Patents

Literature

2396results about "Gas separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

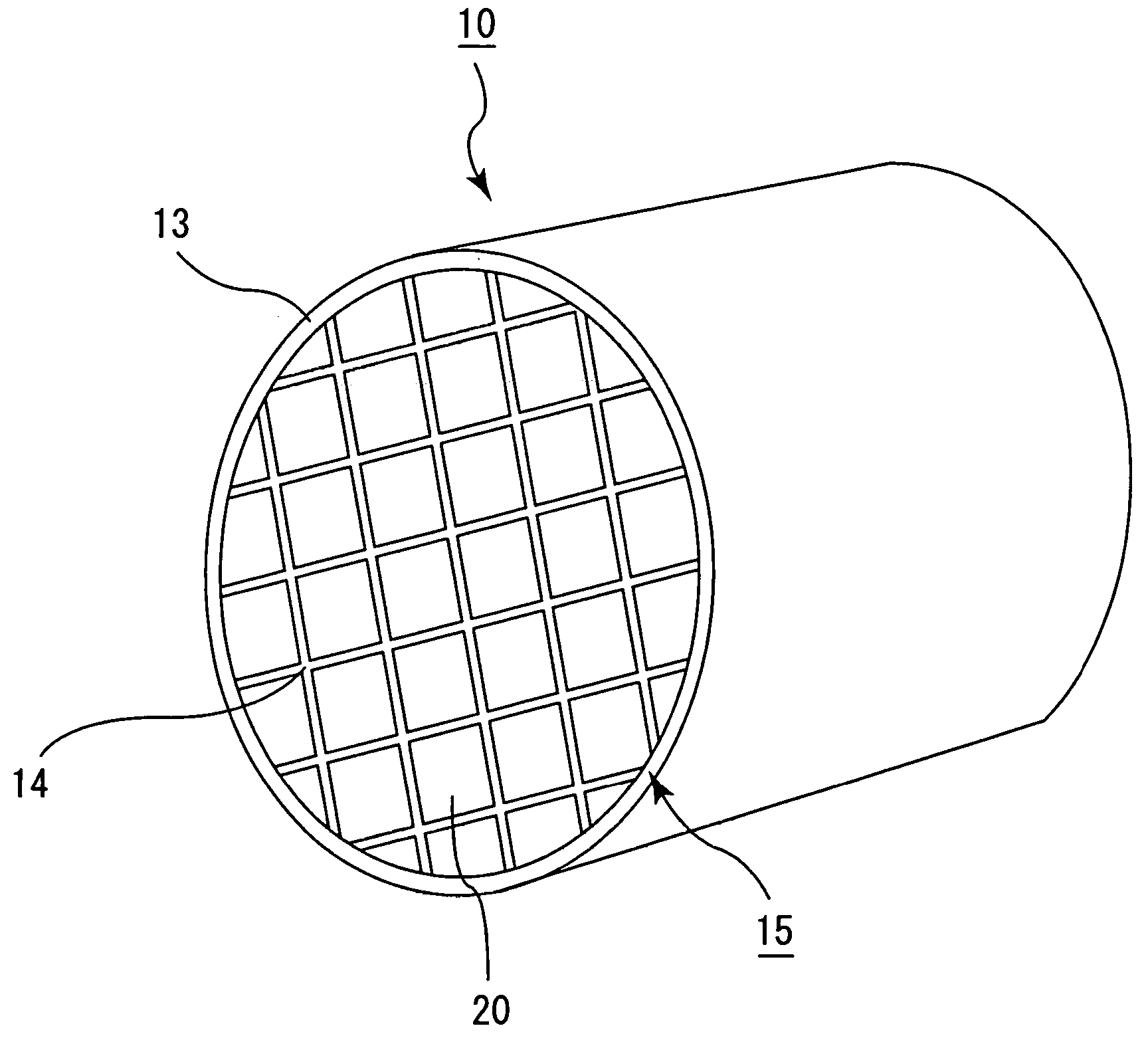

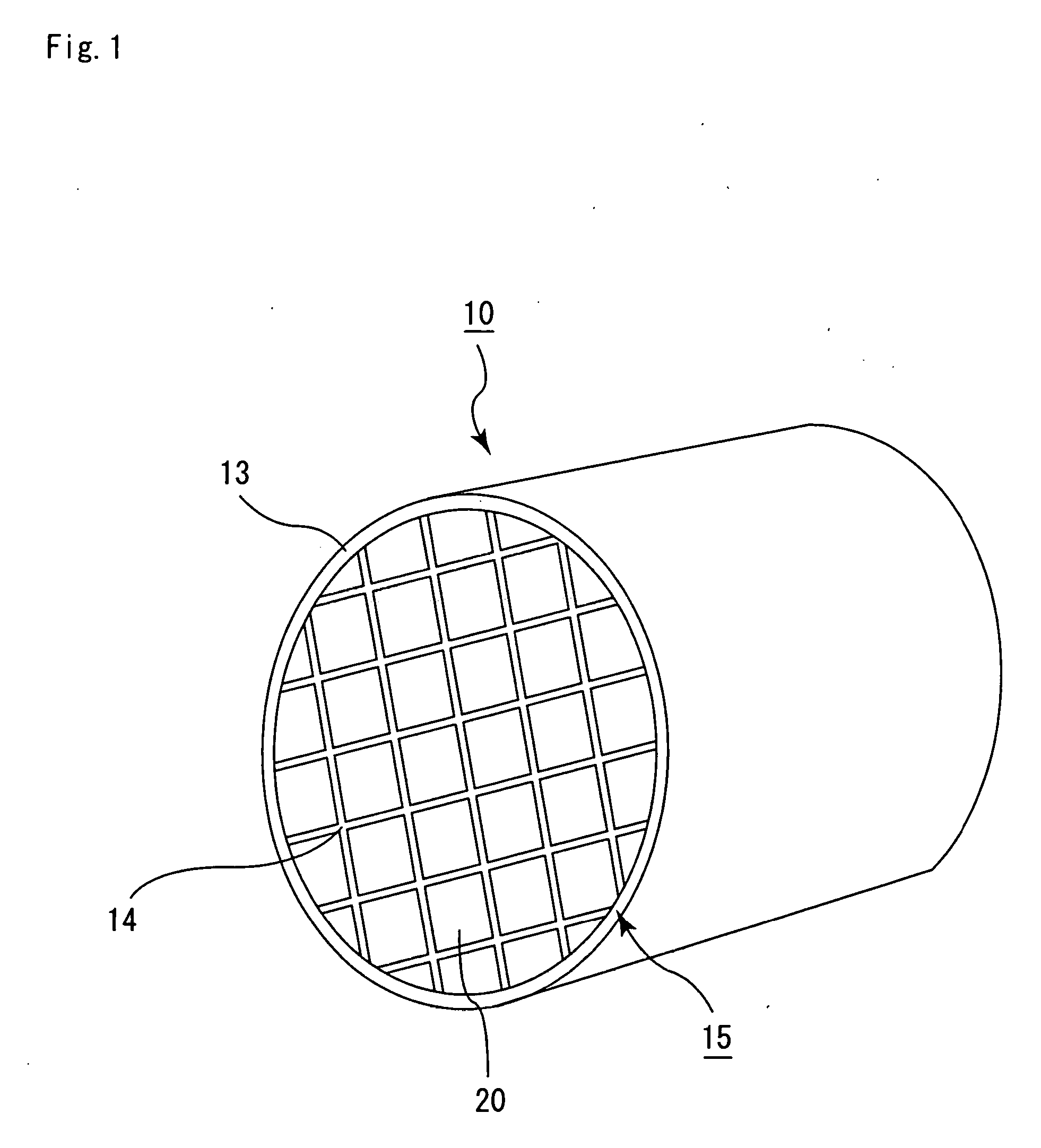

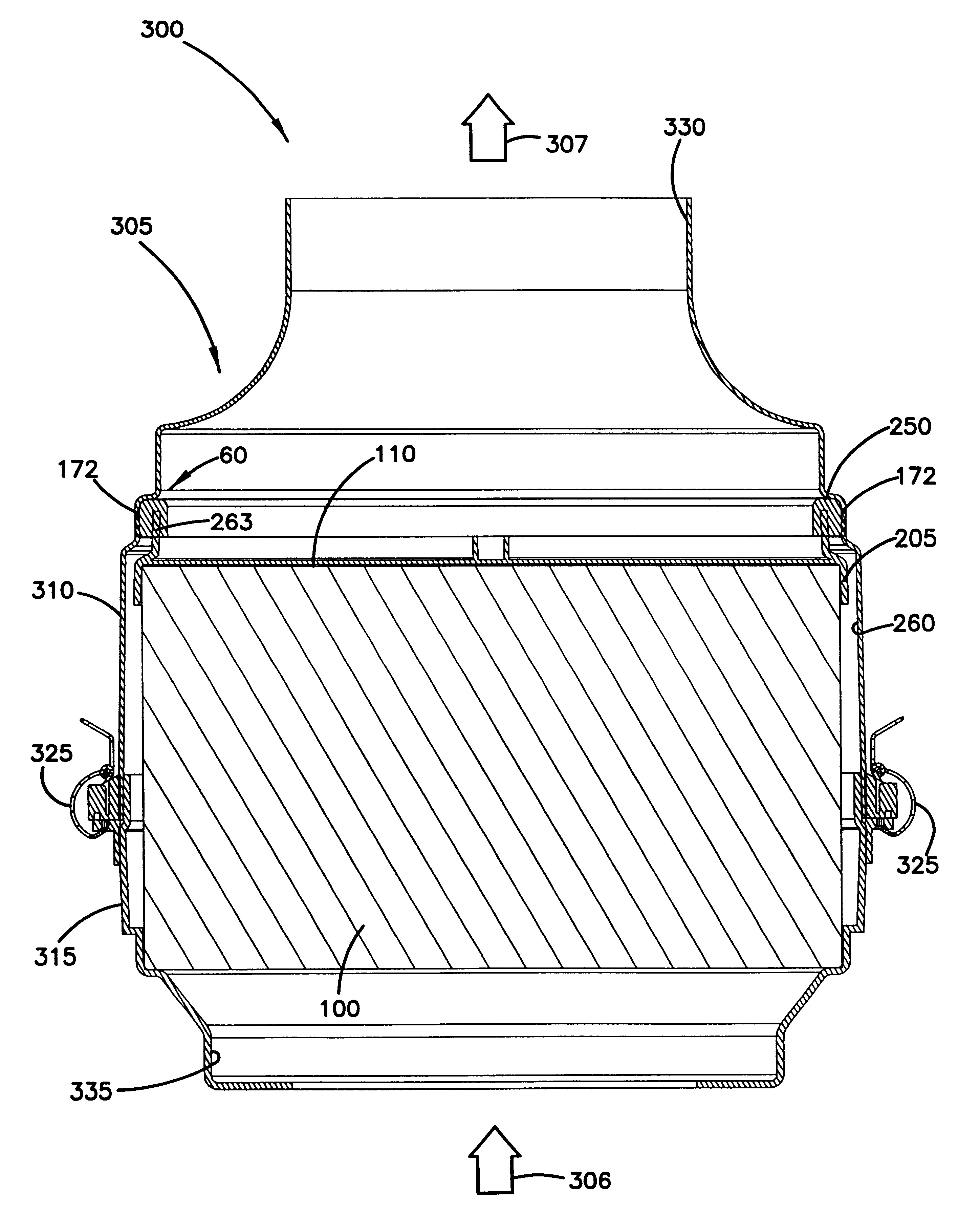

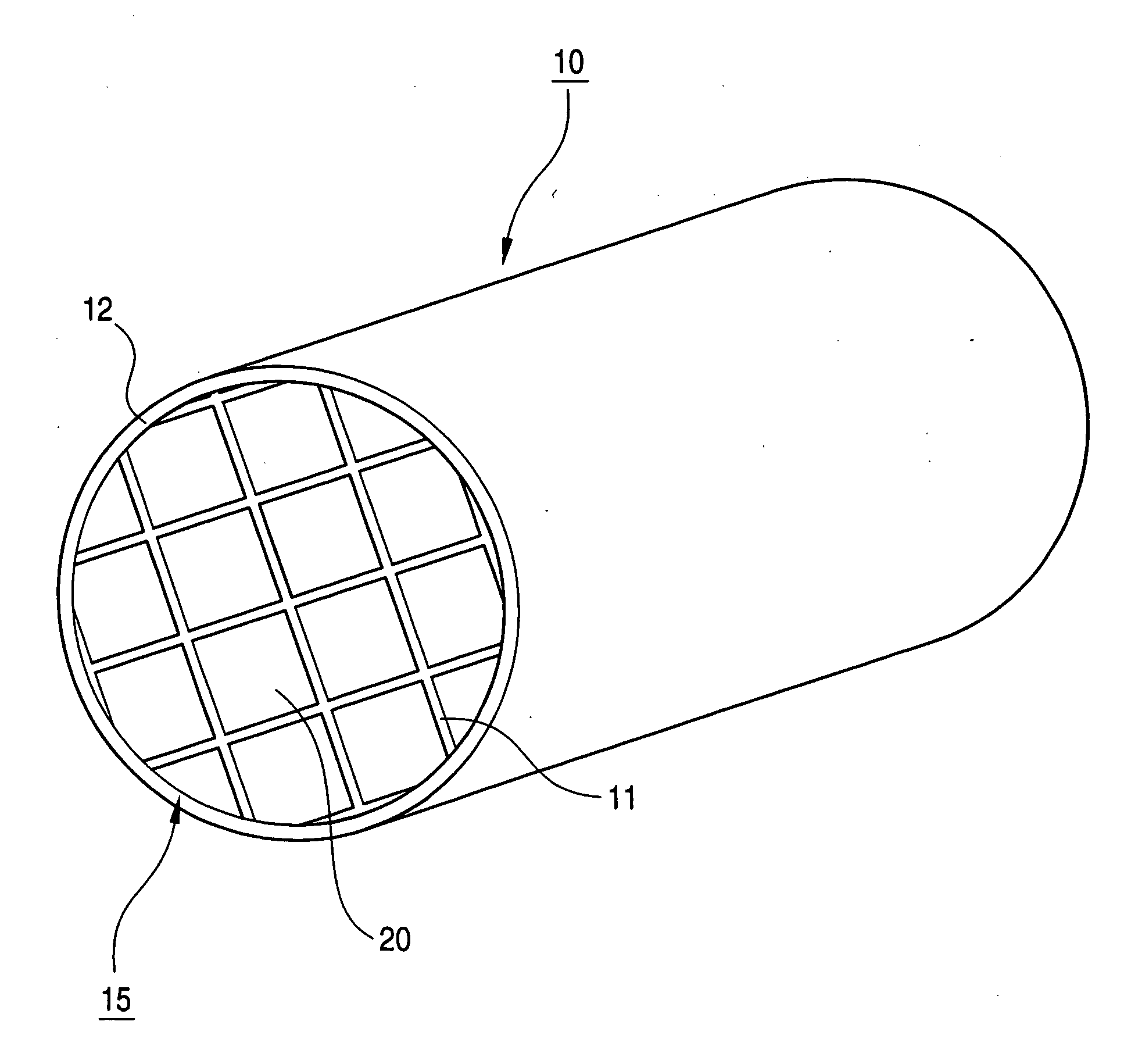

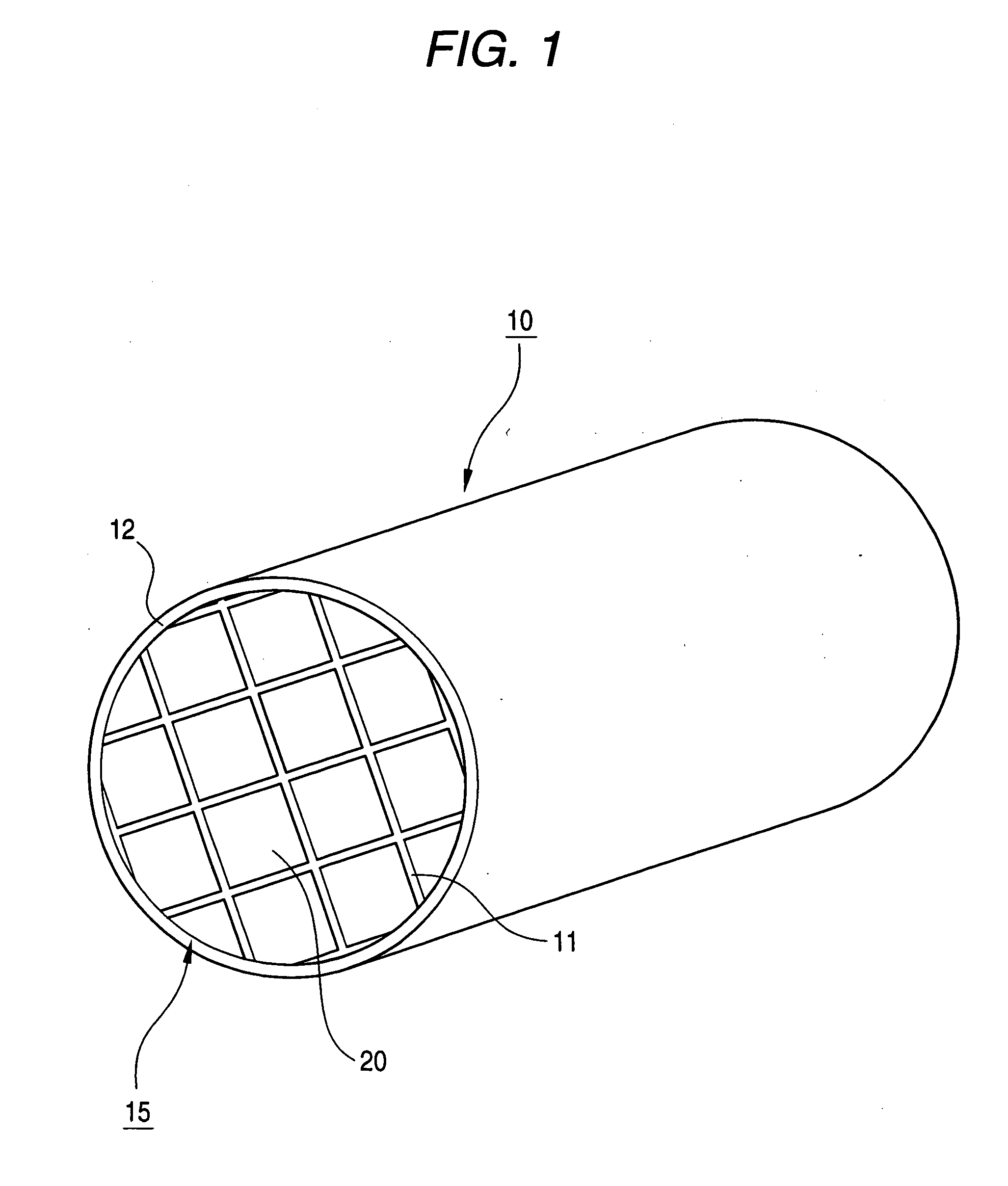

Filter arrangement; sealing system; and methods

InactiveUS6190432B1Prevent crashAvoid passingHuman health protectionCombination devicesEngineeringMechanical engineering

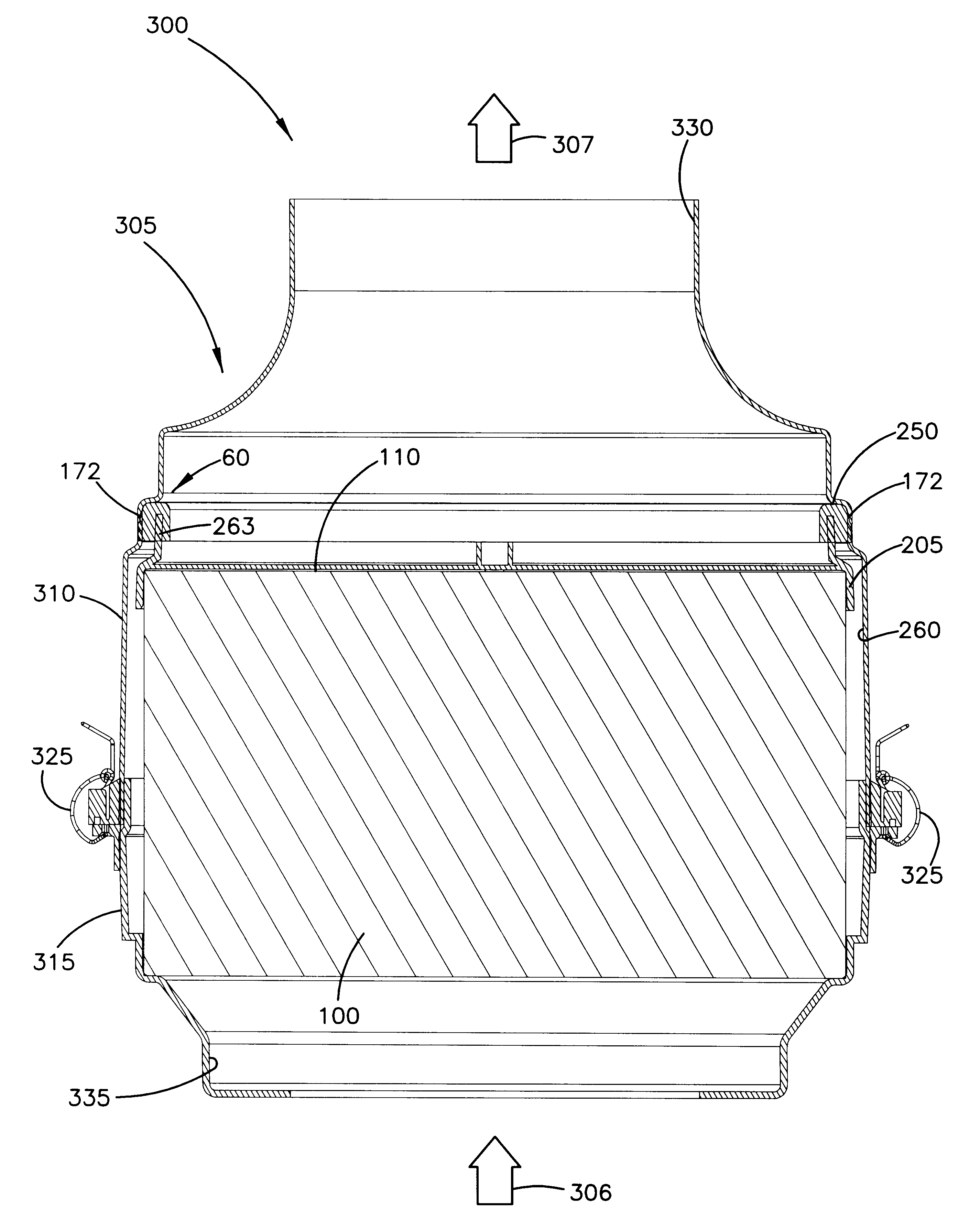

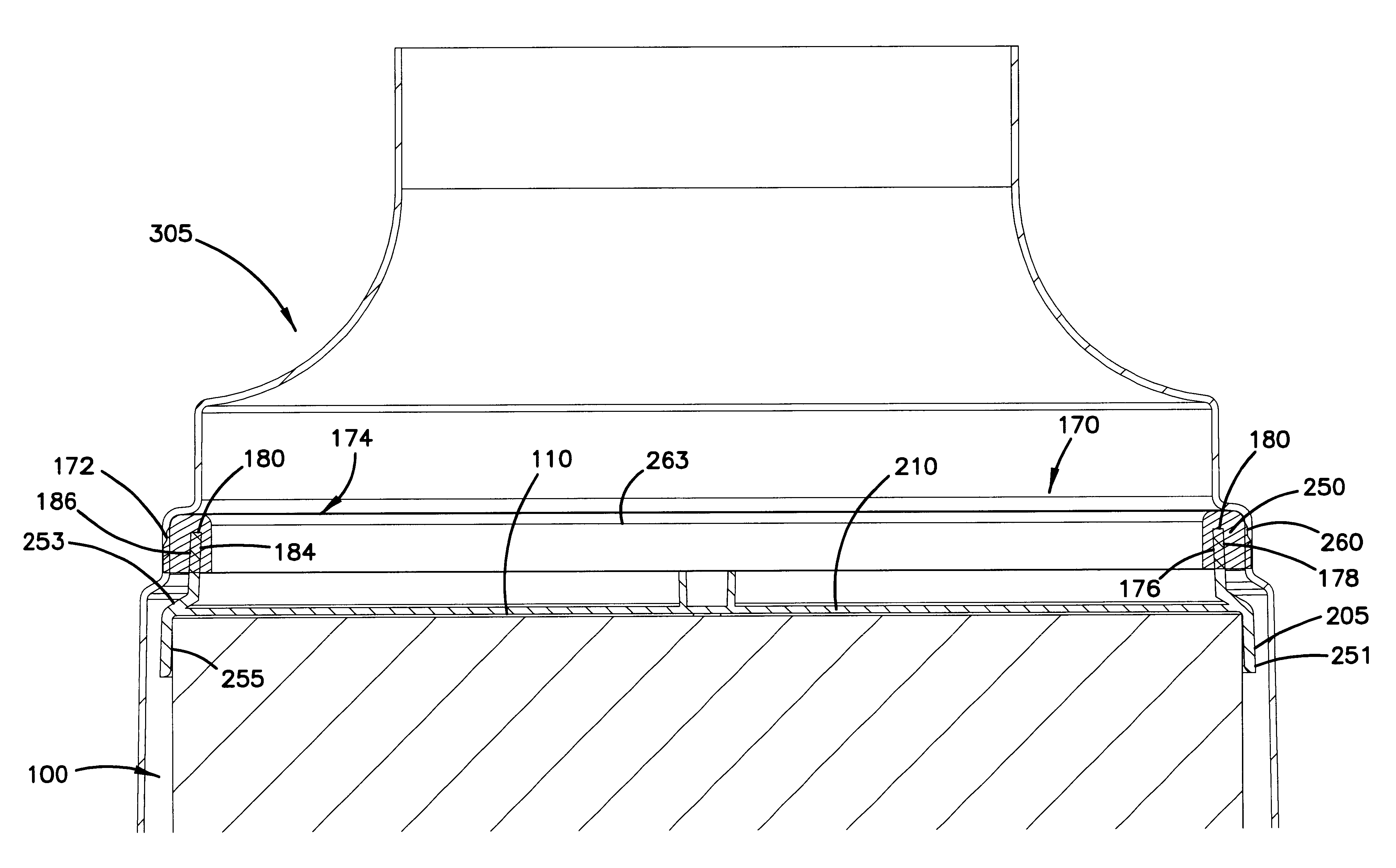

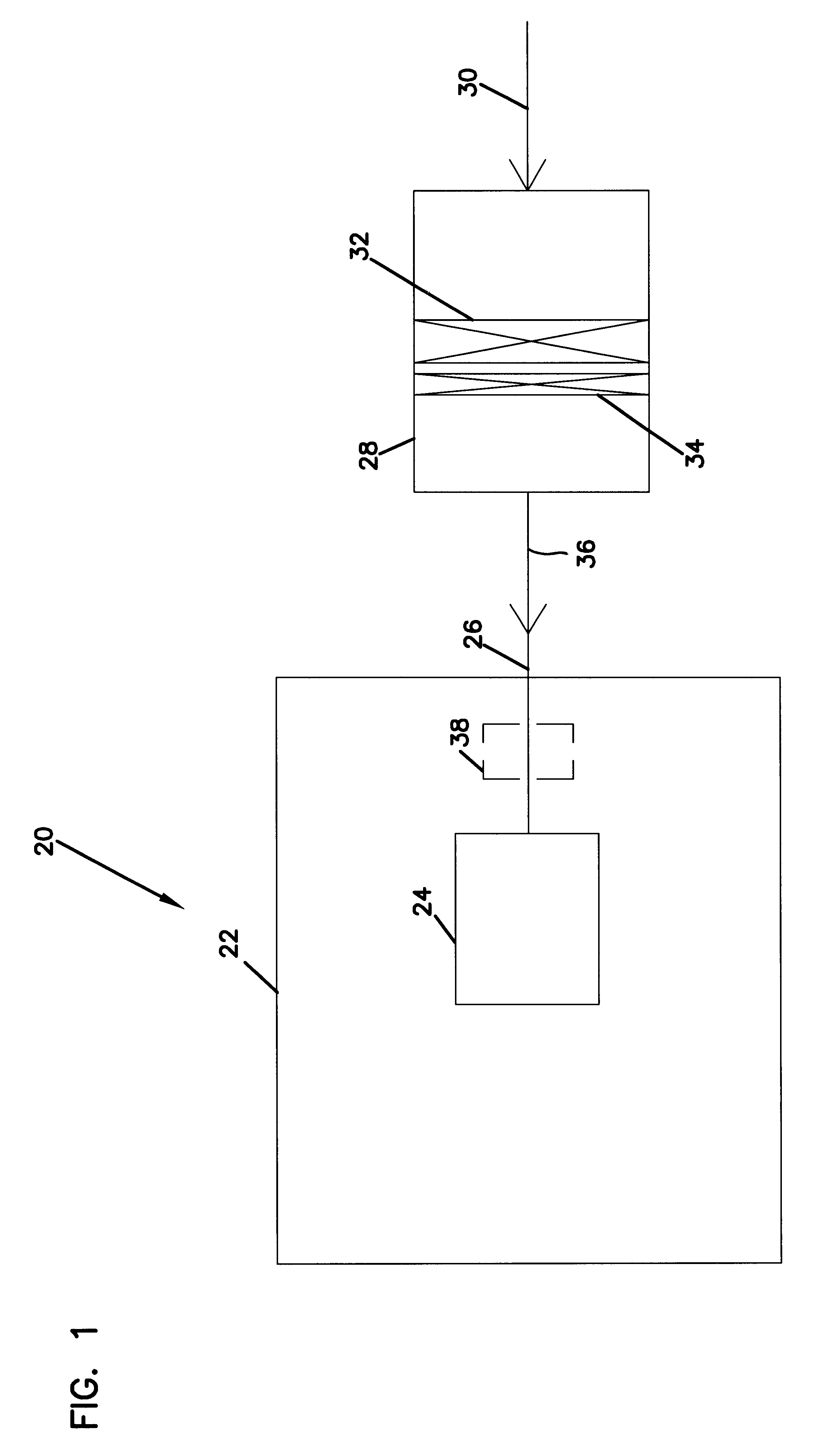

A filter pack includes a filter construction and a sealing system for sealing the construction within a duct or housing. The filter construction has first and second opposite flow faces and is configured for a straight-through flow. The sealing system includes a frame construction and a compressible seal member. The compressible seal member is molded around a portion of the frame construction. The compressible seal member is sufficiently compressible to form a radial seal between and against the frame construction and a surface of a housing when the filter pack is inserted within the housing.

Owner:DONALDSON CO INC

Filter arrangement; sealing system; and methods

InactiveUS6350291B1Avoid passingObstruct passageHuman health protectionCombination devicesEngineeringMechanical engineering

A filter pack includes a filter construction and a sealing system for sealing the construction within a duct or housing. The filter construction has first and second opposite flow faces and is configured for a straight-through flow. The sealing system includes a frame construction and a compressible seal member. The compressible seal member is molded around a portion of the frame construction. The compressible seal member is sufficiently compressible to form a radial seal between and against the frame construction and a surface of a housing when the filter pack is inserted within the housing.

Owner:DONALDSON CO INC

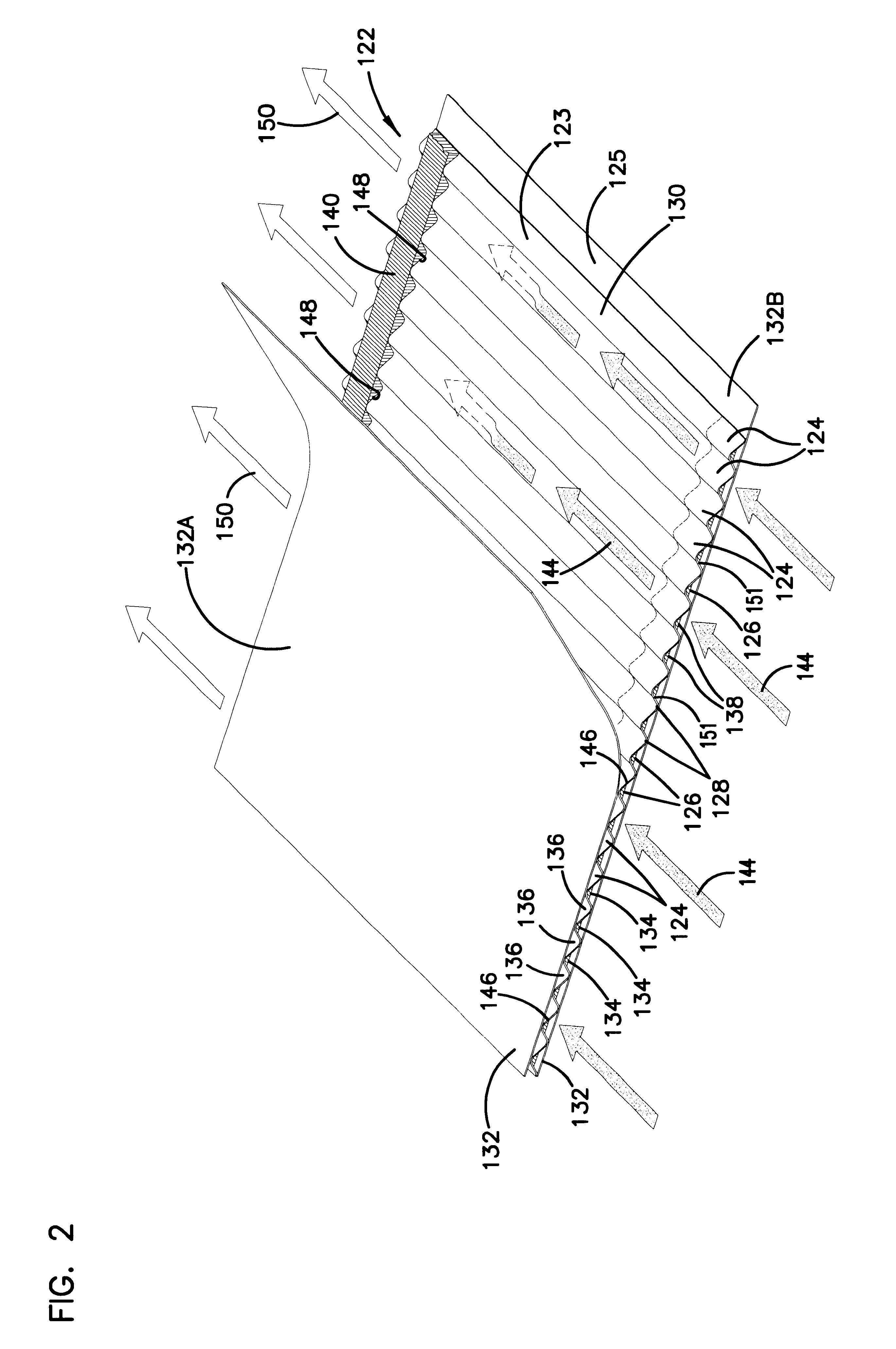

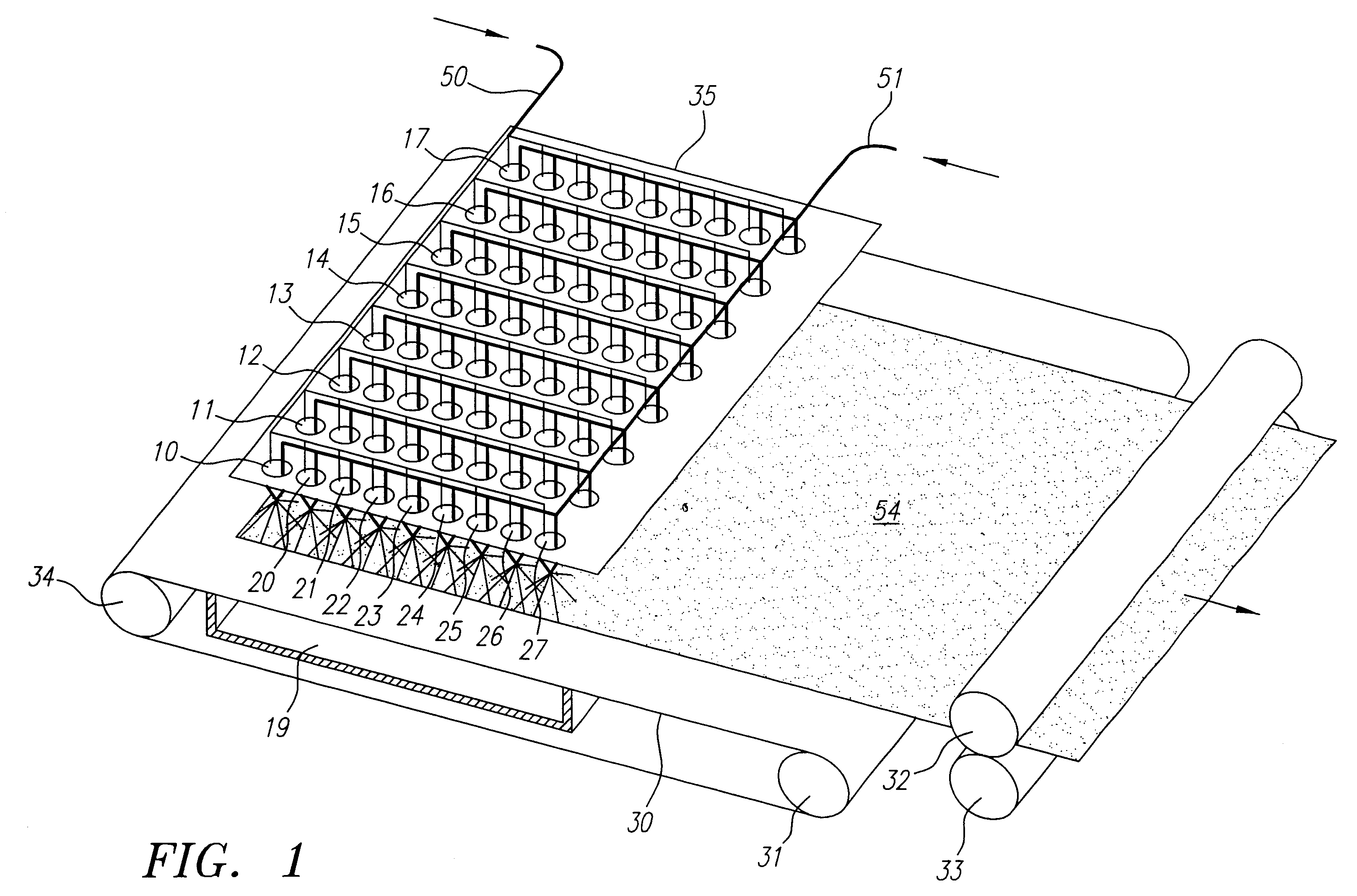

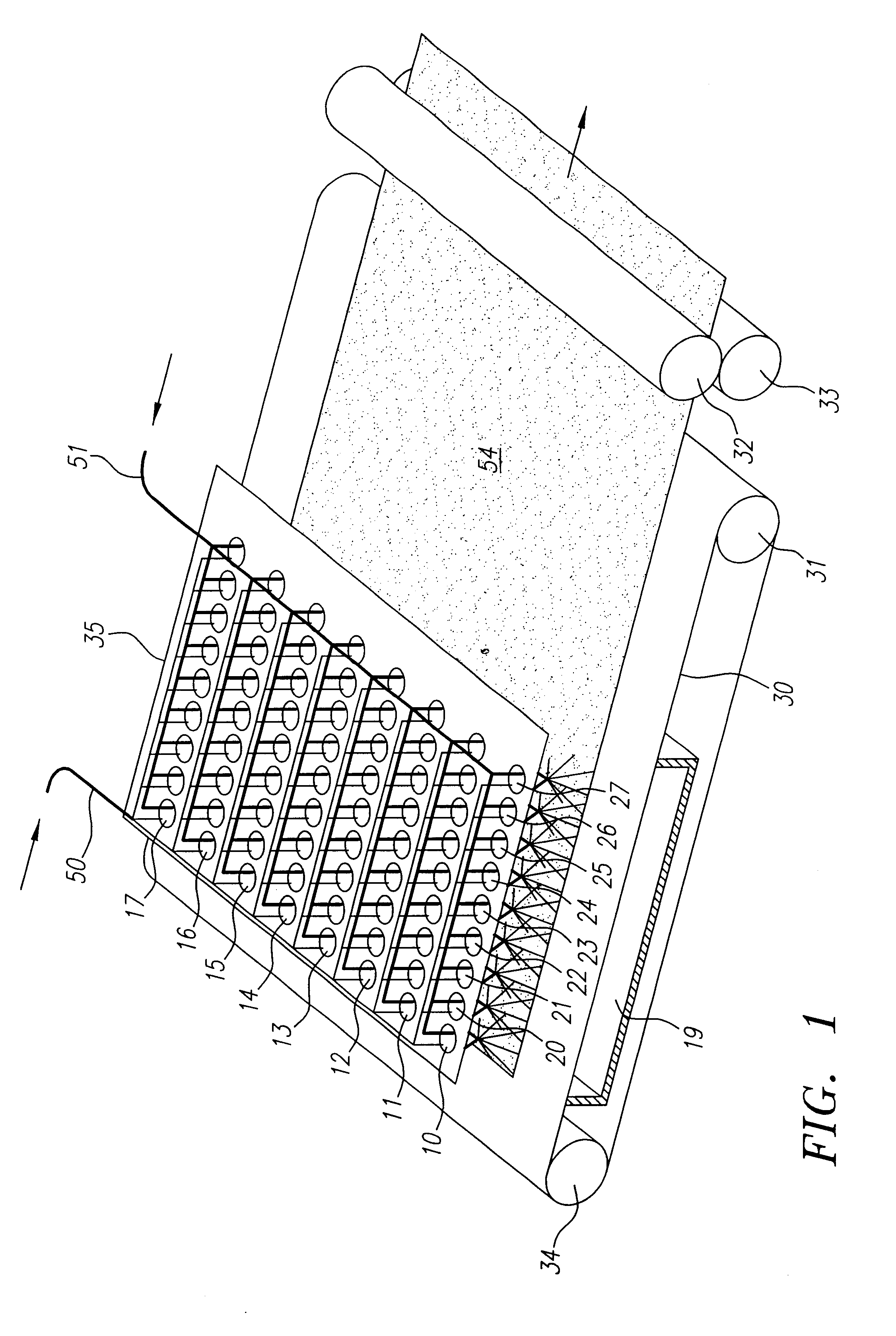

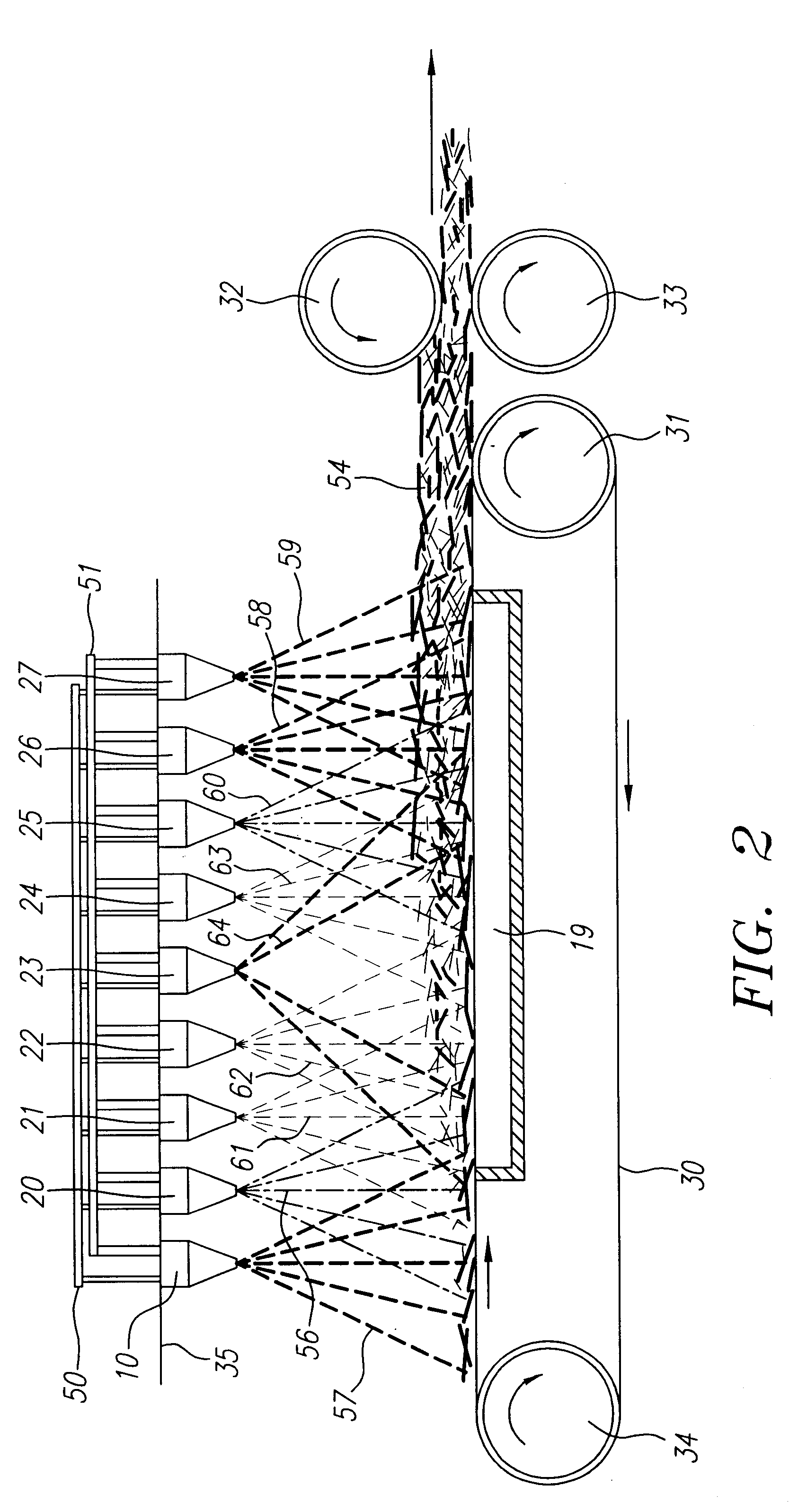

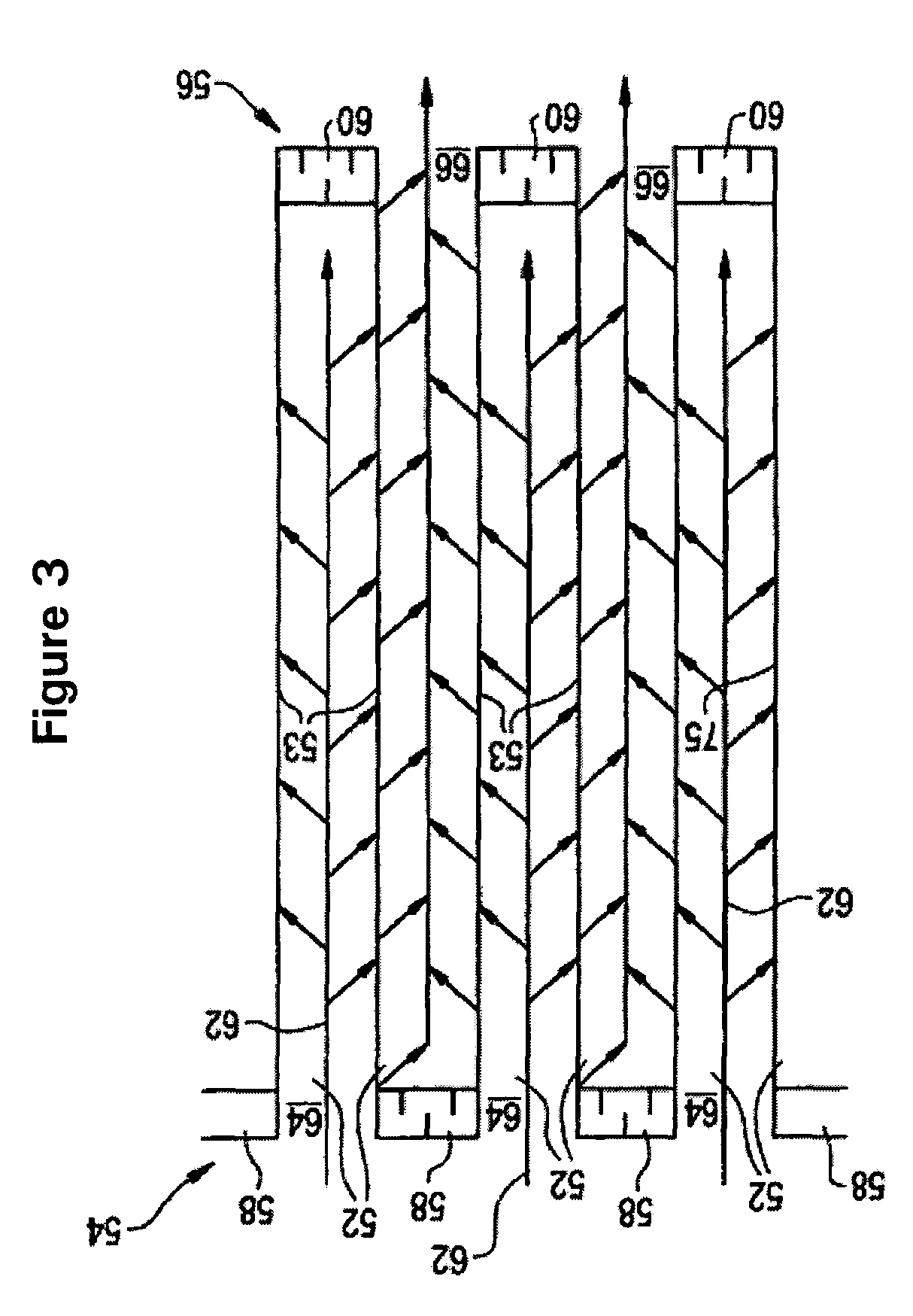

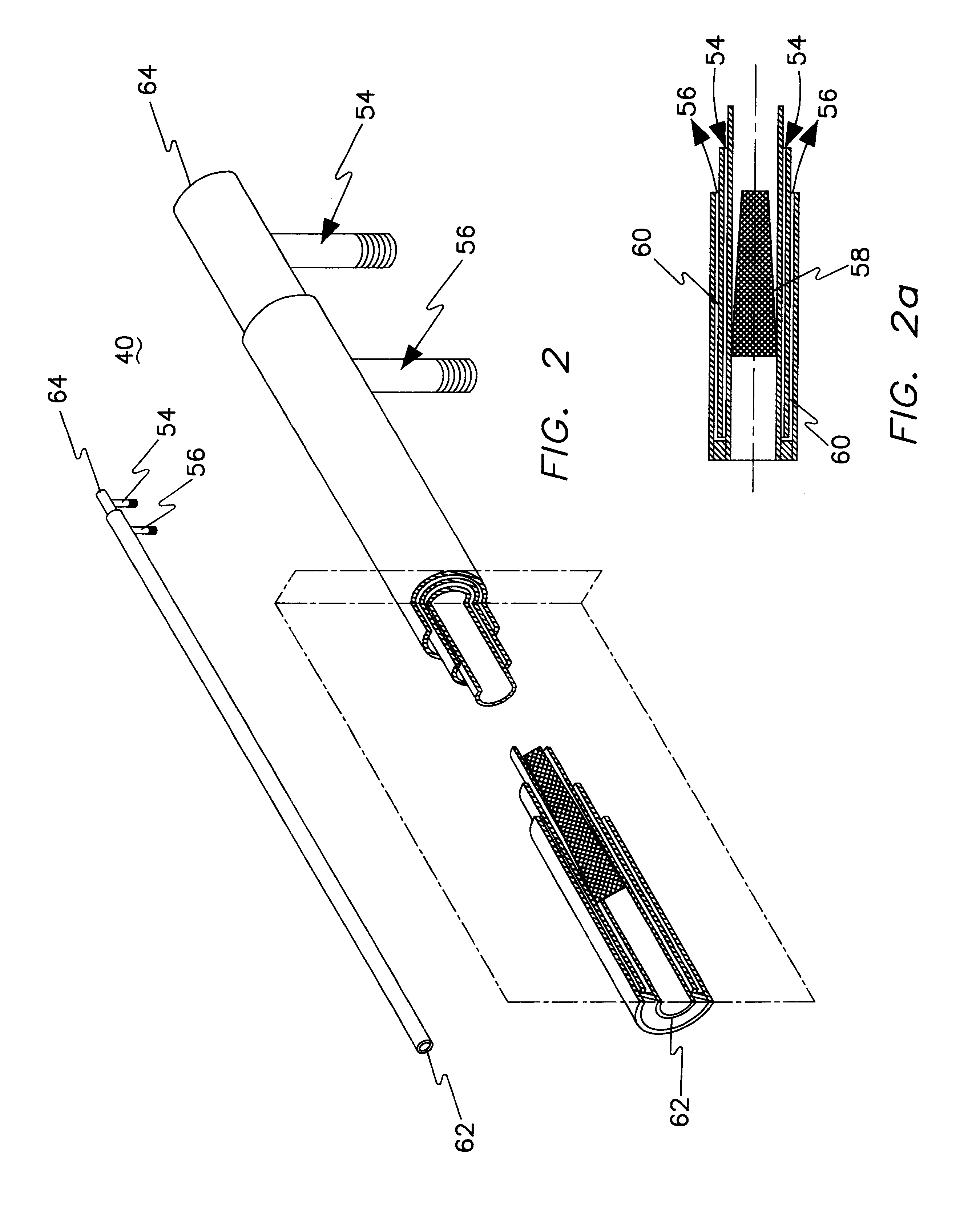

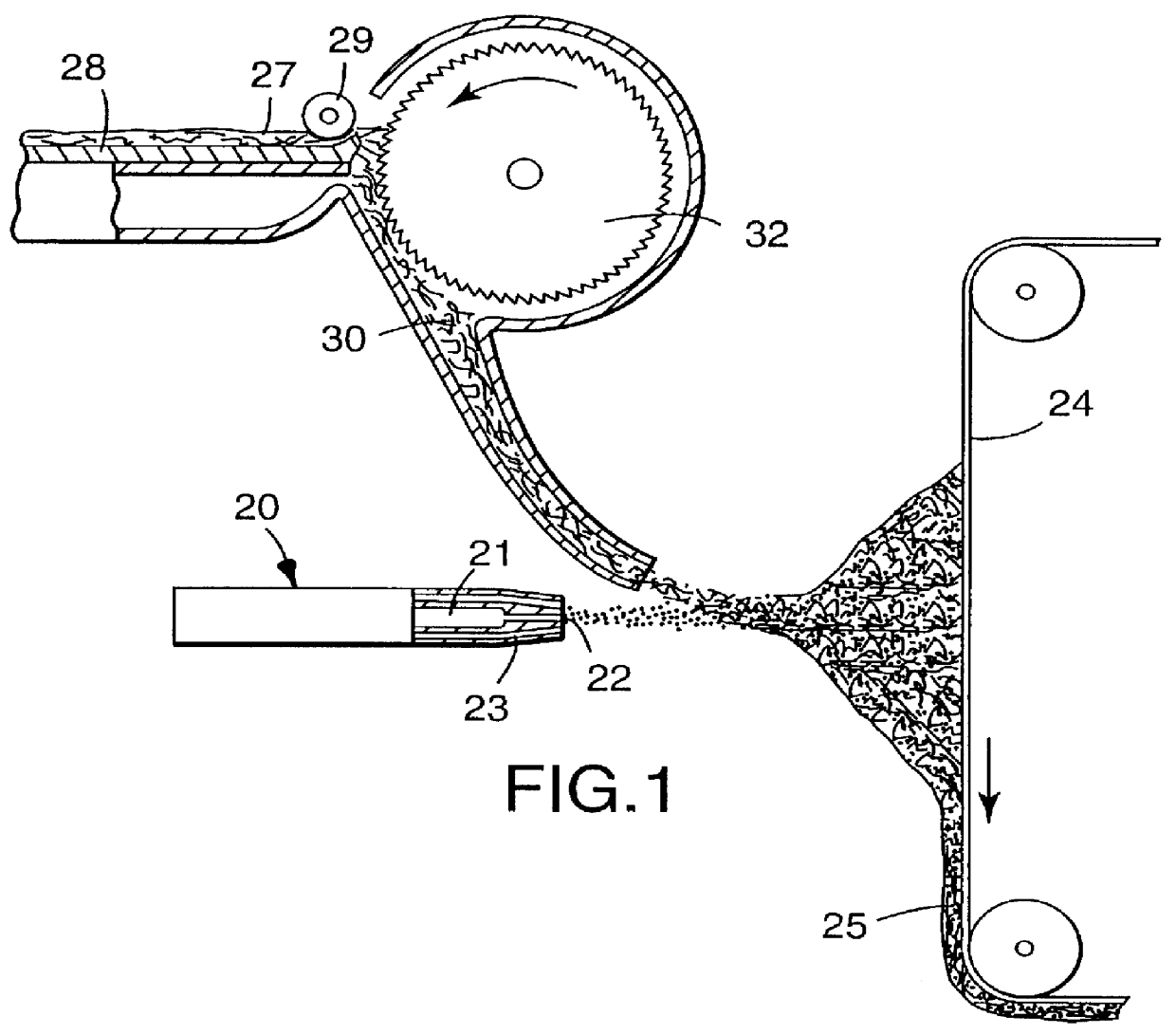

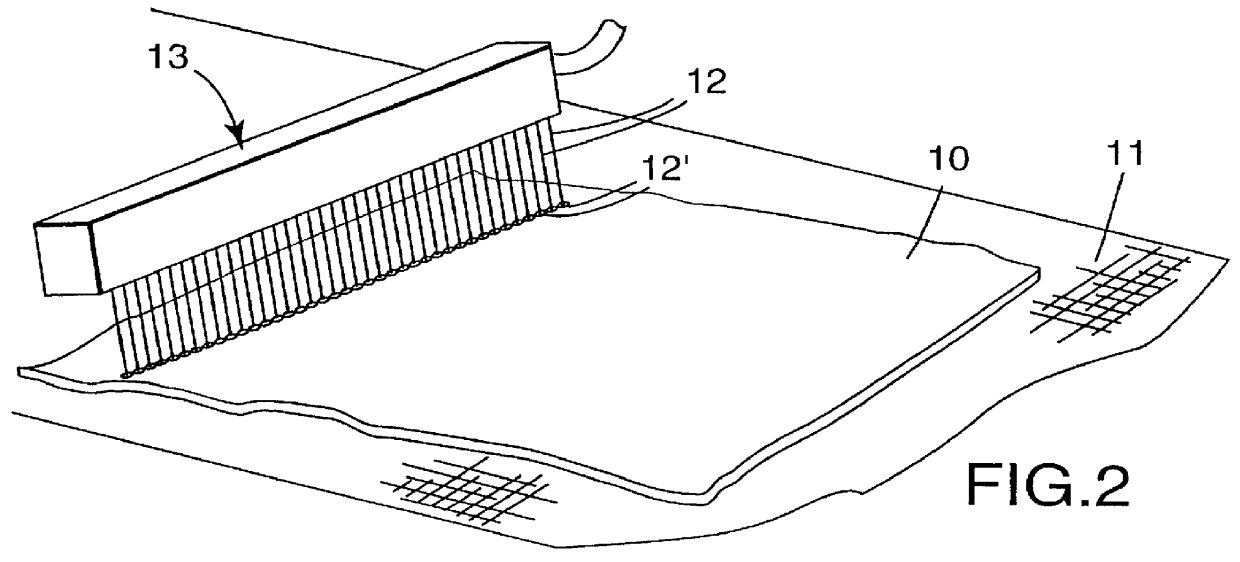

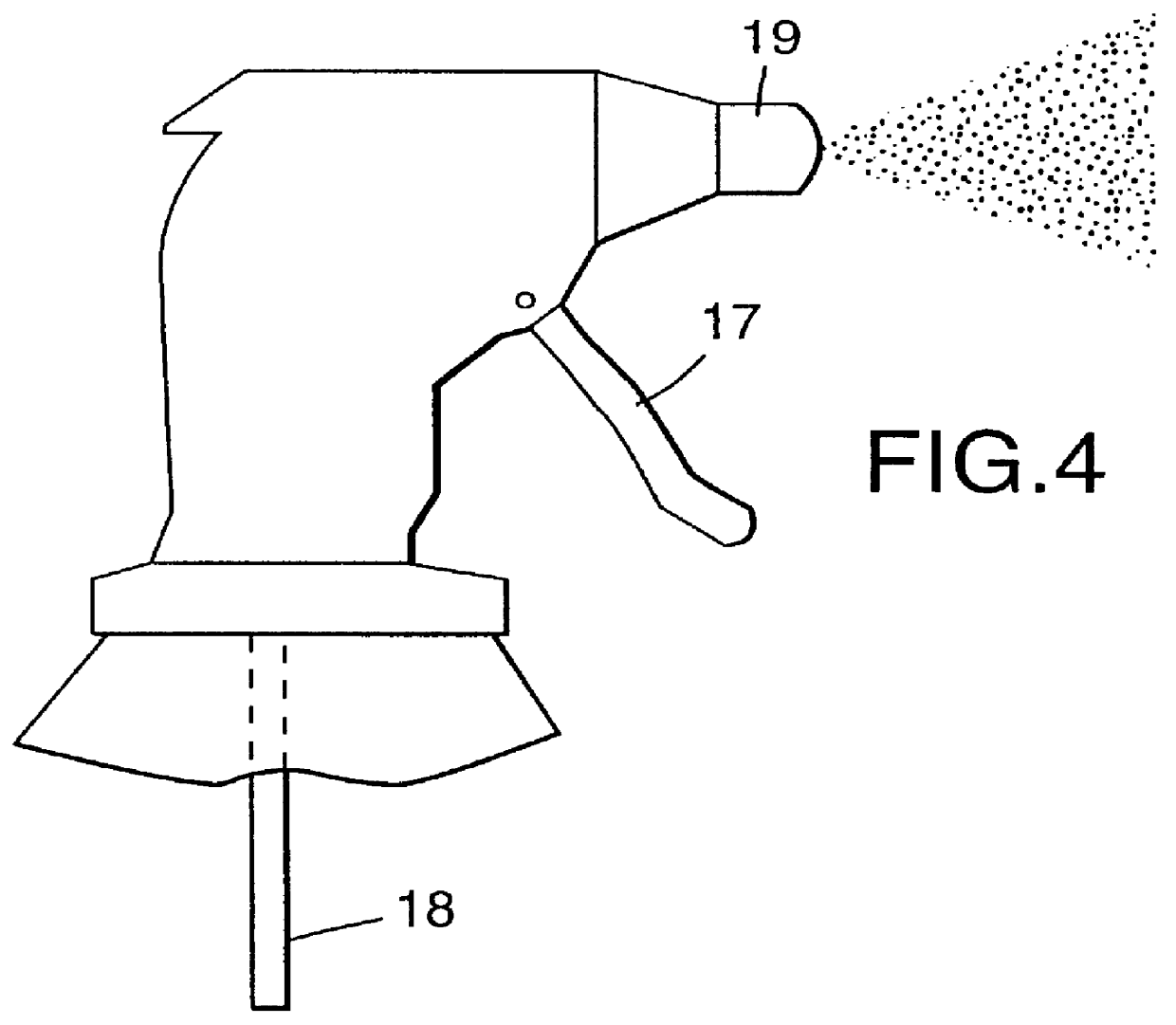

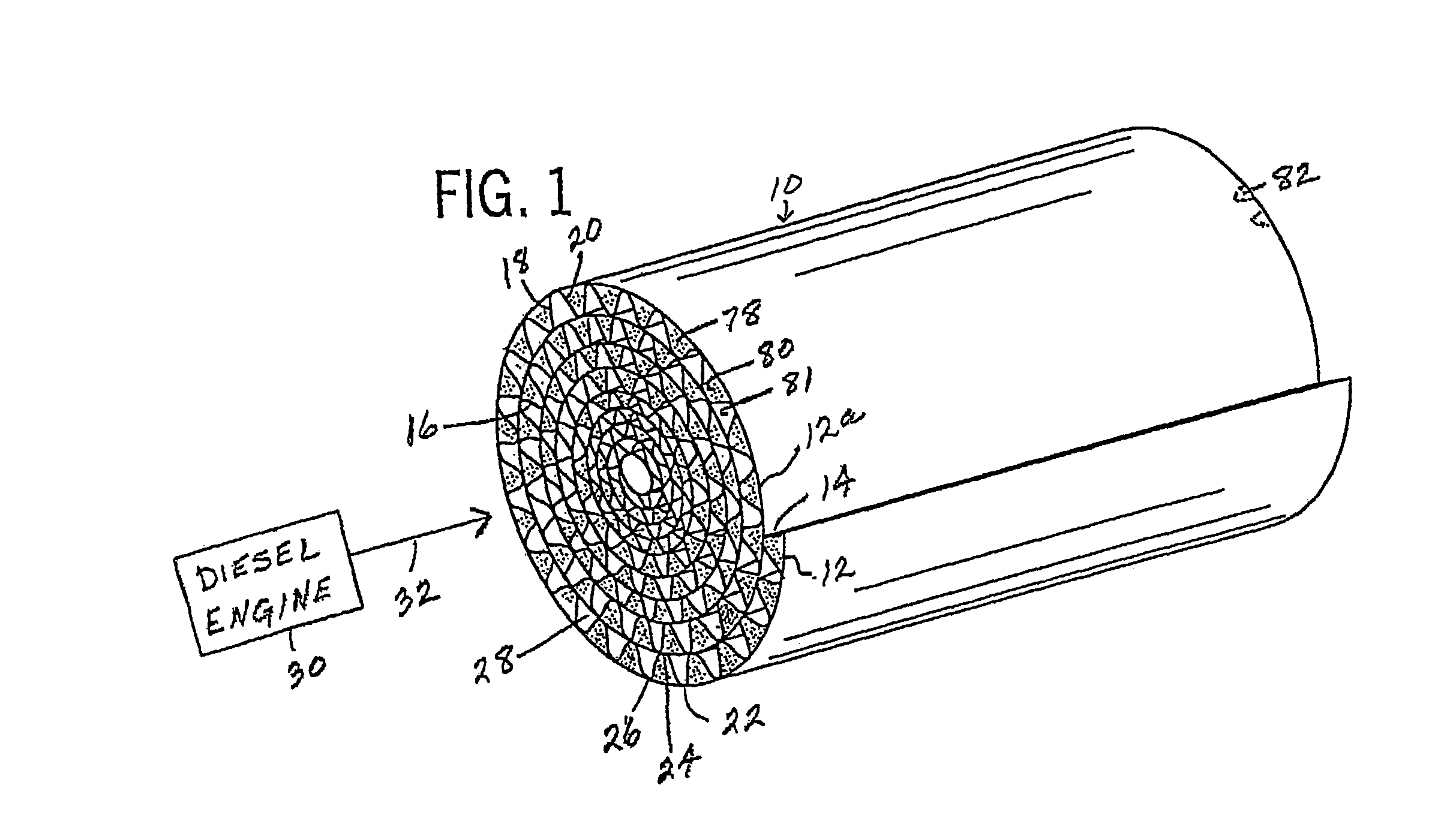

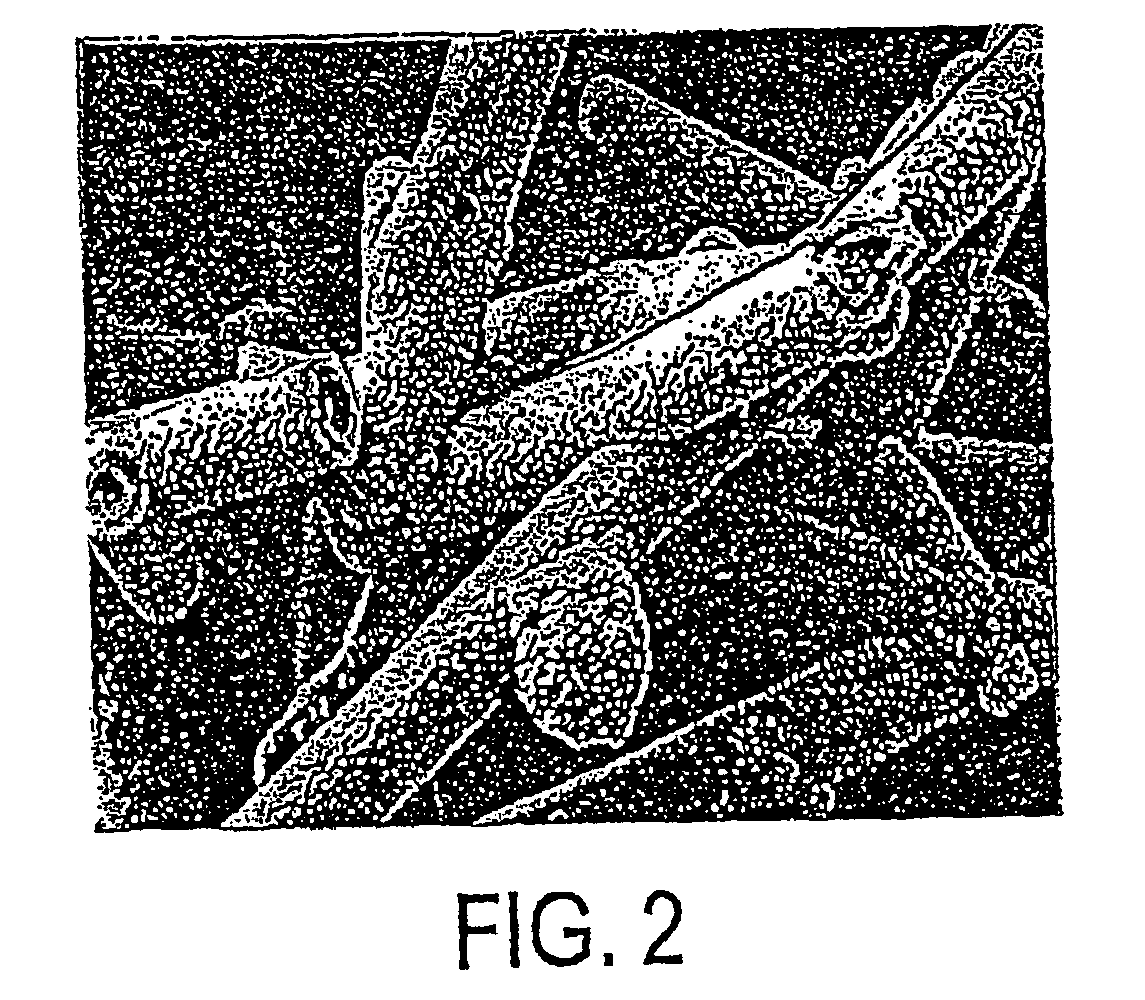

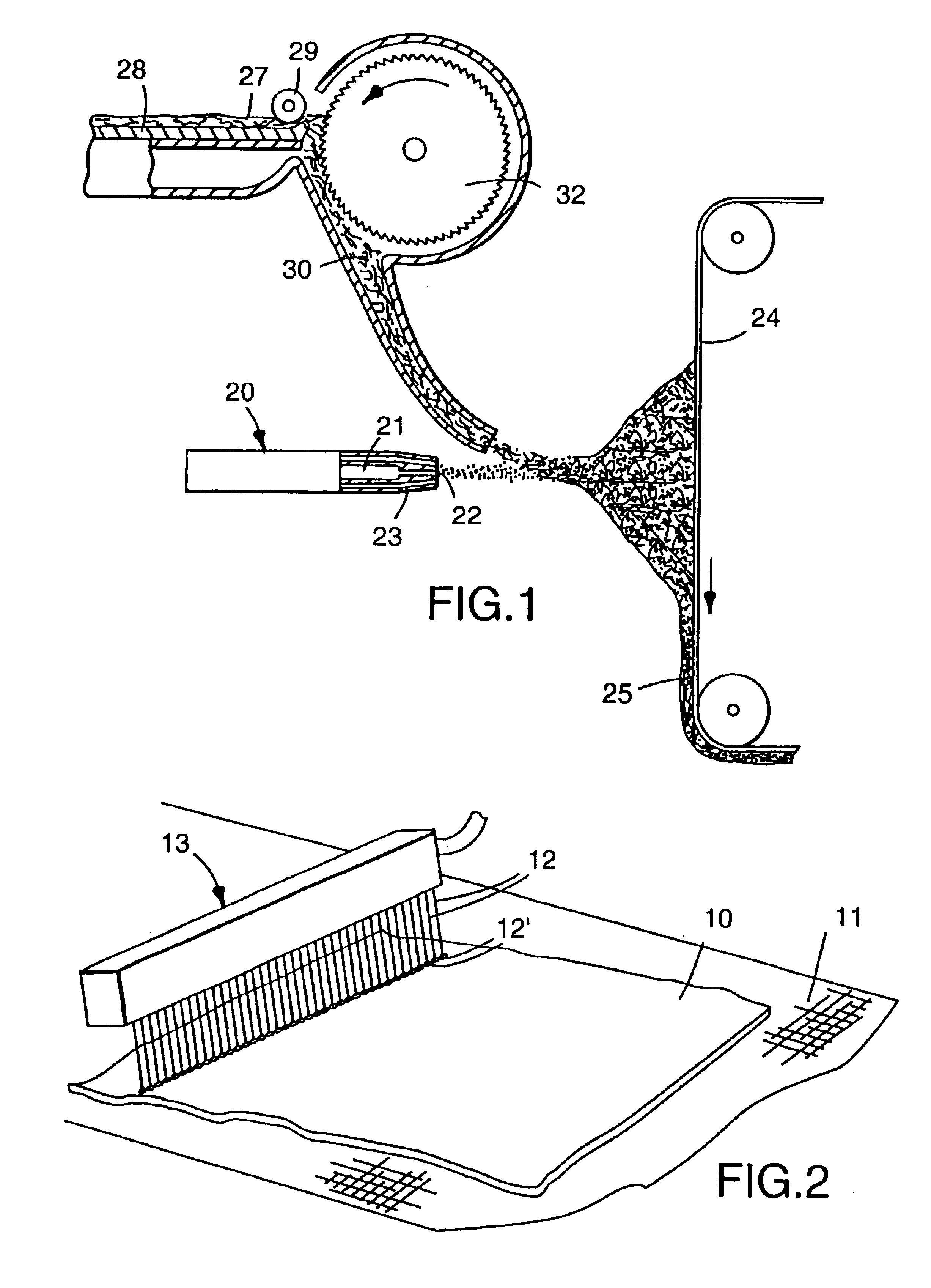

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6315806B1Increase distanceReduce resistanceFilament/thread formingLoose filtering material filtersMean diameterFiber

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

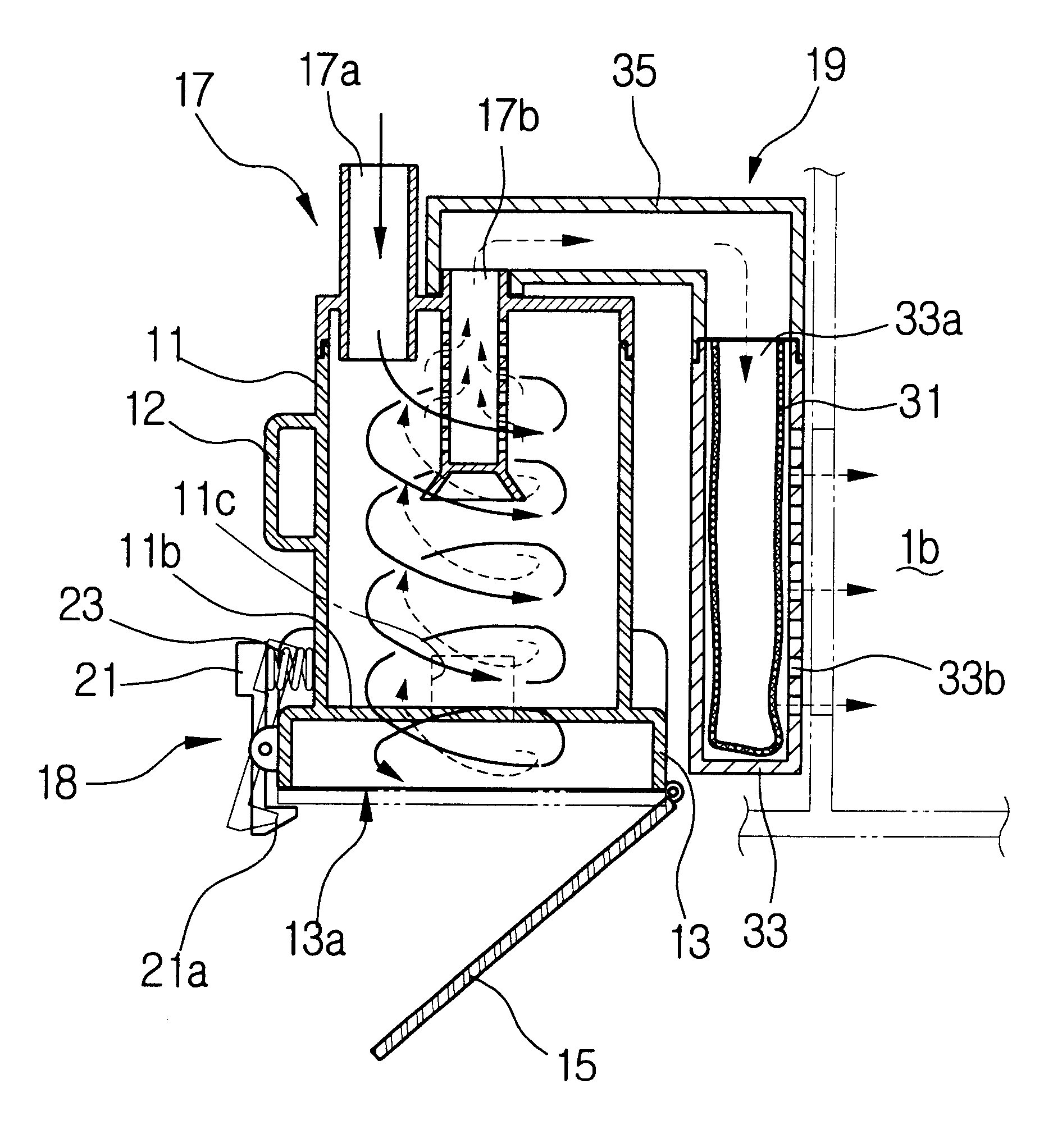

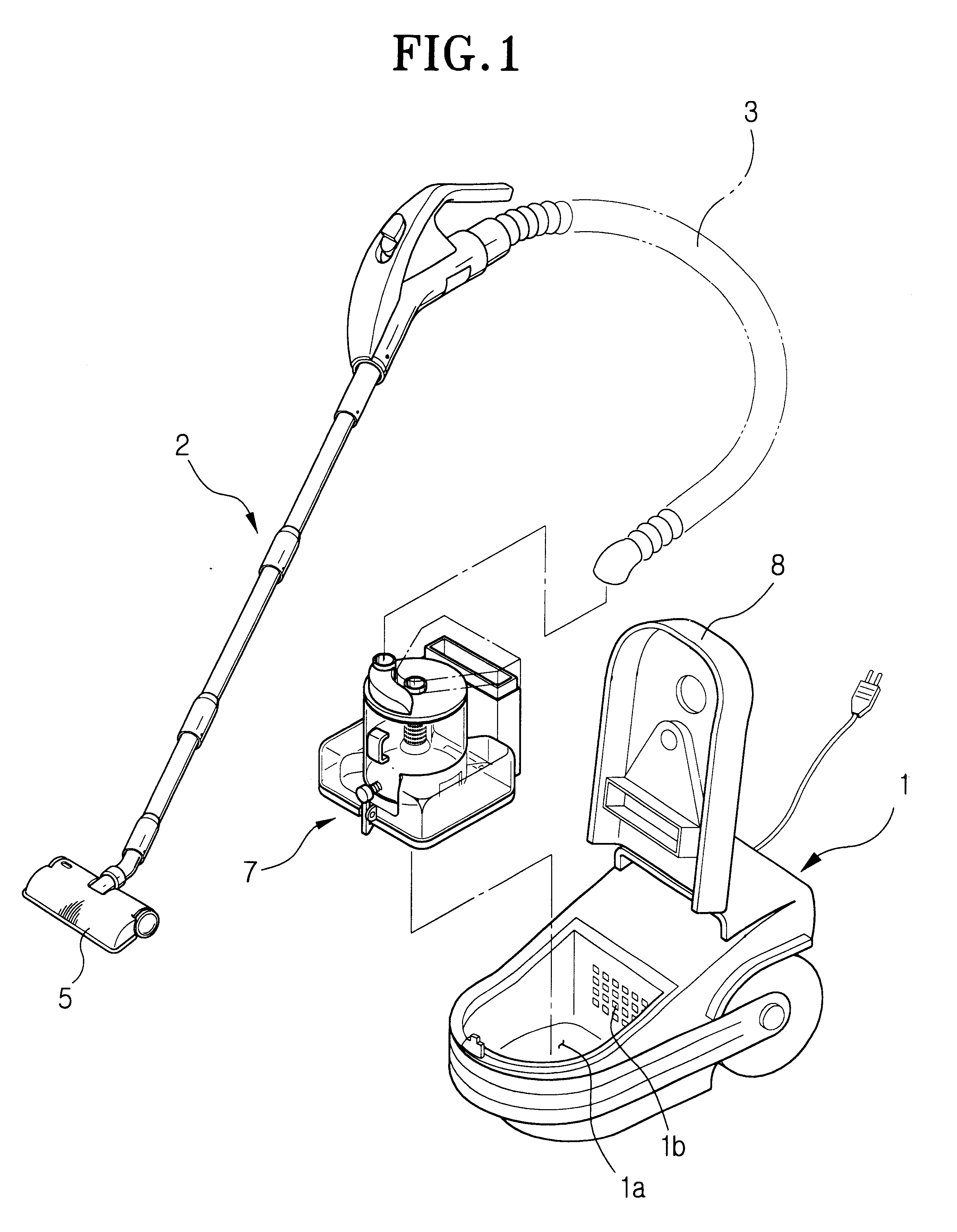

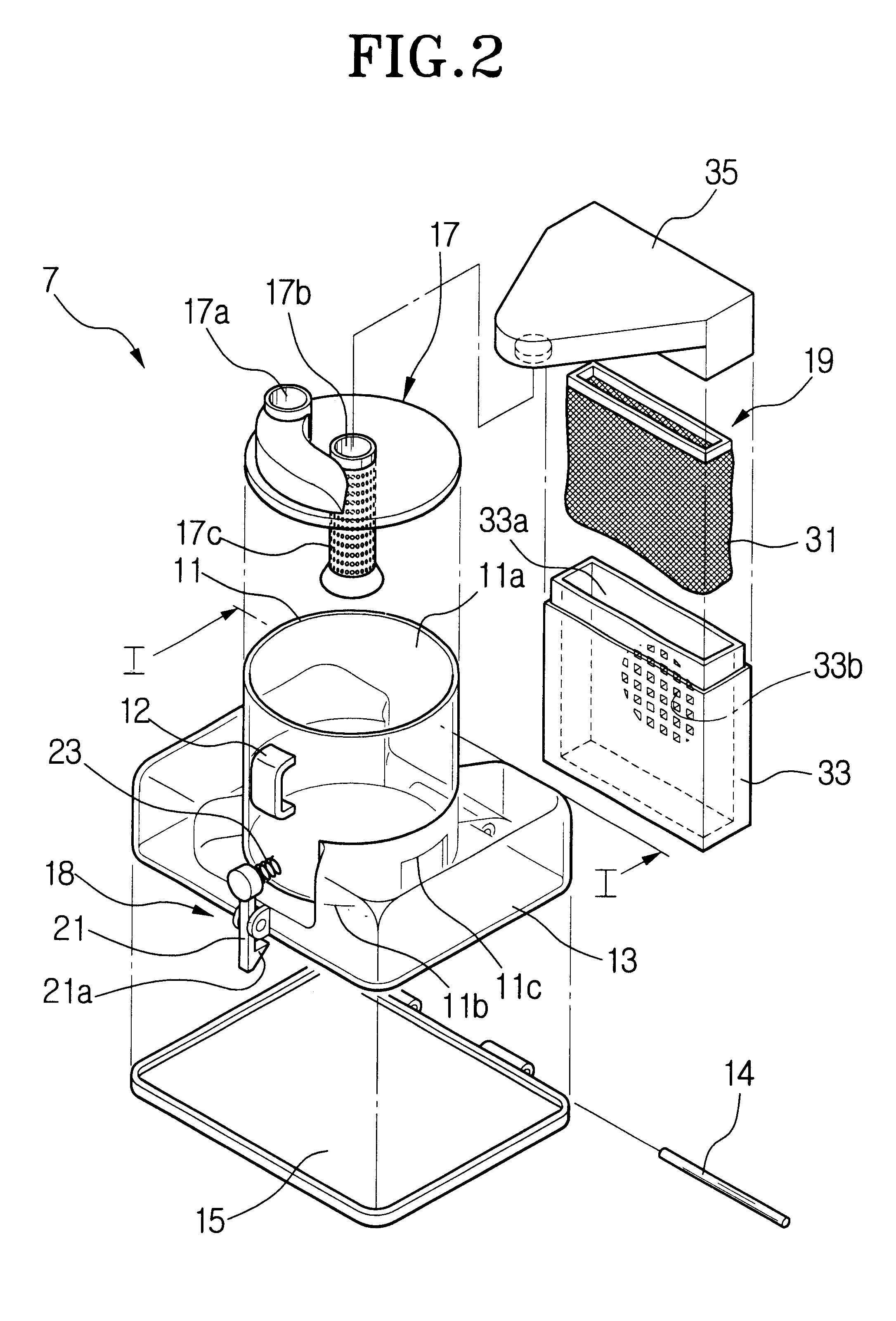

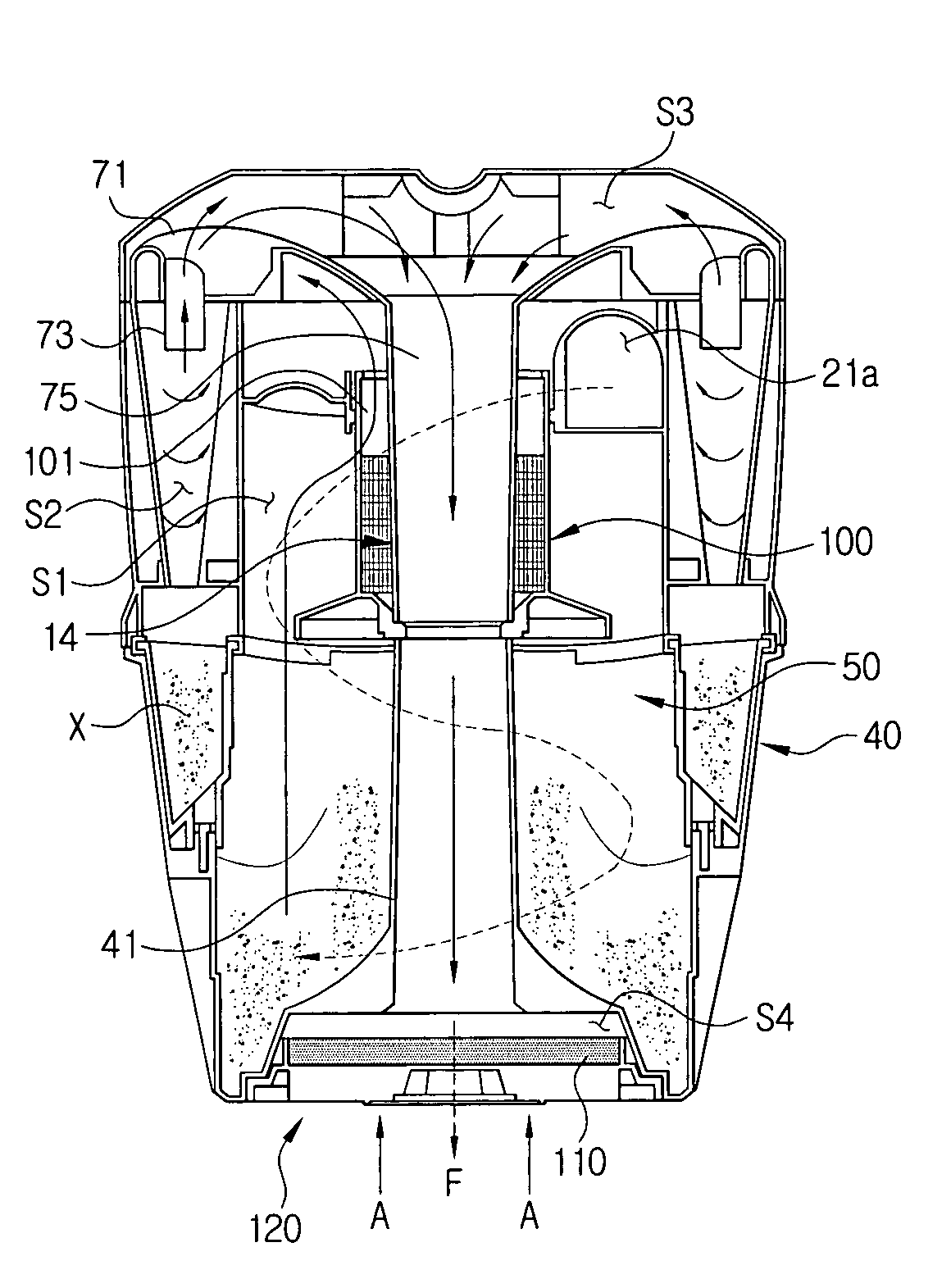

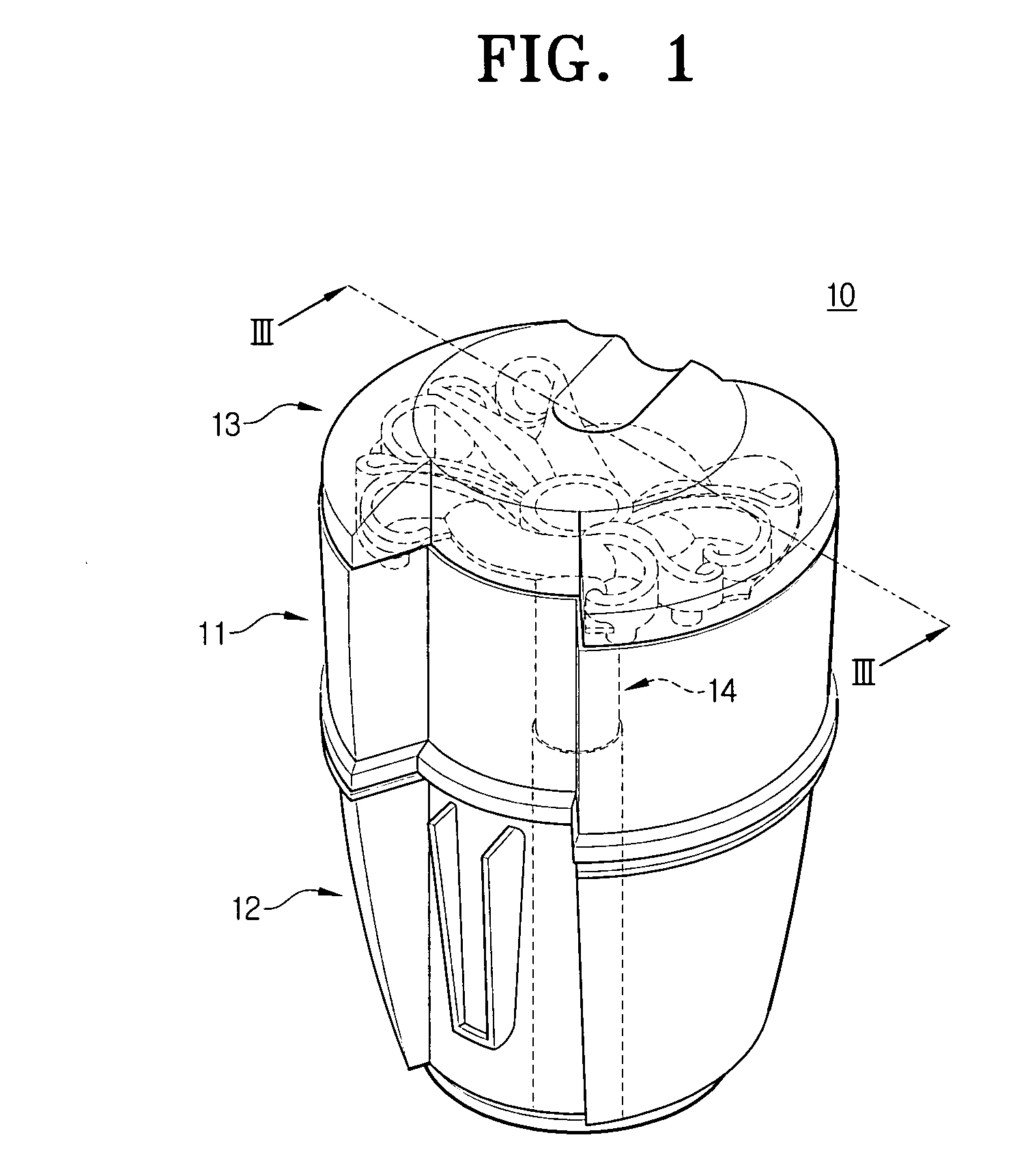

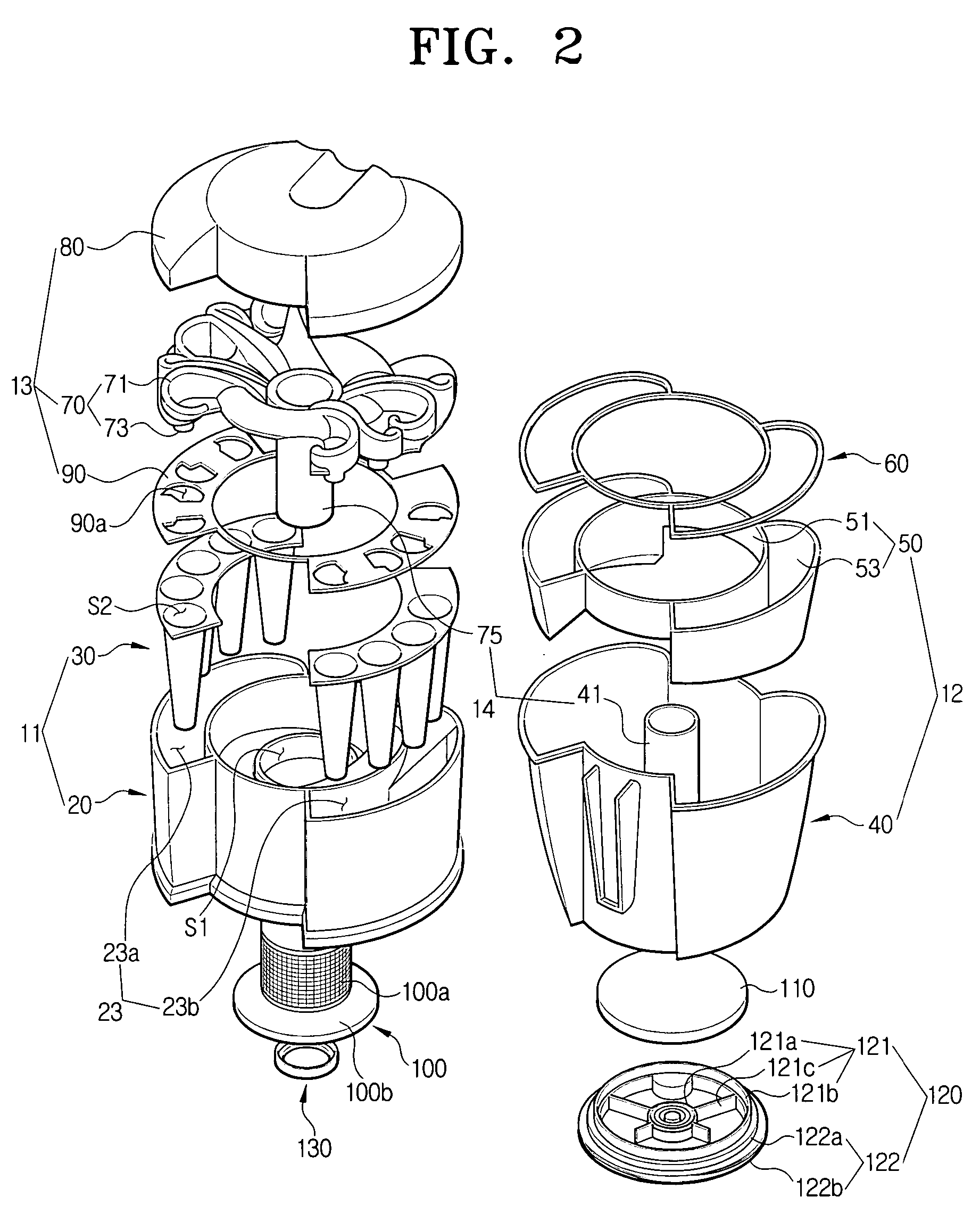

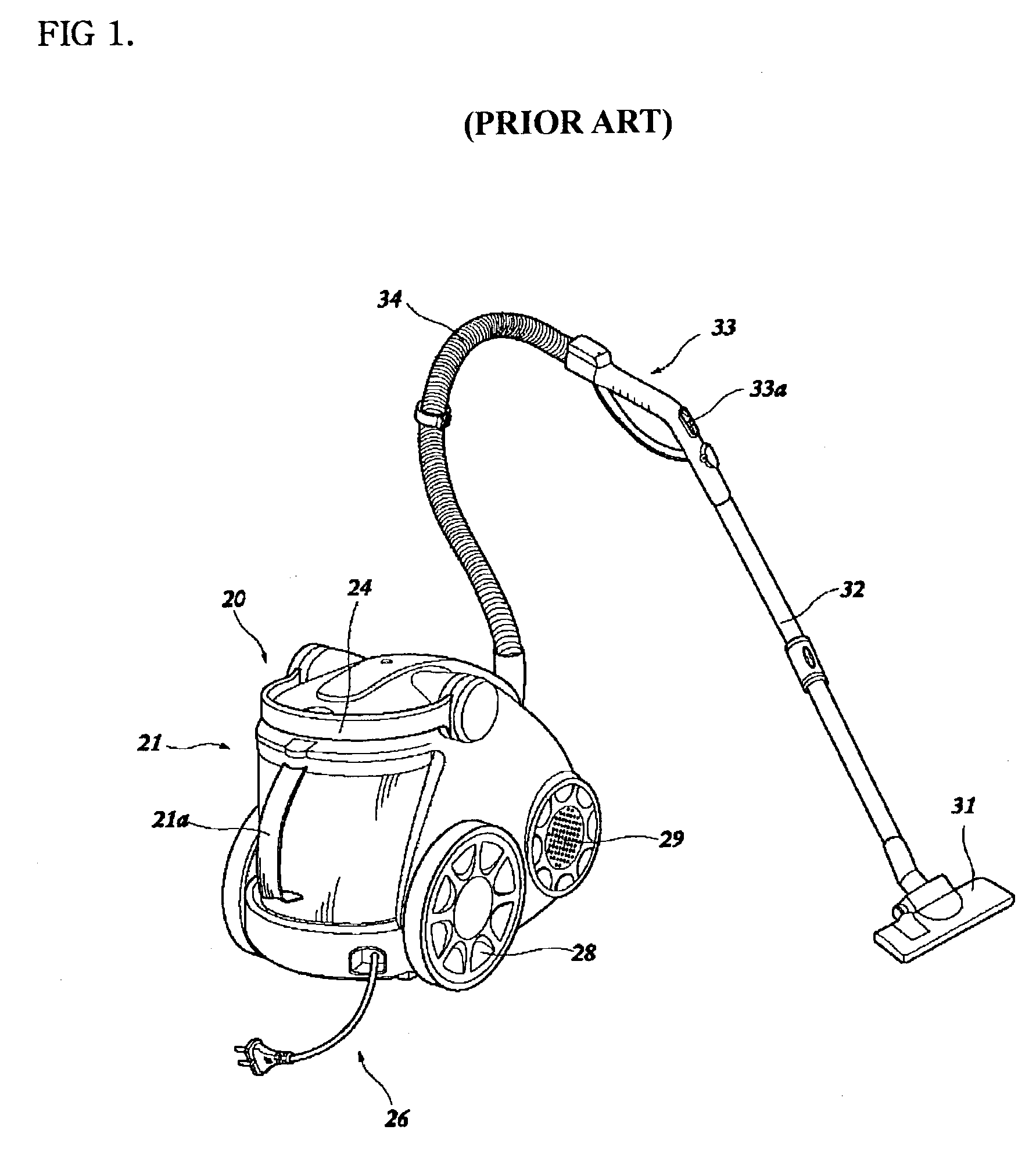

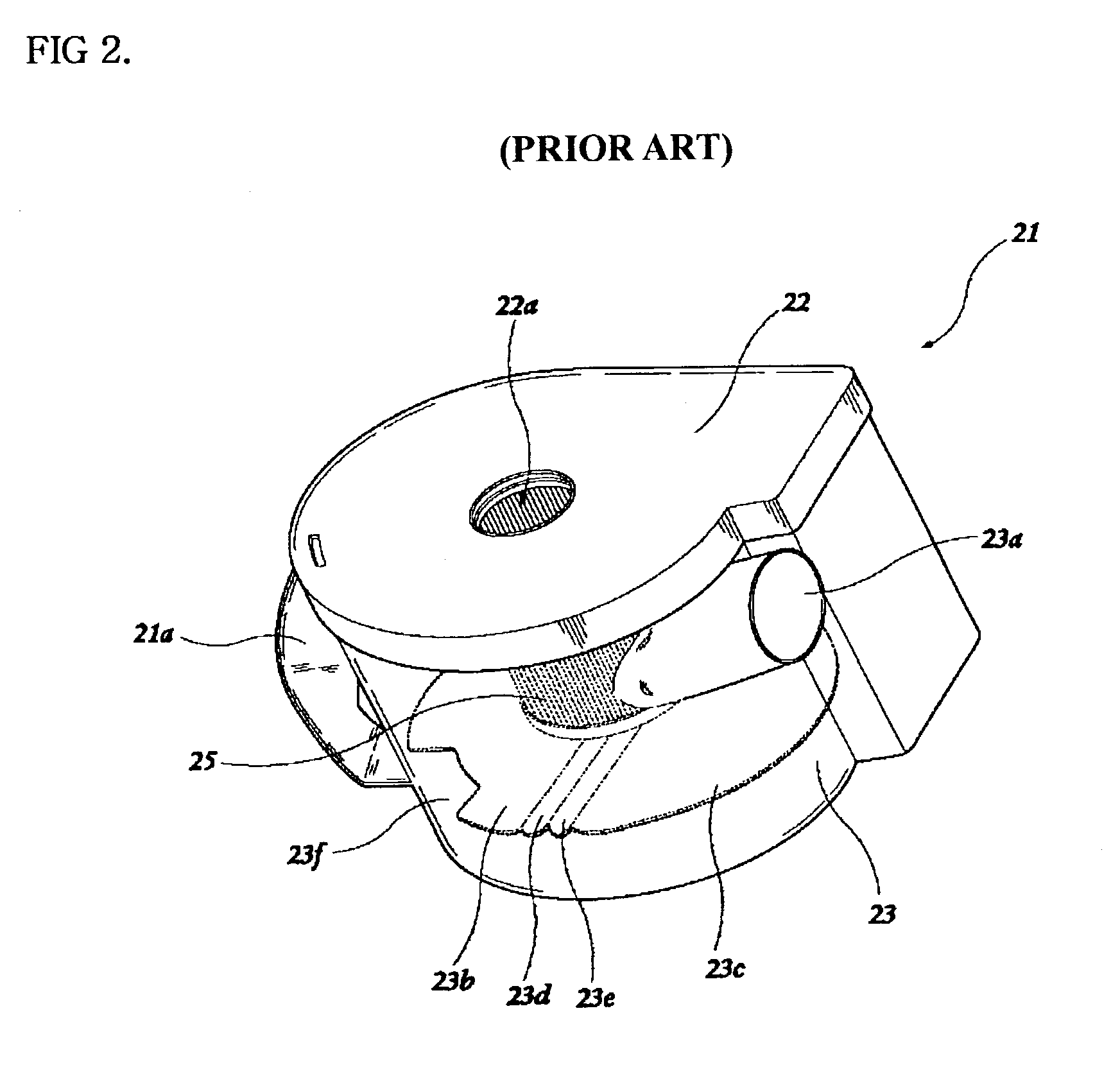

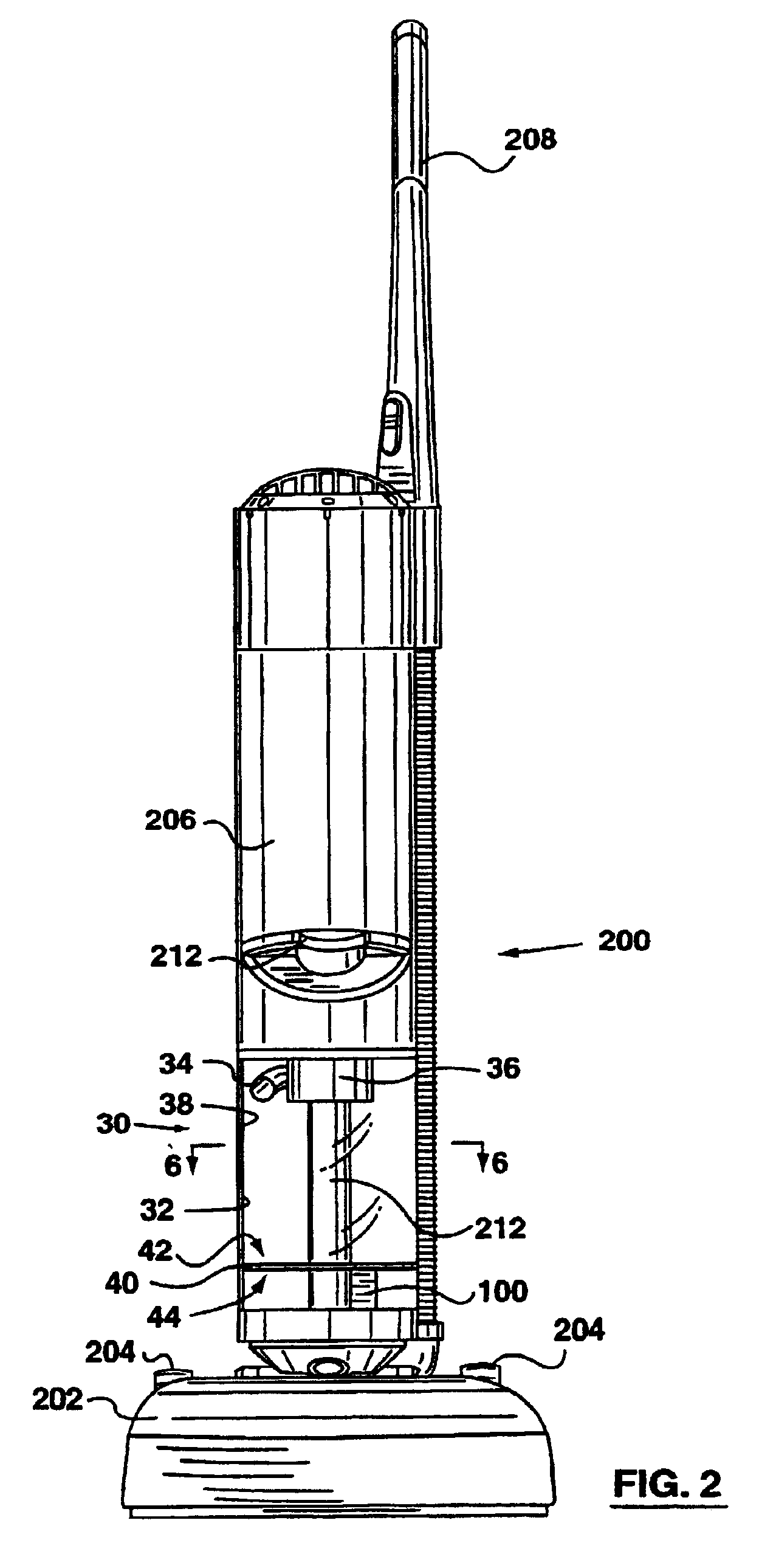

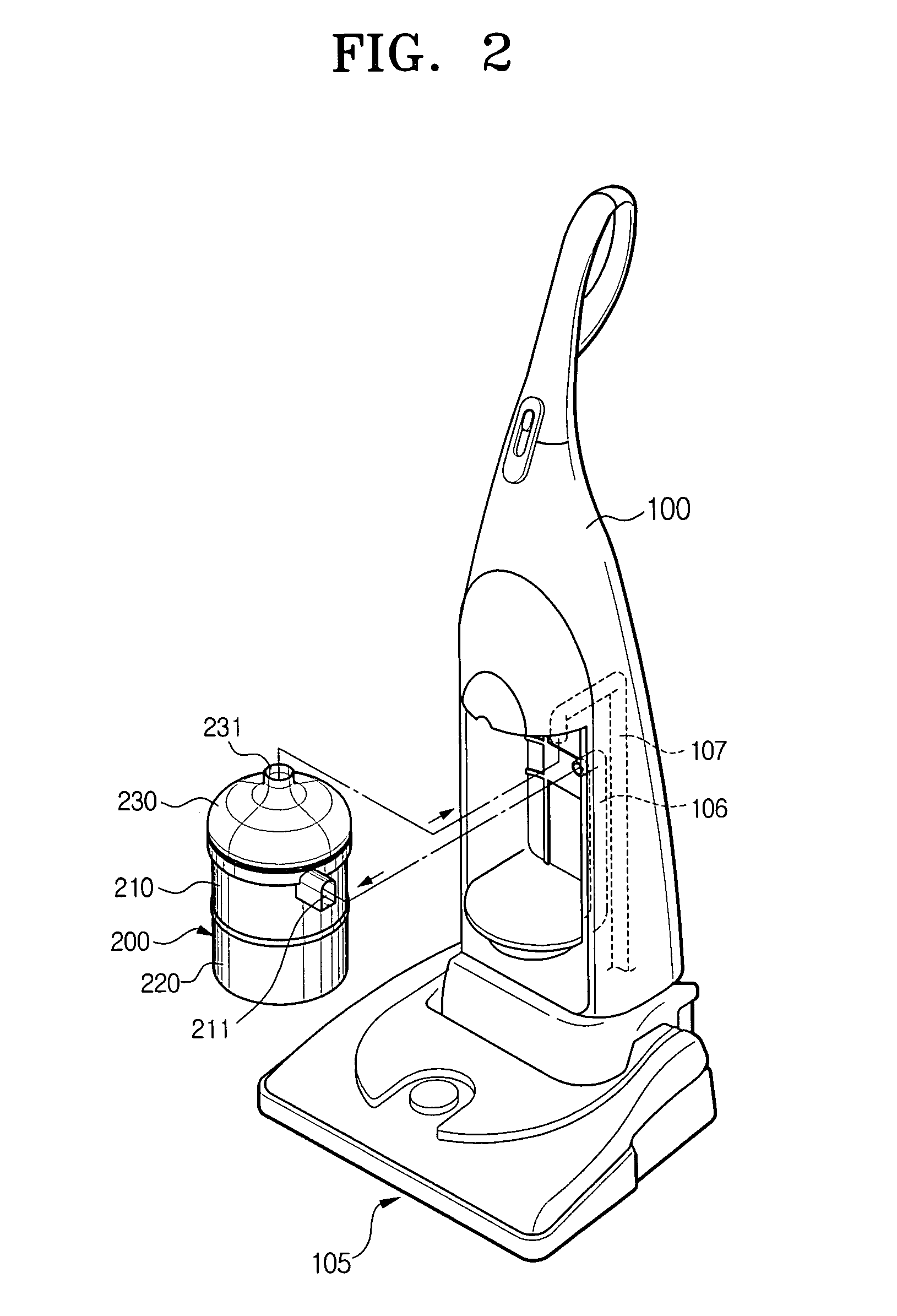

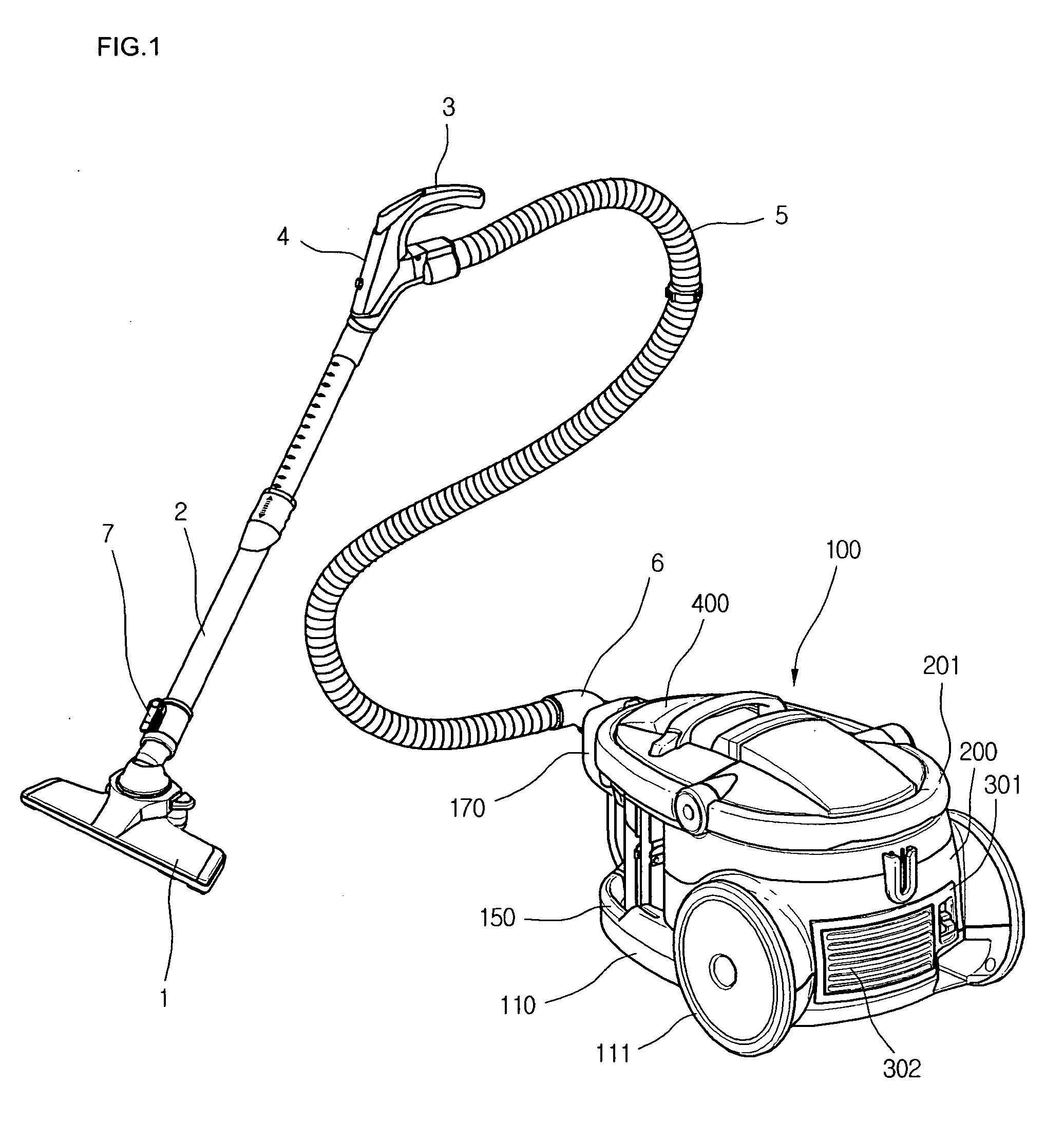

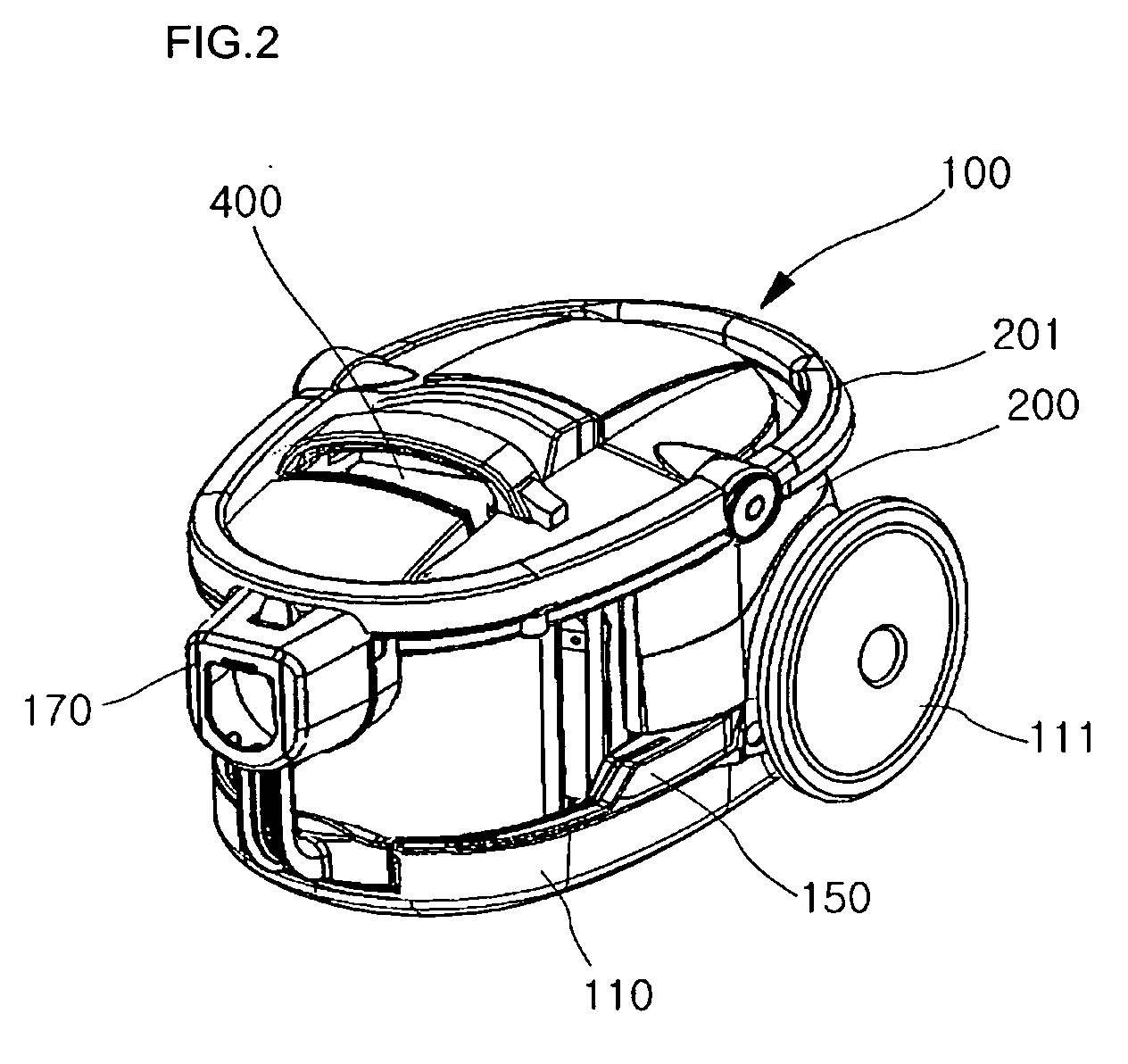

Vacuum cleaner having a cyclone type dust collecting apparatus

A vacuum cleaner includes a cleaner body, a suction brush, through which air and contaminants are drawn in, and a cyclone type dust collecting device. The cleaner body has a motor driving chamber and a dust collecting chamber in communication with the motor driving chamber. The cyclone type dust collecting device is mounted in the dust collecting chamber and separates by centrifugal force the contaminants from the air. The cyclone type dust collecting device includes a hollow cylindrical cyclone body having an open top, a closed bottom, and a contaminant outlet. The open top allows air and contaminants into the cyclone body, where the contaminants are separated from the air by centrifugation. The contaminants are then discharged from the cyclone body through the contaminant outlet. The cyclone type dust collecting device further includes a contaminant receptacle for collecting the contaminants discharged through the contaminant outlet, a base member hingedly connected to the contaminant receptacle, and a cover for covering the top of the cyclone body. The cover has an air inlet passage, through which air and contaminants drawn in through the suction brush enter into the cyclone body, an air outlet passage, through which the air is discharged from the cyclone body, and a contaminant separating grill. The grill extends downward from the air outlet passage into the cyclone body and has a plurality of fine holes.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

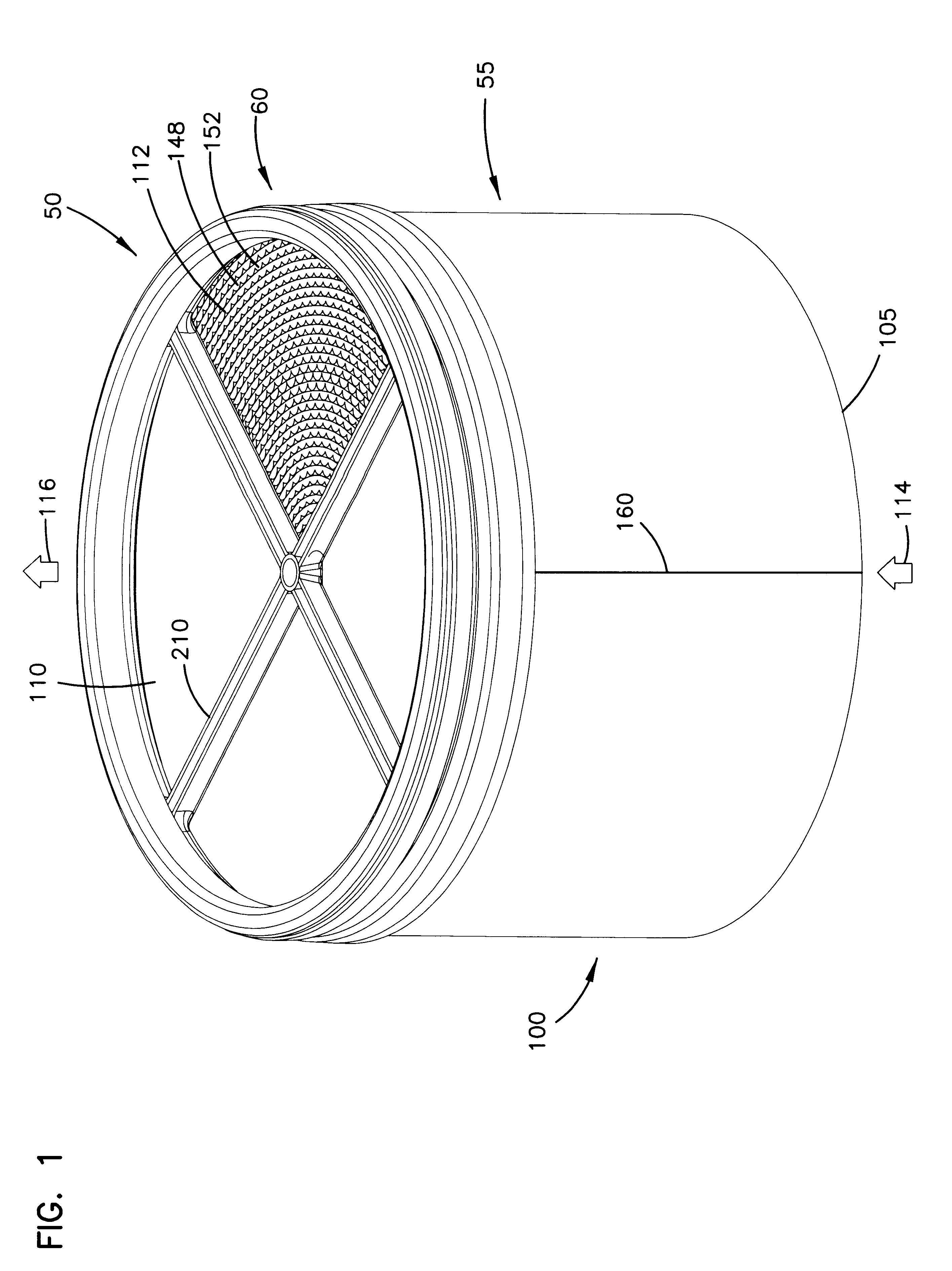

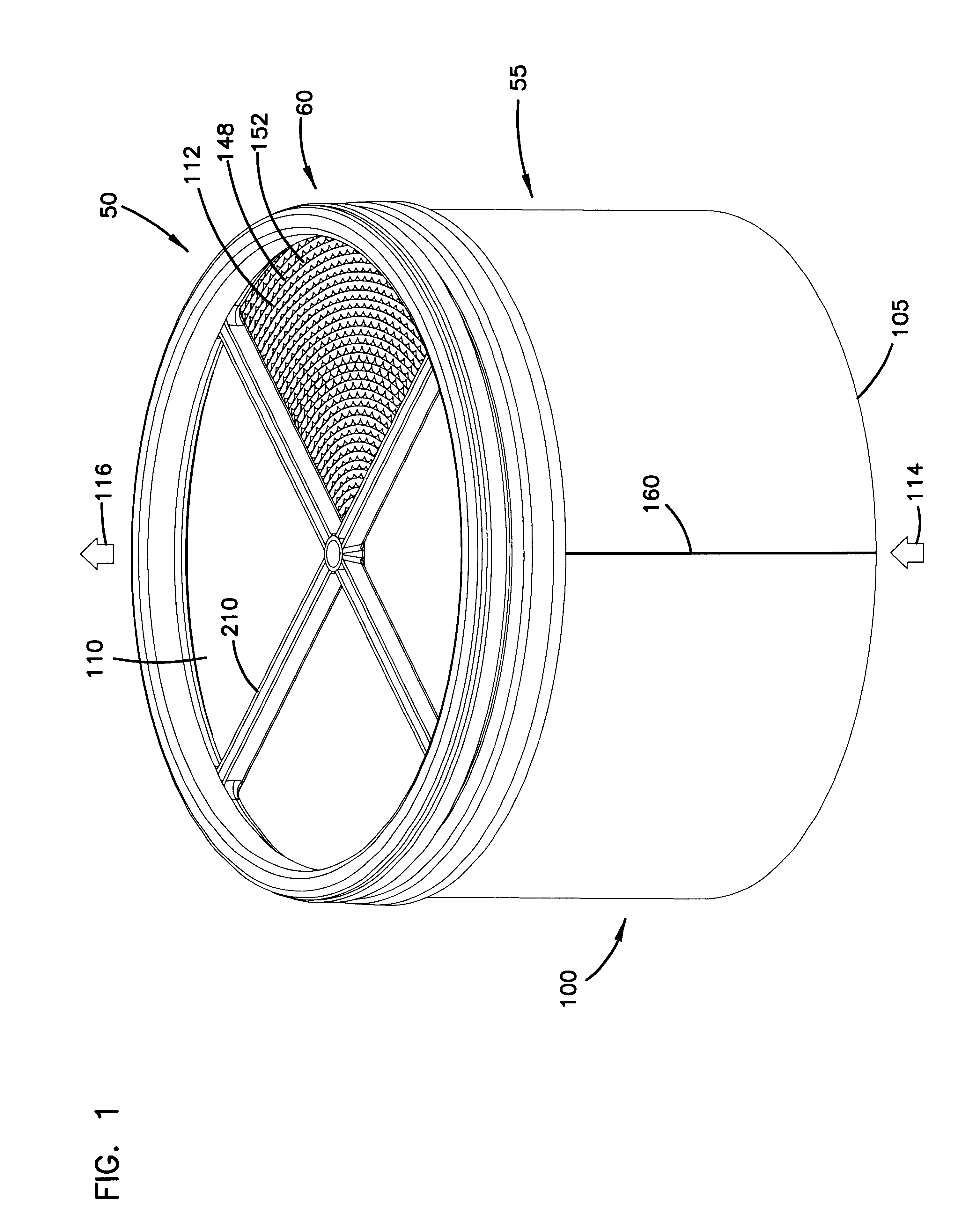

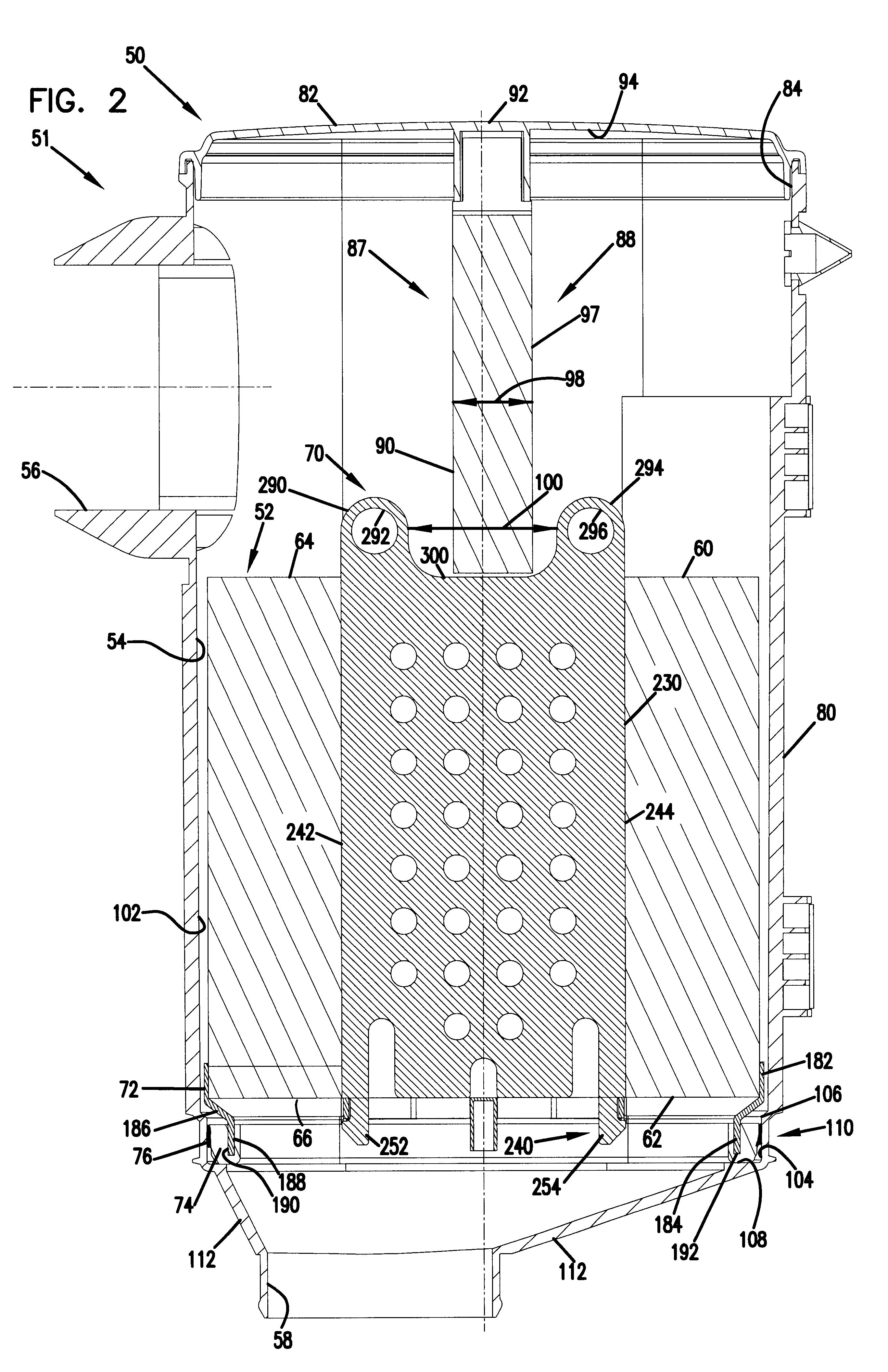

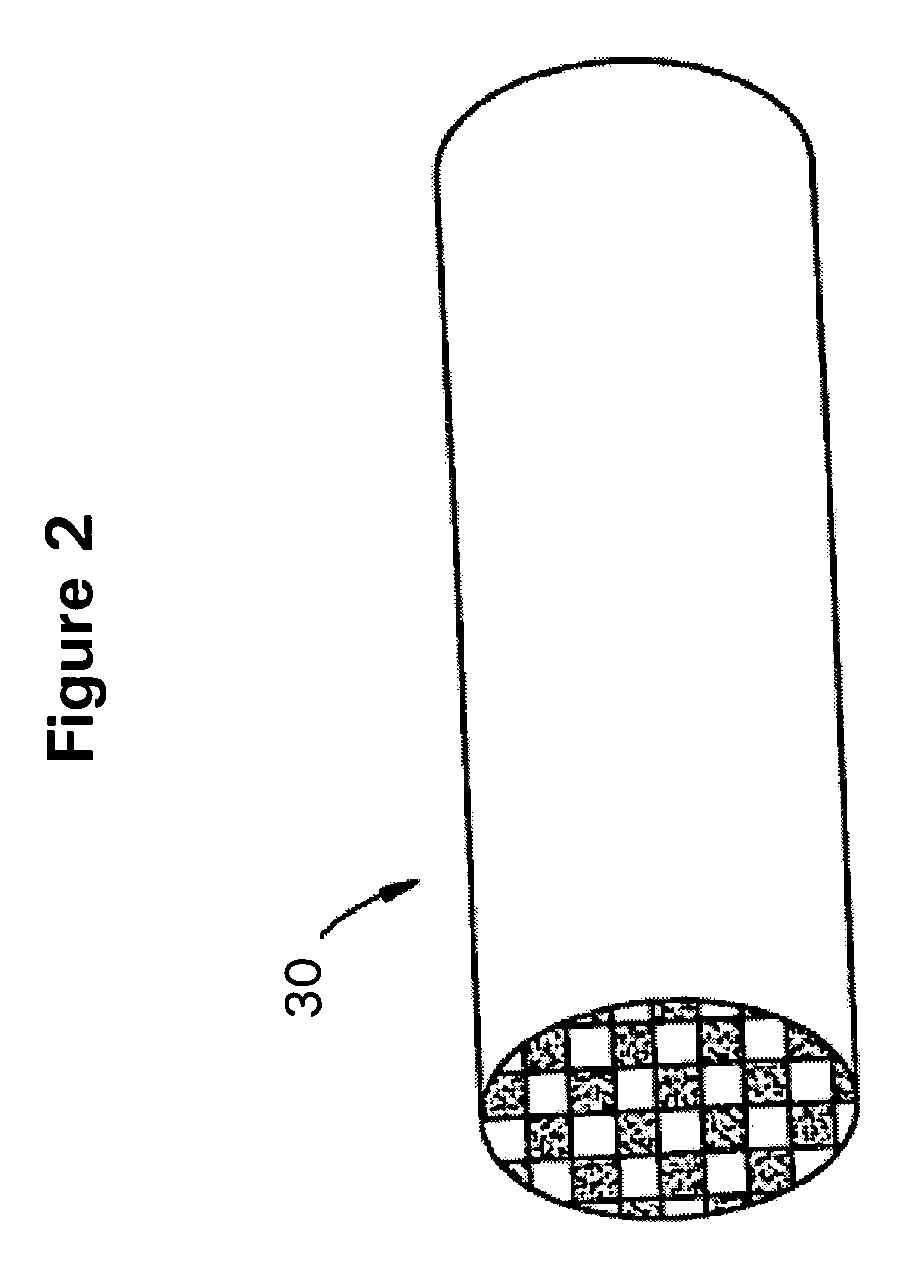

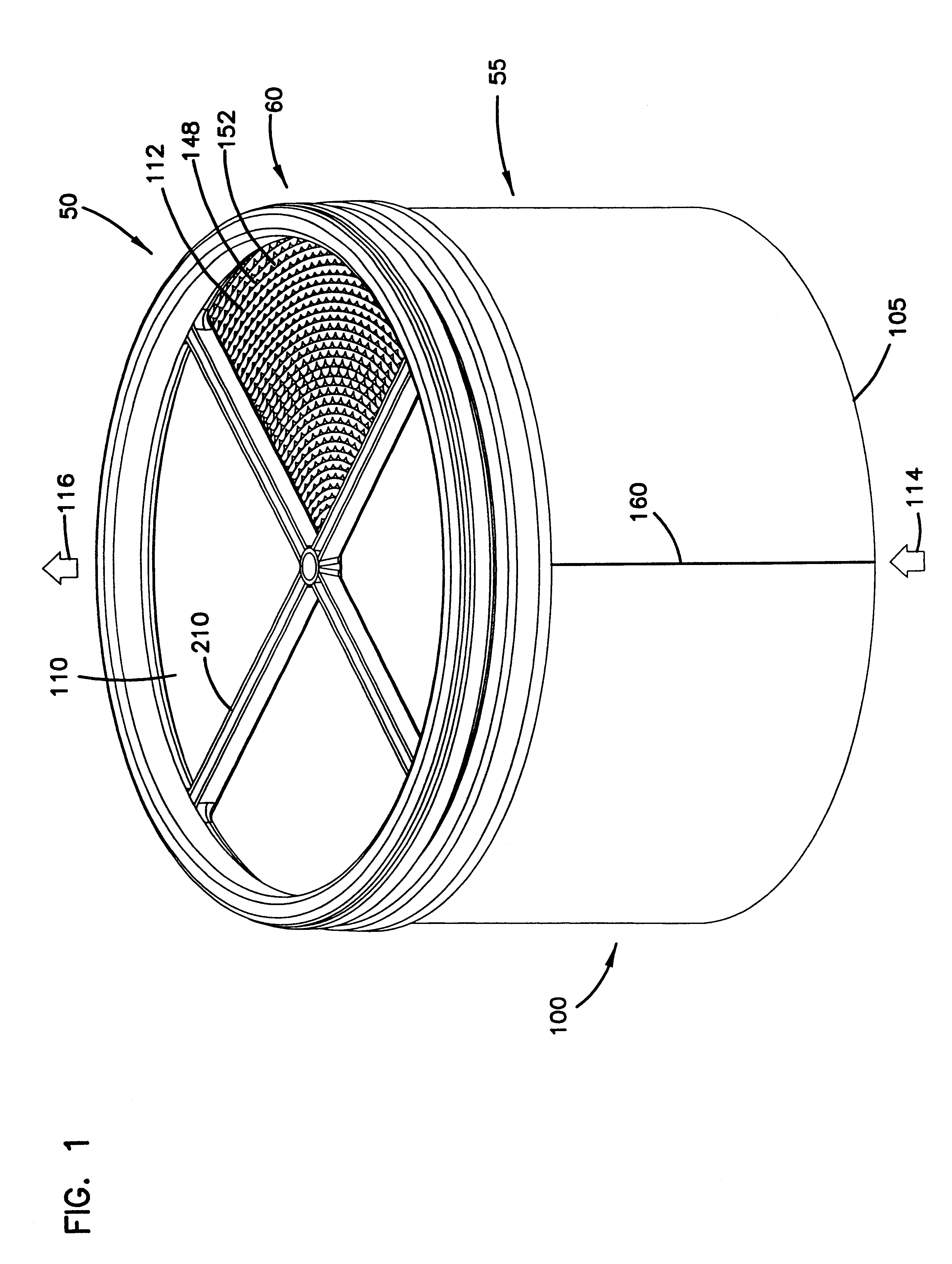

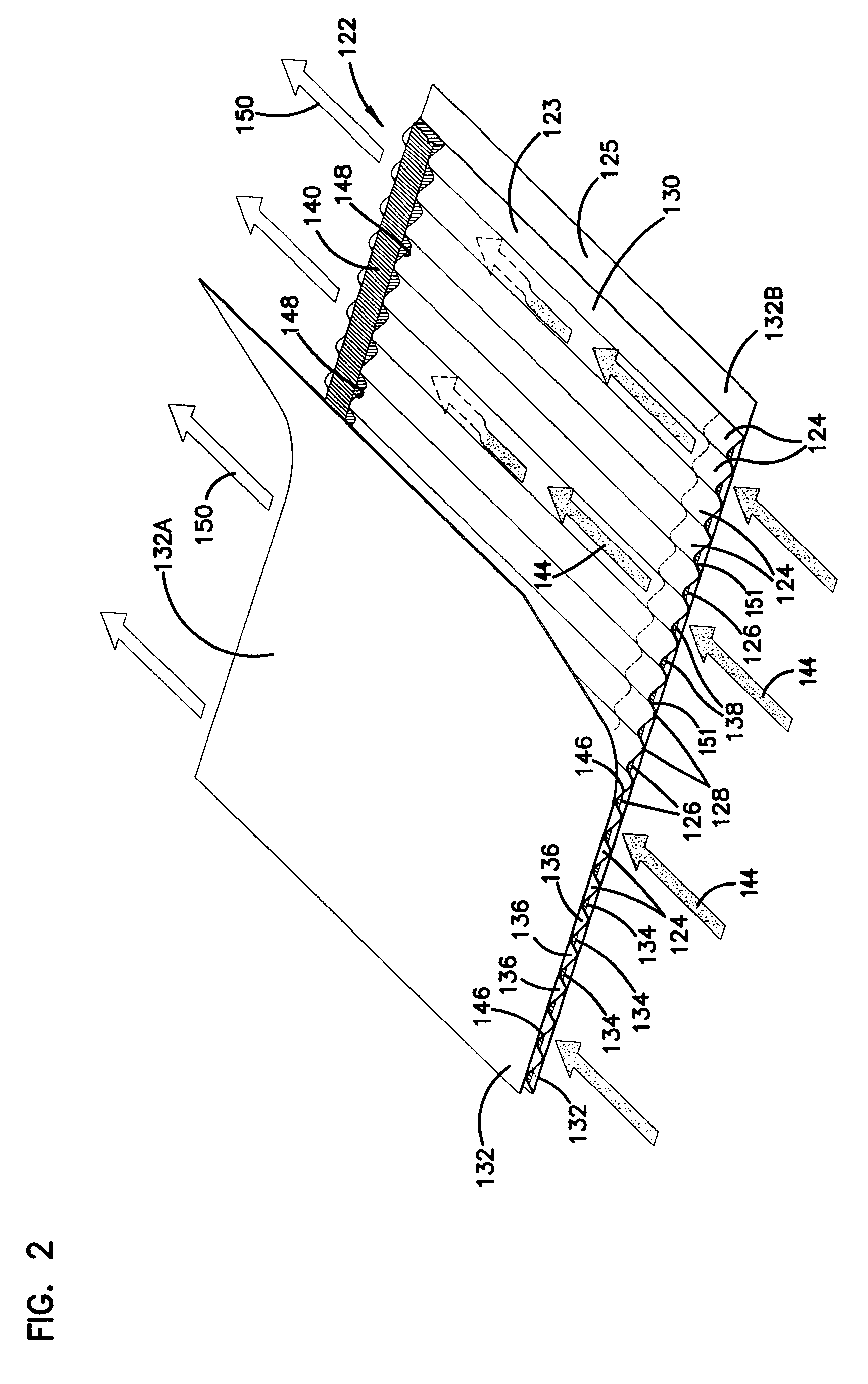

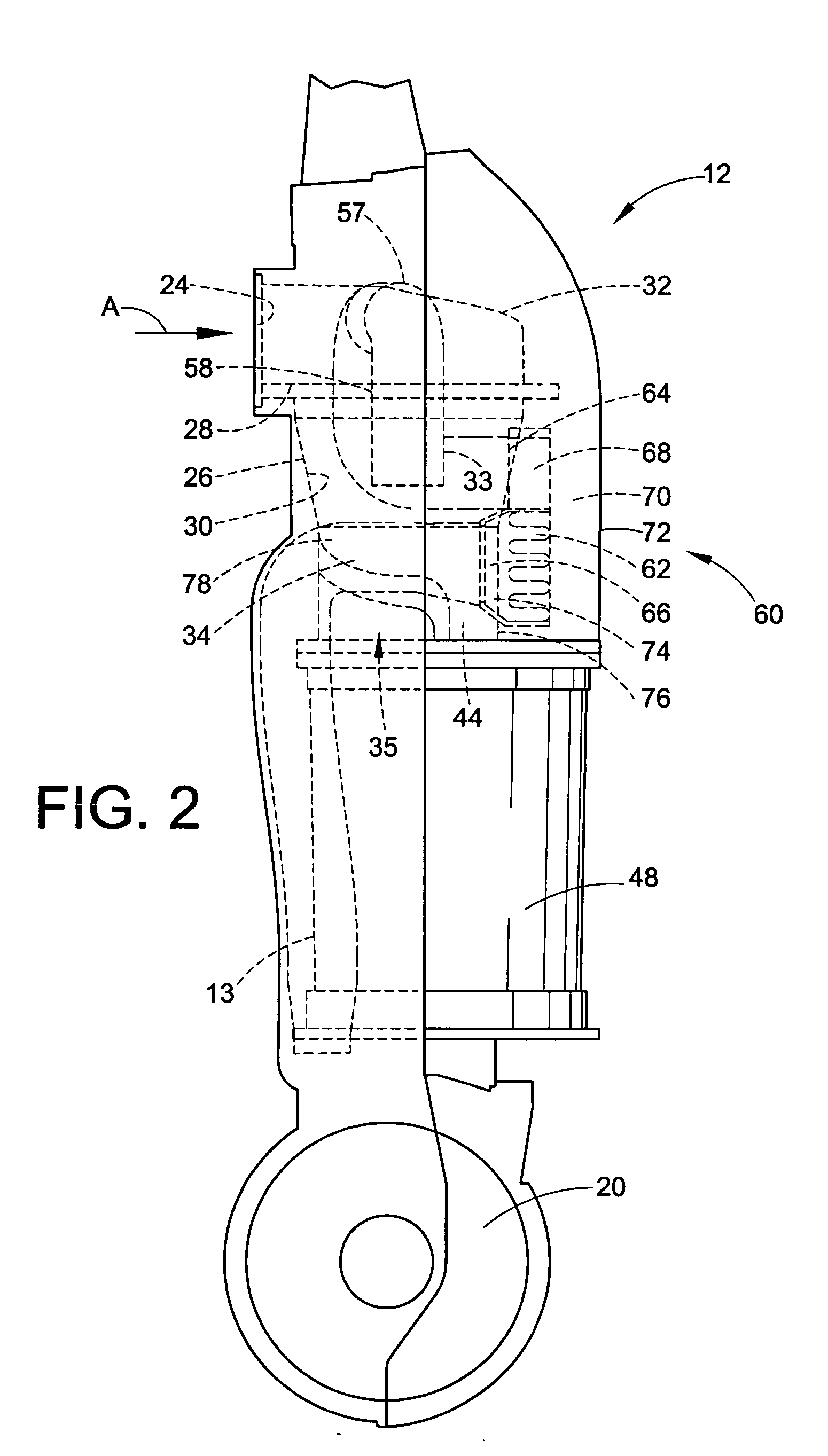

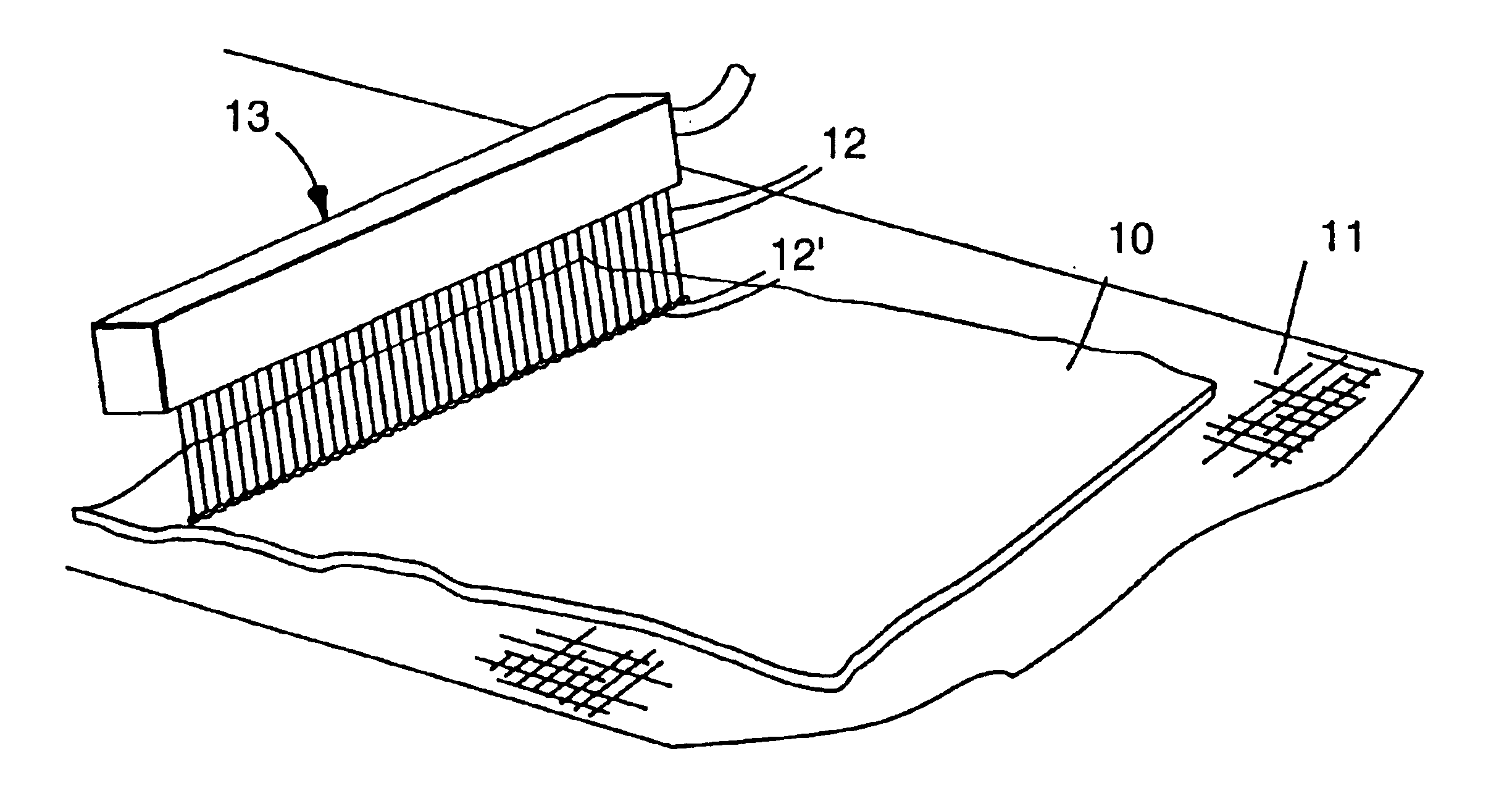

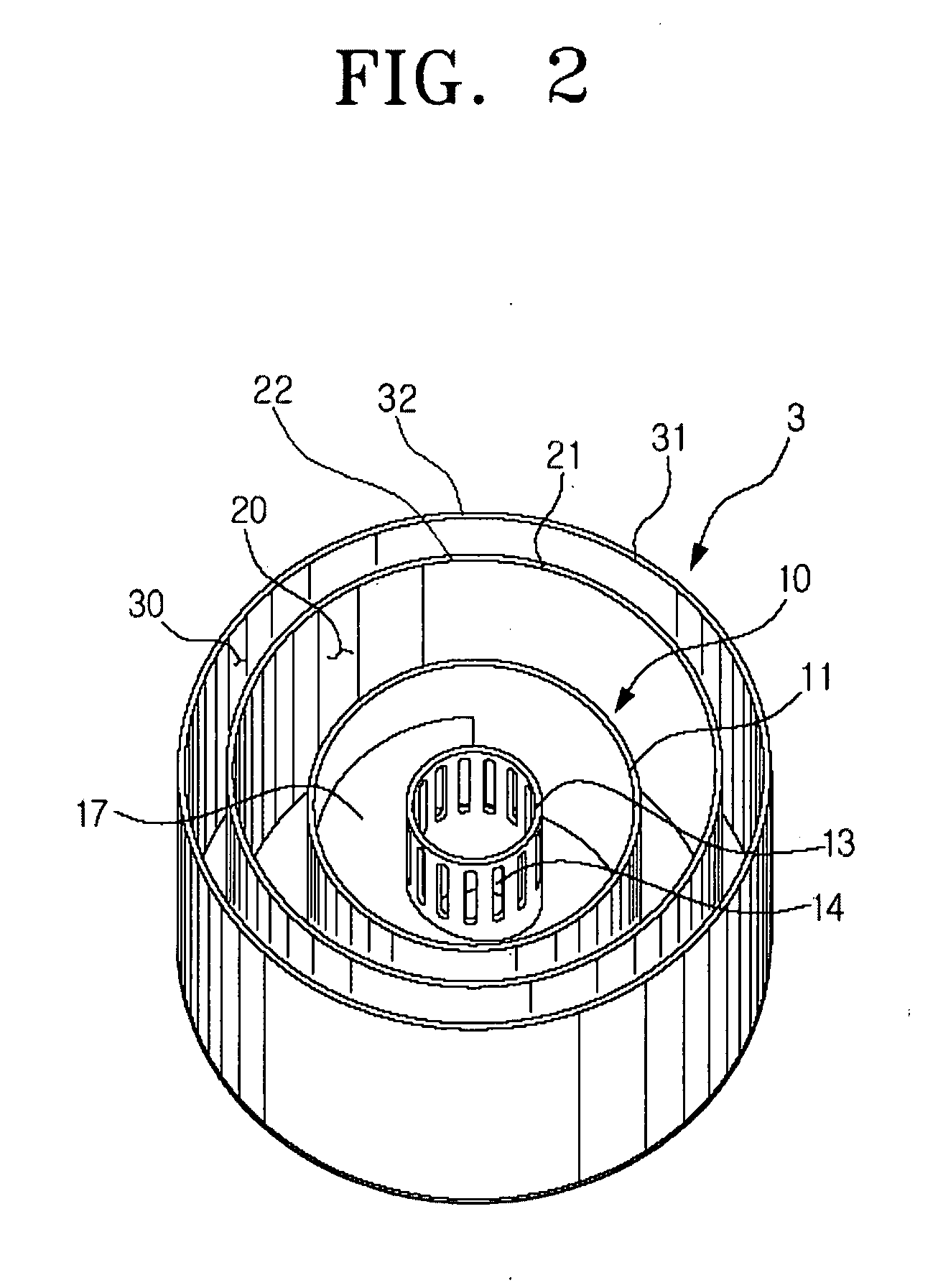

Filter element, air cleaner, and methods

A filter arrangement includes a filter element, a frame construction secured to the filter element, and a handle member secured to the filter element. In preferred embodiments, the handle member is secured to the frame construction. Preferably, the filter element includes a central core member, wherein fluted filter media is coiled around the central core member. Preferably, the central core member includes a plurality of corrugations, wherein the corrugations mateably engage at least some flutes. Preferably, the handle member is integral with the central core member, and also includes a fastening member for connection to a frame construction on the filter element. Methods for cleaning air and servicing an air cleaner preferably include constructions as described herein.

Owner:DONALDSON CO INC

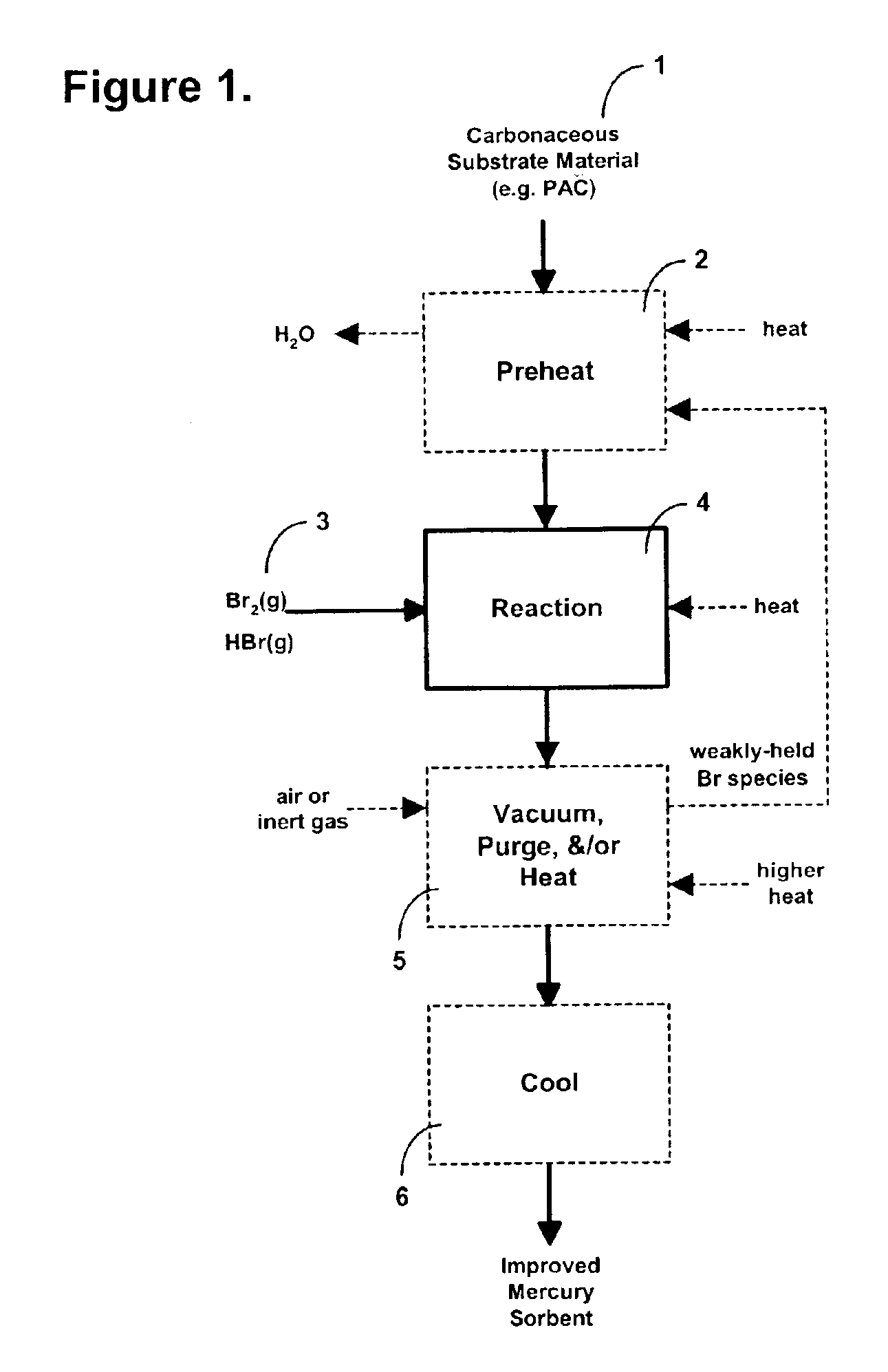

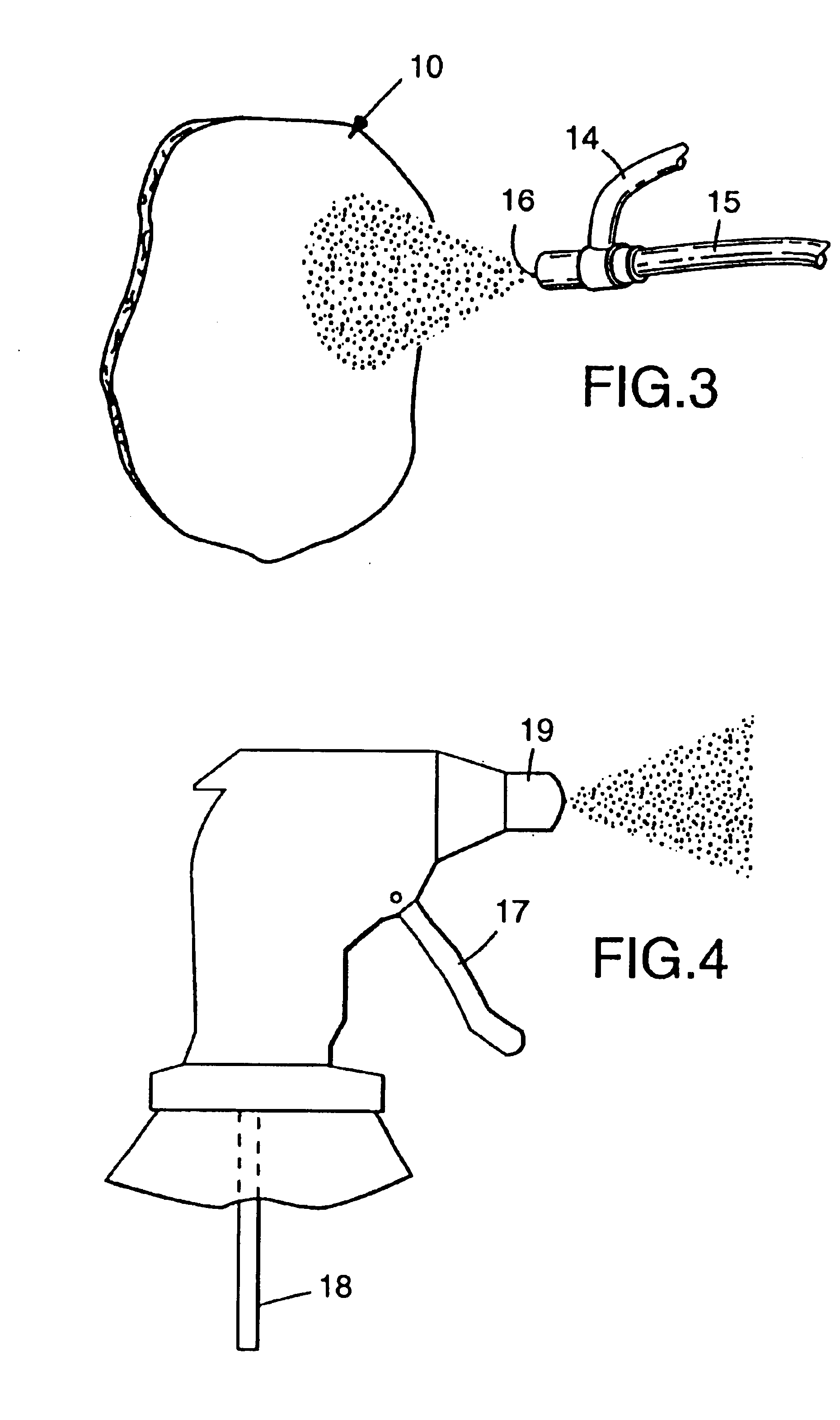

Sorbents and methods for the removal of mercury from combustion gases

InactiveUS6953494B2Improve abilitiesUnified processingGas treatmentOther chemical processesSufficient timeCombustion

A method for removing mercury and mercury-containing compounds from a combustion gas in an exhaust gas system has the steps of providing a mercury sorbent; injecting the mercury sorbent into a stream of the mercury-containing combustion gas for a sufficient time to allow at least an effective amount of the mercury and mercury-containing compounds in the combustion gas to adsorb onto the mercury sorbent, and collecting and removing the mercury sorbent from the combustion gas stream. The mercury sorbent is prepared by treating a carbonaceous substrate with an effective amount of a bromine-containing gas, especially one containing elemental bromine or hydrogen bromide, for a time sufficient to increase the ability of the carbonaceous substrate to adsorb mercury and mercury-containing compounds. The points of injecting and collecting and removing the mercury sorbent may be varied, depending upon the exact configuration of the exhaust gas system.

Owner:SORBENT TECH +1

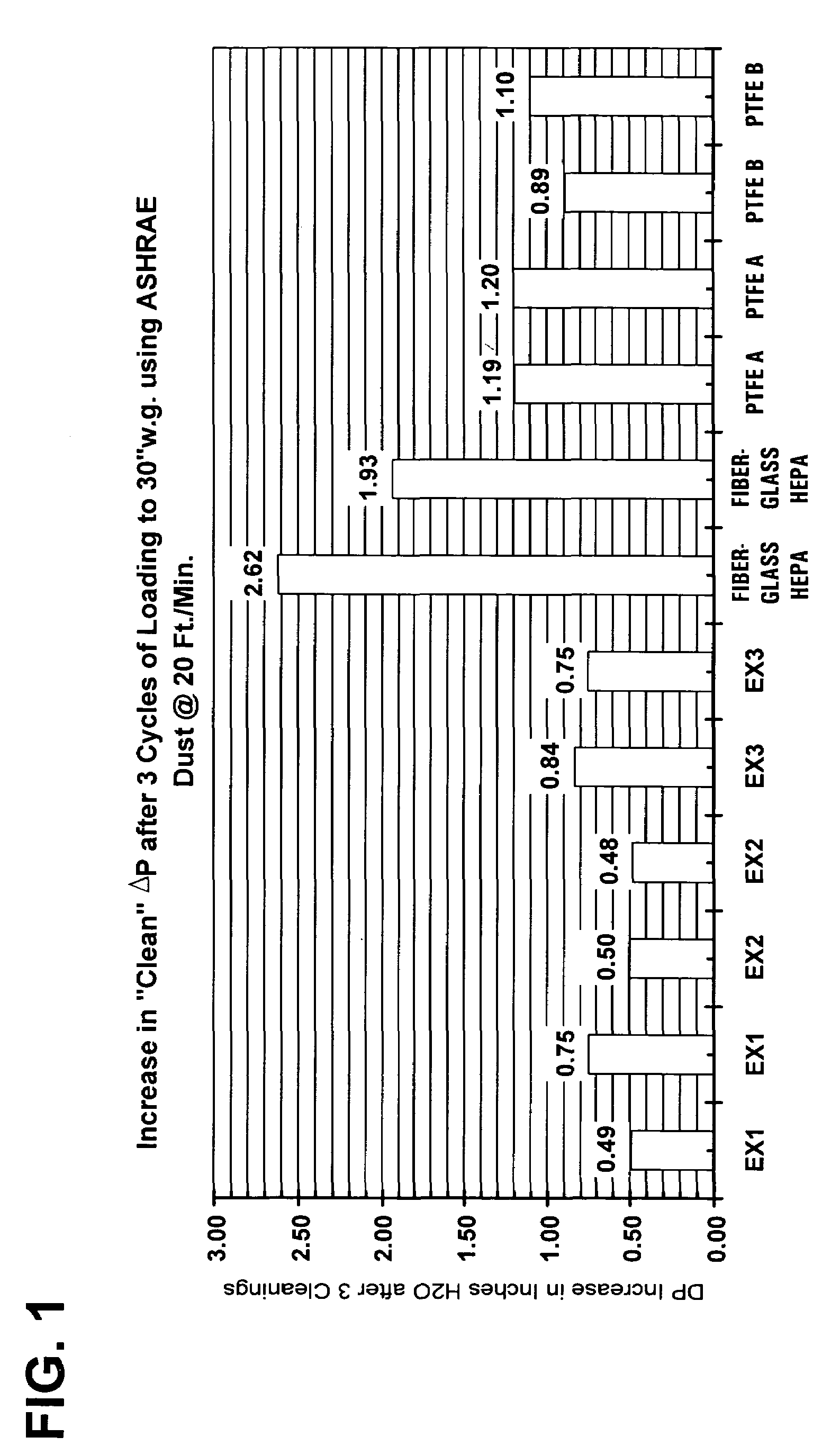

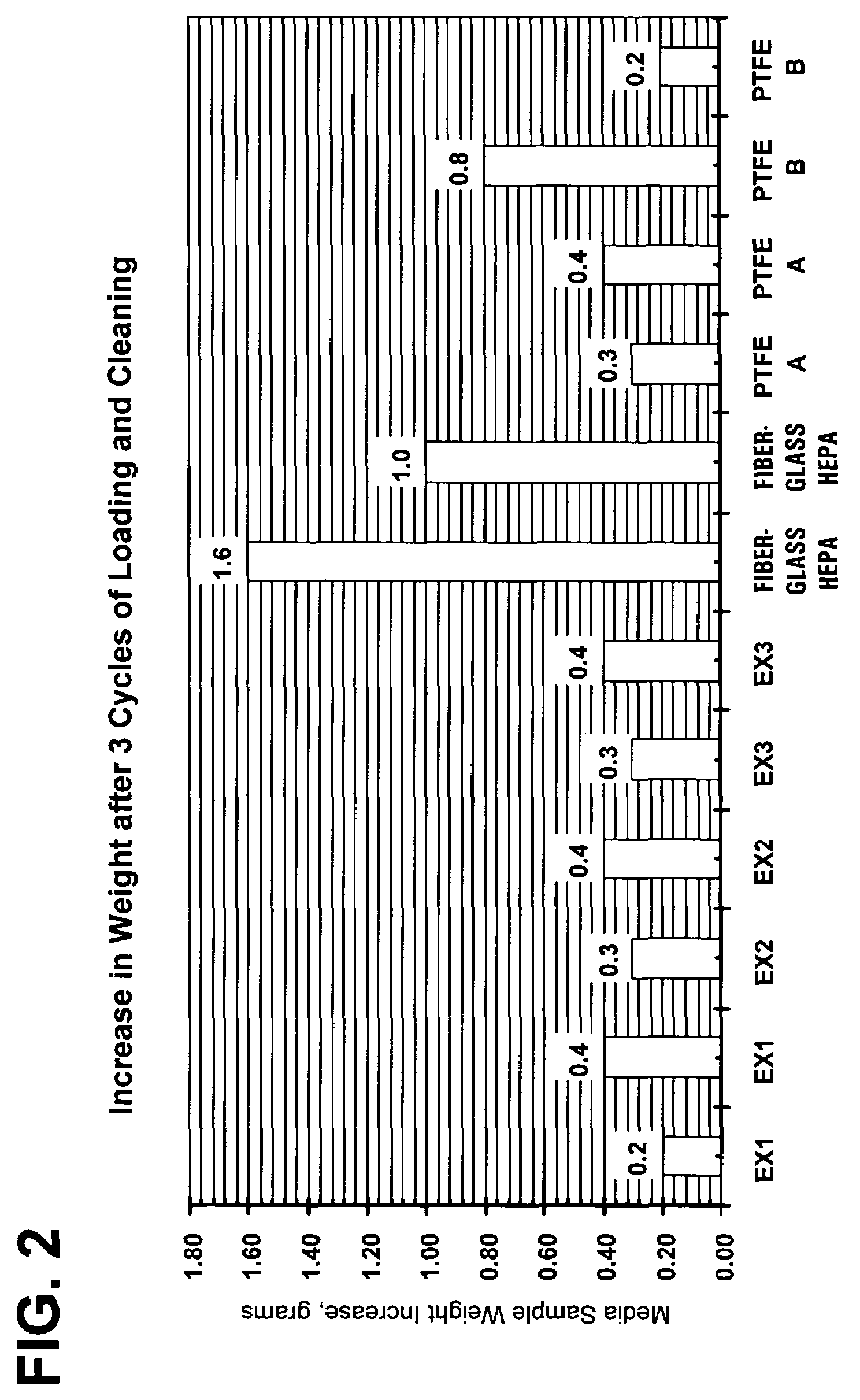

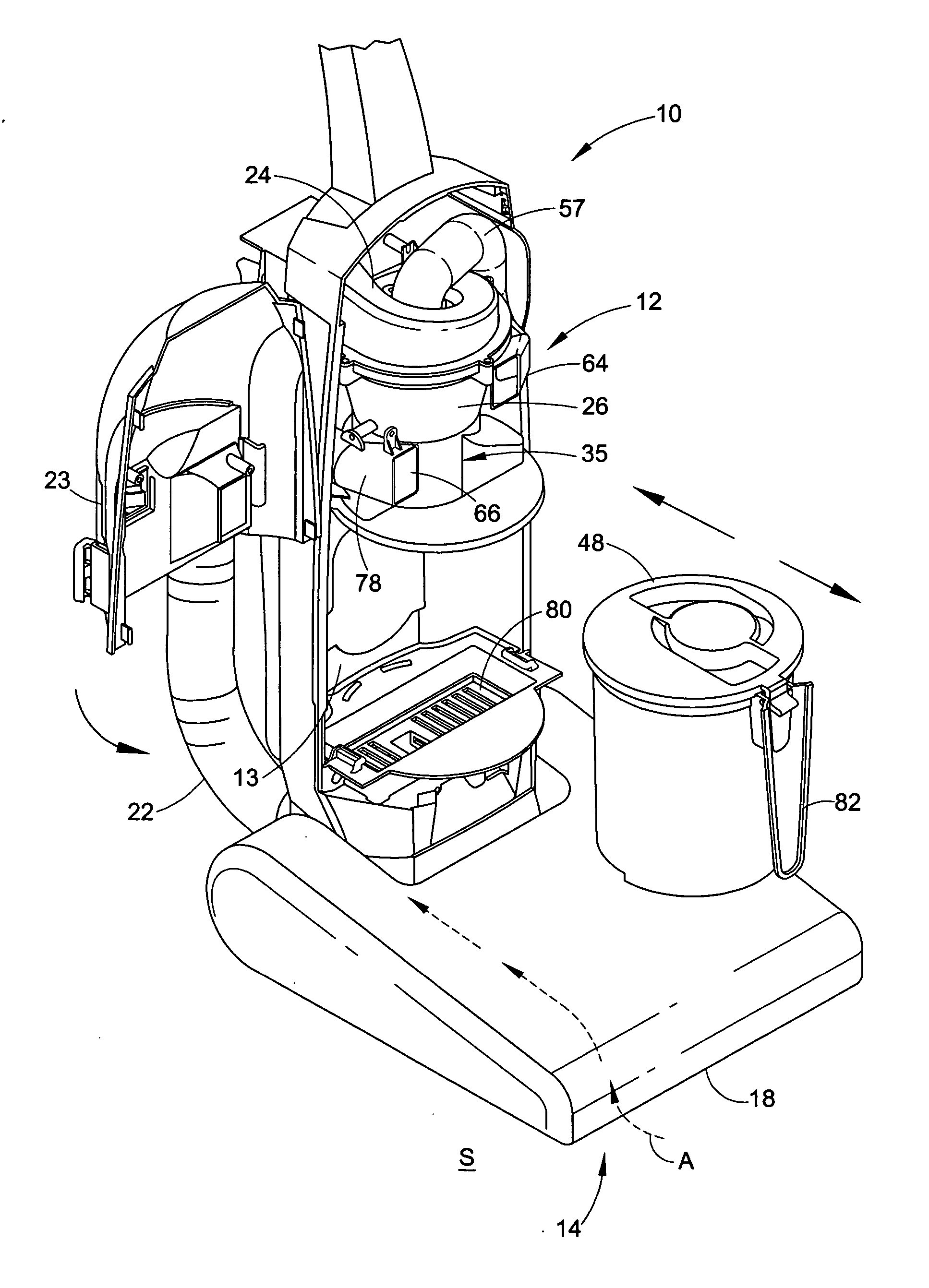

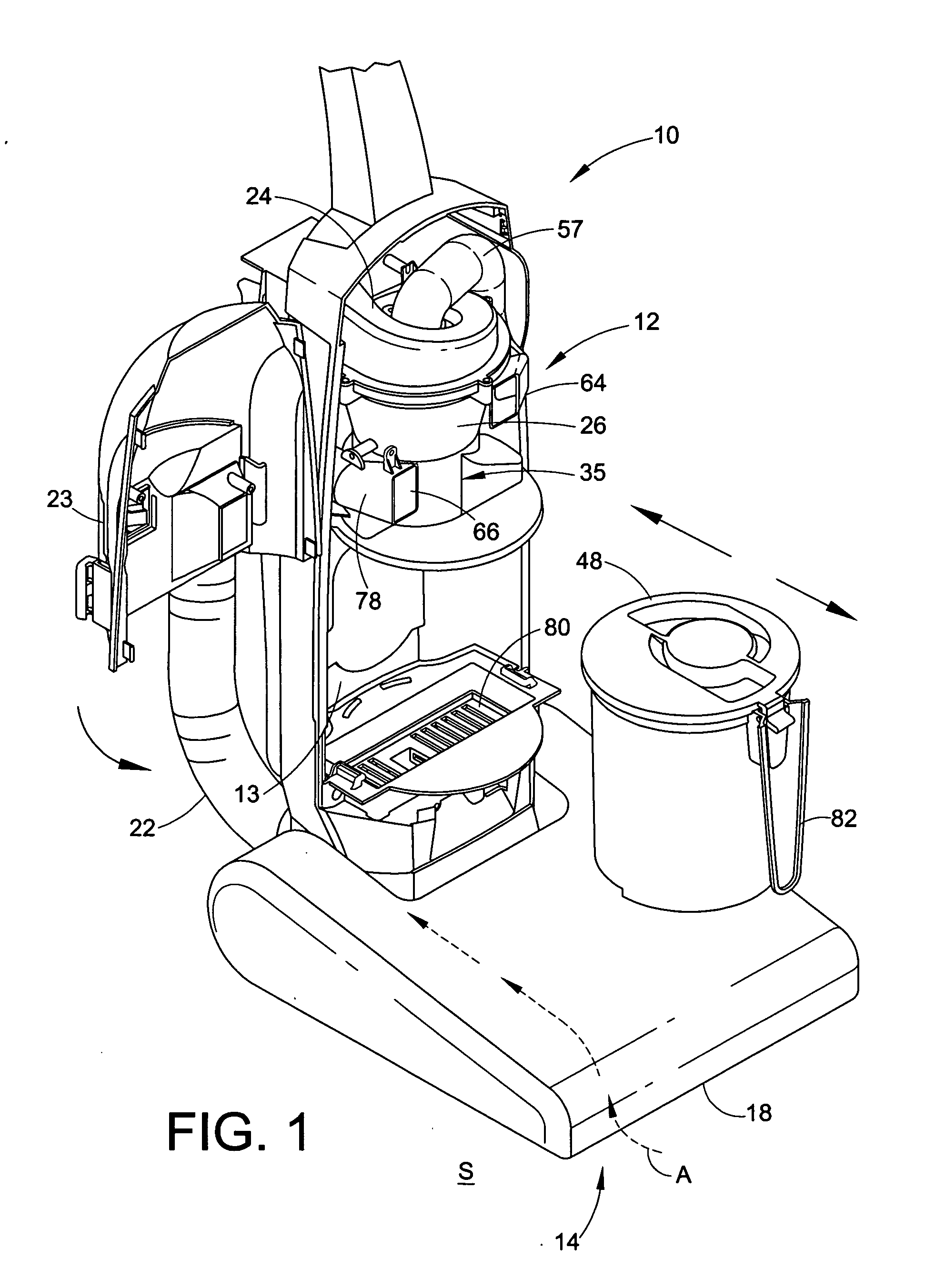

Cleanable high efficiency filter media structure and applications for use

ActiveUS7008465B2Improve filtering effectHigh particle captureCombination devicesAuxillary pretreatmentParticulatesFiber

An improved cartridge, typically in cylindrical or panel form that can be used in a dry or wet / dry vacuum cleaner. The cartridge is cleanable using a stream of service water, or by rapping on a solid object, or by using a compressed gas stream, but can provide exceptional filtering properties even for submicron particulate in the household or industrial environment. The cartridge has a combination of nanofiber filtration layer on a substrate. The nanofiber and substrate are engineered to obtain a maximum efficiency at reasonable pressure drop and permeability. The improved cartridge constitutes at least a substrate material and at least a layer including a non-woven, fine fiber separation layer.

Owner:DONALDSON CO INC

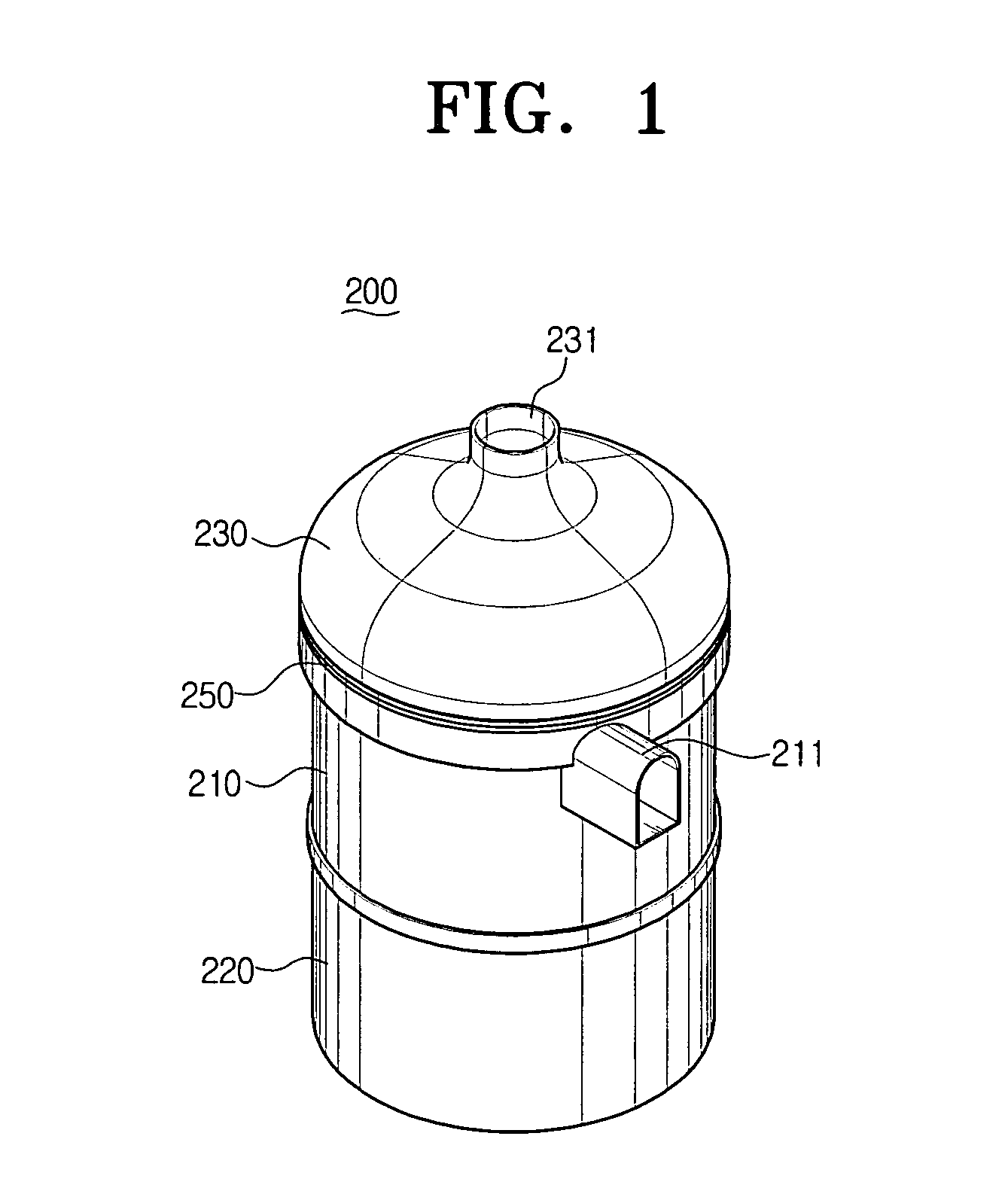

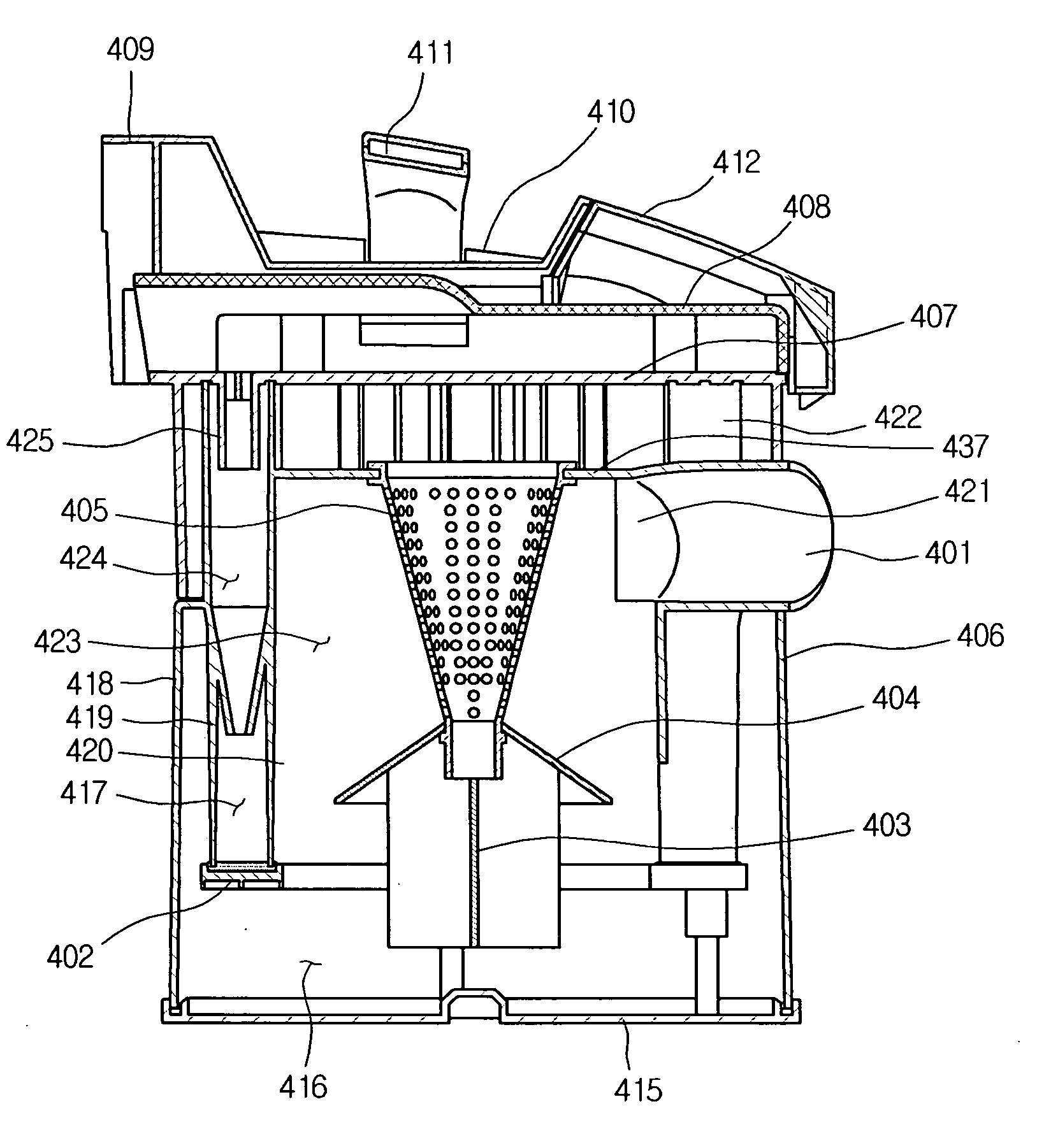

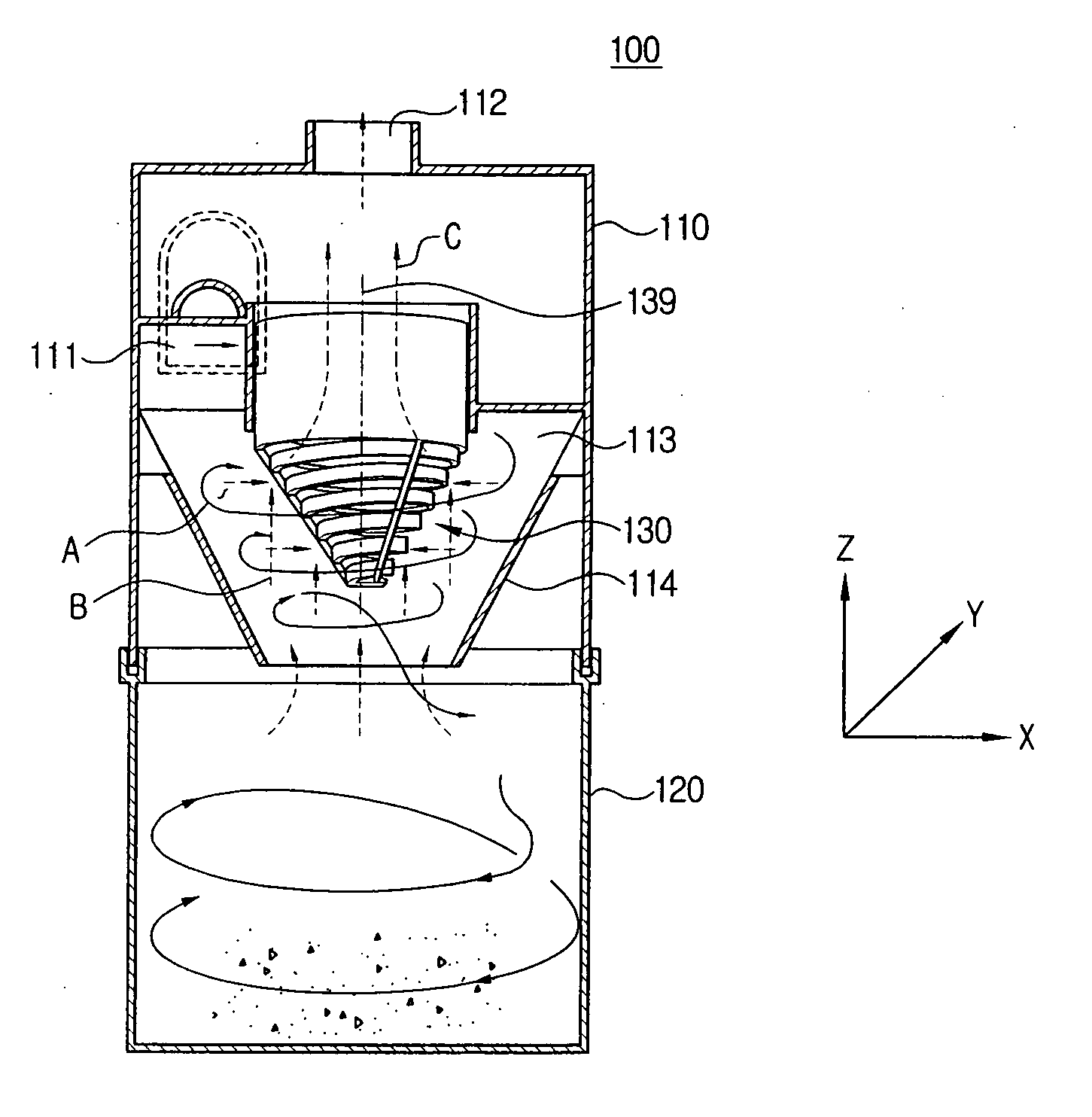

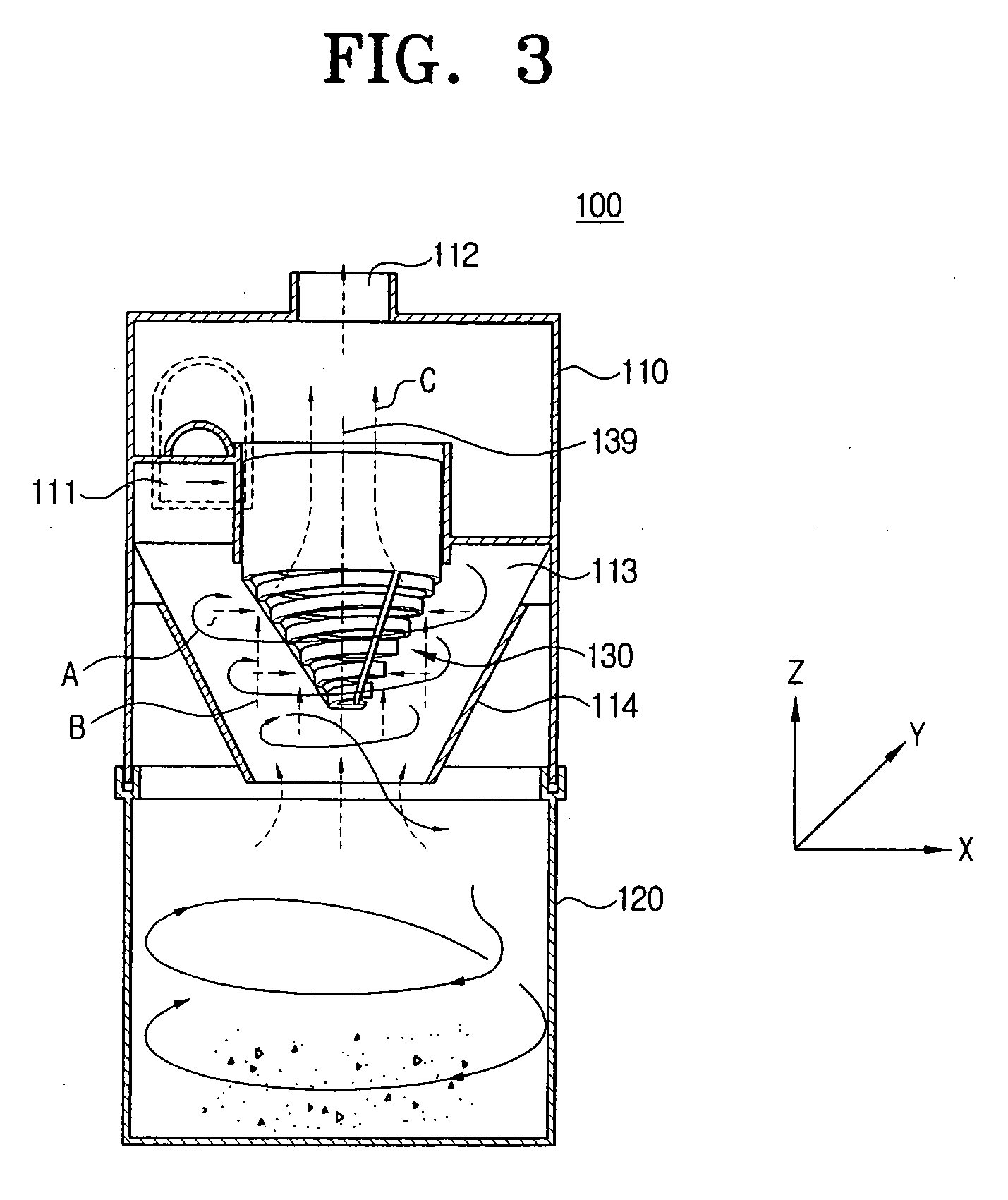

Multi cyclone vessel dust collecting apparatus for vacuum cleaner

A multi cyclone vessel dust collecting apparatus comprises a first cyclone vessel for centrifugally separating contaminants from drawn in air; a plurality of a second cyclone vessels configured on the first cyclone vessel; and a contaminant collecting unit attached to a bottom portion of the first cyclone vessel. Each of a plurality of the second cyclone vessels are parallel to each other. The center axis line of air rotation movement of the second cyclone vessel is substantially perpendicular to that of the first cyclone vessel. The contaminants collecting unit comprises a body which can be used as a handle.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

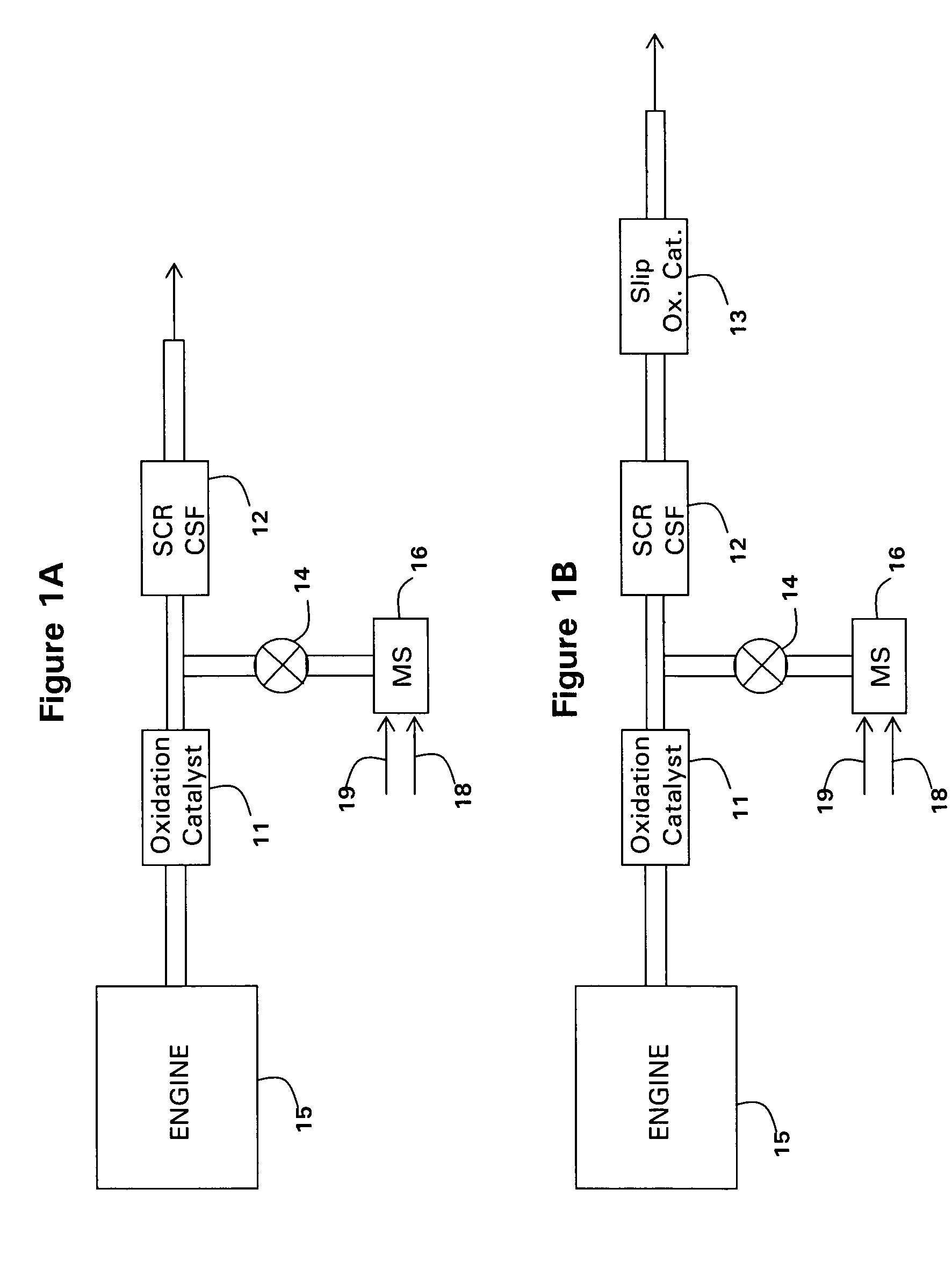

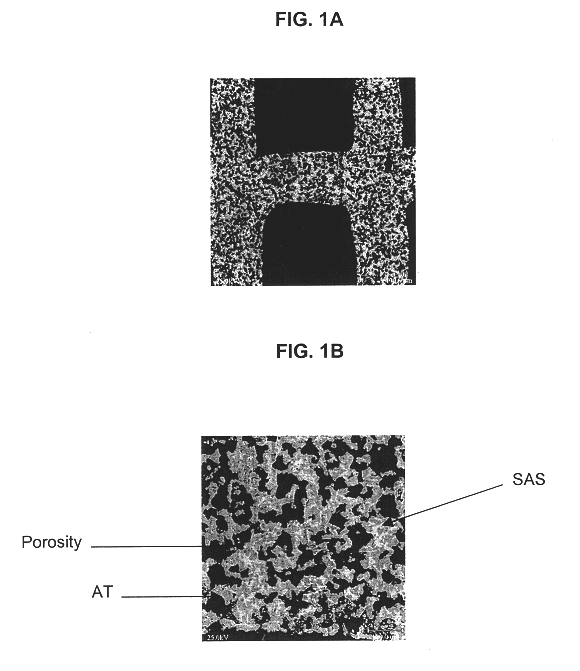

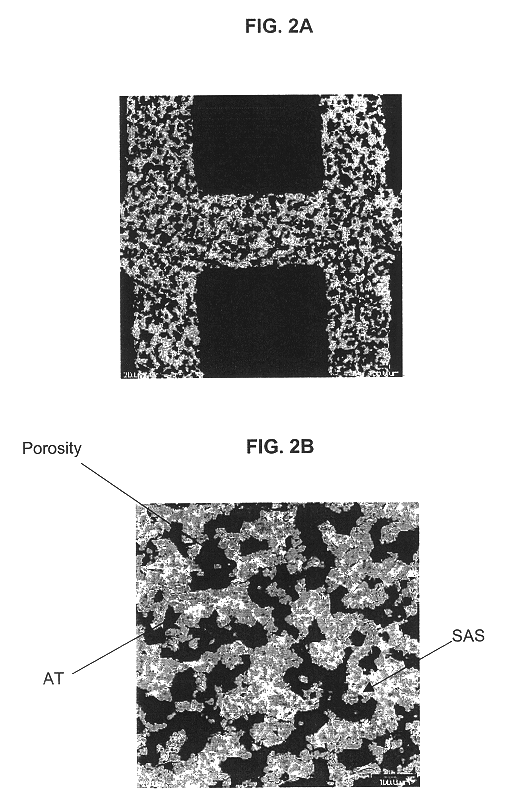

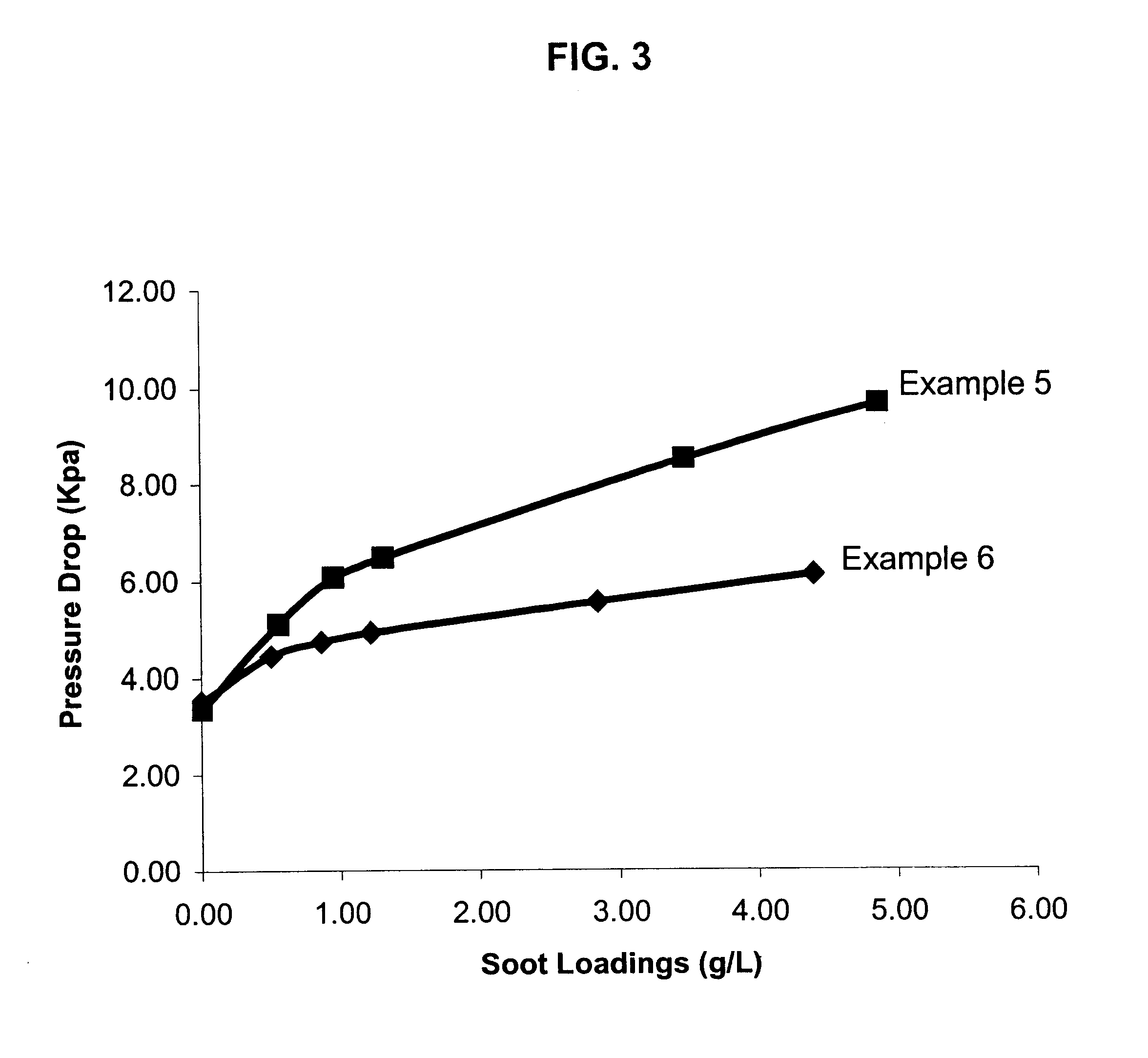

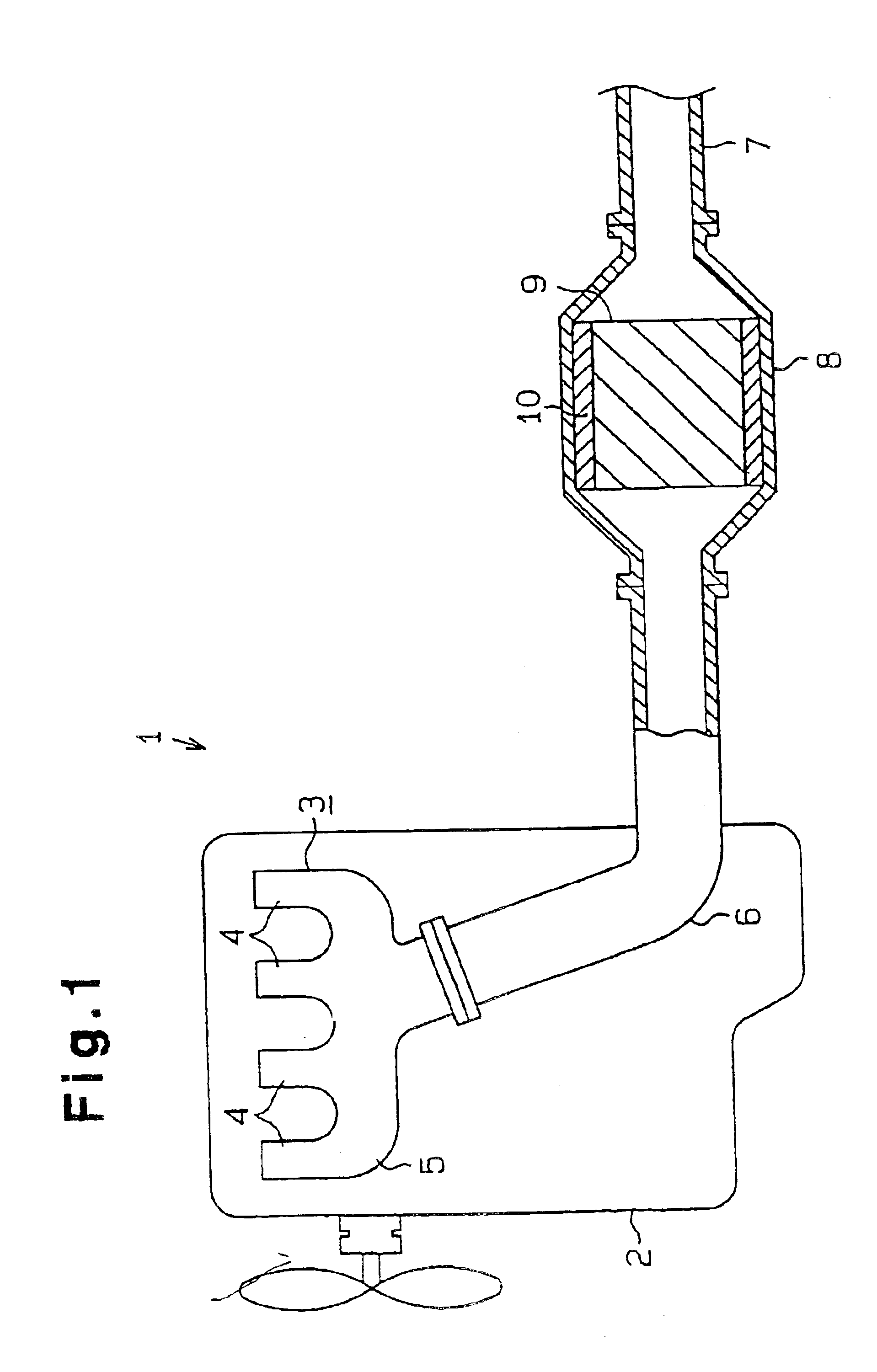

Catalyzed SCR filter and emission treatment system

ActiveUS7229597B2Reduce the temperaturePromote regenerationCombination devicesLiquid degasification with auxillary substancesNitrogen oxideSoot

Provided is an emission treatment system and method for simultaneously remediating the nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons present in diesel engine exhaust streams. The emission treatment system has an oxidation catalyst upstream of a soot filter coated with a material effective in the Selective Catalytic Reduction (SCR) of NOx by a reductant, e.g., ammonia. Also provided is a method for disposing an SCR catalyst composition on a wall flow monolith that provides adequate catalyst loading, but does not result in unsuitable back pressures in the exhaust.

Owner:BASF CORP

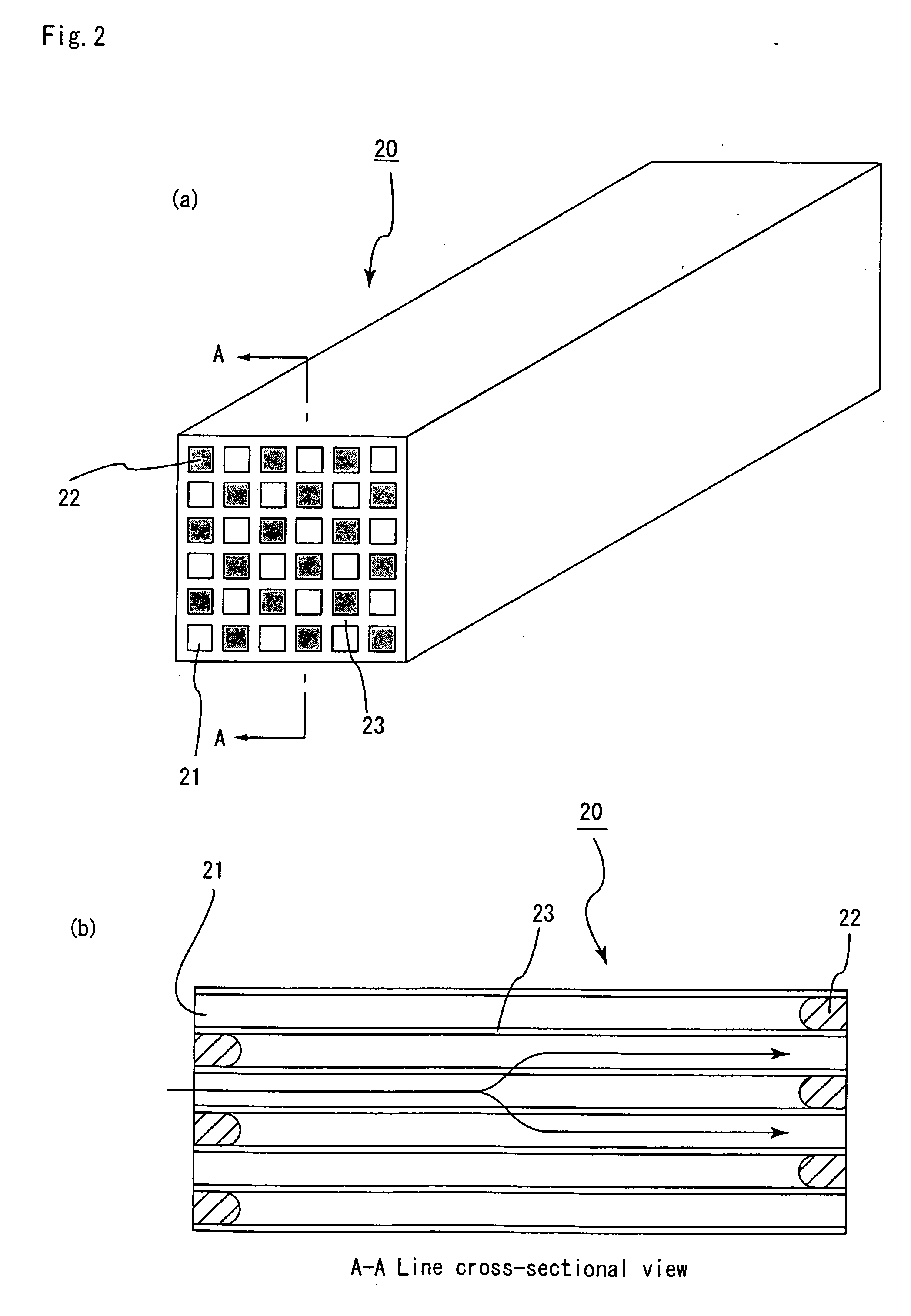

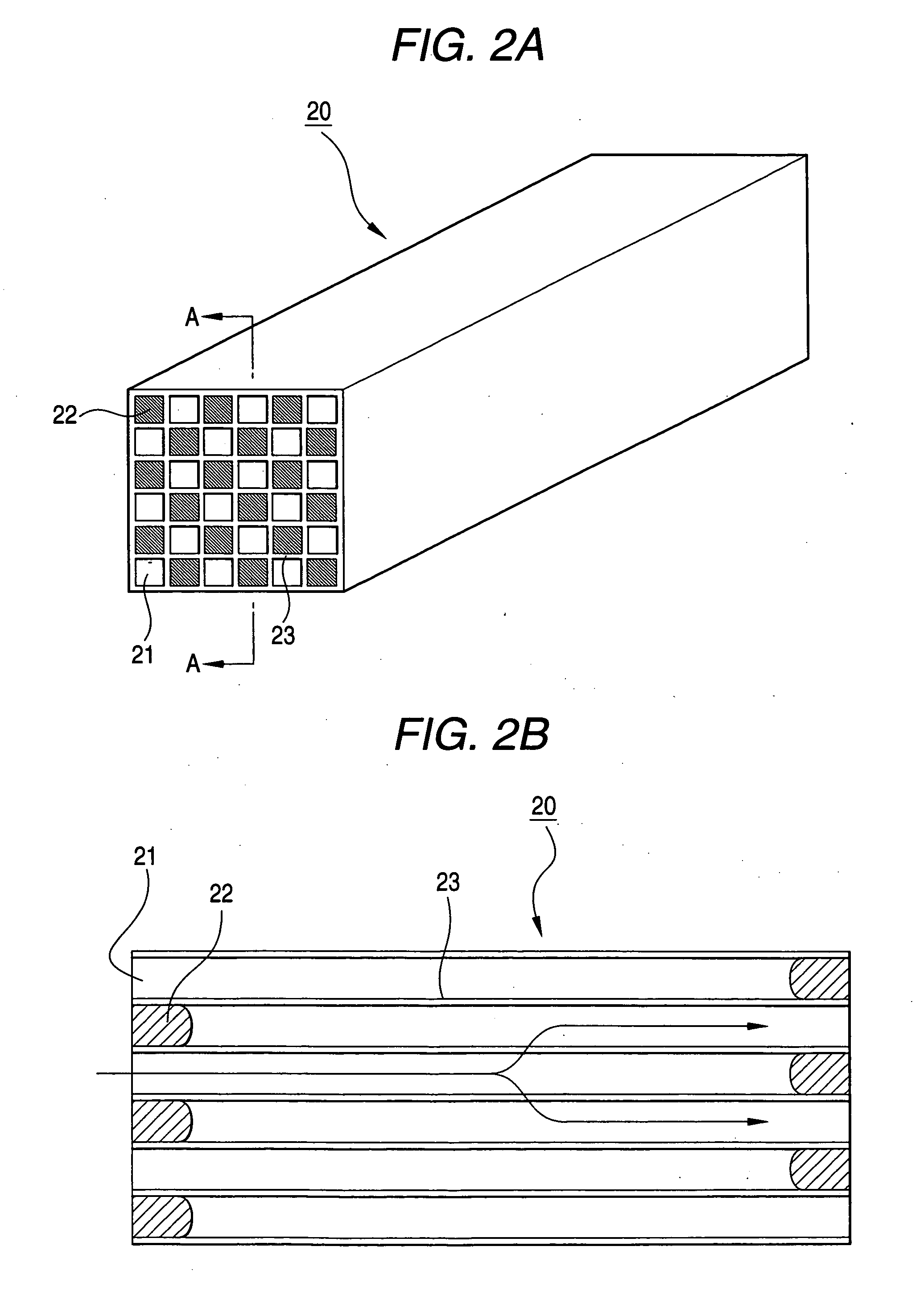

Honeycomb filter for exhaust gas decontamination, adhesive, coating material and process for producing honeycomb filter for exhaust gas decontamination

ActiveUS20050109023A1Reduce thermal stressAlleviating generated thermal stressCombination devicesDispersed particle filtrationParticulatesAdhesive

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change and which is less likely to generate cracks and superior in strength and durability, an adhesive that has a low thermal capacity and is capable of alleviating the thermal stress, a coating material that has a low thermal capacity with a superior heat insulating property and is capable of alleviating the thermal stress, and a manufacturing method of the honeycomb filter for purifying exhaust gases that can improve precision in the outside dimension, and reduce damages in the manufacturing processes. The present invention relates to a honeycomb filter for purifying exhaust gases, having a structure in that a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separate the through holes are allowed to function as a filter for collecting particulates, and in this structure, the thermal expansion coefficient αL of the adhesive layer and the thermal expansion coefficient αF of the porous ceramic member are designed to have the following relationship: 0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

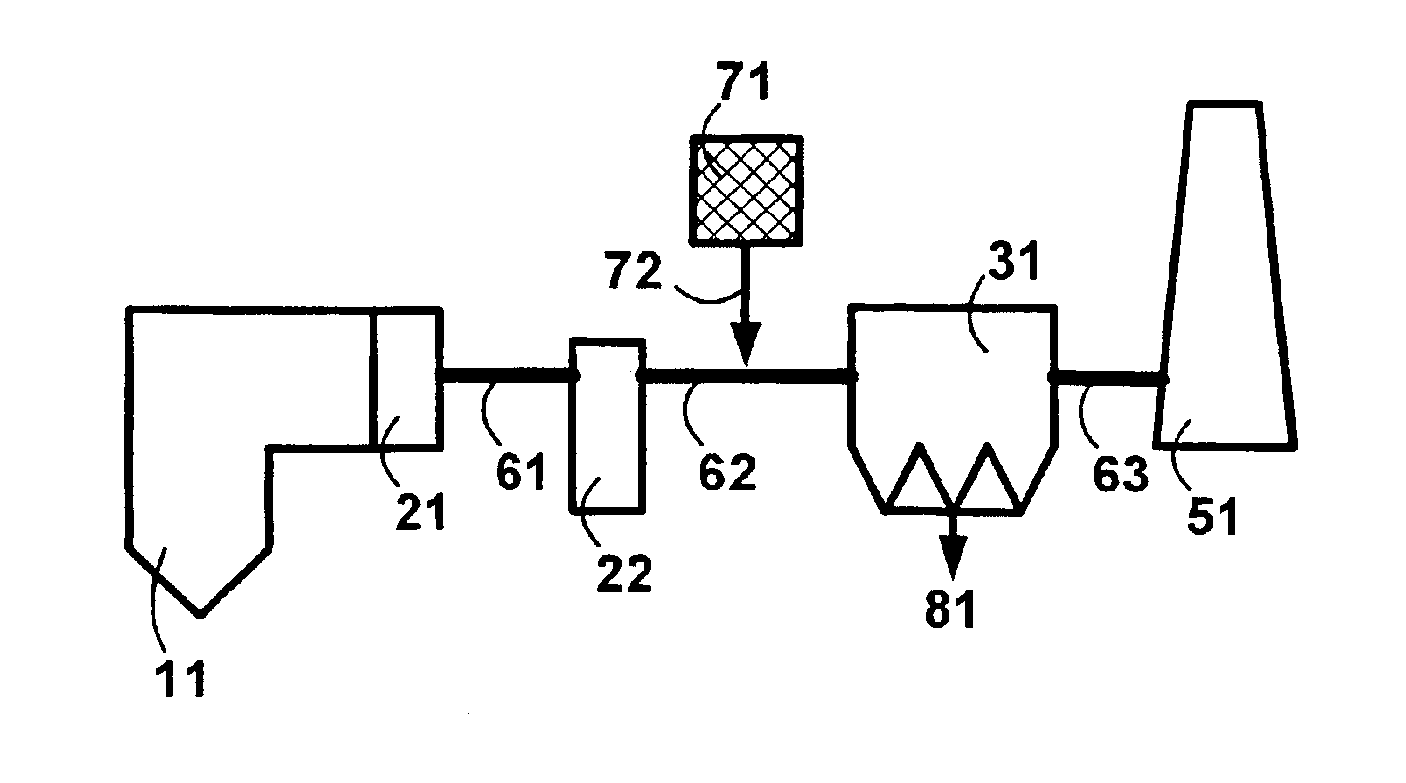

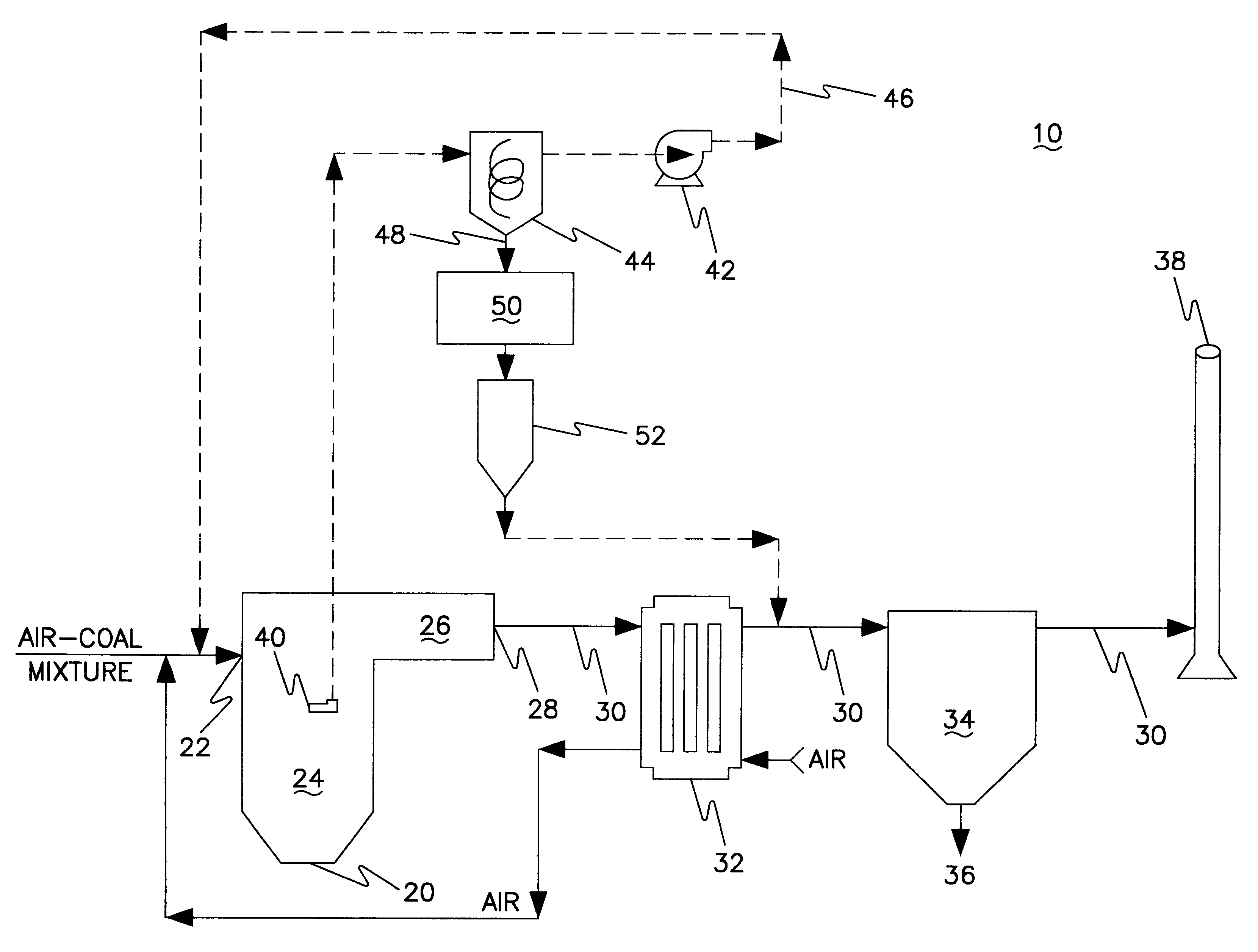

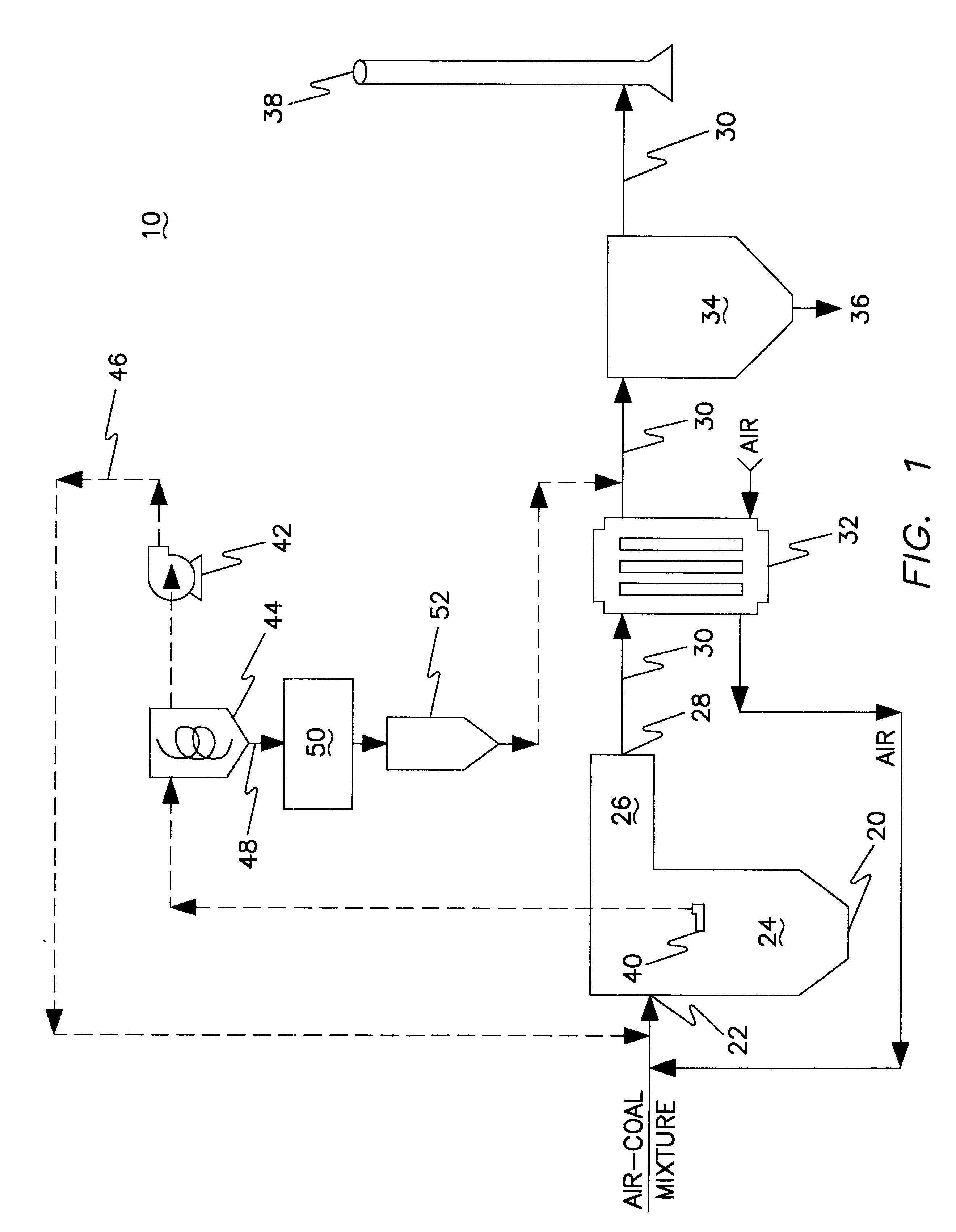

Thief process for the removal of mercury from flue gas

InactiveUS6521021B1Low costQuench oxidationGas treatmentUsing liquid separation agentParticulatesCombustion chamber

A system and method for removing mercury from the flue gas of a coal-fired power plant is described. Mercury removal is by adsorption onto a thermally activated sorbent produced in-situ at the power plant. To obtain the thermally activated sorbent, a lance (thief) is inserted into a location within the combustion zone of the combustion chamber and extracts a mixture of semi-combusted coal and gas. The semi-combusted coal has adsorptive properties suitable for the removal of elemental and oxidized mercury. The mixture of semi-combusted coal and gas is separated into a stream of gas and semi-combusted coal that has been converted to a stream of thermally activated sorbent. The separated stream of gas is recycled to the combustion chamber. The thermally activated sorbent is injected into the duct work of the power plant at a location downstream from the exit port of the combustion chamber. Mercury within the flue gas contacts and adsorbs onto the thermally activated sorbent. The sorbent-mercury combination is removed from the plant by a particulate collection system.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Electret filter media

InactiveUS6119691AReduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersMicrometerFilter media

An electret filter media, and mask, that is made of a nonwoven web of thermoplastic microfibers. The thermoplastic microfibers are of substantially the same composition, are nonconductive, and have an effective fiber diameter less than about 15 micrometers. The nonwoven web also has sufficient unpolarized trapped charge to exhibit an initial filtration quality factor of at least 0.31 when measured under the DOP Penetration and Pressure Drop Test.

Owner:3M CO

Filter arrangement; sealing system; and methods

InactiveUS6610117B2Avoid passingObstruct passageCombination devicesGas treatmentMechanical engineeringStructural engineering

A filter pack includes a filter construction and a sealing system for sealing the construction within a duct or housing. The filter construction has first and second opposite flow faces and is configured for a straight-through flow. The sealing system includes a frame construction and a compressible seal member. The compressible seal member is molded around a portion of the frame construction. The compressible seal member is sufficiently compressible to form a radial seal between and against the frame construction and a surface of a housing when the filter pack is inserted within the housing.

Owner:DONALDSON CO INC

Cyclonic vacuum cleaner

InactiveUS20050138763A1Improve efficiencyEasy to emptyCleaning filter meansCombination devicesCycloneVacuum cleaner

A cyclonic vacuum cleaner includes a body portion, a nozzle portion and a dirt cup which is removable from the body portion. The dirt cup collects dirt and other debris separated by a cyclone and a cyclone slinger portion in the body portion. A main filter may be housed in a transparent filter door downstream of the cyclone. The dirt cup may be inserted into and sealingly held within the body portion by using a rotational camming structure.

Owner:MIDEA AMERICA CORP

High temperature nanofilter, system and method

InactiveUS7052532B1More laminar flowShort pleat heightDispersed particle filtrationTransportation and packagingFiberNanoparticle

A filter, system and method is provided for filtering nanoparticles in a hot gas, namely particles <about 1 micron in a gas >about 200° C. and further particularly >about 450° C. including diesel exhaust. The filter includes filter media material composed of fibrous filter media having a plurality of fibers and granular filter media having a plurality of granules extending from the surfaces of the fibers. The filter is characterized by a permeability >about 3×10−12 m2 and an inertial resistance coefficient <about 1×106 m−1. The filter captures particles in the Most Penetrating Region (MPR). A filter system includes a nanoparticle filter in series with a diesel exhaust treatment element.

Owner:3M INNOVATIVE PROPERTIES CO +1

Electret filter media and filtering masks that contain electret filter media

InactiveUS6783574B1Reduce filtration efficiencyImprove filtering effectSynthetic fibresBreathing filtersFilter mediaRespiratory mask

Electret filter media comprising a nonwoven web of thermoplastic nonconductive microfibers having trapped charge, said charge provided by (1) subjecting the nonwoven web to a corona treatment, followed by (2) impingement of jets of water or a stream of water droplets on the web at a pressure sufficient to provide the web with filtration enhancing electret charge and (3) drying the web. This electret filter media may be used in a respiratory mask to provide extraordinarily good filtration properties.

Owner:3M CO

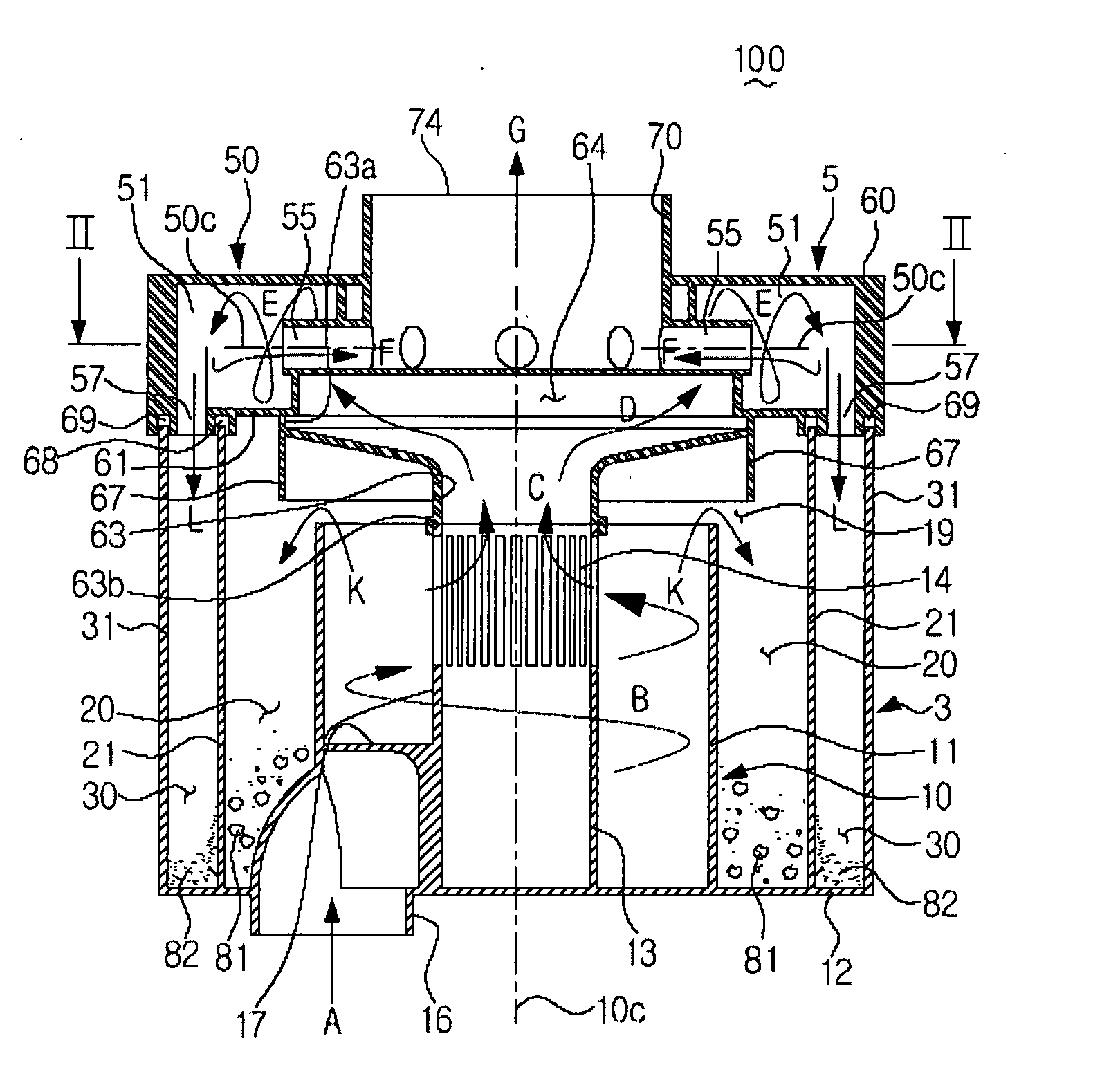

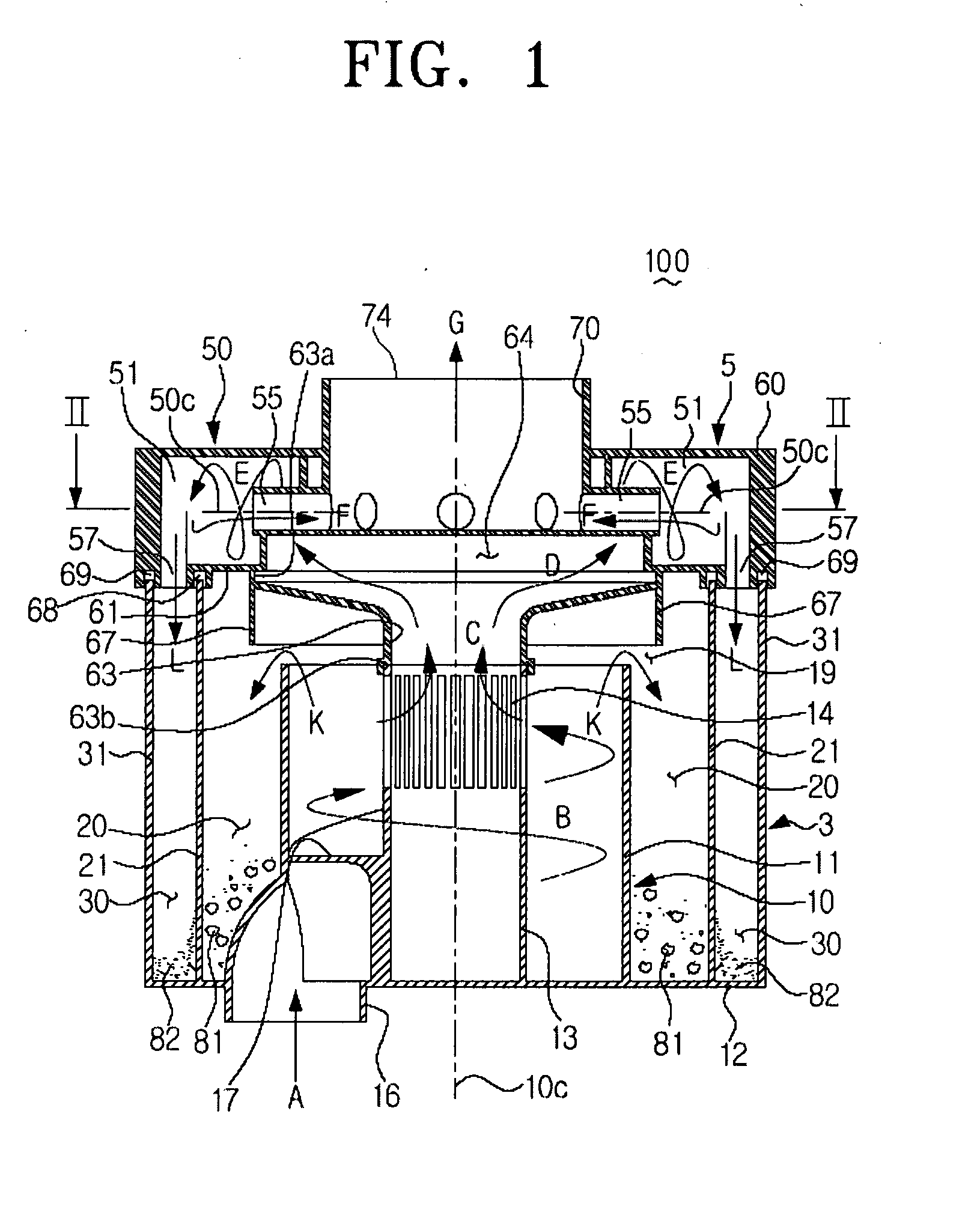

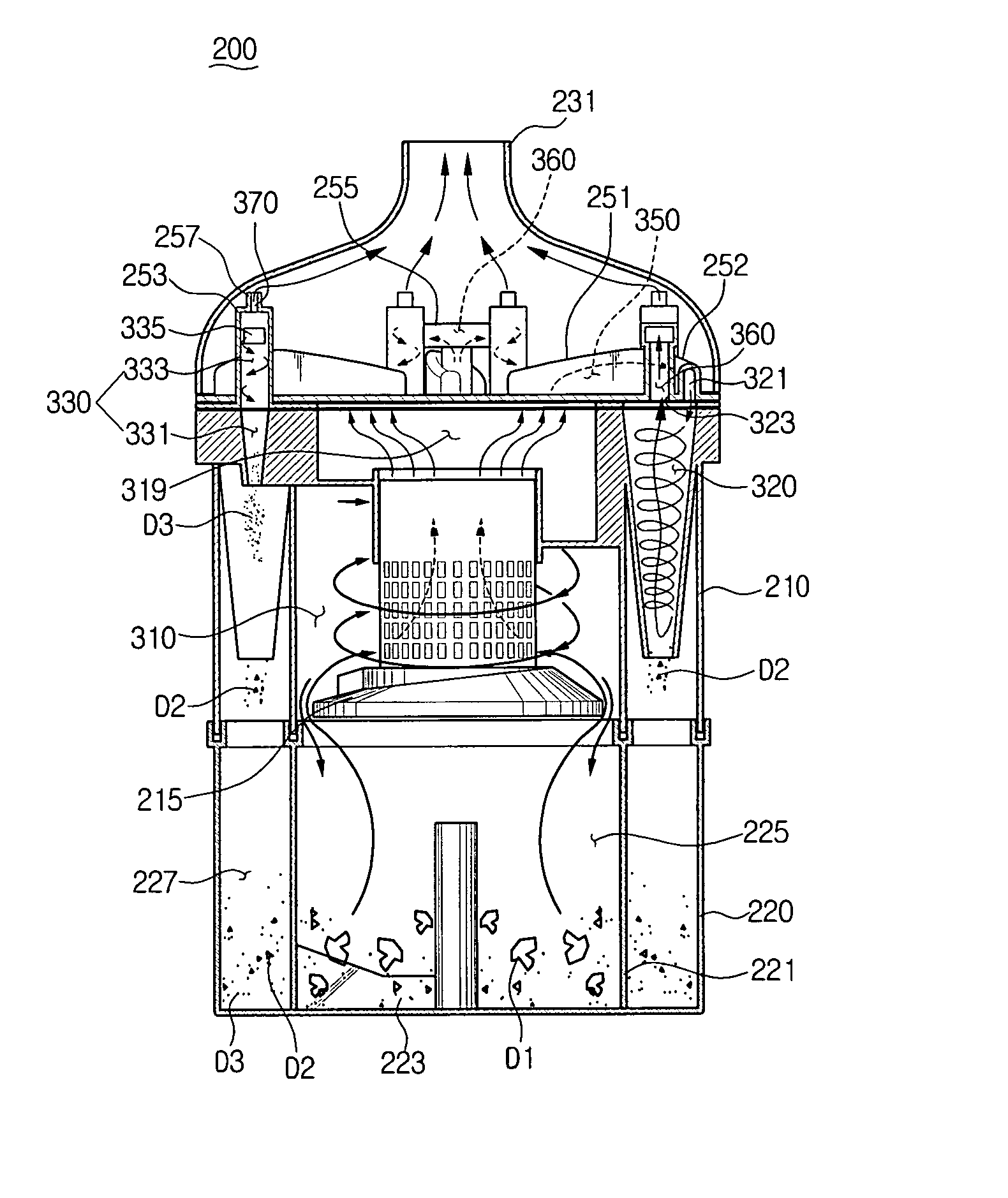

Multi-cyclone dust separating apparatus

A multi-cyclone dust separating apparatus includes: a multi-cyclone unit including a first cyclone chamber body having a first cyclone chamber and at least one protection chamber formed around at least a portion of an outer circumference of the first cyclone chamber, and at least one secondary cyclone chamber body disposed in the protection chamber, each secondary cyclone chamber body having at least one secondary cyclone chamber; a cover unit connecting an upper end of the multi-cyclone unit and guiding air discharged from the first cyclone chamber to the at least one secondary cyclone chamber; a dirt collecting unit adapted to connect to a lower end of the multi-cyclone unit and configured to collect dirt separated from the air in the first and secondary cyclone chambers; and an air discharge duct configured to discharge air that has passed through the multi-cyclone unit.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Cyclone separating apparatus for vacuum cleaner

InactiveUS20080190080A1High contaminant separating efficiencyProblem and drawbackCleaning filter meansCombination devicesCycloneCyclonic separation

A cyclone separating apparatus for a vacuum cleaner includes a first cyclone with an air entrance disposed on a lower portion of the first cyclone and an air exit disposed at an upper portion of the first cyclone; a first contaminants chamber substantially enclosing the first cyclone to collect contaminants discharged from the first cyclone; a plurality of second cyclones above the first cyclone, the plurality of second cyclones being substantially perpendicular to a center axis of the first cyclone; and a second contaminants chamber disposed outside the first contaminants chamber to collect contaminants discharged from the plurality of second cyclones.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

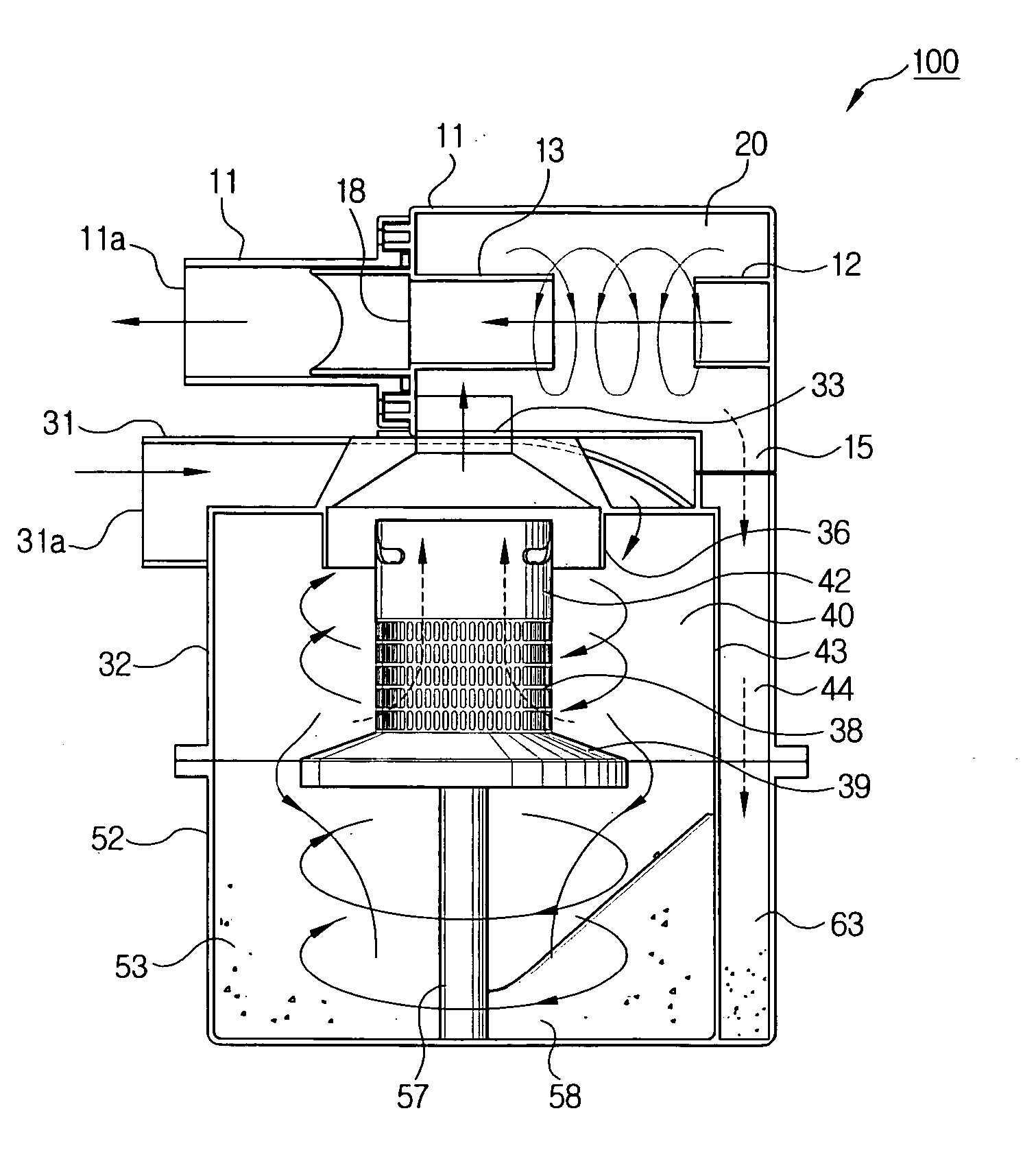

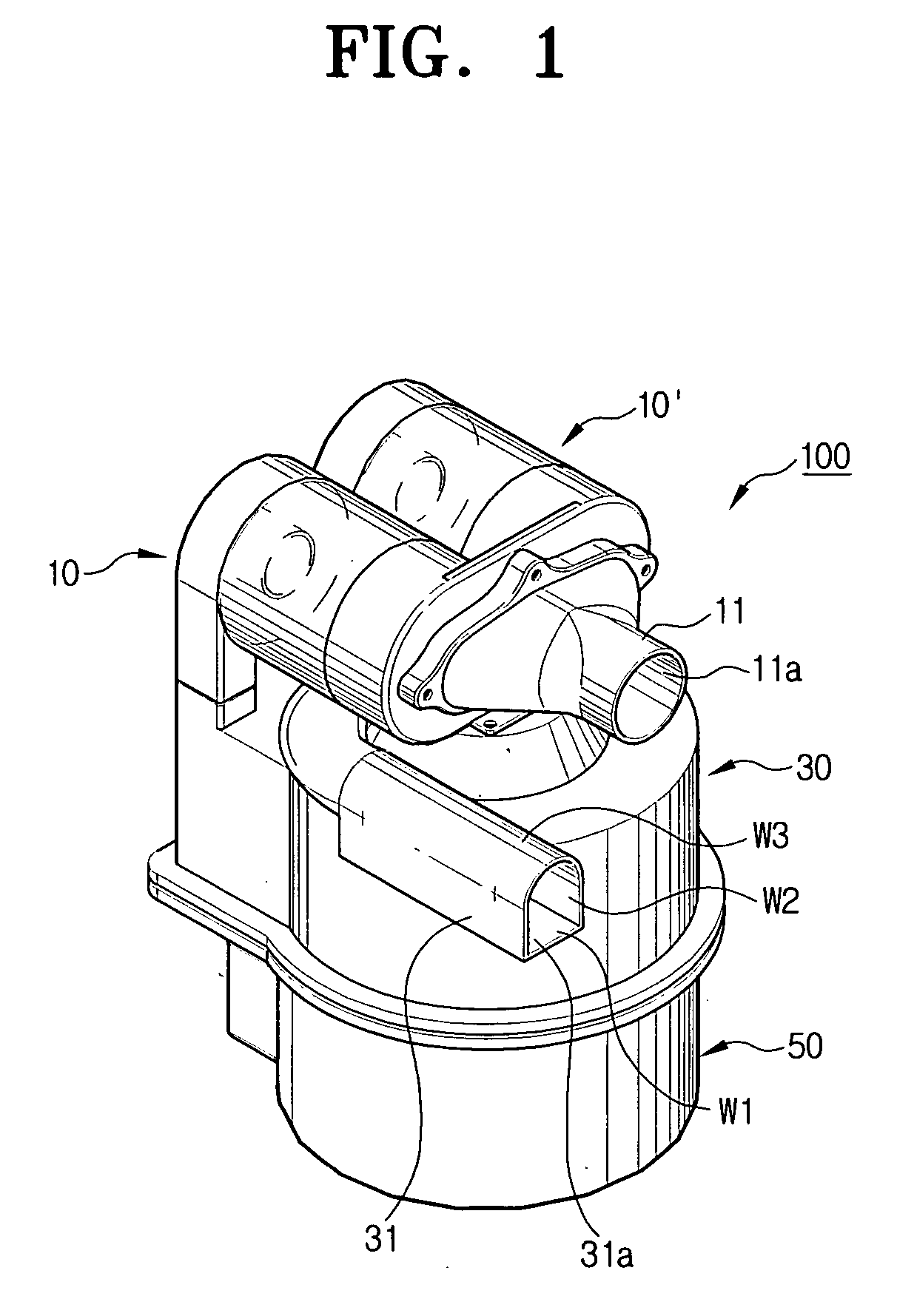

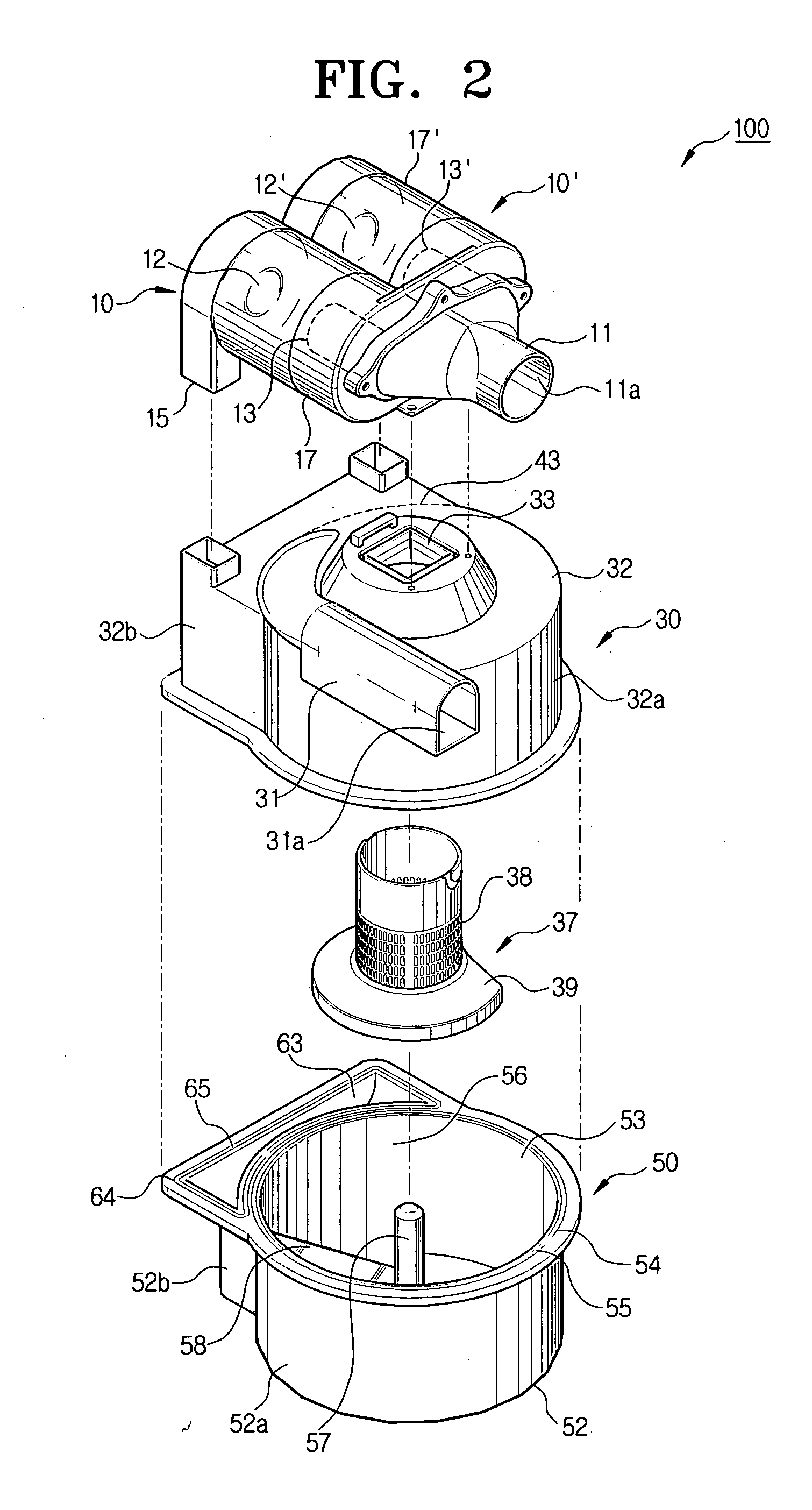

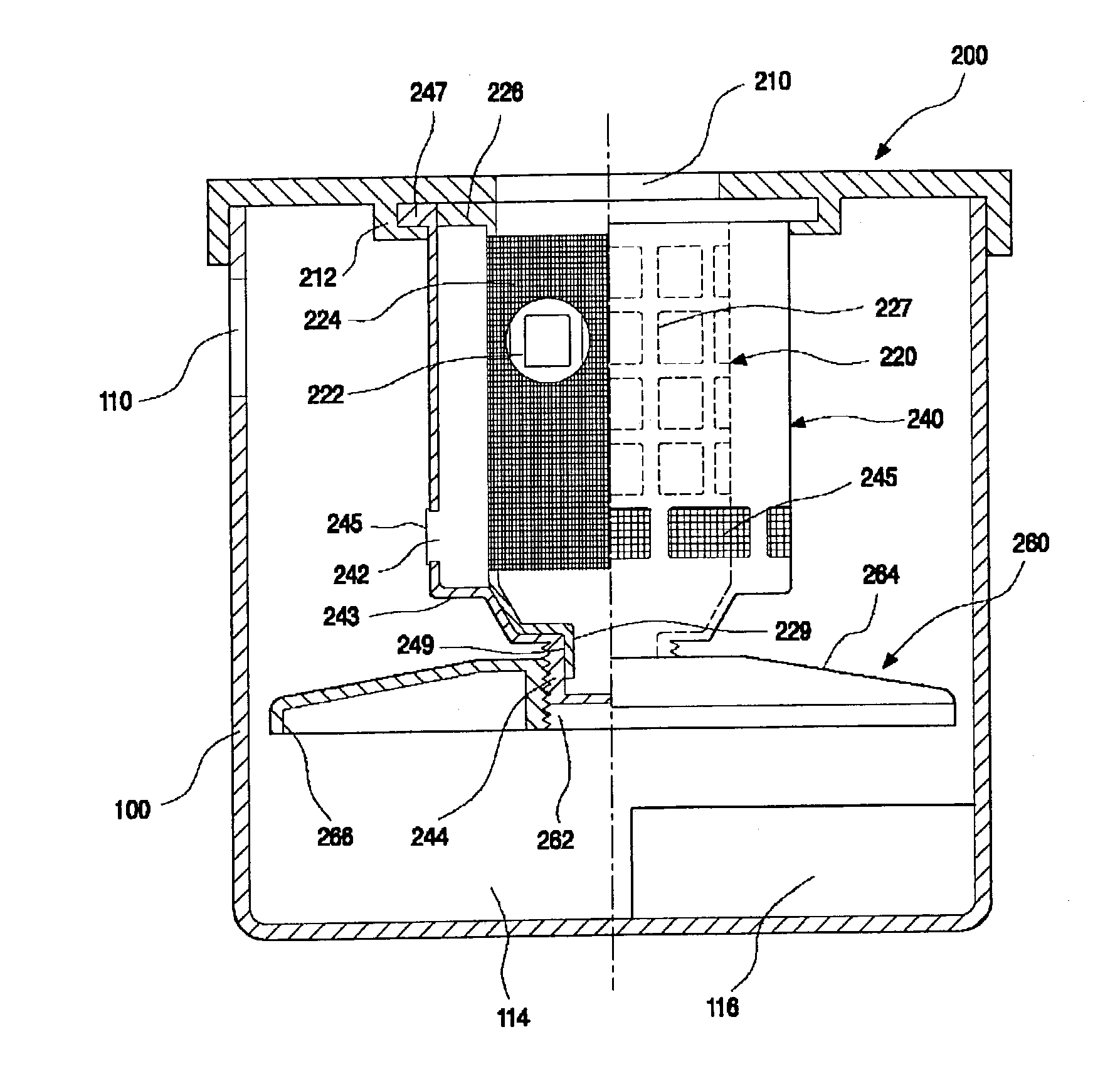

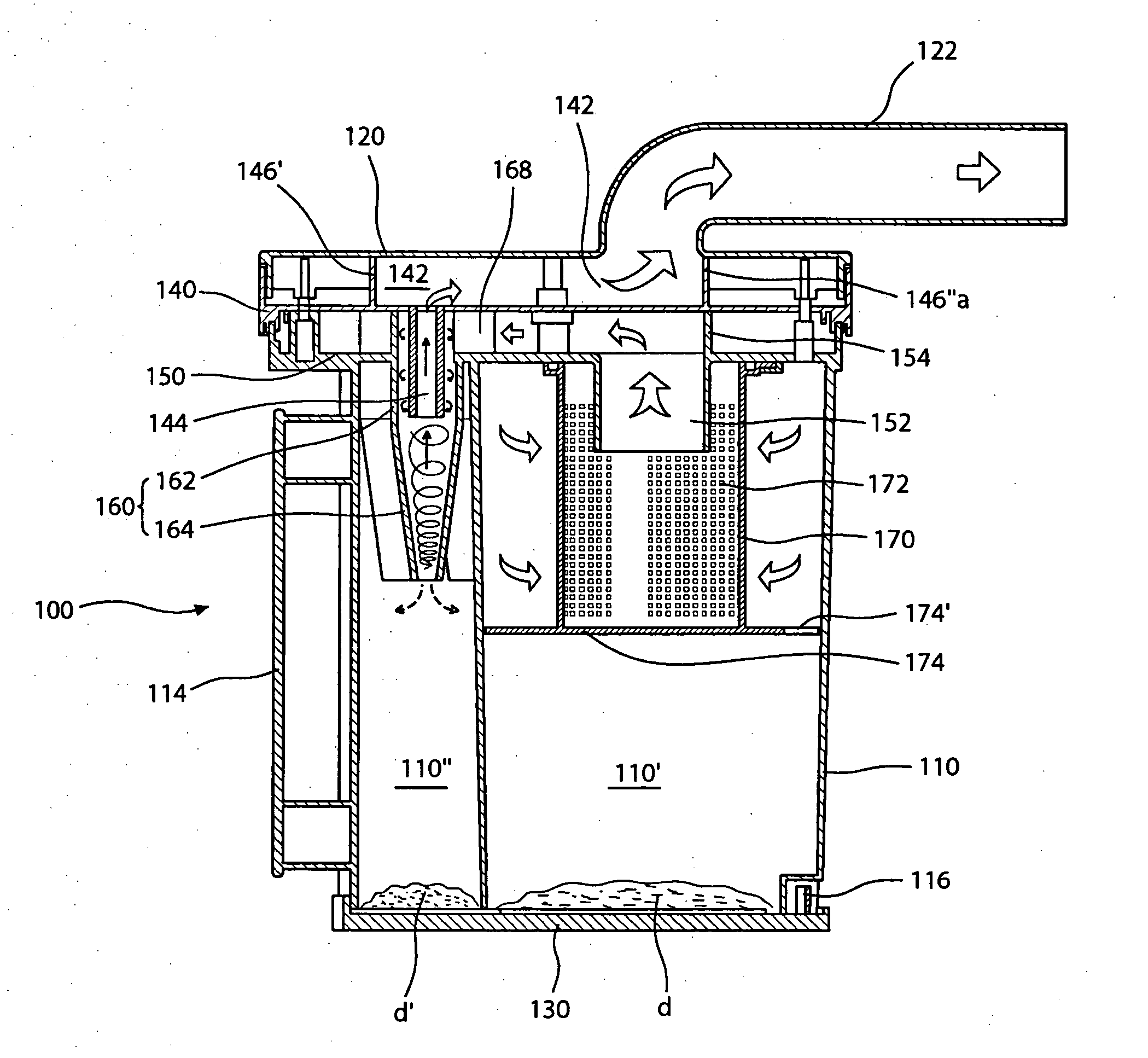

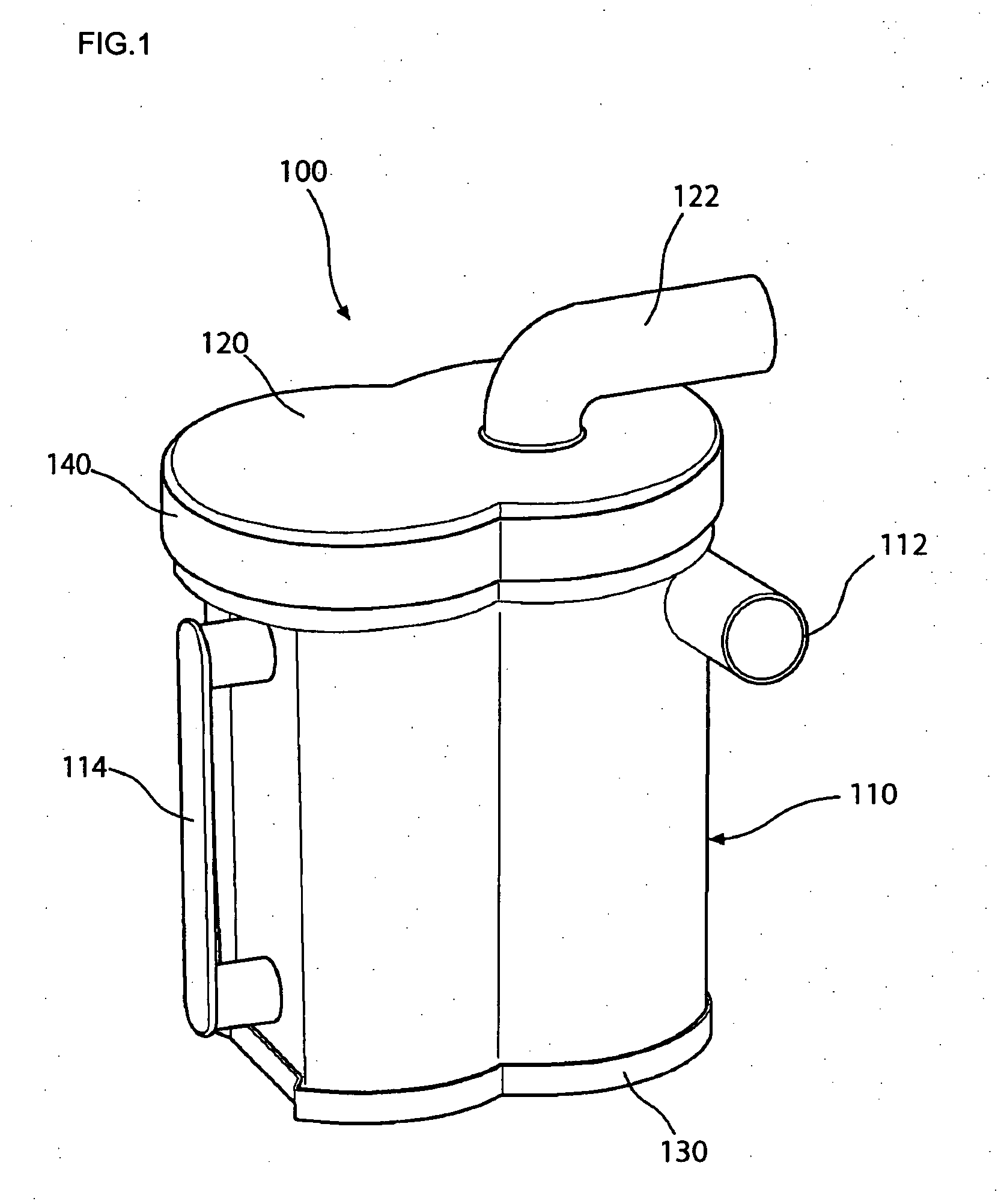

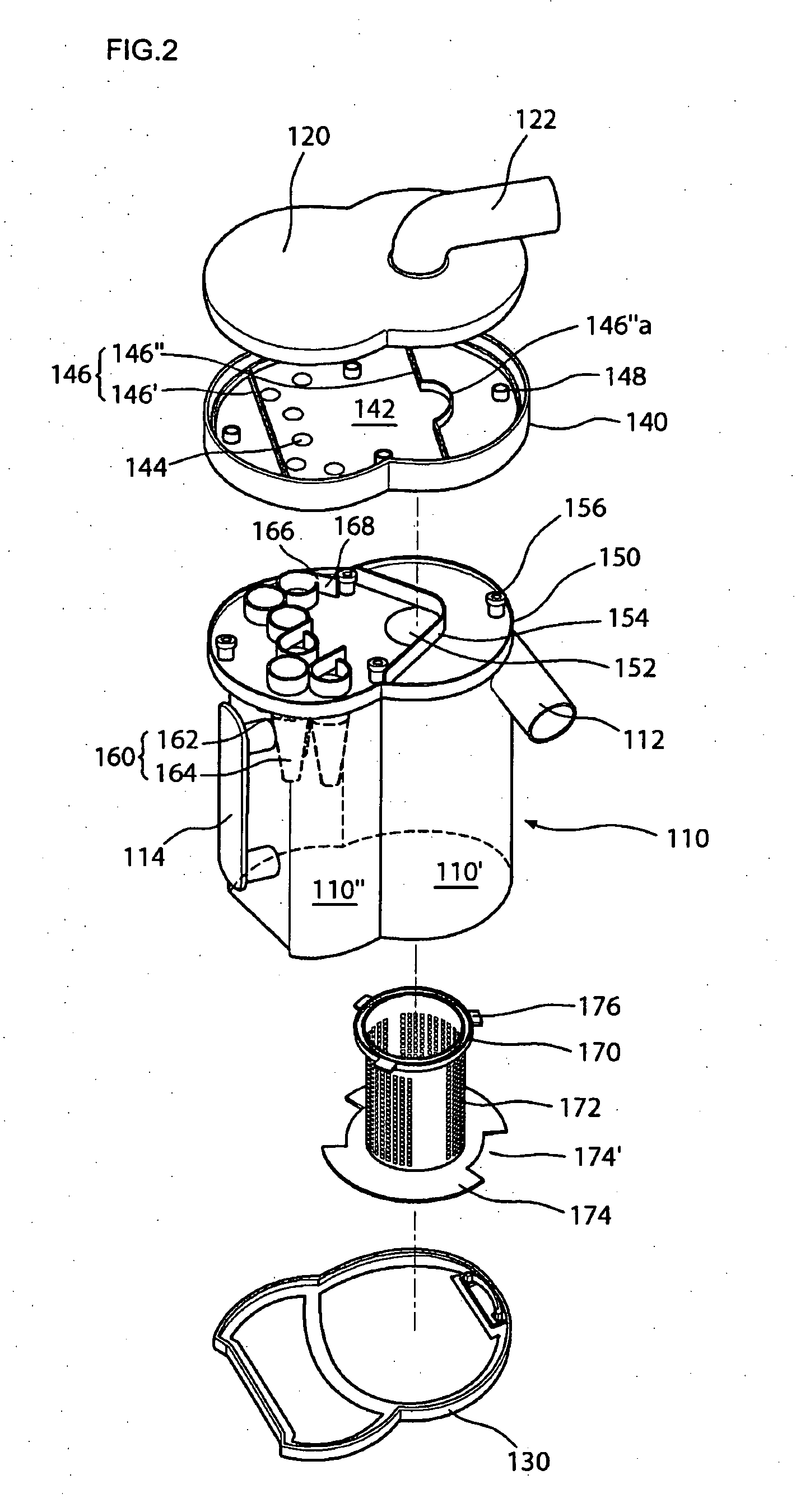

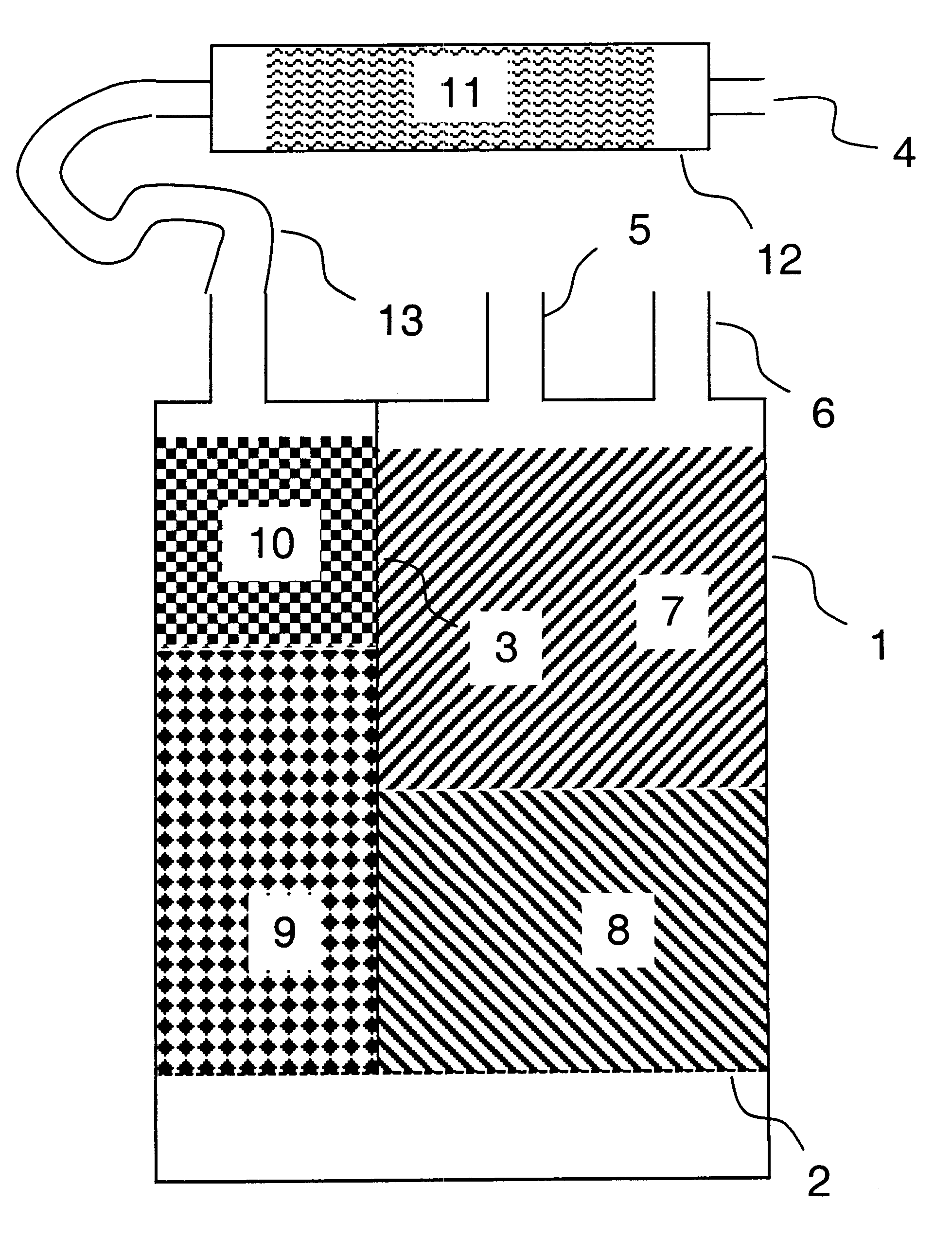

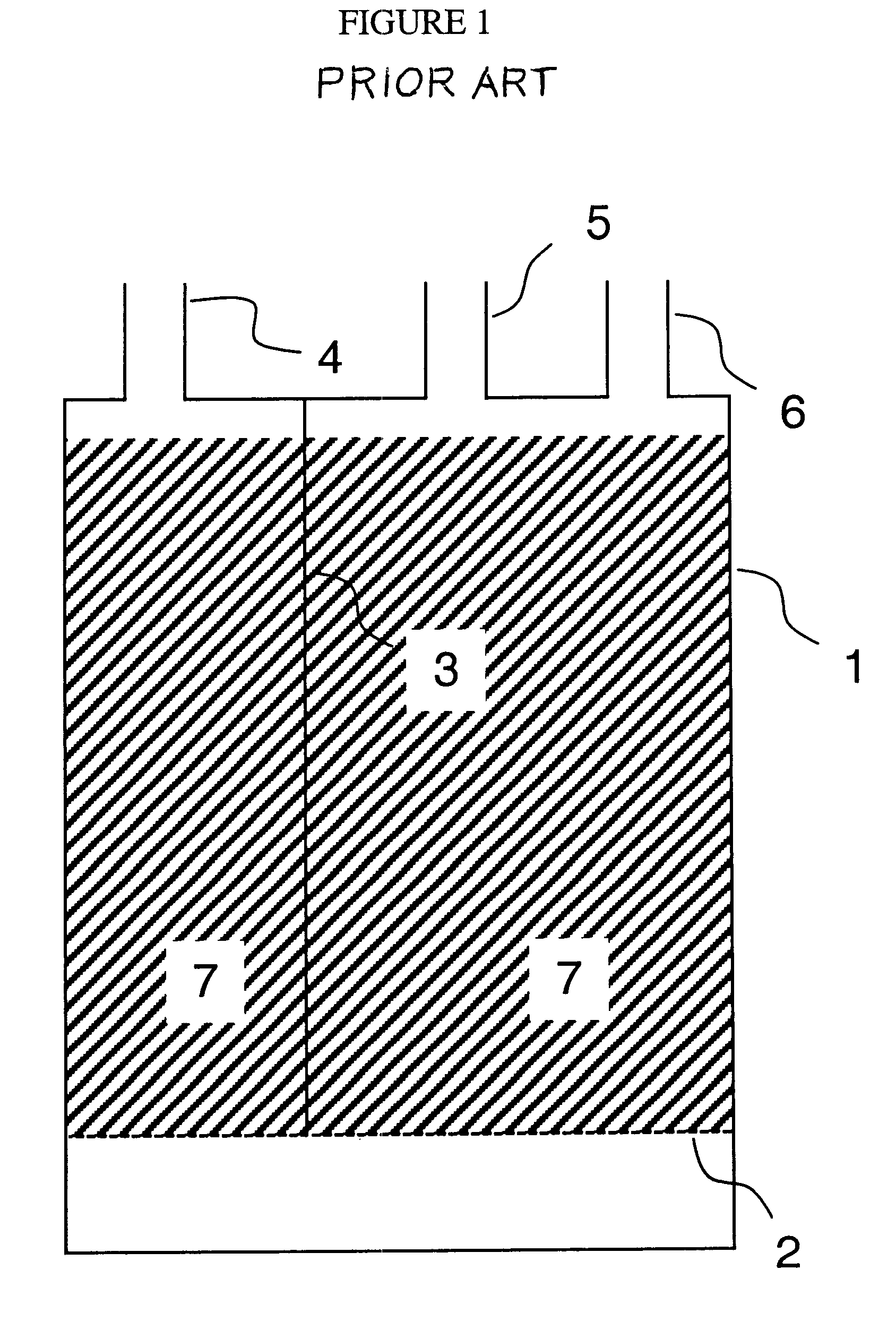

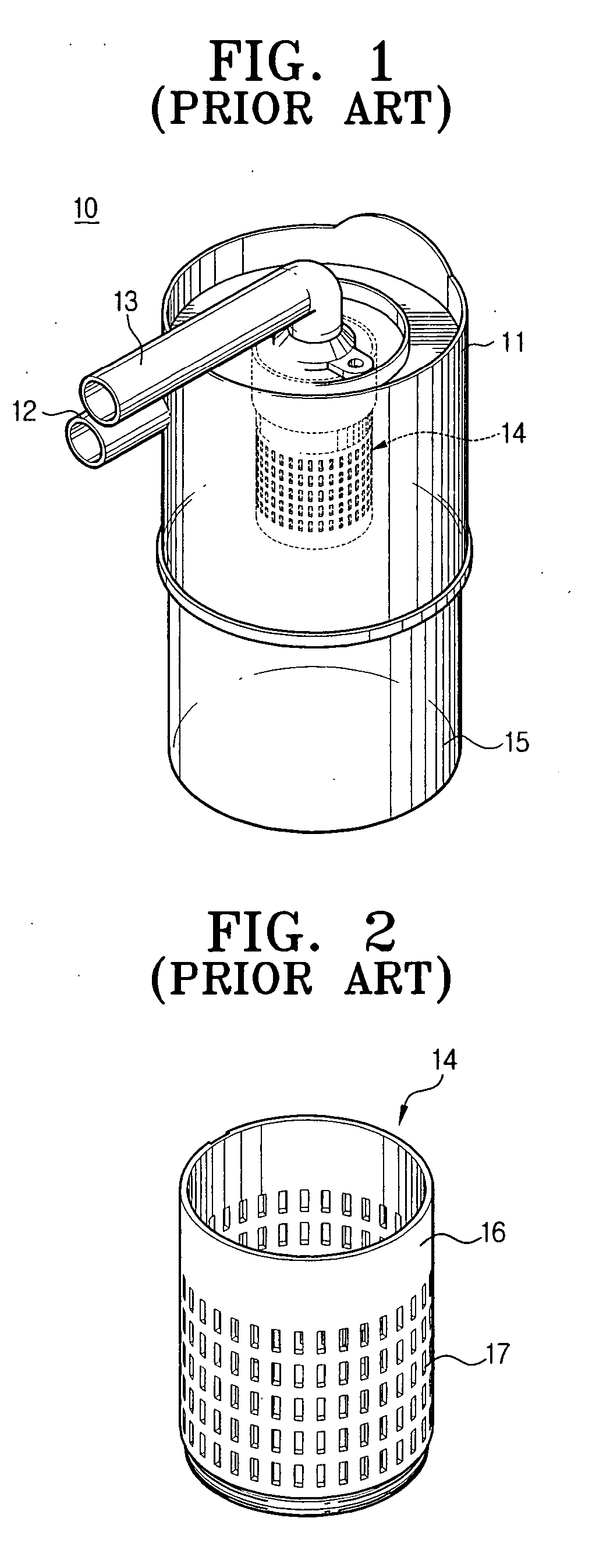

Dust and dirt collecting unit for vacuum cleaner

InactiveUS7160346B2Preventing mesh clogging of filterCleaning filter meansCombination devicesForeign matterEngineering

The present invention relates to a dust and dirt collecting unit for a vacuum cleaner capable of simultaneously performing a primary cyclonic dust collection and a secondary filter dust collection. According to the present invention, there is provided a dust and dirt collecting unit for a vacuum cleaner, which is mounted to one side of a main body of the vacuum cleaner to filter sucked air containing foreign substances. The dust and dirt collecting unit of the present invention comprises a dust casing which has an inlet formed in a direction tangential thereto for introducing the air containing the foreign substances thereinto and of which a top portion is open; a cover which is used to open and close the top portion of the dust casing and is provided at the center thereof with an outlet for discharging air from which the foreign substances have been filtered out; a filter assembly which is installed at a bottom surface of the cover corresponding to the outlet and includes a cylindrical filter of which the interior communicates with the outlet; a protective cylindrical body which is formed to wrap around an outer periphery of the filter assembly and installed below the cover so that the interior thereof can communicate with the exterior thereof through a plurality of vent holes formed at a lower portion thereof; and a separating plate which is coupled with the bottom of the filter assembly and extends radially to be spaced apart from an inner circumferential surface of the dust casing by a predetermined gap.

Owner:LG ELECTRONICS INC

Strontium feldspar aluminum titanate for high temperature applications

InactiveUS6620751B1Improve stabilityReduce bloatInternal combustion piston enginesDispersed particle filtrationMicrometerRoom temperature

A structure for use in high temperature applications and including a porous ceramic material consisting essentially of about 50-90 percent by weight iron or magnesium stabilized aluminum titanate (AlTiO5) and about 10-50 percent by weight strontium feldspar (SrO.Al2O3.2SiO2), and having a coefficient of thermal expansion over a temperature range from room temperature to 1000° C. of about -10x10-7 / ° C. to +15x10-7 / ° C., a heat capacity at 500° C. greater than 3.2 J / cm3K, a porosity of about 15-50 percent by volume, preferably 40-50 percent by volume, and a median pore size of about 5-50 micrometers, preferably 8-15 micrometers. The structure is especially useful as a diesel exhaust particulate filter.

Owner:CORNING INC

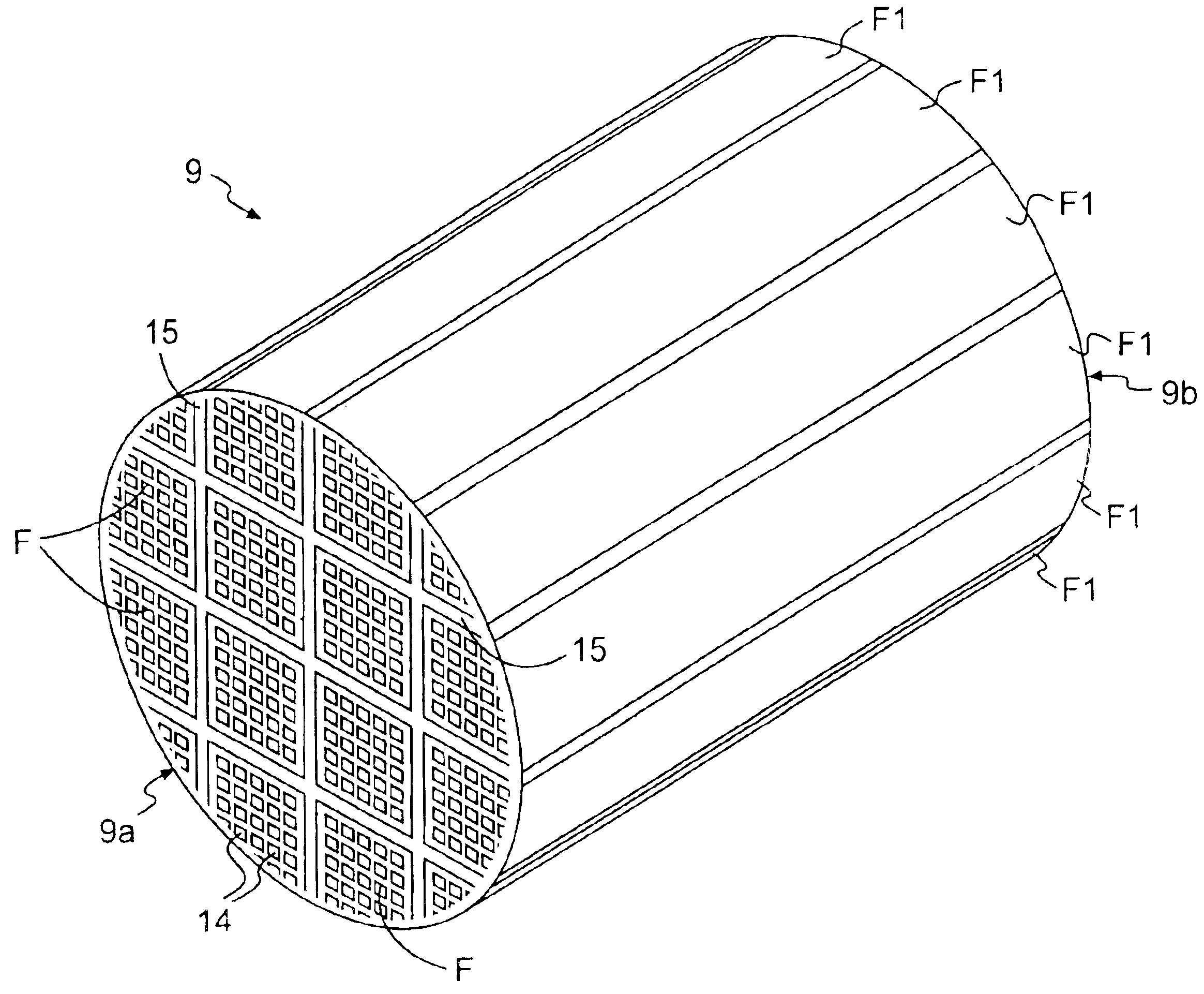

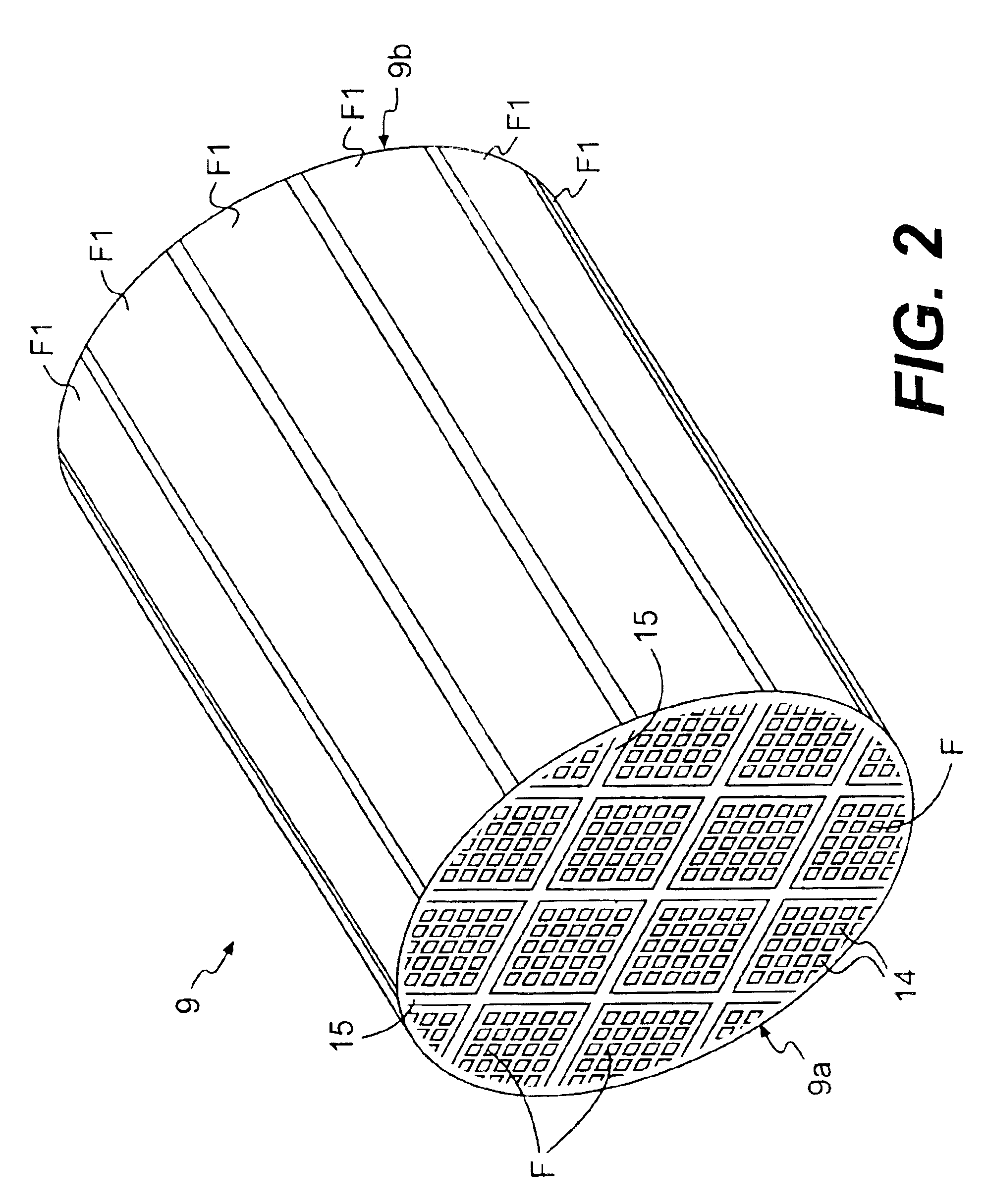

Honeycomb filter and ceramic filter assembly

A ceramic filter assembly having improved exhaust gas processing efficiency. The ceramic filter assembly (9) is produced by adhering with a ceramic seal layer (15) outer surfaces of a plurality of filters (F1), each of which is formed from a sintered porous ceramic body. The seal layer (15) has a thickness of 0.3 mm to 3 mm and a thermal conductance of 0.1 W / mK to 10 W / mk.

Owner:IBIDEN CO LTD

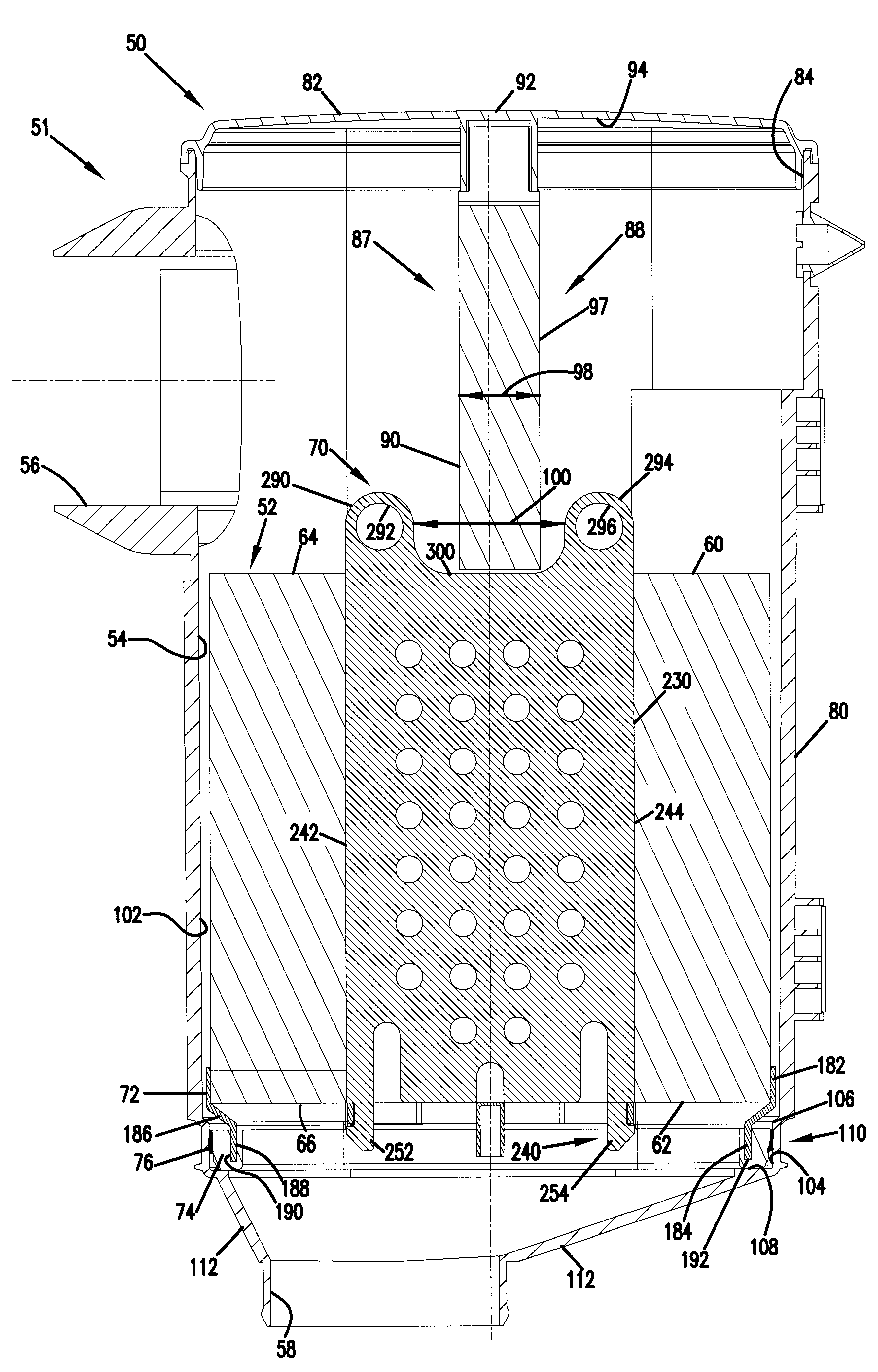

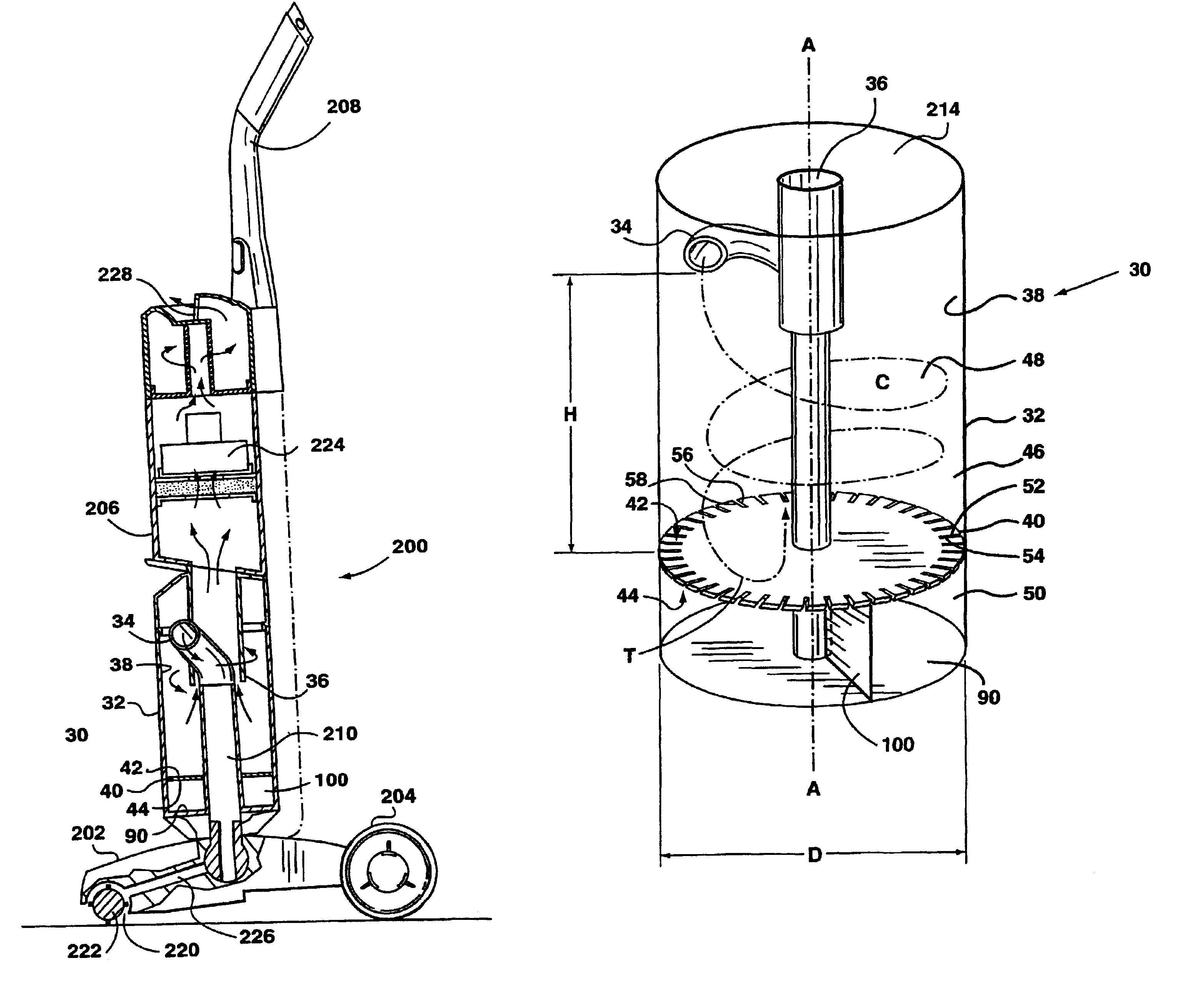

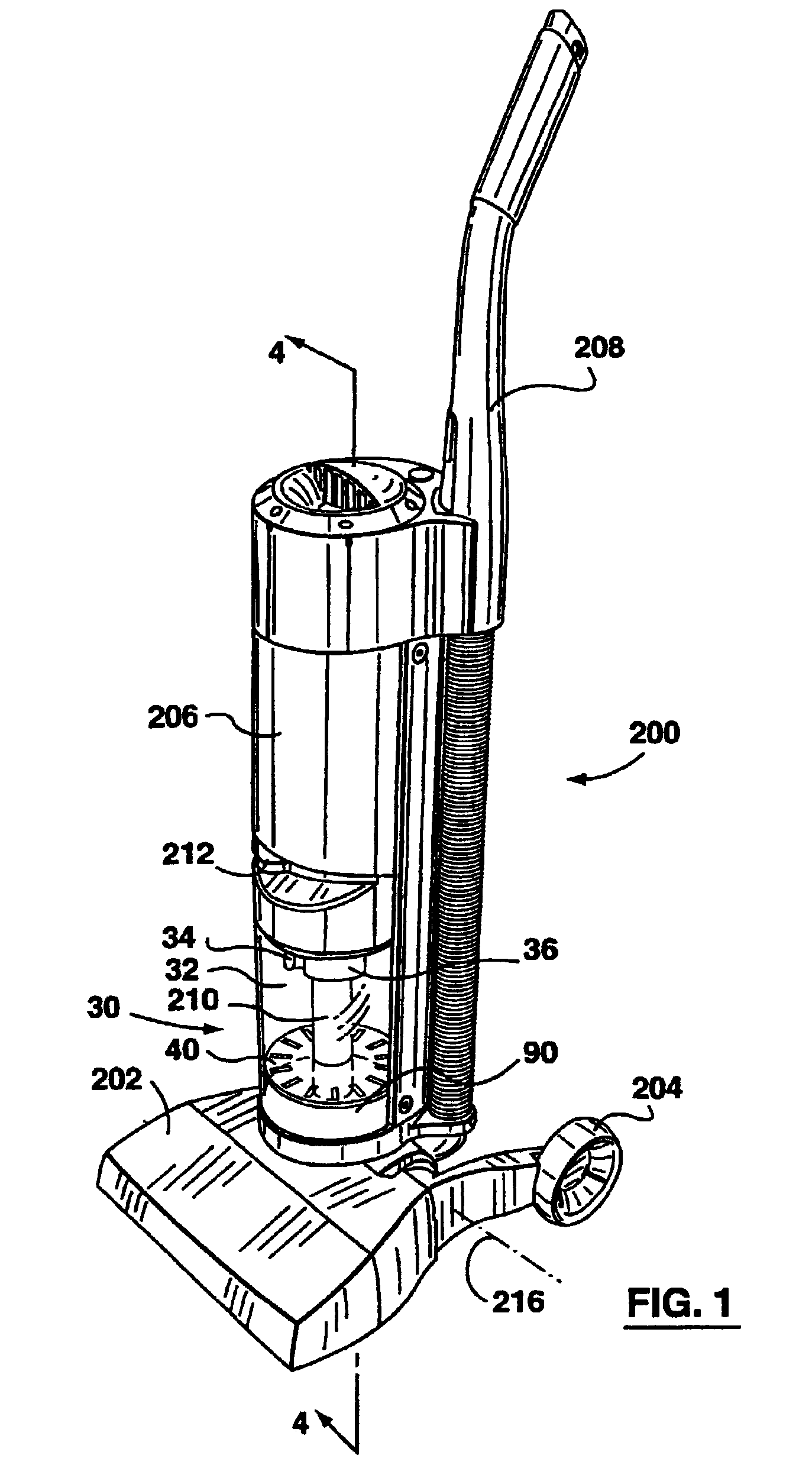

Apparatus and method for separating particles from a cyclonic fluid flow

InactiveUS6874197B1Improve efficiencyPrevent reentrainmentCleaning filter meansSuction filtersEngineeringParticle separation

A particle separation member (40) is provided for use with a cyclone separator (30). The particle separation member (40) divides the separator (30) into a cyclone chamber (46) and a particle receiving chamber (50). The cyclone chamber (46) and the particle receiving chamber (50) communicating via a plurality of apertures (52) in the particle separation member (40).

Owner:OMACHRON INTPROP

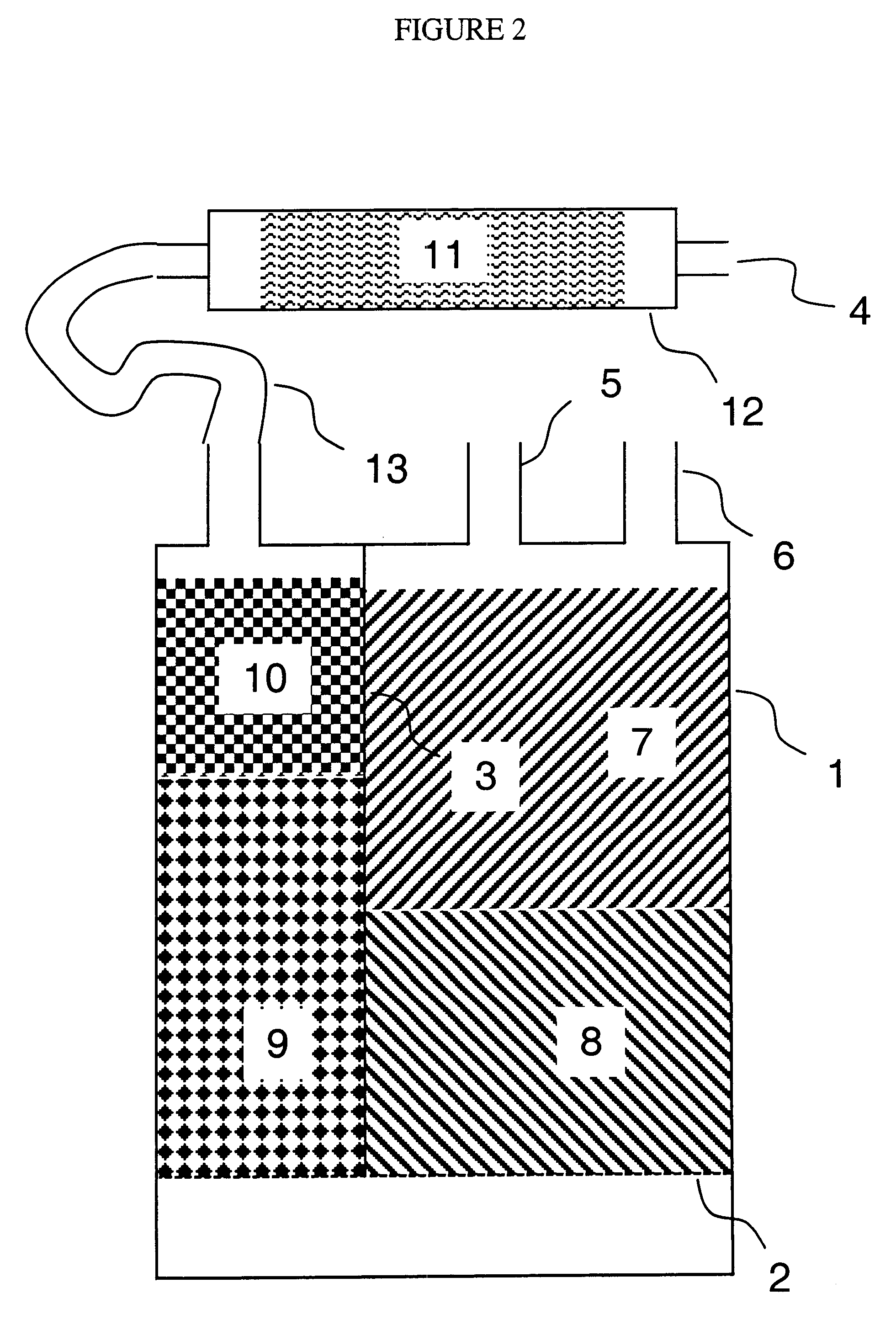

Dust collection assembly of vacuum cleaner

InactiveUS20060137304A1Improve dust removal efficiencyEasy constructionCombination devicesSuction filtersCycloneForeign matter

A dust collection assembly of a vacuum cleaner is provided. The dust collection assembly includes a dust collecting box, a filter, a flow guide unit, an exhaust guider, and an upper cover. The dust collecting box and the flow guide unit are integrally formed in a single body. The dust collecting box includes a first and second dust collecting spaces for collecting foreign objects. The filter is disposed in the inside of the dust collecting space to primarily filter foreign objects during operation of a cyclone. The flow guide unit guides airflow and has small cyclones integrally formed therein, for secondarily filtering the foreign objects in air. The exhaust guider guides airflow and has a plurality of discharge holes through which air filtered by the small cyclone flows. The upper cover is disposed on the upper side of the exhaust guider.

Owner:LG ELECTRONICS INC

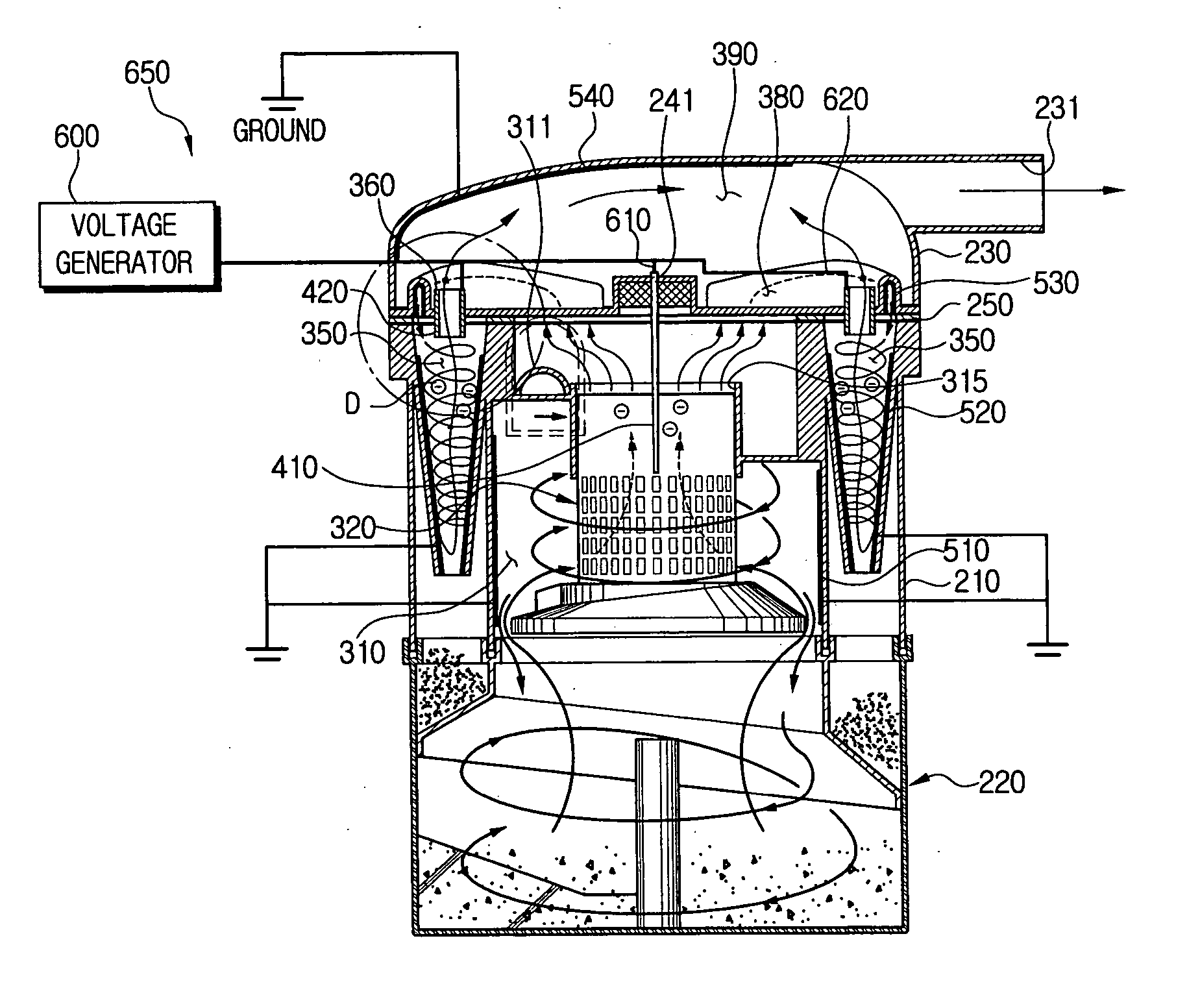

Cyclone dust collecting device for vacuum cleaner

InactiveUS20060278081A1Separation efficiency can be improvedIncreased durabilityCleaning filter meansSuction filtersCorona dischargeConductive materials

A cyclone dust collecting device using a corona discharge is provided. The cyclone dust collecting device includes a cyclone chamber rotating air drawn in from the outside to separate contaminants from the air, a discharge pipe guiding the air separated from the contaminants to the outside of the cyclone chamber and including a discharge electrode part with at least a part made of a conductive material and a power supply unit supplying a power to the discharge electrode part for the discharge electrode part to perform a corona discharge.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

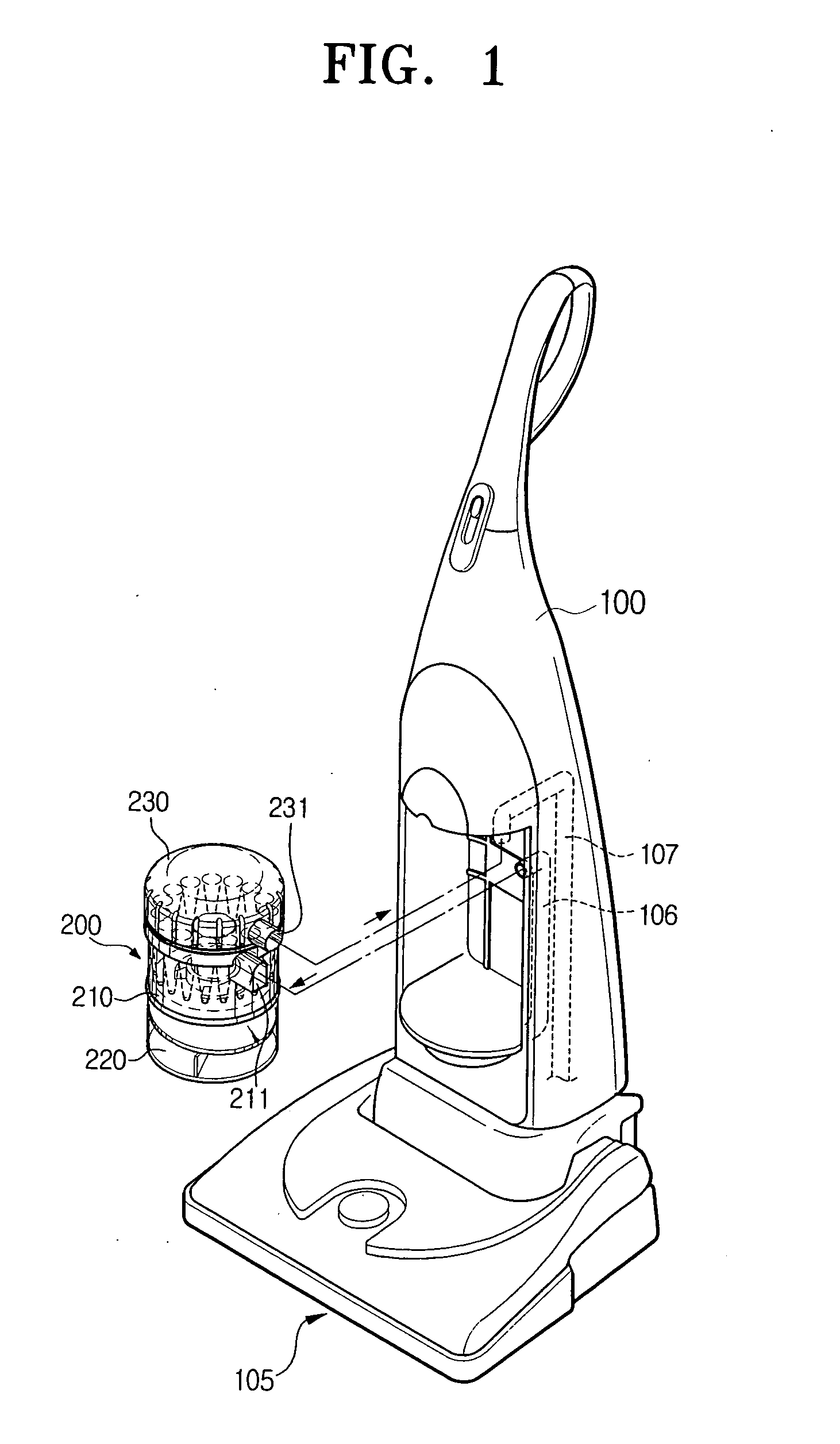

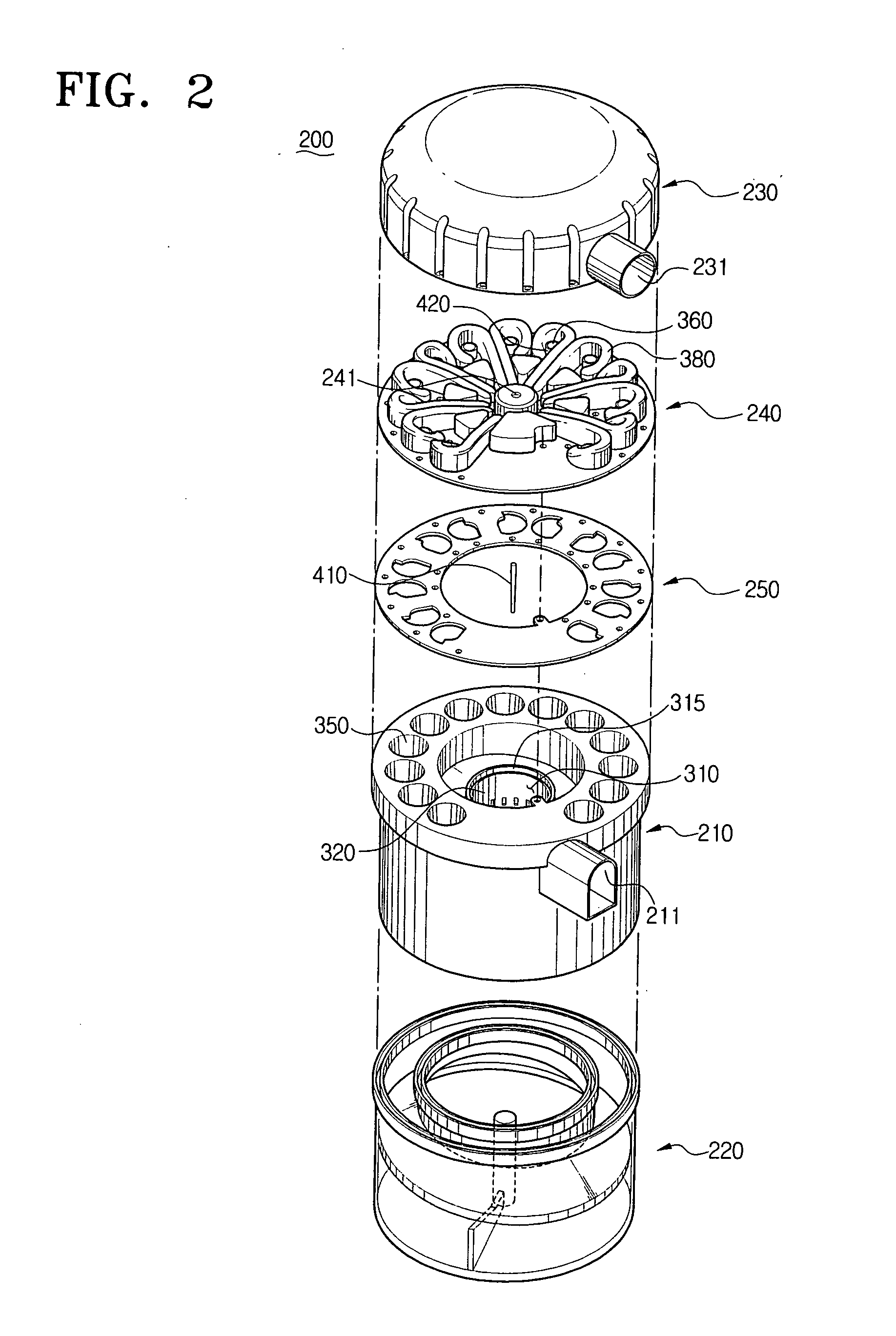

Cyclone dust separating apparatus for vacuum cleaner and vacuum cleaner having the same

ActiveUS20060230724A1Improved contaminant separation efficiencySmall sizeSuction filtersReversed direction vortexCycloneEngineering

A cyclone dust separating apparatus has a first cyclone chamber for separating particles from the externally-drawn fluid by centrifugal force, one or more second cyclone chambers for separating particles from the fluid discharged from the first cyclone chamber by centrifugal force, and one or more third cyclone chambers for separating particles from the fluid discharged from the second cyclone chambers, and causing the fluid to be discharged out via a discharge passage. The second and the third cyclone chambers are arranged in radial relation with respect to the first cyclone chamber, and thus, surround the first cyclone chamber. Therefore, the cyclone dust separating apparatus provides multi-stage centrifugal cleaning process and improved cleaning efficiency, while remaining compact-sized.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

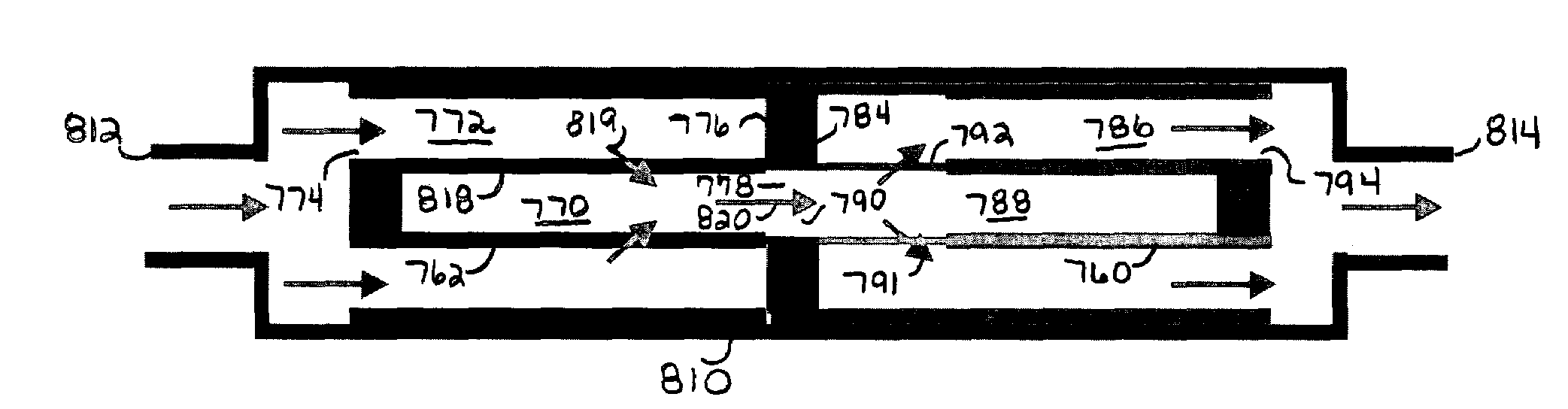

Method for reducing emissions from evaporative emissions control systems

InactiveUS6540815B1Loss in working capacityEmission reductionGas treatmentNon-fuel substance addition to fuelHigh concentrationSorbent

Disclosed is a method for sharply reducing diurnal breathing loss emissions from automotive evaporative emissions control systems by providing multiple layers, or stages, of adsorbents. On the fuel source-side of an emissions control system canister, high working capacity carbons are preferred in a first canister (adsorb) region. In subsequent canister region(s) on the vent-side, the preferred adsorbent should exhibit a flat or flattened adsorption isotherm on a volumetric basis and relatively lower capacity for high concentration vapors as compared with the fuel source-side adsorbent. Multiple approaches are described for attaining the preferred properties for the vent-side canister region. One approach is to use a filler and / or voidages as a volumetric diluent for flattening an adsorption isotherm. Another approach is to employ an adsorbent with the desired adsorption isotherm properties and to process it into an appropriate shape or form without necessarily requiring any special provision for dilution. The improved combination of high working capacity carbons on the fuel source-side and preferred lower working capacity adsorbent on the vent-side provides substantially lower diurnal breathing emissions without a significant loss in working capacity or increase in flow restriction compared with known adsorbents used in canister configurations for automotive emissions control systems.

Owner:INGEVITY SOUTH CAROLINA

Dust collection unit and vacuum cleaner with the same

ActiveUS20060137309A1Improve foreign object removal efficiencyEasy to disassembleCombination devicesAuxillary pretreatmentForeign matterForeign object

A dust collection unit for a vacuum cleaner includes a first filtering chamber filtering foreign objects using a cyclone airflow, a separation plate defining a top surface of the first filtering chamber, a filter having a diameter that is reduced as it goes downward in response to airflow rate variation in the first filtering chamber, and a blocking member provided under the filter to prevent the foreign objects filtered in the first filtering chamber from flying.

Owner:LG ELECTRONICS INC

Filter assembly and cyclone dust collecting apparatus having the same

InactiveUS20060236663A1Improve suction capacityImprove liquidityCleaning filter meansCombination devicesCyclonePerpendicular direction

A filter assembly and a cyclone dust collecting apparatus using the same are provided. The filter assembly is employed by a cyclone dust collecting apparatus which centrifugally separates contaminant from drawn-in air to remove the contaminant and filters and discharges the air and has a filter part, and an air path. The air path is formed in the filter part to guide the air into the filter part and enables the air to flow in a three-dimensional direction, in other words, in a perpendicular direction to a central axis of the filter part, simultaneously flow in a parallel direction with the central axis of the filter part.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

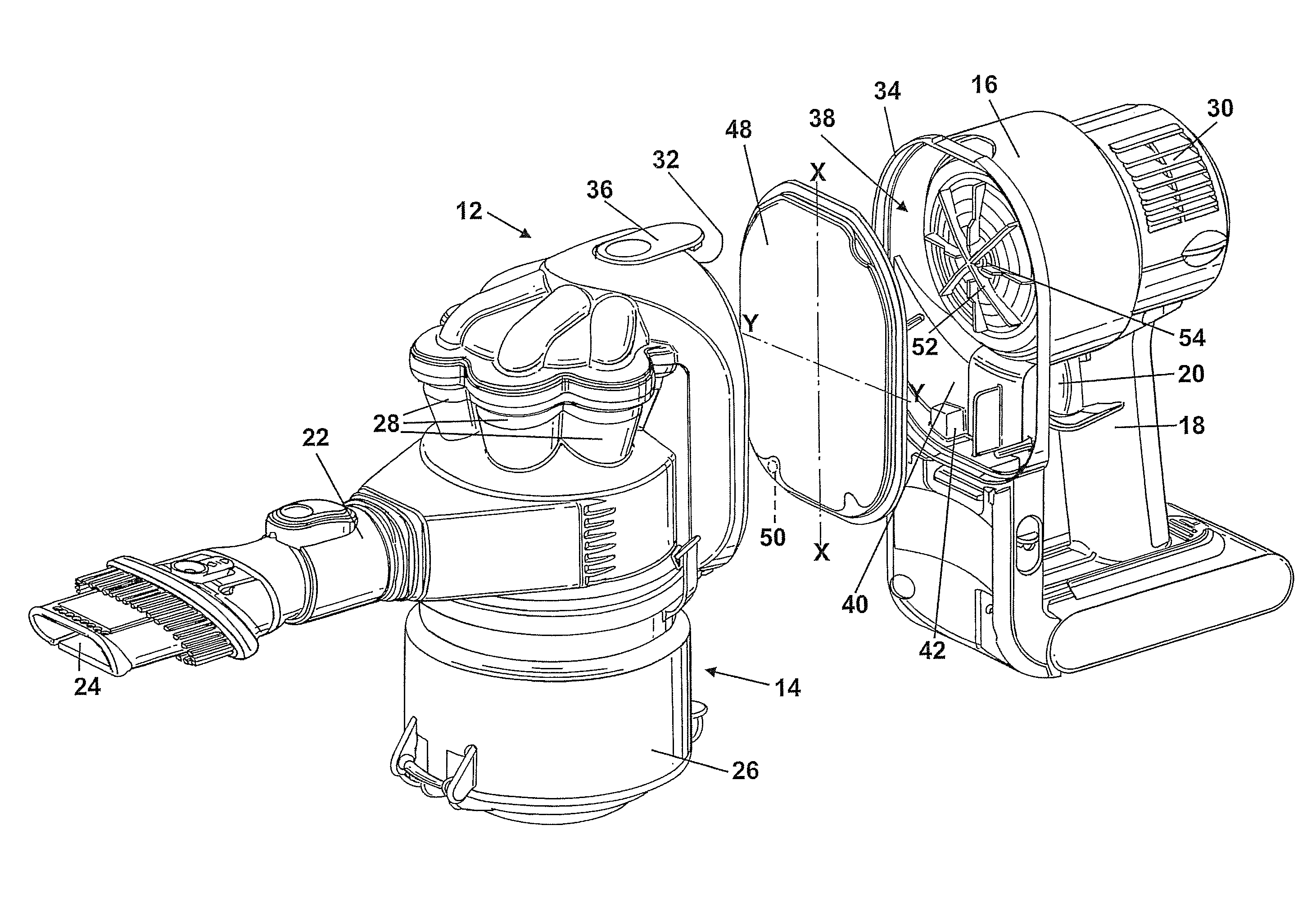

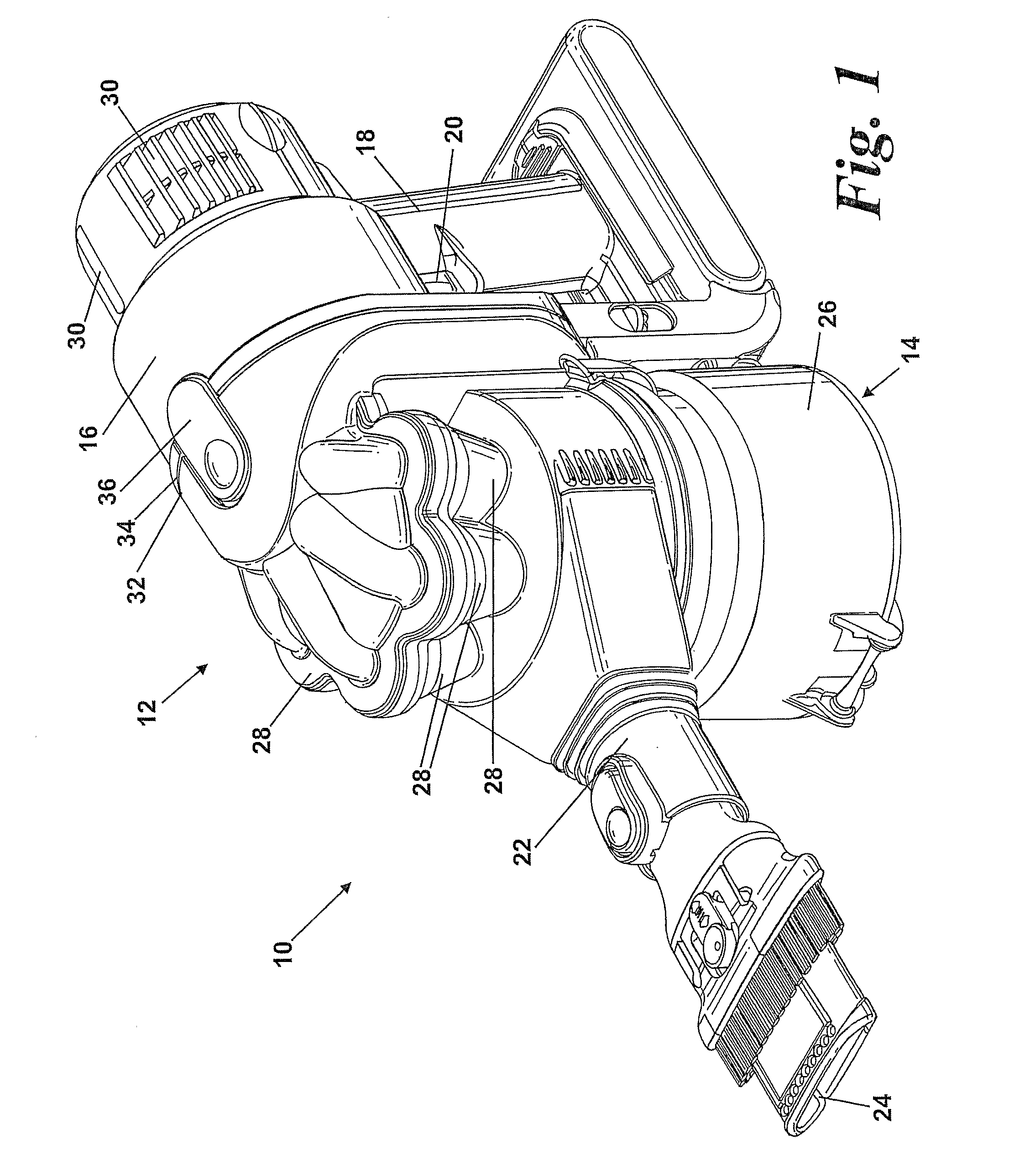

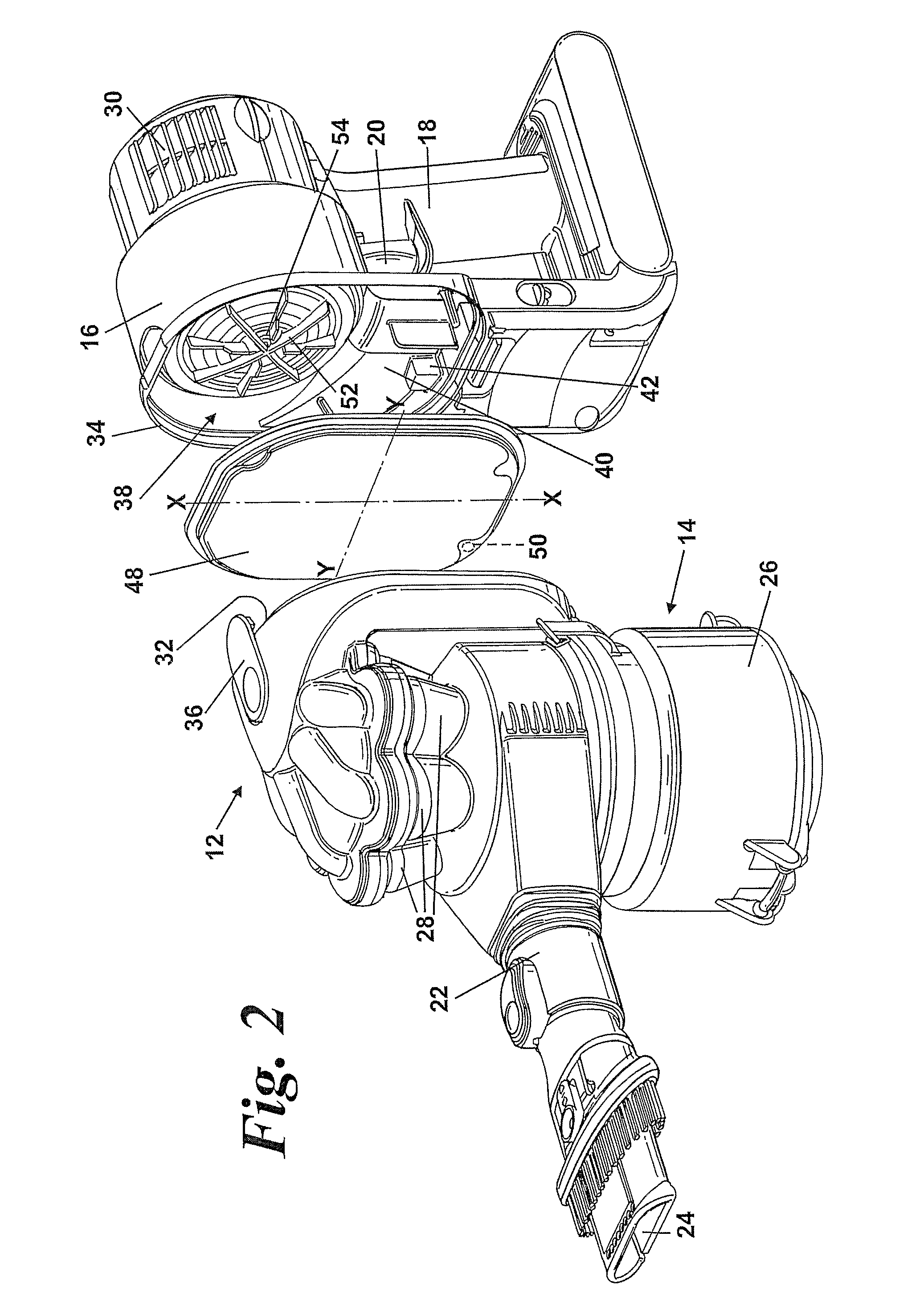

Handheld cleaning appliance

InactiveUS7931716B2Reduce cloggingLess prone to failureCombination devicesAuxillary pretreatmentHand heldWaste management

A cleaning appliance includes a main body, a filter and an interlock. The main body includes an airflow generator, a separating apparatus separating dirt and dust from an airflow, and a flowpath between the separating apparatus and the airflow generator delimited by a wall. The interlock has a first part located on the filter and a second part located on the main body outside the flowpath, arranged to communicate remotely when the filter is correctly located in the pre-determined position. The interlock is arranged selectively to allow or prevent operation of the airflow generator depending upon the relative separation between the first and second parts. By providing an interlock which has first and second parts which communicate remotely, the second part located on the main body can be isolated from the airflow path so that the second part is not subject to dirt and dust carried by the airflow.

Owner:DYSON TECH LTD

Honeycomb structure

ActiveUS20060230732A1Light weightSmall heat capacityDispersed particle filtrationOther chemical processesApparent densityYoung's modulus

A honeycomb structure including a plurality of porous ceramic members which are bonded through an adhesive layer, each of the porous ceramic members has a plurality of cells, which are arranged in parallel while being separated by cell walls. The cells extend in a longitudinal direction of the honeycomb structure. In the honeycomb structure, the following relationship is satisfied: 2≦B≦100 / 3×A−10 / 3 (1) where A (g / cm3) designates apparent density of the porous ceramic members, and B (GPa) designates Young's modulus of the adhesive layer.

Owner:IBIDEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com