Gas lift reverse circulation sand washover well washing process and equipment for sandstone geothermal well

A technology of gas-lift reverse circulation and geothermal wells, which is applied in the direction of flushing wellbore, wellbore/well components, cleaning equipment, etc., which can solve the problems of equipment wear, increased sand washing cost, shortened sand washing cycle, etc., and reduce liquid drainage time, improve the efficiency of sand washing, and avoid the effects of formation leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

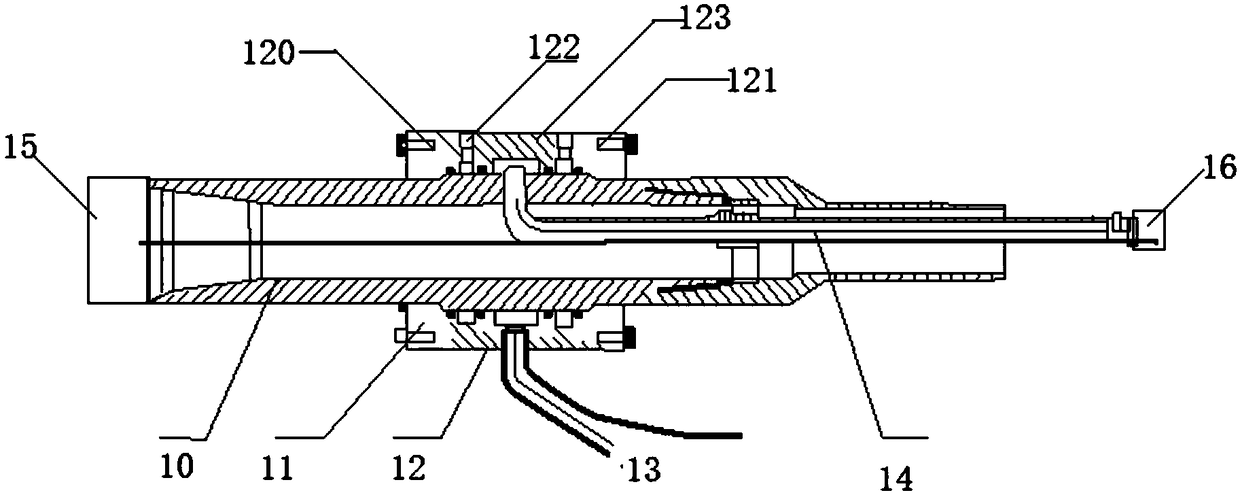

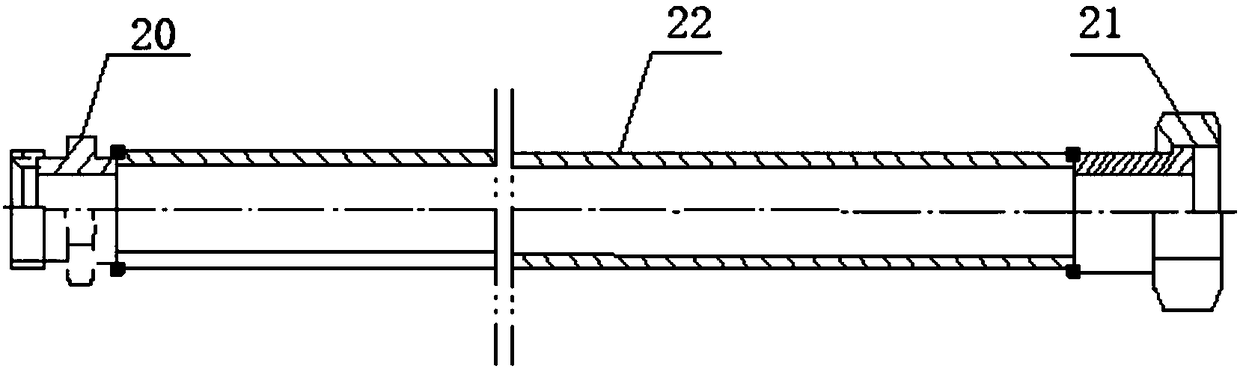

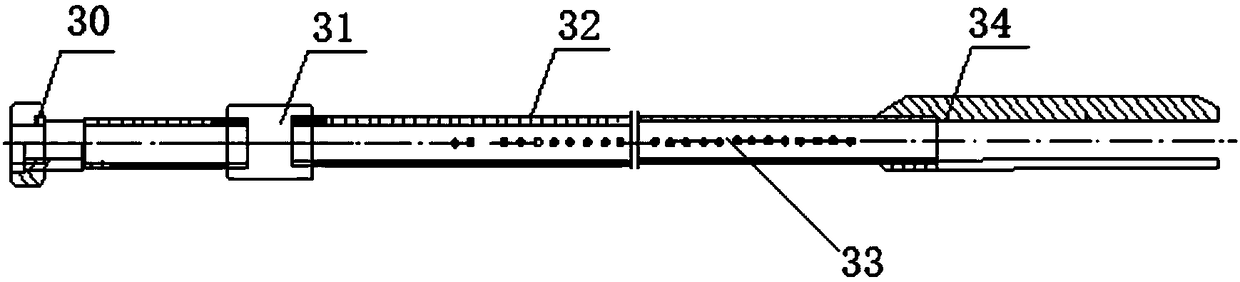

[0064] refer to Figure 1 to Figure 6 , gas lift reverse circulation sand flushing technology is to use a special equipment specially designed to inject sand flushing fluid into the tubing and at the same time, inject gas to reduce the pressure of the liquid column, so that the pressure of the annular liquid column is lower than that of the water layer Under the action of pressure difference between the tubing and technical casing annular space, the sand is carried to the ground by the sand flushing fluid, thereby protecting the thermal reservoir, and the pumping test can be carried out after sand flushing and well flushing. The research and application of gas lift reverse circulation san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com