Patents

Literature

639results about "Exhaust-air diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

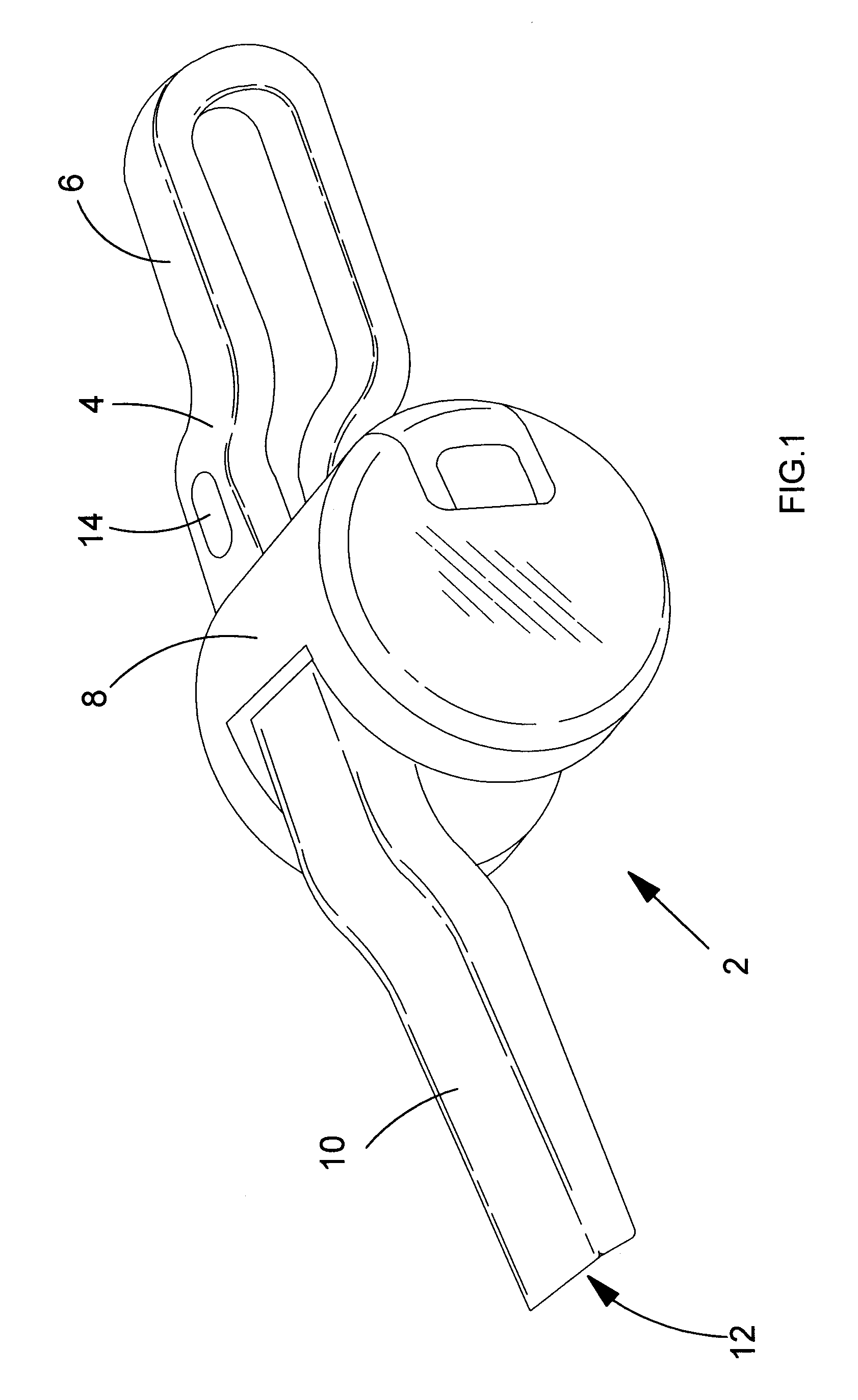

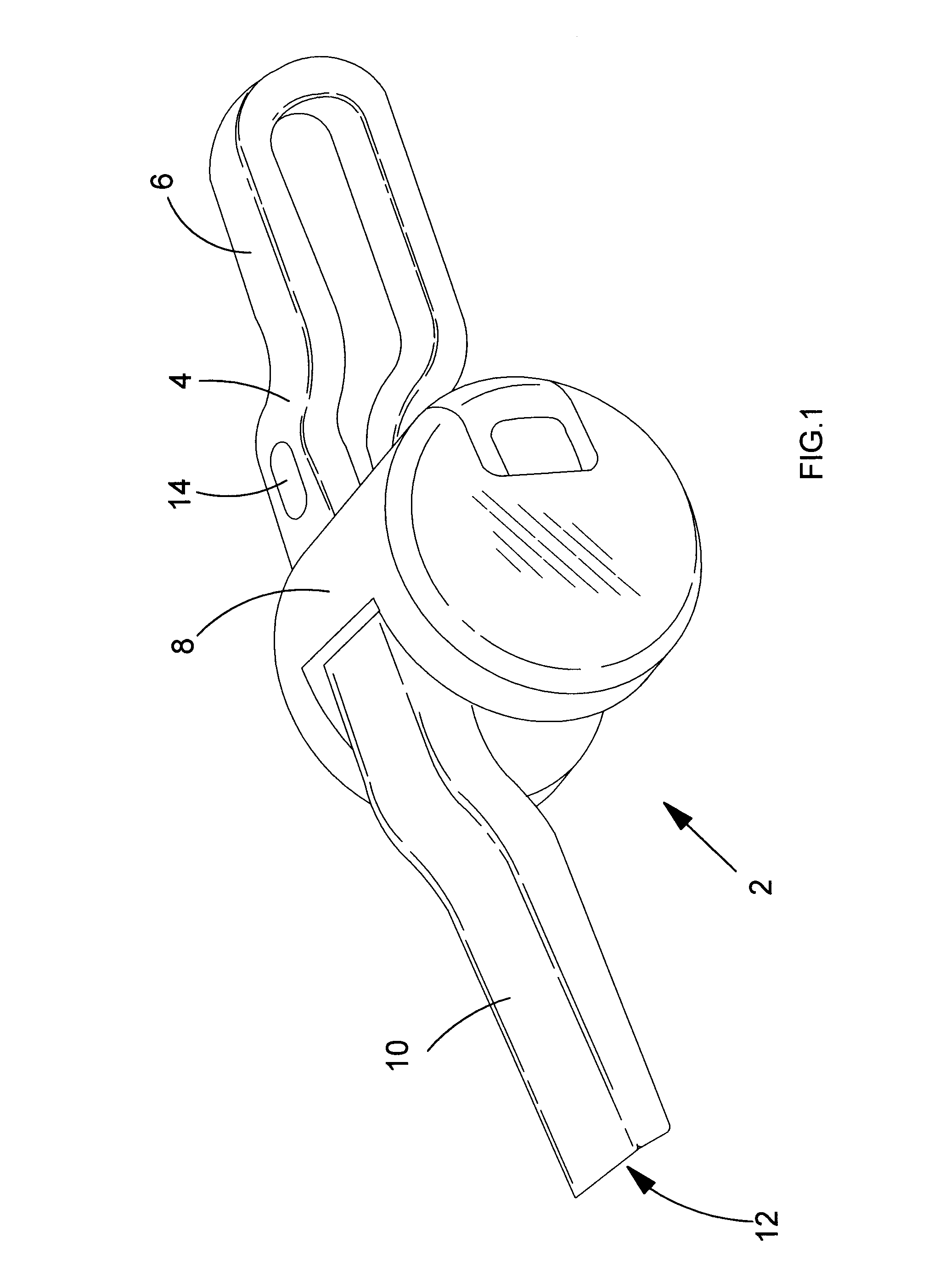

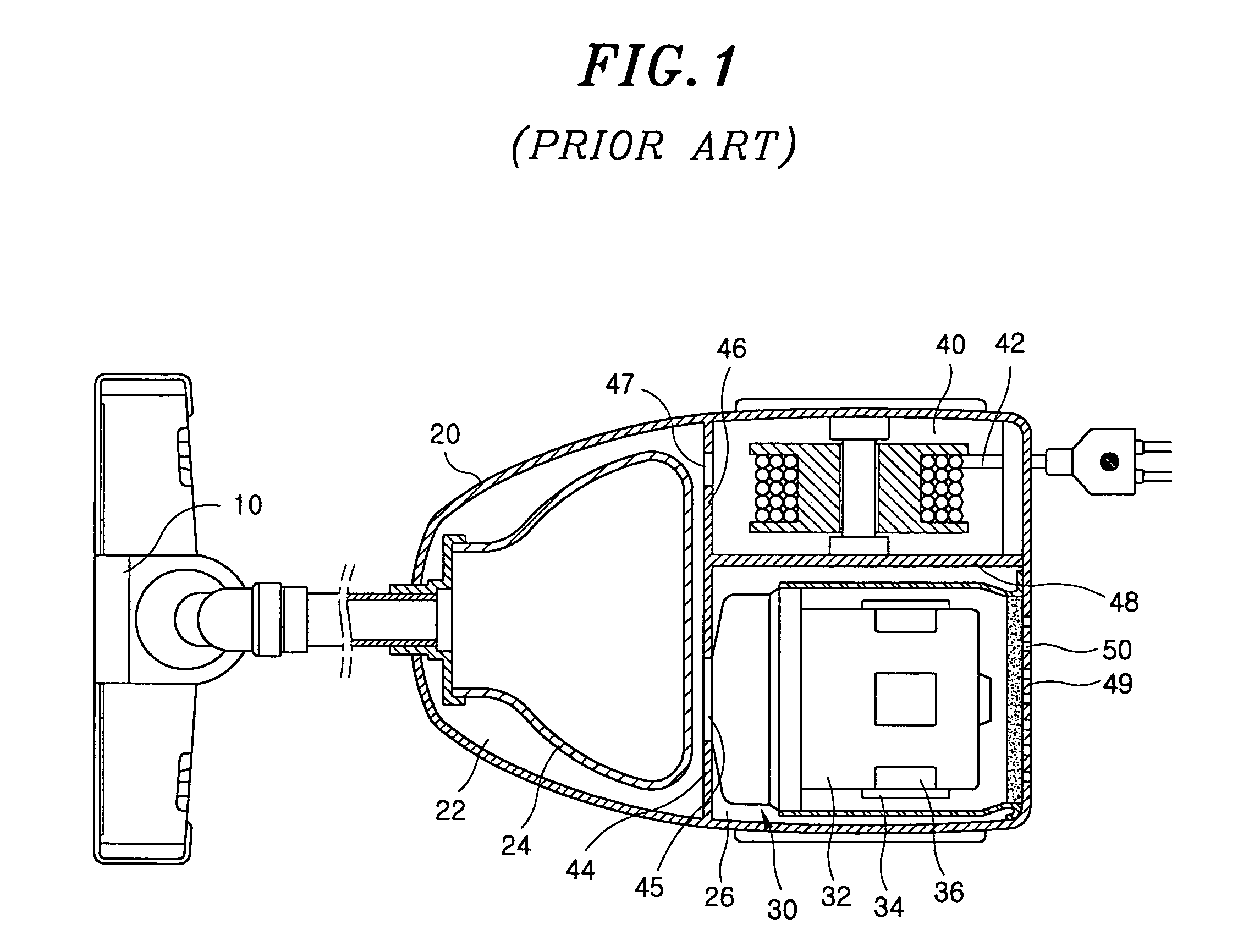

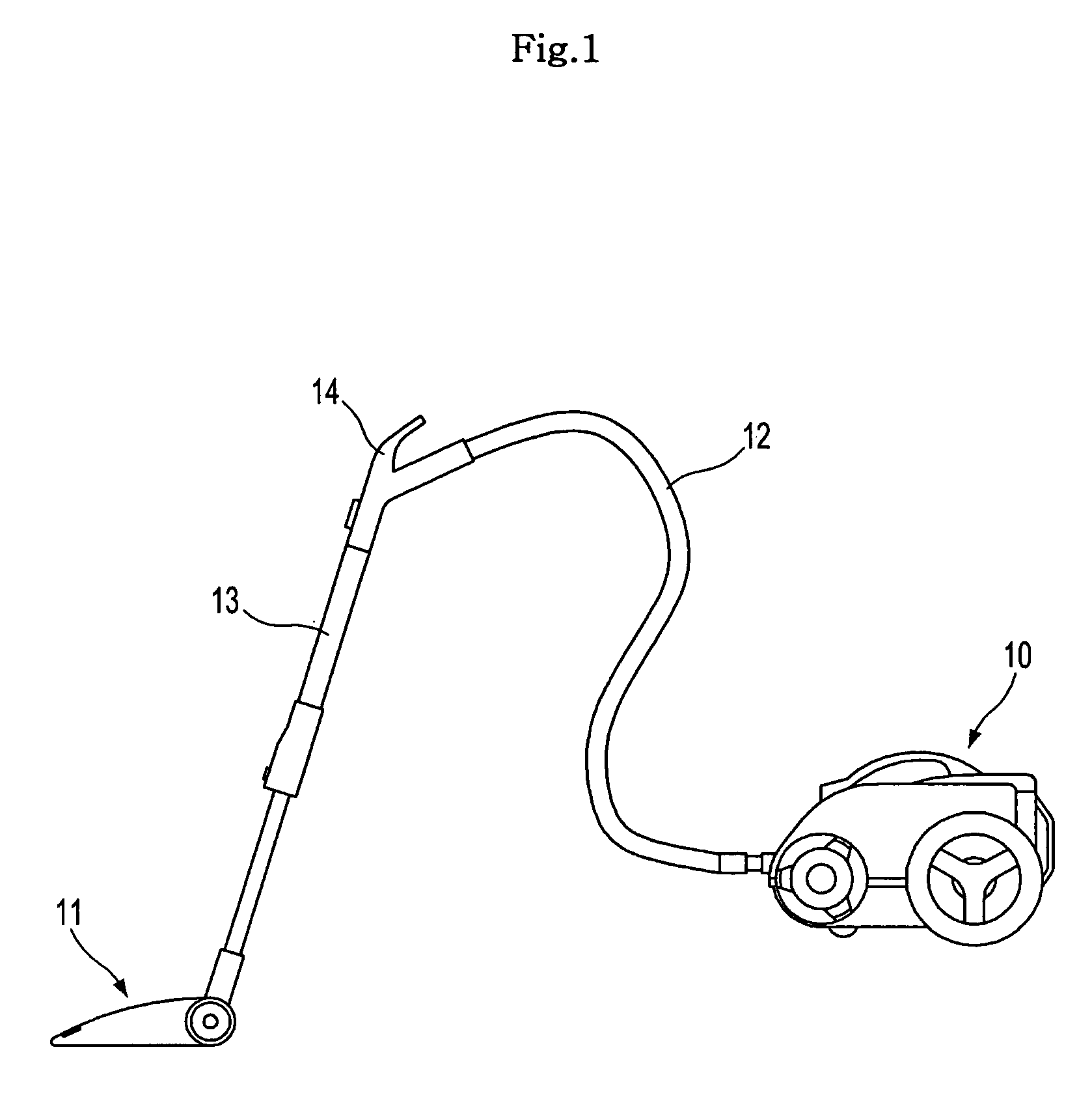

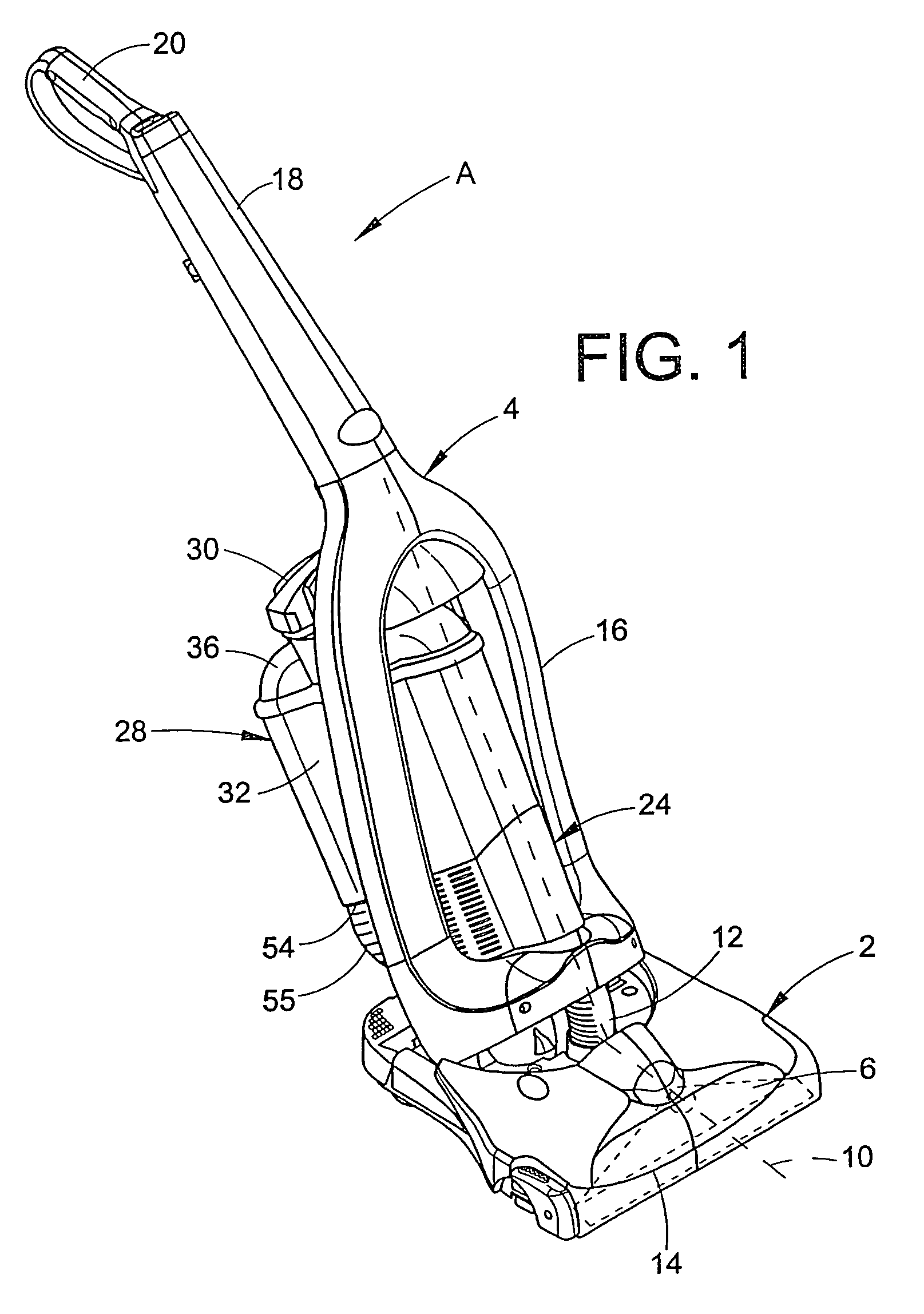

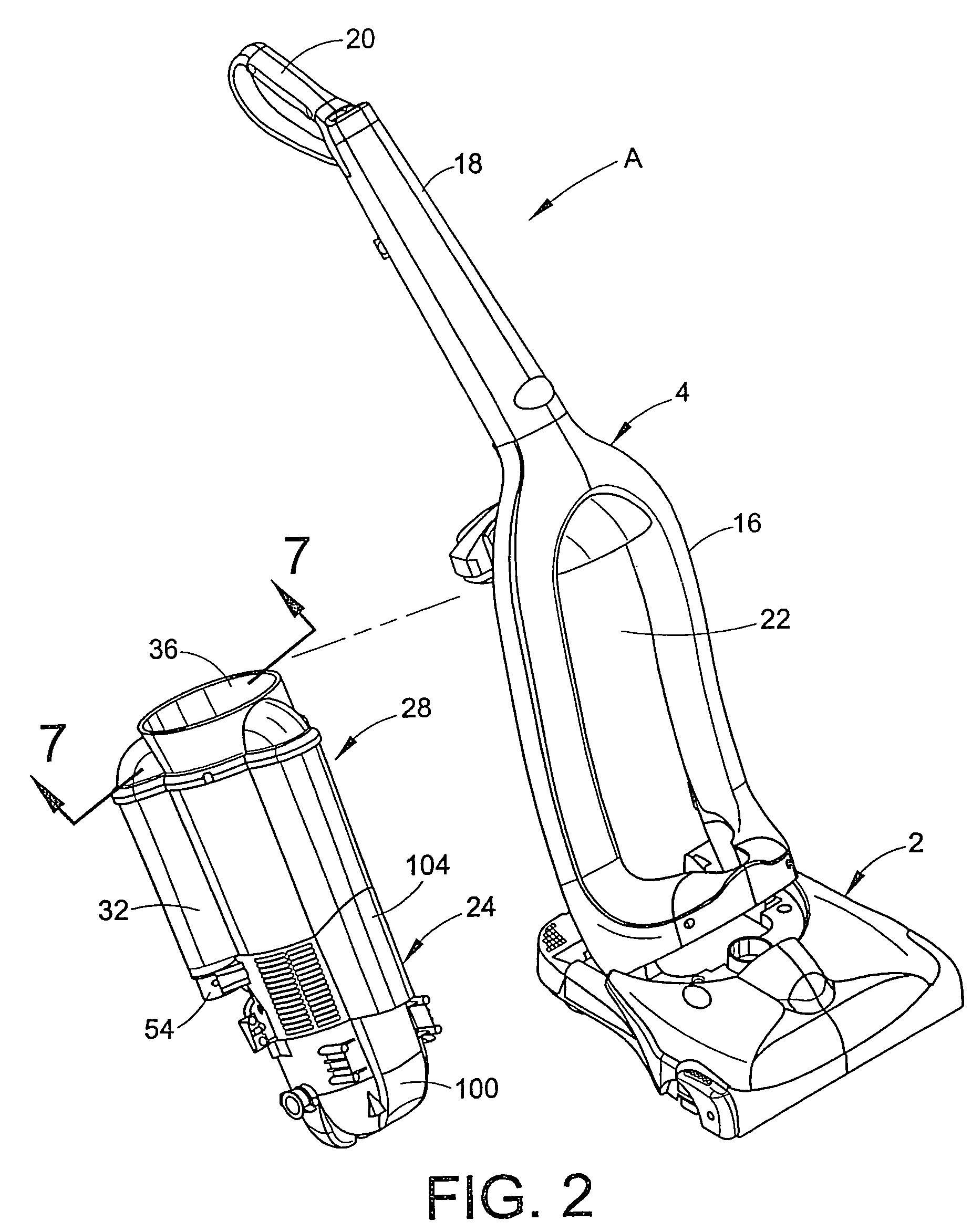

Air Flow Losses in a Vacuum Cleaners

A vacuum cleaner having a handle with a handle air passage, a base attached to a first end of the handle by an articulating joint and having a base inlet positioned to face a surface to be cleaned, a base air passage extending from the base inlet and past the articulated joint by a flexible hose and to the handle air passage, a dirt collection assembly associated with the handle and in fluid communication with the handle air passage, a fan associated with the handle and in fluid communication with the handle air passage, and a motor associated with the handle and adapted to drive the fan to thereby generate an airflow through the base inlet, flexible hose, handle air passage, and dirt collection assembly. The flexible hose has a generally rectangular cross-section along a substantial portion thereof.

Owner:AB ELECTROLUX

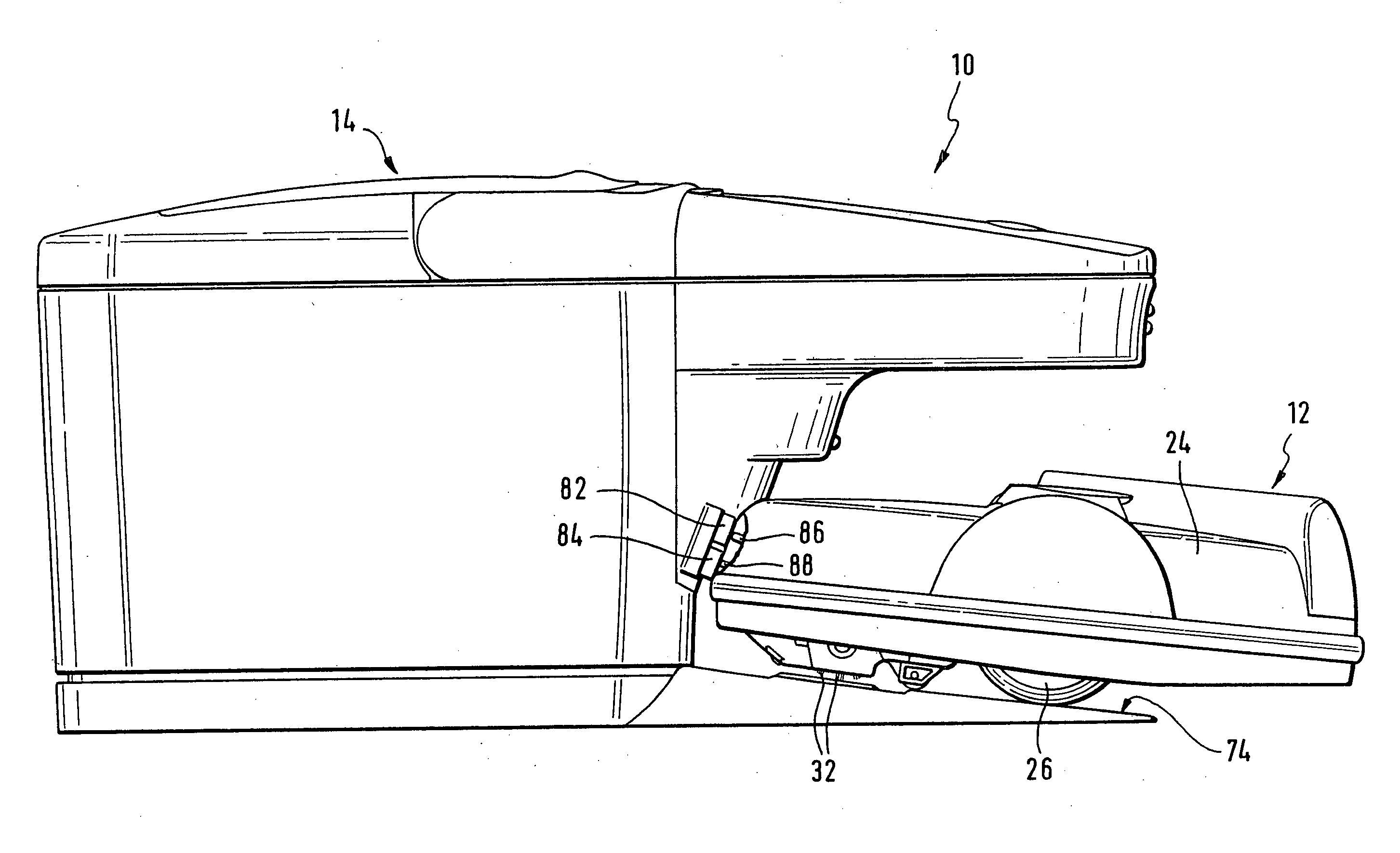

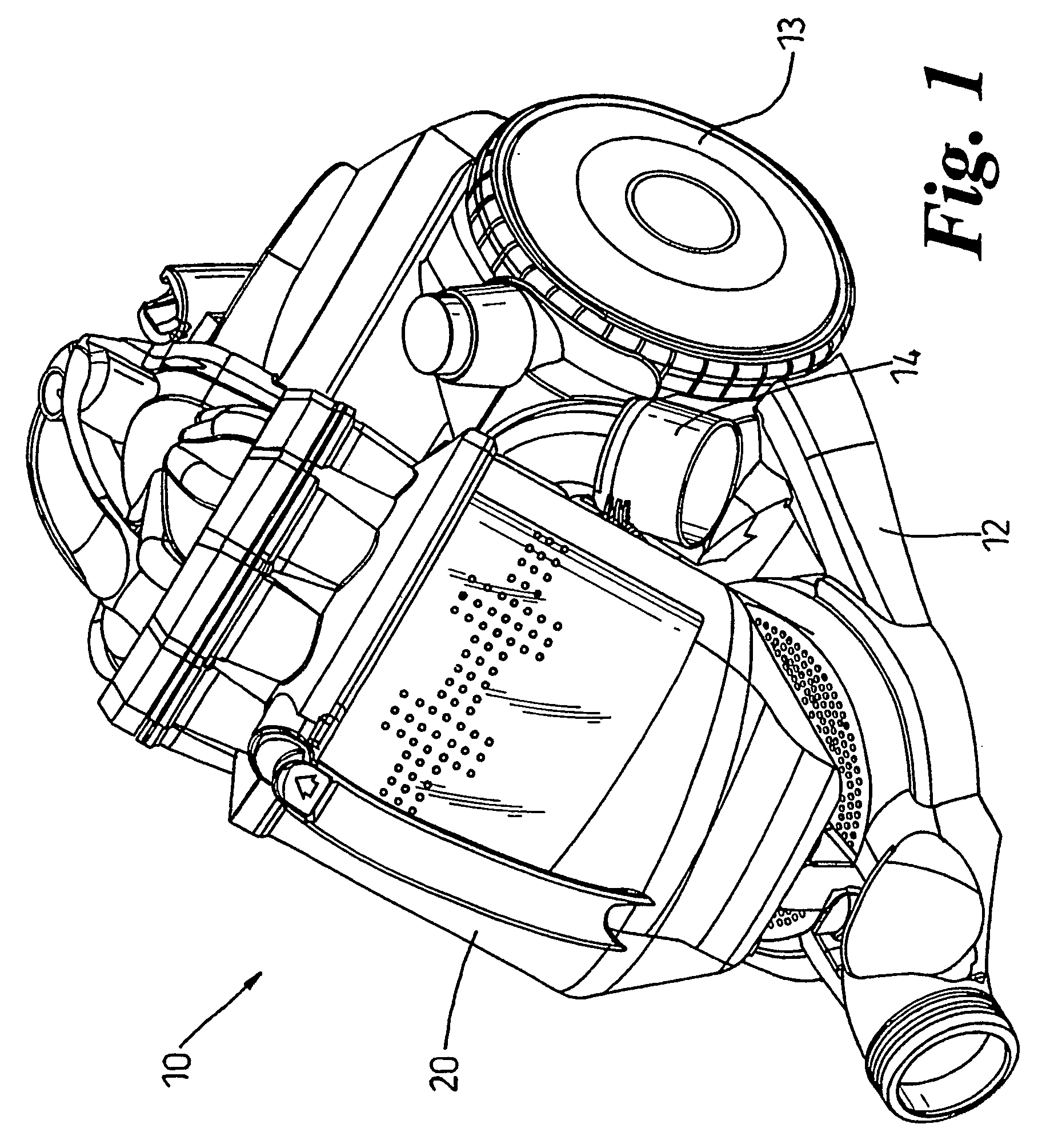

Method for operating a floor cleaning system, and floor cleaning system for use of the method

InactiveUS20050150519A1Reduce noiseReduce cleaningSuction filtersLighting and heating apparatusEngineeringMechanical engineering

The invention relates to a method for operating a floor cleaning system having a central suction station with which there is associated a self-propelled and self-steering suction appliance, dirt being picked up from a floor surface that is to be cleaned by means of the suction appliance and being transferred into a dirt collection vessel of the suction appliance, and the suction station having a suction unit, and the dirt collection vessel being sucked out by means of the suction unit. To refine the method in such a manner that the levels of noise produced by the floor cleaning system can be reduced, it is proposed, according to the invention, that the suction unit is optionally operated with a maximum suction power or a reduced suction power. The invention also proposes a floor cleaning system for carrying out the method.

Owner:ALFRED KARCHER GMBH & CO KG

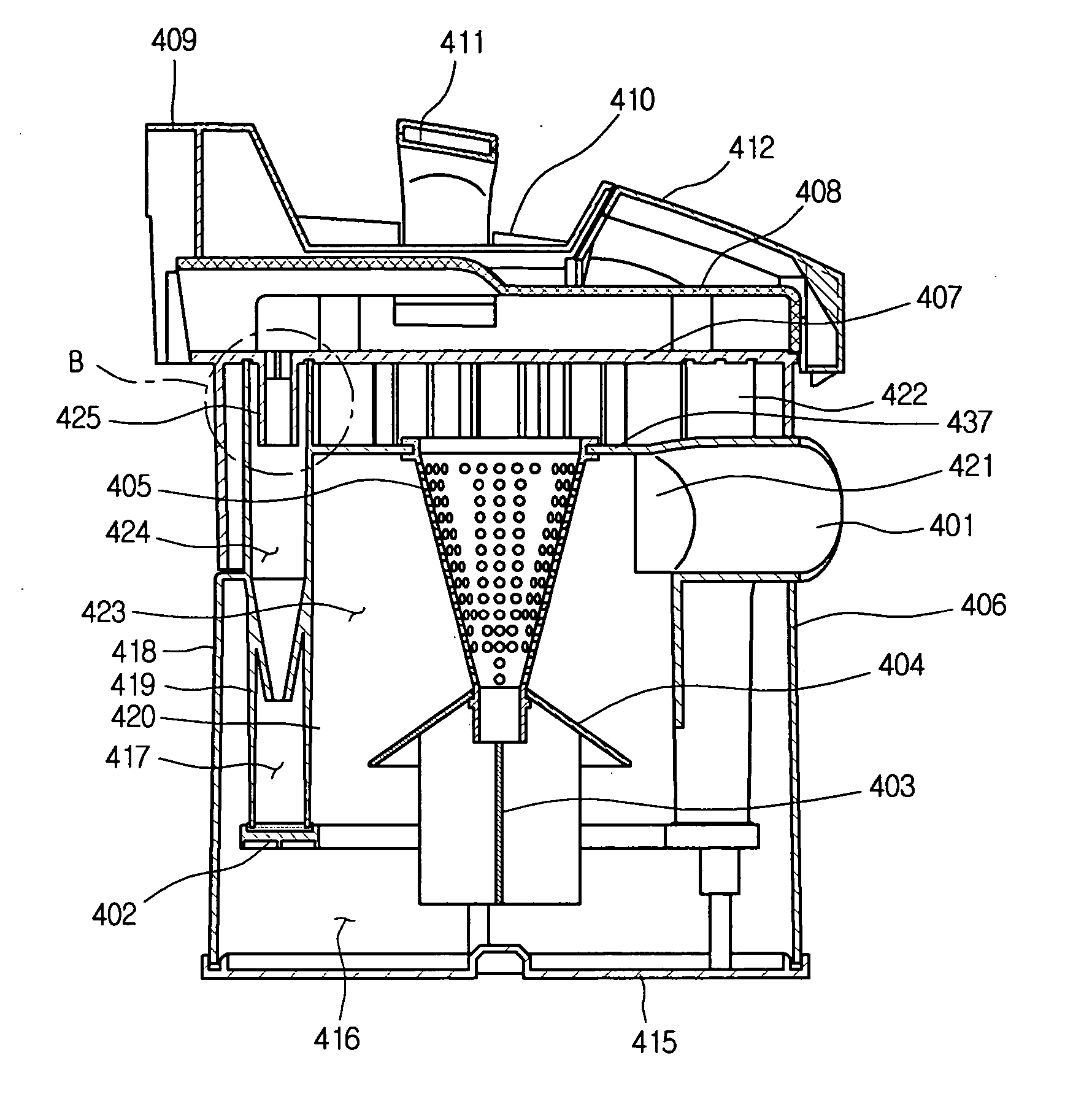

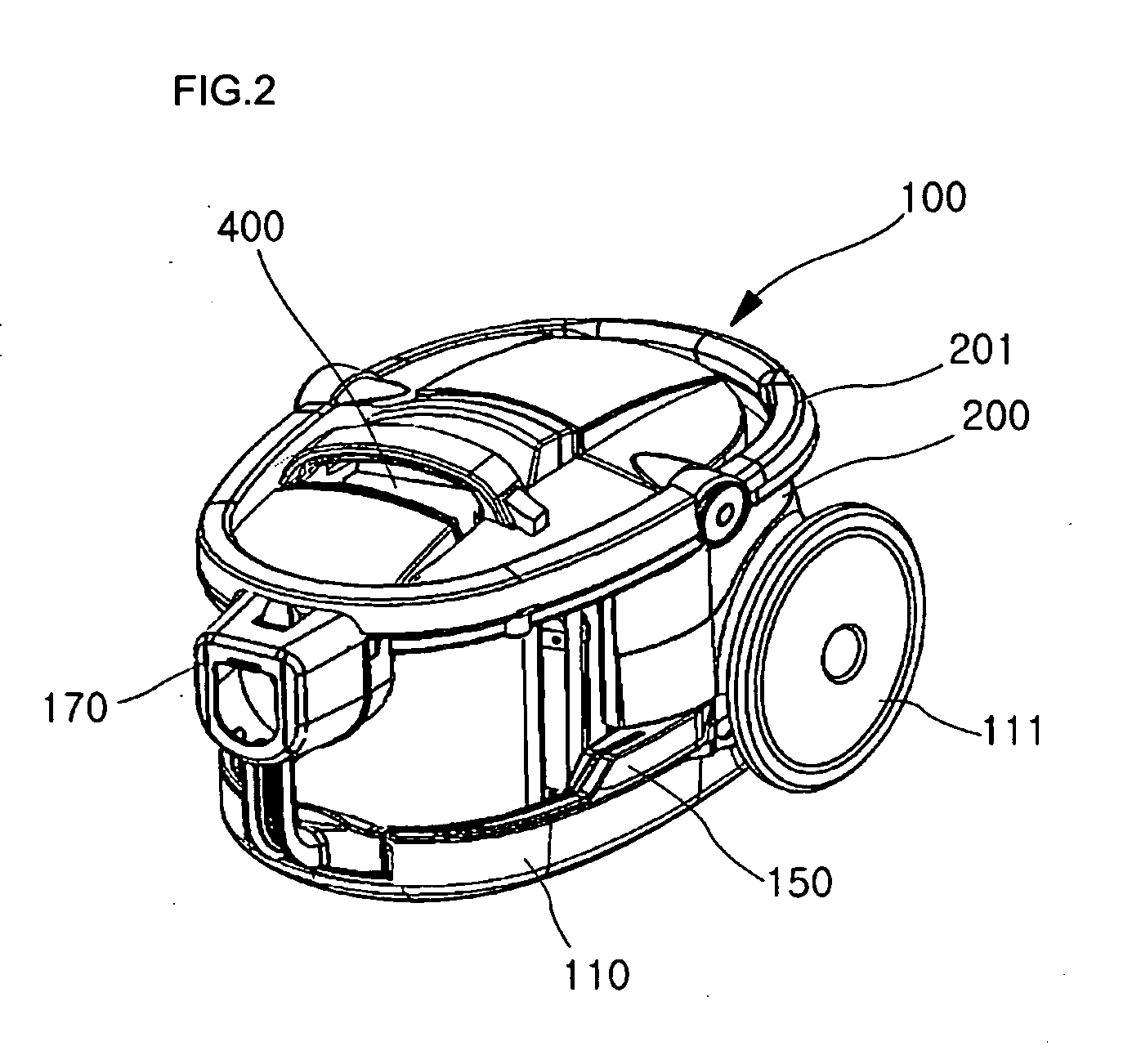

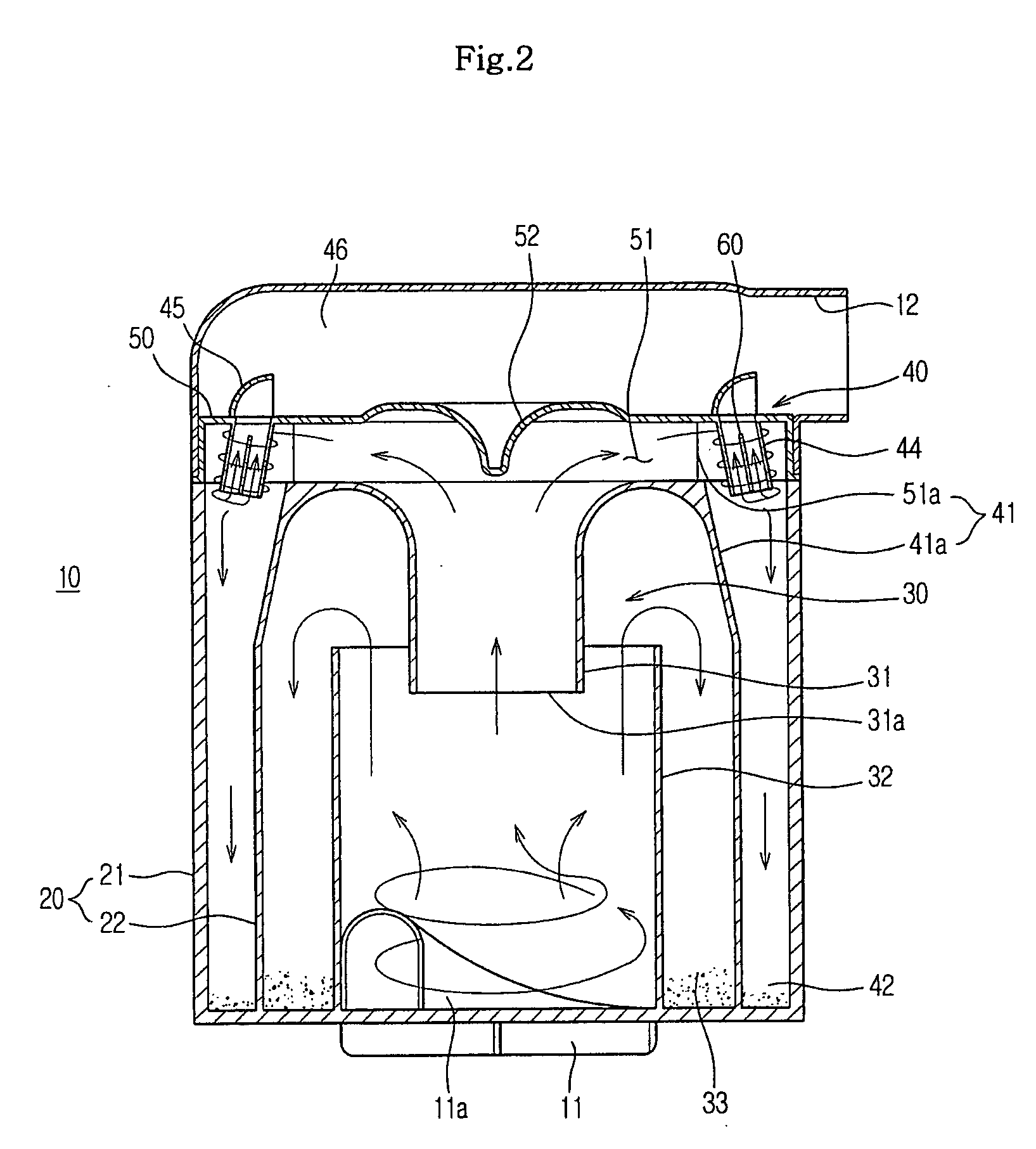

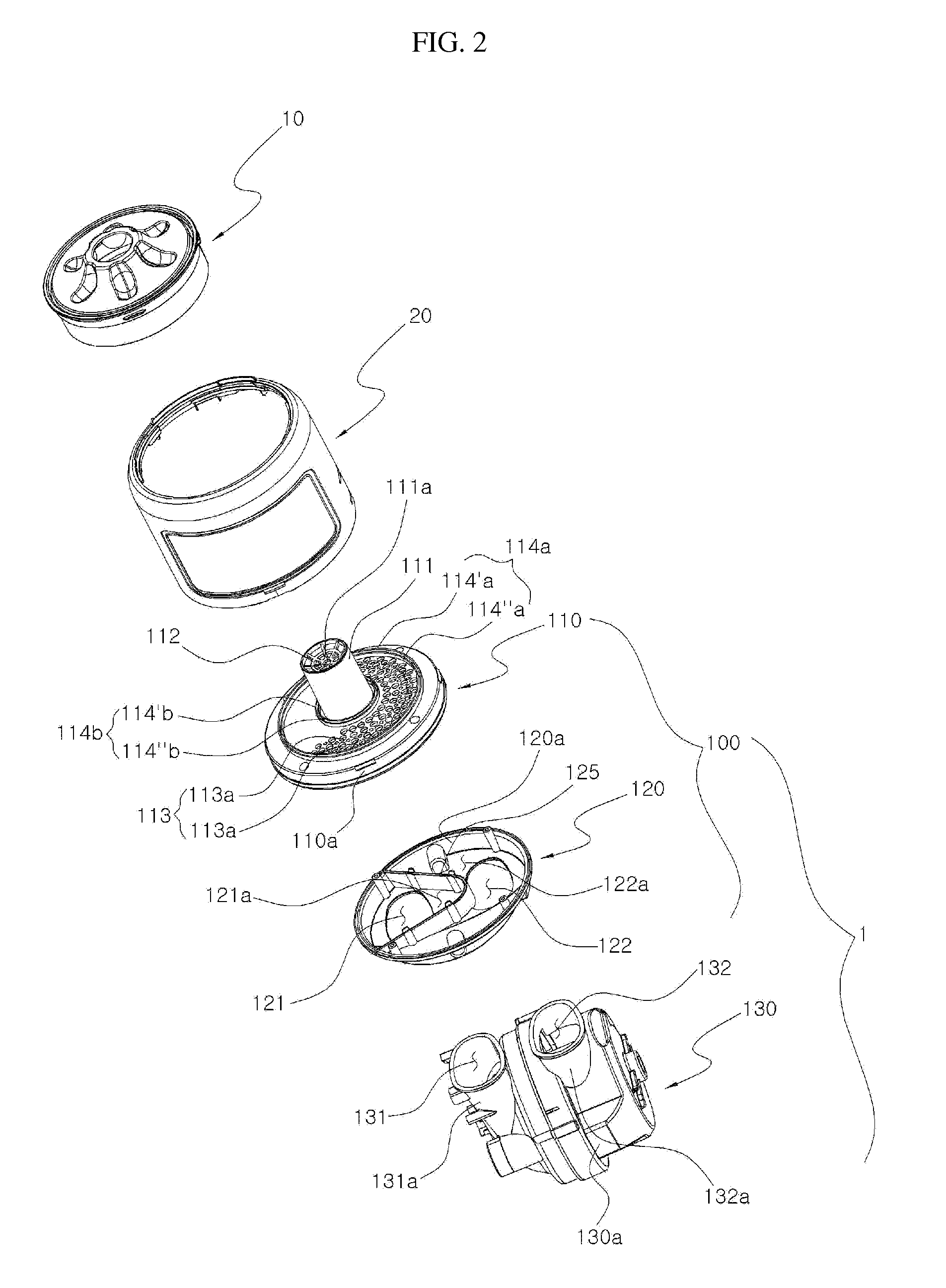

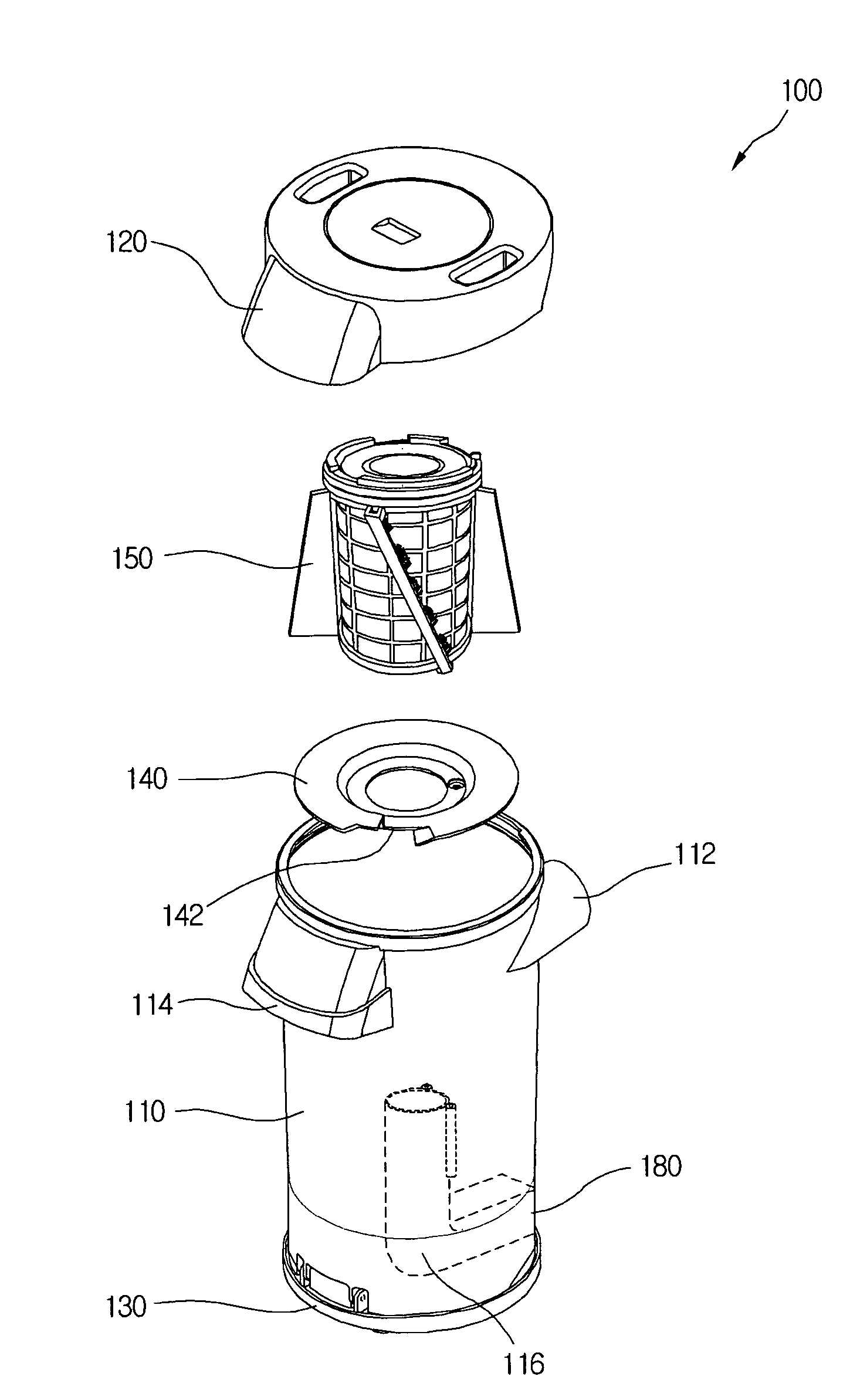

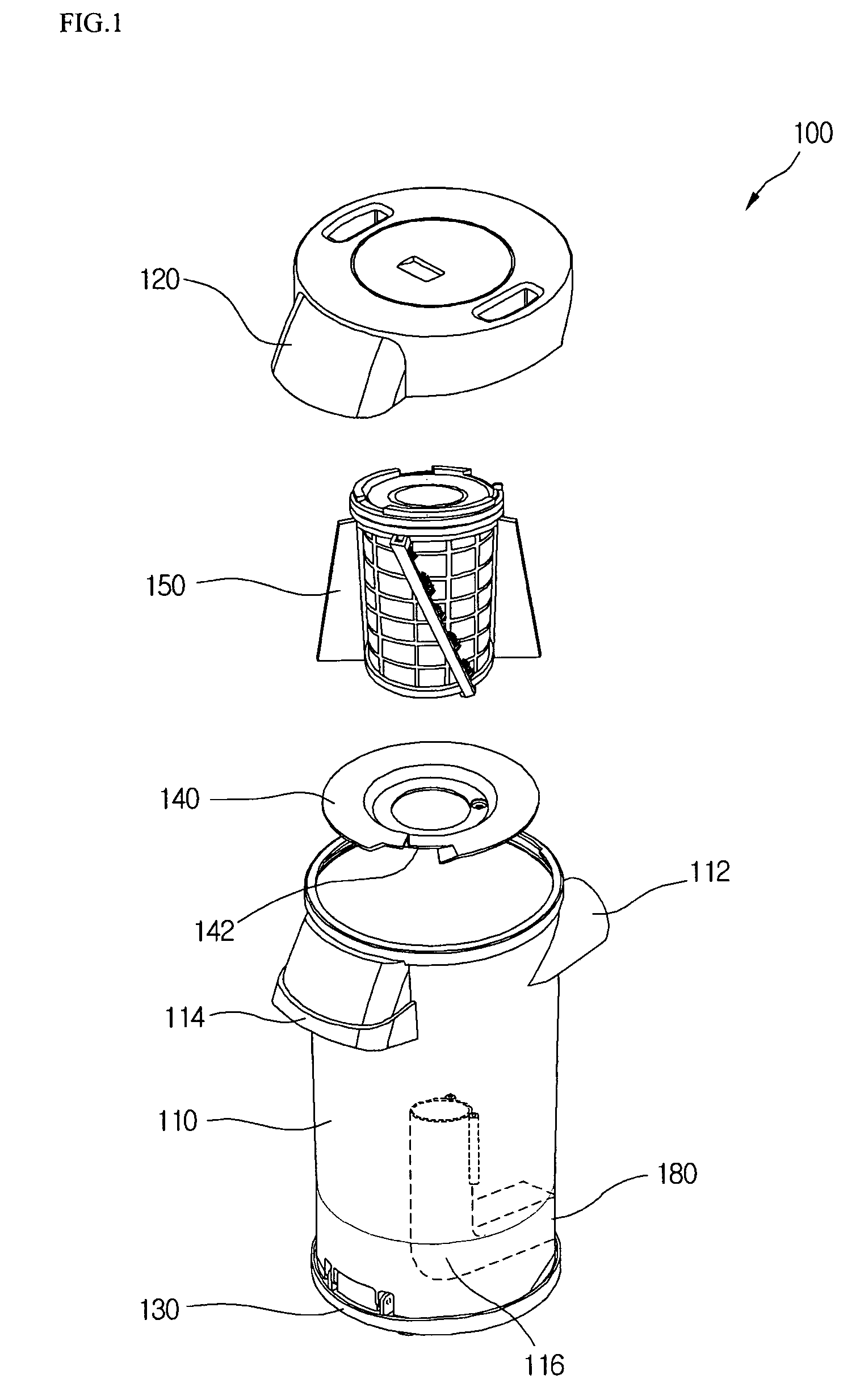

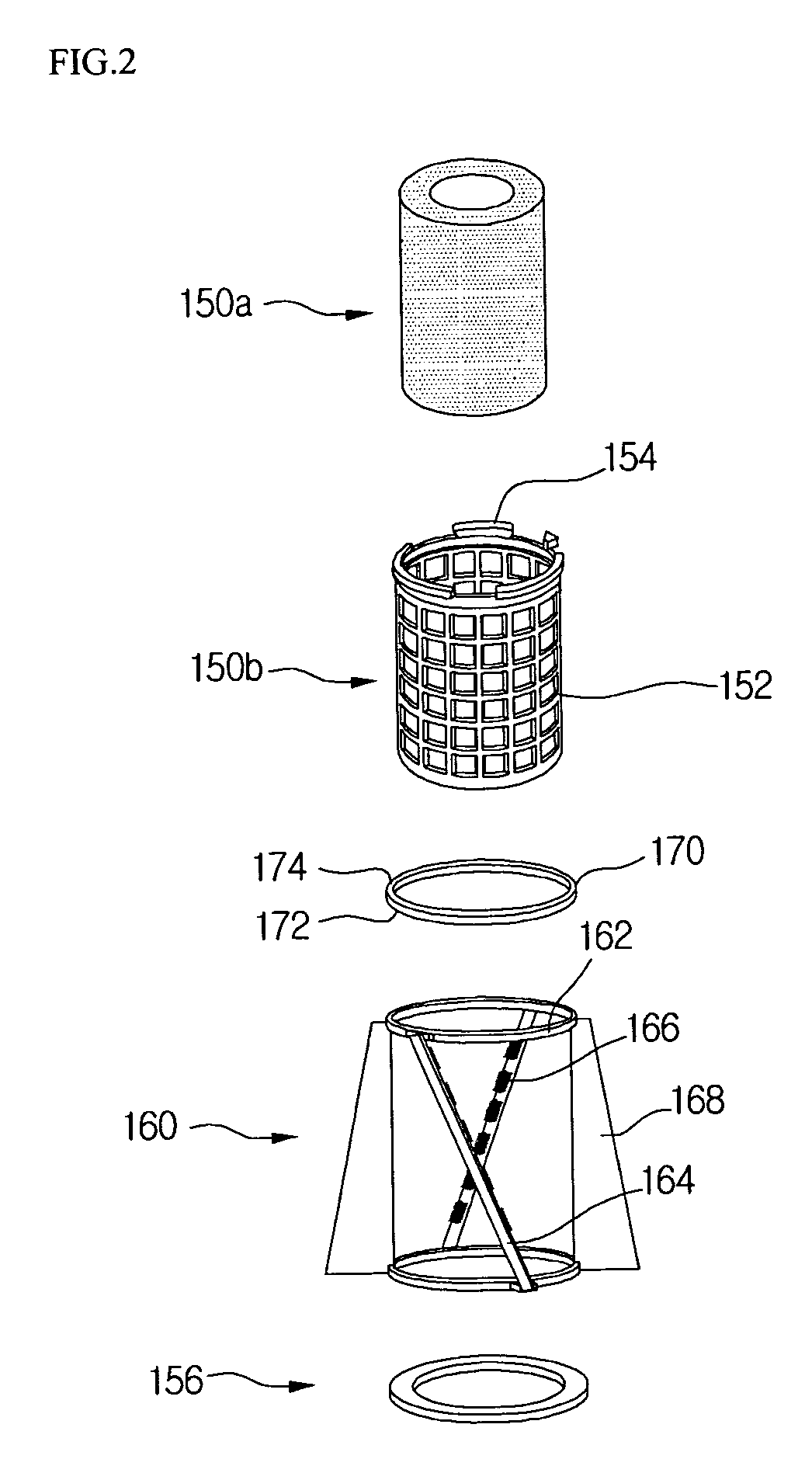

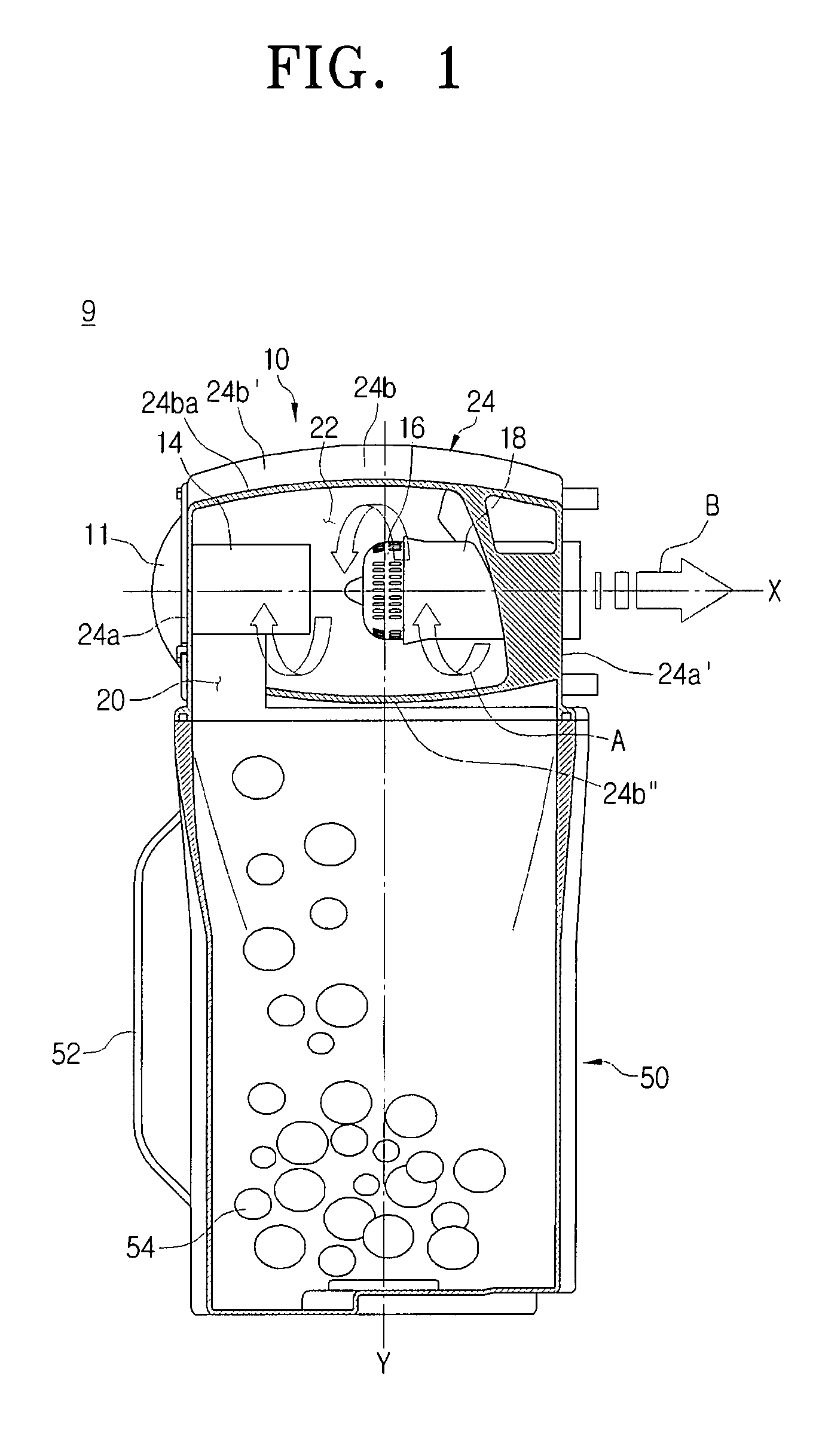

Dust collection unit and vacuum cleaner with same

ActiveUS20060137306A1Reduce noiseAttenuating unpleasant sensationCombination devicesSuction filtersForeign matterVacuum cleaner

A dust collection unit for a vacuum cleaner includes a first filtering chamber filtering relatively large foreign objects, a second filtering chamber filtering relatively small foreign objects when air exhausted from the first filtering chamber is introduced into the second filtering chamber, an exhaust member disposed above the filtering chambers to guide airflow, a storing chamber disposed under the filtering chambers to store the foreign objects filtered in the filtering chambers, a sealing member sealing bottoms of the filtering chambers, and a rectifying unit formed on an exhaust side of the second filtering chamber to rectify airflow, thereby reducing noise generated by the airflow.

Owner:LG ELECTRONICS INC

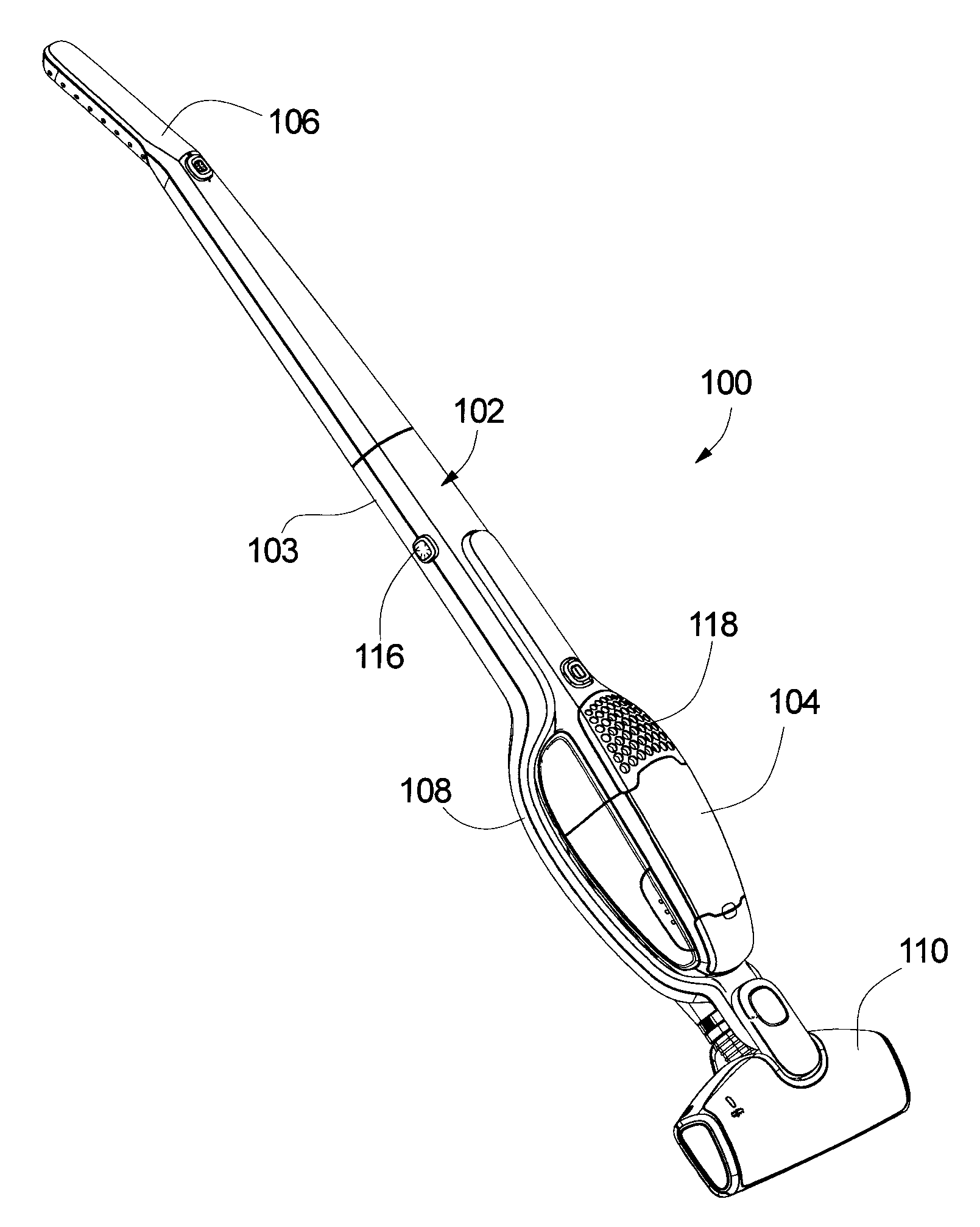

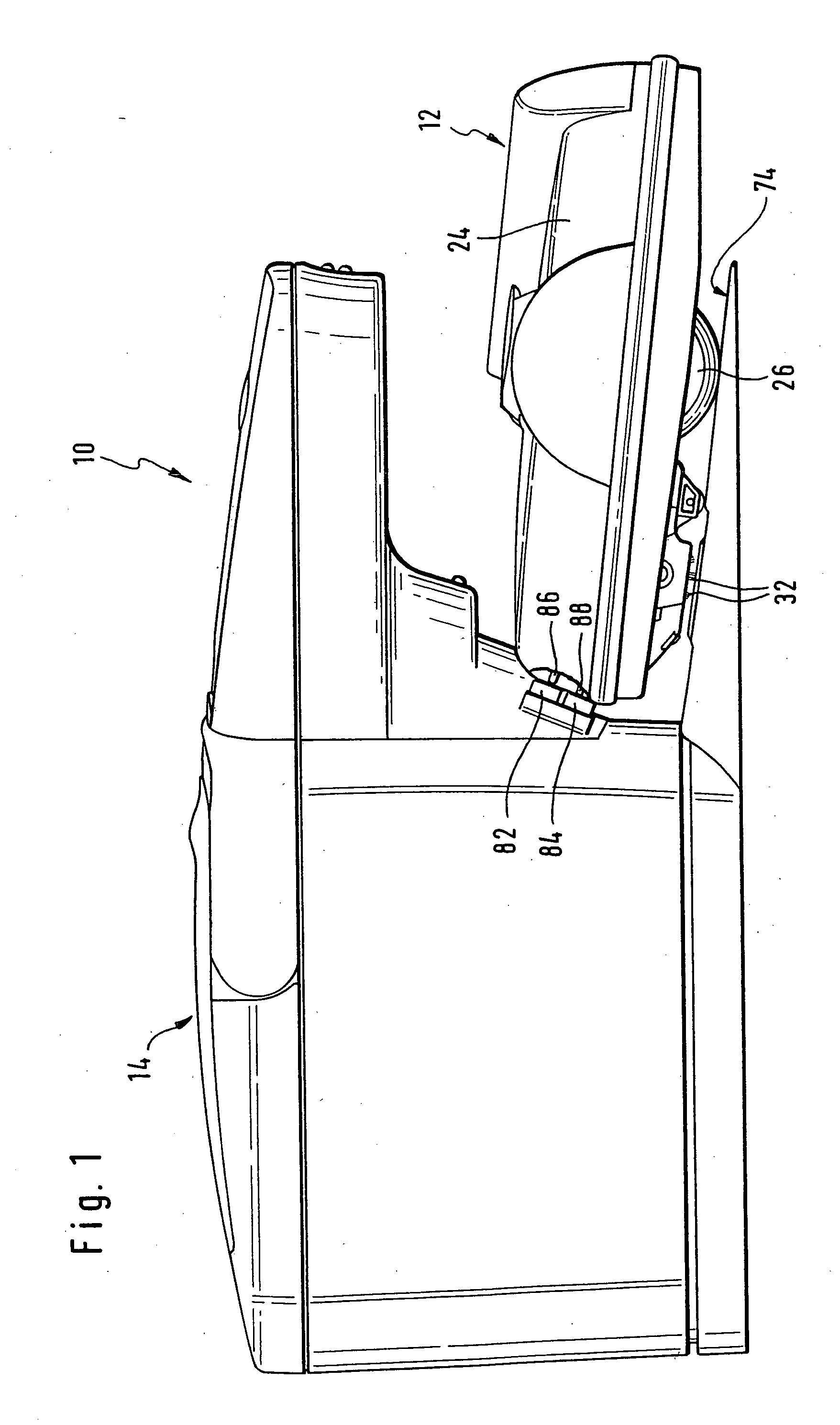

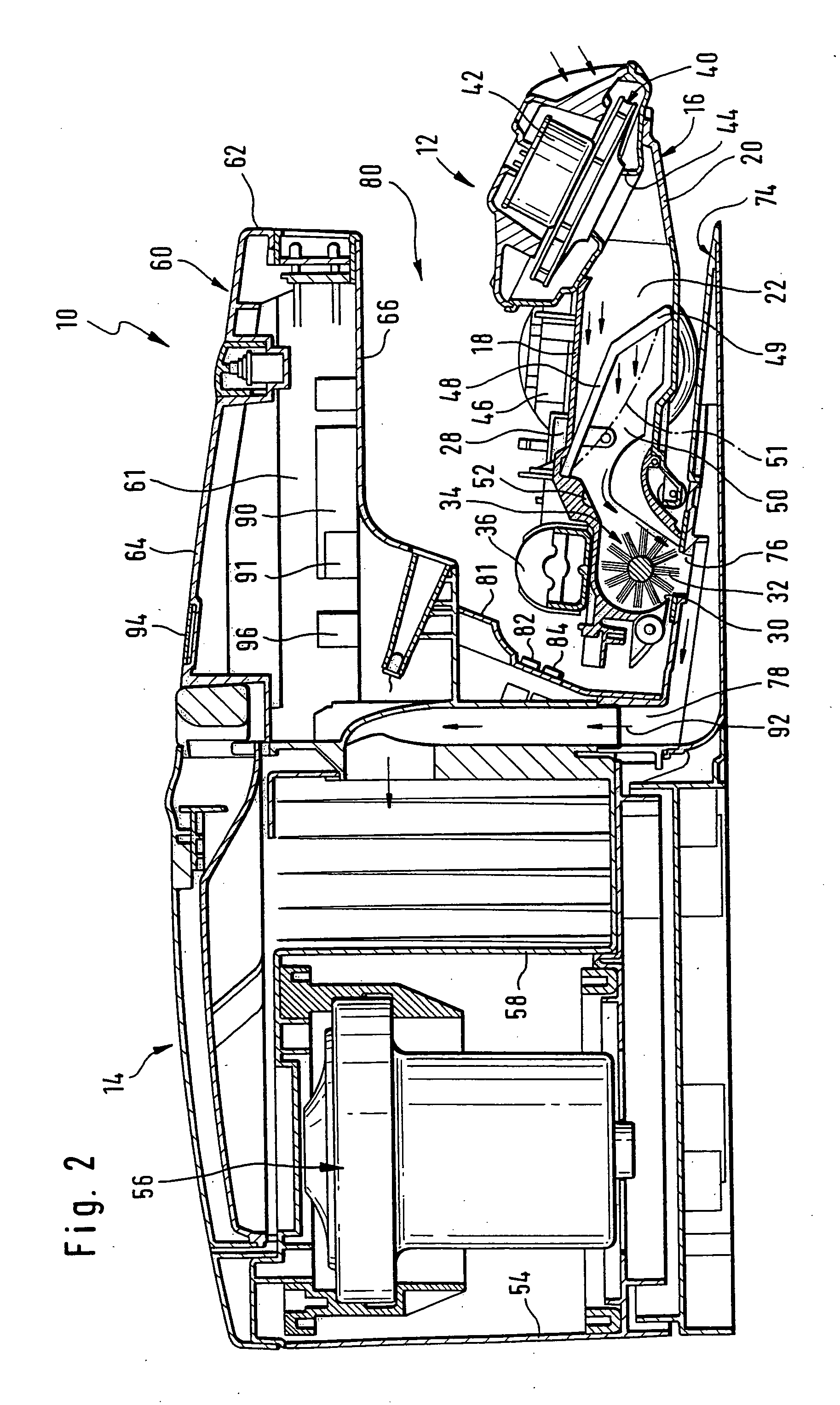

Dirt separator system for a vacuum cleaner

ActiveUS7882593B2Reducing air flow lossImprove suction efficiencyCleaning filter meansSuction filtersEngineeringVacuum cleaner

A vacuum cleaner having an elongated support body, a nozzle attached to a lower end of the elongated support body by an articulated joint, a motor, a fan unit, a debris container, and an air passage that extends from the nozzle device, past the articulated joint by a flexible hose and to an air passage in the support body. The flexible hose is formed with a generally rectangular cross section.

Owner:AB ELECTROLUX

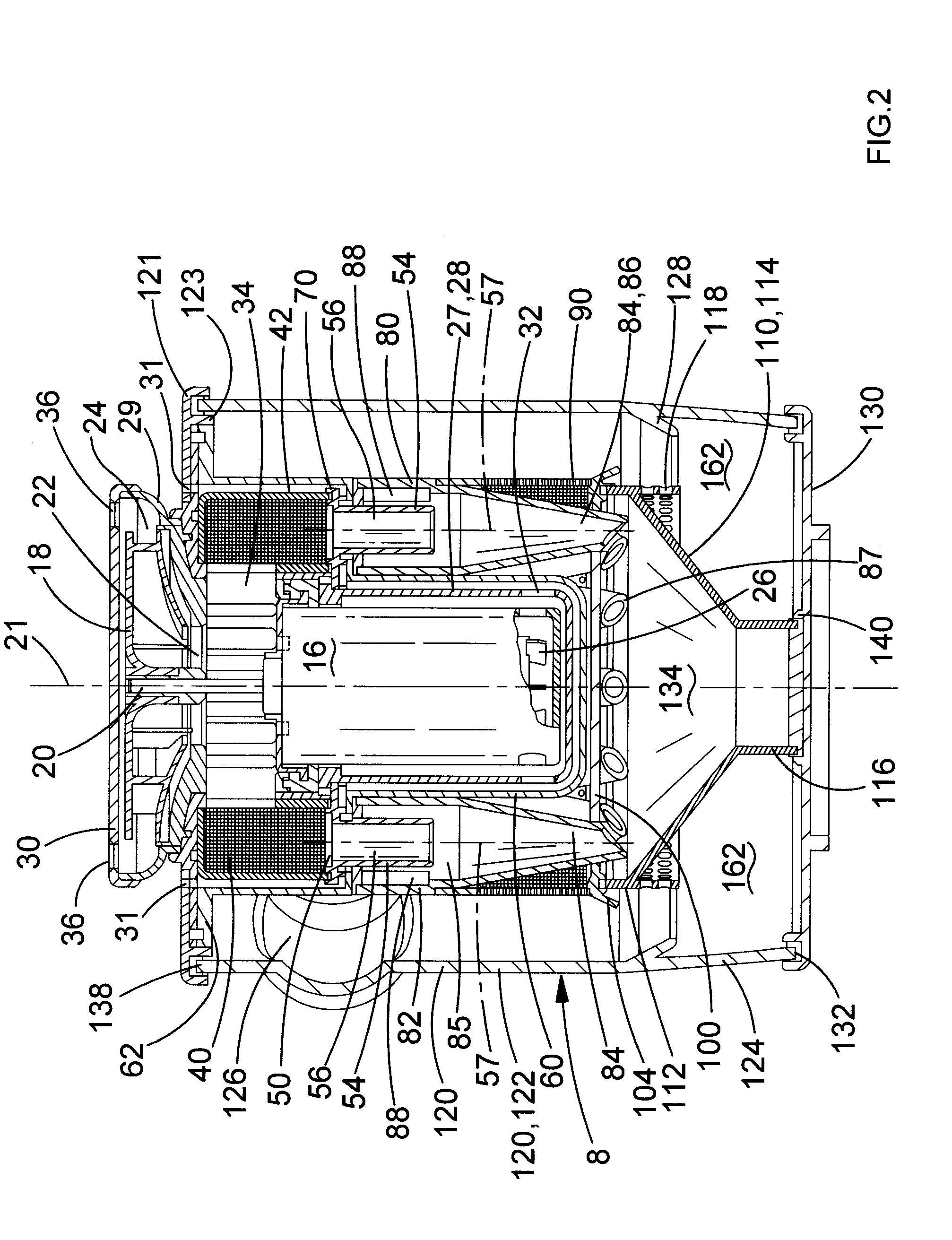

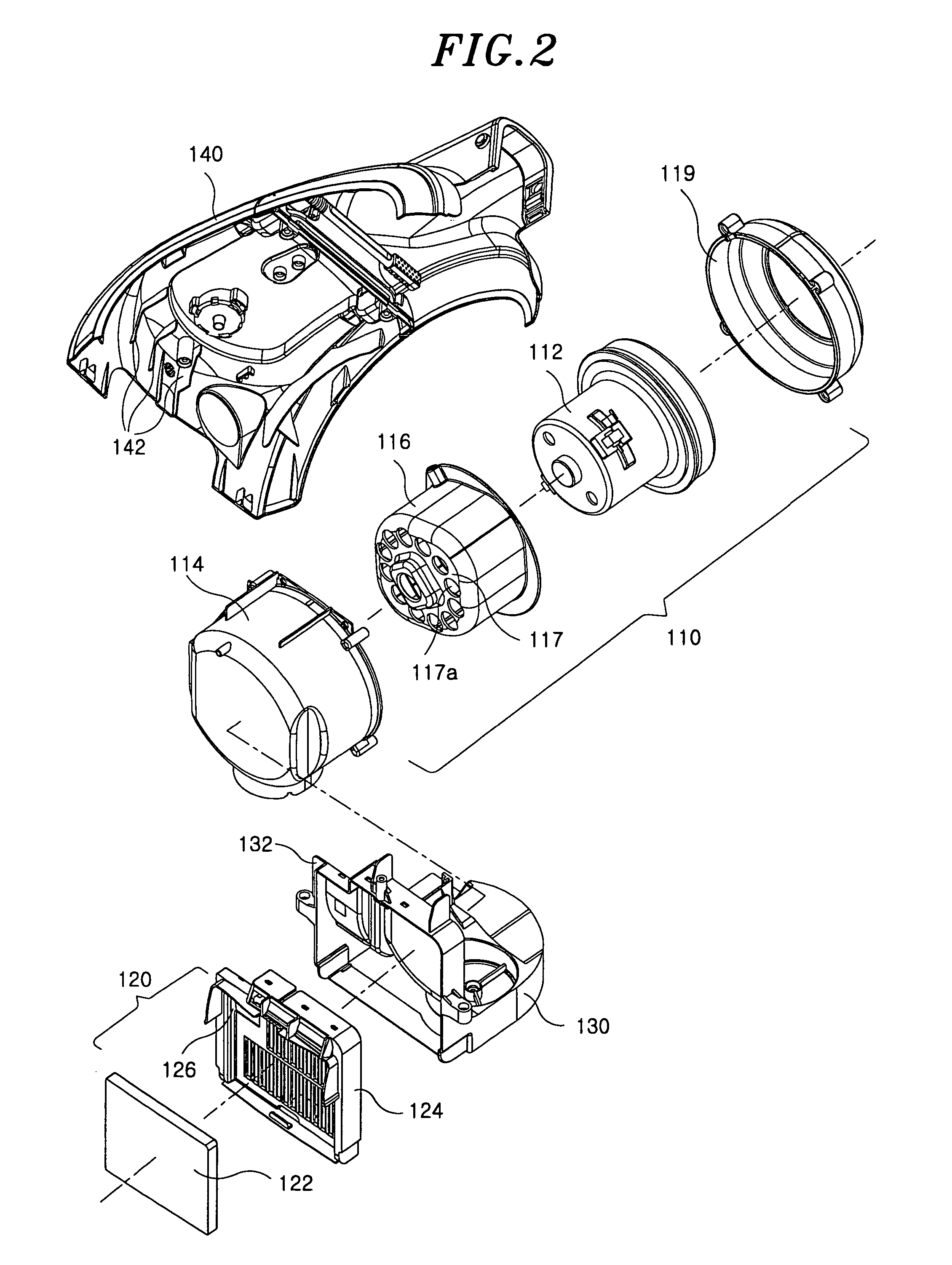

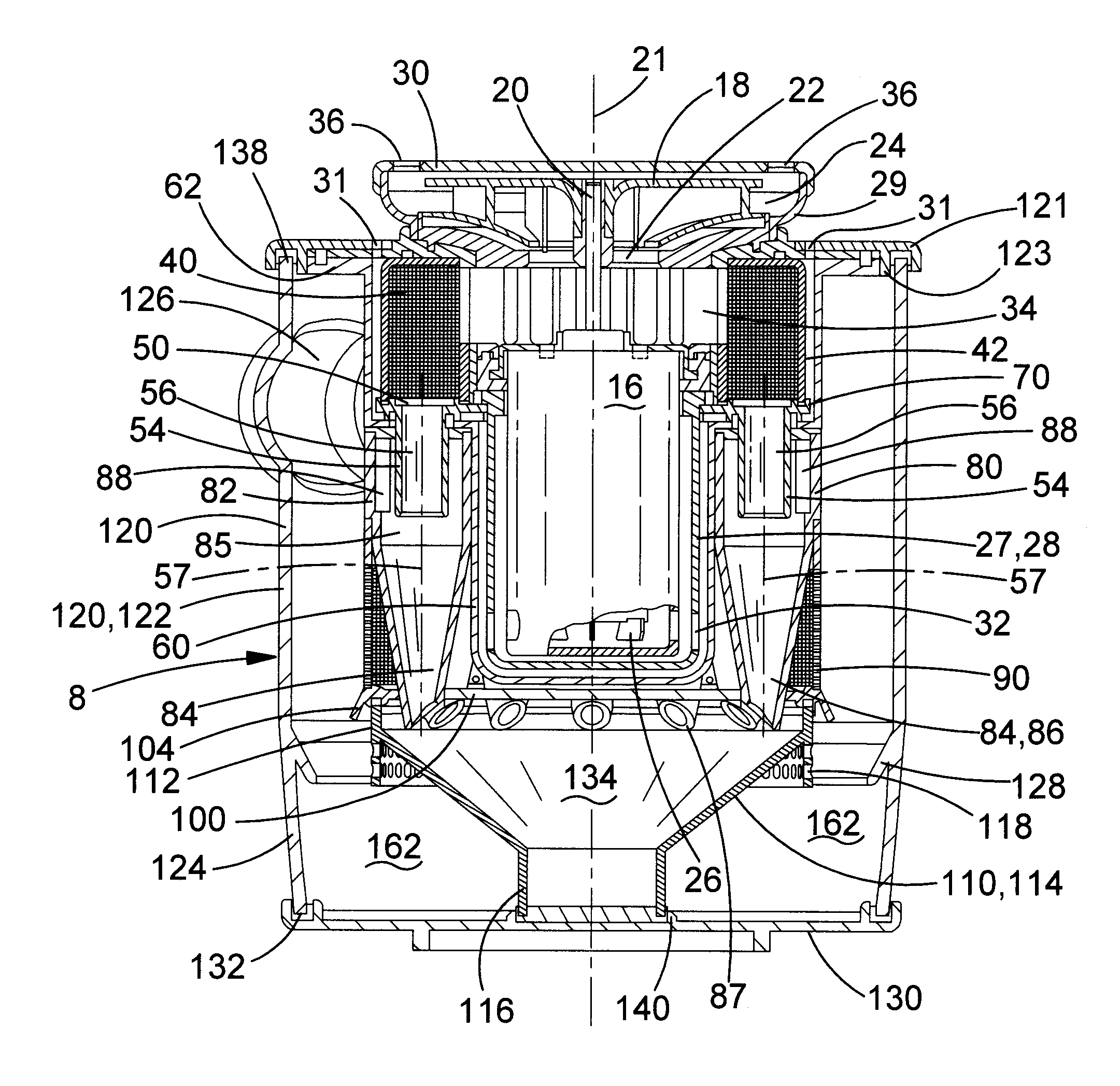

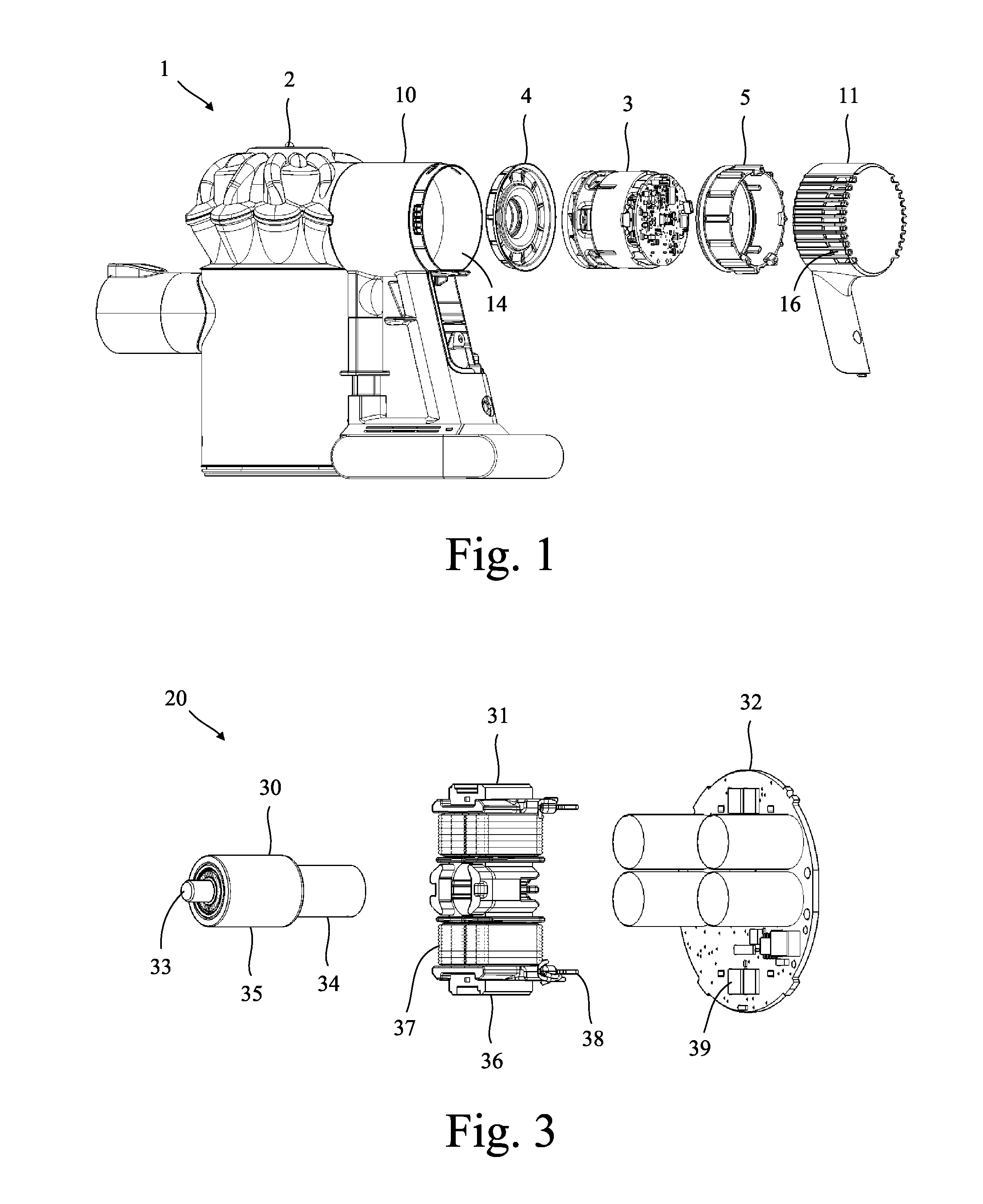

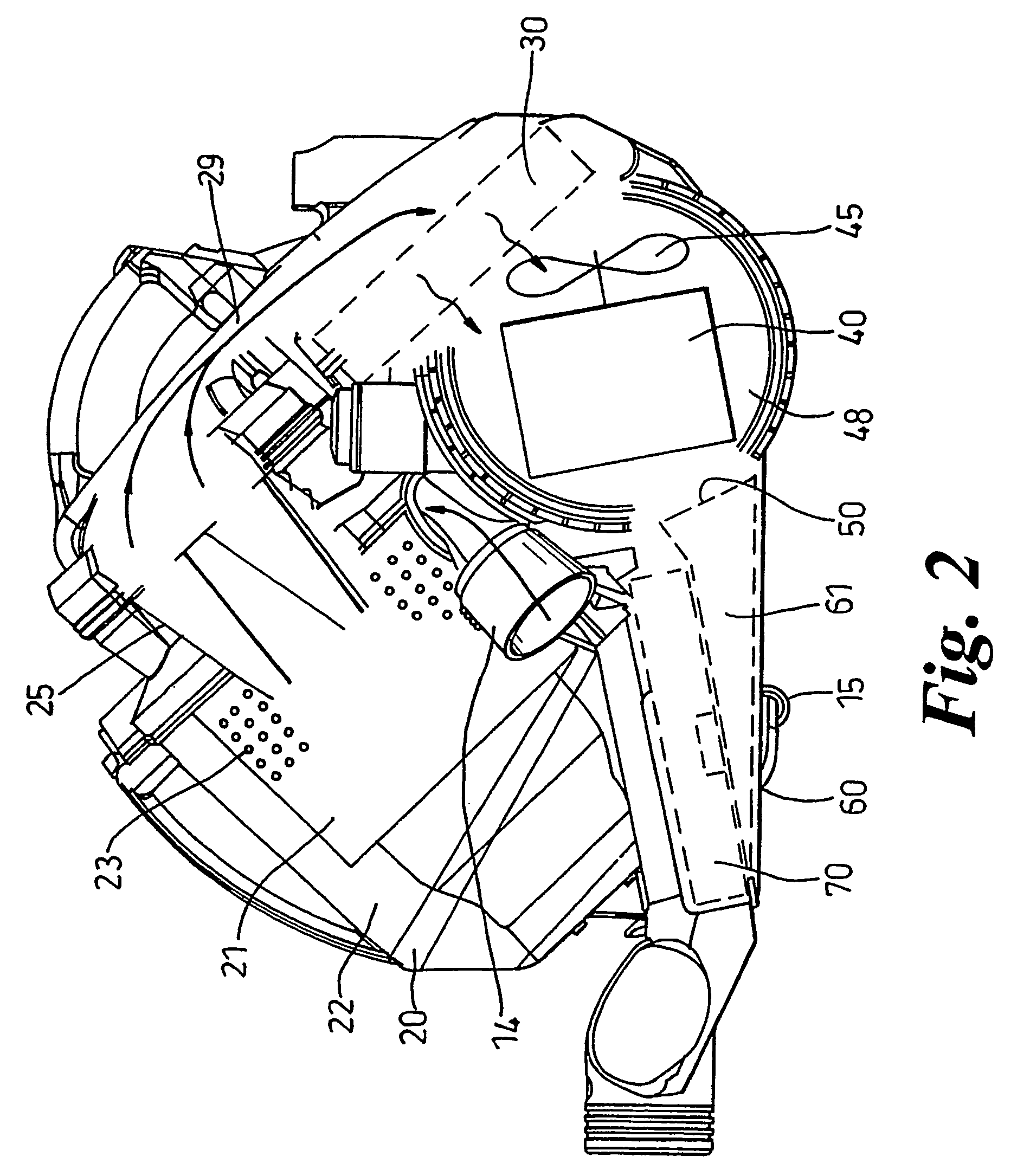

Motor, fan and cyclonic separation apparatus arrangement for a vacuum cleaner

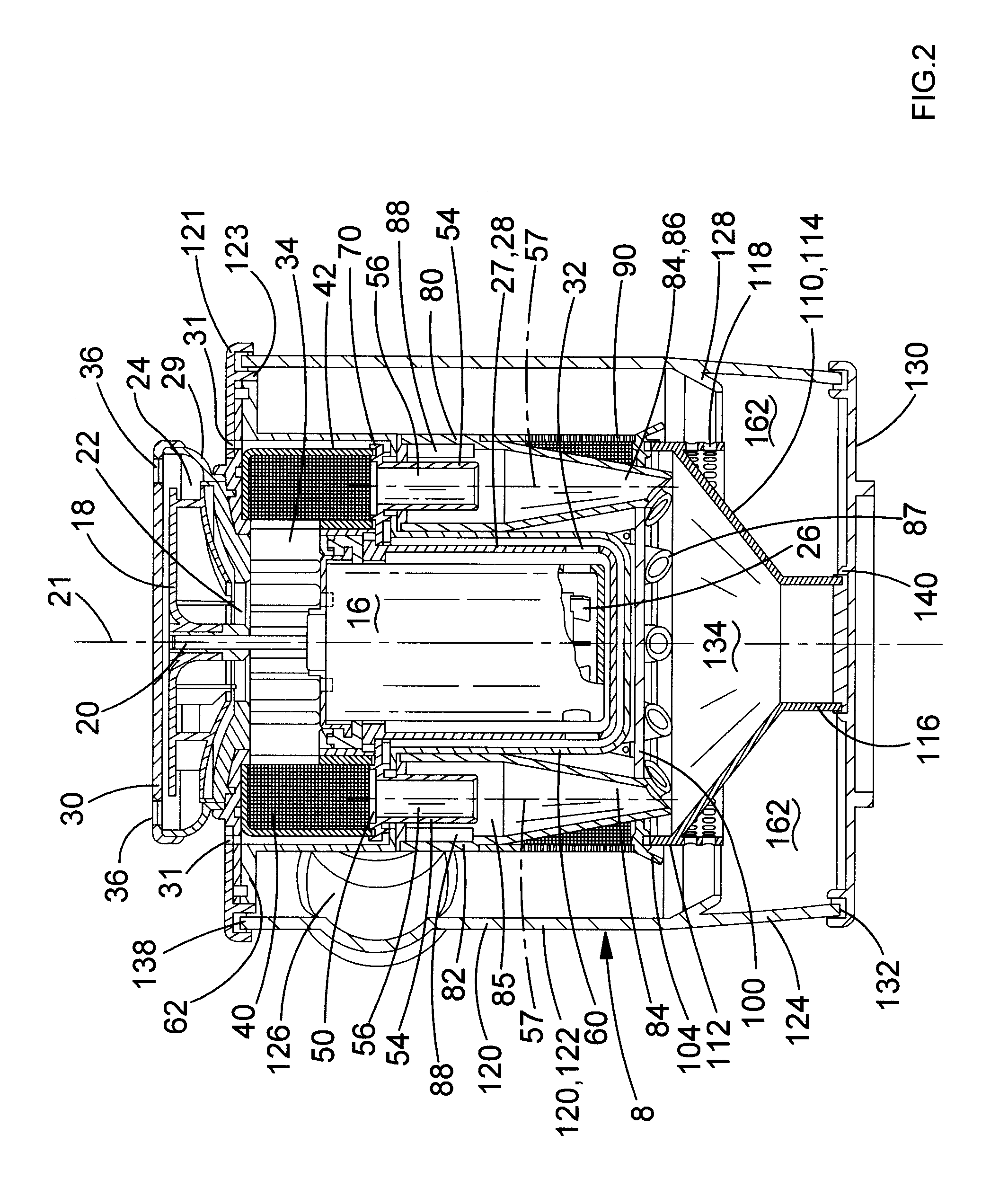

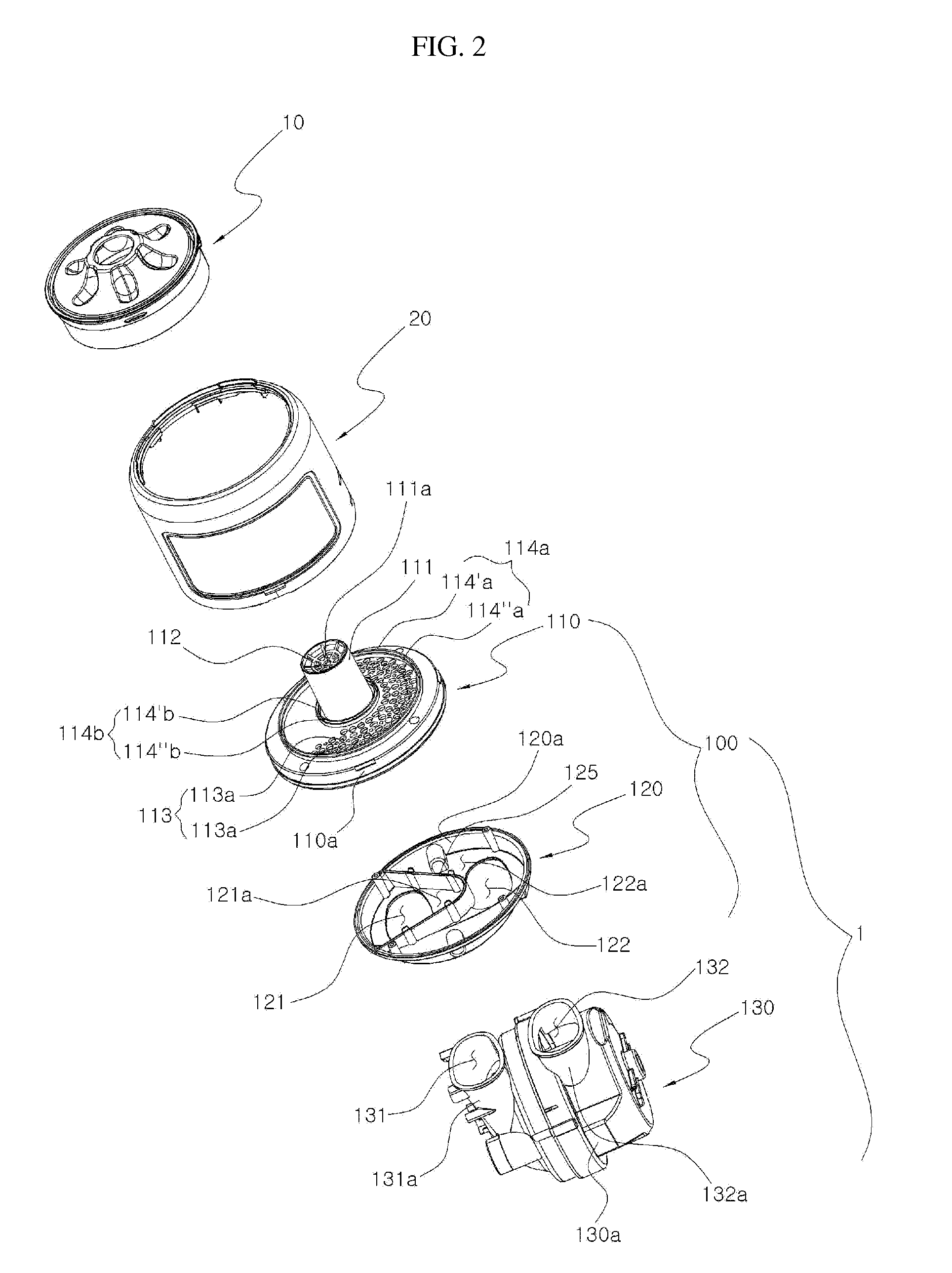

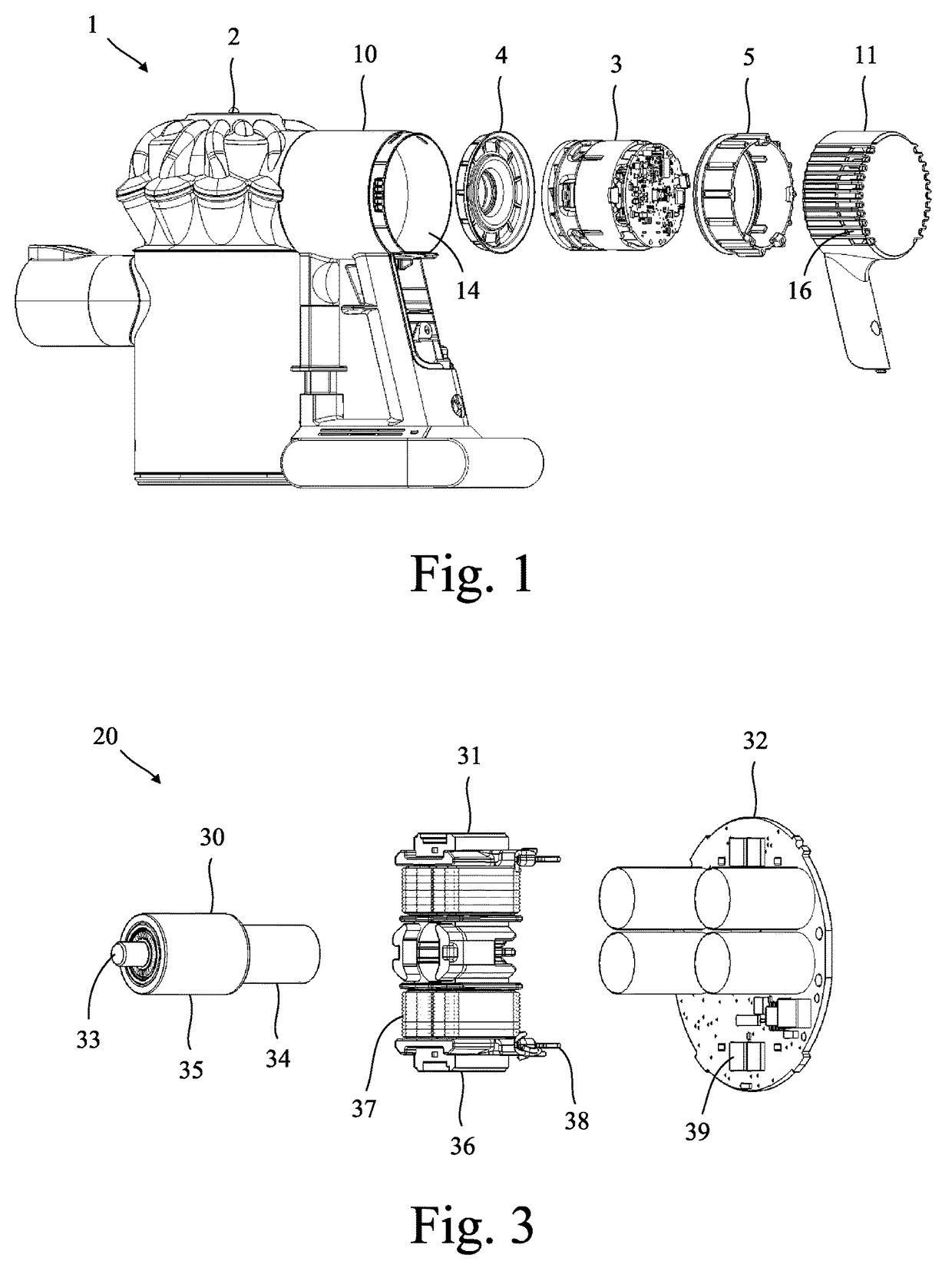

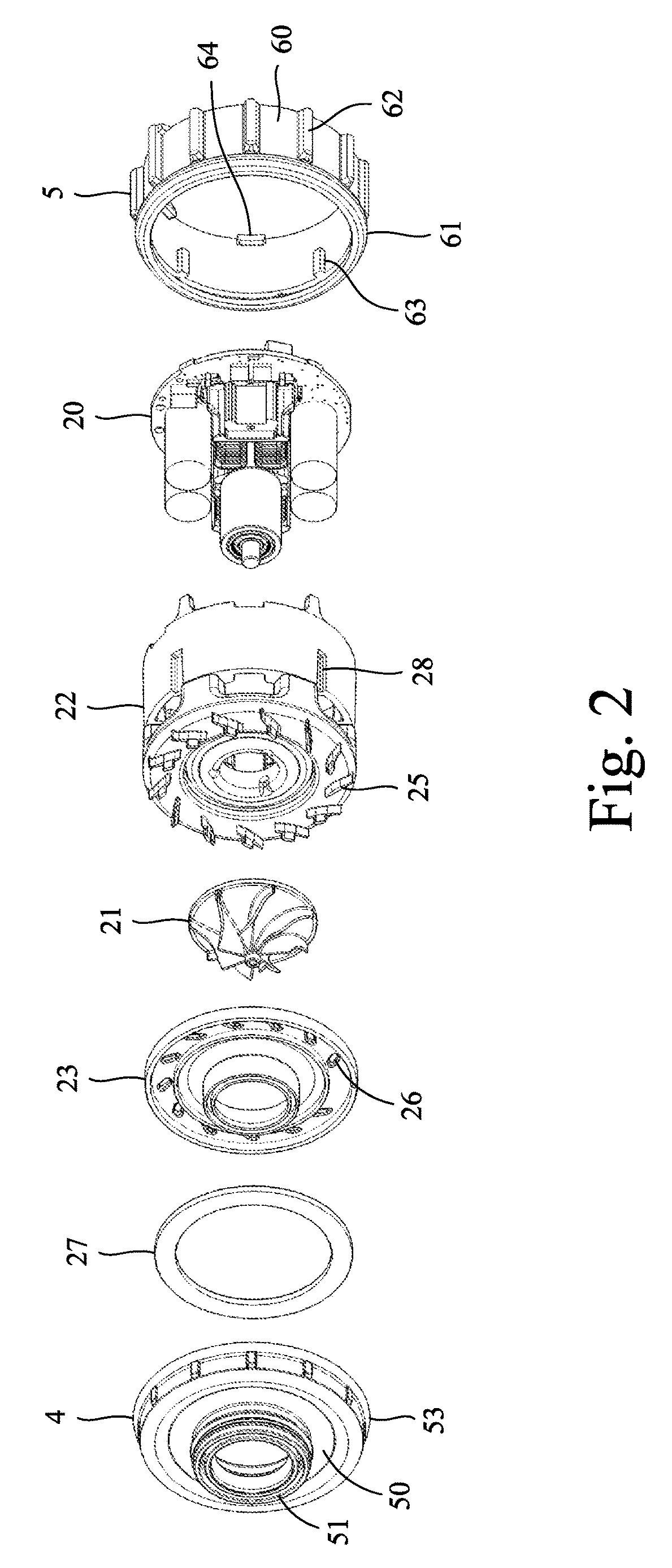

ActiveUS20130091813A1Reduce energy lossShorten the lengthMotor fan assembly mountingDispersed particle separationCycloneCyclonic separation

A motor, fan and cyclonic separation apparatus arrangement for a vacuum cleaner, the arrangement comprising: a motor coupled to a fan for generating air flow; and a cyclonic separation apparatus located in a path of the air flow generated by the fan, wherein the cyclonic separation apparatus comprises: a plurality of cyclones each with an air inlet port and an air outlet port wherein the cyclones are arranged in a generally circular array about a central axis of the cyclonic separation apparatus; and a cooling air flow path, wherein the motor is nested within the generally circular array of cyclones and wherein the motor is located in the cooling air flow path. A vacuum cleaner comprising the motor, fan and cyclonic separation apparatus arrangement.

Owner:BLACK & DECKER INC

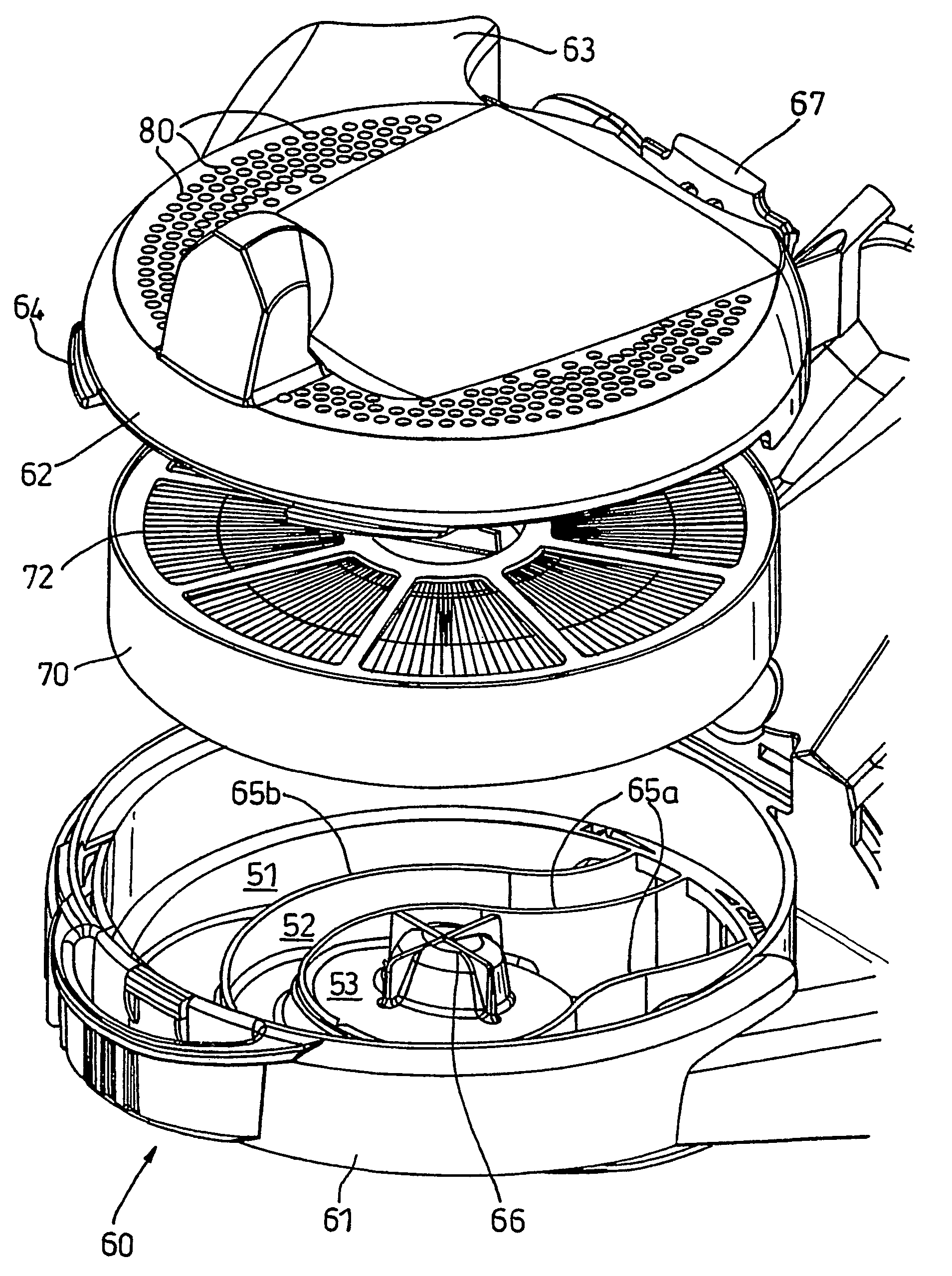

Cyclonic cleaner

InactiveUS20070144116A1Reduce noiseLow efficiencyDispersed particle separationExhaust-air diffusionForeign matterCyclone

A cyclonic cleaner which includes a cyclone unit enabling a reduction of noise generated from the cyclone unit, and reduction in pressure loss by forming a smooth air flow. The cyclone unit includes a body having an air inlet and an air outlet, a primary cyclone to primarily separate foreign matter from air drawn through the air inlet, a plurality of secondary cyclones to secondarily separate foreign matter from air discharged from the primary cyclone and to discharge the air having the foreign matter removed therefrom through discharge holes of the secondary cyclones, and a noise reduction member positioned in the discharge hole of each secondary cyclone to reduce noise. The cyclone unit also includes a guide plate to allow the air discharged through the discharge holes of the secondary cyclones to be smoothly discharged through the air outlet.

Owner:SAMSUNG ELECTRONICS CO LTD

Discharging apparatus and vacuum cleaner having the same

InactiveUS20090113659A1Avoid breakingCleaning filter meansCombination devicesVacuum cleanerWaste management

A discharge apparatus of a vacuum cleaner, which does not allow a sealing to break due to a discharge force, and a vacuum cleaner having the same, are provided. The discharge apparatus includes a motor to generate a discharge force, a discharge filter unit to filter discharged air, a housing to support the motor, and comprising a filter accommodating unit integrally foxed thereon to receive the discharge filter unit therein, and a sealing member to seal a space defined between the discharge filter unit and the filter accommodating unit.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

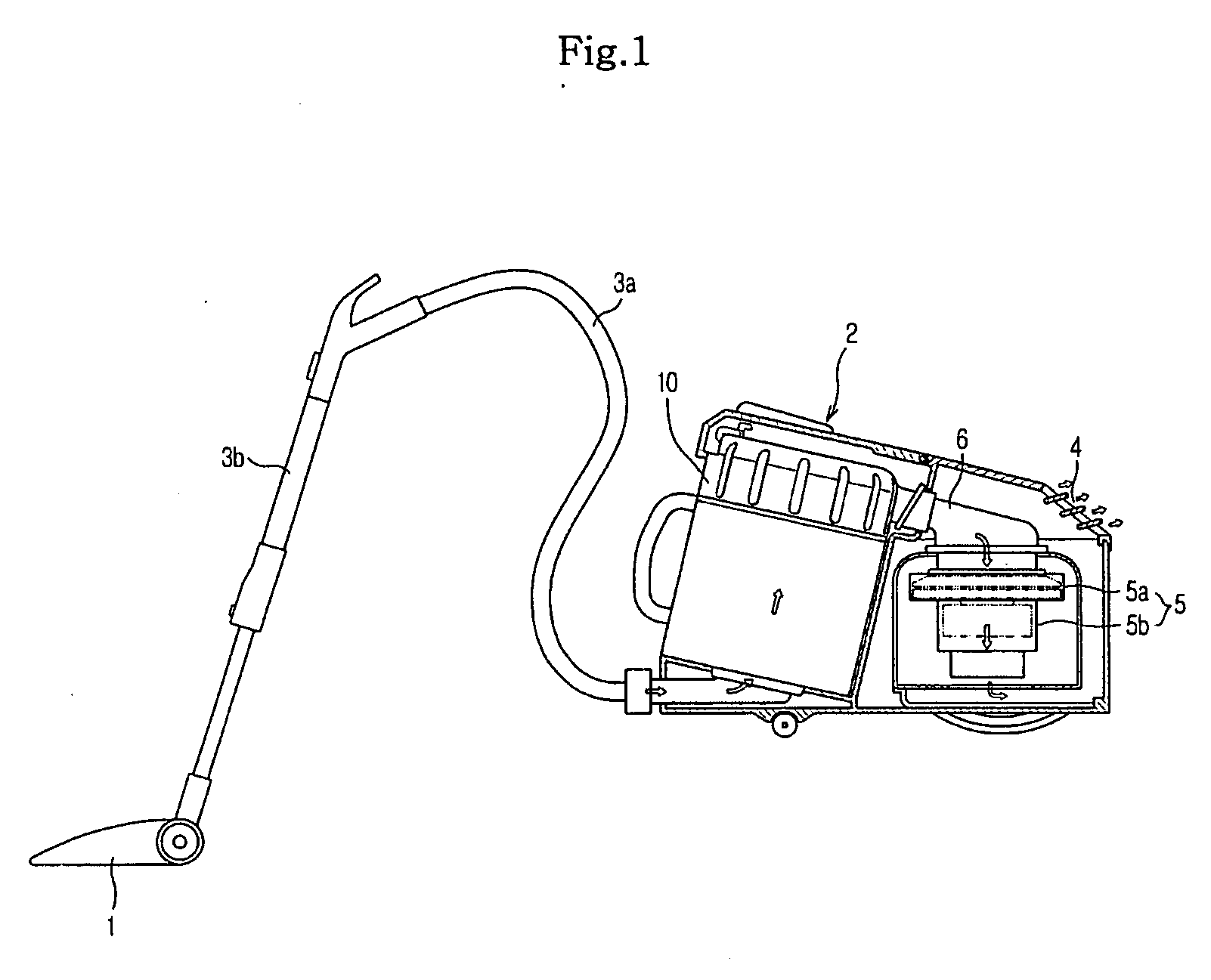

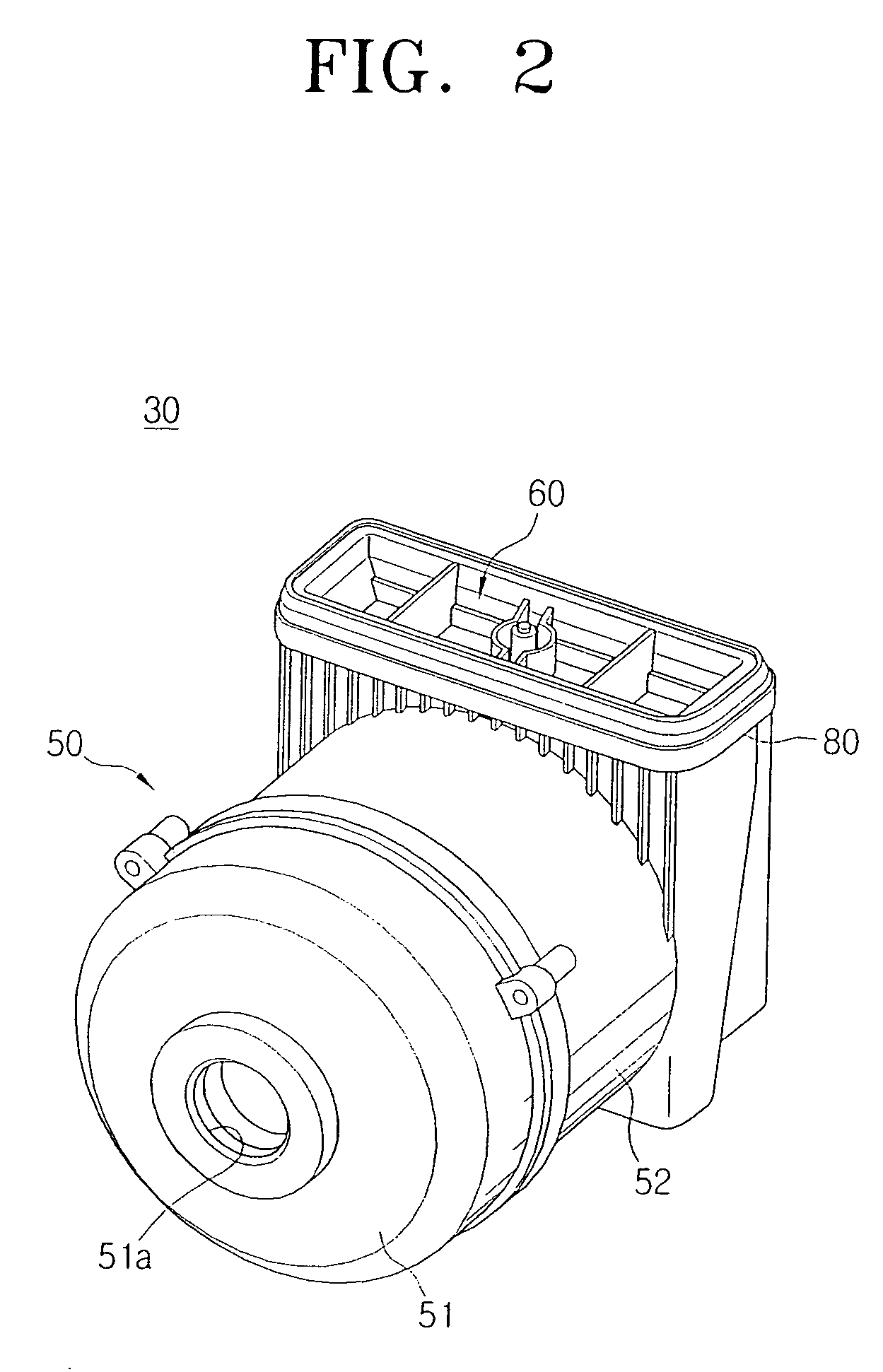

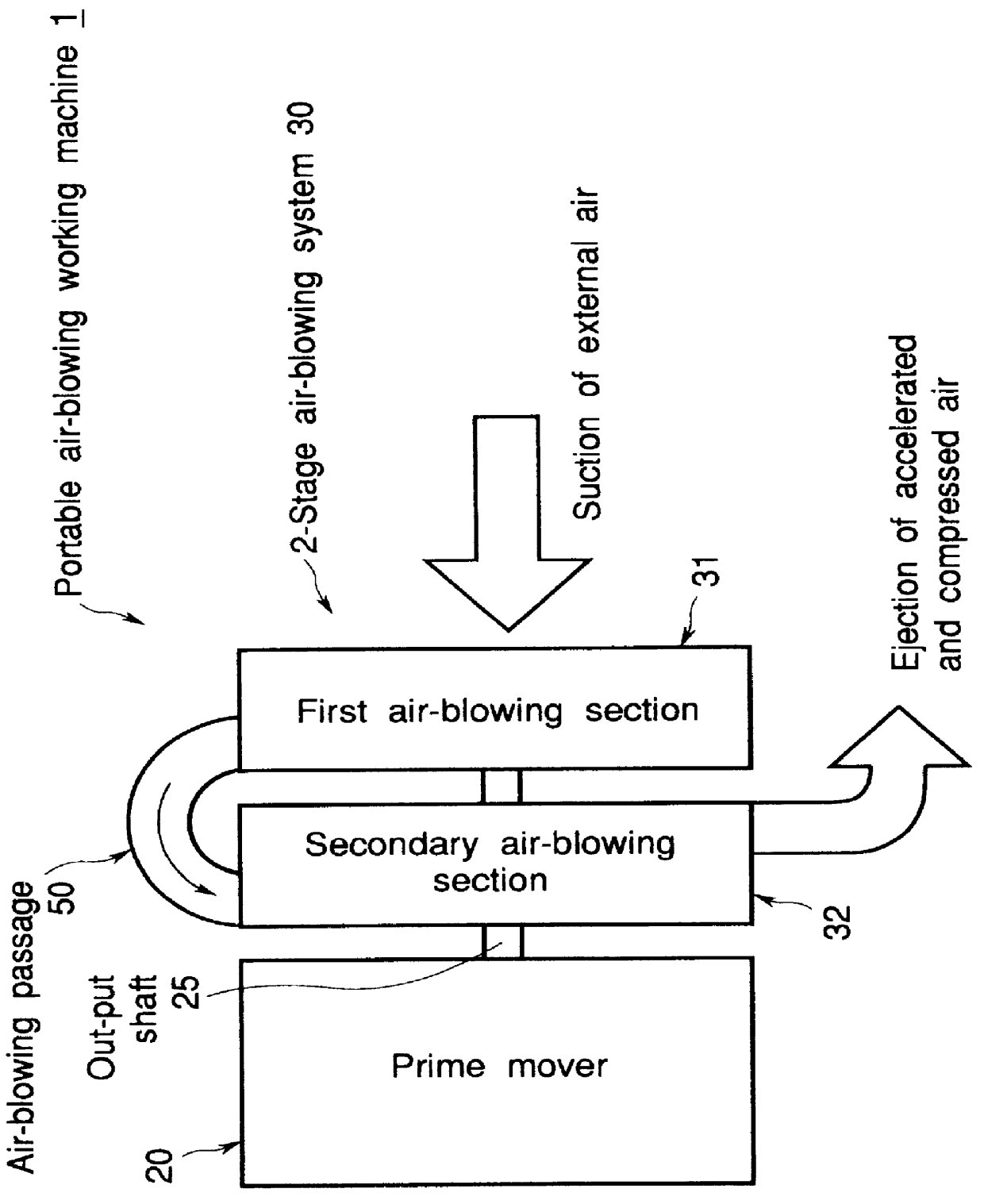

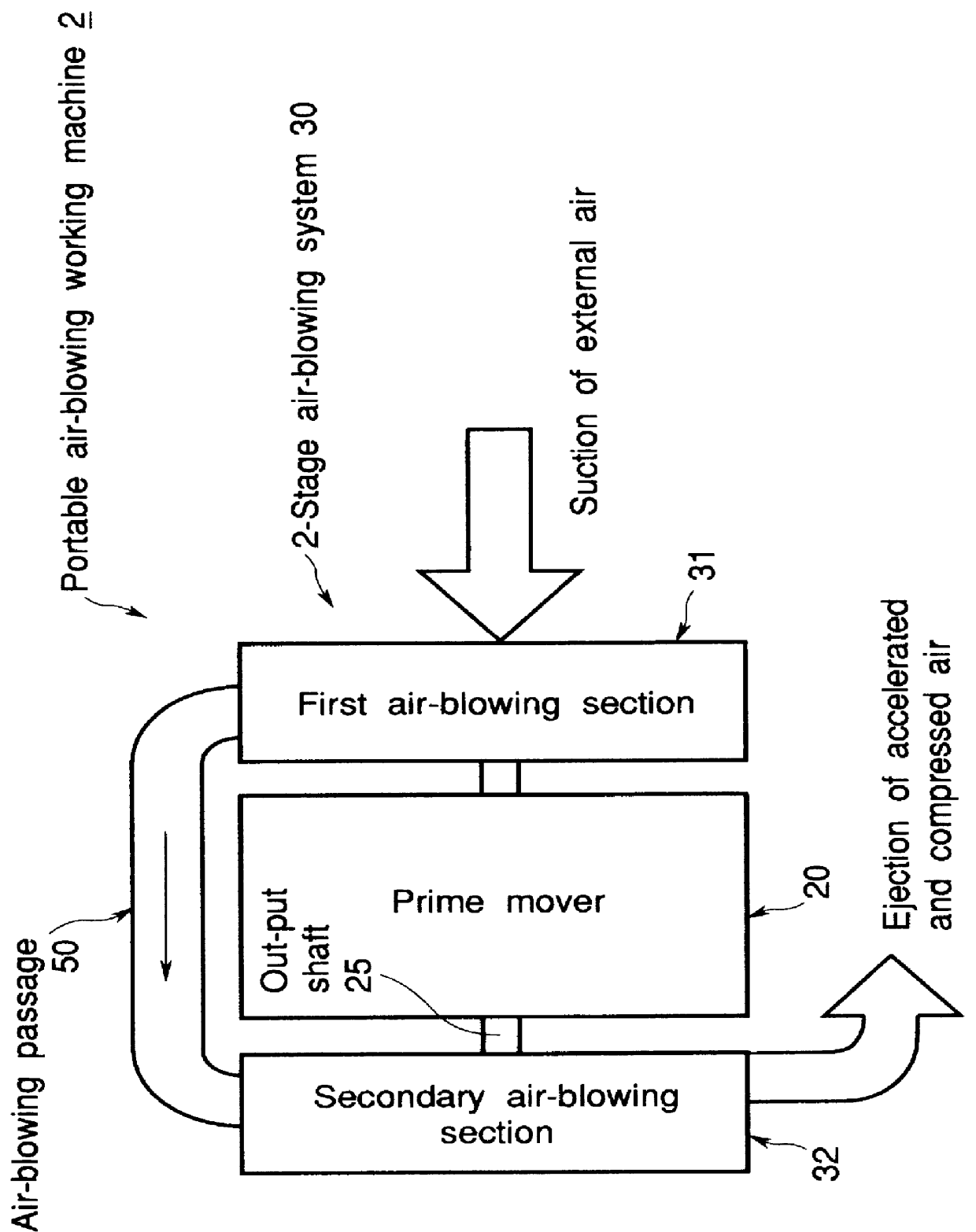

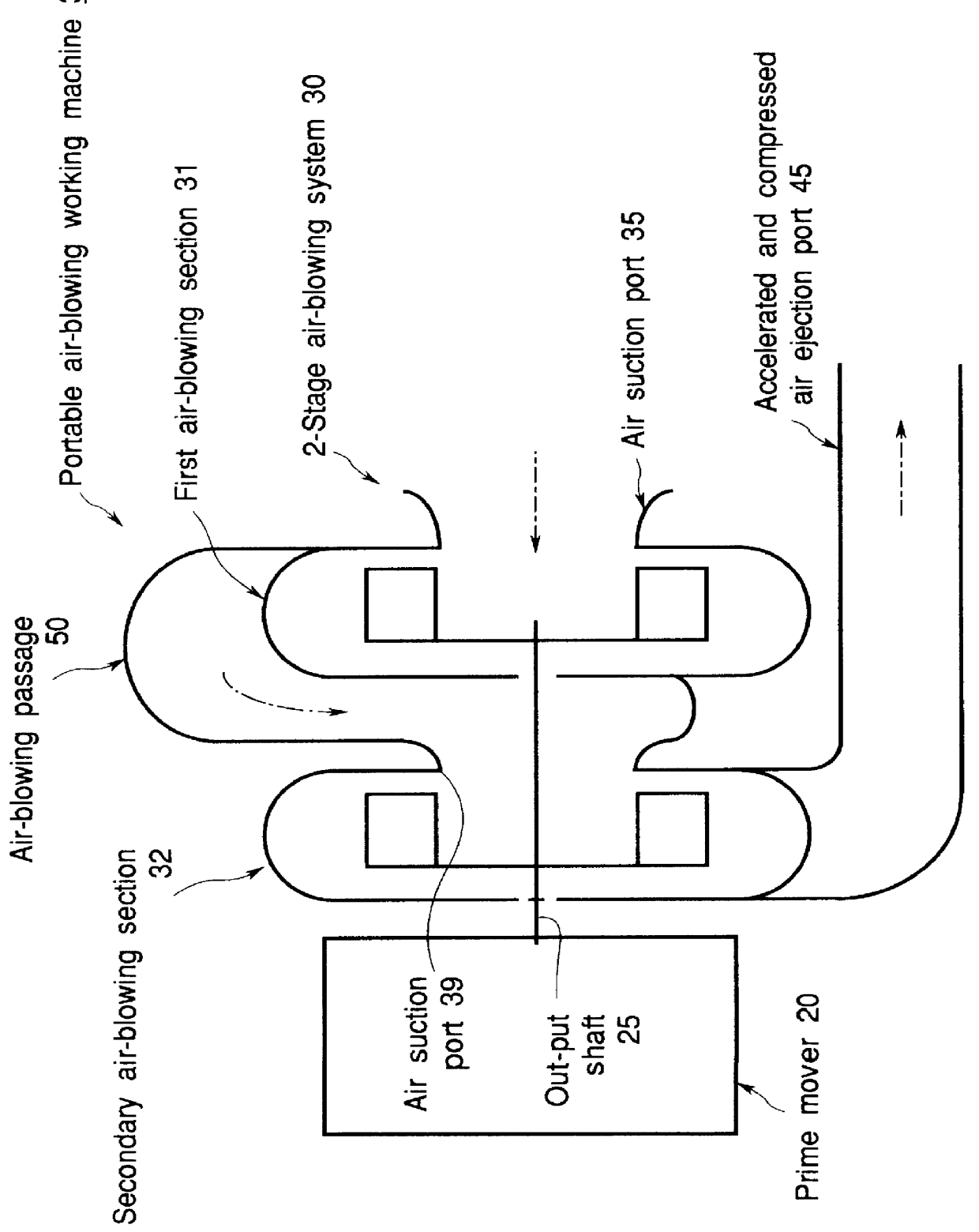

Portable air-blowing working machine

InactiveUS6109865ARevolution can be reducedReduce noiseHops/wine cultivationTurf growingAtmospheric airAtmosphere

A portable air-blowing working machine includes a prime mover and an air-blowing system. The air-blowing system incorporates first-stage and second-stage centrifugal air-blowing sections, which are rotatably driven by an output shaft of the prime mover and are interconnected by an air-blowing passage for delivering air discharged from the first-stage air-blowing section to the intake of the second-stage. In operation, external air is drawn into the first-stage air-blowing section, increased therein in velocity and pressure, and then continuously discharged via the air-blowing passage to the second-stage air-blowing section, where the air is further accelerated and compressed before being finally discharged to the atmosphere.

Owner:KIORITZ

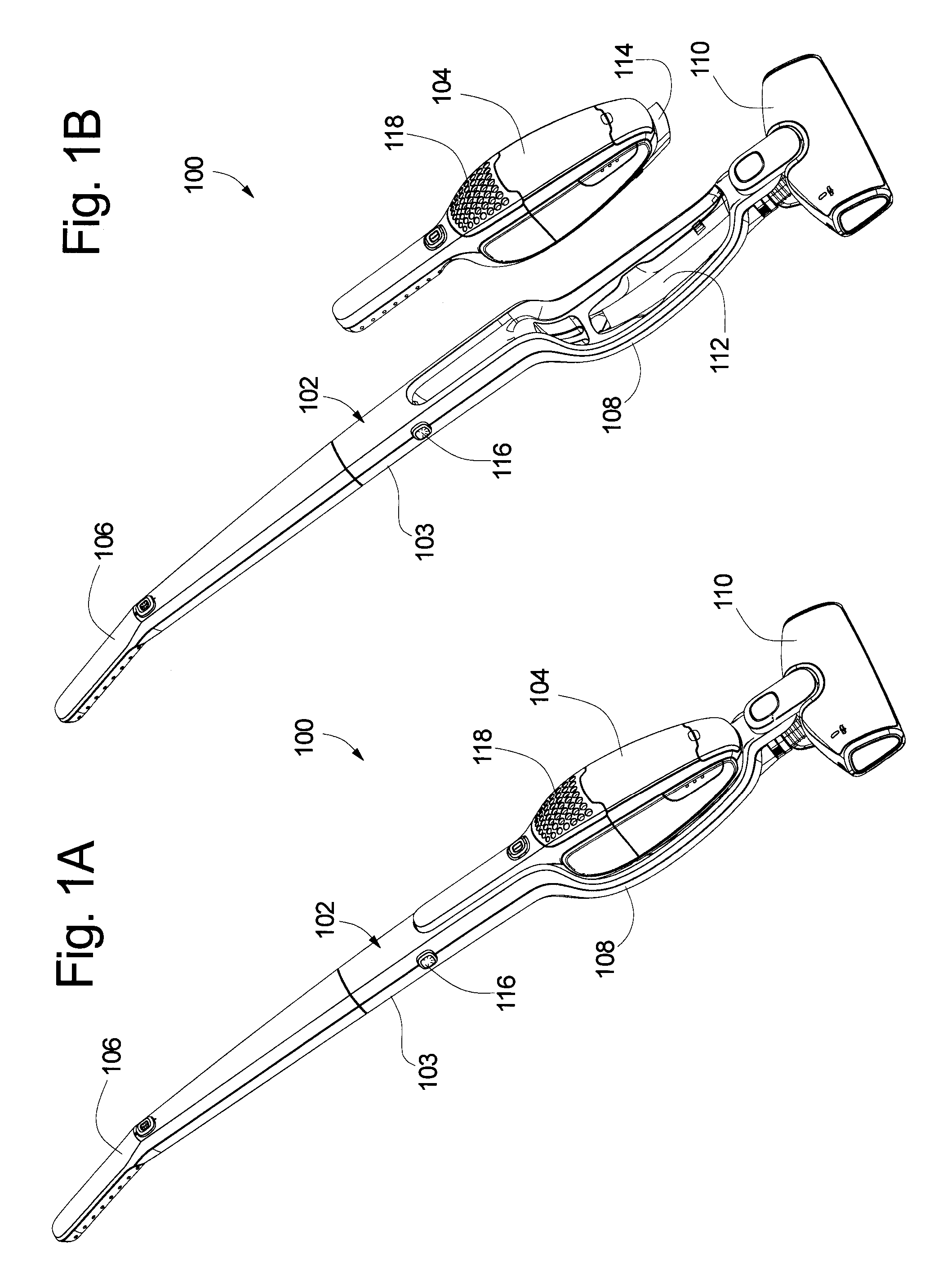

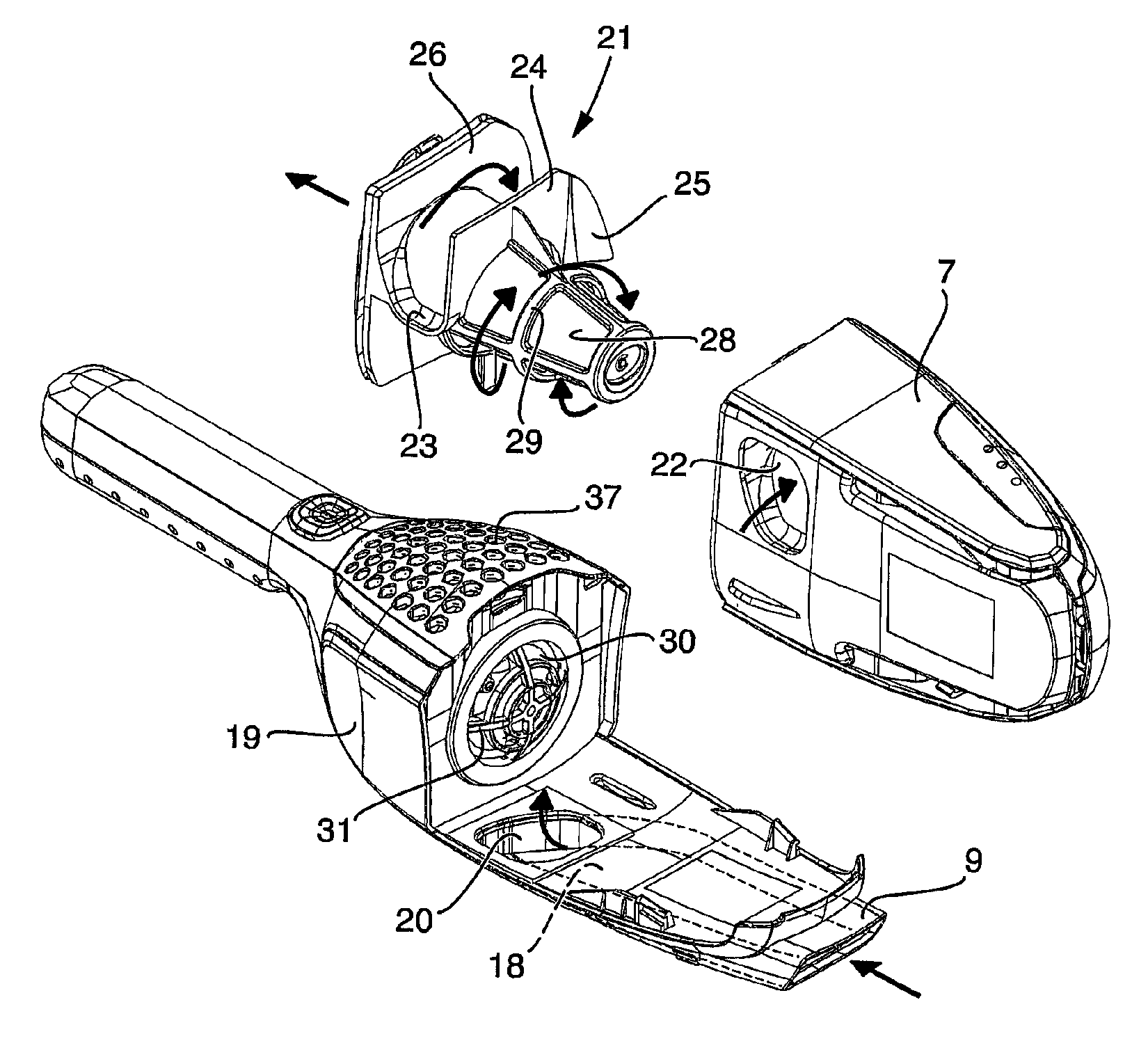

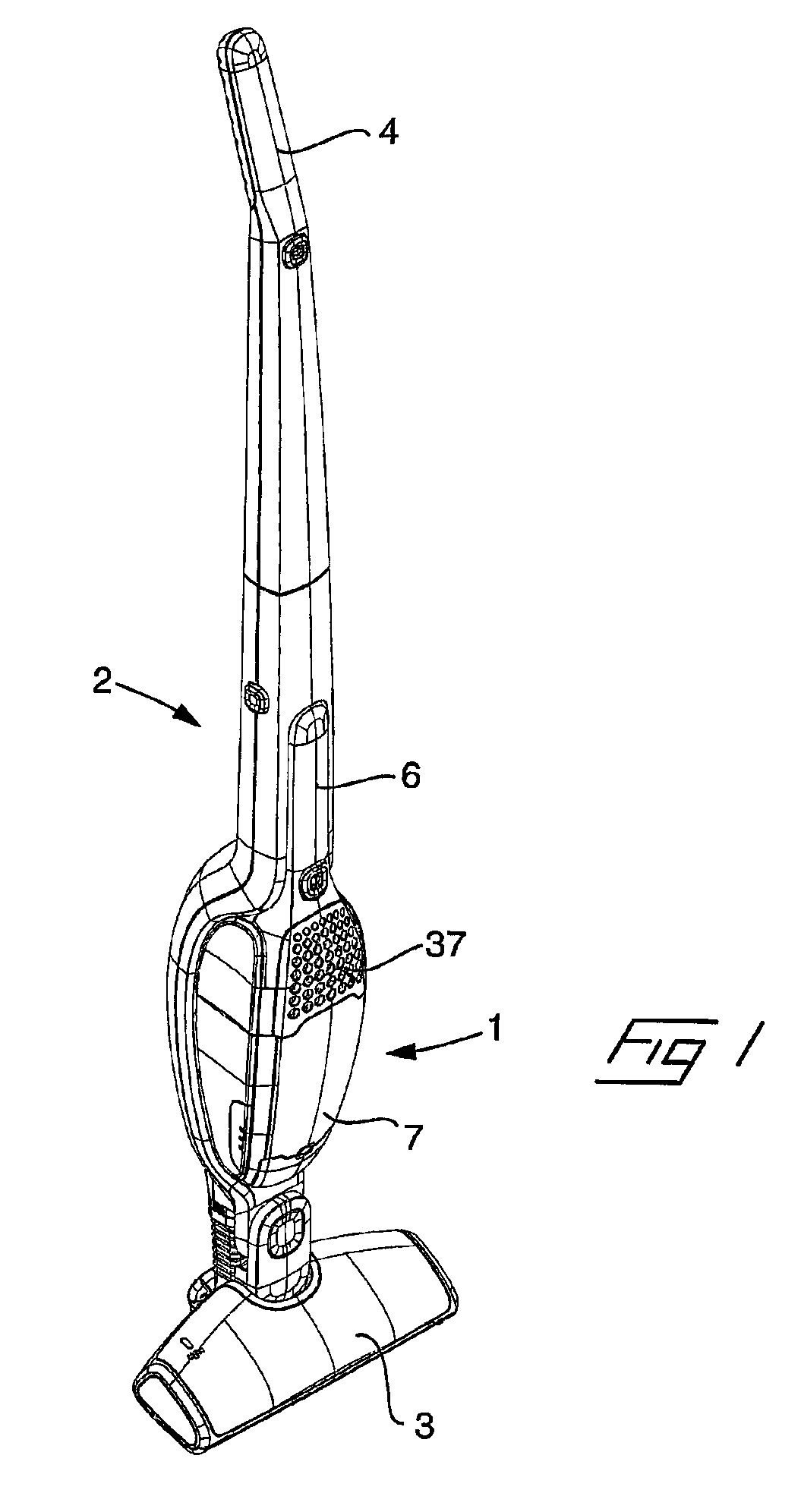

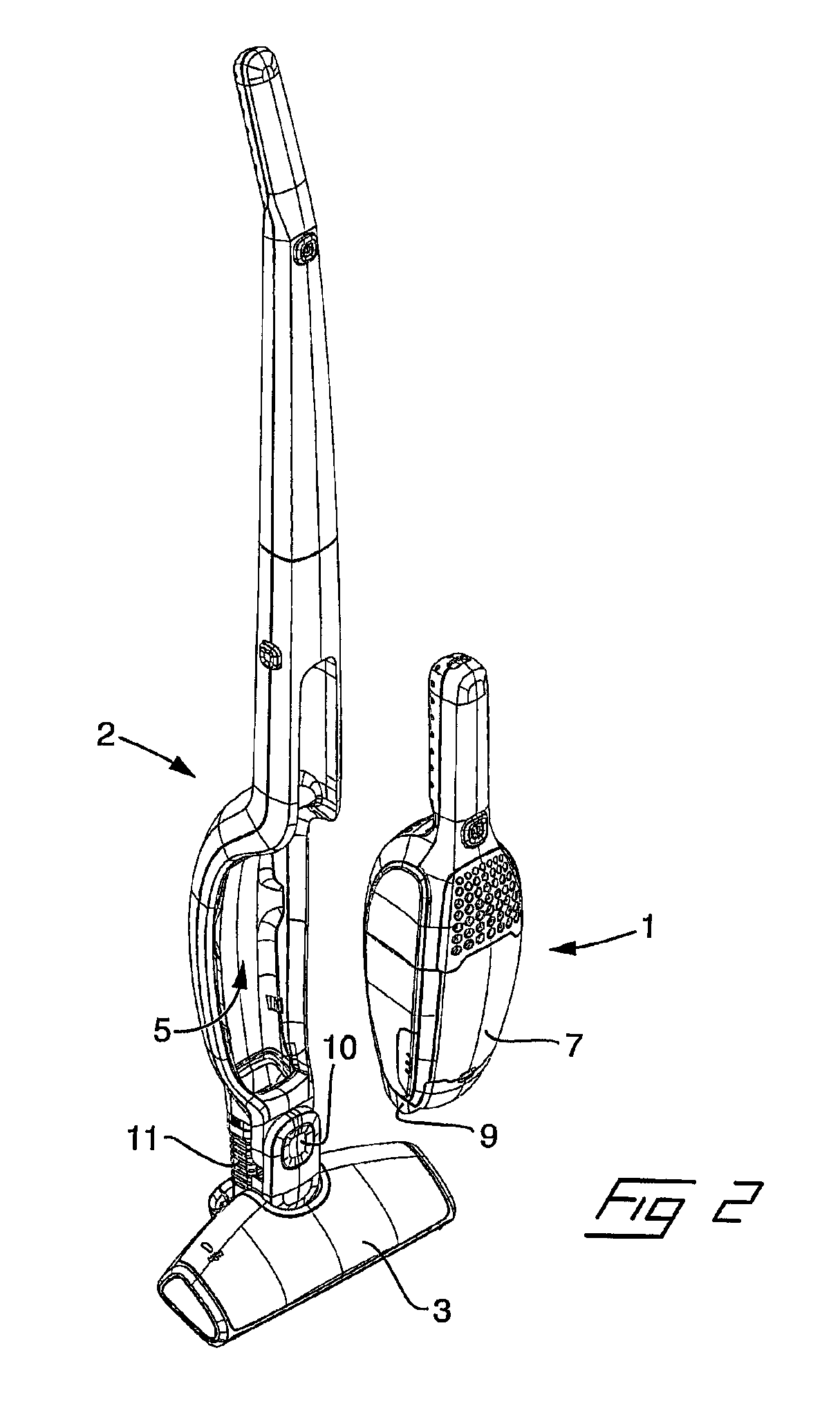

Air Flow Losses in Vacuum Cleaners

ActiveUS20100083459A1Improve suction efficiencyReducing air flow lossCleaning filter meansSuction filtersVacuum cleanerAirflow

A vacuum cleaner having an elongated support body, a nozzle attached to a lower end of the elongated support body by an articulated joint, a motor, a fan unit, a debris container, and an air passage that extends from the nozzle device, past the articulated joint by a flexible hose and to an air passage in the support body. The flexible hose is formed with a generally rectangular cross section.

Owner:AB ELECTROLUX

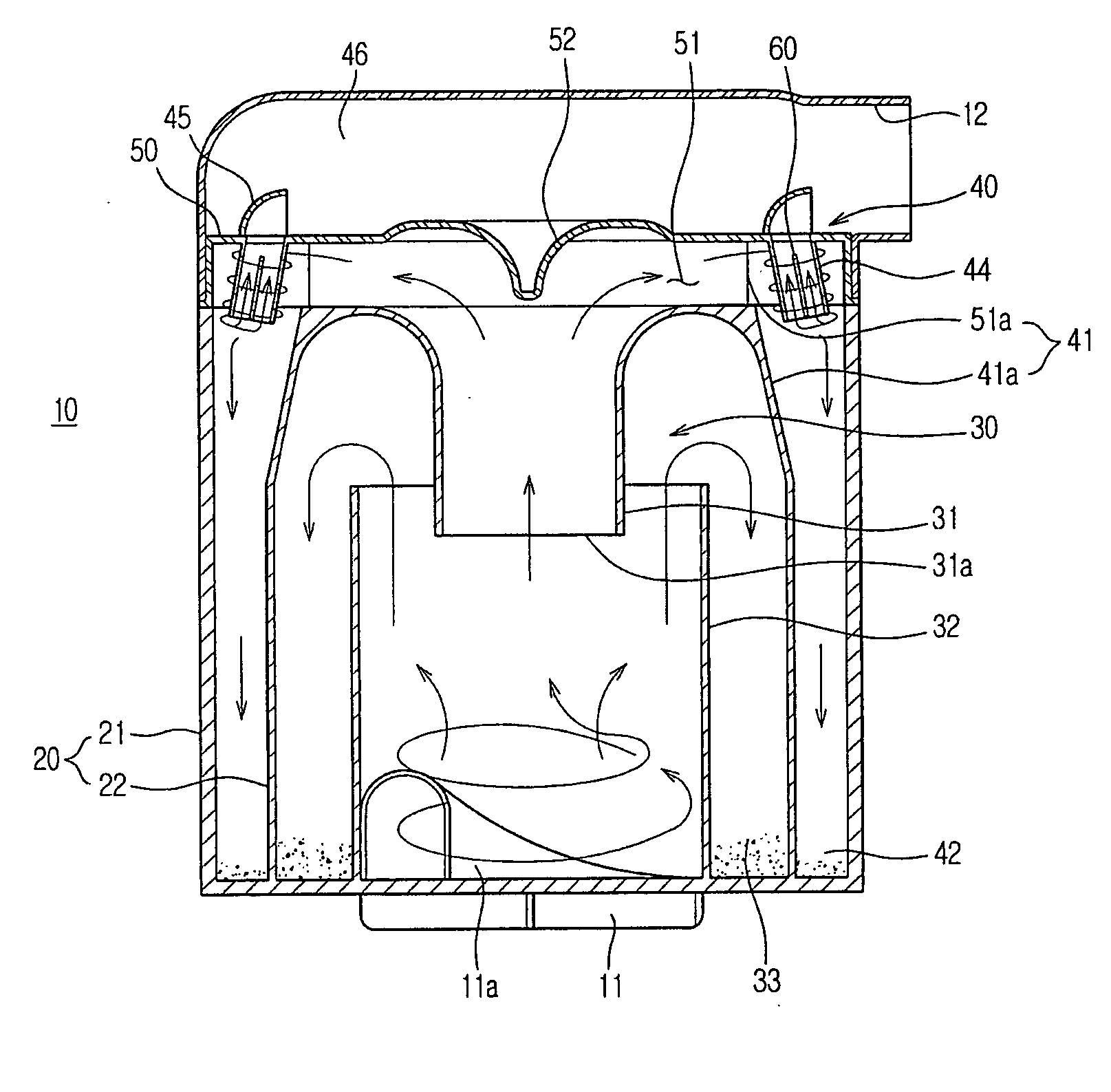

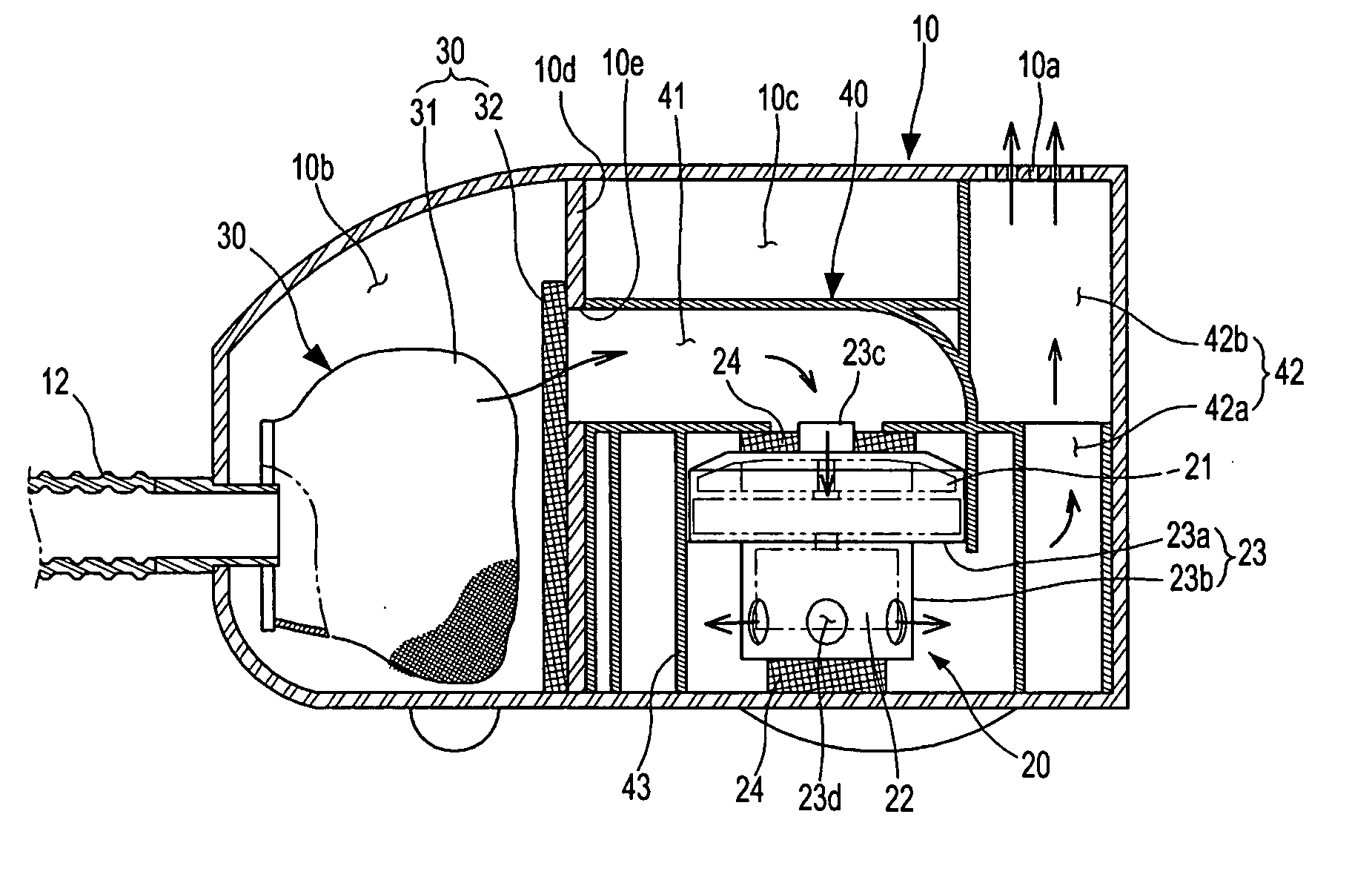

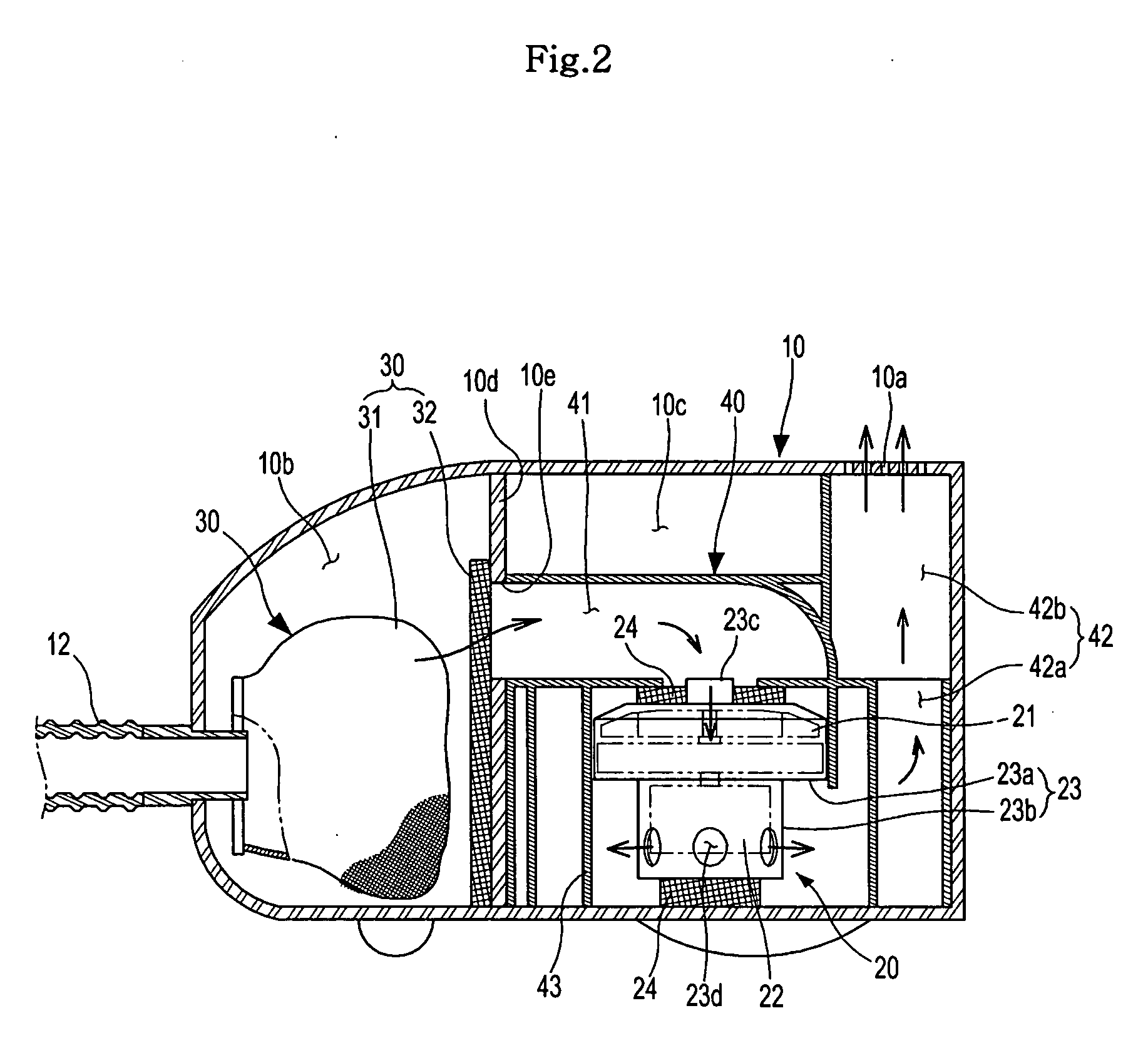

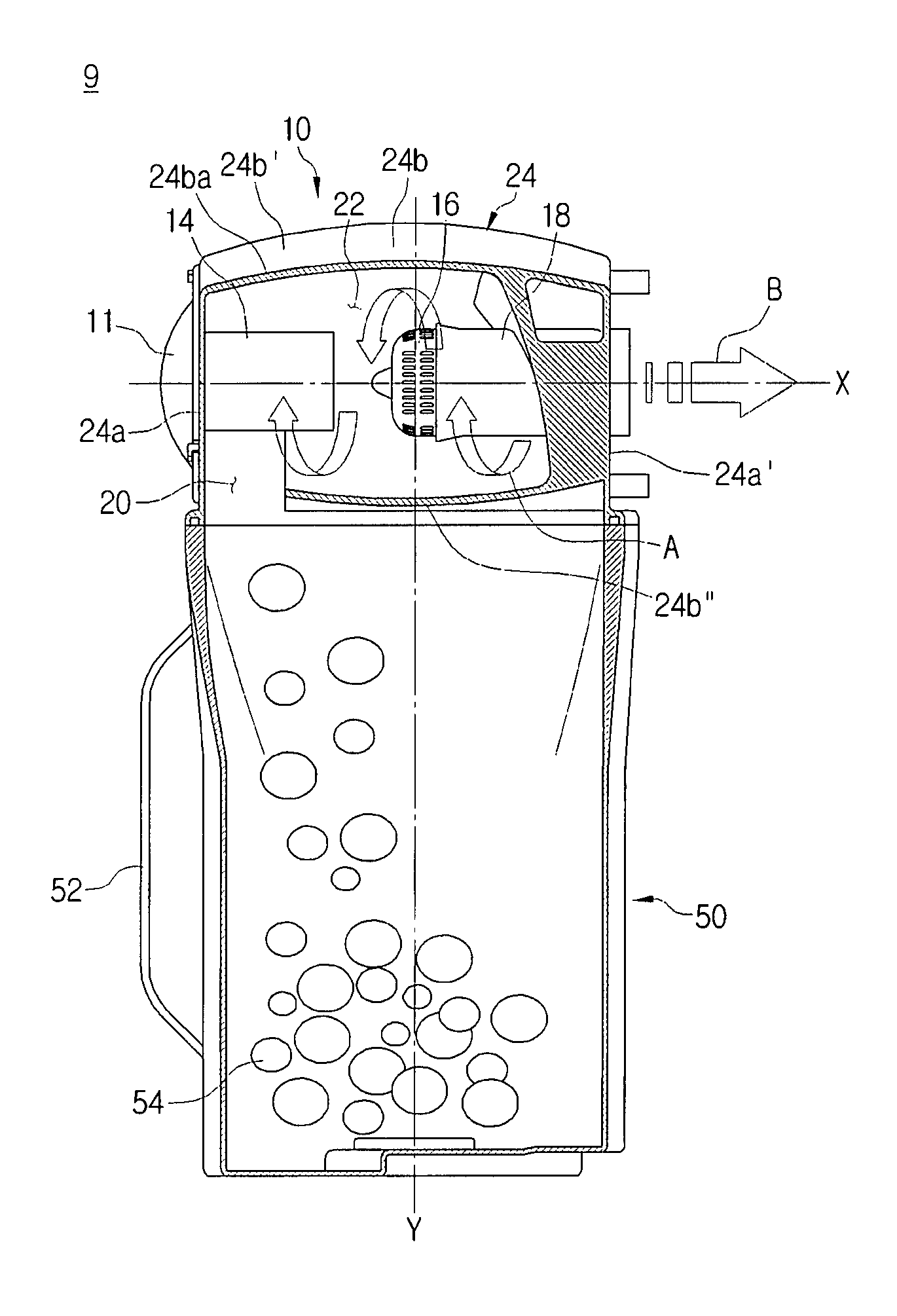

Electric vacuum cleaner

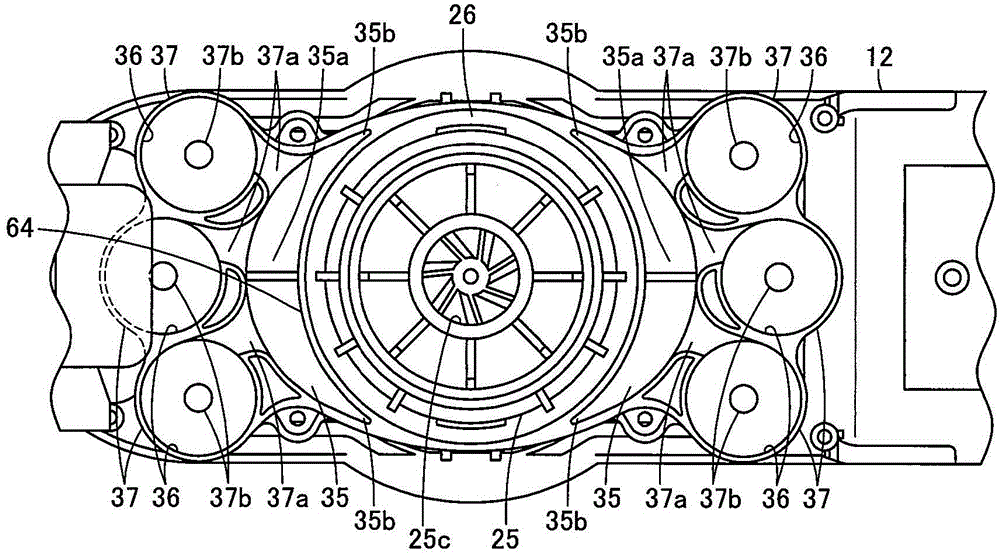

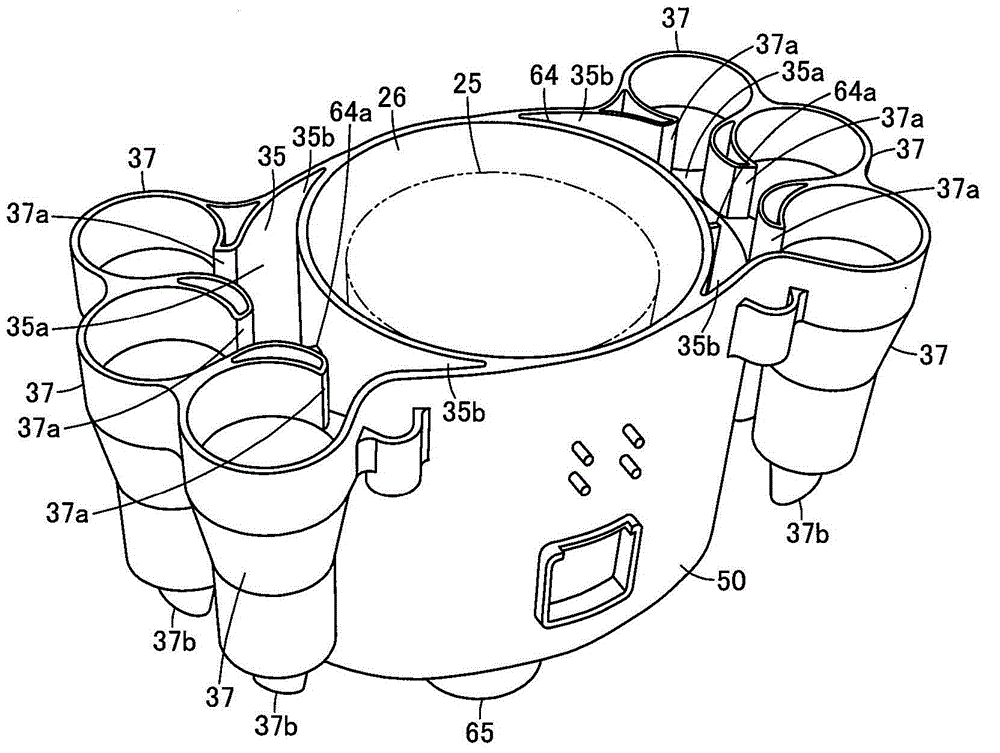

Provided is an electric vacuum cleaner in which quietness can be improved without increasing size while air-intake balance is guaranteed. The electric vacuum cleaner has an electric air blower (25). The electric vacuum cleaner has a separating section (39) for separating dust drawn in by the electric air blower (25). The separating section (39) is provided with a first centrifugal separating section (32) for centrifugally separating dust drawn in by the electric air blower (25). The separating section (39) is provided with a plurality of second centrifugal separating sections (36) for centrifugally separating dust that is smaller than the dust separated in the first centrifugal separating section (32). The second centrifugal separating sections (36) are in communication with the downstream side of the first centrifugal separating section (32), and are respectively arranged in positions on opposite sides of the electric air blower (25).

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

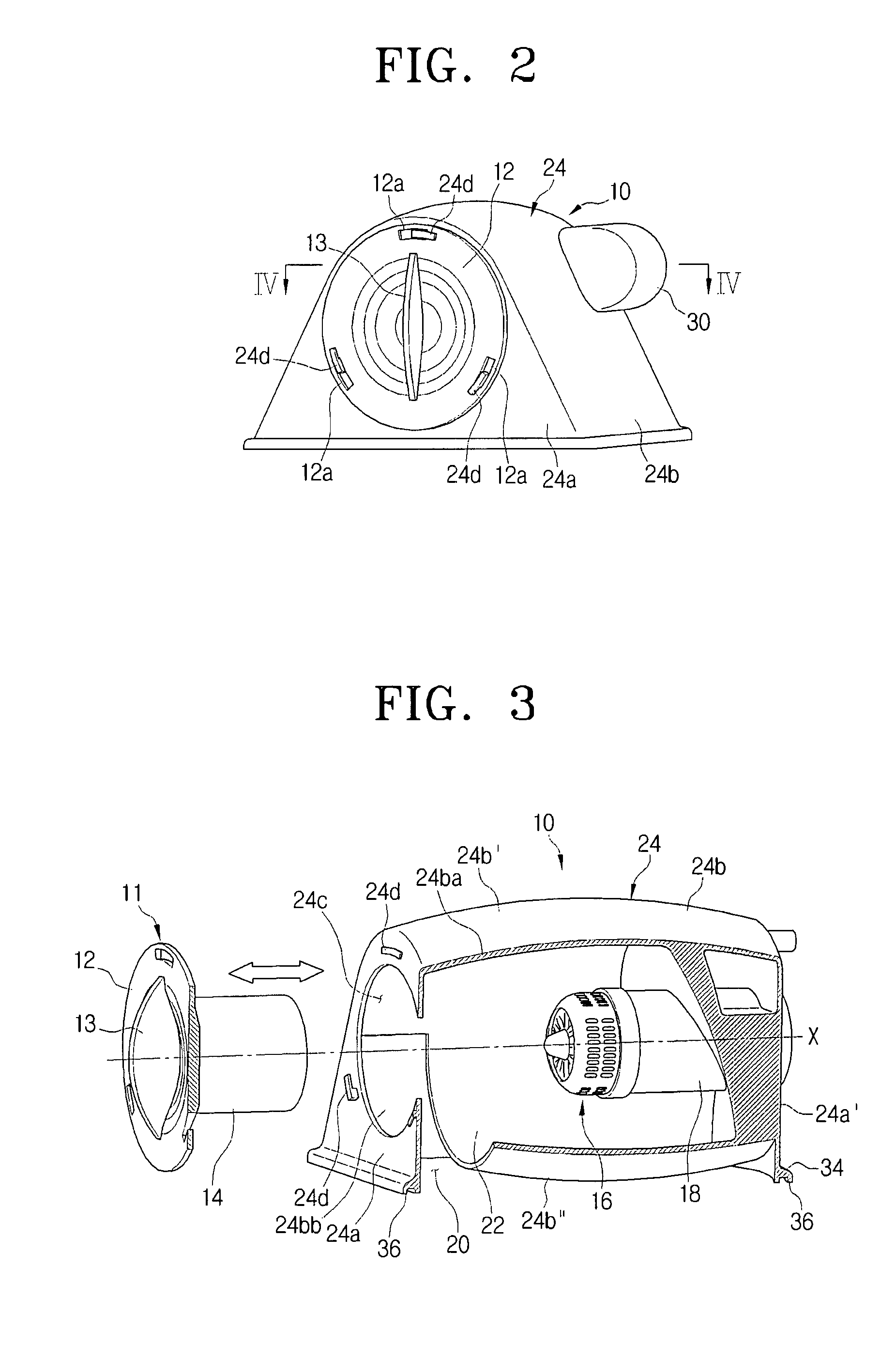

Fan motor apparatus having diffuser unit for vacuum cleaner

Owner:SAMSUNG ELECTRONICS CO LTD

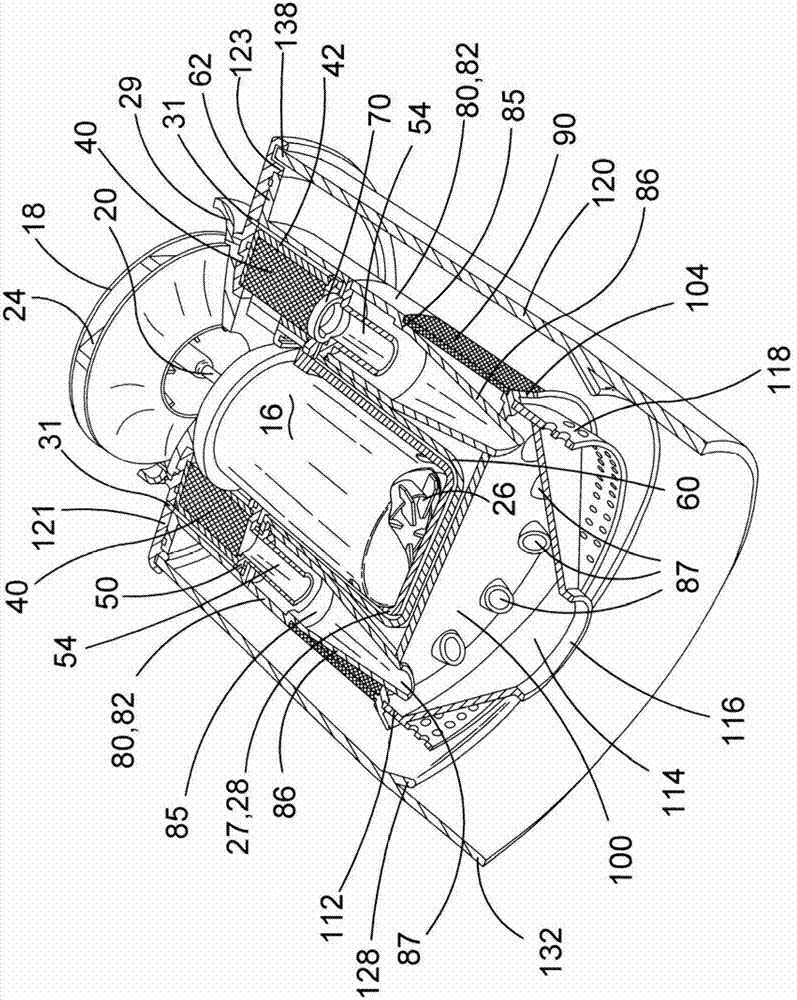

Structure for motor, fan and cyclonic separation apparatus

InactiveCN103040412AShortened fluid communicationReduce in quantitySuction filtersMotor fan assembly mountingCycloneCyclonic separation

A motor, fan and cyclonic separation apparatus arrangement for a vacuum cleaner, the arrangement comprising: a motor (16) coupled to a fan (18) for generating air flow,a cyclonic separation apparatus (8) located in a path of the air flow generated by the fan,and a pre-fan filter (40) located in the path of the air flow downstream of the cyclonic separation apparatus and upstream of the fan (18), wherein the cyclonic separation apparatus comprises at least one cyclone (84) comprising: a cyclone body (85,86) with a longitudinal axis (57),an air inlet port (88) arranged tangentially through a side of the cyclone body,and an air outlet port (56) through a longitudinal end of the cyclone body, wherein the pre-fan filter (40) is arranged upon the air outlet port of the or each cyclone.

Owner:BLACK & DECKER INC

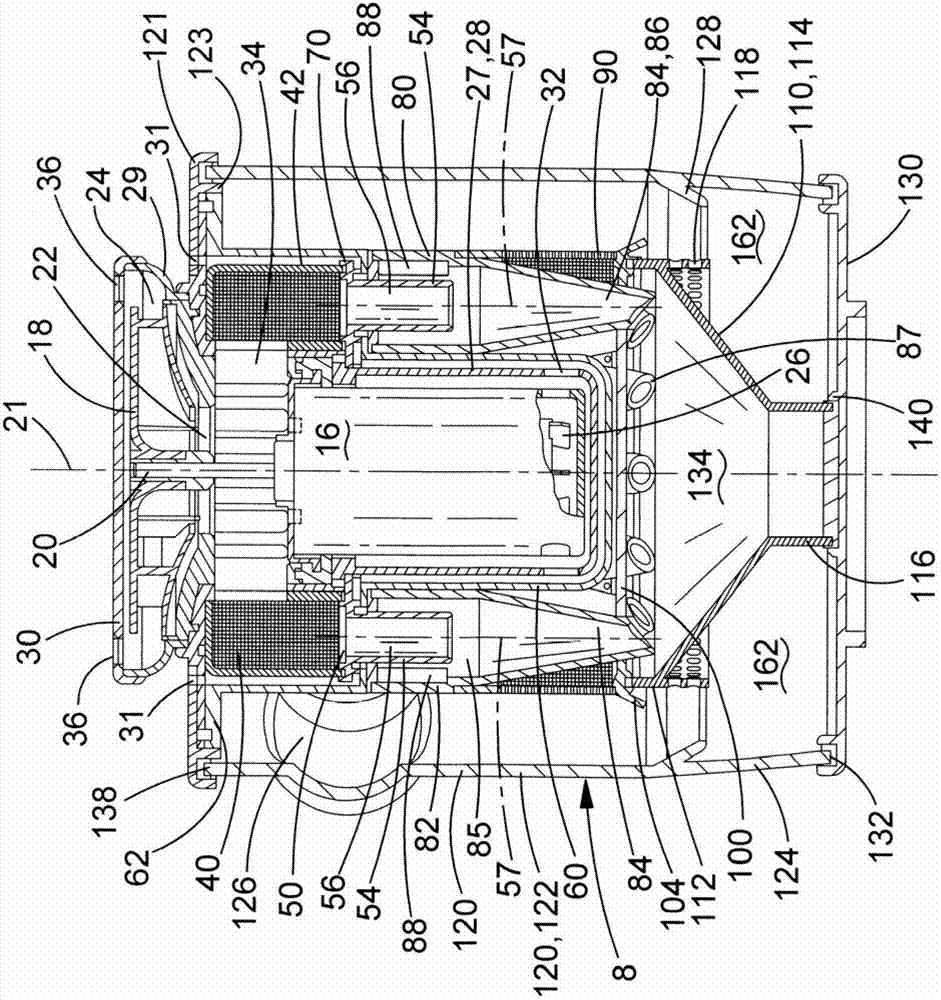

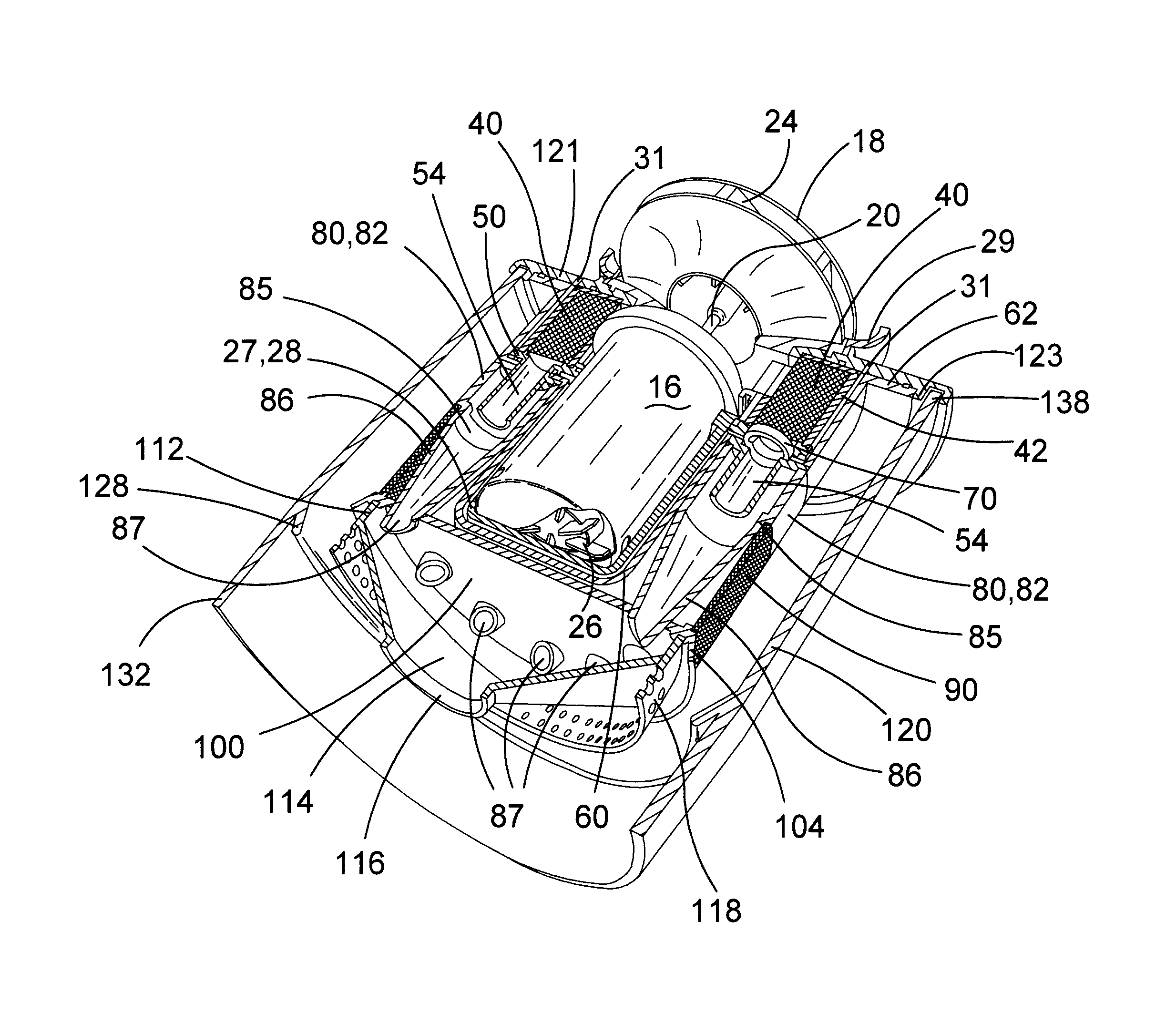

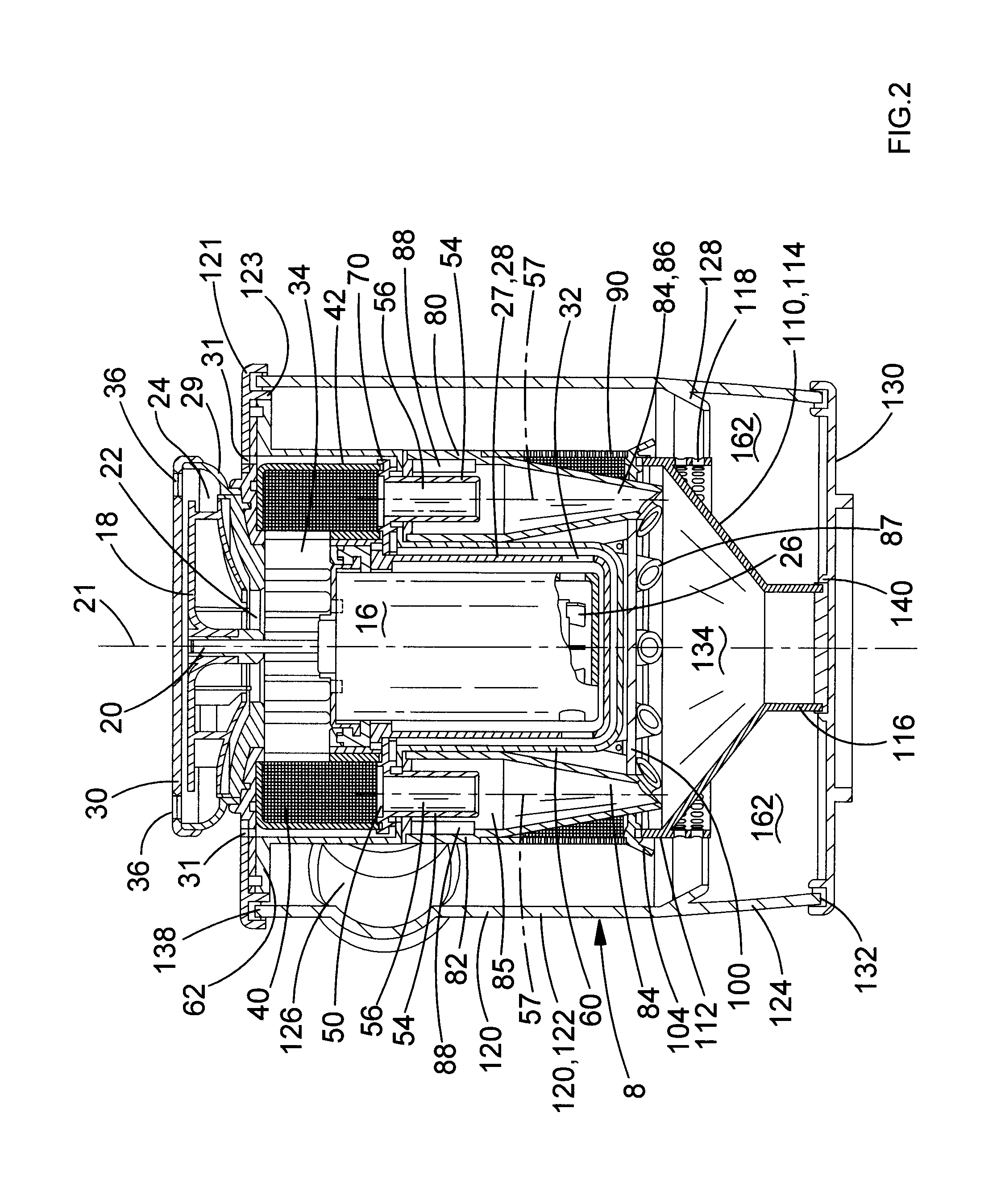

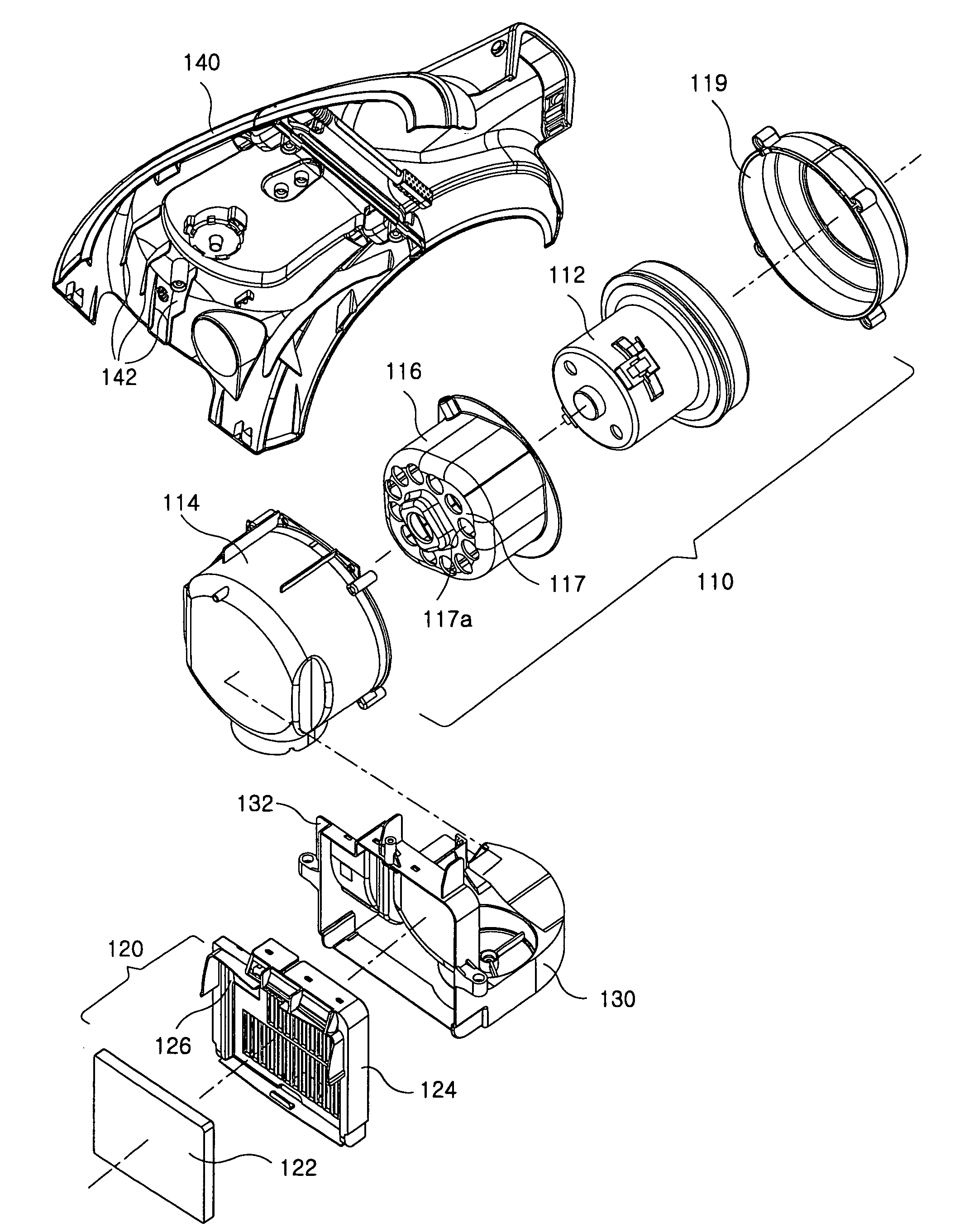

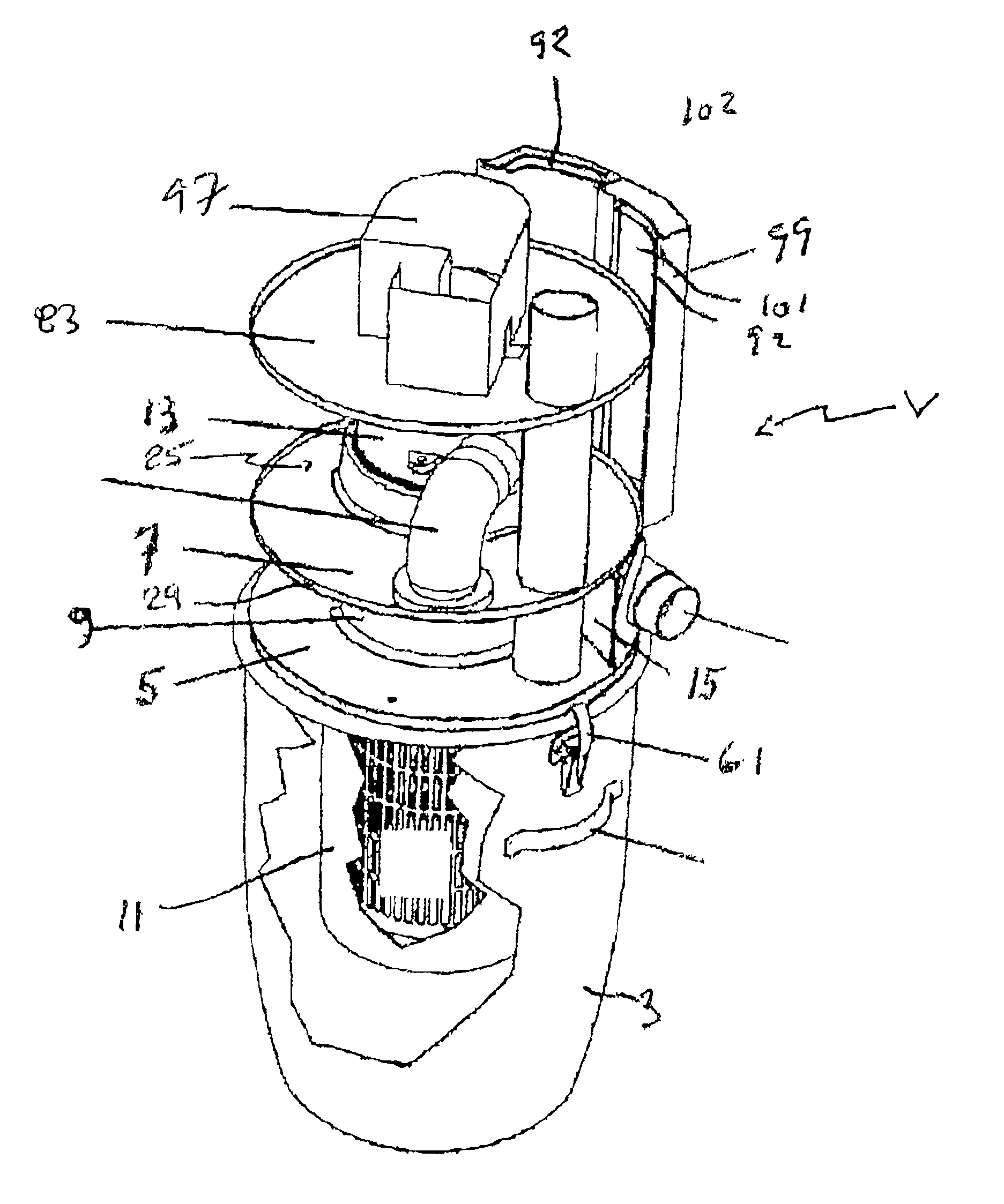

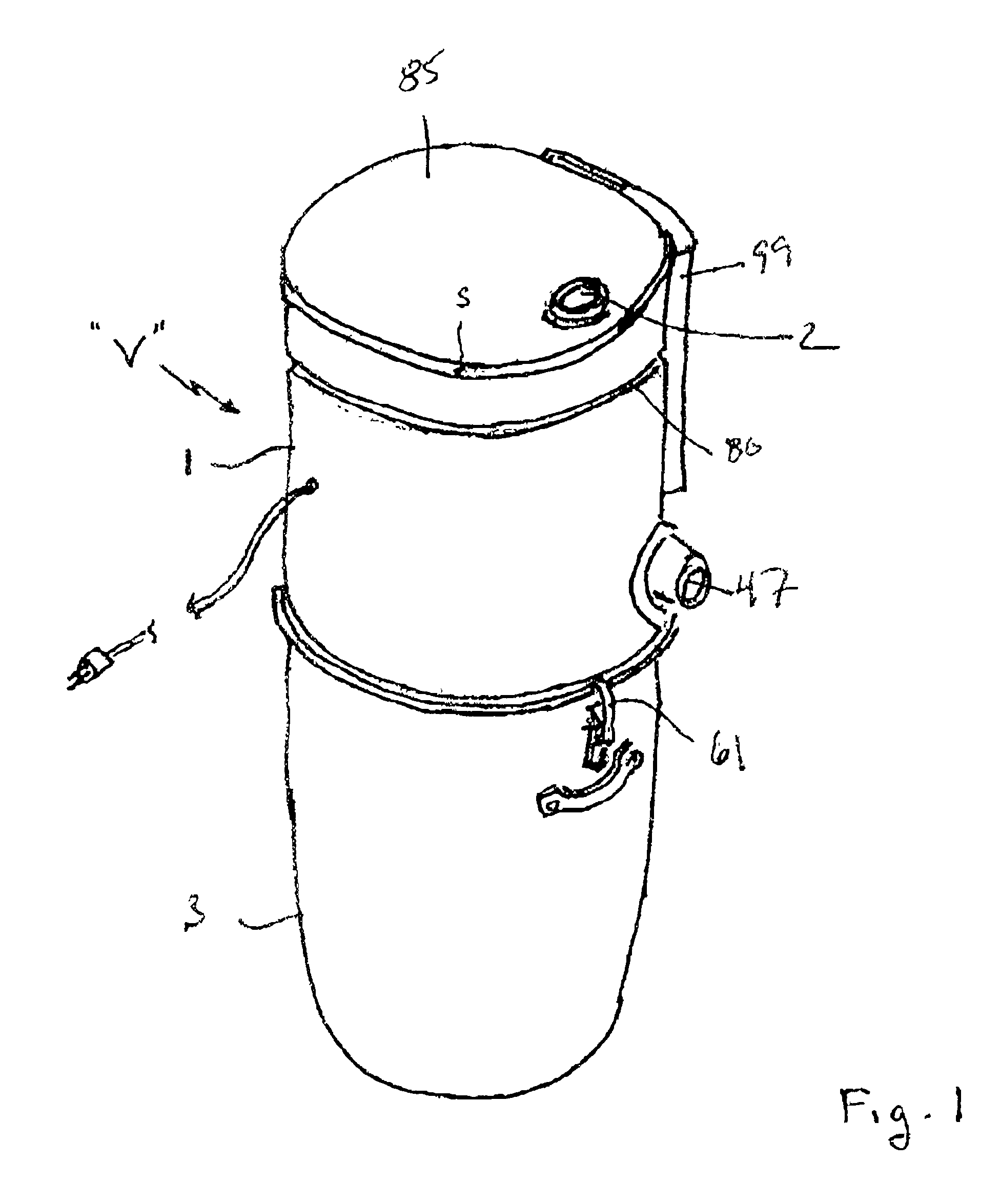

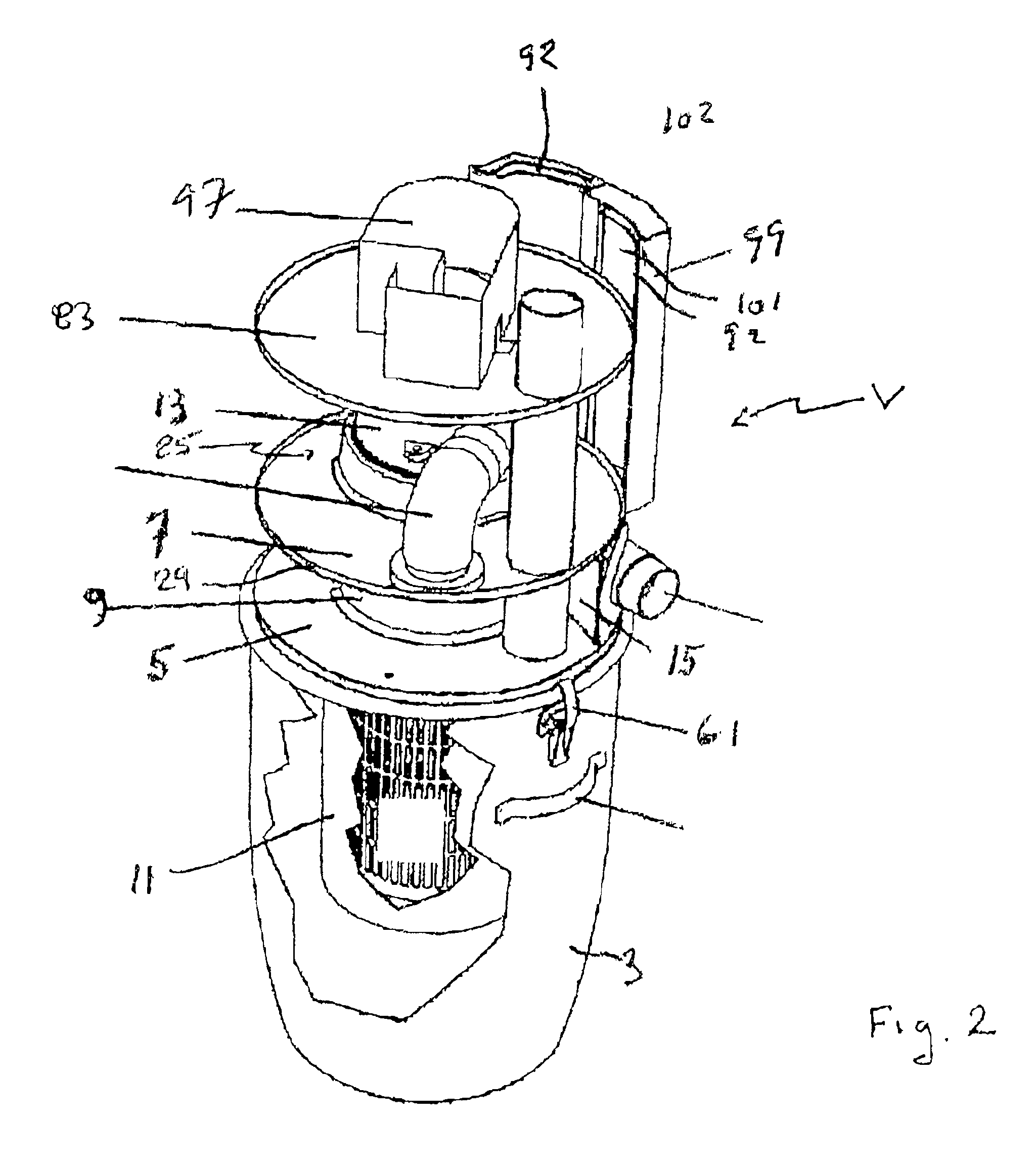

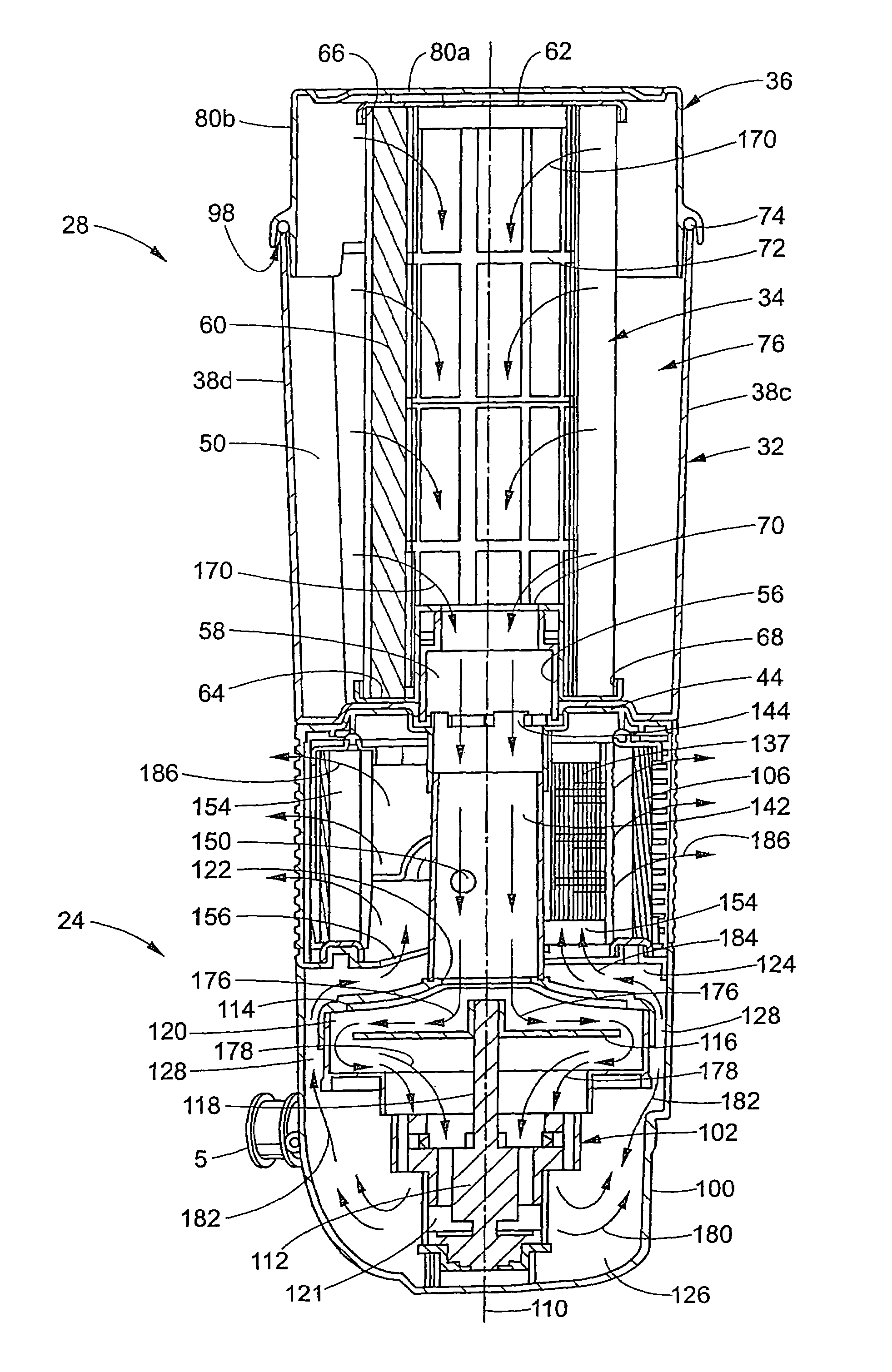

Motor, fan and dirt separation means arrangement

ActiveUS9144358B2Easy to useImproved internal coolingCombination devicesSuction filtersDrive shaftControl theory

A motor, fan and dirt separating means arrangement for a vacuum cleaner, the arrangement comprising: a motor with a drive shaft; a fan coupled to the motor for generating air flow; and a dirt separating means located in a cleaning path of the air flow, the cleaning path being between a dirty air inlet and the fan, wherein the motor is located in a cooling path of the air flow, the cooling path being between a clean air inlet and the fan, wherein the air flow through the cleaning path is substantially greater than through the cooling path in normal operating conditions and wherein the cleaning path and the cooling path of the air flow combine substantially at the fan inlet. A vacuum cleaner comprising the motor, fan and dirt separating means arrangement.

Owner:BLACK & DECKER INC

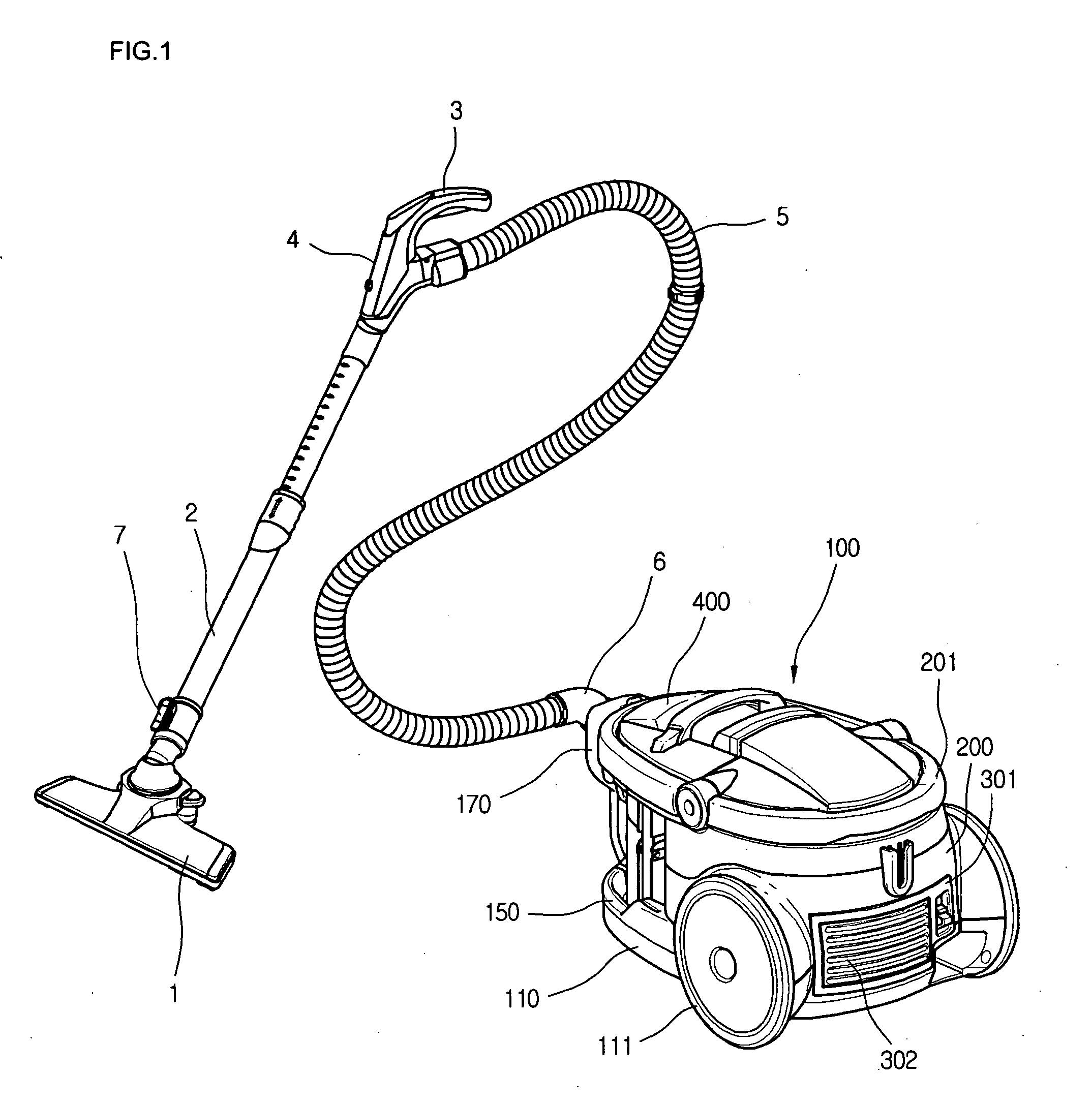

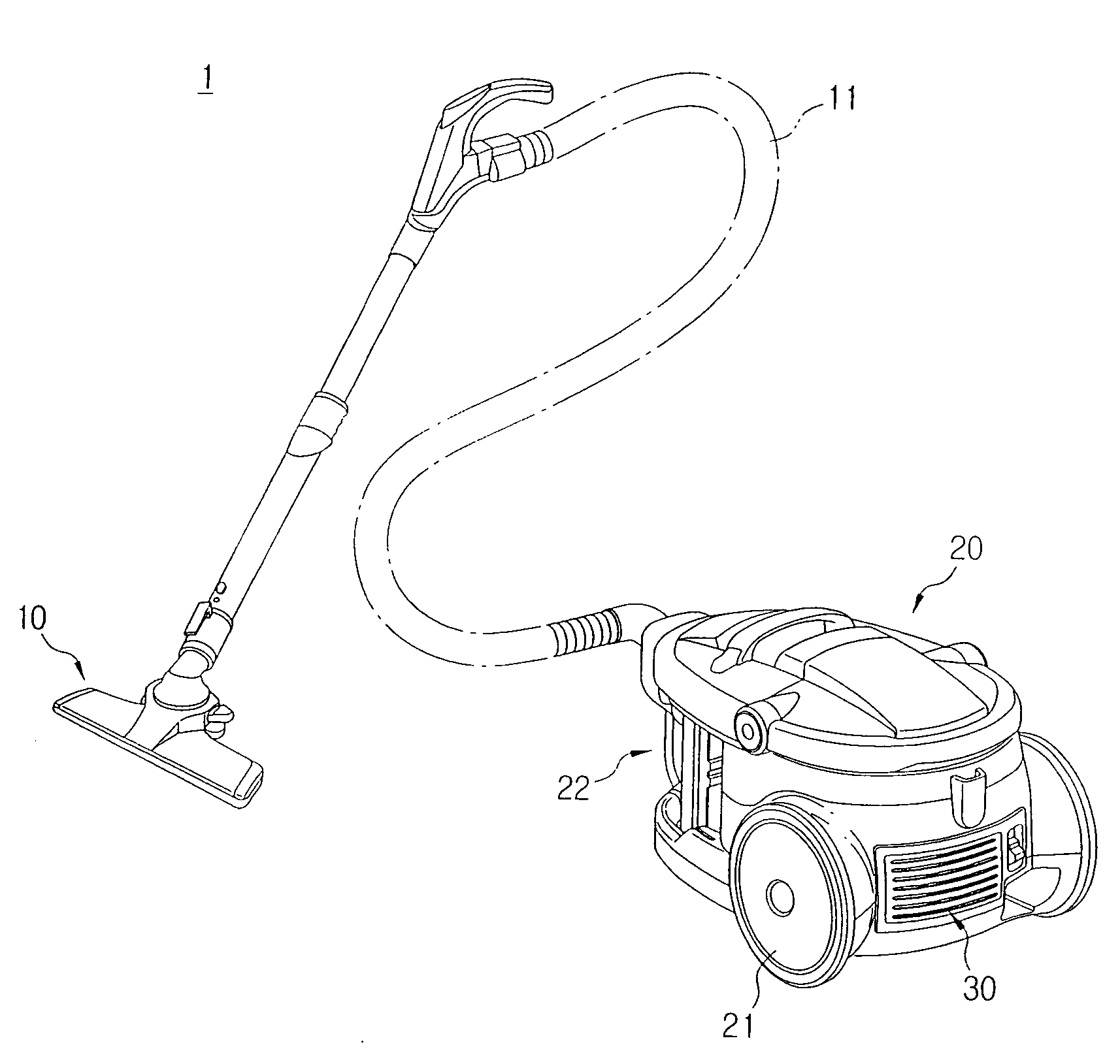

Vacuum cleaner

A vacuum cleaner includes a main body, a motor assembly installed at the main body, the motor assembly including a motor for generating a suction force, an exhaust filter for filtering fine foreign substances from air passing through the motor assembly, and a guide member for guide a portion of air going via the exhaust filter to the inside of the main body. The guide member has a horizontal guide member and a vertical guide member for guiding portions of air passing through the exhaust filter to the side and the top of the main body respectively.

Owner:DAEWOO ELECTRONICS CO LTD

Motor, fan and cyclonic separation apparatus arrangement for a vacuum cleaner

ActiveUS9005324B2Shorten the lengthReduce energy lossCombination devicesSuction filtersCycloneCyclonic separation

A motor, fan and cyclonic separation apparatus arrangement for a vacuum cleaner, the arrangement comprising: a motor coupled to a fan for generating air flow; and a cyclonic separation apparatus located in a path of the air flow generated by the fan, wherein the cyclonic separation apparatus comprises: a plurality of cyclones each with an air inlet port and an air outlet port wherein the cyclones are arranged in a generally circular array about a central axis of the cyclonic separation apparatus; and a cooling air flow path, wherein the motor is nested within the generally circular array of cyclones and wherein the motor is located in the cooling air flow path. A vacuum cleaner comprising the motor, fan and cyclonic separation apparatus arrangement.

Owner:BLACK & DECKER INC

Quiet central vacuum power unit

The present invention relates to a central vacuum power unit comprising in combination a canister, a chamber for collecting debris, a first plate, a second plate, a third plate, a duct, a motor-fan assembly, a filter, and a first baffle. The duct extends between the first and second plates and is in fluid flow communication with respective openings defined in the first and second plates. The sidewall of the canister, the first and the second plates and the duct defines an acoustic damping chamber covered with a lining of sound absorbing material.

Owner:NUERA SOLUTIONS AIR NUERA AIR SOLUTIONS

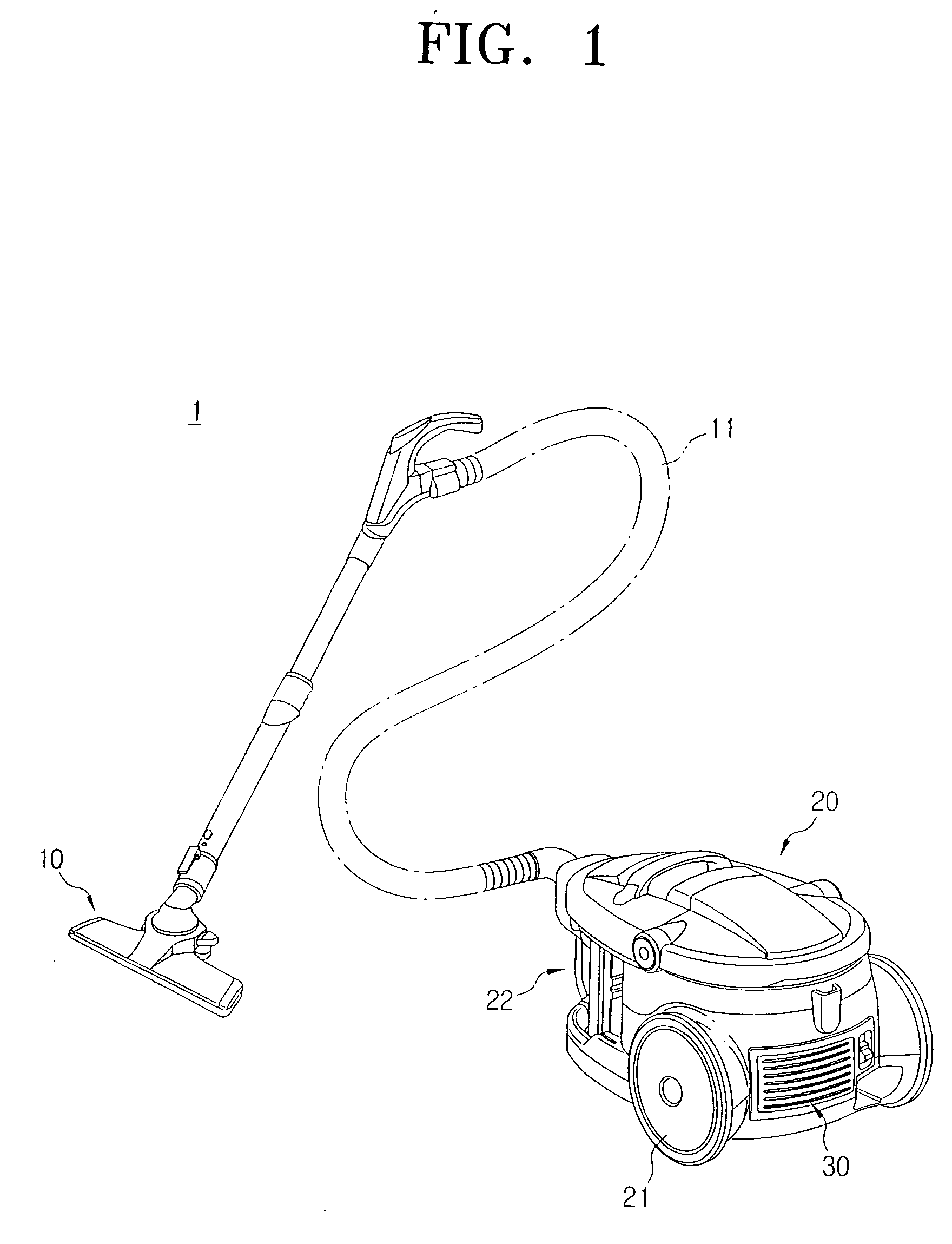

Vacuum cleaner

InactiveUS20060277711A1Avoid noiseReduce noise transmissionSuction filtersPump componentsForeign matterSuction force

A vacuum cleaner for reducing noise from being transmitted to the exterior. The vacuum cleaner includes a main body forming an outer appearance of the vacuum cleaner and including a blower unit for generating suction force and blowing force and a discharge hole through which purified air from which foreign matter has been filtered is discharged, a discharge passage for guiding air discharged from the blower unit to the discharge hole, and a spiral shaped intercepting passage for forming a part of the discharge passage and for preventing noise of the blower unit from being transmitted to the exterior. A guide member forming the intercepting passage is disposed at the outside of the blower unit and serves as an acoustic absorber so that noise transmission to the exterior is reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

Dust collection unit and vacuum cleaner with the same

ActiveUS7419520B2Prevent overloadImprove dust removal efficiencyCleaning filter meansCombination devicesForeign matterEngineering

A dust collection unit for a vacuum cleaner includes a dust collection container for collecting foreign objects contained in air introduced therein, covers defining a top and bottom of the dust collection container, and a filter-cleaning unit having a plurality of brushes rotating around the porous filter unit to remove the foreign objects clogging the outer surface of the porous filter unit.

Owner:LG ELECTRONICS INC

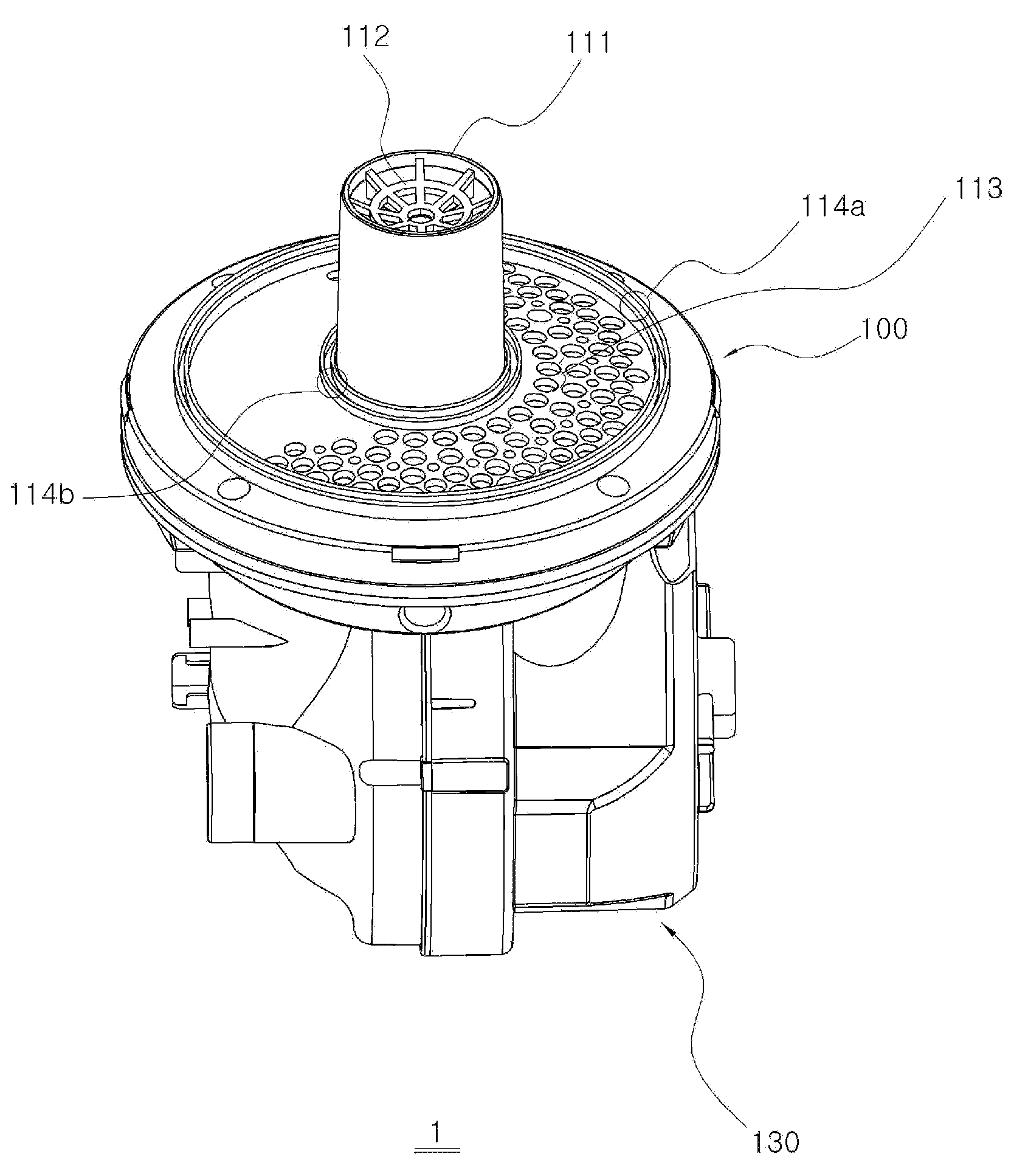

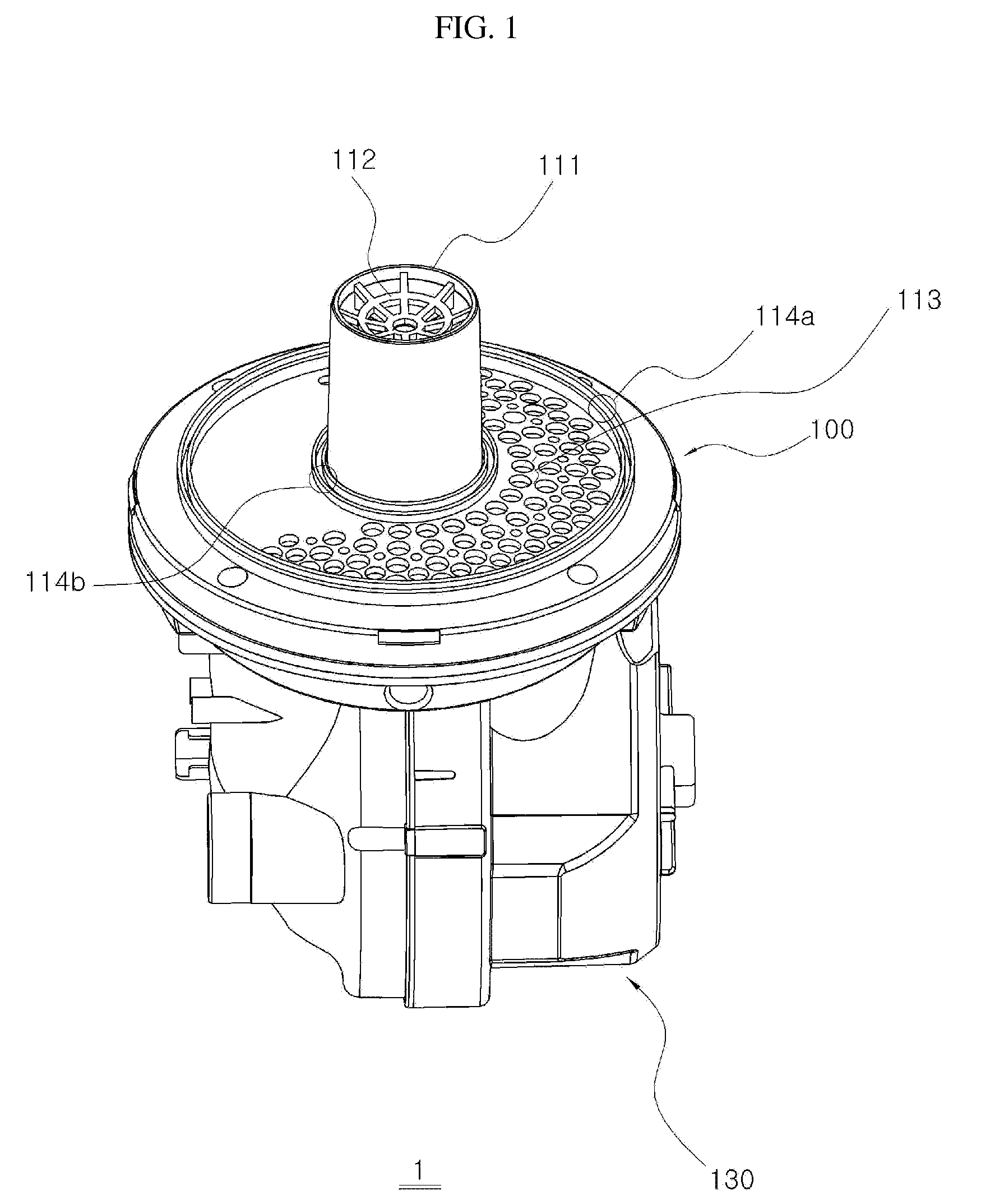

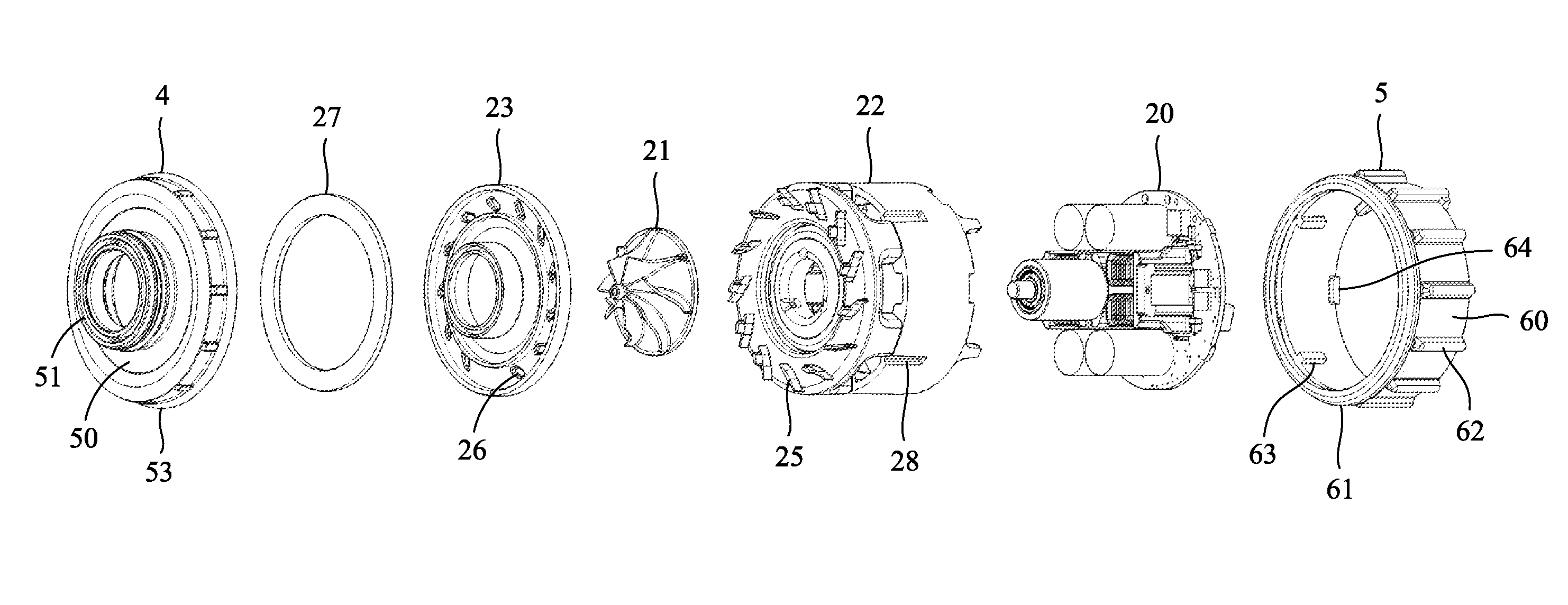

Fan motor apparatus having diffuser unit for vacuum cleaner

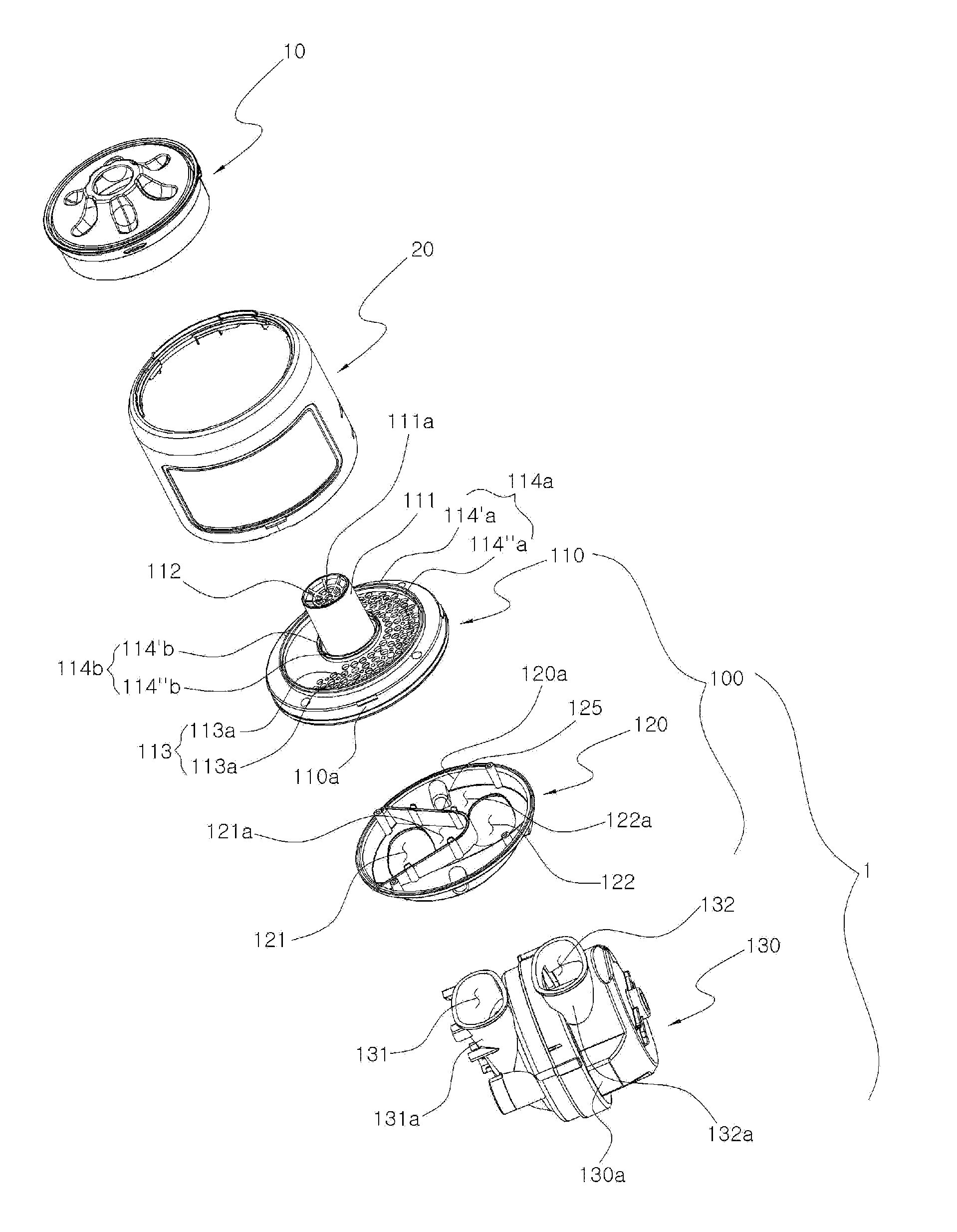

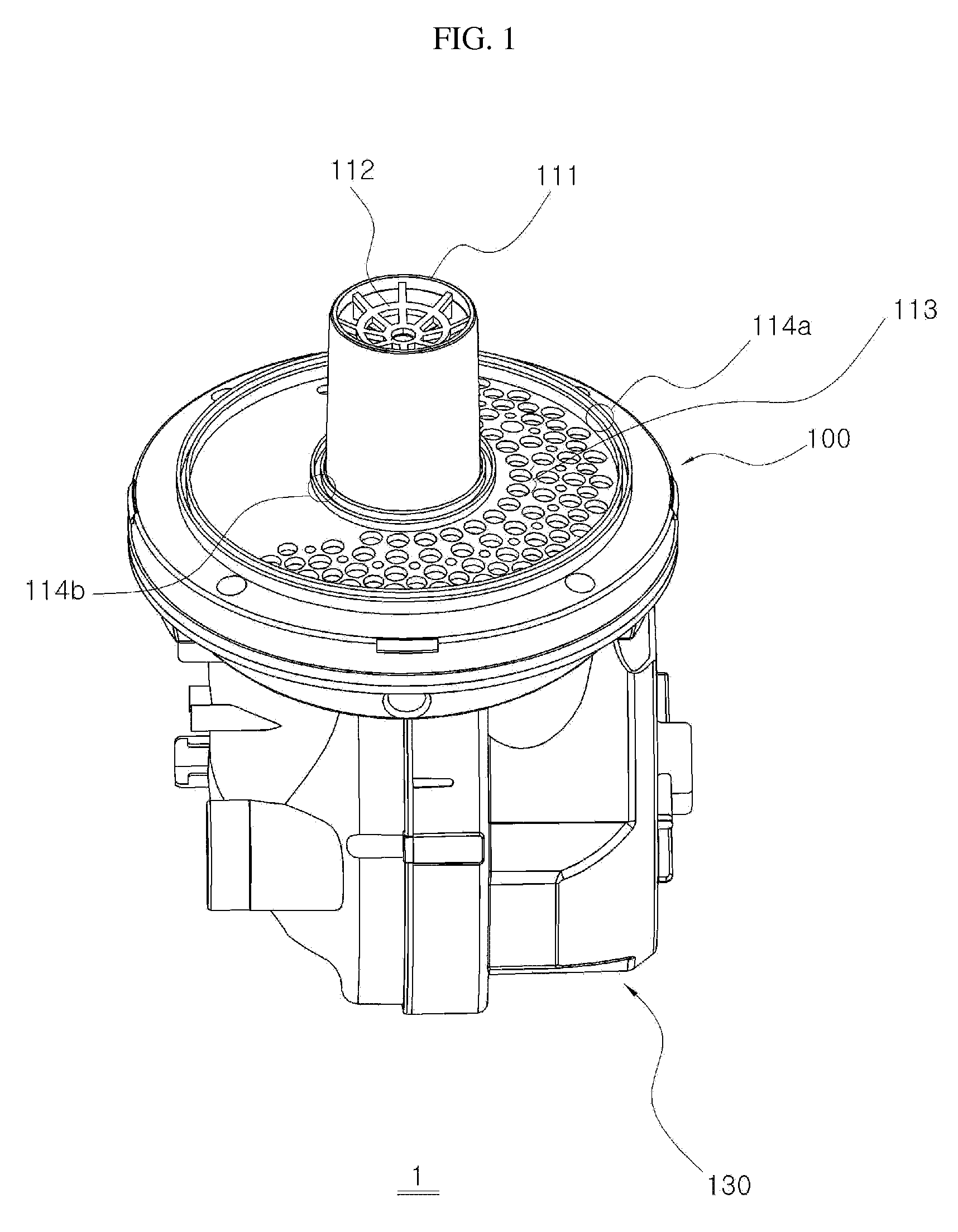

A fan motor apparatus of a vacuum cleaner having a diffuser unit is provided. The fan motor apparatus of a vacuum cleaner includes a fan motor unit into and from which an air stream is introduced and discharged in the same direction, and a diffuser unit having an air suction area to discharge an air stream to the fan motor unit through a fluid passage surface, the fluid passage surface through which an air stream is drawn in and discharged out of the diffuser. An air discharge area of the diffuser unit may receive the air stream discharged from the fan motor unit, and distribute and discharge the air stream through a perimeter of the air suction area of the fluid passage surface.

Owner:SAMSUNG ELECTRONICS CO LTD

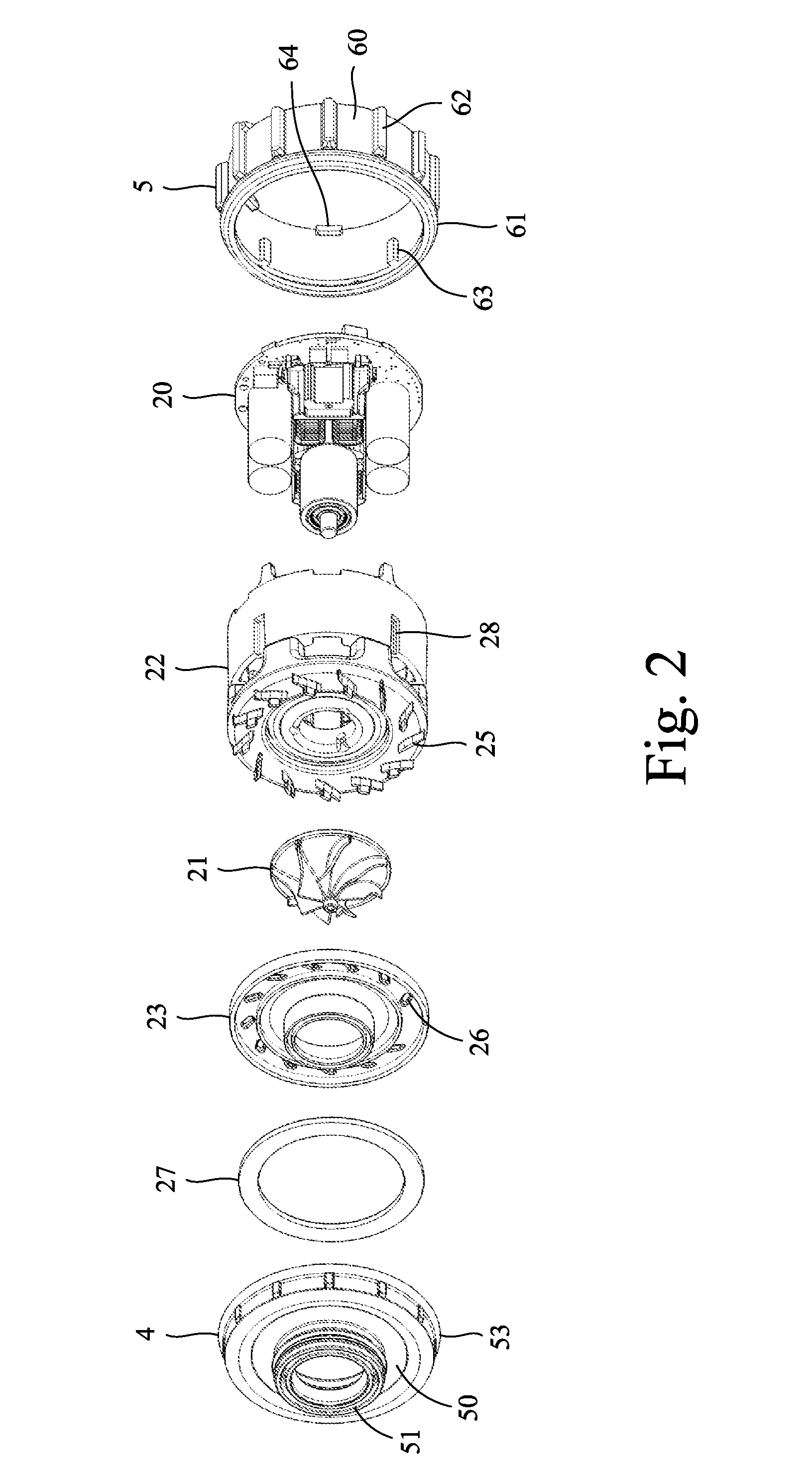

Vacuum cleaner

ActiveUS20160037984A1Simple structureGreat suctionEngine manufacturePump componentsImpellerVacuum cleaner

A vacuum cleaner having an improved structure capable of enhancing suction performance includes a suction unit provided in a main body, the suction unit including an impeller disposed to suck air by rotating about an axis thereof, and a diffuser disposed to guide air discharged from the impeller. The diffuser includes an inner casing, an outer casing disposed to be spaced apart from an outer circumference of the inner casing and to form a path through which the air discharged from the impeller flows, and a plurality of vanes disposed at the inner casing to guide the air discharged from the impeller to the path, and the plurality of vanes protrude toward the outer casing to cross at least a part of the path.

Owner:SAMSUNG ELECTRONICS CO LTD

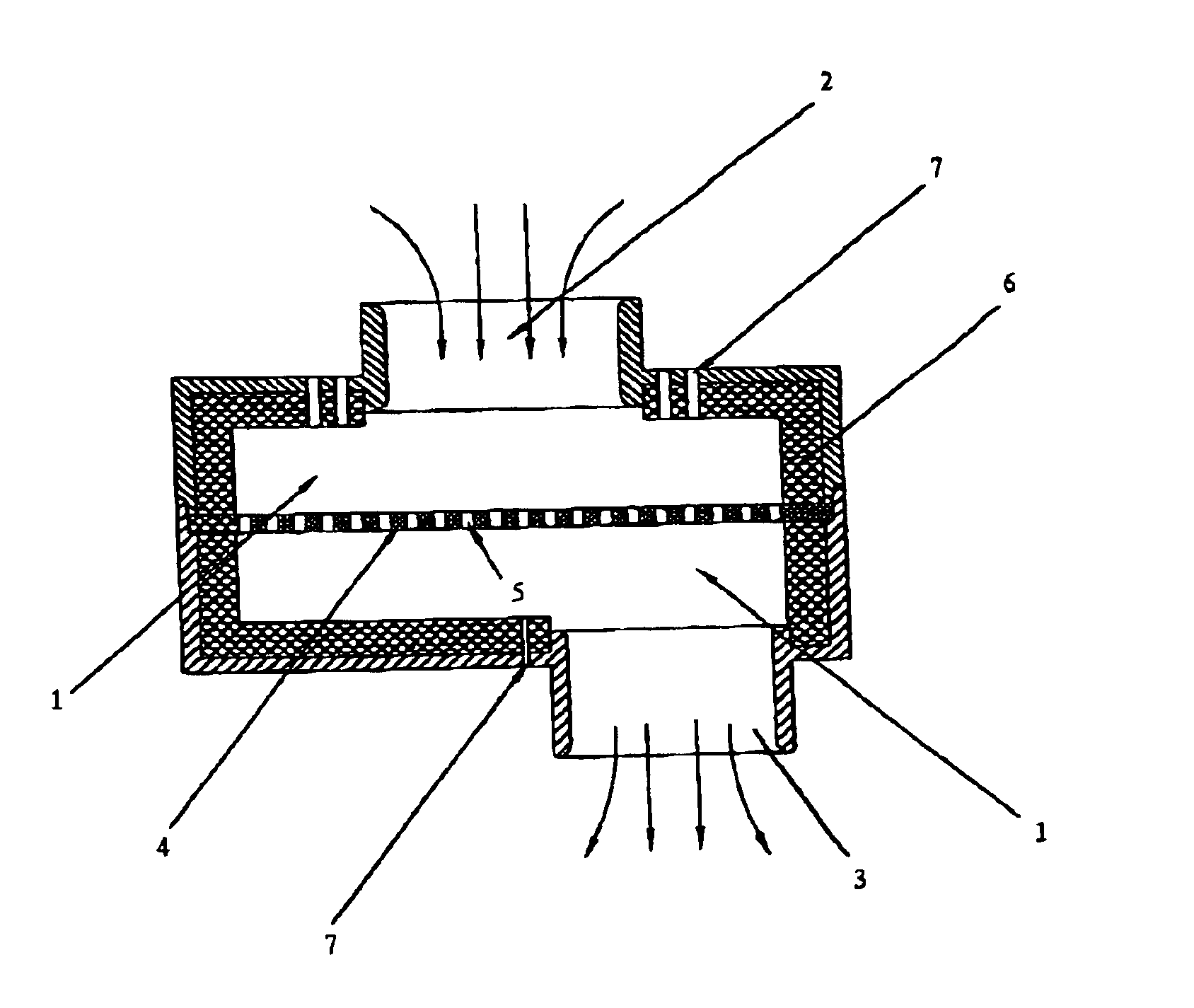

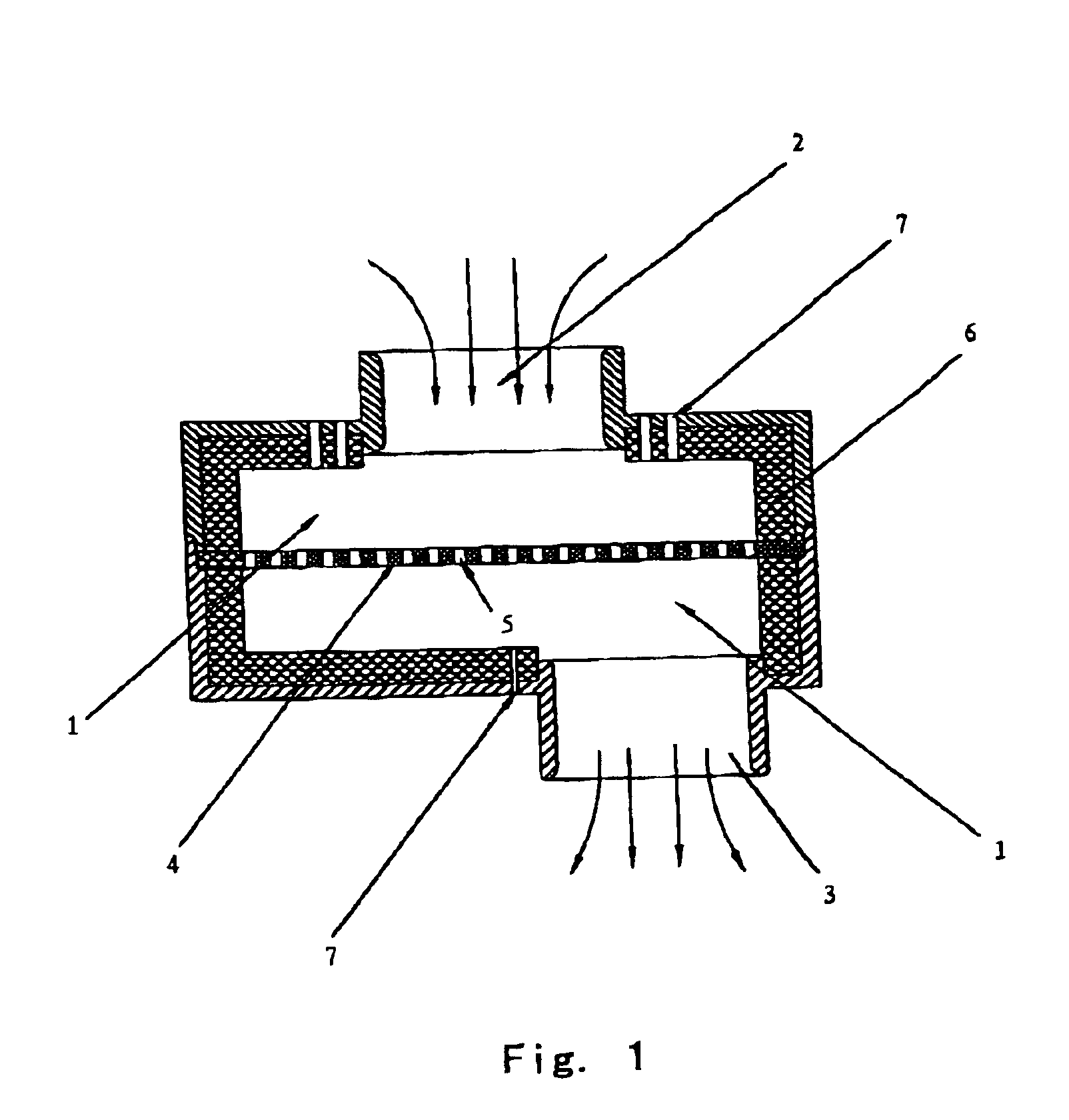

Silencer for vacuum cleaner

InactiveUS6932188B2Reduce noiseImprove noise reductionCombination devicesSuction filtersExpansion chamberMuffler

A silencer for a vacuum cleaner is provided and includes at least one hermetic expansion chamber mounted in an exhaust channel of the vacuum cleaner and allowing an exhaust airflow from the vacuum cleaner to pass through. The expansion chamber at its two sides has an inlet and an outlet connected to the exhaust channel. A silencing board is mounted in the expansion chamber, separating the inlet from the outlet. Pores are distributed throughout in the silencing board. The silencer integrates several different silencing structures together, and, when mounted to the exhaust port of the vacuum cleaner, can considerably diminish the noise generated by the vacuum cleaner in operation.

Owner:SUZHOU KINGCLEAN FLOORCARE

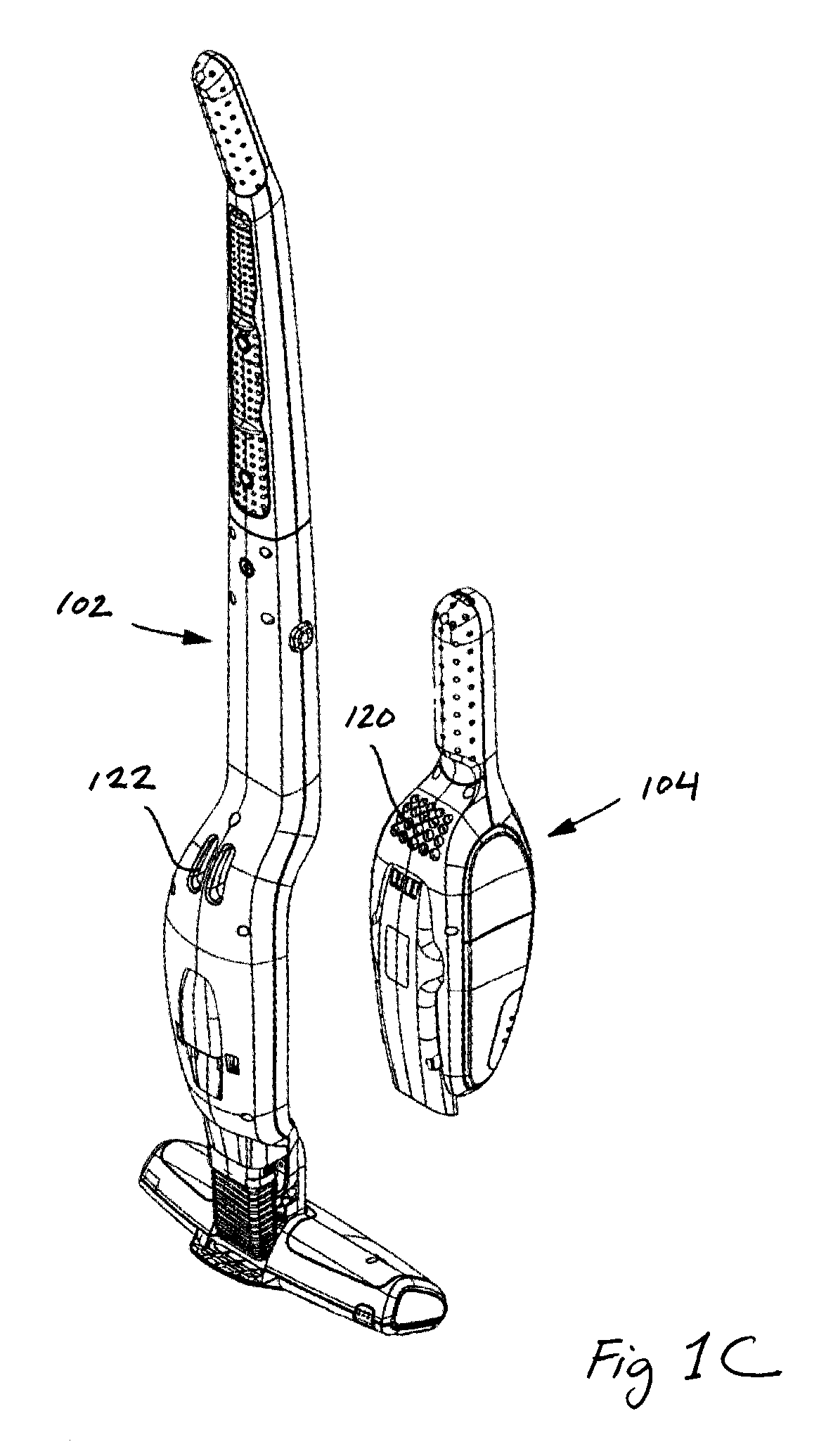

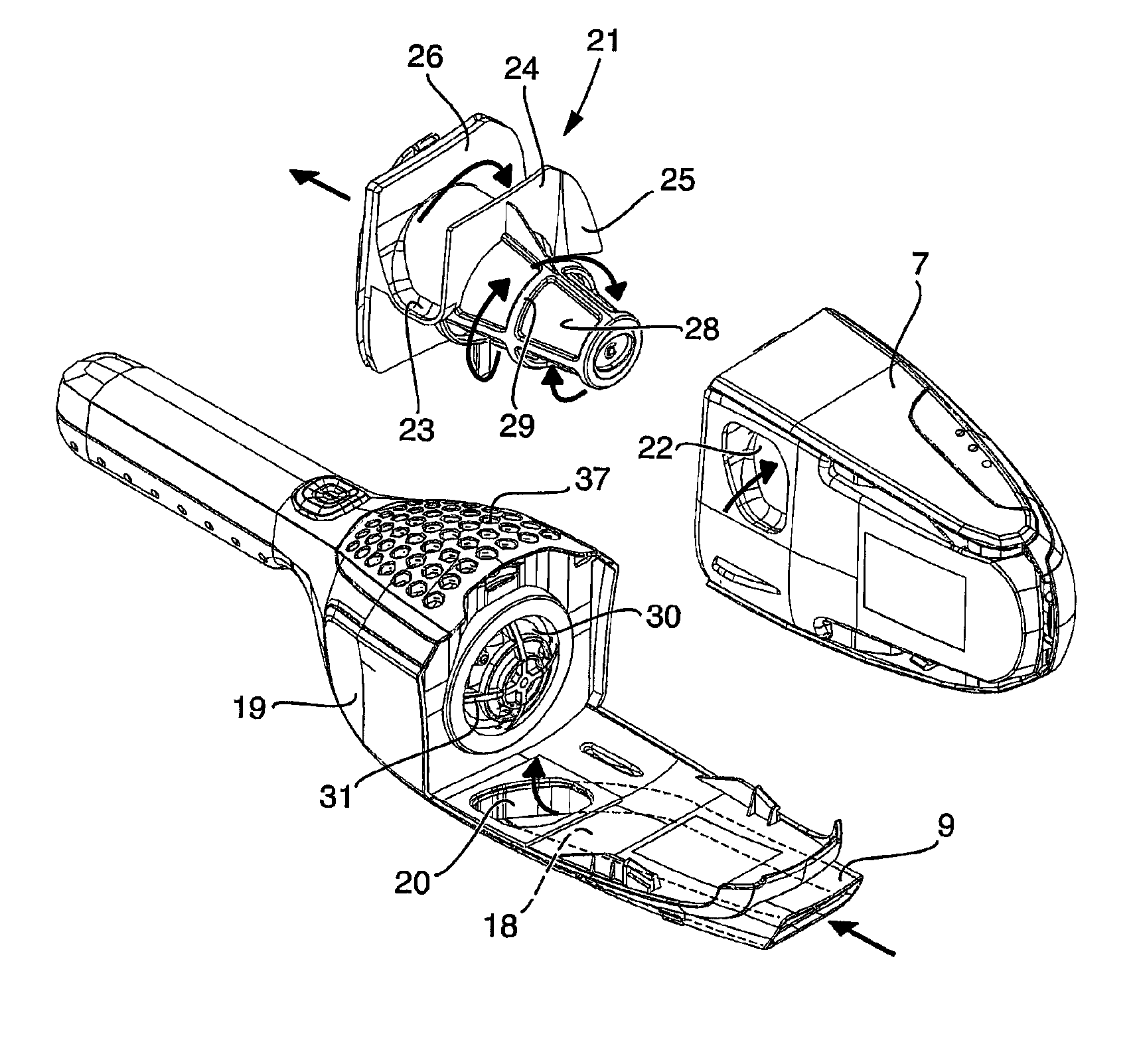

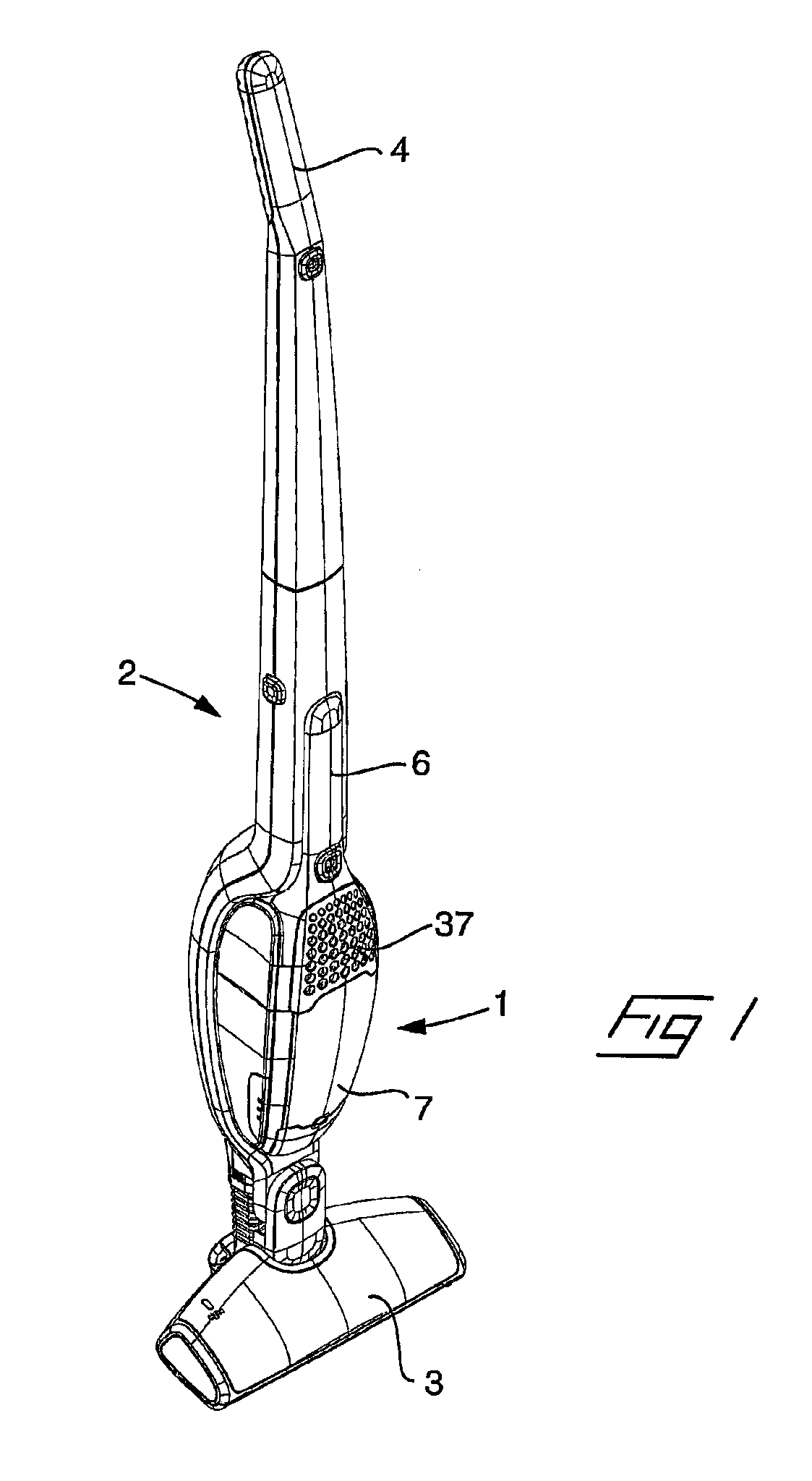

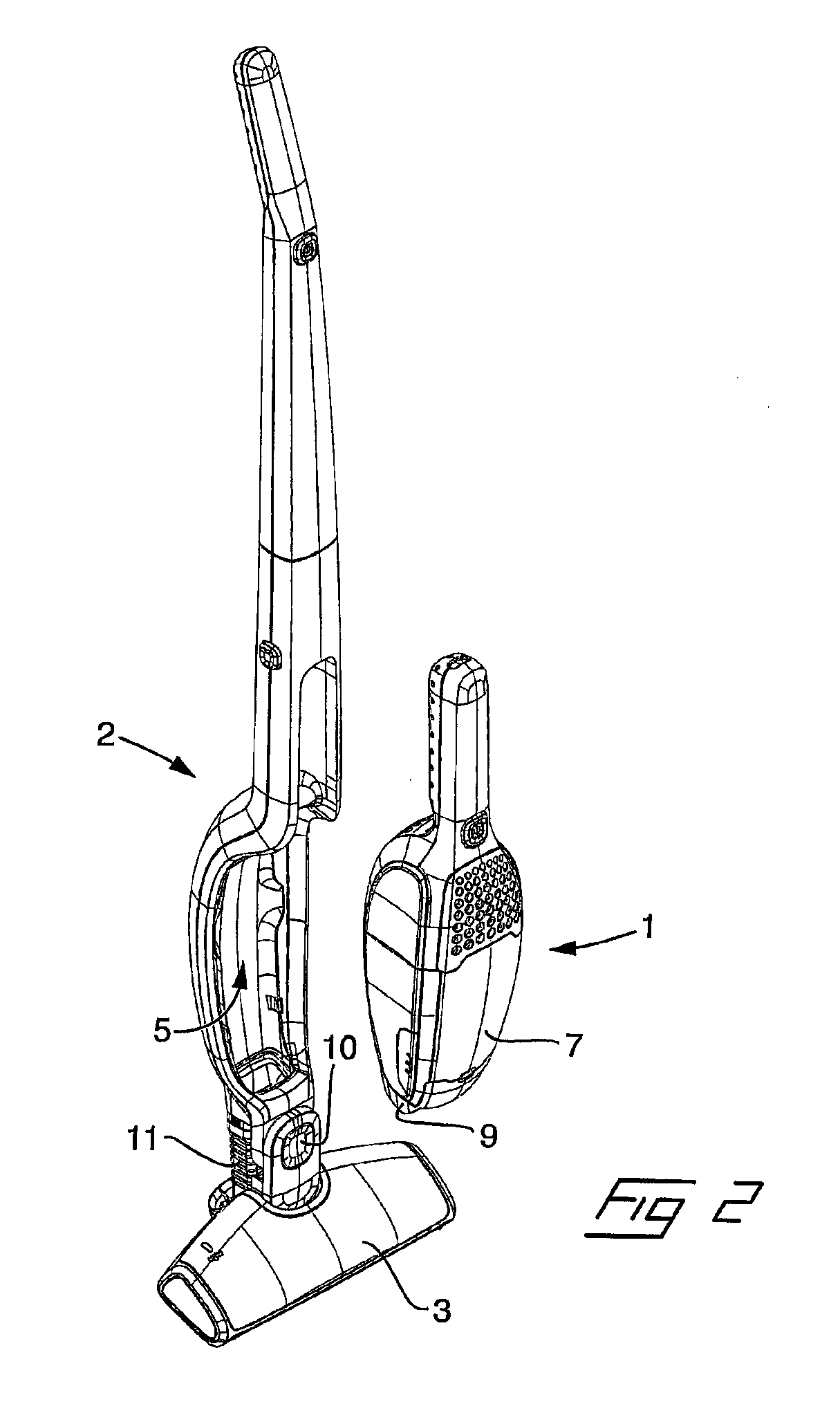

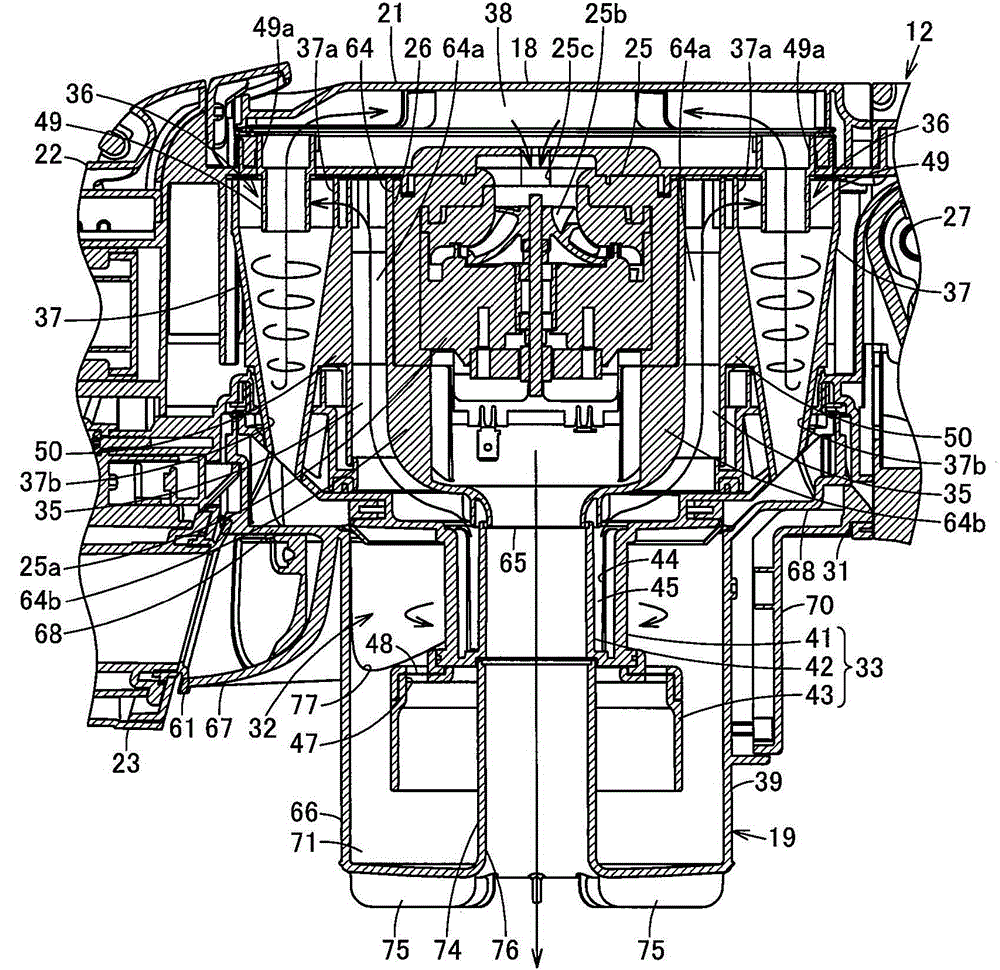

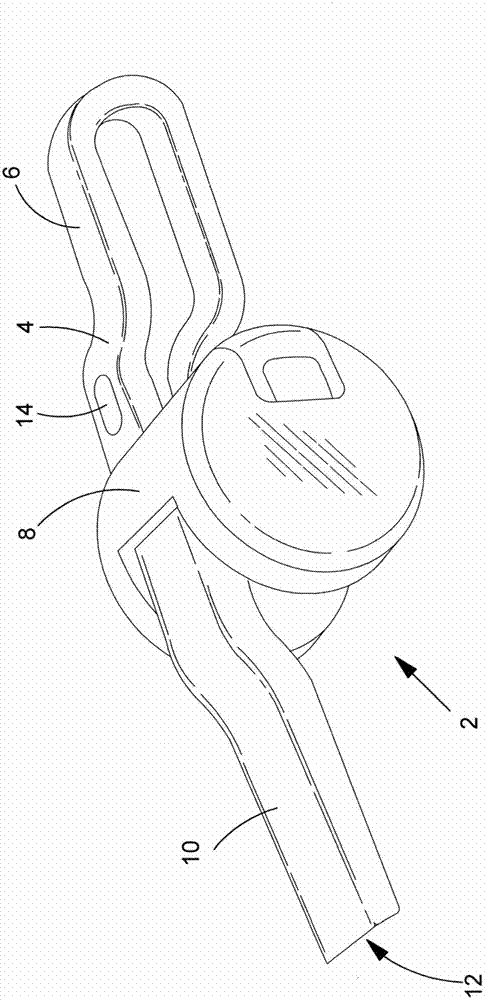

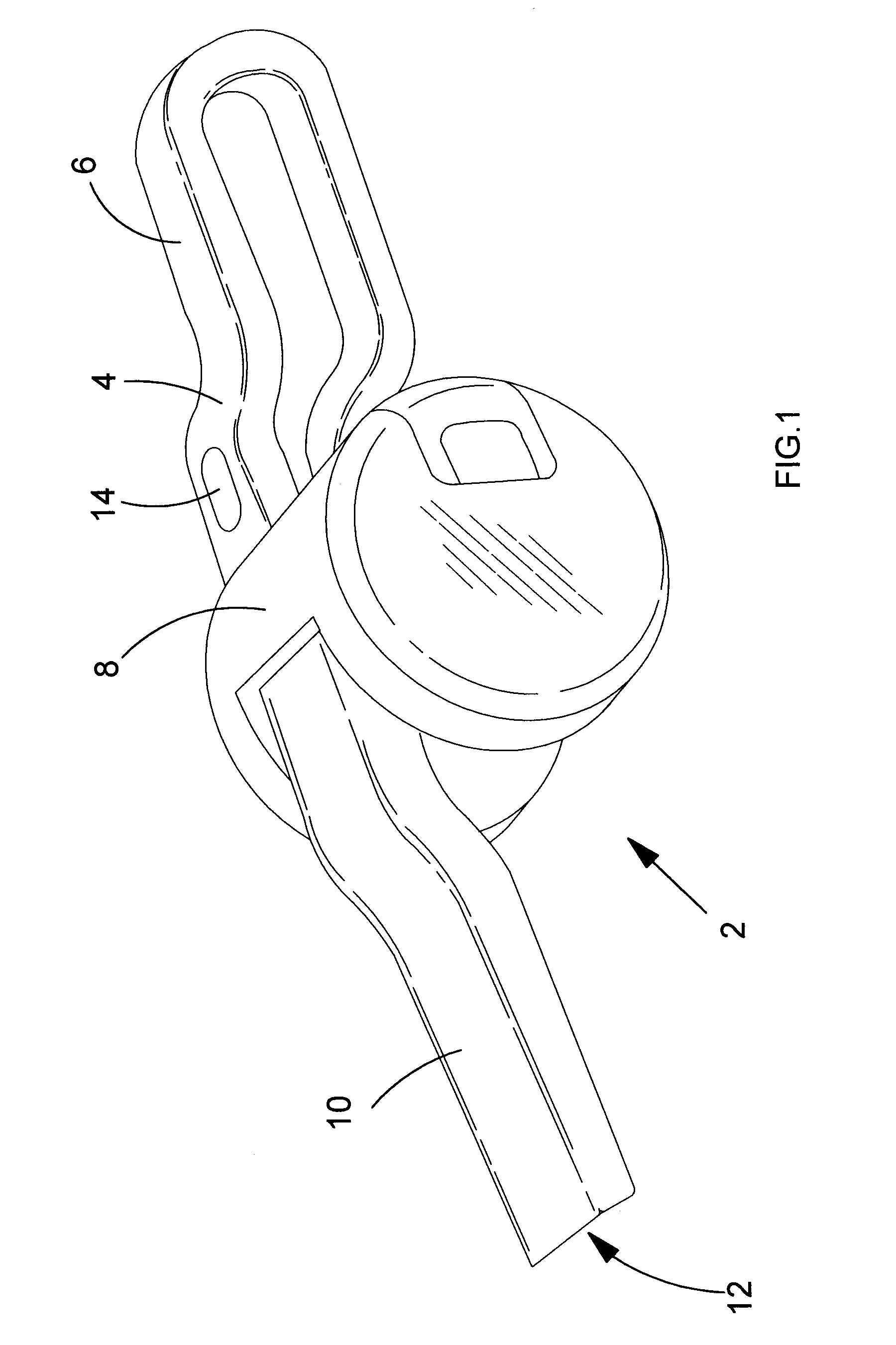

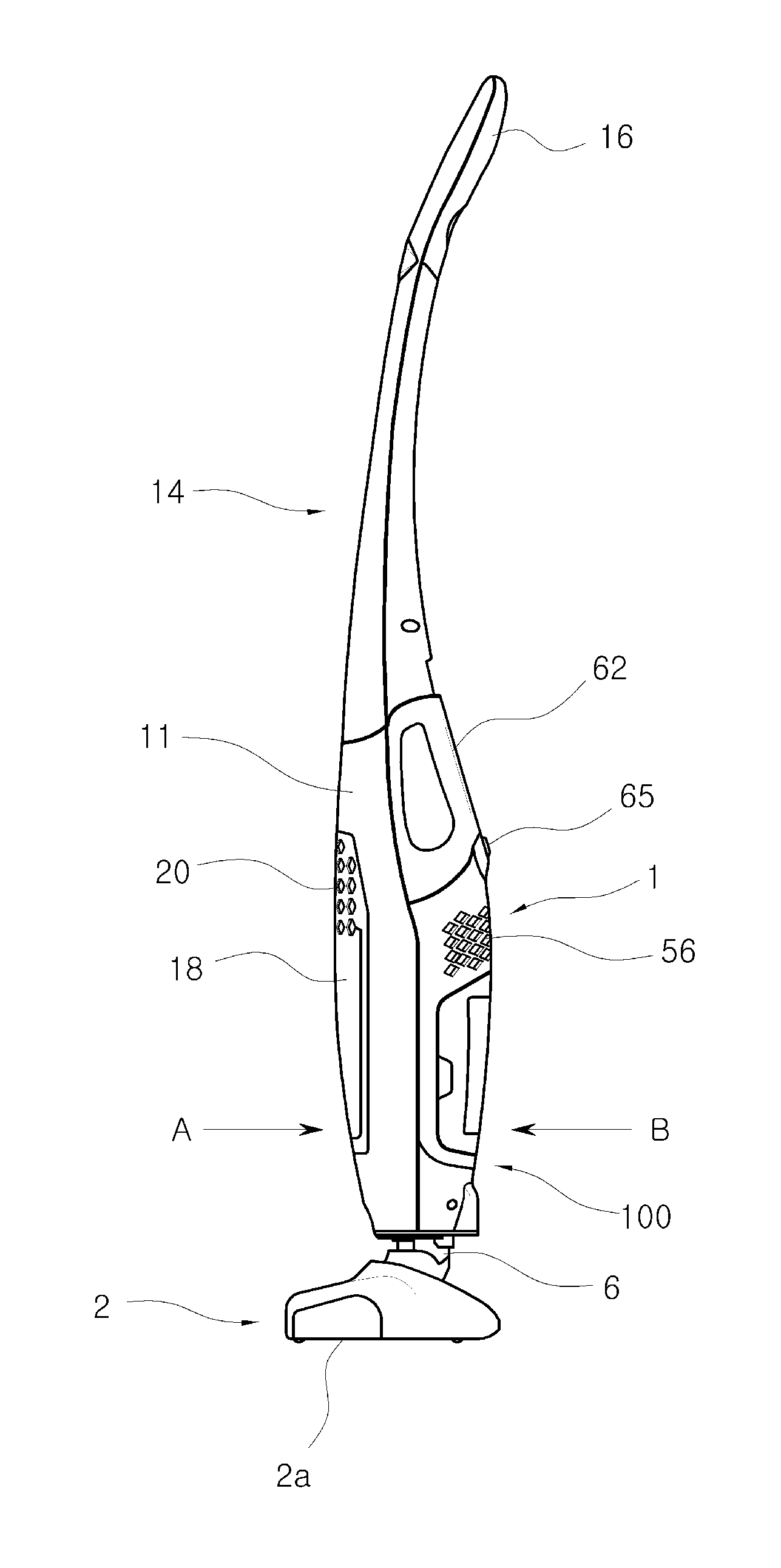

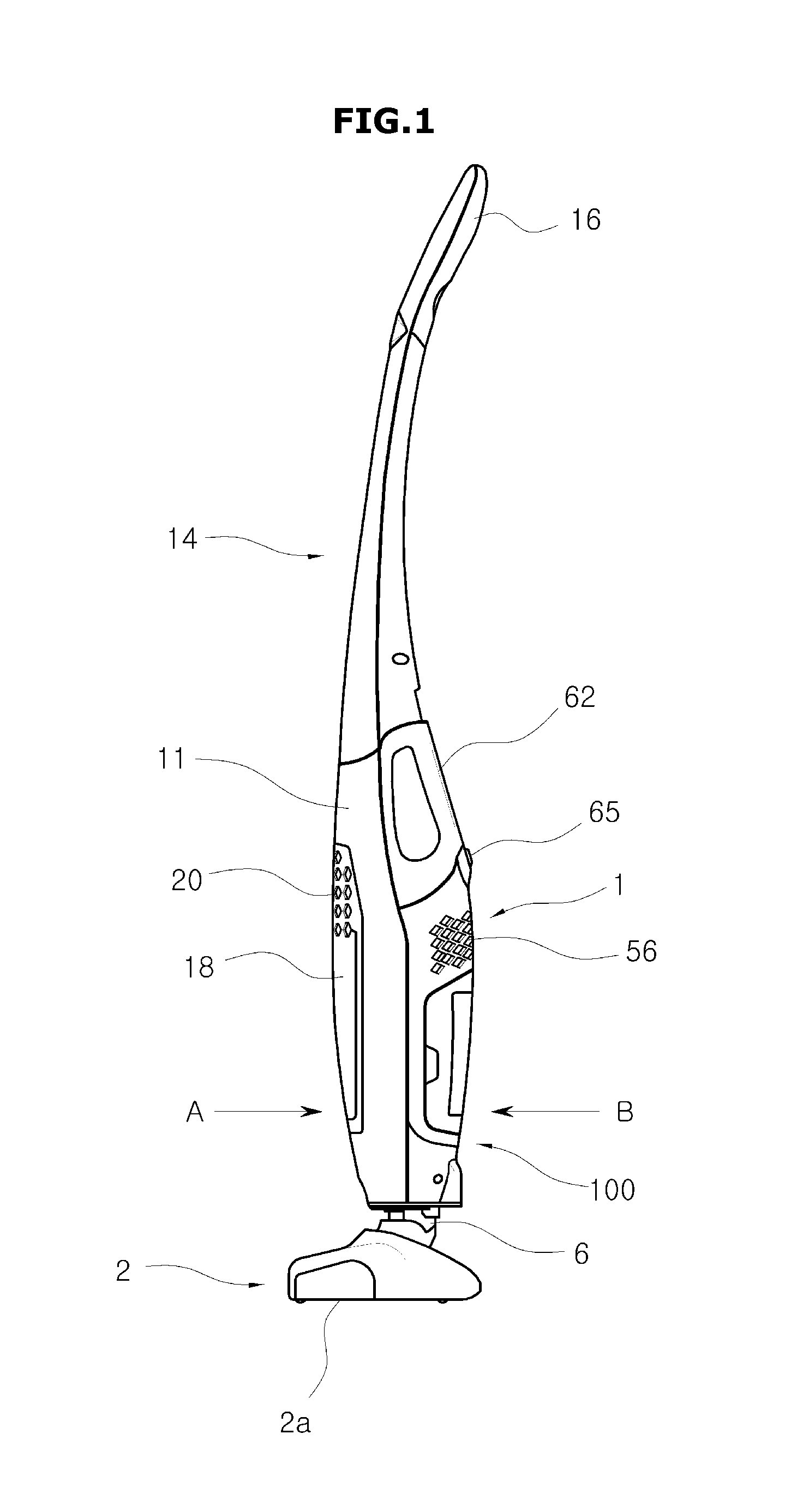

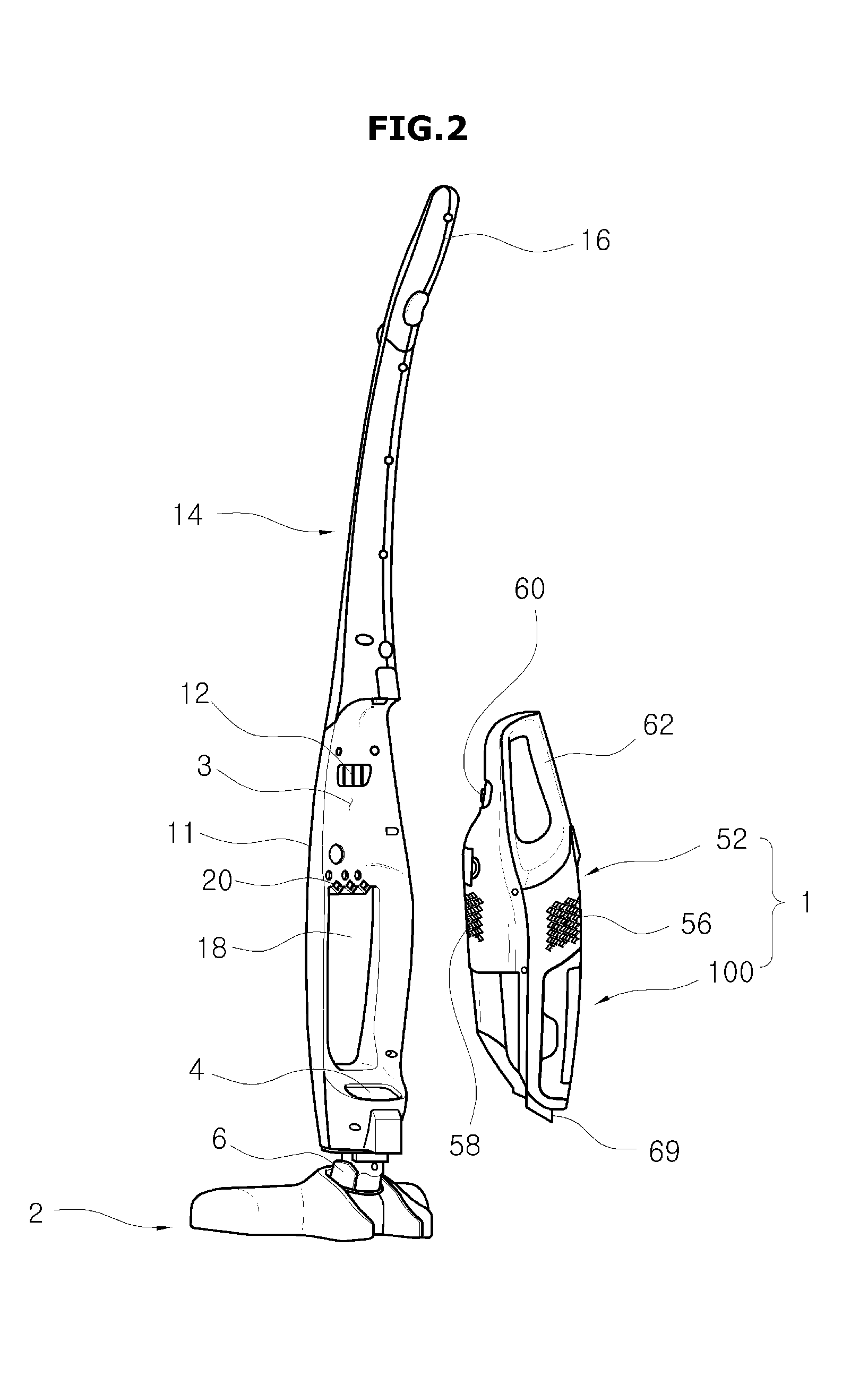

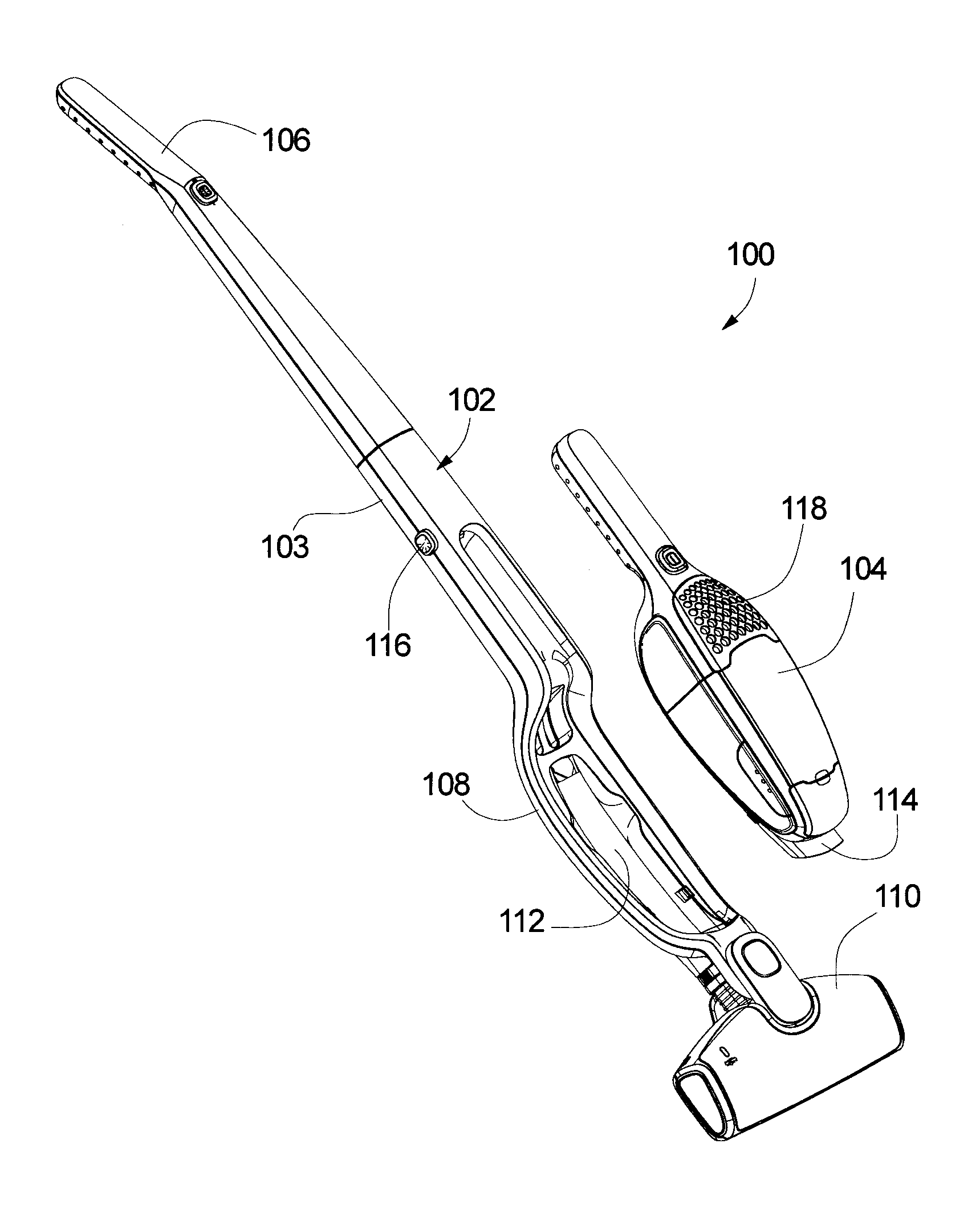

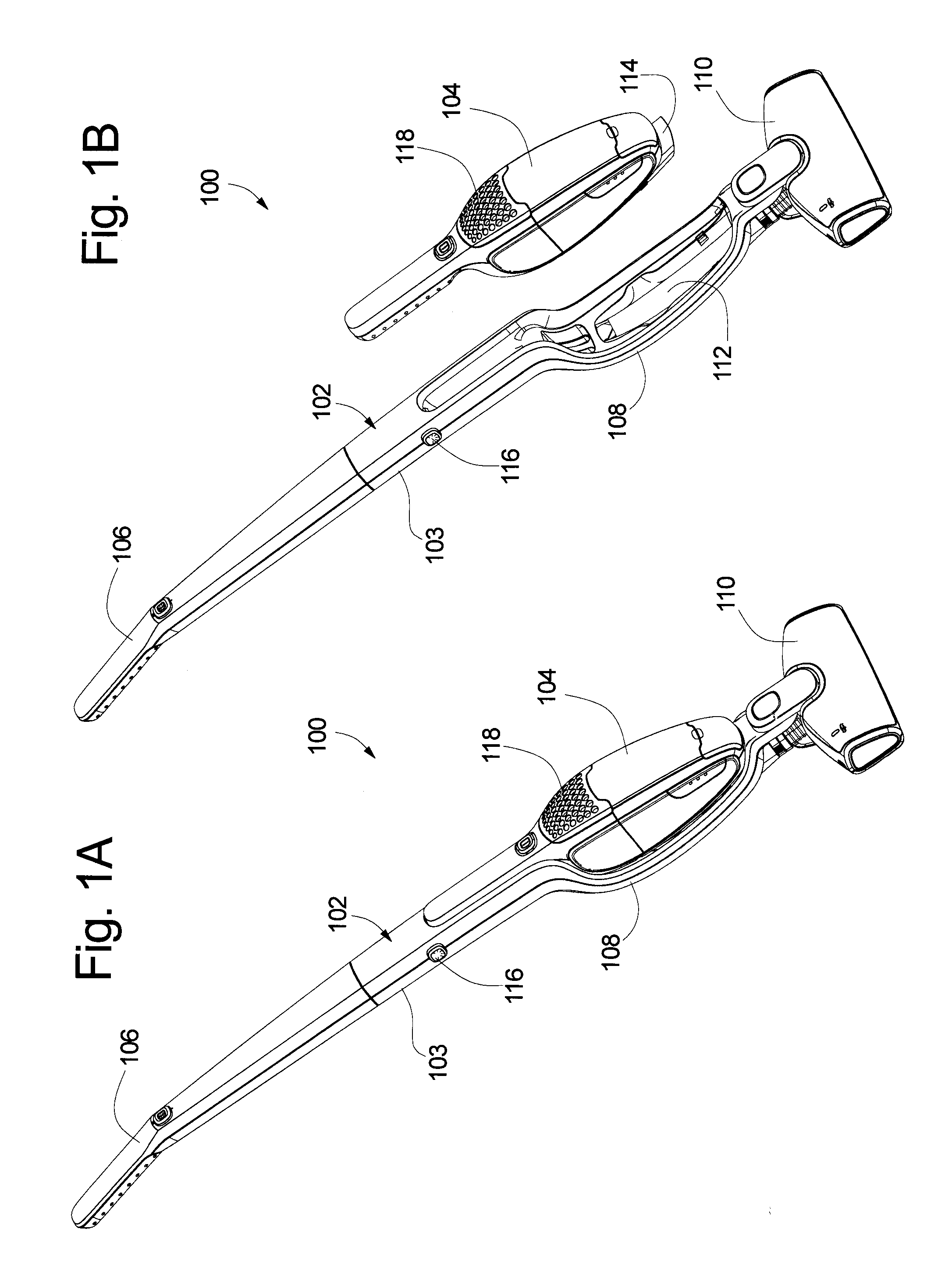

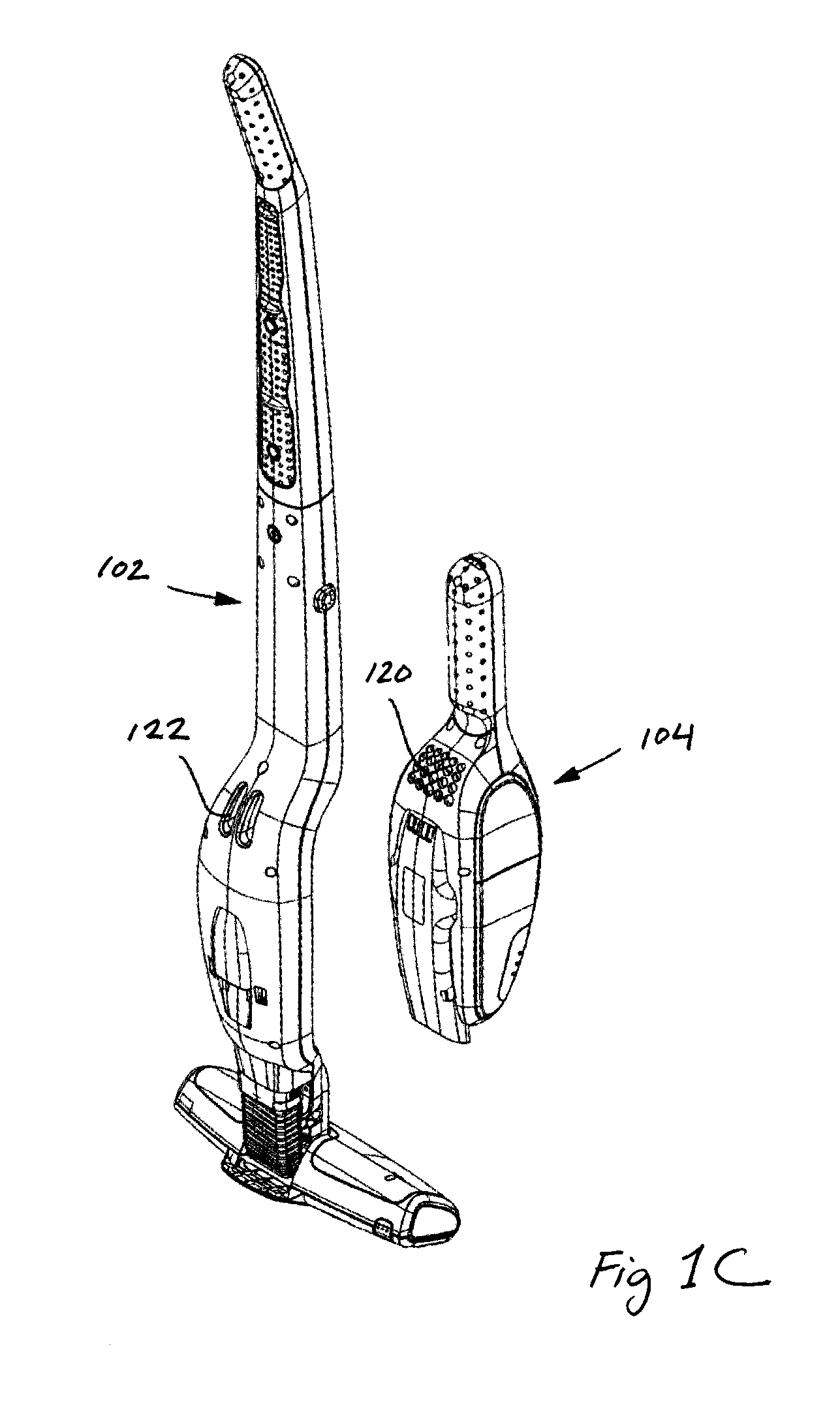

Handheld Vacuum Unit Retention Features

A vacuum cleaner having a base with an inlet facing a surface, a handle connected to the base, an air passage connecting the base inlet to the handle, and a removable handheld unit. The handheld has an inlet nozzle, a dirt separator, a vacuum fan to generate a working airflow into the inlet nozzle and through the dirt separator, and a housing joining the handheld, the dirt separator and the vacuum fan. The vacuum has a docking latch with a first latch position in which the latch holds the handheld in an operating position on the handle, and a second position in which the latch permits removal of the handheld from the operating position. The vacuum also has a safety catch with a catch member on the handle and a second member on the handheld. The catch members resiliently hold the handheld unit on the handle in a partially-removed position.

Owner:AB ELECTROLUX

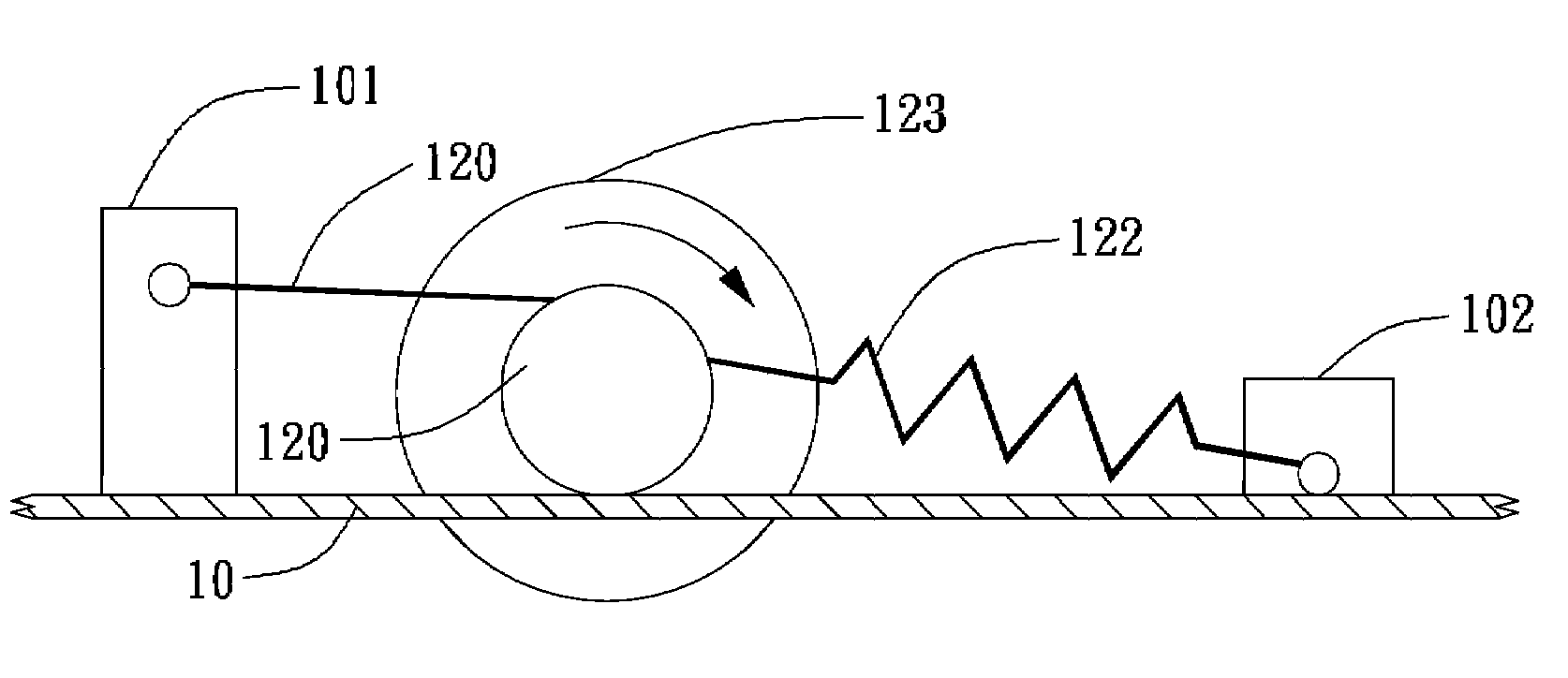

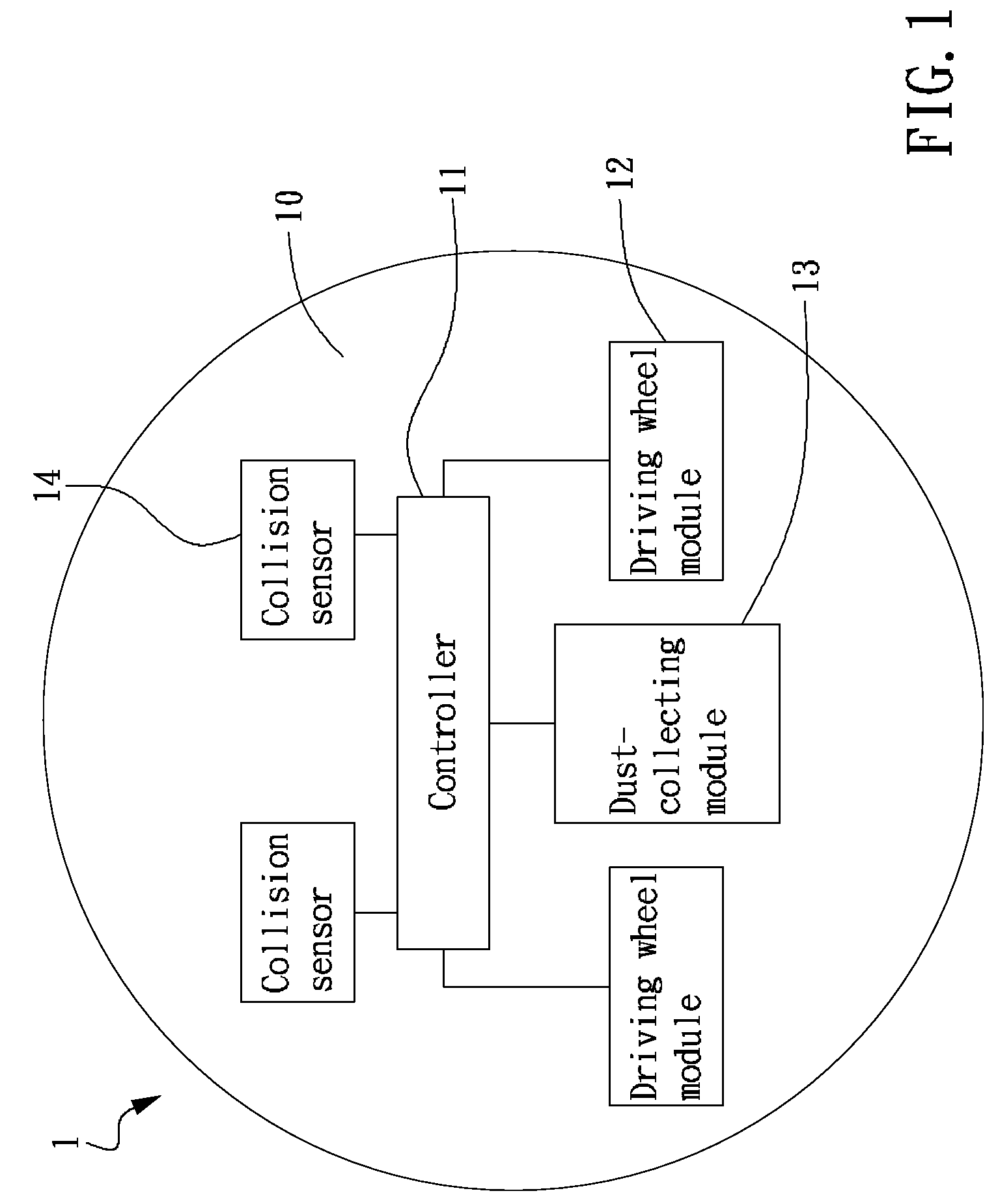

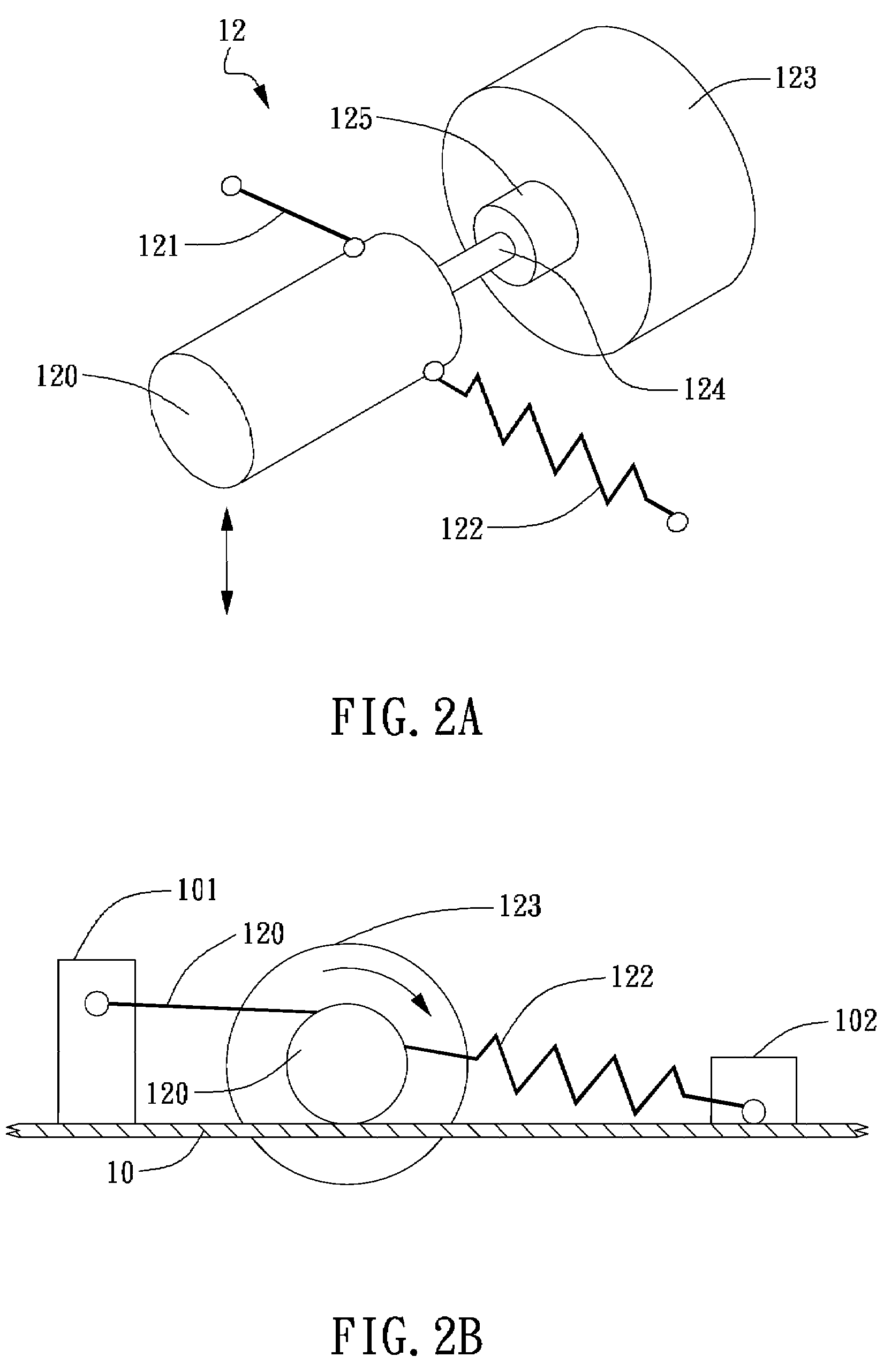

Robotic vacuum cleaner

InactiveUS7861365B2Simplify the maintenance processEfficient workCleaning filter meansAutomatic obstacle detectionDrive wheelEngineering

A robotic vacuum cleaner is disclosed in the present invention, which comprises a controller, at least a driving wheel module, and a dust-collecting module. The controller is disposed on a housing plate. The driving wheel module, electrically connecting to the controller, further includes: a driver; a wheel connecting to the output shaft of the driver; a linkage rod, having two ends pivotally fixed on the housing plate and the driver respectively; and a resilience element, having two ends pivotally connected to the housing plate and the driver respectively. The dust-collecting module, disposed on the housing plate, is capable of vacuuming for filtering and collecting dust.

Owner:IND TECH RES INST

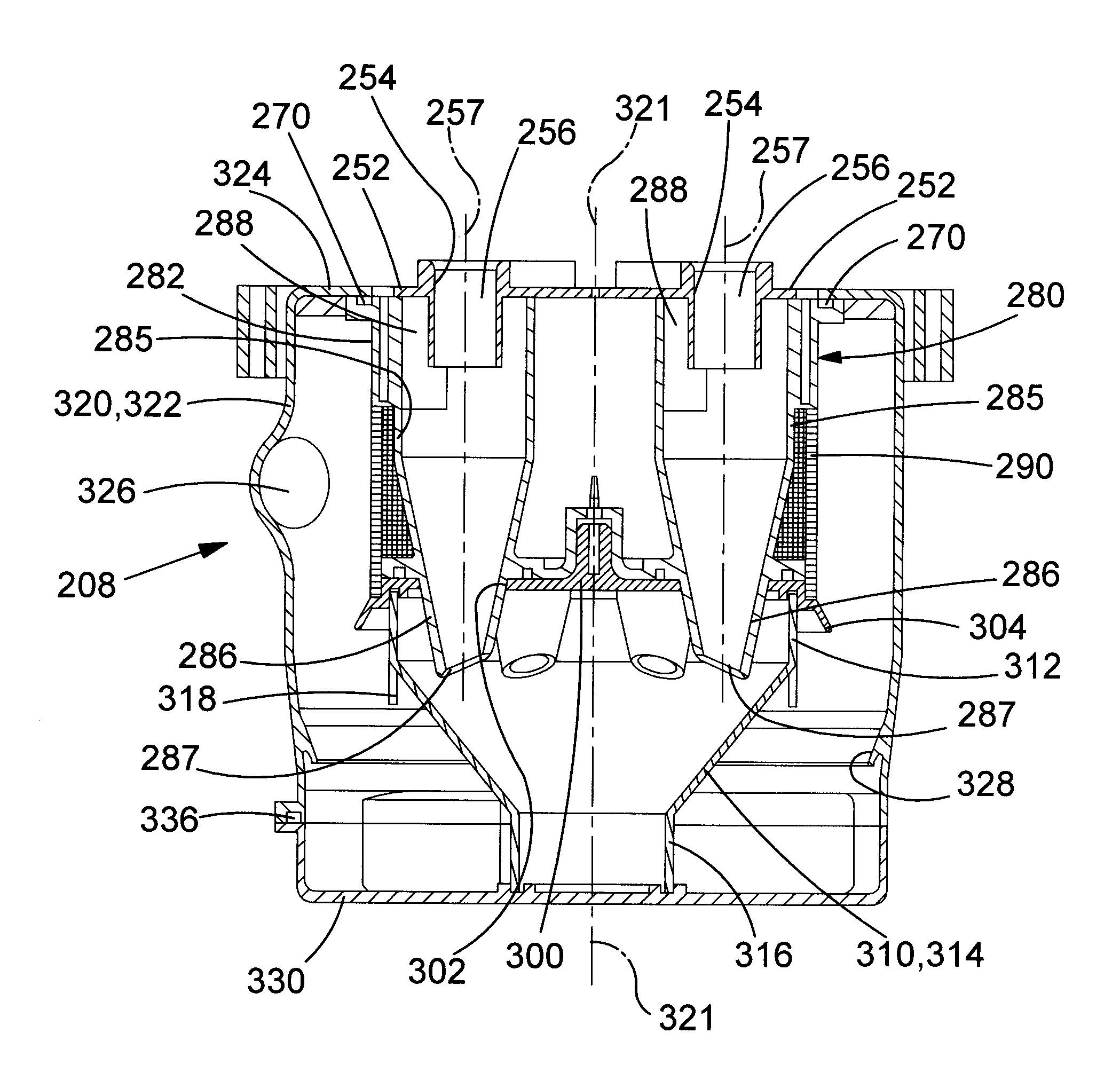

Vibration isolation mount

ActiveUS20140328670A1Compact compressorReduce traffic lossPump componentsMotor fan assembly mountingEngineeringVibration isolation

A vibration isolation mount for a compressor that is formed of an elastomeric material and includes a sleeve, tapered studs or axial ribs spaced around the sleeve, and a lip seal extending around the sleeve. The mount is intended to be located between a compressor and a housing. The studs or ribs then deform to isolate the housing from radial vibration of the compressor, and the lip seal creates an annular seal between the housing and the compressor.

Owner:DYSON TECH LTD

Cyclone dust-separating apparatus of vacuum cleaner

ActiveUS7776116B2Reduce running noiseReduce total pressure lossSuction filtersReversed direction vortexCycloneEngineering

A cyclone dust-separating apparatus of a vacuum cleaner is disclosed. The cyclone dust-separating apparatus includes at least one cyclone having a cyclone body, which rotates air to separate dust or dirt therefrom, which has an air inflow part and an air discharging part, and which is installed in such a manner that a longitudinal axis thereof is substantially horizontally arranged, and a dust collecting unit to store the dust or dirt separated by the cyclone unit. The cyclone body is formed in a convex cylinder shape, so that a diameter thereof in the vicinity of an entrance of the air discharging part through which the air is discharged comes maximum.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

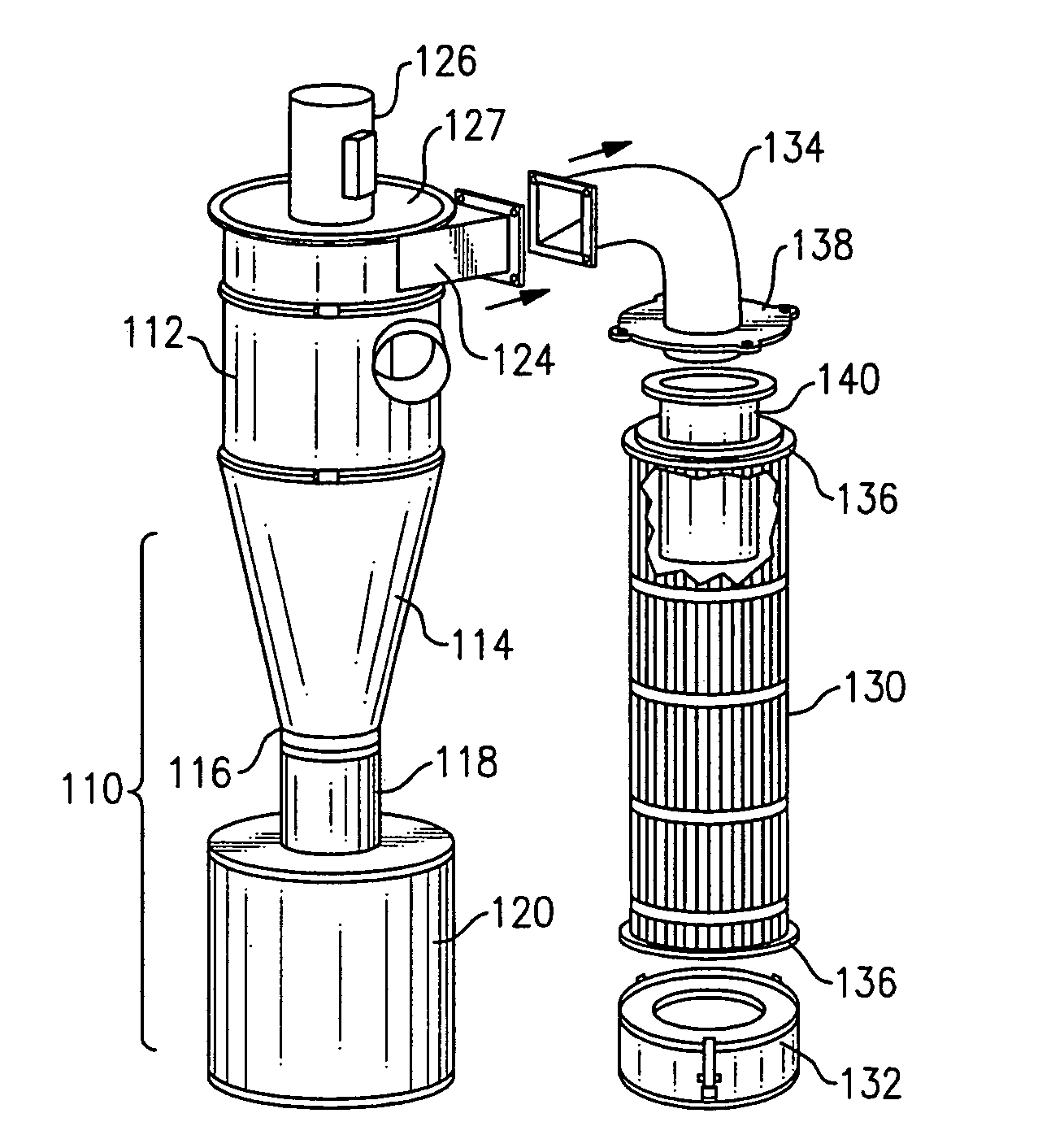

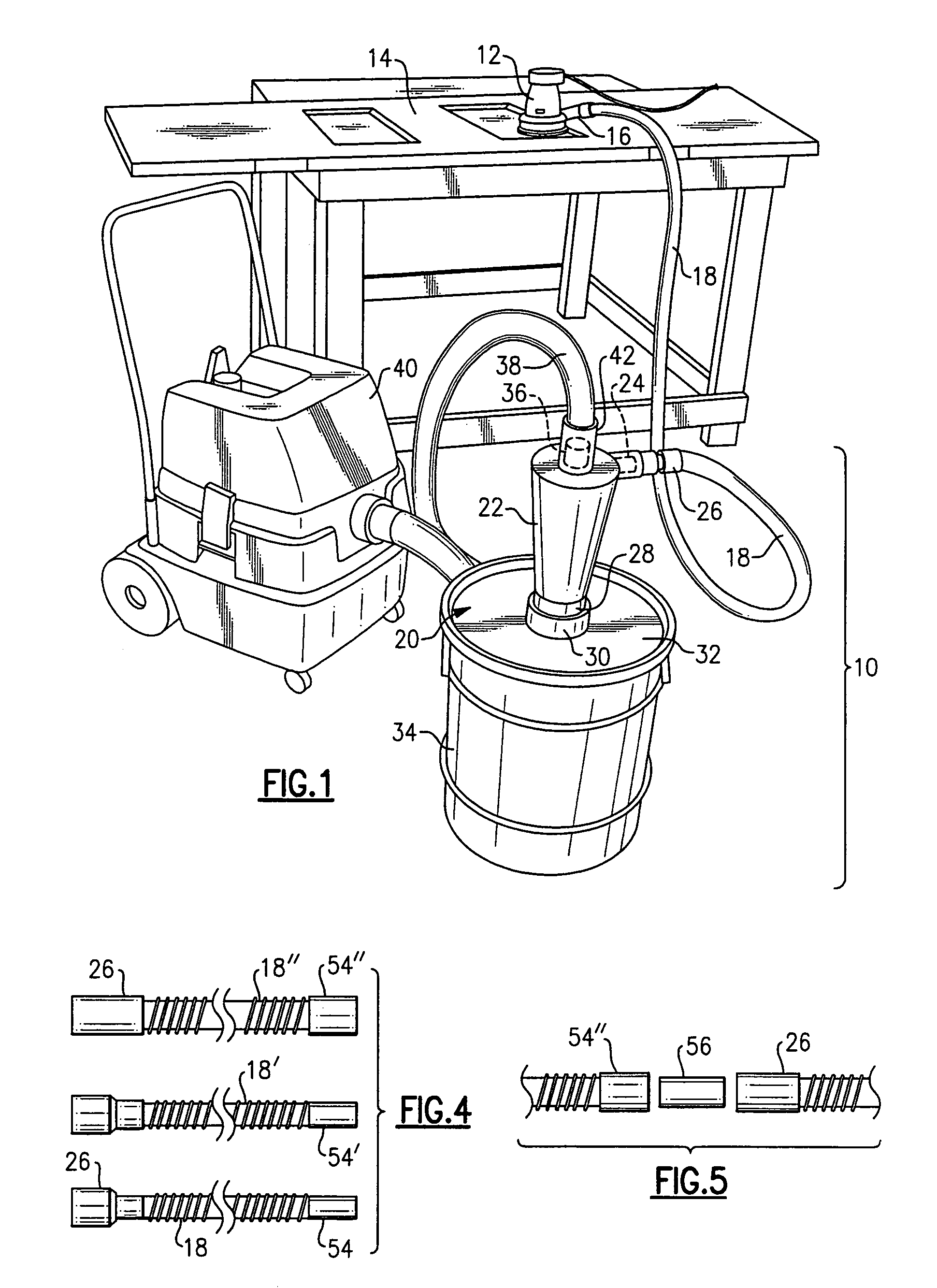

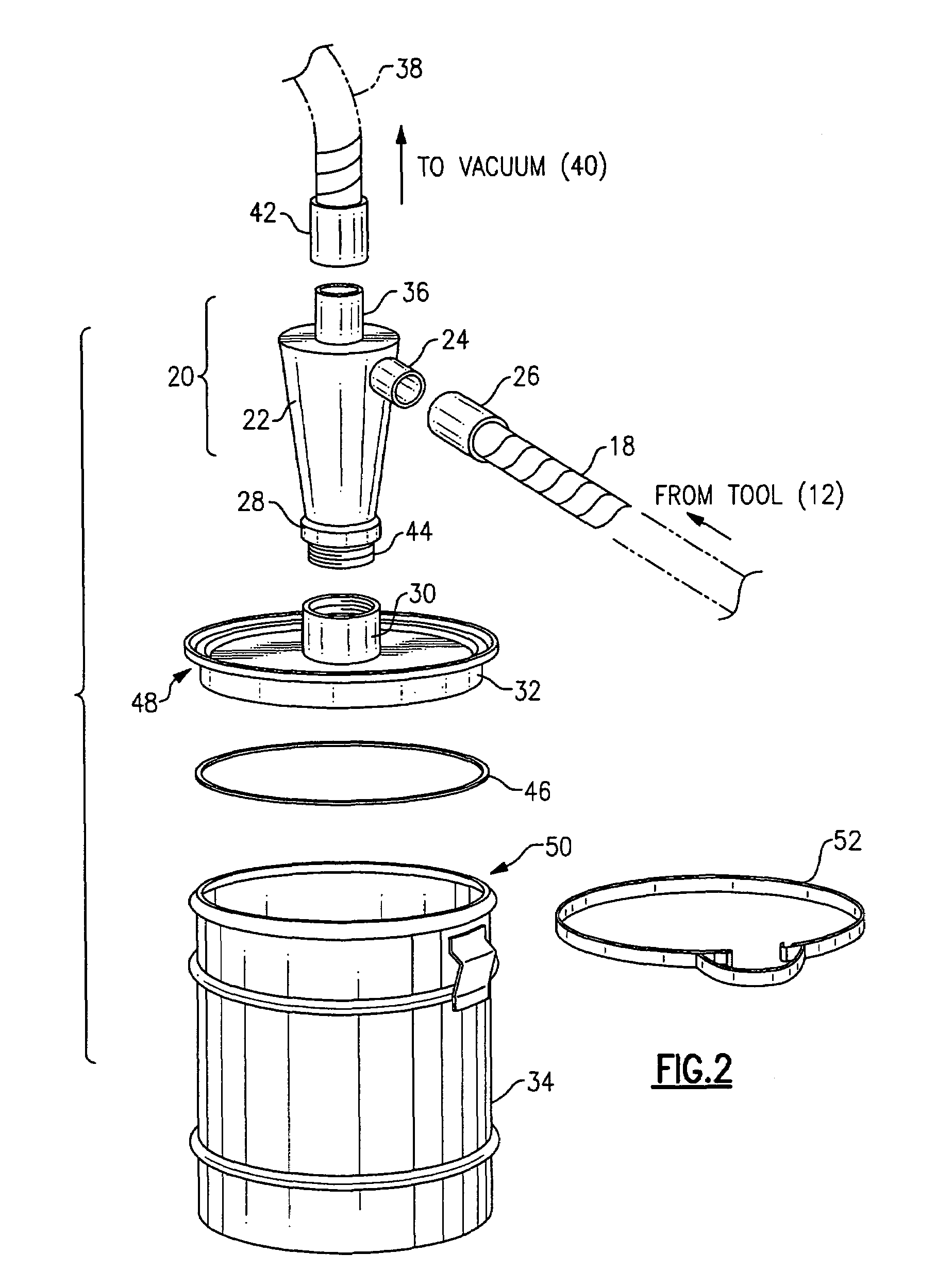

Silencer for dust collection system

ActiveUS7247180B1Simple and straightforward in constructionImprove reliabilityCombination devicesAuxillary pretreatmentProcess noiseSander

An auxiliary dust collection system can be interposed between a sander or other dust producing tool and a vacuum source, e.g., shop vacuum. A cyclonic separator is connected by a flexible hose to the tool and by another hose to the vacuum source. The cone of the separator is mounted onto the lid of a drum into which the dust precipitates. For a tool that has its own blower, the vacuum source can be omitted, and the air leaving the outlet duct of the separator can be filtered and returned to the ambient. A drop in silencer formed of a sleeve or tube of acoustic foam can be positioned into the inlet side of a filter cartridge following a cyclonic separator. The silencer absorbs a significant fraction of the process noise. The acoustic foam can have a textured surface on the sound-facing side.

Owner:ONEIDA AIR SYST

Vacuum cleaner with noise suppression features

A vacuum cleaner includes a cyclonic airflow chamber that facilitates the separation of contaminants from a suction airstream. The airflow chamber includes a chamber inlet and a chamber outlet, with the chamber inlet being fluidically connected with at least one of a suction nozzle and an above-the-floor cleaning tool. An exhaust filter housing includes a suction duct and an exhaust plenum, with the suction duct communicating with the chamber outlet. A suction source housing includes an open end communicating with the exhaust plenum and a closed end. A suction source is positioned within the suction source housing to define an annular exhaust flow passageway surrounding the suction source from the housing closed end to the housing open end. The suction source includes a suction inlet communicating with the suction duct and an exhaust outlet communicating with the housing closed end.

Owner:ROYAL APPLIANCE MFG

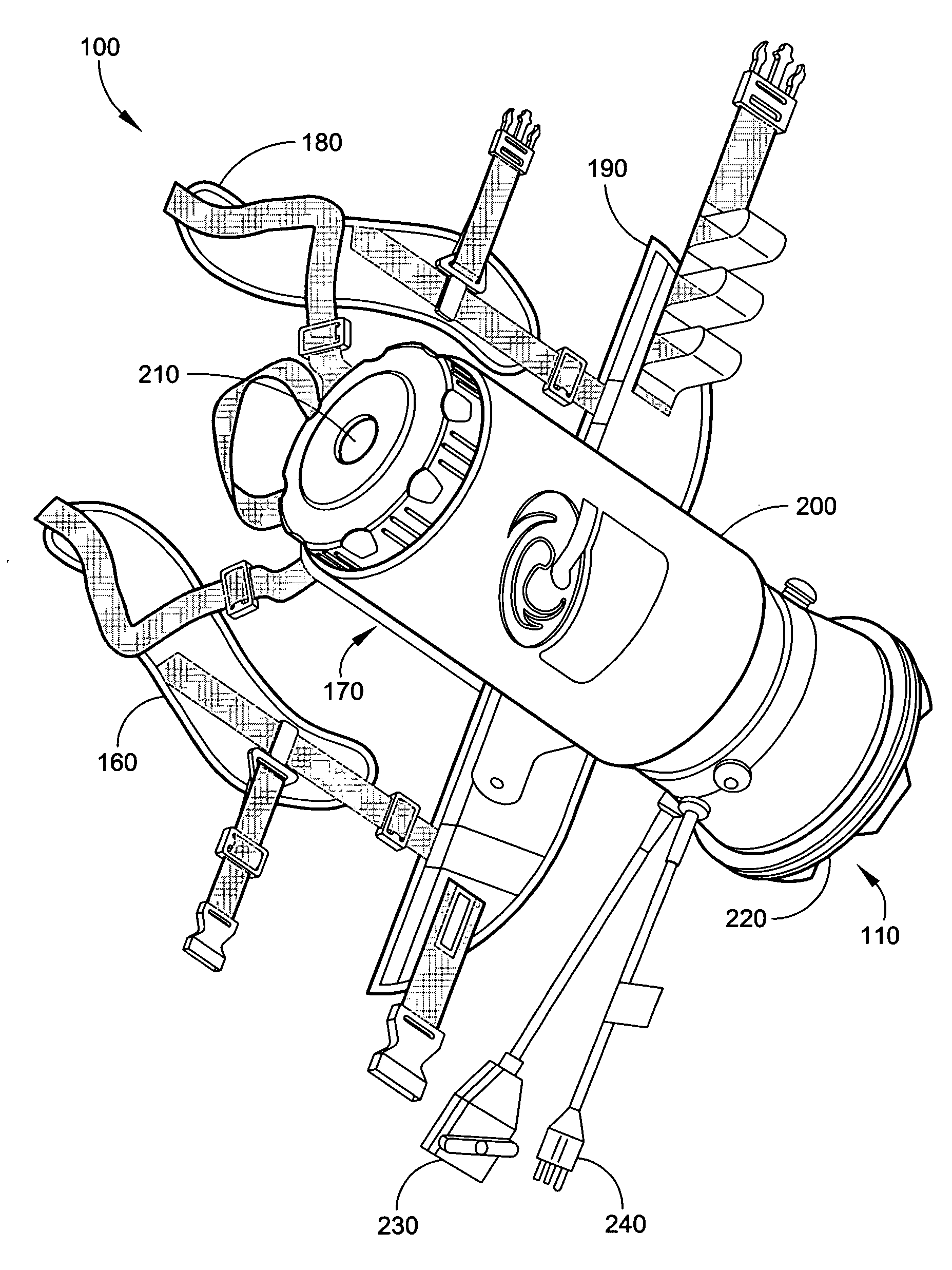

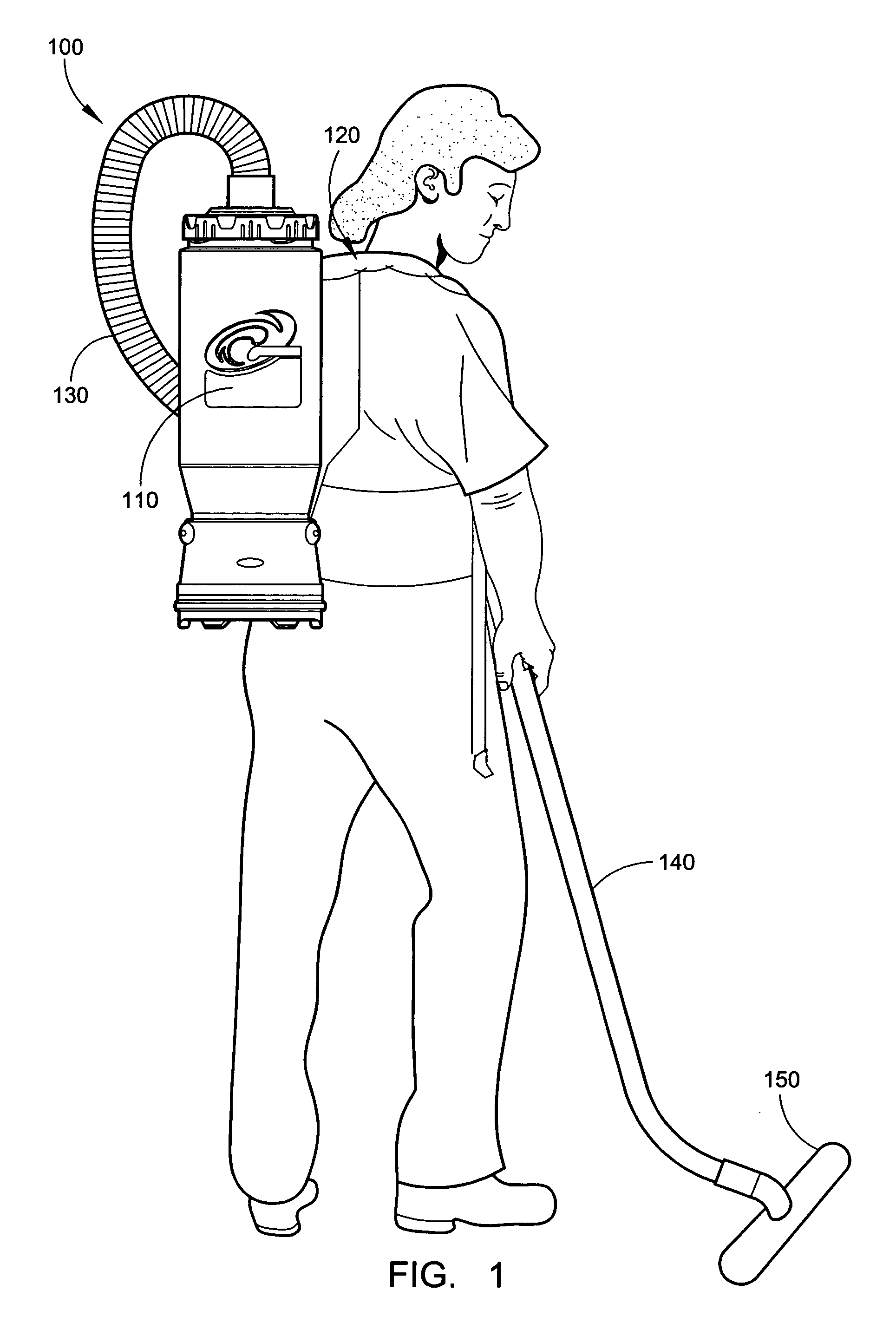

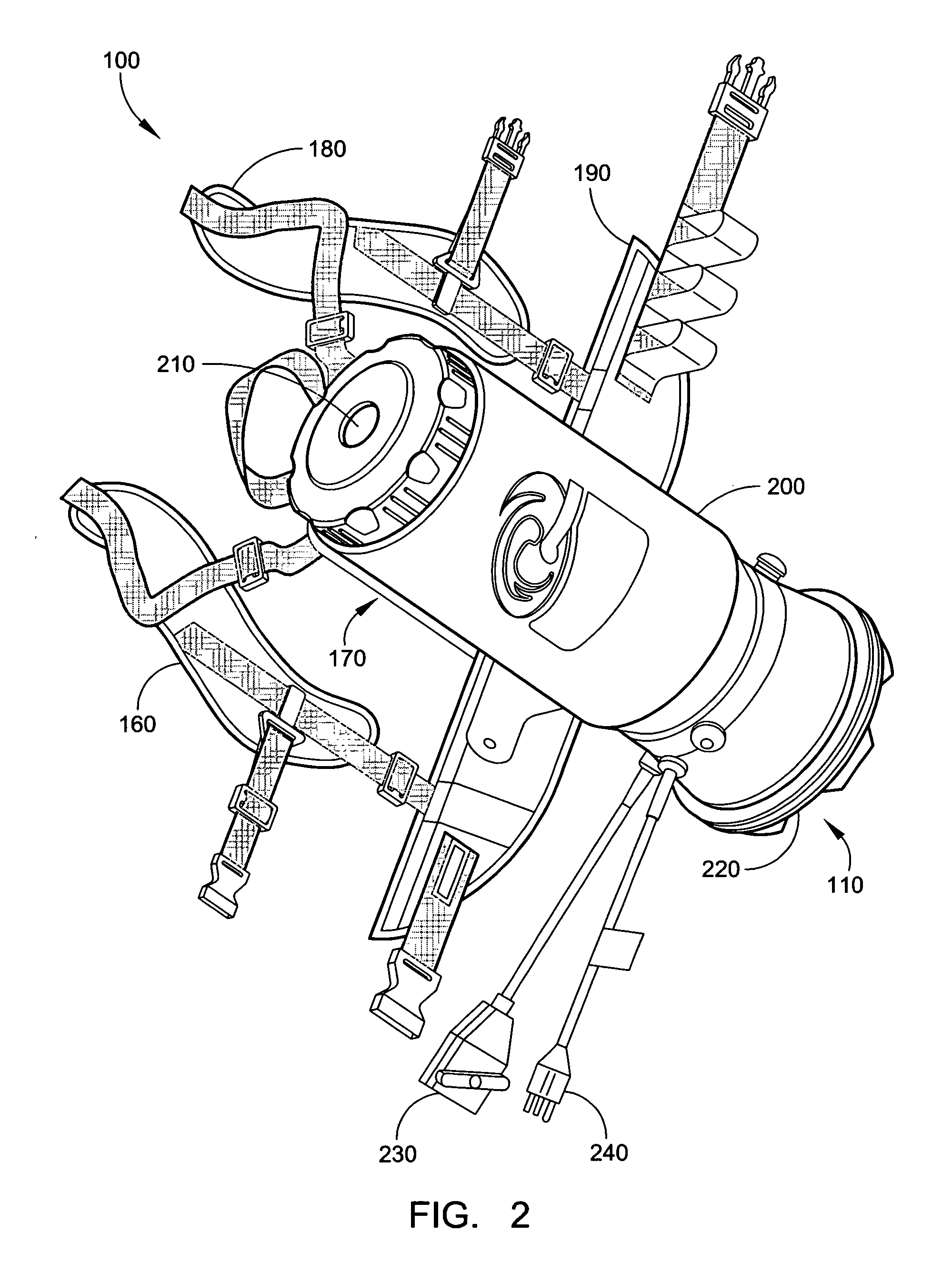

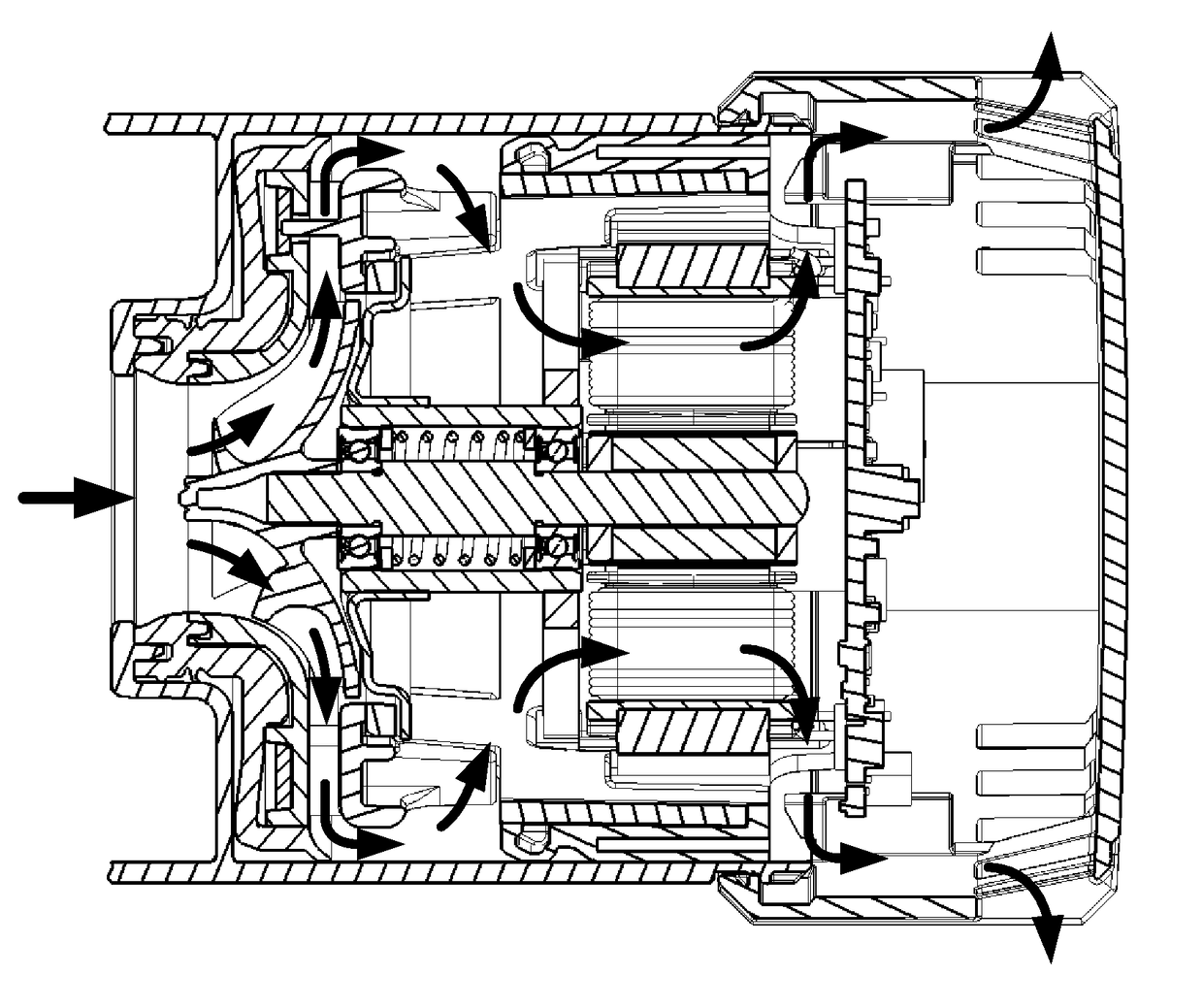

Quiet vacuum cleaner

InactiveUS20070174992A1Reduce noise levelImprove performanceExhaust-air diffusionEngineeringVacuum cleaner

A light-weight, quiet vacuum cleaner assembly for a backpack vacuum cleaner includes an air inlet for communicating with a vacuum cleaner hose and a filter; a vacuum motor for drawing air through the vacuum cleaner hose, air inlet, and filter; a quiet exhaust assembly module in communication with the vacuum motor for expelling and quieting exhaust from the vacuum motor, and wherein the vacuum cleaner assembly weighs 2-12 lbs. and includes a flow rate (CFM) to noise (dbA) ratio (flow rate / noise) of at least 0.6.

Owner:PROTEAM

Compressor flow path

ActiveUS9848745B2Closely arrangedReduce traffic lossAssociation with control/drive circuitsPump componentsImpellerEngineering

A product that includes a compressor, a housing and a vibration isolation mount located between the compressor and the housing. The compressor includes an impeller, a first inlet located upstream of the impeller, a first outlet located downstream of the impeller, a second inlet located downstream of the first outlet, and a second outlet located downstream of the second inlet. During operation, fluid enters the compressor via the first inlet and exits the compressor via the first outlet. The mount creates a restriction between the compressor and the housing that causes fluid exiting the first outlet to re-enter the compressor via the second inlet.

Owner:DYSON TECH LTD

Exhaust assembly

InactiveUS7425225B2Slow exhaust airflowReduce noiseCleaning filter meansCombination devicesExhaust pipeWaste management

An exhaust assembly for an appliance includes a filter housing for retaining a filter and an exhaust duct which receives airflow from the filter housing. One or more vanes are positioned in the filter housing for guiding airflow from the exhaust side of the filter to the exhaust duct. The vanes spread the airflow entering the exhaust duct across the width thereof so as to reduce noise and to reduce the velocity of the exiting air. The exhaust duct increases in cross-sectional area in the direction of flow through the exhaust duct so as to further reduce the velocity of the exiting air.

Owner:DYSON TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com