Zinc bromine single flow cell

A liquid flow battery, zinc-bromine single technology, applied in battery electrodes, fuel cell additives, regenerative fuel cells, etc., can solve the problems of unable to charge and discharge with high current, low energy density of batteries, etc., to improve zinc deposition structure, solve Corrosion and leakage problems, cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

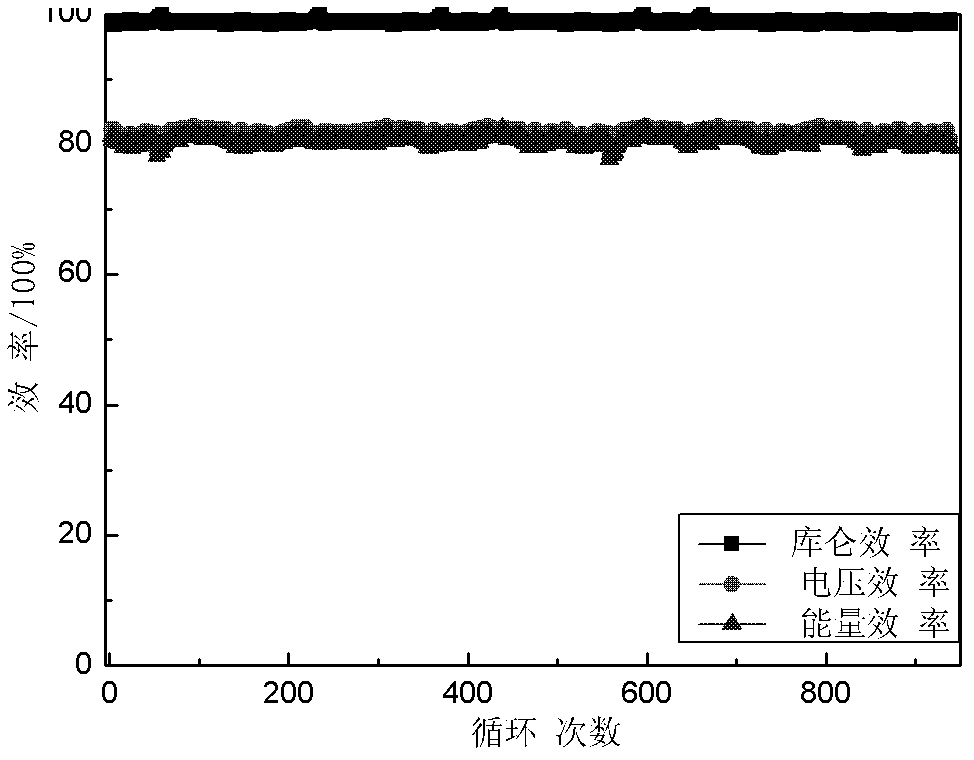

Embodiment 1

[0036] Preparation of positive electrode paste:

[0037] 1) Electrode paste slurry configuration: by weight, mechanically mix 5 parts of carbon powder, N-methyl bromide, 2 parts of ethylpyrrolidine, 40 parts of zinc bromide, and 3 parts of deionized water to form a paste standby;

[0038] 2) Use the method of spraying to evenly coat the paste slurry on one side of the carbon paper, loading: 5mg / cm 2 ;

[0039] 3) Zinc bromide solution configuration: Prepare a 4mol / L zinc bromide solution, soak the prepared positive electrode in the solution for 10 minutes, assemble the battery, and assemble the side coated with the electrode paste facing the separator.

[0040] Negative electrolyte preparation:

[0041] Prepare a 2mol / L zinc bromide solution for use.

[0042] Battery assembly:

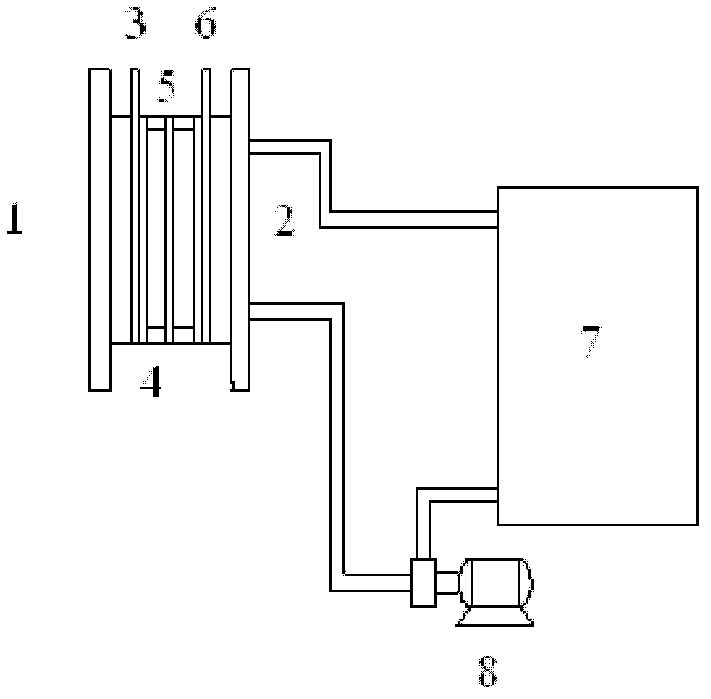

[0043] A single cell sequentially includes a positive terminal plate, a positive electrode current collector, a positive electrode, a membrane, a negative electrode, and a negative terminal plate....

Embodiment 2

[0046] Preparation of positive electrode paste:

[0047] 1) Electrode paste slurry configuration: in parts by weight, mechanically mix 1 part of carbon powder, 1 part of trimethylammonium bromide, 10 parts of zinc bromide, and 3 parts of deionized water into a paste for later use;

[0048] 2) Use the method of scraping to evenly coat the electrode paste slurry on one side of the carbon felt; load: 20mg / cm 2 .

[0049] 3) Zinc bromide solution configuration: Prepare a 4mol / L zinc bromide solution, soak the prepared positive electrode in the solution for 20 minutes, assemble the battery, and assemble the side coated with the electrode paste facing the separator.

[0050] Negative electrolyte preparation:

[0051] Prepare a 2mol / L zinc bromide solution for use.

[0052] Battery assembly:

[0053] A single cell sequentially includes a positive terminal plate, a positive electrode current collector, a positive electrode, a membrane, and a negative electrode and a negative termi...

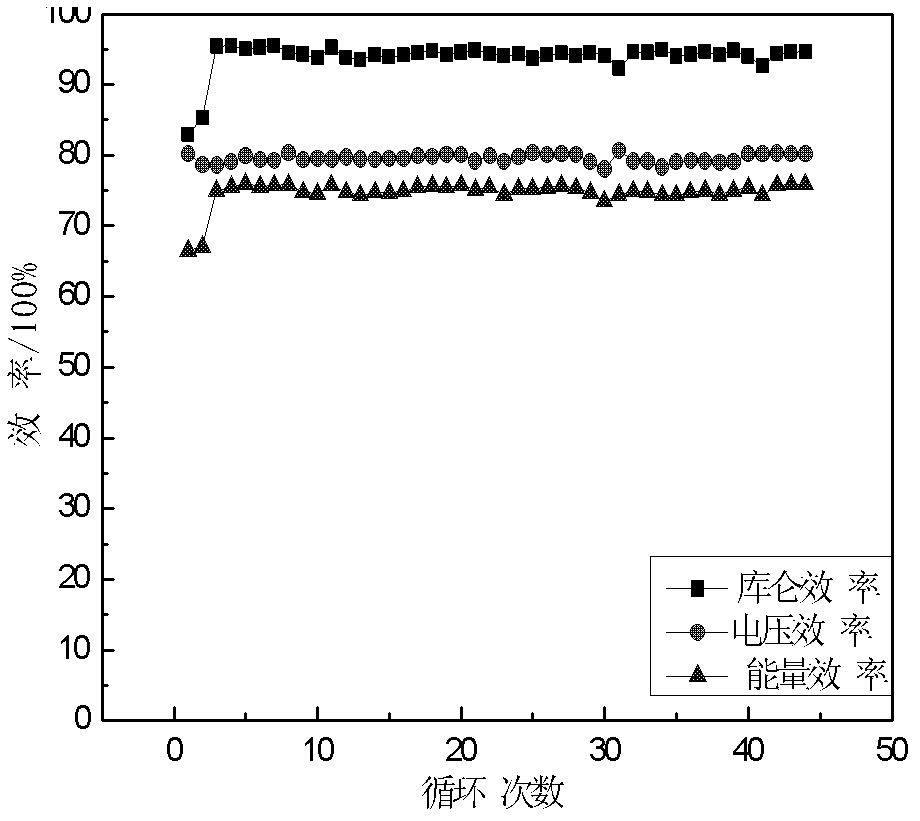

Embodiment 3

[0056] Assembly of zinc bromine flow battery

[0057] 1) The positive pole is 36cm 2 , carbon felt with a thickness of 4mm

[0058] 2) The negative pole is 36cm 2 , the graphite plate

[0059] 3) Preparation of the negative electrode from the electrolyte: prepare 80 ml of 2 mol / L zinc bromide solution for use, and 40 ml of the positive and negative electrolytes.

[0060] Battery assembly:

[0061] A single cell sequentially includes a positive terminal plate, a positive electrode current collector, a positive electrode, a membrane, and a negative electrode and a negative terminal plate.

[0062] Assembly of zinc-bromine battery

[0063] Preparation of positive and negative electrode paste:

[0064] 1) Electrode paste slurry configuration: in parts by weight, mechanically mix 1 part of carbon powder, 1 part of trimethylammonium bromide, 10 parts of zinc bromide, and 3 parts of deionized water into a paste for later use;

[0065]2) Use the method of scraping to evenly coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Charge and discharge current density | aaaaa | aaaaa |

| Charge and discharge current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com