Patents

Literature

60results about How to "Avoid affecting yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

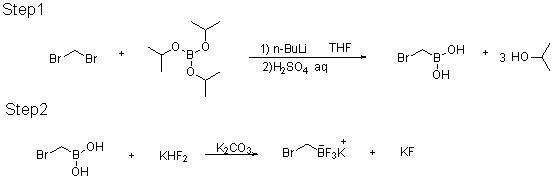

Method for preparing potassium trifluoroborate series compounds

InactiveCN102060867ASolve corrosiveAvoid affecting yieldGroup 3/13 element organic compoundsOrganic baseBoronic acid

The invention relates to synthesis of organic compounds, and provides a method for preparing potassium trifluoroborate series compounds. The method comprises the following steps of: adding organic boric acid or organic borate and solvent (THF (tetrahydrofuran), or MTBE (Methyl Tertiary Butyl Ether), or ethyl acetate, or methanol) into a reaction kettle lined with tetrafluoroethylene plastic at room temperature; adding potassium bifluoride and water at normal temperature, stirring for 1 to 12 hours, and reacting to prepare a solid-liquid mixture; adding solid potassium ion containing inorganic or organic alkali into the solid-liquid mixture after the reaction is completed, neutralizing until the pH is between 7 and 9, and continuously stirring for 1 to 5 hours; directly filtering to obtain a solid coarse product after stirring is completed; dissolving the coarse product with solvent, filtering and concentrating, adding nonpolar solvent, and pulping to obtain high-quality RBF3K series compounds. The method is easy to operate, has mild reaction conditions, and can realize scale-up production; and the product prepared by the method has high yield and excellent purity, and the cost is greatly reduced.

Owner:大连联化医药技术有限公司

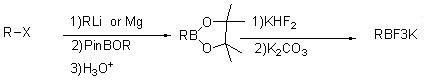

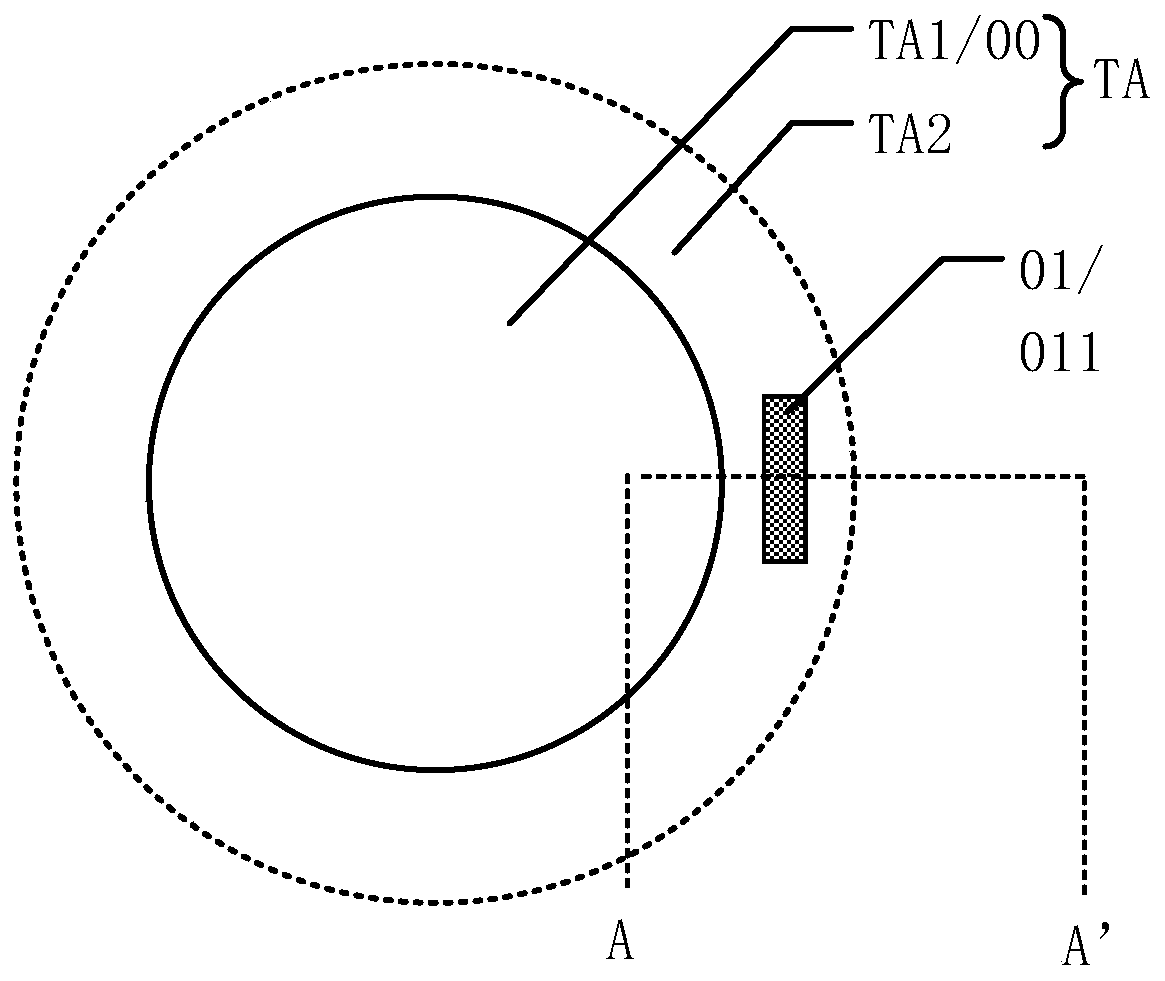

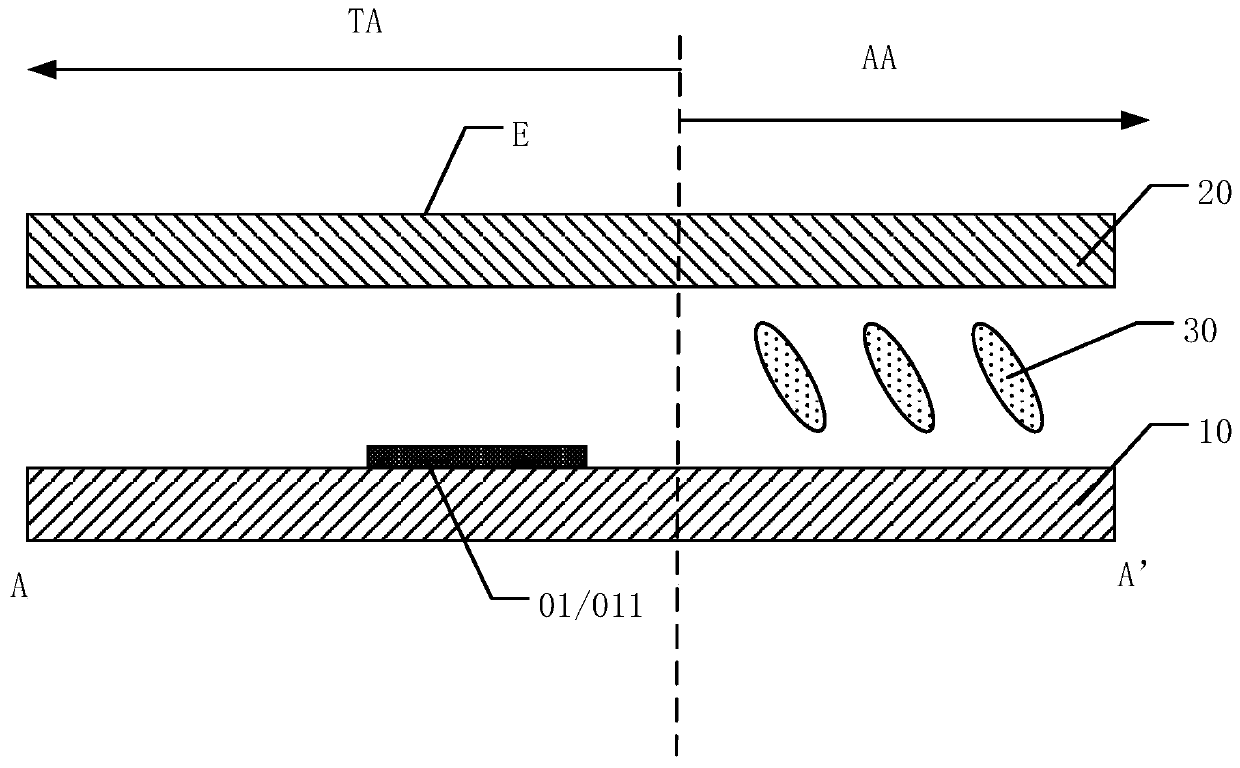

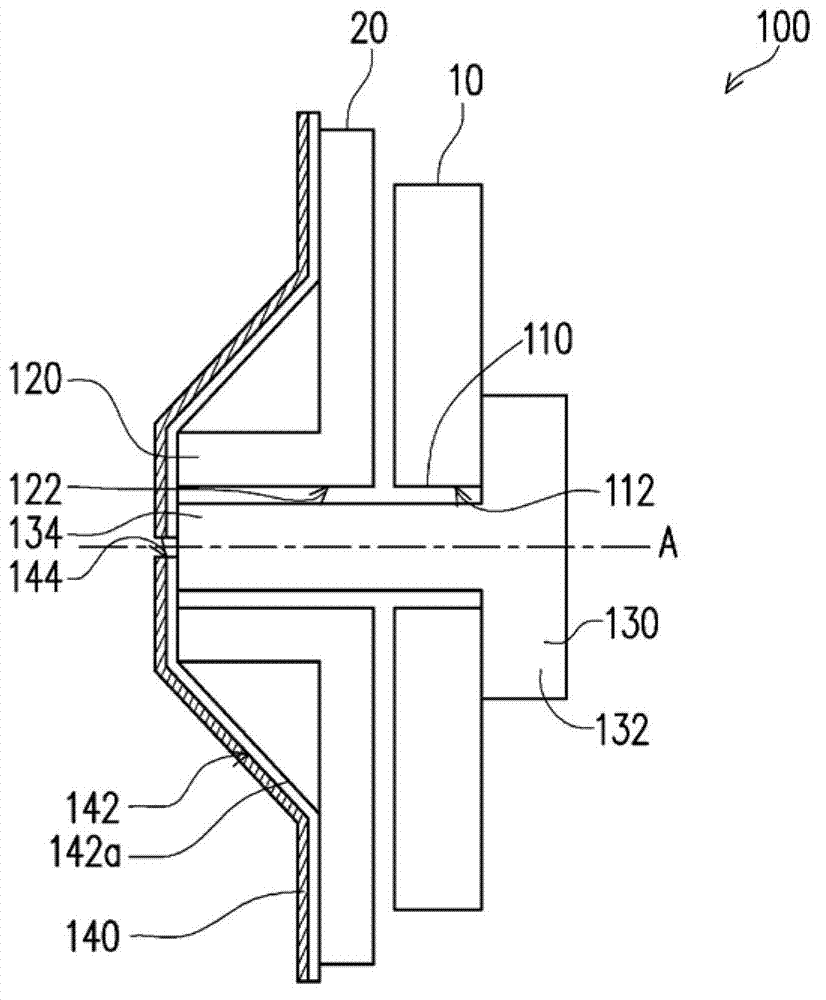

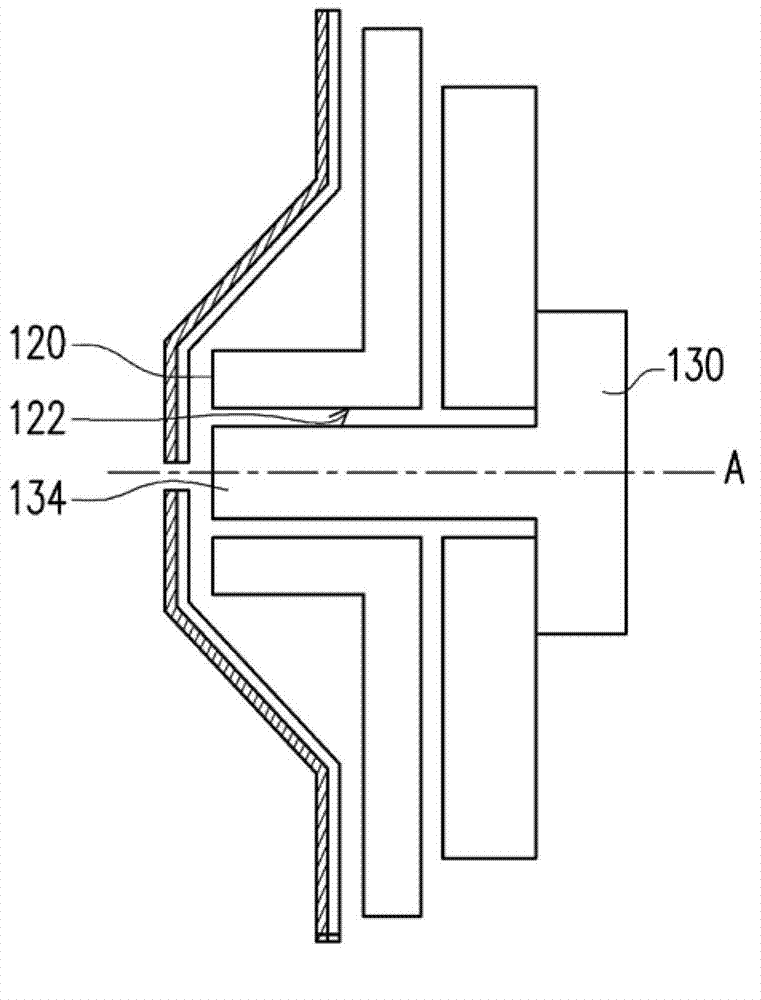

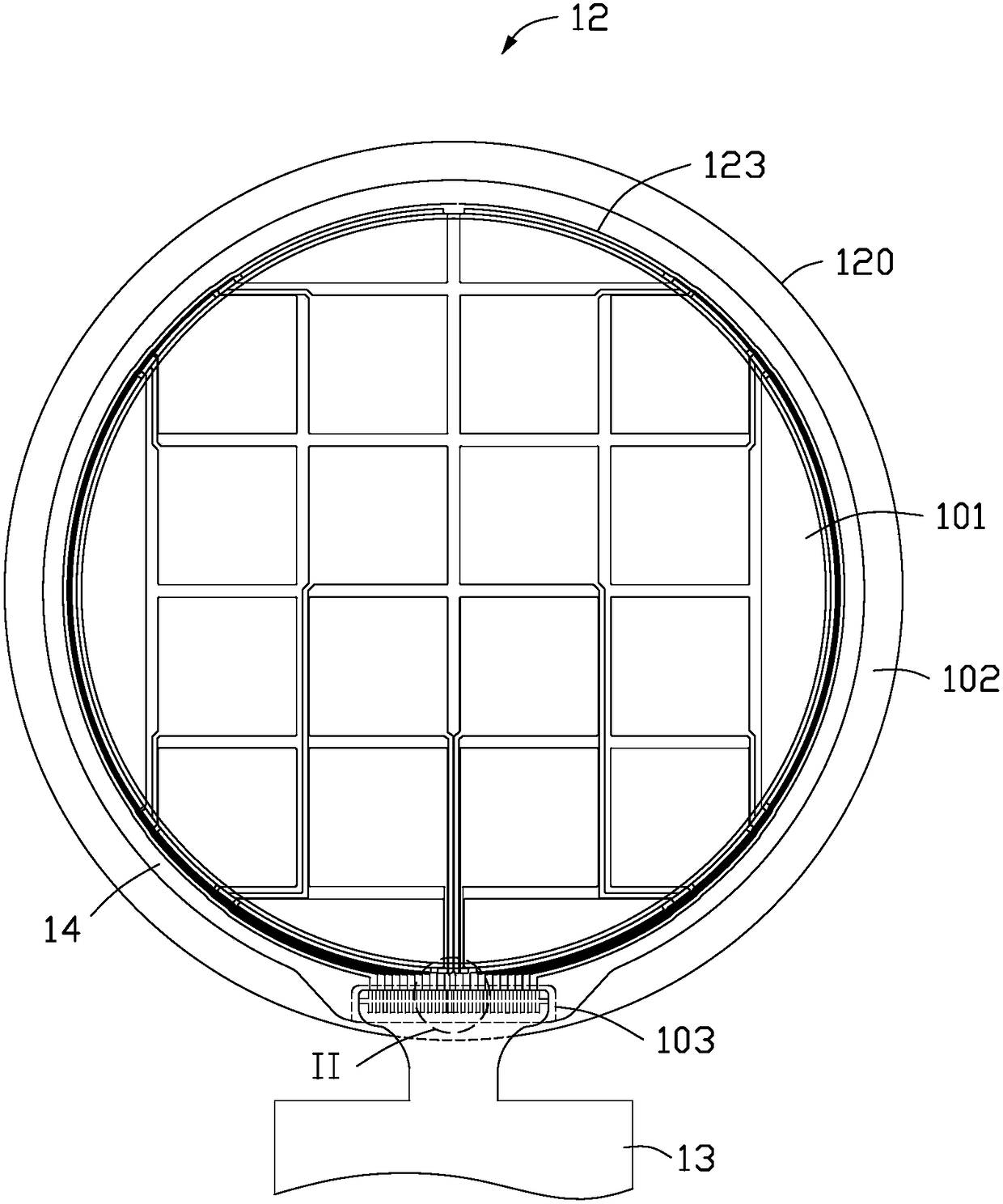

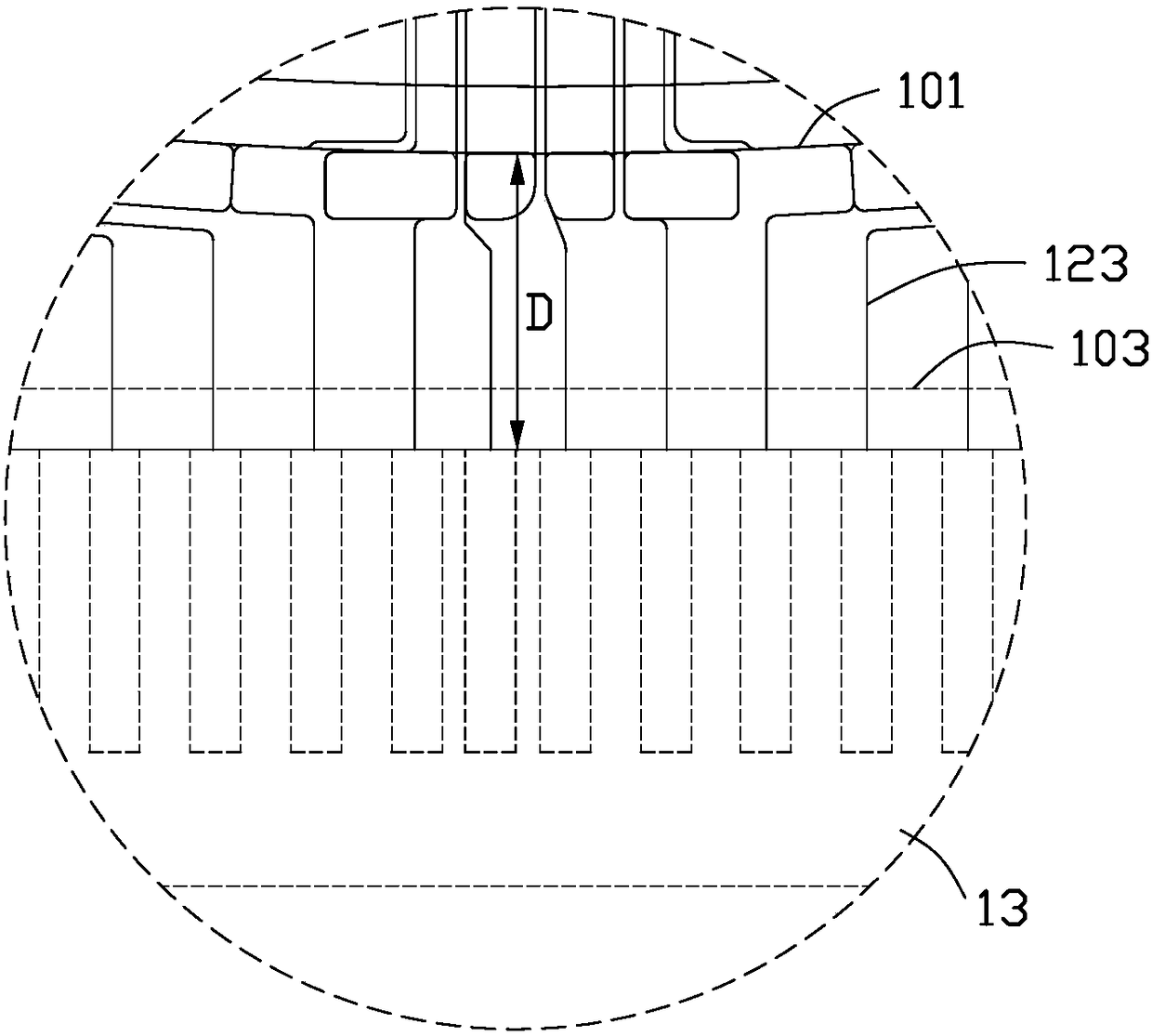

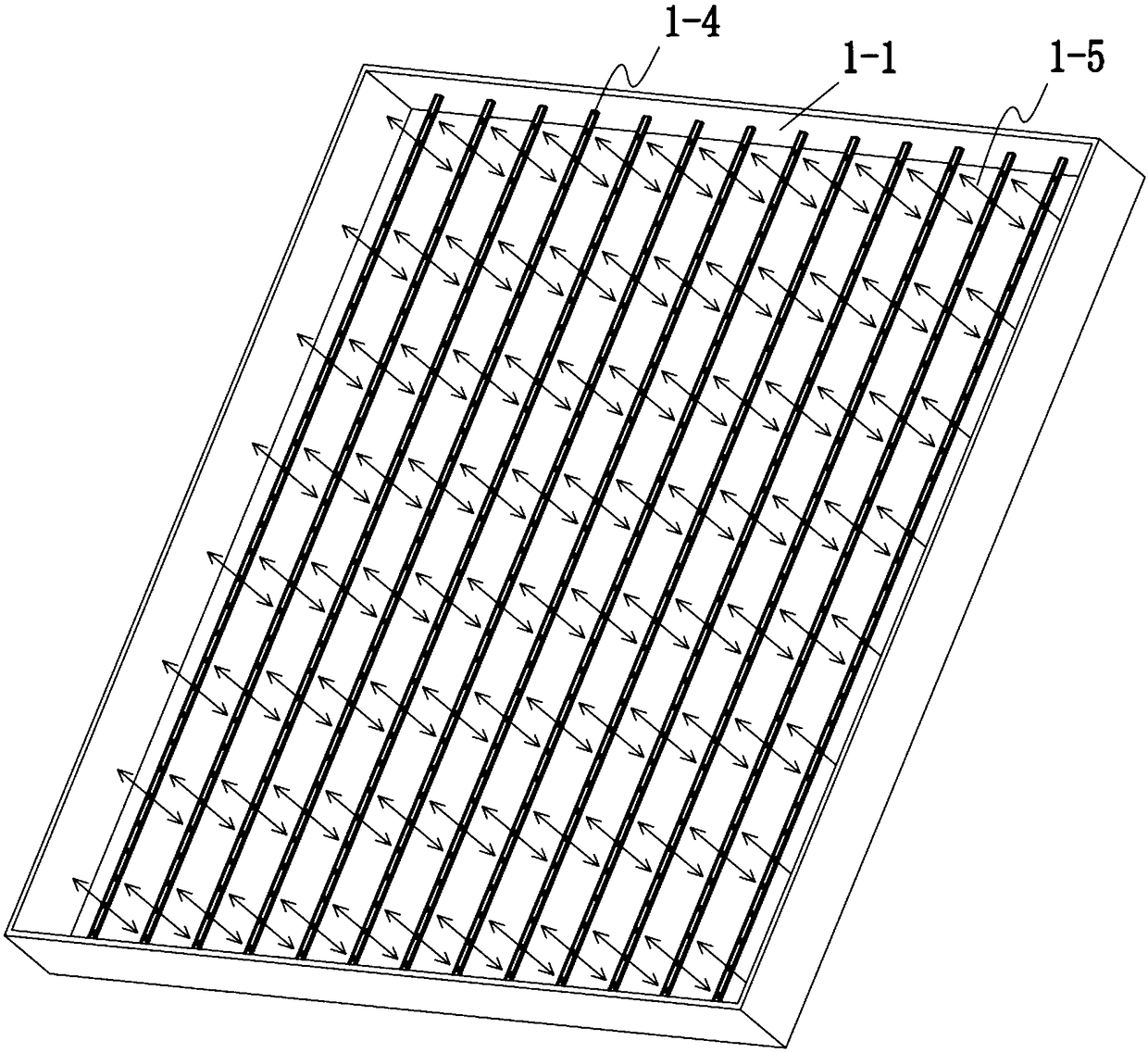

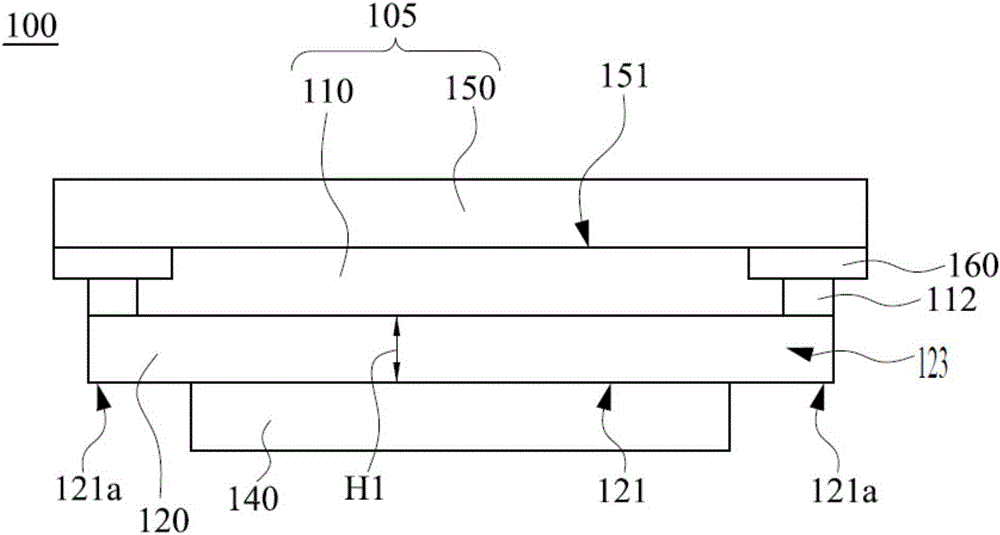

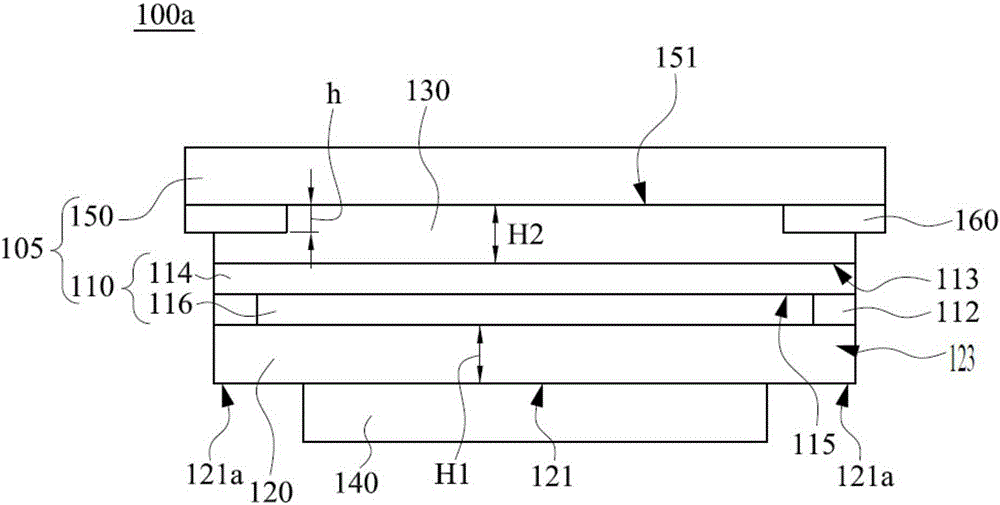

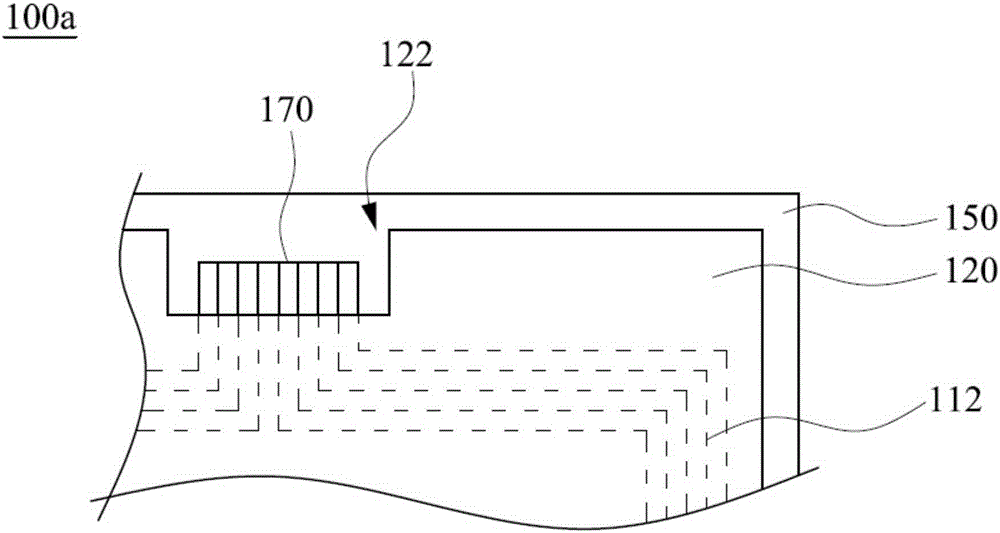

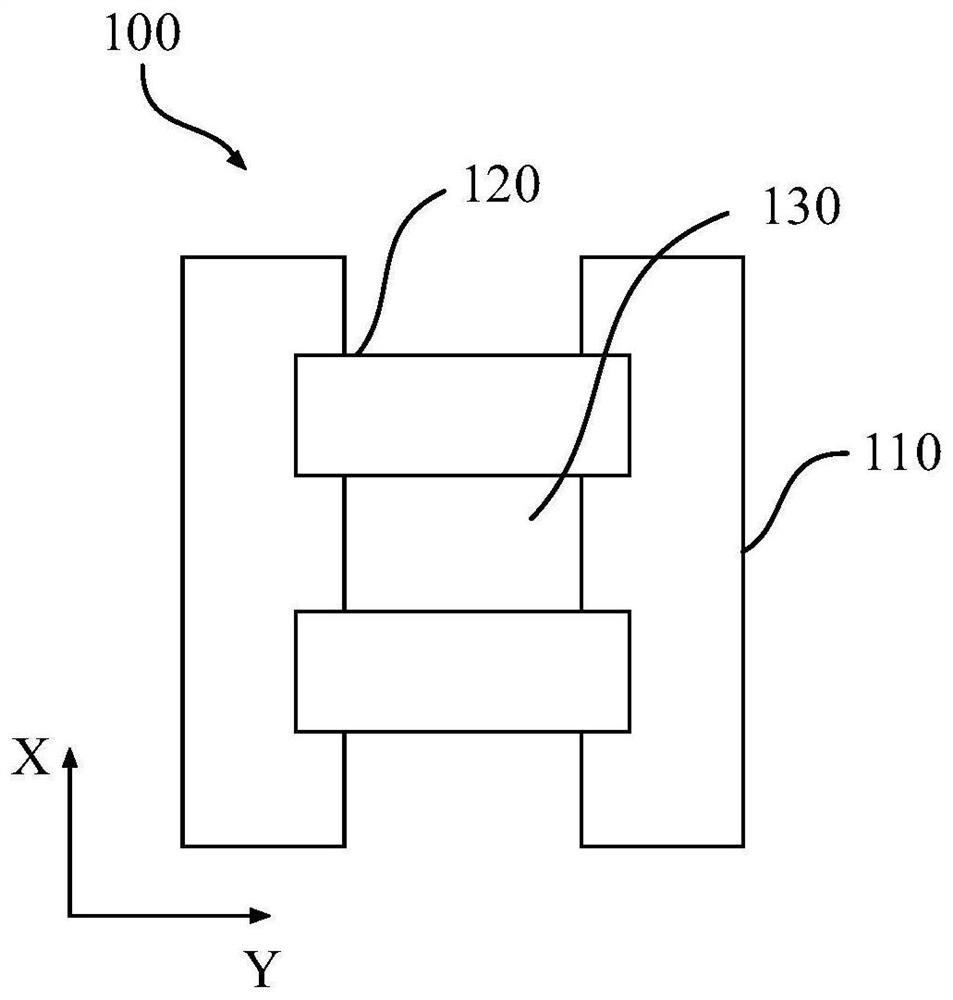

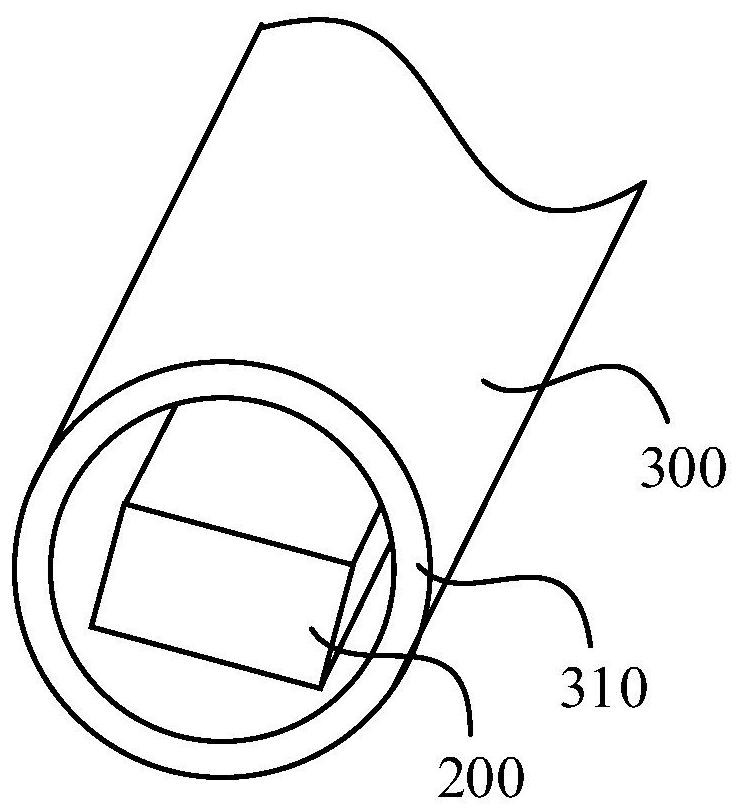

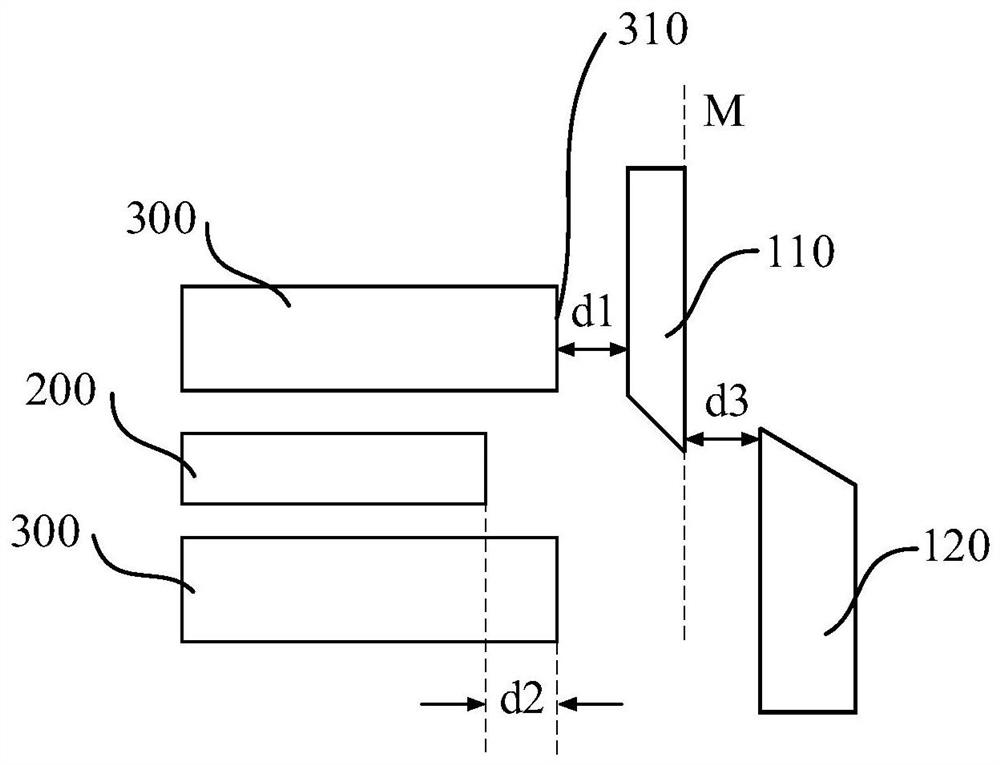

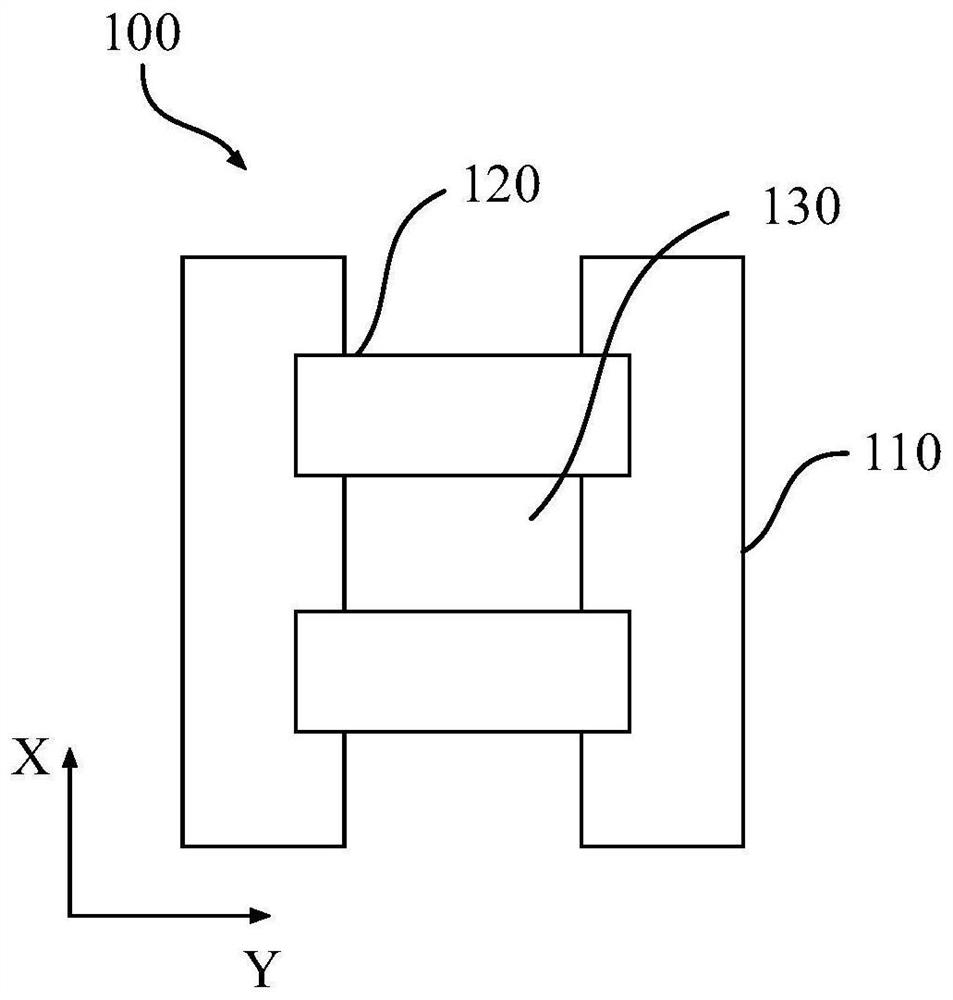

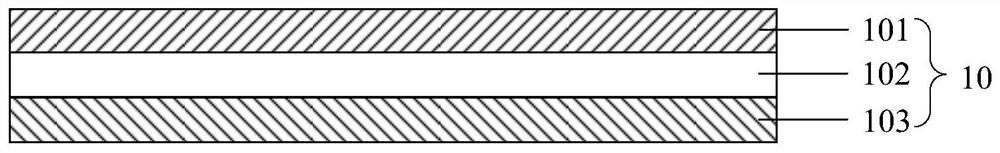

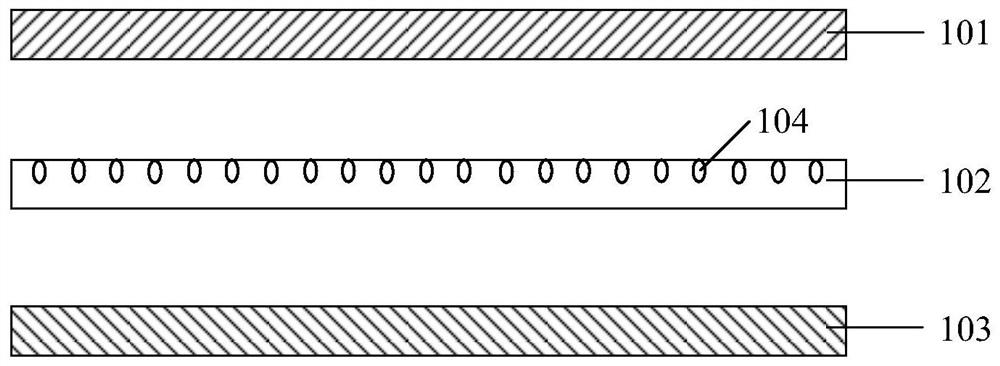

Display panel and display device

ActiveCN110262108ASmall footprintSimple designTelephone set constructionsNon-linear opticsDisplay deviceComputer science

The invention discloses a display panel and a display device, and belongs to the technical field of display. The display panel comprises a display area and a through hole area, the through hole area comprises a through hole penetrating area and a boundary area, and the boundary area is positioned between the display area and the through hole penetrating area; a through hole is arranged in the through hole penetrating area; and the boundary area includes at least one aligning identification group arranged surrounding the through hole penetrating area, and each aligning identification group includes at least one aligning identification. The display panel comprises first and second substrates opposite to each other and a liquid crystal layer arranged therebetween; and at least one aligning identification is positioned on the first substrate and / or the second substrate. The display device comprises the display panel. Thus, a narrow frame design is easier, the screen occupation ratio is higher, the hole depth and box-forming aligning precision can be monitored, and deformation is prevented from causing aligning accuracy in the through hole area and further influencing the yield rate of products in the box forming process.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

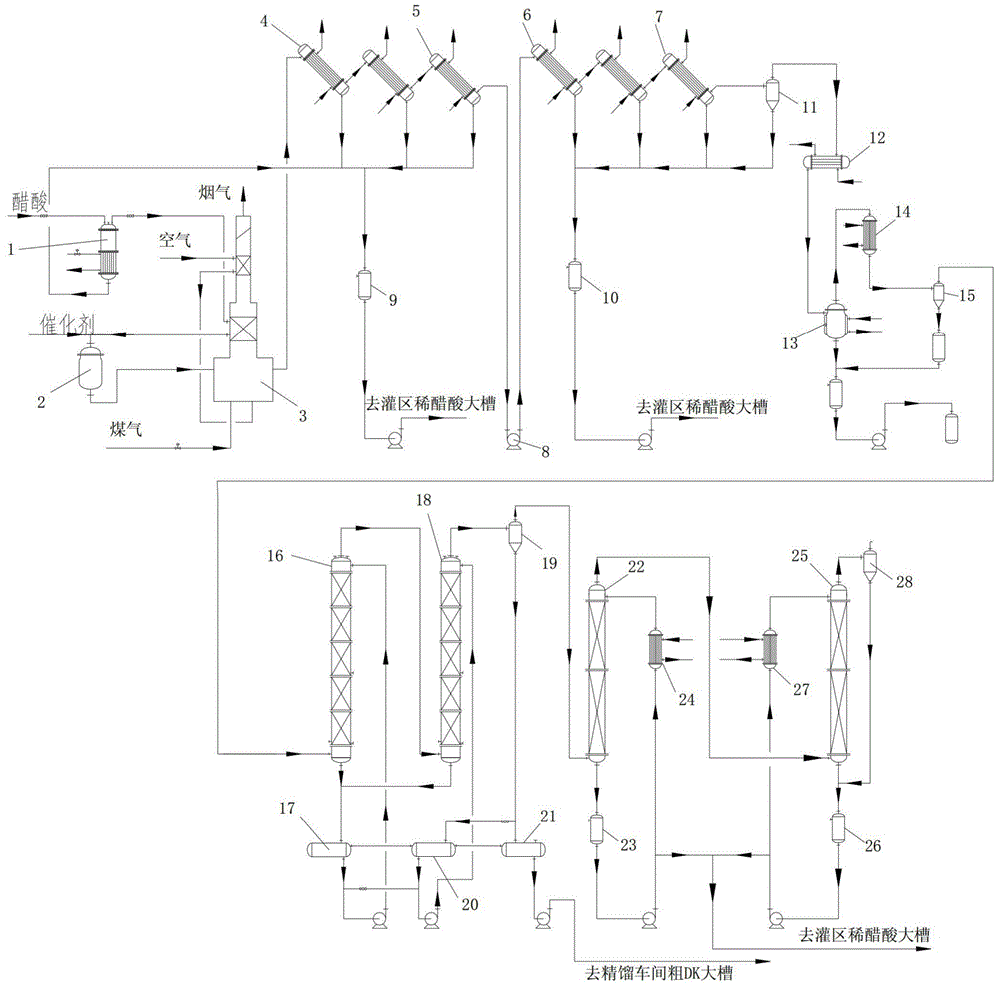

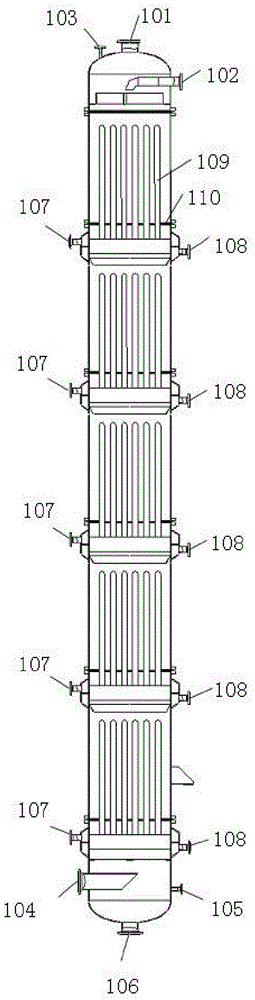

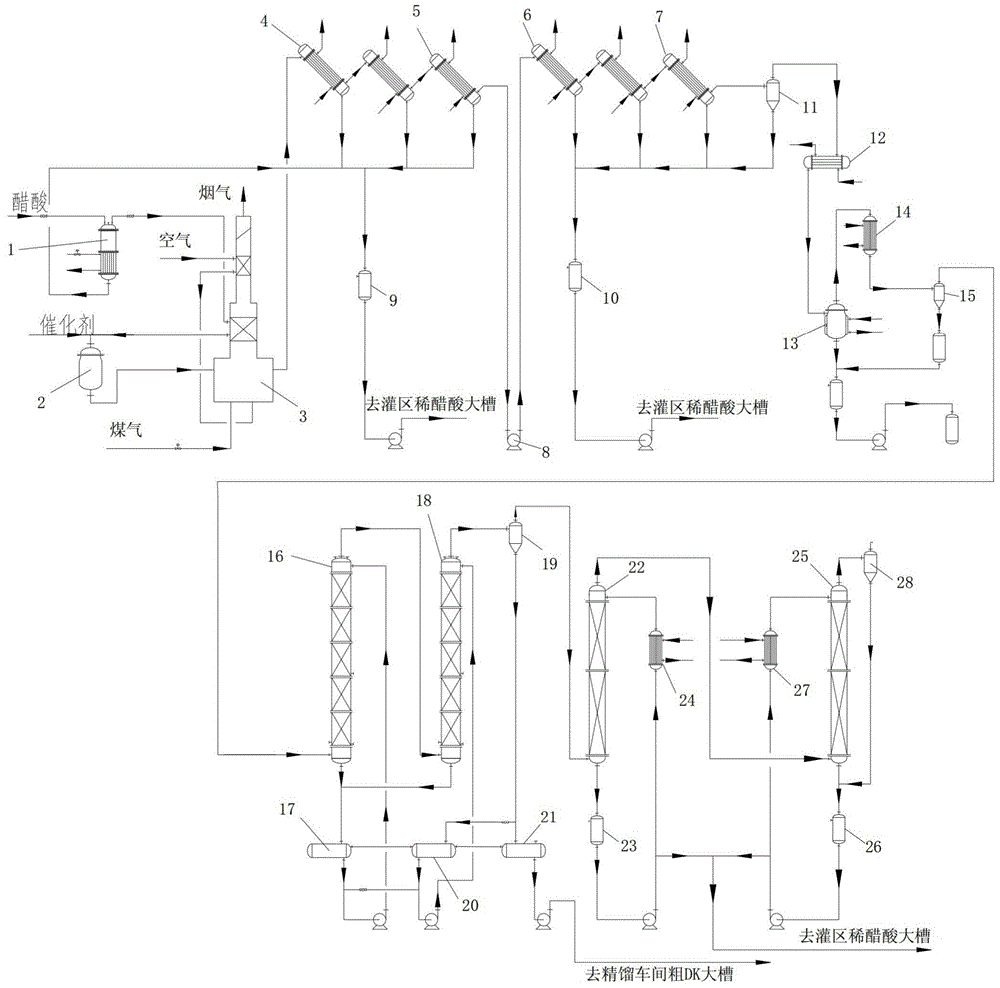

Diketene preparation device and diketene preparation method

ActiveCN104592172AEasy to condense and separateDowngradeOrganic chemistryAcetic acidAcetic anhydride

The invention relates to a diketene preparation device and a diketene preparation method. The diketene preparation device comprises an acetic acid evaporator, a mixer, a cracking furnace, a quenching condenser and an absorption tower. The outlets of the acetic acid evaporator and the mixer are connected with the cracking furnace; the cracking furnace is then connected with the multi-level quenching condenser; the quenching condenser is then connected with the absorption tower; one branch of the absorption tower is connected with a polymerization tank, and the other branch of the absorption tower is connected with a water absorption tower; and the outlet of the third-level quenching condenser is connected with the quenching condenser behind through a liquid ring pump. The diketene preparation device and diketene preparation method provided by the invention have the beneficial effects that when the cracked gas is pressurized, the impurities such as acetic acid, water and acetic anhydride in the cracked gas can be condensed out more sufficiently, and thus the quality of the cracked gas before entering the absorption tower is improved while the freezing level is lowered; and compared with the traditional technology in which the energy consumption accounts for 45% of the total cost of diketene, the device and method provided by the invention have the advantage that the energy consumption only accounts for 25% of the total cost of diketene through improvement.

Owner:QINGDAO UNIV OF SCI & TECH

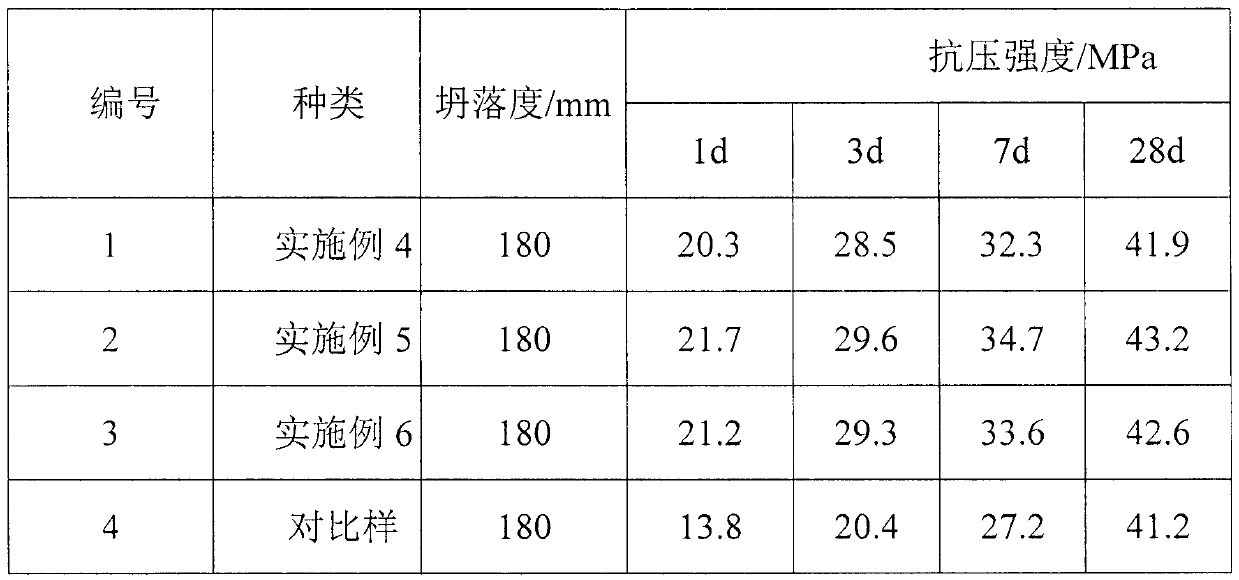

Early-strength polycarboxylate superplasticizer preparation method

ActiveCN107686540AAvoid problems such as separation and recyclingSimple production processSuperplasticizerPrecast concrete

The invention discloses an early-strength polycarboxylate superplasticizer and a preparation method. The early-strength polycarboxylate superplasticizer is prepared from maleic acid, triethanolamine,aminobenzene sulfonic acid, hydroxyl-terminated polyoxyethylene monomethyl ether, acrylamide, acrylic acid and isoamyl polyoxyethylene ether. The early-strength polycarboxylate superplasticizer is excellent in performance, stable in process, high in water reducing efficiency, remarkable in early strength effect, high in aggregate adaptability and high in cost performance. A production process is environmentally friendly and free of waste water, waste gas and industrial residues and accords with environment-friendly and sustainable development concepts. The early-strength polycarboxylate superplasticizer is widely applicable to various concrete engineering construction with early strength requirements and especially applicable to production and manufacturing of precast concrete components and has a promising application prospect.

Owner:南京建高新材料科技有限公司

Cleaning system for wet etching

InactiveCN105080877AAvoid affecting yieldEfficient removalSolid-state devicesSemiconductor/solid-state device manufacturingEtchingEngineering

The invention relates to the technical field of display, and in particular to a cleaning system for wet etching. The cleaning system comprises a cleaning unit, an etching section, a buffer section and a cleaning section, wherein the etching section, the buffer section and the cleaning section are communicated in sequence. An air knife unit is arranged on an inlet of the cleaning section, and the cleaning unit is arranged corresponding to the air knife unit and used for cleaning the air knife unit. According to the cleaning system, etching liquid crystals and dust particles attached to edges and peripheries of air knives are effectively removed through the cleaning unit. The cleaning system can replace manpower to clean the air knives, the working ratio of equipment is increased, the cleaning effect is ensured, and meanwhile manpower waste is reduced to the maximum extent. Meanwhile, the situation that due to the fact that an equipment chamber is opened for a long time, particles in the equipment are increased, and the yield of products is influenced can be avoided.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

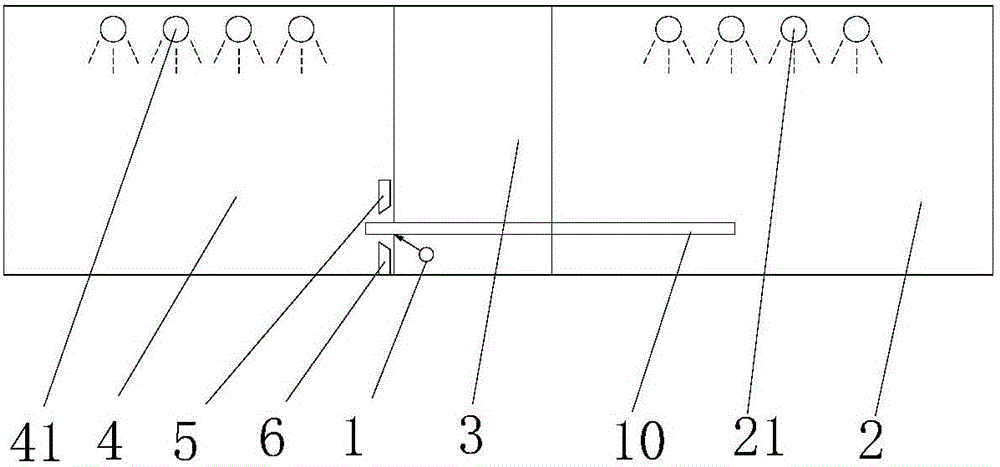

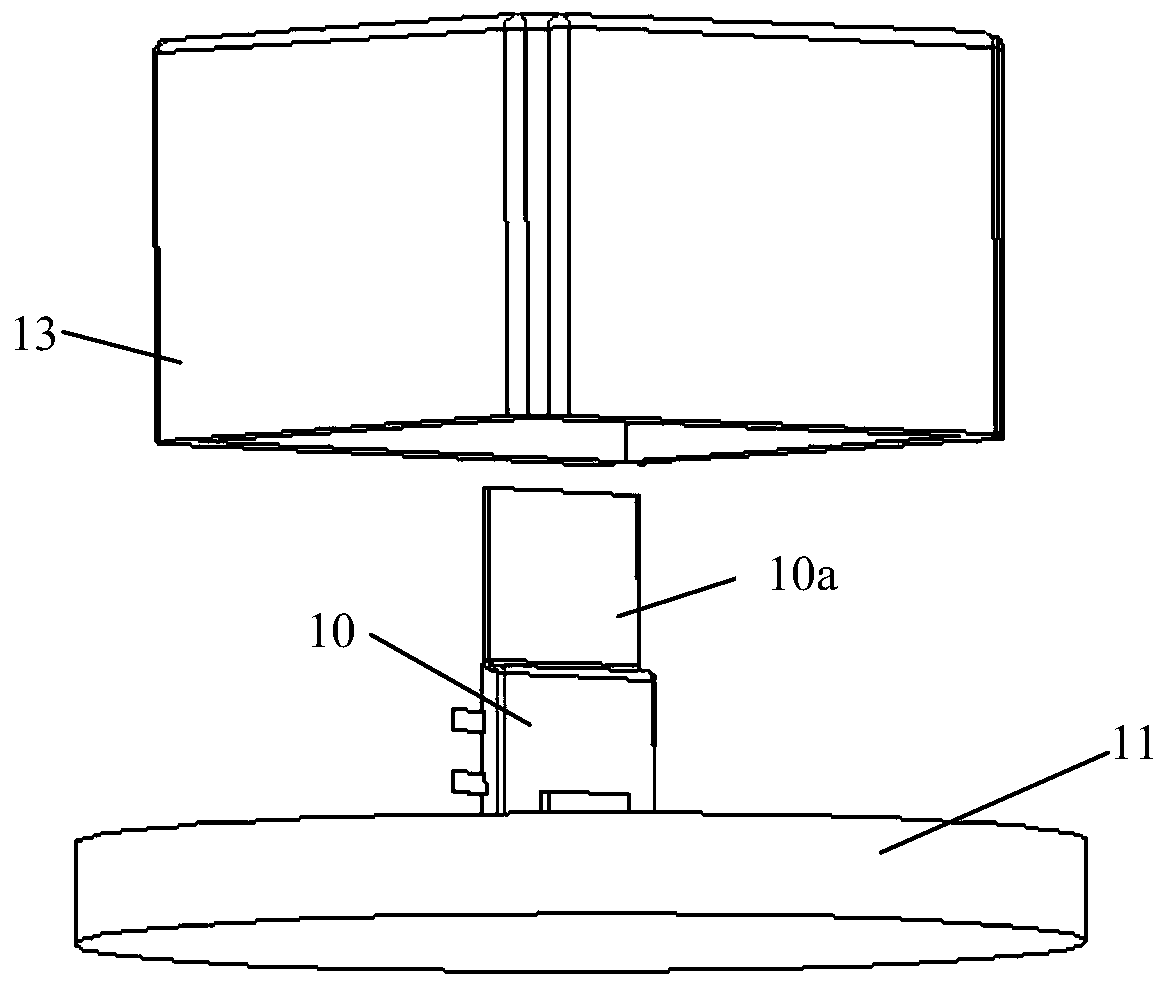

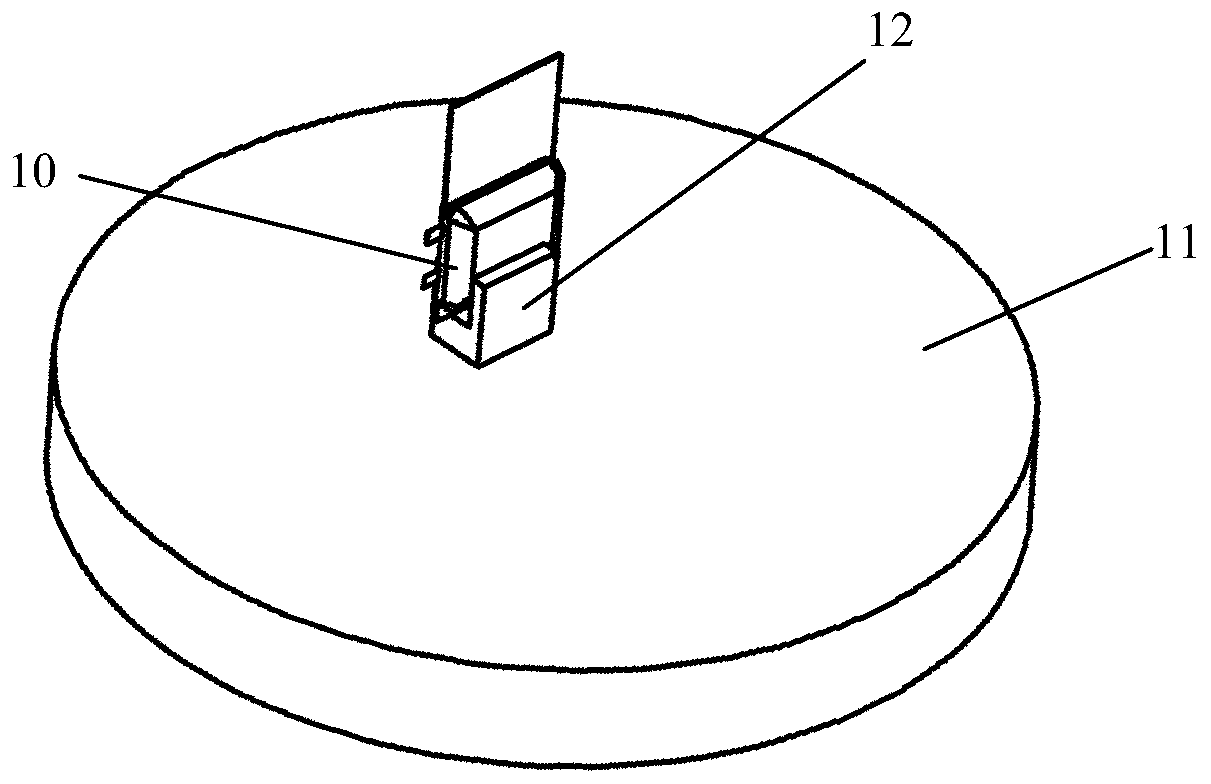

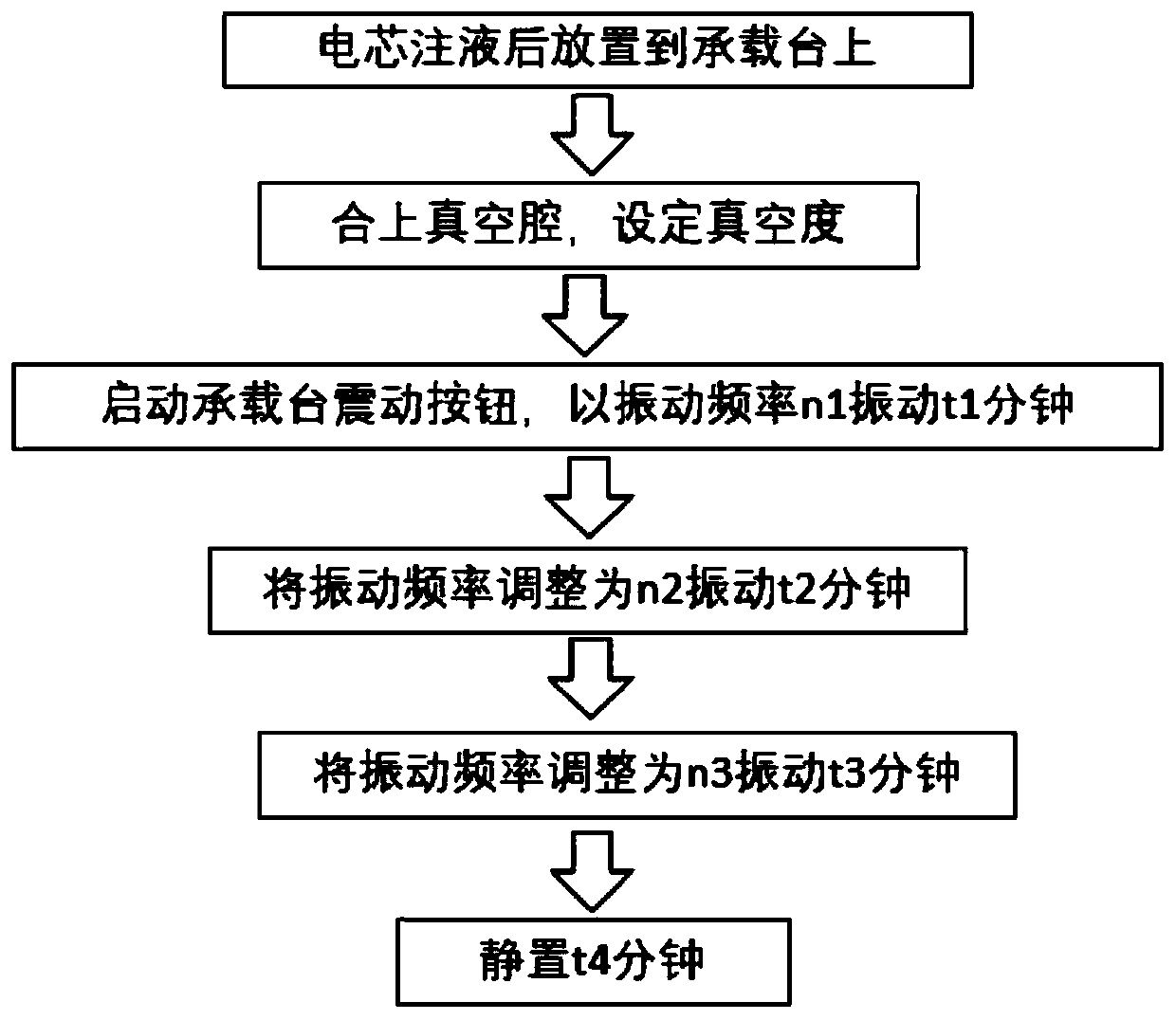

Aging method of lithium ion battery cell

ActiveCN110797578ARapid infiltrationShorten the manufacturing cycleFinal product manufactureElectrolyte accumulators manufactureManufacturing cost reductionPole piece

The invention relates to an aging method of a lithium ion battery cell, which comprises the following steps: vertically placing a battery cell after liquid injection in a manner that an air bag facesupwards, and placing the battery cell in a closed cavity; adjusting the pressure in the closed cavity to enable the interior of the closed cavity to be in a negative pressure state; vibrating the battery cell up and down, and aging the battery cell through vibration; and stopping the vibration of the battery cell and keeping standing to finish aging. According to the method disclosed by the invention, negative pressure and mechanical vibration are simultaneously introduced in the aging process of the battery cell, so that a wound core pole piece can be infiltrated by the electrolyte more quickly, the manufacturing period of the battery cell can be shortened, and the manufacturing cost can be reduced.

Owner:ZHUHAI COSMX BATTERY CO LTD

Production of crystal jade glass

InactiveCN1778736AQuality improvementLow softening pointGlass reforming apparatusFlat glassGlass production

Owner:邱文正 +3

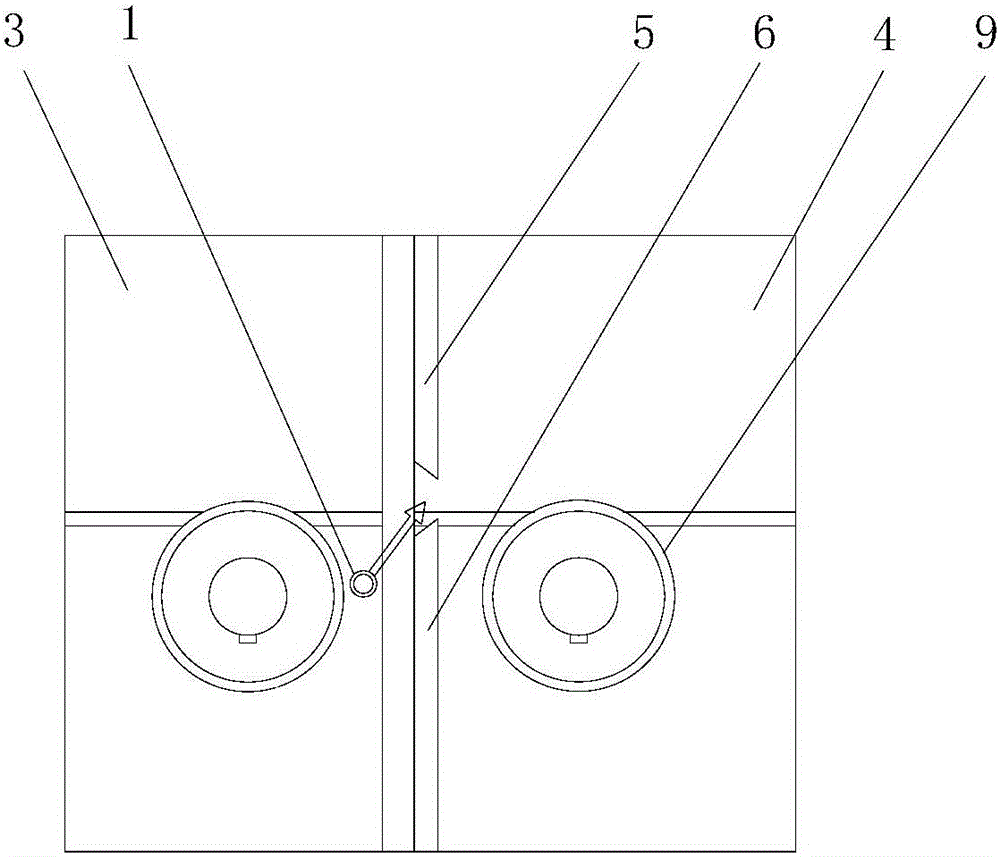

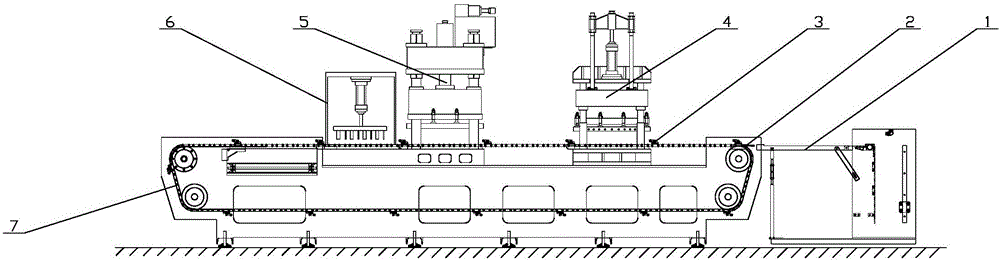

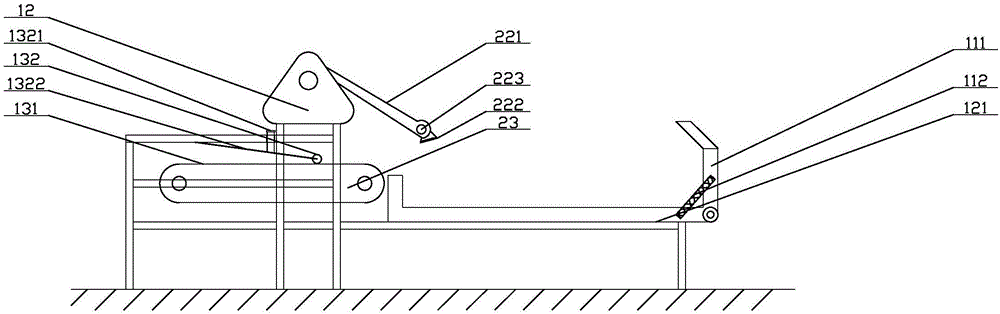

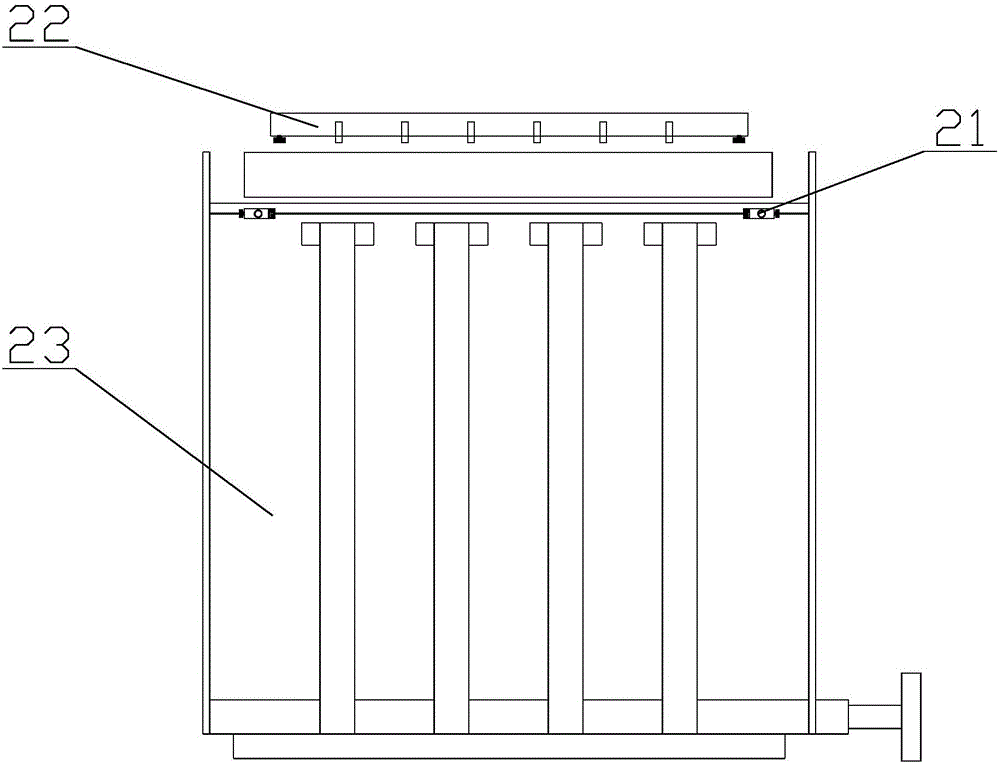

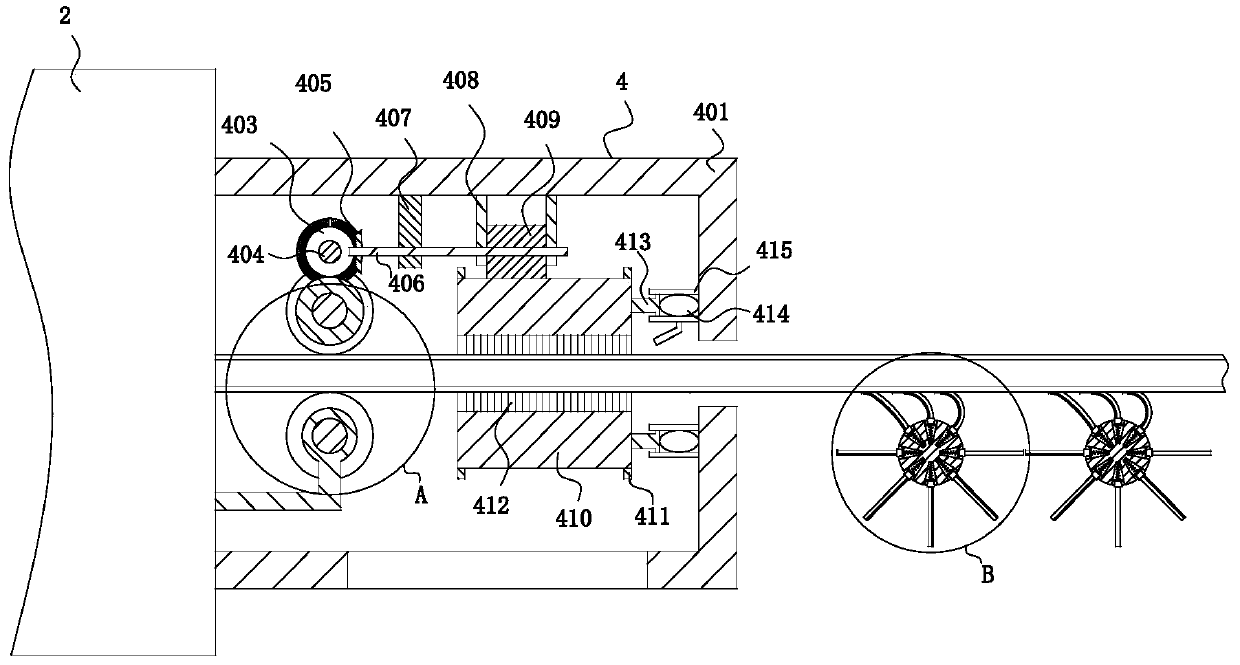

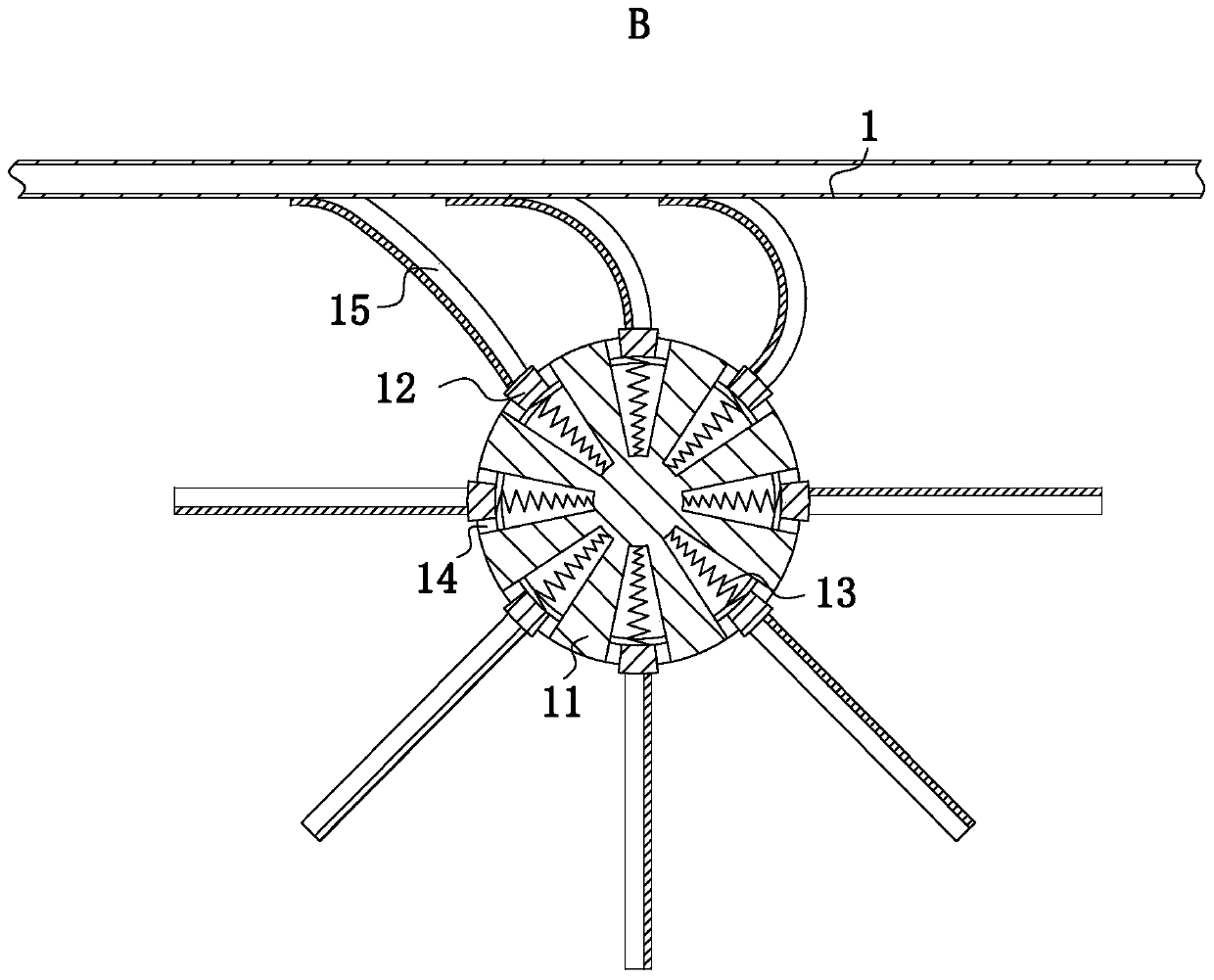

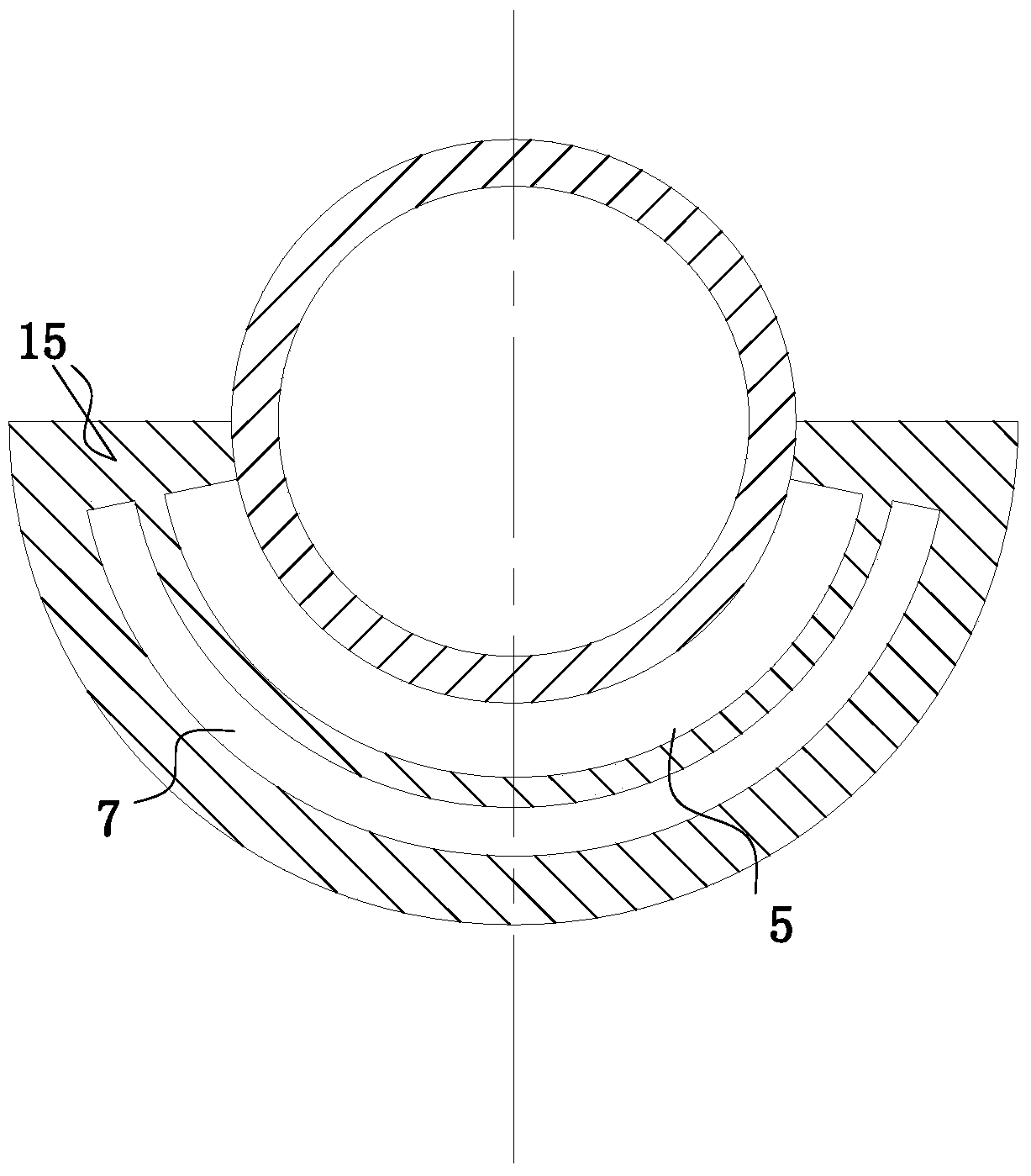

Full-automatic soft-line sectional die-cutting machine and operating method thereof

InactiveCN106739137ASave human effortReduce labor intensityPaper-makingBox making operationsMechanical engineeringEngineering

The invention relates to a packing box processing device, in particular to a full-automatic soft-line sectional die-cutting machine and an operating method thereof. The full-automatic soft-line sectional die-cutting machine is simple in structure and is characterized in that two procedures of indentation and slitter edge removal of a plastic sheet are finished during one-time clamping to realize high-precision processing and high processing efficiency. The full-automatic soft-line sectional die-cutting machine comprises a rack and a controller, wherein a closed-cycle chain conveyor is arranged on the rack, a plurality of clamping and conveying mechanisms are uniformly distributed in the conveying direction of the chain conveyor, and a support wheel part at the head ends of the rack and the chain conveyor is a feeding end; and adjustment holes are formed in the two ends of stiffeners, adjustable bolts are arranged in the adjustment holes, and a stop block is arranged on the rear side of each adjustment hole. The full-automatic soft-line sectional die-cutting machine has the advantages that dents and cut edges are integrally formed, the borders of the cut edges are smooth, the dents are equal in depth, the processing efficiency is high and the structure is simple.

Owner:YANGZHOU SU PACK NEW MATERIAL TECH CO LTD

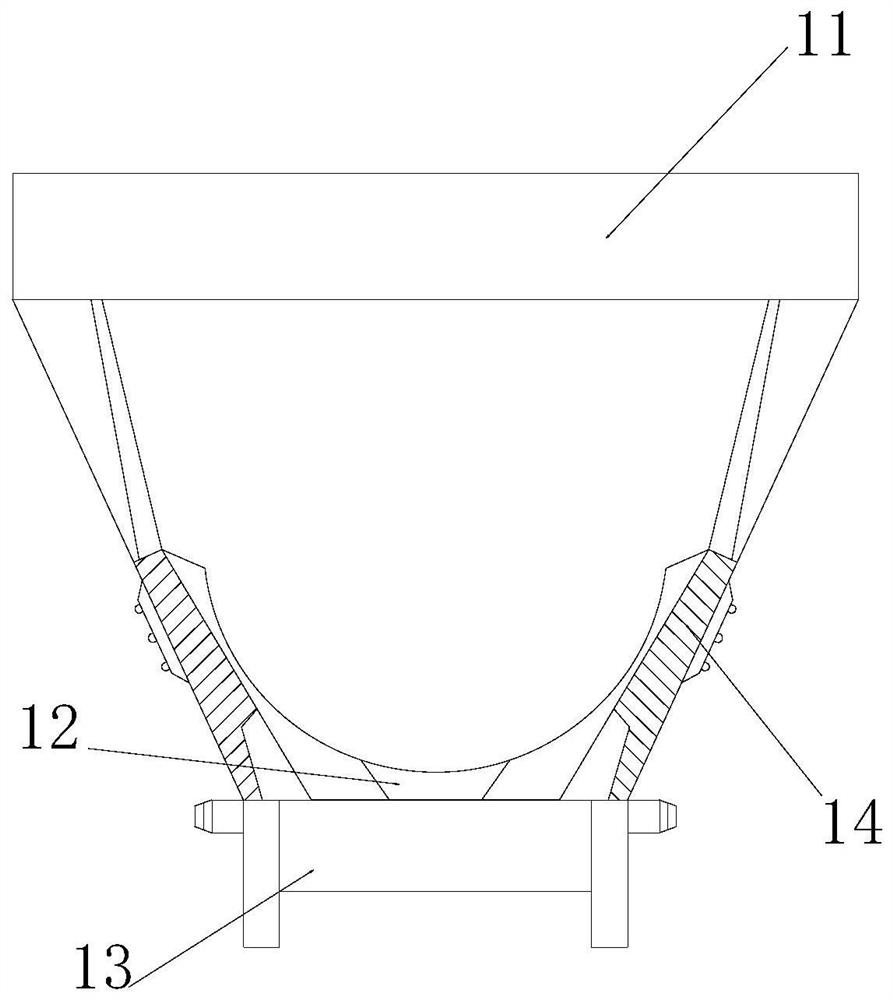

Aluminum profile conveyor

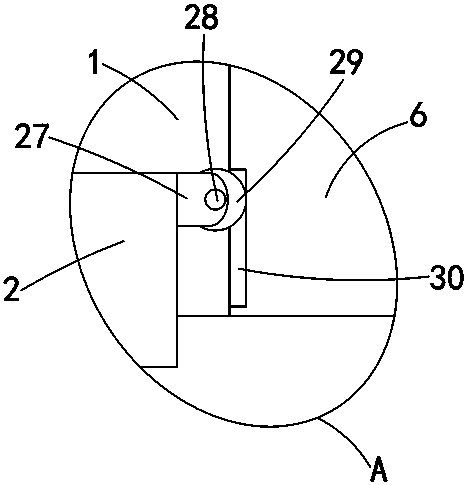

ActiveCN109675952AAvoid bendingIncrease the support areaExtrusion cleaning devicesEngineeringRotating disc

The invention belongs to the field of aluminum profile production equipment, in particular to an aluminum profile conveyor. The aluminum profile conveyor comprises a plurality of supporting power transmission mechanisms, an extrusion forming machine, a fixed anti-shaking mechanism and a burr cleaning mechanism; the supporting power transmission mechanisms are uniformly and closely arranged and consist of rotating discs, sliding blocks, springs, sliding brackets and string rubber strips; the rotating discs are arranged directly at the lower end of an aluminum profile; the sliding brackets are uniformly and fixedly arranged in the rotating discs; the number of the sliding brackets is two in total; the sliding brackets are symmetrically and oppositely arranged; sliding blocks are slidably arranged on the upper surfaces in the sliding brackets; the lower surfaces of the sliding blocks are fixedly connected with the springs; and the string rubber strips are fixedly arranged in the sliding blocks; the lower ends of that springs are fixedly connected to the inner centers of the rotating discs; and the springs are mainly used for fixing the sliding blocks to prevent the sliding blocks frombeing separated from a main body of the aluminum profile conveyor. The aluminum profile conveyor is mainly used for solving the problems that the parts of the aluminum profile are easy to bend and surface burrs are difficult to clean after extrusion molding.

Owner:昆山宏翔铝业有限公司

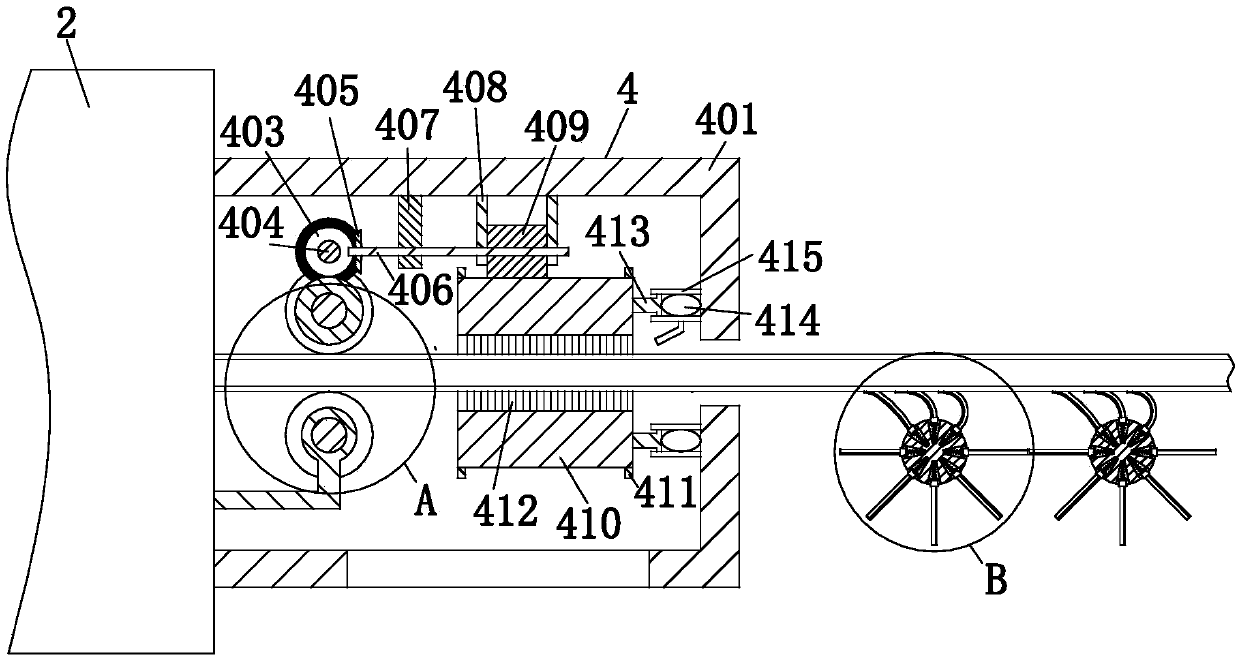

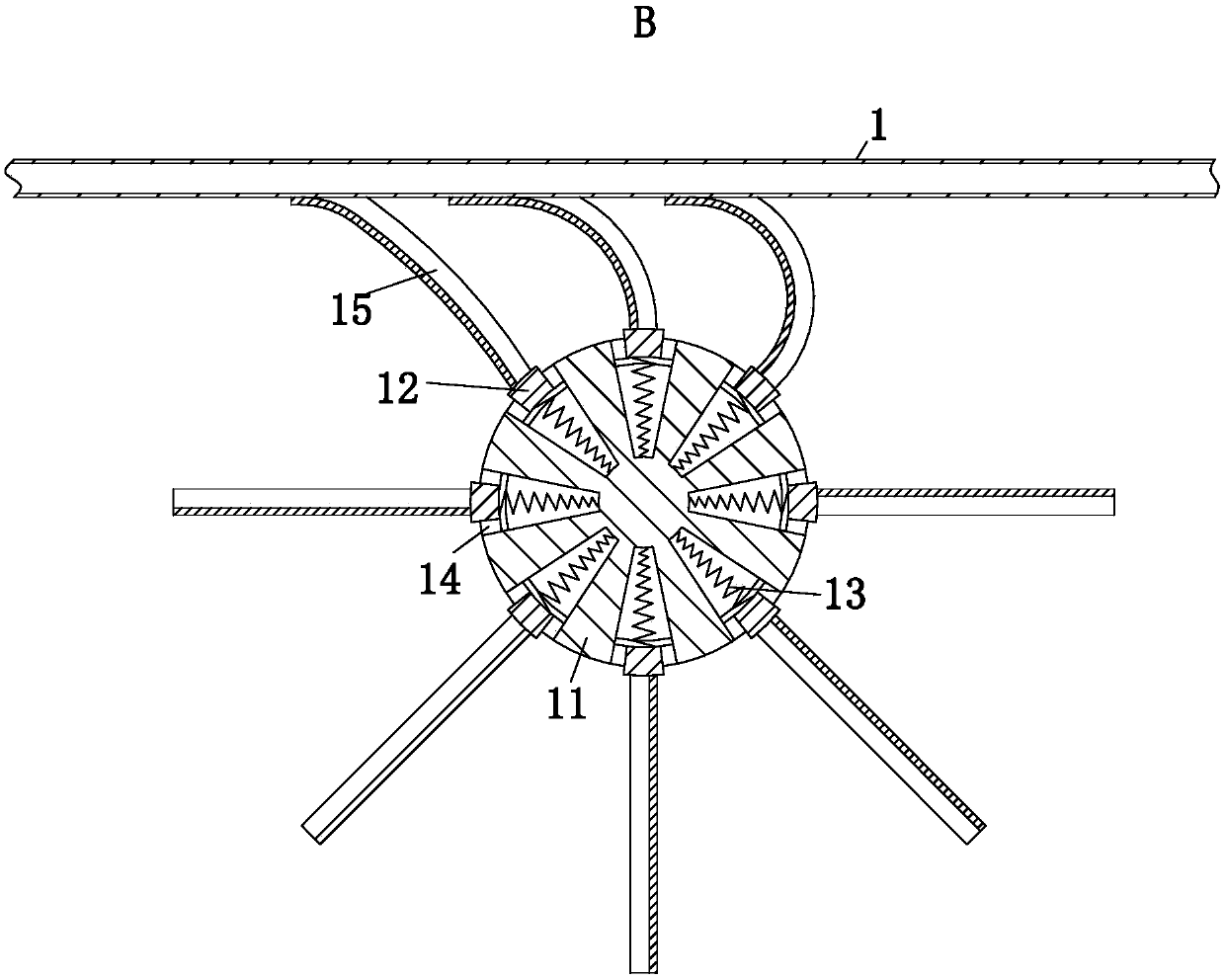

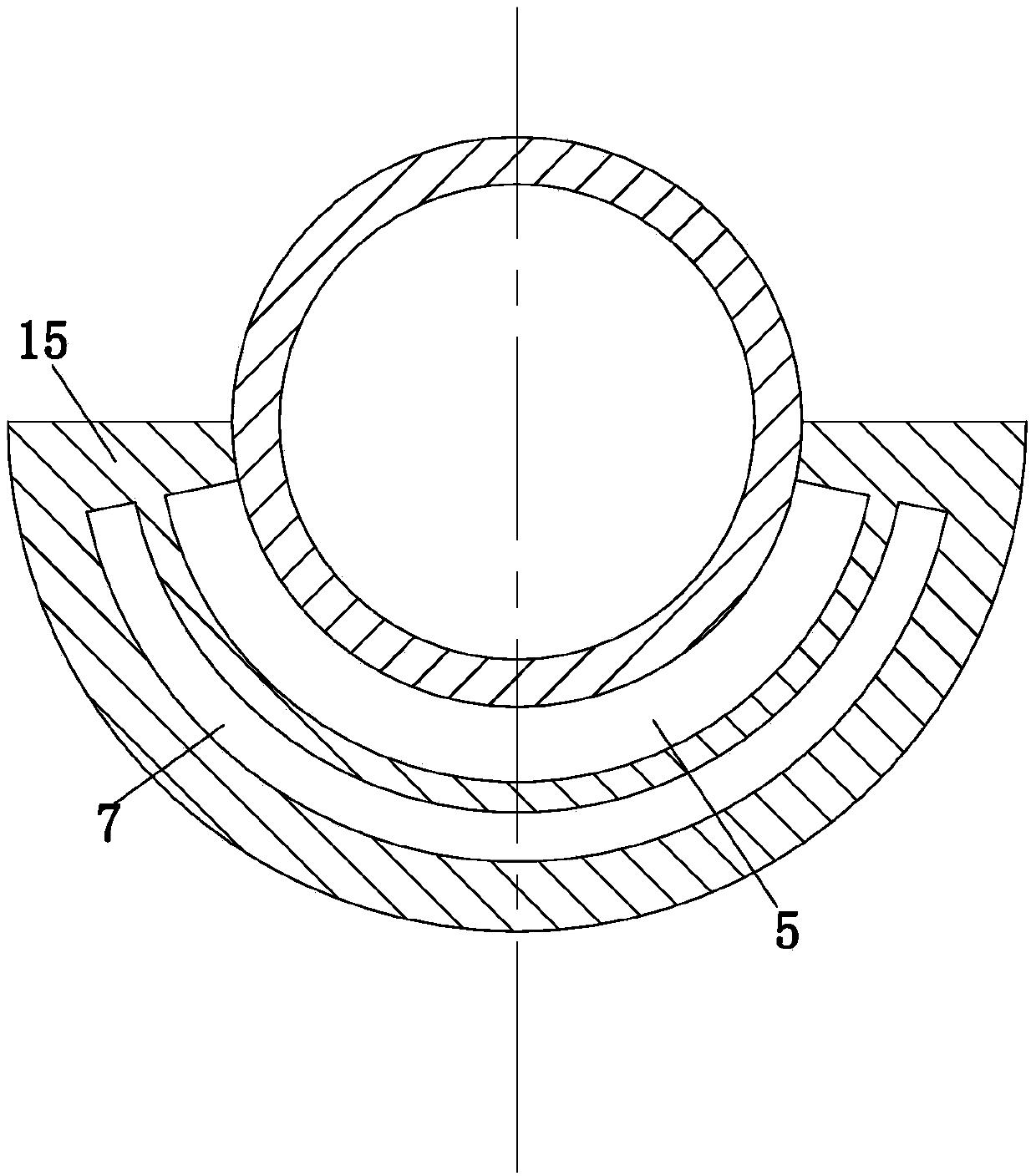

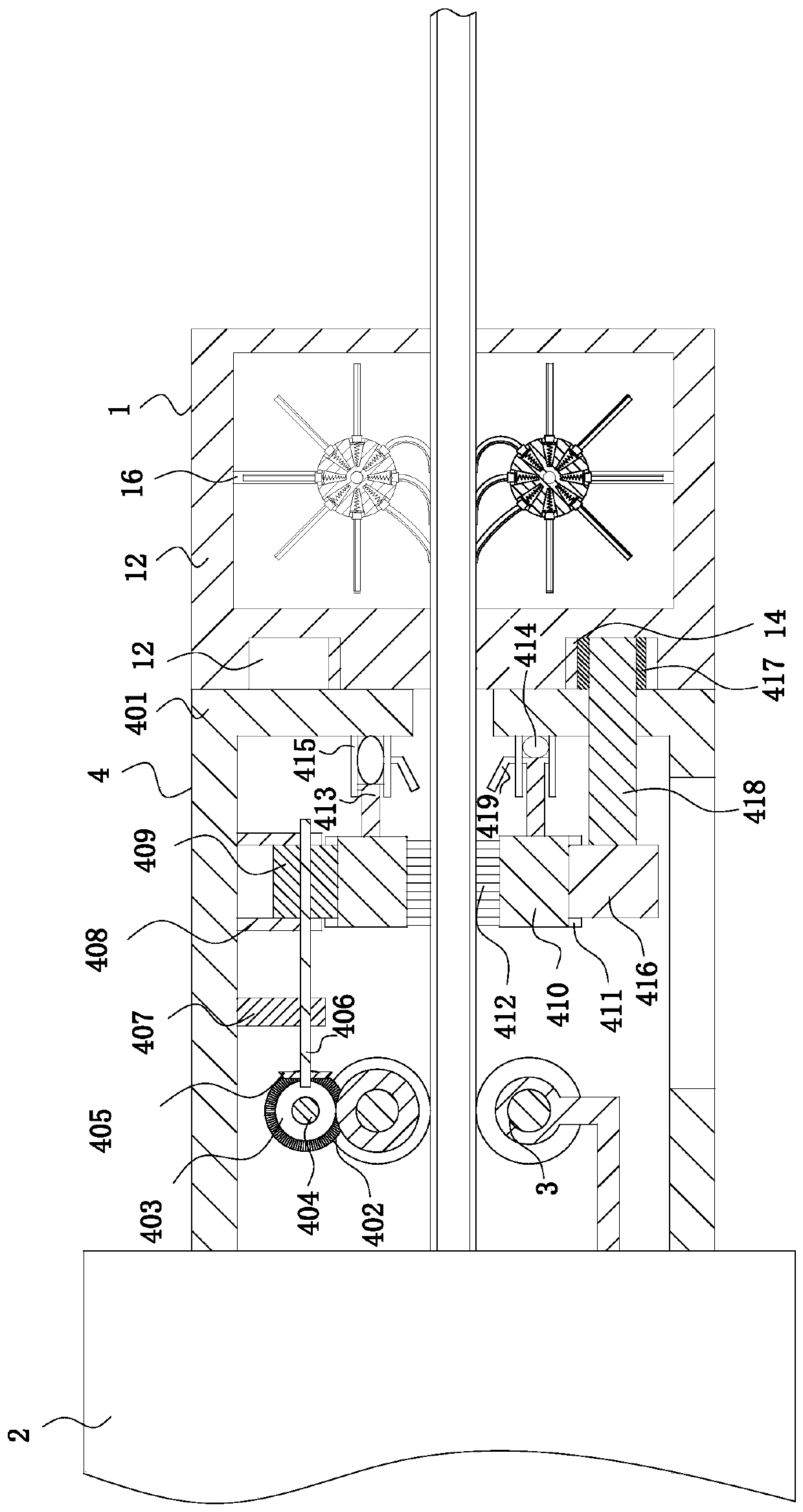

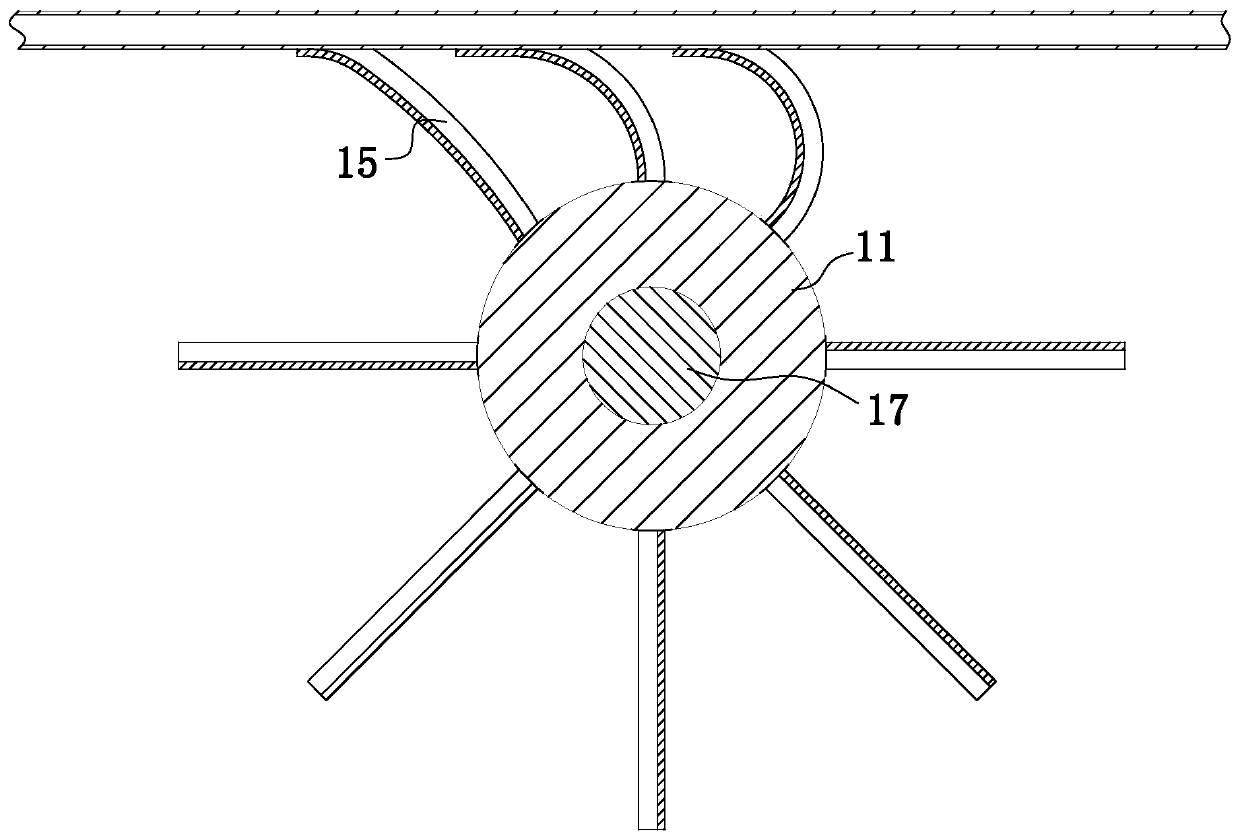

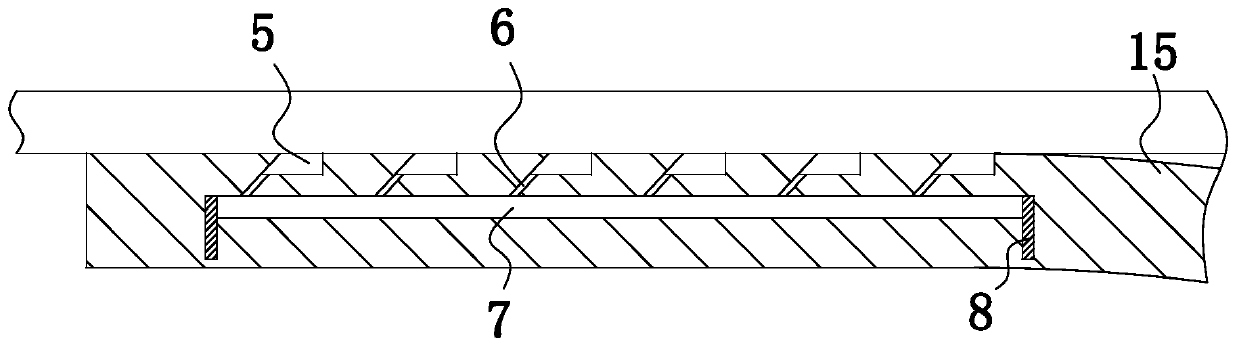

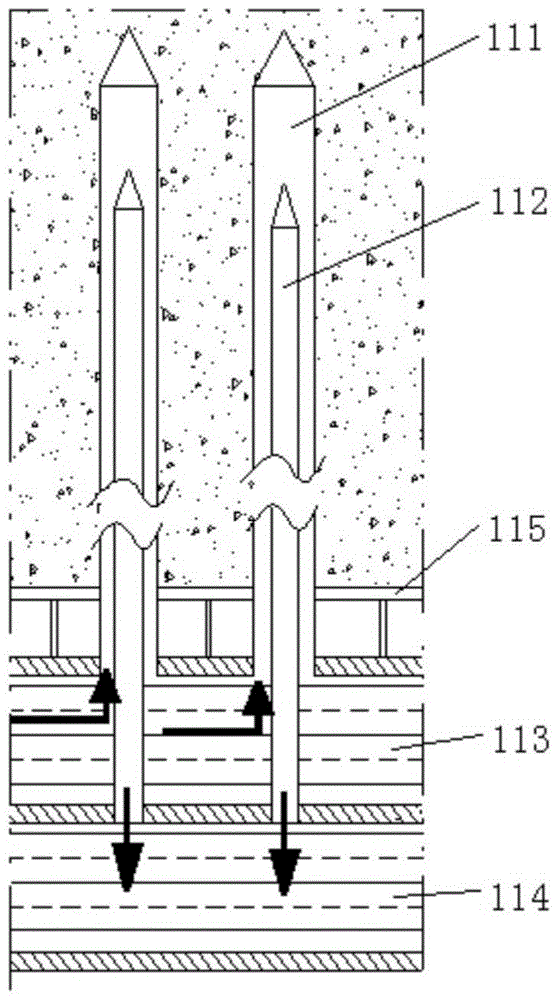

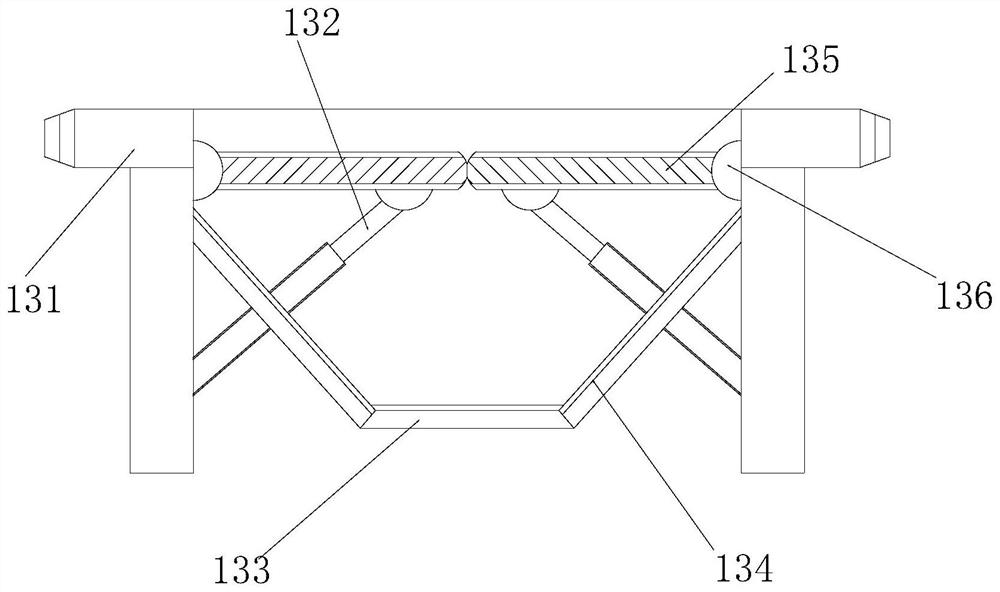

Reinforcing steel bar forming conveyor

The invention belongs to the field of reinforcing steel bar production equipment, and particularly relates to a reinforcing steel bar forming conveyor. The conveyor comprises a circulating smoothing mechanism, an extrusion forming machine, a fixing anti-shaking mechanism and a burr clearing mechanism, wherein the circulating smoothing mechanism comprises a fixing ring, the fixing ring is rotationally connected to the burr clearing mechanism, uniformly arranged supporting rods are fixedly connected to the inner wall of the fixing ring, transmission shafts are rotationally connected to the ends,away from the inner wall of a rotating ring, of the supporting rods correspondingly, servo motors are fixedly connected to the surfaces of the supporting rods, one ends of the transmission shafts arefixedly connected to driving shafts of the servo motors, the other ends of the transmission shafts are fixedly connected with rotary discs, the surfaces of the rotary discs are fixedly connected withstring rubber strips which are circumferentially and uniformly arranged, absorbing grooves are evenly formed in the inner walls of the ends, close to a steel bar, of the string rubber strips, and airholes are formed in the lower surfaces of the left ends of the absorbing grooves. The conveyor is mainly used for solving the problems of easy local bending and difficult clearing of surface burrs after extrusion forming of reinforcing steel bars.

Owner:孙自强

Rebar forming conveyor

The invention belongs to the field of steel bar production equipment, in particular to a rebar forming conveyor. The conveyor comprises supporting power delivery mechanisms, an extrusion forming machine, a fixed anti-shaking mechanism and a burr-removing mechanism, the supporting power delivery mechanisms are uniformly provided with a plurality of abutting, consists of turntables, slide blocks, springs, sliding supports and chord rubber strips, the turntables are arranged at the lower end of the reinforcing steel bar inside the turntable being uniformly, the turntables fixedly installed on thesliding supports, the sliding supports are provided with two, sliding brackets are symmetrically and oppositely arranged on the inner turntables, the inner surface of the sliding supports are slidably provided with sliding blocks, the sliding blocks are fixedly connected with the lower surface of the interior of the springs, sliding blocks are fixedly provided with chord rubber strips, the lowerend of the springs are fixedly connected with the turntables, and the internal center of the springs are mainly used for fixing the sliding blocks for preventing the sliding blocks are separated fromthe device body. The equipment is mainly used for solving the problem that the reinforced extrusion forming after local-curved surface burr is difficult to clean is solved.

Owner:孙自强

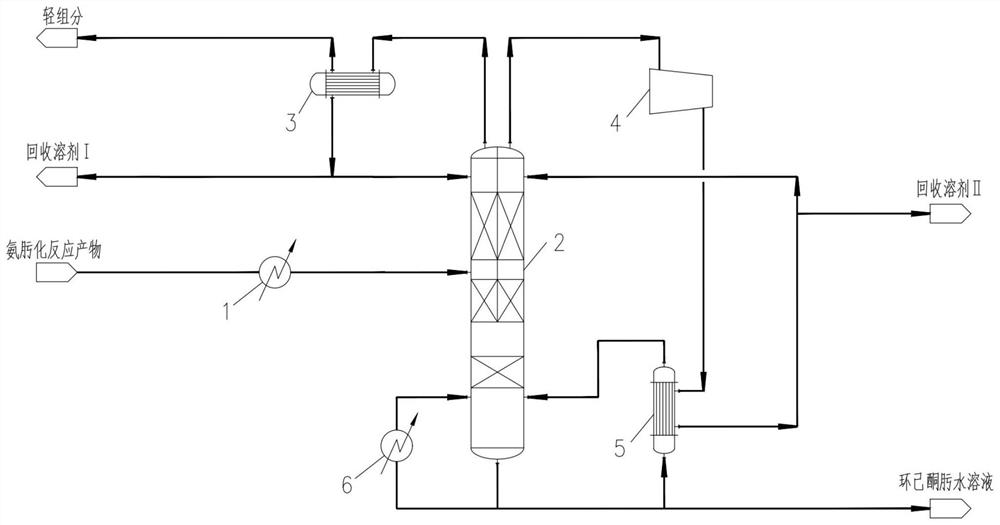

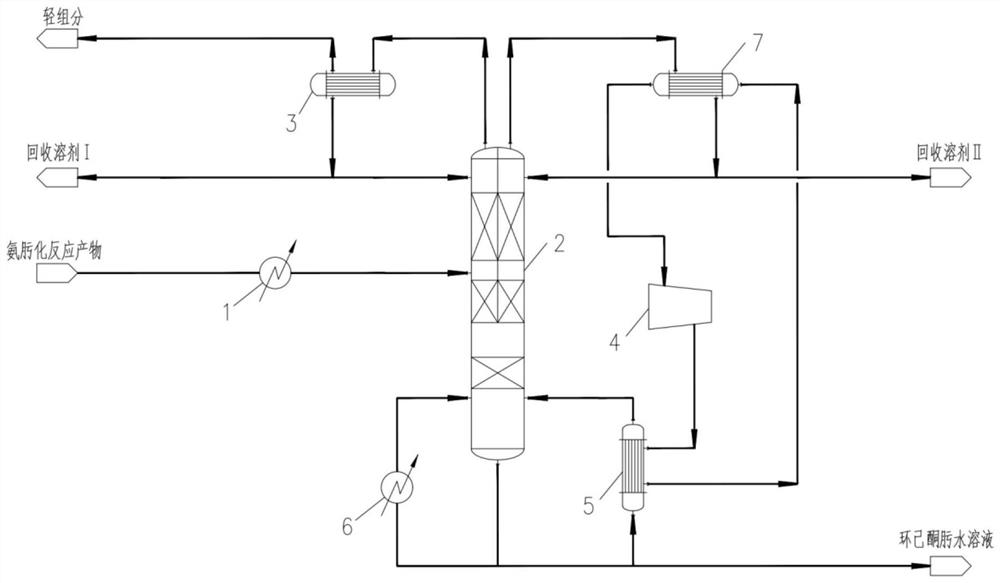

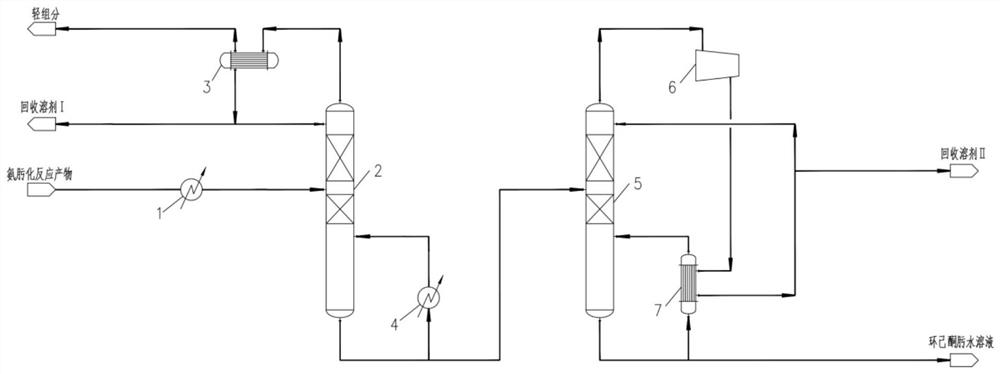

Device and method for recovering tert-butyl alcohol by using dividing-wall column in combination with heat pump technology

PendingCN113121314AAchieve reuseReduce consumptionOrganic compound preparationChemical industryReboilerSeparation technology

The invention relates to a device and method for recovering tert-butyl alcohol by combining a dividing-wall column with a heat pump technology, belonging to the technical field of chemical separation. The device disclosed by the invention comprises a dividing-wall rectifying tower, a condenser I, a compressor, a dividing-wall rectifying tower bottom reboiler I and a dividing-wall rectifying tower bottom reboiler II. According to the method for energy-saving recovery of the ammoximation reaction solvent tert-butyl alcohol by using the device, steam consumption and cooling water consumption can be greatly reduced, a good energy-saving effect is achieved, impurity separation capacity is high, the content of tert-butyl alcohol in an obtained aqueous cyclohexanone-oxime solution is very low, and influence on a subsequent cyclohexanone-oxime refining procedure is avoided.

Owner:吴嘉

Lock attaching structure and backlight module

InactiveCN102734761APrevent fallingAvoid affecting the appearanceLighting support devicesNon-linear opticsEngineeringElectrical and Electronics engineering

The present invention discloses a lock attaching structure and a backlight module, wherein the lock attaching structure is used for fixing a first object and a second object, the lock attaching structure comprises a first lock attaching portion, a second lock attaching portion, a lock attaching member and a diaphragm, the first lock attaching portion belongs to one portion of the first object and is provided with a first assembling hole, the second lock attaching portion belongs to one portion of the second object and is provided with a second assembling hole, the lock attaching member comprises a head portion and an insertion portion, the first lock attaching portion is located between the second lock attaching portion and the head portion, the insertion portion passes through the first assembling hole and is locked to attach to the second assembling hole, the diaphragm is configured on one side of the second lock attaching portion, opposite to the first lock attaching portion and covers the second assembling hole, the diaphragm is provided with a dust collection surface opposite to the second assembling hole, and the diaphragm is provided with a through hole at a position corresponding to the second assembling hole. The present invention also discloses a backlight module containing the lock attaching structure.

Owner:AU OPTRONICS CORP

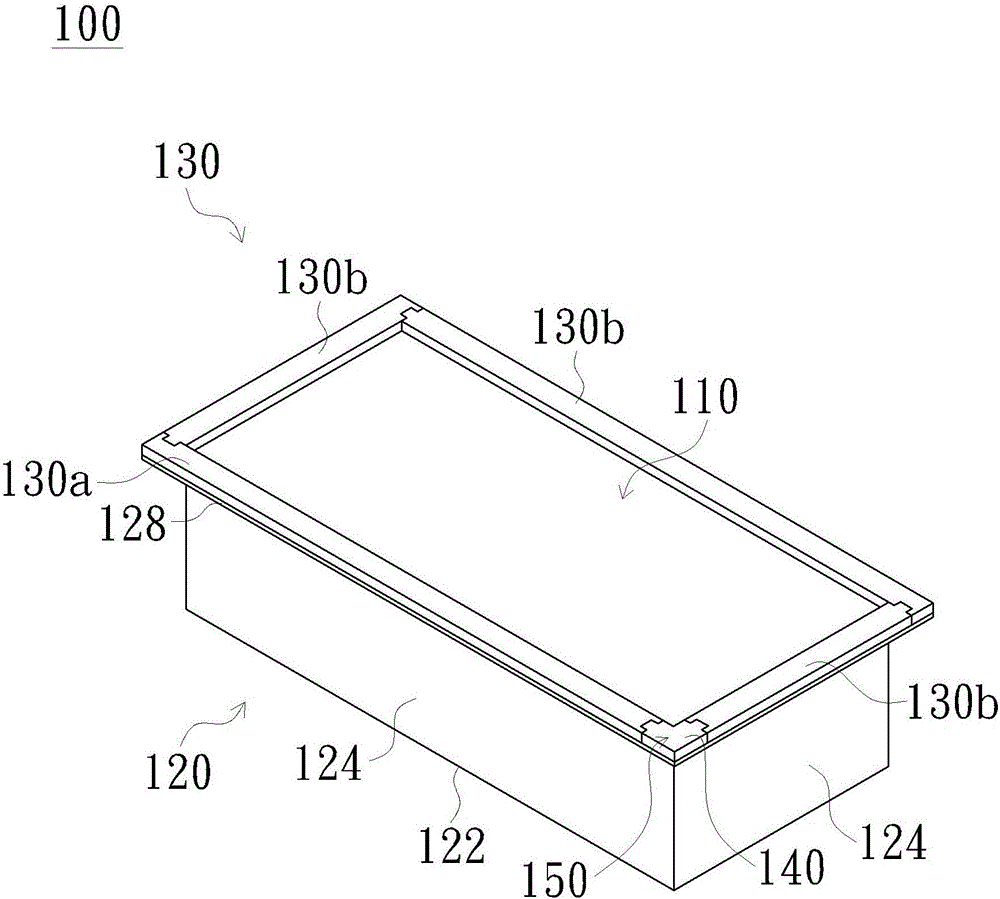

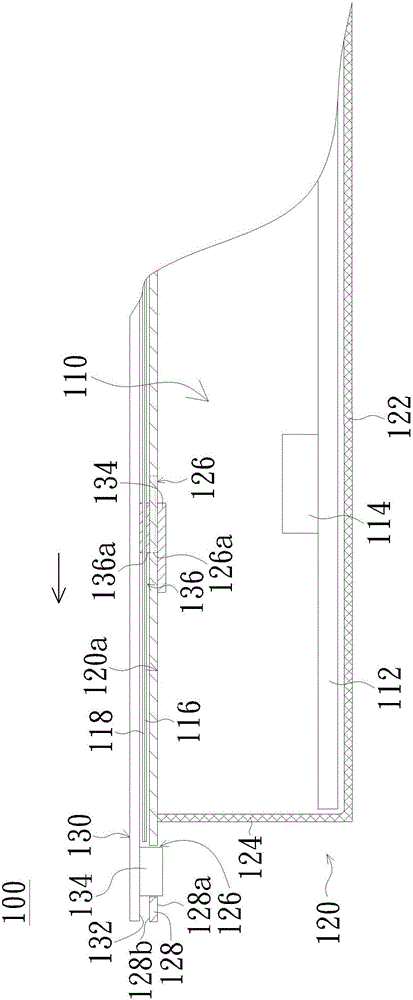

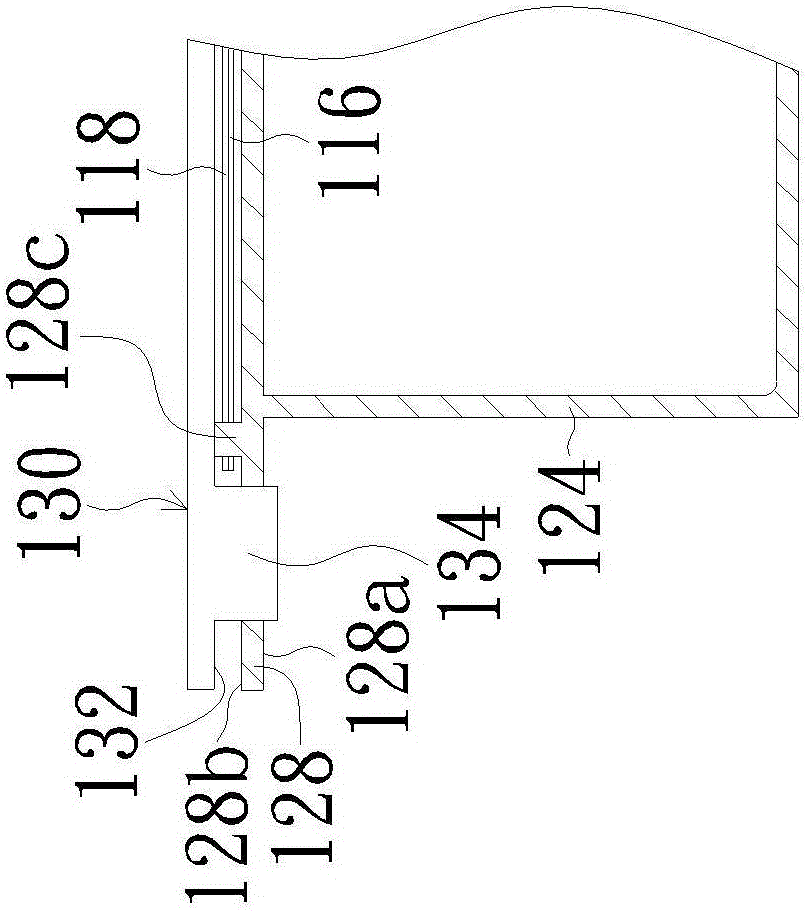

Backlight module

ActiveCN106338858AEasy to assembleEasy to disassembleNon-linear opticsMultiple frameStructural engineering

The invention discloses a backlight module comprising a backlight combination, a back plate, multiple frame strips and an assembly. The back plate is provided with multiple side walls which are connected with each other and surround the backlight combination, and the top of each side wall is provided with multiple groove bodies. The multiple frame strips are installed on the top of the side walls. The bottom face of each frame strip is provided with multiple clamp members which are opposite to the groove bodies of corresponding side walls; the clamp members of each frame strip are installed inside the groove bodies of the corresponding side walls, and the frame strips can slide in relative to the side walls to drive each clamp member of the frame strips to be clamped at one side wall, corresponding to the groove body, of the side walls so that the frame strips can be assembled on the side walls in order, and the frame strips are combined in order with each other to form notches. The combination is combined at two frame strips close to the notch for covering the top of the side walls together with the frame strips. The frame strips of the backlight module of the invention can be assembled and disassembled conveniently.

Owner:CORETRONIC OPTOTECHSUZHOU CO LTD

Flexible circuit board, touch panel, touch module and electronic apparatus

InactiveCN108459768AAvoid affecting yieldIncrease wiring spaceDetails for portable computersInput/output processes for data processingFlexible circuitsTouch panel

The invention provides a touch module. The touch module comprises a touch panel and a flexible circuit board; the touch panel defines a central region and a peripheral region surrounding the central region; the flexible circuit board is connected to the peripheral region of the touch panel; the flexible circuit board has an outer edge close to the central region; and at least part of the outer edge is sunken in a direction far away from the central region. The invention furthermore provides the flexible circuit board, the touch panel and an electronic apparatus. According to the touch module,at least part of the flexible circuit board is sunken in the direction far away from the central region, so that the wire arrangement space is expanded, and the influence of the product yield due to the fold and bubble problem of a bonding layer due to insufficient space can be effectively avoided.

Owner:INTERFACE TECH CHENGDU CO LTD +2

Light distribution method for advertising lamp box and advertising lamp box

InactiveCN108735119ASave man hoursReduce labor costsIlluminated signsLight fasteningsDistribution methodEffect light

The invention discloses a light distribution method for an advertising lamp box and the advertising lamp box. The light distribution method comprises an edge lighting step and a middle lighting step,wherein the edge lighting step comprises a sub-step of arranging an LED light bar capable of realizing single-side lighting in the advertising lamp box along the inner wall of the lamp box so as to perform lighting from the inner wall of the frame to the middle; the middle lighting step comprises a sub-step of arranging a plurality of LED light bars capable of realizing double-side lighting in themiddle of the interior of the advertising lamp box so as to perform lighting on double sides; and the central plane of lighting surfaces of the single-side lighting LED light bar and the double-sidelighting LED light bar is configured to be parallel to the advertising surface of the advertising lamp box. The light distribution method disclosed by the invention is particularly applicable to illumination of the advertising lamp box, and under the condition that the effect of the advertising lamp box is the same as that of the traditional lighting tool, the advertising lamp box has the advantages of being environmental-friendly, capable of firmly fixing the lens without easy falling, high in structural strength, applicable to a large lamp box, low in manual installation cost and the like.

Owner:NINGBO LEVI LIGHTING TECH CO LTD

Touch device

ActiveCN106557189AAvoid breakingImprove drop resistanceInput/output processes for data processingProtection layerComputer science

The invention provides a touch device, which comprises a touch panel, a display module and a first gluing layer, wherein a circuit layer is arranged around the touch panel; the first gluing layer is laminated between the touch panel and a display module; the first gluing layer covers the display module and is provided with an extrusion part which extrudes out of the edge of the display module; the extrusion part of the first gluing layer at least covers the circuit layer; and the surface, which is far away from the circuit layer, of the extrusion part does not have viscosity. The first gluing layer not only can laminate the display module and the touch panel but also covers the circuit layer, and a protection layer does not need to be additionally arranged on the circuit layer so as to guarantee that the circuit layer can not be easily broken due to external force pulling.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

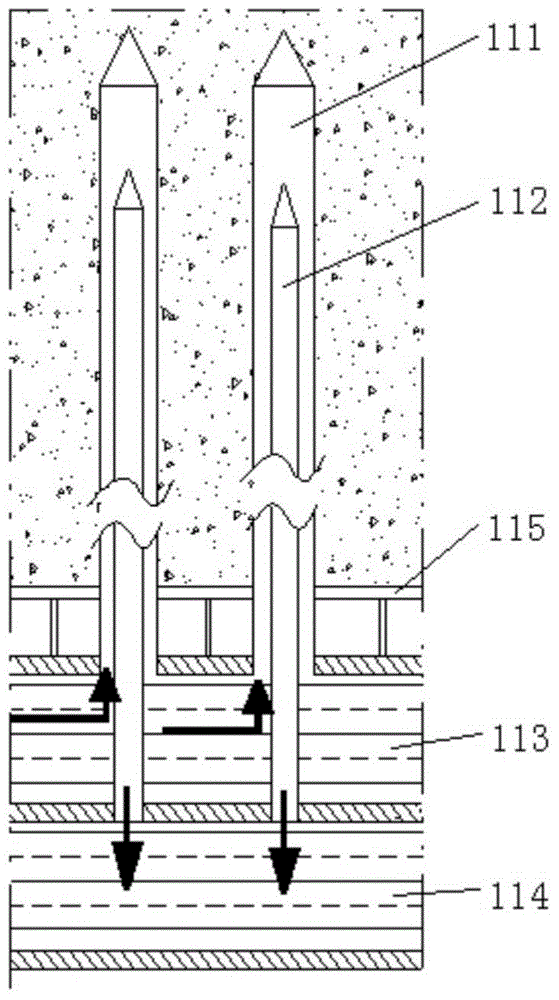

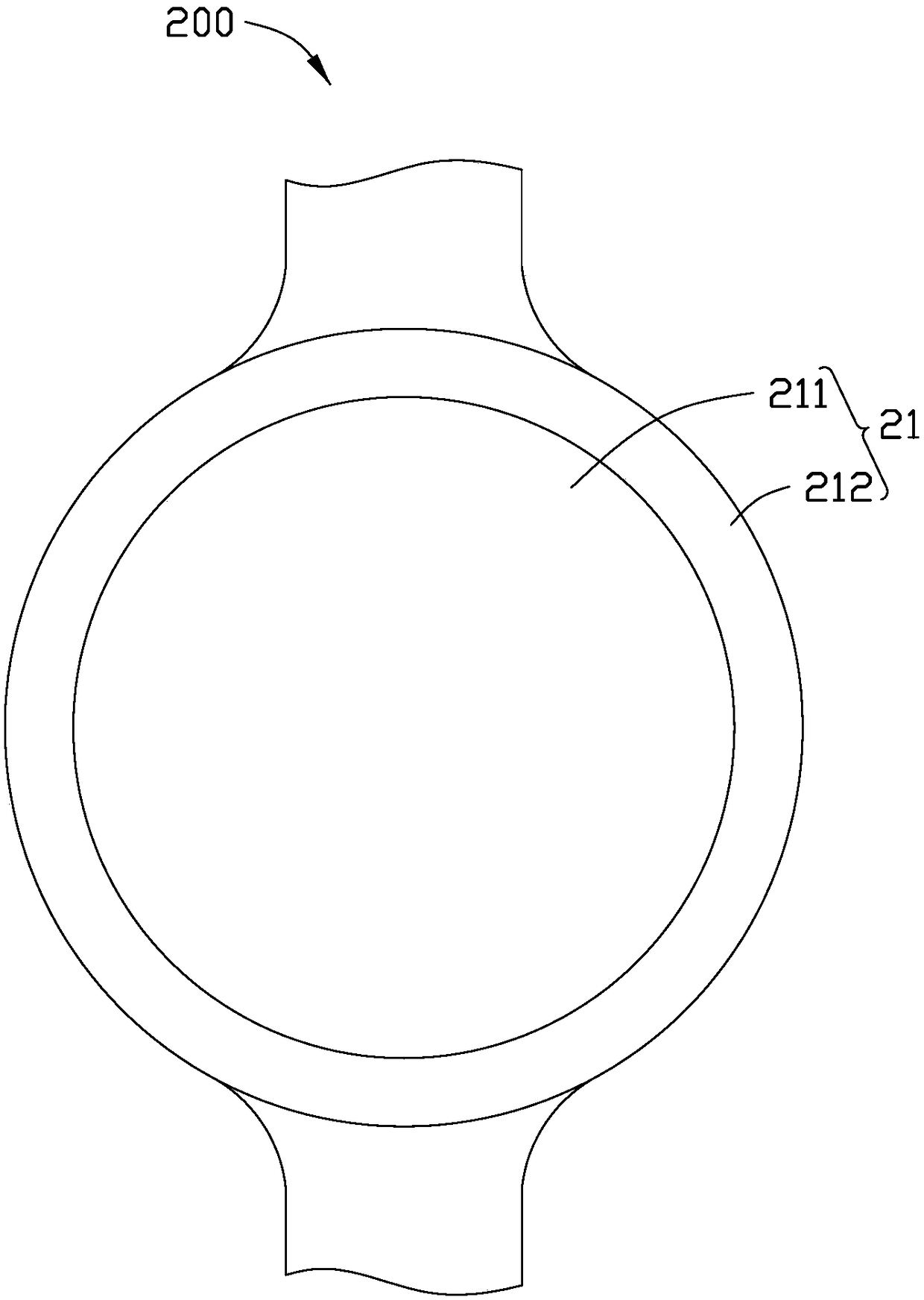

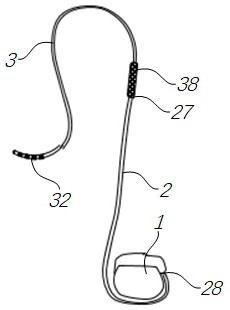

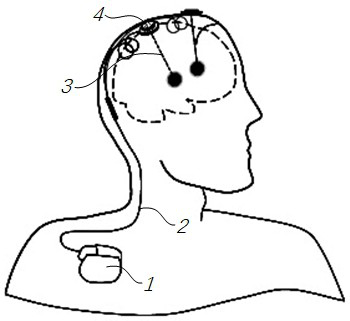

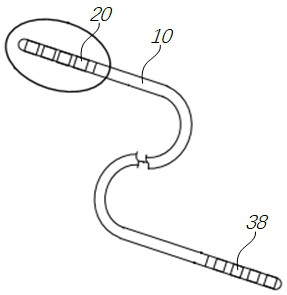

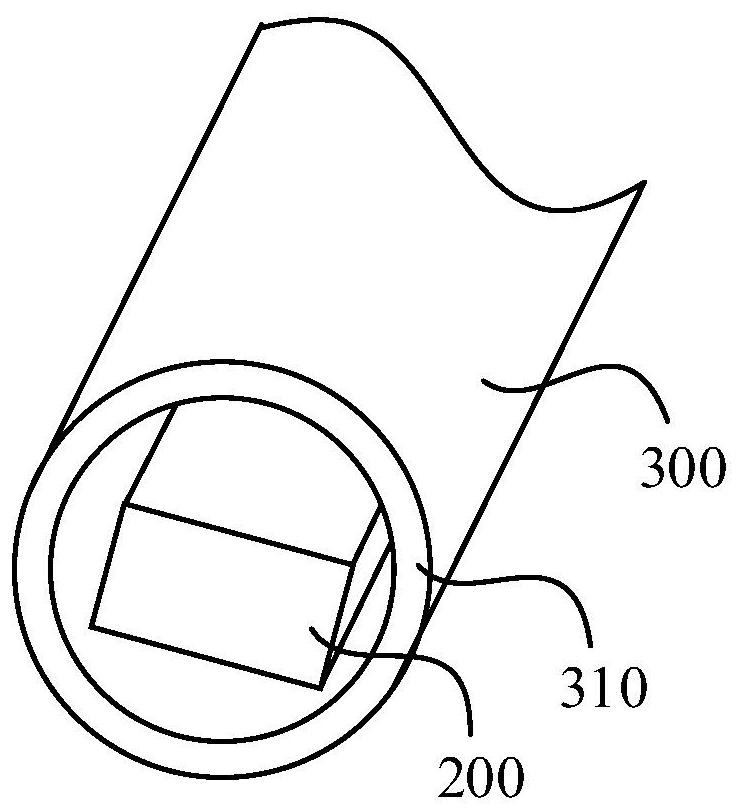

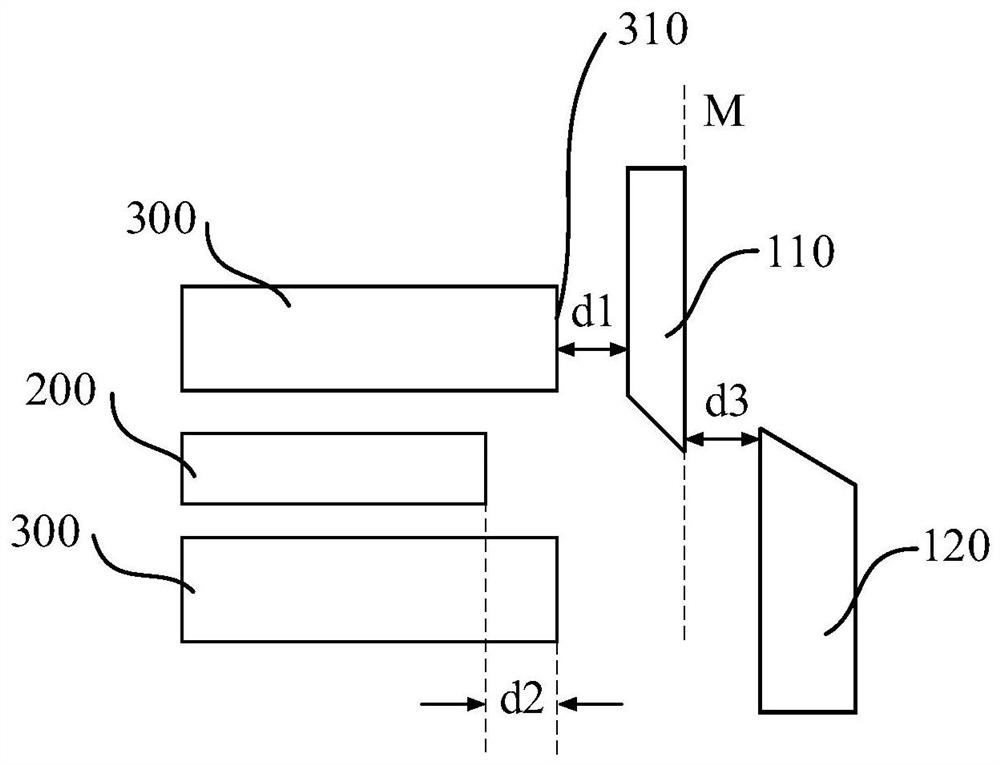

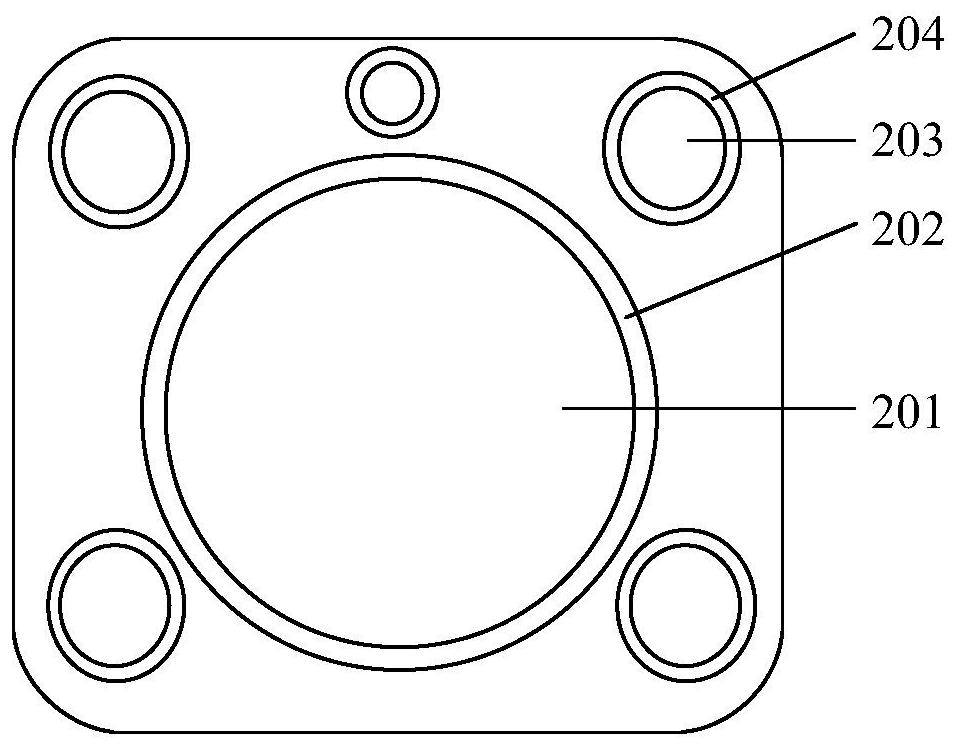

Implanted electrode and implanted electrical stimulation system

ActiveCN113713259AGuaranteed parallelAvoid affecting yieldHead electrodesExternal electrodesBiomedical engineeringAnatomy

The invention provides an implanted electrode and an implanted electrical stimulation system. The implanted electrode comprises a base body and electrode stimulation pieces, wherein the base body is tubular or columnar, at least two mounting grooves are formed in the same axial position of the base body in the circumferential direction of the base body, and guide grooves are formed in the positions, at the two axial ends of the mounting grooves, of the inner wall of the base body; the at least two electrode stimulation pieces are respectively and correspondingly arranged in the mounting grooves; each electrode stimulation piece comprises an electrode plate and an anchor structure connected with the corresponding electrode plate; and each electrode plate is located in the corresponding mounting groove, the outer surface of each electrode plate is exposed outside the base body, and at least part of the anchor structures is located in the guide groove and cooperates with the guide grooves, so that the center line of the outer surface of each electrode plate is parallel to the axis of the base body. According to the configuration, the implanted electrode realizes initial positioning before the electrode plates and the base body are fixed through cooperation of the anchor structures and the guide grooves, so that the central lines of the outer surfaces of the electrode plates are parallel to the axis of the base body, orientation and positioning during processing are facilitated, and the situation that the yield is influenced due to rotation dislocation of the electrode plates in the subsequent fixing and processing process is avoided.

Owner:SHANGHAI NEURAZING CO LTD

A kind of preparation method of mushroom stick

ActiveCN104956918BFacilitate the cultivation of hair bacteriaIncrease productionCultivating equipmentsMushroom cultivationBiotechnologyBud

The invention relates to a method for preparing mushroom sticks. The method comprises the following steps of culture compost preparing, culture compost sterilizing, cooling, inoculating and bagging, stick spawn running culture, stick coloring management and mushroom bud pressing fruiting, harvesting and flushing management. According to the method for preparing the mushroom sticks, bags are not prone to being damaged, sterilization is achieved thoroughly, the sterilizing and cooling time is short, strains are distributed evenly, and the fruiting period is short.

Owner:翔天科技股份有限公司

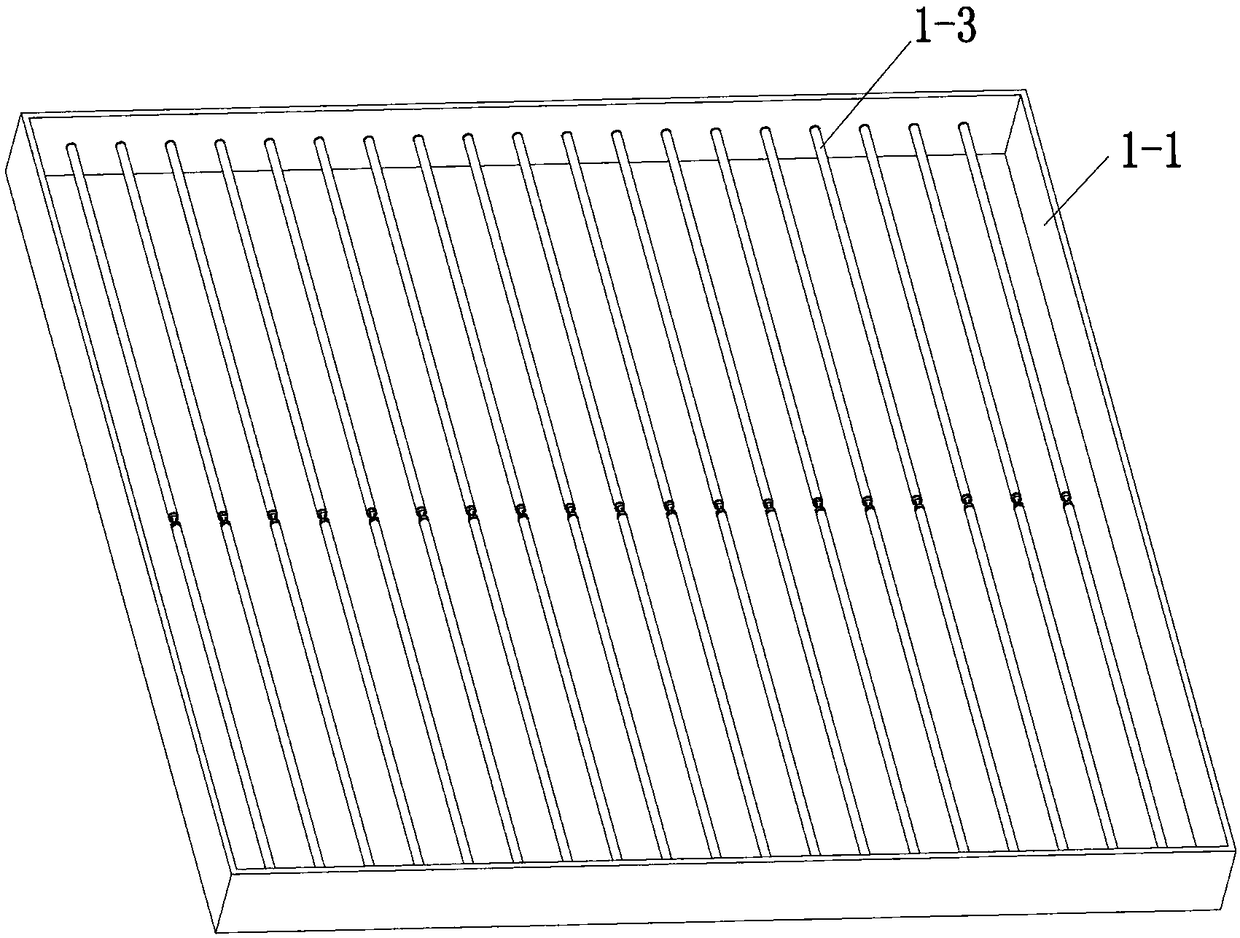

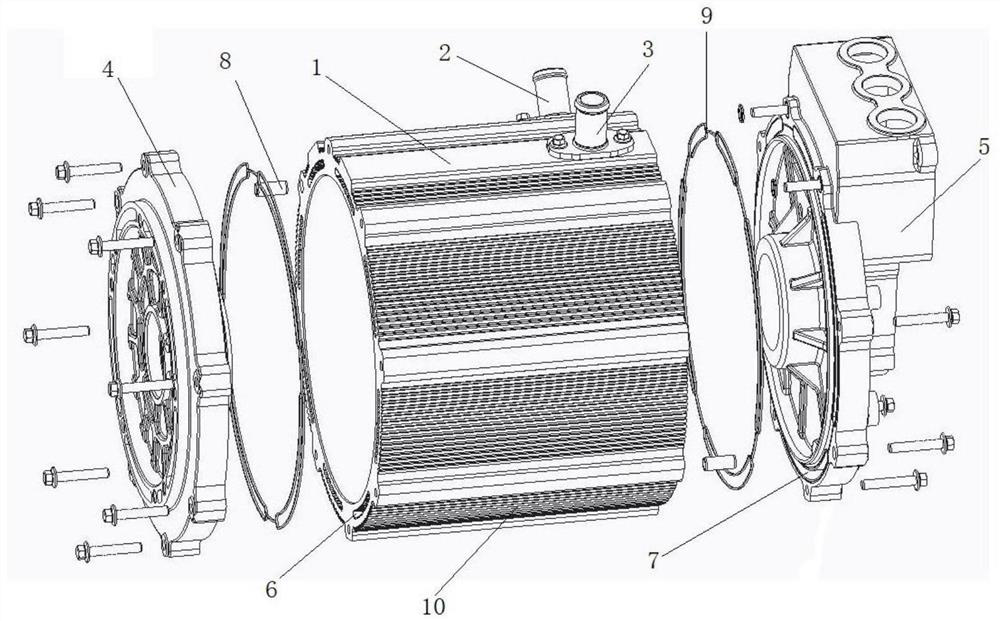

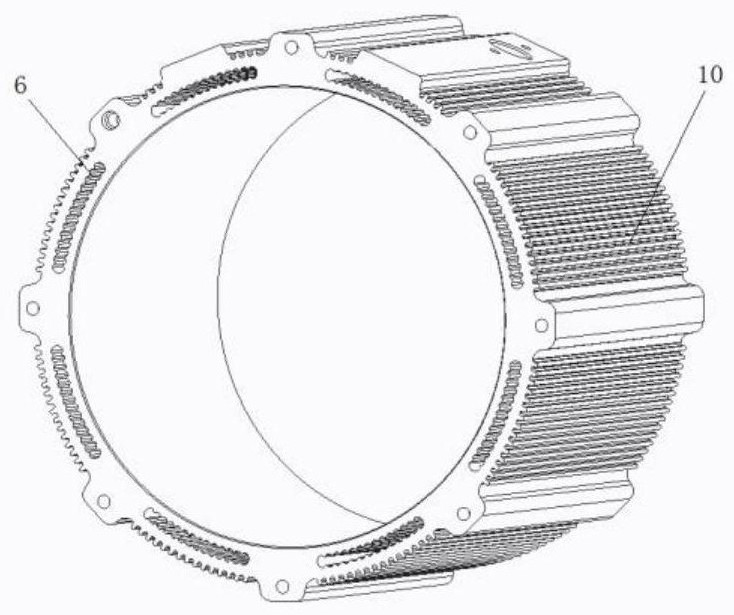

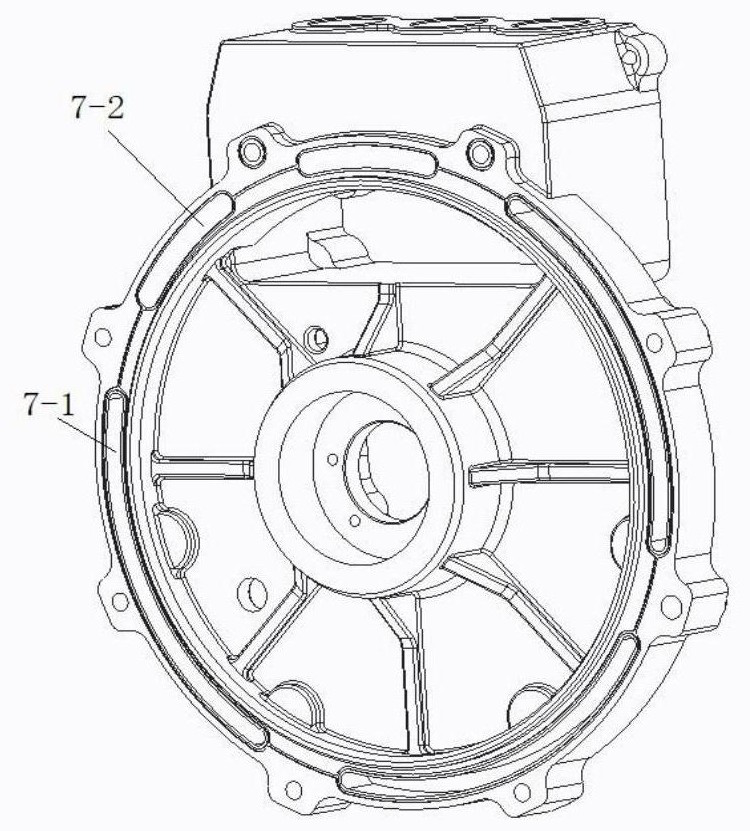

Welding-free water-cooled motor shell and motor thereof

PendingCN113394906AAvoid affecting yieldReduce process stepsSupports/enclosures/casingsSlag (welding)Electric machinery

The invention discloses a welding-free water-cooled motor shell, which comprises a shell, a water inlet and a water outlet arranged on the shell, a front end cover arranged at the front end of the shell and a rear end cover arranged at the rear end of the shell, and is characterized in that the shell is fixedly connected with the front end cover and the rear end cover, and is provided with a plurality of axial water channels which are circumferentially distributed and penetrate through the shell; and the front end cover and the rear end cover are provided with a plurality of arc-shaped water channels used for being connected with the axial water channels, the axial water channels are connected in series through the arc-shaped water channels, and water inlets and water outlets are formed in the water channels. The axial water channels of the casing and the arc-shaped water channels of the front end cover and the rear end cover jointly form the U-shaped water channel, and the two ends of the water channel do not need to be blocked by a welding process, so that the influence on the product quality and the yield caused by welding defects or welding slag falling into the water channel is avoided, the product yield is improved, and the product cost is reduced.

Owner:河南通宇新源动力有限公司

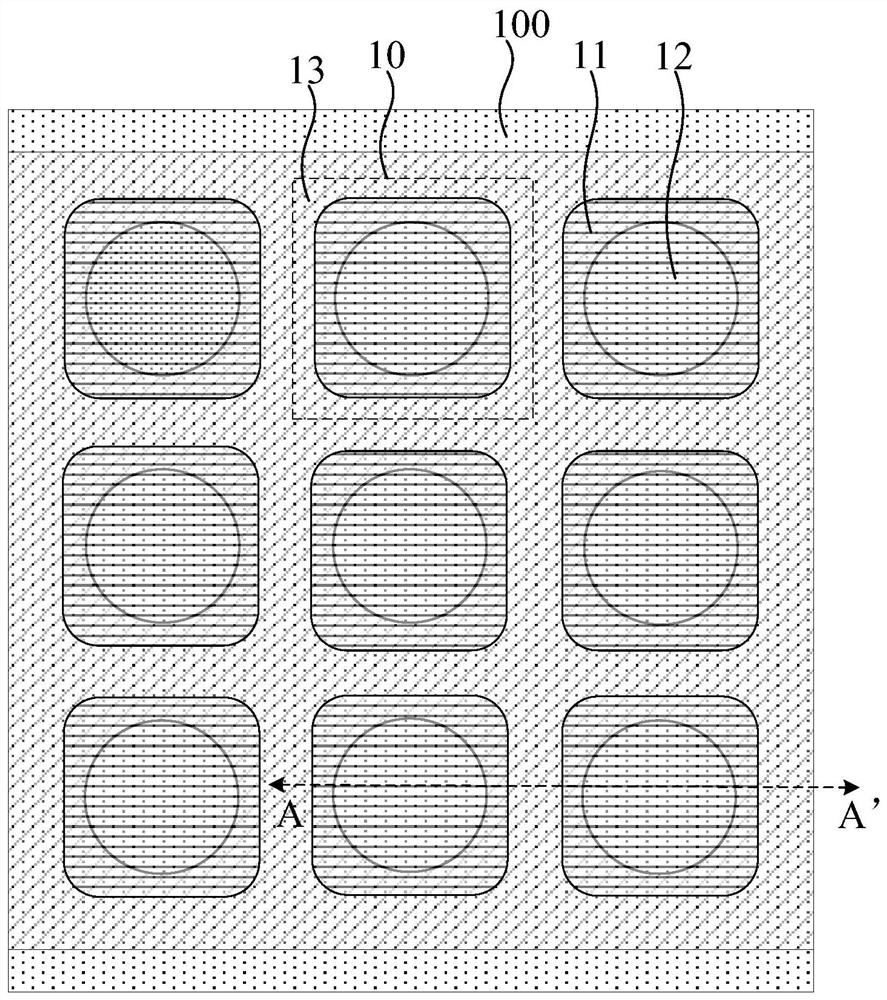

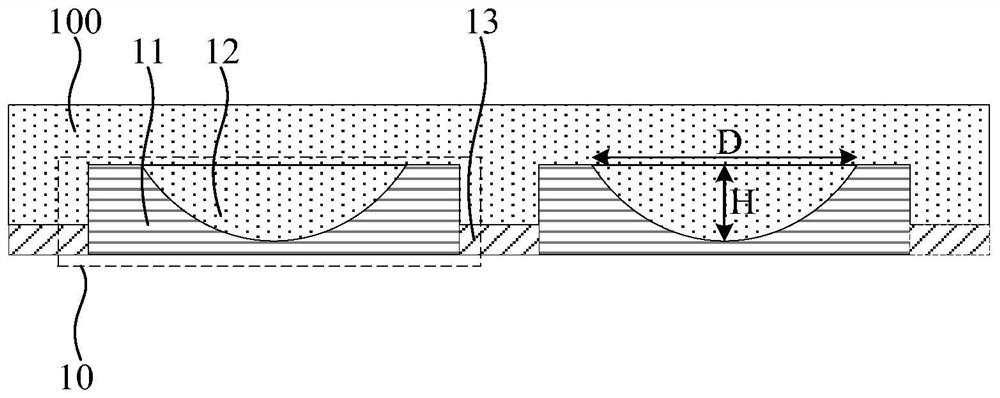

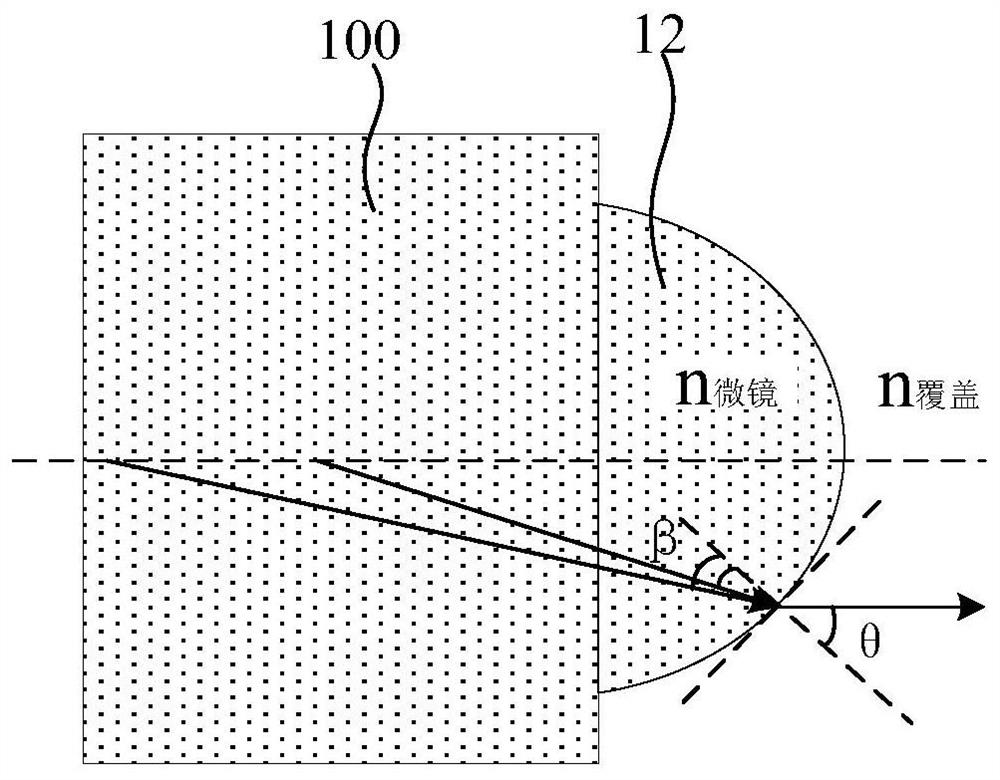

Variable-focal-length semiconductor surface micro lens, manufacturing method thereof and laser

ActiveCN113189684AAvoid dependenceAvoid affecting yieldLaser detailsSemiconductor lasersRefractive indexErbium lasers

The embodiment of the invention discloses a variable-focal-length semiconductor surface micro lens, a manufacturing method thereof and a laser. The variable focal length semiconductor surface microlens includes a substrate and a lens unit, wherein the lens unit is located on one side of the substrate; the lens unit comprises a micro lens and a varifocal layer, the varifocal layer is located on the side, away from the substrate, of the micro lens and covers the light-emitting surface of the micro lens, and the varifocal layer is used for adjusting the refractive index of the lens unit; the refractive index of the lens unit is difference between the refractive index of the micro lens and the refractive index of the varifocal layer. According to the micro lens, the variable focal length of the surface micro lens is realized, namely, different focal lengths of the micro lens are realized, the method is simple and practical, dependence on a high-precision surface micro lens etching process when a long-focal-length micro lens is realized is avoided, cost is low, and meanwhile, the overall product yield is ensured.

Owner:VERTILITE CO LTD

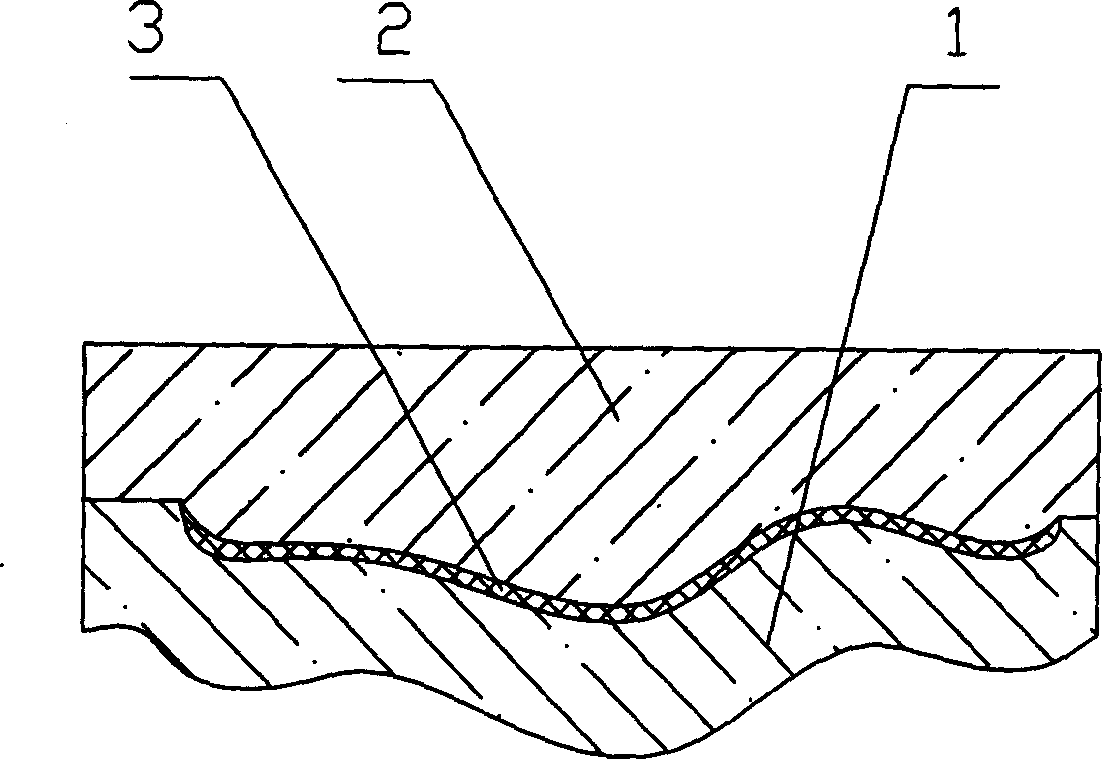

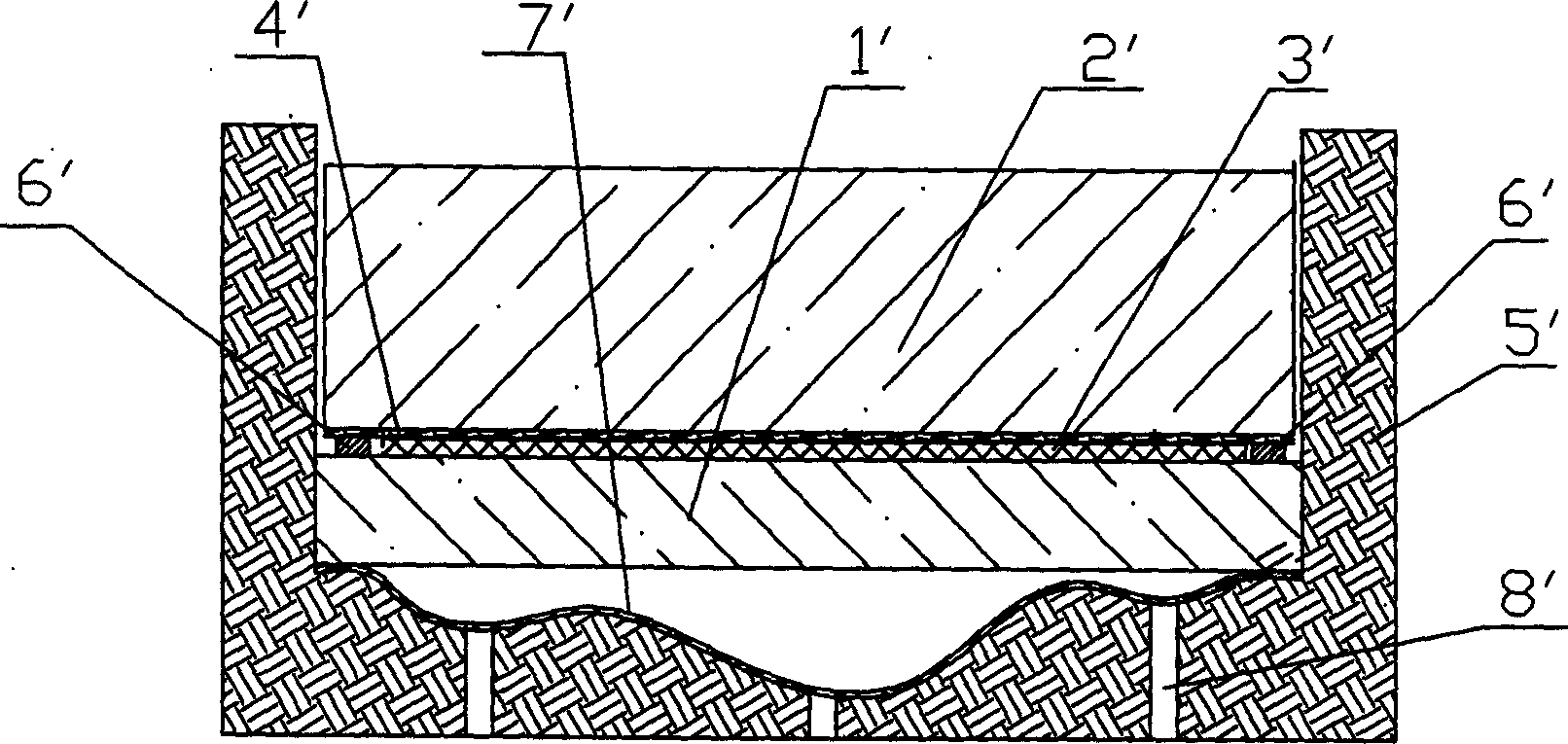

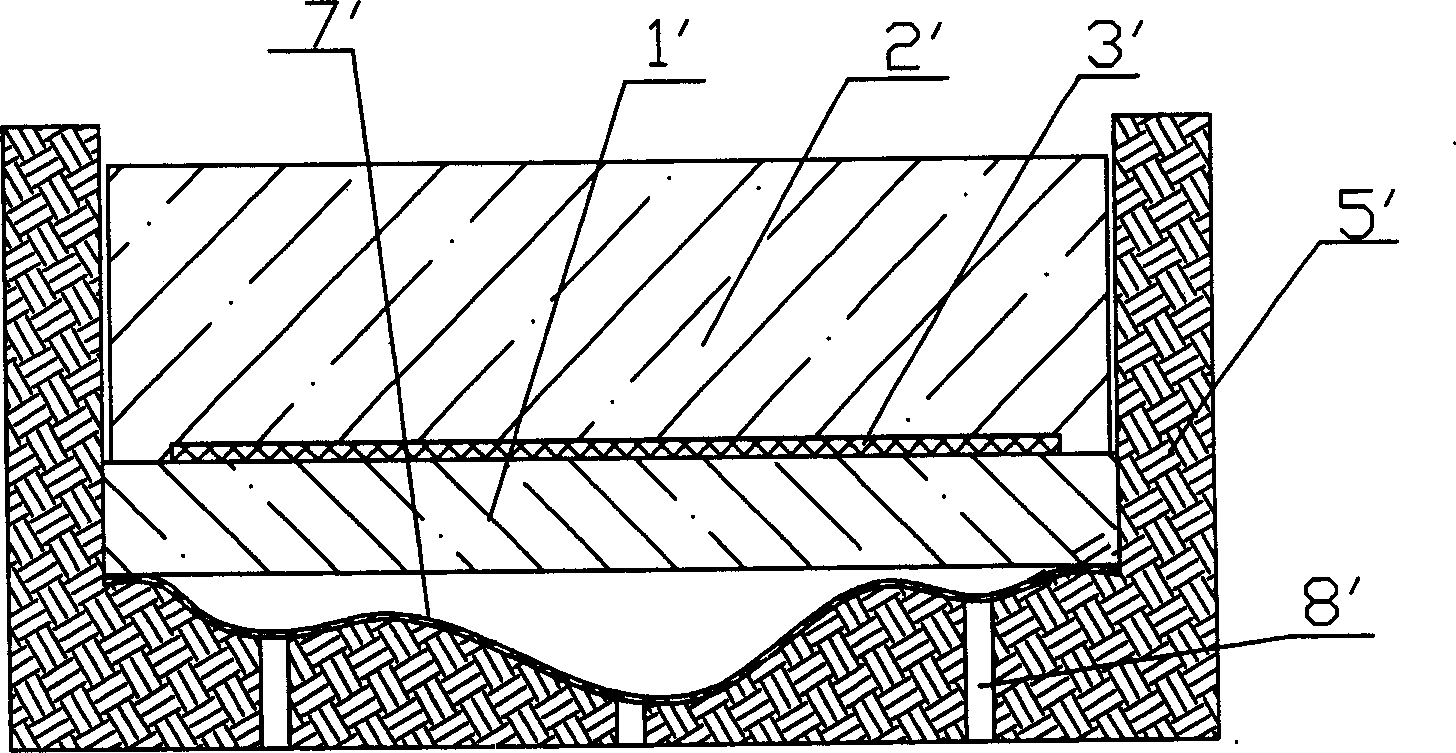

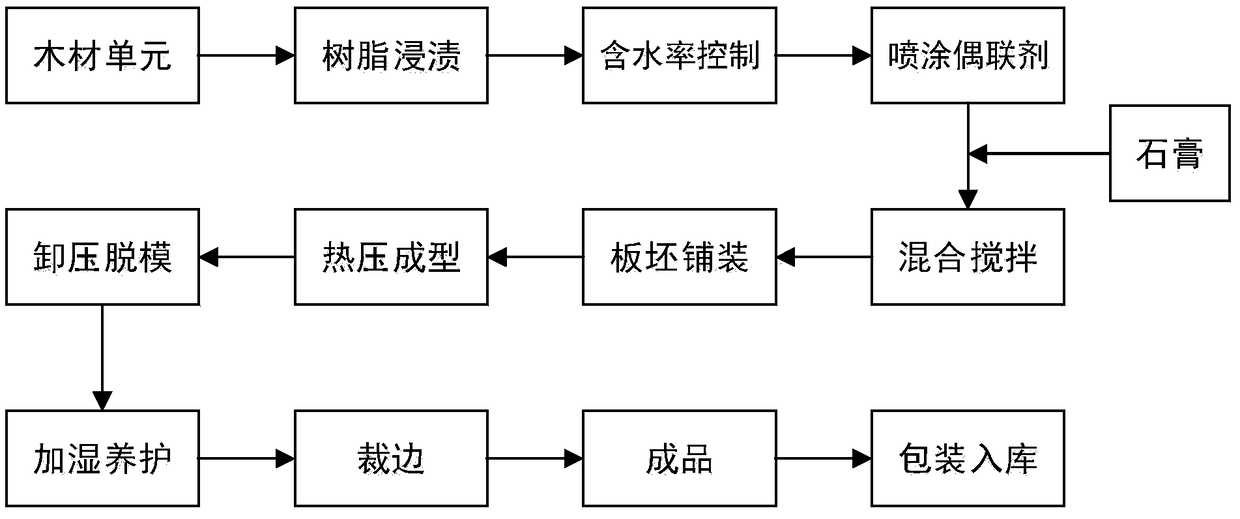

Structural wood-based gypsum composite material and preparation method thereof

ActiveCN108724382ASimple process structureReasonable designWood treatment detailsCeramic shaping apparatusFire resistanceMoisture

Belonging to the construction field, the invention discloses a structural wood-based gypsum composite material and a preparation method thereof. The method includes: wood shaving impregnation, moisture content control, mixing, pavement, hot pressing and curing. According to the invention, phenolic resin can be added to a wood unit to improve the fire resistance and mechanical properties, and a silane coupling agent is added to improve the interface bonding properties of the wood unit and gypsum. The process firstly performs hot-pressing pre-forming and then conducting cold pressing and humidifying curing, is in favor of the formation of needle-like gypsum crystals with high mechanical properties, further improves the mechanical properties of the wood-based gypsum composite material, and has the advantages of simple procedure, reasonable design and easy manufacturing.

Owner:NANJING UNIV OF TECH

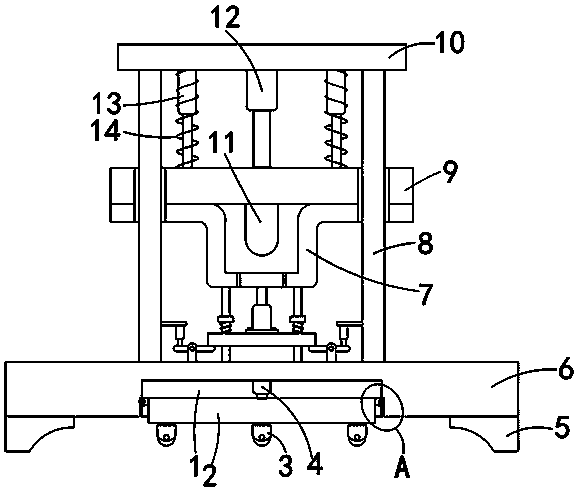

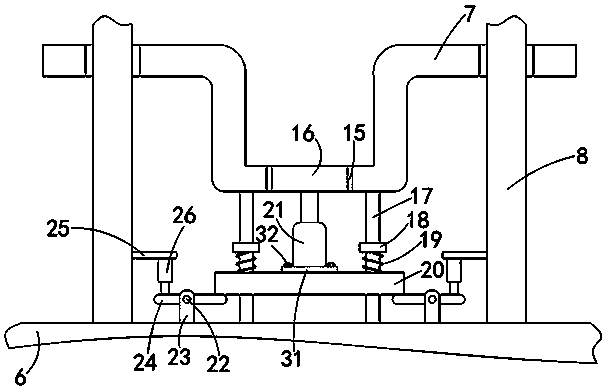

Automatic mold-opening machine for rotary-disc shoemaking machine

PendingCN109177097AAvoid affecting yieldEasy accessDomestic articlesHydraulic cylinderMechanical engineering

The invention discloses an automatic mold-opening machine for a rotary-disc shoemaking machine. The automatic mold-opening machine comprises a base plate, wherein support legs are arranged at the bottom of the base plate, a mounting slot is formed in the center of the bottom of the base plate and faces towards, and a walking mechanism is arranged in the mounting slot; two vertical rods are symmetrically and fixedly mounted on the upper surface of the base plate and are fixedly sleeved with mold cavities, and a transverse plate is arranged above the mold cavities and sleeves on the two inner rods in a sliding manner; a mold core is fixedly connected to the center of the bottom of the transverse plate; and a top plate is commonly and fixedly connected to one ends, far from the base plate, ofthe two vertical rods, and a second hydraulic cylinder is fixedly mounted in the center of the bottom of the top plate. According to the automatic mold-opening machine, a formed shoe body is slowly separated from the inner walls of the mold cavities through the small-extent shaking of a slide block to the formed shoe body, so that the problems that the material block of the formed shoe body is adhered to the inner walls of the mold cavities, gaps are formed in the surface of the formed shoe body, and the rate of finished products is influenced are avoided.

Owner:YANCHENGSHI YUZHENG PRECISION MACHINE

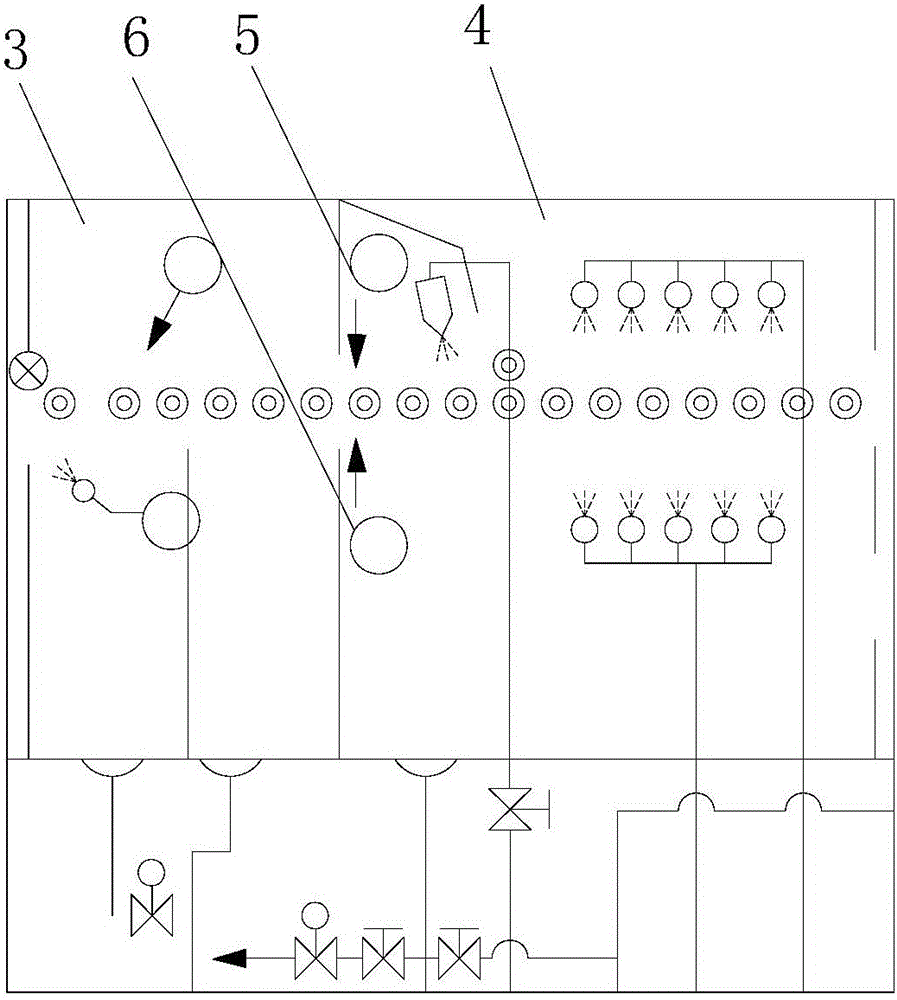

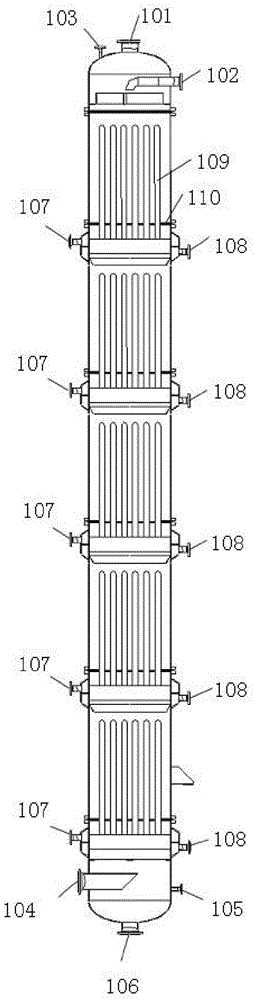

Diketene preparation device and preparation method

ActiveCN104592172BAvoid affecting yieldIncrease pressureOrganic chemistryAcetic acidAcetic anhydride

The invention relates to a diketene preparation device and a diketene preparation method. The diketene preparation device comprises an acetic acid evaporator, a mixer, a cracking furnace, a quenching condenser and an absorption tower. The outlets of the acetic acid evaporator and the mixer are connected with the cracking furnace; the cracking furnace is then connected with the multi-level quenching condenser; the quenching condenser is then connected with the absorption tower; one branch of the absorption tower is connected with a polymerization tank, and the other branch of the absorption tower is connected with a water absorption tower; and the outlet of the third-level quenching condenser is connected with the quenching condenser behind through a liquid ring pump. The diketene preparation device and diketene preparation method provided by the invention have the beneficial effects that when the cracked gas is pressurized, the impurities such as acetic acid, water and acetic anhydride in the cracked gas can be condensed out more sufficiently, and thus the quality of the cracked gas before entering the absorption tower is improved while the freezing level is lowered; and compared with the traditional technology in which the energy consumption accounts for 45% of the total cost of diketene, the device and method provided by the invention have the advantage that the energy consumption only accounts for 25% of the total cost of diketene through improvement.

Owner:QINGDAO UNIV OF SCI & TECH

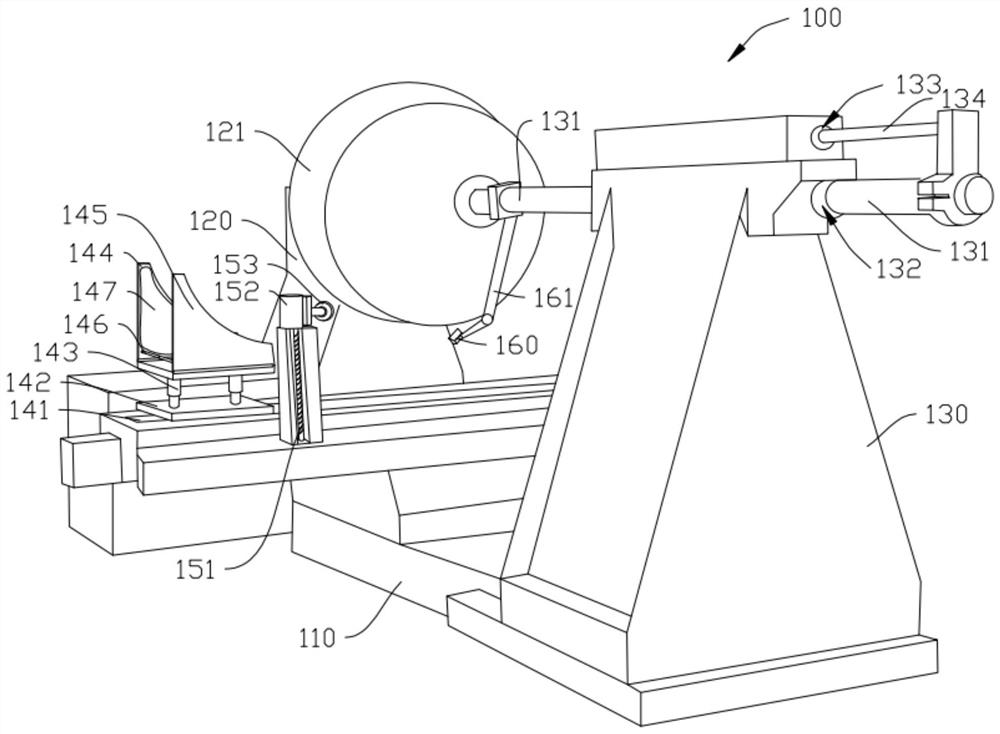

Numerical control spinning machine

PendingCN113857322AImprove stabilityImprove reliabilityEdge grinding machinesGrinding drivesNumerical controlSpinning

The invention discloses a numerical control spinning machine. The numerical control spinning machine comprises a rack, a first spinning frame, a second spinning frame and a conveying mechanism, wherein the first spinning frame is arranged on one side of the rack, and the first spinning frame is provided with a first spinning assembly used for rotating products; the second spinning frame is arranged on the other side of the rack, a first rotating hole and a second rotating hole are formed in the second spinning frame, the second spinning frame is further provided with a second spinning assembly used for penetrating through the first rotating hole and a sliding rod used for penetrating through the second rotating hole, the sliding rod is connected with the second spinning assembly, and the second spinning assembly can move relative to the first spinning assembly through the sliding rod; and the conveying mechanism comprises a sliding rail, a sliding block installed on the sliding rail and a conveying component installed on the sliding block, the sliding rail is arranged between the first spinning frame and the second spinning frame, and the conveying component can move relative to the first spinning frame and the second spinning frame through the sliding block. The numerical control spinning machine can automatically complete material conveying operation, and the production efficiency and the product manufacturing precision are improved.

Owner:江门市盛誉金属制品有限公司

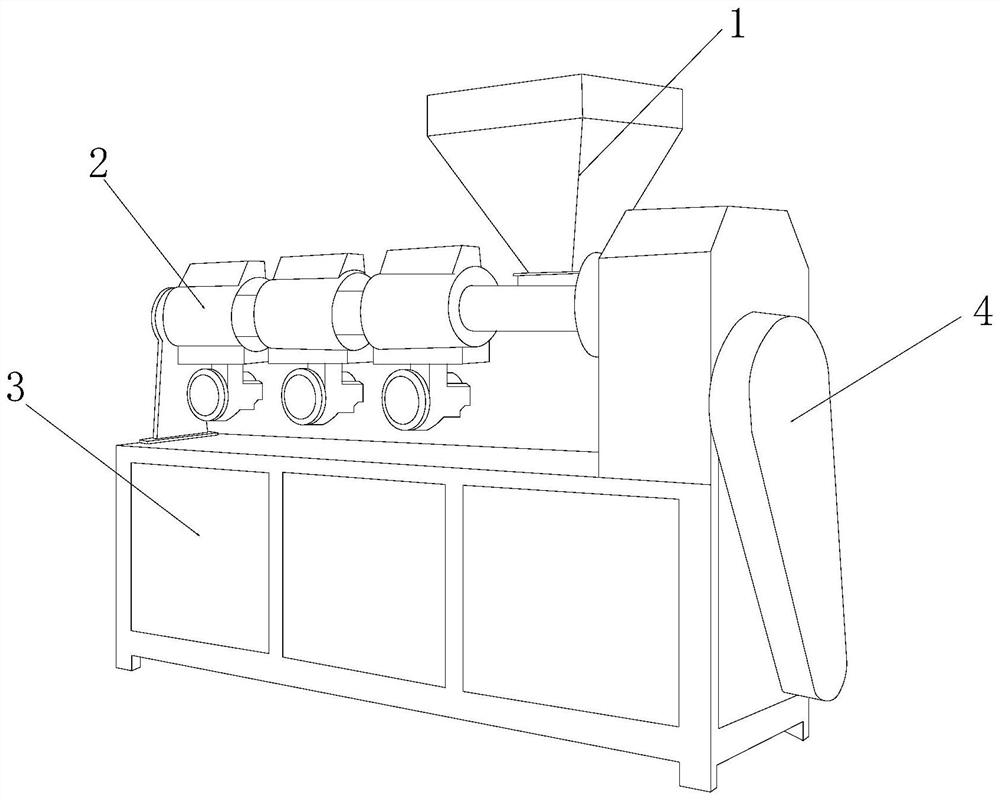

Mechanical-hydraulic combined extruder used for extrusion molding of plastic materials

The invention discloses a mechanical-hydraulic combined extruder used for extrusion molding of plastic materials. The mechanical-hydraulic combined extruder structurally comprises a hot melting mechanism, a plastic film block, an equipment base and a transmission shaft. The hot melting mechanism is fixedly installed over the equipment base in an embedded manner, the plastic film block is installedon the left side of the transmission shaft in a welded manner, the end face of the right side of the equipment base is fixedly connected with the transmission shaft in an embedded manner, and the transmission shaft is located below the right side of the hot melting mechanism. An concentric shaft can be driven to rotate together while an intercepting plate swings, an elastic rope connected with amovable block in an embedded manner can pull embedded beads outwards, hollowed-out grooves connected with the embedded beads move outwards, the hollowed-out grooves in the upper end and the lower endare overlapped in the moving process, an empty groove is reserved to allow plastic solutions to flow so that the intercepting plate and a movable plate can be coaxial and cut off, and the situation that the yield is affected due to the fact that solutions are left in equipment excessively to form wiredrawing is avoided.

Owner:陈伟敏

Mask plate shielding blade scratch monitoring system

ActiveCN112526825BAvoid affecting yieldAvoid affecting productionForce measurement using piezo-resistive materialsPhotomechanical exposure apparatusComputer hardwareIntegrator

The invention relates to a scraping monitoring system for shielding blades by a mask plate. A mask plate shielding blade scratch monitoring system is used to monitor the scratch between the mask plate shielding blade and the rod integrator housing. The mask plate shielding blade scratch monitoring system includes: a pressure detection module, which is arranged on the The end face of the rod integrator housing opposite to the mask plate shielding blade is used to detect the pressure between the mask plate shielding blade and the end face; the analog-to-digital conversion module is connected to the pressure detection module and Its output signal is converted into a digital signal; and a monitoring module is used to receive the digital signal of the analog-to-digital conversion module and output the detection result of the pressure detection module according to the digital signal. The above-mentioned mask plate shielding blade scratch monitoring system enables the user to monitor the scratch between the mask plate shielding blade and the end surface through the monitoring system, so as to avoid scratching the mask plate shielding blade.

Owner:CHANGXIN MEMORY TECH INC

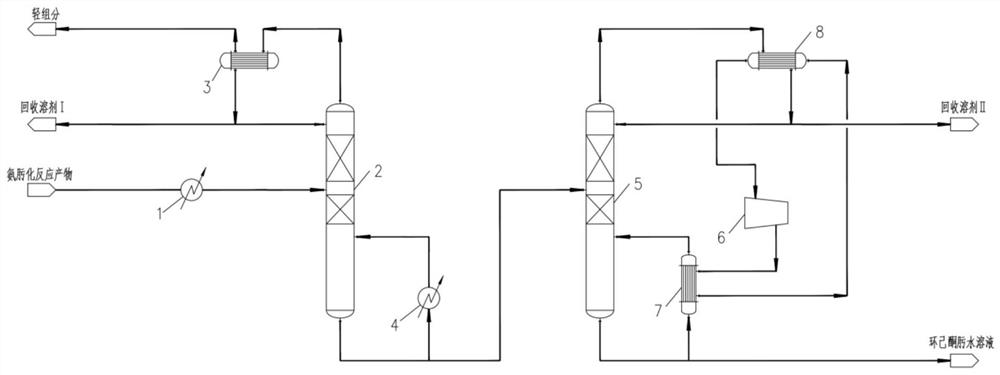

Energy-saving recovery device and method for ammoximation reaction solvent tert-butyl alcohol

PendingCN113121313AAchieve reuseReduce consumptionHeat recovery systemsOrganic compound preparationReboilerCyclohexanone oxime

The invention relates to an energy-saving recovery device and method for an ammoximation reaction solvent, namely tert-butyl alcohol, belonging to the technical field of chemical separation. The device disclosed by the invention comprises a rectifying tower I, a rectifying tower I condenser, a rectifying tower I bottom reboiler, a rectifying tower II, a compressor and a rectifying tower II bottom reboiler. According to the energy-saving recovery device for the ammoximation reaction solvent, namely tert-butyl alcohol, steam consumption and cooling water consumption can be greatly reduced, a good energy-saving effect is achieved, impurity separation capacity is high, the content of the tert-butyl alcohol in the obtained aqueous cyclohexanone-oxime solution is very low, and influence on a subsequent cyclohexanone-oxime refining procedure is avoided.

Owner:吴嘉

Monitoring system for scratching of mask plate shielding blade

ActiveCN112526825AAvoid affecting yieldAvoid affecting productionForce measurement using piezo-resistive materialsPhotomechanical exposure apparatusMonitoring systemMechanical engineering

The invention relates to a monitoring system for scratching of a mask plate shielding blade. The monitoring system is used for monitoring scratching between the mask plate shielding blade and a rod integrator shell. The monitoring system comprises: a pressure detection module, which is arranged on the end surface, opposite to the mask plate shielding blade, of the rod integrator shell, and is usedfor detecting pressure between the mask plate shielding blade and the end surface; an analog-to-digital conversion module, which is connected with the pressure detection module and converts an outputsignal of the pressure detection module into a digital signal; and a monitoring module, which is used for receiving the digital signal of the analog-to-digital conversion module and outputting a detection result of the pressure detection module according to the digital signal. According to the monitoring system for the scratching of the mask plate shielding blade, a user can monitor scratching between the mask plate shielding blade and the end face through the monitoring system, so the mask plate shielding blade is prevented from being scratched.

Owner:CHANGXIN MEMORY TECH INC

Hydrophobic membrane structure, detection method and detection system thereof, and wafer carrier

ActiveCN113278376AFix damageTimely replacementMaterial analysis by observing effect on chemical indicatorFilm/foil adhesivesSemiconductorMaterials science

The embodiment of the invention relates to the field of semiconductors, and discloses a hydrophobic membrane structure, a detection method and a detection system thereof, and a wafer carrier. The hydrophobic membrane structure provided by the invention comprises a color-changing layer and a hydrophobic layer covering the surface of the color-changing layer; and when the color-changing layer is in contact with liquid, the color of the area, in contact with the liquid, of the color-changing layer changes to form a color-changing area. Compared with the prior art, according to the embodiment, the hydrophobic layer covers the surface of the color-changing layer, when the hydrophobic layer is broken, liquid flows into the color-changing layer through the broken area of the hydrophobic layer, and the color of the color-changing layer changes due to the fact that the color-changing layer makes contact with the liquid. Therefore, in the detection process of the hydrophobic membrane structure, whether the hydrophobic membrane structure is damaged or not is detected through the change of the color, so that the hydrophobic membrane structure is replaced in time, and the problem that the hydrophobic membrane structure is damaged only when a product or equipment goes wrong is solved.

Owner:CHANGXIN MEMORY TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com