Rebar forming conveyor

A conveyor and forming machine technology, which is applied to machine tools, grinders, metal processing equipment and other directions suitable for grinding the edge of workpieces, can solve the problems of surface burrs that are difficult to clean, easy to bend, etc., to avoid secondary damage and increase support area, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

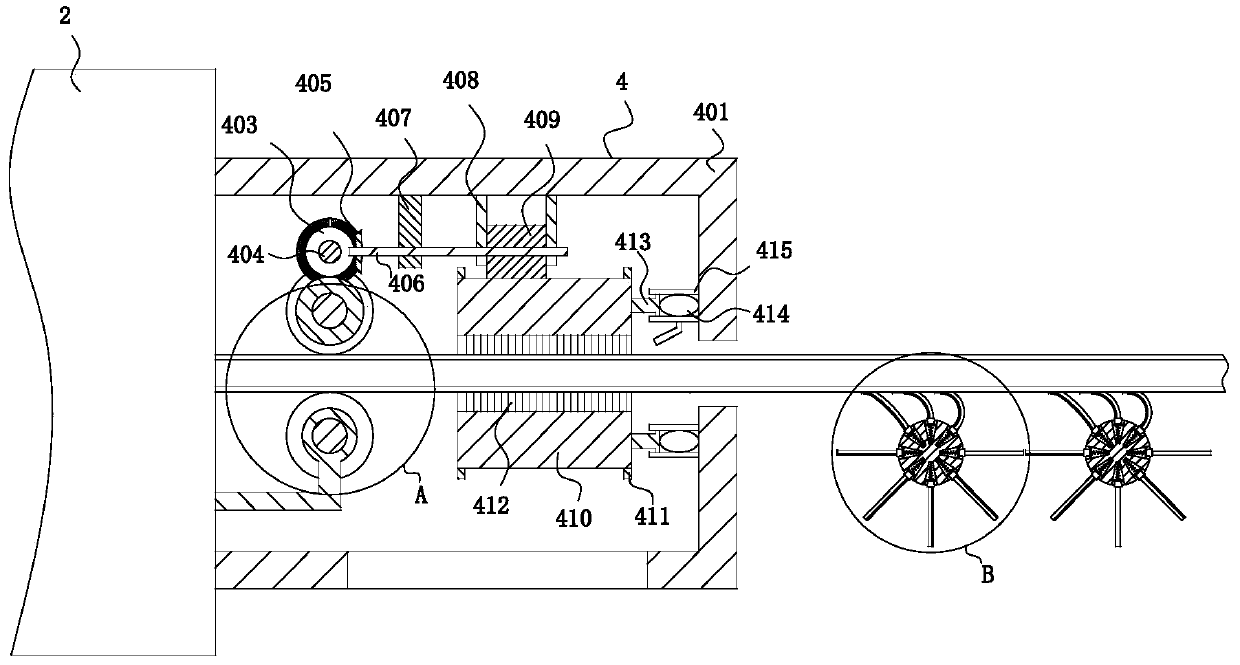

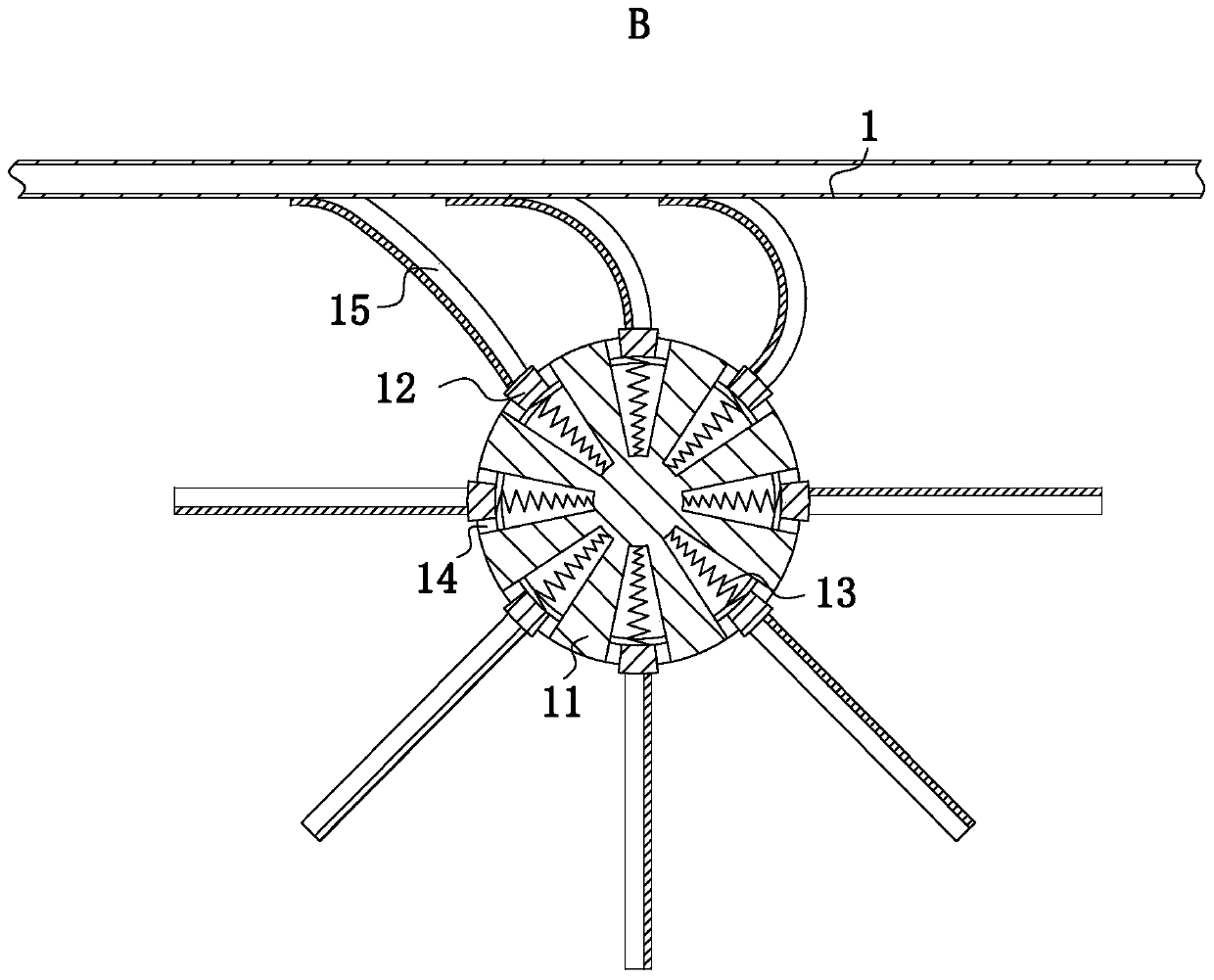

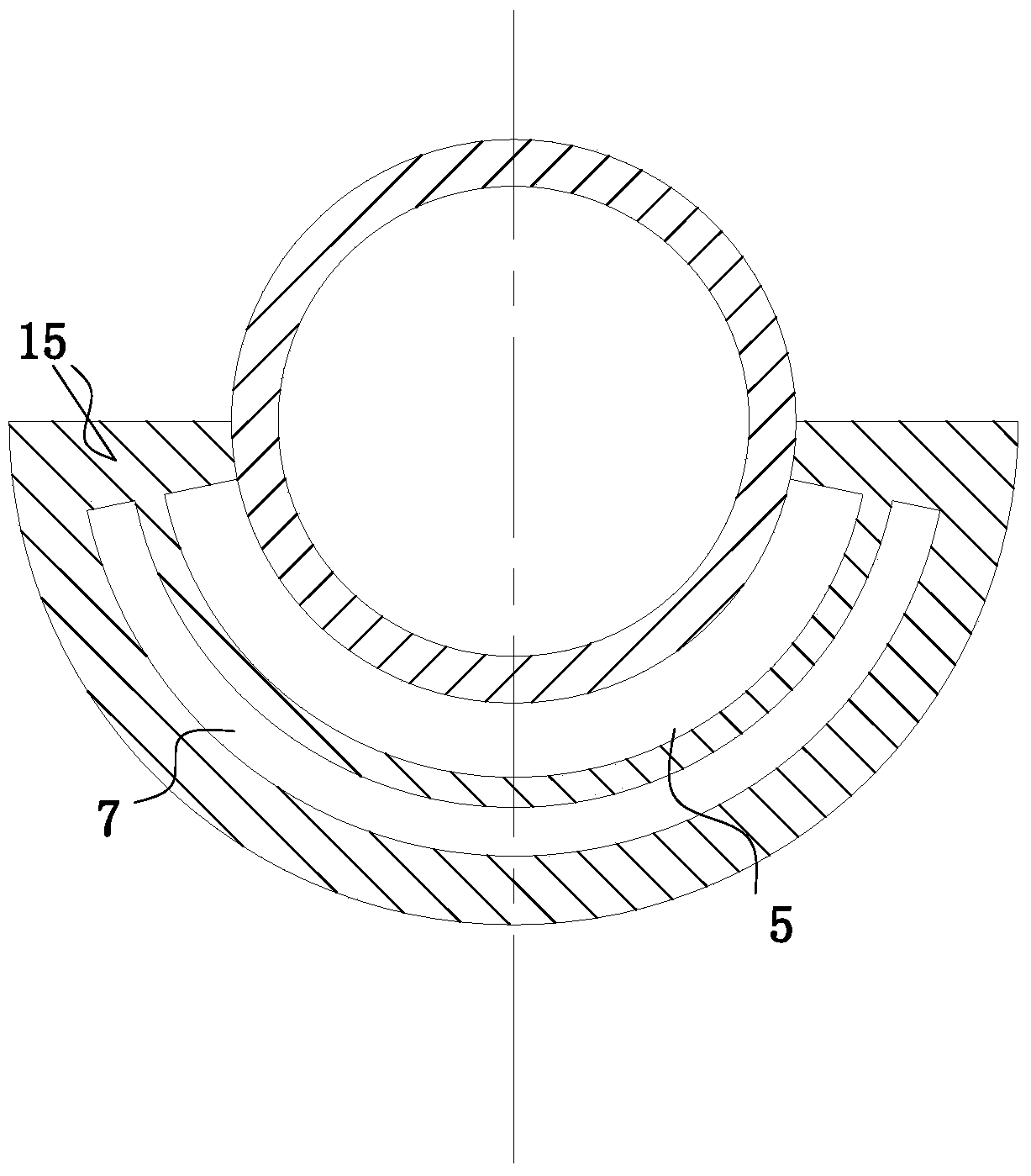

[0023] use Figure 1-Figure 7 A reinforcement forming conveyor according to one embodiment of the present invention will be described below.

[0024] Such as Figure 1-Figure 7 As shown, a steel bar forming conveyor according to the present invention includes a supporting power conveying mechanism 1, an extrusion molding machine 2, a fixed anti-shaking mechanism 3 and a burr cleaning mechanism 4; the supporting power conveying mechanism 1 is arranged evenly close to There are several, made up of a rotating disk 11, a slider 12, a spring 13, a sliding bracket 14 and a chord rubber strip 15; 14 is provided with two altogether, and sliding bracket 14 is arranged symmetrically opposite, and sliding block 12 is slidably installed on the inner surface of sliding bracket 14; The lower surface of described slider 12 is fixedly connected with spring 13, and the inside of sliding block 12 is fixedly installed with string rubber Strip 15; the lower end of the spring 13 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com