Electric-controlled permanent magnetic chuck

An electronically controlled permanent magnet and suction cup technology, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve problems such as easy generation of residual magnetism, influence on suction force, and large power consumption, so as to expand the scope of use, improve suction efficiency, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

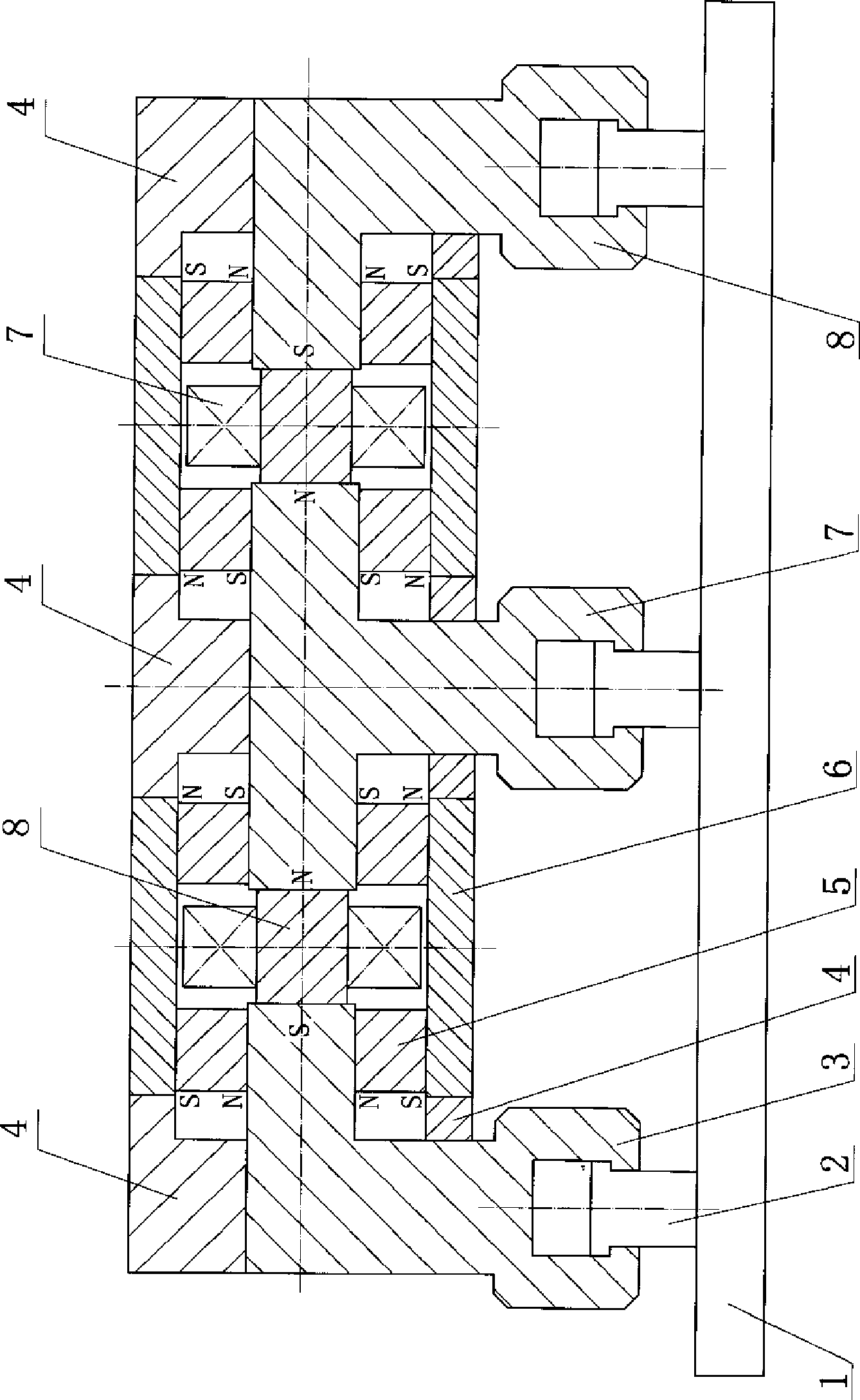

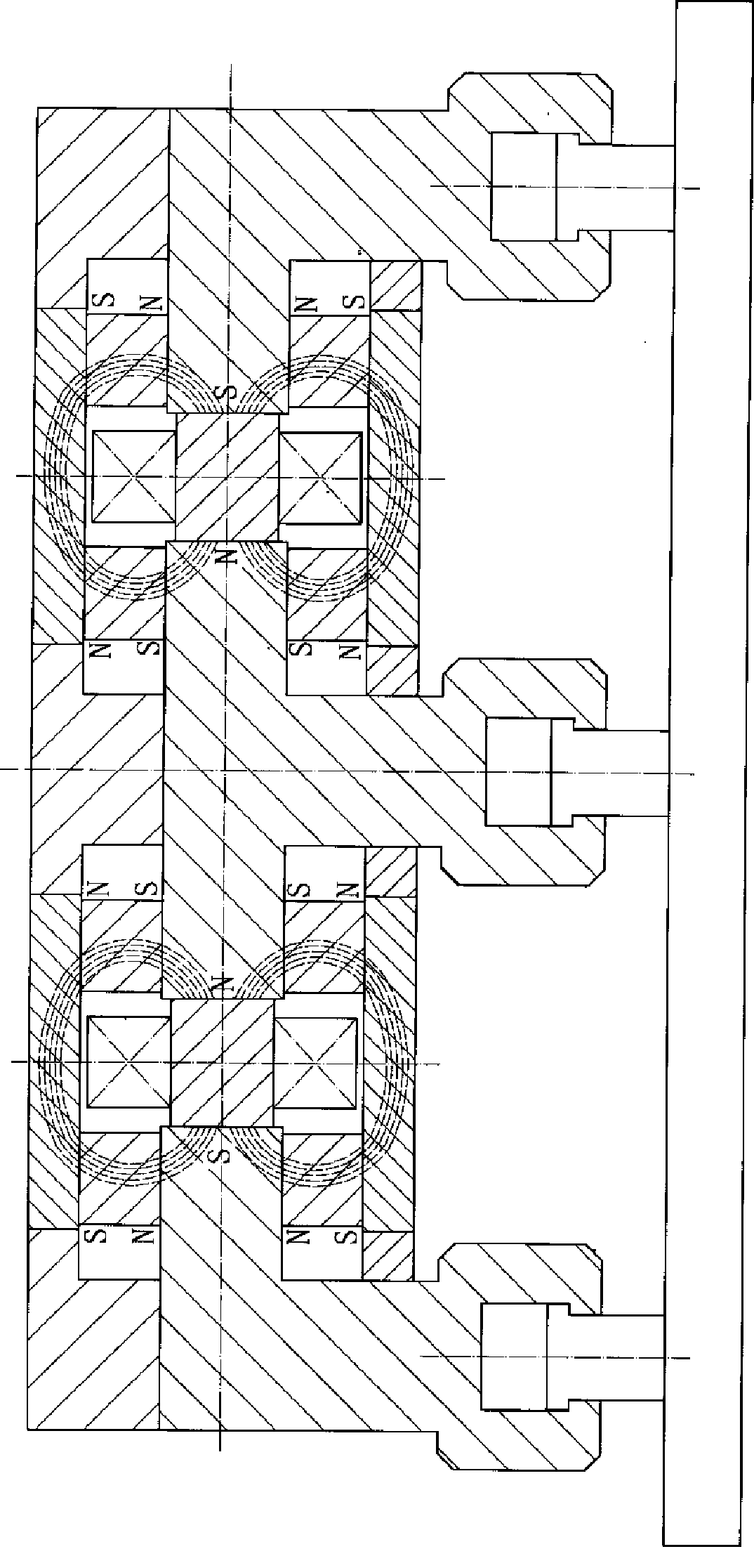

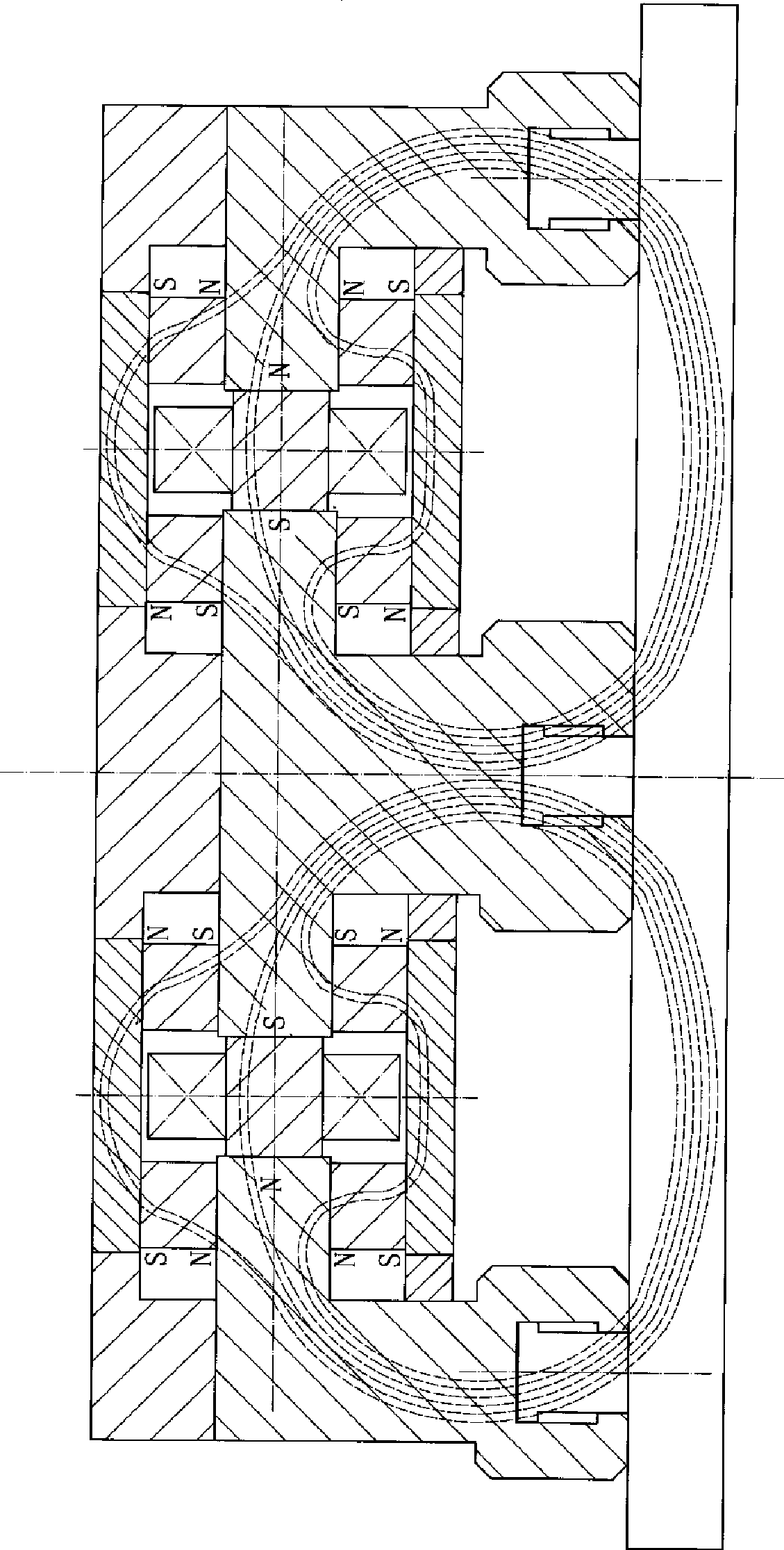

[0015] Depend on Figures 1 to 3 It can be seen that the present invention includes a coil, a magnetic steel, a yoke, and a magnetic pole, wherein:

[0016] The magnetic steel is composed of reversible magnetic steel 8 and irreversible magnetic steel 5. The reversible magnetic steel 8 is used in the main magnetic circuit, the coil 7 is arranged around the reversible magnetic steel 8, and the irreversible magnetic steel 5 is an auxiliary magnetic steel. side;

[0017] A yoke 3 is arranged on both sides of the reversible magnetic steel 8 and the irreversible magnetic steel 5, and the ends of the yoke 3 are connected to the magnetic pole 2;

[0018] The reversible magnetic steel 8, the coil 7, the yoke 3, the magnetic pole 2 and the attracted object 1 form the main magnetic circuit, and the irreversible magnetic steel 5 and the irreversible magnetic steel magnetic connection plate 6 form the auxiliary magnetic circuit;

[0019] The main magnetic circuit structure and the auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com