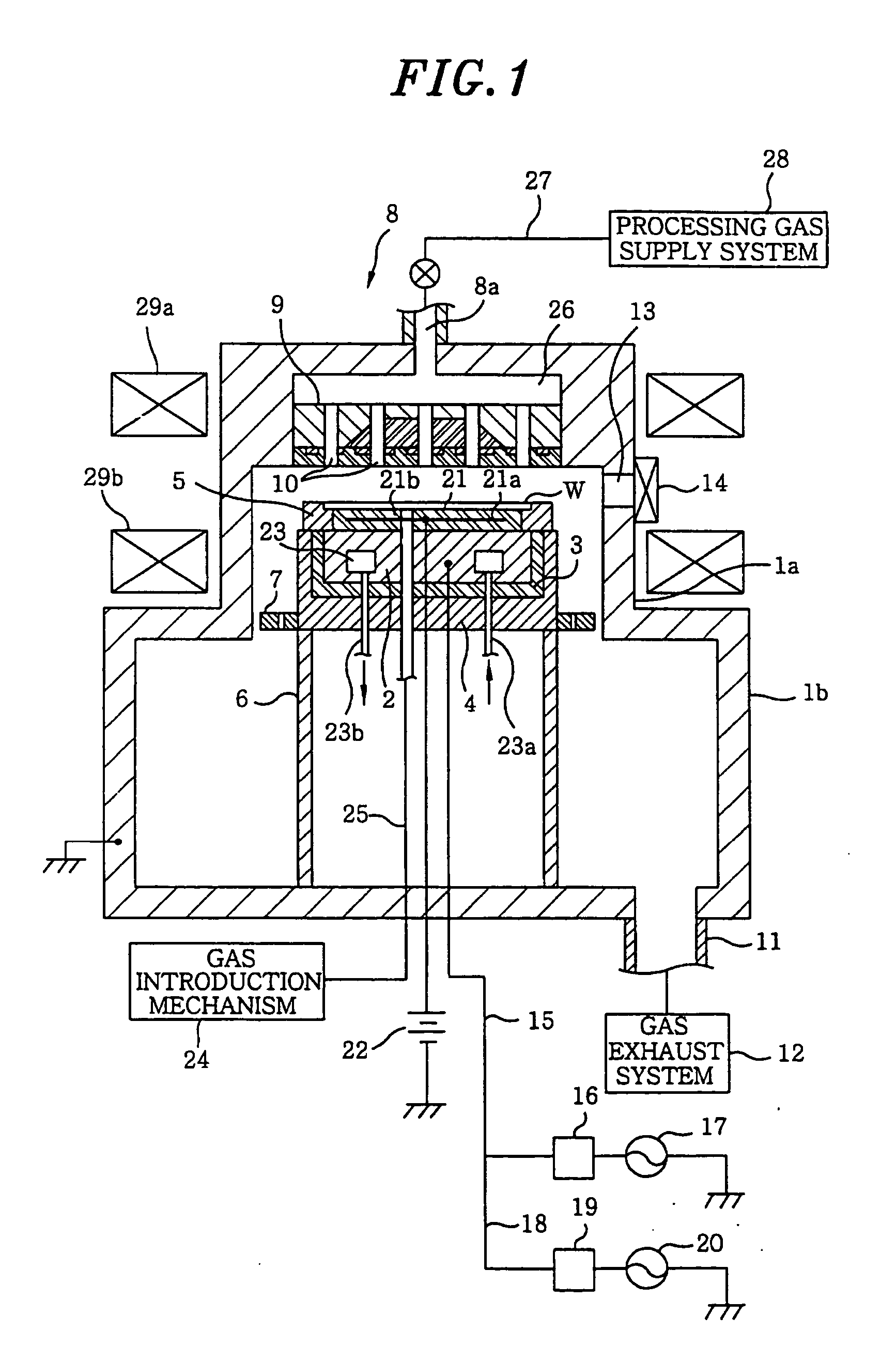

Thermally sprayed member, electrode and plasma processing apparatus using the electrode

ActiveUS20050211384A1High-frequency powerAvoid flowMolten spray coatingElectric discharge tubesThermal sprayingInter layer

A thermally sprayed member or an electrode includes a basic material, a thermally sprayed film formed on the surface of the basic material, the thermally sprayed film being made of an insulating ceramic and a metallic intermediate layer provided between the basic material and the thermally sprayed film for increasing a bonding force therebetween, wherein the thermally sprayed film side of the member is exposed to a high frequency plasma atmosphere and the electrode is intended to form a high frequency plasma on the side of the thermally sprayed film. The basic material includes a base portion made of a conductive material and a dielectric portion provided to include a part of a surface of the basic material. Further, the intermediate layer is comprised of a plurality of island-shaped parts isolated from each other.

Owner:TOKYO ELECTRON LTD

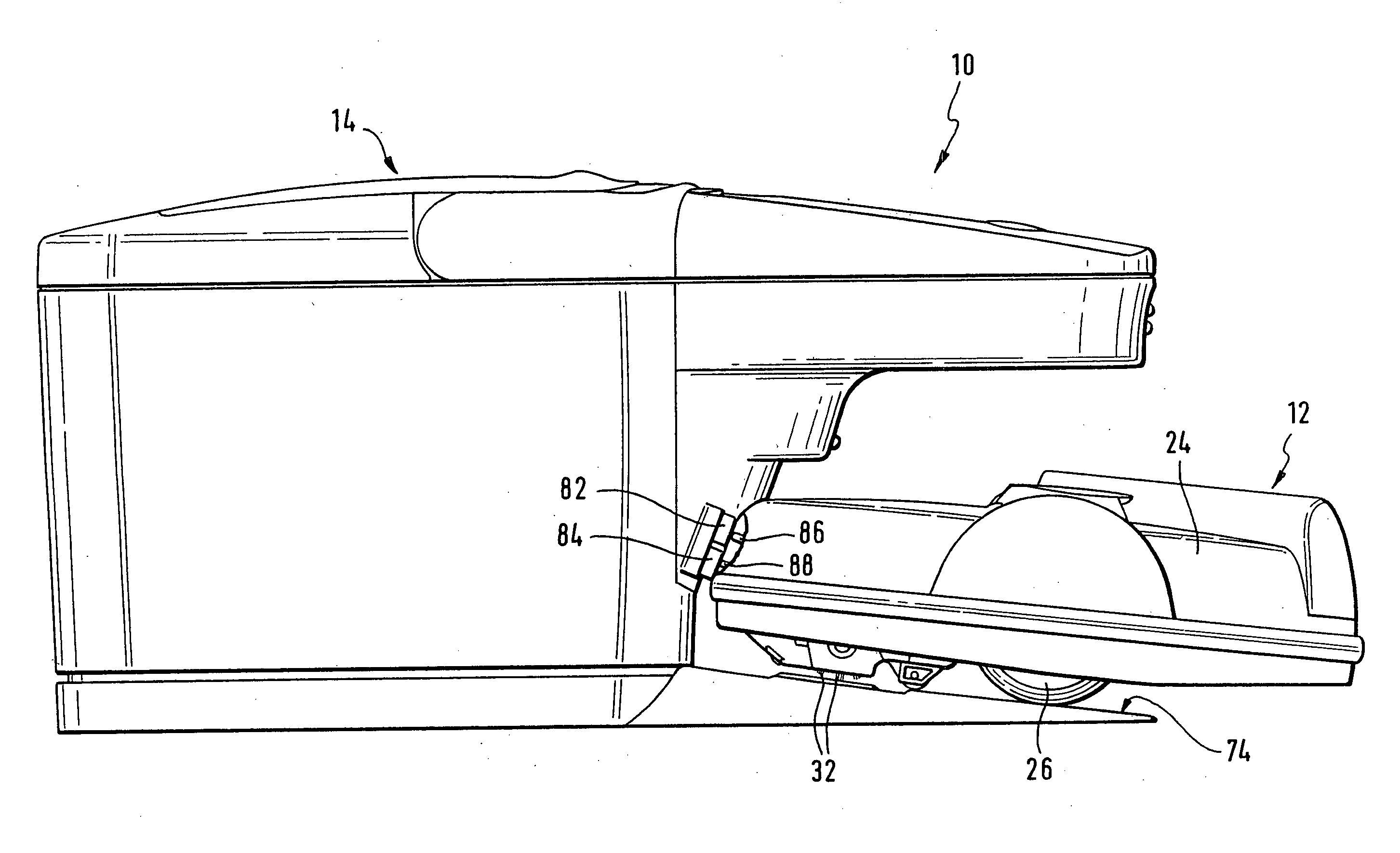

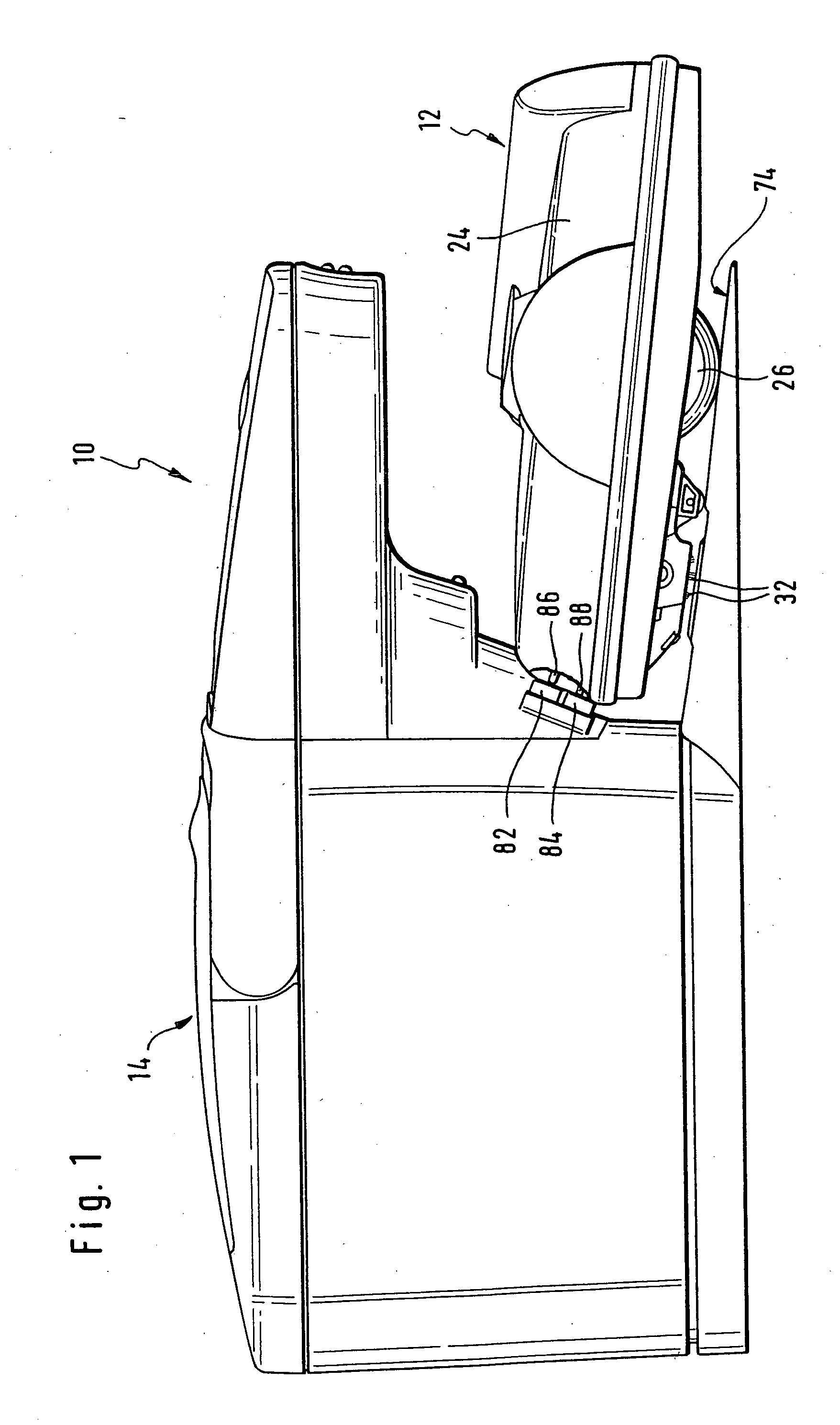

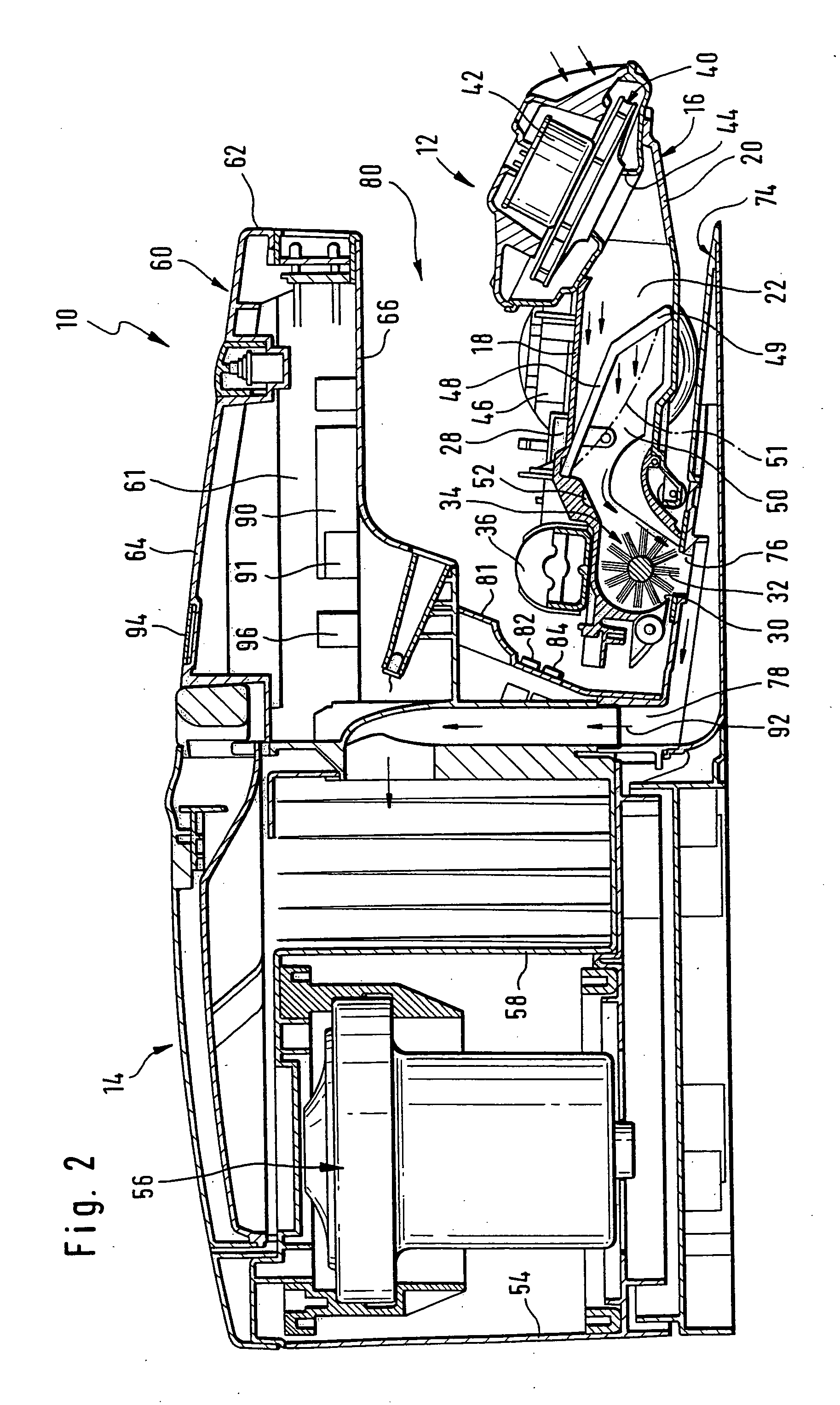

Method for operating a floor cleaning system, and floor cleaning system for use of the method

InactiveUS20050150519A1Reduce noiseReduce cleaningSuction filtersLighting and heating apparatusEngineeringMechanical engineering

The invention relates to a method for operating a floor cleaning system having a central suction station with which there is associated a self-propelled and self-steering suction appliance, dirt being picked up from a floor surface that is to be cleaned by means of the suction appliance and being transferred into a dirt collection vessel of the suction appliance, and the suction station having a suction unit, and the dirt collection vessel being sucked out by means of the suction unit. To refine the method in such a manner that the levels of noise produced by the floor cleaning system can be reduced, it is proposed, according to the invention, that the suction unit is optionally operated with a maximum suction power or a reduced suction power. The invention also proposes a floor cleaning system for carrying out the method.

Owner:ALFRED KARCHER GMBH & CO KG

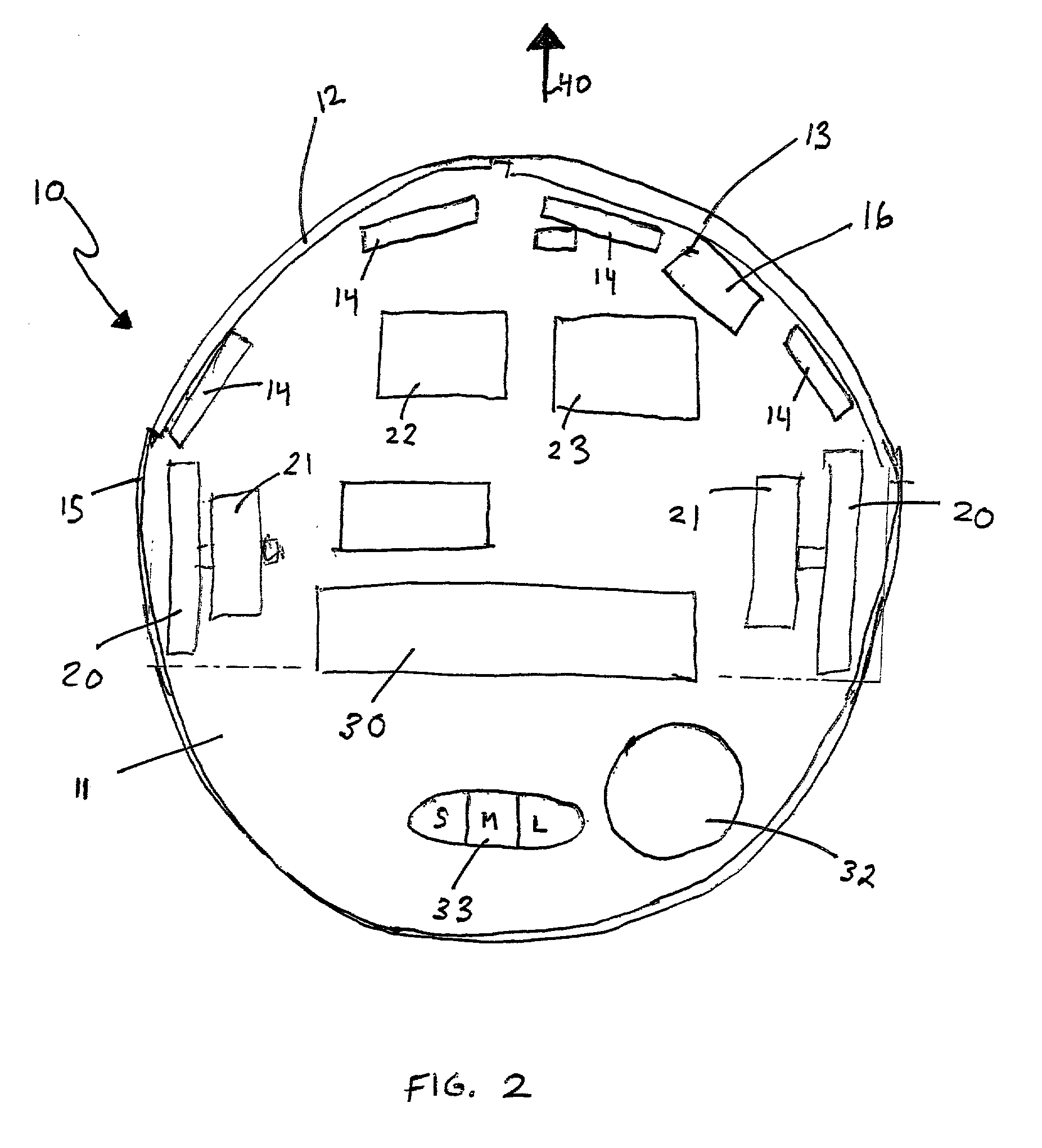

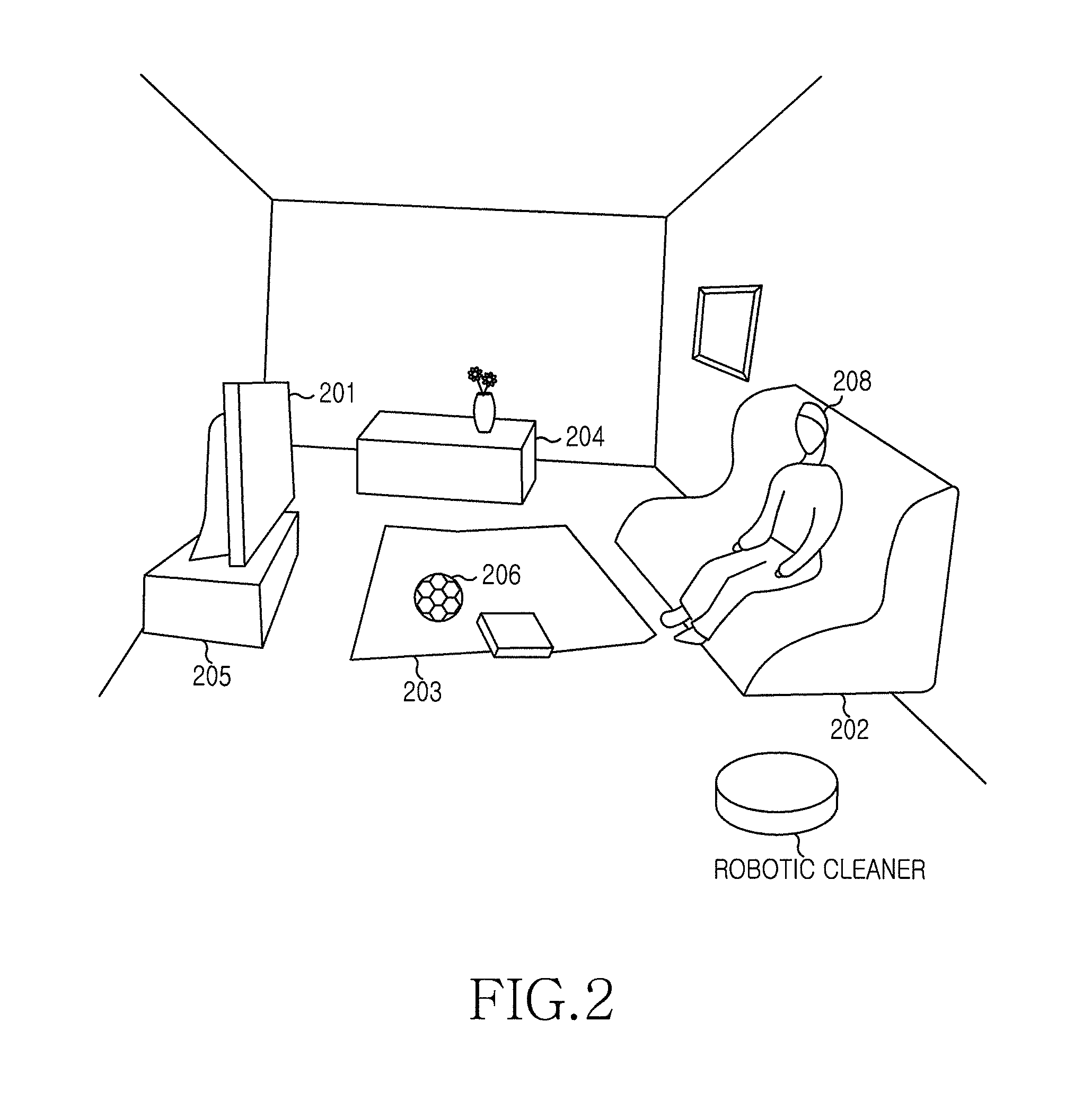

Method and system for multi-mode coverage for an autonomous robot

A control system for a mobile robot (10) is provided to effectively cover a given area by operating in a plurality of modes, including an obstacle following mode (51) and a random bounce mode (49). In other embodiments, spot coverage, such as spiraling (45), or other modes are also used to increase effectiveness. In addition, a behavior based architecture is used to implement the control system, and various escape behaviors are used to ensure full coverage.

Owner:IROBOT CORP

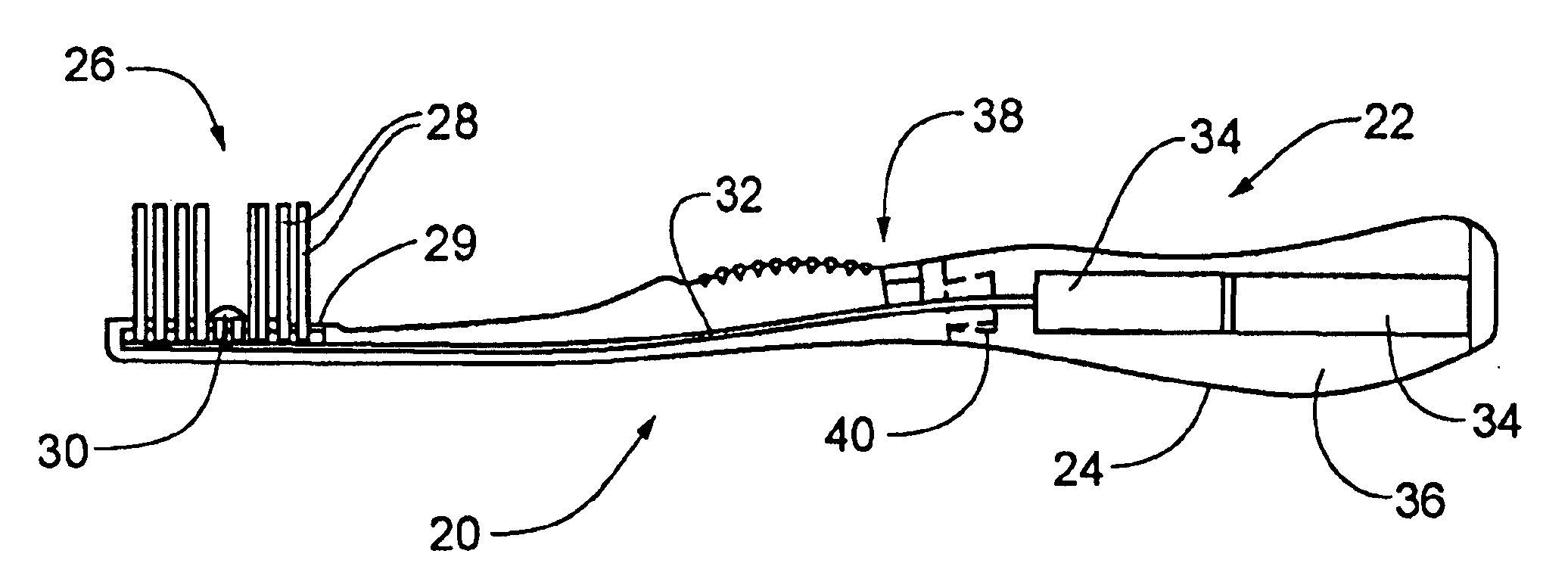

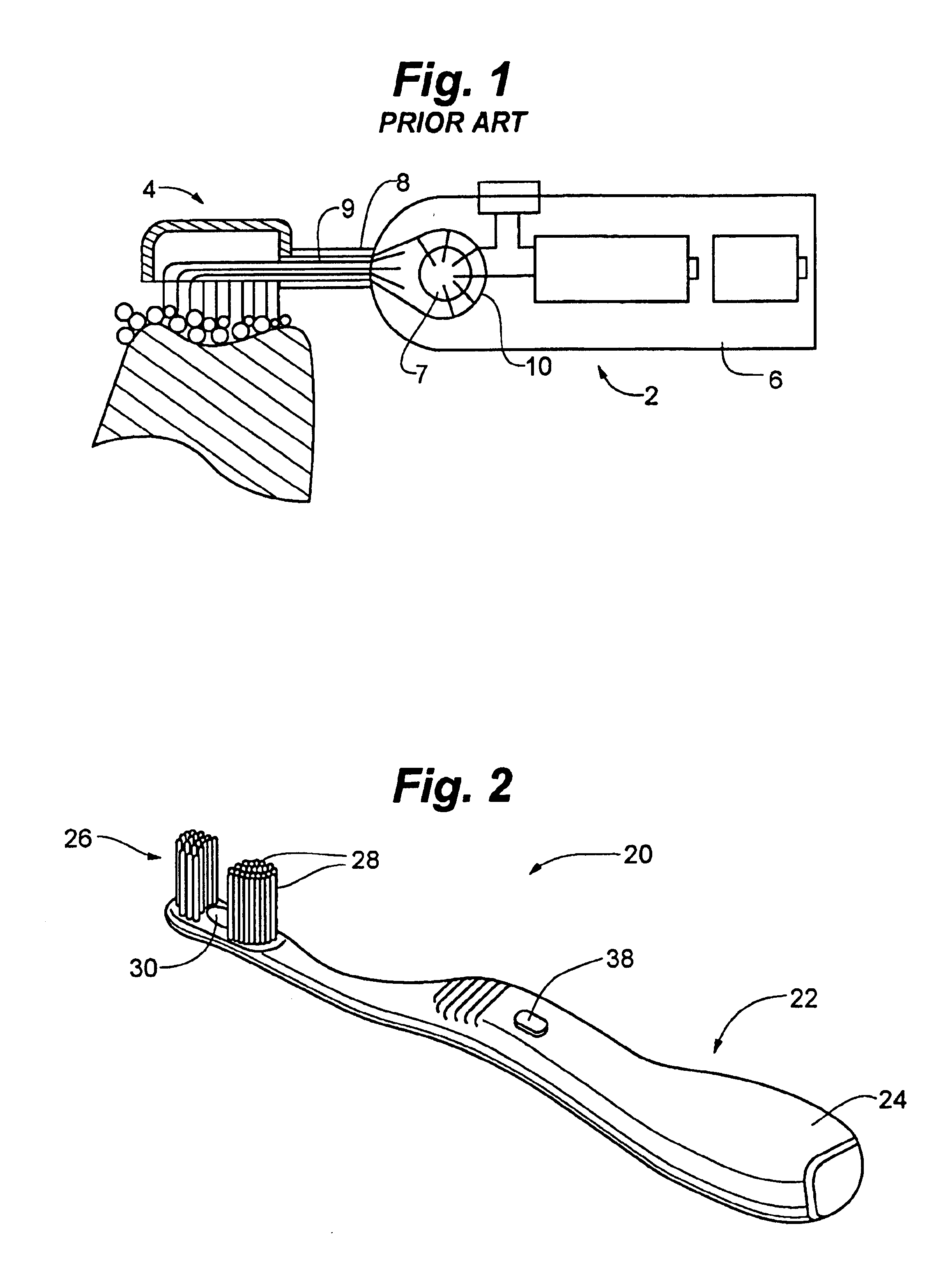

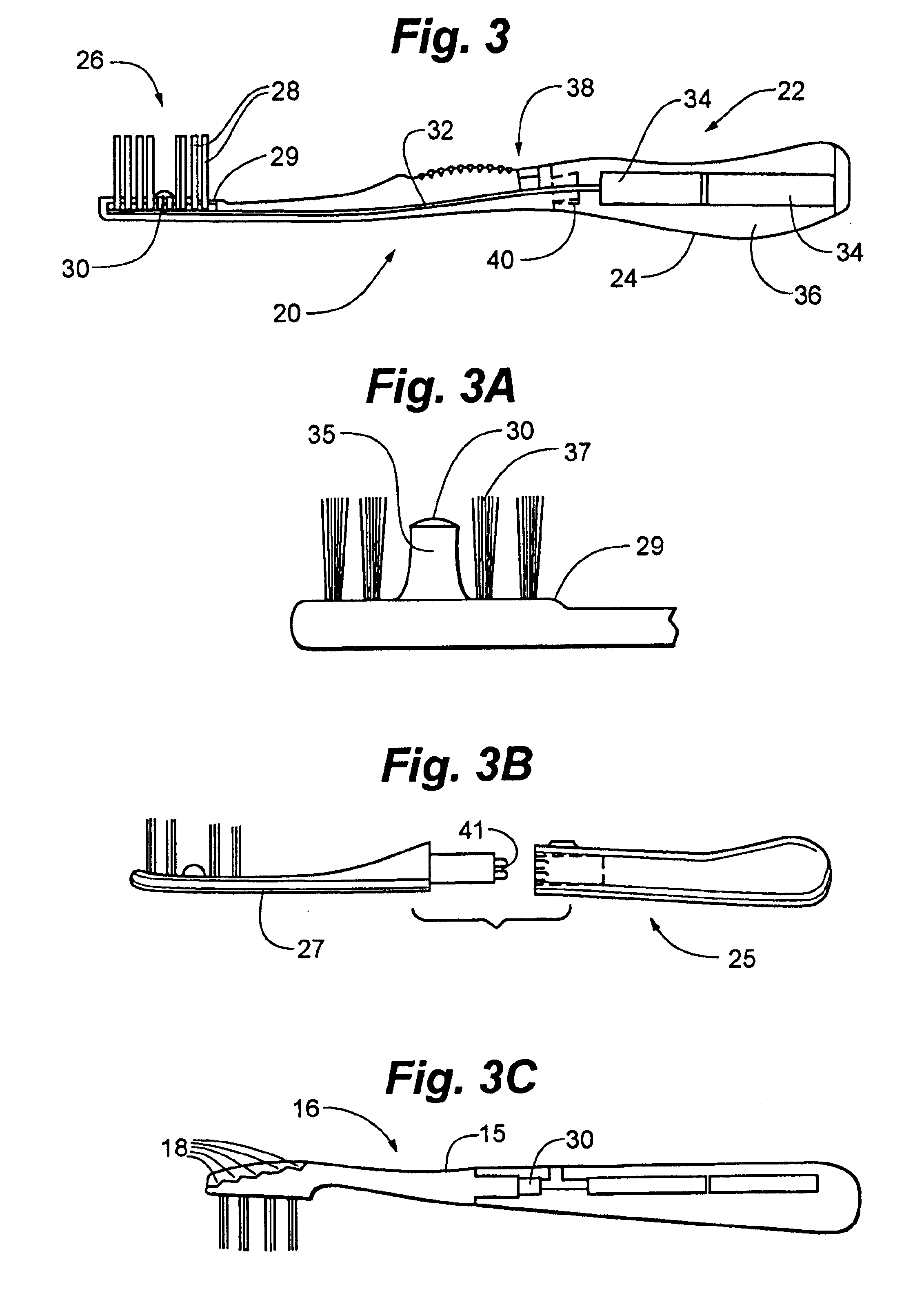

Enhanced dental hygiene system with direct UVA photoexcitation

A device and a method for delivering UVA light to the mouth in which a photocatalytic agent is distributed in the mouth and a UVA light source is located contiguously to the head of the device so that the photocatalytic agent distributed in the mouth is efficiently activated by UVA light produced by the device. The UVA light delivery device of the invention may be, inter alia, a toothbrush, a tongue scraper, an interdental toothbrush, a denture brush, a flossing device, a dental hand tool, or a wand adapted exclusively to applying UVA light to photocatalyst coated surfaces.

Owner:SUSR AMERICAS

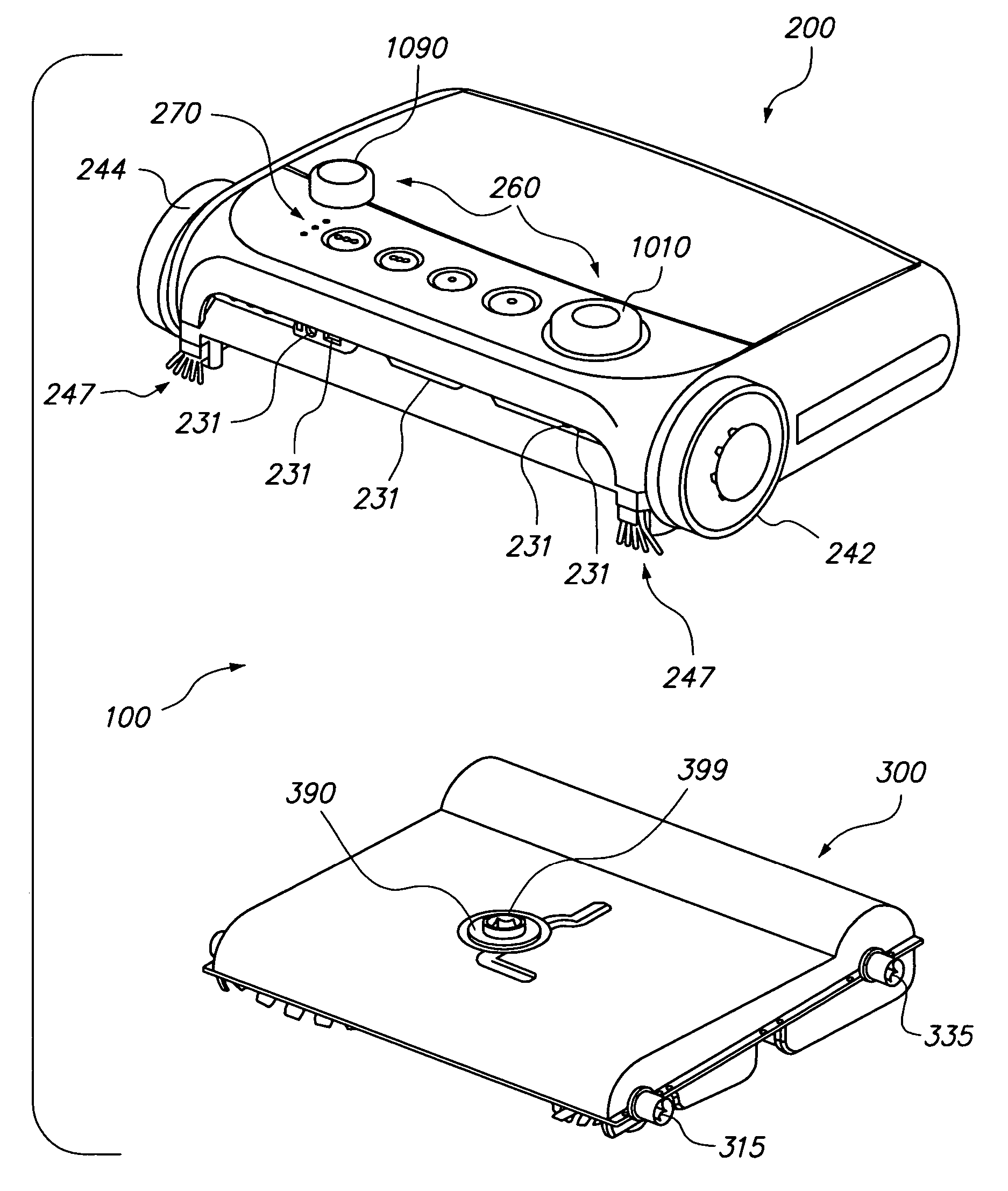

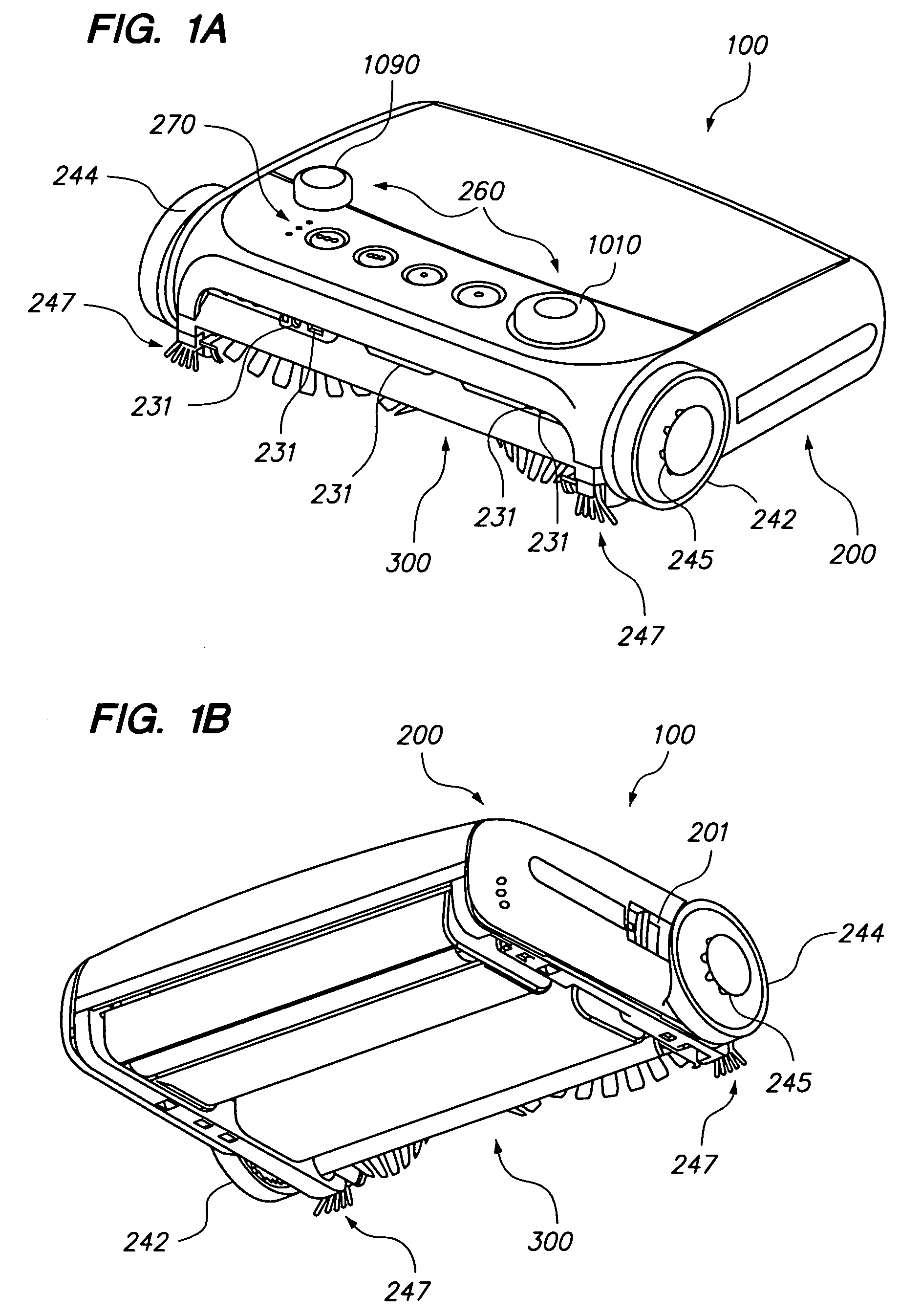

Multi-function robotic device

ActiveUS7555363B2Programme-controlled manipulatorAutomatic obstacle detectionData compressionEngineering

A multi-function robotic device may have utility in various applications. In accordance with one aspect, a multi-function robotic device may be selectively configurable to perform a desired function in accordance with the capabilities of a selectively removable functional cartridge operably coupled with a robot body. Localization and mapping techniques may employ partial maps associated with portions of an operating environment, data compression, or both.

Owner:VORWERK & CO INTERHOLDING GMBH

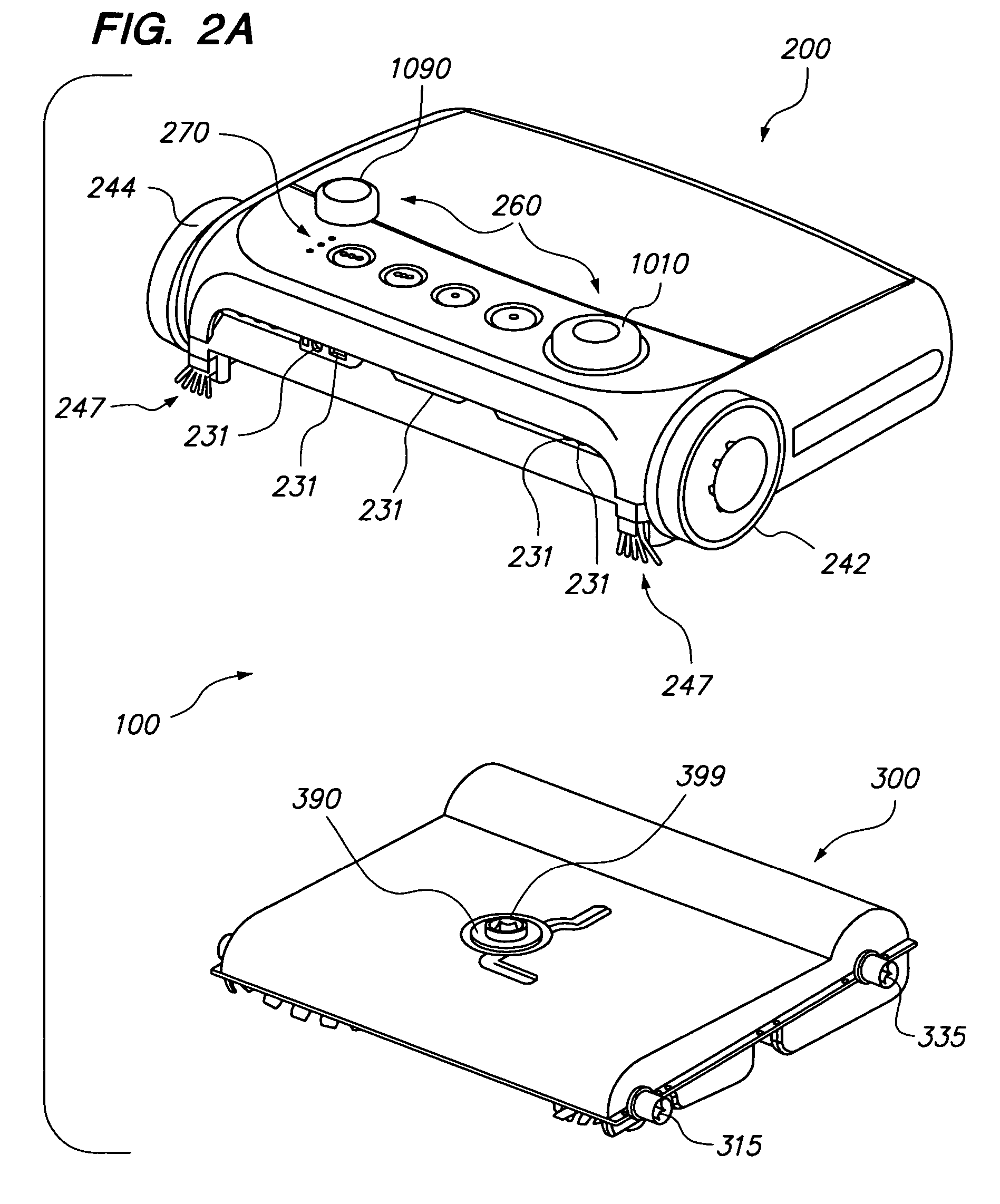

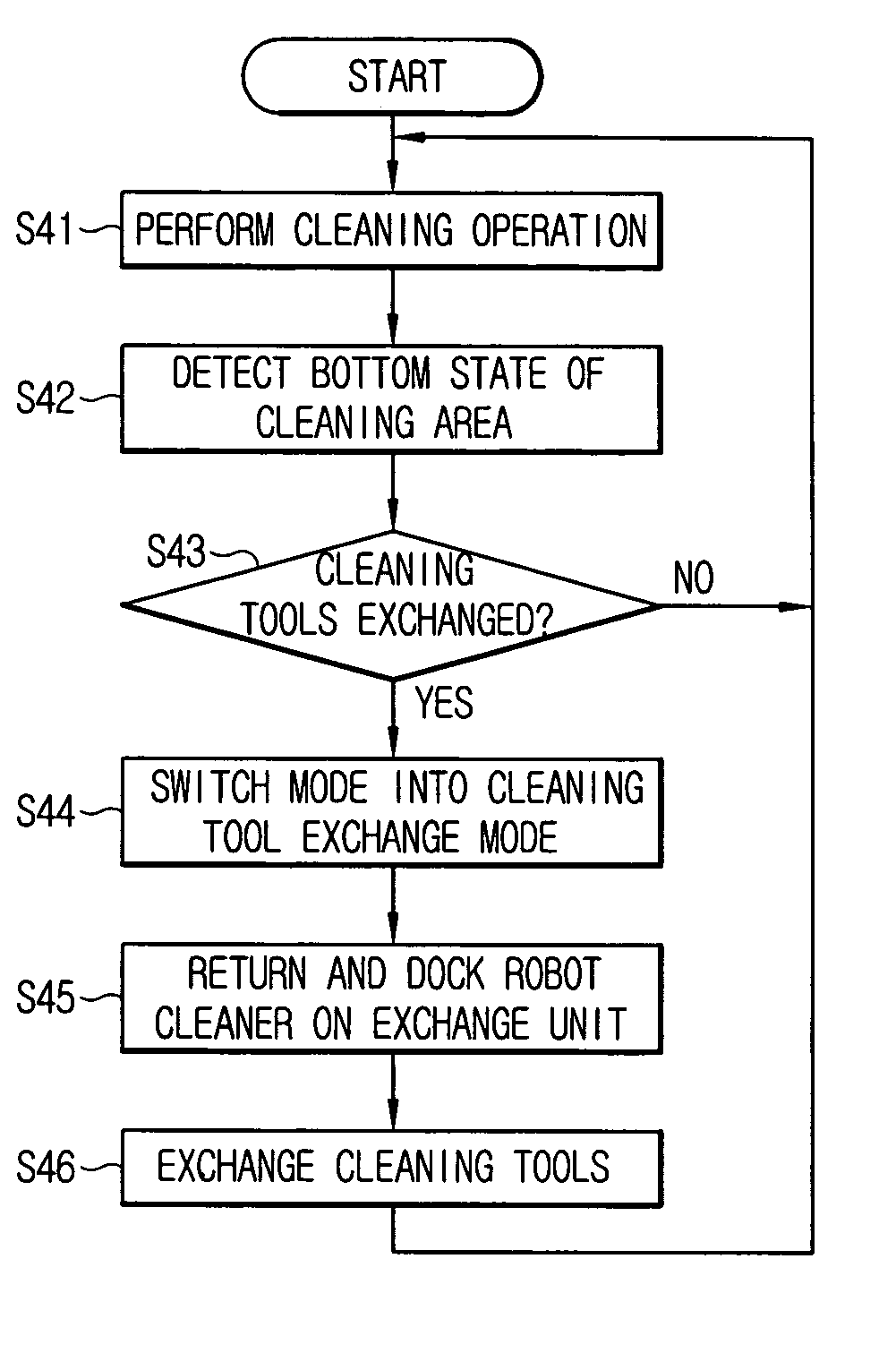

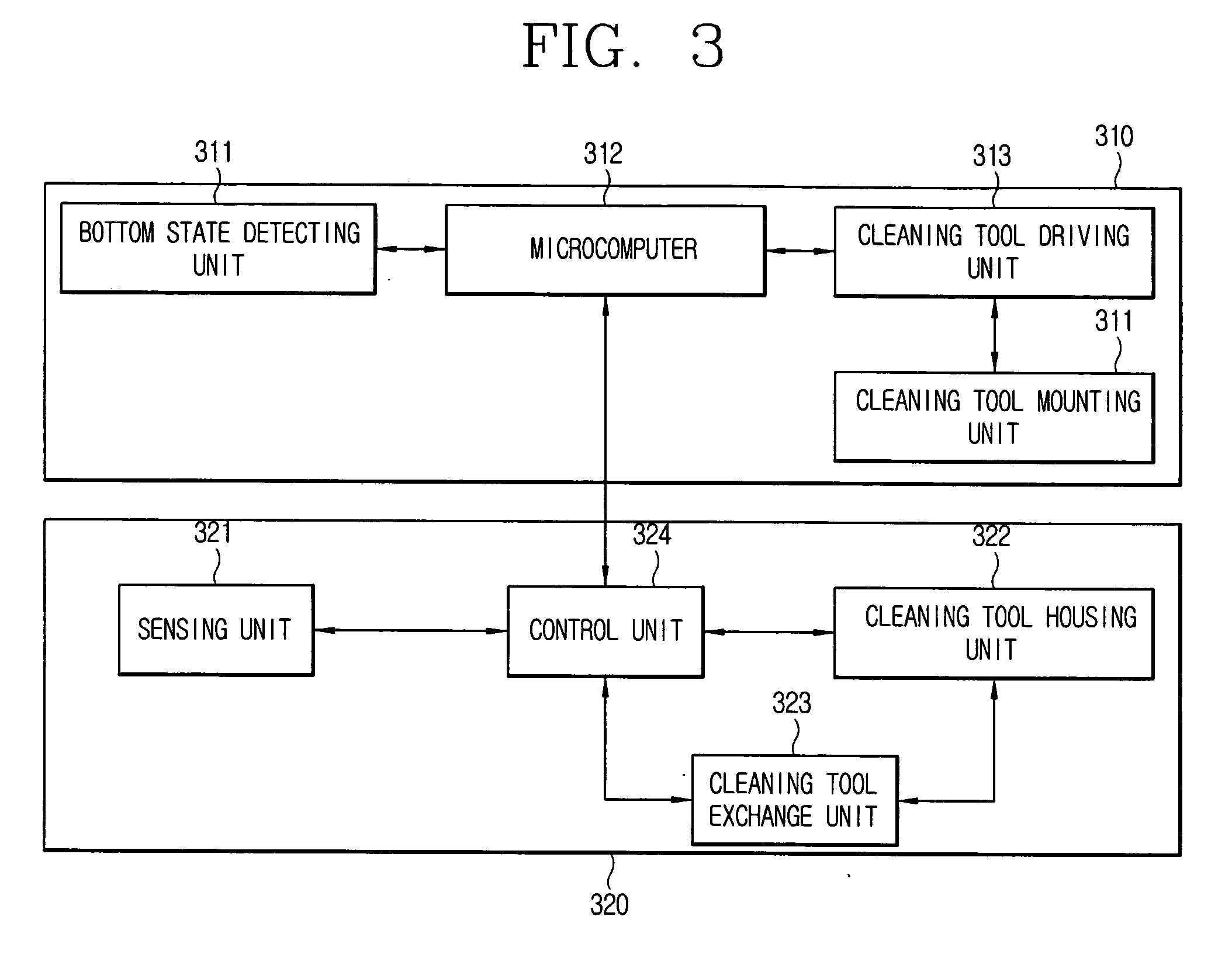

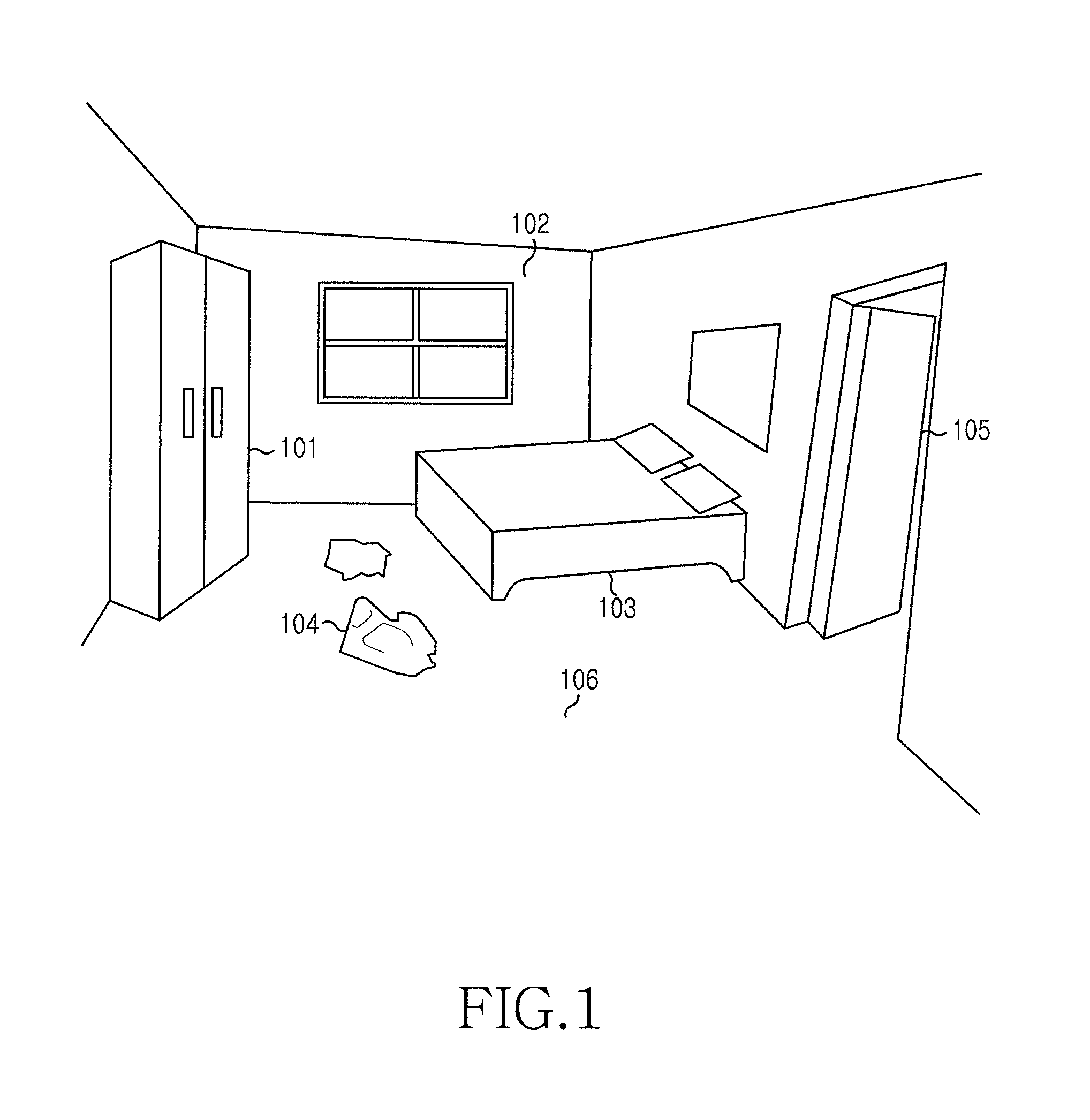

System for automatically exchanging cleaning tools of robot cleaner, and method therefor

InactiveUS20060060216A1Avoid swappingReduce overall weight and volumeCarpet cleanersCleaning action controlEngineeringElectrical and Electronics engineering

The present invention discloses a system for automatically exchanging cleaning tools of a robot cleaner and a method therefor. The system for automatically exchanging the cleaning tools of the robot cleaner includes the robot cleaner for deciding whether a currently-mounted first cleaning tool is suitable for a bottom state of a cleaning area, and returning to and being docked on an exchange unit when the first cleaning tool is not suitable for the bottom state, and the exchange unit for exchanging the first cleaning tool currently mounted on the robot cleaner with a second cleaning tool suitable for the bottom state when the robot cleaner is docked.

Owner:LG ELECTRONICS INC

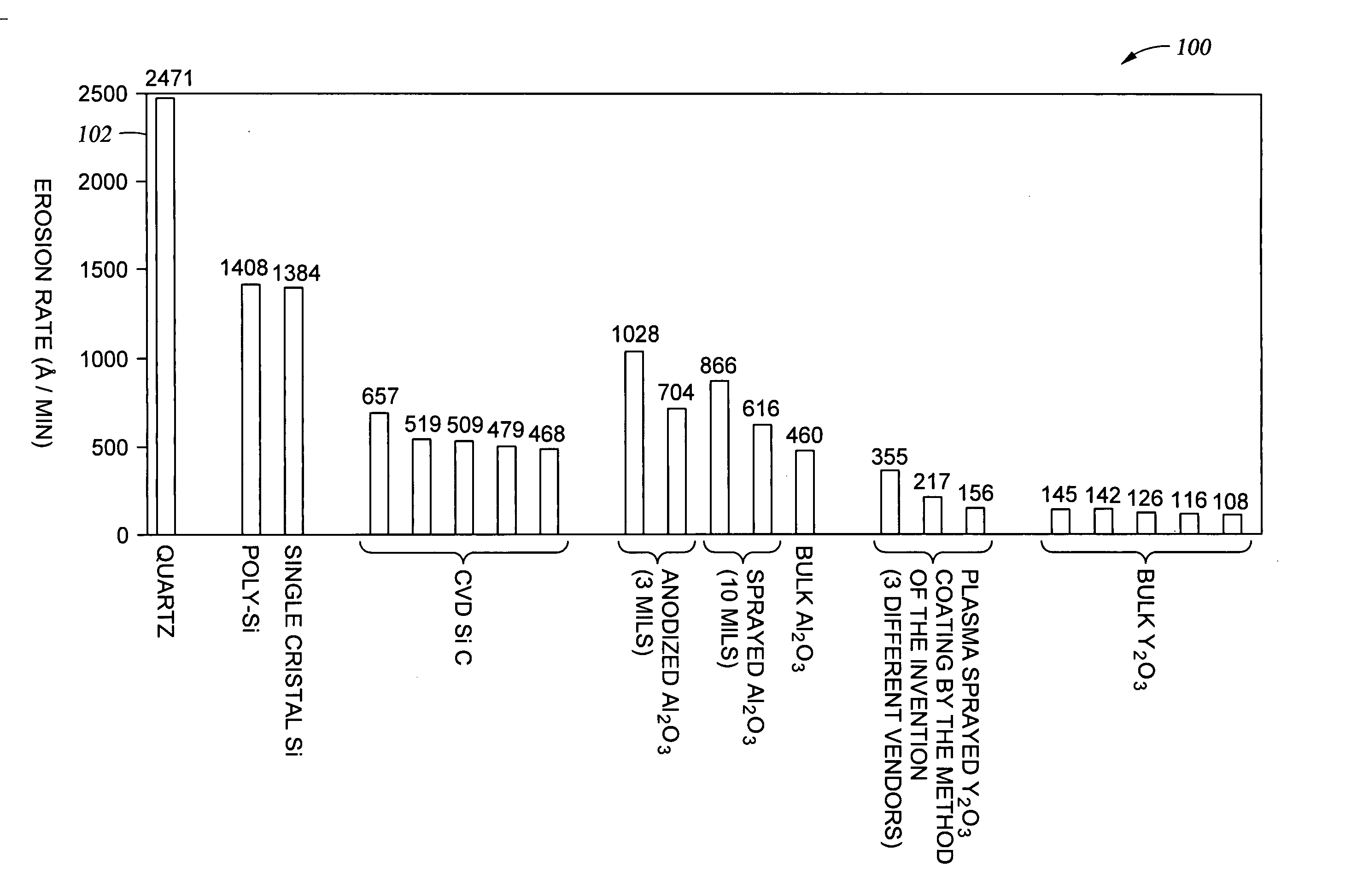

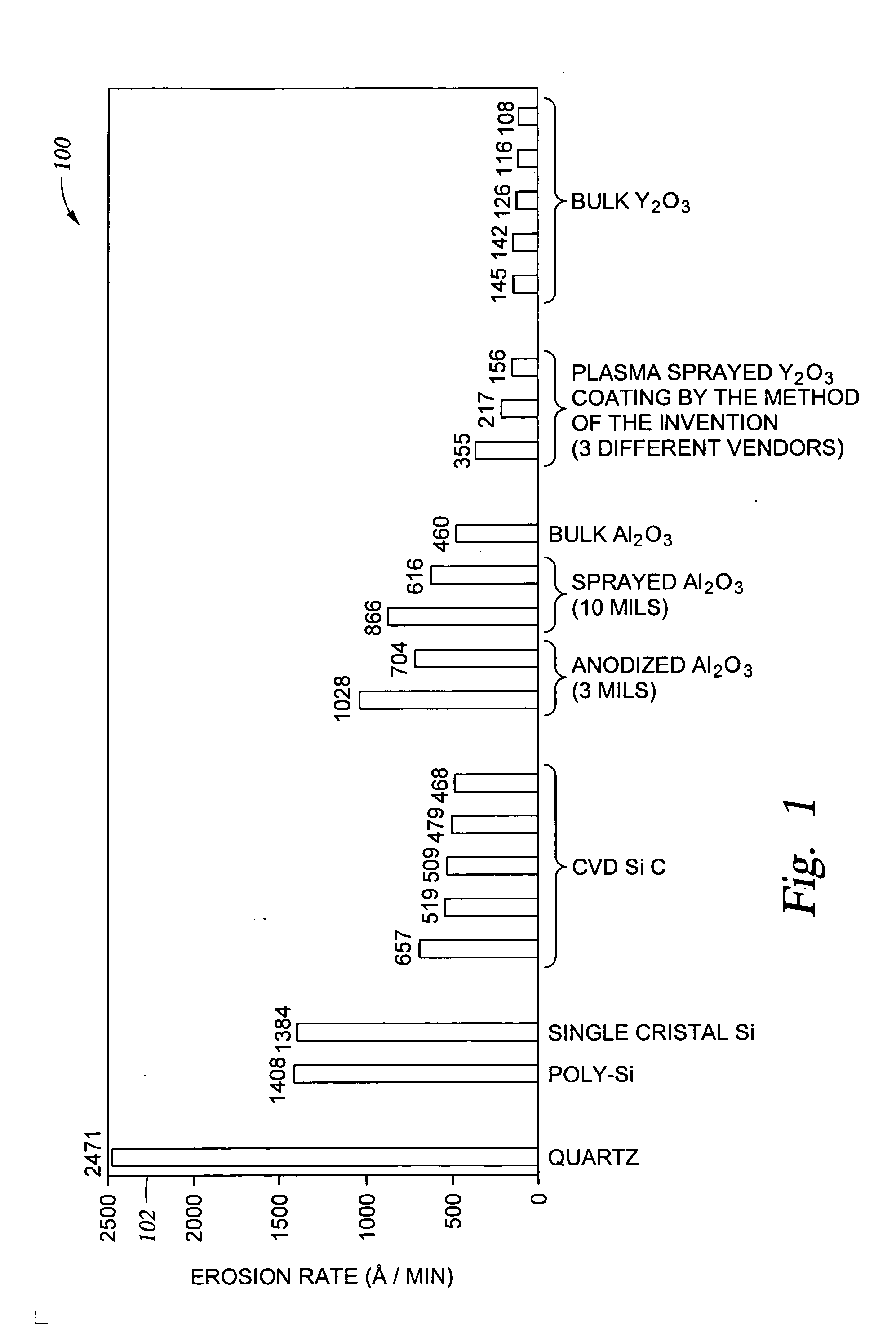

Clean, dense yttrium oxide coating protecting semiconductor processing apparatus

ActiveUS20050037193A1Extended service lifeExcellent plasma corrosion-resistanceLiquid surface applicatorsMolten spray coatingPlasma coatingChemical vapor deposition

Disclosed herein is a method for applying plasma-resistant coatings for use in semiconductor processing apparatus. The coatings are applied over a substrate which typically comprises an aluminum alloy of the 2000 series or the 5000 through 7000 series. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3. The coatings are typically applied to a surface of an aluminum alloy substrate or an anodized aluminum alloy substrate using a technique selected from the group consisting of thermal / flame spraying, plasma spraying, sputtering, and chemical vapor deposition (CVD). To provide the desired corrosion resistance, it is necessary to place the coating in compression. This is accomplished by controlling deposition conditions during application of the coating.

Owner:APPLIED MATERIALS INC

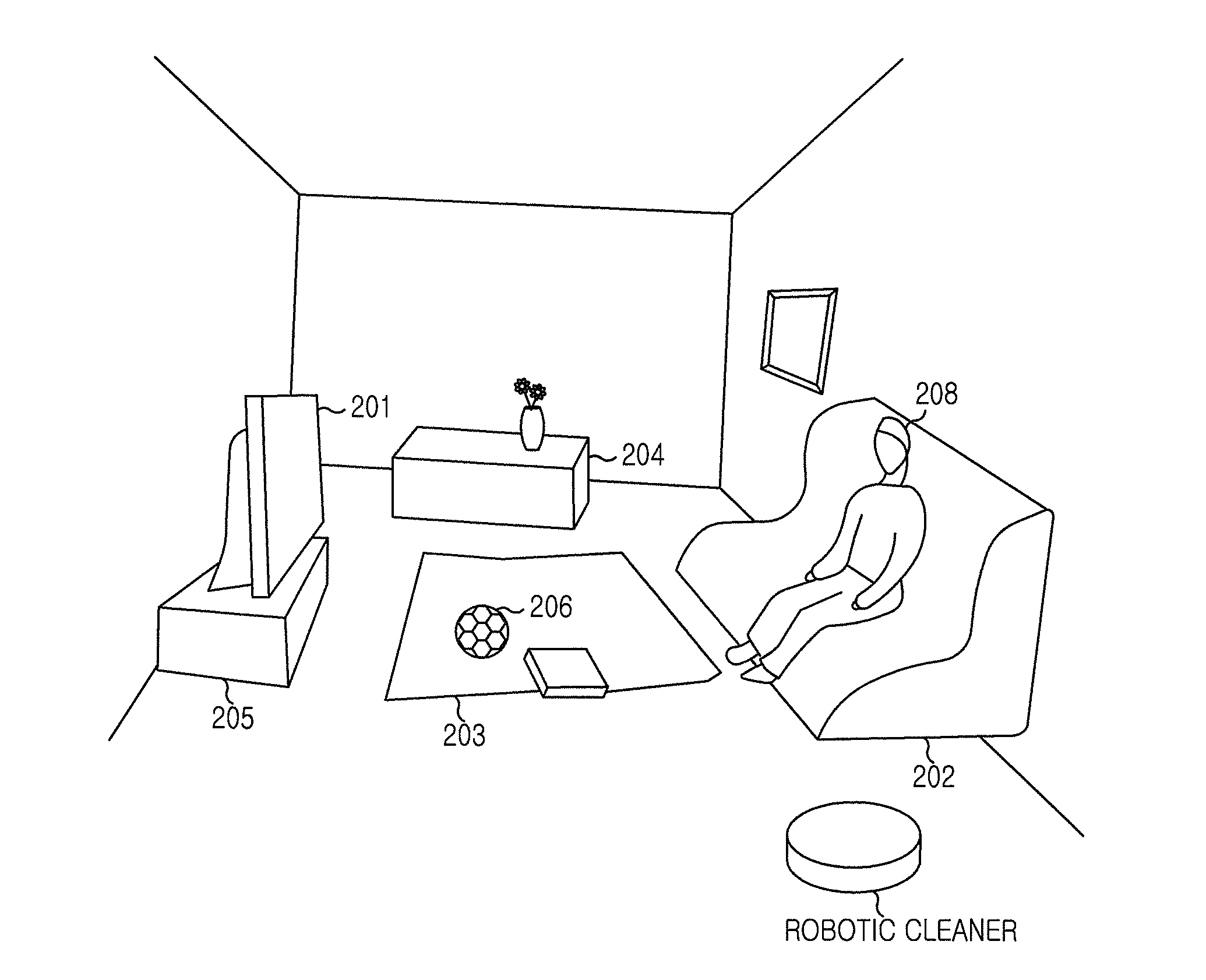

Apparatus and method for controlling cleaning in robotic cleaner

ActiveUS20130206177A1Programme-controlled manipulatorAutomatic obstacle detectionElectrical and Electronics engineeringInformation measure

Owner:SAMSUNG ELECTRONICS CO LTD

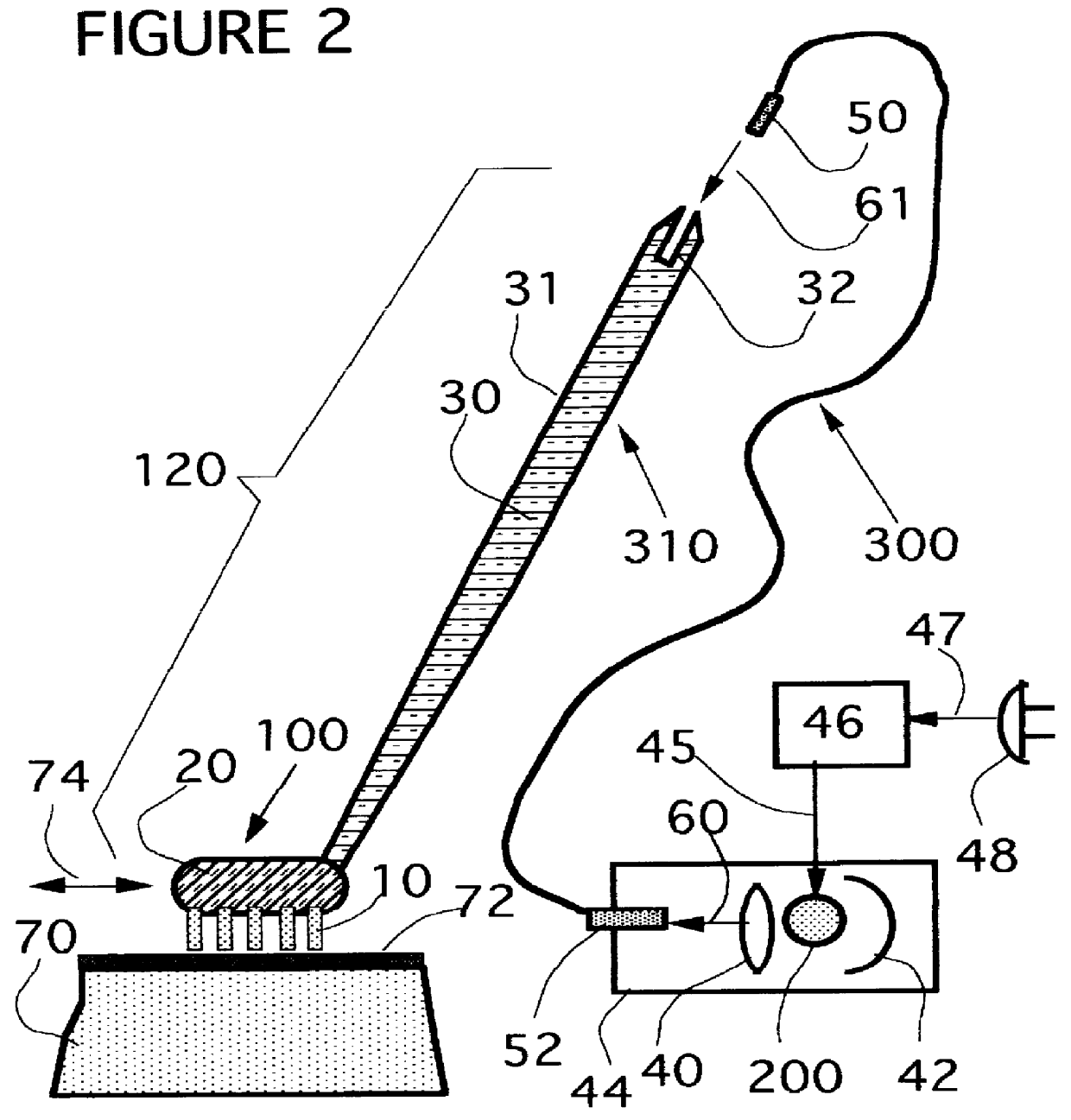

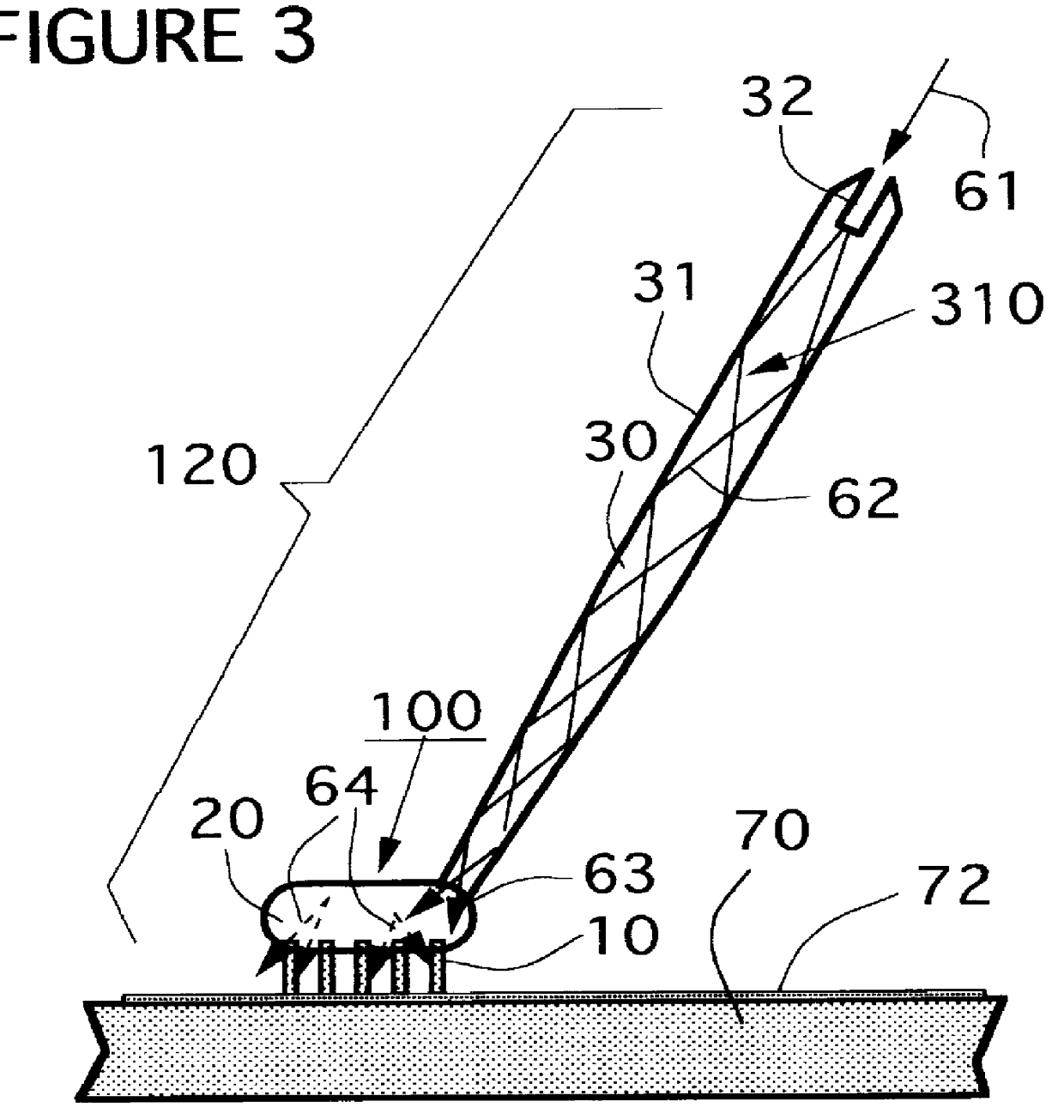

Cleaning apparatus using photocatalyst

InactiveUS6094767AEasy to removeEasy to eliminateElectrotherapyChiropractic devicesLight guideEngineering

Cleaning apparatus includes a cleaning head, a light source and a light guide. The cleaning head has a flexible contact member including photo-activating catalyst (photocatalyst). The light source emits short wave light rays to activate the photocatalyst. The light guide transmits the light rays from the light source to the contact member(brushes). The cleaning head may have a transparent brush supporter to support a group of brushes with many photocatalyst particles. The light guide may preferably include a transparent rod and / or an optical fiber. The cleaning apparatus may be applied for a vacuum cleaner. Therefore, such dirty component can be cleaned as bacteria, molds etc. by use of the cleaning apparatus of the invention.

Owner:IIMURA KEIJI

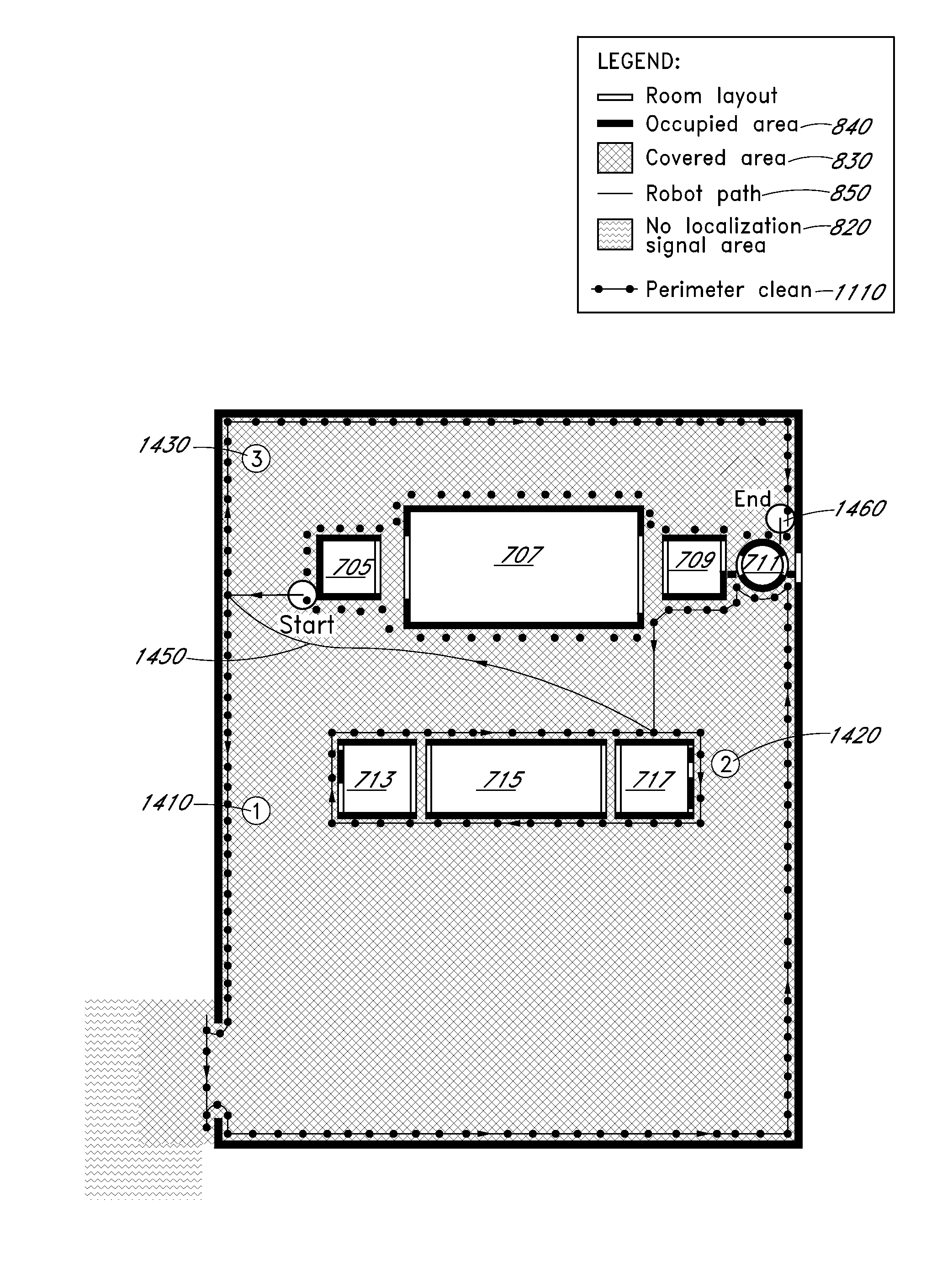

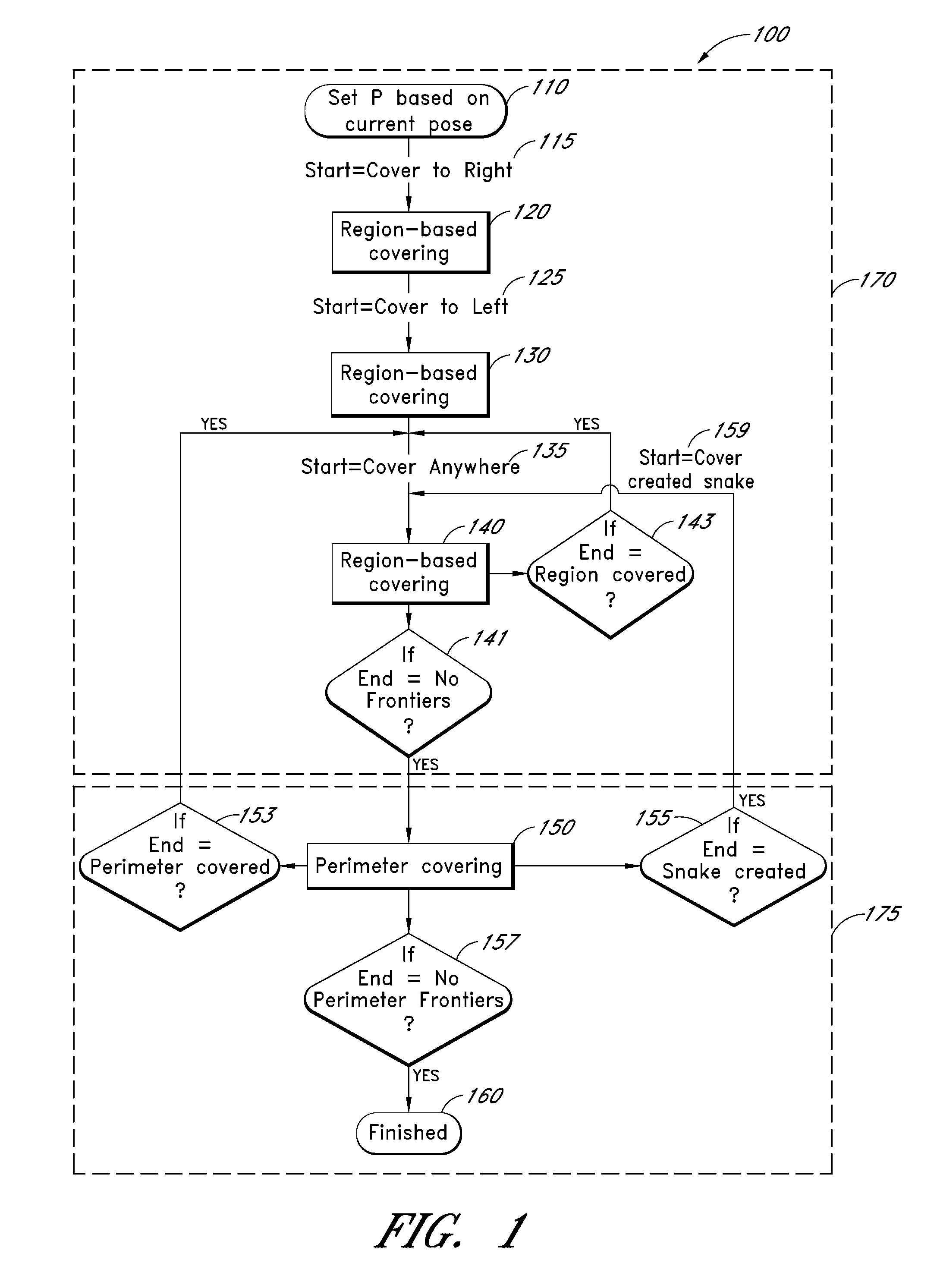

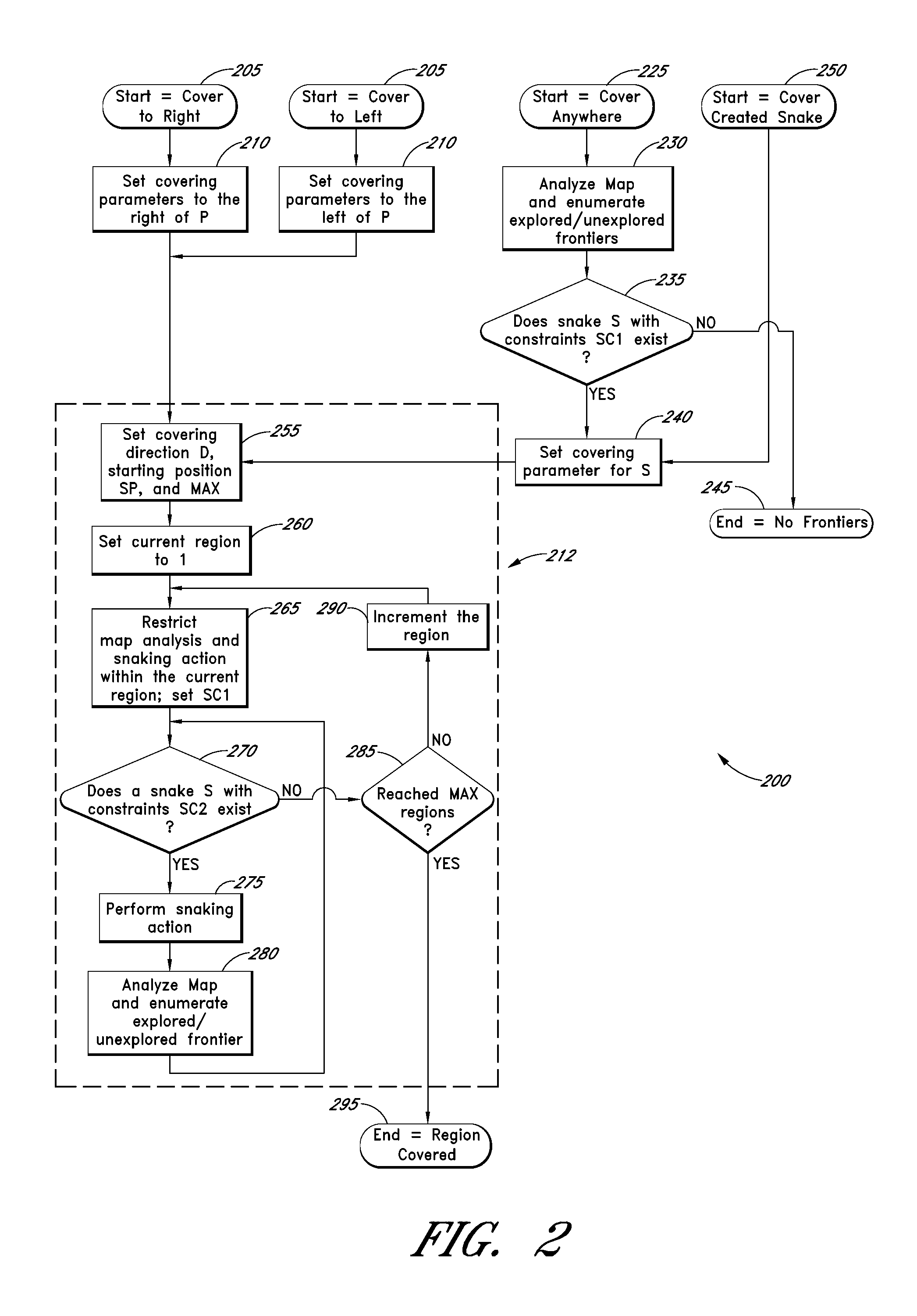

Methods and systems for complete coverage of a surface by an autonomous robot

A robot configured to navigate a surface, the robot comprising a movement mechanism; a logical map representing data about the surface and associating locations with one or more properties observed during navigation; an initialization module configured to establish an initial pose comprising an initial location and an initial orientation; a region covering module configured to cause the robot to move so as to cover a region; an edge-following module configured to cause the robot to follow unfollowed edges; a control module configured to invoke region covering on a first region defined at least in part based at least part of the initial pose, to invoke region covering on least one additional region, to invoke edge-following, and to invoke region covering cause the mapping module to mark followed edges as followed, and cause a third region covering on regions discovered during edge-following.

Owner:IROBOT CORP

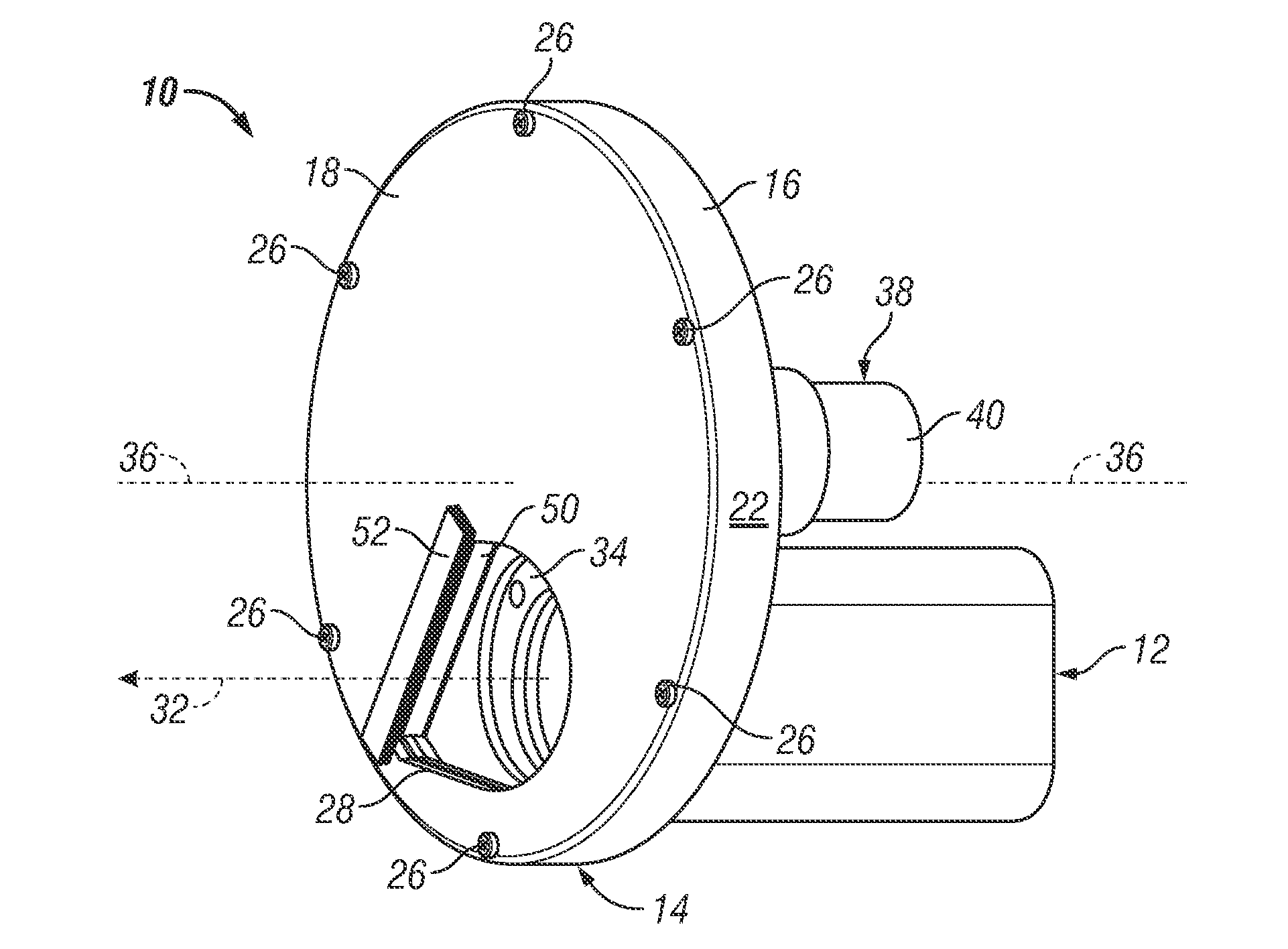

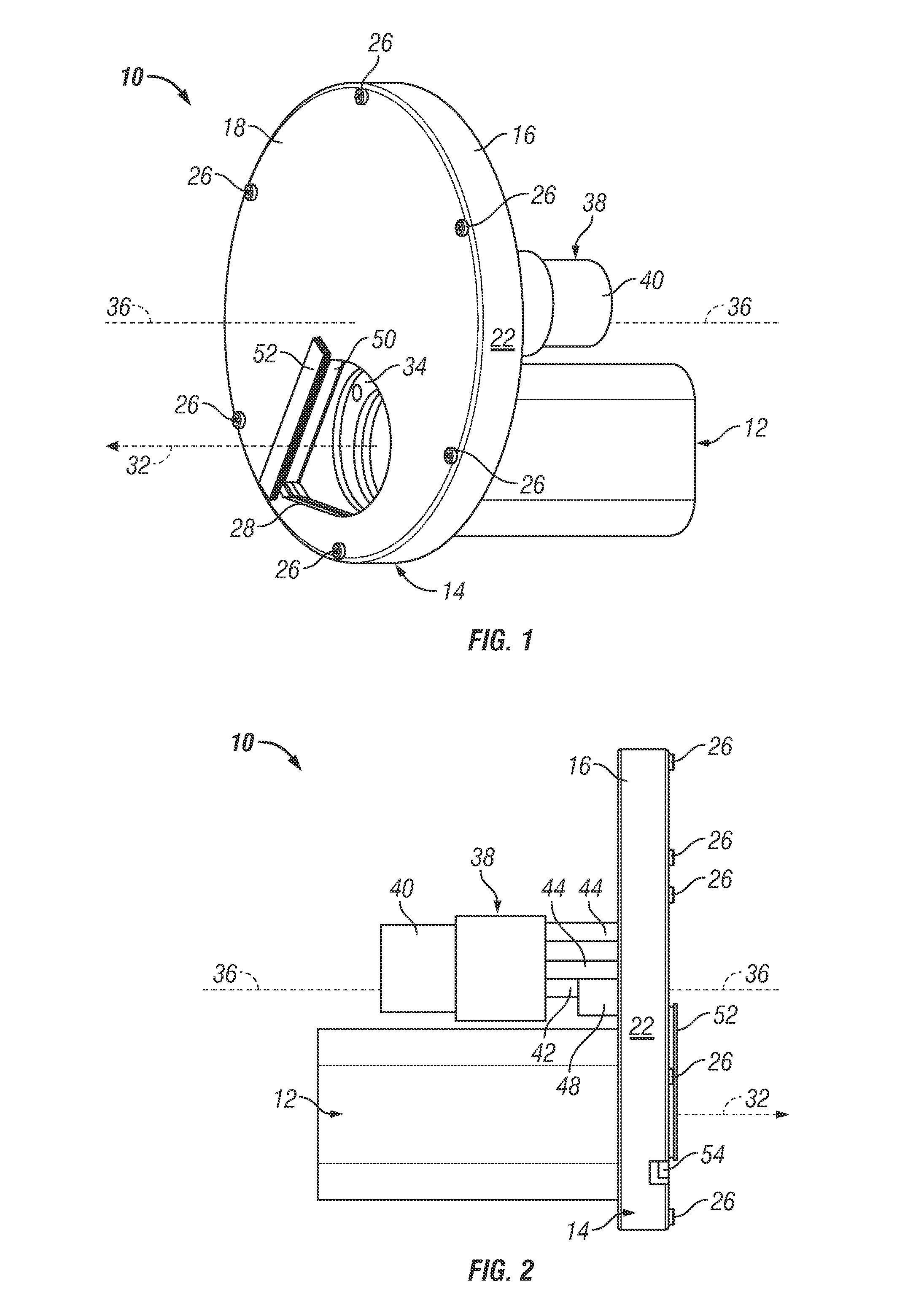

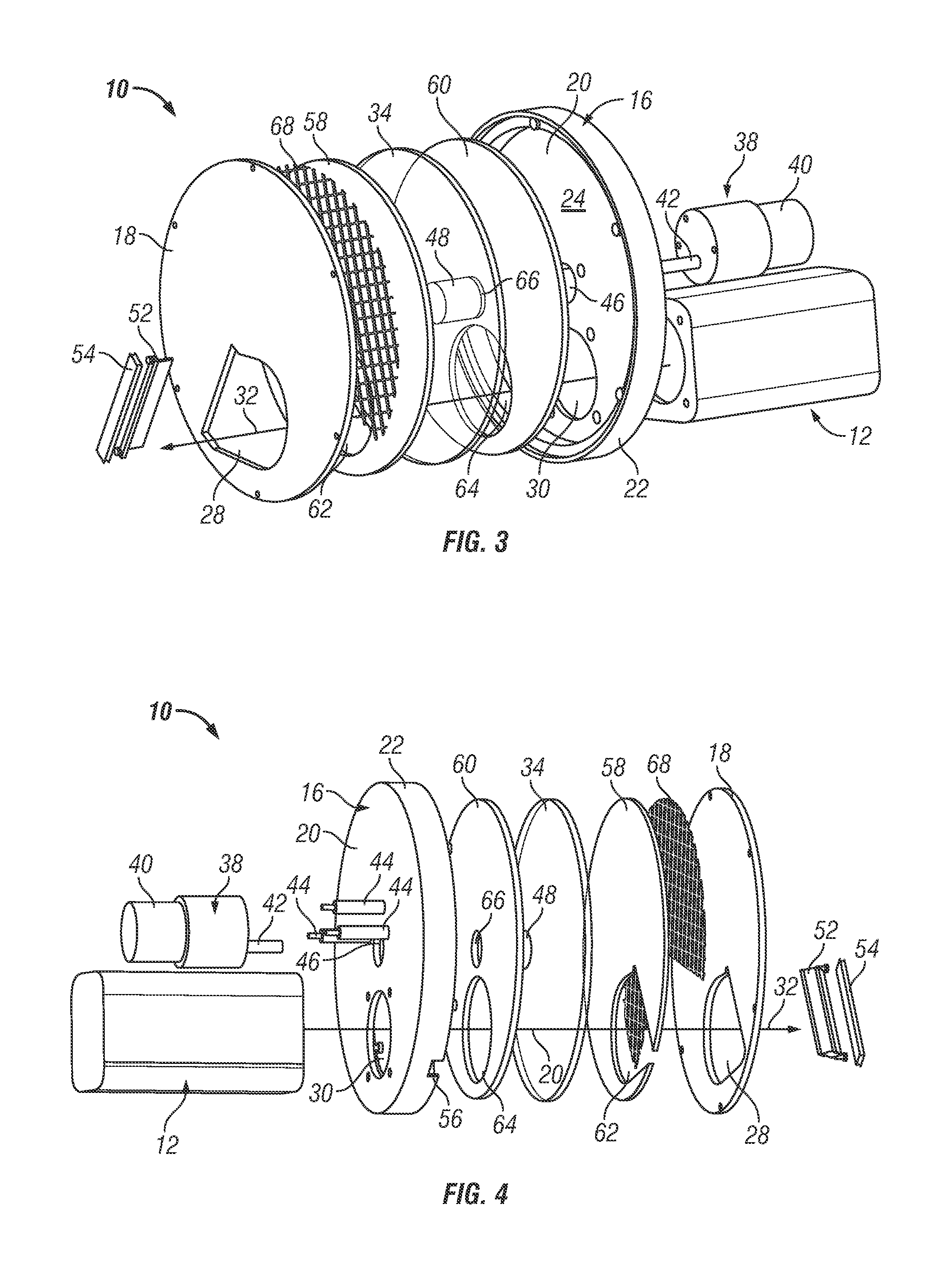

Automated camera cleaning system

Embodiments of an automated camera cleaning system are provided. In one embodiment, the automated camera cleaning system includes an optical path, an optically-transmissive lens shield through which the optical path extends, a housing in which the optically-transmissive lens shield is at least partially disposed, and a motor coupled to the lens shield. When energized, the motor moves the optically-transmissive lens shield relative to the housing to vary the region of the optically-transmissive lens shield positioned in the optical path.

Owner:RAYTHEON CO

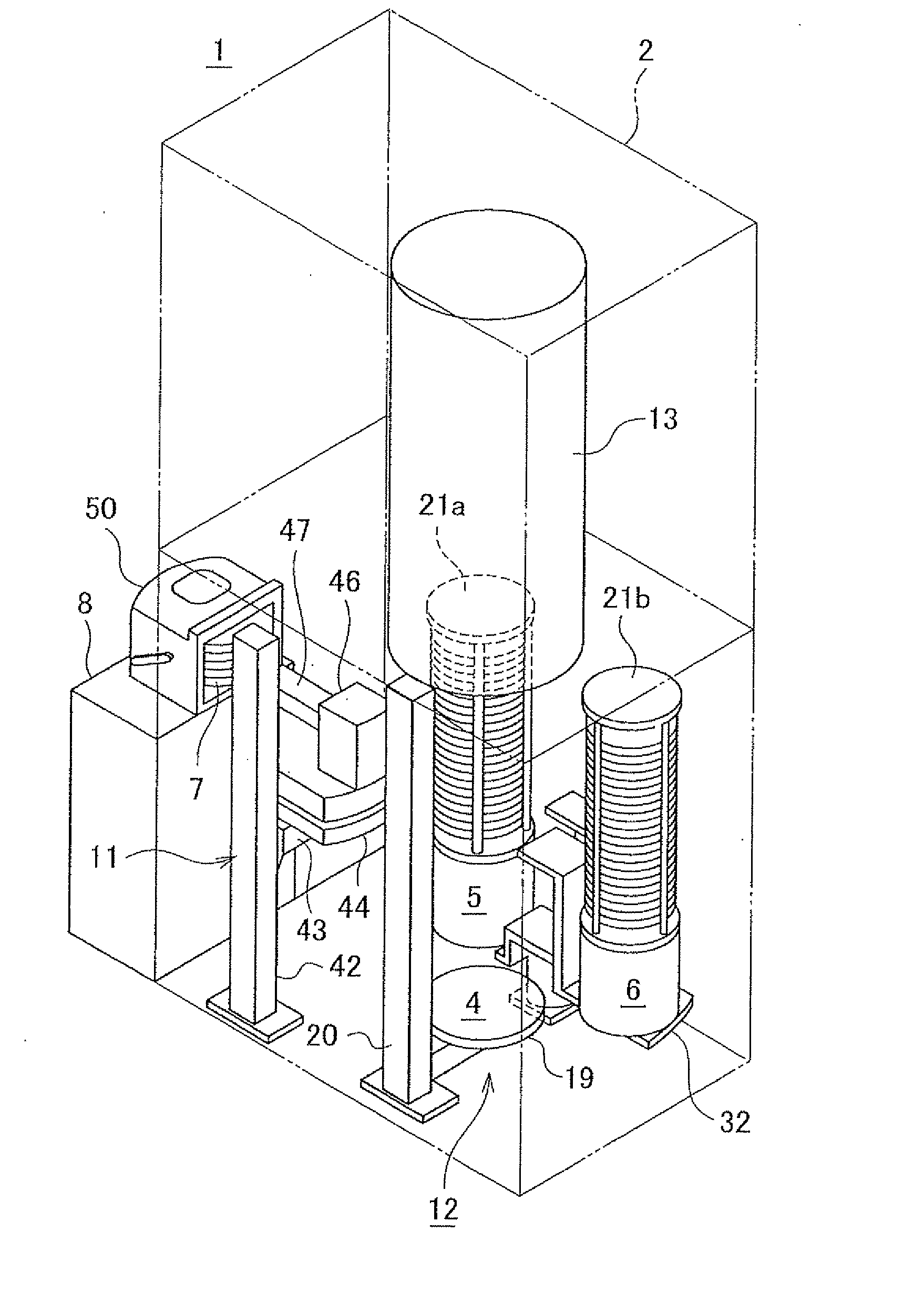

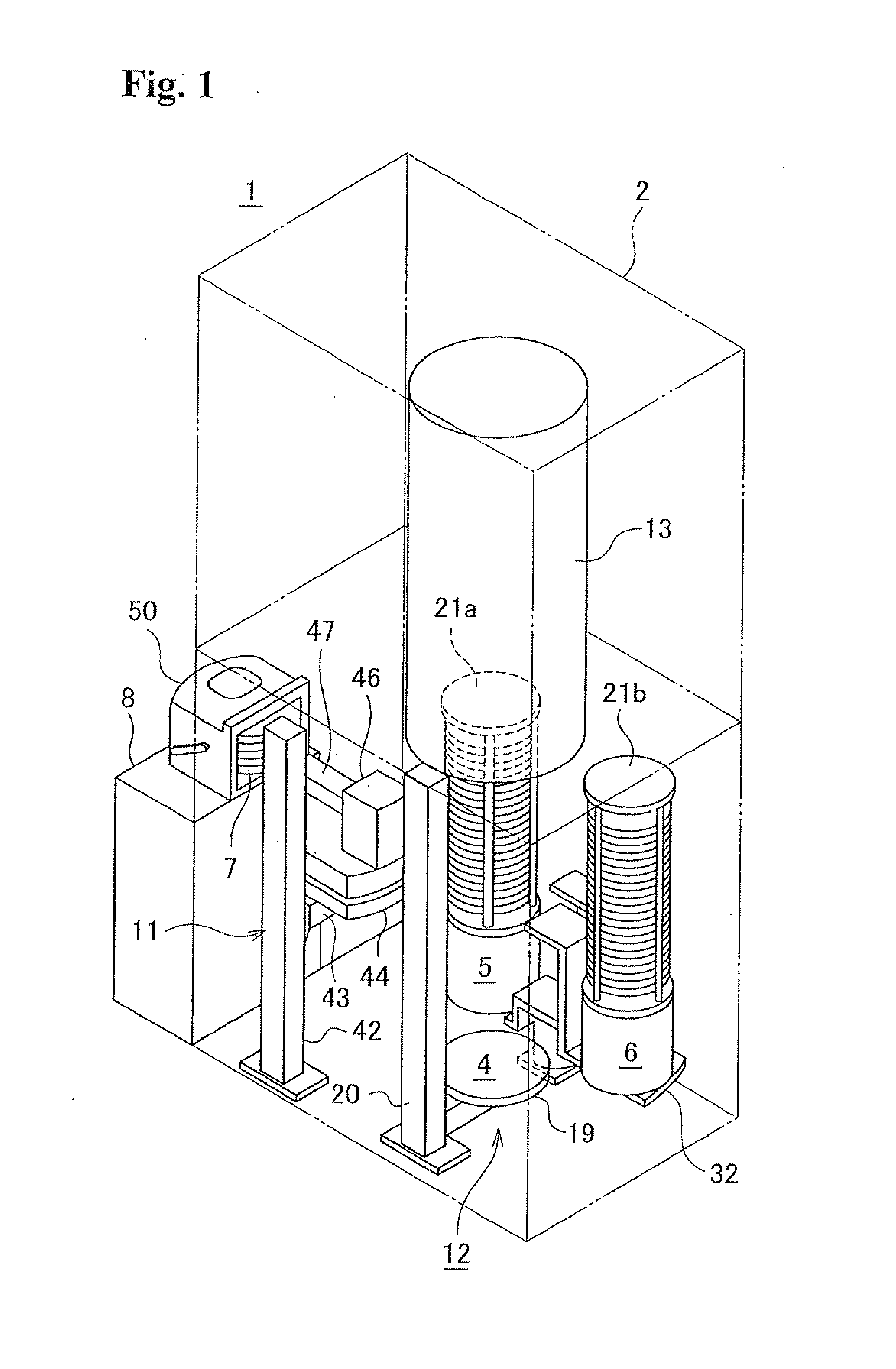

Substrate processing apparatus and its maintenance method, substrate transfer method and program

InactiveUS20130247937A1Semiconductor/solid-state device manufacturingCleaning processes and apparatusProcess engineeringIndustrial engineering

There is provided a substrate processing apparatus, including at least: a substrate holder that holds a substrate; a processing furnace including a reaction tube in which the substrate holder is loaded, and is configured to apply a specific processing to the substrate held by the substrate holder in a state that the substrate holder is loaded in the reaction tube; an operation part configured to select a maintenance recipe for the reaction tube used for substrate processing, and a maintenance recipe for both of the reaction tube and the substrate holder loaded in the reaction tube; and a control part configured to execute the maintenance recipe selected by the operation part, when a maintenance timing of the reaction tube and / or the substrate holder arrives.

Owner:KOKUSA ELECTRIC CO LTD

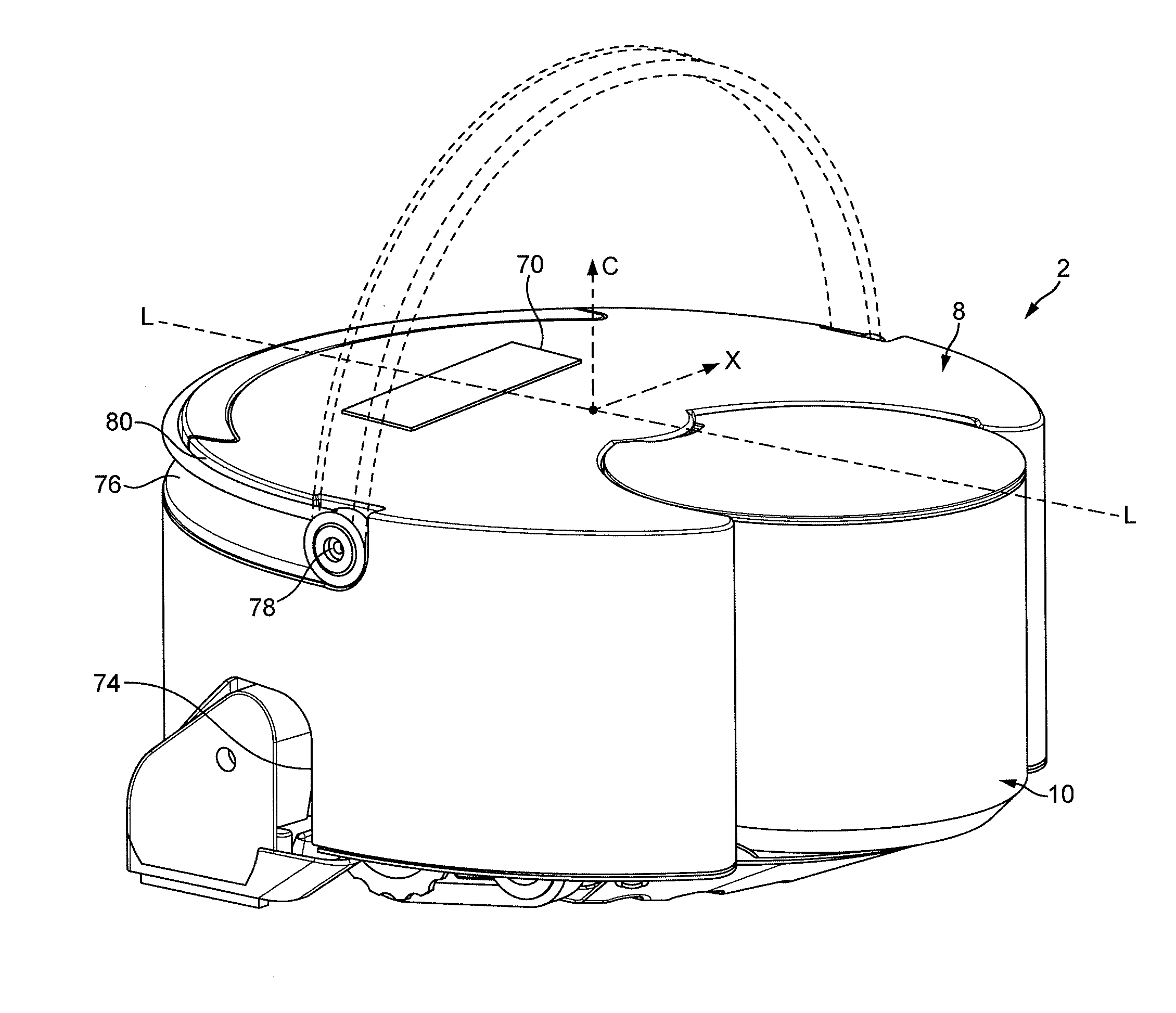

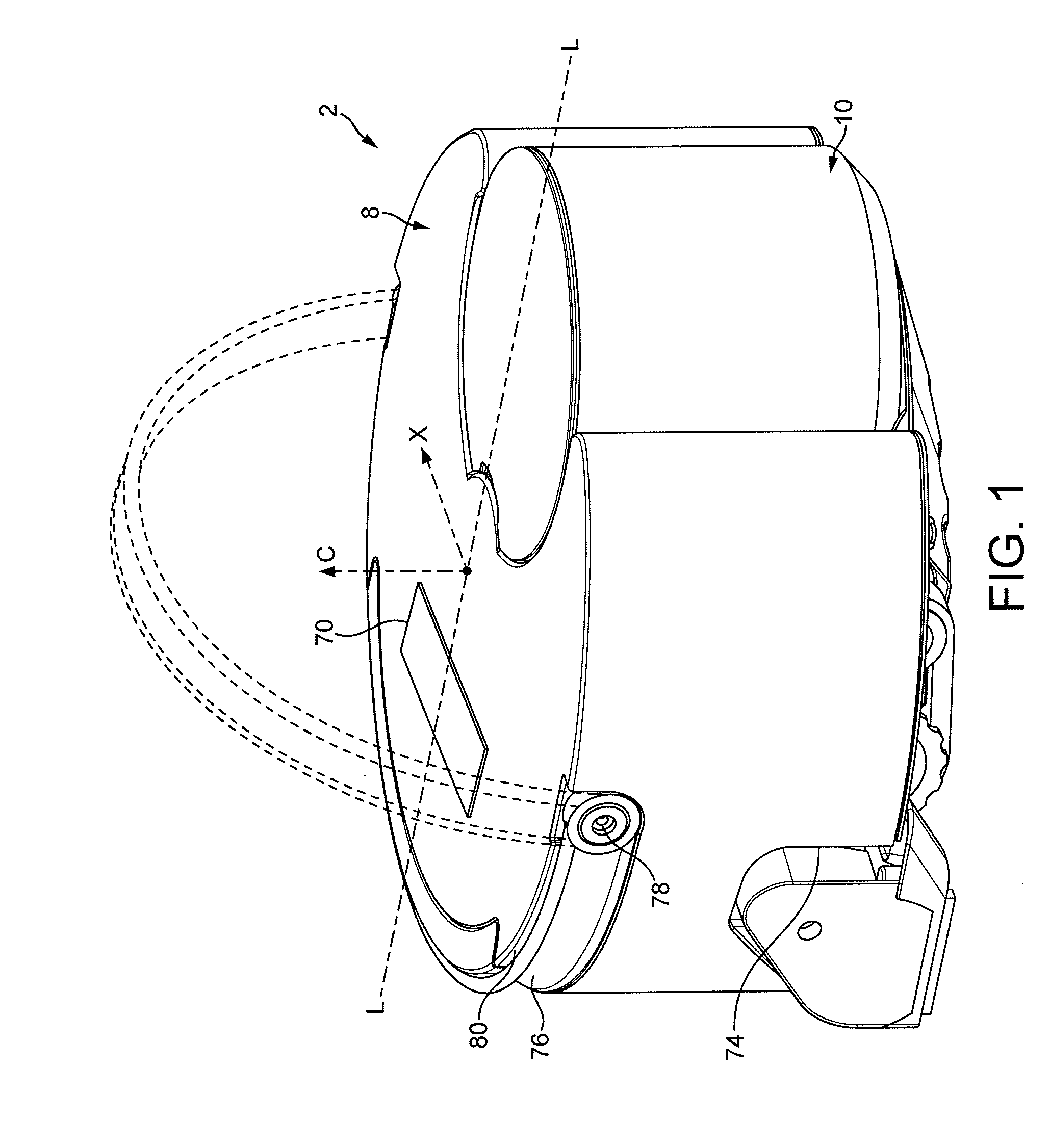

Autonomous surface treating appliance

ActiveUS20130061420A1Good body shapeCleaning machinesCleaning equipmentMarine engineeringSurface processing

An autonomous surface treating appliance comprising a main body defining an outer plan profile, and having a drive arrangement mounted inboard of the outer plan profile of the main body and configured to propel the appliance in a direction of movement across a surface to be cleaned, a surface treating assembly associated with the main body and carried transversely to the direction of movement, the surface treating assembly being generally elongate in form and having side edges extending substantially at a tangent to respective circular portions of the outer plan profile of the main body.

Owner:DYSON TECH LTD

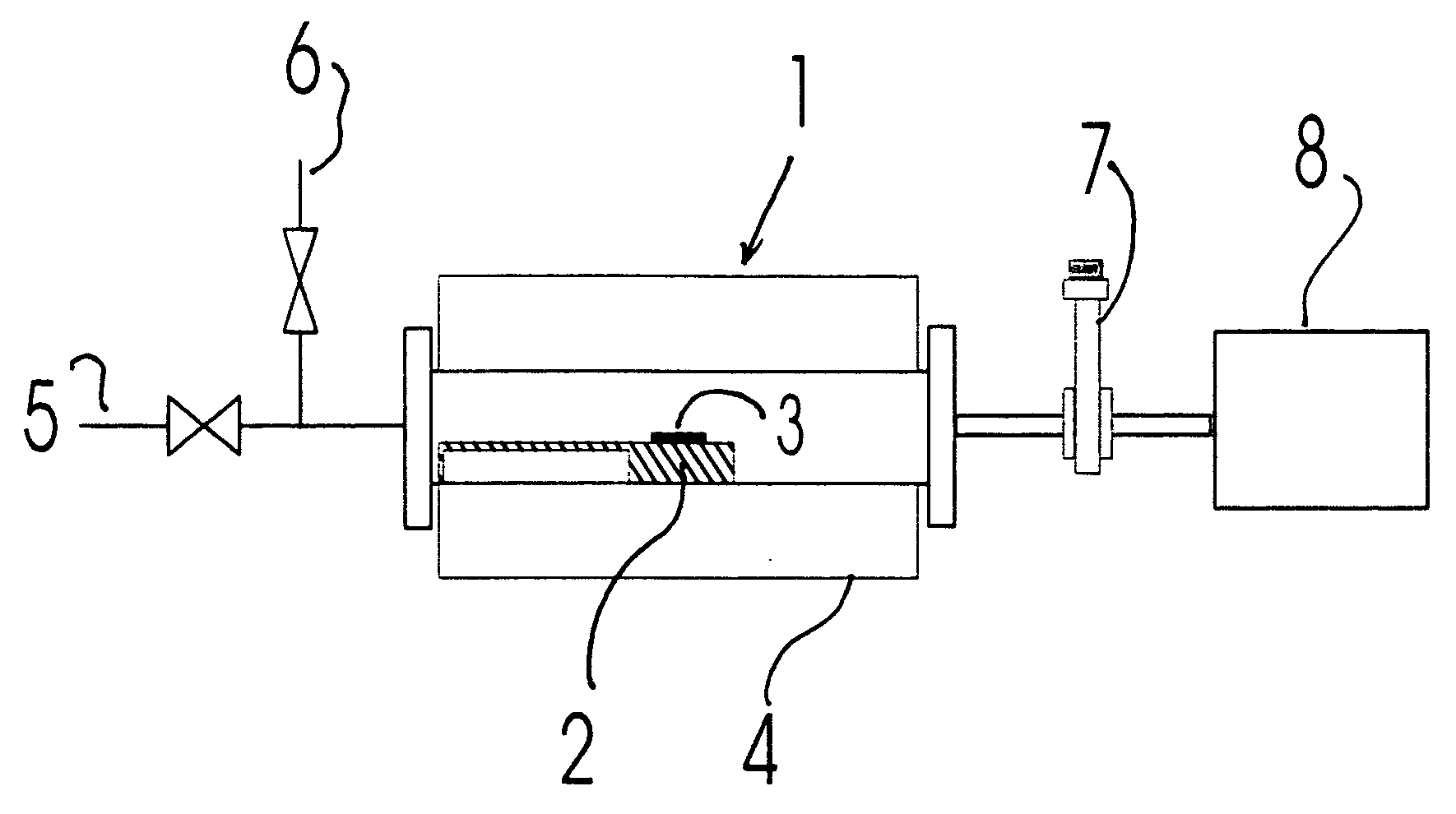

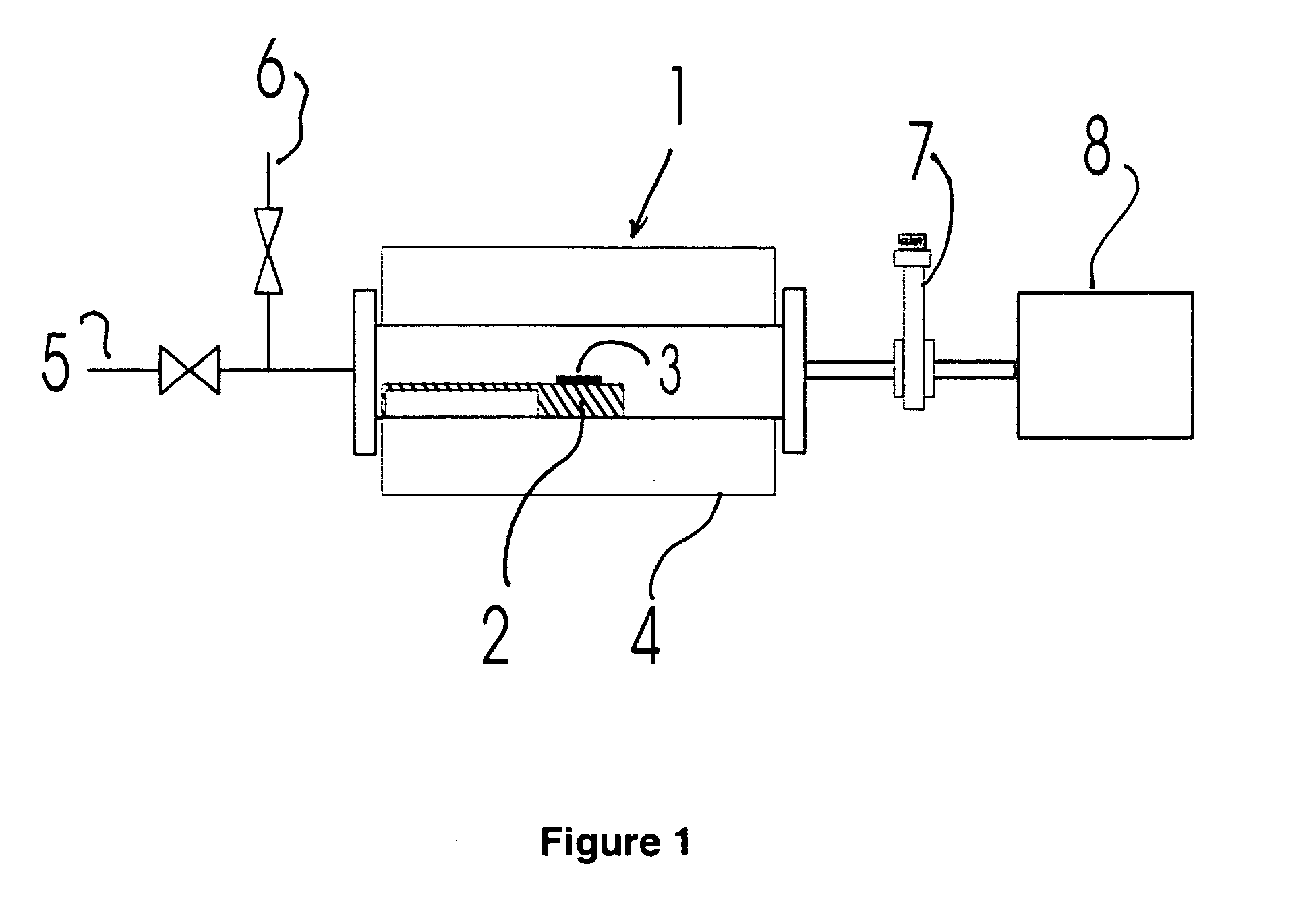

Thermal F2 etch process for cleaning CVD chambers

InactiveUS20080142046A1Lighting and heating apparatusSemiconductor/solid-state device manufacturingChemical reactionSemiconductor

A thermal process for cleaning equipment surfaces of undesired silicon nitride in semiconductor processing chamber with thermally activated source of pre-diluted fluorine is disclosed in the specification. The process comprising:(a)flowing pre-diluted fluorine in an inert gas through the chamber;(b)maintaining the chamber at an elevated temperature of 230° C. to 565° C. to thermally disassociate the fluorine;(c)cleaning undesired silicon nitride from the surfaces by chemical reaction of thermally disassociated fluorine in (b) with the undesired silicon nitride to form volatile reaction products;(d)removing the volatile reaction products from the chamber.

Owner:AIR PROD & CHEM INC

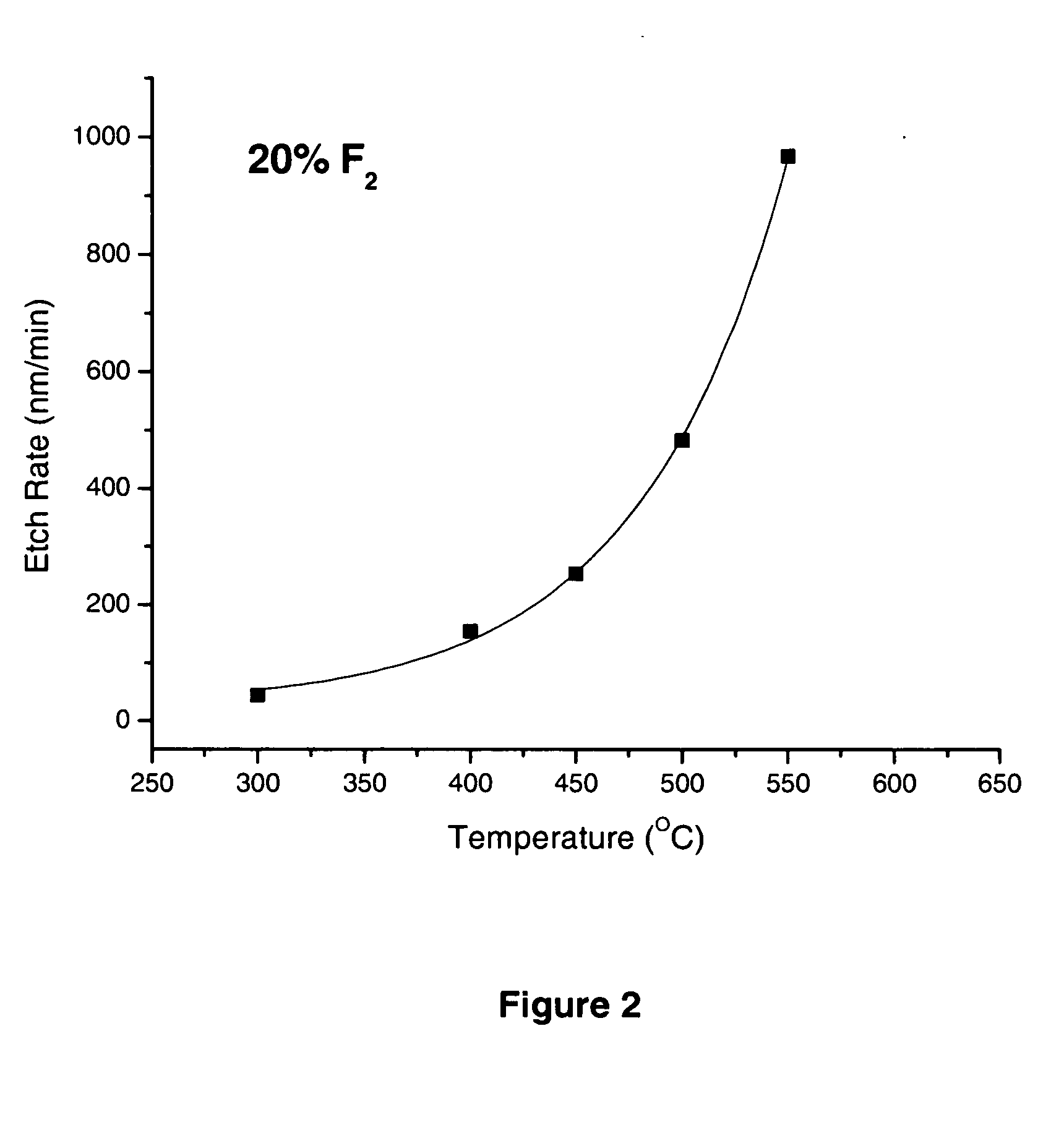

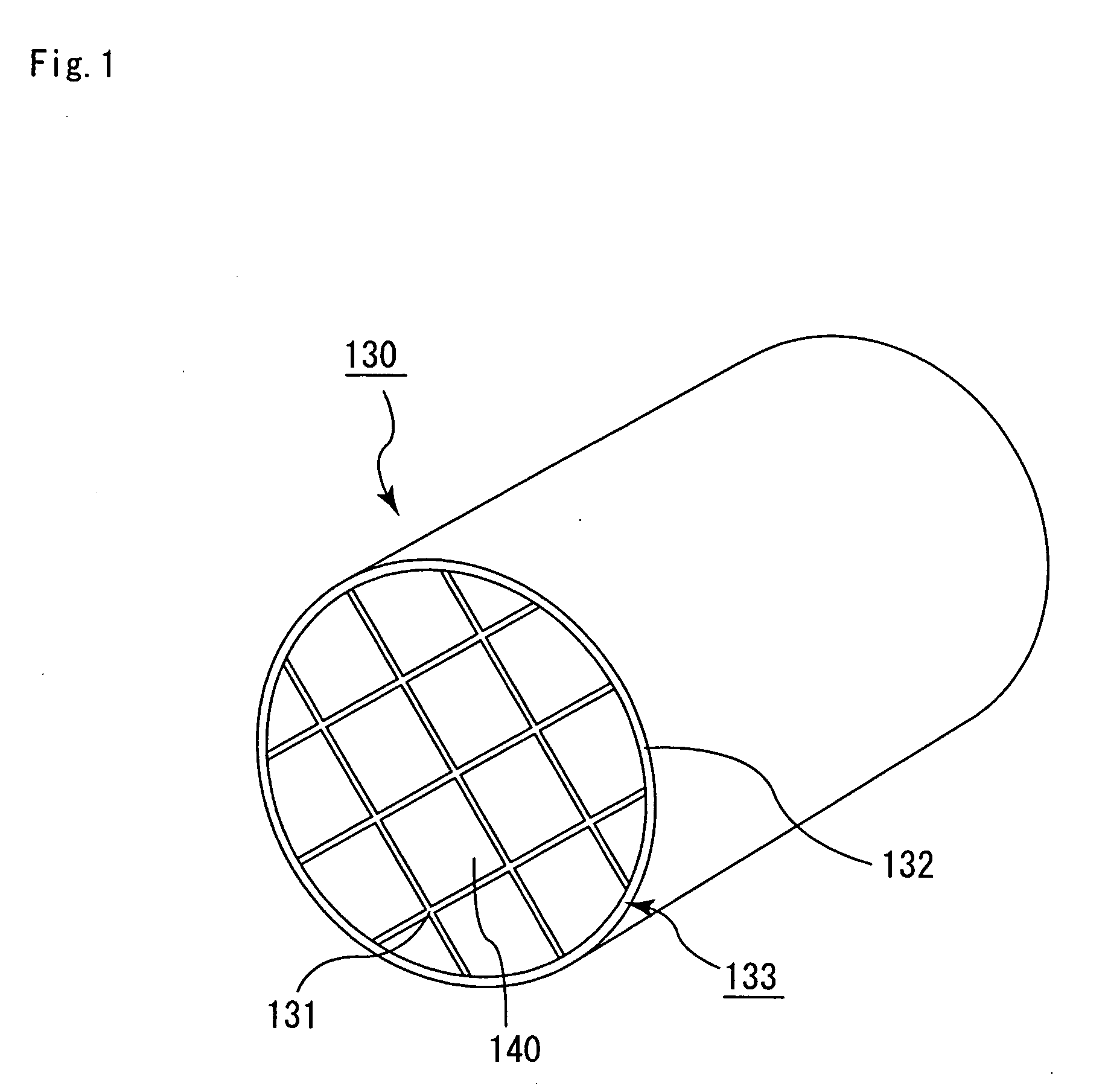

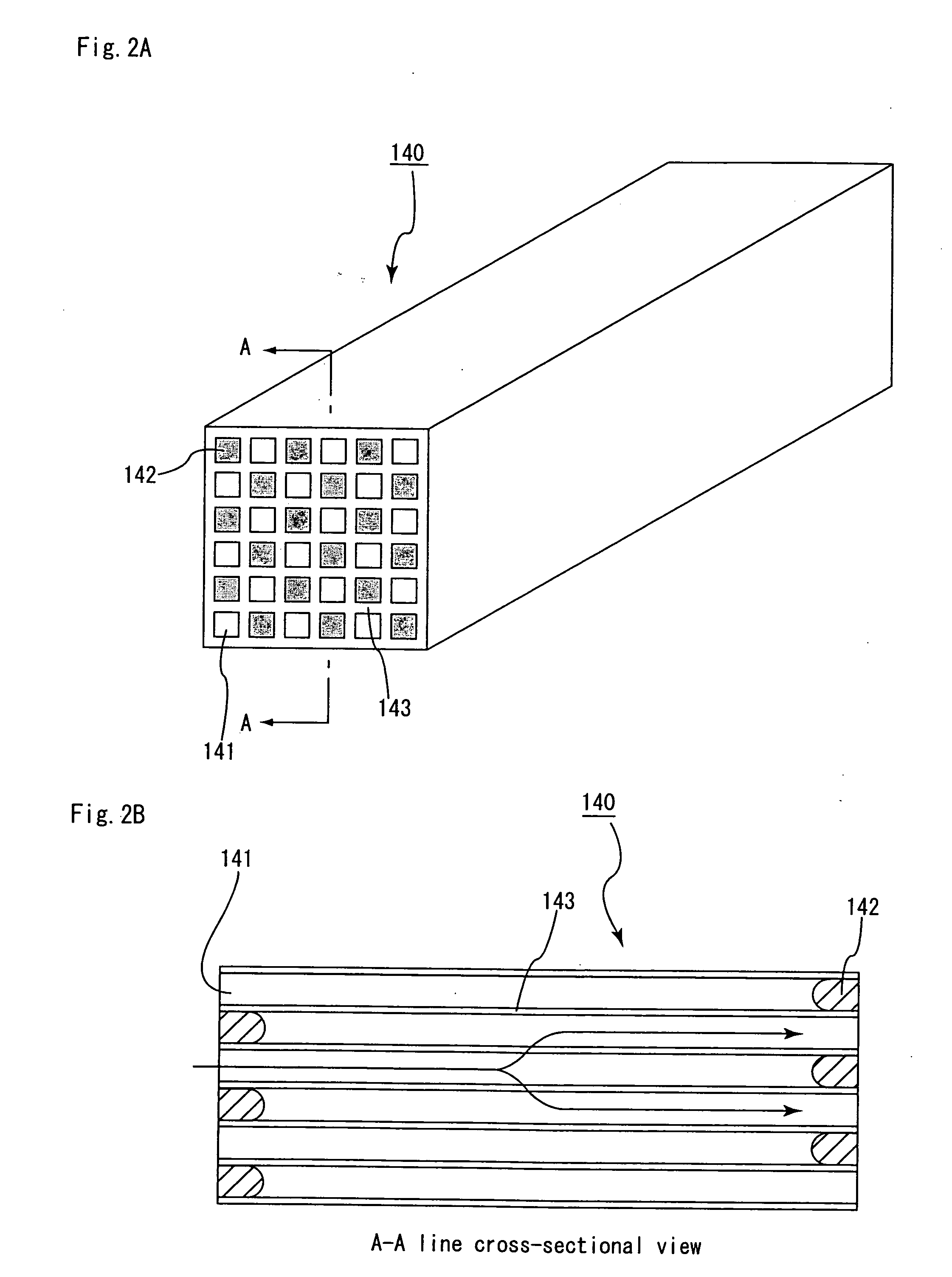

Degreasing jig, method for degreasing ceramic molded body, and method for manufacturing honeycomb structured body

A degreasing jig according to the present invention is a degreasing jig for degreasing of a ceramic molded body containing a ceramic powder, a binder, and a dispersion medium, comprising a bottom plate for placing the ceramic molded body thereon, and an air-permeable cover member provided in a manner to cover the ceramic molded body.

Owner:IBIDEN CO LTD

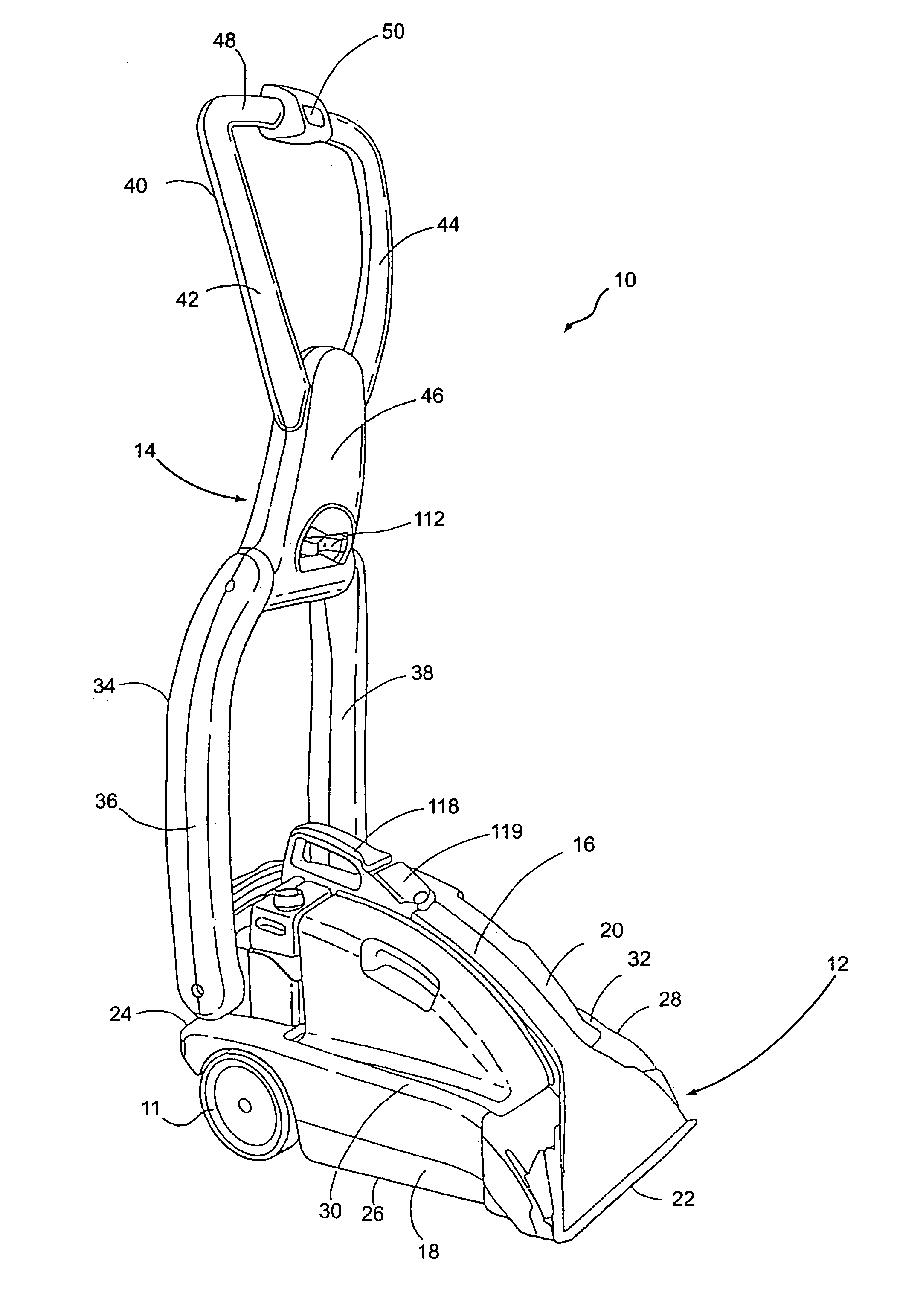

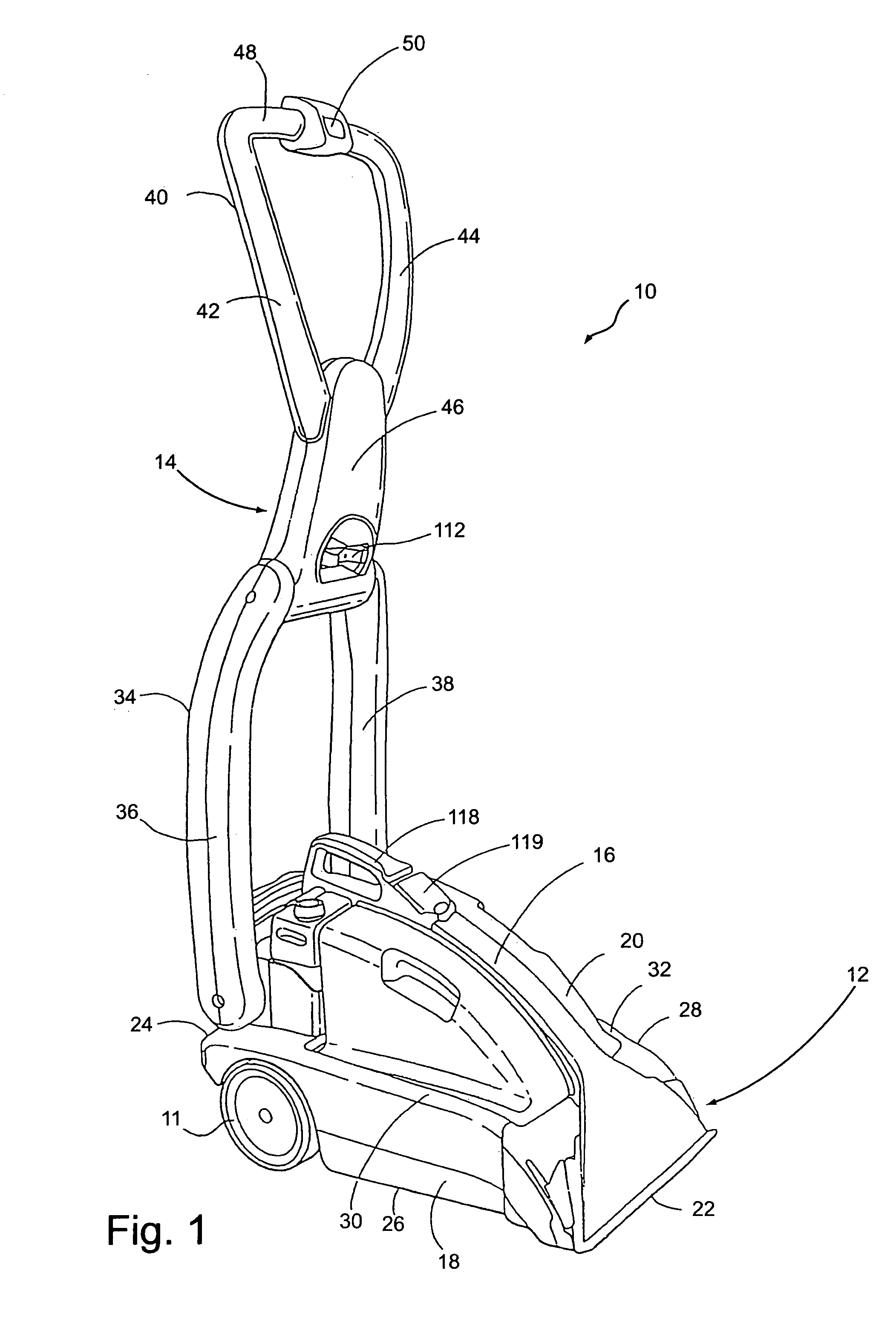

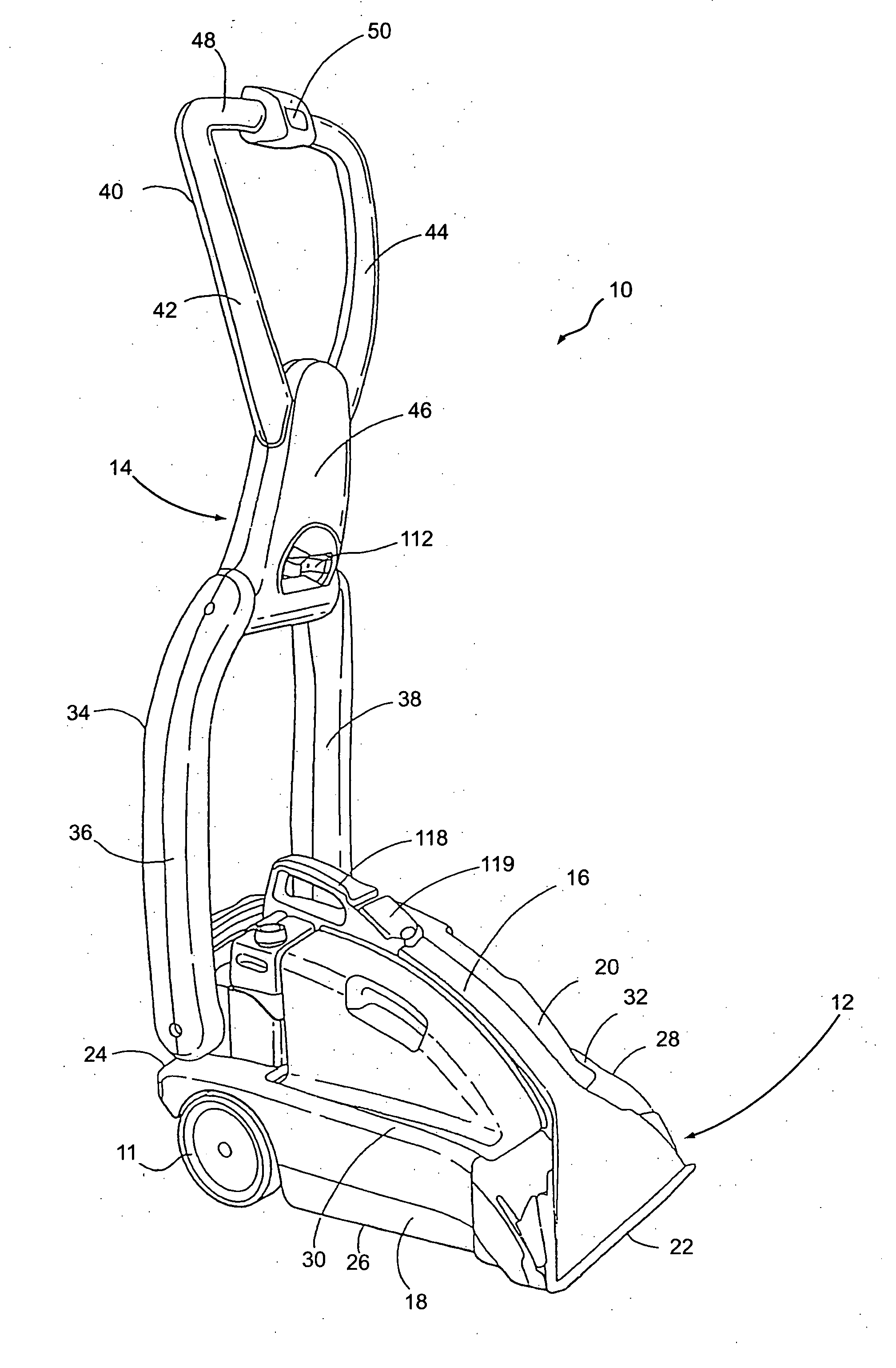

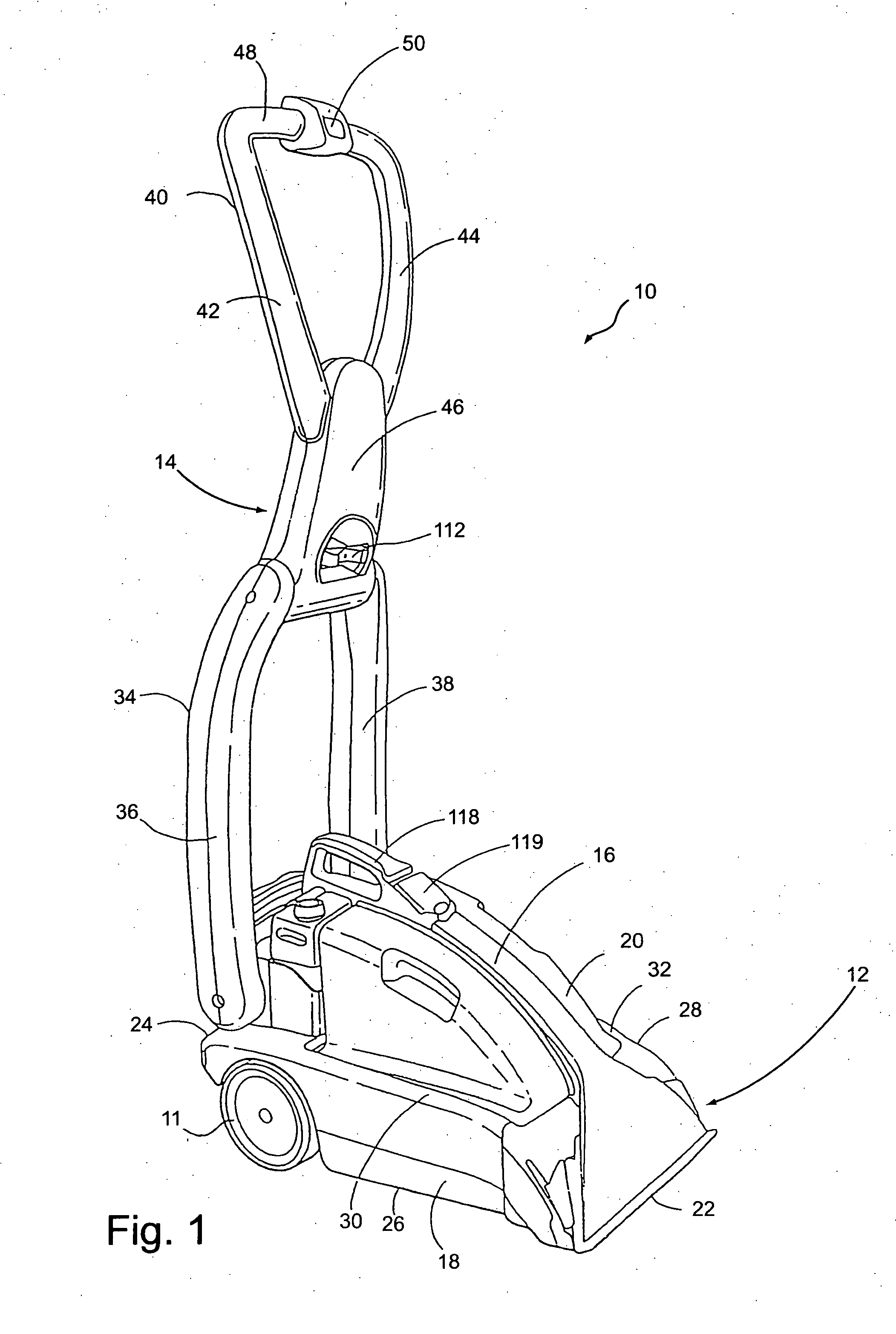

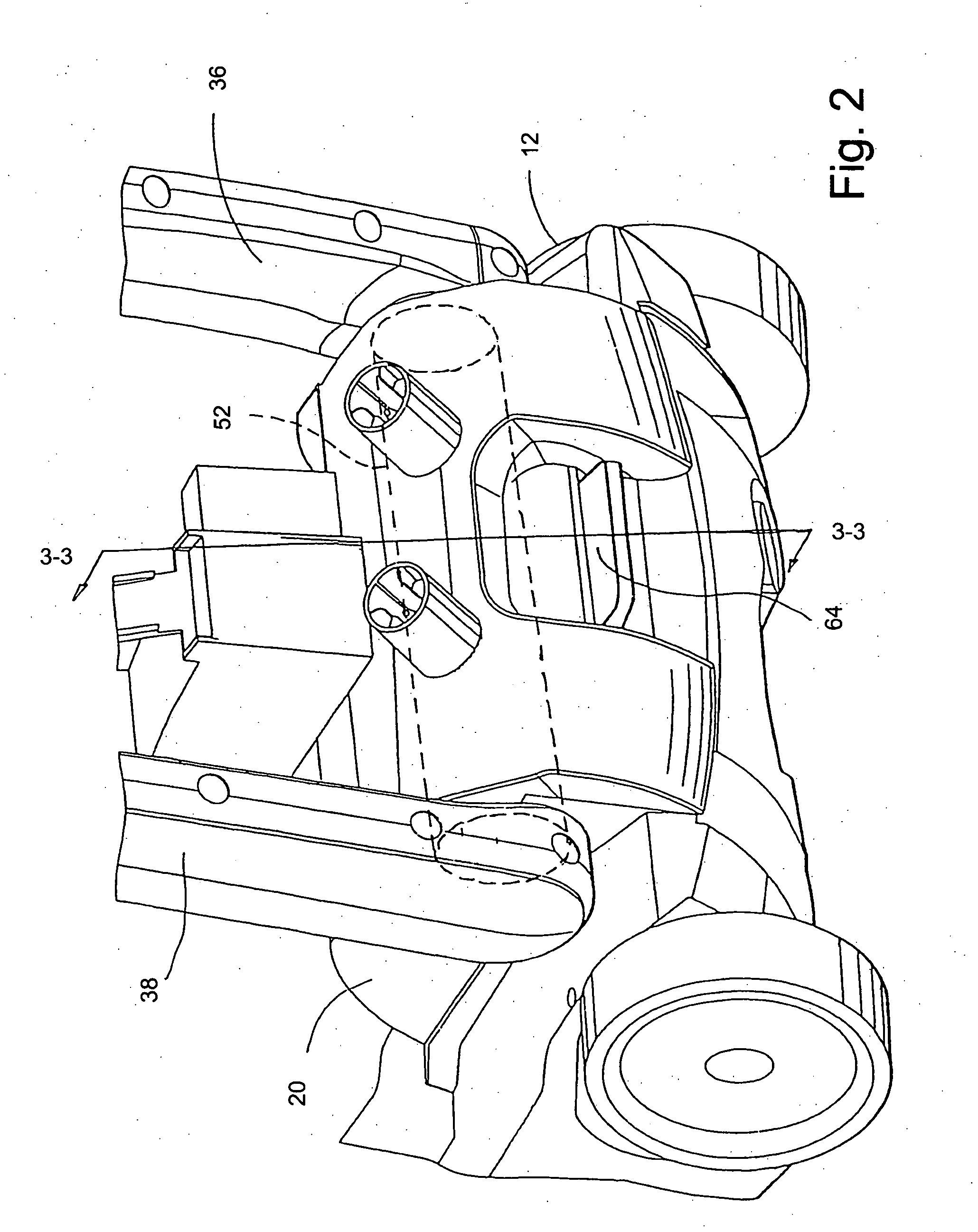

Wet extractor cleaning device fluid tank arrangement

A wet extraction floor cleaning device having a base assembly adapted for movement on a surface being cleaned, an operating handle pivotally attached to the base assembly, a supply tank having a supply tank outlet, and a recovery tank having a recovery tank inlet and a recovery tank outlet. The base assembly has an inlet nozzle that extends from an inlet slit proximal the surface being cleaned to a nozzle outlet. The device further includes a fluid deposition assembly that can be selectively placed in fluid communication with the supply tank outlet, a vacuum source, and first and second external pockets. The supply and recovery tanks are adapted to be selectively placed in the first and second external pockets, thereby placing the supply tank outlet in fluid communication with the fluid deposition system, the recovery tank inlet in fluid communication with the nozzle outlet, and the recovery tank outlet in fluid communication with the vacuum source inlet.

Owner:ELECTROLUX HOME CARE PRODS NORTH AMERICA A DIV OF ELECTROLUX HOME CARE PRODS

Methods and compositions for paint removal

InactiveUS20060089281A1Chemical paints/ink removersCleaning processes and apparatusPlasticizerSolvent

The present invention relates to compositions and their use for removing coatings from a substrate. The present invention is directed to a composition comprising (a) surfactants, (b) a sequestrant, and (c) a plasticizer / solvent. The composition may also contain (d) a hydrolyzing agent, e.g., a strong base compound and other additives. The composition of the present invention is free of chlorinated solvents, environmentally safe and user-friendly. In one embodiment, the composition further comprises a hydrolyzing agent present in an amount sufficient to reduce at least one of mechanical strength and adhesion between the coating and the substrate. Another embodiment of the invention is a method for removing paint or a coating from a substrate comprising applying a paint or coating removing effective amount of a composition comprising the compositions described herein to the substrate. Yet another embodiment of the invention is a method for cleaning a substrate comprising applying a cleaning effective amount of the composition of the present invention to the substrate. In one particular embodiment of the present invention, an immersion method for the removal of cured and uncured paint and coatings from ferrous metals is provided.

Owner:APPLIED CHEM TECH

Supercritical fluid cleaning of semiconductor substrates

InactiveUS20030125225A1Inorganic/elemental detergent compounding agentsSurface-active detergent compositionsChemical reactionSURFACTANT BLEND

Chemical formulations and methods for removing unwanted material, such as unexposed photoresist, metal oxides, CMP residue, and the like, from semiconductor wafers or other substrates. The formulations utilize a supercritical fluid-based cleaning composition, which may further include (I) co-solvent(s), (II) surfactant(s), (III) chelating agent(s), and / or (IV) chemical reactant(s).

Owner:ADVANCED TECH MATERIALS INC

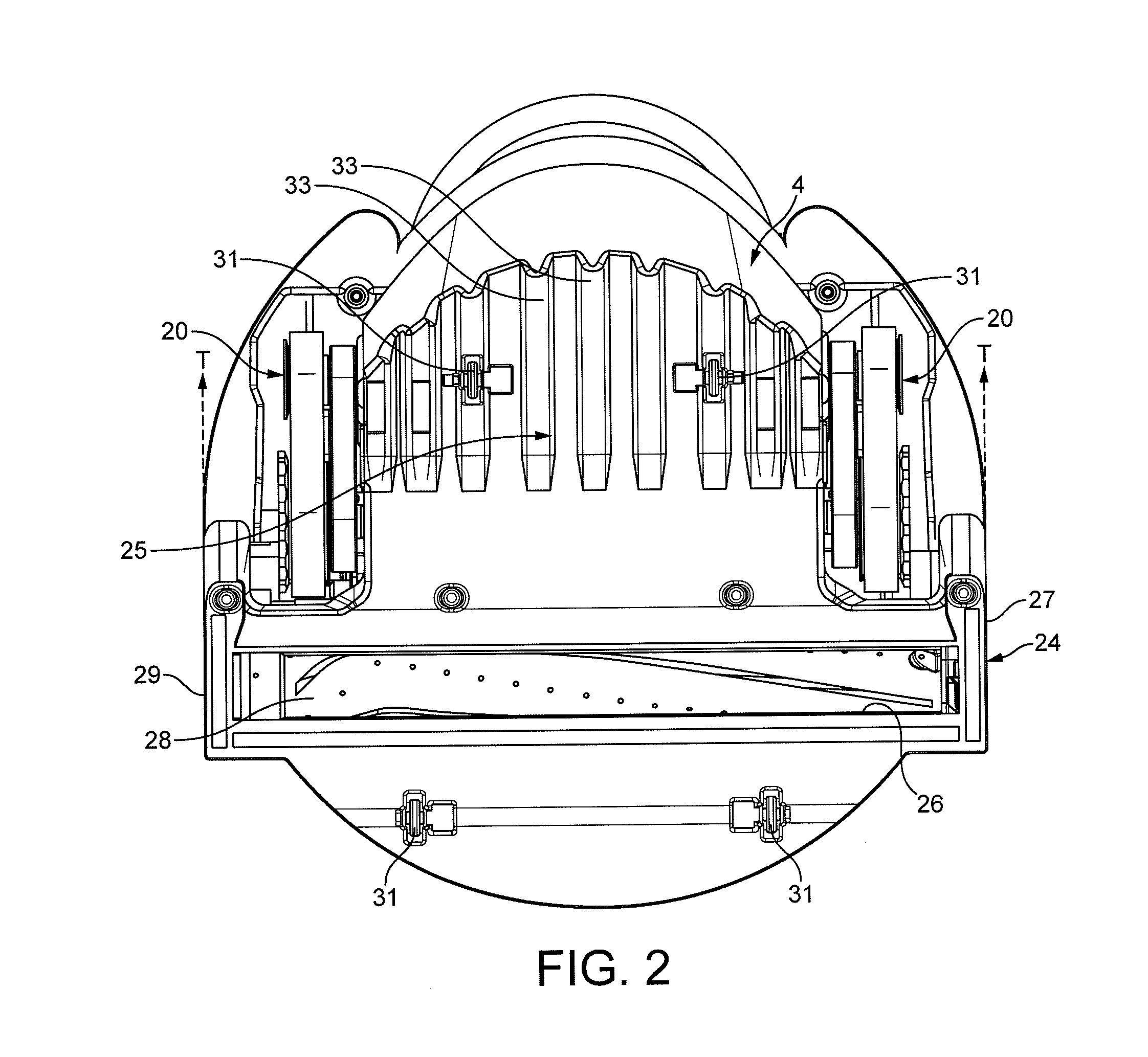

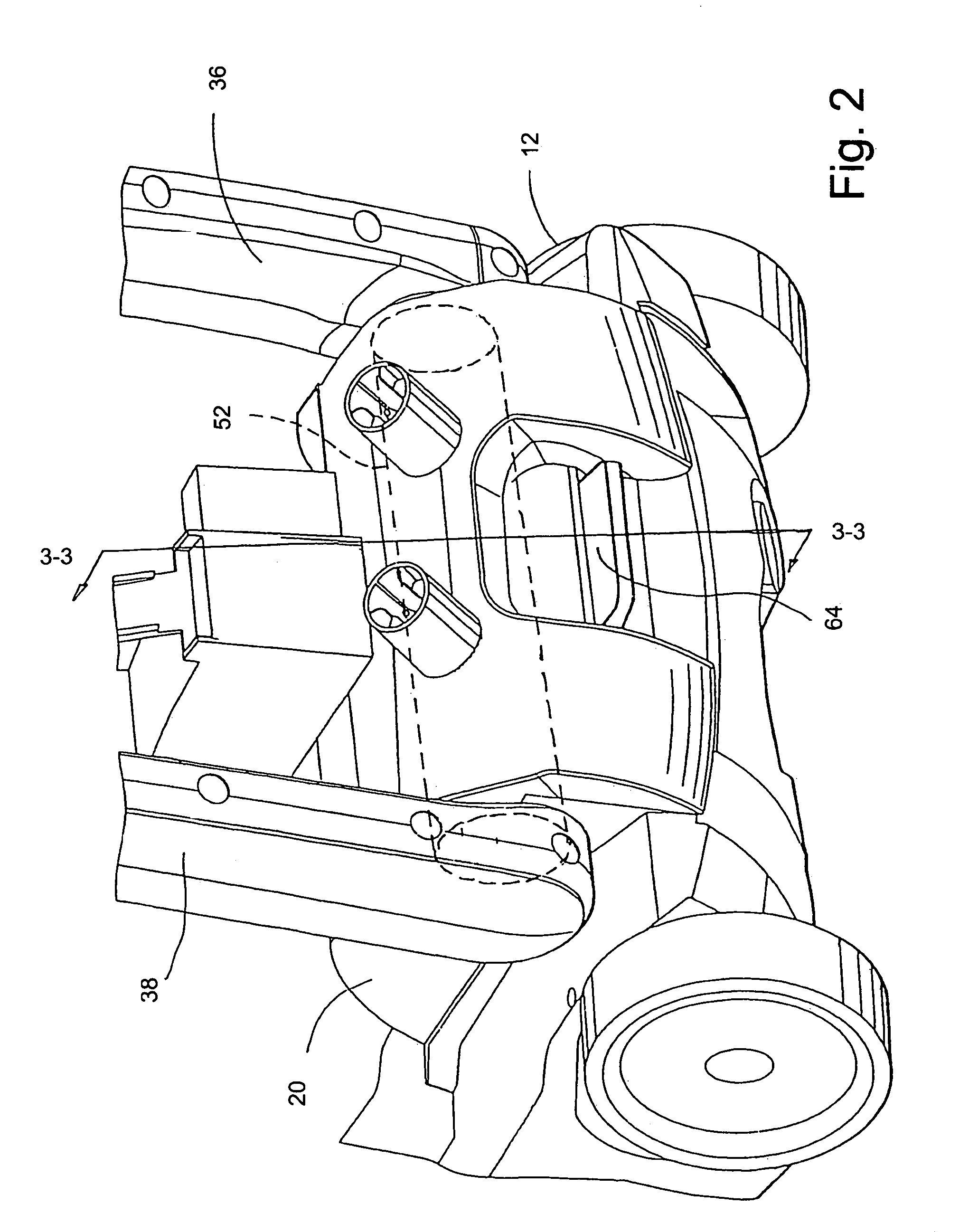

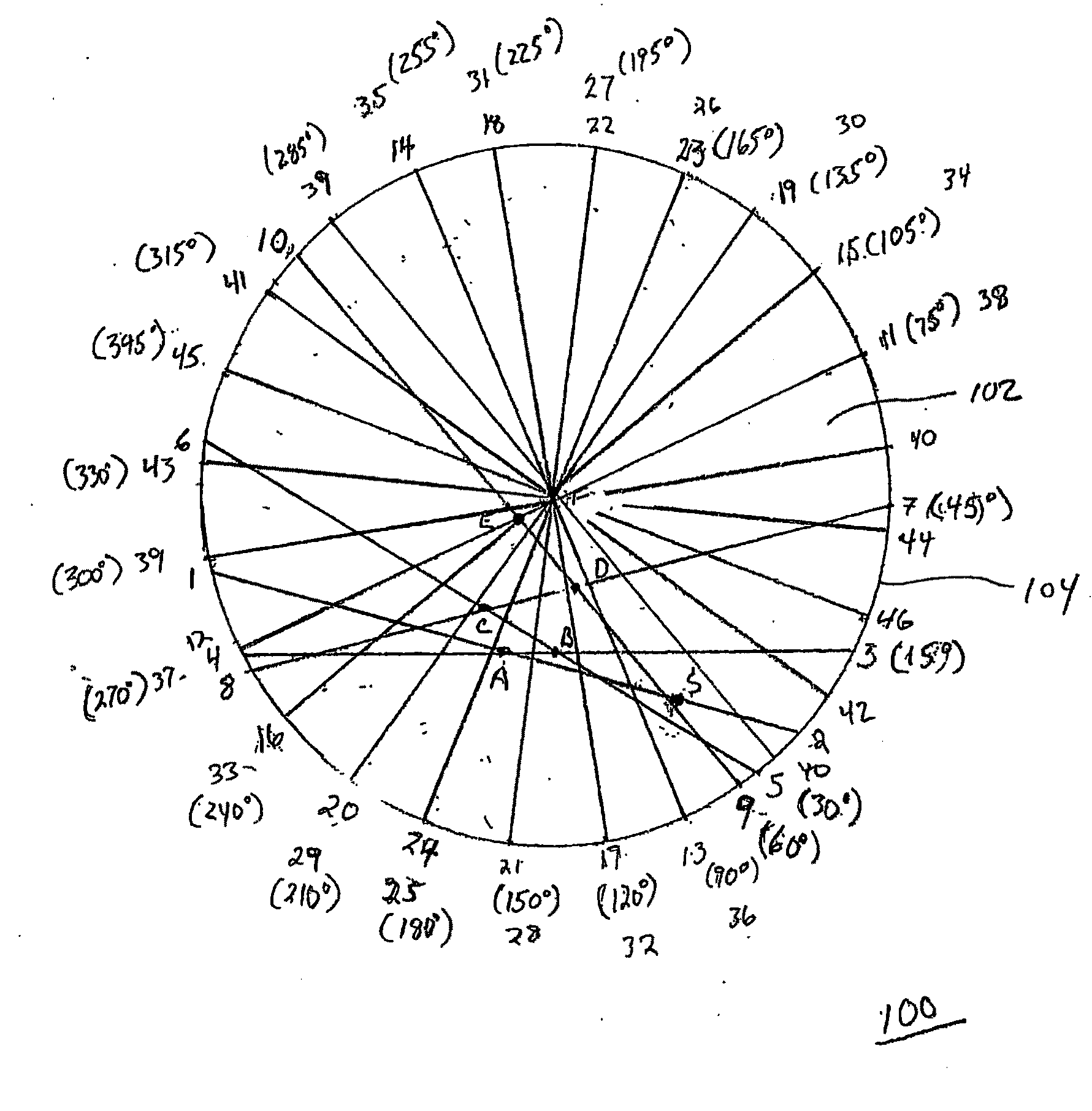

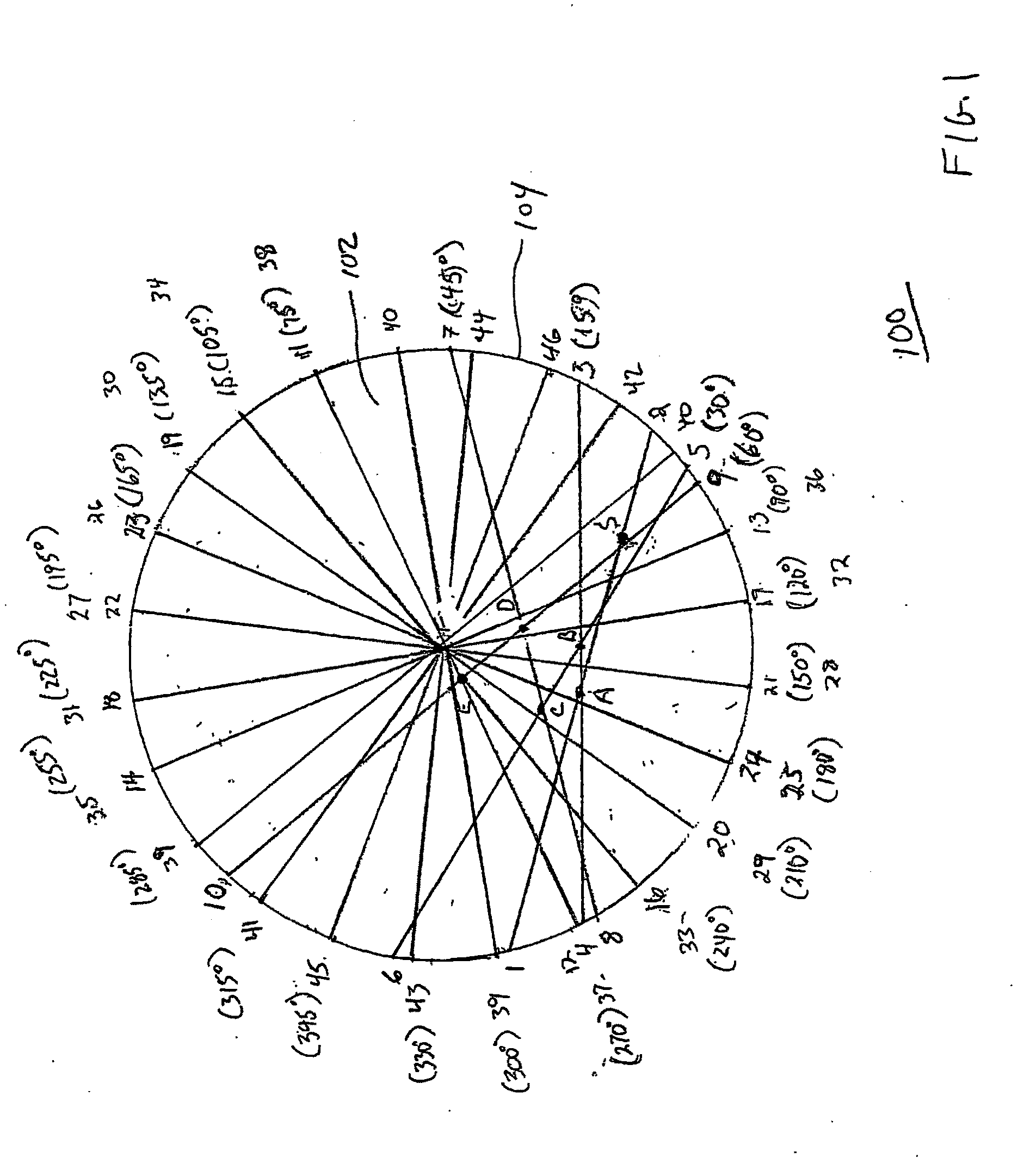

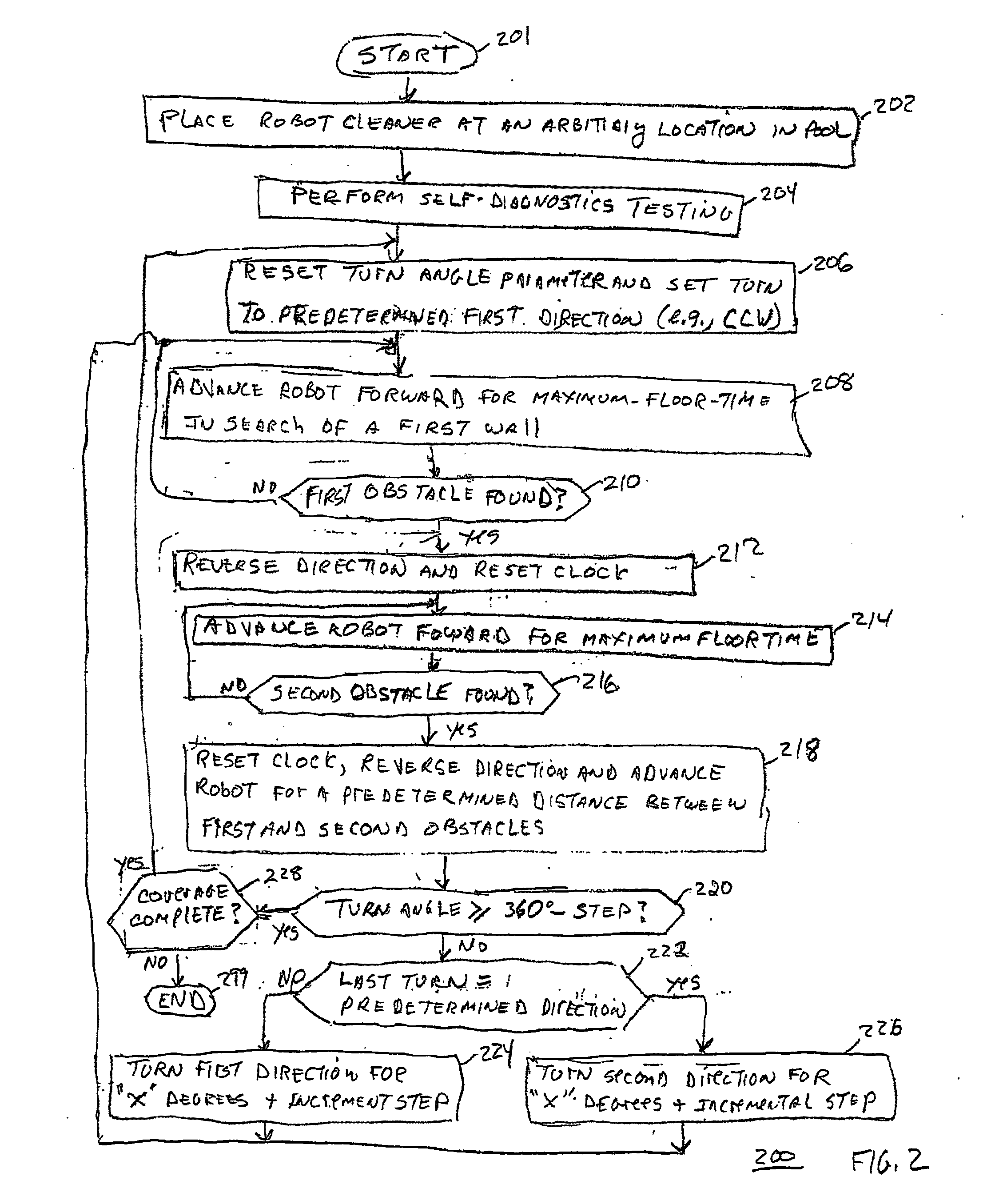

Customized Programmable Pool Cleaner Method and Apparatus

InactiveUS20090301522A1Eliminates and minimizes twistingCleaning processes and apparatusSwimming poolsCleaning methodsControl theory

A method and apparatus for cleaning the surfaces of a pool by a programmed robotic pool cleaner initially set at an arbitrary position in the poll. The pool can be of any standard or non-standard shapes, and the surfaced with any conventional materials. The robot is advanced until it encounters a first obstacle (1), then reverses direction and advances along the same path to an opposing second obstacle (2) to form a first path between the opposing first (1) and second (2) obstacles. At the second obstacle (2), the robot reverses and advances to a predetermined point (A) between the opposing obstacles along said first path. At the predetermined point (A), the robot stops and turns in a first direction at a predetermined angle of turn, and repeats the above steps along additional paths until the sum of the predetermined angle of turns generates a quantity of paths sufficient to substantially clean the pool surfaces.

Owner:AQUATRON

Floor cleaning device

A wet extraction floor cleaning device having a base assembly adapted for movement on a surface being cleaned, an operating handle pivotally attached to the base assembly, a supply tank having a supply tank outlet, and a recovery tank having a recovery tank inlet and a recovery tank outlet. The base assembly has an inlet nozzle that extends from an inlet slit proximal the surface being cleaned to a nozzle outlet. The device further includes a fluid deposition assembly that can be selectively placed in fluid communication with the supply tank outlet, a vacuum source, and first and second external pockets. The supply and recovery tanks are adapted to be selectively placed in the first and second external pockets, thereby placing the supply tank outlet in fluid communication with the fluid deposition system, the recovery tank inlet in fluid communication with the nozzle outlet, and the recovery tank outlet in fluid communication with the vacuum source inlet.

Owner:ELECTROLUX HOME CARE PRODS NORTH AMERICA A DIV OF ELECTROLUX HOME CARE PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com