Patents

Literature

136results about How to "Improve suction capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

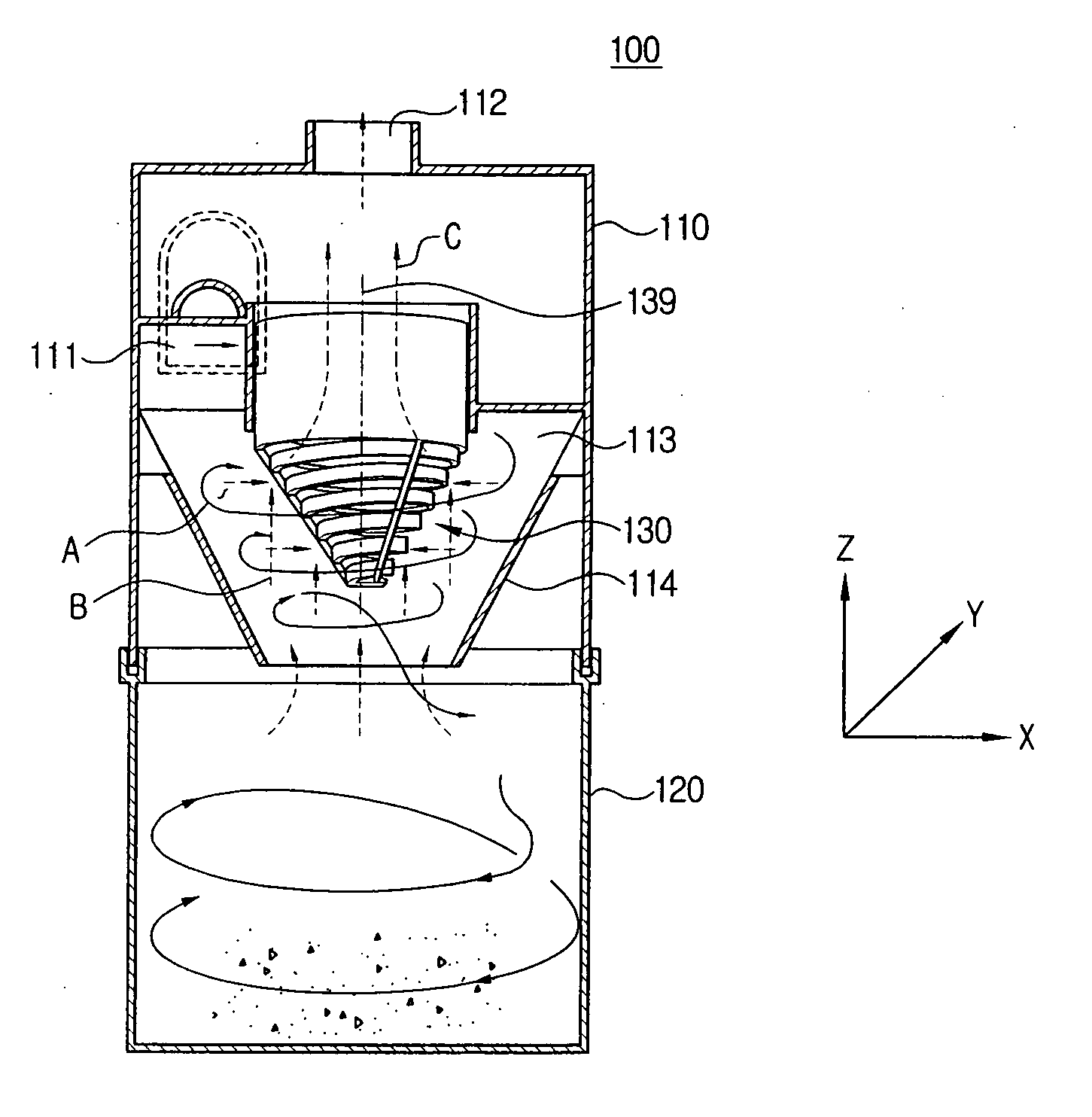

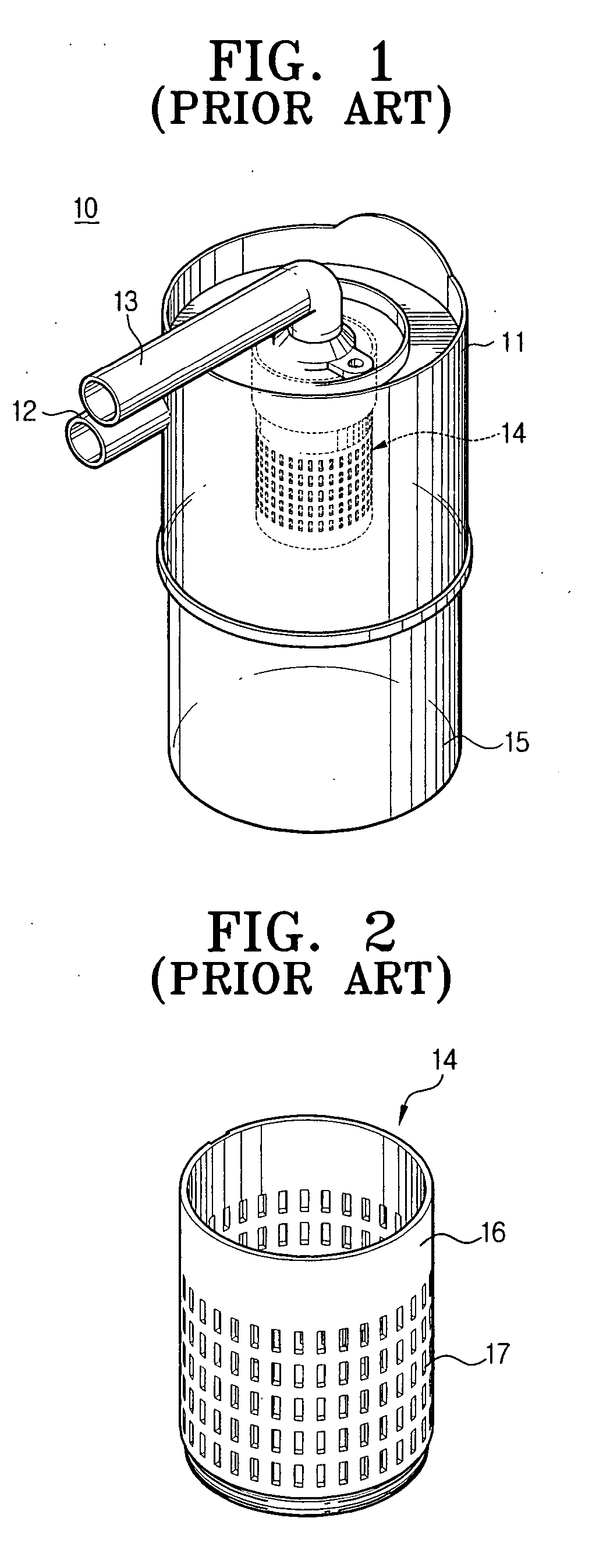

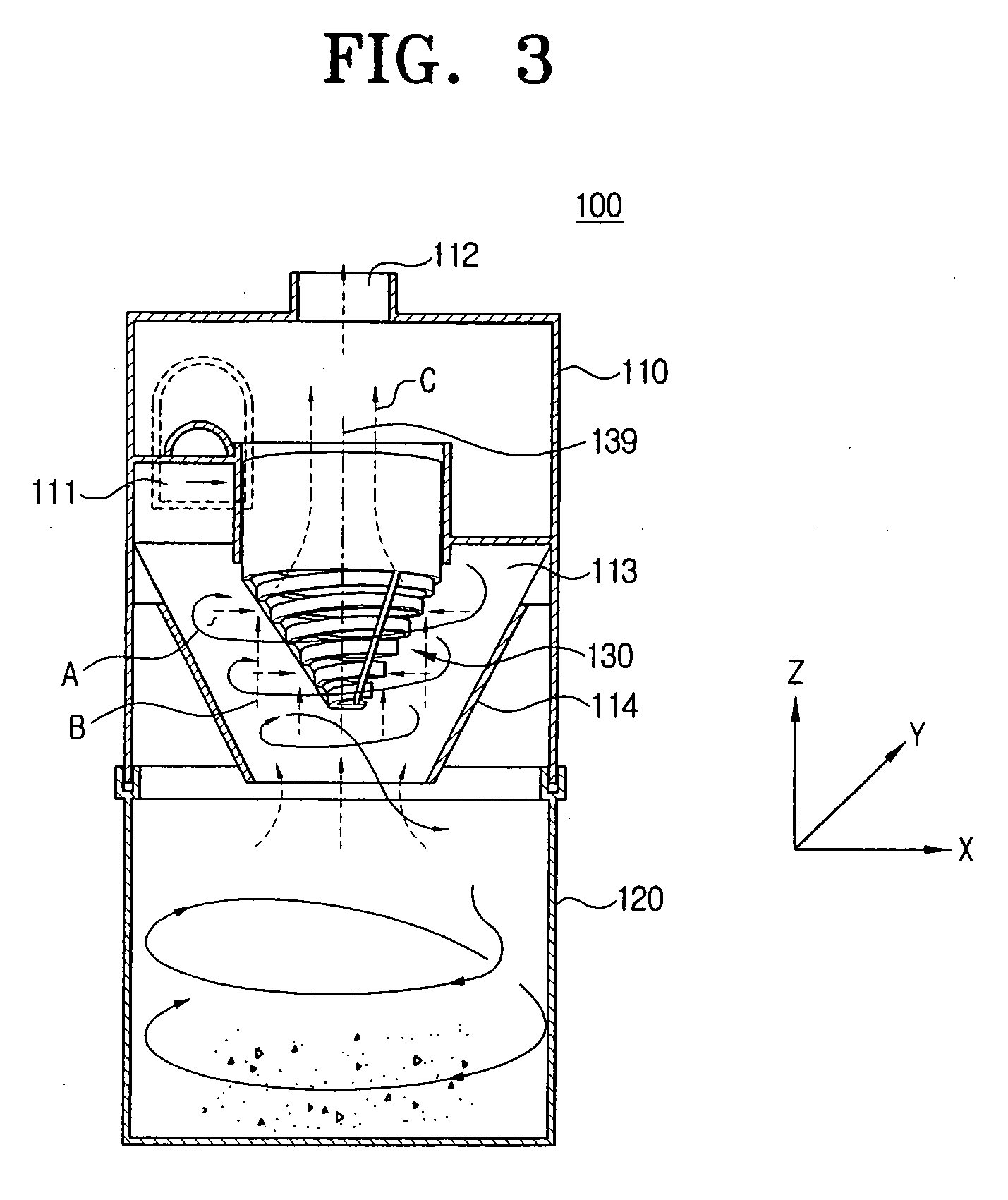

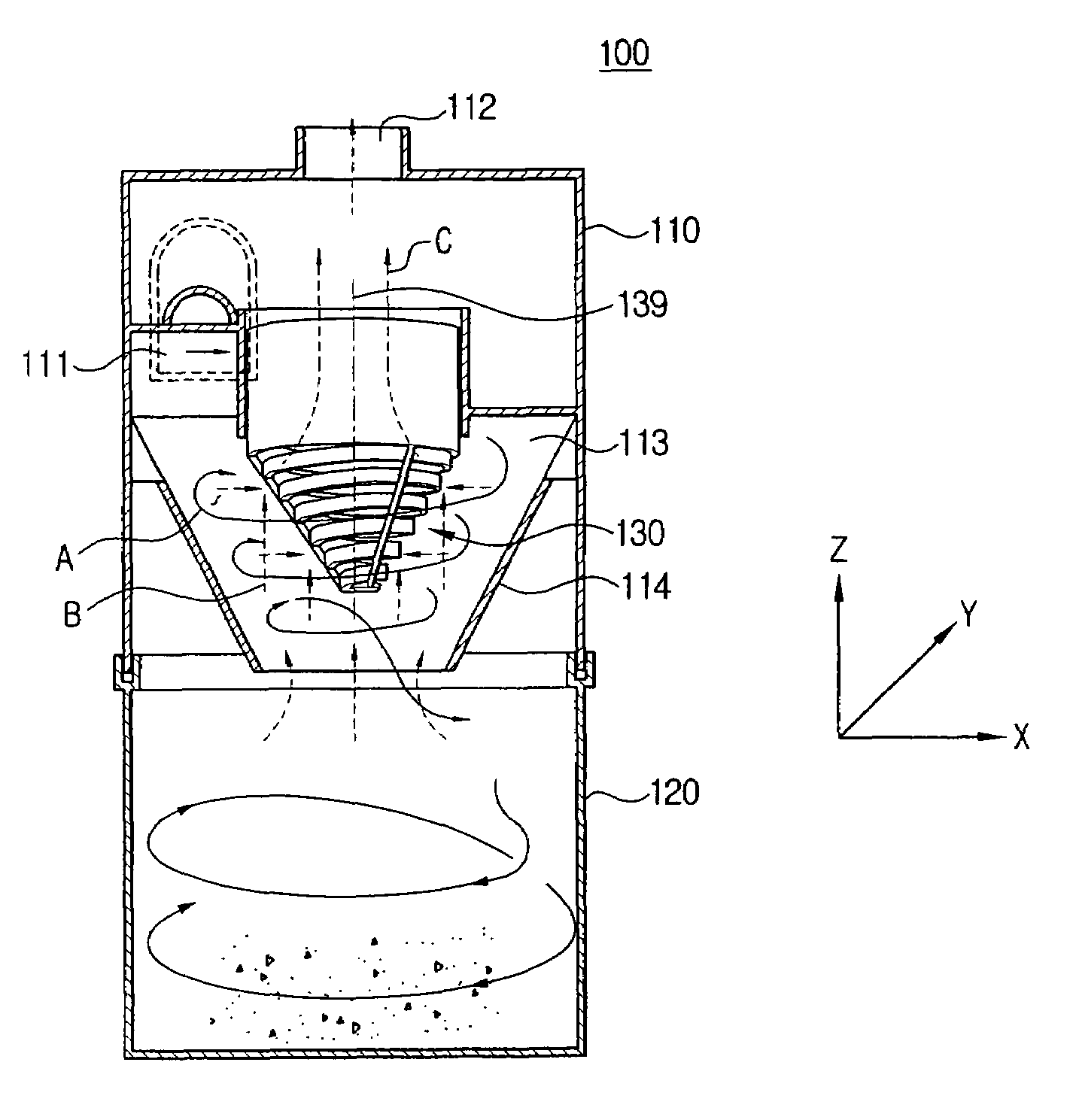

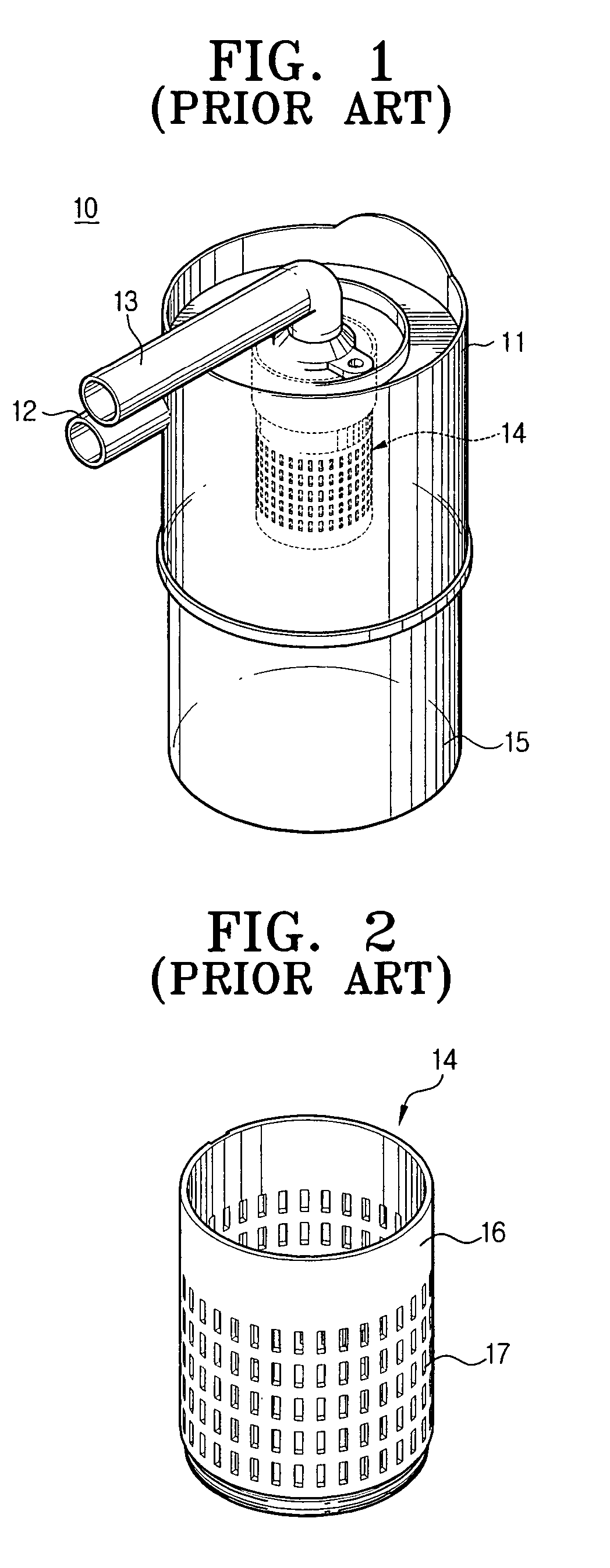

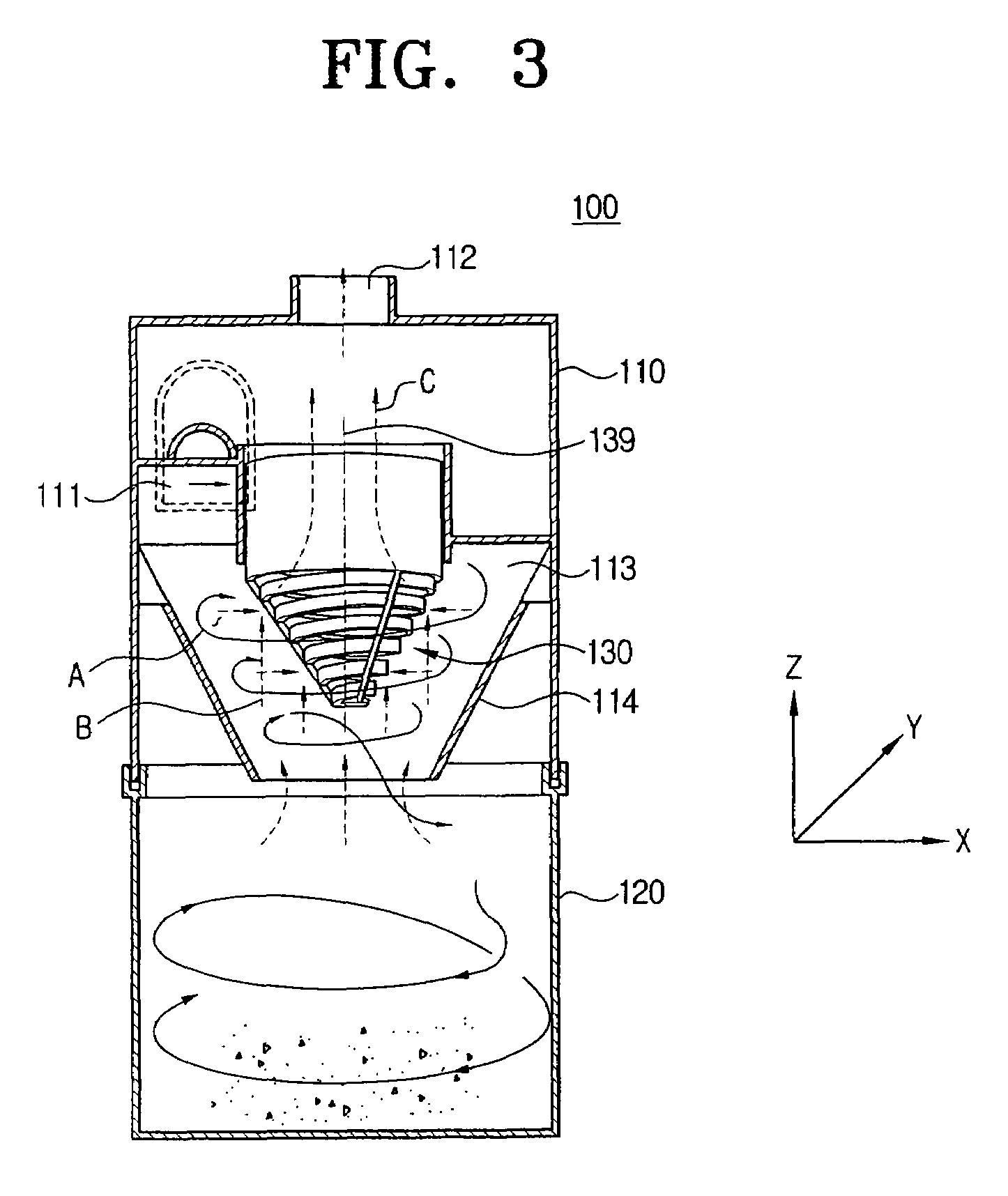

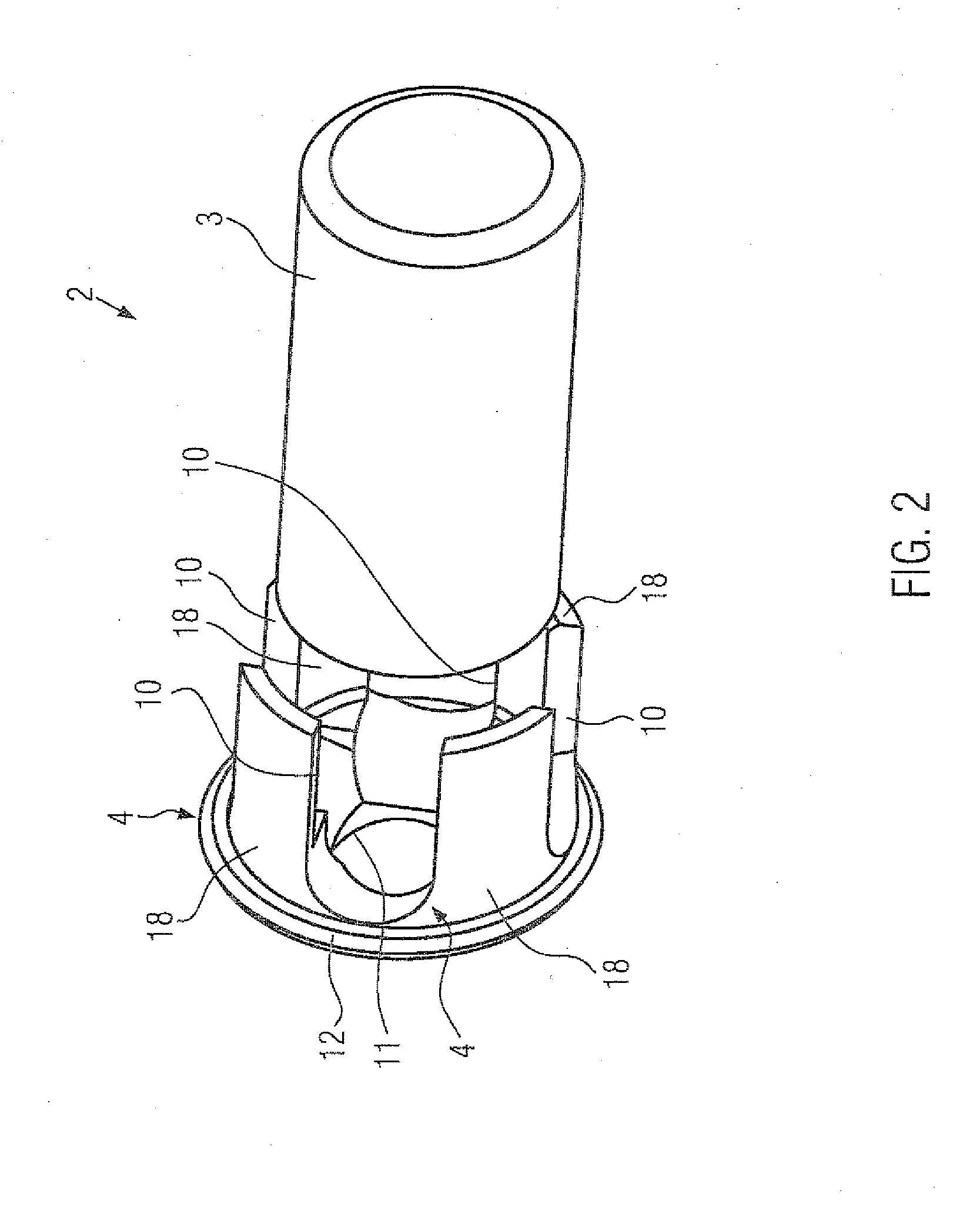

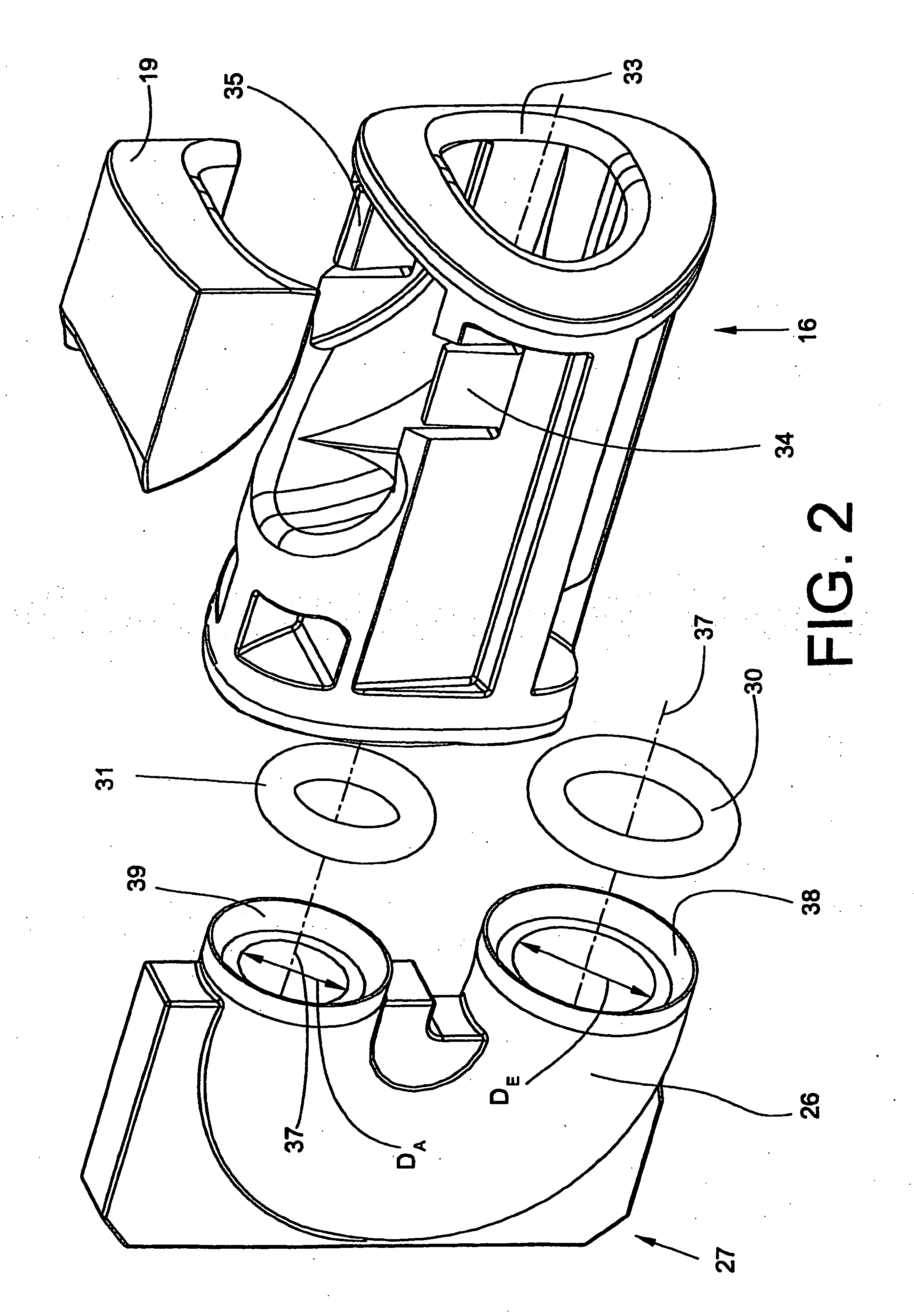

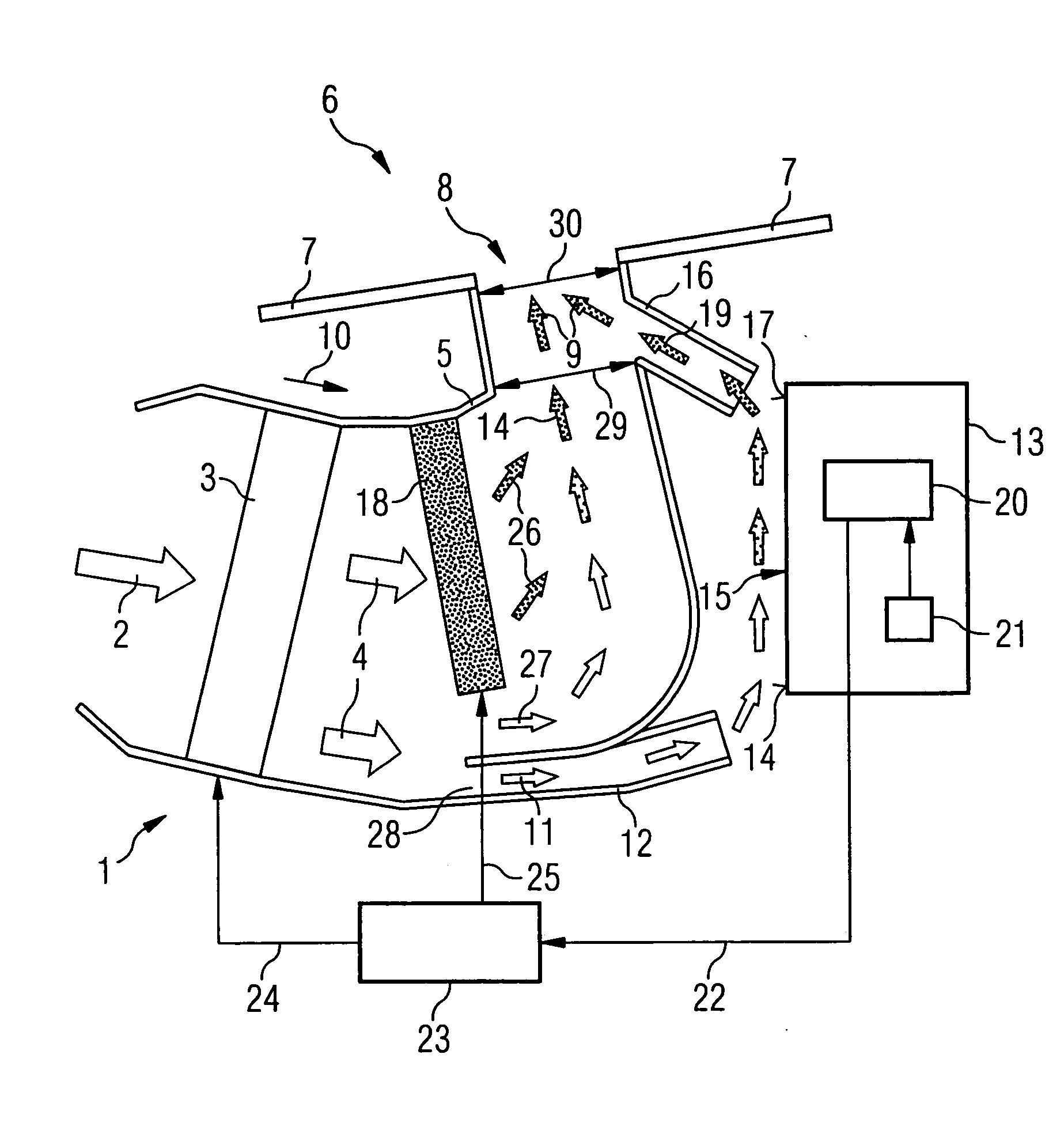

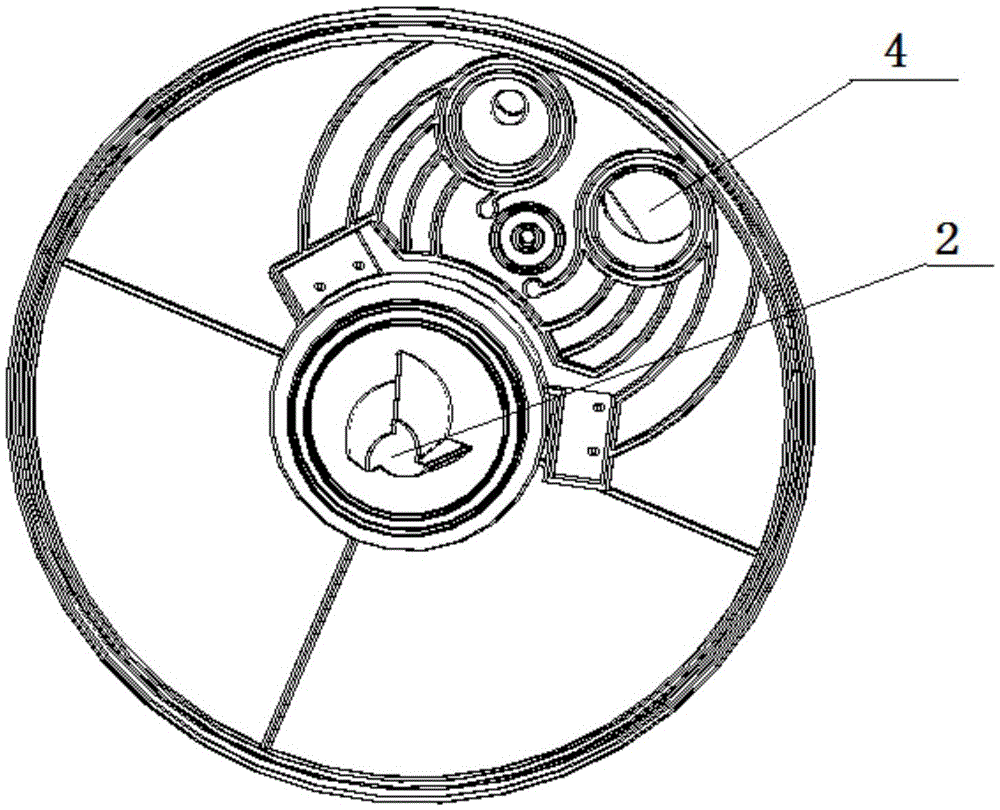

Filter assembly and cyclone dust collecting apparatus having the same

InactiveUS20060236663A1Improve suction capacityImprove liquidityCleaning filter meansCombination devicesCyclonePerpendicular direction

A filter assembly and a cyclone dust collecting apparatus using the same are provided. The filter assembly is employed by a cyclone dust collecting apparatus which centrifugally separates contaminant from drawn-in air to remove the contaminant and filters and discharges the air and has a filter part, and an air path. The air path is formed in the filter part to guide the air into the filter part and enables the air to flow in a three-dimensional direction, in other words, in a perpendicular direction to a central axis of the filter part, simultaneously flow in a parallel direction with the central axis of the filter part.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

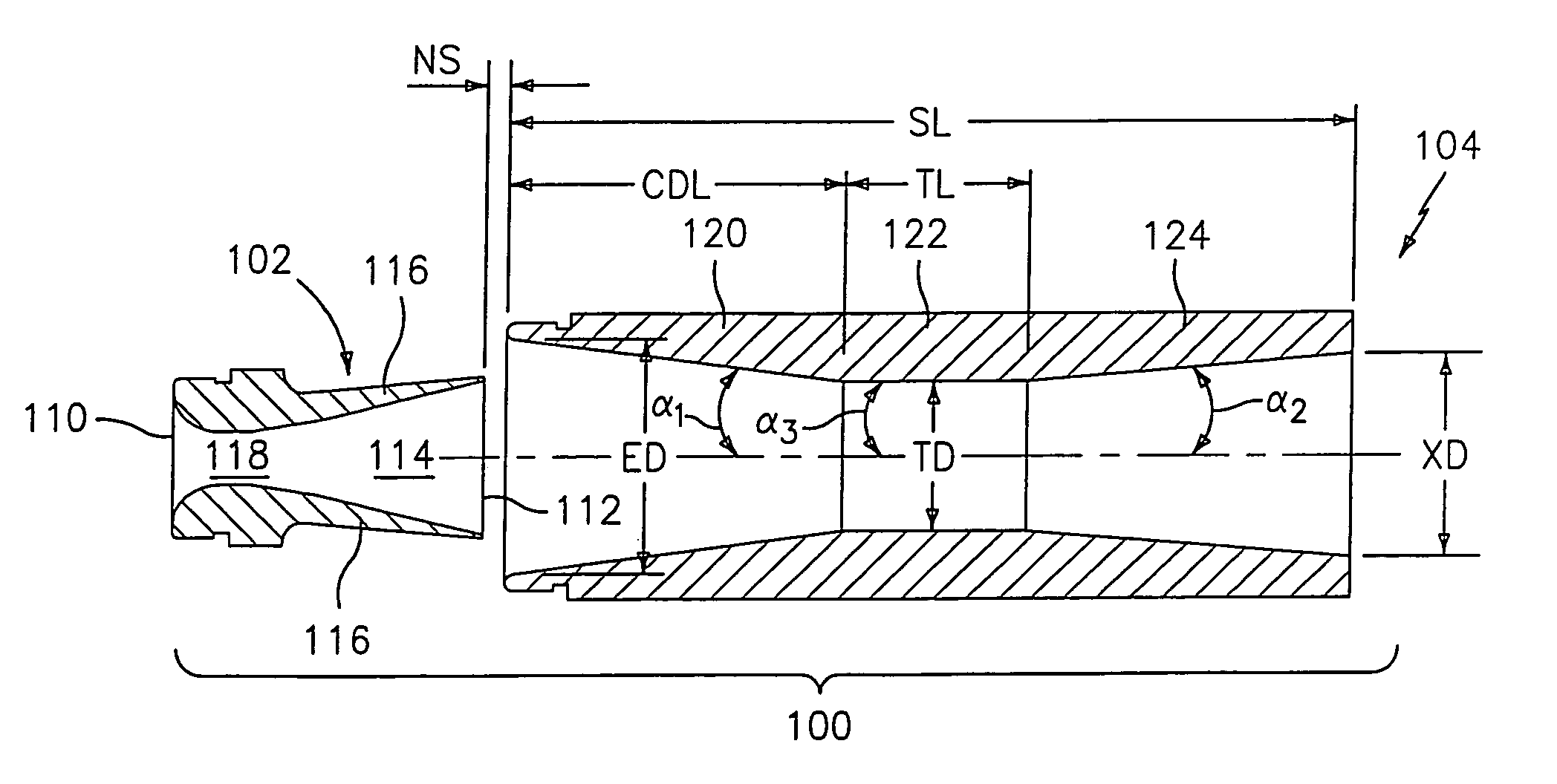

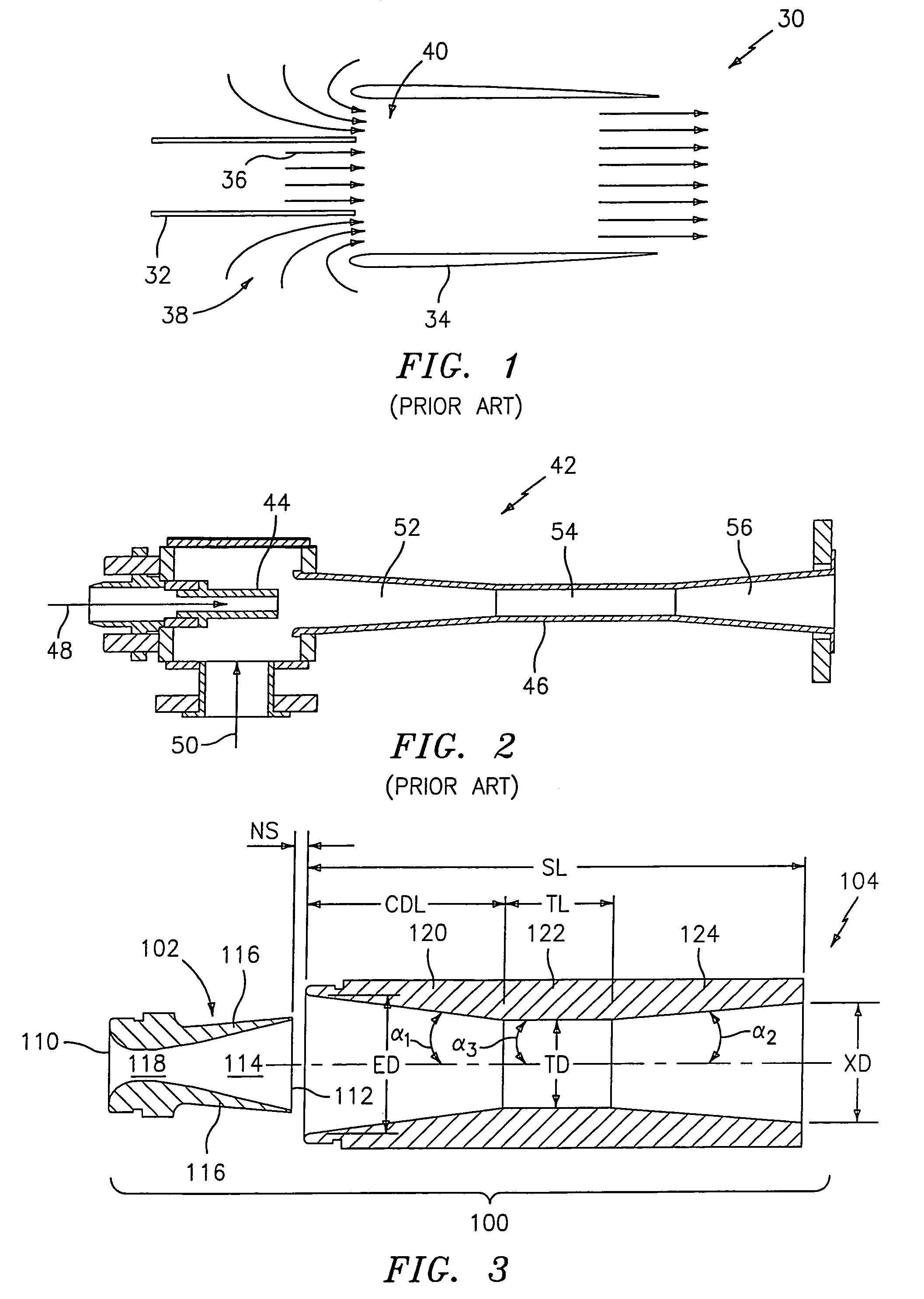

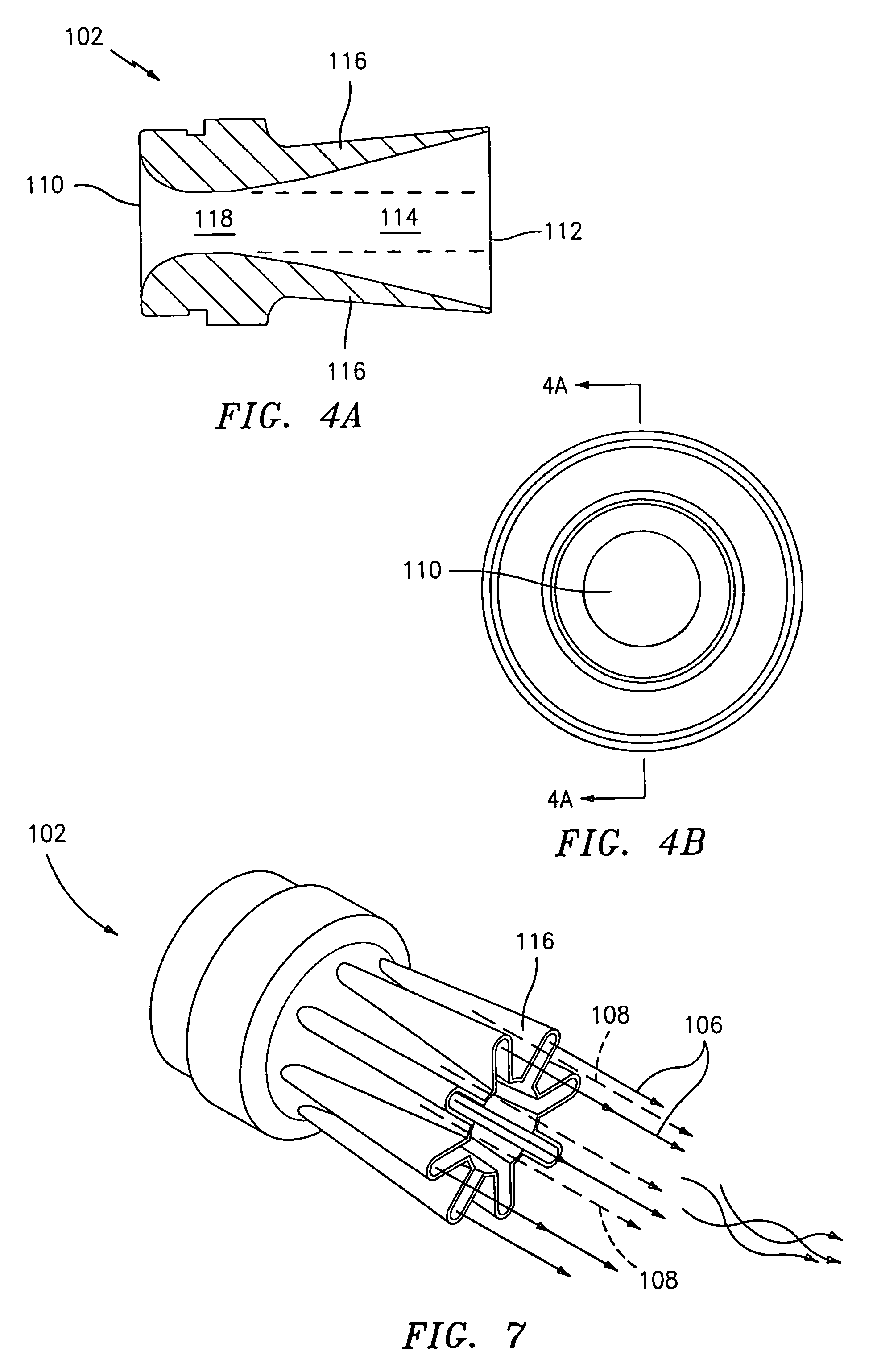

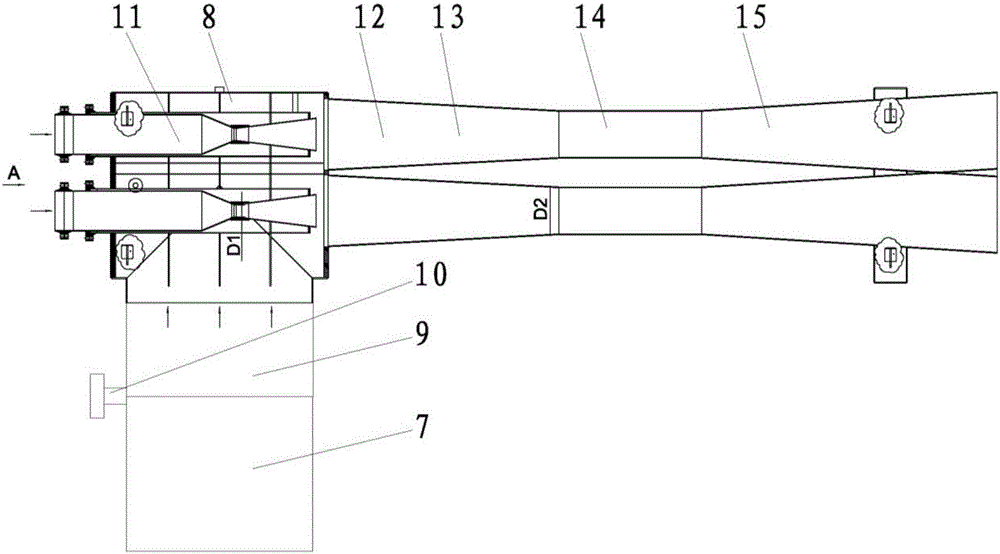

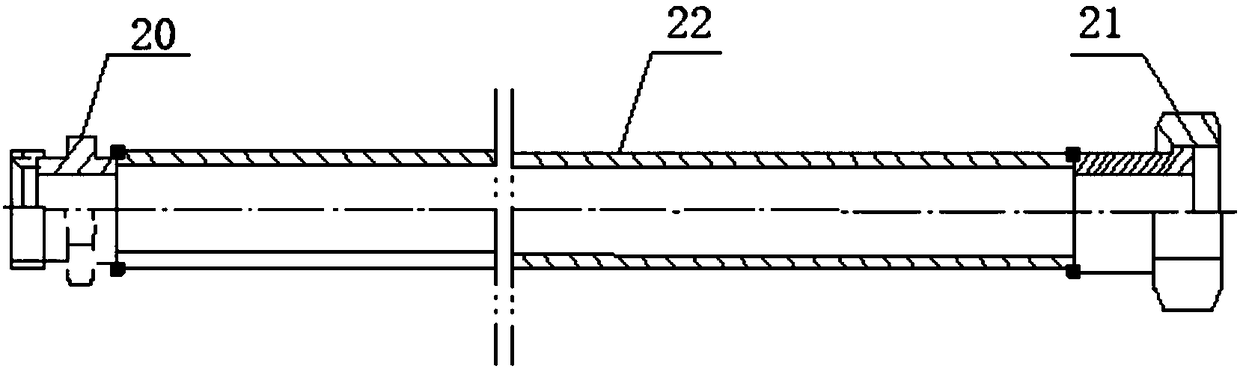

Lobed convergent/divergent supersonic nozzle ejector system

InactiveUS6877960B1Smaller length-to-entrance-diameter ratioIncrease flow pressureJet pumpsMachines/enginesDiameter ratioHigh pressure

An ejector system comprises a lobed, supersonic primary nozzle and a convergent / divergent ejector shroud. The lobed nozzle is just upstream from the ejector shroud, such that there is an annular space between the nozzle and shroud for admitting a secondary flow. In operation, a primary flow of high-pressure steam or air is directed through the primary nozzle, where it is accelerated to supersonic speed. The primary flow then exits the primary nozzle, where it entrains and is mixed with the secondary flow, creating a low pressure region or vacuum. The ejector shroud subsequently decelerates the combined flow while increasing the flow pressure, which increases suction performance and reduces energy loss. Because the primary nozzle mixes the two flows, the ejector shroud is able to have a length-to-entrance-diameter ratio significantly smaller than typical shrouds / diffusers, which decreases the system's size and increases performance.

Owner:FLODESIGN WIND TURBINE

Pleated filter made of a multi-layer filter medium

InactiveUS6488731B2Improve suction capacityHigh of circulationCleaning filter meansCombination devicesFilter mediaEngineering

The present invention relates to a pleated filter made of a multi-layer filter medium, including at least one filter paper layer having area weights of 30-100 g / m2, a microfiber nonwoven fabric layer having area weights 5-120 g / m2 and a support nonwoven fabric layer made of synthetic, polymeric fibers having area weights of 10-120 g / m2. The layers of the pleated filter contain fused polymer areas by which the fabric layers are bonded to the paper layer, and by which the fabric layers are made firmer within themselves. When subject to a fractional efficiency test at an initial pressure difference of at most 180 Pa, at a boundary speed of approximately 2.62 m / s and a flow speed through the filter medium of approximately 0.13 m / s, the pleated filter is able to separate at least 90% of particles greater than 0.3 mum, at least 92% of particles greater than 0.5 mum, at least 93% of particles greater than 1 mum, and at least 97% of particles greater than 3 mum, as measured using the standard method DIN EN 60312 (IEC 60312) § 5.1.2.5.

Owner:CARL FREUDENBERG KG

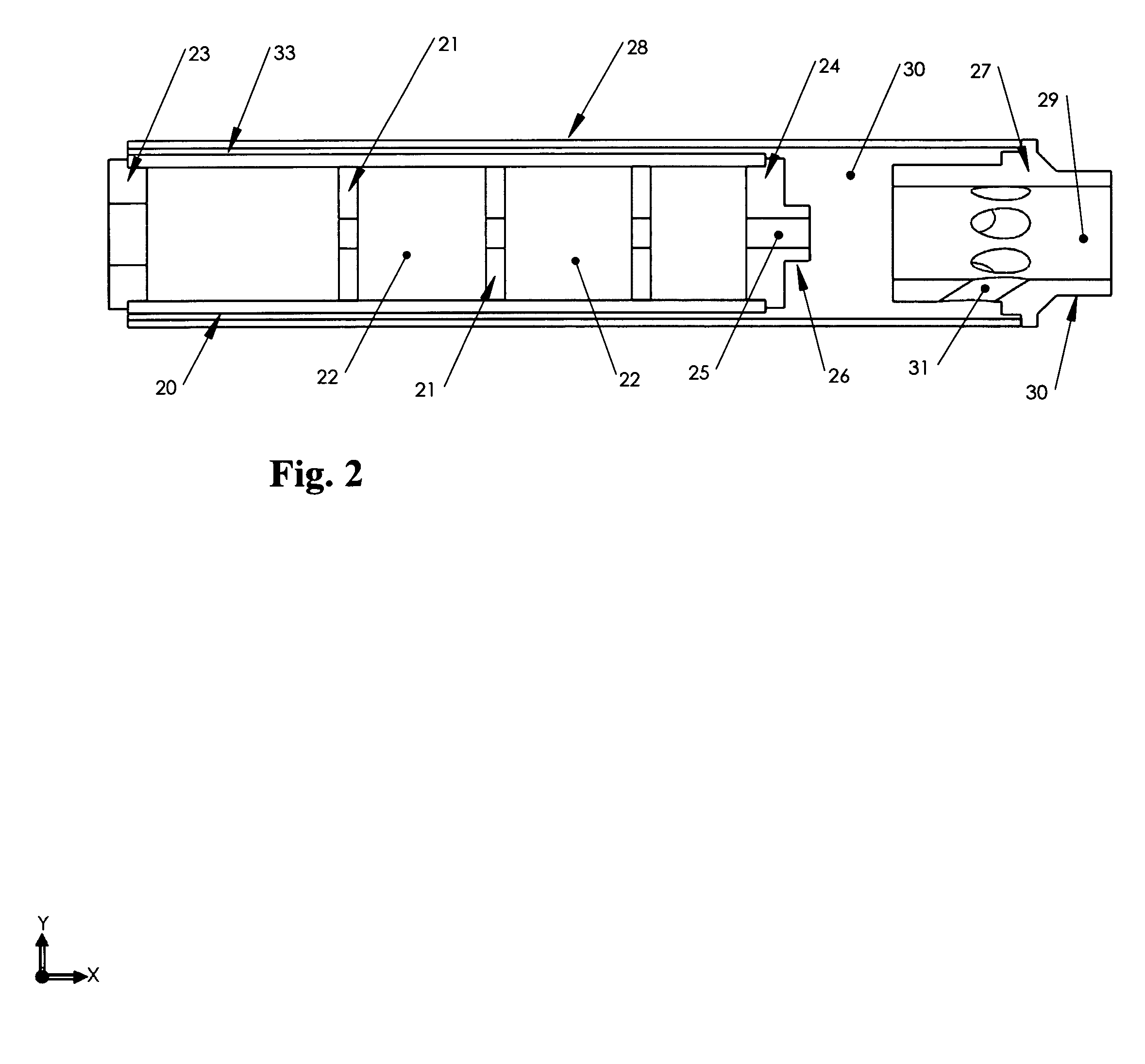

Sound suppressor cooling system

InactiveUS8967325B1Speed up the flowImprove cooling effectVentillation systemsBarrelsSuppressorSpray nozzle

A firearm sound suppressor cooling system comprising a sound suppressor housing with means for reducing the pressure of gases exiting from a discharged firearm with a shroud that is attached to the exterior of the sound suppressor housing, an annular chamber formed between the sound suppressor housing and the shroud, and a nozzle positioned at the distal end of the sound suppressor and the shroud. The nozzle produces a suction effect upon discharge of the firearm and due to the suction effect, ambient air is aspirated through the annular chamber, and cools the firearm sound suppressor.

Owner:CRONHELM PETER WILLIAM

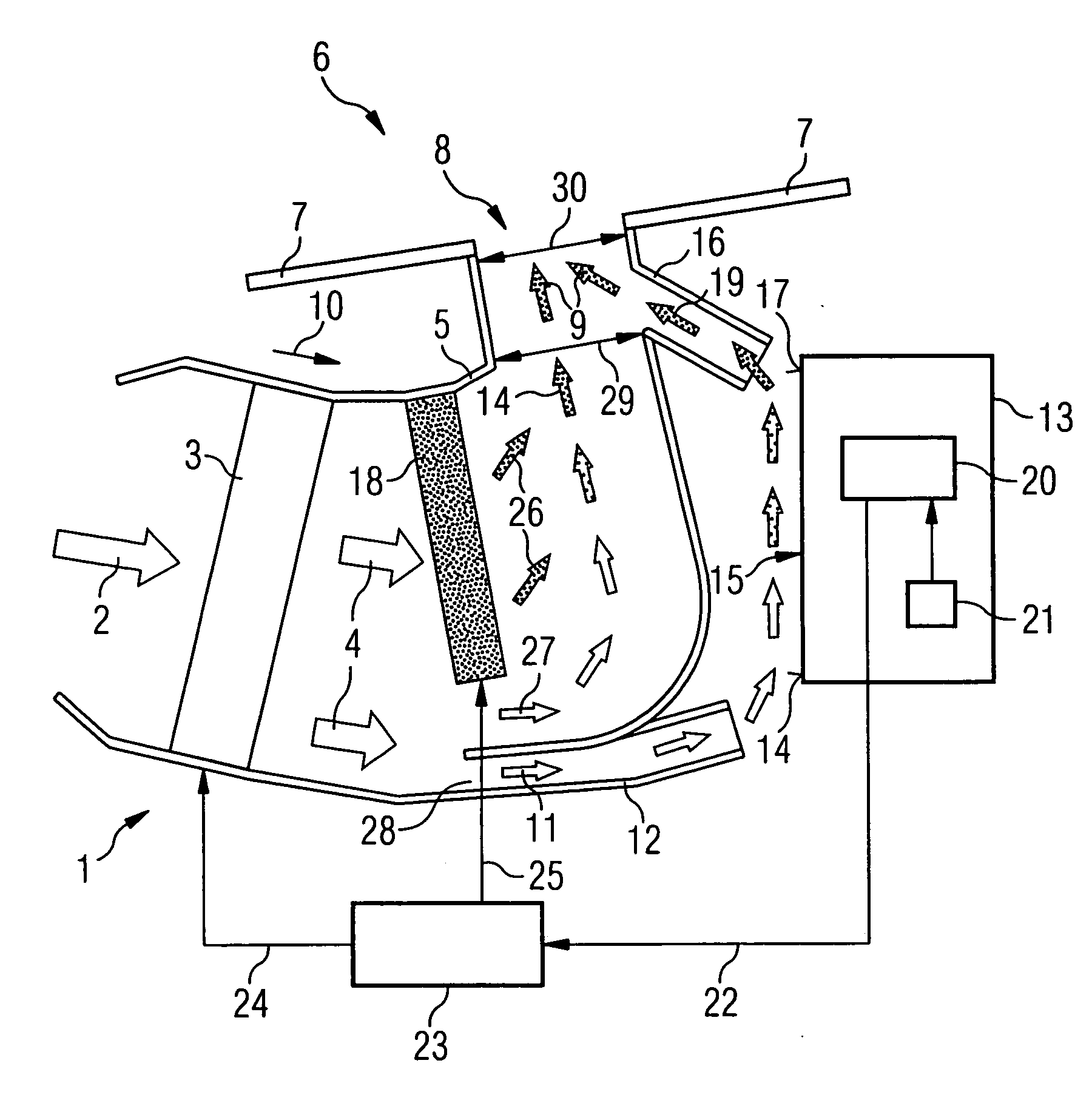

Filter assembly and cyclone dust collecting apparatus having the same

InactiveUS7615089B2Improve suction capacityImprove liquidityCleaning filter meansCombination devicesCyclonePerpendicular direction

A filter assembly and a cyclone dust collecting apparatus using the same are provided. The filter assembly is employed by a cyclone dust collecting apparatus which centrifugally separates contaminant from drawn-in air to remove the contaminant and filters and discharges the air and has a filter part, and an air path. The air path is formed in the filter part to guide the air into the filter part and enables the air to flow in a three-dimensional direction, in other words, in a perpendicular direction to a central axis of the filter part, simultaneously flow in a parallel direction with the central axis of the filter part.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

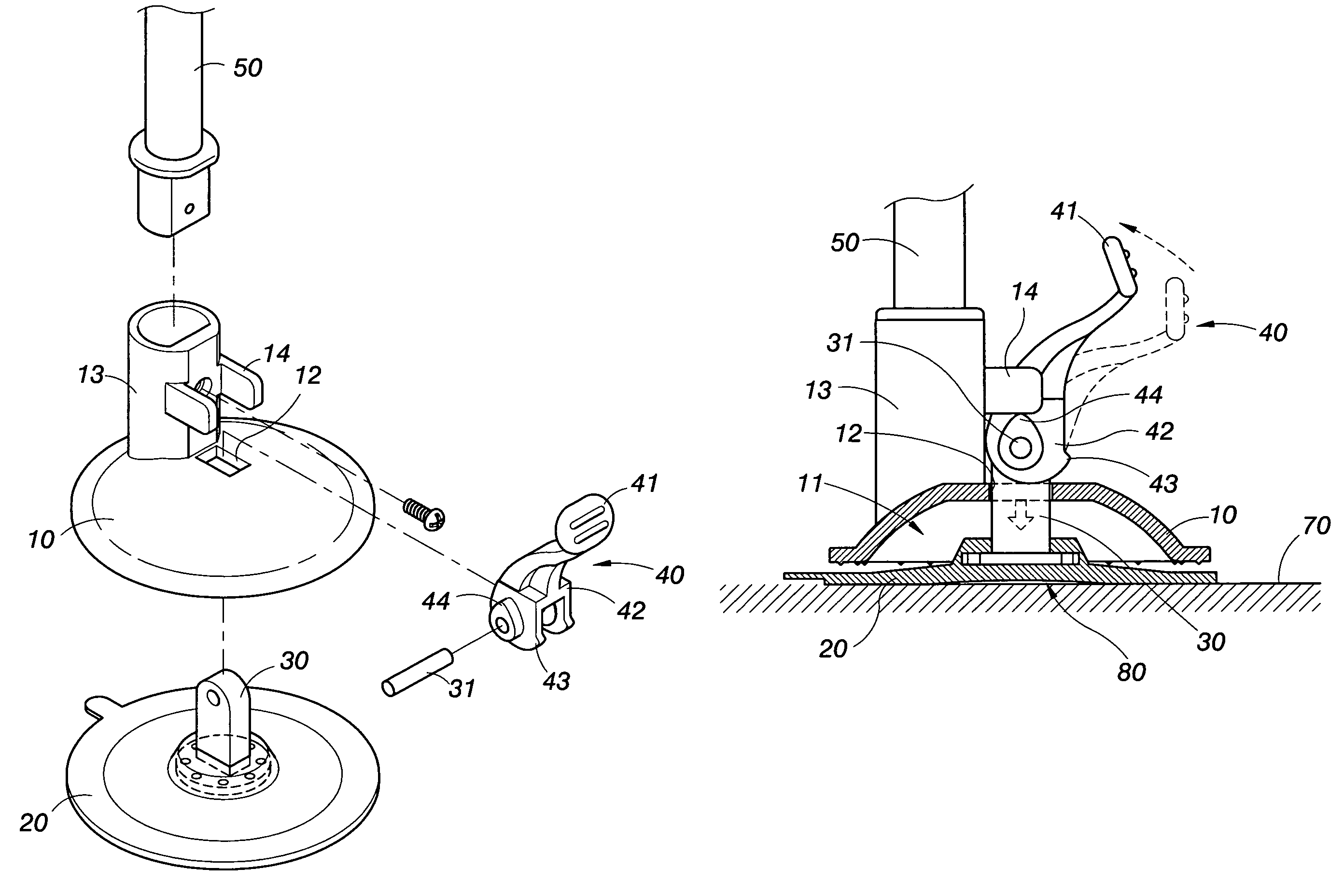

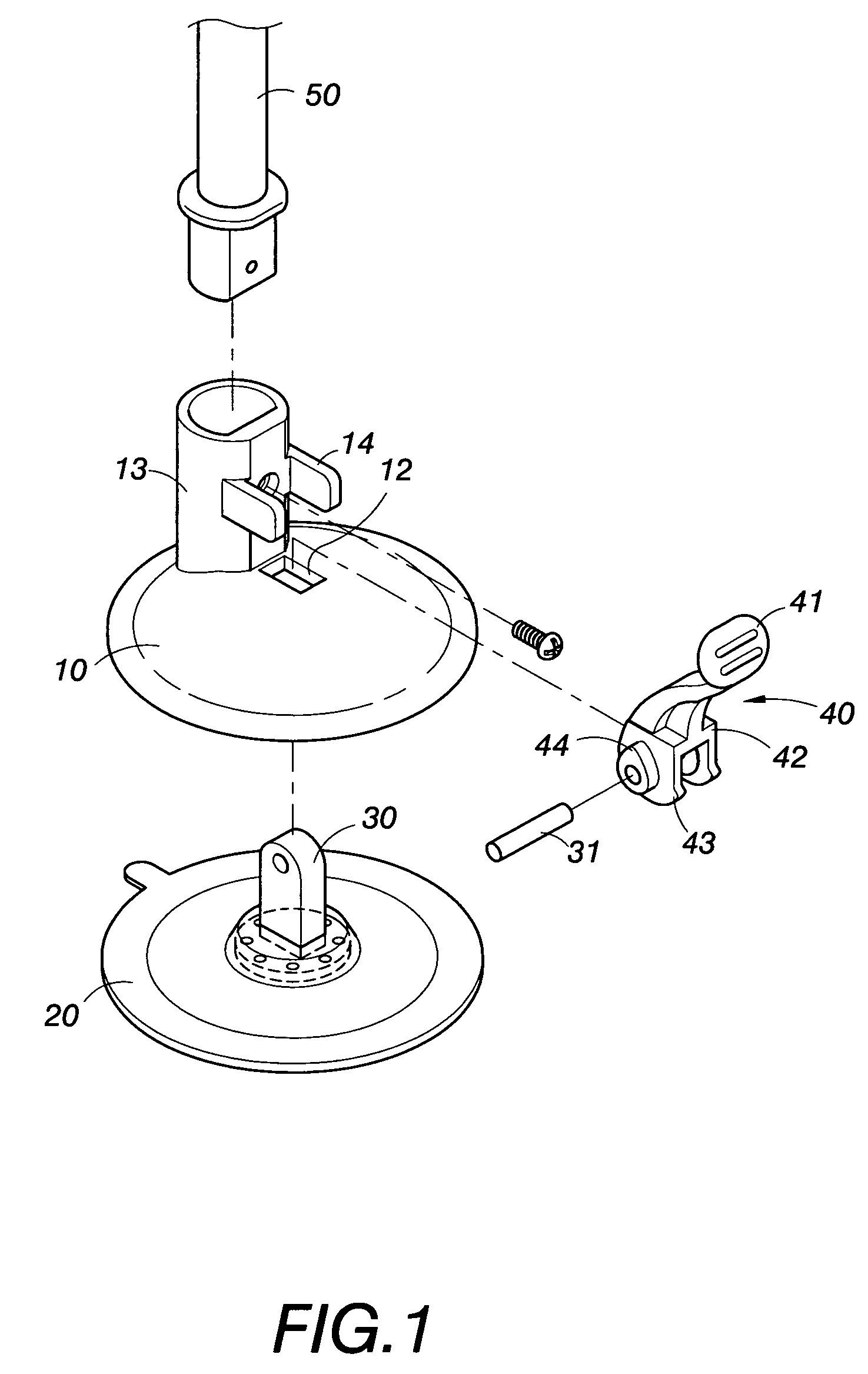

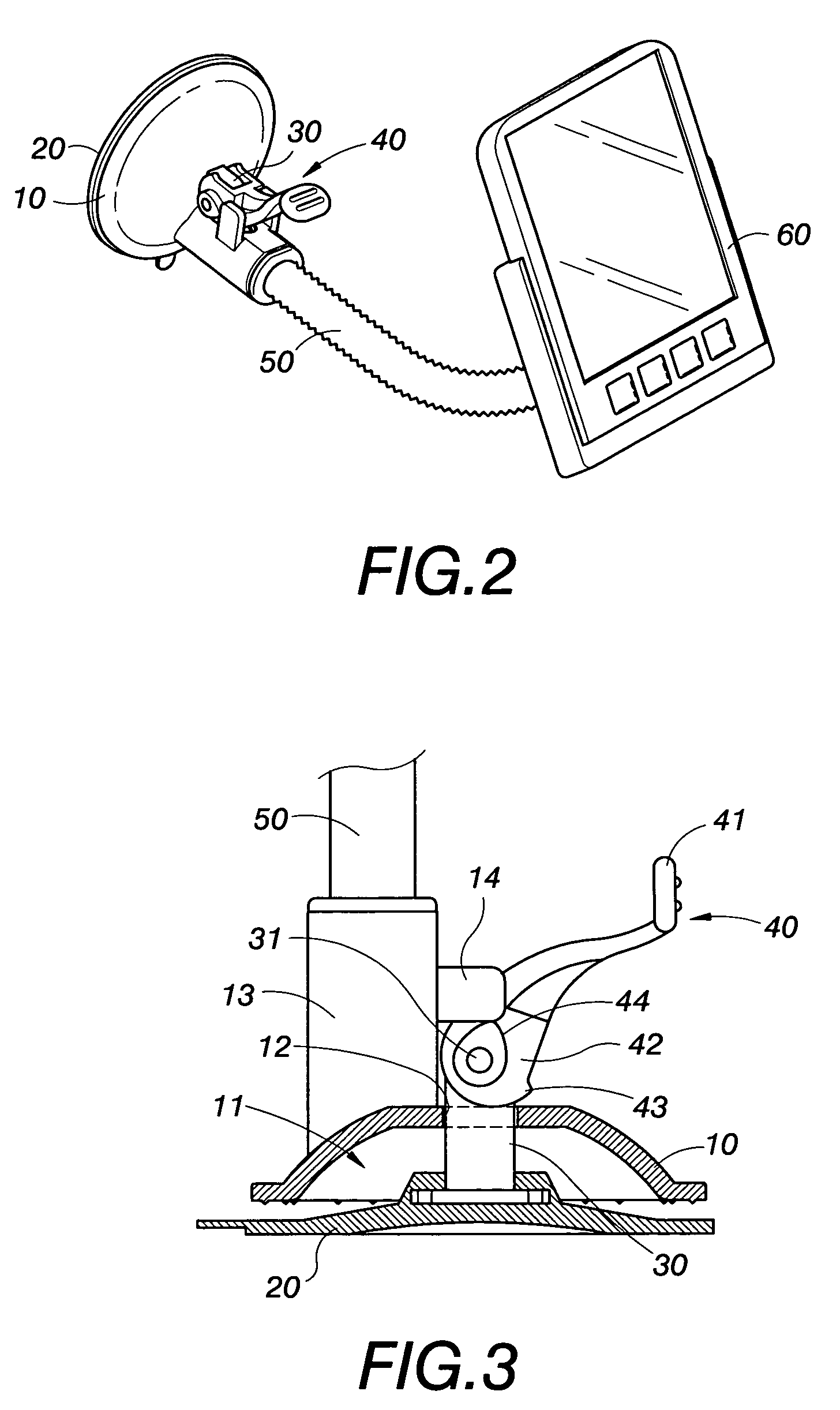

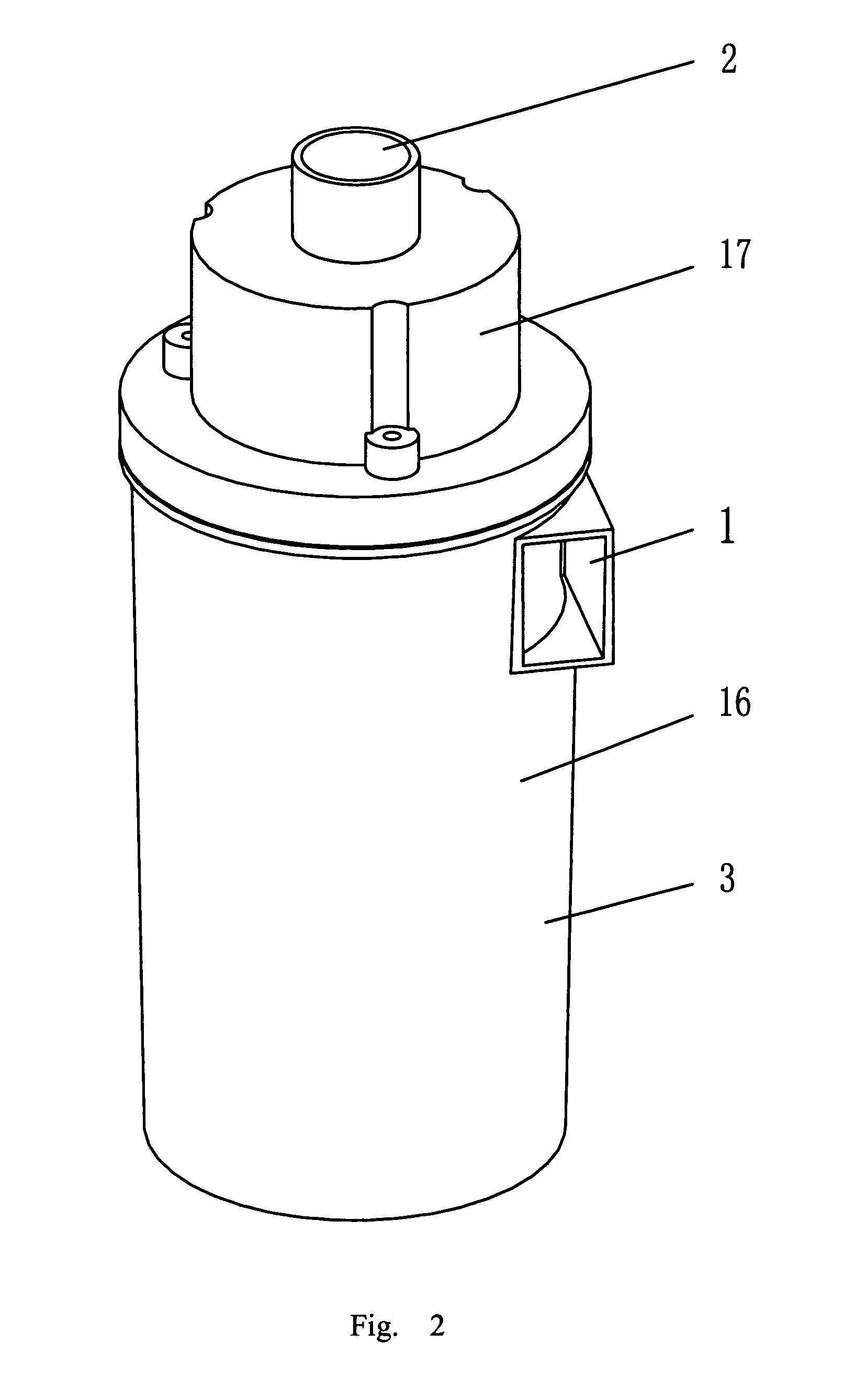

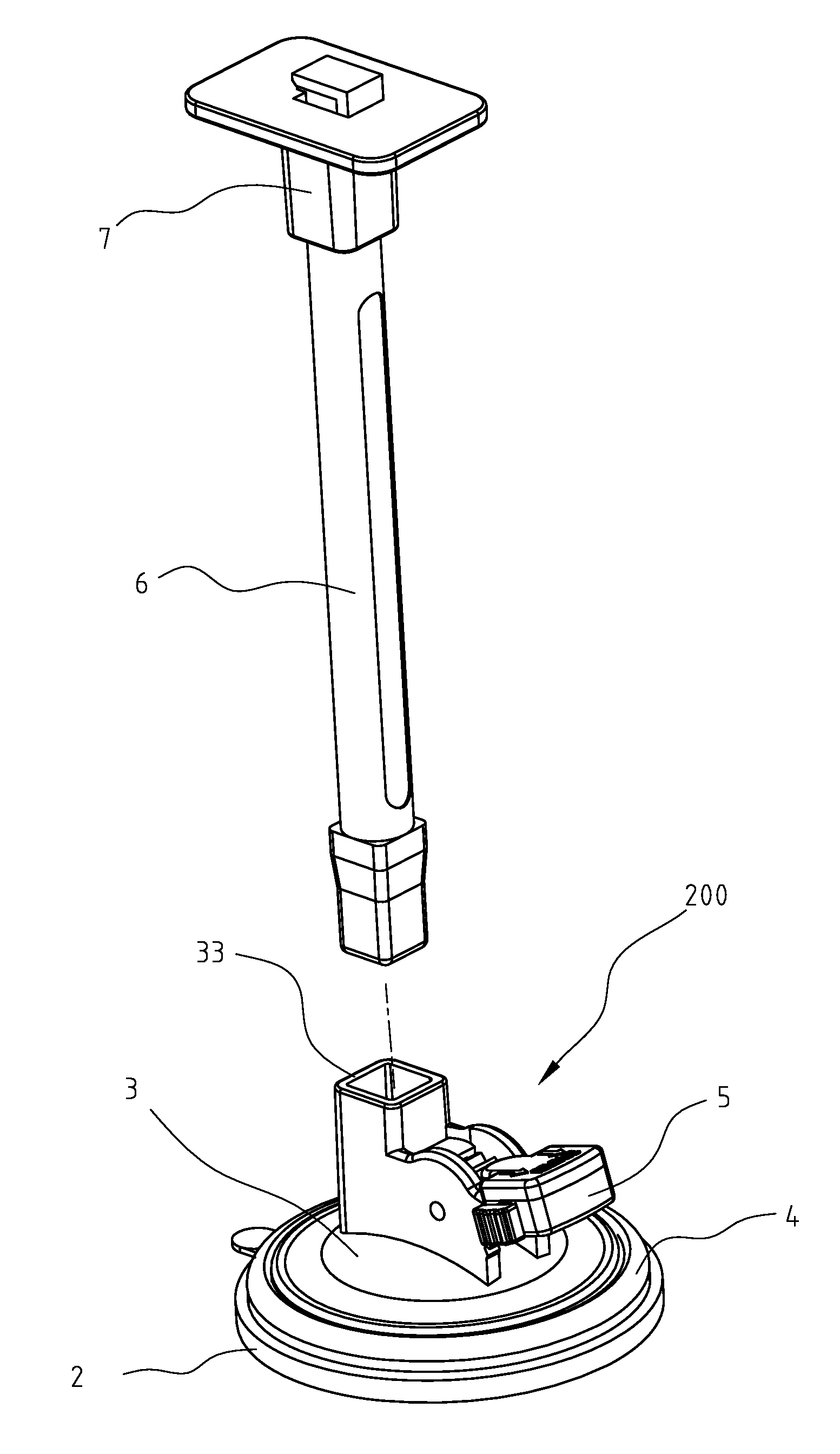

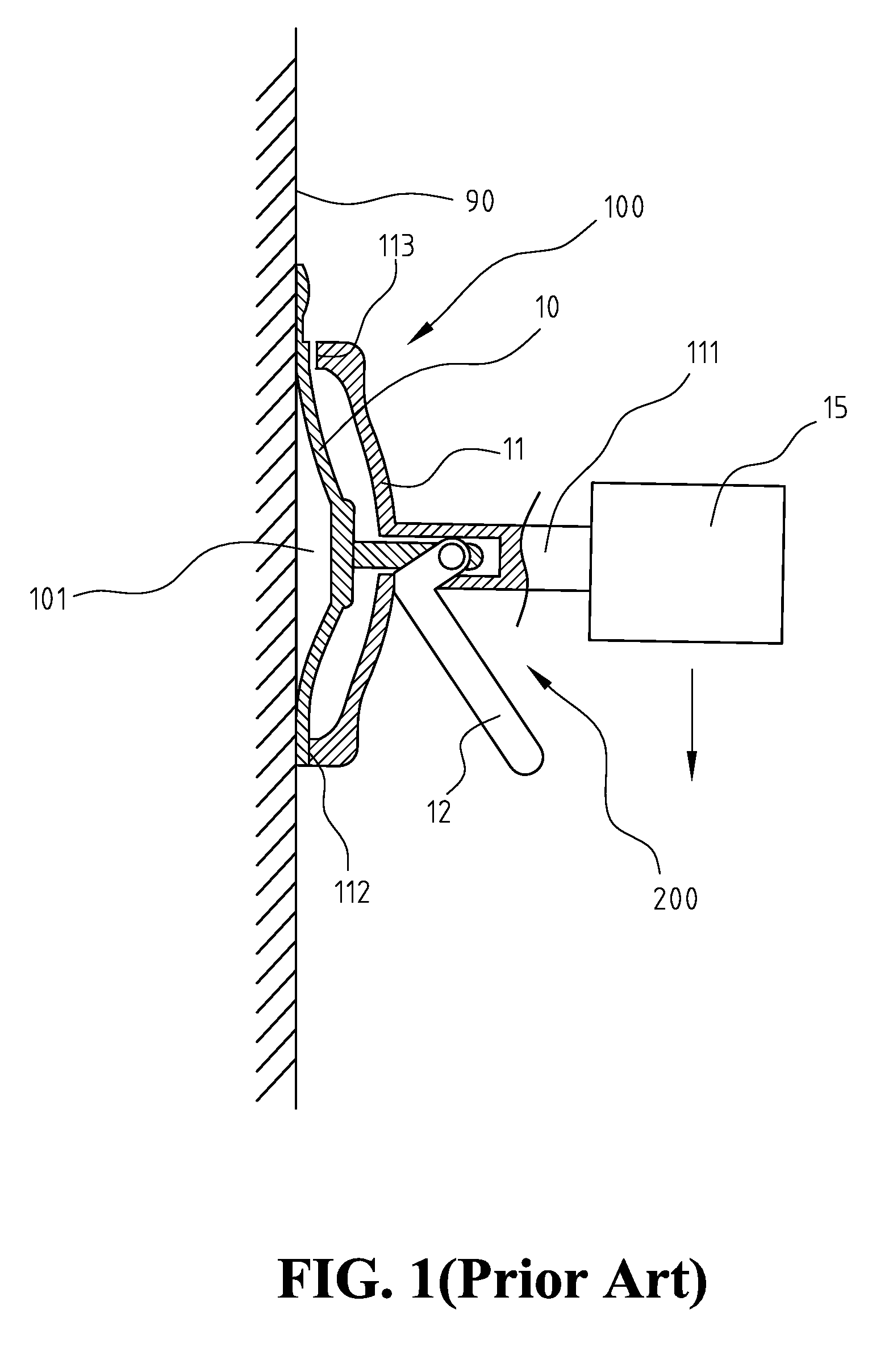

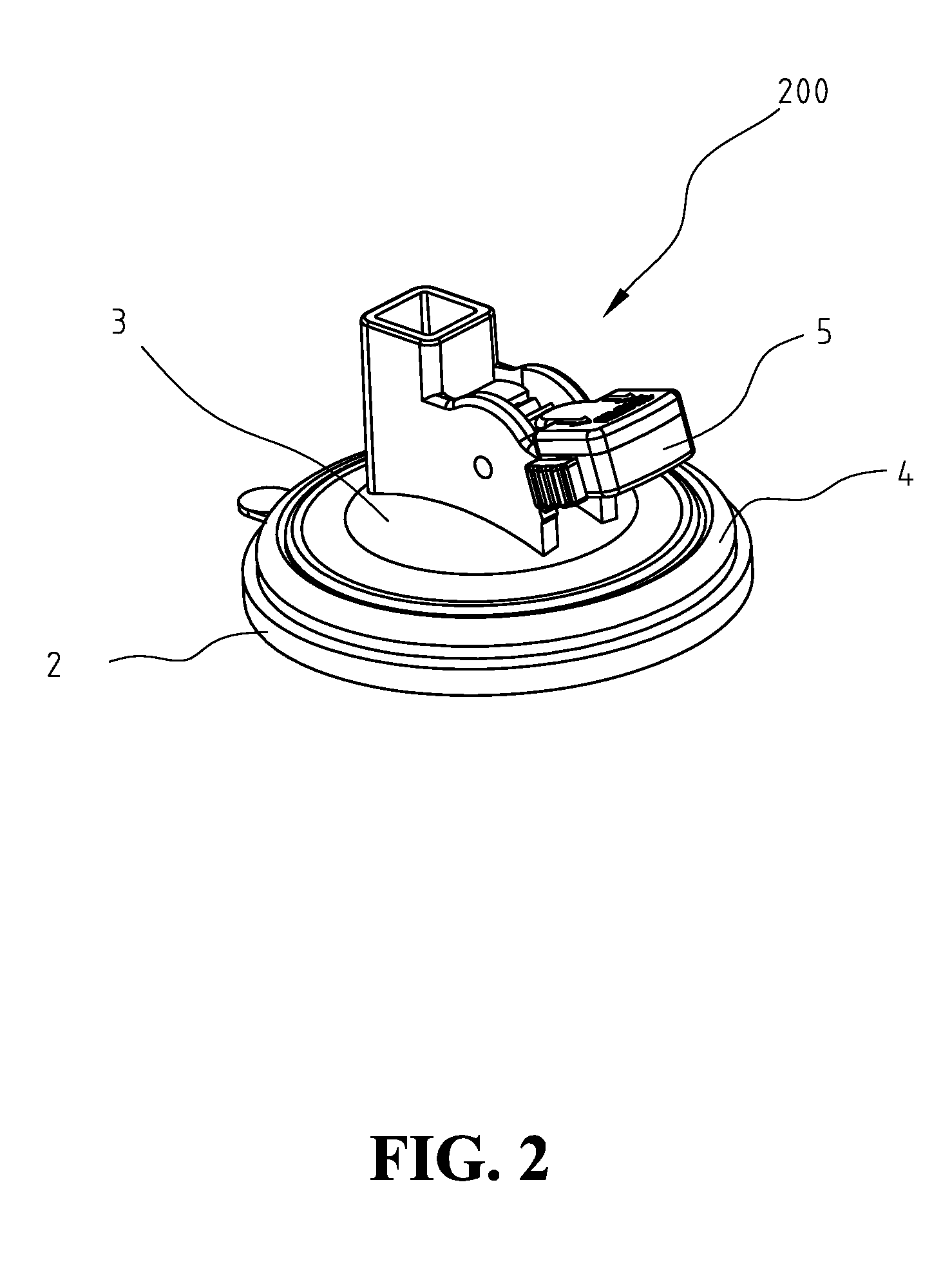

Suction disc unit

A suction disc unit, especially a suction disc unit that can be adsorbed on a smooth surface to support a hung article, it comprises a pressing lid, a suction disc, a link and a pressing rod; wherein the pressing rod at least has a first eccentric protruding portion and a second eccentric protruding portion; when the pressing lid is pulled up to make abutment of the suction disc against the smooth surface by pushing of the pressing rod, the air in the gap between the suction disc and the smooth surface is removed as much as it can; when the pressing rod is pressed down, the pressing lid abuts against the periphery of the suction disc, and the central portion of the suction disc is pulled up tight, the air pressure in the gap is much lower than that of the atmosphere to thereby induce a strong suction force, and thereby to increase the bearing strength of the suction disc unit.

Owner:COMART CORP

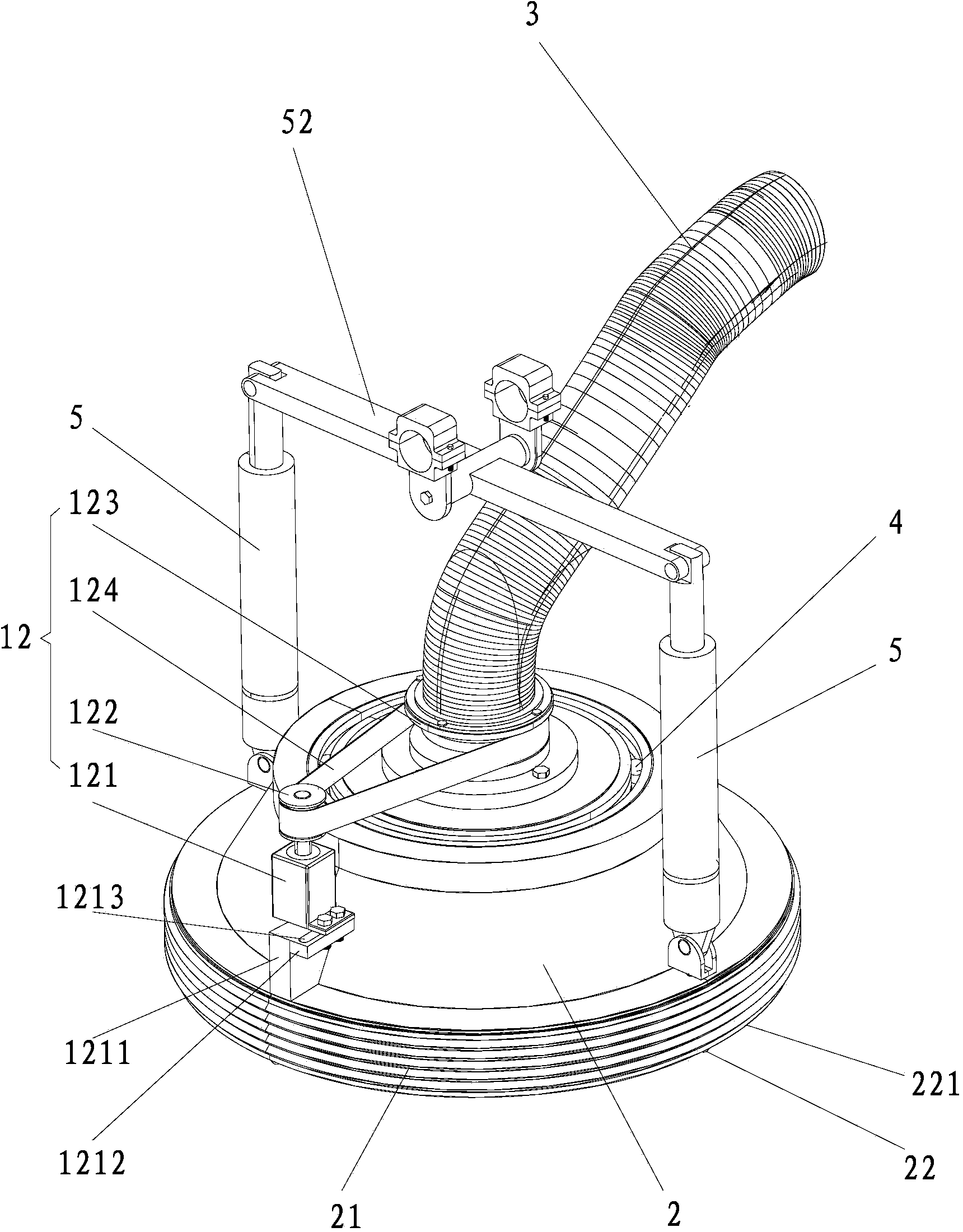

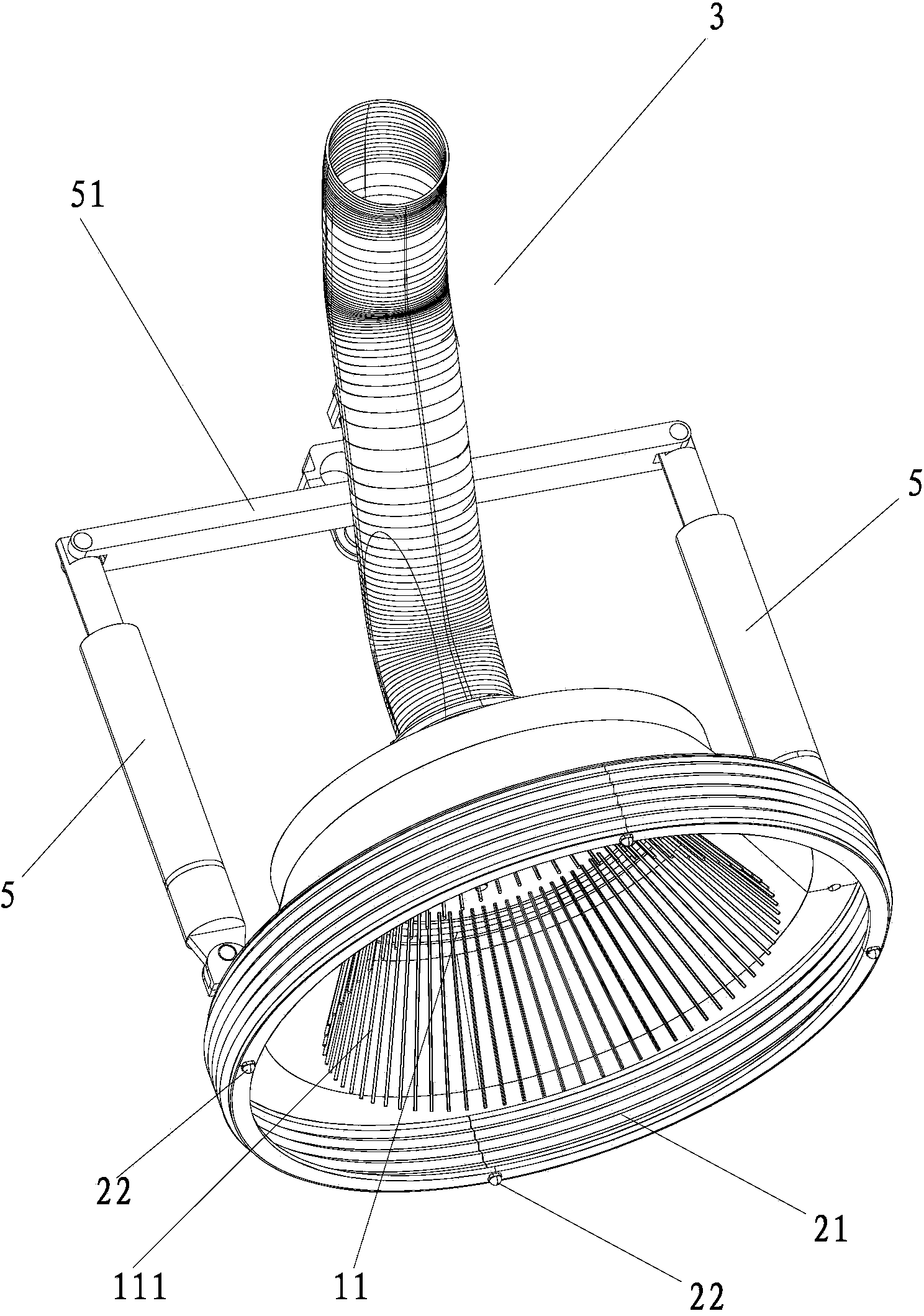

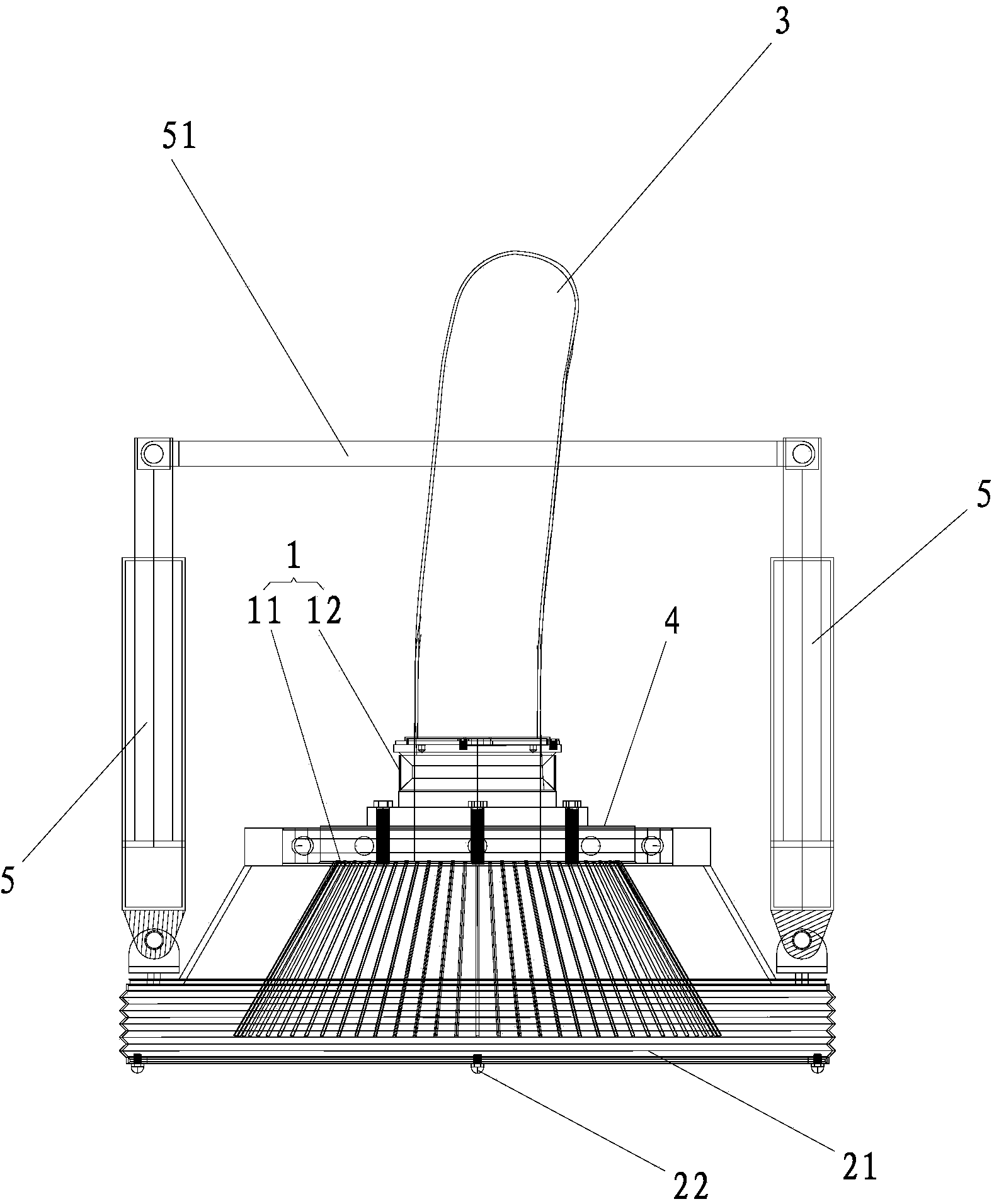

Novel sweeping and absorbing integrated cleaning mechanism

ActiveCN103510484AOvercome structureOvercome the defect of poor cleaning abilityRoad cleaningRoad surfaceEngineering

The invention provides a novel sweeping and absorbing integrated cleaning mechanism. The novel sweeping and absorbing integrated cleaning mechanism comprises a rotating cleaning brush carried by a sweeper. A shell making contact with the ground in a soft mode covers the rotating cleaning brush. A pumping pipeline is communicated with the upper portion of the shell. Due to the adoption of the technical scheme, the novel sweeping and absorbing integrated cleaning mechanism breaks through the structural form of traditional sweepers and integrates a rubbish brushing and sweeping mechanism and a rubbish pumping mechanism; the cleaning brush is rotated to brush and sweep rubbish in the shell in a rotating mode, is prevented from being absorbed on the ground and is in a free floating state. Negative pressure is formed in the shell through the pumping pipeline, the rubbish is pumped to a rubbish can of the sweeper through the pumping pipeline and is stored, and the cleaning brush is rotated to be matched with the shell and the pumping pipeline to form an Archimedes spiral type rubbish absorbing structure. The novel sweeping and absorbing integrated cleaning mechanism is strong in rubbish pumping and intake capacity and overcomes the defects that the traditional sweepers are single in structure and poor in cleaning ability. Compared with the prior art, the novel sweeping and absorbing integrated cleaning mechanism is thorough in road surface rubbish cleaning, efficient, novel and reasonable in structure and strong in practicability.

Owner:HUAQIAO UNIVERSITY

Pervasive dedusting device for a vacuum cleaner

InactiveUS7563296B2Low air flow pressure lossImprove vacuuming effectCleaning filter meansCombination devicesPollutionVacuum cleaner

Owner:SUZHOU KINGCLEAN FLOORCARE

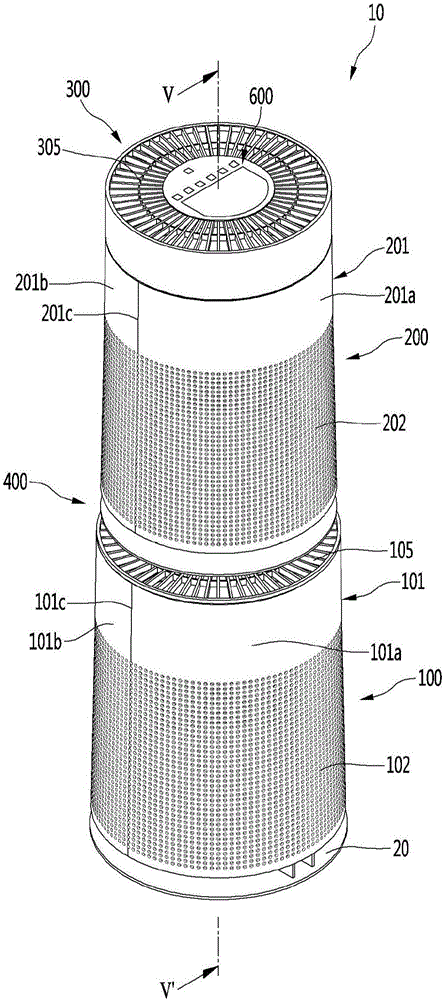

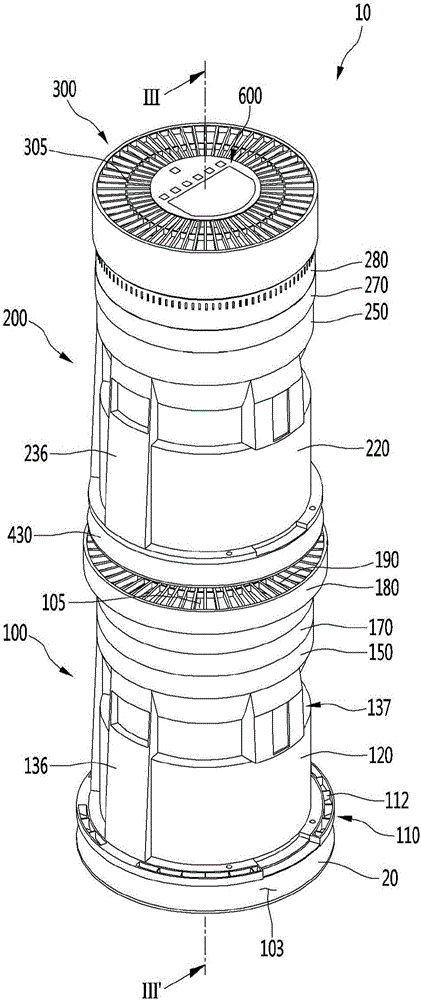

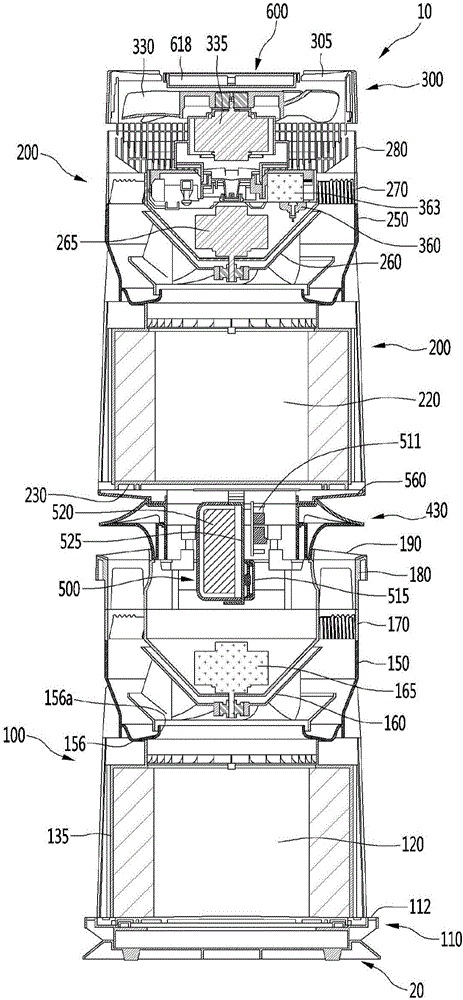

Air purifier

ActiveCN106813315AOptimize space utilizationNo hindranceMechanical apparatusSpace heating and ventilation safety systemsElectricityElectrical and Electronics engineering

The present invention provides an air purifier, which comprises: a power supply PCB connected to the fan motor to receive a power supply supplied from an external power supply port; a main PCB receiving a power source supplied from the power supply PCB; a sensor device electrically connected to the main PCB; a flow conversion PCB that receives a power supply from the power supply PCB and controls the driving of the gear motor to switch the direction of the air flow generated in the blower fan; and a plurality of PCB cables connecting any of the power supply PCB, the main PCB, and the flow conversion PCB.

Owner:LG ELECTRONICS INC

Pleated filter made of a multi-layer filter medium

InactiveUS20020011051A1Improve suction capacityHigh of circulationCleaning filter meansCombination devicesFilter mediaEngineering

The present invention relates to a pleated filter made of a multi-layer filter medium, including at least one filter paper layer having area weights of 30-100 g / m2, a microfiber nonwoven fabric layer having area weights 5-120 g / m2 and a support nonwoven fabric layer made of synthetic, polymeric fibers having area weights of 10-120 g / m2. The layers of the pleated filter contain fused polymer areas by which the fabric layers are bonded to the paper layer, and by which the fabric layers are made firmer within themselves. When subject to a dust removal test at an initial pressure difference of at most 180 Pa, at a boundary speed of approximately 2.62 m / s and a flow speed through the filter medium of approximately 0.13 m / s, the pleated filter is able to separate at least 90% of particles greater than 0.3 mum, at least 92% of particles greater than 0.5 mum, at least 93% of particles greater than 1 mum, and at least 97% of particles greater than 3 mum, as measured using the standard method DIN EN 60312 (IEC 60312) § 5.125.

Owner:CARL FREUDENBERG KG

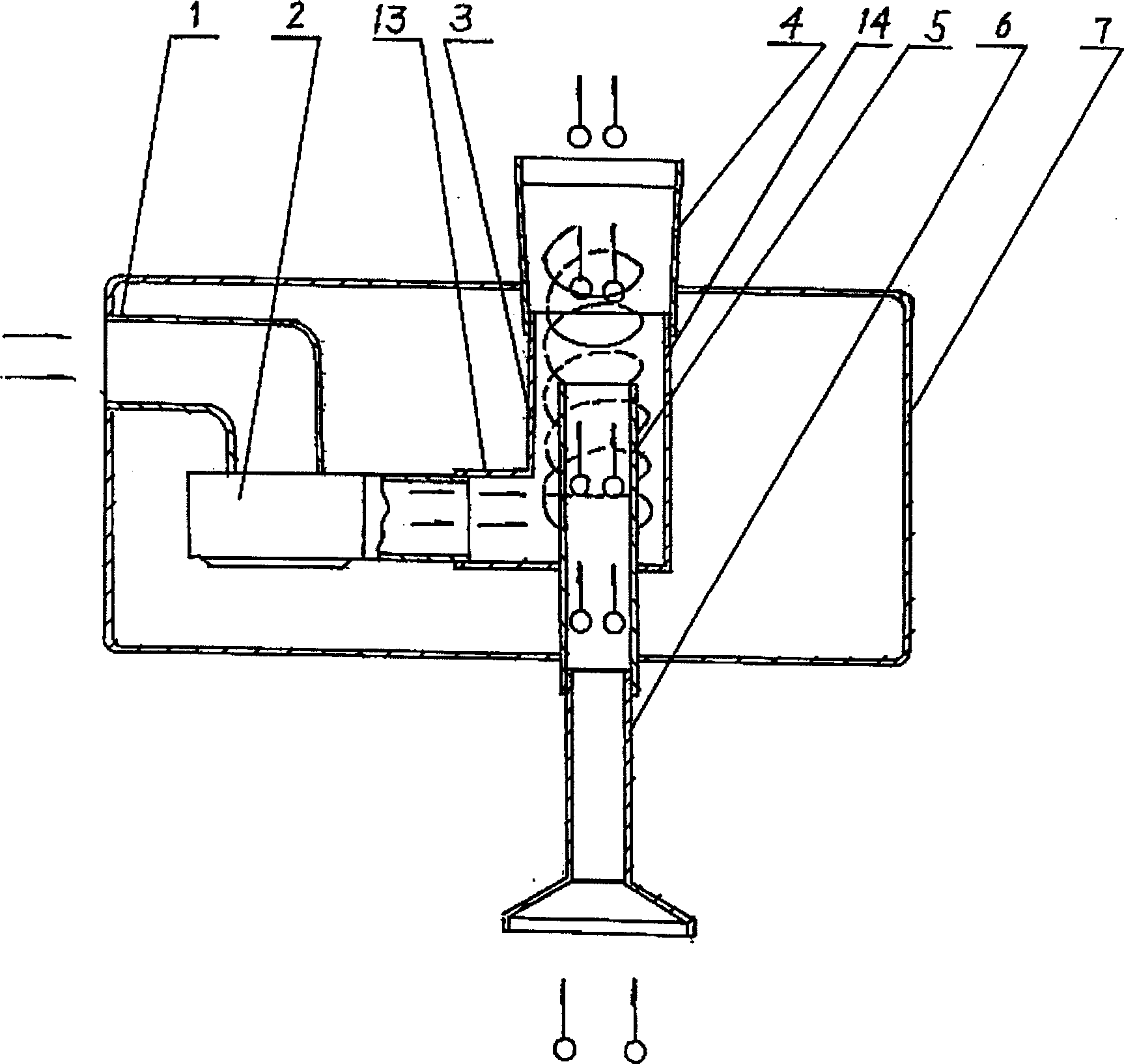

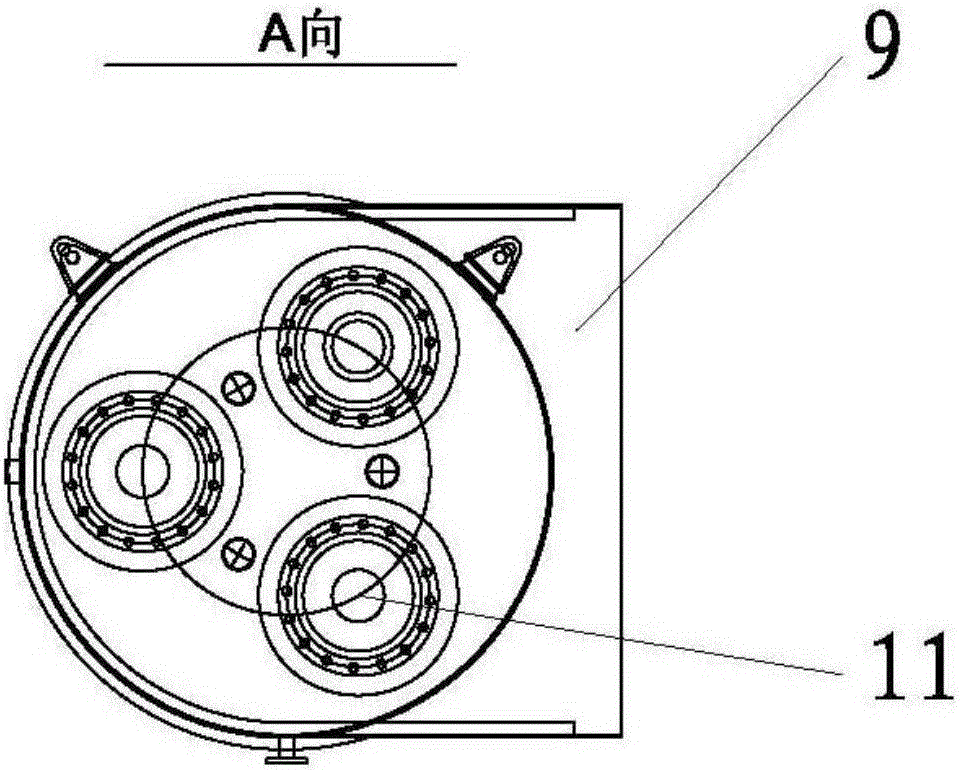

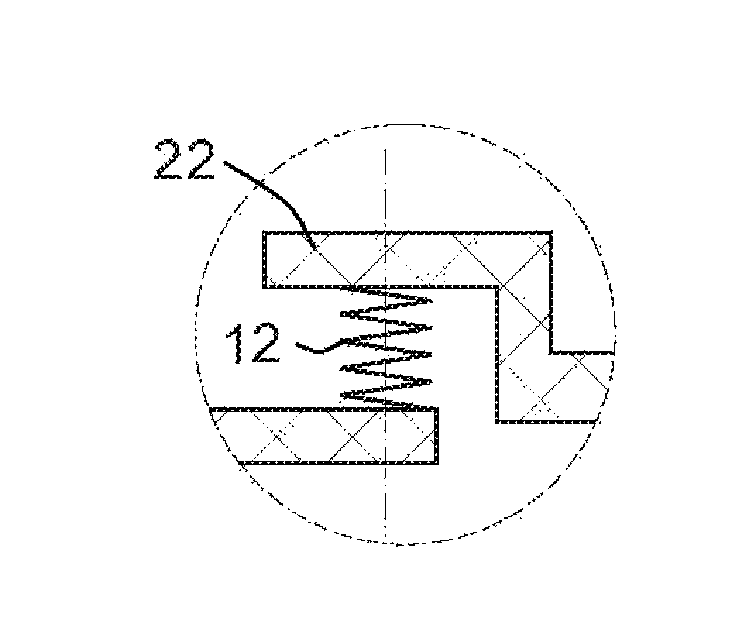

Cyclone-type sucking-exhausting mechanism

InactiveCN1397769AImprove performanceReduce noiseDomestic stoves or rangesLighting and heating apparatusCycloneLow noise

A cyclone-type sucking-exhausting machine features that the clean air is blown by blower into a cyclone chamber, where a cyclone is generated, which rotates along the inner surface of cyclone chamber to generate a central negative region for sucking the dust, garbage, oil soot, and harmful gas or substances into an exhaust barrel and then exhausting them. Its advantages are high efficiency and safety, reasonable structure, low noise and wide application range.

Owner:刘定国

Structure for a suction device

ActiveUS7793899B2Increased durabilityImprove suction capacityConveyorsWork holdersEngineeringMechanical engineering

Owner:FAN EAGLE

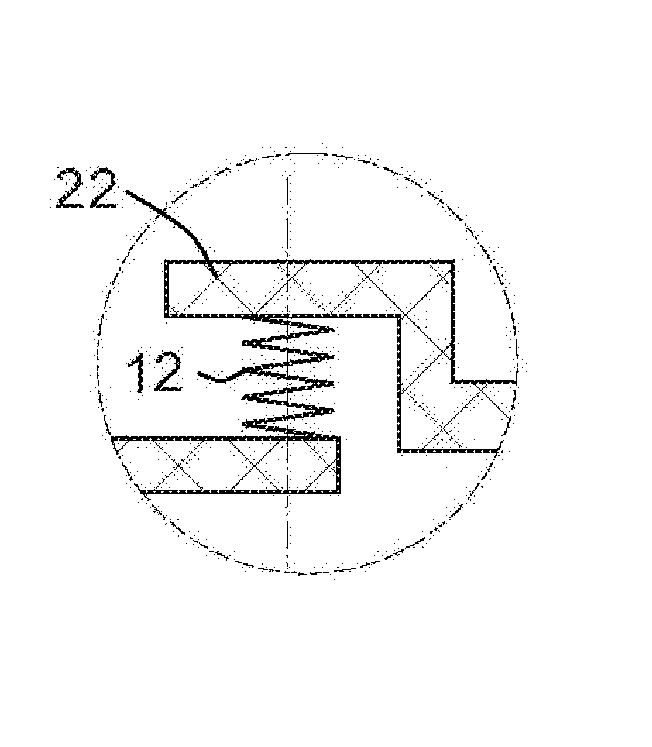

Piston Pump With Improved Piston

ActiveUS20080226479A1Produced simply and economicallyLow flow resistancePositive displacement pump componentsPlungersEngineeringPiston rod

The invention relates to a piston pump for conveying a fluid, in particular in a vehicle brake system. The piston pump has a cylinder and a piston movably disposed in the cylinder. A restoring element preloads the piston, and a drive unit for actuates the piston in the cylinder to pump the fluid into a pressure chamber formed in the cylinder. The piston is embodied by a first piston par and a second piston part. The first piston part is a cylindrical body, which can be moved by the drive unit. The second piston part form the piston base, in which four radial inlet openings and one axial connection opening for communication with the pressure chamber are disposed. A flange for the disposition of a seal is disposed on the outer circumference of the piston base element. The openings are simple to make in the face ends and circumferential regions of the second piston part.

Owner:ROBERT BOSCH GMBH

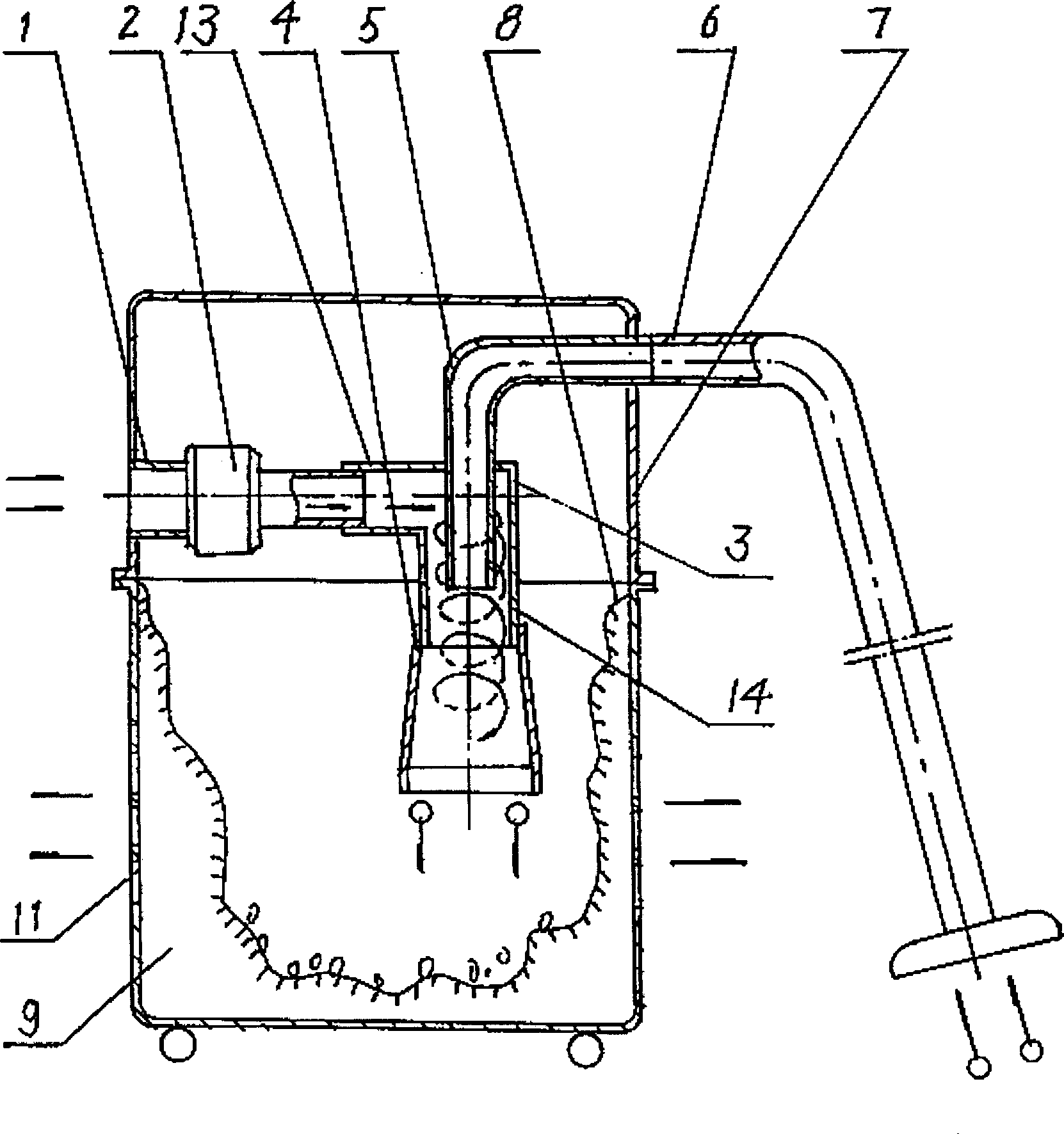

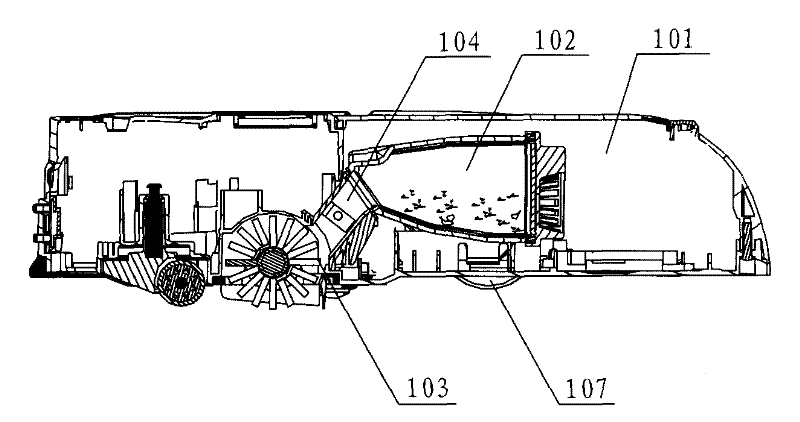

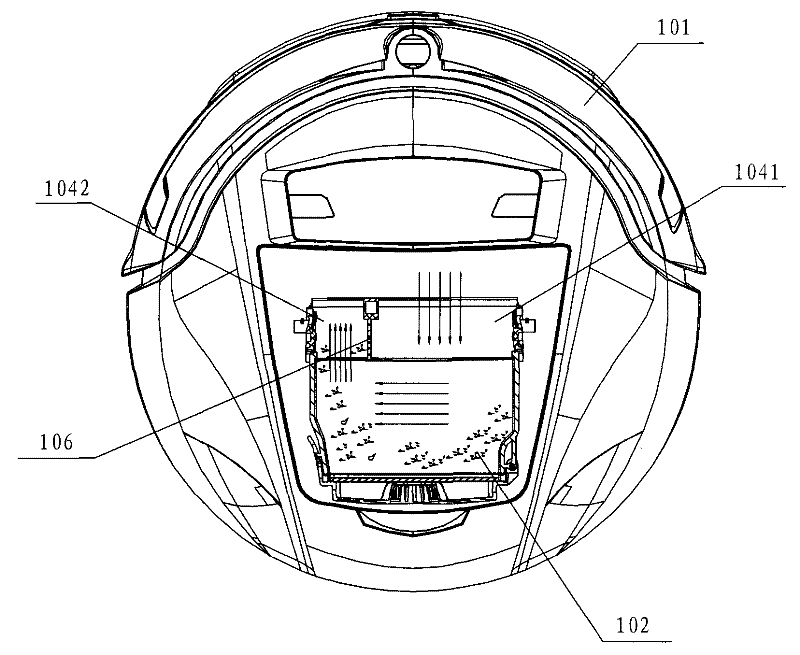

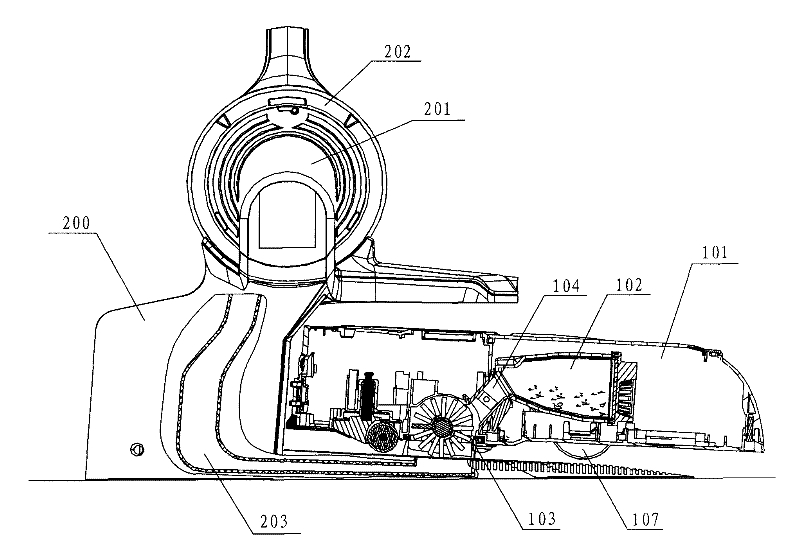

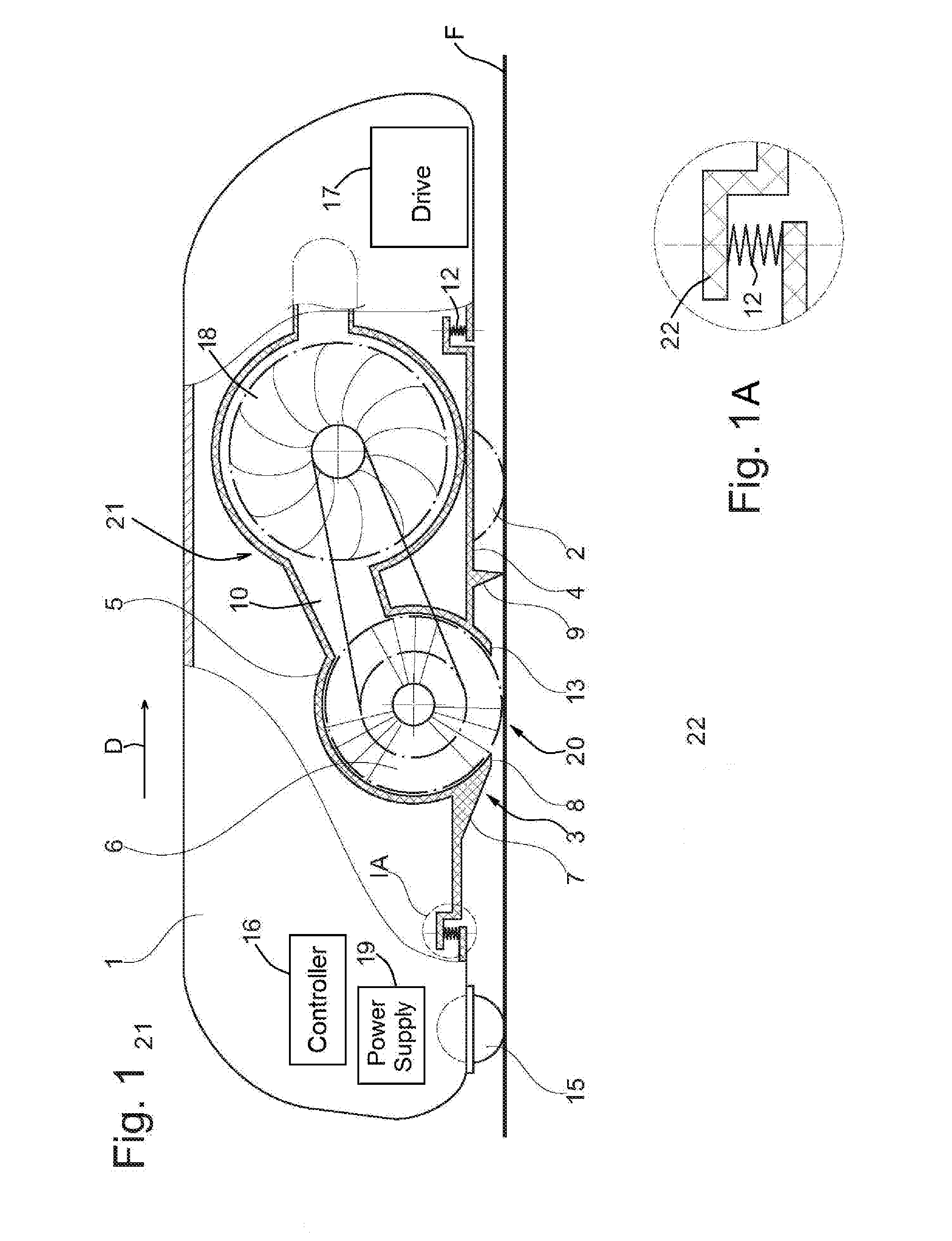

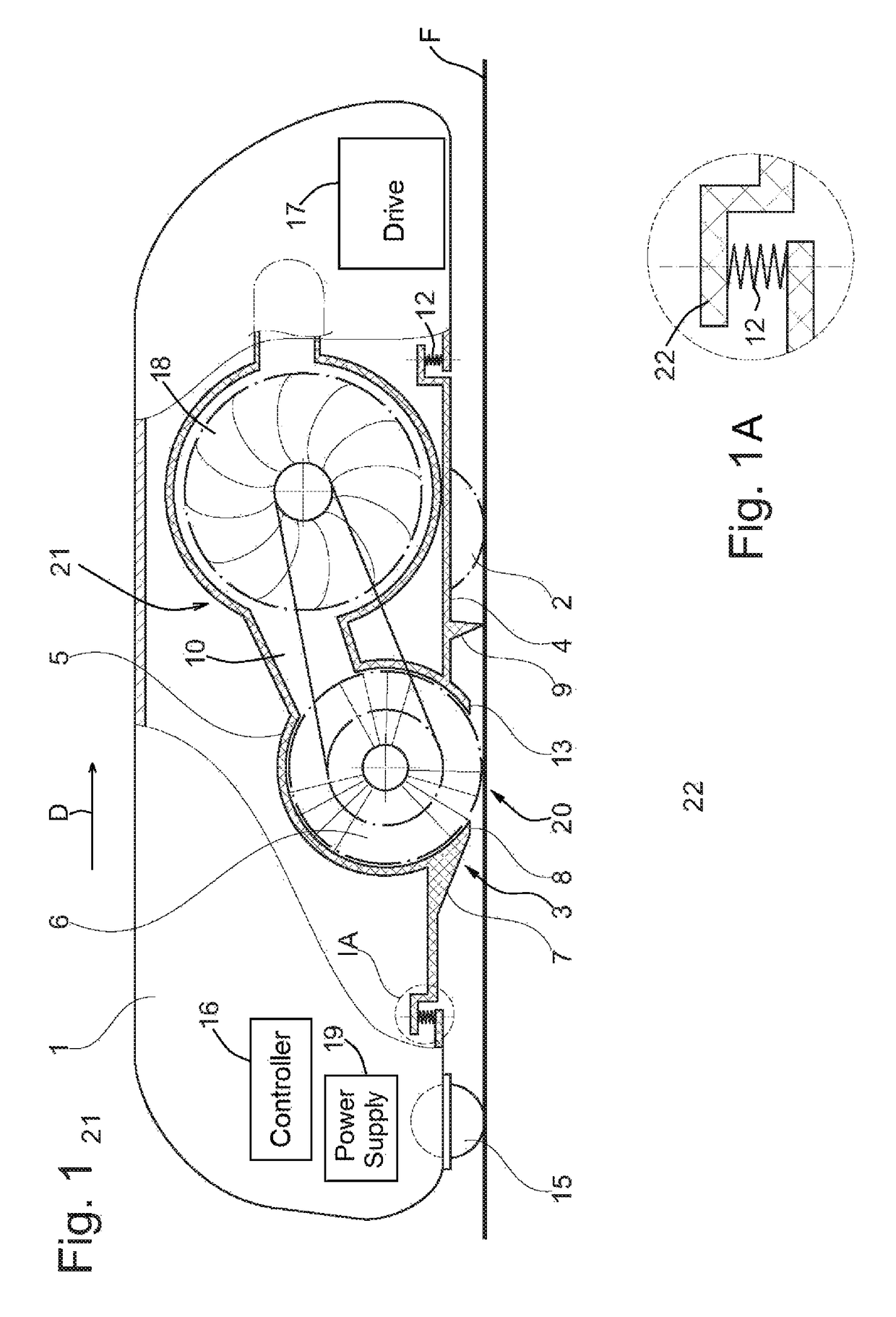

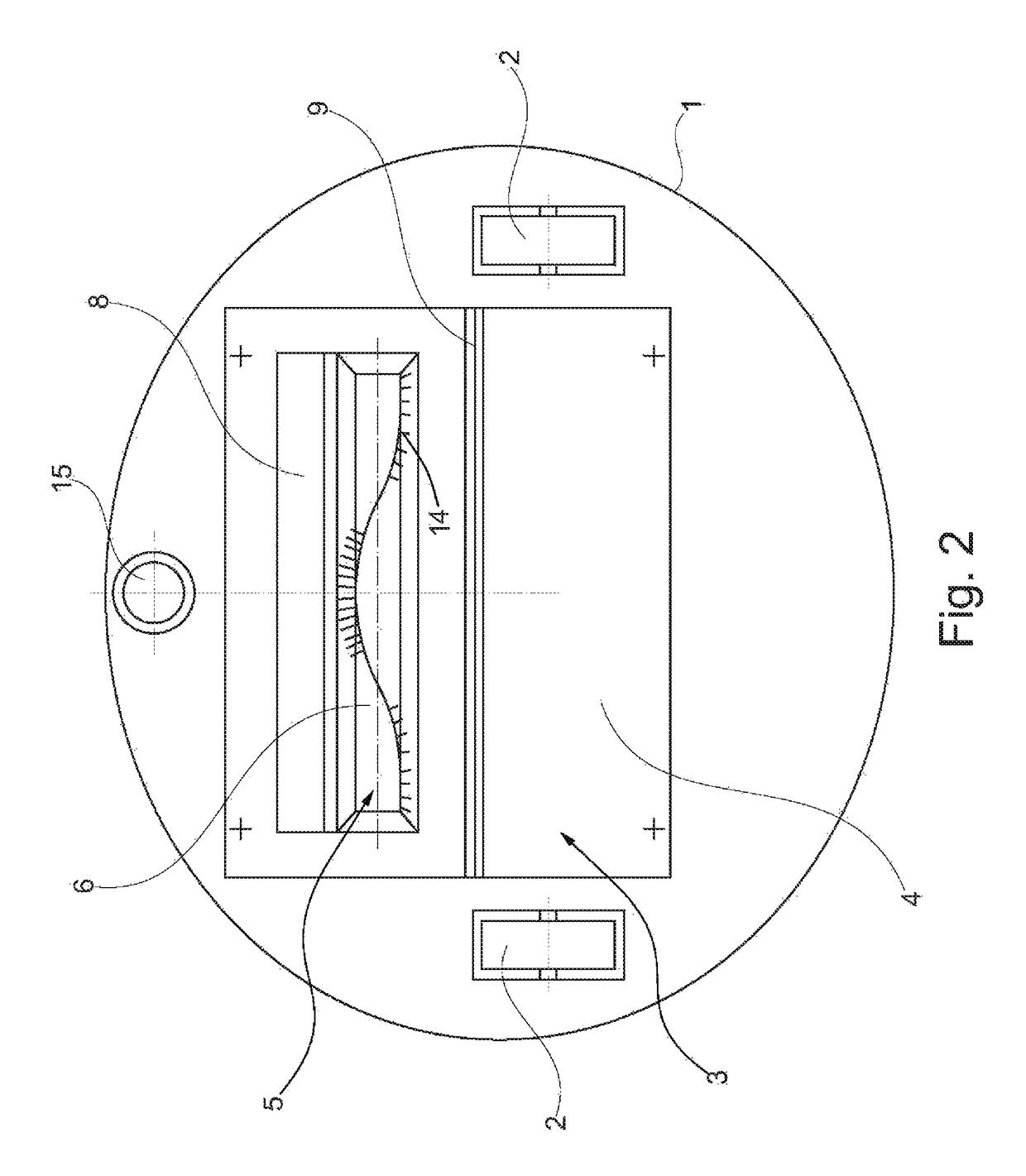

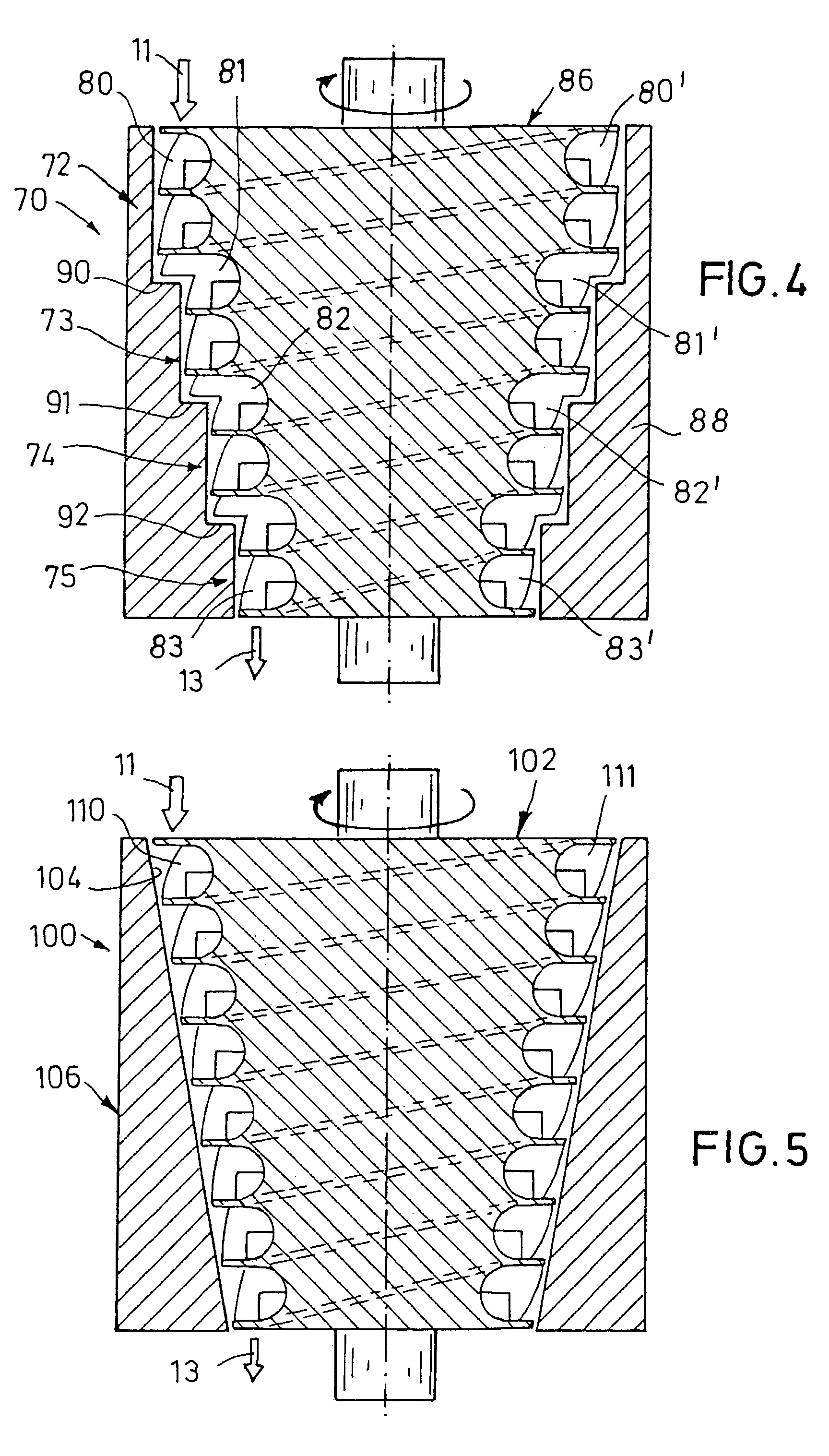

Robot system

ActiveCN102217914AIncrease motivationUnder the condition of constant power, the velocity of air flow increasesSuction cleanersMachine detailsRobotic systemsAir velocity

The invention relates to a robot system, comprising a robot and a base, wherein the robot comprises a robot body (101), the bottom of the robot body (101) is provided with an ash entrance (103), the robot body (101) is internally provided with a dust box (102), and an air channel (104) is formed among the ash entrance, the ash inlet of the dust box (102) and the case of the robot body (101); the base (200) comprises a dust collection box (202) and a vacuum source (201); the air channel (104) is internally provided with a rib plate (106), the space of the air channel (104) is divided into a first air channel (1041) and a second air channel (1042), the ports of the two parts are a first ash entrance and a second ash entrance respectively; in an ash discharge mode, under the suction action of the vacuum source (201), gas enters into the dust box (102) along the first ash entrance, and ash is discharged into the dust collection box (202) from the second ash entrance. In the invention, the rib plate (106) is arranged, and the air velocity in the dust box (102) is improved, thus the ash sucking capability is greatly improved.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

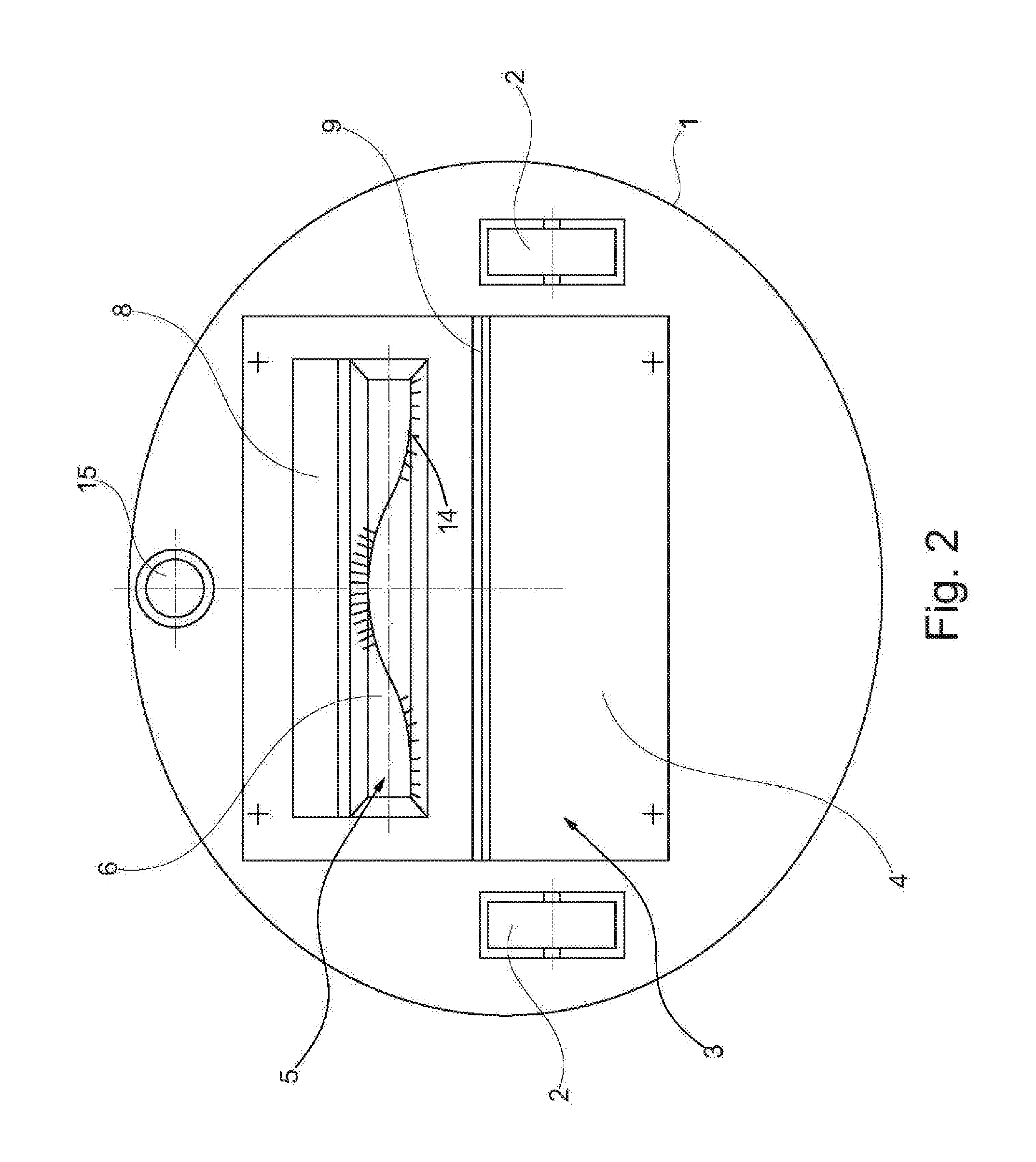

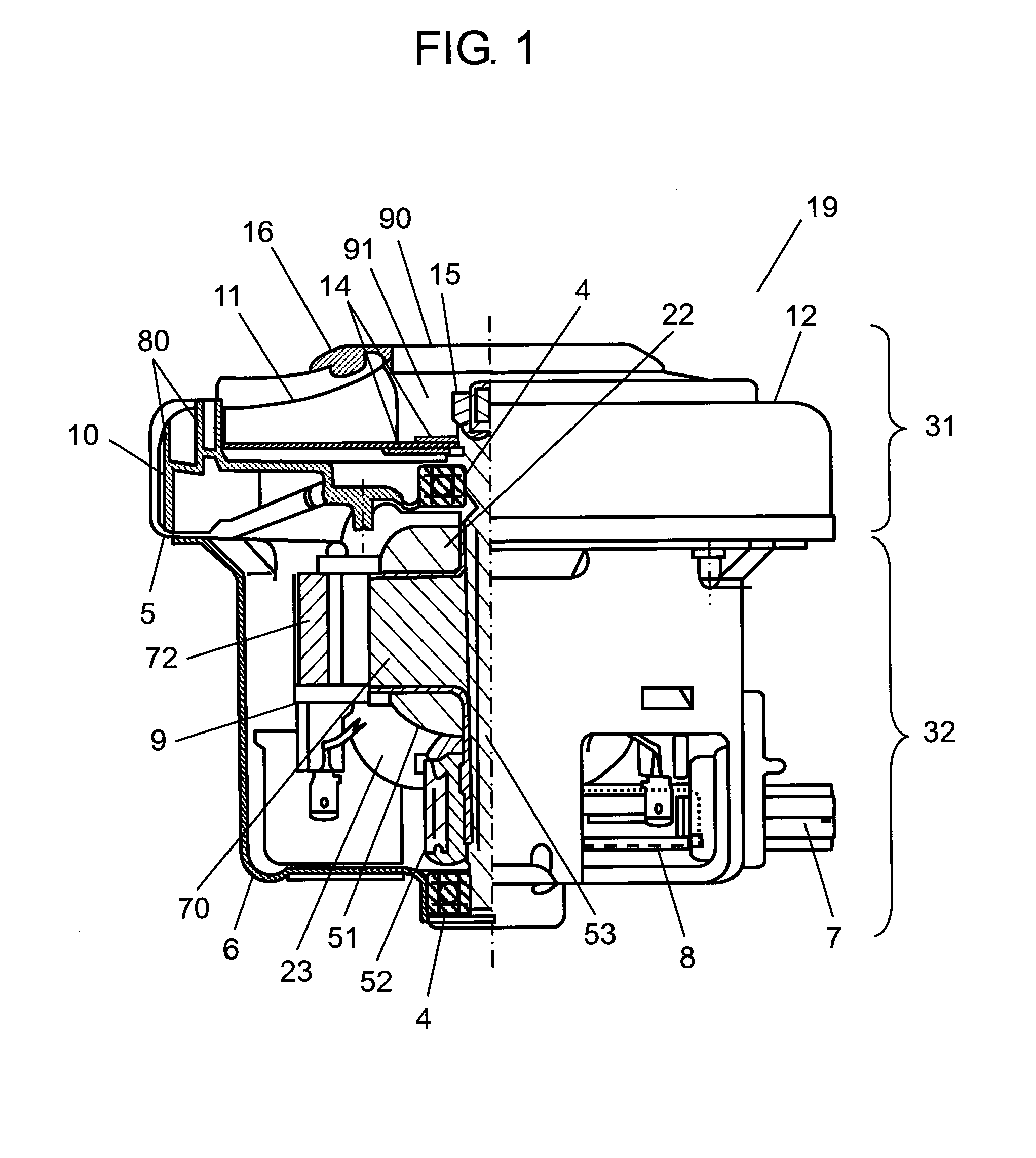

Vacuum-cleaning robot

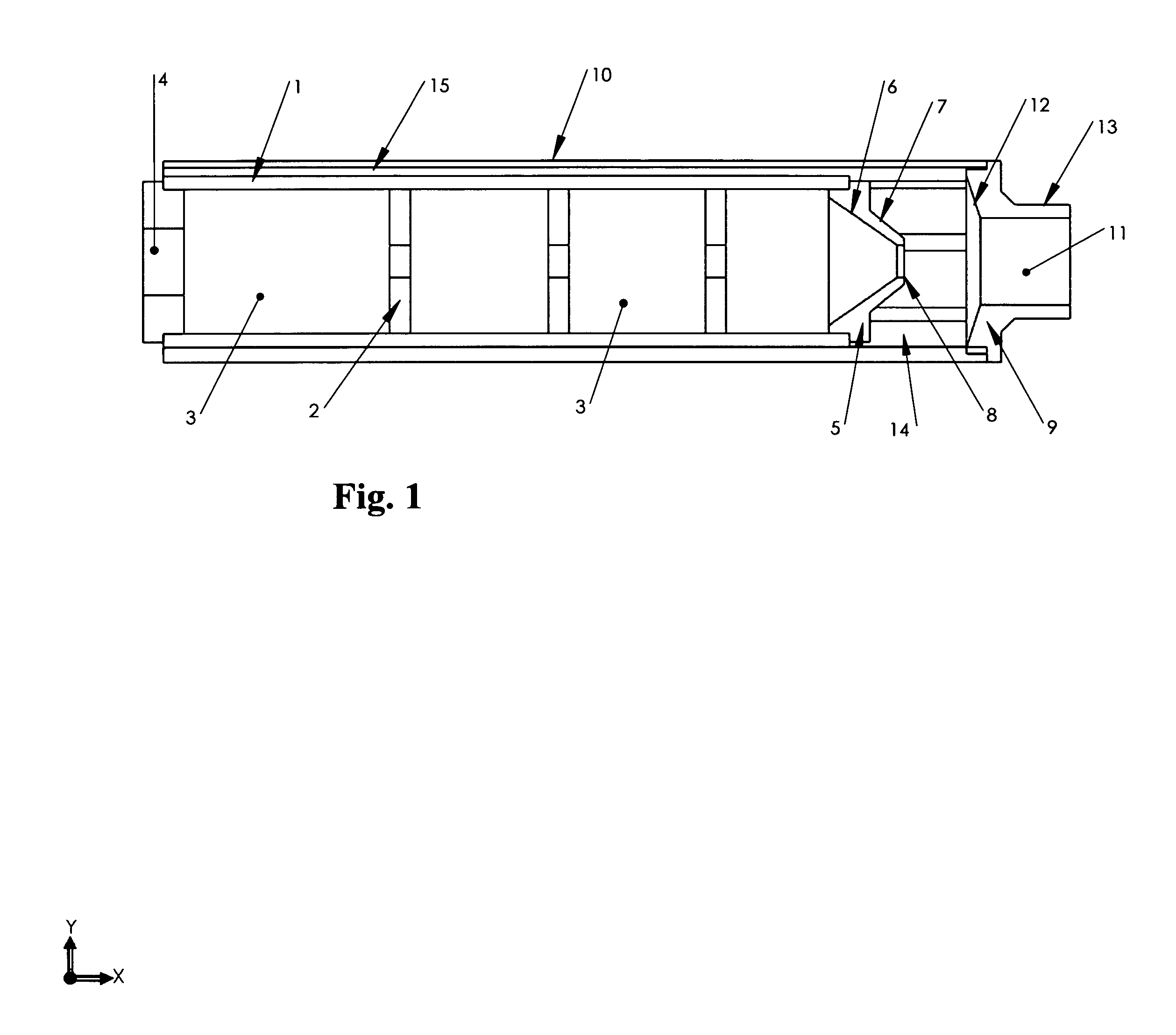

ActiveUS20150059120A1Improve suction capacityGreat suctionCarpet cleanersFloor cleanersLeading edgeTrailing edge

A self-propelled vacuum cleaner has a main housing having a bottom wall formed with an aperture, floor-engaging wheels on the main housing, and a drive in the main housing for rotating the wheels and advancing the main housing in a normal horizontal travel direction. A module housing projecting through the aperture forms a brush compartment defining a downward directed suction opening having relative to the direction a leading edge and a trailing edge. The module housing is supported in the main housing for limited vertical movement of the module housing relative to the main housing. A brush in the module housing is engageable through the opening with a floor beneath the opening, and a blower in the module housing having an intake connected via a duct to the brush compartment for aspirating air through the opening and past the brush into the module housing.

Owner:WESSEL WERK

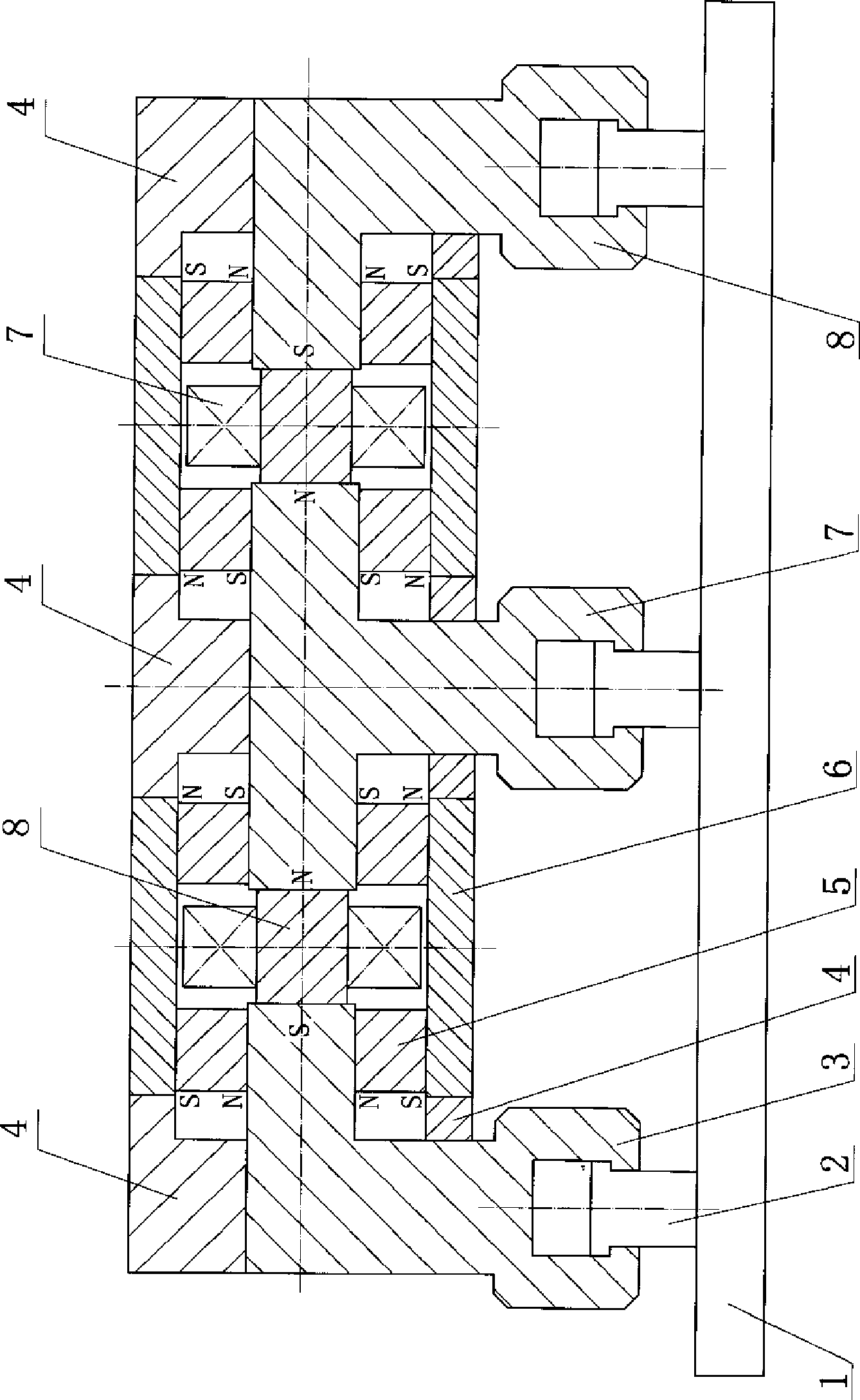

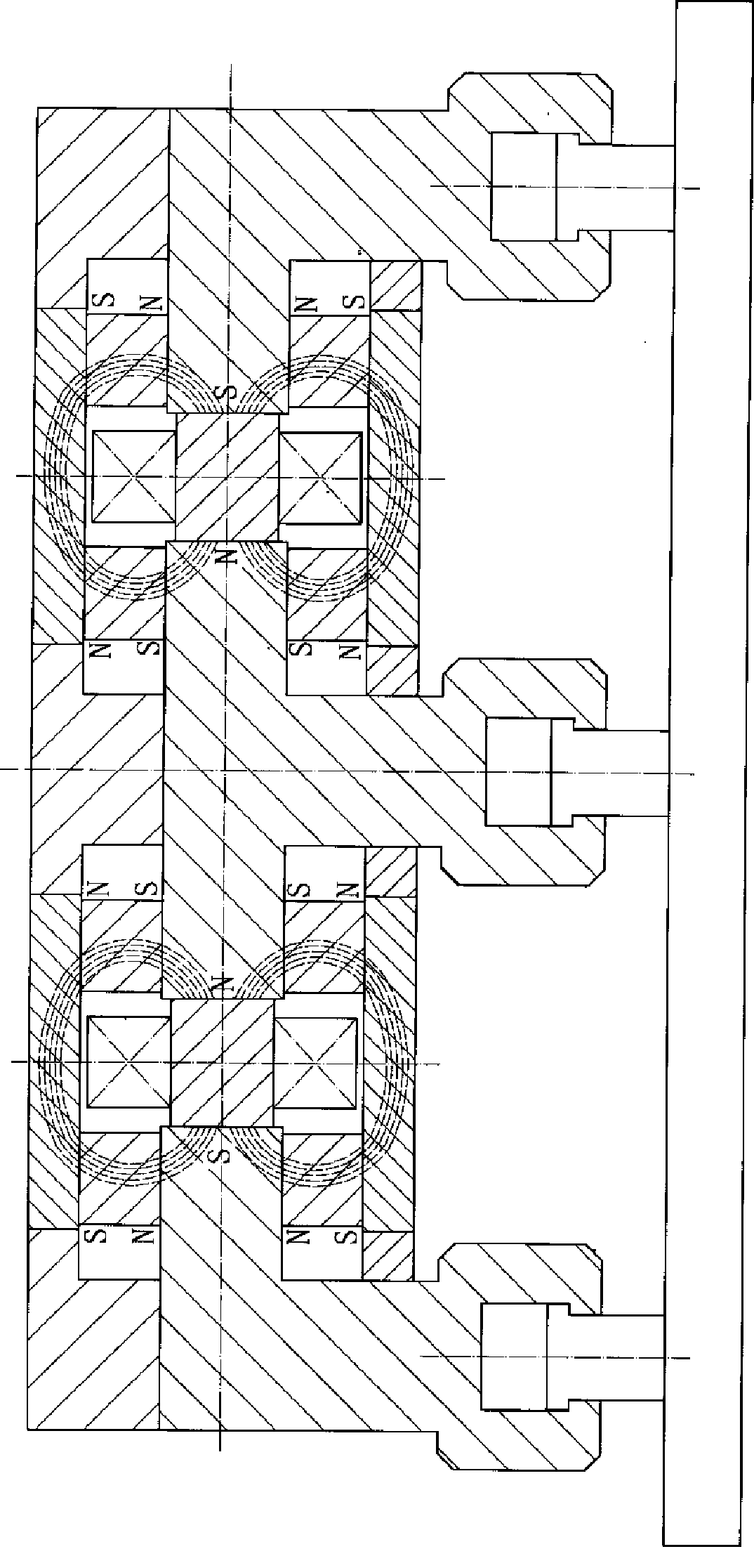

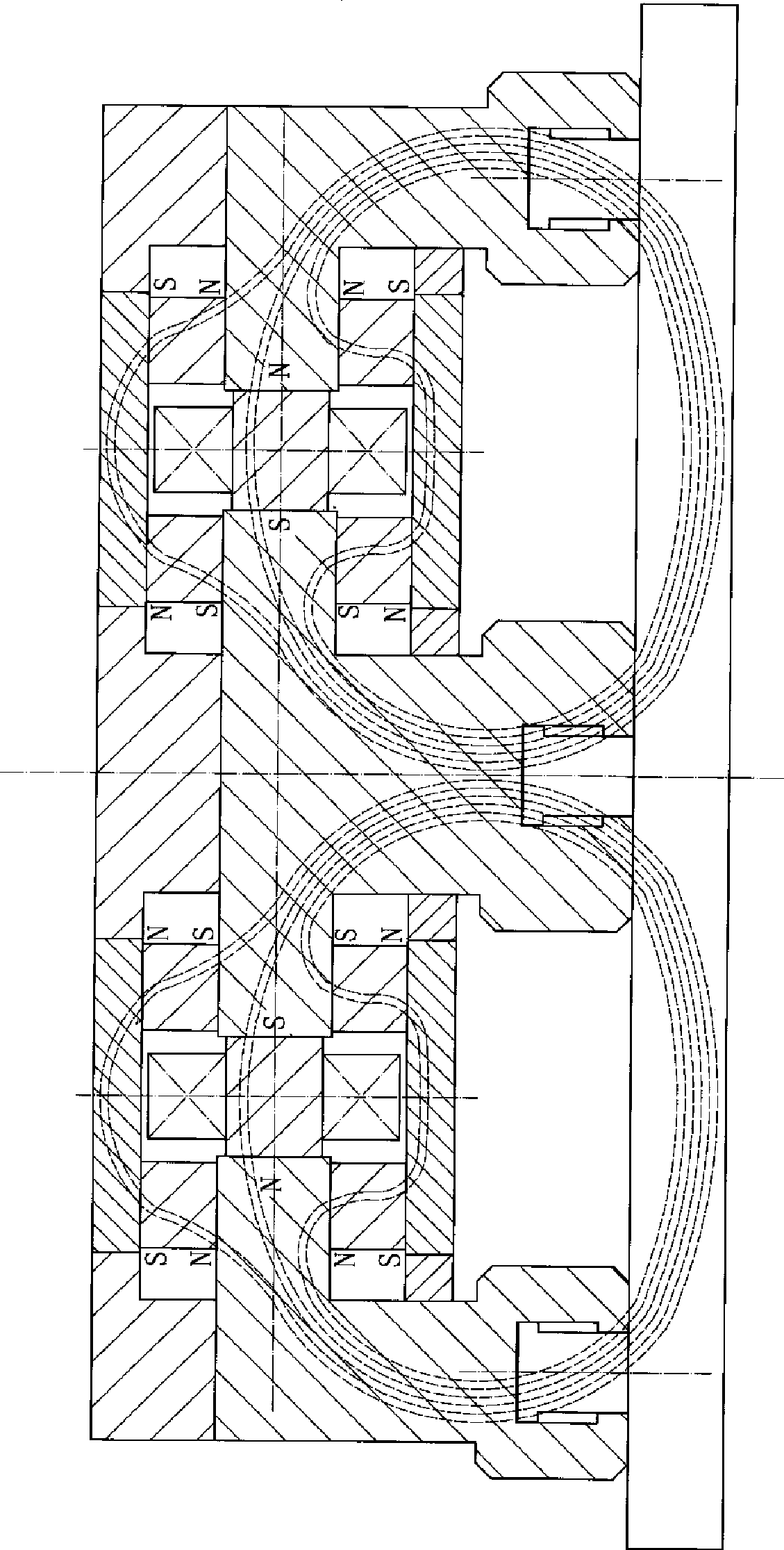

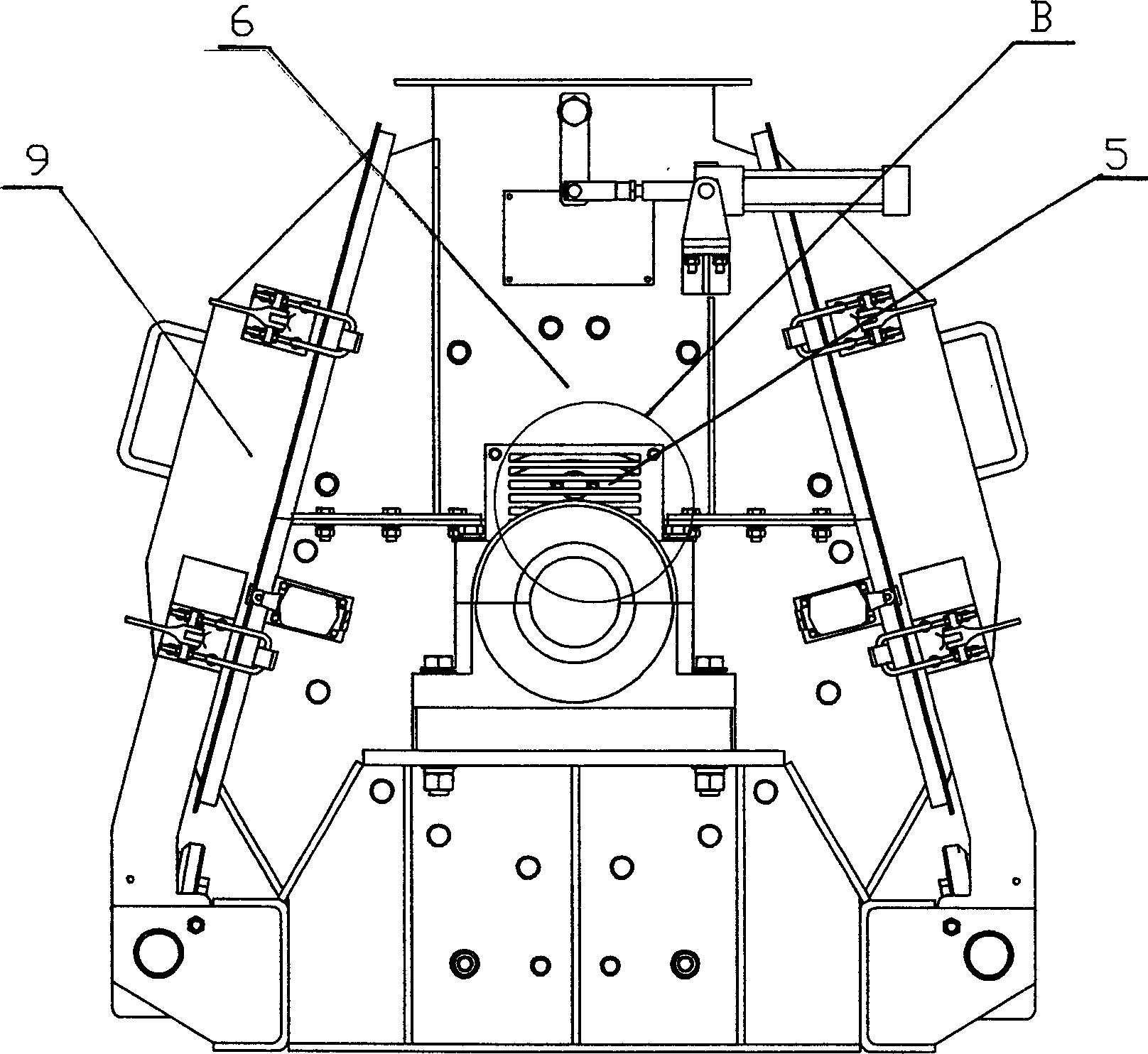

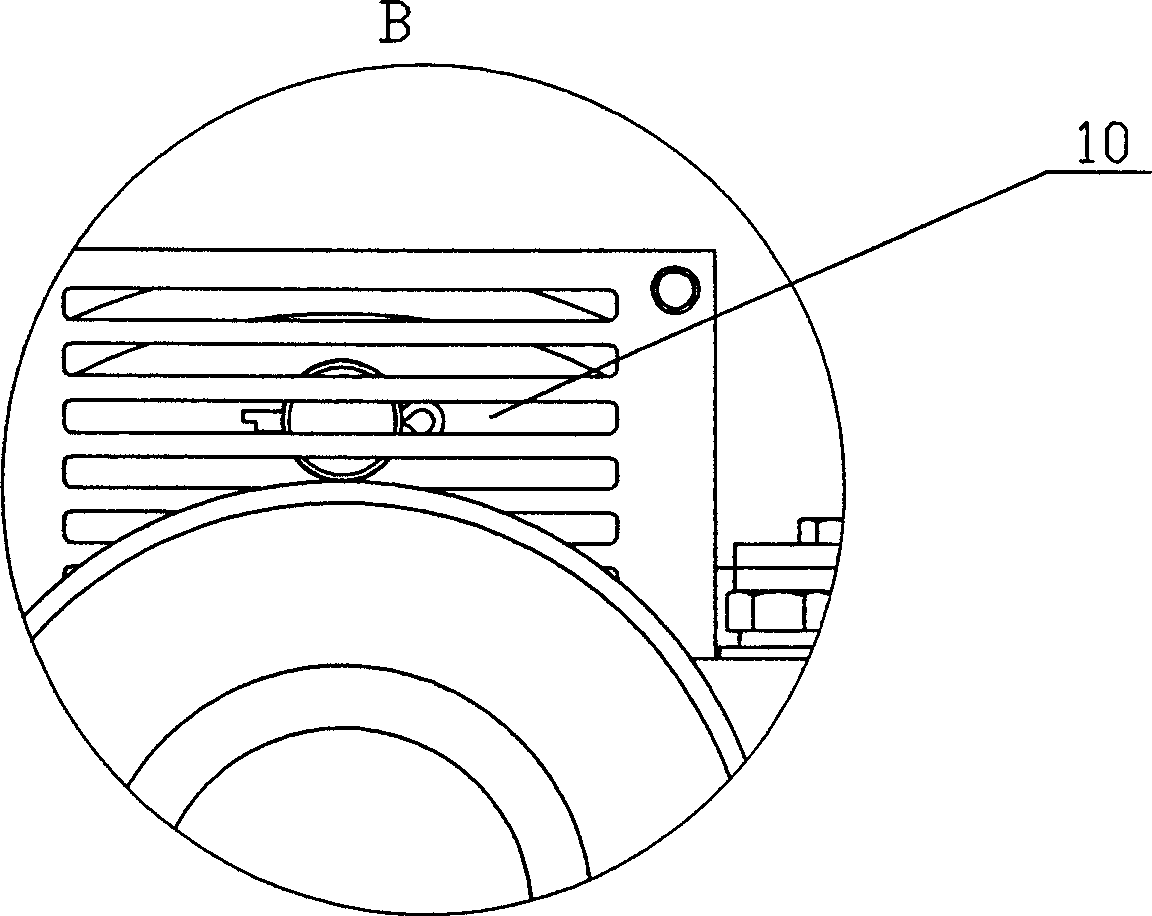

Electric-controlled permanent magnetic chuck

InactiveCN101544337AImprove suction capacityEasy to useLoad-engaging elementsSuction stressMagnetic poles

The invention relates to an electric-controlled permanent magnetic chuck, comprising a coil, a magnet steel, a magnet yoke and a permanent magnetic chuck of a magnetic pole, wherein the magnet steel is composed of a reversible magnet steel and a non-reversible magnet steel. The reversible magnet steel is used in a main magnetic circuit; the coil is arranged around the reversible magnet steel and the non-reversible magnet steel is arranged at two sides of the reversible magnet steel as the auxiliary magnet steel. The magnet yokes are arranged at two sides of the reversible magnet steel and the non-reversible magnet steel. The end of the magnet yoke is connected with the magnetic pole. The main magnetic circuit consists of reversible magnet steel, coil, magnet yoke, magnetic pole and sucked objects and the auxiliary magnetic circuit consists of the non-reversible magnet steel and the non-reversible magnet steel magnetic conduction connecting board. The main magnetic circuit structure and the auxiliary magnetic circuit are connected into an integral structure by a non-magnetic conductor. The invention is suitable for swinging a plurality of square billets and high-temperature square billets after heat insulating process. The mobile magnetic pole can greatly increase the suction efficiency for a long period application. The invention greatly expands the application range of the electric-controlled permanent magnetic chuck and provides a new way for the development of the hoisting electromagnet.

Owner:岳阳鸿升电磁科技有限公司

Two-For-One Twisting Spindle Having a Pneumatically Actuated Threading Device

InactiveUS20100018178A1Easy to produceReduce weightPiercing arrangementsDrafting machinesRotational axisEngineering

Two-for-one twisting spindle having a pneumatically actuated threading device, with a spindle shaft rotatable about a vertical axis partially configured as a hollow shaft with a lower feed bore extending coaxially to the rotational axis, and with an injector element opening into a thread guide channel of a thread guide ring temporarily connectable during threading to a compressed air source. Part of the compressed air feed to the injector element is formed by the feed bore. The compressed air feed comprises a connection element (27) with a curved air channel (26), which connects the feed bore (24) to the injector element (16). The connection element (27) is configured as a separate component and the air channel (26) is adapted to the flow requirements.

Owner:SAURER TECH GMBH & CO KG

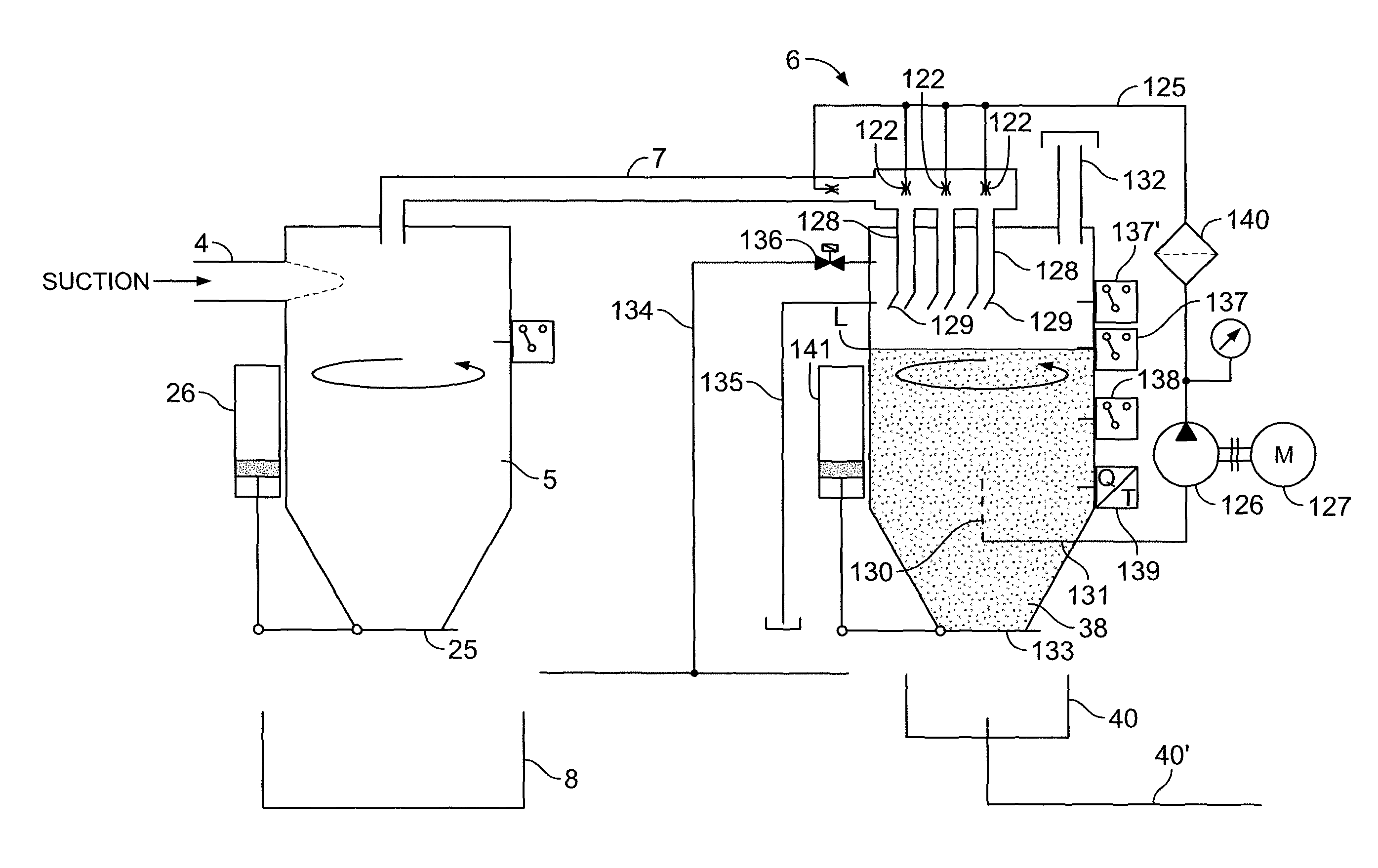

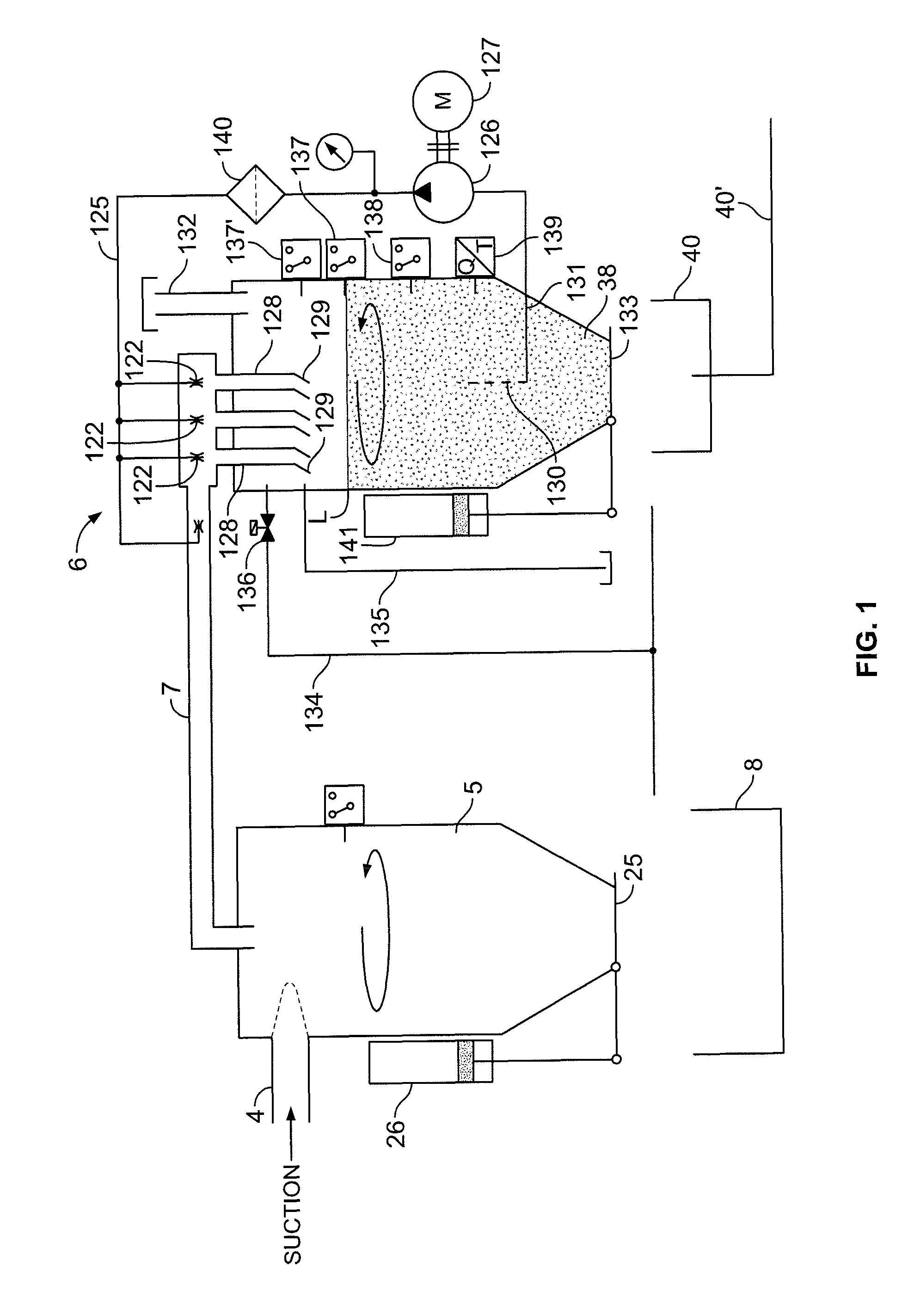

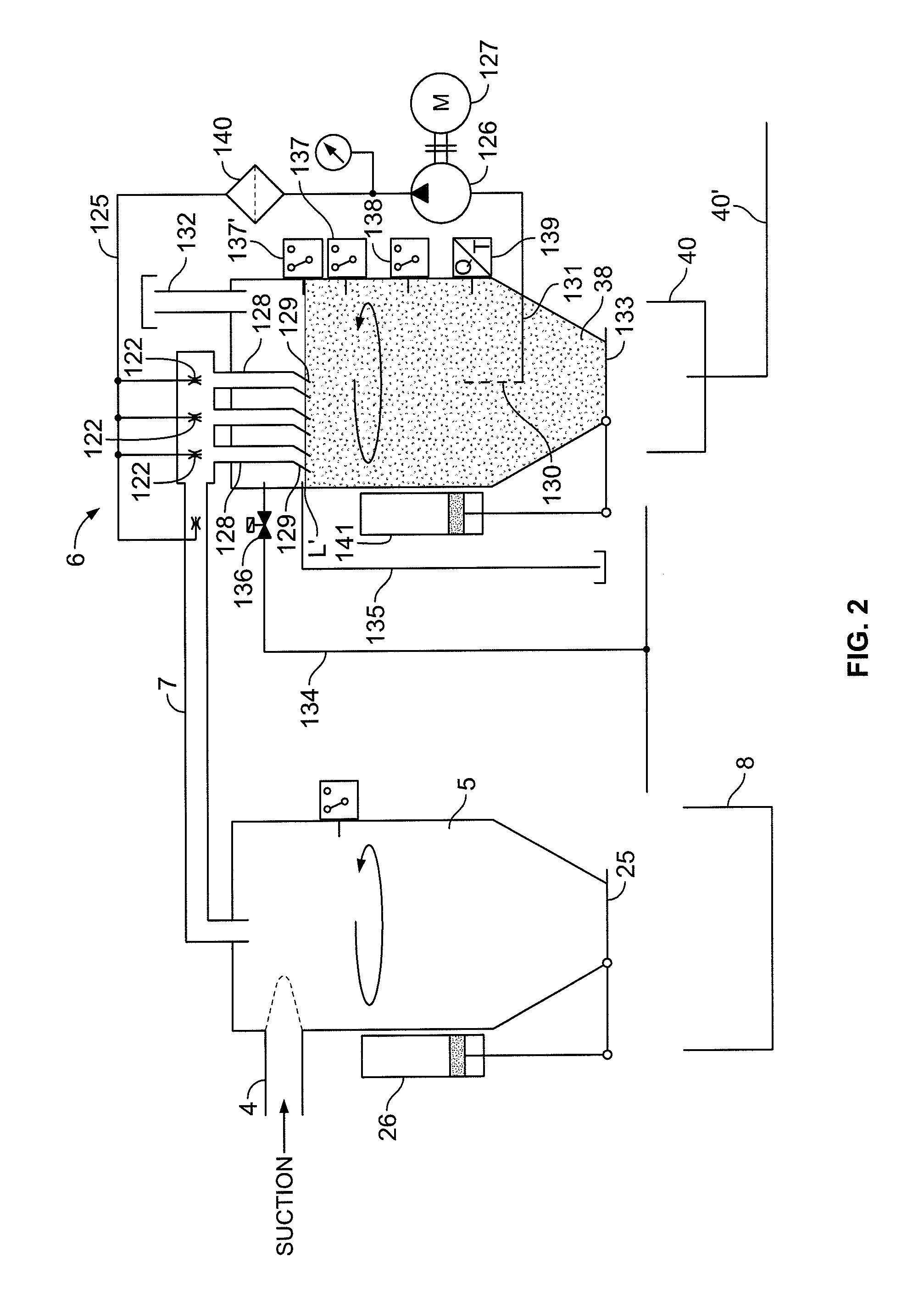

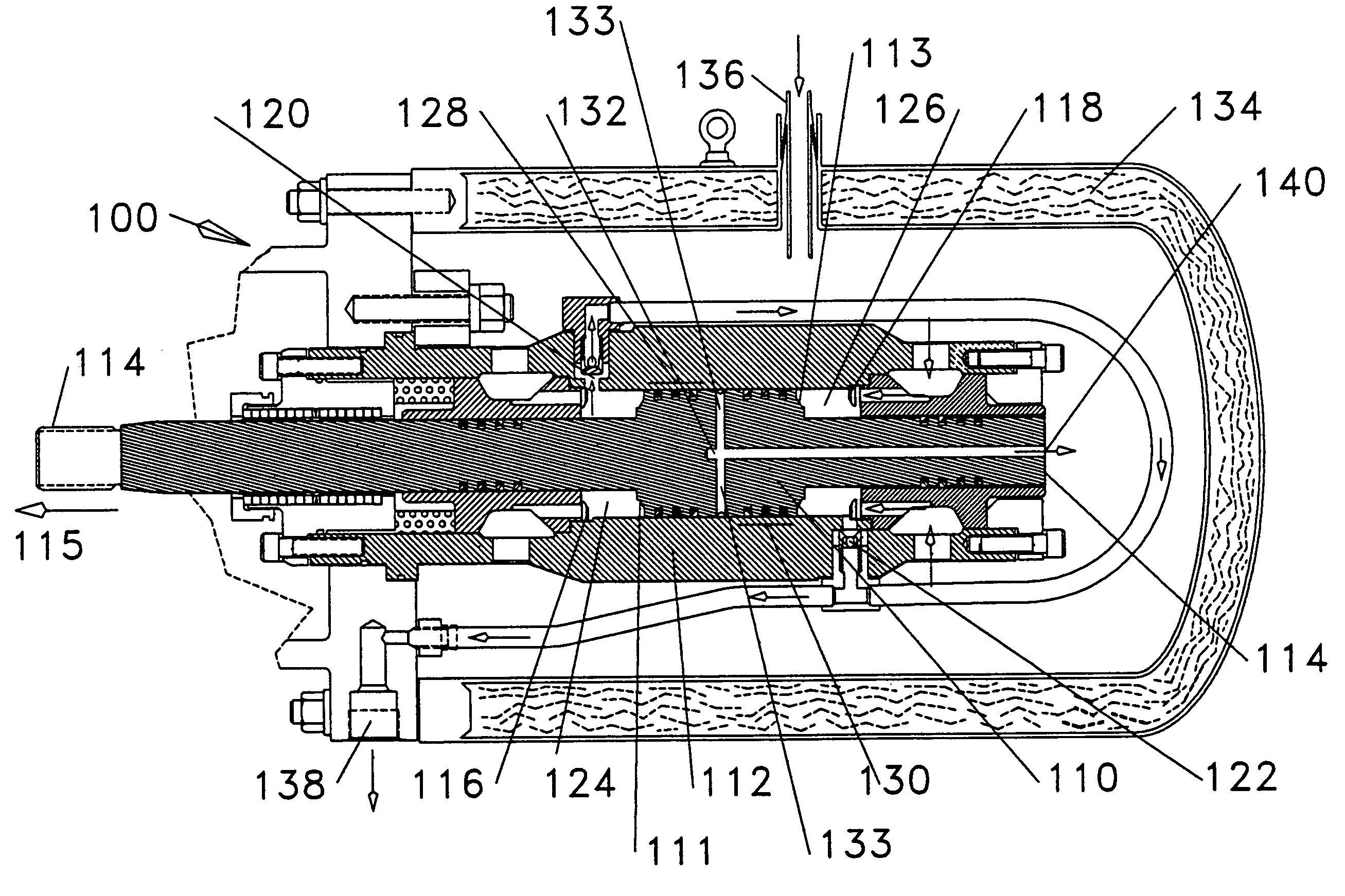

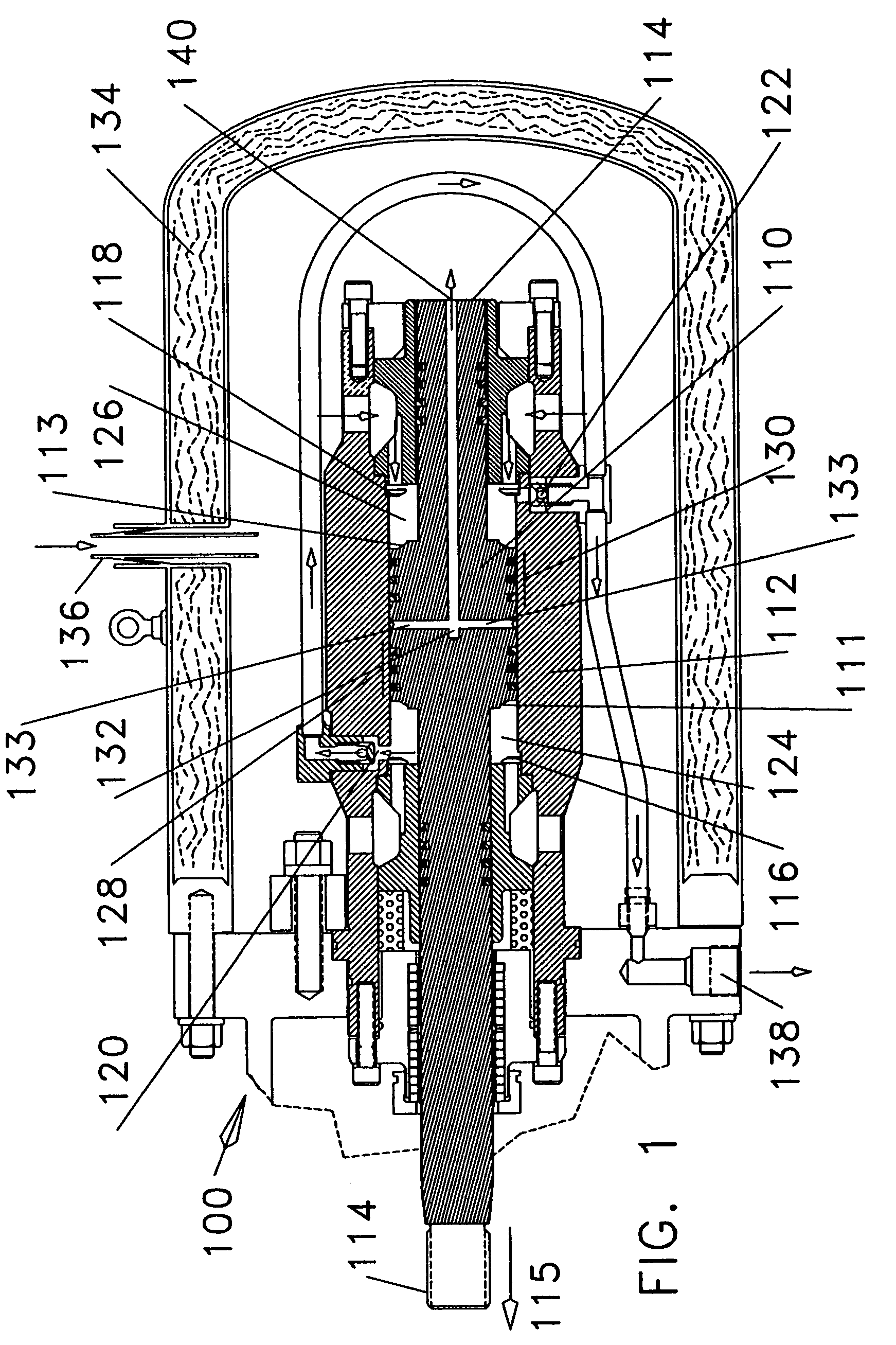

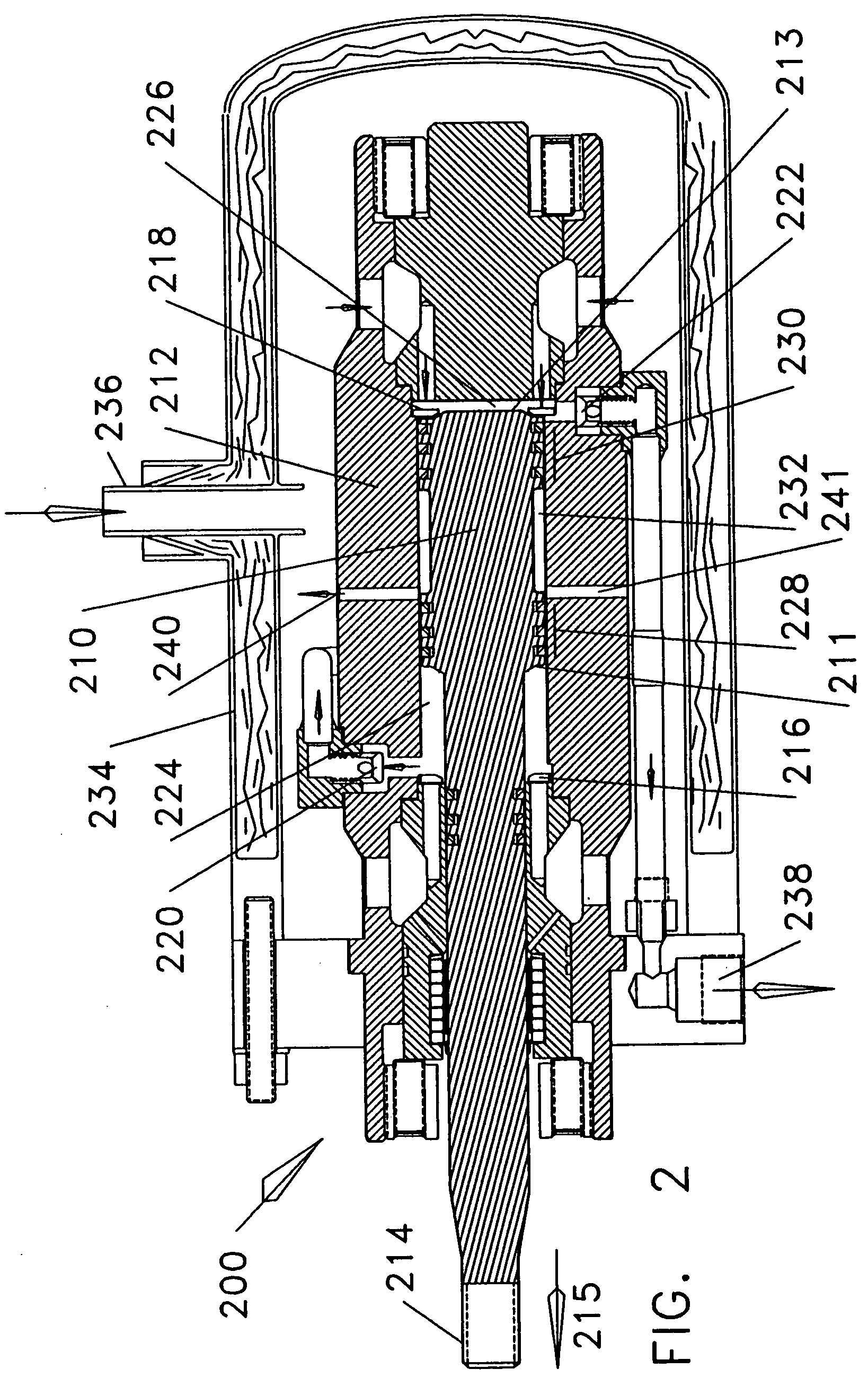

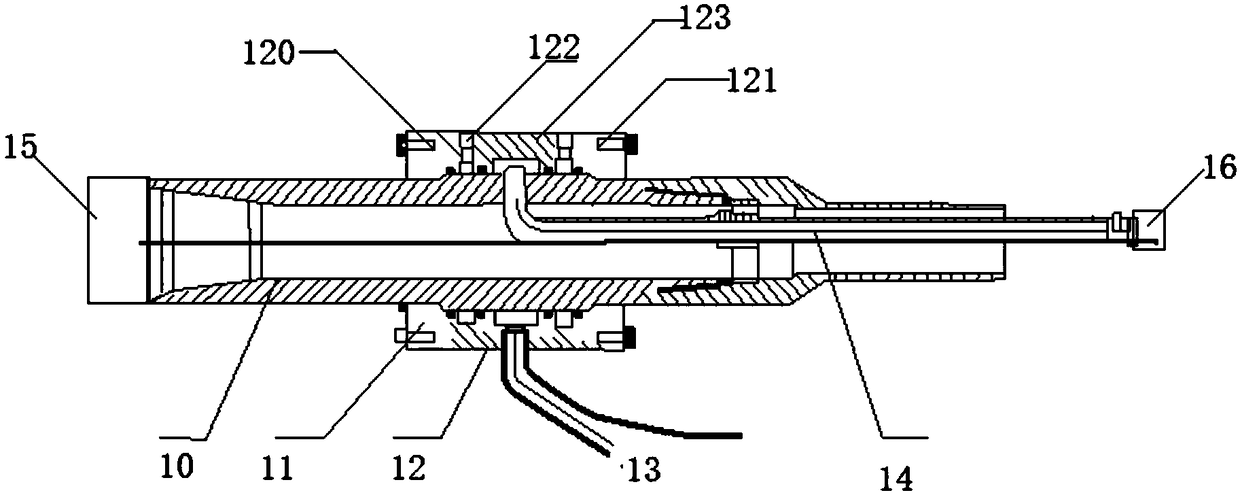

Method and apparatus for conveying material and ejector apparatus

ActiveUS7785044B2Improve efficiencyEfficient removalUsing liquid separation agentJet pumpsProduct gasPressure difference

A method for conveying material by applying a pressure difference in a conveying conduit (4), in which method the material is fed into the conveying conduit (4) and in the conveying conduit further into a separating device (5), where the material being conveyed is separated from conveying air, in which method a negative pressure is created in the conveying conduit (4) by means of an ejector apparatus (6), whose suction side is connected to the separating device (5), said ejector apparatus being operated using an operating medium consisting of a liquid mist, especially an aqueous liquid mist, said medium being sprayed through at least one spraying nozzle (122) into an ejector tube (128) directed into a separating element (38). In the method, the generation of the negative pressure to be produced is intensified according to need by limiting the flow of gases, such as air, into the ejector tube (128) from the direction opposite to the spraying direction of its operating medium, i.e. from the outlet end (129) of the ejector tube. The invention also relates to an apparatus and an ejector device.

Owner:MARICAP OY

Arrangement for cooling components in a vehicle

InactiveUS20070137235A1Price to produceReinforce effectAir-treating devicesDomestic cooling apparatusWaste management

Owner:SIEMENS AG

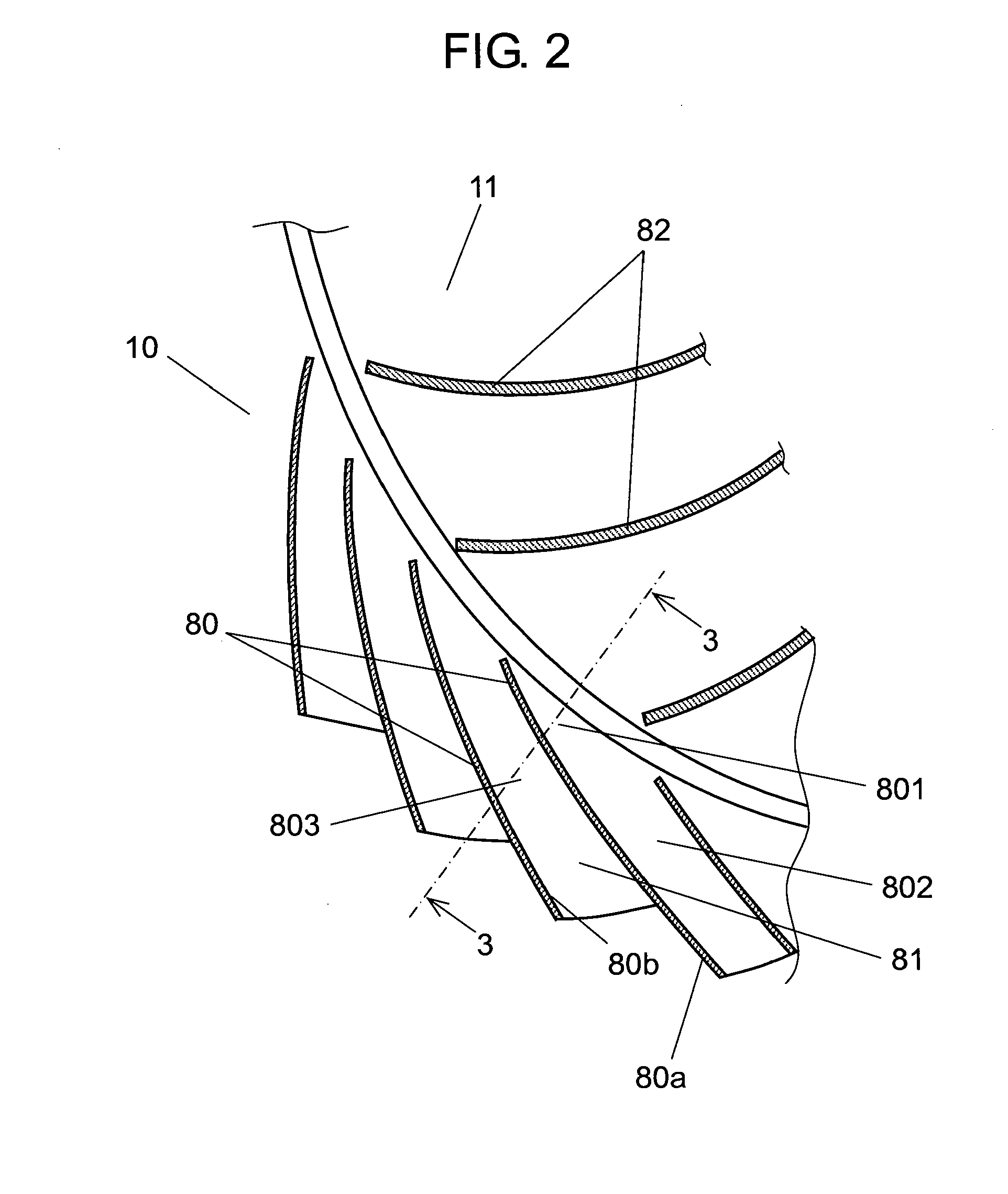

Electric blower and electric vacuum cleaner utilizing the same

InactiveUS20110277267A1High suction performanceReduce lossMechanical cleaningPressure cleaningImpellerEngineering

Air guide (10) that rectifies air blown out from an impeller includes a plurality of guide vanes (80) having a circular arc shape. In a cross-sectional shape of each one of flow passages (81) of air guide (10), length B of a straight-line portion in a shaft direction of an inner wall-surface formed by one of guide vanes (80) on an outer peripheral side is small compared with length A of a straight-line portion in a shaft direction of an inner wall-surface formed by one of guide vanes (80) on an inner peripheral side. This provides a uniformed flow velocity distribution inside flow passages (81), resulting in a reduced loss caused by differences in flow velocity.

Owner:PANASONIC CORP

Double-acting, high pressure cryogenic pump

ActiveUS7223080B2Small volumeReduce the overall diameterPositive displacement pump componentsContainer filling methodsHigh pressureDischarge pressure

Owner:DURON PAUL DAVID MR

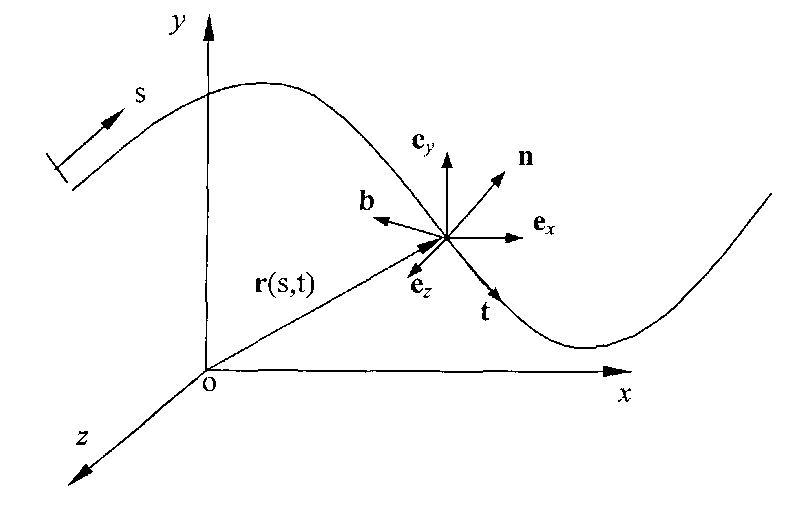

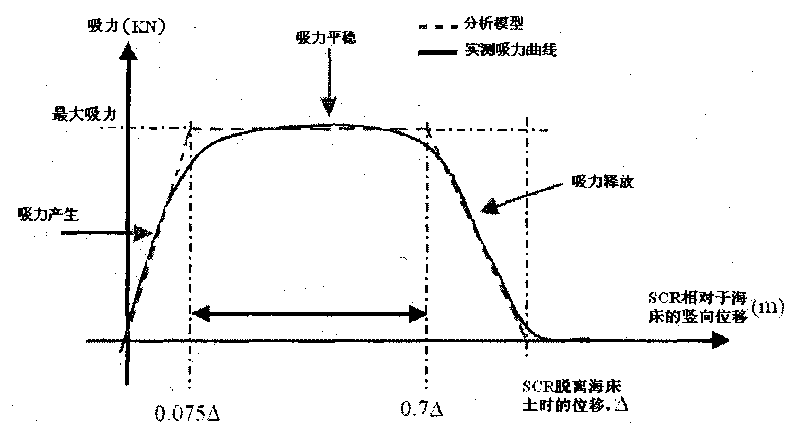

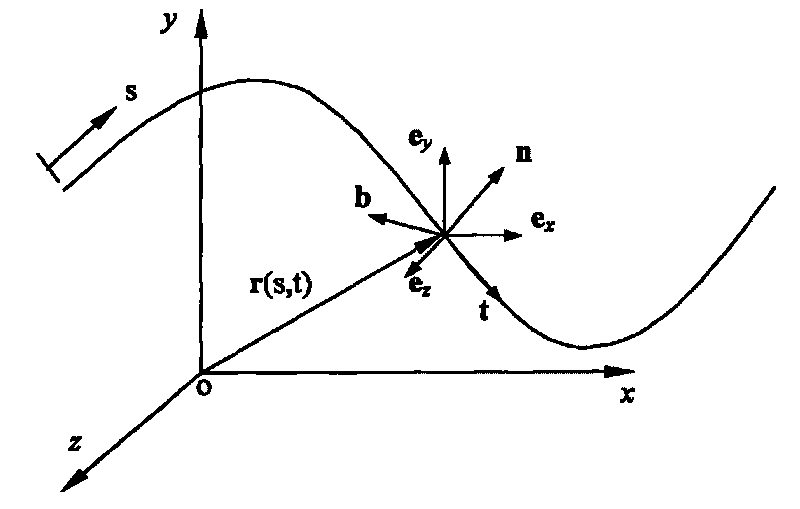

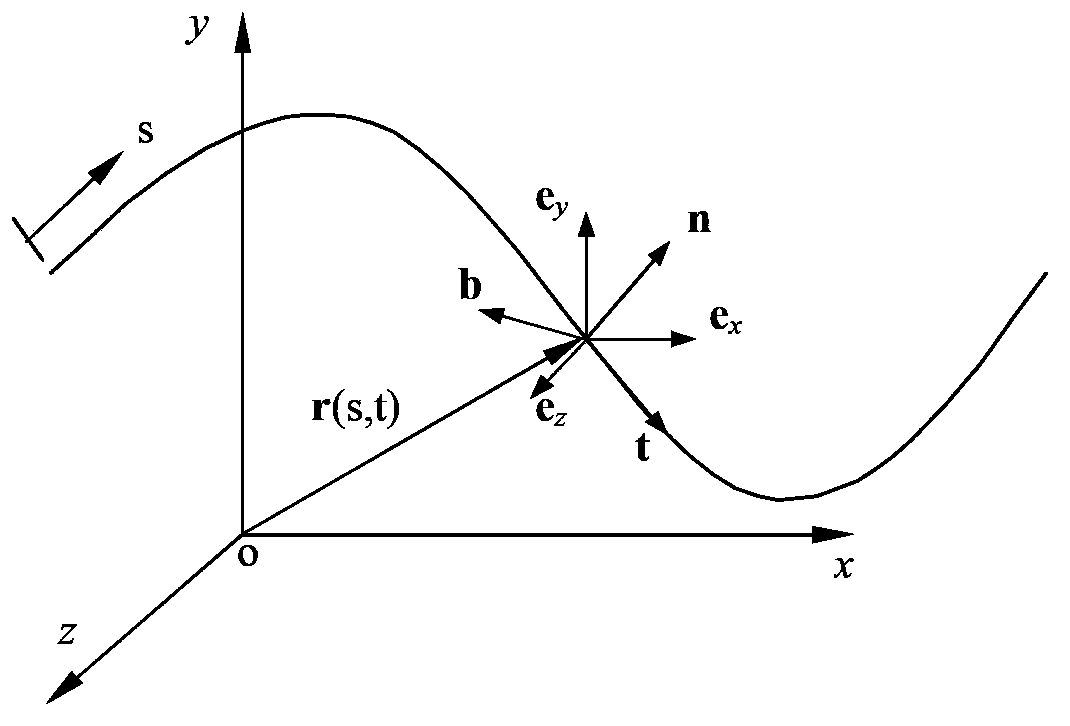

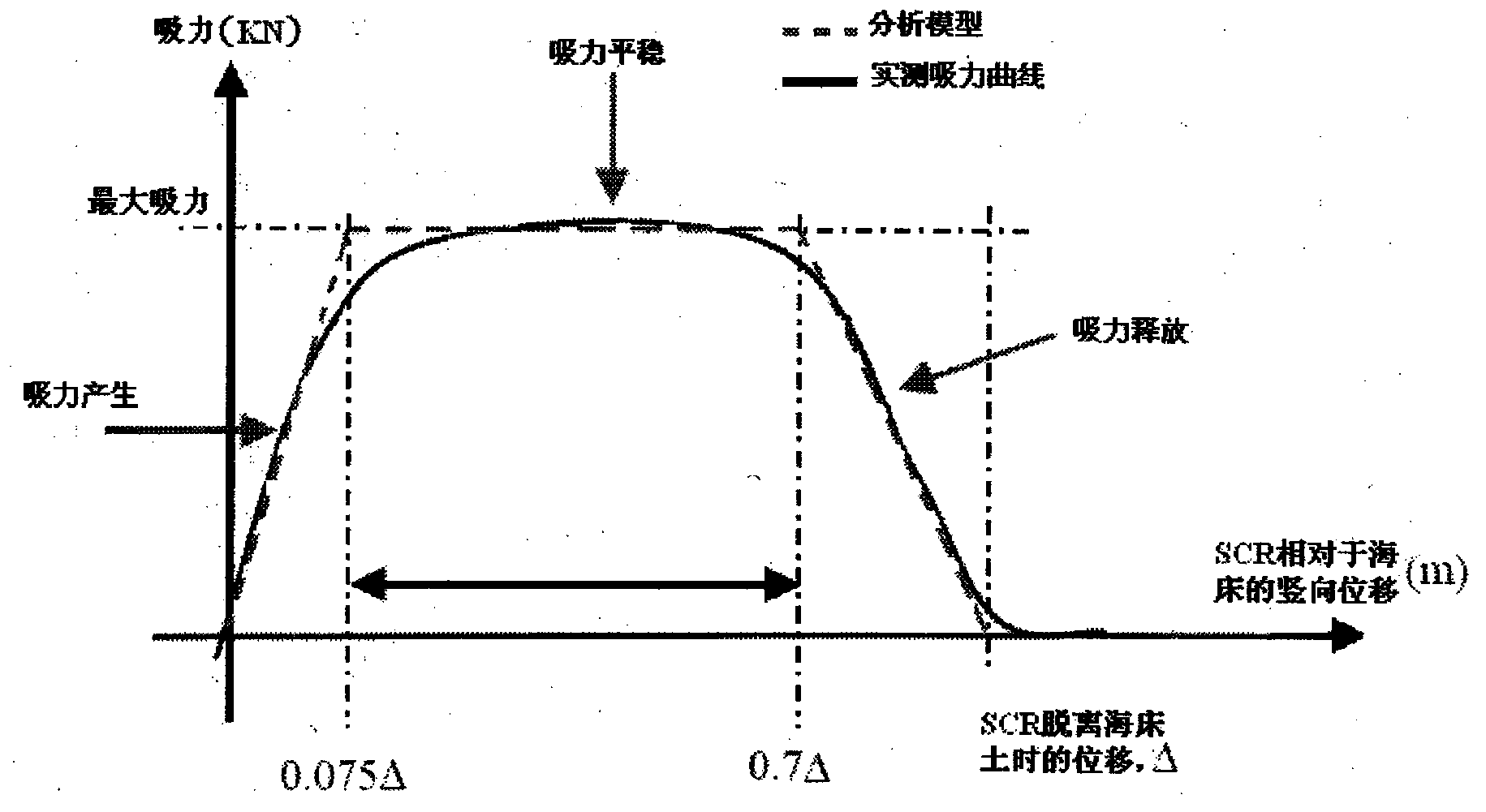

Method for analyzing response of steel catenary riser to waves

InactiveCN101713707AIncreased power couplingCreate an analysis methodStructural/machines measurementCatenaryFloating platform

The invention belongs to a technique for researching a steel catenary riser of a deep-sea oil and gas platform and particularly relates to a method for analyzing the response of a steel catenary riser to waves. In the method, a model of an elastic ground beam is used to simulate a streamline section of the steel catenary riser and the simulative models of the overhung section and the streamline section of the steel catenary riser are combined with the equation of motion of a floating platform to built an integrated motion analysis model of the steel catenary riser and the floating platform, the equation of the integrated motion analysis model is solved to obtain the response of the steel catenary riser to waves, and at the same time, a model of the suction of sea bed soil is built according to the influence of the suction of the sea bed soil to the steel catenary riser and is used in the analysis of the response of the steel catenary riser to waves. The method can improve the accuracy of the calculation of the steel catenary riser and makes the analysis of the steel catenary riser closer to the actual situation of a project.

Owner:OCEAN UNIV OF CHINA

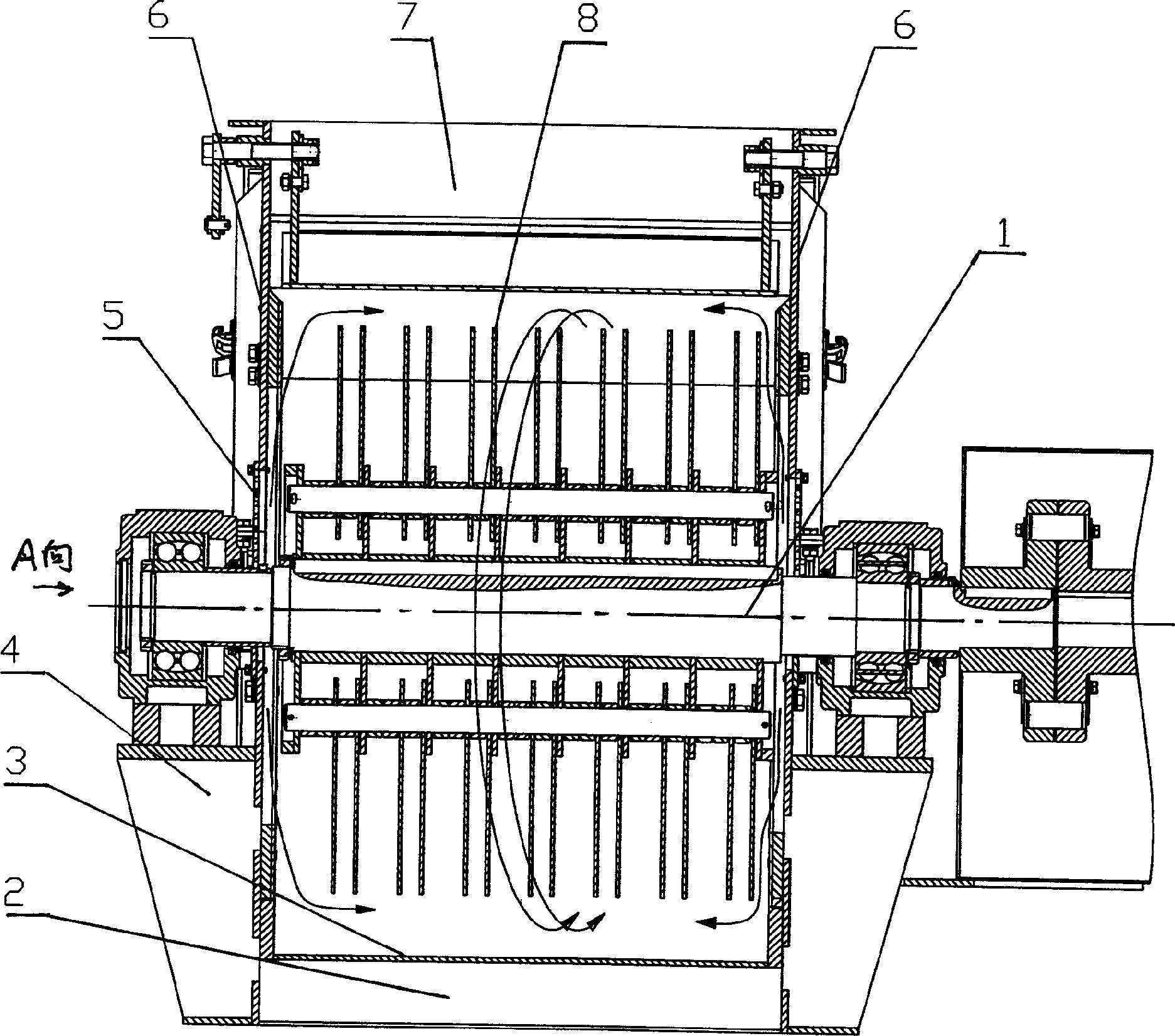

Horizontal pulverizer

The invention discloses a horizontal crusher belongs to the crusher technical fields, including a crushing chamber formed of the closing end plate and the lateral plate, the top of the chamber sets a feed inlet, while the inner of the chamber sets a rotor which is fixed on a chief axis horizontal crossing two end plate, the chief axis is fixed on the frame through the bearing, the lower of the chamber sets a discharge door, the space between the chamber and the discharge door is separated with the cribellum with many holes, the cribellum is fixed outside of the rotor half encompassing, and at least on side of the end plate which is in the excircle orthogonal projection of the rotor is fitted with a secondary air inlet. Said invention can destroy the circulating layer in the crushing chamber, which improves the efficiency of the crusher.

Owner:JIANGSU MUYANG GRP CO LTD

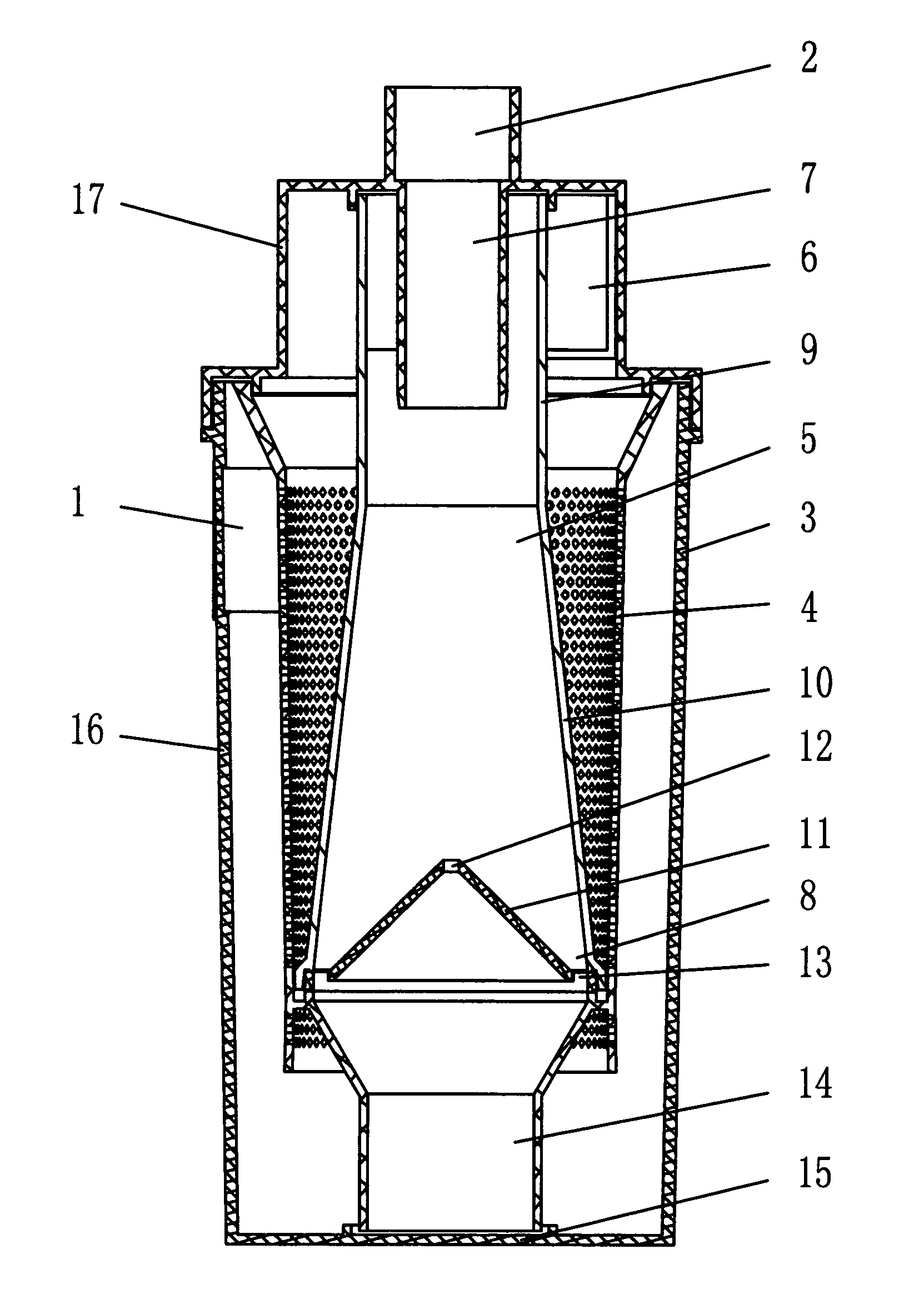

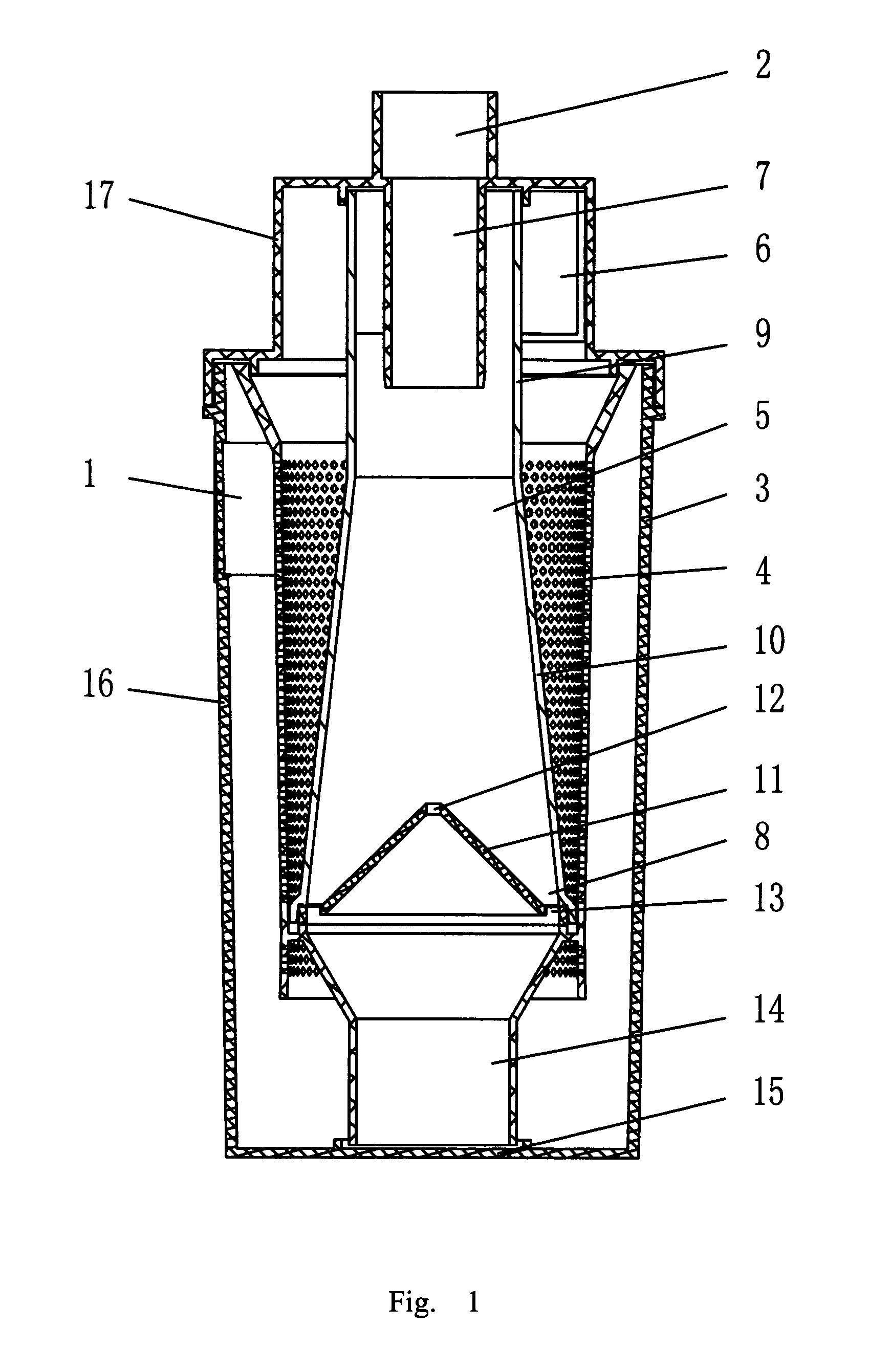

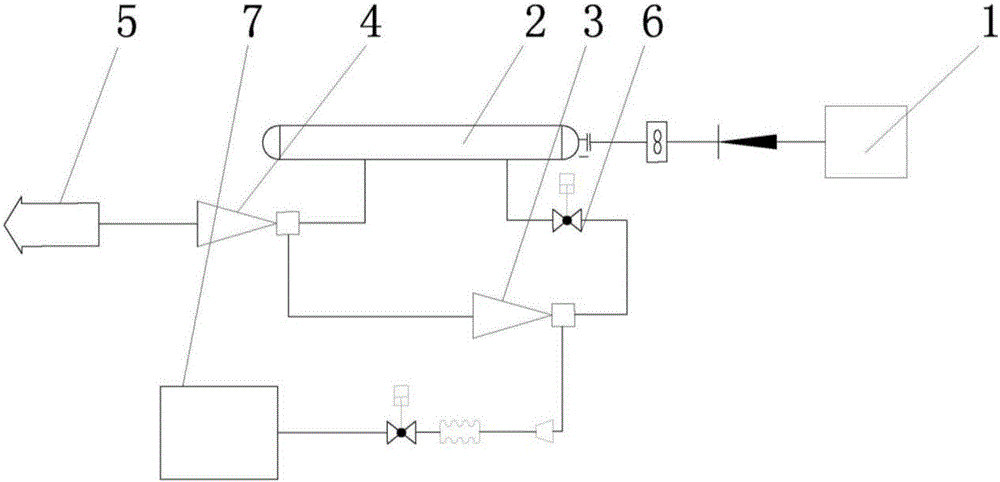

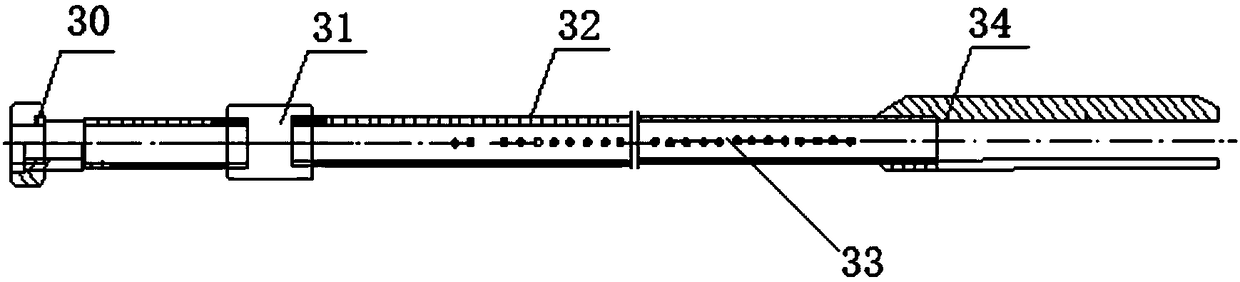

Vacuumizing system and method for vacuum cabin of ramjet engine

ActiveCN106368990AImprove test capabilitiesIncrease air flowGas-turbine engine testingJet pumpsRamjetWorking range

The invention belongs to the technical field of ramjet engine tests, and in particular relates to a vacuumizing system and a vacuumizing method for a vacuum cabin of a ramjet engine. The system comprises a vapor source, a vapor distributer, a first-stage ejection device, a second-stage ejection device, a muffling tower and a switch valve, wherein the first-stage ejection device and the second-stage ejection device are connected in series; a vapor inlet of the first-stage ejection device communicates with the vapor distributor through the switch valve; a vapor inlet of the second-stage ejection device communicates with the vapor distributor; a vapor outlet of the second-stage ejection device communicates with the external environment through the muffling tower; a vacuumizing inlet of the first-stage ejection device communicates with the vacuum cabin to be vacuumized; and the vapor distributor is connected with the vapor source. The system and the method, provided by the invention, have the advantages of large working range and high vacuumizing ability.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

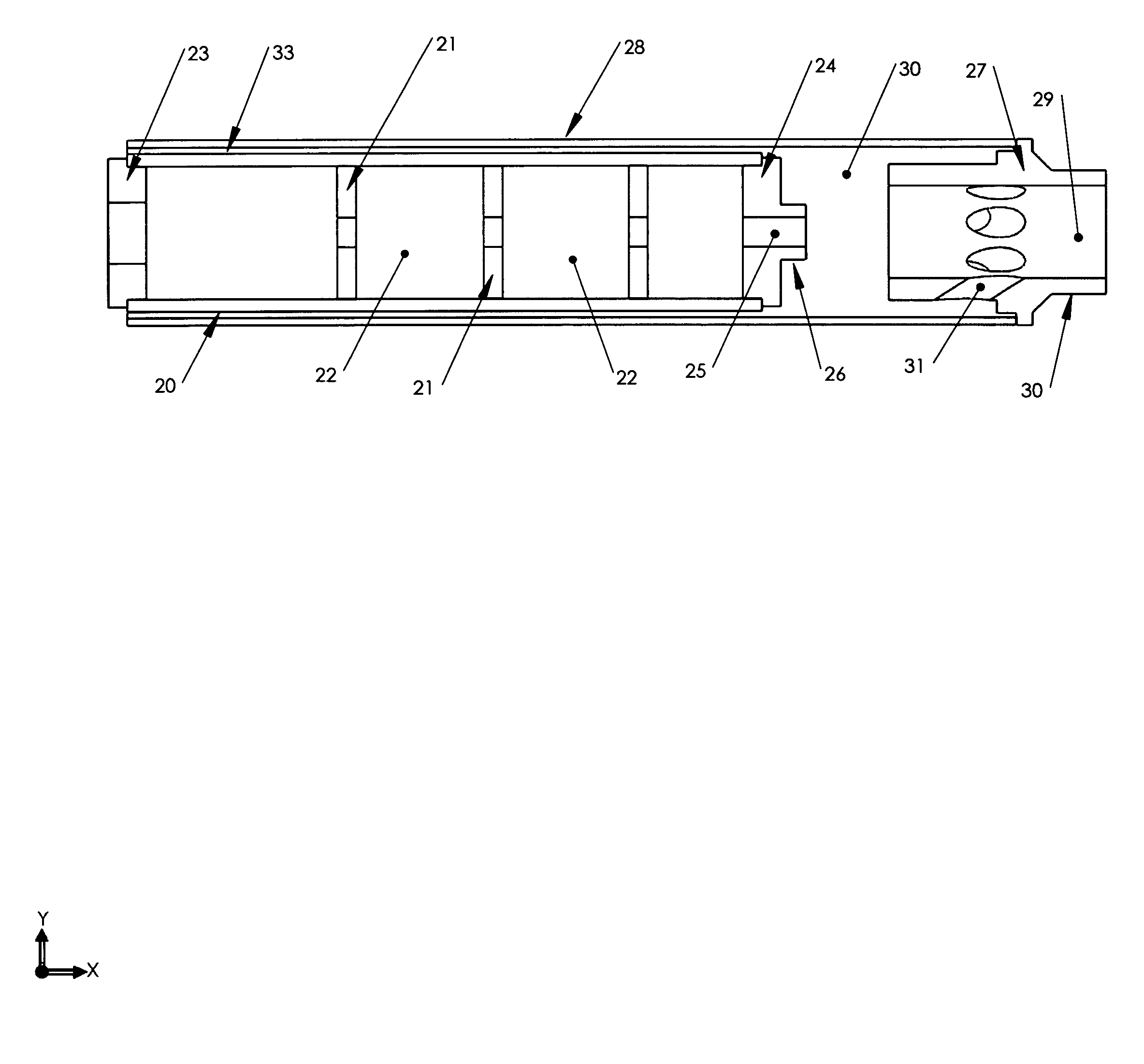

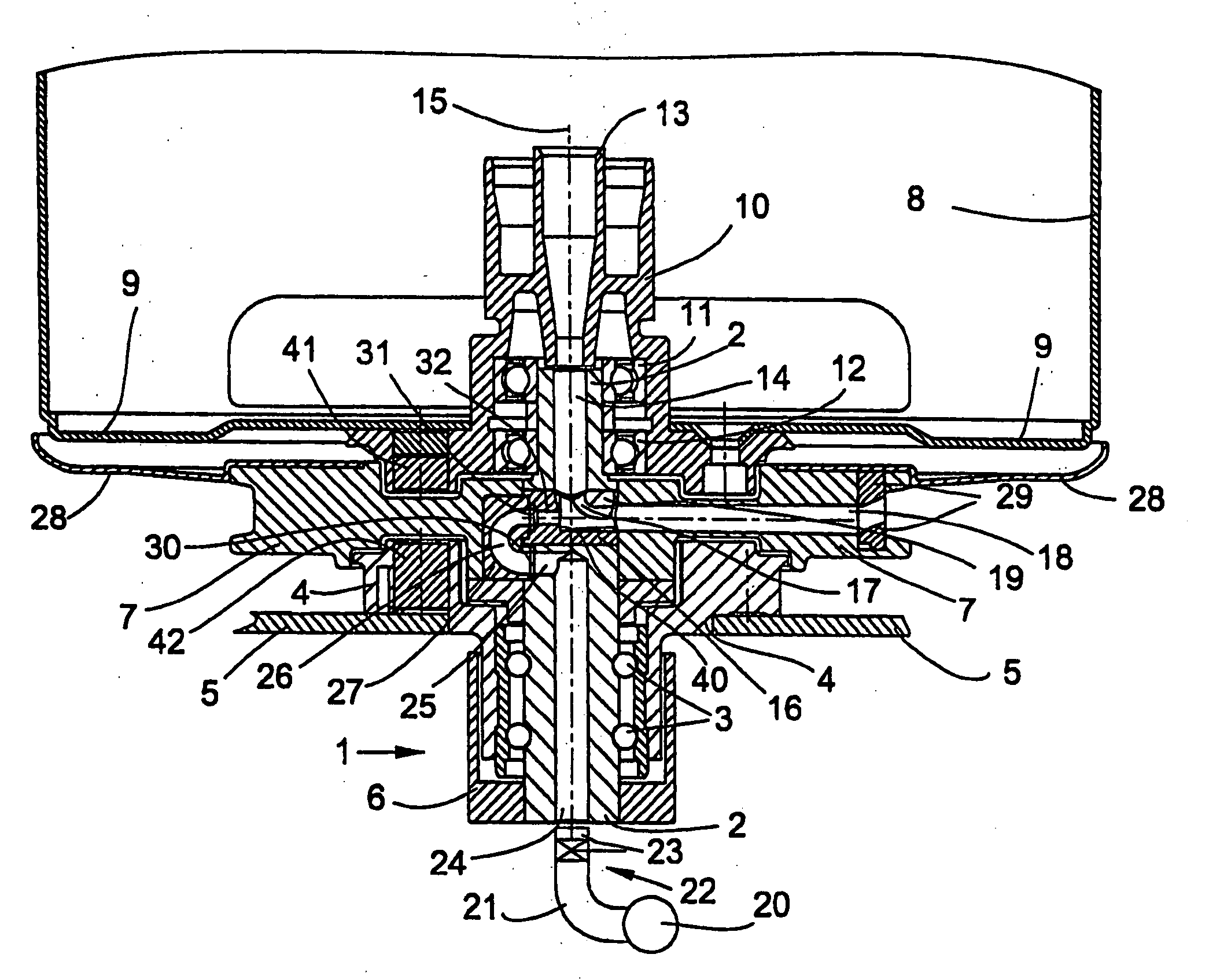

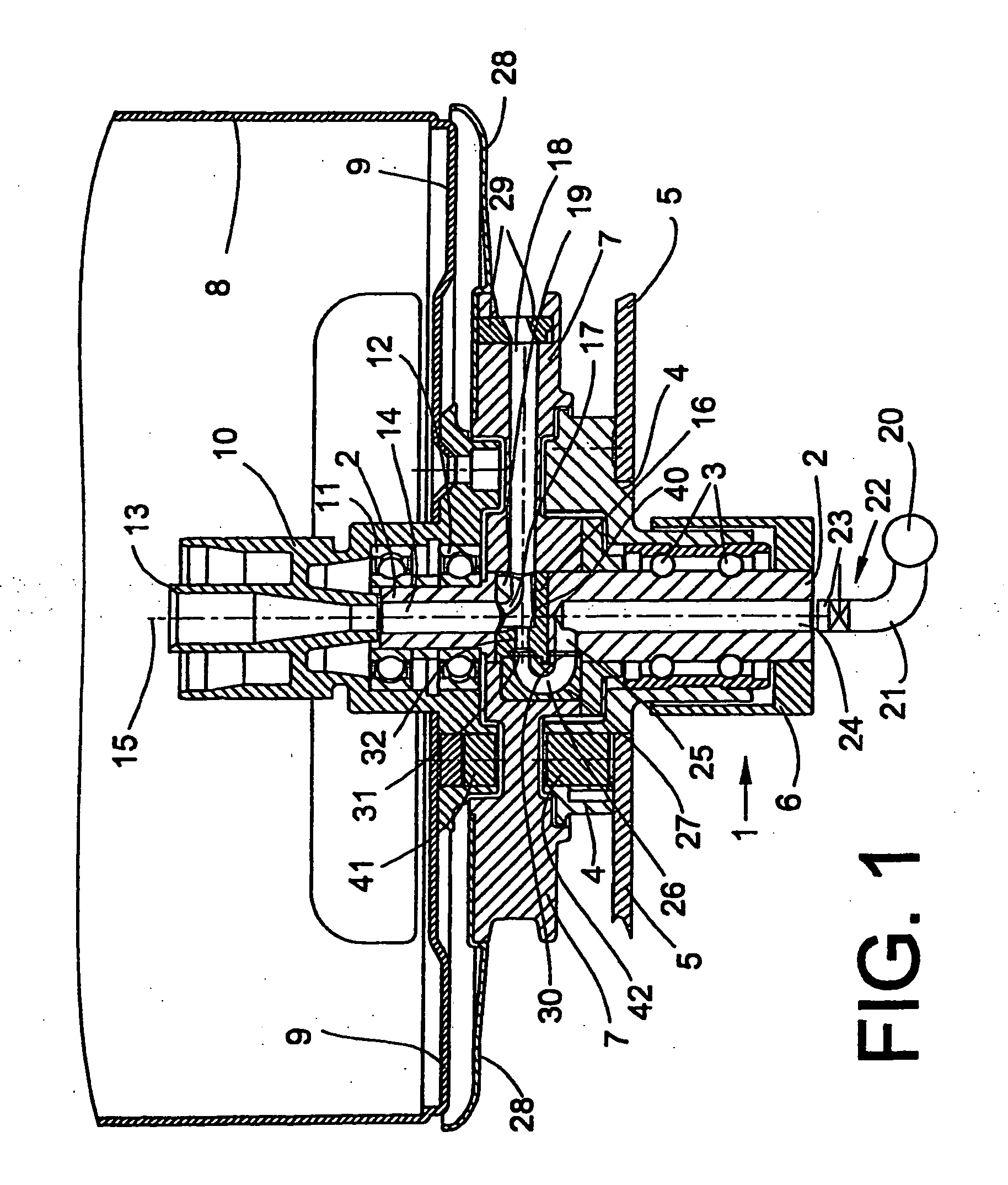

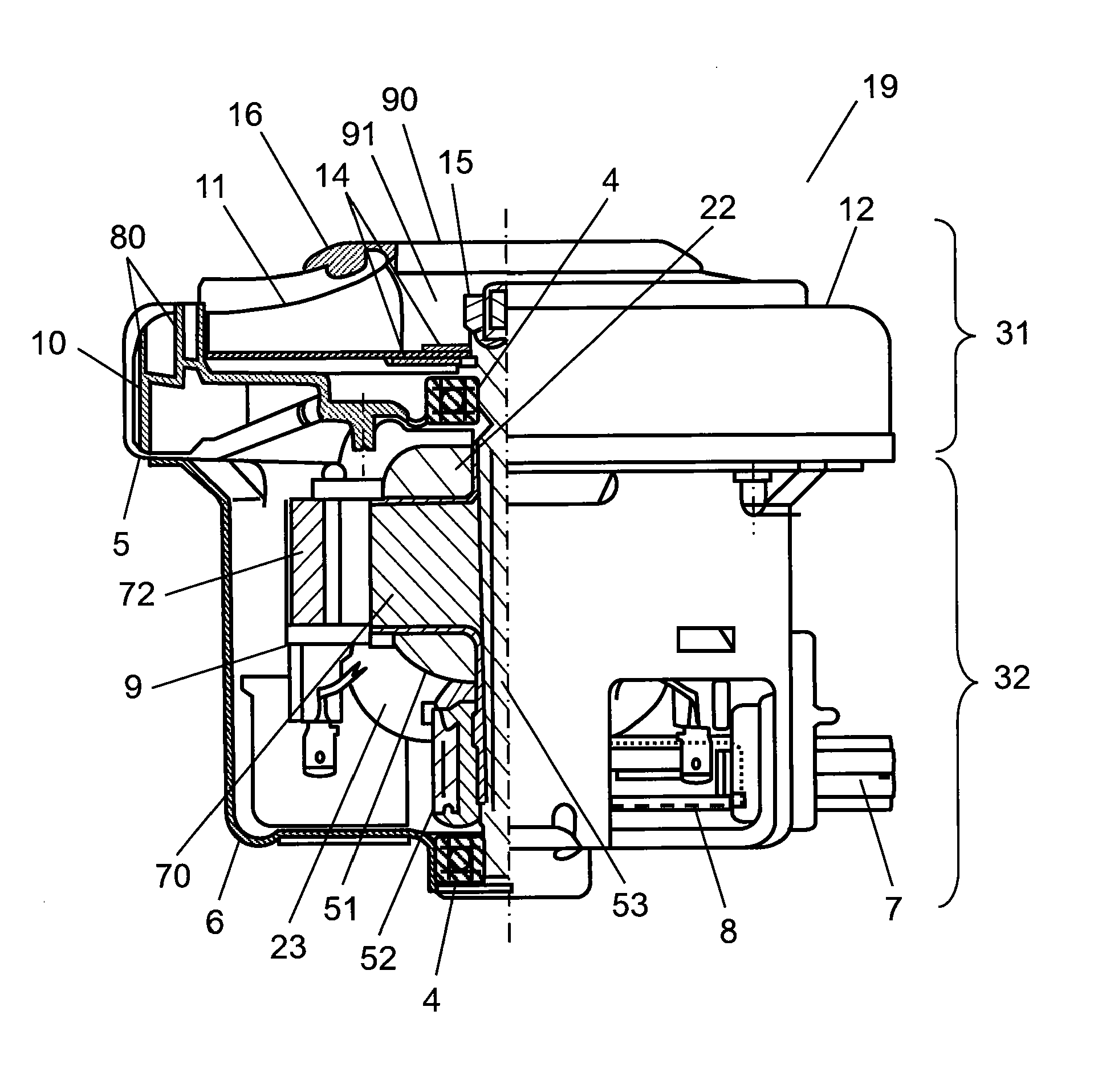

Vacuum-cleaning robot

ActiveUS9661971B2Improve suction capacityGreat suctionCarpet cleanersFloor cleanersLeading edgeEngineering

A self-propelled vacuum cleaner has a main housing having a bottom wall formed with an aperture, floor-engaging wheels on the main housing, and a drive in the main housing for rotating the wheels and advancing the main housing in a normal horizontal travel direction. A module housing projecting through the aperture forms a brush compartment defining a downward directed suction opening having relative to the direction a leading edge and a trailing edge. The module housing is supported in the main housing for limited vertical movement of the module housing relative to the main housing. A brush in the module housing is engageable through the opening with a floor beneath the opening, and a blower in the module housing having an intake connected via a duct to the brush compartment for aspirating air through the opening and past the brush into the module housing.

Owner:WESSEL WERK

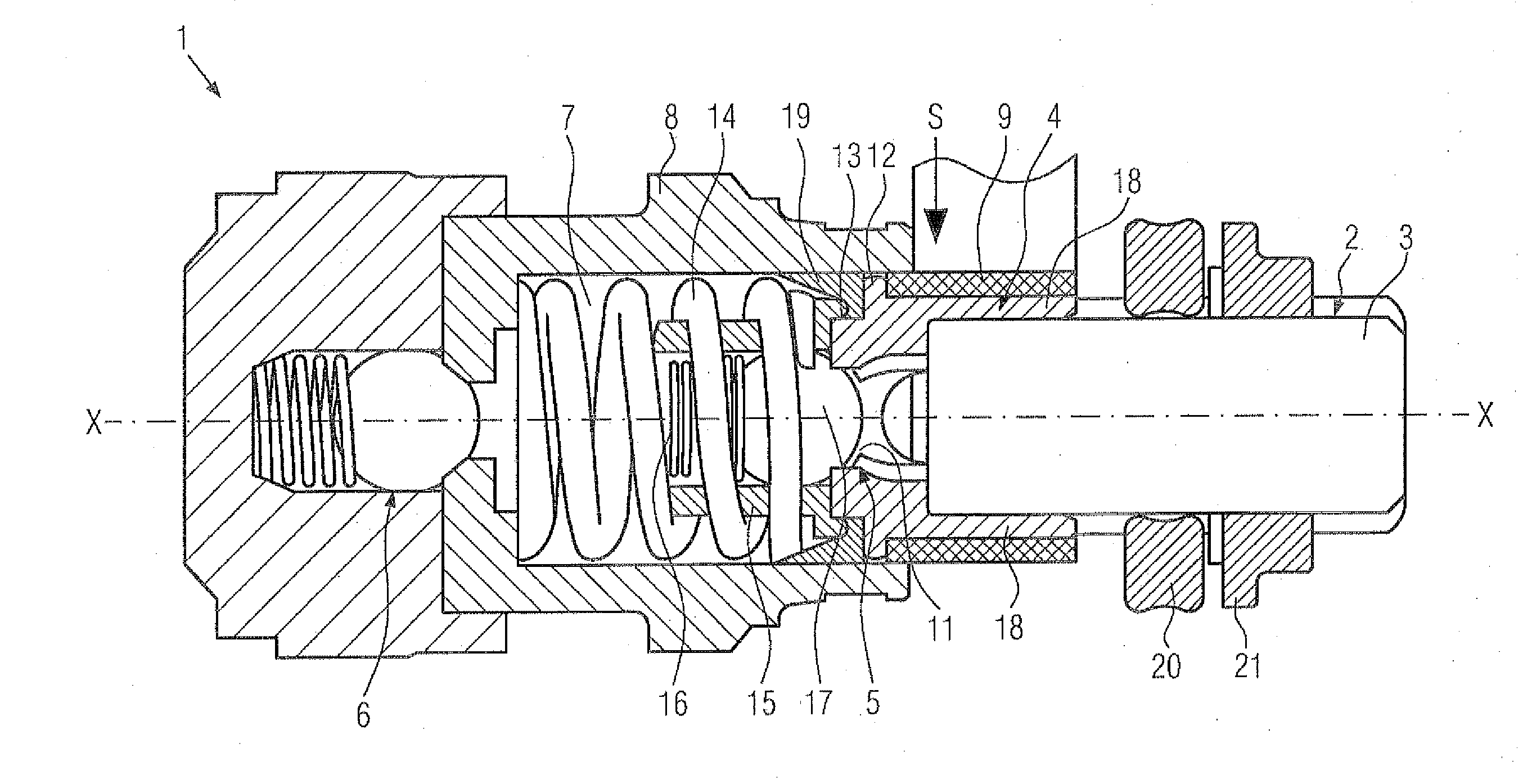

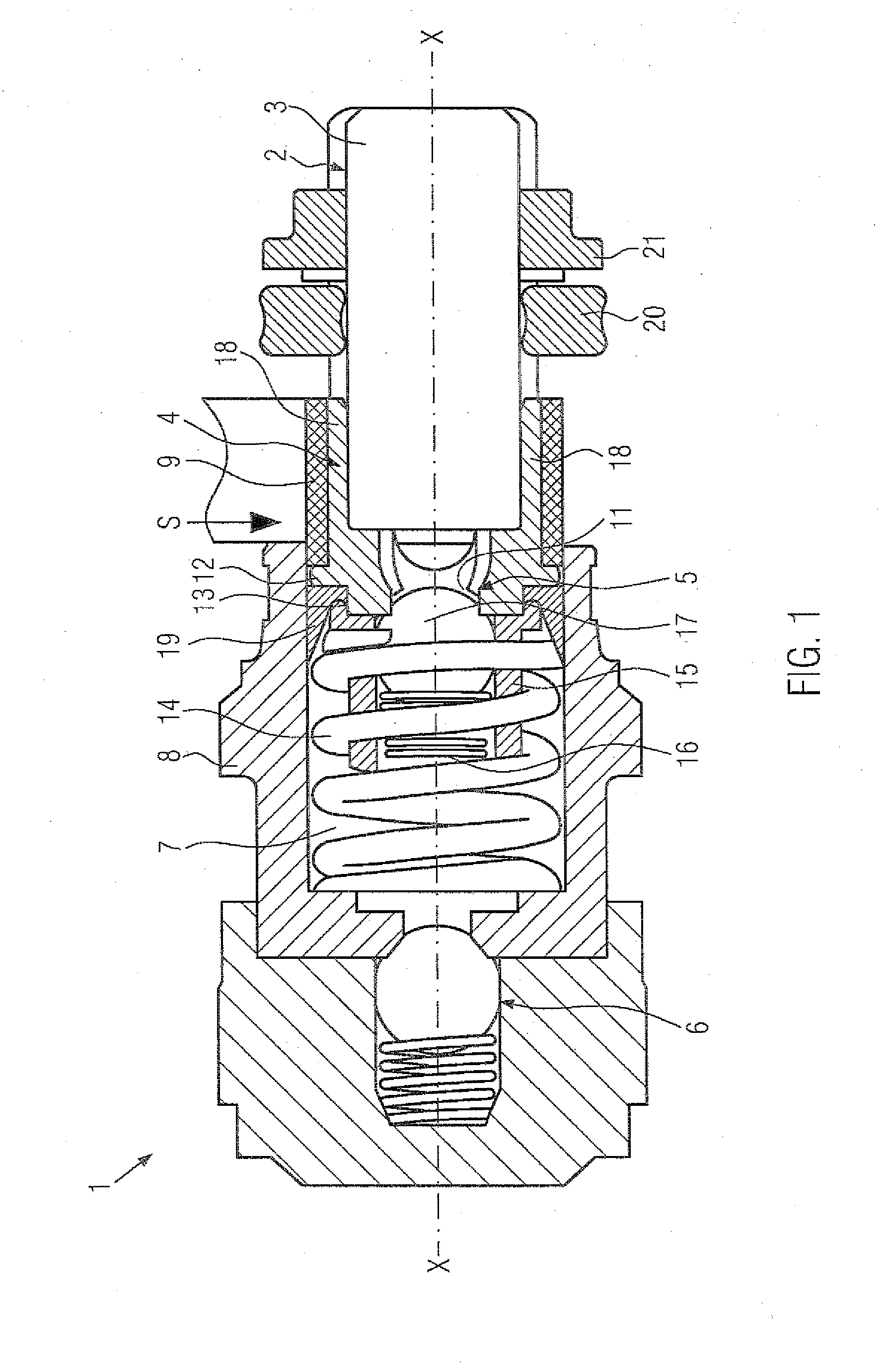

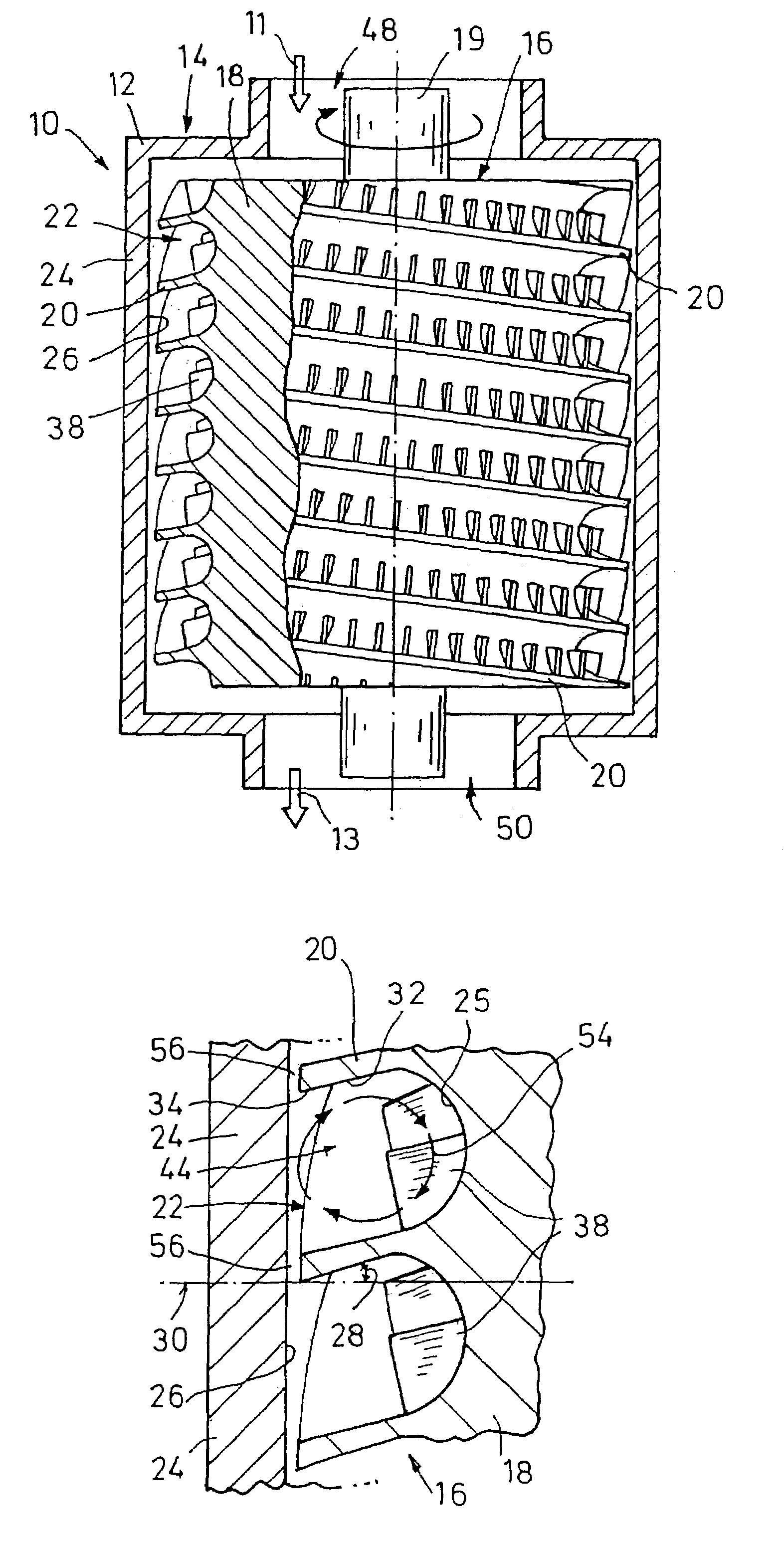

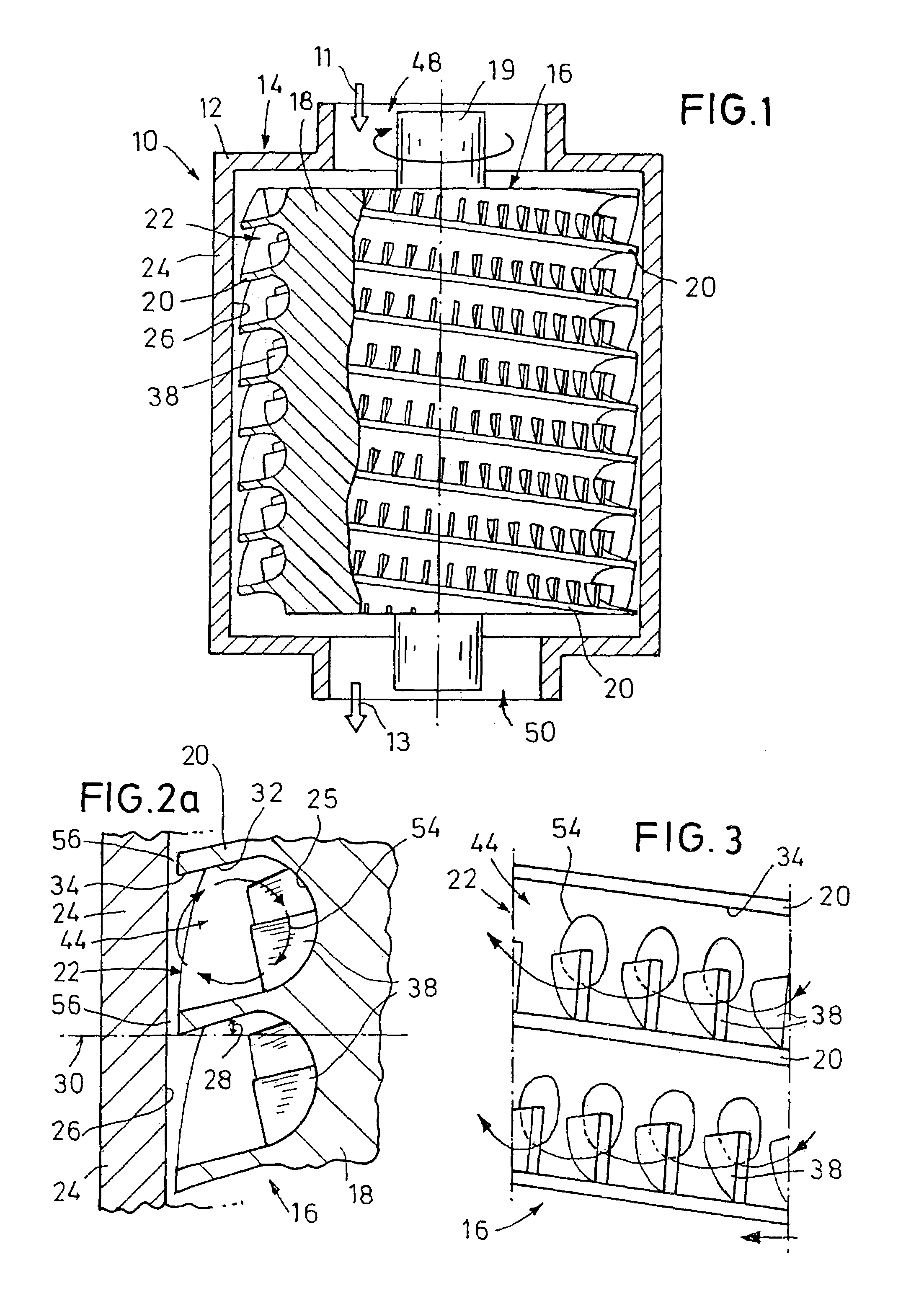

Pump embodied as a side channel pump

InactiveUS7090460B2Easy to compressReduce noisePropellersCircumferential flow pumpsConductor CoilVacuum pump

A side channel pump, preferably a vacuum pump, includes a driven rotor (16) and a fixed stator (14). The rotor (16) and the stator (14) define a pump channel circulating in a peripheral direction. Blades are fixed onto the rotor, protruding into the cross-section of the pump channel. The pump channel also includes a blade-free side channel (44). The pump channel (22) containing the side channel (44) extends in a helical manner around the rotor (16). The pump channel is advantageously not limited to the length of a winding but can have the length of substantially any number of uninterrupted windings. As a result, a high suction performance and a high compression ratio in the pump can be obtained.

Owner:LEYBOLD VAKUUM GMBH

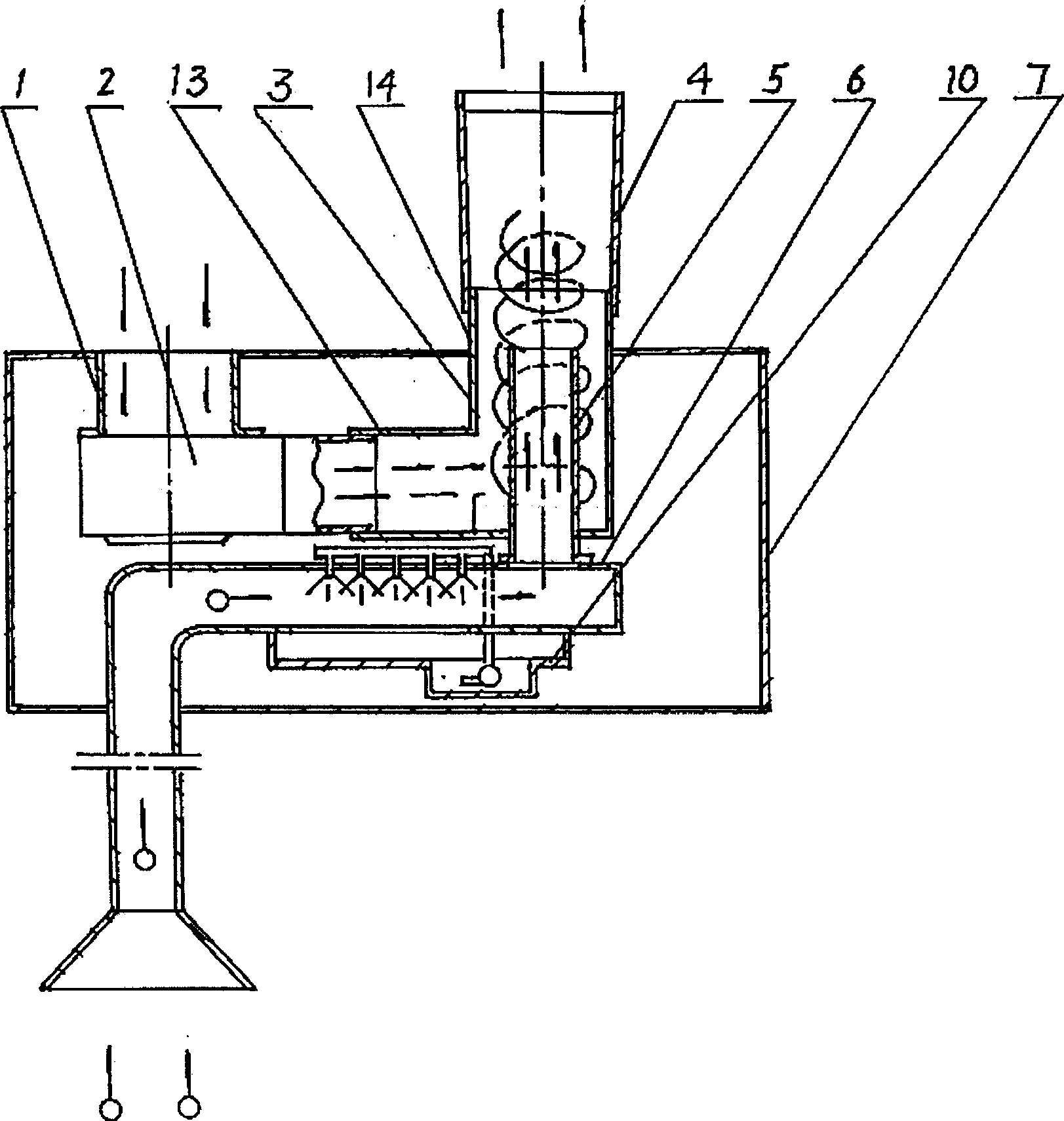

Suction structure and suction method for air suction device of sewing machine

InactiveCN105544105AStrong suctionImprove suction capacitySewing-machine elementsDirt cleaningSuction forceEngineering

The invention provides a suction structure and a suction method for an air suction device of a sewing machine. The air suction device comprises a dustbin storing waste materials. The top cover of the dustbin is provided with an air inlet and a suction outlet. The exhaust inlet is communicated with an air suction motor. The dustbin is internally provided with a spiral air suction channel communicated with the suction outlet. The spiral air suction channel is used to make spiral airflow form in the dustbin under the suction forces of the air suction motor, so as to form a strong negative pressure region, and make the air inlet of the dustbin have very strong suction forces. Under the condition that the power of the air suction motor is not changed, the strongest air suction effect is achieved.

Owner:JACK SEWING MASCH CO LTD

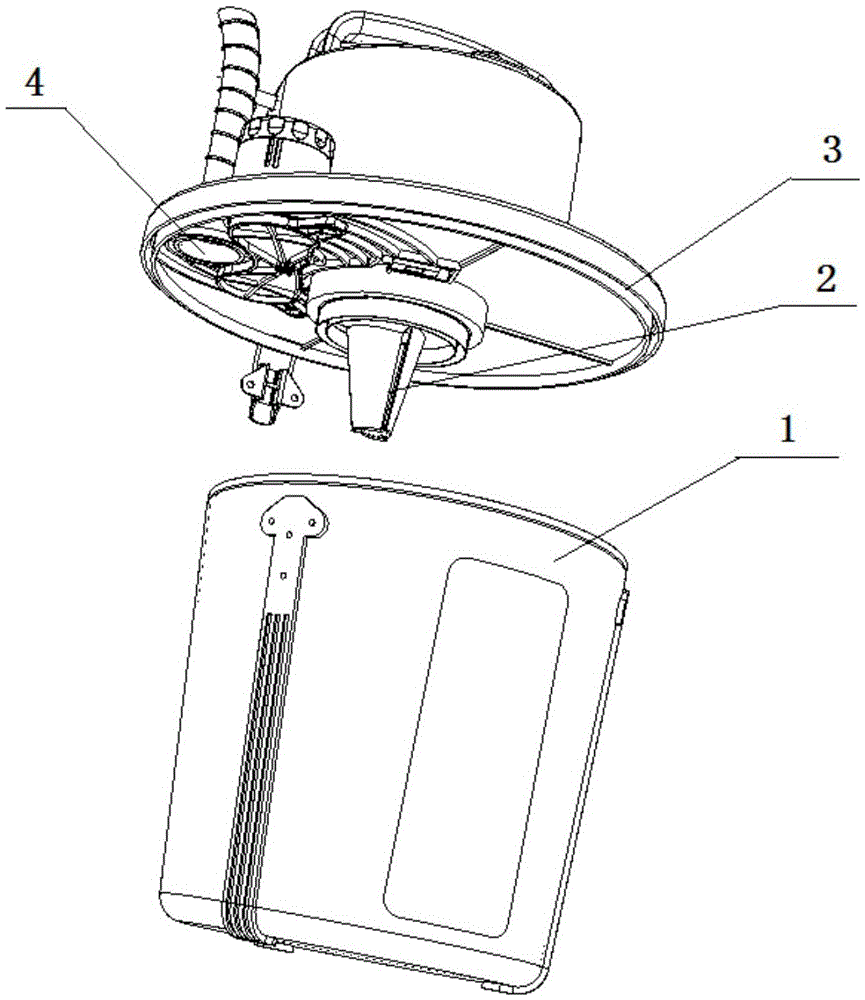

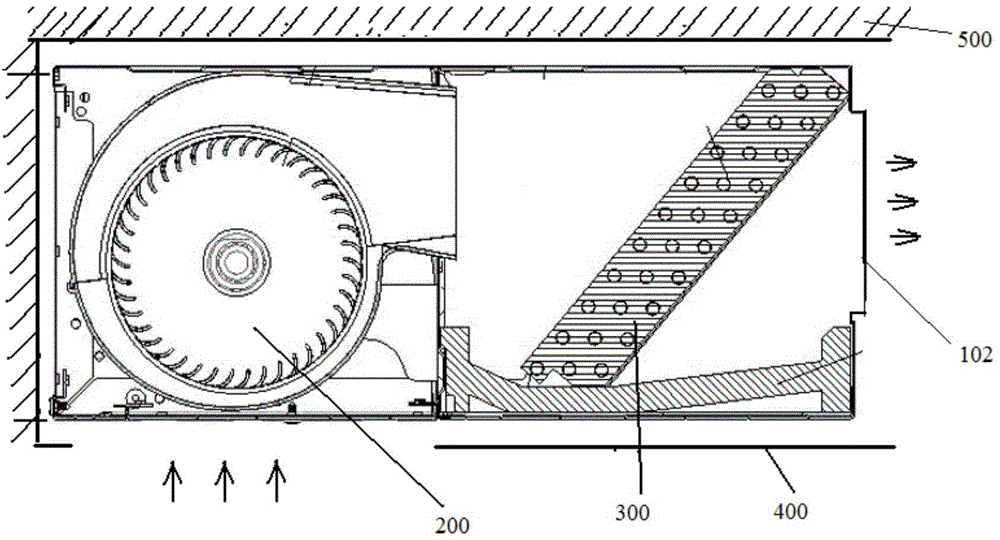

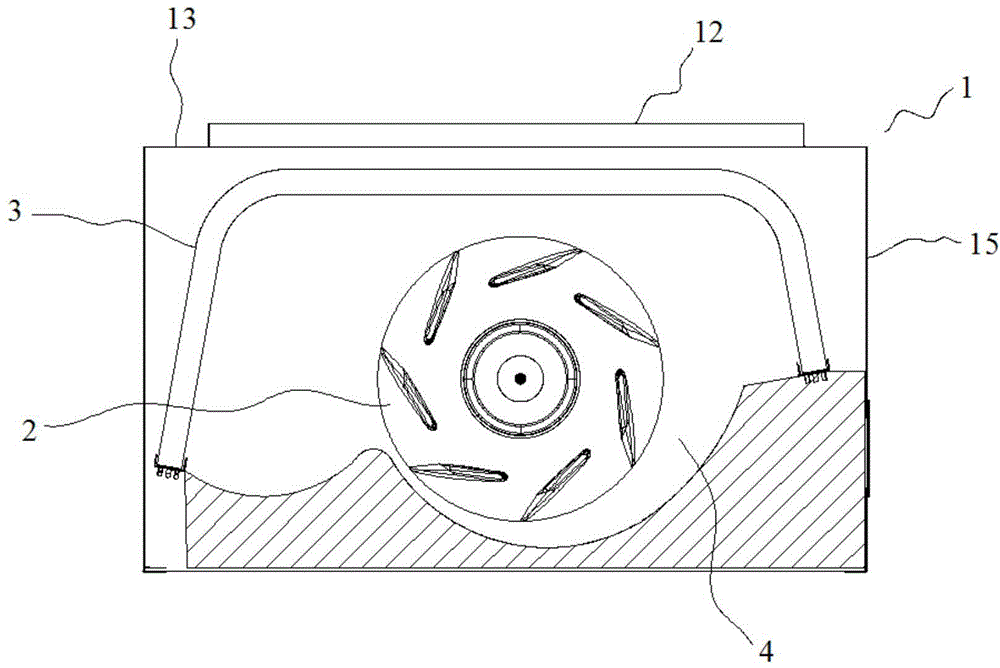

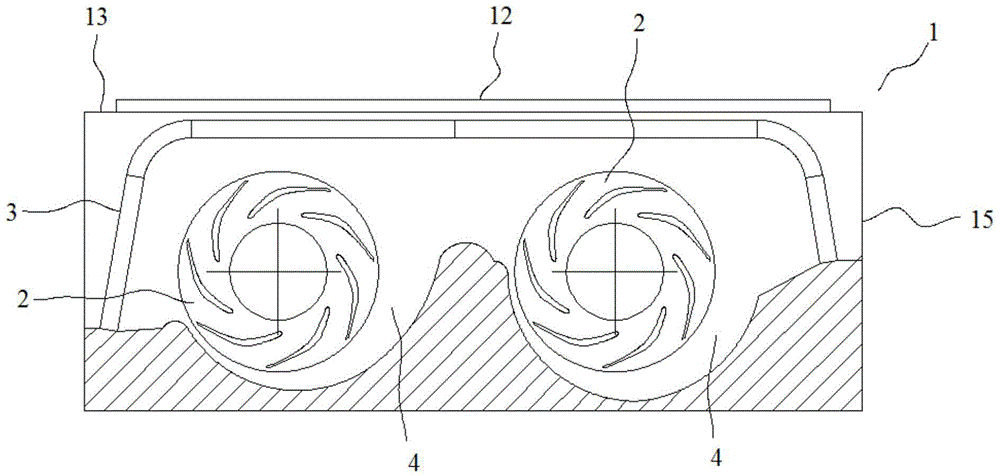

Ducted air conditioner and air conditioner

InactiveCN105588185ASmall footprintImprove suction capacityLighting and heating apparatusAir conditioning systemsTurbofanEngineering

The invention provides a ducted air conditioner and an air conditioner, and relates to the technical field of air conditioners. The air supply effect is guaranteed, meanwhile, the occupied space of the ducted air conditioner can be reduced, and noise can be lowered. The ducted air conditioner comprises a shell, at least one turbofan and a heat exchanger. The shell comprises a top face, the top face is used for being connected with an indoor ceiling, and an air return opening and an air outlet are formed in the shell. The turbofans are arranged in the shell, and rotary shafts of the turbofans are perpendicular to the top face of the shell. The heat exchanger is arranged in the shell and located among the turbofans and the air outlet. The ducted air conditioner is used for the air conditioner.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

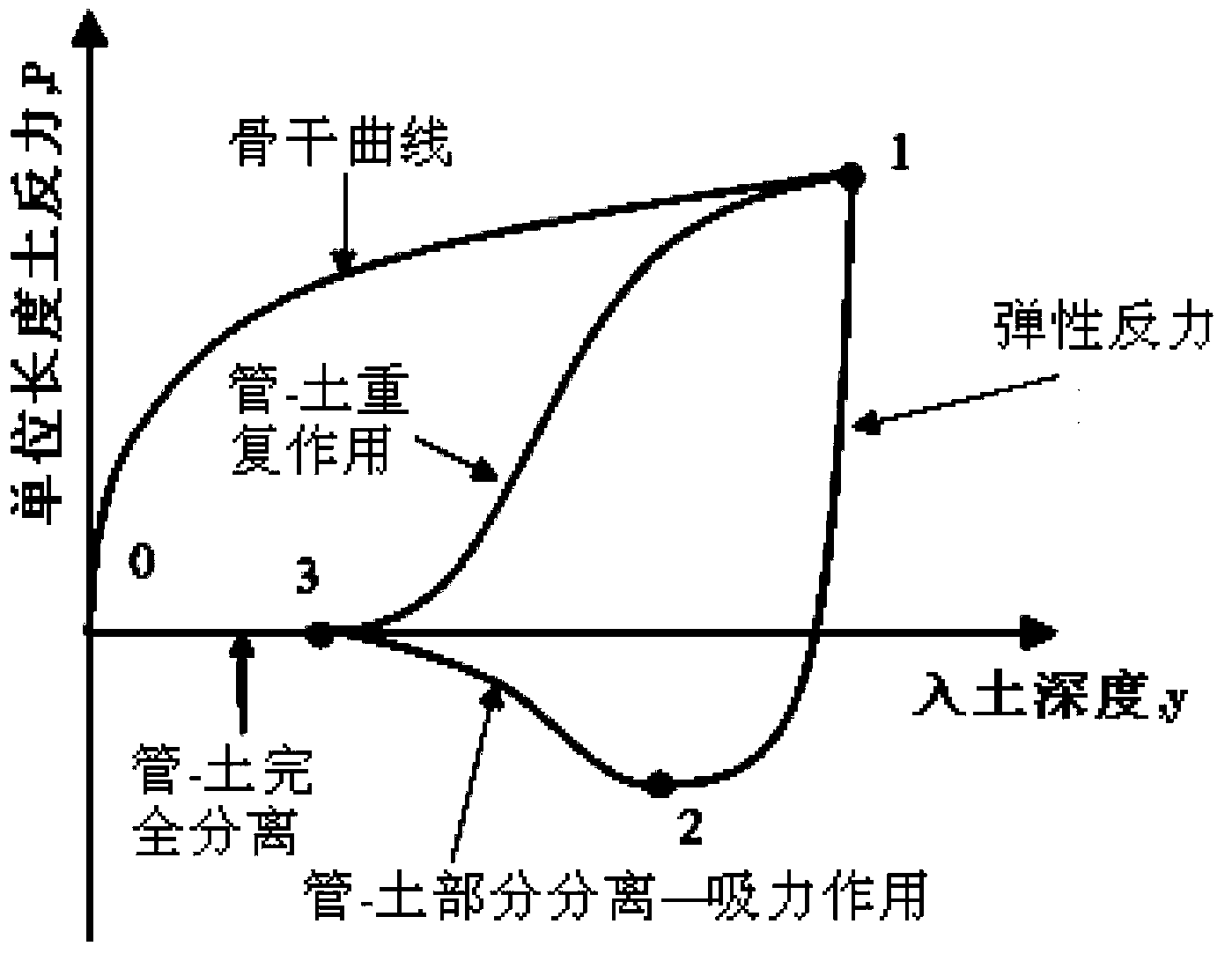

Deep sea steel catenary vertical pipe touchdown point power response analyzing method

InactiveCN103902754AAdd nonlinear stiffness modelImprove suction capacitySpecial data processing applicationsSuction forceEngineering

The invention relates to a deep sea steel catenary vertical pipe touchdown point power response analyzing method. The method includes: simulating a steel catenary vertical pipe a large-deflection camber beam model, using the movement of a floating platform as the top end boundary condition of the vertical pipe, using a P-y curve method to numerically simulate the mutual effect, including linear elasticity rigidity when a seabed does not deform, the suction force effect when the vertical pipe leaves the seabed and nonlinear rigidity in a reciprocation effect, of the steel catenary vertical pipe and the seabed, building the mutual effect model of the steel catenary vertical pipe and the seabed, combining the mutual effect model with the movement equation of the floating platform and the simulating module of the steel catenary vertical pipe, and applying the combined model to the steel catenary vertical pipe touchdown point power response analyzing. The method has the advantages the existing methods simulating the seabed into a linear elastic spring or a rigid seabed are modified, the mutual effect of the steel catenary vertical pipe and the seabed can be accurately simulated, and calculation precision of steel catenary vertical pipe touchdown point power response analyzing is increased.

Owner:ZHEJIANG OCEAN UNIV

Gas lift reverse circulation sand washover well washing process and equipment for sandstone geothermal well

PendingCN108104749AStrong circulation suction abilityBeneficial to appearCleaning apparatusFlushingLiquid storage tankAir compressor

The invention provides a gas lift reverse circulation sand washover well washing process and equipment for a sandstone geothermal well. The process comprises the following steps: in a sand washover process, compressing gas in a gas storage tank by an air compressor to form compressed gas; feeding the compressed gas into a gas injection tube from a high-pressure pipeline through a gas feeding tubevia a cavity between an internal body and an external body; then delivering the compressed gas from a gas injection tubular column and a gas mixing tubular column to a gas mixer and mixing the compressed gas with sand washover liquid to generate a gas lift effect; and raising gas, liquid and solid three-phase liquid flow lifted by gas from a sand washover oil tube and then enabling the gas, liquidand solid three-phase liquid flow to enter the internal body of a double-walled gas injector and a water eye of a lower joint so as to reach a ground liquid storage tank via the high-pressure pipeline. The equipment comprises the double-walled gas injector, the gas injection tubular column, the gas mixing tubular column, a sand washover nib and a sand washover drill bit. By a gas lift reverse circulation sand washover technology, a circular suction ability is high, raising of well bottom or water layer settled sand is facilitated, moreover, the sand washover liquid flow can carry large dirtysand particles, repeated breakage of the dirty sand particles is reduced, and therefore, the sand washover efficiency is improved.

Owner:中石化绿源地热能(陕西)开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com